Page 1

ORDER NO.MTNC130213CE

B01 Canada: B61

LCD TV

Model No. TC-L32B6

TC-L32B6P

©Panasonic Corporation 2013.

Unauthorized copying and distribution is a

violation of law.

Page 2

CONTENTS

1. Safety precautions .................................................................................................

2. Alignment instructions and method of software upgrading.....................................

3. Working principle analysis of the unit ...................................................................

4. Specifications.......................................................................................................13

5. Block diagram ......................................................................................................14

6. Boards Layout......................................................................................................17

7. Wiring diagram ...................................................................................................18

8. Troubleshooting guide..........................................................................................22

9. Exploded View .....................................................................................................26

10. Replacement Parts List......................................................................................28

11. Disassembly and Assembly Instructions............................................................29

3

5

12

2

Page 3

Attention:

please read the following points carefully.

Safety precautions

This service manual is only for service personnel to take reference with. Before

servicing

1. Instructions

Be sure to switch off the power supply before replacing or welding any components or

inserting/plugging in connection wire Anti static measures to be taken (throughout the entire production

process!):

a) Do not touch here and there by hand at will;

b) Be sure to use anti static electric iron;

c) It’s a must for the welder to wear anti static gloves.

Please refer to the detailed list before replacing components that have special safety requirements.

Do not change the specs and type at will.

2. Points for attention in servicing of LED

2.1 Screens are different from one model to another and therefore not interchangeable. Be sure to

Use the screen of the original model for replacement.

2.2 The operation voltage of LED screen is

protecting yourself and the machine when testing the system in the course of normal operation or

right after the power is switched off. Please do not touch the circuit or the metal part of the module

high voltage. Be

sure to take proper measures in

That is in operation mode. Relevant operation is possible only one minute after the power is switched

off.

2.3 Do not use any adapter that is not identical with the TV set. Otherwise it will cause fire or damage

to the set.

2.4 Never operate the set or do any installation work in bad environment such as wet bathroom,

laundry, kitchen, or nearby fire source, heating equipment and devices or exposure to sunlight etc.

Otherwise bad effect will result.

2.5 If any foreign substance such as water, liquid, metal slices or other matters happens to fall into the

module, be sure to cut the power off immediately and do not move anything on the module lest it should

cause fire or electric shock due to contact with the high voltage or short circuit.

2.6 Should there be smoke, abnormal smell or sound from the module, please shut the power off at

once. Likewise, if the screen is not working after the power is on or in the course of operation, the

power must be cut off immediately and no more operation is allowed under the same condition.

2.7 Do not pull out or plug in the connection wire when the module is in operation or just after the

power is off because in this case relatively high voltage still remains in the capacitor of the driving

circuit. Please wait at least one minute before the pulling out or plugging in the connection wire.

2.8 When operating or installing LED please don’t subject the LED components to bending, twisting or

extrusion, collision lest mishap should result.

2.9 As most of the circuitry in LED TV set is composed of CMOS integrated circuits, it’s necessary to

pay attention to anti statics. Before servicing LED TV make sure to take anti static measure and

ensure full grounding for all the parts that have to be grounded.

2.10 There are lots of connection wires between parts behind the LED screen. When servicing or

moving the set please take care not to touch or scratch them. Once they are damaged the screen

would be unable to work and no way to get it repaired.

If the connection wires, connections or components fixed by the thermo tropic glue need to disengage

when service, please soak the thermo tropic glue into the alcohol and then pull them out in case of

damage.

3

Page 4

2.11 Special care must be taken in transporting or handling it. Exquisite shock vibration may lead to

breakage

before

2.12 For the storage make sure to put it in a place where the environment can be controlled so as to

prevent

prolonged

place.

of

screen glass or damage to driving circuit. Therefore it must be packed in a strong case

the transportation or handling.

the temperature and humidity from exceeding the limits as specified in the manual. For

storage, it is necessary to house it in an anti-moisture bag and put them altogether in one

The ambient conditions are tabulated as follows:

Temperature

Scope for operation

0

~ + 35

oC

Humidity

2.13

Display of a fixed picture for a long time may result in appearance of picture residue on the

as

screen,

of LED screen. This phenomenon doesn’t represent failure. This “ghost shadow” may remain

in the picture for a period of time (several minutes). But when operating it please avoid displaying still

picture in high brightness for a long time.

commonly called “ghost shadow”. The extent of the residual picture varies with the maker

Scope for storage

Scope for operation

Scope for storage

-20 ~

+ 60oC

20% ~

10% ~ 90%

80

%

3. Points for attention during installation

3.1 The front panel of LED screen is of glass. When installing it please make sure to put it in place.

3.2 For service or installation it’s necessary to use specified screw lest it should damage the screen.

3.3 Be sure to take anti dust measures. Any foreign substance that happens to fall down between the

screen and the glass will affect the receiving and viewing effect

3.4 When dismantling or mounting the protective partition plate that is used for anti vibration and

insulation

3.5 Be sure to protect the cabinet from damage or scratch during service, dismantling or mounting.

please take care to keep it in intactness so as to avoid hidden trouble.

4

Page 5

2. Alignment instructions

(1) Test equipment

VG-859 (YPbPr, VGA, HDMI signal generator)

FLUKE 54200(TV signal generator)

CA310 (white balancer)

(2) Power test

Connect main board, power board and IR board according the wiring diagram, connect

the power and press power key (Remote controller or Keypad) button to turn on the TV.

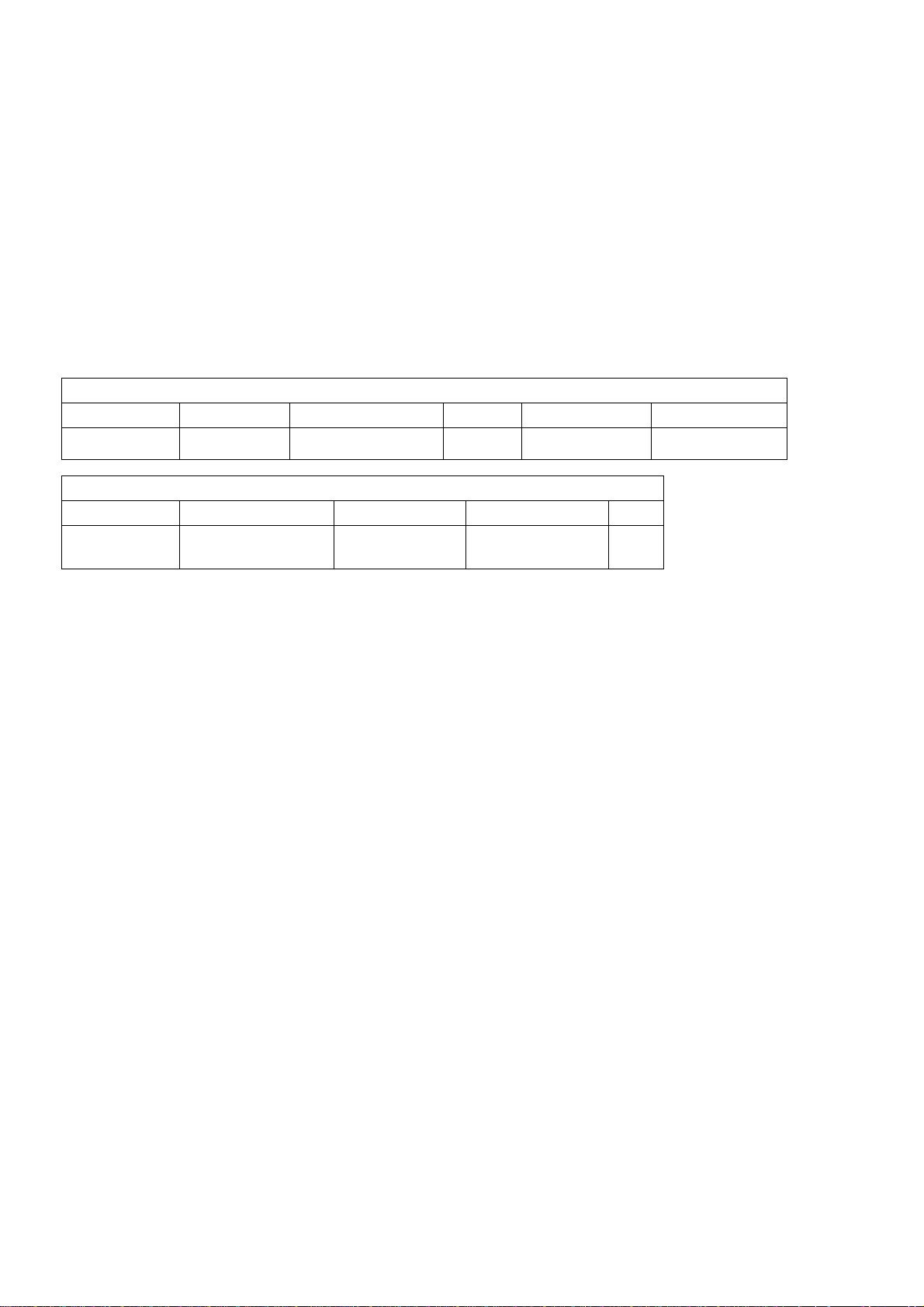

a) Test the pin voltage of P802/power board , the data is shown in table1:

Table1 voltage data of P802

For 32”

P802 Pin1,2 Pin3,4 Pin5,6,7

Voltage GND 11.4V~12.6V GND 11.4V~12.6V 4.75V~5.25V

For 32”

Pin12 Pin13 Pin 14 Pin15 Pin16

On:2.5V~5.25V

Off: 0~0.5V

Normal: 2.0~5V

Abnormal :0~0.5V

On:2.5V~5.25V

Off: 0~0.5V

Pin8,9 Pin10,11

Duty 5%~100% NC

5

Page 6

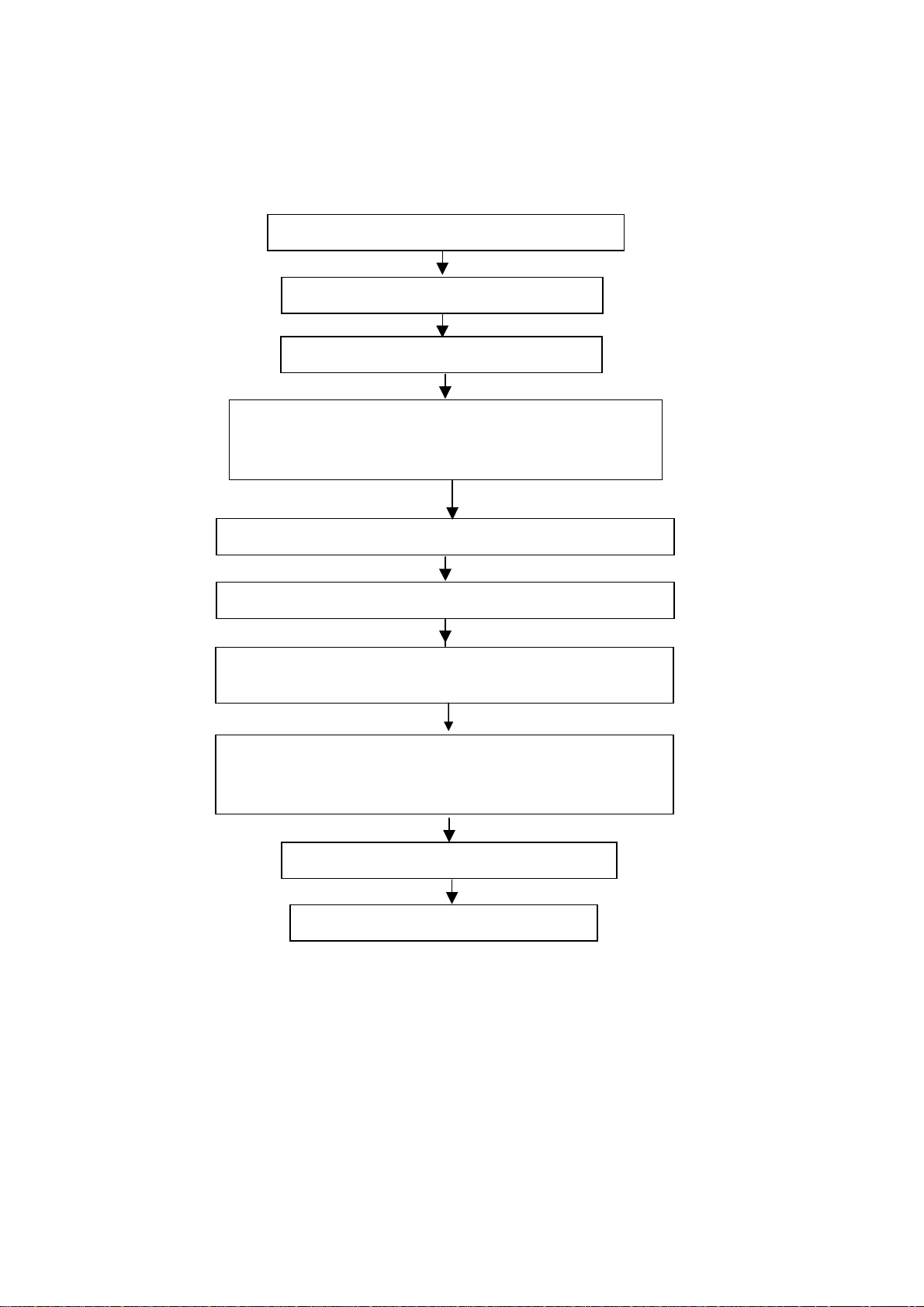

(3) Alignment flow-chart

The alignment flow-chart is shown as fig-1

Connect to the center signal source and check each

Funct

Check the output of speaker.

Check if EDID, HDCP KEY, FLASH are written

Combined test for general assembly

Auto Gamma adjustment

ion of TV (station leaking, analog control, etc.)

Input AV signal and check the function

Input HD signal and check the function of YPbPr

Input USB signal and check if the display is normal, check

the fu

nction (analog control), horizontal/vertical center, etc.

Input HDMI signal and check if the display is normal, check

the function (analog control), horizontal/vertical center, etc.

Checking SPDIF will output the signal on Amplifier.

Preset ex-factory

Check the accessories and packing

Fig-1 adjustment flow-chart

6

Page 7

(4) Adjustment instruction

At any input source then press the “←”, “EXIT” and “OK” (using RC within 1 sec) to enter factory mode

During Factory menu, if “EXIT” key is pushed, system will exit factory mode.

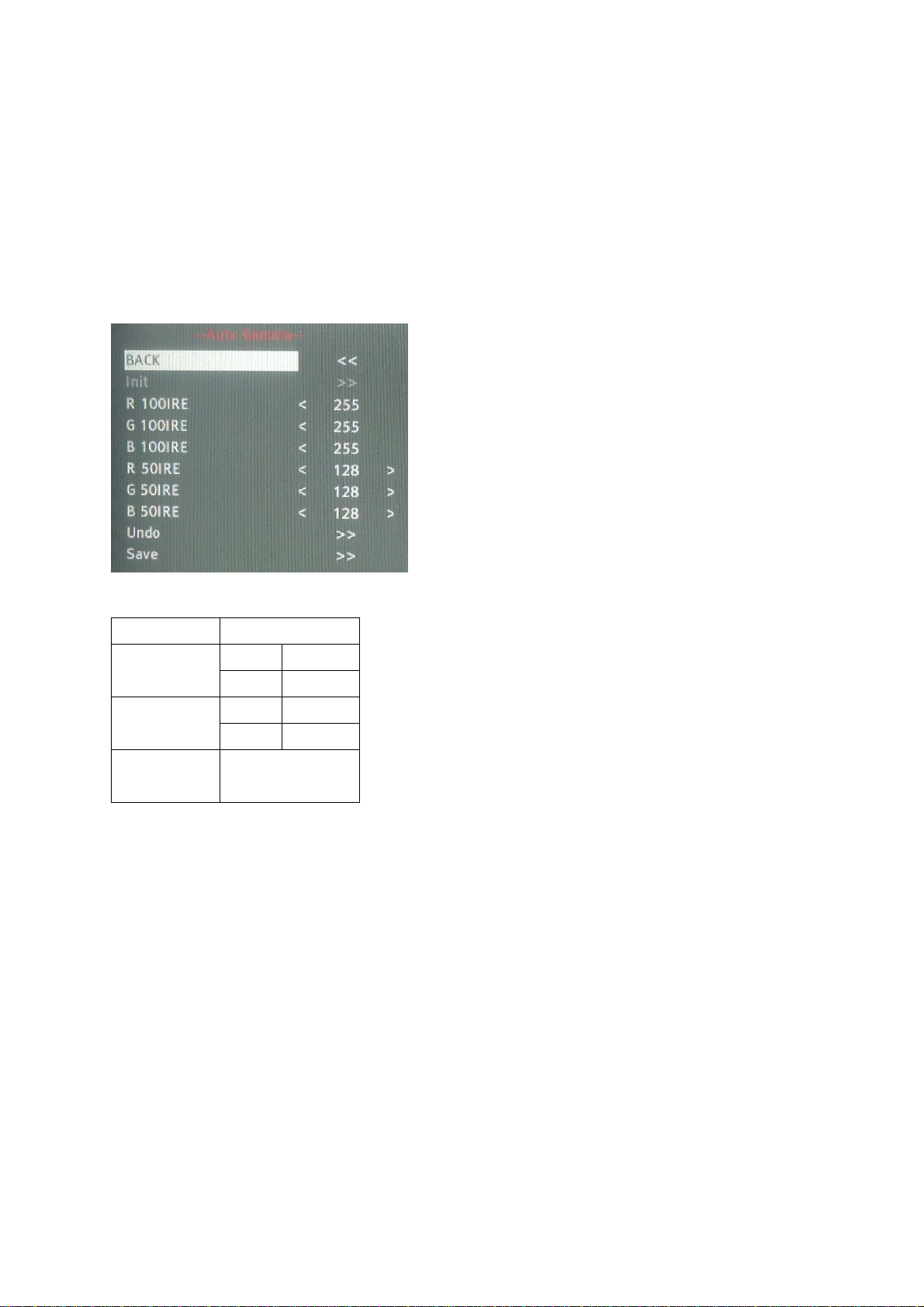

4-1. Auto Gamma Adjustment & Check

4-2.1. Set into factory mode then choose Auto Gamma Adjust,

4-2.2. Press "2" "3" "2" "4" in turn within 1sec to enter the item, and push Init will self-generate gray pattern

for adjusting.

4-2.3. Following the Cool spec as bellow.

Color Cool

x

100IRE 0.2677

50IRE 0.2684

y

Adjust

Tolerance

100IRE 0.2655

50IRE 0.2671

±0.005

(1) Adjust 100IRE

First, Decrease G to meet y spec(0.2655).

Second, Decrease R to meet x spec(0.2677).

(2) Adjust 50IRE

First, Decrease G to meet y spec(0.2671).

Second, Decrease R to meet x spec(0.2684).

Note: Do not adjust the B GAIN on both 100IRE and 50IRE.

When match the spec, pressing “Save” then exit the adjustment page.

(5) When match the spec, pressing right key in "Save" position then exit the adjustment page.

4-2.4. Exit Factory Mode:

After finish Gamma adjust press [EXIT] to exit factory mode.

7

Page 8

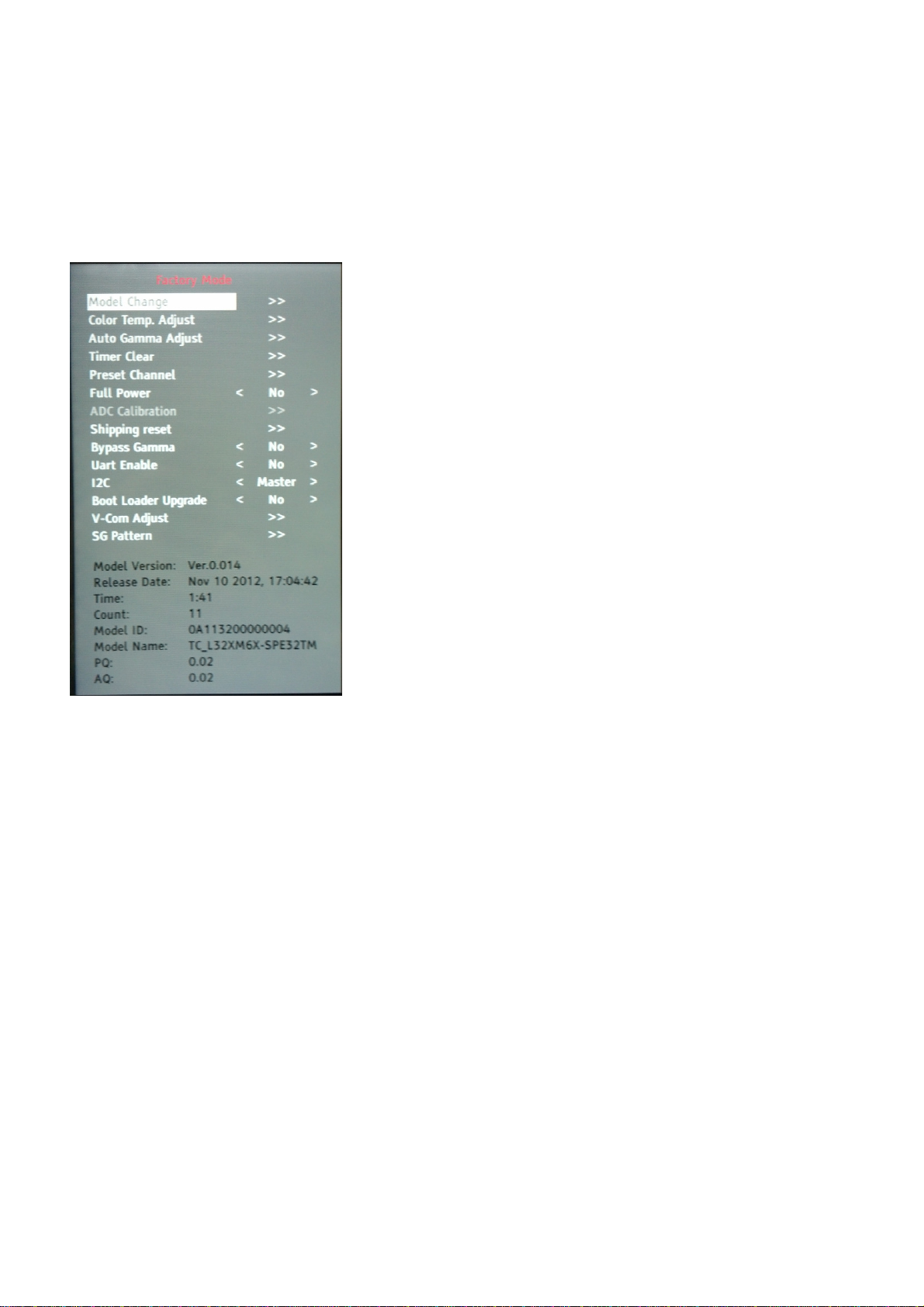

(5) Items of Factory menu

When in any source, press the “Left -> Exit -> Enter” key of remote control can enter into factory mode.

During Factory menu, only “EXIT” key is pushed, system will exit factory mode.

Press up and down key can move high light item from Model Change -> Color Temp. Adjust -> Auto Gamma

Adjust -> Timer Clear -> Preset Channel -> Full Power -> ADC Calibration -> Shipping reset -> Bypass Gamma ->

UART Enable -> I2C -> Boot Loader Upgrade -> V-Com Adjust -> SG Pattern.

Push “Enter” key can enter high light item function. (Press left and right can adjust value)

Display Model version, Release Date, firmware version and released date on the bottom.

1)Model ID

Press

up or down key can select high light item function

Press enter or right key to enter the item.

It's only used for FW engineer.

2)Color Temp. Adjust

Press up or down key can select high light item function

Press enter or right key to enter the item.

It's only used for PQ engineer.

3)Auto Gamma Adjust

Press up or down key can select high light item function

Press enter or right key to enter the item.

It's only used for PQ engineer.

4)Timer Clear

Reset the timer which records hours of LED panel burn in

This item will have a check dialog “yes or no” to do or not.

- Time in factory mode: Time function shall be displayed automatically. Saving the total time of system

power on (LED turn on), and count the time automatically. The timer is continuous and saved (per 10

minutes) forever, unless it will be reset by doing “Timer Clear”.

5)P

6)Full Power

reset channel

Load p

This is for power consumption testing.

To measure the maximum power consumption of TV set, we adjust the value of following items to

maximum.

- Video: Contrast maximum value, Brightness maximum value, Backlight maximum value.

- Audio: Volume maximum value, Bass default value, Treble default value.

Press enter key to turn on Full Power and OSD stay display until press enter key to recover from Full

Power.

reset channel for production line.

8

Page 9

7)ADC Calibration

LINE (pixel)

LINE (pixel)

LINE (pixel)

3 15

62 60

6 30

40

5 20

44

5 15

44

5 36

ADC Calibration function is reserved for calibration by hand (PQ engineer only).

8)Shipping reset

Reset all settings of OSD menu to default value.

Reset settings: Channel table, Model table (H/V Position, Clock, Phase), Source dependent setting

(Contrast, Brightness etc.), Common setting (Volume, Language etc.), Parental Control (Rating,

Password etc), Closed Caption.

9)Bypass Gamma

For factory test value of gamma.

10)UART Enable

Enable to communicate with Auto-Alignment system.

11)I2C

Enable to communicate with Eeprom burn-in tool.

12)Boot Loader Upgrade

For firmware downgrade used.

13)V-Com Adjust

It's reserved for BMS function.

14)SG Pattern

Aging is for factory burn in and PTN ID provides each pattern for tester using.

(6) Pe

6-1 TV function

Connect RF to the center signal source, enter Channel menu → auto tuning, check if there are channels be

skipped, check if the picture and speaker are normal.

6-2 AV terminals

Input Video signal, check if the picture and sound are normal.

6-3 YPbPr terminal

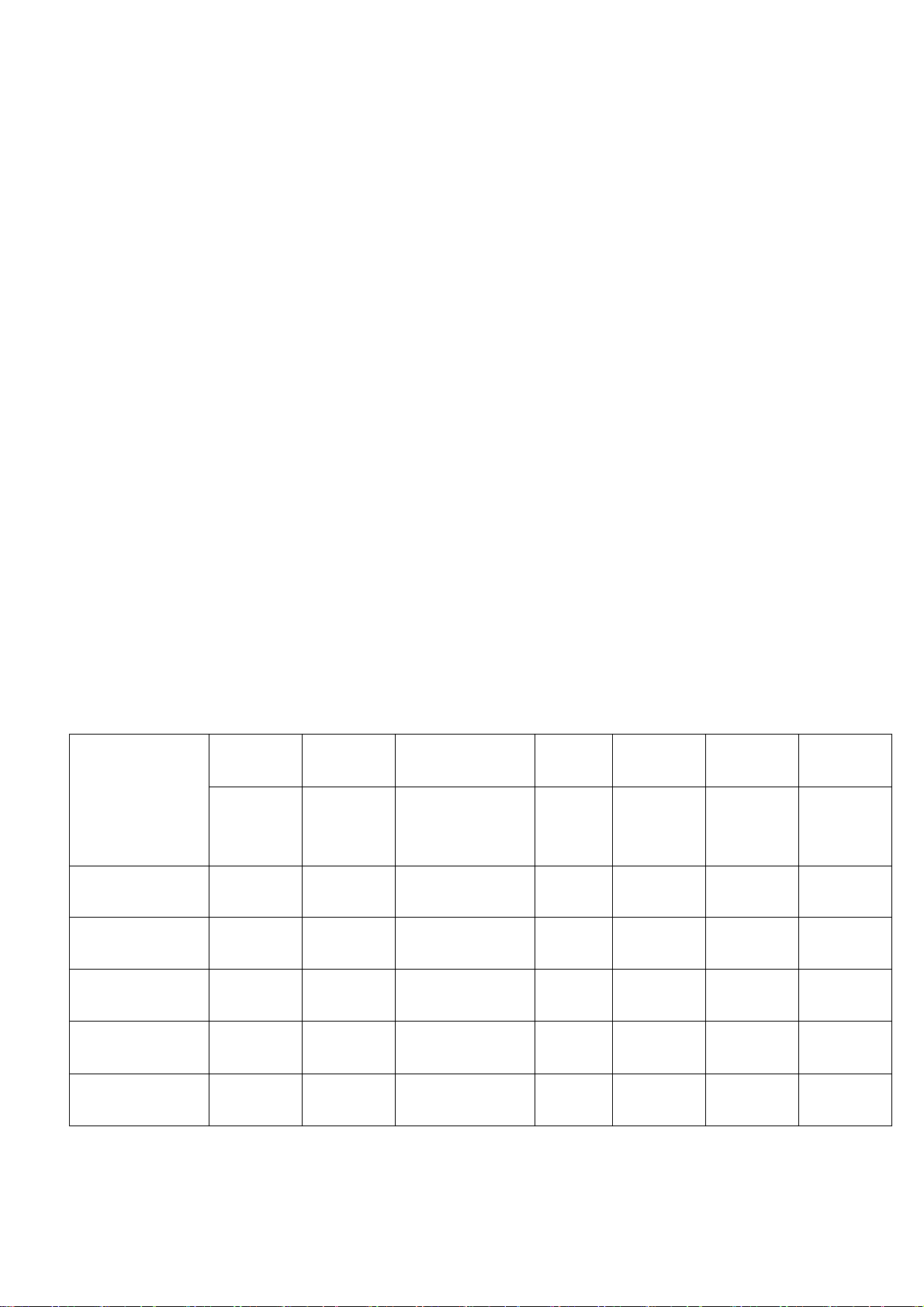

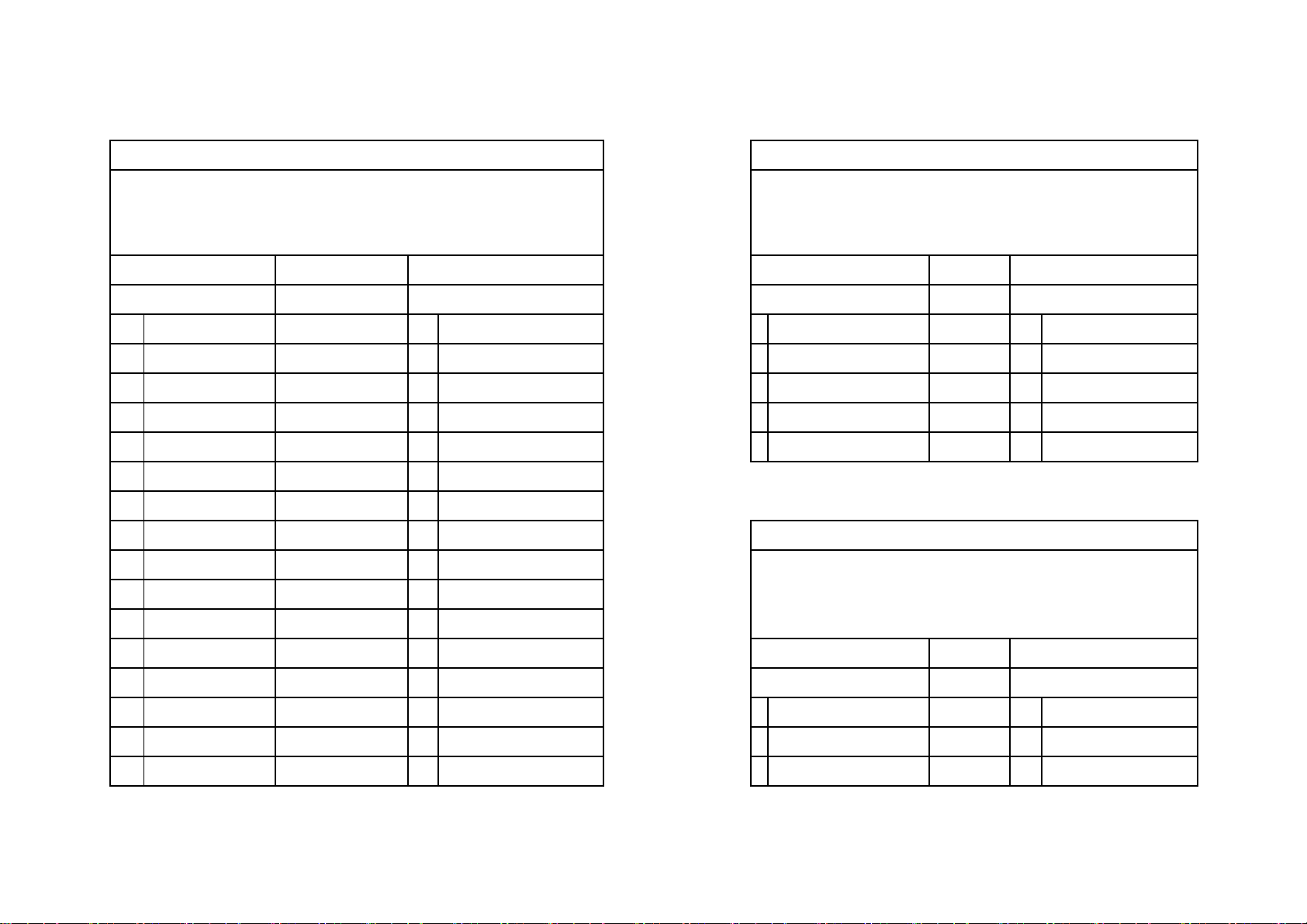

Input YUV signal (VG859 signal generator), separately input the YUV signals listed in table4 and check if the

display and sound are normal at any situation (power on, channel switch and format convert, etc.)

rformance check

FREQ PERIOD

Table4 YUV signal format

SYNC

POLARITY

CLOCK

PIXEL

Display

SYNC

WIDTH

BACK

PORCH

MODE

15.734

59.94Hz 720x480i

59.94Hz 720x480P

60Hz 1280x720P

60Hz 1920X1080i

60Hz 1920X1080P

LINE(kHz)

FRAME

(Hz)

59.94

31,469

59.94

45

60

33.75

60

67.5

60

LINE (pixel)

FIELD

(lines)

1716

525

858

525

1650

750

2200

1125

2200

1125

LINE

FIELD

Negitive 27

Negitive 480

Negitive 27

Negitive 480

Positive 74.25

Positive 720

Positive 74.25

Positive 1080

Positive 148.5

Positive 1080

9

(MHz)

FRAME

(lines)

1440

720

1280

1920

1920

FRAME

(lines)

124

FRAME

(lines)

114

220

148

148

Page 10

6-4 HDMI terminal

Input HDMI signal (VG859 signal generator), separately input the signals listed in table6 and check the display and

sound (32 KHz, 44.1 KHz, 48 KHz) at any situation (power on, channel switch and format convert, etc.)

HDMI signal format

SYNC

POLARITY

PIXEL

CLOCK

Display

SYNC

WIDTH

BACK

PORCH

HDMI

1/2/

DVI

Timing

Table

Table6

FREQ FREQ PERIOD

MODE

640x480

800x600

1024x768

1280x768 (1280cvt)

1280x768

1280x1024

1360x768

1366x768

1920x1080

59.94Hz 1440x480i

59.94Hz 720x480P

60Hz 1280x720P

60Hz 1920X1080i

24Hz 1920x1080P

30Hz 1920x1080P

60Hz 1920X1080P

LINE(kHz)

FRAME(Hz)

31.47 800 Negitive 25.175 640 96 48

LINE (pixel)

FIELD(lines)

LINE

FIELD

(MHz)

LINE (pixel)

FRAME

(lines)

LINE (pixel)

FRAME

(lines)

LINE (pixel)

FRAME

(lines)

59.94 525 Negitive 480 2 33

37.88 1056 Positive 40 800 128 88

60.32 628 Positive 600 4 23

48.36 1344 Negitive 65 1024 136 160

60 806 Negitive 768 6 29

47.4 1440 Positive 68.25 1280 32 80

59.99 790 Negitive 768 7 12

47.78 1664 Negitive 79.5 1280 128 192

59.87 798 Positive 768 7 20

63.98 1688 Positive 108 1280 112 248

60.02 1066 Positive 1024 3 38

47.71 1792 Positive 85.5 1360 112 256

60.02 795 Positive 768 6 18

47.71 1792 Positive 85.5 1366 112 256

59.79 795 Positive 768 6 18

67.5 2200 Positive 148.5 1920 44 148

60 1125 Positive 1080 5 36

15.73 1716 Negitive 27 1440 124 114

59.94 262.5 Negitive 480 3 15

31.47 858 Negitive 27 720 62 60

59.94 525 Negitive 480 6 30

45 1650 Positive 74.25 1280 40 220

60 750 Positive 720 5 20

33.75 2200 Positive 74.25 1920 44 148

60 562.5 Positive 1080 5 15

27 2750 Positive 74.25 1920 44 148

24 1125 Positive 1080 5 36

33.75 2200 Positive 74.25 1920 44 148

30 1125 Positive 1080 5 36

67.5 2200 Positive 148.5 1920 44 148

60 1125 Positive 1080 5 36

10

Page 11

6-5 other functions check

a) Check the sleep timer, picture/sound mode, OSD, stereo and analog TV Teletext, etc.

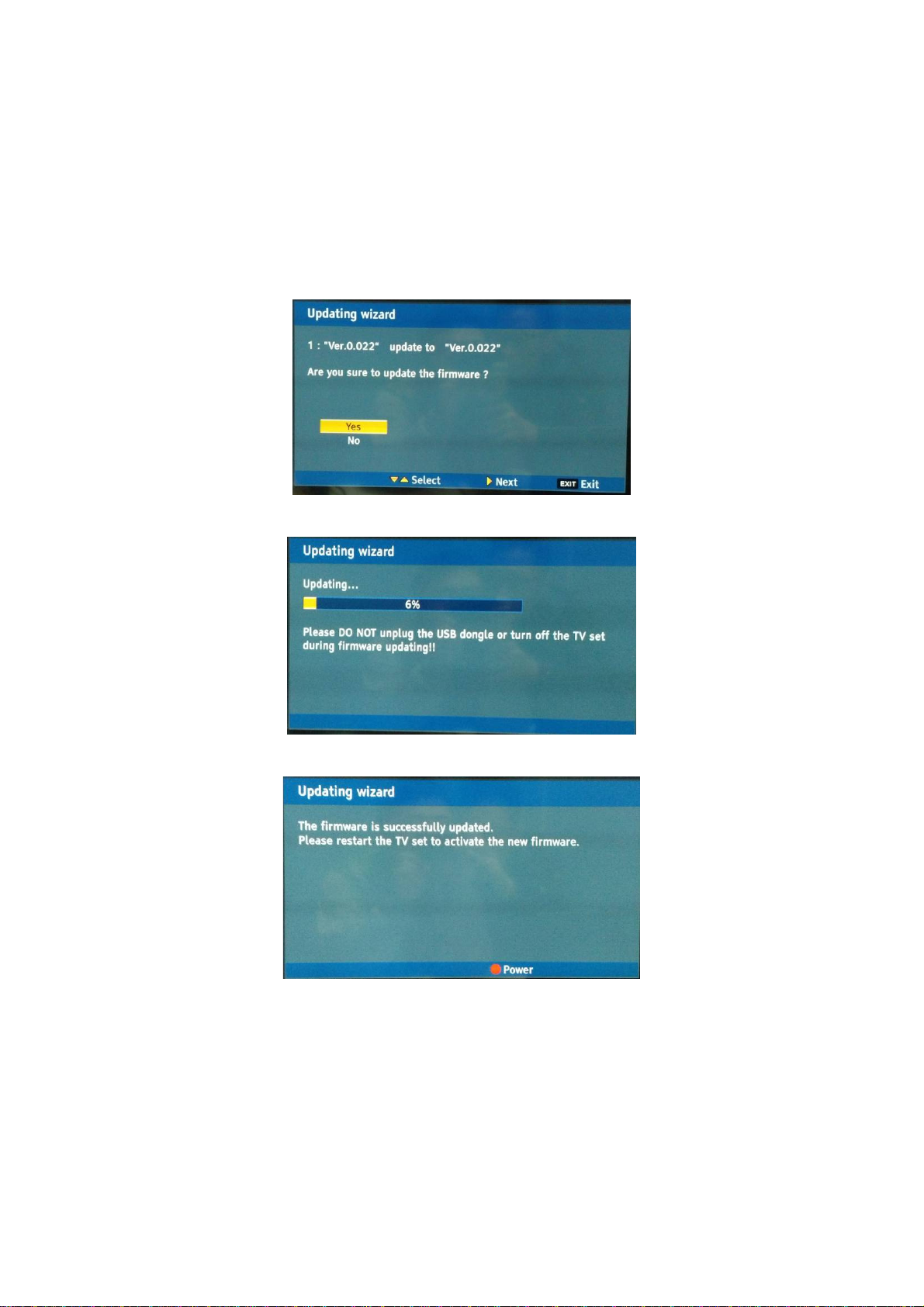

(7) Firmware update process

(1) Plug the USB with the firmware file named upgrade_2013_NA.pkg

(2) If system detect upgrade_2013_NA.pkg, USB upgrade message would appear automatically.

(3) Press Up key to select Yes, and then press OK key to start the upgrading.

(4) Upgrading is starting, please wait for the progress finish.

(5) When the progress completed, please follow the instruction to remove USB and restart Power off

then on.

11

Page 12

Working principle analysis of the unit

1.

NTSC

Antenna signal will be send to tuner TDST-H021F,

output standard video signal TV-CVBS, and sound SIF signal

signals flow:

t h en T un e r wil l b e

.

demodulating and

TV-CVBS will send to the master control IC MT5385 to video decode, de-interlace and scaler, then

output

LVDS level drive for panel display.

The sound IF (SIF) will be fed into MT5385, after demodulating, pre-amplifying, bass adjusting and

volume control, the sound signal

digital amplifier TAS5707.

2. Composite/Component signal flow

will be tr a nsf or m into digital I2S s i g n a l

and sent to

Composite signal and Component signal will be fed to MT5385 to perform video decode, deinterlace and scaler, then output LVDS drive level for panel display.

Audio signal from Composite/Component

adjust and volume control, the sound signal will

to digital amplifier TAS5707.

3. HDMI signal flow

terminal

via matched resistance is fed to MT5385 to bass

b e t r a n sf o r m i n t o d i g i t a l I 2 S s ignal

and sent

Two HDMI video signals are directly fed to the master control IC MT5385 to digital decode, image

scale, then output LVDS drive level for panel display. HDMI audio signal via decoder built-in

bass adjust and volume control, the sound signal will

sent to digital amplifier TAS5707.

be tra n sf o r m i n t o d i g i t a l I 2 S s i g n a l

MT5385

4. USB signal flow

USB signal via USB connector sent to

MT5 385, then out put

image scale, then send to LVDS level drive for panel display.

Sound signal of USB signal

volume control, the sound signal will

amplifier TAS5707.

5. SPDIF signal flow

The master control IC MT5385 will transfer digital sound signal out by format Dobly Digital or PCM.

MT5385 and it s

R/G/B of 24 bit to back end module to Video decode,

A/D conversion to

YPb Pr

output

fo r

de -interlace and

v i a

matched resistance

be tr a n sf o r m i n t o d i g i t a l I 2 S s i g n a l

a n d

sent to MT5385 to bass adjust and

and sent to digital

and

to

12

Page 13

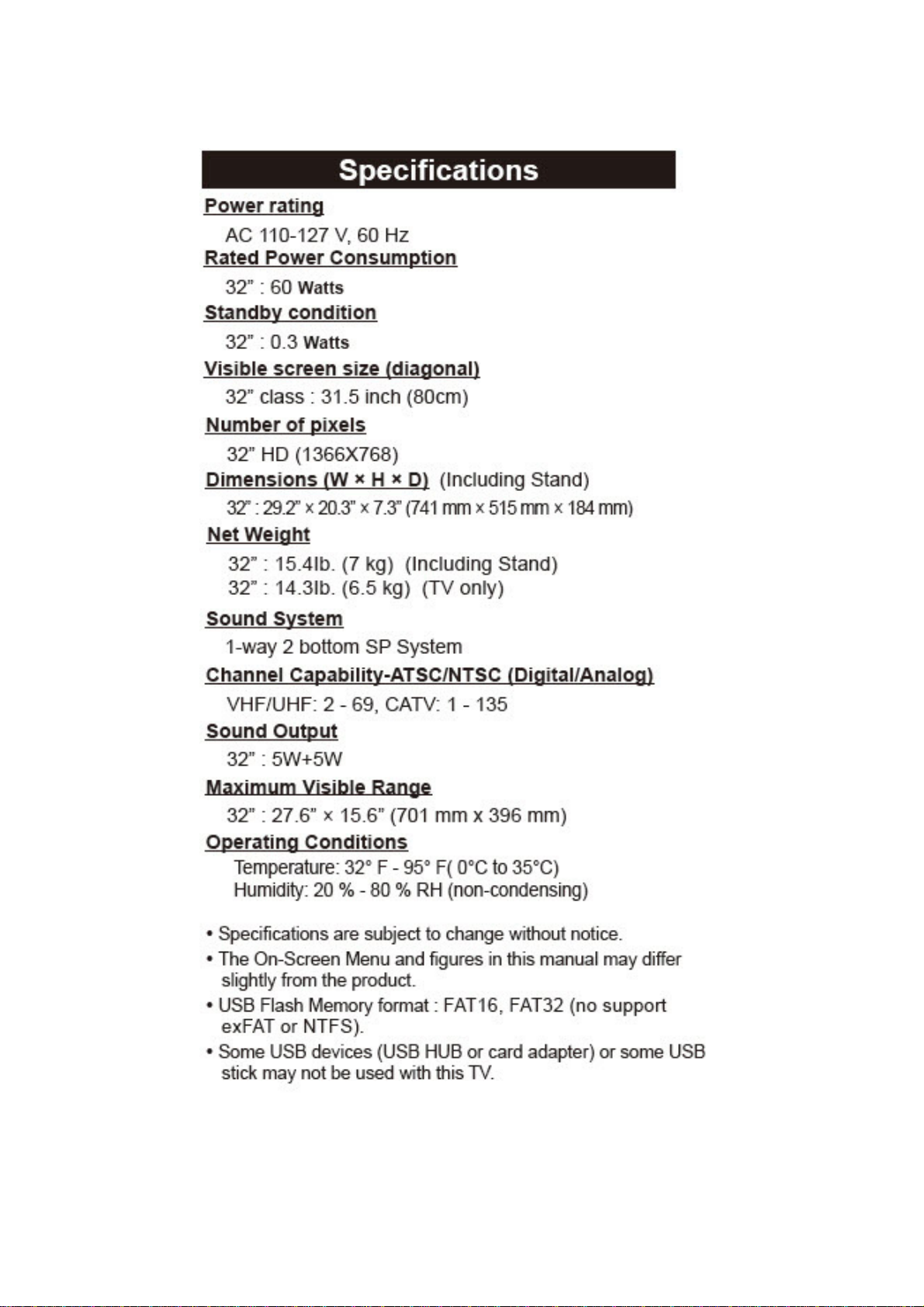

4.

4. Specifications

4. 4.

13

Page 14

5-1 Block Diagram

EE:

SPD32T 32” Block Diagram

A70 60Hz Models by

MTK MT5835 Platform

Tuner

LG

TDSTH021F

ANT /

CABLE

DDR3 1G-1600

H5TQ1G63DFR-PBC

Flash 16MB

MX25L12845EMI-10G

IF +/-

CVBS/Y Pb Pr

& Audio R/L

Y

Pb

Pr

L

R

COLOR STREAM HD

& COMPOSITE IN

& Audio R/L in

WXGA :2x10

D :2x20

Full-H

DTV system IC

MTK

MT5385

Enable

ARC

Buffer

S/PDIF

SPDIF

OUT

Panel out

Audio I2S output

EEPROM 64KB

24C32

Crystal

27MHz

Audio

AMP

TAS5707

HDMI 1

R_out

L_out

HDMI 2

IR

USB

Keypad

IR / LED-R

Board

14

Page 15

Power board:FSP

15

Page 16

Power board:DARFON

16

Page 17

6. Boards Layout

A

e

11

2

1

Ref No. Board Name Function Remrks

1 PCBA IR/B Remote Receiver, LED

2 FIRMWARE M/B Main Board, Audio & Video Signal Processing

11 PWR MODU Power (AD/DC), DC-DC, Control Button

ll boards are non servicabl

and should be exchanged for

service

17

Page 18

7-1 BLOCK

SPD32T 32-inch Wiring Diagram

18

Page 19

7-2 Wiring Connection

AUO panel

Main board to Panel Main board to Speaker

SPD32T SPD32T

DC02L00700I DC02A00130I

280 mm

Panel side Main board CN1 Main board CN4 Speaker

FI-X30SSL-HF LVDS cable JWT A2006WR0-2X10P JWT A2001WR2-4P Color Right

1 VCC Red 1 LVDS_PWR 1 SPK_OUTL+ Red P3 Speaker +

2 VCC Red 2 LVDS_PWR 2 SPK_OUTL- Black P2 Speaker -

3 VCC NC Left

4 VCC NC 3 SPK_OUTR- Green P5 Speaker -

5 GND NC 4 SPK_OUTR+ White P4 Speaker +

6 GND NC

7 GND NC

8 GND NC Main board to IR board/ Key

9 SELLVDS Yellow 8 LVVDS_SEL SPD32T

10 NC NC DC02V04140I

11 GND NC IR:450 mm & Key:750mm

12 RX0- Yellow 20 LVDS_D0O_N IR board CN1 Main board CN3

L:280 & R:480 mm

13 RX0+ White 19 LVDS_D0O_P JWT A2001WR2-11P Color JWT A2001WR2-5P

14 GND NC 1 VCC3V3_STB Red 1 VCC5_0_STB

15 RX1- Red 18 LVDS_D1O_N 2 IRR White 2 IRR

16 RX1+ White 17 LVDS_D1O_P 3 GND Black 3 GND

19

Page 20

17 GND Black 5

18 RX2- Orange 16 LVDS_D2O_N NC 5 LEDR

19 RX2+ White 15 LVDS_D2O_P NC 6 Light_S_C

20 GND Black 6 GND NC 7 Light_S_D

21 RXCLK- Brown 14 LVDS_CO_N 1 GND Black 8 GND

22 RXCLK+ White 13 LVDS_CO_P 2 Power Red 9 Power Key

23 GND Black 7 GND 3 SAR0 Orange 10 SAR0

24 RX3- Black 12 LVDS_D03_N 4 SAR1 Yellow 11 SAR1

25 RX3+ White 11 LVDS_D03_P

26 GND NC

27 NC NC

28 NC NC

29 NC NC

30 GND NC

GND 4 LED_G Orange 4 LEDG

20

Page 21

Main board to Power board:

21

Page 22

8. Trouble shooting

1. Fault clearance

Before calling your dealer or service center for assistance, check the matters below once again.

(1) Make sure you have connected LED TV to your equipment as described in the section

“ CONNECTING LED TV”.

(2) Check cable connection. Verify that all external equipment and power cord are properly

connected.

(3) Verify that all power is switched on.

(4) If LED TV still does not produce an image, re-start the external equipment.

(5) If the image still does not appear, unplug LED TV from the external equipment and check the

external equipment. The problem may be with your graphics controller rather than with LED TV.

(When you reconnect LED TV, remember to turn the external equipment and TV off before you

power up LED TV. Power the equipment back on in order of LED TV and external equipment.)

(6) If the problem still exists, check the following chart.

Problem Try these Solutions

NO POWER

Remote

Control does

not work

No image

No sound

There are tiny

black points

and/or bright

point on the TV

Abnormal

color of image

Plug this LED TV into the AC outlet.

Press POWER button on side control or on Remote Control to turn on LED TV.

Check POWER Indicator. If this indicator blank, this TV has getting trouble.

Check the batteries.

Make sure nothing is between the Remote Receiver and the Remote Control.

Make sure you are not too far from LED TV when using Remote Control.

Maximum operating range is 5m.

Is direct sunlight or strong artificial light shining on LED TV‘s Infrared Remote

Receiver? Eliminate the light by closing curtains, pointing the light in a different

direction, etc.

Check the connection between the external equipment and LED TV.

When turning LED TV on, it takes within 7 seconds (ATV mode) to display the

image.

Check the system that you select is corresponding with the external equipment

or the video equipment.

Make sure the temperature is not out of the Operating Temperature (0°C ~

40°C).

Turn off power, then turn on again, re-start LED TV.

Check Audio cable connection from Audio input source.

Adjust the Sound System.

Press VOLUME (+) button.

Press MUTE button.

Dark or bright points of light (red, green, or blue) may appear on the screen.

This is a characteristic of the LED panel, not a malfunction of the LED TV.

LED panel is produced with very high accuracy technology. There is 99.99% or

more dot pixel, but there is also 0.01 % or less of dot pixel lack or dot pixel that

is constantly lighted. This is not defect.

Regarding LED panel characteristic, it may occur picture remain (look like a

mirror) when the screen is changed if it displays same screen for a long time.

Changing the picture or turn-off the power supply may recover.

Stripe pattern (more, interference stripes) may show up on the screen depends

on the reflected picture.

Adjust the value of color.

Select different color system.

22

Page 23

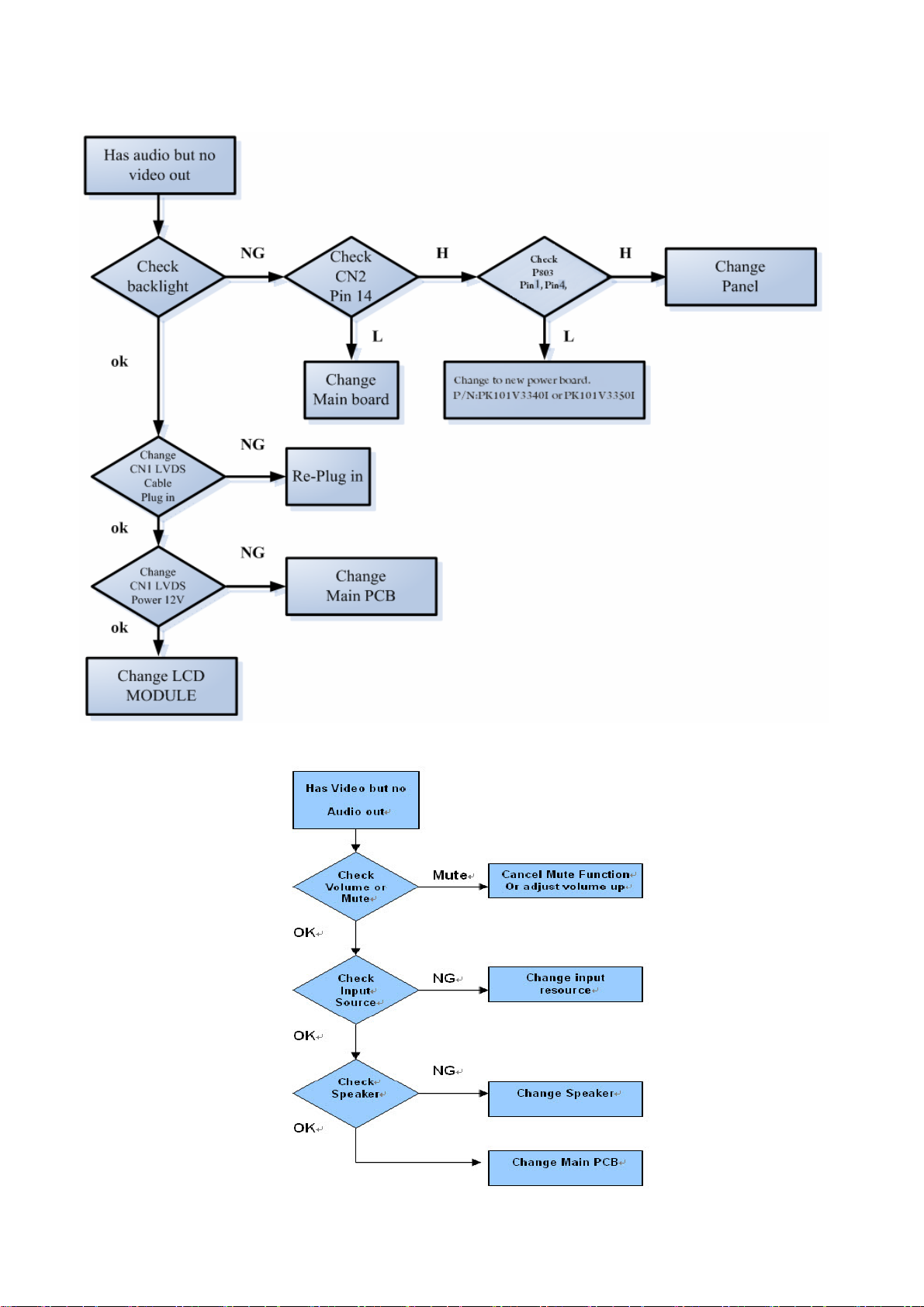

2. Troubleshooting guide

The flow chart shown below will help you to troubleshoot your Televison set with it doesn’t display

normally. Each procedure offers a simple way to check for system errors. Before starting, ensure

that there is a signal in and that the Televison is turned on.

2-1 Power LED no light

23

Page 24

2-2 Has audio but no video out

2-3 Has video but no audio out step 1

24

Page 25

2-4 Has video but no audio out step 2

25

Page 26

9. Exploded View

12

17

03

21

17

29

04

23

15

16

26

20

18

02

19

01

17

09

21

29

04

10

14

25

08

28

24

06

05

27

27

13

07

28

10

29

18

20

11

22

28

30

29

30

Page 27

36

40

POP label

34

38

37

33

31

41

42

39

Type A

44

45

Type B

35

32

43

Page 28

10. Replacement Parts List

Note: All parts aresupplied by PAVCA.

Safety Ref.No. Part No. Part Name & Description Pcs Remarks

1 TZZ00000766A PCBA IR/B 1

2 TZZ00000767A FIRMWARE M/B 1 TC-L32B6

2 TZZ00000768A FIRMWARE M/B 1 TC-L32B6P

3 TZZ00000772A LCD MODU 1

4 TZZ00000780A SPK SET(90d)(PIN90d) 2

5 TZZ00000781A H-CON SET 1

6 TZZ00000782A H-CON SET 1

7 TZZ00000783A H-CON SET 1

8 TZZ00000784A H-CON SET 1

9 TZZ00000786A H-CON SET 1

10 TZZ00000079A MYLAR AL TAPE 2

11 TZZ00000844A PWR MODU(SPD32T) 28 1

12 TZZ00000774A CABINET ASSY 1

13 TZZ00000775A BACK COVER ASSY 1

14 TZZ00000787A METAL VERTICAL-L 1

15 TZZ00000788A METAL VERTICAL-R 1

16 TZZ00000789A METAL CH FRAME-A 1

17 TZZ00000790A LCD MTG SIDE(32B6) 6

18 TZZ00000794A GROND SPRING (32B6) 2

19 TZZ00000804A SIDE AV BRACKET(32B6) 1

20 TZZ00000805A CH MOUNT BOSS(32B6) 2

21 TZZ00000806A SPEAKER BRACKET(32B6) 4

22 TZZ00000809A KEY BUTTON BRACKET(32B6) 1

23 TZZ00000078A LOCKING CABLE TIE 1

24 TZZ00000832A SUPPORT(32B6) 3

25 TZZ00000834A SCREW 3

26 TZZ00000835A SCREW 3

27 TZZ00000083A SCREW+LOCK WASHER(8) 4

28 TZZ00000838A SCREW(NL) 7

29 TZZ00000843A TAPPING SCREW 10

30 TZZ00000656A TAPPING SCREW 6

31 TZZ00000796A RATING NP-TC-L32B6 1 Model Name Plate TC-L32B6

31 TZZ00000799A RATING NP-TC-L32B6P 1 Model Name Plate TC-L32B6P

32 TZZ00000821A CARTON-TC-L32B6 1 TC-L32B6

32 TZZ00000824A CARTON-TC-L32B6P 1 TC-L32B6P

33 TZZ00000828A ENERGY GUIDE-TC-L32B6 1

34 TZZ00000831A PE BAG FOR TV 1

35 TZZ00000846A MANUAL KITS-32B6 1 TC-L32B6

35 TZZ00000848A MANUAL KITS-32B6P 1 TC-L32B6P

36 TZZ00000819A PWR CORD(S) 1 TC-L32B6

36 TZZ00000820A PWR CORD(S) 1 TC-L32B6P

37 N2QAYB000820 REMO CTRL AA 1

38 TZZ00000776A PEDESTAL ASSY 1

39 TZZ00000803A STAND MOLD 1

40 TZZ00000811A EPS FOAM(T-L) 1

41 TZZ00000812A EPS FOAM(T-R) 1

42 TZZ00000813A EPS FOAM(B-L) 1

43 TZZ00000814A EPS FOAM(B-R) 1

44 TZZ00000842A TAPPING SCREW 4 Type A screw

45 TZZ00000840A SCREW+2WASHER(10) 4 Type B screw

28

Page 29

11 Disassembly and Assembly Instructions

11.1. Base cover + stand mold

1. Lay down the unit so that the rear cover faces upward.

2. Remove the 4 screws.

3. Remove the Base cover + stand mold

11.2. Back cover

1. Remove the total 19 screws.

2. Re

move the back cover.

Page 30

11.3. P-Board

1. Remove the 2 screws.

2. Disconnect the connectors (P1, P2, P3).

3. Remove the P-Board.

4. Remove the key button bracket

11.4. M-Board

1. Remove the 2 screws.

2. Di

sconnect the connectors (M1, M2, M3, M4).

3. Remove the M-Board.

4.Remove the side AV bracket

5. Remove the CH-mount boss

Page 31

11.5. Speaker unit

1. Remove the 4 screws.

2. Remove the speaker units.

3. Remove the speaker bracket.

11.6. IR-Board

1. Disconnect the connectors (I1).

2. Remove the IR-Board.

Page 32

11.7. Metal parts I

1. Remove the 6 screws.

2. Remove the metal parts (M1,M2, M3,M4).

11.8. Panel

1. Remove the Panel.

Loading...

Loading...