Page 1

!

Manufactured by:

81-IN3071

Before attempting to connect or operate this product, please read these instructions completely.

for

MODEL: Pressurized Housing

PPFD8C

DESCRIPTION:

The PPFD8C is a 24 VAC pressurized housing enclosure

constructed of .125 Engineered plastic, aluminum and stainless

steel. All plastic components are designed to be UV stable; the

housing top is rated at 94VO. The unit measures 11.5" (w) by

12.9”(h) with a weight of 8 lbs. The housing is capable of

containing a maximum of 5 psi of nitrogen gas injected through a

Schraeder valve located at the top of the unit. A pressure relief

valve, located under the vented top cover, is designed to release

pressure in excess of 5 psi. A 10-pin hermetic connector located

in the center of the top coupling bracket contains 10.2” long leads

for all incoming power and video connections. The leads are

supplied with a standard BNC and (2) screw-down connectors.

The housing is supplied with standard dual 25 watt heater and (2)

circulation blowers. Service to the unit is accomplished by

removing the lower dome and ring assembly.

ELECTRICAL SPECIFICATIONS:

PRODUCT INSTRUCTIONS

NOTE: Be sure to periodically examine the unit and the

supporting structure to which it's attached. If the

dome shows any signs of wear, such as stress

cracking, it should be replaced immediately.

GENERAL INSTRUCTIONS:

Tools Required: .100" Flat Head Screwdriver

Phillips Head Screwdriver

7/16" socket

Preparing Mounting Brackets

1. Carefully remove the housing from the packaging material.

Check to be sure all parts are present, and that there is no

damage to the unit.

2. The standard model is designed as a pendant mount housing

with a 1.5" NPT housing coupling provided (to be used with a

standard 1.5" (NPT) pipe. The housing can also be used with

other brackets designed with 1.5" male pipe threads, such as

the PWM20G and PWM20 Panasonic wall mount brackets.

3. Install the pendant pipe or wall mount bracket in the desired

location.

Power 24VAC, Class 2 Only

!

52 watts at 24 VAC (accessories)

Heaters (2) at 25 Watts Each

Blowers (2) at .84 Watts each

Camera Power 16 Watts

Input Connectors:

BNC

(2) screw-down 4 position connectors

10 position Glass filled Hermetic Connector

IMPORTANT SAFEGUARDS

NOTE: Remember that the PPFD8C is a pressurized enclosure.

To prevent damage, care should be used at all times

when handling this product.

1. Inspect the enclosure upon opening the box to be sure that the

unit has not been damaged during shipping. Domes that have

been cracked or show any signs of damage should be

replaced immediately.

2. Always use safety goggles when servicing the unit.

Never use an unregulated gas supply to pressurize the

3.

enclosure. The valve should be regulated with a

!

maximum of 10 psi output.

Be sure the bracket is properly and securely

mounted to a supporting structure capable of

rigidly holding the weight of the entire unit.

4. Pipe threads should be clean and rust free. Although a

hermetic connector protects the inside of the enclosure from all

moisture, it is still recommended that a thread sealer be used

on the threads of the housing coupling. Attach the housing

coupling to the bracket or pendant pipe (Figure 1).

Add thread

sealing tape

Figure 1

4. PRESSURIZE USING AIR OR INERT GAS ONLY!

!

Page 2

INSTALLING QUICK RELEASE BRACKET AND PAN/TILT

CAMERA ASSEMBLY

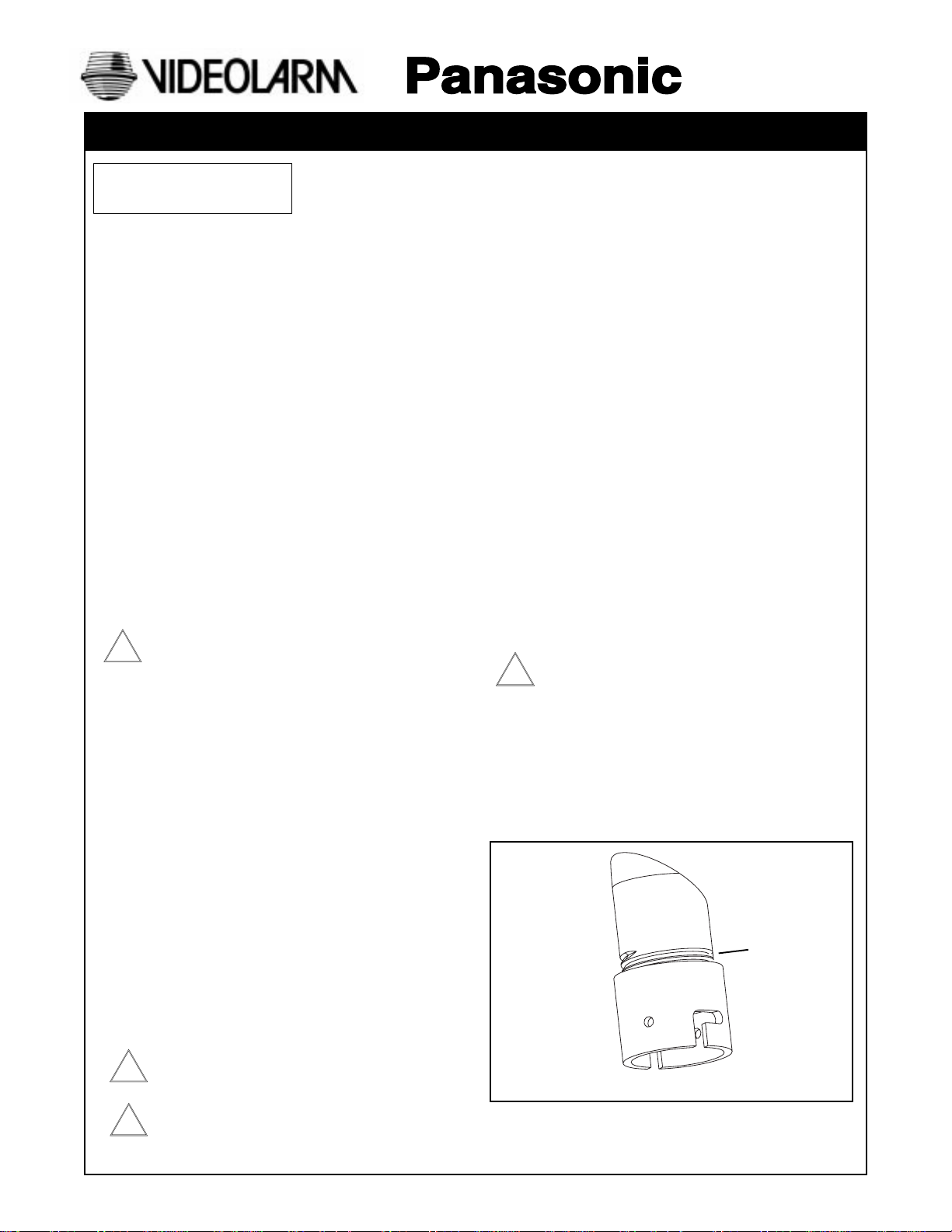

5. Open the housing by loosening the (9) captive screws located on

the housing ring next to the lower clear dome. Twist the dome

slightly in a counter clockwise motion to remove (Figure 2).

Loosen screws only,

do not remove

Remove dome by

twisting counterclockwise

Figure 2

8. Attach the unitized camera to the quick-release bracket. Secure

the safety screw (Figure 5). Connect the BNC and power cables.

Make sure all wiring is clear of the blowers and heater on the

housing bracket. Use the cable tie provided to secure the wires

and connectors.

Safety Screw

Figure 5

6. Spacers are provided to adjust the level of the WV-CS854

camera. Attach the spacers, two-high, to the quick-release

bracket (Figure 3).

Figure 3

7. Connect the quick-release bracket to the spacers using the (4) 8 x

32 x 1/2" bolts and #8 star washers (Figure 4).

9. A small 2” section of humidity sensitive paper is included in the

housing packet. Tape this to the side of the pan/tilt unit assembly

or inside the housing a visible location. The tape will appear blue

in tint when the humidity is low and turn pink under humid

conditions. This can provide a check to confirm that the housing

is sealed properly. The paper requires about 30 minutes to adjust

to the appropriate color.

10. Clean the inside of the dome, with the tex-wipe provide. Reattach

the housing dome and secure the (9) captive screws. Do not

overtighten the screws. Tighten only to the point at which the

gap between the ring and the housing top closes. Each screw

should then be turned 1/2 rotation beyond this point.

INSTALLING THE HOUSING ASSEMBLY

11. Mount the housing assembly to the mounting bracket and

housing coupling. A safety cable is included with the housing to

temporarily hold it while wiring connections. Loop the safety

cable over one of the set screws on the housing coupling and

make the appropriate connections using the (2) screw-down

connectors supplied.

Wiring Color Code

Power Inputs

(Outside housing)

CAMERA POWER

1 Camera Power (24 VAC) Red

2 Camera Power (24 VAC) Orange

3 Ground White

4 N/C

Figure 4

ACCESSORY POWER

1 Accessory Power (24 VAC) Yellow

2 Accessory Power (24 VAC) Green

3 N/C

4 N/C

- 2 -

Page 3

CAUTION: TO PREVENT FIRE OR SHOCK HAZARD, THE UL-

!

LISTED WIRE VW-1, STYLE 1007, SHOULD BE USED FOR THE

CABLE FOR 24 VAC INPUT TERMINALS.

OPERATING DISTANCES FOR POWER LINES

Awg Size Impedance Max Distance

Awg #12 1.71 ohm/1000 ft. 440 ft.

Awg #14 2.73 ohm/1000 ft. 270 ft.

Awg #16 4.35 ohm/1000 ft. 170 ft.

Awg #18 6.92 ohm/1000 ft. 100 ft.

PRESSURIZING THE ENCLOSURE

Air is inserted in the enclosure through the Schraeder valve located

on the top of the unit. A pressure release valve is located under the

housing cap located in this same location. Air vents from the

pressure release valve between the housing top and the cap.

Vent holes

Figure 4

Schraeder

valve

12. Undo the safety cable and twist the housing onto the

housing coupling. Secure all (3) set-screws provided on the

housing coupling (Figure 3).

Set screws

Figure 3

13. Clean the outside of the dome with the text wipe

Before inserting air into the housing be sure the (2) cap

vents are free of obstructions such as ice or debris. (Fig 4)

Pressurized housings provide maximum protection for CCTV

cameras and lenses. The charge of dry nitrogen inside the housing

eliminates the effects of moisture, dust, insects and corrosive

exhaust fumes, allowing a longer life for your surveillance equipment.

To pressurize the housing, you must have the following:

1. A tank of dry nitrogen

2. A regulator on the tank

3. A hose with air chuck to connect the regulator to the housing’s

intake valve

Dry Nitrogen

Nitrogen is a readily available; check your local yellow pages for a

medical or industrial gas provider. If the tank is to be carried from

location to location, a size of 40 cubic foot is recommended. This

should be enough to refill 30 individual housings. Handle the tanks

with care. Although nitrogen is an inert gas, the tank is highly

pressurized and if the valve or regulator is damaged the tank could

be dangerous. Tanks of dry nitrogen can be kept for several years.

The Regulator

The tank will have a standard 580 fitting, but a regulator will be

required. A recommended regulator for the tank would be a Harris

#9296-15-580 or #425-15-580. For local distribution you can contact

Harris at 800-241-0804.

The Hose

The purge valve, called a “Schraeder” or “dill” valve, is similar to the

air intake valve on car or bicycle tires. To connect the regulator to

the purge valve on the housing, you’ll need a hose with a 1/4” barb

on one end and an air chuck on the other. The barb connects to the

regulator, the air chuck to the Schraeder valve. These hoses can be

obtained at local auto parts stores.

Pressurizing the Housing

Set the gauge on the regulator to between 5 and 10 psi. Place the

air chuck on the Schraeder valve, just as you would on a tire, and

press down to begin filling. Air should start venting from the pressure

release valve after a few minutes. Once you’ve completed filling the

housing, check the pressure with a pressure gauge. It should be 3 5 psi. When you have verified the pressure, reconnect the air chuck

and purge the housing for an additional two minutes.

- 3 -

Page 4

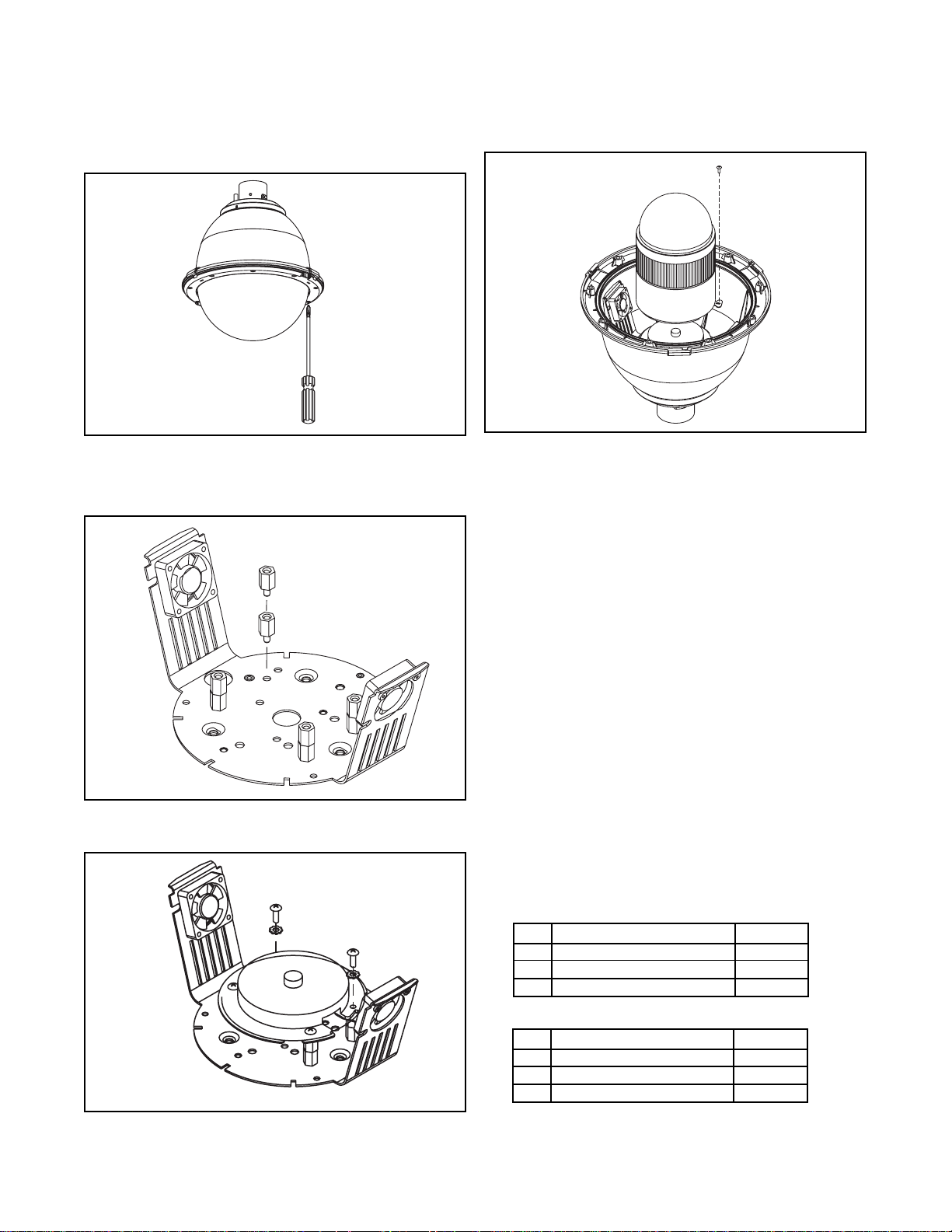

EXPLODED VIEW OF HOUSING

Parts List

1. Pressured Sealed Housing

2. Housing Coupling

3. Housing Packet

a. (2) Screw down connectors

b. (4) Mounting 8 x 32 x 1/2" Mounting Screws

c. (4) #8 star washers

d. Humidity strip

e. Instruction Manual

f. Cable ties

g. (8) Metal spacers

Item No. Description Part No. Quantity

1 25W Heater w/ Leads 72-HT1752 2

2 PFD8 Housing Top 21-TOPFD8 1

3 Dome Support Ring 30-VL1695 1

4 Captive Screw 30-VL1749 9

n/s Captive Screw Spring 92-SPR01 9

n/s Captive Screw Retainer 94-FSRT04 9

5 PFD8 Clear Dome 20-DCPFD8 1

n/s PFD8 Tinted Dome 20-DTPFD8 1

6 9.25" O-ring 96-RSORG11 2

7 Main Housing Bracket 30-VL1742 1

n/s Main Housing 10 x 32 x 1/2” Bolts 3

8 Housing Fan 71-VLBL03 2

9 1/4 x 20 Set Bolts 3

10 Black Plastic Housing Cover 30-VL1802 1

11 4.50” O-ring 96-RSORG10 1

12 Inner Sealing Plate 30-VL1760 1

13 Housing Mounting Coupling 30-VL1759 1

14 Main Bracket Standoffs 30-VL1797 3

n/s 1/4 Lock Washers 92-WSSL01 3

17 PFD8 PCB 76-FPD8P2 1

18 3-5 lbs Pressure Relief Valve 95-VALV04 1

19 Shraeder Valve 95-VALV07 1

20 Housing Coupling 30-VL917 1

21 Shraeder Valve Grommet 30-VL1795 1

22 Housing Gasket 96-PSGK06 1

23 8 x 32 x 1/2” Flat Head 3

24 Hermetic Connector 70-PT08 1

n/s Eternal Leads to Hermetic Connect 40-CAPD801 1

n/s Hermetic to PCB Cable Assembly 40-CAPD802 1

n/s Housing Lanyard 30-VL1821 1

n/s Housing Packet 40-PKPFD8K 1

22

13

2

6

11

19

18

14

7

20

9

21

10

23

24

12

17

1

8

5

3

4

- 4 -

Page 5

1. Read Instructions - All the safety and operating instructions

!

should be read before the unit is operated.

2. Retain Instructions - The safety and operating instructions

should be retained for future reference.

3. Heed Warnings - All warnings on the unit and in the operating

instructions should be adhered to.

4. Follow Instructions - All operating and user instructions should

be followed.

5. Electrical Connections - Only a qualified electrician should

make electrical connections.

6. Attachments - Do not use attachments not recommended by the

product manufacturer as they may cause hazards.

7. Cable Runs - All cable runs must be within permissible distance.

8. Mounting - This unit must be properly and securely mounted to

a supporting structure capable of sustaining the weight of the

unit. Accordingly:

a. The installation should be made by a qualified service

person, and should conform to all local codes.

b. Care should be exercised to select suitable hardware to

install the unit, taking into account both the composition of the

mounting surface and the weight of the unit. Be sure to

periodically examine the unit and the supporting structure to

make sure that the integrity of the installation is intact. Failure

to comply with the foregoing could result in the unit separating

from the support structure and falling, with resultant damages

or injury to anyone or anything struck by the falling unit.

SAFETY PRECAUTIONSIMPORTANT SAFEGUARDS

CAUTION

RISK OF

ELECTRIC SHOCK!

CAUTION: TO REDUCE THE RISK OF

ELECTRICAL SHOCK, DO NOT EXPOSE

COMPONENTS TO WATER OR MOISTURE.

The lightning flash with an arrowhead symbol,

within an equilateral triangle, is intended to

alert the user to the presence of non-insulated

"dangerous voltage" within the product's

enclosure that may be of sufficient magnitude

to constitute a risk of electric shock to persons.

The exclamation point within an equilateral

triangle is intended to alert the user to

!

UNPACKING

Unpack carefully. Electronic components can be

damaged if improperly handled or dropped. If an item

appears to have been damaged in shipment, replace it

properly in its carton and notify the shipper.

presence of important operating and

maintenance (servicing) instructions in the

literature accompanying the appliance.

Be sure to save:

1. The shipping carton and packaging material. They are the

safest material in which to make future shipments of the

equipment.

2. These Installation and Operating Instructions.

SERVICE

For service on Panasonic/Videolarm equipment contact:

Panasonic Technical Center

54 West Gude Dr.

Rockville MD 20850-1150

Phone: 301-762-5125

Fax: 301-251-0347

PANASONIC TECHNICAL SUPPORT

1-800-528-6747

9:00 AM - 5:00 PM EASTERN TIME

- 5 -

Loading...

Loading...