Panasonic TC-65DX900U Schematic

ORDER NO. MTV1605077CE

LED TV

Model No. TC-65DX900U

Chassis: LA65

Destination: U : USA

© Panasonic Corporation 2016.

TC-65DX900U

TABLE OF CONTENTS

PAG E PAG E

1 Safety Precautions -----------------------------------------------3

1.1. General Guidelines ----------------------------------------3

1.2. Touch-Current Check--------------------------------------3

2Warning--------------------------------------------------------------4

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices ----------4

2.2. About lead free solder (PbF) ----------------------------5

3 Service Navigation------------------------------------------------6

4 Specifications ------------------------------------------------------7

5 CS Maintenance Menu-------------------------------------------8

5.1. How to enter into CS Maintenance Menu ------------8

5.1.1. Purpose --------------------------------------------------8

5.1.2. Key command ------------------------------------------8

5.1.3. How to exit ----------------------------------------------8

5.2. Repack--------------------------------------------------------8

5.3. EDID Clock --------------------------------------------------9

5.4. USB HDD Drive Check -----------------------------------9

5.5. White Balance Adjustment----------------------------- 10

5.6. Version------------------------------------------------------ 11

5.6.1. How to access---------------------------------------- 11

5.7. Hotel mode------------------------------------------------- 12

5.7.1. Purpose ------------------------------------------------ 12

5.7.2. Access command to the Hotel mode setup

menu---------------------------------------------------- 12

5.7.3. To exit the Hotel mode setup menu------------- 12

5.7.4. Explain the Hotel mode setup menu------------ 12

5.8. Data Copy by USB Memory --------------------------- 13

5.8.1. Purpose ------------------------------------------------ 13

5.8.2. Preparation-------------------------------------------- 13

5.8.3. Data copy from TV set to USB Memory ------- 14

5.8.4. Data copy from USB Memory to TV set ------- 15

6 Troubleshooting Guide---------------------------------------- 16

6.1. Check of the IIC bus lines------------------------------ 16

6.1.1. How to access---------------------------------------- 16

6.1.2. Screen display --------------------------------------- 16

6.1.3. Check Point ------------------------------------------- 16

6.1.4. Exit ------------------------------------------------------ 16

6.2. Power LED Blinking timing chart --------------------- 17

6.3. LCD Panel test mode ----------------------------------- 17

7 Disassembly and Assembly Instructions --------------- 18

7.1. Panel Preparation ---------------------------------------- 18

7.2. VESA, Bottom Metal & Ornamnet-------------------- 19

7.3. PCB & AV Bracket Ass’y ------------------------------- 20

7.4. Screw Fixing -1 -------------------------------------------21

7.5. Screw Fixing -2 -------------------------------------------22

7.6. Fan Ass’y--------------------------------------------------- 23

7.7. Screw Fixing -3 -------------------------------------------24

7.8. Bottom Backcover Prep. ------------------------------- 25

7.9. Bottom & Backcover Ass’y----------------------------- 26

7.10. Handling SPEC ------------------------------------------- 27

8 Measurements and Adjustments -------------------------- 28

8.1. Voltage chart of A-board-------------------------------- 28

8.2. Voltage chart of P-board-------------------------------- 28

9 Block Diagram --------------------------------------------------- 29

10 Wiring Connection Diagram --------------------------------- 30

10.1. Wire Dressing -1------------------------------------------ 30

10.2. Wire Dressing -2------------------------------------------ 31

10.3. Wire Dressing -3------------------------------------------ 32

2

TC-65DX900U

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

4. When conducting repairs and servicing, do not attempt to modify the equipment, its parts or its materials.

5. When wiring units (with cables, flexible cables or lead wires) are supplied as repair parts and only one wire or some of the

wires have been broken or disconnected, do not attempt to repair or re-wire the units. Replace the entire wiring unit instead.

6. When conducting repairs and servicing, do not twist the Fasten connectors but plug them straight in or unplug them straight

out.

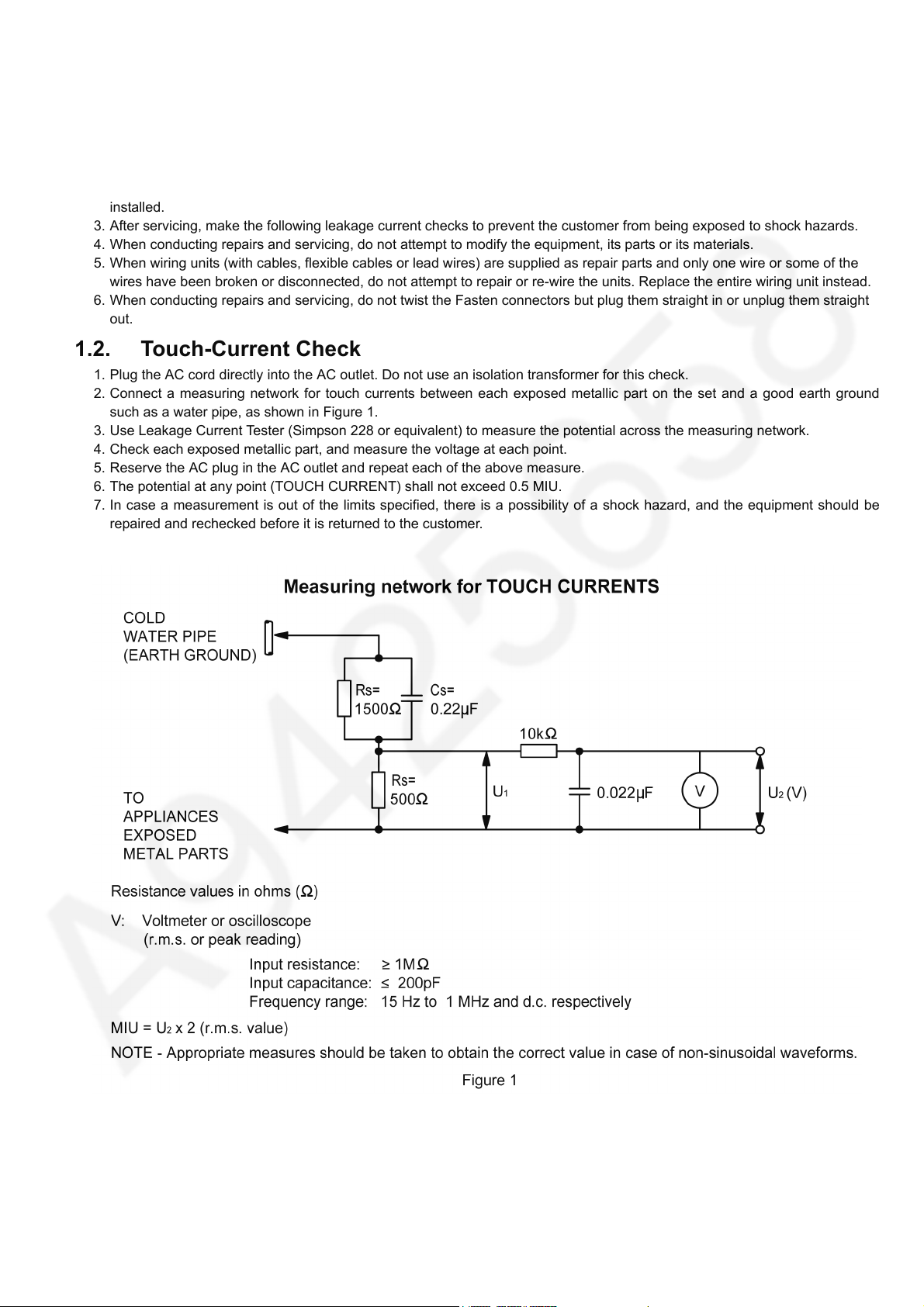

1.2. Touch-Current Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a measuring network for touch currents between each exposed metallic part on the set and a good earth ground

such as a water pipe, as shown in Figure 1.

3. Use Leakage Current Tester (Simpson 228 or equivalent) to measure the potential across the measuring network.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reserve the AC plug in the AC outlet and repeat each of the above measure.

6. The potential at any point (TOUCH CURRENT) shall not exceed 0.5 MIU.

7. In case a measurement is out of the limits specified, there is a possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the customer.

3

TC-65DX900U

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor [chip] components. The following techniques should be used to help reduce the incidence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as [anti-static (ESD protected)] can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise ham less motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

4

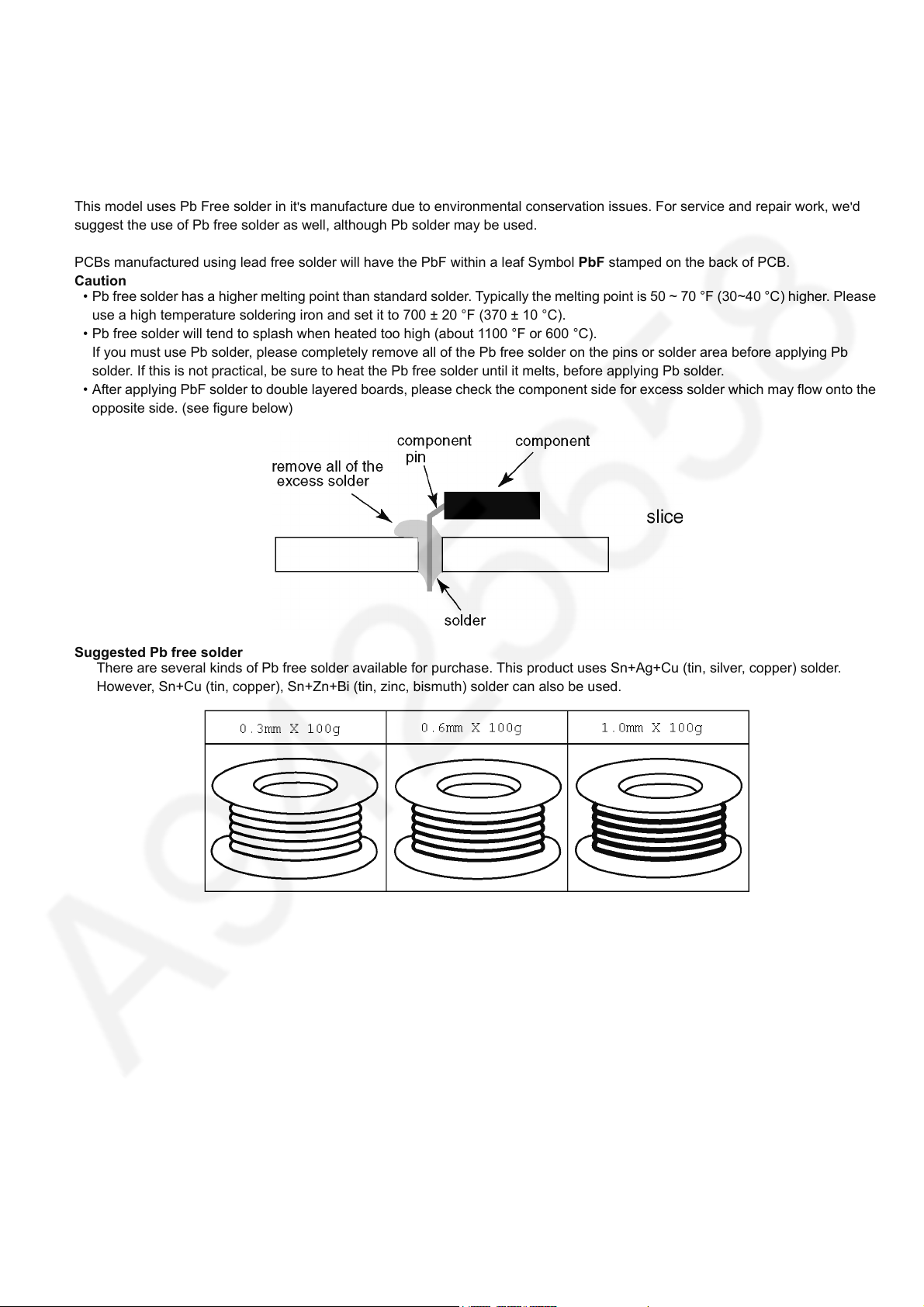

2.2. About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

TC-65DX900U

This model uses Pb Free solder in it

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol PbF stamped on the back of PCB.

Caution

• Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40 °C) higher. Please

use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

• Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb

solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

• After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto the

opposite side. (see figure below)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder.

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

's manufacture due to environmental conservation issues. For service and repair work, we'd

5

TC-65DX900U

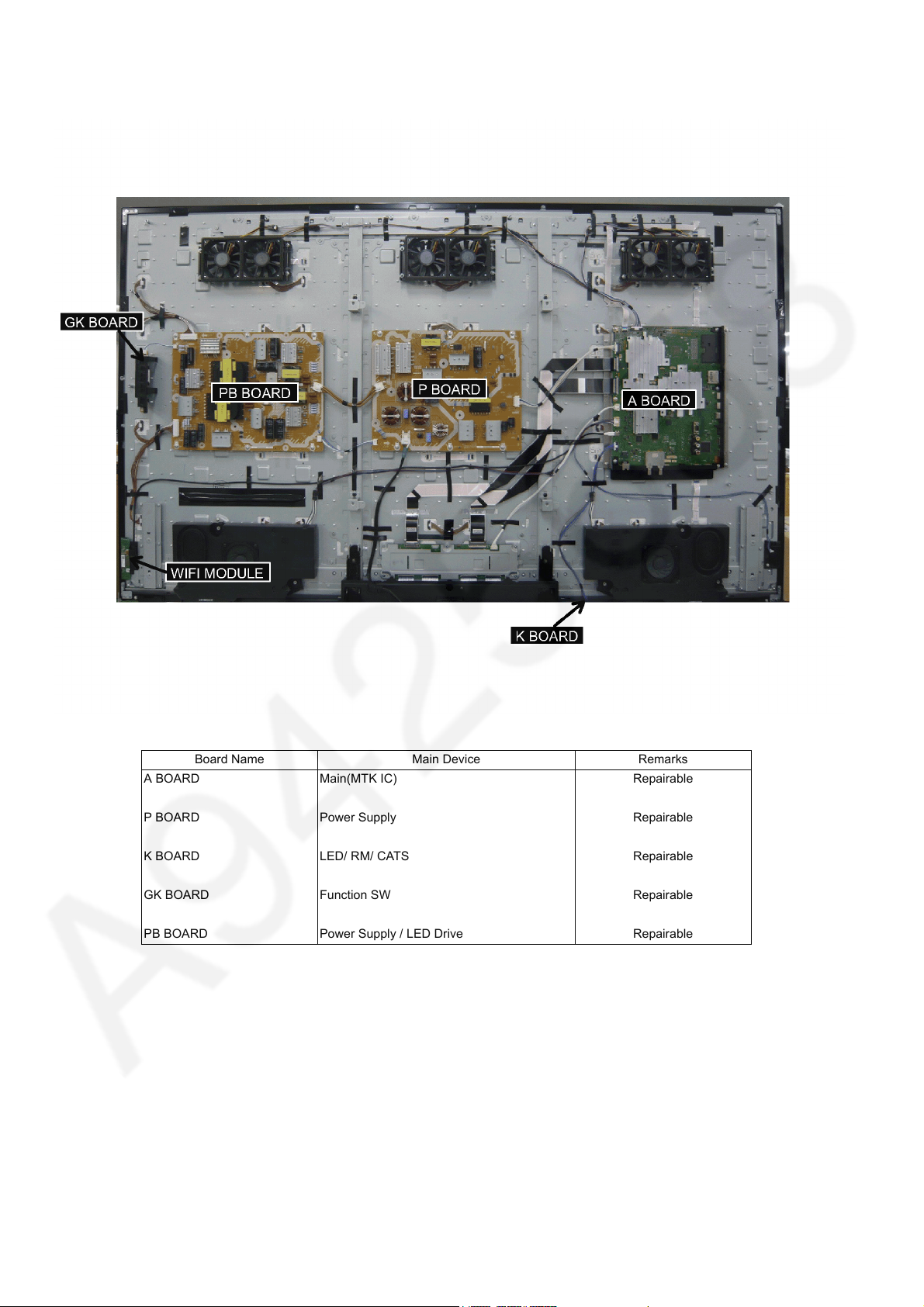

3 Service Navigation

Board Name Main Device Remarks

A BOARD Main(MTK IC) Repairable

P BOARD Power Supply Repairable

K BOARD LED/ RM/ CATS Repairable

GK BOARD Function SW Repairable

PB BOARD Power Supply / LED Drive Repairable

6

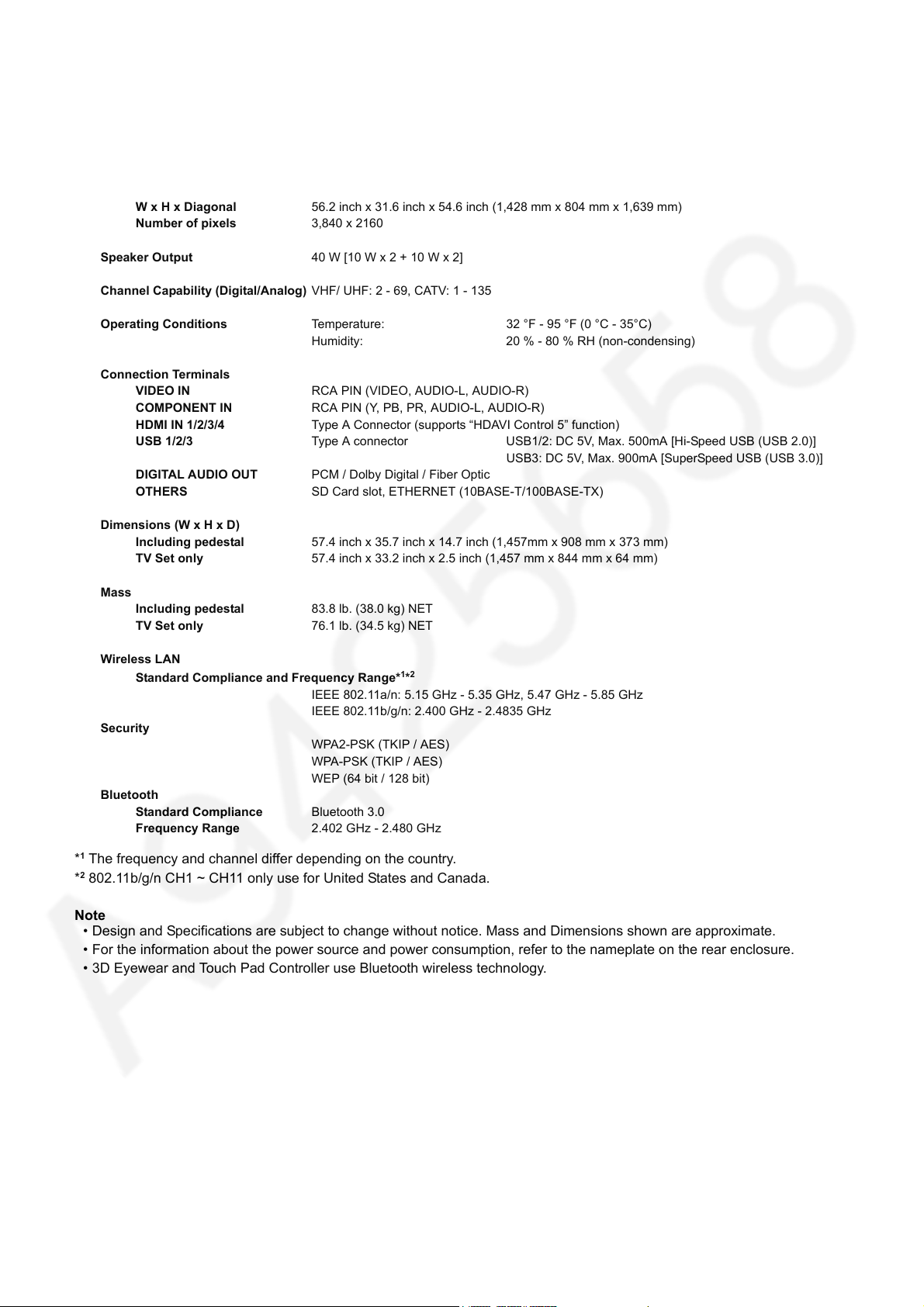

4 Specifications

Display Panel

Panel System LCD panel with LED backlight

Refresh Rate 120Hz

Screen size 65 inch class (64.5 inches measured diagonally)

W x H x Diagonal 56.2 inch x 31.6 inch x 54.6 inch (1,428 mm x 804 mm x 1,639 mm)

Number of pixels 3,840 x 2160

Speaker Output 40 W [10 W x 2 + 10 W x 2]

Channel Capability (Digital/Analog) VHF/ UHF: 2 - 69, CATV: 1 - 135

Operating Conditions Temperature: 32 °F - 95 °F (0 °C - 35°C)

Humidity: 20 % - 80 % RH (non-condensing)

Connection Terminals

VIDEO IN RCA PIN (VIDEO, AUDIO-L, AUDIO-R)

COMPONENT IN RCA PIN (Y, PB, PR, AUDIO-L, AUDIO-R)

HDMI IN 1/2/3/4 Type A Connector (supports “HDAVI Control 5” function)

USB 1/2/3 Type A connector USB1/2: DC 5V, Max. 500mA [Hi-Speed USB (USB 2.0)]

USB3: DC 5V, Max. 900mA [SuperSpeed USB (USB 3.0)]

DIGITAL AUDIO OUT PCM / Dolby Digital / Fiber Optic

OTHERS SD Card slot, ETHERNET (10BASE-T/100BASE-TX)

TC-65DX900U

Dimensions (W x H x D)

Including pedestal 57.4 inch x 35.7 inch x 14.7 inch (1,457mm x 908 mm x 373 mm)

TV Set only 57.4 inch x 33.2 inch x 2.5 inch (1,457 mm x 844 mm x 64 mm)

Mass

Including pedestal 83.8 lb. (38.0 kg) NET

TV Set only 76.1 lb. (34.5 kg) NET

Wireless LAN

Standard Compliance and Frequency Range*

IEEE 802.11a/n: 5.15 GHz - 5.35 GHz, 5.47 GHz - 5.85 GHz

IEEE 802.11b/g/n: 2.400 GHz - 2.4835 GHz

Security

WPA2-PSK (TKIP / AES)

WPA-PSK (TKIP / AES)

WEP (64 bit / 128 bit)

Bluetooth

Standard Compliance Bluetooth 3.0

Frequency Range 2.402 GHz - 2.480 GHz

1*2

*1 The frequency and channel differ depending on the country.

2

*

802.11b/g/n CH1 ~ CH11 only use for United States and Canada.

Note

• Design and Specifications are subject to change without notice. Mass and Dimensions shown are approximate.

• For the information about the power source and power consumption, refer to the nameplate on the rear enclosure.

• 3D Eyewear and Touch Pad Controller use Bluetooth wireless technology.

7

TC-65DX900U

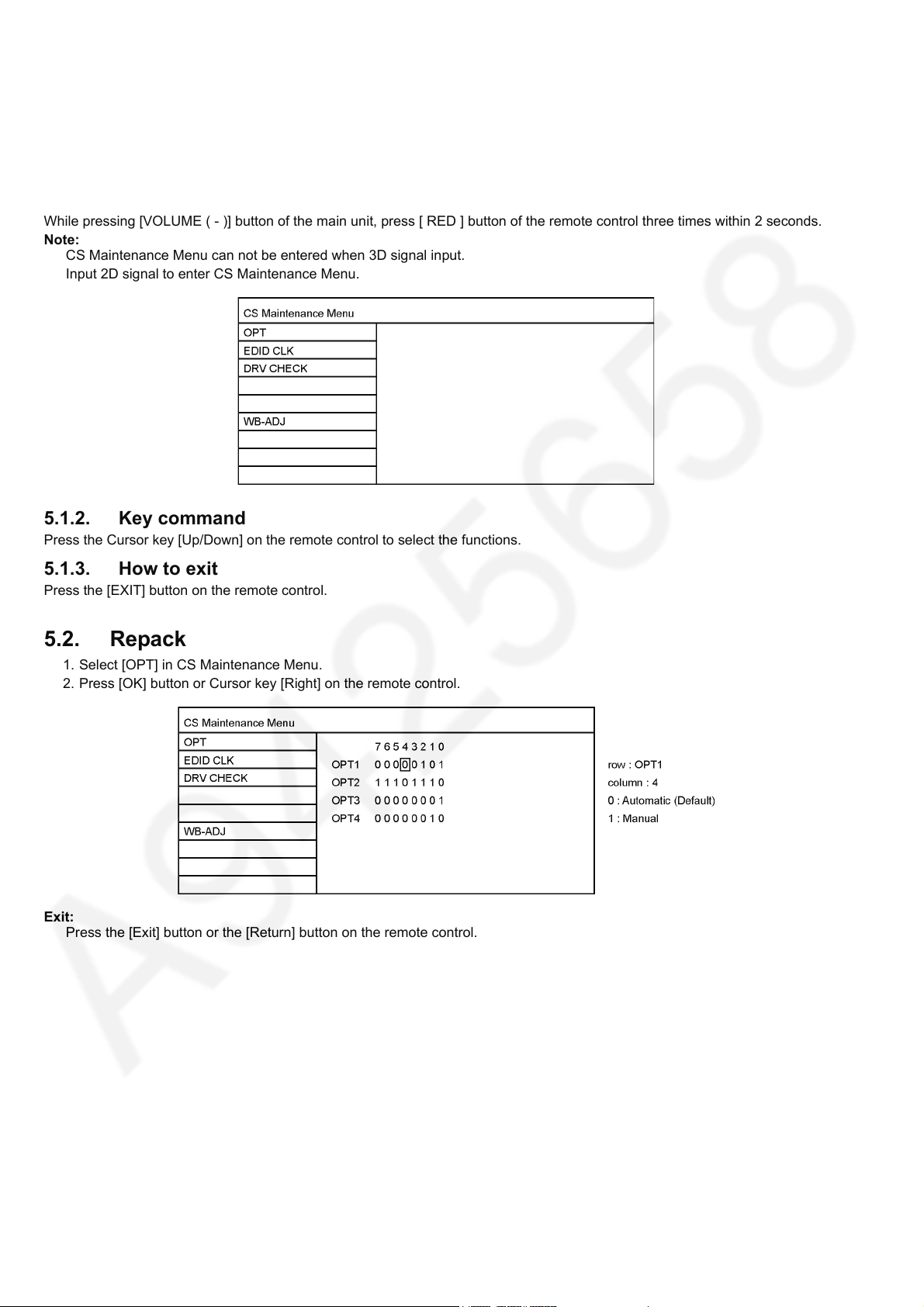

5 CS Maintenance Menu

5.1. How to enter into CS Maintenance Menu

5.1.1. Purpose

After exchange parts, check and adjust the contents of adjustment mode.

While pressing [VOLUME ( - )] button of the main unit, press [ RED ] button of the remote control three times within 2 seconds.

Note:

CS Maintenance Menu can not be entered when 3D signal input.

Input 2D signal to enter CS Maintenance Menu.

5.1.2. Key command

Press the Cursor key [Up/Down] on the remote control to select the functions.

5.1.3. How to exit

Press the [EXIT] button on the remote control.

5.2. Repack

1. Select [OPT] in CS Maintenance Menu.

2. Press [OK] button or Cursor key [Right] on the remote control.

Exit:

Press the [Exit] button or the [Return] button on the remote control.

8

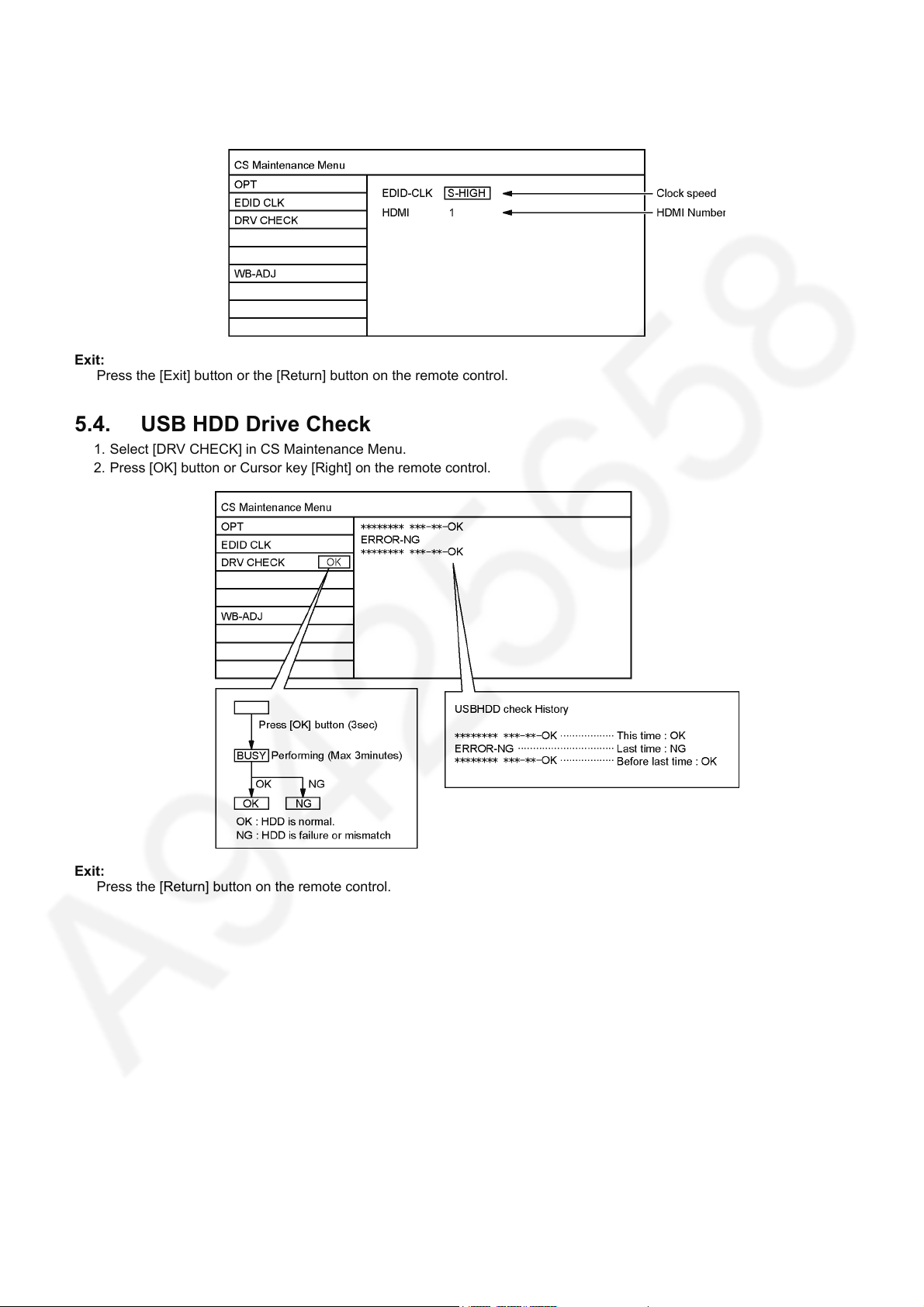

5.3. EDID Clock

1. Select [EDID CLK] in CS Maintenance Menu.

2. Press [OK] button or Cursor key [Right] on the remote control.

Exit:

Press the [Exit] button or the [Return] button on the remote control.

5.4. USB HDD Drive Check

1. Select [DRV CHECK] in CS Maintenance Menu.

2. Press [OK] button or Cursor key [Right] on the remote control.

TC-65DX900U

Exit:

Press the [Return] button on the remote control.

9

TC-65DX900U

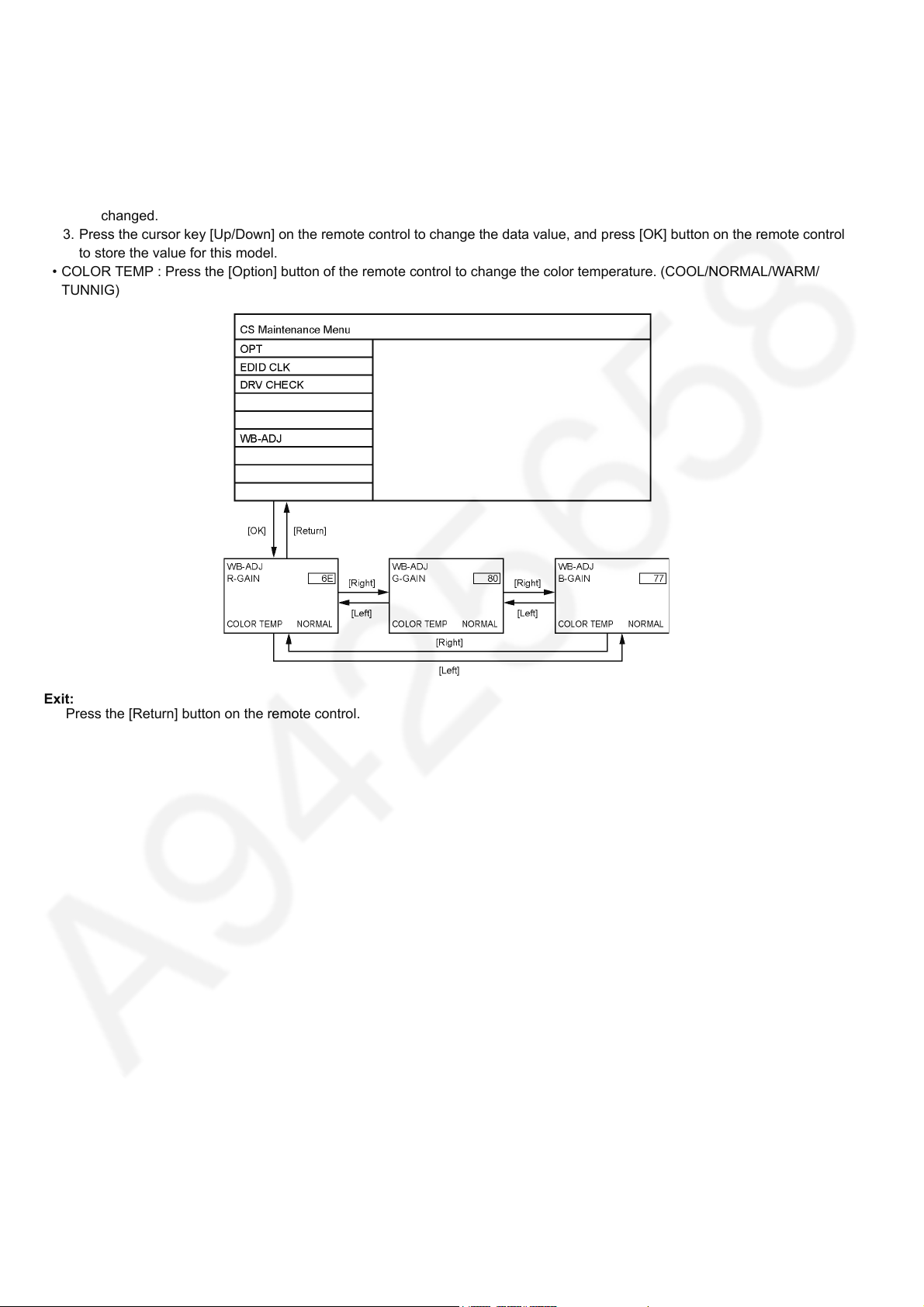

5.5. White Balance Adjustment

After LCD PANEL or A-Board is replaced and repaired, perform [White balance adjustment] in case of necessity for test / check

([White balance adjustment] is not required basically).

1. Select [W/B ADJ] in CS Maintenance Menu.

2. Press [OK] button on the remote control.

Note for performing [White balance adjustment]

Make a note for the setting values before changing if the settings of [R-GAIN], [B-GAIN] and [G-GAIN] in [WB-ADJ] will be

changed.

3. Press the cursor key [Up/Down] on the remote control to change the data value, and press [OK] button on the remote control

to store the value for this model.

• COLOR TEMP : Press the [Option] button of the remote control to change the color temperature. (COOL/NORMAL/WARM/

TUNNIG)

Exit:

Press the [Return] button on the remote control.

10

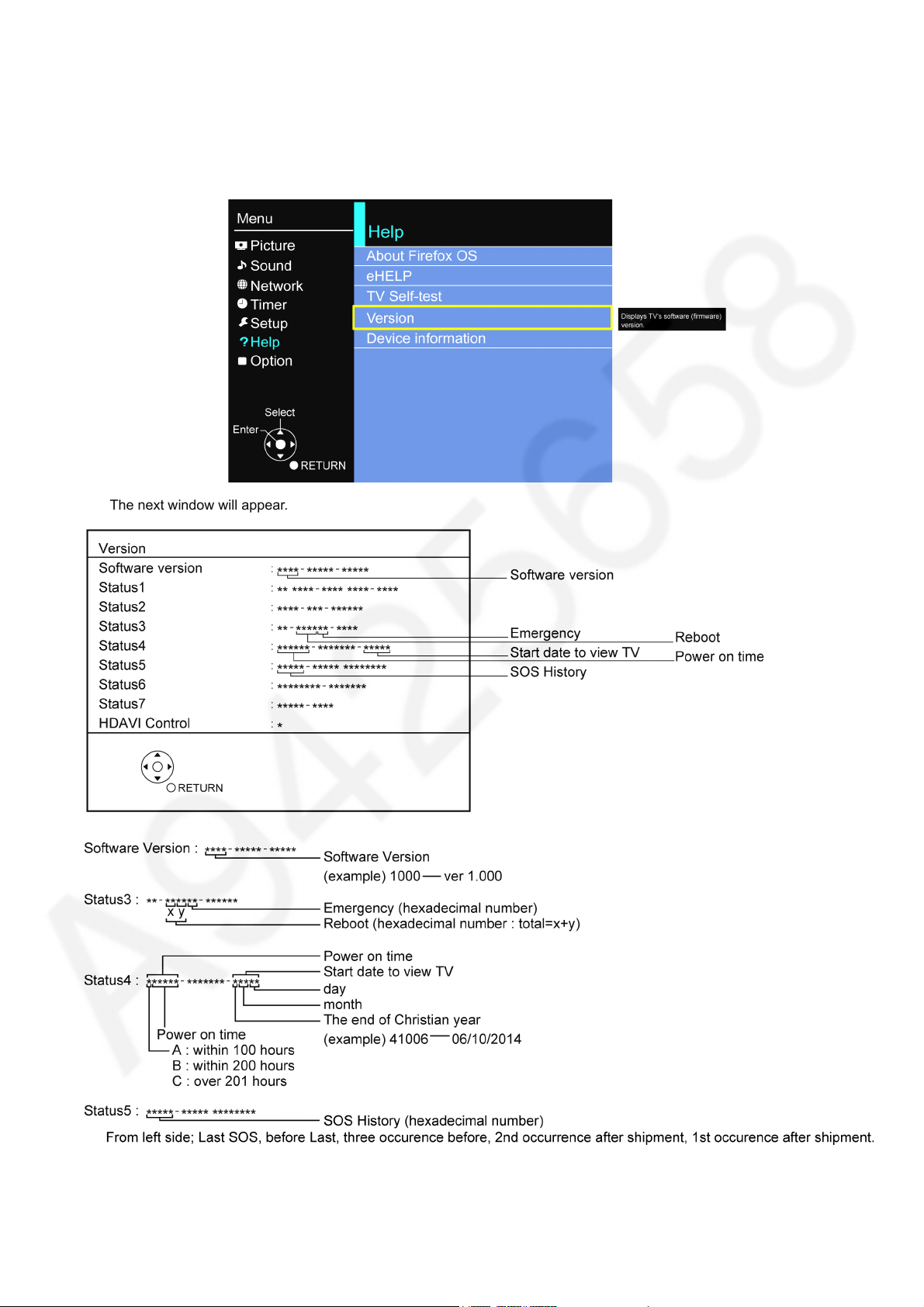

5.6. Version

5.6.1. How to access

1. Display the [Main Menu] with [MENU] on the remote control.

2. Select [Help] with Cursor Key [Up] or [Down] on the remote control and press [OK] to access.

3. Select [Version] with cursor Key [Up] or [Down] on the remote control and press [OK] to access.

TC-65DX900U

The next window will appear.

11

TC-65DX900U

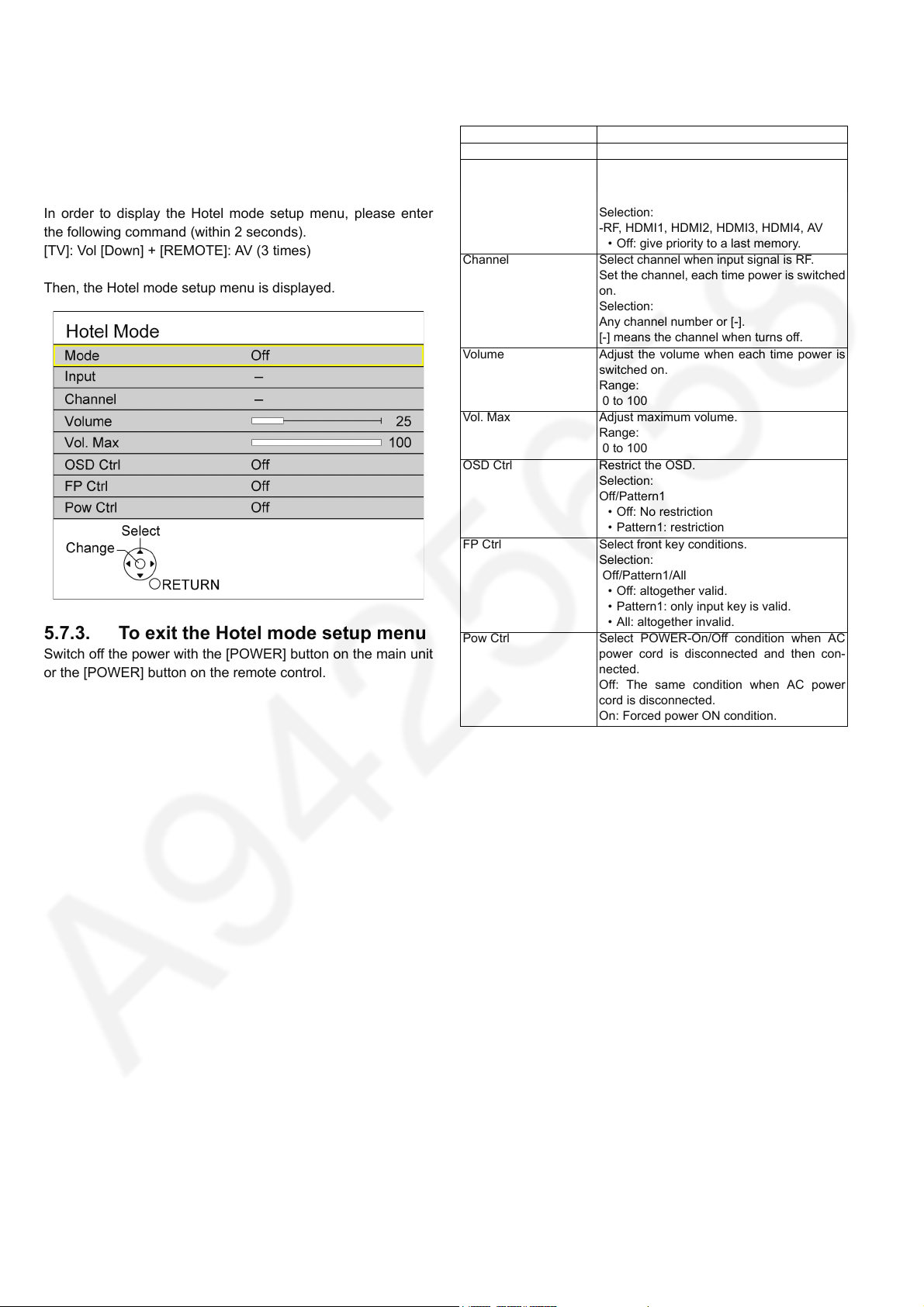

5.7. Hotel mode

5.7.1. Purpose

Restrict a function for hotels.

5.7.2. Access command to the Hotel mode setup menu

In order to display the Hotel mode setup menu, please enter

the following command (within 2 seconds).

[TV]: Vol [Down] + [REMOTE]: AV (3 times)

Then, the Hotel mode setup menu is displayed.

5.7.3. To exit the Hotel mode setup menu

Switch off the power with the [POWER] button on the main unit

or the [POWER] button on the remote control.

5.7.4. Explain the Hotel mode setup menu

Item Function

Mode Select hotel mode On/Off

Input Select input signal modes.

Set the input, when each time power is

switched on.

Selection:

-RF, HDMI1, HDMI2, HDMI3, HDMI4, AV

• Off: give priority to a last memory.

Channel Select channel when input signal is RF.

Set the channel, each time power is switched

on.

Selection:

Any channel number or [-].

[-] means the channel when turns off.

Volume Adjust the volume when each time power is

switched on.

Range:

0 to 100

Vol. Max Adjust maximum volume.

Range:

0 to 100

OSD Ctrl Restrict the OSD.

Selection:

Off/Pattern1

• Off: No restriction

• Pattern1: restriction

FP Ctrl Select front key conditions.

Selection:

Off/Pattern1/All

• Off: altogether valid.

• Pattern1: only input key is valid.

• All: altogether invalid.

Pow Ctrl Select POWER-On/Off condition when AC

power cord is disconnected and then con-

nected.

Off: The same condition when AC power

cord is disconnected.

On: Forced power ON condition.

12

TC-65DX900U

5.8. Data Copy by USB Memory

Note:

SD card can not be used for Data Copy.

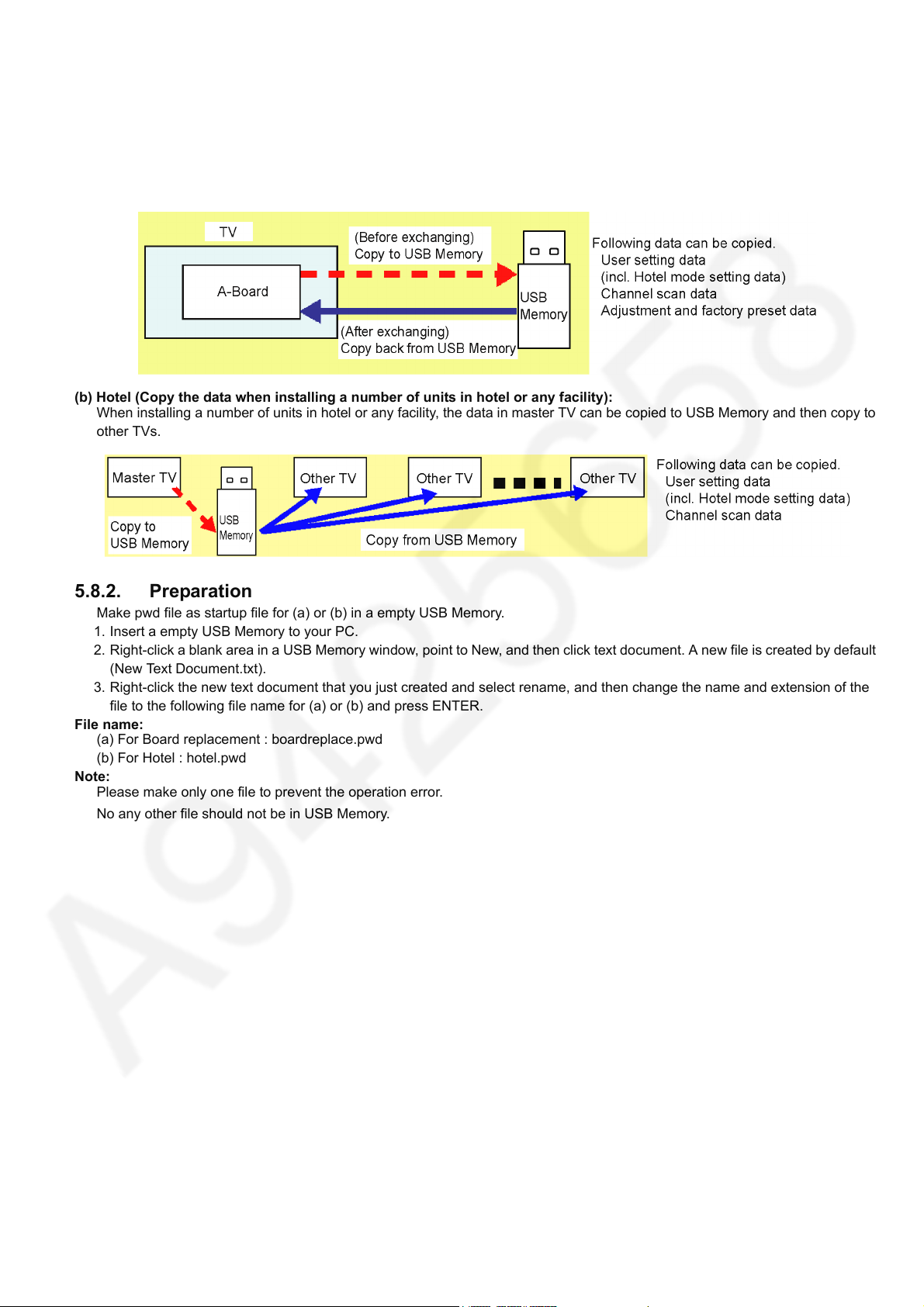

5.8.1. Purpose

(a) Board replacement (Copy the data when exchanging A-board):

When exchanging A-board, the data in original A-board can be copied to USB Memory and then copy to new A-board.

(b) Hotel (Copy the data when installing a number of units in hotel or any facility):

When installing a number of units in hotel or any facility, the data in master TV can be copied to USB Memory and then copy to

other TVs.

5.8.2. Preparation

Make pwd file as startup file for (a) or (b) in a empty USB Memory.

1. Insert a empty USB Memory to your PC.

2. Right-click a blank area in a USB Memory window, point to New, and then click text document. A new file is created by default

(New Text Document.txt).

3. Right-click the new text document that you just created and select rename, and then change the name and extension of the

file to the following file name for (a) or (b) and press ENTER.

File name:

(a) For Board replacement : boardreplace.pwd

(b) For Hotel : hotel.pwd

Note:

Please make only one file to prevent the operation error.

No any other file should not be in USB Memory.

13

TC-65DX900U

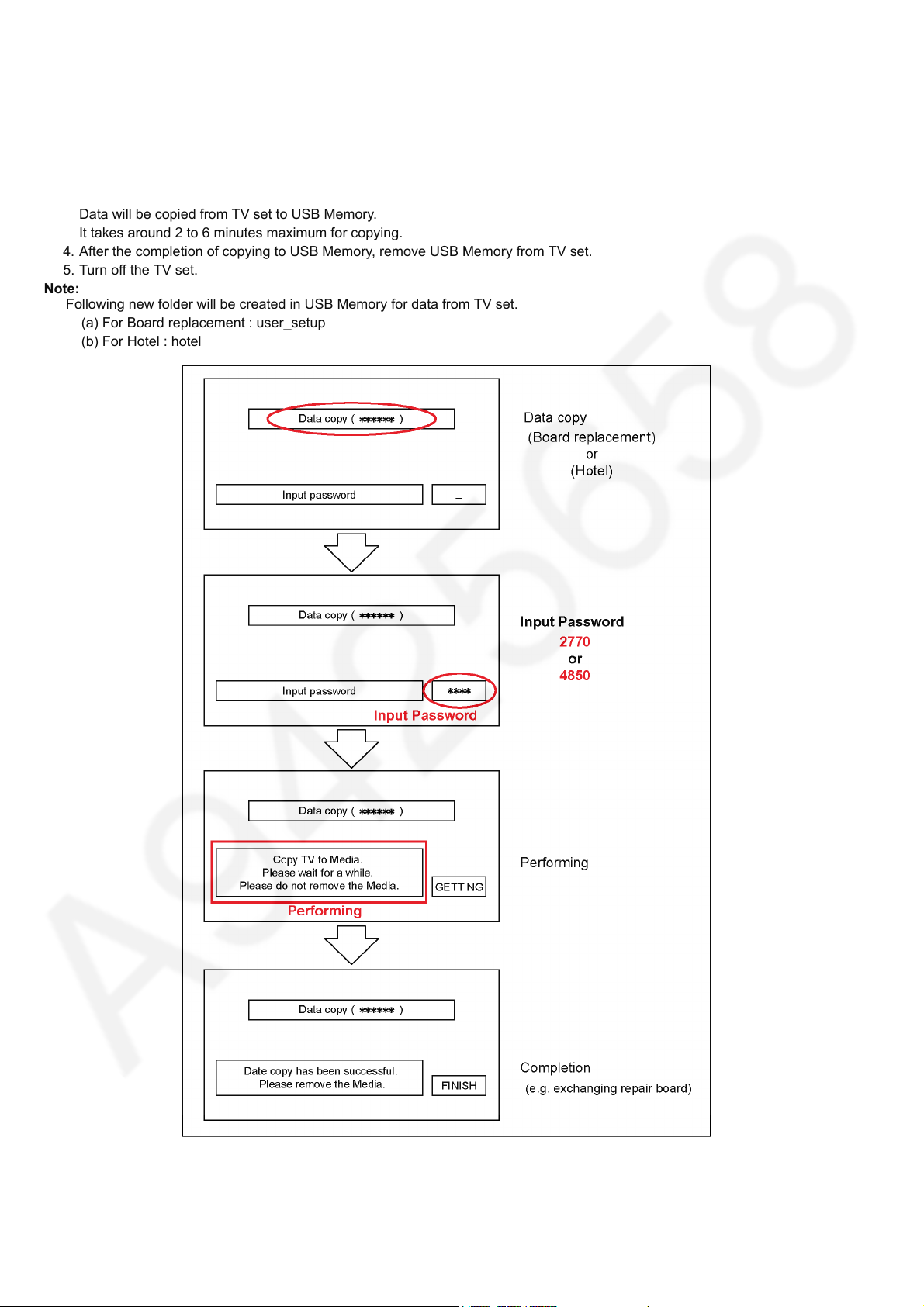

5.8.3. Data copy from TV set to USB Memory

1. Turn on the TV set.

2. Insert USB Memory with a startup file (pwd file) to USB terminal.

On-screen Display will be appeared according to the startup file automatically.

3. Input a following password for (a) or (b) by using remote control.

(a) For Board replacement : 2770

(b) For Hotel : 4850

Data will be copied from TV set to USB Memory.

It takes around 2 to 6 minutes maximum for copying.

4. After the completion of copying to USB Memory, remove USB Memory from TV set.

5. Turn off the TV set.

Note:

Following new folder will be created in USB Memory for data from TV set.

(a) For Board replacement : user_setup

(b) For Hotel : hotel

14

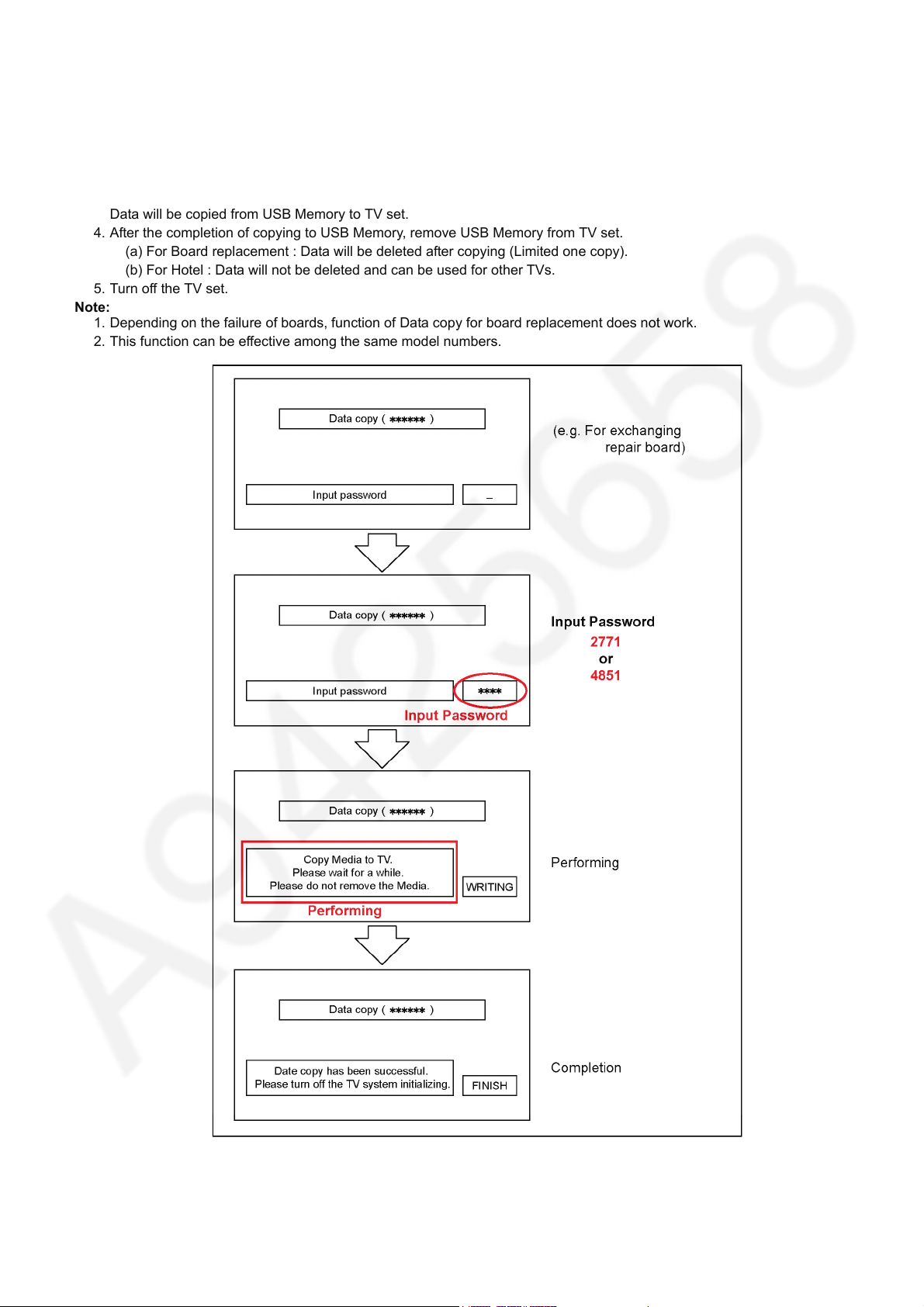

5.8.4. Data copy from USB Memory to TV set

1. Turn on the TV set.

2. Insert USB Memory with Data to USB terminal.

On-screen Display will be appeared according to the Data folder automatically.

3. Input a following password for (a) or (b) by using remote control.

(a) For Board replacement : 2771

(b) For Hotel : 4851

Data will be copied from USB Memory to TV set.

4. After the completion of copying to USB Memory, remove USB Memory from TV set.

(a) For Board replacement : Data will be deleted after copying (Limited one copy).

(b) For Hotel : Data will not be deleted and can be used for other TVs.

5. Turn off the TV set.

Note:

1. Depending on the failure of boards, function of Data copy for board replacement does not work.

2. This function can be effective among the same model numbers.

TC-65DX900U

15

TC-65DX900U

6 Troubleshooting Guide

Use the self-check function to test the unit.

1. Checking the IIC bus lines

2. Power LED Blinking timing

6.1. Check of the IIC bus lines

6.1.1. How to access

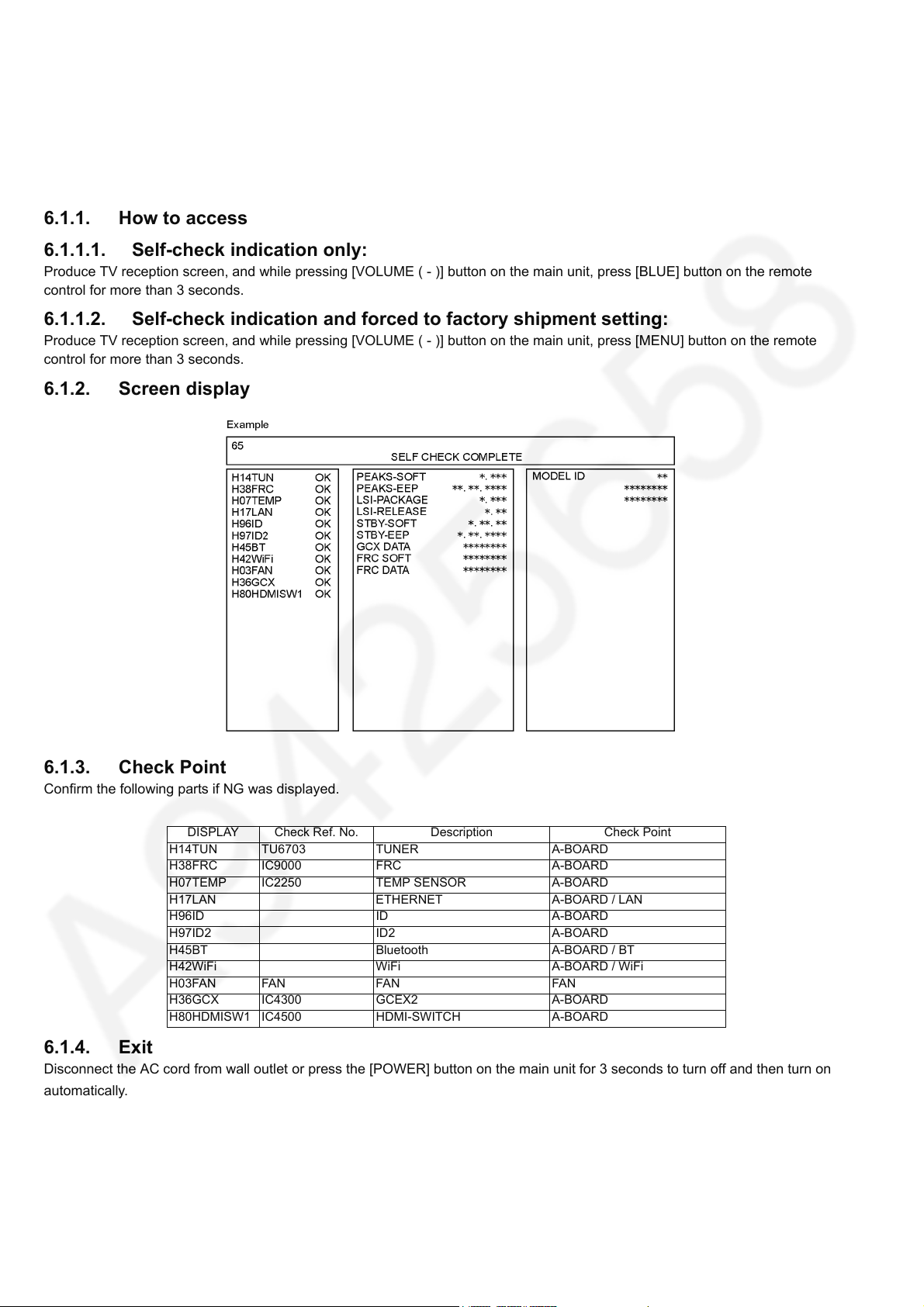

6.1.1.1. Self-check indication only:

Produce TV reception screen, and while pressing [VOLUME ( - )] button on the main unit, press [BLUE] button on the remote

control for more than 3 seconds.

6.1.1.2. Self-check indication and forced to factory shipment setting:

Produce TV reception screen, and while pressing [VOLUME ( - )] button on the main unit, press [MENU] button on the remote

control for more than 3 seconds.

6.1.2. Screen display

6.1.3. Check Point

Confirm the following parts if NG was displayed.

DISPLAY Check Ref. No. Description Check Point

H14TUN TU6703 TUNER A-BOARD

H38FRC IC9000 FRC A-BOARD

H07TEMP IC2250 TEMP SENSOR A-BOARD

H17LAN ETHERNET A-BOARD / LAN

H96ID ID A-BOARD

H97ID2 ID2 A-BOARD

H45BT Bluetooth A-BOARD / BT

H42WiFi WiFi A-BOARD / WiFi

H03FAN FAN FAN FAN

H36GCX IC4300 GCEX2 A-BOARD

H80HDMISW1 IC4500 HDMI-SWITCH A-BOARD

6.1.4. Exit

Disconnect the AC cord from wall outlet or press the [POWER] button on the main unit for 3 seconds to turn off and then turn on

automatically.

16

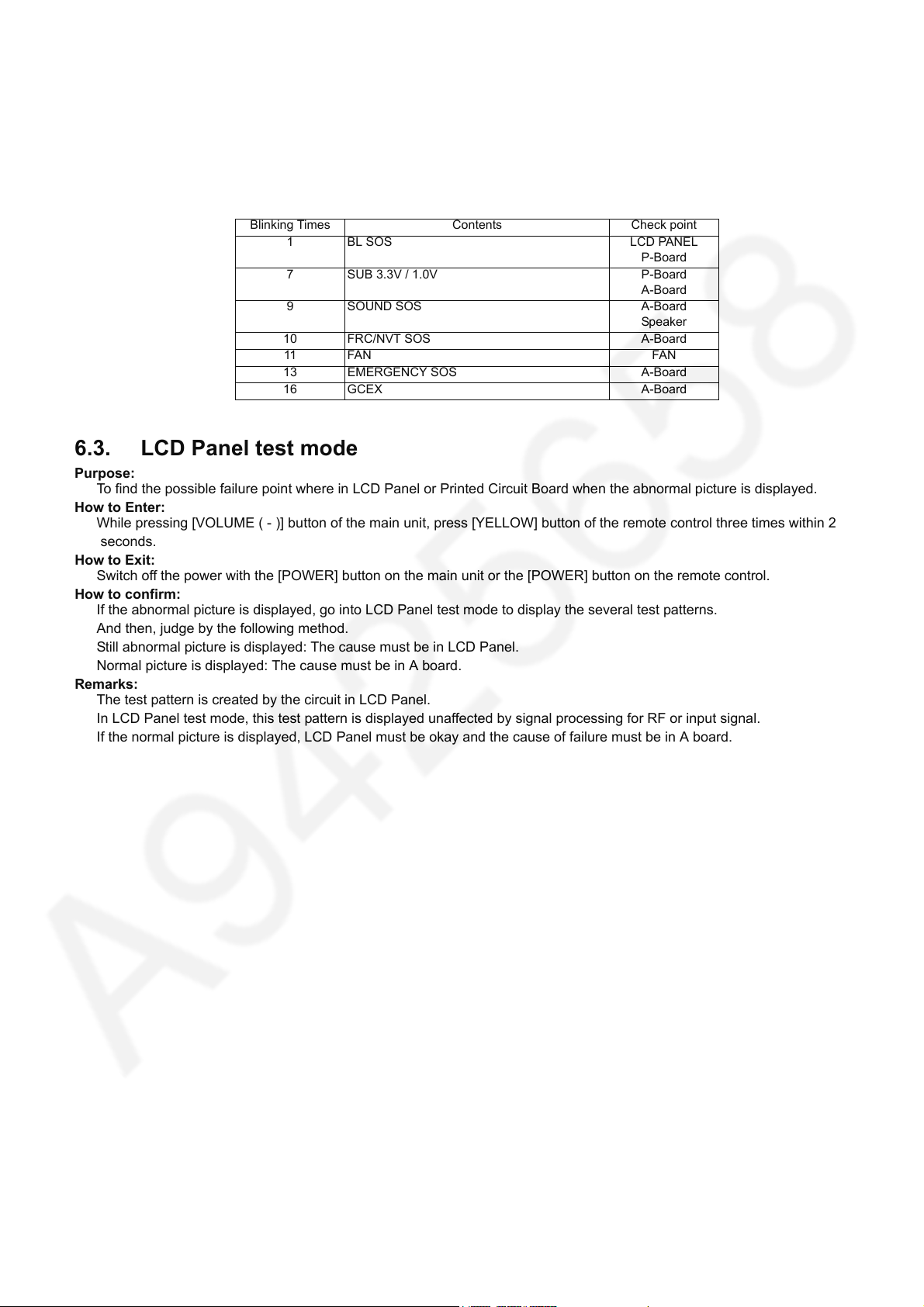

6.2. Power LED Blinking timing chart

1. Subject

Information of LED Flashing timing chart.

2. Contents

When an abnormality has occurred the unit, the protection circuit operates and reset to the stand by mode. At this time, the

defective block can be identified by the number of blinks of the Power LED on the front panel of the unit.

Blinking Times Contents Check point

1 BL SOS LCD PANEL

P-Board

7 SUB 3.3V / 1.0V P-Board

A-Board

9 SOUND SOS A-Board

Speaker

10 FRC/NVT SOS A-Board

11 FAN FAN

13 EMERGENCY SOS A-Board

16 GCEX A-Board

6.3. LCD Panel test mode

Purpose:

To find the possible failure point where in LCD Panel or Printed Circuit Board when the abnormal picture is displayed.

How to Enter:

While pressing [VOLUME ( - )] button of the main unit, press [YELLOW] button of the remote control three times within 2

seconds.

How to Exit:

Switch off the power with the [POWER] button on the main unit or the [POWER] button on the remote control.

How to confirm:

If the abnormal picture is displayed, go into LCD Panel test mode to display the several test patterns.

And then, judge by the following method.

Still abnormal picture is displayed: The cause must be in LCD Panel.

Normal picture is displayed: The cause must be in A board.

Remarks:

The test pattern is created by the circuit in LCD Panel.

In LCD Panel test mode, this test pattern is displayed unaffected by signal processing for RF or input signal.

If the normal picture is displayed, LCD Panel must be okay and the cause of failure must be in A board.

TC-65DX900U

17

TC-65DX900U

7 Disassembly and Assembly Instructions

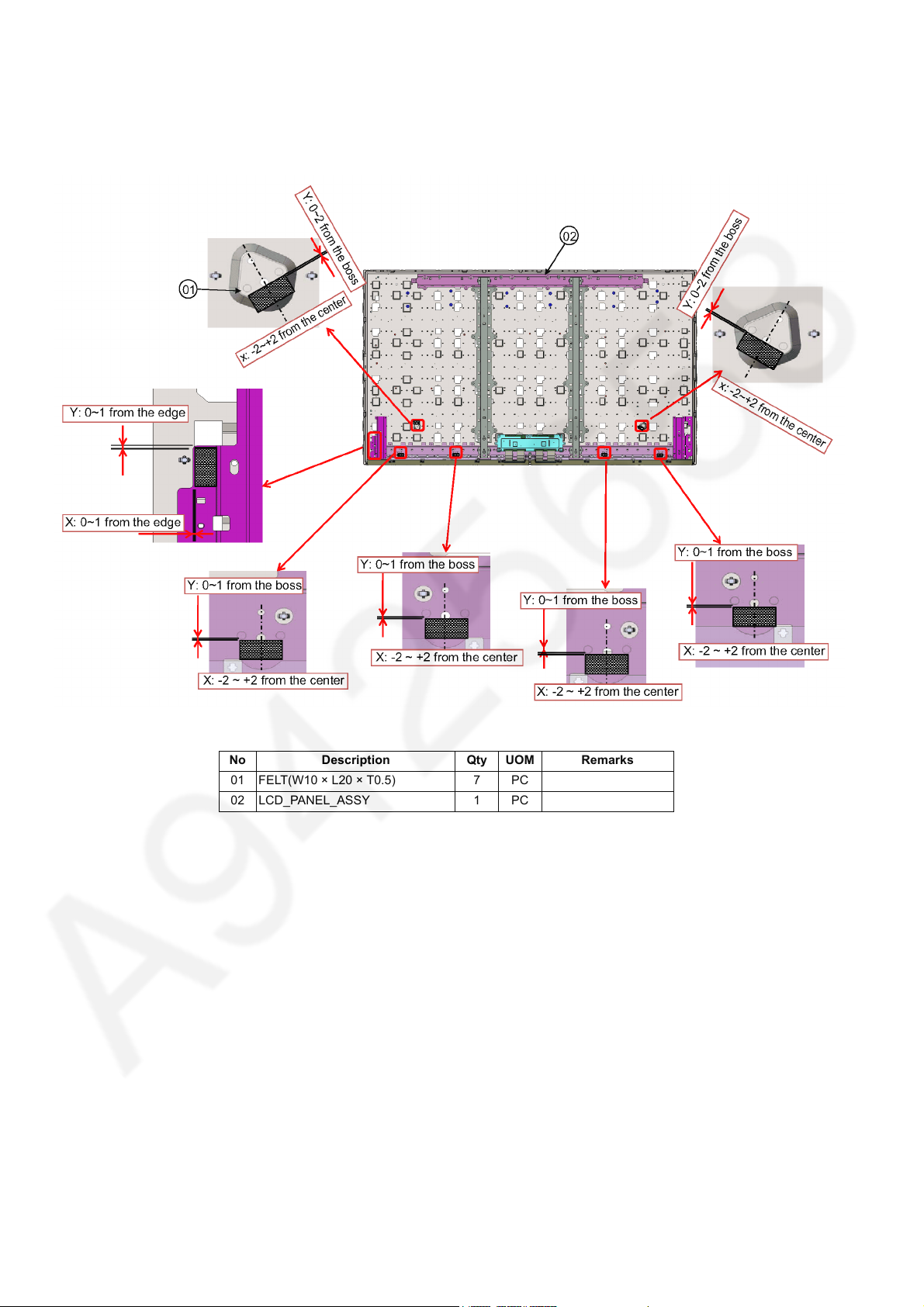

7.1. Panel Preparation

1. Fix follow diagram.

No Description Qty UOM Remarks

01 FELT(W10 × L20 × T0.5) 7 PC

02 LCD_PANEL_ASSY 1 PC

18

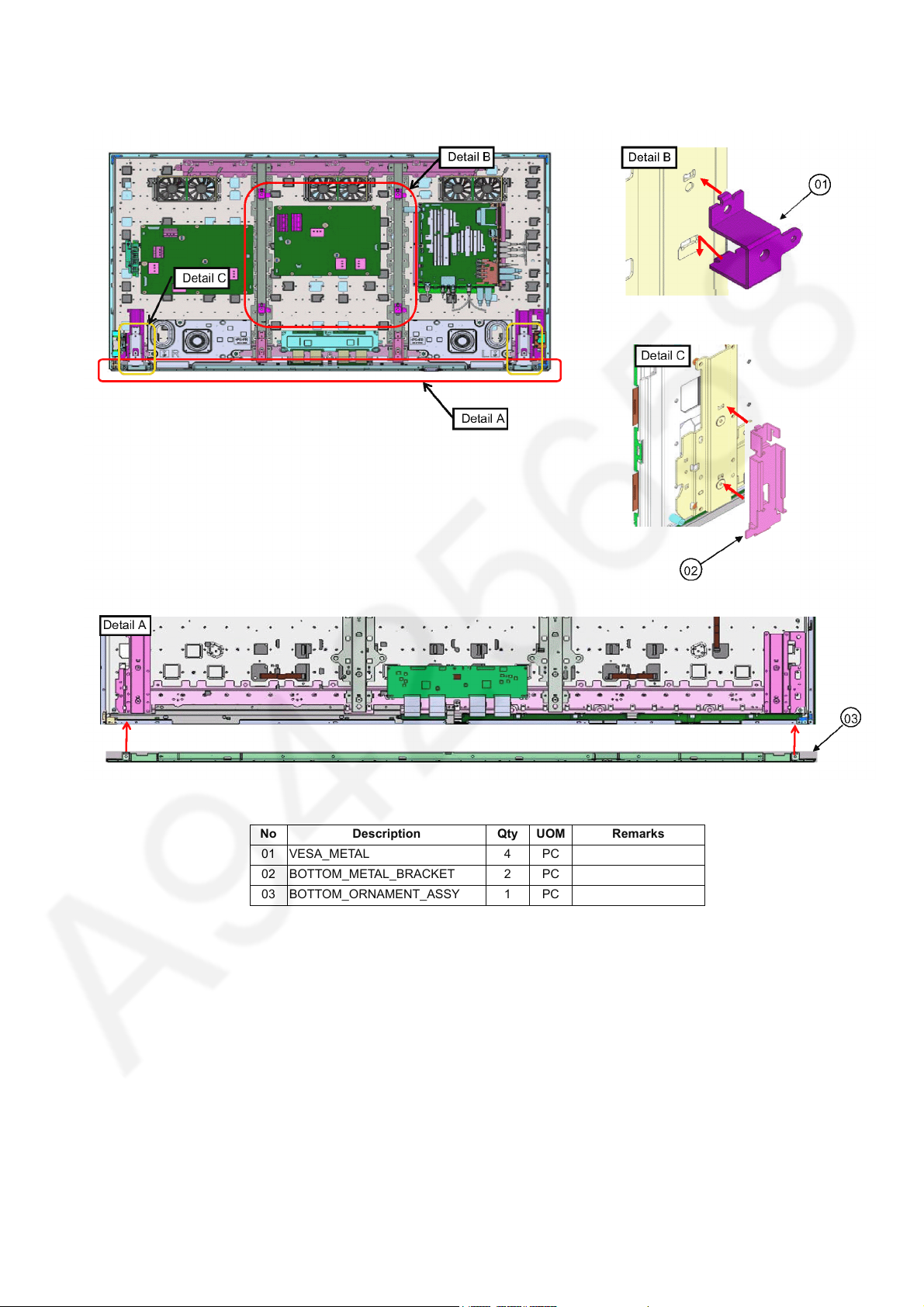

7.2. VESA, Bottom Metal & Ornamnet

1. Fix follow diagram.

TC-65DX900U

No Description Qty UOM Remarks

01 VESA_METAL 4 PC

02 BOTTOM_METAL_BRACKET 2 PC

03 BOTTOM_ORNAMENT_ASSY 1 PC

19

TC-65DX900U

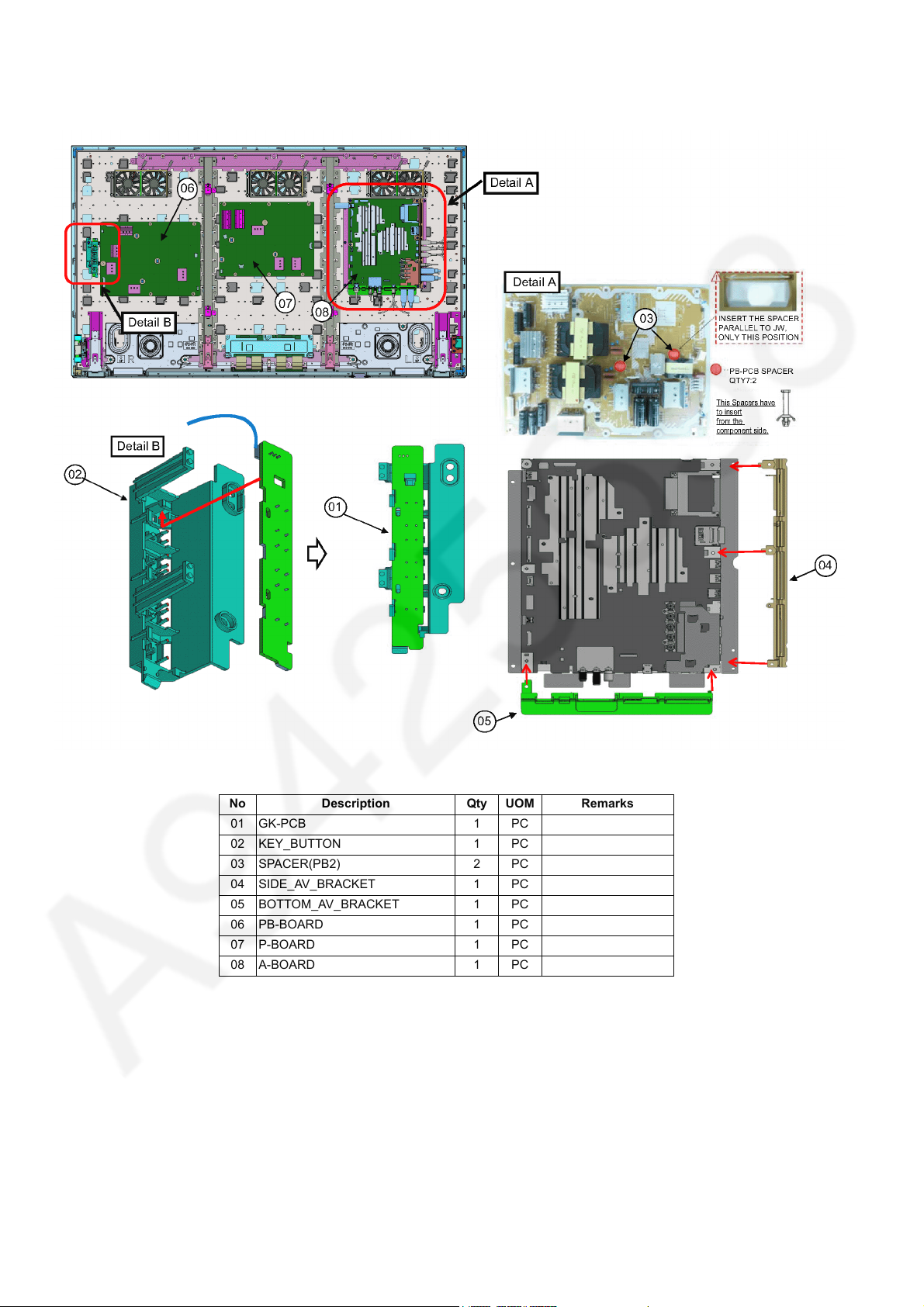

7.3. PCB & AV Bracket Ass’y

1. Fix follow diagram.

No Description Qty UOM Remarks

01 GK-PCB 1 PC

02 KEY_BUTTON 1 PC

03 SPACER(PB2) 2 PC

04 SIDE_AV_BRACKET 1 PC

05 BOTTOM_AV_BRACKET 1 PC

06 PB-BOARD 1 PC

07 P-BOARD 1 PC

08 A-BOARD 1 PC

20

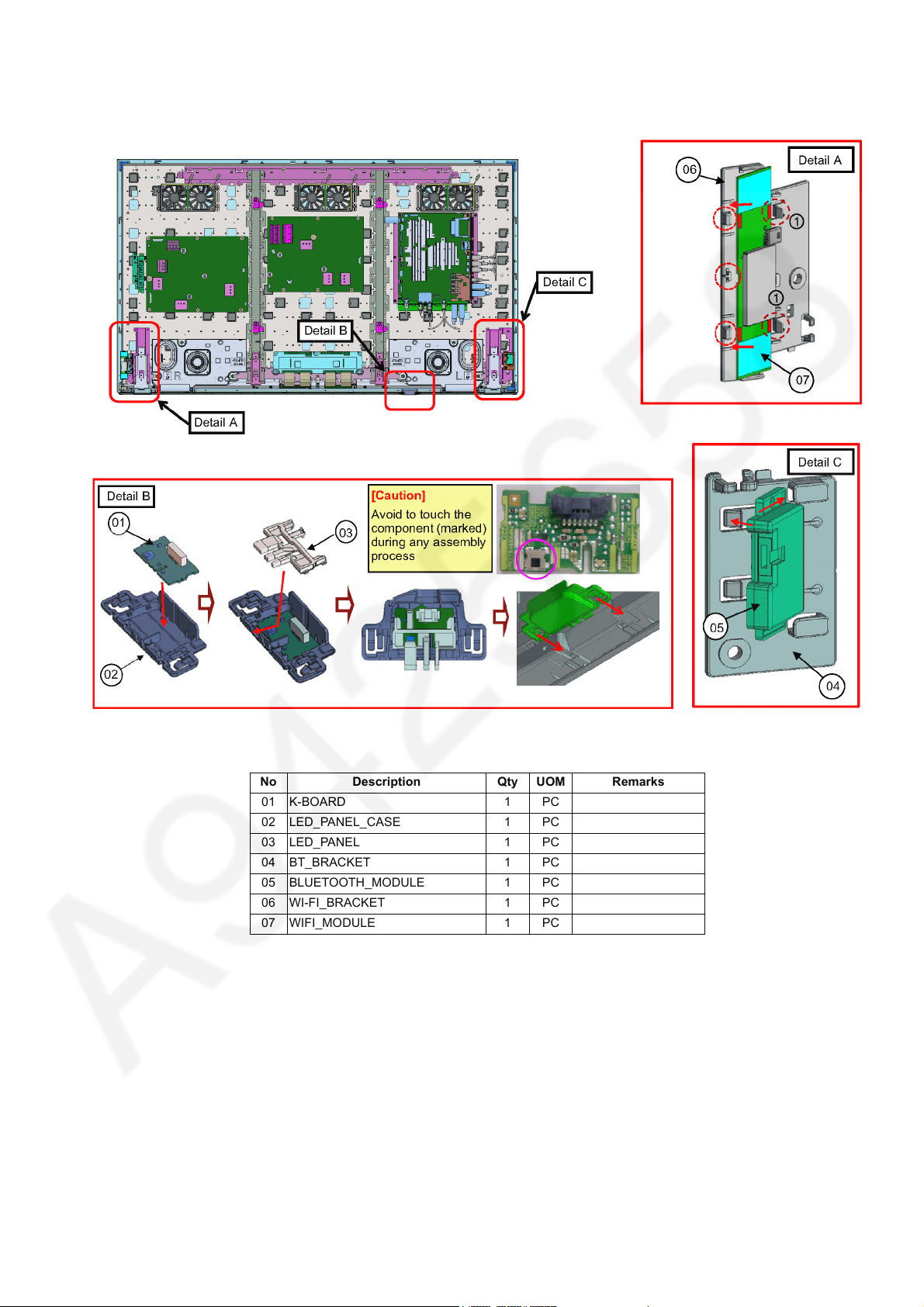

7.4. Screw Fixing -1

1. Fix follow diagram.

TC-65DX900U

No Description Qty UOM Remarks

01 K-BOARD 1 PC

02 LED_PANEL_CASE 1 PC

03 LED_PANEL 1 PC

04 BT_BRACKET 1 PC

05 BLUETOOTH_MODULE 1 PC

06 WI-FI_BRACKET 1 PC

07 WIFI_MODULE 1 PC

21

TC-65DX900U

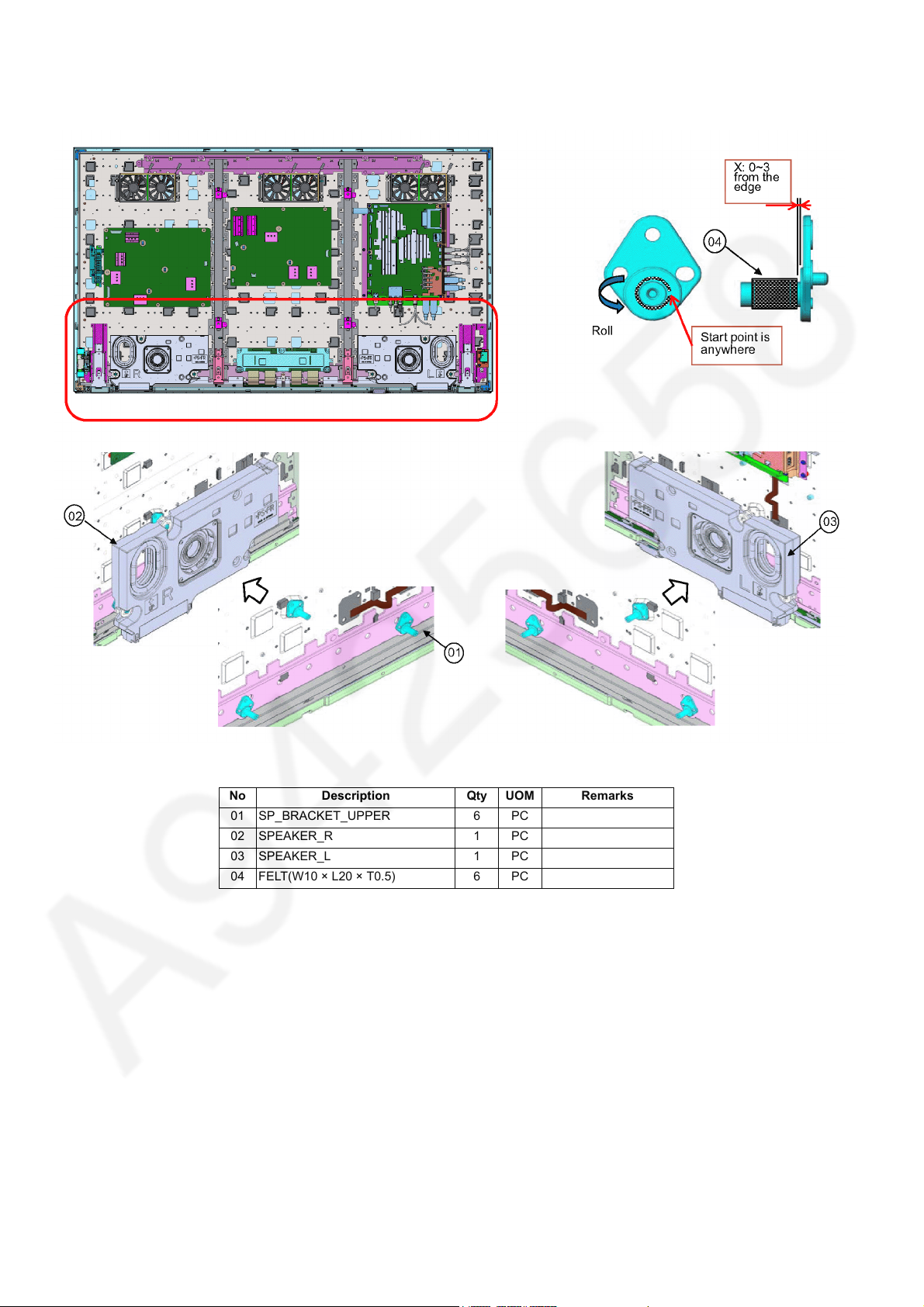

7.5. Screw Fixing -2

1. Fix follow diagram.

No Description Qty UOM Remarks

01 SP_BRACKET_UPPER 6 PC

02 SPEAKER_R 1 PC

03 SPEAKER_L 1 PC

04 FELT(W10 × L20 × T0.5) 6 PC

22

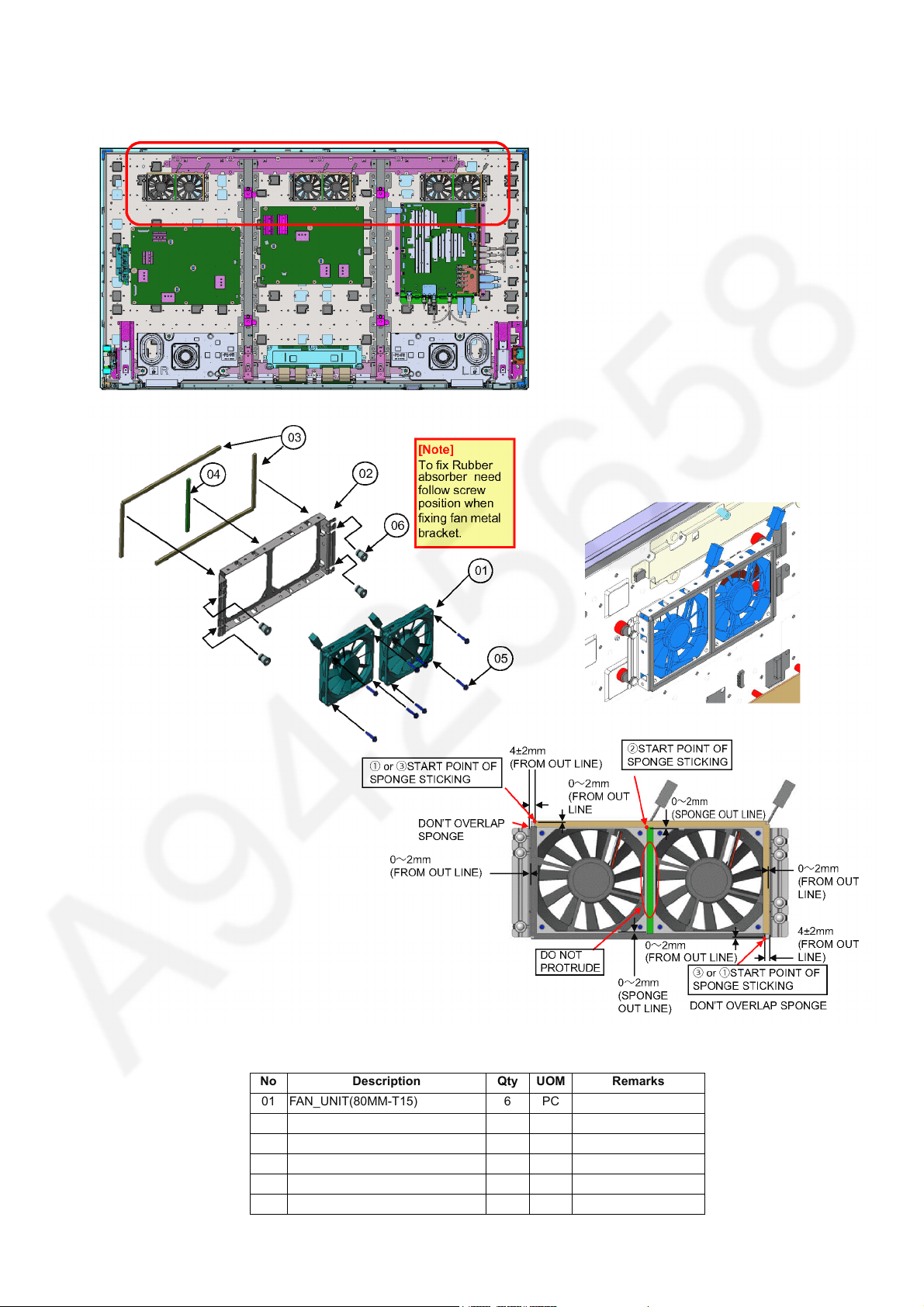

7.6. Fan Ass’y

1. Fix follow diagram.

TC-65DX900U

No Description Qty UOM Remarks

01 FAN_UNIT(80MM-T15) 6 PC

02 FAN_METAL_BRACKET 3 PC

03 FAN SPONGE 6 PC

04 FAN SPONGE 3 PC

05 SCREW 24 PC 4~6 kgf

06 RUBBER(ABSORBER) 12 PC

23

TC-65DX900U

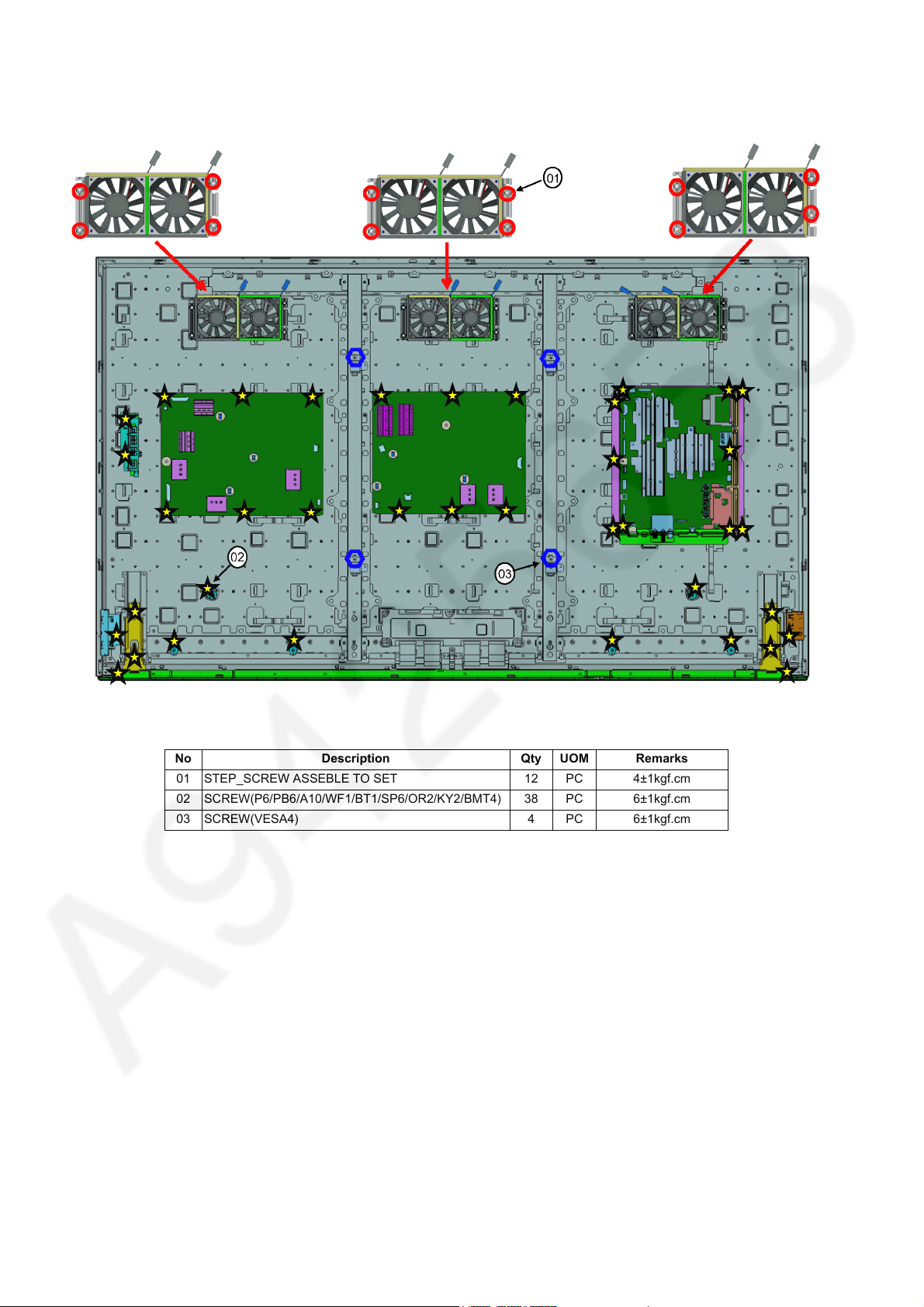

7.7. Screw Fixing -3

1. Fix follow diagram.

No Description Qty UOM Remarks

01 STEP_SCREW ASSEBLE TO SET 12 PC 4±1kgf.cm

02 SCREW(P6/PB6/A10/WF1/BT1/SP6/OR2/KY2/BMT4) 38 PC 6±1kgf.cm

03 SCREW(VESA4) 4 PC 6±1kgf.cm

24

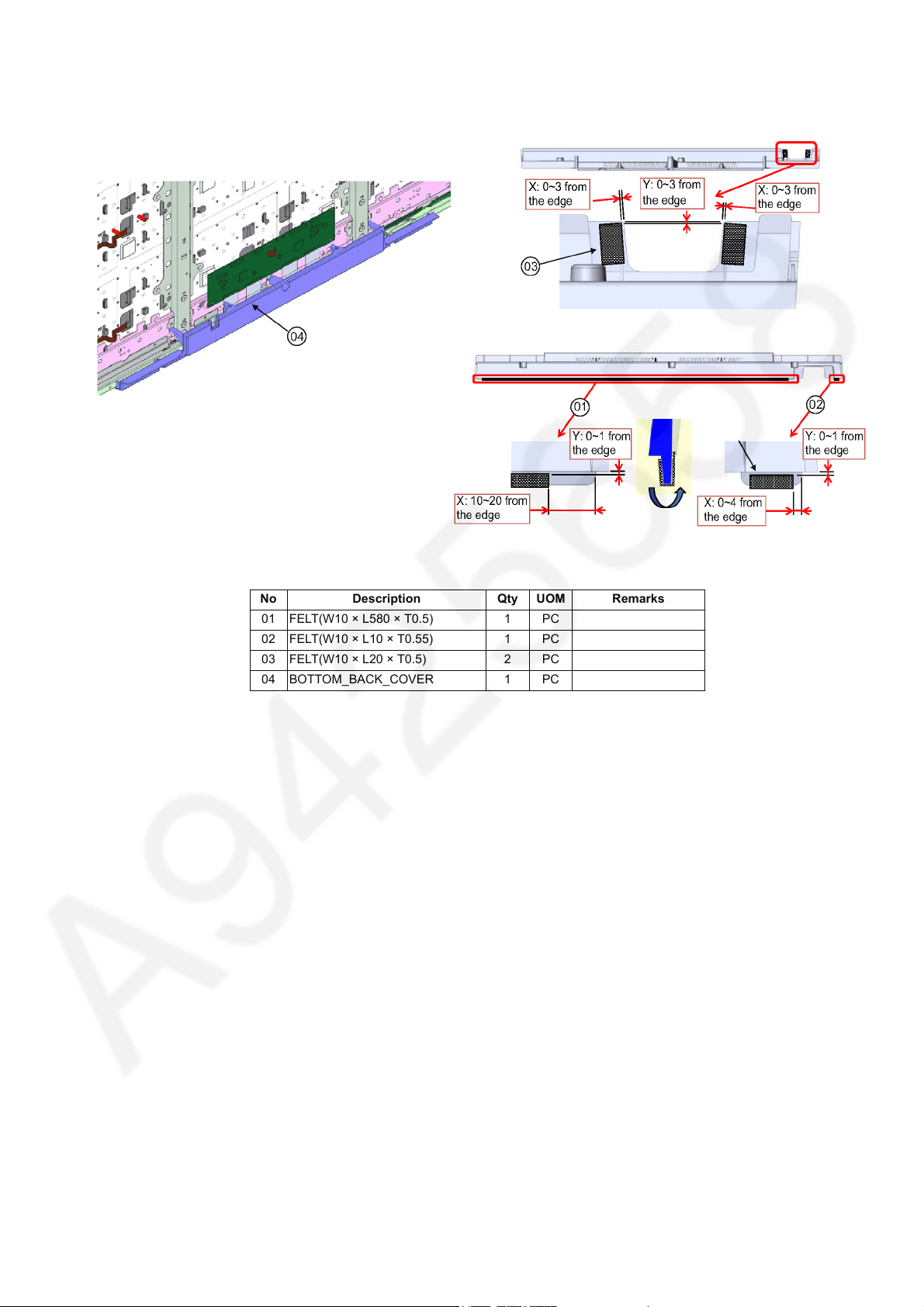

7.8. Bottom Backcover Prep.

1. Fix follow diagram.

TC-65DX900U

No Description Qty UOM Remarks

01 FELT(W10 × L580 × T0.5) 1 PC

02 FELT(W10 × L10 × T0.55) 1 PC

03 FELT(W10 × L20 × T0.5) 2 PC

04 BOTTOM_BACK_COVER 1 PC

25

TC-65DX900U

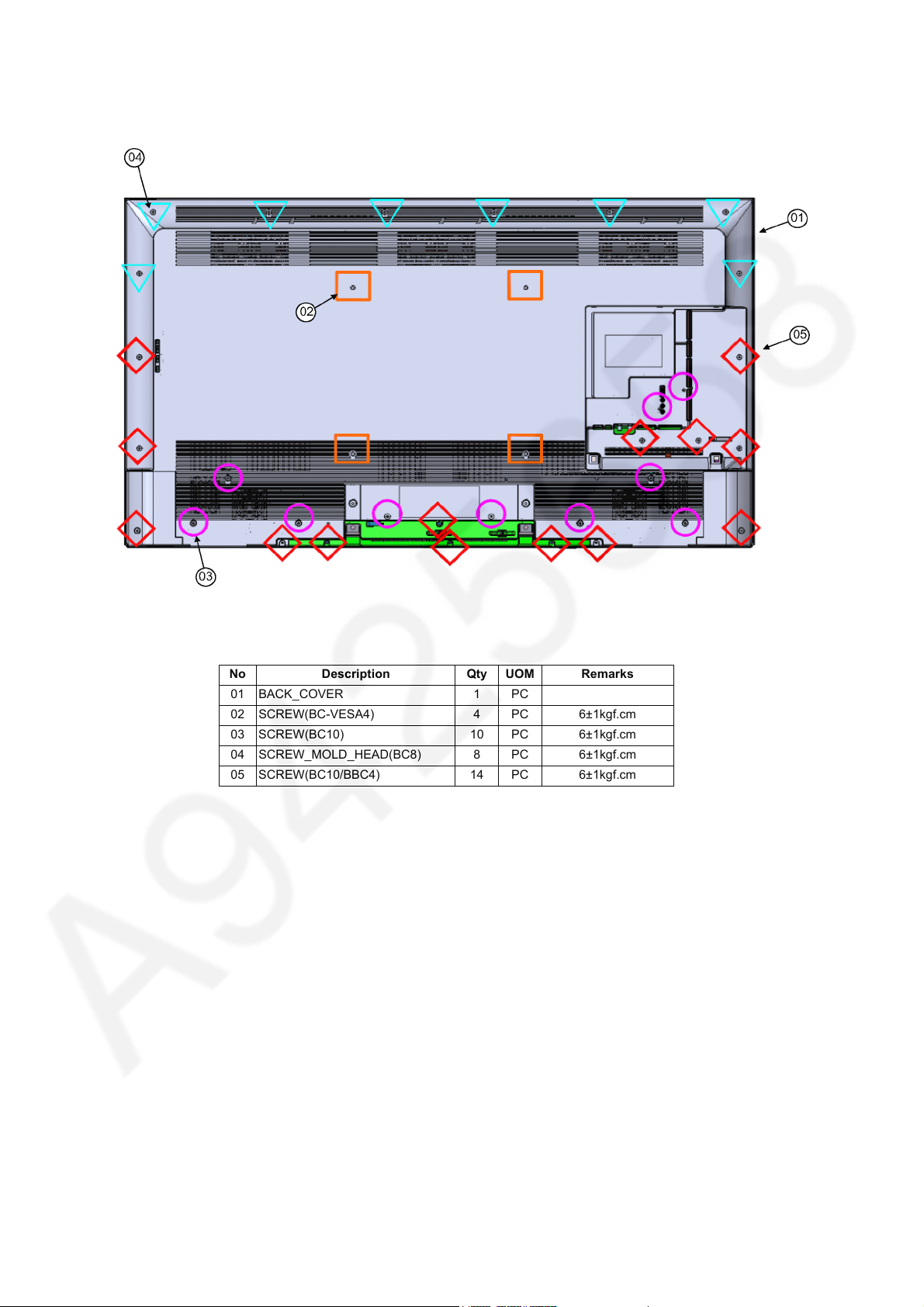

7.9. Bottom & Backcover Ass’y

1. Fix follow diagram.

No Description Qty UOM Remarks

01 BACK_COVER 1 PC

02 SCREW(BC-VESA4) 4 PC 6±1kgf.cm

03 SCREW(BC10) 10 PC 6±1kgf.cm

04 SCREW_MOLD_HEAD(BC8) 8 PC 6±1kgf.cm

05 SCREW(BC10/BBC4) 14 PC 6±1kgf.cm

26

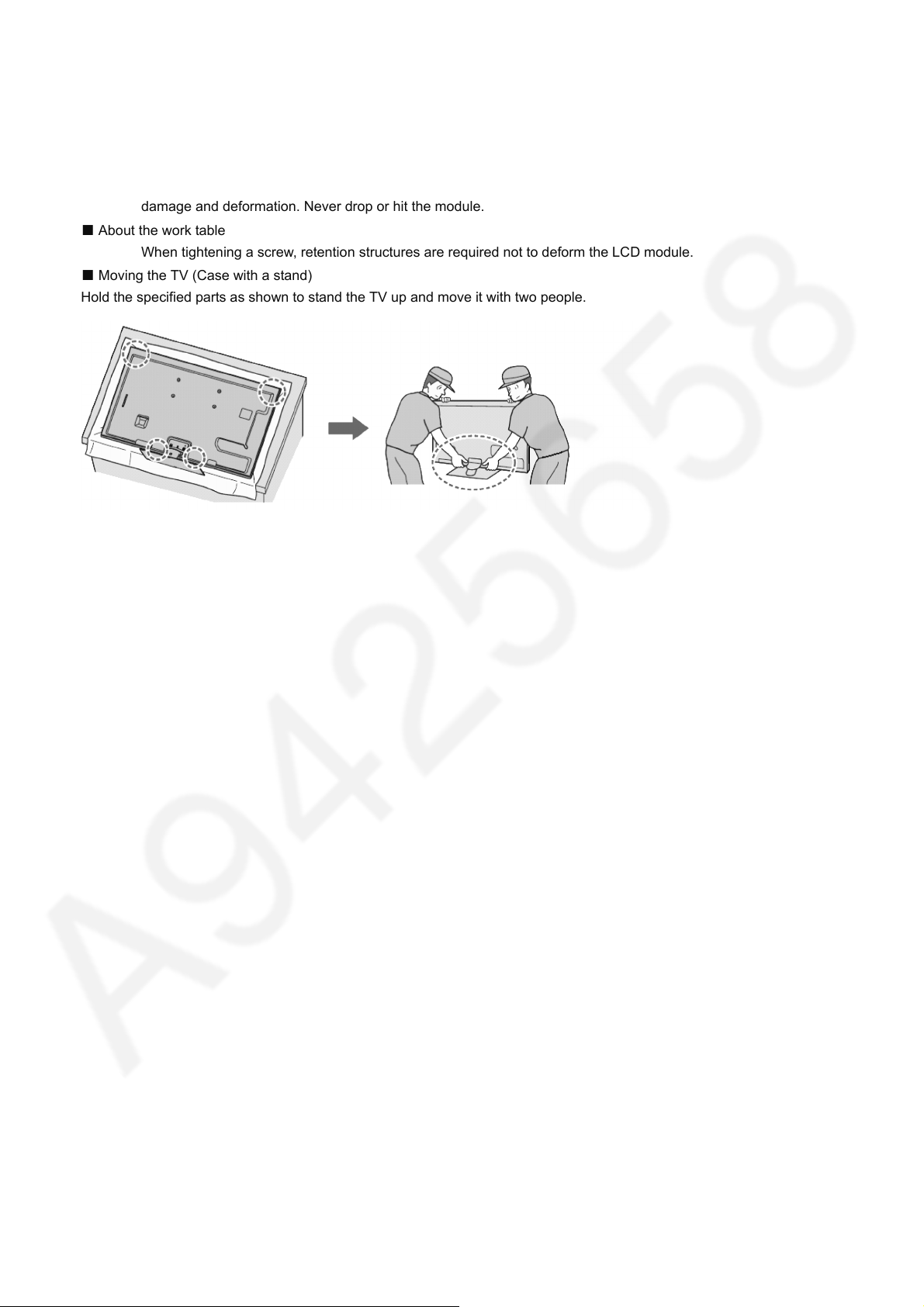

7.10. Handling SPEC

■ Moving the LCD module

The module should be handle by two people and hold on that top and bottom long side by both hands without module

warping. Never handle the module with keeping horizontal position when moving the module in order to avoid internal

damage and deformation. Never drop or hit the module.

■ About the work table

When tightening a screw, retention structures are required not to deform the LCD module.

■ Moving the TV (Case with a stand)

Hold the specified parts as shown to stand the TV up and move it with two people.

TC-65DX900U

27

TC-65DX900U

8 Measurements and Adjustments

8.1. Voltage chart of A-board

Set A-Board to a dummy set and check the satisfaction with the specified voltage as following table.

Checked Name Test Point Specification In/Out Target Board Suffix

PNL12V TP4059 12V ± 1.2V output ALL

USB5V TP5221 5.18V ± 0.25V output ALL

USB1 TP8701 5.0V ± 0.25V output ALL

USB2 TP8705 5.0V ± 0.25V output ALL

USB3 TP8711 5.0V ± 0.25V output ALL

USB-WiFi TP8718 5.14V ± 0.20V output ALL

SUB3.3V TP5201 3.33V ± 0.15V output ALL

HDMI1.1V TP4503 1.13V ± 0.06V output

HDMISW3.3V TP4514 3.35V ± 0.17V output ALL

SUB_AI_3.3V TP2206 3.3V ± 0.17V output ALL

STB_1.5V TP8101 1.52V ± 0.07V output ALL

SUB1.0V TP8100 1.02V +0.03V -0.05V output ALL

AVDD1.0V TP8102 1.06V ± 0.05V output ALL

NT2.5V TP9170 2.52V ± 0.12V output ALL

NT1.5V TP9160 1.25V ± 0.07V output ALL

NT1.1V TP9150 1.13V ± 0.06V output ALL

GE_1.1V TP4450 1.10V - 1.19V output

WOL3.3V/PHY3.3V TP8606 3.3V ± 0.17V output ALL

EU_TU_1.8V TP5704 1.84V ± 0.1V output ALL

SD3.3V TP8644 3.34V ± 0.17V output ALL

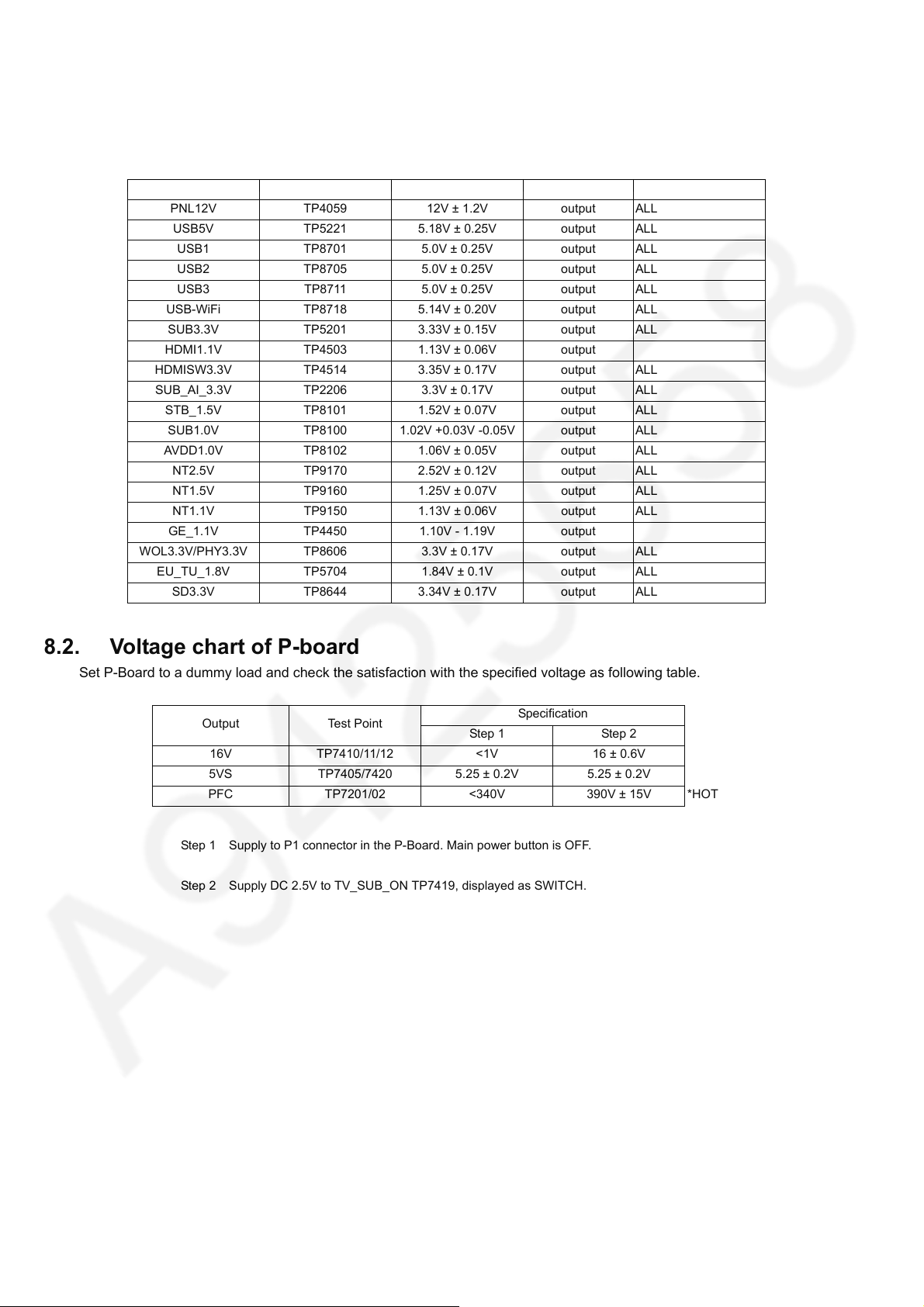

8.2. Voltage chart of P-board

Set P-Board to a dummy load and check the satisfaction with the specified voltage as following table.

Output Test Point

16V TP7410/11/12 <1V 16 ± 0.6V

5VS TP7405/7420 5.25 ± 0.2V 5.25 ± 0.2V

PFC TP7201/02 <340V 390V ± 15V *HOT

Step 1 Supply to P1 connector in the P-Board. Main power button is OFF.

Step 2 Supply DC 2.5V to TV_SUB_ON TP7419, displayed as SWITCH.

Step 1 Step 2

Specification

28

9 Block Diagram

S3.3

YPbPr

L/R in x 2

OPT

Analog AV

Y

Pb

Pr

R

L

Optical OUT

S5/ S3.3

S3.3

eMMC

32Gbit

Debug

Connector

A-SW

(Thru)

V-SW

HDMI

Rx

MUX

x4

ADC

[3:1]

Analog Video

Processor

ADC

DAC

ADC

Pre

Processor

A-Chip

SPDIF

SW

D-Chip

Trans Port Demux

DDR3

Controller

Audio

DSP

STB3.3

AV

Decoder

EASTER

Serial

Serial1

IIC

STM-IIC

Serial

STM-Serial0

24MHz

CLK

GEN

SOUND_VCC

LVD S-T x/

mini-LVDS-Tx

V-by-One

T-CON

S1.5

ATV

Decoder

DVB-C

Decoder

USB

IF

x4

ETHER-IF

FEAINP

FEAINN

Internal CI

controller

Low-IF

DMD

I2S(MCLK/LRCLK/BCLK/SDAT[1:0])

XRST/#SOS/#AMP_MUTE

I2S(MCLK/LRCLK/BCLK/SDAT[1:0])

XRST/#SOS/#AMP_MUTE

ADC

[0]

TV Decoder

SAW

FLT

Digital CVBS

DVB-T

Decoder

ATSC/QAM

Decoder

Digital SIF

MIB

(IPNR)

Main

Sub

OSD

1,2,3

cursor

External Video(Analog)

External Video(HDMI)

Dec video

x80

TVE

OSD

5

VDAC

PQ

MJC

(FRC,

3D)

Scaler

Dec Audio

ADx8

B2R

SPI-IF

SCLK

SDI

SDO

CE#1

S1.5

S3.3

S1.0

IIC

BE_IIC0

BE_IIC1

BE_IIC2

S1.8

I2S AMP

YDA176-QZ

(YAMAHA)

IFAGC0

IF0

P

ARM

XRST

POWER_DET

< TV_SOS

AMP/HP MUTE

MONITOROUT MUTE

F15V

STB5V

Analog

ASIC

OVP

SOS

Safety

Circuit

< MON_MUTE

< SP_HP_MUTE

PWMA

PWM_ENB >

PWMOUT

Common-Reset

Paragon

Reset

Circuit

USB2.0

(Port1)

USB2.0

(port0)

USB3.0

(Port2)

USB2.0

(Port3)

DDR3

x16

DDR3 1866 4Gbx5

MMCCLK

MMCCMD

XERST

MMCDAT0-7

eMMC-IF

S1.05

MAIN

SUB

SPI-IF

Rx0

Rx1

Rx2

Rx3

HPD* < Easter

HDMI_5V_DET* > Easter

DDC* > Easter

HPD* < Easter

HDMI_5V_DET* > Easter

HPD* < Easter

HDMI_5V_DET* > Easter

DDC* > Easter

HDMI1

HDMI2

HDMI3

R2R

HDMI1.4

HDMI1.4

HDMI2.0

HDMI2.0

ARC OUT

Lch:10W

Rch:10W

ETHER

STB5.3

S5

IEEE802.11n/11ac

Wireless UNIT

USB

Power SW

S5

HDD-USB

Power SW

USB3.0-IF

For Wake up On Wireless

WOW_ON_IRQ <

< PHY_PWR_ON

> WOW_OVP

USB*VBUS >

< OVCUR*

USB

Power SW

S5

USB*VBUS >

< OVCUR*

USB

Power SW

S5

USB*VBUS >

< OVCUR*

USB-1

USB-2

USB-3

(3.0 HDD)

HPD* < Easter

HDMI_5V_DET* > Easter

DDC* > Easter

HDMI4

24MHz

S3.3

BT Module

S3.3

USB-HUB

GL850G

USB2.0-IF

USB2.0-IF

HUB_XRST

CVBS

SD-IF

SDCLK,SDCMD,

SDDAT[3:0],SDCD,SDWP

SD XC

/UHS-I

S3.3

REG

S5

S3.3/1.8

UHS-I

HDMI2.0

HDCP2.2

HDMI2.0

HDCP2.2

HDMI2.0

HDCP2.2

HDMI2.0

HDCP2.2

27MHz

S3.3

SOUND_VCC

S1.8

I2S AMP

YDA176-QZ

(YAMAHA)

Lch:10W

Rch:10W

S16

20MHz

12MHz

10/100M

100Base-TX

USB2.0-IF

ARC

LED Information

G_LED_ON >

R_LED_ON >

< KEY3

< KEY1

CONTROL PANEL KEY

REMOCON

Reciever

LUMINANCE

Sensor

AI_SENSOR

<

RMIN

<

Main SW Soft Control

I2S

S3.3/ S1.1

HDMI

SW

MN864

788

<

HDMI_XRST

BE-IIC

<

HDMI_IRQ

Tx1

Tx0

HDCP2.2

HDCP2.2

HDCP2.2

HDCP2.2

SDVOLC

FAN

Control

FAN

FAN_ON >

FAN_CTR0 >

FAN_CTR1 >

FAN_SOS <

Bluetooth Glass

INX

Activ e 3D

Panel

P1.1/1.8/3.3

SPI

Flash

Adjust CON

8Mbit

SPI

Flash

Adjust CON

16Mbit

P1.1/1.5/2.5/3.3

Panel

T-CON

VbyOne 16 Lane

PANEL

Power

DCDC

PANEL_VCC_ON

P12

Novatek

LED Driver

BL_ON >

BL_SOS <

SPI-IF Bac klight Cont rol

VSYNC,HSYNC,CLK,CS[0:3]

,DO,DI

VbyOne 16Lane 3.75Gbps

For 4k2k x 2

PNL_3D_ON >

HTPDN <

LOCKN <

DDR3DDR3

x16

DDR3

x16

1Gbit x4

512 area

X:32 Y:16

3D_LRID

>

DDR3

x16

GCEX2

VbyOne 8 Lane

HTPDN <

LOCKN <

BE-IIC

BE-IIC

DISPEN >

PWM_ENB >

LOGO_ON>

NT_DONE <

VbyOne 8 Lane

HTPDN <

<

LOCKN <

PANEL_T EST_ ON >

3D_LRID_OSD >

VbyOne 4 Lane forOSD

HTPDN <

LOCKN <

GCX_AMREADY

FRC_XRST >

GCEX_XRST >

INX

S16

S3.3/S1.8

TUNER

IFAGC0

F

TU-IIC1

IF0

On Board

TC-65DX900U

29

TC-65DX900U

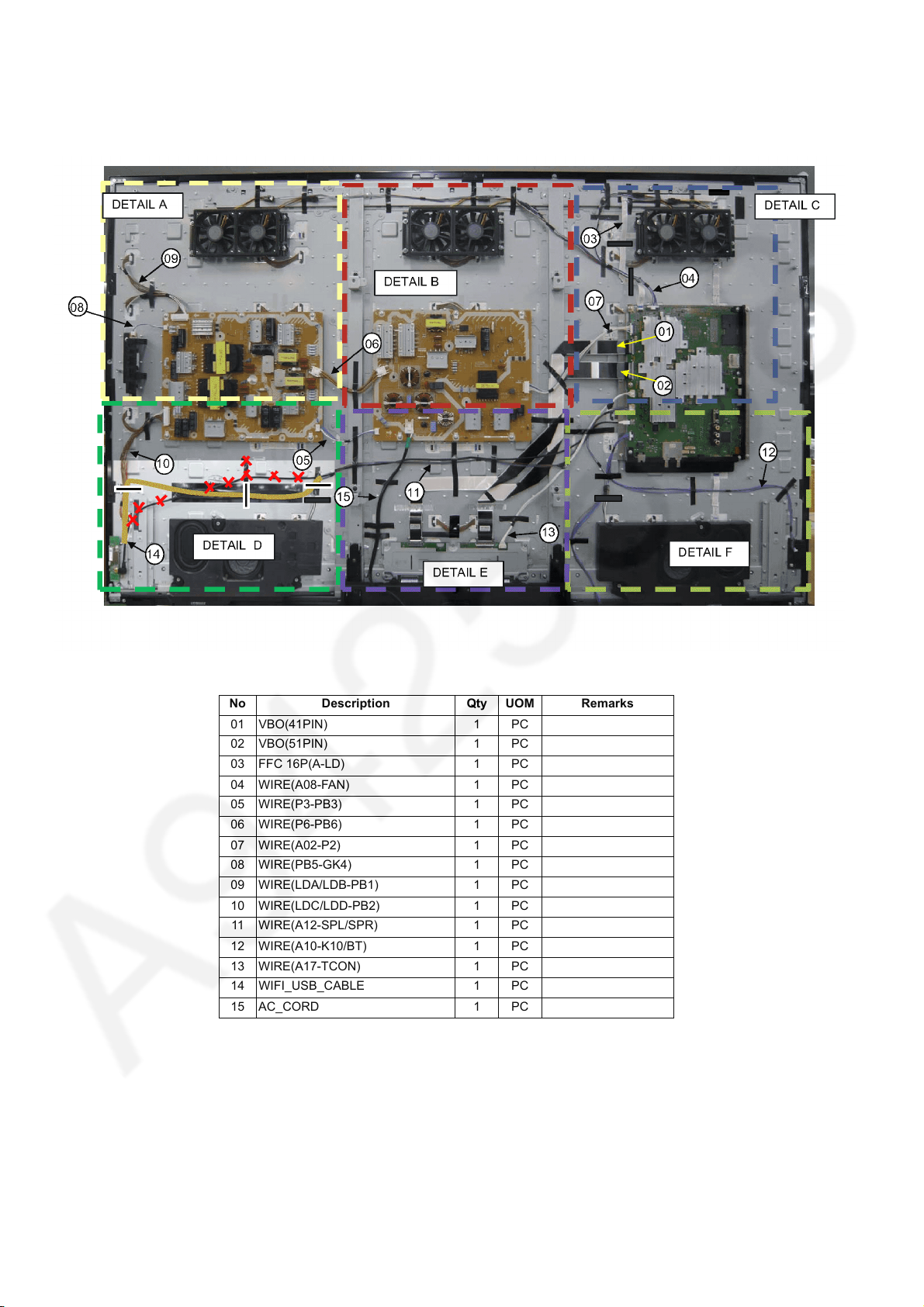

10 Wiring Connection Diagram

10.1. Wire Dressing -1

No Description Qty UOM Remarks

01 VBO(41PIN) 1 PC

02 VBO(51PIN) 1 PC

03 FFC 16P(A-LD) 1 PC

04 WIRE(A08-FAN) 1 PC

05 WIRE(P3-PB3) 1 PC

06 WIRE(P6-PB6) 1 PC

07 WIRE(A02-P2) 1 PC

08 WIRE(PB5-GK4) 1 PC

09 WIRE(LDA/LDB-PB1) 1 PC

10 WIRE(LDC/LDD-PB2) 1 PC

11 WIRE(A12-SPL/SPR) 1 PC

12 WIRE(A10-K10/BT) 1 PC

13 WIRE(A17-TCON) 1 PC

14 WIFI_USB_CABLE 1 PC

15 AC_CORD 1 PC

30

Loading...

Loading...