Panasonic SLCT-720-EB, SLCT-720-EG, SLCT-720-EE, SLCT-720-P, SLCT-720-PC Service manual

AD0502011C5

Portable CD Player

SL-CT720P

SL-CT720PC

SL-CT720EB

SL-CT720EE

SL-CT720EG

Colours

(A)...........Blue Type [Except for SL-CT720P]

(S)...........Silver Type [Except for SL-CT720PC]

(D)...........Orange Type [SL-CT720PC only]

A6

© 2005 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

SL-CT720P / SL-CT720PC / SL-CT720EB / SL-CT720EE / SL-CT720EG

CONTENTS

Page Page

1 Accessories 3

2 Location of Controls

3 Precaution of Laser Diode

4 Handling Precautions for Traverse Deck

4.1. Handling of traverse deck (optical pick-up)

4.2. Caution when replacing traverse deck

4.3. Grounding for electrostatic breakdown prevention

5 Operation Checks and Component Replacement Procedures

5.1. Checking for the P.C.B.

5.2. Replacement for the CD lid unit, shaft plate, spring A and

spring B

5.3. Replacement for the traverse motor and optical pick-up

5.4. Replacement for the rest switch

5.5. Replacement for the spindle motor

6 Display of Self-Diagnostic Function

7 Checking the Operation Problems on the Traverse Deck

(Optical Pick-up)

7.1. Check the operations described below on the traverse

deck after replacing

8 Automatic Adjustment Results Display Function (Self-Check

Function)

10

10

10

11

11

12

3

4

5

5

5

5

6

6

7

9

8.1. How to display automatic adjustment results

8.2. Display of automatic adjustment results (Self-Check

Function)

9 Type Illustration of ICs, Transistors and Diodes

10 Schematic Diagram Notes

11 Schematic Diagram

12 Printed Circuit Board and Wiring Connectio n Diagram

13 Block Diagram

14 Terminal Function of ICs

14.1. IC301(C2BBGF000656): System Control

14.2. IC501(MN6627962JB): Servo Amp, Servo Processor,

Digital Signal Processor, Digital Filter & D/A Converter

15 Supply of Rechargeable Battery as Replaceme nt Parts

16 Caution in use of Rechargeable Battery

17 Replacement Parts List

18 Cabinet Parts Location

19 Traverse Unit Parts Location

20 Packaging

20.1. For SL-CT720P/PC

20.2. For SL-CT720EB/EE/EG

21 Schematic Diagram for printing with letter size

12

12

13

13

15

19

21

23

23

23

25

25

26

29

30

31

31

32

33

2

1 Accessories

SL-CT720P / SL-CT720PC / SL-CT720EB / SL-CT720EE / SL-CT720EG

· AC adaptor for SL-CT720P/PC

(RFEA415C-1S)..............................................1 pc.

· AC adaptor for SL-CT720EB

(RFEA435B-S)................................................1 pc.

· AC adaptor for SL-CT720EE/EG

(RFEA431E-S)................................................1 pc.

· Stereo earphones

(L0BAB0000190)...........................................1 pc.

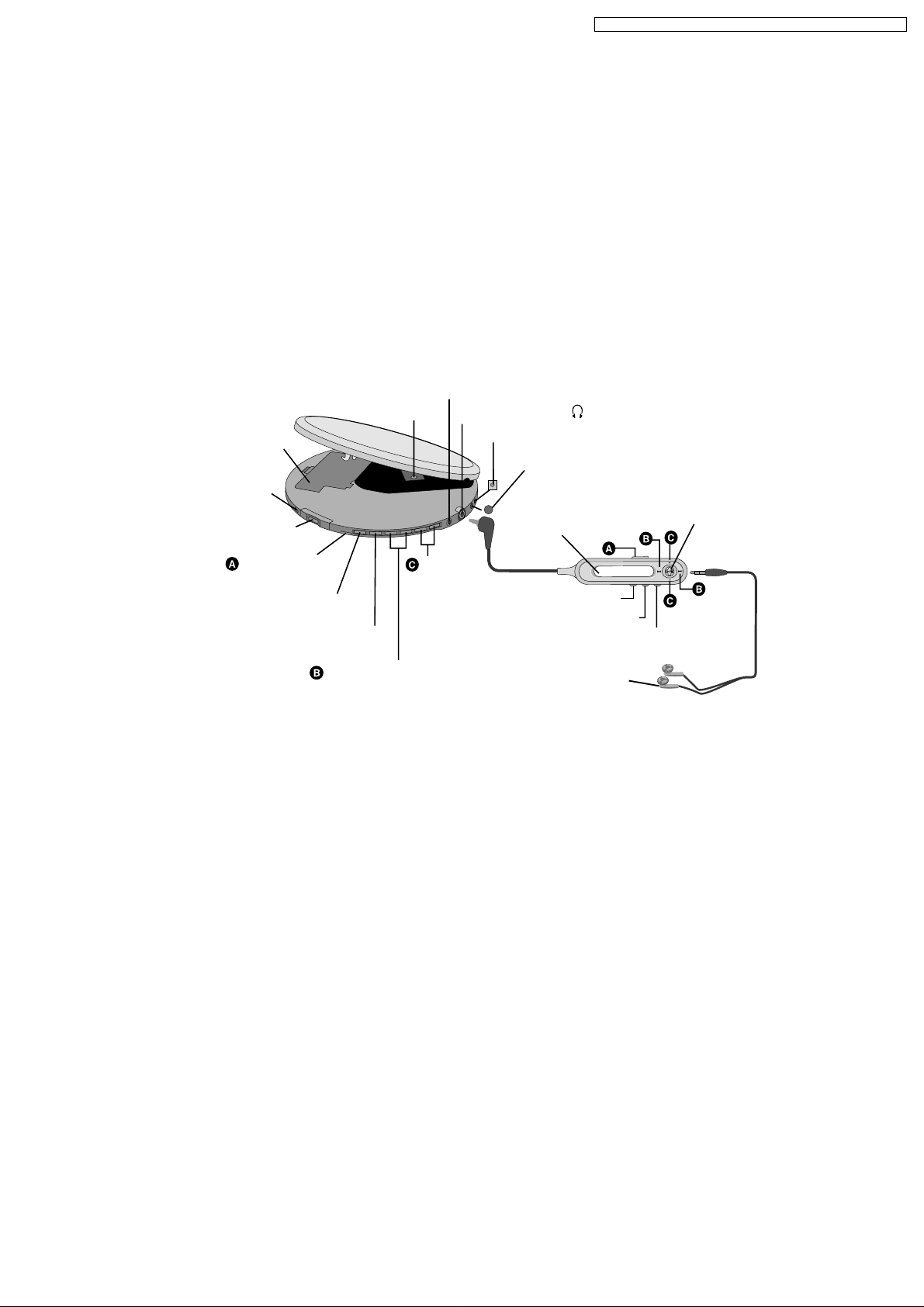

2 Location of Controls

Optical digital/line out jack

Rechargeable

battery

compartment

Charge lamp

Open switch

Hold switch

Play/Pause

Stop/Turn off

Lens

Headphone jack

Battery case terminal

Volume

control

· Wired remote control

(N2QCBD000046).........................................1 pc.

· External battery case

(RFA2666-H)..................................................1 pc.

· Rechargeable batteries (with case) for SL-CT720P/PC

(RFKFHFAZ09PM).........................................2 pcs.

· Rechargeable batteries (with case) for SL-CT720EB/EE/EG

(RFKFHFAZ09EM).........................................2 pcs.

)

(

DC IN jack

Display

Tone selection

Play mode selection

Memory/Recall/Display

Play/Stop/Turn off

Skip/Search

Earphones

3

SL-CT720P / SL-CT720PC / SL-CT720EB / SL-CT720EE / SL-CT720EG

3 Precaution of Laser Diode

· For SL-CT720P/PC

Caution:

This product utilizes a class 1 laser. Invisible laser radiation is emitted from the optical pick-up lens when the unit is turned

on:

1. Do not look directly into the pick-up lens.

2. Do not use optical instruments to look at the pick-up lens.

3. Do not adjust the preset variable resister on the optical pick-up.

4. Do not disassemble the optical pick-up unit.

5. If the optical pick-up is replaced, use the manufacture’s specified replacement pick-up only.

6. Use of control or adjustments or performance of procedures other than those specified herein may result in hazardous

radiation exposure.

· For SL-CT720EB/EE/EG

4

SL-CT720P / SL-CT720PC / SL-CT720EB / SL-CT720EE / SL-CT720EG

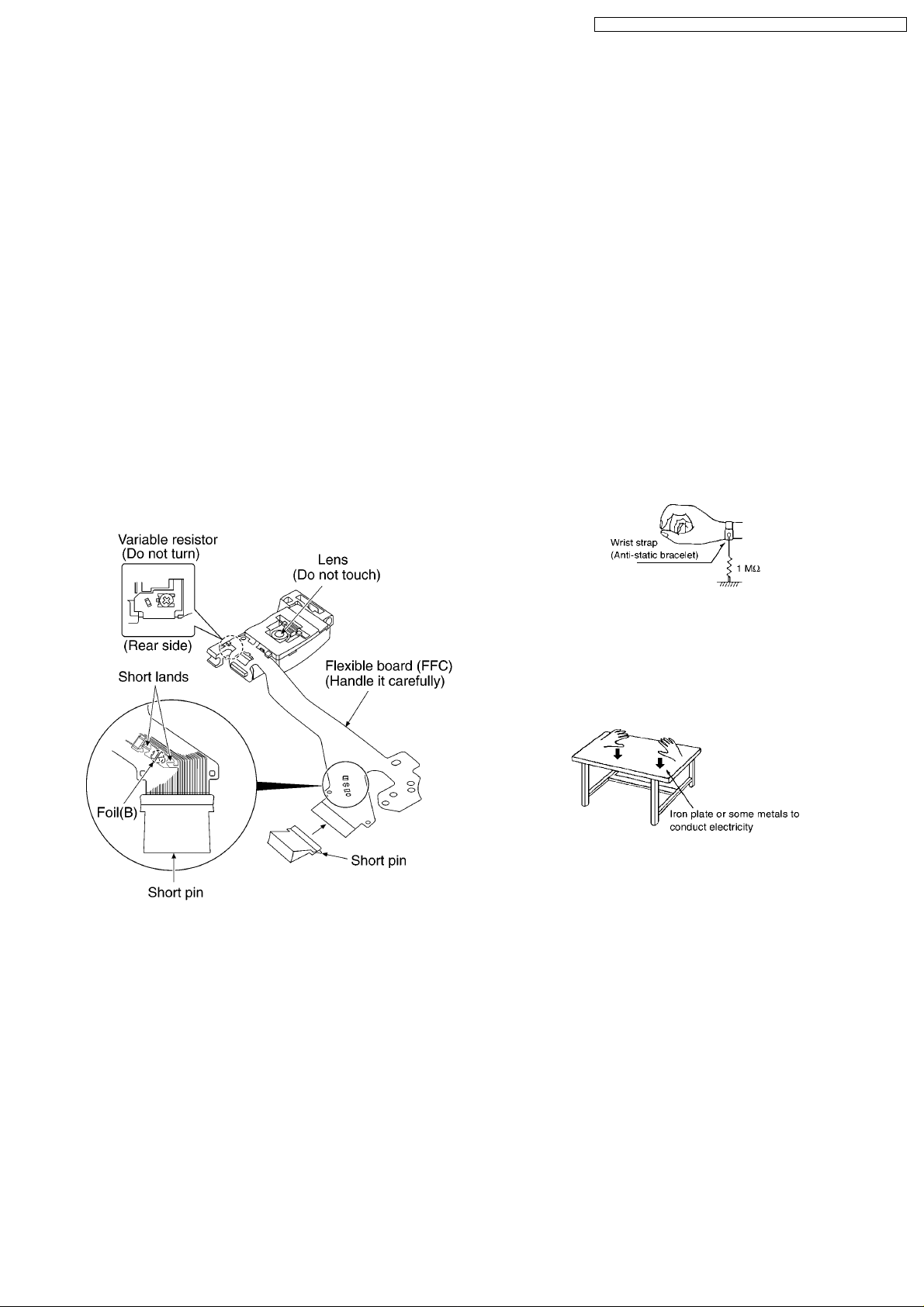

4 Handling Precautions for Traverse Deck

The laser diode in the traverse deck (optical pick-up) may break

down due to potential difference caused by static electricity of

clothes or human body.

So, be careful of electrostatic breakdown during repair of the

traverse deck (optical pick-up).

4.1. Handling of traverse deck

(optical pick-up)

1. Do not subject the optical pick-up to static electricity as it is

extremely sensitive to electrical shock.

2. To protect the laser diode against electrostatic breakdown,

be sure that the short land of the flexible board (FFC board)

should be short-circuit by solder before pulling out the FFC.

Then inserting a short pin or similar object into the tip of the

flexible board.

(Refer to Fig. 4-1.)

3. Take care not toapply excessive stress to the flexible board

(FFC board).

4. Do not turn the variable resistor (laser power adjustment). It

has already been adjusted. (Refer to Fig. 4-1.)

4.2. Caution when replacing

traverse deck

The new traverse deck short-circuits by the short pin, the foil

(B) and short lands to protect the laser diode against

electrostatic breakdown. Be sure to replace to new one

following procedures.

1. Remove the short pin from the FFC, and then connect it to

the connector.

2. Cut the foil (B). (Refer to Fig. 4-1.) (Take care not to make

contact with cutting point each other.)

3. Unsolder the short lands. (Refer to Fig. 4-1.)

4.3. Grounding for electrostatic

breakdown prevention

4.3.1. Human body grounding

Use the anti-static wrist strap to discharge the static electricity

from your body. (Refer to Fig. 4-2.)

Fig. 4-1.

Fig. 4-2.

4.3.2. Work table grounding

Put a conductive material (sheet) or steel sheet on the area

where the traverse deck (optical pick-up) is placed, and ground

the sheet. (Refer to Fig. 4-3.)

Fig. 4-3.

Caution:

The static electricity of your clothes will not be grounded

through the wrist strap.

So take care not to let your clothes touch the traverse deck

(optical pick-up).

5

SL-CT720P / SL-CT720PC / SL-CT720EB / SL-CT720EE / SL-CT720EG

5 Operation Checks and Component Replacement

Procedures

· This section describes procedures for checking the

operation of the major printed circuit boards and

replacing the main components.

· For reassembly after operation checks or replacement,

reverse the respective procedures. Special reassembly

procedures are described only when required.

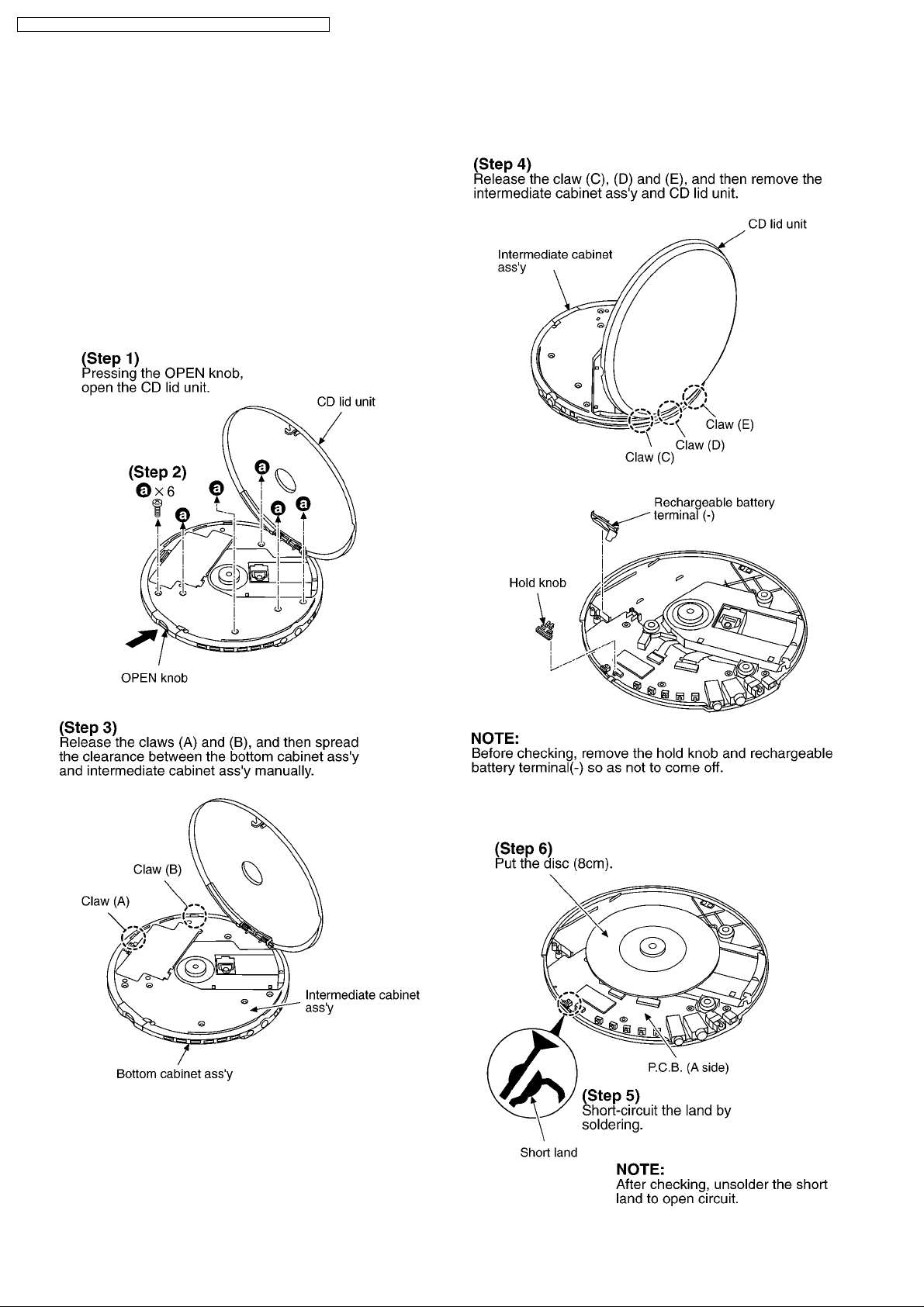

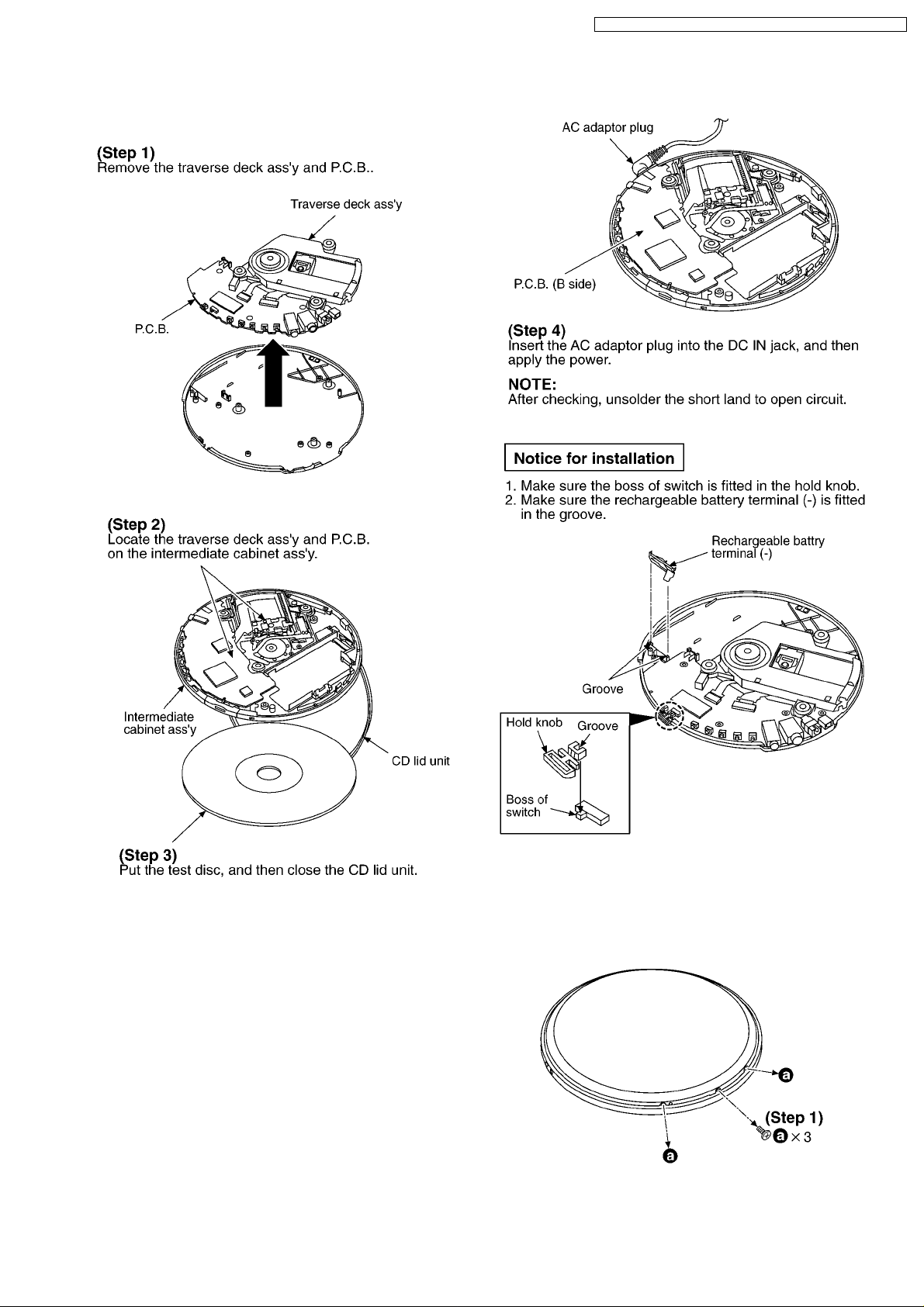

5.1. Checking for the P.C.B.

5.1.1. Checking for the P.C.B. (A side)

· Check the P.C.B. (A side) as shown below.

6

SL-CT720P / SL-CT720PC / SL-CT720EB / SL-CT720EE / SL-CT720EG

5.1.2. Checking for the P.C.B. (B side)

· Follow the (Step 1) - (Step 5) of item 5.1.1.

· Check the P.C.B. (B side) as shown below.

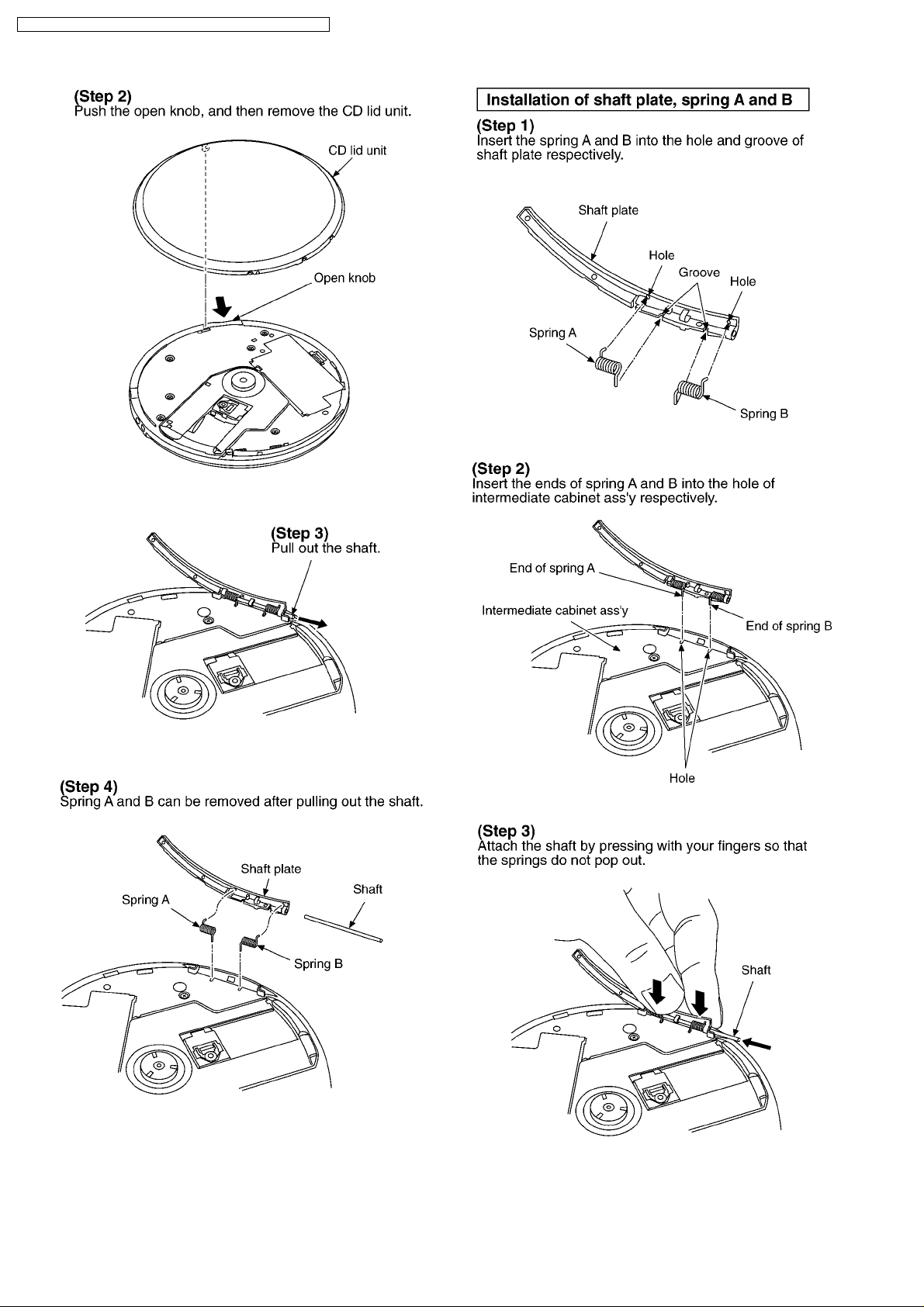

5.2. Replacement for the CD lid

unit, shaft plate, spring A and

spring B

7

SL-CT720P / SL-CT720PC / SL-CT720EB / SL-CT720EE / SL-CT720EG

8

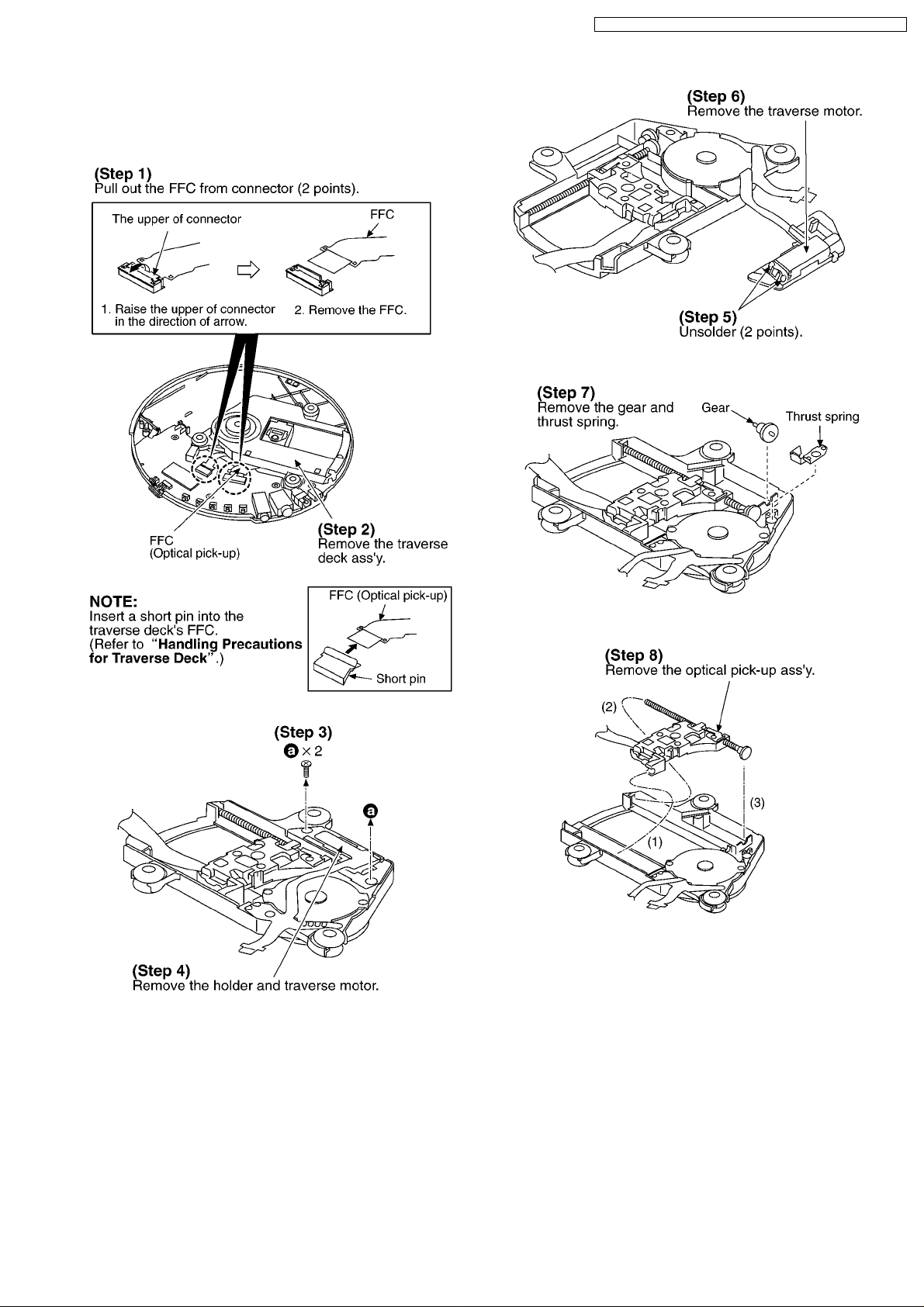

5.3. Replacement for the traverse

motor and optical pick-up

· Follow the (Step 1) - (Step 4) of item 5.1.1.

SL-CT720P / SL-CT720PC / SL-CT720EB / SL-CT720EE / SL-CT720EG

9

SL-CT720P / SL-CT720PC / SL-CT720EB / SL-CT720EE / SL-CT720EG

5.5. Replacement for the spindle

motor

· Follow the (Step 1) - (Step 4) of item 5.1.1.

· Follow the (Step 1) , (Step 2) of item 5.3.

5.4. Replacement for the rest

switch

· Follow the (Step 1) - (Step 4) of item 5.1.1.

· Follow the (Step 1) , (Step 2) of item 5.3.

6 Display of Self-Diagnostic

Function

This unit (SL-CT720) has self-diagnostic function. It may

display below-mentioned on the remote control display.

· The substance of self-diagnostic display.

Remote control display

(Press PLAY and STOP button. After 15 seconds, it is

displayed for 2 seconds.)

In case of this display, it may be causing for abnormally

movements of traverse deck, touching failure of REST detect

switch and coming off or cutting off the flexible P.C.B.. It is

necessary for confirmation or repair and replacement each

parts.

10

SL-CT720P / SL-CT720PC / SL-CT720EB / SL-CT720EE / SL-CT720EG

7 Checking the Operation Problems on the Traverse Deck

(Optical Pick-up)

Make sure to follow the procedures below to check the

operation problems of the traverse deck (optical pick-up) before

replacing it.

Replace the traverse deck only after the problem is identified.

7.1. Check the operations described below on the traverse deck after

replacing

7.1.1. Checking skip search

1. Play an ordinary musical program disc.

2. Press the skip button to check for normal skip search

operation (in both the forward and reverse directions).

7.1.2. Checking manual search

1. Play an ordinary musical program disc.

2. Press the manual search button to check for smooth

manual search operation at either low or high speed (in

both the forward and reverse directions).

7.1.3. Checking playability

1. Play the 0.7 mm black dot and the 0.7 mm wedge on the

playability test disc (SZZP1054C) and verify that no sound

skip or noise occurs.

2. Play the middle tracks of theuneven test disc (SZZP1056C)

and verify that no sound skip or noise occurs.

11

SL-CT720P / SL-CT720PC / SL-CT720EB / SL-CT720EE / SL-CT720EG

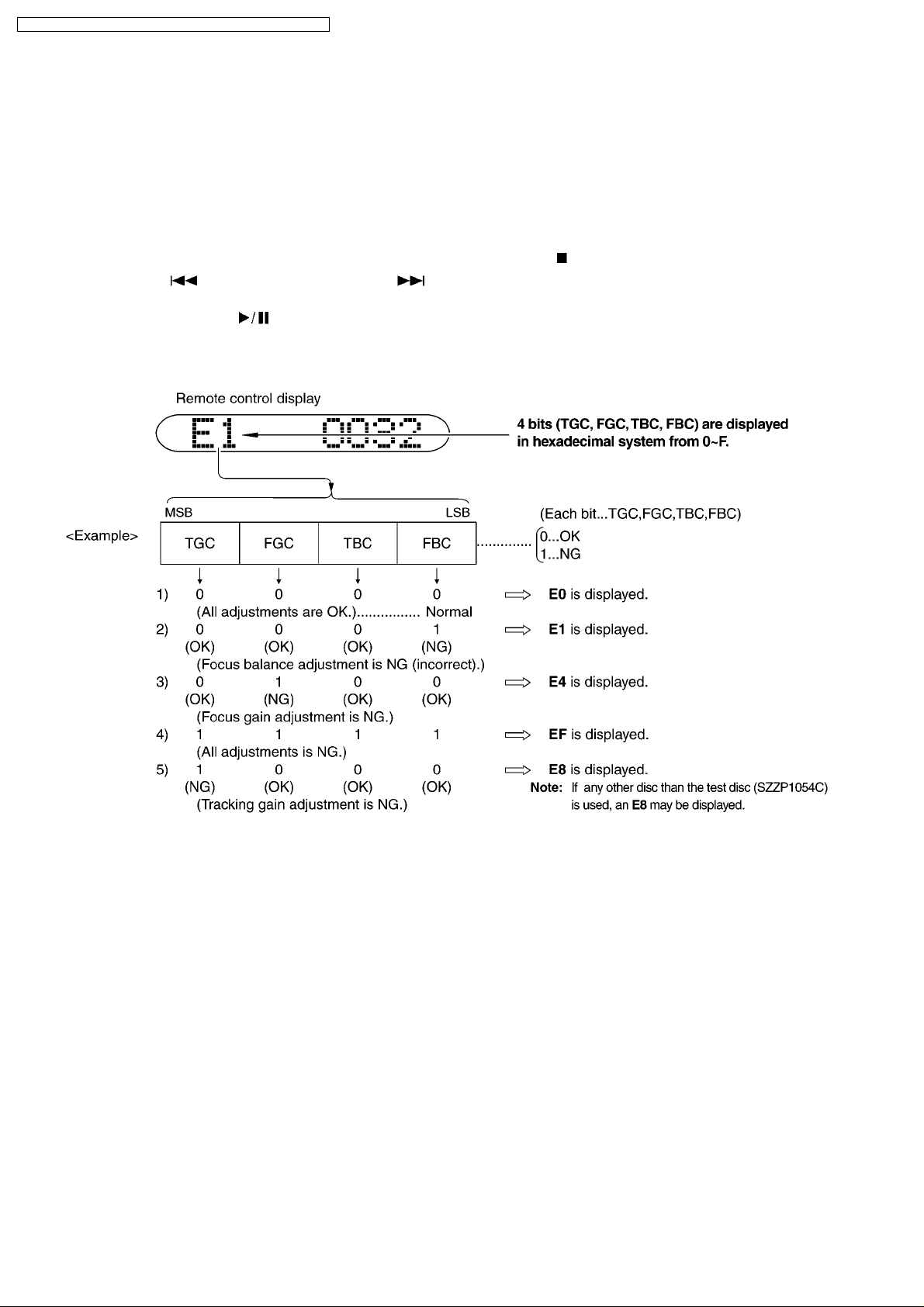

8 Automatic Adjustment Results Display Function

(Self-Check Function)

On the unit (SL-CT720), each automatic adjustment result are

displayed on the remote control display. This function is

convenient to check or identify which automatic adjustment

circuit is incorrect.

The followings are the contents of the automatic adjustment

result displays (Self-Check Function).

8.1. How to display automatic adjustment results

1. Load the test disc (SZZP1054C).

2. Press the

(SKIP/SEARCH) buttons simultaneously and hold them,

and additionally press the

(SKIP/SEARCH) and

(PLAY/PAUSE) button.

3. Press the

4. An automatic adjustment result is displayed on the remote

control display.

(STOP/TURN OFF) button once.

8.2. Display of automatic adjustment results (Self-Check Function)

<Example>

Follow the below steps when E1 is displayed.

(Cause: Focus balance (FBC) is set beyond the limit.)

· Check if

1. the waveform or voltage of the focus servo circuit is

correct, and

2. the optical pick-up returns to the normal state by

exchanging the traverse deck.

Follow the below steps when E4 is displayed.

(Cause: Focus gain (FGC) is set beyond the limit.)

· Check if

1. the waveform or voltage of the focus servo circuit is

correct,

2. the focus coil of the optical pick-up is correct (around 8

ohms), and

3. the optical pick-up returns to the normal state by

exchanging the traverse deck.

Follow the below steps when EF is displayed.

(Cause: All adjustments (TGC, FGC, TBC, FBC) are set

beyond the limit.)

· Check if

1. the optical pick-up returns to the normal state by

exchanging the traverse deck, and

2. the waveform or voltage of the servo ICs are correct.

Note:

It is not always necessary to exchange the traverse

deck when an error message is displayed.

Be sure to check if the circuit is defective or not before

exchanging the traverse deck.

Note:

If any other disc than the test disc (SZZP1054C) is used, an

error message may be displayed.

This is not a malfunction.

12

Loading...

Loading...