Panasonic SJMJ-55, SJMJ-55-GH Service manual

ORDER No.AD0211153C3

Portable MD Player

SJ-MJ55GH

Colour

(S)...................Silver Type

SPECIFICATIONS

Specifications

Audio

System:MiniDisc digital audio system

Beam source:Semiconductor laser

Wave length:780 nm

Sampling frequency:44.1 kHz

Coding:Adaptive Transform Acoustic

Coding (ATRAC/ ATRAC3)

No. of channels:2 (left and right, stereo)

1 (monaural)

Frequency response:20 Hz~20 kHz (+0 dB, -6dB)

Wow and flutter:Below measurable limit

General

Headphones:

Output level (approx.):3.0 mW+3.0 mW

Inpedance (approx.):32

Speakers (ceramic card type):

Output level (approx.):45 mW+45 mW

Inpedance (approx.):200 / 1kHz

Power supply

Rechargeable battery:DC 1.2V

(included rechargeable battery)

Battery:DC 1.5V (One LR6, AA, UM-3 battery)

Dimensions (WxHxD)

Cabinet dimensions:79.9x72.7x14.1 mm

incl.projecting parts:80.9x74.2x17.0 mm

Weights:96 g (with battery)

69 g (without battery)

Play time

[Approximate operating time in hours (in hold mode, at 25°C, on

a flat, stable surface)]

Battery type:Play time (Stereo/ LP2/ LP4)

Rechargeable:40 hours/ 53 hours/ 70 hours

Panasonic alkaline:63 hours/ 93 hours/ 121 hours

Both together:103 hours/ 148 hours/ 193 hours

[When the rechargeable battery (included) is fully recharged.]

AC adaptor and charger

AC adaptor input:AC220 V, 50/60 Hz, 5 VA

AC adaptor output and

DC 3.5 V, 0.5A

Charger input:

Charger output:DC 2V, 0.5 A

Recharging time:About 3.5 hours

Notes:

- The play time may be less depending on the operating

conditions.

- Specifications are subject to change without notice. Weight

and dimensions are approximate.

2002 Matsushita Electric Industrial Co., Ltd. All rights reserved.

Unauthorized copying and distribution is a violation of law.

1. Accessories

- Stereo earphones...................................................1 pc. /

(L0BAB0000174)

- Wired remote control..............................................1 pc. /

(N2QCBD000020)

- External battery case..............................................1 pc. /

(K3ZZ00200038)

- Nickel-metal hydride rechargeable battery.............1 pc. /

(RFKFFAZ01EM1)

- Soft case.................................................................1 pc. / (RFC0074-H)

- Speaker/Battery charger............................................1 pc. /

(L0EAAB000011)

- AC adaptor...............................................................1 pc. /

(N0JCBD000001)

2. Precaution of Laser Diode

3. Operating Instructions

4. Handling Precautions for MD Mechanism (Optical

pickup)

The laser diode in the MD mechanism (optical pickup) may break down due to potential

difference caused by static electricity of clothes or human body.

So, be careful of electrostatic breakdown during repair of the traverse deck (optical pickup).

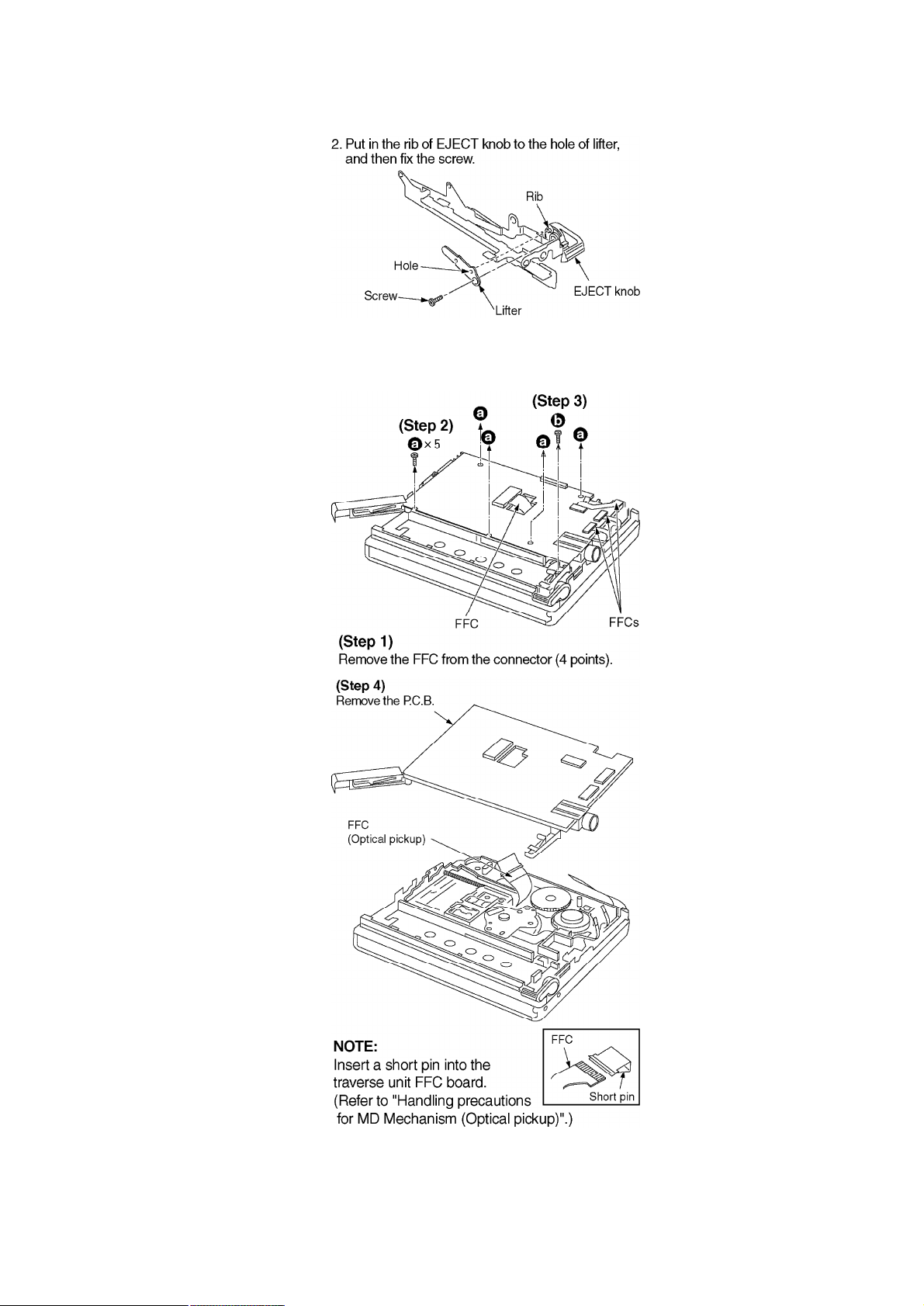

4.1. Handling the MD mechanism (optical pickup)

1. The MD mechanism (optical pickup) is an extremely high-

precision construction and must not be subjected to impact,

excessive vibration, or other types of rough handling.

2. In order to prevent static electricity damage to the laser diode,

use a short pin or similar tool to short the optical pickup’s flexible

circuit boards after they have been disconnected from the main

circuit board. (as shown in Fig. 1 )

3. Handle the flexible circuit boards with care; excessive force could

cause them to be broken.

4. Do not turn the pre-set variable resistor (for adjustment of the

laser power); it has been adjusted at the factory.

(as shown in Fig. 2 )

Fig. 1

Fig. 2

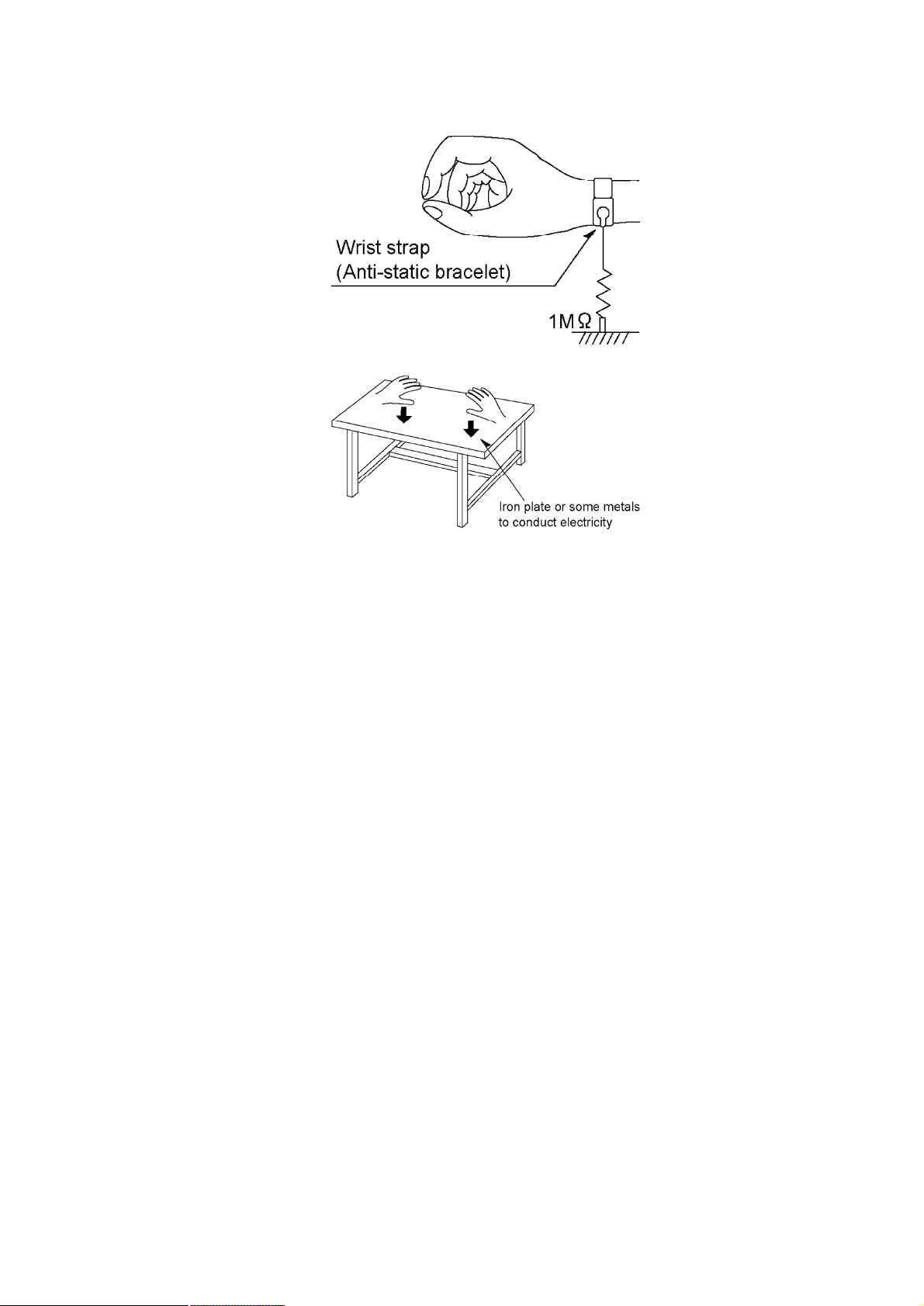

4.2. Grounding for electrostatic breakdown prevention

1. Human body grounding

Use the anti-static wrist strap to discharge the static electricity

from your body. (as shown in Fig. 3 )

2. Work table grounding

Put a conductive material (sheet) or steel sheet on the area where

the traverse deck (optical pickup) is placed, and ground the sheet.

(as shown in Fig. 4 )

Caution

The static electricity of your clothes will not be grounded through

the wrist strap.

So, take care not to let your clothes touch the traverse deck (optical

pickup).

Fig. 3

Fig. 4

5. Operation Checks and Component Replacement

Procedures

- This section describes procedures for checking the operation of

the major printed circuit boards and replacing the main

components.

- For reassembly after operation checks or replacement, reverse the

respective procedures. Special reassembly procedures are

described only when required.

- After replacing the main components (optical pickup or traverse

motor, etc.) of mechanism unit block, change to the adjust mode,

and then perform the adjustments (Laser power, off-set, ROM/

RAM).

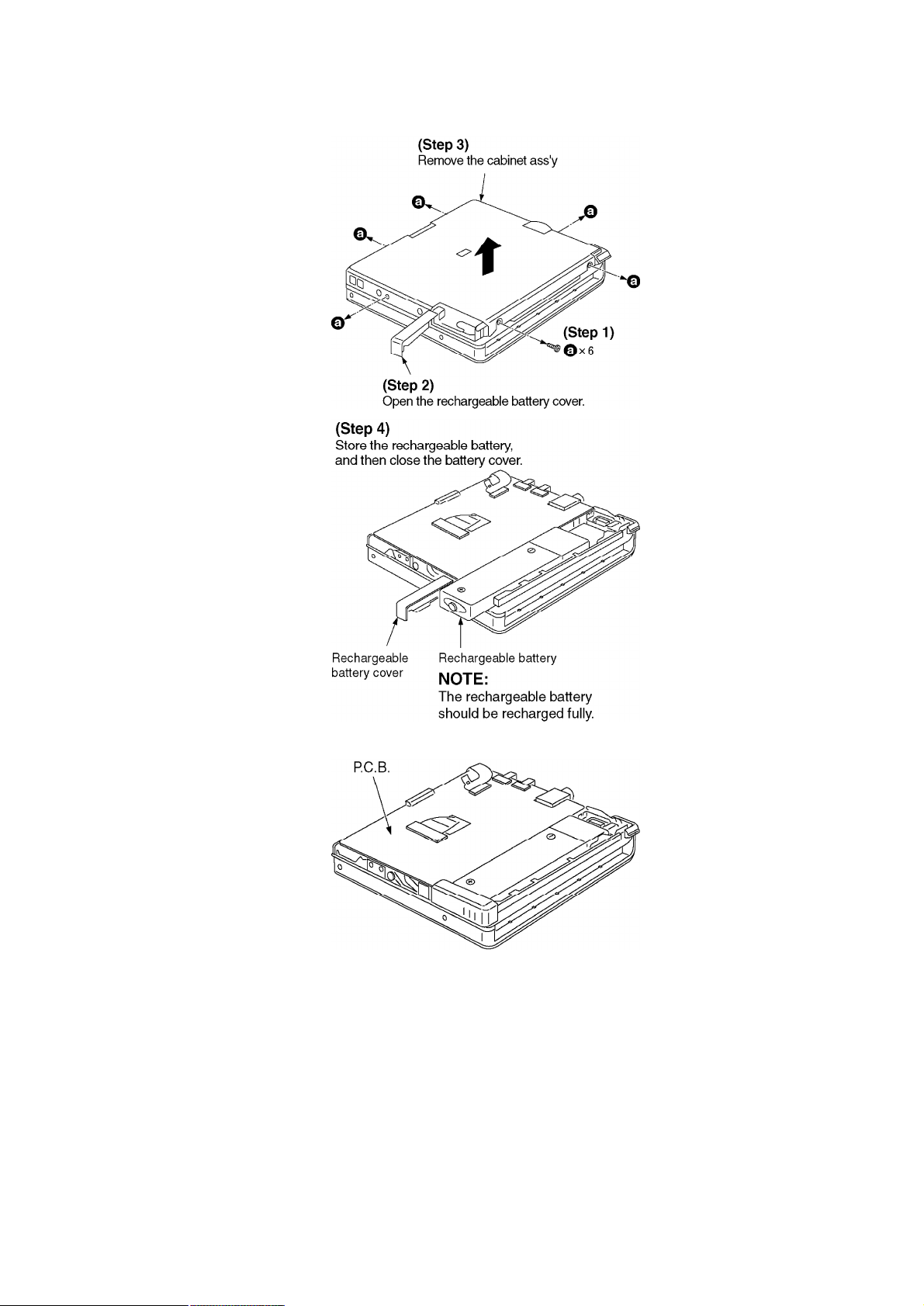

5.1. Checking for the P.C.B.

- Check the P.C.B. as shown below.

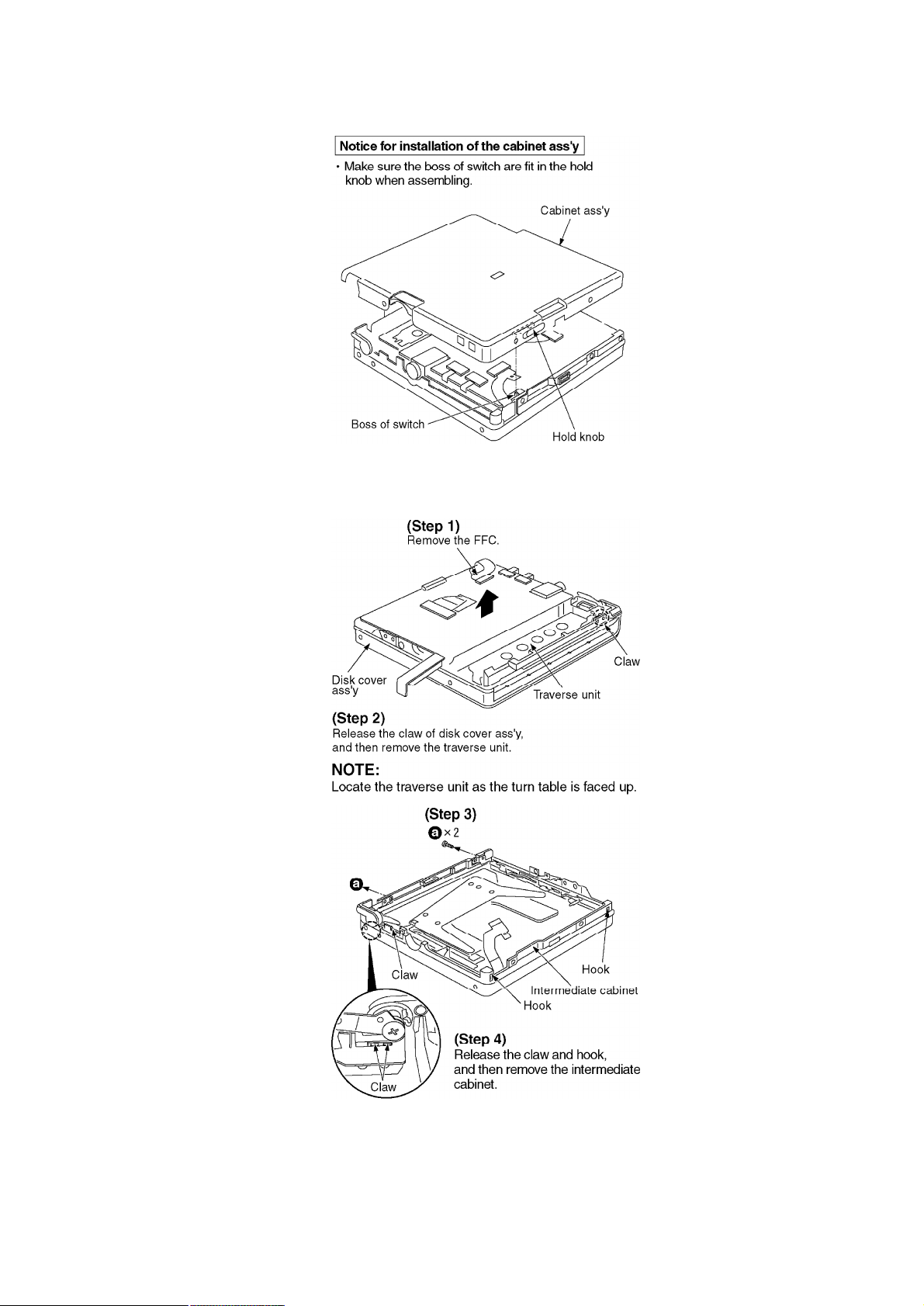

5.2. Replacement for the intermediate cabinet

- Follow the (Step1)-(Step3) of item 5.1.

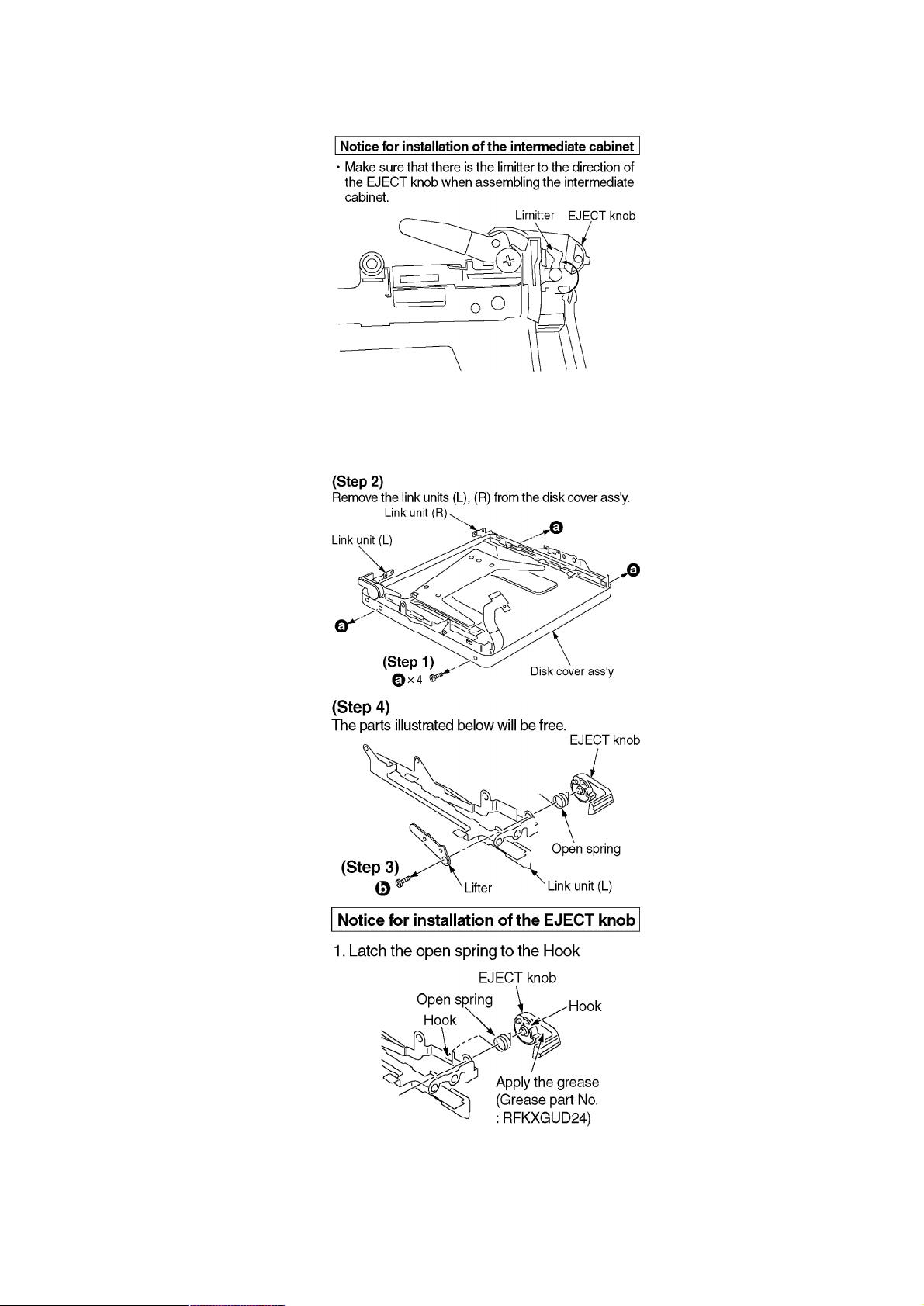

5.3. Replacement for the disk cover ass’y and the link units (L), (R)

- Follow the (Step1)-(Step3) of item 5.1.

- Follow the (Step1)-(Step4) of item 5.2.

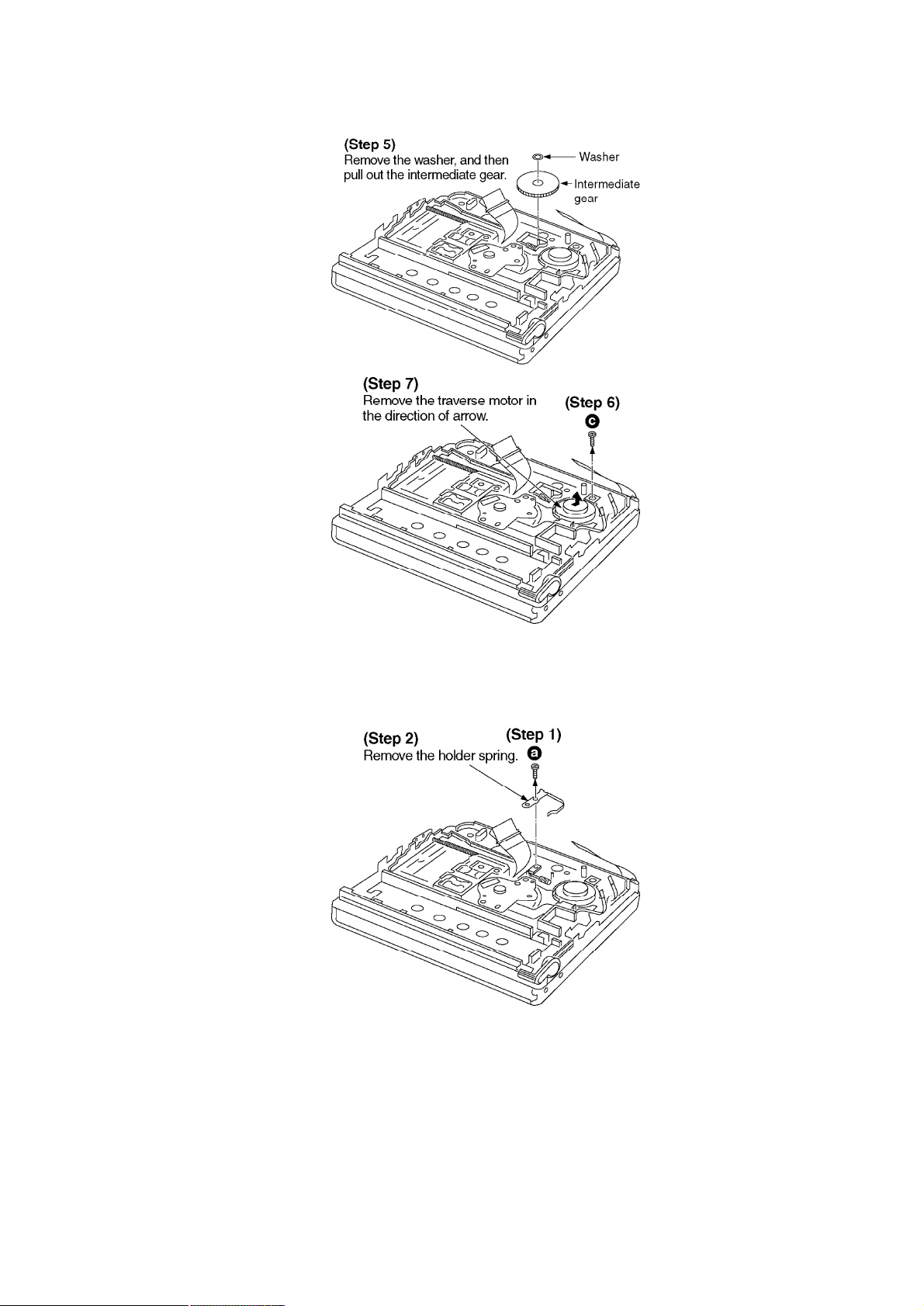

5.4. Replacement for the traverse motor

- Follow the (Step1)-(Step3) of item 5.1.

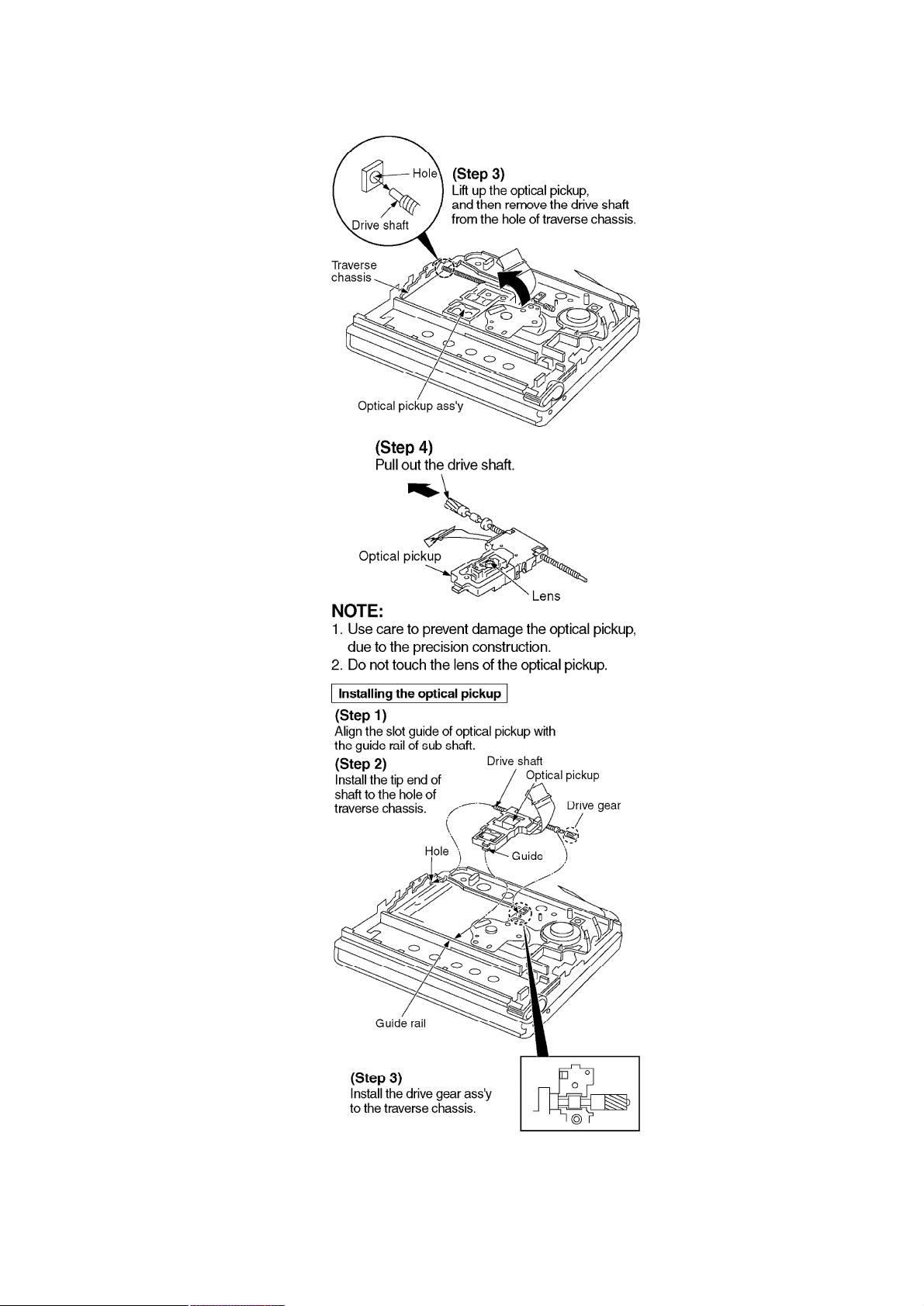

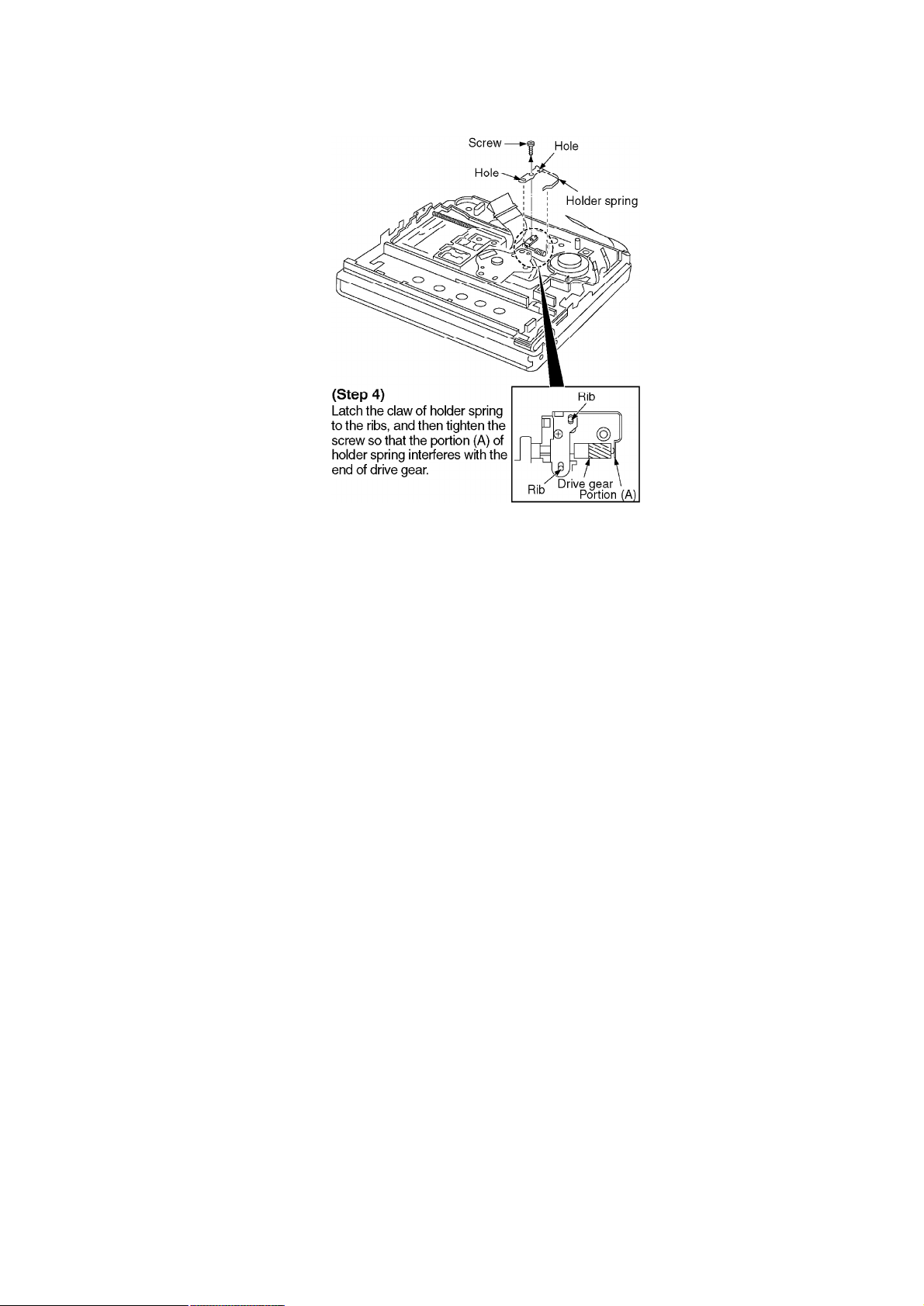

5.5. Replacement for the optical pickup

- Follow the (Step1)-(Step3) of item 5.1.

- Follow the (Step1)-(Step5) of item 5.4.

6. Measurements and Adjustments

Note:

After replacing the main components (optical pickup, traverse motor, IC201, IC202 or P.C.B.

ass’y, etc.) of mechanism unit block, change to the adjust mode, and then perform the “Laser

power adjustment”, “Off-setautomatic adjustment” and “Playback-only disc/magneto-optical

disc automatic adjustment”.

6.1. Instruments to prepare

1. Playback-only disc (Test disc RFKV0006)

2. Commercially available recordable disc (fully recorded with

music) (magneto-optical disc)

3. Laser power meter (LE8010 or compatible meter)

4. Remote controller (Parts No: N2QCBD000020) [or Remote

controller of SJ-MJ88 etc. (Parts No: RFEV025P-SM)]

6.2. Laser power adjustment, Off-set automatic adjustment, Playback

-only disc/magneto-optical disc automatic adjustment magnet

6.2.1. Enter the adjustment mode

Note:

For use of MD cartridge type laser power meter, disassemble this unit into the state of only the

mechanism unit before perform the laser power adjustment (as for the method of disassembly,

refer to “5.2. Replacement for the intermediatecabinet”).

1. Set the battery and connect the remote controller. (The position of

the HOLD switch of remote controller is “OFF”.)

2. Turn off the power, and switch main unit’s HOLD switch off.

3. Press the VOL+( ), VOL-( ), ( ), and ( )keys on the

remote controller within two seconds. (asshown in Fig. 5 )

Fig. 5

4. When the adjustment mode is activated, “T0E ” will be displayed

on the LCD of remote controller. After “T0E ” is displayed, select

the desired adjustment item with the button or button of

the remote controller. (If it is not displayed, perform the

procedures written above again.)

*In the display of T0E ~ TFE shown above, you must adjust T0E , T1E , T2E and T3E . You must

perform the adjustment by observing the order T0E T1E T2E T3E .

Note:

If it is going to perform “T2E” and “T3E”, without performing “T1E”, it will be displayed as “NG”.

If it is going to perform “T3E” when “T2E” is “NG”, it will be displayed as “NG”.

6.2.2. Laser Power Adjustment

Adjust each laser power: read power for reading (play).

6.2.2.1. Set the Unit to the Adjustment Mode

Cautions

About handling the optical pickup and the magnetic head.

- The optical pickup is structured precisely; therefore, it is very

fragile. Be careful not to touch it with the edge of the laser power

meter. Do not touch the lens.

- The sensor of the laser power meter is a very fine part. Be careful

not to touch it to the optical pickup lens.

- The focus point of the laser reaches to 356°F. Therefore, avoid

adjusting using laser power for a long time because the sensor of

the laser power meter may be burned.

- Do not set the unit to the laser power adjustment mode with the

MD loaded. Doing so may result in damage to the MD.

- Laser diode in the optical pickup may be destroyed by the static

electricity generated in your clothes or body. Be especially careful

with the static electricity.

6.2.2.2. Adjustment Procedure

1. Have “T0**” indicated on display, and move the optical pickup to

the most inside (only when a MD cartridge type laser power meter

is used).

2. Set the laser power meter.

[For use of stick type laser power meter.]

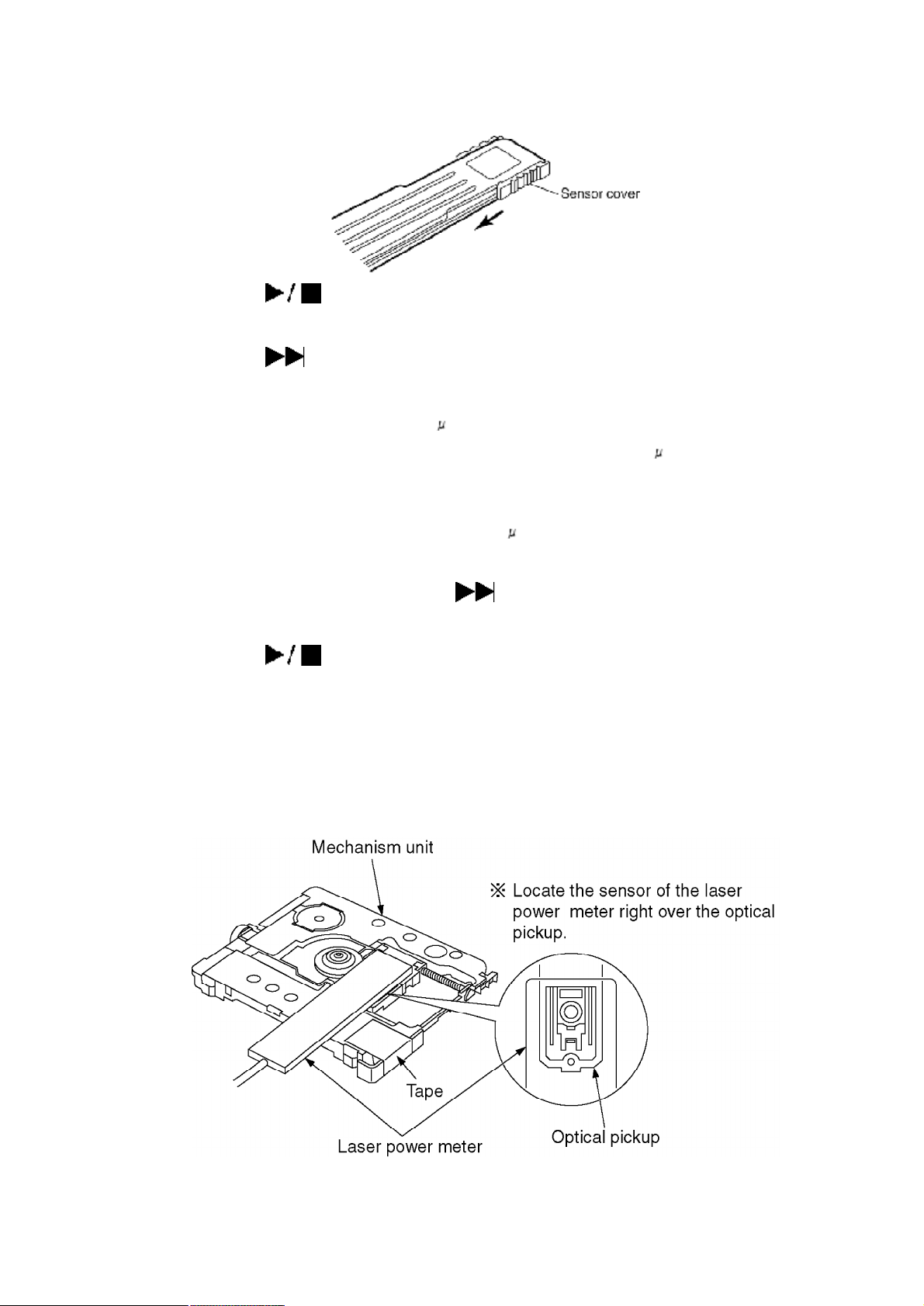

2-1 Uncover the laser power meter (as shown in Fig. 6 ).

2-2 Locate the sensor of the laser power meter right over above

the optical pickup (horizontally at a level of the disc position).

(as shown in Fig. 7 )

[For use of MD cartridge type laser power meter.]

2-1 Open the shutter of the laser power meter. (as shown in Fig. 9 )

2-2 Set the laser power meter. (as shown in Fig. 8 )

Fig. 6

3. Press the key of the remote controller (“T0E ” changes to

“LD ” of the LCD).

4. Press the key of the remote controller (“LD ” changes to “LP ”

of the LCD).

5. Set the laser power at 600 W±10% by using VOL+ and VOL- key

of the remote controller. / [Specified range: 600 W±10%]

Caution:

Proceeding on to the subsequent adjustment procedure with the

read power exceeding “over 660 W” will result in damage to the

optical pickup.

6. Set the laser power with the key of the remote controller (“LP

” changes to “LDOK ” in the LCD).

7. Press the key of the remote controller (“LDOK ” changes to

“T0E ” on the LDC.

8. Remove the laser power meter. Laser power adjustment is

finished.

<Stick type>

Fig. 7

Loading...

Loading...