Page 1

INSTRUCTION MANUAL

Light Curtain Ultraslim / Type 4

SF4C Series

SUNX Limited MJE-SF4C No.0011-08V

Page 2

(MEMO)

1 SUNX Limited MJE-SF4C No.0011-08V

Page 3

Thank you for purchasing SUNX’s Ultraslim Light Curtain,

SF4C

series.

Please read this instruction manual carefully and thoroughly for the correct and optimum use of this device.

Kindly keep this manual in a convenient place for quick reference.

This device is a light curtain for protecting a person from dangerous parts of a machine which can cause injury or accident.

This manual has been written for the following personnel who have undergone suitable training and have

knowledge of light curtains, as well as, safety systems and standards.

who are responsible for the introduction of this device

who design the system using this device

who install and connect this device

who manage and operate a plant using this device

Notes

1) All the contents of this instruction manual are the copyright of the publishers, and may not be reproduced (even extracts) in any form by any electronic or mechanical means (including photocopying,

recording, or information storage and retrieval) without permission in writing from the publisher.

2) The contents of this instruction manual may be changed without prior notice for further improvement

of the device.

3) Though we have carefully drawn up the contents of this instruction manual, if there are any aspects

that are not clear, or any error that you may notice, please contact our local SUNX of ce of the nearest distributor.

2SUNX Limited MJE-SF4C No.0011-08V

Page 4

Contents

Chapter 1 Introduction ············································································································· 5

1-1 Attention Marks ·······················································································································5

1-2 Safety Precautions ··················································································································5

1-3 Applicable Standards / Regulations ························································································8

1-4 Con rmation of Packed Contents

Chapter 2 Before Using This Device ······················································································ 9

2-1 Features ··································································································································9

2-2 Part Description ······················································································································9

2-3 Protection Area ····················································································································· 11

2-3-1 Sensing Area ··················································································································· 11

2-3-2 Safety Distance ··············································································································· 12

2-3-3 In uence of Re ective Surfaces

2-3-4 Device Placement ············································································································ 17

2-4 Mounting ·······························································································································18

2-4-1 Mounting of the Mounting Bracket ··················································································· 18

2-5 Wiring ····································································································································19

2-5-1 Power Supply Unit ··········································································································· 19

2-5-2 I/O Circuit Diagrams and Output Waveform ···································································· 20

2-5-3 Wiring / Connecting Procedures and Terminal Arrangement ··········································· 23

2-5-4 Basic Wiring ····················································································································· 24

2-5-5 Wiring for Manual Reset (Interlock is Valid) (Wiring Example of the Control Category 4) 26

2-5-6 Wiring for Auto Reset (Interlock is Invalid) (Wiring Example of the Control Category 4) ·28

2-5-7 Wiring Con guration for Valid Safety Input Function

2-5-8 Wiring Con guration for Invalid External Device Monitor Function

2-5-9 Wiring Con guration for Valid Muting Function

2-6 Adjustment ····························································································································36

2-6-1 Beam-axis Alignment ·······································································································36

2-6-2 Operation Test ················································································································· 38

2-6-3 Operation ························································································································· 39

··················· ································ ································ ········8

·································· ···················································· 16

······················································· 30

································ 32

······························································ 34

Chapter 3 Functions ·············································································································· 44

3-1 Self-diagnosis Function ········································································································44

3-2 Interlock Function ·················································································································44

3-2-1 Manual Reset ·················································································································· 44

3-2-2 Auto Reset ······················································································································· 44

3-3 Test Input Function ···············································································································45

3-4 Safety Input Function ············································································································46

3-5 Large Multi-purpose Indicator Function ················································································47

3-6 Auxiliary Output (Non-safety Output) ····················································································48

3-7 External Device Monitor Function ·························································································49

3-8 Muting Function ····················································································································50

3-9 Override Function ·················································································································53

Chapter 4 Maintenance ··········································································································55

4-1 Daily Inspection ····················································································································55

4-2 Periodic Inspection (Every Six Months) ················································································56

4-3 Inspection after Maintenance ································································································56

3 SUNX Limited MJE-SF4C No.0011-08V

Page 5

Contents

Chapter 5 Troubleshooting ··································································································· 57

5-1 Troubleshooting of Emitter ····································································································57

5-2 Troubleshooting of Receiver ·································································································59

Chapter 6 Speci cations / Dimensions · ················· ················· ·················· ··················· ········ 61

6-1 Speci cations························································································································61

6-2 Options ·································································································································63

6-3 Dimension ·····························································································································64

6-3-1 In Case Mounting on the Center with Standard Mounting Brackets ································ 64

6-3-2 In Case Mounting with Standard Mounting Brackets without Dead Space ····················· 65

6-3-3 Mounting Bracket ············································································································· 66

Chapter 7 Others ···················································································································· 67

7-1 Glossary ································································································································67

4SUNX Limited MJE-SF4C No.0011-08V

Page 6

Chapter 1 Introduction

1-1 Attention Marks

This instruction manual employs the following attentions marks , depending on the degree

of the danger to call operator’s attention to each particular action. Read the following explanation of these

marks thoroughly and observe these notices without fail.

If you ignore the advice with this mark, death or serious injury could result.

If you ignore the advice with this mark, injury or material damage could result.

<Reference>

It gives useful information for better use of this device.

1-2 Safety Precautions

Use this device as per its speci cations. Do not modify this device since its functions and capabilities may

not be maintained and it may malfunction.

This device has been developed / produced for industrial use only.

This device is suitable for indoor use only.

Use of this device under the following conditions or environment is not presupposed. Please consult us if

there is no other choice but to use this device in such an environment.

1) Operating this device under conditions or environments not described in this manual.

2) Using this device in the following elds: nuclear power control, railroad, aircraft, automobiles, combustion facilities, medical systems, aerospace development, etc.

When this device is to be used for enforcing protection of a person from any danger occurring around an

operating machine, the user should satisfy the regulations established by national or regional security

committees (Occupational Safety and Health Administration: OSHA, the European Standardization Committee, etc.). Contact the relative organization(s) for details.

In case of installing this device to a particular machine, follow the safety regulations in regard to appropriate usage, mounting (installation), operation and maintenance. The users including the installation operator are responsible for the introduction of this device.

Make sure not to have a impact on this device like falling. It may cause breakage of this device.

Use this device by installing suitable protection equipment as a countermeasure for failure, damage, or

malfunction of this device.

Before using this device, check whether the device performs properly with the functions and capabilities as

per the design speci cations.

In case of disposal, dispose this device as an industrial waste.

5 SUNX Limited MJE-SF4C No.0011-08V

Page 7

Introduction

Machine designer, installer, employer and operator

The machine designer, installer, employer and operator are solely responsible to ensure that all applicable legal requirements relating to the installation and the use in any application are satis ed and all

instructions for installation and maintenance contained in the instruction manual are followed.

Whether this device functions as intended to and systems including this device comply with safety

regulations depends on the appropriateness of the application, installation, maintenance and operation. The machine designer, installer, employer and operator are solely responsible for these items.

Engineer

The engineer would be a person who is appropriately educated, has widespread knowledge and experience, and can solve various problems which may arise during work, such as a machine designer,

or a person in charge of installation or operation etc.

Operator

The operator should read this instruction manual thoroughly, understand its contents, and perform

operations following the procedures described in this manual for the correct operation of this device.

In case this device does not perform properly, the operator should report this to the person in charge

and stop the machine operation immediately. The machine must not be operated until correct performance of this device has been con rmed.

Environment

Do not use a mobile phone or a radio phone near this device.

If there exists a re ective surface in the place where this device is to be installed, make sure to install

this device so that re ected light from the re ective surface does not enter into the receiver, or take

countermeasures such as painting, masking, roughening, or changing the material of the re ective

surface, etc. Failure to do so may cause the device not to detect, resulting in death or serious injury.

Do not install this device in the following environments.

1) Areas exposed to intense interference (extraneous) light such as high-frequency uorescent lamp

(inverter type), rapid starter uorescent lamp, stroboscopic lights or direct sunlight.

2) Areas with high humidity where condensation is likely to occur

3) Areas exposed to corrosive or explosive gases

4) Areas exposed to vibration or shock of levels higher than that speci ed

5) Areas exposed to contact with water

6) Areas exposed to too much steam or dust

Installation

Always keep the correctly calculated safety distance between this device and the dangerous parts of

the machine.

Install extra protection structure around the machine so that the operator must pass through the

sensing area of this device to reach the dangerous parts of the machine.

Install this device such that some part of the operator’s body always remains in the sensing area

when operator is done with the dangerous parts of the machine.

Do not install this device at a location where it can be affected by wall re ection.

If this device is used in multiple sets, arrange them to avoid mutual interference.

For details, refer to “

Do not use any re ection type or recursive re ection type arrangement.

The corresponding emitter and receiver must have the same serial No. and be correctly oriented.

2-3-4 Device Placement

.”

6SUNX Limited MJE-SF4C No.0011-08V

Page 8

Introduction

Machine in which this device is installed

When this device is used in the “PSDI Mode,” an appropriate control circuit must be con gured between this device and the machinery. For details, be sure to refer to the standards or regulations applicable in each region or country.

In Japan, do not use this device as a safety equipment for a press machine.

Do not install this device with a machine whose operation cannot be stopped immediately in the middle of an operation cycle by an emergency stop equipment.

This device starts the performance after 2 sec. from the power ON. Have the control system started

to function with this timing.

Wiring

Be sure to carry out the wiring in the power supply OFF condition.

All electrical wiring should conform to the regional electrical regulations and laws. The wiring should

be done by engineer(s) having the special electrical knowledge.

Do not run the wires together with high-voltage lines or power lines or put them in the same raceway.

This can cause malfunction due to induction.

In case of extending the cable of the emitter or the receiver, each can be extended up to 40.5m by

using the exclusive cable. Furthermore, if the cable is extended, the muting lamp is used, the total

extendable length of the cable. For details, refer to WARNING under “

Procedures and Terminal Arrangement

Do not control the device only at one control output (OSSD 1 / 2).

In order that the output is not turned ON due to earth fault of the control output (OSSD 1 / 2) wires, be

sure to ground to 0V side (PNP output) / +V side (NPN output).

2-5-3 Wiring / Connecting

.”

Maintenance

When replacement parts are required, always use only genuine supplied replacement parts. If substitute parts from another manufacturer are used, the device may not come to detect, result in death or

serious injury.

The periodical inspection of this device must be performed by an engineer having the special knowledge.

After maintenance or adjustment, and before starting operation, test this device following the procedure speci ed in “

Clean this device with a clean cloth. Do not use any volatile chemicals.

Others

Never modify this device. Modi cation may cause the device not to detect, resulting in death or serious injury.

Do not use this device to detect objects ying over the sensing area.

Do not use this device to detect transparent objects, translucent objects or objects smaller than the

speci ed minimum sensing objects.

Chapter 4 Maintenance

.”

7 SUNX Limited MJE-SF4C No.0011-08V

Page 9

Introduction

1-3 Applicable Standards / Regulations

This device complies with the following standards / regulations.

<EU Directives>

EU Machinery Directive 98/37/EC, EMC Directive 2004/108/EC

<European Standards>

EN 61496-1 (Type 4), EN 55011

<International Standards>

IEC 61496-1 / 2 (Type 4), ISO 13849-1: 2006 (Category 4, PLe), IEC 61508-1 to 7 (SIL3)

<Japanese Industrial Standards (JIS)>

JIS B 9704-1 / 2 (Type 4), JIS B 9705-1 (Category 4), JIS C 0508 (SIL3)

<Standards in US / Canada)>

UL 61496-1 / 2 (Type 4), UL 508, UL 1998 (Class 2), CSA 61496-1 / 2 (Type 4), CSA C22.2 No.14

<Regulations in US>

OSHA 1910.212, OSHA 1910.217 (C), ANSI B11.1 to B11.19, ANSI/RIA 15.06

Regarding EU Machinery Directive, a Noti ed Body, TUV SUD, has certi ed with the type examination certi cate.

With regard to the standards in US / Canada, TUV SUD, has certi ed for cTUVus Mark.

<Reference>

The conformity to JIS, OSHA and ANSI for this device has been evaluated by ourselves.

The cTUVus Mark

This device conforms to the EMC Directive and the Machinery Directive. The Mark on the main body indicates that

this device conforms to the EMC Directive.

indicates compliance with both Canadian and US requirements.

In Japan, never use this device as a safety equipment for any press machine or shearing machine.

When this device is used in a place other than the places shown above, be sure to con rm the standards or regulations applicable in each region or country before use.

1-4 Con rmation of Packed Contents

Sensor: Emitter, Receiver 1 pc. each

Test rod:

Instruction Manual 1 pc.

SF4C-TR25

(ø25 × 220mm) 1 pc.

8SUNX Limited MJE-SF4C No.0011-08V

Page 10

Chapter 2 Before Using This Device

2-1 Features

This device is the light curtain with the following features.

No special controller is required.

Cable type or pigtailed type is available.

The control output (OSSD 1 / 2) is PNP / NPN output switching type.

Large multi-purpose indicators (red, green) which are bright and easy-to-see are incorporated.

Refer to “

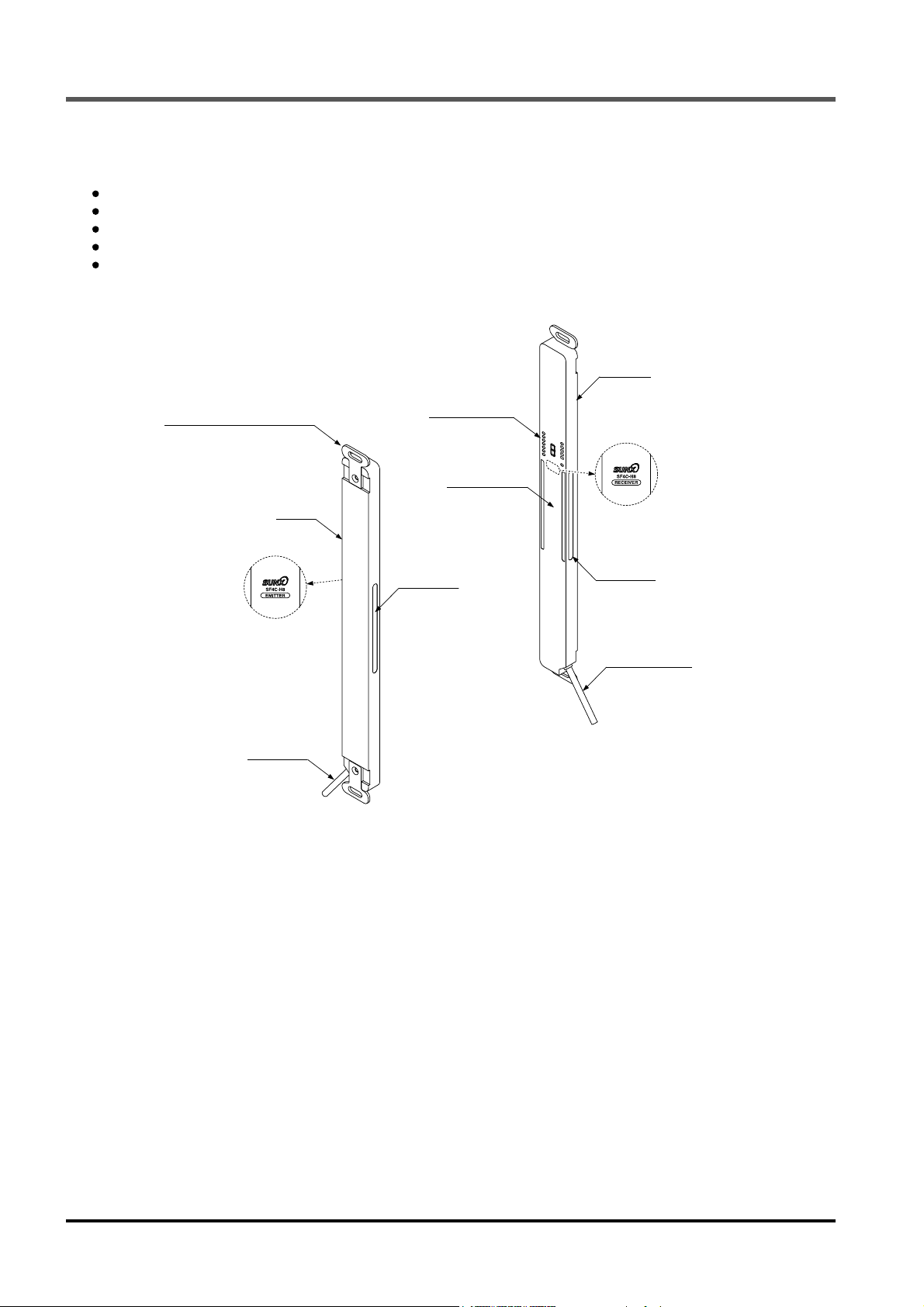

2-2 Part Description

6-2 Options

” for details of options.

Receiver

Standard mounting bracket

MS-SFC-1

(Accessory)

Emitter

Model

information

Gray cable

Display section

Beam-channel

Large multi

-purpose

indicator

Model

information

Large multi

-purpose

indicator

Gray cable

(with black line)

<Emitter>

It emits light to the receiver facing it. Furthermore, the status of the emitter and the receiver is indicated on its

display section.

<Receiver>

It receives light from the emitter facing it. Simultaneously, it turns ON the control output (OSSD 1 / 2) when

the all beam channels receive light from emitter, and it turns OFF the control output (OSSD 1 / 2) when one

or more beam channels are blocked light. [Except when using the muting function (Note 1).]

Besides, the receiver displays its status on the display section.

Notes: 1) In case of using the muting function, muting sensors are required. Furthermore, incase desiring muting lamp, arrange them

separately.

<Beam channel>

The light emitting elements of the emitter and the light receiving elements of the receiver are placed at the

intervals of 20mm.

<Standard mounting bracket MS-SFC-1 (Accessory)>

The mounting brackets are attached to this device.

This brackets are to be used for mounting both emitter and receiver.

9 SUNX Limited MJE-SF4C No.0011-08V

Page 11

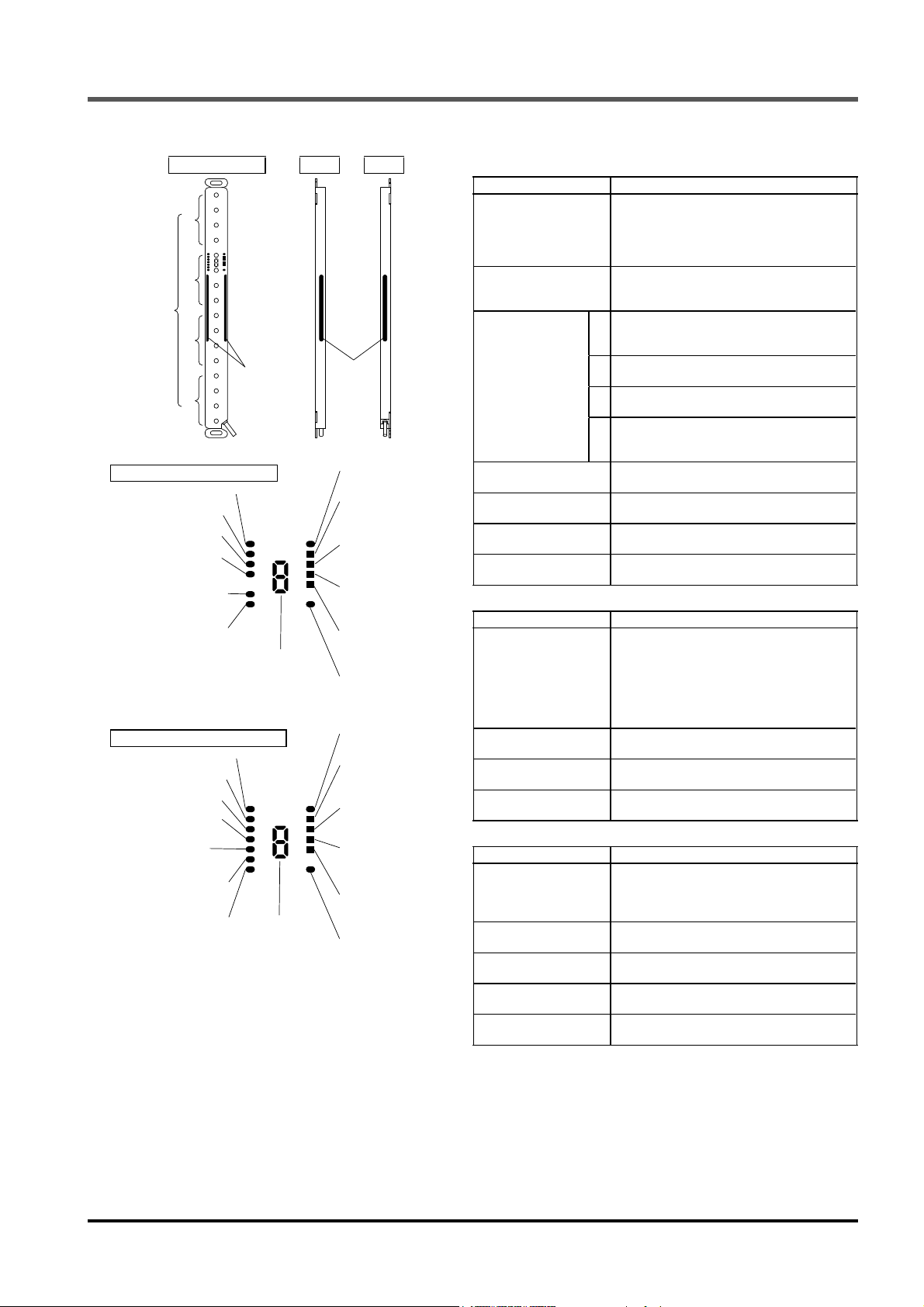

Functional Description

<Indicator section>

Beam-axis side

A

Location of

Beam-axis

alignment

indicator

Indicator section of emitter

Fault indicator [FAULT]

PNP indicator [PNP]

NPN indicator [NPN]

Test input indicator

[TEST]

Safety input 1 indicator

[S1]

Safety input 2 indicator

[S2]

Indicator section of receiver

Fault indicator [FAULT]

PNP indicator [PNP]

NPN indicator [NPN]

Function setting indicator

[FUNCTION]

Interlock indicator

[INTERLOCK]

Muting input 1 indicator

[MU1]

Muting input 2 indicator

[MU2]

Notes: 1) “When light is blocked” refers to the status that there exists any object blocking light in the sensing area.

2) Since the color of the operation indicator changes according to ON / OFF status of the control output (OSSD 1 / 2), the opera-

3) The description given in [ ] is marked on the device.

B

C

Large multi

D

tion indicator is marked as “OSSD” on the device.

-purpose

indicator

Digital error

indicator

Digital error

indicator

Front Back

Large

multipurpose

indicator

Incident light intensity

indicator [STB]

Beam-axis alignment

indicator A

[RECEPTION]

Beam-axis alignment

indicator B

[RECEPTION]

Beam-axis alignment

indicator C

[RECEPTION]

Beam-axis alignment

indicator D

[RECEPTION]

Operation indicator

[OSSD]

Incident light intensity

indicator [STB]

Beam-axis alignment

indicator A

[RECEPTION]

Beam-axis alignment

indicator B

[RECEPTION]

Beam-axis alignment

indicator C

[RECEPTION]

Beam-axis alignment

indicator D

[RECEPTION]

OSSD indicator

[OSSD]

<Common to emitter and receiver>

Description Function

Large multi-purpose

indicator

(Red / Green)

Incident light intensity

indicator

(Green / Orange) [STB]

Beam-axis alignment indicator

(Red / Green)

[RECEPTION]

Digital error indicator

(Red)

Fault indicator (Yellow)

[FAULT]

PNP indicator (Orange)

[PNP]

NPN indicator (Orange)

[NPN]

Lights up in red when the large multipurpose indicator input is valid.

Lights up in green when the large multipurpose indicator input is valid.

Turns OFF when the input is invalid.

Lights up in green when stable light is received.

Lights up in orange when unstable light is received.

Turns OFF when light is blocked. (Note 1)

Lights up in red when device top receives light.

A

Blinks in red when device top end receives light.

Lights up in green when control output (OSSD 1 / 2) is ON.

Lights up in red when device upper middle receives light.

B

Lights up in green when control output (OSSD 1 / 2) is ON.

Lights up in red when device lower middle receives light.

C

Lights up in green when control output (OSSD 1 / 2) is ON.

Lights up in red when device bottom receives light.

D

Blinks in red when device bottom end receives light.

Lights up in green when control output (OSSD 1 / 2) is ON.

Error contents are indicated when device is

lockout.

Lights up or blinks when fault occurs in the

device.

Lights up when PNP output is set.

Lights up when NPN output is set.

<Emitter>

Description Function

Lights up when device operation is as follows.

Operation indicator

(Red / Green) [OSSD]

(Note 2)

Test input indicator

(Orange) [TEST]

Safety input 1 indicator

(Orange) [S1]

Safety input 2 indicator

(Orange) [S2]

[sequential operation to control output

(OSSD 1 / 2)]

Lights up in red when control output (OSSD

1 / 2) is OFF.

Lights up in green when control output

(OSSD 1 / 2) is ON.

Lights up when test input is valid.

Turns OFF when test input is invalid.

Lights up when safety input 1 is valid.

Turns OFF when safety input 1 is invalid.

Lights up when the safety input 2 is valid.

Turns OFF when the safety input 2 is invalid.

<Receiver>

Description Function

OSSD indicator

(Red / Green) [OSSD]

Function setting indicator

(Orange) [FUNCTION]

Interlock indicator

(Yellow) [INTERLOCK]

Muting input 1 indicator

(Orange) [MU1]

Muting input 2 indicator

(Orange) [MU2]

Lights up in red when control output (OSSD

1 / 2) is OFF.

Lights up in green when control output

(OSSD 1 / 2) is ON.

Turns OFF

Lights up when interlock is valid.

Turns OFF

Lights up when muting input 1 is valid.

Turns OFF when muting input 1 is invalid.

Lights up when muting input 2 is valid.

Turns OFF when muting input 2 is invalid.

when interlock is invalid.

10SUNX Limited MJE-SF4C No.0011-08V

Page 12

Protection Area

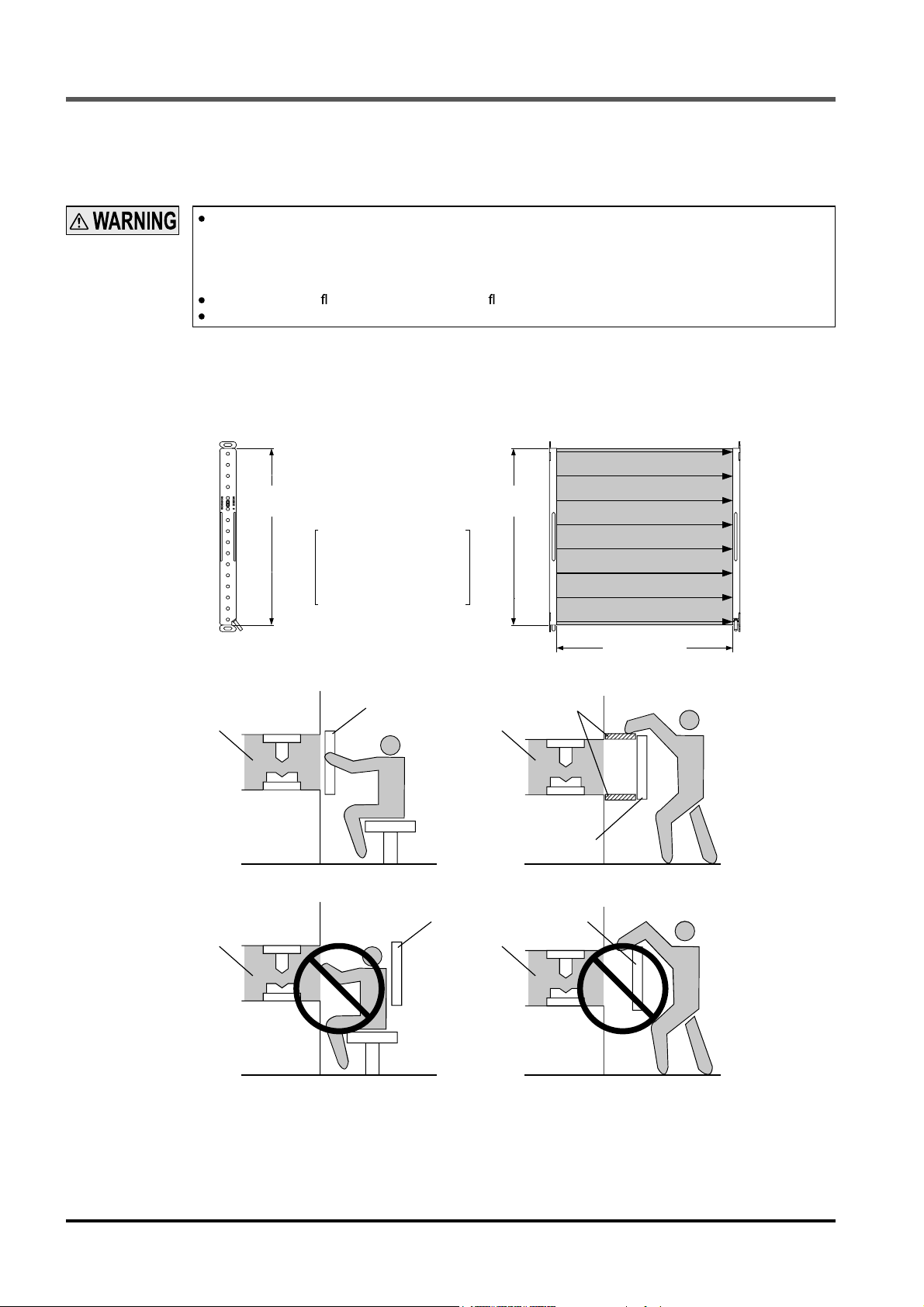

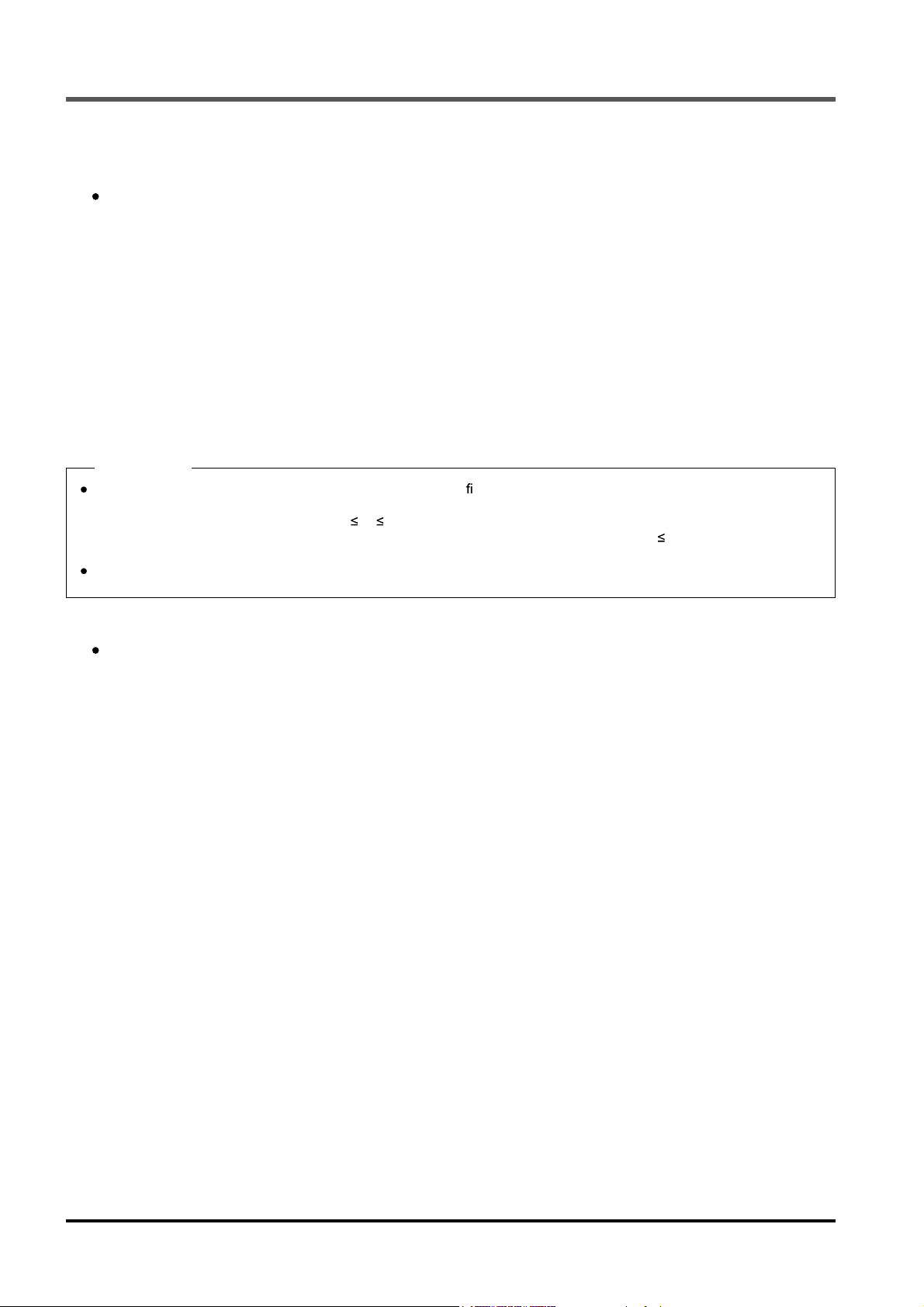

2-3 Protection Area

2-3-1 Sensing Area

Be sure to install protection structure around the machine so that the operator must pass through the

sensing area of this device to reach the dangerous parts of the machine.

Furthermore, ensure that some part of the operator’s body always remains in the sensing area when

operation is done with the dangerous parts of the machine. Failure to do so can result in death or

serious injury.

Do not use any re ection type or recursive re ection type arrangement.

Furthermore, never use this device facing several receivers towards one emitter or vice versa.

The sensing area is the zone formed by the sensing height (protective height) of the device and the valid

range between the emitter and the receiver. The sensing height (protective height) is determined by the number of beam channels. Furthermore, the valid range can be 0.1 to 3m.

Take care that if the valid range is under 0.1m, malfunction may occur due to the optical structure.

Emitter Receiver

To p

Sensing height

(Protective height)

The sensing height (protective height) is the area

between the line indicated

in the top part and line indicated in the bottom part.

Bottom

<Example of correct installation>

Dangerous

part

<Example of incorrect installation>

Dangerous

part

Sensing

area

Sensing height

(Protective height)

Protective structure

Dangerous

part

Sensing area

Sensing area Sensing

Dangerous

part

area

Sensing area

Valid range

11 SUNX Limited MJE-SF4C No.0011-08V

Page 13

Protection Area

2-3-2 Safety Distance

Calculate the safety distance correctly, and always maintain the distance which is equal to or greater

than the safety distance, between the sensing area of this device and the dangerous parts of the machine. If the safety distance is miscalculated or if suf cient distance is not maintained, the machine will

not stop quickly before reaching to the dangerous parts, which can result in death or serious injury.

The safety distance is the minimum distance that must be maintained between this device and the dangerous parts of the machine so that the machine can be stopped before a human body or an object can reach

the dangerous parts.

The safety distance is calculated based on the equation described in the next page when a person moves

perpendicular (normal intrusion) to the sensing area of the device.

Safety distance S

Sensing area

Dangerous

part

Intrusion direction

Before designing the system, refer to the relevant standards of the region where this device is to be

used, and then install this device.

Furthermore, the equation described in the next pages is to be used only in case the intrusion direction

is perpendicular to the sensing area. In case the intrusion direction is not perpendicular to the sensing

area, be sure to refer to the relevant standard (regional standard, speci cation of the machine, etc.) for

details of the calculation.

The max. response time of the machine is from the point that the machine receives the halt signal from

this device to the point that the dangerous parts of the machine stops. The max. response time of the

machine should be timed with the machine to be actually used.

12SUNX Limited MJE-SF4C No.0011-08V

Page 14

Protection Area

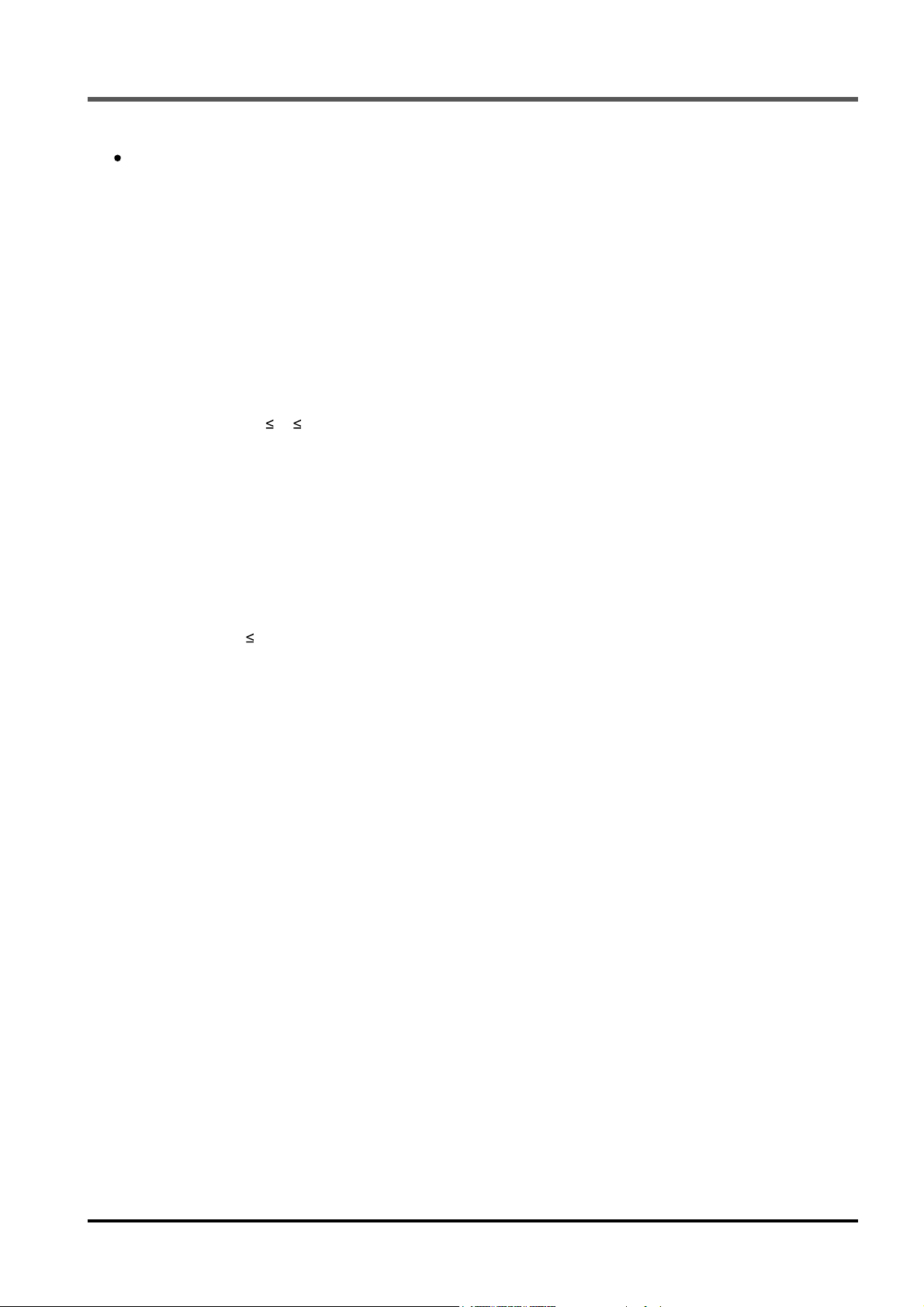

[For use in Europe (EU) (as EN 999)] (Also applicable to ISO 13855 / JIS B9715)

(For intrusion direction perpendicular to the sensing area)

<In case that the minimum sensing object is ø40mm or less>

Equation 1 S = K × T + C

S : Safety distance (mm)

Minimum required distance between the sensing area surface and the dangerous parts of the

machine

K : Intrusion velocity of operator’s body or object (mm/sec.)

Taken as 2,000 (mm/sec.) for calculation.

T

: Response time of total equipment (sec.)

m

T = T

Tm: Maximum halting time of machine (sec.)

T

SF4C

C : Additional distance calculated from the size of the minimum sensing object of the device (mm)

However, the value of C cannot be under 0.

C = 8 × (d

d: Minimum sensing object diameter (mm)

<Reference>

For calculating the safety distance S, there are the following ve cases.

First, calculate by substituting the value K = 2,000 (mm/sec.) in the equation above. Then, classify the obtained value

of S into three cases, 1) S < 100, 2) 100 S 500, and 3) S > 500. For Case 3) S > 500, recalculate by substituting

the value K = 1,600 (mm/sec.). After that, classify the calculation result into two cases, 4) S 500 and 5) S > 500.

For details, refer to “Calculation example 1 For use in Europe.”

When this device is used in the “PSDI mode,” an appropriate safety distance S must be calculated.

For details, be sure to refer to the standards or regulations applicable in each region or country.

SF4C

+ T

: Response time of this device (sec.)

-

14)

<In case that the minimum sensing object is over ø40mm>

Equation 1 S = K × T + C

S : Safety distance (mm)

Minimum required distance between the sensing area surface and the dangerous parts of the

machine

K : Intrusion velocity of operator’s body or object (mm/sec.)

Taken as 1,600 (mm/sec.) for calculation.

T

: Response time of total equipment (sec.)

m

T = T

+ T

SF4C

Tm: Maximum halting time of machine (sec.)

SF4C

T

: Response time of this device (sec.)

C : Additional distance calculated from the size of the minimum sensing object of the device (mm)

C = 850 (mm)

13 SUNX Limited MJE-SF4C No.0011-08V

Page 15

<Calculation example>

Calculation example 1: For use in Europe

(OFF response time: 7ms or less, minimum sensing object diameter: 25mm)

First, calculate with K = 2,000.

S = K × T + C

= K × (T

= 2,000 × (T

= 2,000 × T

= 2,000 × T

= 2,000 × T

m

+ T

SF4C

) + 8 × (d -14)

m

+ 0.007) + 8 × (25 -14)

m

+ 2,000 × 0.007 + 8 × 11

m

+ 14 + 88

m

+ 102

If the result is:

1) In case S < 100 (mm)

Safety distance S is taken as 100 (mm)

2) In case 100 S 500 (mm)

Safety distance S is taken as 2,000 × Tm + 102 (mm)

3) In case S > 500 (mm)

m

S = K’× (T

= 1,600 × (T

= 1,600 × T

= 1,600 × T

= 1,600 × T

SF4C

+ T

) + 8 × (d -14)

m

+ 0.007) + 8 × (25 -14)

m

+ 1,600 × 0.007 + 8 × 11

m

+ 11.2 + 88

m

+ 99.2

Protection Area

then, calculate again.

If the result is:

4) In case S 500 (mm)

Safety distance S is taken as 500 (mm)

5) In case S > 500 (mm)

Safety distance S is taken as 1,600 × T

m

+ 99.2 (mm)

In case this device is installed in a system with a maximum halting time 0.1 (sec.)

S = 2,000 × T

m

+ 102

= 2,000 × 0.1 + 102

= 302

Since this value matches with the case 2) above, S is 302 (mm).

In case this device is installed in a system with a maximum halting time 0.4 (sec.)

S

= 2,000 × T

m

+ 102

= 2,000 × 0.4 + 102

= 902

Since this value matches with the case 3) above,

S = 1,600 × T

m

+ 99.2

= 1,600 × 0.4 + 99.2

= 739.2

Since this value matches with the case 5) above, S is 739.2 (mm).

14SUNX Limited MJE-SF4C No.0011-08V

Page 16

Protection Area

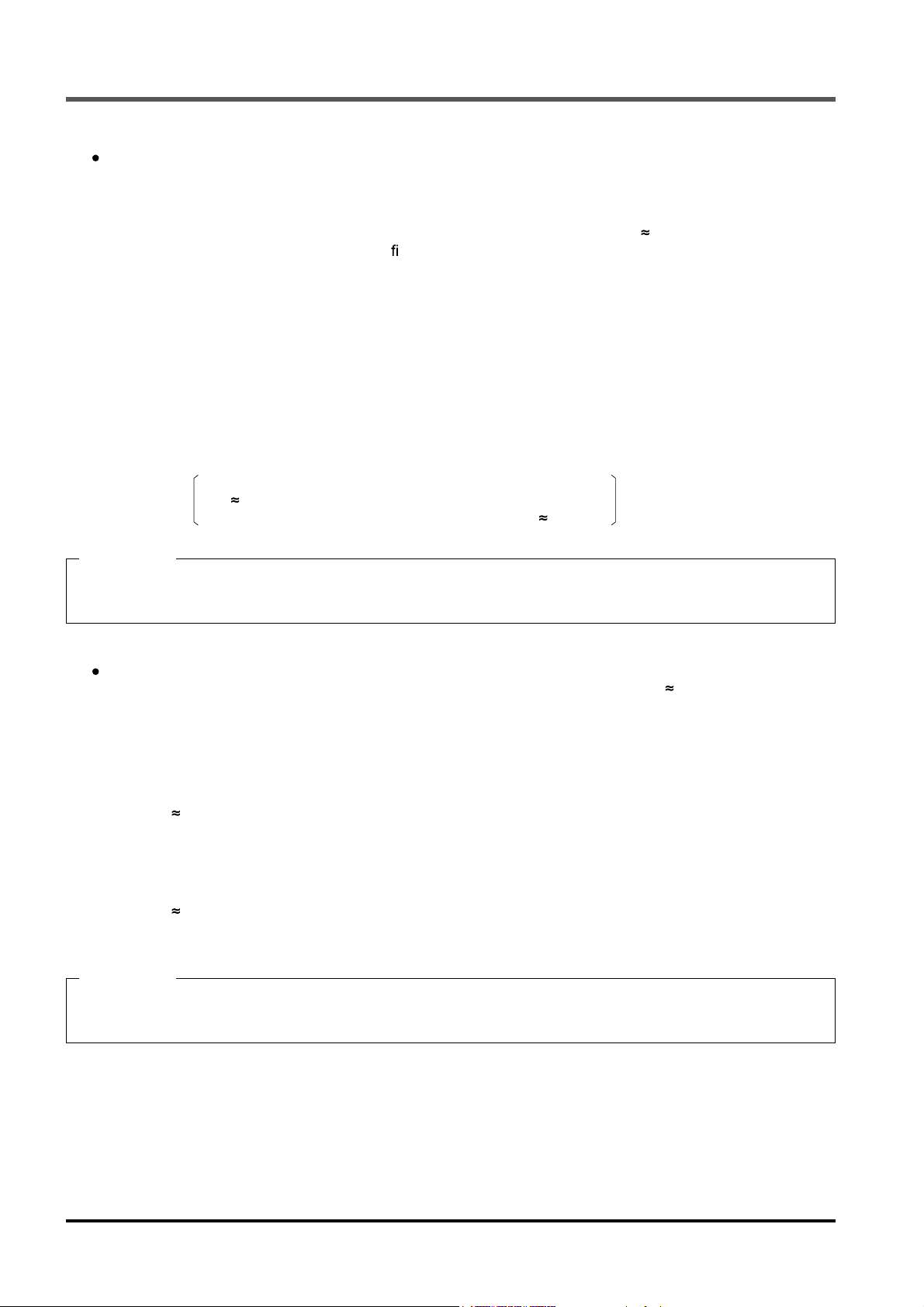

[For use in the United States of America (as per ANSI/RIA 15.06)]

Equation 2 DS = K × (TS + TC + T

DS : Safety distance (mm)

Minimum required distance between the sensing area surface and the dangerous parts of the

machine

K : Intrusion speed {Recommended value in OSHA is 63 (inch/sec.) [ 1,600 (mm/sec.)]}

ANSI/RIA 15.06 does not de ne the intrusion speed “K”. When determining K, consider pos-

sible factors including physical ability of operators.

S

: Halting time calculated from the operation time of the control element (air valve, etc.) (sec.)

T

T

C

: Maximum response time of the control circuit required for functioning the brake (sec.)

SF4C

T

: Response time of this device (sec.)

bm

T

: Additional halting time tolerance for the brake monitor (sec.)

The following equation holds when the machine is equipped with a brake monitor.

T

bm

= Ta-

(TS + TC)

Ta: Setting time of brake monitor (sec.)

When the machine is not equipped with a brake monitor, it is recommended that 20% or more

S

of (T

+ TC) is taken as additional halting time.

pf

D

: Additional distance calculated from the size of the minimum sensing object of the device (mm)

D

pf

= 61.2mm

pf

D

= 3.4 × (d - 0.276) (inch)

-

3.4 × (d

7) (mm)

d: Minimum sensing object diameter 0.985 (inch) 25 (mm)

SF4C

+ Tbm) + D

pf

<Reference>

Since the calculation above is performed by taking 1 (inch) = 25.4 (mm), there is a slight difference between the representation in (mm) and that in (inch).

Refer to the relevant standard for the details.

<Calculation example>

Calculation example 2: For use in the United States of America

[OFF response time: 7ms or less, minimum sensing object diameter: 0.985 (inch) 20 (mm)]

S = K × (TS + TC + T

SF4C

+ Tbm) + D

pf

= 63 × (Ta + 0.007) + 3.4 × (d - 0.276) (inch)

a

= 63 × (T

= 63 × T

= 63 × T

= 63 × T

63 × T

+ 0.007) + 3.4 × (0.985 - 0.276)

a

+ 63 × 0.007 + 3.4 × 0.709

a

+ 0.441 + 2.4106

a

+ 2.8516

a

+ 2.85 (inch)

In case this device is installed in a system with a maximum halting time 0.1 (sec.)

S = 63 × T

a

+ 2.85

= 63 × 0.1 + 2.85

= 9.15 (inch)

232.41 (mm)

Hence, as per the calculations S is 232.4 (mm).

<Reference>

Since the calculation above is performed by taking 1 (inch) = 25.4 (mm), there is a slight difference between the representation in (mm) and that in (inch).

Refer to the relevant standard for the details.

15 SUNX Limited MJE-SF4C No.0011-08V

Page 17

Protection Area

2-3-3 In uence of Re ective Surfaces

If there exists a re ective surface in the place where this device is to be installed, make sure to install

this device so that re ected light from the re ective surface does not enter into the receiver, or take

countermeasures such as painting, masking, roughening, or changing the material of the re ective surface, etc. Failure to do so may cause the device not to detect, resulting in death or serious injury.

Install this device at a distance of at 0.16m or more from re ective surfaces such as metal walls, oors, ceilings, sensing objects, covers, panels or glass surfaces.

<Side view>

Re ective ceiling

Emitter Receiver

0.16m

Sensing range

0.1 to 3m

0.16m

Re ective oor

Emitter Receiver

<Top view>

Re ective surface

0.16m

Sensing range

0.1 to 3m

16SUNX Limited MJE-SF4C No.0011-08V

Page 18

Protection Area

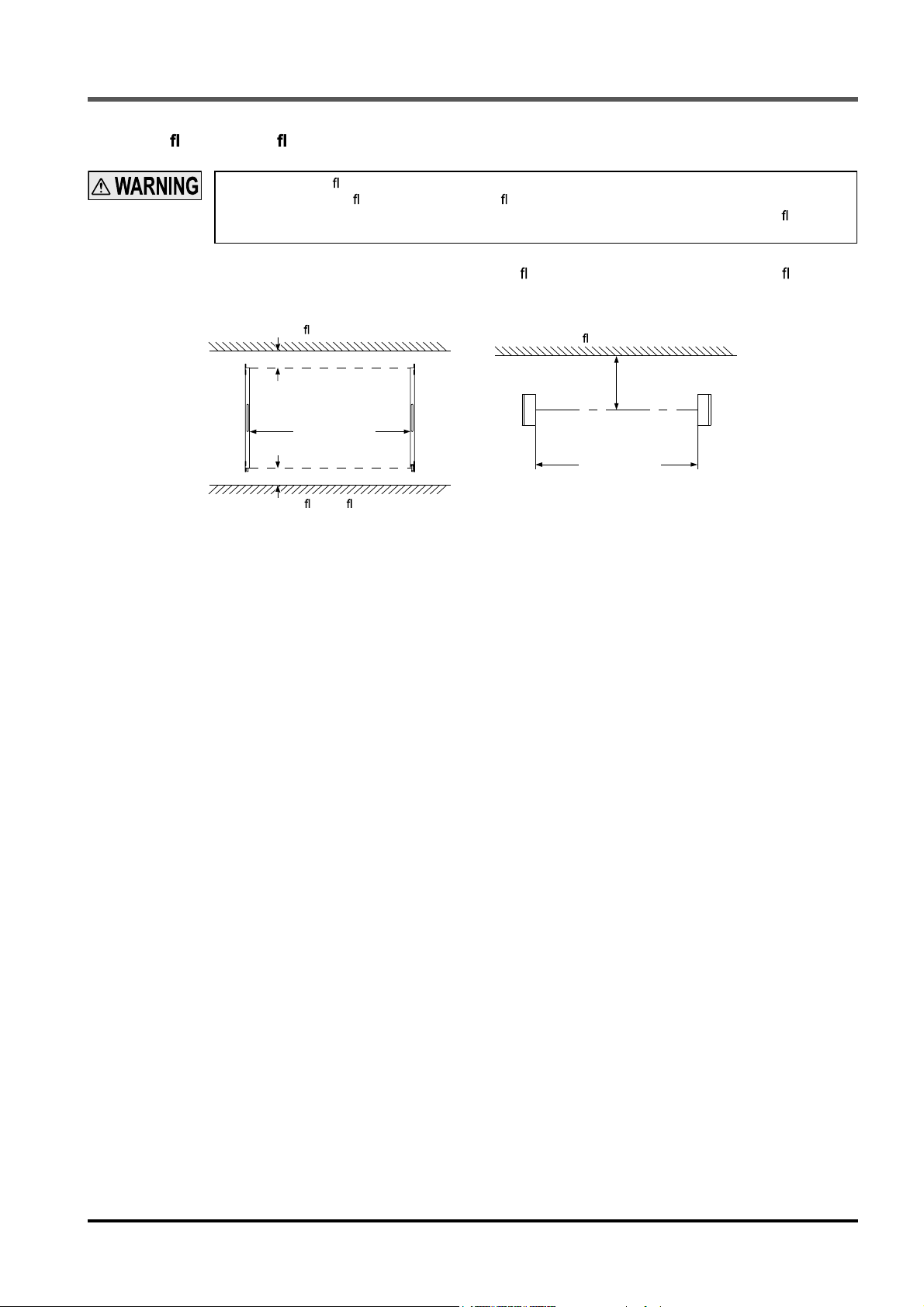

2-3-4 Device Placement

This is the con guration when two or more sets of emitter and receiver facing each other are placed. It is

used for system evaluation in case of addition of equipment. Perform an operation test by referring to “

Operation Test

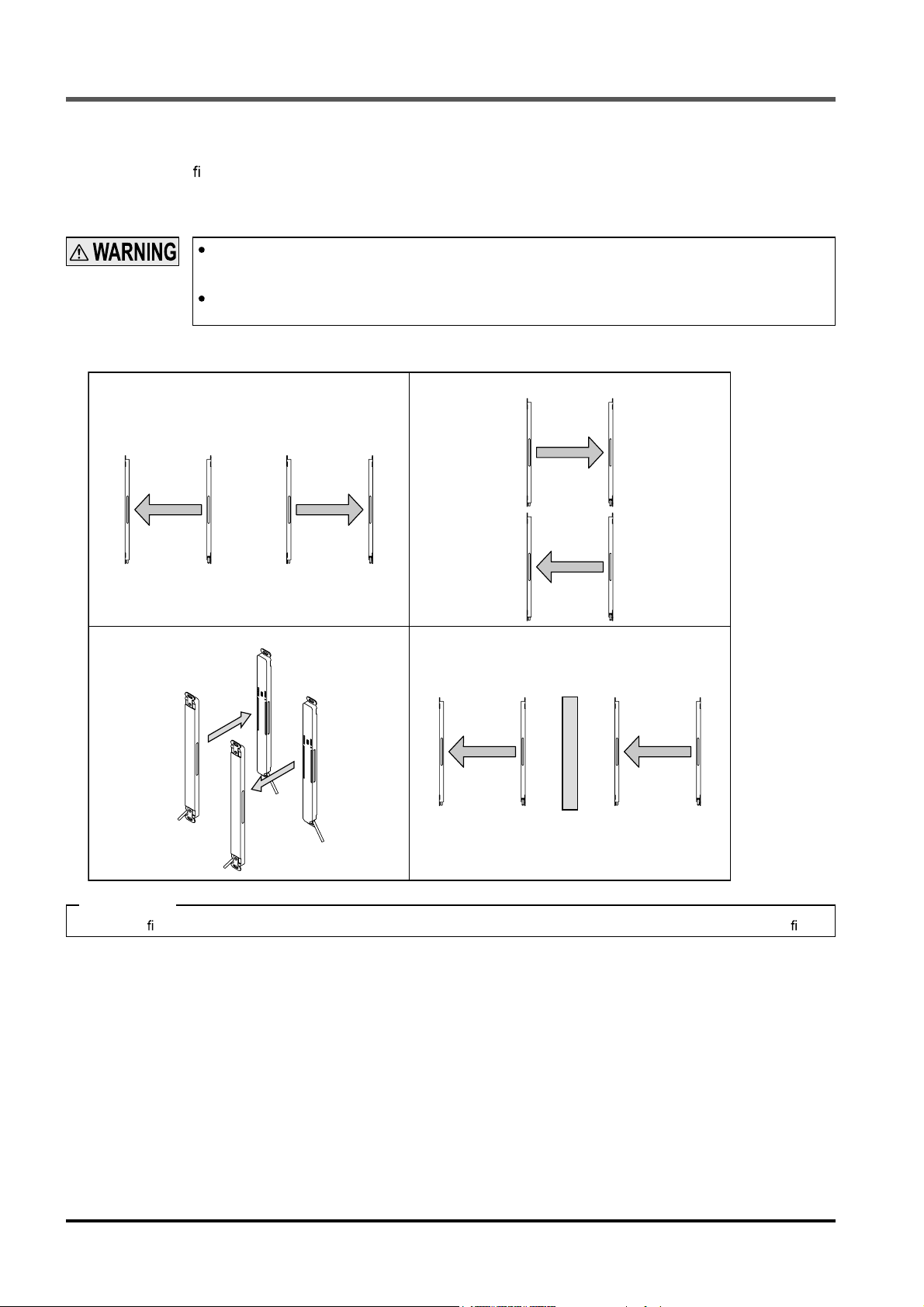

<Example of device placement>

.”

Refer to the examples of device placement given below and understand them thoroughly before installing the devices.

Improper sensor placement could cause device malfunction, which can result in death or serious injury.

If this device is used in multiple sets, arrange them to avoid mutual interference.

If mutual interference occurs, it can result in death or serious injury.

2-6-2

1) Install the emitter and the receiver back to back.

Receiver Emitter Emitter Receiver

3) Arrange the emitter and the receiver horizontally on

opposite sides.

Emitter

Receiver

Emitter

2) Arrange the emitter and the receiver vertically on

opposite sides.

Emitter

Receiver

4) Install a barrier

Receiver Emitter Receiver Emitter

Barrier

Receiver

Emitter

Receiver

<Reference>

The above gures are just examples of device placement. If there are any questions or problems, please contact our of ce.

17 SUNX Limited MJE-SF4C No.0011-08V

Page 19

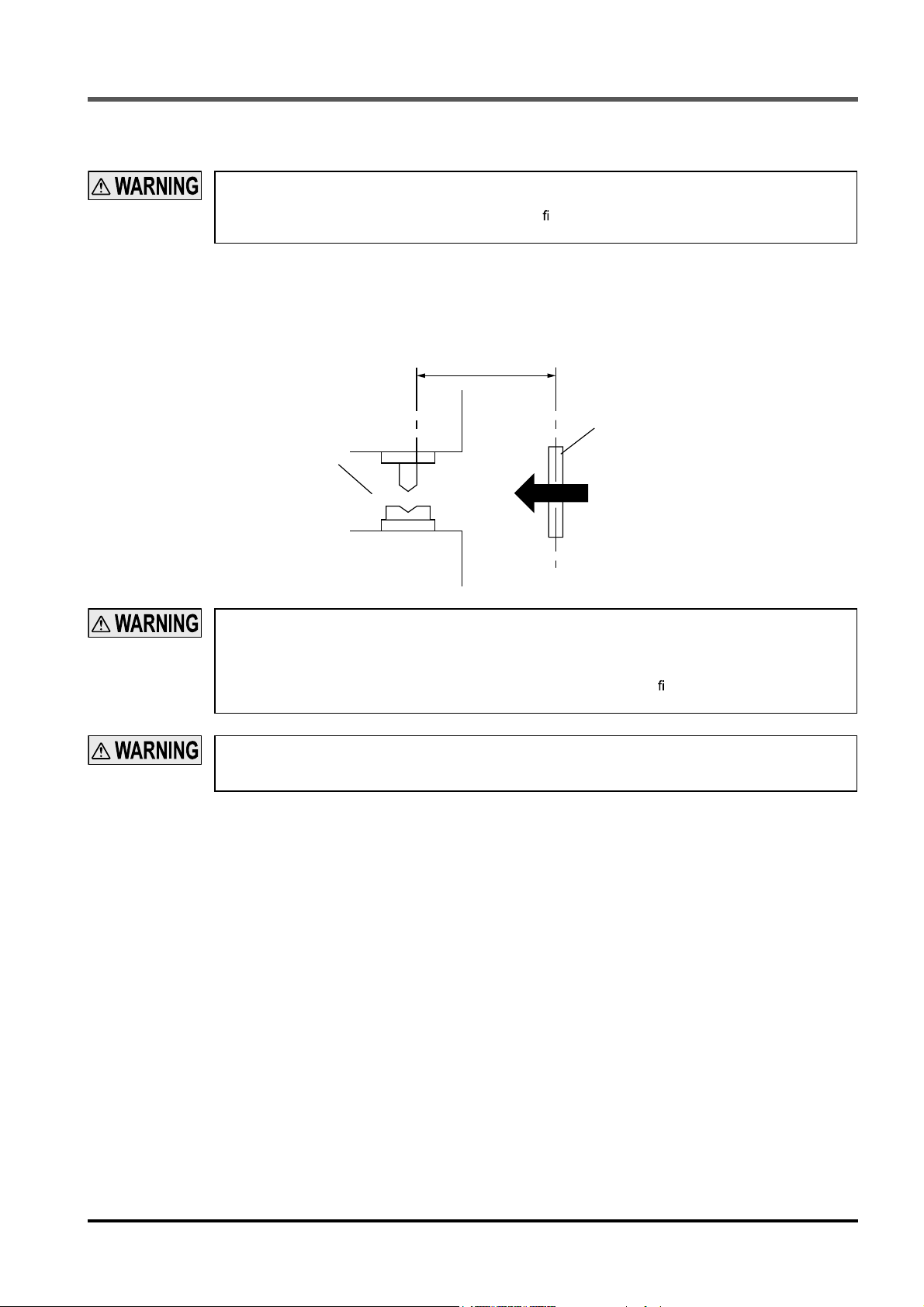

Mounting

2-4 Mounting

2-4-1 Mounting of the Mounting Bracket

Do not apply the load such as forced bending to the cable of this device. Applying improper load

could cause the wire breakage.

The minimum bending radius of the cable is R6mm. Mount the device with considering the cable

bending radius.

<Reference>

Mount the emitter and the receiver at the same level and parallel to each other. The effective aperture angle of this device is ±2.5° or less at a sensing distance of 3m.

Unless otherwise speci ed, the following mounting procedure is common for both emitter and receiver. For the preparation of the mounting, prepare the mounting holes on the mounting surface by referring to “

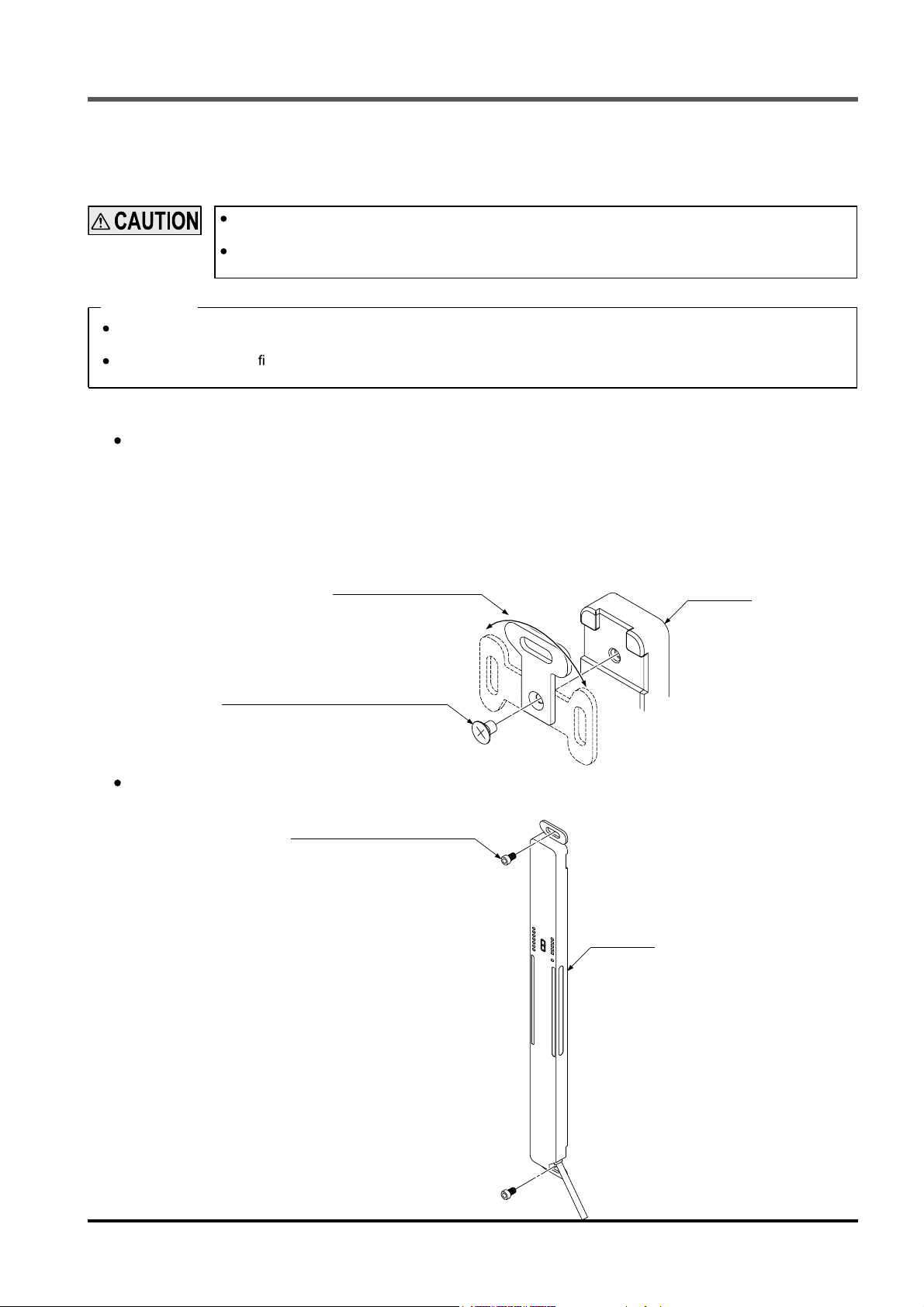

<In case of using standard mounting bracket MS-SFC-1 (Accessory)>

Direction of the standard mounting bracket

MS-SFC-1

which is attached to this device can be changed de-

pending on the mounting position of the device.

1. Remove the M3 countersunk head screw [with anti-loosening agent (length 4mm)] which is attached to the

back of the device.

2 Decide the direction of the standard mounting bracket.

3. Tighten with the M3 countersunk head screw [with anti-loosening agent (length 4mm)].

The tightening torque should be 0.3 N·m.

Standard mounting bracket

MS-SFC-1

(Accessory)

Mountable in three directions

6-3 Dimensions

This device

.”

M3 countersunk head screw

[With anti-loosening agent (length 4mm)]

Install the standard mounting brackets in the mounting surface with two hexagon-socket head bolts

[M5 (please arrange separately)].

Hexagon-socket head bolt

[M5 (Please arrange separately.)]

This device

18SUNX Limited MJE-SF4C No.0011-08V

Page 20

Wiring

2-5 Wiring

Earth the machine or the support where the device is mounted on to frame ground (F.G.).

Failure to do so could cause the malfunction of the product by noise, resulting in death or serious

injury. Furthermore, the wiring should be done in a metal box connected to the frame ground (F.G.).

Take countermeasure against the system to be applied for this device so as not to carry out the dangerous performance caused by the earth failure.

Failure to do so could cause invalid for the system stop, resulting in death or serious injury.

In order that the output is not turned ON due to earth fault of the control output (OSSD 1 / 2) wires,

be sure to ground to 0V side (PNP output) / +V side (NPN output).

Make sure to insulate the ends of the unused lead wires.

<Reference>

Use a safety relay unit or an equivalent control circuit in safety for FSD.

2-5-1 Power Supply Unit

Wire correctly using a power supply unit which conforms to the laws and standards of the region where

this device is to be used.

If the power supply unit is non-conforming or the wiring is improper, it can cause damage or malfunction of this device.

<Reference>

A specialist who has the required electrical knowledge should perform the wiring.

The power supply unit must satisfy the conditions given below.

1) Power supply unit authorized in the region where this device is to be used.

2) Power supply unit SELV (safety extra low voltage) / PELV (protected extra low voltage) conforming to EMC Directive and Low-voltage Directive (only for requiring CE marking conformation).

3) Power supply unit conforming to the Low-voltage Directive and with an output of 100VA or less.

4) The frame ground (F.G.) terminal must be connected to the ground when using a commercially available

switching regulator.

5) Power supply unit with an output holding time of 20ms or more.

6) In case a surge is generated, take countermeasures such as connecting a surge absorber to the origin of the

surge.

7) Power supply unit corresponding to CLASS 2 (only for requiring cTUVus Mark conformation).

19 SUNX Limited MJE-SF4C No.0011-08V

Page 21

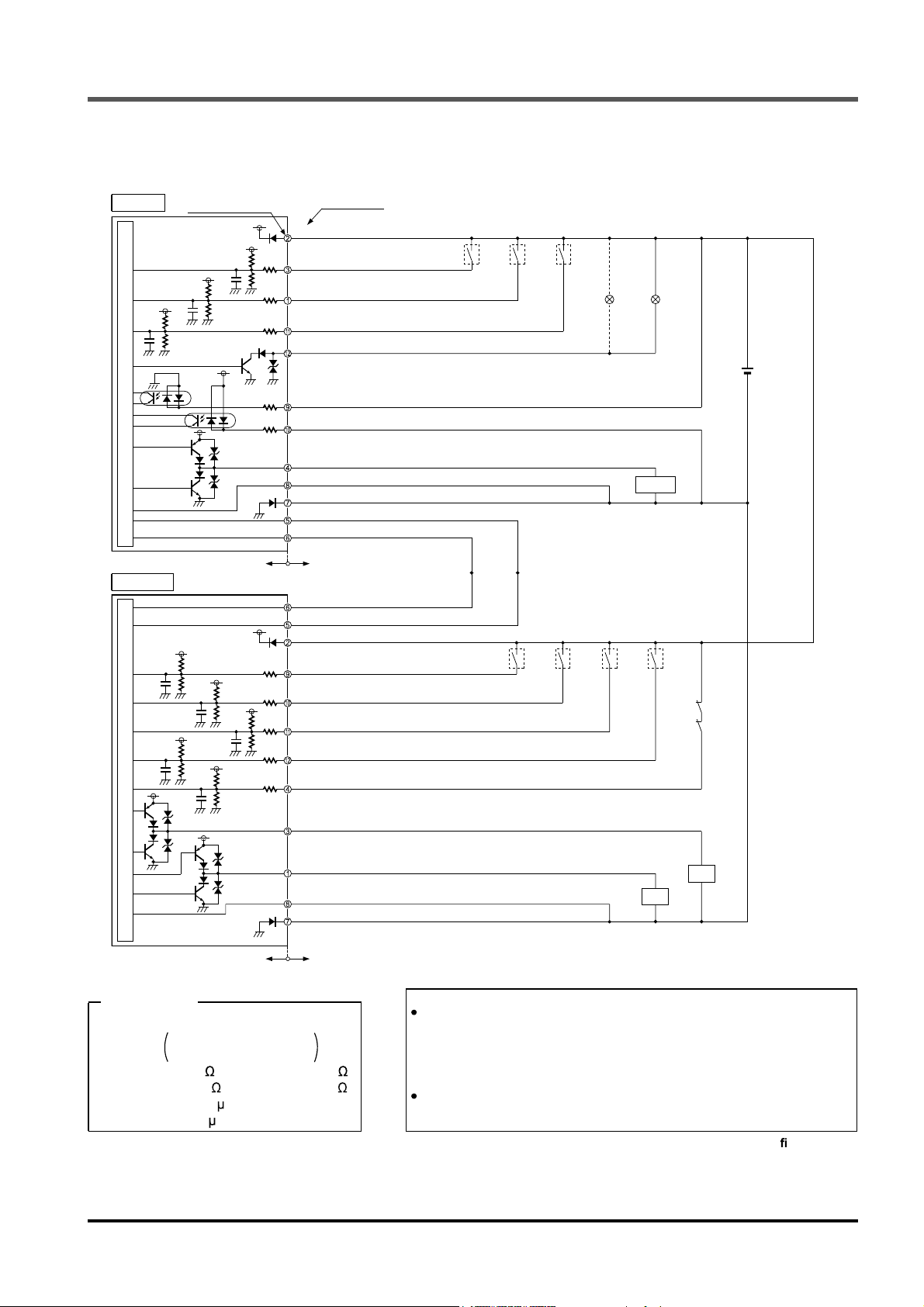

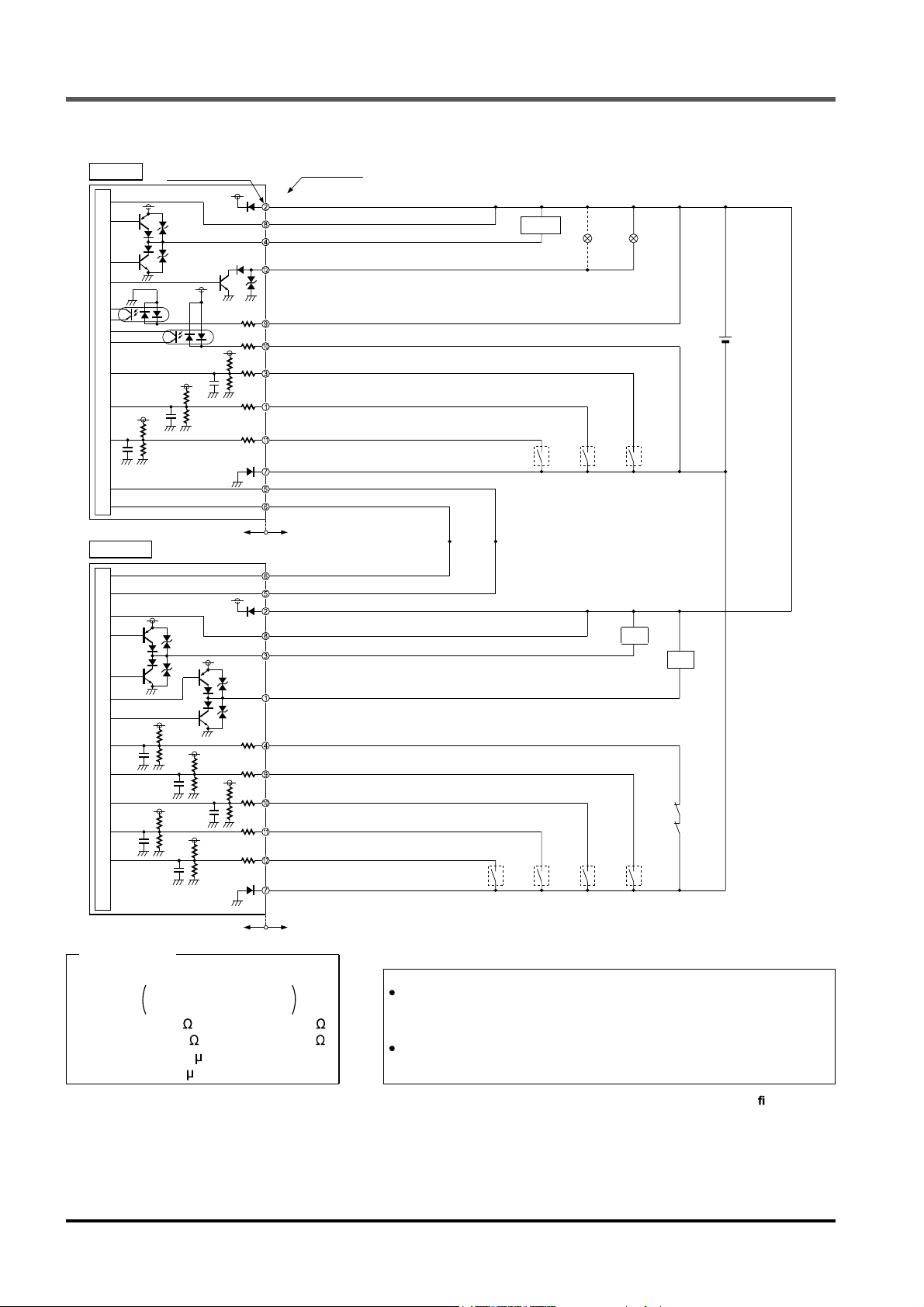

2-5-2 I/O Circuit Diagrams and Output Waveform

<For PNP output>

Emitter

E

Main circuit

Terminal No. of

pigtailed type

E

B

B

B

C

B

E

B

B

C

C

A

A

Color code

(Brown) +V

(Pink) Test input / Reset input

(Pale purple) Interlock setting input

(Yellow) Override input

(Red) Muting lamp output

(Gray) Safety input 1 (Note 1)

(Gray / Black) Safety input 2 (Note 1)

(Yellow-green / Black) Auxiliary output

(Shield) Output polarity setting wire

(Blue) 0V

(Orange) Synchronization +

(Orange / Black) Synchronization -

*S1 *S2 *S2

Load

+

-

Wiring

24V DC

±10%

Users’ circuitInternal circuit

Receiver

D

F

D

D

D

F

B

B

F

Main circuit

E

B

F

B

B

<Reference>

K1, K2: External device

Forced guided relay or

magnetic contactor

Resistance A: 3k , Resistance B: 6.8k

Resistance C: 470 , Resistance D: 47k

Condenser E: 0.47 F

Condenser F: 0.1 F

Notes 1) For wiring of the safety input 1 wire (gray) and the safety input 2 wire (gray / black), refer to “

2)

3) Vs is the applying supply voltage.

Valid Safety Input Function

Large multi-purpose indicator lights up in red when connecting large multi-purpose indicator input 1 wire (grey) and +V, and large

multi-purpose indicator lights up in green when connecting large multi-purpose indicator input 2 wire (grey / black) and +V.

(Orange / Black)

Synchronization

(Orange) Synchronization +

(Brown) +V

(Gray) Large multi-purpose

C

indicator input 1 (Note 2)

C

(Gray / black) Large multi-purpose indicator input 2 (Note 2)

C

(Sky-blue / White) Muting input 1

B

C

(Sky-blue / Black) Muting input 2

C

(Yellow-green) External device monitor input

(Black) Control output 1 (OSSD 1)

(White) Control output 2 (OSSD 2)

(Shield) Output polarity setting wire

(Blue) 0V

Users’ circuitInternal circuit

.”

-

*S1, S2

Switch S1

Test input / Reset input

For manual reset: Vs to Vs - 3.5V (sink current 5mA or less): OFF (Note 3)

Open: ON

For auto reset: Vs to Vs - 3.5V (sink current 5mA or less): ON (Note 3)

Open: OFF

Switch S2

Override input, Interlock setting input, Large multi-purpose indicator input 1 / 2,

Muting input 1 / 2 and External device monitor input

Vs to Vs - 3.5V (sink current 5mA or less): Valid (Note 3), Open: Invalid

*S2 *S2 *S2 *S2

K2

K1

K2

K1

2-5-7 Wiring Con guration for

20SUNX Limited MJE-SF4C No.0011-08V

Page 22

Wiring

<For NPN output>

Emitter

Main circuit

E

B

BE

Terminal No. of

pigtailed type

B

B

E

B

B

Color code

(Brown) +V

(Shield) Output polarity setting wire

(Yellow-green / Black) Auxiliary output

(Red) Muting lamp output

A

(Gray) Safety input 1 (Note 1)

A

(Gray / Black) Safety input 2 (Note 1)

C

(Pink) Test input / Reset input

C

(Pale purple) Interlock setting input

C

(Yellow) Override input

(Blue) 0V

(Orange) Synchronization +

(Orange / Black) Synchronization -

Load

*S2 *S2 *S1

+

-

24V DC

±10%

Internal circuit

Receiver

B

B

E

Main circuit

F

D

F

B

B

B

F

Internal circuit

D

D

D

F

B

<Reference>

K1, K2: External device

Forced guided relay or

magnetic contactor

Resistance A: 3k , Resistance B: 6.8k

Resistance C: 470 , Resistance D: 47k

Condenser E: 0.47 F

Condenser F: 0.1 F

Notes 1) For wiring of the safety input 1 wire (gray) and the safety input 2 wire (gray / black), refer to “

2)

Valid Safety Input Function

Large multi-purpose indicator lights up in red when connecting large multi-purpose indicator input 1 wire (grey) and 0V, and large

multi-purpose indicator lights up in green when connecting large multi-purpose indicator input 2 wire (grey / black) and 0V.

Users’ circuit

(Orange / Black)

Synchronization

(Orange) Synchronization +

(Brown) +V

(Shield) Output polarity setting wire

(Black) Control output 1 (OSSD 1)

(White) Control output 2 (OSSD 2)

C

(Yellow-green) External device monitor input

C

(Gray) Large multi-purpose indicator input 1 (Note 2)

C

(Gray / Black) Large multi-purpose indicator input 2 (Note 2)

C

(Sky-blue / White) Muting input 1

C

(Sky-blue / Black) Muting input 2

(Blue) 0V

Users’ circuit

.”

-

*S2 *S2 *S2 *S2

*S1, S2

Switch S1

Test input / Reset input

For manual reset: 0 to +2.5V (source current 5mA or less): OFF, Open: ON

For auto reset: 0 to +2.5V (source current 5mA or less): ON

Switch S2

Override input, Interlock setting input, Large multi-purpose indicator input 1 / 2,

Muting input 1 / 2 and External device monitor input

0 to +2.5V (source

current 5mA or less): Valid, Open: Invalid

K1

K2

K1

K2

,

Open: OFF

2-5-7 Wiring Con guration for

21 SUNX Limited MJE-SF4C No.0011-08V

Page 23

Wiring

<Output waveform [when control output (OSSD 1 / 2) is ON]>

Since the receiver performs the self-diagnosis of the output circuit when the device is in light receiving status

(ON status), the output transistor becomes OFF status periodically. (Refer to the gure below.)

When the OFF signal is fed back, the receiver judges the output circuit as normal. When the OFF signal is

not fed back, the receiver judges either the output circuit or wiring as error, and the control output (OSSD 1 / 2)

maintains OFF status.

Perform the wiring with paying attention to the input response time of the machine to be connected to

this device, since the OFF signal of this device might cause malfunction.

<Time chart>

Power supply

Control output 1

(OSSD 1)

Control output 2

(OSSD 2)

ON

OFF

ON

OFF

ON

OFF

Approx. 2 sec.

Approx. 35 to 60 s

Approx. 2.5ms

Approx. 20 s

Approx. 35 to 60 s

Approx. 35 to 60 s

Approx. 20 s

Approx. 35 to 60 s

22SUNX Limited MJE-SF4C No.0011-08V

Page 24

Wiring

2-5-3 Wiring / Connecting Procedures and Terminal Arrangement

Connect the mating cable (with connector on one end or connector on both ends) to the pigtailed type of this

device (emitter and receiver) according to the customer’s application referring to the terminal arrangement

given below. In addition, in case of the cable type (emitter and receiver) as well, wire the cables according to

the customer’s application referring to the terminal arrangement given below.

When extending the cable, use the exclusive cable up to the total length of 40.5m or less (for each

emitter / receiver). Extending the cable longer than 40.5m may cause malfunction, which can result

in death or serious injury.

In case of using the muting lamp, a total length should be 30.5m or less (for each emitter / receiver).

When the synchronization cable is extended with a cable other than exclusive cable, use a 0.2mm

or more shielded twisted pare cable.

2

<Cable with connector on one end>

A si de

<Terminal arrangement of A side>

Cable / Connector color Terminal No. Color code Description

Emitter Gray / Gray

Receiver Gray (with black line) / Black

<Cable with connector on both ends>

A side B side

<Terminal arrangement of B side><Terminal arrangement of A side>

1 Pale purple Interlock setting input

2Brown +V

3 Pink Test input / Reset input

4 Yellow-green / Black Auxiliary output

5 Orange Synchronization +

6 Orange / Black Synchronization

7Blue 0V

8 (Shield) Output polarity setting wire

9 Gray Safety input 1

10 Gray / Black Safety input 2

11 Yellow Override input

12 Red Muting lamp output

1 White Control output 2 (OSSD 2)

2Brown +V

3 Black Control output 1 (OSSD 1)

4 Yellow-green External device monitor input

5 Orange Synchronization +

6 Orange / Black Synchronization

7Blue 0V

8 (Shield) Output polarity setting wire

9 Gray Large multi-purpose indicator input 1

10 Gray / Black Large multi-purpose indicator input 2

11 Sky-blue / White Muting input 1

12 Sky-blue / Black Muting input 2

-

-

<Reference>

The connectors can be distinguished from their colors as follows:

Connector for emitter: Gray, connector for receiver: Black

For details of the cable with connector on one end and the cable with connector on both ends, refer to “

23 SUNX Limited MJE-SF4C No.0011-08V

6-2 Options

.”

Page 25

Wiring

2-5-4 Basic Wiring

This is the general con guration using one set of the emitter and receiver facing each other. The control output (OSSD 1 / 2) turns OFF if the light is blocked, while it automatically turns ON if receives the light.

The auxiliary output is used to invalid the external device monitor function. The auxiliary output cannot be

connected to external devices.

<For PNP output>

Receiver

Emitter

Grey cable

Grey cable

(with black line)

(Red) Muting lamp output

(Yellow) Override input

(Pale purple) Interlock setting input

(Brown) +V

(Pink) Test input / Reset input

(Gray) Safety input 1

(Gray / Black) Safety input 2

(Shield) Output polarity setting wire

(Blue) 0V

(Yellow-green / Black) Auxiliary output

(Orange) Synchronization +

(Orange / Black) Synchronization (Orange / Black) Synchronization (Orange) Synchronization +

(Yellow-green) External device monitor input

(Brown) +V

(Black) Control output 1 (OSSD 1)

(White) Control output 2 (OSSD 2)

(Shield) Output polarity setting wire

(Blue) 0V

(Sky-blue / White) Muting input 1

(Sky-blue / Black) Muting input 2

(Gray) Large multi-purpose indicator input 1

(Gray / Black) Large multi-purpose indicator input 2

K1

K2

+

-

24V DC

%

Interlock function Invalid (Auto-reset)

External device monitor function Invalid

Auxiliary output Cannot be used

24SUNX Limited MJE-SF4C No.0011-08V

Page 26

Wiring

<For NPN output>

Receiver Emitter

Grey cable

Grey cable

(with black line)

(Red) Muting lamp output

(Yellow) Override input

(Pale purple) Interlock setting input

(Brown) +V

(Shield) Output polarity setting wire

(Pink) Test input / Reset input

(Gray) Safety input 1

(Gray / Black) Safety input 2

(Blue) 0V

(Yellow-green / Black) Auxiliary output

(Orange) Synchronization +

(Orange / Black) Synchronization (Orange / Black) Synchronization (Orange) Synchronization +

(Yellow-green) External device monitor input

(Brown) +V

(Black) Control output 1 (OSSD 1)

(White) Control output 2 (OSSD 2)

(Shield) Output polarity setting wire

(Blue) 0V

(Sky-blue / White) Muting input 1

(Sky-blue / Black) Muting input 2

(Gray) Large multi-purpose indicator input 1

(Gray / Black) Large multi-purpose indicator input 2

K1

K2

+

-

24V DC

%

Interlock function Invalid (Auto-reset)

External device monitor function Invalid

Auxiliary output Cannot be used

25 SUNX Limited MJE-SF4C No.0011-08V

Page 27

Wiring

2-5-5 Wiring for Manual Reset (Interlock is Valid) (Wiring Example of the Control Category 4)

This is the general con guration using one set of the emitter and receiver facing each other. The control output (OSSD 1 / 2) turns OFF if the light is blocked.

<For PNP output>

Receiver Emitter

Grey cable

Grey cable

(with black line)

(Red) Muting lamp output

(Yellow) Override input

(Brown) +V

(Pale purple) Interlock setting input

(Pink) Test input / Reset input

(Gray) Safety input 1

(Gray / Black) Safety input 2

(Yellow-green / Black) Auxiliary output

(Shield) Output polarity setting wire

(Blue) 0V

(Orange) Synchronization +

(Orange / Black) Synchronization (Orange / Black) Synchronization (Orange) Synchronization +

(Yellow-green) External device monitor input

(Brown) +V

(Black) Control output 1 (OSSD 1)

(White) Control output 2 (OSSD 2)

(Shield) Output polarity setting wire

(Blue) 0V

(Sky-blue / White) Muting input 1

(Sky-blue / Black) Muting input 2

(Gray) Large multi-purpose indicator input 1

(Gray / Black) Large multi-purpose indicator input 2

K1

K2

Load

S1

K1 K2

+

-

24V DC

%

Interlock function Valid (Manual reset)

External device monitor function Valid

Auxiliary output Can be used

The device output is selected depending on the connecting state of the output polarity setting wire (shield). Incorrect

wiring may cause the lockout state.

* Symbols

Switch S1

Test input / Reset input

Vs to Vs - 3.5V (sink current 5mA or less): OFF (Note 1), Open: ON

K1, K2: External device (Forced guided relay or magnetic contactor)

Notes: 1) Vs is the applying supply voltage.

2) For resetting, refer to “

3-2 Interlock Function

.”

26SUNX Limited MJE-SF4C No.0011-08V

Page 28

Wiring

<For NPN output>

Receiver Emitter

Grey cable

Grey cable

(with black line)

(Red) Muting lamp output

(Yellow) Override input

(Brown) +V

(Yellow-green / Black) Auxiliary output

(Shield) Output polarity setting wire

(Gray) Safety input 1

(Gray / Black) Safety input 2

(Pink) Test input / Reset input

(Pale purple) Interlock setting input

(Blue) 0V

(Orange) Synchronization +

(Orange / Black) Synchronization (Orange / Black) Synchronization (Orange) Synchronization +

(Yellow-green) External device monitor input

(Brown) +V

(Black) Control output 1 (OSSD 1)

(White) Control output 2 (OSSD 2)

(Shield) Output polarity setting wire

(Blue) 0V

(Sky-blue / White) Muting input 1

(Sky-blue / Black) Muting input 2

(Gray) Large multi-purpose indicator input 1

(Gray / Black) Large multi-purpose indicator input 2

K1

K2

Load

S1

K1 K2

+

-

24V DC

%

Interlock function Valid (Manual reset)

External device monitor function Valid

Auxiliary output Can be used

The device output is selected depending on the connecting state of the output polarity setting wire (shield). Incorrect

wiring may cause the lockout state.

* Symbols

Switch S1

Test input / Reset input

0 to +2.5V (source current 5mA or less): OFF, Open: ON

K1, K2: External device (Forced guided relay or magnetic contactor)

Note: For resetting, refer to “

3-2 Interlock Function

.”

27 SUNX Limited MJE-SF4C No.0011-08V

Page 29

Wiring

2-5-6 Wiring for Auto Reset (Interlock is Invalid) (Wiring Example of the Control Category 4)

<For PNP output>

(Red) Muting lamp output

Receiver Emitter

Grey cable

Grey cable

(with black line)

(Yellow) Override input

(Pale purple) Interlock setting input

(Brown) +V

(Pink) Test input / Reset input

(Gray) Safety input 1

(Gray / Black) Safety input 2

(Yellow-green / Black) Auxiliary output

(Shield) Output polarity setting wire

(Blue) 0V

(Orange) Synchronization +

(Orange / Black) Synchronization (Orange / Black) Synchronization (Orange) Synchronization +

(Yellow-green) External device monitor input

(Brown) +V

(Black) Control output 1 (OSSD 1)

(White) Control output 2 (OSSD 2)

(Shield) Output polarity setting wire

(Blue) 0V

(Sky-blue / White) Muting input 1

(Sky-blue / Black) Muting input 2

(Gray) Large multi-purpose indicator input 1

(Gray / Black) Large multi-purpose indicator input 2

K1

K2

Load

S1

K1 K2

+

-

24V DC

%

Interlock function Invalid (Auto reset)

External device monitor function Valid

Auxiliary output Can be used

The device output is selected depending on the connecting state of the output polarity setting wire (shield). Incorrect

wiring may cause the lockout state.

* Symbols

Switch S1

Test input / Reset input

Vs to Vs - 3.5V (sink current 5mA or less): ON (Note 1), Open: OFF

K1, K2: External device (Forced guided relay or magnetic contactor)

Notes: 1) Vs is the applying supply voltage.

2) For resetting, refer to “

3-2 Interlock Function

.”

28SUNX Limited MJE-SF4C No.0011-08V

Page 30

Wiring

<For NPN output>

Receiver Emitter

Grey cable

Grey cable

(with black line)

(Red) Muting lamp output

(Yellow) Override input

(Pale purple) Interlock setting input

(Brown) +V

(Yellow-green / Black) Auxiliary output

(Shield) Output polarity setting wire

(Gray) Safety input 1

(Gray / Black) Safety input 2

(Pink) Test input / Reset input

(Blue) 0V

(Orange) Synchronization +

(Orange / Black) Synchronization (Orange / Black) Synchronization (Orange) Synchronization +

(Yellow-green) External device monitor input

(Brown) +V

(Black) Control output 1 (OSSD 1)

(White) Control output 2 (OSSD 2)

(Shield) Output polarity setting wire

(Blue) 0V

(Sky-blue / White) Muting input 1

(Sky-blue / Black) Muting input 2

(Gray) Large multi-purpose indicator input 1

(Gray / Black) Large multi-purpose indicator input 2

K1

K2

Load

S1

K1 K2

+

-

24V DC

%

Interlock function Invalid (Auto reset)

External device monitor function Valid

Auxiliary output Can be used

The device output is selected depending on the connecting state of the output polarity setting wire (shield). Incorrect

wiring may cause the lockout state.

* Symbols

Switch S1

Test input / Reset input

0 to +2.5V (source current 5mA or less): ON, Open: OFF

K1, K2: External device (Forced guided relay or magnetic contactor)

Note: For resetting, refer to “

3-2 Interlock Function

.”

29 SUNX Limited MJE-SF4C No.0011-08V

Page 31

Wiring

2-5-7 Wiring Con guration for Valid Safety Input Function

(Wiring Example of the Control Category 4)

The safety contacting point can be connected to safety input 1 wire (gray) and the safety input 2 wire (gray /

black) of the emitter.

Refer to “

<For PNP output>

3-4 Safety Input Function

Safety contacting point

” for detail of safety input function.

This device

Receiver Emitter

Grey cable

Grey cable

(with black line)

Interlock function Invalid (Auto-reset)

External device monitor function Invalid

Auxiliary output Cannot be used

(Gray / Black)

Safety input 2

(Gray) Safety input 1

(Red) Muting lamp output

(Yellow) Override input

(Pale purple) Interlock setting input

(Brown) +V

(Pink) Test input / Reset input

(Shield) Output polarity setting wire

(Blue) 0V

(Yellow-green / Black) Auxiliary output

(Orange) Synchronization +

(Orange / Black) Synchronization (Orange / Black) Synchronization (Orange) Synchronization +

(Yellow-green) External device monitor input

(Brown) +V

(Black) Control output 1 (OSSD 1)

(White) Control output 2 (OSSD 2)

(Shield) Output polarity setting wire

(Blue) 0V

(Sky-blue / White) Muting input 1

(Sky-blue / Black) Muting input 2

(Gray) Large multi-purpose indicator input 1

(Gray / Black) Large multi-purpose indicator input 2

+

24V DC

%

-

K1

K2

Safety input

Short-circuit (sink current 5 to 10mA), Source current 5 to 10mA: Valid

Open: Invalid

30SUNX Limited MJE-SF4C No.0011-08V

Page 32

Wiring

<For NPN output>

Safety contacting point

This device

Receiver Emitter

Grey cable

Grey cable

(with black line)

Interlock function Invalid (Auto-reset)

External device monitor function Invalid

Auxiliary output Cannot be used

(Gray / Black)

Safety input 2

(Gray) Safety input 1

(Red) Muting lamp output

(Yellow) Override input

(Pale purple) Interlock setting input

(Brown) +V

(Pink) Test input / Reset input

(Shield) Output polarity setting wire

(Blue) 0V

(Yellow-green / Black) Auxiliary output

(Orange) Synchronization +

(Orange / Black) Synchronization (Orange / Black) Synchronization (Orange) Synchronization +

(Yellow-green) External device monitor input

(Brown) +V

(Black) Control output 1 (OSSD 1)

(White) Control output 2 (OSSD 2)

(Shield) Output polarity setting wire

(Blue) 0V

(Sky-blue / White) Muting input 1

(Sky-blue / Black) Muting input 2

(Gray) Large multi-purpose indicator input 1

(Gray / Black) Large multi-purpose indicator input 2

+

24V DC

%

-

K1

K2

Safety input

Short-circuit (sink current 5 to 10mA), Source current 5 to 10mA: Valid

Open: Invalid

31 SUNX Limited MJE-SF4C No.0011-08V

Page 33

2-5-8 Wiring Con guration for Invalid External Device Monitor Function

(Wiring Example of the Control Category 4)

This is the con guration for connecting auxiliary output and external device monitor input.

cannot be connected to external devices.

<For PNP output>

(Red) Muting lamp output

Receiver Emitter

Grey cable

Grey cable

(with black line)

(Yellow) Override input

(Pale purple) Interlock setting input

(Brown) +V

(Pink) Test input / Reset input

(Gray) Safety input 1

(Gray / Black) Safety input 2

(Shield) Output polarity setting wire

(Blue) 0V

(Yellow-green / Black) Auxiliary output

(Orange) Synchronization +

(Orange / Black) Synchronization (Orange / Black) Synchronization (Orange) Synchronization +

(Yellow-green) External device monitor input

(Brown) +V

(Black) Control output 1 (OSSD 1)

(White) Control output 2 (OSSD 2)

(Shield) Output polarity setting wire

(Blue) 0V

(Sky-blue / White) Muting input 1

(Sky-blue / Black) Muting input 2

(Gray) Large multi-purpose indicator input 1

(Gray / Black) Large multi-purpose indicator input 2

K1

K2

S1

Wiring

The auxiliary output

+

24V DC

%

-

Interlock function Invalid (Auto reset)

External device monitor function Invalid

Auxiliary output Cannot be used

The device output is selected depending on the connecting state of the output polarity setting wire (shield). Incorrect

wiring may cause the lockout state.

* Symbols

Switch S1

Test input / Reset input

Vs to Vs - 3.5V (sink current 5mA or less): ON (Note), Open: OFF

K1, K2: External device (Forced guided relay or magnetic contactor)

Note: Vs is the applying supply voltage.

32SUNX Limited MJE-SF4C No.0011-08V

Page 34

Wiring

<For NPN output>

Receiver Emitter

Grey cable

Grey cable

(with black line)

(Red) Muting lamp output

(Yellow) Override input

(Pale purple) Interlock setting input

(Brown) +V

(Shield) Output polarity setting wire

(Pink) Test input / Reset input

(Gray) Safety input 1

(Gray / Black) Safety input 2

(Blue) 0V

(Yellow-green / Black) Auxiliary output

(Orange) Synchronization +

(Orange / Black) Synchronization (Orange / Black) Synchronization (Orange) Synchronization +

(Yellow-green) External device monitor input

(Brown) +V

(Black) Control output 1 (OSSD 1)

(White) Control output 2 (OSSD 2)

(Shield) Output polarity setting wire

(Blue) 0V

(Sky-blue / White) Muting input 1

(Sky-blue / Black) Muting input 2

(Gray) Large multi-purpose indicator input 1

(Gray / Black) Large multi-purpose indicator input 2

K1

K2

S1

+

-

24V DC

%

Interlock function Invalid (Auto reset)

External device monitor function Invalid

Auxiliary output Cannot be used

The device output is selected depending on the connecting state of the output polarity setting wire (shield). Incorrect

wiring may cause the lockout state.

* Symbols

Switch S1

Test input / Reset input

0 to +2.5V (source current 5mA or less): ON, Open: OFF

K1, K2: External device (Forced guided relay or magnetic contactor)

33 SUNX Limited MJE-SF4C No.0011-08V

Page 35

2-5-9 Wiring Con guration for Valid Muting Function

(Wiring Example of the Control Category 4)

<For PNP output>

(Pale purple) Interlock setting input

Receiver Emitter

Grey cable

Grey cable

(with black line)

Interlock function Invalid (Auto reset)

External device monitor function Valid

Auxiliary output Can be used

(Brown) +V

(Red) Muting lamp output

(Pink) Test input / Reset input

(Yellow) Override input

(Gray) Safety input 1

(Gray / Black) Safety input 2

(Yellow-green / Black) Auxiliary output

(Shield) Output polarity setting wire

(Blue) 0V

(Orange) Synchronization +

(Orange / Black) Synchronization (Orange / Black) Synchronization (Orange) Synchronization +

(Yellow-green) External device monitor input

(Brown) +V

(Sky-blue / White) Muting input 1

(Sky-blue / Black) Muting input 2

(Black) Control output 1 (OSSD 1)

(White) Control output 2 (OSSD 2)

(Shield) Output polarity setting wire

(Blue) 0V

(Gray) Large multi-purpose indicator input 1

(Gray / Black) Large multi-purpose indicator input 2

(Note 1)

K1

K2

Load

S1

S2

K1 K2

S2

S2

+

-

Wiring

24V DC

%

The device output is selected depending on the connecting state of the output polarity setting wire (shield). Incorrect

wiring may cause the lockout state.

* Symbols

Switch S1

Test input / Reset input

Vs to Vs - 3.5V (sink current 5mA or less): ON (Note 2), Open: OFF

Switch S2

Muting input, Override input

Vs to Vs - 3.5V (sink current 5mA or less): Valid (Note 2), Open: Invalid

K1, K2: External device (Forced guided relay or magnetic contactor)

Notes: 1) The incandescent lamp or LED with total 6W or less shall be used when connecting lamp to the muting lamp output.

2) Vs is the applying supply voltage.

34SUNX Limited MJE-SF4C No.0011-08V

Page 36

Wiring

<For NPN output>

(Pale purple) Interlock setting input

(Brown) +V

Receiver Emitter

Grey cable

Grey cable

(with black line)

Interlock function Invalid (Auto reset)

External device monitor function Valid

Auxiliary output Can be used

(Red) Muting lamp output

(Yellow-green / Black) Auxiliary output

(Shield) Output polarity setting wire

(Gray) Safety input 1

(Gray / Black) Safety input 2

(Yellow) Override input

(Pink) Test input / Reset input

(Blue) 0V

(Orange) Synchronization +

(Orange / Black) Synchronization (Orange / Black) Synchronization (Orange) Synchronization +

(Yellow-green) External device monitor input

(Brown) +V

(Black) Control output 1 (OSSD 1)

(White) Control output 2 (OSSD 2)

(Shield) Output polarity setting wire

(Sky-blue / White) Muting input 1

(Sky-blue / Black) Muting input 2

(Blue) 0V

(Gray) Large multi-purpose indicator input 1

(Gray / Black) Large multi-purpose indicator input 2

(Note)

K1

K2

Load

S1

S2

K1 K2

S2

S2

+

-

24V DC

%

The device output is selected depending on the connecting state of the output polarity setting wire (shield). Incorrect

wiring may cause the lockout state.

* Symbols

Switch S1

Test input / Reset input

0 to +2.5V (source current 5mA or less): ON, Open: OFF

Switch S2

Muting input, Override input

0 to +2.5V (source current 5mA or less): Valid, Open: Invalid

K1, K2: External device (Forced guided relay or magnetic contactor)

Note: The incandescent lamp or LED with total 6W or less shall be used when connecting to lamp the muting lamp output.

35 SUNX Limited MJE-SF4C No.0011-08V

Page 37

Adjustment

2-6 Adjustment

2-6-1 Beam-axis Alignment

1. Turn ON the power supply unit of this device.

2. Check that the digital error indicator (red) and the fault indicator (yellow) of the emitter and the receiver are

OFF respectively.

If the digital error indicator (red) or the fault indicator (yellow) lights up or blinks, refer to “

Troubleshooting

3. Loosen the hexagon-socket head bolts [M5 (please arrange separately)] which holds the standard mounting bracket

4. Move the emitter in the left and right directions in order to determine the range of the light received condition with the help of the beam-axis alignment indicator (red). Then, set the emitter at the center of this

range.

5. Similar to the step 4, perform the beam-axis alignment for the receiver.

MS-SFC-1

” and report the symptoms to the maintenance in charge.

.

Chapter 5

6. Tighten the standard mounting bracket

separately)].

7. Check, once again, that the beam-axis alignment indicators (red), operation indicator (green) and OSSD

indicator (green) in the display of the emitter and receiver do light up.

Receiver

MS-SFC-1

by the hexagon-socket head bolt [M5 (please arrange

Emitter

36SUNX Limited MJE-SF4C No.0011-08V

Page 38

Adjustment

<Reference>

The beam-axis alignment indicator indicates the reception status for each section of the device which is divided into 4

sections.

Furthermore, the A (D) of the beam-axis alignment indicates the light-receiving status of the device top end (bottom end).

For example, when using a 16-beam channel device, there are 4 beam channels per section (i.e., 16/4=4).

When the top end (bottom end) beam channel is received, the A (D) of the beam-axis alignment indicator blinks in red.

(Example) 16 beam channels

Only top end beam

channel is received

Light received

Light blocked

3 beam channels including

the top end beam channel

are received

4 beam channels in top

section are received

3 beam channels excluding

the top end beam channel

are received

Beam-axis alignment

indicator

A: Blinks

B to C: Turns OFF

Beam-axis alignment

indicator

A: Blinks

B to C: Turns OFF

Beam-axis alignment

indicator

A: Lights up

B to C: Turns OFF

Beam-axis alignment

indicator

All: Turns OFF

When all the 4 beam channels divided into each section are received, the beam-axis alignment indicator lights up in red.

The indicators corresponding to the different sections light up in red, one by one, when the beam channels of the respective sections are received. When all the beam channels are received and the control output (OSSD 1 / 2) turns ON,

all the four indicators of the beam-axis alignment indicator turn into green.

Refer to “

2-6-2 Operation Test

” for details.

37 SUNX Limited MJE-SF4C No.0011-08V

Page 39

Adjustment

2-6-2 Operation Test

1.Turn ON the power supply unit of this device.

2. Check that the digital error indicator (red) and the fault indicator (yellow) of the emitter and the receiver are

OFF respectively.

If the digital error indicator (red) or the fault indicator (yellow) lights up or blinks, refer to “

Troubleshooting

” and report the symptoms to the maintenance in charge.

3. Move the test rod up and down 1,600 mm/sec. or less at three positions, just in front of the emitter (A), between the emitter and receiver (B) and just in front of the receiver (C).

(C)

Receiver

(B)

(A)

Emitter

Tes t ro d

Chapter 5