Page 1

TC-26LX60L

TC-32LX60L

LH58

MTNC060583CE

B05

LCD TV

CONTENTS

Page Page

1 Safety precautions 3

2 Warning

2.1. Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

3 About lead free solder (PbF)

4 Receiver feature table

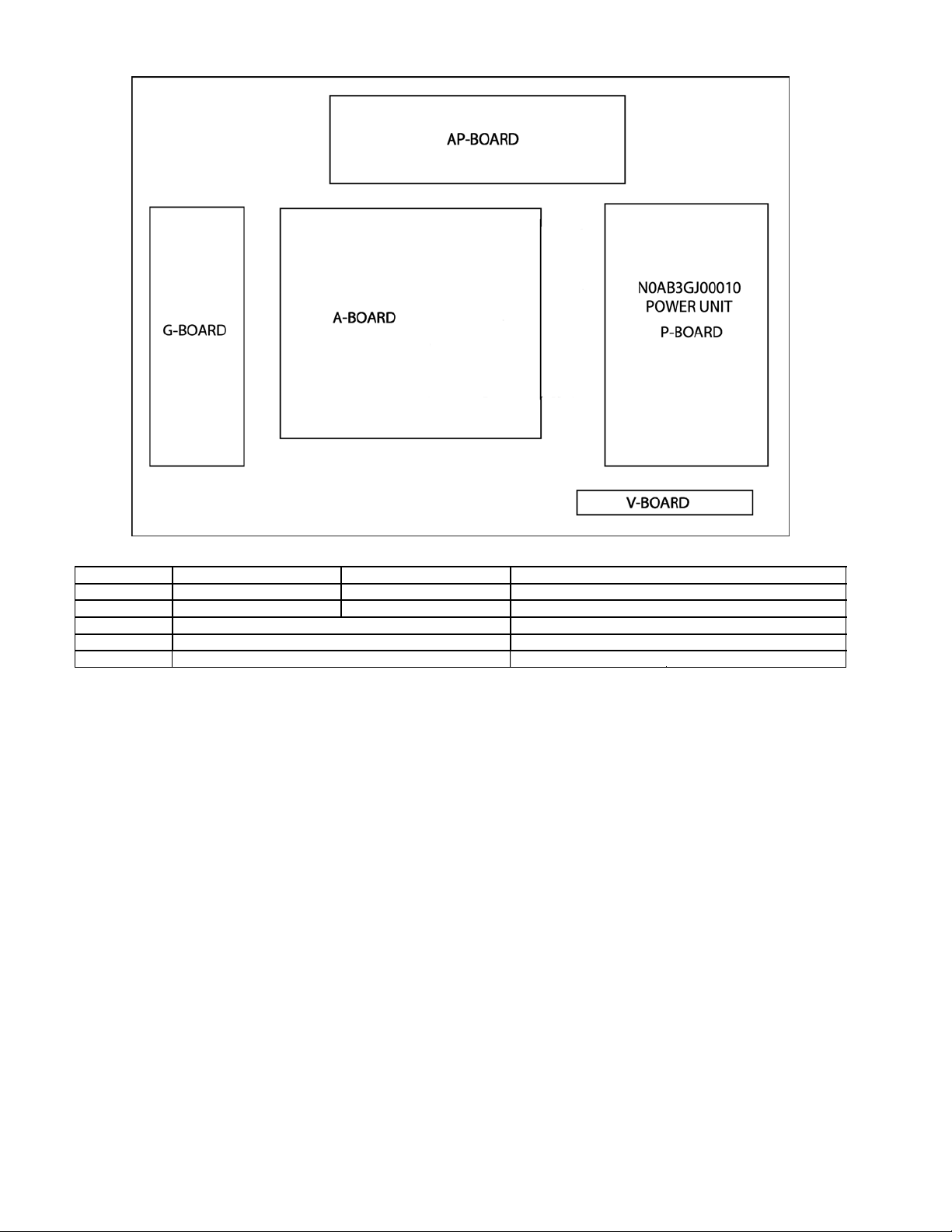

5 Chassis Board Layout

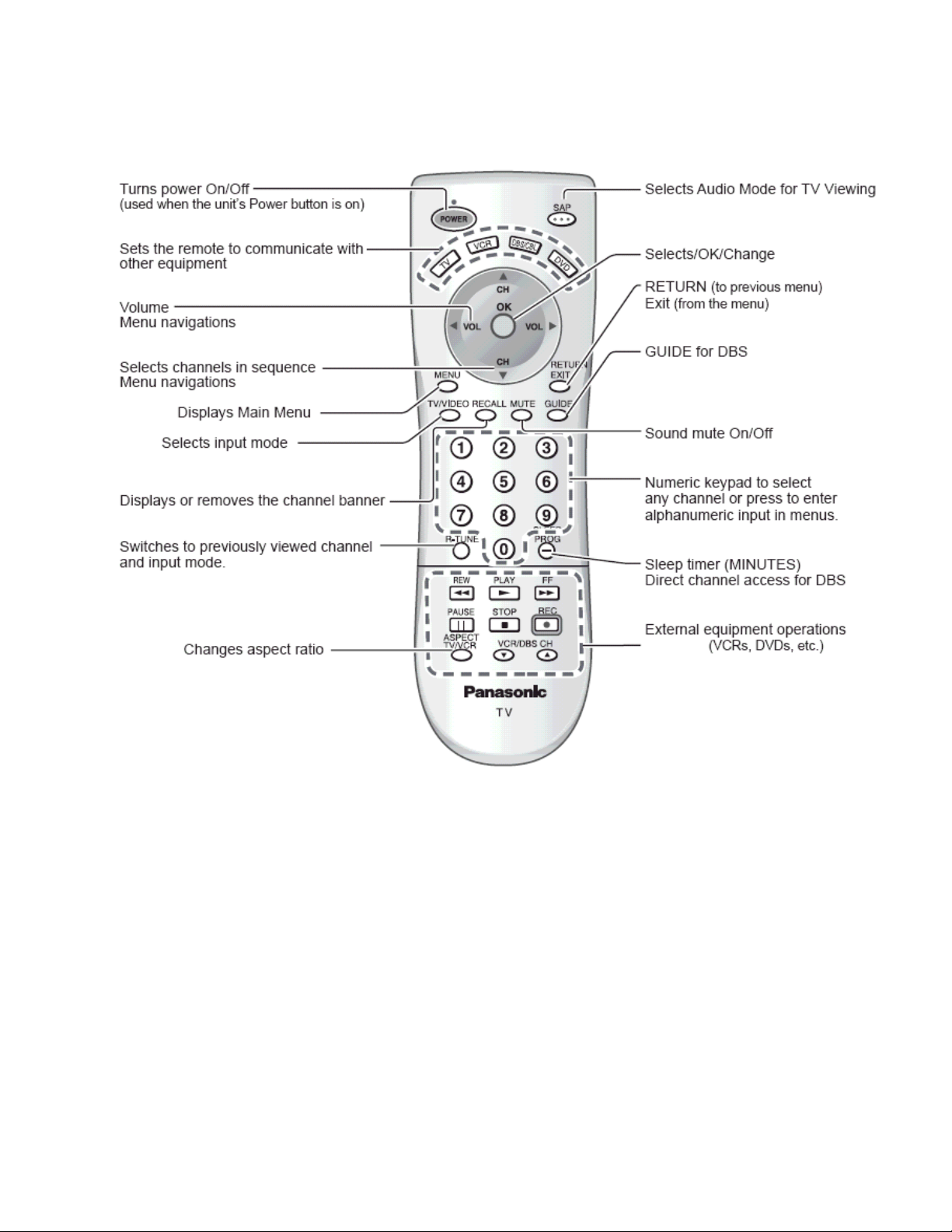

6 Location of controls (EUR7613Z90R or EUR7613ZE0)

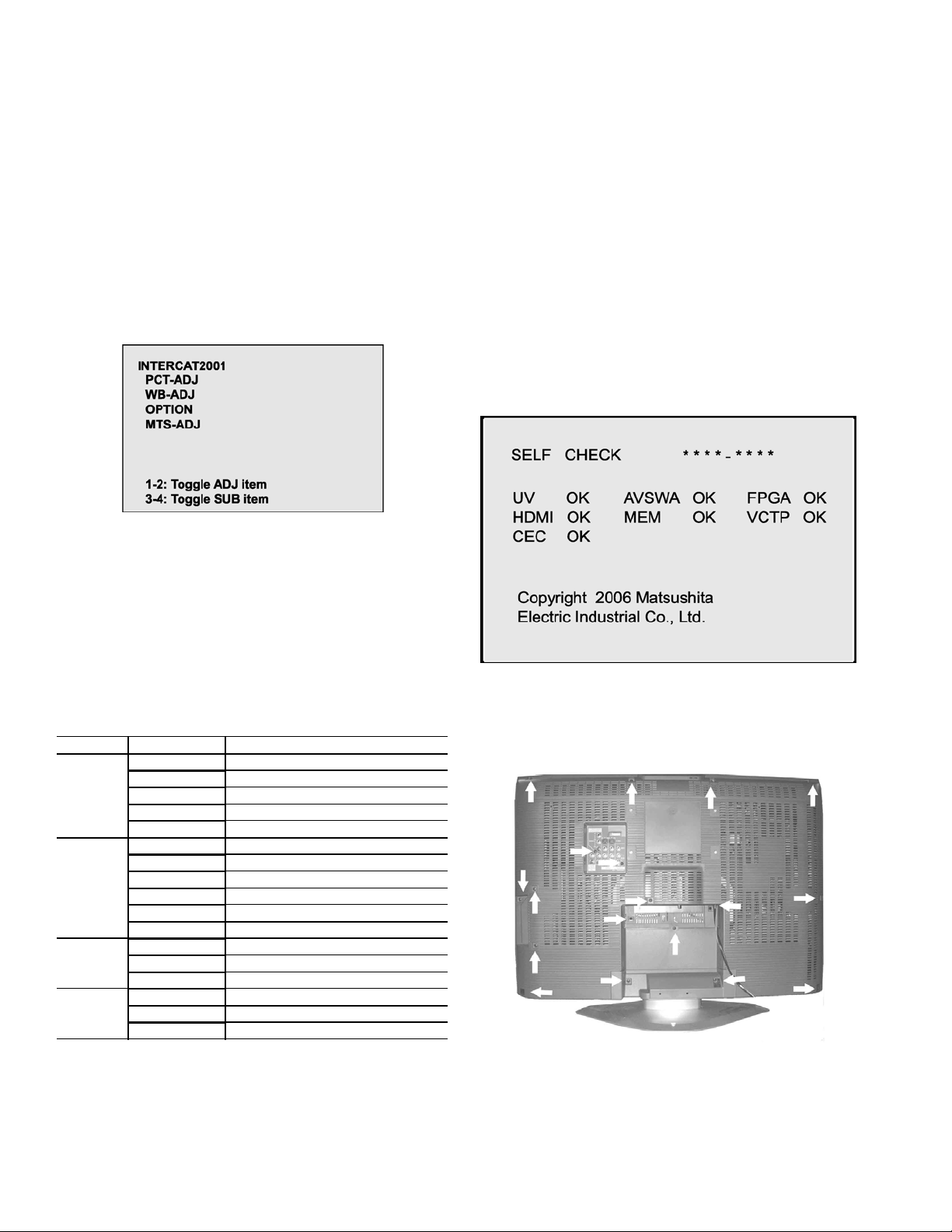

7 Service Mode

7.1. How to enter into adjustment mode

7.2. Adjustment method.....Use the remote control.

7.3. Cancellation

7.4. Contents of adjustment mode

8 Troubleshooting Guide

8.1. Self-check function

8.2. How to access

8.3. Screen Display

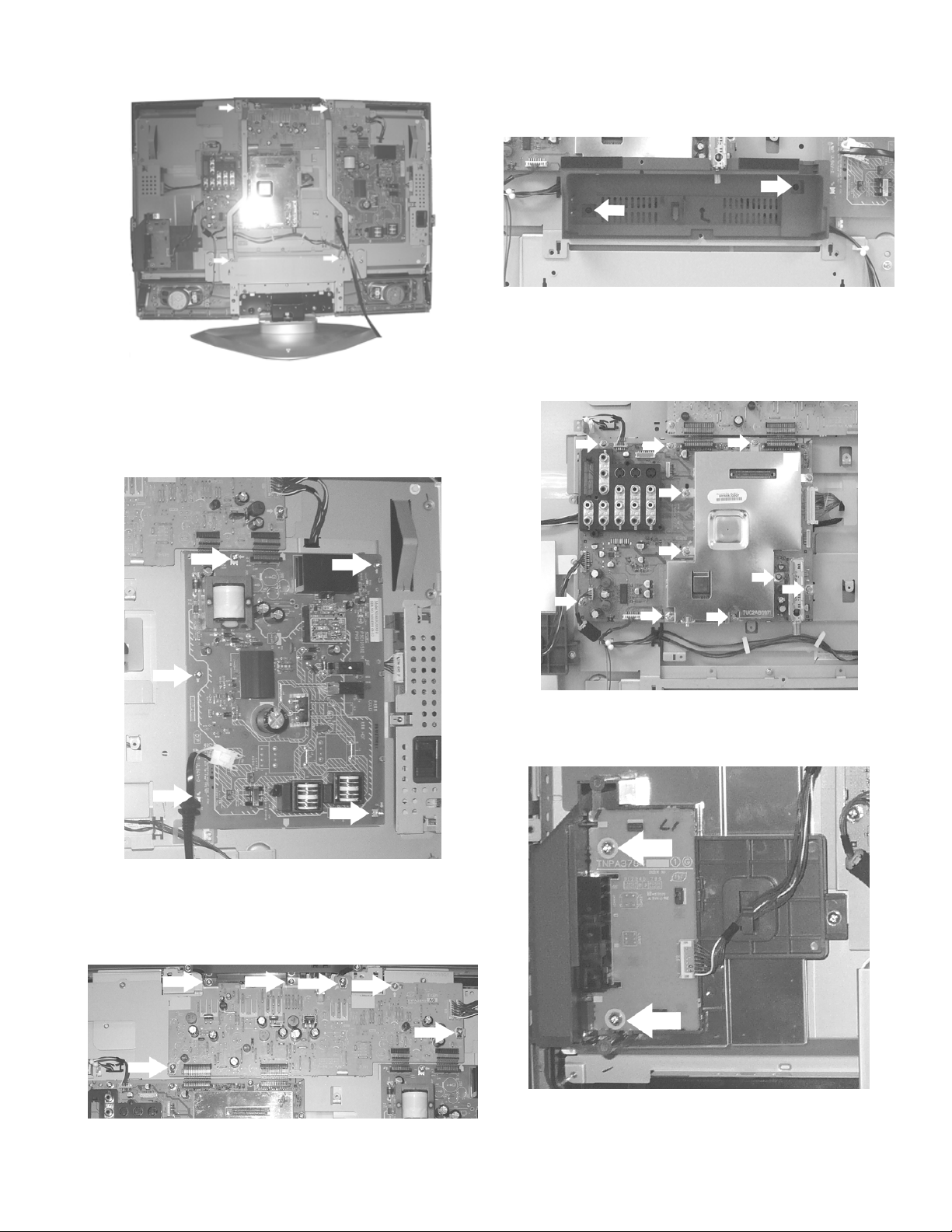

9 Disassembly Instructions 8

3

3

4

5

6

7

8

8

8

8

8

8

8

8

8

9.1. Removing the LCD panel assembly and LCD L/R MTG

9.2. Removing the LCD panel and LCD T/B MTG

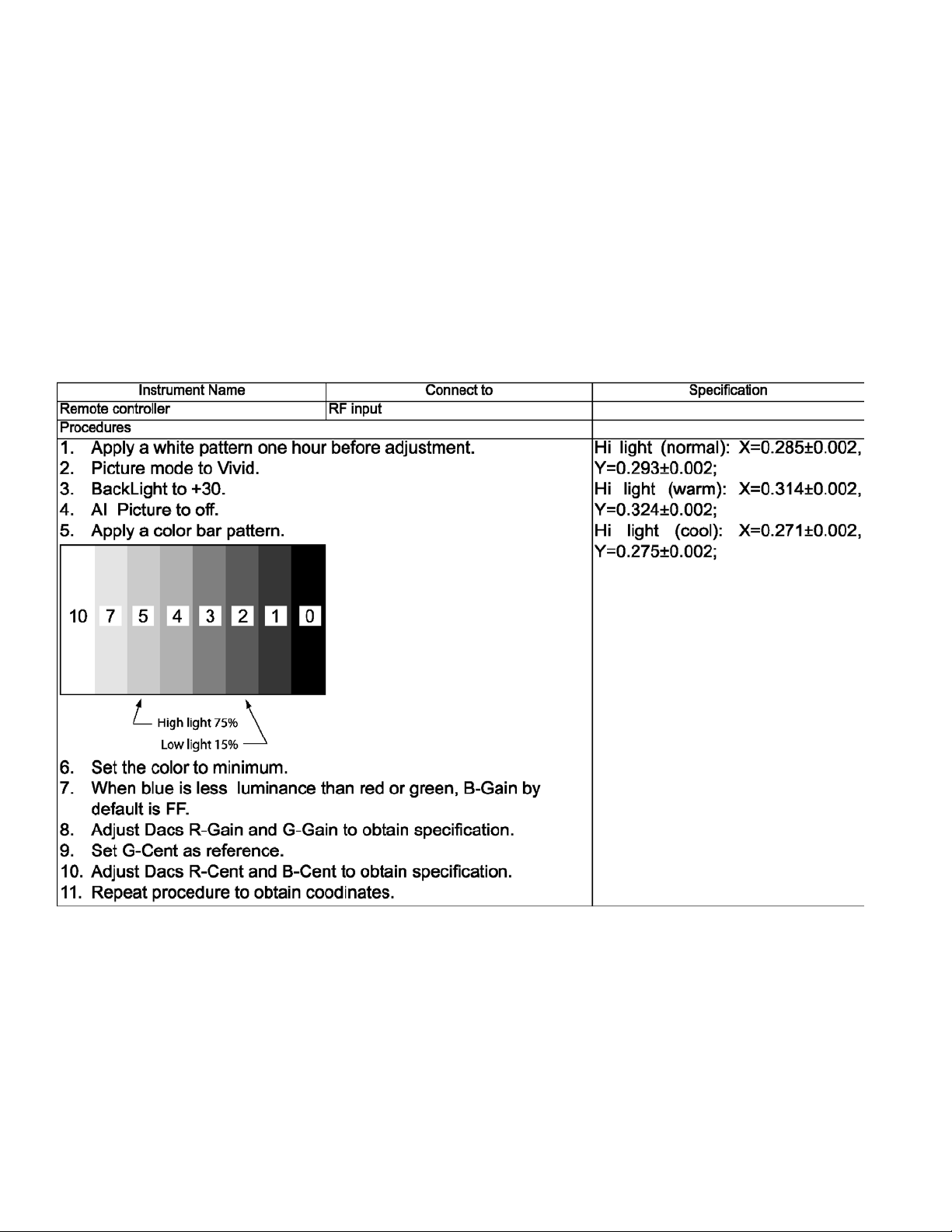

10 Measurements and Adjustments

10.1. White Balance Adjustment

11 MTS circuit adjustment

12 Boards Assemblies

12.1. AP-Board

12.2. A-Board

12.3. P-Board

12.4. G-Board

12.5. V-Board

13 Block Diagram

13.1. Block Diagram for P and AP (DC-DC CONV.) (1 of 2)

13.2. Block Diagram for P and AP (DC-DC CONV.) (2 of 2)

14 Schematic Diagrams

14.1. Schematic Diagram Notes

© 2006 Panasonic Corporation of North America. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

11

11

12

12

13

14

14

15

16

17

18

19

19

20

21

21

Page 2

14.2. Reference of PDF links color 22

14.3. A-Board (1 of 7) Schematic Diagram

14.4. A-Board (2 of 7) Schematic Diagram

14.5. A-Board (3 of 7) Schematic Diagram

14.6. A-Board (4 of 7) Schematic Diagram

14.7. A-Board (5 of 7) Schematic Diagram

14.8. A-Board (6 of 7) Schematic Diagram

14.9. A-Board (7 of 7) Schematic Diagram

14.10. AP-Board (1 of 3) Schematic Diagram

14.11. AP-Board (2 of 3) Schematic Diagram

14.12. AP-Board (3 of 3) Schematic Diagram

14.13. V-Board Schem atic Diagram

23

24

25

26

27

28

29

30

31

32

33

14.14. G-Board Schematic Diagram

15 Printed Circuit Boards

15.1. A-Board Top Side

15.2. A-Board Bottom Side

15.3. AP-Board

15.4. V & G-Board

16 Parts Location

16.1. Packing Exploded View

17 Parts list

17.1. Description of abbreviations guide

17.2. Parts list

34

35

35

36

37

38

39

39

40

40

41

2

Page 3

1 Safety precautions

General guidelines

1. When servicing, observe the original lead dress. If a

short circuit is found, replace all parts which have been

overheated or damaged by the short circuit.

2. After servicing, see to it that all the protective devices

such as insulation barriers, insulation papers shields are

properly installed.

3. After servicing, make the following leakage current

checks to prevent the customer from being exposed to

shock hazards.

Leakage current cold check

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed

metallic cabinet part on the equipment such as

screwheads, connectors, control shafts, etc. When the

exposed metallic part has a return path to the chassis,

the reading should be between 1MΩ and 5.2MΩ. When

the exposed metal does not have a return path to the

chassis, the reading must be infinite.

Figure 1. Hot check circuit

Leakage current hot check

1. Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer for this check.

2. Connect a 1.5k, 10 watts resistor, in parallel with a

0.15F capacitors, between each exposed metallic part

on the set and a good earth ground such as a water

pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks,

leakage current must not exceed 0.5 milliamp. In case a

measurement is outside of the limits specified, there is

a possibility of a shock hazard, and the equipment

should be repaired and rechecked before it is returned

to the customer.

2 Warning

2.1. Prevention of Electro Static

Discharge (ESD) to

Electrostatically Sensitive (ES)

Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some fieldeffect transistors and semiconductor "chip" components.

The following techniques should be used to help reduce the

incidence of component damage caused by electro static

discharge (ESD).

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain off

any ESD on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging ESD wrist strap, which should be removed for

potential shock reasons prior to applying power to the unit

under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as alminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static solder removal device. Some solder

removal devices not classified as "anti-static (ESD

protected)" can generate electrical charge sufficient to

damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, alminum

foil or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and

observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise hamless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static

electricity (ESD) sufficient to damage an ES device).

3

Page 4

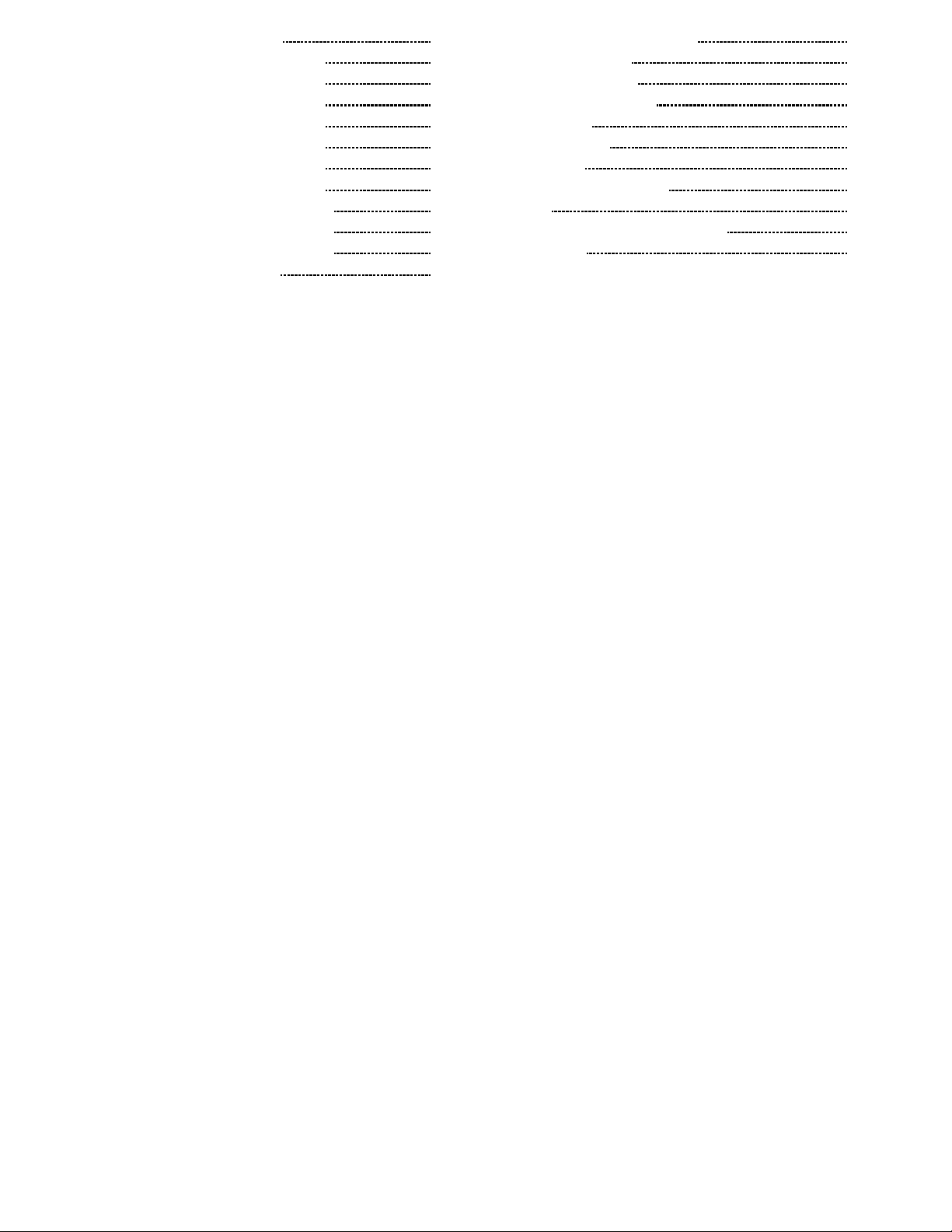

3 About lead free solder (PbF)

NOTE

Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to lead solder, and PbF will refer to Lead Free Solder.

The lead free solder used in our manufacturin g process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the “PbF” or a leaf symbol

CAUTION

• Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30 ~ 40 °C) higher.

Please use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

• Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb

solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

• After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto

the opposite side.

stamped on the back of PCB.

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder.

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

4

Page 5

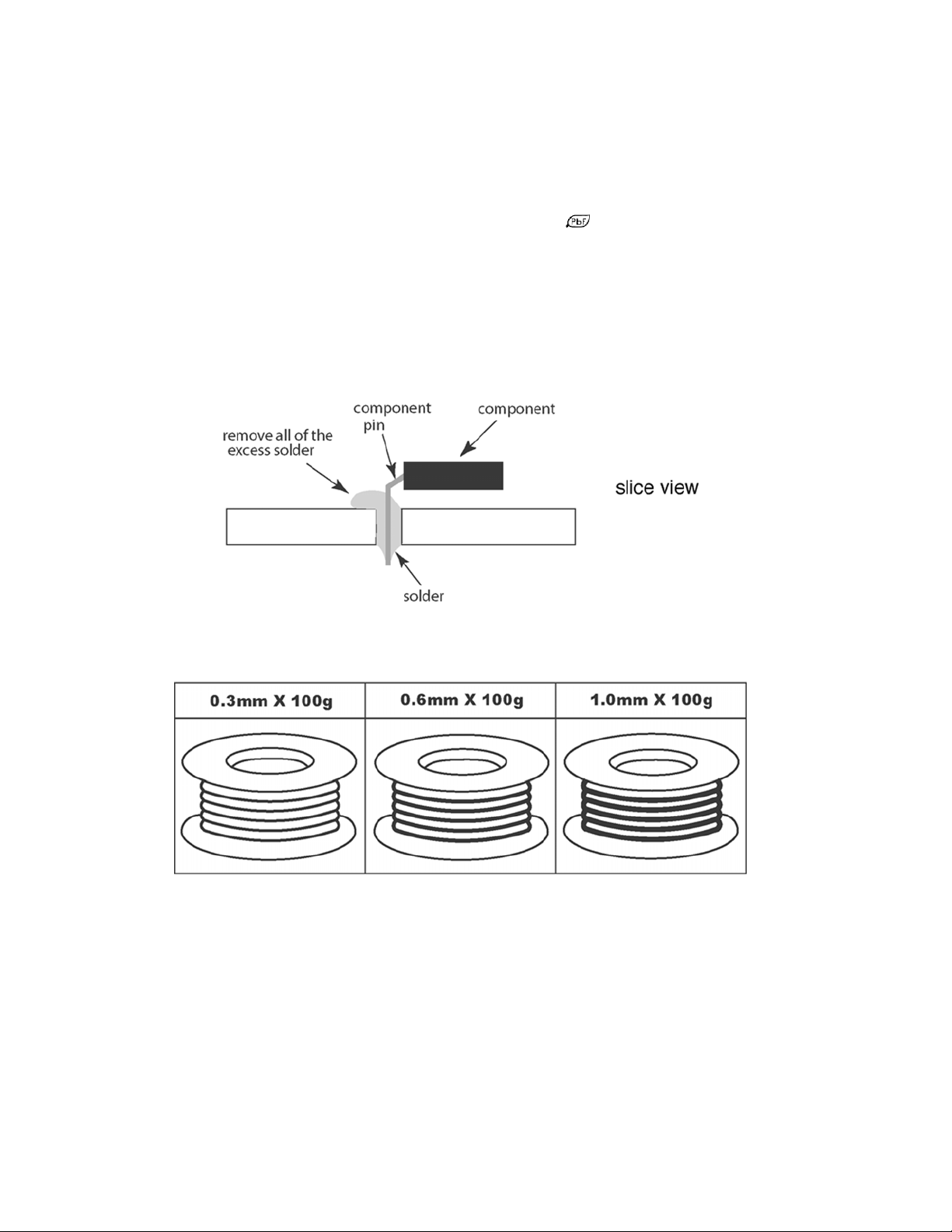

4 Receiver feature table

FEATURE / MODEL TC-26LX60L TC-32LX60L

LCD TYPE IPS (WXG A) IPS (WXGA)

LCD PANEL MAKER LG LG

CHASSIS LH58 LH58

SYSTEM NTSC NTSC

TUNING FST FST

STEREO MTS/SAP MTS/SAP

CATV USA CATV 181CH USA CATV 181CH

POWER SUPPLY AC120-127V, 60HZ AC120-127V, 60HZ

AV-IN 2 (RCA) 2 (RCA)

S-VHS-IN 2 2

COMPONENT VIDEO-IN VIDEO 1 / AUDIO 1 (RCA) VIDEO 1 / AUDIO 1 (RCA)

AV-OUT 1 (RCA) 1 (RCA)

HDMI 1 1

DVI NONE NONE

PC-INPUT NONE NONE

HEAD PHONE X X

PEAKS SYSTEM ----- ----GC SYSTEM MICRONAS VCTP MICRONAS VCTP

PROGRESSIVE X X

3D Y/CCOMB FILTER X X

SUB PIXCEL CONTROLER NONE NONE

GRS NONE NONE

AUDIO OUTPUT 10W + 10W 10W + 10W

SPEAKER SYSTEM UNDER/1 WAY - SPEAKER UNDER/1 WAY - SPEAKER

BASS/TREBLE X X

BALANCE X X

DTS NONE NONE

SURROUND X X

AUDIO OUT PERFORMANCE FAO FAO

SAFETY-STANDARD NOM NOM

STANDARD-ORGANIZATION E-STAR E-STAR

EMC (EMISSION) BETS-7 BETS-7

MECHANICAL ISTA ISTA

JPEG NONE NONE

MPEG4 NONE NONE

MPEG2 NONE NONE

ASPECT X X

CHANNEL BANNER NONE NONE

VIDEO PICTURE MEMORY NONE NONE

MULTI WINDOW NONE NONE

BLUE BACK (AV) NONE NONE

GAME MODE NONE NONE

GAME GUARD NONE NONE

OFF TIMER X X

AUTO SEARCH X X

DEMOSTRATION MODE ----- ----CLOSED CAPTION X X

V-CHIP X X

VESA COMPATIBLE COMPATIBLE

OSD LANGUAGE ENGLISH (US) / FRENCH / SPANISH ENGLISH (US) / FRENCH / SPANISH

REMOTE CONTROLLER EUR7613Z90R or EUR7613ZE0 EUR7613Z90R

CEC OF HDMI CONNECTION DIGA DIGA

PEDESTAL SWIVEL ONLY (NO TILTED) SWIVEL ONLY (NO TILTED)

SD SLOT FOR DL NONE NONE

Note:

Specifications are subject to change without notice or obligation.

5

Page 6

5 Chassis Board Layout

Board Layout

Board Name TC-26LX60L TC-32LX60L Function

A-Board TZRXN010MTJE TZRXN010MSJE Main (AV Switch, Audio, MCU, Global Core, AV connector)

AP-Board TZRXN020MSJE TZRXN020MSJE DC-DC

G-Board TNPA3784S Side Terminal

V-Board TNPA3749ACS Remote Reciever, LED

P-Board LSEP1221A1HB AC-DC

6

Page 7

6 Location of controls (EUR7613Z90R or EUR7613ZE0)

7

Page 8

7 Service Mode

7.1. How to enter into adjustment

mode

While pressing [VOLUME-] button of the main unit, press

[RECALL] button of the remote control transmitter three times

in a row (within 2 seconds).

can be used to confirm the occurrence and to limit the

scope for the defective circuits. Also, when "the power fails

from time to time", display on the screen can be used to

confirm the occurrence and to limit the scope for the

defective circuits.

Any programmed channels, channels caption data and

some other user defined settings will be erased and return

to factory setting.

7.2. Adjustment method.....Use the

remote control.

“1” button...Main items Selection in forward direction

“2” button...Main items Selection in reverse direction

“3” button...Sub items Selection in forward direction

“4” button...Sub items Selection in reverse direction

7.3. Cancellation

Switch off the power with the [POWER] button on the main unit

or the [POWER] button on the remote control.

7.4. Contents of adjustment mode

• Value is shown as a hexadecimal number.

• Preset value differs depending on models.

• After entering the adjustment mode, take note of the value

in each item before starting adjustment.

Main Item Sub Item Remarks

PCT-ADJ COLOR Sub color Adjustment

R-Y-A recovery axis (R-Y)

B-Y-G Gain (B-Y)

BACK-L Sub-backlight

TINT Tint Adjustment

WB-ADJ (White

balance

adjustment)

OPTION OPTOO TV (for TV) (Not ADJ)

MTS-ADJ MTSIN RF Audio input level detection

B-CENT Blue Gain by test pattern (50% white)

G-CENT Green Gain by test pattern (50% white)

R-CENT Red Gain by test pattern (50% white)

B-GAIN Blue Gain by test pattern (100% white)

G-GAIN Green Gain by test pattern (100% white)

R-GAIN Red Gain by test pattern (100% white)

CEC-CHK For service only

EEP-COPY For service only

SEPAH Stereo separation Hi

SEPAL Stereo separation low

8.2. How to access

Access

Produce TV reception screen and, while pressing

[VOLUME -] button on the main unit, press [SLEEP] button

on the remote controller unit simultaneously.

Exit

Press the POWER button twice (off/on) to return to the

normal screen.

8.3. Screen Display

9 Disassembly Instructions

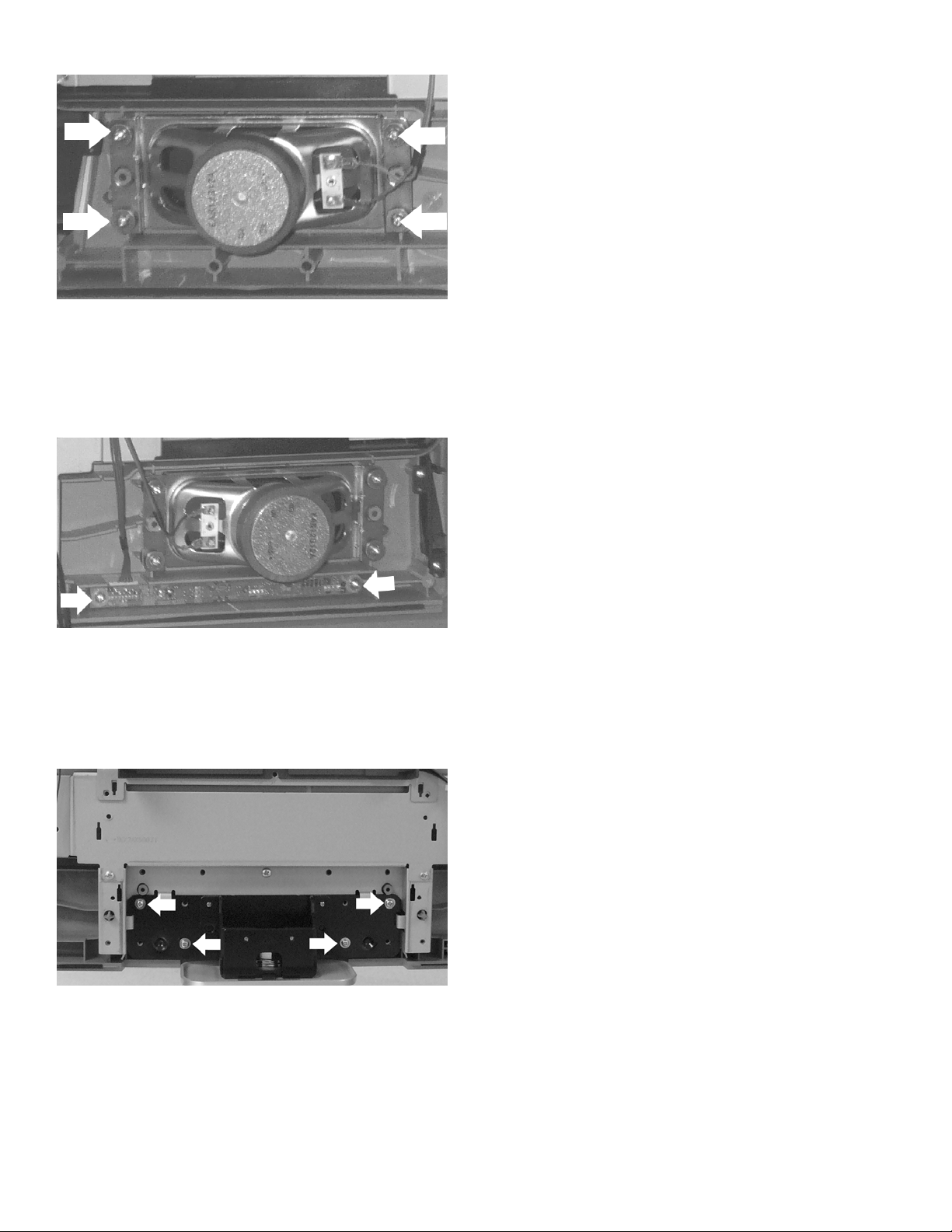

Back cover removal (screw location)

8 Troubleshooting Guide

8.1. Self-check function

When phenomena like "the power fails from time to time" or

"the video/audio fails from time to time" can not be

confirmed at the time of servicing, the self-check function

1. Remove all the screw from the back cover indicated with

arrows.

8

Page 9

Without the back cover

1. First remove the two screws from each bracket one

located on top and one on the bottom.

P-Board Disassembly

then remove the screws indicated on the figure above

by arrows.

Bracket Disassembly

1. To remove the bracket shown above remove the screws

indicated on the figure above by arrow.

A-Board Disassembly

1. To remove the P-Board remove the screws indicated on

the figure above by arrows.

AP-Board Disassembly

1. To remove the A-Board bracket shown above remove

the screws indicated on the figure above by arrows.

G-Board Disassembly

1. To remove the G-Board shown above remove the screw

indicated on the figure by arrow.

1. To remove the AP-Board first lift the four connectors

9

Page 10

Speaker Disassembly

1. To remove the speaker remove the screws indicated on

the figure by arrows, each speaker is located on sides.

V-Board Disassembly

1. To remove the V-Board remove the screws indicated on

the figure by arrows.

Removing the pedestal

1. Lay down the unit so that the rear cover faces upward.

2. Remove the 4 screws.

3. Then remove the pedestal.

10

Page 11

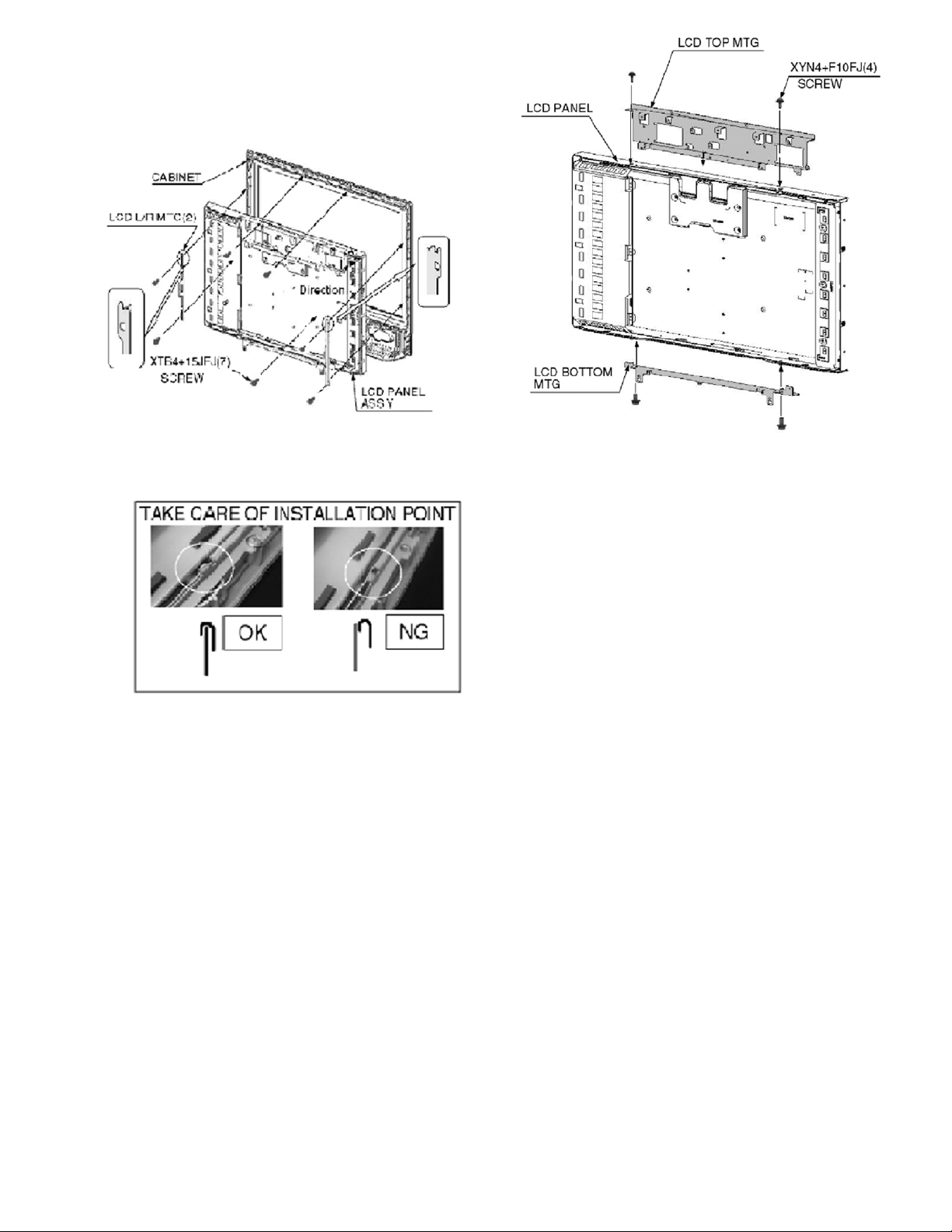

9.1. Removing the LCD panel

assembly and LCD L/R MTG

1. Remove the 4 screws.

2. Remove the LCD panel ass’y and LCD L/R MTG.

9.2. Removing the LCD panel and

LCD T/B MTG

1. Remove the 4 screws.

2. Remove the LCD panel and LCD T/B MTG.

11

Page 12

10 Measurements and Adjustments

10.1. White Balance Adjustment

12

Page 13

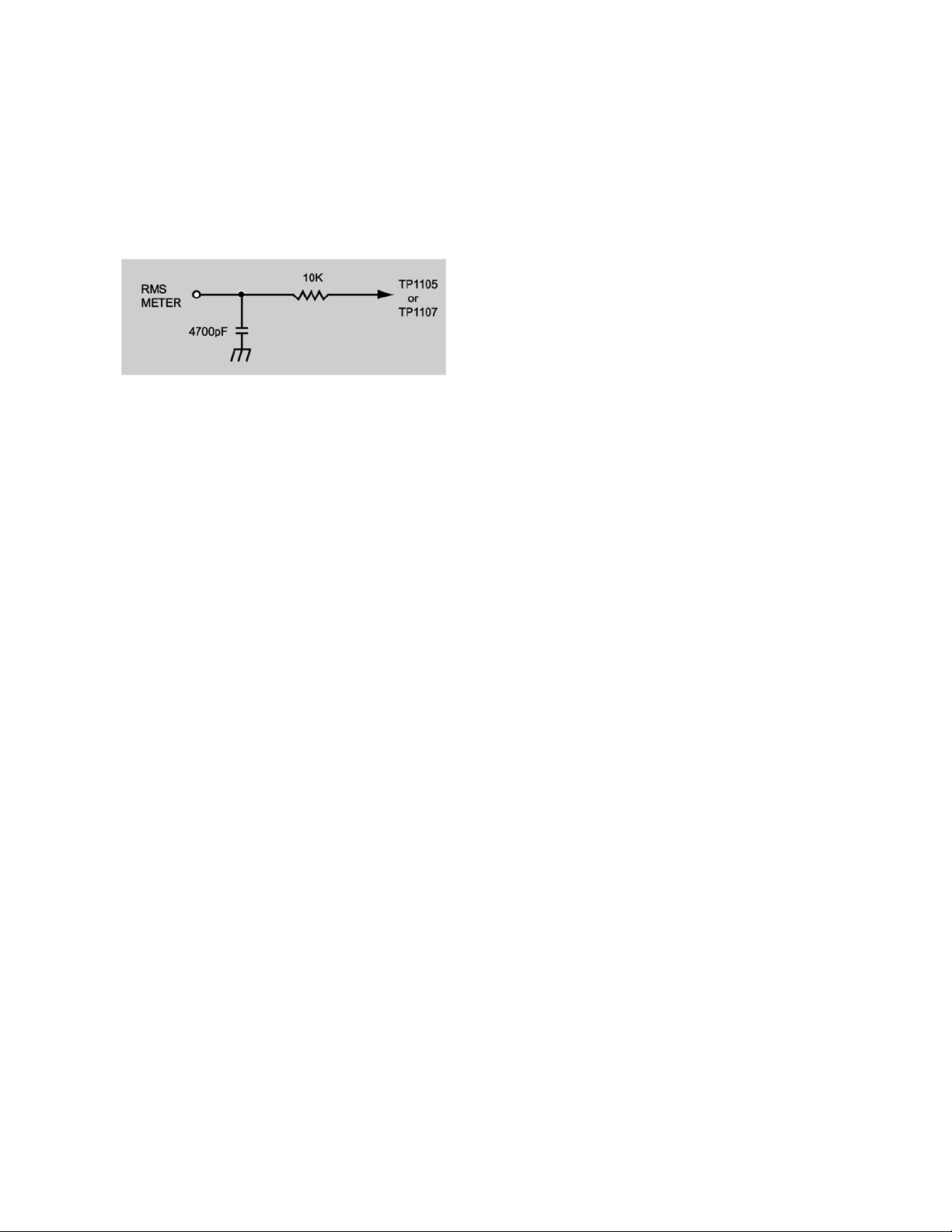

11 MTS circuit adjustment

The MTS circuit adjustment require two steps:

1. Input level adjustment.

2. Stereo separation adjustment.

Input level adjustment

Service DAC adjustment (MTSIN)

PREPARATION

1. Connect an RMS meter with filter jig as shown in figure

to TP1105 or TP1107 and gound.

2. Connect an RF sigal generator to the RF antenna Input.

PROCEDURE

1. Apply the following signal from the RF signal generator.

• Video: flat field, 30% modulation (70±5dB, 75 ohm

OPEN, P/S 10dB).

• Audio: 300Hz, 100% modulation, monaural

(70±5dB, 75 ohm OPEN, P/S 10dB.) Make sure that

the 75µs pre-emphasis is OFF.

2. Adjust the MTS input level adjustment “MTSIN” data

until the RMS voltage measured is 106mVrms ±

6.0mVrms.

Stereo separation adjustment (SEPAH)

PREPARATION

1. Connect an R.F. signal generator to the RF antenna

input.

2. Connect a scope to TP1104 or TP1106 and ground.

PROCEDURE

1. Select stereo mode in audio menu.

2. Apply the following signal from the RF signal generator.

• Video: flat field, 30% modulation.

• Audio: 300Hz, 30% modulation, stereo (left only)

(70±5dB, 75 ohm OPEN, P/S 10dB.)

Note: After setting 30% modulation with P.L. SW

and N.R. SW OFF, turn P.L. SW and N.R. SW ON.

3. In service mode, adjust the MTS Low-Level separation

adjustment “SEPAL” data until the amplitude displayed

on the scope is minimum.

4. Apply the following signal from the RF signal generator.

• Video: flat field, 30% modulation.

• Audio: 300Hz, 30% modulation, stereo (left only)

(70±5dB, 75 ohm OPEN, P/S 10dB.)

Note: After setting 30% modulation with P.L. SW

and N.R. SW OFF, turn P.L. SW and N.R. SW ON.

5. Adjust the MTS High-level separation adjustment

“SEPAH” until the amplitude displayed on the scope is

minimum.

6. Repeat above steps 2 through 5 until the amplitude is at

minimum for both signals.

13

Page 14

12 Boards Assemblies

12.1. AP-Board

14

Page 15

12.2. A-Board

15

Page 16

12.3. P-Board

16

Page 17

12.4. G-Board

17

Page 18

12.5. V-Board

18

Page 19

13 Block Diagram

2

T

O

H

N

B

13.1. Block Diagram for P and AP (DC-DC CONV.) (1 of 2)

2

AP

DC-DC CONV.

1

1

1

IC7218

SOUND_20V

+20V

IC7205

MAIN_5V

+5V

IC7209

SUB9V

+9V

10V OVP

*D7223

(+15V)

24V OVP

D7203

(+27V)

5

5

5

*D7224

D7204

2

Q7301

SOUND+18V ON

2

Q7303

MAIN+5V ON

2

UNREG_30V

MIX

10V,24V,SUB+9V

MAIN+5V,MAIN+9V

SOUND VCC,PANEL VCC

OVP DET

Q7204-Q7207

O.V.P, DET CIRCUIT

(DET:AC RELAY OFF)

SOUND_20V OVP

D7303

(+22V)

D7301

(+7.5V)

D7601

D7602

5V OVP

L:NORMAL

H:ABNORMAL

PANEL_Vcc OVP

D7703

(+18V)

Q7

SHOR

10V,

SOU

S

MAIN9V

D7452

D

(+13V)

D7704

D7304

D7302

(+13V)

D7404

D7403

9V OVP

IC7210

MAIN_9V

+9V

IC7212

+9V

Q7701

2

5

*Q7450

MAIN+9V ON

2

5

1

PANEL_Vcc(12V)

1

PANELVCC_ON

1

K

KEY SCAN

Note:

K-board is included in the control panel assy.

0

KEY SCAN

/

P

POWER UNIT

LSEP1221AHB

Exchange board only

.

1

3

-

CN1

AC CORD

K1

1

CN3

1

2

3

4

5

11

12

13

CN2

1

2

3

4

5

6

7

8

9

,

KEY

RELAY

SUB_ON

INV 24V

INV 24V

INV 24V

INV 24V

INV 24V

INV 24V

INV 24V

INV 24V

INV 24V

TO

LCD PANEL

(INVERTER)

TO

LCD PANEL

(INVERTER)

24V

24V

24V

10V

10V

7VS

INV 24V

INV 24V

INV 24V

INV 24V

INV 24V

INV 24V

INV 24V

INV 24V

AP6

1

AP2

1

2

3

4

5

11

12

13

AP1

1

2

3

4

5

6

7

8

9

AP3

2

3

6

7

*Q7224

*Q7223

RELAY ON/OFF

AP7

1

2

3

4

+

TC-26/32LX60L Block Diagram (1 of 2)

*

)

! "#$ %& ' (

*34567,89:;9<77=4;7>?7@79AB7)@7C!74=7"D7E+F"&GH&IG?7E+F#"GH&IG

19

Page 20

13.2. Block Diagram for P and AP (DC-DC CONV.) (2 of 2)

O

2

AP3

A3

SOUND_VCC

2

SOUND_VCC

*D7220

N

UNREG_30V

MIX

,SUB+9V

V,MAIN+9V

VCC,PANEL VCC

VP DET

204-Q7207

DET CIRCUIT

C RELAY OFF)

SOUND_20V OVP

D7303

(+22V)

D7301

(+7.5V)

D7601

D7602

5V OVP

D7304

D7302

(+13V)

D7404

D7403

9V OVP

IC7210

1

+9V

IC7212

PANEL_Vcc(12V)

1

+9V

Q7701

PANELVCC_ON

MAIN_9V

2

5

*Q7450

MAIN+9V ON

2

5

1

0

/

.

-

L:NORMAL

H:ABNORMAL

(+13V)

PANEL_Vcc OVP

D7703

(+18V)

Q7210

SHORT SOS

10V, BT30V

SOUND VCC,PANEL VCC

SHORT SOS DET

MAIN9V OVP

D7452

D7453

D7704

D7207

Q7702

PANELVCC_ON

Q7211

SHORT SOS

D7206

(+15V)

Q7208

24V DET

MAIN_9V

MAIN_5V

SOUND_16V

DC-DC ON/OFF CONTROL

Q7508

24V DET

SOUND VCC SHORT SOS

Panel Vcc SHORT SOS

D7470

Q7212

10V SHORT SOS

D7208

BT 30V SHORT SOS

D7469

D7472

Q7214

24V DET

D7471

D7474

D7473

Q7805

INV_ON

Q7806

INV_ON

POWER SWITCH

*SW7203

PUSH

3

BT_30V

7

MAIN_9V

17

MAIN_9V

18

19

MAIN_9V

MAIN_5V

21

MAIN_5V

22

A4

AP4

TV_SOS

1

3

STB_7V

6

TV_MAIN_ON

7

ALL_OFF

TV_SUB_ON

8

11

PANEL_12V

12

PANEL_12V

KEYSCAN

14

15

PANELVCC_ON

INV_ON

18

SUB_9V

22

22

SUB_9V

,

+

TC-26/32LX60L Block Diagram (2 of 2)

*

)

! "#$ %& ' (

*34567,89:;9<77=4;7>?7@79AB7)@7C"74=7"D7E+F"&GH&IG?7E+F#"GH&IG

20

Page 21

14 Schematic Diagrams

14.1. Schematic Diagram Notes

21

Page 22

14.2. Reference of PDF links color

22

Page 23

14.3. A-Board (1 of 7) Schematic Diagram

2

1

0

/

.

-

,

+

*

)

! "#$ %& ' (

)F*J)K,777777!74=7'777777EL@0I&'')-M).77777E+F"&GH&IG?7E+F#"GH&IG

23

Page 24

14.4. A-Board (2 of 7) Schematic Diagram

2

1

0

/

.

-

,

+

*

)

! "#$ %& ' (

)F*J)K,777777"74=7'777777EL@0I&'')-M).77777E+F"&GH&IG?7E+F#"GH&IG

24

Page 25

14.5. A-Board (3 of 7) Schematic Diagram

2

1

0

/

.

-

,

+

*

)

! "#$ %& ' (

)F*J)K,777777#74=7'777777EL@0I&'')-M).77777E+F"&GH&IG?7E+F#"GH&IG

25

Page 26

14.6. A-Board (4 of 7) Schematic Diagram

2

1

0

/

.

-

,

+

*

)

! "#$ %& ' (

)F*J)K,777777$74=7'777777EL@0I&'')-M).77777E+F"&GH&IG?7E+F#"GH&IG

26

Page 27

14.7. A-Board (5 of 7) Schematic Diagram

2

1

0

/

.

-

,

+

*

)

! "#$ %& ' (

)F*J)K,777777%74=7'777777EL@0I&'')-M).77777E+F"&GH&IG?7E+F#"GH&IG

27

Page 28

14.8. A-Board (6 of 7) Schematic Diagram

2

1

0

/

.

-

,

+

*

)

! "#$ %& ' (

)F*J)K,777777&74=7'777777EL@0I&'')-M).77777E+F"&GH&IG?7E+F#"GH&IG

28

Page 29

14.9. A-Board (7 of 7) Schematic Diagram

2

1

0

/

.

-

,

+

*

)

! "#$ %& ' (

)F*J)K,777777'74=7'777777EL@0I&'')-M).77777E+F"&GH&IG?7E+F#"GH&IG

29

Page 30

14.10. AP-Board (1 of 3) Schematic Diagram

2

1

0

/

.

-

,

+

*

)

! "#$ %& ' (

)@F*J)K,7777777!74=7#777777EL@)#($N),7777777E+F"&GH&IG?7E+F#"GH&IG

30

Page 31

14.11. AP-Board (2 of 3) Schematic Diagram

2

1

0

/

.

-

,

+

*

)

! "#$ %& ' (

)@F*J)K,7777777"74=7#777777EL@)#($N),7777777E+F"&GH&IG?7E+F#"GH&IG

31

Page 32

14.12. AP-Board (3 of 3) Schematic Diagram

2

1

0

/

.

-

,

+

*

)

! "#$ %& ' (

)@F*J)K,777777#74=7#777777EL@)#($N),7777777E+F"&GH&IG?7E+F#"GH&IG

32

Page 33

14.13. V-Board Schematic Diagram

2

1

0

/

.

-

,

+

*

)

! "#$ %& ' (

OF*J)K,7777777EL@)#'$N)+7777777E+F"&GH&IG?7E+F#"GH&IG

33

Page 34

14.14. G-Board Schematic Diagram

2

1

0

/

.

-

,

+

*

)

! "#$ %& ' (

/F*J)K,7777777EL@)#'($7777777E+F"&GH&IG?7E+F#"GH&IG

34

Page 35

15 Printed Circuit Boards

15.1. A-Board Top Side

2

JS2004

C2130

C2130

L2001

1

0

JS2005

JS2013

A1

C1180

18

C4133

C4134

R4238

R4321

C2134

C2135

C2136

C2137

D2002

A7

A7

1

4

C2127

C2140

R2101

C2181

C2180

C2126

C2140

L2001

R2099

R2100

C2124

C2122

C2119

C2114

C2178

C2179

C2125

32

IC2001

IC2001

C2113

C2101

C2132

1

C2102

C2110

R2115

R2140

R2114

L2005

C2103

R2107

R2139

C2173

R2103

R2104

R2159

C2175

L2003

C2223

C1179

C1178

C1143

A1

JS2021

JS2016

D2003

C2131

C2129

C2128

R2102

L2002

L2002

C2138

17

JS2014

C2133

16

C2111

C2106

C2109

R2108

R2105

R2106

R2160

C2139

C2131

Q2312

Q2313

A6

A6

1

C2100

R2153

C2157

JS2015

C2142

R2122

R2120

Q2020

R2121

Q2020

C2068

R2161

Q2030

R2110

R2314

Q2306

R2310

R2313

R2309

Q2312

Q2305

R2382

R2306

R2307

Q2313

C2375

Q2305

R2381

R2383

Q2303

JS2301

R2304

D2309

R2303

D2005

Q2303

R2116

Q2306

C2367

JS2020

9

R2154

C2172

C2141

IC2005

8

1

R2117

IC2005

R2113

4

5

C2145

C2144

C2146

C2147

R2112

R2152

R2096

R2097

Q2019

Q2030

Q2019

D2004

C2368

JS2306

R3020

/

C5006

R5025

R5006

R5002

C5004

C5002

R5128 R5129

Q5002

R5004

Q5002

C5023

FL5001

R5060

R5115

19

.

JK5002

1

C5005

R5024

Q5001

C5001

-

19

JK5001

JK5001 JK5002

1

,

ZA4006

L5009

R5015

D5002

L5013

R5016

R5116

L5008

D5004

R5017

D5006

FL5005

R5018

D5008

R5019

D5010

R5020

37

D5013

R5021

D5018

R5022

D5020

Pad

Thermal

R5005

C5003

C5010

Q5001

R5001

R5003

FL5002

R5007

D5001

72

R5008

R5009

D5003

IC5004

D5005

73

R5010

D5007

R5011

D5009

R5012

D5012

R5013

C5009

D5016

R5014

D5019

C5053

Q5019

Q5019

R5094

R5096

D5023

R5102

Q5018

Q5018

R5095

Q5020

R5093

R5098

R5100

C5054

C5055

R5097

Q5021

R5101

R5099

+

C003

AGCADJ

C002 C003

C002

+B

C014

TP2200

TP2200

*

)

ZA4005

R1187

C009

AGCCONT

APANAMALAK

JS3079

JS3080

JS3081

JS3082

JS3083

AEAFAG

AH

C4145

+

C4120

L4016

IC4001

L4014

C4111

R4266

C4064

C4072

X4001

R4082

C4071

R4326

C4182

R4325

C4183

R4262

C4177

R4261

C4176

R4260

R4259

R4211

R4212

R4258

C1169

R4257

C1168

R4011

R1172

R1171

104

5

8

IC1102

IC1102

1

4

C1853

C1845

C1843

R003

Q001

C010

TP1104

Q001

R005

R004

JS002

SIF-OUT

VIDEO

AUDIO

R5054

C5050

C5049

R5119

FL5007

1

4

Q5023

R5055

Q5023

R5061

R5062

R5064

C5018

36

C5019

D5021

D5025

D5027

Q5020

Q5021

L001

C004

TU001

TU001

C5051

IC5005

IC5005

R5114

L5011

FL5003

5

R5066

R5068

R5070

7

C5024

C5027

C5022

R5063

R5065

R5105

R5106

ZA4007

L001

BT

C5042

C5025

C5026

C5031

C5033

C5028

C5040

C5041

1

R5111

144

R5083R5084

IC5004

R5075

R5073

R5069

R5067

C5030

R5130

R5131

Q5024

Q5024

C015

R010

R009

RF-AGF

SCL

IFOUT

R5087

R5085

R5086

R5081

R5082

109

108

L5007

C5038

R5078

R5079

R5080

X5001

R5077

C5034

R5091

R1192

R1190

Q1152

R1186

Q1152

TP1105

C011

JS004

C008

JS003

C016

R001

SDA

AFT

BTL

1

4

A8

A8

S3002

S3001

C2143

S3021

C2158

S3022

S3020

S3019

10

S3014

A21

1

A21

C3064

Q3002

Q3001

Q3002

R3021

Q3003

C3067

R3025

Q3001

R3026

R3030

R3028

R3027

R3033

Q3004

R3032

Q3004

AJ

JS3077

JS3078

ABACAD

S3017

S3015 S3016

S3010S3011

S3009

R3023

S3005

Q3003

S3003 S3004

C3065

3

A

C4142

JK3002

JK3002

TNPH0677

S3008

S3007

A15

1

R1236

R1237

SUFFIX

IC4005

ZA4003

D1809

C1891

C1890

D4801

R4806

R4803

D1816

24

IC4801

IC4801

1

R4807

56

A12

R4760

CL4656

CL4533

A12

CL4530

CL4529

R4640

R4639

R4644

R4643

R4650

R4188

110

C1874

D1815

+

L1811

C1875

D1813

ZA4004

R4015

R4005

Q4001

R4042

R4040

Q4001

C4033

L4008

C4113

R4050

R4048

R4197

R4053

R4055

R4057

R4063

R4061

R4147

C4055

R4047

R4065

R4148

53

C4065

C4066

C4067

R4254

R4255

105

R4079

R4324

R4077

R4323

C1851

4

5

C1852

4

5

C1844

10

A14

R4049

C4056

C4058

52

C4060

R4246

R4248

R4247

R4080

C4104 C4105

L4009

C1849

3

IC1805

1

R1821

R1822

C1847

C1850

C1848

IC1804

1

R1819

C1846

R1820

C1842

C4046

R4251

IC4001

C4059

R4245

C4049

C4054

C4050

R4755

R4757

C4068

R4244

C4057

R4756

R4752 R4753

R4754

R4758 R4759

L4007

C4095

C4094

L4011

R4202

C4089

C4075

R4200

IC1805

R4198

C4093

L4010

R4196

R4098

R4194

C4092

C4101

3

C4102

L4012

R4142

R4146

C4166

R4192

IC1804

C4091

R4224

ZA4008

1

A14

R4018

R4026

R4023

R4044

R4029

R4039

R4032

R4195

C4045

R4751

R4750

73

R4025

R4028

R4031

R4034

C4106

R4021

C4036

C4037

1

R4213

R4190

R4004

R4009

208

L4005

L4004

C4031

C4020

C4030

C4023

C4018

R4280

R4278

C4017

C4027

C4015

R4275

R4273

C4004

R4272

C4003

R4810

C4025

L4003

C4024

C4021

C4148

L4002

C4019

C4029

R4001

R4003

R1155

R1156

C1177

157

CL4024

CL4015

C4032

CL4014

156

R4012

C4042

C4035

C4034

L4006

L4001

CL4020

C4009

C4022

CL4021

CL4022CL4023

R4223

R4038

C4163

R4222

R4218

C4165

C4164

R4130

R4133

C4099

C4090

C4097

C4088

72

108

C4074

C4087

C4084

109

R4126

R4127

1

A2

1

Q1150

R1161

Q1150

C4160

R1169

C4162

R1170

R1166

R4267

R4214

R4230

C4083

R4120

R4128

R4121

C4085

IC4004

Q4120

D4121

C4161

R4220

C4159

R4201

R4229

Q4120

R4116

R4092

R4217

R4119

C4082

C4080

R4084

R4281

R4110

37

36

R4108

R4083

C4078

R4210

R4209

R4104

C4077

C4076

1

144

R4107

R4109

R4111

R4113

R4115

R4123

R4125

R4117

IC4004

R4204 R4205

R4206

R4207 R4208

FL4001

FL4002

FL4003

1

1

A2

25

48

Q4801

Q4801

C4806

R4808

Q1145

Q1145Q1146

Q1146

R1157

R4219

Q4121

R4282

C4158

Q4121

R4093

R4106

R4105

R4124

C4118

C4096

C4098

C4157

C4100

R4136

R4140

R4141

14

8

R4129

C4103

IC4005

R4215

R4118

C4156

1

7

C4086

R4114

C4153

R4131

R4135

R4132

C4152

C4146

R4090

C4151

C4115

Q4003

Q4002

R4087

Q4003

Q4002

C4150

C4139

C4810

C4811

R4814

R4815

ZA4030

32

S3018

JS2022

S3013

S3012

V1

S3006

V2

R1193

D1102

R1864

MONOUT

A15

8

R1239

TP1821

R1846

C1889

1

A5

A5

C1859

5

L1808

C1856

A16

L1807

8

C1855

A16

R1854

C1896

C1895

C1854

JS2023

1

TP1831

TP1823

TP1816

C1831

C1832

A3

23

22

C1830

TP1830

A3

C1888

+

D1818

L1813

Q1142

Q1143

Q1141

55

C4175

JS4079

JS4078

L4023

L4022

JS4076

JS4077

C4174

JS4050

CL4580

JS4049

R4658

R4652

R4665

R4664

R4659

R4656

R4663

R4662

R4654

R4657

FL4021

JS4080

C4173

JS4081

L4021

1

C1824

C1867

C1868

C4140

C1899

C1898

C022C023

TP1832

2

C1881

C1882

C1880

L1812

C4816

C4817

R4820

R4821

C1825

R1880

JS1801

JS1802

C1823

L1809

L1810

C1866

IC1808

R1859

IC1808

C1897

R022

R023

1

R1148

R1149

C1141

Q1142

R1144

Q1143

R1146

Q1141

R1145

R1142

Q1144

R1147

Q1144

Q1811

C4119

C1906

R1877

R1878

D1825

Q1811

R1876

Q1810

R1874

R1875

Q1810

A4

23

22

A4

ZA4001 ZA4002

2

1

D1821

D1822

C1900

C1901

TP1829

R1860

TP1815

! "#$ %& ' (

)F*J)K,7777777EL@0I&''F#7777EJ@7777E+F"&GH&IG?7E+F#"GH&IG

35

Page 36

15.2. A-Board Bottom Side

2

1

0

/

.

-

,

+

*

TU001

AGCADJ

+B

C002

C003

JK5001

R5023

JK5002

R5026

TP2200

JK5001

R5127

JK5002

C003

TP2200

TP5001

TP5003

R5045

R5044

TP5002

TP5004

C002

R4235

C4126

C4125

R5132

R5043

L5003

D5011

R5042

L5004

R5039

R5038

D5015

C5008

R5035

C5011

C5007

R5125

R5126

R5030

TP5006

TP5005

4

1

IC5002

TP5010

R5031

IC5002

C5012

8

5

R5041

R5040

R5036

L5006

L5005

D5017

D5014

R5120

3

Q5008

C5014

Q5008

R5121

4

C5015

R5052

R5048

TP5009

R5103

D5024

A

C2162

R2109

JS2011

L2001

L2001

C2130

C2130C2131

RF-AGF

BT

TU001

IFOUT

L001

L001

C026

Q5025

Q5025

Q5022

5

Q5022

4

IC5001

1

C5057

8

R5088

C5020

R5058

C5029

IC5001

C5056

R5034

Q5004

R5028

R5032

C5016

C5017

TP5011

Q5009

C5013

Q5009

1

R5122

FL5006

IC5003

R5123

R5049

R5117

R5053

5

R5071

C5021

R5072

R5057

IC5003

R5104

R5074

D5026

3

TP2008

D2001

C2115

1

TP2009

R2098

C2112

R2111

C2120

C2163

C2116

C2117

R2155

R2156

C2118

C2140

L2002

C2140

4

A7

A7

SCL

AFT

SIF-OUT

BTL

AGCCONT

AUDIO

SDA

R2210

R2211

R2212

R2209

24

R2220

IC2202

IC2202

+

1

TP1108

C2211

C2212

C2201

C2213

CL5001

C5060

R5109

C5032

C5036

L5010

C5048

Q5004

C5047

Q5003

C5046

Q5003

R5124

R5113

R5029

C5045

R5033

R5027

C5044

R5110

D5022

C5043

R5112

C5039

R5076

C5037

C5035

TP5008

R5118

FL5004

L5012

C5061

C4135 C4136

R4322

R4239

JS2012

L2002

C2131

VIDEO

TP1107

C2221

C2222

C2214

C2215

SUFFIX

Q2307

C024

R024R025

C025

TP1705

TP1707

TP1709

TP1708

TP1710

TP1706

C4181

C4178

TP077

C4179

TP1106

R2208

JS2018

JS2019

C2206

C2205

C2220

13

C2219

C2218

12

+

C2217

C2216

Q1149

R1173

R1195

R1194

R5108

IC4002

R5107

C4070

C4069

TP3

TP7

TP5

TP9

TP3

TP5

TP7

TP9

TP0

TP2

TP4

TP6

TP8

TP8

TP0

TP2

TP4

TP6

Q1149

TP1101

R1167

D1101

R4225

R4060

R4014

R4008

R4264

D4122

IC4002

R4243

R4221

R4075

R4066

R4073

R4191

R4199

R4263

R4252

R4007

R4112

R4253

C4061

R4265

C4062

C4073

TP078

C4180

TP081

TP079

R4143

R4193

C4170

C4168

C4167

R4138

R4139

TP056

TP1

TP1

R4242

R4241

TP1176

C4053

R4250

R4249

CL4018

R4240

C4041

C4051

C4044

C4109

C4052

JS4082

C4110

C4043

C4040

C5058

Q1153

R1189

Q1153

C4081

TP068

TP062

TP074

TP065

TP071

TP069

TP075TP076

TP063

TP066

TP072

TP070

TP064

TP073

TP067

R4144

R4228

R4145

TP054

C4169

TP055

R4122

1

R1159

7

CL4016

CL4017

CL4019

R4232

R4069

R4059

R4072

R4081

R4227

R4058

R4256

C4001

C4026

R4271

R4274

C4028

R4276

R4279

R4010

C4039

JS4075

R4062

C4038

JS4074

R1188

R4149

R4150

D4001

PbF

SEE REVERS E FOR

TNPH0677

D3002

Q3006

D3023

R3100

C4116C4117

R4231

D2304

D2305

D2301

R2308

R3031

C3071

C3072

L3002

L3001

C3070

C3069

C3068

R3029

R3024

R3022

R4237

C4131 C4132

R4320

D3001

R3103

R3019

R3104

FL3030

1

JK3002

R2323

R2319

R2320

R2321

C2369

Q2307

Q2308

C2310

C2104

R3053

R3052

C2314

Q2308

C2105

FL3052

1

R3051

C2176

R3043

FL3031

R3034

1

D3024

D3003

1

R3109

D3007

D3008

R3111

D3009

R3117

D3013D3014

R3119

D3015

D3019

R3126

D3020

D3032

R3128

D3022

R3005

FL3033

R3108

D3025

FL3034

D3026D3027D3028

1

FL3036

FL3037

1

D3029

FL3049

D3030D3031

1

FL3050

1

D3021

R1700

C4809

R1701

R1702

TP1711

TP1713

TP1712

C4808

C4128

TP1701

TP1703

TP1702

TP1704

R4203

C4079

TP082

R4189

R4216

R4089

TP084

R4094

R4101

R4100

R4103

R4102

R4097

4

R4099

TP086

R4318

IC1101

R1158

IC1101

R4074

R4071

R4078

C4002

R4813

C4010

R4809

C4011

C4012

C4013

C4016

R4277

C4006

C4007

C4149

+

R4064

R3042

R3041

R3037

R3038

R3039

Q3006

C3076

R3102

C3075

R3036

R3035

C3074

C3073

R3101

R3131

Q3008

R3137

Q3008

C2171

R2131

C2160

R3112

R3006

R2132

C2161

C2121

C2123

R3110

R3007

R2118

1

C2148

R3010

R3116

R3118

R3011

R3120

R3012

R3016

R3127

R3017

R3125

R3130

R3002

R3129

R3001

IC2007

L4904

C4807

C4121C4122

R4233

R4226

C4147

R4269

R4268

C4155

R4134

C4154

L4015

R4137

C4129

C4112

1

8

IC4003

5

C4171

IC4003

C4172

C2374

R4317

R4666

Q1147

R4667

R1160

Q1147

C1167

R1165

14

Q1148

R1162

R1163

R1168

8

R1164

Q1148

R4812

R4811

C4014

C4005

C4008

R4746

C4114

R4744

R4748

R4747

C4137

C3077

Q2031

R3040

Q3007

Q2031

Q3007

Q2032

Q2032

C4143

R3132

Q3009

Q3009

Q3005

Q3005

R3133

R3134

C3080

C3078

C3135

R3136

R3135

R3138

C3079

C3081

R2141

R2142

R2137

R2138

R2149

R2148

C2170

R2135

R2136

C2174

R2150

R2151

R2143

32

17

IC2006

16

1

R2119

R2123

R2124

R2125

R2126

R2127

R2130

R2128

R2129

C2149

C2150

C2151

C2152

C2153

C2154

C2155

C2156

JK3002

C2165

C2164

D3018

C2370

JS2017

L2004

R2144

R2147

C2167

5

R2145

C2166

IC2007

C2107

R2146

1

R1839

R1838

R1843

C1878R1850

C1873

R1872

R1841

TP1826

7

C1876

C1877

R1840

D1808

R1852

R1866

R1867

R4655

JS4048

A12

JS4041

JS4039

JS4038

JS4046

JS4047

JS4045

C5059

C4141

L4801

R4762

C4802

C4801

R4761

C4803

C4804

R1848

R4801

R4804

R4763 R4764

R4802

R4805

C4805

R1845

C1905

C4127

C4130

R4236

C2372

R1232

R1238

TP1202

R3003

C3062

C2169

R3105

C2168

D3006

D3012

D3004

C2371

IC2006

R2134

R2133

C2159

R3124

R3014

D3017

R3015

R3123

C2108

1

R4819

C4814

C2177

C4815

R4818

C1865

R1842

C1872

IC1806

IC1806

R4319

Q1215

TP1203

FL3032

FL3048

JS4073

C1879

R1844

C4123C4124

Q1215

R1235

R3004

C1840

Q1802

Q1802

R1816

R1818

C1839

R1817

1

TP1811

TP1809

D4123

TP4008

CL4554

TP1201

JS4072

JS4044

Q1807

C2373

C1884

C1885

R1851

1

C1886

R1847

C1887

TP1828

7

C1892

R1849

R021

+

R4234

R1233

R1234

Q1216

Q1216

R1228

R1229

R1230

R1231

TP1205

TP1207

TP1206

TP1208

R1873

Q1801

Q1801

C1836

C1871

C1870

C1869

TP1810

C1907

TP1812

D1802

R1868

R1858

R1857

D1823

C1841

C1835

IC1803

R1811

C1837

R1869

R1856

R1180TP1818

R1181

R1183

R1184

R1185

R1179

R1178

R1813

C1181

R1814

Q1151

IC1803

C1838

Q1151

R1812

TP1813

C1821

C1834

TP1805

C1822

D1810

D1811

L1805

R1815

TP1204

TP1040

D1824

TP1814

TP1042

TP1806

TP1808

D1801

D1803

R1863

D2006

TP1807

R1865

C1893

R1871

C1894

R1853

R1870

TP1036

Q1809

Q1809

D3870

R3875

Q3860

Q1808

C1902

Q1807

C1904

C1883

IC1807

R020

R3862

R3861

Q3860Q3861

R1879

Q3861

Q1808

R3863

R3880

C1903

R1861

R1862

C3860

D3862

Q3862

R3876

Q3862

R3879

R3866

TP1825

R3864

D3866

D3863

R3873

R3877

D3868

C4138

D3860

D3861

R3860

R3874

R1143

D3869

C1864

IC1807

R1836

R1837

TP1817

TP1024

TP1820

C1826

C1827

D3867

R3867

C020 C021

C1833

L1806

TP1819

R3878

R3865

JS1804

JS1805

JS1806

JS1803

D3864

D3865

TP1822

C1829

C1828

TP1021

TP1824

1

C4812

C4813

R4817

R4816

R3106

R3107

D3005

MONOUT

R1174

R1175

TP4061

TP1074

V2

TP1077

C1857

D3010

R3113

R3008

R3114

V1

R3115

R3009

D3011

D3016

R3122

R3121

R3013

Q1806

TP1078

Q1803

C4144

TP1076

Q1803

R1823

R1827

TP1075

R1825

R1824

R1826

R1176

Q1804

Q1804

R1177

R1835

R1833

Q1806

TP1079

D1812

R1834

R1828

R1829

R1830

D1819

R1832

D1820

Q1805

R1831

C3063

Q1805

C1858

FL1805

TP052

C1863

JS1810

FL3035

TP051

FL1804

C1862

JS1809

TP050

C1861

JS1808

FL1803

TP049

1

C1860

TP053

JS1807

FL1802

)

! "#$ %& ' (

)F*J)K,7777777EL@0I&''F#7777*JEEJP7777E+F"&GH&IG?7E+F#"GH&IG

36

Page 37

15.3. AP-Board

2

1

0

/

.

-

,

+

*

Q7901

R7352

C7904

AP11

C7905

D7901

R7903R7904

C7903

R7906

D7476

R7353

D7208

R7234

D7470

D7472

R7223

R7487

D7469

R7486

R7243

R7247

D7207

R7227

R7224

R7229

Q7211

R7492

C7209

D7474

D7473

D7471

D7302

1

AP6

2

D7452

D7453

R7304

C7248

R7305

C7247

C7258

R7342

R7299

R7330

R7329

TP7902

R7332

JS7977

JS7979

ZA7004

JS7973

JS7974

JA9

TP7903

1

3

TP7901

D7904

R7311

R7288

R7309

R7310

D7475

R7488

C7211

R7490

R7337

D7404

D7403

C7344

JS7976

SW7203

JS7975

C7902

R7901

D7903

Q7902

R7287

D7205

D7231

D7220

1

2

C7210

R7218

3

R7228

Q7210

4

5

R7321

R7485

C7230

R7493

C7228

L7201

Q7303

R7336

D7301

JA11

L7450

TP7207

C7244

C7252

D7237

1

2

R7302

3

5

IC7210

JA16

JA10

C7249

R7453

C7253

Q7450

R7343

D7233

IC7209

1

2

3

5

Q7451

D7303

C7236

D7304

R7296

R7334

R7295

L7202

D7229

R7335

Q7301

3

R7303

C7223

5

L7301

R7331

TP7200

L7455

JA8

C7346

TP7206

2

3

5

PbF

IC7203

C7256

AP

1

D7222

TNPA3849

SEE REVERSE FOR ORDER NO.

Q7223

R7314

Q7224

R7312

R7215

C7207

Q7207

R7216

JA1

C7204

R7210

R7211

C7205

Q7212

R7238

R7232

R7241

R7217

Q7214

D7224

D7704

D7204

R7270

D7206

R7219

R7250

C7212

R7242

D7223

D7703

D7203

JA6

R7269

R7245

Q7213

R7712

R7239

R7225

R7221

C7103

R7220

Q7208

C7208

8

R7222

Q7209

C7215

8

R7226

IC7215

L7801

R7313

C7206

R7213

R7301

TP7801

Q7206

R7214

R7212

R7208

R7209

Q7204

Q7205

R7233

R7707

Q7702

R7345

C7702

R7708

R7709

Q7701

R7344

R7237

R7711

C7707

C7706

Q7508

R7710

R7704

AP5

1

C7104

AP7

1

D7902

C7235

IC7218

C7701

TP7701

TP7502

C7906

R7905

JA4

R7346

R7902

C7955

R7347

C7901

L7203

C7255

D7478

IC7205

D7230

C7225

R7292

C7229

R7293

D7238

L7305

C7245

C7246

D7236

C7612

D7240

4

C7611

C7602

TP7402

D7477

TP7205

L7204

4

C7232

C7231

D7233A

R7294

C7234

D7228

C7218

1

2

4

C7222

C7219

R7290

R7291

C7238

C7237

D7235

1

R7460

4

R7307

C7241

R7306

R7300

Q7222

Q7221

R7266

R7267

R7341

R7268

4

1

D7802

C7802

L7316

4

L7701

L7702

R7907

L7962

Q7503

C7502

C7504

L7955

R7506

R7348

R7510

C7349

C7350

L7313

TP7203

L7307

C7226

TP7202

C7251

D7480

L7207

JA14

C7409

JA2

C7410

L7314

C7609

C7610

C7601

D7232

TP7204

C7254

L7302

TP7201

C7221

L7205

D7239

D7479

D7234

Q7452

C7242

D7458

R7338

C7239

JA17

R7265

C7214

Q7804

R7803

C7806

R7340

C7807

5

R7801

3

C7804

2

D7801

L7802

TP7802

C7801

C7101

TP7904

F7200

IC7212

C7100

R7703

R7701

R7702

3

D7701

152

D7702

D7705

C7703

D7481

C7102

TP7702

R7327

ZA7006

R7504

L7959

L7501

22

C7957

C7964

Q7504

R7509

JA13

Q7506

C7966

L7956

L7966

JA12

L7452

L7315

TP7451

JA7

JA5

L7600

D7601

D7602

L7453

R7805

L7312

Q7805

R7349

R7351

R7806

C7257

R7339

C7345

23

C7961

AP3

C7958

R7308

C7967

2

1

C7956

L7964

C7963

L7960

R7494

JA3

C7603

C7605

C7606

TP7601

C7499

R7482R7483

R7484

C7500

22

D7468

23

C7965

L7965

R7489

AP4

C7952

1

2

L7953

C7954

TP7151

R7804

R7350

Q7806

D7225

R7298

R7289

R7286

D7226

L7968

D7459

D7804

JA15

D7803

R7802

C7805

C7808

L7803

C7809

C7803

14

15

AP2

TP7905

1

2

C7708

C7704

C7705

R7705

L7703

L7704

R7706

19

18

AP1

1

2

ZA7002

)

! "#$ %& ' (

)@F*J)K,7777777EL@)#($NF!777777*JEEJP77777E+F"&GH&IG?7E+F#"GH&IG

37

Page 38

15.4. V & G-Board

R014

Q004

R003

R019

R031

D001

R006

2

R022 R023

Q006

CR NO.1

C001

R017

Q002

R002

R020

Q007

R008

R015

Q003

Q008

R016

Q009

R027

SEE REVERSE FOR ORDER NO.

R018

R010

R004

R005

R011

D002

R007

Q001

TNPA3749

PbF

R013

C002

R012

RM001

R009

C007

R028

D005

R021

1

V

R032

R029

Q005

D006

C006

R026

V1

C005

R025

C003

SN001

8

C009

D004

C008

D003

1

C004

R030

R024

!"#$%&'()$*

1

TP001

TP002

TP003

SN001

TP005

TP006

TP007

TP008

0

1

8

V1

TP004

TNPA3749 V1

RM001

PbF

CR NO.1

D002

ORDER

NO.

D001

!"#$%&'(#$++$,

/

.

-

,

+

TNPA3784 G1

SEE REVERSE FOR ORDER NO.

9

G4

1

TP3853

PbF

JA55

JA52

TP3806

D3815

R3811

JA58

D3810

JA56

R3817

D3809

R3818

D3806

TP3809 TP3818

D3805

D3813

TP3855

D3812

JA51

D3811

TP3852

L3402

TP3820

D3814

R3802

R3804

R3803

R3801

LF3401

R3805

JA54

V

R3819

L

JA57

JK3801

R

JA53

*

-"#$%&'(#$++$,

)

! "#$ %& ' (

/F*J)K,77777EL@)#'($F!7777OF*J)K,7777777EL@)#'$NF!777777EJ@77777)L,7777*JEEJP777777Q1,-Q77777E+F"&GH&IG?7E+F#"GH&IG

38

Page 39

16 Parts Location

16.1. Packing Exploded View

LCD TV Exploded View

Package contents

39

Page 40

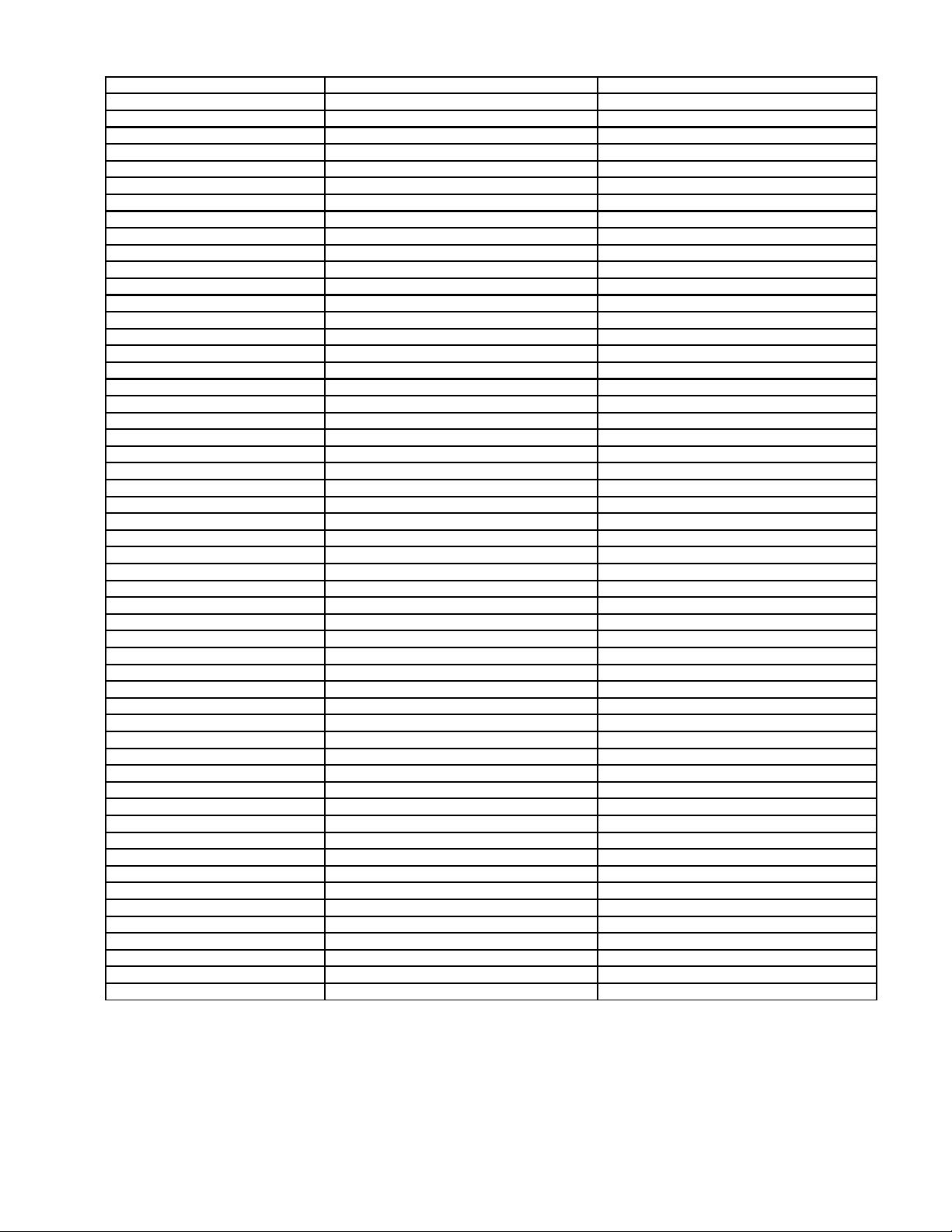

17 Parts list

17.1. Description of abbreviations guide

40

Page 41

17.2. Parts list

Note: All parts except parts mentioned [PAVCA] in the

Remarks column are supplied by PAVC-CSG.

Parts mentioned [PAVCA] are supplied by PAVCA.

Ref. No. Part No. Part Name &

C002 F2A0J681A272 E 680UF 6.3V

C003 F2A0J681A272 E 680UF 6.3V

C004 ECJ1VB0J225K C 2.2UF K 6.3V

C008 ECJ1VB1C224K C 0.22UF K 16V

C009 ECJ1VF1H104Z C 0.1UF Z 50V

C010 ECJ0EB1A104K C 0.1UF K 10V

C011 EEEHB1V100R E 10UF 35V

C014 EEEHB0J101P C 100PF J 6.3V

C015 ECJ1XC1H100D C10PFD50V

C016 ECJ1XC1H100D C10PFD50V

C026 ECJ0EB1A104K C 0.1UF K 10V

C1006 F2G0J470A019 E 47UF 6.3V

C1007 ECJ1VB1H103K C 0.001UF K 50V

C1143 ECJ0EB1C103K C 0.010UF K 16V

C1168 ECJ1XB1C104K C 0.1UF Z 16V

C1178 ECJ0EB1C103K C 0.010UF K 16V

C1180 ECJ0EB1C103K C 0.010UF K 16V

C1181 ECJ1XC1H102J C 1000PF J 50V

C1821 ECJ0EB1C103K C 0.010UF K 16V

C1822 ECJ0EB1A104K C 0.1UF K 10V

C1828 EEEHB1C470P C47PFJ16V

C1830 EEEHB1A471UP C 470PF J 10V

C1831 ECJ0EB1A104K C 0.1UF K 10V

C1832 ECJ0EB1C103K C 0.010UF K 16V

C1834 ECJ2FB1C474K C 0.47UF Z 16V

C1835 ECJ1VB1C563K C 0.056UF K 16V

C1836 ECJ1XB1C104K C 0.1UF Z 16V

C1838 ECJ0EB1C103K C 0.010UF K 16V

C1839 ECJ0EC1H101J C 100PF K 50V

C1840 ECJ1VF1A105Z C 1UF Z 10V

C1842 ECJ1XB0J105K C 1UF K 16V

C1843 ECJ1XB0J105K C 1UF K 16V

C1844 EEEHB0G470R C47PFJ4V

C1845 EEEHB0G470R C47PFJ4V

C1848 ECJ1XB0J105K C 1UF K 16V

C1849 ECJ1XB0J105K C 1UF K 16V

C1850 ECJ0EB1A104K C 0.1UF K 10V

C1851 ECJ0EB1A104K C 0.1UF K 10V

C1852 EEEHB0G470R C47PFJ4V

C1853 EEEHB0G470R C47PFJ4V

C1854 EEEHB1C470P C47PFJ16V

C1855 ECJ1XB1C104K C 0.1UF Z 16V

C1856 ECJ1XB1C104K C 0.1UF Z 16V

C1857 EEEHB0J220R C22PFJ6.3V

C1858 ECJ1VB1H103K C 0.001UF K 50V

C1859 EEEHB1C470P C47PFJ16V

C1860 ECJ1VB1H103K C 0.001UF K 50V

C1861 ECJ1VB1H103K C 0.001UF K 50V

C1862 ECJ1VB1H103K C 0.001UF K 50V

C1863 ECJ1VB1H103K C 0.001UF K 50V

C1866 EEEHB1A101P C 100PF J 10V

C1867 ECJ3YB1C475K C 0.047UF K 16V

C1868 ECJ3YB1C475K C 0.047UF K 16V

C1869 EEEHB1A101P C 100PF J 10V

C1870 ECJ3YB1C475K C 0.047UF K 16V

C1871 ECJ3YB1C475K C 0.047UF K 16V

C1872 ECJ1VB1E272K C 2700PF K 25V

C1874 EEEHB0G471P C 470PF J 4V

C1875 EEFCD0G560R 56UF

C1876 ECJ3YB1C475K C 0.047UF K 16V

C1877 ECJ1XB1C104K C 0.1UF Z 16V

C1878 ECJ1XB1C104K C 0.1UF Z 16V

C1880 EEEHB1A101P C 100PF J 10V

C1881 ECJ3YB1C475K C 0.047UF K 16V

C1882 ECJ3YB1C475K C 0.047UF K 16V

C1883 EEEHB1A101P C 100PF J 10V

Description

CAPACITORS

Remarks Safety

mark

Ref. No. Part No. Part Name &

C1884 ECJ3YB1C475K C 0.047UF K 16V

C1885 ECJ3YB1C475K C 0.047UF K 16V

C1886 ECJ1VB1E272K C 2700PF K 25V

C1888 EEEHB0G471P C470PFJ4V

C1889 EEFCD0G560R 56UF

C1890 ECJ3YB1C475K C 0.047UF K 16V

C1891 ECJ1XB1C104K C0.1UFZ16V

C1892 ECJ1XB1C104K C0.1UFZ16V

C1898 ECJ1XB1C104K C0.1UFZ16V

C1900 ECJ3YB1A106M C10UFM6.3V

C1901 ECJ3YB1A106M C10UFM6.3V

C1902 ECJ0EC1H101J C100PFK50V

C1903 ECJ1VF1A105Z C 1UF Z 10V

C1904 ECJ3XB1C106M C1.0UFK16V

C1905 EEFCD0G560R 56UF

C1906 ECJ1VB0J225K C2.2UFK6.3V

C2068 ECJ1VB1A105K C 0.01UF Z 50V

C2101 ECJ1VB1E104K C 0.10UF K 25V

C2102 ECJ2FB1E105K C 1UF K 25V

C2103 ECJ2FB1E105K C 1UF K 25V

C2106 ECJ2FB1E105K C 1UF K 25V

C2109 ECJ2FB1E105K C 1UF K 25V

C2110 ECJ1VB1E104K C 0.10UF K 25V

C2111 ECJ2FB1E105K C 1UF K 25V

C2112 ECJ1VB1E104K C 0.10UF K 25V

C2113 ECJ1VB1E104K C 0.10UF K 25V

C2114 ECJ1VB1E104K C 0.10UF K 25V

C2115 ECJ1VB1H153K C 0.015UF K 50V

C2116 ECJ1VB1E104K C 0.10UF K 25V

C2117 ECJ1VB1E104K C 0.10UF K 25V

C2118 ECJ1VB1H153K C 0.015UF K 50V

C2119 ECJ1VB1E104K C 0.10UF K 25V

C2120 ECJ1VB1E104K C 0.10UF K 25V

C2122 ECJ0EB1H102K C 1000PF K 50V

C2124 ECJ0EB1H102K C 1000PF K 50V

C2125 ECJ1VB1E104K C 0.10UF K 25V

C2126 ECJ1VB1C224K C 0.22UF K 16V

C2127 ECJ2FB1E475M C4.7UFK25V

C2128 ECJ1VB1C224K C 0.22UF K 16V

C2129 ECJ2FB1E475M C4.7UFK25V

C2130 ECA1CM102 E 1000UF 16V

C2131 ECA1CM102 E 1000UF 16V

C2132 ECJ1XB1H102K C 1000UF Z 50V

C2133 ECJ1XB1H102K C 1000UF Z 50V

C2138 ECJ1VB1E104K C 0.10UF K 25V

C2139 EEEHB1E101P C100PFJ25V

C2140 EEUFC1V221E E 220UF 35V

C2141 ECJ1VB1H103K C 0.001UF K 50V

C2142 EEEHB0J221UP C220PFJ6.3V

C2143 EEEHB0J221UP C220PFJ6.3V

C2144 ECJ1VB1A105K C 0.01UF Z 50V

C2145 EEEHB0J470R C47PFJ6.3V

C2146 ECJ3YB1A106M C10UFM6.3V

C2147 ECJ3YB1A106M C10UFM6.3V

C2148 ECJ1VB1A105K C 0.01UF Z 50V

C2149 ECJ1VB1A105K C 0.01UF Z 50V

C2150 ECJ1VB1A105K C 0.01UF Z 50V

C2151 ECJ1VB1A105K C 0.01UF Z 50V

C2152 ECJ1VB1A105K C 0.01UF Z 50V

C2153 ECJ1VB1A105K C 0.01UF Z 50V

C2154 ECJ1VB1A105K C 0.01UF Z 50V

C2155 ECJ1VB1A105K C 0.01UF Z 50V

C2156 ECJ3YB1A106M C10UFM6.3V

C2159 ECJ3YB1A106M C10UFM6.3V

C2160 ECJ1VB1A105K C 0.01UF Z 50V

C2161 ECJ1VB1A105K C 0.01UF Z 50V

C2162 ECJ2FB1E475M C4.7UFK25V

C2163 ECJ2FB1E475M C4.7UFK25V

C2164 EEEHB1C101UP C100PFJ16V

C2165 EEEHB1C101UP C100PFJ16V

C2168 EEEHB1C101UP C100PFJ16V

Description

Remarks Safety

mark

41

Page 42

Ref. No. Part No. Part Name &

C2169 EEEHB1C220UR C 22PF J 16V

C2170 ECJ3XB1C106M C 1.0UF K 16V

C2171 EEEHB1C101UP C 100PF J 16V

C2172 EEEHB0J101P C 100PF J 6.3V

C2173 EEEHB1C101UP C 100PF J 16V

C2174 ECJ1VB1E104K C 0.10UF K 25V

C2178 ECJ0EB1H102K C 1000PF K 50V

C2179 ECJ0EB1H102K C 1000PF K 50V

C2180 ECJ1VB1C224K C 0.22UF K 16V

C2181 ECJ1VB1C224K C 0.22UF K 16V

C2201 ECJ0EB1C103K C 0.010UF K 16V

C2211 ECJ1VB0J225K C 2.2UF K 6.3V

C2212 ECJ2FF1A475Z C 4.7UF Z 10V

C2213 F3H1E106A052 C 10UF J 25V

C2214 ECJ1VB1A105K C 0.01UF Z 50V

C2215 ECJ0EB1C223K C 0.022UF K 16V

C2216 F3F1C335A045 C 3.3UF J 16V

C2217 ECJ2FB1H104K C 0.1UF K 50V

C2218 ECJ2FB1H104K C 0.1UF K 50V

C2219 ECJ2FB1H104K C 0.1UF K 50V

C2220 EEEHB1C100R C 10PF J 16V

C2221 ECJ1VB1A474K C 0.47UF Z 50V

C2222 ECJ0EB1A473K C 0.047UF K 10V

C2223 EEEHB1E101P C 100PF J 25V

C2367 EEEHB1C101UP C 100PF J 16V

C3062 ECJ1VF1A105Z C 1UF Z 10V

C3063 ECJ1VF1A105Z C 1UF Z 10V

C3064 EEEHB1A471UP C 470PF J 10V

C3065 ECJ1XB1C104K C 0.1UF Z 16V

C3067 ECJ2FB0J106M C 10UF Z 6.3V

C3068 ECJ0EC1H820J C 820PF K 50V

C3069 ECJ0EC1H330J C 330PF K 50V

C3070 ECJ0EC1H121J C 120PF K 50V

C3071 ECJ0EC1H100D C 10PF K 50V

C3072 ECJ0EC1H330J C 330PF K 50V

C3073 ECJ3YB1A106M C 10UF M 6.3V

C3076 ECJ3YB1A106M C 10UF M 6.3V

C3077 ECJ1VB1E104K C 0.10UF K 25V

C3078 ECJ1VB1A105K C 0.01UF Z 50V

C3079 ECJ1VB1A105K C 0.01UF Z 50V

C3080 ECJ1VB1A105K C 0.01UF Z 50V

C3081 ECJ1VB1A105K C 0.01UF Z 50V

C3860 ECJ2FB0J106M C 10UF Z 6.3V

C4001 ERJ3GEY0R00 M 0 OHM 1/16W

C4004 ECJ1XB1C104K C 0.1UF Z 16V

C4005 ECJ1XB1C104K C 0.1UF Z 16V

C4006 ECJ1XB1C104K C 0.1UF Z 16V

C4007 ECJ1XB1C104K C 0.1UF Z 16V

C4008 ECJ1XB1C104K C 0.1UF Z 16V

C4009 ECJ2FB0J106M C 10UF Z 6.3V

C4013 ECJ1XB1C104K C 0.1UF Z 16V

C4014 ECJ1XB1C104K C 0.1UF Z 16V

C4015 ECJ1XB1C104K C 0.1UF Z 16V

C4016 ECJ1XB1C104K C 0.1UF Z 16V

C4017 ECJ1XB1C104K C 0.1UF Z 16V

C4018 ECJ1XB1C104K C 0.1UF Z 16V

C4019 ECJ2FB0J106M C 10UF Z 6.3V

C4020 ECJ2FB0J106M C 10UF Z 6.3V

C4021 ECJ2FB0J106M C 10UF Z 6.3V

C4022 ECJ2FB0J106M C 10UF Z 6.3V

C4023 ECJ2FB0J106M C 10UF Z 6.3V

C4024 ECJ1XB1C104K C 0.1UF Z 16V

C4025 ECJ1XB1C104K C 0.1UF Z 16V

C4026 ECJ1XB1C104K C 0.1UF Z 16V

C4027 ECJ1XB1C104K C 0.1UF Z 16V

C4028 ECJ1XB1C104K C 0.1UF Z 16V

C4029 ECJ1XB1C104K C 0.1UF Z 16V

C4030 ECJ1XB1C104K C 0.1UF Z 16V

C4031 ECJ1XB1C104K C 0.1UF Z 16V

C4033 ECJ0EC1H101J C 100PF K 50V

C4034 ECJ0EB1A104K C 0.1UF K 10V

C4035 ECJ0EB1A104K C 0.1UF K 10V

C4036 ECJ1VB1A105K C 0.01UF Z 50V

Description

Remarks Safety

mark

Ref. No. Part No. Part Name &

C037 ECJ1VB1A105K C 0.01UF Z 50V

C4038 ECJ3YB1A106M C 10UF M 6.3V

C4039 ECJ3YB1A106M C 10UF M 6.3V

C4040 ECJ0EB1A104K C 0.1UF K 10V

C4041 ECJ0EB1A104K C 0.1UF K 10V

C4042 ECJ0EB1A104K C 0.1UF K 10V

C4043 ECJ0EB1A104K C 0.1UF K 10V

C4044 ECJ0EB1A104K C 0.1UF K 10V

C4045 ECJ0EB1A104K C 0.1UF K 10V

C4046 ECJ0EB1A104K C 0.1UF K 10V

C4049 ECJ0EB1A104K C 0.1UF K 10V

C4050 ECJ0EB1A104K C 0.1UF K 10V

C4051 ECJ0EB1A104K C 0.1UF K 10V

C4054 ECJ0EB1A104K C 0.1UF K 10V

C4055 ECJ2FB0J106M C 10UF Z 6.3V

C4056 ECJ0EB1A104K C 0.1UF K 10V

C4057 ECJ2FB0J106M C 10UF Z 6.3V

C4058 ECJ0EB1A104K C 0.1UF K 10V

C4059 ECJ0EB1A104K C 0.1UF K 10V

C4060 ECJ0EB1A104K C 0.1UF K 10V

C4061 ECJ1VB1A105K C 0.01UF Z 50V

C4062 EEEHB1C470P C47PFJ16V

C4064 ECJ0EB1A104K C 0.1UF K 10V

C4065 ECJ0EB1H102K C 1000PF K 50V

C4066 ECJ0EB1A104K C 0.1UF K 10V

C4067 ECJ0EB1A104K C 0.1UF K 10V

C4068 ECJ2FB0J106M C 10UF Z 6.3V

C4069 ECJ1VB1A105K C 0.01UF Z 50V

C4070 ECJ0EB1A104K C 0.1UF K 10V

C4071 ECJ1XC1H150J C15PFJ50V

C4072 ECJ1XC1H150J C15PFJ50V

C4073 EEEHB1C470P C47PFJ16V

C4074 ECJ0EB1A104K C 0.1UF K 10V

C4075 ECJ2FB0J106M C 10UF Z 6.3V

C4076 ECJ0EB1A104K C 0.1UF K 10V

C4077 ECJ0EB1A104K C 0.1UF K 10V

C4078 ECJ0EB1A104K C 0.1UF K 10V

C4079 ECJ0EB1A104K C 0.1UF K 10V

C4080 ECJ0EB1A104K C 0.1UF K 10V

C4081 ECJ0EB1A104K C 0.1UF K 10V

C4082 ECJ0EB1A104K C 0.1UF K 10V

C4083 ECJ0EB1H102K C 1000PF K 50V

C4084 ECJ0EB1A104K C 0.1UF K 10V

C4085 ECJ0EB1A104K C 0.1UF K 10V

C4086 ECJ0EB1A104K C 0.1UF K 10V

C4087 ECJ0EB1A104K C 0.1UF K 10V

C4088 ECJ0EB1A104K C 0.1UF K 10V

C4089 ECJ0EB1A104K C 0.1UF K 10V

C4090 ECJ0EB1A104K C 0.1UF K 10V

C4091 ECJ0EB1A104K C 0.1UF K 10V

C4092 ECJ0EB1A104K C 0.1UF K 10V

C4093 ECJ0EB1A104K C 0.1UF K 10V

C4094 ECJ0EB1A104K C 0.1UF K 10V

C4095 ECJ2FB0J106M C 10UF Z 6.3V

C4096 ECJ1XB1C104K C 0.1UF Z 16V

C4097 ECJ0EB1A104K C 0.1UF K 10V

C4098 ECJ1XB1H102K C 1000UF Z 50V

C4099 ECJ2FB0J106M C 10UF Z 6.3V

C4100 ECJ0EB1A104K C 0.1UF K 10V

C4101 ECJ0EB1A104K C 0.1UF K 10V

C4102 ECJ2FB0J106M C 10UF Z 6.3V

C4103 ECJ0EC1H120J C 120PF K 50V

C4104 ECJ0EC1H220J C 220PF K 50V

C4105 ECJ0EC1H220J C 220PF K 50V

C4109 ECJ0EB1A104K C 0.1UF K 10V

C4110 ECJ2YF1A335Z C33PFZ10V

C4111 ECJ2FB0J106M C 10UF Z 6.3V

C4112 ECJ0EB1A104K C 0.1UF K 10V

C4114 EEFCD0G560R 56UF

C4115 ECJ0EC1H120J C 120PF K 50V

C4128 EEEHB1C470P C47PFJ16V

C4129 ECJ2FB0J106M C 10UF Z 6.3V

C4139 ECJ0EB1H102K C 1000PF K 50V

Description

Remarks Safety

mark

42

Page 43

Ref. No. Part No. Part Name &

C4140 ECJ0EB1H102K C 1000PF K 50V

C4141 ECJ0EB1H102K C 1000PF K 50V

C4142 ECJ0EB1H102K C 1000PF K 50V

C4143 ECJ0EB1H102K C 1000PF K 50V

C4144 ECJ0EB1H102K C 1000PF K 50V

C4145 EEFCD0G560R 56UF

C4146 ECJ0EC1H120J C 120PF K 50V

C4147 ECJ1XB1H102K C 1000UF Z 50V

C4148 ECJ2FB0J106M C10UFZ6.3V

C4149 ECJ2FB0J106M C10UFZ6.3V

C4150 ERJ2GEJ472 M 4.7KOHM J 0.063W

C4801 ECJ0EB1C103K C0.010UF K 16V

C4802 ECJ2FB0J106M C10UFZ6.3V

C4803 ECJ0EB1A104K C 0.1UF K 10V

C4807 ECJ0EB1C103K C0.010UF K 16V

C4808 ECJ0EB1C103K C0.010UF K 16V

C5002 ECJ0EB1A104K C 0.1UF K 10V

C5004 ECJ0EB1A104K C 0.1UF K 10V

C5006 ECJ1VF1A105Z C 1UF Z 10V

C5008 ECJ0EB1A104K C 0.1UF K 10V

C5010 ECJ2FB0J106K C10UFZ6.3V

C5012 ECJ0EB1A104K C 0.1UF K 10V

C5016 ECJ2FB0J106M C10UFZ6.3V

C5017 ECJ0EB1A104K C 0.1UF K 10V

C5018 ECJ1XF1C104Z C 0.1UF Z 16V

C5019 ECJ0EB1A104K C 0.1UF K 10V

C5020 ECJ1XF1C104Z C 0.1UF Z 16V

C5021 ECJ1VF1H103Z C 0.010UF Z 50V

C5022 ECJ1XF1C104Z C 0.1UF Z 16V

C5023 ECJ1VF1H103Z C 0.010UF Z 50V

C5024 ECJ0EB1A104K C 0.1UF K 10V

C5025 ECJ0EB1A104K C 0.1UF K 10V

C5026 ECJ2FB0J106M C10UFZ6.3V

C5027 ECJ1XF1C104Z C 0.1UF Z 16V

C5028 ECJ0EB1A104K C 0.1UF K 10V

C5029 ECJ0EB1A104K C 0.1UF K 10V

C5030 ECJ1XC1H150J C15PFJ50V

C5031 ECJ0EB1A104K C 0.1UF K 10V

C5032 ECJ0EB1A104K C 0.1UF K 10V

C5033 ECJ0EB1A104K C 0.1UF K 10V

C5034 ECJ1XC1H150J C15PFJ50V

C5036 ECJ1XF1C104Z C 0.1UF Z 16V

C5038 ECJ0EB1A104K C 0.1UF K 10V

C5040 ECJ0EB1A104K C 0.1UF K 10V

C5041 ECJ0EB1A104K C 0.1UF K 10V

C5042 ECJ2FB0J106M C10UFZ6.3V

C5043 ECJ0EB1A104K C 0.1UF K 10V

C5044 ECJ0EB1A104K C 0.1UF K 10V

C5045 ECJ0EB1A104K C 0.1UF K 10V

C5046 ECJ0EB1A104K C 0.1UF K 10V

C5047 ECJ0EB1A104K C 0.1UF K 10V

C5049 ECJ2FB0J225K C 2.2UF Z 16V

C5050 ECJ1XC1H471J C 470PF J 50V

C5051 ECJ1VB1A105K C 0.01UF Z 50V

C5056 ECJ0EB1A104K C 0.1UF K 10V

C5060 ECJ0EB1A104K C 0.1UF K 10V

C5061 ECJ0EB1A104K C 0.1UF K 10V

C7100-04 ECJ2FB1H104K C 0.1UF K 50V

C7101 ECJ2FB1H104K C 0.1UF K 50V

C7102 ECJ2FB1H104K C 0.1UF K 50V

C7103 ECJ2FB1H104K C 0.1UF K 50V

C7104 ECJ2FB1H104K C 0.1UF K 50V

C7204 ECJ2FB1A105K C 1UF K 10V

C7205 ECJ2FB1A105K C 1UF K 10V

C7206 ECJ2FB1A105K C 1UF K 10V

C7207 ECJ2FB1A105K C 1UF K 10V

C7208 ECJ2FB0J225K C 2.2UF Z 16V

C7209 F2A1C101A121 E 100UF 16V

C7210 ECJ2VB1C224K C 0.22UF K 16V

C7211 ECA1HM330 E 33UF 50V

C7212 ECJ2XB1H103K C 0.01UF K 50V

C7218 ECJ2XB1H103K C 0.01UF K 50V

C7219 ECA1HM221 E 220UF 50V

Description

Remarks Safety

mark

Ref. No. Part No. Part Name &

C7221 ECJ2XB1H103K C 0.01UF K 50V

C7223 ECJ2FB1H104K C0.1UFK50V

C7225 ECJ2XB1H103K C 0.01UF K 50V

C7226 ECA1HM221 E 220UF 50V

C7228 ECJ2XB1H103K C 0.01UF K 50V

C7230 ECJ2FB1H104K C0.1UFK50V

C7231 ECJ2XB1H103K C 0.01UF K 50V

C7232 ECA1HM221 E 220UF 50V

C7234 ECJ2XB1H103K C 0.01UF K 50V

C7236 ECJ2FB1H104K C0.1UFK50V

C7253 ECA1CM102 E 1000UF 16V

C7254 EEUFC1E102 E 1000UF 25V

C7255 ECA1CM102 E 1000UF 16V

C7258 ECJ2VB1C224K C 0.22UF K 16V

C7349 ECJ2FB1H104K C0.1UFK50V

C7350 ECJ2FB1H104K C0.1UFK50V

C7409 ECJ2FB1H104K C0.1UFK50V

C7410 ECJ2FB1H104K C0.1UFK50V

C7601 ECJ2FB1E105K C 1UF K 25V

C7602 ECJ2FB1H104K C0.1UFK50V

C7603 ECJ2FB1H104K C0.1UFK50V

C7605 ECJ2FB1H104K C0.1UFK50V

C7606 ECA1HM221 E 220UF 50V

C7609 ECJ2FB1E105K C 1UF K 25V

C7610 ECJ2FB1E105K C 1UF K 25V

C7611 ECJ2FB1H104K C0.1UFK50V

C7612 ECJ2FB1H104K C0.1UFK50V

C7701 ECJ2XB1H103K C 0.01UF K 50V

C7702 ECA1HM221 E 220UF 50V

C7703 EEUFC1C681 E 680UF 16V

C7705 ECJ2XB1H103K C 0.01UF K 50V

C7706 ECJ2FB1H104K C0.1UFK50V

C7952 ECJ2FB1H104K C0.1UFK50V

C7954 ECJ2FB1H104K C0.1UFK50V

C7956 ECJ2FB1H104K C0.1UFK50V

C7957 ECJ2FB1H104K C0.1UFK50V

C7965 ECJ2FB1H104K C0.1UFK50V

D1001 B3CKE0000007 DIODE

D1102 MA22D3900L DIODE

D1801 MA22D3900L DIODE

D1802 MA22D3900L DIODE

D1803 MA22D3900L DIODE

D1808 MAZ8043M ZENER DIODE

D1809 MAZ8043M ZENER DIODE

D1810 MA111 DIODE

D1811 MA111 DIODE

D1812 MA111 DIODE

D1813 B0JCPG000005 DIODE

D1815 MA111 DIODE

D1816 B0JCPG000005 DIODE

D1818 MA111 DIODE

D1823 MA111 DIODE

D1825 MAZ81500ML ZENER DIODE

D2001 MA704WA DIODE

D2006 MA8051M ZENER DIODE

D2301 MA111 DIODE

D2304 MA111 DIODE

D2305 MA111 DIODE

D3001 MA8140M ZENER DIODE

D3002 MA8140M ZENER DIODE

D3003 MA8140M ZENER DIODE

D3004 MA8140M ZENER DIODE

D3005 MA8140M ZENER DIODE

D3006 MA8140M ZENER DIODE

D3007 MA8140M ZENER DIODE

D3008 MA8140M ZENER DIODE

D3009 MA8140M ZENER DIODE

D3010 MA8140M ZENER DIODE

D3011 MA8140M ZENER DIODE

D3012 MA8140M ZENER DIODE

D3013 MA8140M ZENER DIODE

D3014 MA8140M ZENER DIODE

Description

DIODES

Remarks Safety

mark

43

Page 44

Ref. No. Part No. Part Name &

D3015 MA8140M ZENER DIODE

D3016 MA8140M ZENER DIODE

D3017 MA8140M ZENER DIODE

D3018 MA8140M ZENER DIODE

D3019 MA8140M ZENER DIODE

D3020 MA8140M ZENER DIODE

D3021 MA8140M ZENER DIODE

D3022 MA8140M ZENER DIODE