Page 1

OPERATING INSTRUCTIONS

TorqBee®

TB-P-xxx-xx / TB-A-xxx-xx / TB-S-xxx-xx

Release date: January 2018

PC-Software: 2.0.2.25 and higher

Firmware: 2.0.3.4 and higher

Page 2

Table of contents

1. IMPORTANT INFORMATION 8

2. GENERAL INFORMATION 9

2.1.0. Importance of the operating instructions 9

2.2.0. Proper Intended Use 9

2.3.0. Improper use 9

2.4.0. Guarantee and liability 10

2.5.0. Copyright 11

3. BASIC SAFETY INSTRUCTIONS 12

3.1.0. Notices in the operating instructions 12

3.2.0. Operator's responsibility 12

3.2.1. Personnel's responsibility 12

3.2.2. Personnel training 12

3.3.0. Risks when working with the tool 12

3.4.0. Danger from electrical energy 13

3.4.1. Fundamental safety measures 13

3.4.1. Workplace safety 14

3.4.2. Electrical safety 14

3.4.3. Personal safety 15

3.4.4. Using and handling the power tool 15

3.4.5. Service 17

3.5.0. Lithium-ion battery 17

3.8.0. Cleaning and disposing of the tool 20

3.9.0. Risk of injury and damage to the tool 20

4. STARTUP 22

4.1.0. Installing or removing the battery 22

4.1.1. Trigger 23

4.1.2. Rotating direction switch 23

4.1.3. LED / Barcode scanner 24

4.1.4. Multi color LED control light 25

4.2.0. Setting the tightening torque 26

4.3.0. Cancel job 28

4.3.0. Back-up strategy 28

4.5.0. Operation 32

- 2 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 3

5. DISPLAY 32

5.1.0. Displays 34

6. ACCESSORIES 42

7. TECHNICAL DATA 44

7.1.0. Pistol screwdriver 44

7.2.0. Angle screwdriver 46

CE CONFORMITY DECLARATION 48

NOTICE

This warning symbol indicates additional information that will

make your work easier.

WARNING

General warning to prevent operating errors and failures.

DANGER

This indicates a direct hazard for the worker or the tool. This

warning symbol is especially important and must be observed.

- 3 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 4

Disposal

Power tools, batteries, accessories and packaging must be

disposed of at an environmentally-compatible recycling facility.

Power tools and batteries do not go into the household trash.

Only for EU countries:

Directive 2002/96/EG:

Defective power tools must be collected separately and disposed of at an

environmentally-compatible recycling facility.

Directive 2006/66/EG:

Defective or drained batteries must be collected separately and disposed

of at an environmentally-compatible recycling facility.

Drained batteries can be disposed of directly:

Germany:

Recyclingzentrum Elektrowerkzeuge

Osteroder Landstraße 3

37589 Kalefeld

Transport

Li-Ion batteries are subject to the specications in the laws pertaining to

hazardous goods. The batteries can be transported on roads by the user

without further constraints.

When shipping with third parties (e.g.: freight forwarders), special

requirements must be observed for packaging and labeling!

Only ship batteries if the casing is not damaged. Cover the contacts with

tape and package the battery so it cannot move around in the packaging.

Please comply with other national and international requirements.

- 4 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 5

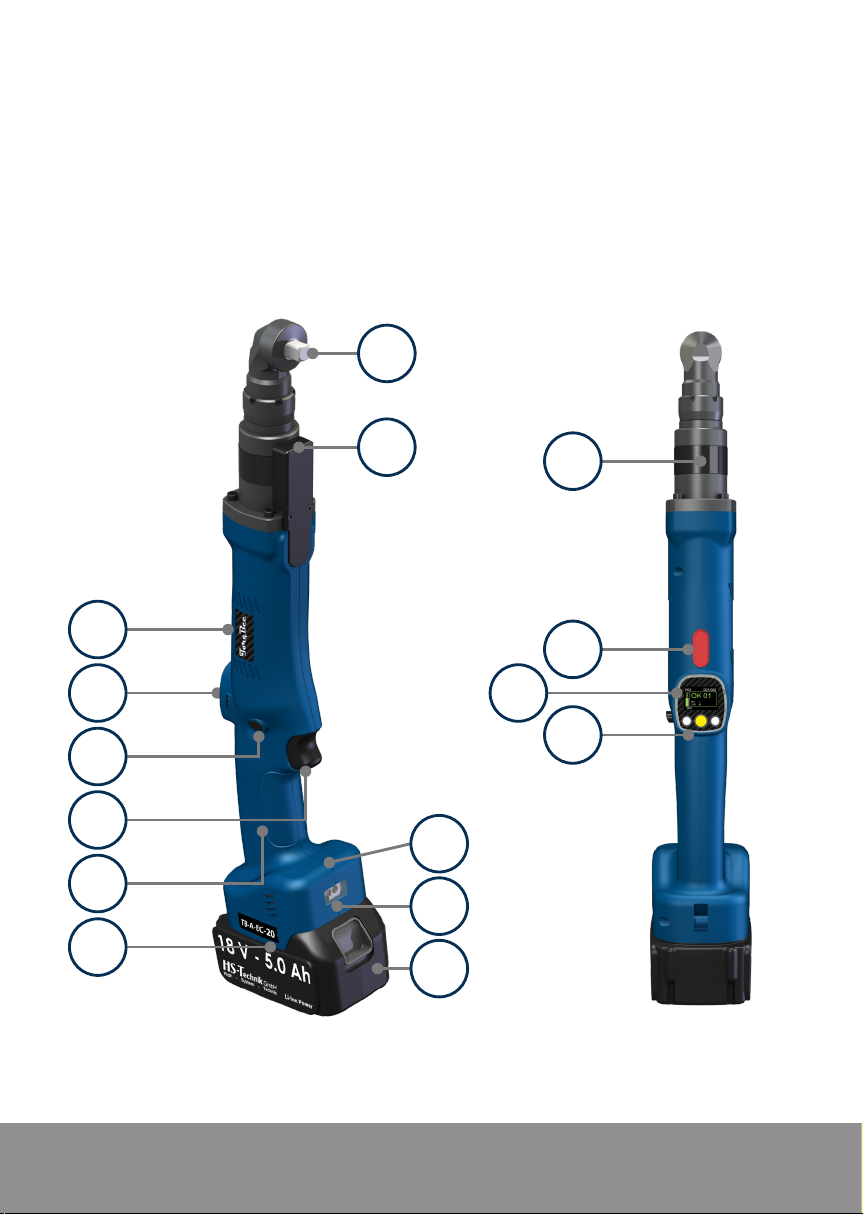

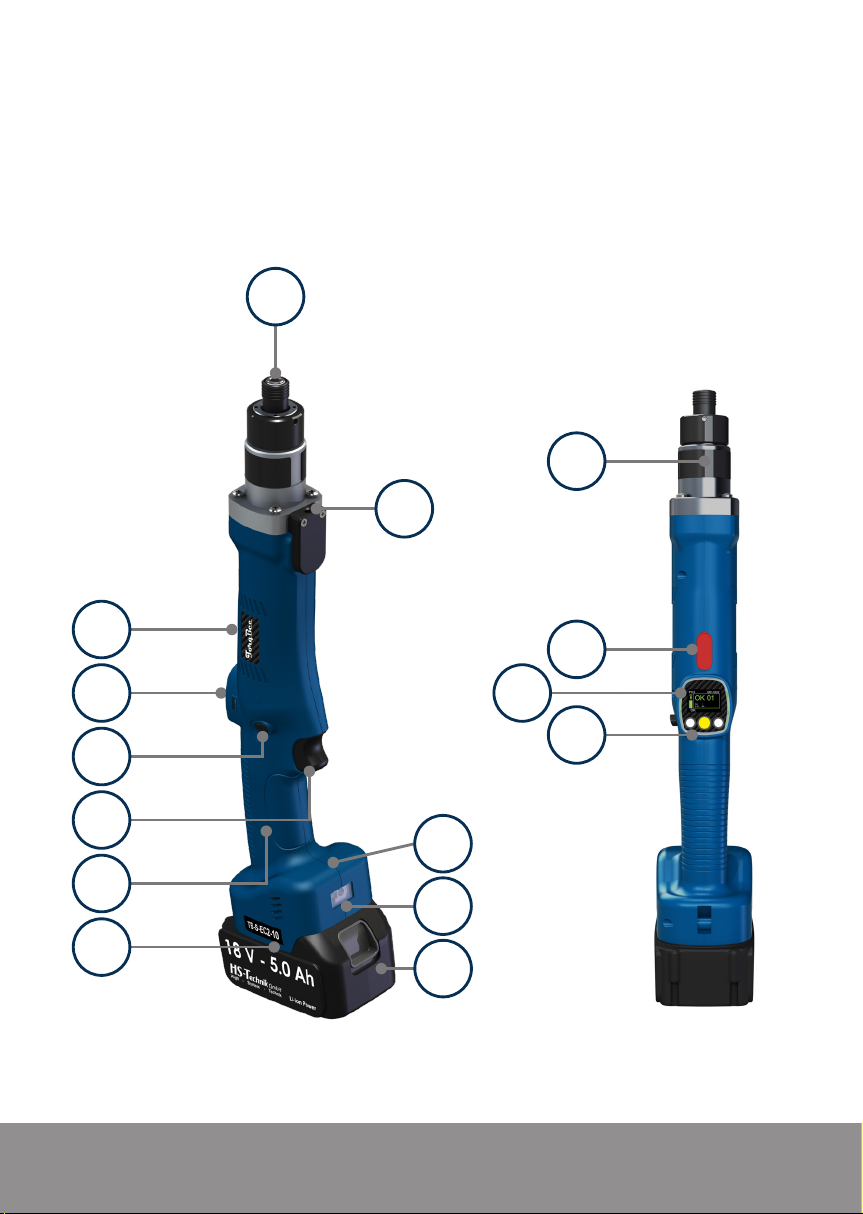

2 4

1

6

8

9

7

3

5

10

11

12

13

1

14

5 Clutch access

not available in the

PRO-M & EC² version

6 CW / CCW

7 Large trigger

8 Ergonomical handle

9 USB interface

10 Powerful LED

11 Optional Wi- module

1 OLED-Display to led the

worker through the process

not available in the

Light version

2 Multi color LED

control light

3 Brushless high-powered

motor

4 Color index

- 5 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

not available in the

Light version

12 Optional scanner

not available in the

Light version

13 Premium Li-Ion battery

14 1/4“ hex. socket adapter

15 3/8“ square adapter

Page 6

15

3

1

6

7

8

9

10

5

4

1

2

11

12

13

- 6 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 7

14

5

10

3

4

1

1

2

6

7

11

8

12

9

13

- 7 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 8

NOTE

The Light version is equipped with a multi color status LED but

do not have a display.

- 8 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 9

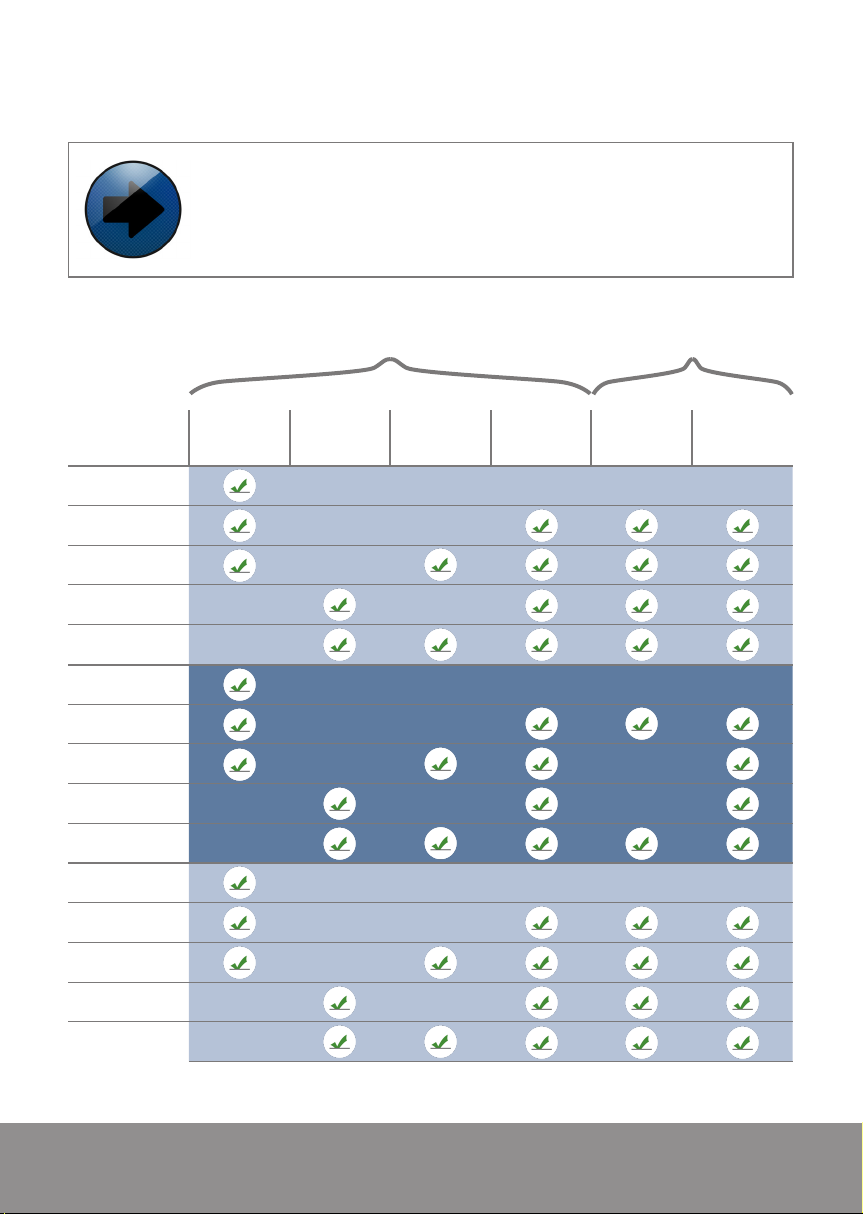

NOTE

Depending on the tool conguration the different functions

described in the manual can be used. Furthermore each

basic function have many subfunctions.

Article Shut-o

TB-P-L-xx

TB-P-SO-xx

TB-P-SOP-xx

TB-P-EC-xx

Pistol screwdriverAngle screwdriverStraight screwdriver

TB-P-EC2-xx

TB-A-L-xx

TB-A-SO-xx

TB-A-SOP-xx

TB-A-EC-xx

TB-A-EC2-xx

TB-S-L-xx

clutch

Included in the

delivery content

Torque

transdurcer

Reaction

sensor

Optional available

Display Scanner Wi-

TB-S-SO-xx

TB-S-SOP-xx

TB-S-EC-xx

TB-S-EC2-xx

- 9 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 10

1. IMPORTANT INFORMATION

Danger!

Before you put the tool down, wait until it has come to a

complete stop as otherwise, the tool can jam and you may

lose control of the screwdriver.

Danger!

When tightening and unscrewing screws, high reaction

torques may arise. Therefore, always keep a tight grip on the

tool.

Danger!

Switch the electrical device off immediately if the tool used

locks up and be prepared for high reaction torques that can

cause kickback. The tool locks up when it is overladed or

jams in the workpiece.

- 10 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 11

2. GENERAL INFORMATION

2.1.0. IMPORTANCE OF THE OPERATING INSTRUCTIONS

This information was written with the intention of being read, understood

and complied with in all points by persons responsible for the operation of

the TorqBee® screwdriver (hereinafter referred to as the tool).

Prior to start-up, please read the operating instructions and comply with the

safety instructions. Work station faults can only be prevented if the contents

of these operating instructions are known and fault-free operation can be

ensured.

We are not liable for damages and operational errors that result from non-

compliance with these operating instructions. If difculties arise nonetheless,

please contact us and we will gladly provide assistance.

2.2.0. PROPER INTENDED USE

The tool may only be used, as described in these instructions, to create

screw joints suitable for the type of tool.

NOTICE

Proper intended use also includes:

• complying with all instructions in the operating instructions

• complying with the inspection and maintenance work.

Any other use beyond this is not considered proper intended use.

HS-Technik GmbH is not liable for any damages resulting from noncompliance.

2.3.0. IMPROPER USE

We are not liable for damages and operational errors that result from noncompliance with these operating instructions or improper use.

- 11 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 12

Danger!

The tool is not a torque wrench. This tool cannot be used

for already tightened connections as otherwise very high

reaction torques arise and the motor control and the motor

can overheat.

2.4.0. GUARANTEE AND LIABILITY

Guarantee and liability claims for personal and material damages are

excluded if they can be traced back to one or more of the following causes:

• improper use

• improper assembly, start-up, operation and maintenance

• operating the tool with defective safety equipment or

improperly installed or non-functioning safety and protective

equipment

• non-compliance with the instruction in the operating instructions

pertaining to transport, storage, assembly, start-up, operation and

maintenance of the tool

• unauthorized structural modications to the tool

• improper repair

• catastrophes caused by foreign bodies and force majeure

- 12 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 13

High - System - Technik

2.5.0. COPYRIGHT

These operating instructions are only for the operator and its personnel.

They contain the regulations and instructions, which may neither be

completely nor partially

• reproduced

• edited or

• otherwise published.

The copyrights to these operating instructions remain with

HS-Technik GmbH.

Manufacturer address:

Im Martelacker 12

D-79588 Efringen-Kirchen

Telephone: +49 (0) 76 28 - 91 11-0

Telefax: +49 (0) 76 28 - 91 11-90

E-mail: info@hs-technik.com

Internet: www.hs-technik.com

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

- 13 -

Page 14

3. BASIC SAFETY INSTRUCTIONS

3.1.0. NOTICES IN THE OPERATING INSTRUCTIONS

• The basic requirement for safe and proper use and fault-free operation

is knowledge of the basic safety instructions and safety regulations.

• In addition, the rules and regulations for the place of use must be

followed.

3.2.0. OPERATOR'S RESPONSIBILITY

The operator is obligated to only allow persons to work with this tool who are

familiar with the basic regulations for work safety and accident prevention

and are trained in how to use the tool. Safety-conscious work of the personnel

must be checked at regular intervals.

3.2.1. PERSONNEL'S RESPONSIBILITY

All persons working with this tool are obligated to comply with the basic

regulations for work safety and accident prevention prior to starting work.

3.2.2. PERSONNEL TRAINING

Only trained and qualied personnel may work with this tool. The responsibilities

of the personnel for the assembly, start-up, operation, maintenance and

servicing must be clearly dened. Personnel-in-training may only operate

the machine in the presence of an experienced person.

3.3.0. RISKS WHEN WORKING WITH THE TOOL

Faults that may hinder safety must be immediately rectied.

- 14 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 15

WARNING

The tool was built in accordance with the state of the art in

technology and the approved safety regulations. Still, when

using it, risks to life and limb of the user or third parties or other

material assets may arise.

WARNING

Only use the tool

• for the proper intended use

• in working order with regards to safety

3.4.0. DANGER FROM ELECTRICAL ENERGY

DANGER

Only allow a qualied electrician to perform work on this

tool. The electrical equipment of the tool must be regularly

inspected. Loose connections and charred cables must be

immediately repaired. If work must be performed with the

tool, remove the battery prior to opening the device.

WARNING

The tool must be kept closed at all times. Access is only

permitted for authorized persons with a tool.

3.4.1. FUNDAMENTAL SAFETY MEASURES

NOTICE

The terms "tool" and "power tool" used in the safety instructions

pertain to mains-operated power tools (with power cable)

and battery operated power tools (without power cord).

- 15 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 16

3.4.1. WORKPLACE SAFETY

a) Keep your workspace clean and well lit.

Disorder or poorly lit workspaces can lead to accidents.

Do not use the tool in an explosive environment,

b)

in which

Power tools can generate sparks which can ignite the dust of vapors.

c) Take environmental inuences into account.

Never subject tools to rain.

Do not use tools in moist or wet environments.

d) Keep other persons away from tool while in use.

If you are distracted, you can lose control of the device.

3.4.2. ELECTRICAL SAFETY

a)

Avoid physical contact with grounded surfaces such a pipes, heaters,

etc.

There is an increased risk of electrical shock if your body is grounded.

b) Keep the device away from rain or moisture.

Water penetrating into the tool increases the risk of an electrical shock.

c) Keep the tool away from heat, oil, sharp edges or moving device parts.

ammable liquids, gases or dusts are located.

.

- 16 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 17

3.4.3. PERSONAL SAFETY

a)

Be careful, pay attention to what you are doing and use

responsibly.

Do not use power tools when you are tired or under the inuence of

drugs,

alcohol or medication.

One moment of carelessness when using the tool can lead to severe

injuries.

b) Wear personal safety equipment and always wear protective eyewear.

Wearing protective safety equipment such as a dust mask, safety

shoes, a protective helmet and hearing protection, depending on the

type and use of of the tool, decreases the

risk of injuries.

c) Avoid unintended start-up.

Ensure that the power tool is shut off before you connect it to the

battery

pick it up, or carry it.

If you have your nger on the trigger while carrying the power tool, or

the device

is connected to the power supply, this can lead to

accidents.

d) Avoid non-ergonomic posture.

Make sure you are standing stably and always maintain your balance.

You can then

control the power tool in unexpected situations.

e) Wear suitable clothing.

Do not wear loose clothing or jewelry.

gloves away from moving parts.

Loose clothing, jewelry or long hair can

Keep your hair, clothing and

get caught in moving parts.

power tools

3.4.4. USING AND HANDLING THE POWER TOOL

a)

Do not overload the tool.

Use the proper tool for your work. You work better

and more safely in the dened output range when using the proper

tool

.

b) Do not use power tools with defective switches.

A tool that cannot be shut off is dangerous and must be repaired.

- 17 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 18

c)

Remove the battery before you change tool settings, replace

accessories

or lay the tool down.

This safety measure prevents the power tool from starting

unintentionally.

Store unused tools out of reach of children.

d)

Do not allow persons to use the device who are not familiar with it

or

have not read these instructions. Power tools are dangerous if they

are used by inexperienced persons.

Take good care of the power tool.

e)

Check that moving parts

work properly and do not jam, that there are

no broken or damaged parts and that the functionality is not hindered.

Have damaged parts repaired prior to using the device.

Many accidents are caused

by poorly maintained power tools.

f) Keep the tools clean.

Carefully maintained tools jam less often and are easier to use.

g) Use the tool, accessories, etc. in accordance with these instructions.

Take the working conditions and task to be executed into account.

use of power tools for other purposes than the intended use can lead

to

hazardous situations.

h) Use the right tool

Do not use low-output tools for heavy loads. Do not use the tool for

purposes and work for which it is not intended.

i) Check your tool for damage

Prior to further use of the tool, the safety equipment or damaged parts

must be inspected to ensure proper functionality.

Check to ensure the functionality of moving parts, that they don't jam,

that no parts are broken and that all parts are properly and correctly

installed and all conditions

required for the operation of the device

have been fullled.

Damaged safety equipment and parts should be properly repaired or

replaced by a customer service workshop

in the operating instructions

a customer service workshop.

. Damaged switches must be replaced by

Do not use tools on which the trigger

unless otherwise indicated

cannot be easily switched on and off.

The

- 18 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 19

3.4.5. SERVICE

NOTICE

Only allow your power tool to be repaired by a qualied

technician using only original

HS-Technik GmbH. This ensures that the safety of your device

is maintained.

3.5.0. LITHIUMION BATTERY

NOTICE

Please make sure to follow the following instructions for using

lithium-ion batteries!

spare parts, available from

- 19 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 20

a) Only charge the batteries in chargers recommended by the

manufacturer.

If the battery is not charged on a suitable charger, it can be

permanently damaged

.

b) Only use the provided battery for power tools.

The use of other batteries can lead to injuries and re hazards.

If the battery is not used for a longer period of time, it must not remain

c)

on the charger or on the tool.

If a work break of more than 3 hours is expected, the battery must be

removed from the tool. Otherwise, the battery may be permanently

damaged.

The lithium-ion battery should not remain on the charger for longer

d)

than 36 hours for safety reasons.

Remove the battery from the charger immediately after the charging

process is completed.

e)

An empty battery should not be in contact with the tool or a

charger that is disconnected from the mains for a longer period of

time.

In both cases, currents are owing that

deep discharge the battery

and can permanently damage it.

Recharge the lithium-ion batteries immediately and

f)

never store them

when empty.

If the battery is stored while disconnected from the tool

and the

charger, it will maintain a constant capacity over a long period of time.

(Loss approx. 5% per year)

Always transport the battery separately from the tool.

g)

You thus prevent accidentally switching on the tool and deep

discharging the battery.

h)

Do not subject the lithium-ion battery to high temperatures

(+ 50°C) or direct

sunlight.

If the battery gets warmer than 50°C during operation (charging or

discharging), it must be removed from the charger or tool immediately.

- 20 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 21

i)

Keep the unused battery away from paper clips, coins, keys, nails,

screws or other small metal objects which might bridge the contacts.

Do not open the battery and do not short-circuit it.

A short-circuit between the battery contacts can lead to burns, re or

explosions.

Under extreme use or temperature conditions, batteries can leak.

j)

Avoid contact with the skin or eyes if the battery leaks.

The battery

uid is acidic and can cause chemical burns on tissue. If the uid

comes into contact with skin, immediately wash it with soap and water

and then

rinse it with lemon juice or vinegar. If the uid gets into the eyes,

ush with water for at least 10 minutes and immediately go to the

doctor.

Make sure that the Li-Ion battery does not fall down or is subject to

k)

vibrations and

Clean the contacts regularly with a cotton swab soaked in a

l)

impacts.

high-percent alcohol.

NOTICE

Lithium-ion batteries have nearly no self-discharge and

do not have a

reliably supply your tool with power for several years

(approx. 700 - 1000 charge cycles).

In general the following applies:

Avoid deep discharging or overcharging the lithium-ion

battery under any circumstances. It will be permanently

damaged from this.

memory effect. If properly used, they will

- 21 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 22

3.8.0. CLEANING AND DISPOSING OF THE TOOL

Use and dispose of used materials and substances properly, in particular

cleaning agents and solvents.

Do not throw the used battery in the household trash, a re or in water; have

it properly disposed of by a specialist shop or the manufacturer.

3.9.0. RISK OF INJURY AND DAMAGE TO THE TOOL

1. Make sure that none of the tool parts are damaged.

All damaged parts must be repaired prior to using the

device. If you work with damaged tool parts, you risk

injury.

2. If you work on raised platforms, wear a safety belt and

avoid letting the tool fall down. Non-compliance may

lead to injury and signicant damage.

3. First remove the battery before you clean the device

or perform general maintenance.

4. Never hold your face near the exhaust holes.

5. Avoid skin contact with substances such as lubricating

grease and oil. These substances are ammable on

skin. If you do come into contact with them, thoroughly

wash the area.

6. Avoid unstable working positions. You might fall down

and injure yourself.

7. Maintain your tool carefully. Follow the operating

instructions for maintenance and cleaning.

Keep the handle free of lubrication greases and dirt.

8. Use the tool carefully and pay attention to proper use.

Use the tool carefully. When working, the framework

conditions should be fullled. Always concentrate while

working.

- 22 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 23

4. STARTUP

Do not let the tool fall or allow other objects to fall on the device. Protect

it from impact damage.

contact with sprayed water or oil.

4.1.0. INSTALLING OR

REMOVING THE BATTERY

•

To remove the battery, set the

rotational direction switch to the

center position,

the front side of the battery back

and pull it forward away from the

machine.

•

To install the battery, align the

tongue of the battery with the

groove in the casing so it can easily

slide

into place.

• Always slide it on completely until

it locks with a click. Check that the

battery is correctly locked in place

before starting to work.

If the battery is not installed properly,

it can

fall out of the tool and lead to

injuries.

Make sure that the device does not come into

slide the clip on

1

2

1 – Clip

2 – Remove battery

•

Never use force when installing

the battery. If the battery cannot

be easily slide in,

correctly installed.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

it has not been

- 23 -

Page 24

4.1.1. TRIGGER

WARNING

Before you remove the battery or install it in the screwdriver,

please check that the rotating direction switch is in the

neutral position.

– Trigger

*

* *

- 24 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 25

4.1.2. ROTATING DIRECTION SWITCH

WARNING

Always check the rotating direction prior to operation.

*

– Rotating direction switch

*

*

- 25 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 26

• To change the rotating direction,

the screwdriver is equipped with a

rotating direction switch.

Only use the rotating direction

switch after the screwdriver has come

to a complete stop.

Changing the rotating direction

during operation damages the

device.

*

• If you are not using the screwdriver,

set the rotating direction switch to

the neutral position.

•

To change or set the direction, press

the rotating direction switch

- out to the left

- for

or

- out to the right

- for counter-clockwise

rotation

If the rotating direction switch is set to the

center position, the trigger cannot be

activated.

4.1.3. LED / BARCODE SCANNER

clockwise rotation

WARNING

Never look directly at the LED or barcode scanner!

– Rotating direction switch

*

- 26 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 27

After pressing the trigger, the LED and the barcode scanner will switch on.

The afterrun illumination of the LED after the trigger has been pressed can

be dened in the HST-Tool-Manager under Settings - General. The released

barcode scanner goes off after a barcode is successfully scanned and/or

the trigger has been released.

NOTICE

Do not clean the LED with aggressive cleaning agents!

NOTICE

The optional barcode scanner need to be activated in the

hardware settings of the HST-Tool-Manager software to be

used.

4.1.4. MULTI COLOR LED CONTROL LIGHT

®

The TorqBee

function which is near the display and

goes arround the tool. The light informs

the worker at all time about the tools

status:

series has a LED control

The light can be programmed as

glowing, ashing or pulsating with

different time periods for each LED

signal and different colors.

More information about the program-

Color:

ming you´ll nd in the HST-Tool-Manager

manual.

- 27 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 28

4.2.0. SETTING THE TIGHTENING TORQUE

For the TorqBee® / TorqBee® PRO series the tightening torque will be adjusted

with a mechanical clutch.

•

To adjust the clutch the

protection clip has to be

2

1 – Push down the clip

2 – Slide the clip backwards

1 – Clutch adjustment

1

1

removed

•

Push down the clip at the back

carefully. Then the clip can easily

slide backwards. The clutch is visible

now.

•

Now the clutch is adjustable with

an adjustment tool.

anti-clockwise: lower torque

clockwise: higher torque

After the adjustment the clip

needs to be put back in its initial

position. It will close and lock then

automatically.

Now the torque must be checked with

a torque measurement unit.

If the requested value isn´t reached the

clutch needs to be adjusted again.

- 28 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 29

®

For the TorqBee

PRO-M series the tool will be programmed with the

HST-Tool-Manager software. Check, that the screwdriver is congured and

parameterized correctly.

NOTICE

See HST-Tool-Manager operating instructions

RISK OF INJURY

If a low torque is expected and a very high torque is set

unintentionally.

- 29 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 30

4.3.0. CANCEL JOB

If you want to execute a job later or you have

scanned the wrong barcode, you can cancel this

after the release.

To do this, hold down the display button for

approx. 3 seconds. The cancel symbol will

appear. Conrm this by pressing the left side

display button.

4.3.0. BACK-UP STRATEGY

If the connection to the controller (process controls) via wireless connection

through an access point is interrupted and a job has already been released

in the screwdriver, it should be further processed if possible. After completing

the job, the screwdriver will try to send the screwing process results. If the

connection to the process controls cannot be restored, the screwing

process results must be manually secured (read out the tool using the

HST-Tool-Manager software and saved).

Then, after removing the battery, the back-up strategy can be used to

continue working.

To do this, hold down the trigger and slide the battery back on. After approx.

3 seconds, the "set-up symbol" will appear on the display. You can now

release the trigger and will be in the set-up menu.

By pressing the menu button, you can go to the next menu point. By pressing

the trigger, you can select a menu point. Using the left button, conrm your

selection; with the right button, cancel the selection.

- 30 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 31

NOTICE

To activate the back-up strategy, the "Set-up" menu must

be activated in the software under the general settings. Also

activate the "scanner selectable" so the set-up menu point

"Scanner" can be selected. If you also activate "Manual

mode selectable", the set-up menu points "M" and "Scanner

M" will be released. So you can select different programs per

display, the check mark next to "Manual mode active" must

also be selected.

With the left button,

conrm the

entry / selection.

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Using the menu button

on the display, you

can go to the next

menu point.

- 31 -

With the right button,

cancel / decline the

entry / selection.

Page 32

In the "Scanner M" menu point, select the scan mode for scanning barcodes

for program selection. Scan the barcodes for the screwing job as in regular

mode. Then, you will receive the release for the corresponding program

with the number of screws.

The screwing results are not transmitted to the process controls for central

storage. You can, however, read out the screwing process results with the

Tool-Manager software and save them as le.

Go forward with the menu button until the "Scanning M" logo appears. The

tool have to be programmed accordingly with the HST-Tool-Manager.

Press the trigger to select the setting.

To conrm the back-up strategy with scanning function, press the left button

on the display.

- 32 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 33

In the Info menu point, the most current battery

voltage, network coverage RSSL and the version of the

rmware can be displayed.

In the Scanner menu point, the scanner can be

selected to read in network settings using a barcode.

Scanning for program selection is not possible in this

mode.

In the Program menu point, a program can be selected

from the list of stored programs.

In the M menu point, manual mode can be selected

(M = manual mode).

This activates the "standard program" (yellow star).

In the Scanner M menu point, the scanner can be

selected to scan barcodes for program selection. The

barcodes and their assignment to a program must be

stored in the tool.

By activating the Exit menu point, you will exit the setup

menu. The tool will switch back into normal mode.

- 33 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 34

4.5.0. OPERATION

WARNING

Hold the screwdriver with its tool insert straight against the

screwing location with the necessary compression force,

otherwise, it may be damaged (cam-out effect).

To ensure the SAFETY and RELIABILITY of the product, repairs, all other potential maintenance or adjustments should be performed by HS-Technik GmbH

or an authorized specialist.

5. DISPLAY

Tool serial number or program

number of the active

program, e.g.: P03

Function display:

green: connected

yellow: searching for

connection

red: no connection

of the battery in 5 different

Counting function:

Counts the processed screws

per screwing instance e.g. 01/03

means 1. screw of 3 successfully

screwed in

Battery display:

Shows the charging status

statuses.

- 34 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 35

The display elements can be modied in the HST-Tool-Manager so the worker

is shown, for instance, precise values for the screw joints, rotational angle,

only an OK or NOK or the counting process. The display elements can be

presented in German or English. Furthermore, you can set in which unit the

values are output (Nm, lbf.in, lbf.ft).

Main display window:

In the main display window, the worker is shown the results of the

screwing processes, warnings, commands and symbols and texts

to make controlling the tool easier. This way, the worker always

knows directly whether his work was correct, which torque range is

specied for the next screw joint or why the tool is not executing a

screwing process. Furthermore, the worker is notied in time by the

integrated battery management system that the battery needs to

be changed before it can be damaged due to deep discharging.

Display text window:

Shows the text for the current

status or expected action.

- 35 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 36

5.1.0. DISPLAYS

Status displays

Battery status:

50% - 100%

Battery status:

30% - 50%

Battery status:

10% - 30%

Battery status:

5% - 10%

Battery status:

less than 5%

Screwdriver is released for the selected / scanned

screwing process. When using the barcode scanner,

if there is "NO NUMBER", the corresponding barcode

appears on the blue display element as a release.

- 36 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 37

Status displays

The device is ready to use.

The rst of two screw joints was successful. Second

screwing process must still be executed. Results of the

rst screw joint are displayed. This notice is also available as an NOK notice.

Both of the screwing processes were successful and

have reached the specied reference (e.g. Nm) or

were in the specied differential range. This notice is

also available as an NOK notice.

Scanning request:

Component 1, 2 or 3, depending on the number in the

component of the display has to be scanned before

the screwdriver is released.

Airplane / product ID must be scanned before the

screwdriver is released. Symbol can also be a car.

Screwdriver is locked and is currently being congured

using the HST-Tool-Manager via Wi-.

Battery must not be removed.

- 37 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 38

Status displays

The screwing process for one or more screws was not

processed within the specied time.

Specications were not achieved during the screwing

process. Values of the screw joint are displayed.

Maximum battery voltage exceeded

Battery voltage too low

Screwdriver has successfully started up, but cannot

connect to the superordinate controls.

NOK must be separately conrmed by the worker

pressing a button on the display.

- 38 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 39

Status displays

Screwdriver has received a release for program 3.

This will unscrew the screw with 3.00 Nm.

Screwdriver has received a release for program 3.

This will process the screw with 3.00 Nm.

Screwdriver tries to dial into the network.

Screwdriver has found the network connection and

connects.

Previously lost connections to the network were

restored.

Screwdriver has lost the connection to the network.

- 39 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 40

Status displays

Releasing the trigger during a screwing process is

permitted. Trigger was released during the screwing

process. The screwing process can continue. When

using the barcode scanner, if there is "NO NUMBER", the

corresponding barcode appears on the blue display

element as a release.

Screwing process is running

When using the barcode scanner, if there is

"NO NUMBER", the corresponding barcode appears on

the blue display element as a release.

Releasing the trigger during an unscrewing

process is permitted. Trigger was released during the

unscrewing process. The unscrewing process can

continue. When using the barcode scanner, if

there is "NO NUMBER", the corresponding barcode

appears on the blue display element as a release.

Unscrewing process is running

When using the barcode scanner, if there is

"NO NUMBER", the corresponding barcode appears on

the blue display element as a release.

After conrming the NOK ("CONFIRM OK" display), the

screw must rst be unscrewed prior to the next release.

The rotating direction switch stands on counter-clockwise

rotation, unscrewing is not allowed. The NOK-scewing in front needs to be acknowledged. This can be

programmed in the settings with the HST-Tool-Manager.

- 40 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 41

Status displays

Battery was installed, screwdriver starts, but cannot

connect to the network. Press the trigger to start a new

connection.

Current redundancy of the torque was too low.

Current redundancy of the torque was too high.

The worker must inspect the screw after a screwing

process, a time frame for this can be set (e.g. 15

seconds) and conrm it on the display himself.

The timer runs backward to its reference point.

(Graphic stops at 10.9 seconds) If the screw is not

conrmed within the set time, NOK is automatically

selected.

The tool has to be calibrated and will be released after

the calibration.

The tool must be serviced and will not be released until

after the conrmation from the service personnel.

- 41 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 42

Status displays

Maximum screwing time for the released program was

exceeded.

Released program is deactivated on this screwdriver.

Released program does not exist on this screwdriver.

Released program sequence does not exist on this

screwdriver.

Most common error notications are illustrated for you here. Since there

are several status and error notications in the electronics area, it is not

possible to list them all. If you come across a status or error notication that

doesn't make sense, please feel free to contact us. Many displays can

deviate slightly depending on the software settings. For more information,

look at your settings and the operating instructions from HST-Tool-Manager.

If an error occurs several times, please contact our support team.

The display elements (status notications) were created partially with and

partially without a Wi- connection to a superordinate control system. As

soon as the power tool is connected to a control system, the Wi- symbol

appears over the battery display.

- 42 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 43

Error displays

Maximum allowable torque exceeded, contact the

manufacturer

Maximum allowable current exceeded, contact the

manufacturer

Temperature of the controls exceeded, contact

manufacturer

Temperature of the motor exceeded, contact

manufacturer

Maximum logic voltage exceeded, tool must be

repaired!

SD card not found in the screwdriver or is defective. If

the problem is not solved by inserting a new SD card,

please contact the manufacturer.

- 43 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 44

6. ACCESSORIES

• Software

NOTICE

Improper use of potential supplemental devices or

accessories from other manufacturers may pose a

risk (of injury) to persons.

NOTICE

Only use supplemental devices or accessories for

the intended purpose. We will gladly assist you if you have

questions.

You can request exploded drawings and spare parts list with the

article no. at info@hs-technik.com or via telephone +49 (0) 7628 / 9111-0.

NOTICE

All screwdrivers are delivered with software.

- 44 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 45

HST-3123

Adjustment tool for

TorqBee Light

TorqBee

TorqBee PRO

HST-3580

Suspension (without balancer) for:

TB-A-EC-30 TB-A-EC2-30

TB-A-EC-55 TB-A-EC2-55

TB-A-EC-85 TB-A-EC2-85

HST-3581

Adaption for torque reaction arms:

TB-A-EC-55 TB-A-EC2-55

TB-A-EC-85 TB-A-EC2-85

- 45 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 46

7. TECHNICAL DATA

7.1.0. PISTOL SCREWDRIVER

TorqBee Light Torque Speed max. Adapter Dimensions

in mm

TB-P-L-4 1.0 - 4.0 Nm 1,050 rpm 1/4“ - Form E 230 x 51 x 206 1.25

TB-P-L-5 1.5 - 5.0 Nm 850 rpm 1/4“ - Form E 230 x 51 x 206 1.25

TB-P-L-6 1.5 - 6.5 Nm 850 rpm 1/4“ - Form E 230 x 51 x 206 1.25

TB-P-L-10 1.5 - 9.0 Nm 570 rpm 1/4“ - Form E 230 x 51 x 206 1.25

TB-P-L-12 3.0 - 13.0 Nm 460 rpm 1/4“ - Form E 230 x 51 x 206 1.25

TB-P-L-24 5.0 - 24.0 Nm 170 rpm 1/4“ - Form E - -

TorqBee Standard Torque Speed max. Adapter Dimensions

in mm

TB-P-SO-4 1.0 - 4.0 Nm 1,050 rpm 1/4“ - Form E 230 x 51 x 206 1.25

TB-P-SO-5 1.5 - 5.0 Nm 850 rpm 1/4“ - Form E 230 x 51 x 206 1.25

TB-P-SO-6 1.5 - 6.5 Nm 850 rpm 1/4“ - Form E 230 x 51 x 206 1.25

TB-P-SO-10 1.5 - 9.0 Nm 570 rpm 1/4“ - Form E 230 x 51 x 206 1.25

TB-P-SO-12 3.0 - 13.0 Nm 460 rpm 1/4“ - Form E 230 x 51 x 206 1.25

TorqBee PRO Torque Speed max. Adapter Dimensions

in mm

TB-P-SOP-4 1.0 - 4.0 Nm 1,050 rpm 1/4“ - Form E 230 x 51 x 206 1.25

TB-P-SOP-5 1.5 - 5.0 Nm 850 rpm 1/4“ - Form E 230 x 51 x 206 1.25

TB-P-SOP-6 1.5 - 6.5 Nm 850 rpm 1/4“ - Form E 230 x 51 x 206 1.25

TB-P-SOP-10 1.5 - 9.0 Nm 570 rpm 1/4“ - Form E 230 x 51 x 206 1.25

TB-P-SOP-12 3.0 - 14.0 Nm 460 rpm 1/4“ - Form E 230 x 51 x 206 1.25

Weight

in kg

Weight

in kg

Weight

in kg

TorqBee PRO-M Torque Speed max. Adapter Dimensions

in mm

TB-P-EC-10 0.8 - 11.0 Nm 570 rpm 1/4“ - Form E 230 x 51 x 206 1.15

TB-P-EC-12 1.0 - 14.0 Nm 460 rpm 1/4“ - Form E 230 x 51 x 206 1.15

- 46 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Weight

in kg

Page 47

TorqBee EC² Torque Speed max. Adapter Dimensions

in mm

Weight

in kg

TB-P-EC2-10 0.8 - 11.0 Nm 570 rpm 1/4“ - Form E 230 x 51 x 206 1.15

TB-P-EC2-12 1.0 - 14.0 Nm 460 rpm 1/4“ - Form E 230 x 51 x 206 1.15

18 V batteries without deep discharge protection can be used.

Special types are not considered in this listing.

Data of weight and length are without battery.

51

206

73

230

51

Dimensions in mm

- 47 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 48

7.2.0. ANGLE SCREWDRIVER

TorqBee Light Torque Speed max. Adapter Dimensions

in mm

TB-A-L-10 1.5 - 9.0 Nm 540 rpm 1/4“ - Form E 411 x 73 x 92 1.35

TB-A-L-12 3.0 - 13.0 Nm 550 rpm 3/8“ square 436 x 73 x 92 1.30

TB-A-L-20 5.0 - 20.0 Nm 360 rpm 3/8“ square 436 x 73 x 92 1.30

TB-A-L-30 8.0 - 30.0 Nm 200 rpm 3/8“ square 483 x 73 x 92 1.50

TB-A-L-50 15.0 - 50.0 Nm 160 rpm 3/8“ square 483 x 73 x 92 1.50

TB-A-L-75 25.0 - 75.0 Nm 90 rpm 1/2“ square 526 x 73 x 92 1.80

TorqBee Standard Torque Speed max. Adapter Dimensions

in mm

TB-A-SO-10 1.5 - 9.0 Nm 540 rpm 1/4“ - Form E 411 x 73 x 92 1.35

TB-A-SO-12 2.5 - 13.0 Nm 550 rpm 3/8“ square 436 x 73 x 92 1.30

TB-A-SO-20 5.0 - 20.0 Nm 360 rpm 3/8“ square 436 x 73 x 92 1.30

TB-A-SO-30 8.0 - 30.0 Nm 200 rpm 3/8“ square 483 x 73 x 92 1.50

TB-A-SO-50 15.0 - 50.0 Nm 160 rpm 3/8“ square 483 x 73 x 92 1.50

TB-A-SO-75 25.0 - 75.0 Nm 90 rpm 1/2“ square 526 x 73 x 92 1.80

TorqBee PRO Torque Speed max. Adapter Dimensions

in mm

TB-A-SOP-10 1.5 - 9.0 Nm 540 rpm 1/4“ - Form E 411 x 73 x 92 1.35

TB-A-SOP-12 2.5 - 13.0 Nm 550 rpm 3/8“ square 436 x 73 x 92 1.30

TB-A-SOP-20 5.0 - 20.0 Nm 360 rpm 3/8“ square 436 x 73 x 92 1.30

TB-A-SOP-30 8.0 - 30.0 Nm 200 rpm 3/8“ square 483 x 73 x 92 1.50

TB-A-SOP-50 15.0 - 50.0 Nm 160 rpm 3/8“ square 483 x 73 x 92 1.50

TB-A-SOP-75 25.0 - 75.0 Nm 90 rpm 1/2“ square 526 x 73 x 92 1.80

Weight

in kg

Weight

in kg

Weight

in kg

- 48 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 49

TorqBee PRO-M Torque Speed max. Adapter Dimensions

in mm

TB-A-EC-10 1.5 - 10.0 Nm 540 rpm 1/4“ - Form E 411 x 73 x 92 1.35

TB-A-EC-12 2.0 - 13.0 Nm 600 rpm 3/8“ square 451 x 73 x 92 1.40

TB-A-EC-15 1.5 - 15.0 Nm 430 rpm 1/4“ - Form E - -

TB-A-EC-20 5.0 - 20.0 Nm 320 rpm 3/8“ square 441 x 73 x 92 1.20

TB-A-EC-30 8.0 - 32.0 Nm 290 rpm 3/8“ square 541 x 73 x 92 1.20

TB-A-EC-55 15.0 - 55.0 Nm 160 rpm 3/8“ square 600 x 73 x 92 1.40

TB-A-EC-85 25.0 - 85.0 Nm 90 rpm 1/2“ square 644 x 73 x 92 2.90

Weight

in kg

TorqBee EC² Torque Speed max. Adapter Dimensions

in mm

TB-A-EC2-10 1.5 - 10.0 Nm 540 rpm 1/4“ - Form E 411 x 73 x 92 1.35

TB-A-EC2-12 2.0 - 13.0 Nm 600 rpm 3/8“ square 451 x 73 x 92 1.40

TB-A-EC2-15 1.5 - 15.0 Nm 430 rpm 1/4“ - Form E - -

TB-A-EC2-20 5.0 - 20.0 Nm 400 rpm 3/8“ square 441 x 73 x 92 1.20

TB-A-EC2-30 8.0 - 32.0 Nm 290 rpm 3/8“ square 541 x 73 x 92 1.20

TB-A-EC2-55 15.0 - 55.0 Nm 160 rpm 3/8“ square 600 x 73 x 92 1.40

TB-A-EC2-85 30.0 - 85.0 Nm 90 rpm 1/2“ square 644 x 73 x 92 2.90

From 60 Nm on a torque reaction arm is recommended.

18 V batteries without deep discharge protection can be used.

Special types are not considered in this listing.

Data of weight and length are without battery.

Weight

in kg

- 49 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 50

TorqBee Light / Standard / PRO

440

94

40

44

Außenvierkant DIN 3121-E10

72

28

21

283639

52

TB-A-L-10

TB-A-SO-10

TB-A-SOP-10

TB-A-L-12

TB-A-L-20

TB-A-SO-12

TB-A-SO-20

TB-A-SOP-12

TB-A-SOP-20

223639

22

48

46

Innensechskant DIN 3126-F6,3

52

72

439

94

Dimensions in mm

Not to scale

- 50 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 51

TorqBee Light / Standard / PRO

73

TB-A-L-30

TB-A-L-50

TB-A-SO-30

TB-A-SO-50

TB-A-SOP-30

TB-A-SOP-50

TB-A-L-75

TB-A-SO-75

TB-A-SOP-75

54

41

39

28

43

40

37

45

11

Außenvierkant DIN 3121-E10

205

35

39

52

72

489

94

311

60

92

R18

52

516

Dimensions in mm

Not to scale

- 51 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 52

TorqBee PRO-M / EC²

TB-A-EC-10

TB-A-EC2-10

TB-A-EC-20

TB-A-EC2-20

223639

22

48

46

Innensechskant DIN 3126-F6,3

25

31

52

72

439

94

32

39

28

52

72

453

47

41

Außenvierkant DIN 3121-E10

94

Dimensions in mm

Not to scale

- 52 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 53

TorqBee PRO-M / EC²

TB-A-EC-30

TB-A-EC2-30

TB-A-EC-55

TB-A-EC2-55

42

33

364239

353930

28

35

49

45

Außenvierkant DIN 3121-E10

46

52

46

72

531

94

52

72

577

59

56

Außenvierkant DIN 3121-E12,5

94

Dimensions in mm

Not to scale

- 53 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 54

TorqBee PRO-M / EC²

TB-A-EC-10

TB-A-EC2-10

36

40

42

39

52

46

50

627

63

60

Außenvierkant DIN 3121-E12,5

72

94

Dimensions in mm

Not to scale

- 54 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 55

- 55 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 56

7.2.0. STRAIGHT SCREWDRIVER

TorqBee Light Torque Speed max. Adapter Dimensions

in mm

TB-S-L-3 0.5 - 2.5 Nm 1,600 rpm 1/4“ - Form E 410 x 73 x 92 1.00

TB-S-L-4 1.0 - 4.0 Nm 1,050 rpm 1/4“ - Form E 410 x 73 x 92 1.00

TB-S-L-6 1.75 - 6.5 Nm 850 rpm 1/4“ - Form E 410 x 73 x 92 1.00

TB-S-L-10 2.0 - 10.0 Nm 570 rpm 1/4“ - Form E 410 x 73 x 92 1.00

TB-S-L-12 3.0 - 13.0 Nm 460 rpm 1/4“ - Form E 410 x 73 x 92 1.00

TB-S-L-24 8.0 - 33.0 Nm 170 rpm 3/8“ square 410 x 73 x 92 1.00

TorqBee Standard Torque Speed max. Adapter Dimensions

in mm

TB-S-SO-3 0.5 - 2.5 Nm 1,600 rpm 1/4“ - Form E 410 x 73 x 92 1.00

TB-S-SO-4 1.0 - 4.0 Nm 1,050 rpm 1/4“ - Form E 410 x 73 x 92 1.00

TB-S-SO-6 1.75 - 6.5 Nm 850 rpm 1/4“ - Form E 410 x 73 x 92 1.00

TB-S-SO-10 2.0 - 10.0 Nm 570 rpm 1/4“ - Form E 410 x 73 x 92 1.00

TB-S-SO-12 3.0 - 13.0 Nm 460 rpm 1/4“ - Form E 410 x 73 x 92 1.00

TorqBee PRO Torque Speed max. Adapter Dimensions

in mm

TB-S-SOP-3 0.5 - 2.5 Nm 1,600 rpm 1/4“ - Form E 410 x 73 x 92 1.00

TB-S-SOP-4 1.0 - 4.0 Nm 1,050 rpm 1/4“ - Form E 410 x 73 x 92 1.00

TB-S-SOP-6 1.75 - 6.5 Nm 850 rpm 1/4“ - Form E 410 x 73 x 92 1.00

TB-S-SOP-10 2.0 - 10.0 Nm 570 rpm 1/4“ - Form E 410 x 73 x 92 1.00

TB-S-SOP-12 3.0 - 13.0 Nm 460 rpm 1/4“ - Form E 410 x 73 x 92 1.00

Weight

in kg

Weight

in kg

Weight

in kg

- 56 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 57

TorqBee PRO-M Torque Speed max. Adapter Dimensions

in mm

TB-S-EC-3 0.35 - 3.5 Nm 1,600 rpm 1/4“ - Form E 410 x 73 x 92 0.95

TB-S-EC-5 0.5 - 5.0 Nm 1,050 rpm 1/4“ - Form E 410 x 73 x 92 0.95

TB-S-EC-6 0.6 - 6.5 Nm 850 rpm 1/4“ - Form E 410 x 73 x 92 0.95

TB-S-EC-10 0.8 - 11.0 Nm 570 rpm 1/4“ - Form E 410 x 73 x 92 0.95

TB-S-EC-12 1.0 - 14.0 Nm 460 rpm 1/4“ - Form E 410 x 73 x 92 0.95

Weight

in kg

TorqBee EC² Torque Speed max. Adapter Dimensions

in mm

TB-S-EC2-3 0.35 - 3.5 Nm 1,600 rpm 1/4“ - Form E 410 x 73 x 92 0.95

TB-S-EC2-5 0.5 - 5.0 Nm 1,050 rpm 1/4“ - Form E 410 x 73 x 92 0.95

TB-S-EC2-6 0.6 - 6.5 Nm 850 rpm 1/4“ - Form E 410 x 73 x 92 0.95

TB-S-EC2-10 0.8 - 11.0 Nm 570 rpm 1/4“ - Form E 410 x 73 x 92 0.95

TB-S-EC2-12 1.0 - 14.0 Nm 460 rpm 1/4“ - Form E 410 x 73 x 92 0.95

18 V batteries without deep discharge protection can be used.

Special types are not considered in this listing.

Data of weight and length are without battery.

Weight

in kg

- 57 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 58

CE CONFORMITY DECLARATION

We herewith declare that the devices specified below comply with the relevant

CE guidelines with regards to design and construction type.

If the devices are modified without our authorization, this declaration will be

null and void.

The devices specified below comply with the valid EGB / EMV

standards applicable at the time of publication.

Manufacturer:

Company: HS-Technik GmbH

Location: Im Martelacker 12

D-79588 Efringen-Kirchen

Phone: 07628-9111-0

Fax: 07628-9111-90

Description of the device:

Programmable battery-operated screwdriver

Model:

TorqBee® -TB-x-xxx-xx

Applied CE guidelines:

2006/42/EG

2014/30/EU

EN55014

DIN EN 60745-1

HS-Technik GmbH

Im Martelacker 12, D-79588 Efringen-Kirchen

H.-Martin Hanke

Manager Date: 09.03.2018

- 58 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 59

Notes

- 59 -

Im Martelacker 12 – D-79588 Efringen-Kirchen – Phone 0 76 28 - 91 11- 0 – Fax 0 76 28 - 91 11-90

E-Mail: info@hs-technik.com – Web: www.hs-technik.com

Page 60

High - System - Technik

Im Martelacker 12

D-79588 Efringen-Kirchen

Phone: +49 (0) 76 28 - 91 11- 0

Fax: +49 (0) 76 28 - 91 11- 90

E-Mail: info@hs-technik.com

Internet: www.hs-technik.com

HST20170529POPJSFHHMHHZMRMH

Die technischen Daten in dieser Drucksache geben einen Anhalt, sind aber ohne Gewähr!

Konstruktionsänderungen vorbehalten. Unsere Konstruktionsvorschläge sind unverbindlich!

The technical data in these printed material provide support, but are not guaranteed!

Constructional changes reserved. Our construction recommendations are non-binding!

Loading...

Loading...