Page 1

ORDER NO. MKE0008107C1

B6

Combination VCR

PVQ-130W

PVQ-130WA

PVQ-1300W

PVQ-1300WA

SPECIFICATIONS

1

Page 2

1

1. SAFETY PRECAUTIONS

GENERAL GUIDELINES

1. IMPORTANT SAFETY NOTICE

There are special components used in this equipment which are important for

safety. These parts are marked by

Layout, Exploded Views and Replacement Parts List. It is essential that these

critical parts should be replaced with manufacturer's specified parts to prevent

X-RADIATION, shock, fire, or other hazards. Do not modify the original design

without permission of manufacturer.

in the Schematic Diagrams, Circuit Board

2. An Isolation Transformer should always be used during the servicing of

Combination VCR whose chassis is not isolated from the AC power line. Use a

2

Page 3

transformer of adequate power rating as this protects the technician from

accidents resulting in personal injury from electrical shocks. It will also protect

Combination VCR from being damaged by accidental shorting that may occur

during servicing.

3. When servicing, observe the original lead dress, especially the lead dress in the

high voltage circuits. If a short circuit is found, replace all parts which have been

overheated or damaged by the short circuit.

4. After servicing, see to it that all the protective devices such as insulation barriers,

insulation papers, shield, and isolation R-C combinations are properly installed.

5. Before turning the receiver on, measure the resistance between B+ line and

chassis ground. Connect (-) side of an ohmmeter to the B+ lines, and (+) side to

chassis ground. Each line should have more resistance than specified, as follows :

B+ Line

Minimum Resistance

115 V

ΩΩΩΩ

1 k

(Cold chassis ground)

24 V

ΩΩΩΩ

180

(Cold chassis ground)

15 V

ΩΩΩΩ

110

(Cold chassis ground)

6. When the TV set is not used for a long period of time, unplug the power cord from

the AC outlet.

7. Potentials, as high as 25.0 kV are present when this TV set is in operation.

Operation of the TV set without the rear cover involves the danger of a shock

hazard from the TV set power supply. Servicing should not be attempted by

anyone who is not thoroughly familiar with the precautions necessary when

working on high voltage equipment. Always discharge the anode of the picture

tube to the CRT ground of receiver before handling the tube.

8. After servicing make the following leakage current checks to prevent the customer

from being exposed to shock hazards.

LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. For physically operated power switches, turn power on. Otherwise skip step 2.

3. Measure the resistance value, with an ohmmeter, between the jumpered AC plug

and each exposed metallic cabinet part on the receiver, such as screwheads,

connectors, etc. When the exposed metallic part has a return path to the chassis,

the reading should be between 1 M

ΩΩΩΩ

and 12 M

ΩΩΩΩ

. When the exposed metal does not

have a return path to the chassis, the reading must be infinity.

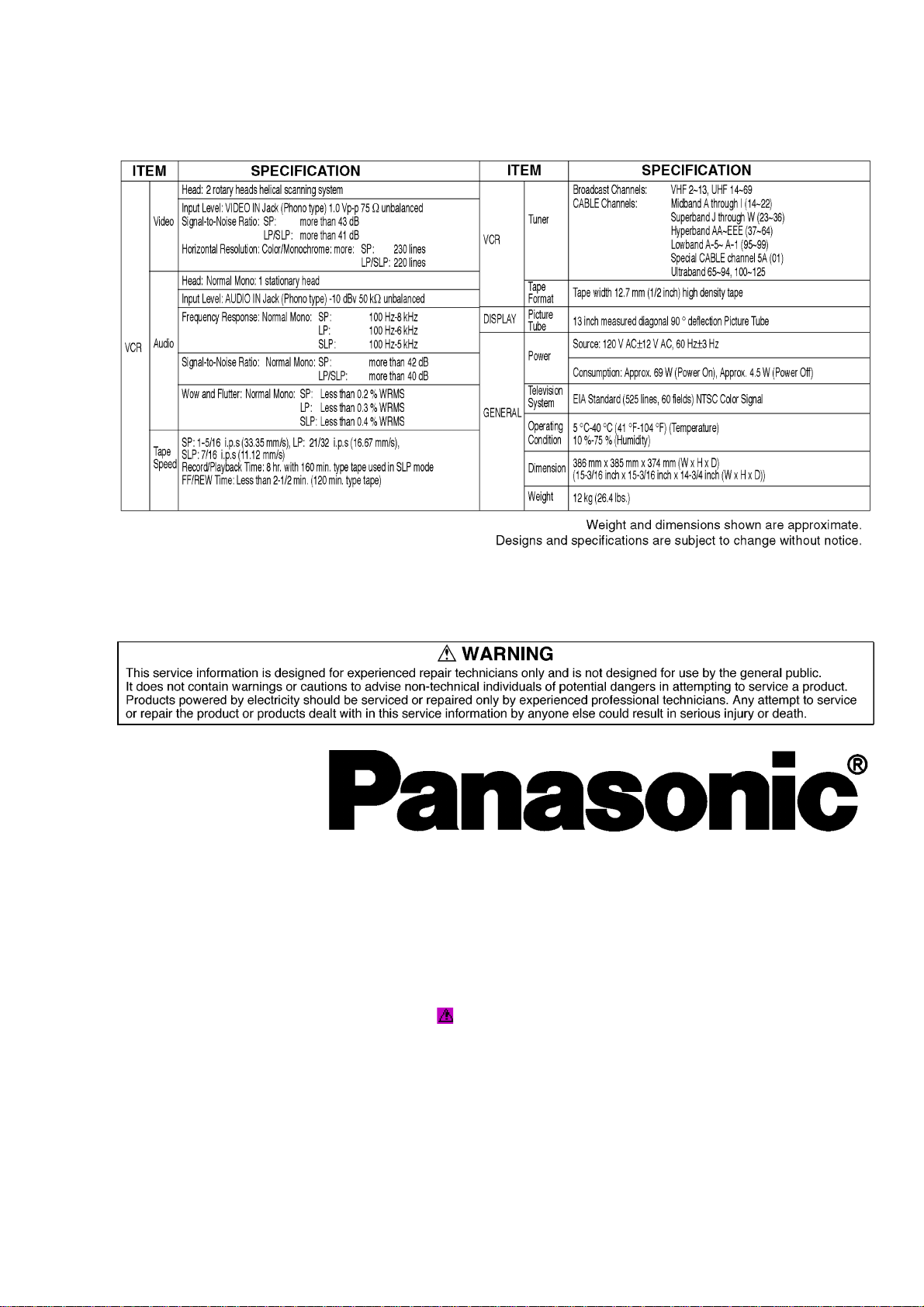

LEAKAGE CURRENT HOT CHECK

3

Page 4

1. Plug the AC cord directly into the AC outlet.

Do not use a isolation transformer for this check.

2. Connect a 1.5 k

exposed metallic part on the set and a good earth ground , as shown in Figure 1.

3. Use an AC voltmeter, with 1 k

across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 V RMS.

A leakage current tester (Simpson Model 229 equivalent) may be used to make the

hot checks. Leakage current must not exceed 1/2 mA. In case a measurement is

outside of the limits specified, there is a possibility of shock hazard, and the

receiver should be repaired and rechecked before it is returned to the customer.

ΩΩΩΩ

, 10 W resistor, in parallel with a 0.15

ΩΩΩΩ

/V or more sensitivity, to measure the potential

Figure 1

µµµµ

F capacitor, between each

2. X-RADIATION

WARNING :

1. The potential source of X-Radiation in TV sets is the High Voltage section and the

picture tube.

2. When using a picture tube test fixture for service, ensure that the fixture is capable

4

Page 5

of handling 25.0 kV without causing X-Radiation.

NOTE :

It is important to use an accurate periodically calibrated high voltage meter.

1. Reduce the brightness to minimum.

2. Set the SERVICE switch to SERVICE .

3. Measure the High Voltage. The meter reading should indicate 23.5 kV±1.5 kV.

If the meter indication is out of tolerance, immediate service and correction is

required to prevent the possibility of premature component failure.

4. To prevent an X-Radiation possibly, it is essential to use the specified picture tube.

HORIZONTAL OSCILLATOR DISABLE CIRCUIT TEST SERVICE WARNING :

The test must be made as a final check before set is returned to the customer.

CONFIRMATION OF X-RAY MOVEMENT

1. Turn off TV set.

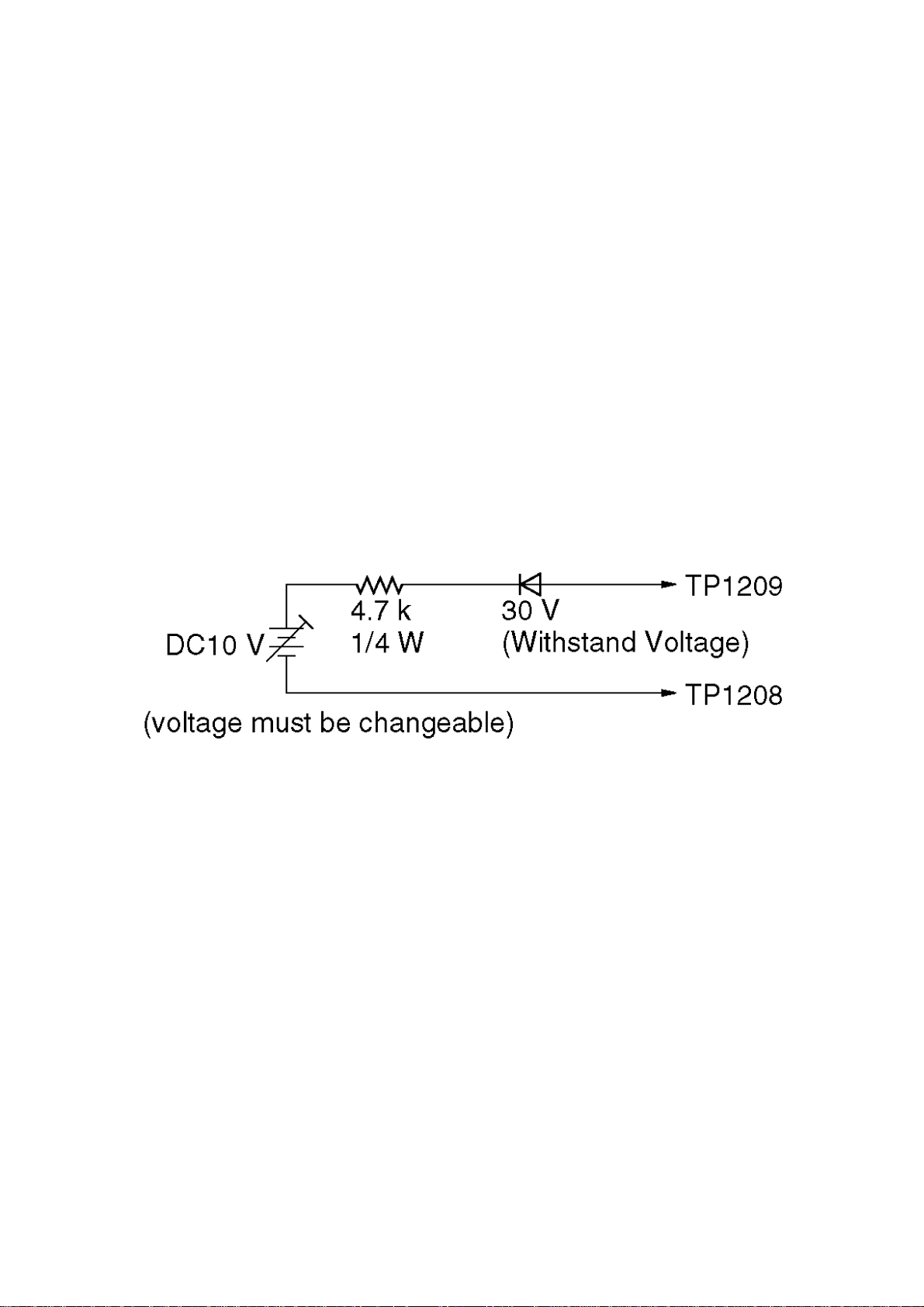

2. Connect the circuit below between TP1209 and TP1208.

Figure 2

3. Turn on DC Power, and then turn on the set. Confirm that the picture is on the

screen properly.

4. Confirm that the picture goes out of horizontal sync while getting down the voltage

to DC Power.

5. If this does not occur even when getting down the voltage of DC Power to 0 V, it

means that X-ray protect circuit is not operating.

Further confirmation and repair is required.

REPAIR PROCEDURES OF HORIZONTAL OSCILLATOR DISABLE CIRCUIT

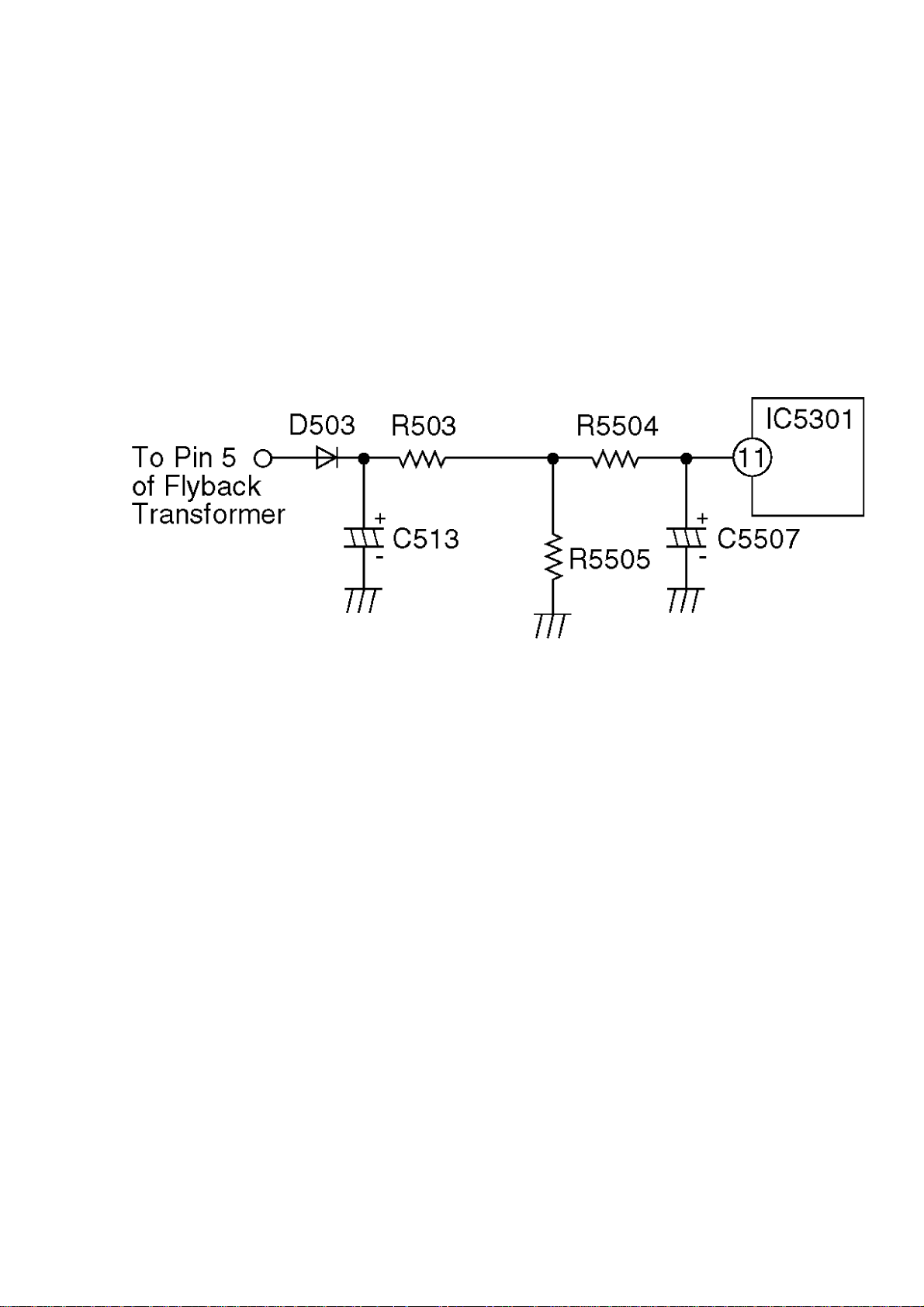

1. Connect a DC voltmeter between capacitor C513 (+) on the Main circuit board and

chassis ground.

2. If approximately +21.9 V is not present at that point when 120 V AC is applied, find

the cause. Check R503, R5505, C5507, C513 and D503.

3. Carefully check above specified parts and related circuits and parts. When the

circuit is repaired, try the horizontal oscillator disable circuit test again.

CIRCUIT EXPLANATION

5

Page 6

HORIZONTAL OSCILLATOR DISABLE CIRCUIT

The positive DC voltage, supplied from the D503 cathode for monitoring high voltage,

is applied to the IC5301 Pin11 through R503 and R5504. Under normal conditions, the

voltage at IC5301 Pin 11 is less than approx 3 V. If the high voltage at Flyback Tr Pin 5

exceeds the specified voltage, the positive DC voltage which is supplied from the

D503 cathode also increases. The increased voltage is applied to IC5301 Pin11

through R503 and R5504. Due to the increased voltage at IC5301 Pin11, the horizontal

oscillator frequency increases, the picture goes out of horizontal sync, the beam

current decreases and the picture becomes dark in order to keep X-radiation under

specification.

Figure 3

3. PREVENTION OF ELECTROSTATIC DISCHARGE

(ESD) TO ELECTROSTATICALLY SENSITIVE (ES)

DEVICES

Some semiconductor (solid state) devices can be damaged easily by static electricity.

Such components commonly are called Electrostatically Sensitive (ES) Devices.

Examples of typical ES devices are integrated circuits and some field-effect

transistors are semiconductor "chip" components. The following techniques should

be used to help reduce the incidence of component damage caused by electrostatic

discharge (ESD).

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any ESD on your body touching a

known earth ground. Alternatively, obtain and wear a commercially available

discharging ESD wrist strap, which should be removed for potential shock

reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the

assembly on a conductive surface such as aluminum foil, to prevent electrostatic

charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

6

Page 7

4. Use only an antistatic solder removal device. Some solder removal devices not

classified as "antistatic (ESD protected)" can generate electrical charge sufficient

to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges

sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until

immediately before you are ready to install it. (Most replacement ES devices are

packaged with leads electrically shorted together by conductive foam, aluminum

foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a

replacement ES device, touch the protective material to the chassis or circuit

assembly into which the device will be installed.

CAUTION:

Be sure no power is applied to the chassis or circuit, and observe all other safety

precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices.

(Otherwise harmless motion such as the brushing together of your clothes fabric

or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

"NOTE to CATV system installer :

This reminder is provided to call the CATV system installer's attention to Article

820-40 of the NEC that provides guidelines for proper grounding and, in particular,

specifies that the cable ground shall be connected to the grounding system of the

building, as close to the point of cable entry as practical."

4. OPERATION GUIDE

5. SERVICE NOTES (PLEASE READ)

5.1. SERVICE NOTES

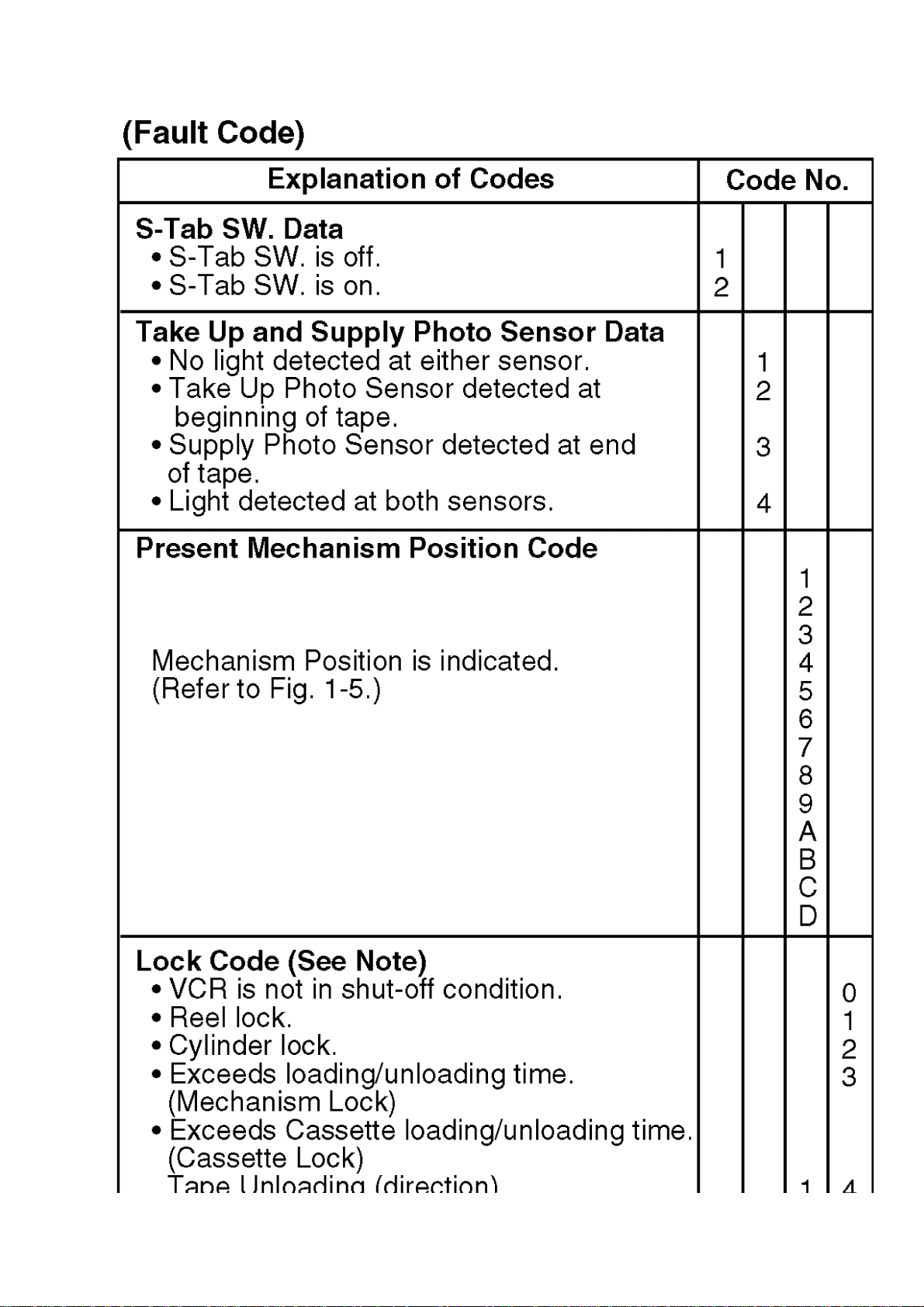

5.1.1. SIMPLIFIED FAULT FINDING DATA

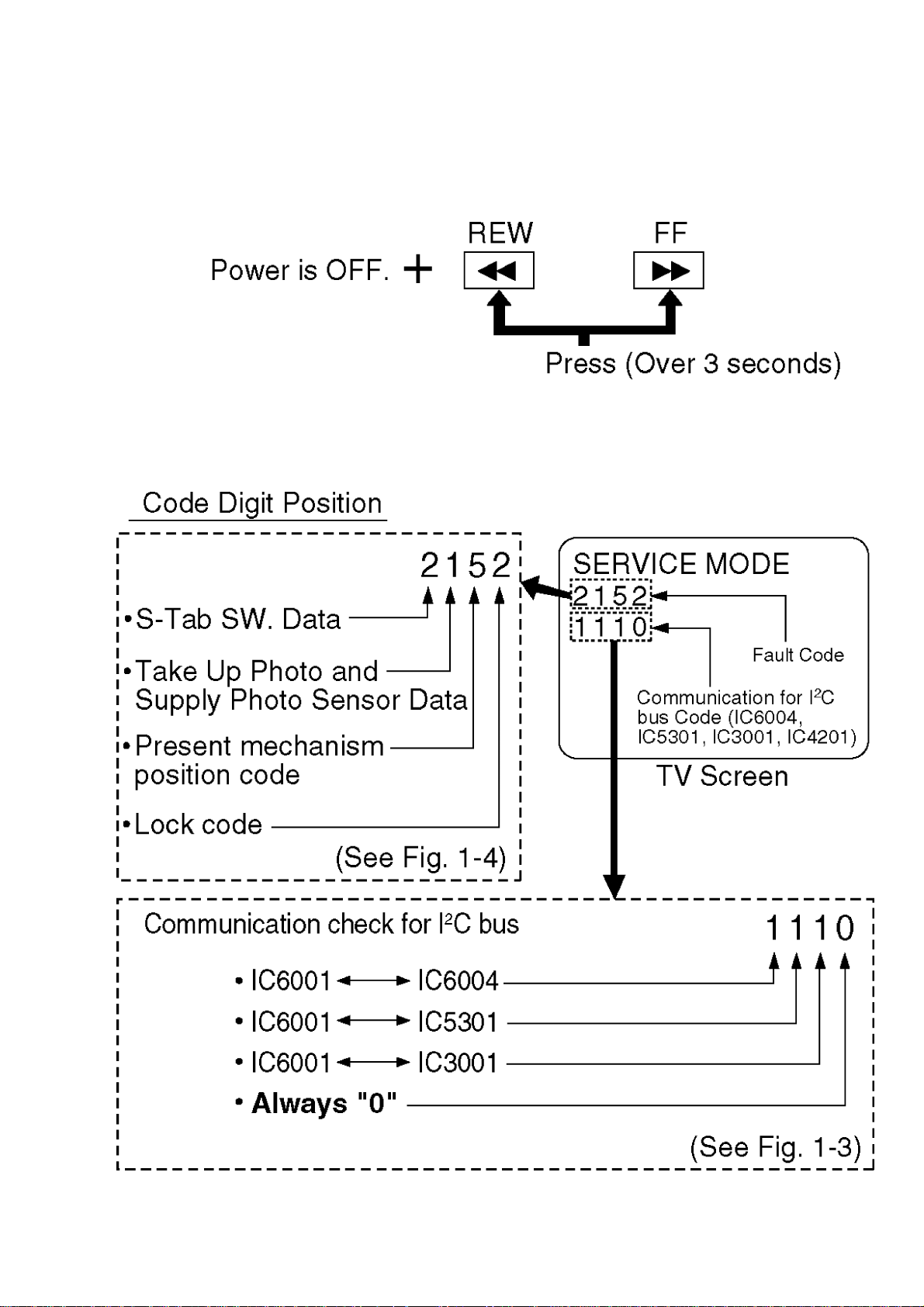

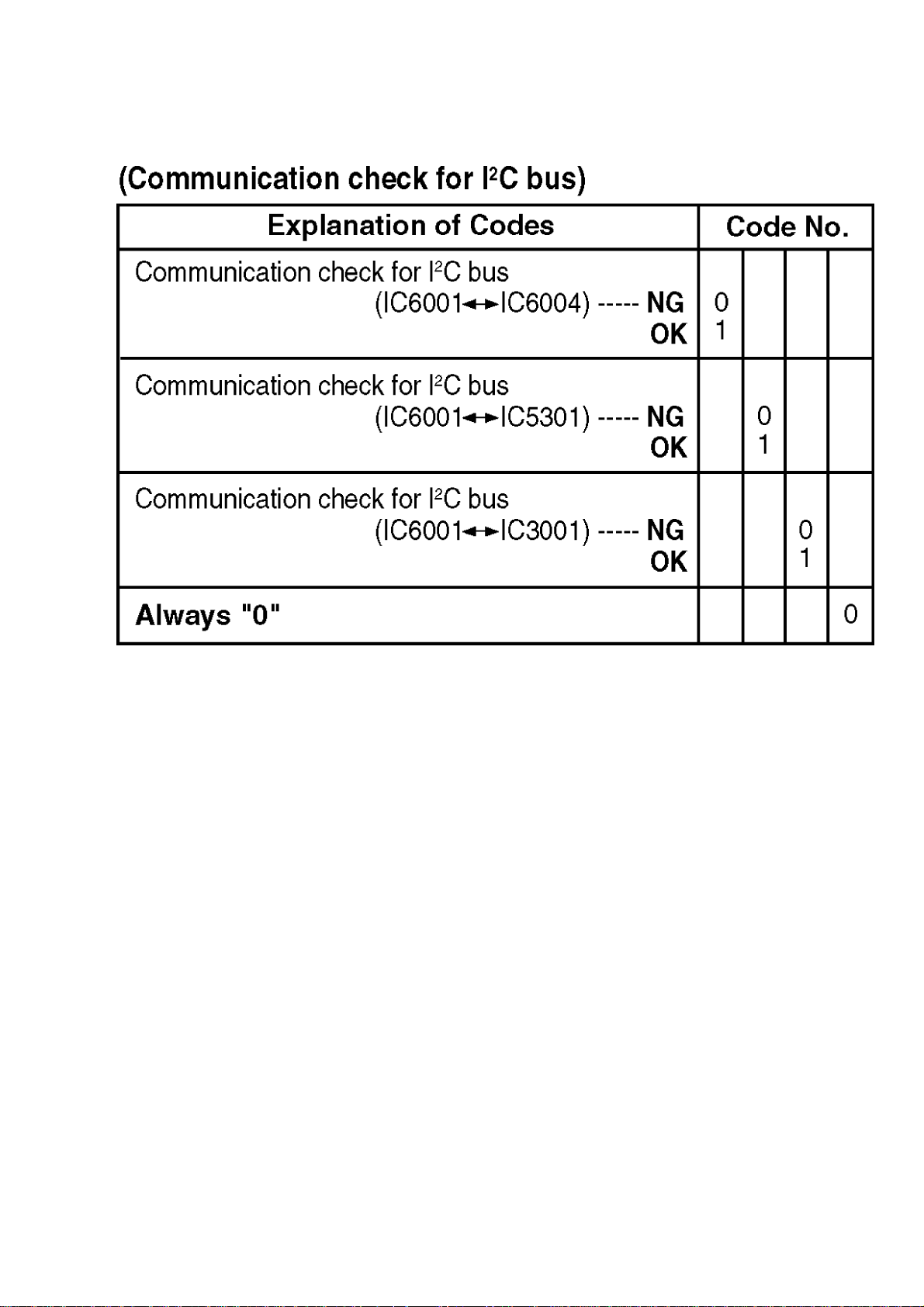

Simplified Self-Diagnostic System facilitates finding the cause of the fault. A 4 digit

for fault code and communication for I2C bus code will be displayed on TV screen.

The Simplified Fault finding data is stored in the Memory IC (IC6004). This data is

cleared after it is displayed, and then the POWER button is pressed back on.

7

Page 8

1. With power turned off, press FF and REW buttons on unit together for over 3

seconds.

Fig. 1-1

2. TV power goes on and the unit goes into service mode.

4 digit for fault code and communication for I2C bus code will be displayed.

Fig. 1-2

8

Page 9

Fig. 1-3

Fig. 1-4

9

Page 10

10

Page 11

Fig. 1-5

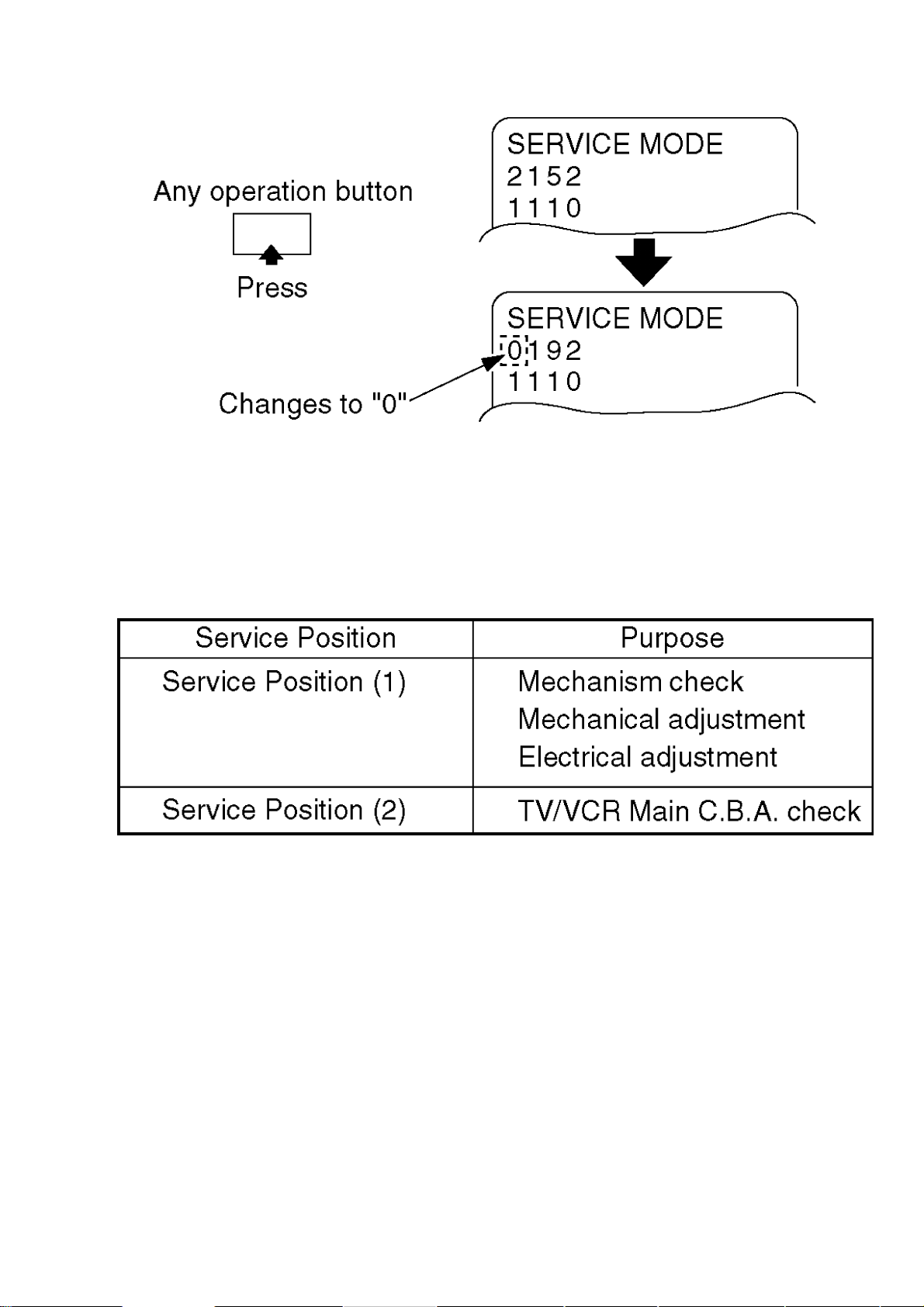

3. Press any operation button except for POWER on either the unit, or the remote to

detect that a key has been pressed.

The 1st digit changes to "0" only when key is detected.

Fig. 1-6

11

Page 12

Note:

When 1 to 4 listed in Lock code occurs, the VCR stops and all VCR function buttons

except for power become non-operational.

5.1.2. SERVICE POSITION

5.1.2.1. Service Position

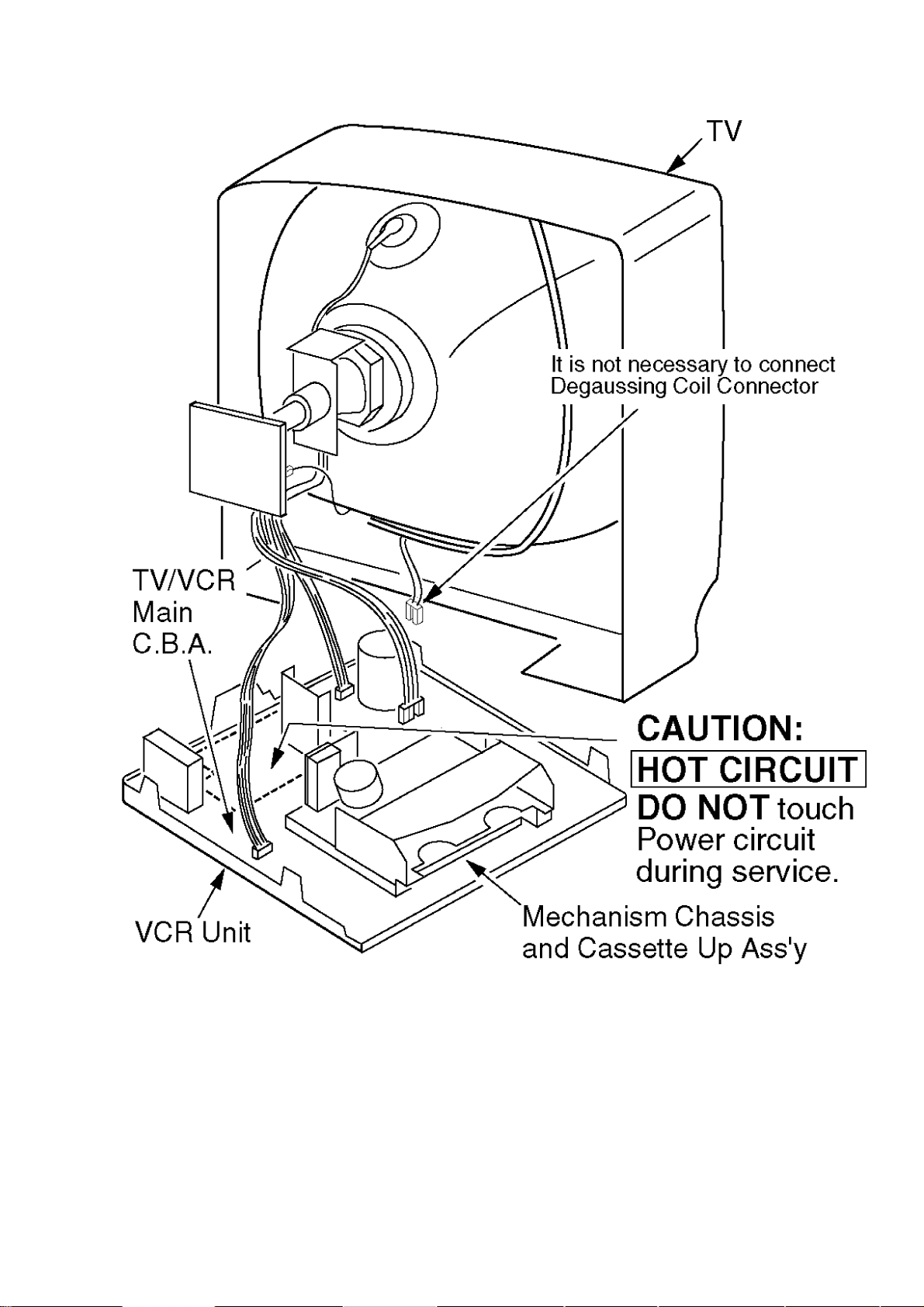

CAUTION:

HOT CIRCUIT (Primary circuit) exists on the TV/VCR Main C.B.A. Use extreme care to

prevent accidental shock when servicing.

5.1.2.1.1. Service Position (1)

Fig. 2-1

12

Page 13

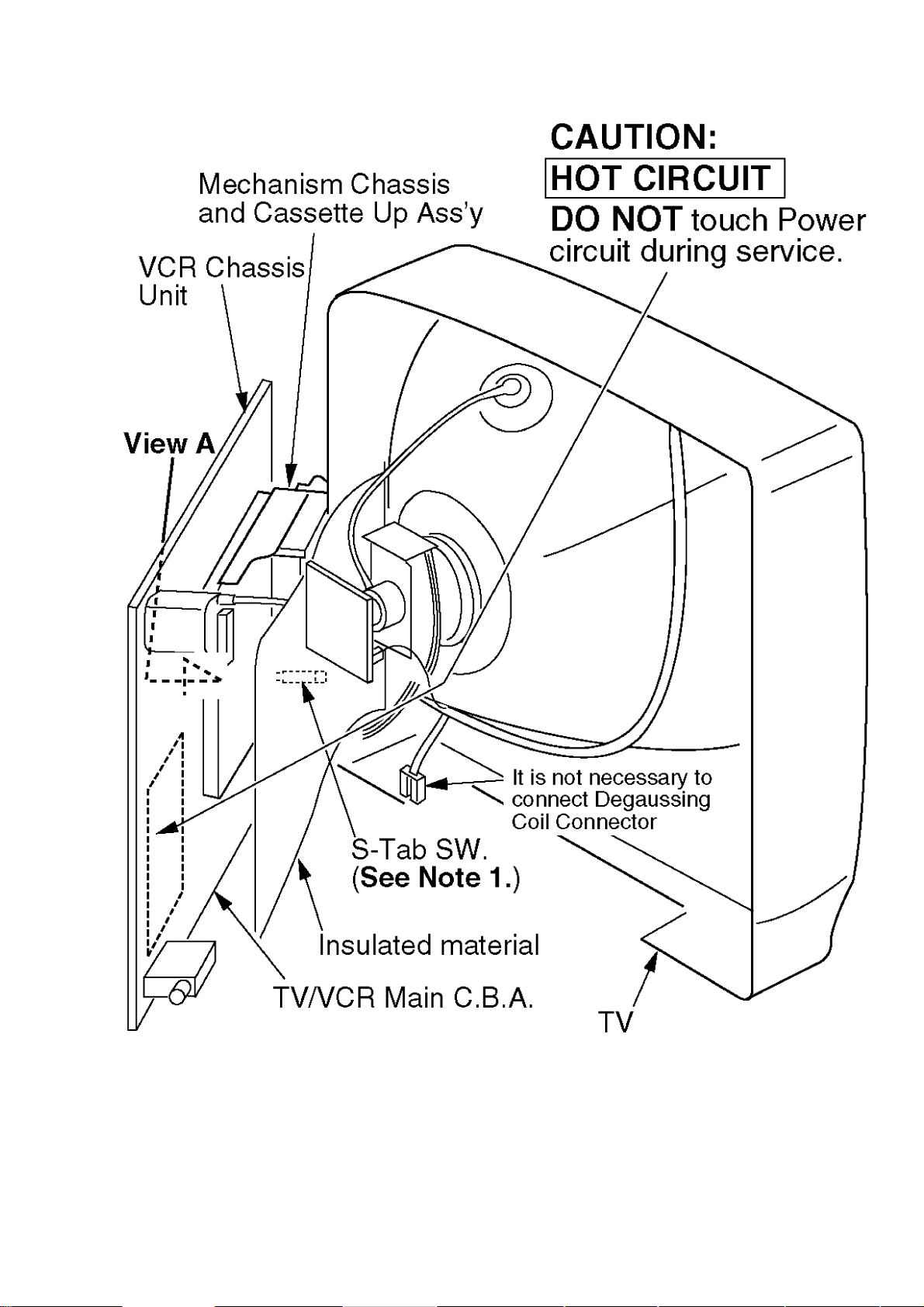

5.1.2.1.2. Service Position (2)

Fig. 2-2

13

Page 14

Note:

1. When recording in Service Position (2), short the S-Tab SW. Pins on foil side of

TV/VCR Main C.B.A. to turn this SW. on.

Fig. 2-3

14

Page 15

2. When disassembling/assembling, refer to "CABINET SECTION" in

DISASSEMBLY/ASSEMBLY PROCEDURES.

5.1.3. HOT CIRCUIT

Primary circuit exists on the TV/VCR Main C.B.A.

This circuit is identified as "HOT" on the C.B.A. and in the Service Manual. Use

extreme care to prevent accidental shock when servicing.

5.1.4. SERVICE MODE

In order to inhibit detection of the Supply & Takeup Photo Transistors, Reel Sensor,

and Cylinder Lock, place a jumper between TP6001 and GND.

In this mode, Mechanism movement can be confirmed. When removing Cassette Up

Ass'y, it can be confirmed without a cassette.

To release from this mode, remove the jumper between TP6001 and GND.

5.1.5. CAUTION FOR INSTALLATION OF VCR UNIT

CAUTION:

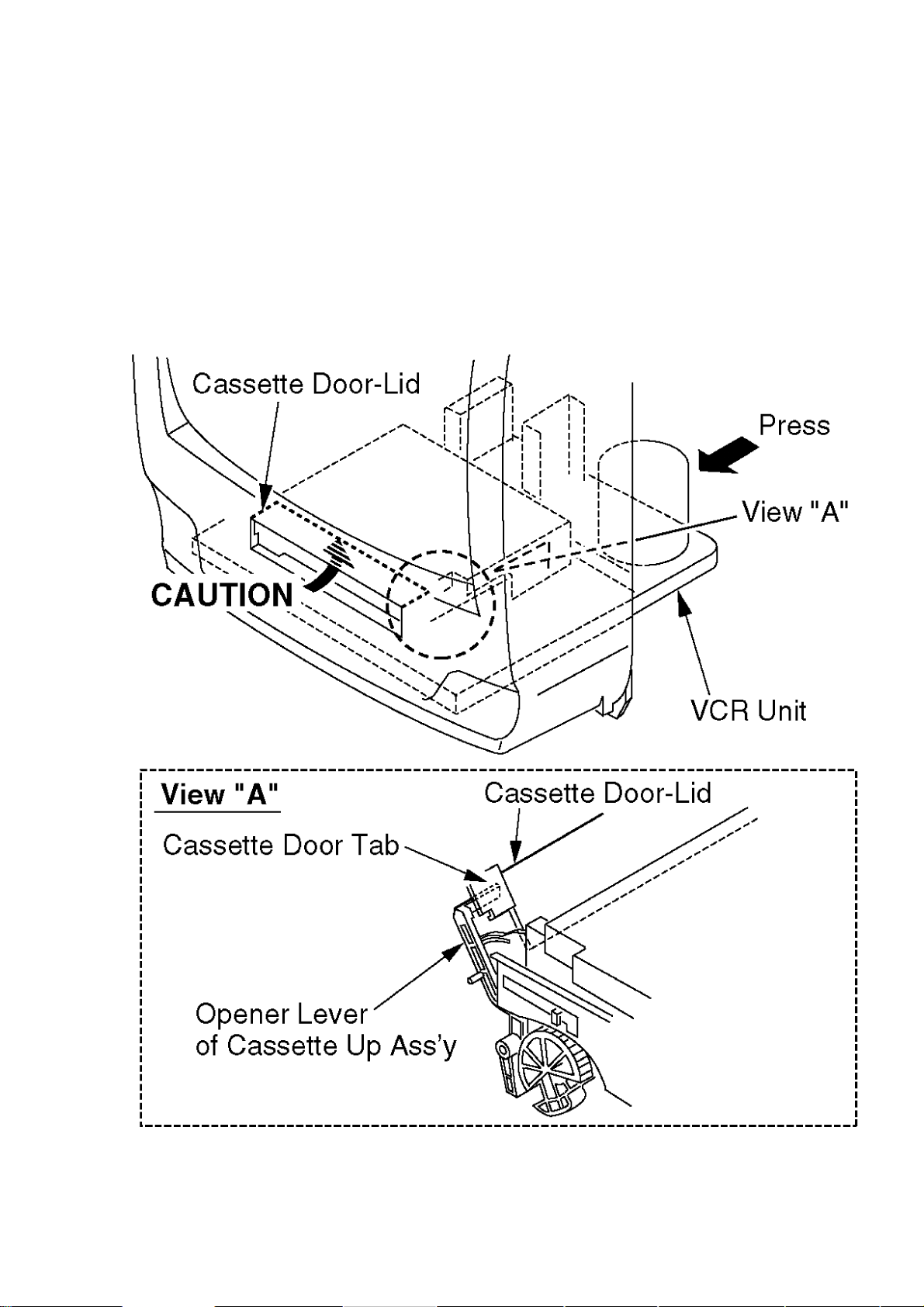

Opener Lever may be damaged when VCR Unit is installed, with Cassette Door-Lid

and Opener Lever of Cassette Up Ass'y set incorrectly.

15

Page 16

Install the VCR Unit as follows:

1. Swing the Cassette Door-Lid all the way open until the Cassette Door tab clears the

Opener Lever.

2. Make sure that all guide tabs are aligned properly. Then, press the VCR Unit

straight in.

Fig. 3

5.1.6. HOW TO INITIALIZE MEMORY IC

16

Page 17

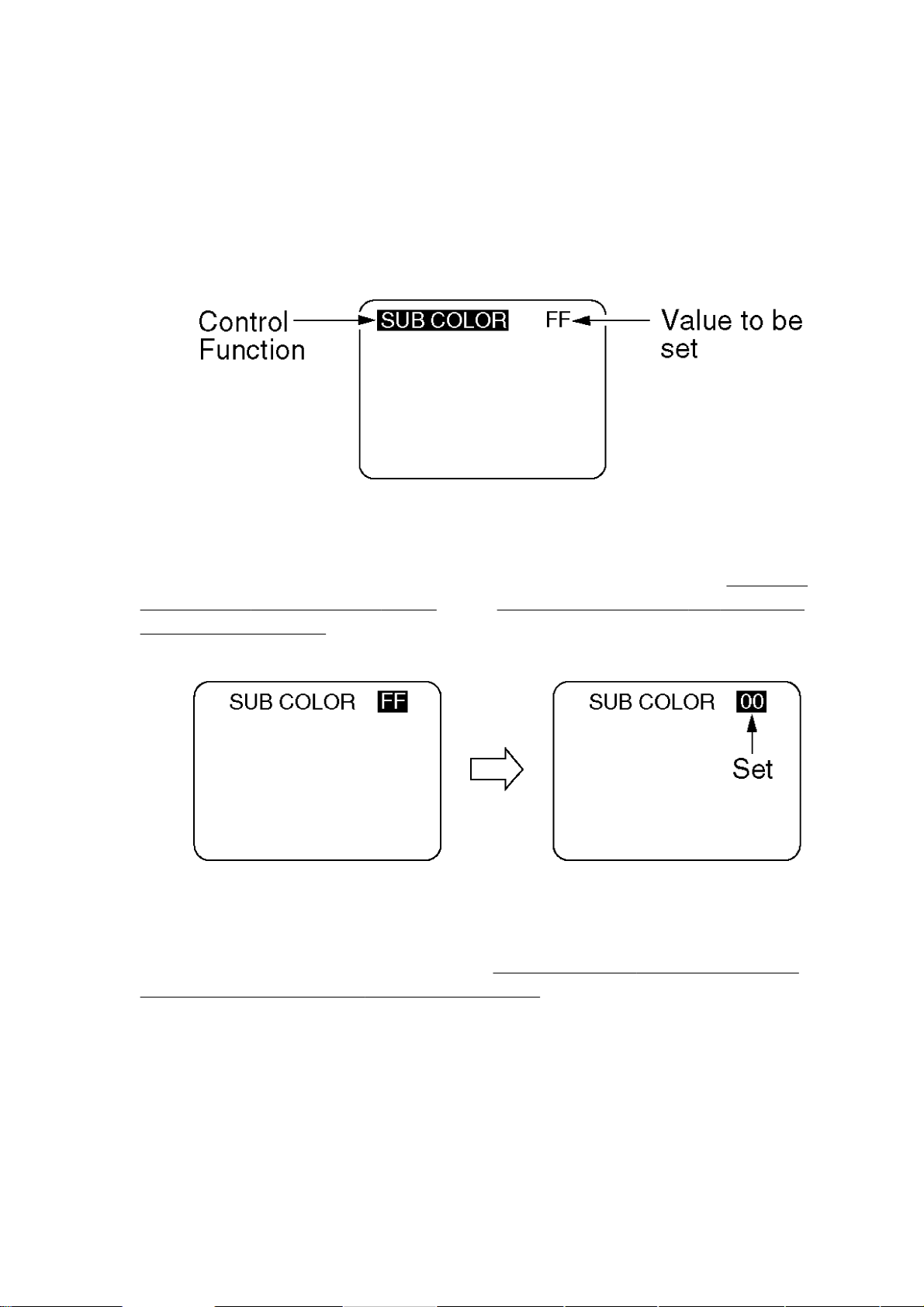

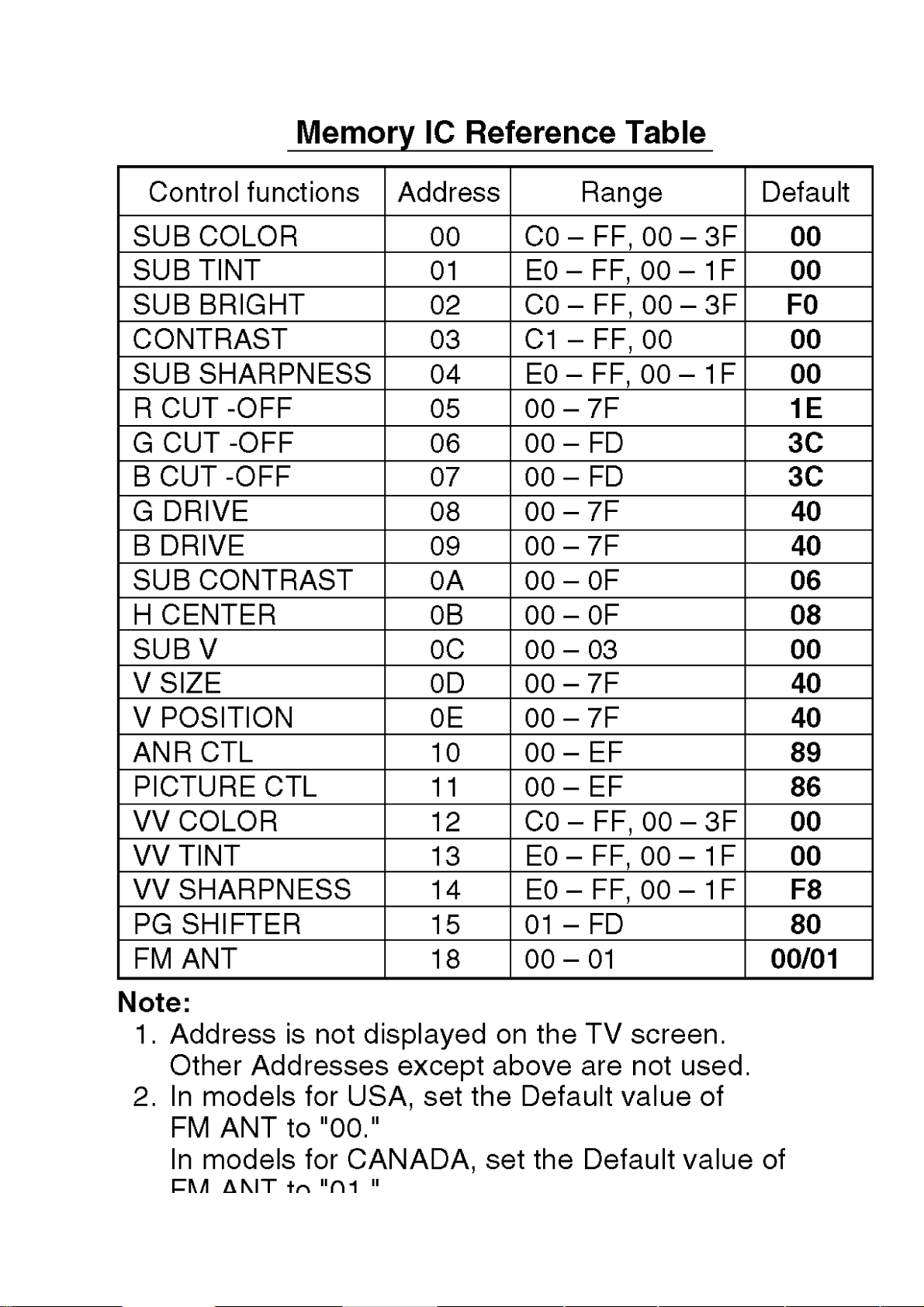

After the Memory IC (IC6004) or TV/VCR Main C.B.A. is replaced, be sure to set the

Default value to Memory IC as shown in "Memory IC Reference Table" below.

1. Press and hold STOP, PLAY, and VOL DOWN buttons on the unit together over 5

seconds with no cassette inserted.

The adjustment overlay will appear to Enter EVR Adjustment mode.

Fig. 4-1

2. Set the Default value of all Control functions using a remote control as shown in

"Memory IC Reference Table."

Note:

For Selecting Control functions and setting Default value, refer to "

HOW TO

ENTER EVR ADJUSTMENT MODE" and "HOW TO ENTER EVR PG SHIFTER

ADJUSTMENT MODE" in ELECTRICAL ADJUSTMENT procedures.

Fig. 4-2

3. Press and hold STOP, PLAY, and VOL DOWN buttons on the unit together over 5

seconds again or press the POWER button OFF to release EVR Adjustment Mode.

The Default value will be written to Memory IC (IC6004).

4. Perform all EVR Adjustments. (Refer to "

EVR (Electronic Variable Register)

ADJUSTMENT WITH THE REMOTE CONTROL" in ELECTRICAL ADJUSTMENT

procedures.)

17

Page 18

18

Page 19

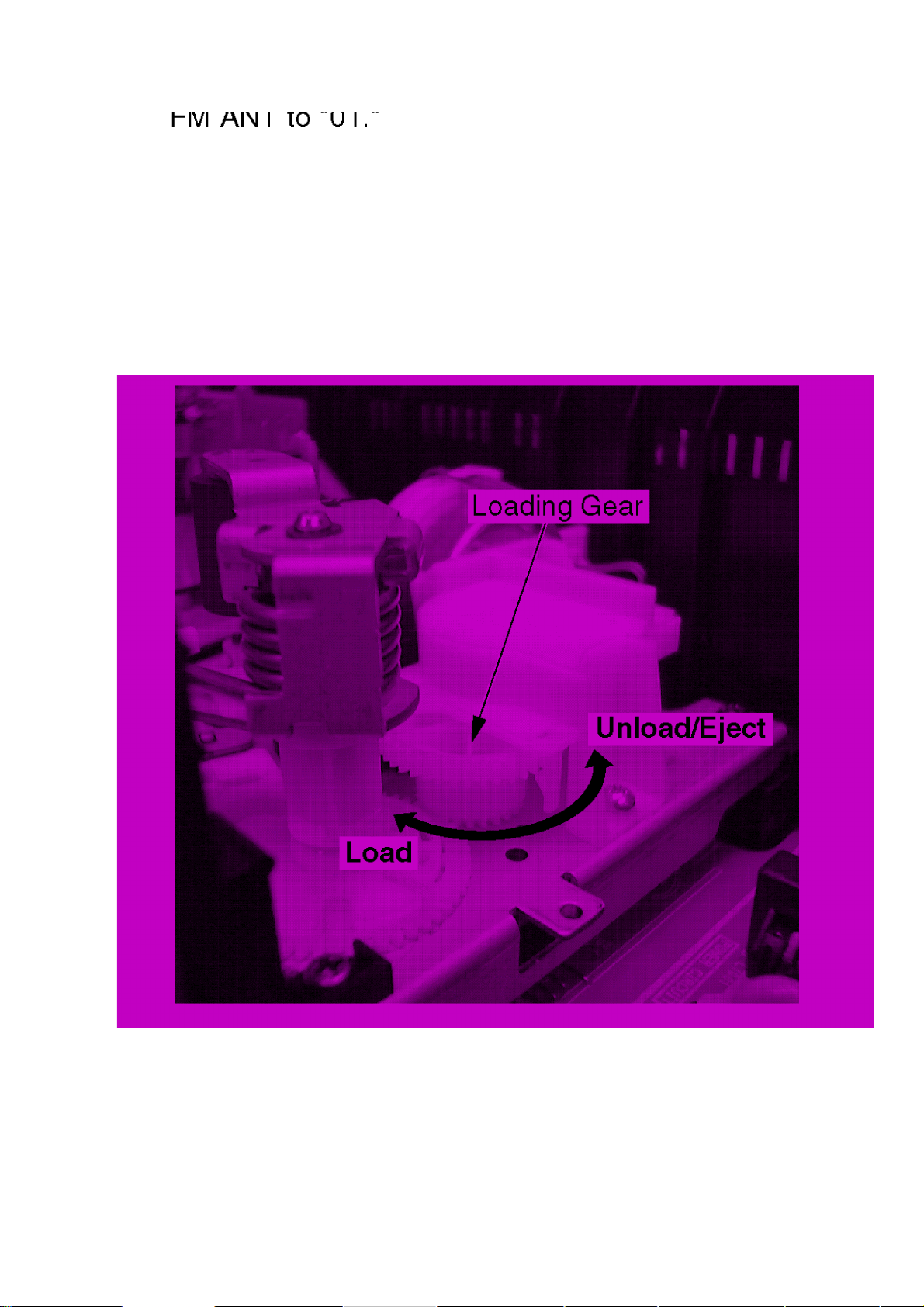

5.1.7. METHOD FOR LOADING/UNLOADING OF MECHANISM

5.1.7.1. (Manual Method)

Turn the Loading Gear clockwise (for loading) or counterclockwise (for unloading)

using needlenose pliers etc.

Note:

Do not use this method if Mechanism is jammed or locked.

Fig. 5-1

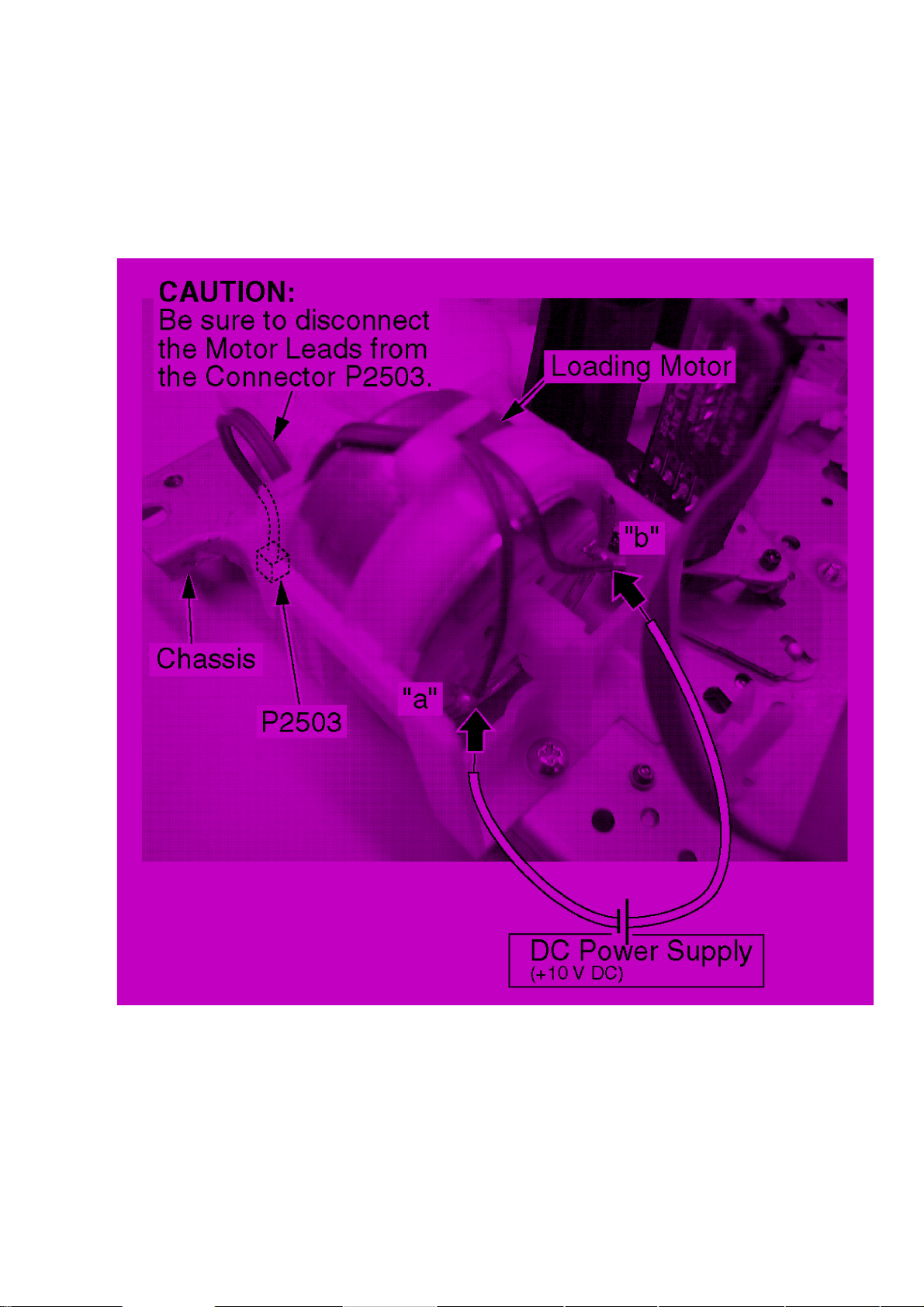

5.1.7.2. (Electrical Method)

Apply +10.0 V DC Power Supply to the Loading Motor terminals.

Loading

DC + to Portion "a," DC - to Portion "b"

Unloading

DC - to Portion "a," DC + to Portion "b"

19

Page 20

CAUTION:

Before applying DC Power Supply, be sure to disconnect the Motor Leads from the

Connector P2503.

Otherwise, the Loading Motor Drive IC (IC2501) may be damaged.

Fig. 5-2

When loading without a cassette, push Portion "a" on the Holder Unit of Cassette Up

Ass'y so that the Lever clear the First Tab and Second Tab.

Fig. 5-3

20

Page 21

5.1.8. HOW TO REMOVE A JAMMED TAPE

CAUTION:

Wiper Arm Unit may be damaged or its spring may be out of place when the jammed

tape is removed by force.

Remove a jammed tape as follows:

5.1.8.1. Manual Method

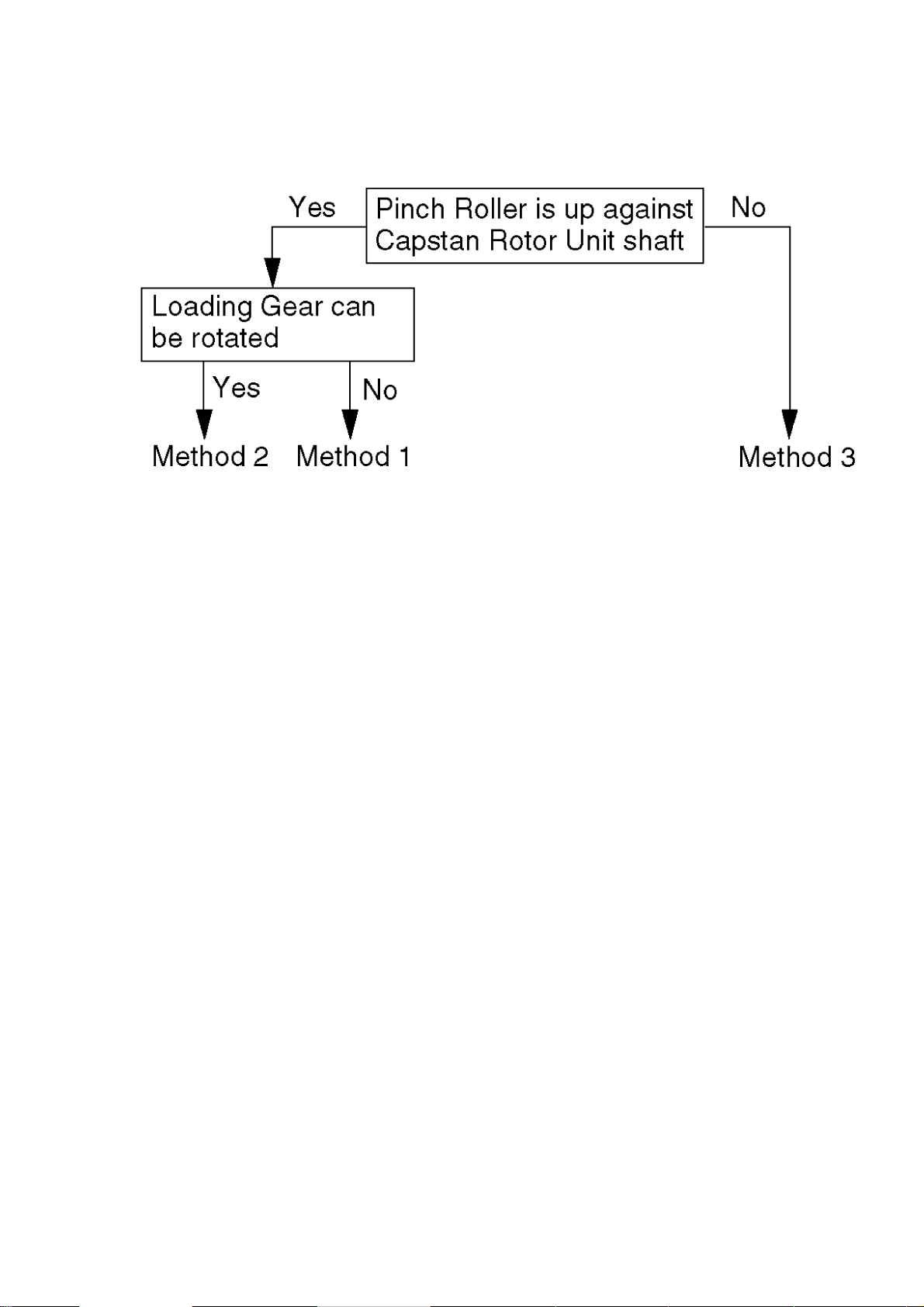

When a tape jam is encountered, check the tape loading condition and use the

21

Page 22

following procedure to remove a tape jam.

Fig. 6-1

5.1.8.1.1. Method -1:

1. Move the Pinch Roller Unit out by unhooking the Pin of Pinch Arm Unit so that the

Pinch Roller is separated from the Capstan Rotor Unit shaft.

Fig. 6-2

22

Page 23

2. Remove the tape from the tape path.

3. Rewind the tape into the cassette by rotating the Center Clutch Unit

counterclockwise.

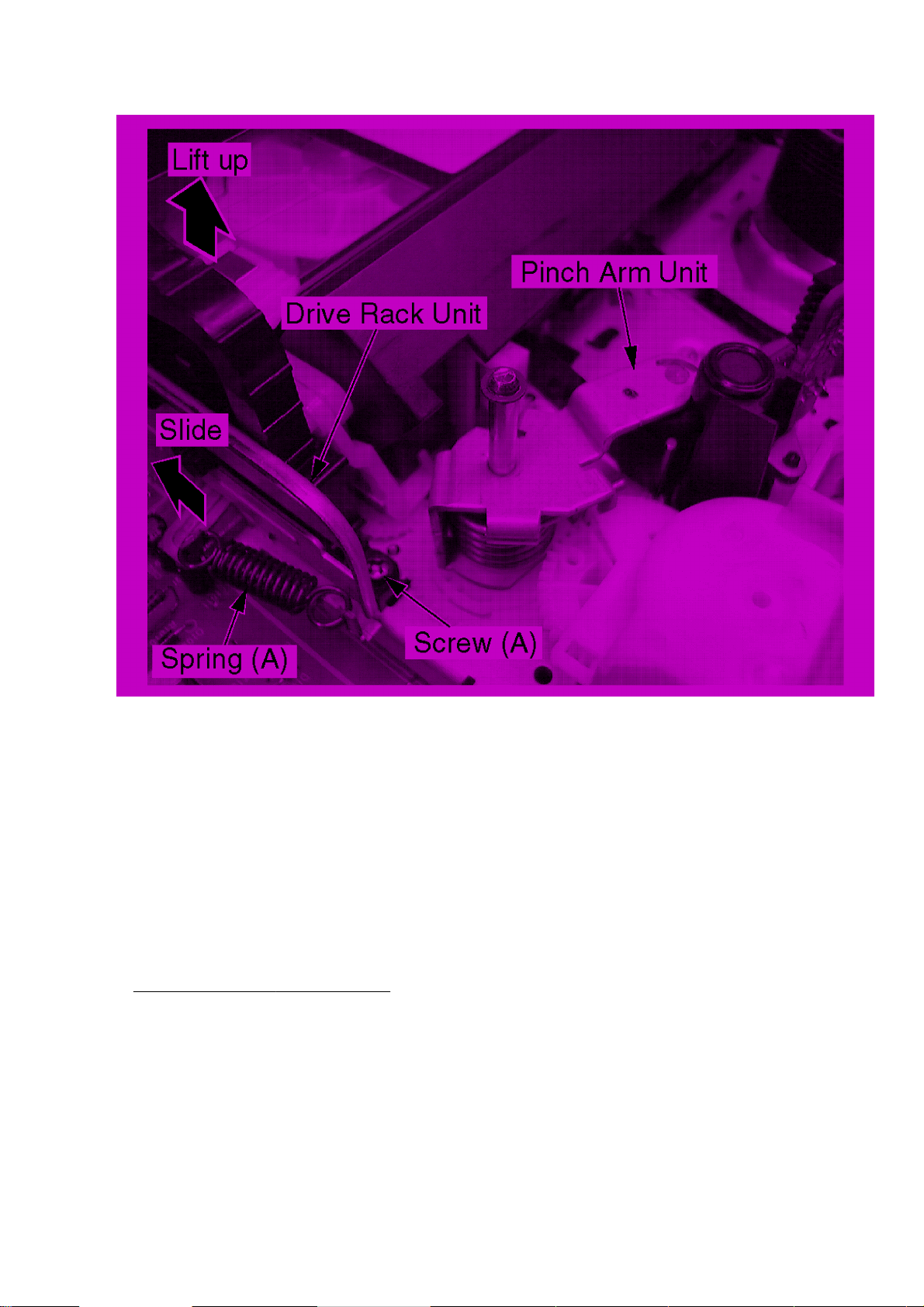

4. Unhook Spring (A) of the Drive Rack Arm.

5. Remove Screw (A).

6. Lift the Cassette Up Ass'y. While pulling the Cassette Up Ass'y out far enough so

that it clears the Drive Rack Arm, slide the Drive Rack Unit as indicated by the

arrow to remove the cassette tape from the Cassette Up Ass'y.

7. Check the cause of mechanical trouble and repair.

Fig. 6-3

23

Page 24

5.1.8.1.2. Method -2:

1. Rotate Loading Motor counterclockwise with needlenose pliers, etc. so that the

Pinch Roller is separated from the shaft of the Capstan Rotor Unit.

2. Perform Step 2 through Step 7 of Method -1.

5.1.8.1.3. Method -3:

1. Perform Step 2 through Step 7 of Method -1.

Note:

After repairing mechanical trouble, make sure that all gear alignments are correct,

especially the Wiper Arm Unit and Drive Rack Unit of Cassette Up Ass'y. (Refer to

"

EJECT Position Confirmation" in DISASSEMBLY/ASSEMBLY PROCEDURES.)

5.1.8.2. Electrical Method

Electrical method can only be performed when the mechanism is moved by rotating

the Loading Gear.

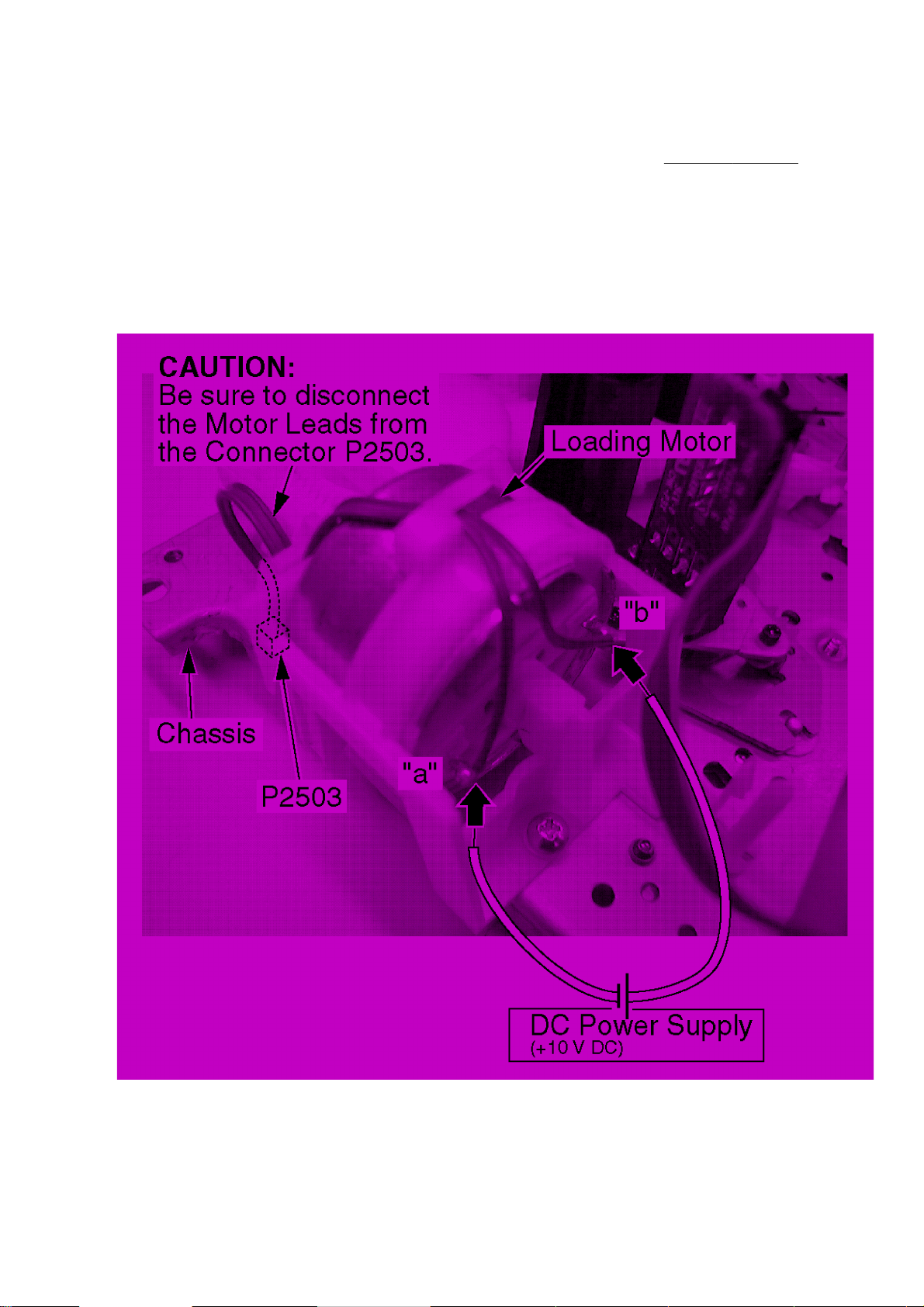

CAUTION:

1. Before applying DC Power Supply, be sure to disconnect the Motor Leads from the

Connector P2503.

Otherwise, the Loading Motor Drive IC (IC2501) may be damaged.

24

Page 25

2. If loading does not start in approx. 2 seconds after DC Power Supply is applied, DO

NOT continue to apply DC Power Supply. Instead, perform "

Manual Method."

1. Be sure to disconnect the Motor Leads from the Connector P2503.

2. Apply +10.0 V DC Power Supply to the Loading Motor terminals.

3. When the Loading Posts reach the fully unloaded position, remove the Power

Supply.

Fig. 7

4. Rewind the tape into the cassette by turning the Center Clutch Unit

counterclockwise.

5. Eject the cassette by applying +10.0 V DC Power Supply again.

25

Page 26

5.1.9. VCR Test Mode

High Voltage is inhibited by connecting Jumper J801 on the TV/VCR Main C.B.A.,

however, it is possible to check the VCR even when CRT C.B.A. and Anode Cap are

removed.

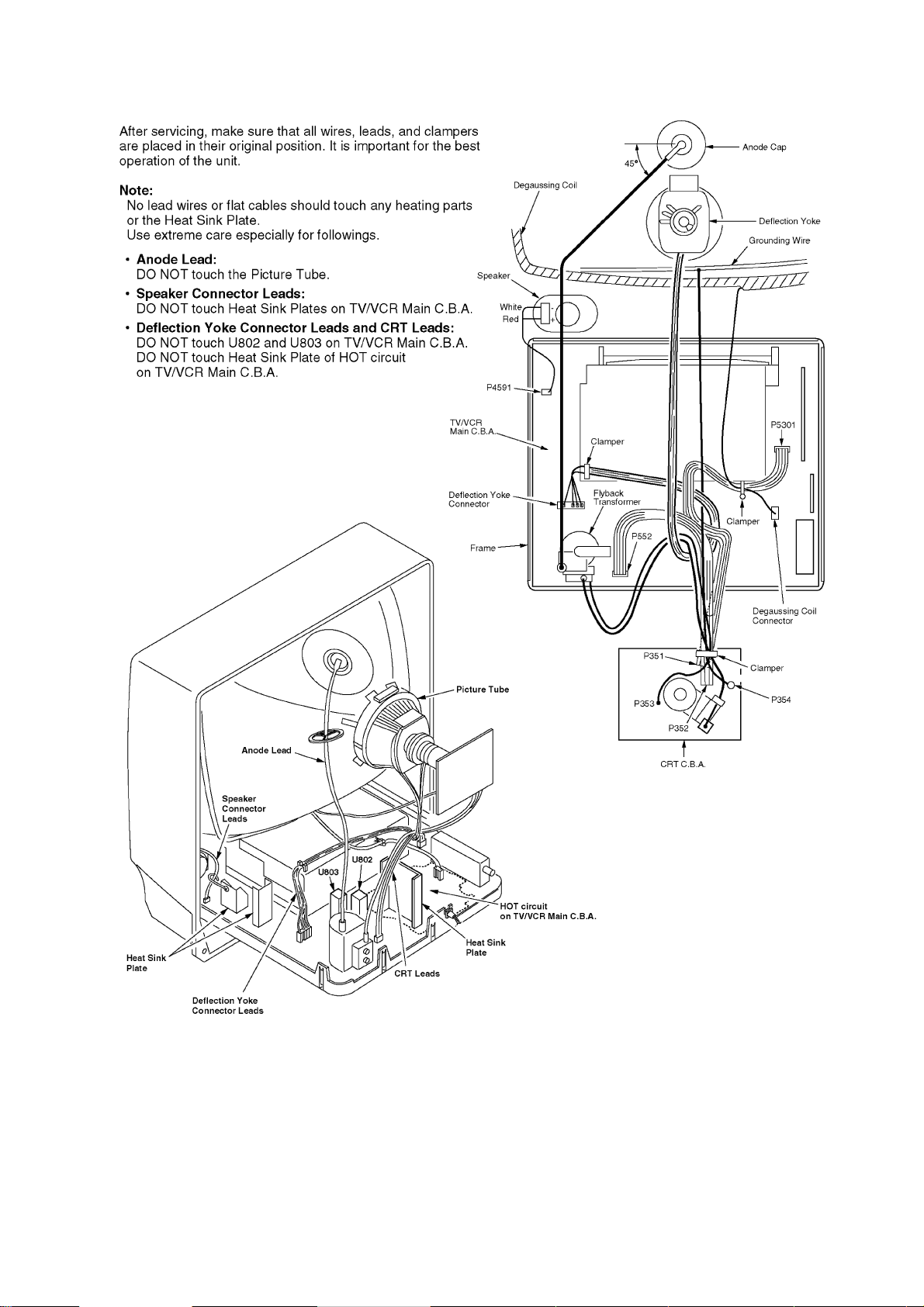

5.1.10. WIRE AND LEAD POSITION DIAGRAM

Fig. 8

26

Page 27

5.1.11. DEFEATING THE AUTO TRACKING

To defeat the Auto Tracking Function, place the instrument in the STOP mode and

place a jumper between TP6003 and TP6009 on the TV/VCR Main C.B.A. The tracking

will be placed in the neutral position.

27

Page 28

5.1.12. HOW TO SET TRACKING TO THE NEUTRAL POSITION

Ejecting the cassette tape and then reinserting it will reset the tracking to the Neutral

position.

5.1.13. BLACK SCREWS ON THE CHASSIS

Black Screws are used on the Mechanism Chassis to identify screws that require

adjustment.

5.1.14. HOW TO RESET ALL COMBINATION VCR MEMORY FUNCTIONS

To reset (clear) the select language, channel auto set and set clock functions to their

initial power on condition (power on, no cassette inserted), hold down the PLAY and

FF buttons on the unit together for more than 5 seconds.

Power will shut off.

5.1.15. HOW TO CONFIRM AUTO CLOCK SET FEATURE

1. Connect an RF cable from the output of one unit to the input of the test unit.

2. Select corresponding RF channels.

3. Playback a recording of P.B.S. channel including clock set data and confirm this

feature.

5.1.16. VARIABLE VOLTAGE ISOLATION TRANSFORMER

An Isolation Transformer should always be used during the servicing of Combination

VCR whose chassis is not isolated from the AC power line. Use a transformer of

adequate power rating as this protects the technician from accidents resulting in

personal injury from electrical shocks. It will also protect Combination VCR from

being damaged by accidental shorting that may occur during servicing.

Also, when troubleshooting the above type of Power Supply Circuit, a variable

isolation transformer is required in order to increase the input voltage slowly.

5.1.17. SPECIAL NOTE

All integrated circuits and many other semiconductor devices are electrostatically

sensitive and therefore require the special handling techniques described under the

"ELECTROSTATICALLY SENSITIVE (ES) DEVICES" section of this service manual.

5.1.18. REPLACEMENT PROCEDURE FOR LEADLESS (CHIP)

COMPONENTS

The following procedures are recommended for the replacement of the leadless

components used in this unit.

1. Preparation for replacement

28

Page 29

A. Soldering Iron

Use a pencil-type soldering iron that uses less than 30 watts.

B. Solder

Eutectic Solder (Tin 63%, Lead 37%) is recommended.

C. Soldering time

Do not apply heat for more than 4 seconds.

D. Preheating

Leadless capacitor must be preheated before installation. -(266°F ~ 302°F)

(130°C ~150°C) for about two minutes.

Note:

A. Leadless components must not be reused after removal.

B. Excessive mechanical stress and rubbing of the component electrode must be

avoided.

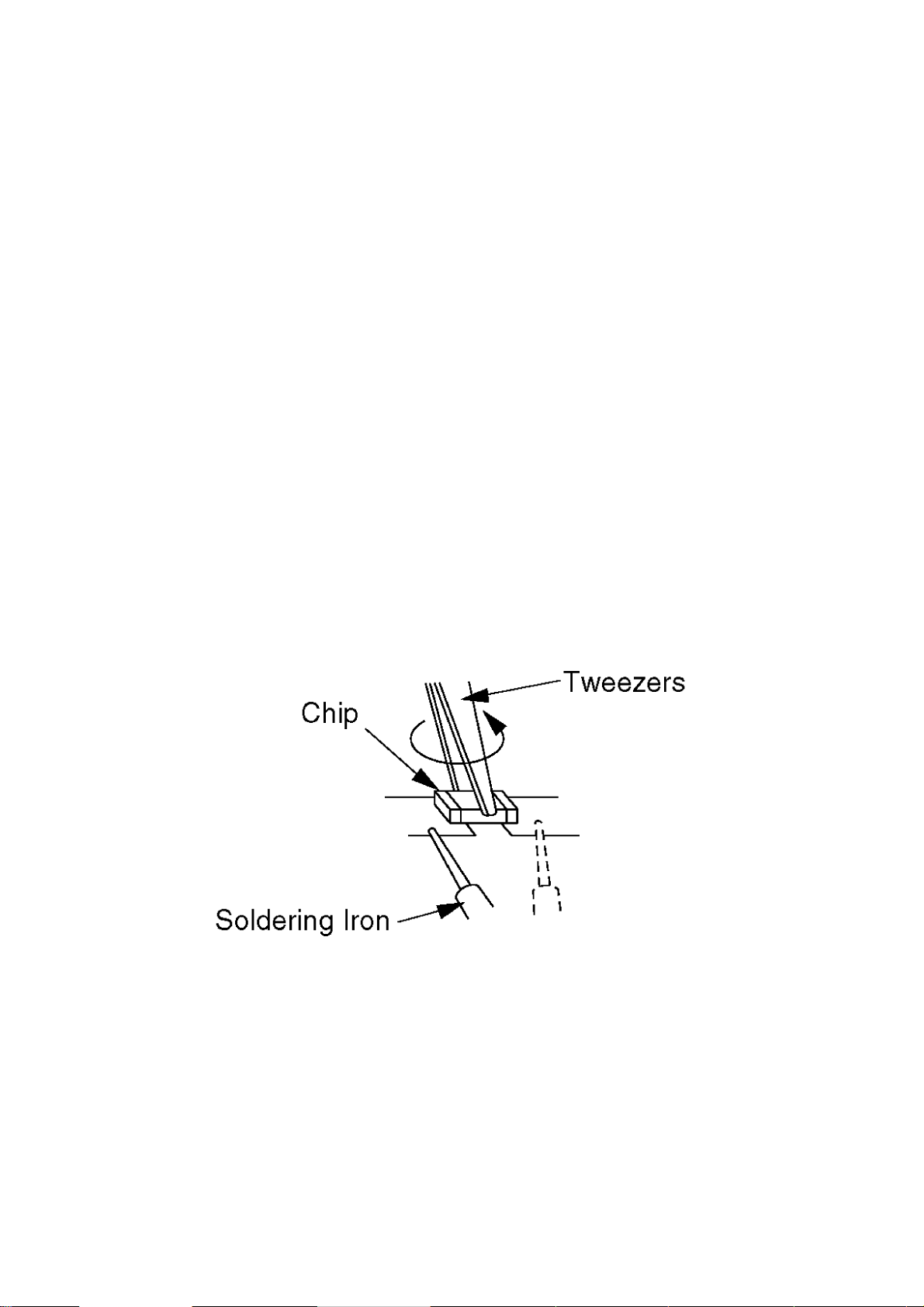

2. Removing the leadless component

Grasp the leadless component body with tweezers and alternately apply heat to

both electrodes. When the solder on both electrodes is melted, remove the

leadless component with a twisting motion.

Note:

A. Do not attempt to lift the component off the board until the component is

completely disconnected from the board by a twisting action.

B. Be careful not to break the copper foil on the printed circuit board.

Fig. 9-1

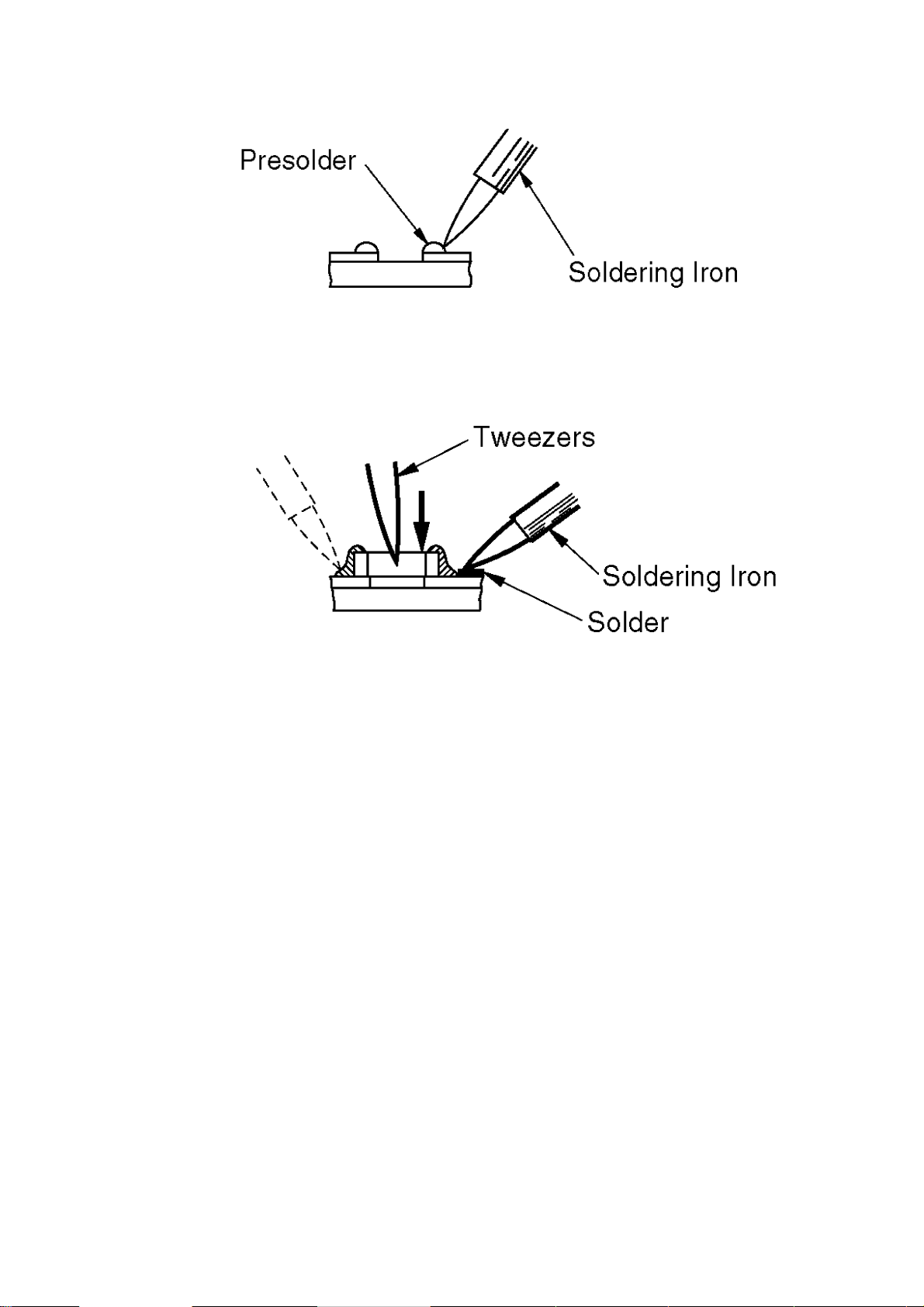

3. Installing the leadless component

A. Presolder the contact points on the circuit board.

Fig. 9-2

29

Page 30

B. Press the part downward with tweezers and solder both electrodes as shown

below.

Fig. 9-3

Note:

Do not glue the replacement leadless component to the circuit board.

5.2. IC, TRANSISTOR AND CHIP PART INFORMATION

30

Page 31

5.2.1. HOW TO READ THE IDENTIFICATION MARK OF CHIP

COMPONENTS.

31

Page 32

5.2.2. HOW TO READ THE VALUES OF THE CYLINDRICAL TYPE CHIP

COMPONENTS.

The widest color band must be read first for value.

1. RESISTOR

There are two types (ERD10LLJ... and ERD10TLJ...) of chip parts.

A. ERD10LLJ: Refer to above type.

B. ERD10TLJ: The narrow color band must be read first for value.

If this part is included in the parts list, be sure that the color band is read properly

when servicing.

2. CAPACITOR

Because of the width of the color bands, the reading direction cannot be specified.

However, the color band can be read on either side. Be sure to confirm the value

using the schematic diagram.

CAUTION :

Once chip parts are removed, they must not be reused.

Always use a new part when installing a chip part.

6. DISASSEMBLY/ASSEMBLY PROCEDURES

6.1. CABINET SECTION

6.1.1. Disassembly Flowchart

32

Page 33

Perform all disassembly procedures in the order described in the "Disassembly

Flowchart" shown below. When reassembling, use the reverse procedure.

CAUTION:

Disconnect AC plug before disassembly.

Fig. D1

33

Page 34

6.1.2. Disassembly Method

34

Page 35

35

Page 36

How to read chart shown above:

A:Order of Procedure steps.

When reassembling, perform steps(s) in reverse order.

These numbers are also used as the identification (location) No. of parts in Figures.

B: Part to be removed or installed.

C: Fig. No. showing Procedure or Part Location.

D: Identification of part to be removed, unhooked, unlocked, released, unplugged or

unsoldered.

6(S-1) = 6 Screws (S-1), 6(L-1) = 6 Locking Tabs (L-1),

(P-1) = Spring (P-1)

E: Refer to "

Notes in chart."

Fig. D2

Fig. D3

36

Page 37

Fig. D4

37

Page 38

Fig. D5

38

Page 39

6.1.2.1. Notes in chart

1. Installation of VCR Unit

CAUTION:

Opener Lever may be damaged when VCR Unit is installed, with Cassette Door-Lid

and Opener Lever of Cassette Up Ass'y set incorrectly.

A. When installing the VCR Unit, swing the Cassette Door-Lid all the way open until

the Cassette Door tab clears the Opener Lever.

39

Page 40

B. Make sure that all guide tabs are aligned properly.

Then, press the VCR Unit straight in.

Fig. D6

2. Removal of CRT Unit

Place the Unit face down on a soft cloth before removing the CRT Unit.

Installation of CRT Unit

40

Page 41

When installing Degaussing Coil, place the Degaussing Coil correct position.

Fig. D7

3. Installation of VCR Chassis Unit

When installing 2 Screws (S-5), slide the Holder Unit of the Cassette Up Ass'y

(Refer to "

METHOD FOR LOADING/UNLOADING OF MECHANISM" in SERVICE

NOTES) to tighten screws. Then, slide it back to theEJECT Position.

Make sure that Mechanism and Cassette Up Ass'y are in theEJECT Position. (Refer

to "

EJECT Position Confirmation" in DISASSEMBLY/ASSEMBLY PROCEDURES.)

4. Removal of TV/VCR Main C. B. A.

Work carefully so as not to break Sensor LED when lifting the Mechanism Chassis

and Cassette Up Ass'y.

Installation of Mechanism Chassis and Cassette Up Ass'y onto TV/VCR Main C.B.A.

A. Make sure the Mode Select SW. on the TV/VCR Main C.B.A. is inEJECT position.

If not, rotate the Mode Select SW. until the alignment projection is in theEJECT

Position.

B. Make sure the Mechanism and Cassette Up Ass'y are in theEJECT Position.

(Refer to "

EJECT Position Confirmation" in DISASSEMBLY/ASSEMBLY

PROCEDURES.)

Fig. D8

41

Page 42

C. Install the Mechanism Chassis and Cassette Up Ass'y straight onto the TV/VCR

Main C.B.A. so that the Sensor LED clears the hole in the Mechanism Chassis

and that 4 Connectors (P6201, P6202, P3001, and P4001) are aligned and seated

securely.

5. Installation of Cassette Up Ass'y

A. Confirm that the Locking Tab (L-2) under the Cassette Up Ass'y is in Hole on the

Mechanism Chassis when installing the Cassette Up Ass'y. Then, slide the

Cassette Up Ass'y towards the back.

B. When installing 2 Screws (S-7), slide the Holder Unit (Refer to "

LOADING/UNLOADING OF MECHANISM" in SERVICE NOTES) to tighten screws.

Then, slide it back to theEJECT Position.

C. Hook Spring (P-1) to the Drive Rack Arm on the Mechanism Chassis.

METHOD FOR

6.2. MECHANISM SECTION

6.2.1. Disassembly/Reassembly Method

42

Page 43

6.2.2. Inner Parts Location

Fig. J1-1

43

Page 44

6.2.3. EJECT Position Confirmation

Fig. J1-2

44

Page 45

6.2.4. Grounding Plate Unit, Full Erase Head, and Cylinder Unit

Fig. J2-1

45

Page 46

46

Page 47

6.2.4.1. Reassembly Notes

1. Adjustment of Grounding Plate Unit

A. After installing, make sure that the Grounding Plate Unit, on the top side of

mechanism chassis, is positioned on the front side of the Cylinder shaft so that

the center line of the plate is just less than 1.0 mm measured from the center of

the Cylinder shaft.

If required, adjust the plate position by loosening Screw (S-1).

Never install the Grounding Plate Unit on the rear side of the Cylinder shaft.

Incorrect positioning will cause cylinder buzz.

Fig. J2-2

47

Page 48

6.2.5. Capstan Belt, Support Angle, Intermediate Gear B, and Main Cam

Gear

Fig. J3-1

48

Page 49

49

Page 50

6.2.5.1. Reassembly Notes

1. Alignment of Main Cam Gear, Drive Rack Arm, and Main Rod

A. Confirm that the hole on Main Rod is a Through Hole with a hole on chassis.

B. Confirm that the hole on Drive Rack Arm is a Through Hole with a hole on

chassis.

C. Install the Main Cam Gear so that the projection of Main Cam Gear is in the

upward position as shown.

Fig. J3-2

50

Page 51

2. Confirmation/Alignment of Intermediate Gear B, Main Cam Gear, and Intermediate

Gear A

A. Confirm that the Hole A on Lift Gear is a Through Hole with a hole on chassis.

B. Confirm that the hole on Intermediate Gear A is aligned with the hole on Lift

Gear.

Fig. J3-3

51

Page 52

C. Install the Intermediate Gear B so that the hole on the Intermediate Gear B is

aligned with the hole on the Main Cam Gear.

Fig. J3-4

52

Page 53

3. Holes on Main Cam Gear

A. The EJECT mode Hole on Main Cam Gear should be a Through Hole with Hole A

on Support Angle in EJECT mode. The each mode Hole on Main Cam Gear

should be a Through Hole with Hole B on Support Angle in each mode.

Fig. J3-5

53

Page 54

4. Main Cam Gear Kit

A. Main Cam Gear is supplied as a Main Cam Gear Kit only (Kit No. VVGS0009).

Main Cam Gear Kit consists of a Main Cam Gear and a Main Cam Push Nut.

However, Main Cam Push Nut is available separately as a replacement part.

5. Installation of Main Cam Gear and Main Cam Push Nut

A. After installing the Support Angle, install the Main Cam Push Nut with

Needlenose Pliers etc. so that it is flush with the chassis.

There may be some slight scratches on the Shaft of Main Cam Gear, when

removing the Main Cam Gear. In case that the Main Cam Gear can be installed

securely without tottering, it is fine to use the one. If any tottering, install all

new parts.

Fig. J3-6

6. The Main Cam Push Nut is not reusable. Install a new one.

6.2.6. Center Clutch Unit, Changing Gear Spring, Changing Gear, and

Idler Arm Unit

Fig. J4-1

54

Page 55

6.2.6.1. Reassembly Notes

1. Installation of Center Clutch Unit

A. Fit the Center Clutch Unit into the Changing Gear.

Fig. J4-2

55

Page 56

6.2.7. Reel Gear and Main Rod

Fig. J5-1

56

Page 57

6.2.7.1. Reassembly Notes

1. Alignment of Main Rod and T Loading Arm Unit

A. Align the Gear of T Loading Arm Unit with Gear of Main Rod. Confirm that the

Hole on Main Rod is a Through Hole with a hole on chassis.

Fig. J5-2

57

Page 58

6.2.8. Stopper Angle, Capstan Rotor Unit, Oil Seal, Capstan Stator C.B.A.,

and MR Head

Fig. J6-1

58

Page 59

59

Page 60

6.2.8.1. Reassembly Notes

1. Application of Silicon Grease

CAUTION:

When installing the IC2501 (AN3845SC or AN3846SC) or Capstan Stator C.B.A., be

sure to apply Silicon Grease (VFK1301) as shown. Be careful not to touch other

parts with greased portion to prevent grease depletion.

Fig. J6-2

60

Page 61

61

Page 62

2. Installation of Capstan Rotor Unit and Oil Seal

A. Install the 2 Oil Seals into the Capstan Holder Unit. Then, insert the Capstan

Rotor Unit Shaft into the hole of the Capstan Holder Unit so that shaft passes

through 2 Oil Seals. Be careful not to scratch the Shaft or Capstan Holder Unit.

B. Align the bottom of Oil Seal (A) with notch line (A). Align the top of Oil Seal (B)

with notch line (B).

Fig. J6-3

6.2.9. T Loading Arm Unit and S Loading Arm Unit

Fig. J7-1

62

Page 63

6.2.9.1. Reassembly Notes

1. Alignment of T Loading Arm Unit and S Loading Arm Unit

A. Install the S Loading Arm Unit onto the chassis.

B. Install the T Loading Arm Unit so that the hole on T Loading Arm Unit is aligned

with the hole on S Loading Arm Unit.

C. Confirm that the holes on the S & T Loading Arm Unit are Through Holes with

hole on chassis.

Fig. J7-2

63

Page 64

6.2.10. T Brake Unit, Tension Control Arm Unit, T Reel Table, S Reel

Table, and Tension Arm Unit

Fig. J8-1

64

Page 65

6.2.10.1. Reassembly Notes

65

Page 66

1. How to distinguish between S Reel Table and T Reel Table

Fig. J8-2

6.2.11. Loading Post Base -T Unit and Loading Post Base -S Unit

Fig. J9

66

Page 67

6.2.12. Opener Piece, Drive Rack Arm, Pinch Arm Unit, P5 Arm Unit, and

Intermediate Gear A

Fig. J10-1

67

Page 68

6.2.12.1. Reassembly Notes

1. Installation/Alignment of Intermediate Gear A, Lift Gear and P5 Arm Unit

A. Rotate the Lift Gear so that Hole A on Lift Gear is a Through Hole with a hole on

chassis.

B. Install the Intermediate Gear A so that the hole on Intermediate Gear A is

aligned with the hole on Lift Gear.

C. Install the P5 Arm Unit so that it contacts with the tab of chassis.

68

Page 69

Fig. J10-2

2. Installation of Opener Piece

A. Install the Opener Piece so that the slot of the Opener Piece is inserted to the

Pin of Pinch Arm Unit

Fig. J10-3

69

Page 70

6.2.13. Motor Block Unit, Audio Control Head Unit, Lift Gear, Capstan

Holder Unit, and Tension Arm Boss

Fig. J11

70

Page 71

6.3. CASSETTE UP ASS'Y SECTION

71

Page 72

6.3.1. Top Plate, Wiper Arm Unit, and Holder Unit

Fig. K1-1

72

Page 73

73

Page 74

6.3.1.1. Reassembly Notes

1. Alignment of Wiper Arm Unit and Drive Rack Unit

A. Slide the Drive Rack Unit to the far right as indicated by the arrow.

B. Install the Wiper Arm Unit so that the hole on the Wiper Arm Unit is aligned with

the hole on the Drive Rack Unit.

Fig. K1-2

74

Page 75

75

Page 76

2. Installation of Holder Unit

A. Turn the Wiper Arm Unit so that the grooves on each end are aligned with the

each groove on Side Plate L and R.

B. Insert Holder Unit boss (A) and (B) into the grooves as shown in Fig. K1-1.

C. Finally, in theEJECT Position, confirm that the protrudence on the Wiper Arm

Unit is aligned with the indentation on the Drive Rack Unit.

Fig. K1-3

3. Make sure to hook the spring to the Drive Rack Arm of Mechanism chassis.

6.3.2. Opener Lever and Drive Rack Unit

Fig. K2

76

Page 77

7. ADJUSTMENT PROCEDURES

7.1. SERVICE FIXTURES AND TOOLS

77

Page 78

7.2. MECHANICAL ADJUSTMENT

7.2.1. CLEANING PROCEDURE FOR THE UPPER CYLINDER UNIT

1. While slowly turning the Upper Cylinder Unit counterclockwise by hand, gently rub

the Video Heads with a Head Cleaning Stick (VFK27) moistened with Ethanol.

When using a Cleaning Cassette, make sure to use "DRY" type only and be aware

that excessive use can shorten head life.

Fig. M1

78

Page 79

Note:

A. Do not rub vertically or apply excess pressure to the Video Heads.

Do not turn the Upper Cylinder Unit clockwise while cleaning.

B. After cleaning, use a Dry Head Cleaning Stick (VFK27) to remove any Ethanol

remaining on the cylinder tape path. Otherwise, tape damage will occur.

7.2.2. ADJUSTMENT PROCEDURES

7.2.2.1. BACK TENSION CONFIRMATION

Purpose:

To fine adjust the Back Tension so that the tape runs smoothly with a constant

tension.

Symptom of Misadjustment:

1) If the tape tension is less than the specified value, the tape cannot come into

proper contact with the Video Heads, resulting in poor picture playback.

2) If the tape tension is too high, the tape will soon be damaged.

Equipment Required:

Back Tension Meter (Made in U.S.A., Purchase Locally)

VHS Cassette Tape (120-Minute Tape)

Specification:

20 gf±2.5 gf

(0.196 N±0.025 N)

1. Play back a T120 cassette tape from the beginning for approx. 10 to 20 seconds to

79

Page 80

stabilize tape movement.

2. Insert a Tension Meter into tape path and measure the back tension.

Fig. M2-1

3. If the reading is out of specification, make sure that there is no dust or foreign

material between the Brake Pad of Tension Control Arm Unit and the S Reel Table.

After cleaning, the reading of tension measurement is still out of specification,

replace the Tension Arm Unit and the Tension Control Arm Unit.

Fig. M2-2

80

Page 81

Note:

A. Be sure that the three probes of the meter are all in solid contact with the tape,

but not touching any other parts of the mechanism.

B. It is recommended that measurements should be repeated at least three (3)

times because the tension meter is very sensitive to external vibrations.

7.2.2.2. MR HEAD GAP ADJUSTMENT

Purpose:

To properly pick up the FG Signal.

Symptom of Misadjustment:

If the FG Signal is not properly picked up, Servo Operation cannot be achieved.

Equipment Required:

Oscilloscope

Specification:

0.1 mm ~ 0.13 mm

1. Remove the VCR Chassis Unit and then place it upside down.

81

Page 82

2. Remove the TV/VCR Main C.B.A.

3. Slightly loosen Screw (A). Then set the Screwdriver (Phillips Driver) into the Hole

(A). Turn the screwdriver clockwise until the MR Head touches the rotor. Then turn

it slightly counterclockwise to make the clearance as specified.

4. Tighten Screw (A).

5. Reinstall the TV/VCR Main C.B.A.

Fig. M3-1

82

Page 83

Note:

Do not touch the outside circumference of the rotor surface with any tool and keep

magnetic material away from the rotor magnet (especially metal particles).

83

Page 84

Confirmation of Signal Level

1. Place the unit in Service Position (2). Refer to "

SERVICE POSITION" in SERVICE

NOTES.

2. Supply a Video Signal to the video input jack.

3. Insert a cassette tape and place the unit in SLP recording mode.

4. Connect the oscilloscope to Pin 9 of P6201 on the TV/VCR Main C.B.A. Confirm that

the signal level is greater than 20 mV [P-P].

Fig. M3-2

7.2.2.3. TAPE INTERCHANGEABILITY ADJUSTMENT

Note:

To perform these adjustment/confirmation procedures, set the tracking to the

neutral position.

Equipment Required:

Dual Trace Oscilloscope

VHS Alignment Tape (VFMS0003H6)

84

Page 85

Post Adjustment Driver (VFK0329)

H-Position Adjustment Driver (VFK0330)

7.2.2.3.1. ENVELOPE OUTPUT ADJUSTMENT

The height of the P2 and P3 Posts replacement part is preadjust at the factory.

Purpose:

To achieve a satisfactory picture and secure precise tracking.

Symptom of Misadjustment:

If the envelope is output poorly, much noise will appear in the picture. Then the

tracking will lose precision and the playback picture will be distorted by any slight

variation of the tracking control circuit.

Equipment Required:

Post Adjustment Driver (VFK0329)

1. Place a jumper between TP6003 and +5V(TP6009) on the TV/VCR Main C.B.A. to

defeat Auto Tracking.

2. Eject the tape and insert it again to access the Neutral Tracking position.

3. Play back the alignment tape.

4. Connect the oscilloscope to TP3002 on the Video Signal Process Section of the

TV/VCR Main C.B.A. Use TP6205 as a trigger.

5. Confirm that the RF envelope is flat enough (V1/V-max. is 0.7 or more). If not, with

Post Adjustment Driver, adjust P2 and P3 post height so that the envelope

waveform becomes as flat (V1/V-max. is 0.7 or more) as possible (No envelope

drop). If the envelope drop appears on the left-half of the waveform, adjust P2 post

height. If the envelope drop appears on the right-half of the waveform, adjust P3

post height.

CAUTION:

Overtightening P2 and P3 posts may cause the threads to strip.

Note:

It will be possible to confirm Step 5 according to following steps.

A. Press the Tracking Control Up or Down button on remote control. Make sure

that the envelope waveform remains flat. If not, readjust P2 and/or P3 post

heights.

Fig. M4-1

85

Page 86

Fig. M4-2

6. After adjustment, confirm that the tape travels without curling at P2 and P3 posts.

Fig. M4-3

86

Page 87

7. Remove the jumper after completing the adjustment procedure.

7.2.2.3.2. AUDIO CONTROL HEAD TILT ADJUSTMENT

Purpose:

To confirm that the tape runs smoothly. In particular, confirm that the tape

properly picks up the Audio Signal at the upper part of the head and the Control

Signal at the lower part of the head.

Symptom of Misadjustment:

If the tilt of the Audio Control Head is poorly adjusted, the tape will eventually be

damaged. An intermittent Blue screen may be seen in Playback.

1. Play back a T120 cassette tape and check that the tape travels smoothly between

the upper and lower guides of the P4 post.

2. If necessary, adjust Black Screw (B) clockwise until the tape begins to curl at the

lower edge of the P4 post. Then adjust the screw counterclockwise until the

curling is eliminated.

Fig. M5

87

Page 88

7.2.2.3.3. AUDIO CONTROL HEAD HEIGHT ADJUSTMENT

The height of the Audio Control Head replacement part is preset at the factory.

Purpose:

To be sure the tape runs properly along the Control Head.

Symptom of Misadjustment:

If the control signal is not properly picked up, Servo Operation cannot be

achieved. A Blue screen will be seen in Playback.

This confirmation is required when the Audio Control Head is replaced.

1. Play back a T120 cassette tape and check that the lower edge of the tape runs

approximately 0.25 mm above the lower edge of the Audio Control Head.

2. If necessary, adjust Black Screws (A) and (B) clockwise to lower the tape or

counterclockwise to raise.

Fig. M6

88

Page 89

7.2.2.3.4. AUDIO CONTROL HEAD AZIMUTH ADJUSTMENT

Purpose:

To adjust the position and height of the Audio Control Head so that it meets the

tape tracks properly.

Symptom of Misadjustment:

If the position of the Audio Control Head is not properly adjusted, the Audio S/N

Ratio is poor.

1. Connect the oscilloscope to the TP4002 on the TV/VCR Main C.B.A.

2. Play back the 6 kHz Monaural Audio portion of the alignment tape.

3. Adjust Black Screw (C) on the Audio Control Head base so that the output level is

at maximum.

89

Page 90

Fig. M7

4. Confirm the height of the Audio Control Head is proper. If not, readjust Black

Screws (A) and (B).

7.2.2.3.5. AUDIO CONTROL HEAD HORIZONTAL POSITION ADJUSTMENT

Purpose:

To adjust the Horizontal Position of the Audio Control Head.

Symptom of Misadjustment:

If the Horizontal Position of the Audio Control Head is not properly adjusted, a

maximum envelope cannot be obtained at the Neutral Position of the Tracking

Control Circuit.

1. Place a jumper between TP6003 and +5V(TP6009) on the TV/VCR Main C.B.A. to

defeat Auto Tracking.

2. Eject the tape and insert it again to access the Neutral Tracking position.

3. Play back the alignment tape.

4. Connect the oscilloscope to TP3002 on the Video Signal Process Section of the

TV/VCR Main C.B.A. Use TP6205 as a trigger.

5. Loosen the Black Screw (D) and tighten it slightly. Set the H-Position Adjustment

Driver into the Hole (A). Then slowly turn the fixture either clockwise or

counterclockwise so that the envelope is at maximum.

Fig. M8

90

Page 91

6. Tighten Black Screw (D).

7. Remove the jumper between TP6003 and +5V(TP6009).

Note:

Old type of H-Position Adjustment Driver (VFK0136) can be used for this adjustment.

7.3. ELECTRICAL ADJUSTMENT

7.3.1. TEST EQUIPMENT

To do all of these electrical adjustments, the following equipment is required.

1. Dual-Trace Oscilloscope

Voltage Range: 0.001 V to 50 V/Div.

Frequency Range: DC to 50 MHz

Probes: 10:1, 1:1

2. NTSC Video Pattern Generator

3. DVM (Digital Volt Meter)

4. MTS/SAP Signal Generator

(TV Multi-Channel Sound Modulator (U.S.A.))

5. Frequency Counter

Frequency Range: 0 to 150 MHz

6. Plastic Tip Driver and Non-Metal Driver

91

Page 92

7. Isolation Transformer (Variable)

8. VHS Alignment Tape (VFMS0003H6)

9. Degaussing Coil

10. White Pattern Generator

11. Audio Generator

7.3.2. HOW TO READ THE ADJUSTMENT PROCEDURES

Fig. E1

92

Page 93

7.3.3. 115 V ADJUSTMENT

Purpose:

To set the optimum voltage.

Symptom of Misadjustment:

The picture is dark and unit does not operate correctly.

Test Point:

TP1203, TP804 (TV/VCR Main C.B.A.)

Adjustment:

R850 (TV/VCR Main C.B.A.)

Specification:

115 VDC±0.2 VDC

Input:

Video Input Jack, Monoscope Pattern Signal

Mode:

STOP

Equipment:

DVM (Digital Volt Meter)

1. Supply a Monoscope Pattern Signal to the Video Input Jack.

2. Connect the DVM (Digital Volt Meter) to TP1203 (+) and TP804 (-) on the TV/VCR

Main C.B.A.

3. Adjust R850 (115 V ADJ) so that the voltage is 115 VDC±0.2 VDC.

7.3.4. EVR (Electronic Variable Register) ADJUSTMENT WITH THE

REMOTE CONTROL

93

Page 94

94

Page 95

7.3.4.1. EVR ADJUSTMENT ITEM

The following Items need to be adjusted for EVR adjustment.

-

PG SHIFTER ADJUSTMENT

-

SUB CONTRAST ADJUSTMENT

-

CUT OFF, DRIVE ADJUSTMENT

-

SUB COLOR/SUB TINT ADJUSTMENT

-

V. HEIGHT/H. POSITION ADJUSTMENT

-

WHITE BALANCE ADJUSTMENT

-

SUB BRIGHTNESS ADJUSTMENT

7.3.4.2. HOW TO ENTER EVR ADJUSTMENT MODE

Press and hold STOP, PLAY, and VOL DOWN buttons on the unit together over 5

seconds with no cassette inserted.

The adjustment overlay will appear.

Fig. E2-1

95

Page 96

7.3.4.2.1. How to adjust:

1. Press CH UP/DOWN key on the remote control to select control function to be

adjusted.

Important Note:

Make a note of the original value of the controls before modifying in case the

wrong control is adjusted.

2. Press VOL UP/DOWN key on the remote control so that the shaded area moves to

the value.

Fig. E2-2

3. Press CH UP/DOWN key on the remote control to adjust the value of the selected

control.

Fig. E2-3

Note:

You can select a desired channel by using the numbered keys on the remote

control in EVR adjustment mode.

4. Press VOL UP/DOWN key on the remote control so that the shaded area moves to

the control function.

Fig. E2-4

96

Page 97

5. Press CH UP/DOWN key on the remote control to select a control function for the

next adjustment if necessary.

Fig. E2-5

7.3.4.2.2. How to release from EVR Adjustment Mode:

Press and hold STOP, PLAY, and VOL DOWN buttons on the unit together over 5

seconds again or press the POWER button OFF.The adjusted value will be written to

Memory IC (IC6004).

7.3.4.3. HOW TO ENTER EVR PG SHIFTER ADJUSTMENT MODE

1. Enter EVR adjustment mode.

2. Insert the VHS Alignment Tape and playback in SP mode.

The adjustment overlay will appear.

Fig. E2-6

97

Page 98

7.3.4.3.1. How to adjust:

Press CH UP/DOWN key on the remote control to adjust the value.

Fig. E2-7

7.3.4.3.2. How to release from EVR PG Shifter Adjustment Mode:

Press STOP button or press the POWER button OFF.

The adjusted value will be written to Memory IC (IC6004).

7.3.4.4. HOW TO ENTER SERVICE MODE

1. Enter EVR adjustment mode.

2. Press DISPLAY key on the remote control for collapse scan.

Note:

Before pressing DISPLAY key on the remote control for collapse scan, select the

desired control function and move the shaded area to the value for adjustments you

will proceed.

Fig. E2-8

98

Page 99

7.3.4.4.1. How to release from Service Mode:

Press DISPLAY key again on the remote control.

7.3.5. PG SHIFTER ADJUSTMENT

Purpose:

Determine the Video Head Switching Point during Playback.

Symptom of Misadjustment:

May cause Head Switching Noise and/or Vertical Jitter.

Test Point:

TP3001 (TV/VCR Main C.B.A.),

TP6205 (TV/VCR Main C.B.A.)

Adjustment:

PG SHIFTER (EVR)

Specification:

T = 6 H±1 H (0.38 ms±0.06 ms)

Input:

----------

Mode:

SP Playback

Equipment:

Oscilloscope, VHS Alignment Tape (VFMS0003H6)

1. Enter EVR PG Shifter Adjustment mode, refer to "

SHIFTER ADJUSTMENT MODE."

2. Connect the channel-1 scope probe to TP3001 and the channel-2 scope probe to

TP6205. Use TP6205 as a trigger.

3. Adjust value so that the trailing edge of the head switching pulse is placed 6 H±1 H

(0.38 ms±0.06 ms) before the start of the vertical sync pulse.

4. Release EVR PG Shifter Adjustment Mode.

The adjusted value will be written to Memory IC (IC6004).

99

HOW TO ENTER EVR PG

Page 100

Fig. E3

7.3.6. SUB CONTRAST ADJUSTMENT

Purpose:

To set the optimum sub contrast level.

Symptom of Misadjustment:

The picture is too dark or too light.

Test Point:

Pin 5 of P6001 (TV/VCR Main C.B.A.)

or TP49 (CRT C.B.A.)

Adjustment:

SUB CONTRAST (EVR)

Specification:

3.0 V[p-p]±0.1 V[p-p]

Input:

Video Input Jack, Crosshatch Pattern Signal 1 V[p-p] (75

Mode:

STOP

ΩΩΩΩ

terminated)

100

Loading...

Loading...