Page 1

ORDER NO. MKE0503601C1

TV/DVD Combination

PV-20DF25

PV-27DF25

PV-27DF5

PV-20DF25-K

PV-27DF25-K

B6, B22

© 2005 Matsushita Kotobuki Electronics Industries

LTD. All rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

CONTENTS

Page Page

1 SAFETY PRECAUTIONS 3

1.1. GENERAL GUIDELINES

1.2. LEAKAGE CURRENT COLD CHECK

1.3. LEAKAGE CURRENT HOT CHECK

2 X-RADIATION

2.1. HORIZONTAL OSCILLATOR DISABLE CIRCUIT TEST

2.2. REPAIR PROCEDURES OF HORIZONTAL OSCILLATOR

DISABLE CIRCUIT

2.3. CIRCUIT EXPLANATION

2.4. LASER PRODUCT

2.5. PRECAUTION OF LASER DIODE

3 PREVENTION OF ELECTROSTATIC DISCHARGE (ESD) TO

ELECTROSTATICALLY SENSITIVE (ES) DEVICES

4 ABOUT LEAD FREE SOLDER (PbF)

5 SERVICE NOTES (PLEASE READ)

5.1. SERVICE NOTES

6 DISASSEMBLY/ASSEMBLY PROCEDURES

6.1. CABINET SECTION

7 ADJUSTMENT PROCEDURES

7.1. SERVICE FIXTURES AND TOOLS

7.2. ELECTRICAL ADJUSTMENT

7.3. TEST POINTS AND CONTROL LOCATION

8 SCHEMATIC DIAGRAMS

8.1. SCHEMATIC DIAGRAM AND CIRCUIT BOARD LAYOUT

NOTES

15

15

21

21

22

29

31

31

3

3

3

4

4

4

4

5

5

6

7

8

8

8.2. MAIN SCHEMATIC DIAGRAMS

8.3. DEFLECTION SCHEMATIC DIAGRAMS

8.4. OPERATION / CRT (Models : PV-20DF25 / PV-20DF25K) SCHEMATIC DIAGRAMS

8.5. CRT SCHEMATIC DIAGRAM (Models : PV-27DF25 / PV27DF25-K / PV-27DF5)

8.6. DVD MAIN / DVD SUB SCHEMATIC DIAGRAMS

8.7. INTERCONNECTION SCHEMATIC DIAGRAM

8.8. VOLTAGE CHART

9 CIRCUIT BOARD LAYOUT

9.1. MAIN C.B.A.

9.2. OPERATION C.B.A.

9.3. DEFLECTION / CRT C.B.A.

9.4. DVD MAIN / DVD SUB C.B.A.

10 B LOCK DIAGRAMS

11 EXPLODED VIEWS

11.1. DVD SECTION

11.2. CHASSIS FRAME SECTION (1)

11.3. CHASSIS FRAME SECTION (2)

11.4. CHASSIS FRAME SECTION (3)

11.5. PACKING PARTS AND ACCESSORIES SECTION

12 REPLACEMENT PARTS LISTS

12.1. REPLACEMENT NOTES

12.2. MECHANICAL REPLACEMENT PARTS LIST

12.3. ELECTRICAL REPLACEMENT PARTS LIST

32

39

40

41

42

47

48

51

51

52

53

54

55

67

67

68

69

70

71

72

72

73

74

2

Page 3

1 SAFETY PRECAUTIONS

1.1. GENERAL GUIDELINES

1. IMPORTANT SAFETY NOTICE

There are special components used in this equipment

which are important for safety. These parts are marked by

in the Schematic Diagrams, Circuit Board Layout,

Exploded Views and Replacement Parts List. It is essential

that these critical parts should be replaced with

manufacturer’s specified parts to prevent X-RADIATION,

shock, fire, or other hazards. Do not modify the original

design without permission of manufacturer.

2. An Isolation Transformer should always be used during the

servicing of Combination TV/DVD whose chassis is not

isolated from the AC power line. Use a transformer of

adequate power rating as this protects the technician from

accidents resulting in personal injury from electrical shocks.

It will also protect Combination TV/DVD from being

damaged by accidental shorting that may occur during

servicing.

3. When servicing, observe the original lead dress, especially

the lead dress in the high voltage circuits. If a short circuit is

found, replace all parts which have been overheated or

damaged by the short circuit.

4. After servicing, see to it that all the protective devices such

as insulation barriers, insulation papers, shield, and

isolation R-C combinations are properly installed.

5. Before turning the receiver on, measure the resistance

between B+ line and chassis ground. Connect (-) side of an

ohmmeter to the B+ lines, and (+) side to chassis ground.

Each line should have more resistance than specified, as

follows :

B+ Line Minimum Resistance

130 V 110 Ω (Cold chassis ground)

28 V 180 Ω (Cold chassis ground)

220 V 1 kΩ (Cold chassis ground)

6. When the TV set is not used for a long period of time,

unplug the power cord from the AC outlet.

7. Potentials, as high as 33.0 kV is present when this TV set

is in operation. Operation of the TV set without the rear

cover involves the danger of a shock hazard from the TV

set power supply. Servicing should not be attempted by

anyone who is not thoroughly familiar with the precautions

necessary when working on high voltage equipment.

Always discharge the anode of the picture tube to the CRT

ground of receiver before handling the tube.

8. After servicing make the following leakage current checks to

prevent the customer from being exposed to shock

hazards.

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

1.2. LEAKAGE CURRENT COLD

CHECK

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2. For physically operated power switches, turn power on.

Otherwise skip step 2.

3. Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the receiver, such as screwheads, connectors, etc.

When the exposed metallic part has a return path to the

chassis, the reading should be between 1 MΩ and 12 MΩ.

When the exposed metal does not have a return path to the

chassis, the reading must be infinity.

1.3. LEAKAGE CURRENT HOT

CHECK

1. Plug the AC cord directly into the AC outlet.

Do not use a isolation transformer for this check.

2. Connect a 1.5 kΩ, 10 W resistor, in parallel with a 0.15 µF

capacitor, between each exposed metallic part on the set

and a good earth ground, as shown in Figure 1.

3. Use an AC voltmeter, with 1 kΩ/V or more sensitivity, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the

above measurements.

6. The potential at any point should not exceed 0.75 V RMS.

A leakage current tester (Simpson Model 229 equivalent)

may be used to make the hot checks. Leakage current must

not exceed 1/2 mA. In case a measurement is outside of

the limits specified, there is a possibility of shock hazard,

and the receiver should be repaired and rechecked before

it is returned to the custom er.

Figure 1

3

Page 4

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

2 X-RADIATION

WARNING :

1. The potential source of X-Radiation in TV sets is the High

Voltage section and the picture tube.

2. When using a picture tube test fixture for service, ensure

that the fixture is capable of handling 33.0 kV without

causing X-Radiation.

NOTE:

It is important to use an accurate periodically calibrated high

voltage meter.

1. Reduce the brightness to minimum.

2. Set the SERVICE switch to SERVICE.

3. Measure the High Voltage. The meter reading should

indicate 28.0 kV±1.5 kV (For model with 20 inch CRT), 31.0

kV±2.0 kV (For model with 27 inch CRT).

If the meter indication is out of tolerance, immediate service

and correction is required to prevent the possibility of

premature component failure.

4. To prevent an X-Radiation possibly, it is essential to use the

specified picture tube.

2.1. HORIZONTAL OSCILLATOR

DISABLE CIRCUIT TEST

SERVICE WARNING :

The test must be made as a final check before set is returned

to the customer.

2.2. REPAIR PROCEDURES OF

HORIZONTAL OSCILLATOR

DISABLE CIRCUIT

1. Connect a DC voltmeter between capacitor C513 (+) on the

Main circuit board and chassis ground.

2. If approximately +21.5 V (For model with 20 inch CRT),

+20.0 V (For model with 27 inch CRT) is not present at that

point when 120 V AC is applied, find the cause. Check

R508, R503, R5504, D5505, D503, C513 and C5507.

3. Carefully check above specified parts and related circuits

and parts. When the circuit is repaired, try the horizontal

oscillator disable circuit test again.

2.3. CIRCUIT EXPLANATION

2.3.1. HORIZONTAL OSCILLATOR

DISABLE CIRCUIT

The positive DC voltage, supplied from the D503 cathode for

monitoring high voltage, is applied to the IC5301 Pin 11 through

R508, R503 and R5504. Under normal conditions, the voltage

at IC5301 Pin 11 is less than approx. 6 V. If the high voltage at

Flyback Transformer Pin 5 exceeds the specified voltage, the

positive DC voltage which is supplied from the D503 cathode

also increases. The increased voltage is applied to IC5301 Pin

11 through R508, R503 and R5504. Due to the increased

voltage at IC5301 Pin 11, the horizontal oscillator frequency

increases, the picture goes out of horizontal sync, the beam

current decreases and the picture become dark in order to

keep X-radiation under specification.

CONFIRMATION OF X-RAY MOVEMENT

1. Turn off TV set.

2. Connect the circuit below between TP554 and TP553 on

the Deflection C.B.A.

Figure 2

3. Turn on SW1 and then turn on the set. Confirm that the

picture is on the screen properly.

4. Confirm that the picture goes out of horizontal sync while

getting down by varying VR.

5. If this does not occur, it means that X-ray protect circuit is

not operating. Further confirmation and repair is required.

Figure 3

4

Page 5

2.4. LASER PRODUCT

CLASS I LASER PRODUCT

· This equipment is certified to comply with DHHS Rules 21

CFR Chapter 1, Subchapter J in effect as of date of

manufacture. (Only for U.S.A.)

This equipment is classified as a Class I (Class 1) level LASER

Product and there is no hazardous LASER radiation with the

safety protection.

Caution:

Use of controls or adjustments or performance of

procedures other than those specified herein may result in

hazardous radiation exposure.

Never touch the internal parts in order to avoid EXPOSURE TO

VISIBLE LASER RADIATION.

Unplug the AC power cord to the equipment when opening the

top cover.

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

When the power switch is On, do not place your eyes close to

the front panel opening door or the other openings to look into

the interior unit.

LASER Specification

Class I level A LASER Product (Class 1 level A LASER

Product)

Wave Length: 640 - 677 nm (at DVD)

770 - 810 nm (at CD)

Laser Power: No hazardous radiation is emitted with

the safety protection.

2.5. PRECAUTION OF LASER

DIODE

CAUTION:

This unit utilizes a class III a laser. Visible laser radiation is

emitted from the optical pickup lens when the unit is turned

on:

1. Do not look directly into the pickup lens.

2. Do not use optical instruments to look at the pickup lens.

3. Do not adjust the preset variable resistor on the optical

pickup.

4. Do not disassemble the optical pickup unit.

5. If the optical pickup is replaced, use the manufactures

specified replacement pickup only.

6. Use of control or adjustment or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

5

Page 6

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

3 PREVENTION OF ELECTROSTATIC DISCHARGE (ESD)

TO ELECTROSTATICALLY SENSITIVE (ES) DEVICES

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors are

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap, which

should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable

conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION:

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

"NOTEtoCATVsysteminstaller:

This reminder is provided to call the CATV system installer’s attention to Article 820-40 of the NEC that provides guidelines for

proper grounding and, in particular, specifies that the cable ground shall be connected to the grounding system of the building,

as close to the point of cable entry as practical."

6

Page 7

4 ABOUT LEAD FREE SOLDER (PbF)

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

7

Page 8

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

5 SERVICE NOTES (PLEASE READ)

5.1. SERVICE NOTES

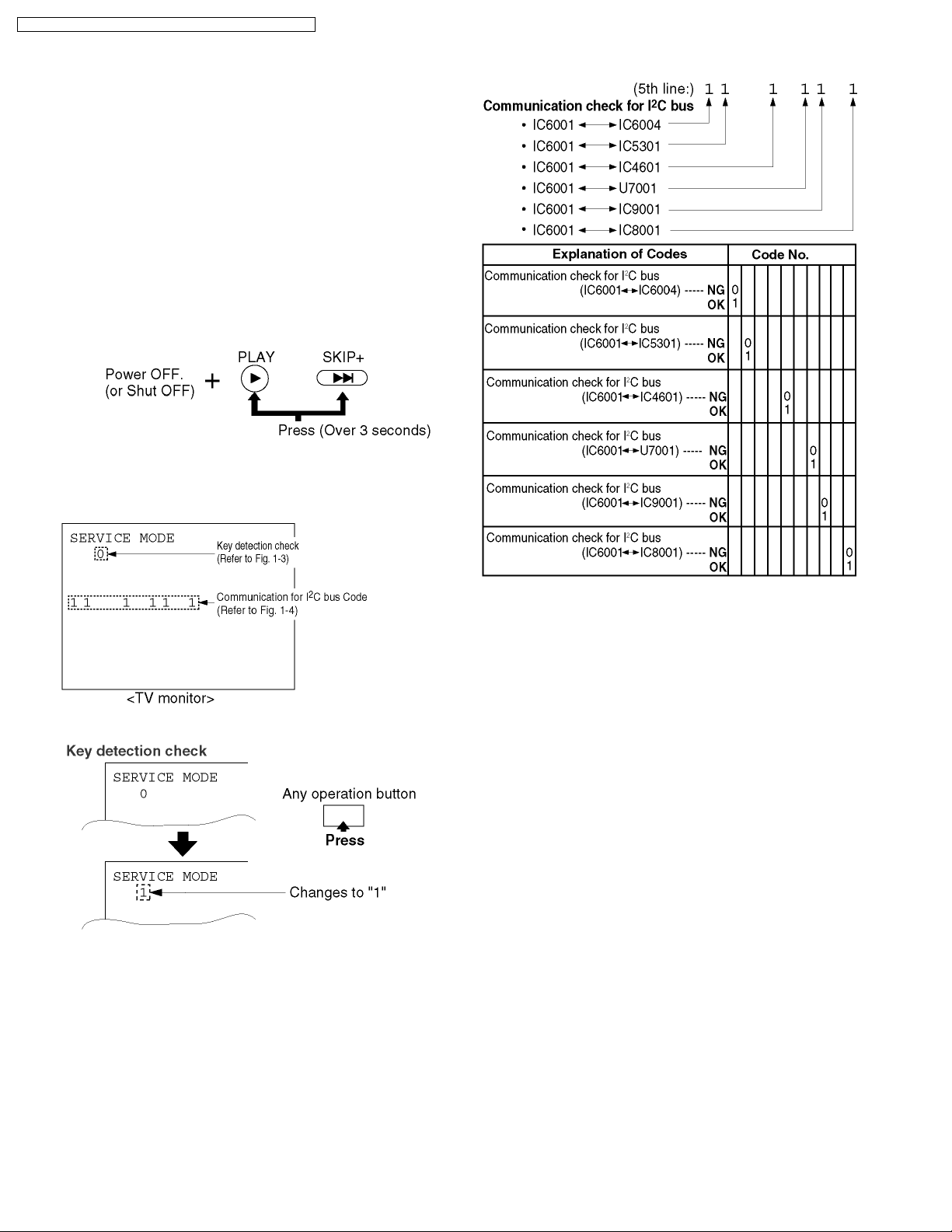

5.1.1. SIMPLIFIED FAULT FINDING DATA

Simplified Self-Diagnostic System facilitates finding the cause

of the fault. The Communication for I

displayed on the TV screen.

The Simplified Fault finding data is stored in the Memory IC

(IC6004). This data is cleared after it is displayed, and then the

POWER button is pressed back on.

1. With power turned off, press PLAY and SKIP+ buttons on

the unit together for over 3 seconds.

Fig. 1-1

2. TV power comes on and the unit goes into service mode.

The Communication for I

2

C bus code will be displayed.

2

C bus code will be

Fig. 1-4

Fig. 1-2

Fig. 1-3

Note:

Press any operation button except for POWER or PLAY

buttons on either the unit, or DVD key on the remote to

detect that a key has been pressed. The 3rd digit

changes to "1" only when key is detected.

8

Page 9

5.1.2. USAGE SCREEN MODE

This function is displayed on the TV monitor:

· the total AC plugged in AC socket (in days)

· the total elapsed "DVD play" time (in hours).

1. With power turned, press STOP button on the unit and 7

key on the remote together.

The USAGE SCREEN will be displayed on the TV Monitor.

Fig. 2

Note:

1. After replacing the DVD Unit, press ADD/DLT button on

remote in this mode. Only Total elapsed time "DVD Play"

time (in hours) will be cleared to 0.

2. To release from Usage Screen Mode, press any operation

button or insert a cassette tape in this mode. The unit will

return to normal operation mode.

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

5.1.4. METHOD FOR EJECTING THE DVD

TRAY MANUALLY

1. Insert a Screwdriver or similar object into the Eject hole.

2. Press it gently, and then pull the Tray fully out.

Fig. 4

5.1.3. GROUNDING FOR

ELECTROSTATIC BREAKDOWN

Prevention

1. Human body grounding

Use the antistatic wrist strap to discharge the static

electricity from your body.

2. Work table grounding

Put a conductive material (sheet) or steel sheet on the area

where the optical pickup is placed and ground the sheet.

Caution:

The static electricity of your clothes will not be grounded

through the wrist strap. So take care not to let your clothes

touch the optical pickup.

Fig. 3

9

Page 10

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

5.1.5. DVD SERVICE MODE

This unit has a Self-Diagnostic function which detects a

problem or malfunction within the unit and displays it on the TV

screen.

5.1.5.1. How to enter DVD Service Mode

1. Set the unit to DVD mode.

2. Press and hold the STOP, SKIP+, and VOL- buttons on the

unit together for over 5 seconds. The adjustment overlay

will appear on the TV screen.

Fig. 5-1

3. Press the DISPLAY key on the remote control to enter DVD

Service Mode I.

defective by checking the value of JITTER and the value of

LASER (current).

Fig. 5-2

4. Press the LEFT or RIGHT key on the remote again to enter

DVD Service Mode II.

Fig. 5-3

Note:

a. After replacing the DVD Unit, press the CLEAR key

on the remote in this mode. The total elapsed "Disc

Motor on" time (in hours/minutes) will be cleared to

0.

b. If 01 or 02 is always displayed in 9 DM STATUS,

replace the DVD Unit because the Disc Motor is

defective.

5. To confirm the value of JITTER and the value of LASER

(current), insert the DVD Test Disc into the DVD Unit.

6. To release from this mode, turn off the power.

5.1.5.2. Troubleshooting hint (standard)

for this mode

It can be determine whether the DVD Mechanism Unit is

10

Page 11

5.1.6. SERVICE POSITION

CAUTION:

1. HOT CIRCUIT (Primary circuit) exists on the Main

C.B.A.

Use extreme care to prevent accidental shock when

servicing.

2. Before connecting the AC plug, be sure to confirm the

connection between the Connector P502 on the

Deflection C.B.A. and P851/P852 on the Main C.B.A.

Otherwise, some electrical parts may be damaged due

to a sudden power surge.

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

5.1.6.1.2. Service Position (2)

1. Remove the Rear Cover. Then, turn the DVD Ass´y to the

right.

2. Connect the DVD Main C.B.A. using the Extension Cable

16P.

5.1.6.1. How to obtain Service Position

for Combination TV/DVD models

To obtain these Service Positions, the 2 Extension Cables 13P

(LSUA0047) and 16P (LSUA0048) are necessary.

5.1.6.1.1. Service Position (1)

1. Remove the Rear Cover. Then, pull the DVD Ass´y out and

place it upright.

Fig. 6-2

5.1.6.1.3. Service Position (3)

1. Remove the Rear Cover. Then, pull out the DVD Ass´y.

2. Place the Deflection C.B.A. and the Main C.B.A. upright.

Then, connect them using the Extension Cable 13P.

Fig. 6-1

Fig. 6-3

11

Page 12

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

5.1.7. HOT CIRCUIT

Primary circuit exists on the Main C.B.A.

This circuit is identified as " HOT " on the C.B.A. and in the

Service Manual. Use extreme care to prevent accidental shock

when servicing.

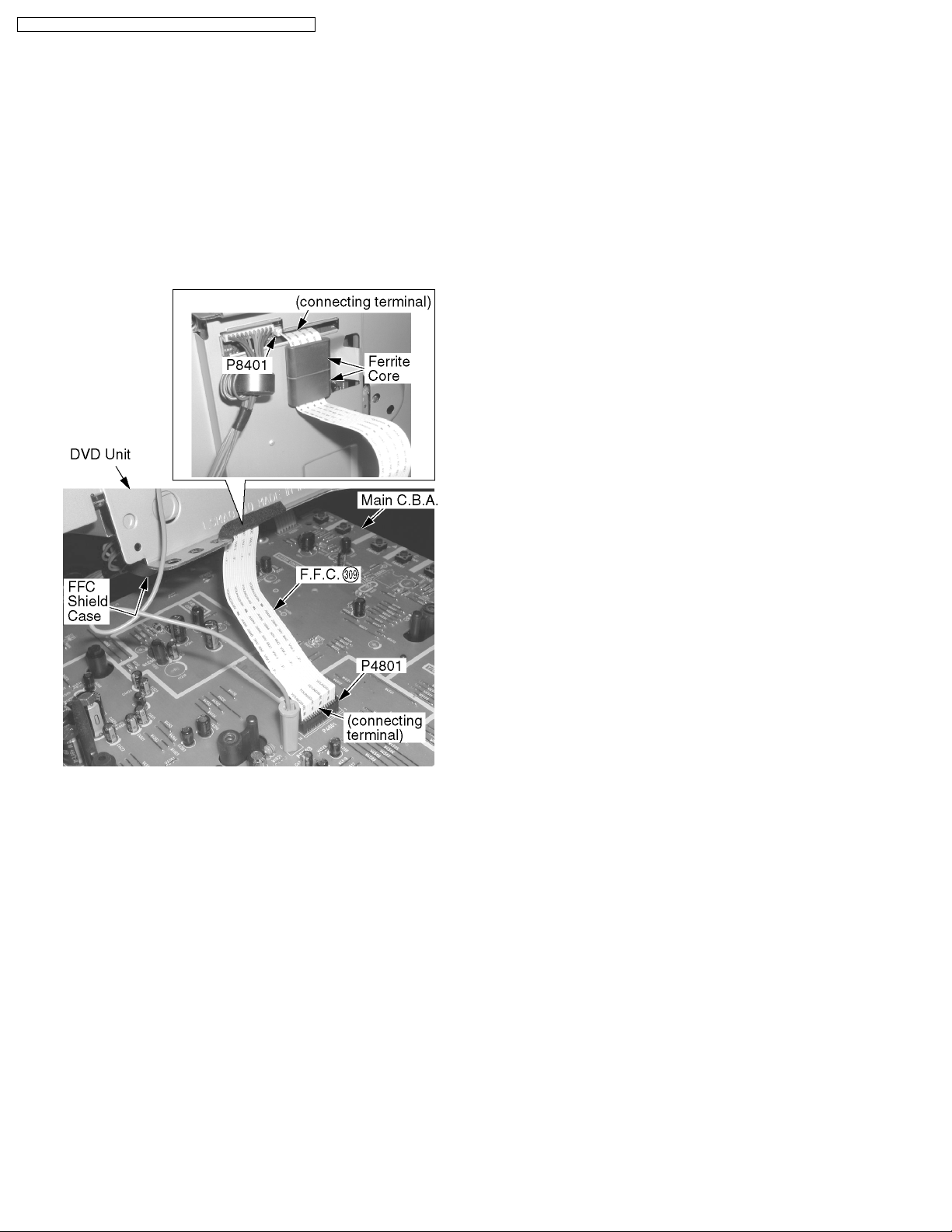

5.1.8. F.F.C. CONNECTION NOTE

5.1.8.1. F.F.C. between the DVD Unit

(DVD Main C.B.A.) and the Main

C.B.A.

Be careful with the direction of F.F.C. to connector as shown.

Fig. 7

12

Page 13

5.1.9. WIRE AND LEAD POSITION DIAGRAM

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

Fig. 8

13

Page 14

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

5.1.10. HOW TO RESET ALL

COMBINATION TV/DVD MEMORY

FUNCTIONS

To reset (clear) the select language, channel auto set and set

clock functions to their initial power on condition, hold down the

PLAY and SKIP- buttons of operation panel on the unit together

for more than 5 seconds.

Power will shut off.

5.1.11. HOW TO CONFIRM AUTO CLOCK

SET FEATURE

1. Connect an RF cable from the output of one unit to the input

of the test unit.

2. Select corresponding RF channels.

3. Playback a recording of P.B.S. channel including clock set

data and confirm this feature.

5.1.12. VARIABLE VOLTAGE ISOLATION

TRANSFORMER

An Isolation Transformer should always be used during the

servicing of Combination TV/DVD whose chassis is not isolated

from the AC power line. Use a transformer of adequate power

rating as this protects the technician from accidents resulting in

personal injury from electrical shocks. It will also protect

Combination TV/DVD from being damaged by accidental

shorting that may occur during servicing.

Also, when troubleshooting the above type of Power Supply

Circuit, a variable isolation transformer is required in order to

increase the input voltage slowly.

5.1.13. SPECIAL NOTE

All integrated circuits and many other semiconductor devices

are electrostatically sensitive and therefore require the special

handling techniques described under the

"ELECTROSTATICALLY SENSITIVE (ES) DEVICES" section

of this service manual.

5.1.14. MODEL NO. IDENTIFICATION

MARK

Use Marks shown in the chart below to distinguish the different

models included in this Service Manual.

14

Page 15

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

6 DISASSEMBLY/ASSEMBLY PROCEDURES

6.1. CABINET SECTION

6.1.1. Disassembly Flowchart

Perform all disassembly procedures in the order described in the "Disassembly Flowchart" shown below. When reassembling, use

the reverse procedure.

CAUTION:

1. Disconnect AC plug before disassembly.

2. Before connecting the AC plug, be sure to confirm the connection between the Connector P502 on the Deflection C.B.A.

and P851/P852 on the Main C.B.A. Otherwise, some electrical parts may be damaged due to a sudden power surge.

Fig. D1

15

Page 16

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

Fig. D2

16

Page 17

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

Fig. D3

17

Page 18

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

Fig. D4

18

Page 19

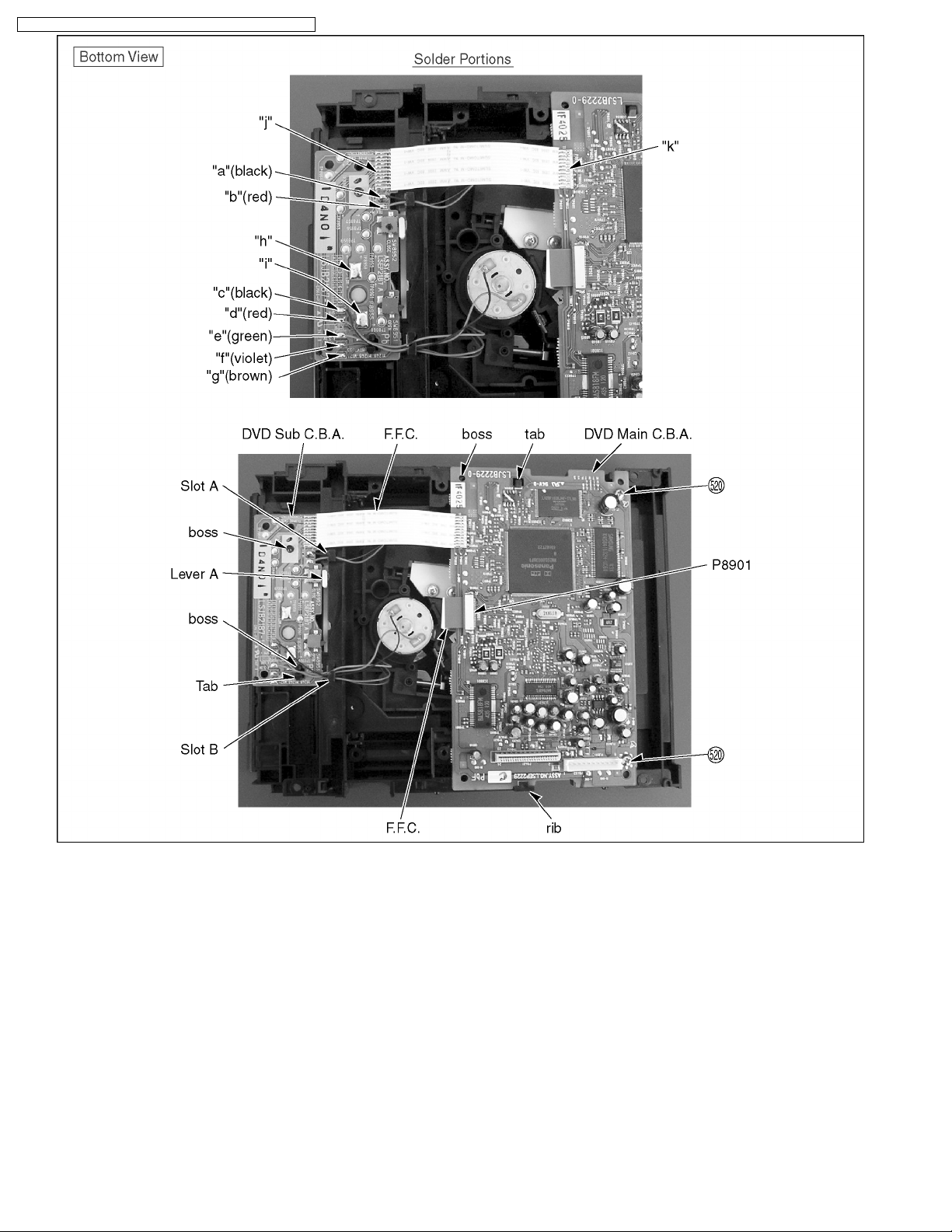

6.1.1.1. Notes in chart

1. Removal of DVD Ass’y

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

Fig. D5

2. Removal of Color Picture Tube Unit

Place the Unit face down on a soft cloth before removing the Color Picture Tube Unit.

3. Removal of DVD Sub C.B.A.

a. Remove solder portions "a, b, c, d, e, f, g, h, i, j" on the DVD Sub C.B.A.

b. Remove the DVD Sub C.B.A. while releasing the Locking Tab.

Installation of DVD Main C.B.A. and DVD Sub C.B.A.

a. Confirm that the Lever A is positioned as shown, and install the DVD Sub C.B.A. with the Locking Tab and 2 bosses.

b. Install the DVD Main C.B.A. with the Locking Tab and the rib.

c. Pass the leads through the slots A and B.

d. Solder portions "a, b, c, d, e, f, g, h, i, j, k" on the C.B.A.

Note:

Solder portions "h" and "i" while pushing down the DVD Sub C.B.A. securely.

e. Connect the F.F.C.s to Connectors P8901 on the DVD Main C.B.A.

f. Tighten the 2 Screws (520).

19

Page 20

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

Fig. D6

20

Page 21

7 ADJUSTMENT PROCEDURES

7.1. SERVICE FIXTURES AND TOOLS

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

21

Page 22

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

7.2. ELECTRICAL ADJUSTMENT

NOTE:

Following Adjustments have been preadjusted at factory and

are not required.

· Purity Adjustment

· Convergence Adjustment

7.2.1. TEST EQUIPMENT

To do all of these electrical adjustments, the following

equipment is required.

1. Dual-Trace Oscilloscope

Voltage Range: 0.001 V to 50 V/Div.

Frequency Range: DC to 50 MHz

Probes: 10:1, 1:1

2. NTSC Video Pattern Generator

3. Isolation Transformer (Variable)

4. Degaussing Coil

5. White Pattern Generator

7.2.3. EVR (Electronic Variable Register)

ADJUSTMENT WITH THE REMOTE

CONTROL

This unit has electronic technology using I2C Bus concept.

The following control functions are adjusted by using "On

Screen Displays" and the remote control instead of adjusting

mechanical controls (VR).

7.2.2. HOW TO READ THE ADJUSTMENT

PROCEDURES

Fig. E1

7.2.4. EVR ADJUSTMENT ITEM

The following Items need to be adjusted for EVR adjustment.

· SUB CONTRAST ADJUSTMENT

· FOCUS, SCREEN, CUT OFF, DRIVE ADJUSTMENT

· SUB COLOR/SUB TINT ADJUSTMENT

· DEFLEC TION DISTORTION CORRECTION

ADJUSTMENT

· WHITE BALANCE ADJUSTMENT

· SUB BRIGHTNESS ADJUSTMENT

7.2.5. HOW TO ENTER EVR

ADJUSTMENT MODE

Press and hold STOP, SKIP + and VOL - buttons on the unit

together over 5 seconds.

The adjustment overlay will appear to Enter EVR adjustment

mode.

Fig. E2-1

7.2.5.1. How to adjust:

1. Press UP/DOWN key on the remote control to

select control function to be adjusted.

22

Page 23

Important Note:

Make a note of the original value of the controls

before modifying in case the wrong control is

adjusted.

2. Press RIGHT/LEFT

that the shaded area moves to the value.

3. Press UP/DOWN key on the remote control to

adjust the value of the selected control.

key on the remote control so

Fig. E2-2

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

7.2.5.3. HOW TO ENTER SERVICE MODE

1. Set the unit to TV Mode.

2. Enter EVR adjustment mode.

3. Press DISPLAY key on the remote control for collapse

scan.

Note:

Before pressing DISPLAY key on the remote control for

collapse scan, select the desired control function and move

the shaded area to the value for adjustments you will

proceed.

Fig. E2-6

Fig. E2-3

Note:

You can select a desired channel by using the

numbered keys on the remote control in EVR

adjustment mode.

4. Press RIGHT/LEFT

that the shaded area moves to the control function.

5. Press UP/DOWN key on the remote control to

select a control function for the next adjustment if

necessary.

key on the remote control so

Fig. E2-4

Fig. E2-5

7.2.5.4. How to release from Service

Mode:

Press DISPLAY key again on the remote control.

7.2.5.2. How to release from EVR

Adjustment Mode:

Press and hold STOP, SKIP + and VOL - buttons on the unit

together over 5 seconds again or press the POWER button

OFF to release EVR adjustment mode. The adjusted value will

be written to Memory IC (IC6004).

23

Page 24

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

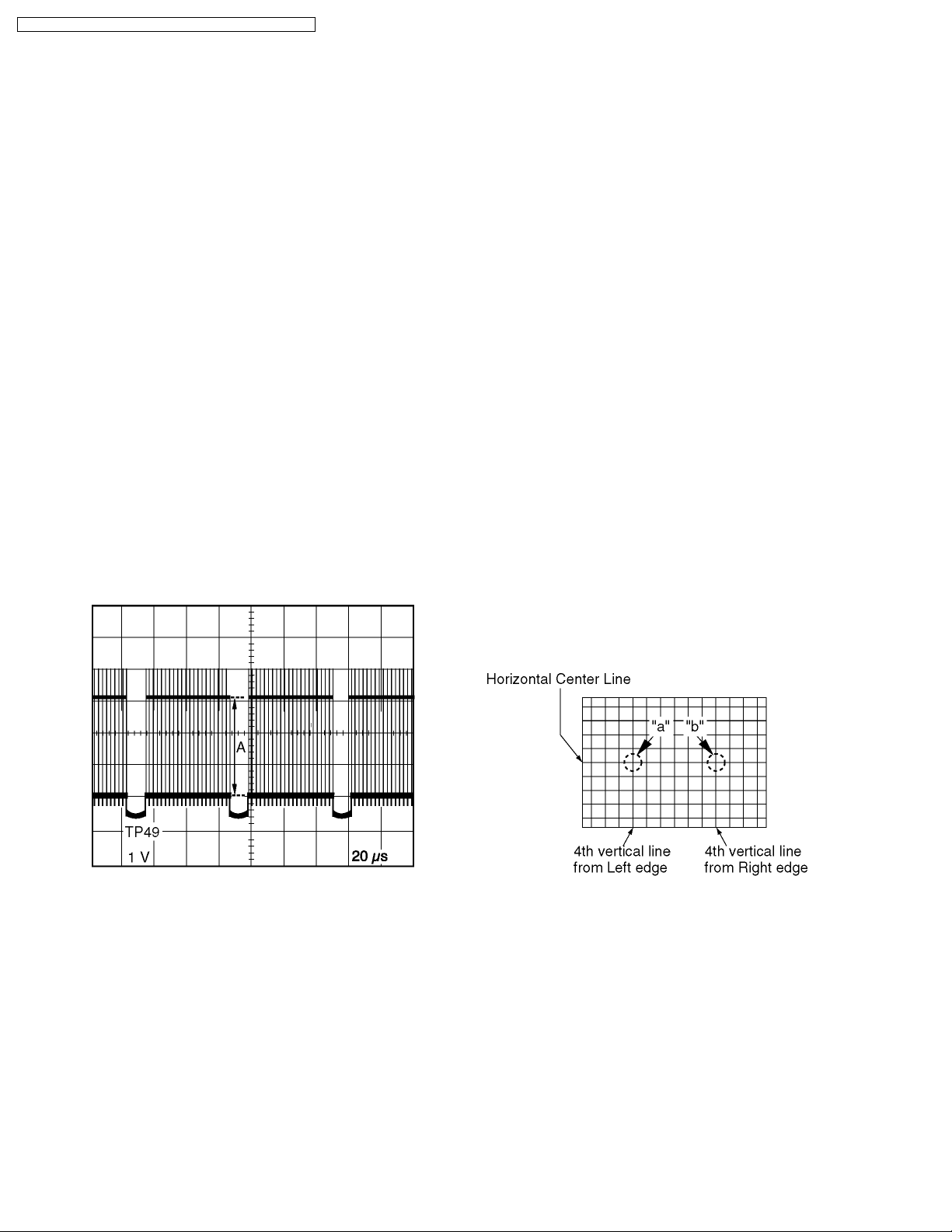

7.2.6. SUB CONTRAST ADJUSTMENT

Purpose: To set the optimum sub contrast level.

Symptom of

Misadjustment:

Test Point : TP49 (CRT C.B.A.)

Adjustment : SUB CONTRAST (EVR),

Specification : Refer to descriptions below.

Input : Video Input Jack,

Mode : STOP

Equipment : Oscilloscope,

1. Supply a Crosshatch Pattern Signal to the Video Input Jack.

2. Connect the Oscilloscope to TP49 on the CRT C.B.A.

(Use TP47 for GND.)

3. Select SUB BRIGHT in EVR adjustment mode. Then, after

making a note of the original value, adjust to the (C0).

4. Select SUB CONTRAST in EVR adjustment mode and

adjust so that the level A is (3.0 V[p-p]±0.1 V[p-p]: For

model with 20 inch CRT), or (3.15 V[p-p]±0.1 V[p-p]: For

model with 27 inch CRT).

5. Select SUB BRIGHT in EVR adjustment mode and reset to

the original value.

The picture is too dark or too light.

Crosshatch Pattern Signal 1 V[p-p] (75 Ω

terminated)

NTSC Video Pattern Generator

7.2.7. FOCUS, SCREEN, CUT OFF, DRIVE

ADJUSTMENT

Purpose: To set the optimum Screen.

Symptom of

Misadjustment:

Test Point : TP50 (CRT C.B.A.)

Adjustment : FOCUS CONTROL

Specification : Refer to descriptions below.

Input : Video Input Jack,

Mode : STOP

Equipment : Oscilloscope,

1. Supply a Crosshatch Pattern Signal to the Video Input Jack.

2. Adjust the FOCUS CONTROL on the Flyback Transformer

so that the "a" and "b" are the sharpest.

The picture is will be an improper screen

color mix.

(Flyback Transformer),

SCREEN CONTROL (Flyback

Transformer),

SUB BRIGHT (EVR),

G DRIVE (EVR),

B DRIVE (EVR),

R CUT-OFF (EVR),

G CUT-OFF (EVR),

B CUT-OFF (EVR)

Crosshatch Pattern Signal,

Monoscope Pattern Signal

NTSC Video Pattern Generator

Fig. E3

Fig. E4-1

3. Supply a Monoscope Pattern Signal to the Video Input

Jack.

4. Connect the Oscilloscope to TP50 on the CRT C.B.A.

(Use TP47 for GND.)

5. Select SUB BRIGHT and move the shaded area to the

value in EVR adjustment mode.

6. Turn the SCREEN CONTROL on the Flyback Transformer

fully counterclockwise.

7. Press DISPLAY key on the remote control for collapse

scan. (Refer to "HOW TO ENTER SERVICE MODE.")

8. Adjust SUB BRIGHT in EVR adjustment mode so that the

level A is (170 VDC±5 VDC: For model with 20 inch CRT),

or (185 VDC±5 VDC: For model with 27 inch CRT).

24

Page 25

Fig. E4-2

9. Turn the SCREEN CONTROL on the Flyback Transformer

clockwise carefully and stop at the point where any color is

first observed.

10. In EVR adjustment mode, select the two colors not

observed in step 8 from the following control functions (R

CUT-OFF, G CUT-OFF, B CUT-OFF) and adjust so that the

horizontal line becomes white.

For example, if the horizontal line appeared red in step 8,

select and adjust the B CUT-OFF and G CUT-OFF. (See

NOTE)

11. Press DISPLAY key on the remote control again to return

for full frame scan.

12. Select SUB BRIGHT in EVR adjustment mode and adjust

so that the picture has adequate brightness.

13. Select G DRIVE and B DRIVE in EVR adjustment mode

and adjust so that the entire screen is white.

Note:

Before pressing DISPLAY key on the remote control for

collapse scan, select the desired control function and move

the shaded area to the value.

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

7.2.8. SUB COLOR/SUB TINT

ADJUSTMENT

Purpose : To set the standard color phase.

Symptom of

Misadjustment :

Test Point : TP49 (CRT C.B.A.)

Adjustment : SUB COLOR (EVR),

Specification : Refer to descriptions below.

Input : Video Input Jack,

Mode : STOP

Equipment : Oscilloscope,

1. Supply the Rainbow Color Bar signal to Video Input Jack.

2. Connect the Oscilloscope to TP49 on the CRT C.B.A.

3. Select SUB BRIGHT in EVR adjustment mode. Then, after

making a note of original value, adjust to the (C0).

4. Select SUB TINT in EVR adjustment mode and adjust so

that level A and B should be equal in amplitude.

Color phase will be shifted.

SUB TINT (EVR),

Rainbow Color Bar

NTSC Video Pattern Generator

Fig. E5-1

5. Select SUB COLOR in EVR adjustment mode and adjust

which higher level that level C is 1.40 V[p-p]±0.15 V[p-p].

Fig. E5-2

25

Page 26

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

6. Select SUB TINT in EVR adjustment mode and increase

level B 1 clicks above the same level.

Fig. E5-3

7. Select SUB BRIGHT in EVR adjustment mode and reset to

the original value.

7.2.9. DEFLECTION DISTORTION

CORRECTION ADJUSTMENT

Purpose : To set the optimum picture.

Symptom of

Misadjustment :

Test Point : ---------Adjustment : V POSITION (EVR),

Specification : Refer to descriptions below.

Input : Video Input Jack,

Mode : STOP

Equipment : NTSC Video Pattern Generator

The picture is distortion.

V SIZE (EVR),

H-CENTER (EVR),

(For model with 27 inch CRT)

R763 (Deflection C.B.A.),

R753 (Deflection C.B.A.),

R766 (Deflection C.B.A.)

Crosshatch Pattern Signal,

Monoscope Pattern Signal

1. Supply a Crosshatch Pattern Signal to the Video Input Jack.

2. Confirm that the Horizontal Center Line is within the limits of

A.

Fig. E6-1

3. (For model with 27 inch CRT)

Adjust R763 so that vertical lines should be almost straight.

4. (For model with 27 inch CRT)

Adjust R753 so that vertical lines at Left edge and Right

edge should be almost straight.

5. Supply a Monoscope Pattern Signal to the Video Input

Jack.

6. Select V POSITION in EVR adjustment mode and adjust

Horizontal Center Line is within the limits of A.

26

Page 27

Fig. E6-2

7. Select V SIZE in EVR adjustment mode and adjust so that

the top 4th line is just in view, and that the Bottom edge is

between the 9th line and the 11th line.

8. Select H-CENTER in EVR adjustment menu and adjust so

that B is approximately equal to width C.

9. (For model with 27 inch CRT)

Adjust R766 so that the left 4th line is just in view.

10. Supply a Crosshatch Pattern Signal to the Video Input Jack.

Then, confirm that the picture is no distortion.

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

7.2.10. WHITE BALANCE ADJUSTMENT

Purpose: To set the standard white level for each

color temperature.

Symptom of

Misadjustment :

Test Point : TP50 (CRT C.B.A)

Adjustment : FOCUS CONTROL

Specification : Refer to descriptions below.

Input : Video Input Jack,

Mode : STOP

Equipment : NTSC Video Pattern Generator,

1. Supply a Monoscope Pattern Signal to the Video Input

Jack.

2. Connect the Oscilloscope to TP50 on the CRT C.B.A.

(Use TP47 for GND.)

3. Select SUB BRIGHT and move the shaded area to the

value in EVR adjustment mode.

4. Adjust the FOCUS CONTROL on the Flyback Transformer

so that the "a" and "b" are the sharpest.

White becomes bluish or reddish.

(Flyback Transformer),

SCREEN CONTROL (Flyback

Transformer),

SUB BRIGHT (EVR),

G DRIVE (EVR),

B DRIVE (EVR),

R CUT-OFF (EVR),

G CUT-OFF (EVR),

B CUT-OFF (EVR)

Monoscope Pattern Signal,

White Pattern Signal

White Pattern Generator,

Oscilloscope

Fig. E7-1

5. Turn the SCREEN CONTROL on Flyback Transformer fully

counterclockwise.

6. Press DISPLAY key on the remote control for collapse

scan. (Refer to "HOW TO ENTER SERVICE MODE.")

7. Adjust SUB BRIGHT in EVR adjustment mode so that the

level A is 175 VDC±5 VDC.

27

Page 28

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

Fig. E7-2

7.2.11. SUB BRIGHTNESS ADJUSTMENT

Note:

Perform this adjustment in a darkened room.

Purpose : To set the optimum brightness level.

Symptom of

Misadjustment :

Test Point : ---------Adjustment : SUB BRIGHT (EVR),

Specification : Refer to descriptions below.

Input : ---------Mode : STOP

The picture is too white or too black.

8. Turn the SCREEN CONTROL on the Flyback Transformer

clockwise carefully and stop at the point where red or blue

is first observed.

9. In EVR adjustment mode, select the two colors not

observed in step 8 from the following control functions (R

CUT-OFF, G CUT-OFF, B CUT-OFF) and adjust so that the

horizontal line becomes white.

For example, if the horizontal line appeared red in step 8,

select and adjust the B CUT-OFF and G CUT-OFF. (See

NOTE)

10. Supply a White Pattern Signal to the Video Input Jack.

11. Press DISPLAY key on the remote control again to return

for full frame scan.

12. Select G DRIVE and B DRIVE in EVR adjustment mode

and adjust so that the entire screen is white.

13. Confirm that the screen is tracking the White Pattern

properly. If NG, repeat the above steps 8, 9 and 12 until the

screen is properly tracking the White Pattern.

14. Select SUB BRIGHT in EVR adjustment mode and adjust

correctly.

Note:

Before pressing DISPLAY key on the remote control for

collapse scan, select the desired control function and move

the shaded area to the value.

1. Do not input any signal to the unit.

2. Set INPUT SELECT item to LINE in SET UP TV menu to

display black screen.

3. Select SUB BRIGHT in EVR adjustment mode, and adjust

so that the black screen starts to turn gray (lighting only).

28

Page 29

7.3. TEST POINTS AND CONTROL LOCATION

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

29

Page 30

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

30

Page 31

8 SCHEMATIC DIAGRAMS

8.1. SCHEMATIC DIAGRAM AND CIRCUIT BOARD LAYOUT NOTES

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

1. Important safety notice

Components identified by the sign

have special

characteristics important for safety. When replacing any

of these components. Use only the specified parts.

2. Do not use the part number shown on this drawing for

ordering.

The correct part number and part value is shown in the

parts list, and may be slightly different or amended since

this drawing was prepared.

3. Use only original replacement parts:

To maintain original function and reliability of repaired

units, use only original replacement parts which are listed

with their part numbers in the parts list section of the

service manual.

4. Parts different in shape or size may be used.

However, only interchangeable parts will be supplied as

service replacement parts.

5. Test point information

:Test point with a jumper wire across a hole in P.C.B.

:Test point with a component lead on the foil side.

:Test point with no test pin.

:Test point with a test pin.

Schematic Diagram Notes

1. Indication for Zener Voltage of Zener Diodes

The Zener Voltage of Zener Diodes are indicated as such

on Schematic Diagrams.

3. Parts marked "PT" are not used in any models included

in this service model.

Example:

C6011

100P

C6011

PT

R6097

PT

PT

4. Jumper wires are used for WA10, WA5 etc and these are

not supplied as replacement parts.

Signal Waveform Note

How to read Signal Waveform

9

CH1 TP3002

CH2 TP6205

0.1V 5ms 2

1 2 3 4 5 6 7

WF1

+250mVp-pV1

REC SP/LP/SLP

5V

8

Voltage Chart Note

Voltage Measurement

a. Color bar signal in SP mode.

b. ---:Unmeasurable or not necessary to measure.

1 Connecting Point

2 Volts/Div

3 Volts/Div

4 Connecting Point

5 Time/Div

6 Trigger Channel of

the scope

(1:CH1,2:CH2)

7 Operation Mode of

VCR

8 Waveform Point on

Schematic

9 V1:Peak to Peak

Example:

(6.2V)......Zener Voltage

2. How to identify Connectors

Each connector is labeled with a Connector No. and Pin

No. Indicating what it is connected to,

in other words, its counter part.

Use the interconnection schematic diagram to find the

connection between associated connectors.

Example:

The connections between C.B.A.s are shown below.

Ref. No. of the connection parts such as lead cable,

flexible cable which is supplied as a replacement parts.

The Number of pins of the Connector.

POWER SUPPLY

C.B.A.

P1503

244

(10 Pins)

MAIN C.B.A.

P3004

Connector No.

on Main C.B.A.

Circuit Board Layout Note

Circuit Board Layout shows components installed for

various models.

For proper parts content for the model you are servicing,

please refer to the schematic diagram and parts list.

NOTE:

Circuit Board Layout includes components which are not

used.

Model No. Identification Mark

MODEL

PV-20DF25

PV-20DF25-K

PV-27DF25

PV-27DF25-K

PV-27DF5

Not Used

Note : Refer to item 3 of Schematic Diagram Notes for mark "PT".

SCHEMATIC DIAGRAM & CIRCUIT BOAD LAYOUT NOTES

PV-20DF25/PV-20DF25-K/PV-27DF25/PV-27DF25-K/PV-27DF5

MARK

A

B

C

D

E

PT

31

Page 32

NOTE:

PARTS MARKED "PT" ARE NOT USED.

NOTE: For placing a purchase order of the parts,

be sure to use the part number listed in the parts list.

Do not use the part number on this diagram.

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

8.2. MAIN SCHEMATIC DIAGRAMS

MAIN I SCHEMATIC DIAGRAM

TTL

C6010

C6011

0.1

PT

456

RESET

123

R6174

PT

R6112

R6113

IC6005

C0EBJ0000080

(RESET)

TP6099

PT

22K

18K

J6002

WA5

C6009

PT

J6001

C6031

PT

PT

TP6009

WA7.5

TP6008

WA7.5

R6114

390

[1/10W]

R6115

10K

R6116

PT

Q6003

2SD601A0L

SWITCHING

POWER ON-ON

C6030

0.01

Q6005

2SB0709A0L

SWITCHING

POWER ON-ON

Q6004

PT

SWITCHING

POWER ON-ON

D6009

MA2C165001VT

TO M III,M IV 2

TO M IV 3

TO M IV 4

TO M II 5

TO M IV 6

TO M V 7

TO M V 8

D_RDY

1TO M II

TV_POWER_ON_H

DEGAUSS_H

DVD_POWER_ON_H

LINE_SD_L

UNSW+5V_SYSCON

POWER_ON_H

SW+5V_VIDEO

TP6007

PT

R6118

4R7M

D6002

MA2C165001VT

D6010

MA2C165001VT

220

R6121

R6122

220

5678

WP

VDD

SDA

SCL

[2Kb]

IC6004

LSSK0066 A,B

C,D,E

LSSK0065

(EEPROM)

A0

A2

VSS

A1

1234

*

R6117

56

(1/4W)

C6001

330/6.3V

L6001

C6008

47/6.3V

*

WA5

R6119

3300

R6120

1500

TP6104

PT

PTR6519

ESD_GND

TO M II,M III 9

TP6111

PTR6520

PT

C6007

100/6.3V

R6517

22K

D6008

D6007 PT

Q6006

2SD601A0L

IC6001

RESET

C6012

PT

C6006

0.1[KB]

R6518

PT

1

(NO CONNECTION)

IIC_CLK2IIC_DATA3IIC_JIG_L4GND5R_OUT_ADJ

P6001

D6004

MA2C165001VT

TP6101

5600

NOTE:

FOR SCHEMATIC DIAGRAM AND CIRCUIT BOARD LAYOUT NOTES,

REFER TO BEGINNING OF SCHEMATIC SECTION.

TO M II33

TO M II34

TO M II35

TO M III36

TO M II37

V_MUTE_2_L

H_RDY

V_MUTE_H

AUDIO_MUTE_H

F_LINE2/R_LINE1

PTR6022

PTR6023

1KR6025

1KR6026

1KR6027

1KR6028

1KR6029

2627282930

POS_4

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

C6401

0.1

C6402

100/6.3V

IIC_DATA

13TO M II,M III

POS_3

POS_2

POS_1

RST_L

S_TAB_L

D_RDY_L

DVDD

X_IN

X_OUT

DVSS

TV_P_ON_H

IIC_JIG_L

12M_START_H

LC_OSC_IN

LC_OSC_OUT

NUB

DEGAUSS_H

DVD_PON_H

VSS_OSD

(no use)

L6401

100U

H_RDY_L

V_MUTE_H

A_MUTE_H

F_LINE2/R_LINE1

12MHz

LINE_SD_L

(CV_OUT)

VDD_OSD

V_HOLD

HLF

51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75

1KR6051

2200

R6054

C6403

1000P[KB]

0.033[KB]

C6404

*

C6406

560P[JC]

R6401

1M

V_MUTE_2_L

CV_IN(EDS)

1000P[KB]C6405

R6056

C6407

CC_VIDEO

14TO M II

TNR/LINE

DVD_H/REC_L

NUA

OSD_H

1KR6058

1KR6059

470

0.1[KB]

V_PULSE

H_PULSE_INV

15TO M II

16TO M II

PTR6061

DEFEAT_H

OSD_V

CRSS_L

BLK_H

R6403

R6404

C6004

PT

R6034

3300

PT

P6001 IS USED

R6036

22K

C6005

0.01

C6003

18P[JC]

C6409

100P[JC]

R6408

R_OUT

FOR ADJ0STMENT

AT FACTORY ONLY

10TO M II

H0A120500003

X6001

C6002

22P[JC]

L6402

4R7U

PT

R6050

PT

R6039

R6035

*

10K

1K

82PC6408

J6401

WA5

IIC_CLK

IIC_GND

11TO M III

12TO M II,M III

1KR6041

1KR6042

22KR6043

1KR6047

1KR6048

TL

MTS_MODE

IIC_CLK

COMPO_H

1KR6070

0R6071

100R6072

100R6516

COMPOSITE_H

26TO M II

NOTE:

PARTS MARKED "PT" ARE NOT USED.

31 TO M III

R_TNR_AFC

R6124

PT

TR_ENV

T_PHOTO

S_PHOTO

IIC_DAT

CAP_F/R

TNR/YCA//(750KHz)

TP6013

PTR6073

0R6522

1KR6006

SOS_L

DTS_AFC

CAP_EC_PWM

A_DVD_H

76 77 78 79 80

C6032

100P[JC]

OPT

KEY_2

A_CTL_A

CYL_EC_PWM

P_DOWN_L

C6033

PT

KEY_1

C6016

0.01

12345678910111213141516171819202122232425

A_CTL_B

TP6106

KEY_0

OVER_CUR_H

CTL_AMP_REF

TNR_LOCK_L

EX_FF/REW_L

PT

4700R6511

4700R6512

2200R6513

4700R6514

C6105

PT

AVDD_AD

AVDD_AMP

CTL_OUT

HF_PLAY_H

V_REF_IN

V_REF_OUT

Y_PFG_IN

TNR_SD_L

AVSS_AMP

C_FG_IN

C_FG_OUT

LOAD_H

UNLD_H

P_ON_H

CTL+

CTL-

1KR6080

1KR6079

NOTE:

FOR SCHEMATIC DIAGRAM AND CIRCUIT BOARD LAYOUT NOTES,

REFER TO BEGINNING OF SCHEMATIC SECTION.

TO M III32

V_CHIP_MUTE_H

100R6012

0R6014

PTR6015

PTR6016

470R6017

IR

HSW

HF_HSW

V_D_REC_H

SYSTEM CONTROL/OSD/CCV

MICROCONTOROLLER

LINK TO I/O CHART

B

G

SP_MUTE_H

L6404 0

0

L6405 0

L6403

PTC6411

PTC6412

PTC6413

PTC6414

2200R6062

2200R6063

1KR6060

PTR6402

PT

PT

VOB

OSD_B

OSD_G

17TO M II

18TO M II

19TO M II

ON_T_LED

SLEEP_LED

IC6001

C2CBHG000160

DVD

R

H_DAT_OUT

560R6065

560R6066

L6406 0

2200R6064

MA2C165001VTD6006

TTL

HOST_DATA

DVD_DATA

OSD_R

20TO M II

21TO M II

22TO M II

ANGLE_LED

D_SCK

D_DAT_IN

1KR6067

R6515

2200

D6005

MA2C165001VT

C6035

PT

C6034

PT

TTL

DVD_SCK

23TO M II

V_L_PLS

D_RST_L

1KR6068

D_RST_L

24TO M II

TNR_H VCH_MUTE_H

1KR6069

TNR_H

25TO M II

NOTE: For placing a purchase order of the parts,

be sure to use the part number listed in the parts list.

Do not use the part number on this diagram.

KEY MATRIX (SW6301~SW6304, SW6307~SW6309, SW6316~SW6318)

1.2V 1.2V0.4V 2.1V 2.1V 3.0V0V 0.4V

CH UP

VOLUME

DOWN

VOLUME

UP

CH DOWN

POWER

47KR6123

10KR6005

100

99

98

97

96

95

94

93

R6093

92

91

90

89

88

87

86

85

84

83

82

81

10KR6078

R6095

10K

R6086

R6098 PT

C6026

PT

10K

1KR6090

10KR6089

1M

R6318

11K[F]

C6027

C6037

0.01

PT

100/6.3VC6036

10KR6085

1KR6081

R6129

R6317

11K[F]

R6130

22K

2200

R6316

11K[F]

PTD6011

47KR6175

D6003

MA2C165001VT

POWER

SW6318

EVQ21405R

-----

R6311

2200[F]

R6312

3300[F]

SKIP

SKIP

+

DVD

STOP

CH_UP

SW6307

EVQ21405R

VOL +

SW6308

EVQ21405R

SKIP+

SW6309

EVQ21405R

OPEN

/CLOSE

-----

DVD

PLAY

R6306

2200[F]

R6307

3300[F]

OPERATION

BUTTON

CH_DOWN

SW6301

EVQ21405R

VOL -

SW6302

EVQ21405R

SKIP-

SW6303

EVQ21405R

TERMINAL

VOLTAGE

R6301

2200[F]

R6302

3300[F]

R6303

5600[F]

COMPARISON CHART

OF MODELS & MARKS

MODEL

PV-20DF25

PV-20DF25-K

PV-27DF25

PV-27DF25-K

PV-27DF5

Not Used

5600[F]R6313

P6301

7

ON_T_LED

6

KEY_IN_0

5

KEI_IN_01

4

IR

3

UNSW+5V_SYS

2

KEY_IN_2

1

GND

SOS_L

OVER_CURRENT_H

A_CTL_B

A_CTL_A

TO OPERATION

C.B.A.P6302

MARK

A

B

C

D

E

PT

I/O CHART OF IC6001

Signal Name

Pin No. I/O

I

KEY_0

1

I

KEY_1

2

I

KEY_2

3

-

OPT

4

I

SOS_L

5

I

DTS_AFC

6

-

S_PHOTO

7

-

T_PHOTO

8

-

TR_ENV

9

-

MTS_MODE

10

-

TL

11

O

VCH_MUTE_H

12

-

V_L_PLS

13

I

IR

14

-

ANGLE_LED

15

-

SLEEP_LED

16

O

ON_T_LED

17

-

HSW

18

-

HF_HSW

19

-

V_D_REC_H

20

-

CRSS_L

21

-

DEFEAT_H

22

-

TNR/LINE

23

-

DVD_H/REC_L

24

O

V_MUTE_2_L

25

F_LINE2/R_LINE1

O

26

H_RDY_L

O

27

A_MUTE_H

28

O

V_MUTE_H

29

O

POS_4

30

-

31

POS_3

-

32

POS_2

-

-

33

POS_1

34

RST_L

I

35

S_TAB_L

-

36

D_RDY_L

I

37

DVDD

I

38

X_IN

I

39

X_OUT

O

TO M II30

TO M II29

40

DVSS

-

41

TV_P_ON_H

O

-

42

IIC_JIG_L

43

12M_START_H

I

44

LC_OSC_IN

I

45

LC_OSC_OUT

O

46

NUB

-

47

DEGAUSS_H

O

48

DVD_PON_H

O

49

VSS_OSD

-

50

(no_use)

-

51

LINE_SD_L

I

52

(CV_OUT)

I

53

VDD_OSD

54

HLF

-

55

V_HOLD

-

56

CV_IN(EDS)

I

57

NUA

-

58

OSD_H

I

OSD_V

59

I

BLK_H

60

O

SP_MUTE_H

61

O

B

62

O

G

63

O

TO M III28

TO M III27

64

O

65

O

66

I

67

I

68

O

69

O

70

O

71

O

72

I/O

73

-

74

-

75

-

76

-

-

77

78

I

79

O

80

O

81

O

82

-

83

-

-

84

85

-

86

-

87

-

88

-

89

-

90

-

-

91

92

-

93

-

94

-

95

-

96

-

97

-

98

I

99

I

100

I

R

H_DAT_OUT

D_DAT_IN

D_SCK

D_RST_L

TNR_H

COMPO_H

IIC_CLK

IIC_DAT

TNR/YCA//(750KHz)

CAP_F/R

A_DVD_H

CAP_EC_PWM

CYL_EC_PWM

P_DOWN_L

A_CTL_A

A_CTL_B

P_ON_H

UNLD_H

LOAD_H

EX_FF/REW_L

TNR_LOCK_L

C_FG_OUT

C_FG_IN

AVSS_AMP

TNR_SD_L

Y_PFG_IN

V_REF_OUT

V_REF_IN

HF_PLAY_H

CTLCTL+

CTL_AMP_REF

CTL_OUT

AVDD_AMP

AVDD_AD

OVER_CUR_H

COMPARISON CHART

OF MODELS & MARKS

Description

MODEL

KEY DATA 0

KEY DATA 1

PV-20DF25

KEY DATA 2

PV-20DF25-K

NOT USED

ABNORMAL VOLTAGE DETECTION(L)

PV-27DF25

TUNER AFC

PV-27DF25-K

NOT USED

NOT USED

PV-27DF5

NOT USED

NOT USED

Not Used

NOT USED

V-CHIP MUTE(H)

NOT USED

IR-DATA

NOT USED

NOT USED

ON TIMER LED ON(L)

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

VIDEO MUTE2(L)

LINE1(L)/LINE2(H)

HOST READY(L)

AUDIO MUTE(H)

VIDEO MUTE(H)

NOT USED

NOT USED

NOT USED

NOT USED

RESET(L)

NOT USED

DVD READY(L)

VDD(+5V)

12MHz OSCILLATOR

12MHz OSCILLATOR

GROUND

TV POWER ON(H)

NOT USED

12MHz CLOCK START(H)

LC OSCILLATOR

LC OSCILLATOR

NOT USED

DEGAUSSING ON(H)

DVD POWER ON(H)

GROUND

NOT USED

TV SIGNAL(L)

NOT USED

VDD (+5V)

NOT USED

NOT USED

COMPOSITE VIDEO

NOT USED

OSD H-SYNC

OSD V-SYNC

BLANKING PULSE

SPEAKER MUTE(H)

OSD-B

OSD-G

OSD-R

DVD SERIAL DATA 0

DVD SERIAL DATA 1

DVD SERIAL CLOCK

DVD RESET(L)

TUNER(H)/LINE(L)

COMPOSITE(H)

I2C SERIAL CLOCK

I2C SERIAL DATA

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

POWER DOWN(L)

AUDIO SW CONTROL A

AUDIO SW CONTROL B

POWER ON(H)

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

GROUND

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

NOT USED

VDD (+5V)

VDD (+5V)

OVER CURRENT DETECT(H)

MARK

A

B

C

D

E

PT

LINK TO VOLTAGE CHART

LSJB2220

MAIN I SCHEMATIC DIAGRAM

PV-20DF25/PV-20DF25-K/PV-27DF25/PV-27DF25-K/PV-27DF5

32

Page 33

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

MAIN II SCHEMATIC DIAGRAM

TP5019

WA7.5

0J4702

C4702

PT

PT

R4704

(OP AMP)

PT

R4702

C4701

PT

J4703

0

J4701

PT

JK4701

FRONT

VIDEO IN

AUDIO IN

LCH

AUDIO IN

RCH

TO M III 38

TO M I 34

TO M I 25

TO M III 39

TO M III 40

TO M III 41

TO M III 42

TO M III 43

TO M III 44

TO M III 45

TO M I 35

TO M I 23

TO M I 22

TO M I 21

TO M I 1

TO M I 24

9TO M I

ESD_GND

FRONT_ESD_GND

REAR_VIDEO

F_LINE2/R_LINE1

TNR_H

TNR_VIDEO

AUDIO+6V

LINE_IN_FRONT_L

LINE_IN_FRONT_R

DVD_AUDIO_L

DVD_GND

DVD_AUDIO_R

TO DVD MAIN

C.B.A.P8401

H_RDY

DVD_SCK

DVD_DATA

HOST_DATA

D_RDY

D_RST_L

AV_GND

AV_GND

AV_GND

S-COUT

AV_GND

S-YOUT

SW+12V

HOST_DATA

DVD_DATA

DVD_SCK

1

2

3

4

5

6

RESET

A_GND

D_RDY

H_RDY

MIXR

MIXL

R5321

75

D5307 MA2C165001VT

D5308 MA2C165001VT

D4701

MA2C165001VT

JA

PT

JBPT

1

Z6203

P4801

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

D4702

MA2C165001VT

J5301

WA5

D5309

MAZ40510MF

(5.1V)

D5310

MAZ40510MF

(5.1V)

D4703PTD4705

PT

D4704PTD4706

PT

TP5009

WA7.5

L5301 0

C5365

0.1[KB]

TP4011

WA7.5

R4701

1K

C5366

TP4014

WA10

R4703

1K

C4710

100P[JC]

C4709

100P[JC]

PT

5678

V+

IC4701

PT

V-

1234

PT

C4703

C4704

COMPARISON CHART

OF MODELS & MARKS

MODEL

PV-20DF25

PV-20DF25-K

PV-27DF25

PV-27DF25-K

PV-27DF5

Not Used

TO M I10

A,B

C,D,E

TO M I17

TO M I37

TO M I29

TO M I30

TO M I16

TO M I5

TO M I15

TO M I33

MARK

A

B

C

D

E

PT

LSJB2220

D5304

MA2C165001VT

4700

IC5301

AN15167A-VT

D5501

0.22[KB]

C5501

0.018[KB]

470

R5501

R5661

100

180P[JC]

C5669

C5668

0.01

GND

VDD

NOTE:

PARTS MARKED "PT" ARE NOT USED.

TO M I18

19 TO M I

20 TO M I

OSD_R

OSD_G

OSD_B

R5302

22K

3300R5604

0R5315

0R5316

R5314 0

C5605

0.015[KB]

1/50V

C5604

MAZ40620LIKT(6.2V)

8200R5405

L5654

27U

FL5651

F1Y2A1030005

123

R5677

C5661

C5673

PT

0.1

C5662

100R5406

18P[JC]

2200R5327

C5507

47/6.3V

2200

2200R5328

15P[JC]

C5603

R5329

X5601

R5504

100

R5505

3240[F]

L5655

100U

24

23

22

21

20

19

18

17

16

15

14

13

H0B357400003

X5501

H2A503300012

C5508

220P[S]

TP5401

PT

R5676

2700

Q5657

2SD1819A0L

(AMP)

R5673

3900

Q5659

UNR221200L

SWITCHING

TUNER MODE-ON

252627282930313233343536

10/16V

R5679

R5658

C5681

0.01

NOTE: For placing a purchase order of the parts,

be sure to use the part number listed in the parts list.

Do not use the part number on this diagram.

AUDIO SIGNALVIDEO SIGNAL

[MA165]

PTD5504

TP5313

R_OUT

P5302

1

SW+12V

2

R_OUT

3

G_OUT

4

B_OUT

VOB

V_MUTE_H

OVER_CURRENT_H

P5501

SW+12V

13

HOLD_DOWN

12

V_OUT

11

V_SIZE

10

H_OUT

9

H_AFC

8

OVER_CURRENT_H

7

H_PULSE

6

ABL

5

SOS_L

4

H_GND

3

H_GND

2

H_GND

1

SOS_L

V_PULSE

LINE_SD_L

H_PULSE_INV

V_MUTE_2_L

P5502

DVD_FRAME_GDN_1

1

P5503

DVD_FRAME_GDN_2

1

P5504 PT

DVD_FRAME_GDN_3

1

TO CRT

C.B.A.P351

TO CRT

C.B.A.P351

TO DEFLECTION

C.B.A.P501

[MA165]

[MA165]

[MA165]

PTD5303

PT

PTD5301

330R5311

330R5312

330R5313

R5317

100

R5512

150

R5515

2700

R5513

100

R5506

22K

R5510

100

C5517 PT

0.033[KB]C5516

R5514

PT

C5505

220/16V

C5506

0.01

R5503

*

470

C5511

0.033[KB]

C5510

1/50V

Q5658

2SD1819A0L

(BUFFER)

PT

1200

R5659

2200

Q5652

2SD1819A0L

(AMP)

820

R5655

R5511

2200

D5302

R5657

R5656

TP5652

PT

TP5303

TP5302

TP5301

PT

PT

PT

D5505

PT

PT

C5665

33K

C5664

15K

TP5501

0.01

PT

TP5505

PT

TP5506

PT

TP5503

PT

TP5402

TP5504

TP5310

PT

PT

PTD5311

PT

R5381

5600

Q5381

2SD1819A0L

(INVERTER)

33P

C5381

R5382

4700

J5502

PT

WA5

R5383

5600

LINK TO VOLTAGE CHART

MAIN II SCHEMATIC DIAGRAM

NOTE:

FOR SCHEMATIC DIAGRAM AND CIRCUIT BOARD LAYOUT NOTES,

REFER TO BEGINNING OF SCHEMATIC SECTION.

TO M I12

C5618

0.01

C5619

W/O COMB

J5901

J5902

TO M I14

CC_VIDEO

IIC_CLK

PT

PT

PT

2SB1218A0L

13 TO M I

IIC_DATA

TP5651

PT

Q5653

(BUFFER)

46 TO M III

SW+9V

R5665

TP5305

WA25

5600

8 TO M V

SW+5V_VIDEO

C5904

0.1[KB]

5V

L5901

100U

Q5303

2SD1819A0L

(BUFFER)

R5664

2200

R5666

3900

C5675

PT

C5903

47/16V

Q5301

2SB1218AHL

(BUFFER)

C5674

R5651

330

39P

R5310

1K

C5653

PT

L5652

R5301

2200

15U

TP5312

WA12.5

C5901

PT

Q5901

2SD225900A

+9V

REGULATOR

L5658

100U

R5662

100

R5652

1K

*

R5903

WA10

0.47/50VC5303

0.01C5932

TP5308

R5653

6800

Q5651

2SB1218A0L

(BUFFER)

C5301

10/16V[N]

C5307

L5653

C5656 47/6.3V

R5308

C5601

0.01

4R7/25VC5302

22KR5306

220KR5305

R5902

1K

C5902

47/16V

37

38

39

40

41

42

43

100R5932

44

100R5933

45

56P

C5907

C5908

56P

46

47

48

0.01

C5905

C5906

10/16V

100U

0.1

100/6.3V

C5934

10/16V

C5677

0.1

C5657

IC5651

C1AB00002241

Y/C

SEPARATION

123456789101112

220

R5403

PTR5404

C5403

2R2/50V

C5678

22/16V

C5672

VDD

Y/C

SEPARATION

GND

12345678

0.01

0.01

C5659

C5658

C5654

1/50V

Q5302

2SD1819A0L

(BUFFER)

39K

39K

R5304

180K

R5309

R5303

0.1[KB]C5602

0.47/50V

C5305

LUMINANCE

/CHROMINANCE

SIGNAL PROCESS

560R5508

R5402

390K

C5401

C5402

2200P[KB]

R5502

390K

C5502

680P[KB]

560

R5401

L5661

100U

0.01

C5670

820

R5660

0.01

0.01

C5671

111213141516 910

0.01

C5660

2LINE_COM

TO M I26

TO M V47

COMPOSITE_H

SW+12V

L4701

PT

R4705

Q4701

PT

(BIAS)

PT

C4706

PT

R5620

MA2C165001VT

R5622

470

GND

8

7

B

6

VCC

C5356

10/16V

R5363

10K

Q5355

UNR221100L

(SWITHING)

Q5614

2SD1819A0L

(BUFFER)

D5612

MA2C165001VT

R5356

100

R5362

2200

PT

R5621

1800

C5358

22P[JC]

C5364

PT

R5674

2700

Q5612

R5618

2SD1819A0L

27K

(BUFFER)

C5617

R4706 PT

C4707 PT

R4707 PT

C4708 PT

0.01

R5615

R5619

1K

56K

D5611

Q5613

UNR221100L

SWITCING

COMPOSITE-ON

IC5351

(SW)

C1AB00001682

1

L

L

H

2

H

3

45

Q5354

2SD1819A0L

(DC CLAMP)

D5354

MA2C165001VT

R5361

220

C5351

10/16V

C5352

10/16V

R5616

1K

R5351

100

R5352

100

MA2C165001VT

Q5353

2SD1819A0L

(BUFFER)

D5353

PT

PTC4705

PV-20DF25/PV-20DF25-K/PV-27DF25/PV-27DF25-K/PV-27DF5

33

Page 34

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

IC5301 LUMINANCE/CHROMINANCE PROCESS IC- DETAIL BLOCK DIAGRAM

REC VIDEO SIGNAL

B L A C K L E V E L

A C C

D E T E C T O R

3 7

9 . 6 V

P E D E S T A L

C L A M P

C O L O R

C O N T R O L

3 8

V C C 1

3 9

4 0

4 1

4 2

4 3

I2C B U S

/ D A C

4 4

4 5

4 6

V C C 2

4 7

4 8

A C C

H P F

3 . 5 8 M H z

C H R O M A T R A P

L I N E

T U N E R

P B

M U T E

D E T E C T O R

S W

D E L A Y

V . S Y N C

S E P A R A T I O N

V C O

T I N T

C O N T R O L

S H A R P N E S S

C O N T R O L

A P C

C O N T R A S T

C O N T R O L

S E R V I C E

S W

H . S Y N C

S E P A R A T I O N

H . L O C K

D E T E C T O R

C O L O R K I L L E R

D E T E C T O R

V . C O U N T

D O W N

G N D

C O L O R

D E M O D U L A T O R

B R I G H T N E S S

C O N T R O L

A P L D E T E C T O R

B G P

A F C 1

V .

O U T

H O L D

D O W N

D E T E C T O R

A F C 2

PB VIDEO SIGNAL

2 52 62 72 82 93 03 13 23 33 43 53 6

M A T R I X

B L A N K I N G

H . C O U N T

D O W N

H . V C O

1 21 11 0987654321

S P O T K I L L E R

D E T E C T O R

T V / O S D

R G B M I X

B L A N K I N G

R G B D R I V E

/ R G B C U T

O F F

H .

O U T

R

G

B

G N D

V C C

6 . 1 V

2 4

2 3

2 2

2 1

2 0

1 9

1 8

1 7

1 6

1 5

1 4

1 3

34

IC5301 DETAIL BLOCK DIAGRAM

PV-20DF25/PV-20DF25-K/PV-27DF25/PV-27DF25-K/PV-27DF5

Page 35

PV-20DF25 / PV-27DF25 / PV-27DF5 / PV-20DF25-K / PV-27DF25-K

MAIN III SCHEMATIC DIAGRAM

2 TO M I

TV_POWER_ON_H

0.01

C4301

C4302

LINE_IN_FRONT_R

42TO M II

LINE_IN_FRONT_L

TO M II 41

C4304

10/16V

C4303

10/16V

100/16V

C4308

10/16V

IC4301

C0JBAR000344

(SW)

100K

R4301

VDD

12345678

100K

R4302

100K

R4312

R4315

R4303

100K

100K

10/16V

R4304

R4305

C4307

100K

100K

R4313

100K

R4314

R4307

0

100K

R4306

111213141516 910

100K

SW

CONTROL

C4305

10/16V

Q4301

PT

GND

R4308

PT

Q4302

PT

R4309

10K

Q4303

UNR221200L

(INVERTER)

C4371

10/16V

51 TO M IV

AUDIO_GND

TP4509

C4306

10/16V

R4371

Q4356

2SD1819A0L

SWITCHING

AUDIO MUTE-ON

R4310

10K

Q4304

UNR221200L

(INVERTER)

A_CTL_B

A_CTL_A

27TO M I

28TO M I

U4501

LXPUSO1275

12345678910111213

C4501

22/16V

R4503

10K

C4503

1200P[KB]

R4502

PT

TP4508

1K

L_IN

PT

R_IN

R4373

100

J4371

100K

WA10

C4372

10/16V

R4372

R4368

820

D4353

MA2C165001VT

D4354

MA2C165001VT

V_CHIP_MUTE_H

AUDIO_MUTE_H

36TO M I

32TO M I

IC4501

C1BA00000367

GND GNDSTBY VCC

1/50V

C4505

1/50V

C4502

R4504

R4505

C4504

1200P[KB]

R4374

100

100K

UNSW+5V_SYSCON

6TO M IV

(AUDIO AMP)

C4506

4R7/50V

C4507

470/25V

10K

C4509

100/16V

C4508

DVD_AUDIO_L

43TO M II

DVD_GND

44TO M II

470/25V

DVD_AUDIO_R

45TO M II

R4506

4700

1K

50 TO M IV

J4501

WA12.5

C4510

L4351

100U

R4605

5600

C4603

0.1[KB]

C4601

R4606

390K

2324

(TONE CONTROL)

123456789

0.01[KB]

C4604

C4602

SW+12V

AUDIO+6V

47TO M V

40TO M II

470/25V

C4351

R4607

5600

0.1[KB]

0.1[KB]

C4605

R4608

390K

2122 1314151617181920

IC4601

C1BB00000815

C4606

0.01[KB]

PT

C4623

1/50V

0.1[KB]

C4607

C4352

100/16V

1000/16V

AUDIO_POWER

TP4507

0.01

L_OUT

C4609

PT

C4624

1/50V

C4629

WA7.5

C4353

C4608

10/16V

C4354

4R7/50V

R_OUT

0.01

4R7/50V

C4610

L_LINE_OUT

1M

R4609

C4616

R4351

R4352

C4611

C4612

PT

PT

GND

(TO SPEAKER L-CH)

SP_OUT_L_+

2

1

P4501

TP4502

WA7.5

4700

Q4351

2SD601A0L

(BIAS)

5600

4700

R4353

R4610

PT

C4613

R_LINE_OUT

10

C4614

0.082[KB]

C4615

22/16V

4R7/50V

C4617

0.01

NOTE:

FOR SCHEMATIC DIAGRAM AND CIRCUIT BOARD LAYOUT NOTES,

REFER TO BEGINNING OF SCHEMATIC SECTION.

JK4591

HEADPHONE JACK

49 TO M IV

GND

(TO SPEAKER R-CH)

SP_OUT_R_+

1

2

P4502

AMP_L_OUTAMP_R_OUT

TP4501

WA10

0.01

C4355

R4354

100K

C4358

10/16V[N]

100

100

R4611

C4627 56P

C4628 56P

IIC_DATA

IIC_CLOCK

L_IN

12

11

C4622

C4618

C4621

PT

1/50V

C4357

R4356

C4356

47/16V

C4619

0.33[KB]

R_IN

1/50V

C4620

PT

D4601

B0AAML000001

TP4591

10/16V

220

R4355

100K

TP4202

WA10

L4501

J0JBC0000014

L4502

PT

[S2]

R4591

IC4351

C0ABBB000256

(OP AMP)

1234

C4359

10/16V

220

R4358

2SD132800L

SWITCHING

AUDIO MUTE-ON

R4365

100K

C4360

10/16V[N]

3300

R4601

PT

2200

R4603

C4626

L4601

100U

L4503

J0JBC0000014

J0JBC0000014

[S2]

680

680

R4592

5678

Q4352

Q4354

PT

R4360

100K

TP4201

WA10

3300

R4602

2200

R4604

TP4592

[S2]

R4593

R4366

2700

C4625

46TO M II

680

J4302

PT

SW+9V

PT

[S2]

R4594

WA5

IIC_GND

11TO M I

680

IIC_CLK

12TO M I

D4593

SP_GND

MA2C165001VT

D4594

MA2C165001VT

D4591

D4588

MAZ42400MF

MAZ42400MF

(24V) (24V)

D4592

D4587

MAZ42400MF

MAZ42400MF

Q4353

2SD132800L

SWITCHING

AUDIO MUTE-ON

R4367

2700

Q4355

UNR511500L

MUTE

DRIVE

IIC_DATA

13TO M I

(24V)(24V)

NOTE:

PARTS MARKED "PT" ARE NOT USED.

9 TO M I

U7001 J3AAABB00002 (UHF/VHF TUNER UNIT)

ESD_GND

SCK9NC8NC7NC6NC5NC4NC3BC2NC1NC

10/16V

10P

C7004

AGC

MATRIX

& MODE SW

OFFSET

CANCEL

C9003

C9502

PT

R9504

PT

R9505

PT

WA5

PT

C7007

C7008

C7009

C9004

0.33/50V

J9502

PT

C9504

J9504

C7005

D7003

D7004

PT

R9001 PT

L+R

L-R/SAP

3R3/50V

PT

PTC7006

PT

10P

PT

PT

10

PT

R7001

C9005

100P[JC]

1K

R9002

100

C9006 PT

272829303132 1920212223242526

IIC

DECORDER

C9007

0.1[KB]

C9503

100

R7002

C9008

NC

WIDEBAND

EXPAND

WIDEBAND

RMS DET

IIC/PARA

0.022[KB]

R9509

220

R9510

220

J4593

WA5

1K

R9006

1K

R9507

Q9501

PT

(BIAS)

PT

TP9001

PT

PT

TP9002

C9508

PT

C9022

2R2/50V

C9021

2R2/50V

C9507

R9007

47K

R9008

C9024

0.01[KB]

47K

R9005

C9019

0.01[KB]

L9501

PT

PT

R9506

PT

PT

PT

C9510

R9508

C9509

J1201

PT

L7001

10U

C7040

56P[JC]

C9506

PT

C9505

PT

+5V

C7001

0.01[KB]

C7002

D7001

PT

C9001

IC9001

AN5832SA-E1V

(FM SIGNAL PROCESS)

J9503

WA5

V+

IC9501

PT

(OP AMP)

PT

1234

C7003

1000/6.3V

2R2/50V

NC

123456789

C9002

5678

V-

NOTE: For placing a purchase order of the parts,

be sure to use the part number listed in the parts list.

Do not use the part number on this diagram.

AUDIO SIGNALVIDEO SIGNAL

VIDEO_OUT

BTL14SIF_OUT

AUDIO_OUT

AFT11SDA(0.25VDD)

12

R7003

R9003

100

100/6.3V

SPECTRAL

EXPAND

SPECTRAL

RMS DET

AGC SW

L9001

C9501

100P[JC]

100

C9026

56P

GND

100U

13

C7015

C9009

R9502

1K

R9503

1K

R7022

PT