Panasonic MADLN01SE, MADLN11SE, MADLN05SE, MADLN15SE, MBDLN21SE Reference Specifications

...Page 1

No.SX-DSV03015

REFERENCE SPECIFICATIONS

MODEL

Product Name: AC servo driver

Part Number : MINAS-A6 series (Basic type)

Issued on Sept. 1, 2015

Revised on Sept. 14, 2016

Motor Business Unit, Electromechanical Control Business Division

Automotive & Industrial Systems Company, Panasonic Corporation

7-1-1 Morofuku , D aito-City, Osaka 574-0044 Japan

Page 2

No. SX-DSV03015

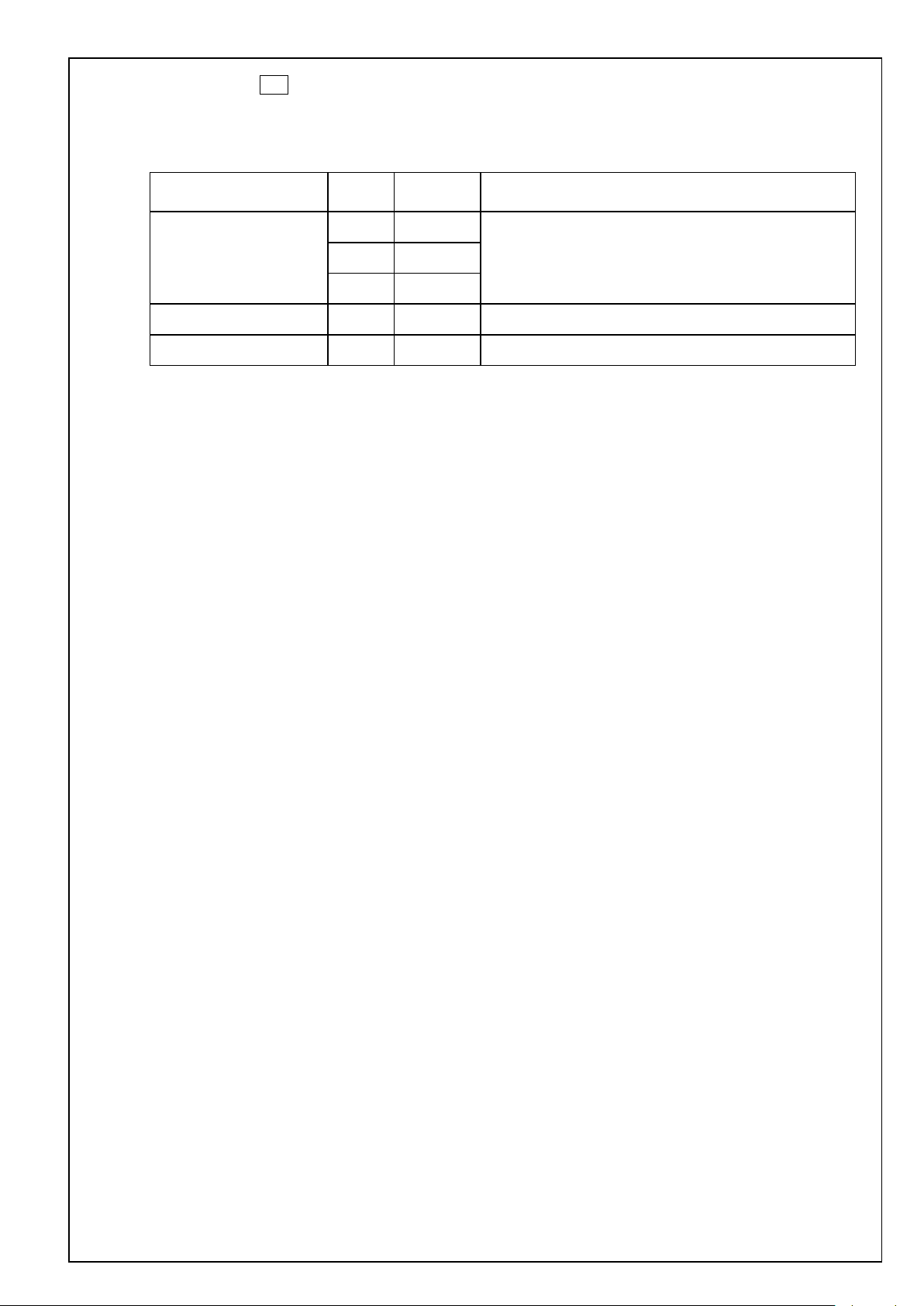

REVISIONS

Date Page Rev. Description Signed

Spt. 1, 2015

Nov. 1, 2015

Sept.14,2016

P1, P3,P53, P65

P5

P56 ADDED THE HARMONIC SUPPRESSION MEASURES

- NEWLY ISSUED -

- 1.0 DEFAULT VALUE OF THE PARAMETERS CHANGED -

P1 2.0 UPDATE THE MODEL DESIGNATION CODE -

P1 CHANGED THE NAME OF COMPANY

ADDED THE MODEL OF MEDLN93SE

ADDED THE FUNCTIONS

P63~65

CORRECT THE INRUSH CURRENTS AT CONTROL POWER SUPPLY

Motor Business Unit, Panasonic Corporation

Page 3

No. SX-DSV03015

Contents

1. Scope ································································································································· 1

2. Model designation code ············································································································ 1

3. Product line-up ······················································································································ 2

4. General specifications ·············································································································· 4

4-1 General specification ········································································································· 4

4-2 Specifications by model ······································································································ 5

5. Appearance and part names ········································································································ 6

6. Configuration of connectors and terminal blocks ··············································································· 11

6-1 Power connector XA , XB , XC , XD and terminal block ························································ 11

6-2 USB connector X1 ··········································································································· 15

6-3 Parallel I/O connector, X4 ·································································································· 16

6-4 Encoder connector X6 ······································································································· 20

7. Dimensions ·························································································································· 23

8. Wiring ································································································································ 35

8-1 Used cables and maximum cable lengths ·················································································· 35

8-2 Various connectors ············································································································ 35

8-3 Precautions for wiring ········································································································ 36

9. Compliance with global standards ································································································ 49

9-1 Conforming standards ········································································································ 49

9-2 European EC directive········································································································ 49

9-3 Peripheral device configuration ····························································································· 50

9-4 List of peripheral devices applicable to servo driver ····································································· 53

9-5 Compliance with UL stand a r d ······························································································· 55

9-6 Radio waves act (South Korea) precautions ··············································································· 56

9-7 Compliance with SEMI F47 instantaneous stop standard ······························································· 56

9-8 Harmonic suppression measures ···························································································· 56

10. Safety precautions ················································································································· 57

11. Life and warranty ·················································································································· 61

11-1 Life expectancy of the driver ······························································································· 61

11-2 Typical life ··················································································································· 61

11-3 Warranty period ·············································································································· 61

12. Others ······························································································································· 62

13. Specification for each model ····································································································· 63

The maximum value of torque limit setup

Default value of the parameters

Motor Business Unit, Panasonic Corporation

Page 4

Custom specification (Alphanumeric)

Size

1. Scope

These specifications relate to the servo driver for the AC servo system that is comprised of the AC servo motor

manufactured and supplied by Motor Business Unit, Electromechanical Control Business Division, Automotive &

Industrial amplifier Systems Company, Pan ason ic C orporat ion .

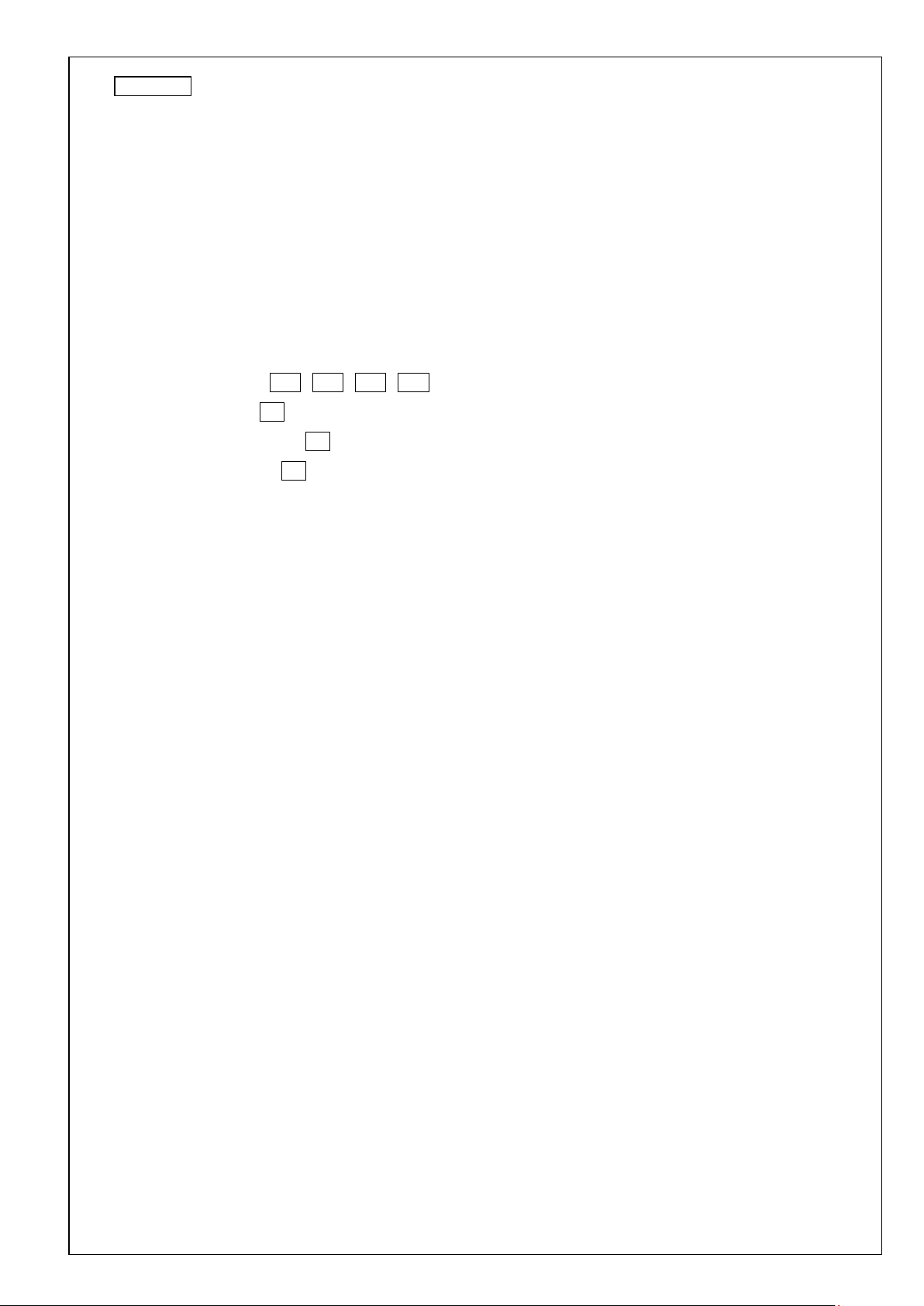

2. Model designation code

Notation of the machine designation code is as follows:

A : Size A

B : Size B

C : Size C

D : Size D

E : Size E

F : Size F

AC Servo drive

L : A6 series

Safety function

N : Without functional safety

Maximum instantaneous

output current

0 : 6 A

1 : 8 A

2 : 12 A

3 : 22 A

4 : 24 A

5 : 40 A

8 : 60 A

9 : 80 A

A : 100 A

B : 120 A

1 2 3 4 5 6 7 8 9 10 11 12

M A D L N 1 5 S E * * *

User Interface

• Rotary type

Power supply voltage

No. SX-DSV03015 - 1 -

E : Basic type

1 : Single phase 100 V

3 : 3 phase 200 V

5 : Single or 3 phase 200 V

Motor Business Unit, Panasonic Corporation

Page 5

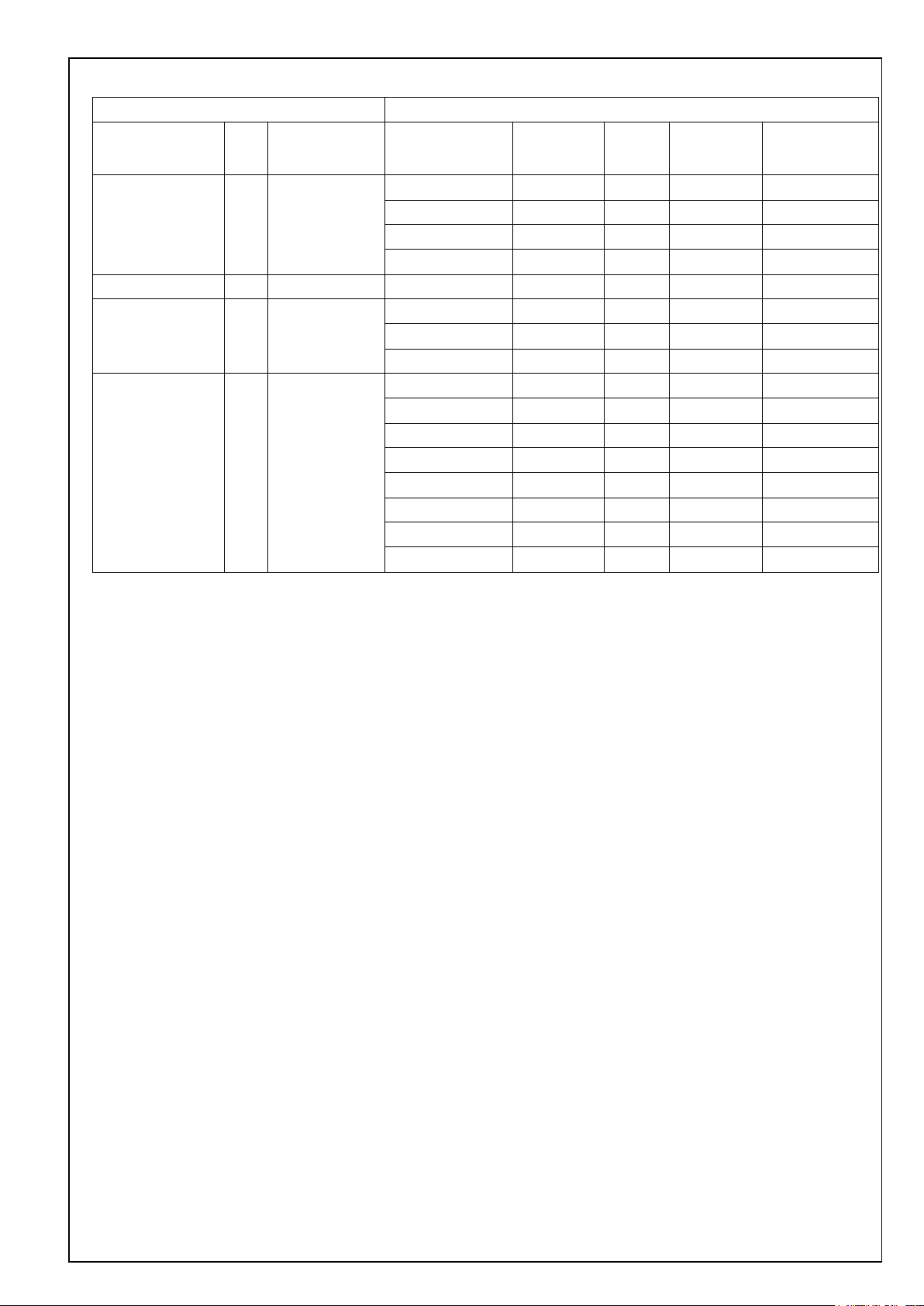

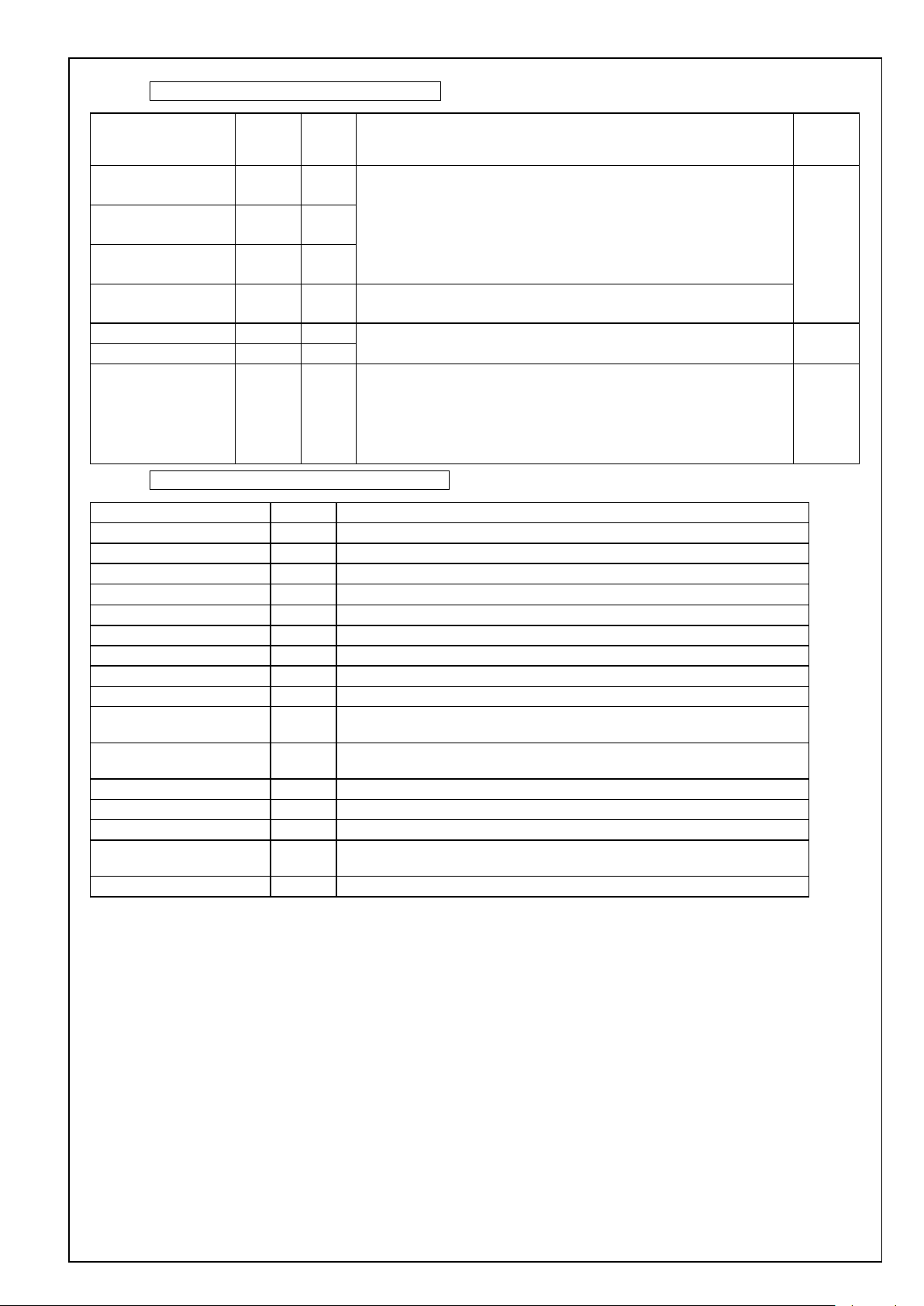

No. SX-DSV03015 - 2 -

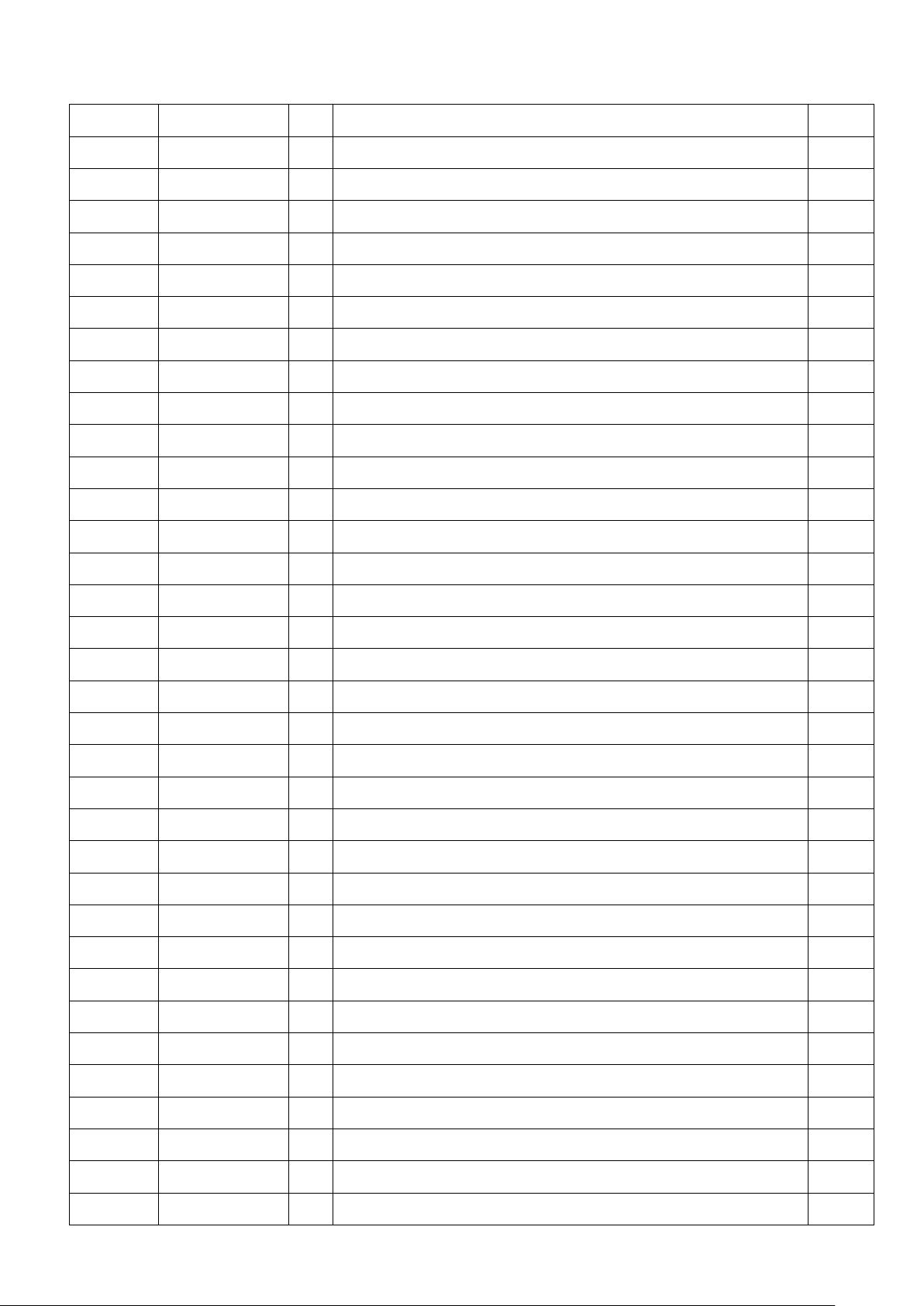

3. Product line-up

Servo driver Motor used

Model Size

Power supply

input

Model

Voltage

specification

Rated

output

Rated speed

MADLN01SE A Single MSMF5AZL1** 100 V 50 W 3000 r/min 7 cores, 23 bits

100 V MHMF5AZL1** 100 V 50 W 3000 r/min

MADLN11SE A Single MSMF011L1** 100 V 100 W 3000 r/min

100 V MQMF011L1** 100 V 100 W 3000 r/min

MHMF011L1** 100 V 100 W 3000 r/min

MADLN05SE A Single / 3 phase MSMF5AZL1** 200 V 50 W 3000 r/min

200 V MHMF5AZL1** 200 V 50 W 3000 r/min

MSMF012L1** 200 V 100 W 3000 r/min

MQMF012L1** 200 V 100 W 3000 r/min

MHMF012L1** 200 V 100 W 3000 r/min

MADLN15SE A Single / 3 phase MSMF022L1** 200 V 200 W 3000 r/min

200 V MQMF022L1** 200 V 200 W 3000 r/min

MHMF022L1** 200 V 200 W 3000 r/min

MBDLN21SE B Single MSMF021L1** 100 V 200 W 3000 r/min

100 V MQMF021L1** 100 V 200 W 3000 r/min

MHMF021L1** 100 V 200 W 3000 r/min

MBDLN25SE B Sin gle / 3 phase MSMF042L1** 200 V 400 W 3000 r/min

200 V MQMF042L1** 200 V 400 W 3000 r/min

MHMF042L1** 200 V 400 W 3000 r/min

MCDLN31SE C Single MSMF041L1** 100 V 400 W 3000 r/min

100 V MQMF041L1** 100 V 400 W 3000 r/min

MHMF041L1** 100 V 400 W 3000 r/min

MCDLN35SE C Single / 3 phase MSMF082L1** 200 V 750 W 3000 r/min

200 V MHMF082L1** 200 V 750 W 3000 r/min

MDDLN45SE D Single / 3 phase MGMF092L1** 200 V 850 W 1500 r/min

200 V MSMF092L1** 200 V 1.0 kW 3000 r/min

MDMF102L1** 200 V 1.0 kW 2000 r/min

MHMF102L1** 200 V 1.0 kW 2000 r/min

MDDLN55SE D Single / 3 phase MHMF092L1** 200 V 1.0 kW 3000 r/min

200 V MSMF102L1** 200 V 1.0 kW 3000 r/min

MGMF132L1** 200 V 1.3 kW 1500 r/min

MSMF152L1** 200 V 1.5 kW 3000 r/min

MDMF152L1** 200 V 1.5 kW 2000 r/min

MHMF152L1** 200 V 1.5 kW 2000 r/min

Encoder

specification

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

7 cores, 23 bits

Motor Business Unit, Panasonic Corporation

Page 6

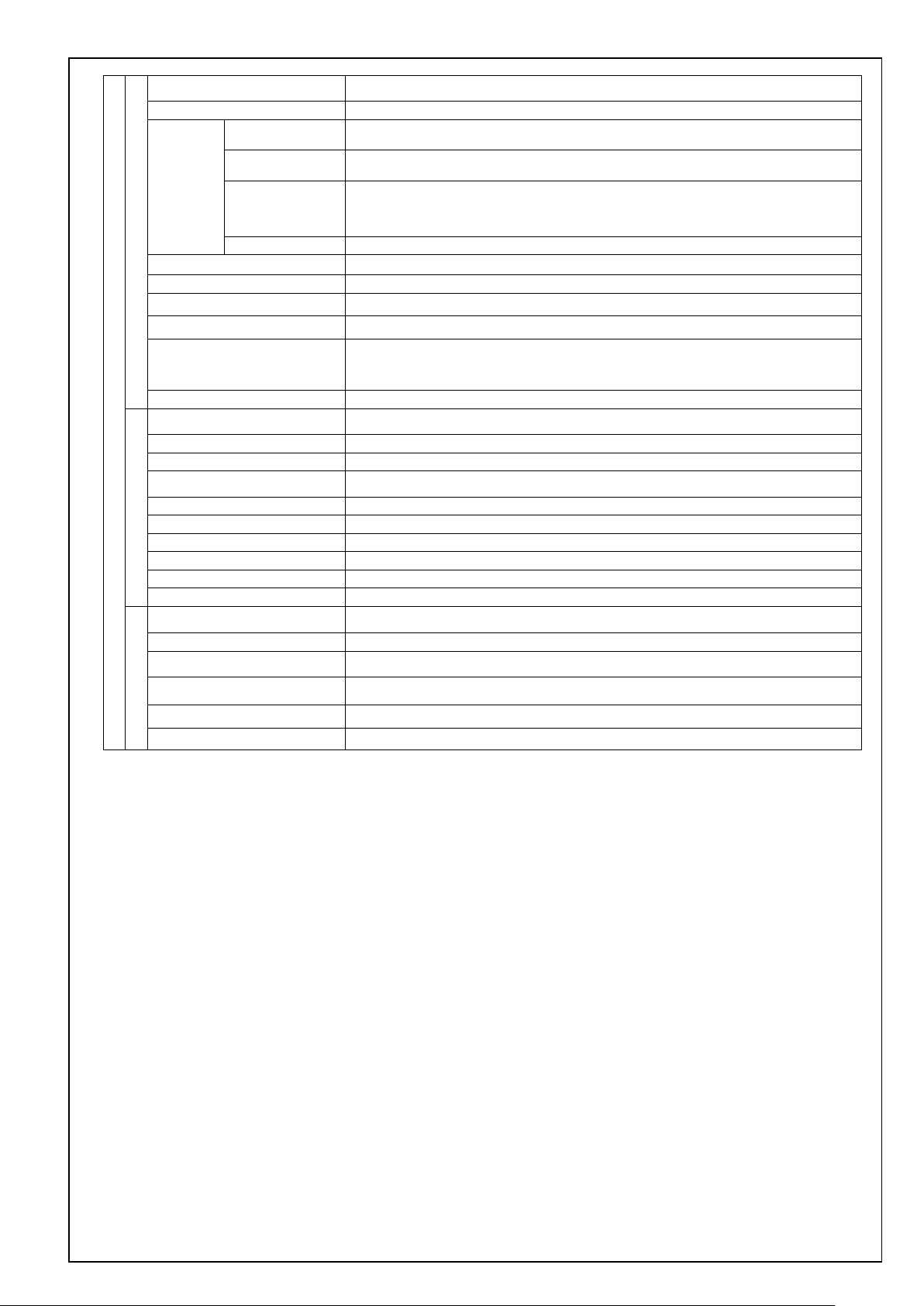

No. SX-DSV03015 - 3 -

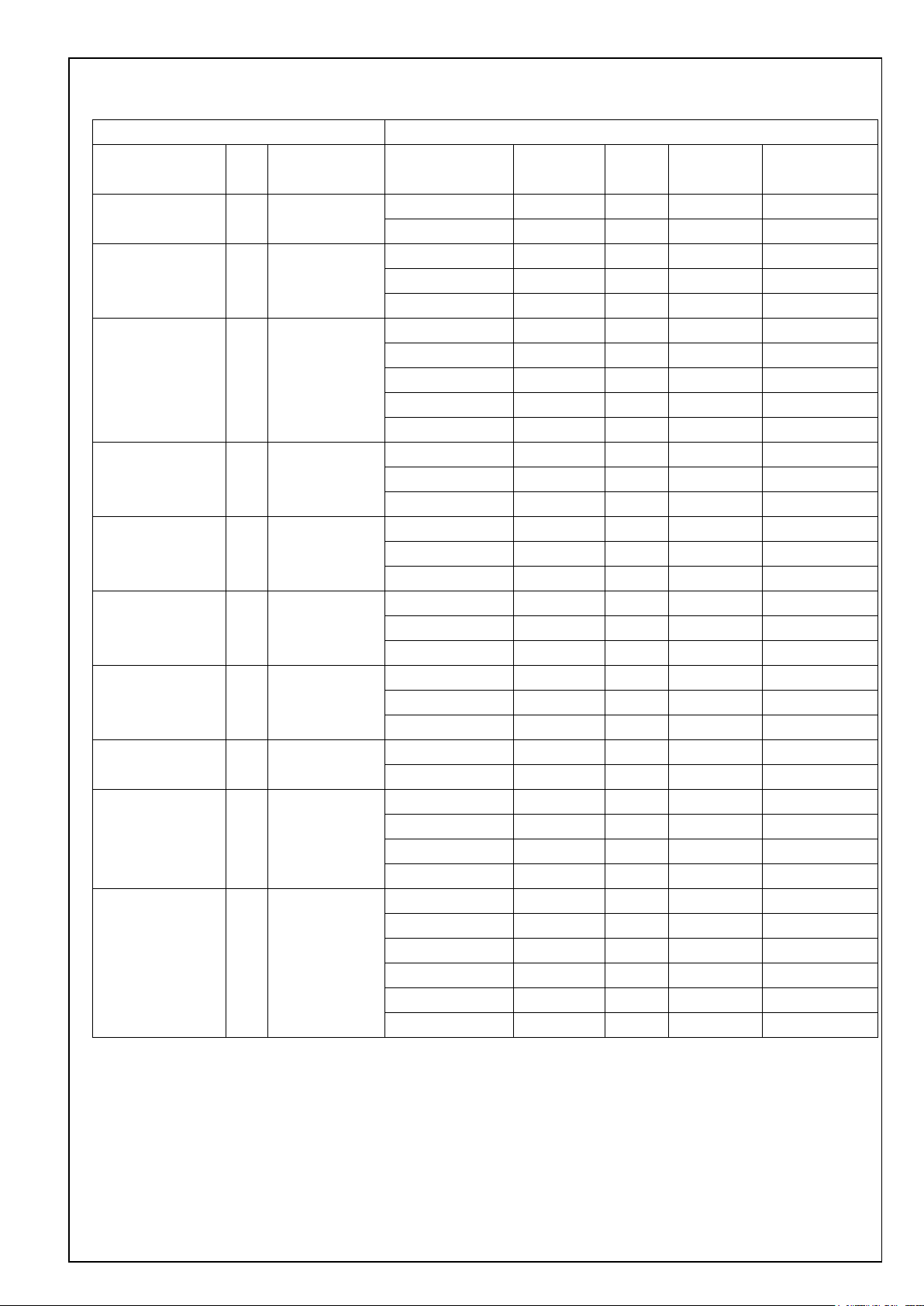

Servo driver Motor used

Model Size

Power supply

input

Model

Voltage

specification

Rated

output

Rated speed

MEDLN83SE E 3 phase MGMF182L1** 200 V 1.8 kW 1500 r/min 7 co r es, 23 bits

200 V MSMF202L1** 200 V 2.0 kW 3000 r/min 7 cores, 23 bits

MDMF202L1** 200 V 2.0 kW 2000 r/min 7 cores, 23 bits

MHMF202L1** 200 V 2.0 kW 2000 r/min 7 cores, 23 bits

MEDLN93SE E 3 phase 200 V MGMF242L1** 200 V 2.4 kW 1500 r/min 7 cores, 23 bits

MFDLNA3SE F 3 phase MSMF302L1** 200 V 3.0 kW 3000 r/min 7 cores, 23 bits

200 V MDMF302L1** 200 V 3.0 kW 2000 r/min 7 cor es, 23 bits

MHMF302L1** 200 V 3.0 kW 2000 r/min 7 cores, 23 bits

MFDLNB3SE F 3 phase MGMF292L1** 200 V 2.9 kW 1500 r/min 7 co r es, 23 bits

200 V MSMF402L1** 200 V 4.0 kW 3000 r/min 7 co res, 23 bits

MDMF402L1** 200 V 4.0 kW 2000 r/min 7 cor es, 23 bits

MHMF402L1** 200 V 4.0 kW 2000 r/min 7 cores, 23 bits

MGMF442L1** 200 V 4.4 kW 1500 r/min 7 cor es, 23 bits

MSMF502L1** 200 V 5.0 kW 3000 r/min 7 cores, 23 bits

MDMF502L1** 200 V 5.0 kW 2000 r/min 7 cor es, 23 bits

MHMF502L1** 200 V 5.0 kW 2000 r/min 7 cores, 23 bits

Encoder

specification

Motor Business Unit, Panasonic Corporation

Page 7

No. SX-DSV03015 - 4 -

Storage temperature: -20 – 65 degrees C (Max.temperature gu arantee : 80 degrees C for 72 hours no condensation*)

Height above the sea

Height above the sea level: 1000 meters or less

Vibration

5. 88 m/s2 or less, 10 – 60 Hz

Insulation voltage

Resistant to 1500 V AC between primary power supply and ground for a minute (Sensed current: 20 mA)

Control method

IGBT PWM method, sinusoidal drive

Encoder feedback

23Bit(resolution:8388608) 7cores-serial absolute encoder

Function of each multi-funct i o n i np ut is assigned by the parameter.

Function of each multi-function output is assigned by the parameter.

Analogue signal

Output

2 outputs for analog monitor

High speed line driver interface can be connected.

collector output also available for Z or EXZ signal

Communication

USB

USB interface to connect to computers for parameter setting or status monitoring.

Front panel

5 key switches, 6-digit 7-se g ment LED

Regeneration

Size A, B: External r egen resistor only Size C - F: Built-in regen resistor (External regen is also available)

Dynamic brake

Size A - F: Built-in

4. General specifications

4-1 General specification

100 V

Input

power

supply

200 V

Operation conditions

Basic specifications

Control signal

Main circuit power

Control circuit power Single phase 100 - 120 V

Main circuit

power

Control circuit

power

Temperature

Humidity Operation and storage humidity 20 - 85 % RH or less (no condensation*)

A - D

E - F 3 phase 200 - 240 V

A - D

E - F Single phase 200 - 240 V

Input

Output

Multi-function input x 10

Multi-function output x 5 + dedicated output x 1 (alarm output)

Single phase 100 - 120 V

Single/3 phase 200 - 240 V

Single phase 200 - 240 V

+ 10%

50/60 Hz

- 15%

+ 10 %

50/60 Hz

- 15 %

+ 10 %

50/60 Hz

- 15 %

+ 10 %

50/60 Hz

- 15 %

+ 10 %

50/60 Hz

- 15 %

+ 10 %

50/60 Hz

- 15 %

Operation tempera ture: 0 - 55 degrees C (no freezing)

2 inputs

Input

Pulse signal

Output

Control mode

Please note that condensation tend to occur when temperature fall.

Both open collector and line driver interface can be connected.

4 outputs

Line driver output for encoder pulses (A/B/Z signal) or external feedba c k pulses (EXA/EXB/EXZ sig nal) open

Selectable from the fo llowing 3 modes by parameter:

[1]position cont rol [2]velocity control [3]position/velocity c ontrol

Motor Business Unit, Panasonic Corporation

Page 8

No. SX-DSV03015 - 5 -

Deviation counter clear, command pulse input inhibition, command division/multiplication switching,

vibration suppression control sw itc hing, etc.

1/1000 to 8000 times

Smoothing Filter

Available

ion origin return invalidation sett ing is s et to

invalid)

Internal command velocity selection 1, Internal command velocity selection 2, Internal command velocity selection 3,

speed zero clamp, etc.

Control output

Speed arrival, etc.

0 to 10s/1000 r/min r/min Setting is possible for acceleration and deceleration respectively. S shaped

acceleration/deceleration is possible.

Velocity command filter

Available

Block operation

Not available

This function identifies the load inertia real-time and automatically sets up the gain that meets the stiffness setting

when the motor is running with ho st and inte r nal driver operation co mmands.

Overvoltage, undervoltage, overspeed, overload, overheat, overcurrent, encoder failure, positional overdeviation,

command pulse division, EEPROM failure, etc.

Control input

Control output Positioning co mpletion, etc.

Max command pulse

frequency

Command pulse input

Pulse input

Vibration suppression control Maximum of 3 may be used simultaneously

Position control

Model type vibration damping filter Maximum of 2 may be used simultaneously

2 degrees of freedom control Available

Load fluctuation suppression control Available

mode

Command pulse scaling

(Electronic gear)

500 K[pulse/s] (w hen using the photo coup ler input)

8 M[pulse/s] (when using the line receiver input of A-phase /B-phase)

Differential inp ut . D iffe rential input can be selected by parameters. ((1) Positive direction/ negative direction,

(2) A-phase/B-phase (3) Command/ direction)

Although electronic g ear rati o of the en coder resolu tion (num erator) and command number of pulses per revoluti on of the

motor (denominator) can be arbitrarily set in the range of 1 to 223 f or th e numerator and in the rang e of 1 to 223 f or the

denominator, this product should be u sed within the afor ementioned range.

Primary delay filter or FIR filter is selectable for command input.

Position compare output function

Block operation Available

Contro l i np u t

Function

Internal velocity command It is possible to switch 8 speeds of internal velocity with control input.

Soft start/down function

Speed zero clamp I nternal velocity command can be clamped to 0 with speed zero clamp input.

Velocity control

2 degrees of freedom control Available

Load fluctuation suppression control Available

Position compare output function Not available

Auto-tuning

Pulse signal output division function Number of pulses can be arbitrarily set. (However, the number of encoder pulses is the maximum number.)

Protectio n f u nction

Alarm data trace back function Reference of history of alarm data is available.

Common

Infinite rotation absolute funct ion Available

Deterioration diagnosis function Available

[Condition] Block operation valid setting

Return to origin completed state in incre me nt mo de (when block operat

4-2 Specifications by model

Refer to specification for each model.

Motor Business Unit, Panasonic Corporation

Page 9

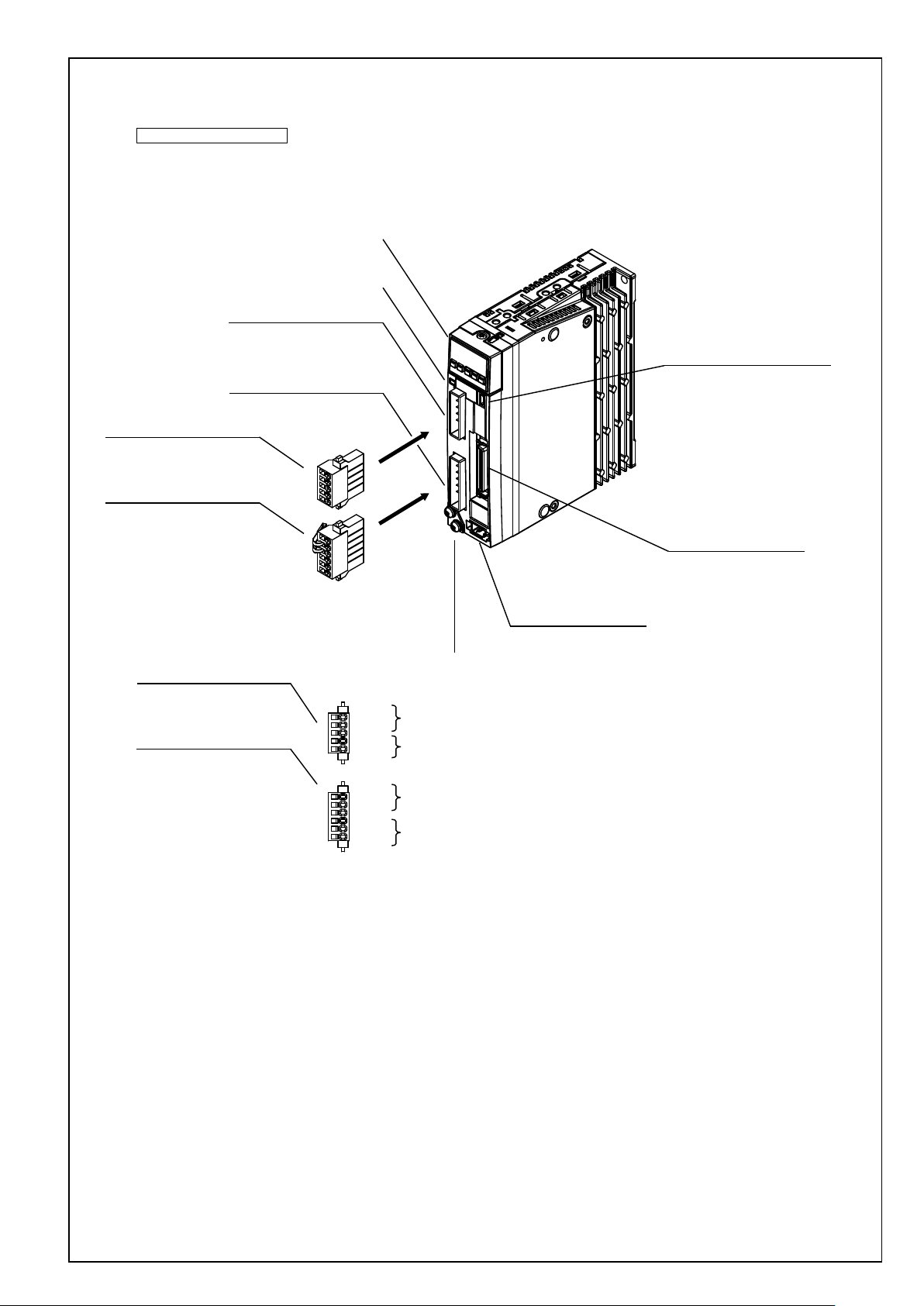

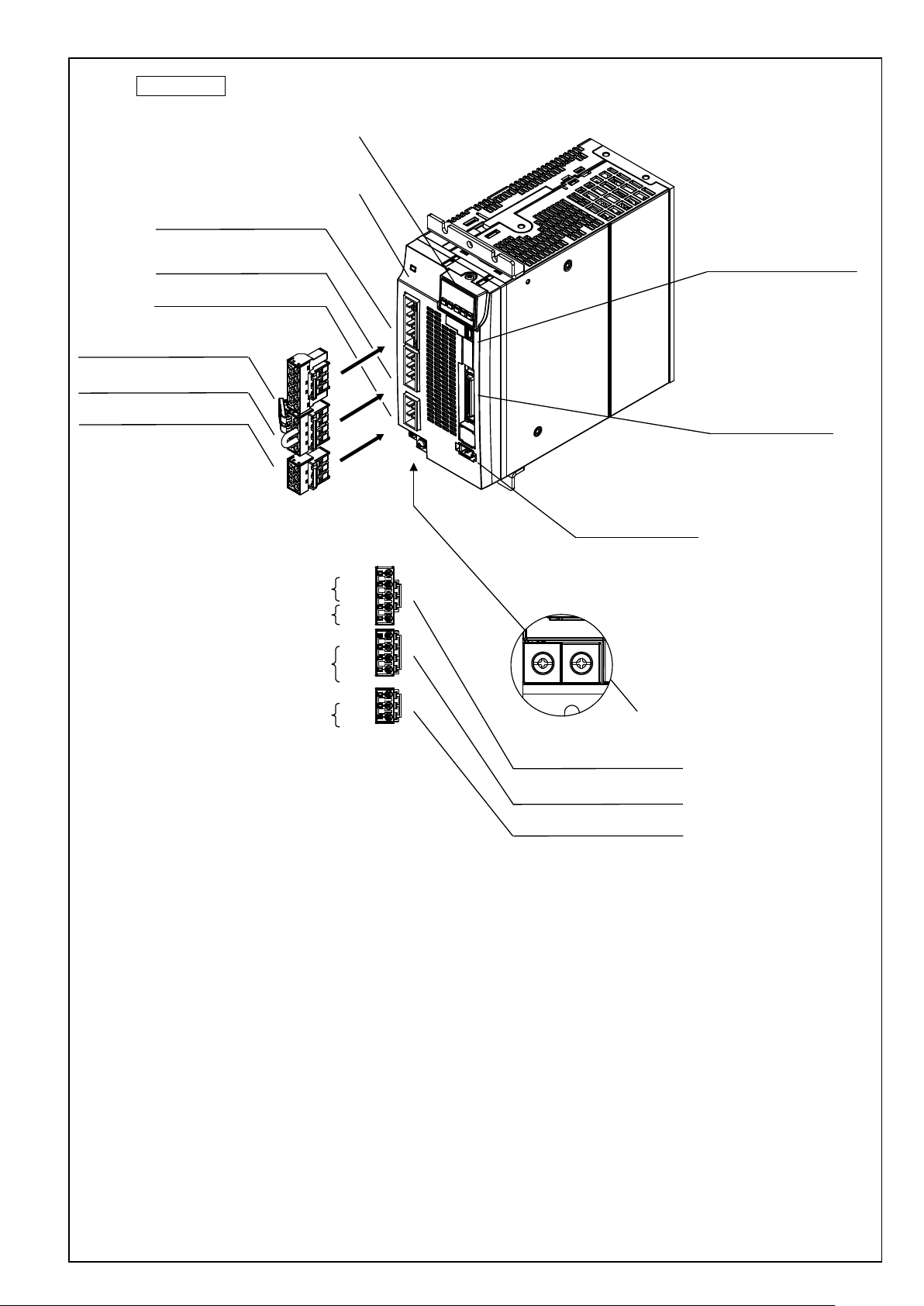

5. Appearance and part names

100 V,200 V size A, B

XA:Power supply input connection

05JFAT-SAXGGKK-A (JST)

(or equivalent)

Front panel

Charge lamp

XA: Power supply input

S05B-F32SK-GGXR (JST)

(or equivalent)

XB: Motor output

S06B-F32SK-GGXR (JST)

(or equivalent)

No. SX-DSV03015 - 6 -

X1:USB connection

UB-M5BR-S14-4S(LF)(SN) (JST)

(or equivalent)

XB:Motor connection

06JFAT-SAXGGKK-A (JST)

(or equivalent)

XA:Power supply input connection

XB:Motor connection

L1

L2

L3

L1C

L2C

P

N

B

U

V

W

Earth connection screw

Main power supply

input

Control power supply

input

Regenerative resistor

connection

Motor output

X6:Encoder connection

3E106-223AKV(3M)

(or equivalent)

X4:Parallel I/O connection

DF02R050NA2 (JAE)

(or equivalent)

Motor Business Unit, Panasonic Corporation

Page 10

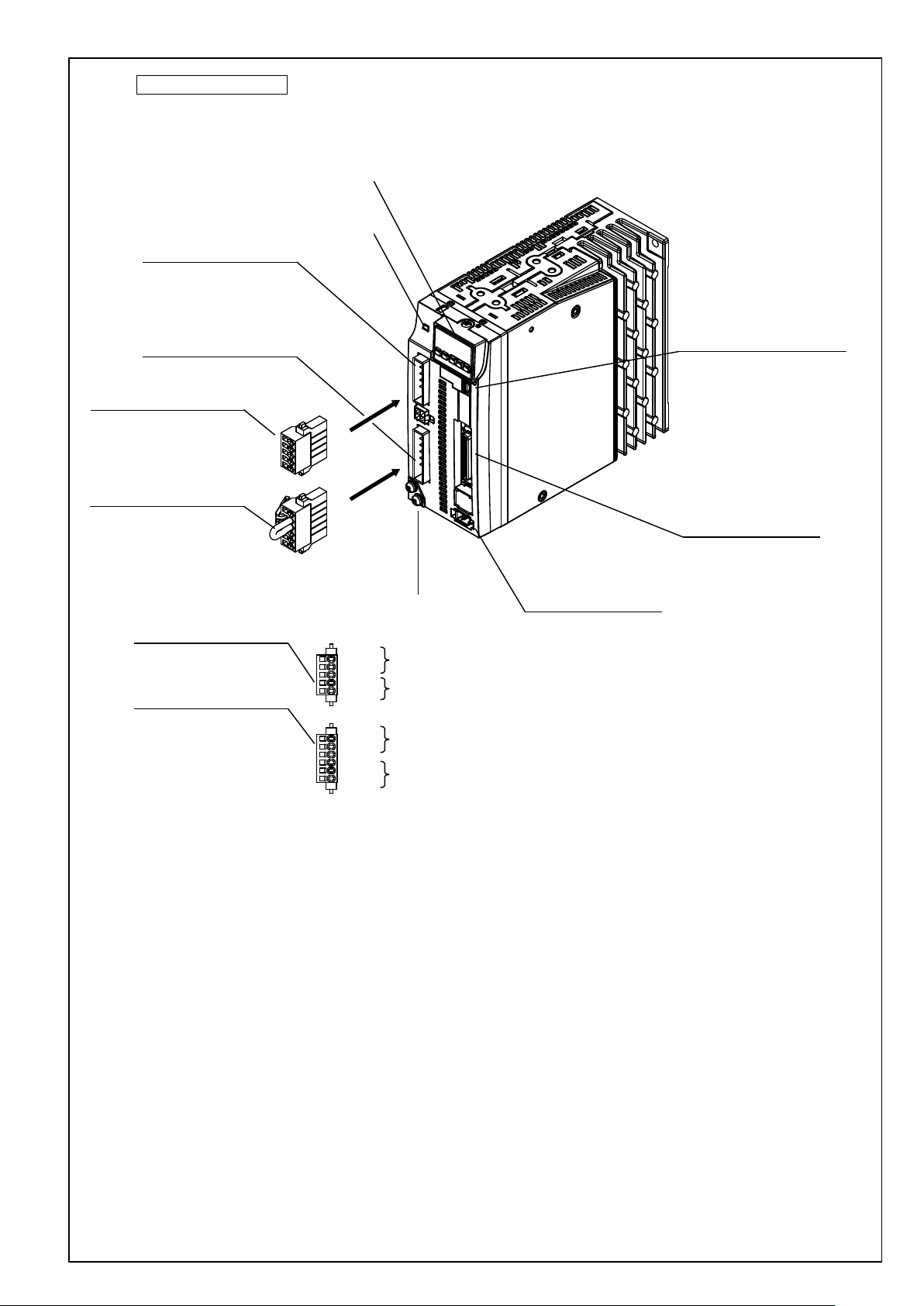

No. SX-DSV03015 - 7 -

100 V,200 V size C, D

Front panel

Charge lamp

XA: Power supply input

S05B-F32SK-GGXR (JST)

(or equivalent)

XB: Motor output

S06B-F32SK-GGXR (JST)

(or equivalent)

XA:Power supply input connection

05JFAT-SAXGGKK-A (JST)

(or equivalent)

XB:Motor connection

06JFAT-SAXGGKK-A (JST)

(or equivalent)

XA:Power supply input connection

XB:Motor connection

Earth connection screw

L1

L2

L3

L1C

L2C

P

RB

B

U

V

W

Main power supply

input

Control power supply

input

Regenerative resistor

connection

Motor output

X6:Encoder connection

3E106-223AKV(3M)

(or equivalent)

X1:USB connection

UB-M5BR-S14-4S(LF)(SN) (JST)

(or equivalent)

X4:Parallel I/O connection

DF02R050NA2 (JAE)

(or equivalent)

Motor Business Unit, Panasonic Corporation

Page 11

No. SX-DSV03015 - 8 -

X1:USB connection

UB-M5BR-S14-4S(LF)(SN) (JST)

(or equivalent)

X4:Parallel I/O connection

DF02R050NA2 (JAE)

(or equivalent)

X6:Encoder connection

3E106-223AKV(3M)

(or equivalent)

Charge lamp

Front panel

Earth connection screw

XA:Power supply input connection

XC:Regenerative resistor connection

XB:Motor connection

XA:Power supply input connection

05JFAT-SAXGSA-L (JST)

(or equivalent)

XC:Regenerative resistor connection

04JFAT-SAXGSA-L (JST)

(or equivalent)

XB:Motor connection

03JFAT-SAXGSA-L (JST)

(or equivalent)

XA: Power supply input

S05B-JTSLSK-GSANXR (JST)

(or equivalent)

XB: Motor output

S03B-JTSLSK-GSANXR (JST)

(or equivalent)

XC: Regenerative resistor connection

S04B-JTSLSS-GSANXR (JST)

(or equivalent)

L1

L2

L3

L1C

L2C

P

RB

B

N

U

V

W

Main power supply

input

Control power supply

input

Regenerative resistor

connection

Motor output

200 V size E

Motor Business Unit, Panasonic Corporation

Page 12

No. SX-DSV03015 - 9 -

200 V size F

Front panel

Charge lamp

X1:USB connection

UB-M5BR-S14-4S(LF)(SN) (JST)

(or equivalent)

X4:Parallel I/O connection

DF02R050NA2 (JAE)

(or equivalent)

Earth connection screw

Main power supply

input

Control power supply

input

Regenerative resistor

connection

Motor output

L1

L2

L3

L1C

L2C

P

RB

B

N

U

V

W

X6:Encoder connection

3E106-223AKV(3M)

(or equivalent)

Motor Business Unit, Panasonic Corporation

Page 13

No. SX-DSV03015 - 10 -

Model number

Serial number

e.g.):

P 1 5 0 7 0 0 0 1 N

Lot number

Month of

production

Year of production

(Lower 2 digit of AD year)

Input/output voltage

Number of phase

Rated input/output

current

Input/output

frequency

Rated output of

applicable motor

QR code

standard mark

Country of

origin

Manufacture date

e.g.):

2 0 1 5 0 7 0 1

Manufacture date

Manufacture month

Manufacture year

Name plate

Motor Business Unit, Panasonic Corporation

Page 14

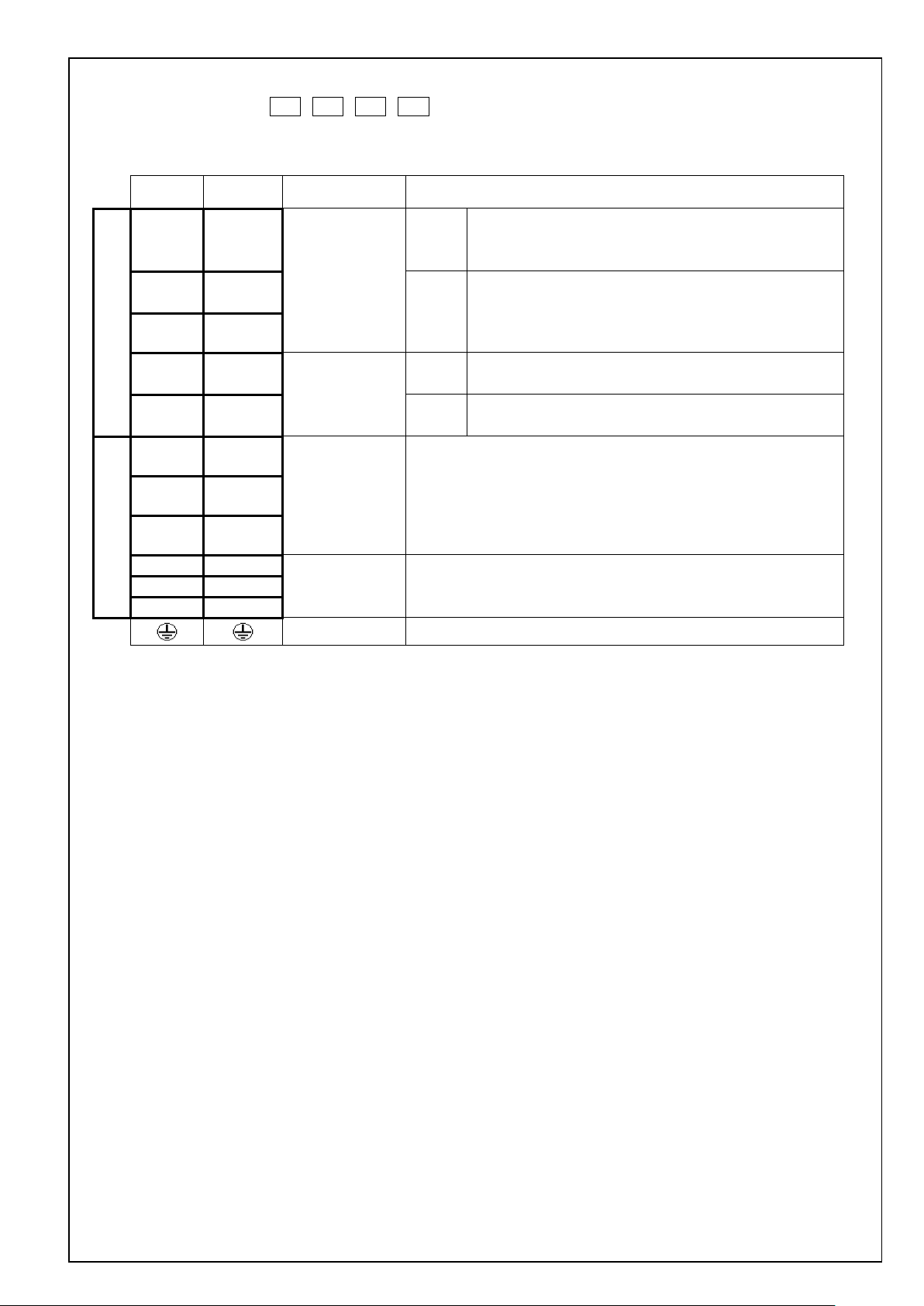

No. SX-DSV03015 - 11 -

Connector

pin No.

Terminal

symbol

+ 10 %

- 15 %

Use L1 and L3 terminal for single phase input

+ 10 %

- 15 %

+ 10 %

- 15 %

+ 10 %

- 15 %

When a trip happens due to a regenerative load protection error, connect

3

U

2 V 1

W

6. Configuration of connectors and terminal blocks

6-1 Power connector XA , XB , XC , XD and terminal block

[1] Size A, B of 100 V and 200 V system

XA

XB

5 L1

4 L2

3 L3 Use L1 and L3 terminal for single phase input

2 L1C

1 L2C 200 V Single phase 200-240 V

6 P

5 N

4 B

Name Description

Single phase 100-120 V

Single or 3 phase 200-240 V

an external regenerative resistor (prepared by customer) between P and

B.

U: U phase V: V phase W: W phase

Main power

supply input

Control power

supply input

Regen resistor

connection

Motor connection

Earth

100 V

200 V

100 V Single phase 100-120 V

Then, specify the extern al regenerative resistor for the parameter

Pr0.16.

Do not connect N terminal.

Connect each phase of the motor winding.

Earth terminal for grounding

50/60 Hz input

50/60 Hz input

50/60 Hz input

50/60 Hz input

* Tighten the earth screws M4 with the 0.7-0.8 Nm torque respectively.

Motor Business Unit, Panasonic Corporation

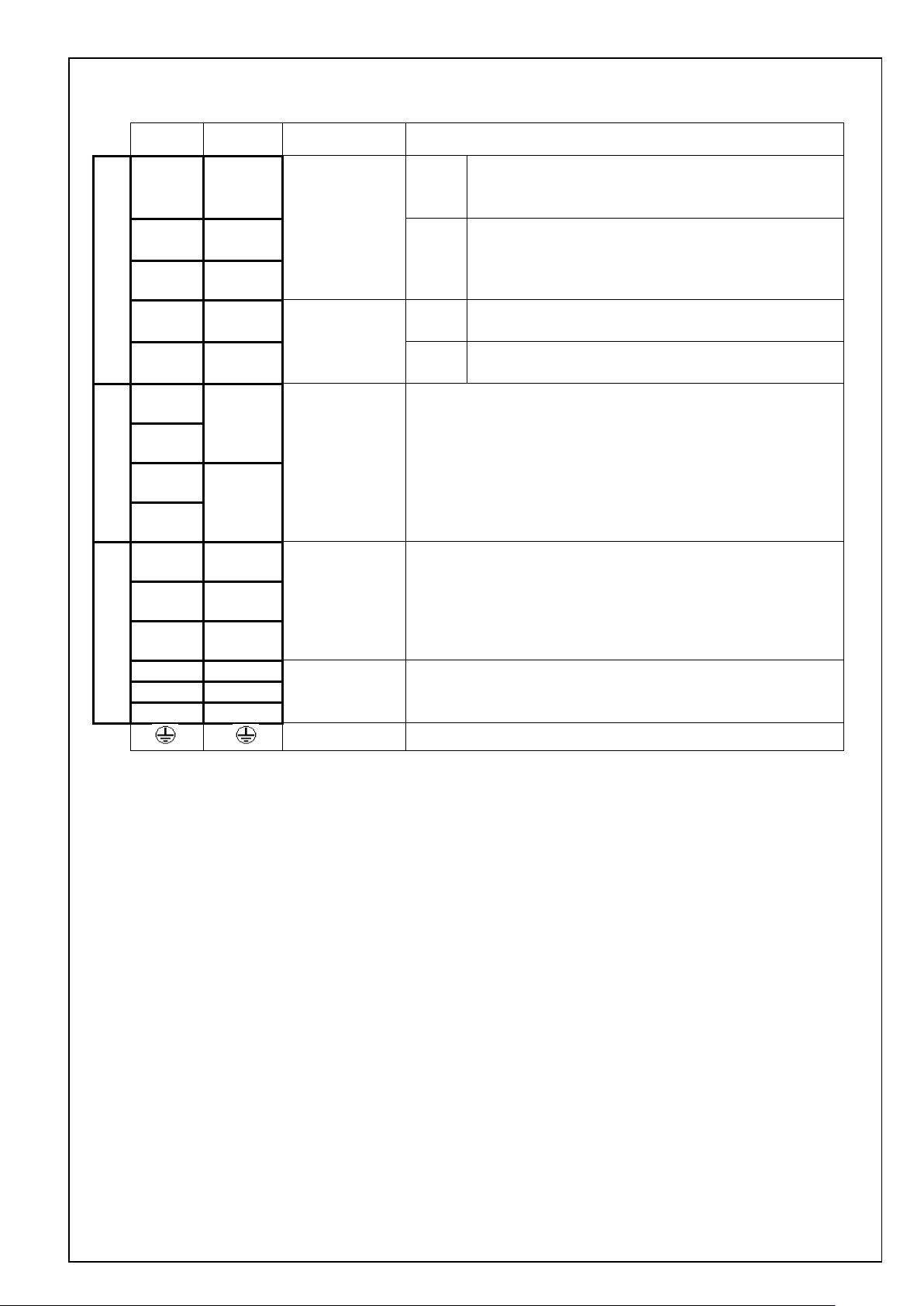

Page 15

No. SX-DSV03015 - 12 -

Connector

pin No.

Terminal

symbol

+ 10 %

- 15 %

Use L1 and L3 terminal for single phase input

+ 10 %

- 15 %

+ 10 %

- 15 %

+ 10 %

- 15 %

Normally, short out the circuit between B and RB. (Sizes C, D)

3

U

2 V 1

W

[2] Size C, D of 100 V and 200 V system

Name Description

XA

XC

XB

5 L1

Main power s upply

4 L2

3 L3 Use L1 and L3 terminal for single phase input

2 L1C

1 L2C 200 V Single phas e 200 – 240 V

4

N

3

2

P

1

6 P

5 RB

4 B

input

Control power

supply input

- Do not connect.

Regen resistor

connection

100 V

200 V

100 V Single phase 100-120 V

When a trip happens due to a re ge ner ati ve load prote c ti on e rror , o pen t h e

Then, specify the extern al regenerative resistor for the parameter

Pr0. 16.

Single phase 100-120 V

Single or 3 pha se 20 0 – 240 V

circuit between B and RB and conn ect an external regenerative resistor

(prepared by customer) bet w een P and B.

50/60 Hz input

50/60 Hz input

50/60 Hz input

50/60 Hz input

Motor connection

Earth

Connect each phase of the motor winding.

U: U phase V: V phase W: W phase

Earth terminal for grounding

* Tighten the earth screws M4 with the 0.7-0.8 Nm torque respectively.

Motor Business Unit, Panasonic Corporation

Page 16

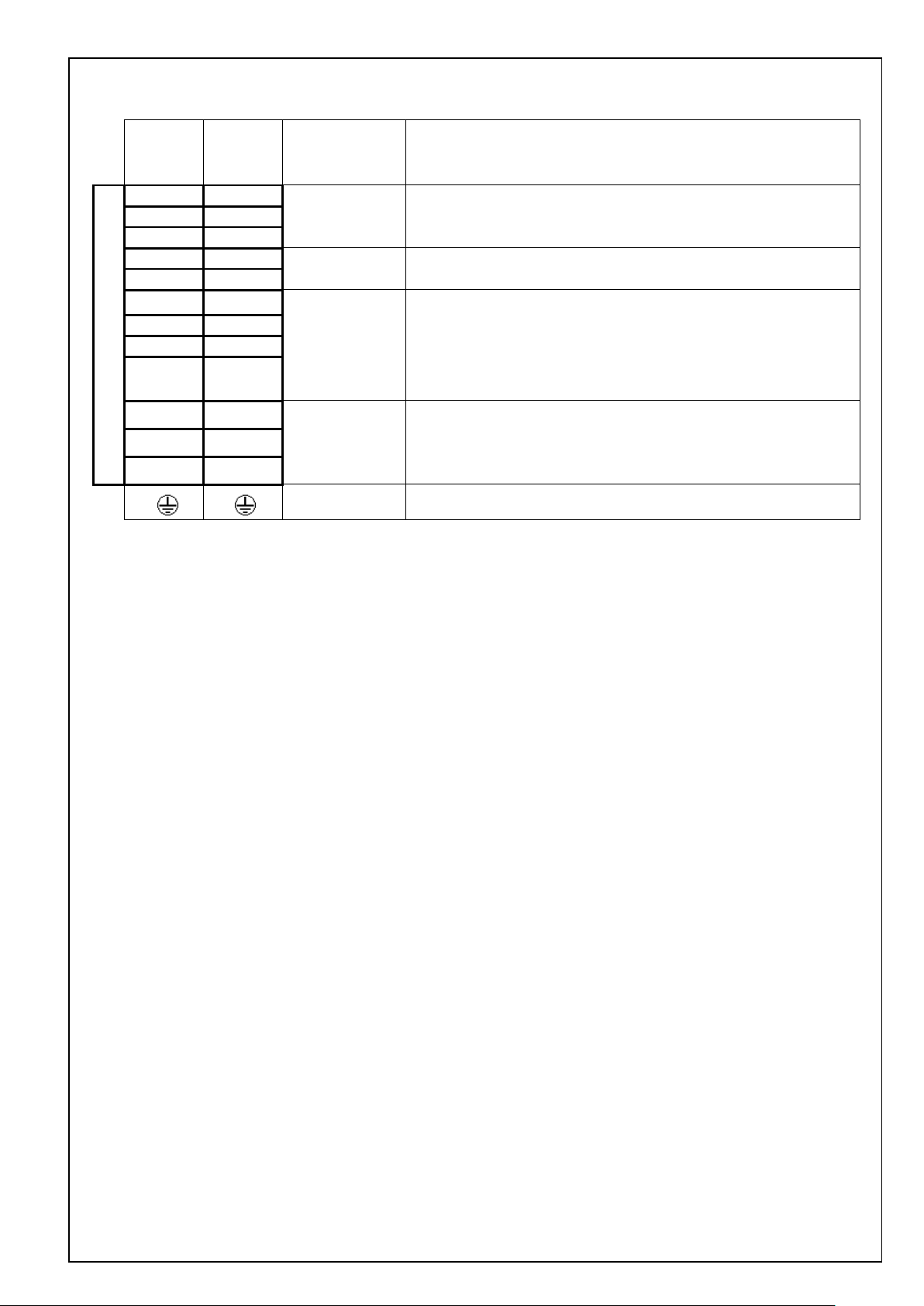

No. SX-DSV03015 - 13 -

Connector

pin No.

Terminal

symbol

5

L1

4

L2 3 L3

2

L1C

1

L2C

3

U

2 V 1

W

[3] Size E of 200 V system

Name Description

XA

XC

XB

4 P

3 RB

2 B

1 N

Earth Earth terminal for grounding

Main power s upply

input

Control power

supply input

Regen resistor

connection

Motor connection

200 V 3 phase 200 - 240 V

200 V Single phase 200 - 240 V

Normally, short out the circuit between RB and B.

When a trip happens due to a regenerative load protection error, open the

circuit between RB and B and connect an external regenerative resisto r

(prepared by customer) between P and B.

Then, specify the external regenerative resistor for parameter Pr0. 1 6.

Do not connect N terminal.

Connect each phase of the motor winding.

U: U phase V: V phase W: W phase

+ 10 %

- 15 %

+ 10 %

- 15 %

50/60 Hz input

50/60 Hz input

* Tighten the earth screws M4 with the 0.7-0.8 Nm torque respectively.

Motor Business Unit, Panasonic Corporation

Page 17

No. SX-DSV03015 - 14 -

Terminal

bottom)

1

L1

2

L2 3 L3 4 L1C

- 15 %

5

L2C

Normally, short out the circuit between RB and B.

When a trip happens due to a regenerative load protection error, open the

7

RB 8 B

[4] Size F of 200V system

Terminal block is used instead of connector.

Terminal block

No.

(Upper to

6 P

9 N

10 U

11 V

12 W

Terminal

symbol

Name Description

Main power s upply

input

Control power

supply input

Regen resistor

connection

Motor connection

Earth

3 phase 200 - 240 V

Single phase 200 - 240 V

circuit between RB and B and connect an external regenerative resistor

(prepared by customer) b etween P and B.

Then, specify the external regenerative resistor for parameter Pr0. 16.

Do not connect N terminal.

Connect each phase of the motor winding.

U: U phase V: V phase W: W phase

Earth terminal for grounding

+ 10 %

- 15 %

+ 10 %

50/60 Hz input

50/60 Hz input

* Tighten the earth s crews M5 with the 1.4 -1.6 Nm torques respectively.

* Tighten the terminal block screws M5 with the 1.0-1.7 Nm torques respectively.

* Tighten the fixin g s crew M3 for the terminal block cover with the 0.2 Nm torque.

* If the maximum value of tightening torque is exceeded, the terminal block could be damaged.

Motor Business Unit, Panasonic Corporation

Page 18

No. SX-DSV03015 - 15 -

Connector

6-2 USB connector X1

By connecting to a computer or a controller via USB interface, the following operations are available

parameter reference / change parameter save / load monitoring of status checkin g ala rm status or alarm history

Name Symbol

VBUS 1

USB signal

D+ 3

For manufacturer use

Signal ground GND 5 Signal ground

−

pin No

Communicate with a computer or a controller D- 2

4 Do not connect

Description

Motor Business Unit, Panasonic Corporation

Page 19

nector

pin No.

Multi-function input 1

SI1

8

Multi-function input 2

SI2

9

Multi-function input 3

SI3

26

Multi-function input 4

SI4

27

Multi-function input 5

SI5

28

SI6

29

SI7

30

SI8

31

Multi-function input 9

SI9

32

Multi-function input 10

SI10

33

Name

Symbol

Description

When turned ON, the servo is turned on (power is supplied to the motor).

Po sitive overtravel limit.

Negative overtravel limit.

When this input is OF F, a ne ga tiv e tor que doe s not occ ur.

Deviation counter clear

CL

Clears the position deviation counter.

Command pulse inhibition

INH

Ignores the position comm a nd pul se.

Preset velocity 1

INTSPD1

Preset velocity 2

INTSPD2

Preset velocity 3

INTSPD3

Speed zero clamp

Sets the speed command to zero.

Anti-vibration switch 1

Anti-vibration switch 2

Gain switch

GAIN

Input to switch the gains.

Torque limit switch

TL-SEL

Switches the torque limits.

Alarm clear

A-CLR

Digital input to clear the alarm.

Command scaling switch

VC-SIGN

Specifies the sign of the speed command during the speed control.

Torque comm a nd sig n

TC-SIGN

Specifies the sign of the torque command during the torque control.

Command scaling switch 1

DIV1

Switches the scaling numerators of the command pulse.

Allows you to switch up to 4 numerators by combining DIVs 1, 2.

Command sca ling sw i tch 2

DIV2

Forced alarm input

E-STOP

Generates Err87. 0 "Abnormal forced alarm input."

Inertia ratio switch

Switches the inertia ratios.

6-3 Parallel I/O connector, X4

Common digital inputs

Name Symbol

Power supply input COM+ 7

Con

-

Description Circuit

・Connect to the + terminal of an external DC power supply (12 to 24 V)

・Use a 12 V (±5 %) to 24 V (±5 %) power supply

・Insulat ion i s needed against the prim ary s ide pow e r sup ply .

Please do not connect th em wit h the same power supply.

No. SX-DSV03015 - 16 -

Multi-function input 6

Multi-function input 7

Multi-function input 8

Functions allocatable to multi-function inputs

Servo ON SRV-ON

Control mode switch

Positive overtravel limit

Negative overtravel limit

C-MODE

POT

NOT

The function changes according to the parameter settin gs. See below. i-1

When turned OFF, t he s er vo is t urn ed of f a nd the m otor p ow er i s tur ne d of f .

Switches the contr ol m ode s.

Make sure to connect this so that the contact point will be opened when the movable

module positively exceeded the movable range.

When this input is OF F, a pos it ive t orq ue does no t occ ur .

Make sure to wire this input to be activated as the work over travels the limit in the

negative direction.

Preset s peed.

Allows you to set up t o 8 int er na l ve loci tie s by com bi ning I NT SPDs 1 - 3.

ZEROSPD

VS-SEL1

VS-SEL2

Switches the appli e d fr eque nc ies f or anti-vibration control.

J-SEL

Motor Business Unit, Panasonic Corporation

Page 20

No. SX-DSV03015 - 17 -

Con

pin No.

Command direction

Con

Pin No.

kpps for line driver input, and

Command direction

Input signals (command pulse train) and their functions

A suitable interface can be chosen from two kind of interface based on the specification of command pulses.

A. Pulse train interface with line driver

Command pulse

input 1

input 1

Command pulse

input 2

input 2

Name Symbol

PULSH1 44

PULSH2 45

SIGNH1 46

SIGNH2 47

-nector

Input t er min al for the position command pulse. It can be select ed by setting

corresponding parameters.

Disabled in such control modes as the speed control or the torque control,

which does not require position commands.

The maximum allowable input frequency is 8 Mpps.

B. Pulse train interface with optocoupler

Name Symbol

OPC1 1

PULS1 3

PULS2 4

OPC2 2

SIGN1 5

-nector

Input t er min al for the position command pulse. It can be selected by setting

corresponding parameters.

Disabled in such control modes as the speed control or the torque control,

which does not require position commands.

The maximum allowable input frequency is 500

200 kpps for open collector input.

Description Circuit

Di-2

Description Circuit

Di-1

SIGN2 6

Motor Business Unit, Panasonic Corporation

Page 21

Con

pin No.

SO1-

SO1+

10

11

SO2-

34

SO4-

SO4+

38

39

ALM-

36

Multi-function outp ut 5

SO5

12

Multi-function outp ut 6

SO6

40

The power capacity varies depending on a composition of I/O circuit.0.5A

Name

Symbol

Description

Servo alarm

ALM

Digital output to indicate the driver is in alarm status..

Motor holding break releas e

BRK-OFF

Digital output to provide the timing signal to control the motor holding brake.

Zero speed

ZSP

Outputs the zero speed detection signals.

Torque limited

TLC

Outputs the torque limit signal.

In-position

INP

Outputs the positioning completion signal.

At speed

AT-SPD

Outputs the at-speed signal.

V-COIN

V-COIN

Outputs the speed coincidence signal.

Outputs the warning output signal configured in Pr4. 40 "Warning output

selection 1".

Outputs the warning output signal configured in Pr4. 41 "Warning output

Position command ON/OFF

P-CMD

Outputs meaning positional command applied.

Speed in –limit output

V-LIMIT

Outputs meaning the speed is limited at torque control mode.

Alarm attribute output

Output s meani ng occur an alarm that can be cleared.

Turns on output transistor when the speed command is applied while the speed is

Servo on status output

SRV-ST

Turn on output transistor when servo is on.

Output signals (Common) and their functions

Name Symbol

Multi-function outp ut 1

-nector

No. SX-DSV03015 - 18 -

Description Circuit

Multi-function outp ut 2

Multi-function output 4

Servo alarm

Power supply input

SO2+

ALM+

COM- 41

The function changes according to the parameter settin gs. See below.

35

Digital output to indicate alarm status.

37

The function changes according to the parameter settin gs. See below. o-3

・Connect to the - terminal of an external DC power supply (12 to 24 V)

・

or more is recommended.

・Insulat ion i s needed against the prim ary s ide pow e r sup ply

Please do not connect the m w ith t he sa m e pow e r supply.

Functions allocatable to multi-function outputs

Servo ready S-RDY Digital output to indicate the driver is ready to be enabled.

Positioning comple tion 2 INP2 Outp uts the positioning completion signal 2.

Warning output 1 WARN1

o-1

Warning output 2 WARN2

Speed command ON/OFF V-CMD

ALM-ATB

selection 2".

controlled.

Motor Business Unit, Panasonic Corporation

Page 22

Connector

Connector

Pin No.

Pin No.

50,

shell

Sign a l ground

Internally insulated from the control signal power supply (COM-).

Do not conne ct

Output signals (Pulse output) and its function

Name Symbol

A phase output

B phase output

Z phase output

Z phase output CZ 19

pin No.

OA+ 21

OA- 22

OB+ 48

OB- 49

OZ+ 23

OZ- 24

No. SX-DSV03015 - 19 -

Description Circuit

Scaling processed encoder signal or external scale signal ( A/B/Z-phase) is

output in differential mode. (RS422 equivalent)

Scaling ratio can be set by parameters.

The ground pin of the line driver on the output circuit is not insulated and is

connected to signal ground (GND).

The maximum output frequency is 8 Mpps (after quadrature).

Open collector output of Z-phase signal.

Ground of line driver of the output circuit is connected to signal ground

(GND); not insulated.

Do-1

Do-2

Analog monitor signals and their functions

Name Symbol

Analog monitor output

Others

Name Symbol

Frame ground FG

Signal ground GND

−

IM 42

SP 43

Connector

13,15,

17,25

−

20

Description Circuit

Analog signal output for monitoring

Monitoring object changes according to the parameter setting.

Description Circuit

Internally connected to the earth terminal.

Ao-1

Motor Business Unit, Panasonic Corporation

Page 23

No. SX-DSV03015 - 20 -

Connector

pin No.

1

E5V 2 E0V (*Note 1)

3

Do not connect.

4

Do not connect.

Encoder signal I/O

(serial signal)

5

PS

6

/PS

Frame ground

shell

FG

6-4 Encoder connector X6

Name

Encoder power supply output

-

*Note 1) The E0V of the encoder power supply output is connected with the control circuit ground of the connector X4 .

Description

Motor Business Unit, Panasonic Corporation

Page 24

No. SX-DSV03015 - 21 -

o - 1

Do - 2

Di - 1

Ao - 1

V

DC

12 to 24 V

4.7 k

4.7 k

or

1 k

1 k

1000 p

1000 p

V

DC

12 to 24 V

Pins;

S:(X4) 8,9,26,27,28,29,30,31,32,33

P:(X4) 7

P

P

S

S

Pins;

+:(X4)11,35,37,39 -:(X4)10,34,36,38

Note) To directly run the relay, attach a diode in

Parallel with the relay and in the direction

shown in the figure above.

VCE sat = 1.2 V

50 mA

or less

R

10

V

DC

12 to 24 V

+

-

GND

1 k

Pins;

+: (X4) 42,43

-: (X4) 13,17,25

Note)Outputting signal amplitude is ±10 V

+

-

Twisted pair

220

GND

13

4,6

3,5

SIGN

PULS

H/L

H/L

220

GND

13

4,6

3,5

10 mA

R

Vp

12 to 24 V

SIGN

PULS

L/H

ON/OFF

1,2

2.2 k

220

GND

13

4,6

3,5

24 V

SIGN

PULS

L/H

ON/OFF

1,2

2.2 k

2.2 k

1000 p

2.2 k

1000 p

2.2 k

1000 p

<Line Driver>

<Open Collector>

①12-24 V Powersupply with external resistor

②24 V Power supply without external resistor

Vp-1.5

R+220

≒10 mA

Twisted pair

Equivalent of

AM26C31

GND

13

Pins;

+:21,23,48

-:22,24,49

+

-

Twisted pair

CZ

V

DD

30 V MAX

50 mA MAX

GND

17

19

10

Input and output interface

i - 1

Do - 1

Motor Business Unit, Panasonic Corporation

Page 25

Di - 2

Equivalent of

AM26C32

20 k

20 k

2 k

2 k

120

Twisted pair

H/L

13

GND

45

H/L

PULS

SIGN

44

47

46

Pins;

+:40,12

Note) To directly run the relay, attach a diode in

Parallel with the relay and in the direction

shown in the figure above.

50 mA

or less

R

10

V

DC

12 to 24 V

+

41

o-2

No. SX-DSV03015 - 22 -

Motor Business Unit, Panasonic Corporation

Page 26

7. Dimensions

External dimension size A

[Base-mounting TYPE (Standard: Mounting on the back)]

No. SX-DSV03015 - 23 -

2-M4 Effective screw depth 7

Name

plate

*Please do not use the screw holes of no description of the size value.

2-M4 Effective screw depth 7

Motor Business Unit, Panasonic Corporation

Page 27

[Rack-mounting TYPE (Option: Mounted on the front)]

Mounting bracket (Option)

No. SX-DSV03015 - 24 -

Name

plate

Mounting bracket (Option)

*Please do not use the screw holes of no description of the size value.

*Mounting bracket is optional parts. Mounting bracket does not shipped with the product.

Motor Business Unit, Panasonic Corporation

Page 28

No. SX-DSV03015 - 25 -

External dimension size B

[Base-mounting TYPE (Standard: Mounting on the back)]

2-M4 Effective screw depth 6.5

Name

plate

*Please do not use the screw holes of no description of the size value.

2-M4 Effective screw depth 7

Motor Business Unit, Panasonic Corporation

Page 29

[Rack-mounting TYPE (Option: Mounted on the front)]

Mounting bracket (Option)

No. SX-DSV03015 - 26 -

Name

plate

Mounting bracket (Option)

*Please do not use the screw holes of no description of the size value.

*Mounting bracket is optional parts. Mounting bracket does not shipped with the product.

Motor Business Unit, Panasonic Corporation

Page 30

No. SX-DSV03015 - 27 -

External dimension size C

[Base-mounting TYPE (Standard: Mounting on the back) ]

2-M4 Effective screw depth 6.5

Name

plate

*Please do not use the screw holes of no description of the size value.

2-M4 Effective screw depth 6

Motor Business Unit, Panasonic Corporation

Page 31

[Rack-mounting TYPE (Option: Mounted on the front)]

Mounting bracket (Option)

No. SX-DSV03015 - 28 -

Name

plate

Mounting bracket (Option)

*Please do not use the screw holes of no description of the size value.

*Mounting bracket is optional parts. Mounting bracket does not shipped with the product.

Motor Business Unit, Panasonic Corporation

Page 32

No. SX-DSV03015 - 29 -

External dimension size D 200V

[Base-mounting TYPE (Standard: Mounting on the back)]

2-M4 Effective screw depth 6.5

Name

plate

*Please do not use the screw holes of no description of the size value.

2-M4 Effective screw depth 6

Motor Business Unit, Panasonic Corporation

Page 33

Mounting bracket (Option)

Mounting bracket (Option)

Name

plate

[Rack-mounting TYPE (Option: Mounted on the front)]

No. SX-DSV03015 - 30 -

*Please do not use the screw holes of no description of the size value.

*Mounting bracket is optional parts. Mounting bracket does not shipped with the product.

Motor Business Unit, Panasonic Corporation

Page 34

No. SX-DSV03015 - 31 -

External dimension size E 200V

[Rack-mounting TYPE (Standard)]

4-M4 Effective screw depth 6

Name

plate

4-M4 Effective screw depth 6

Motor Business Unit, Panasonic Corporation

Page 35

[Base-mounting TYPE (Change from standard)]

No. SX-DSV03015 - 32 -

Name

plate

Motor Business Unit, Panasonic Corporation

Page 36

No. SX-DSV03015 - 33 -

External dimension size F 200V

[Rack-mounting TYPE (Standard)]

4-M4 Effective screw depth 9

Name

plate

4-M4 Effective screw depth 9

Motor Business Unit, Panasonic Corporation

Page 37

[Base-mounting TYPE (Change from standard)]

No. SX-DSV03015 - 34 -

Name

plate

Motor Business Unit, Panasonic Corporation

Page 38

No. SX-DSV03015 - 35 -

Maximum

cable length

Main power supply

L1, L2, L3

Refer to specification

Control power supply

L1C, L2C

Refer to specification

Encoder connection

X6

20m

Batch twisted shielded pair

Core cable: 0.18mm2 or more

I/O connection

X4

3m

Solder plug

(soldering type)

8. Wiring

8-1 Used cables and maximum cable lengths

Name

Motor connection

Earth cable

Symbol

Used cable

U, V, W, 20m Refer to specification

Refer to specification

8-2 Various connectors

Connector symbol Part name Part number Manufacturer

DF02P050F22A1

X4

JAE

Shell kit DF02D050B22A

X6 Connector 3E306-3200-008 3M Company

Please use the above part number connector, or equivalent connector.

Motor Business Unit, Panasonic Corporation

Page 39

No. SX-DSV03015 - 36 -

L1

L2

L3

L

ON

MC1

OFF

ALM

Coli surge suppression units

L1C

L2C

P

MC

U

V

W

motor

ALM+

ALM-

ALM

Main power

supply

Control power

supply

Motor

connection

MCCB

37

36

Built-in thermostat of an external

regenerative resistor (light yellow)

B

Red

White

Green or

Green/Yellow

Insulated

DC12 to 24 V

(±5 %)

+

-

Noise filter

N

External

regenerative

resistor

XA

XB

X4

*When you use single phase,

connect the main power

between L1 and L3 terminals.

Power supply

(3-phase)

Black

In case of using the external

regenerative resistor

In case of not using the external

regenerative resistor

Between P and B:

regenerative resistor.

8-3 Precautions for wiring

(1) Wiring to power connector and terminal block

100/ 200 V sizes A - B

■Connection of regenerative resistor

Shorting

Size

cable

regenerative

(Accessories)

A

B

Not attached

installed

- The circuit con nected to term inal X1 – X6 are secondary circuits.

Insulation is needed against the prim ary si de pow er su pply (powe r su pply of the m otor bra ke) .

Please do not connect them with the s ame power su pply.

Internal

resistor

Not

Connect the external

Connection of the connector XB

Between P and B:

Keep open

Motor Business Unit, Panasonic Corporation

Page 40

No. SX-DSV03015 - 37 -

In case of using the external

regenerative resistor

In case of not using the external

regenerative resistor

Between RB and B:

regenerative resistor

100/ 200 V sizes C - D

Built-in thermostat of an external

regenerative resistor (light yellow)

Power supply

(3-phase)

*When you use single phase,

connect the main power

between L1 and L3 terminals.

MCCB

Noise filter

Insulated

DC12 to 24 V

(±5 %)

Short cable

External

regenerative

resistor

motor

+

-

ON

MC

Red

White

Black

Green or

Green/Yellow

ALM

OFF

ALM

Coli surge suppression units

L

L1

L2

L3

L1C

L2C

P

N

P

RB

B

U

V

W

37

ALM+

36

ALM-

XA

Main power

supply

Control power

supply

XC

XB

Motor

connection

X4

MC1

■Connection of regenerative resistor

Shorting

Size

cable

(Accessories)

C

D

Supplied Installed

- The circuit con nected to term inal X1 – X6 are secondary circuits.

Insulation is needed against the pr im ary si de pow er s upply (powe r su pply of the m otor bra ke) .

Please do not connect them with the s ame power su pply.

Internal

regenerative

resistor

Disconnect the short cable

Between P and B:

Connect the external

Connection of the connector XB

Between RB and B:

Connect the shorting cable

Motor Business Unit, Panasonic Corporation

Page 41

No. SX-DSV03015 - 38 -

In case of using the external

regenerative resistor

In case of not using the external

regenerative resistor

Between RB and B:

regenerative resistor

200 V size E

Built-in thermostat of an external

regenerative resistor (light yellow)

Power supply

(3-phase)

MCCB

ON

Noise filter

Short cable

External

regenerative

resistor

Red

White

Black

Green or

Green/Yellow

motor

Insulated

DC12 to 24 V

(±5 %)

+

-

ALM

MC

OFF

ALM

Coli surge suppression units

L

L1

Main power

L2

supply

L3

L1C

Control power

supply

L2C

P

RB

B

N

U

Motor

V

connection

W

37

ALM+

36

ALM-

XA

XC

XB

X4

MC1

■Connection of regenerative resistor

Shorting

Size

cable

(Accessories)

E Supplied Installed

- The circuit con nected to term inal X1 – X6 are secondary circuits.

Insulation is needed agains t the prim ary s ide pow er s upply ( po w er su pply of the m otor brak e).

Please do not connect them with the s ame power su pply.

Internal

regenerative

resistor

Disconnect the short cable

Between P and B:

Connect the external

Connection of the connector XC

Between RB and B:

Connect the shorting cable

Motor Business Unit, Panasonic Corporation

Page 42

No. SX-DSV03015 - 39 -

L1

L2

L3

L

ON

MC1

OFF

ALM

L1C

L2C

P

MC

U

V

W

Motor

ALM+

ALM-

ALM

MCCB

37

36

+

-

RB

X4

N

B

Short bar

Noise filter

Power supply

(3-phase)

Built-in thermostat of an external

regenerative resistor (light yellow)

Coli surge suppression units

Main power

supply

Control power

supply

Motor

connection

External

regenerative

resistor

Red

White

Black

Green or

Green/Yellow

Insulated

DC12 to 24 V

(±5 %)

In case of using the external

regenerative resistor

In case of not using the external

regenerative resistor

Between RB and B:

regenerative resistor

200 V size F

■Connection of regenerative resistor

Internal

regenerative

resistor

Size

Short bar

(Accessories)

F Supplied Installed

-The standard of the ability of the built-in dynamic brake resistor is up

to continuousness three times in the stop from the allowance and maximum inertia and the rated speed.

Resistor is damaged and the dynamic brake might not work when using it under more critical operating condition.

- The circuit con nected to term inal X1 – X6 are secondary circuits.

Insulation is needed against the primary side pow er su pply (power su pply of the m otor bra ke).

Please do not connect them with the s ame power su pply.

Disconnect the short bar

Between P and B:

Connect the external

Connection of the connector XC

Between RB and B:

Connect the short bar

Motor Business Unit, Panasonic Corporation

Page 43

No. SX-DSV03015 - 40 -

[1] When the servo driver uses single p hase power supply for sizes A - D, co nnect the servo driver to the

terminals L1, L3 of main power supply i nput. Do not connect anything to the terminal L2.

[2] Surely insert the co nnector into place until it clicks.

[3] Make sure to use an insulation coated crimp terminal when connecting to each terminal on the terminal

block.

[4] Te rminal b lock co ver i s fixe d wit h scre ws. W hen wirin g to the ter minal b loc k, unscr ew t hese scre ws to

uncover the cover. Tighten the c over fixing screw with the torque of 0.2 Nm or less.

[5] To not use an external regenerative resistor, short out th e circuit between terminals RB and B. (For sizes C,

D, E, F)When a trip occurs due to the regenerative load protection error No.18.0, externally install a

regenerative resistor.

To externally install a regenerative resistor, remove a connection cable between terminals RB, B and then

connect the regenerative resistor between terminals P, B.

The products (Sizes A, B) supporting only the external regenerative resistor, connect an external

regenerative resistor if necessary.

To use an external regenerative resistor, se t Pr.0.16 (external regenerative resistor selection) to 1 or 2.

[6] Apply the power supply of the voltage indicated on the nameplate.

[7] Do not reverse-connect the power input terminals (L1, L2, and L3) and the motor output terminals (U, V,

and W).

[8] Do not connect the motor output terminals (U, V, and W) to ground or short out them.

[9] Because high voltage is applied to the power connectors XA , XB , XC , and XD , a nd the ter mina l

block, never touch them on any ac count. It may cause electric shock.

[10] Suitable for use on a circuit capable of delivering n ot more than 5000 rms symmetrical amperes, below the

maximum input voltage of the product.

[11] An AC servomo tor, unl ike an i nducti on moto r, ca nnot cha nge the rotat ion dir ectio n by exchanging three

phases.

Make sure to coincide the motor output terminals (U, V, and W) of the servo driver with the colors

(pin number for cannon plugs) of the motor output cables.

[12] Surely connect the ground terminals of the motor and the servo driver and earth the ground terminal as well

as that of the noise filter. In addition, earth the equipment unit. To earth them, ground resistance should be

100 ohm or less for grounding.

When the power supply voltage is over 300 V ground resistance should be 10ohm or less.

Please tight the earth screws by appropriate torque and use correct size earth cable decided in the

specifications.

In order to avoid the impact of electrolytic corrosion, do not immediately have any contact between

aluminum and copper.

[13] Attach the serge absorbing circuits for preventing n oises to an electromagnetic contactor placed around the

servo driver, a coil between relay contact points, and a brake winding of motor with a brake.

[14] Attach the no fuse breaker. In case of emergency, make sure to power off outside the servo driver. To use

an earth leakage circuit breaker, use that in which a high frequency wave c ountermeasure is taken.

[15] In order to reduce the terminal noise voltage, install a noise filter.

[16] Customer is responsible for the power supply of the brake attached to a motor.

[17] Turn ON the power after the wiring was finished.

Motor Business Unit, Panasonic Corporation

Page 44

No. SX-DSV03015 - 41 -

Input power voltage

Single phase

100 V

A

DV0P4280

DV0P4281 (100 W or less), DV0P4283 (20 0 W)

B

DV0P4283

DV0P4283

C

DV0P4282

DV0P4283

D

DV0P4284

F

DV0P4285 x 2 in parallel

Built-in thermal protector

operational temperature

Manu

model

Free air

Fan used

(1 m/s)

Ω [W]

[W]

DV0P4280

RF70M

50

10

25

140 ± 5 deg. Celsius

DV0P4281

RF70M

100

10

25

Contact point B

Open/close capacity (resistance

load)

DV0P4283

RF180B

50

17

50

1 A 125 VAC, 6000 times

DV0P4284

RF240

30

40

100

0. 5 A 250 VAC, 10000 times

DV0P4285

RH450F

20

52

130

* As for external regenerative resistor, we recommend the resistors below:

Size

E

-

Single/3 phase 2 00 V

DV0P4284 x 2 in parallel

or

DV0P4285 x 1

Manufacturer by Iwaki Musen K enkyusho

Specification

Part number

DV0P4282 RF180B 25 17 50

-facturer's

Resis

-tance

value

Rated power

(for reference) *

* Electric power available without running the built-in thermal protector.

For safety, a temperature fuse and a thermal protector are built in.

Configure the circuit so as to tur n off the power supply when the thermal protector is running.

The built-in temperature fuse can break according to the radiation condition, the used temperature range, the

power supply voltage, and the load change.

Make sure that the surface temperature of regenerative resistor is being kept 100 deg. Celsius or less under

bad conditions (high power supply voltage, large load inertia, short deceleration time, etc.) subject to

regeneration by embedding the regenerative resistor in equipments and running the equipments.

Attach the regenerative resistor on the incombustibles such as metal.

Install the regenerative resistor so that people can not directly touch it, such as the incombustible to cover it.

Keep the temperature of places, which people can directly touch, below 70 deg. Celsius.

Motor Business Unit, Panasonic Corporation

Page 45

No. SX-DSV03015 - 42 -

d Sizes A-F

10 mm or more

*) Dynamic brake

Servo driver(size A-F) has built-in dynamic brake function to stop motor in an em ergency.

Dynamic brake can be operated in the f ollowing cases

1. The m ain power off

2. The servo off

3. Protection action

4. Connector X4 driv in g ban import ati on ( PO T, NO T) acti on

On the above 1~4 cases, valid or inv alid of dyn amic brake can be determ in ed by the parameters .

However, when the control power off, dynamic brake of size A-F keep valid condition.

Dynamic brake shall be using in rated short time for emergency stop using. Please note the following points.

1. Do not start / stop the motor by the servo signal (SRV-ON) . Built-in dynamic brake circuit may be damag ed.

2. Do not drive the motor with external torque. Motor generates electricity by external torque.

Dynamic brake circuit will be damaged and it is possible that short-circuit current cause smok e or com bust ion.

3. Allow approx. 10 minutes pause when the dynamic brake is activated during high-speed running.

Resistor is damaged and the dynamic brake might not work when using it under more critical o perating

condition.

*) Mounting direction and spacing

-To perform effectiv e cooling, allow suff icient ambien t space.

-Provide a fan so as to m ake uniform t he tem perature in the control panel.

-Each of Sizes D to F is equipped with a cooli ng fan on t he bot tom .

-Adhere to environmental conditions for the environment in the control panel.

Fan

40mm

or

more

In case the portion to receiv e a f an is coated , peelin g off the coat ing before ins talling a f an or usin g hom ebuilt bracket

s with conductive plating provides eff ective ant i-noise measures.

d d

Direction of air flowing from

the internal cooling fan (Sizes D – F)

Control panel

Fan

d

100mm

or more

40mm

or

more

100mm

or more

Motor Business Unit, Panasonic Corporation

Page 46

No. SX-DSV03015 - 43 -

(2) Wiring to connector X4

[1] Customer is responsible for the control signal power supply at 12-24 VDC for external control connected

between COM+ and COM-.Insulation is needed against the primary side power supply (power supply of

the motor brake).

Please do not connect them with the same power supply.

[2] Place the servo driver and its peripheral device as nearly as possible (up to 3 m) so as to shorten the wiring.

[3] Wire the wiring as far away as possible (30 cm or more) from the power lin es (L1, L2, L 3, L1C, L2C, U, V ,

W,

). Do not p ut them in the same duct or bind them together.

Digital input

7

33

30

29

27

28

26

32

31

9

8

COM+

4.7 kΩ

INH

CL

SRV-ON

GAIN

DIV1

VS-SEL1

C-MODE

A-CLR

POT

NOT

V

DC

12 to 24 V

Command pulse

Inhibition input

Deviation counter

clear input

Servo-ON input

Gain switching input

Electronic gear

switching input 1

Damping control

switching input 1

Control mode

switching input

Alarm clear input

Positive direction

Over-travel inhibition input

Negative direction

Over-travel inhibition input

The functions of pins 8, 9, 26-33 are allocatable with parameters. The figure above shows the default setting.

Motor Business Unit, Panasonic Corporation

Page 47

No. SX-DSV03015 - 44 -

[4] Be aware of the polarity of the power supply for control signals. The polarity connection contrary to the

figure shown above can damage the servo driver.

[5] To directly drive the relay with each output signal, make sure to attach a diode in parallel to the relay and in

the direction as shown in the figure below. The servo driver can be dam aged if the diode is n ot attached or

the diode is attached in the oppo site direction.

[6] When a logic circuit such as a gate receives each output signal, take care so that a n oise doe s n ot im pact on

the circuit.

[7] Apply 50 mA or less of current to each output.

Digital output

35

34

37

36

39

38

11

BRKOFF+

10

BRKOFF-

40

S-RDY+

S-RDY-

ALM+

ALM-

AT-

SPEED+

AT-

SPEED-

TLC

V

DC

12 to 24 V

Servo-ready output

Servo-alarm output

At-speed output

External brake

release output

Torque in-limit output

Zero speed detection output

12

41

ZSP

COM-

The functions of pins 10, 11, 34, 35, 38, 39 are allocatable with parameters. The figure above shows the

default setting.

Motor Business Unit, Panasonic Corporation

Page 48

No. SX-DSV03015 - 45 -

PULS

44

45

46

47

13

represents twisted pair

120 Ω

2 kΩ

2 kΩ

20 kΩ

20 kΩ

120 Ω

2 kΩ

2 kΩ

20 kΩ

20 kΩ

SIGN

Pulse train command

A. Pulse train interface exclusively for line driver

B. Pulse train interface

The pulse train command input can support both line driver and open collector interfaces, but in order to

increase the certainty of signal transmissions, we recommend you to use the pulse train command input as an

line driver interface as shown in the figure below.

Be aware that the line driver and open collector interfaces differ from each other in the connection to the servo

driver.

Line driver interface

PULS1

3

4

5

6

13

PULS2

SIGN1

SIGN2

2.2 kΩ

220 Ω

2.2 kΩ

220 Ω

represents twisted pair

Motor Business Unit, Panasonic Corporation

Page 49

No. SX-DSV03015 - 46 -

1

4

2

6

13

OPC1

2.2 kΩ

220 Ω

PULS2

2.2 kΩ

OPC2

SIGN2

24 V

DC

2.2 kΩ

220 Ω

2.2 kΩ

represents twisted pair

Open collector interface

V

DC

- 1.5

R + 220

≒ 10 mA

3

PULS1

2.2 kΩ

13

4

5

6

PULS2

220 Ω

SIGN1

SIGN2

220 Ω

2.2 kΩ

R

V

DC

R

represents twisted pair

Note: Precautions for using the command pulse input as an open collector interface

Shorten the wire length (up to 1 m).

Be aware that the maximum pulse frequency of the open collector interface is small (200 kpps)

compared with that (500 kpps) of the line driver interface.

Motor Business Unit, Panasonic Corporation

Page 50

No. SX-DSV03015 - 47 -

Feedback pulse of rotary encoder

AM26LS32

(or equivalent)

AM26LS31

(or equivalent)

OA+

OA-

OB+

OB-

OZ+

OZ-

GND

21

22

48

49

23

24

25

A

Max. rating 30 V,

B

Z

High speed photo-coupler

1925CZ

GND

50 mA

TLP554

(or equivalent)

Connect signal ground of the host

and the driver without fail.

represents twisted pair

Note:

[1] As well as being output in the line driver, only the Z-phase signals are output to the pin 19 (CZ) in the

open collector. When using this CZ signal, be careful not to be subject to the noise impact.

[2] Use a line receiver (AM26C32 or equivalent) for receiving the output pulses. Then, attach ppropriate

terminating resistor between inputs of the line receiver.

[3] In the Z-phase signal output, be aware that the logic of line driver output (OZ) is the reverse of that of

the open collector output (CZ).

[4] Use the pulses at less than or equal to the maximum output frequency 4 Mpps (after quad edge

valuation).

Motor Business Unit, Panasonic Corporation

Page 51

No. SX-DSV03015 - 48 -

172169-1

Tyco Electronics

(or equivalent)

Motor side

Encoder cable

Driver side

E0V

BAT+

BAT-

PS

PS

FG

E5V

E0V

PS

PS

Shell (FG)

+5 V

0 V

1

2

3

4

5

6

7

8

1

2

4

5

3

Twisted pair

Regulator

172161-1

Tyco Electronics

(or equivalent)

E5V

Motor

White

Black

Red

Pink

Cyan

Purple

Yellow/Green

E5V

JL10-2A20-29P

JAE

(or equivalent)

Motor

Encoder cable

Driver side

E0V

BAT+

BAT-

PS

PS

FG

E5V

E0V

PS

PS

Shell (FG)

+5 V

0 V

1

2

3

4

5

6

H

G

T

S

K

L

J

Twisted pair

Regulator

JL10-6A20-29S-EB

N/M3057-12A

JAE

(or equivalent)

(3) Wiring to connector X6

[1] As for the e ncoder cable, use the batch shielded twisted wire pairs whose core is 0.18 mm2 or more.

[2] The cable length should be up to 20 m. When the wiring is long, we recommend you to use the double wiring

for the 5 V power supply in order to reduce the impact of voltage drop.

[3] Connect the coat of shielded cable at the motor side to the shield of shielded cable from the encoder.

Make sure to connect the coat of shielded cable at the servo driver side to the shell (FG) of X6 .

[4] Wire the wiring as far away as possible (30 cm or more) from the power lines (L1, L2, L3, L1C, L 2C, U, V, W,

).

Do not put them in the same duct or bind them together.

[5] Do not connect anything to the empty pins of X6 .

In case of using as singleturn encoder

In case of lead wire type:

In case of canon plug type:

Motor Business Unit, Panasonic Corporation

Page 52

No. SX-DSV03015 - 49 -

CSA standard

C22. 2 No. 14

KN11

KN61000-4-2,3,4,5,6,8,11

9. Compliance with global standards

9-1 Conforming standards

EN55011

European EC

EMC directive

directive

Low voltage directive

UL standard UL508C (File No. E164620)

KC

EN61000-6-2

EN61000-6-4

EN61800-3

EN61800-5-1

EN50178

IEC : International Electrotechnical Commissio n

EN : Europa i s chen Norman

EMC : Electromagnetic Compatibility

UL : Under writers Laboratoris

CSA : Canadian Standards Association

KC : Radio Waves Act(South Korea)

9-2 European EC directive

Our products, in orde r to make it easy for th e embedded equ ipmen ts and devi ces to be compli ant with EC direct ive,

provide the compliance with the standards associated with low voltage directive.

9-2-1 Compliance with EMC directive

Our servo sys t em determines the model (conditions) such as the installed distance and the wir ing of the servo

driver and the servomotor and makes the model compliant with the standards associated with EMC directive.

When equipments and devices are embedded in practice, wiring and grounding conditions, etc. may be not the

same as the model. Thus, it is necessary to m easure how t he final equipments and devices w here the servo driver

and the servo motor are embedded are compliant (especially unnecessary radiation noise, noise terminal voltage)

with EMC directive.

Motor Business Unit, Panasonic Corporation

Page 53

No. SX-DSV03015 - 50 -

Metallic control box

Driver

L1

L2

L3

L1C

L2C

U

V

W

Residual

current

device

(RCD)

Circuit

breaker

Noise filter

Surge

absorber

Ferrite core

<Dedicated to power supply cable>

Ferrite core

Insulated power

supply for interface

Ferrite core

Controller

Ferrite core

<Dedicated to

power supply cable>

XA

XB

M

RE

X6

Ferrite core

Safety

controller

X3

Ground (PE)

Motor

X4

Power

supply

9-3 Peripheral device configuration

9-3-1 Installation environment

Use the servo driver under the environment of pollution level 2 or 1 defined in IEC60664-1.

(Example: Installed in the IP54 c ontrol panel.)

100 V/200 V type

Motor Business Unit, Panasonic Corporation

Page 54

No. SX-DSV03015 - 51 -

9-3-2 Power supply

100 V system: Single phase 100 V - 120 V

+10 %

-15%

50/60 Hz

+10 %

-15%

+10 %

-15%

50/60 Hz

50/60 Hz

200 V system (Sizes A-D): Single / 3 phase 200 V - 240 V

200 V system (Sizes E-F): 3 phase 200 V - 240 V

(1) Use it under the environment of overvoltage category III defined in IEC60664-1.

(2) As for the pa rallel I/O power supply, use the CE marking conforming product or the 12-24 VDC power

supply of insulation type compliant with EN standard (E N 60 950).

Motor Business Unit, Panasonic Corporation

Page 55

No. SX-DSV03015 - 52 -

L

9-3-3 Power supply

Make sure to connect a circuit breaker compliant with IEC standard and UL certification (marked with

LISTED, ) between the power supply and the noise filter.

U

Integral solid state short circui t protection does not provide branch circuit protection. Br a nch circ uit p rotection

must be provided in accordance with the National Electrical Code and any additional local codes.

9-3-4 Noise filter

To install one noise filter as a whole i n the power unit when multiple servo drivers are used, consult the noise

filter manufacturer.

9-3-5 Surge absorber

Install the surge absorber in the primary side of the noise filter.

- Please!

To carry out a pressure test of equipments and devices, make sure to detach the surge absorber.

Otherwise, the surge absorber can be damaged.

9-3-6 Ferrite core

Install the noise filters for signal lines in all cables (power supply, motor, encoder, and interface cables).

9-3-7 Grounding

(1) In order to avoid an electric shock, make sure to connect a protection ground terminal (

) of the ser vo

driver and the protection ground (PE) of the control panel.

(2) Do not tighte n the co nnection to the protection ground terminal (

) along wit h other parts. The servo

driver has two protection ground terminals.

Motor Business Unit, Panasonic Corporation

Page 56

No. SX-DSV03015 - 53 -

Electromagnetic

current)

Single

DV0PM20043

9-4 List of peripheral devices ap plicable to servo driver

Servo driver

MADL*01**

MADL*11**

MADL*05**

MADL*15**

MBDL*21**

MBDL*25**

MCDL*31**

MCDL*35**

MDDL*45**

MDDL*55**

Voltage

spec

Single

phase

100 V

Single/

3 phase

200 V

phase

100 V

Single/

3 phase

200 V

Single

phase

100 V

Single/

3 phase

200 V

Single/

3 phase

200 V

Power capacity

(Rated current)

Approx.

0.4 kVA

Approx.

0.5 kVA

Approx.

0.5 kVA

Approx.

0.9 kVA

Approx.

0.9 kVA

Approx.

1.3 kVA

Approx.

1.8 kVA

Approx.

2.3 kVA

contactor

(Rated current/

Released heat

20 A

30 A 20 A

Circuit breaker

(Rated current)

10 A

15 A

Noise f ilter Surge absor ber

DV0P4170

(for s ingle

phase)

/

DV0PM20042

/

RTHN-5010

DV0P4190

(for s ingle phase )

DV0P1450

DV0PM20042

/

RTHN-5010

DV0P4220

/

RTHN-5030

(for 3 phase)

Noise filter for signals

Power

cable

/

DV0P

1460

DV0P

1460

Motor

cable

DV0P

1460

MEDL*83**

MEDL*93**

MFDL*A3**

MFDL*B3**

3phase

200 V

Approx.

3.8 kVA

Approx.

4.5 kVA

Approx.

7.5 kVA

60 A 30 A

100 A 50 A

/

RTHN-5050

DV0P3410

/

RTHN-5050

DV0P1450 RJ8035

Select the specification common to single/ 3 phase 200 V according to the power supply.

To become compliant with European EC directive, make sure to connect a circuit breaker compliant with

IEC standard and UL certification (marked with LISTED) between the power supply and the noise filter.

- Please!

Select a circuit breaker and a noise filter with the capacity comparable to the power capacity

(by taking into account the load condition).

Terminal block and earth terminal

For wiring, use the copper conductor cable of the temperature rating 75deg. Celsius or more.

For the protection earth terminal, use M4 for Sizes A-E, M5 for Sizes F.

The terminal block can be damaged if the screw tightening torque exceeds the maximum value.

(See the page for explanation of terminal blocks.)

Motor Business Unit, Panasonic Corporation

Page 57

No. SX-DSV03015 - 54 -

2

Use earth cable having a cross section area of 2.0 mm

2

3.5 mm

6.0 kW to 11.0 kW, or 21.1 mm

(AWG 12) or more for an ou tpu t of 3.0 kW to 5.0 kW, 13.3 mm2 (AWG 6) or more for an output of

2

(AWG 4) or more for an output of 15 kW.

(AWG 14) or more for an output of 50 W to 2.5 kW,

For Sizes A - E, use the dedicated connector which came with the product.

In this case, the stripped cable length should be 8-9 mm.

The tightening torque of connec tor (X4) with the upper controller should be 0.3 - 0.35 Nm.

The torque which exceeds 0.35 Nm can damage the driver's connector.

Optional part number

DV0P1450 RAV-781BXZ-4

Part number of

manufacturer

Manufacturer

Absorber

Ferrite core

Noise filter

DV0P4190 RAV-781BWZ-4

DV0PM20050

DV0P1460 ZCAT3035-1330 TDK

-

DV0P4170 SUP-EK5-ER-6

DV0P4220 3SUP-HU30-ER-6

DV0P3410 3SUP-HL50-ER-6B

DV0PM20042 3SUP-HU10-ER-6

DV0PM20043 3SUP-HU50-ER-6

-

-

-

-

-

-

RAV-801BXZ-4

RJ8035 Konno Kogyousho

FN258L-16-07(29)

FN258L-30-07(33)

FS5559-60-34

FS5559-80-34