Page 1

Specifications

A

A

A

Y

A

Y

V

A

A

PowerSource

PowerConsumption

LCD 1280 × 768 pixels widescreen LCD panel (TC-19LX50, TC-19LE50)

Screen Size 16.3 “ × 9.8 “ ×18.9 “ (413 mm × 248 mm × 481 mm) (TC-19LX50, TC-19LE50)

(W × H × diagonal) 20.0 “ × 11.3 “ ×23.0 “ (508 mm × 286 mm × 583 mm) (TC-23LX50, TC-23LE50)

Channel Capability VHF-12 : UHF-56 : Cable-125

Sound

Speakers Ø5 cm × 2 pcs, 8 W (TC-19LX50, TC-19LE50)

Audio Output 8 W [4 W + 4 W] (10%THD)

Headphones M3 (3.5 mm) Jack × 1

FEATURES 3D Y/C Digital Comb Filter, CLOSED CAPTION, V-Chip

Operating Conditions Temperature : 41 °F - 95 °F (5 °C - 35 °C)

Connection Terminals

INPUT VIDEO (RCA PIN Type ×1) ×2 1.0 Vp-p (75 W)

COMPONENT

IDEO INPUT (including synchronization)

OUTPUT

LCD Television

TC-19LX50

TC-23LX50

TC-19LE50

TC-23LE50

LH44 Chassis

C 120 V, 60 Hz

verage use : 66 W (TC-19LX50, TC-19LE50)

verage use : 83 W (TC-23LX50, TC-23LE50)

Stand-bycondition : 0.11 W

Power off : 0.1 W

1366 × 768 pixels widescreen LCD panel (TC-23LX50, TC-23LE50)

Ø6 cm × 2 pcs, 8 W (TC-23LX50, TC-23LE50)

Humidity: 5 % - 90 % RH (non-condensing)

S-VIDEO (MINI DIN 4pin ×1) ×2

UDIO L-R (RCA PIN Type ×2) ×2 0.5 Vrms

×1 1.0 Vp-p

PB/PR×1 ±0.35 Vp-p

UDIO L-R (RCA PIN Type ×2) ×1 0.5 Vrms

UDIO L-R (RCA PIN Type ×2) ×1 0.5 Vrms

: 1.0 Vp-p (75 W ),

C : 0.286 Vp-p (75 W)

ORDER NO. ITD0503010CE

B05 Canada:B07

© 2005 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

Dimensions ( W × H × D )

Including TV Stand 20.2 “ × 18.1 “ × 10.2 “ (514 mm × 459 mm × 259 mm) (TC-19LX50, TC-19LE50)

24.1 “ × 19.9 “ ×10.2 “ (612 mm × 505 mm × 259 mm) (TC-23LX50, TC-23LE50)

TV Set Only 20.2 “ × 15.6 “ ×4.9 “ (514 mm × 395 mm × 125 mm) (TC-19LX50, TC-19LE50)

24.1 “× 17.4 “ ×4.9 “ (612 mm × 441 mm × 125 mm) (TC-23LX50, TC-23LE50)

Mass (Weight) 8.5 kg (18.7 lb.) NET (TC-19LX50, TC-19LE50)

9.5 kg (20.9 lb.) NET (TC-23LX50, TC-23LE50)

Note:

Design and Specifications are subject to change without notice. Weight and Dimensions shown are approximate.

CONTENTS

Page Page

1 Safety Precautions 3

1.1. General Guidelines

2 Warning

2.1. Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

2.2. About lead free solder (PbF)

3 Location of Controls and Components

4 Service Mode

4.1. How to enter into adjustment mode

4.2. Cancellation

4.3. Contents of adjustment mode

5 Troubleshooting Guide

5.1. Self-check function

6 Disassembly and Assembly Instructions

6.1. Removing the hinge cover

6.2. Removing the pedestal

6.3. Removing the back cover (TC-23LX50/LE50)

6.4. Removing the back cover (TC-19LX50/LE50)

6.5. Removing the tuner cover

6.6. Removing the shield cover

6.7. Removing the button panel and K-board

6.8. Removing the chassis

6.9. Removing the A-Board, AP-Board and Power Unit

6.10. Removing the speaker, and V-Board

6.11. Removing the LCD mount metal

6.12. Removing the LCD panel (TC-23LX50/LE50)

6.13. Removing the LCD panel (TC-19LX50/LE50)

6.14. Removing the LCD fixing metal

6.15. Location of Lead Wiring

7 Measurements and Adjustments

3

3

3

4

5

6

6

6

6

7

7

8

8

8

8

8

8

9

9

9

9

10

10

10

11

11

12

7.1. Video Signal Level Adjustment (RF)

8 Block Diagram

8.1. Block Diagram (1 of 3)

8.2. Block Diagram (2 of 3)

8.3. Block Diagram (3 of 3)

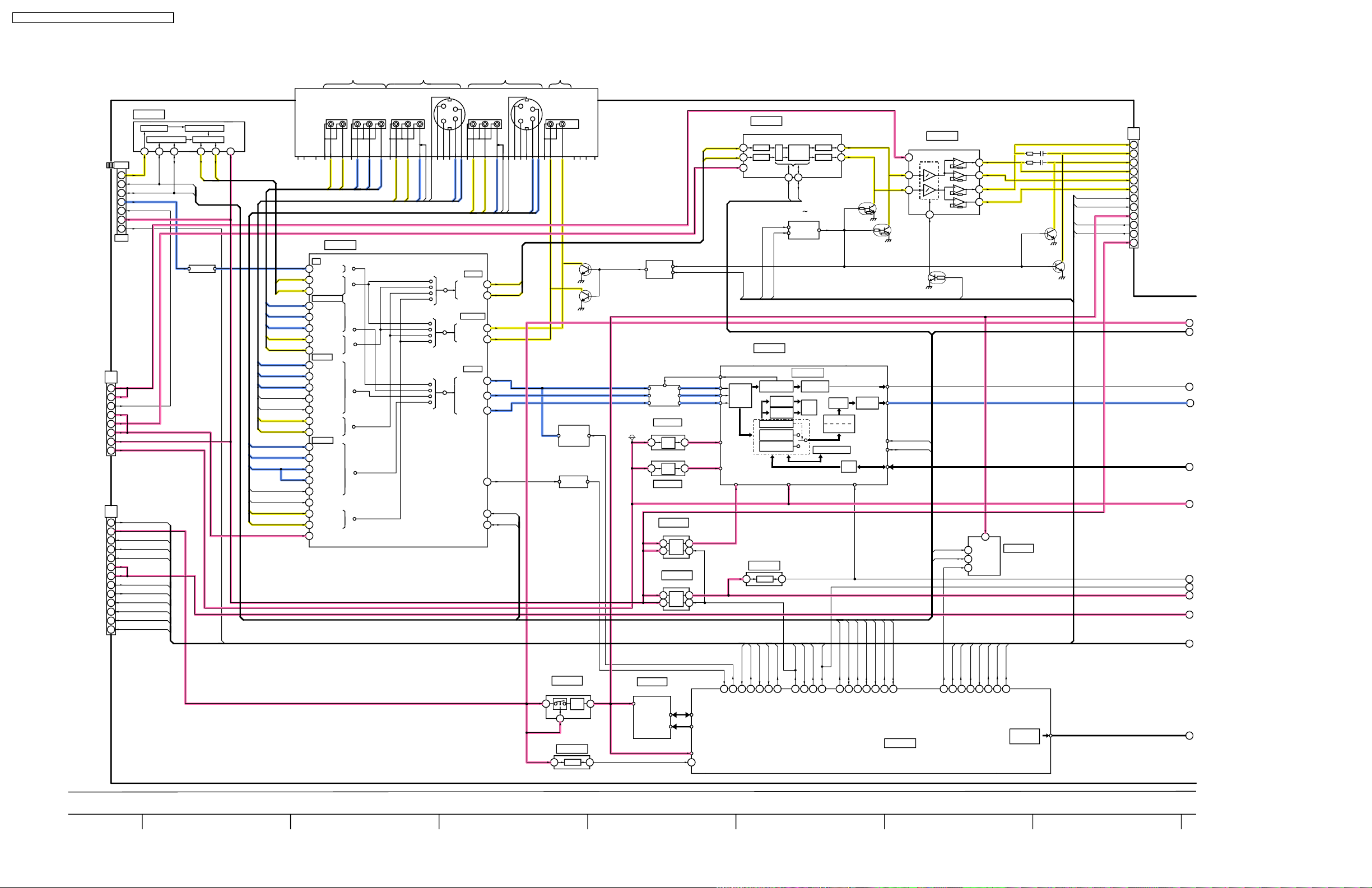

9 Wiring Connection Diagram

10 Schematic Diagrams

10.1. Schematic Diagram Notes

10.2. A-Board (1 of 6) Schematic Diagram

10.3. A-Board (2 of 6) Schematic Diagram

10.4. A-Board (3 of 6) Schematic Diagram

10.5. A-Board (4 of 6) Schematic Diagram

10.6. A-Board (5 of 6) Schematic Diagram

10.7. A-Board (6 of 6) Schematic Diagram

10.8. AP-Board Schematic Diagram

10.9. K-Board and V-Board Schematic Diagram

11 Printed Circuit Views

11.1. A-Board

11.2. AP-Board

11.3. K-Board and V-Board

12 Exploded View and Replacement Parts List

12.1. Parts Layout

12.2. Packing Exploded Views

12.3. Mechanical Replacement Parts List

13 Electrical Parts List

13.1. Electrical Parts List Notes

13.2. Electrical Replacement Parts List

13

13

15

15

16

17

19

21

21

22

23

24

25

26

27

28

29

31

31

34

35

37

37

38

39

40

40

41

2

Page 3

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise hamless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

2.2. About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol

Caution

· Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40°C) higher.

Please use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

· Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb

solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

· After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto

the opposite side. (see figure below)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder.

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

stamped on the back of PCB.

4

Page 4

http://getMANUAL.com

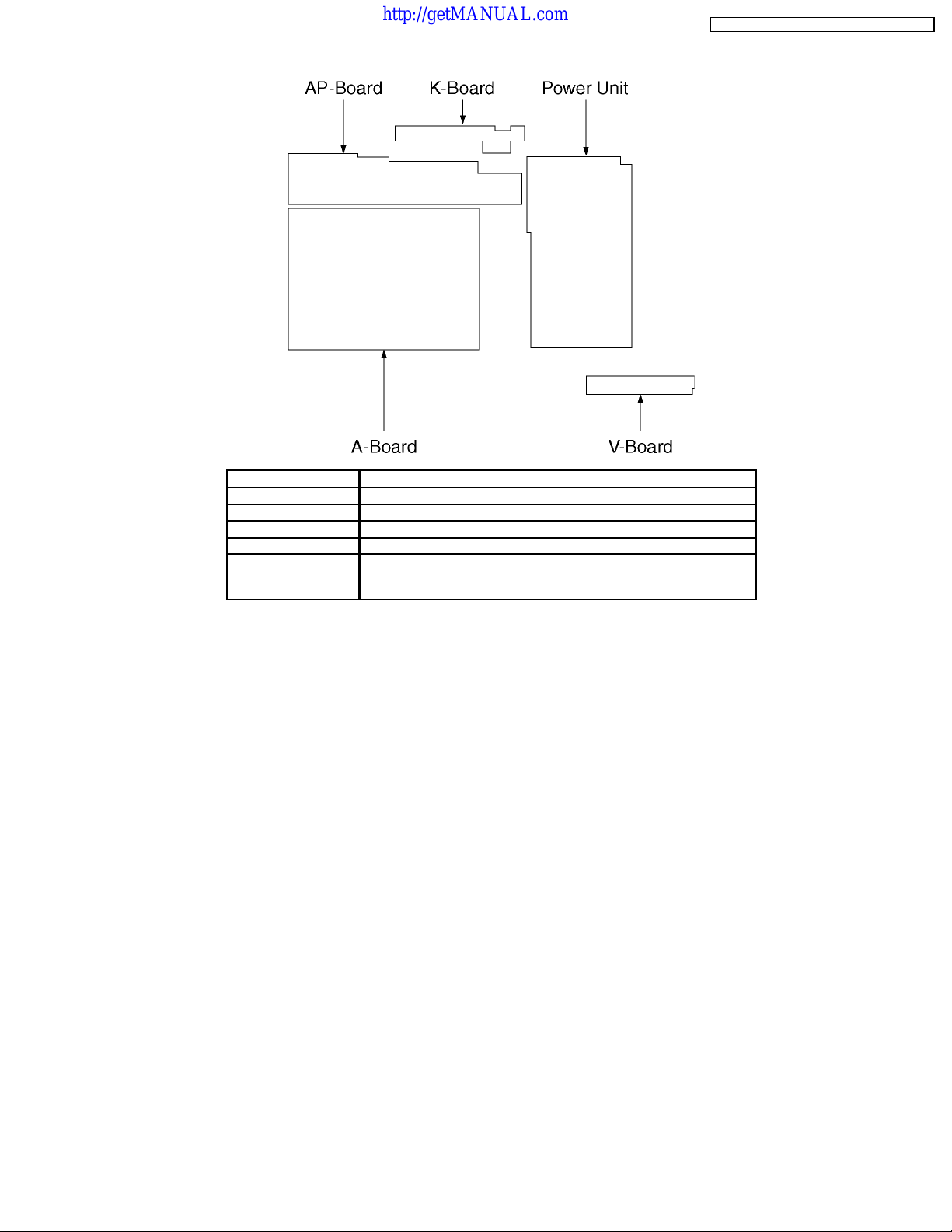

3 Location of Controls and Components

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

Board Name Function

A-Board Main (AV Switch, Audio, MCU, Grobal Core, AV connector )

V-Board Remote Reciever

K-Board Power switch, Control swtich

AP-Board DC-DC

Power Unit Power (AC/DC),

None serviceable.

Power Unit should be exchange for service.

5

Page 5

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

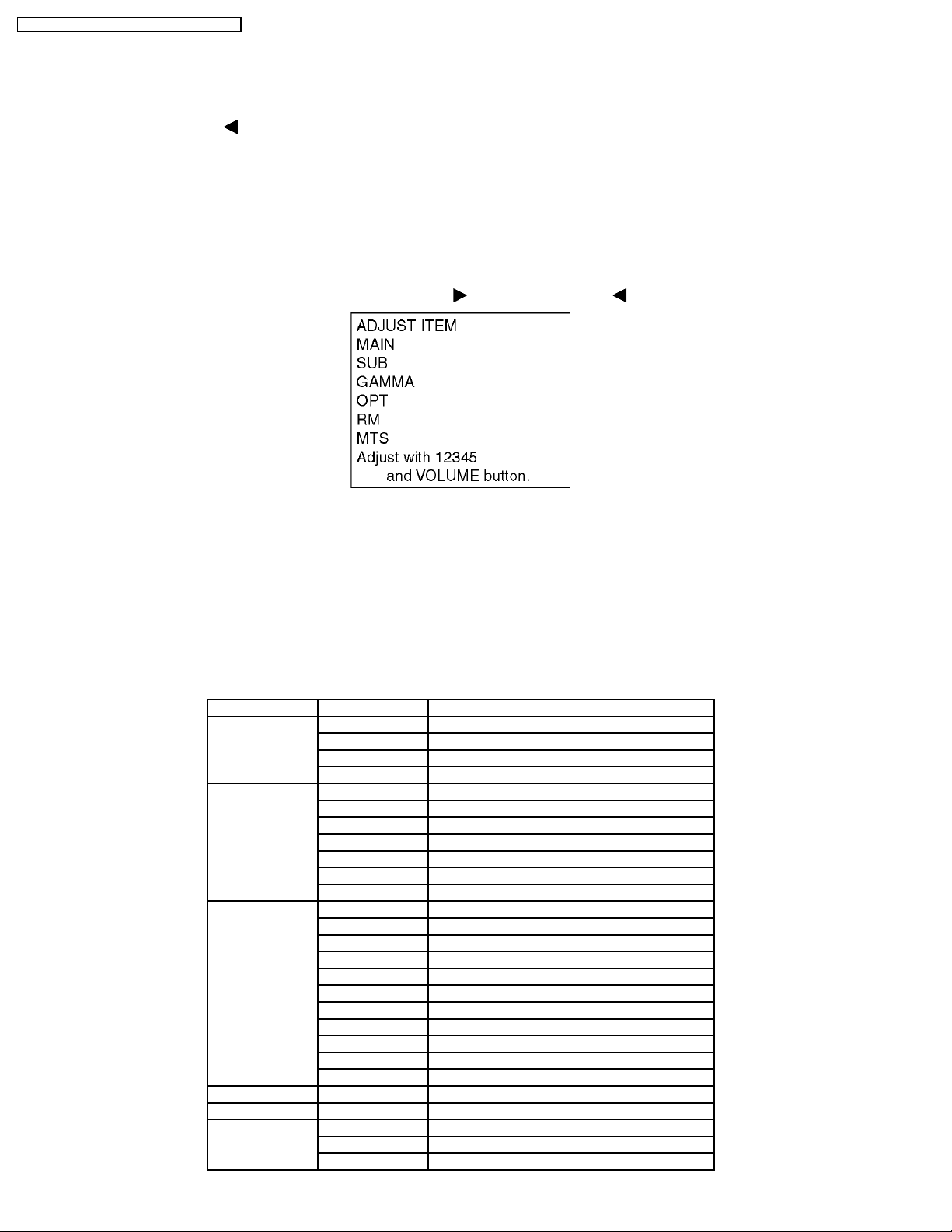

4 Service Mode

4.1. How to enter into adjustment mode

While pressing [VOLUME- ] button of the main unit, press [RECALL] button of the remote control three times in a row (within 2

seconds).

4.1.1. Adjustment method.....Use the remote control.

“1” button...Main items Selection in forward direction

“2” button...Main items Selection in reverse direction

“3” button...Sub items Selection in forward direction

“4” button...Sub items Selection in reverse direction

“VOL” button...Value of sub items change in forward direction (

), in reverse direction ( )

4.2. Cancellation

Switch off the power with the [POWER] button on the main unit or the [POWER] button on the remote control.

4.3. Contents of adjustment mode

· Value is shown as a hexadecimal number.

· Preset value differs depending on models.

· After entering the adjustment mode, take note of the value in each item before starting adjustment.

Main item Sub item Remarks

MAIN YGAIN Video Level (RF, VIDEO, S, COMPONENT)

B-Y Video Level (RF, VIDEO, S, COMPONENT)

R-Y Video Level (RF, VIDEO, S, COMPONENT)

PILEN PILEN Current

SUB COLOR Sub color

TINT Sub tint

BACK-L Sub back light

BRIGHT Sub bright

B-Y-G B-Y Gain

R-Y-A R-Y demodulation axis

TEMP Temp data

GAMMA WHITE Test pattern (100% White)

RED Test pattern (100% Red)

GREEN Test pattern (100% Green)

BLUE Test pattern (100% Blue)

GRAY Test pattern (50% White)

R-GAIN Test pattern (100% White) R-GAIN

G-GAIN Test pattern (100% White) G-GAIN

B-GAIN Test pattern (100% White) B-GAIN

R-CENT Test pattern (50% White ) R-CENT

G-CENT Test pattern (50% White) G-CENT

B-CENT Test pattern (50% White) B-CENT

OPT OPT00 (TV)

RM CODE Remote control code A or B

MTS MTSIN RF Audio input

SEPAH Stereo separation Hi

SEPAL Stereo separation Low

6

Page 6

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

5 Troubleshooting Guide

5.1. Self-check function

When phenomena like "the power fails from time to time" or "the video/audio fails from time to time" can not be confirmed at the

time of servicing, the self-check function can be used to confirm the occurrence and to limit the scope for the defective circuits.Also,

when "the power fails from time to time", display on the screen can be used to confirm the occurrence and to limit the scope for

the defective circuits.

Any programmed channels, channels caption data and some other user defined settings will be erased and return to factory setting.

5.1.1. How to access

5.1.1.1. Access

Produce TV reception screen and, while pressing [VOLUME-] button on the main unit, press [SLEEP] button on the remote

controller unit simultaneously.

5.1.1.2. Exit

When one of the buttons for channel selection etc. is pressed, the display returns to the normal screen.

5.1.2. Screen display

Display Ref No. Description P.C.B

UV TU001A Tuner A-Board

SND IC2301 Sound Control A-Board

AVSW IC3007 AV Switch A-Board

GC3FM IC4023 Global Core Main A-Board

GC4U IC4016 Global Core A-Board

MEM IC1104 EEPROM A-Board

7

Page 7

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

6 Disassembly and Assembly Instructions

6.1. Removing the hinge cover

1. Lay down the unit so that the rear cover faces upward.

2. Remove the screw.

3. Remove the hinge cover.

6.2. Removing the pedestal

1. Remove the 4 screws.

2. Remove the pedestal.

6.4. Removing the back cover (TC19LX50/LE50)

1. Remove the 14 screws.

2. Remove the back cover.

6.5. Removing the tuner cover

6.3. Removing the back cover (TC23LX50/LE50)

1. Remove the 15 screws.

2. Remove the 2 screws.

3. Remove the back cover.

1. Remove the 2 screws.

2. Remove the tuner cover.

8

Page 8

6.6. Removing the shield cover

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

6.8. Removing the chassis

1. Remove the 5 screws.

2. Remove the shield cover.

6.7. Removing the button panel

and K-board

1. Remove the 2 screws.

2. Remove the 2 screws.

3. Remove the button panel.

1. Remove the 5 screws.

2. Disconnect the coupler (A2, A5, AP5 and AP6).

3. Remove the chassis.

6.9. Removing the A-Board, APBoard and Power Unit

1. Remove the 10 screws.

2. Disconnect the coupler (A3-AP3, A4-AP4 and AP1-CN1).

3. Remove A-Board, AP-Board and Power Unit.

4. Disconnect the coupler (K5).

5. Remove the K-Board.

9

Page 9

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

6.10. Removing the speaker, and VBoard

6.11. Removing the LCD mount

metal

1. Remove the 8 screws.

2. Remove the speaker.

3. Remove the 2screw.

4. Disconnect the coupler (V1 and V2).

5. Remove the V-Board.

1. Remove the 5 screws.

2. Remove the LCD mount metal (bottom).

3. Remove the screw.

4. Remove the LCD mount metal (top).

6.12. Removing the LCD panel (TC23LX50/LE50)

1. Remove the 2 screws.

2. Remove the LCD panel.

10

Page 10

6.13. Removing the LCD panel (TC19LX50/LE50)

1. Remove the 14 screws.

2. Remove the LCD panel.

6.14. Removing the LCD fixing

metal

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

1. Remove the 4 screws.

2. Remove the LCD fixing metal (L/R)

11

Page 11

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

6.15. Location of Lead Wiring

12

Page 12

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

7 Measurements and Adjustments

7.1. Video Signal Level Adjustment (RF)

Instrument Name Connect to Remarks

1. Remote controller

2. RF signal

3. SG

1. Receive studio color bar by RF signal input.

(Viewing mode: standard, LCD AI: OFF, Back Light: +30 )

2. In service mode choose adjust item then press remote button 1 into main mode then press remote 3 into Y Gain and press

remote button “8” to do auto adjustment.

3. Press remote button “2” go back main menu.

RF in

13

Page 13

8 Block Diagram

8.1. Block Diagram (1 of 3)

http://getMANUAL.com

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

K-BOARD

SW3805

R3818

R3821

SW3804

VOLVOL

K5

2

KEYSCAN

3

RELAY

4

STB+5V

5

MAIN_SW_DET

6

+5VS

R3816

SW3808

R3817

SW3806

CH

PUSH

R3815

SW3803

A

TV/VTR

SW3807

CH

POWER SWITCH

AP-BOARD

AP6

2

3

4

MAIN_SW_DET

5

6

MAIN+9V

Q861

Q862

2

2

7.5V(PANEL_5V OVP)

DC-DC ON/OFF

D869

D873

11V(SUB_9V OVP)

D872

D876

D882

D884

D890

D889

R913

L:NORMAL

H:ABNORMAL

Q865

+30V(BT)/+5V(P)

SHORT DET

Q864

SOS DET

IC851

SUB+9V

1

AVR

KEY

IC854

PANEL+5V

AVR

1

5

Q856

PANEL 5V ON/OFF

Q857

R910

B

D879

R891

R896

R900

Q859

R892

D887

POWER UNIT

RC1

R3

0.1

D14

D11

D13

D12

RECTIFIER

1

2

SWITCHING REG

+

C6

330u

R9

DRIVE

CONTROL

Z2

4

3

D7

D6

22K

4

OSC

5

3

D10

D8

DD1

STBY 5V

GENE

COLD

C

D

AC CORD

2

1

CN1

HOT

COLD

SWITCHING TRANS

D17

6

5

HOT

T2

7

6

D24

4

D5

1

2

D18

C12

47u

RL1

5V

+

C21

1000u

HOT

C13

2200p

15

13

12

D9

COLD

RC3

RC2

PC2

FEED BACK

POWER ON/OFF

+32V

+

C23

220u

+24V

+++

+

C17

100u

R14

1K

R14

150

Q2

C19

C18

100u

100u

+32V

RELAY

+5VS

AP1

19

1

2

3

4

14

13

11

CN2

1

19

+24V(INV)

18

D23

D21

R19

1K

R18

2.2K

+24V(INV)

17

+24V(INV)

16

+24V(INV)

6

7

9

POWER_ON

IC855

Q869

R932

R930

R931

Q868

D886

SOUND+10V

AVR

1

5

Q854

DC-DC ON/OFF

IC853

SUB+5V

1

2

AVR

R933

2

BT_30V

R935

Q870

R934

13V(SOUND_10V OVP)

MAIN+3.3V

1

D871

R936

R937

D877

D878

IC852

AVR

5

Q855

DC-DC ON/OFF

D875

7.5V(SUB_5V OVP)

2

DC-DC ON/OFF CONTROL

Q866

TO

LCD PANEL

(INVERTER)

Q867

AP3

4

5

9

13

15

18

20

22

AP4

1

3

MAIN_SW_DET

KEY

INV_SOS

INV_ADIM

INV_PWM

INV_ON

INV_ON

INV_PWM

INV_SOS

INV_ADIM

1417131812

11

4

1

2

+24V(INV)

+24V(INV)

+24V(INV)

5143

+24V(INV)

+24V(INV)

INV_SOS

INV_ON

INV_ADIM

INV_PWM

AP4

6

7

8

10

11

13

14

15

16

E

TC-19/23LX50, TC-19/23LE50

Block Diagram (1/3)

TC-19/23LX50, TC-19/23LE50 Block Diagram (1/3)

2

746

81 53

15

Page 14

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

8.2. Block Diagram (2 of 3)

TUNER

UV IN

S_CLOCK

S_ DATA

VIDEO

BT30V

5V(S)

SOUND_10V

SOUND_10V

BT_30V

SUB_9V

MAIN_9V

SUB9V

SUB_5V

MAIN_3.3V

TV_SOS

STB_5V

MAIN_ON

MAIN_SWDET

SUB_ON

PANEL_5V

PANEL_5V

KEY

INV_SOS

PANEL_ON

INV_ADIM

INV_PWM

INV_ON

TU001

SIF

AFT

A-BOARD

14

10

11

17

15

3

12

A3

4

5

9

13

15

18

20

22

A4

1

3

6

7

8

10

11

13

14

15

16

17

18

IC2202

SIF

SCL

SDA

VIDEO

BTL

+B

AFT

FILTER

14

TV_SOS

MAIN_ON

MAIN_SW

SUB_ON

INV_SOS

PANEL_ON

INV_ADIM

INV_PWM

INV_ON

MTS DEMODULATER

IIC

19 22

18

SCL1

SDA1

KEY

DEMODU

21

Q001

BUFFER

MATRIX

L

TV-L

COMPONENT

PR

PB

D1_PR

PRGLRG

AV SW

D1_PB

Y

PB

D1_Y

L

R

+5V(M)

R

7

TV-R

NCNCNC

D1_R

D1_L

IC3001

TV

U/V-V

24

TV-L

TV-R

D1-Y

D1-PB

D1-PR

D1-L

D1-R

V1-Y

V1-V

V1-C

V1_DET

V1-S

V1-L

V1-R

V2-Y

V2-V

V2-C

V2_DET

V2-S

V2-L

V2-R

AFT

V

21

L

22

R

COMPONENT

26

Y

28

PB

30

PR

27

L

29

R

VIDEO1

8

Y

V

2

6

C

33

V1 DET

S DET

7

4

L

5

R

VIDEO2

14

Y

10

V

12

C

44

S2 DET

19

V2 DET

13

S DET

9

L

11

R

57

+9V(S)

VIDEO1

AV1

C

V

L

R

Y

V1_L

V1_R

V1_V

V1_DET

V1_S

Y

C-GGV-SWVLRG

V1_C

V1_Y

MONITOR

S CLOCK

S DATA

AUDIO

L-OUT

R-OUT

L-OUT

R-OUT

VIDEO

VIDEO2

V

L

R

V2_V

V2_S

V2_L

V2_DET

V2_R

MAIN-L

49

MAIN-R

51

39

40

54

V/Y

C/Pb

56

Pr

64

52

SY

SCL1

59

SDA1

61

MONITOR

AV2

C

R

Y

C-GGV-SWVLRGCYGY-G

V2_C

V2_Y

IR

OUT

MONITOR

L

NCNCLRGCYGY-G

NC

Q3002

AUDIO DEF

JK3001A

NC

Q3003

AUDIO DET

Q3001

AUDIO

DEFFET

CONTROL

MAIN-L

MAIN-R

IC2301

SOUND CONTROL

L AMP

1

R AMP

2

26

+9V(M)

MAIN_SW

MON_DEF

BASS

TREBLE

VOL

BLANCE

30 31

SDA1

SCL1

Q2303 Q2306,

Q2312,Q2314

MUTE

CIRCUIT

MUTE

L OUT

R OUT

25

24

Q2311

MUTE(R)

Q2310

MUTE(L)

1

6

8

Q1107

INV

IC2302

AUDIO OUT

+11V(SOUND)

AMP

9

ADJ

C2323

16V

100u

R2329

R2333

C2326

16V

Q2308

HP MUTE(L)

Q2307

HP MUTE(R)

+

+

100u

G_LED

R_LED

RM

AI

L(+)

2

L(-)

4

R(+)

12

R(-)

10

VOL

A2

2

SP(R+)

7

HP(R+)

6

HP(L+)

5

SP(L+)

3

SP(L-)

4

SP(R-)

10

LED G

11

LED R

12

STB+3.3V

13

REMOTE

15

16

+5V(S)

AI

1

2

IC4023

DIGITAL CORE, 3D Y/C SEP

IC4032

Q4045-Q4047

Q4022-Q4024

IC1103

STB+3V

1

5

IC1102

2

CVBS

FILTER

SELECT

H:fc 30MHz

L:fc 14MHz

CC

CIRCUIT

RESET

Q4006-Q4014

MAIN3.3V

CLAMP

CIRCUIT

IC4021

AD+2.5V

5

5

IC4020

PLL+2.5V

AVR

AVR

IC4029

MAIN+2.5V

1

AVR

8

V/Y

C/Pb

Pr

4

4

2

5

(10bit)

2.5V(AD)

2.5V(PLL)

+2.5V(M)

A/D

IC4024

IC4030

MAIN+1.8V

1

2

AVR

8

5

IC1105

FLASH MEMORY

AVR

2

4

+3.3V(STB)

DATA

ADR

125

DATA_I/O

ADDRESS

STB+3.3V

RESET

78

RESET

51

INV_ON

INV_SOS

MAIN_SW

110

105

115

89

CC

INV ON

MAIN SW DET

CVBS FLTR ON/OFF

CLAMP

ID1/ED2

MOVE DET

2D

Y/C SEP

3D

Y/C SEP

KEY

97

KEYSCAN

INV SOS

SELF

WIDE

DET

+3.3V(M)

SUB_ON

22

AC ON

GC3FM

SYNC SEP

DET

TV_SOS

MAIN_ON

111

21

MAIN ON

LINE MEMORY

AFT

96

15

AFT

TV SOS

CHROMA

LUMINANCE

PANEL_ON

PANEL5V_ON

SKEW

DEMODU

PROCESS

SCL0A

56

S CLOCK0A

I/F

55

RESET

SDA0A

S D ATA0A

DIGITAL

I/F

S_CLOCK2

SCL0B

24

S CLOCK0B

S_DATA2

SDA0B

23

S D ATA0B

CLK

HS/VS

YUV

(10bit)

SCL2

SDA2

8

109

EEPROM WP

VOL

MON_DEF

92

VOL

6

5

7

MUTE

MON DEF

STB_3.3V

SCL

SDA

WP

AI

66

91

A MUTE

RM

102

REMOTE

AI SENSOR

R_LED

26

27

LED R

IC1104

EEPROM

G_LED

LED G

OSD OUT

(16bit)

OSD DATA

16bit

HV/CLK

SCL0A

SDA0A

SRQ

SCL1

SDA1

117

116

60

SRQ

S DATA1

S CLOCK1

114

IC1103

3

4

5

6

7

8

9

10

11

12

MCU

TC-19/23LX50, TC-19/23LE50 Block Diagram (2/3)

8

11 159 1410 12

16

TC-19/23LX50, TC-19/23LE50 Block Diagram (2/3)

13

Page 15

8.3. Block Diagram (3 of 3)

V-BOARD

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

V1

2

7

6

5

3

4

10

11

12

13

15

16

1

2

3

4

5

6

7

8

9

R(+)

R_hp(+)

L_hp(+)

L(+)

L_ch(-)

R_ch(-)

SN1001

C.A.T.S. SENSOR

R1031

R1032

R LED DRIVE

REMOTE CONTROL SENSER

R1005

AVR

1

5

SDRAM PLL 1.8V

Q1008

RM1001

VOUT

IC4025

V2

L_ch(+)

Q1002

VCC

G

2

1

3

2

Q1004

G LED DRIVE

D1008

G

R

POWER LED

Q1007

AVR

1

2

5

IC4026

L_ch(-)

R_ch(-)

R_ch(+)

L_ch(+)

L_hp(+)

R_hp(+)

R_ch(+)

1

SPEAKER(L)

2

3

SPEAKER(R)

4

7

6

L(+)

2

3

4

R(+)

5

1

JK1001

HEADPHONE

SYNC

DIGITAL

I/F

SDRAM PLL 1.8V

DDIF/OUT PLL 3.3V

FIFO

IC4027

64M SDRAM

I/F

SCL2

SDA2

S_DATA2

PIXEL CONV

S_CLOCK2

V-SCALEH-SCALE

INTERFACE

SDRAM

ADDRESS DATA

+3.3V(M)

IC4014

LCD PROCESSOR

I/F1

FACTORY USED

GC4U

V-POS

NR

SDRAM

I/F2

RESET

S DATA0B

S CLOCK0B

S CLOCK0A

SRQ

STBY+5V

A16

16547272

SRQ

SCL0B

SDA0B

SCL0A

LCD AI

HPK

Y GAMMA

CORR

RGB

MATRIX

OSD MIX

OSD

RGB GAMMA

I/F

CORR

3.3V(M)

1.8V(M)

16bit

HV/CLK

OSD DATA

S D ATA0A

SDA0A

LCD I/F

FACTORY USED

APWM

PWRPWM

BACK

LIGHT

PWM

LCD MUTE

A17

SRQ

INV_ADIM

INV_PWM

R/G/B

(8bit)

CLK

HS/VS

SRQ

S CLOCK1

SCL1

S DATA1

S DATA2

S CLOCK2

654

SDA2

SCL2

SDA1

LCD PANEL

IC4028

LVDS DRIVER

TTL

PARALLEL

DATA

LVD S

CONV

+3.3V

BUFFER

RX0-

RX0+

RX1-

RX1+

RX2-

RX2+

RXCLK-

RXCLK+

RX3-

RX3+

LCD PANEL

A5

2

4

6

8

10

12

14

16

18

20

26

27

28

29

30

RXCLK-

RXCLK+

RX3-

RX3+

+5V(P)

+5V(P)

+5V(P)

+5V(P)

+5V(P)

RX0-

RX0+

RX1-

RX1+

RX2-

RX2+

CN11

2

4

6

8

10

12

14

16

18

20

26

27

28

29

30

PANEL CONTROLLER

DDIF/OUT PLL 3.3V

10

11

12

TC-19/23LX50, TC-19/23LE50 Block Diagram (3/3)

1816 17 21 22 232019

17

BACK LIGHT

INVERTER

2145131211143

CN1

INV_ON

INV_PWM

INV_SOS

+24V(INV)

INV_ADIM

+24V(INV)

+24V(INV)

+24V(INV)

+24V(INV)

TC-19/23LX50, TC-19/23LE50 Block Diagram (3/3)

Page 16

9 Wiring Connection Diagram

A

SPEAKER(L)

SPEAKER(R)

B

V2

12L_ch(+)

L_ch(-)

R_ch(-)

3

4

R_ch(+)

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

V-BOARD

GND

R(+)

L_hp(+)

R_hp(+)

L(+)

L_ch(-)

R_ch(-)

V1

3

A2

GND

10

713

59612412 8 14

G_LED

11

11

R_LED

12 151013

STB_3.3V

GNDAIREMOTE

SUB_5V

16327

14869514

15

16

A16

STBY+5V

1

2

SRQ

GND

A-BOARD

S CLOCK0B

S DATA0B

S CLOCK0A

S DATA0A

3

4

5

6

7

8

FACTORY USED

A17

S CLOCK1

S DATA1

S CLOCK2

S DATA2

1

2

SRQ

GND

3

4

FACTORY USED

5

6

7

C

SOUND_10V

GND

GND

GND

SOUND_10V

GND

618211413 239171521112 2219514 207161038

BT_30V

GND

SUB_9V

GND

GND

GND

GND

MAIN_9V

K-BOARD

GND

A3

AP3

K5

AP6

GND

1

1

KEYSCAN

2

2

RELAY

3

3

STBY5V

4

4

ALLOFF

5

5

5VS

6

6

D

CN2

POWER UNIT

E

AC CORD

CN1

AC120V

1

2

AC120V

AP1

1

19

24V

2

18

24V

3

17

24V

4

16

24V

GND

5

15

GND

6

14

7

13

GND

8

12

GND

9

11

10

10

AC ON

11

9

12

8

13

7

STB 7V

14

6

RELAY

GND

15

5

GND

16

4

GND

17

3

18

2

GND

19

1

33V

AP-BOARD

MAIN_3.3V

GND

GND

GND

SUB_5V

GND

TV_SOS

STB_5V

GND

MAIN_ON

MAIN_SWDET

SUB_ON

A4

32710 1611 17 19

GND

AP4

PANEL_5V

GND

PANEL_5V

INV_SOS

INV_ON

ZERO_X

PANEL_ON

KEY

INV_ADIM

1312 15 2320821622514914

GND

INV_PWM

GND

GND

18 19321

GND

2225 2021193141379 1715 1812623164108111222 5 20 21193141379 1715 1812623164108111

RX0(-)

A5

214

1

2

RX1(+)

RX2(-)

RX0(+)

RX1(-)

5227

623

520

GND

126

10 26

8

911

101

12

82411

RX2(+)

134

13

GND

GND

RXCLOCK(-)

15 2516

164

15

RXCLOCK(+)

17

AP5

1

1

24V

2

2

24V

3

3

24V

4

4

24V

5

5

24V

6

6

GND

7

7

INV_SOS

INV_ON

INV_ADIM

INV_PWM

GND

8

8

GND

9

9

GND

10

10

GND

11

11

12

12

13

13

14

14

LCD PANEL

LVDS OPTION

RX3(-)

GND

GND

RX3(+)

18

20

21193

18

GND

GND

GND

GND

22

23 24

25

+5V(P)

27

27

+5V(P)

28

2814 2679 17

+5V(P)

29

29

+5V(P)

30

30

+5V(P)

TC-19/23LX50, TC-19/23LE50

Wiring Connection Diagram

TC-19/23LX50, TC-19/23LE50

Wiring Connection Diagram

3

42 8

5

61

7

19

Page 17

10 Schematic Diagrams

10.1. Schematic Diagram Notes

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

21

Page 18

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

10.2. A-Board (1 of 6) Schematic Diagram

SDA1

*R2208

A-BOARD (1/6)

A

B

C

D

E

TXN/A10LFM (TC-19LE50/LX50)

TXN/A10LEM (TC-23LE50/LX50)

AS_L+

AS_R+

AS_RHP

AS_LHP

AS_L-

AS_R-

AK_MAIN_SW_DET

PANEL_5V

D2309

MAZ80330HL

0

0.6

R2381

1k

R2383

10k

AL_A_MUTE

AL_A_MON_DEF

2SD0602ASL

R2382

100k

Q2313

2SD0602ASL

0

Q2312

C2323

C2326

100u

16V

16V

100u

+

+

R2329

R2333

56

56

1/2W

1/2W

IC2302

SUB9V

+

C2367

35V

10u

*JS2307

9.9

0

0

Q2304

UNR221100L

0

Q2303

2SC584500L

0

R2303

1k

R2304

1k

9.9

0

R2305

22k

R2306

100k

R2307

0

0

R2310

2.2k

0

Q2305

9.9

2SA207700L

0

A_MUTE

9.9

10k

D2301

MA2J11100L

R2308

100k

R2313

100k

9.9

R2314

MA2J11100L

JS2306

Q2306

2SA207700L

9.9

D2305

MA2J11100L

0

1M

D2304

R2320

470

R2321

470

Q2309

UNR221100L

MAIN9V

+

C2305

Q2307

2SD0602ASL

0.2

C2310

0

16V

0.01u

0

0.2

0

0

Q2308

2SD0602ASL

0

0

0

SCL1

SDA1

R2318

22

R2315

22

C2309

16V

0.01u

16V

47u

5.200.6

5.2

0.2

30

SCL31SDA32GND

IC2301

1Lin

2Rin

3 ADDout

4.5

4.5

4.5

4.504.5

R2325

4.7k

C2315

5600p

16V

AK_MAIN_L

AK_MAIN_R

R2311

5.6k

R2316

24k

R2312

5.6k

R2317

24k

C2303

10V

Lch_IN

10u

NP

C2301

1800p

50V

C2304

10V

RcH_IN

10u

NP

C2302

1800p

50V

C2346

10V

0.1u

C2368

10V

0.1u

R2347

2.2

C2314

16V

0.01u

R2326

1k

R2324

33k

28

29

PORT

4 Bout

5 Sout

C2369

10V

0.1u

C2320

10V

1u

10V

4.7u

C2318

4.5

9.0

26

27

Vcc

ADJ

Vref

SOUND CTRL

6 ADDin

7 DIFin

4.5

C2324

10V

0.1u

R2330

2.2

C2325

C2370

4.5

4.5

8SWin

4.5

4.5

10V

0.1u

10V

0.1u

R2331

2.2

Q2310

UNR221100L

*R2336

43k:TC-19LE50/LX50

56k:TC-23LE50/LX50

C2329

330p

25V

*R2337

82k:TC-19LE50/LX50

75k:TC-23LE50/LX50

4.5

4.5

23

24

Rout25Lout

SWout

C1BB00000800

9 HPout

10 HPin

11 PeqL11

4.5

4.5

R2335

100k

*C2330

*C2335

0.022u

16V

R2339

C2333

10V

0.1u

C2371

SOUND_10V

10V

0.1u

R2338

2.2

C2342

0.01u

16V

R2343

68k

R2344

270k

0

0

0

Q2311

UNR221100L

*R2345

43k:TC-19LE50/LX50

56k:TC-23LE50/LX50

C2337

25V

330p

C2334

25V

330p

C2340

330p

25V

75k:TC-23LE50/LX50

82k:TC-19LE50/LX50

*R2342

4.5

4.5

4.5

4.5

4.5

PeqR2118PeqR2219PeqL3120PeqL3221PeqR3122PeqR32

12 PeqL12

13 PeqR11

14 PeqR12

15 PeqL21

16 PeqL22 17

4.5

4.5

4.5

4.5

4.5

R2340

*R2348

100k

82k

*C2341

0.022u

16V

68k

C2344

820p

0.022u

25V

16V

*C2338

0.022u

16V

R2346

68k

L-OUT

VCC2OUT1+3GND4OUT1-5STBY6IN17GND8IN29VOL10OUT2-11GND12OUT2+

1

10.0 3.9 0 4.0 6.6 1.4 0 1.3 0 3.9 0 3.9

+

C2347

16V

220u

*R2352

2k

0

0

0

*R2350

47k

*R2367

C2343

25V

820p

C2350

820p

25V

*R2351

47k

10k

C2349

25V

820p

*C2355

16V

*R2349

2.2u

82k

*R2302

1k

*R2364

10k

*C2356

16V

2.2u

AN17822A

L-IN

+

C2353

16V

10u

C2354

16V

2.2u

R2353

6.8k

C2365

16V

2.2u

*C2364

16V

0.01u

*R2373

18k

*R2377

3.3k

*R2363

10k

R2354

0

R2355

0

R2356

0

R2357

0

R2384

0

R2385

0

R2386

0

R2387

0

AUDIO OUT

R-IN

C2360

16V

2.2u

*R2358

2k

R2359

6.8k

C2366

16V

2.2u

+

*C2307

16V

47u

9.1

4.5

4.5

4.5

*R2371

4.3k

+

*C2306

16V

10u

*R2376

47k

STB3.3V

C2362

10V

4.7u

R2360

2.2k

*IC2303

C0ABBA000073

8

VCC

7

6

+

VAO

*R2365

10k

R-OUT

*C2361

16V

0.018u:TC-23LE50/LX50

0.01u:TC-19LE50/LX50

4.5

1

2.9

2

-

4.5

3

0

45

GND

*R2301

1k

*C2359

16V

0.018u:TC-23LE50/LX50

0.01u :TC-19LE50/LX50

R2322

100

*R2374

18k

*R2368

*R2378

10k

3.3k

*C2358

*R2372

16V

4.3k

2.2u

+

*R2366

*C2308

10k

16V

10u

*C2357

*R2375

16V

47k

2.2u

2.2k

50V

+

0.1u

*C2219

*C2220

*C2201

16V

0.01u

3.2

2.0

14

MPX IN

SAP DET

11 SPEC DET

12 NOISE DET 13

2.6

2.1

0.1u

0.1u

*C2217

*C2218

50V

50V

SDA1

R009

22

C010

10V

0.1u

R006

0

0.47u

*C2221

16V

10u

15

PILOT DET

10 SPEC TIME

+

3.3u

*C2216

16V

10V

10V

*C2222

3.8

3.7

16

PLL17GND18SCL19SDA

9 SPEC FILTR

2.3

0.3

*C2215

0.022u

16V

SCL1

R010

22

*C008

16V

0.22u

TUNER5V_1

R003

270

2SB0709A0L

22

22

0.047u

*R2210

*R2209

5.2

0

7VCC

8WB DET

5.3

0

+

1u

*C2214

10V

3.3

0

1k

1k

*R2211

*R2212

2.1

2.1

2.1

0

2.1

5.2

20PE21

23

24

L OUT22R OUT

*IC2202

AN5829S-E1V

MTS

123

4 OFFCAN1

5 OFFCAN2

6 WB TIME

0.2

10u

25V

*C2213

*R001

2.7

1.6

2.1

2.1

2.2

2.1

2.2u

4.7u

6.3V

*C2212

10V

*C2211

1k

+

*C014

6.3V

100u

R004

330

JS2201

ERJ3GEY0R00V

NC_(SIF-OUT)

TUNER

*TU001A

ENG36A16GF

<

AGC_ADJ

+B_(5V)

(BT)

(RF-AGC)

(IF_OUT)

AUDIO-OUT

BTL_(30V)

AGC_CONT

VIDEO_OUT

TUNER5V_1

NC

1

2

3

NC

4

NC

5

NC

6

7

8

9

SCL

10

SDA

11

AFT

12

13

14

15

16

17

Q001

SCL1

AU_RFAGC1_ADJ

*JS001

TV1_L

TV1_R

TUNER5V_1

L001

47u

+

+

C003

6.3V

C001

10V

0.1u

*C004

2.2u

C009

50V

0.1u

680u

C002

6.3V

680u

6.3V

BT30V

+

C011

35V

10u

TV1_V

1

2

3

F

TC-19/23LX50, TC-19/23LE50

A-Board (1/6) Schematic Diagram

1

AH_GLED

AH_RLED

C2345

10V

0.1u

SUB5V

4

AK_VOL

AK_RM

AL_AI_SENSER

3.3

0.802.4

5.0

AI

GND

SUB_5V

REMOTE

STB_3.3V

2

3

4

5

AS_RHP

0.300

3.0

0

10111213141516

GND

HP_R

G_LED

R_LED

MODEM_LED

6897

AS_LHP

0.4

AS_R+

AS_R-

AS_L-

AS_L+

0

3.9

3.9

3.9

3.9

HP_L

123456789

A2

L+

R_ch(-)+L_ch(-)

TO

R+

V-BOARD

S_GND

(V1)

TC-19/23LX50, TC-19/23LE50

A-Board (1/6) Schematic Diagram

5

6

22

Page 19

10.3. A-Board (2 of 6) Schematic Diagram

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

1

2

TO

AP-BOARD

A-BOARD (2/6)

(AP3)

A3

GND

123456789

000

10.0

SOUND_10V

10.000

SOUND_GND

SOUND_GND

GND

GND

SOUND_10V

UNREG_30V

GND

BT_30V

101112

34.0

31.70005.009.10000

MAIN_9V

SUB_9V

ODU_15V

GND

GND

1314151617181920212223

TXN/A10LFM (TC-19LE50/LX50)

10V

C4299

0.1u

75

1%

180k

180k

1%

180k

R3086

180k

R3125

180k

R3158

75

1%

MAZ81400ML

SOUND_10V

JS4021

BT30V

MAIN9V

0.1u

0.1u

0.1u

C4411

C4409

C4413

10V

10V

10V

10V

10V

10V

0.1u

0.1u

0.1u

10V

10V

C4414

C4412

C4410

C4301

0.1u

0.1u

R4390

R4391

R3151

C3134

1u

75

1%

16V

R3150

R3137

R3136

C3135

R3152

1u

75

1%

16V

R3074

10k

D3011

MAZ81400ML

R3178

75

R3176

R3177

180k

D3007

MAZ81400ML

D3009

MAZ81400ML

D1_Y

C3091

6.3V

10u

R3159

75

1%

D3036

MAZ81400ML

10

10

C3064

16V

0.01u

R4392

R4393

D3025

MAZ81400ML

D3024

MAZ81400ML

R3144

75

1%

R3145

75

1%

D3023

MAZ81400ML

D3022

MAZ81400ML

10

10

R4394

10

10

R4395

D3019

MAZ81400ML

D3015

MAZ81400ML

C3111

1u

C3115

1u

TXN/A10LEM (TC-23LE50/LX50)

10V

10V

10V

C4297

C4302

C4300

C4298

0.1u

0.1u

0.1u

IR

*JK3001A

K1U936A00001

MONITOR

OUT

AV2

C

AV1

C

3

4

NC

NC

NC

NC

L

L

R

R

G

C

Y

G

Y

Y-G

C-G

G

V-SW

V

V

L

L

R

R

G

C

Y

G

Y

Y-G

C-G

G

V-SW

V

V

L

L

R

R

G

Y

Y

PB

PB

PR

PR

G

L

L

R

R

G

NC

NC

NC

D1_PB

D1_PR

C3101

10V

R3160

75

1%

C3096

1u

D3034

MAZ81400ML

10V

1u

D3037

0

C4303

MAZ81400ML

10V

10V

0

JS4022

SUB9V

0

JS4019

MAIN9V

+

C4150

16V

47u

BASUB9V

0.1u

C4304

C4405

10V

10V

10V

10V

10V

0.1u

C4415

C4305

0.1u

0.1u

0.1u

C4306

10

R4396

10

R4397

MON_L

MON_R

R3075

10k

C3065

D3012

16V

0.01u

D1_L

D1_R

SUB_5V

BAGND

GND

BASUB9V

GND

J0JHC0000078

0.1u

0.1u

C4407

10V

10V

10V

10V

0.1u

C4406

C4408

10

10

R4388

R4386

10

10

R4387

R4389

MON_L

MON_R

GND

GND

MAIN_3.3V

5.303.2

0

10V

16V

0.1u

C4148

0.01u

C4147

+

L4018

C4010

SUB5V

10V

470u

0.1u

0.1u

0.1u

C4276

C4275

C4277

10V

10V

10V

0.1u

10V

10V

C4350

C4351

C4352

0.1u

0.1u

10

10

R4233

R4234

R4235

D3027

MAZ81400ML

D3013

MAZ81400ML

D3008

MAZ81400ML

MAZ81400ML

D3016

MAZ81400ML

D3020

MAZ81400ML

R3064

100

R3065

C3130

100

1u

MAIN3.3V

JS4012

0

TUNER5V_1

JS4011

JS4010

0

0

SUB5V

0.1u

0.1u

0.1u

C4387

C4274

C4386

10V

10V

10V

10V

10V

10V

C4388

C4353

C4389

0.1u

0.1u

0.1u

10

10

10

R4232

R4378

R4377

D3039

MAZ81400ML

D3040

MAZ81400ML

6.3V

D3014

MAZ81400ML

D3018

MAZ81400ML

D3031

MAZ81400ML

D3030

MAZ81400ML

AV2_DET

AV1_DET

C3075

6.3V

D3029

C3078

D3010

10V

MAZ81400ML

D3017

C3081

10V

MAZ81400ML

C3131

1u

10V

10V

*R4321

100k

AK_DL

*R4322

100k

AK_DR

*R4323

100k

AK_DY/JPEG_Y

*R4324

100k

AK_DC/JPEG_C

2.9

2.2

AK_DC/JPEG_C

R3172

9.0

330

Q3009

2SA207700L

2.8

2.2

AK_DY/JPEG_Y

R3175

330

Q3010

0.1u

C4385

10V

10V

10V

C4390

0.1u

0.1u

10

10

R4376

C3067

10V

1u

C3070

6.3V

10u

C3071

10u

C3077

10V

C3080

10V

C3072

6.3V

10u

C3066

10V

1u

AV1_S_DET

10u

1u

1u

AV2_C

AV2_Y

AV2_S_DET

AV2_V

AV2_L

1u

AV2_R

1u

AV2_S2

AV1_Y

AV1_C

AV1_S2

AV1_V

AV1_L

AV1_R

AV2_S2

AAM_L

AAM_R

2SA207700L

AK_DL

AK_DR

TV1_L

TV1_R

TV1_V

D1_Y

D1_L

D1_PB

D1_R

D1_PR

10p

R3170

1k

1%

G1C5R6K00007

R3168

220

C3147

56p

50V

R3173

10p

1k

1%

G1C5R6K00007

R3166

220

0

C3142

33p

50V

C3122

10V

R3078

C3121

1u

10V

R3088

10V

C3123

1u

C3068

R3102

6.3V

10u

220

R3117

1k

R3080

R3115

220

1k

R3082

220

R3108

C3088

1000p

50V

C3097

50V

1000p

*C3150

C3148

L3004

C3143

L3002

1u

C3092

1000p

50V

50V

180p

50V

L3005

G1C5R6K00007

*C3151

C3149

180p

100p

50V

50V

C3145

50V

50V

33p

L3003

G1C5R6K00007

C3146

C3144

50V

120p

82p

50V

C3124

1u

10V

R3087

1k

R3094

1k

C3112

50V

1000p

C3113

1k

1k

220

+

C3074

R3073

C3102

1000p

10u

220k

50V

16V

SW9V

*Q3007

2SC584500L

8.9

C3060

2.8

2.2

8.9

2.7

0

2.1

*R3118

560

AV2_Y

AV2_S_DET

220

1k

R3091

R3101

4.4

4.5

4.4

14

15

16

17

18

19

SY-3

20

L-4

21

R-4

22

AGC

23

SDET-3

CV-4

24

DDET-1

25

Y-1

26

L-5

V-131D-L-132Y-2

27

U-1

28

R-5

29

30

34

35

33

4.3

3.1

4.4

50V

C3083

1000p

C3094

50V

1000p

10V

1u

*R3112

560

C3061

6.3V

10u

AV1_Y

AV1_L

AV1_R

AV1_C

AV1_S_DET

AV2_C

AV2_L

AV2_V

AV2_R

1k

220

220

1k

1k

220

1k

220

R3105

R3092

R3106

R3107

R3093

R3089

R3113

R3076

4.4

4.5

4.2

4.4

4.4

4.4

4.4

4.5

4.2

13

SDET-2

SC-3

R-637V-238D-L-239LOUT-240ROUT-241TC-BASS42S2-143TC-TRE44S2-245BASS-L

36

4.4

12

SC-2

SY-2

L-3

CV-3

R-3

IC3007

DDET-2

L-6

U-2

4.3

50V

C3099

1000p

R3072

9

10

11

L-2

R-2

CV-2

AV-SW

AN15857A

AN15857A

4.4

0.1

4.4

50V

1000p

C3085

1.8k

AAM_R

AAM_L

MAIN9V

J0JHC0000078

*R4274

470

*Q4022

2SC584500L

BASS-R

6

7

8

SC-1

SY-1

SDET-1

S2-3

CV-1

MUTE

VOUT

LOUT-150SCOUT-251ROUT-1

TRE-R

TRE-L

1.4

0.1

1.4

0.1

1k

50V

C3107

1000p

*R3084

C3127

10V

0.22u

1.8k

R3071

*L4034

9.1

4.5

1k

R3095

4.4

4

L-15R-1

CVOUT-2

ADDRESS

SCOUT-1

CVOUT-1

4.4

3.9

AV1_V

AV1_S2

220

1k

R3111

DCOUT

SYOUT

C3128

0.22u

C3104

50V

1000p

C3079

C3082

50V

50V

1000p

1000p

C3089

50V

1000p

C3120

2.2u

16V

4.5

0.1

4.4

1

2

3

64

4.5

63

0

62

SDA

61

YOUT

60

SCL

59

58

VCC

57

56

GND

55

54

53

52

49

46

47

48

4.4

4.4

4.4

C3132

16V

8200p

10V

*C4318

10V

1u

*R4272

220

1k

R3096

4.5

22

5.2

R3100

5.2

22

5.2

4.5

8.9

JS3001

4.5

0

0

4.5

0.1

R3120

0

4.5

4.4

R3119

4.5

4.5

0

C3133

16V

8200p

R3128

15.8k

1%

C3125

4.7u

10V

C3126

R3129

3.16k

10V

1%

4.7u

*Q4023

2SC584500L

*R4276

12k

*C4315

*C4314

4.0

*R4275

3.3u

10k

6.3V

*R4273

*C4313

240

470p

50V

16V

1u

*C4317

560p

25V

SDA1

SCL1

ELJPA330KF

+

SW9V

R3130

15.8k

1%

R3131

3.16k

1%

9.1

4.3

4.3

*R4277

AA_PR

SUB9V

L3001

C3076

16V

47u

AA_Y

AA_PB

AK_MAIN_R

AK_MAIN_L

*Q4024

9.1

2SC584500L

3.7

*C4316

1k

6.3V

AK_CC

NP

47u

*R3090

UOUT

*R4278

R3109

0

*R3169

1%

6.8k

*Q3008

2SC584500L

R3114

1%

*R3167

6.8k

C3084

50V

1000p

50V

1000p

4.4

4.4

0

4.5

4.4

4.4

1.9

4.4

3.1

4.4

4.4

4.4

4.4

4.4

0.1

4.4

C3090

50V

1000p

C3106

50V

1000p

C3109

50V

1000p

11

12

13

14

5

6

TC-19/23LX50, TC-19/23LE50

A-Board (2/6) Schematic Diagram

TC-19/23LX50, TC-19/23LE50

15

A-Board (2/6) Schematic Diagram

151413 17 181210 1611

23

Page 20

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

10.4. A-Board (3 of 6) Schematic Diagram

11

12

A-BOARD (3/6)

TXN/A10LFM (TC-19LE50/LX50)

TXN/A10LEM (TC-23LE50/LX50)

13

14

AA_PB

AA_PR

AA_Y

AL_FIL

15

TC-19/23LX50, TC-19/23LE50

A-Board (3/6) Schematic Diagram

L4005

MAIN9V

J0JHC0000078

R4411

0

R4415

0

C4424

50V

33p

G1C1R5K00004

0.6

R4427

R4431

0.6

C4035

C4030

50V

56p

G1C1R5K00004

C4029

50V

56p

L4002

G1C1R5K00004

L4036

2.1 2.1 0

1

IN/OUT

1k

VDD4CONT

5

9.1 0.1

22k

0

0

+

10V

1u

L4003

2

GND

OUT/IN

Q4047

2SC584500L

C4037

10V

0.1u

Q4007

2SC584500L

*R4280

0

*R4282

0

R4038

*R4281

9.1

220

0

4.6 3.5

Q4008

3.9

2SC584500L

R4045

1k

1%

C4031

50V

R4047

220

1%

L4004

C4028

G1C1R5K00004

50V

10p

Q4046

UNR221500L

0

FIL

H:fc 30MHz

L:fc 14MHz

9.1

4.5

R4046

4.5

Q4045

XN0650100L

270

3.8

1%

C4027

R4044

33p

1k

50V

1%

9.1

R4048

270

3.8

1%

R4043

C4026

1k

50V

1%

33p

R4421

0

C4427

33p

L4037

50V

0

G1C1R5K00004

0.6

C1

C2

0

B1

B2

1k

R4426

E1

E2

0

R4429

47k

R4430

2.2k

R4042

220

Q4006

2SC584500L

R4041

220

10p

R4425

0

R4428

10k

0

0

C4036

25V

33u

C4033

50V

56p

C4032

50V

56p

R4422

0

C4425

33p

50V

3

IC4032

C0JBAS000243

21

22

23

L4019

R4408

560

R4410

AH_ODU_OFF

GND

0.104.803.2

J0JHC0000078

0

AH_MAIN_ON

ODU_OFF

AH_AC_ON

MAIN_SWDET

MAIN_ON

PANEL_5V

AK_MAIN_SW_DET

GND

GND

KEY

PANEL_5V

PANEL_5V

SUB_ON

1314151617181920212223

101112

3.204.9

4.902.202.6

G

G

FL4006

F1J1A1050020

JS4043

0

AL_KEYSCAN

C4417

50V

1000p

AH_INV_SOS

INV_SOS

0.1

D4409

MA2J72800L

C4418

1000p

AH_PANEL5V_ON

2.9

50V

AB_CURRENT

PANEL_ON

1.8

AB_INV_PWM0

INV_PWM

INV_ADIM

4.4

AH_INV_ON

3.1

C4419

10V

0.1u

INV_ON

GND

ZEROX_DET

GND

GND

GND

00000

AL_ZEROX_DET

AL_YMAX

X4001

C4092

H0J202500011

20.25MHz

1.6

11A

3.2

23Y

1.6

32A

4GND 5

IC4031

C0JBAB000620

R4294

1M

8

VCC

7

1Y

6

3A

2Y

50V

22p

C4091

50V

22p

R4409

8.2M

R4293

1k

MAIN3.3V

R4292

3.2

1.6

0

1.50

0

C4319

10V

0.1u

24

R4295

22

R4296

22

R4400

100

Q4039

2SC24800VL

AH_TV_SOS

TO

AP-BOARD

(AP4)

MAIN9V

R4402

10k

7.4

1.1

R4403

0.5

R4401

470

C4155

16V

0.01u

8.1

7.4

1.9 0

1.1k

1%

C4416

1%

Q4042

UNR521100L

R4404

220

Q4040

2SA207700L

R4405

50V

27p

SOS

STBY_5V

GND

123456789

A4

C4156

10V

0.1u

STB5V

R4406

1k

Q4041

470

2SC24800VL

0

0

R4407

1k

0

3.2

0

25

SDA2

SCL2

JTAG_TMS

TDO_FM_U

MAIN3.3V

Q4014

2SC584500L

9.1

C4076

R4053

6.3V

1k

10u

2.1

R4412

0

2.7

Q4010

2SA207700L

*R4050

0

820

1%

C4077

R4052

10u

1k

6.3V

3.5

R4416

0

2.8

0

Q4009

*R4049

2SA207700L

820

1%

R4054

1k

C4075

R4424

0

6.3V

10u

2.9

0

*R4051

270

Q4011

1%

2SA207700L

1.8

R4057

33

R4061

470

Q4013

2SC584500L

9.1

1.8

R4056

33

1.2

R4059

470

C4040

9.1

R4055

33

Q4012

1.6

2SD10300TL

1.1

R4058

330

C4044

10V

1u

R4063

0

1.2

J0JCC0000241

C4039

1u

10V

R4062

0

1u

10V

R4060

0

PLL2.5V

C4426

0.1u

10V

MAIN3.3V

J0JCC0000241

L4006

IC4020

C0CBCAC00095

3.2 0 1.2

1

2

Cont

GND

Vin4Vo

5

2.43.2

C4038

1u

10V

C4041

16V

0.01u

3

C4045

50V

Noise

68p

L4007

R4064

G1C100KA0009

0

C4043

C4042

0.01u

1u

16V

6.3V

MAIN3.3V

C4048

L4008

10V

0.1u

L4009

G1C100KA0009

IC4021

C0CBCAD00035

AD2.5V

3.2

0

1

Vcont

GND

Vin4Vout

5

3.2

C4053

C4050

6.3V

10V

1u

LPF2M

C4054

50V

68p

R4066

MAIN2.5V_GC

C4052

16V

0.01u

1.3

2

3

Np

2.5

C4055

16V

1u

0.01u

C4061

0.1u

10V

C4062

0.1u

10V

C4063

0.1u

R4077

10V

33

C4064

0.1u

10V

C4065

0.1u

10V

10V

C4066

0.1u

C4067

10V

0.1u

R4079

33

C4068

10V

0.1u

C4069

R4068

0.1u

0

10V

R4069

0

R4070

0

R4071

1%

1.4k

1%

C4057

470

R4067

6.3V

1u

R4074

1%

R4072

1.4k

C4058

L4010

6.3V

1u

J0JCC0000241

0

JS4045

0

R4065

C4046

1k

10V

0.1u

C4059

10V

0.1u

R4075

1%

33

R4076

33

1%

1%

R4078

1%

1%

33

1%

R4080

1%

1%

33

R4081

2.7k

1%

1k

R4073

R4083

1k

1%

R4082

470

C4072

10V

0.1u

JS4044

0

MAIN3.3V

37

0

2.5

C4060

0

0.1u

10V

R4084

1%

R4085

150

R4086

150

1%

C4070

6.3V

1u

C4071

6.3V

1u

1%

AVDAD11

40

2.5

VRH1

41

2.0

VIN1

42

1.2

150

VRL1

43

0.4

AVSAD22

44

0

AVDAD22

45

2.5

AVSAD21

46

0

AVDAD21

47

2.5

VRH2

48

2.0

VIN2

49

1.2

VRL2

50

0.4

AVSAD32

51

0

AVDAD32

52

2.5

AVSAD31

53

0

AVDAD31

54

2.5

VRH3

55

2.0

VIN3

56

1.1

VRL3

57

0.5

AVDCLP

58

2.5

AVSCLP

59

0

UCLP

60

1.8

VCLP

61

1.8

YCLP

62

1.6

VRO1

63

1.0

VREF1

64

1.0

AVSDA1

65

0

AVDDA1

66

2.5

AOUT1

67

1.0

2.7k

VRO2

1%

68

1.0

VREF2

69

1.0

70

0

2.5

1.1

10V

C4073

JTAG_TDI

22

22

R4089

31

EXVPIN

EXHPIN

TDO

R4091

10V

10V

0.1u

C4081

C4084

0.1u

1.5

2.7

3.2

2.5

2.503.2

24

25

30

SCL26SDA27VPD28TMS29TDI

FRCLKIN

VDDE

VDDI

100

R4087

0.1u

10V

C4079

000

3.2

2.8

3.2

32

34

35

36

VSS

VDDE33NRST

AVSAD1238AVDAD1239AVSAD11

YUVO4

YUVO2

YUVO3

YUVO1

YUVO0

YUVO5

R4092

EXB38V560JV

10V

0.1u

C4087

1.2

0.9

1.2

1.5

1.1

2.503.2

21

22

23

VSS

VDDI

IC4023

C1AB00002165

GC3FM

AVSDA271AVDDA272AOUT2

VDDE

BXSDDIF

VDDI

DDIF35877VSS78AVSPL179AVDPL180CPO181VGS182VGS283CPO284AVDPL285AVSPL286VSS87FRNT35888VDDI89BXSFRNT90VDDE91VSS92TEST93TRST94TCK95HADIN996HADIN897HADIN798HADIN699HADIN5

73

74

75

76

1.5

0

3.2

0.1u

L4013

J0JCC0000241

1.502.5

2.4

1.3

1.2

0

000

0

2.4

10V

0.1u

C4074

0.01u

C4080

6.3V

16V

C4082

VGS1

C4078

1u

10V

C4088

180p

2.7k

1.5k

R4090

R4088

50V

C4085

1u

6.3V

6.3V

CPO2

C4083

1u

0

1.5

3.201.5

0

2.5

0.2

10V

10V

0.1u

C4089

0.1u

C4090

0.1u

JTAG_TCK

JTAG_TRST

L4015

6.3V

1u

C4086

J0JCC0000241

YUVO6

YUVO7

C4093

10V

0.1u

1.1

1.303.2

13

YUVO714YUVO615YUVO516YUVO417YUVO318YUVO219YUVO120YUVO0

0

R4093

0

R4094

1.2

VDDE

R4095

EXB38V560JV

C4094

11

12

VSS

0

003.2

EXB38V560JV

0.1u

10V

2.500.1

10

VDDI

YUVCLKO

YUVO8

HADCLK

FRCLK

HADIN4

MDO0

MDO2

MDO1

YUVO9

YUVHPO

YUVVPO

YUVCLKO

56

56

56

39

R4099

R4097

R4098

R4096

C4096

10V

0.1u

3.2

1.3

1.3

1.8

0.4

1.2

0.8

6

8

MDO15MDO0

YUVO99YUVO8

MDO2

YUVHPO(VP)7YUVVPO(HP)

VDDE

VSS

MDO4

MDO3

MHVPO

MHPO

MCLK

VSS

HADIN3

HADIN2

HADIN1

HADIN0

VDDE

100

101

102

103

104

0

0

0

0.7

R4103

1

2

3

4

D1HG5608A002

144

0

143

1.1

142

1.6

MDO5

141

1.1

MDO6

140

1.3

MDO7

139

1.2

MDO8

138

1.3

MDO9

137

1.3

MDO10

136

1.2

VDDI

135

2.5

VDDE

134

3.2

VSS

133

0

MDIN0

132

0

MDIN1

131

1.8

MDIN2

130

1.3

MDIN3

129

1.8

MDIN4

128

1.8

MDIN5

127

0.9

MDIN6

126

1.3

MDIN7

125

1.2

VSS

124

0

VDDI

123

2.5

MDIN8

122

1.2

MDIN9

121

1.2

MDIN10

120

1.6

MDIN11

119

1.3

MDIN12

118

1.2

MDIN13

117

1.2

MDIN14

116

1.2

MDIN15

115

1.6

VDDI

114

2.5

VDDE

113

3.2

VSS

112

0

39

R4100

111

1.3

R4101

110

109

107

108

105

106

0

3.2

1.5

0

C4095

10V

0.1u

56

0

R4102

56

0

MDO3

MDO4

MDO5

MDO6

MDO7

C4097

MDO8

MDO9

10V

0.1u

MDO10

MDIN0

C4100

MDIN1

MDIN2

10V

0.1u

MDIN3

MDIN4

MDIN5

C4098

MDIN6

10V

0.1u

MDIN7

MDIN8

MDIN9

MDIN10

MDIN11

MDIN12

MDIN13

C4099

MDIN14

10V

0.1u

MDIN15

MCLK

MHPO

C4101

MVPO

10V

0.1u

26

27

28

29

30

TC-19/23LX50, TC-19/23LE50

A-Board (3/6) Schematic Diagram

20 2319 24 2521 26 2722

24

Page 21

10.5. A-Board (4 of 6) Schematic Diagram

21

22

23

24

25

26

27

28

29

30

TC-19/23LX50, TC-19/23LE50

A-Board (4/6) Schematic Diagram

NC

IC4016

A1 NC

MAIN3.3V

JS4013

0

+

C4103

C4102

0.1u

220u

10V

4V

A

YUVO0

YUVO1

YUVO2

YUVO3

YUVO4

YUVO5

YUVO6

YUVO7

YUVO8

YUVO9

B

IC4016 B5 HSIB

IC4016 A5 VSIB

IC4016 B4 FRCLKIN

IC4016 B9 CLKINB

IC4016 A2 CLKINB2

R4108

SDA2

SCL2

VSS

22

R4109

22

IC4016 A11 GND

IC4016 A20 GND

IC4016 B11 GND

IC4016 B20 GND

IC4016 C12 GND

IC4016 C19 GND

IC4016 D19 GND

IC4016 E11 GND

IC4016 E18 GND

IC4016 E19 GND

IC4016 F22 GND

IC4016 G22 GND

IC4016 K22 GND

IC4016 L22 GND

IC4016 M1 GND

IC4016 M2 GND

IC4016 N3 GND

IC4016 P5 GND

IC4016 P22 GND

IC4016 R22 GND

IC4016 A4 SDA

IC4016 A3 SCL

+

C4104

4V

220u

C4105

0.1u

10V

C4106

1000p

50V

C4107

10V

0.1u

C4108

1000p

50V

C4109

10u

6.3V

C4115

0.1u

10V

C4110

0.1u

10V

C4111

1000p

50V

C4112

0.1u

10V

C4113

1000p

50V

C4114

10V

0.1u

IC4016 B3 YUVINA0

IC4016 B2 YUVINA1

IC4016 B1 YUVINA2

IC4016 C4 YUVINA3

IC4016 C3 YUVINA4

IC4016 C2 YUVINA5

IC4016 C1 YUVINA6

IC4016 D4 YUVINA7

IC4016 D3 YUVINA8

IC4016 D2 YUVINA9

GC4

IC4016 A26 NC

VDDE

M3.3V_V2

IC4016 D6 VCC

IC4016 D11 VCC

IC4016 D12 VCC

IC4016 H4 VCC

IC4016 M4 VCC

IC4016 N4 VCC

IC4016 W4 VCC

IC4016 V4 VCC

IC4016 AC5 VCC

IC4016 AC6 VCC

IC4016 AC7 VCC

IC4016 AC11 VCC

IC4016 AC12 VCC

IC4016 AC13 VCC

IC4016 Y4 VCC

MDO0

MDO1

MDO2

MDO3

MDO4

MDO5

MDO6

MDO7

MDO8

MDO9

MDO10

IC4016 T5 GND

IC4016 U3 GND

IC4016 U4 GND

IC4016 V1 GND

IC4016 V2 GND

IC4016 V22 GND

IC4016 W22 GND

IC4016 AB14 GND

IC4016 AB15 GND

IC4016 AC14 GND

IC4016 AC15 GND

IC4016 AC16 GND

IC4016 AD13 GND

IC4016 AD14 GND

IC4016 AD15 GND

IC4016 AD16 GND

IC4016 AE13 GND

IC4016 AE16 GND

IC4016 AF13 GND

IC4016 AF16 GND

C1AB00002186

IC4016 AF1 NC

C4118

0.1u

C4119

1000p

C4120

C4121

IC4016 E4 MDINA0

IC4016 E2 MDINA1

IC4016 E1 MDINA2

IC4016 F5 MDINA3

IC4016 F4 MDINA4

IC4016 F3 MDINA5

IC4016 F2 MDINA6

IC4016 F1 MDINA7

IC4016 G4 MDINA8

IC4016 G3 MDINA9

IC4016 G2 MDINA10

IC4016 B7 YGINB0

IC4016 A7 YGINB1

IC4016 E6 YGINB2

IC4016 C6 YGINB3

IC4016 B6 YGINB4

IC4016 A6 YGINB5

IC4016 D5 YGINB6

IC4016 C5 YGINB7

IC4016 K10 GND

IC4016 K11 GND

IC4016 K12 GND

IC4016 K13 GND

IC4016 K14 GND

IC4016 K15 GND

IC4016 K16 GND

IC4016 K17 GND

IC4016 L10 GND

IC4016 L11 GND

IC4016 L12 GND

IC4016 L13 GND

IC4016 L14 GND

IC4016 L15 GND

IC4016 L16 GND

IC4016 L17 GND

C4117

50V

1000p

10V

50V

0.1u

10V

0.1u

10V

C4122

0.1u

10V

C4116

0.1u

10V

IC4016 AF26 NC

IC4016 D22 VCC

IC4016 D23 VCC

IC4016 F23 VCC

IC4016 G23 VCC

IC4016 J23 VCC

IC4016 K23 VCC

IC4016 L23 VCC

IC4016 P23 VCC

IC4016 R23 VCC

IC4016 T23 VCC

IC4016 V23 VCC

IC4016 W23 VCC

IC4016 AB23 VCC

IC4016 AC17 VCC

IC4016 AC18 VCC

IC4016 AC19 VCC

IC4016 AC23 VCC

D1HG5608A002

MDIN0

MDIN1

MDIN2

MDIN3

MDIN4

MDIN5

MDIN6

MDIN7

D1HG5608A002

MDIN8

MDIN9

MDIN10

MDIN11

MDIN12

MDIN13

MDIN14

MDIN15

IC4016 M10 GND

IC4016 M11 GND

IC4016 M12 GND

IC4016 M13 GND

IC4016 M14 GND

IC4016 M15 GND

IC4016 M16 GND

IC4016 M17 GND

IC4016 N10 GND

IC4016 N11 GND

IC4016 N12 GND

IC4016 N13 GND

IC4016 N14 GND

IC4016 N15 GND

IC4016 N16 GND

IC4016 N17 GND

C4123

10u

6.3V

R4106

R4107

IC4016 C9 UBINB0

IC4016 A9 UBINB1

IC4016 D8 UBINB2

IC4016 C8 UBINB3

IC4016 B8 UBINB4

IC4016 A8 UBINB5

IC4016 D7 UBINB6

IC4016 C7 UBINB7

MAIN1.8V_GC

J0JHC0000078

+

C4124

4V

220u

C4126

0.1u

C4127

1000p

C4128

0.1u

C4129

1000p

C4130

0.1u

C4131

1000p

C4132

0.1u

10V

C4133

0.1u

10V

C4134

1000p

C4135

0.1u

C4136

0.1u

C4137

1000p

C4138

0.1u

C4139

1000p

C4140

0.1u

10V

C4141

1000p

C4142

0.1u

10V

C4143

0.1u

IC4016 G1 MDOA0

IC4016 H3 MDOA1

IC4016 H2 MDOA2

IC4016 H1 MDOA3

IC4016 J5 MDOA4

IC4016 J4 MDOA5

IC4016 J3 MDOA6

IC4016 J2 MDOA7

IC4016 J1 MDOA8

IC4016 K5 MDOA9

IC4016 K4 MDOA10

IC4016 K3 MDOA11

IC4016 K2 MDOA12

IC4016 K1 MDOA13

IC4016 L5 MDOA14

IC4016 L1 MDOA15

IC4016 P10 GND

IC4016 P11 GND

IC4016 P12 GND

IC4016 P13 GND

IC4016 P14 GND

IC4016 P15 GND

IC4016 P16 GND

IC4016 P17 GND

IC4016 R10 GND

IC4016 R11 GND

IC4016 R12 GND

IC4016 R13 GND

IC4016 R14 GND

IC4016 R15 GND

IC4016 R16 GND

IC4016 R17 GND

http://getMANUAL.com

TC-19LX50 / TC-23LX50 / TC-19LE50 / TC-23LE50

41

42

43

44

E

MCLK

MHPO

MVPO

YUVVPO

YUVHPO

YUVCLKO

MAIN1.8V_L

VDDI

IC4016 E8 VCC

IC4016 E7 VCC

IC4016 G5 VCC

IC4016 H5 VCC

IC4016 M5 VCC

IC4016 U5 VCC

IC4016 V5 VCC

IC4016 AB6 VCC

IC4016 AB7 VCC

IC4016 AB12 VCC

IC4016 AB13 VCC

IC4016 E22 VCC

IC4016 H22 VCC

IC4016 J22 VCC

IC4016 M22 VCC

IC4016 N22 VCC

IC4016 T22 VCC

IC4016 U22 VCC

IC4016 AB16 VCC

IC4016 AB17 VCC

IC4016 AB21 VCC

IC4016 AB22 VCC

IC4016 L4 MCLKA

IC4016 L3 MHPINA

IC4016 L2 MVPINA

IC4016 D1 VSIA

IC4016 E5 HSIA

IC4016 E3 CLKA

IC4016 N5 CLKO

IC4016 C11 VRINB0

IC4016 E10 VRINB1

IC4016 D10 VRINB2

IC4016 C10 VRINB3

IC4016 B10 VRINB4

IC4016 A10 VRINB5

IC4016 E9 VRINB6

IC4016 D9 VRINB7

IC4016 T10 GND

IC4016 T11 GND

IC4016 T12 GND

IC4016 T13 GND

IC4016 T14 GND

IC4016 T15 GND

IC4016 T16 GND

IC4016 T17 GND

IC4016 U10 GND

IC4016 U11 GND

IC4016 U12 GND

IC4016 U13 GND

IC4016 U14 GND

IC4016 U15 GND

IC4016 U16 GND

IC4016 U17 GND

AB_LCD_VS

PLL

R4111

AB_LCD_ENB

C4167

6.3V

1u

56

R4142

DA/AD

AB_LCD_G0

AB_LCD_G1

470

AB_LCD_G2

JS4026

JS4027

AB_LCD_G3

AB_LCD_G4

R4143

2.2k

C4171

6.3V

1u

AB_LCD_G5

AB_LCD_G6

R4144

1.1k

C4169

6.3V

C4170

6.3V

1u

R4147

R4148

C4177

AB_LCD_G7

1u

1%

1%

1%

C4175

6.3V

1u

1%

1u

L4017

C4125

10V

0.1u

10V

50V

10V

50V

10V

50V

50V

10V

10V

50V

10V

50V

50V

10V

IC4016 AA5 GOE0

IC4016 AA4 GOE1

IC4016 Y2 GOE2

IC4016 Y3 GOE3

IC4016 Y5 GOE4

IC4016 W1 GOE5

IC4016 W2 GOE6

IC4016 W3 GOE7

IC4016 W5 GOE8

IC4016 V3 GOE9

R4113

EXB2HV680JV

IC4016 P2 PLL1_AVS2

IC4016 P4 PLL1_AVD2

IC4016 N2 PLL1_VCI

IC4016 N1 PLL1_CPO

IC4016 P1 PLL1_AVS1

IC4016 P3 PLL1_AVD1

L4023

J0JCC0000241

C4172

10V

0.1u

R4145

2.2k

1%

R4146

2.7k

C4174

1u

6.3V

75

1u

C4176

6.3V

75

6.3V

C4173

10V

0.1u

LCD_ENB

LCD_BL2

22

R4116

33k

R4114

C4152

50V

82p

MAIN3.3V

R4115

IC4016 A17 DA1_COMP

IC4016 A16 DA1_VREF

IC4016 B17 DA1_VRO

IC4016 C17 DA1_AVS1

IC4016 D17 DA1_AVD1

IC4016

B16 DA1_AOUT

IC4016 E17 DA1_AVD2

IC4016 C16 DA1_AVS2

IC4016 C15 DA2_AVS2

IC4016 D16 DA2_AVD2

IC4016 B15 DA2_AOUT

IC4016 E16 DA2_AVD1