Page 1

INSTRUCTION MANUAL

Sensor Option Handy Controller Exclusive for

SFC-HC

SF4C

Series

SUNX Limited MJE-SFCHC No.0013-09V

Page 2

(MEMO)

1 SUNX Limited MJE-SFCHC No.0013-09V

Page 3

Thank you for purchasing SUNX’s Handy Controller

Please read both the instruction manual of this manual and

SFC-HC

exclusive for

SF4C

series carefully and thoroughly for

SF4C

series.

the correct and optimum use of this device.

Kindly keep this manual in a convenient place for quick reference.

This manual has been written for the following personnel who have undergone suitable training and

have knowledge of light curtains, as well as, safety systems and standards (ANSI, etc.).

who are responsible for the introduction of this device

who design a system using this device

who install and connect this device

who manage and operate a plant using this device

NOTICE

1) Drawings in this instruction manual may be little different with actual product. Please be forewarned.

2) The contents of this instruction manual may be changed without prior notice for further improvement of the device.

3) A part of / all of this instruction manual or the software may not be copied without permission

from the publisher.

4) Though we have carefully drawn up the contents of this instruction manual, if there are any

aspects that are not clear, or any error that you may notice, please contact our local SUNX

of ce or the nearest distributor.

5) We shall not be responsible for any consequences of use regardless of the descriptions

above.

6) English and Japanese versions of this instruction manuals are original.

2SUNX Limited MJE-SFCHC No.0013-09V

Page 4

Contents

CHAPTER 1 INTRODUCTION ..............................................................................4

1-1 Attention Marks ..................................................................................................... 4

1-2 Safety Precautions ................................................................................................4

CHAPTER 2 GENERAL OUTLINE .......................................................................6

2-1 Features ................................................................................................................6

2-2 Part Descriptions ..................................................................................................6

2-3 Connecting / Setting Procedures .......................................................................... 7

CHAPTER 3 FUNCTIONS ....................................................................................9

3-1 Functional Descriptions ........................................................................................9

3-1-1 Fixed Blanking Function·····················································································9

3-1-2 Floating Blanking Function·················································································10

3-1-3 Auxiliary Output Switching Function···································································11

3-1-4 Muting Setting Changing Function ·····································································12

3-1-5 Override Setting Changing Function ··································································14

3-1-6 Muting Lamp Diagnosis Function·······································································14

3-1-7 Safety Input Setting Changing Function ····························································14

3-1-8 Large Multi-purpose Indicator Setting Changing Function ·································15

3-1-9 Interlock setting changing function·····································································16

3-1-10 External Device Monitor Setting Changing Function ·······································16

3-1-11 Protective Function ··························································································16

3-1-12

3-1-13 Copy Function (Only for Ver. 2.0 or later of

3-1-14 Initialization Function ·······················································································17

3-2 Function Setting (Operation Procedure) ............................................................... 18

3-2-1 Fixed Blanking Function·····················································································20

3-2-2 Floating Blanking Function·················································································21

3-2-3 Auxiliary Output Switching Function···································································22

3-2-4 Muting Setting Changing Function ·····································································23

3-2-5 Override Setting Changing Function ··································································26

3-2-6 Muting Lamp Diagnosis Function·······································································27

3-2-7 Safety Input Setting Changing Function ····························································28

3-2-8 Large Multi-purpose Indicator Setting changing Function ·································29

3-2-9 Interlock Setting Changing Function ··································································30

3-2-10 External Device Monitor Setting Changing Function ·······································31

3-2-11 Protective Function ··························································································32

3-2-12

3-2-13 Copy Function (Only for Ver. 2.0 or later of

3-2-14 Initialization Function ·······················································································37

Setting Contents Monitoring Function (Only for Ver. 2.0 or later of

SF4C

series)································17

Setting Contents Monitoring Function (Only for Ver. 2.0 or later of

SF4C

series)································35

SF4C

SF4C

series)

series)

···16

···33

CHAPTER 4 TROUBLESHOOTING .....................................................................38

CHAPTER 5 SPECIFICATIONS / DIMENSIONS ..................................................39

5-1 Speci cations........................................................................................................39

5-2 Dimensions ........................................................................................................... 39

3 SUNX Limited MJE-SFCHC No.0013-09V

Page 5

CHAPTER 1 INTRODUCTION

1-1 Attention Marks

This instruction manual employs the following attention marks , depending on the

degree of the danger to call operator’s attention to each particular action. Read the following explanation of these marks thoroughly and observe these notices without fail.

Besides, the attention mark is prepared for the helpful information, detail instruction related to each

part, and reference item or page

If you ignore the advice with this mark, death or serious injury could result.

If you ignore the advice with this mark, injury or material damage could result.

The supplementary content is described with this mark.

REFERENCE The related content is described with this mark.

1-2 Safety Precautions

Use this device as per its speci cations. Do not modify this device since its functions and capabilities may not be maintained and it may malfunction.

This device has been developed / produced for industrial use only.

Before using this device, check whether the device performs properly with the functions and capabilities as per the design speci cations.

In case of disposal, dispose this device as industrial waste.

User in charge

The user in charge has responsible to indicate the person to take the training required for the

safety system, using method, installation, operation, and maintenance.

This device is used and managed by the specialist, never use this device by other operator.

Specialist

A person who is appropriately educated, has widespread knowledge and experience, and

can solve various problems which may arise during work.

Operator

The operator should read this instruction manual thoroughly, understand its contents, and

perform operations following the procedures described in this manual, for the correct operation of this device.

In case this device does not perform properly, the operator should report this to the person in

charge and stop the machine operation immediately. The machine must not be operated until

correct performance of this device has been con rmed.

4SUNX Limited MJE-SFCHC No.0013-09V

Page 6

INTRODUCTION

Fixed blanking function, oating blanking function

With the xed blanking function, this device prevents the person or object from entering into

the dangerous parts of the machine through the invalid sensing area. However, even though

this device can prevent the interference of the person or object into the invalid sensing area

with the xed blanking function, there might exist the more space between the

and already-existence object. Therefore, set the protecting structure so as not to exist any

space in the dangerous sensing area. Detecting human body in the sensing area could result in death or serious injury.

With the oating blanking function, this device changes the size of the minimum sensing object of the

calculate and measure the safety distance again, and check that the device has the wider

space than the safety distance between the dangerous parts of the machine and the sensing

area of the

before its dangerous parts are reached, which can result in death or serious injury.

Set and change the function of the device following the relative laws, regulation, and standard without fail.

Muting setting changing function

The muting setting changing function temporarily invalidates safety function of the connected

devices. Con rm all of the applied laws and standards, and install or operate this device and

peripheral devices correctly. Failure to do so, the operator may suffer a serious injury.

SF4C

seri es that is pre-set the function. When setting or changing the function,

SF4C

series.

If the suf cient distance is not maintained, the machine will not stop

SF4C

series

Environment

Do not use a mobile phone or a radio phone near this device.

Do not use this device in the following environments.

1) Areas with high humidity where condensation is likely to occur

2) Areas exposed to corrosive or explosive gases

3) Areas exposed to vibration or shock of high levels

4) Areas exposed to contact with water

5) Areas exposed to too much steam or dust

Wiring

Be sure to carry out the wiring in the power supply OFF condition.

All electrical wiring should conform to the regional electrical regulations and laws. The wiring

should be done by engineer(s) having the special electrical knowledge.

Do not run the wires together with high-voltage lines or power lines or put them in the same

raceway. This can cause malfunction due to induction.

Maintenance

Clean this device with a clean cloth. Do not use any volatile chemicals.

Other

Never reassemble or remodel this device.

5 SUNX Limited MJE-SFCHC No.0013-09V

Page 7

CHAPTER 2 GENERAL OUTLINE

This chapter gives the system construction, part description, etc. of this device.

2-1 Features

This device is the handy controller for setting each function of the light curtain

series.

Besides, this device performs the checking and copying the setting contents of the function, and protection of writing.

<Functions>

Fixed blanking function

Floating blanking function (Invalid setting of both end beam channels can be set in Ver. 2.1 of

SF4C

series only)

Auxiliary output switching function

Muting setting changing function

(Muting sensor output operation setting can be set in Ver. 2.1 of

Override setting changing function

Muting lamp diagnosis function

SF4C

series only)

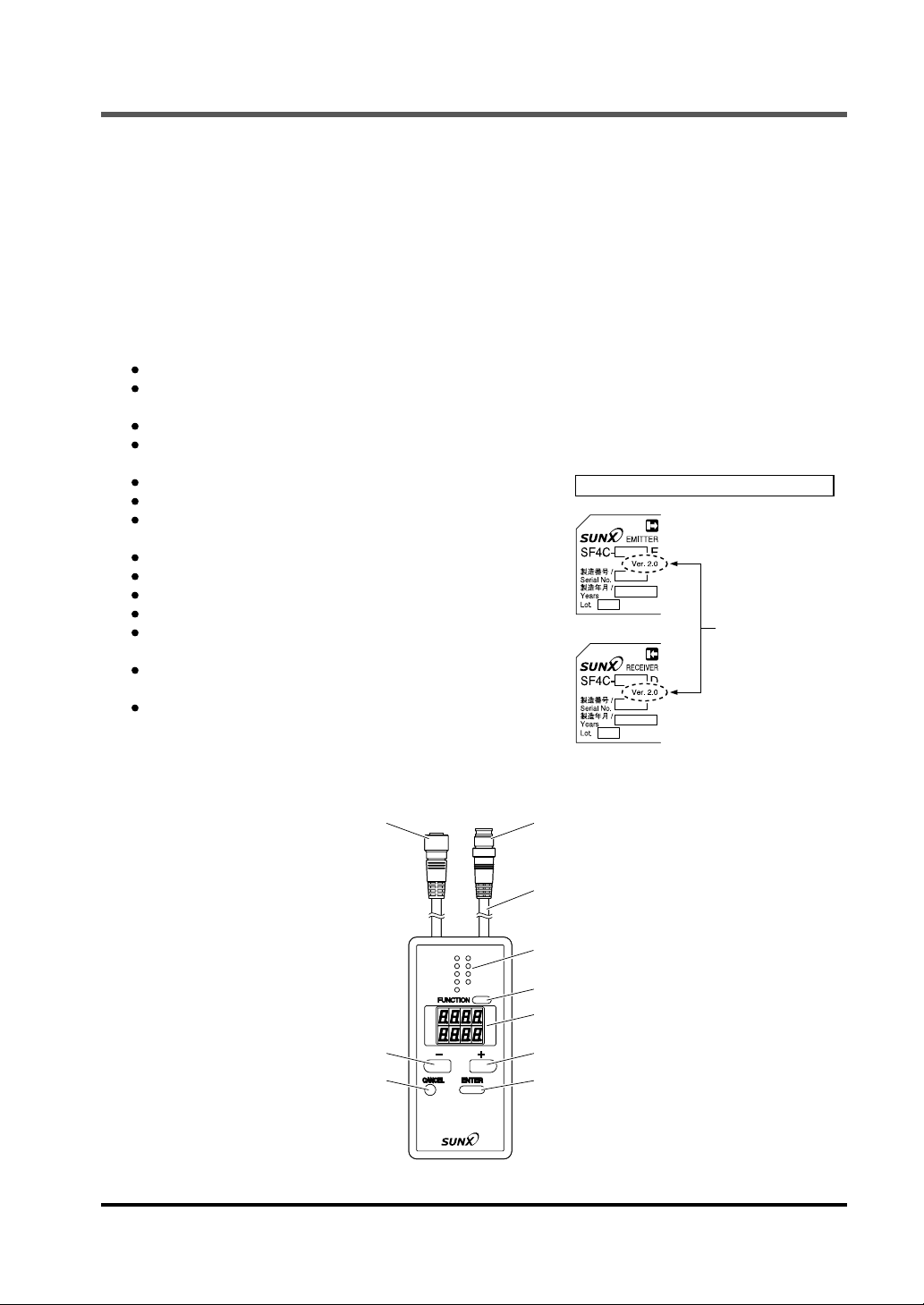

Indicated place of Ver. infomation of

<Plate of emitter side>

SF4C

Safety input setting changing function

(Invalid setting can be set in only Ver. 2.0 or later of

SF4C

series)

Large multi-purpose indicator setting changing function

Interlock setting changing function

External device monitor setting changing function

Protective function

Setting contents monitoring function

(Can be set in only Ver. 2.0 or later of

SF4C

series)

<Plate of receiver side>

For Ver. 2.0 or later

of

SF4C

Not indicated in Ver.

1.0 of

series.

SF4C

Copy function

(Can be set in only Ver. 2.0 or later of

SF4C

series)

Initialization function

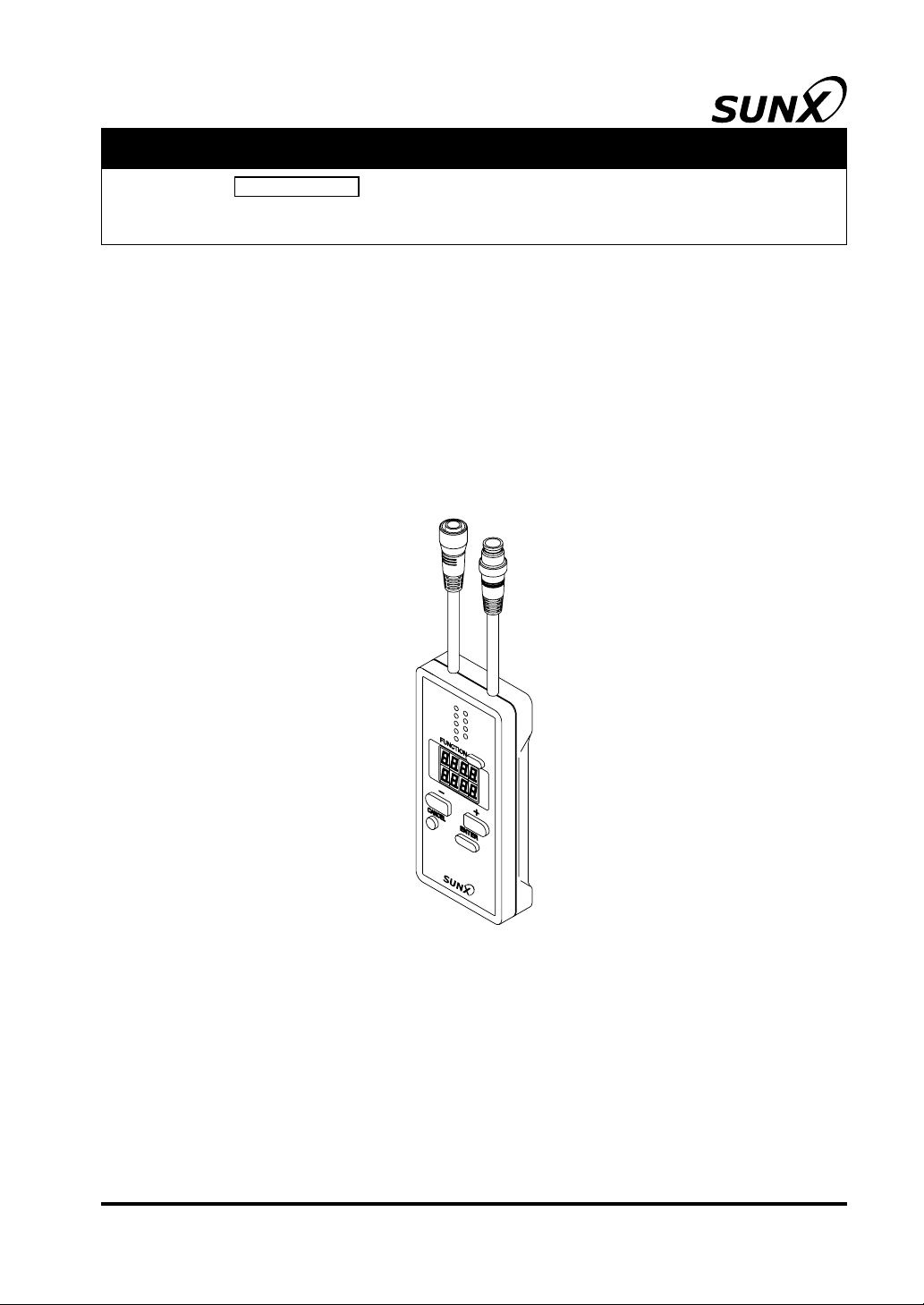

2-2 Part Descriptions

SF4C

series

series.

Female connector

- switch

CANCEL switch

Male connector

Cable (0.5m)

FUNCTION indicator × 9

(Green)

FUNCTION switch

Digital display (Red)

+ switch

ENTER switch

6SUNX Limited MJE-SFCHC No.0013-09V

Page 8

Connecting / Setting Procedures

2-3 Connecting / Setting Procedures

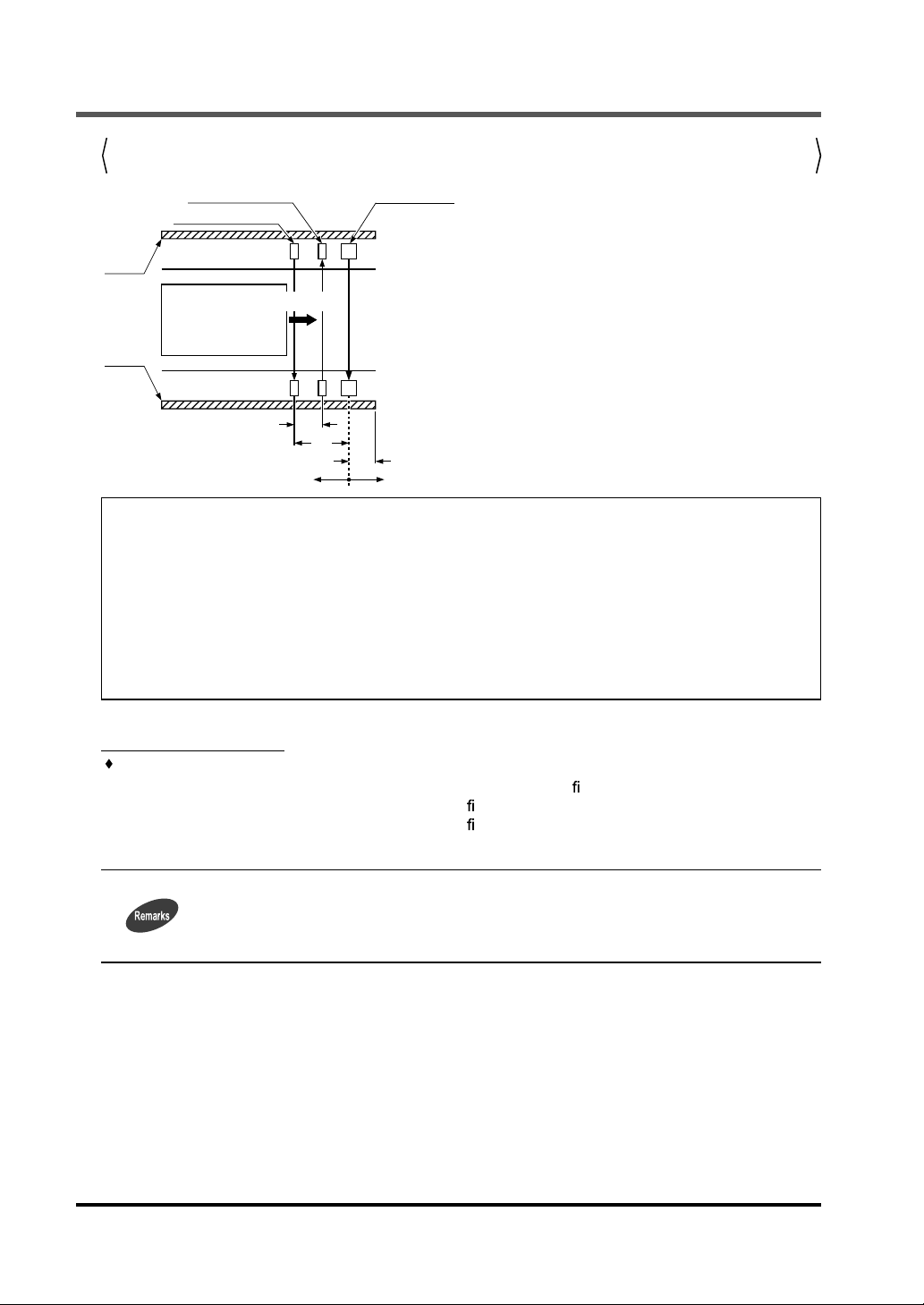

This section describes the connecting / setting procedures for both this device and

SF4C

series.

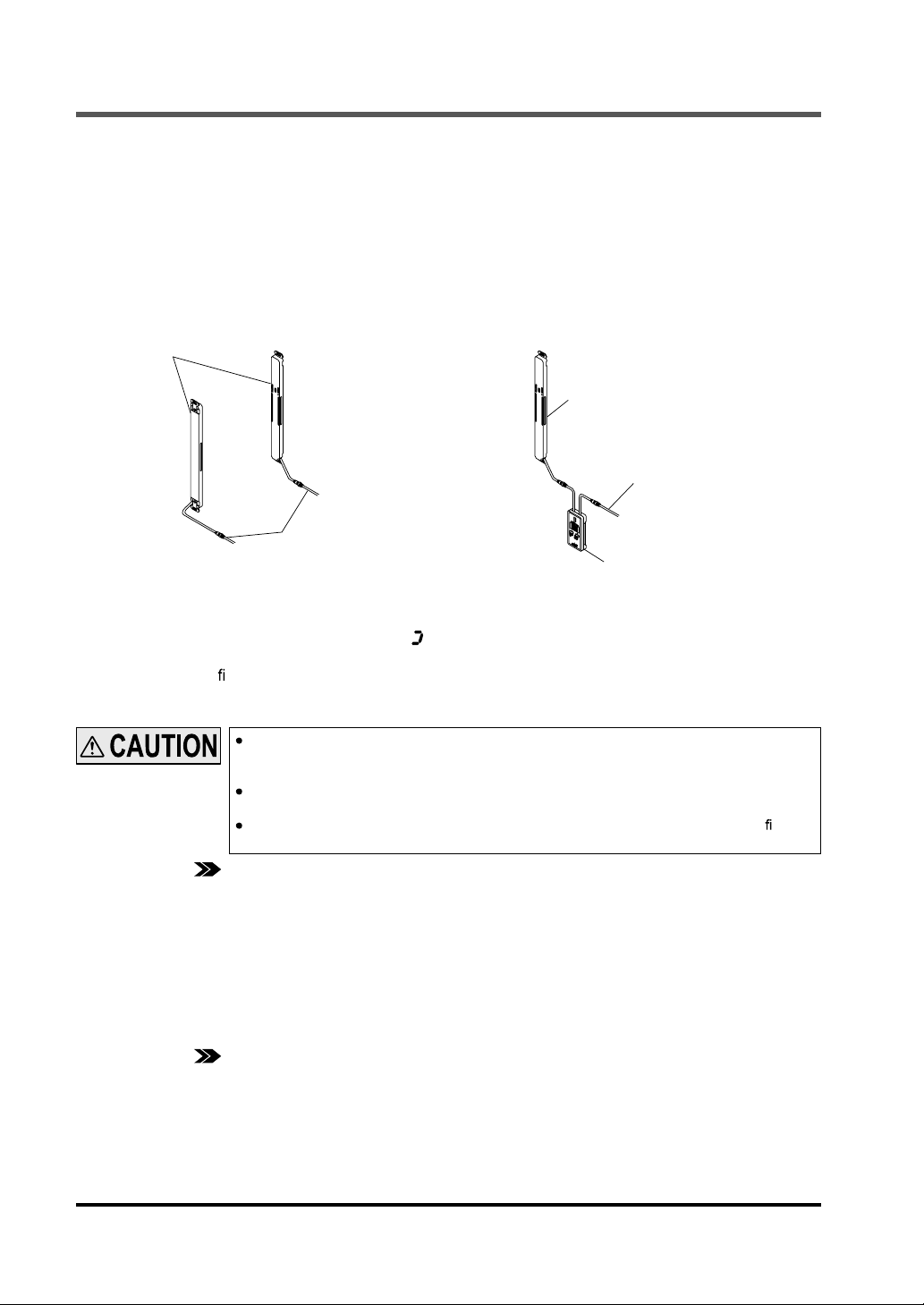

<In case using intermediate connector type to this device>

1. Set the

SF4C

method of

SF4C

series, and check that the

series works properly. For mounting

SF4C

series, refer to the respec-

tive Instruction Manuals.

2. Turn OFF the power, and disconnect the extension cable with connectors connected to

SF4C

series, then connect this device be-

tween emitter (or receiver) of

SF4C

series

and the extension cable with connectors.

SF4C

series

SF4C

series

Emitter (or receiver)

Extension cable

with connectors

To power supply

To power supply

Extension cable

with connectors

This device

3. Turn ON the power, and set the function with this device.

After the power of this device turned ON, approx. 10 sec. will be taken for data transmission with

SF4C

series. While data transmission,

[The control output (OSSD 1 / 2) of

In case of con rming operation of changed setting contents of

the power supply of

SF4C

series once.

“ ”

lights up in revolving.

SF4C

series is set to “OFF” while this device has been connected.]

SF4C

series, turn OFF and turn ON of

In case control is set as shutting OFF power of

when the control output 1 / 2 (OSSD 1 / 2) becomes OFF, supply power from another

power supply.

Do not turns OFF or disconnect wires during setting. in case power is shut OFF during

setting contents, set the contents again after initialization.

When “good” in the check result after changing setting is displayed, the setting is xed. In

case the “good” is not displayed, set the setting contents again.

REFERENCE Refer to “

Function Setting (Operation Procedure)

respectively.

3-1 Functional Descriptions

4. Turn OFF the power of emitter and receiver of

5. Connect both

SF4C

series and the extension cable with connectors and return the device to the

” for the details of the functions, and refer to “

SF4C

series, then remove this device.

SF4C

series from the power supplely

” for the setting procedures of the functions

3-2

state described in procedure 1.

6. Turn ON the power of emitter and receiver of

SF4C

series, and check that the

SF4C

series works

as set at the procedure 3.

Then, inspect the

REFERENCE Refer to “

7 SUNX Limited MJE-SFCHC No.0013-09V

SF4C

series.

inspection of the

Chapter 4 Maintenance

SF4C

series.

” of the

SF4C

series instruction manual for the details of the

Page 9

Connecting / Setting Procedures

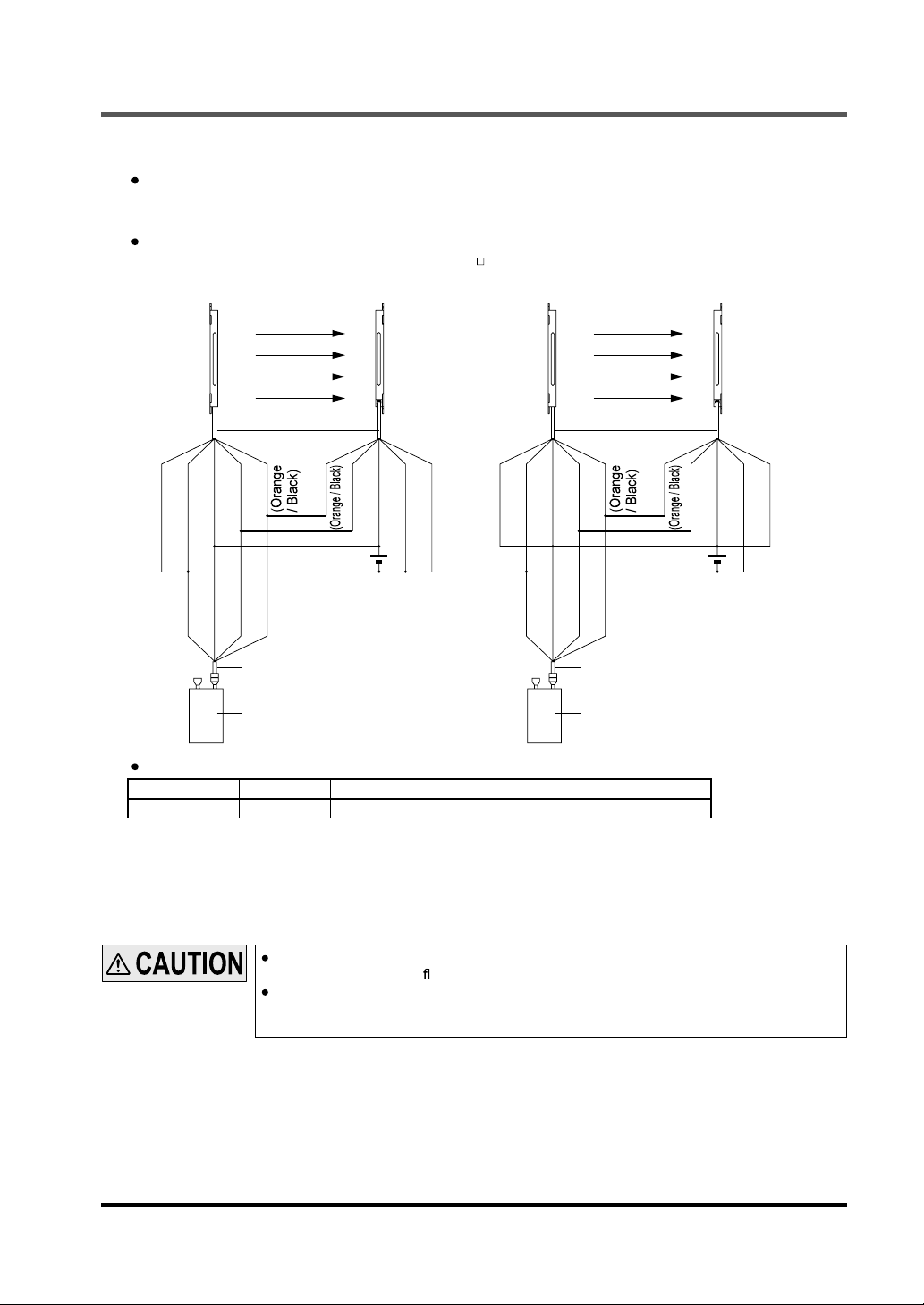

<In case using this device with cable type of SF4C series>

Wire a discrete connection cable with connector on one end

And wire a clip of the discrete connection cable with connector on one end to a lead wire of cable

type of

SF4C

series.

It is also possible to use in condition that an intermediate connector type of

to a cable with connector on one end

SFB-CC -MU

(optional).

<For PNP output> <For NPN output>

SFC-WNC1

(optional) to this device.

SF4C

series is wired

Emitter

(Shield)

(Blue)

(Brown)

(Orange)

24V±10% 24V±10%

(Blue)

(Brown)

(Orange)

(Orange

/ Black)

Connection cable with a

connector on one end

This device This device

Receiver

(Orange)

Emitter Receiver

(Blue)

(Shield)

(Brown)

+

-

(Blue)

(Shield)

(Brown)

(Orange)

(Blue)

(Brown)

(Orange)

(Orange

/ Black)

Connection cable with a

connector on one end

(Blue)

(Shield)

(Brown)

(Orange)

+

-

Connection cable with a connector on one end: 1 pc./set

Model No. Cable length Description

SFC-WNC1

The setting procedure remains the same.

•

The control output (OSSD 1 / 2) of

•

3m Cable which incorporates clips on end of the discrete wire.

SF4C

series is set to “OFF” while this device has been connected. Once the setting is completed, turn OFF the power, remove this device and then turn ON

the power again.

When the lead wire contacts with other lead wires, maximally 26.4V DC of voltage is applied and 3A of current ows.

In case the connecting cable with connector on one end connected the cable type of

SF4C series or the intermediate connector type to this device, lead wire may be disconnected. Be sure the lead wire is not disconnected.

8SUNX Limited MJE-SFCHC No.0013-09V

Page 10

CHAPTER 3 FUNCTIONS

3-1 Functional Descriptions

If con guration of the system is changed (replace the

again.

SF4C

series etc.), set the function

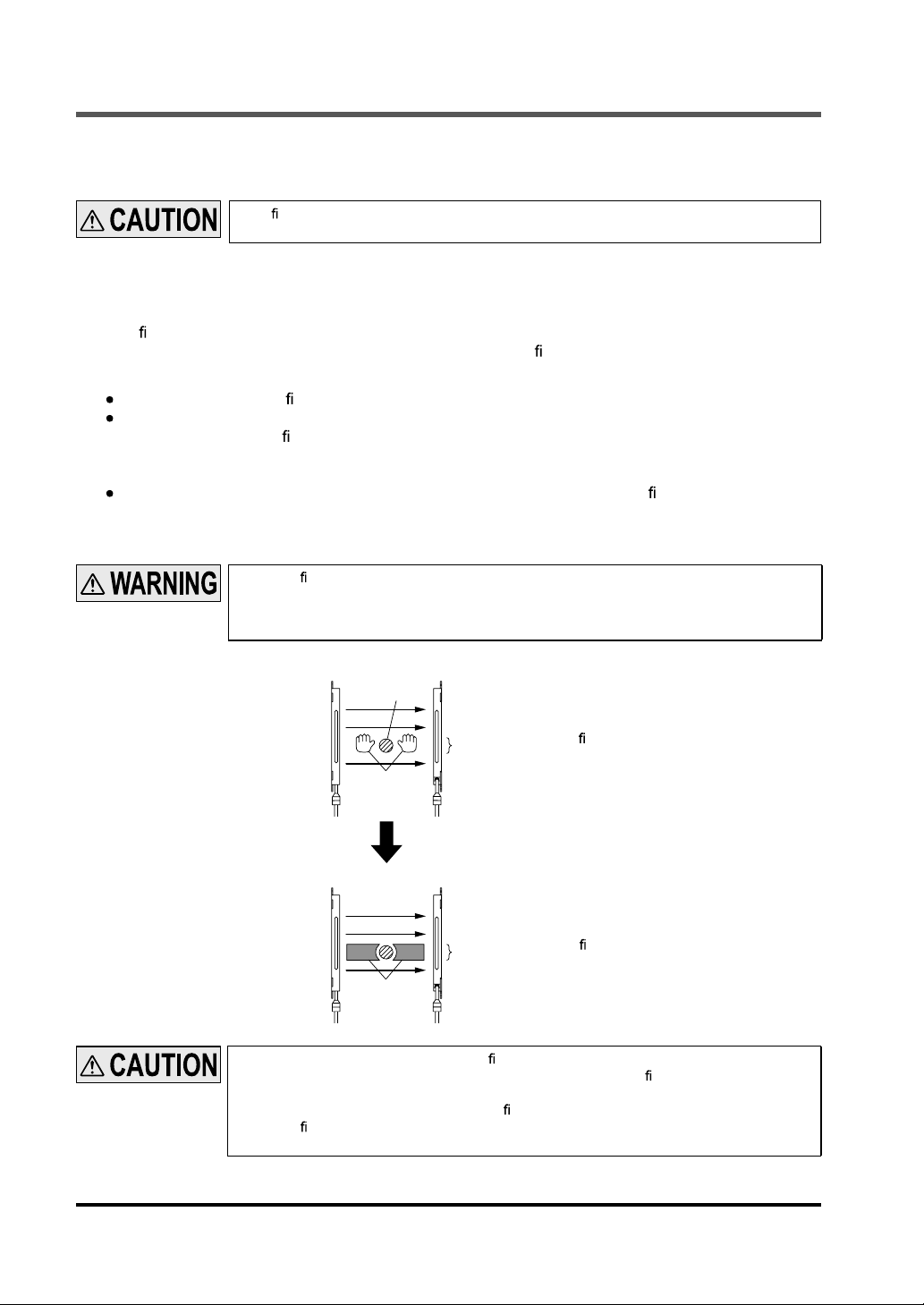

3-1-1 Fixed Blanking Function

This is a function that the control output (OSSD 1 / 2) of

speci ed beam channel(s) is blocked OFF.

This is useful when an obstacle always blocks OFF the speci c beam channel(s).

There are “Clear,” “Auto” and “Manual” for the setting method.

Clear setting : The xed blanking function is to be invalid (factory setting).

Auto setting : The currently blocked OFF beam channels are set as “valid beam channels” in

the xed blanking function. Be sure to set this function in the state where the

emitter emits light. Furthermore, this function cannot be set in the state where

all beam channels receive lights / are blocked.

Manual setting : Each beam channel can be set to “valid / invalid” in the xed blanking function

respectively.

The all light beam channel can not be selected all valid / all invalid

When the xed blanking function is used, the control output (OSSD 1 / 2) of

not turned OFF even if the particular beam channels are blocked.

By using a protection structure etc., make the dangerous parts of the machine inaccessible

to personnel through the sensing area of the particular beam channels.

<Before measures>

Emitter Receiver

Obstacle

SF4C

series is not turned OFF, even if the

SF4C

series is

Beam channels the xed blanking function has been set to ON

Dangerous area

<After measures>

9 SUNX Limited MJE-SFCHC No.0013-09V

Emitter Receiver

Beam channels the xed blanking function has been set to ON

Protection structure

When the valid beam channel(s) in the xed blanking function receive(s) the beam(s) from

the emitter, the control output (OSSD 1 / 2) of the

check the mounting condition and turn the power ON again.

(Even if the power is turned ON again, the xed blanking function still stays valid.)

When the xed blanking function is used, the received light intensity indicator of

ries is turned OFF regardless of the received light intensity.

SF4C

series is xed to “OFF.” In this case,

SF4C

se-

Page 11

Functional Descriptions

3-1-2 Floating Blanking Function

If the number of the blocked beam channels is less than the set number of the beam channels, the

control output (OSSD 1 / 2) of

This function is useful when an obstacle moves within the sensing area.

The factory setting of this function is “invalid.”

The following items can be set.

Set number of beam channels

Selectable among 0 (the oating blanking function is invalid), 1, 2 or 3.

Invalid setting of both end beam channels (only for Ver. 2.1 of SF4C series)

Be able to select valid or invalid of oating blanking function in both ends of beam channels.

SET (Valid) : The

•

•

CLR (Invalid) : The oating blanking function becomes effective for all beam channels includ-

Non-serial beam channel setting

•

SET (Valid) :

•

CLR (Invalid) : When the beam channels are blocked discontinuously even in the set beam

SF4C

series is not turned “OFF.”

oating blanking function becomes invalid at both ends of beam channels. In

case either end of the beam channel is blocked, the control output (OSSD 1 / 2) of

SF4C

series is turned “OFF” regardless of the set number of the beam channels.

ing both end beam channels.

Even if the beam channels are blocked discontinuously in the set beam channels,

the control output (OSSD 1 / 2) of

channels, the control output (OSSD 1 / 2) of

SF4C

series is turned “ON.” (Discontinuous mode)

SF4C

series is turned “OFF.”

(Continuous mode)

When using the oating blanking function, the size of the minimum sensing object becomes larger, and the safety distance is longer as well. For the calculation of the safety

distance, refer to the instruction manual enclosed with

Before designing the system, refer to the relevant laws and standards of the region

where

SF4C

The minimum sensing object differs depending on the set number of the beam channels.

series is to be used and then install

SF4C

SF4C

series.

series.

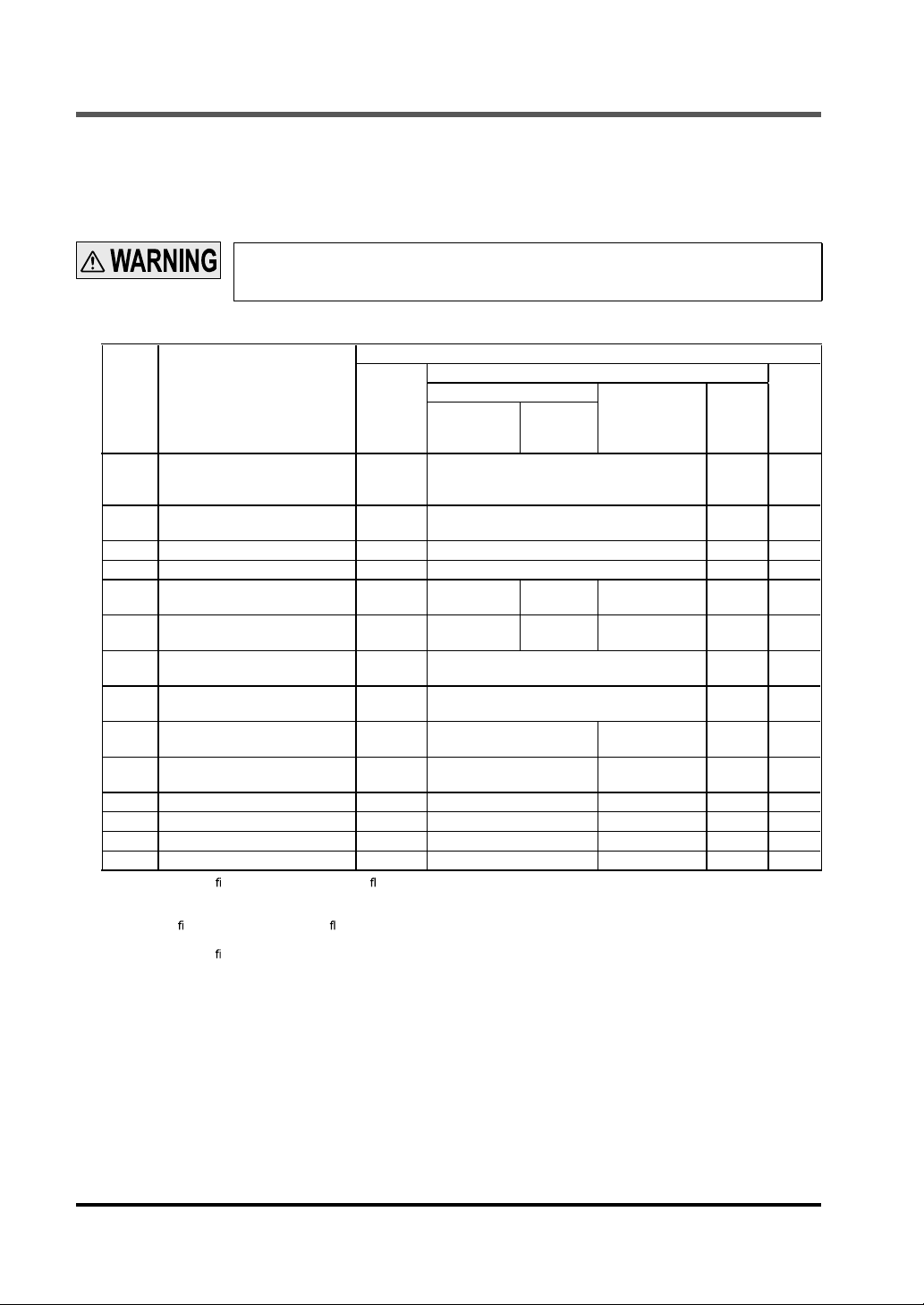

[For use in Europe (EU) (as EN 999)] (Also applicable to ISO 13855 / JIS B 9715)

(For intrusion direction perpendicular to the sensing area)

<In case that the minimum sensing object is over ø40mm>

Equation S = K × T + C

S : Safety distance (mm)

Minimum required distance between the sensing area surface and the dangerous parts of

the machine.

K : Intrusion velocity of operator’s body or object (mm/sec.)

Taken as 1,600 (mm/sec.) for calculation

T : Response time of total equipment (sec.)

T = T

m

+ T

SF4C

Tm: Maximum halting time of machine (sec.)

T

: Response time of

SF4C

SF4C

series (sec.)

C : Additional distance (mm)

C = 850 (mm)

<Minimum sensing object>

Floating blanking function

Val id

SF4C-H

,

SF4C-H -J05

Invalid

ø25mm ø45mm ø65mm ø85mm

1 beam channel 2 beam channels 3 beam channels

If the oating blanking function is used, the incident light intensity indicator is turned OFF

when an obstacle exists in the sensing range regardless of the incident light intensity.

10SUNX Limited MJE-SFCHC No.0013-09V

Page 12

Functional Descriptions

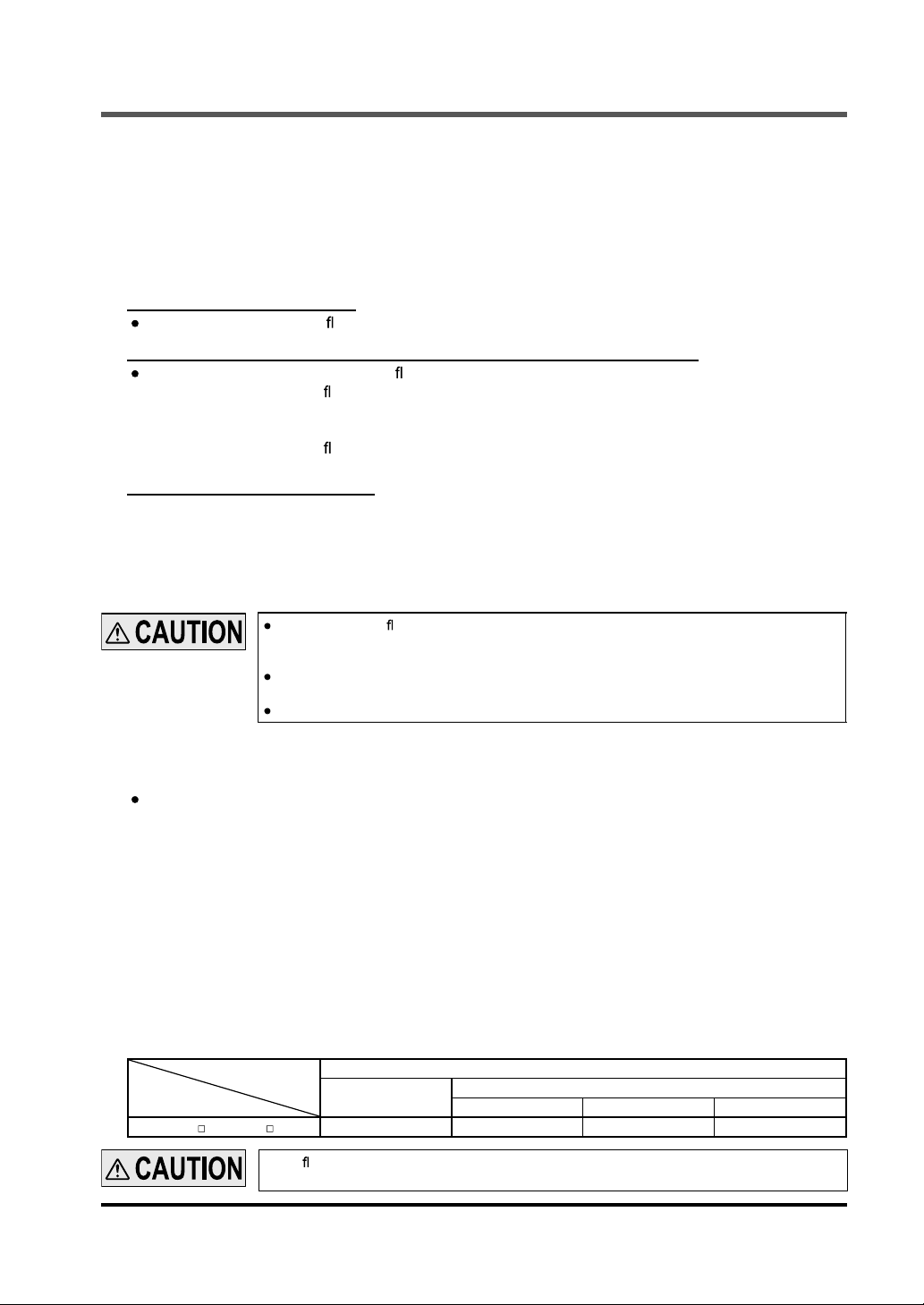

3-1-3 Auxiliary Output Switching Function

This function changes the operation state of the auxiliary output. It is useful when desired to make an

indicator to operate or inform the operation state of the

The auxiliary output is a non-safety output. Therefore, do not use the auxiliary output for the

purpose of stopping the machine that the

result in death or serious injury.

The following settings are selectable.

Operation of the auxiliary output corresponding to

Setting

mode

Auxiliary output setting

Negative logic of the control

0

output (OSSD 1 / 2)

(factory setting)

Positive logic of the control

1

output (OSSD 1 / 2)

2 OFF when test output is valid OFF ON

3 ON when test output is invalid ON OFF

OFF under unstable light

4

receiving condition (Note 1)

ON under unstable light

5

receiving condition (Note 1)

6 ON during muting OFF

7 OFF during muting ON

ON in light receiving condition

8

(Note 2)

OFF in light receiving condition

9

(Note 2)

10 ON during safety input valid

11 OFF during safety input valid

12 OFF during lockout

13 ON during lockout

Notes: 1) When the xed blanking function, the oating blanking function or the muting function is used, the setting of ON / OFF

2) By the setting of ON / OFF in light receiving condition, light-receiving / light interrupted condition is output regardless of

<e.g.>

When the xed blanking function is used, if an obstacle exists in the set area and other area is in light receiving condi-

3) The state of the auxiliary output remains the same even if the

under unstable light-receiving condition does not work.

the xed blanking function, the oating blanking function or the muting function.

tion, the control output (OSSD 1 / 2) is in ON sate, however, the auxiliary output becomes OFF since the

has been detecting the obstacle.

When

test

input is

valid

Unstable

light-receiving

condition

ON

OFF

(Note 3) OFF ON (Note 3)

(Note 3) ON OFF (Note 3)

-

-

-- -

-- -

-- --

-- --

SF4C

series to PLC.

SF4C

series is installed. Failure to do so could

SF4C

series state

State of sensing area when test input is invalid

Unshielded

Others

Shielded

When

safety

input is

valid

OFF when OSSD is ON

ON when OSSD is OFF

ON when OSSD is ON

OFF when OSSD is OFF

ON during muting

Others: OFF

OFF during muting

Others: ON

ON OFF

OFF ON

ON

OFF

SF4C

series state changes.

-

-

--

--

-

-

-

-

-

-

SF4C

Lockout

ON

OFF

(Note 3)

(Note 3)

OFF

ON

OFF

ON

-

-

OFF

ON

series

11 SUNX Limited MJE-SFCHC No.0013-09V

Page 13

Functional Descriptions

3-1-4 Muting Setting Changing Function

The setting of the muting function can be changed.

Setting of the muting function on each beam channel

Each beam channel can be set to “valid / invalid” in the muting function respectively. (Note)

All beam channel can not be all invalid.

The factory setting of this function is valid for all beam channels.

Note: If the beam channel set to invalid in the muting function is blocked, the control output (OSSD 1 / 2) becomes “OFF” and the

muting function is canceled.

There are two setting methods, “Auto” and “Manual” to set muting beam channel.

Auto setting : The beam channel which is currently blocked is set as the “valid” beam chan-

•

nel. When all beam channels are in light receiving condition, the setting is not

accepted. Furthermore, in the state that all beam channels are blocked, the all

beam channels become “valid” in the muting function.

Manual setting : Each beam channel can be set to “valid / invalid” in the muting function.

•

ON: The muting function is valid

OFF: The muting function is invalid

Muting maximum continuous valid time setting

Maximum continuous valid time setting for muting function can be changed.

The maximum continuous valid time is 1 to 600 sec. (1 sec. unit) or no limit.

Muting sensor output operation setting (only for Ver. 2.1 of SF4C series)

Output operation of muting sensor can be selected

Factory setting is NONO (Normally Open • Normally Open)

NONO (Normally Open, Normally Open)

•

A muting sensor which is to be connected to the muting input 1

(ON with light non-received status, ON with object approaching status and ON with object contacted status)

A muting sensor which is to be connected to the muting input 2

(ON with light non-received status, ON with object approaching status and ON with object contacted status)

NONC (Normally Open, Normally Close)

•

A muting sensor which is to be connected to the muting input 1

(ON with light non-received status, ON with object approaching status and ON with object contacted status)

A muting sensor which is to be connected to the muting input 2

(ON with light received status, ON with object non-approaching status and ON with object non-contacted status)

Muting function only for the sensing object exit

Muting function only for the sensing object exit can be set.

When setting to the muting function only for the sensing object exit, install the muting sensor only

in the dangerous zone and the installation in the safety zone is not required.

Using conditions of the muting function only for the sensing object exit is as follows.

The sensing object should move to one side.

•

(The sensing object should move from the dangerous zone to the safety zone.)

The sensing object should pass through the sensing area within 4 sec. after the muting sensor

•

turns OFF. (Note)

Note: Muting time only for the sensing object exit can be set between 0 (Invalid) to 4,000ms (Unit: 100ms).

In case using the muting function only for the sensing object exit and the oating blanking

function, set by being sure listed below.

The set beam channel number of the oating blanking function is 0 or 1 beam channel

only.

In case making valid the invalid setting of both end beam channels of the oating blanking function, set invalid the muting function of both ends of beam channels in each beam

channel setting of muting function.

12SUNX Limited MJE-SFCHC No.0013-09V

Page 14

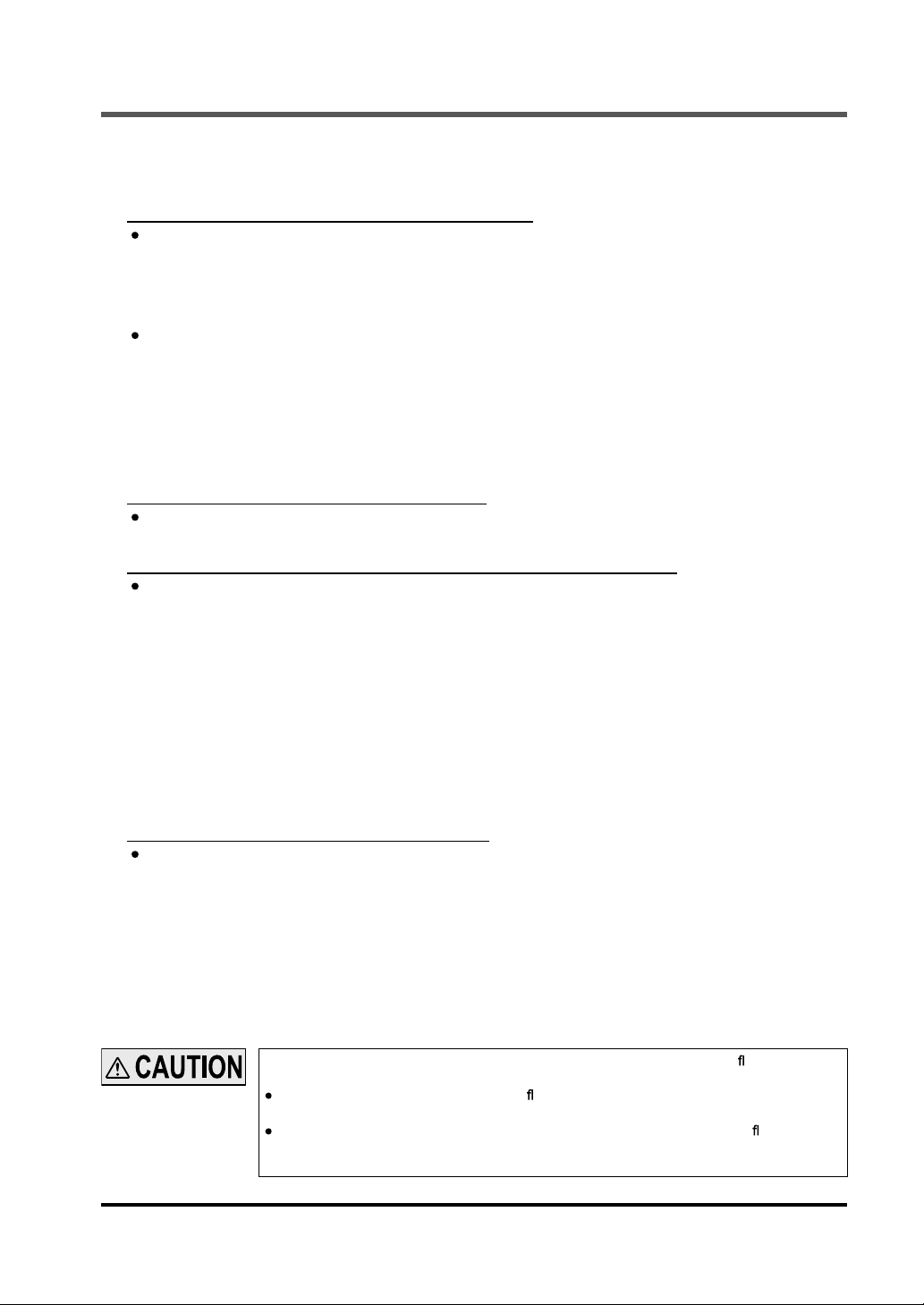

Functional Descriptions

Installation condition example of muting sensors when setting the muting function

only for the sensing object exit

Muting sensor B

Muting sensor A

Guard

S (m/sec.)

Sensing object

Guard

1

2

Safety zone Dangerous zone

1. The time of the sensing object to be passed through the muting sensors A to B shall be 0.03 to under 3 sec.

Distance between A and B (m) < S (m/sec.) × 3 (sec.)

S: The moving speed (m/sec.) of the sensing object

2. The time of the sensing object to be passed through the muting sensor A to the light curtain shall be under 4

sec.

Distance between muting sensor A and the light curtain (m) < S (m/sec.) × 4 (sec.)

Distance between muting sensor A and the light curtain (m) < Total length of the sensing object (m)

S: The moving speed (m/sec.) of the sensing object

3. The time of the sensing object to be passed through the light curtain to the end of guard zone shall be under

4 sec.

Distance between the light curtain and the end of guard zone (m) < S (m/sec.) × 4 (sec.) - 0.2

S: The moving speed (m/sec.) of the sensing object

Note: If a beam channel whose muting function is set to be invalid is blocked during the muting, the control output (OSSD 1 / 2)

will be turned OFF and the muting function will be released.

Muting input conditions

The order for inputting the muting input 1 and 2, which the muting function activates, can be set.

1 = 2: Valid even either muting input 1 or muting input 2 comes rst

1 2: Valid only when the muting input 1 comes rst

2 1: Valid only when the muting input 2 comes rst

Note: The setting is possible for each beam channel.

Light curtain

3

Combination of using muting input conditions and setting of each beam channel of the muting

function allows to set making muting function valid when muting input conditions are 1 to 2 or 2

to 1.

The setting method is to set the each beam channel setting of muting input condition 1 to 2 and

set the each beam channel setting of muting input condition 2 to 1.

13 SUNX Limited MJE-SFCHC No.0013-09V

Page 15

Functional Descriptions

3-1-5 Override Setting Changing Function

Maximum continuous valid time set at the override function can be changed.

The maximum continuous valid time can be set in the range of 1 to 600 sec. (in units of 1 sec.).

The factory setting is 60 sec.

3-1-6 Muting Lamp Diagnosis Function

The muting lamp diagnosis function can be set to “valid / invalid.” (Note)

The factory setting of this function is valid.

ON : The muting lamp diagnosis function is valid.

OFF : The muting lamp diagnosis function is invalid.

Note: If the muting lamp diagnosis function is set to invalid, the muting function is maintained even if the lamp blew.

3-1-7 Safety Input Setting Changing Function

This function enables to select the safety contacting point input mode or the safety sensor input mode

with this controller. Furthermore, safety input can be set to invalid for Ver. 2.0 or later of

Safety contacting point input mode

A safety contacting point can be connected. It is at the time of factory setting

Safety sensor input mode

A safety sensor can be connected.

<Output operations of a safety contacting point and a safety sensor>

NC (Normally Closed) type Operation at ON state

Safety contacting point

Safety

sensor

Note: the safety contacting point which is connected to the safety input 1 / 2 or safety sensor and control out-

put of

ON with object non-contacted status

(Emergency stop switch, etc.)

ON with light received status (Light

curtain, etc.)

ON with object non-approaching

status (Safety switch, etc.)

SF4C

series should be kept OFF.

PNP output: Connect to +V

NPN output: Connect to 0V

Invalid (only for Ver. 2.0 or later of SF4C series)

Safety input can be invalid. In this case, safety contact point and safety sensor cannot be connected.

SF4C

series.

Operation at OFF state

Open (Note)

Use 0.2mm2 or more shielded cable when connecting other

safety input 1 / 2.

When extending the cable of other

use the exclusive cable and the total cable length should be 40.5m or less (for each emitter / receiver). If the total cable length is exceeding 40.5m, the device may malfunction,

resulting in death or serious injury.

Response time of safety sensor is sum of a response time of this device and safety sensor itself.

SF4C

series

Control output 1

(OSSD 1)

Control output 2

(OSSD 2)

SF4C

series which is connected to the safety input 1 / 2,

Safety sensor

Response time of

7ms

Response time of safety sensor

<Ex.>

In case of using

Response time of safety sensor + response time of

= 7ms + 7ms = 14ms

SF4C

series cable to the

SF4C

series

SF4C

as safety sensor.

SF4C

series

14SUNX Limited MJE-SFCHC No.0013-09V

Page 16

Functional Descriptions

When using the device in PNP output (or NPN output), use PNP output (or NPN output)

safety sensor. The control output (OSSD 1 / 2) becomes OFF by using wrong output type

of sensor.

Series connection is also available when connecting other

put 1 / 2. However, this device does not incorporate the interference prevention function.

Thus, take suf cient care when installing the devices.

Use a safety sensor which incorporates a crossover short-circuit function in the control

output and connect both the safety input 1 wire (gray) and the safety input 2 wire (gray /

black). Take care that if only one wire is connected, the device may not operate normally.

Use a safety contacting point which incorporates two NC (Normally Closed) contacting

points and connect both the safety input 1 wire (gray) and the safety input 2 wire (gray /

black). Take care that if only one wire is connected, the device may not operate normally.

In case setting the safety contacting point input mode or the safety sensor input mode,

connect to +V or 0V as a following table when safety input function is not used.

Safety input

setting changing function

Safety contacting point

input mode

Safety sensor

input mode

SF4C

series to the safety in-

For PNP output For NPN output

Safety input 1 wire

(gray)

Connect to +V Connect to 0V Connect to +V Connect to 0V

Connect to +V Connect to +V Connect to 0V Connect to 0V

Safety input 2 wire

(gray / black)

Safety input 1 wire

(gray)

Safety input 2 wire

(gray / black)

3-1-8

Large Multi-purpose Indicator Setting Changing Function

One mode can be selected from the following 8 modes

Factory setting is mode 0.

Operation of large multi-purpose indicator

Mode

(Note 1)

(Note 1)

(Note 1)

(Note 1)

Notes: 1) Blinking takes precedence in case of same color brinks or light up in the large multi-purpose indicator.

2) The large multi-purpose indicator (red) and the large multi-purpose indicator (green) can be lit up and blinked in same

Large multi-purpose

indicator input 1

PNP output:

High

0 Lights up in red Lights up in green

1 Blinks in red Blinks in green

2 Lights up in red Blinks in green

3 Blinks in red Lights up in green

4

5

6

7

Lights up in red Blinks in red

Lights up in red Blinks in red

time.

NPN output:

Low

Blinks in green Lights up in green

--

Large multi-purpose

indicator input 2

PNP output:

Low

NPN output

High

Control output 1 / 2

(OSSD 1 / 2)

ON OFF Valid Valid

----

----

----

----

----

----

Lights up

in green

--

Lights up

in red

Muting

function

Blinks in

green

Lights up

in green

Override

function

Blinks in

green

-

Furthermore, large multi-purpose indicator (red) can be blinked in lockout status.

Lockout blinking display function Lockout ON

Valid Blinks in red

Invalid

-

15 SUNX Limited MJE-SFCHC No.0013-09V

Page 17

Functional Descriptions

3-1-9 Interlock setting changing function

It is selectable one interlock state among the following three interlock settings (Mode 3)

•

Start / Restart interlock (Mode 0)

SF4C

series goes into the interlock state after the power is turned ON, or when the light of

SF4C

series is blocked.

The factory setting is start / restart interlock.

•

Start interlock (Mode 1)

SF4C

series goes into the interlock state when the power supply is turned ON. Once this inter-

lock is reset, the device does not go into the interlock state.

Restart interlock (Mode 2)

•

SF4C

series does not go into the interlock state when turning ON the power supply. Only when

the control output (OSSD 1 / 2) becomes ON and the light for

is turned ON and this device receives the light, the device goes into the interlock state.

3-1-10 External Device Monitor Setting Changing Function

The setting of the external device monitor can be changed

1. Allowable time for response time: 100 to 600ms (Unit: 10ms)

Factory setting is 300ms.

2. The external device monitor function can be selected to valid or invalid

The factory setting is set to valid for the external device monitor function.

3-1-11 Protective Function

SF4C

is blocked after the power

The functional settings are not allowed to change without the input of a password of

When the protective function is set to “valid,” the setting can be changed by inputting the password.

The setting contents monitor function can be used regardless of the protective function “valid / invalid.”

The password should be a 4-digit number from 0 to 9. (The password of the factory setting is “0000.”)

The protective function is set on the receiver.

When the protecting function is set to “invalid,” the third person may change the setting. It is recommended that the protecting function should be set to “valid” so as not to

change the setting by the third person.

Take sufficient care not to forget the set password. In case you forget the password,

please contact us.

SF4C

series.

3-1-12 Setting Contents Monitoring Function (Only for Ver. 2.0 or later of SF4C series)

Each setting of the

Setting of the xed blanking function (Reading out the record of the latest 5 times is possible)

Setting of the oating blanking function (Reading out the record of the latest 5 times is possible)

Setting of the auxiliary output switching function

Setting of the muting setting changing function

(Reading out the record of the latest 5 times is possible, however, only for setting beam channel.)

Setting of the override setting changing function

Setting of the muting lamp diagnosis function

Setting of the safety input setting changing function

Setting of the large multi-purpose indicator setting changing function

Setting of the interlock setting changing function

Setting of the external device monitor setting changing function

Setting of the protect function

Model No. / the number of beam channels of

SF4C

series can be monitored. The following can be monitored.

SF4C

series.

16SUNX Limited MJE-SFCHC No.0013-09V

Page 18

Functional Descriptions

3-1-13 Copy Function (Only for Ver. 2.0 or later of SF4C series)

This is a function to copy the setting of a

SF4C

series to other

SF4C

series.

This function is available only under the same system con guration (the number of beam channels,

same model No.).

All functions that can be set with this device can be copied.

Note that the password is also copied with this function.

The following operations are available with this function.

Upload : Upload the functional setting data of

Download : Download the functional setting data of this device to

SF4C

series to this device.

SF4C

series.

Monitoring : Check the functional setting data saved in this device.

SF4C

Original

Upload Download

(Storage area for

series

This device

SF4C

series)

SF4C

Copied

series

3-1-14 Initialization Function

The settings of

The factory setting of each function is as follows.

Fixed blanking function Invalid

Floating blanking function Invalid

Auxiliary output switching function Mode 0 [Negative logic of control output (OSSD 1 / 2)]

Muting setting changing

function

Override setting changing

function

Muting lamp diagnosis function Invalid

Safety input setting

changing function

Large multi-purpose

indicator setting changing

function

Interlock setting changing function Mode 0 (Start / restart interlock function is valid)

External device monitor

setting changing function

Protective function

(Note1)

Notes: 1) Protective function in Ver. 2.1 of

2) Setting data of copy function is not initialized.

SF4C

series can be initialized. (factory setting) (Note)

Function Setting

Muting sensor output

operation setting

Maximum continuous valid

time

Muting function only for the

sensing object exit

Muting input conditions 1 = 2

Select beam channel All beam channels

Select function Valid

Maximum continuous valid

time

Select function Valid

Select input mode Safety contacting point input mode

Select mode

Lockout blinking display function

Select function Valid

Time setting 300ms

Password 0000

Select function Invalid

SF4C

series is not initialized.

NONO (Normally Open, Normally Open)

No limit

Invalid

60 sec.

Mode 0 (Lights up in red when the large multipurpose indicator input 1 is ON, Lights up in green

when the large indicator input 2 is ON)

Invalid

17 SUNX Limited MJE-SFCHC No.0013-09V

Page 19

3-2 Function Setting (Operation Procedure)

This section describes the setting of each function (operation procedure).

<Selecting the setting item>

Select a setting item with FUNCTION or CANCEL switch, and con rm it with ENTER.

key operation

To “

3-2-1 Fixed Blanking Function

3-2-2 Floating Blanking Function

To “

To “

3-2-3 Auxiliary Output Switching Function

”

”

”

Function Setting

: FUNCTION

: ENTER

: CANCEL

: : +

3-2-4 Muting Setting Changing Function

To “

3-2-5 Override Setting Changing Function

To “

To “

3-2-6 Muting Lamp Diagnosis Function

3-2-7 Safety Input Setting Changing Function

To “

3-2-8 Large Multi-purpose Setting Indicator Changing Function

To “

3-2-9 Interlock Setting Changing Function

To “

To “

3-2-10 External Device Monitor Setting Changing Function

To “

3-2-11 Protect Function

To “

3-2-12 Setting Contents Monitoring Function

3-2-13 Copy Function

To “

”

” (Only for Ver. 2.0 or later of

”

”

”

”

”

” (Only for Ver. 2.0 or later of

”

”

SF4C series

SF4C

)

series)

To “

3-2-14 Initialization Function

”

18SUNX Limited MJE-SFCHC No.0013-09V

Page 20

Function Setting

<Inputting a password>

The procedure for inputting a password is as follows.

Input password

NG

CH1

Complete inputting password

1) “

3-2-12 Setting Contents Monitoring Function

2) Once the password is input, you do not need to input the password again till the power is

turned OFF. (Except “

without changing the protective function to invalid, the password have to be input again since

the protective function is still valid.

3-2-11 Protective Function

” is not “locked.”

”) However, if the power is turned ON again

19 SUNX Limited MJE-SFCHC No.0013-09V

Page 21

3-2-1 Fixed Blanking Function

Function Setting

: ENTER

: FUNCTION

: CANCEL

: -

Key operation

: +

20SUNX Limited MJE-SFCHC No.0013-09V

Page 22

Function Setting

3-2-2 Floating Blanking Function

: FUNCTION

: ENTER

: CANCEL

: -

: +

Key operation

21 SUNX Limited MJE-SFCHC No.0013-09V

Page 23

3-2-3 Auxiliary Output Switching Function

Key operation

: FUNCTION

: ENTER

: CANCEL

: -

Function Setting

: +

22SUNX Limited MJE-SFCHC No.0013-09V

Page 24

Function Setting

3-2-4 Muting Setting Changing Function

23 SUNX Limited MJE-SFCHC No.0013-09V

Page 25

Function Setting

24SUNX Limited MJE-SFCHC No.0013-09V

Page 26

Function Setting

: ENTER

: FUNCTION

: CANCEL

: -

: +

Key operation

25 SUNX Limited MJE-SFCHC No.0013-09V

Page 27

3-2-5 Override Setting Changing Function

Key operation

: FUNCTION

: ENTER

: CANCEL

: -

Function Setting

: +

26SUNX Limited MJE-SFCHC No.0013-09V

Page 28

Function Setting

3-2-6 Muting Lamp Diagnosis Function

: FUNCTION

: ENTER

: CANCEL

: -

: +

Key operation

27 SUNX Limited MJE-SFCHC No.0013-09V

Page 29

3-2-7 Safety Input Setting Changing Function

: FUNCTION

: ENTER

: CANCEL

: -

Key operation

Function Setting

: +

28SUNX Limited MJE-SFCHC No.0013-09V

Page 30

Function Setting

3-2-8 Large Multi-purpose Indicator Setting changing Function

: FUNCTION

: ENTER

: CANCEL

: -

: +

Key operation

29 SUNX Limited MJE-SFCHC No.0013-09V

Page 31

3-2-9 Interlock Setting Changing Function

: FUNCTION

Key operation

: ENTER

: CANCEL

: -

Function Setting

: +

30SUNX Limited MJE-SFCHC No.0013-09V

Page 32

Function Setting

3-2-10 External Device Monitor Setting Changing Function

: FUNCTION

: ENTER

: CANCEL

: -

: +

Key operation

31 SUNX Limited MJE-SFCHC No.0013-09V

Page 33

3-2-11 Protective Function

Function Setting

: FUNCTION

: ENTER

: CANCEL

: -

: +

Key operation

32SUNX Limited MJE-SFCHC No.0013-09V

Page 34

Function Setting

3-2-12 Setting Contents Monitoring Function (Only for Ver. 2.0 or later of SF4C series)

33 SUNX Limited MJE-SFCHC No.0013-09V

Page 35

Function Setting

: ENTER

: FUNCTION

: CANCEL

: -

Key operation

: +

34SUNX Limited MJE-SFCHC No.0013-09V

Page 36

Function Setting

3-2-13 Copy Function (Only for Ver. 2.0 or later of SF4C series)

35 SUNX Limited MJE-SFCHC No.0013-09V

Page 37

Function Setting

: FUNCTION

: ENTER

: CANCEL

: -

: +

Key operation

36SUNX Limited MJE-SFCHC No.0013-09V

Page 38

Function Setting

3-2-14 Initialization Function

NONO (Normally Open, Normally Open)

No limit

Invalid

Muting function only for the

sensing object exit

Muting input conditions 1 = 2

Function Set contents

: ENTER

: FUNCTION

: CANCEL

: -

: +

Fixed blanking function Invalid

Floating blanking function Invalid

Key operation

Auxiliary output switching function Mode 0 [Negative logic of control output (OSSD 1 / 2)]

Muting setting changing function

Select beam channel All beam channels

Select function Valid

Override setting changing function

60 sec.

Muting lamp diagnosis function Invalid

Select function Valid

Safety input setting changing

Select input mode Safety contacting point input mode

function

Select mode

Large multi purpose input function

Invalid

Select function Valid

Time setting 300ms

Password 0000

Select function Invalid

changing function

Interlock setting changing function

External device monitor setting

changing function

Protective function (Note)

Note:

37 SUNX Limited MJE-SFCHC No.0013-09V

Page 39

CHAPTER 4 TROUBLESHOOTING

Symptoms Cause Remedy

Control output (OSSD

1 / 2) is not turned ON.

The settings are not

changed

Lighting up fault

indicator [FAULT] of

SF4C

series

Light up all indicators

of

SF4C

series

Sequentially light up

all indicators of

series

Lost a password

Error indication Cause Remedy

Note: The factory setting of the

This device is connected to the

series.

Turning the power OFF and ON is not

done

Disconnection, cutting down power and so on

SF4C

SF4C

-

series

series

EEPROM error in

(Data error of EEPROM)

EEPROM error in

(Data error of EEPROM)

SF4C

The fixed blanking function is set in all

lights received / all lights blocked condition, or the muting function is set in all

lights received condition.

The copy function is used for the units

having different system con guration.

In the copy function, download the data

without uploading or select monitor of

copy function.

The password does not match.

Sensor communication error 1

(Model No. is wrong)

Sensor communication error 2

Wrong wiring between the emitter and

receiver.

Disconnection, cutting down power and so on

Sensor communication error 3

Effect from noise or failure of internal

circuit

Failure of EEPROM in this device.

(Failure on device)

Failure of EEPROM in this device.

(Failure on EEPROM data)

SF4C

series password is “0000.”

SF4C

Disconnect this device.

Remove the device from

Turn the power OFF and ON again.

After initialization, set again.

After initialization, set again.

Contact our of ce.

Contact our of ce.

Do not set the xed blanking function in all

lights received / all lights blocked condition,

or the muting function in all lights received

condition.

Use the copy function for the units having

identical system con guration.

Upload the data before downloading or select monitor of copy function.

Input the correct password. In case you forget the password, Contact our of ce. (Note)

Connect this device to

Connect the emitter and receiver correctly.

After initialization, set again

Check the noise state around the

series.

Contact our of ce..

Contact our of ce..

SF4C

SF4C

series.

series and

SF4C

If the device does not work correctly after checking the items above, please consult us.

38SUNX Limited MJE-SFCHC No.0013-09V

Page 40

CHAPTER 5 SPECIFICATIONS / DIMENSIONS

5-1 Speci cations

Model No.

Item

Applicable model Light curtain

Supply voltage 24V DC±10% Ripple P-P 10% or less (common to sensor power supply)

Current consumption

Communication method

Digital display 4-digit red LED display × 2 (selected beam channels, setting contents etc. are displayed.)

FUNCTION indicator

Fixed blanking function, Floating blanking function, Auxiliary output switching function

Functions

Protection IP40

Ambient temperature

Ambient humidity 30 to 85% RH, Storage: 30 to 85% RH

Voltage withstandability

Insulation resistance 20M or more, with 500V DC megger between all supply terminals connected together and enclosure

Cable 8-core shielded cable with a connector on one end 0.5m long (2 pcs.)

Weight Approx. 200g

Note: There may be a case that the copied data through the copy function is deleted due to external causes. After the copy func-

tion was used, check the copied data.

Muting setting changing function, Override setting changing function Muting lamp diagnosis function

Safety input setting changing function, Large multi-purpose indicator setting changing function

Interlock setting changing function, External device monitor setting changing function, Protective function

Setting contents monitoring function, Copy function (Note), Initialization function.

-10 to +55°C (No dew condensation or icing allowed), Storage: -25 to +45°C

1,000V AC for one minute between all supply terminals connected together and enclosure

RS-485 two-way communications (speci c procedure)

Green LED × 9 (lights up when each functional setting is ON)

SFC-HC

SF4C

65mA or less

series

5-2 Dimensions

65

30

(Unit: mm)

25.4

23

ø6 cable 0.5m long

140

39 SUNX Limited MJE-SFCHC No.0013-09V

Page 41

Revision history

First edition September 10, 2009

Second edition November 20, 2009

40SUNX Limited MJE-SFCHC No.0013-09V

Page 42

(MEMO)

41 SUNX Limited MJE-SFCHC No.0013-09V

Page 43

1. WARRANTIES:

(1) Subject to the exclusions stated in 2 (EXCLUSIONS) herein below, SUNX warrants the Products to be free of

defects in material and workmanship for a period of one (1) year from the date of shipment under normal usage in environments commonly found in manufacturing industry.

(2) Any Products found to be defective must be shipped to SUNX with all shipping costs paid by Purchaser or of-

fered to SUNX for inspection and examination. Upon examination by SUNX, SUNX will, at its sole discretion,

repair or replace at no charge, or refund the purchase price of, any Products found to be defective.

2. EXCLUSIONS:

(1) This warranty does not apply to defects resulting from any cause:

(i) which was due to abuse, misuse, mishandling, improper installation, improper interfacing, or improper

repair by Purchaser;

(ii) which was due to unauthorized modi cation by Purchaser, in part or in whole, whether in structure,

performance or speci cation;

(iii) which was not discoverable by a person with the state-of-the-art scienti c and technical knowledge at

the time of manufacture;

(iv) which was due to an operation or use by Purchaser outside of the limits of operation or environment

speci ed by SUNX;

(v) which was due to normal wear and tear;

(vi) which was due to Force Majeure; and

(vii) which was due to any use or application expressly discouraged by SUNX in 4 (CAUTIONS FOR SAFE

USE) hereunder.

(2) This warranty extends only to the rst purchaser for application, and is not transferable to any person or entity

which purchased from such purchaser for application.

3. DISCLAIMERS

(1) SUNX's sole obligation and liability under this warranty is limited to the repair or replacement, or refund of the

purchase price, of a defective Product, at SUNX's option.

(2) THE REPAIR, REPLACEMENT, OR REFUND IS THE EXCLUSIVE REMEDY OF THE PURCHASER, AND

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION, THE WARRAN-

TIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NON-INFRINGEMENT OF

PROPRIETARY RIGHTS, ARE HEREBY EXPRESSLY DISCLAIMED. IN NO EVENT SHALL SUNX AND

ITS AFFILIATED ENTITIES BE LIABLE FOR DAMAGES IN EXCESS OF THE PURCHASE PRICE OF THE

PRODUCTS, OR FOR ANY INDIRECT, INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES OF ANY

KIND, GENERAL TERMS AND CONDITIONS 4 OR ANY DAMAGES RESULTING FROM LOSS OF USE,

BUSINESS INTERRUPTION, LOSS OF INFORMATION, LOSS OR INACCURACY OF DATA, LOSS OF

PROFITS, LOSS OF SAVINGS, THE COST OF PROCUREMENT OF SUBSTITUTED GOODS, SERVICES

OR TECHNOLOGIES, OR FOR ANY MATTER ARISING OUT OF OR IN CONNECTION WITH THE USE OR

INABILITY TO USE THE PRODUCTS.

4. CAUTIONS FOR SAFE USE

(1) The applications shown in the catalogue are only suggestions, and it is Purchaser's sole responsibility to as-

certain the tness and suitability of the Products for any particular application, as well as to abide by Purchas-

er's applicable local laws and regulations, if any.

(2) Never use the Products NOT rated or designated as “SAFETY SENSOR” in any application involving risk to

life or property. When such a use is made by Purchaser, such Purchaser shall indemnify and hold harmless

SUNX from any liability or damage whatsoever arising out of or in relation to such use.

(3) In incorporating the Products to any equipment, facilities or systems, it is highly recommended to employ fail-

safe designs, including but not limited to a redundant +++design, ame propagation prevention design, and

malfunction prevention design so as not to cause any risk of bodily injury, re accident, or social damage due

to any failure of such equipment, facilities or systems.

(4) The Products are each intended for use only in environments commonly found in manufacturing industry,

and, unless expressly allowed in the catalogue, speci cation or otherwise, shall not be used in, or incorpo-

rated into, any equipment, facilities or systems, such as those:

(a) which are used for the protection of human life or body parts;

(b) which are used outdoors or in environments subject to any likelihood of chemical contamination or

electromagnetic in uence;

(c) which are likely to be used beyond the limits of operations or environments speci ed by SUNX in the

catalogue or otherwise;

(d) which may cause risk to life or property, such as nuclear energy control equipment, transportation

equipment (whether on rail or land, or in air or at sea), and medical equipment;

(e) which are operated continuously each day for 24 hours; and

(f) which otherwise require a high level of safety performance similar to that required in those equipment,

facilities or systems as listed in (a) through (e) above.

5. EXPORT CONTROL LAWS

In some jurisdictions, the Products may be subject to local export laws and regulations. If any diversion or re-

export is to be made, Purchaser is advised to abide by such local export laws and regulations, if any, at its

own responsibility.

42SUNX Limited MJE-SFCHC No.0013-09V

Page 44

Loading...

Loading...