Panasonic PT-51D31CE, PT-61D31CE Service Manual

ORDER NO. MTNC010420A1

B2

Service Manual

Color Video Projection System

S

m

i

p

l

i

f

i

e

d

Simplified Manual

P6

Panasonic

Models

PT-51D31CE AP821

PT-61D31CE AP821

Chassis

Note: Refer to Technical Guide (P6) for

functional descriptio ns and Bloc k Diag rams .

(MTNC010308G1).

This Simplified Se rvice Manual is issued to add listed model to the Main Ser vice Manual order No. MTNC010 307C1

(PT-51G36E). A full set of schematics, disassembly procedures, and a complete parts list are included in this Simplified

Manual. Please file and use this manual together with Main Service Manual, order No. MTNC010307C1 (PT-51G36E).

“WARNING! This Service Manual is desig ned for expe rienced repa ir technici ans only and is not de signed for u se by the general pub lic.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repai red only by exp erienced profe ssional techn icians. Any attemp t to

service or repair the product or products dealt with in this Service Manual by anyone else could result in serious injury or death.”

The service technician is required to read and follow the “Safety Precautions” and “Important Safety Notice” in this Manual.

Copyright 2001 by Matsushita Electric Corporation of

America. All rights reserved. Unauthorized copying

and distribution is a violation of law.

Service Mode (Electronic Controls)

To toggle between Aging and Service

modes:

While the “CHK” is di splayed on the left top corner

of the Screen, pressing “ACTION” and “VOL UP” on

the PTV simultaneously toggles between the

modes. Red “CHK” for Service and yellow “CHK” for

Aging.

This PTV has electronic techno logy using the I²C Bus

Concept. It performs as a control function and it

replaces many mechanical controls. Instead of

adjusting mechanical controls indivi dually, many of the

control functions are now performed by using “On

Screen Display Menu”. (The Service Adjustment

Mode.)

Note: It is suggested that the techni cian r eads al l the

way through and understand the following

procedure for Entering/Exiting the Service

Adjustment Mode and then proceed with the

instructions working with the PTV.

Quick Entry to Service Mode:

When minor adjustments need to be done to the

electronic controls, the me thod of Entering the S ervice

Mode without removal of th e cabi net bac k is as fo llows

using the Remote Control:

1. Select SET-UP icon and select CABLE mode.

2. Select TIMER icon and set SLEEP time for 30 Min.

3. Press “ACTION” twice to exit menus.

4. Tune to the Channel 124.

5. Adjust VOLUME to minimum (0).

6. Press VOL (decrease) on PTV. Red “CHK”

appears in upper corner.

8. “CHK” = Normal operation of CHANNEL

and VOLUME .

b

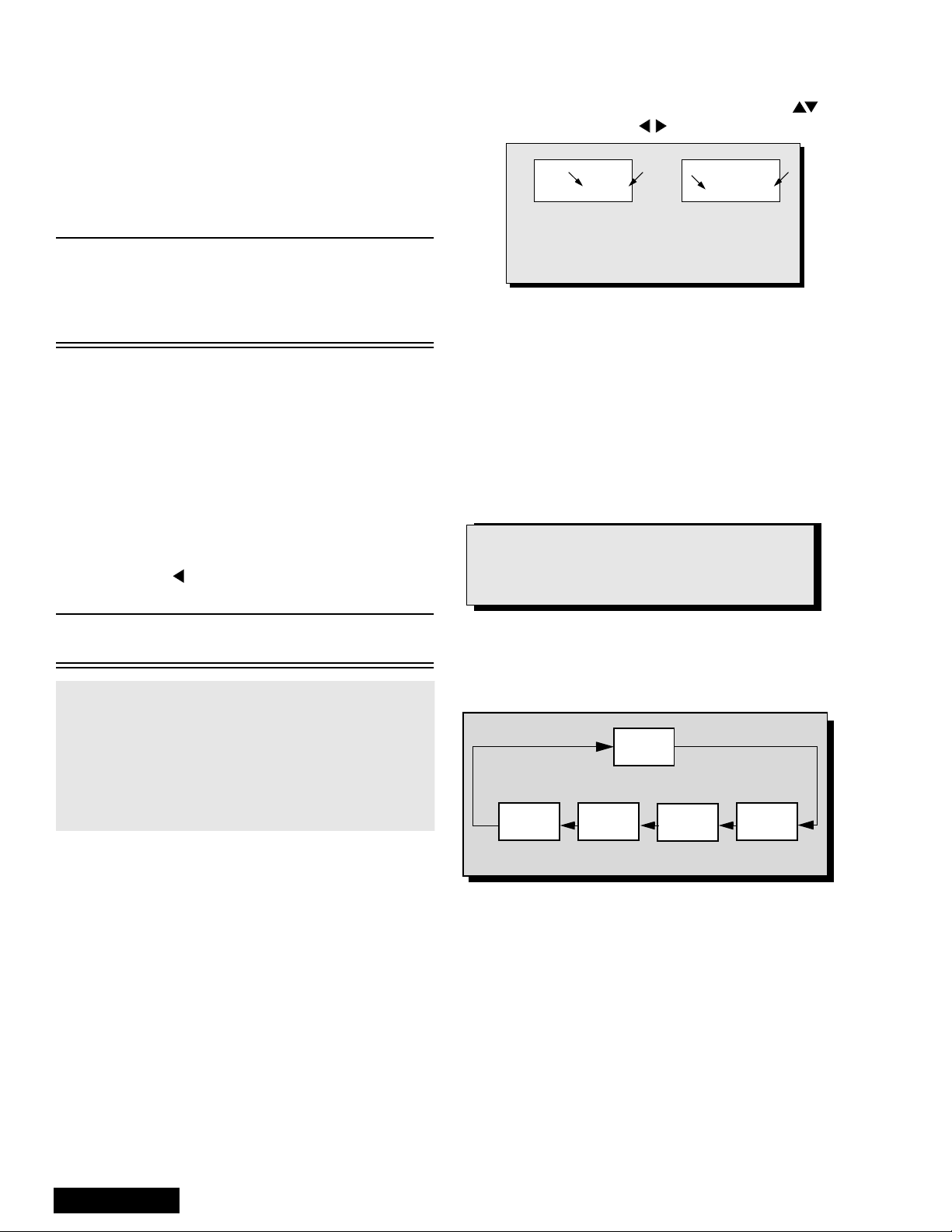

32 B 0 2 215 C 0

An address Menu appears in the right

hand corner of the screen

a

b

a

Figure 7. Service Mode Menu Adjustments.

Exiting the Service Mode:

Press “ACTION” and “POWER” on the PTV

simultaneously for at least 2 second s.

THE PTV EXITS SERVICE MODE.

The PTV momentarily shuts off; then comes back on

tuned to channel 3 with a preset level of audio.

Any programmed c hannel s, ch annels capt ion data an d

some others user defined settings will be erased.

NOTE

Always Exit the Service Mode

Following Adjustments.

Note: After PTV is set into SERVICE mode, set

TIMER back to NO.

7. Press “POWER” on the Remote Control to select

one of the Service Adjustment Modes.

1. B= Service VCJ SUB-DATA Adjustment s.

2. C= Service VCJ CUT-OFF Adjustments.

3. D= Service PINCUSHION Adjustments.

4. P= Servic e PIP Adjustments.

5. S =Service S OPTION Adjustments.

6. X =Service X OPTION Adjustments.

7. V= Service Y OPTION Adjustments.

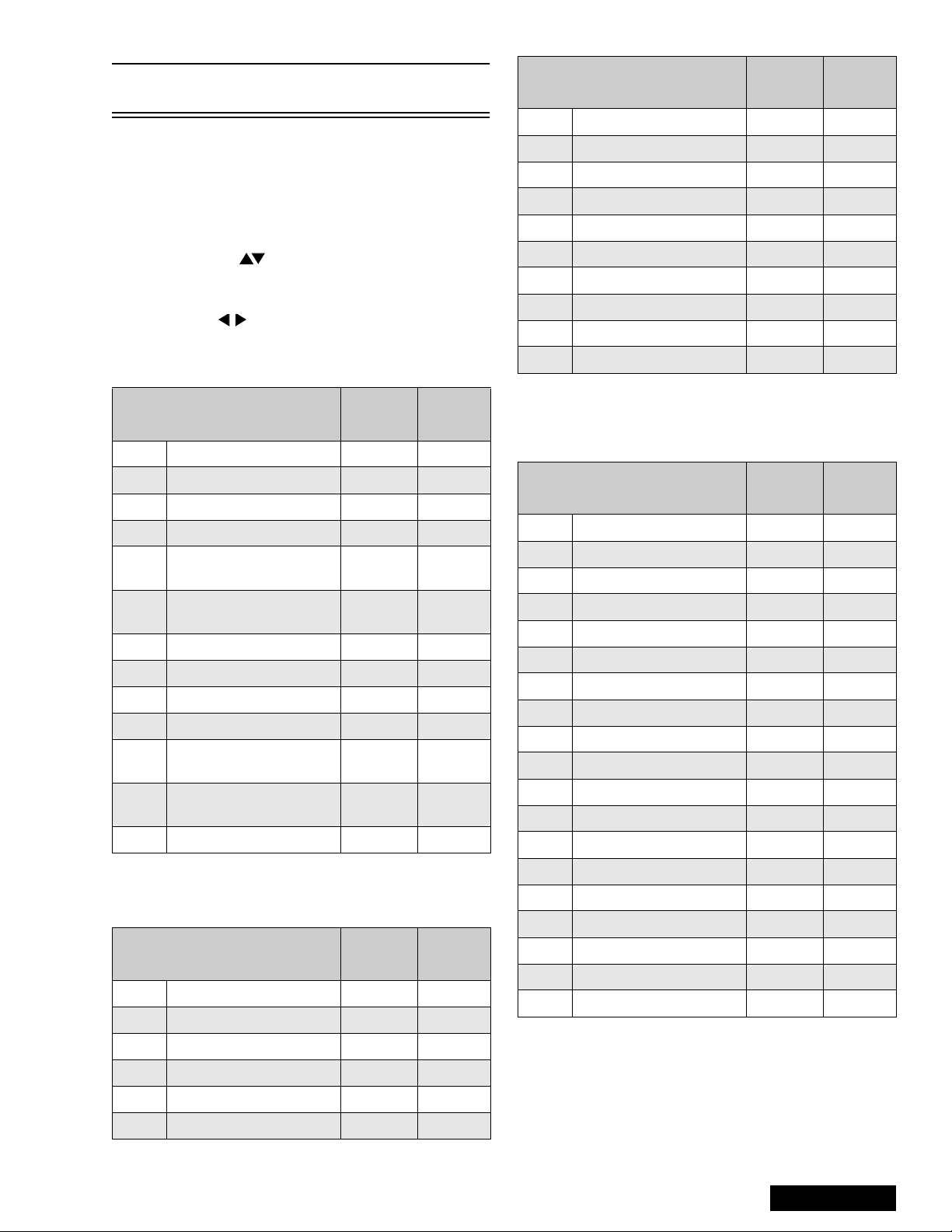

To Check Purity:

Press “RECALL” on the Remote Control when in

Service Mode (red “CHK” is displayed) to enter the

Purity Field Check Mode.

NORMAL

SCREEN

Press “RECALL” again to select desired field.

BLUE

SCREEN

GRN.

SCREEN

RED

SCREEN

Figure 8. Purity Check Field Mode.

WHITE

SCREEN

Service Manual

- 10 -

Note: Registers marked as FIXED are factory preset.

The default value must not be changed.

Important Note:

Write down the original values (“b” in the

adjustment mode details, Fig. 7) for each address

adjustment before modifying values.

Follow the procedure bel ow to access various Servic e

adjustments. (Same procedures apply to each section.)

a. Press CH on the Remote Control to select

any of the seven Service Sub Adjustment

Addresses. (“a” in Fig. 7.)

b. Press on the Remote Control to adjust

the level of the selected Service Adj ustments.

B Items: Service Sub Adjustments

Service Adjustment

B00 Sub B rightness 0 ~ 127 44

B01 Sub Contrast (RF) 0 ~ 15 5

B02 Sub C olor 0 ~ 63 18

B03 Sub Tint 0 ~ 63 34

B04

B05

B06 Sub Color (Video) FIXED 127

B07 Sub Tint (Video) FIXED 127

B08 Sub C olor (Component) FIXED 127

B09 Sub Tint (Component) FIXED 75

B0A

B0B

B0C Sub Contrast ---- ----

Sub Brightness

(Video/Component)

Sub Contrast

(Video/Component)

Sub Sharpness

(RF/Video)

Sub Sharpness

(Component)

Adj.

Range

FIXED 127

FIXED 16

FIXED 15

FIXED 20

Table 3: Ser vi ce Adj. B00 ~ B0C

Default

Level

Service Adjustment

C06 G CutOff (Video) FIXED 127

C07 B CutOff (Video) FIXED 127

C08 G Drive (Video) FIXED 127

C09 B Drive (Video) FIXED 127

C0A G CutOff (Component) FIXED 127

C0B B CutOff (Component) FIXED 127

C0C G Drive (Component) FIXED 127

C0D B Drive (Component) FIXED 127

C0E Drive Color Temp. FIXED 8

C0F Contrast Color Temp. FIXED 5

Adj.

Range

Default

Level

Table 4: Service Adj. C00 ~ C0F (Continued)

D Items: Pincushion Adjustments

Service Adjustment

D00 Vertical Amplitude 0 ~ 30 20

D01 Vertical Linearity 0 ~ 15 13

D02 Vertical S Correction 0 ~ 7 6

D03 Horizontal Amplitude 0 ~ 63 30

D04 Horizontal Centering 0 ~ 31 17

D05 EW Parabola 0 ~ 31 6

D06 Trapezoid 0 ~ 15 5

D07 EW Corner 2 0 ~ 15 8

D08 H EHT Correction 0 ~ 255 8

D09 Vertical Amplitude FIXED 3

D0A V BLK Start Phase FIXED 12

D0B V BLK Stop Phase FIXED 14

D0C V AGC FIXED 1

D0D Vertical Cente r in g FIXED 63

Adj.

Range

Default

Level

C Items: VCJ Cutoff Adjustments

Service Adjustment

C00 R Cutoff 0 ~ 255 128

C01 G Cutoff (RF) 0 ~ 255 128

C02 B Cutoff 0 ~ 255 129

C03 Brightness FIXED 31

C04 G Drive (RF) 0 ~ 127 65

C05 B Drive (RF) 0 ~ 127 66

Adj.

Range

Table 4: Service Adj. C00 ~ C0F

Default

Level

D0E V Cent. DAC SW FIXED 0

D0F Conver. FIXED 0

D10 Free Run ON/OFF FIXED 0

D11 V Size Off Set FIXED 2

D12 V Lin Off Set FIXED 8

Table 5: Service Adj. D0 0 ~ D12

- 11 -

Service Manual

P Items: PIP Adjustments

X Option Items

Service Adjustment

P00 PIP Color FIXED 92

P01 PIP Tint FIXED 54

P02 PIP Brightness 0 ~ 31 22

P03 PIP Contrast 0 ~ 12 7 80

P04 PIP V Position 9 Up FIXED 27

P05 PIP V Position 9 Down FIXED 143

P06 PIP H Position 9 Left FIXED 12

P07 PIP H Position 9 Right FIXED 103

P08 PIP V Position 16 Up FIXED 27

P09 PIP V Posit 16 Down FIXED 161

P0A PIP H Position 16 Left FIXED 12

P0B PIP H Position 16 Right FIXED 118

P0C PIP Freerun ---- ---P0D PIP Y Delay FIXED 4

P0E PIP BG Start FIXED 17

Adj.

Range

Default

Level

Table 6: Service Adj. P00 ~ P0E

S Option Items

Service Adjustment

X00 Clip Level FIXED 8

X01 Correct Gain ---- ---X02 Limit Level FIXED 24

X03 Core Level FIXED 41

X04 C Delay (RF) FIXED 2

X05 C Delay (Video) FIXED 5

X06 VM Limit Level FIXED 90

X07 VM Core Level FIXED 8

X08 Sharpness FIXED 50

X09 VM Limit Level A FIXED 255

X0A VM Freq. SW FIXED 1

Adj.

Range

Default

Level

Table 8: Service Adj. X00 ~ X0A

V Option Adjustments

Service Adjustment

V00 Static Conv. Mode ---- ---V01 Point Conv . Mo de ---- ----

Adj.

Range

Default

Level

Service Adjustment

S00 B.S. Point FIXED 7

S01 RGB Gamma FIXED 1

S02 Col Gamma FIXED 0

S03 ABL Gain FIXED 2

S04 ABL Point FIXED 0

S05 RGB Brightness FIXED 10

S06 MTS Input Level 0 ~ 63 33

S07 MTS Low Separation 0 ~ 63 8

S08 MTS H i gh Separatio n 0 ~ 63 30

S09 Clock Adjustment 0 ~ 255 128

S0A Loudness Comp FIXED 7

S0B Caption Digital Filter SW FIXED 1

S0C Caption Scroll FIXED 1

S0D RGB MTX (RF/Video) FIXED 6

S0E RGB MTX (Component) FIXED 5

S0F BBE ON/OFF FIXED 1

S10 BBE Low Level FIXED 4

S11 BBE High Level FIXED 6

S12 Surround Effect FIXED 3

Adj.

Range

Default

Level

Table 7: Serviceman Adj. S00 ~ S12

Service Manual

V02 DAF Mode ---- ---V03 DAF ON/OFF FIXED 0

V04 ABL Input Level FIXED 10

V05 Blue Gamma FIXED 0

V06 VM ON/OFF FIXED 0

V07 ABL ON/OFF FIXED 0

V08

V09

V0A

V0B V1 Delay 0 ~ 255 1

V0C

V0D

V0E

V0F

V10

Test Pattern

Vertic al Phas e

Test Pattern

Vertical OSD

Test Pattern

Horizontal OSD

User St at ic Data

(Vertical, Red)

User St at ic Data

(Vertical, Green)

User St at ic Data

(Vertical, Blue)

User St at ic Data

(Horizon, Red)

User St at ic Data

(Horizon, Green)

0 ~ 255 20

0 ~ 255 29

0 ~ 255 65

FIXED 100

FIXED 100

FIXED 100

FIXED 100

FIXED 100

Table 9: Service Adj. V00 ~ V15

- 12 -

Service Adjustment

V1 1

V12

V13

V14

V15 Start Line (LOW) FIXED 11

User Static Data

(Horizon, Blue)

Test Pattern Horizon t al

Phase (LOW)

Test Pattern Fine

Horizontal Phase (LOW)

Test Pattern Coarse

Horizontal Phase (LOW)

Adj.

Range

FIXED 100

FIXED 90

FIXED 235

FIXED 0

Default

Level

Table 9: Service Adj. V00 ~ V15 (Continued)

HV_Feedback Voltage (D08)

Procedure:

1. Apply a NTSC all black pattern.

2. Connect meter (+) to TPA38 and (-) to TPA20.

3. Adjust DAC D08 until reading on meter is

5.0V ± 0.2V.

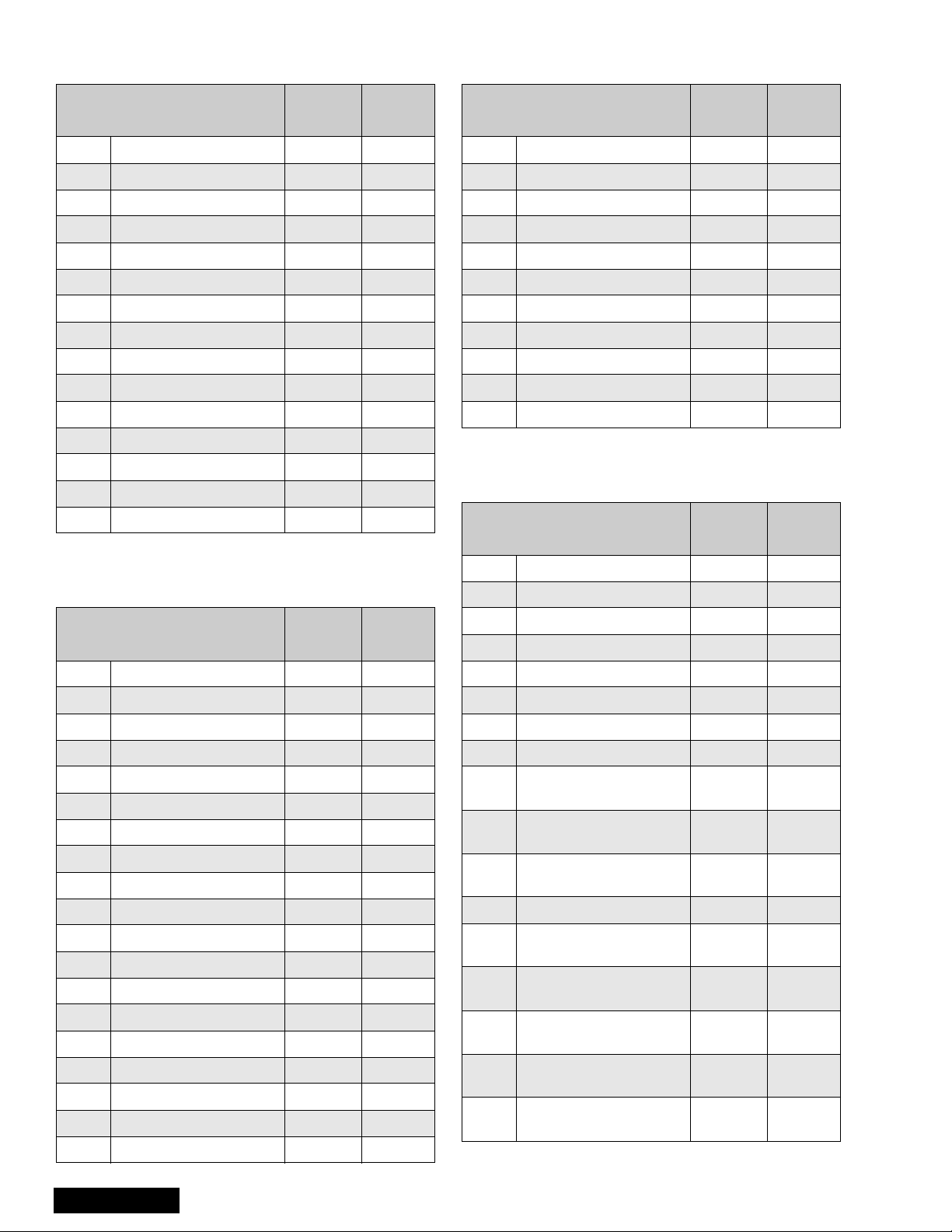

Sub-Bright Adjustment (B00)

Procedure:

1. Normalize picture.

2. Connect meter (+) to TPA18 and (-) to TNPA19.

3. Apply a black level pattern.

4. Adjust DAC B00 (Sub-Brightn ess) until reading on

meter is 17.0V ± 1V (7.5 IRE part is same light

output as 3 IRE part. See Fig. 9.

5. Apply a monoscope pattern and adjust bright

control to max. and confirm same reading on

meter.

Contrast Adjustment

Preparation:

1. Set Auto Color and AI Picture to “OFF”.

2. Set the following in the user picture menu as

follows:

COLOR: min. (0)

PICTURE: max (63)

BRIGHT: center (31)

SHARPNESS: min. (0)

Set Cut Off Data:

• DAC C00 (R_CutOff) to 128.

• DAC C01 (G_RF CutOff) to 128.

• DAC C02 (B_CutOff) to 128.

• DAC C06 (G_Video CutOff) to 127.

• DAC C07 (B_Video CutOff) to 127.

• DAC C0A (G_Video Component) to 127.

• DAC C0B (B_Video Component) to 127.

Set Drive Data:

•DAC C04 (

•DAC C05 (B_Drive RF) to 64.

Procedure:

1. Use 100:1 probe for measurements.

2. Apply a black/white pattern. See Fig. 9.

G_Drive RF) to 64.

Figure 9. Black/white Pattern

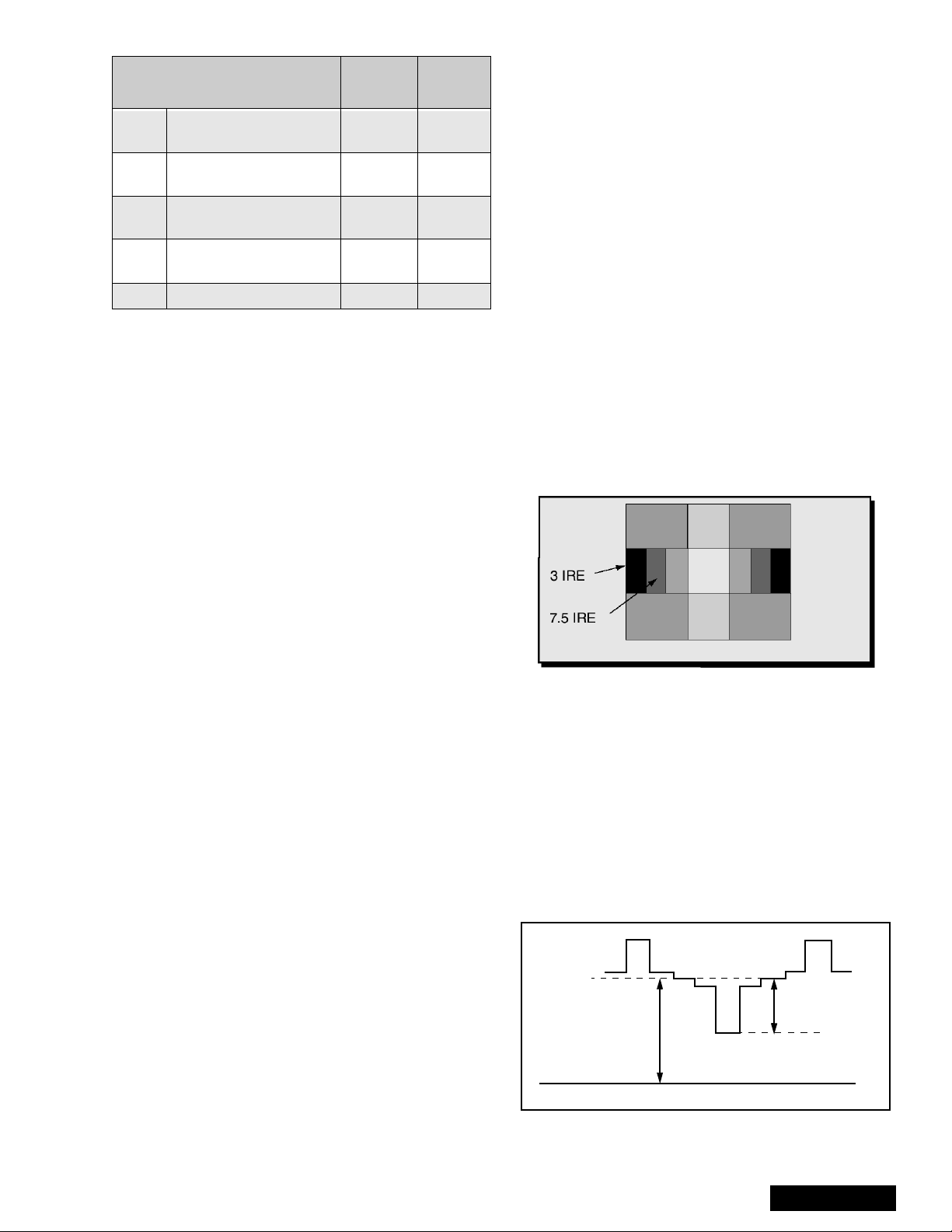

3. Connect scope to TPLR1 and adjust Sub-Bright

(B00) data until voltage measured is 190V ± 2V.

See Fig. 10.

4. Connect scope to TPLG1 and adjust R-CutOff

(C00) data until voltage measured is 190V ± 2V.

See Fig. 10.

5. Connect scope to TPLB1 and adjust B-CutOff

(C02) data until voltage measured is 190V ± 2V.

See Fig. 10.

6. Connect scope to TPLR1 an d adjust Sub-Co ntrast

(B01) data to obtain 85V ± 2V between black

(7.5 IRE) and White level. See Fig. 10.

7.5 IRE

85V ± 2V (R)

190V±2V (R, G, B)

Use 100:1 Probe

GND

100 IRE

Figure 10. Contrast Adjustment.

- 13 -

Service Manual

Red, Green & Blue Screen Cutoff

1. Use either a no input signal condition or raster from

the NTSC generator.

2. Observing the green tube directly or via a reflective

surface, adjust the VR on the green tube for

minimum noise.

3. Adjust the noise level i n the red and blue tubes to

match the noise level in the green tube.

White Balance Adjustment

Prior to this adjustment, perform Contrast Adjustment.

This adjustment requires that the service technician

use skills in observing what a screen without color

should look like (White Picture).

1. Enter the service mode.

2. Apply a black and white pattern to one of the vi de o

inputs.

High Light White Balance Adjustment

1. Adjust DAC C04 for green and C05 for blue

adjustments.

2. Make sure the screen is not blue or green. The

screen should be white in all areas.

3. Check the black and white pattern for a black and

white picture with even shades of gray and no color

tint in the picture.

Low Light White Balance Adjustment

1. Adjust DAC C01 for green and DAC C02 for blue.

2. Check the screen for even pure white in all areas.

3. Check the black and white pattern for a black and

white picture, even shades of gray and no color tint

in the low light areas.

4. Repeat the High Light and Low Light White

Balance again until the white bal ance tracks from

high light to low light.

Tint and Color Check

Again, the service technician ability to see color and

the balance of color is important for these adjustments.

Tint Check

1. In Picture Menu set Picture Norm to YES.

2. Apply color bars to the video input.

3. Magenta is composed of two colors, blue and red.

4. Check to see that magenta does not have too

much blue or too much red.

5. Check cyan. Cyan is c omposed of blu e and green .

It should not have too much blue or green.

6. Use a test signal from a V CR or la se r dis k that has

a pre-recorded close up of a sign al that has good

flesh tones.

7. The signal on the VCR or laser disk should look

normal.

Color Check

Using a clean RF or video s ignal, s et the col or level so

that it does not sat urate or appear harsh. Make sure

that color is n ot set so that it a ppears du ll and washed

out. Look for natural co lors; try to adjust the pic ture to

appear as a normal photograph.

MTS Circuit Adjustments

Note: It is important to a djust the MTS circuit in th e

order shown below.

The MTS Circuit Adjustments require two steps:

1. Input Level Adjustment.

2. Stereo Separation Adjustment.

Input Level Adjustment (S06)

Preparation:

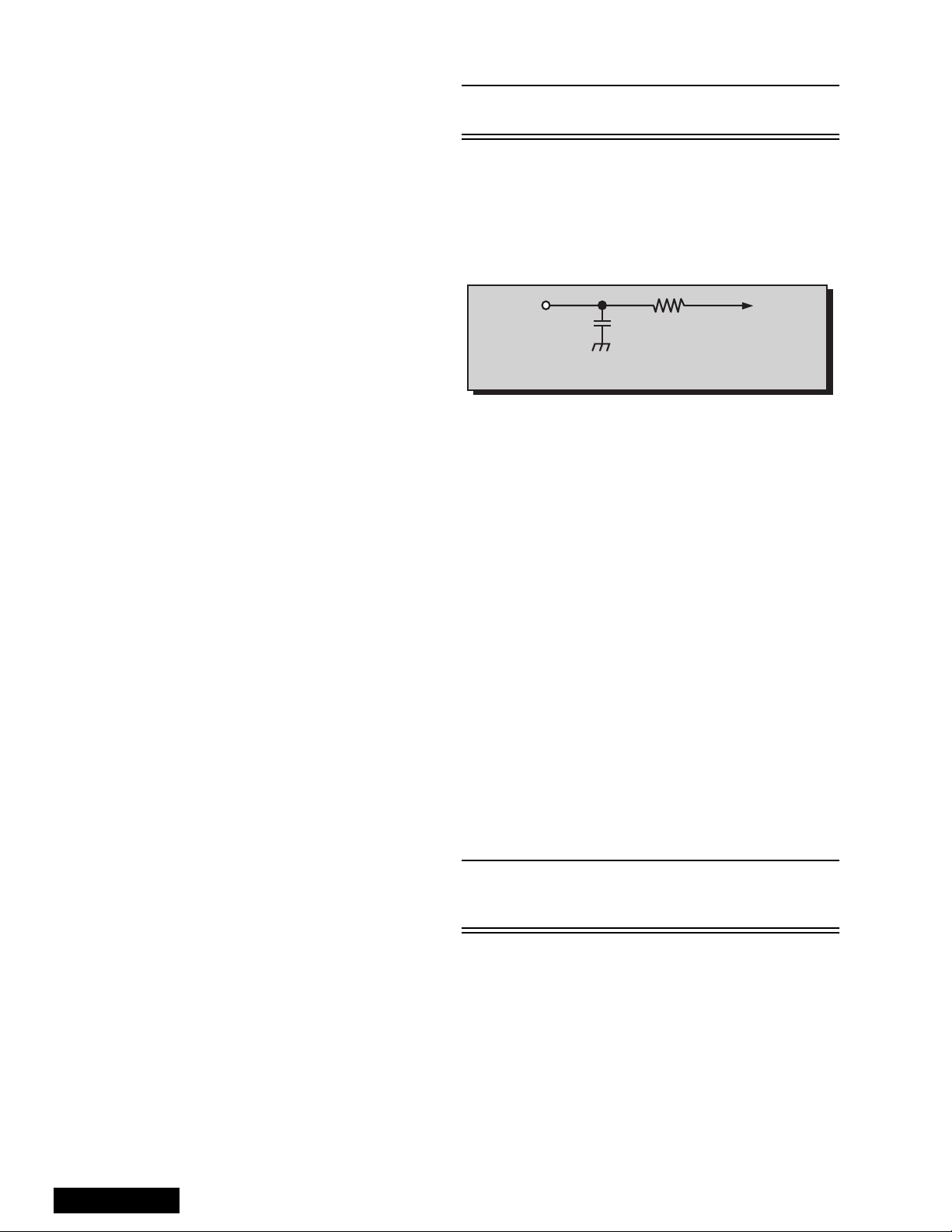

1. Connect an RMS meter (AC Range) with fil ter jig

as shown in Fig. 11.

RMS

METER

10k

TPE11

L_OUT

4700p

Figure 11. Filter Jig

2. Connect an RF signal generator to the RF

antenna input.

Procedure:

1. Apply the following signal from the RF signal

generator:

Video: 100 IRE flat field, 30% modulation.

Audio: 300Hz, 100% modulation, monaural

(70 ± 5dB/mV, 75Ω OPEN, P/S 10dB). Make sure

to turn off 75ms pre-emphasis.

2. Adjust (S6)

measured is 106mV ± 6.0mV rms.

MTS-INPUT

data until the voltage

Stereo Separation Adjustment (S07 & S08)

Preparation:

1. Connect an RF signal generator to the RF

antenna input.

2. Connect an oscilloscope probe to TPE10 (R_out).

Procedure:

1. Set PTV to Stereo Mode (in the Audio Menu).

2. Apply the following signal from the RF signal

generator:

Video: 100 IRE flat field, 30% modulation.

Audio: 300Hz, 30% modulation, stereo (left only)

(70 ± 5dB/mV, 75Ω OPEN, P/S 10dB).

Note: Set the 30% modulation with the pilot ligh t SW

and N.R. switches “OFF” then turn the m “ON”

while testing.

3. Adjust MTS Low-Level Separation (S07) data (in

the Service Adjus tment Menu) until the amplitude

of the measured waveform on the scope is

minimum.

4. Apply the following signal from the RF

signal generator:

Video: 100 IRE flat field, 30% modulation. Audio:

3KHz, 30% modulation, stereo (left only).

(70 ± 5dB/mV, 75Ω OPEN, P/S 10dB) .

Service Manual

- 14 -

Loading...

Loading...