Page 1

ServiceManual

MC-V5203

ORDER NO. MAC060503U

E4

SPECIFICATIONS

2003 PANASONIC CONSUMER ELECTRONICS COMPANY,

DIVISION OF MATSUSHITA ELECTRIC CORPORATION OF AMERICA

All rights reserved. Unauthorized copying and distribution is a violation of law.

PANASONIC CONSUMER ELECTRONICS

COMPANY, DIVISION OF MATSUSHITA

ELECTRIC CORPORATION OF AMERICA

One Panasonic Way

Secaucus, New Jersey 07094

World Wide Web Address

http://www.panasonic.com

Printed in U.S.A.

PANASONIC SALES COMPANY, DIVISION

OF MATSUSHITA ELECTRIC OF

PUERTO RICO INC. (“PSC”)

Ave. 65 de Infanteria, Km. 9.5

San Gabriel Industrial Park

Carolina, Puerto Rico 00985

Tel. (809) 750-4300 Fax (809) 768-2910

Commercial Vacuum Cleaner

Model MC-V5203

Power Source AC 120V (60 Hz

)

Power Consumption 10.0 Amps

Cord Length 50Ft.

Motor Protector Yes

Height Adjust Automatic

Weight 17 lbs.

Page 2

- 19 -- 2 -

TABLE OF CONTENTS

SPECIFICATIONS ........................................................................................................................... Front Cover

SCHEMATIC DIAGRAM .................................................................................................................................. 3

WIRE MANAGEMENT DRAWING................................................................................................................... 3

EXPLODED VIEW (NOZZLE HOUSING) ....................................................................................................... 4

PARTS LIST (NOZZLE HOUSING)................................................................................................................. 5

EXPLODED VIEW (AGITATOR ASSEMBLY).................................................................................................. 4

PARTS LIST (AGITATOR ASSEMBLY) ........................................................................................................... 5

EXPLODED VIEW (MOTOR HOUSING, MOTOR, HANDLE, AND BODY) .................................................... 6

PARTS LIST (MOTOR HOUSING, MOTOR, HANDLE, AND BODY).............................................................. 7

EXPLODED VIEW (MOTOR FAN ASSEMBLY)................................................................................................8

PARTS LIST (MOTOR FAN ASSEMBLY)..........................................................................................................8

EXPLODED VIEW (PACKING MATERIALS)................................................................................................... 9

PARTS LIST (PACKING MATERIALS)............................................................................................................ 9

LOWER PLATE REMOVAL/INSTALLATION ................................................................................................. 10

AGITATOR ASSEMBLY REMOVAL/INSTALLATION..................................................................................... 11

BELT REPLACEMENT................................................................................................................................... 11

BRUSH REPLACEMENT .............................................................................................................................. 12

NOZZLE HOUSING AND NOZZLE HOSE REPLACEMENT........................................................................ 13

SWITCH COVER AREA WIRING MANAGEMENT....................................................................................... 14

POWER CORD/ON-OFF SWITCH REPLACEMENT................................................................................ 14-15

HOSE REPLACEMENT ................................................................................................................................ 15

MOTOR REPLACEMENT ............................................................................................................................. 16

CARBON BRUSH REPLACEMENT.............................................................................................................. 16

MOTOR FAN REPLACEMENT........................................................................................................................17

NOTES .......................................................................................................................................................18-19

This service information is designed for experienced repair technicians only and is not

designed for use by the general public. It does not contain warnings or cautions to advise

non-technical individuals of potential dangers in attempting to service a product. Products

powered by electricity should be serviced or repaired only by experienced professional

technicians. Any attempt to service or repair the product or products dealt with in this

service information by anyone else could result in serious injury or death.

WARNING

NOTES

Page 3

- 3 -- 18 -

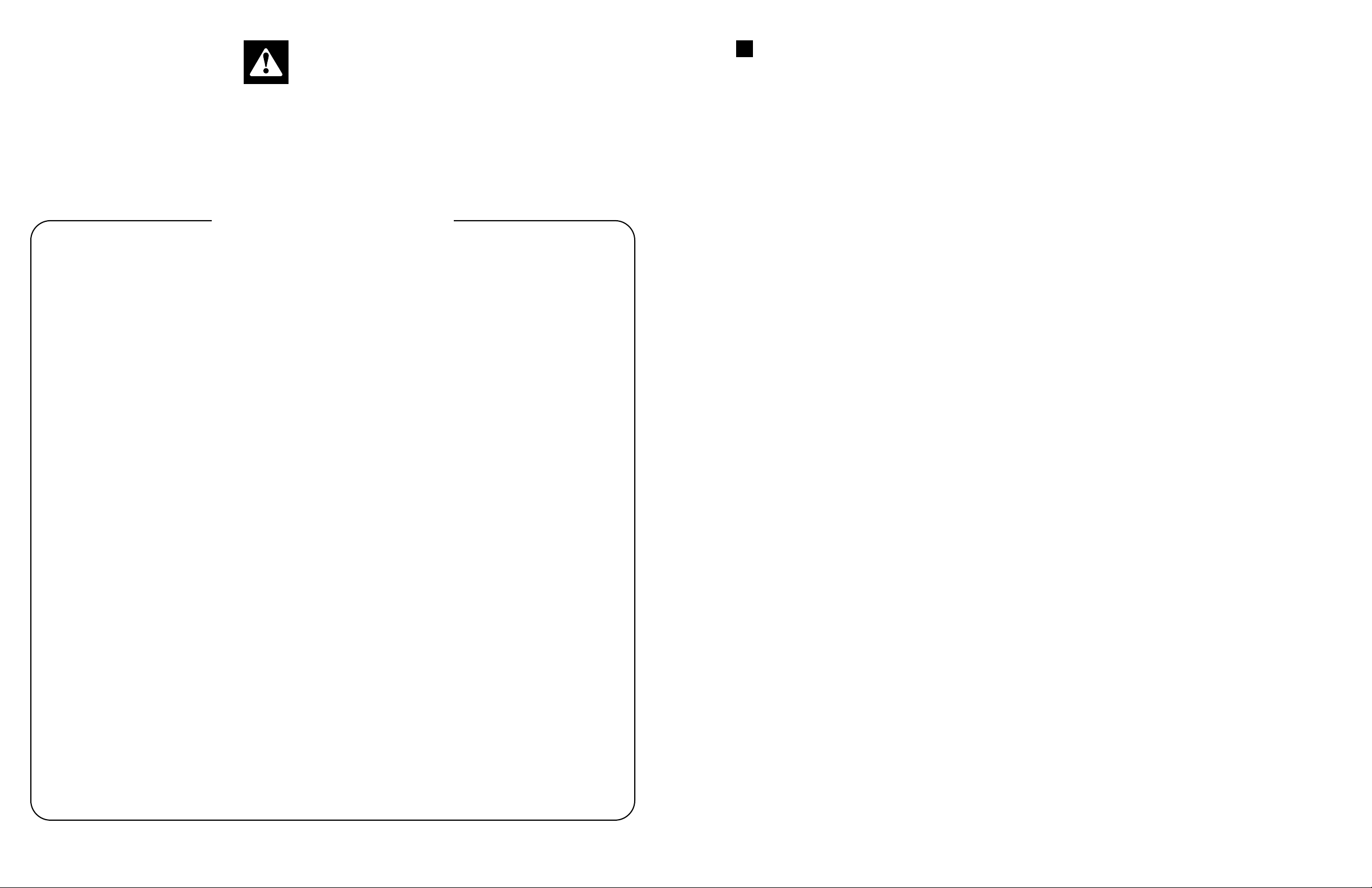

SCHEMATIC DIAGRAM

NOTE: For general servicing, it is necessary to eliminate pinching of any wire during reassembly. After servicing

any electrical component or electrical enclosure, the unit should be reassembled and checked for dielectric

breakdown or current leakage.

WIRING MANAGEMENT DRA WING

NOTE: Do not pinch any wires during reassembly. After servicing any electrical

component or electrical enclosure, the unit should be reassembled and checked for

dielectric breakdown or current leakage.

NOTES

Page 4

- 4 - - 17 -

EXPLODED VIEW

(NOZZLE HOUSING)… BLOCK

A

A-10

EXPLODED VIEW (AGITATOR ASSEMBLY)... BLOCK

B

MOTOR FAN REPLACEMENT

Removal

1. Mark the position of the fan case's location on the motor with a pencil, or score it with a

sharp object before disassembly. This will aid you in reassembling the fan case, (Fig. 21).

2. The fan case has three (3) crimped sections on it to hold the case onto the motor. These

will have to be straightened by using a pair of needle nose pliers and by tapping out on the

crimp area with a flat blade screwdriver. Be sure and straighten all three (3) crimped areas,

(Fig. 21). Remove the fan case from the motor unit.

3. Tools required to remove the fan from the shaft will be a 1/8 - inch Allen wrench, a 1/2 -inch

offset box wrench, torque wrench, and a hammer.

NOTE: Be careful when handling the sheet metal parts as there could be sharp edges. Do

not scratch or bend the motor shaft. Scratches will cause belt breakage during operation.

4. Place the 1/2 - inch box wrench over the 1/2 -inch hex nut that holds the fan onto the

motor shaft, (Fig. 22). While holding the wrench on the nut, place the 1/8 -inch Allen wrench into

the end of the motor shaft and loosen the nut while holding the Allen wrench still. The nut will

have to be turned clockwise as it is a left-hand thread. After removing the nut, remove the fan,

(Fig. 22). There is a spacer left on the motor that is not required to be removed. If spacer is

removed, reassemble per exploded view, (Fig. 22).

* Some models will have this washer and spacer.

Installation

1. Place the new fan onto the motor shaft, making sure that the spacer is still

on the motor. The large diameter hole, approximately 1 1/8 inch, will be on

the top of the fan as you install it.

2. Install the flat washer with the burr side of the washer

facing away from the fan, (Fig. 23). Screw the nut onto the motor shaft,

turning it counterclockwise, left-hand threads, and torque to 20-30-inch

pounds. Be sure to hold the motor shaft by placing the 1/8-inch allen

wrench into the motor shaft end while torquing the

nut, (Fig. 22).

3. Align your marks on the fan case as you put the fan case back on and

tap around the case uniformly. Tap the three (3) crimped areas over and

then use a flat blade screwdriver to recrimp them.

4. See (Fig. 24) for reassembly specifications.

EXPLODED VIEW

(Fig. 24)

(Fig. 21)

(Fig. 23)

(Fig. 22)

A-17

A-27

A-16

A-19

A-3

A-7

A-8

A-12

A-9

A-13

A-14

A-6

A-4

A-5

A-2

A-16

A-15

A-6

A-28

A-22

A-29

A-27

A-1

A-24

A-20

A-21

A-18

A-22

A-24

A-21

A-28

A-25

A-26

A-23

A-11

Tap Down on the

3 Crimped Areas

Mark Case

As Shown

Washer

*

Spacer

Ref

No.

1

8/ " Allen

Wrench

*

Part

Name

1. Fan Case

2. Nut

3. Washer -

Crimped

Area (3)

½" Offset

Box Wrench

½" Nut

Flat

Washer

Fan

Spacer

Burr Side

B-36

B-34

B-33

B-31

B-39

B-32

B-41

B-35

A-30

B-34

Use these specifications

to assure that the fan

case has been tapped

back to the original position.

B-38

B-37

B-40

4.2"/4.5"

(106/114 mm)

These measurements

are approximate.

5a.

5b.

4. Fan

Smooth Side

*

*

5. Spacer

NOTE: Space 5

*

is used on some models.

5a washer and

5b space used on

other models.

6. Brush Assembly

7. Bracket

8. Screw A

Page 5

- 16 - - 5 -

PARTS LIST (NOZZLE HOUSING)… BLOCK

A

Ref. No. Part Name & Description Part No. Quantity Remarks

A - 1 Nozzle Housing ACØ1ACCAZUU3 1

A - 2 Window AC21HAFVZUØ3 1

A - 3 Plastic Shaft AMC25S-VØØ 1

A - 4 Furniture Guard AC1ØAAGZVØ7 1

A - 5 Light Cover AC24HAFVZUØ3 1

A - 6 Screw, Light Cover AXTN4+2ØBFY 2

A - 7 Frame AMC43A-2VØ 1

A - 8 Pedal Spring AC58AAFVZØØ 1

A - 9 Pedal Shaft AMC51A-V3Ø 1

A - 10 Screw, Pedal Assembly AXTN4+1ØBFY 2

A - 11 Screw, Pedal Assembly AXTN4+16BFY 1

A - 12 Pedal, Handle Release AMC47A-2VØU 1

A - 13 Belt AC28SJPZØØ 1

A - 14 Lower Plate Assembly AC91AATEZVØ7 1 (Includes A-15, A-16, A-17, A-22, A-23,

A-24, A-26, A-27, A-28, A-29)

A - 15 Lower Plate AC27AATEZVØ7 1

A - 16 Lower Plate Packing AC19AARKZVØØ 1

A - 17 Belt Cover AC43SAFVZØØ 1

A - 18 Screw, Slider Support AC68AZAZØØ 1

A - 19 Nozzle Hose AC34PAJDZVØ6 1

A - 20 Slider Support AC53KAFVZØØ 1

A - 21 Screw, Slider Support AXTN4+16BFY 2

A - 22 Latch, Lower Plate AMC68N-AVØK 2

A - 23 Stop Latch Spring AC7ØNYUZØØ 2

A - 24 Screw, Latch AMC68A-V3Ø 2

A - 25 Body, Lower Plate ACØ6AAJUZØØ 1

A - 26 Wheel AC9ØQNGZVØ6 2

A - 27 Roller Shaft AC16CNXZØØ 2

A - 28 Screw, Lower Plate AXTN4+16BFY 2

A - 29 Agitator Assembly AC92SATEZØØ 1 (Includes B-31 thru B-41)

PARTS LIST (AGITATOR ASSEMBLY)... BLOCK

B

Ref. No. Part Name & Description Part No. Quantity Remarks

B-31 Brush, Strips (Set of 4) AC85RBFTØØØØ 1

B-32 Pulley, Agitator AC29SARGZØØ 1

B-33 Holder, Agitator AC41SJM1ØØ 1

B-34 Filter, Agitator AC44KJMZØØ 2

B-35 Cap, Left End AC97DJMZØØ 1

B-36 Cap, Right End AC96DJMZØØ 1

B-37 Shaft, Agitator AC57RATEZØØ 1

B-38 E-Clip AMC-XUC4FY 1

B-39 Holder, Brush AC84RJMZØØ 1

B-40 Pin, Spring AMC-XPL16A8WFR 1

B-41 Spacer AC74SATEZØØ 1

Removal

1. Remove the dust cover by grasping the top near the ON/OFF switch and pulling

sharply out toward you.

2. Remove the lower plate, agitator assembly, belt, the plastic shaft, and the nozzle

housing as instructed in the respective removal sections.

3. Turn the vacuum over to the front side and remove the four (4) screws from the motor case

and then remove the motor case, (Fig. 17).

4. Disconnect the motor leads and ground wire and remove the motor.

5. Remove the plastic motor cover by carefully prying out the tabs which secure it to the

motor, (Fig. 18). Snap the motor cover onto the new motor.

6. Remove the motor support rubber (rear), noise suppressor, and the motor support rubber

(front). Place these items on the new motor. See the C Block for a view of these.

Installation

1. Connect all wires according to the SCHEMATIC DIAGRAM.

2. Place the motor into the dust compartment with brushes aligned to the front edge of the

dust compartment. The motor support (rear) must also align with the tabs in the same direction.

3. Route all wires according to the WIRE MANAGEMENT DRAWING.

4. Replace the motor case and the four (4) screws.

5. Turn the vacuum back over and replace the plastic shaft, nozzle housing, belt,

agitator assembly, and lower plate according to the respective installation instructions.

MOTOR REPLACEMENT

(Fig. 17)

(Fig. 18)

CARBON BRUSH REPLACEMENT

Removal and Installation

1. After removing the motor and plastic motor cover, see MOTOR

REPLACEMENT, make sure that you have properly identified it. Note

specifically that this motor is made in the U.S.A. as identified by the label on

the side of the motor, or Made in U.S.A. stamped on the bottom.

2. Remove the amp terminals located on each brush end, (Fig. 19).

Replace the brush assembly which should include the brush holder.

Reinstall the amp terminals onto the new brush assembly. Complete brush

change on one side before starting on the other side.

NOTE: Do not drop screws into the motor.

3. There are two (2) brushes located on the motor as identified in (Fig. 19).

A phillips head screwdriver will be required to remove the four (4) screws that

hold the brush holders onto the motor.

See (Fig. 19) for screw location.

NOTE: When inserting the brush assembly, be sure that the

TAB on the bottom of the brush holder is positioned in the trough as

shown in (Fig. 20).

4. Check and clean commutator.

5. Replace the brush holder bracket with two (2) Phillips screws on each

side of the motor.

6. As a final check to assure proper installation of brushes,

measure across the brushes for the approximate dimension as shown in

(Fig. 20).

7. Place the plastic motor cover back on the unit and re-install the motor back into the unit by following the installation instructions in

the MOTOR REPLACEMENT.

(Fig. 19)

(Fig. 20)

Amp

Terminal

Carbon Brushes

Made in U.S.A.

Label

Screws

Trough

Brush Holder

Tab Location

Motor Case

Green Ground Wire

(Some Models)

Brush

Screws

115-120 mm

4.5-4.7"

Brush to Brush

Dimension is Approximate

Page 6

- 6 - - 15 -

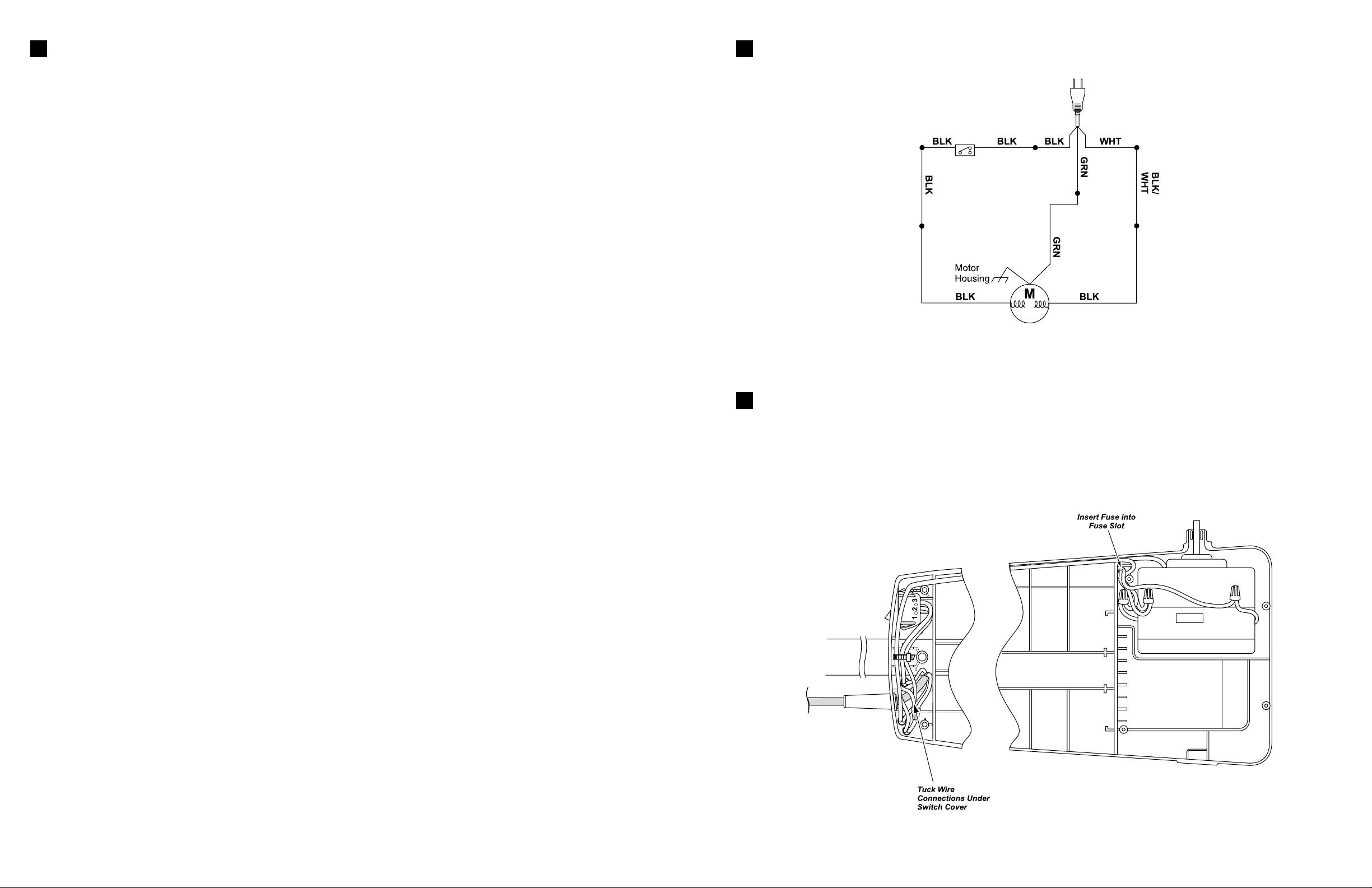

EXPLODED VIEW

(BODY, MOTOR HOUSING, AND MOTOR)… BLOCK

C

Removal

1. Remove the dust cover and dust bag.

2. Remove the end of the hose from the wand. Remove the hose by removing the two screws which secure it to the dust container.

Replacement

1. Install the new hose by replacing the two screws which secure it to the dust container.

2. Replace the hose onto the wand.

3. Replace the dust bag and dust cover.

HOSE REPLACEMENT

Installation

1. Insert the new power cord (power cord replacement only) into the dust compartment as far as necessary in order to place a new cord

retainer in proper location on power cord. The proper location is approximately one and one eighth inches/thirty millimeters (1 1/8”/30

mm) of new power cord yellow outer jacket extending past the cord retainer and washer. The washer goes between the cord retainer and

the dust compartment. Attach wires with wire connectors according to the wiring diagram in the front of this manual. ONLY USE A NEW

CORD RETAINER, DO NOT REUSE A CORD RETAINER.

2. For switch replacement only, insert the new ON/OFF switch with the numbers 1,2,3, facing toward you, into the dust compartment

until secured by the retaining tabs. Use a wire tie with the part number listed in the C Block parts list and place it in the location shown in

(Fig. 15) taking care not to overtighten it. Tuck the wire connectors back into the dust compartment as shown in the close-up view in (Fig. 15).

3. Ensure that the Insulator Packing is installed correctly, (see Fig. 16).

4. Replace the switch cover, the two (2) switch cover screws, and the dust cover. Care should be taken not to pinch wires and make sure

that the switch cover goes on easily and stays flat. If there is resistance to the switch cover lying flat and in place, stop, remove the cover

and make sure that no wires are being pinched. DO NOT USE A POWER SCREWDRIVER TO SECURE THE COVER.

NOTE: Any service involving the handle or switch cover area should be followed up with a dielectric or current leakage check

of the unit. If you do not have the equipment or are not familiar with the test procedures, take the unit to an authorized servicer.

POWER CORD/ON-OFF SWITCH REPLACEMENT (Cont.)

C-50

C-48

C-49

C-5

C-54

C-33

C-37

C-18

Tabs

C-17

C-35

C-7

C-15

C-8

C-51

C-13

C-16

C-44

C-6

C-4

C-38

C-46

C-45

C-20

C-10

C-47

C-43

C-26

C-1

C-2

C-9

C-52

C-42

C-31

C-27

C-39

C-40

C-19

C-41

C-3

C-36

C-24

C-21

C-22

C-23

C-16

C-13

C-30

C-15

C-32

C-53

C-34

C-25

C-28

C-29

C-12

C-11

C-14

Page 7

- 7 -- 14 -

PARTS LIST

(MOTOR HOUSING, MOTOR, HANDLE, AND BODY)... BLOCK

C

Ref. No. Part Name & Description Part No. Quantity Remarks

C-1 Dust Container, Machined AC88KAPNZV17 1 (Includes C-38, C-44, C-45, C-46, C-47, C-48)

C-2 Switch, ON/OFF AMC98E-VØØØU 1 (Includes C-38, C-46)

C-3 Power Cord AC94EAPNZYØ2 1 (Includes C-38, C-44, C-45, C-46)

C-4 Wire Nut AMC-1CTCE23 4

C-5 Packing Dust Container AC66KVØ1VØ6 2

C-6 Switch, Cover ACØ3EVØ7VØ6 1 (Includes C-46)

C-7 Packing Switch Cover AC73KVØZVØ6 1

C-8 Switch Cover Screw AXTN+16BFY 2

C-9 Screw, Handle AMC73B-VØØ 1

C-10 Nut, Handle Screw AMP21B-17Ø 1

C-11 Supporter, Filter AMC32K-VØØ 1

C-12 HEPA Filter, Secondary AC37KAAEZØØ 1

C-13 Wheel AMCØ1C-VØØU 2

C-14 Roller Shaft AC16CUSZØØ 1

C-15 Wheel Stopper AC74SUSZØØ 2

C-16 Washer AXWG6E115FY 2

C-17 Dust Bag AC16KBYTZØØØ 1

C-18 Screw, Hose Holder AXTN4+45BFY 1

C-19 Cover, Inlet ACØ2HYUZVØ6 1

C-20 Screw, Inlet AXTN4+16BFY 2

C-21 Motor Case AC99FAAEZVØ7 1

C-22 Packing, Rear Cover AMCØ2L-VØØ 1

C-23 Packing, Motor Case AC19FJPZVØ6 1

C-24 Screw, Motor Case AXTN4+2ØBFY 4

C-25 Fan Motor AC92FAPNZØØ 1

C-26 Cover Cap AC38HAPNZØU 1

C-27 Screw, Ground AXYN4+E1ØFFY 1

C-28 Noise Suppressor AC99GAMMZØØ 1

C-29 Motor Support, Rear AMCØ3F-VØØ 1

C-30 Motor Support, Front AMCØ2F-EØØ 1

C-31 Wirecord AC37GTEZØU 1

C-32 Wire Nut AMC-1CTCE23 3

C-33 Handle AC64BATNZØØ 1

C-34 Motor Lead Assembly AC99WARGZØØ 1

C-35 Dust Cover AC6ØKCCAZUU3 1

C-36 Stretch Hose AC84PJPZVØ6 1

C-37 Hose Holder AC23PJPZVØ7 1

C-38 Tie Cable AMC596-7ØØ 1

C-39 Motor Protector AC69KJMZVØ6 1

C-40 Protector Spring, Silver AC7ØKJMZØØ 1

C-41 Protector Support AC18MJMZVØ6 1

C-42 Protector Case AC68KJMZVØ6 1

C-43 Rubber Protector AC51E4GZUØ1 1

C-44 Flat Washer AXWE1ØJ223FE 1

C-45 Cord Retainer ACØ6WAPNZØØ 1

C-46 Packing AC61LAGMZØØ 1

C-47 Hose Hook AC53RJPZVØ7 1

C-48 Crevice Tool AC6ØRZFZVU6 1

C-49 Dusting Brush AC88RYUZVØ6 1

C-50 Wand, Extension AC4ØPJP1VØ6 1

C-51 Wand Holder AC7ØPJPZVØ7 1

C-52 Screw, Tool Holder AXTN4+16BFY 3

C-53 Cap, Motor AC93FTEZØU 1

C-54 Handle Assembly AC95BATNZVØ7 1 (Includes C-18, C-33, C-37)

Removal

1. Remove the dust cover and switch cover to expose the electrical connections of the power cord, ON/OFF switch, and wire cord.

2. Pull the power cord into the dust compartment in order to remove the strain relief (for power cord replacement) by prying or cutting,

remove the wire connectors, and wire tie, if present.

3. Remove the ON/OFF switch (for ON/OFF switch replacement) by depressing the switch retaining tabs while pushing up out of the

dust compartment at the same time.

4. Pull the power cord out of the dust compartment (for power cord replacement).

(Continued on p. 14)

POWER CORD/ON-OFF SWITCH REPLACEMENT

SWITCH COVER AREA WIRING MANAGEMENT

(Fig. 15)

(Fig. 16)

DUST COMPARTMENT COMPONENT LOCATIONS

To Plug End

Power Cord

(With Yellow

Outer Jacket)

Wire

Connectors

Cord

Retainer

Insulator

Packing

(Approx. 1 1/8 in./30 mm

Beyond the Strain Relief)

123

Wire

Tie

On/Off

Switch

Wire

Cord

(3 Wire)

Page 8

- 13 -- 8 -

PARTS LIST

(MOTOR FAN ASSEMBLY)

EXPLODED VIEW

(MOTOR F AN ASSEMBLY)

Ref. No. Part Name & Description Part No. Quantity Remarks

1 Fan Case AMC53F-AVØØU 1

2 Nut AMC33F-ACØØU 1

3 Washer AMC62F-AVØØU 1

4 Fan AC98FRFZØØ 1

5 Washer AC62FRFZØØ 1

6 Spacer AC6ØFRFZØØ 1

7 Brush Assembly AC27FRFZØØ 1(Set)

8 Bracket ACØ2DV3ZØU 2

9 Screws AC4ØDV3ØØU 4

NOZZLE HOUSING AND SHORT HOSE REPLACEMENT

Removal

1. Remove the lower plate as outlined in the LOWER

PLATE REMOVAL/INSTALLATION section.

2. Remove the belt and agitator assembly as outlined in

the respective sections.

3. Remove the nozzle hose by pulling it up out of the

nozzle housing and then pulling it, while twisting, out of

the wand holder.

4. Insert a flat blade screwdriver between the nozzle

housing and the plastic shaft, pry out the plastic shaft as

illustrated, (Fig. 10).

5. Remove the nozzle housing as illustrated, (Fig 11).

6. Remove the handle release assembly as outlined in its removal

section.

7. Remove the light cover, (Fig. 12) by removing the two (2) screws from

the nozzle housing and pushing out on the cover (Fig. 12).

8. Remove window, furniture guard and slider support.

NOTE: If the motor case cover is removed, DO NOT turn vacuum

over as the motor may fall out.

Installation

1. Install the light cover, handle release assembly, furniture guard,

window and slider support in the new nozzle housing. (Fig. 12).

2. Fit the nozzle from the motor shaft side first and rotate it into

place on the dust container as illustrated, (Fig. 13).

3. Slide the plastic shaft through the nozzle housing and into

the dust container. Make sure that the slot on the bottom of

the plastic shaft is down and fitted onto the projection.

4. Reassemble the nozzle hose by inserting it into the wand holder

then place the other end into the nozzle housing with the tab fitting into the slot.

5. Install the belt, agitator assembly, and the lower plate according to the respective instructions.

(Fig.11)

(Fig. 12)

(Fig. 10)

(Fig. 13)

(Fig. 14)

1

2

3

4

5

6

7

8

9

Handle Release

Assembly

Furniture

Guard

Light

Cover

Light Cover Screws

Plastic

Shaft

Nozzle

Housing

Projection

Page 9

- 9 -- 12 -

EXPLODED VIEW

(PACKAGING)

PARTS LIST

(PACKAGING)

Ref. No. Part Name & Description Part No. Quantity Remarks

1 Packaging Assembly AC61ZCCAZØØØ 1 Includes 1 and items a-i

2 Operating Instructions ACØ1ZCCAZØØØ 1

When to replace brushes

1. The agitator brushes should be replaced when they are worn. Brushes should be checked by

holding a card across the lower plate, (Fig. 5). If the bristles on the agitator assembly do not

touch the card you should replace all the brushes for best cleaning results.

Removal

NOTE: Use extreme care when prying or depressing these items with a screwdriver in

order to help prevent personal injury or damage to the vacuum.

Be careful when working around the ends of the metal brush holder since sharp edges

may be present.

1. Remove the lower plate as outlined in the LOWER PLATE REMOVAL/

INSTALLATION section.

2. Remove the agitator assembly as outlined in the AGITATOR ASSEMBLY

REMOVAL/INSTALLATION section.

3. The agitator assembly may now be dissassembled and the brushes replaced.

4. Using a small screwdriver, carefully remove the E-clip from the agitator shaft,

(Fig. 6), DO NOT misplace. Remove the right end cap. Pull the agitator shaft out of the opposite

end of the agitator.

5. Pull or pry out the agitator pulley and agitator holder, (Fig. 7).

6. The brushes can now be replaced, (Fig. 8). Each brush must be inserted so that the end with

eleven (11) tufts is placed on the side of the brush holder closest to the belt pulley. Push each

brush as shown in the illustration until it is free from the agitator body. Install the new brushes by

reversing the procedure.

Installation

1. Pull the new brushes into the slots in the brush holder.

2. Reinstall the agitator holder and agitator pulley, making sure they are completely

and firmly inserted. See (Fig. 9) for an exploded view.

3. Reinstall the agitator shaft, brush support, and the small E-clip.

4. Reinstall the agitator assembly as outlined in the AGITATOR ASSEMBLY

REMOVAL/INSTALLATION section.

5. Reinstall the lower plate as outlined in the LOWER PLATE REMOVAL/

INSTALLATION section.

NOTE: When the brushes are properly installed they will not hit the lower plate

as the agitator assembly rotates.

BRUSH REPLACEMENT

(Fig. 5)

(Fig. 6)

(Fig. 7)

(Fig. 8)

AGITATOR ASSEMBLY

(Fig. 8)

(Fig. 9)

e

Unit Bag

(Handle)

a

Cushion “A”

Operating

Instructions

2

d

Unit Bag

(Power Cord)

b

Cushion “B”

Unit Bag

(Body)

1

Carton

Pedal

Protector

i

c

g

Unit Bag

(Attachment

Assembly)

Spacer

Filter

Agitator Shaft

Belt Pulley

Agitator

Body

End Caps

Brush

Filter

Agitator Holder

E- Clip

fPacking

Insert

Page 10

- 11 -- 10 -

Removal

1. Place the handle in the upright position.

2. Turn the vacuum cleaner over exposing the underside. Release the lower

plate by pressing inward the two (2) latches and depressing the two locking

tabs that secure the lower plate, (Fig. 1).

3. Remove the lower plate and remove any residue that may exist in the belt area.

Installation

1. Hook the front of the lower plate into the slots on the front of the nozzle housing. Press the lower plate down until the

locking tabs snap into place.

2. Press outward on the two (2) lower plate latches to fasten.

NOTE: For general servicing, it is necessary to eliminate pinching of any wire during reassembly. After servicing any

electrical component or electrical enclosure, the unit should be reassembled and checked for dielectric breakdown or current

leakage.

LOWER PLATE REMOVAL/INSTALLATION

(Fig. 1)

Removal

The brushes are replaceable separately. When the brushes need replacing, the

agitator assembly will have to be removed.

1. Remove the lower plate as outlined in the LOWER PLATE REMOVAL/

INSTALLATION section.

2. Carefully lift up on the agitator assembly until it clears both sides of the nozzle housing,

(Fig. 2).

3. Remove the belt from the motor shaft by sliding it off between the end of the shaft and the

nozzle housing.

Installation

1. Place the belt around the motor shaft, (Fig. 3).

2. Start the agitator assembly back into the nozzle housing by placing the side

opposite the belt partially into the slot. This will hold the agitator in place and leave

both hands free to place enough tension on the belt to allow that side of the agitator

to return to the nozzle housing slot.

3. Place the belt around the agitator pulley on the agitator assembly.

NOTE: There is a place for the belt to fit on one end of the agitator

assembly only. This is the agitator pulley.

4. Use both hands to pull the belt tight, (Fig. 4), and slide the agitator

assembly firmly into the slots on each end of the nozzle housing.

5 Rotate the agitator assembly by hand to insure nothing rubs and to check

for correct assembly.

6. Replace the lower plate as outlined in the LOWER PLATE

REMOVAL/INSTALLATION section.

AGITATOR ASSEMBLY REMOVAL/INSTALLATION

(Fig. 2)

(Fig. 3)

(Fig. 4)

BELT REPLACEMENT

Removal

1. Follow all of the removal instructions outlined in the AGITATOR ASSEMBLY REMOVAL/INSTALLATION section.

Installation

2. Place the new belt around the motor shaft and follow the installation instructions in the AGITATOR ASSEMBLY

REMOVAL/INSTALLATION section.

Motor Shaft

Loading...

Loading...