Panasonic TX-32LX60F, TX-32LX60P, TX-26LX60F, TX-26LX60P Service manual

ORDER No. PCZ0603015CE

Service Manual

Colour LCD Television

TX-32LX60F

TX-32LX60P

TX-26LX60F

TX-26LX60P

GLP21 Chassis

Specifications

(Informations in brackets [ ] refers to models 26´´)

Power Source: 220-240V AC

Power Consumption: 143W [90W]

Stand-by Power

Cons

umption: 1W [1W]

Aerial Impedance: 75Ω unbalanced,

Receiving System: PAL-I, B/G

Receiving Channels:

VHF E2-E12 VHF H1-H2 (ITALY)

VHF A-H (ITALY) VHF R1-R2

VHF R3-R5 VHF R6-R12

UHF E21-E69 CATV (S01-S05)

CATV S1-S10 (M1-M10) CATV S11-S20 (U1-U10)

CATV S21-S41 (Hyperband)

Operating Conditions:

Temperature: 5°C ÷ 35

Humidity: 5% ÷ 90

Intermediate Frequency:

Video/Audio

Video

Audio 33,4MHz (B/G), 33,16MHz (A2)

Colour 34,47MHz (PAL)

Terminals:

AV1 IN Video (21 pin) 1V p-p 75Ω

AV1 OUT Video (21 pin) 1V p-p 75Ω

SECAM B/G, D/K, L/L’

PAL-525/60 (AV only)

M.NTSC (AV only)

NTSC (AV o

38,9MHz, 33,9MHz

33,05MHz (NICAM B/G, D/K, L)

32,4MHz (D/K), 32,66MHz (CZ STEREO)

40,4MHz (L’), 39,75Mhz (L’NICAM),

34,5MHz, 34,65MHz (SECAM)

38,3MHz, 38,15MHz (SECAM L’)

Audio (21 pin) 500mV rms 10kΩ

RGB (21 pin) 0,7V p-p 75Ω

Audio (21 pin) 500mV rms 1kΩ

, 50Hz

Coaxial Type

, D/K,

nly)

°C

% RH (non-condensing)

AV2 IN Video (21 pin) 1V p-p 75Ω

AV2 OUT Video (21 pin) 1V p-p 75Ω

AV3 IN S-Video IN Y: 1V p-p 75Ω

HDMI1, HDMI2 Type A Connector

COMPONENT YUV Video (RCAx3) Y:1V p-p 75Ω

AUDIO IN Audio (RCAx2) 500mV rms 10kΩ

LCD screen: L5EDD8

Audio Output: 2x10W RMS

Headphones: 3,5mm, 8Ω Imp

Accessories

supplied : Remote Con

Dimensions:

Including TV stand 615mm 791mm 301mm

TV set only 563mm 791mm 107mm

Net weight: 19kg

Specifications are subject to change w

Weights and dimensions shown are approximate.

Audio (21 pin) 500mV rms 10kΩ

RGB (21 pin) 0,7V p-p 75Ω

S-video IN Y: 1V p-p 75Ω

(21-pin) C:0,3V p-p 75Ω

Audio (21 pin) 500mV rms 1kΩ

(4-pin) C:0,3V p-p 75Ω

Audio (RCAx2) 500mV rms 10kΩ

Video (RCAx1) 1V p-p 75Ω

Pb, Pr: 0,7V p-p 75Ω

Q00019 [L5EDD6Q00013]

1366 x 768 XGA, 16:9

Visible Diagonal 800mm [660mm]

8Ω impedance

edance

trol

2 x R6 (UM3) Batteries

Height: Width: Depth:

[525mm] [657mm] [301mm]

[473mm] [657mm] [107mm]

[14,5kg]

ithout notice.

CONTENTS

SAFETY PRECAUTIONS........................................... 3

GENERAL QUIDE LINES...................................... 3

TOUCH – CURRENT CHECK

PREVENTION OF ELECTROSTATIC DISCHARGE

(ESD) TO ELEC

DEVICES.................................................................... 4

ABOUT LEAD FREE SOLDER (PBF)

SUGGESTED PB FREE SOLDER

SERVICE HINT

CHASSIS BOARD LAYOUT

SETTING INSPECTION.............................................. 7

SELF-CHECK

ADJUSTMENT ME

BLOCK DIAGRAMS

PARTS LOCATI

REPLACEMENT PARTS LIST.................................. 14

SCHEMATIC DIAGRAMS.........................................

A-BOARD - 3,3V SUPPLY

A-BOARD - 3,3V HDMI SUPPLY

A-BOARD - 5V SUPPLY ..................................... 27

A-BOARD - 33V SUPPLY

A-BOARD - 12V SUPPLY

A-BOARD - 8V SUPPLY

A-BOARD - STBY 3,3V SUPPLY........................ 29

A-BOARD - STBY 1,8V SUPPLY

A-BOARD - PSU CONNECTION

A-BOARD - AV1.................................................. 31

A-BOARD - AV2

A-BOARD - AV3

TROSTATICALLY SENSITIVE (ES)

S ........................................................ 6

............................................................. 8

THOD ........................................... 9

.................................................. 10

ON................................................... 13

.................................................. 31

.................................................. 32

............................... 3

......................... 5

........................ 5

....................................... 7

25

.................................. 26

........................ 26

................................... 27

................................... 28

..................................... 28

........................ 29

........................ 30

A-BOARD - YUV

A-BOARD - VIDEO SWITCH............................... 33

A-BOARD - QLINK

A-BOARD - HDMI_CEC

A-BOARD - LCD PANEL CONNECTOR, PANEL 5V

SUPPLY .............................................................. 34

A-BOARD - TUNER CONNECTION

A-BOARD - AUDIO AMPLIFIER

A-BOARD - AUDIO MA

A-BOARD - HDMI AUDIO DAC

A-BOARD - HEADPHONE AMPLIFIER

A-BOARD - KEYSCAN........................................

A-BOARD - SERVICE.........................................

A-BOARD - IR LED

A-BOARD - PRO

A-BOARD - LEVEL SHIFTER .............................42

A-BOARD - IRD PRO

A-BOARD - EAROM

A-BOARD - INVERT

A-BOARD - BACKLIGHT..................................... 44

A-BOARD - VCT

A-BOARD - HDMI

H-BOARD

B-BOARD............................................................ 48

V-BOARD............................................................ 49

K-BOARD............................................................ 50

P-BOARD............................................................ 51

KEY CONTROL

CONDUCTOR VIEWS

.................................................. 32

.............................................. 33

...................................... 34

.................... 35

.......................... 36

TRIX............................... 37

........................... 38

.............. 39

............................................. 41

TECTION ................................. 41

TECTION .......................... 42

............................................ 43

ER.......................................43

69P ........................................... 45

................................................ 46

............................................................ 47

................................................... 52

.............................................. 53

40

40

2

Safety Precautions

A

Ω

Ω

Ω

Ω

General Guide Lines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated

or damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following touch current checks to prevent the customer from being exposed to shock hazards.

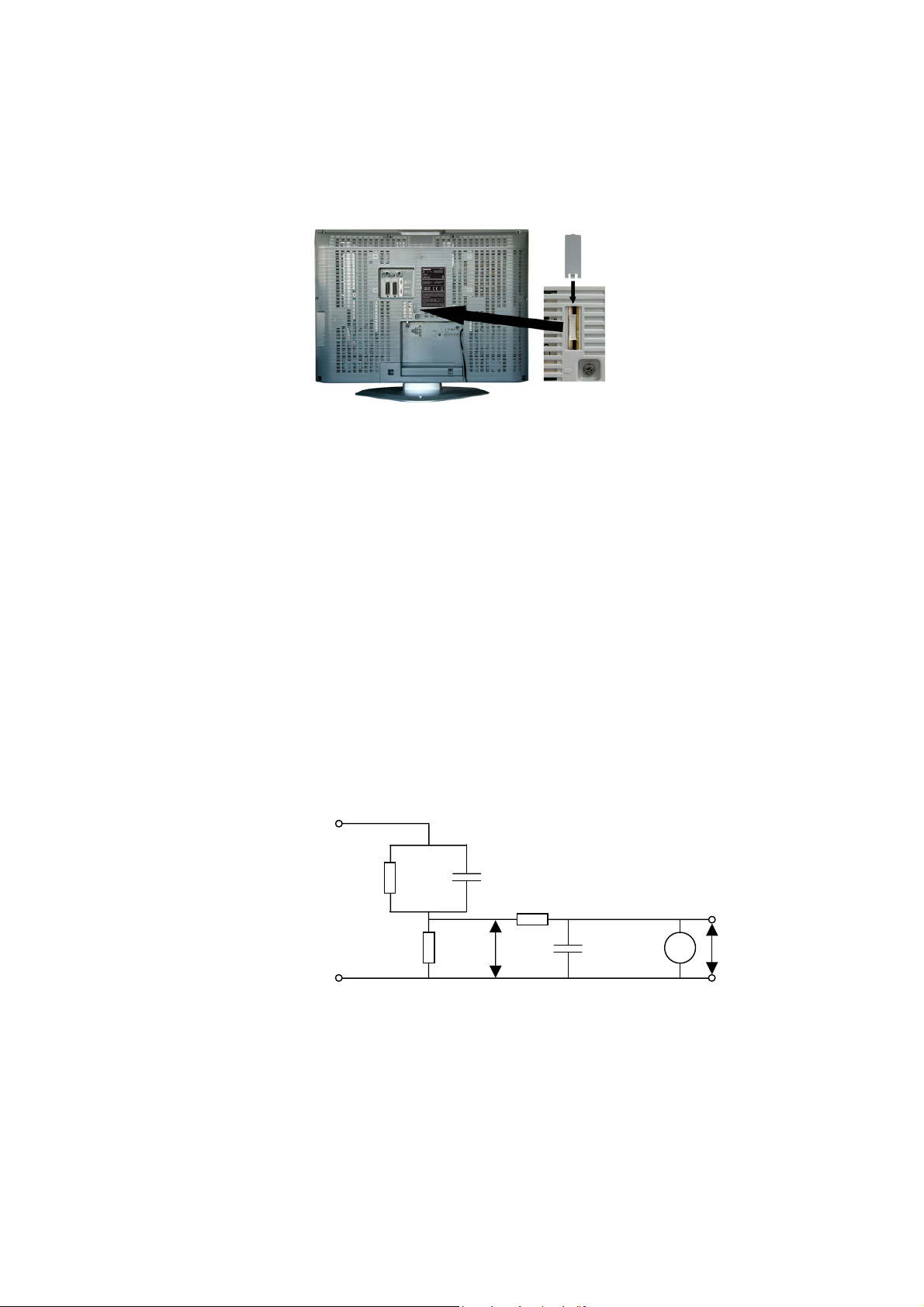

4. Always ensure panel TKKL5290 is correctly replaced before returning to customer (see Fig.1).

Fig. 1

Touch-Current Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

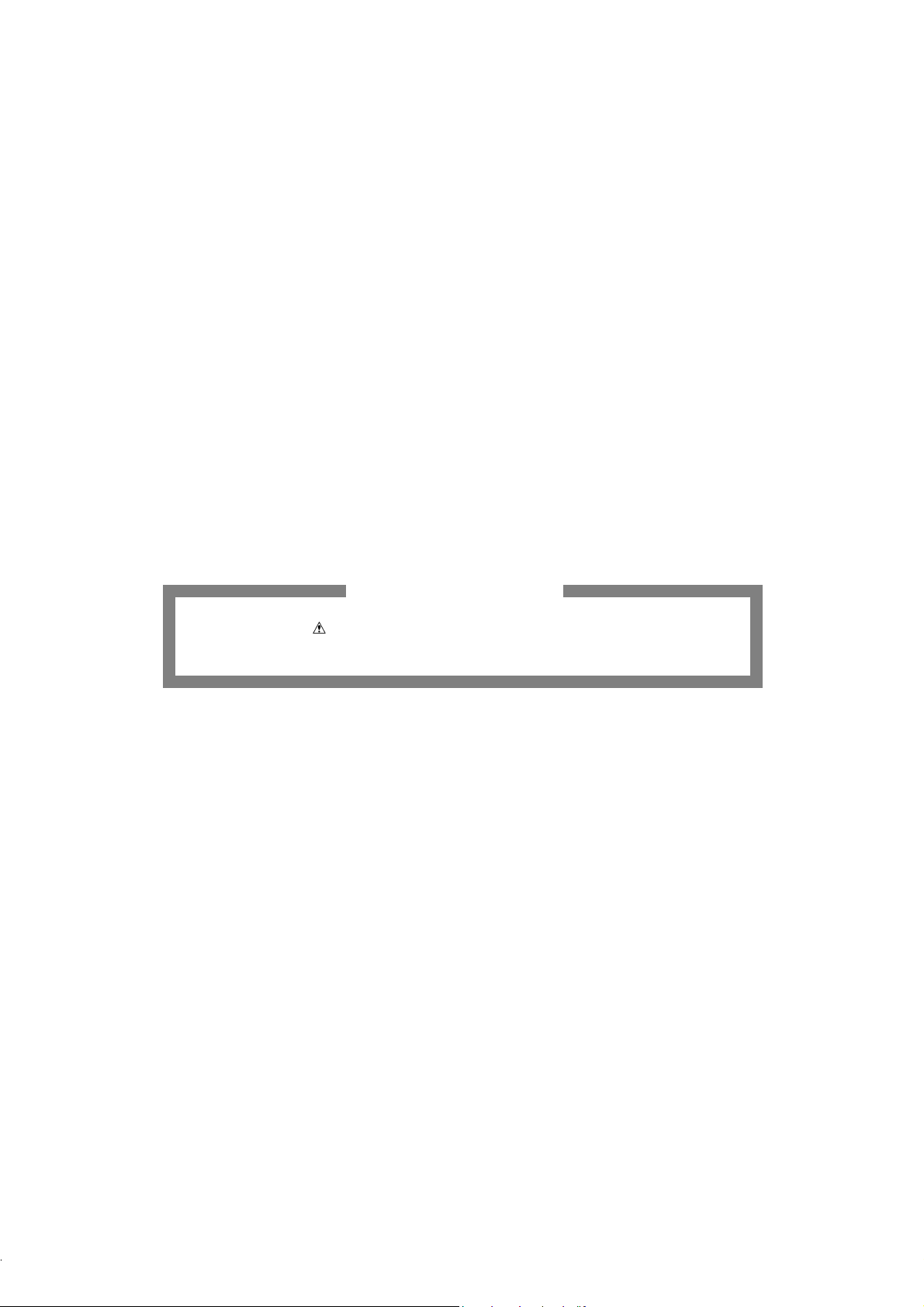

2. Connect a measuring network for touch currents between each exposed metallic part on the set and a go od earth

ground such as a water pipe, as shown in Fig. 2.

3. Use Leakage Current Tester (Simpson 228 or equivalent) to measure the potential across the measuring network.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reserve the AC plug in the AC outlet and repeat each of the above measure.

6. The potential at any point (TOUCH CURRENT) expressed as voltage U1 and U2, does not exceed the following values:

For a. c.: U1 = 35 V (peak) and U2 = 0.35 V (peak);

For d. c.: U1 = 1.0 V,

Note:

The limit value of U2 = 0.35 V (peak) for a. c. and U1 = 1.0 V for d. c. correspond to the values 0.7 mA (peak) a. c. and

2.0 mA d. c.

The limit value U1 = 35 V (peak) for a. c. correspond to the value 70 mA (peak) a. c. for frequencies greater than 100

kHz.

7. In case a measurement is out of the limits specified, there is a possibility of a shock hazard, and the equipment should

be repaired and rechecked before it is returned to the customer.

Measuring network for TOUCH CURRENTS

COLD

WATER PIPE

(EARTH GROUND)

Fig. 2

CS=500µF

10k

U

1

0.022µF

V

U2 (V)

RS=500

TO

PPLIANCES

EXPOSED

METAL PARTS

Resistance values in ohms (Ω)

V: Voltmetr or oscilloscope

(r.m.s. or peak reading)

NOTE – Appropriate measures should be taken to obtain the correct value in case of non-sinusoidal waveforms

Input resistance: ≥ 1M

Input capacitance: ≤ 200pF

Frequency range: 15Hz to 1MHz and d.c.respectively

R0=500

3

Prevention of Electrostatic Discharge (ESD) to Electrostatically

Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect

transistors and semiconductor "chip" components. The following techniques should be used to help reduce the incidence of

component damage caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on

your body by touching a known earth ground. Alternatively, obtain and wear a commerciall y av ailable discharging ESD

wrist strap, which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge build up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD

protected)" can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil

or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity

(ESD) sufficient to damage an ES device).

IMPORTANT SAFETY NOTICE

There are special components used in this equipment which are important for safety.

These parts are marked by in schematic diagrams, exploded views and replacement parts list. It is essential that

these critical parts should be replaced with manufacturer’s specified parts to prevent shock, fire, or other hazards. Do

not modify the original design without permission of manufacturer.

4

About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead s

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work,

we’d suggest the use of Pb free solder as well, although Pb solder may be used.

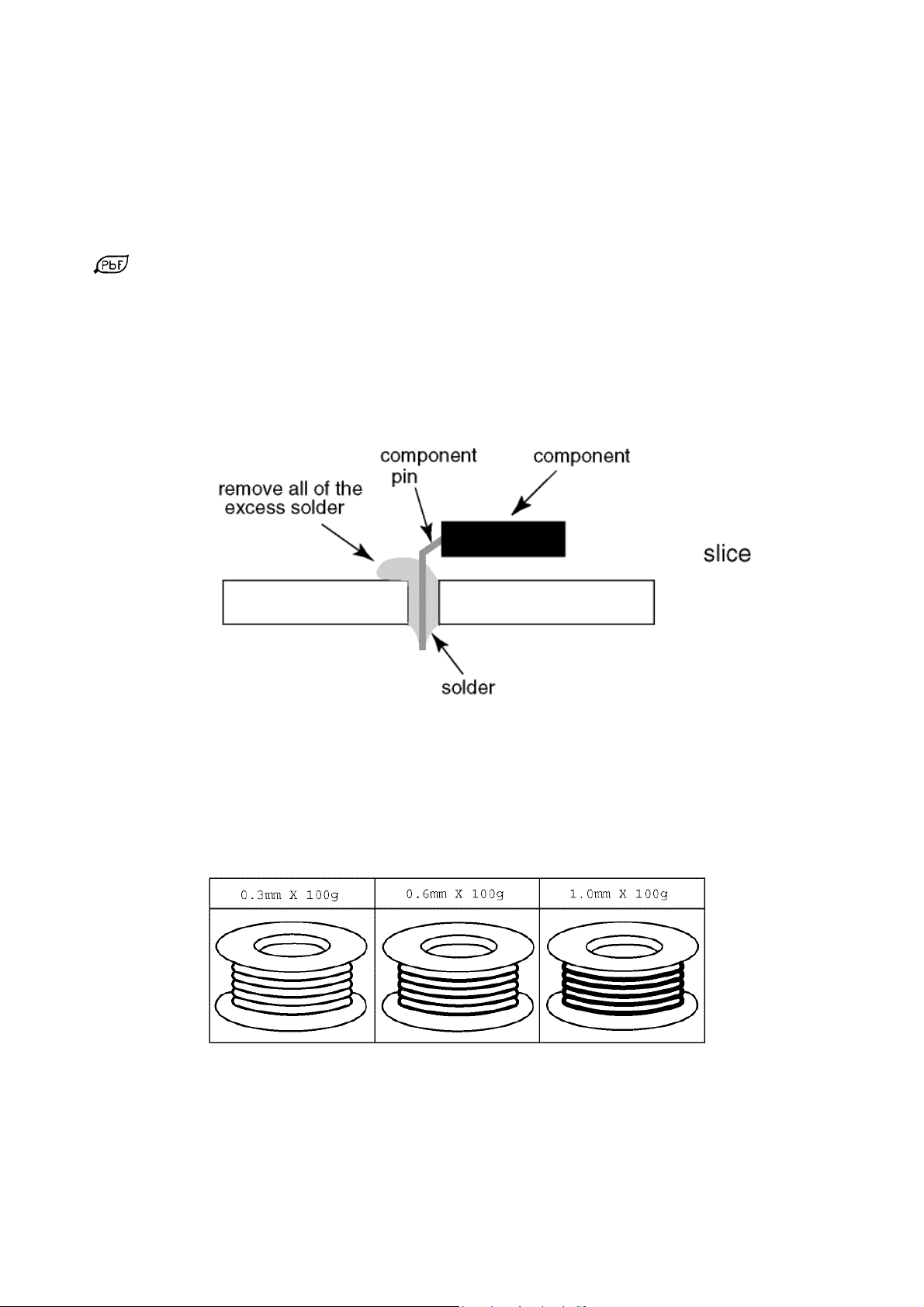

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol

stamped on the back of PCB.

Caution

• Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40°C)

higher. Please use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

• Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free so

applying Pb solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

• After applying PbF solder to double layered boards, please check the component side for excess solder which may

flow onto the opposite side. (see Fig.3)

older, and PbF will refer to Lead Free Solder.

lder on the pins or solder area before

Fig.3

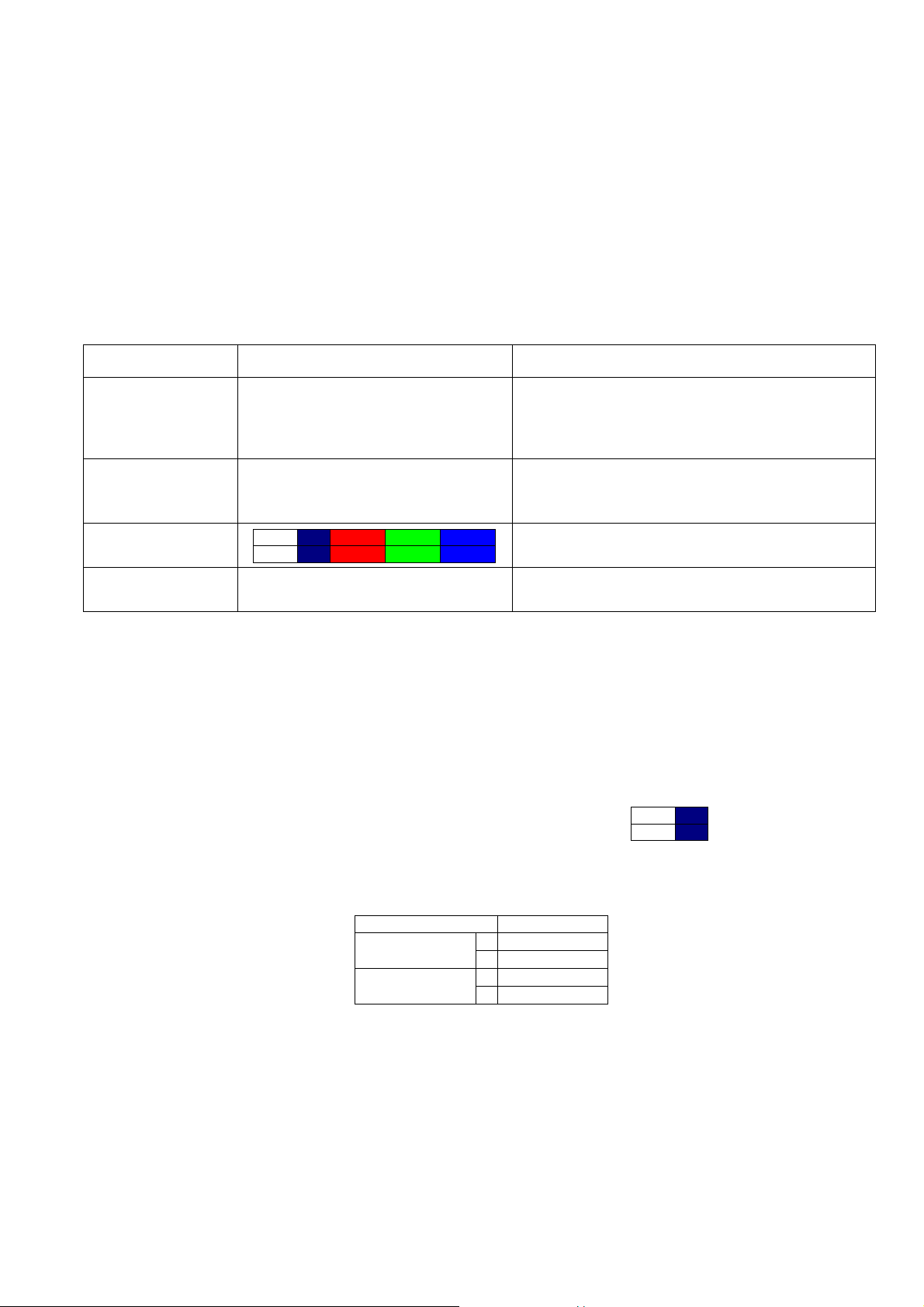

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. T

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used. (see Fig.4)

his product uses Sn+Ag+Cu (tin, silver, copper) solder.

Fig.4

5

Service Hints

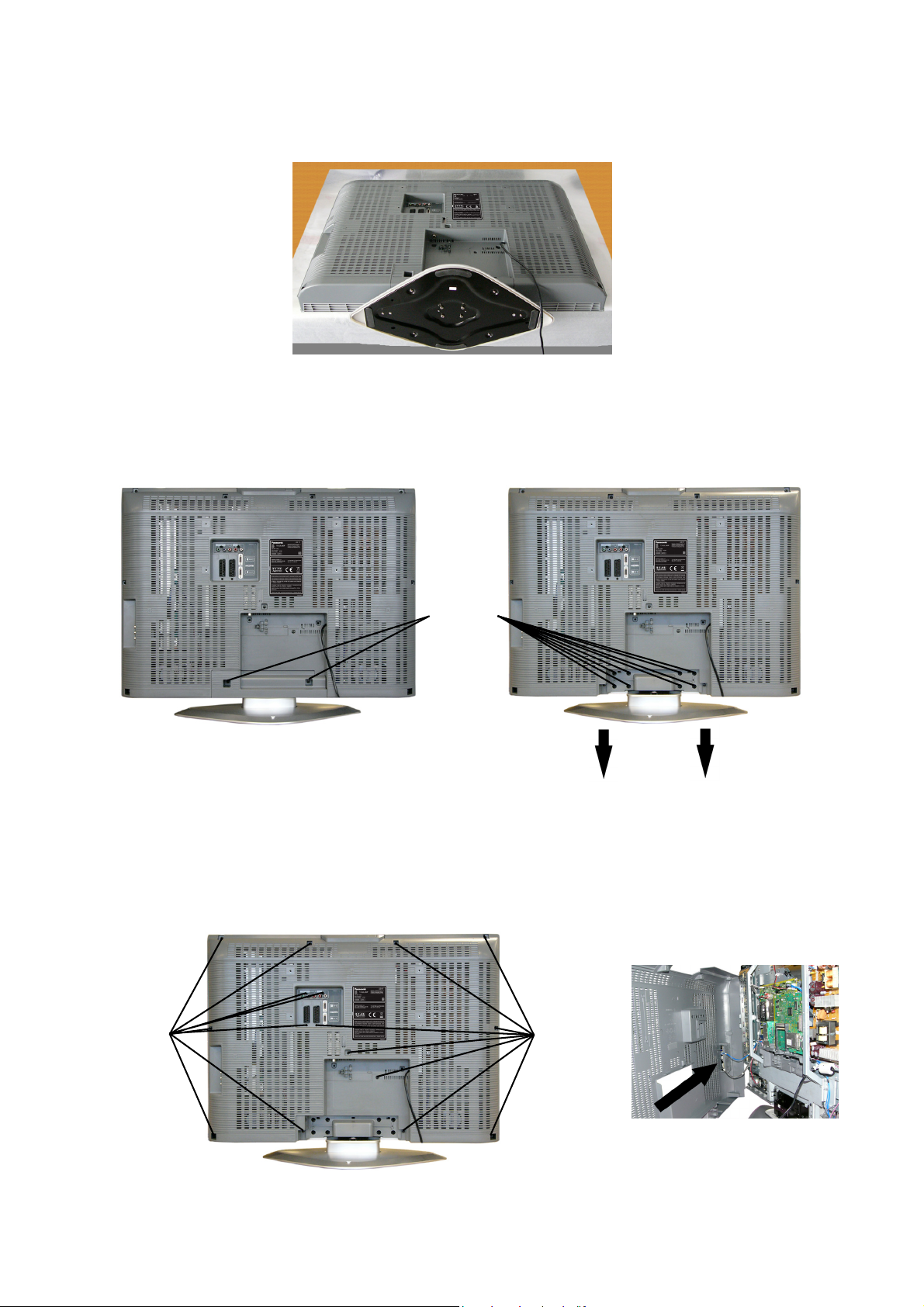

How to remove the Pedestal assembly

Lay the main unit face down. (see Fig.5)

Fig.5

Remove the 2 fixing screws and hinge cover. (see Fig.6)

Remove the 8 fixing screws and the pedestal assembly. (see Fig.7)

SCREWS

Fig.6

How to remove the backcover

Remove the 2 fixing screws and hinge cover. (see Fig.6)

Remove the 16 fixing screws. (see Fig.8)

Carefully remove the backcover and disconnect two AV3 wires. (see Fig.9)

SCREWS

Fig.7

SCREWS

Fig.8

Fig.9

6

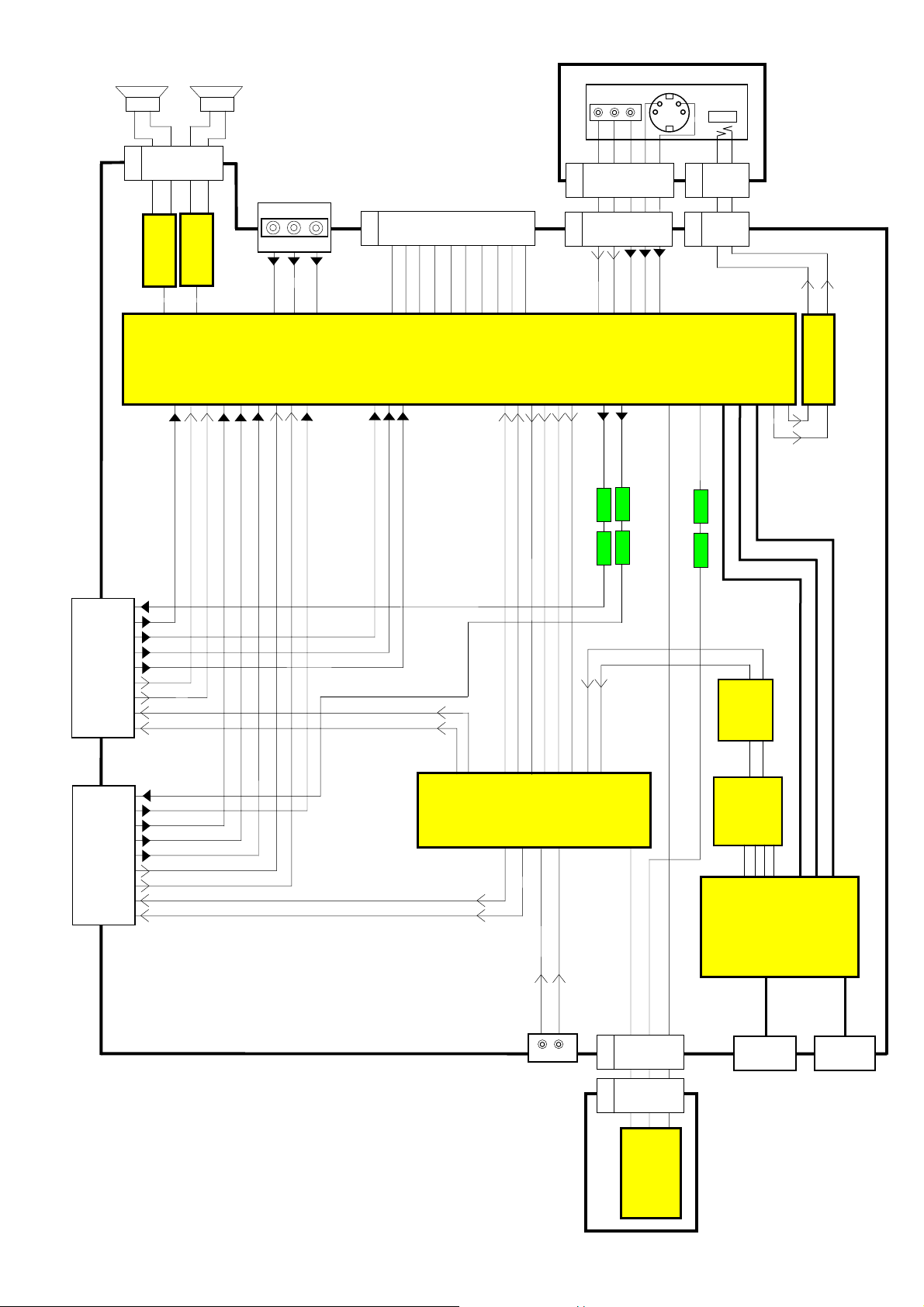

Chassis Board Layout

KEY CONTROL

K-BOARD

A-BOARD

H-BOARD

B-BOARD

Board Name Function

A-Board Main Board

B-Board Tuner

H-Board AV3 Terminal

Key Control Key Control

K-Board Mains Input, Power Switch

P-Board Power Supply

V-Board Remote Receiver, LED IR, Bats

Setting Inspection

Voltage Confirmation

A board Normal mode

Test point Position Voltage

TP004 C870, + pin

TP005 Connector A7, pin 22 12V [15V]

TP006 C1500, + pin

TP008 C1700, + pin

TP010 C890 - R898

TP012 Q878, pin 1

TP017 C872, + pin

TP018 IC252, pin 5 24V

TP019 IC862, pin 1 24V

TP023 Connector A7, pin 12 24V

P-BOARD

V-BOARD

Confirm the following voltages:

33V ± 3V

8V ± 0,3V

5V ± 0,2V

3,3V ± 0,1V

3,3V ± 0,1V

10,5V ÷ 16V

TP009 C883, + pin

TP013 C868, + pin

P board

TP001

TP002 Connector P2, pin 8

TP003 Connector P2, pin 9

TP002 Connector P2, pin 8 24V

TP003 Connector P2, pin 9

Connector P2, pin 20

7

Standby mode

1,8V ± 0,1V

3,3V ± 0,1V

Normal mode

12V ± 2V [15V± 2V]

24V ± 2V

24V ± 1V

Standby mode

<2V

Self Check

A

Self-check is used to automatically check the bus lines and hexadecimal code of the TV set. To enter Self-Check mode, kee p

pressing the STATUS button on the remote control and press the down (-/v) button on the TV set. To exit Self Check,

switch off the TV set at the power button.

E2 O.K.

DPS O.K.

VSP O.K.

VSW O.K.

TUN O.K.

MSP O.K.

DPL --MAS ---

TX-32LX60F TX-32LX60P TX-26L X60F TX-26LX60P

OPTION 1 0F 0F 0F 0F

OPTION 2 00 00 00 00

OPTION 3 B9 B9 B9 B9

OPTION 4 11 11 11 11

OPTION 5 00 00 00 00

OPTION 6 15 15 15 15

OPTION 7 FD FD FD FD

OPTION 8 D0 50 D0 50

OPTION 9 00 00 00 00

OPTION 10 00 00 00 00

OPTION 11 13 13 13 13

OPTION 12 20 20 40 40

OPTION 13 18 18 18 18

CHECK 06 86 26 A6

Display Ref. No. Description P.C.B.

E2 IC1120 EAROM A-Board

DPS IC1501 DISPLAY PROCESSOR AND SCALER A-Board

VSP IC1501 VIDEOSIGNAL PROCESSOR A-Board

AVSW IC1501 AV SWITCH A-Board

TUN TNR001 TUNER B-Board

MSP IC1501 MULTISTANDART SOUND PROCESSOR A-Board

DPL --- DOLBY PROLOGIC PROCESSOR ---

MAS --- MPEG1 AUDIO PROCESSOR ---

If the CCU ports have been checked and found to be incorrect or not located then " - - " will appear in place of "O.K.".

8

Adjustment Method

How to enter Service 1

• Set the Bass to maximum position, set the Treble to minimum position then keep pressing the INDEX button on the

remote control and press the down button (-/v) on the TV set, this will place the TV set into the Service Mode 1.

Key Command

• Press the RED / GREEN buttons to step up / down through the functions.

• Press the YELLOW / BLUE buttons to alter the function values, to alter White Rasters use +/- buttons

• Press the OK button after each adjustment has been made to store the required values.

• To exit the Service Mode, press the "N" button.

Keep adjusting sequence: DVCO, Sub-Contrast, other items.

Item

Sub-Contrast

DVCO

Highlight

Lowlight

Sub-Brightness

Note: All setting values are approximate

High 12 0415 0410 0425

Low 4 0056 0064 0043

Setting indication

Sub-Contrast

23

DVCO

4

Sub-Brightness

0

Settings / Special features

Receive a 80% white level Philips Pattern with correct

sound sy

Contrast alignment press "Blue" button, wait until the

figure colour is changed from red to black colour.

Receive a 80% white level Philips Pattern via aerial

inp

until the figure colour is changed from red to black

For correct setting see W

stem (B/G, D/K) via aerial input. For Sub-

Press the OK.

ut. For DVCO alignment press "Blue" button, wait

colour. Press the OK.

hite Balance Adjustment

Optimum setting.

White Balance Adjustment

Instrument

• Remote Control

• LCD WB meter (Minolta CA-210 or equivalent)

Condition

• Switch on the TV Set. Enter Service1. Step down to Highlight line and keep the aging time more than 20 minutes.

Procedure

• After aging time above set White Raster No.12 for Highlight and No.4 for Lowlight Press the OK button

to store.

• Put Minolta Sensor to the center of the LCD Panel with 25mm gap between Minolta Sensor and LCD Panel. Adjust "x"

and "y" values by changing Red and Blue values.

• Press OK button to store setting.

Item Value

x

Highlight

Lowlight

0,275±0,005

y

0,275±0,005

x

0,275±0,005

y

0,285±0,005

High 12

Low 4

9

V

A5

L

L +

4

L -

16

13

AMP

IC251

4

SP L

28

321

R +

16

IC252

4

SP R

27

L

R

R

C

Y

R

L

H-BOARD

4

8

R -

13

AMP

JK3001

V

PR IN

PB IN

174

U

172

Y

Y IN

173

TO LCD PANEL

2

4

A2

TX0-

TX0+

TX1-

141

140

6

138

8

10

121814

16

20

TX1+

TX2-

137

135

TX3-

TX2+

TCLK-

TCLK+

TX3+

134

132

131

129

128

H1

A12

8

AV3 R IN

13

1

6

6

AV3 L IN

14

3

4

1

3

AV3 Y IN

AV3 C IN

AV3 CVBS IN

184

187

188

H2

A6

1

3

1

3

HP RIGHT

HP LEFT

1

7

IC1501

VIDEO PROCESSOR

1901211

AV2 CVBS IN

CVBS OUT 19

CVBS IN 20

R IN/C IN 15

G IN 11

B IN 7

L IN 6

R IN 2

L OUT 3

R OUT 1

AV2 21 PIN SCART

CVBS OUT 19

CVBS IN 20

R IN 15

G IN 11

B IN 7

AV1 21 PIN SCART

L IN 6

R IN 2

L OUT 3

R OUT 1

VIDEO & STEREO AUDIO BLOCK DIAGRAM

178

177

176

109189

AV2 L IN

AV1 RED IN

AV1 GREEN IN

AV1 BLUE IN

AV1 LEFT IN

AV1 RIGHT IN

AV2 R IN

AV1 CVBS IN

181

179

180

IRD AV2 RED/C IN

IRD AV2 GREEN IN

IRD AV2 BLUE IN

AV2 R OUT

15

IC3300

AUDIO MATRIX

15

16

212324

AV1 R OUT VCTP

AV2 R OUT VCTP

AM IRD YUV/DVI R IN

AV2 L OUT

AM IRD YUV/DVI L IN

25

24

16

17

14

12

13

18

AV1 L OUT

AV1 R OUT

YUV/DVI PO L IN

IC270

HP AMPLIFIER

5

3

25

73-66

65-58

7

OP AMP

IC1381

2

11

123

D/A CONVERTER

I2SCL

MCLK

888684

1

6

10

I2SDI

26

4

I2SWS

85

R 8bit data bus

B 8bit data bus

G 8bit data bus

22

194

195

AV1 CVBS OUT

AV2 CVBS OUT

Q3205

Q3204

Q3202

Q3201

HDMI DAC L

HDMI DAC R

AV2 L OUT VCTP

AV1 L OUT VCTP

6

5

4

23

191

SIFIN+

TUNER CVBS INTUNER CVBS IN

Q123 Q122

SIF+

57-50

31

IC1380

11

YUV/DVI PO R IN

10

AM

IC5003

HDMI RECEIVER

39-52

SIF+

A-BOARD

L

R

A1

13

10

11

8Bit data

HDMI

PORT 1

JK3002

13

10

11

B1

AM 13

SIF_OUT 14

VIDEO OUT 17

TUNER

B-BOARD

144-140,137,136,133

132-129,126-123

119-116,114-110

HDMI

PORT 2

58-71

8Bit data

10

,

,

,

,

,

,

,

,

C

3,3

,

,

,

,

,

,

K-BOARD

D5000

K3

SW 800

F800

K1

MAIN IN

D5003

+

32

COMP

STB

VREF

VCC

~

LF802

LF803

13

3

1

LINE

FILTER

LINE

FILTER

IC801

MAIN PS CONTROL

L801

4

1

23

11

15

10

7

19

20

T801

1

4

LCF´S

3V

3V

P-BOARD

3V

3V

8

8

SIGNAL24V

PROTECTOR

3V

SIGNAL24V

9

101112

9

101112

IRD24V

AUDIO24V

RELAY24V

BACKLIGHT

12V

20-22

20-22

12V

1,8

REG

IC862

2

Q873

D851

D852

D853

2

REG

IC881

1

Q881

AUD12_16

D801

-

10,11 [3,4]

14,15 [7,8]

LCF´S

~

P3

24V

1-4

RL850

[17] 8

[13] 5

[14,15] 6

9 [2]

16 [9]

Q850

PC802

PC803

IC 850

REF

LCD PANEL

A2

26-30

PANEL 5V

PANEL 5V

Q1701

Q875

LCF

18-21

REG

IC885

11-14

LCF

IC3850

6-7

REG

IC866

5

1

REG

2

LCF

7

LCF

REG

IC5000

1

LCF´S

SUPDRI 3,3V

RM1050

VSUPDIG 3,3V

VCC

SUPCOM 3,3V

5V MIXED P1

5V

5V MIXED P0

POWER SUPPLY BLOCK DIAGRAM

SN 1063

V2

3,3V STBY

6

V-BOARD

B1

B2

1

SERVICE

5V

33V

TUN IRD5V

15

3124

TUNER 5V

2

3

SUPFE 3

SUPVO 3

A8

6

SUPLVDS 3

SUPDAC 3

SUPSIF 5V

VSUPAU 8V

183336

STBY 3,3V

AUDIO 24V

3V

3V

SUPDRI 3

SUPDIG 3

45,75

8V

VSUPIO1 3,3V

SUPLVDS 1

VSUPLVDS 3,3V

77

114

124

96

86

IC1501

VIDEO PROCESSOR

127,133,139,150,156

SUPIO3 3

SUPIO1 3,3V

STBY 1,8V

V

PDA

142

VSUPFE 1,8V

VSUPFE 3,3V

185

164

169

VSUPVO 3,3V

170

SUPDIG 1.8V

192

A1

1V8 HD

3V3 HD

3124

IC5003

134

HDMI RECEIVER

122

22,23,35,74,79,92,94,105,

114,128,139

5,6,7,13,16,19,26,76,89,10

9

3V3 REG

3V3 XTAL

3V3 PVCC

3V3 AVCC

99

98

37,55

38,42,46,50,57,61,65,69

TUNER

B-BOARD

A-BOARD

SUPLVDS 1.8V

3V

SUPIO3 3

197

SUPFE 1.8V

5V

5V MIXED P1

5V MIXED P0

8V

14,9,8,7

8

8

8

33V

5V

DAC

IC1380

IC5002

EDID EPROM

IC5001

EDID EPROM

OP AMP

IC1381

SUPSIF 5V

TUNER 5V

8V

AUDIO 24V

AUDIO 24V

8

18,5

18,5

HDMI3.3V

HP AMP

IC270

IC252

AUDIO AMP

IC251

AUDIO AMP

5V

3V3 REG

8V

VSUPAU 8V

3V3 HD

STBY 3,3VSTBY 3,3VSTBY 3,3V

16

IC1220

8

IC1120

2

IC1500

8V 9V AUD SW

3

IC3300

3V3 XTAL

3V3 AVCC

3V3 PVCC

1V8 HD

SWITCH

EPROM

RESET

AUD MATRIX

11

HDMI_AUDIO_MUTE

V

V

HDMI_HP_MUTE

HDMI_SMUTE_INHIBIT

AUDIO _MUTE

AMP Mute

UDIO

12-16V

Q1721

ENABLE 7

IC251

C1BB00000998

8

7

ENABLE

IC252

C1BB00000998

NOT_STBY

SDA3,3V

SCL3,3V

POWER

SUPPLY

Q877

HP Mute

BACKLIGHT_PWM

PWM_OUT

HDMI_HP_MUTE

33V

Q872

Q1101

SCL_TUNER

12V

SDA_TUNER

Q1100

3,3

Q879

LEVEL

SHIFTER

27

SCL

SDA 28

IC3300

TEA6422DT

DAC

IC1380

C0FBBK000047

ANALOG

IC1220

74HC4053D

MULTIPLEXER

6 HDMI_MUTE

1 SCL3,3V

4 AV_LINK_IN

14 SDA3,3V

12 EEPROM_SDA

9 AV1_IS_QLINK

5 AV2_SCL

10,11 SERVICE

5 HDMI_SMUTE_INHIBIT

13 AV1_SDA

15 AV1_SCL

Q1380

Q1220

Q1228

Q1221

Q1219

AV1_IS_QLINK

SCL3,3V

AV_LINK_IN

AV_LINK_OUT

AV2_SCL

SERVICE

SDA3,3V

Q1223

Q1224

16 FBL1

10 AV2_SCL

HDMI_SMUTE_INHIBIT

HDMI_MUTE

8 AV2 SLOW

AV1_SCL

EEPROM_SDA

AV1_SDA

HDHS

STBY_LED

AUDIO_MUTE

BUS_REQUEST

AV_LINK_IN

AV_LINK_OUT

AV2_FBL

EDID_WP_DISABLE

SERVICE

AV1_FBL

BACKLIGHT_PWM

HDMI_HPD_P0

HDMI_HPD_P1

KEYSCAN

Q1213

200

HDHS 171

STBY_LED 208

1 IR

AUDIO_MUTE 205

2 HDMI_5V_DET

BUS_REQUEST 204

3 PANEL ON

CT69XYP

83 SCL3,3V

AV2_FBL 183

EDID_WP_DISABLE 199

VIDEO PROCESSOR

84 SDA3,3V

87 HDMI_CEC_OUT

88 HDMI_CEC_IN

AV_LINK_IN 201

AV_LIN K_OUT

IC1501

48 HDEN

47 HDVS

7 PROTECTION

49 HCLK

AV1_FBL 175

SERVICE 168

BACKLIGHT_PWM 167

89 NOT_STBY

91 INVERTER_OFF

92 HDMI_INT

90 INV_PSU_ON

HDMI_HPD_P1 166

115 HDMI_RST

KEYSCAN 162

HDMI_HPD_P0 165

116 HDMI_SMUTE_INHIBIT

159 AI_OFF

Q1700

Q1212

Q1205

Q952

Q1217

Q1701

IR

HDMI_5V_DET

LCD PANEL 5V

HDEN

HCLK

HDVS

PROTECTION

CONTROL BLOCK DIAGRAM

SCL3,3V

SDA3,3V

SCL_TUNER

SDA_TUNER

- BOARD

CEC_3,3V

SDA3,3V

SCL3,3V

NOT_STBY

INV_PSU_ON

HDMI_INT

INV_OFF

IR

STBY_LED

BATS_OFF

HDMI_RST

BATS_OFF

HDMI_SMUTE_INHIBIT

HCLK

HDMI_INT

AV1_SLOW

HDMI_RST

HDMI_SCDET

MUTE_OUT

HDMI_5V_DET_P1

HDMI_5V_DET_P0

5000

HDMI_5V_DET

MUTE_OUT

HDMI_MUTE

HDMI_SCDET

HDMI_AUDIO_MUTE

161

121

AV1_SLOW

HCLK

XTAL_IN 97

HDMI_RST 102

IC5003

SII9023CTU

HDMI RECEIVER

XTAL_OUT 96

HDMI_INT 104

HDMI_SCDET 103

33

MUTE_OUT 77

HDMI_5V_DET_P0 34

HDMI_5V_DET_P1

HDMI mute

STBY1,8V

5V

8V

33V

STBY3,3V

PROTECTION

3,3V_HDMI

160 AV2_SLOW

1 HDEN

3 HDVS

2 HDHS

27 SDA3,3V

Q5008

HDHS

HDVS

SDA3,3V

HDEN

AV2_SLOW

KEYSCAN

30 SCL3,3V_P1

31 SDA3,3V_P0

28 SCL3,3V

29 SDA3,3V_P1

Q5007

SCL3,3V

SDA3,3V_P1

32 SCL3,3V_P0

SCL_P0

SDA_P0

Q5000

PROTECTION

SDA_3,3V_P0

SCL3,3V_P1

SDA3,3V_P0

SCL3,3V_P0

NOT_STBY

INV_PSU_ON

SCL_3,3V_P0

+5V_HDMI_P0

HDMI_5V_DET_P0

EDID_WP_DISABLE

Q5001

EAROM

IC1120

Q5011

7

IC5001

EDID_WP_DISABLE

6 SCL_P0

5 SDA_P0

SCL_P0

SDA_P0

SCL_P1

HPDT_5V_P0

Q5002

HDMI_HPD_P0

SCL_3,3V_P1

INV_OFF

EEPROM_SDA 5

SCL 6

Q5012

7

EDID_WP_DISABLE

C3EBFC000037

5 SDA_P1

SDA_P1

SDA_P1

HPDT_5V_P1

+5V_HDMI_P1

Q5003

Q5004

SDA_3,3V_P1

HDMI_HPD_P1

HDMI_5V_DET_P1

PWM_OUT

IC5002

C3EBFC000037

6 SCL_P1

SCL_P1

CEC

Q5006

Q5005

CEC_3,3V

16 FBL1

12 AV1_SDA

10 AV1_SCL

8 AV1_SLOW

13 CEC

15 SCL_P1

17 SDA_P1

18 +5V_HDMI_P1

19 HPDT_P1

13 CEC

15 SCL_P0

17 SDA_P0

18 +5V_HDMI_P0

19 HPDT_P0

AV2 21 PIN SCART

AV1 21 PIN SCART

HDMI2

HDMI1

A1

B1

9

9

SDA_TUNER

33V

SCL_TUNER

8

8

SDA3,3V

5

6

7

5

5V

SCL3,3V

BUS_REQUEST BUS_REQUEST

A8

V2

4

4

BATS

Q1065

11

10

Q1063

TUNER

SN1063

B - BOARD

B2

2

7

6

- BOARD

SERVICE

1

1

STBY_LED

D1051

3

3

IR

ROUT

REMOTE

CONTROL

RM1050

A10

K2

KEY CONTROL

3

3

KEYSCAN

MATRIX

LOCAL KEYS SWITCHING

12

A7

P2

1

23

1

23

A4

3

5

Q851

Q854

PC802

B3PAA0000363

POWER SUPPLY

P - BOARD

POWER SUPPLY 24V

LCD PANEL

6

7

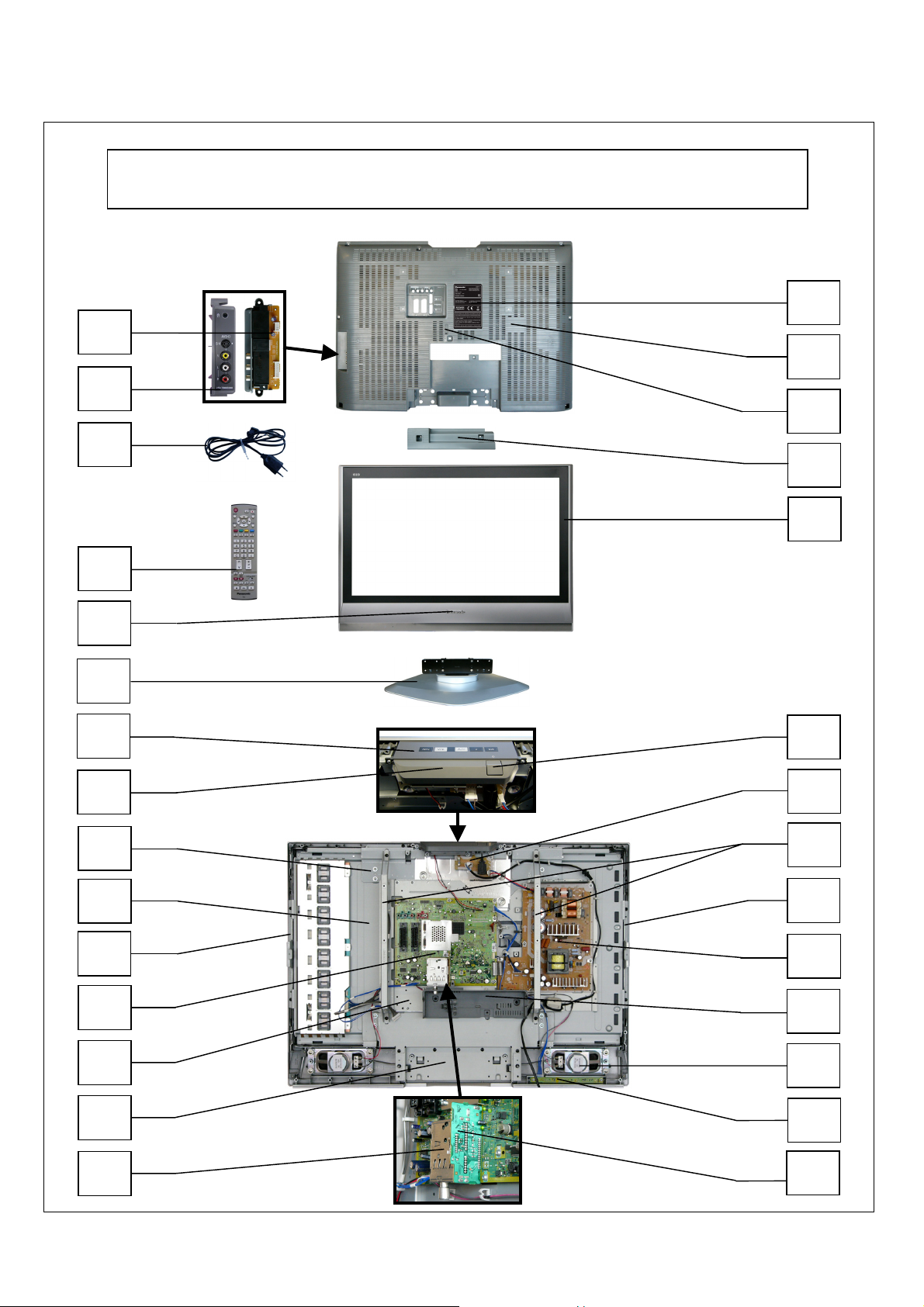

Parts Location

NOTE:

The numbers on the exploded view below refer to the exploded view section of the Replacement Parts List.

21

13

16

26

19

9

10

20

3

6

5

4

8

25

24

27

17

7

22

11

27

28

12

15

23

2

1

14

18

13

Components Identified by mark have special characteristics important for safety.

* When replacing any of these components, use only manufacturers specified parts.

In case of ordering these spare parts, please always add the complete Model-Type

number to your order.

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

COMMON PARTS

EXPLODED VIEW

SPEAKER 1 EAS12S11B

TUNER 2 ENG37A21GF

REMOTE CONTROL 3 EUR7651030A

KEY BUTTON MODULE 4 K0RB00500002

PEDESTAL ASSY 5 TBLA0194

PANASONIC BADGE 6 TBMA180

POWER BUTTON 7 TBX0E81700

POWER BUTTON PANEL 8 TKK0E9518

CONNECTOR COVER 9 TKKL5290

HINGE COVER 10 TKP0E15501

WALL MOUNT METAL 11 TKZ0E9901

TUNER COVER 12 TMW0E107

AV3 BRACKET 13 TMW0E502

V P.C.B. 14 TNP8EVL40AC

CHASSIS FRAME 15 TUA0E400

AC CORD ASSY 16 TXASX01AERE

MISCELLANEOUS COMPONENTS

FERRITE CORE . J0KF00000018

BATTERY . R6RC/2P

REAR AV LABEL . TBM0E0576

AV3 LABEL . TBM0E0606

LED/IR WINDOW . TKP0E15401

BOTTOM CUSHION . TPD0E0101

TOP CUSHION . TPD0E0102

SCREW . XTB3+12JFNK

SCREW . XTB4+12JFJ

SCREW . XTB4+15JFJK

SCREW . XTV3+8JFJK

SCREW . XTW3+8TFJ

SCREW . XTW4+Z15DFN

SCREW . XYN4+F10FJ

I.C.s

AUDIO AMPLIFIER IC251 C1BB00000998

AUDIO AMPLIFIER IC252 C1BB00000998

HEADPHONE AMPLIFIER IC270 NJM4556AD

MAIN PS CONTROL IC801 F9222L-F219

REGULATOR IC802 TL431BIDBZR

REGULATOR IC850 TL431BIDBZR

REGULATOR IC862 C0DBAMH00018

DC-DC CONVERTER IC866 TB7100F

1.8V REGULATOR IC881 XC6365D105MR

5V REGULATOR IC885 C0DBAJH00016

ANALOG MULTIPLEXERIC1220 74HC4053D

REPLACEMENT PARTS LIST

Important Safety Notice

D/A CONVERTER IC1380 C0FBBK000047

OP-AMPLIFIER IC1381 BA15218FDXE2

I.C. RESET IC1500 C0EBE0000120

VIDEO PROCESSOR IC1501 VCT6973B2A00

AUDIO MATRIX IC3300 TEA6422DT

REGULATOR IC3850 AN78L08-TA

1.8V REGULATOR IC5000 C0DBFFD00003

2KBIT EEPROM IC5001 C3EBDC000067

2KBIT EEPROM IC5002 C3EBDC000067

HDMI RECEIVER IC5003 C1AB00002535

PHOTO COUP LER PC802 B3PAA0000363

PHOTO COUP LER PC803 B3PAA0000363

LED RECEIVER RM1050 PNA4701M05TV

FUSES

FUSE F800 K5D502BNA005

FS LINK F850 K5G2523A0003

DIODES

DIODE D250 MA22D3900L

DIODE D254 MA22D3900L

DIODE D255 MAZ802400L

DIODE D270 MA22D3900L

DIODE D271 MA22D3900L

DIODE D272 MA22D3900L

DIODE D273 MA22D3900L

DIODE D274 MA22D3900L

DIODE D275 B0ACCK000005

DIODE D801 RS606M-CCR01

ZENER DIODE D802 B0BC022A0007

DIODE D803 UDZSTE-1711B

ZENER DIODE D804 UDZSTE-1720B

DIODE D805 1N4004-F

DIODE D806 1N4004-F

DIODE D807 B0HAKM000011

DIODE D808 B0HCMM000014

DIODE D809 MAZ82700ML

DIODE D810 MAZ82700ML

DIODE D811 CMS16TE12LQ

DIODE D812 B0HCMM000014

DIODE D813 B0BA5R600016

DIODE D814 B0ACCK000005

DIODE D816 B0AAMV000001

DIODE D817 B0AAMV000001

DIODE D818 B0ACCK000005

DIODE D819 BZX79B75A26A

DIODE D820 BZX79B75A26A

DIODE D824 B0ACCK000005

DIODE D825 B0ACCK000005

DIODE D827 MAZ22000B

DIODE D851 YG868C10RF91

DIODE D852 YG868C10RF91

DIODE D853 YG868C10RF91

14

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

DIODE D854 B0HCMM000014

DIODE D855 B0HCMM000014

DIODE D856 MAZ2160000LS

DIODE D857 B0BA01200046

DIODE D858 B0BA01600007

DIODE D859 B0BA01600007

DIODE D860 B0ACCK000005

DIODE D861 B0ACCK000005

DIODE D862 B0ACCK000005

DIODE D863 B0ACCK000005

DIODE D866 CMS16TE12LQ

DIODE D870 B0HCMM000014

DIODE D871 B0HCMM000014

DIODE D872 B0ACCK000005

ZENER DIODE D873 B0BC01600013

ZENER DIODE D874 B0BC01600013

DIODE D875 B0HCMM000014

DIODE D876 B0HCMM000014

DIODE D877 USF5G49TE16Q

DIODE D878 UDZSTE176.2B

DIODE D881 CMS16TE12LQ

DIODE D885 B0HCMM000014

DIODE D886 CMS16TE12LQ

DIODE D887 MA22D3900L

DIODE D889 MA22D3900L

DIODE D892 B0ACCK000005

LED D1051 SML72923CT15

DIODE D1061 B0ACCK000005

DIODE D1062 UDZSTE178.2B

DIODE D1101 CMS16TE12LQ

DIODE D1102 CMS16TE12LQ

DIODE D1201 MA2J72800L

VARISTOR D1220 EZJZ0V80008B

VARISTOR D1221 EZJZ0V80008B

VARISTOR D1222 EZJZ0V80008B

DIODE D1501 B0ACCK000005

DIODE D1502 B0ACCK000005

DIODE D1700 B0ACCK000005

DIODE D3817 SD83304TE12R

DIODE D3818 MAZ23300B

DIODE D3839 SD83304TE12R

DIODE D3850 B0ACCK000005

DIODE D3862 UDZSTE178.2B

DIODE D3863 UDZSTE178.2B

DIODE D3864 UDZSTE178.2B

DIODE D3865 B0ACCK000005

DIODE D3866 B0ACCK000005

DIODE D3867 B0ACCK000005

DIODE D3871 B0ACCK000005

DIODE D5000 CMS16TE12LQ

DIODE D5001 B0ACCK000005

DIODE D5003 CMS16TE12LQ

DIODE D5004 B0ACCK000005

VARISTOR D5008 EZJZ0V80008B

VARISTOR D5009 EZJZ0V80008B

VARISTOR D5010 EZJZ0V80008B

VARISTOR D5011 EZJZ0V80008B

VARISTOR D5012 EZJZ0V80008B

VARISTOR D5013 EZJZ0V80008B

VARISTOR D5016 EZJZ0V80008B

VARISTOR D5017 EZJZ0V80008B

VARISTOR D5018 EZJZ0V80008B

VARISTOR D5019 EZJZ0V80008B

VARISTOR D5020 EZJZ0V80008B

VARISTOR D5021 EZJZ0V80008B

VARISTOR D5022 EZJZ0V80008B

TRANSISTORS

VARISTOR D5023 EZJZ0V80008B

VARISTOR D5024 EZJZ0V80008B

VARISTOR D5025 EZJZ0V80008B

VARISTOR D5026 EZJZ0V80008B

VARISTOR D5027 EZJZ0V80008B

VARISTOR D5028 EZJZ0V80008B

VARISTOR D5029 EZJZ0V80008B

VARISTOR D5030 EZJZ0V80008B

VARISTOR D5031 EZJZ0V80008B

DIODE D5032 B0ACCK000005

DIODE D5033 B0ACCK000005

DIODE D5034 B0ACCK000005

DIODE D5035 B0ACCK000005

DIODE D5036 B0ACCK000005

DIODE D5037 B0ACCK000005

DIODE D5038 B0ACCK000005

DIODE R301 1N4148WS

PHOTO COUP LER SN1063 B3L000000020

TRANSISTOR Q121 BC847B

TRANSISTOR Q122 BC847B

TRANSISTOR Q123 BC847B

TRANSISTOR Q250 BC847B

TRANSISTOR Q251 BC857B

TRANSISTOR Q254 BC847B

TRANSISTOR Q270 BC857B

TRANSISTOR Q271 BC857B

TRANSISTOR Q272 BC857B

TRANSISTOR Q273 BC847B

TRANSISTOR Q274 BC847B

TRANSISTOR Q275 BC847B

TRANSISTOR Q276 BC847B

TRANSISTOR Q277 BC847B

TRANSISTOR Q801 BC847B

TRANSISTOR Q802 2SK2009TE81L

TRANSISTOR Q803 2SK2231Q

TRANSISTOR Q804 BC847B

TRANSISTOR Q805 2SK3767L103Q

TRANSISTOR Q806 BC847B

TRANSISTOR Q807 2SB0710ARL

TRANSISTOR Q808 BC857B

TRANSISTOR Q822 XN0140100L

TRANSISTOR Q851 UNR221500L

TRANSISTOR Q852 B1ABPF000010

TRANSISTOR Q853 BC857B

TRANSISTOR Q854 BC847B

TRANSISTOR Q855 BC847B

TRANSISTOR Q865 2SD10300SL

TRANSISTOR Q872 UNR221500L

TRANSISTOR Q873 B1DHED000013

TRANSISTOR Q875 B1ABPF000010

TRANSISTOR Q876 BC847B

TRANSISTOR Q877 UNR221500L

TRANSISTOR Q878 B1DHDC000028

TRANSISTOR Q879 UNR221500L

TRANSISTOR Q881 XP162A12A6PR

TRANSISTOR Q882 2SD10300SL

TRANSISTOR Q952 UNR221500L

TRANSISTOR Q1063 BC847B

TRANSISTOR Q1064 BC857B

TRANSISTOR Q1065 BC857B

TRANSISTOR Q1100 2N7002

TRANSISTOR Q1101 2N7002

TRANSISTOR Q1207 2SC584500L

TRANSISTOR Q1208 2SC584500L

TRANSISTOR Q1209 2SC584500L

15

COILS

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

TRANSISTOR Q1212 BC847B

TRANSISTOR Q1213 BC847B

TRANSISTOR Q1215 BC847B

TRANSISTOR Q1217 UNR221500L

TRANSISTOR Q1219 NDC7002N-NL

TRANSISTOR Q1222 B1MBACA00008

TRANSISTOR Q1223 B1MBACA00008

TRANSISTOR Q1229 BC847B

TRANSISTOR Q1230 BC847B

TRANSISTOR Q1231 BC847B

TRANSISTOR Q1232 BC847B

TRANSISTOR Q1380 BC847B

TRANSISTOR Q1700 UNR221500L

TRANSISTOR Q1701 B1DHED000013

TRANSISTOR Q1721 2N7002

TRANSISTOR Q3201 BC857B

TRANSISTOR Q3202 BC857B

TRANSISTOR Q3204 BC847B

TRANSISTOR Q3205 BC847B

TRANSISTOR Q3860 BC847B

TRANSISTOR Q3861 BC857B

TRANSISTOR Q3862 BC847B

TRANSISTOR Q5000 B1MBACA00008

TRANSISTOR Q5001 2SK2009TE81L

TRANSISTOR Q5002 2N7002

TRANSISTOR Q5003 B1MBACA00008

TRANSISTOR Q5004 2SK2009TE81L

TRANSISTOR Q5005 2N7002

TRANSISTOR Q5007 2N7002

TRANSISTOR Q5008 2N7002

TRANSISTOR Q5009 2SC584500L

TRANSISTOR Q5010 2SC584500L

TRANSISTOR Q5011 2SC584500L

TRANSISTOR Q5012 2SC584500L

COILL100 EXCELSA35T

COIL L101 ELJFC2R2KFB

COIL L102 ELJFC2R2KFB

COIL TALV35VB100KL103 G0C100K00008

COIL TALV35VB6R8JL121 G0C6R8JA0021

COIL TALV35VB100KL122 G0C100K00008

COIL L201 G1C470MA0188

COIL L202 G1C470MA0188

PFC COIL L801 G0A553G00001

COIL L803 EXCELSA35V

COILL804 EXCELDR35V

COILL805 EXCELDR35V

COILL806 EXCELDR35V

COILL807 EXCELDR35V

COIL L865 ELLATV470M

COIL L867 ELL6SH4R7ME

COIL L881 ELL6SH100ME

COIL L885 ELLATV6R8N

COIL L886 J0JJC0000015

COIL L887 J0JJC0000015

COIL L1100 ELJFC2R2KFB

COIL L1101 ELJFC2R2KFB

COIL BLM18PG121SN1DL1380 J0JHC0000045

COIL L1381 ELJPA1R0MFB

COIL TALV35VB100KL1500 G0C100K00008

COIL TALL08T100KAL1501 G0A100GA0013

COIL TALV35VB100KL1502 G0C100K00008

COIL TALV35VB100KL1503 G0C100K00008

COIL TALV35VB100KL1504 G0C100K00008

COIL TALV35VB100KL1505 G0C100K00008

COIL TALV35VB100KL1506 G0C100K00008

FILTERS

CRYSTALS

RESISTORS

COIL TALV35VB100KL1507 G0C100K00008

COIL TALV35VB100KL1509 G0C100K00008

COIL TALV35VB100KL1514 G0C100K00008

COIL TALV35VB100KL1515 G0C100K00008

COIL L1518 J0JHC0000078

COIL L1519 J0JHC0000078

COIL L1520 J0JHC0000078

COIL L2352 G0C331JA0064

COIL L3021 ELJFCR68KFB

COIL L3022 ELJFCR68KFB

COIL L3023 ELJFCR68KFB

COIL L3024 ELJFCR68KFB

COIL L3025 ELJFCR68KFB

COIL L3026 ELJFCR68KFB

COIL L3600 ELJFA6R8KFB

COIL L3601 ELJFA6R8KFB

COIL BLM18PG121SN1DL5000 J0JHC0000045

COIL BLM18PG121SN1DL5001 J0JHC0000045

COIL BLM18PG121SN1DL5002 J0JHC0000045

COIL L5003 J0JHC0000034

COIL L5004 J0JHC0000034

COIL L5005 J0JHC0000034

COIL L5006 J0JHC0000034

COIL BLM18PG121SN1DL5007 J0JHC0000045

COIL BLM18PG121SN1DL5008 J0JHC0000045

COIL BLM18PG121SN1DL5010 J0JHC0000045

COIL BLM18PG121SN1DL5012 J0JHC0000045

COIL L5013 J0JCC0000166

LINE FILTER LF802 G0B103H00002

LINE FILTER LF803 G0B103H00002

CERAMIC FILTER X120 EFCT7004BN

FILTER X121 EFCT6504BN

CRYSTAL X1500 AI202504E

CRYSTAL X5000 H0J283500018

SMDR101 ERJ6GEYJ101Z . 125W 5% 100 Ω

SMDR104 ERJ6GEYJ101Z . 125W 5% 100 Ω

SMDR105 ERJ6GEYJ101Z . 125W 5% 100 Ω

SMDR106 ERJ6GEYJ101Z . 125W 5% 100 Ω

S.M.CARBR121 ERJ3GEY0R00V 0.1W - 0 Ω

S.M.CARBR123 ERJ3GEY0R00V 0.1W - 0 Ω

S.M.CARBR124 ERJ6GEYJ223V 0.1W 5% 22K Ω

S.M.CARBR125 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR126 ERJ3GEYJ272V 0.1W 5% 2K7 Ω

S.M.CARBR128 ERJ3GEYJ222V 0.1W 5% 2K2 Ω

S.M.CARBR129 ERJ3GEY0R00V 0.1W - 0 Ω

S.M.CARBR130 ERJ3GEYJ332V 0.1W 5% 3K3 Ω

SMDR131 ERJ3GEYJ681V 0.1W 5% 680 Ω

S.M.CARBR132 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR133 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR134 ERJ6GEYJ680V 0.1W 5% 68 Ω

S.M.CARBR135 ERJ3GEYJ471V 0.1W 5% 470 Ω

S.M.CARBR200 ERJ6GEY0R00Z - - 0 Ω

S.M.CARBR201 ERJ3GEYJ222V 0.1W 5% 2K2 Ω

S.M.CARBR202 ERJ3GEYJ473V 0.1W 5% 47K Ω

SMDR203 ERJ3GEYJ105V 1W 5% 1MΩ

S.M.CARBR204 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR205 ERJ3GEYJ392V 0.1W 5% 3K9 Ω

S.M.CARBR206 ERJ6GEY0R00Z - - 0 Ω

S.M.CARBR207 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR208 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR209 ERJ3GEYJ222V 0.1W 5% 2K2 Ω

S.M.CARBR210 ERJ6GEYJ100V 0.1W 5% 10 Ω

16

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

SMDR211 ERJ8GEYJ153V 0.25W 5% 15K Ω

S.M.CARBR213 ERJ6GEYJ223V 0.1W 5% 22K Ω

S.M.CARBR214 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR215 ERJ3GEYJ222V 0.1W 5% 2K2 Ω

S.M.CARBR216 ERJ3GEYJ473V 0.1W 5% 47K Ω

SMDR217 ERJ3GEYJ105V 1W 5% 1MΩ

S.M.CARBR218 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR219 ERJ3GEYJ392V 0.1W 5% 3K9 Ω

S.M.CARBR220 ERJ6GEY0R00Z - - 0 Ω

S.M.CARBR221 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR222 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR223 ERJ3GEYJ222V 0.1W 5% 2K2 Ω

S.M.CARBR224 ERJ6GEYJ100V 0.1W 5% 10 Ω

SMDR225 ERJ8GEYJ153V 0.25W 5% 15K Ω

S.M.CARBR228 ERJ6GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR229 ERJ6GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR241 ERJ6GEY0R00Z - - 0 Ω

S.M.CARBR242 ERJ6GEY0R00Z - - 0 Ω

S.M.CARBR243 ERJ6GEY0R00Z - - 0 Ω

S.M.CARBR244 ERJ6GEY0R00Z - - 0 Ω

S.M.CARBR250 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR251 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR253 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR254 ERJ3GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR256 ERJ3GEY0R00V 0.1W - 0 Ω

S.M.CARBR259 ERJ3GEYJ562V 0.1W 5% 5K6 Ω

S.M.CARBR261 ERJ3GEY0R00V 0.1W - 0 Ω

S.M.CARBR264 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR265 ERJ3GEYJ471V 0.1W 5% 470 Ω

S.M.CARBR266 ERJ3GEYJ471V 0.1W 5% 470 Ω

S.M.CARBR267 ERJ3GEYJ104V 0.1W 5% 100K Ω

S.M.CARBR268 ERJ3GEYJ104V 0.1W 5% 100K Ω

S.M.CARBR272 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR273 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR274 ERJ3GEYJ562V 0.1W 5% 5K6 Ω

S.M.CARBR275 ERJ6GEYJ681V 0.1W 5% 680 Ω

S.M.CARBR276 ERJ6GEYJ681V 0.1W 5% 680 Ω

S.M.CARBR277 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR278 ERJ3GEYJ332V 0.1W 5% 3K3 Ω

S.M.CARBR279 ERJ3GEYJ332V 0.1W 5% 3K3 Ω

S.M.CARBR280 ERJ3GEYJ104V 0.1W 5% 100K Ω

S.M.CARBR281 ERJ3GEYJ104V 0.1W 5% 100K Ω

SMDR282 ERJ6RBD103V 0.1W 0.5 10K Ω

SMDR283 ERJ6RBD103V 0.1W 0.5 10K Ω

S.M.CARBR284 ERJ6GEYJ473V 0.1W 5% 47K Ω

SMDR285 ERJ6RBD103V 0.1W 0.5 10K Ω

S.M.CARBR286 ERJ6GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR287 ERJ6GEYJ473V 0.1W 5% 47K Ω

SMDR288 ERJ6RBD103V 0.1W 0.5 10K Ω

S.M.CARBR289 ERJ6GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR290 ERJ6GEYJ472V 0.1W 5% 4K7 Ω

S.M.CARBR291 ERJ3GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR292 ERJ3GEYJ102V 0.1W 5% 1K Ω

S.M.CARBR295 ERJ3GEYJ222V 0.1W 5% 2K2 Ω

S.M.CARBR299 ERJ3GEYJ104V 0.1W 5% 100K Ω

S.M.CARBR809 ERJ6GEY0R00Z - - 0 Ω

SOLIDR810 ERC12ZGK105C 0.5W 10% 1MΩ

S.M.CARBR811 ERJ6GEYJ102V 0.1W 5% 1K Ω

CARBONR812 ERDS1FJ824T 0.5W 5% 820K Ω

SMDR813 ERJ6RED244V 0.1W 0.5 240K Ω

SMDR814 ERJ6RBD473V 0.1W 0.5 47K Ω

SMDR815 ERJ6GEYJ133V .125W 5% 13K Ω

CARBONR816 ERDS1FJ824T 0.5W 5% 820K Ω

CARBONR817 ERDS2TJ824T 0.25W 5% 820K Ω

CARBONR818 ERDS2TJ824T 0.25W 5% 820K Ω

CARBONR819 ERDS2TJ824T 0.25W 5% 820K Ω

METALR820 ERG3FJ683H 3W 5% 68K Ω

S.M.CARBR823 ERJ6GEYJ104V 0.1W 5% 100K Ω

S.M.CARBR824 ERJ6GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR825 ERJ6GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR826 ERJ6GEYJ154V 0.1W 5% 150K Ω

S.M.CARBR828 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR829 ERJ6GEYJ223V 0.1W 5% 22K Ω

METALR830 ERX1SJ2R2P 1W 5% 2R2 Ω

CARBONR831 ERDS1TJ105T 0.5W 5% 1M Ω

METALR832 ERG1SJ330P 1W 5% 33 Ω

METALR833 ERG1SJ271P 1W 5% 270 Ω

SMDR834 ERJ8GEYJ332V 0.25W 5% 3K3 Ω

S.M.CARBR835 ERJ6GEYJ333V 0.1W 5% 33K Ω

S.M.CARBR836 ERJ6GEYJ223V 0.1W 5% 22K Ω

S.M.CARBR837 ERJ6GEYJ221V 0.1W 5% 220 Ω

S.M.CARBR838 ERJ6GEYJ104V 0.1W 5% 100K Ω

LEADEDR839 D0XB106J0003 1W 5% 10M Ω

S.M.CARBR840 ERJ6GEYJ104V 0.1W 5% 100K Ω

S.M.CARBR841 ERJ6GEYJ272V 0.1W 5% 2K7 Ω

S.M.CARBR842 ERJ6GEYJ472V 0.1W 5% 4K7 Ω

S.M.CARBR843 ERJ6GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR844 ERJ6GEYJ154V 0.1W 5% 150K Ω

S.M.CARBR845 ERJ6GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR846 ERJ6GEYJ561V 0.1W 5% 560 Ω

S.M.CARBR847 ERJ6GEYJ473V 0.1W 5% 47K Ω

SMDR852 ERJ6GEYJ102Z 0.125 5% 1KΩ

S.M.CARBR853 ERJ6GEYJ222V 0.1W 5% 2K2 Ω

S.M.CARBR854 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR855 ERJ6GEYJ103V 0.1W 5% 10K Ω

S.M.CARBR856 ERJ6GEYJ103V 0.1W 5% 10K Ω

SMDR857 ERJ6RBD303V 0.1W 0.5 30K Ω

SMDR858 ERJ6RBD822V 0.1W 0.5 8K2 Ω

SMDR859 ERJ6RBD432V 0.1W 0.5 4K3 Ω

SMDR860 ERJ6GEYJ102Z 0.125 5% 1KΩ

S.M.CARBR861 ERJ6GEYJ104V 0.1W 5% 100K Ω

S.M.CARBR862 ERJ6GEYJ223V 0.1W 5% 22K Ω

S.M.CARBR864 ERJ3GEYJ472V 0.1W 5% 4K7 Ω

SMDR866 ERJ6ENF1203V .125W 1% 120K Ω

SMDR867 ERJ6RBD103V 0.1W 0.5 10K Ω

SMDR868 ERJ6ENF2202V . 125W 1% 22K Ω

S.M.CARBR869 ERJ6GEYJ274V 0.1W 5% 270K Ω

SMDR870 ERJ6ENF2372V . 125W 1% 23K7 Ω

S.M.CARBR872 ERJ6GEYJ472V 0.1W 5% 4K7 Ω

S.M.CARBR873 ERJ3GEYJ272V 0.1W 5% 2K7 Ω

S.M.CARBR874 ERJ6GEYJ473V 0.1W 5% 47K Ω

S.M.CARBR875 ERJ6GEYJ104V 0.1W 5% 100K Ω

S.M.CARBR876 ERJ6GEYJ153V 0.1W 5% 15K Ω

S.M.CARBR877 ERJ6GEYJ220V 0.1W 5% 22 Ω

S.M.CARBR878 ERJ6GEYJ331V 0.1W 5% 330 Ω

S.M.CARBR881 ERJ6GEYJ334V 0.1W 5% 330K Ω

SMDR882 ERJ6RED244V 0.1W 0.5 240K Ω

SMDR883 ERJ6RED274V 0.1W 0.5 270K Ω

S.M.CARBR884 ERJ3GEYJ101V 0.1W 5% 100 Ω

S.M.CARBR885 ERJ6GEYJ105V 0.1W 5% 1M Ω

S.M.CARBR886 ERJ6GEYJ104V 0.1W 5% 100K Ω

SMDR888 ERJ6ENF5102V .125W 1% 51KΩ

SMDR889 ERJ6GEYJ430V .125W 5% 43 Ω

SMDR890 ERJ12RSJR10U 0.5W 5% R1 Ω

SMDR891 ERJ12RSJR10U 0.5W 5% R1 Ω

S.M.CARBR892 ERJ6GEYJ103V 0.1W 5% 10K Ω

SMDR893 ERJ6ENF5600V .125W 1% 560 Ω

SMDR894 ERJ6ENF1801V .125W 1% 1K8 Ω

SMDR895 ERJ6ENF2201V .125W 1% 2K2 Ω

SMDR896 ERJ6ENF6202V .125W 1% 62K Ω

S.M.CARBR897 ERJ6GEYJ242V 0.1W 5% 2K4 Ω

SMDR898 ERJ6ENF7502V .125W 1% 75K Ω

17

Loading...

Loading...