Page 1

NN-C2000P

NN-C2000W

MOD0009237C3

Microwave Oven

© 2000 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

NN-C2000P / NN-C2000W

CONTENTS

Page Page

1 FEATURE CHART 4

2 CONTROL PANEL

3 OPERATION AND DIGITAL PROGRAMMER CIRCUIT TEST

5

PROCEDURE

2

6

Page 3

4 SCHEMATIC DIAGRAM (FOR QPQ, JPG) 7

W

5 SCHEMATIC DIAGRAM (FOR MNQ, YNQ, TNE, LNK, SNM,

KNQ, KKE)

6 DESCRIPTION OF OPERATING SEQUENCE

7 CAUTIONS TO BE OBSERVED WHEN TROUBLESHOOTING

8 DISASSEMBLY AND PARTS REPLACEMENT PROCEDURE

9 COMPONENT TEST PROCEDURE

10 MEASURE MENTS AND ADJUSTMENTS

11 TROUBLE SHOOTING GUIDE (NEW H.V.)

12

14

18

21

22

12 HOW TO CHECK THE SEMICONDUCTORS USING AN OHM

METER

29

13 EXPLODED VIEW AND PARTS LIST

14 PARTS LIST

15 DOOR ASSEMBLY

8

9

16 ESCUTCH EON BASE ASSEMBLY

17 PACKING AND ACCESOR IES

18 WIRING MATERIAL

19 REF. NO. 47 H. V. INVERTER (U)

20 R EF NO . E2 P. C. BOARD D (U)

21 R EF NO . E3 P. C. BOARD F (U)

22 DIGITAL PROGRAMMER CIRCUIT

23 INVERTER CIRCUIT

NN-C2000P / NN-C2000

30

31

33

34

35

36

37

37

38

40

42

3

Page 4

NN-C2000P / NN-C2000W

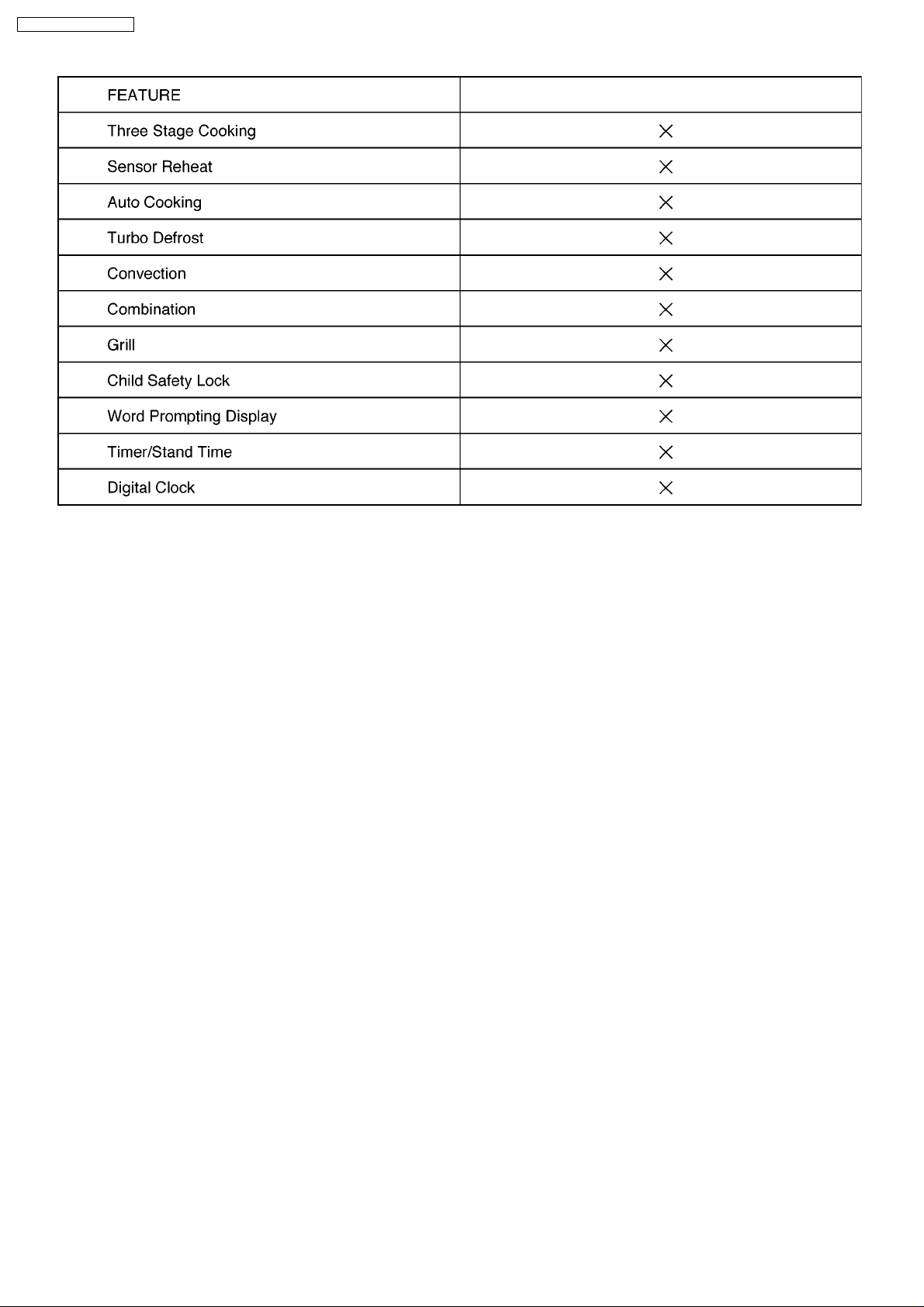

1 FEATURE CHART

4

Page 5

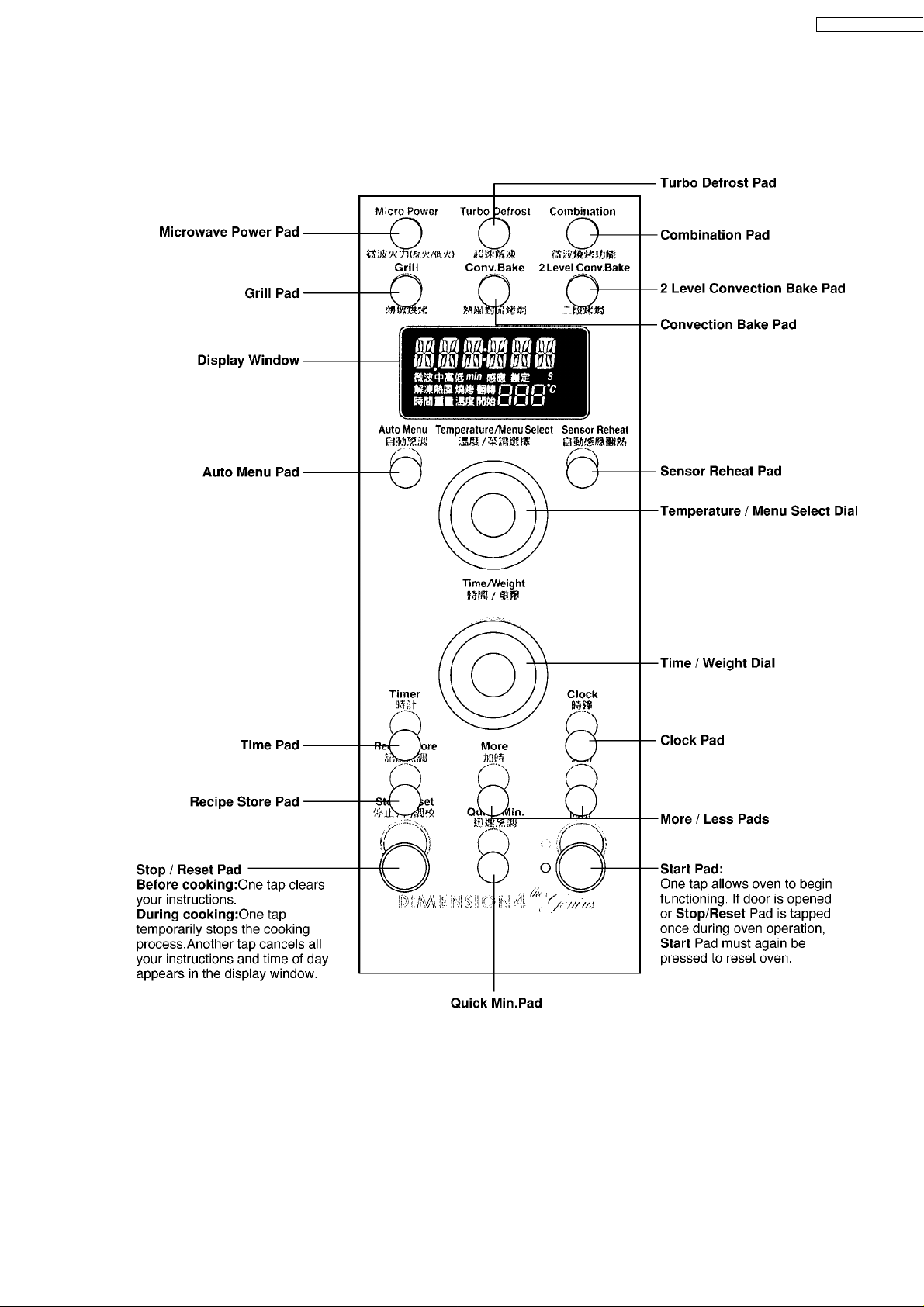

2 CONTROL PANEL

W

NN-C2000P / NN-C2000

5

Page 6

NN-C2000P / NN-C2000W

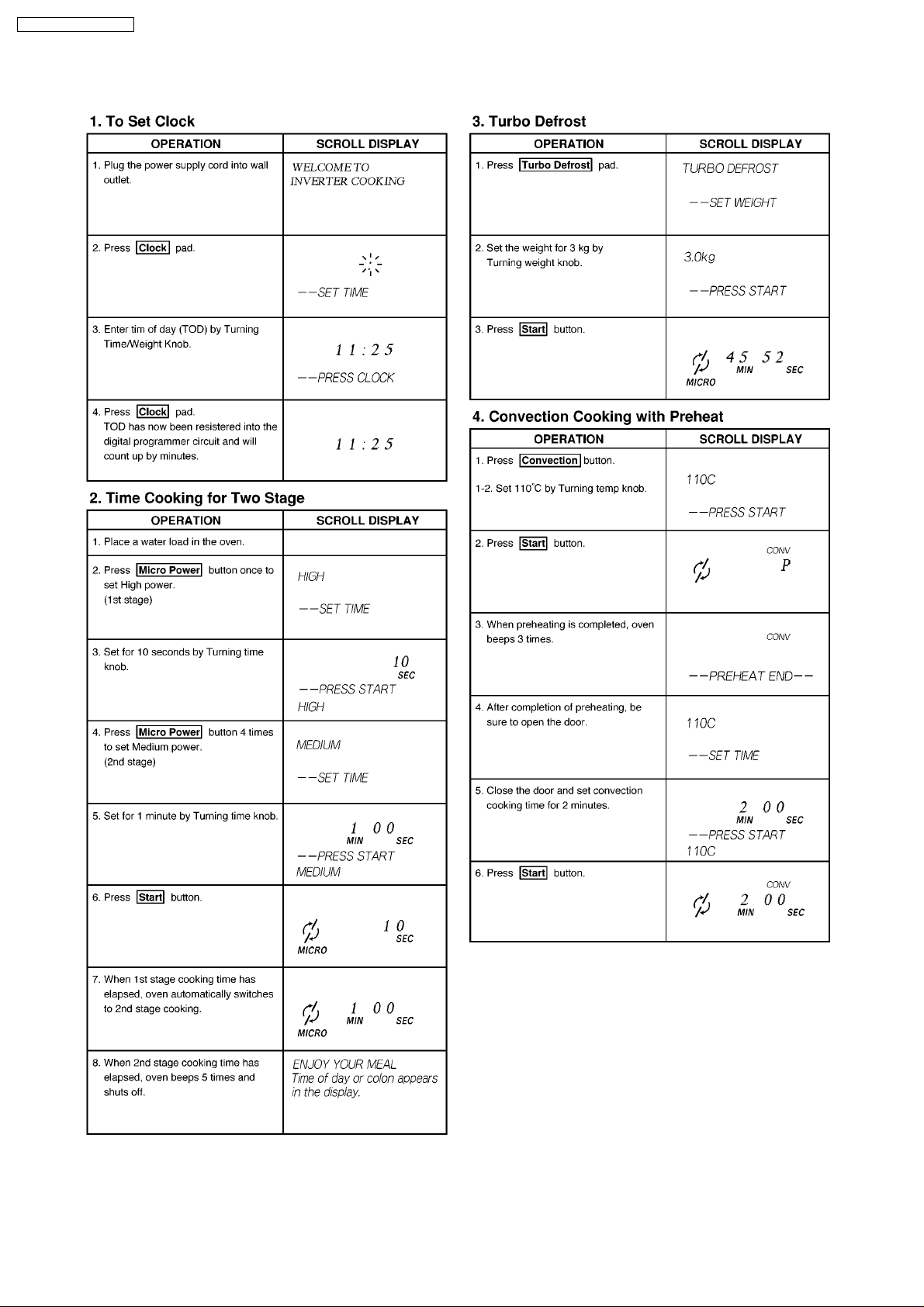

3 OPERATION AND DIGITAL PROGRAMMER CIRCUIT

TEST PROCEDURE

6

Page 7

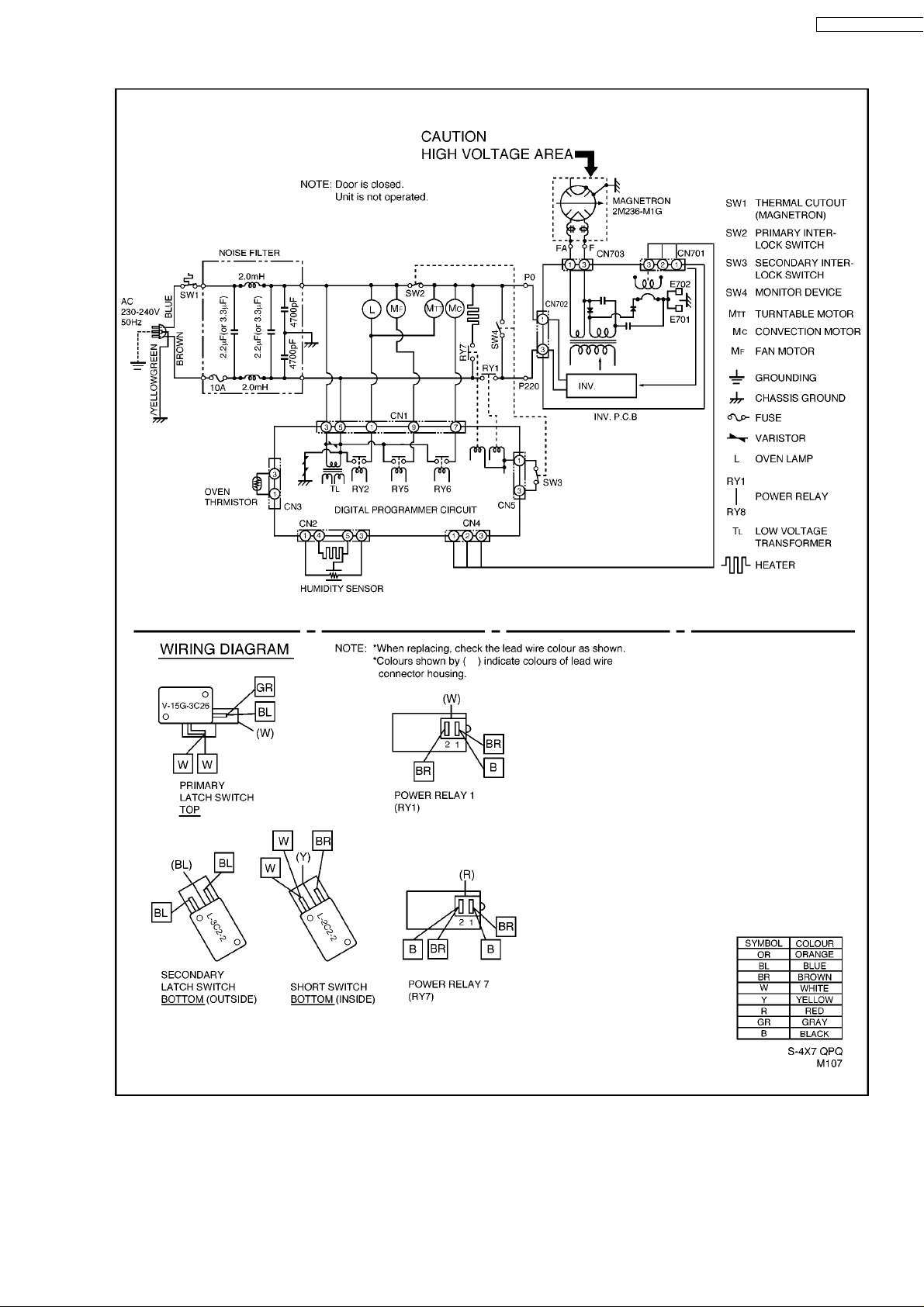

4 SCHEMATIC DIAGRAM (FOR QPQ, JPG)

W

NN-C2000P / NN-C2000

7

Page 8

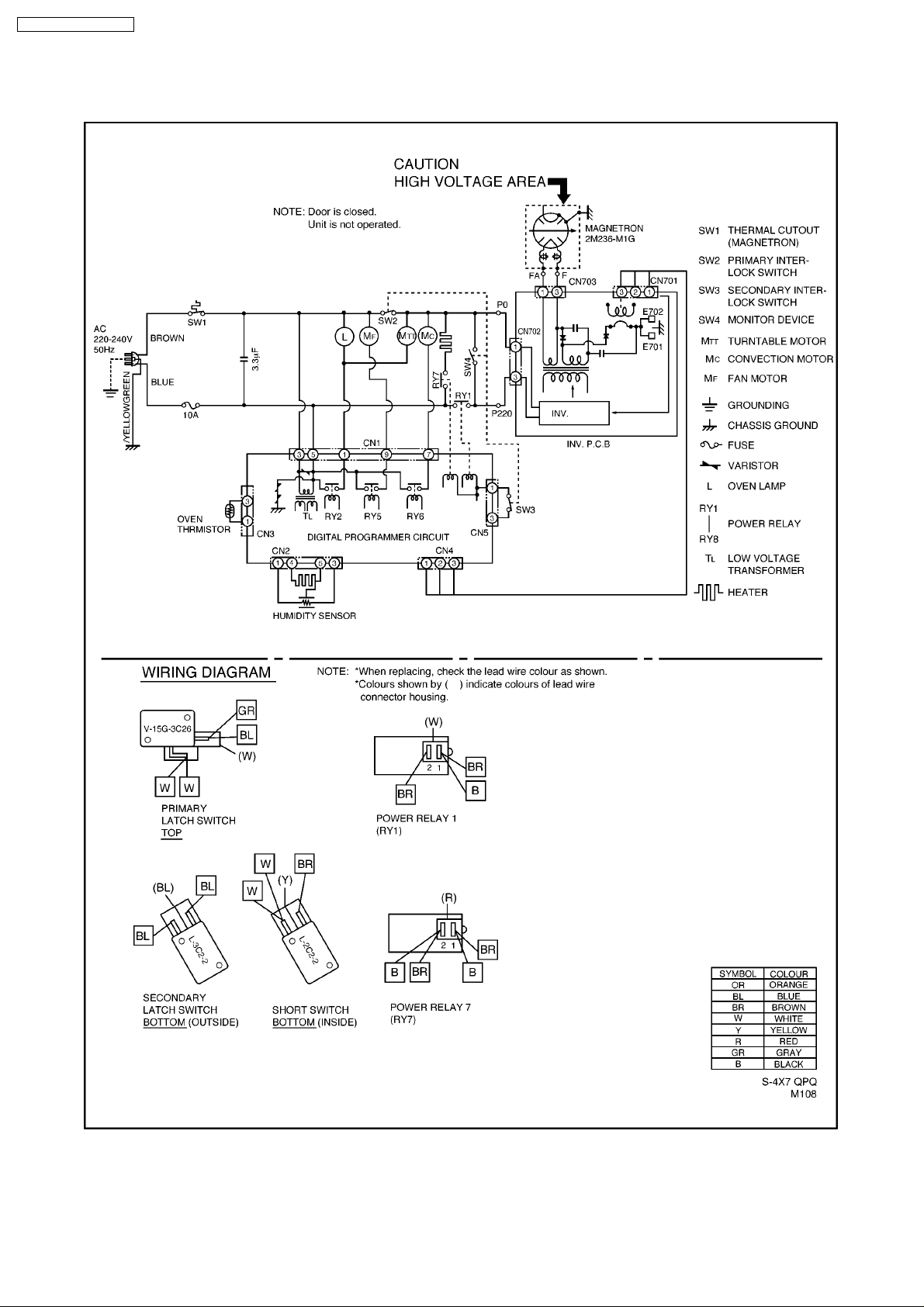

NN-C2000P / NN-C2000W

5 SCHEMATIC DIAGRAM (FOR MNQ, YNQ, TNE, LNK,

SNM, KNQ, KKE)

8

Page 9

6 DESCRIPTION OF OPERATING SEQUENCE

W

NN-C2000P / NN-C2000

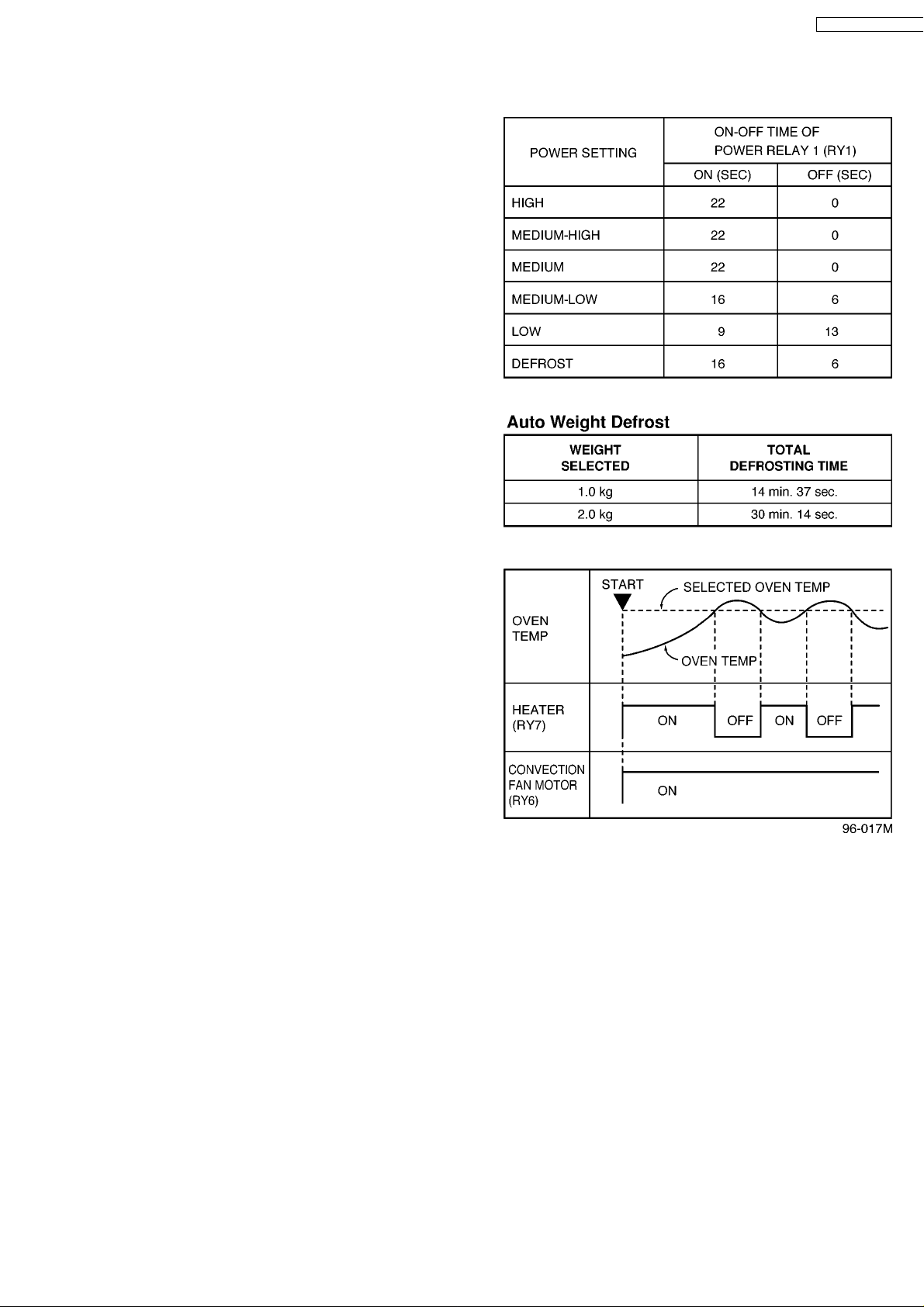

6.1. Variable power cooking

control

HIGH VOLTAGE INVERTER POWER SUPPLY (U) controls

output power by the signal from Digital Programmer Circuit

(DPC). Power relay 1 stays on but the inverter drive signal to

control it's output power.

NOTE: The ON/OFF time ratio does not correspond with

the percentage of microwave power since approximately 2

seconds are required for heating of magnetron filament.

6.2. Turbo weight defrost

When auto weight defrost is selected and the Start Pad is

tapped:

1. The digital programmer circuit determines the power level

and cooking time to complete cooking and indicates the

operating state in the display window. Table shows the

corresponding cooking times for respective serving by

categories.

2. When cooking time in the display window has elapsed, the

oven turns off automatically by a control signal from the

digital programmer circuit.

6.3. Convection/Grill cooking

control

NOTE: When Broil feature is selected, oven temperature is

determined automatically as shown in Figure.

The digital programmer circuit controls the ON-OFF time of the

heater in order to control oven cavity temperature.

1. After the start pad is tapped with the desired Bake/Broil

program set, an 18V DC signal comes out of the digital

programmer circuit and is applied to coil of power relay 7

(RY7).

2. When the contacts of power relay 7 close, power source

voltage is applied to the heater and the heater turns on.

3. When the oven temperature reaches the set temperature,

the digital programmer circuit senses the temperature

through oven temp sensor and stops supplying an 18V DC

signal to the coil of power relay 7 and the heater turns off.

4. After the heater turns off, the oven temperature will

continue increasing a while and then decrease as shown in

Figure. When the oven temperature drops below the set

temperature, the digital programmer circuit senses the

signal and starts supplying an 18V DC signal to the coil of

power relay again.

9

Page 10

NN-C2000P / NN-C2000W

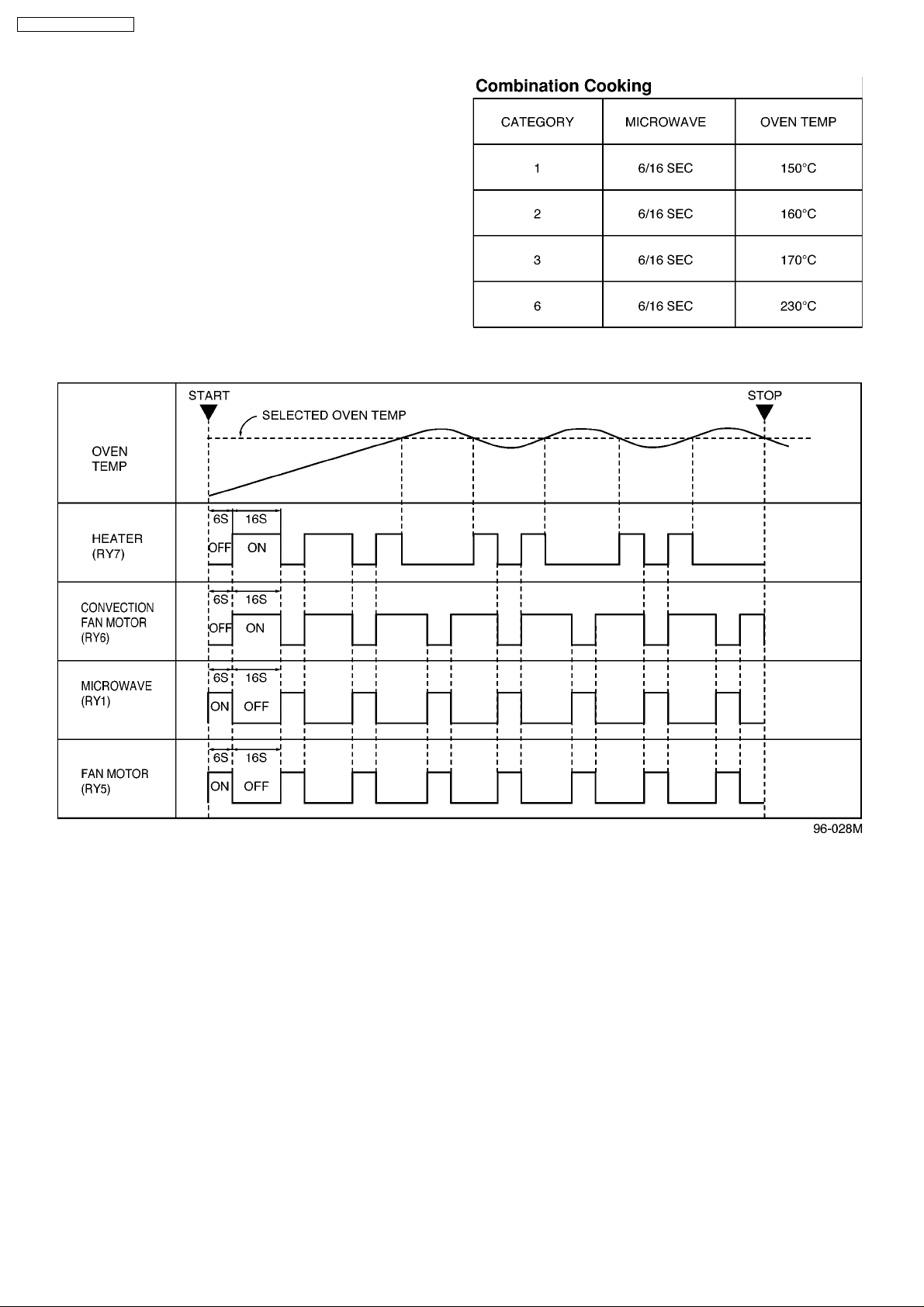

6.4. Combination cooking control

Combination cooking is accomplished by microwave and

convection cooking being done alternately during one

combination cooking cycle. One combination cooking cycle is

22 seconds.

1. During combination cooking, the digital programmer circuit

controls ON-OFF time of both power relay 1 and 7 as

shown in Figure.

2. When the power relay 1 (RY1) is turned on, heater turns off

and after the power relay 1turns off, power relay 7 turns on.

NOTE 1: Note that the heater may not be on during a heater

on period if the preprogrammed oven temperature has

been reached. This is due to the fact that the oven is

keeping the preprogrammed oven temperature constant,

so of course the heater will only be on when it is needed

and off when it is not needed.

NOTE 2: As for temperatures of combination cooking for

convection, the temperatures by each program are

preprogrammed in the microprocessor as shown in Figure.

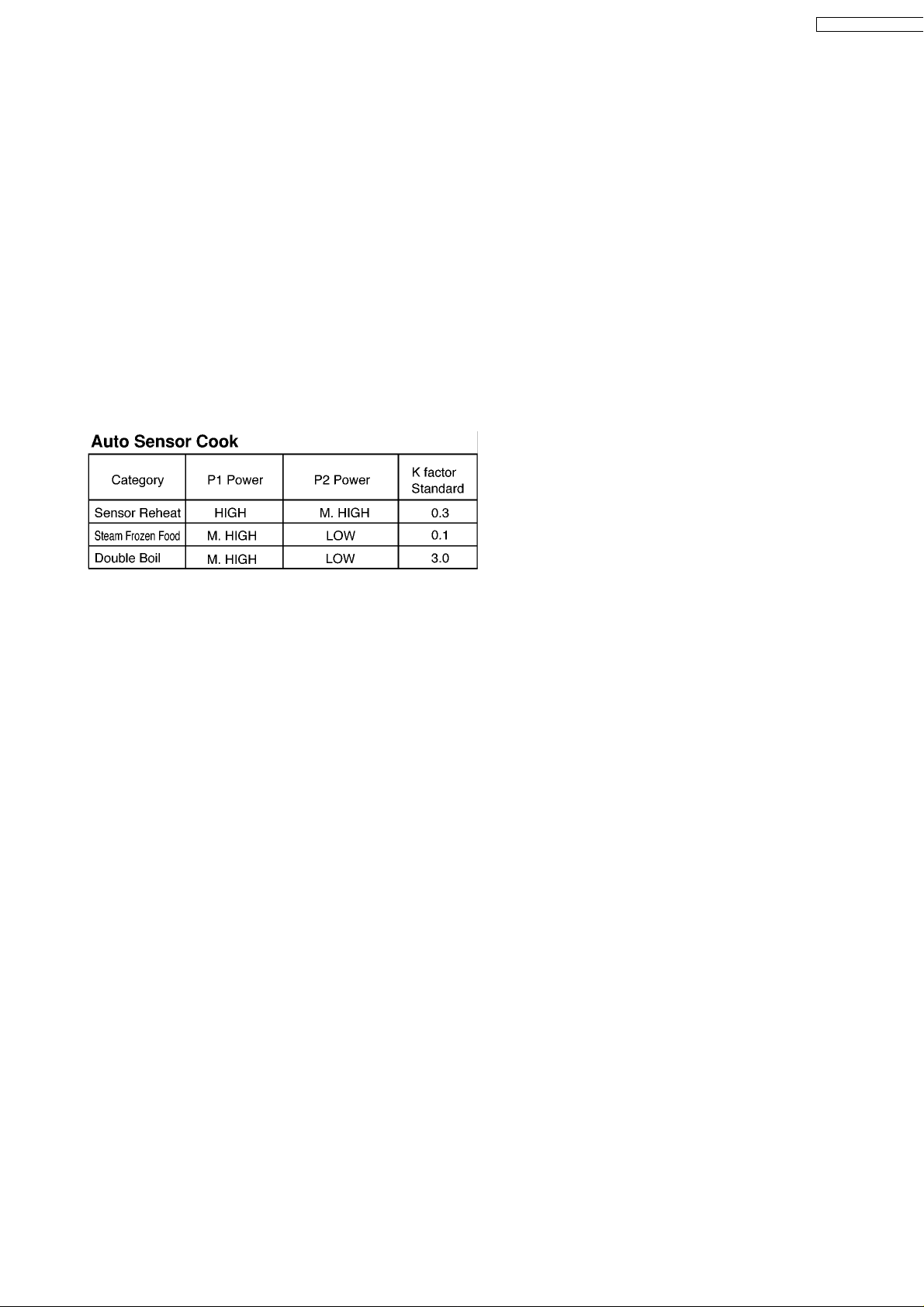

6.5. One touch Auto sensor

cooking

Auto sensor cooking is a revolutionary way to cook by

microwave without setting a power level or selecting a time. All

that is necessary is to select an Auto sensor Program before

starting to cook.

Understanding of Cooking

As food cooks, a certain amount of steam is produced. If the

food is covered, this steam builds up and eventually escapes

from the container. In Auto Sensor Cooking, carefully designed

instrument, called the humidity sensor element, senses this

escape of steam. Then, based upon the Auto Sensor Program

selected, the unit will automatically determine the correct power

level and the proper length of time it will take to cook the food.

NOTE: Auto Sensor Cooking is successful with the foods

and recipes found in the Auto Sensor Cooking Guide.

Because of the vast differences in food composition, items

not mentioned in the Cooking Guide should be prepared in

the microwave oven using power select and time features.

Please consult Variable Power Microwave Cookbook for

procedures.

Explanation of the Auto Sensor Cooking process

1) The shaded columns in Figure indicate when the humidity

sensor heater is on.

2) During the 30 second period there is no microwave activity.

When calculating the T2 timeby using the formula below, make

sure this 30 seconds is subtracted from the T0 time.

3) T1 time To time - 30 seconds

4) T2 time When the steam escapes from the cooking

container placed in the oven, the humidity sensor detects it and

the microprocessor calculates the balance of cooking time.

This T2 time is then shown in the display and begins counting

down.

10

Page 11

Balance of cooking time (T2 time)

W

The balance of cooking time which is called T2 time, can be

calculated by the following formula.

T2 time (in sec.) = T1 time × K factor

NOTE: Remember, the T1 time starts after the Start pad is

tapped. The coefficient K is programmed into the

microprocessor memory and they are listed in the

following tables along with the P1 and P2 powers.

NOTE: When "More" or "Less" pad is selected, the K factor

varies resulting in T2 time to be increased or decreased.

NOTE: For T2 time of Category Casserole, HEATER

operation programmed.

Example of calculating theT2 time

Example 1: If the T1 time is measured to be 2 minutes and 40

seconds, and the Auto Sensor program selected is Sensor

Reheat.

T2 = T1 × K

= 2 min. and 40 sec. × 0.3

= 48 sec.

NN-C2000P / NN-C2000

11

Page 12

NN-C2000P / NN-C2000W

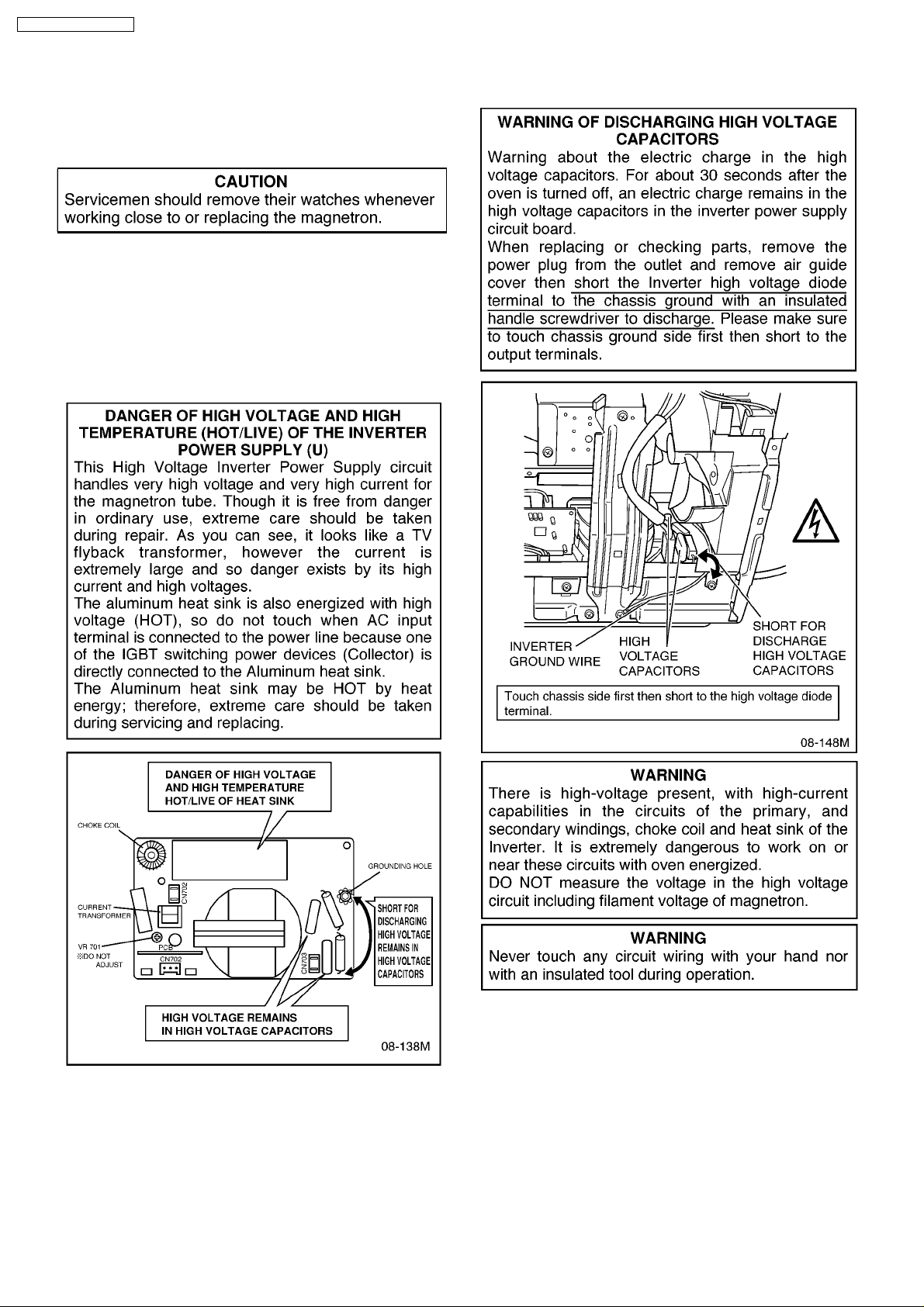

7 CAUTIONS TO BE OBSERVED WHEN

TROUBLESHOOTING

Unlike many other appliances, the microwave oven is highvoltage, high-current equipment. Though it is free from danger

in ordinary use, extreme care should be taken during repair.

7.1. Check the grounding

Do not operate on a 2-wire extension cord. The microwave

oven is designed to be used when grounded. It is imperative,

therefore, to make sure it is grounded properly before

beginning repair work.

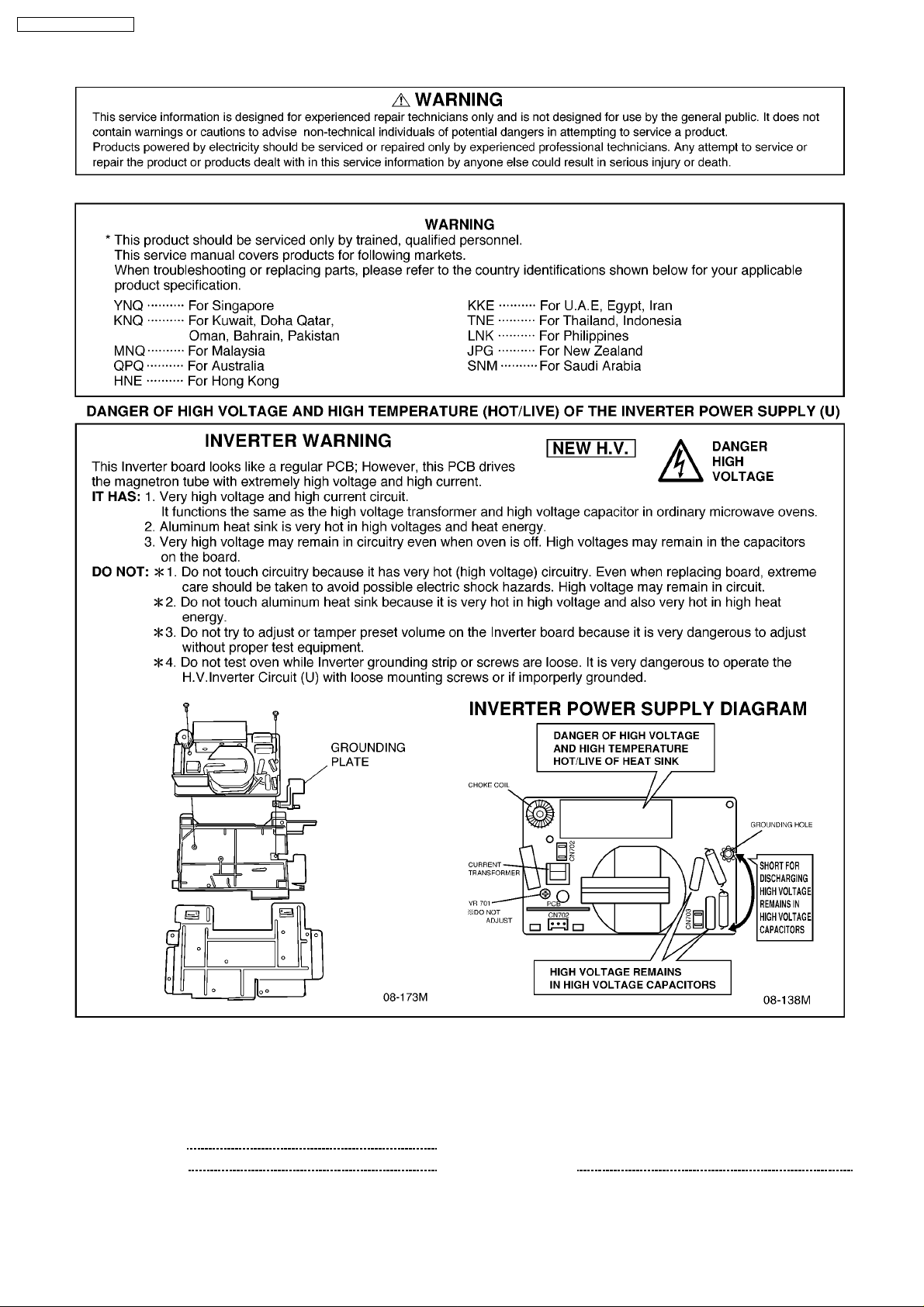

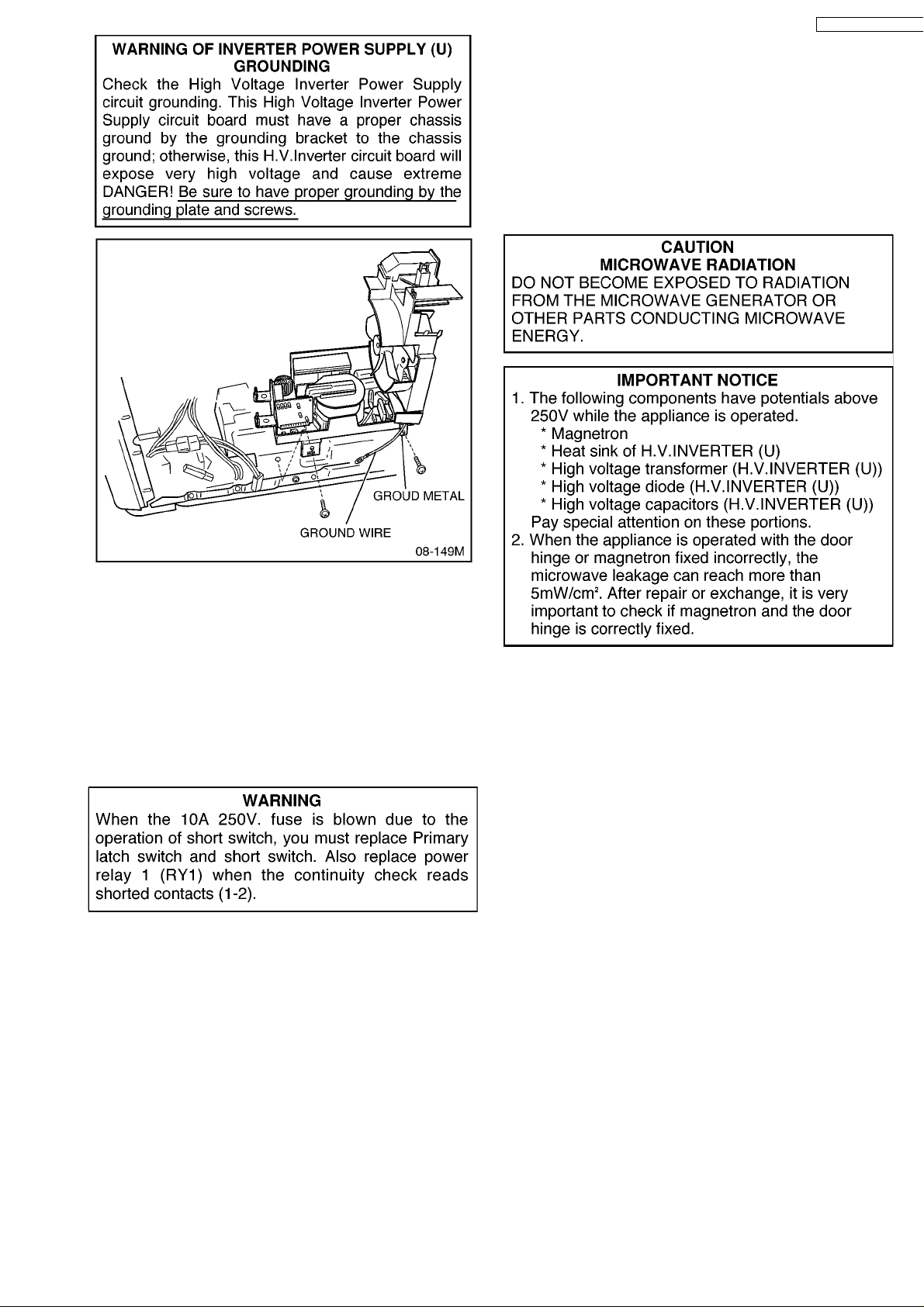

7.2. Inverter Warnings (NEW H.V.)

12

Page 13

NN-C2000P / NN-C2000

W

lamp holes on the cavity or any other holes gaps, because such

objects may work as an antenna and cause microwave

leakage.

7.6. Confirm after repair

1. After repair or replacement of parts, make sure that the

screws of the oven, etc. are neither loose nor missing.

Microwaves might leak if screws are not properly tightened.

2. Make sure that all electrical connections are tight before

inserting the plug into the wall outlet.

7.3. When parts must be replaced,

remove the power plug from

the outlet.

7.4. When the 10A 250V fuse is

blown due to the operation of

short switch:

1. This is mandatory. Refer to "Adjustments and

Measurement" for these switches.

2. When replacing the fuse, confirm that it has the appropriate

rating for these models.

3. When replacing faulty switches, be sure mounting tabs are

not bent, broken or otherwise deficient in their ability to hold

the switches.

7.5. Avoid inserting nails, wire, etc.

through any holes in the unit

during operation.

Never insert a wire, nail or any other metal object through the

13

Page 14

NN-C2000P / NN-C2000W

8 DISASSEMBLY AND PARTS REPLACEMENT

PROCEDURE

8.1. Magnetron

1. Discharge the high voltage capacitor.

2. Remove 2 screws holding magnetron thermal cutout

bracket.

3. Disconnect 2 high voltage lead wires from magnetron

filament terminals.

4. Remove 4 screws holding the magnetron.

NOTE: After replacement of the magnetron, tighten

mounting screws properly making sure there is no gap

between the waveguide and the magnetron to prevent

microwave leakage.

8.2. Digital programmer circuit

(DPC) and membrane key

board.

NOTE: Be sure to ground any static electric charge built up

on your body, before handling the DPC.

1. Disconnect all connectors from D.P.C.

2. Remove 3 screws holding escutcheon base and slide the

escutcheon base upward slightly.

3. Remove flat cable of CN5.

4. Remove 5 screws holding DPC.

To replace switch PCB.

5. Remove 2 knobs.

6. Remove 6 screws.

To replace buttons

1. Remove escutcheon bracket from escutcheon base by

freeing 6 catch hooks on the escutcheon base.

2. Replace whole button assembly.

8.3. Low voltage transformer

and/or power relays

NOTE: Be sure to ground any static electric charge built up

on your body before handling the DPC.

1. Using solder wick or a desoldering tool and 30W soldering

iron, carefully remove all solder from the terminal pins of the

low voltage transformer and/or power relays.

NOTE: Do not use a soldering iron or desoldering tool

of more than 30 watts on DPC contacts.

2. With all the terminal pins cleaned and separated from DPC

contacts, remove the defective transformer/power relays

and install new transformer/power relays making sure all

terminal pins are inserted completely. Resolder all terminal

contacts carefully.

14

Page 15

8.4. Fan motor

W

NN-C2000P / NN-C2000

1. Disconnect 2 lead wires from fan motor terminals.

2. Disconnect 2 lead wires from fuse holder terminals. (some

models)

3. Remove 4 screws holding fan motor and orifice assy and

detach the orifice assy with fan motor from oven assy.

4. Remove fan blade from the fan motor shaft by pulling it

straight out.

5. Separate the fan motor from the orifice assy by freeing 2

catch hooks on the orifice assy.

8.5. Heater

1. Remove lead wires from lead wire holders.

2. Remove belt from pulleys of circulation fan.

3. Remove 2 screws holding heater fan motor bracket.

4. Remove 1 screw holding exhaust guide.

5. Remove 2 screws holding oven temp sensor.

6. Disconnect 2 lead wires from heater terminals.

7. Remove 4 screws holding the both sides of heater unit and

lift it up carefully.

8. Remove 3 screws holding heater supports and detach the

heater.

8.6. Door assemble

1. Open the door and remove 4 screws holding door C.

15

Page 16

NN-C2000P / NN-C2000W

2. Remove the door C from door E bycarefully pulling outward

starting from upper right hand corner.

3. Separate the door A from the door E by freeing 8 catch

hooks on the door A.

4. Remove door key spring and door key.

After replacement of the defective component parts of the

door, reassemble it and follow the instructions below for

proper installation and adjustment so as to prevent an

excessive microwave leakage.

1. When mounting the door to the oven, be sure to adjust the

door parallel to the bottom line of the oven face plate by

moving the upper hinge and lower hinge in the direction

necessary for proper alignment.

2. Adjust so that the door has no play between the inner door

surface and oven front surface. If the door assembly is not

mounted properly, microwave may leak from the clearance

between the door and oven.

8.8. Inverter PCB

1. Remove 2 screws holding inverter bracket to oven chassis.

2. Remove A screw holding air guide.

3. Remove grounding lead wire.

4. Remove 2 screws holding noise filter PCB. (some models

only)

5. Remove all lead wires from inverter PCB.

6. Slide left and take out inverter PCB with brackets.

7. Remove A screw holding inverter PCB to bracket from

bottom.

8. Remove 3 screws holding inverter PCB to bracket.

9. Remove inverter PCB from its bracket by releasing several

catch hooks.

10. When re-install, make sure to place grounding plate in its

place.

8.7. Turntable motor

1. Remove 2 screws holding motor cover.

2. Disconnect 2 lead wires from turntable motor.

3. Remove 2 screws holding turntable motor.

16

Page 17

Missing grounding is very danger.

W

NN-C2000P / NN-C2000

17

Page 18

NN-C2000P / NN-C2000W

9 COMPONENT TEST PROCEDURE

9.1. Primary Latch Switch,

Secondary (Secondary Latch

Switch and Power Relay 1)

Interlocks.

1. Unplug the lead connectors to Power Relay 1 and verify

continuity of the power relay 1 1-2 terminals.

2. Unplug lead connectors to Primary Latch Switch and

Secondary Latch Switch.

3. Test the continuity of switches at door opened and closed

positions with ohm meter (low scale).

Normal continuity readings should be as follows.

9.3. Magnetron (NEW H.V.)

Continuity checks can only indicate an open filament or a

shorted magnetron. To diagnose for an open filament or

shorted magnetron.

1. Isolate magnetron from the circuit by disconnecting the

leads.

2. A continuity check across magnetron filament terminals

should indicate one ohm or less.

3. A continuity check between each filament terminal and

magnetron case should read open.

9.4. Membrane key board

(Membrane switch assembly)

Check continuity between switch terminals, by tapping an

appropriate pad on the key board. The contacts assignment of

the respective pads on the key board is as shown in digital

programmer circuit.

9.2. Short Switch / Monitor Circuit

1. Unplug lead wires from H. V. Inverter primary terminals.

2. Connect test probes of ohm meter to the disconnected

leads which were connected to H. V. Inverter.

3. Test the continuity of short switch with door opened and

closed positions using lowest scale of the ohm meter.

Normal continuity readings should be as follows.

18

Page 19

9.5. Inverter Power Supply (U)

W

(NEW H.V.)

NN-C2000P / NN-C2000

DO NOT try to REPAIR this H. V. Inverter power supply (U).

Replace as whole H. V. Inverter (U) Unit.

Refer to warning on page 2.

9.6. Inverter Power Supply (U)

(NEW H,V,)

DANGER HIGH VOLTAGE

Test 1

1. Place 1 liter of water load into oven cavity.

2. Unplug 2 pin H. V. lead wire connector CN703 from

magnetron tube.

3. Program oven at High power for 1 minute and press start.

a. After approx. 23 seconds, oven stops.

b. During oven operation, input current is approx. at 0.5 to

1.0A . If input current is OK, please proceed to test 2.

Test 2

Continued from Test 1

1. Unplug 3 pin connector, CN701 CN703 remaisn unplug.

2. Set oven at High power for 1 minute and start.

a. After approx. 3 seconds, oven.

b. During oven operation, input current should be lessthan

0.4A.

If both 1 and 2 are OK, the Inverter Power Supply (U) can be

determined OK.

9.7. Steam Sensor and Digital

Programmer Circuit

In order to determine if the steam sensor function of the digital

programmer circuit is in working order or not, do the following

test.

1. Place a water load (150 cc) in the oven.

2. Tap Sensor Reheat pad.

3. Tap Start Pad.

4. Steam Sensor detects steam about 1.5 to 4 minutes after

the Start Pad is tapped.

5. T1 time cooking automatically switches to remaining time

cooking (T2).

6. The remaining cooking time (T2) appears in display

window. If the following cooking time appears, Steam

Sensor function is normal.

9.8. Oven temp sensor thermistor

This sensor monitors the heat produced by the heater circuit

and maintains the oven temperature the user had selected.

Normal room 10°C to 30°C. The reading across the oven

sensor thermistor should be within 100K ohm to 300K ohm

when reading in an area with the 50°F to 90°F room

temperature range.

If the resistance reading is out of the range stated here, the

sensor is detective and must be replaced.

NOTE 1: When measuring resistance disconnect the 3-pin

19

Page 20

NN-C2000P / NN-C2000W

connector (CN6) from the DPC otherwise a false reading

may be indicated.

NOTE 2: If checking an oven sensor thermistor just after

the microw ave oven has been operating, the sensor of

course won't be room temperature. In this case the sensor

must be removed and allowed to cool down to the 10°C to

30°C range.

9.9. Humidity Sensor and digital

programmer circuit

1. Check across sensor heater terminals. Normal cold

resistance should read approx. 4.5 ohm.

2. In order to determine if the Auto/Humidity Sensor function

of the digital programmer circuit is in working order or not,

do the following test.

a. Place a water load in the oven.

b. Unsolder 2 black wires connected to sensor terminals.

c. Tap Sensor Reheat Pad to set auto sensor cooking and

tap Start Pad.

d. About 10 seconds after Start Pad is touched, short 2

black wires for 5 seconds and then remove them.

Before shorting the 2 black wires you can watch the

sensor heater glow red.

e. Approx. 75 seconds after the Start Pad is pressed (T0

TIME), short the 2 black wires again.

f. "AUTO" should disappear in display window and

following digits (see chart) should appear indicating

**balance of cooking time (T2 TIME). The time should

start to count down and oven should shut off when the

time has elapsed.

the microw ave oven has been operating, the sensor of

course won't be room temperature. In this case the sensor

must be removed and allowed to cool down to the 50°F to

90°F range.

The Auto Sensor function in the digital programmer circuit is

working in order if above condition is obtained.

9.10. Oven temp sensor thermistor

This sensor monitors the heat produced by the heater circuit

and maintains the oven temperature the user had selected.

Normal room temperature, especially in a kitchen can vary

anywhere from 10°F to 30°F. The reading across the oven

sensor thermistor should be within 100K ohm to 500K ohm

when reading in an area within the 10°F to 30°F room

temperature range.

If the resistance reading is out of the range stated here, the

sensor is detective and must be replaced.

NOTE 1: When measuring resistance disconnect the 4-pin

connector (CN3) from the DPC otherwise a false reading

may be indicated.

NOTE 2: If checking an oven sensor thermistor just after

20

Page 21

10 MEASUREMENTS AND ADJUSTMENTS

W

NN-C2000P / NN-C2000

10.1. Adjustment of Primary latch

switch, Secondary latch

switch and short switch

1. When mounting Primary latch switch, Secondary latch

switch and short switch to door hook assembly, mount the

Primary latch switch, the Secondary latch switch and the

short switch to the door hook assembly as shown in table.

NOTE: No specific adjustment during installation of

Primary latch switch, Secondary latch switch and short

switch to the door hook is necessary.

2. When mounting the door hook assembly to the oven

assembly, adjust the door hook assembly by moving it in

the direction of arrow in table so that the oven door will not

have any play in it. Check for play in the door by pulling the

door assembly. Make sure that the latch keys move

smoothly after adjustment is completed. Completely tighten

the screws holding the door hook assembly to the oven

assembly.

3. Reconnect the short switch and check the continuity of the

monitor circuit and all latch switches again by following the

components test procedures.

10.2. Measurement of microwave

output

The output power of the magnetron can be determined by

performing IEC standard test procedures. However, due to the

complexity of IEC test procedures, it is recommended to test

the magnetron using the simple method outlined below.

Necessary Equipment:

*1 liter beaker *Glass thermometer

*Wrist watch or stopwatch

NOTE: Check the line voltage under load. Low voltage will

lower the magnetron output. Take the temperature

readings and heating time as accurate as possible.

1. Fill the beaker with exactly one liter of tap water. Stir the

water using the thermometer and record the beaker ユ s

temperature (recorded as T1).

2. Place the beaker on the center of glass cook plate. Set the

oven for High power and heat it for exactly one minute.

3. Stir the water again and read the temperature of the beaker

(recorded as T2).

4. The normal temperature rise at High power position for

each models is as shown in table.

21

Page 22

NN-C2000P / NN-C2000W

11 TROUBLESHOOTING GUIDE (NEW H.V.)

22

Page 23

NN-C2000P / NN-C2000

W

23

Page 24

NN-C2000P / NN-C2000W

24

Page 25

NN-C2000P / NN-C2000

W

1. Discharge high voltage before touching Inverter PCB.

1. Unplug oven and leave it for more than 30 seconds before

removing outer cabinet.

2. Use insulated lead wire to short across D701 Anode to

D702 Cathode or short across magnetron filament

terminals to the chassis ground. Please refer to service

manual for detail of the specified model.

2. Remove inverter PCB from oven before troubleshooting.

Refer to related service manual for inverter PCB removal.

1. Visual check:

a. PCB board: Any crack on board, burnt printed copper

foil pattern? Any cockroach, bugs excrements, any mark

of wet?

b. Components: Any damaged components? Any burnt,

broken or missing?

3. Check component by circuit tester.

25

Page 26

NN-C2000P / NN-C2000W

1. How to check power transistors (Q701, Q702). To measure,

suck a solder from its legs completely unless faulse reading

may observe and mislead a troubleshooting. Measure

across pins between E-C, E-G, C-G, E-black lead, C-red

lead of tester should be infinite and may have some reading

in reverse, it is normal. Refer to attached table for normal

reading.

2. DB701 Diode Bridge

3. C704, C705 High voltage Capacitors. D702 and C705,

D701 and C704 are parallel connected therefore, remove

component to measure when diode is shorted.

4. D701, D702 High voltage Diodes

4. How toreplace power transistors Q701, Q702 and Bridge

Diode DB701.

1. To remove Q701, Q702 and DB701 unsolder their legs first,

next remove ascrew that holding the heatsink onto the PCB

then dtach the heatsink as shown below.

Service Hints: For easy solder removal, use one soldering

iron to heat a solder and use solder sucker iron to suck

solder.

2. Make sure to replace both Q701 and Q702 at a time with

the same maker.

3. Make sure to apply heat conduction grease between

transistor and heat sink.

4. NO DUST SHOULD CAUGHT between heat sink and

power transistor unless if causes looseness of heat

conduction and insufficient cooling to blow components.

26

Page 27

5. Screw must be tighten securely.

W

6. Install the heatsink onto the PCB by a screw and make

sure to apply extra solder between legs and PCB pattern

so that it's able to flow 15A or more main current.

NN-C2000P / NN-C2000

7. Apply extra solder onto Q701 and Q702 legs and printed

foil pattern to be able to hold main large current of more

than 15A.

Service hint:

For easy removal of solder, apply some solder first than suck it

all.

8. How to test repaired Inverter PCB.

WARNING:

1. Do not test Inverter PCB with using any extention cable

Open gounding of inverter PCB is so DANGER.

2. Make sure to check no Bridge solder nor cold solder joint.

1. Install Inverter PCB into oven with screws securely, plug in

CN701, CN702 and CN703.

2. Insert AC plug through the Amper meter with specified

voltage.

NOTE: Current will be changed by the input AC voltage.

3. Operate the oven at High power setting for 1 minute.

4. Read input current which should be within oven

specification.

NOTE: Input current will be decreased after a certain

cooking period.

5. Adjustment is not necessary when replacing transistors

You may adjust the preset volume control VR701 to meet

the specified input current when Transformer is replaced.

27

Page 28

NN-C2000P / NN-C2000W

28

Page 29

NN-C2000P / NN-C2000

W

12 HOW TO CHECK THE SEMICONDUCTORS USING AN

OHM METER

29

Page 30

NN-C2000P / NN-C2000W

13 EXPLODE D VIEW AND PARTS LIST

30

Page 31

14 PARTS LIST

W

NN-C2000P / NN-C2000

When ordering replacement part(s) please use part number(s) shown in this parts list.

Do not use description of the part.

Important safety notice:

Components identified by

mark have special characteristics important for safety.

When replacing any of these components, use only manufacturer's specified parts.

Alphabet marks in Remarks colums (l. e. HNE etc.) indicate parts applicable to only specified country models as follows.

HNE: For Hong Kong, JPG: For New Zealand, KKE: For U.A.E., Egypt, Iran,

KNQ: For Kuwait, Doha, Qatar, Oman, Baharain, Pakistan, LNK: For Philippines,

MNQ: For Malaysia, QPQ: For Australia, SNM: For Saudi Arabia,

TNE: For Thailand, Indonesia, YNQ: For Singapore

Parts without these marks can be used for all models.

Ref.

No.

1 ANE00057J0XN EARTH LABEL 1 NN-C2000P TNE

2 A00065460JP CAUTION LABEL 1

2 A00065540MN CAUTION LABEL 1 NN-C2000P YNQ

3 ANE0033730GN FUSE LABEL 1 NN-C2000P

4 ANE0239L00XN CORD LABEL 1 NN-C2000P KKE/KNQ/SNM

5 ANE0902000CA CUSHION RUBBER A 1

6 ANE0921000BK CUSHION RUBBER C 1

7 ANE0924000AQ CUSHION RUBBER C 1

7 ANE0924000AQ CUSHION RUBBER C 1

8 ANE0922000DD CUSHION RUBBER C 1

9 ANE0902000AV CUSHION RUBBER A 1

10 ANE0924000GE CUSHION RUBBER C 1

11 A10014X00AP BASE 1

12 ANE1008-3W0 RUBBER FOOT 4

12 ANE1008-3W0 RUBBER FOOT 4

12 ANE1008-3W0 RUBBER FOOT 4

12 ANE1008-3W0 RUBBER FOOT 4

13 A10094X70GMN CABINET BODY 1 NN-C2000P

13 A10094X70HQP CABINET BODY 1 NN-C2000W

14 A10266660QP BASE C 1

15 A11294X00AP BASE B 1

16 A11406660QP STOPPER 2

16 A11406660HMK STOPPER 2 NN-C2000P YNQ

17 A200A4X00AP OVEN 1

18 ANE22392L0AP CIRCULATION FAN 1

19 A20554X00AP COVER 1

20 A20764X00AP REINFORCE BRACKET C 1

21 A21315870GP PULLEY SHAFT 1

22 ANE2177-F80 WASHER 1

23 A22365450AP RIGHT HEATER PANEL 1

24 A290D4J00XN ROLLER RING (U) 1

25 A30076660QP LOWER HINGE 1

26 A3020-1200 DOOR HOOK A 1

27 A3136-1200 HOOK SPACER A 1

28 A31374650AP HOOK SPACER B 1

29 A31384650AP HOOK SPACER C 1

30 A400A5500QP FAN MOTOR 1 NN-C2000P HNE/KKE/KNQ/MNQ/SNM/TNE/YNQ NN-C2000W (24.8W)

30 A400A4000LN FAN MOTOR 1 NN-C2000P LNK (26W)

31 A400K5040AQ EXHAUST GUIDE 1

32 ANE40086W0AP FAN 1

33 A40085020AQ FAN 1

34 A40256660QP AIR GUIDE A 1

35 A40264X00AP AIR GUIDE B 1

36 A40306660QP AIR GUIDE D 1

37 A40474X00AP AIR GUIDE E 1

38 ANE4057-F50 SPRING 1

39 A40606660QP BELT 1

40 A41206660QP EXHAUST COVER 1

41 A41446660SN ORIFICE 1

42 A41799190QP HEATER FAN MOTOR 1 NN-C2000P HNE/KKE/KNQ/MNQ/TNE/YNQ NN-C2000W (16W)

42 A41795080BP HEATER FAN MOTOR 1 NN-C2000P LNK/SNM (35/33.5W)

43 A41804X00AP HEATER FAN MOTOR BRACKET 1

44 A601L4780AP HUMIDITY SENSOR 1

Part No. Part Name & Description Pcs/

Set

Remarks

31

Page 32

NN-C2000P / NN-C2000W

Ref.

No.

45 A60304080BP INCANDESCENT LAMP 1 (20W/240V)

46 A605A4X70QP THERMISTOR 1

47 A606Y4V00GP H.V.INVERTER (U) 1

48 ANE6142-F60 MICRO SWITCH 2 (V-15G-3C26-1) (PRIMARY)

49 A61425180AP MICRO SWITCH 2 (L-3C2-2) (SECONDARY)

50 A61456670AP THERMAL CUTOUT 1

51 A61524650AP SOCKET 1

52 A61785180AP MICRO SWITCH 2 (L-2C2-2) (SHORT SW)

53 A62304210BP FUSE 1 (10A/250V)

53 A62304210BP FUSE 1 (10A/250V)

54 A62314000AP FUSE HOLDER 1 NN-C2000P

55 A63266660HN TURNTABLE MOTOR 1 NN-C2000P HNE/KKE/LNK/SNM/TNE (3.3W)

55 A63265850QP TURNTABLE MOTOR 1 NN-C2000P KNQ/MNQ/YNQ NN-C2000W (2.5W)

56 A6585-1B10 P.C.B.HOLDER A 1

57 A66036000BP OVEN LAMP BRACKET 1

58 A6662-1880 EARTH SPACER 1

59 A67634X00AP P.C.B.HOLDER B 1

60 A67974X00CP P.C.B.HOLDER C 1 NN-C2000W

61 A692Y4T00QP NOISE FILTER (U) 1 NN-C2000W

62 A900C6660HN AC CORD W/PLUG 1 NN-C2000P HNE (220-240V)

62 A900C5450MK AC CORD W/PLUG 1 NN-C2000P KKE/KNQ/MNQ/YNQ (220-240V)

62 A900C6240CP AC CORD W/PLUG 1 NN-C2000P LNK (230-240V)

62 A900C9770SN AC CORD W/PLUG 1 NN-C2000P SNM (220-240V)

62 A900C5450TN AC CORD W/PLUG 1 NN-C2000P TNE (220V)

62 A900C6660JP AC CORD W/PLUG 1 NN-C2000W (240V)

63 XST4+5VS SCREW 1 4X5 (FOR COVER)

64 XTT4+8RDN SCREW 1 4X8 (FOR CABINET BODY)

65 XTWANE3+10S4 SCREW 1 3X10 (FOR LAMP SOCKET)

66 XTWANE4+10RU SCREW 4 4X10 (FOR MAGNETRON)

66 XTWANE4+10RU SCREW 4 4X10 (FOR MAGNETRON)

67 XTWA3+8CF SCREW 1 3X8 (FOR INVERTER EARTH)

68 XTW3+18B SCREW 4

69 XYD4+EE12F SCREW 1 4X12 (FOR EARTH)

70 2M236-M1G MAGNETRON 1

71 ANE6501-C41 HEATER HOLDER C 2

72 XWS4VL WASHER 2

73 A21446660QP UPPER PANEL 1

74 A21776660QP WASHER 1

75 A22784X00AP UPPER HEATER PANEL 1

76 A41325020AQ PULLEY B 1

77 A41575450AP FAN BRACKET A 1

78 A41585450AP FAN BRACKET B 1

79 A41635020AQ FAN SPACER C 1

80 A400S6660QP SHAFT U 1

81 A630G6660QP HEATER A 1 NN-C2000P MNQ/YNQ/KNQ NN-C2000W QPQ

81 A630G6660HN HEATER A 1 NN-C2000P HNE/LNK/TNE/SNM/KKE

81 A630G6660JP HEATER A 1 NN-C2000W JPG

82 A64175130AP HEATER SUPPORT 3

82 A64175130AP HEATER SUPPORT 3

82 A64175130AP HEATER SUPPORT 3

83 XTWANE35+14N SCREW 3 3.5X14 (FOR HEATER SUPPORT)

83 XTWANE35+14N SCREW 3 3.5X14 (FOR HEATER SUPPORT)

84 XNG4EVS NUT 2

84 XNG4EVS NUT 2

85 A41074X70QP EXHAUST GUIDE B 1

85 A41074X70QP EXHAUST GUIDE B 1

86 A01574X70HN NAME LABEL 1 NN-C2000P HNE

86 A01574X70KK NAME LABEL 1 NN-C2000P KKE

86 A01574X70KN NAME LABEL 1 NN-C2000P KNQ

86 A01574X70LN NAME LABEL 1 NN-C2000P LNK

86 A01574X70MN NAME LABEL 1 NN-C2000P MNQ

86 A01574X70SN NAME LABEL 1 NN-C2000P SNM

86 A01574X70TN NAME LABEL 1 NN-C2000P TNE

86 A01574X70YN NAME LABEL 1 NN-C2000P YNQ

86 A01574X70QP NAME LABEL 1 NN-C2000P QPQ

86 A01574X70JP NAME LABEL 1 NN-C2000P JPG

87 A02444X70QP CAUTION LABEL 1

88 A09254X70QP CUSHION RUBBER C 1

89 ANE0922000AQ CUSHION RUBBER C 1

Part No. Part Name & Description Pcs/

Set

Remarks

32

Page 33

15 DOOR ASSEMBL Y

W

NN-C2000P / NN-C2000

Ref.

No.

D1 ANE0245X00AP DHHS LABEL 1 NN-C2000P LNK

D1 A01726210JP CAUTION LABEL 1 NN-C2000W JPG

D2 XTBANE4+12FK SCREW 4 4X12(FOR DOOR C)

D2 XTBANE4+12FK SCREW 4 4X12(FOR DOOR C)

D3 A300B5450AP UPPER HINGE 1

D4 A302K6660QP DOOR E(U) 1

D5 A30186660QP DOOR KEY A 1

D6 A30214000AP DOOR KEY SPRING 1

D7 A30856660QP DOOR C 1

D8 A302A4X70GMN DOOR A (U) 1 NN-C2000P HNE/LNK/MNQ/TNE/YNQ (NOTE 1)

D8 A302A4X70GKN DOOR A (U) 1 NN-C2000P KKE/KNQ/SNM (NOTE 1)

D8 A302A4X70HQP DOOR A (U) 1 NN-C2000W QPQ (NOTE 1)

Part No. Part Name & Description Pcs/

Set

NOTE 1: Please order DHHS LABEL or CAUTION LABEL together.

Remarks

33

Page 34

NN-C2000P / NN-C2000W

16 ESCUTCHEON BASE ASSEMBLY

Ref.

No.

E1 A02840000MK NUMBER LABEL 1 NN-C2000P YNQ

E2 A603Y4X70QP PC BOARD D (U) 1 NN-C2000P NN-C2000W QPQ

E3 A605Q4X70HN PC BOARD F (U) 1 NN-C2000P HNE (W/COMPONENT)

E3 A605Q4X70SN PC BOARD F (U) 1 NN-C2000P KKE/SNM (W/COMPONENT)

E3 A605Q4X70KN PC BOARD F (U) 1 NN-C2000P KNQ (W/COMPONENT)

E3 A605Q4X70LN PC BOARD F (U) 1 NN-C2000P LNK (W/COMPONENT)

E3 A605Q4X70MN PC BOARD F (U) 1 NN-C2000P MNQ (W/COMPONENT)

E3 A605Q4X70TN PC BOARD F (U) 1 NN-C2000P TNE (W/COMPONENT)

E3 A605Q4X70YN PC BOARD F (U) 1 NN-C2000P YNQ (W/COMPONENT)

E3 A605Q4X70QP PC BOARD F (U) 1 NN-C2000W QPQ (W/COMPONENT)

E3 A605Q4X70JP PC BOARD F (U) 1 NN-C2000W JPG (W/COMPONENT)

E4 A6590-3280 FLAT CABLE 1

E5 A80094X70QP INDICATOR A 1

E5 A80094X70QP INDICATOR A 1

E6 A80204X70QP TIMER KNOB 2

E7 A80244X70QP OPERATION BUTTON 1

E8 A80344X70GMN ESCUTCHEON BASE 1 NN-C2000P (NOTE 2)

E8 A80344X70HQP ESCUTCHEON BASE 1 NN-C2000W (NOTE 2)

E9 ANE80378A0AG SPRING 1

E10 A80724X70GMN DOOR OPENING BUTTON 1 NN-C2000P

E10 A80724X70HQP DOOR OPENING BUTTON 1 NN-C2000W

E11 A81274X70QP BACK PANEL 1

E12 A82569770AP DOOR OPENING LEVER 1

E13 A82874X70QP SPACER A 2

E13 A82874X70QP SPACER A 2

E14 A83374X70GMN ESCUTCHEON SHEET 1 NN-C2000P HNE/LNK/MNQ/TNE/YNQ

E14 A83374X70GKN ESCUTCHEON SHEET 1 NN-C2000P KKE/KNQ/SNM

E14 A83374X70HQP ESCUTCHEON SHEET 1 NN-C2000W

Part No. Part Name & Description Pcs/

Set

Remarks

NOTE 2: Please order NUMBER LABEL together.

34

Page 35

17 PACKING AND ACCESORIES

W

NN-C2000P / NN-C2000

Ref.

No.

P1 A000B4X70MN COOK BOOK 1 NN-C2000P HNE/LNK/MNQ/TNE/YNQ

P1 A000B5820KN COOK BOOK 1 NN-C2000P KKE/KNQ/SNM

P2 A00034X70HN INSTRUCTION BOOK 1 NN-C2000P HNE/LNK/MNQ/TNE/YNQ

P2 A00034X70KN INSTRUCTION BOOK 1 NN-C2000P KKE/KNQ/SNM

P2 A00034X70QP INSTRUCTION BOOK 1 NN-C2000W

P3 A00324040XN EARTH CAUTION LABEL 1 NN-C2000P TNE

P4 A01024X70HMN PACKING CASE PAPER 1 NN-C2000P HNE/LNK/MNQ/TNE/YNQ

P4 A01024X70HKN PACKING CASE PAPER 1 NN-C2000P KKE/KNQ/SNM

P4 A01024X70HQP PACKING CASE PAPER 1 NN-C2000W QPQ

P4 A01024X70HJP PACKING CASE PAPER 1 NN-C2000W JPG

P5 A01046660MN UPPER FILLER 1 NN-C2000P HNE/LNK/MNQ/TNE/YNQ

P5 A01046660KN UPPERFILLER 1 NN-C2000P KKE/KNQ/SNM

P5 A01046660QP UPPER FILLER 1 NN-C2000W

P6 A01056660MN LOWER FILLER 1 NN-C2000P HNE/LNK/MNQ/TNE/YNQ

P6 A01056660KN LOWER FILLER 1 NN-C2000P KKE/KNQ/SNM

P6 A01056660QP LOWER FILLER 1 NN-C2000W

P7 A01065130AP VINYL COVER 1

P8 ANE0107580AP DOOR SHEET 1

P9 A01086660QP TRAY PACKING 1

P10 A01136660QP TRAY STYROL 1

P11 A01265820HKN REINFORCE MATERIAL 1 NN-C2000P KKE/KNQ/SNM

P12 ANE02072L0AP STYROL SHEET 1

P13 A04454X70MN MENU LABEL 1 NN-C2000P MNQ

P14 A060V4X00AP HIGH BAKING RACK 1 MID(50MM)

P15 A060V4X00CP HIGH BAKING RACK 1 HIGH(135MM)

P16 A06014X70QP COOKING TRAY 1

P17 A91644000XN EARTH LEAD 1 NN-C2000P TNE

P18 A01459770KN DOOR SHEET B 1

Part No. Part Name & Description Pcs/

Set

Remarks

35

Page 36

NN-C2000P / NN-C2000W

18 WIRING MATERIAL

Ref.

No.

W1 A030A4X70MN LEAD WIRE HARNESS 1 NN-C2000P

W1 A030A4X70QP LEAD WIRE HARNESS 1 NN-C2000W

W2 A030E4X00AP LEAD WIRE 1 NN-C2000P

W2 A030E4X00CP LEAD WIRE 1 NN-C2000W

W3 A03509770LN LEAD WIRE 1 NN-C2000P LNK

W4 A03536660QP LEAD WIRE 1

W5 AECQJ5335KRP CAPACITOR 1 3.3MF

Part No. Part Name & Description Pcs/

Set

Remarks

36

Page 37

19 REF. NO. 47 H. V. INVERTER (U)

W

Ref.

No.

C701 ECWF5104N300 FILM CAPACITOR 1 0.1MF 500VDC

C702 ECQE2405T847 POLYESTER CAPACITOR 1 4MF 250VDC

C703 ECWF5454N300 FILM CAPACITOR 1 0.45MF

C704

705

CN701 AEEMXH00703G CONNECTOR 1

CT701 A66904T00AP TRANSFORMER 1

D701

702

D703 AEDNERA3806 DIODE SI 0.5A 1 ERA38-06

D704

705

D706 MA196-(TA5) DIODE SI 0.1A 1 MA196

DB701 AESTRBV6206 DIODE SI 15A 1 15A 600V

DB701 XTW3+12B SCREW 2 3X12

H.S. A66914T00AP HEAT SINK 1

IC702

703

IC801 AN9DB07SB IC 1

L701 A50204T00AP COIL 1

Q701 AESCGT60M303 TRANSISTOR SI 170W 1

Q702 AESPGT30J322 TRANSISTOR SI 75W 1 GT30J322

Q702 XTN3+12B SCREW 1 3X12

Q703

704

Q705 2SA1309AQSTA TRANSISTOR SI 1 2SA1309AQRS

R701 AERG419S107M 1

R715 AERGS215J452 RESISTOR 1 4.5KΩΩΩΩ 15W

T701 A609A4V00GP INERTER TRANS. 1 P20T S296T

VR701 AEVTZ6TLT102 VARIABLE RESISTOR 1 1KΩΩΩΩ 30%

ZD701

703

704

705

ZD702 AESZ12JS2T1 ZENNER DIODE SI 1 RD12JS2

Part No. Part Name & Description Pcs/

2SA1175TFK TRANSISTOR SI 0.25W 1

2SC2785TFK TRANSISTOR SI 0.25W 2

ECWH30822JUA FILMCAPACITOR 2 8200PF 3KVDC

A6202-4N10T DIODE SI 0.3A 2

AEDNERA1506 DIODE SI 1A 2 ERA1506

AEICP25011HL IC 2 PS2501-1 HL

2SC3311AQSTA TRANSISTOR SI 2 2SC3311AQRS

AEDZ10ES2T1 ZENNER DIODE SI 4 RD10ES2T1

NN-C2000P / NN-C2000

Remarks

Set

500VDC

(FOR Q701)

4P

(FOR Q702)

20 REF NO. E2 P. C. BOARD D (U)

Ref.

No.

BZ210 AEFB22EP20TL BUZZER 1 2.0KHZ

C10 ECA1HM102E ELECTROLYTIC CAPACITOR AL 1 1000MF/50V

C12 13

220

C14 ECA1HM101B ELECTROLYTIC CAPACITOR AL 1

C330

502

C500 ECEA1HKA010B ELECTROLYTIC CAPACITOR AL 1 1MF/50V

C501 ECSF1VE6842B ALUMINIUM CAPACITOR 1 0.68MF/35V

CN1 AEEMMD15509W CONNECTOR 1 9 PIN WHITE

CN2 AEEMMF01D05W CONNECTOR 1 5 PIN

CN3 AEEMXF00703B CONNECTOR 1 3 PIN BLUE

CN4 AEEMMF00D04W CONNECTOR 1 4 PIN

CN5 AEEMHLEM21S CONNECTOR 1 3 PIN RED

CN6 AEEMMF00703R CONNECTOR 1

D10 11

220

D25 ERZV10D511CS VARISTOR 1 V10511U

D26 27 ERZV10D112C1 VARISTOR 2 V10112U

D221

222

D500 AESM05DSMM5A TRIAC 5A 1

F1 A62309770AP FUSE 0.8A 1

Q10 A6244UE1625 HEAT SINK 1

Part No. Part Name & Description Pcs/

AECF50F104Z CERAMIC CAPACITOR 3 0.1MF/50V

ECBT1E103ZF5 CERAMIC CAPACITOR 2 0.01MF/25V

AEDNERA1502 DIODE SI 1A 3

AESS133T-77 DIODE SI 0.1A 2

37

Set

Remarks

Page 38

NN-C2000P / NN-C2000W

Ref.

No.

Q10 XYN3+F8S6 SCREW 1 3X8

Q10 2SD2012 TRANSISTOR SI 2W 1 2SD2012

Q220 AESAKTA200Y TRANSISTOR SI 0.6W 1

Q500

502

Q501 AESC14EST TRANSISTOR SI 0.3W 1

Q502 AESC23JST TRANSISTOR SI 0.3W 1

R10 12

210

R13 14

15 222

R211 ERDS2TJ332T CARBON FILM RESISTOR 1 3.3KΩΩΩΩ1/4W

R220

511

R221

230

R223

224

225

226

R227

228

229

R330

521

R500

501

502

503

R504

505

R506 ERDS2TJ512T CARBON FILM RESISTOR 1 5.1KΩΩΩΩ 1/4W

R507 ERDS2TJ153T CARBON FILM RESISTOR 1 15KΩΩΩΩ1/4W 5%

R508 ERDS2TJ223T CARBON FILM RESISTOR 1 22KΩΩΩΩ 1/4W

R509 ERDS2TJ105T CARBON FILM RESISTOR 1 1MΩΩΩΩ 1/4W 5%

RY1 7 AEGG5G1A18 POWER RELAY 2 G5G-1A-

RY2 56AEBGG5N1A18 POWER RELAY 3

Part No. Part Name & Description Pcs/

2SC2785TFK TRANSISTOR SI 0.25W 2 2SC2785TFEK

ERDS2TJ102T CARBON FILM RESISTOR 3 1.0KΩΩΩΩ1/4W

ERDS2TJ104T CARBON FILM RESISTOR 4 100KΩΩΩΩ 1/4W

ERDS2TJ103T CARBON FILM RESISTOR 2 10KΩΩΩΩ 1/4W

ERDS2TJ242T CARBON FILM RESISTOR 2 2.4KΩΩΩΩ 1/4W

ERDS2TJ820T CARBON FILM RESISTOR 4 82ΩΩΩΩ 1/4W 5%

ERDS2TJ301T CARBON FILM RESISTOR 3 300ΩΩΩΩ 1/4W

ERDS2TJ333T CARBON FILM RESISTOR 2 33KΩΩΩΩ 1/4W

ERDS2TJ221T CARBON FILM RESISTOR 4 220ΩΩΩΩ 1/4W

ERDS2TJ751T CARBON FILM RESISTOR 2 750ΩΩΩΩ 1/4W

Set

Remarks

5%

5%

5%

5%

5%

5%

5%

5%

5%

5%

5%

ER18

T10 ETP48SFC93EP L.V.TRANSFORMER 1

ZD10 AEDZ5R6ES2T1 ZENNER DIODE SI 1 RD5.6ES2

ZD11 AEDZ4R7ES3T1 ZENNER DIODE SI 1 RD4.7ES3

ZD501 AEDZ4R3ES3T1 ZENNER DIODE SI 1 RD4.3ES3

21 REF NO. E3 P. C. BOARD F (U)

Ref.

No.

C11 ECEA1CKA100B ELECTROLYTIC CAPACITOR AL 1 10MF/16V

C15 16

17 440

C40 AECU1C101J50 CERAMIC CAPACITOR 1 0.0001MF/50V

C80 81

82 83

350

351

C320

321

CN7 AEEMHLEM20R CONNECTOR 1

CX320 EFOEC8004T4 RESONATOR 1 NN-C2000P

CX320 AEYXAT49-8MA RESONATOR 1 NN-C2000P TNE

D40 41

223

D180

181

182

183

184

185

186

187

188

Part No. Part Name & Description Pcs/

AECU1F104Z25 CERAMIC CAPACITOR 4 0.1MF/25V

AECU1F103Z50 CERAMIC CAPACITOR 6 0.01MF/50V

AECU1C270J50 CERAMIC CAPACITOR 2 NN-C2000P TNE

AESS133T-77 DIODE SI 0.1A 3 1SS133T

AESQTLGE260T LED 9

Set

Remarks

HNE/KKE/KNQ/LNK/MNQ/

SNM/YNQ 8MHZ

38

Page 39

Ref.

W

No.

Part No. Part Name & Description Pcs/

Set

Remarks

D189 AESQSEL4414E LED 1 SEL4414ETP5

DISP110AEDDHLC4X8XN DISPLAY (LCD) 1 NN-C2000P

DISP110AEDDHLC4X7QP DISPLAY (LCD) 1 NN-C2000P

HNE/LNK/MNQ/TNE/YNQ

KKE/KNQ/SNM NN-

C2000W QPQ/JPQ

HOLDER A611A4J00XN DISPLAY HOLDER 1

IC1 MN101C54CDD IC 1 MN101C54C

IC220 AEICU2004GR2 IC 1 A2004G

JPR1 ERDS2TJ103T CARBON FILM RESISTOR 1 NN-C2000P HNE 10KΩΩΩΩ

JPR1 ERDS2TJ163T CARBON FILM RESISTOR 1 NN-C2000P KKE/SNM

JPR1 ERDS2TJ303T CARBON FILM RESISTOR 1 NN-C2000P KNQ 30KΩΩΩΩ

JPR1 ERDS2TJ622T CARBON FILM RESISTOR 1 NN-C2000P LNK

JPR1 ERDS2TJ332T CARBON FILM RESISTOR 1 NN-C2000P MNQ 3.3KΩΩΩΩ

JPR1 ERDS2TJ152T CARBON FILM RESISTOR 1 NN-C2000P TNE 1.5KΩΩΩΩ

JPR1 ERDS2TJ683T CARBON FILM RESISTOR 1 NN-C2000P JPG 68KΩΩΩΩ

Q180

183

2SD1859TV2Q TRANSISTOR SI 1W 3 2SD1859TV QR120MHZ

1/4W 5%

16KΩΩΩΩ 1/4W 5%

1/4W 5%

6.2KΩΩΩΩ1/4W 5%

1/4W 5%

1/4W 5%

1/4W 5%

186

Q181

184

2SC2412KT146 TRANSISTOR SI 0.2W 3 2SC2412K180MHZ

187

Q182

185

AESC43ZKE TRANSISTOR SI 0.3W 3 DTC143ZKA/E23 100MHZ

188

Q221

503

AESA14EKE TRANSISTOR SI 0.2W 2 DTA114EKA/14

Q440 AESC43XKE TRANSISTOR SI 0.3W 1 DTC143XKA/43100MHZ

R11

231

AERJ3GSYJ104 RESISTOR 2 100KΩΩΩΩ 1/16W 5%

R40 AERJ3GSYJ123 RESISTOR 1 12KΩΩΩΩ 1/16 5%

R41

440

ERJ3GSYJ242 RESISTOR 2 2.4KΩΩΩΩ 1/16W 5%

R42 AERJ3GSYJ472 RESISTOR 1 4.7KΩΩΩΩ 1/16W 5%

R43

180

182

184

R80 81

84 85

331

442

AERJ3GSYJ223 RESISTOR 4 22KΩΩΩΩ 1/16 5%

AERJ3GSYJ102 RESISTOR 7 1KΩΩΩΩ 1/16W 5%

510

R82 83

86 87

340

341

AERJ3GSYJ103 RESISTOR 6 10KΩΩΩΩ 1/16W 5%

R181 AERJ3GSYJ470 RESISTOR 3 47ΩΩΩΩ 1/16W 5%

R186

187

ERDS2TJ621T CARBON FILM RESISTOR 3 620ΩΩΩΩ 1/4W 5%

188

R189 ERDS2TJ331T CARBON FILM RESISTOR 1 330ΩΩΩΩ 1/4W 5%

R320 AERJ3GSYJ000 RESISTOR 1 NN-C2000P TNE 1MΩΩΩΩ

1/16W 5%

R441 AERJ3GSYJ823 RESISTOR 1 82KΩΩΩΩ 1/16W 5%

RE8081EVEGA1F2224B ROTARY ENCODER 2 EVEGA1F2224B

NN-C2000P / NN-C2000

SW1 2

345

678

910

11 12

13 14

15 16

R183

185

EVQ11L05R SWITCH 16 EVQ21505R

AERJ3GSYJ750 RESISTOR 2 75ΩΩΩΩ 1/16W 5%

39

Page 40

NN-C2000P / NN-C2000W

22 DIGITAL PROGRAMMER CIRCUIT

SCHEMATIC DIAGRAM

40

Page 41

NN-C2000P / NN-C2000

W

41

Page 42

NN-C2000P / NN-C2000W

23 INVERTER CIRCUIT

SCHEMATIC DIAGRAM

42

Loading...

Loading...