Panasonic PT-50LCZ70, PT-56LCZ70, PT-61LCZ70, PT-50LCZ7, PT-56LCZ7 Service Manual

...

Multi Media Display

PT-50LCZ70

PT-56LCZ70

PT-61LCZ70

PT-50LCZ7

PT-56LCZ7

PT-61LCZ7

PT-50LCZ70-K

ORDER NO. MKE0706852CE

B2

PT-56LCZ70-K

PT-61LCZ70-K

Vol. 1

© 2007 Panasonic Shikoku Electronics Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

CONTENTS

Page Page

1 Safety Precautions 3

1.1. General Guidelines

1.2. Leakage Current Cold Check

1.3. Leakage Current Hot Check

1.4. Disposal Lamp

2 Warning

2.1. Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

3 Service Navigation

3.1. Introduction

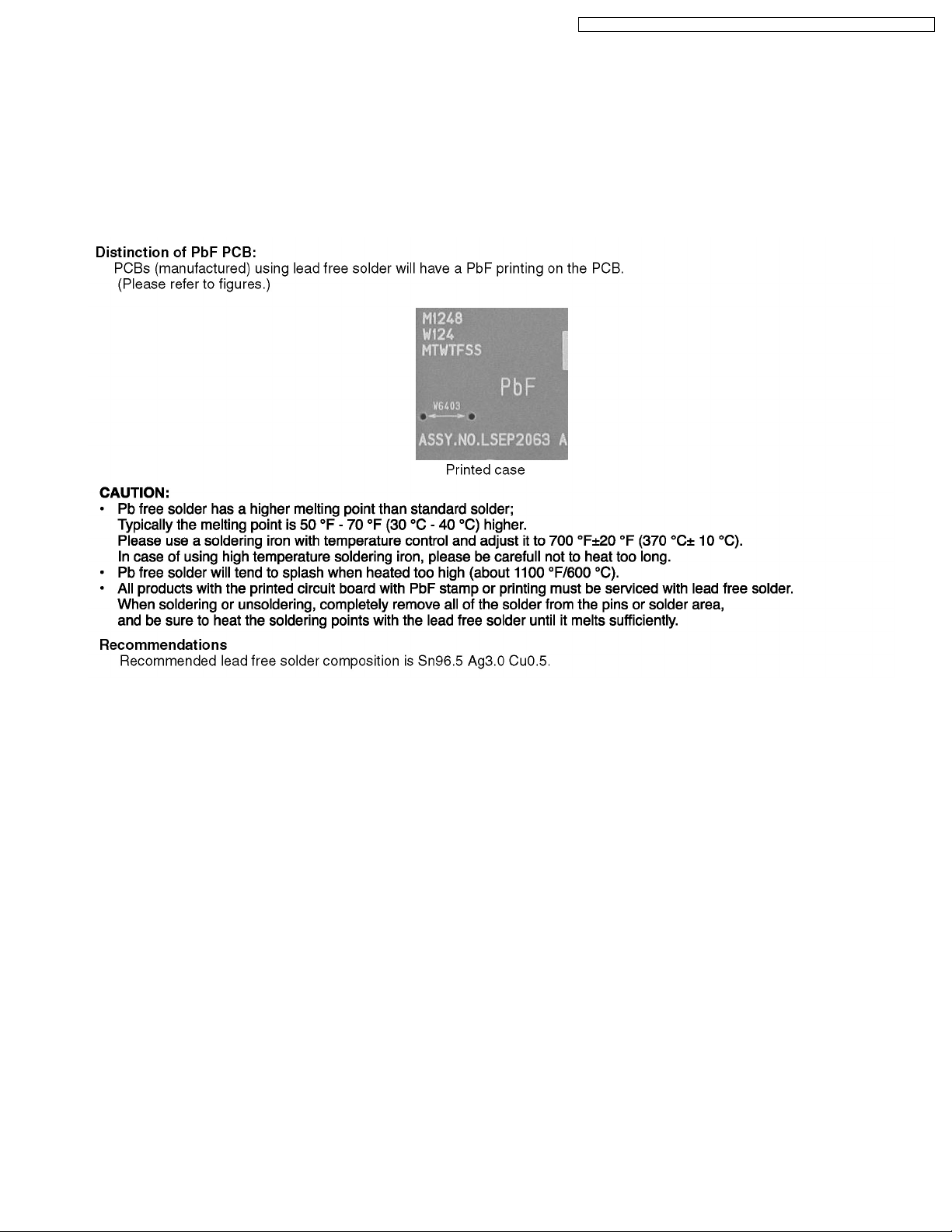

3.2. About Lead Free Solder (PbF)

4 Specifications

5 Service Mode

6 Troubleshooting Guide

6.1. Troubleshooting Hints for Block Level Repair

7 Disassembly and Assembly Instructions

7.1. Cabinet Section

8 Measurements and Adjustments

8.1. Adjustment Procedures 1

9 Maintenance

9.1. Cleaning Methods

10 Voltage Chart and Waveform of Connectors

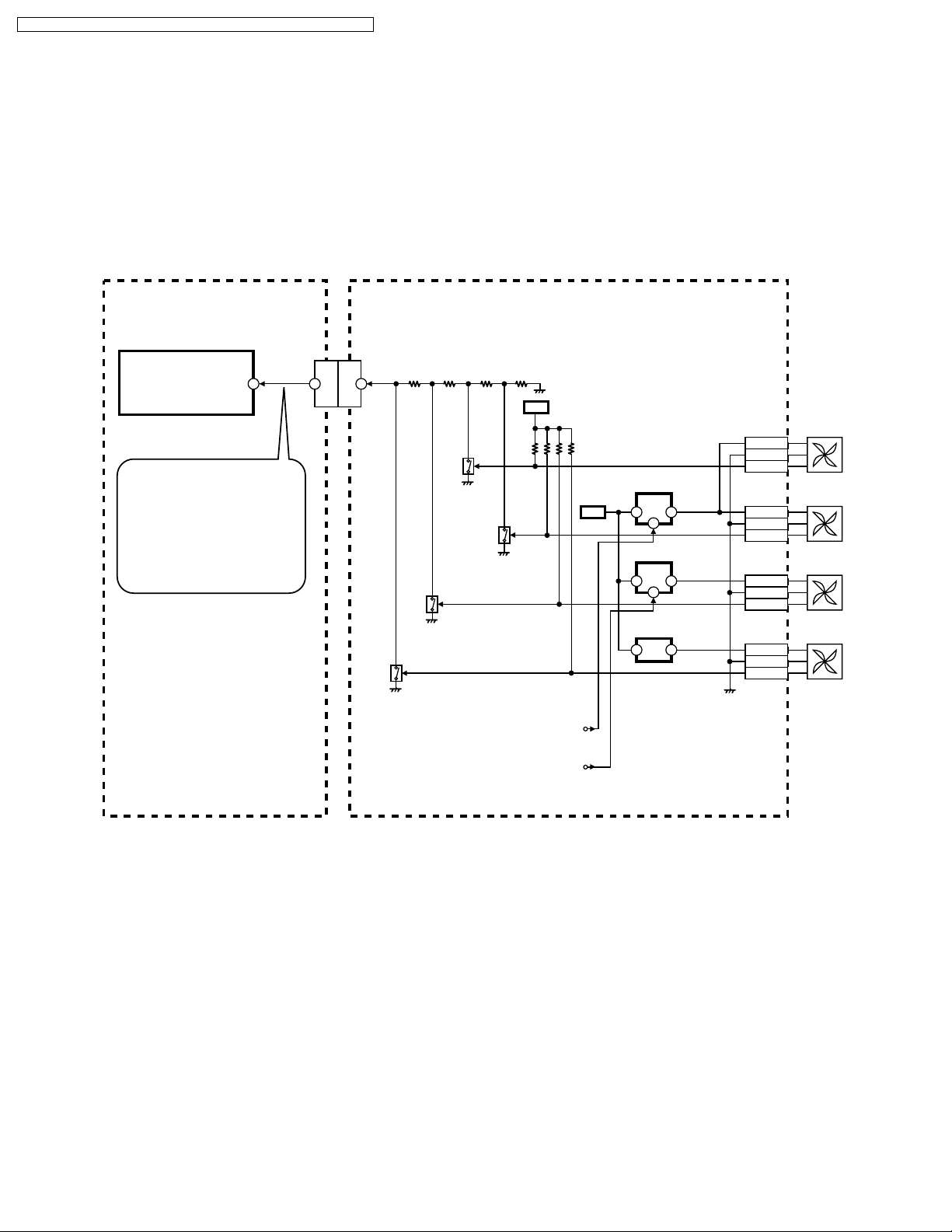

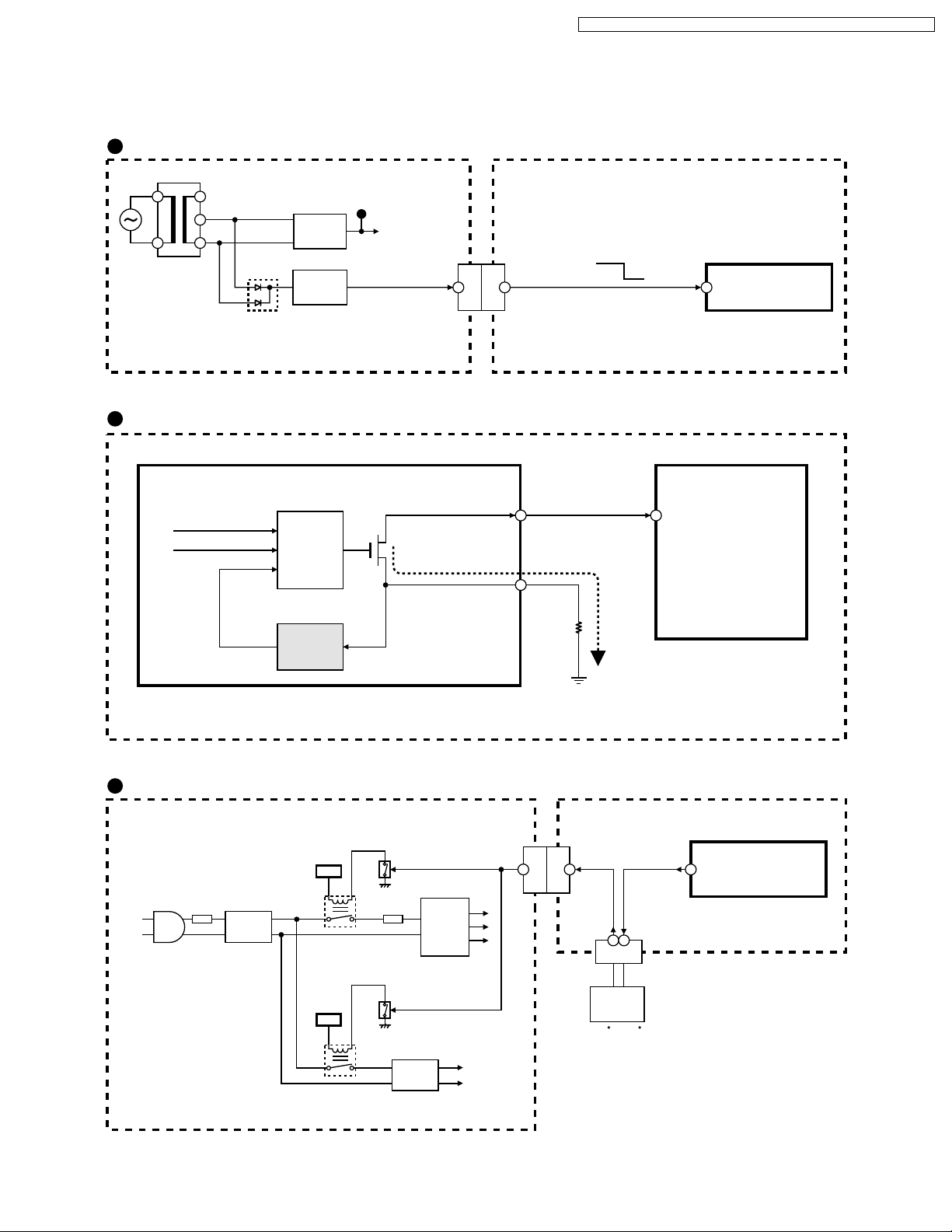

11 Block Diagrams

12 Schematic Diagrams

12.1. SCHEMATIC DIAGRAM & CIRCUIT BOARD LAYOUT

NOTES

19

19

33

33

55

55

58

58

59

63

65

65

3

3

3

3

4

4

5

5

5

6

7

12.2. INTERCONNECTION SCHEMATIC DIAGRAM

12.3. POWER SCHEMATIC DIAGRAMS

12.4. SD/HDMI SCHEMATIC DIAGRAM

12.5. REAR JACK SCHEMATIC DIAGRAM

12.6. FRONT JACK/OPERATION / POWER SWITCH / TUNER

SCHEMATIC DIAGRAM

13 Printed Circuit Board

13.1. POWER P.C.B.

13.2. SD/HDMI P.C.B.

13.3. REAR JACK P.C.B.

13.4. FRONT JACK/OPERATION P.C.B. / TUNER P.C.B. /

POWER SWITCH/OPERATION P.C.B.

14 Ex ploded Vie w s

14.1. MAIN PARTS SECTION

14.2. BASE BODY SECTION

14.3. DISPLAY SECTION

14.4. SCREEN SECTION

14.5. OPT/TV UNIT SECTION

14.6. LAMP UNIT SECTION

14.7. PACKING PARTS AND ACCESSORIES SECTION

15 Replacement Parts List

15.1. REPLACEMENT NOTES

15.2. MECHANICAL REPLACEMENT PARTS LIST

15.3. ELECTRICAL REPLACEMENT PARTS LIST

66

67

68

69

74

75

75

76

77

78

79

79

81

82

84

86

87

88

89

89

90

91

2

1 Safety Precautions

1.1. General Guidelines

1. For continued safety, no modification of any circuit should

be attempted.

2. Disconnect AC Plug before disassembling this unit.

3. It is advisable to use an isolation transformer in the AC

supply before servicing.

4. When servicing, observe the original lead dress. If a short

circuit is found, replace all parts which have been

overheated or damaged by the short circuit.

5. After servicing, see to it that all the protective devices such

as insulation barriers, insulation papers, shield, and

isolation R-C combinations etc. are properly installed.

6. After servicing, be sure to restore the wires, leads,

insulation barriers, shields, etc.

7. After servicing, make the leakage current checks to prevent

the customer from being exposed to shock hazards.

Caution:

Use a separate Isolation Transformer for this unit when

servicing.

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

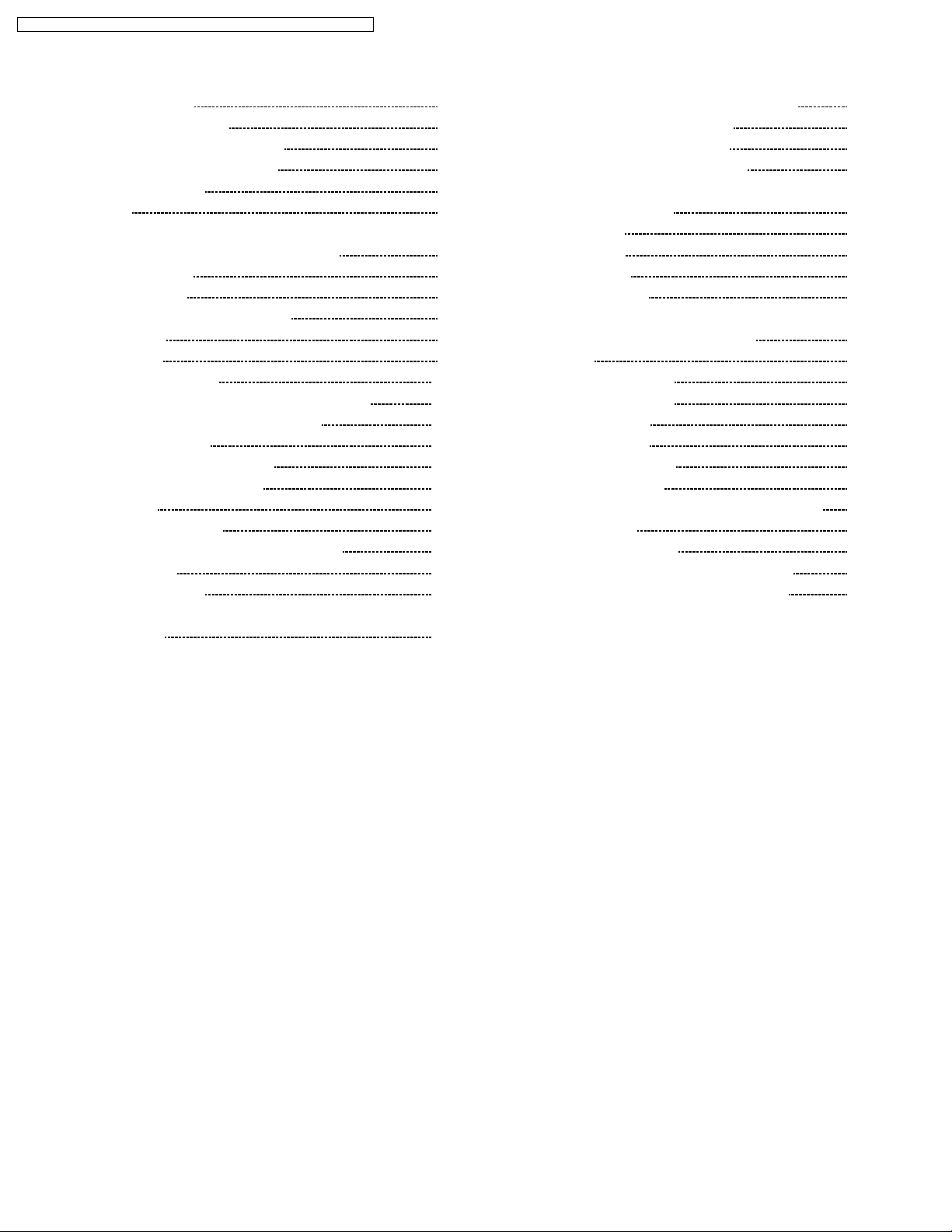

Figure 1

1.4. Disposal Lamp

1.2. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2. For physically operated power switches, turn power on.

Otherwise skip step 2.

3. Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the receiver, such as screwheads, connectors, etc.

When the exposed metallic part has a return path to the

chassis, the reading should be between 1 MΩ and 12 MΩ.

When the exposed metal does not have a return path to the

chassis, the reading must be infinity.

1.3. Leakage Current Hot Check

1. Plug the AC cord directly into the AC outlet.

Do not use an isolation transformer for this check.

2. Connect "A" to exposed metallic part on the set. And

connect "B" to a good earth ground, as shown in Figure 1.

3. Use an AC voltmeter, with 1 kΩ/V or more sensitivity, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the

above measurements.

6. The potential at any point should not exceed 0.25 V RMS.

A leakage current tester (Simpson Model 228 equivalent)

may be used to make the hot checks. Leakage current must

not exceed 1/2 mA. In case a measurement is outside of

the limits specified, there is a possibility of shock hazard,

and the receiver should be repaired and rechecked before

it is returned to the custom er.

3

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

2 Warning

2.1. Prevention of Electro Static Discharge (ESD) to Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an antistatic solder removal device. Some solder removal devices not classified as "antistatic (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable

conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION :

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

4

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

3 Service Navigation

3.1. Introduction

This service manual contains technical information which will allow service personnel´s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, this information will be followed by supplement service manual to be filed with original service

manual.

3.2. About Lead Free Solder (PbF)

5

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

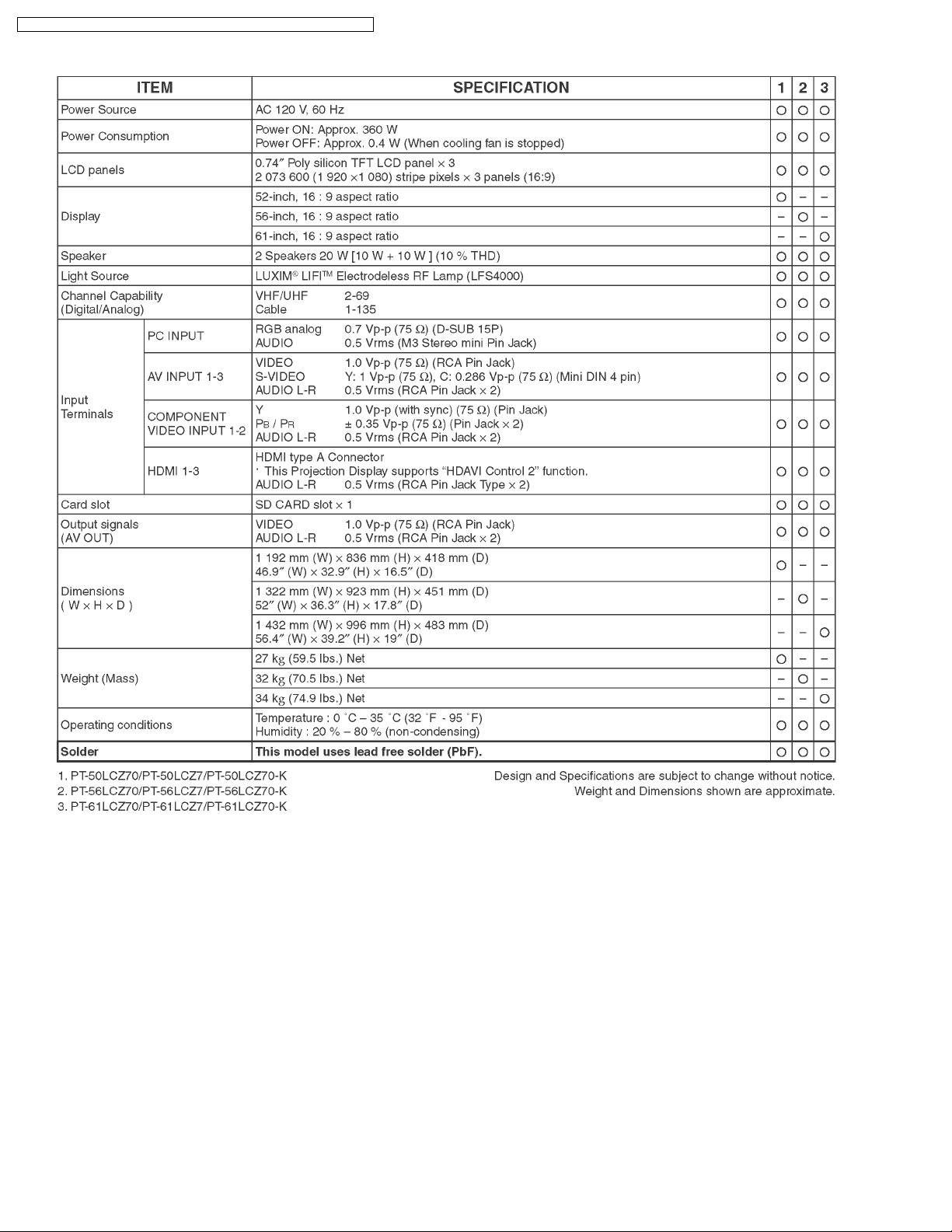

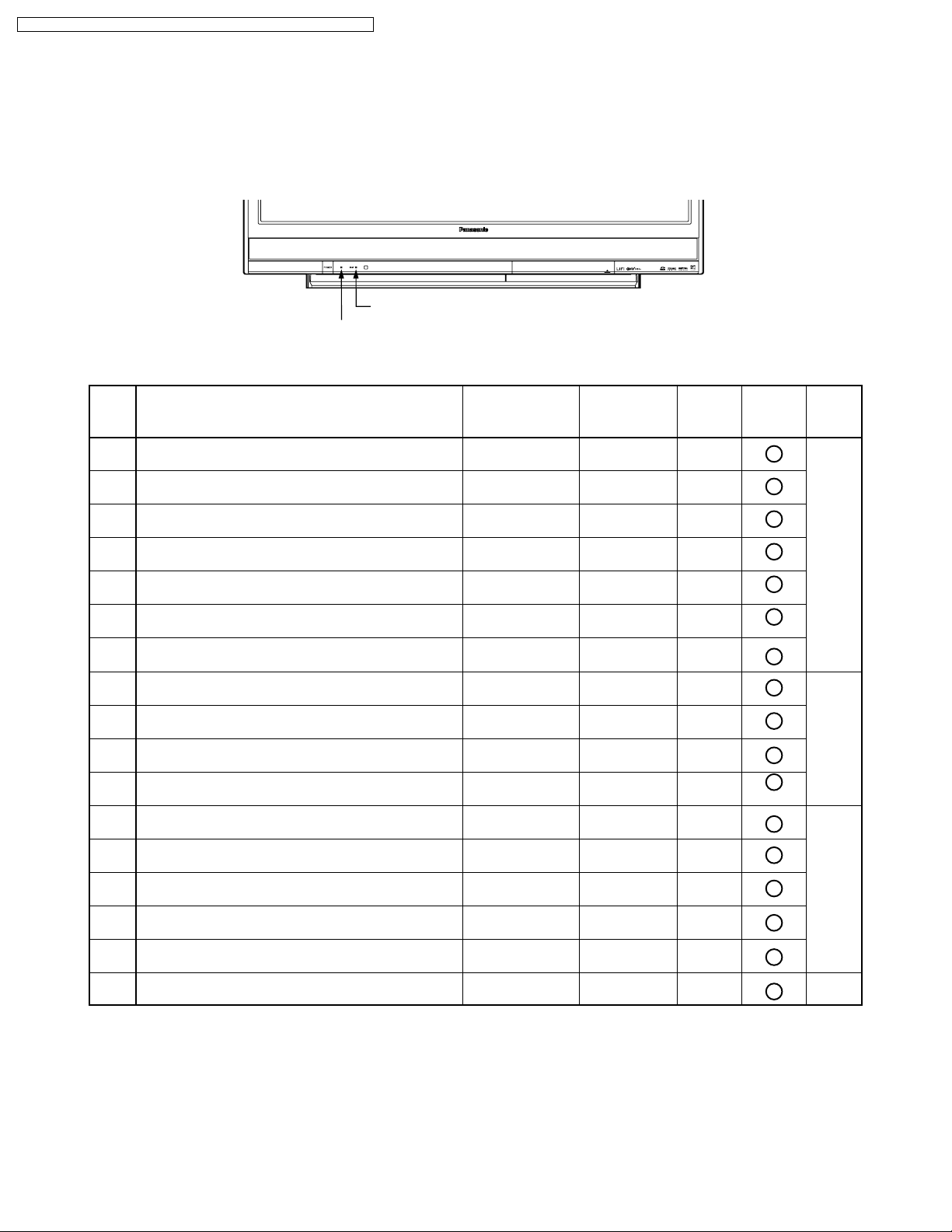

4 Specifications

6

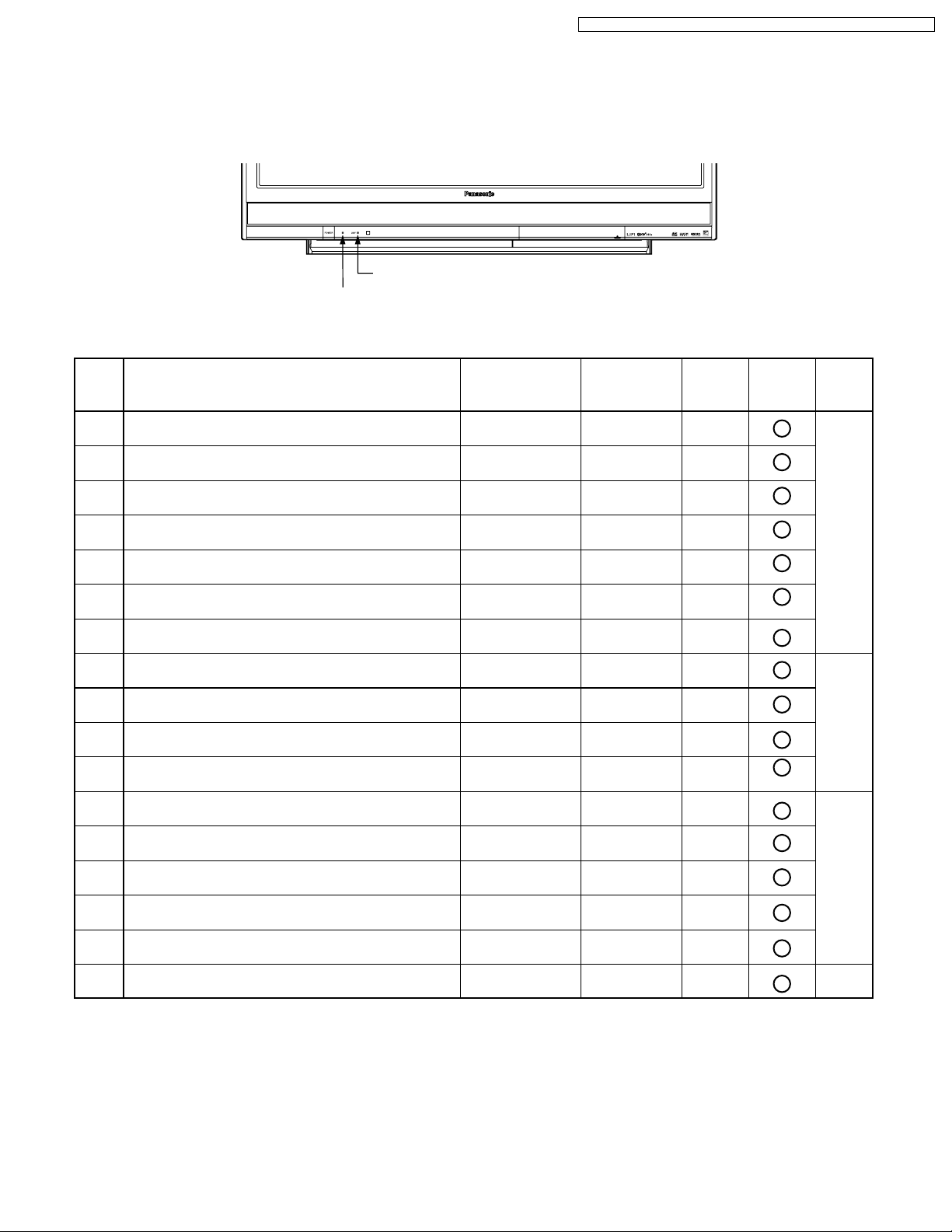

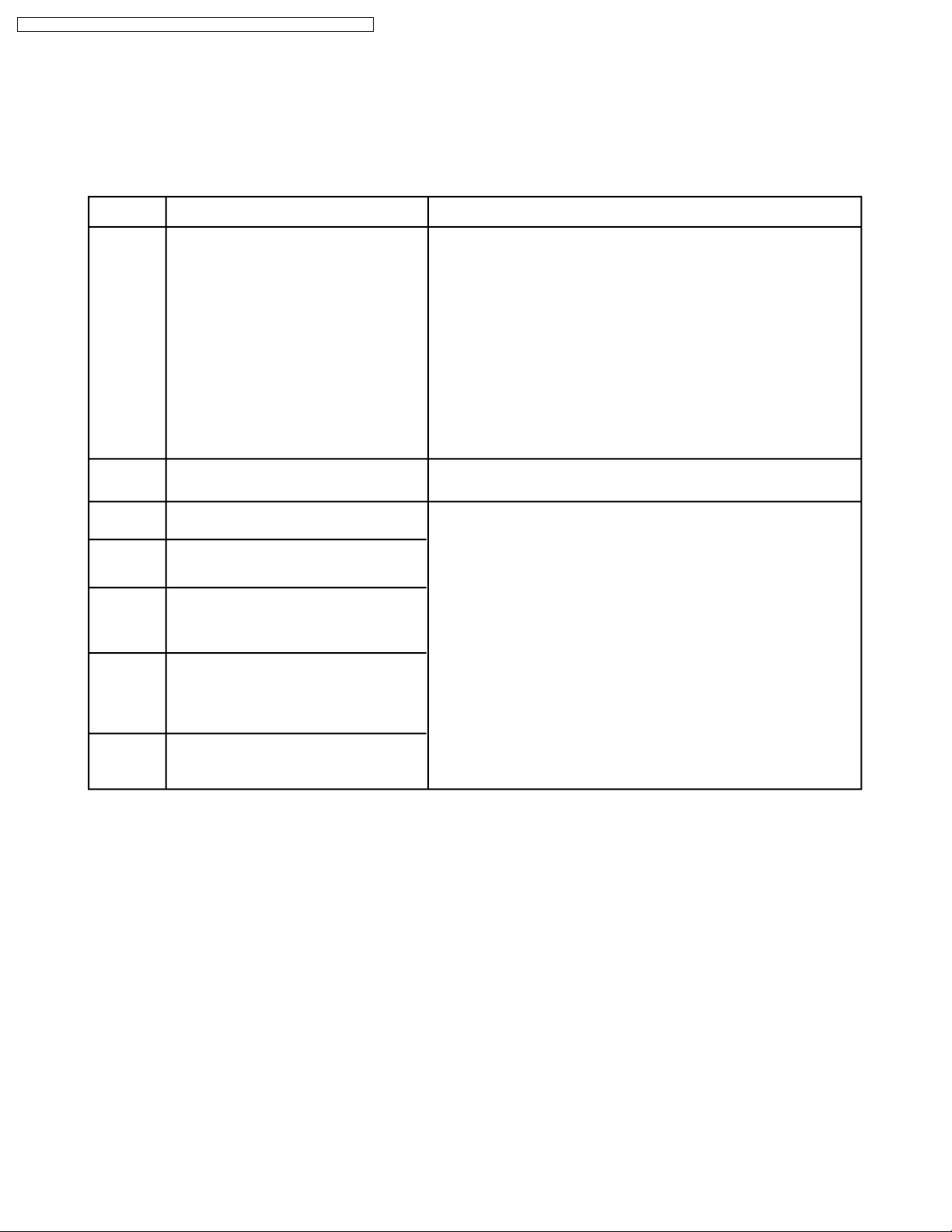

5 Service Mode

INDICATIONS FOR ERROR CONDITIONS

Each Indicator facilitates finding the cause of an error.

When an error is detected, the Lamp goes off and the indicators on the front flash.

LAMP Indicator

POWER Indicator

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

(Note 1)

Priority

1

Over voltage/Over current (SOS)

2

Abnormal voltage (DTV+9V line)

Abnormal voltage (SUB+5V line)

3

4

Abnormal voltage (MAIN+3.3V line)

5

IC4501 (Audio Amp) failure

Communication error between Peaks (IC8001)

6

and TV Microcontroller (IC6004)

Communication error between Peaks (IC8001)

7

and TV Microcontroller (IC6004)

12

Lamp does not light up

9

Lamp failure

10

Abnormal Lamp temperature

11

Lamp communication error

14

Lamp Fan stops

Error Information

POWER Indicator

flashes orange

1

2

3

4

6

7

9

-

-

-

-

-

LAMP Indicator

flashes red

-

-

-

-

-

-

-

2

3

4

5

8

SOS

01

02

03

04

06

07

09

02

03

04

05

08

LAMP OFF

RESET

AC

ON/OFF

Power

ON/OFF

(Note 2)

15

Fan Case Unit (OPT Fan) stops

16

Front Fan or Rear Fan stops

17

Rear Fan or Front Fan stops

13

Rear Jack PCB connection error

8

Abnormal Lamp input voltage (+26V)

Note:

1. The detected Error data will be stored in the EEPROM, and SOS History (Code) is displayed in Self Check mode

or Service Adjust mode (SRV-TOOL).

2. The Lamp Indicator will flash X5 immediately after the Lamp goes off. For this SOS only, the TV power will remain on.

-

-

-

-

-

7

9

10

11

12

13

09

0A

0B

0C

0D

AC

ON/OFF

Power

ON/OFF

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

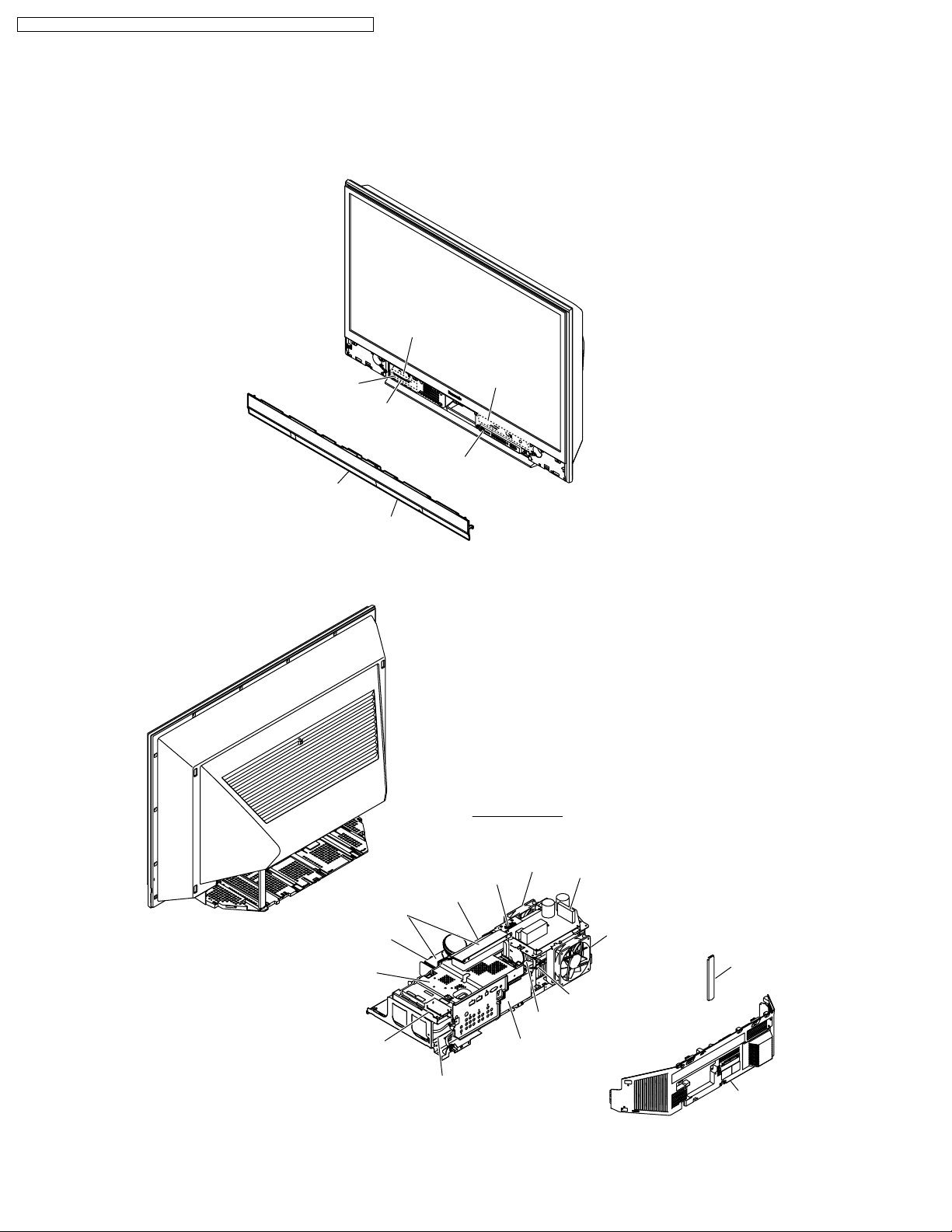

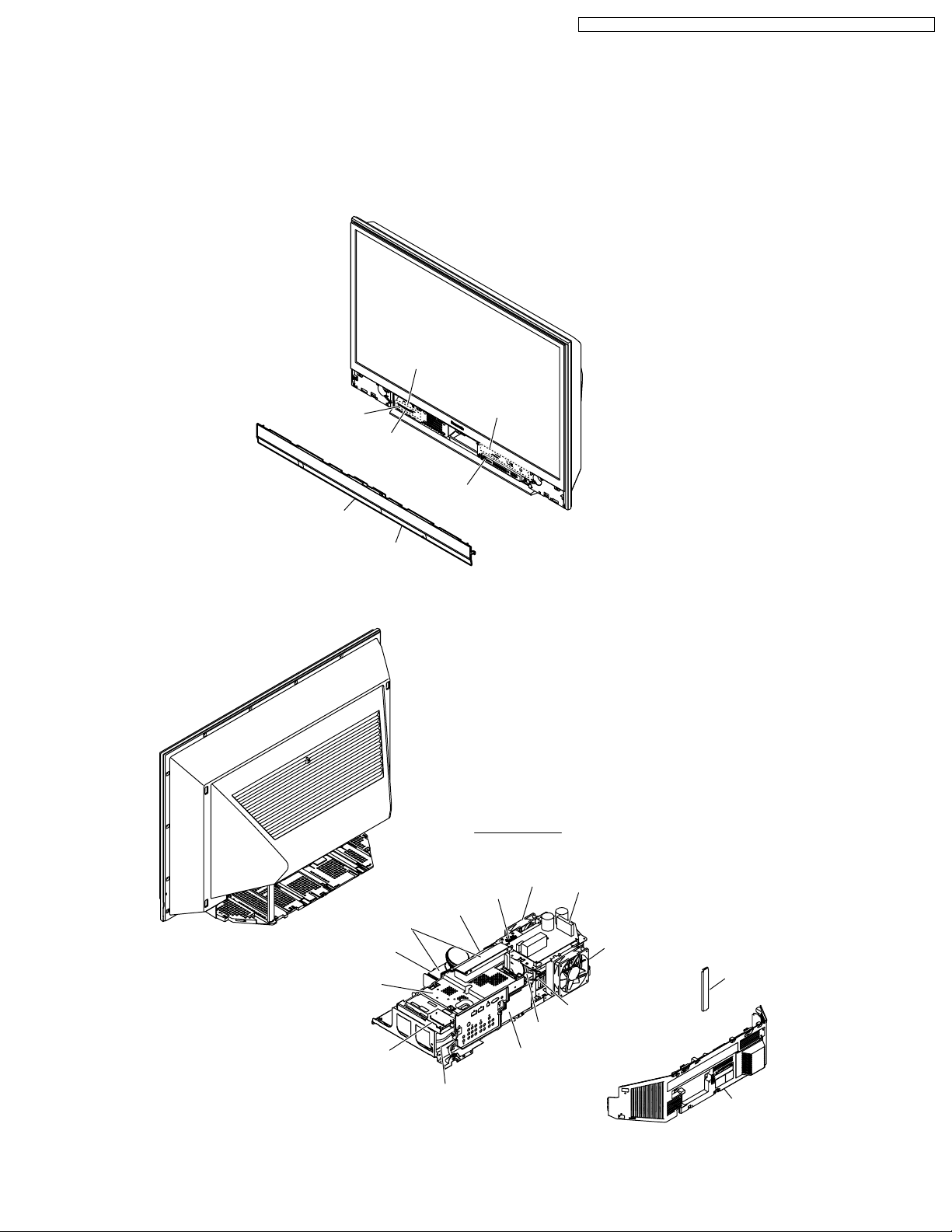

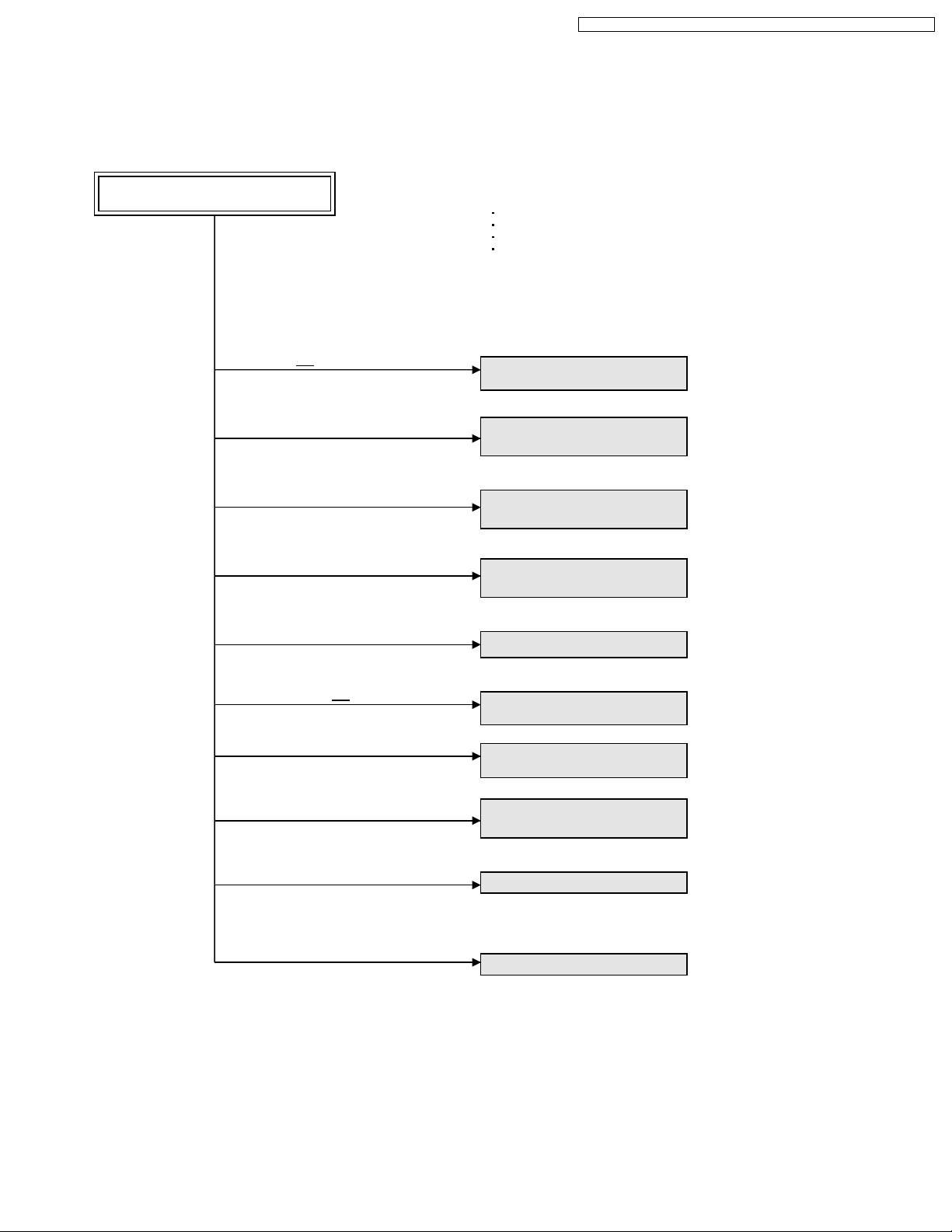

MAIN PARTS LOCATION

POWER LED

LAMP LED

Front Cover Unit

<Front View>

Power Switch

/Operation P.C.B.

Front Jack

/Operation P.C.B.

SD/HDMI P.C.B.

Front Door

Air Filters

Fan Case Unit

(OPT Fan)

Main P.C.B./

Drive P.C.B.

<Rear View>

Lamp Fan

Top Duct Unit

OPT/TV Unit

Front Fan

Lamp Unit

RF AMP

Power Supply P.C.B.

Rear Fan

Support

Shield

Thermal Fuse

Tuner P.C.B.

Rear Jack P.C.B.

Power P.C.B.

Rear Cover

8

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

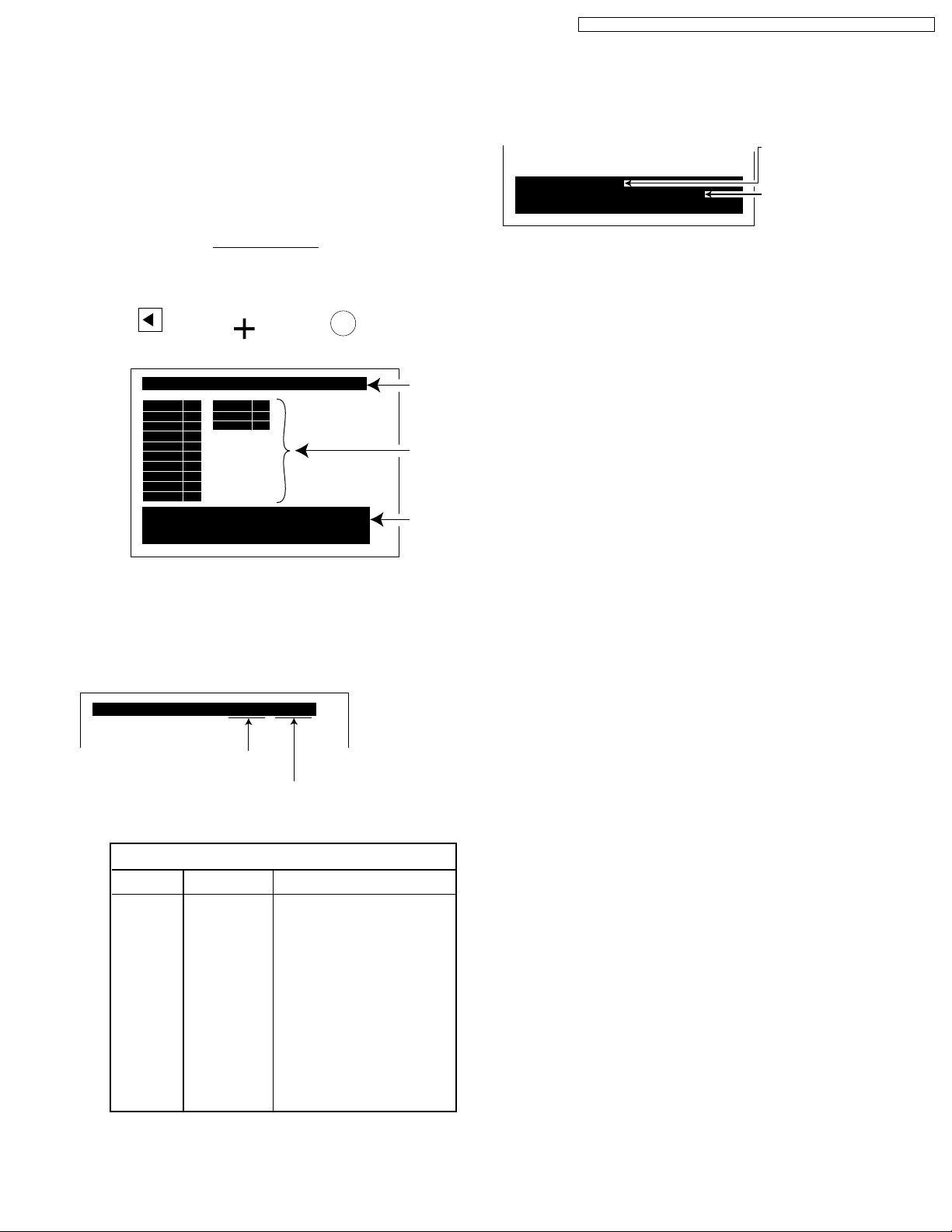

SELF CHECK

In this mode, the following information can be confirmed on the

screen:

- Peaks software version and EEPROM data version

- Communication check between Peaks IC and each ICs

- SOS History

Self Check

Enter:

VOLUME DOWN button + OK key

(for more than 3 seconds in power on condition)

_

VOL

(on the front)

SELF CHECK 0.480-00.16

DT

ADV

VSW

ADAV

ASW

TUN1

TUN2

FE

GenX4

MEM1

SOS POWER: 02 04

SOS LAMP : 08 09 0A 0B

Copyright 2007 Matsushita Electric Industrial Co., Ltd.

MEM2 OK

OK

GC5P OK

OK

FPGA OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

(on the remote)

*1

*2

*3

*3. SOS History

SOS History

The number of time

Power Indicator flashed

: 01 ~ 09

SOS POWER: 02 04

SOS LAMP : 08 09 0A 0B

Copyright 2007 Matsushita Electric Industrial Co., Ltd.

The number of time

Lamp Indicator flashed

: 02 ~ 0D

Note:

If the same SOS error occurs more than once, only one

code will be displayed.

<Self Check>

Exit:

Unplug the AC cord.

Fig. 1-1

*1. Peaks software version and Peaks EEPROM data version

SELF CHECK 0.480-00.16

Peaks software version

Peaks EEPROM data version

*2. Communication check results (OK or NG) between Peaks

IC8001 and each of the following ICs.

(Communication check for I2C bus)

Display Item

DT

ADV

VSW

ADAV

ASW

TUN1

TUN2

FE

GenX 4

MEM1

MEM2

GC5P

FPGA

ICs Description

IC8001

IC5510

IC3001

IC4001

IC4101

TU8201

TU8201

IC8802

IC6004

IC6005

IC8201

IC7101

IC7119

PEAKS internal check

AD/HDMI Interface

Video SW

Audio DSP

Audio SW

Tuner PLL block

Tuner MTS block

Demodulator

TV Microcontroller

GenX4 EEPROM

Peaks EEPROM

GC

FPGA

9

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

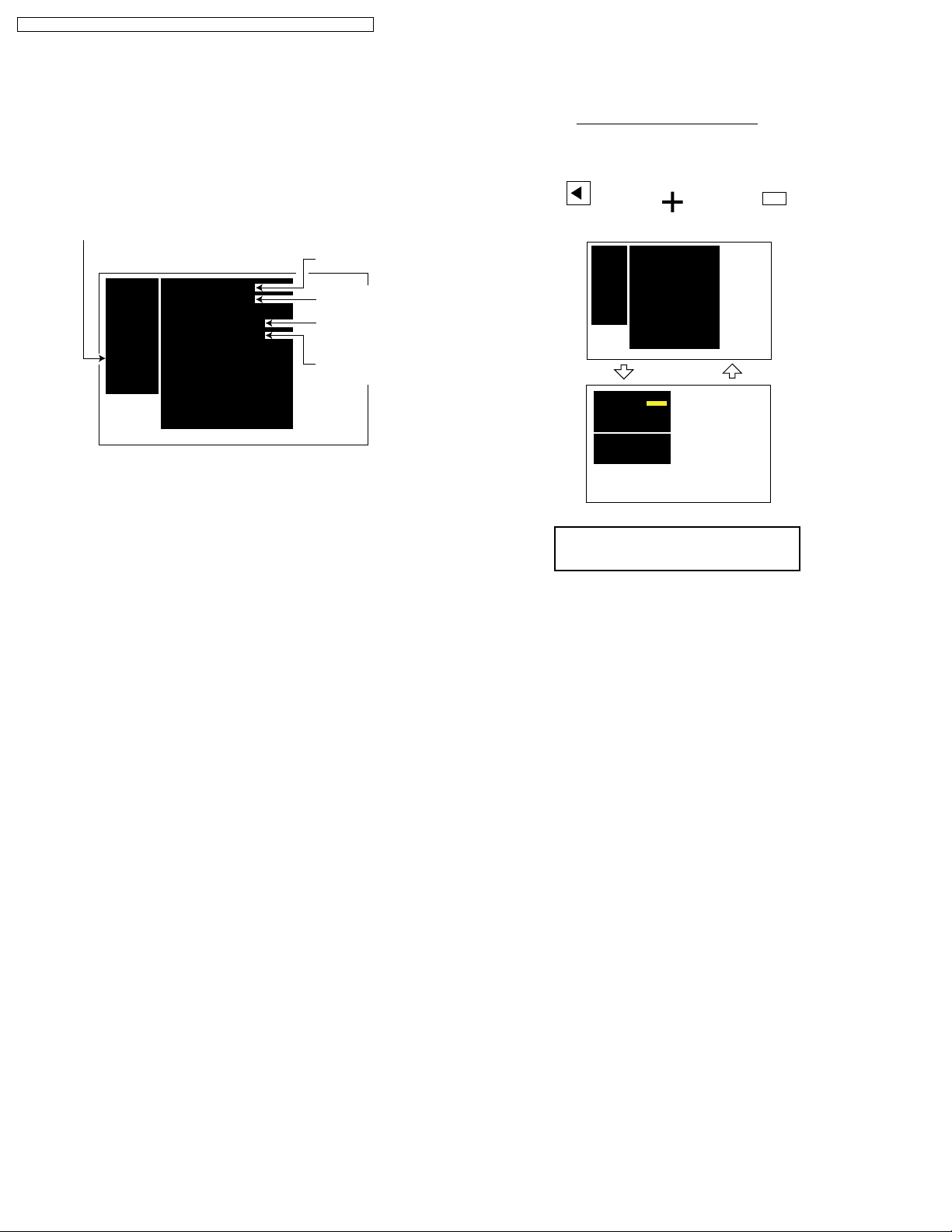

SERVICE ADJUST MODE

In this mode, the following information can be confirmed on the

screen:

MMD-CHK

- Focus, Tilt, H/V Picture Position adjustment

- Internal pattern for LCD-CHK, GC-CHK

Peaks software

version

SRVICE

ADJUST

WB-ADJ

OPTION

RM-SET

SRV-TOOL

MMD-CHK

Peaks SOFT

Peaks EEP

LSI DATA

GenX SOFT

GenX EEP

GenX ROMCOR

GC5P EEP

FPGA

FACTDATA

<Main Menu>

0.480

0.16

0.00.5b

0.15.60

0.00.00

0.00.00

20

0.3a

12FF-FFFF

Peaks EEPROM

data version

TV Microcontroller

software version

TV Microcontroller

EEPROM data version

Service Adjust Mode

Enter:

VOLUME DOWN button + RECALL key (3 times)

(in power on condition)

RECALL (X3)

_

VOL

(on the front)

SRVICE

Peaks SOFT

ADJUST

WB-ADJ

OPTION

RM-SET

SRV-TOOL

MMD-CHK

MMD-CHK

FREQ

1,2:MAIN SELECT

3,4:SUB SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

0.480

Peaks EEP

0.16

LSI DATA

0.00.5b

GenX SOFT

0.15.60

GenX EEP

0.00.00

GenX ROMCOR

0.00.00

GC5P EEP

20

FPGA

0.3a

FACTDATA

12FF-FFFF

<Main Menu>

VIVID

ON

<MMD-CHK 1/8>

CAUTION:

Do not change any parameters!

(on the remote)

1 key2 key

Exit from Main Menu:

Power OFF.

Fig. 2-1

10

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

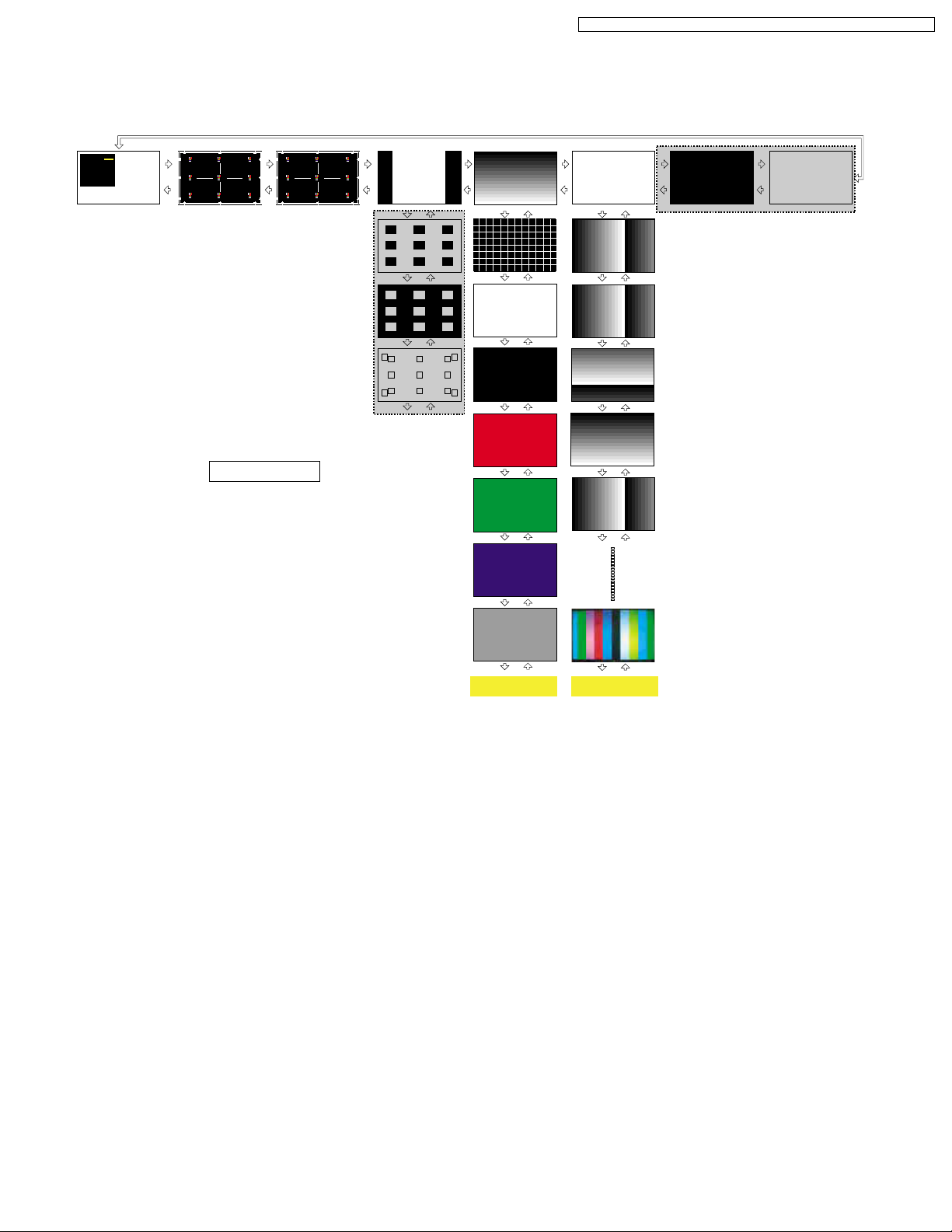

MMD-CHK 1/8~8/8 and internal pattern

Perform the Picture Position adjustment by pressing VOL+/- key, and display the internal pattern for LCD-CHK, GC-CHK.

3 key

MMD-CHK

VIVID

FREQ

ON

1,2:MAIN SELECT

3,4:SUB SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

<MMD-CHK 1/8> <MMD-CHK 2/8> <MMD-CHK 3/8> <MMD-CHK 4/8> <MMD-CHK 5/8> <MMD-CHK 6/8> <MMD-CHK 7/8> <MMD-CHK 8/8>

3 key

OPT HPOS 0024 OPT HPOS 001F

4 key

3 key

4 key

3 key

(Not used for service)

4 key

VOL+ key VOL- key

<SRV-TOOL>

3 key

4 key

VOL+ key

VOL- key

3 key

4 key

VOL+ key VOL- key

3 key

4 key

(Not used for service)

3 key

4 key

4 key

(Not used for service)

CAUTION:

Do not change any parameters!

Note:

Press 1 key to return Main Menu.

VOL+ key VOL- key

VOL+ key VOL- key

VOL+ key VOL- key

VOL+ key VOL- key

VOL+ key VOL- key

VOL+ key VOL- key

VOL+ key VOL- key

VOL+ key VOL- key

VOL+ key VOL- key

VOL+ key VOL- key

Internal Pattern for

LCD-CHK (Figure. A)

VOL+ key VOL- key

VOL+ key VOL- key

VOL+ key VOL- key

VOL+ key VOL- key

VOL+ key VOL- key

VOL+ key VOL- key

Internal Pattern for

GC-CHK (Figure. B)

11

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

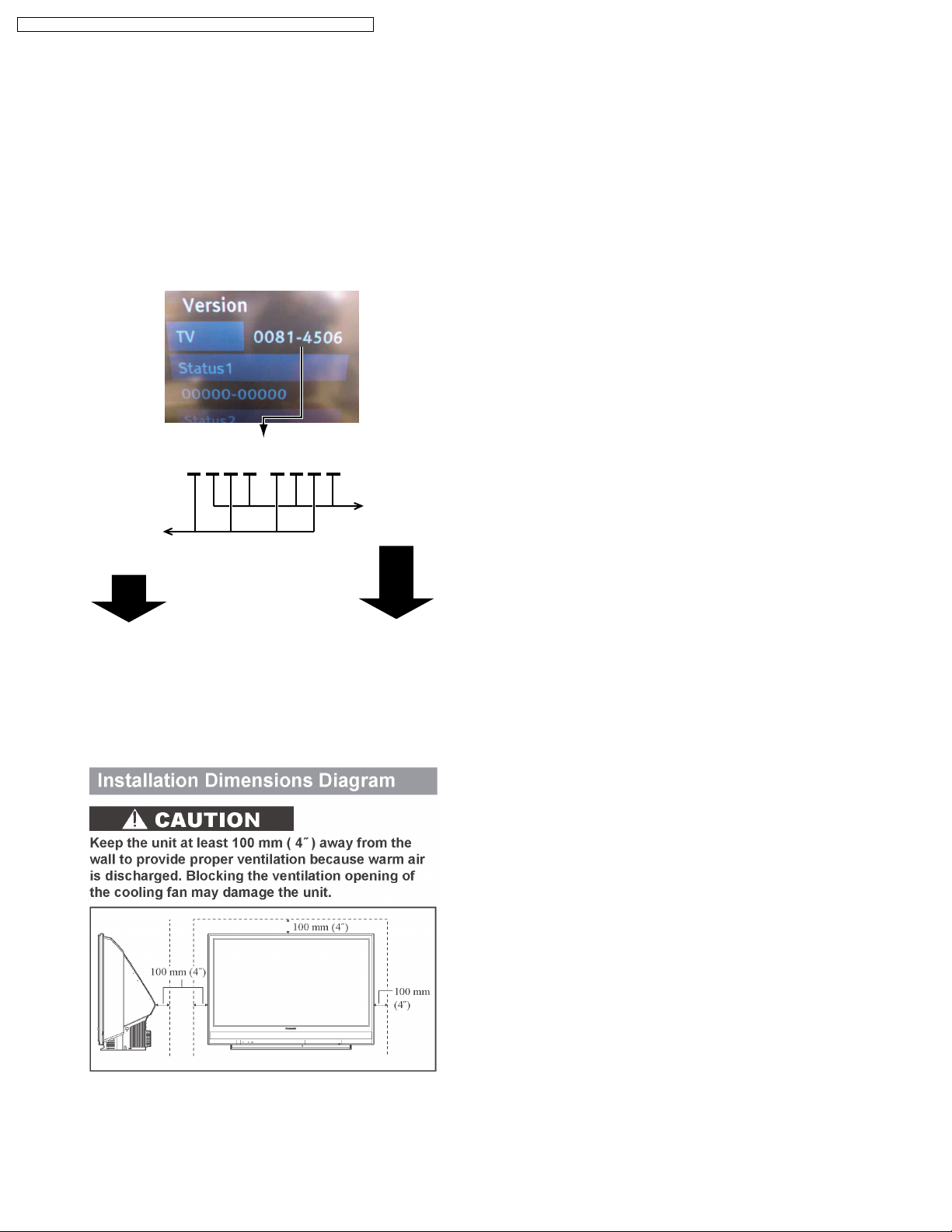

TO READ THE PEAKS SOFTWARE

VERSION AND TV MICROCONTROLLER

SOFTWARE VERSION

1. Press MENU key with the power on.

2. Press CH UP/DOWN key and select "Setup."

Then press OK key.

3. Press CH UP/DOWN key and select "About."

Then press OK key.

4. Select "Version" and press OK key.

Version menu will appear as shown below.

0081-4506

Read every

Read every

other number

from the right:

other number

from the left:

LAMP CAUTION

The Lamp Unit becomes very hot during operation. When

replacing the Lamp Unit, wait until it has cooled off (1 hour or

more).

TOP DUCT UNIT NOTE

The optical parts will be exposed to the dust in the air when the

Top Duct Unit is removed. Therefore, it is strongly recommend

to remove the Top Duct Unit only in a clean room.

Peaks software

Ver. : 0.480

TV Microcontroller

software Ver. : 0.156

INSTALLATION DIMENSIONS DIAGRAM

12

MODEL

PT-50LCZ70

PT-56LCZ70

PT-61LCZ70

PT-50LCZ7

PT-56LCZ7

PT-61LCZ7

PT-50LCZ70-K

PT-56LCZ70-K

PT-61LCZ70-K

NOT USED

MARK

A

B

C

D

E

F

G

H

I

PT

Note:

Refer to Item 3 of Schematic Diagram Notes of

Schematic Diagram and Circuit Board Layout Notes,

for mark "PT."

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

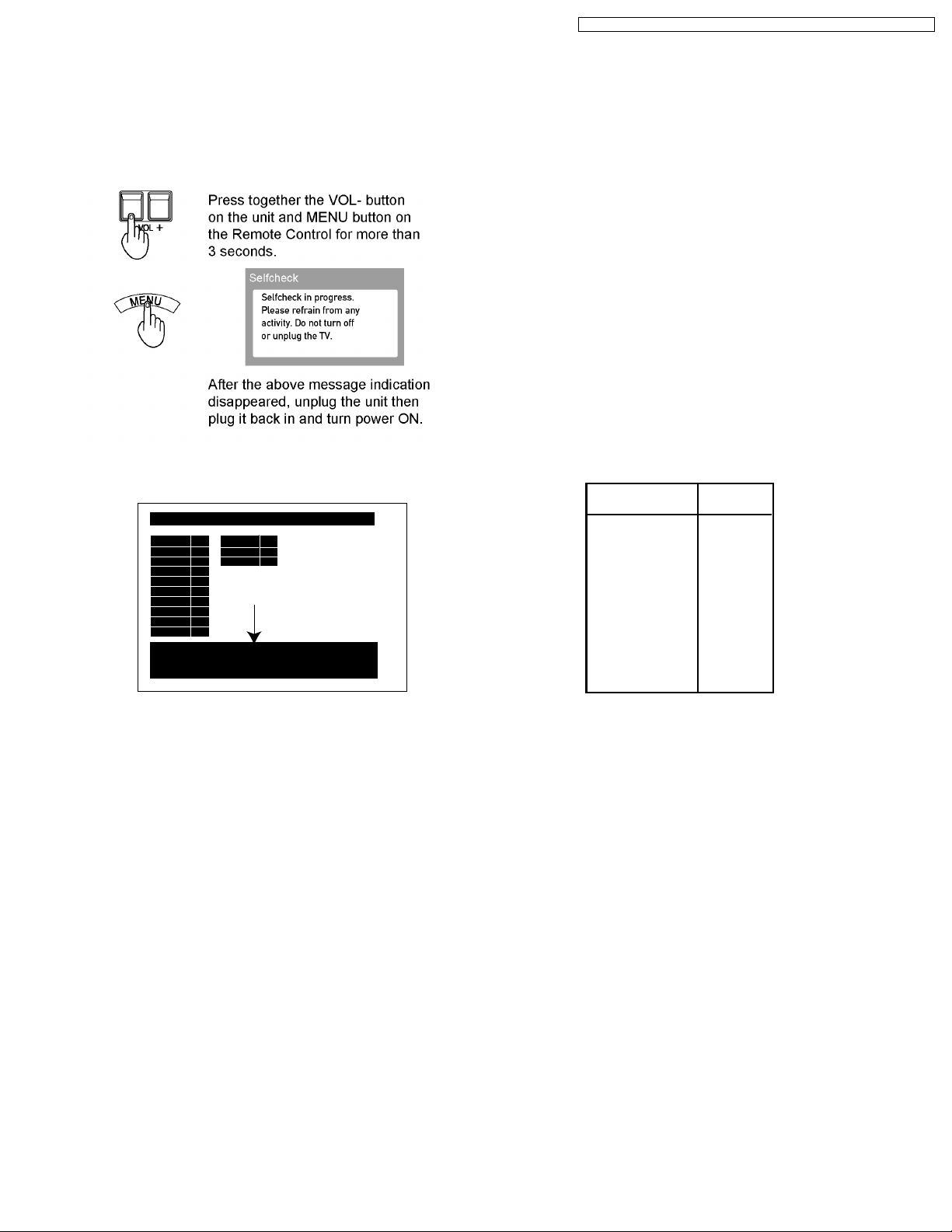

RESET USER’S MEMORY FUNCTIONS

Use when moving unit to a new location, or when First

Time Setup needs to be done over, or if the password

for V-chip has been forgotten.

Note:

SOS History will be cleared after it is displayed.

SELF CHECK 0.480-00.16

DT

ADV

VSW

ADAV

ASW

TUN1

TUN2

FE

GenX4

MEM1

SOS POWER: 02 04

SOS LAMP : 08 09 0A 0B

Copyright 2007 Matsushita Electric Industrial Co., Ltd.

MEM2 OK

OK

OK

GC5P OK

OK

FPGA OK

OK

OK

OK

OK

OK

OK

OK

SOS History

DO NOT UNPLUG AC CORD DURING

COOLING OPERATION

The lamp cooling fan will continue to operate for approximately

30 seconds after the power is turned off.

At the same time, the POWER LED will flash red.

Do not disconnect the AC Cord from the power outlet and do

not open any circuit breakers while the cooling fan is still

operating.

HOT CIRCUIT

Primary circuit exists on the Power P.C.B.

This circuit is identified as "HOT" on the P.C.B. and in the

Service Manual. Use extreme care to prevent accidental shock

when servicing.

MODEL NO. IDENTIFICATION MARK

Use Marks shown in the chart below to distinguish the different

models included in this Service Manual.

<Self Check-2>

13

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

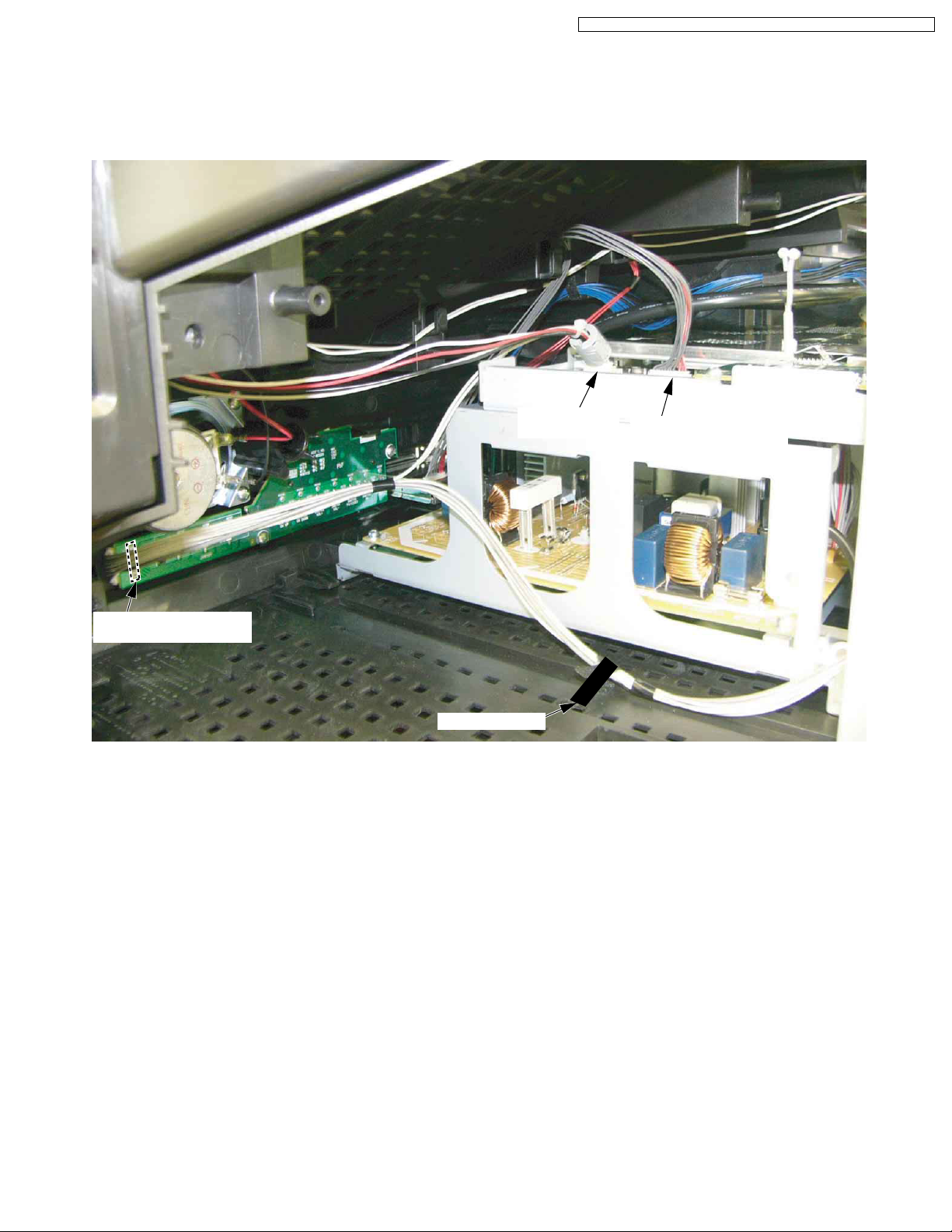

WIRE AND LEAD POSITION DIAGRAM OF THE UNIT

After servicing, make sure that all wires, leads, and clampers are placed in their original position. It is important for the best

operation of the unit.

Note: Use extreme care especially for the following.

AC Cord

OPT/TV Unit

Fig. 9-1

Rear Fan

14

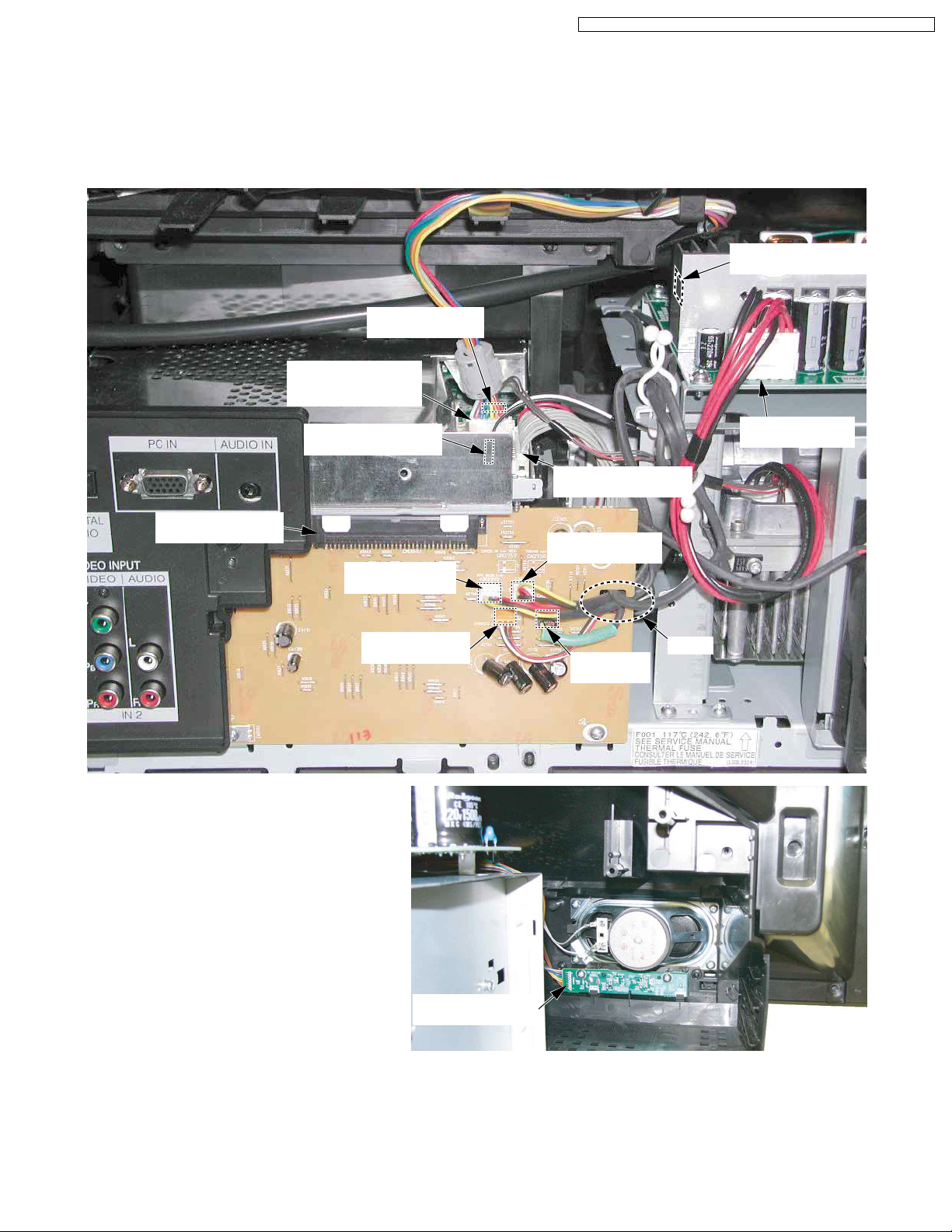

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

After servicing, make sure that all wires, leads, and clampers are placed in their original position. It is important for the best

operation of the unit.

Note: Use extreme care especially for the following.

CN6701

(From Rear Jack P.C.B.)

CN4501

(From Speaker)

Non Fabric Tape

Fig. 9-2

CN8201

(From SD/HDMI P.C.B.)

15

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

After servicing, make sure that all wires, leads, and clampers are placed in their original position. It is important for the best

operation of the unit.

Note: Use extreme care especially for the following.

CN8970

(From Main P.C.B.)

CN5503

(From SD/HDMI P.C.B.)

CN3502

(From Front Jack/Operation P.C.B.)

Fig. 9-3

16

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

After servicing, make sure that all wires, leads, and clampers are placed in their original position. It is important for the best

operation of the unit.

Note: Use extreme care especially for the following.

CN1

(From Power P.C.B.)

CN6005

(From Lamp Unit)

CN6003

(From Power Switch

/Operation P.C.B.)

CN3501

(From Main P.C.B.)

CN1102

(From Thermal Fuse)

CN2752

(From Rear Fan)

CN2754

(From OPT Fan)

CN151

(From Lamp Unit)

CN1101

(From Power P.C.B.)

CN2751

(From Front Fan)

Clamp

CN2753

(Lamp Fan)

CN6801

(From Main P.C.B.)

Fig. 9-4

17

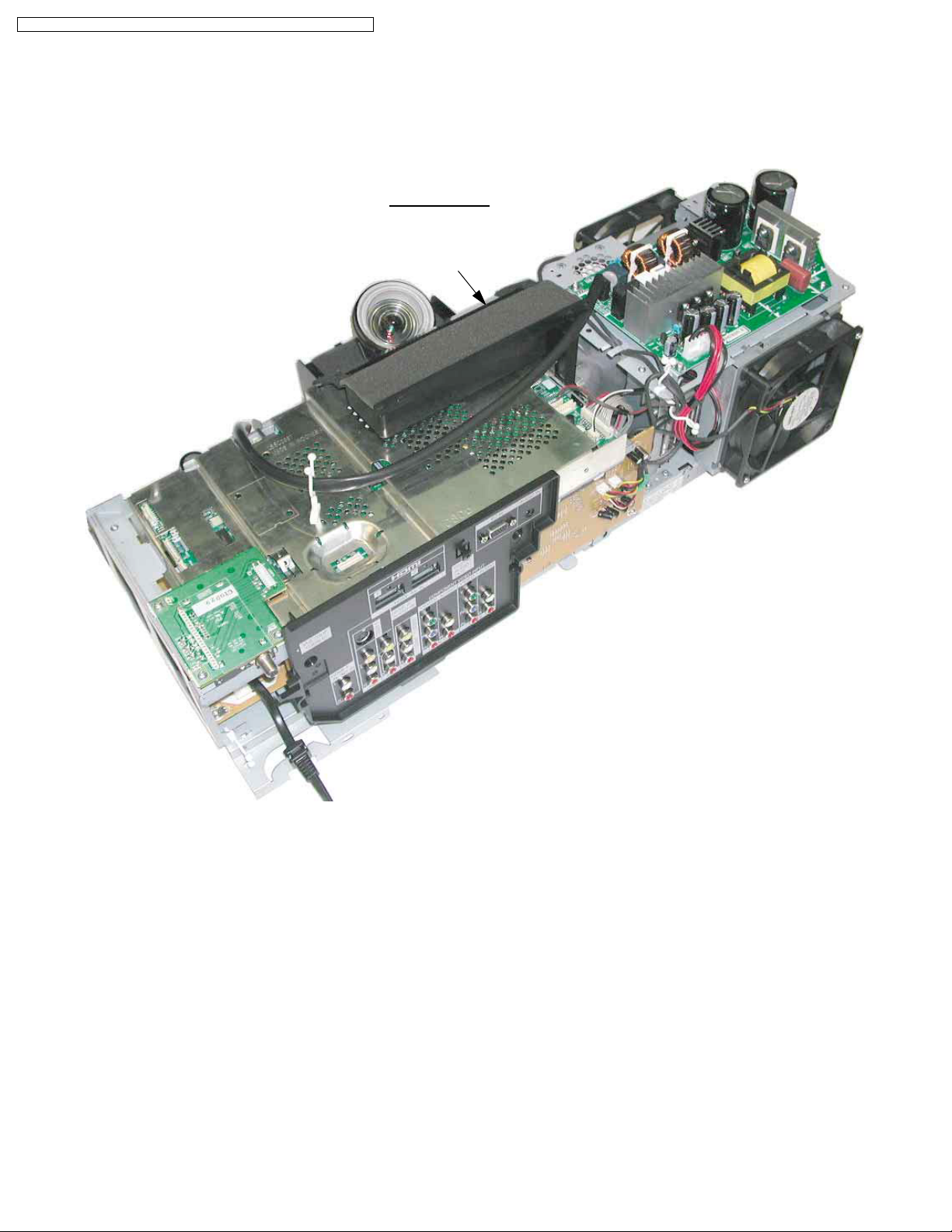

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

After servicing, make sure that all wires, leads, and clampers are placed in their original position. It is important for the best

operation of the unit.

Note: Use extreme care especially for the following.

OPT/TV Unit

Top Duct Unit

Fig. 9-5

18

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

6 Troubleshooting Guide

6.1. Troubleshooting Hints for Block Level Repair

MAIN PARTS LOCATION

<Front View>

Power Switch

/Operation P.C.B.

Front Jack

POWER LED

LAMP LED

/Operation P.C.B.

Front Cover Unit

Front Door

Fan Case Unit

(OPT Fan)

Main P.C.B./

Drive P.C.B.

Tuner P.C.B.

SD/HDMI P.C.B.

<Rear View>

Top Duct Unit

Air Filters

OPT/TV Unit

Front Fan

Lamp Fan

RF AMP

Power Supply P.C.B.

Rear Fan

Support

Shield

Thermal Fuse

Lamp Unit

Rear Jack P.C.B.

Power P.C.B.

19

Rear Cover

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

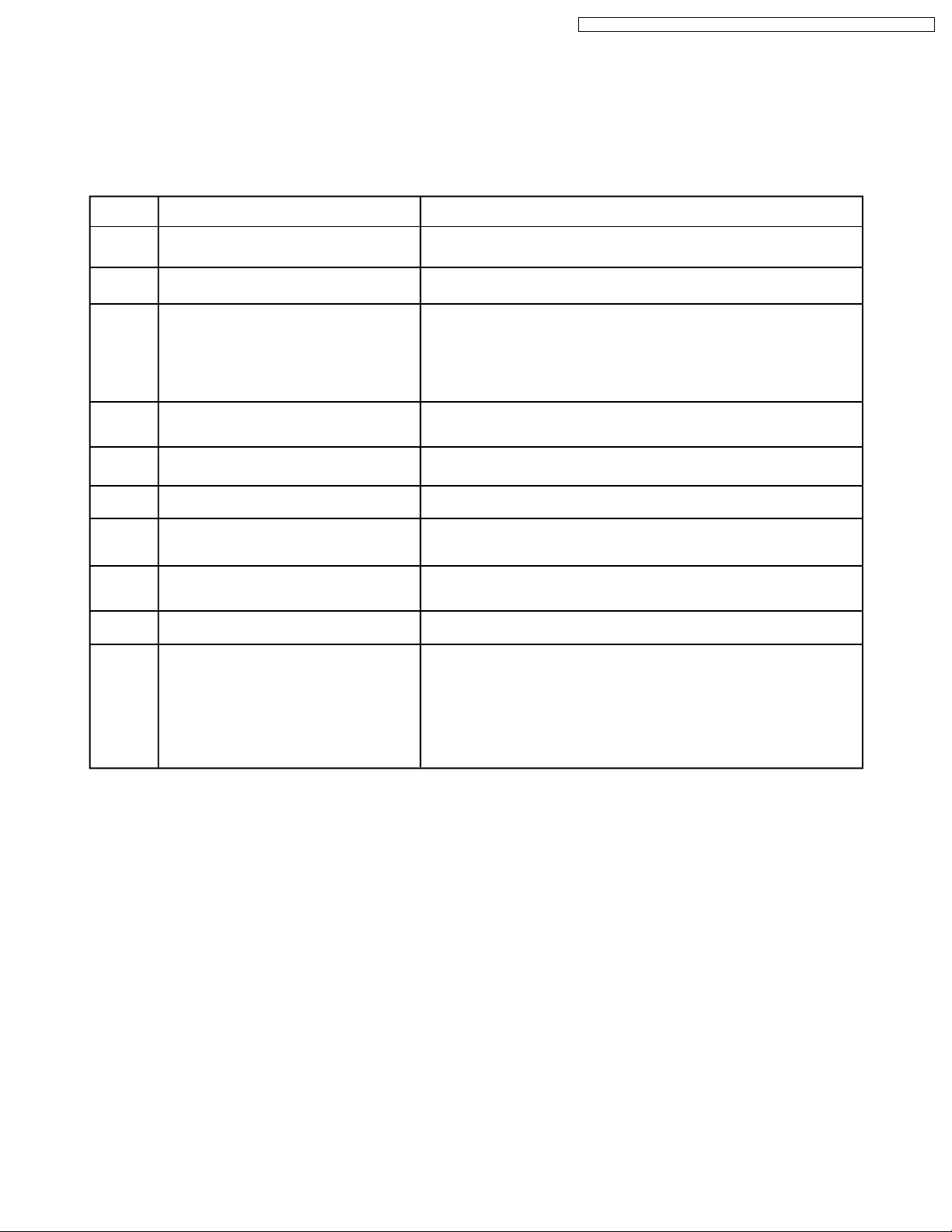

INDICATIONS FOR ERROR CONDITIONS

Each Indicator facilitates finding the cause of an error.

When an error is detected, the Lamp goes off and the indicators on the front flash.

POWER Indicator

LAMP Indicator

(Note 1)

Priority

1

Over voltage/Over current (SOS)

2

Abnormal voltage (DTV+9V line)

Abnormal voltage (SUB+5V line)

3

4

Abnormal voltage (MAIN+3.3V line)

5

IC4501 (Audio Amp) failure

Communication error between Peaks (IC8001)

6

and TV Microcontroller (IC6004)

Communication error between Peaks (IC8001)

7

and TV Microcontroller (IC6004)

12

Lamp does not light up

9

Lamp failure

10

Abnormal Lamp temperature

11

Lamp communication error

14

Lamp Fan stops

15

Fan Case Unit (OPT Fan) stops

Error Information

POWER Indicator

flashes orange

1

2

3

4

6

7

9

-

-

-

-

-

-

LAMP Indicator

flashes red

-

-

-

-

-

-

-

2

3

4

5

8

9

SOS

01

02

03

04

06

07

09

02

03

04

05

08

09

LAMP OFF

RESET

AC

ON/OFF

Power

ON/OFF

(Note 2)

16

Front Fan or Rear Fan stops

17

Rear Fan or Front Fan stops

13

Rear Jack PCB connection error

8

Abnormal Lamp input voltage (+26V)

Note:

1. The detected Error data will be stored in the EEPROM, and SOS History (Code) is displayed in Self Check mode

or Service Adjust mode (SRV-TOOL).

2. The Lamp Indicator will flash X5 immediately after the Lamp goes off. For this SOS only, the TV power will remain on.

20

-

-

-

-

10

11

12

13

0A

0B

0C

0D

AC

ON/OFF

Power

ON/OFF

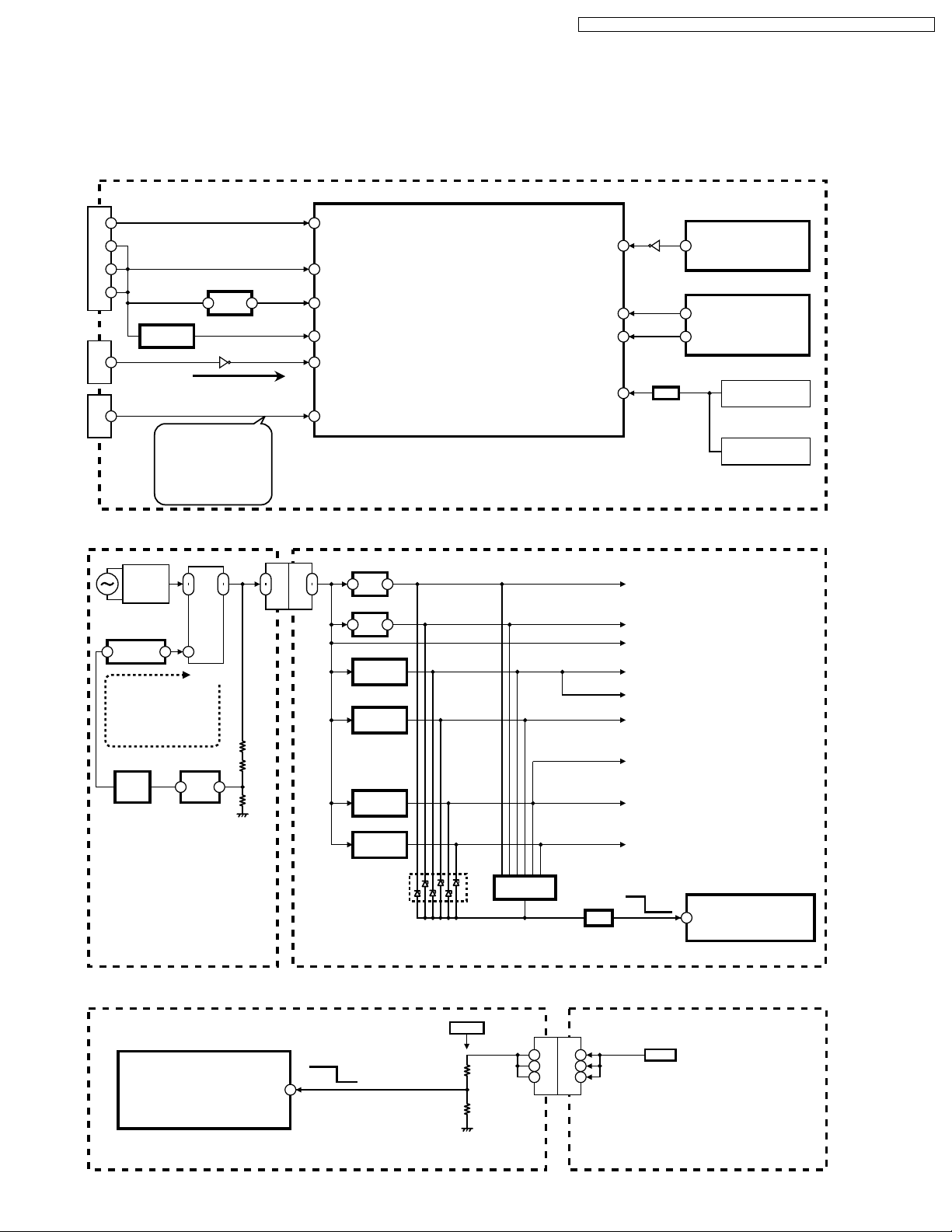

Protection Circuit

SOS terminal of IC6004 (TV microcontroller)

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

IC6004 (TV MICROCONTROLLER)

126

AC STOP(L)

9

10

CN1101

11

7

CN6005

29

CN3001

IC1104,

DC-DC

CONVERTER

LAMP FAN SOS

OPT FAN SOS

FRONT FAN SOS

REAR FAN SOS

NORMAL

REAR JACK P.C.B.

CONNECTION ERROR

IC1107

Q1106

Error Information

+5V

REG.

Q6008

:APPROX. 0V

:APPROX. 0.5V

:APPROX. 1.3V

:APPROX. 2V

:APPROX. 2.8V

:APPROX. 3.3V

21

30

DTV+9V SENS (SOS(L))

34

SUB+5V SENS (SOS(L))

57

MAIN+3.3V SENS (SOS(L))

67

LAMP RXD

117

FAN SOS

[POWER Indicator one blink]

T1002

FULL-WAVE

RECTIFIER

IC1001

SWITCHING

CONTROL

(FEEDBACK LOOP)

IC1002

FEED

BACK

10

11

POWER

TRANS.

1492

IC1003

SHUNT

REG.

8

9

9

11

R1017

R1018

13

R1019

(+9V)

9

11

CN1003

CN1101

(Over voltage Detect)

SOUND SOS (H)

PANEL SOS (L)

PANEL STATUS (SOS(L))

SOS (L)

MAIN P.C.B.

Over voltage/current detection circuit

IC1107

+5V

21

REG.

IC1105

+1.8V

21

REG.

IC1104,

Q1106

DC-DC

CONVERTER

IC1103,

Q1107

DC-DC

CONVERTER

IC1202,

Q1201

DC-DC

CONVERTER

IC1201,

Q1202

DC-DC

CONVERTER

Over current

Detect

IC1101,IC1102,

IC1205

Q1102

SW

Q4502

72

48

13

114

SUB+5V

SUB+1.8V

DTV+9V

SUB+3.3V

MAIN+3.3V

SUB+1.2V

FHD+3.3V

DDR+3.3V

FHD+1.2V

Normal

IC4501

(AUDIO POWER AMP)

5

SOUND SOS (L)

IC8001 (PEAKS)

L6

PANEL SOS (L)

G1

PANEL STATUS (SOS(L))

Q1102

SW

D1104,D1105,ETC

OVER VOLT AGE

DETECT CIRCUIT

IC1101,IC1102,

IC1205

OVER CURRENT

DETECT CIRCUIT

IC6004

(TV

MICROCONTROLLER)

SOS

114

SOS (L)

POWER P.C.B. MAIN P.C.B.

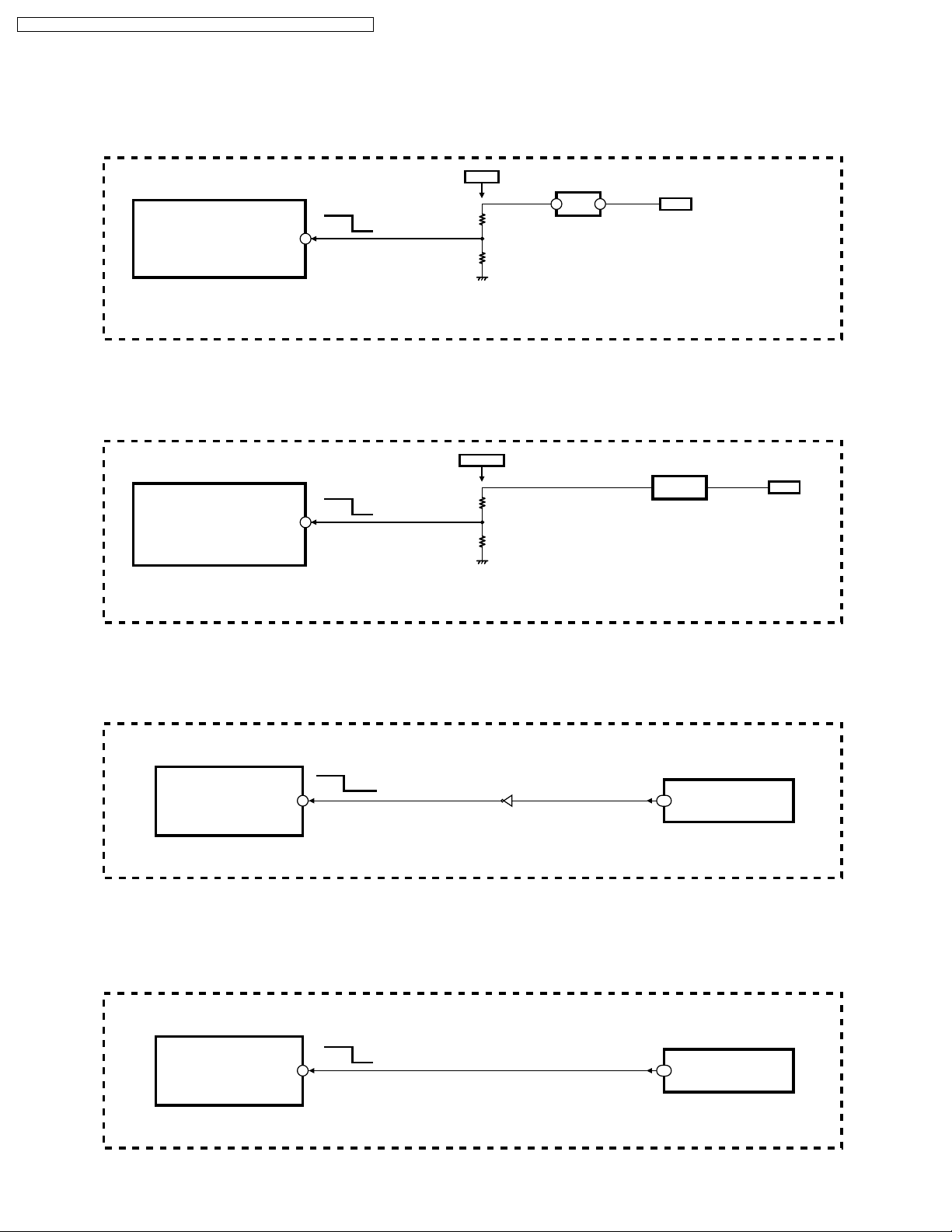

[POWER Indicator two blinks]

IC6004 (TV MICROCONTROLLER)

Normal

DTV+9V SENS

30

Abnormal voltage (DTV+9V) detection circuit

DTV+9V

SOS

SOS: 0V on DTV+9V line

MAIN P.C.B. POWER P.C.B.

21

9 9

10 10

11 11

CN1101

CN1003

+9V

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

[POWER Indicator three blinks]

IC6004 (TV MICROCONTROLLER)

Normal

SUB+5V SENS

34

SOS

SOS: 0V on SUB+5V line

[POWER Indicator four blinks]

IC6004 (TV MICROCONTROLLER)

Normal

MAIN+3.3V SENS

57

SOS

SOS: 0V on MAIN+3.3V line

Abnormal voltage (SUB+5V line) detection circuit

SUB+5V

IC1107

+5V

REG.

12

+9V

MAIN P.C.B.

Abnormal voltage (MAIN+3.3V line) detection circuit

MAIN+3.3V

IC1104,

DC-DC

CONVERTER

Q1106

+9V

MAIN P.C.B.

[POWER Indicator six blinks]

IC6004

(TV MICROCONTROLLER)

SOUND SOS (H)

SOS

72

Audio Amp (IC4501) failure detection circuit

Normal

SOS: Abnormal temperature for Audio amp (IC4501)

Q4502

IC4501

(AUDIO POWER AMP)

5

SOUND SOS (L)

MAIN P.C.B.

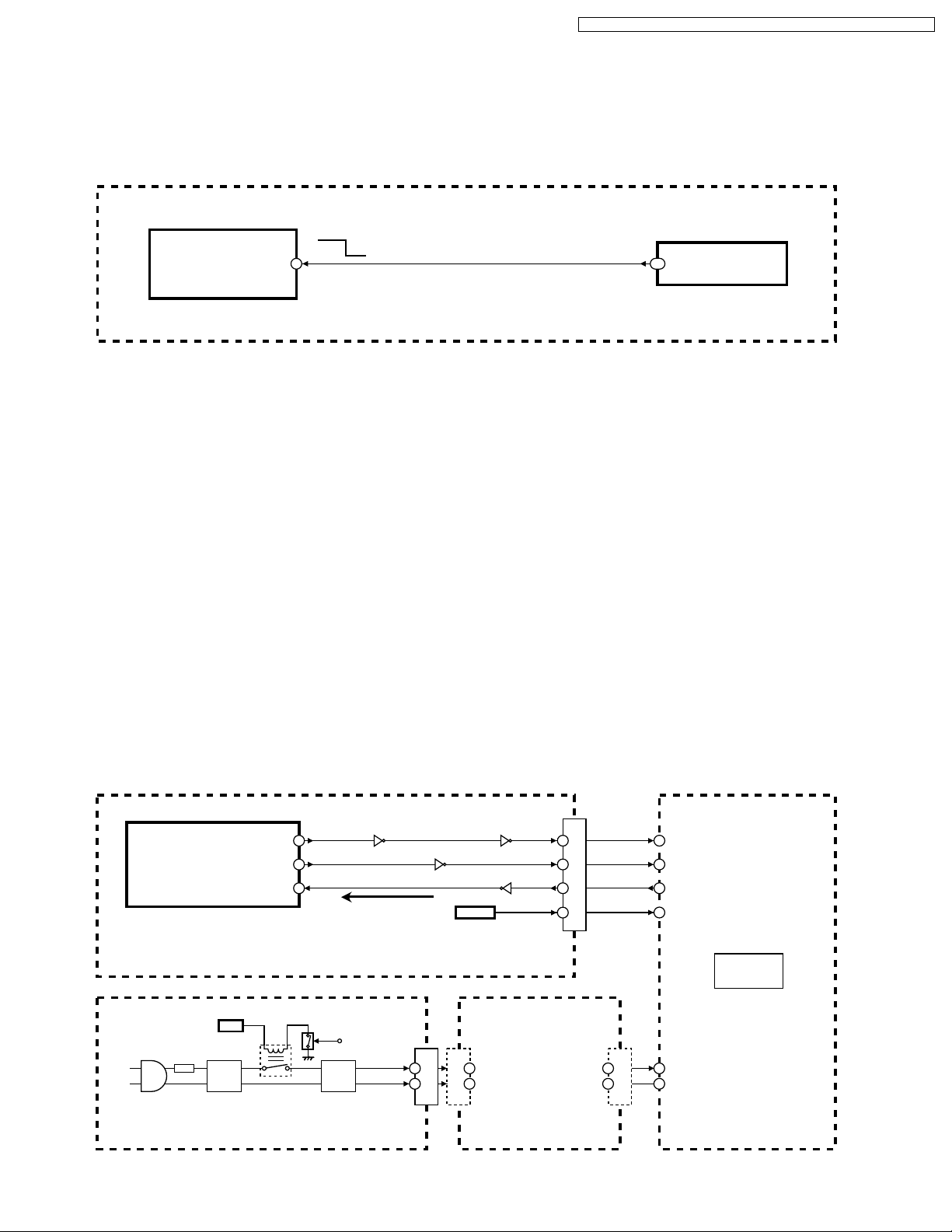

[POWER Indicator seven blinks]

Communication error between Peaks (IC8001) and TV microcontroller (IC6004) detection circuit

IC6004

(TV MICROCONTROLLER)

PANEL SOS (L)

Normal

SOS

48

IC8001 (PEAKS)

L6

PANEL SOS (L)

MAIN P.C.B.

22

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

[POWER Indicator nine blinks]

Communication error between Peaks (IC8001) and TV microcontroller (IC6004) detection circuit

IC6004

(TV MICROCONTROLLER)

PANEL STATUS (SOS (L))

Normal

SOS

13

IC8001 (PEAKS)

G1

PANEL STATUS (SOS (L))

MAIN P.C.B.

[POWER Indicator ten blinks]

Abnormal voltage (LCD+17V line) detection circuit

LCD+17 V

IC6004 (TV MICROCONTROLLER)

Normal

LCD+17V SENS

10

SOS

SOS: 0V on LCD+17V line

MAIN P.C.B. POWER P.C.B.

[LAMP Indicator two blinks]

Lamp does not light up detection circuit

[LAMP Indicator three blinks]

Lamp failure detection circuit

[LAMP Indicator four blinks]

Abnormal Lamp temperature detection circuit

[LAMP Indicator five blinks]

Lamp communication error detection circuit

[LAMP Indicator thirteen blinks]

Abnormal Lamp input voltage (+26V) detection circuit

IC6004 (TV MICROCONTROLLER)

LAMP ON (H)

LAMP TXD

LAMP RXD

88

66

67

Q6008

SOS Information

Q6017

SUB+5 V

Q6005

Q6018

9 9

CN1101

2

1

7

3

CN1003

CN6005

+17V

LAMP ON (H)

LAMP TXD

LAMP RXD

SUB+5V

AC IN

F801

8A/125V

+12V

RL802

AC LINE

FILTER

POWER P.C.B.

MAIN P.C.B.

Q806

TV SUB ON (H)

AC LINE

FILTER

1

2

CN851

AC IN

CN1

AC IN

RF AMP POWER

SUPPLY P.C.B.

23

+26V

GND

CN151

TEMPERATURE

SENSOR

+26V

GND

LAMP UNIT

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

[LAMP Indicator eight blinks]

[LAMP Indicator nine blinks]

[LAMP Indicator ten blinks]

OPT Fan stops detection circuit

Front Fan or Rear Fan stops detection circuit

[LAMP Indicator eleven blinks]

[LAMP Indicator twelve blinks]

IC6004

(TV MICROCONTROLLER)

FAN SOS

LAMP FAN SOS

OPT FAN SOS

FRONT FAN SOS

REAR FAN SOS

NORMAL

REAR JACK P.C.B.

CONNECTION ERROR

117

:APPROX. 0V

:APPROX. 0.5V

:APPROX. 1.3V

:APPROX. 2V

:APPROX. 2.8V

:APPROX. 3.3V

29 29

CN3001

CN3501

Q2754

LAMP Fan stops detection circuit

Rear Fan or Front Fan stops detection circuit

Rear Jack P.C.B. connection error detection circuit

+9V

Q2752

IC2751

(+8 V)

DRIVE

4

+9V

Q2751

Q2753

2

5

IC2753

DRIVE

5

IC2754

DRIVE

(+6.0V~ +6.5 V)

42

(+7 V)

42

CN2751-1

CN2751-2

CN2751-3

CN2752-1

CN2752-2

CN2752-3

CN2754-1

CN2754-2

CN2754-3

CN2753-1

CN2753-2

CN2753-3

FRONT

FAN

REAR

FAN

OPT

FAN

LAMP

FAN

FRONT/REAR FAN SD CONTROL

<FROM TV MICROCONTROLLER (IC6004)>

OPT FAN SD CONTROL

<FROM TV MICROCONTROLLER (IC6004)>

MAIN P.C.B. REAR JACK P.C.B.

24

AC stop detection circuit

T801

2

9

7

3

6

D811

D802

FULL-WAVE

RECTIFIER

Q803-Q805

AC VOLT AGE

DETECT

POWER P.C.B. MAIN P.C.B.

Over current detection circuit

IC1001

(SWITCHING CONTROL)

STBY+7V

6 6

CN1003

CN1101

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

IC6004

Normal

SOS

(TV MICROCONTROLLER)

12

AC STOP (L)

T1002

DRIVE

CONTROL

OVER

CURRENT

DETECT

Over current detect

POWER P.C.B.

Abnormal Temperature (Thermal fuse) detection circuit

Q801

+12V

AC IN

F801

8A/125V

AC LINE

FILTER

RL801

F1001

6.3A/125V

MAIN

POWER

SUPPLY

CIRCUIT

9 14

5

8 8

CN1003

CN1101

1 2

CN1102

SWITCHING

TRANSFORMER

IC6004

(TV MICROCONTROLLER)

1

TV SUB ON(H)

MAIN P.C.B.

Q806

+12V

RL802

POWER P.C.B.

AC LINE

FILTER

TO RF AMP

POWER SUPPLY

P.C. B.

25

THERMAL

FUSE

(on Lamp)

(117 C/242.6 F)

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

How to solve problems indicated by the Error Indication

(The symptom of all errors is that the Lamp goes off)

Note: Before performing troubleshooting, confirm that all connector cables in the unit are connected correctly.

POWER

Indicator

1

2

3

4

[POWER Indicator one blink]

The following voltage lines on the Main P.C.B. is over

current.

• SUB+5V line

• SUB+1.8V line

• SUB+3.3V line

• SUB+1.2V line

• DDR+3.3V line

• FHD+1.2V line

The following voltage lines on the Main P.C.B. is over

voltage.

• DT+9V line

• SUB+5V line

• SUB+1.8V line

• SUB+3.3V line

• SUB+1.2V line

• DDR+3.3V line

• FHD+1.2V line

[POWER Indicator two blinks]

DT+9V line error.

[POWER Indicator three blinks]

SUB+5V line error.

[POWER Indicator four blinks]

MAIN+3.3V line error.

Problem Possible Solution

1. Replace the Power P.C.B.

2. If still NG, replace the OPT/TV Unit.

1. Check that Connector CN1102 (Thermal Fuse) on the Main P.C.B. is connected firmly.

2. If still NG, replace the Power P.C.B.

3. If still NG, replace the OPT/TV Unit.

1. Replace the OPT/TV Unit.

6

7

9

[POWER Indicator six blinks]

AUDIO AMP (IC4501) failure

[POWER Indicator seven blinks]

Communication error between Peaks (IC8001) and

TV microcontroller (IC6004) on the Main P.C.B.

[POWER Indicator nine blinks]

Communication error between Peaks (IC8001) and

TV microcontroller (IC6004) on the Main P.C.B.

26

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

How to solve problems indicated by the Error Indication

(The symptom of all errors is that the Lamp goes off)

Note: Before performing the troubleshooting, confirm that all connector cables in the unit are connected correctly.

LAMP

Indicator

2

3

4

5

8

9

10

11

12

13

[LAMP Indicator two blinks]

Lamp does not light up.

[LAMP Indicator three blinks]

Lamp failure (Internal Lamp thermistor open or short).

[LAMP Indicator four blinks]

Abnormal Lamp temperature (more than 92 ˚C).

[LAMP Indicator five blinks]

Lamp communication error.

[LAMP Indicator eight blinks]

Cooling Fan (Lamp Fan) malfunction.

[LAMP Indicator nine blinks]

Cooling Fan (OPT Fan) malfunction.

[LAMP Indicator ten blinks]

Cooling Fan (Front Fan or Rear Fan) malfunction.

[LAMP Indicator eleven blinks]

Cooling Fan (Rear Fan or Front Fan) malfunction.

[LAMP Indicator twelve blinks]

Rear Jack P.C.B. connection error.

[LAMP Indicator thirteen blinks]

Abnormal Lamp input voltage (+26V)

Normal: +26V

Abnormal: less than +20V

Problem Possible Solution

1. Try to turn on the power several times. (Wait 5 minutes before retrying.)

2. If still NG, replace the Lamp Unit.

1. Try to turn on the power several times. (Wait 5 minutes before retrying.)

2. If still NG, replace the Lamp Unit.

1. Relocate the unit to a proper location.

Keep the unit at least 100 mm (4") away from the wall to provide proper ventilation

because warm air is discharged. Blocking the ventilation opening of the cooling fan may

damage the unit.

2. Wait until the Lamp has cooled off (approximately 1 hour) and try to turn on the power several times.

3. If still NG, check whether the Fans rotate normally.

4. If still NG, replace the Lamp Unit.

1. Try to turn on the power several times. (Wait 5 minutes before retrying.)

2. If still NG, check that the cable between CN6005 on the Main P.C.B. and Lamp Unit is

connected firmly.

1. Check that Connector CN2753 on the Rear Jack P.C.B. is connected firmly.

2. If still NG, replace the Lamp Fan.

1. Check that Connector CN2754 on the Rear Jack P.C.B. is connected firmly.

2. If still NG, replace the OPT/TV Unit (Fan Case Unit (OPT Fan)).

1. Check that Connector CN2751 or CN2752 on the Rear Jack P.C.B. is connected firmly.

2. If still NG, check whether the Front Fan or Rear Fan stopped and replace it.

1. Check that Connector CN2752 or CN2751 on the Rear Jack P.C.B. is connected firmly.

2. If still NG, check whether the Front Fan or Rear Fan stopped and replace it.

1. Check that Connector CN3501 on the Rear Jack P.C.B. is connected into Connector

CN3001 on the Main P.C.B. firmly.

1. Try to turn on the power several times. (Wait 5 minutes before retrying.)

2. If still NG, check that Connector CN1 and CN151 on the RF AMP Power Supply P.C.B. are

connected firmly.

3. If still NG, unplug the AC Cord and disconnect CN151 connector cable and check

voltage at Pin 1, 2 or 3 of CN151 on the RF AMP Power Supply P.C.B. See Figure a.

If OK (+26V), replace the Lamp Unit.

If NG, check the voltage between Pin 1 and Pin 2 of CN1 on the RF AMP Power Supply P.C.B.

If OK (AC120V), replace the RF AMP Power Supply P.C.B.

If NG, replace the Power P.C.B.

(Note: They are same Fan.)

(Note: They are same Fan.)

27

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

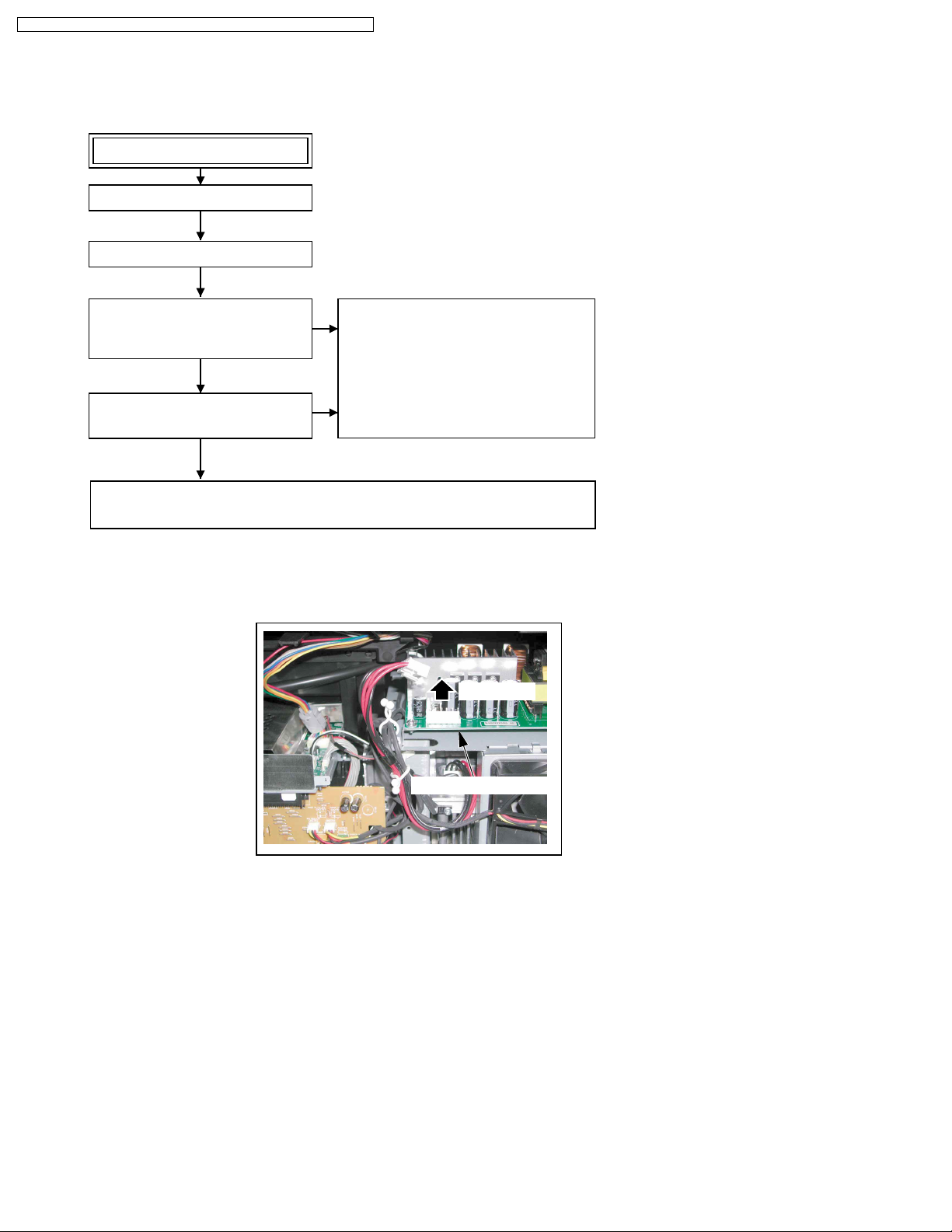

LAMP DOES NOT LIGHT UP

Plug in the AC Cord.

Note:

1.Before performing troubleshooting, confirm that all

2.When repeating troubleshooting, be sure to

3.If the same error indication repeatedly occurs

Turn the power on.

Is there a snap sound of the Relay

turning ON ?

(Relay: RL801/RL802 on the Power

P.C .B. )

YES

Does the Power Indicator (D6803) on

the Power Switch/Operation P.C.B. flash

green?

YES

Power/Lamp Indicator flashes continuously.

Refer to "How to solve problems indicated by the Error Indication."

Perform troubleshooting.

The Power P.C.B. is defective.

NO

Replace the Power P.C.B.

NO

connector cables are connected properly.

turn the power off and unplug the AC Cord.

after several attempts, proceed to the next step.

Pin 1,2 or 3 of CN151

Figure. a

Disconnect

28

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

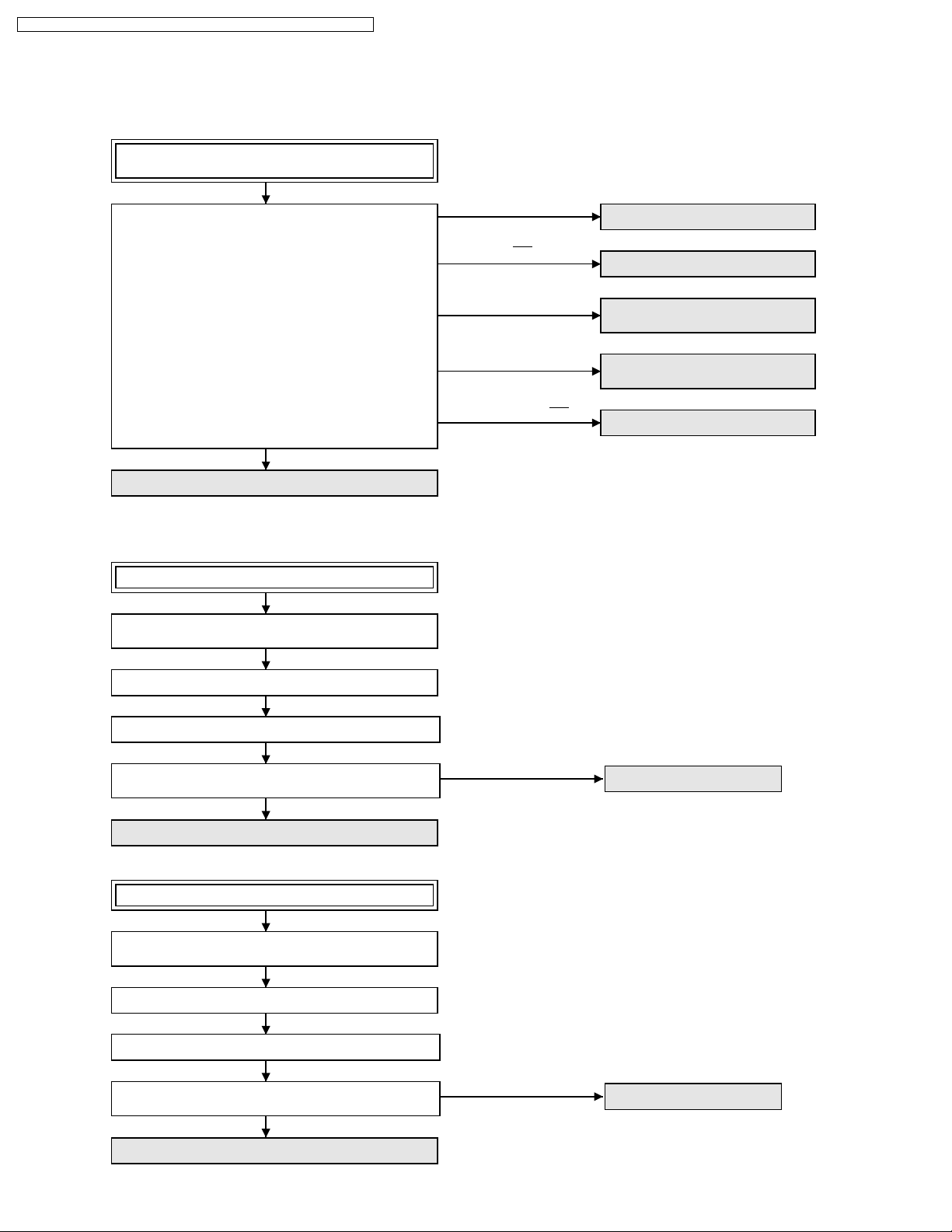

HOW TO DETERMINE WHICH P.C.B. IS DEFECTIVE

No picture or abnormal picture

(Only Video1 OR 2 input is NG.)

(Only Video3 input is NG.)

(Only S-VIDEO 1 input is NG.)

(Only tuner Analog CH input is NG.)

(Only PC input is NG.)

ABNORMAL PICTURE:

No Picture Color (Black and White picture)

Abnormal Picture Color

Unsynchronized Picture

Dark Picture

Replace the OPT/TV Unit or the

Rear Jack P.C.B.

Replace the Front Jack/Operation

P.C.B. or the OPT/TV Unit.

Replace the OPT/TV Unit or the

Rear Jack P.C.B.

Replace the Tuner P.C.B. or the

OPT/TV Unit.

Replace the OPT/TV Unit.

(Only Component 1 OR 2 input is NG.)

(Only Digital Tuner input is NG.)

(Only HDMI3 or SD Card input is NG.)

(Only HDMI1 or HDMI2 is NG.)

(All inputs are NG.)

Replace the OPT/TV Unit or the

Rear Jack P.C.B.

Replace the Tuner P.C.B. or the

OPT/TV Unit.

Replace the SD/HDMI P.C.B. or the

OPT/TV Unit.

Replace the OPT/TV Unit.

Replace the OPT/TV Unit.

29

PT-50LCZ70 / PT-56LCZ70 / PT-61LCZ70 / PT-50LCZ7 / PT-56LCZ7 / PT-61LCZ7

No sound from built-in both L-CH and

R-CH Speakers

Check that there is an audio signal to the Audio Out

Terminal from all input terminals.

OK

Replace the OPT/TV Unit or Power P.C.B.

No sound from built-in L-CH Speaker only

Press MENU key on the remote and select

"Audio" in MENU screen. Then press "OK."

(All input are NG.)

(Only Audio1 OR Audio2

input is NG.)

(Only Audio3 input is NG.)

(Only Tuner input is NG.)

(Only Component 1 OR

Component 2 input is NG.)

Replace the OPT/TV Unit

Replace the Rear Jack P.C.B.

Replace the Rear Jack P.C.B. or

Front Jack/Operation P.C.B.

Replace the OPT/TV Unit or

Tuner P.C.B.

Replace the Rear Jack P.C.B.

Does the "BALANCE" screen becomes center position?

NO

Set to the center position.

Still NG

Swap the Speaker Connectors to confirm the Speaker

failure.

NO

Replace the OPT/TV Unit.

No sound from built-in R-CH Speaker only

Press MENU key on the remote and select

"Audio" in MENU screen. Then press "OK."

Does the "BALANCE" screen becomes center position?

NO

Set to the center position.

Still NG

Swap the Speaker Connectors

to confirm the Speaker failure.

NO

Replace the OPT/TV Unit.

YES

YES

Replace the L-CH Speaker.

Replace the R-CH Speaker.

30

Loading...

Loading...