Page 1

TC-17LA1

A

V

TC-20LA1

LH14 Chassis

ORDER NO. ITD0304003C1

B05 Canada:B07

LCD TV

Specifications

Power Source AC 120V, 60Hz

Power Consumption Average use: 60W (TC-17LA1)

Stand-by condition: 0.8 W (TC-17LA1) Stand-by condition: 0.8 W (TC-20LA1)

TV set DC 15 V, 3.6 A max. (TC-17LA1) TV set DC 15 V, 3.8 A max. (TC-20LA1)

LCD 17-inch (432 mm) (TC-17LA1), 20-inch (510 mm) (TC-20LA1),

4 : 3 aspect ratio LCD panel 4 : 3 aspect ratio LCD panel

Screen Size 13.53" (343.7 mm) (W) × 10.30" (261.9 mm) (H)

(TC-17LA1)

Channel Capability VHF-12: UHF-56: Cable-125

Sound

Speaker 4 cm, 2pcs, 16 9

Headphones M3 (3.5 mm) Jack × 1

FEATURES 3D Y/C Digital Comb Filter

CLOSED CAPTION

Operating Conditions Temperature: 41 °F - 95 °F(5 °C - 35 °C)

Humidity: 5% - 90% RH (non-condensing)

Connection Terminals

INPUT VIDEO (RCA PIN Type × 1) × 2 1.0 Vp-p (75 9)

S-VIDEO (MINI DIN 4 pin × 1) × 2 Y: 1 Vp-p (75 9), C: 0.286 Vp-p (75 9)

AUDIO L-R (RCA PIN Type × 2) × 2 0.5 Vrms

COMPONENT VIDEO INPUT Y 1.0 Vp-p (including synchronization)

PB/P

R

AUDIO L-R (RCA PIN Type × 2) 0.5Vrms

Dimensions (W x H x D)

Including TV Stand 16.69" (424 mm) × 16.35" (415.2 mm) × 8.46" (215

mm) (TC-17LA1)

verage use: 67W (TC-20LA1)

16.06" (408.0 mm) (W) × 12.05" (306.0 mm) (H)

(TC-20LA1)

-Chip

±0.35Vp-p

19.45" (494 mm) ×18.17" (461.4 mm) × 10.04" (255

mm) (TC-20LA1)

© 2003 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

TC-17LA1 / TC-20LA1

TV Set Only 16.69" (424 mm) × 15.02" (381.5 mm) × 2.52" (64.1

mm) (TC-17LA1)

Mass (Weight) 11.46 lb. (5.2 kg) Net (TC-17LA1) 15.87 lb. (7.2 kg) Net (TC-20LA1)

Note:

Design and Specifications are subject to change without notice. Weight and Dimensions shown are approximate.

19.45" (494 mm) × 16.63" (422.3 mm) × 3.21" (81.5

mm) (TC-20LA1)

CONTENTS

Page Page

1 Safety Precautions 3

1.1. General Guidelines

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

3 About lead free solder (PbF)

4 Self-check function

4.1. How to access

4.2. Screen display

4.3. Display phenomenon and treatment method

5 Chassis Board Layout

6 Before servicing

6.1. Kind and location of the flexible cable

6.2. How to remove the connector

7 Disassembly for Service

7.1. Rear cover

7.2. AP-BOARD

7.3. DG-Board

7.4. V-Board

7.5. Speaker (L, R)

7.6. B-Board

7.7. K-Board

7.8. BL-Board

7.9. LCD panel

8 Adjustment method

8.1. How to enter into adjustment mode

8.2. Cancellation

8.3. Contents of adjustment mode

8.4. Video level adjustment

10

11

13

13

14

14

15

16

19

19

19

19

20

3

3

4

5

5

5

5

6

7

7

8

9

9

8.5. Flicker Adjustment

8.6. MTS Adjustment

9 Conductor Views

9.1. AP-Board

9.2. DG-Board (TC-17LA1)

9.3. DG-Board (TC-20LA1)

9.4. B, BL, K and V-Board

10 Block and Schematic Diagram

10.1. Schematic Diagram Notes

10.2. Power Block Diagram

10.3. Signal Block Diagram

10.4. AP-Board (1 of 3) Schematic Diagram

10.5. AP-Board (2 of 3) Schematic Diagram

10.6. AP-Board (3 of 3) Schematic Diagram

10.7. DG-Board (1 of 3) (For TC-17LA1) Schematic Diagram

10.8. DG-Board (2 of 3) (For TC-17LA1) Schematic Diagram

10.9. DG-Board (3 of 3) (For TC-17LA1) Schematic Diagram

10.10. DG-Board (1 of 3) (For TC-20LA1) Schematic Diagram

10.11. DG-Board (2 of 3) (For TC-20LA1) Schematic Diagram

10.12. DG-Board (3 of 3) (For TC-20LA1) Schematic Diagram

10.13. B, BL, K, and V-Board Schematic Diagram

11 Parts Location & Mechanical Replacement Parts List

11.1. Parts Location

11.2. Packing Exploded View

11.3. Mechanical Replacement Parts List

12 Replacement Parts List

12.1. Replacement Parts List Notes

12.2. Electrical Replacement Parts List

23

24

25

25

27

28

29

31

31

32

34

36

37

38

39

40

41

42

43

44

45

47

47

48

49

50

50

51

2

Page 3

TC-17LA1 / TC-20LA1

1 Safety Precautions

1.1. General Guidelines

1.When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2.After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3.After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

1.1.1. Leakage Current Cold Check

1.Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2.Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the equipment such as screwheads, connectors,

control shafts, etc. When the exposed metallic part has a

return path to the chassis, the reading should be between

1M9 and 5.2M9.

When the exposed metal does not have a return path to the

chassis, the reading must be

Figure 1

.

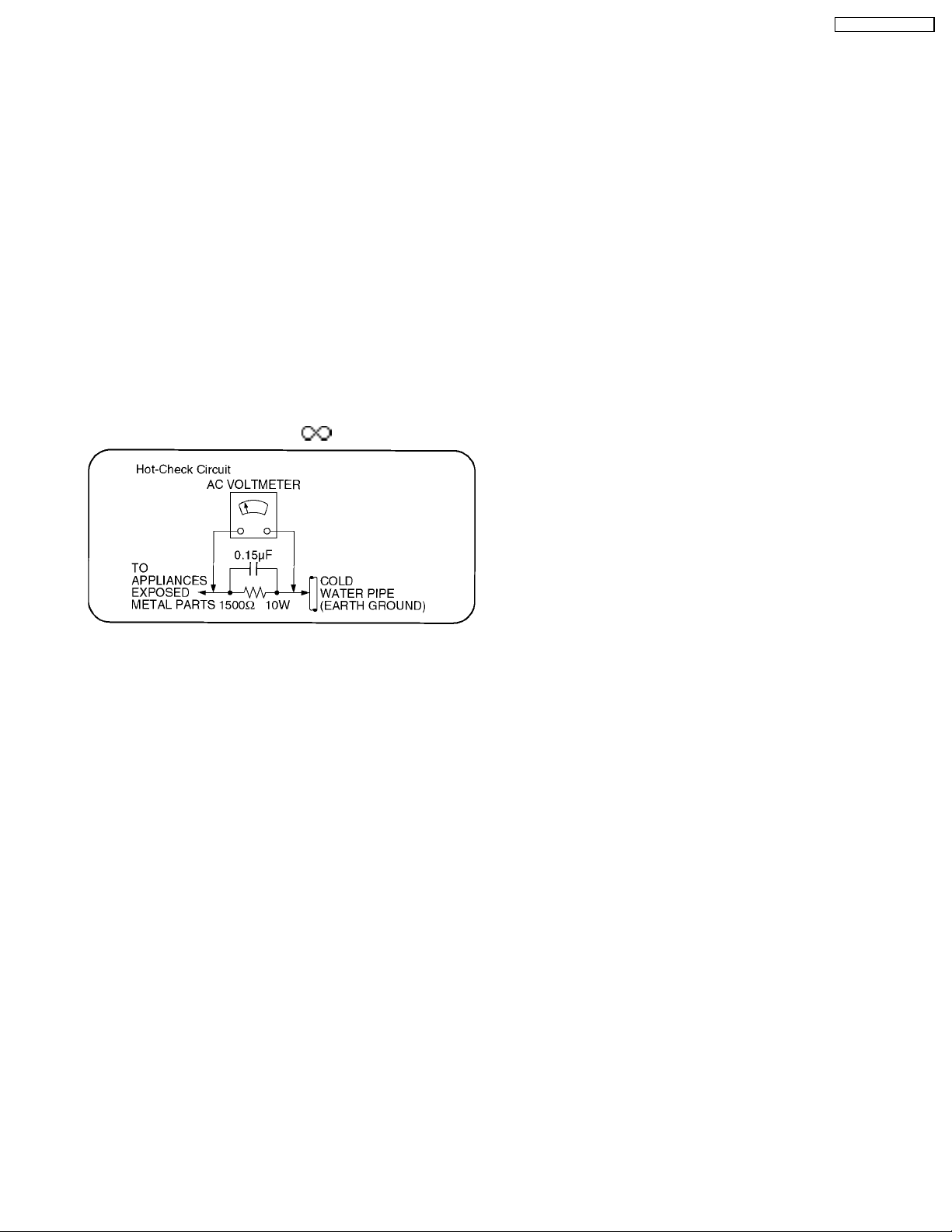

1.1.2. Leakage Current Hot Check (See

Figure 1.)

1.Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2.Connect a 1.5k9, 10 watts resistor, in parallel with a 0.15µF

capacitors, between each exposed metallic part on the set

and a good earth ground such as a water pipe, as shown in

Figure 1.

3.Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4.Check each exposed metallic part, and measure the

voltage at each point.

5.Reverse the AC plug in the AC outlet and repeat each of the

above measurements.

6.The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliamp. In case a

measurement is outside of the limits specified, there is a

possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the

customer.

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1.Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2.After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as alminum

foil, to prevent electrostatic charge buildup or exposure of the assembly.

3.Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4.Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5.Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6.Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, alminum foil or comparable

conductive material).

7.Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

3

Page 4

TC-17LA1 / TC-20LA1

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8.Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise hamless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

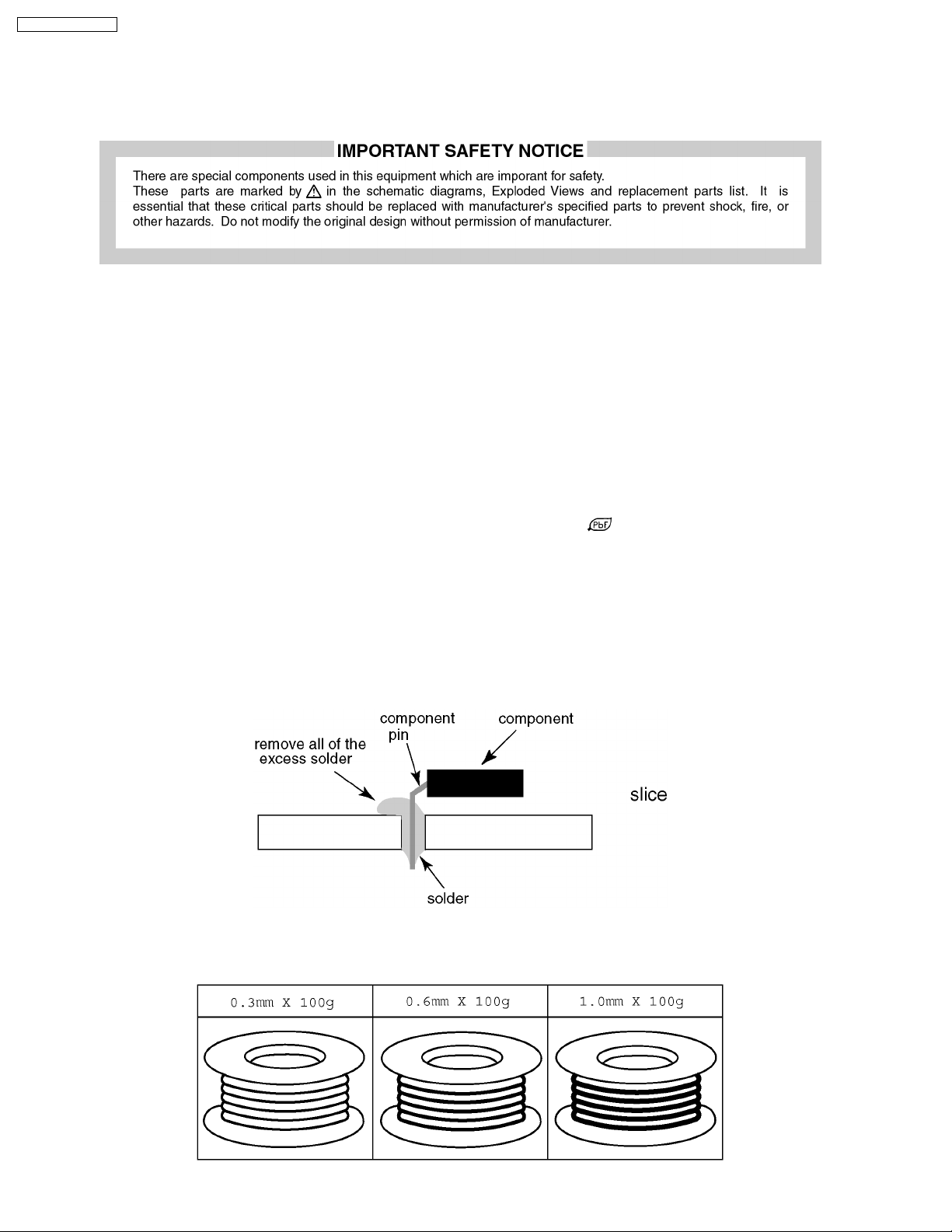

3 About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol

Caution

·

· Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40°C) higher.

· ·

Please use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

·

· Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

· ·

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb

solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

·

· After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto

· ·

the opposite side. (see figure below)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder.

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

stamped on the back of PCB.

4

Page 5

TC-17LA1 / TC-20LA1

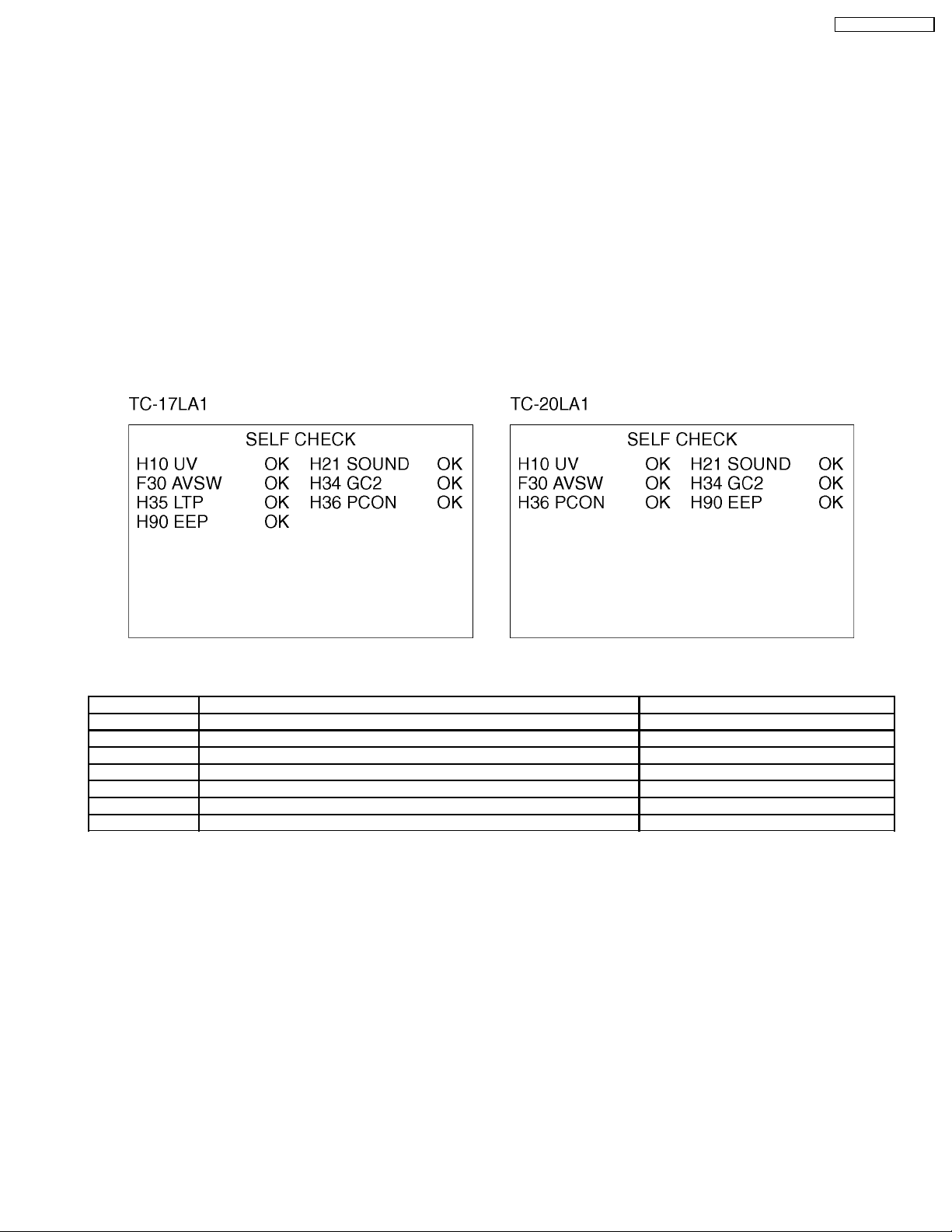

4 Self-check function

When phenomena like "the power fails from time to time" or "the video/audio fails from time to time" can not be confirmed at the

time of servicing, the self-check function can be used to confirm the occurrence and to limit the scope for the defective circuits.Also,

when "the power fails from time to time", display on the screen can be used to confirm the occurrence and to limit the scope for

the defective circuits.

Any programmed channels, channels caption data and some other user defined settings will be erased and return to factory setting.

4.1. How to access

4.1.1. Access

Produce TV reception screen and, while pressing [VOLUME-] button on the main unit, press [SLEEP] button on the remote

controller unit simultaneously.

4.1.2. Exit

When one of the buttons for channel selection etc. is pressed, the display returns to the normal screen.

4.2. Screen display

4.3. Display phenomenon and treatment method

Display symbol Phenomenon/condition Treatment method

H10 No output of video and audio. Replace tuner (TNR001A (B-BOARD)).

H21 No audio output. Surround function not effective. Replace IC2300 (AP-BOARD).

F30 No video and audio output. Input switching disabled. Replace IC3000 (AP-BOARD).

H34 Black and white stripes pattern. Enhanced back light. Replace IC4003 (DG-BOARD).

H35 No video Replace IC6400 (DG-BOARD).

H36 No video Replace IC6300 (DG-BOARD).

H90 Power interrupted with self-check. Replace IC1002 (DG-BOARD).

* Any button operation or switching off the power will reset the self-check data.

5

Page 6

TC-17LA1 / TC-20LA1

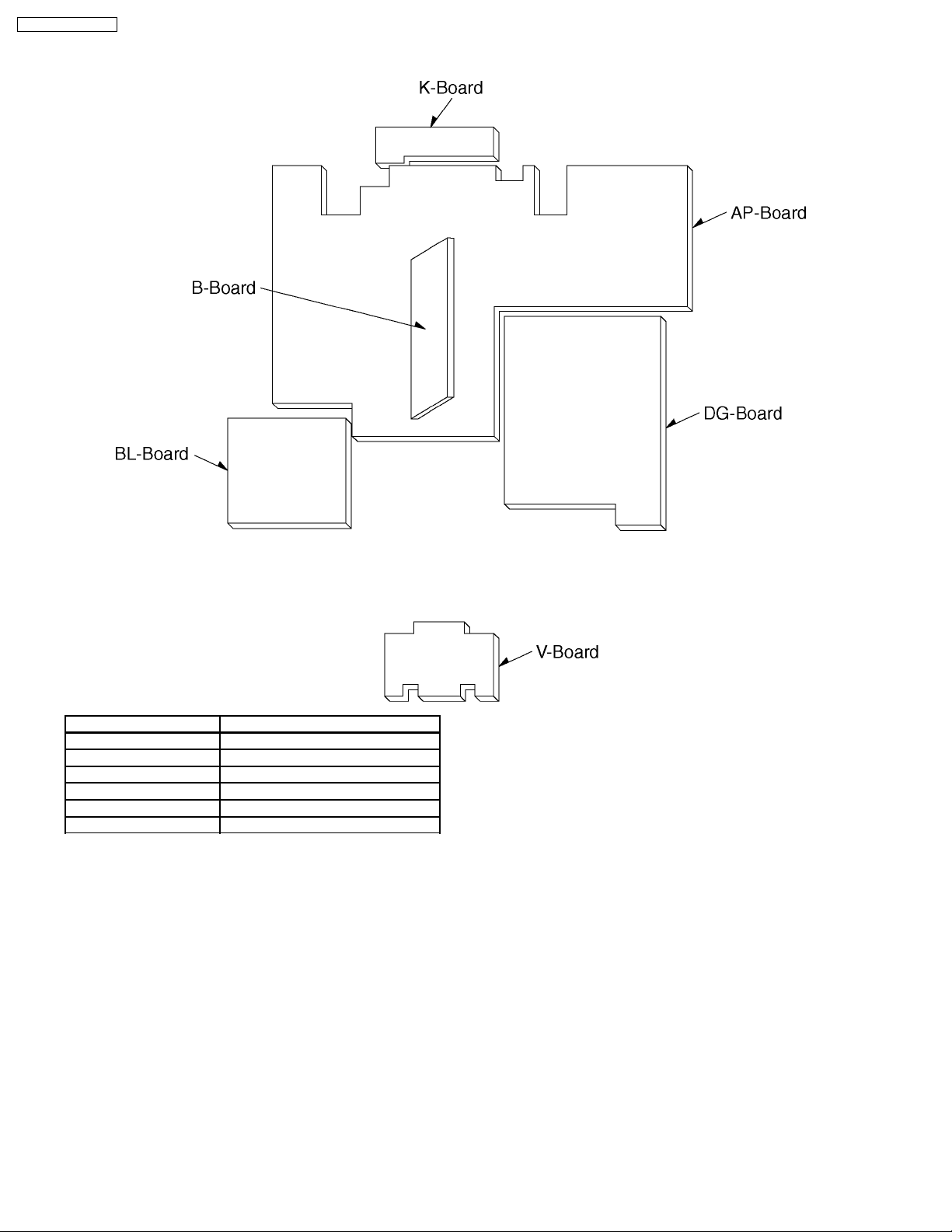

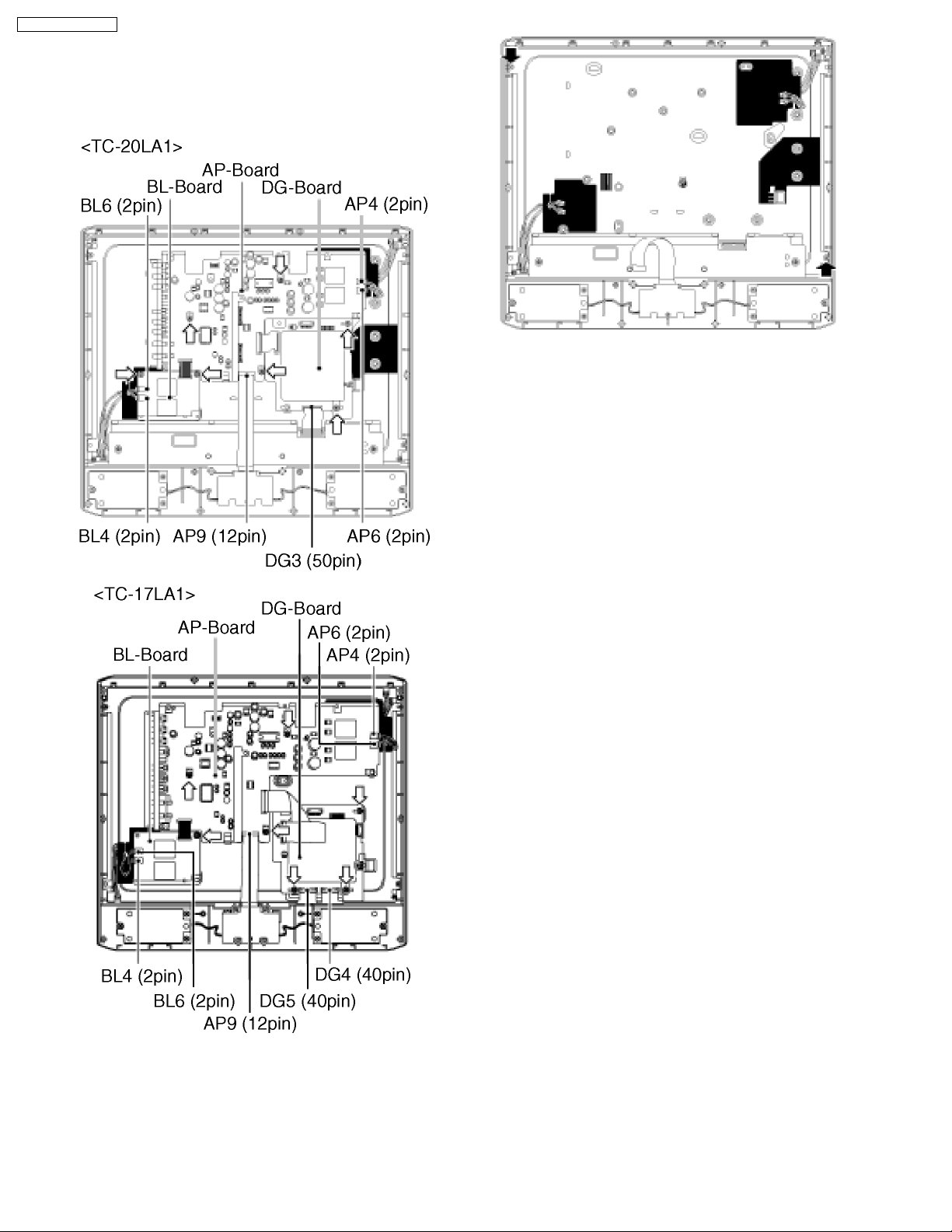

5 Chassis Board Layout

Board Name Function

AP-Board Audio, Power, Inverter, AV SW

B-Board Tuner

BL-Board Inverter

DG-Board GC2, PCN, MICOM, EEPROM

K-Board Switch

V-Board Remote sensor, LED

6

Page 7

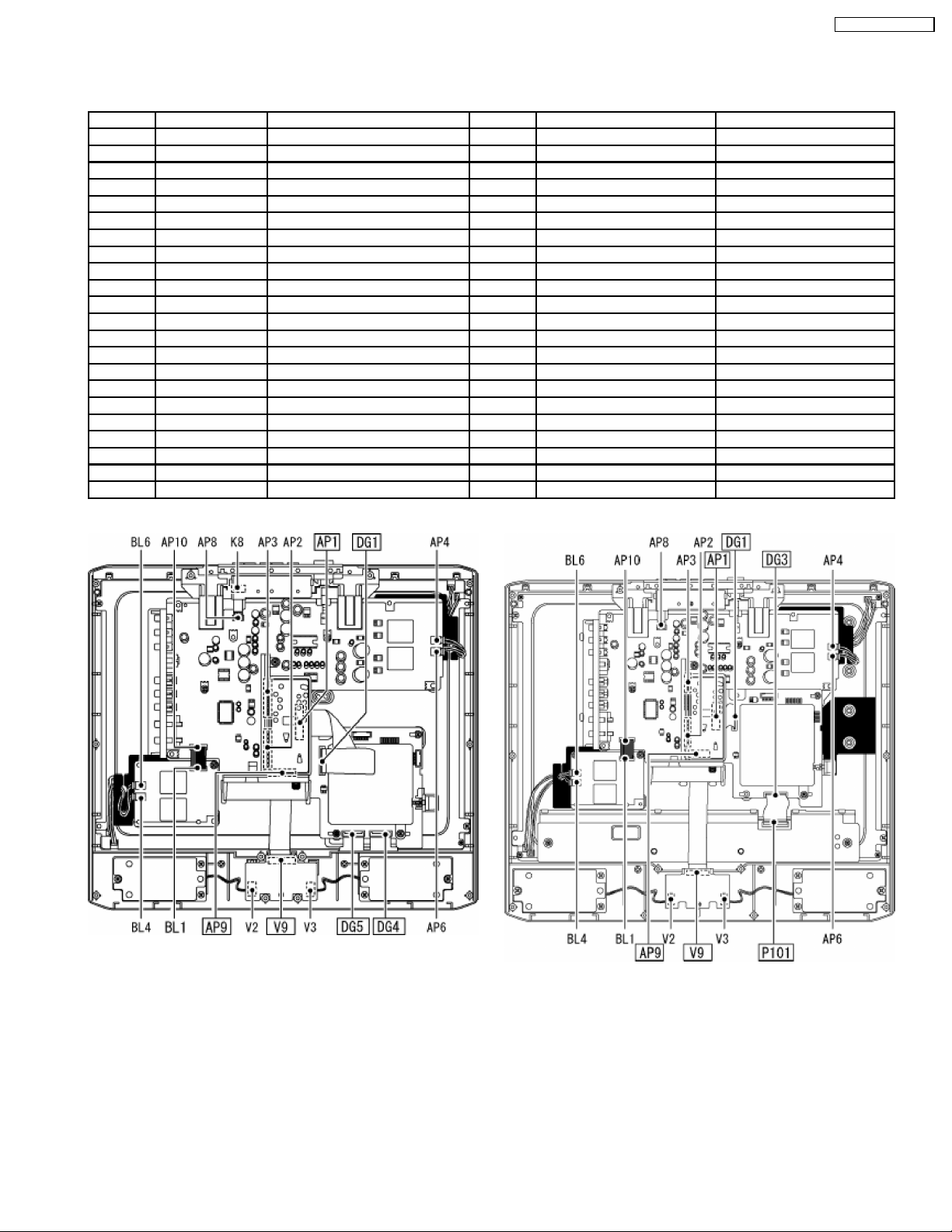

6 Before servicing

6.1. Kind and location of the flexible cable

Ref No. Flexible cable Connector type Pins Location Opposite Ref No.

AP1 l type1 50 pin AP-BOARD DG1

AP2 - - 15 pin AP-BOARD B2

AP3 - - 9pin AP-BOARD B3

AP4 - - 2pin AP-BOARD Back Light (U)

AP6 - - 2 AP-BOARD Back Light (U)

AP8 - - 4pin AP-BOARD K8

AP9 l type2 12 pin AP-BOARD V9

AP10 - - 11 pin AP-BOARD BL1

B2 - - 15 pin B-BOARD AP2

B3 - - 9pin B-BOARD AP3

BL1 - - 11 pin BL-BOARD AP10

BL4 - - 2pin BL-BOARD Back Light (D)

BL6 - - 2pin BL-BOARD Back Light (D)

DG1 l type3 50 pin DG-BOARD AP10

DG3 l type3 50 pin DG-BOARD (TC-20LA1 only) P101

DG4 l type5 40 pin DG-BOARD (TC-17LA1 only) LCD Panel

DG5 l type5 40 pin DG-BOARD (TC-17LA1 only) LCD Panel

K8 - - 4pin K-BOARD AP8

P101 l type5 50 pin LCD Panel DG3

V2 - - 2pin V-BOARD Speaker (R)

V3 - - 2pin V-BOARD Speaker (L)

V9 l type4 12 pin V-BOARD AP9

TC-17LA1 / TC-20LA1

<TC-17LA1> <TC-20LA1>

7

Page 8

TC-17LA1 / TC-20LA1

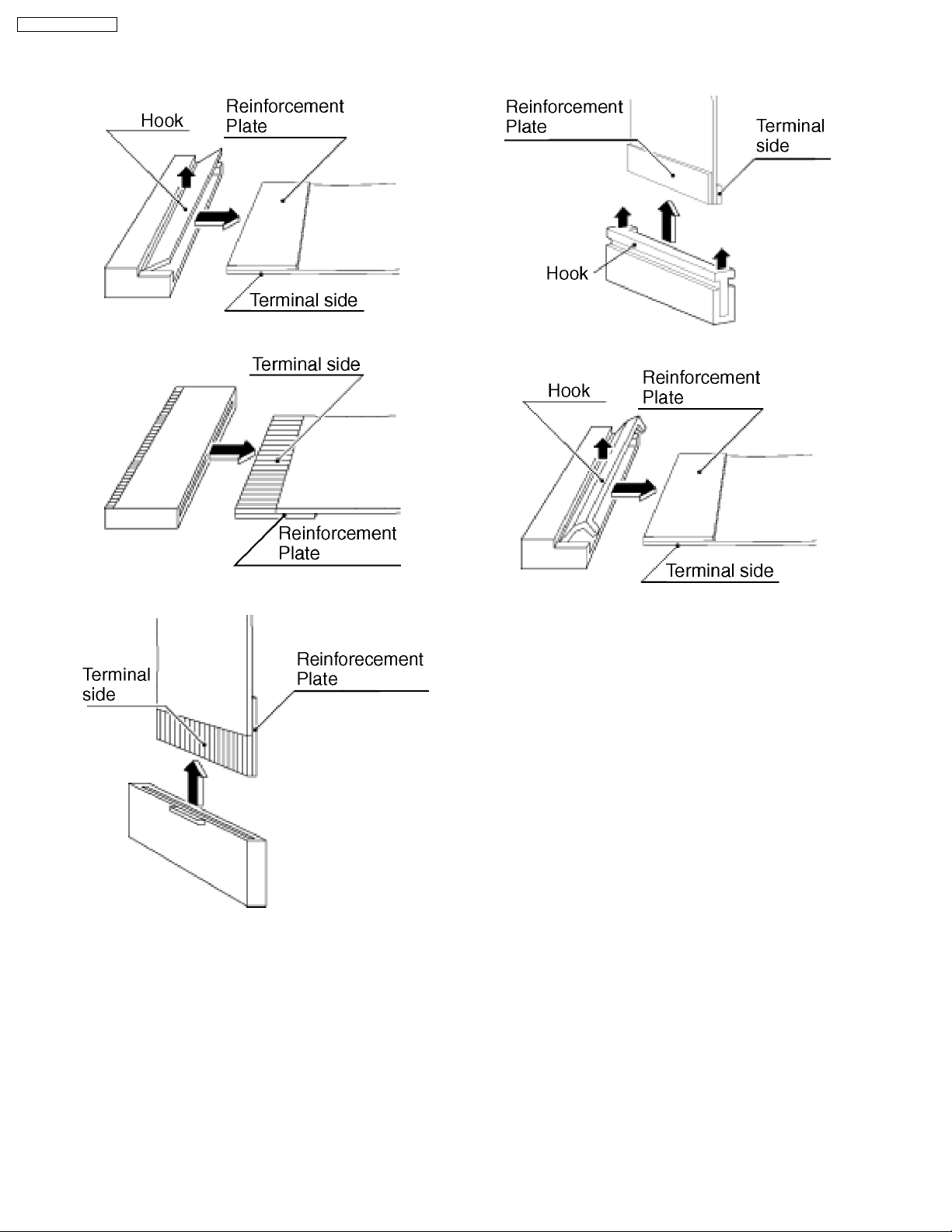

6.2. How to remove the connector

Connector type1

Connector type2

Connector type4

Connector type5

Connector type3

8

Page 9

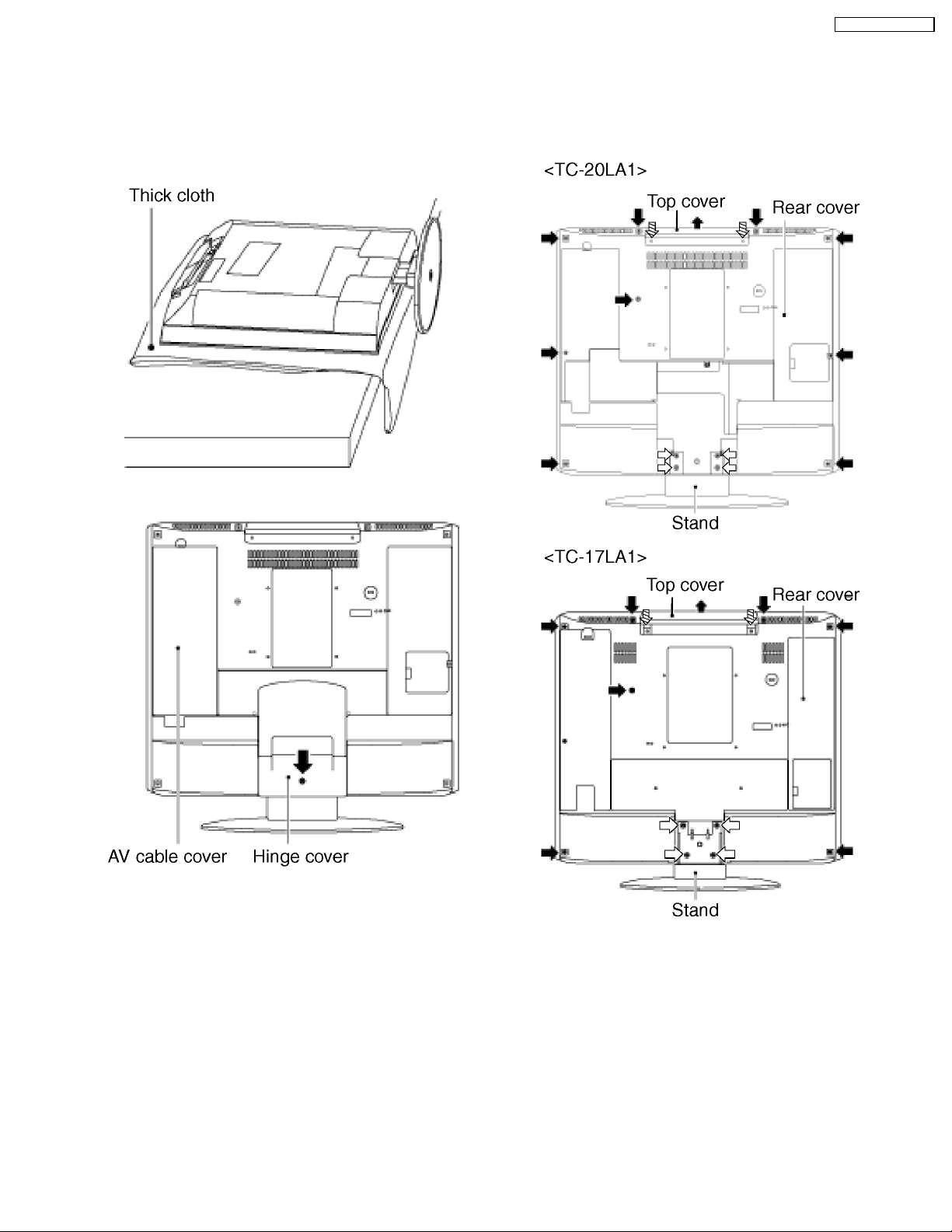

7 Disassembly for Service

7.1. Rear cover

1.Thick cloth and so on is down not to damage a LCD screen,

and the unit is pushed down.

TC-17LA1 / TC-20LA1

3.Remove the screws (9 pcs) (TC-20LA1) / (7 pcs) (TC17LA1), the screws (2 pcs), and the screws (4 pcs), and

detach the rear cover and top cover.

2.Remove the screw (1 pcs), and detach the hinge cover and

the AV cable cover.

9

Page 10

TC-17LA1 / TC-20LA1

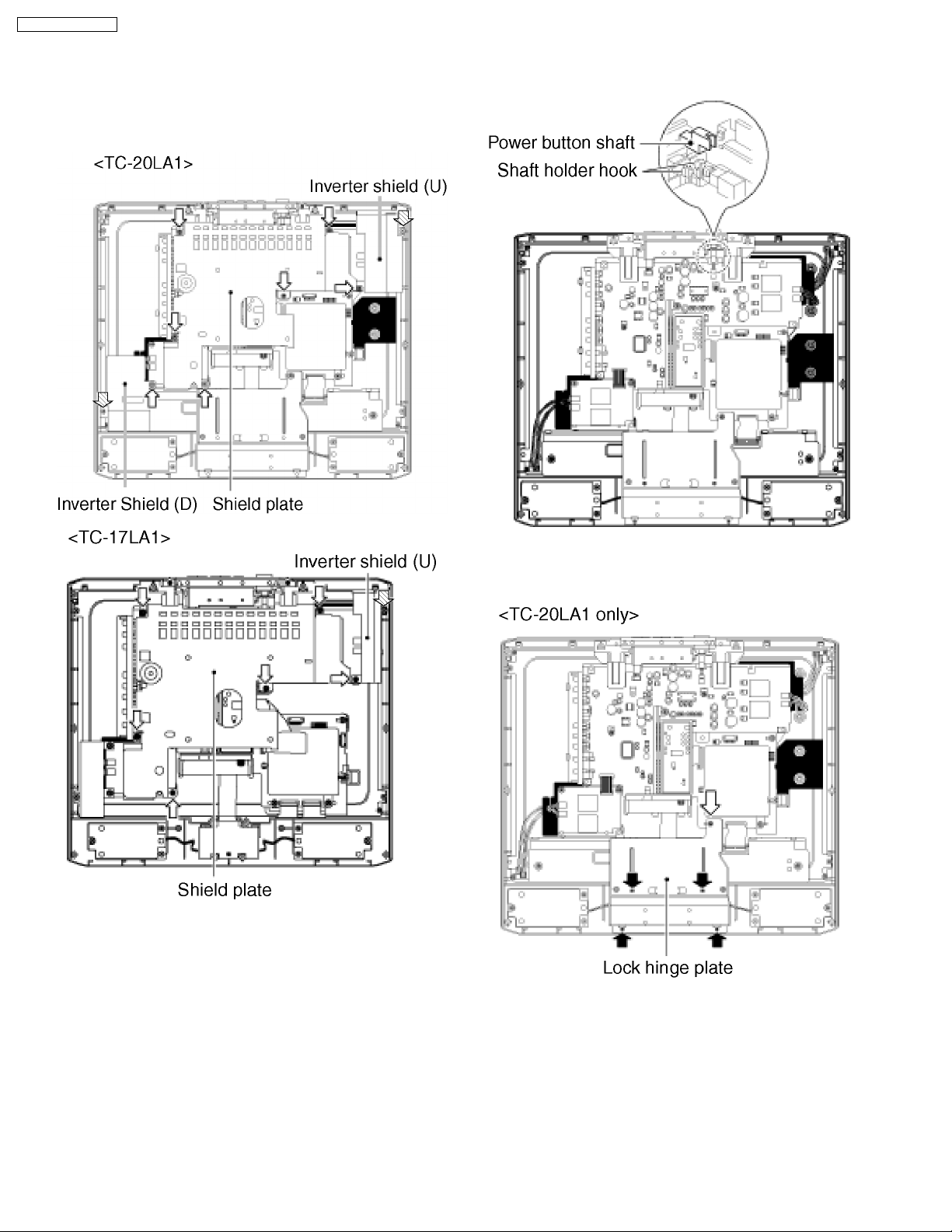

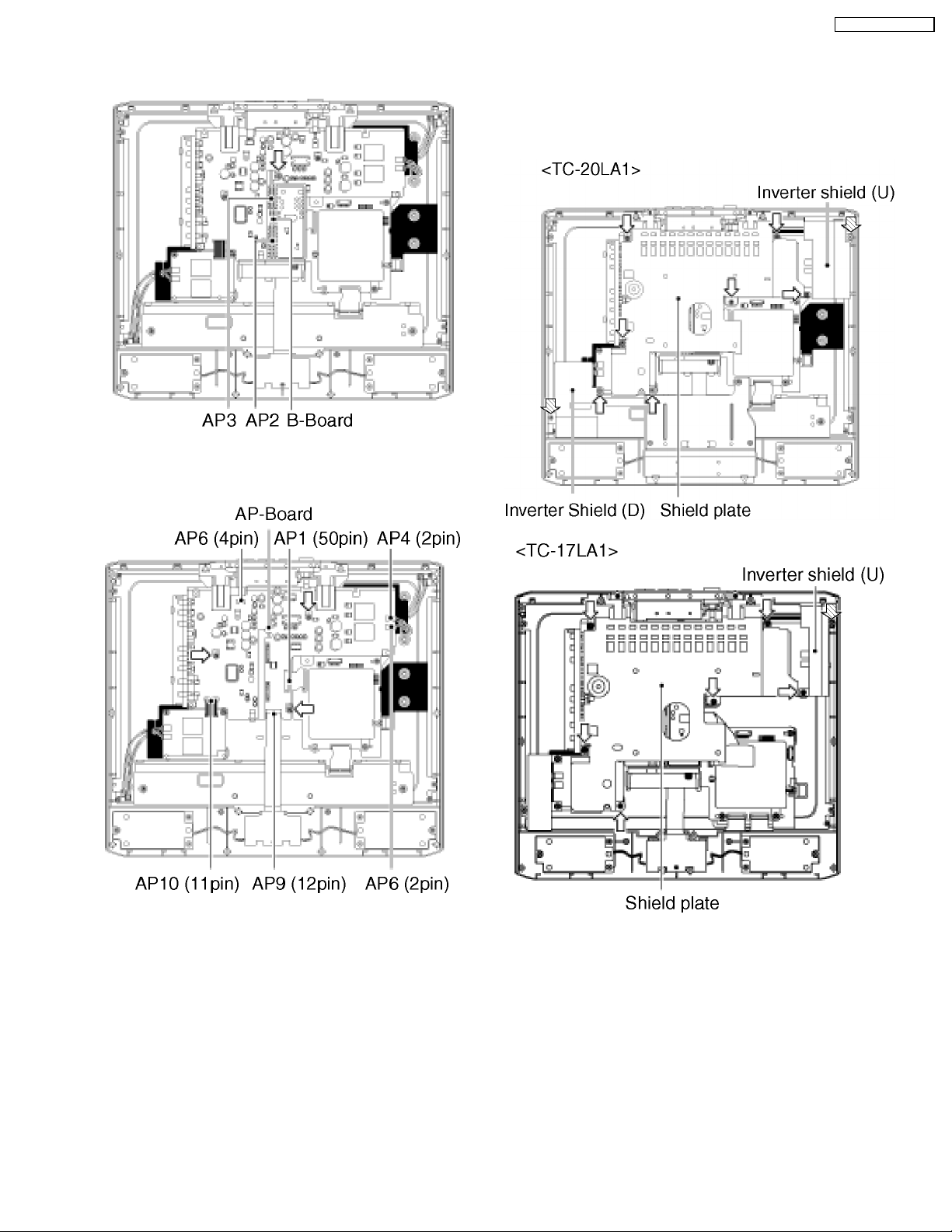

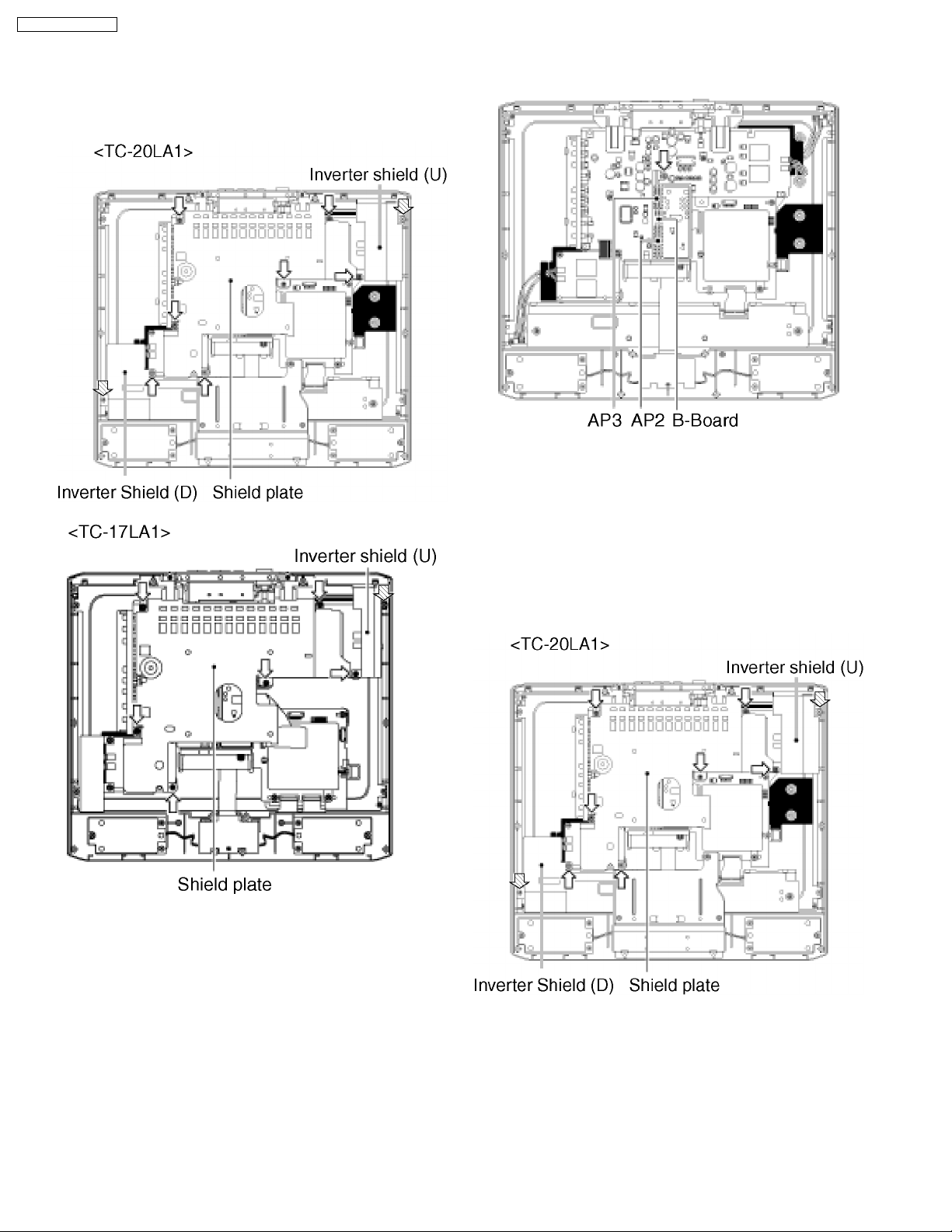

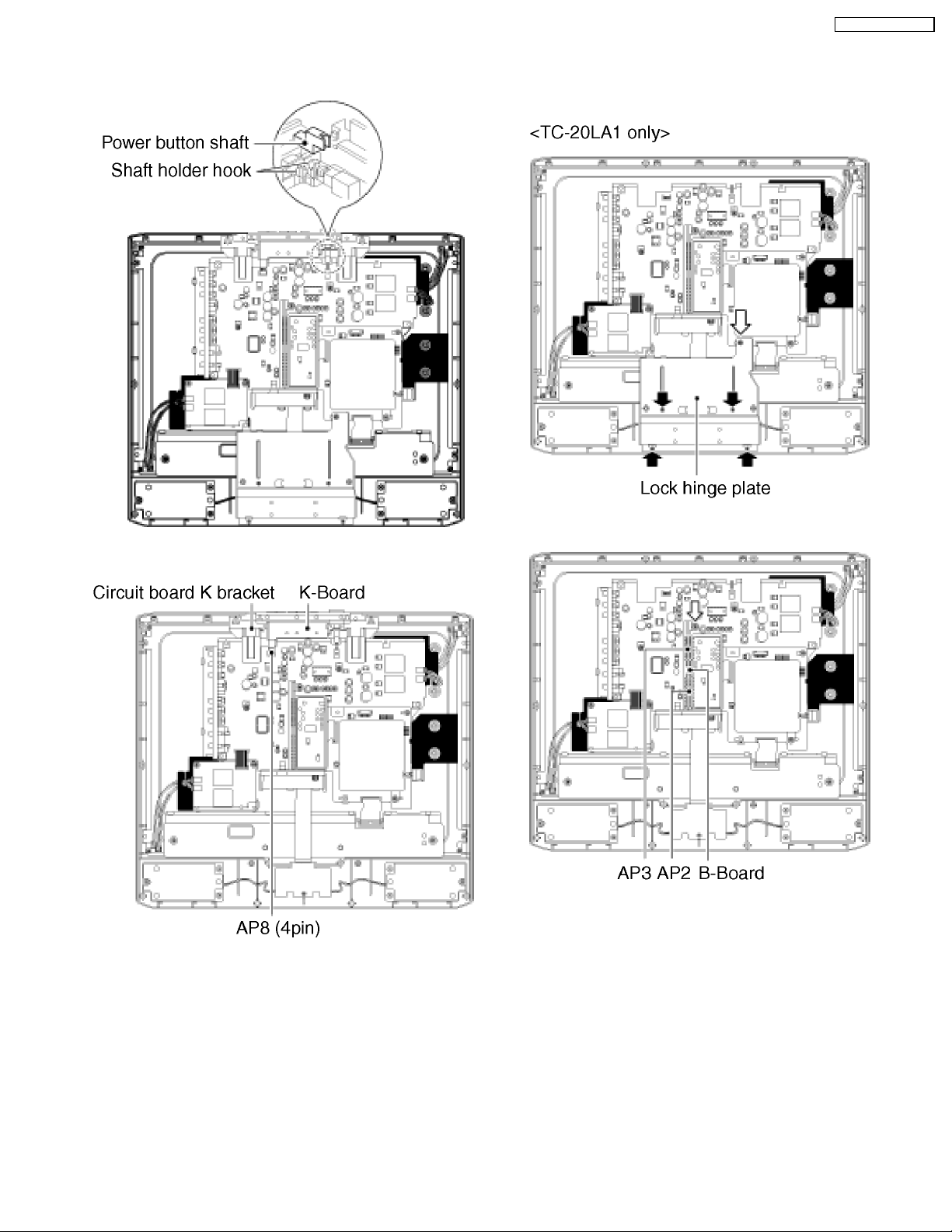

7.2. AP-BOARD

1.Remove the rear cover.

2.Remove the screws (6 pcs) and the screws (2 pcs) (TC20LA1) / (1 pcs) (TC-17LA1) and detach the shield plate

and Inverter plate (U, D).

3.Disengage the shaft holder hook and detach the power

button shaft.

4.<TC-20LA1 only>

Remove the screw (1 pcs) and the screws (4 pcs) and

detach the lock hinge plate.

Caution:

PCB Fixing screws driving torque: 0.2-0.3 N·m (23kg·mm)

Do not tighten screws so hard.

10

Page 11

5.Remove the screw (1 pcs) and disconnect the couplers (B2

(AP2) and B3 (AP3)) between B-Board and the AP-Board.

6.Disconnect the couplers (AP4, AP6, AP8 and AP10) the

flexible cable (AP1 and AP9) and remove the screws (3

pcs) and detach the AP-Board.

TC-17LA1 / TC-20LA1

7.3. DG-Board

1.Remove the rear cover.

2.Remove the screws (6 pcs) and the screws (2 pcs) (TC20LA1) / (1 pcs) (TC-17LA1) and detach the shield plate

and Inverter plate (U, D).

11

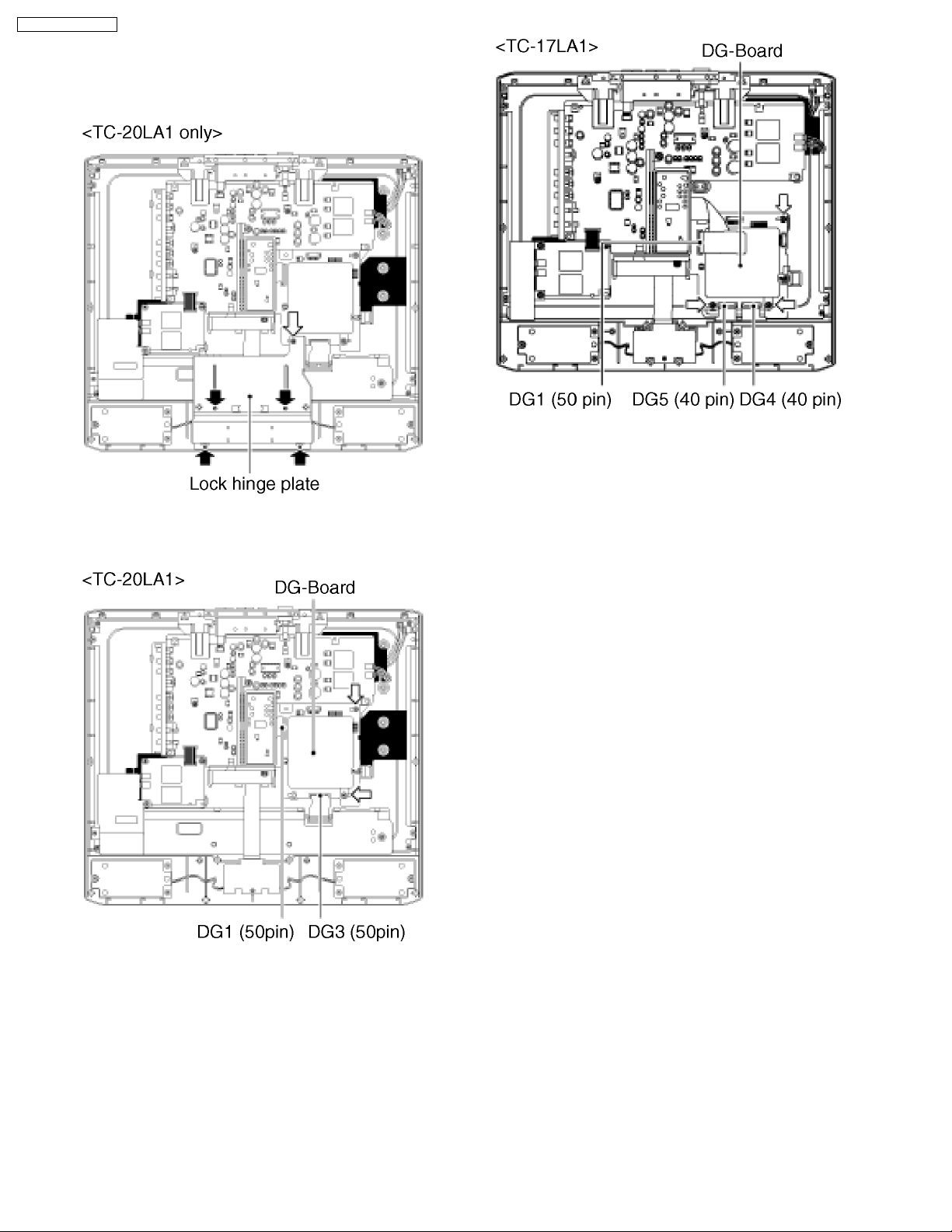

Page 12

TC-17LA1 / TC-20LA1

3.<TC-20LA1 only>

Remove the screw (1 pcs) and the screws (4 pcs) and

detach the lock hinge plate.

4.Disconnect the flexible cable (DG1 and DG3 (TC-20LA1)/

DG4, DG5 (TC-17LA1) ) and remove the screws (2 pcs) and

detach the DG-Board.

Caution:

PCB Fixing screws driving torque: 0.2-0.3 N·m (23kg·mm)

Do not tighten screws so hard.

12

Page 13

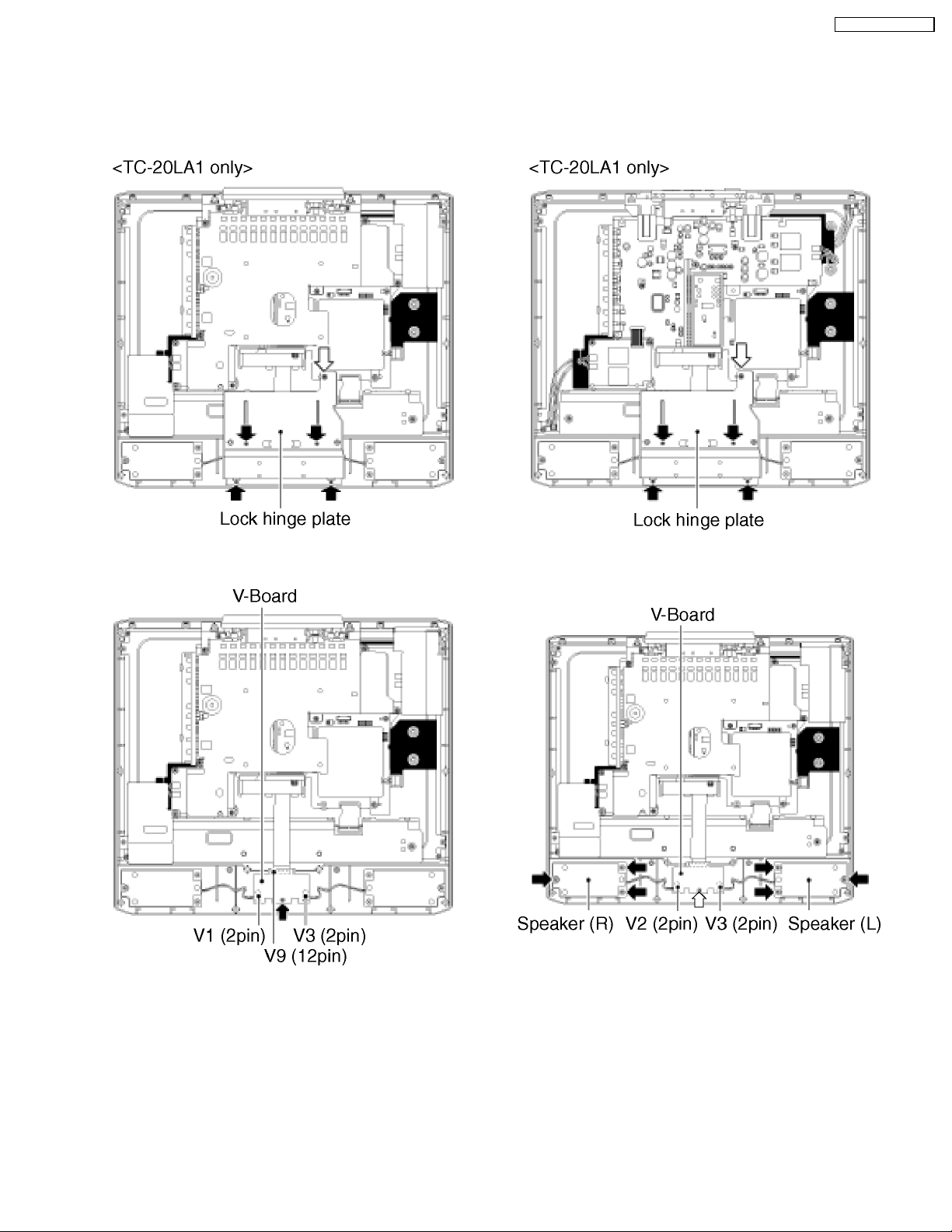

7.4. V-Board

TC-17LA1 / TC-20LA1

7.5. Speaker (L, R)

1.Remove the rear cover.

2.<TC-20LA1 only>

Remove the screw (1 pcs) and the screws (4 pcs) and

detach the lock hinge plate.

1.Remove the rear cover.

2.<TC-20LA1 only>

Remove the screw (1 pcs) and the screws (4 pcs) and

detach the lock hinge plate.

3.Remove the screw (1 pcs) and disconnect the couplers (V2

and V3) and the flexible cable (V9) and detach the V-Board.

Caution:

PCB Fixing screws driving torque: 0.2-0.3 N·m (2-3kg·mm)

Do not tighten screws so hard.

3.Remove the screw (1 pcs) and the screws (6 pcs) and

disconnect the couplers (V2 and V3) and the Speakers (L,

R).

Caution:

PCB Fixing screws driving torque: 0.2-0.3 N·m (2-3kg·mm)

Do not tighten screws so hard.

13

Page 14

TC-17LA1 / TC-20LA1

7.6. B-Board

1.Remove the rear cover.

2.Remove the screw (1 pcs) and the screws (4 pcs) and

detach the lock hinge plate.

3.Remove the screw (1 pcs) and disconnect the couplers (B2

(AP2) and B3 (AP3)) between B-Board and the AP-Board.

Caution:

PCB Fixing screws driving torque: 0.2-0.3 N·m (2-3kg·mm)

Do not tighten screws so hard.

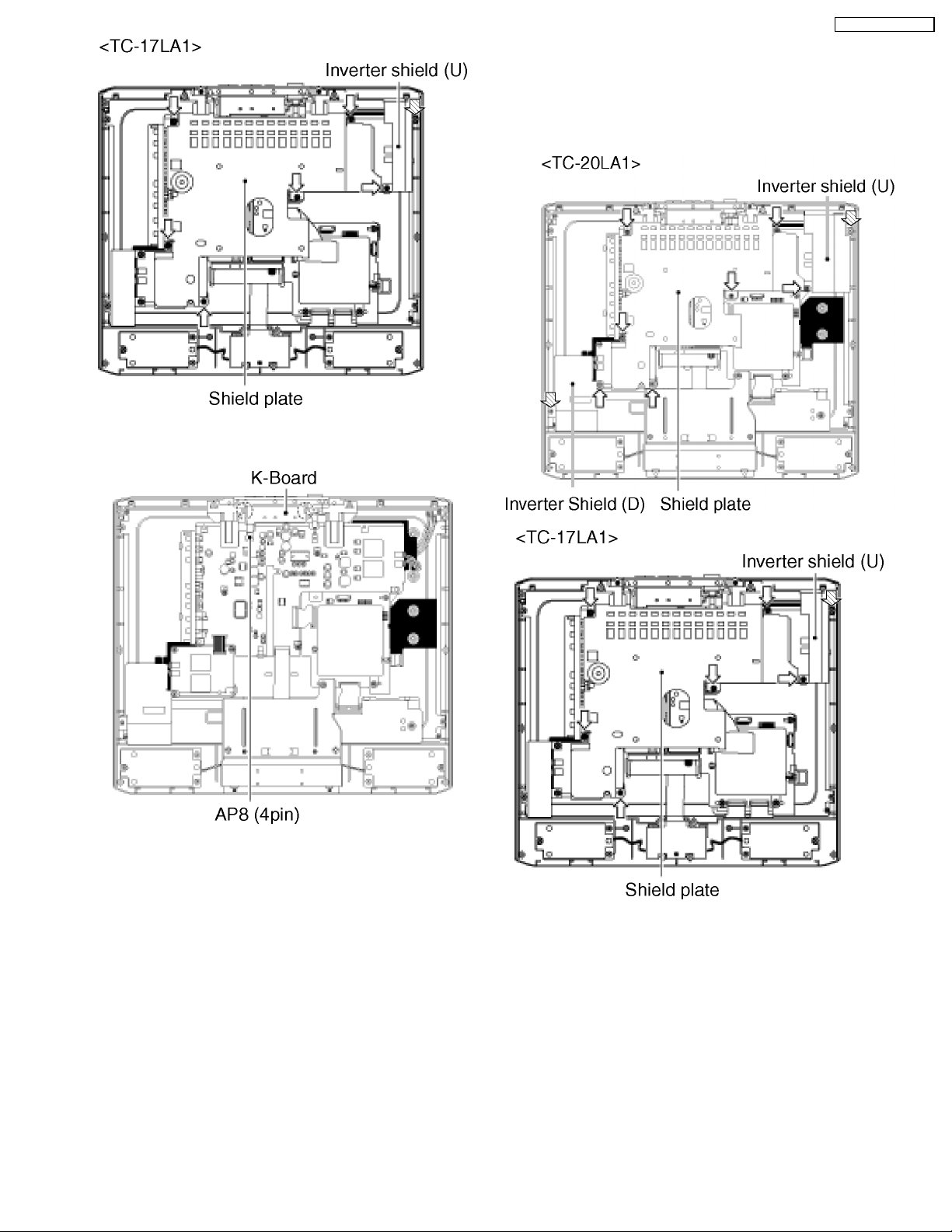

7.7. K-Board

1.Remove the rear cover.

2.Remove the screws (6 pcs) and the screws (2 pcs) (TC20LA1) / (1 pcs) (TC-17LA1) and detach the shield plate

and Inverter plate (U, D).

14

Page 15

3.Disconnect the coupler (AP8) and disengage the hook (2

pcs) and detach the K-Board.

TC-17LA1 / TC-20LA1

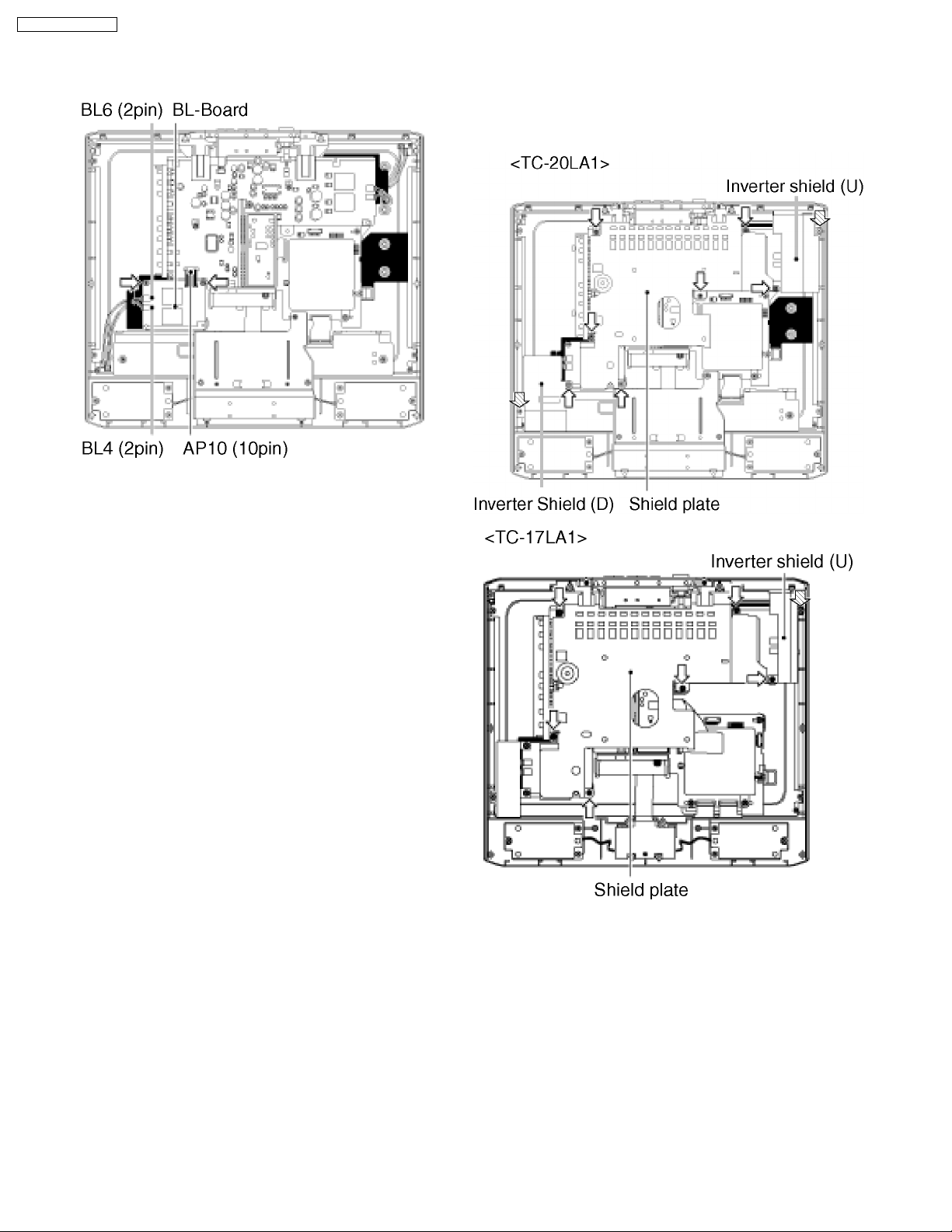

7.8. BL-Board

1.Remove the rear cover.

2.Remove the screws (6 pcs) and the screws (2 pcs) (TC20LA1) / (1 pcs) (TC-17LA1) and detach the shield plate

and Inverter plate (U, D).

Caution:

PCB Fixing screws driving torque: 0.2-0.3 N·m (2-3kg·mm)

Do not tighten screws so hard.

15

Page 16

TC-17LA1 / TC-20LA1

3.Disconnect the couplers (AP10, BL4 and BL6) and remove

the screws (2 pcs) and detach the BL-Board.

7.9. LCD panel

1.Remove the rear cover.

2.Remove the screws (6 pcs) and the screws (2 pcs) (TC20LA1) / (1 pcs) (TC-17LA1) and detach the shield plate

and Inverter plate (U, D).

Caution:

PCB Fixing screws driving torque: 0.2-0.3 N·m (2-3kg·mm)

Do not tighten screws so hard.

16

Page 17

TC-17LA1 / TC-20LA1

3.Disengage the shaft holder hook and detach the power

button shaft.

5.<TC-20LA1 only>

Remove the screw (1 pcs) and the screws (4 pcs) and

detach the lock hinge plate.

4.Disconnect the coupler (AP8) and detach the circuit board

K bracket with K-Board.

6.Remove the screw (1 pcs) and disconnect the couplers (B2

(AP2) and B3 (AP3)) between B-Board and the AP-Board.

17

Page 18

TC-17LA1 / TC-20LA1

7.Disconnect the couplers (AP4, AP6, BL4 and BL6) and the

flexible cable (AP9 and DG3 (TC-20LA1)/ DG4, DG5 (TC17LA1)) and remove the screws (7 pcs) and detach the APBoard, DG-Board and BL-Board.

Caution:

PCB Fixing screws driving torque: 0.2-0.3 N·m (2-3kg·mm)

Do not tighten screws so hard.

8.Remove the screws (2 pcs), detach the LCD panel.

18

Page 19

TC-17LA1 / TC-20LA1

8 Adjustment method

8.1. How to enter into adjustment mode

While pressing [VOLUME-] button of the main unit, press [RECALL] button of the remote control transmitter three times in a row

(within 2 seconds).

8.1.1. Adjustment method.....Use the remote control.

“1” button...Main items Selection in forward direction

“2” button...Main items Selection in reverse direction

“3” button...Sub items Selection in forward direction

“4” button...Sub items Selection in reverse direction

8.2. Cancellation

Switch off the power with the [POWER] button on the main unit or the [POWER] button on the remote control.

8.3. Contents of adjustment mode

·

· Value is shown as a hexadecimal number.

· ·

·

· Preset value differs depending on models.

· ·

·

· After entering the adjustment mode, take note of the value in each item before starting adjustment.

· ·

Main item Sub item Remarks Sample Data

TC-20LA1 TC-17LA1

MAIN YGAIN Video level (RF, video, component) 97 92

B-Y Video level (RF, video, component) 9B 9C

R-Y Video level (RF, video, component) 40 3F

FLICKR Panel flicker (TC-17LA1 Only) --- 74

SUB COLOR Sub color 27 2C

TINT Sub tint 80 80

BACK-L Sub Back light B0 B0

BRIGHT Sub Bright 800 800

B-Y-G B-Y Gain 40 40

R-Y-A R-Y demodulation axis 00 00

GAMMA R-GAIN Test Pattern (100% White) Red gain FE FF

G-GAIN Test Pattern (100% White) Green gain FF EE

B-GAIN Test Pattern (100% White) Blue gain F2 E8

R-CENT Test Pattern (50% White) Red gain 90 5E

G-CENT Test Pattern (50% White) Green gain 80 80

B-CENT Test Pattern (50% White) Blue gain 7D 65

OPT OPT00 (TV) 00 00

RM CODE Remote Control Transmitter Code A A

DVD MTSIN RF Audio input level 20 18

SEPAH Stereo separation Hi 1A 1B

SEPAL Stereo separation Low 04 05

Note:

GAMMA adjustment is for factory adjustment only. Do not change the value.

19

Page 20

TC-17LA1 / TC-20LA1

8.4. Video level adjustment

Test Point Location

8.4.1. NTSC picture RF

Measuring instrument Connection Mode

Remote control transmitter

RF signal

Oscilloscope

·

· Receive 75% color bar signal

· ·

·

· Enter the adjustment mode and adjust the amplitude level of each signal in the following steps.

· ·

TP236~TP239 (GND) :R

TP237~TP239 (GND) :G

TP238~TP239 (GND) :B

ASPECT : 4:3

PIC MODE : STANDARD

BACK LIGHT: +30

AI PICTURE : OFF

1.Y signal

With [VOLUME+/-] buttons of the remote control transmitter, adjust the value appearing below YGAIN indication so that the

value below MAX indication becomes B8.

2.B-Y signal (TP238)

With [VOLUME+/-] buttons of the remote control transmitter, adjust the value appearing below B-Y indication so that the

amplitude (white-blue) at TP238 becomes 0±0.03V.

3.R-Y signal (TP236)

With [VOLUME+/-] buttons of the remote control transmitter, adjust the value appearing below R-Y indication so that the

amplitude (white-red) at TP236 becomes 0±0.03V.

20

Page 21

TC-17LA1 / TC-20LA1

8.4.2. NTSC picture video (VBS)

Measuring instrument Connection Mode

Remote control transmitter

Video signal

Oscilloscope

·

· Receive 100% color bar signal at video input 1.

· ·

·

· Enter the adjustment mode and adjust the amplitude level of each signal in the following steps.

· ·

1.Y signal

With [VOLUME+/-] buttons of the remote control transmitter, adjust the value appearing below YGAIN indication so that the

value below MAX indication becomes B8.

2.B-Y signal (TP238)

With [VOLUME+/-] buttons of the remote control transmitter, adjust the value appearing below B-Y indication so that the

amplitude (yellow-blue) at TP238 becomes 0±0.03V.

TP236~TP239 (GND) :R

TP237~TP239 (GND) :G

TP238~TP239 (GND) :B

ASPECT : 4:3

PIC MODE : STANDARD

BACK LIGHT : + 30

AI PICTURE : OFF

3.R-Y signal (TP236)

With [VOLUME+/-] buttons of the remote control transmitter, adjust the value appearing below R-Y indication so that the

amplitude (cyan-red) at TP236 becomes 0±0.03V.

8.4.3. NTSC picture video (S terminal)

Measuring instrument Connection Mode

Remote control transmitter

Video signal

Oscilloscope

·

· Receive 100% color bar signal at video input 1 (S terminal).

· ·

·

· Enter the adjustment mode and adjust the amplitude level of each signal in the following steps.

· ·

1.Y signal

With [VOLUME+/-] buttons of the remote control transmitter, adjust the value appearing below YGAIN indication so that the

value below MAX indication becomes B8.

2.B-Y signal (TP238)

With [VOLUME+/-] buttons of the remote control transmitter, adjust the value appearing below B-Y indication so that the

amplitude (yellow-blue) at TP238 becomes 0±0.03V.

TP236~TP239 (GND) :R

TP237~TP239 (GND) :G

TP238~TP239 (GND) :B

ASPECT : 4:3

PIC MODE : STANDARD

BACK LIGHT : + 30

AI PICTURE : OFF

21

Page 22

TC-17LA1 / TC-20LA1

3.R-Y signal (TP236)

With [VOLUME+/-] buttons of the remote control transmitter, adjust the value appearing below R-Y indication so that the

amplitude (white-red) at TP236 becomes 0±0.03V.

8.4.4. NTSC Component (525i) level adjustment

Measuring instrument Connection Mode

Remote control transmitter

525i signal

Oscilloscope

·

· Receive 100% color bar signal at video input 1 (S terminal).

· ·

·

· Enter the adjustment mode and adjust the amplitude level of each signal in the following steps.

· ·

1.Y signal

With [VOLUME+/-] buttons of the remote control transmitter, adjust the value appearing below YGAIN indication so that the

value below MAX indication becomes DC.

2.B-Y signal (TP238)

With [VOLUME+/-] buttons of the remote control transmitter, adjust the value appearing below B-Y indication so that the

amplitude (yellow-blue) at TP238 becomes 0±0.03V.

TP236~TP239 (GND) :R

TP237~TP239 (GND) :G

TP238~TP239 (GND) :B

ASPECT : 4:3

PIC MODE : STANDARD

BACK LIGHT : + 30

AI PICTURE : OFF

3.R-Y signal (TP236)

With [VOLUME+/-] buttons of the remote control transmitter, adjust the value appearing below R-Y indication so that the

amplitude (cyan-red) at TP236 becomes 0±0.03V.

8.4.5. NTSC Component (525p) level adjustment

Measuring instrument Connection Mode

Remote control transmitter

525p signal

Oscilloscope

·

· Receive 100% color bar signal at video input1 (S terminal).

· ·

·

· Enter the adjustment mode and adjust the amplitude level of each signal in the following steps.

· ·

1.Y signal

With [VOLUME+/-] buttons of the remote control transmitter, adjust the value appearing below YGAIN indication so that the

value below MAX indication becomes B8.

TP236~TP239 (GND) :R

TP237~TP239 (GND) :G

TP238~TP239 (GND) :B

ASPECT : 4:3

PIC MODE : STANDARD

BACK LIGHT : + 30

AI PICTURE : OFF

22

Page 23

TC-17LA1 / TC-20LA1

2.B-Y signal (TP238)

With [VOLUME+/-] buttons of the remote control transmitter, adjust the value appearing below B-Y indication so that the

amplitude (white-blue) at TP238 becomes 0±0.03V.

3.R-Y signal (TP236)

With [VOLUME+/-] buttons of the remote control transmitter, adjust the value appearing below R-Y indication so that the

amplitude (white-red) at TP236 becomes 0±0.03V.

8.5. Flicker Adjustment

1.Enter the adjustment mode and select the " FLICKR".

2.Adjust the Flicker Adjustment until the flicker displayed on the screen is minimum.

Note:

Adjustment shall be done after it is made to overrun value of adjustment once as shown figure A.

Note:

Make the adjustment to look for the optimum point because the level of flicker doesn´t disappear on the screen completely as

shown figure A.

Figure A

23

Page 24

TC-17LA1 / TC-20LA1

8.6. MTS Adjustment

Caution:

MTS adjustment shall be after the aging of 30 minutes or longer.

8.6.1. RF Audio Input level Adjustment

Instrument name Connection Remarks

1.Filter jig

2.RF signal generator

3.RMS voltage meter

1.Apply following RF signal at Antenna input.

VIDEO : Flat field, 30 % modulation

AUDIO : 300 Hz, 100 % modulation, monaural

(70dB±5dB,759, P/S 10 dB)

Note:

Make sure 75 us PRE-EMPHASIS is off.

2.Adjust "MTSIN" data (Input level) until the RMS voltage meter indicates 106 mVrms ± 6 mVrms

TPA180 - GND (TP181)

RF ANT. INPUT

Filter jig

Filter jig

8.6.2. Stereo Separation Adjustment

Instrument name Connection Remarks

1.RF signal generator

2.Oscilloscope

3.Headphone jig

1.Select STEREO mode in the AUDIO Menu.

2.Set “Audio volume” DAC to “40”.

3.Apply following RF signal at Antenna input.

VIDEO : Flat field, 30% modulation

AUDIO : 300Hz, 30% modulation, STEREO (LEFT only)

(70dB ± 5dB, 75 9 OPEN, P/S 10dB)

Note:

After setting 30% modulation with PL SW and NR SW off, turn PL SW and NR SW on.

4.Adjust "SEPAL" data (Low-level separation) until the amplitude.

5.Apply following RF signal at Antenna input.

VIDEO : Flat field, 30% modulation

AUDIO : 3kHz, 30% modulation, STEREO (LEFT only)

(70dB ± 5dB, 759 OPEN, P/S 10dB)

Note:

After setting 30% modulation with PL SW and NR SW off, turn PL SW and NR SW on.

6.Adjust "SEPAH" data (High-level separation) until the amplitude of the waveform on the oscilloscope is minimum.

7.Repeat steps 3. to 6. until Low-level separation and High-level separation satisfy above-mentioned conditions.

Note:

The separation must be more than 20 dB at 300Hz and 3kHz.

RF ANT. INPUT

TPA150 - GND (TP181)

Headphone jig

24

Page 25

9 Conductor Views

9.1. AP-Board

AP-BOARD(FOIL SIDE)

6

TNPH0541

TC-17LA1 / TC-20LA1

PbF

TP610

5

TP609

TP606

TP605

4

JK1006

3

2

Parts Location

IC

IC802 G-5

IC2001 E-5

TRANSISTOR

Q2000 F-4

Q2001 F-5

Q2002 F-4

Q2006 F-3

Q3001 G-3

AP-BOARD (FOIL SIDE)

TEST POINT

TP100 F-5

TP102 F-3

TP605 B-4

TP606 B-4

TP609 B-5

TP610 B-5

TP800 D-5

TP801 F-5

TP802 D-5

TP803 H-5

TP804 G-4

TP805 F-5

TP806 G-4

1AP

7

10

7

SEE REVERSE FOR ORDERNO.

TNPH0541

T620

1

6

T610

1

6

JK1005

JS805

D621

C635

C636

JS803

D612

D622

D630 D631

D611

D641

R618

D640

C630

R631

R641

R621

C627

R630

C616

C640

R623

R613

C626

C631

R640

C615

C632

C617

C641

C625

C642

JS804

L620

L610

C619

C629

C606

R605

TP800

C628

C601

C602

C603

JK1004

R642

TP802

L611

5

C654

R647

R3045

D816

L807

C846

D813

3

C836

L3002

D818

C831

D815

C3033

C3031

C813

R839

C834

C852

R837

R840

C844

C832

C2205

JK801

TP805

152

C833

L2200

C2215

TP102

C848

D817

4

C842

C830

D812

C2211

R2221

D811

R835

C841

1

C829

D3012

C3100

R834

R2210

C2206

L804

C828

R2220

L3003

IC802

R833

TP806

R846

L805

R2222

L3101

4

R845

C840

D810

C2218

C3042

C3105

AP8

C838

C851

R2207

C3041

D809

R2206

C2219

C3039

R3058

C804

C850

C3045

R825

R832

Q3001

R831

C826

C3047

C3049

C819

C827

D806

JK1001

YL

R3016

C825

C3013

11

D804

L802

10

C823

R3053

R3049

R3031

D808

R3015

AP10

TP803

R3014

C3000

D3004

C3014

R3017

D807

C3012

C3019

JK1002

R3020

R3026

C3020

2

1

C3015

R3022

C3021

C3001

R3003

C3017

R3021

C3009

R3012

R3025

R3023

R3004

R3024

R3018

RPB

C3011

C3002

PR

R3002

R3001

C3016

10

11

4

C3003

V1.C

V1.Y

3

9

C3018

R3010

C3007

C3005

R3008

R3009

C3006

D3001

D3011

7

JK3003

D3008D3009

D3007

RL1

D3000

JK1007

JK3002

V2.C

V2.Y

L2L1V1 V2 R1 R2

6

28913

8

2

JK3000

56

1

7

12

JK3001

14

R817 R818

C817

C821

R830

R827

C822

R814

R829

C810

R815

L803

C824

TP804

C2230

C2201

C3052

JS3005

C3043

C3044

C3032

R3043

C3035

R3041

R3029

R3030

R3032

C2022

C800

R801

S800

4

3

2

C2032

C2034

C2039

1

6

R811

15

IC2001

C2030

C2031

C2038

C2029

C2025

C2027

C2021

D2004

C2018

20

C2024

R2013

R2014

L2003

28

C2006

C2016

R2006

R2004

C2007

14

C2315

C2317

C2015

C2014

C2011

C2013

C2012

R2012

R2010

R2322

C2008

Q2002

JS2386

R645

C2300

C2307

R648

R632

R2020

C2319

R2018

C2308

C2321

C2023

10

C2310

C2306

C2020

C2318

R2300

C2019

R2302

C2017

R2303

C2301

1

C2303

C2313

JS2383

Q2006

C802

C2005

R2321

Q2001

C2009

AP3

1

TP801

9

C2010

R2011

R2009

D802

Q2000

C835

TP100

D803

R838

C845

R836

AP

1

JK1008

C815

C814

AP9

2

1

C820

AP2

R2305

C2323

15

12

11

1

TC-17/20LA1

AP-BOARD TNPH0541

ABCDEFGH I

TC-17/20LA1

AP-BOARD TNPH0541

25

Page 26

TC-17LA1 / TC-20LA1

6

AP-BOARD(COMPONENT SIDE)

TNPH0541

Q2005

JS2384

50

C2019

JS2003

JS606

R2016

R2005

C2318

JK1008

C

C800

R800

B

C2020

R2319

R2320

R2017

C2306

C2026

C2021

NP

16

17

C2037

20

E

C2032

10

R2003

IC2300

R2021

C2023

C2321

R2023

C2319

1

32

15

14

C2033

R2019

R2022

4

3

2

5

6

1

S800

C2034

IC2001

C2028

C2307

C2300

C604

7

C2304

C2302

R2301

JK1004

Q802

R606

R636

R633

JS604

JS605

C806

PA625

IC600

C601

R634

C654

C602

L611

NP

1

IC601

8

14

C603

R2304

C2305

C2309

C2311

C629

R601

R603

R637

C622

L624

Q625

R635

5

8

1

D601

PA605

C618

R611

C614

R627

4

C619

D602

Q607

R628

R629

Q608

R619

R617

C623

C607

L620

R607

L610

D610

D620

R620

Q615

C624

C633

E

B

R622

E

C631

B

L614

R610

E

B

R612

E B

C641

R626

D605

R616

R615

R614

R625

R624

D625

C

Q620

C

Q621

C

Q610Q611

C

ABACAD

JK1005

T620

1

67

T610

1

6

Parts Location

IC

AP

IC600 F-4

IC601 F-4

IC800 C-4

IC801 C-4

IC802 C-5

IC803 D-3

IC2001 D-5

IC2201 C-3

IC2300 E-3

IC3000 C-2

IC3001 C-2

IC3003 D-3

TRANSISTOR

Q607 F-3

Q608 F-4

Q610 G-4

Q611 G-4

Q615 G-4

Q620 G-5

Q621 G-5

Q625 F-4

C2022

R805

R806

R807

R809

L2003

R2325

D2353

R3038

Q804

Q2008

IC3003

JS3003

JS2387

JS2388

C801

R2027

R2323

R3050

R3037

R2007

C2004

R2002

R2025

R802

R2308

R803

C803

R2008

D2005

R2029

R2028

R2327

Q2007

R2324

C2326

C808

2

Q2003

R2326

JS3004

D2352

1

R804

C2036

Q2010

JS2005

JS2002

JS2382

JS2385

R2307

D800

JS2004

C2325

JS2389

JS2390

Q801

28

Q2004

1

C2017

AP1

R2015

C2018

L2300

C2320

C2312

C2314

C2316

JS2381

1

C805

C844

C843

13

R3101

D3100

R3100

C3101

+

R847

C848

R823

2

5

9

8

L806

C813

C831

IC801

C2209

C2205

R824

4

C812

C811

JK801

C847

R844

Q813

Q812

C2208

C832

C2216

C2207

C849

15

L3002

C3033

L807

3

L2200

C2210

C2215

IC803

23

R843

1

R821

C839

D805

R822

C845

R810

D801

R808

C2009

Q800

Q803

C802

C2010

1

Q2009

C3056

1

4

11

JS2001

JS2000

9

R2306

C2324

15

C2006

AP3

1

AP2

12

NP

C2005

R2024

R2026

NP

58

AP9

JK1001

JK3002

YLPBRPR

5

C823

JS601

C817

C816

9

V2.C V1.C

10

4

56

12

123

789

V2.Y

4

3

D3002

R3055

JS603

JK1002

C3048

C3059

R3056

IC3000

R3057

16

L803

C3050

1

19

20

L802

11

D3003

V1.Y

D3006

D3010

D3005

V1

R3007

C3004

V2

R3011

L1

C3008

JS602

JK3000

L2

JK3001

R1R2

L

R3054

R3052

R3048

R3044

R3042

R3039

C3034

C3029

64

R3060

C818

C2230

C2201

R2201

C3051

C819

IC800

C3046

8

1

C824

R3059

C809

R3061

C804

R820

C850

C851

1

R3062

52

32

R819

L805

C2218

24

C2219

51

33

AP8

L804

+

C3041

L3101

C807

16

1

IC2201

C2204

14

C2212

IC802

JS600

R816

1

4

C2211

12

R848

C3042

JK3003

C3024

2

R

JK1007

JS802

10

2

AP10

1

11

TP180 TP181

C3025

R3033

R3065

Q3101

R3103

R3066

Q3100

C3057

C3105

C3058

C3106

D3102

4

58

C3103

R3102

1

C3102

L3100

C3100

IC3001

C3104

1

TNPH0541

JS3000

JS3001

JS3002

ORDER

NO.

10

AP 1

C621

BLACK

AP4

2

C620

1

10

7

CAUTION:HIGH VOLTAGE

C611

C610

2

AP6

1

WHITE

JK1006

AP-BOARD (COMPONOENT SIDE)

TRANSISTOR

Q800 D-5

Q801 E-5

Q802 F-5

Q803 D-5

Q804 D-5

Q812 D-4

Q813 D-5

Q2003 D-4

Q2004 E-5

Q2005 E-6

Q2007 D-3

Q2008 D-4

Q2009 D-4

Q2010 E-4

Q3100 C-2

Q3101 C-2

TP

TP180 B-2

TP181 C-2

TC-17/20LA1

AP-BOARD TNPH0541

ABCDEFGH I

TC-17/20LA1

AP-BOARD TNPH0541

26

Page 27

9.2. DG-Board (TC-17LA1)

6

TC-17LA1 / TC-20LA1

5

4

3

2

DG-BOARD(FOIL SIDE)

TXNDG10JAK (TC-17LA1)

C6439

R4078

R4089

B

R6423

R6428

C6304

C6301

R4095

C6483

C4108

C6305

R6442

C4117

5

C6302

C6348

R1065

R1072 R1073

R1066

R1069

LC6350

C4107

C6300

C4103

R4097

L4009

LC6351

C4099

C4076

C4077

R4098

R4099

C6335

14

IC1003

1

R6412

R6481

4

1

8

R6431

R6455

C6481

R6306

TNPA2852

SEE REVERSE FOR ORDER NO.

1

L6305

L6304

C6331

D2302

C6334

JS1050

D2301

JS1053

C6404

D6409

C6415

C6416

C6414

C6480

C6330

JS1051

JS1052

L2301

C2339

R6480

C6435

JS1054

R6427

LC6401

C6417

C6434

R6407

C6412

M6V

C6326

DG

R4060

C4033

R4050 R4051

C4029

R4061

C4028

R4047

R4048

R4062

R4052

C4039

C4036

C

C6318

C6317

C6323

C6325

E

C4064

R4086

C4101

R4093

R4074

R4075

R6323

R6485

R6477

R6478

R6479

R6469

R6472

R6473

C6431

C6428

R6422

C6443

R6475

R6474

C6432

C6429

C6442

R6483

R6437

R6430

R6426

R6470

R6476

Q6402

16

9

Q6404

IC6402

1

8

Q6401

C6422

C6425

C6405

R6406

5V

C6315

5.36V 11V

C6459

R6301

R6300

R6302

C6441

R6429

R6424

R6305

R6319

R4071

C4070

R6458

IC6406

D6404

Q6406

R4057

R6411

C6303

C6437

R4083

R4084

R4094

R4096

R4055

7

C6457

R6309

R4063

R4070

C6309

C6456

8

R4077

R6308

R4054

C4073

C4071

C6400

C6336

R6200

R4080

R6401

C6436

C6312

Q6408

C6455

C4094

C4085

R4092

C4097

C4098

R4076

C6308

R6303

R6304

R6310

C6401

C6306

R4079

R4088

C4072

C4065

R4069

1

14

C6482

R4091

C4100

R4090

R4073

C4102

C4089

C4090

C4091

IC6408

R1064

R6438

C1062

R1050

C1034

C4087

C4116

R6441

R4082

R6433

C6337

R1032

C4081

8

R1035

C6338

R4087

7

C1027

C6339

L4008

R1017

C6340

Q1004

Q1005

D

C4079

R1046

R4067

C4055

C4025

C6341

C1011

IC6409

1

R1077

14

R1039

R1037

C1053

IC1006

R6439

C6342

E

R1067

C1003

R1080

C6343

C1063

C4067

R1068

R4045

Q4011

C4060

R4081

C4088

8

7

C6344

R1085

R4085

C1030

C1029

C1049

C6345

B

R1022

R1049

C6346

C1004

C1065

C4124

R1041

R6454

R4046

D1001

C1032

R1038

C4110

C4109

C

1

R1082

R1045

C1033

C4058

3

C4027

C1038

R1007

C4026

C4057

C4068

4

R1084

JS4018

5

IC1004

R4053

C1048

R1042

R1074

R4039

LC4001

D

R1019

C1040

C4061

C1064

R4037

C4047

R1043

R1070

1

R1008

Q4009

Q4006

Q4010

R4041

R1091

L4000

R1201

C4051

DG-BOARD(COMPONENT SIDE)

TXNDG10JAK (TC-17LA1)

LC4000

R4017

R4012

C4023

C4008

C4009

C4111

C4016

L4002

A

F

NP

C4005

Q4005

C4044

R4049

1

R4058

R4016

R4066

C4056

R4068

C1007

C4063

16

9

R4015

IC1005

35

8

R1062

C1066

R1006

R1031

NP

D1003

C1031

C1026

C1025

R1034

R1026

R1033

Q1019

D1008

JS1059

R1051

R1052

Q1016

Q1017

JS1060

C1043

C1051

C1018

C4017

C1039

C1045

C1050

R4114

C4112

C4010

R4019

R4013

70

C1002

R4043

R1004

C4014

R1003

C1001

R1202

R1028

C1020

Q1010

Q1009

R1029

R1030

C1019

Q1018

R1053

Q1020

JS1058

R4111

R4009

C4003

F

R4020

R4010

R4112

C4004

R4011

C1016

36

R1018

C4024

IC4002

C4021

Q1008

C1060

C4019

C4020

R1023

R1016

C4022

C4018

C1035

R1048

C1041

C1042

C1017

Q4000

C1021

Q4003

C1044

Q4001

Q4004

Q4002

JS4015

JS4016

R4038

R4036

R4024

R4027

R4025

R4018

R4040

R4044

R4028

R4021

A

R4023

R4026

R4022

JS4019

R1021

R1024

C1056

JS1032

JS1031

AB

AC

AD

AE

AF

JS1035

C4126

JS1033

H

C4030

C4040

R4006

C4041

R4001

C4001

1

R4004

C4127

R4007

C4121

NO.

R1098

ORDER

TNPA2852

E

R4100

R4064

C4114

R4034

C4115

R4033

R4056

C4007

R4101

R4102

R4103

R4104

R4105

R4110

R4109

R4108

R4107

Q1006

Q1002

Q1007

R1002

R1005

R1009

Q1003

R1010

C4119

R1100

D1100

R1101

L4001

JS1034

L4011

C4035

C4120

L4012

C1100

Q1100

34

C4031

C4032

C4034

C4037

C4038

R1102

C1057

12

DG

R4042

R1020

R1097

C6438

JK1012

PbF

G

R6320

R6321

R6322

R6324

R6325

C6321

R6207

C6310

157

DG7

1

156

C6324

Parts Location

DG

DG-BOARD

7

F

C1047

C6327

C1008

R1013

R1060

C1009

R6208

C6320

105

104

R6336

C6319

10

10

11

10

11

R6471

A

8

R6484

R6405

5V5.36V 11V

R6327

R6328

C6328

LG5

C6314

C6403

Q6300

C6427

C6430

C6433

1

IC6403

20

1

Q6301

IC6404

C2340

L2302

C6458

20

JK2300

1

20

R6400

L6401

C6413

C6409

IC6405

D6401

D6402

C6407

L6404

L6402

C6411

R6467

Q6412

Q6411

C6406

L6403

D6400

R6466

C6408

L6400

Q6400

C6423

D

M6V

IC1000 E-3

IC1001 E-2

IC1002 F-3

IC1003 B-3

IC1004 C-3

IC1005 C-3

IC1006 B-3

IC1007 E-3

IC1008 E-3

IC4000 E-3

IC4001 E-5

IC4002 D-3

IC4003 E-3

IC4004 F-3

IC6300 F-3

IC6400 F-2

IC6401 F-2

IC6402 A-2

IC6403 G-3

IC6404 G-3

IC6405 G-2

IC6406 B-2

IC6407 G-2

IC6408 B-2

IC6409 B-2

TRANSISTOR

Q1002 D-3

Q1003 D-3

Q1004 B-2

Q1005 B-2

Q1006 D-3

Q1007 D-3

Q1008 D-3

Q1009 D-2

Q1010 D-2

Q1014 F-4

Q1015 F-4

IC

Q1016 C-2

Q1017 C-2

Q1018 C-2

Q1019 C-2

Q1020 C-2

Q1100 E-3

Q4000 D-4

Q4001 D-4

Q4002 D-4

Q4003 D-4

Q4004 D-4

Q4005 C-3

Q4006 C-5

Q4009 C-5

Q4010 C-5

Q4011 B-5

Q6300 G-3

Q6301 G-3

Q6400 G-1

Q6401 A-2

Q6402 A-2

Q6403 F-2

Q6404 B-2

Q6405 F-2

Q6406 B-2

Q6407 F-2

Q6408 B-2

Q6409 F-2

Q6410 E-2

Q6411 G-1

Q6412 G-2

Q6413 F-2

TP

TP236 F-5

TP237 F-5

TP238 G-5

TP239 G-5

R6205

R6435

R6206

TP238

C6440

1

Blue

G

16

40

JK1011

C6313

C6322

R6326

C6311

IC6407

C6448

R6440

GND

TP239

10

C6316

1

C6460

128

11

97

96

9

C

R6408

Green

C4075

L4007

C6419

B

Q1015

LC1000

C6426

R6402

R6421

R6338

D

DG2

C6451

1

C4095

C4096

C6424

R6419

C4083

C4093

C4105

Q6413

Q1014

1

C6420

C1054

R1086

C4106

R4065

C4084

C4086

4

C6332

DG6

X4500

C4092

C4129

IC1002

5

C4082

5

13

R6403

R6404

Q6407

R6337

TP236

1

IC6300

C1014

IC6401

R6486

Q6405

R1094

3

C6452

R6409

C6453

R6456

R6457

Red

TP237

1

208

52

C6307

53

IC4004

R6201

1

C4125

2

R6204

R6202

R6203

C6402

32

R1025

C1015

33

4

64

65

IC6400

C6418

C6454

R6432

Q6403

R6434

R6425

R6436

D6403

R6410

D6408

D6406

C6449

R6444

R6443

C6446

R6353

DG4

IC4001

1

JK1013

JS1056

5

R1061

JS1055

R4059

JS4013

C1059

C4043

R4014

C1061

C4118

R4003

C4122

C4123

C4011

C4015

R4002

R4005

C1010

R1089

IC1001

LG2

C1006

R6358

R1040

C4042

C1058

64

65

H

128

C4128

E

129

C4045

R4035

C1013

20

IC1008

1

21

22

42

43

R1092

R6352

R6351

R6350

R6359

JK1010

1

C4000

JS1057

R4000

LG4

C1052

DG1

JS4017

50

C4002

L4013

R4008

C4113

C4006

IC4000

R4106

C4012

C4013

R1090

R1014

R1015

IC1007

R1071

C1046

R1047

C1055

R1056

D1005

D1006

R1075

R1036

C1028

Q6410

R6416

C

R6415

C6447

C1005

IC4003

R6349

R6348

1

1

C4052

LG3

C4048

C4049

C4046

C4050

R4200

C4130

R1012

11

1

10

3

C4059

C4066

IC1000

C4054

L4005

D1000

R1087

5

4

R1011

F

1

84

64

63

R1044

R1093

R6341

R6344

R6342

R6343

R6340

DG5

R6347

R6339

C1023

R6346

R6357

C1024

C4053

R6345

C4069

R6356

R1078

R6355

D1002

40

C4074

X1001

R6354

8

R1088

C4062

C4080

1

256

193

192

R4072

C4078

L4006

B

C1012

R1027

5

8

C1036

C1037

C1022

Q6409

R6468

A

C6421

R6420

R6360

R6413

R6414

R6417

R6418

1

TC-17LA1

DG-BOARD TXNDG10JAK

ABCDEFGH I

TC-17LA1

DG-BOARD TXNDG10JAK

27

Page 28

TC-17LA1 / TC-20LA1

9.3. DG-Board (TC-20LA1)

6

5

DG-BOARD(FOIL SIDE)

TXNDG10HZK(TC-20LA1)

LC4000

R4039

Q4009

R4017

Q4006

C1048

R4012

L4000

C4023

Q4010

C4008

C4009

JS4012

C4016

R4037

C4047

A

F

C4005

NP

R4011

Q4005

R4058

C4044

1

R4049

R4066

16

1

C1031

R1043

R1046

R1037

C1066

C1053

R1039

R4016

C4056

C4063

R4068

C1007

C4132

R4015

35

IC1005

89

R1062

R1006

NP

D1003

R1033

C1026

R1026

C1025

Q1010

C1019

R1034

D1008

R1051

R1052

JS1059

JS1060

JK1010

R1031

C1045

R1004

L4002

C1039

C1002

C4017

C4010

R4019

R4013

R1003

C1001

C1051

R4114

Q1019

Q1020

R1053

C4014

Q1018

R1029

Q1009

R1030

JS1058

C1050

R1028

C1016

C1020

C1018

70

C1060

C1043

36

R4043

R1018

C4021

R1202

C4024

R1023

C4020

C4022

C4019

IC4002

R1048

C4018

C1056

Q1008

R1021

C1042

R1016

C1041

C1044

R1024

C1035

C1017

C1021

Q4000

Q4003

Q4001

Q4004

Q4002

JS4015

JS4016

JS4014

R4050 R4051

C4033

R4060

C4028

R4047

C4029

JK1012

R4061

R4048

R4062

C4036

R4052

C4039

C

R4083

R4084

R4094

R4096

R4077

R6319

R4022

B

R4026

JS1054

R4078

R4089

C6323

JS4019

R4057

R4071

C4070

C4051

C6326

R4055

C4073

C4071

R6208

R4063

C4065

R4069

JK1011

C2339

R4054

C4072

R4070

L2301

C6325

JS1052

C6318

JS1051

LC6303

C6317

R6304

R6310

R6305

R4036

R4025

R4040

R6301

R6302

R6303

R6308

LC6301

R6300

R4038

R4024

R4044

C6303

LC6302

R4027

R4028

R4021

R4023

R4086

R4075

R4018

C6311

A

LC6304

C6335

C6309

C6348

C4064

R4074

LC6306

SEE REVERSE FOR ORDERNO.

4

TNPA2860

1

DG

JK2300

JS1050

JS1053

D

R4041

R4045

Q4011

R4067

C4060

C4055

D2302

D2301

R4079

R4088

3

2

C4101

R4093

R4080

R6200

C6312

C4094

C4085

R4092

C4097

C4098

R4076

E

LC6308

C6336

R6309

C6306

C4088

C4087

C4089

C4117

LC6310

R4098

C6301

C4003

R4020

C4004

C6333

C6308

R4095

R4099

C1049

R1007

C6305

C4116

C4108

C1004

C4102

C6302

LC6350

L4009

LC6327

R1069

C6300

LC6351

R4111

R4009

R4010

R1066

C1062

R1050

C1034

R4112

C6304

C4103

R4097

F

LC6325

C4077

C4107

C4090

C4091

Q1004

Q1005

C4099

14

1

C1003

R1008

R4091

C4100

R4090

R4073

R4082

R1049

LC6323

C4076

R1041

LC6321

C4081

R4087

R1017

7

IC1003

R1073

L4008

R1065

C4079

R4081

C4067

C1063

14

8

8

1

IC1006

C1011

R1067

C1027

R1032

R1035

R6330

C6330

C6334

C6331

L6305

C4110

R1072

R1064

C4026

C4025

R4085

B

7

R1068

R1022

E

R1077

C4124

L6304

C1065

D1001

R4046

R1084

C4109

3

R1082

LC4001

JS4018

C4027

C

R4053

D

C4057

C4068

C4061

C4058

R1070

C1040

C1038

R1019

R1201

1

5

4

C1064

IC1004

C1030

C1029

R1042

R1038

C1033

DG-BOARD(COMPONENT SIDE)

TXNDG10HZK(TC-20LA1)

JS1031

AB

AC

JS1033

AD

AE

AF

JS1034

R4006

1

JS1035

R4001

C4001

R4004

C4127

C4121

R4007

TNPA2860

DG

ORDERNO.

PbF

R1101

R4101

R1100

R4102

R4103

R4104

L4001

R4105

R4110

C4007

R4109

R4108

R4107

R4106

IC4000

Q1002

R1020

Q1007

R1002

R1005

R1009

Q1003

R1010

R1098

2

Q1006

JS1032

C4119

C4120

R1102

3

C1100

C1057

IC1007

D1100

R4042

R1061

JS1056

JS4013

JS1055

A

1

JS1057

LG4

C1052

DG1

1

4

C1061

C1046

R1047

R1056

C4006

D1005

R4002

JS4017

50

R4005

C4002

C4122

R4008

C4123

Q1100

R4014

R1089

C1013

R1097

C1006

R1090

R1014

R1015

C1010

R1071

D1006

42

LG2

C1055

43

R1075

C1028

C4128

L4013

R1036

C1058

IC4001

1

C4050

C1005

1

LG3

IC4003

D1000

IC1000

R1012

11

5

1

10

4

3

C

R1087

R4200

C4062

C4074

C4069

C4059

C4066

C4054

C4130

1

R1094

84

5

R4059

C1059

C4043

C4046

64

65

128

B

129

C4045

R4035

20

C4015

1

IC1008

21

22

64

63

IC1001

R1091

R1093

R6328

Q1016

R1040

R1044

JK1010

R1092

Q1017

Q6301

R6327

C6328

C6314

Q6300

LC6313

LC6312

1

Q1015

D1002

R1078

LC6314

C4080

192

1

C4078

L4006

R1086

5

8

C1022

193

Q1014

R1074

LC6315

DG

R6204

R6205

TP238

R6206

C4012

C4013

LC6307

GND

Blue

TP239

JK1012

10

DG6

Parts Location

L4005

C1047

156

R6325

DG7

1

C6324

7

C6327

105

LG5

C6320

C6319

R6323

IC

IC1000 F-3

IC1001 F-2

IC1002 F-3

IC1003 B-2

IC1004 C-3

IC1005 C-3

IC1006 B-3

IC1007 E-2

IC1008 E-3

IC4000 E-3

IC4001 F-4

IC4002 D-3

IC4003 F-4

IC4004 F-3

IC6300 F-3

TRANSISTOR

L2302

C2340

Q1002 E-3

Q1003 E-2

Q1004 B-2

Q1005 B-2

Q1007 E-3

Q1008 D-3

Q1009 C-2

Q1010 C-2

Q1014 F-3

DG-BOARD

TP

Q1015 F-3

Q1016 E-2

Q1017 F-2

Q1018 C-2

Q1019 C-2

Q1020 C-2

Q1100 E-3

Q4000 D-4

Q4001 D-4

Q4002 D-3

Q4003 D-4

Q4004 D-3

Q4005 C-3

Q4006 C-4

Q4009 C-4

Q4010 C-4

Q4011 A-3

Q6300 F-2

Q6301 F-2

TP236 F-4

TP237 G-4

TP238 G-4

TP239 G-4

C6313

R6207

C4113

C4011

B

LC6305

R4056

LC6300

R6322

C6316

C4114

R4034

R6329

R6326

R4033

R4064

R4100

C4115

JK1011

R1060

C6329

R6324

R1013

C6310

157

104

R6336

C6321

R6320

R6321

C6315

C6322

C

R1011

C1008

R1088

C1009

JK2300

Green

Red

C6332

TP236

X4500

5

IC4004

IC1002

IC6300

52

LC6322

C4126

1

C4053

1

53

32

LC6324

LC6319

C4082

C4000

R4000

208

C4118

R4003

50

R6201

1

C4125

LC6326

R6203

C1014

L4012

A

L4011

C4037

C4038

C4030

C4040

C4041

C4042

R1025

C4031

C4032

C4034

C4035

LC6328

R6335

C6307

TP237

R1027

C1015

LC6311

R6202

LC6309

C1054

DG2

8

C4048

C4049

C4052

256

C4083

C4093

C4084

C4095

C4086

C4096

C4105

C4106

C4092

C4075

R4072

R4065

C4129

L4007

C1012

4

1

C1037

LC1000

X1001

C1036

C1023

C1024

LC6320

LC6316

LC6317

LC6318

DG3

1

TC-20LA1

DG-BOARD TXNDG10HZK

ABCDEFGH I

TC-20LA1

DG-BOARD TXNDG10HZK

28

Page 29

9.4. B, BL, K and V-Board

TC-17LA1 / TC-20LA1

B-BOARD(FOIL SIDE)

TNPA2857

6

SEE REVERSE FOR

ORDER NO.

1B

TNPA2857

SDA

SCL

R008

R

L

R002

B3

1

9

C005

L005

R019

C004

GND

AFT

C003

GND

R009

R014

R016

3

4

1

2

C008

R020

R013

R005

R007

C015

C007

R004

Q001

VIDEOOUT

AUDIO

AGCCONT

BV

TP

AGCOUT

C011

C013

C010

BTL

IF1

C006

R012

1

L001

C009

R011

+B

R006

L002

SDA

C002

SCL

C001

ADRS

R003

AGC

TU

R001

R010

C016

TNR001

PbF

B2

15

BL-BOARD(FOIL SIDE)

TNPA2861

11

5

4

BL 1

BL1

PbF

1

210

D651

67

1

D661

6

SEE REVERSE FOR ORDERNO.

TNPA2861

1

TP660 TP661 TP664 TP665

T650

7

T660

B-BOARD(COMPONENT SIDE)

TNPA2857

AGCTUADRS

TNR001

SCL

SDA

+B

BTL

IF1

L002

C014

15

B2

R017

R015

L001

1

C010

BL-BOARD(COMPONENT SIDE)

TNPA2861

CAUTION:

HIGH VOLTAGE

BLACK

BL6

BL4

WHITE

T650

7

C650

1

C663

10

10

T660

7

C651

2

1

C662

2

6

1

6

TNPA2861

ORDER

1

BV

TP

AUDIO

C013

GND

AFT

VIDEOOUT

AGCCONT

AGCOUT

C008

SCL

SDALR

GND

34

9

L005

12

TNPA2857

ORDER

NO.

K

B3

B

1

1

B

1

11

0

BL1

BL

R651

R661

NO.

BL

1

V

K-BOARD(FOIL SIDE)

TNPA2858

3

2

1

TC-17/20LA1

B-BOARD TNPA2857 K-BOARD TNPA2858

BL-BOARD TNPA2861 V-BOARD TNPA2859

ABCDEFGH I

PbF

S057

R063

S056

TV/VTR

R062

S054

VOL_DNVOL_UPCH_DNCH_UP

R061

TNPA2858

V-BOARD(FOIL SIDE)

TNPA2859

V3

2

1

R1154

Q1153

Q1152

R1155

D1054

R1156

R1157

C1152

D1151

11

12

R060

R1151

C1151

S055

2

K-BOARD(COMPONENT SIDE)

TNPA2858

1

4

K8

R058

S052

1

K

SEE REVERSE FOR ORDERNO.

S053

R059

CH_UP

K8

14

CH_DN

VOL_UP

S055 S057S052S053 S054 S056

TNPA2858

ORDER

NO.

K

1

TV/VTRVOL_DN

V-BOARD(COMPONENT SIDE)

TNPA2859

1

2

SEE REVERSE FOR ORDERNO.

TNPA2859

V1

V2

PbF

D1152

R1152

RM001

1

V9

1

2

TNPA2859

ORDERNO.

C1152

R1153

RM001

1

2

D1054

11

V9

12

2

1

V3V2

1

V

TC-17/20LA1

B-BOARD TNPA2857 K-BOARD TNPA2858

BL-BOARD TNPA2861 V-BOARD TNPA2859

29

Page 30

TC-17LA1 / TC-20LA1

30

Page 31

10 Block and Schematic Diagram

10.1. Schematic Diagram Notes

Important Safety Notice

Components identified by mark have special characteristics important for safety.

When replacing any of these components, use only manufacture's specified parts.

TC-17LA1 / TC-20LA1

Notes:

1. Resistor

All resistors are cabon 1/4W resistor, unless marked as follows:

Unit of resistance is OHM [W] (K=1,000, M=1,000,000).

: Nonflammable : Metal Oxide

: Solid : Metal Film

: Wire Wound : Fuse:

2. Capacitor

All capacitors are ceramic 50V capacitor, unless marked as follows:

Unit of capacitance is mF, unless otherwise noted.

: Temperature Compensation : Electrolytic

: Polyester : Bipolar

M

m T

: Metalized Polyester : Dipped Tantalum

: Polypropylene : Z-Type

NP

+

-

Z

3. Coil

Unit of inductance is mF, unless otherwise noted.

4. Test Point

: Test Point position

5. Earth Symbol

: Chassis Earth (Cold) : Line Earth (Hot)

6. Voltage Measurement

Voltage is measured by a DC voltmeter.

Conditions of the measurement are the following:

Power Source ................................................... AC 100-240V, 50/60Hz

Receiving Signal ............................................... Colour Bar signal (RF)

All customer's controls ...................................... Maximum positions

7. Number in red circle indicates waveform nember.

(See waveform pattern table.)

8. When arrow mark ( ) is found, connection is easily found from the direction of arrow

Remarks:

1. The Power Circuit contains a circuit area which uses a separate power supply to isolate the

earth connection.

The circuit is defined by HOT and COLD indications in the schematic diagram. Take the

follwing precautions.

All circuits, except the Power Circuit, are cold.

Precautions

a. Do not touch the hot part or the hot and cold parts at the same time or you may

be shocked.

b. Do not short- circuit the hot and cold circuits or a fuse may blow and parts may

break.

c. Do not connect an instrument, such as an oscilloscope, to the hot and cold

circuits simultaneously or a fuse may blow.

Connect the earth of instruments to the earth connection of the circuit being

measured.

d. Make sure to disconnect the power plug before removing the chassis.

2. Following diodes are interchangeable.

MA150- MA162 (Replacement part)

9. Indicates the major signal flow. : Video Audio

10. This schematic diagram is the latest at the time of printing and subject to change without

notice.

TC-17/20LA1

Schematic Diagram Notes

TC-17/20LA1

Schematic Diagram Notes

31

Page 32

TC-17LA1 / TC-20LA1

10.2. Power Block Diagram

TC-17/20LA1

Power Block Diagram TC-17/20LA1 Power Block Diagram

32

Page 33

TC-17LA1 / TC-20LA1

TC-17/20LA1 Power Block Diagram

TC-17/20LA1

Power Block Diagram

33

Page 34

TC-17LA1 / TC-20LA1

10.3. Signal Block Diagram

TC-17/20LA1

Signal Block Diagram

TC-17/20LA1

Signal Block Diagram

34

Page 35

TC-17LA1 / TC-20LA1

TC-17/20LA1

Signal Block Diagram

TC-17/20LA1

Signal Block Diagram

35

Page 36

TC-17LA1 / TC-20LA1

10.4. AP-Board (1 of 3) Schematic Diagram

AP-BOARD TNPH0541(1/3)

AP-BOARD TNPH0541(1/3)

A

A

D3002

D3002

MAZ81400ML

MAZ81400ML

C3002

C3002

16V

16V

1u

1u

R3014

R3014

R3002

R3002

75

75

1%

1%

6.8k

6.8k

C3000

C3000

50V

50V

0.01u

0.01u

R3001

R3001

10k

10k

D3004

D3004

MAZ81400ML

MAZ81400ML

D3003

D3003

MAZ81400ML

MAZ81400ML

C3003

C3003

16V

16V

1u

1u

R3017

R3017

R3004

R3004

75

75

6.8k

6.8k

C3001

C3001

50V

50V

0.01u

0.01u

R3003

R3003

10k

10k

D3006

D3006

MAZ81400ML

MAZ81400ML

Y

Y

Y

Y

Y

Y

V

V

V

V

G

G

Pb

Pb

PB

PB

PB

PB

L

L

L

L

G

G

Pr

Pr

PR

PR

PR

PR

R

R

R

R

G

G

2

2

S-VIDEO2

S-VIDEO2

B

B

C

C

D

D

E

E

F

F

G

G

TC-17/20LA1

AP-Board (1 of 3) Schematic Diagram

JK3000

JK3000

K1CB211B0001

K1CB211B0001

JK3001

JK3001

K2HA612B0034

K2HA612B0034

1

1

S-VIDEO1

S-VIDEO1

VIDEO2

VIDEO2

VIDEO1

VIDEO1

COMPONENT IN

COMPONENT IN

V2

V2

V1

V1

L2

L2

L1

L1

R2

R2

R1

R1

JK3002

JK3002

K2HA612B0038

K2HA612B0038

C

C

Y

Y

C

C

Y

Y

V2

V2

V1

V1

G

G

L2

L2

L1

L1

G

G

R2

R2

R1

R1

G

G

L_ch

L_ch

R_ch

DC IN

DC IN

7

7

L2200

L2200

10u

10u

R811

R811

0

0

TP800

TP800

R821

R821

0

0

R822

R822

0

0

C2211

C2211

50V

50V

10u

10u

+

+

C2212

C2212

16V

16V

0.047u

0.047u

AA_SCL1

AA_SCL1

AA_SDA1

AA_SDA1

R2206

R2206

1k

1k

R2207

R2207

1k

1k

R800

R800

330

330

1/2W

1/2W

+

+

C800

C800

25V

25V

100u

100u

Q800

Q800

B1DHDD000013

B1DHDD000013

FSS140-TL

FSS140-TL

C805

C805

50V

50V

0.01u

0.01u

JK801

JK801

K2EE2B000003

K2EE2B000003

R_ch

C2210

C2210

50V

50V

0.1u

0.1u

C2218

C2218

0.47u

0.47u

50V

50V

+

+

R2221

R2221

22

22

R2220

R2220

22

22

TP181

TP181

POWER SW

POWER SW

PUSH

PUSH

R801

R801

33k

33k

14.7

14.7

1

1

8

8

14.7

14.7

1

1

2

2

3

IC2201

IC2201

AN5849S-E1V

AN5849S-E1V

MTS

MTS

C2209

3.6

2.1

2.1

3.5

3.5

3.7

3.7

0

0

5.0

5.0

5.0

5.0

0

0

2.1

2.1

2.1

2.1

0

0

0

0

S800

S800

K0F122B00012

K0F122B00012

SPPJ222200

SPPJ222200

C801

C801

16V

16V

0.1u

0.1u

R802

R802

15k

15k

14.7

14.7

14.7

5.7

14.7

5.7

4

4

2

3

2

3

5

6

7

5

6

7

14.7

14.7

14.7

14.7

14.7

14.7

R823

R823

0

0

R824

R824

0

0

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

STBY5V

STBY5V

B1GBBFJJ0001

B1GBBFJJ0001

UNR521100L

UNR521100L

MPX IN

MPX IN

PILOT DET

PILOT DET

PLL

PLL

GND

GND

SCL

SCL

SDA

SDA

PE

PE

L OUT

L OUT

R OUT

R OUT

CONTRAST

CONTRAST

GND

GND

Q801

Q801

SPEC DET

SPEC DET

SPEC TIME

SPEC TIME

SPEC FILTR

SPEC FILTR

WB DET

WB DET

VCC

VCC

WB TIME

WB TIME

OFFCAN2

OFFCAN2

OFFCAN1

OFFCAN1

OSD-B in

OSD-B in

Ys in

Ys in

YM in

YM in

R804

R804

10k

10k

R805

R805

10k

10k

D801

D801

MA2J11100L

MA2J11100L

Q803

Q803

2SD0601A0L

2SD0601A0L

OVP

OVP

0

0

0

0

5.5

5.5

OVP

OVP

4

4

5.7

5.7

3

3

14.7

14.7

14.7

2

14.7

2

14.7

14.7

1

1

Q802

Q802

B1DDED000003

B1DDED000003

C806

C806

0.01u

0.01u

50V

50V

NOISE DET

SAP DET

NOISE DET

SAP DET