Page 1

Specifications

A

A

A

A

V

V

V

ORDER NO.PCZ0510096C2

Digital High Definition Plasma Television

TH-65PV500E

TH-65PV500B

GPH8DE Chassis

Power Source

Power Consumption

Plasma Display panel

Drive method

Aspect Ratio 16:9

Contrast Ratio 3000:1

Visible screen size 165 cmV

(No. of pixels) 1,434 mm (W) × 806 mm (H) × 1,645 mm (diagonal)

Sound

Audio Output 30 W (15 W + 15 W ), 10% THD

Headphones M3 (3.5 mm) Jack × 1

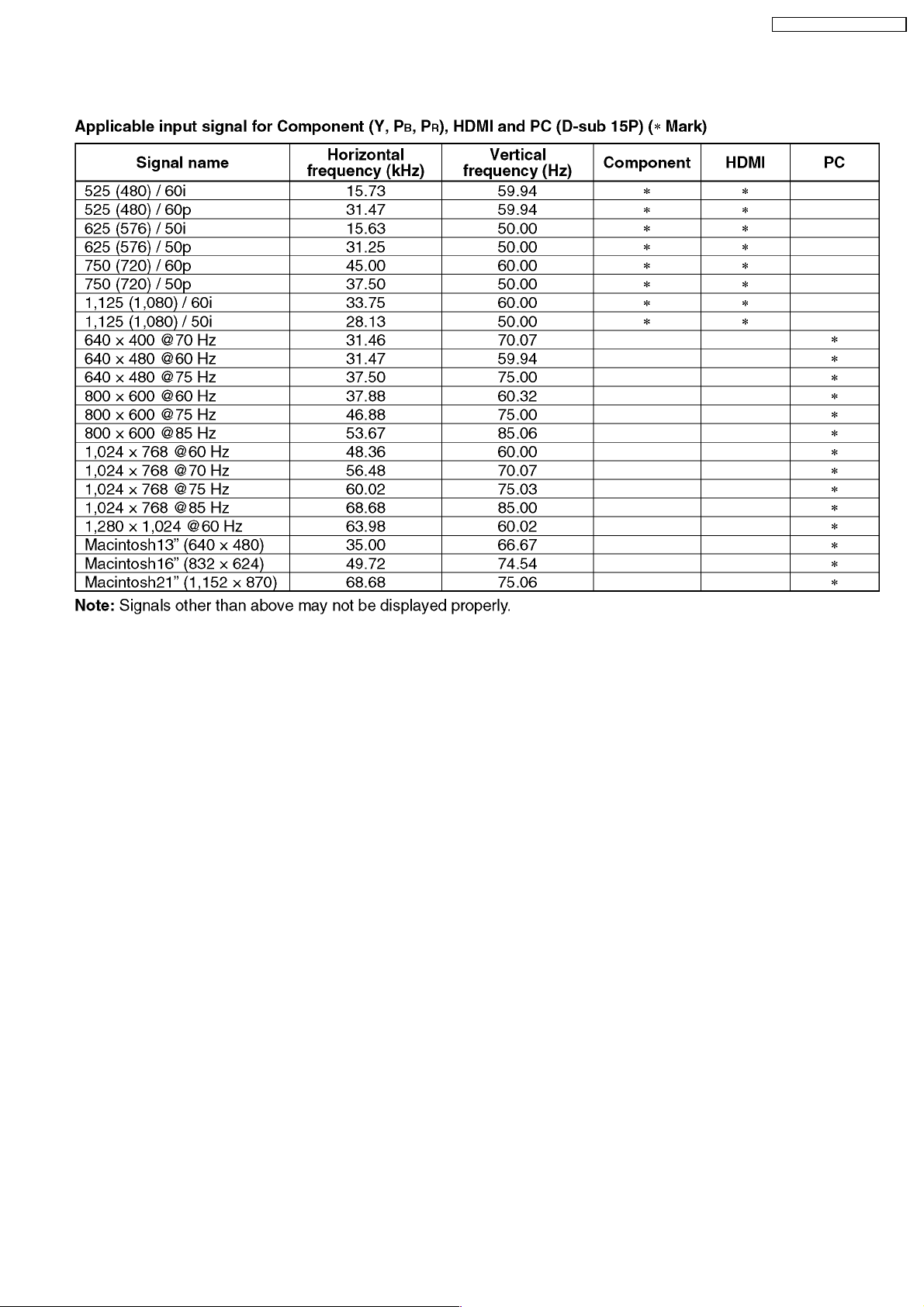

Applicable signals

Colour System NTSC, PAL, PAL60, SECAM, Modified NTSC

Scanning format 480i(60Hz), 480p(60Hz), 576i(50Hz), 576p(50Hz), 720p(50Hz), 720p(60Hz), 1080i(50Hz), 1080i(60Hz)

PC signals

Receiving Systems /

Band name (PV500E)

C 220-240 V, 50 / 60 Hz

verage use : 640 W (TH-65PV500E)

verage use : 649 W (TH-65PV500B)

Standby condition : 0.3 W (TH-65PV500E)

Standby condition : 0.3 W (Without DVB recording) (TH-65PV500B)

Standby condition : 16 W (With DVB recording) (TH-65PV500B)

Ctype

1,049,088 (1,366 (W) × 768 (H)) [4,098 × 768 dots]

GA, SVGA, XGA

SXGA (compressed)

Horizontal scanning frequency 31 - 69 kHz

ertical scanning frequency 59 - 86 Hz

PALB,G,H,I,SECAMB,GSECAML/L’

VHF E2 - E12

VHF A - H (ITALY) UHF E21 - E69

CATV (S01 - S05) CATV S1 - S10 (M1 - M10)

CATV S11 - S20 (U1 - U10) CATV S21 - S41 (Hyperband)

PAL D, K, SECAM D, K

HF H1 - H2 (ITALY)

© 2005 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

V

TH-65PV500E / TH-65PV500B

VHF R1 - R2

HF R3 - R5

VHF R6 - R12 UHF E21 - E69

PAL 525/60

Playback of NTSC tape from some PAL Video recorders (VCR)

M.NTSC

Playback from M. NTSC Video recorders (VCR)

NTSC (AV input only)

Playback from NTSC Video recorders (VCR)

Receiving Systems /

Band name (PV500B)

PAL I

UHF E21 - 68.

PAL 525/60

Playback of NTSC tape from some PAL Video recorders (VCR) or NTSC disc playback from DVD

player and recorder.

DVB

Digital terrestrial services via UHF aerial input.

M.NTSC

Playback from M.NTSC Video recorders (VCR).

NTSC (AV input only)

Playback from NTSC Video recorders (VCR).

Aerial - Rear UHF / VHF (PV500E)

UHF (PV500B)

Operating Conditions Temperature : 0 °C - 40 °C

Humidity : 20 % - 80 % RH (non-condensing)

Connection Terminals

AV1 (Scart connecter) 21 Pin terminal (Audio / Video in, Audio / Video out, RGB in)

AV2 (Scart connecter) 21 Pin terminal (Audio / Video in, Audio / Video out, S-Video in, Q-Link)

AV3 VIDEO RCA PIN Type × 1 1.0 Vp-p (75 W)

S-VIDEO Mini DIN 4-pin Y:1.0 Vp-p (75 W) C:0.286 Vp-p (75 W )

AUDIO L - R RCA PIN Type × 2 0.5 Vrms

AV4 (Scart connecter) 21 Pin terminal (Audio / Video in, Audio / Video out, RGB in, S-Video in, Q-Link)

Others COMPONENT Y

P

B,PR

1.0 Vp-p (including synchronization)

±0.35 Vp-p

HDMI TYPE A Connector

PC HIGH-DENSITY D-SUB 15PIN R,G,B / 0.7 Vp-p (75 W)

HD, VD / TTL Level 2.0 - 5.0 Vp-p (high impedance)

AUDIO L - R RCA PIN Type × 2 0.5 Vrms

Card slot SD CARD slot × 1, PC CARD slot × 1

Output AUDIO L - R RCA PIN Type × 2 0.5 Vrms (high impedance)

Dimensions ( W × H × D )

Without pedestal stand

1,554 mm × 985 mm × 145 mm

and speakers

With pedestal stand and

1,754 mm × 1,058 mm × 419 mm

speakers

Weight

Without pedestal stand

84.0 kg Net

and speakers

With pedestal stand and

114.9 kg Net

speakers

Notes:

· Design and Specifi cations are subject to change without notice. Weight and Dimensions shown are approximate.

· This equipment complies with the EMC standards listed below.

EN55013, EN61000-3-2, EN61000-3-3, EN55020, EN55022, EN 55024.

2

Page 3

TH-65PV500E / TH-65PV500B

CONTENTS

Page Page

1 Applicable signals 5

2 Safety Precautions

2.1. General Guidelines

2.2. Touch-Current Check

3 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

4 About lead free solder (PbF)

5 Service Hint

6 Plasma panel replacement method

6.1. Remove the Back cover

6.2. Remove the P-Board

6.3. Remove the PB-Board

6.4. Remove the D-Board

6.5. Remove the rear terminal cover

6.6. Remove the metal frame

6.7. Remove the XV-Board (PV500 only) and DV-Board

6.8. Remove the DG-Board

6.9. Remove the H-Board and TA-Board

6.10. Remove the PA-Board

6.11. Remove the Z-Board

6.12. Remove the Fan (Middle/R)

6.13. Remove the Fan (Big and Middle/L)

6.14. Remove the Fan (SC)

6.15. Remove the Fan (SS)

6.16. Remove the SU-Board

6.17. Remove the SD-Board

6.18. Remove the SC-Board

6.19. Remove the SS2-Board

6.20. Remove the SS3-Board

6.21. Remove the SS-Board

6.22. Remove the C1-Board

6.23. Remove the C2-Board

6.24. Remove the C3-Board

6.25. Remove the H3-Board (L, R)

6.26. Remove the C4-Board

6.27. Remove the C4-Board

6.28. Remove the C6-Board

6.29. Remove the front bracket

6.30. Remove the G-Board

6.31. Remove the GK-Board

6.32. Remove the GS-Board and SD-Module

6.33. Remove the K-Board and the S-Board

6.34. Remove the Plasma panel section from the Front frame

(glass)

6.35. Remove the Reinforcement Angles (L, R) and the

Connection Plate (A, B, C, D)

10

10

10

11

11

12

12

12

12

13

13

13

13

14

14

14

14

15

16

16

16

16

17

17

17

17

18

18

18

19

19

19

19

20

21

21

6

6

6

7

8

9

6.36. Replace the plasma panel (finished)

7 Location of Lead Wiring

7.1. Lead of Wiring (1)

7.2. Lead of Wiring (2)

7.3. Lead of Wiring (3)

8 Self Check

8.1. Power LED Blinking timing chart

8.2. No Power

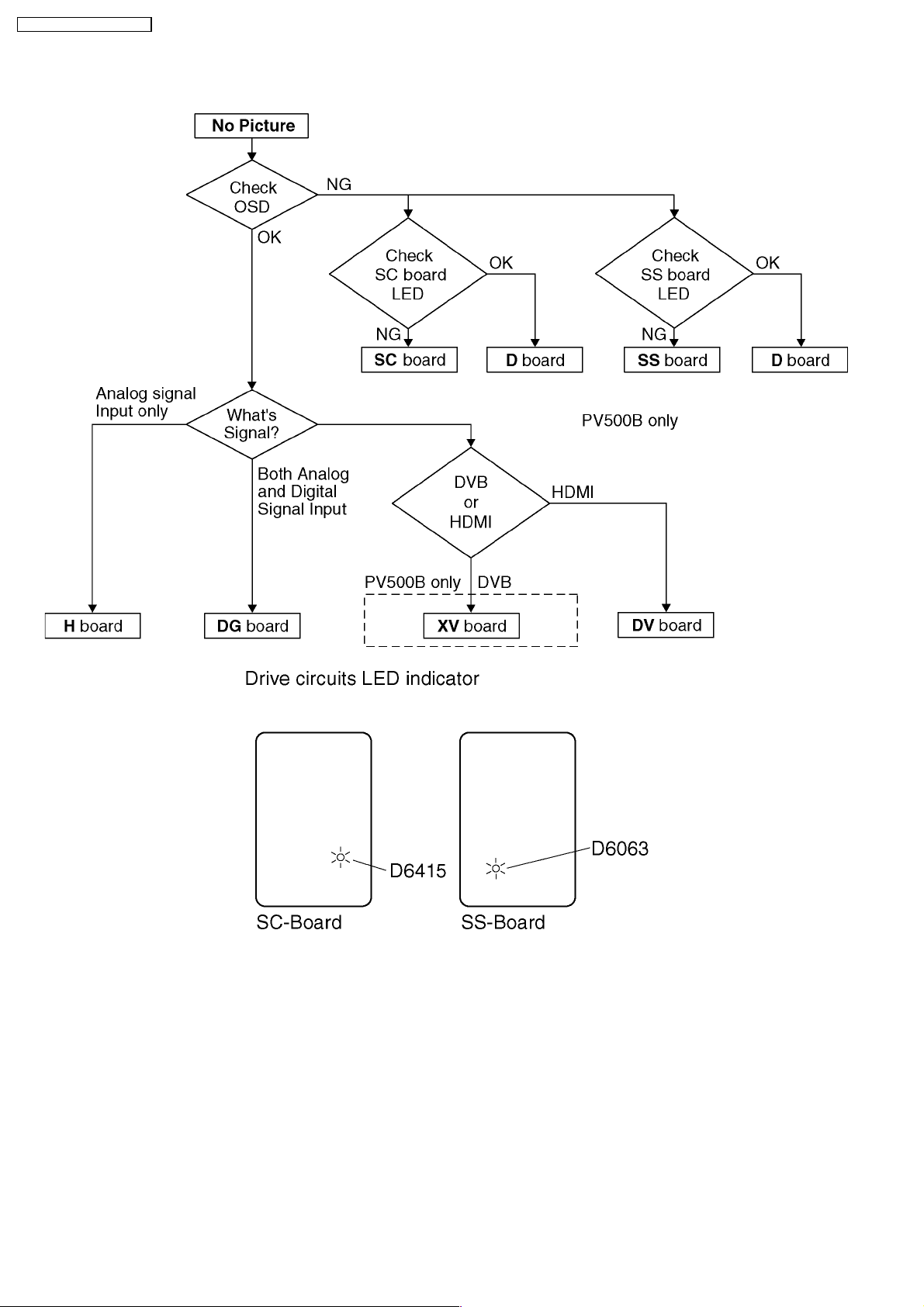

8.3. No Picture

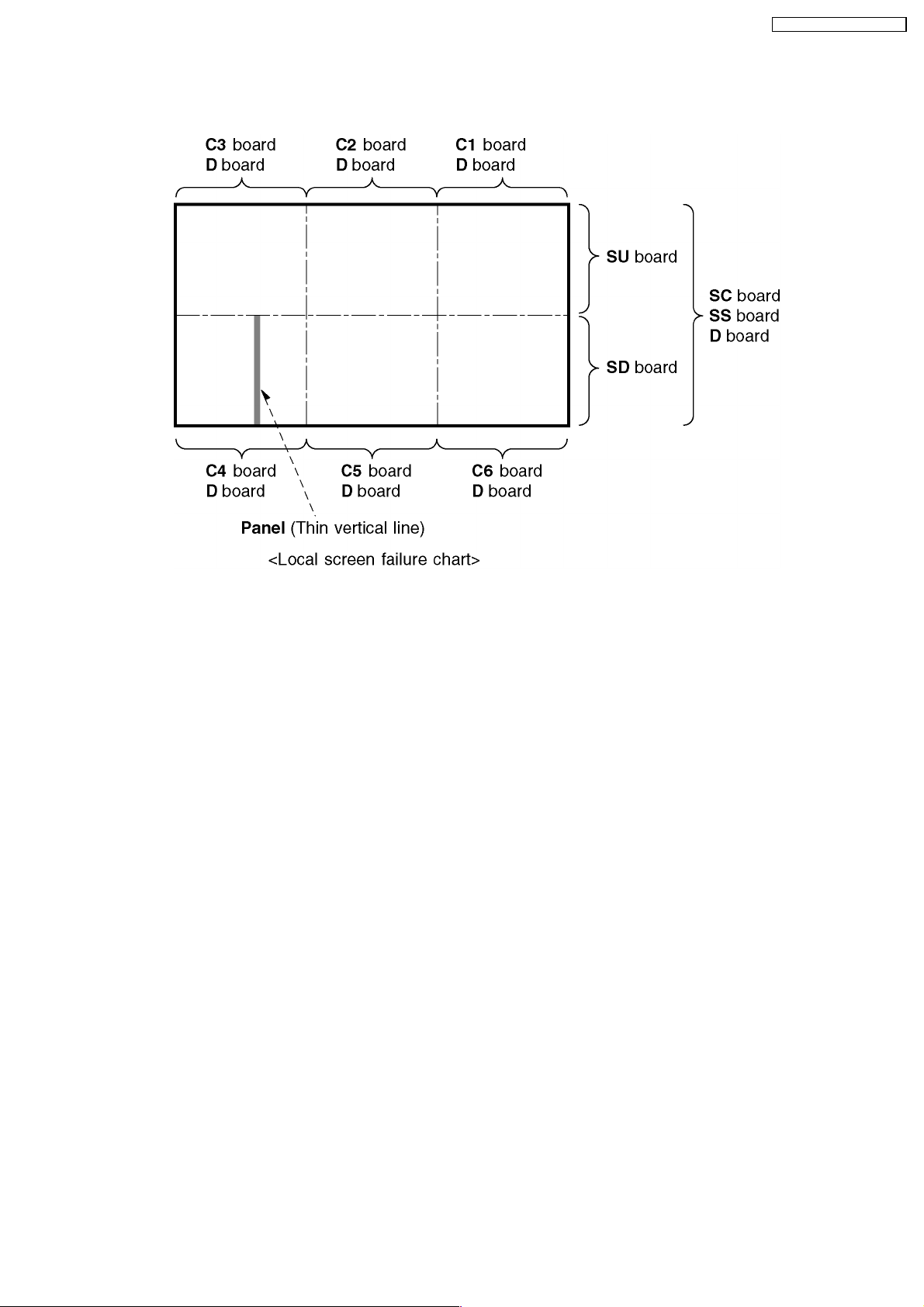

8.4. Local screen failure

9 Service Mode Function

9.1. How to enter SERVICE 1

9.2. How to enter SERVICE 2

9.3. Option Description

10 Adjustment Procedure

10.1. Driver Set-up

10.2. Initialization Pulse Adjust

10.3. P.C.B. (Printed Circuit Board) exchange

10.4. Adjustment Volume Location

10.5. Test Point Location

11 Adjustment

11.1. PAL panel white balance adjustment

11.2. 1080i white balance adjustment

11.3. Sub bright adjustment

11.4. ABL adjustment

11.5. TEXT Vref Auto Adjustment

12 Hotel mode

13 Conductor Views

13.1. P-Board

13.2. PA-Board

13.3. PB-Board

13.4. H-Board

13.5. TA-Board

13.6. G-Board

13.7. H3, GK, GS and K-Board

13.8. DG-Board

13.9. DV-Board

13.10. XV-Board (PV500B)

13.11. Z-Board

13.12. D-Board

13.13. C1-Board

13.14. C2-Board

13.15. C3-Board

13.16. C4-Board

13.17. C5-Board

13.18. C6-Board

21

22

22

23

24

25

26

27

28

29

30

30

30

32

34

34

35

36

36

36

37

37

38

39

39

40

41

43

43

47

48

49

51

52

53

54

56

57

59

60

63

64

65

66

67

68

3

Page 4

TH-65PV500E / TH-65PV500B

13.19. SC-Board 69

13.20. SU-Board

13.21. SD-Board

13.22. SS-Board

13.23. S, SS2 and SS3-Board

14 Block and Sche matic Diagram

14.1. Schematic Diagram Notes

14.2. Main Block Diagram

14.3. P-Board (1 of 2) Block Diagram

14.4. P-Board (2 of 2) Block Diagram

14.5. P-Board (1 of 3) Schematic Diagram

14.6. P-Board (2 of 3) Schematic Diagram

14.7. P-Board (3 of 3) Schematic Diagram

14.8. PA-Board Block Diagram

14.9. PA-Board Schematic Diagram

14.10. PB-Board Block and Schematic Diagram

14.11. H and TA-Board Block Diagram

14.12. G, GK, GS, and K-Board Block Diagram

14.13. H-Board (1 of 2) Schematic Diagram

14.14. H-Board (2 of 2) Schematic Diagram

14.15. G-Board Schematic Diagram

14.16. GK, K and TA-Board Schematic Diagram

14.17. GS-Board Schematic Diagram

14.18. DG-Board (1 of 2) Block Diagram

14.19. DG-Board (2 of 2) Block Diagram

14.20. DG-Board (1 of 13) Schematic Diagram

14.21. DG-Board (2 of 13) Schematic Diagram

14.22. DG-Board (3 of 13) Schematic Diagram

14.23. DG-Board (4 of 13) Schematic Diagram

14.24. DG-Board (5 of 13) Schematic Diagram

14.25. DG-Board (6 of 13) Schematic Diagram

14.26. DG-Board (7 of 13) Schematic Diagram

14.27. DG-Board (8 of 13) Schematic Diagram

14.28. DG-Board (9 of 13) Schematic Diagram

14.29. DG-Board (10 of 13) Schematic Diagram

14.30. DG-Board (11 of 13) Schematic Diagram

14.31. DG-Board (12 of 13) Schematic Diagram

14.32. DG-Board (13 of 13) Schematic Diagram

14.33. DV-Board Block Diagram

14.34. DV-Board Schematic Diagram

14.35. XV-Board Block Diagram (PV500B)

14.36. XV-Board (1 of 5) Schematic Diagram (PV500B)

14.37. XV-Board (2 of 5) Schematic Diagram (PV500B)

14.38. XV-Board (3 of 5) Schematic Diagram (PV500B)

14.39. XV-Board (4 of 5) Schematic Diagram (PV500B)

72

73

74

77

79

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

14.40. XV-Board (5 of 5) Schematic Diagram (PV500B)

14.41. Z and H3-Board Block Diagram

14.42. Z and H3-Board Schematic Diagram

14.43. D-Board Block Diagram

14.44. D-Board (1 of 6) Schematic Diagram

14.45. D-Board (2 of 6) Schematic Diagram

14.46. D-Board (3 of 6) Schematic Diagram

14.47. D-Board (4 of 6) Schematic Diagram

14.48. D-Board (5 of 6) Schematic Diagram

14.49. D-Board (6 of 6) Schematic Diagram

14.50. C1, C2, C5 and C6-Board Block Diagram

14.51. C2, C3, C4 and C5-Board Block Diagram

14.52. C1-Board (1 of 2) Schematic Diagram

14.53. C1-Board (2 of 2) Schematic Diagram

14.54. C2-Board (1 of 2) Schematic Diagram

14.55. C2-Board (2 of 2) Schematic Diagram

14.56. C3-Board (1 of 2) Schematic Diagram

14.57. C3-Board (2 of 2) Schematic Diagram

14.58. C4-Board (1 of 2) Schematic Diagram

14.59. C4-Board (2 of 2) Schematic Diagram

14.60. C5-Board (1 of 2) Schematic Diagram

14.61. C5-Board (2 of 2) Schematic Diagram

14.62. C6-Board (1 of 2) Schematic Diagram

14.63. C6-Board (2 of 2) Schematic Diagram

14.64. SC, SU and SD-Board Block Diagram

14.65. SC-Board (1 of 3) Schematic Diagram

14.66. SC-Board (2 of 3) Schematic Diagram

14.67. SC-Board (3 of 3) Schematic Diagram

14.68. SU-Board (1 of 2) Schematic Diagram

14.69. SU-Board (2 of 2) Schematic Diagram

14.70. SD-Board (1 of 2) Schematic Diagram

14.71. SD-Board (2 of 2) Schematic Diagram

14.72. SS, S1, SS2 and SS3-Board Block Diagram

14.73. SS-Board (1 of 2), S1, SS2 and SS3-Board Schematic

Diagram

14.74. SS-Board (2 of 2) Schematic Diagram

15 Parts Locatio n & Mech anica l Replaceme n t Parts List

15.1. Parts Location

15.2. Packing Exploded Views (1)

15.3. Packing Exploded Views (2)

15.4. Packing Exploded Views (3)

15.5. Mechanical Replacement Parts List

16 Elect ri cal Replacement Parts List

16.1. Replacement Parts List Notes

16.2. Electrical Replacement Parts List

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

153

154

155

156

157

159

159

160

4

Page 5

1 Applicable signals

TH-65PV500E / TH-65PV500B

5

Page 6

TH-65PV500E / TH-65PV500B

2 Safety Precautions

2.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

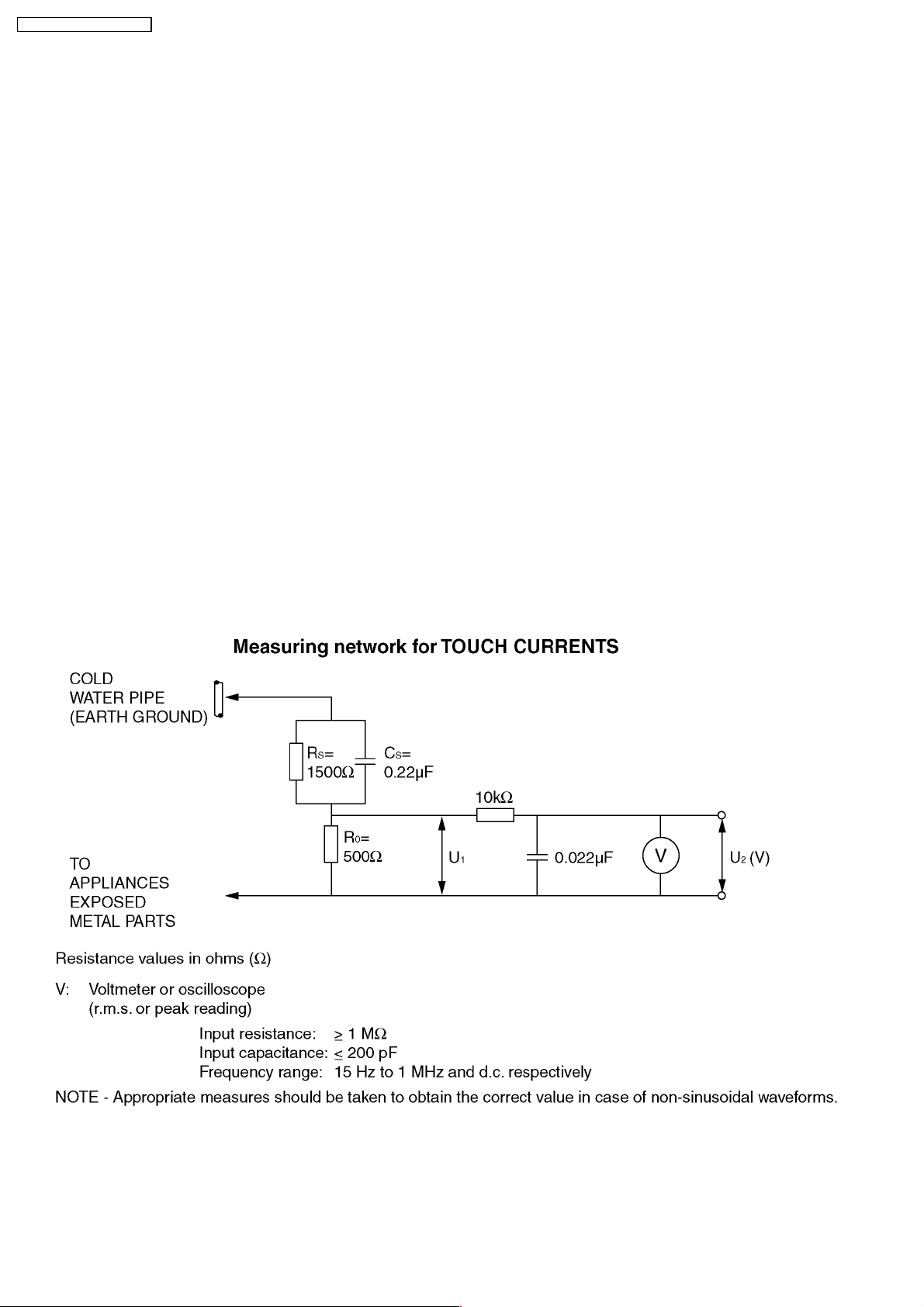

2.2. Touch-Current Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a measuring network for touch currents between each exposed metallic part on the set and a good earth ground such

as a water pipe, as shown in Figure 1.

3. Use Leakage Current Tester (Simpson 228 or equivalent) to measure the potential across the measuring network.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reserve the AC plug in the AC outlet and repeat each of the above measure.

6. The potential at any point (TOUGH CURRENT) expressed as voltage U

For a. c.: U

For d. c.: U

= 35 V (peak) and U2= 0.35 V (peak);

1

=1.0V,

1

Note:

The limit value of U

= 0.35 V (peak) for a. c. and U1= 1.0 V for d. c. correspond to the values 0.7 mA (peak) a. c. and 2.0

2

mA d. c.

The limit value U

= 35 V (peak) for a. c. correspond to the v alue 70 mA (peak) a. c. for frequencies greater than 100 kHz.

1

7. In case a measurement is out of the limits specified, there is a possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the customer.

and U2, does not exceed the following values:

1

Figure 1

6

Page 7

TH-65PV500E / TH-65PV500B

3 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as alminum

foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, alminum foil or comparable

conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise hamless motion such asthe brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

7

Page 8

TH-65PV500E / TH-65PV500B

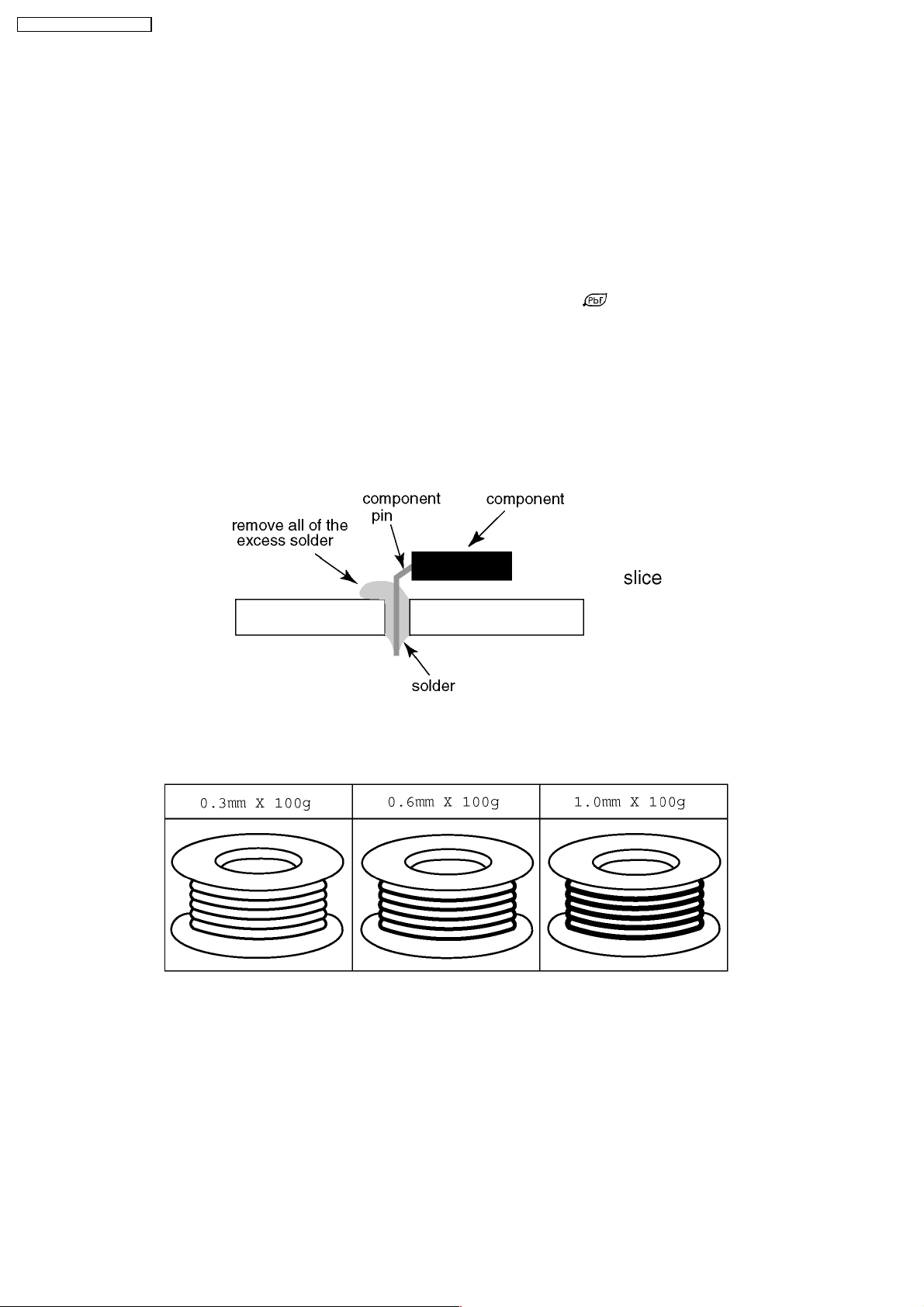

4 About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol

Caution

· Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40 °C) higher.

Please use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

· Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb

solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

· After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto

the opposite side. (see figure below)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder.

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

stamped on the back of PCB.

8

Page 9

5 Service Hint

TH-65PV500E / TH-65PV500B

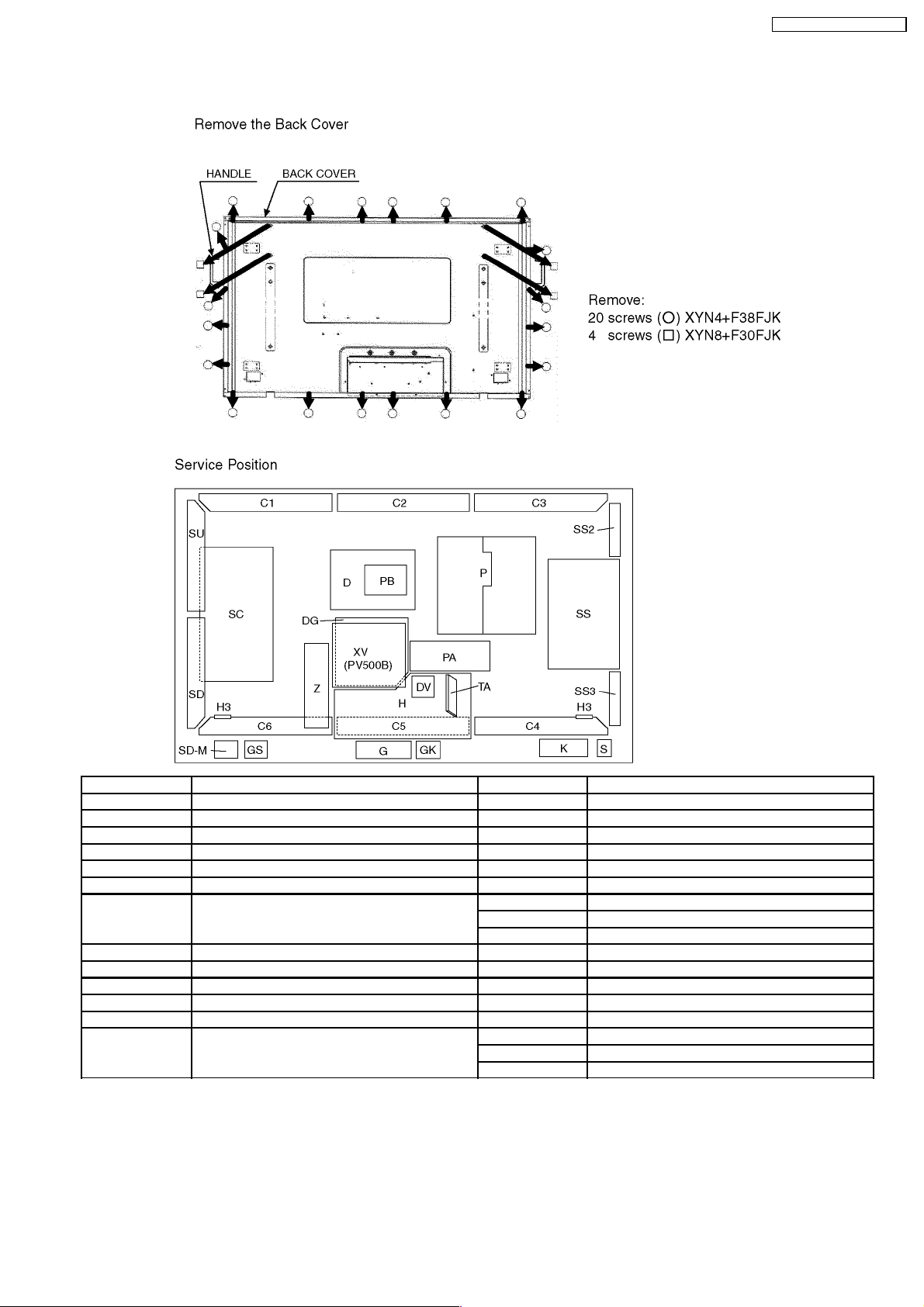

Board Name Function Board Name Function

P Power Supply C1 Data Driver (Upper Right)

PA DC-DC Converter, Power SOS C2 Data Driver (Upper Center)

PB Fan control C3 Data Driver (Upper Left)

H AV Terminal, AV Switch, MSP C4 Data Driver (Lower Left)

TA Tuner C5 Data Driver (Lower Center)

XV D-TV Interface (PV500B only) C6 Data Driver (Lower Right)

DV HDMI Interface

None serviceable.

DV-Board should be exchanged for service.

DG Digital Signal Processor, Micon SS Sustain Drive

Z Sound Control, Audio AMP SS2 Sustain Connector (Upper)

D Format Converter, Plasma AI Processor SS3 Sustain Connector (Lower)

K Remote receiver, OPT G PC Card Slot, Front Terminal

S Power Switch GS SD Card Slot

SD-M SD Module (MPEG4/PHOTO view, SD recording)

None serviceable.

SD Module should be exchanged for service.

SC Scan Drive

SU Scan out (Upper)

SD Scan out (Lower)

GK Key Switch

H3 Speaker Terminal

9

Page 10

TH-65PV500E / TH-65PV500B

6 Plasma panel replacement method

6.1. Remove the Back cover

1. See Service Hint (Section 5)

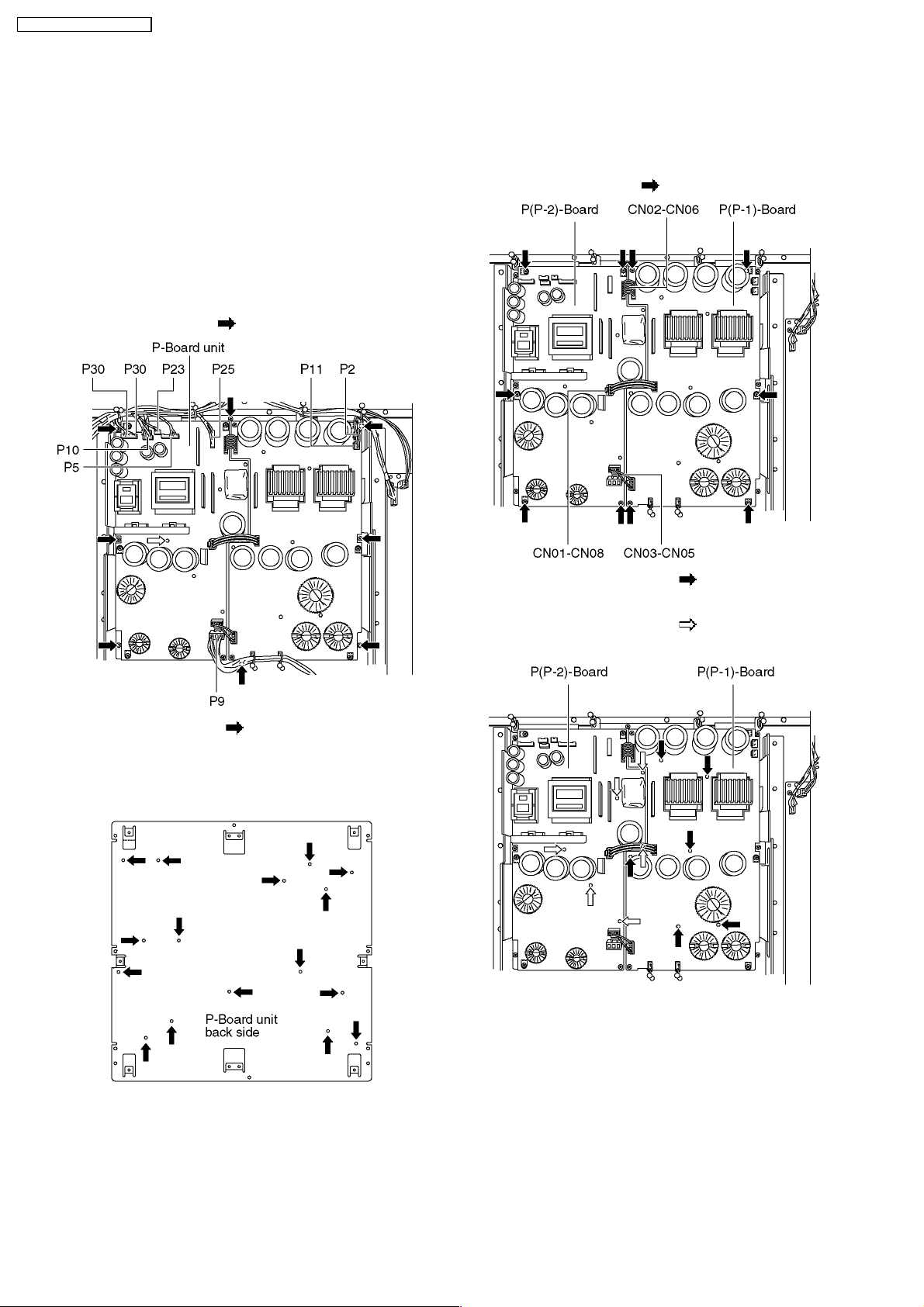

6.2. Remove the P-Board

Caution:

To remove P.C.B. wait 1 minute after power was off for

discharge from electrolysis capacitors.

1. Disconnect the couplers (P2, P5, P9, P10, P11, P12, P23,

P25 and P30).

2. Remove the screws (×8

) and remove the P-Board unit.

4. Disconnect the couplers (CN01-CN08, CN02-CN06 and

CN03-CN05).

5. Remove the screws (×10

).

3. Remove the screws (×16 ) on the back side.

6. Remove the molding props (×6 ).

7. Remove the P(P-1)-Board.

8. Remove the molding props (×6

9. Remove the P(P-2)-Board.

).

10

Page 11

TH-65PV500E / TH-65PV500B

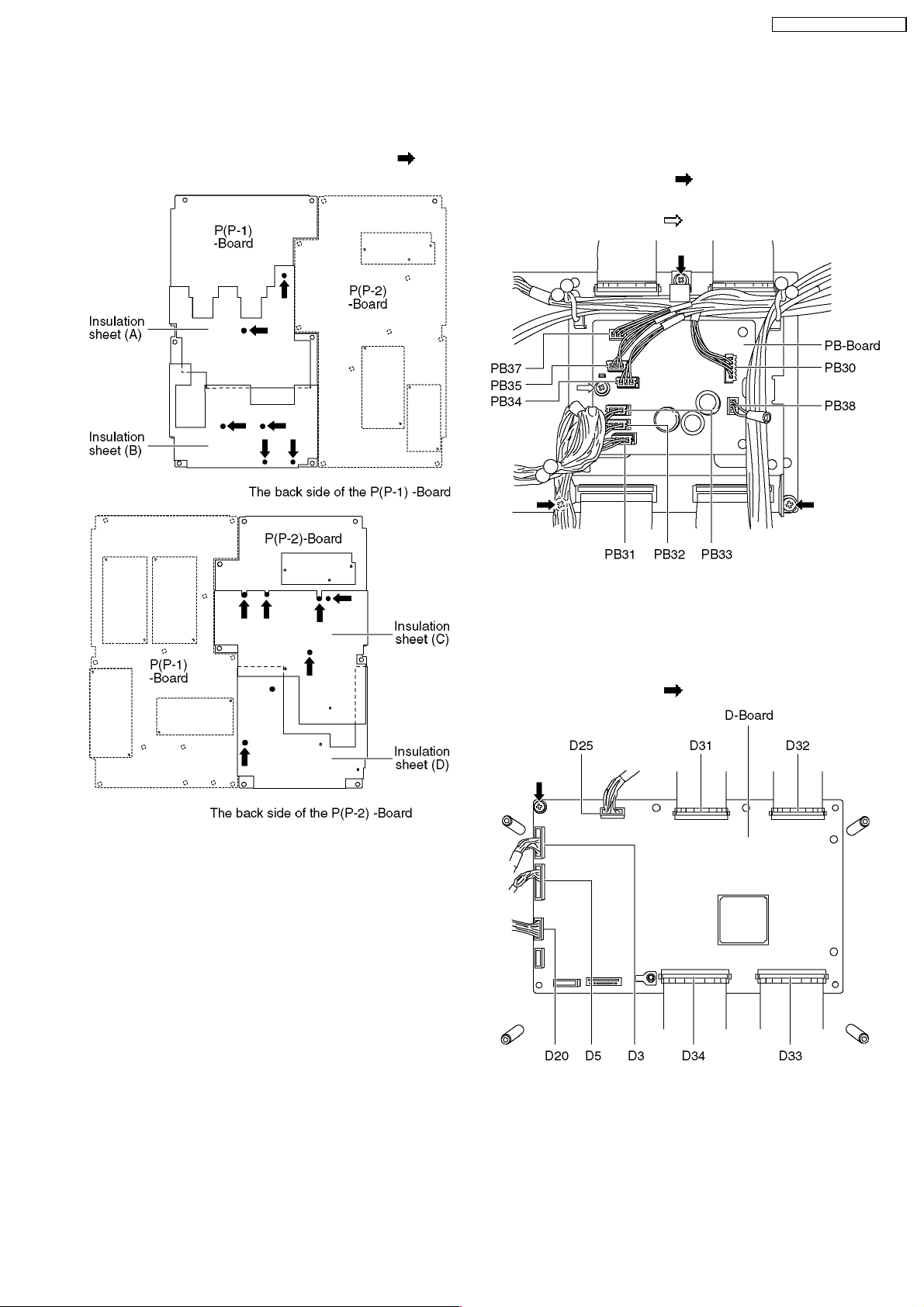

Note:

When assembling the P(P-1)-Board and the P(P-2)- Board,

the position of each hole of the insulation sheets(A, B, C, D)

is set to the position of each hole of the P(P-1)-Board and

the P(P-2)-Board and then assemble them. (

indicate setting positions.)

marks

6.3. Remove the PB-Board

1. Unlock the cable clampers to free the cable.

2. Disconnect the couplers (PB30, PB31, PB32, PB33, PB34,

PB35, PB37 and PB38).

3. Remove the screws (×3

unit.

4. Remove the screws (×1

) and remove the PB-Board

) and remove the PB-Board.

6.4. Remove the D-Board

1. Remove the PB-Board unit.

2. Disconnect the couplers (D3, D5, D20 and D25).

3. Disconnect the flexible cables (D31, D32, D33 and D34).

4. Remove the screws (×1

) and remove the D-Board.

11

Page 12

TH-65PV500E / TH-65PV500B

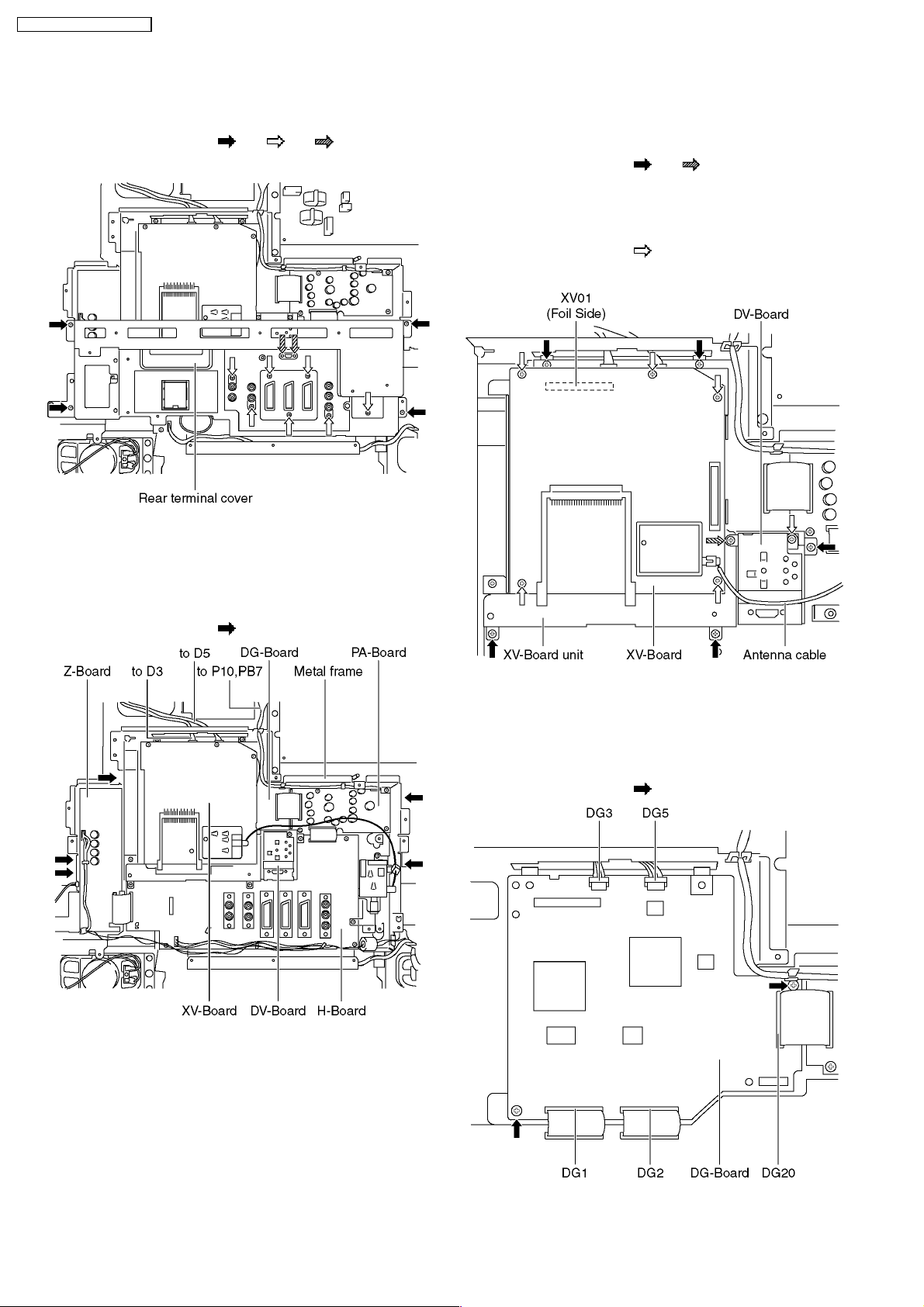

6.5. Remove the rear terminal

cover

1. Remove the screws (×4 ,×7 ,×2 ).

2. Remove the rear terminal cover.

6.6. Remove the metal frame

6.7. Remove the XV-Board (PV500

only) and DV-Board

1. Disconnect the antenna cable.

2. Remove the screws (×5

3. Remove the XV-Board unit.

(Be careful the couplers (XV01 and DG22) when remove

the XV-Board unit.)

4. Remove the screws (×6 ).

5. Remove the XV-Board and DV-Board.

,×1 ).

1. Unlock the cable clampers to free the cable.

2. Disconnect the couplers (D3, D5, H7, P10 and PB7) and

relay connector (SP-R, SP-L).

3. Remove the screws (×5

) remove the metal frame.

6.8. Remove the DG-Board

1. Unlock the cable clampers to free the cable.

2. Disconnect the couplers (DG3 and DG5).

3. Disconnect the flexible cables (DG1, DG2 and DG20).

4. Remove the screws (×2

) and remove the DG-Board.

12

Page 13

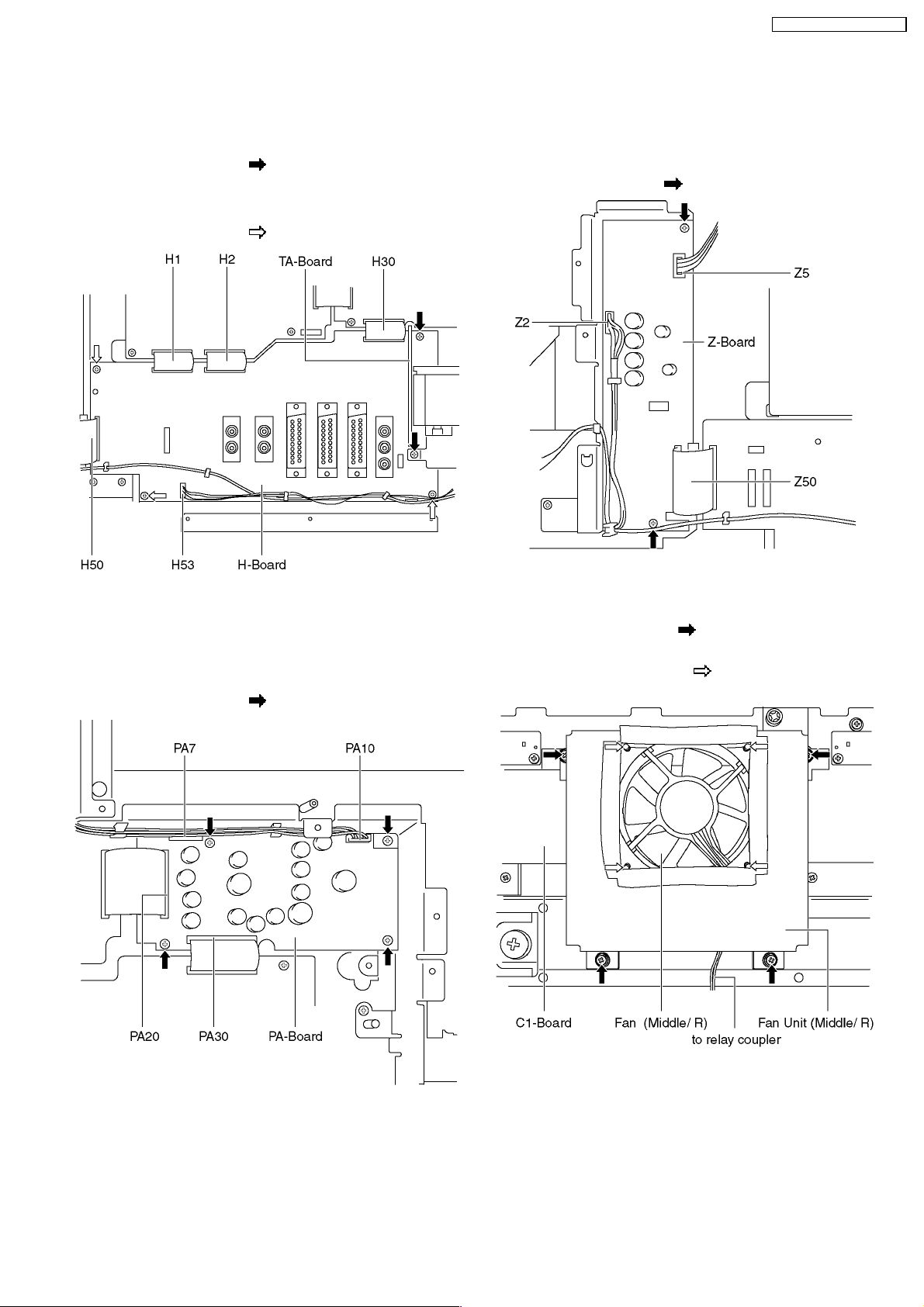

TH-65PV500E / TH-65PV500B

6.9. Remove the H-Board and TABoard

1. Unlock the cable clampers to free the cable.

2. Remove the screws (×2

3. Disconnect the coupler (H53).

4. Disconnect the flexible ables (H1, H2, H30 and H50).

5. Remove the screws (×3

) and remove the TA-Board.

) and remove the H-Board.

6.11. Remove the Z-Board

1. Unlock the cable clampers to free the cable.

2. Disconnect the coupler (Z2 and Z5).

3. Disconnect the flexible cable (Z50).

4. Remove the screws (×2

) and remove the Z-Board.

6.10. Remove the PA-Board

1. Unlock the cable clampers to free the cable.

2. Disconnect the couplers (PA7 and PA10).

3. Disconnect the flexible cables (PA20 and PA30).

4. Remove the screws (×4

) and remove the PA-Board.

6.12. Remove the Fan (Middle/R)

1. Disconnect the relay couper.

2. Remove the screws (×4

(Middle/R).

3. Remove the screws (×4

(Middle/R).

) and remove the Fan unit

) and remove the Fan

13

Page 14

TH-65PV500E / TH-65PV500B

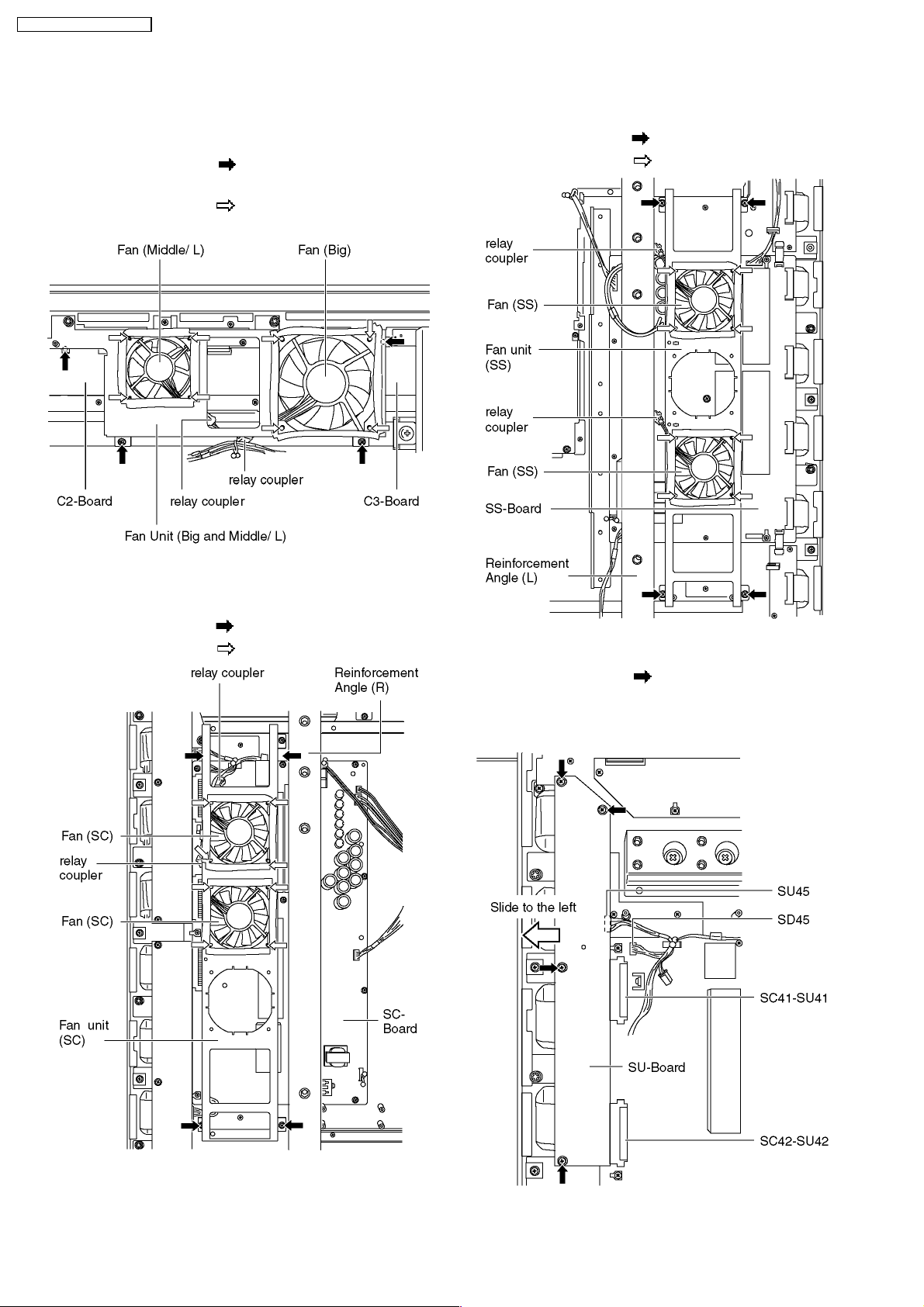

6.13. Remove the Fan (Big and

Middle/L)

1. Disconnect the relay coupers.

2. Remove the screws (×4

and Middle/R).

3. Remove the screws (×8

the Fan (Middle/R).

) and remove the Fan unit (Big

) and remove the Fan (Big) and

6.15. Remove the Fan (SS)

1. Disconnect the relay coupers.

2. Remove the screws (×4

3. Remove the screws (×8

) and remove the Fan unit (SS).

) and remove the Fan (SS).

6.14. Remove the Fan (SC)

1. Disconnect the relay coupers.

2. Remove the screws (×4

3. Remove the screws (×8

) and remove the Fan unit (SC).

) and remove the Fans (SC×2).

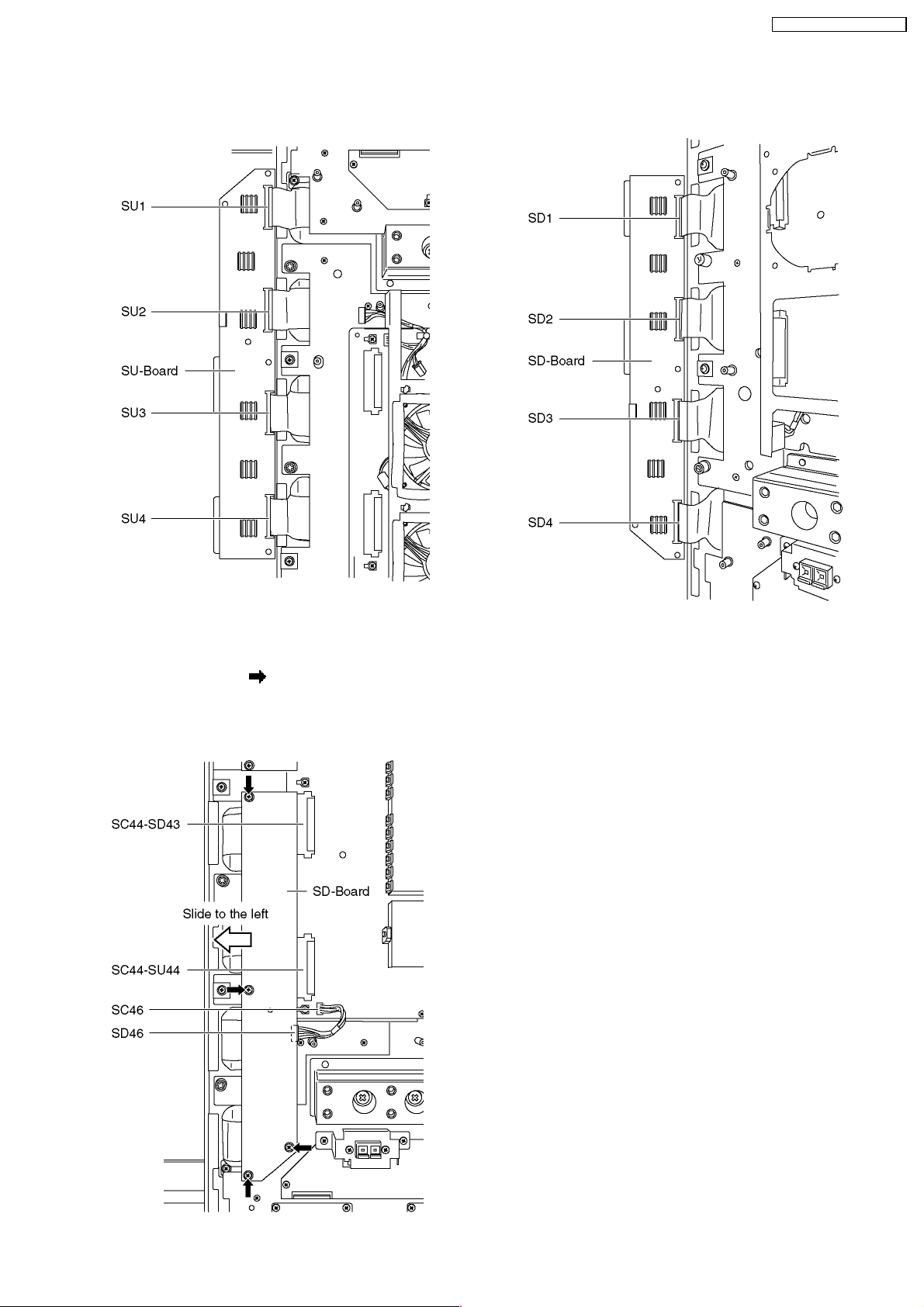

6.16. Remove the SU-Board

1. Remove the screws (×4 ).

2. Slide the SU-Board to the left to disconnect from a coupler

(SC41-SU41 and SC42-SU42) on the SC-Board and

remove a coupler (SU45 or SC45).

14

Page 15

TH-65PV500E / TH-65PV500B

3. Remove the flexible cables (SU1, SU2, SU3 and SU4)

connected to the SU-Board, and remove the SU-Board.

3. Remove the flexible cables (SD1, SD2, SD3 and SD4)

connected to the SD-Board, and remove the SD-Board.

6.17. Remove the SD-Board

1. Remove the screws (×4 ).

2. Slide the SD-Board to the left to disconnect from a coupler

(SC43-SD43 and SC44-SD44) on the SC-Board and

remove a coupler (SD46 or SC46).

15

Page 16

TH-65PV500E / TH-65PV500B

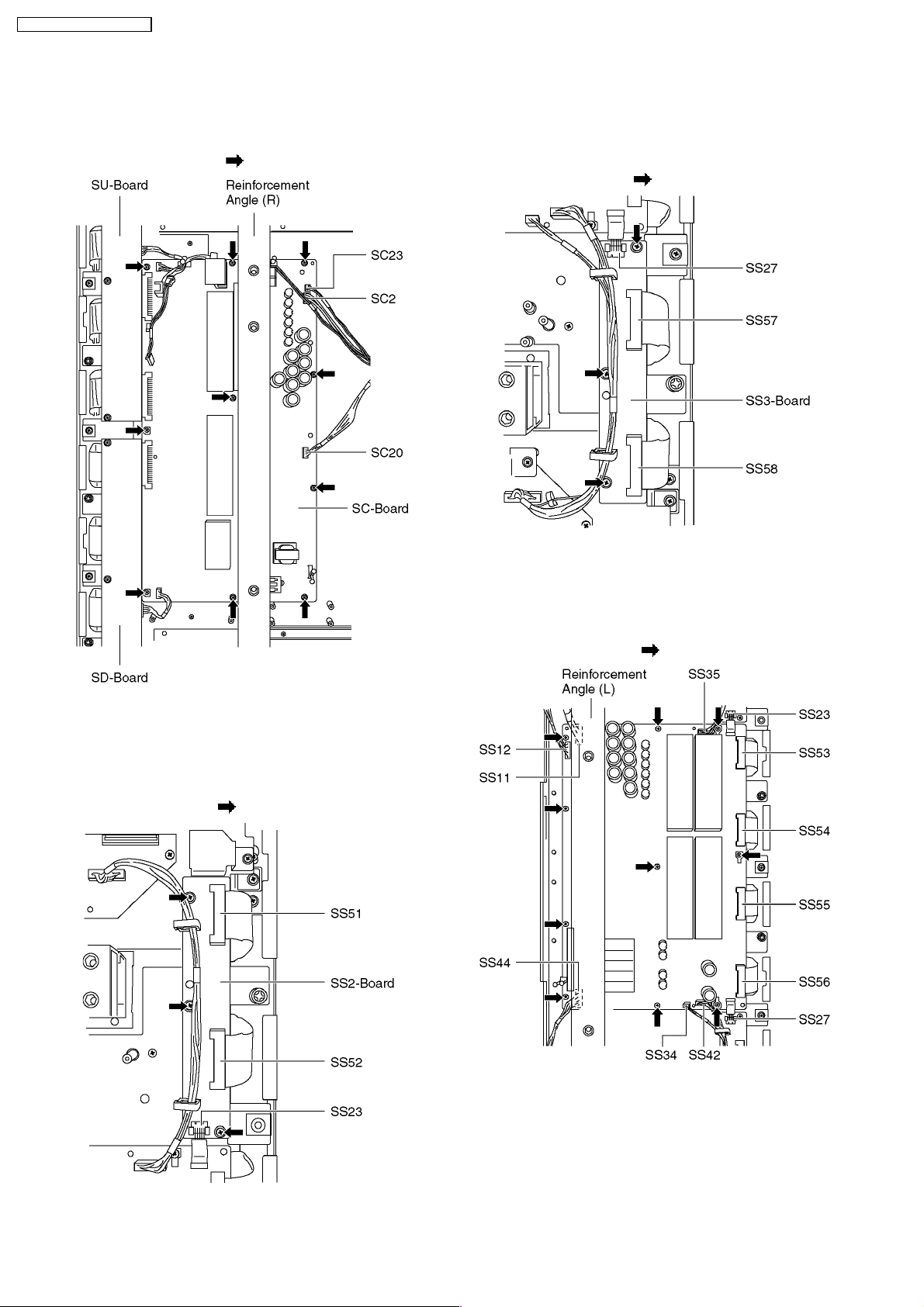

6.18. Remove the SC-Board

1. Unlock the cable clampers to free the cable.

2. Disconnect the couplers (SC2, SC20 and SC23).

3. Remove the screws (×10

) and remove the SC-Board.

6.20. Remove the SS3-Board

1. Unlock the cable clampers to free the cable.

2. Disconnect the couplers (SS27) and disconnect the flexible

cables (SS57 and SS58).

3. Remove the screws (×3

) and remove the SS3-Board.

6.19. Remove the SS2-Board

1. Unlock the cable clampers to free the cable.

2. Disconnect the couplers (SS23) and disconnect the flexible

cables (SS51 and SS52).

3. Remove the screws (×3

) and remove the SS2-Board.

6.21. Remove the SS-Board

1. Disconnect the couplers (SS11, SS12, SS23 and SS34).

2. Disconnect the flexible cables (SS53, SS54, SS55 and

SS56).

3. Remove the screws (×10

) and remove the SS-Board.

16

Page 17

TH-65PV500E / TH-65PV500B

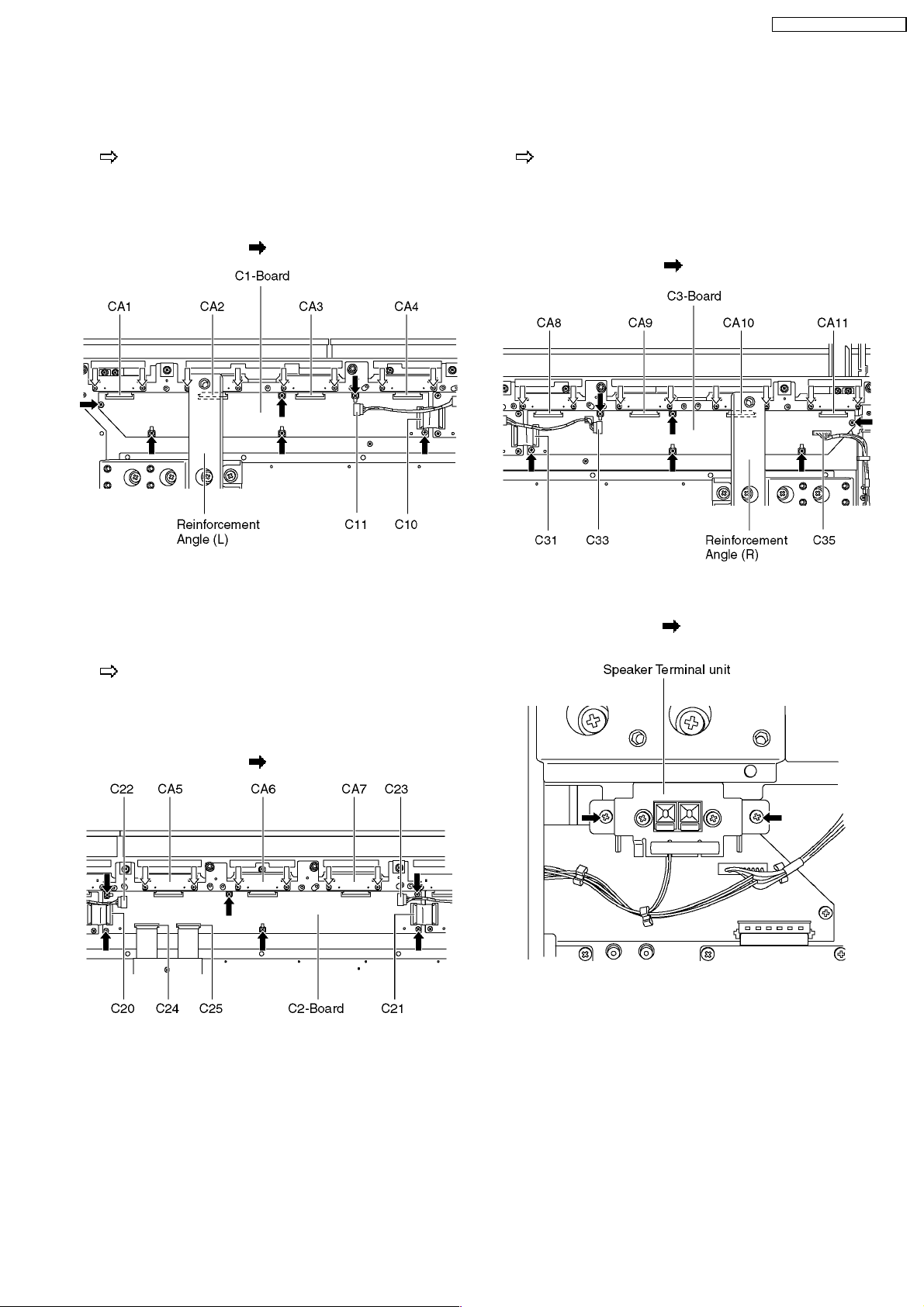

6.22. Remove the C1-Board

1. Remove the Fan unit (Middle/L).

2. Remove the flexible cables holder fastening screws (×8

).

3. Disconnect the flexible cables (CA1, CA2, CA3 and CA4).

4. Disconnect the flexible cable (C10).

5. Disconnect the coupler (C11).

6. Remove the screws (×6

) and remove the C1-Board.

6.24. Remove the C3-Board

1. Remove the Fan unit (Big and Middle/R)

2. Remove the flexible cables holder fastening screws (×8

).

3. Disconnect the flexible cables (CA8, CA9, CA10 and

CA11).

4. Disconnect the flexible cable (C31).

5. Disconnect the couplers (C33 and C35).

6. Remove the screws (×6

) and remove the C3-Board.

6.23. Remove the C2-Board

1. Remove the Fan unit (Big and Middle/R)

2. Remove the flexible cables holder fastening screws (×6

).

3. Disconnect the flexible cables (CA5, CA6, and CA7).

4. Disconnect the flexible cables (C20, C21, C24 and C25).

5. Disconnect the couplers (C22 and C23).

6. Remove the screws (×6

) and remove the C2-Board.

6.25. Remove the H3-Board (L, R)

1. Remove the screws (×2 each) and remove the Speaker

Terminal unit (L, R).

17

Page 18

TH-65PV500E / TH-65PV500B

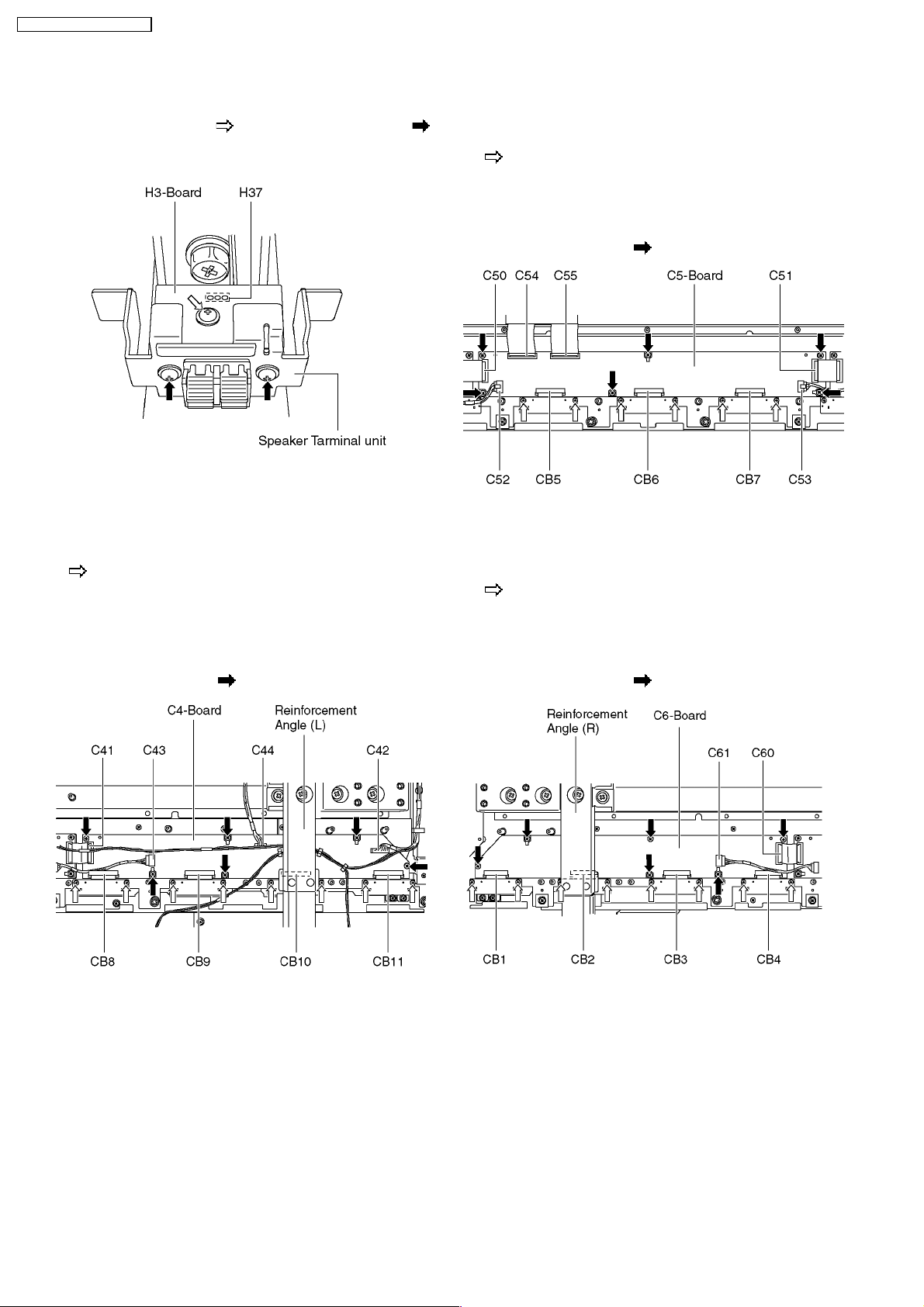

2. Disconnect the coupler (H37).

3. Remove the screw (×1

each).

4. Remove the H3-Board.

each) and the screws ( ×2

6.27. Remove the C4-Board

1. Remove the metal frame.

2. Remove the flexible cables holder fastening screws (×6

).

3. Disconnect the flexible cables (CB5, CB6, and CB7).

4. Disconnect the flexible cables (C50, C51, C54 and C55).

5. Disconnect the couplers (C52 and C53).

6. Remove the screws (×6

) and remove the C5-Board.

6.26. Remove the C4-Board

1. Unlock the cable clampers to free the cable.

2. Remove the Speaker Terminal unit (L).

3. Remove the flexible cables holder fastening screws (×8

).

4. Disconnect the flexible cables (CB8, CB9, CB10 and

CB11).

5. Disconnect the flexible cable (C41).

6. Disconnect the couplers (C42, C43 and C44).

7. Remove the screws (×6

) and remove the C4-Board.

6.28. Remove the C6-Board

1. Remove the Speaker Terminal unit (R).

2. Remove the flexible cables holder fastening screws (×8

).

3. Disconnect the flexible cables (CB1, CB2, CB3 and CB4).

4. Disconnect the flexible cable (C60).

5. Disconnect the coupler (C61).

6. Remove the screws (×6

) and remove the C6-Board.

18

Page 19

TH-65PV500E / TH-65PV500B

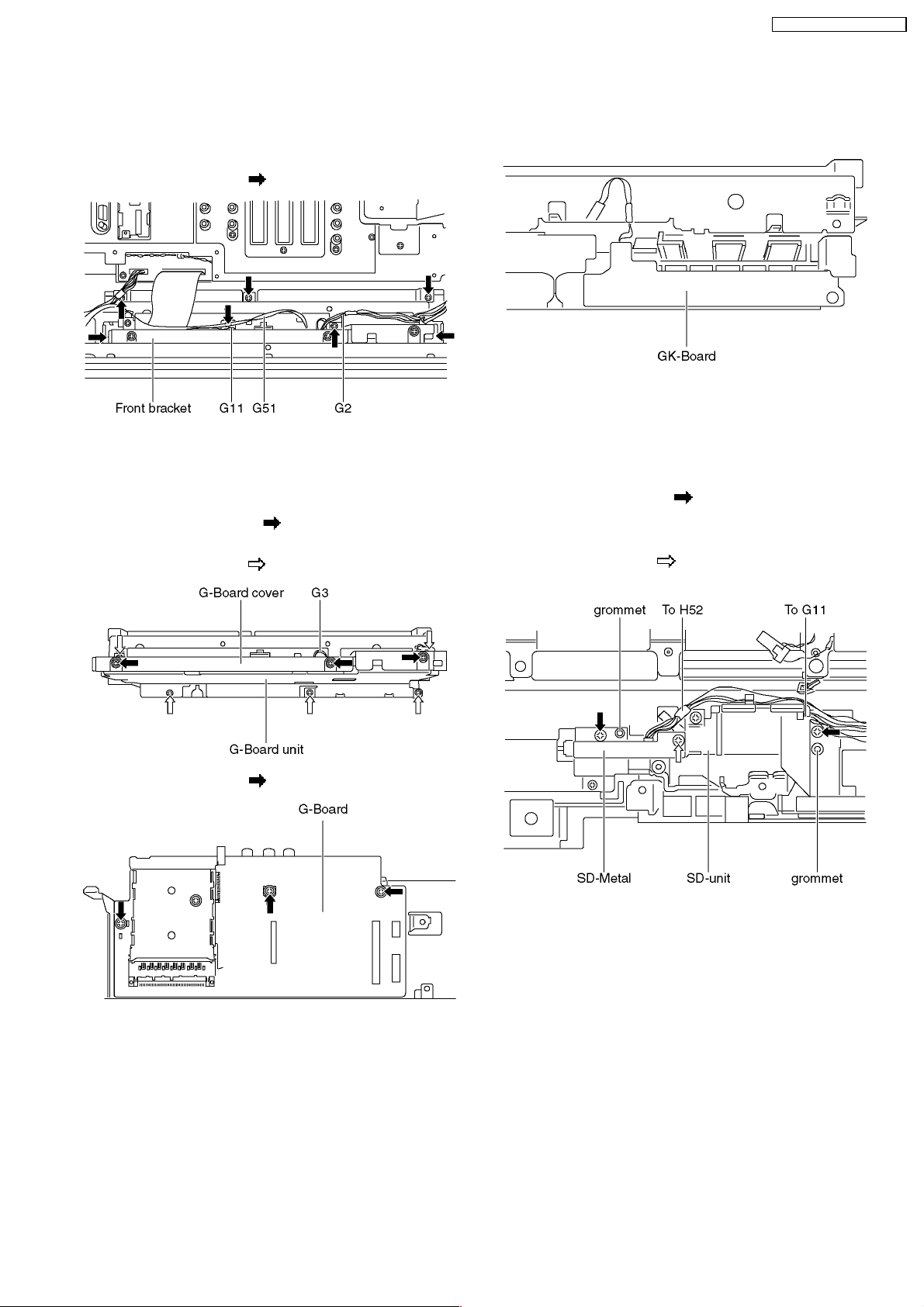

6.29. Remove the front bracket

1. Unlock the cable clampers to free the cable.

2. Disconnect the coupler (G2) and the flexible cables (G11

and G51).

3. Remove the screws (×7

) and remove the front bracket.

6.30. Remove the G-Board

1. Remove the front bracket.

2. Disconnect the coupler (G3).

3. Remove the screws (×3

cover.

4. Remove the screws (×5

) and remove the G-Board

) and remove the G-Board unit.

6.31. Remove the GK-Board

1. Remove the G-Board.

2. Remove the GK-Board.

6.32. Remove the GS-Board and SDModule

1. Unlock the cable clampers to free the cable.

2. Disconnect the coupler (H52) and the flexible cable (G11).

3. Remove the screws (×2

(×2).

4. Remove the SD-Unit.

5. Remove the screw (×1

6. Remove the SD-Metal.

) and remove the grommets

).

5. Remove the screws (×3 ) and remove the G-Board.

19

Page 20

TH-65PV500E / TH-65PV500B

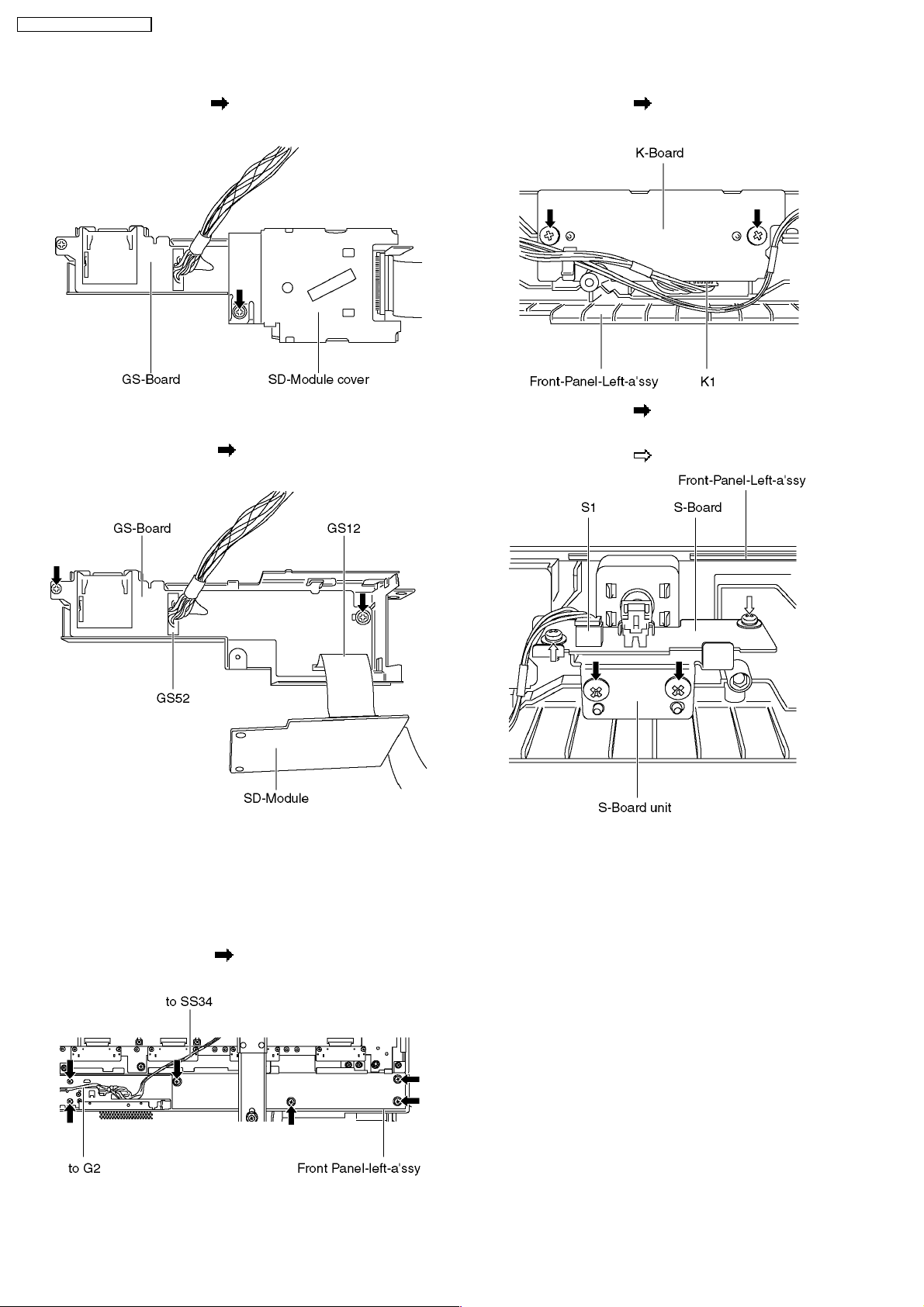

7. Remove the screw (×1 ).

8. Remove the SD-Module cover.

9. Disconnect the coupler (GS52) and the flexible cable

(GS12).

10. Remove the screws (×2

11. Remove the GS-Board and SD-Module.

).

4. Remove the screws (×2 ).

5. Disconnect the couplers (K1) and remove the K-Board.

6. Remove the screws (×2 ) and remove the S-Board unit.

7. Disconnect the couplers (S1).

8. Remove the screws (×2

) and remove the S-Board.

6.33. Remove the K-Board and the

S-Board

1. Unlock the cable clampers to free the cable.

2. Disconnect the couplers (G2 and SS34). (See section 6.21.

and 6.29.)

3. Remove the screws (×6

left-a´ssy.

) and remove the L/Front Panel-

20

Page 21

TH-65PV500E / TH-65PV500B

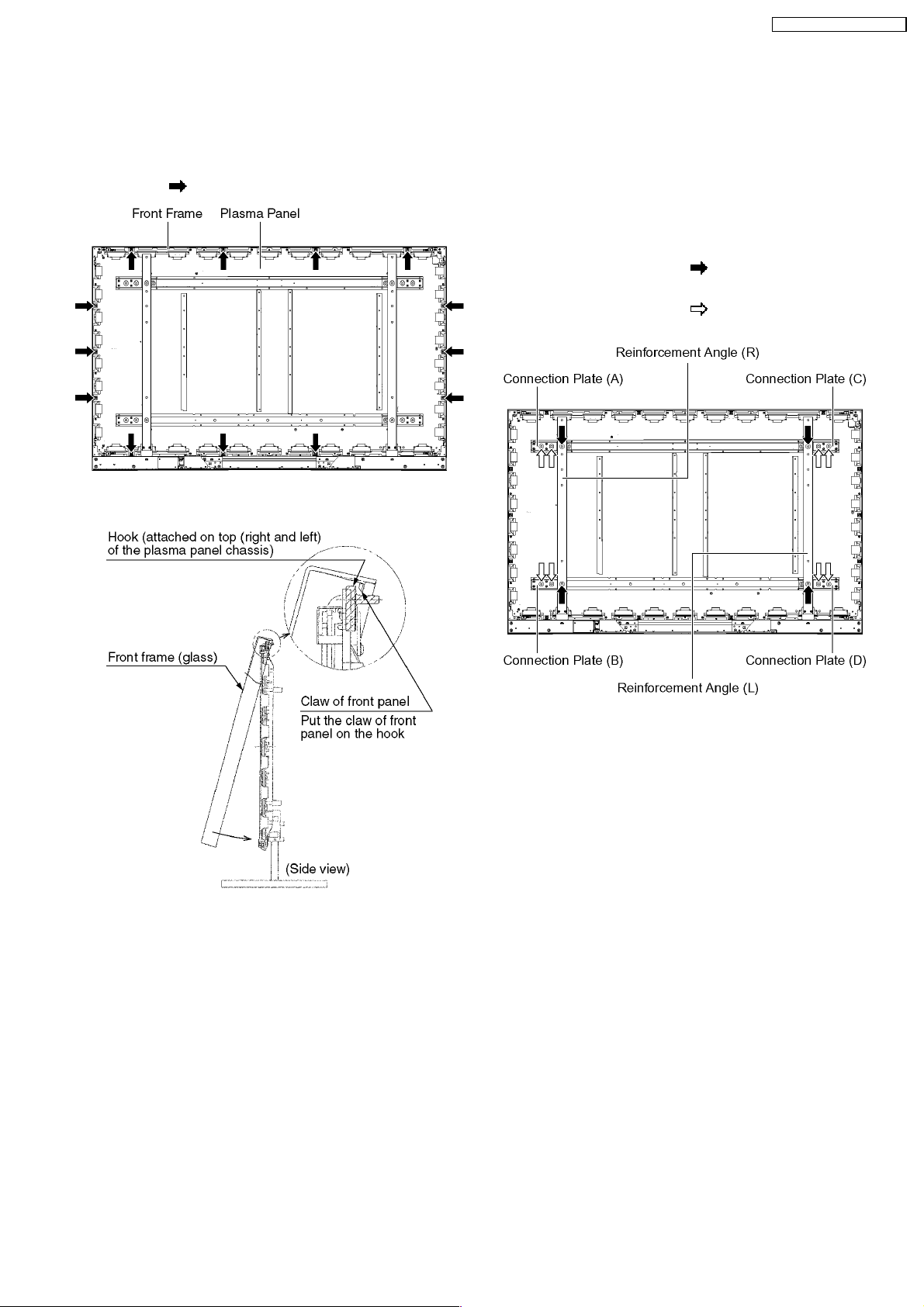

6.34. Remove the Plasma panel

section from the Front frame

(glass)

1. Remove the front frame and the plasma panel fastening

screw (×13

2. For leaving the plasma panel from the front frame, pull the

bottom of the front frame forward, lift, and remove.

).

6.35. Remove the Reinforcement

Angles (L, R) and the

Connection Plate (A, B, C, D)

1. Remove the plasma panel section from the servicing stand

and lay on a flat surface such as a table (covered), with the

plasma panel surface facing downward.

Spread a soft cloth or similar on the table for protection, so

the panel surface is not scratched.

2. Remove the screws (×2

Reinforcement Angles (L, R).

3. Remove the screws (×2

Connection Plate (A, B, C, D).

each) and remove the

each) and remove the

6.36. Replace the plasma panel

(finished)

1. Place the new plasma panel (finished) on the flat surface of

the table (covered by a soft cloth), with the plasma panel

surface facing downward.

2. Attach the C1, C2, C3,C4,C5-Board and the C6-Board,

connect the flexible cables (×22) from the Plasma panel to

the C1, C2, C3,C4,C5-Board and the C6-Board, and fit the

flexible cable holders.

3. Attach the Hooks (left, right) and fit the Reinforcement

Angles (L, R) and the Connection Plate (A, B, C, D) to the

new plasma panel.

4. Place the plasma panel section on the servicing stand.

5. Attach the front frame and each P.C.Board and so on, to

the new plasma panel.

* When fitting the front frame, be careful to allow any debris,

dust or handling residue to remain between the front glass and

plasma panel.

21

Page 22

TH-65PV500E / TH-65PV500B

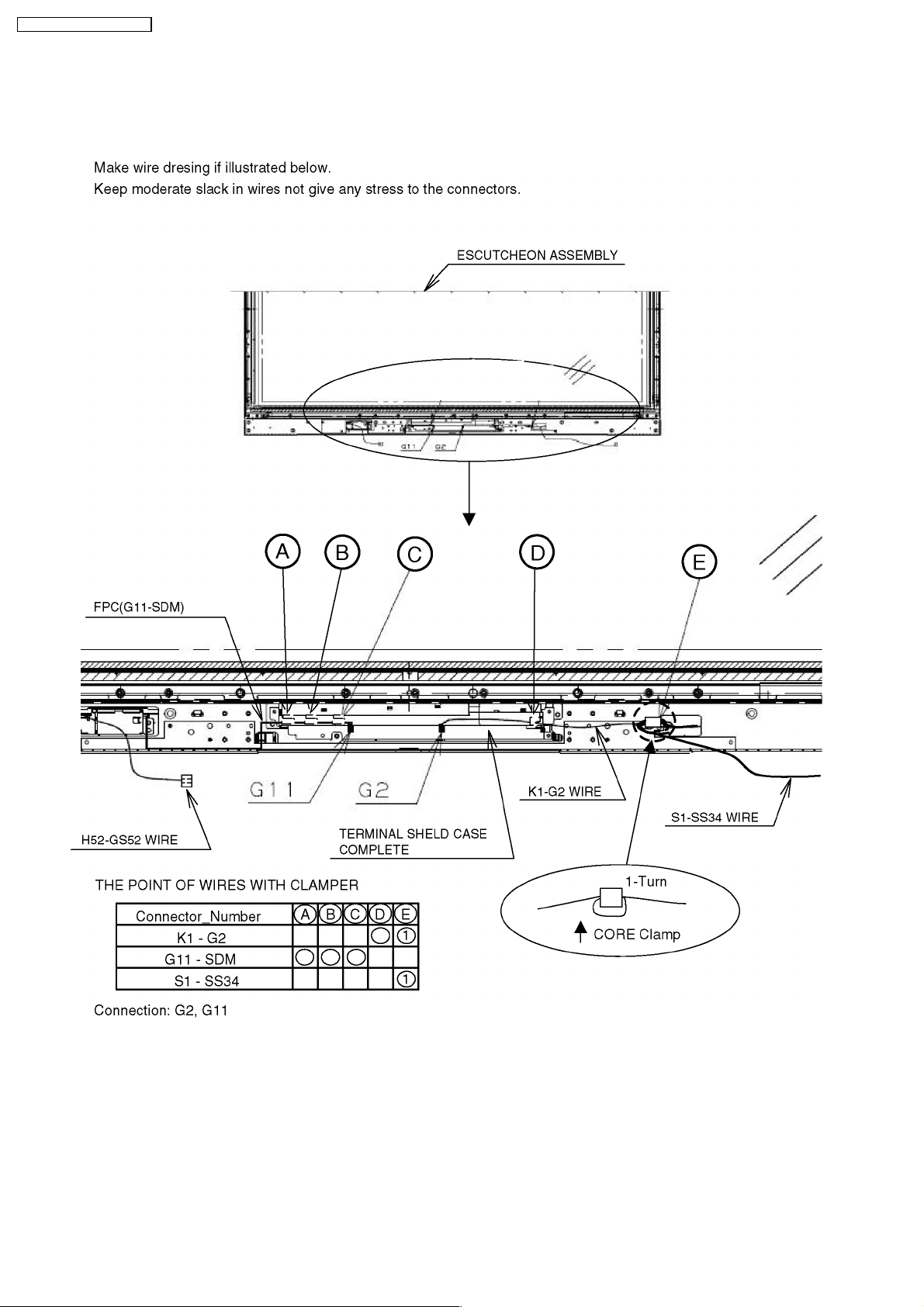

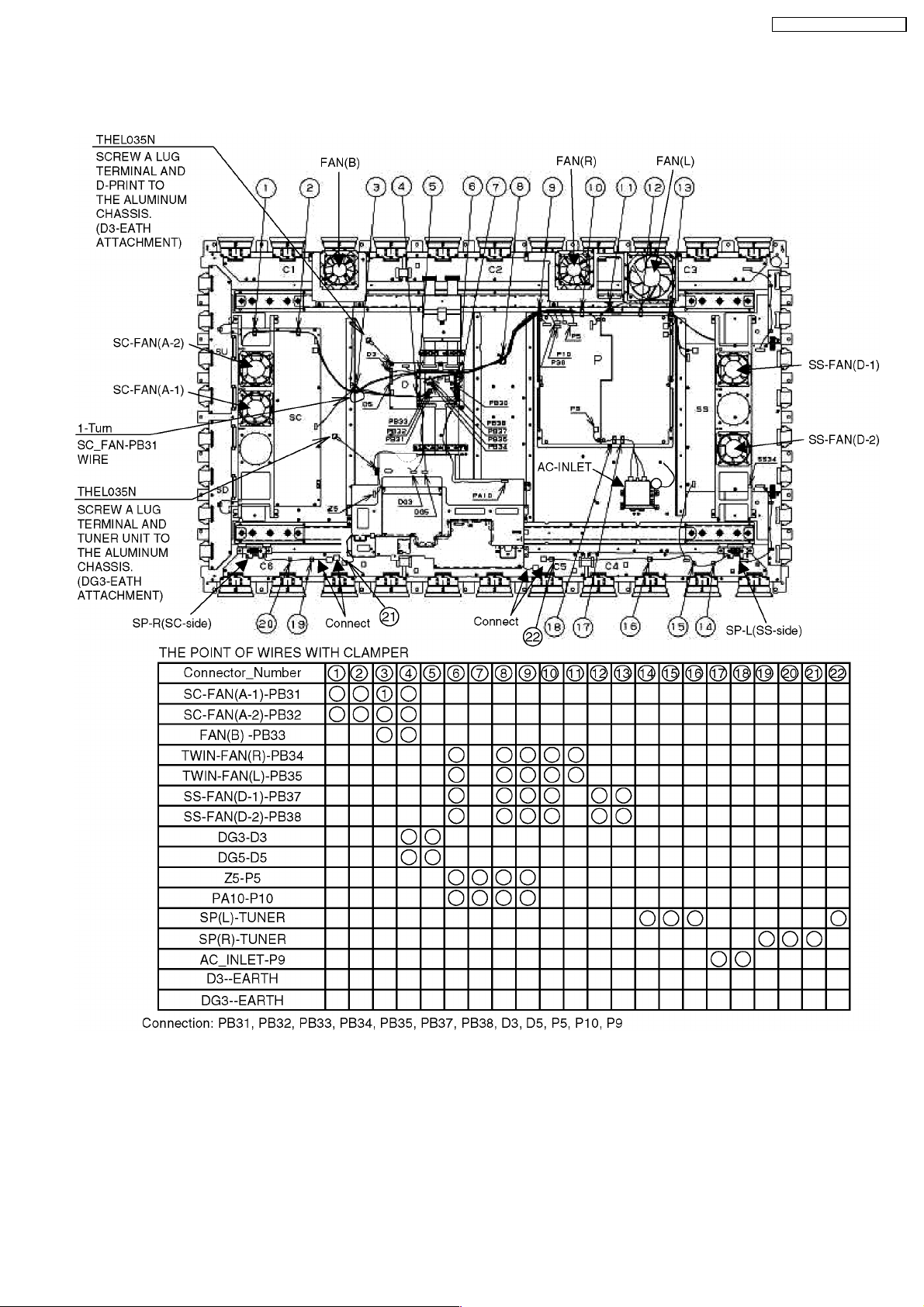

7 Location of Lead Wiring

7.1. Lead of Wiring (1)

22

Page 23

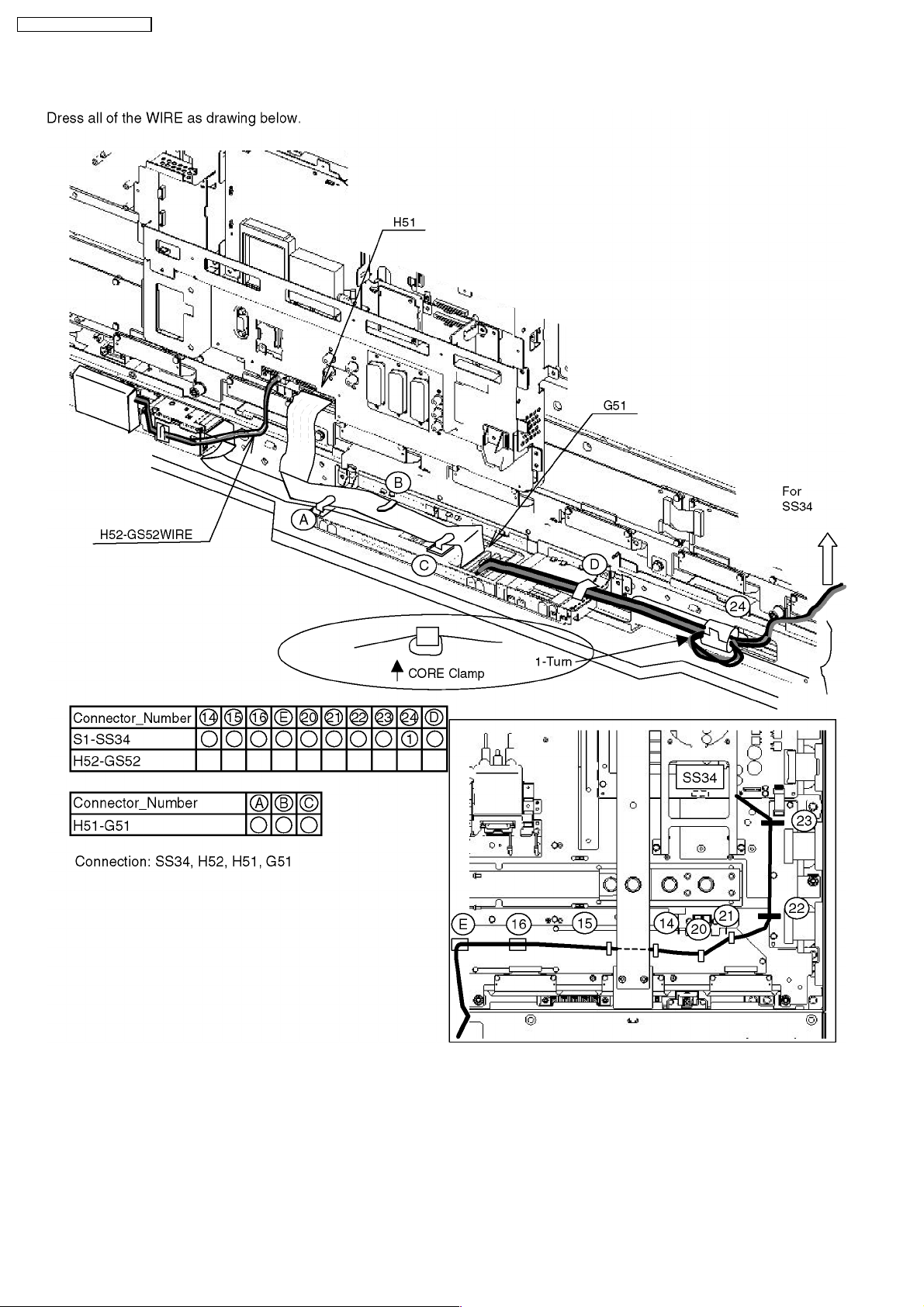

7.2. Lead of Wiring (2)

TH-65PV500E / TH-65PV500B

23

Page 24

TH-65PV500E / TH-65PV500B

7.3. Lead of Wiring (3)

24

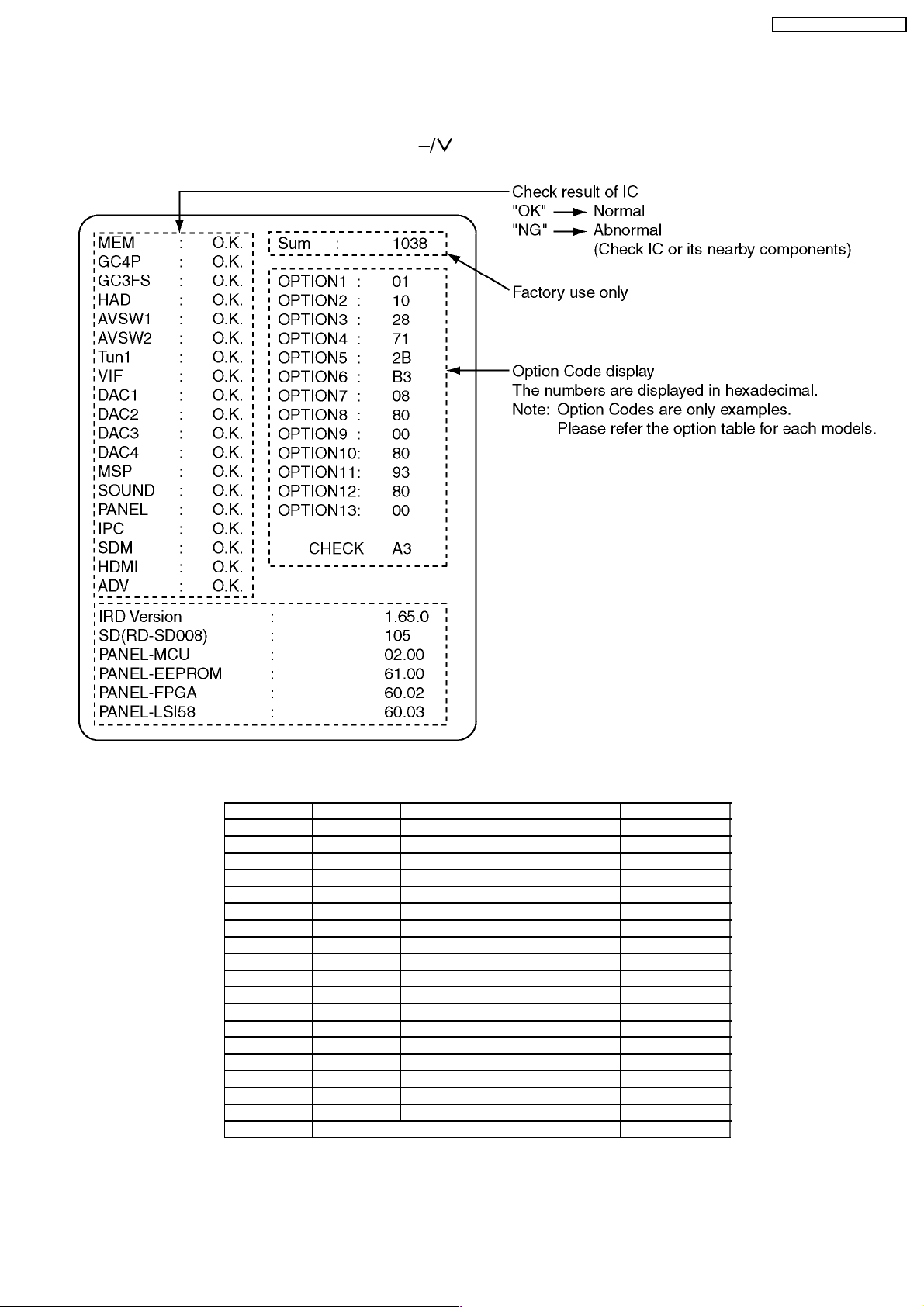

Page 25

8 Self Check

1. Self-Check is used to automatically check the bus lines and hexadecimal code of the TV set.

2. To get into the Self -Check mode press the Down (

time pressing the Information button on the remote control, and the screen will show :

) button on the customer controls at the front of the set, at the same

TH-65PV500E / TH-65PV500B

If the CCU ports have been checked and found to be incorrect or not located then “--” will appear in place of “O.K.”.

Display Ref.No. Description Board

MEM IC1107 EEPROM DG-Board

GC4P IC4054 Global Core Processor DG-Board

GC3FS IC4013 Global Core for Sub DG-Board

HAD IC4012 OSD RGB A/D DG-Board

AVSW1 IC3005 Video SW H-Board

AVSW2 IC2105 Audio SW H-Board

Tun1 TU001 Tuner TA-Board

VIF - - DAC1 IC1106 Ext. DAC DG-Board

DAC2 IC1116 Ext. DAC DG-Board

DAC3 IC3006 Ext. DAC H-Board

DAC4 - - MSP IC2106 Multi Sound Processor H-Board

SOUND IC2300 Sound Control Z-Board

PANEL IC9003 Convert Micon D-Board

IPC IC8013 PEAKS Lite XV-Board

SDM SD-Module MPEG4/PHOTO view, SD recording SD-Module

HDMI IC5003 HDMI I/F Reciever DV-Board

ADV IC4005 10bit A/D DG-Board

25

Page 26

TH-65PV500E / TH-65PV500B

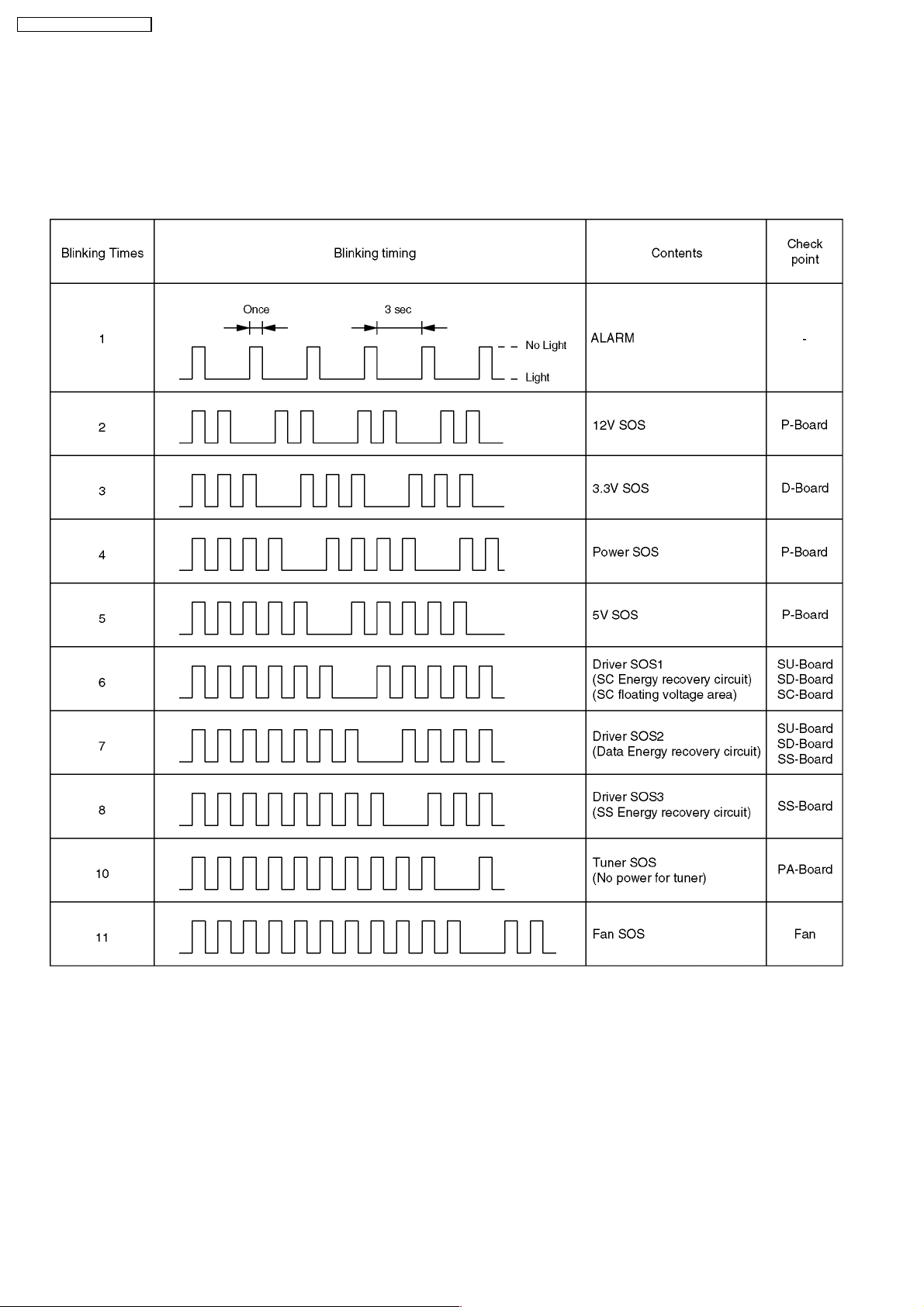

8.1. Power LED Blinking timing chart

1. Subject

Information of LED Flashing timing chart.

2. Contents

When an abnormality has occurred the unit, the protection circuit operates and reset to the stand by mode. At this time, the

defective block can be identified by the number of blinkes of the Power LED on the front panel of the unit.

26

Page 27

8.2. No Power

First check point

There are following 3 states of No Power indication by power LED.

1. No lit

2. Green is lit then turns red blinking a few seconds later.

3. Only red is lit.

TH-65PV500E / TH-65PV500B

27

Page 28

TH-65PV500E / TH-65PV500B

8.3. No Picture

28

Page 29

8.4. Local screen failure

Plasma display may have local area failure on the screen. Fig-1 is the possible defect P.C.B. for each local area.

TH-65PV500E / TH-65PV500B

Fig-1

29

Page 30

TH-65PV500E / TH-65PV500B

9 Service Mode Function

MPU controls the functions switching for each IICs through IIC bus in this chassis. The following setting and adjustment can be

adjusted by remote control in Service Mode.

9.1. How to enter SERVICE 1

1. In sound menu, set BASS to MAXIMUM, and set TREBLE to MINIMUM.

2. Simultaneously press INDEX button on remote control and DOWN button [

9.2. How to enter SERVICE 2

1. Set the channel to CH99.

2. Select the SD Auto check.

3. Press HOLD button on remote control.

Note:

To exit to Service mode, press EXIT or Power button on remote control.

]ontheTVset.

30

Page 31

TH-65PV500E / TH-65PV500B

31

Page 32

TH-65PV500E / TH-65PV500B

9.3. Option Description

32

Page 33

TH-65PV500E / TH-65PV500B

33

Page 34

TH-65PV500E / TH-65PV500B

10 Adjustment Procedure

10.1. Driver Set-up

10.1.1. Item / Preparation

1. Input a white signal of the RGB signal generator

2. Set the picture setting as follows

Picture menu: Standard

Color temperature: Normal

Picture: 25

Aspect: Full

10.1.2. Adjustments

Adjust driver section voltages referring the panel data on the panel data label.

34

Page 35

10.2. Initialization Pulse Adjust

1. Input a Cross hatch signal.

2. Set the picture setting as follows

Picture menu: Standard

Color temperature: Normal

Picture:25

Aspect: Full

Adjust the indicated test point for the specified wave form.

Test point Volume Level Remark

T1 TPSC1 (SC) --- 20 ± 15µ Sec

T2 TPSC1 (SC) VR6602 (SC) 155 ± 10µ Sec

TH-65PV500E / TH-65PV500B

35

Page 36

TH-65PV500E / TH-65PV500B

10.3. P.C.B. (Printed Circuit Board) exchange

10.3.1. Caution

1. To remove P.C.B. , wait 1 minute after power was off for discharge from electrolysis capacitors.

10.3.2. Quick adjustment after P.C.B. exchange

P.C.B. Name Test Point Voltage Volume Remarks

P Board Vsus TPVSUS (SS) Vsus ± 2V VR351 (P) *

SC Board Vad TPVAD (SC) -85V ± 1V VR6801(SC)

Vbk TPVBK (SC) 140V ± 1V VR6802(SC)

SS Board Ve TPVE (SS) Ve ± 1V VR6250 (SS) *

*See the Panel label.

10.4. Adjustment Volume Location

10.5. Test Point Location

36

Page 37

11 Adjustment

11.1. PAL panel white balance adjustment

Instrument Name Connection Remarks

· W/B pattern

· Color analyzer (Minolta CA-100 or equivalent)

Procedure Remarks

· Ensure aging is adequate (Longer than 15min.)

· Make sure the front panel to be used on the final set is fitted.

· Make sure a color signal is not being shown before adjustment.

· Put the color analyzer where there is little color variation.

RF input

Panel surface

TH-65PV500E / TH-65PV500B

User setting: Normal

Picture menu : Dynamic

ASPECT : 16:9

1. Display the white balance pattern.

2. Check that the color balance is "cool".

3. Enter the "Service-Menu1" mode.

4. Select "G-CUTOFF" item, using the color-key "Red" or "Green", and set to "128", using the

color-key "Yellow" or "Blue".

Also, "B-CUTOFF" and "R-CUTOFF" set to "128"

5. Set "G-DRIVE" at "208".

6. Touch the signal receiver of color analyzer to the highlight window´s center, and adjust B

drive and R drive so x, y become the "Color balance Cool" in the below table1.

7. Set "ALL-DRIVE" to "252".

8. Set colorbalance to "Normal".

9. Fix G cutoff , B cutoff and R cutoff at "128".

10. Fix G drive at "208".

11. Adjust B drive and R drive so the highlight window´s x, y become the "Color balance

Normal" in the below table1.

12. Set "ALL-DRIVE" to "252".

13. Set color balance to "Warm".

14. Set G cutoff, B cutoff and R cutoff to "128".

15. Set G drive to "208".

16. Adjust B drive and R drive so the highlight window´s x, y become the "Color balance Warm"

shown in the below table1.

17. Set "ALL-DRIVE" to "252".

· Highlight section

Signal amplitude 75%

37

Page 38

TH-65PV500E / TH-65PV500B

11.2. 1080i white balance adjustment

Instrument Name Connection Remarks

· 1080i W/B pattern

· Color analyzer (Minolta CA-100 or equivalent)

Procedure Remarks

· Ensure aging is adequate (Longer than 15min.)

· Make sure the front panel to be used on the final set is fitted.

· Make sure a color signal is not being shown before adjustment.

· Put the color analyzer where there is little color variation.

Comonent terminal

Panel surface

User setting: Normal

Picture menu: Dynamic

ASPECT:16:9

1. Display the white balance pattern.

2. Check that the color balance is "cool".

3. Enter the "Service-Menu1" mode.

4. Select "G-CUTOFF" item, using the color-key "Red" or "Green", and set to "128", using the

color-key "Yellow" or "Blue".

Also, "B-CUTOFF" and "R-CUTOFF" set to "128"

5. Set "G-DRIVE" at "208".

6. Touch the signal receiver of color analyzer to the highlight window´s center, and adjust B

drive and R drive so x, y become the "Color balance Cool" in the below table1.

7. Set "ALL-DRIVE" to "252".

8. Set colorbalance to "Normal".

9. Fix G cutoff , B cutoff and R cutoff at "128".

10. Fix G drive at "208".

11. Adjust B drive and R drive so the highlight window´s x, y become the "Color balance

"Normal" in the below table1.

12. Set "ALL-DRIVE" to "252".

13. Set color balance to "Warm".

14. Set G cutoff, B cutoff and R cutoff to "128".

15. Set G drive to "208".

16. Adjust B drive and R drive so the highlight window´s x, y become the "Color balance Warm"

shown in the below table1.

17. Set "ALL-DRIVE" to "252".

· Highlight section

Signal amplitude 75%

* The Color balance COOL differs from

Japanese model values.

38

Page 39

11.3. Sub bright adjustment

Instrument Name Connection Remarks

1. PAL signal generator (or RF) Connect to the input terminal User setting: Normal

Procedure Remarks

· Color balance adjustment is finished for each signal.

· Do adjustments in a dark room.

· Complete the adjustment within 10 minutes after the turn on electricity.

Turn on the power supply again when it is not possible to complete it by aging etc.

1. Display the pattern for adjusting subbright from video input.

2. Pull down SRQ of the panel D-Board to L.

3. Use "Sub-Bright" in the <Sevice-Menu1> mode to adjust so the 6th section shows up and

the 7th fades away.

Data

Sub-Bright total 12bit data addresses

LSB 8bit A0-016c bit7-0

MSB 4bit A0-016d bit3-0

Picture menu: Dynamic

Color balance: Normal

ASPECT: 16:9

* If using RF ch.E04 or E43

TH-65PV500E / TH-65PV500B

11.4. ABL adjustment

Instrument Name Connection Remarks

1. HD signal emitter (Color bar signal)

2. Wattmeter

Procedure Remarks

· Make sure the set is aged for 30 minutes or more before adjustment. (Do not switch off

during or after aging.)

· Voltage 230V 50Hz (variation within 1%)

· Volume at minimum and screen size at "16:9"

Setting

Component input, dynamic, standard

1. Connect the set´s AC power to the wattmeter.

2. Input the signal (top half: color bar, Bottom half: Horizontal 10 step bar).

3. Select the "APL MULT" item in the Serivice1.

4. Adjust APL MULT so the set´s power consumption is

TH-65PV500E 620 ± 20W

TH-65PV500B 629 ± 20W

Remarks

There is a possibility that the adjustment value can do two places, adjust it in that case, that the

value of APL_MULT is large.

COMPONENT input terminal

Connect the AC power of the

adjustment set to the wattmeter.

39

Page 40

TH-65PV500E / TH-65PV500B

11.5. TEXT Vref Auto Adjustment

Procedure Remarks

Receive a steady signal.

Adjust it after aging enough.

1. Enter in service mode 1 then select "TXT adj. Access" item.

2. Start Auto adjustment by push "Blue" key

[Test pattern]

Note:

Under operating,

The character "TXT Adj. Access" becomes red.

Detection window will appear near bottom.

Detection window move R - G - B at the bright test pattern,

Then,

Detection window move R - G - B at the dark test pattern.

And finish auto adjustment.

40

Page 41

12 Hotel mode

TH-65PV500E / TH-65PV500B

1. Purpose

Restrict a function for hotels.

2. Access command

· Enter to the Service 2 Mode.

· Press Information button on remote control and entry to

the EAROM EDITOR Mode.

· Press the RED/GREEN button to step up/down through

the address.

· Press the YELLOW/BLUE button to step left/right

through the address.

· Press the PROGRAMME UP/DOWN button to step

up/down through the page.

· Press the VOLUME UP/DOWN button to change the

function values.

· Set the data of EEPROM(ADDRESS 140) to 80.

· Press the OK button to memorize the data.

Push the Power switch(button) off/on the set(the remote

control) to turn the set off/on.

It can be made Hotel mode.

3. Exit command

· First, set the data of EEPROM(ADDRESS 140) to 00.

Next, Push the Power switch(button) off/on the set(the

remote control) to turn the set off/on.

Then, it is no longer hotel mode.

4. Access command to the Hotel mode setup menu

· Prerequisite : It is conditions that the data of

EEPROM(ADDRESS 140) is 80.

In order to display the Hotel mode setup menu, please

enter the following command (within 2 second).

[TV]:down + [REMOTE]:TV/AV(3 times)

Then, the Hotel mode setup menu is displayed.

item Function

Initial INPUT Select input signal modes.

Initial VOL level Adjust output Volume.

Maximum VOL

level

Initial POS Select programme number.

Button lock Select local key conditions.

Remote lock Select remote control key conditions.

Set this signal, each time power is switched on.

Selection :

Off/TV/AV1/AV2/AV2S/AV3/Av3S/AV4/Av4S/Co

mponent/PC/HDMI

· Off: give priority to a last memory. However,

Euro model is compulsorily set to TV.

· AVnS/AVnC: only Euro model selectable

· PC: selectable with VGA option

Set this volume, each time power is switched on.

If the value of InitVol is changed, volume will

change. However, priority is given to a last

memory when InitVol is Off. When "InitVol" is

larger than "MaxVol", make "InitVol" and "MaxVol"

the same.

Selection/Range :

Off/0 to 63

· Off: give priority to a last memory

Adjust maximum volume.

Set this max. volume, each time power is

switched on.

When "MaxVol" is smaller than "InitVol", make

"MaxVol" and "InitVol" the same, if "InitVol" is not

Off.

Range :

0to63

Set this programme number, each time power is

switched on.

Selection :

Off/0 to 99 (Euro model)

· Off: give priority to a last memory

Set this condition, each time power is switched

on.

Selection :

Off/SETUPMENU/All

· Off: altogether valid

· SETUP: restrict F-key selection

(Tuning guide(menu) can not be selected.)

· MENU: restrict F-key selection

(only Volume/Mute can be selected.)

· All: altogether invalid.

Set this condition, each time power is switched

on.

Selection :

Off/SETUP/MENU

· Off: altogether valid

· SETUP: only Setup menu is invalid

· MENU: Picture/Sound/Setup menu are invalid

5. Explain the Hotel mode setup menu

41

Page 42

TH-65PV500E / TH-65PV500B

42

Page 43

13 Conductor Views

13.1. P-Board

6

P(P-1)-BOARD (FOIL SIDE)

5

ETXMM584MEK (NPX584ME-1)

TH-65PV500E / TH-65PV500B

P-1

4

3

Parts Location

P-BOARD (FOIL SIDE)

IC

MC301 D-2

MC302 D-4

MC303 B-4

MC601 E-4

MC602 E-4

MC604 D-2

MC605 F-4

2

TRANSISTOR

Q332 D-4

Q333 C-4

Q602 E-4

Q603 E-4

Q605 E-3

Q606 E-3

TP

TP1 D-2

TP2 D-2

1

TH-65PV500B/E

P-BOARD ETXMM584MEK

ABCDEFGH I

TH-65PV500B/E

P-BOARD ETXMM584MEK

43

Page 44

TH-65PV500E / TH-65PV500B

6

5

P-1

P(P-1)-BOARD (COMPONENT SIDE)

ETXMM584MEK (NPX584ME-1)

4

3

Parts Location

P-BOARD (COMPONENT SIDE)

IC

MC301 D-2

MC302 D-4

MC303 E-4

MC601 B-4

MC602 B-4

MC604 C-2

MC605 B-4

TP

TP1 C-2

TP2 C-2

2

1

TH-65PV500B/E

P-BOARD ETXMM584MEK

ABCDEFGH I

TH-65PV500B/E

P-BOARD ETXMM584MEK

44

Page 45

TH-65PV500E / TH-65PV500B

6

P-2

P(P-2)-BOARD (FOIL SIDE)

5

ETXMM584MEK (NPX584ME-2)

4

Parts Location

P-BOARD (FOIL SIDE)

3

IC

IC401 C-4

IC701 C-4

IC901 C-2

MC401 C-3

MC701 C-4

MC801 B-3

MC901 D-3

MC902 C-3

MC1601 D-3

MC1602 E-4

MC1604 F-4

2

TRANSISTOR

Q402 C-3

Q451 B-4

Q452 A-4

Q453 B-4

Q454 A-4

Q703 C-5

Q951 B-2

Q952 B-2

Q953 B-3

Q954 B-2

Q955 B-3

Q956 B-3

Q1601 E-3

Q1602 E-4

Q1603 E-4

Q1605 E-4

Q1606 E-4

1

TH-65PV500B/E

P-BOARD ETXMM584MEK

ABCDEFGH I

TH-65PV500B/E

P-BOARD ETXMM584MEK

45

Page 46

TH-65PV500E / TH-65PV500B

6

5

P-2

P(P-2)-BOARD (COMPONENT SIDE)

ETXMM584MEK (NPX584ME-2)

4

Parts Location

P-BOARD (COMPONENT SIDE)

3

IC

IC401 D-4

IC701 D-4

IC901 E-2

MC401 E-3

MC701 E-4

MC801 F-3

MC901 C-3

MC902 E-3

MC1601 C-3

MC1602 B-3

MC1604 B-4

TRANSISTOR

Q1601 C-3

2

1

TH-65PV500B/E

P-BOARD ETXMM584MEK

ABCDEFGH I

TH-65PV500B/E

P-BOARD ETXMM584MEK

46

Page 47

13.2. PA-Board

TH-65PV500E / TH-65PV500B

6

PA-BOARD(FOIL SIDE)

TNPA3620AC

PA10

ZA5602

C5614

R5611

R5612

D5618

C5685

C5604

16

C5612

C5686

C5607

R5663

C5613

C5637

D5616

L5609

1

R5609

TP5603

Q5607

TP5609

C5672

R5624

R5618

5

C5611

L5607

C5616

R5614

R5680

R5678

R5658

R5626

R5627

R5657

R5632

16

C5630

R5696

R5636

R5631

R5671

R5637

R5676

ZA5603

4

C5641

R5638

C5642

IC5602

R5601

C5618

R5621

R5610

C5617

C5601

D5615

C5602

L5612

PA-BOARD(COMPONENT SIDE)

TNPA3620AC

3

R5697

PA5601

R5651

C5619

R5664

D

R5685 R5686

R5633

A

C5605

C5631

L5615

PA30

L5606

L5604

Q5601

30

R5628

C5633

R5623

C5632

C5615

C5610

C5609

C5601

L5612

R5630

8

PA7

1

ZA5601

PbF

1

E

R5615

R5617

Q5603

2

1

R5692

R5656

Q5606

R5662

Q5605

R5653

Q5612

B

R5677

PA20 C5622

C5606

R5693

30

TP5617

TP5615

TP5616

L5613

ZA5604

R5661

C5673

1

R5694

C

R5695

D5646

IC5601

1

L5611

R5613

C5626

16

R5652

R5622

R5660

C5636

R5646

Q5642

D5647

C5632

C5615

C5603

R5670

R5672

C5672

D5614

TP5604

C5603

C5608

NIL

C5633

AB

L5606

R5629

E

R5673

F

C5602

C5617

JS5602

R5635

D5643

JS5601

TP5605

C5610

R5616

C5609

R5619

Q5602

L5614

R5675

R5634

R5606

R5605

L5609

L5615

L5604

TP5608

D5617

TP5601

C5631

L5616

R5687

R5688

TP5621

C5612

16

D5648

ZA5601

1

IC5601

C5605

R5603

TNPA3620

R5607

16

SEE REVERSE FOR ORDER NO.

C5688

JS5612

JS5611

C5607

L5608

C5685

L5605

1

C5611

B

IC5602

C5630

C

Q5613

R5674

D

D5641

D5645

TNPA3620

ORDER NO.

Q5644

C5623

PbF

F

1

C5622

TP30V

TPM33V

C5670

TPS5V

JS5610

1

D5610

PA5602

L5607

Q5610

R5679

1PA

Q5611

PA10

R5644

R5625

PA7

TPM25V

C5690

C5604

C5644

Q5609

TPS12V

C5606

1PA

5

1

R5648

IC5603

R5649

R5698

D5639

R5620

D5640

D5658

R5641

ZA5603

6

TP5613

D5637

TPB5V

ZA5604

4

3

R5645

D5659

R5643

Q5641

Q5614

D5642

D5638

R5639

TP16V

TPS33V

TPS9V

TPM9V

TPM5V

Q5643

8

JS5613

L5610

R5642

D5644

R5655

R5640

ZA5602

TPW12V

D5649

R5659

Q5604

JS5609

R5647

A

R5683

C5643

R5650

R5684

R5654

Parts Location

IC

IC5601 B-2

IC5602 D-2

IC5603 E-2

TRANSISTOR

Q5601 C-2

Q5602 D-5

Q5603 A-2

Q5604 E-1

Q5605 A-2

Q5606 A-2

Q5607 C-5

Q5609 E-1

Q5610 E-1

Q5612 A-2

Q5613 D-1

Q5614 E-3

Q5641 E-1

Q5642 B-1

Q5643 E-1

Q5644 D-1

PA-BOARD

TP

PA

TP5601 C-4

TP5603 C-5

TP5604 C-4

TP5605 C-5

TP5608 C-5

TP5609 C-5

TP5621 C-5

TP16V E-5

TP30V E-5

TPB5V E-4

TPM25V E-5

TPM33V E-5

TPM5V E-5

TPM9V E-5

TPS12V E-5

TPS33V E-5

TPS5V E-4

TPS9V E-5

TPW12V E-4

TH-65PV500B/E

PA-BOARD TNPA3620AC

ABCDEFGH I

TH-65PV500B/E

PA-BOARD TNPA3620AC

47

Page 48

TH-65PV500E / TH-65PV500B

13.3. PB-Board

6

5

Parts Location

PB-BOARD (FOIL SIDE)

IC

IC850 C-2 Q850 B-3

TRANSISTOR

TP

TPFAN B-2

Parts Location

PB-BOARD (COMPONENT SIDE)

IC

IC850 G-3 Q850 G-3

TRANSISTOR

PB

4

3

2

PB-BOARD (FOIL SIDE)

TNPA3655AC

R851

C851

Q850

C

E

R853

5

R864

1

PB38

PB30

13

R860

L852

D856

C852

JS852

C853

TPFAN

C854

R850

R863

D859

TNPA3655

SEE REVERSE FOR ORDER NO.

B

D860

D858

JS851

R852

4

IC850

C850

1

L851

1

R862

R858

5

2

PB

D855

3

D852

R855

D851

D850

D857

D854

D853

R854

PbF

R857

R861

3

3

R859

3

R856

3

3

PB-BOARD (COMPONENT SIDE)

TNPA3655AC

1

3

PB35

PB37

PB36

1

3

3

1

1

3

1

1

3

PB36PB37

1

3

PB35

1

PB34

1

1

PB32PB33

1

PB31

1

PB32 PB33

1

PB31

3

1

R861

PB34

3

3

R854

TNPA3655

ORDER

D857

R859

D855

R858

D854

R857

D853

R856

D852

R855

D851

D850

NO.

J2

C850

3

L851

JS851

D858

R852

R862

5

2

PB

R863

4

IC850

1

D860

D859

C854

J101

R850

C852

1

C853

Q850

J1

D856

R851

JS852

R860

L852

C851

R853

5

R864

1

PB30

13

PB38

1

TH-65PV500B/E

PB-BOARD TNPA3655AC

ABCDEFGH I

TH-65PV500B/E

PB-BOARD TNPA3655AC

48

Page 49

13.4. H-Board

6

5

H-BOARD (FOIL SIDE)

TNPA3520AF (PV500B)

TNPA3520AG (PV500E)

Parts Location

IC

IC2102 G-1

IC2103 G-3

IC2104 G-3

IC3001 D-3

IC3002 D-3

IC3004 C-4

IC3006 F-2

H-BOARD (FOIL SIDE)

TRANSISTOR

Q2001 D-2

Q2002 E-2

Q3001 C-3

Q3002 D-3

Q3003 C-3

Q3004 C-3

Q3005 C-3

Q3006 D-3

Q3011 C-4

Q3012 B-4

Q3013 B-4

Q3014 C-4

Q3015 D-3

Q3016 B-4

Q3017 C-4

Q3018 B-4

Q3019 C-3

Q3020 C-3

Q3021 D-3

Q3022 D-3

TH-65PV500E / TH-65PV500B

H

Q3013

R3117

L3201

D3033

R3128

R3120

R3086

L3009

JK3005

JS3033

R3078

C3058

R3013

JS3242

C3038

R3052

R3083

D3002

R3024

Q3011

R3115

D3010

JS3007

C2016

R3127

R3121

R3147 R3148

Q3019

L3003

D3007

JS3018

R3008

D3014

R3019

R3022

C3003

R2010

C2017

R3044

D3009

L2011

Q3017

R3126

R3131

20

R2011

R3133

R3045

2

R3141

R3140

R3007

L2012

R3143

Q3003

Q3014

R3118

JK3004

R3125

R3123

JS2033

C3020

C3019

R3066

TNPA3520

SEE REVERSE FOR ORDER NO.

4

6

R3175

1

C3018

L3008

3

IC3004

R3056

Q3005

D3015

R3041

R3043

R3029

R3040

R3037

Q3004

D3019

R3032

R3033

C3007

Q3001

Q3020

R3134

R3136

R3025

R3042

R3026

R3038

C3006

R3036

D3018

JS3019

R3010

R3011

R3009

JS3017

JS3020

D3005

R3028

L3002

R3006

JS3005

D3008

D3031

C2013

R2008

D3013

R3018

L2007

21

20

R3012

JK3003

21

2

1

C2018

L2013

L2014

C2009

D3032

R3163

D3025

R3021

C3002

C2014

C2020

R2009

1

L2008

JS2032

D2014

R2054

R2053

C2019

D3006

D2013

C3013

6

1

IC3002

R3031

JS3015

R2048

D3100

Q3006

D3003

JS3016

R3023

C3014

R3035

D3004

R3002

L2009

L2010

C3008

C3009

C3001

R3146

JS3011

R3030

L2003

R3017

3

20

L3001

R2007

R3039

2

H1

PbF

C3011

4

L3004

C2183

H53H53

C2171

JS2105

R2118

C2119

C2115

11

1

C2112

L2105

R2112

C2181

R2117

C2179

JS2106

C2170

R2111

C2117

C2114

R2119

12

C2182

C2106

2

JS3303

JS3304

R2169

R2168

C2111

C2180

JS2109

C2178

R3403

R3402

R3405

R3404

R3407

R3406

R3401

R2110

C2105

8

5

IC2102

4

1

IC2103

C2146

C2131

D2104

C3330

R2113

C2132

R2114

R3319

R3318

C3306

C3334

R3350

9

R3316

R3311

R3313

R3310

C3304

C3303

R3351

R3352

C3337

C3336

C3338

1

H12

R2116

R2125

JS2101

C2217

C2118

C3238

C3237

D2102

JS3239

C3247

C3239

C3240

R3145

L2004

Q3021

Q3002

R3034

R3144

JK3002

JS2031

D3017

Q3016

R3004

R3005

1

R3130

21

R3003

JS3014

R3132

JS3010

L2006

JS3012

JS3013

L2005

L2101

C2012

C2007

R3027

C3243

JS2111

R2204

C2213

C2211

R2215

R2213

JS3136

X2102

X2103

R2214

R2217

C2004

C2003

R2004

C2209

R2003

R2209

L2001

R2052

L2002

R2012

Q2001

R2013

JS3135

L2015

C2006

JK2002

R2015

D3027

D3028

D3030

R2051

C2021

L2120

L2119

JK2003

C2022

L2118

C2206

C3060

R3161

L2113

R2195

L2114

R2196

C2207

R2134

C2198

R3152

R3153

16

1

R3155

R3160

R3162

C2201

L2117

R3151

R3159

C2202

R3150

L2121

R3154

R2194

R2133

X2101

C2192

R3156

R3157

9

IC3006

8

C2154

L2107

C2161

C2191

D2001

L2123

D2002

JS2012

L2111

JS2011

C2147

R2014

R2047

L2016

R2016

Q2002

R2005

C2005

D2103

JS2102

D2121

D2122

R2124

R2222R2223

L2102

L2204

C3335

R2221

JS2103

JS3312

C2216

L2202

L2106

C2134

R2149

L3301

2

C3339

R2220

R2002

R2166

C2143

3

4

1

L2201

C2002

JS2104

C2129

C2133

R2148

8

1

C2130

L3302

341234

JS3310

JS3311

2

1

JK3001

1

C2001

R2001

JK2001

R2132

R2138

IC2104

5

ZA3403

4

L3303

C2127

JS3307

JS3309

JS3308

D3303

15

5

11

JS3306

JS3305

R3333

R3332

C3302

R3307

R3304

2

1

R3309

D3302

R3308

R3349

C3301

R3306

D3301

R3348

JS3243

H50

35

34

C3004

4

6

3

1

L3005

IC3001

D3016

Q3022

C3005

R3001

R3016

R3020

C2010

R2006

C2011

C2015

C2008

C3059

C3063

Q3015

R3170

4

3

2

JS3416

JS3413

JS3414

JS3417

JS3415

R3122

R3137

R3138R3139

R3173

R3172

R3168

Q3018

R3142

Q3012

JS3418

R3124

R3129

R3135

R3116

R3119

R3080

C3236

1

4

JS3205

JS3202

23

C3207

C3208

JS3215

L3211

R3014

D3011

JS3008

R3015

D3012

JS3009

1

JS3208

9

H6

1

15

H5

1

TH-65PV500B H-BOARD TNPA3520AF

TH-65PV500E H-BOARD TNPA3520AG

ABCDEFGH I

TH-65PV500B H-BOARD TNPA3520AF

TH-65PV500E H-BOARD TNPA3520AG

49

Page 50

TH-65PV500E / TH-65PV500B

6

5

H-BOARD (COMPONENT SIDE)

TNPA3520AF (PV500B)

TNPA3520AG (PV500E)

Parts Location

H-BOARD (COMPONENT SIDE)

IC

IC2105 C-2

IC2106 C-3

IC2107 D-3

IC2108 D-3

IC2111 D-1

IC2112 D-1

IC3005 G-3

IC3301 A-2

IC3302 A-2

TRANSISTOR

Q2003 F-1

Q2004 F-1

Q2005 F-1

Q2006 E-1

Q2007 E-2

Q2008 E-1

Q2009 E-2

Q2010 E-2

Q2011 F-1

Q2012 F-1

Q2013 F-1

Q2102 C-2

Q2103 C-3

Q2104 C-3

Q2105 C-3

Q2106 C-3

Q2107 E-3

Q2108 E-3

Q2109 F-3

Q2110 D-1

Q2111 D-1

Q3008 B-2

Q3009 A-2

Q3010 G-3

Q3023 G-4

Q3101 D-2

Q3203 G-3

Q3331 B-3

Q3332 B-2

Q3333 B-2

H

30

JS3405

H30

C3226

C3227

C3244

C3212

C3064

C3040

R3089

R3081

R3084

C3044

R3236

C3058

C3015

JS3022

D3024

JK3005

JS3023

Q3010

R3053

1

HMM4

4

C2195

C2200

C2204

JS3403

ZA3403

C3331

D3330

C3332

D3331

JS3402

R3334

3

H50

2

2

34

R3335

FL3331

C2127

R3331

D3333R3330

D3332

FL3330

1

L3330

C3242

8

5

4

1

C3333

IC3302

R3305

R3312

1

4

8

5

IC3301

L2200

R3051

35

D3026

R3158

Q3009

HMM1

R3323

4

1

JK3001

15

11 1

R3049

Q3008

R2131

R2137

C2128

R2147

R2165

R3320

L3302

L3303

3

3

4

2

1

2

R3314

FL3305

5

NP

JK2001

D3023

D3021

R3317

C3305

R3048

R3050

1

40

L2106

JS2121

JS2122

R2130

4

12

C3334

NP

C3336

C3338

NP

R3303

R3301

R3302

D3020

R2128

C2125

R2129

R2179

R3324

JS2026

L3301

C2172

C2174

3

C2173

C2175

C3330

D3334

D3335

JS3313

Q3331

R3339

R3347

R2171

R2172

R2173

R2174

R2175

R2176

R2177

R2170

FL3302

C2162

C2163

C2164

C2165

R2180

C2124

FL3301

R3225

R3226

R3228

R3224

R3227

C3234

R3223

R3232

C3232

JS3401

30

JS3302

R2178

Q2104

Q2105

R2188

L2178

L2179

L2109

R2182

R2183

R2184

R2185

JS2108

C2132

R3336R3337

R3338

C3340

Q2103

C3341

9

Q3332

R3343

C3342

R3321

FL3304

Q3333

R3315

FL3303

1

C2168

C2169

C2166

C2167

R3229

JS3237

H52

29

C2126

L2182

L2183

L2184

L2185

C2178

C2179

L2108

C2116

R2127

R2126

R2186

L2186

C2176

Q2102

D3336

D3337

R3341

R3340

JS3138

JS3314

R3342

D3338

D3339

R2189

R2191

R3344

R3346

C2187

JS3315

R3345

H12

R2115

C3246

R2150

R2151

C2105

R2154

R2152

C2158

C2221

C2156

R2163

C2220

R2161

C2118

C2113

NP

1

C3231

JS3238

12

2

1

H1

L2112

L2110

24

25

40

41

C2184

C2183

R2187

L2187

C2177

NP

C2170 C2171

NP

R2224

C2188

R2159

R2157

NP

D2112

C2119

D2110

D2117

D2114

D2105

L2105

L2203

C2144

C2218

H53

R2135

1

2

JS3230

11

40

R3213

C3217

C2224

C2225

C2185

IC2106

C2223

64

JS2021

JS2022

22

23

33

IC2105

34

C2147

D2106

R3233

R2136

1

C3230

R3214

R3215

C3218

C3219

C2226

1

80

R2200

JS2114

X2101

L2116

65

C2192

Q3101

12

11

1

44

C2161

D2119

HMM2

C2135

C2136

R2225

R3234

R2140

R2139

C2219

C2145

1

5

R2198

C2197

C2206

C2198

C2222

L2118

L2117

L2121

R2199

C2194

R2192

R2193

R2190

C2193

C2189

C2190

JS2110

R2155

R2153

C2138

C2137

C2141

C2142

C2139

C2140

R2141

R2142

R2143

R2144

R2145

R2146

IC2112

L2102

IC2111

C2120

C3241

H51

35

R3216

R3217

R3218

R3219

R3220

R3221

C3220

C3221

C3222

C3223

C3224

C3225

H2

1

JS3139

JK2003

Q2110

IC2108

C2214C2215

R2218

R2181

L2122

Q2106

X2102

C2108

R2122

R2106

C2110

R2123

R2104

C2107

R2120

R2105

C2109

R2121

R2103

C2151

R2109

R2100

Q2111

R2108

R2107

IC2107

R2201

R2207

D2120

L2119

IN

C3233

R2197

L2115

C2196

C2153

C2199

JS3140

X2103

JK2002

C2123

C2104

C2102

C2121

C2103

C2122

D2124

C2101

8

1

45

1

4

R2202

C2205

C2203

R2206

Q2108

Q2109

Q2107

C2212

R2208

R2216

R2205

C2210

R2210

R2211

R2212

C2208

AV1

JK3002

JS3404

21

OUT

R2039

R2037

1

R2036

R2035

Q2009

Q2010

JS2113

R2102

R2101

8

5

L2101

JS2112

D2123

HMM3

R2044

R2040

R2038

21

20

R2028

R2032

Q2007

R2033

R2034

R2041

D2011

2

1

R2026

R2029

Q2008

R2030

R2027

Q2006

R2031

R2042

R2043

D2012

R3059

C3024

R3060

C3025

C3026

R3061

R3058

R3062

C3027

R3063

C3028

R3070

C3030

C3029

R3068

AV2

JK3003

20

2

R2022

R2018

Q2003

C2020

C2019

R2023

R2050

Q2013

Q2012

R2045

R2046

Q2011

R2049

R3065

R3067

R3069

R3064

C3022

C3023

R3057

AV4

21

1

R2021

R2019

Q2004

R2024

R2025

R2017

R2020

Q2005

JS3240

R3071

C3032

C3021

65

80

R3222

JK3004

20

2

TNPA3520

ORDER

NO.

C3245

JS3241

C3062

IC3005

1

1

C3228

C3216

R3169

JS3002

R3047

R3046

JS3001

C3214

C3229

R3092

R3090

C3049

R3094

R3106

C3047

4164

40

25

24

C3236

L3212

C3235

1

4

L3201

JS3206

2

3

C3207

H15

1

4

C2160

C2159

D2118

H

D2116

C2157

D2115

C2155

D2113

C2152

D2111

C2150

D2109

C2149

D2108

C2148

D2107

JS3406

Q3023

C3061

R3171

H6

1

R3095

C3050

C3051

C3052

C3053

C3054

C3055

C3056

C3057

R3105

R3103

R3104

R3107

R3108

R3096

R3109

R3097

R3098

R3110

R3099

R3111

R3100

R3112

R3101

R3113

R3102

R3114

D3235

D3236

9

1

R3204

R3205

Q3203

JS3201

R3206

H5

JS3410

R2167

R2164

R2162

R2160

R2158

R2156

JS3407

C3036

C3035

R3072

C3031

C3039

C3048

C3041

C3042

C3037

C3033

C3043

C3045

C3046

R3093

R3088

R3091

R3082

R3085

R3087

R3164

R3077

R3079

R3076

R3073

R3074

R3075

C3034

R3322

R3054

JS3411

R3055

JS3412

JS3408

ABACAD

JS3409

15

AE

AF

JS2003

JS2004

JS2001

JS2002

JS2000

TH-65PV500B H-BOARD TNPA3520AF

TH-65PV500E H-BOARD TNPA3520AG

ABCDEFGH I

TH-65PV500B H-BOARD TNPA3520AF

TH-65PV500E H-BOARD TNPA3520AG

50

Page 51

13.5. TA-Board

TA-BOARD (FOIL SIDE)

TNPA3521AB (PV500B)

TNPA3521 (PV500E)

6

TH-65PV500E / TH-65PV500B

5

TA5

4

TA-BOARD (COMPONENT SIDE)

TNPA3521AB (PV500B)

TNPA3521 (PV500E)

3

TA

TNPA3521

SEE REVERSE FOR ORDER NO.

VIDEOOUT

SIFOUT

BTL

PbF

2

C001

AUDIOOUT

AFT

JS011

SCL

SDA

C016

TA6

R008

R005

R009

1

TU001

C002

115

R007

R002

L004

L015

1

C009

JS002

Q002

L005

BT

RFAGC

15

C003

SCL

AUDIOOUT

9

L019

L012

L016

SDA

C018

C019

AFT

BTL

SIFOUT

L008

9

C003

TA6

BT

RFAGC

Q003

L007

D003

15

1

TU001

R006

TNPA3521

ORDER

VIDEOOUT

C007

L003

C020

R003

R004

1

1

JS012

C002

C013

NO.

C021

L017

L002

C001

C030

L006

L018

C031

C022

C006

C024

TA5

C023

C017

TA

15

Parts Location

TA-BOARD

TRANSISTOR

Q002 C-2

Q003 D-2

TA

1

TH-65PV500B TA-BOARD TNPA3521AB

TH-65PV500E TA-BOARD TNPA3521

ABCDEFGH I

TH-65PV500B TA-BOARD TNPA3521AB

TH-65PV500E TA-BOARD TNPA3521

51

Page 52

TH-65PV500E / TH-65PV500B

13.6. G-Board

6

5

4

G-BOARD (FOIL SIDE)

TXN/G1CNTE

C7865

C7861

C7863

C7860

C7862

C7905

IC7908

R7902

C7941

R7977

R7901

R7928

R7907

R7978

11

20

10

1

R7929

JS7901

JS7902

R7903

R7979

R7941

R7922

R7905

R7980

R7904

R7940

1

10

10

11

R7939

R7984

R7938

R7982

11

20

R7983

R7937

C7945

C7904

11

20

1

10

R7930

R7933

R7934

IC7907

R7936

IC7905

R7908

C7906

C7942

TP7900

C7855

C7850

C7901

R7954

C7914

C7923

R7949

R7975

C7854

R7911

C7866

C7867

C7946

1

R7932

14

IC7904

R7925

R7926

C7900

C7944

C7868

R7914

C7907

R7972

R7973

R7970

1

7

8

14

L7904

R7931

R7971

R7967

JS7903

JS7904

R7906

R7935

1

7

8

20

R7921

R7981

C7909

C7910

C7943

IC7906

IC7909

C7908

R7953

R7956

R7955

R7948

R7912

R7910

C3703

L3702

R3703

C3704

R7958

C7928

C7929

R7947

R7951

R7952

R7960

C7864

R7986

R7987

R7913

R3702

D3704

D3703

R3712

RL VRL V

R7959

R7950

ZA3701

JK3701

C7859

C7858

C7857

C7856

C7989

C7851

C7852

L3701

R3701

C7853

C7952

C7950

R7957

C3702

C7939

C7988

C7984

C7978

C7974

C7971

C7963

C7967

C7960

R7909

C7955

D3706

R3704

C3701

D3705

D3707

C7985

C7977

C7973

C7970

C7966