Page 1

Order DCS - NOV2003 - 001 - MS

Service Manual

MX5ZB CHASSIS

TC-20KL03A

TC-29KL03A

Color Television

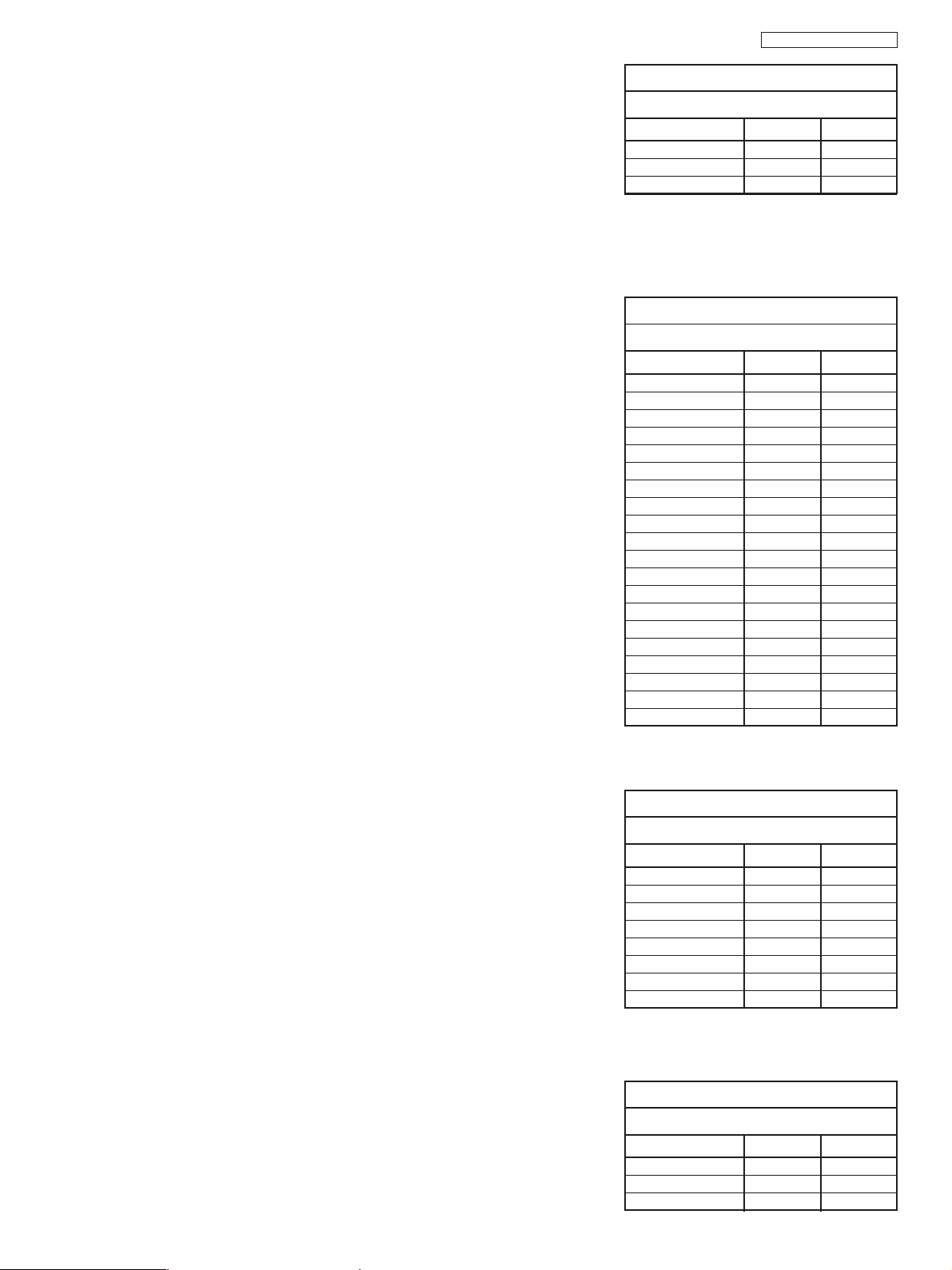

Specifications

TELEVISION

Power source

Consumption

Antenna input jack

Color systems

Tuning system

Channel capability

Picture tube (Diagonal Visual)

Audio system

Video input jack

Audio input jack

Video Outlet

Audio Outlet

Dimension (width, height, depth)

Weight

Remote Control Transmiter:

Power Source 3V (2 AA type batteries)

Infrared Length 9500 A (Angstron)

Number of Buttons 29 keys

Dimensions (W x H x D) (54 x 27 x 135) mm

110/220 V AC, 50/60 Hz automatic switch

TC-20KL03A

79 W

75 ohms - VHF/UHF/CAT V

PAL-M/NTSC/PAL-N

F.S.T.

2 to 13 (VHF)

14 to 69 (UHF)

1 to125 (CATV)

Panablack 48 cm

50 W PMPO

1 (back) + 1 (front)

1 (back) + 1 (front)

1 (back)

1 (back) + 1 (earphone)

600 x 473 x 487 (mm)

17.7 kg

TC-20KL03A

110/220 V AC, 50/60 Hz automatic switch

120 W

75 ohms - VHF/UHF/CATV

PAL-M/NTSC/PAL-N

F.S.T.

2 to 13 (VHF)

14 to 69 (UHF)

1 to125 (CATV)

Panablack 68 cm

82 W PMPO

1 (back) + 1 (front)

1 (back) + 1 (front)

1 (back)

1 (back) + 1 (earphone)

760 x 579 x 512 (mm)

34 kg

Supplied Accessories:

• 1 Remote Control Transmitter

• 1 300Ω/75Ω Balum

• 2 “AA” (or R6) batteries (1.5V; ABNT/IEC)

• 1 Internal antenna (for TC-20KL03A only)

Specifications are subject to change without notice. Weight and dimensions shown are approximate.

®

Panasonic

© 2003 Panasonic da Amazônia S/A

CS Division

Technical Support

Page 2

TC-20KL03A / TC-29KL03A

Important Safety Notice

Special components are used in this television set which are important for safety. These parts are identified on the schematic

diagram by the symbol . It is essential that these critical parts are replaced whit the manufacturers specified replacement

parts to prevent X-ray radiation, shock, fire or other hazards. Do not modify the original design whitout manufacturers permission.

Table of Contents

Operating Instructions ........................................................................... 04

Feature Summary ................................................................................... 05

The DAC Control Functions and Adjustments for MX5ZB .................... 06

SERVICE MODE:

CHK1 - Options ................................................................................ 06

CHK2 - VCJ Adjustments ................................................................ 07

CHK3 - Pincushion Adjustments ..................................................... 07

CHK4 - White Balance Adjustments ............................................... 07

CHK5 - Stereo Adjustments ........................................................... 07

ADJUSTMENTS:

TEST AND MEASUREMENT EQUIPMENTS ........................................ 08

1- RF AGC CALIBRATION .............................................................. 09

2- VIF DETECTOR OUTPUT LEVEL CONFIRMATION ................ 09

3- BUZZING CONFIRMATION (AUDIO CIRCUIT) ......................... 09

4- ANODE AND HEATER VOLTAGE CONFIRMATION ............... 09

5- PAL COLOR OUTPUT LEVEL ADJUSTMENT ............................ 10

6- NTSC SUB-TINT CALIBRATION ................................................... 10

7- MTS CALIBRATION ........................................................................ 10

8- STEREO SEPARATING ADJUSTMENT ..................................... 11

9- PROTECTION CIRCUIT (SHUTDOWN) OPERATION .............. 11

10- FOCUS CALIBRATION ............................................................. 11

11- VERTICAL DEFLECTION CALIBRATION .................................. 12

12- CRT CUT OFF CALIBRATION ................................................. 12

EEPROM MEMORY MAPS ....................................................................... 13

SCHEMATICS DIAGRAMS:

CRT BOARD (L) ........................................................................................ 15

DVD CONECTION BOARD (D) ................................................................ 16

AV FRONTAL BOARD (G) ....................................................................... 17

REMOTE CONTROL RECEIVER (R) ...................................................... 17

MAI BOARD:

Power Supply ........................................................................................... 18

Microprocessor / YUV / Syntony ............................................................ 20

Audio Signal Process .............................................................................. 22

Vertical / Horizontal Process .................................................................. 24

Audio Output ............................................................................................ 26

General Guidelines

An Isolation Transformer should always be used during the servicing of a

receiver whose chassis is not isolated from the AC power line. Use a

transformer of adequate power rating as this protects the technician from

accidents resulting in personal injury from electrical shocks. It will also

protect the Receiver from being damaged by accidental shorting that may

occur during servicing.

When servicing, observe the original lead dress, especially in the high

voltage circuit. Replace all damaged parts (also parts that show signs of

overheating.)

Always Replace Protective Devices, such as fishpaper, isolation resistors

and capacitors, and shields after servicing the Receiver. Use only

manufacturers recommended rating for fuses, circuit breakers, etc.

High potentials are present when this Receiver is operating. Operation of

the Receiver without the rear cover introduces danger from electrical shock.

Servicing should not be performed by anyone who is not thoroughly familiar with the necessary precautions when servicing high-voltage equipment.

Extreme care should be practiced when Handling the Picture Tube. Rough

handling may cause it to implode due to atmospheric pressure (14.7 lbs

per sq. in). Do not sick or scratch the glass or subject it to any undue

pressure. When handling, use safety goggles and heavy gloves for

protection. Discharge the picture tube by shorting the anode to chassis

ground (not to the cabinet or to other mounting hardware). When

discharging, connect cold ground (i.e. dag ground lead) to the anode with

a well insulated wire or use a grounding probe.

Avoid prolonged exposure at close range to unshielded areas of the picture

tube to prevent exposure to X-ray radiation.

The Test Picture Tube used for servicing the chassis at the bench should

incorporate safety glass and magnetic shielding. The safety glass provides

shieldinf for the tube viewing area against X-ray radiation as well as

implosion. The magnetic shield limits X-ray radiation around the bell of the

picture tube in addition to restricting magnetic effects. When using a picture

tube test jig for service, ensure that the jig is capable of handling 31kV

without causing X-ray radiation.

Before returning a serviced receiver to the owner, the service technician

must thoroughly test the unit to ensure that is completely safe to operatore.

Do not use a line isolation transformer when testing.

CIRCUIT BOARD LAYOUT ....................................................................... 28

IC601 - Voltage and Description ............................................................... 30

IC601 - Layout ............................................................................................ 31

IC2201 - Voltage Table .............................................................................. 31

Signal Waveform ........................................................................................ 32

Exploded View ........................................................................................ 34

Mechanical Replacement Parts List ....................................................... 35

Electrical Replacement Parts List .......................................................... 36

Warning !

It is essential that these critical parts are replaced with

the manufacturers specified replacement parts to prevent X-ray radiation, shock, fire or other hazards.

- 2 -

Page 3

ABOUT LEAD FREE SOLDER (PbF)

This model uses lead free solder (PbF).

CAUTION:

TC-20KL03A / TC-29KL03A

• Pb free solder has a higher melting point than standard solder; typically thmelting point is 50

- 70°F (300 - 400°C) higher . Please use a high temperature soldering iron. In case of the

soldering iron with temperature control,please set it to 700 ± 20°F (370 ± 10°C).

• Pb free solder will tend to splash when heated too high (about 1100°F/ 600°C).

When soldering or unsoldering, please completely remove all of the solder on the pins or

solder area, and be sure to heat the soldering points with the Pb free solder until it melts

enough.

- 3 -

Page 4

TC-20KL03A / TC-29KL03A

Operating Instructions

CLICK HERE TO SEE THE COMPLETE OPERATING INSTRUCTIONS

- 4 -

Page 5

TC-20KL03A / TC-29KL03A

Feature Summary

Model : TC-20KL03A / TC-29KL03A

Chassis : MX5ZB

Country : Brasil

System : 3 systems (PAL-M/PAL-N/NTSC) (PAL-M 50hZ)

Power Source : AC Automatic Voltage Selection 110-240 V AC, 60Hz

Memory : 125 positions

TV Tuning Range : 181 channels (TV / CATV)

Language (OSD) : Portuguese, Spanish and English

Audio System : Stereo

Vertical Magnetic field : -0.1 ±0.03 (BRASIL)

Color temperature : (High Light) x=0.270 ±0.010, y=0.275 ±0.001, Y=155 (nit)

(Low Light) x=0.245 ±0.010, y=0.235 ±0.001, Y=7.0 (nit)

Buzzing confirmation

NTSC color output

Anode (EHT) voltage

Model

TC-20KL03A

Reference Voltage

Contents Test Point

+B VOLTAGE

PAL color output

[A]=C0H, [B]=00H, [C]=00H, [D]=3BH, [E]=00H, [F]=00H, [G]=40H, [H]=09H

TPA12

TPA11

TPA10

TPA21

or TPA41

CRT ANODE

Adjustment Point

A22-3

TPL2

TPL1

TPL1

Memory data

D

C

C

Data

Voltage

140 ± 1,5V

8 ±1V

5 ±1V

215 ±1V

0.5 Vp-p

2.45 ±0.1Vo-p

2.45 ±0.5Vo-p

1.2 ±0.5Vo-p

26.5 +0.7 / -1.5 (kV)

TC-29KL03A

[A]=C0H, [B]=00H, [C]=00H, [D]=3BH, [E]=00H, [F]=00H, [G]=40H, [H]=09H

- 5 -

Page 6

TC-20KL03A / TC-29KL03A

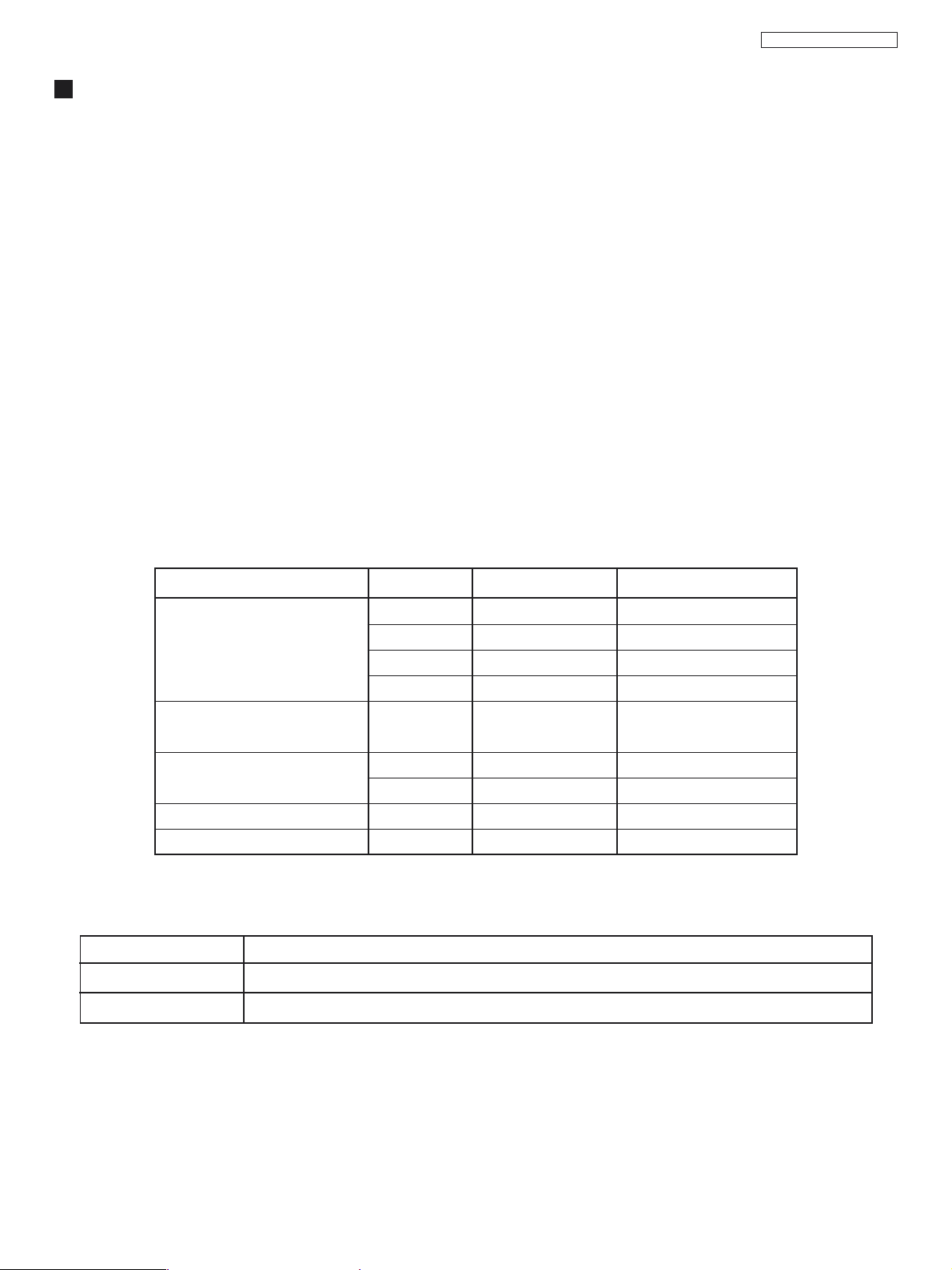

THE DAC CONTROL FOR MX5ZB FUNCTIONS ADJUSTMENTS

HOW TO ENTER IN THE SERVICE MODE:

1- Set the “OFF TIMER” to 30 minutes.

2- Press simultaneously RECALL key on the remote control and VOL(-) button on the unit.

After some seconds, the expression “CHK” should appear on the superior right side of the screen. (To change the

memory data, to press MUTE and e VOLUME(_) simultaneously still with OSD in the way “CHK1”. The key “4” it

moves forward in the memory, and the key “3” it retreats in the memory

Note: To alter in the way CHK1 for the CHK2, CHK3 or CHK4 mode, press the key “2” to move forward and the

key “1” to retreat, as illustrated below.

TO EXIT SERVICE MODE AND RETURN TO THE NORMAL MODE:

Press the “NORMAL” key on the remote control unit or turn off the TV.

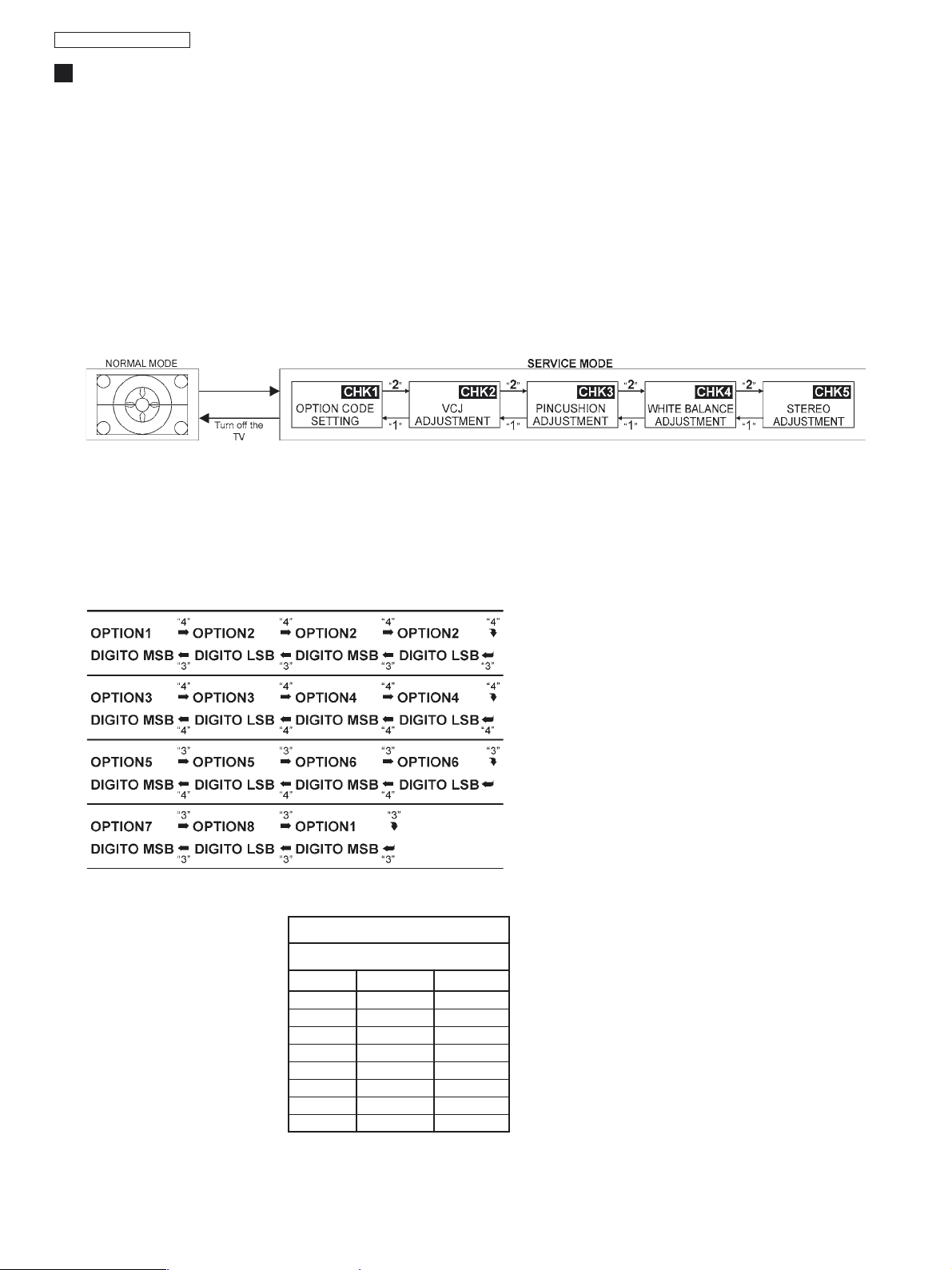

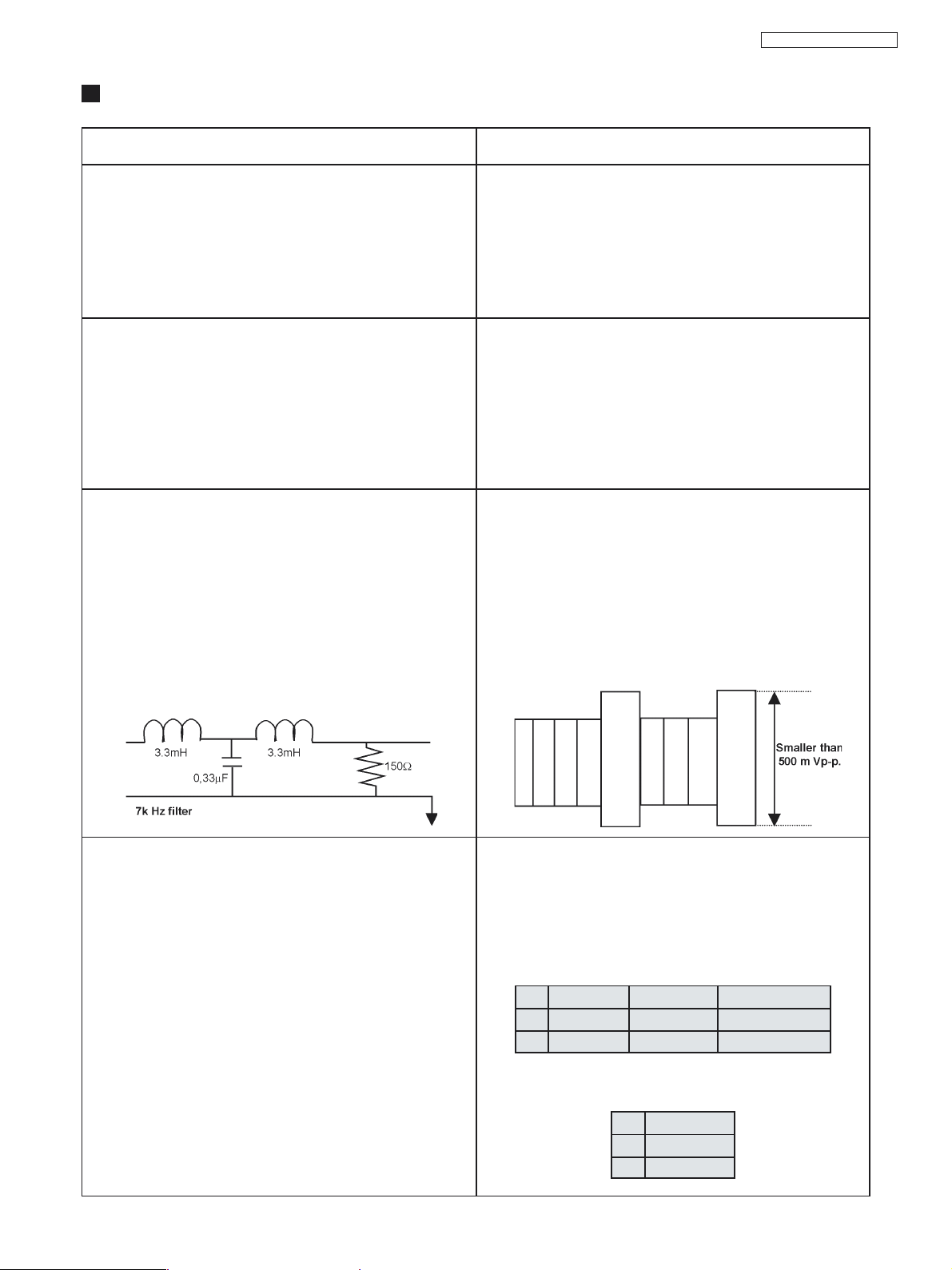

CHK1 - OPTIONS

Being in the way CHK1, it will be possible to adjust the options below:

CHK1 OPTIONS T ABLE

MEDIUM VALUES

OPTION

OPTION 1

OPTION 2

OPTION 3

OPTION 4

OPTION 5

OPTION 6

OPTION 7

OPTION 8

TC-20KL03A

C0

00

00

3B

00

00

40

9

TC-29KL03A

C0

00

00

3B

00

00

40

09

Note:

To select the option, type “4” to move forward

and “3” to retreat.

After having selected the wanted option, adjust

it pressing the “VOL(_)” or “VOL(+)” keys.

Press “0” to memorize the adjustment.

- 6 -

Page 7

TC-20KL03A / TC-29KL03A

CHK2 - VCJ ADJUSTMENTS

In the CHK2 mode is possible to adjust the items of the table.

Note:

T o select the option, type “4” to move forward and “3” to retreat.

After having selected the wanted option, adjust it pressing the “VOL(_)”

or “VOL(+)” keys.

Press “0” T o memorize the adjustment.

CHK3 - PINCUSHION ADJUSTMENTS

In the CHK2 mode is possible to adjust the items of the table.

Note:

T o select the option, type “4” to move forward and “3” to retreat.

After having selected the wanted option, adjust it pressing the “VOL(_)”

or “VOL(+)” keys.

Press “0” T o memorize the adjustment.

CHK2 TABLE

MEDIUM VALUES

ITEM

RF AGC

SUB COULOR

SUB TINT

CHK3 TABLE

MEDIUM VALUES

ITEM

V-SLOP

V-SHIFT 50Hz

V-SHIFT 60Hz

V-AMP 50Hz

V-AMP 60Hz

H-SHIFT

EW-WIDTH

EW-PARA

EW-UP COR

EW-LOW COR

EW-TRAPE

H-PARA

H-BOW

S-CORR-50Hz

S-CORR-60Hz

V-ZOOM-50Hz

V-ZOOM-60Hz

OSD H-POS

OSD V-POS-50Hz

OSD V-POS-60H

TC-20KL03A

23

35

31

TC-20KL03A

35

1

1

27

34

34

23

26

15

15

43

27

32

18

18

25

25

2

27

18

TC-29KL03A

22

37

32

TC-29KL03A

36

2

1

17

23

31

23

26

15

15

43

27

32

26

25

25

25

3

25

21

CHK4 - WHITE BALANCE ADJUSTMENTS

In the CHK2 mode is possible to adjust the items of the table.

Note:

T o select the option, type “4” to move forward and “3” to retreat.

After having selected the wanted option, adjust it pressing the “VOL(_)”

or “VOL(+)” keys.

Press “0” T o memorize the adjustment.

To obtain a horizontal line without vertical sweeping, press the “5” key

when the OSD indicates the marked mode. To return to the “CHK4”

mode, press “5” again.

CHK5 - STEREO ADJUSTMENTS

- 7 -

CHK4 TABLE

MEDIUM VALUES

ITEM

R-CUT

G-CUT

S-BRT

SUB CONTRAST

R-DRIVE

G-DRIVE

B-DRIVE

RGB CONTRASTE

T ABELA CHK5

VALORES MÉDIOS

ITEM

INPUT LEVEL

LB SEPARATION

HB SEPARATION

TC-20KL03A

29

26

26

21

26

31

33

7

TC-20KL03A

40

10

27

TC-29KL03A

33

25

25

21

27

31

35

11

TC-29KL03A

41

9

28

Page 8

TC-20KL03A / TC-29KL03A

ADJUSTMENTS

TEST AND MEASUREMENT EQUIPMENTS

To do all these electrical adjustments, the following equipment is required:

• Dual-Trace Oscilloscope

Voltage Range: 0.001 V to 50 V/Div.

Frequency Range: DC to 50 MHz

Probes: 10:1, 1:1

• NTSC Video Pattern Generator

• DVM (Digital Volt Meter)

• MTS/SAP Signal Generator

• (TV Multi-Channel Sound Modulator (U.S.A.))

• Plastic Tip Driver and Non-Metal Driver

• Isolation Transformer (Variable)

• Degaussing Coil

• White Pattern Generator

• Audio Generator

- 8 -

Page 9

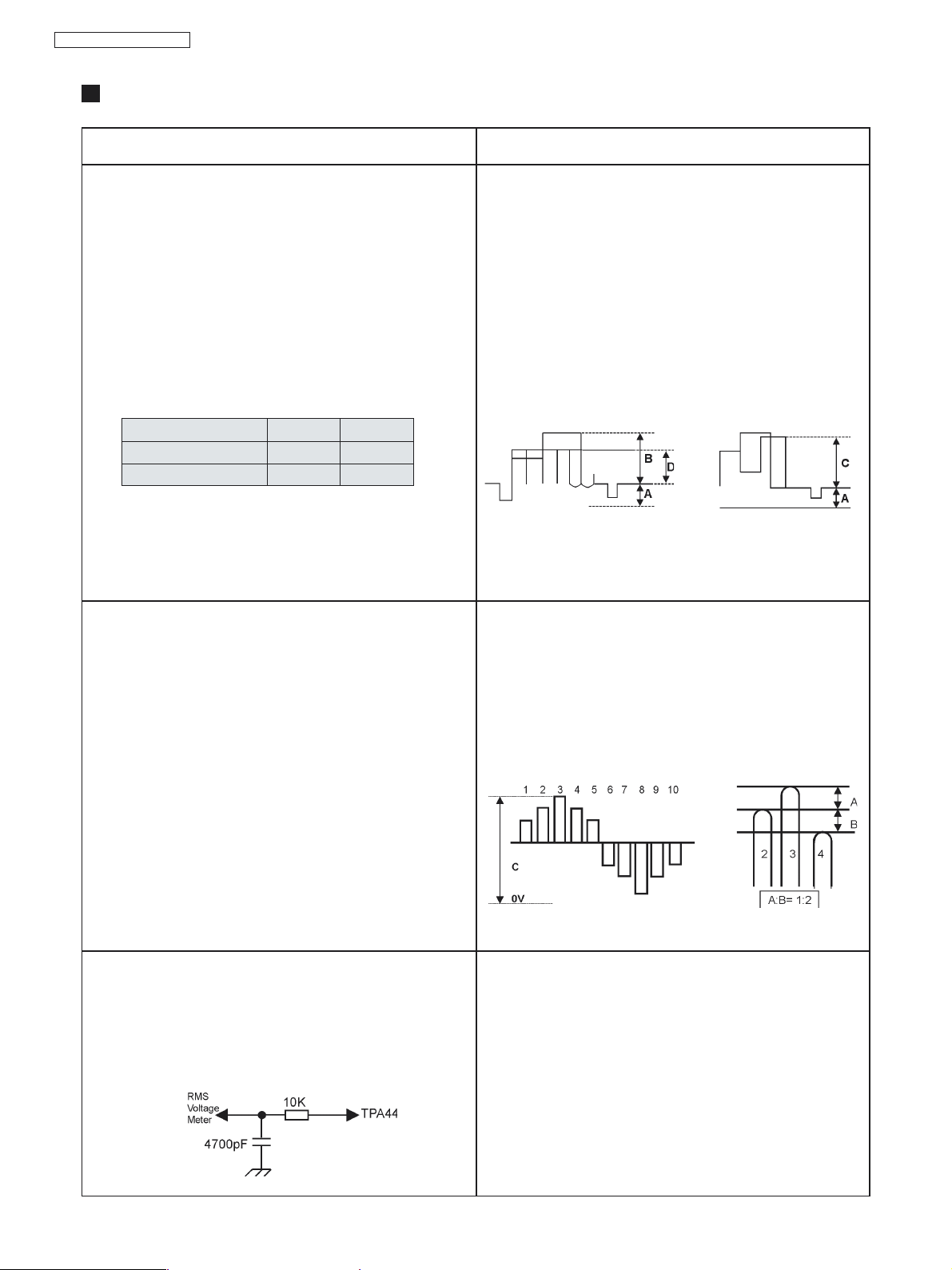

ADJUSTMENTS

ITEM / PREPARATION PROCEDURE

TC-20KL03A / TC-29KL03A

1- RF AGC ADJUSTMENT

1. Supply a color bar pattern and adjust the RF input signal

of to 69 dB.

2. Connect the digital multimeter in TPA15.

2- VIF DETECTOR OUTPUT LEVEL

CONFIRMATION

3- BUZZING CONFIRMATION

(AUDIO CIRCUIT)

1. Connect the oscilloscope with a 7kHz filter between

TPA41 and ground or between the speakers terminals

2. Adjust the sound to the maximum..

3. BALANCE : CENTER

SURROUND : OFF

AVL : OFF

SOUND MENU : DIALOGUE

ADJUSTMENT:

1. Select RF AGC in the CHK2 service mode.

2. Adjusts "RF AGC" pressing VOL(+) or (-) until obtaining

2.2±0.1V in TPA20.

3. Increase the input level by +2 dB and confirm that the

voltage decrease.

CONFIRMATION:

1. Install the chassis in the VIF calibration JIG and tune in a

63 dBU colorbar sign (75W open).

2. To connect the oscilloscope in TPA33.

3. To confirm that the output video sign is 1.05 ± 0.15 Vp-p

in TPA 33.

CONFIRMATION:

1. Supply a colorbar signal channel 2, with local frequency

adjusted and the AFC turned on (Channel with sound

bearer and without modulation).

2. Assure that the width in the buzzing waveform is smaller

than 500 m Vp-p.

4- ANODE AND HEA TER VOL T AGE CONFIRMA TION

1. Supply a crosshatch signal.

2. Adjust the bunch current in zero. (0 beam).

3. Adjust “SCREEN VR” and “CONTRAST” to minimum.

CONFIRMATION

1. Connect a voltage meter between TPA12 and ground.

Confirm that the voltage +B is within a range of 140.5V±

1.5V

2. Connect a high frequency voltage meter (VRMS.) among

the heater, and confirm that the voltage is as below:

20” PHILIPS A48EAK01X 6,15 ± 0,20 Vrms

20” SAMSUNG A48KRD89X 6,30 ± 0,24 Vrms

29” PHILIPS A68AJB82X 6,30 ± 0,24 Vrms

3. Connect the high voltage meter in the CRT anode pin,

and confirm that the high voltage is within a range of [A].

CRT [A] KV

29” 30,5 ~ 27,6

20” 27,2 ~ 25,0

- 9 -

Page 10

TC-20KL03A / TC-29KL03A

ADJUSTMENTS

ITEM / PREPARATION PROCEDURE

5- PAL COLOR OUTPUT SIGNAL ADJUSTMENT

1. Supply a color bar signal and adjust the local frequency.

2. Adjust “IMAGE” to DYNAMIC NORMAL, “CONTRAST” to

63 and “SUB-CONTRAST” to 21.

3. Adjust the “COLOR FOR CHANNEL” level to NORMAL.

4. Set the CHK2 service mode option, press “5” on the remote

control unit and confirm that OSD becomes blue (AKB

turned off).

5. Connect a short circuit jumper between TPA10 and TP A20.

6. Adjust [A] for 2.3 ± 0.2V through the BRIGHT control

variation in the test point TPL2.

7. Confirm:

CRT 20” 29”

RGB Contrast 7 DAC 9 DAC

{354} 17 19

8. Fix G-DRIVE GAIN, R-DRIVE GAIN and B-DRIVE GAIN

data in 1FH or 31 DAC.

R-DRIVE GAIN: [SLV(8A), SUB (16)]

G-DRIVE GAIN: [SLV(8A), SUB (17)]

B-DRIVE GAIN: [SLV(8A), SUB (18)]

6- NTSC SUB-TINT CALIBRATION

CALIBRATION:

1. Connect the oscilloscope in TPL2 (G-OUT) with a 10KΩ

resistor and adjust CONTRAST, so that the [B] waveform

it is 2.6±0.1V according to fig. 1.

2. Adjust SUB-COLOR to obtain 2,45±0.1V in [D]

according to fig. 1.

3. Connect the oscilloscope in TPL1 (R-OUT) with a 10KΩ

resistor and confirm that the [C] waveform it is 2.45±0.1V

according to fig. 2.

4. Remove the jumper between TPA10 and TPA20, press

the key 5 (AKB ON) and confirm that OSD becomes

white.

Fig. 1

A = 2.3 ±0.2Vo-p

B = 2.4±0.1V

D = 2.45±0.1V

Fig. 2

A = 2.3 ±0.2Vo-p

C = 2.45±0.1V

NTSC 3.58 COLOR SYSTEM CALIBRATION

1. Connect the oscilloscope in TPL2 (R-OUT) with a 10KW

resistor.

2. Supply a Rainbow signal (NTSC 3.58 MHz) through

VIDEO IN.

3. Adjust IMAGE to DYNAMIC NORMAL.

4. Adjust COLOR FOR CHANNEL to NORMAL.

5. Set the CHK2 service mode option, press 5 on the

remote control unit and confirm that OSD becomes blue

(AKB turned off).

6. Connect a short circuit jumper between TPA10 and

TPA20.

7- MTS CALIBRATION

1. Connect the RMS voltage meter through the JIG filter in

TPA44.

2. Connect the RF generator in the tuner terminal.

3. Adjust AVL to ON.

1. Adjust [C] for 5.0±0.2V through the BRIGHT control

variation (CHK2) according to fig. 1.

2. Adjust the NTSC SUB-TINT level according to fig. 1

positions 2, 3 and 4.

3. Remove the jumper.

4. Press 5 and confirm that OSD becomes white (AKB

turned on).

Fig. 1 Fig. 2

ADJUSTMENT:

1. Supply the signal through RF antenna input.

VIDEO: 100 IRE FLAT FIELD , 30% of modulation.

AUDIO: 300 Hz , 100% of modulation, monoaural (70 ±

5dB, open, 75W, P/S 10dB) 75 µs with pre-enfasis OFF.

2. Adjust INPUT LEVEL (CHK5) to obtain 106 ± 6 mVrms

in the RMS voltage meter.

- 10 -

Page 11

ADJUSTMENTS

ITEM / PREPARATION PROCEDURE

TC-20KL03A / TC-29KL03A

8- MTS CALIBRATION

STEREO SEPARATING ADJUSTMENT

1. Connect the oscilloscope in TPA42.

2. Connect the RF generator in the tuner terminal.

3. Adjust AVL to ON.

9- PROTECTION CIRCUIT (SHUTDOWN)

OPERATION

1. Supply a CROSS-HATCH signal.

2. Adjust CONTRAST and BRIGHT controls to minimum.

ADJUSTMENT:

1. Select stereo mode in the audio menu.

2. Supply the signal through RF antenna input:

VIDEO: 100 IRE FLAT FIELD, 30% of modulation

AUDIO: 300 Hz, 30% of modulation, stereo (left only)

(70 ± 5 dB, open, 75W, P/S 10dB)

3.Adjust LB SEPARATION (CHK5) so that the sign

visualized in the oscilloscope is minimum.

4. Supply the signal through RF antenna input:

VIDEO: 100 IRE FLAT FIELD, 30% of modulation

AUDIO: 3 kHz, 30% of modulation, stereo (left only) (70

± 5 dB, open, 75W, P/S 10dB)

5. Adjust HB SEPARATION (CHK5) so that the sign

visualized in the oscilloscope is minimum

6. Repeat the steps 2 to 5.

CONFIRMATION:

1. Connect the voLtmeter in TPA22 and confirm that the

voltage is smaller than [A].

2. Connect a DC source in TPA22 and confirm that the

protection circuit doesn't act when the voltage is [B].

3. Confirm that the protection circuit acts with smaller

voltage than [C].

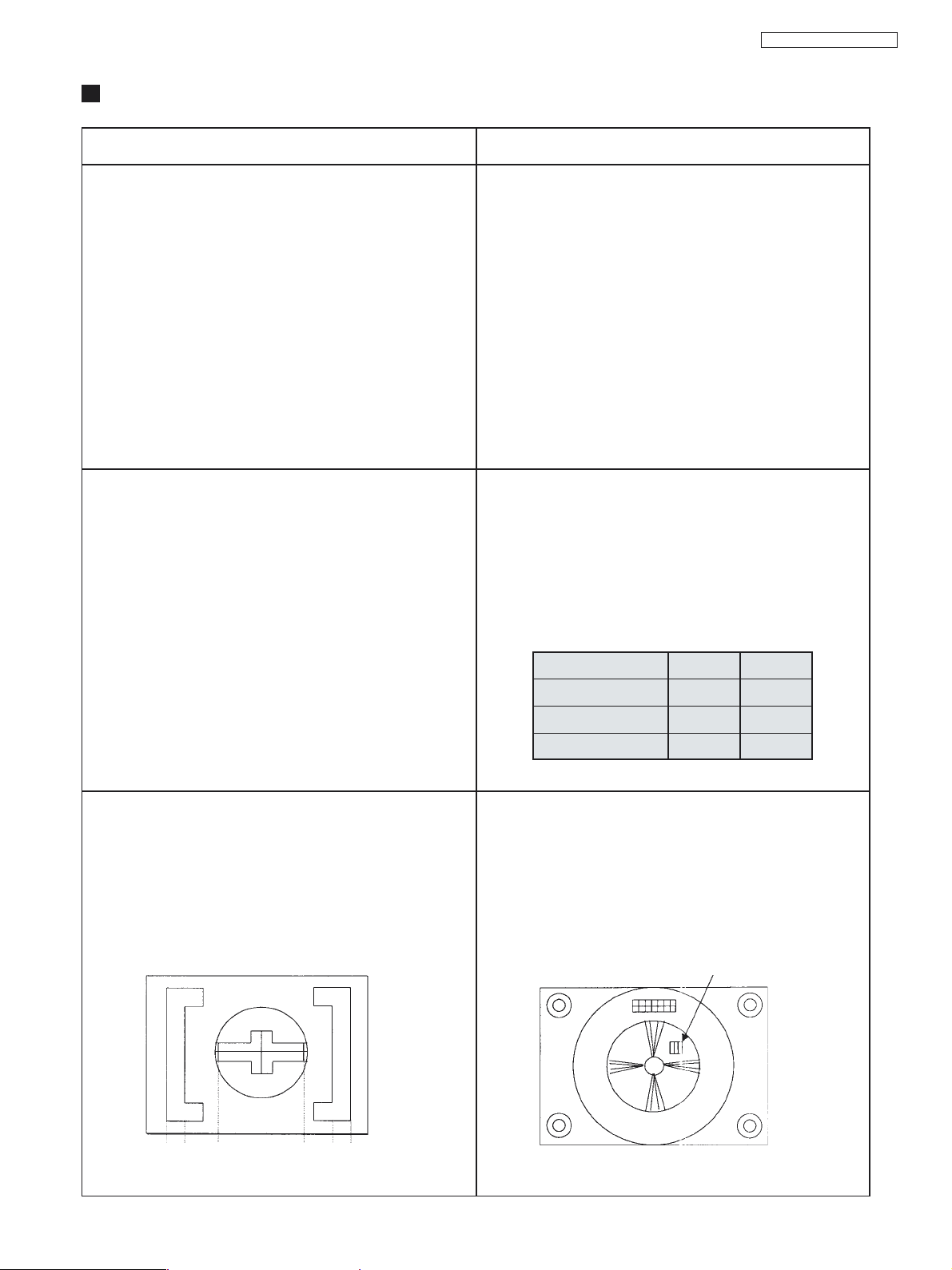

10- FOCUS CALIBRATION

• Assure that the SUB-BRIGHTNESS adjustment has been

done.

1. Supply a Philips or monoscope pattern signal.

2. Adjust MENU OF IMAGE to DYNAMIC NORMAL.

Condition / CRT 20 pol 29 pol

[A] 22,03V 24,12V

[B] 23,02V 24,50V

[C] 25,52V 27,56V

CALIBRATION:

1. Adjust the FOCUS variable resistor for the point of

better adjustment.

with PHILIPS signal .... take as reference for

adjustment the third vertical line (fig. 1).

with MONOSCOPE signal in the number 4 (fig.2).

4

1 2 3

Fig. 1

3 2 1

Fig. 2

- 11 -

Page 12

TC-20KL03A / TC-29KL03A

AJUSTMENTS

ITEM / PREPARATION PROCEDURE

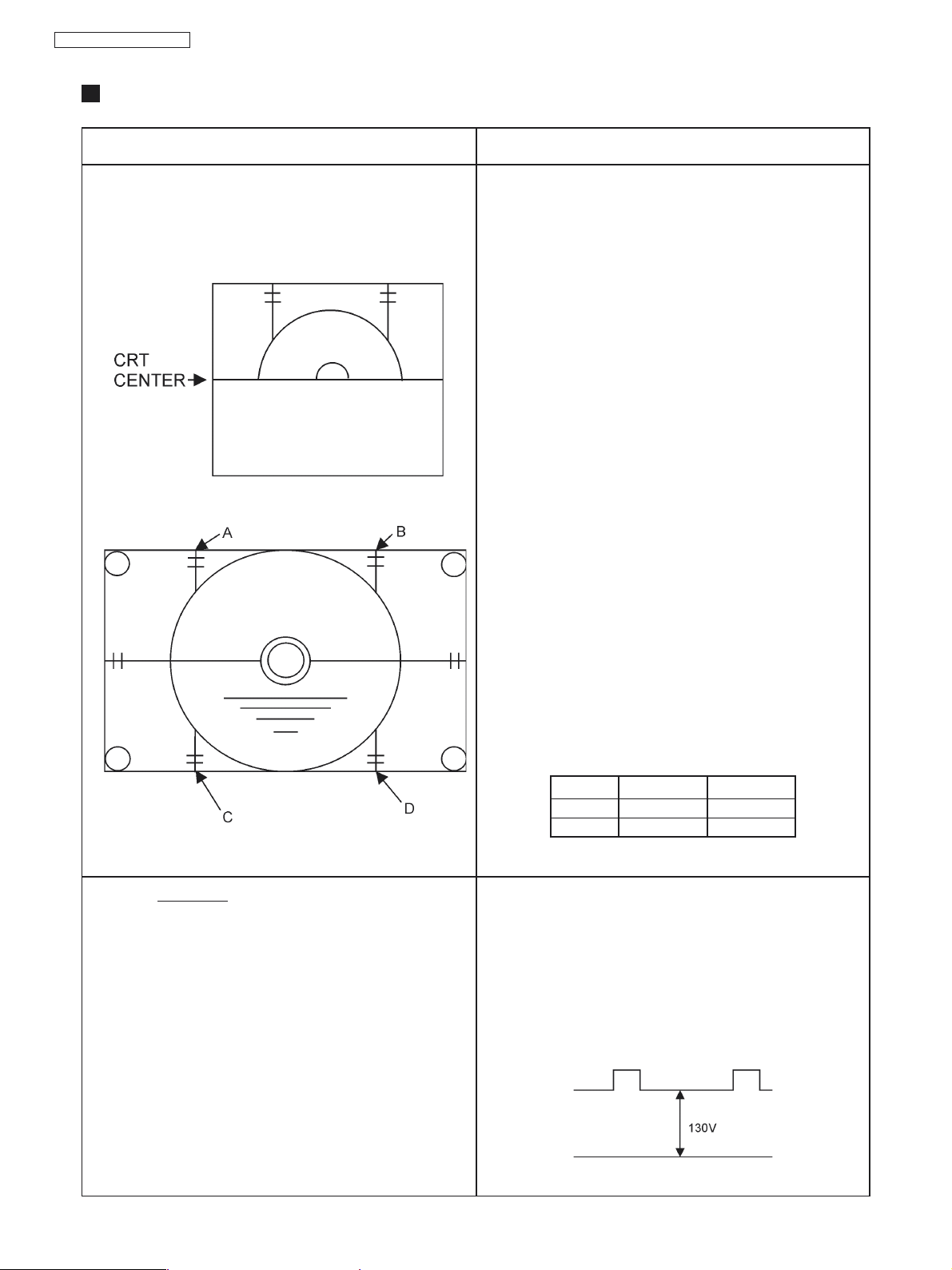

11- VERTICAL DEFLECTION CALIBRATION AND

CONFIRMATION

1. Adjust IMAGE to DYNAMIC NORMAL

Fig. 1

S-CORR CONFIRMATION AND CALIBRATION

1) Confirmation in 50Hz

1. Supply a PHILIPS PAL-N signal.

2. Confirm that S-CORR 50Hz is in [18] DAC.

2) Confirmation in 60Hz

1. Supply a MONOSCOPE signal.

2. Confirm that S-CORR 60Hz is in [18] DAC.

3) V-SLOPE calibration

1. Supply a MONOSCOPE signal.

2. Adjust V_SLOPE (CHK3) so that the beginning of the

black part of the image be aligned with the center of

the CRT as Fig. 1.

4) VERTICAL CENTRALIZATION 50 HZ CALIBRATION

1. Supply a PAL-N Philips signal.

2. Adjust V-SHIFT 50Hz (CHK3) so that the Philips

patterns center it is in the CRT center.

5) VERTICAL CENTRALIZATION 60 HZ CALIBRATION

1. Supply a MONOSCOPE signal.

2. Adjust V-SHIFT 60Hz (CHK3) so that the monoscope

patterns it is in the CRT center

6) VERTICAL HEIGHT (V-AMP 50HZ) CALIBRATION

1. Supply a PHILIPS PAL-N signal.

2. Adjust V-AMP-50Hz (CHK3) so that the Philips patterns

circle height be the same dimension of the width.

Fig. 2

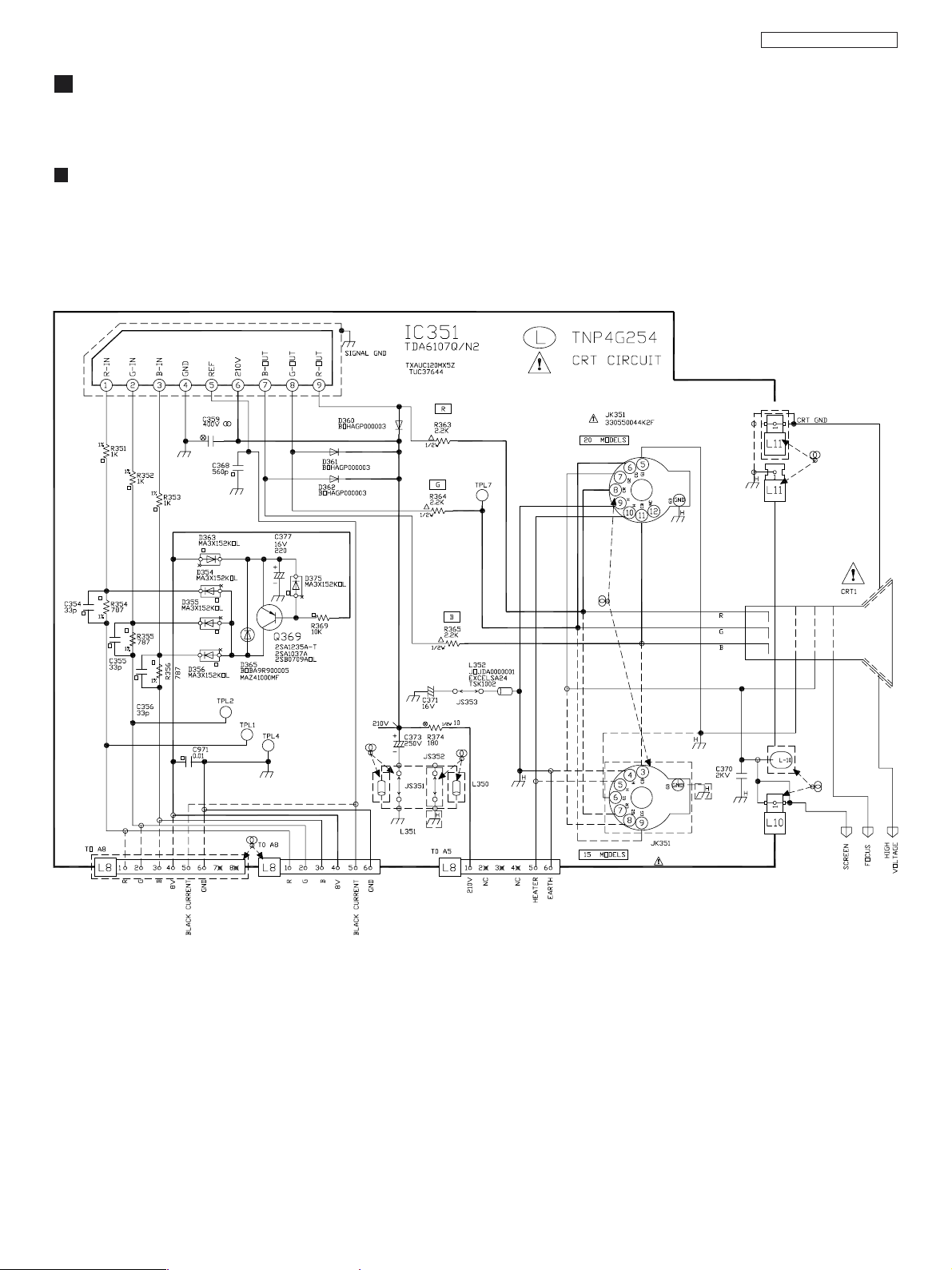

12- CRT CUT OFF CALIBRATION

1. Supply a WINDOWS signal.

2. Position DACs with the data below:

BRT e S-BRT > 32H

RGB CONTRAST > 09H (29 pol) e 07H (20 pol)

SUB-CONTRAST > 21H

R,G,B DRIVE > 31H

R,G CUT > 31H

7) VERTICAL HEIGHT (V-AMP 60HZ) CALIBRATION

1. Supply a MONOSCOPE signal.

2. Adjust V-AMP-60Hz (CHK3) so that, in the Fig.2, be:

CRT->

C,D

A,B

3. MEMORIZE in EEPROM.

20

1.9 ~ 2.2

1.5 ~ 2.3

29

1.5 ~ 2.0

1.5 ~ 1.6

CALIBRATION:

1. Press 5 (AKB OFF) and confirm that OSD becomes blue.

2. Connect the oscilloscope in TPL7 and adjust BRT to obtain

130V as in the Fig. 1 below.

3. Adjust the SCREEN to obtain in the color analyzer

Y = 1.0 +1.0

-0.5

4. Press 5 (AKB OFF) and confirm that OSD becomes blue.

white.

Fig. 1

- 12 -

Page 13

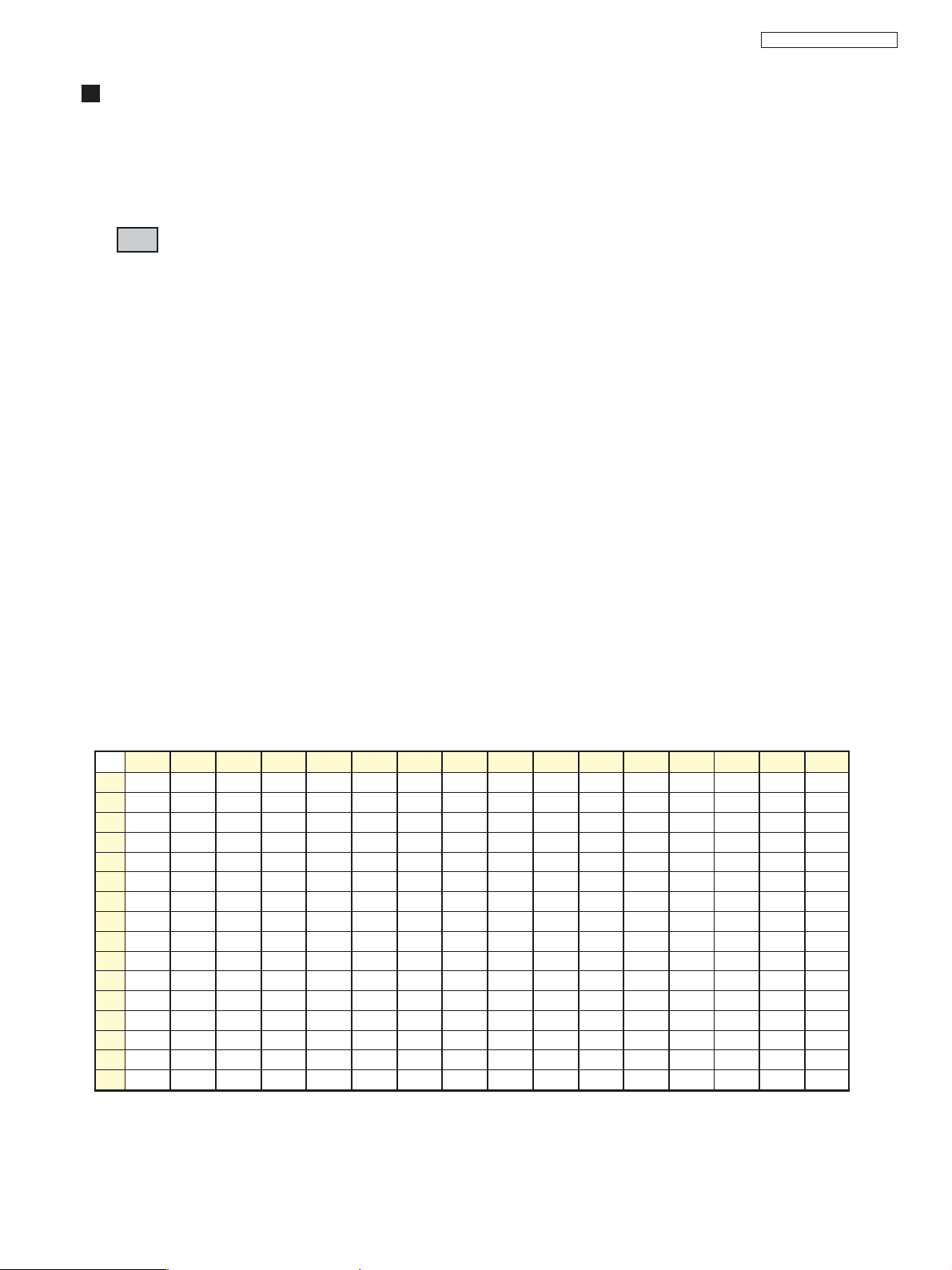

EEPROM MEMORY MAPS

Observation:

*/XX : Data subjects to alterations in the calibration process (values no fixed).

@ : Data of channels

[A-M] : Corresponds to the specification of specific production of each model.

: Fixed data (it doesn't alter in the calibration process)

SUB-ADDRESS

00: Any larger value than 63H will select the channel 0.

01: Bit 1, Bit 2, Bit 3, Bit 5, Bit 6 should be fixed to 0

2: Bit 4, Bit 5, Bit 6 should be 0 and Bit 7 should be 1.

N = AA = ON / 55 OFF (ADJUST: PRESET)

O = AA = ON/ 55 OFF (CLOSED CAPTION)

P = 0 – ENGLISH / CHINESE

1 – SPANISH / PORTUGUESE / ENGLISH

2 – ENGLISH / TAGLISH

3 – ENGLISH

TC-20KL03A / TC-29KL03A

[G] - STEREO

00 – NICAM STEREO (TDA9875)

01 – AV STEREO (TDA9859)

02 – US STEREO

03 – AV STEREO (TDA9870)

TABLE A0 (0XX)

00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0 D 0E 0F

00 02 00 06 01 00 06 02 00 06 03 00 06 04 00 06 05

10 00 06 06 00 06 07 00 06 08 00 06 09 00 06 0A 00

20 06 0B 00 06 0C 00 06 0D 00 06 0E 00 06 0F 00 06

30 10 00 06 11 00 06 12 00 06 13 00 06 14 00 06 15

40 00 06 16 00 06 17 00 06 18 00 06 19 00 06 1A 00

50 06 1B 00 06 1C 00 06 1D 00 06 1E 00 06 1F 00 06

60 20 00 06 21 00 06 22 00 06 23 00 06 24 00 06 25

70 00 06 26 00 06 27 00 06 28 00 06 29 00 06 2A 00

80 06 2B 00 06 2C 00 06 2D 00 06 2E 00 06 2F 00 06

90 30 00 06 31 00 06 32 00 06 33 00 06 34 00 06 35

A0 00 06 36 00 06 37 00 06 38 00 06 39 00 06 3A 00

B0 06 3B 00 06 3C 00 06 3D 00 06 3E 00 06 3F 00 06

C0 40 00 06 41 00 06 42 00 06 43 00 06 44 00 06 45

D0 00 06 46 00 06 47 00 06 48 00 06 49 00 06 4A 00

E0 06 4B 00 06 4C 00 06 4D 00 06 4E 00 06 4F 00 06

F0 50 00 06 51 00 06 52 00 06 53 00 06 54 00 06 55

- 13 -

Page 14

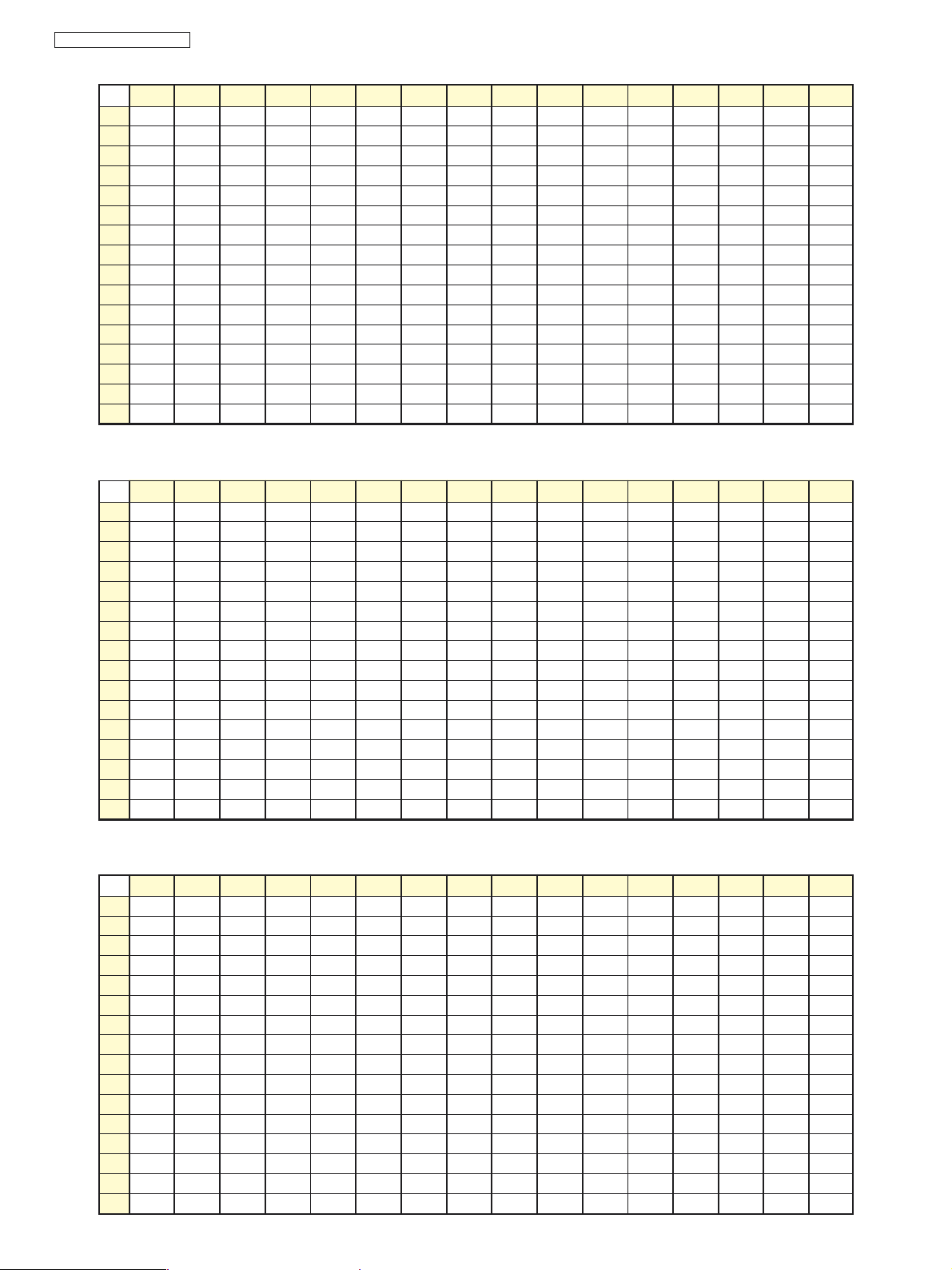

TC-20KL03A / TC-29KL03A

TABLE A2 (1XX)

00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F

00 00 06 56 00 06 57 00 06 58 00 06 59 00 06 5A 00

10 06 5B 00 06 5C 00 06 5D 00 06 5E 00 06 5F 00 06

20 60 00 06 61 00 06 62 00 06 63 00 06 64 00 06 65

30 00 06 66 00 06 67 00 06 68 00 06 69 00 06 6A 00

40 06 6B 00 06 6C 00 06 6D 00 06 6E 00 06 6F 00 06

50 70 00 06 71 00 06 72 00 06 73 00 06 74 00 06 75

60 00 06 76 00 06 77 00 06 78 00 06 79 00 06 7A 00

70 06 7B 00 06 7C 00 06 7D 00 06 00 00 00 00 00 00

80 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

90 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

A0 06 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

B0 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

C0 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

D0 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

E0 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

F0 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

TABLE A4 (2XX)

00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F

00 02 00 A5 5A 00 01 01 00 00 08 00 04 00 00 01 00

10 00 00 00 00 00 00 00 00 20 00 00 00 00 00 00 00

20 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

30 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

40 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

50 20 20 20 3F 2D 20 20 20 2D 20 1E 20 20 23 1E 20

60 2D 2A 34 32 24 24 00 00 00 20 20 20 00 00 00 00

70 00 00 00 00 00 00 00 00 00 00 00 00 00 00 78 BB

80 20 20 20 3F 2D 20 20 20 2D 20 1E 20 20 23 1E 34

90 32 24 24 00 00 00 2D 2A 00 00 00 00 00 00 00 00

A0 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

B0 *1 *2 *3 0C 00 1B 00 00 00 40 40 40 00 00 00 00

C0 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

D0 0C 10 15 04 06 06 00 04 00 00 00 00 00 00 00 00

E0 00 00 00 00 00 00 00 00 [A] [B] [C] [D] [E] [F] [G] [H]

F0 00 00 18 20 15 1A 00 00 00 00 00 00 00 A5 3F A5

TABLE A6 (3XX)

00 01 02 03 04 05 06 07 08 09 0A 0B 0C 0D 0E 0F

00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

10 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

20 00 00 B6 B7 20 10 28 18 B0 00 00 00 00 00 00 00

30 1B 20 00 22 17 1A 0F 0F 2B 24 1F *4 20 19 1F 1F

40 1F 1F 1F 00 06 00 00 00 10 24 C0 00 2A 00 34 20

50 30 21 02 4A *5 44 00 00 00 00 00 *6 FE 00 00 00

60 02 FF 1C *7 19 00 00 00 00 00 00 00 00 00 00 00

70 00 00 00 00 00 00 00 00 10 00 00 00 00 00 00 00

80 00 00 00 00 00 00 00 0E 1 1 0D 06 0C 07 0C 02 00

90 09 00 FA F7 00 00 00 0A F8 *8 00 00 00 00 00 03

A0 01 03 02 03 03 00 34 00 00 00 20 63 03 00 20 30

B0 4A 49 4B 00 33 00 00 FF FC 04 05 05 FC F8 00 F2

C0 20 07 4F 40 40 00 00 00 00 00 00 00 00 00 00 00

D0 86 *9 *10 03 00 00 00 05 *11 *12 *13 F2 03 00 00 00

E0 20 15 02 00 00 08 00 00 00 00 00 00 00 00 00 00

F0 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 11

- 14 -

Page 15

SCHEMA TIC DIAGRAMS

CRT BOARD SCHEMA TIC DIAGRAM (L)

TC-20KL03A / TC-29KL03A

- 15 -

Page 16

TC-20KL03A / TC-29KL03A

DVD CONNECTION SCHEMA TIC DIAGRAM (D BOARD)

- 16 -

Page 17

A V FRONTAL SCHEMATIC DIAGRAM (G BOARD)

TC-20KL03A / TC-29KL03A

REMOTE CONTROL RECEIVER SCHEMA TIC DIAGRAM (R BOARD)

- 17 -

Page 18

TC-20KL03A / TC-29KL03A

MAIN BOARD SCHEMA TIC DIAGRAM (1/10)

Power Supply

- 18 -

Page 19

MAIN BOARD SCHEMA TIC DIAGRAM (2/10)

Power Supply

TC-20KL03A / TC-29KL03A

- 19 -

Page 20

TC-20KL03A / TC-29KL03A

MAIN BOARD SCHEMA TIC DIAGRAM (3/10)

Microprocessor / YUV / Syntony

- 20 -

Page 21

MAIN BOARD SCHEMA TIC DIAGRAM (4/10)

Microprocessor / YUV / Syntony

TC-20KL03A / TC-29KL03A

- 21 -

Page 22

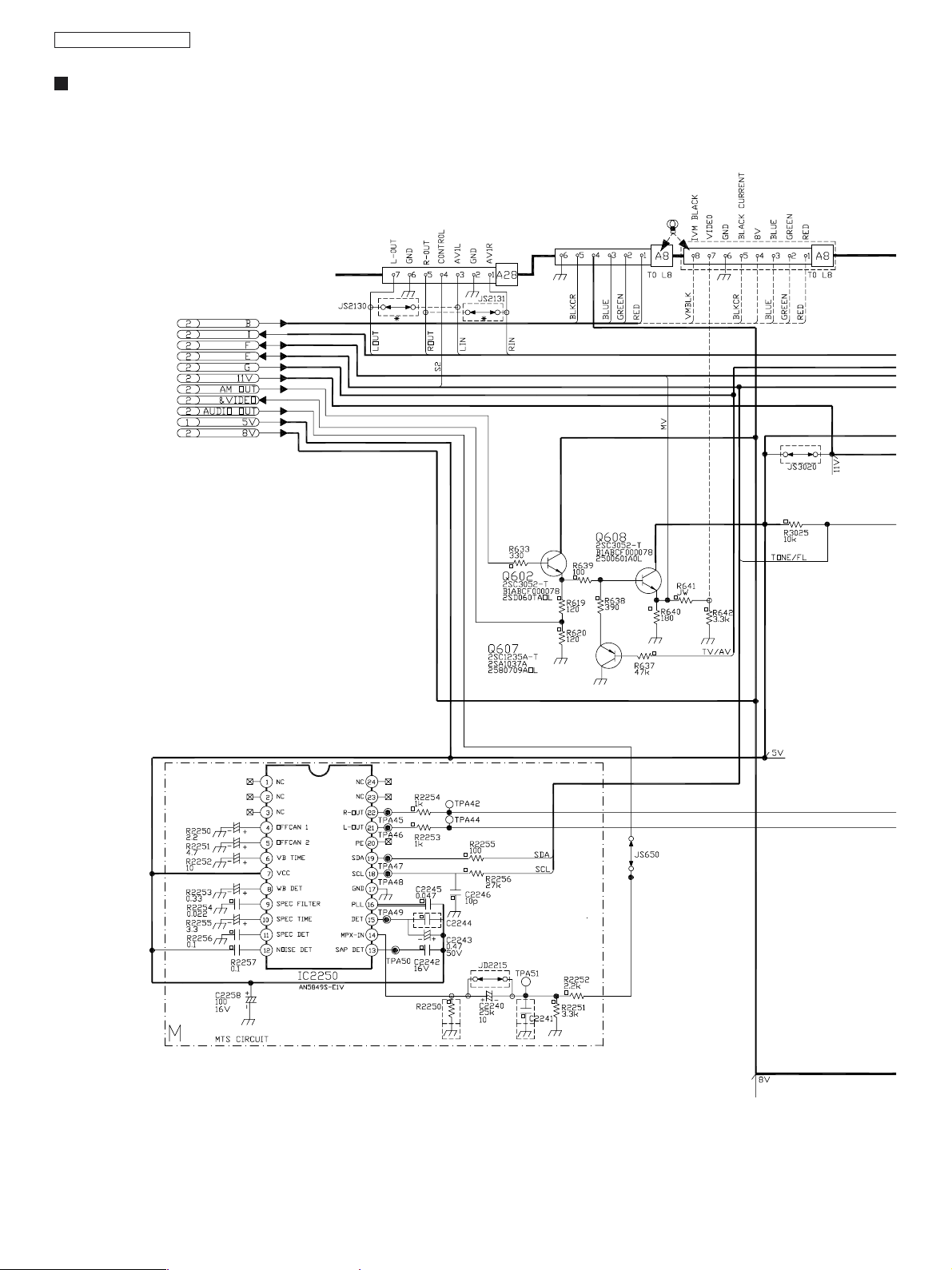

TC-20KL03A / TC-29KL03A

MAIN BOARD SCHEMA TIC DIAGRAM (5/10)

Audio signal process

- 22 -

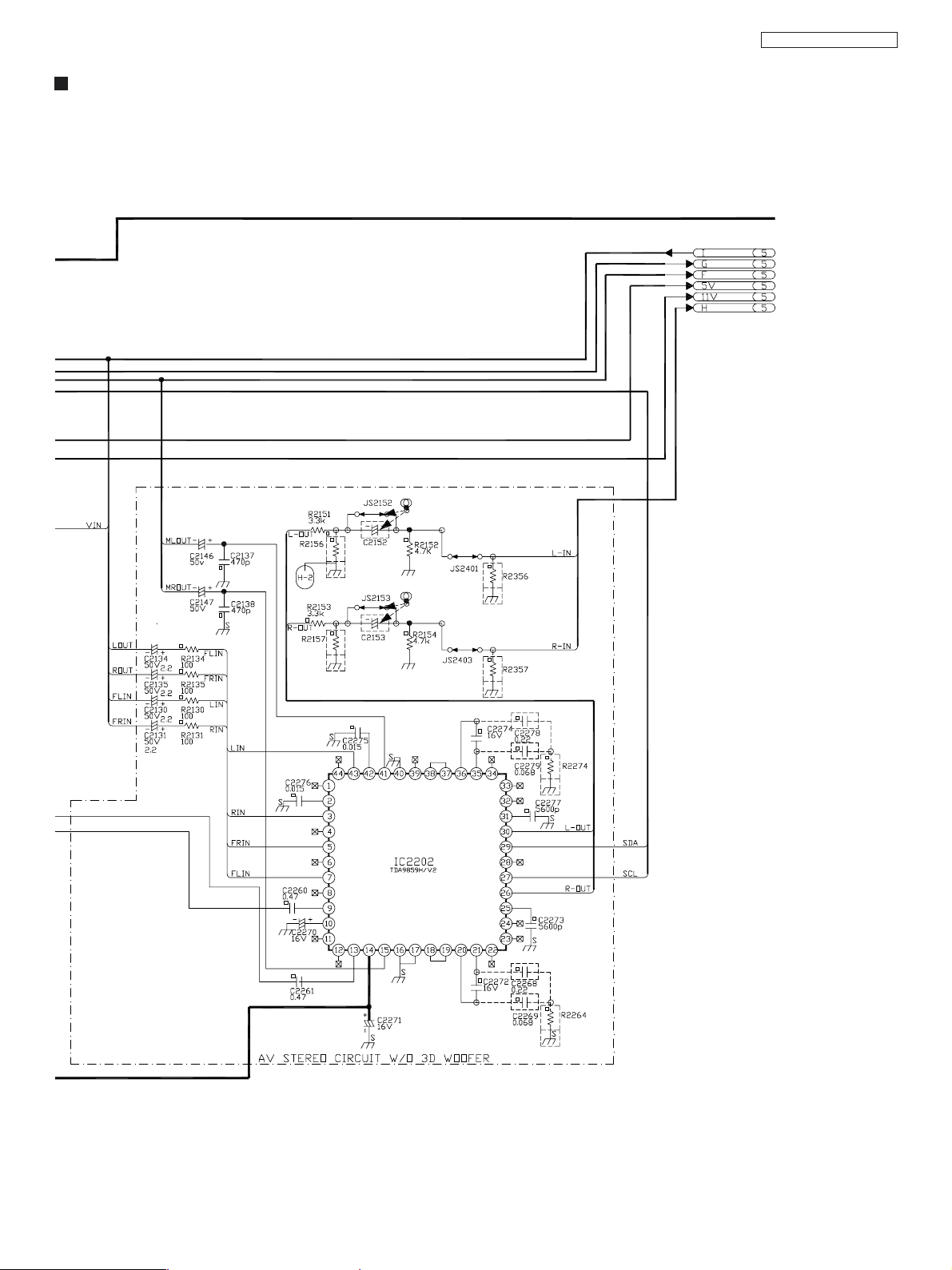

Page 23

MAIN BOARD SCHEMA TIC DIAGRAM (6/10)

Audio signal process

TC-20KL03A / TC-29KL03A

- 23 -

Page 24

TC-20KL03A / TC-29KL03A

MAIN BOARD SCHEMA TIC DIAGRAM (7/10)

Vertical / Horizontal

- 24 -

Page 25

MAIN BOARD SCHEMA TIC DIAGRAM (8/10)

Vertical / Horizontal

TC-20KL03A / TC-29KL03A

- 25 -

Page 26

TC-20KL03A / TC-29KL03A

MAIN BOARD SCHEMA TIC DIAGRAM (9/10)

Audio output

- 26 -

Page 27

MAIN BOARD SCHEMA TIC DIAGRAM (10/10)

Audio output

TC-20KL03A / TC-29KL03A

- 27 -

Page 28

TC-20KL03A / TC-29KL03A

CIRCUIT BOARD LAYOUT

MAIN BOARD (A/L) - (component side)

- 28 -

Page 29

MAIN BOARD (A/L) - (foil side)

TC-20KL03A / TC-29KL03A

- 29 -

Page 30

TC-20KL03A / TC-29KL03A

IC601 - TV signal processor-Teletext decoder with embedded

PIN VOLTAGE SYMBOL DESCRIPTION

1 3,3V P1.3/T1 port 1.3 or Counter/Timer 1 input

2 2,4V P1.6/SCL port 1.6 or I2C-bus clock line

3 2,7V P1.7/SDA port 1.7 or I2C-bus data line

4 4,9V P2.0/TPWM port 2.0 or Tuning PWM output

5 0V P3.0/ADC0 port 3.0 or ADC0 input

6 3,3V P3.1/ADC1 port 3.1 or ADC1 input

7 0,6V P3.2/ADC2 port 3.2 or ADC2 input

8 2,2V P3.3/ADC3 port 3.3 or ADC3 input

9 0V VSSC/P digital ground for m-Controller core and periphery

10 0V P0.5 port 0.5 (8 mA current sinking capability for direct drive of LEDs)

1 1 0V P0.6 port 0.6 (8 mA current sinking capability for direct drive of LEDs)

12 0V VSSA analog ground of T eletext decoder and digital ground of TV-processor

13 2,3V SECPLLSECAM PLL decoupling

14 7,8V VP2 2nd supply voltage TV-processor (+8V)

15 4,9V DECDIG decoupling digital supply of TV-processor

16 3,3V PH2LF phase-2 filter

17 3,9V PH1LF phase-1 filter

18 0V GND3 ground 3 for TV-processor

19 4V DECBG bandgap decoupling

20 5,3V AVL/EWD (1) Automatic Volume Levelling /East-West drive output

21 2,1V VDRB vertical drive B output

22 2,1V VDRA vertical drive A output

23 1,8V IFIN1 IF input 1

24 1,8V IFIN2 IF input 2

25 3,8V IREF reference current input

26 3,8V VSC vertical sawtooth capacitor

27 0,9V TUNERAGC tuner AGC output

28 3,8V AUDEEM/SIFIN1(1) audio deemphasis or SIF input 1

29 2,3V DECSDEM/SIFIN2(1) decoupling sound demodulator or SIF input 2 30 GND2 ground 2 for TV processor

31 2,3V SNDPLL/SIFAGC(1) narrow band PLL filter /AGC sound IF

32 2,4V AVL/SNDIF/REF0/AMOUT(1) AutomaticVol. Levelling/soundIFinput/subcarrierreferenceoutput/AMoutput(non controlled)

33 0,6V HOUT horizontal output

34 0,5V FBISO flyback input/sandcastle output

35 3,6V AUDEXT/QSSO/AMOUT(1) external audio input /QSS intercarrier out /AM audio output (non controlled)

36 1,5V EHTO EHT/overvoltage protection input

37 2,3V PLLIF IF-PLL loop filter

38 3,5V IFVO/SVO IF video output / selected CVBS output

39 7,7V VP1 main supply voltage TV-processor (+8 V)

40 4V CVBSINT internal CVBS input

41 0V GND1 ground 1 for TV-processor

42 3,3V CVBS/Y external CVBS/Y input

43 0V CHROMA chrominance input (SVHS)

44 3,1V AUDOUT /AMOUT(1) audio output /AM audio output (volume controlled)

45 2,5V INSSW2 2nd RGB / YUV insertion input

46 2,5V R2/VIN 2nd R input / V (R-Y) input

47 2,5V G2/YIN 2nd G input / Y input

48 2,5V B2/UIN 2nd B input / U (B-Y) input

49 1,8V BCLIN beam current limiter input

50 5,5V BLKIN black current input / V-guard input

51 3,6V RO Red output

52 3,3V GO Green output

53 3,5V BO Blue output

54 3,3V VDDA analog supply of Teletext decoder and digital supply of TV-processor (3.3 V)

55 0V VPE OTP Programming Voltage

56 3,3V VDDC digital supply to core (3.3 V)

57 0V OSCGND oscillator ground supply

58 1,6V XTALIN crystal oscillator input

59 1,6V XTALOUT crystal oscillator output

60 0V RESET reset

61 3,3V VDDP digital supply to periphery (+3.3 V)

62 0V P1.0/INT1 port 1.0 or external interrupt 1 input

63 1,6V P1.1/T0 port 1.1 or Counter/Timer 0 input

64 4.9V P1.2/INT0 port 1.2 or external interrupt 0 input

µµ

µController

µµ

Note: These voltages were measured with colorbar signal through RF antenna input and 127V power supply.

- 30 -

Page 31

IC601 - LA YOUT

TC-20KL03A / TC-29KL03A

IC2201 - VOL TAGE TABLE

IC2201

Pin Voltage

10V

2 3,9V

3 3,9V

40V

5 3,9V

60V

7 3,9V

80V

9 3,8V

10 7,8V

11 0V

Pin Voltage

12 0V

13 3,9V

14 7,8V

15 3,9V

16 0V

17 0V

18 3,9V

19 3,9V

20 3,9V

21 3,9V

22 0V

Pin Voltage

23 0V

24 4V

25 3,9V

26 3,8V

27 3V

28 3,9V

29 2,8V

30 3,8V

31 3,9V

32 0V

33 0V

Pin Voltage

34 2,9V

35 3,9V

36 3,9V

37 3,9V

38 3,9V

39 2,7V

40 0V

41 3,9V

42 3,9V

43 3,9V

44 2,7V

Note: These voltages were measured with Colorbar signal

through RF antenna input and 127V power supply.

- 31 -

Page 32

TC-20KL03A / TC-29KL03A

SIGNAL WAVEFORM

IC351 - PINO 1 IC351 - PINO 3IC351 - PINO 2

IC351 - PINO 7 IC351 - PINO 9IC351 - PINO 8

LINHA DE CLOCK - SCL IC1601 - PINO 21LINHA DE DADOS - SDA

IC1601 - PINO 22 IC1601 - PINO 51IC1601 - PINO 33

- 32 -

Page 33

IC1601 - PINO 52 IC1601 - PINO 58IC1601 - PINO 53

TC-20KL03A / TC-29KL03A

IC1601 - PINO 59 IC451 - PINO 3IC451 - PINO 2

IC451 - PINO 4 IC451 - PINO 7IC451 - PINO 5

BASE DE Q501 EMISSOR DE Q501COLETOR DE Q501

- 33 -

Page 34

TC-20KL03A / TC-29KL03A

Exploded View

- 34 -

group and send the piece with problem (CRT or YOKE) to the section of pieces for repair.

k CRT and YOKE are supplied together mounted. In case one of these components comes to present problems, disassemble the

Page 35

Replacement Mechanical Parts List

Ref. No. TC-20KL03A Part No. TC-29KL03A Part No. Part Name & Description

1 EASZ12D06A8 EASZ15S01A8 FULL RANGE SPEAKER

2 TLK2BA003 TLK2BA001 DEGAUSSING COIL

3 TBX2B867 TBX2B868 POWER BUTTON

4 TBX2B865 TBX2B866 6 POSITIONS BUTTON

6 TMW2B212 TMW2B212 BRACKET LED

7 TSX2BA02-1 TSX2BA02-1 AC CABLE

7 TSX2BA02A TSX2BA02A AC CABLE ASS´Y

7 TXASX2BA02 TXASX2BA02 CONJUNTO MONT ADO CABO AC C/ ETIQUETA

8 EVQ11G05R EVQ11G05R TOUCH SWITCHES

9 ESB92DA1B ESB92DA1B POWER SWITCH

10 TXAJTA40CB20K TXAJTA40CB20K SPECIAL CABLE

11 A48EAK01X094R - - - - - - o - - - - - - PICTURE TUBE - CRT 20”

11 - - - - - - o - - - - - - A68AJB82X18R PICTURE TUBE - CRT 29" (W/ DY)

12 TPD2B762 TPD2B762 ASSEMBLY OF WEDGES

13 TNQ2B3301 TNQ2B3301 REMOTE CONTROLLER

14 S-U05012 S-U05012 300W ADAPTOR BALLUM

15 TBM4G3003 TBM4G3003 PANASONIC LABEL

16 TMM15496 TMM15496 DEGAUSSING COIL HOLDER

17 TKP2B11161-2 TKP2B11161-2 AC CABLE HOLDE (GRA Y)

18 TXPTKY2B2001-1 TKY2B2101-1 FRONT CABINET

19 TKP2B11291 TKP2B11301 LED GUIDE

20 TMK2B564 TMK2B564 HIMERON

21 TXF3A20C7-1 TXF3A29A10 COIL SPRING

23 TES2B212 TES2B213 POWER BUTTON COIL

24 TBM2B047 TBM2B048 CONTROL P ANEL

25 TGNPA20KL03P TGNPA29KL03A AL BOARD ASS’Y

27 - - - - - - o - - - - - - TGNPGR29KM03 G-R BOARD ASS’Y

28 - - - - - - o - - - - - - TKP2B11281 DOOR

29 TKK2B9524 TKK2B9525 POWER SWITCH ESTENSOR

30 330550044K2F - - - - - - o - - - - - - CRT 20" SOCKET

31 TKX2B1301 - - - - - - o - - - - - - SPEAKER SUPPORT

32 TKX2B0601 - - - - - - o - - - - - - REAR COVER SUPPORT

33 TXITKU2B22503 TKU2B22603 REAR COVER

34 ZTFN33005A KFT4AA448F FLYBACK

35 TEK4G902 TEK4G902 LOCK

36 TMM2B202-1 TMM2B202-1 AC CABLE HOLDER

37 TJB4G635 TJB4G635 AV TERMINAL

38 TJB4T201 TJB4T201 AV TERMINAL (RCA 5 PINS)

39 TJB4G634 TJB4G634 FRONTAL A V TERMINAL

TC-20KL03A / TC-29KL03A

- 35 -

Page 36

TC-20KL03A / TC-29KL03A

Replacement Electrical Parts List

Ref. No. TC-20KL03A Part No.

TC-29KL03A Part No. Part Name & Description

ASSEMBLED BOARDS

PLACA AL TGNP A20KL03A TGNPA29KL03A ASSEMBLED AL BOARD

PLACA G-R - - - - - o - - - - - TGNPGR29KM03 ASSEMBLED G-R BOARD

CAPACITORS

C001 ECEA1CKA220B ECEA1CKA220B CAP. ELET. 22 µF 16V

C002 ECJ2VF1H104Z ECJ2VF1H104Z CAP. CER. SMD 100 nF 50V

C003 ECJ2VF1H103Z ECJ2VF1H103Z CAP. CER. SMD 10 nF 50V

C005 ECJ2VF1H104Z ECJ2VF1H104Z CAP. CER. SMD 100 nF 50V

C006 ECA1AM331B ECA1AM331B CA P. ELETR. 330 µF 10V

C008 ECEA1HKA010B ECEA1HKA010B CAP. ELETR. 1 µF 50V

C117 ECJ2VB1H103J ECJ2VB1H103J CAP. CER. SMD 10 nF 50V

C354 ECJ2VC1H330J ECJ2VC1H330J CAP. CER. SMD 33 PF 50V

C355 ECJ2VC1H330J ECJ2VC1H330J CAP. CER. SMD 33 PF 50V

C356 ECJ2VC1H330J ECJ2VC1H330J CAP. CER. SMD 33 PF 50V

C359 ECQM4104KZB ECQM4104KZB CAP. POL. 100 nF 400V

C368 ECJ2VC1H122J ECJ2VC1H122J CAP. CER. SMD 1,2 nF 50V

C370 ECKW3D102KBP ECKW3D102KBP CAP . CER. DISC 1 nF 2.000V

C371 ECEA1CN100UB ECEA1CN100UB CAP . ELET. 10 µF 16V

C373 ECA2EM100B ECA2EM100B CAP. ELET. 10 µF 250V

C377 ECA1CM221B ECA1CM221B CAP. ELETR. 220 µF 16V

C401 ECJ2VC1H222J ECJ2VC1H222J CAP. CER. SMD 2.200 PF 50V

C402 ECA1VM222E ECA1VM222E CAP. ELETR. 2.200 µF 35V

C403 ECA1HM220B ECA1HM220B CAP. ELETR. 22 µF 50V

C406 ECA1HM101B ECA1HM101B CAP. ELETR. 100 µF 50V

C408 ECQV1H274JL3 ECQV1H274JL3 CAP. POL. MET. 270 nF 50V

C409 ECA1HM330B ECA1HM330B CAP. ELET. 33 µF 50V

C502 ECKR2H821KB5 ECKR2H821KB5 CAP. CER. DISC 820 PF 500V

C504 ECJ2VB1H681K ECJ2VB1H681K CAP. CER. SMD 680 PF 50V

C506 ECCR2H100D5 ECCR2H100D5 CAP. CER. DISC 10 PF 100V

C511 ECA1VM101B ECA1VM101B CAP. ELET . 100 µF 35V

C519 ECA2CM330B ECA2CM330B CAP. ELET. 33 µF 160,0 V

C520 ECA0JM221B ECA0JM221B CAP . ELET. 220 µF 6,3V

C552 ECA2EM100B ECA2EM100B CAP. ELET. 10 µF 250V

C555 ECKR2H471KB5 ECKR2H471KB5 CAP. CER. DISC 470 PF 500V

C558 - - - - - o - - - - - ECQB1104JM3 C A P. POL. 100 nF 100V

C558 ECA2CMR47B - - - - - o - - - - - CAP. EL ET. 0,47 µF 160V

C559 - - - - - o - - - - - ECWH16133JVB CAP. POLIPR. 13 nF 1.600V

C559 ECWH16912JVB - - - - - o - - - - - CAP. POLIPR. 9,1 nF 1.600V

C560 - - - - - o - - - - - ECQM4393JZW C AP. POL. 39 nF 400V

C560 ECQM4273JZW - - - - - o - - - - - CAP. POL. 27 nF 400V

C561 - - - - - o - - - - - ECKW3D561JBR C AP. CER. DISC 0,56 nF 2.000V

C561 ECKW3D821JBR - - - - - o - - - - - CA P. CER. DISC 0,82 nF 2.000V

C562 - - - - - o - - - - - ECKW3D681JBR C AP. CER. DISC 0,68 nF 2.000V

C562 ECKW3D471JBR - - - - - o - - - - - CA P. CER. DISC 0,47 nF 2.000V

C563 ECWF2394JSR - - - - - o - - - - - CA P. POL IPR. 390 nF 250V

C565 ECQP1H183JZ3 ECQP1H183JZ3 CAP. POLIPR. 18 nF 50V

C567 ECQM4332JZW ECQM4183JZW CAP. POL. 18 nF 400V

C568 - - - - - o - - - - - ECWF2394JSR CAP. POL IPR. 390 nF 250V

C570 ECJ2VC1H680J ECJ2VC1H680J CAP. CER. SMD 68 PF 50V

C601 ECEA1CKA101B ECEA1CKA101B CAP. ELET. 100 µF 16V

C602 ECJ2YB1H104K ECJ2YB1H104K CAP. CER. SMD 100 nF 50V

C603 ECJ2VB1H472K ECJ2VB1H472K CAP. CER. SMD 4.700 PF 50V

C604 ECQV1H224JL3 ECQV1H224JL3 CAP. POL. 220 nF 50V

C605 ECQV1H224JL3 ECQV1H224JL3 CAP. POL. 220 nF 50V

- 36 -

Page 37

Ref. No. TC-20KL03A Part No. TC-29KL03A Part No. Part Name & Description

CAPACITORS

C606 ECJ2VB1H332K ECJ2VB1H332K CAP. CER. SMD 3,3 nF 50V

C607 ECEA1HKA010B ECEA1HKA010B CAP. ELETR. 1 µF 50V

C609 ECJ2YB1H104K ECJ2YB1H104K CAP. CER. SMD 100 nF 50V

C610 ECJ2VB1H103J ECJ2VB1H103J CAP. CER. SMD 10 nF 50V

C61 1 ECEA1HKAR22B ECEA1HKAR22B CAP . ELET. 0,22 µF 50V

C612 ECJ2VB1H472K ECJ2VB1H472K CAP. CER. SMD 4.700 PF 50V

C613 ECJ2VB1H472K ECJ2VB1H472K CAP. CER. SMD 4.700 PF 50V

C614 ECQV1H104JL3 ECQV1H104JL3 CAP. POL. 100 nF 50V

C615 ECQV1H224JL3 ECQV1H224JL3 CAP. POL. 220 nF 50V

C616 ECJ2VC1H330J ECJ2VC1H330J CAP. CER. SMD 33 PF 50V

C617 ECEA1CKA100B ECEA1CKA100B CAP. ELETR. 10 µF 16V

C618 ECKR1H331KB5 ECKR2H331KB5 CAP. CER. DISC 330 PF 500V

C620 ECJ2VC1H470J ECJ2VC1H470J CAP. CER. SMD 47 PF 50V

C621 ECJ2VB1H471K ECJ2VB1H471K CAP. CER. SMD 470 PF 50V

C622 ECJ2VF1H104Z ECJ2VF1H104Z CAP. CER. SMD 100 nF 50V

C623 ECJ2VC1H270J ECJ2VC1H270J CAP. CER. SMD 27 PF 50V

C624 ECEA1CKA100B ECEA1CKA100B CAP. ELETR. 10 µF 16V

C625 ECA0JM221B ECA0JM221B CAP . ELET. 220 µF 6,3V

C627 ECJ2YB1H473K ECJ2YB1H473K CAP. CER. SMD 47 nF 50V

C628 ECJ2YB1H473K ECJ2YB1H473K CAP. CER. SMD 47 nF 50V

C629 ECJ2YB1H104K ECJ2YB1H104K CAP. CER. SMD 100 nF 50V

C631 ECJ2VB1H472K ECJ2VB1H472K CAP. CER. SMD 4.700 PF 50V

C633 ECJ2ZF1C105Z ECJ2VF1C105Z CAP. CER. SMD 1 µF 16V

C634 ECJ2ZF1C105Z ECJ2VF1C105Z CAP. CER. SMD 1 µF 16V

C635 ECJ2VF1H104Z ECJ2VF1H104Z CAP. CER. SMD 100 nF 50V

C636 ECEA1CKA101B ECEA1CKA101B CAP. ELET. 100 µF 16V

C639 ECA1HM220B ECA1HM220B CAP. ELETR. 22 µF 50V

C641 ECJ2VC1H100C ECJ2VC1H100C CAP. CER. SMD 10 PF 50V NP0

C653 - - - - - o - - - - - ECEA1HKA4R7B CAP. ELETR. 4,70 µF 50V

C653 ECEA1CKA100B - - - - - o - - - - - CAP. ELETR. 10 µF 16V

C660 ECQV1H105JL3 ECQV1H105JL3 CAP. POL. 1 µF 50V

C801 ECKCNA331MB7 ECKCNA331MB7 CAP. CER. DISC SEG. 330 PF 4.000V

C802 ECKCNA102MB7 ECKCNA102MB7 CAP. CER. DISC SEG. 1 nF 4.000V

C803 ECKWAE472ZE ECKWAE472ZE CAP. CER. DISC 4,7 nF 250VAC

C804 ECKCNA331MB7 ECKCNA331MB7 CAP. CER. DISC SEG. 330 PF 4.000V

C805 ECQU2A224BN9 ECQU2A224BN9 CAP. POLIPR. 220 nF 100,0 V

C806 ECKWAE472ZE ECKWAE472ZE CAP. CER. DISC 4,7 nF 250VAC

C807 ECKWAE472ZE ECKWAE472ZE CAP. CER. DISC 4,7 nF 250VAC

C808 ECQB1H471JF3 ECQB1H471JM3 CAP. POL. 470 PF 50V

C809 ECKWAE472ZE ECKWAE472ZE CAP. CER. DISC 4,7 nF 250VAC

C811 EEUFC1H560B EEUFC1H560B CAP . ELET. 56 µF 50V

C813 ECKCNA332MEB ECKCNA332MEB CAP. CER. DISC SEG. 3,3 nF 250V

C814 ECKR1H471KB5 ECKR1H471KB5 CAP. CER. DISC 470 PF 50V

C815 ECQB1H472JF3 ECQB1H472JM3 CAP. POL. 4,7 nF 50V

C817 ECQU2A224BN9 ECQU2A224BN9 CAP. POLIPR. 220 nF 100,0 V

C818 ECKCNA331MB7 ECKCNA331MB7 CAP. CER. DISC SEG. 330 PF 4.000V

C820 ECKW3D122KBP ECKW3D122KBP CAP . CER. DISC 1,2 nF 2.000V

C821 ECKD3A472KBP ECKD3A472KBP CAP. CER. DISC 4,7 nF 1.000V

C824 - - - - - o - - - - - F2B2G4710007 CAP. ELETR. 470 µF 400V

C824 EETHC2G221C: - - - - - o - - - - - C AP. ELETR. 220 µF 400V

C824 F2B2G2210013 - - - - - o - - - - - CAP . ELETR. 220 µF 400V

C825 ECA2AM101B ECA2AM101B CAP. ELETR. 100 µF 100V

C831 ECKR3A271KBP ECKR3A271KBP CAP. CER. DISC 270 PF 1.000V

C832 F2A1C471A116 F2A1C471A116 CAP. ELET. 470 µF 16V

C840 ECJ2YB1C474K ECJ2YB1C474K CAP. CER. SMD 470 nF 16V

TC-20KL03A / TC-29KL03A

- 37 -

Page 38

TC-20KL03A / TC-29KL03A

Ref. No. TC-20KL03A Part No. TC-29KL03A Part No. Part Name & Description

CAPACITORS

C841 ECJ2YB1A824K ECJ2YB1A824K CAP . CER. SMD 820 nF 10V

C851 ECJ2ZF1C105Z ECJ2VF1C105Z CAP. CER. SMD 1 µF 16V

C853 ECKR2H151KB5 ECKR2H151KB5 CAP. CER. DISC 150 PF 500V

C855 ECJ2ZF1C105Z ECJ2VF1C105Z CAP. CER. SMD 1 µF 16V

C856 ECKR2H122KB5 ECKR2H122KB5 CAP. CER. DISC 1.200 PF 500V

C857 ECA1CM471B ECA1CM471B CAP. ELET. 470 µF 16V

C859 F2A1V681A096 F2A1V681A096 CAP. ELETR. 680 µF 35V

C861 ECA1VM102B ECA1VM102B CAP. ELETR. 1.000 µF 35V

C862 ECEA1VKA100B ECEA1VKA100B CAP. ELET . 10 µF 35V

C863 ECKR2H331KB5 ECKR2H331KB5 CAP. CER. DISC 330 PF 500V

C865 F2A2C680A021 F2A2C680A021 CAP. ELETR. 68 µF 160V

C866 ECKW3D221JBP ECKW3D221JBP CAP. CER. DISC 220 PF 2.000V

C971 ECJ2VF1H103Z ECJ2VF1H103Z CAP. CER. SMD 10 nF 50V

C1001 - - - - - o - - - - - ECJ2VC1H331J CAP. CER. SMD 330 PF 50V

C1002 - - - - - o - - - - - ECJ2VF1H104Z C AP. CER. SMD 100 nF 50V

C1003 - - - - - o - - - - - ECEA1CKA101B CAP. ELET. 100 µF 16V

C1 101 ECJ2VF1H104Z ECJ2VF1H104Z CAP. CER. SMD 100 nF 50V

C1103 ECJ2VC1H331J - - - - - o - - - - - CAP. CER. SMD 330 PF 50,0V

C1104 ECEA1CKA101B - - - - - o - - - - - CAP. ELET. 100 µF 16V

C1105 ECJ2VF1H104Z - - - - - o - - - - - C AP. CER. SMD 100 nF 50V

C1 106 ECJ2VF1H104Z ECJ2VF1H104Z CAP. CER. SMD 100 nF 50V

C1120 ECA1HM4R7B ECA1HM4R7B CAP . ELET. 4,70 µF 50V

C1130 ECJ2VC1H560J ECJ2VC1H560J CAP. CER. SMD 56 PF 50V

C11 31 ECA0JM221B ECA0JM221B CAP. ELET. 220 µF 6,3V

C1132 ECJ2VC1H560J ECJ2VC1H560J CAP. CER. SMD 56 PF 50V

C1203 ECJ2VF1H104Z ECJ2VF1H104Z CAP. CER. SMD 100 nF 50V

C1204 ECEA1CKA101B ECEA1CKA101B CAP. ELET. 100 µF 16V

C1205 ECA1CM101B ECA1CM101B CAP. ELET . 100 µF 16V

C2130 ECA1HM2R2B ECA1HM2R2B CAP. ELET. 2,20 µF 50V

C2131 ECA1HM2R2B ECA1HM2R2B CAP. ELET. 2,20 µF 50V

C2134 ECA1HM2R2B ECA1HM2R2B CAP. ELET. 2,20 µF 50V

C2135 ECA1HM2R2B ECA1HM2R2B CAP. ELET. 2,20 µF 50V

C2137 ECJ2VB1H471K ECJ2VB1H471K CAP. CER. SMD SMD 470 PF 50V

C2138 ECJ2VB1H471K ECJ2VB1H471K CAP. CER. SMD SMD 470 PF 50V

C2146 ECA1HM2R2B ECA1HM2R2B CAP. ELET. 2,20 µF 50V

C2147 ECA1HM2R2B ECA1HM2R2B CAP. ELET. 2,20 µF 50V

C2240 ECA1EM100B ECA1EM100B CAP . ELETR. 10 µF 25V

C2242 ECJ2VB1C104K ECJ2VB1C104K CAP. CER. SMD 100 nF 16V

C2243 ECA1HMR47B ECA1HMR47B CAP. ELET. 0,47 µF 50V

C2245 ECQB1H473KF3 ECQB1H473KF3 CAP. POL. 47 nF 50V

C2246 ECJ2VC1H100D ECJ2VC1H100D CAP. CER. SMD 10 PF 50V

C2250 ECA1HM2R2B ECA1HM2R2B CAP. ELET. 2,20 µF 50V

C2251 ECA1HM4R7B ECA1HM4R7B CAP. ELET. 4,70 µF 50V

C2252 ECSF1CE106VB ECSF1CE106VB CAP. TANTALO 10 µF 16V

C2253 ECA1HMR33B ECA1HMR33B CAP. ELET. 0,33 µF 50V

C2254 ECQB1H223KF3 ECQB1H223KF3 CAP. POL. 22 nF 50V

C2255 ECSF1CE335VB ECSF1CE335VB CAP. TANTALO 3,30 µF 16V

C2256 ECJ2VB1C104K ECJ2VB1C104K CAP. CER. SMD 100 nF 16V

C2257 ECJ2VB1C104K ECJ2VB1C104K CAP. CER. SMD 100 nF 16V

C2258 ECEA1CKA101B ECEA1CKA101B CAP. ELET. 100 µF 16V

C2260 ECJ2VF1C474Z ECJ2VF1C474Z CAP. CER. SMD 470 nF 16V

C2261 ECJ2VF1C474Z ECJ2VF1C474Z CAP. CER. SMD 470 nF 16V

C2270 ECA1CM470B ECA1CM470B CAP. ELET . 47 µF 16V

C2271 ECA1CM470B ECA1CM470B CAP. ELET . 47 µF 16V

C2272 ECJ2VB1C333K ECJ2VB1C333K CAP . CER. SMD 33 nF 16V

- 38 -

Page 39

Ref. No. TC-20KL03A Part No. TC-29KL03A Part No. Part Name & Description

CAPACITORS

C2273 ECJ2VB1H562K ECJ2VB1H562K CAP. CER. SMD 5,6 nF 50V

C2274 ECJ2VB1C333K ECJ2VB1C333K CAP. CER. SMD 33 nF 16V

C2275 ECJ2VB1H153K ECJ2VB1H153K CAP. CER. SMD 15 nF 50V

C2276 ECJ2VB1H153K ECJ2VB1H153K CAP. CER. SMD 15 nF 50V

C2277 ECJ2VB1H562K ECJ2VB1H562K CAP. CER. SMD 5,6 nF 50V

C2301 ECJ2VB1H103K ECJ2VB1H103K CAP . CER. SMD SMD 10 nF 50V

C2302 ECA1CM100B ECA1CM100B CAP. ELET. 10 µF 16V

C2305 ECA1CM100B ECA1CM100B CAP. ELET. 10 µF 16V

C2306 ECA1CM470B ECA1CM470B CAP. ELET. 47 µF 16V

C2307 ECA1VM102B ECA1VM102B CAP . ELETR. 1.000 µF 35V

C2308 ECJ2VF1H103Z ECJ2VF1H103Z CAP. CER. SMD 10 nF 50V

C2309 ECA1EM471B ECA1EM471B CAP . ELET. 470 µF 25V

C2310 ECQV1H224JL3 ECQV1H224JL3 CAP. POL. 220 nF 50V

C2311 ECQV1H224JL3 ECQV1H224JL3 CAP. POL. 220 nF 50V

C2312 ECA1VM470B ECA1VM470B CAP. ELETR. 47 µF 35V

C2313 ECA1HM3R3B ECA1HM3R3B CAP. ELET. 3,30 µF 50V

C2331 ECJ2VB1H103K ECJ2VB1H103K CAP . CER. SMD SMD 10 nF 50V

C2332 ECA1CM100B ECA1CM100B CAP. ELET. 10 µF 16V

C2340 ECQV1H224JL3 ECQV1H224JL3 CAP. POL. 220 nF 50V

C2341 ECQV1H224JL3 ECQV1H224JL3 CAP. POL. 220 nF 50V

C2342 ECA1VM470B ECA1VM470B CAP. ELETR. 47 µF 35V

C2345 ECA1CM100B ECA1CM100B CAP. ELET. 10 µF 16V

C2346 ECA1CM470B ECA1CM470B CAP. ELET. 47 µF 16V

C2347 ECA1VM102B ECA1VM102B CAP . ELETR. 1.000 µF 35V

C2348 ECJ2VF1H103Z ECJ2VF1H103Z CAP. CER. SMD 10 nF 50V

C2349 ECA1EM471B ECA1EM471B CAP . ELET. 470 µF 25V

C2350 ECA1VM102B ECA1VM102B CAP . ELETR. 1.000 µF 35V

C2380 ECA1CM101B ECA1CM101B CAP. ELET. 100 µF 16V

C2381 ECA1CM100B ECA1CM100B CAP. ELET. 10 µF 16V

C2385 ECA1CM470B ECA1CM470B CAP. ELET. 47 µF 16V

C3014 ECEA0JN331UB ECEA0JN331UB CAP . ELET. 330 µF 6,3V

C3015 ECA1HM010B ECA1HM010B CAP. ELET . 1 µF 50V

C3016 ECA1CM471B ECA1CM471B CAP. ELET. 470 µF 16V

C3024 ECA1HM010B ECA1HM010B CAP. ELET . 1 µF 50V

C3103 ECJ2VB1H103J ECJ2VB1H103J CAP. CER. SMD 10 nF 50V

C3104 ECJ2VB1H103J ECJ2VB1H103J CAP. CER. SMD 10 nF 50V

C3111 ECJ2VB1H392K - - - - - o - - - - - C AP. CER. SMD 3.900 PF 50V

C3112 ECJ2VB1H392K - - - - - o - - - - - CAP. CER. SMD 3.900 PF 50V

C3113 ECJ2VB1H392K - - - - - o - - - - - CAP. CER. SMD 3.900 PF 50V

C3114 ECJ2VB1H392K - - - - - o - - - - - CAP. CER. SMD 3.900 PF 50V

DIODES

D002 B0BA01500036 B0BA01500036 ZENER DIODE 15V 0,5W 5mA

D003 B0BA01500036 B0BA01500036 ZENER DIODE 15V 0,5W 5mA

D004 B0BA03000015 B0BA03000015 ZENER DIODE 30V 0,5W 5 mA

D005 B0BA03000015 B0BA03000015 ZENER DIODE 30V 0,5W 5 mA

D011 MA3X152K0L MA3X152K0L SMD DIODE

D354 MA3X152K0L MA3X152K0L SMD DIODE

D355 MA3X152K0L MA3X152K0L SMD DIODE

D356 MA3X152K0L MA3X152K0L SMD DIODE

D360 B0HAGP000003 B0HAGP000003 RECTIFIER DIODE

D361 B0HAGP000003 B0HAGP000003 RECTIFIER DIODE

D362 B0HAGP000003 B0HAGP000003 RECTIFIER DIODE

D363 MA3X152K0L MA3X152K0L SMD DIODE

D365 B0BA9R900005 B0BA9R900005 ZENER DIODE 9,9 V 0,5W 5 mA

D375 MA3X152K0L MA3X152K0L SMD DIODE

TC-20KL03A / TC-29KL03A

- 39 -

Page 40

TC-20KL03A / TC-29KL03A

Ref. No. TC-20KL03A Part No. TC-29KL03A Part No. Part Name & Description

DIODES

D402 B0HAJL000001 B0HAJL000001 RECTIFIER DIODE

D403 B0BA03100002 B0BA03100002 ZENER DIODE 31V 0,5W 5 mA

D511 MAZ4108J0F MAZ4108J0F ZENER DIODE 10,8 V 0,37 W 250 mA

D512 MA2B17100E MA2B17100E SWITCHING DIODE

D520 MA3X152K0L MA3X152K0L SMD DIODE

D551 MAZ30470HL MAZ30470HL ZENER DIODE SMD4,9 V 0,2W 5 mA

D552 B0HAJL000001 B0HAJL000001 RECTIFIER DIODE

D555 MA3X152K0L MA3X152K0L SMD DIODE

D556 B0EAKV000008 B0HANV000002 RECTIFIER DIODE FAST RECOVERY

D557 RU2AMV1 RU2AMV1 RECTIFIER DIODE FAST RECOVER Y

D558 MA2C18500E MA2C18500E DIODE

D603 MA3X152K0L MA3X152K0L SMD DIODE

D606 MA3X152K0L MA3X152K0L SMD DIODE

D630 MAZ30560HL MAZ30560HL ZENER DIODE SMD5,8 V 0,2 W 5 mA

D660 MA3X152E0L MA3X152E0L SWITCHING DIODE SMD

D801 - - - - - o - - - - - TAP4GA0005 POSISTOR 12,0 OHM

D802 B0EBNT000002 B0EBNT000002 RECTIFIER DIODE

D803 TAP4GA0005 TAP4GA0005 POSISTOR 12,0 OHM

D804 B0HAJL000001 B0HAJL000001 RECTIFIER DIODE

D805 B0HAJL000001 B0HAJL000001 RECTIFIER DIODE

D806 ERZV10V621CS ERZV10V621CS VARISTOR

D807 TLP721FD4GR-BR TLP721FD4GR-BR PHOTO ACOPLADOR

D811 B0EAKR000016 B0EAKR000016 RECTIFIER DIODE

D814 MA2B18200E MA2B18200E SWITCHING DIODE

D816 B0HAJL000001 B0HAJL000001 RECTIFIER DIODE

D820 B0AAEV000001 B0AAEV000001 SWITCHING DIODE

D821 B0JAME000058 B0JAME000058 DIODE RET. BARREIRA SCHOTTKY

D824 MAZ40680MF MAZ40680MF ZENER DIODE I 6,8 V 0,250 5 mA

D825 B0BA01200008 B0BA01200008 ZENER DIODE 12V 0,5W 5 mA

D826 B0HAJL000001 B0HAJL000001 RECTIFIER DIODE

D827 B0BA01100004 B0BA01100004 ZENER DIODE 11V 0,5W 5 mA

D828 B0HAJL000001 B0HAJL000001 RECTIFIER DIODE

D829 B0HAJP000015 B0HAJP000015 RECTIFIER DIODE

D831 B0HAPV000009 B0HAPV000009 RECTIFIER DIODE

D837 S3L60P1520 S3L60P1520 SWITCHING DIODE

D855 B0HAJL000001 B0HAJL000001 RECTIFIER DIODE

D856 B0HAMM000101 B0HAMM000101 RECTIFIER DIODE FAST RECOVERY

D862 B0BA5R600016 B0BA5R600016 ZENER DIODE 5,6 V 0,5W 5 mA

D1001 - - - - - o - - - - - EL333ID/S928 DIODE LED

D1002 - - - - - o - - - - - B0BA7R500006 ZENER DIODE 7,5 V 1/2W 5 mA

D1101 MA3X152K0L MA3X152K0L SMD DIODE

D1 1 02 B0BA5R400008 B0BA5R400008 ZENER DIODE 5,4 V 1/2W 5 mA

D1104 EL333ID/S928 - - - - - o - - - - - DIODE LED

D1105 B0BA7R500006 - - - - - o - - - - - ZENER DIODE 7,5 V 1/2W 5 mA

D1130 B0BA5R700008 B0BA5R700008 ZENER DIODE 5,7 V 0,5W 5 mA

D1131 B0BA5R700008 B0BA5R700008 ZENER DIODE 5,7 V 0,5W 5 mA

D1204 B0BA5R600016 B0BA5R600016 ZENER DIODE 5,6 V 0,5W 5 mA

D2333 MA3X152K0L MA3X152K0L SMD DIODE

D2380 MA3X152K0L MA3X152K0L SMD DIODE

D2381 MA3X152K0L MA3X152K0L SMD DIODE

D2385 MA3X152K0L MA3X152K0L SMD DIODE

D2386 MA3X152K0L MA3X152K0L SMD DIODE

D3014 MA3X152K0L MA3X152K0L SMD DIODE

- 40 -

Page 41

Ref. No. TC-20KL03A Part No. TC-29KL03A Part No. Part Name & Description

INTEGRATED CIRCUITS

IC351 - - - - - o - - - - - TDA6107JF/N3 IC (até 01/01/2004)

IC351 TDA6107Q/N2 TDA6107Q/N2 IC (a partir de 01/01/2004)

IC451 AN5539 C1AA00000527 IC VERTICAL-OUT

IC601 TDA9380PS/N2/3I TDA9380PS/N2/3I IC

IC801 STRW6654LF02 STRW6654LF02 IC HIBRID

IC802 C0EAS0000026 C0EAS0000026 IC

IC851 AN7805LB AN7805LB IC V OL T AGEM REGULA T OR

IC852 AN7808LB AN7808LB IC

IC1001 - - - - - o - - - - - B3RAD0000012 IC REMOCON RECEPTOR

IC1103 BR24C08F-E2 BR24C08F-E2 IC SMD MEMORY

IC1104 B3RAD0000012 - - - - - o - - - - - IC REMOCON RECEPTOR

IC1201 C0CBABC00037 C0CBABC00037 IC SMD

IC1202 AN7805LB AN7805LB IC V OL TAGEM REGULA TOR

IC2202 TDA9859H/V2 TDA9859H/V2 IC SM D

IC2250 AN5849S-E1V AN5849S-E1V IC MONOLITHIC

IC2301 C1BA00000271 C1BA00000271 IC AUDIO OUTPUT

JUMPERS

J316 ERDS2TJ221V ERDS2TJ221V CARBON RESISTOR 220 Ohm 1/4W

JA36 - - - - - o - - - - - ERJ6GEYJ102V SMD RESISTOR 1 kOhm 1/8W

E-E - - - - - o - - - - - TXAJTEECB29P22 FLEXIBLE JUMPER WITH TERMINALS

F-FT-T - - - - - o - - - - - B3B0C223PT120T FLEXIBLE JUMPER WITH TERMINALS

F-FT-T - - - - - o - - - - - TXAJTCCCB29P22 FLEXIBLE JUMPER WITH TERMINALS

G - G - - - - - o - - - - - TXAJTFFCB14A12 FLEXIBLE JUMPER WITH TERMINALS

F-F B3B0C223PT120T - - - - - o - - - - - FLEXIBLE JUMPER WITH TERMINALS

T-T B3B0C223PT120T - - - - - o - - - - - FLEXIBLE JUMPER WITH TERMINALS

COILS

L001 G0A100D00001 G0A100D00001 PIC COIL

L002 EXC3BB221H EXC3BB221H SMD COIL

L184 TALV35VB6R8K TALV35VB6R8K PIC COIL

L352 EXCELSA24T EXCELSA24T FERRITE COIL W/ TERMINALS

L501 ELH5L4101Z ELH5L7101Z LINEARITY COIL

L550 G0ZZ00001937 G0ZZ00001937 SMD COIL

L560 EXCELDR35V EXCELDR35V PIC COIL

L620 J0JCC0000009 J0JCC0000009 COIL

L621 EXCELSA39V EXCELSA39V FERRITE COIL

L801 TLP4GD014P ELF18DZ660EZ LINE FIL TER

L820 EXCELDR35C EXCELDR35C PIC COIL

L821 EXCELDR35V EXCELDR35V PIC COIL

L852 G0A101EA0008 G0A101EA0008 PIC COIL

L855 EXCELSA39V EXCELSA39V FERRITE COIL

L856 G0C1R5KA0030 G0C1R5KA0030 PIC COIL

L857 G0C1R5KA0030 G0C1R5KA0030 PIC COIL

L1001 TALV35VB331K TALV35VB331K PIC COIL

L1110 EXCELSA35T EXCELSA35T FERRITE COIL

L3011 EXC3BB221H EXC3BB221H SMD COIL

L3012 EXC3BB221H EXC3BB221H SMD COIL

L3013 EXC3BB221H EXC3BB221H SMD COIL

L3014 EXC3BB221H EXC3BB221H SMD COIL

L3132 EXC3BB221H EXC3BB221H SMD COIL

L3133 EXC3BB221H EXC3BB221H SMD COIL

TRANSISTORS

Q001 B1ABDF000009 B1ABDF000009 SMD TRANSISTOR

Q369 B1ADDF000002 B1ADDF000002 SMD TRANSISTOR

Q401 B1ADDF000002 B1ADDF000002 SMD TRANSISTOR

Q445 2SC3326ATX 2SC3326ATX SMD TRANSISTOR

TC-20KL03A / TC-29KL03A

- 41 -

Page 42

TC-20KL03A / TC-29KL03A

Ref. No. TC-20KL03A Part No. TC-29KL03A Part No. Part Name & Description

TRANSISTORS

Q446 B1ABDF000009 B1ABDF000009 SMD TRANSISTOR

Q447 B1ABDF000009 B1ABDF000009 SMD TRANSISTOR

Q501 2SC4212H00LB 2SC4212H00LB POWER TRANSISTOR

Q520 2SB792ATX 2SB792ATX SMD TRANSISTOR

Q551 B1BAER000004 B1BAER000004 POWER TRANSISTOR

Q601 B1ADDF000002 B1ADDF000002 SMD TRANSISTOR

Q602 B1ABDF000009 B1ABDF000009 SMD TRANSISTOR

Q603 B1ADDF000002 B1ADDF000002 SMD TRANSISTOR

Q605 B1ABDF000009 B1ABDF000009 SMD TRANSISTOR

Q606 B1ABDF000009 B1ABDF000009 SMD TRANSISTOR

Q607 B1ADDF000002 B1ADDF000002 SMD TRANSISTOR

Q608 B1ABDF000009 B1ABDF000009 SMD TRANSISTOR

Q825 2SC1473ATA 2SC1473ATA TRANSISTOR

Q852 B1ABDF000009 B1ABDF000009 SMD TRANSISTOR

Q857 B1ABDF000009 B1ABDF000009 SMD TRANSISTOR

Q1101 B1ABDF000009 B1ABDF000009 SMD TRANSISTOR

Q2380 B1ABDF000009 B1ABDF000009 SMD TRANSISTOR

Q2381 B1ADDF000002 B1ADDF000002 SMD TRANSISTOR

Q2382 B1ADDF000002 B1ADDF000002 SMD TRANSISTOR

RESISTORS

R003 ERJ6GEYJ100V ERJ6GEYJ100V SMD RESISTOR 10 Ohm 1/8 W

R004 ERG3FJ822H ERG3FJ822H OXIDE METAL RESISTOR

R006 ERJ6GEYJ273V ERJ6GEYJ273V SMD RESISTOR 27 kOhm 1/8W

R007 ERJ6GEYJ472V ERJ6GEYJ472V SMD RESISTOR 4,7 kOhm 1/8W

R008 ERJ6GEYJ681V ERJ6GEYJ681V SMD RESISTOR 680 Ohm 1/8W

R01 1 ERJ6GEYJ103V ERJ6GEYJ103V SMD RESISTOR 10 kOhm 1/8W

R012 ERJ6GEYJ332V ERJ6GEYJ332V SMD RESISTOR 3,3 kOhm 1/8W

R021 ERJ6GEYJ273V ERJ6GEYJ273V SMD RESISTOR 27 kOhm 1/8W

R022 ERJ6GEYJ473V ERJ6GEYJ473V SMD RESISTOR 47 kOhm 1/8W

R182 ERJ6GEYJ221V ERJ6GEYJ221V SMD RESISTOR 220 Ohm 1/8W

R351 ERJ6ENF1001V ERJ6ENF1001V PRECISION SMD RESISTOR 1 kOhm 1/10W

R352 ERJ6ENF1001V ERJ6ENF1001V PRECISION SMD RESISTOR 1 kOhm 1/10W

R353 ERJ6ENF1001V ERJ6ENF1001V PRECISION SMD RESISTOR 1 kOhm 1/10W

R354 ERJ6ENF7870V ERJ6ENF7870V PRECISION SMD RESISTOR 787 Ohm 1/10W

R355 ERJ6ENF7870V ERJ6ENF7870V PRECISION SMD RESISTOR 787 Ohm 1/10W

R356 ERJ6ENF7870V ERJ6ENF7870V PRECISION SMD RESISTOR 787 Ohm 1/10W

R363 ERC12GK222V ERC12GK222V CARBON RESISTOR 2,2 kOhm 1/2W

R364 ERC12GK222V ERC12GK222V CARBON RESISTOR 2,2 kOhm 1/2W

R365 ERC12GK222V ERC12GK222V CARBON RESISTOR 2,2 kOhm 1/2W

R369 ERJ6GEYJ103V ERJ6GEYJ103V SMD RESISTOR 10 kOhm 1/8W

R374 ERQ12AJ181P ERQ12AJ181P FUSISTOR

R401 ERDS2TJ1R5T ERX12SJR82E OXIDE METAL RESISTOR 0,82 Ohm 1/2W

R402 ERJ6GEYJ103V ERJ6GEYJ103V SMD RESISTOR 10 kOhm 1/8W

R403 ERJ6ENF2491V ERJ6ENF2491V PRECISION SMD RESISTOR 2,49 kOhm 1/10W

R404 ERJ6ENF2701V ERJ6ENF2701V PRECISION SMD RESISTOR 2,70 kOhm 1/10W

R405 ERJ6ENF2701V ERJ6ENF2701V PRECISION SMD RESISTOR 2,70 kOhm 1/10W

R406 ERJ6GEYJ1R0V ERJ6GEYJ1R0V SMD RESISTOR 1 Ohm 1/8W

R407 ERDS1TJ331T ERDS1TJ331T CARBON RESISTOR 330 Ohm 1/2W

R408 - - - - - o - - - - - ERJ6GEY0R00V SMD RESISTOR 0 Ohm

R409 ERJ6GEYJ823V ERJ6GEYJ823V SMD RESISTOR 82 kOhm 1/8W

R411 - - - - - o - - - - - ERJ6GEYJ222V SMD RESISTOR 2,2 kOhm 1/8W

R411 ERJ6GEYJ152V - - - - - o - - - - - SMD RESISTOR 1,5 kOhm 1/8W

R412 ERJ6GEYJ332V ERJ6GEYJ332V SMD RESISTOR 3,3 kOhm 1/8W

R415 ERJ6GEYJ431V ERJ6GEYJ431V SMD RESISTOR 430 Ohm 1/8W

R416 - - - - - o - - - - - ERX12SJR33E OXIDE MET AL RESISTOR 0,33 Ohm 1/2W

- 42 -

Page 43

Ref. No. TC-20KL03A Part No. TC-29KL03A Part No. Part Name & Description

RESISTORS

R416 ERX12SJ1R0E - - - - - o - - - - - OXIDE METAL RESISTOR 1 Ohm 1/2W

R417 - - - - - o - - - - - ERX12SJR47E OXIDE METAL RESISTOR 0,47 Ohm 1/2W

R417 ERX12SJR82E - - - - - o - - - - - OXIDE METAL RESISTOR 0,82 Ohm 1/2W

R443 ERDS1TJ681T ERDS1TJ681T CARBON RESISTOR 680 Ohm 1/2W

R444 ERG1SJ102E ERG1SJ102E OXIDE METAL RESIST OR 1 kOhm 1W

R445 ERJ6GEYJ473V ERJ6GEYJ473V SMD RESISTOR 47 kOhm 1/8W

R446 ERJ6GEYJ473V ERJ6GEYJ473V SMD RESISTOR 47 kOhm 1/8W

R447 ERJ6GEYJ472V ERJ6GEYJ472V SMD RESISTOR 4,7 kOhm 1/8W

R448 ERJ6GEYJ242V ERJ6GEYJ242V SMD RESISTOR 2,4 kOhm 1/8W

R449 ERJ6GEYJ152V ERJ6GEYJ152V SMD RESISTOR 1,5 kOhm 1/8W

R502 ERJ6GEYJ182V ERJ6GEYJ182V SMD RESISTOR 1,8 kOhm 1/8W

R503 - - - - - o - - - - - ERJ6GEY0R00V SMD RESISTOR 0 Ohm

R504 ERG2SJ682E ERG2SJ682E OXIDE METAL RESIST OR 6,80 kOhm 2W

R505 - - - - - o - - - - - ERG3FJ681H OXIDE METAL RESISTOR 680 Ohm 3W

R507 ERJ6GEYJ101V ERJ6GEYJ101V SMD RESISTOR 100 Ohm 1/8W

R508 - - - - - o - - - - - ERG3FJ681H OXIDE METAL RESISTOR 680 Ohm 3W

R508 ERG3FJ152H - - - - - o - - - - - OXIDE METAL RESISTOR 1,50 kOhm 3W

R509 - - - - - o - - - - - ERG3FJ681H OXIDE METAL RESISTOR 680 Ohm 3W

R509 ERG3FJ102H - - - - - o - - - - - OXIDE METAL RESISTOR 1 kOhm 3W

R511 - - - - - o - - - - - ERJ6ENF1052V PRECISION SMD RESISTOR 10,50 kOhm 1/10W

R511 ERJ6ENF1272V - - - - - o - - - - - PRECISION SMD RESISTOR SMD 12,70 kOhm 1/10W

R512 - - - - - o - - - - - ERJ6ENF1242V PRECISION SMD RESISTOR 12,40 kOhm 1/10W

R512 ERJ6ENF1332V - - - - - o - - - - - PRECISION SMD RESISTOR SMD 13,30 kOhm 1/10W

R513 ERQ14AJ100P ERQ14AJ100P FUSISTOR

R520 - - - - - o - - - - - ERX12SJ2 R0E OXIDE METAL RESISTOR 2 Ohm 1/2W

R520 ERX12SJ3R0E - - - - - o - - - - - OXIDE METAL RESISTOR 3 Ohm 1/2W

R521 - - - - - o - - - - - ERX12SJ2 R0E OXIDE METAL RESISTOR 2 Ohm 1/2W

R521 ERX12SJ3R0E - - - - - o - - - - - OXIDE METAL RESISTOR 3 Ohm 1/2W

R522 ERJ6GEYJ123V ERJ6GEYJ123V SMD RESISTOR 12 kOhm 1/8W

R523 ERJ6GEYJ103V ERJ6GEYJ103V SMD RESISTOR 10 kOhm 1/8W

R524 ERJ6GEYJ104V ERJ6GEYJ104V SMD RESISTOR 100 kOhm 1/8W

R525 ERJ6GEYJ392V ERJ6GEYJ392V SMD RESISTOR 3,9 kOhm 1/8W

R553 ERJ6GEYJ223V ERJ6GEYJ223V SMD RESISTOR 22 kOhm 1/8W

R555 ERQ14AJ2R0E ERQ14AJ2R0E FUSISTOR

R557 - - - - - o - - - - - ER050PHF9532 PRECISION RESISTOR 95,30 kOhm 1/2W

R557 ER050PHF1473 - - - - - o - - - - - PRECISION RESISTOR 147 kOhm 1/2W

R558 ERDS2TJ223T ERDS2TJ223T CARBON RESISTOR 22,0 kOhm 1/4W

R559 ERQ1CJP1R8S ERQ1CJP3R9S FUSISTOR

R560 - - - - - o - - - - - ERG2SJ222E OXIDE METAL RESISTOR 2,20 kOhm 2W

R560 ERG1SJ102E - - - - - o - - - - - OXIDE METAL RESISTOR 1 kOhm 1W

R601 ERJ6GEYJ153V ERJ6GEYJ153V SMD RESISTOR 15 kOhm 1/8W

R602 ERJ6ENF3001V ERJ6ENF3001V PRECISION SMD RESISTOR 3 kOhm 1/10W

R603 ERJ6GEYJ393V ERJ6GEYJ393V SMD RESISTOR 39 kOhm 1/8W

R604 ERJ6GEYJ101V ERJ6GEYJ101V SMD RESISTOR 100 Ohm 1/8W

R605 ERJ6GEYJ101V ERJ6GEYJ101V SMD RESISTOR 100 Ohm 1/8W

R606 ERJ6GEYJ101V ERJ6GEYJ101V SMD RESISTOR 100 Ohm 1/8W

R607 ERJ6GEYJ103V ERJ6GEYJ103V SMD RESISTOR 10 kOhm 1/8W

R608 ERJ6GEYJ332V ERJ6GEYJ332V SMD RESISTOR 3,3 kOhm 1/8W

R609 ERJ6GEYJ332V ERJ6GEYJ332V SMD RESISTOR 3,3 kOhm 1/8W

R610 ERJ6GEYJ103V ERJ6GEYJ103V SMD RESISTOR 10 kOhm 1/8W

R61 1 ERJ6GEYJ472V ERJ6GEYJ472V SMD RESISTOR 4,7 kOhm 1/8W

R612 ERJ6GEYJ102V ERJ6GEYJ102V SMD RESISTOR 1 kOhm 1/8W

R613 ERJ6GEYJ391V ERJ6GEYJ391V SMD RESISTOR 390 Ohm 1/8W

R614 ERJ6GEYJ392V ERJ6GEYJ392V SMD RESISTOR 3,9 kOhm 1/8W

R615 ERJ6GEYJ102V ERJ6GEYJ102V SMD RESISTOR 1 kOhm 1/8W

TC-20KL03A / TC-29KL03A

- 43 -

Page 44

TC-20KL03A / TC-29KL03A

Ref. No. TC-20KL03A Part No. TC-29KL03A Part No. Part Name & Description

RESISTORS

R616 ERJ6GEYJ392V ERJ6GEYJ392V SMD RESISTOR 3,9 kOhm 1/8W

R617 ERJ6GEYJ181V ERJ6GEYJ181V SMD RESISTOR 180 Ohm 1/8W

R619 ERJ6GEYJ121V ERJ6GEYJ121V SMD RESISTOR 120 Ohm 1/8W

R620 ERJ6GEYJ121V ERJ6GEYJ121V SMD RESISTOR 120 Ohm 1/8W

R621 ERJ6GEYJ103V ERJ6GEYJ103V SMD RESISTOR 10 kOhm 1/8W

R622 ERJ6GEYJ103V ERJ6GEYJ103V SMD RESISTOR 10 kOhm 1/8W

R623 ERJ6GEYJ331V ERJ6GEYJ331V SMD RESISTOR 330 Ohm 1/8W

R624 ERJ6GEYJ103V ERJ6GEYJ103V SMD RESISTOR 10 kOhm 1/8W

R625 ERJ6GEYJ222V ERJ6GEYJ222V SMD RESISTOR 2,2 kOhm 1/8W

R626 ERJ6GEYJ104V ERJ6GEYJ104V SMD RESISTOR 100 kOhm 1/8W

R627 - - - - - o - - - - - ERJ6GEYJ823V SMD RESISTOR 82 kOhm 1/8W

R627 ERJ6GEYJ683V - - - - - o - - - - - SMD RESISTOR 68 kOhm 1/8W

R628 ERJ6GEYJ563V ERJ6GEYJ563V SMD RESISTOR 56 kOhm 1/8W

R629 ERJ6GEYJ154V ERJ6GEYJ154V SMD RESISTOR 150 kOhm 1/8W

R630 ERJ6ENF1802V ERJ6ENF1802V PRECISION SMD RESISTOR 18 kOhm 1/10W

R631 ER050PKF5603 ER050PKF5603 PRECISION RESISTOR 560 kOhm 1/2W

R632 ERJ6GEYJ820V ERJ6GEYJ820V OXIDE METAL RESISTOR 82 Ohm 1/8W

R633 ERJ6GEYJ470V ERJ6GEYJ470V SMD RESISTOR 47 Ohm 1/8W

R634 ERJ6GEYJ822V ERJ6GEYJ822V SMD RESISTOR 8,2 kOhm 1/8W

R635 ERJ6GEYJ561V ERJ6GEYJ561V SMD RESISTOR 560 Ohm 1/8W

R636 ERJ6GEYJ562V ERJ6GEYJ562V SMD RESISTOR 5,6 kOhm 1/8W

R637 ERJ6GEYJ473V ERJ6GEYJ473V SMD RESISTOR 47 kOhm 1/8W

R638 ERJ6GEYJ391V ERJ6GEYJ391V SMD RESISTOR 390 Ohm 1/8W

R639 ERJ6GEYJ101V ERJ6GEYJ101V SMD RESISTOR 100 Ohm 1/8W

R640 ERJ6GEYJ181V ERJ6GEYJ181V SMD RESISTOR 180 Ohm 1/8W

R643 ERJ6GEYJ272V ERJ6GEYJ272V SMD RESISTOR 2,7 kOhm 1/8W

R655 ERJ6GEYJ103V ERJ6GEYJ103V SMD RESISTOR 10 kOhm 1/8W

R660 ERJ6GEYJ274V ERJ6GEYJ274V SMD RESISTOR 270 kOhm 1/8W

R661 ERJ6GEYJ103V ERJ6GEYJ103V SMD RESISTOR 10 kOhm 1/8W

R662 ERJ6GEYJ333V ERJ6GEYJ333V SMD RESISTOR 33 kOhm 1/8W

R671 ERJ6GEYJ102V ERJ6GEYJ102V SMD RESISTOR 1 kOhm 1/8W

R801 - - - - - o - - - - - ERF15ZK3R3 WIRE RESISTOR 3,30 Ohm 15W

R801 ERF5ZK2R2 - - - - - o - - - - - WIRE CEMENT RESISTOR 2,20 Ohm 5W

R806 ERJ6GEYJ132V ERJ6GEYJ132V SMD RESISTOR 1,3 kOhm 1/8W

R807 ERJ6GEYJ152V ERJ6GEYJ152V SMD RESISTOR 1,5 kOhm 1/8W

R809 ERX12SJR22E ERX12SJR22E OXIDE METAL RESISTOR 0,22 Ohm 1/2W

R811 ERJ6GEYJ681V ERJ6GEYJ681V SMD RESISTOR 680 Ohm 1/8W

R812 ERD75TAJ825 ERD75TAJ825 CARBON RESISTOR 8,20 MOhm 3/4W

R813 - - - - - o - - - - - ERF5ZJ121 WIRE CEMENT RESISTOR120 Ohm 5W

R814 ERJ6GEYJ332V ERJ6GEYJ332V SMD RESISTOR 3,3 kOhm 1/8W

R817 ERG3FJ473H ERG3FJ473H OXIDE METAL RESIST OR 47 kOhm 3W

R819 ERDS1TJ330T ERDS1TJ330T CARBON RESISTOR 33 Ohm 1/2W

R821 ERG3FJ333H ERG3FJ333H OXIDE METAL RESIST OR 33 kOhm 3W

R823 ERDS1TJ274T ERDS1TJ274T CARBON RESISTOR 270 kOhm 1/2W

R824 ERDS1TJ274T ERDS1TJ274T CARBON RESISTOR 270 kOhm 1/2W

R825 ERJ6GEYJ473V ERJ6GEYJ473V SMD RESISTOR 47 kOhm 1/8W

R826 ERDS2TJ153T ERDS2TJ153T CARBON RESISTOR 15,0 kOhm 1/4W

R827 ERJ6GEYJ1R0V ERJ6GEYJ1R0V SMD RESISTOR 1 Ohm 1/8W

R832 ERDS1TJ152T ERDS1TJ152T CARBON RESISTOR 1,50 kOhm 1/2W

R835 ERX12SJR22E ERX12SJR22E OXIDE METAL RESISTOR 0,22 Ohm 1/2W

R850 ERQ12HKR68P ERQ12HKR68P FUSISTOR

R856 ERQ12HKR56P ERQ12HKR56P FUSISTOR

R857 ERQ1CKPR47S ERQ1CKPR47S FUSISTOR

R864 ERJ6GEYJ103V ERJ6GEYJ103V SMD RESISTOR 10 kOhm 1/8W

R866 ERJ6GEYJ472V ERJ6GEYJ472V SMD RESISTOR 4,7 kOhm 1/8W

- 44 -

Page 45

Ref. No. TC-20KL03A Part No. TC-29KL03A Part No. Part Name & Description

RESISTORS

R870 ER0S2THF5100 ER0S2THF5100 PRECISION RESISTOR 510 Ohm 1/4W

R871 ERDS1TJ223T ERDS1TJ223T CARBON RESISTOR 22 kOhm 1/2W

R1004 - - - - - o - - - - - ERJ6GEYJ471V SMD RESISTOR 470 Ohm 1/8W

R1016 ERJ6ENF1651V ERJ6ENF1651V PRECISION SMD RESISTOR 1,65 kOhm 1/10W

R1017 ERJ6ENF2151V ERJ6ENF2151V PRECISION SMD RESISTOR 2,15 kOhm 1/10W

R1018 ERJ6ENF3091V ERJ6ENF3091V PRECISION SMD RESISTOR 3,09 kOhm 1/10W

R1019 ERJ6ENF4421V ERJ6ENF4421V PRECISION SMD RESISTOR 4,42 kOhm 1/10W

R1020 ERJ6ENF7501V ERJ6ENF7501V PRECISION SMD RESISTOR 7,50 kOhm 1/10W

R1021 ERJ6ENF1871V ERJ6ENF1871V PRECISION SMD RESISTOR 1,87 kOhm 1/10W

R1022 ERJ6GEYJ100V ERJ6GEYJ100V SMD RESISTOR 10 Ohm 1/8 W

R1 101 ERJ6GEYJ332V ERJ6GEYJ332V SMD RESISTOR 3,3 kOhm 1/8W

R1 104 ERJ6GEYJ562V ERJ6GEYJ562V SMD RESISTOR 5,6 kOhm 1/8W

R1 105 ERJ6GEYJ562V ERJ6GEYJ562V SMD RESISTOR 5,6 kOhm 1/8W

R1 106 ERJ6GEYJ102V ERJ6GEYJ102V SMD RESISTOR 1 kOhm 1/8W

R1108 ERJ6GEYJ101V ERJ6GEYJ101V SMD RESISTOR 100 Ohm 1/8W

R1109 ERJ6GEYJ101V ERJ6GEYJ101V SMD RESISTOR 100 Ohm 1/8W

R1117 ERJ6GEYJ471V - - - - - o - - - - - SMD RESISTOR 470 Ohm 1/8W

R1 120 ERJ6GEYJ432V ERJ6GEYJ432V OXIDE METAL RESISTOR 4,3 kOhm 1/10W

R1 122 ERJ6GEYJ332V ERJ6GEYJ332V SMD RESISTOR 3,3 kOhm 1/8W

R1124 - - - - - o - - - - - ERJ6GEY0R00V RESISTOR SMD

R1130 ERJ6GEYJ101V ERJ6GEYJ101V SMD RESISTOR 100 Ohm 1/8W

R1131 ERJ6GEYJ101V ERJ6GEYJ101V SMD RESISTOR 100 Ohm 1/8W

R1132 ERJ6GEYJ101V ERJ6GEYJ101V SMD RESISTOR 100 Ohm 1/8W

R1140 ERJ6ENF1002V ERJ6ENF1002V PRECISION RESISTOR SMD10 kOhm 1/10W

R1 141 ERJ6GEYJ562V ERJ6GEYJ562V SMD RESISTOR 5,6 kOhm 1/8W

R2022 ERJ6GEYJ104V ERJ6GEYJ104V SMD RESISTOR 100 kOhm 1/8W

R2130 ERJ6GEYJ101V ERJ6GEYJ101V SMD RESISTOR 100 Ohm 1/8W

R2131 ERJ6GEYJ101V ERJ6GEYJ101V SMD RESISTOR 100 Ohm 1/8W

R2134 ERJ6GEYJ101V ERJ6GEYJ101V SMD RESISTOR 100 Ohm 1/8W

R2135 ERJ6GEYJ101V ERJ6GEYJ101V SMD RESISTOR 100 Ohm 1/8W

R2151 - - - - - o - - - - - ERJ6GEYJ392V SMD RESISTOR 3,9 kOhm 1/8W

R2151 ERJ6GEYJ472V - - - - - o - - - - - SMD RESISTOR 4,7 kOhm 1/8W

R2152 - - - - - o - - - - - ERJ6GEYJ392V SMD RESISTOR 3,9 kOhm 1/8W

R2152 ERJ6GEYJ332V - - - - - o - - - - - SMD RESISTOR 3,3 kOhm 1/8W

R2153 - - - - - o - - - - - ERJ6GEYJ392V SMD RESISTOR 3,9 kOhm 1/8W

R2153 ERJ6GEYJ472V - - - - - o - - - - - SMD RESISTOR 4,7 kOhm 1/8W

R2154 - - - - - o - - - - - ERJ6GEYJ392V SMD RESISTOR 3,9 kOhm 1/8W

R2154 ERJ6GEYJ332V - - - - - o - - - - - SMD RESISTOR 3,3 kOhm 1/8W

R2251 ERJ6GEYJ332V ERJ6GEYJ332V SMD RESISTOR 3,3 kOhm 1/8W

R2252 ERJ6GEYJ222V ERJ6GEYJ222V SMD RESISTOR 2,2 kOhm 1/8W

R2253 ERJ6GEYJ102V ERJ6GEYJ102V SMD RESISTOR 1 kOhm 1/8W

R2254 ERJ6GEYJ102V ERJ6GEYJ102V SMD RESISTOR 1 kOhm 1/8W

R2255 ERJ6GEYJ101V ERJ6GEYJ101V SMD RESISTOR 100 Ohm 1/8W

R2256 ERJ6GEYJ273V ERJ6GEYJ273V SMD RESISTOR 27 kOhm 1/8W

R2301 ERJ6GEYJ562V ERJ6GEYJ562V SMD RESISTOR 5,6 kOhm 1/8W

R2304 ERDS2TJ222T ERDS2TJ222T CARBON RESISTOR 2,2 kOhm 1/4W

R2305 - - - - - o - - - - - ERQ2CJP1R2S FUSISTOR

R2310 ERDS2TJ1R0T ERDS2TJ1R0T CARBON RESISTOR 1 Ohm 1/4W

R2318 ERJ6GEYJ332V ERJ6GEYJ332V SMD RESISTOR 3,3 kOhm 1/8W

R2319 ERJ6GEYJ102V ERJ6GEYJ102V SMD RESISTOR 1 kOhm 1/8W

R2320 - - - - - o - - - - - ERJ6GEYJ431V SMD RESISTOR 430 Ohm 1/8W

R2320 ERJ6GEYJ102V - - - - - o - - - - - SMD RESISTOR 1 kOhm 1/8W

R2323 ERJ6GEYJ102V ERJ6GEYJ102V SMD RESISTOR 1 kOhm 1/8W

R2331 ERJ6GEYJ562V ERJ6GEYJ562V SMD RESISTOR 5,6 kOhm 1/8W

R2340 ERDS2TJ1R0T ERDS2TJ1R0T CARBON RESISTOR1 Ohm 1/4W

TC-20KL03A / TC-29KL03A

- 45 -

Page 46

TC-20KL03A / TC-29KL03A

Ref. No. TC-20KL03A Part No. TC-29KL03A Part No. Part Name & Description

RESISTORS

R2348 ERJ6GEYJ332V ERJ6GEYJ332V SMD RESISTOR 3,3 kOhm 1/8W

R2349 ERJ6GEYJ102V ERJ6GEYJ102V SMD RESISTOR 1 kOhm 1/8W

R2354 ERDS2TJ222T ERDS2TJ222T CARBON RESISTOR 2,2 kOhm 1/4W

R2380 ERJ6GEYJ151V ERJ6GEYJ151V SMD RESISTOR 150 Ohm 1/8W

R2381 ERJ6GEYJ102V ERJ6GEYJ102V SMD RESISTOR 1 kOhm 1/8W

R2382 ERJ6GEYJ102V ERJ6GEYJ102V SMD RESISTOR 1 kOhm 1/8W

R2383 ERJ6GEYJ103V ERJ6GEYJ103V SMD RESISTOR 10 kOhm 1/8W

R2385 ERJ6GEYJ222V ERJ6GEYJ222V SMD RESISTOR 2,2 kOhm 1/8W

R2386 ERJ6GEYJ222V ERJ6GEYJ222V SMD RESISTOR 2,2 kOhm 1/8W

R3003 ERJ6GEYJ101V ERJ6GEYJ101V SMD RESISTOR 100 Ohm 1/8W

R3004 ERJ6GEYJ101V ERJ6GEYJ101V SMD RESISTOR 100 Ohm 1/8W

R3005 ERJ6GEYJ184V ERJ6GEYJ184V SMD RESISTOR 180 kOhm 1/8W

R3006 ERJ6GEYJ184V ERJ6GEYJ184V SMD RESISTOR 180 kOhm 1/8W

R3007 ERJ6GEYJ184V ERJ6GEYJ184V SMD RESISTOR 180 kOhm 1/8W

R3008 ERJ6GEYJ184V ERJ6GEYJ184V SMD RESISTOR 180 kOhm 1/8W

R3015 ERJ6ENF3300V ERJ6ENF3300V PRECISION SMD RESISTOR 330 Ohm 1/10W

R3019 ERJ6GEYJ104V ERJ6GEYJ104V SMD RESISTOR 100 kOhm 1/8W

R3020 ERJ6GEYJ104V ERJ6GEYJ104V SMD RESISTOR 100 kOhm 1/8W

R3024 ERJ6GEYJ560V ERJ6GEYJ560V SMD RESISTOR 56 Ohm 1/8W

R3025 ERJ6GEYJ103V ERJ6GEYJ103V SMD RESISTOR 10 kOhm 1/8W

R3132 ERJ6GEYJ471V ERJ6GEYJ471V SMD RESISTOR 470 Ohm 1/8W

R3133 ERJ6GEYJ471V ERJ6GEYJ471V SMD RESISTOR 470 Ohm 1/8W

CHAVES

S801 ESB92DA1B ESB92DA1B POWER SWITCH

S1001 EVQ11G05R EVQ11G05R RADIAL TOUCH SWITCH

S1002 EVQ11G05R EVQ11G05R RADIAL TOUCH SWITCH

S1003 EVQ11G05R EVQ11G05R RADIAL TOUCH SWITCH

S1004 EVQ11G05R EVQ11G05R RADIAL TOUCH SWITCH

S1005 EVQ11G05R EVQ11G05R RADIAL TOUCH SWITCH

S1006 EVQ11G05R EVQ11G05R RADIAL TOUCH SWITCH

TRANSFORMADORES

T552 ZTFN33005A KFT4AA448F FLYBACK

T553 ETH19Y70AYZ ETH19Y70AYZ HORIZONT AL DRIVER

T801 ETS35AG1A6AD ETS39AG3V6AD CHOPPER

TUNER

TNR001 ENV56DD7G3-B ENV56DD7G3-B TUNER

CRYST ALS

X101 M1971M M1971M SAW FIL TER

X183 EFCT4R5MW5 EFCS4R5MW5 CERAMIC FILTER

X601 H0D120500006 H0D120500006 ASSEMBLED PIEZO CRYST AL

- 46 -

Page 47

Ref. No. TC-20KL03A Part No. TC-29KL03A Part No. Part Name & Description

OTHERS

A40-A41 TXAJTA40CB20K TXAJTA40CB20K SHIELDED CABLE

A5-L5 - - - - - o - - - - - TXAJTA5CB29K 5 WAY CONNECTOR

A5-L5 TXAJTA5CB14A12 - - - - - o - - - - - 3 WAY CONNECTOR

A8-L8 - - - - - o - - - - - TXAJTA8CB29K 8 WAY CONNECTOR

A8-L8 TXAJTA8CB20A12 - - - - - o - - - - - 6 WAY CONNECTOR

F801 K5D402BK0004 K5D402BK0004 FUSE

F801-L K3GD9BB00001 K3GD9BB00001 FUSE SUPPORT

F801-R K3GD9BB00001 K3GD9BB00001 FUSE SUPPORT

G26-A26 - - - - - o - - - - - TXAJTA26CB29K 7 WA Y CONNECTOR

G27-A27 - - - - - o - - - - - TXAJTA27CB29K-1 8 WA Y CONNECTOR

JK3001 TJB4G635 TJB4G635 AV TERMINAL

JK3101 TJB4G634 - - - - - o - - - - - FRONTAL AV TERMINAL

JK3101L - - - - - o - - - - - ECJ2VB1H272K SMD CERAMIC CAPACITOR 2,7 nF 50V

JK3101R - - - - - o - - - - - ECJ2VB1H272K SMD CERAMIC CAPACITOR 2,7 nF 50V

JK351 330550044K2F 330550044K2F CRT SOCKET

R19-A19 - - - - - o - - - - - TXAJTA19CB29K 4 WA Y CONNECT OR

A22-SPK TXAJTA22CB20K TXAJTA22CB20K 4 WA Y CONNECTOR - SPEAKER

TC-20KL03A / TC-29KL03A

- 47 -

Page 48

Panasonic da Amazônia S.A.

CS DIVISION - TECHNICAL SUPPORT

Rod. Presidente Dutra, Km 155

São José dos Campos - SP

Loading...

Loading...