Page 1

YOUR PROCESS...

...OUR CARE

PACKAGING SYSTEMS

Page 2

PACKAGING SYSTEMS

Dinnissen offers you one-stop-shopping,

in bulk solids applications

Dinnissen Proces s Tech n o l o g y

Dinnissen is a special i s t in the w o rld o f

bulk m a t e r i als an d process technolog y.

Wi th over 115 permanent empl o y e e s

and an e x t e n s i v e network o f agents, we

operate w o r l d-wide i n the most d i v e rse

industries. We look for in n o v ations

and marke t developments t h a t have a

demonstrable benefit for our cus t o m e r s

and help us develop new products.

Improved ergono m i c s , e fficiency and

hygiene are of paramount imp o r t a n c e i n

this. Our proces s k n o w - how, in-hou s e

manufacturing, systems in t e g r ation,

custom-made products, wide ra n g e

of specially de v e l oped machines an d

excellent s e r v i c e ultimately m a k e us

what we a r e. D i nnissen – t he s p ecialist

in process techn o l o g y !

Pa ckagin g

Details make the dif fer e n c e

Due to the arrival of advanced packaging, fi lling

possibilities have increased tremendously. Dinnissen

can help you package your goods effi ciently,

hygienically and safely so that an optimal logistical

solution is reached - as part of a total process or as

a project in itself. Whether you are fi lling one Big Bag

per week or 50 every hour. And in particularly if your

food, feed, chemical or pharmaceutical requirements

are more specifi c - Dinnissen is the company for

you.

Fast and accurate feeding

Do you want to feed large amounts quickly from a

weighing silo or direct using feeding elements, a

feeding valve, a screw or chain conveyor, vibratory

feeder or rotary valve? We can provide you with the

most effi cient solution for your application.

Dust emission and the prevention of product loss

Of course, it is essential to minimise dust emission

and product loss during the packaging process.

The solutions we apply here are among others a

sophisticated extraction system, the correct design of

the fi lling head or the sealing of Big Bags.

Inert packaging

We can help you package sensitive,

hygroscopic, toxic and other critical products

under special gas conditions (e.g. CO2 and

N2). Specially ventilated or conditioned areas

with fast-closing doors are included in our

range.

Reliable volume and weight measurement

We offer a range of solutions for the optimal

determination of the correct contents of

your Big-Bag - weighing systems, high-level

detectors and level sensors.

Effi cient operation and hygiene

Speed and effi cient operation are important

factors in ensuring your production process

is as effi cient as possible. For this reason we

pay a great deal of attention to ergonomics.

Aspects such as arranging operating elements

on one level, the accessibility of hooks,

swivelling fi ller heads and twister heads are

given due attention.

Page 3

WEIGHING

HOPPER

ATMOSPHERIC / INERT PACKAGING

FEEDING PRODUCT

VACUUM SYSTEM

AIR EXHAUST

PI

N2T

HL

PT

N2

N2

PACKAGING SYSTEMS

Commitment is the foundation for

reliable and lasting relationships

Automatic sealing

Due to the automatic and hygienic sealing

of packages, we prevent dust emission or

contamination. Ideal solutions, moreover, to

protect the operator from substances that may

be hazardous.

Quality and safety

Finally we can also offer you automatic coding

and sampling of Big Bags for tracking and

tracing, metal detection and the integration

of control sieving. Of course, we fulfi l all Atex,

HACCP and GMP guidelines. Hygiene, food

safety, dust and the danger of gas explosion

are familiar issues for us.

Calibration approval throughout the world

If calibration approval is important for your

company, we will take care of this for you.

We can supply the required technology and

equipment and have good contacts with

calibration organisations throughout the world

so that procedures do not need to cost you

unnecessary time and money.

Testing facilities

With our own D-innocentre®, we have a testing

facility that offers ample possibilities for developing

new products or testing your products with our

equipment.

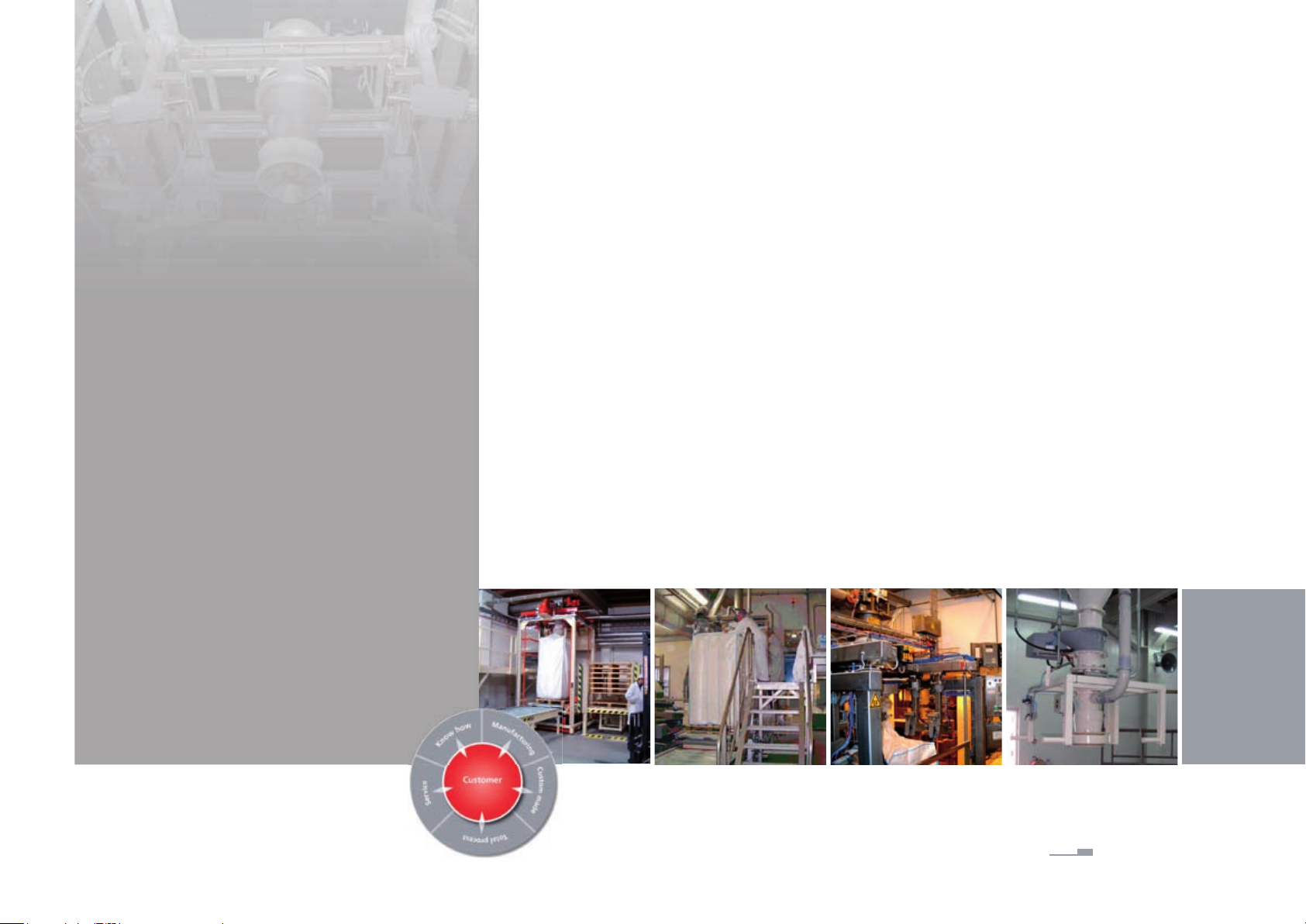

Filling Big Bags / FIBCs

Dinnissen specialises in the fi lling of Big Bags

and FIBCs in situations that are that little bit more

complex. We offer good solutions for the preforming

of Big Bags, for example, so that each corner is fi lled

perfectly. We blow in air or functional gas even before

starting fi lling. Weighing during fi lling and vibrating to

achieve a solid base at the same time for a quick and

reliable result that retains its shape.

Feeding, stacking and transport

We can also take care of the automatic output of

Big Bags, pallets and packaging material via special

dispensers. Just like the transport and stacking of Big

Bags in sea containers or trucks - this reduces work

costs and results in a stable upright load.

Octabins, drums and containers

Factors that are relevant to other packaging are also

applied by us to octabins, drums and containers

as this is our particular speciality. We can offer you

standard, special or completely tailor-made solutions

if necessary.

Page 4

YOUR PROCESS...

...OUR CARE

PRODUCT INTAKE

CONVEYING & HANDLING

FEEDING & WEIGHING

MIXING & PROCESSING

MILLING & GRINDING

SIFTING

PACKAGING

PET FOOD

AQUA F EED

Dinnissen BV

Horsterweg 66

5975 NB Sevenum, Holland

Tel.: +31 (0)77 467 35 55

Fax: +31 (0)77 467 37 85

E-mail: powtech@dinnissen.nl

FEED

FOOD

LIFE S C IENCE

PHARMA C EUTICA L

CHEMIC A L

RECYCL I NG

MINERA L S

DETERG E NTS

PLASTI C S

www.dinnissen.nl

Loading...

Loading...