Panasonic MADHT1105 Installation Manual

Operating Instructions (Overall)

AC Servo Motor & Driver

MINAS A5-series

*

This product image is 200W type of A5-series.

Thank you for purchasing this Panasonic product.

•

Before operating this product, please read the instructions carefully, and save this manual for future use.

•

Thank you for purchasing Digital AC Servo Motor & Driver, MINAS A5-series. This

instruction manual contains information necessary to correctly and safely use the MINAS

A5-series motor and driver. By reading this instruction manual, you will learn how to

identify the model of the motor and driver that will be best suitable your application, how

to wire and set up them, how to set parameters, and how to locate possible cause of

symptom and to take corrective action.

Caution

1) Any part or whole of this document shall not be reproduced without written permission from us.

Contents of this document are subject to change without notice.

2)

2

Organization of this manual

1. Before Using the Products

Check of the Driver Model ... Installation

Describes how to identify and select the desired product and components, how to

read the specications, and how to install the equipment.

2. Preparation

Operating requirements and procedure

Shows the timing chart and the list of parameters, and describes how to make

wiring and to use the front panel.

1

Before Using the Products

2

Preparation

3

Connection

3. Connection

Wiring ... I/O settings

Shows block diagrams for each control mode and connection diagrams to the host

controllor, I/O settings.

4. Setup

Describes parameters ... JOG running

Shows describes parameters and procedure of test operation.

5. Adjustment

Gain adjustment ... Auto tuning

Describes various adjusting method including auto tuning and manual gain tuning.

6. When in Trouble

4

Setup

5

Adjustment

6

When in Trouble

Read this section when you encounter trouble or error.

7. Supplement

Contains S-T characteristic diagram, dimensional outline drawing, supplemental

description on communications and operation.

7

Supplement

3

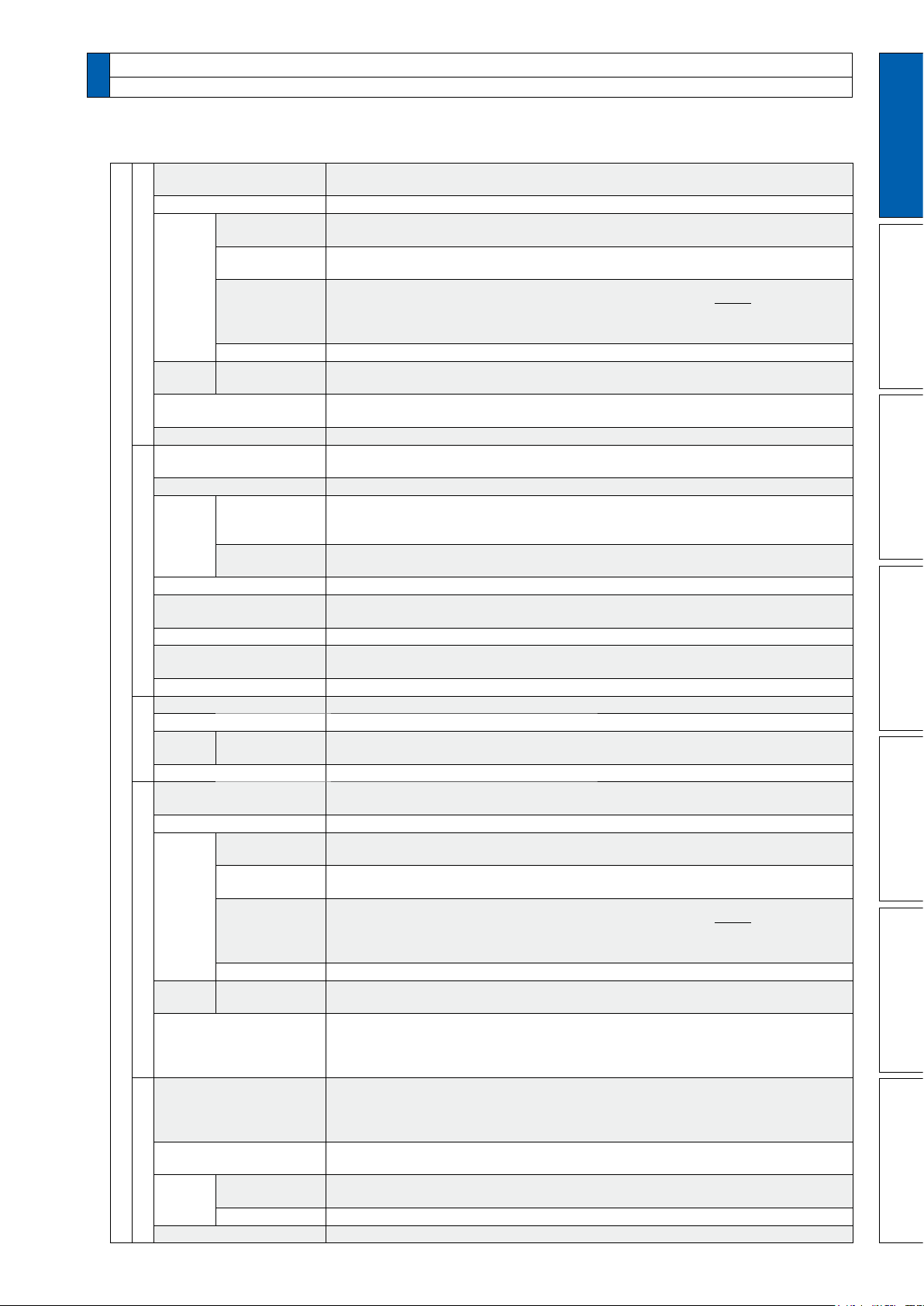

Contents

page

Organization of this manual ............................................................................................3

Safety Precautions .............................................................................................................6

Conformance to international standards ...................................................................10

Maintenance and Inspections .......................................................................................11

Guideline for Parts Replacement .................................................................................12

1. Before Using the Products

1. Introduction ...............................................................................................................1-2

2. Driver ........................................................................................................................1-

3. Motor .......................................................................................................................1-10

4. Check of the Combination of the Driver and the Motor ...........................................1-13

6. Installation ...............................................................................................................1-16

7. Permissible Load at Output Shaft ...........................................................................1-23

...................................................................1-1

2. Preparation .........................................................................................................2-1

1. Conformance to international standards ...................................................................2-2

2. System Conguration and Wiring .............................................................................2-6

3. Wiring to the Connector, X1 ....................................................................................2-20

4. Wiring to the Connector, X2 ....................................................................................2-20

5. Wiring to the Connector, X3 ....................................................................................2-22

6. Wiring to the Connector, X4 ....................................................................................2-23

7. Wiring to the Connector, X5 ....................................................................................2-24

3

8. Wiring to the Connector, X6 ....................................................................................2-26

9. Wiring to the Connector, X7 ....................................................................................2-29

10. Timing Chart ..........................................................................................................2-30

11. Built-in Holding Brake ............................................................................................2-34

12. Dynamic Brake .......................................................................................................2-36

13. Setup of Parameter and Mode ..............................................................................2-42

14. Division Ratio for Parameters ...............................................................................2-52

16. How to Use the Front Panel ..................................................................................2-54

3. Connection

1. Outline of mode .........................................................................................................3-2

2. Control Block Diagram ............................................................................................3-14

3. Wiring to the Connector, X4 ....................................................................................3-18

4. Inputs and outputs on connector X4 .......................................................................3-30

.........................................................................................................3-1

4

page

4. Setup

1. Describes parameters ...............................................................................................4-2

........................................................................................................................4-1

1

1

Before Using the Products

Before Using the Products

2. JOG running ............................................................................................................4-58

5. Adjustment

1. Gain Adjustment ........................................................................................................5-2

2. Real-T

3. Adaptive Filter .........................................................................................................5-10

4. Manual Auto-Gain Tuning (Basic) ............................................................................5-13

5. Manual Auto-Gain Tuning (Application) ...................................................................5-24

6. About Homing Operation .........................................................................................5-39

ime Auto-Gain Tuning .....................................................................................5-4

6. When in Trouble

1. When in Trouble ........................................................................................................6-2

2. Setup of gain pre-adjustment protection .................................................................6-15

3. Troubleshooting ......................................................................................................6-17

..........................................................................................................5-1

.............................................................................................6-1

2

2

Preparation

Preparation

3

3

Connection

Connection

4

4

Setup

Setup

7. Supplement

1. Safety function ..........................................................................................................7-2

2.

3. Setup Support Software, PANATERM .....................................................................7-26

4. Communication .......................................................................................................7-27

5. Motor Characteristics (S-T Characteristics) ............................................................7-56

6. Dimensions .............................................................................................................7-63

7. Options ....................................................................................................................7-72

Warranty .............................................................................................................................7-96

Cautions for Proper Use .....................................................................................................7-97

After-Sale Service .................................................................................................... Back cover

Absolute System .....................................................................................................7-10

........................................................................................................7-1

5

5

Adjustment

Adjustment

6

6

When in Trouble

When in Trouble

7

7

Supplement

Supplement

5

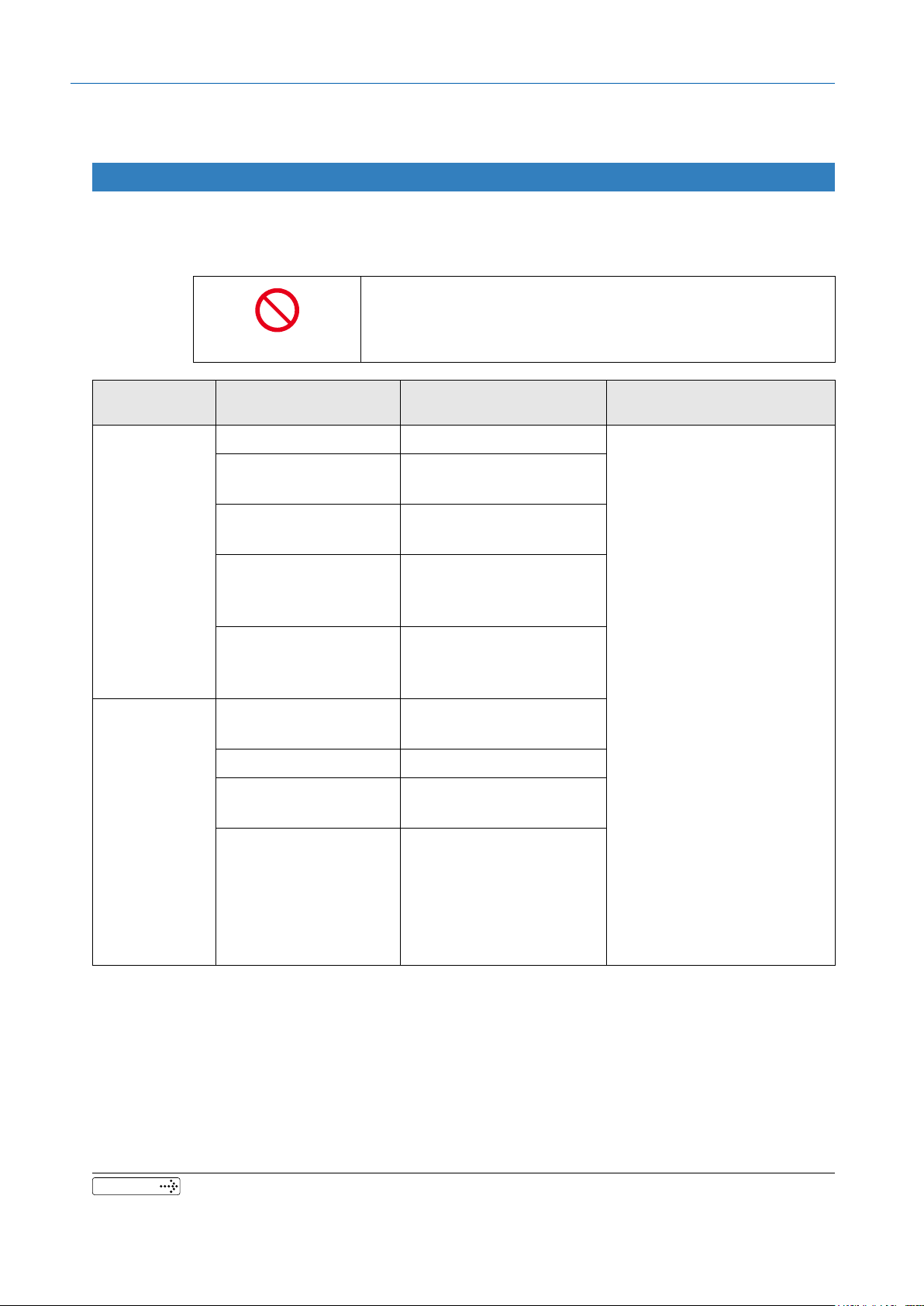

Safety Precautions

The following explanations are for things that must be observed in order to prevent harm to

people and damage to property.

•

Misuses that could result in harm or damage are shown as follows, classied according to the

degree of potential harm or damage.

Please observe safety precautions fully.

Danger

Caution

• The following indications show things that must be observed.

Indicates great possibility of death or serious injury.

Indicates the possibility of injury or property damage.

Indicates something that must not be done.

Indicates something that must be done.

Danger

Do not subject the Product to water, corrosive or

ammable gases, and combustibles.

Do not place combustibles near by the motor,

driver and regenerative resistor.

Don't use the motor in a place subject to excessive vibration or shock.

Don't use cables soaked in water or oil.

Do not place the console close to a heating unit

such as a heater or a large wire wound resistor.

Never connect the motor directly to the commercial power supply.

Don't attempt to carry out wiring or manual operation with wet hand.

Do not put your hands in the servo driver.

Failure to observe this instruc-

tion could result in re.

Failure to observe this instruction could result in electrical

shock, injury or re.

Failure to observe this instruction could result in electrical

shocks, damages and breakdowns.

Failure to observe this instruc-

tion could result in re and

breakdowns.

Failure to observe this instruc-

tion could result in electrical

shock, injury or re.

Failure to observe this instruction could result in burn and

electrical shocks.

6

1

Before Using the Products

In the case of the motor with shaft end keyway, do

not touch the keyway with bare hands.

Do not touch the rotating portion of the motor

while it is running.

Do not touch the motor, servo driver, heat sink

and regenerative resistor, since they become very

hot.

Do not drive the motor with external power.

Do not subject the cables to excessive force,

heavy object, or pinching force, nor damage the

cables.

Installation area should be free from excessive

dust, and from splashing water and oil.

Mount the motor, driver and regenerative resistor

on incombustible material such as metal.

Wiring has to be carried out by the qualied and

authorized specialist.

Correctly run and arrange wiring.

After correctly connecting cables, insulate the live

parts with insulator.

Ground the earth terminal of the motor and driver

without fail.

Install and mount the Product and machinery

securely to prevent any possible re or accidents

incurred by earthquake.

Install an emergency stop circuit externally so that

you can stop the operation and shut off the power

immediately.

Install an overcurrent protection, earth leakage

breaker, over-temperature protection and emergency stop apparatus without fail.

Check and conrm the safety of the operation

after the earthquake.

Before transporting, wiring and inspecting the

driver, turn off power and wait for a time longer

than that specied on the name plate on the side

panel of the product; and make sure that there is

no risk of electrical shock.

Failure to observe this instruction could result in personal

injury.

Failure to observe this instruction could result in burns.

Failure to observe this instruc-

tion could result in re.

Failure to observe this instruction could result in electrical

shocks, damages and breakdowns.

Failure to heed this precaution

will result in electric shock, per-

sonal injury, re, malfunction or

damage.

Installation on a ammable ma-

terial may cause re.

Allowing a person with no expertise to carry out wiring will

result in electrical shocks.

Incorrect wiring will result in

short circuit, electric shock, personal injury, etc.

Incorrect wiring will result short

circuit, electric shock, re or

malfunction.

Floating ground circuit will

cause electric shock.

Failure to heed this requirement

will result in electric shock, per-

sonal injury, re, malfunction or

damage.

Failure to heed these requirements will result in electric

shock, personal injury or re.

Energized circuit will cause

electric shock.

2

Preparation

3

Connection

4

Setup

5

Adjustment

6

When in Trouble

7

Supplement

7

Safety Precautions

Please observe safety precautions fully.

Caution

Do not hold the motor cable or motor shaft during

the transportation.

Don't drop or cause topple over of something during transportation or installation.

Do not step on the Product nor place the heavy

object on them.

Don't use the equipment under direct sunshine.

Do not block the heat dissipating holes or put the

foreign particles into them.

Do not give strong impact shock to the Product.

Do not give strong impact shock to the motor

shaft.

Failure to observe this instruction could result in injuries.

Failure to observe this instruction could result in injuries and

breakdowns.

Failure to observe this instruction could result in electrical

shocks, injuries, breakdowns

and damages.

Failure to heed these instructions will cause personal injury

or re.

Failure to observe this instruction could result in electrical

shocks and re.

Failure to observe this instruction could result in breakdowns.

Failure to observe this instruction could result in a failure of

the detector etc.

Do not turn on and off the main power of the driver repeatedly.

Never run or stop the motor with the electro-magnetic contactor installed in the main power side.

Do not make an extreme gain adjustment or

change of the drive.

Do not keep the machine running/operating unstably.

Do not use the built-in brake as a "Braking" to

stop the moving load.

Do not approach to the machine since it may suddenly restart after the power resumption.

Design the machine to secure the safety for the

operator even at a sudden restart.

Never attempt to perform modication, dismantle

or repair.

Make an appropriate mounting of the Product

matching to its wight and output rating.

Failure to observe this instruction could result in breakdowns.

Failure to observe this instruction could result in injuries.

Failure to observe this instruction could result in injuries and

breakdowns.

Failure to observe this instruction could result in injuries.

Failure to heed this instruction

will result in re, electric shock,

personal injury or malfunction.

Failure to heed these require-

ments will result in personal

injury or malfunction.

8

1

Before Using the Products

Observe the specied mounting method and direction.

Use the eye bolt of the motor for transportation of

the motor only, and never use this for transportation of the machine.

Don't place any obstacle object around the motor

and peripheral, which blocks air passage.

Adjust the motor and driver ambient environmental condition to match the motor operating temperature and humidity.

Create the specied clearance between the driver

and the control panel inner surface or other devices.

Observe the specied voltage.

Connect the brake control relay to the relay which

is to shut off at emergency stop in series.

Provide protection device against idling of electromagnetic brake or gear head, or grease leakage

from gear head.

Failure to heed these requirements will result in personal

injury or malfunction.

Using it for transportation of the

machine will cause personal

injury or malfunction.

Temperature rise will cause

burn injury or re.

Failure to heed these require-

ments will result in personal

injury or malfunction.

Operation from a voltage outside the rated voltage will cause

electric shock, personal injury

or re.

Missing of one of these devices

will result in personal injury or

malfunction.

No protection will cause personal injury, damage, pollution

or re.

2

Preparation

3

Connection

4

Setup

Use the motor and the driver in the specied combination.

Test-run the securely xed motor without loading

to verify normal operation, and then connect it to

the mechanical system.

When any error occurs, remove the cause and

release the error after securing the safety, then

restart.

If the driver fails, shut off the power on the power

supply side of the driver.

Maintenance must be performed by an experienced personnel.

Always keep power disconnected when the power

is not necessary for a long time.

When you dispose the batteries, observe any applicable regulations or laws after

insulating them with tape.

This Product shall be treated as Industrial Waste when you dispose.

Not using the motor and the

driver in the specied combina-

tion will result in re.

Operation using a wrong model

or wrong wiring connection will

result in personal injury.

Not removing the cause of the

error will result in personal injury.

Allowing a large current to con-

tinue to pass will result in re.

Wrong wiring will cause personal injury or electric shock.

Improper operation will cause

personal injury.

5

Adjustment

6

When in Trouble

7

Supplement

9

Conformance to international standards

Conformed Standards

Driver Motor

EMC

Directives

Low-

Voltage

EC Directives

UL Standards UL508C (E16

CSA Standards C22.2 No.1

Directives

Functional

safety

EN55011

EN61000-6-2

EN61800-

EN61800-5-1

EN95

ISO13849-1 (PL d)

EN61508 (SIL 2)

EN62061 (SIL 2)

EN61800-5-2 (STO)

IEC61326-3-1

3

4-1 (Cat. 3)

4620)

4 C22.2 No.100

–

EN600

EN60034-5

UL1004-1 (E327868: Small type)

UL1004 (E166557: Large type)

34-1

–

IEC : International Electrotechnical Commission

EN : Europaischen Normen

: Electromagnetic Compatibility

EMC

UL : Underwriters Laboratories

CSA : Canadian Standards Association

Pursuant to the directive 200

4/108/EC, article 9(2)

Panasonic Testing Centre

Panasonic Service Europe, a division of

Panasonic Marketing Europe GmbH

Winsbergring 15, 22525 Hamburg, F.R. Germany

10

Note

For details on compatibility with international standard, refer to P.2-2 Conformance to

international standards.

Maintenance and Inspections

Routine maintenance and inspection of the driver and motor are essential for the

proper and safe operation.

1

Before Using the Products

Notes on Maintenance and Inspection

1) Turn on and turn off should be done by operators or inspectors themselves.

2) Internal circuit of the driver is kept charged with high voltage for a while even after

power-off. Turn off the power and allow 15 minutes or longer after LED display of the

front panel has gone off, before performing maintenance and inspection.

) Disconnect all of the connection to the driver when performing megger test (Insulation

3

resistance measurement) to the driver, otherwise it could result in breakdown of the

driver.

Do not use benzine, thinner, alcohol, acidic cleaner and alkaline cleaner because they can

)

4

discolor or damage the exterior case.

Inspection Items and Cycles

General and normal running condition

Ambient conditions : 30˚C (annual average), load factor of 80% or

lower, operating hours of 20 hours or less per day.

Perform the daily and periodical inspection as per the items below.

Type Cycles Items to be inspected

2

Preparation

3

Connection

4

Setup

Daily

inspection

Motor

with Gear

Reducer

Daily

Annual

• Ambient temperature, humidity, speck, dust or foreign object

• Abnormal vibration and noise

• Main circuit voltage

• Odor

• Lint or other particles at air holes

• Cleanness at front portion of the driver and connector

• Damage of the cables

• Loose connection or misalignment between the motor and

machine or equipment

• Pinching of foreign object at the load

• Loose tightening

• Trace of overheat

• Damage to the terminal block

• Loose fasteners on terminal block

5

Adjustment

6

When in Trouble

7

Supplement

Note

Inspection cycle may change when the running conditions of the above change.

11

Maintenance and Inspections

Guideline for Parts Replacement

Use the table below for a reference. Parts replacement cycle varies depending on the actual operating conditions. Defective parts should be replaced or repaired when any error

have occurred.

Disassembling for inspection and repair should be

carried out only by authorized dealers or service

Prohibited

company.

Product Component

Smoothing condenser Approx. 5 years

Cooling fan

Aluminum electrolytic

capacitor (on PCB)

Driver

Rush current

preventive relay

Rush current

preventive resistor

Bearing

Oil seal 5000 hours

Encoder

Motor

Battery

for absolute encoder

Standard replacement

cycles (hour)

3 years

2 to

(10,000 to 30,000 hours)

Approx. 5 years

Approx. 100,000 times

(depending on working

condition)

Approx. 20,000 times

(depending on working

condition)

3

to 5 years

(20,000 to 30,000 hours)

3

to 5 years

(20,000 to 30,000 hours)

Life time varies depending

on working conditions.

Refer to the Operating

Instructions attached to the

battery for absolute

encoder.

Note

These hours or cycles are

reference.

When you experience any

error, replacement is required

even before this standard

replacement cycle.

Related page

12

• P.7-96 “Warranty”

1. Before Using the Products

1. Introduction

Outline .........................................................................................................1-2

On Opening the Product Package ...............................................................1-2

2. Driver

Check of the Model ......................................................................................1-3

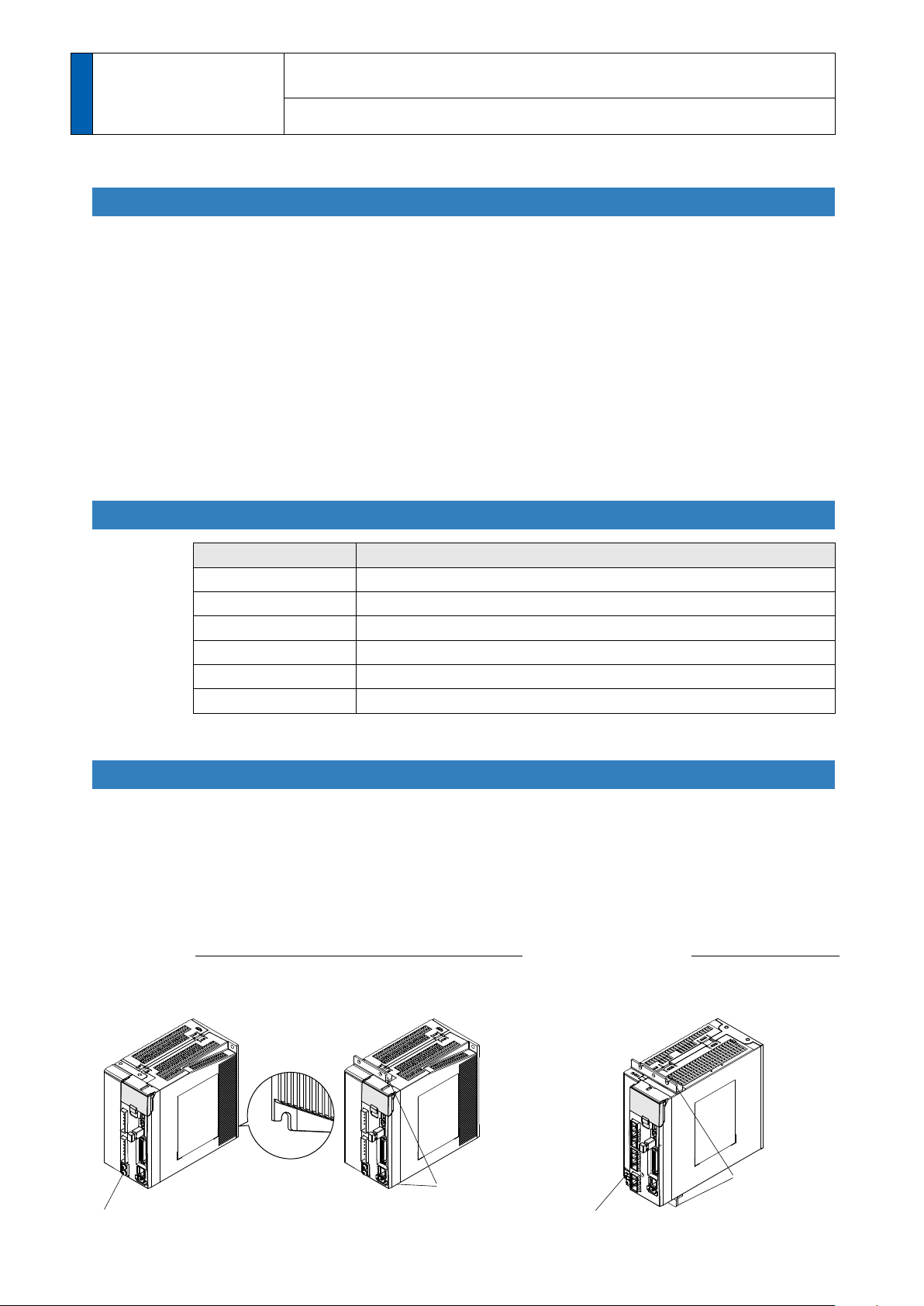

Parts Description (A to E-frame) ..................................................................1-

Parts Description (F-frame) .........................................................................1-5

Specifications...............................................................................................1-6

Block Diagram .............................................................................................1-8

3. Motor

Check of the Model ....................................................................................1-10

Parts Description .......................................................................................1-12

4. Check of the Combination of the Driver and the Motor

Incremental Specifications, 20-bit ..............................................................1-13

Absolute Specifications, 17-bit...................................................................1-1

Junction cable for motor ...........................................................................1-15

5. Installation

Driver .........................................................................................................1-16

Motor..........................................................................................................1-20

4

4

1

Before Using the Products

2

Preparation

3

Connection

4

Setup

6. Permissible Load at Output Shaft

Motor..........................................................................................................1-23

5

Adjustment

6

When in Trouble

7

Supplement

1-1

1 Before Using

1. Introduction

the Products

The AC Servo Motor & Driver, MINAS A5-series is the latest servo system that meets all

demands from a variety of machines which require high speed, high precision and high

performance or which require simplied settings.

ompared with the preceding A4-series, product of A5-series offers superior performance

C

while requiring simple setup and adjustment by the user.

Newly designed motors have wide range of outputs from 50 W to 5.0 kW, associated with

20-bit incremental encoder and reduced cogging torque.

They are compatible with 2 closed controls (serial communication type and A-/B-phase

output type) and provided with various automatic adjusting functions such as real time

auto tuning with many automatic setting parameters to make complex tuning easy.

These motors assure higher stability with low stiffness machine and high-speed, high

accurate operation with high stiffness machine. They can be used in combination with a

wide variety of machines.

This manual is written as a complete guide for you so that you can fully and correctly

make use of all functions available from MINAS A5.

Outline

1 Before Using

the Products

• Make sure that the model is what you have ordered.

• Check if the product is damaged or not during transportation.

• Check if the Operating Instructions (safety) are included or not.

• Check if the power connector, motor connectors, connector for external regenerative

resistor connection (only E-frame) and safety by-pass plug are included or not.

(Neither the power connector nor motor connector are included to F-frame.)

Contact to a dealer if you nd any failures.

1. Introduction

On Opening the Product Package

1-2

1 Before Using

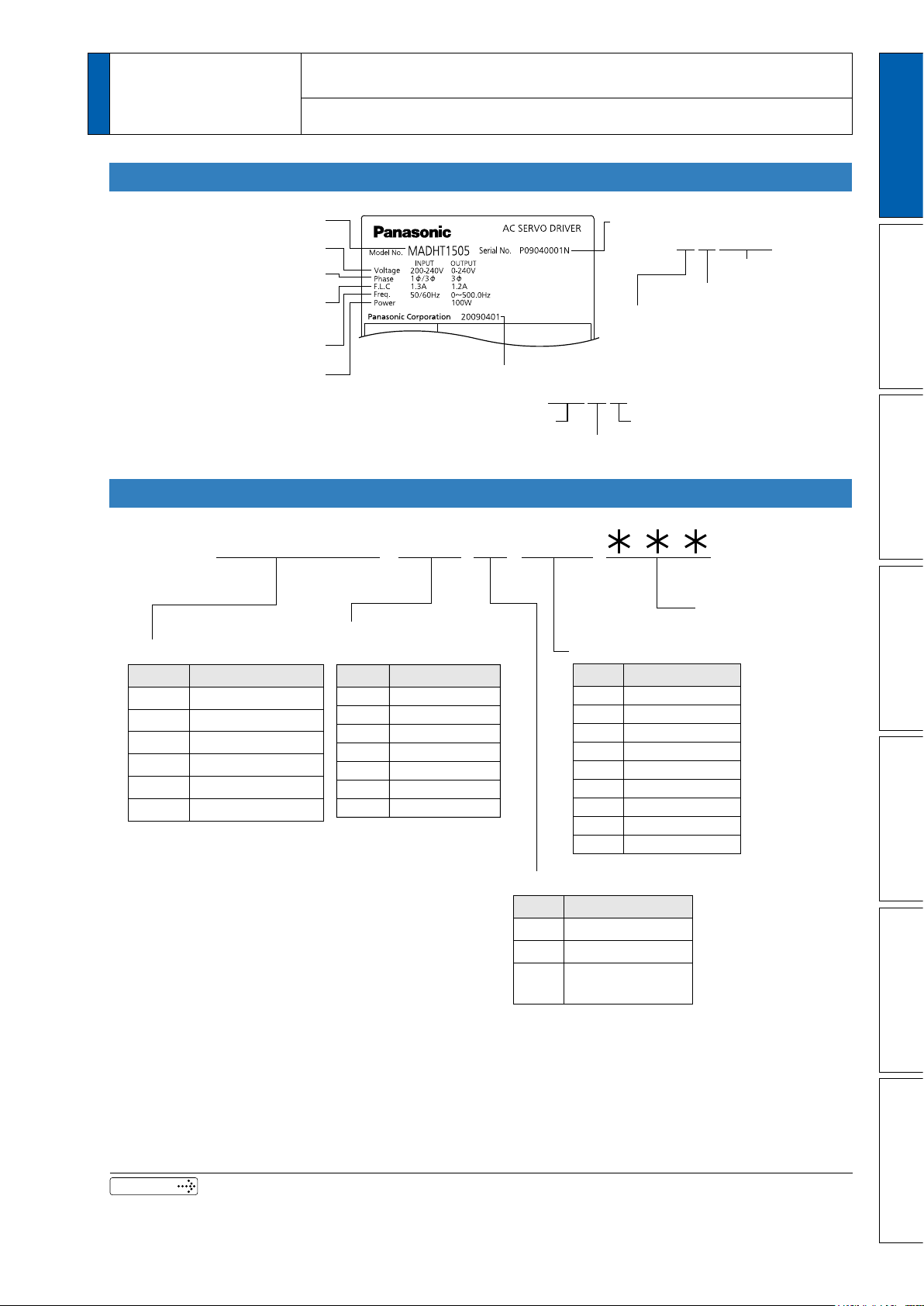

Model number

Input/output voltage

Rated output of

applicable motor

Rated input/output current

Input/output frequency

Number of phase

Serial Number

e.g.) : P09040001N

Lot number

Month of production

Year of production

(Lower 2 digits of AD year)

Manufacture date

e.g.) : 20090401

Manufacture dateManufacture year

Manufacture month

M A D H T 1 5 0 5

Special specifications

(letters and numbers)

Current detector rating

Power supply

Max. current rating

of power device

Frame-size symbol

MADH

MBDH

MCDH

MDDH

MEDH

MFDH

Frame

Symbol

A5-series, A-frame

A5-series, B-frame

A5-series, C-frame

A5-series, D-frame

A5-series, E-frame

A5-series, F-frame

T1

T2

T3

T5

T7

TA

TB

Current rating

Symbol

Specifications

10A

15A

30A

50A

70A

100A

150A

Symbol

1

3

5

Single phase, 100V

3-phase, 200V

Single/3-phase,

200V

05

07

10

20

30

40

64

90

A2

Current rating

Symbol

5A

7.5A

10A

20A

30A

40A

64A

90A

120A

1 to 4 75 to 6 10 to 128 to 9

2. Driver

1

Before Using the Products

the Products

Check of the Model

Contents of Name Plate

Model Designation

2

Preparation

3

Connection

Related page

• P.1-14 “Check of the Combination of the Driver and the Motor”

1-3

4

Setup

5

Adjustment

6

When in Trouble

7

Supplement

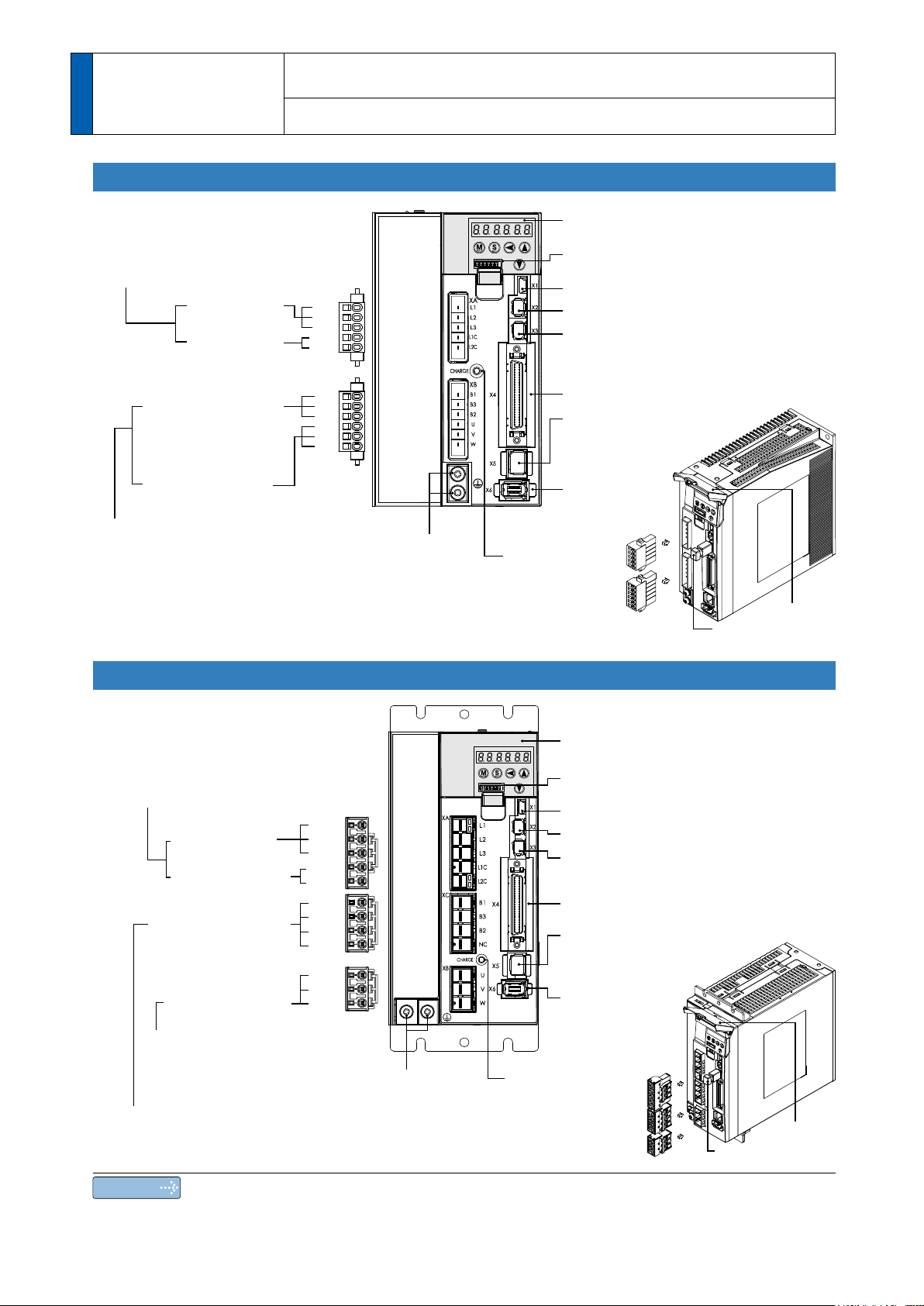

Charge lamp

L1C

L2C

L1

L2

L3

B1

B3

B2

V

U

W

Connector XA:

for main power connection

05JFAT-SAXGF (JST)

Connector XB:

for motor connection

06JFAT-SAXGF (JST)

Terminals for external

regenerative resistor

(Normally short-circuit

B3 to B2)

Connector X6:

for encoder

connection

Connector X4: Parallel I/O connector

Connector X3: Safety function connector

Connector X2: for Serial bus

Connector X1: USB connector

Connector X5:

for feedback scale

connection

Connector X7: Monitor connector

Front panel

LED cover

Safety by-pass prug

Screws for earth (x2)

Main power

input terminals

Control power

input terminals

Terminals for motor

connection

1 Before Using

Screws for earth

(x2)

Charge lamp

L1C

L2C

L1

L2

L3

B1

B3

B2

NC

U

V

W

Connector XA:

for main power connection

05JFAT-SAXGSA-L (JST)

Connector XB:

Connector for external

regenerative resistor

03JFAT-SAXGSA-L (JST)

Connector XC:

for motor connection

04JFAT-SAXGSA-L (JST)

Terminals for external

regenerative resistor

(Normally short-circuit

B3 to B2)

Terminals for motor

connection

Control power

input terminals

Main power

input terminals

Connector X6:

for encoder

connection

Connector X4: Parallel I/O connector

Connector X3: Safety function connector

Connector X2: for Serial bus

Connector X1: USB connector

Connector X5:

for feedback scale

connection

Connector X7: Monitor connector

Front panel

LED cover

Safety by-pass prug

2. Driver

the Products

A to D-frame

Parts Description

F-frame

Note

1-4

Connector X1 and X2 are attached in A to D-frame driver.

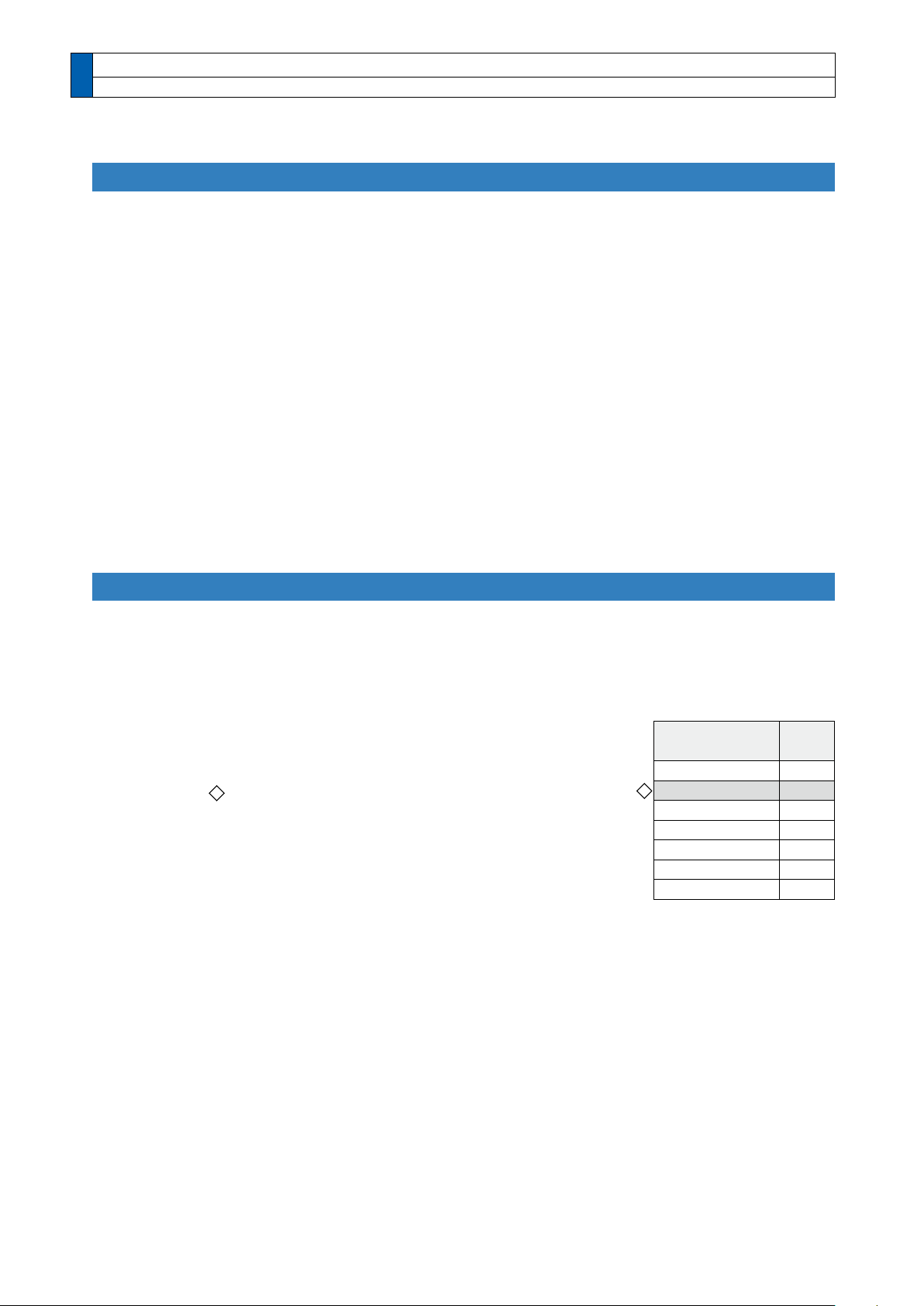

Connector XA, XB and XC are attached in E-frame driver.

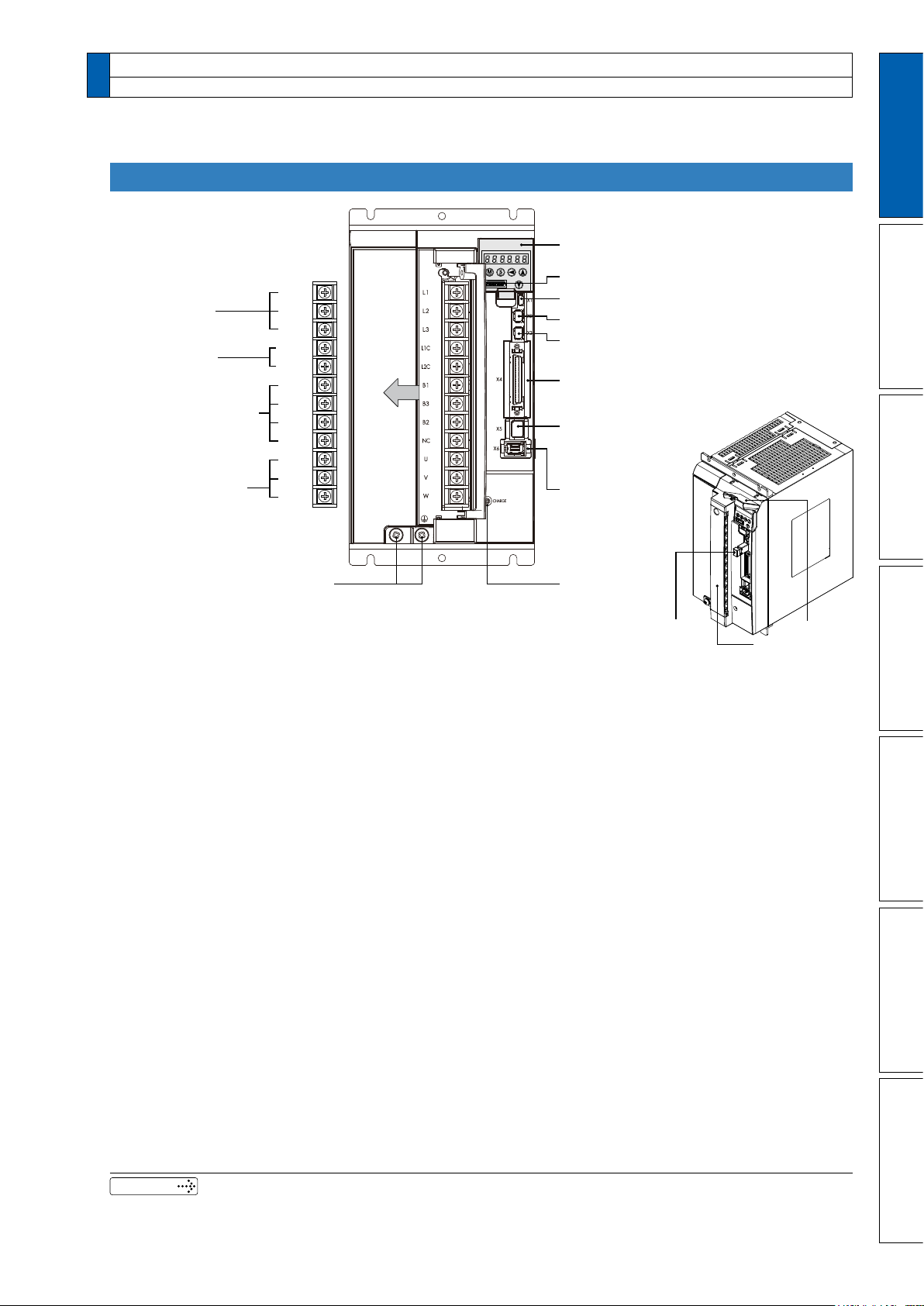

2. Driver

Control power

input terminals

L1

L2

L3

L1C

L2C

B1

B3

B2

NC

U

V

W

Main power

input terminals

Terminals for motor

connection

Screws for earth (x2)

Terminals for external

regenerative resistor

(Normally short-circuit

B3 to B2)

Charge lamp

Terminal cover

LED cover

Connector X6:

for encoder

connection

Connector X4: Parallel I/O connector

Connector X3: Safety function connector

Connector X2: for Serial bus

Connector X1: USB connector

Connector X5:

for feedback scale

connection

Connector X7: Monitor connector

Front panel

Safety by-pass prug

Parts Description

E-frame

1

Before Using the Products

2

Preparation

3

Connection

Related page

• P.1-14 “Check of the Combination of the Driver and the Motor”

• P.1-16 “Installation”

• P.2-6 “Driver and List of Applicable Peripheral Equipments”

4

Setup

5

Adjustment

6

When in Trouble

7

Supplement

1-5

1 Before Using

2. Driver

the Products

Main circuit

100V

Control circuit

Input power

D-frame

Main

circuit

200V

Control

Withstand voltage Primary to earth: withstand 1500 VAC, 1 min,(sensed current: 20 mA)

Environment

Control method IGBT PWM Sinusoidal wave drive

Encoder feedback

Basic Specications

Feedback scale feedback

Control

signal

Analog

/Digital

signal

Pulse

signal

Communication

function

Safety function Used for IEC61800-5-2: STO.

Front panel

Regeneration

Dynamic brake Built-in

Control mode

F-frame

D-frame

circuit

F-frame

temperature

humidity Both operating and storage : 20 to 85%RH or less (free from condensation)

Altitude Lower than 1000m

Vibration 5.88m/s

Input

Output

Input 3 inputs (16Bit A/D : 1 input, 12Bit A/D : 2 inputs)

Output 3 outputs (Analog monitor: 2 output, Digital monitor: 1 output)

Input

Output

USB Connection with PC etc.

RS232 1 : 1 communication to a host.

RS485 1 : n communication up to 31 axes to a host.

Specifications

Single phase, 100 to 120V

Single phase, 100 to 120V

A to

Single/3-phase, 200 to 240V

E to

3-phase, 200 to 230V

A to

Single phase, 200 to 240V

E to

Single phase, 200 to 230V

Ambient temperature: 0˚C to 55˚C (free from freezing)

Storage temperature: –20˚C to 65˚C (Max.temperature guarantee: 80˚C for 72 hours)

2

or less, 10 to 60Hz (No continuous use at resonance frequency)

17-bit (131072 resolution) absolute encoder, 7-wire serial

20-bit (1048576 resolution) incremental encoder, 5-wire serial

A/B phase, initialization signal defferential input.

Manufacturers that support serial communication scale:

Mitsutoyo Corp.

Sony Manufacturing Systems Corp.

General purpose 10 inputs

The function of general-purpose input is selected by parameters.

General purpose 6 outputs

The function of general-purpose input is selected by parameters.

2 inputs (Photo-coupler input, Line receiver input)

Photocoupler input is compatible with both line driver I/F and open collector I/F.

Line receiver input is compatible with line driver I/F.

4 outputs ( Line driver: 3 output, open collector: 1 output)

Feed out the encoder pulse (A, B and Z-phase) or feedback scale pulse (EXA, EXB and

EXZ-phase) in line driver. Z-phase and EXZ-phase pulse is also fed out in open collector.

(1) 5 keys (MODE, SET, UP, DOWN, SHIFT) (2) LED (6-digit)

(3) Analog monitor output (2ch) (4) Digital monitor output (1ch)

A, B-frame: no built-in regenerative resistor (external resistor only)

C to F-frame: Built-in regenerative resistor (external resistor is also enabled.)

Switching among the following 7 mode is enabled,

(1) Position control (2) Velocity control (3) Toque control (4) Position/Velocity control

(5) Position/Torque control (6) Velocity/Torque control (7) Full-closed control

+10%

–15%

+10%

–15%

+10%

–15%

+10%

–15%

+10%

–15%

+10%

–15%

50/60Hz

50/60Hz

50/60Hz

50/60Hz

50/60Hz

50/60Hz

Related page

1-6

• P.1-16 “Installation of Driver”

• P.1-20 “Installation of Motor”

2. Driver

Specifications

1

Before Using the Products

Control input

Control output Positioning complete (In-position) etc.

Max. command

pulse frequency

Position control

Pulse

input

Analog

input

Instantaneous Speed

Observer

Damping Control Available

Control input

Control output Speed arrival etc.

Velocity control

Analog

input

Internal velocity command Switching the internal 8speed is enabled by command input.

Soft-start/down function

Zero-speed clamp 0-clamp of internal velocity command with speed zero clamp input is enabled.

Instantaneous Speed

Observer

Function

Velocity Control lter Available

Torque control

Control input Speed zero clamp, Torque command sign input etc.

Control output Speed arrival etc.

Analog

input

Speed limit function Speed limit value with parameter t is enabled.

Control input

Control output Full-closed positioning complete etc.

Full-closed control

Pulse

input

Analog

input

Setup range of division/

multiplication of

feedback scale

Auto tuning

Common

Division of encoder

feedback pulse

Protective

function

Traceability of alarm data The alarm data history can be referred to.

Input pulse

signal format

Electronic gear

(Division/

Multiplication of

command pulse)

Smoothing lter Primary delay lter or FIR type lter is adaptable to the command input

Torque limit

command input

Velocity

command input

Torque limit

command input

Torque command

input

Max. command

pulse frequency

Input pulse

signal format

Electronic gear

(Division/

Multiplication of

command pulse)

Smoothing lter Primary delay lter or FIR type lter is adaptable to the command input

Torque limit

command input

Hard error

Soft error Excess position deviation, command pulse division error, EEPROM error etc.

(1) Deviation counter clear (2) Command pulse inhibition

(3) Command dividing gradual increase switching (4) Damping control switching etc.

Exclusive interface for Photo-coupler: 500kpps

Exclusive interface for line driver : 4Mpps

Differential input. Selectable with parameter. ((1) Positive and Negative direction,

(2) A and B-phase, (3) Command and direction)

Process command pulse frequency × electronic gear ratio

command input. Use electronic gear ratio in the range 1/1000 to 1000 times.

Individual torque limit for both positive and negative direction is enabled.

Available

(1) Selection of internal velocity setup 1 (2) Selection of internal velocity setup 2

(3) Selection of internal velocity setup 3 (4) Speed zero clamp etc.

Speed command input can be provided by means of analog voltage.

Parameters are used for scale setting and command polarity. (6V/Rated rotational

speed Default)

Individual torque limit for both positive and negative direction is enabled.

Individual setup of acceleration and deceleration is enabled, with 0 to 10s/1000r/min.

Sigmoid acceleration/deceleration is also enabled.

Available

Speed command input can be provided by means of analog voltage.

Parameters are used for scale setting and command polarity. (3V/rated torque Default)

(1) Deviation counter clear (2) Command pulse inhibition

(3) Command dividing gradual increase switching (4) Damping control switching etc.

Exclusive interface for Photo-coupler: 500kpps

Exclusive interface for line driver : 4Mpps

Differential input. Selectable with parameter. ((1) Positive and Negative direction, (2) A

and B-phase, (3) Command and direction)

Process command pulse frequency × electronic gear ratio

command input. Use electronic gear ratio in the range 1/1000 to 1000 times.

Individual torque limit for both positive and negative direction is enabled.

1/40 to 160 times

The ratio of encoder pulse (numerator) to external scale pulse (denominator) can be set

to 1 to 2

range shown above.

The load inertia is identified in real time by the driving state of the motor operating

according to the command given by the controlling device and set up support software

“PANATERM”.

The gain is set automatically in accordance with the rigidity setting.

Set up of any value is enabled (encoder pulses count is the max.).

Over-voltage, under-voltage, over-speed, over-load,

over-heat, over-current and encoder error etc.

20

(numerator) to 1 to 220 (denominator), but should be set to a ratio within the

1 to 2

(

1 to 2

1 to 2

(

1 to 2

30

)

as positional

30

30

)

as positional

30

2

Preparation

3

Connection

4

Setup

5

Adjustment

6

When in Trouble

7

Supplement

1-7

L 1

L 2

L 3

B1

B3

N

P

+

Fuse

抵抗

Fuse

Fuse

Error

detection

Voltage

detection

Sequence control

B2

L1C

L2C

X5

Feedback scale signal

processing limit

Feedback scale unit

DC/DC

X1

X2

X6

U

V

W

M

RE

X4

+

±12V

+5V

PS for gate drive

Gate drive

PS for RE

Front panel

Alarm

signal

USB

Serial

Pulse train

command

Pusle

output

Analog

velocity

command

Control

input

Division/

mulitiplication

+

+

–

–

A/D

A/D

16-bit

Position

Speed

Velocity

Torque

Internal

External

Deviation

counter

Internal speed

command

Speed

detection

Division

processing

Position

deviation amp.

Display

operation

control

Parameter control

Protective

curcuit

EEPROM

Speed

deviation

amp.

Torque

limit

Current

control

PWM

circuit

Encoder signal

processing

limit

Control

output

X3

Safety function

L 1

L 2

L 3

B1

B3

N

P

+

Fuse

抵抗

Fuse

Error

detection

Voltage

detection

Sequence control

B2

L1C

L2C

Division

processing

Feedback scale signal

processing limit

DC/DC

X6

U

V

W

M

RE

+

±12V

+5V

PS for gate drive

Gate drive

PS for RE

Alarm

signal

Pulse train

command

Pusle

output

Analog

velocity

command

Control

input

Division/

mulitiplication

+

+

–

–

A/D

A/D

16-bit

Position

Speed

Velocity

Torque

Internal

External

Deviation

counter

Internal speed

command

Speed

detection

Position

deviation amp.

Display

operation

control

Parameter control

Protective

curcuit

EEPROM

Speed

deviation

amp.

Torque

limit

Current

control

PWM

circuit

Encoder signal

processing

limit

Control

output

Fuse

Fan

(D-frame only)

Front panel

X5

Feedback scale unit

X1

X2

X4

USB

Serial

X3

Safety function

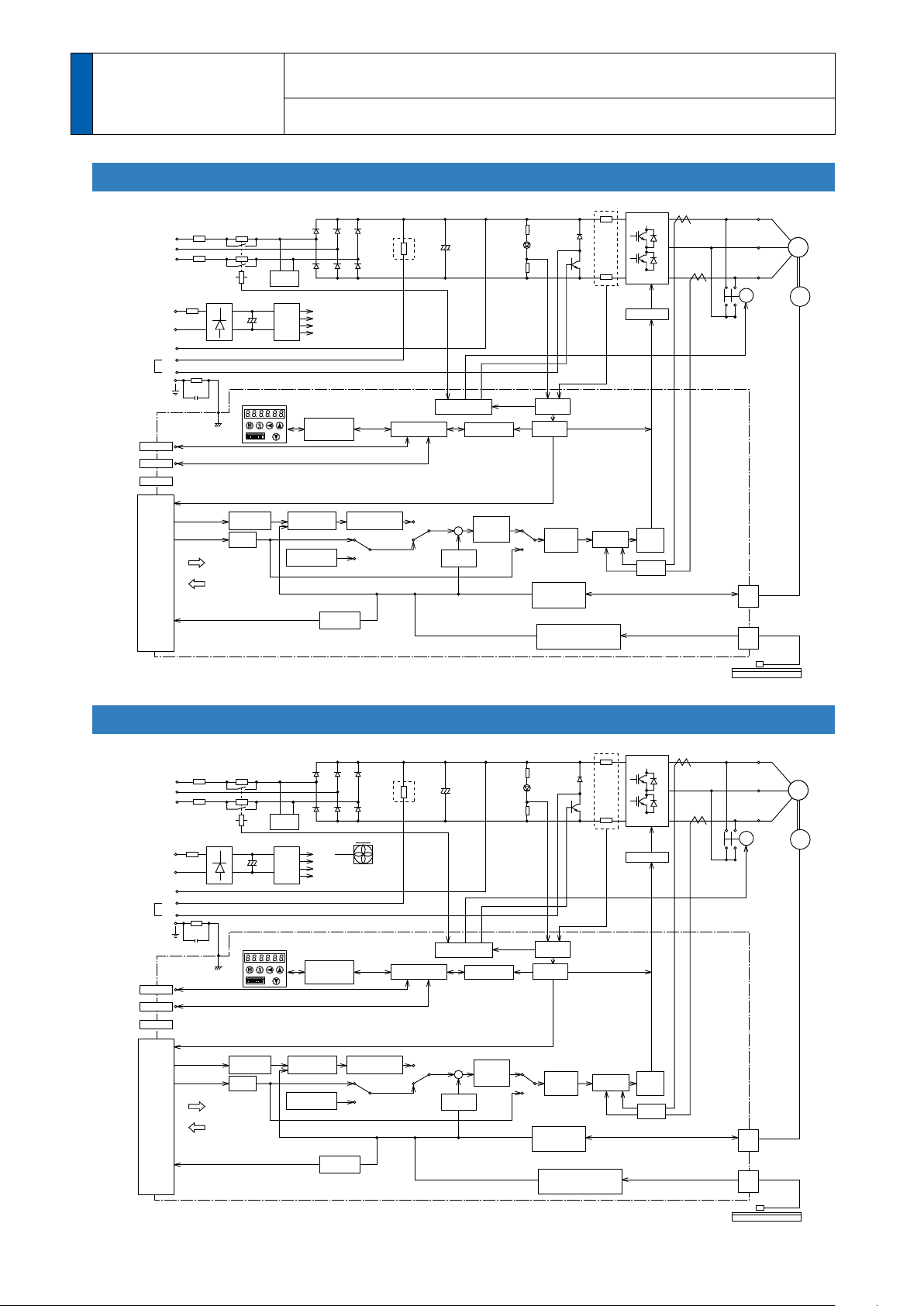

1 Before Using

2. Driver

the Products

A, B-frame

Block Diagram

C, D-frame

1-8

L 1

L 2

L 3

B1

B3

N

P

+

Fuse

抵抗

Fuse

Error

detection

Voltage

detection

Sequence control

B2

L1C

L2C

Division

processing

DC/DC

X6

U

V

W

M

RE

+

±12V

+5V

PS for gate drive

PS for RE

Fuse

Parameter control

EEPROM

Fan

Front panel

Display

operation

control

Protective

curcuit

Alarm

signal

Pulse train

command

Pusle

output

Analog

velocity

command

Control

input

Control

output

Division/

mulitiplication

+

+

–

–

A/D

A/D

16-bit

Position

Speed

Velocity

Torque

Internal

External

Deviation

counter

Internal speed

command

Speed

detection

Position

deviation amp.

Speed

deviation

amp.

Torque

limit

Current

control

PWM

circuit

Encoder signal

processing

limit

Gate drive

X5

Feedback scale signal

processing limit

Feedback scale unit

X1

X2

X4

USB

Serial

X3

Safety function

L 1

L 2

L 3

B1

B3

N

P

+

Fuse

抵抗

Fuse

Error

detection

Voltage

detection

Sequence control

B2

L1C

L2C

Division

processing

DC/DC

X6

U

V

W

M

RE

+

±12V

+5V

PS for gate drive

PS for RE

Fuse

Parameter control

EEPROM

Fan

Front panel

Display

operation

control

Protective

curcuit

Alarm

signal

Pulse train

command

Pusle

output

Analog

velocity

command

Control

input

Control

output

Division/

mulitiplication

+

+

–

–

A/D

A/D

16-bit

Position

Speed

Velocity

Torque

Internal

External

Deviation

counter

Internal speed

command

Speed

detection

Position

deviation amp.

Speed

deviation

amp.

Torque

limit

Current

control

PWM

circuit

Encoder signal

processing

limit

Gate drive

X5

Feedback scale signal

processing limit

Feedback scale unit

X1

X2

X4

USB

Serial

X3

Safety function

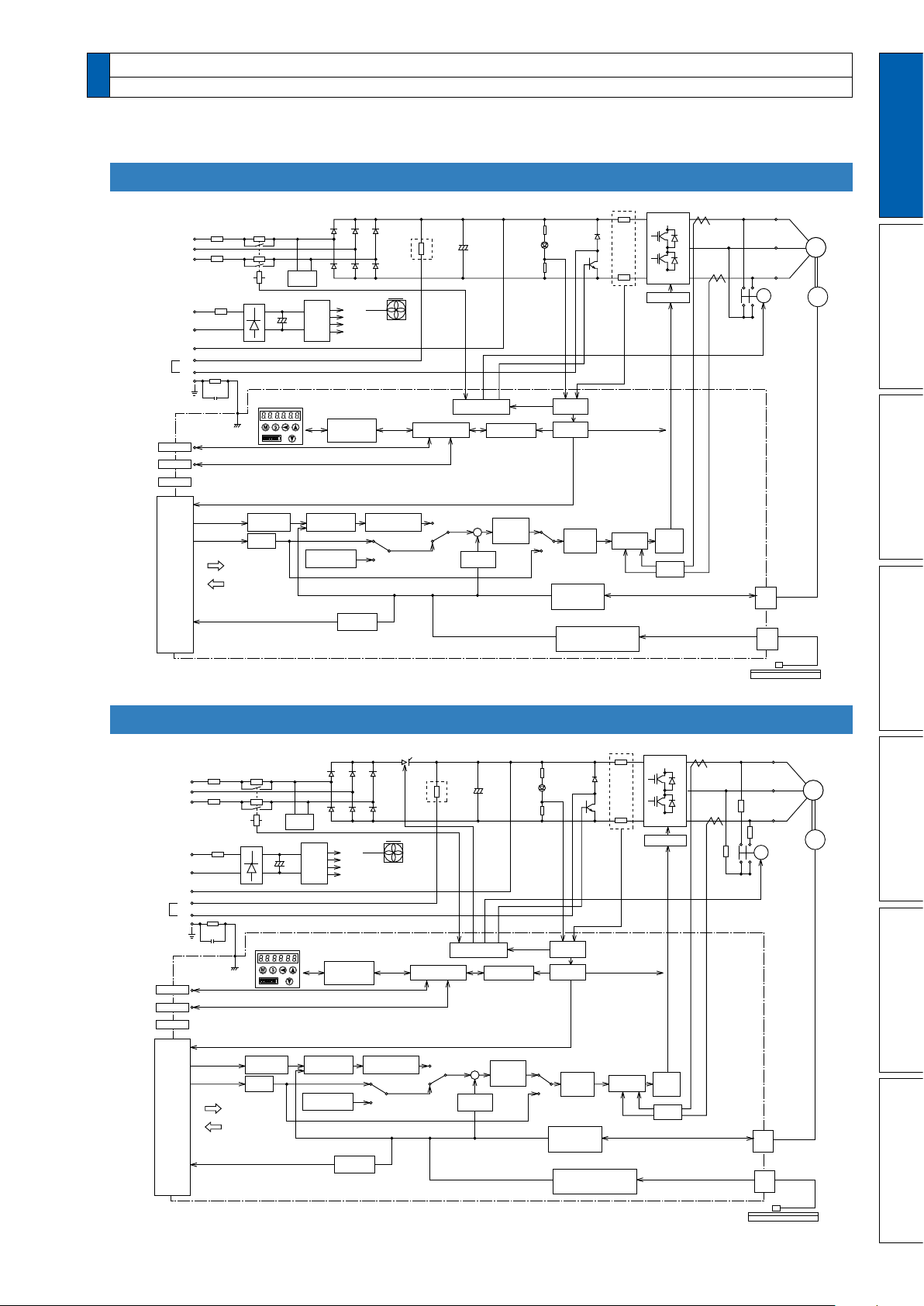

2. Driver

Block Diagram

E-frame

1

Before Using the Products

2

Preparation

3

Connection

F-frame

1-9

4

Setup

5

Adjustment

6

When in Trouble

7

Supplement

1 Before Using

Serial Number

e.g.) : 09 040001N

Lot number

Month of production

Year of production

(Lower 2 digits of AD year)

Manufacture date

e.g.) : 20090401

Manufacture dateManufacture year

Manufacture month

Model

Rated output

Rated input voltage/current

Rated frequency

Rated

rotational speed

3. Motor

the Products

Check of the Model

Contents of Name Plate

1-10

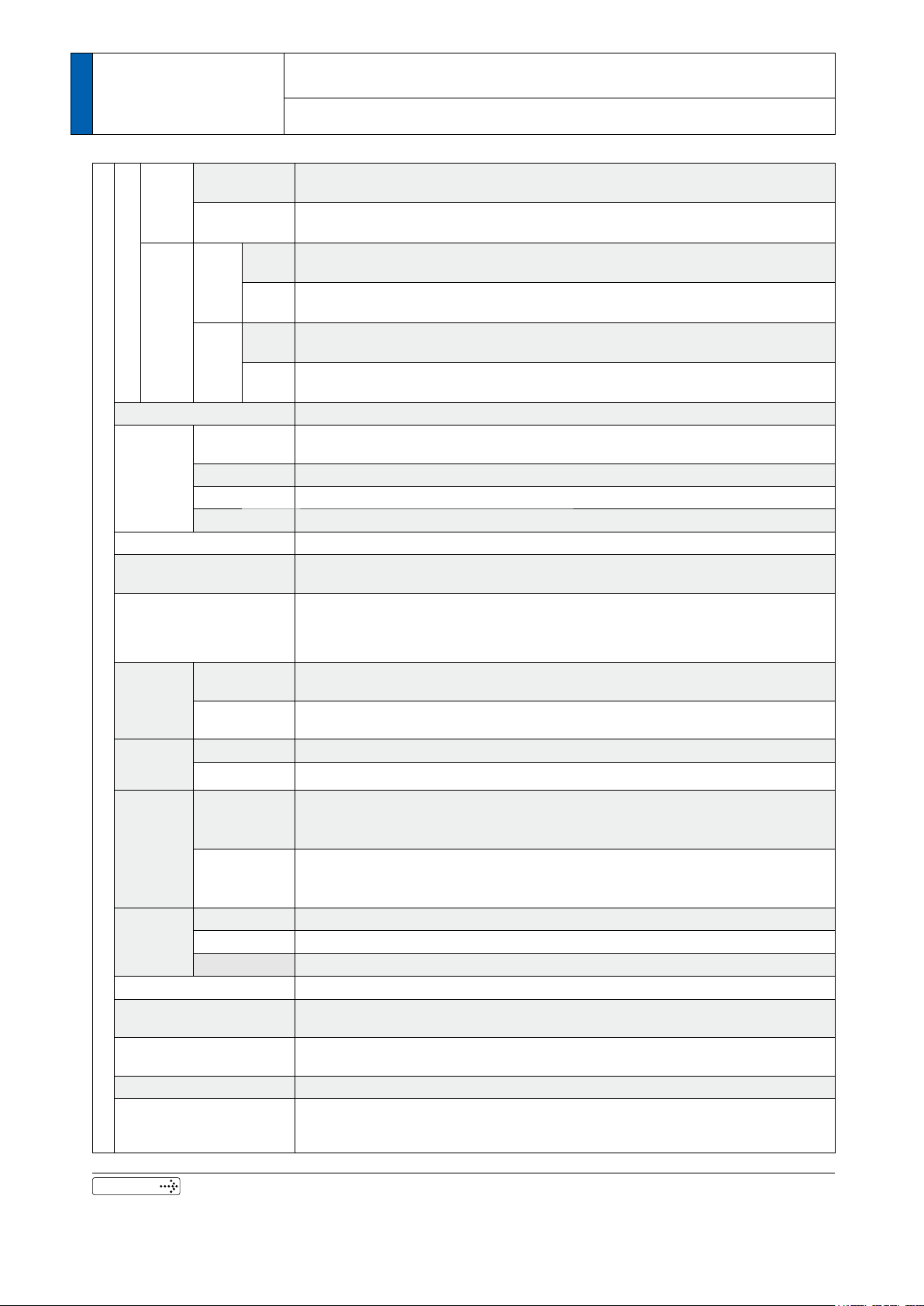

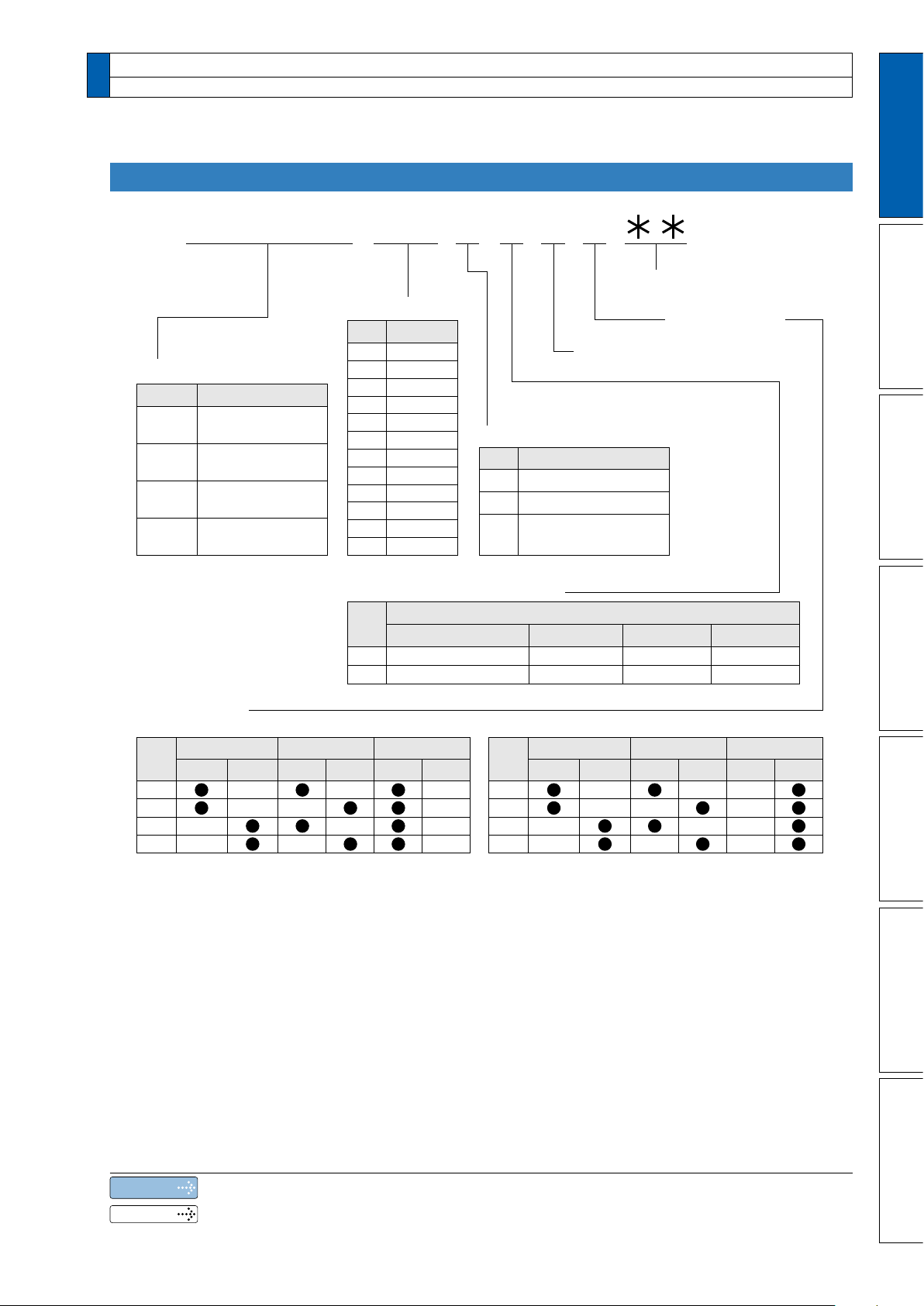

M S M E 5 A Z S 1 S

1 to 4

5 to 6

11 to 12

7

8 9 10

Special specifications

Motor structure

Design order 1: Standard

Rotary encoder specifications

Voltage specifications

Specifications

Type

Symbol

Low inertia

(50W to 5.0kW)

Middle inertia

(1.0kW to 5.0kW)

Middle inertia

(900W to 3.0kW)

High inertia

(1.0kW to 5.0kW)

G

S

Incremental

Absolute

Specifications

Symbol

Format

Pulse count

Output

Motor rated output

Symbol

Specifications

Symbol

Resolution

5-wire

7-wire

Wire count

Motor structure

MSME

(50W to 750W)

*1

The product with oil seal is a special order product.

*2 Key way with center tap

[

Products are standard stock items or manufactured by order. For details, inquire the dealer.]

A

B

S

T

Shaft

Holding brake

Oil seal

Without

With

Round

Key way

Without

With

Symbol

MSME

(1.0kW to 5.0kW)

, MDME, MGME, MHME

C

D

G

H

Shaft

Holding brake

Oil seal

Without

With

Round

Key way

Without

With

Symbol

*1

*2

*2

MSME

MDME

MGME

MHME

5A

01

02

04

08

09

10

15

20

30

40

50

50W

100W

200W

400W

750W

900W

1.0kW

1.5kW

2.0kW

3.0kW

4.0kW

5.0kW

1

2

Z

100 V

200 V

100/200 common

(50W only)

20bit

17bit

1,048,576

131,072

3. Motor

Check of the Model

Model Designation

1

Before Using the Products

2

Preparation

3

Connection

Note

Related page

For details of specic model, refer to the Dimensions of Supplement.

• P.1-14 “Check of the Combination of the Driver and the Motor”

• P.7-66 “Dimensions”

1-11

4

Setup

5

Adjustment

6

When in Trouble

7

Supplement

1 Before Using

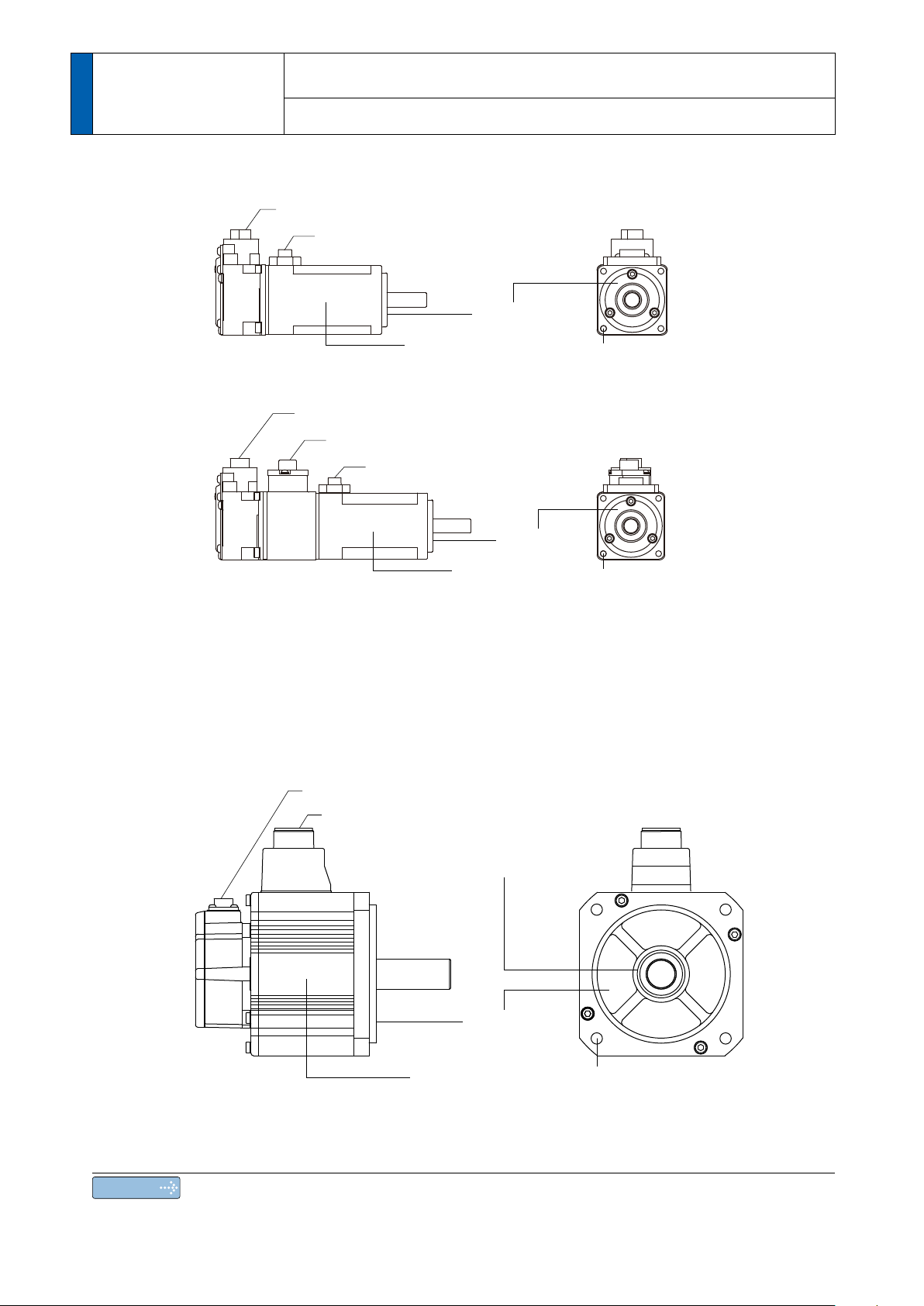

Motor frame

Flange

Connector for motor

Connector for encoder

Connector for motor

Connector for brake

Connector for encoder

[with Brake]

Motor frame

Flange

Mounting holes (X4)

Mounting holes (X4)

Connector for motor

Connector for encoder

Oil seal

Motor frame

Flange

Mounting holes (X4)

3. Motor

the Products

• MSME 50W to 750W

Parts Description

• MSME

• MDME

• MGMA 0.9kW to

• MHME

1.0kW to 5.0kW

1.0kW to 5.0kW

1.0kW to 5.0kW

3.0kW

e.g.) : Low inertia type (MSME series, 50W)

1-12

Note

e.g.) : Middle inertia type (MDME series, 1.0kW)

For details of specic model, refer to the Dimensions of Supplement. (P.7-66)

1 Before Using

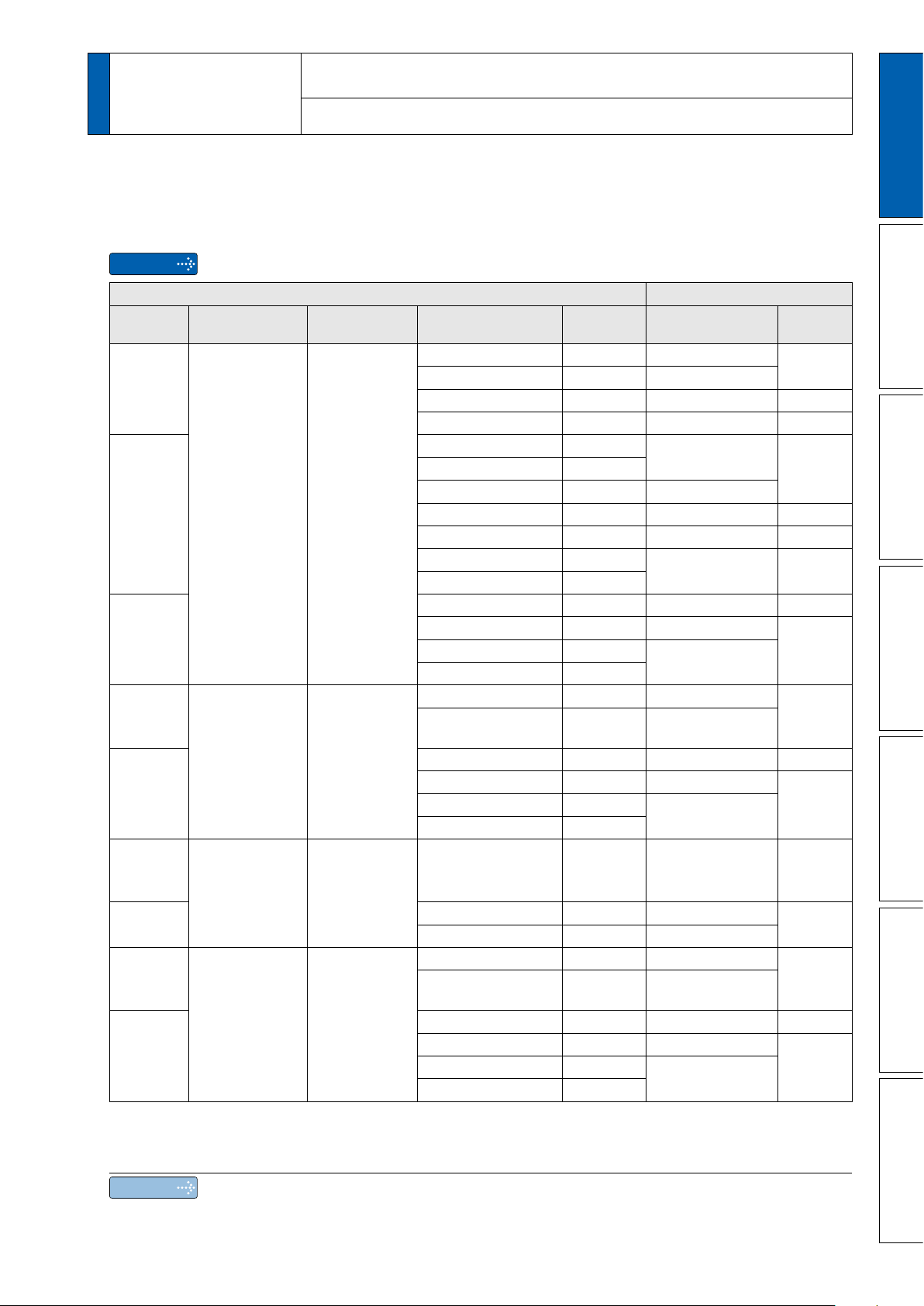

4.

Check of the Combination of the Driver and the Motor

1

Before Using the Products

the Products

This driver is designed to be used in a combination with the motor which are specied by

us. Check the series name of the motor, rated output torque, voltage specications and

encoder specications.

Remarks

Power

supply

Single

phase,

100V

Single/

-phase,

3

200V

-phase,

3

200V

Single/

-phase,

3

200V

3-phase,

200V

Single/

-phase,

3

200V

3-phase,

200V

Single/

-phase,

3

200V

3-phase,

200V

Do not use in other combinations than those listed below.

Type

MSME

Low inertia

MDME

Middle inertia

MGME

Middle inertia

MHME

High inertia

Incremental Specifications, 20-bit

Motor Driver

Rated rotational

speed

3

000r/min

2000r/min

1000r/min

2000r/min

Model

MSME5AZG1

MSME011G1

MSME021G1

MSME0

MSME5AZG1

MSME022G1

MSME0

MSME082G1

MSME102G1

MSME152G1

MSME202G1

MSME302G1

MSME502G1

MDME102G1

MDME152G1

MDME202G1

MDME302G1

MDME502G1

MGME092G1

MGME202G1

MGME

MHME102G1

MHME152G1

MHME202G1

MHME302G1

MHME502G1

41G1

42G1

402G1

402G1

302G1

402G1

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

Rated

output

50W MADHT1105

100W MADHT1107

200W MBDHT2110 B-frame

4

00W MCDHT3120 C-frame

50W

100W

200W MADHT1507

4

00W MBDHT2510 B-frame

750W MCDHT

1.0kW

1.5kW

2.0kW MEDHT7

3

.0kW MFDHTA390

4

.0kW

5.0kW

1.0kW MDDHT3530

1.5kW MDDHT55

2.0kW MEDHT7

3

.0kW MFDHTA390

4

.0kW

5.0kW

0.9kW MDDHT55

2.0kW MFDHT

3

.0kW MFDHTB3A2

1.0kW MDDHT3530

1.5kW MDDHT55

2.0kW MEDHT7

3

.0kW MFDHTA390

4

.0kW

5.0kW

MADHT1505

MDDHT55

MFDHTB3A2

MFDHTB3A2

MFDHTB3A2

Model Frame

A-frame

A-frameMSME012G1

3520 C-frame

40 D-frame

364 E-frame

F-frameMSME

40

364 E-frame

40 D-frame

A390

40

364 E-frame

D-frame

F-frameMDME

F-frame

D-frame

F-frameMHME

2

Preparation

3

Connection

4

Setup

5

Adjustment

6

When in Trouble

7

Note

Supplement

Sufx of " * " in the applicable motor model represents the motor structure.

1-13

1 Before Using

the Products

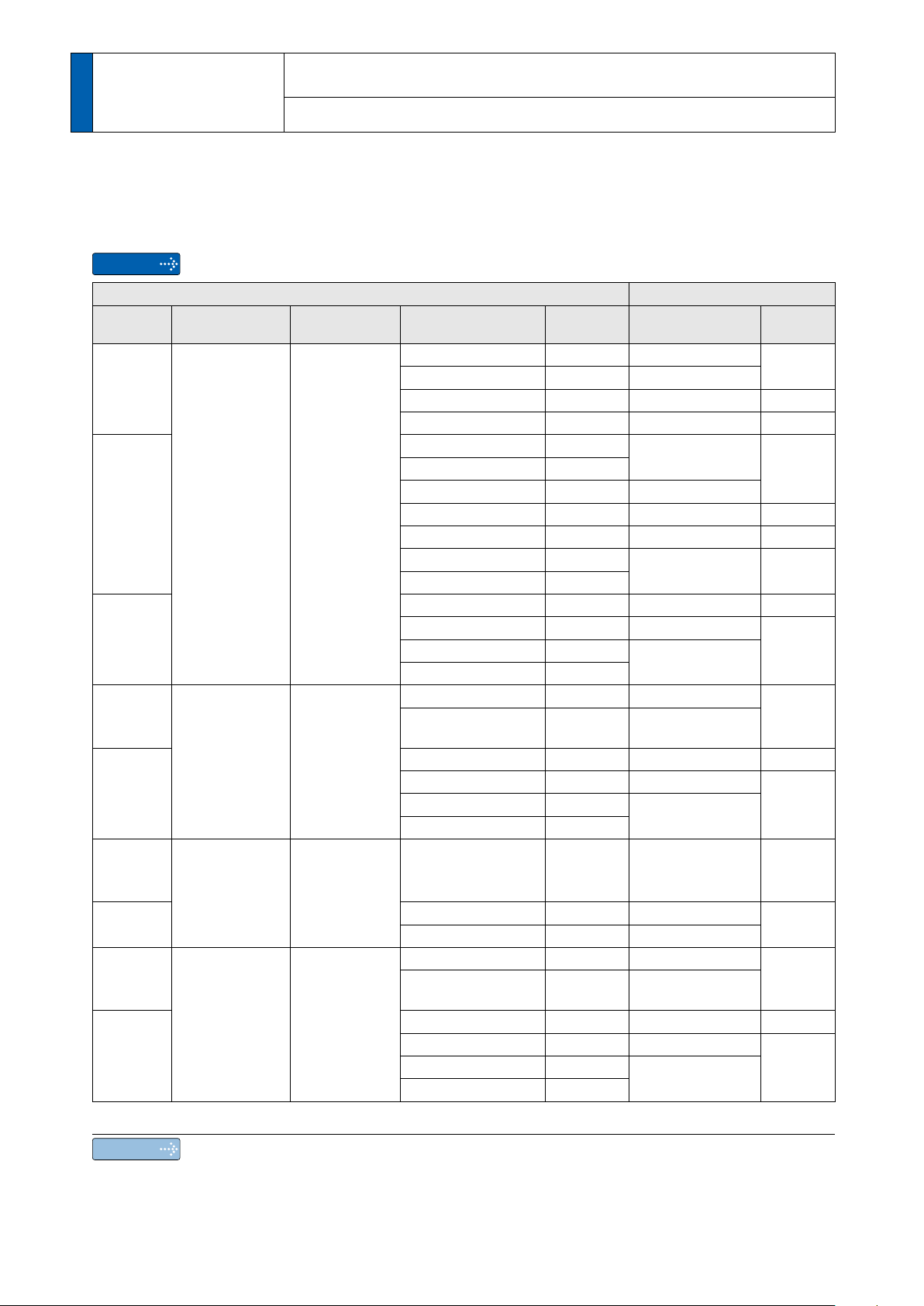

This driver is designed to be used in a combination with the motor which are specied by

us. Check the series name of the motor, rated output torque, voltage specications and

encoder specications.

4.

Check of the Combination of the Driver and the Motor

Absolute Specifications, 17-bit

Remarks

Power

supply

Single

phase,

100V

Single/

-phase,

3

200V

-phase,

3

200V

Single/

-phase,

3

200V

3-phase,

200V

Single/

-phase,

3

200V

3-phase,

200V

Single/

-phase,

3

200V

3-phase,

200V

Do not use in other combinations than those listed below.

Motor Driver

Type

MSME

Low inertia

MDME

Middle inertia

MGME

Middle inertia

MHME

High inertia

Rated rotational

speed

3

000r/min

2000r/min

1000r/min

2000r/min

Model

MSME5AZS1

MSME011S1

MSME021S1

MSME0

MSME5AZS1

MSME022S1

MSME0

MSME082S1

MSME102S1

MSME152S1

MSME202S1

MSME302S1

MSME502S1

MDME102S1

MDME152S1

MDME202S1

MDME302S1

MDME502S1

MGME092S1

MGME202S1

MGME

MHME102S1

MHME152S1

MHME202S1

MHME302S1

MHME502S1

41S1

42S1

402S1

402S1

302S1

402S1

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

Rated

output

50W MADHT1105

100W MADHT1107

200W MBDHT2110 B-frame

4

00W MCDHT3120 C-frame

50W

100W

200W MADHT1507

4

00W MBDHT2510 B-frame

750W MCDHT

1.0kW

1.5kW

2.0kW MEDHT7

3

.0kW MFDHTA390

4

.0kW

5.0kW

1.0kW MDDHT3530

1.5kW MDDHT55

2.0kW MEDHT7

3

.0kW MFDHTA390

4

.0kW

5.0kW

0.9kW MDDHT55

2.0kW MFDHT

3

.0kW MFDHTB3A2

1.0kW MDDHT3530

1.5kW MDDHT55

2.0kW MEDHT7

3

.0kW MFDHTA390

4

.0kW

5.0kW

Model Frame

MADHT1505

3520 C-frame

MDDHT55

MFDHTB3A2

MFDHTB3A2

MFDHTB3A2

40 D-frame

364 E-frame

40

364 E-frame

40 D-frame

A390

40

364 E-frame

A-frame

A-frameMSME012S1

F-frameMSME

D-frame

F-frameMDME

F-frame

D-frame

F-frameMHME

1-14

Note

1) Sufx of " * " in the applicable motor model represents the motor structure.

2) Default of the driver is set for the incremental encoder specications.

When you use in absolute, make the following operations.

a) Install a battery for absolute encoder.

b)

Switch the parameter Pr0.15 (Absolute encoder setup) from "1 (default)" to "0".

1 Before Using

4.

Check of the Combination of the Driver and the Motor

1

Before Using the Products

the Products

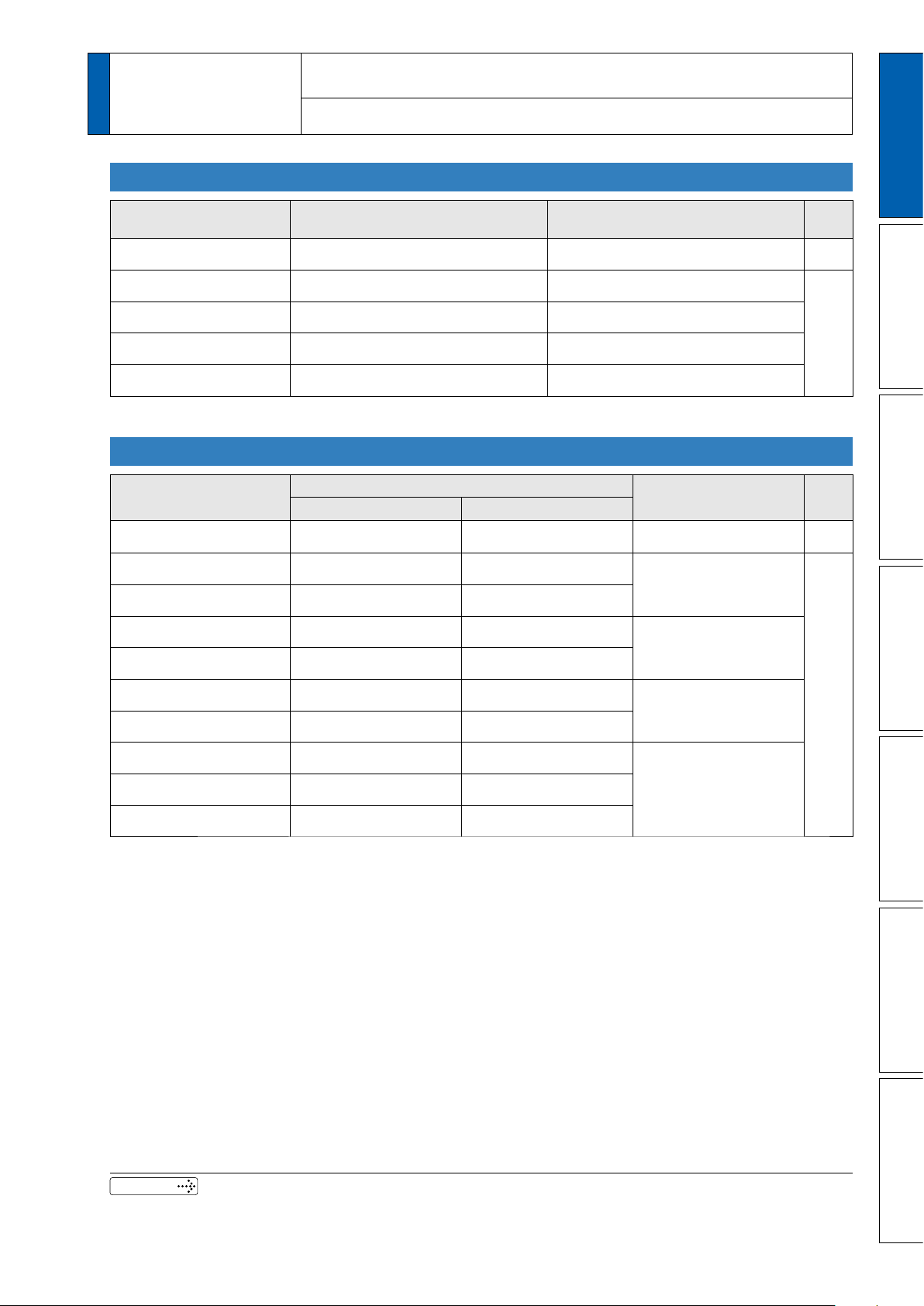

Junction cable for motor

Encoder cable

Motor series Incremental Specications, 20-bit

MSME 50W to 750W MFECA0**0MJD MFECA0**0MJE

MSME 1.0kW to 5.0kW MFECA0**0ETD MFECA0**0ETE

MDME 1.0kW to 5.0kW MFECA0**0ETD MFECA0**0ETE

MGME 0.9kW to 3.0kW MFECA0**0ETD MFECA0**0ETE

MHME 1.0kW to 5.0kW MFECA0**0ETD MFECA0**0ETE

Note)1 “

** ”

represents the cable length.

Note)1

Absolute Specifications, 17-bit

Motor cable/ Brake cable

Motor series

MSME 50W to 750W MFMCA0**0NJD — MFMCB0**0PJT

MSME 1.0kW to 2.0kW MFMCD0**2ECD MFMCA0**2FCD

MSME 3.0kW to 5.0kW MFMCA0**3

Motor cable

ECT MFMCA0**3FCT

Note)1

with Brake

Brake cable

—

Note)1

Note)1

Detail

page

7-76

7-77

Detail

page

7-78

7-82

2

Preparation

3

Connection

4

MDME 1.0kW to 2.0kW MFMCD0**2ECD MFMCA0**2FCD

MDME

MGME 0.9kW MFMCD0**2ECD MFMCA0**2FCD

MGME 2.0kW to

MHME 1.0kW to 1.5kW MFMCD0**2ECD MFMCA0**2FCD

MHME 3.0kW to 5.0kW

Note)1 “

3.0kW to 5.0kW MFMCA0**3

3.0kW MFMCA0**3

MFMCA0**3

** ”

represents the cable length.

ECT MFMCA0**3FCT

ECT MFMCA0**3FCT

ECD MFMCE0**3FCD

ECT MFMCA0**3FCT

—

—

—MHME 2.0kW MFMCE0**3

7-78

…

7-81

Setup

5

Adjustment

6

When in Trouble

Related page

• For other cable, connector and connector kit, refer to P.7-72 “Options”

1-15

7

Supplement

1 Before Using

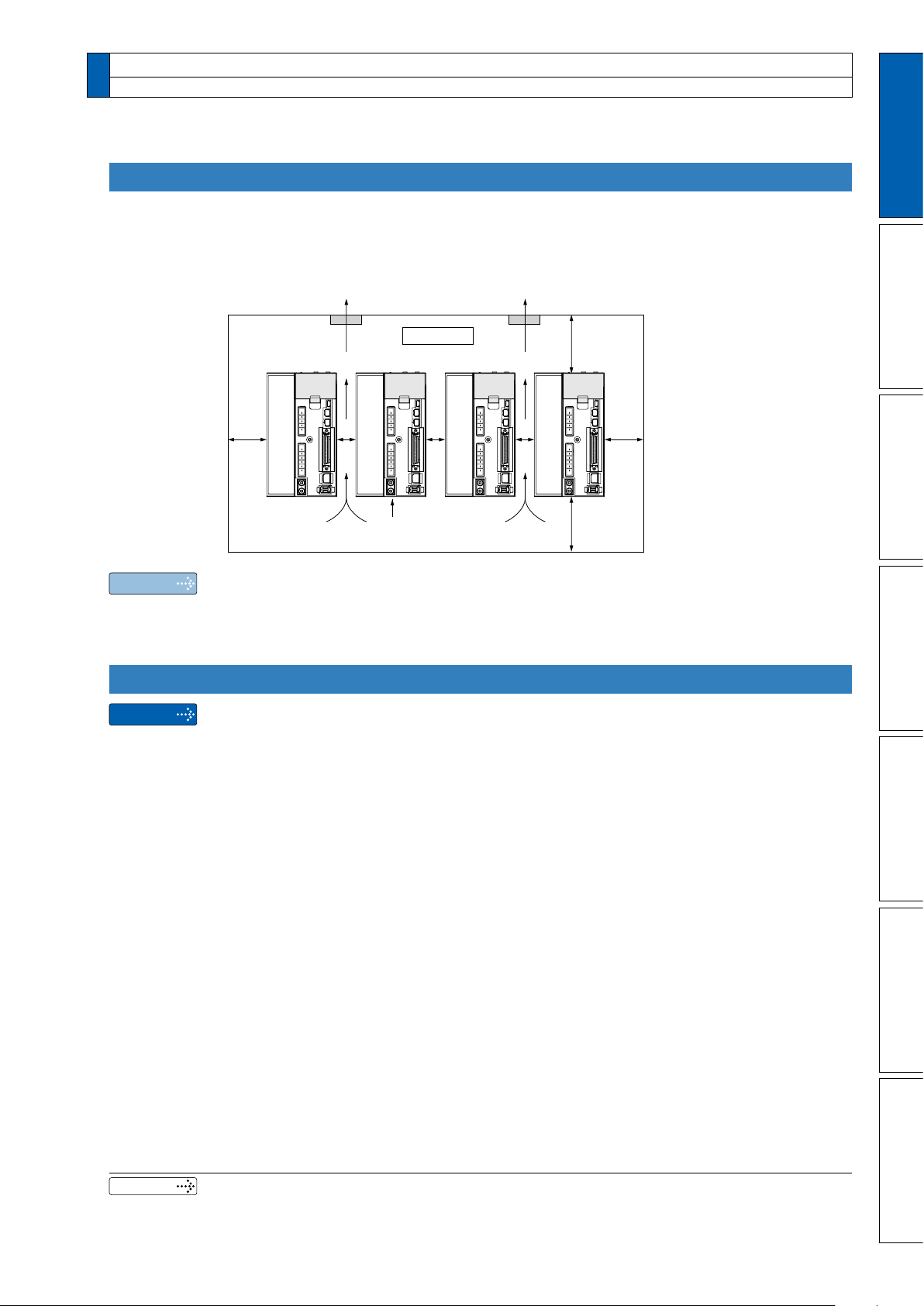

A to D-frame E, F-frame

Basemount (Standard)

[Rear mount]

Frontmount

[Use mounting fixture]

Front or Basemount

[Use mounting fixture]

Mounting fixture

(optional parts)

Mounting fixture

(Attachment)

Fastening torque of earth screws (M4)

to be 0.7 to 0.8 N

•

m.

Fastening torque of earth screws (M5)

to be 1.4 to 1.6 N•m.

5. Installation

the Products

Driver

Install the driver properly to avoid a breakdown or an accident.

Installation Place

1) Install the driver in a control panel enclosed in noncombustible material and placed indoor where the product is not subjected to rain or direct sunlight. The products are not

waterproof.

Where the products are not subjected to corrosive atmospheres such as hydrogen sul-

2)

de, sulfurous acid, chlorine, ammonia, sulfur, chloric gas, sulfuric gas, acid, alkaline

and salt and so on, and are free from splash of inammable gas.

) Where the motor is free from grinding oil, oil mist, iron powder or chips.

3

4) Well-ventilated and low humidity and dust-free place.

5) Vibration-free place.

Do not use benzine, thinner, alcohol, acidic cleaner and alkaline cleaner because they can

6)

discolor or damage the exterior case.

Environmental Conditions

Item Conditions

Ambient temperature 0˚C to 55˚C (free from freezing)

Ambient humidity 20% to 85% RH (free from condensation)

*

Storage temperature

Storage humidity 20% to 85% RH (free from condensation)

Vibration Lower than 5.88m/s

Altitude Lower than 1000m

1

–20˚C to 65˚C (Max.temperature guarantee: 80˚C for 72 hours)

2

(0.6G), 10 to 60Hz

*

Extreme temperatures are permissible only for short period such as during transportation.

1

How to Install

1) Rack-mount type. Install in vertical position, and reserve enough space around the

servo driver for ventilation.

2) Base mount (rear mount) is standard for A/B/C/D-frame driver.

) To change the mounting surface of A/B/C/D-frame driver, use the optional mounting

3

xture. For choosing the correct optional mounting xture, refer to P.7-90 “Mounting

Bracket”.

1-16

Fan Fan

100mm

or more

100mm

or more

40mm

or

more

40mm

or

more

10

mm

or

more

10

mm

or

more

10

mm

or

more

Direction of air flowing

from the internal

cooling fan (D/E/F frame)

Control panel

5. Installation

Driver

Mounting Direction and Spacing

• Reserve enough surrounding space for effective cooling.

• Install fans to provide uniform distribution of temperature in the control panel.

• D/E/F frame is provided with a cooling fan at the bottom.

Observe the environmental conditions of the control panel described in the previous page.

•

1

Before Using the Products

2

Preparation

3

Connection

Note

It is recommended to use the conductive paint when you make your own mounting xture, or repaint after peeling off the paint on the machine for installing the products, in

order to make noise countermeasure.

Caution on Installation

•

Caution

We have been making the best effort to ensure the highest quality, however, application of

exceptionally large external noise disturbance and static electricity, or failure in input power, wiring and components may result in unexpected action. It is highly recommended that

you make a fail-safe design and secure the safety in the operative range.

•

If stranded wires are used as the cable, bunch the conductors of the cable using a rod terminals or a round terminals. If stranded wires are used as they are, unexpected accidents such

as an electric shock and short circuit or injury may result.

• There might be a chance of smoke generation due to the failure of these products. Pay

an extra attention when you apply these products in a clean room environment.

Be sure to ground the protective earth terminal.

•

If the product is grounded insufciently, not only the driver may not deliver its perfor

mance sufciently, but also safety hazards such as a malfunction due to a electrication

or a disturbance may be caused.

If electric wires are bound and run through metal duct, they cannot carry the rated cur-

•

rent due to temperature rise. If they are forced to carry the rated current, they may burn.

When determining size of the wire.

4

Setup

5

Adjustment

6

-

When in Trouble

7

Related page

• P.1-6 “Specications” • P.1-20 “Installation of motor”

• P.7-63 “Dimensions” • P.7-90 “Mounting xture”

Supplement

1-17

27

37

49

61

88

115

139

2 to 3.5 (excl.)

3.5 to 5.5 (excl.)

5.5 to 8 (excl.)

8 to 14 (excl.)

14 to 22 (excl.)

11 to 30 (excl.)

30 to 38 (excl.)

Stranded

conductor

(nominal cross section: mm2)

Copper

wire

(unit: A)

•

Fundamental permissible current

5. Installation

Driver

Recommended Electric Wires for Driver

• For the main circuit, use electric wire that withstands at least 600 VAC with tempera-

ture rating 75℃ or higher.

When using bundled wires running through metallic conduit, the amounts of current

•

determined according to the reduction rate must be subtracted from the nominal allowable current.

Electric wires

•

<In high ambient temperature>

Use heat resistant wire.

Common polyvinyl chloride wires will deteriorate by heat at a higher rate.

<In low ambient temperature>

The surface of vinyl chloride insulation becomes hardened and brittle at low tempera-

ture and needs specic protective measure when used in cold region.

• Bend radius of the cable must be 10 times or more its nish outside diameter.

• Cables cannot be used for continuous regeneration because they are not designed for

such application.

Relationship between Wire Diameter and Permissible Current

• When selecting a cable, refer to the following selection guide showing relationship be-

tween cable specication and current carrying capacity.

Example: Power supply 3-phase, 200 V, 35 A, ambient temperature 30°C

Determine the fundamental permissible current according

to the cable conductor material (example: stranded copper wire).

(For the purpose of this example, the ampere indicated by

Next, determine the number of conductors.

(

ground).)

Determine the applicable permissible current using the

following formula.

Applicable permissible current

=

= 37 x 0.7 x 1.414

.=.

This permissible value is larger than 35 A to be carried though the cable. Therefore,

according to the list of recommended eco-cables, the cable to be selected for the cable

with

1-18

ductor power cable having 13.5 mm nish O.D. (approx. 14.5 mm with shield).

is selected from the table right.)

In this example, the cable contains 4 conductors (3 +

fundamental permissible current x current reduction coefcient x current correction coefcient

36.6 (A)

2

nominal cross section 3.5 mm

is a polyethylene-insulated heat-resistant 4-con-

Loading...

Loading...