Panasonic LP-GS052, LP-GS051, LP-GS051-F, LP-GS051-L, LP-GS051-LF Serial Communication Command Manual

...

Laser Marker

Serial Communication

Command Guide

LP-400/V compatible mode

LP-GS series

LP-RC series

LP-RF series

LP-RV series

ME-LP-GS-SR-COMP-3

2019. 4

panasonic.net/id/pidsx/global

Preface

ME-LP-GS-SR-COMP-3

Thank you for purchasing our product.

For full use of this product safely and properly, please read this document carefully.

This product has been strictly checked and tested prior to its delivery. However, please make sure that this product

operates properly before using it. In case that the product becomes damaged or does not operate as specified in this

document, contact the dealer you purchased from or our sales office.

General terms and conditions of this document

⿎

1. Before using this product, or before every starting operation, please confirm the correct functioning and performance

of this product.

2. Contents of this document could be changed without notice.

3. This document must not be partially or totally copied or revised.

4. All efforts have been made to ensure the accuracy of all information in this document. If there are any questions,

mistakes, or comments in this document, please notify us.

5. Please remind that we assume no liability for any results arising out of operations regardless of the above clauses.

Disclaimer

⿎

The applications described in this document are all intended for examples only. The purchase of our products described in

this document shall not be regarded as granting of a license to use our products in the described applications. We do NOT

warrant that we have obtained some intellectual properties, such as patent rights, with respect to such applications, or that

the described application may not infringe any intellectual property rights, such as patent rights, of a third party.

Trademark

⿎

• Windows is a registered trademark or trademark of Microsoft Corporation in the United States and/or other countries.

• QR Code is a registered trademarks of DENSO WAVE INCORPORATED.

• Adobe, Adobe Logo, Adobe Reader, and Adobe Illustrator are either registered trademarks or trademarks of Adobe

Systems Incorporated in the United States and/or other countries.

• Bluetooth is a registered trademark of U.S.A. Bluetooth SIG Inc.

• All other product names and companies provided in this document are trademarks or registered trademarks of their

respective companies.

2

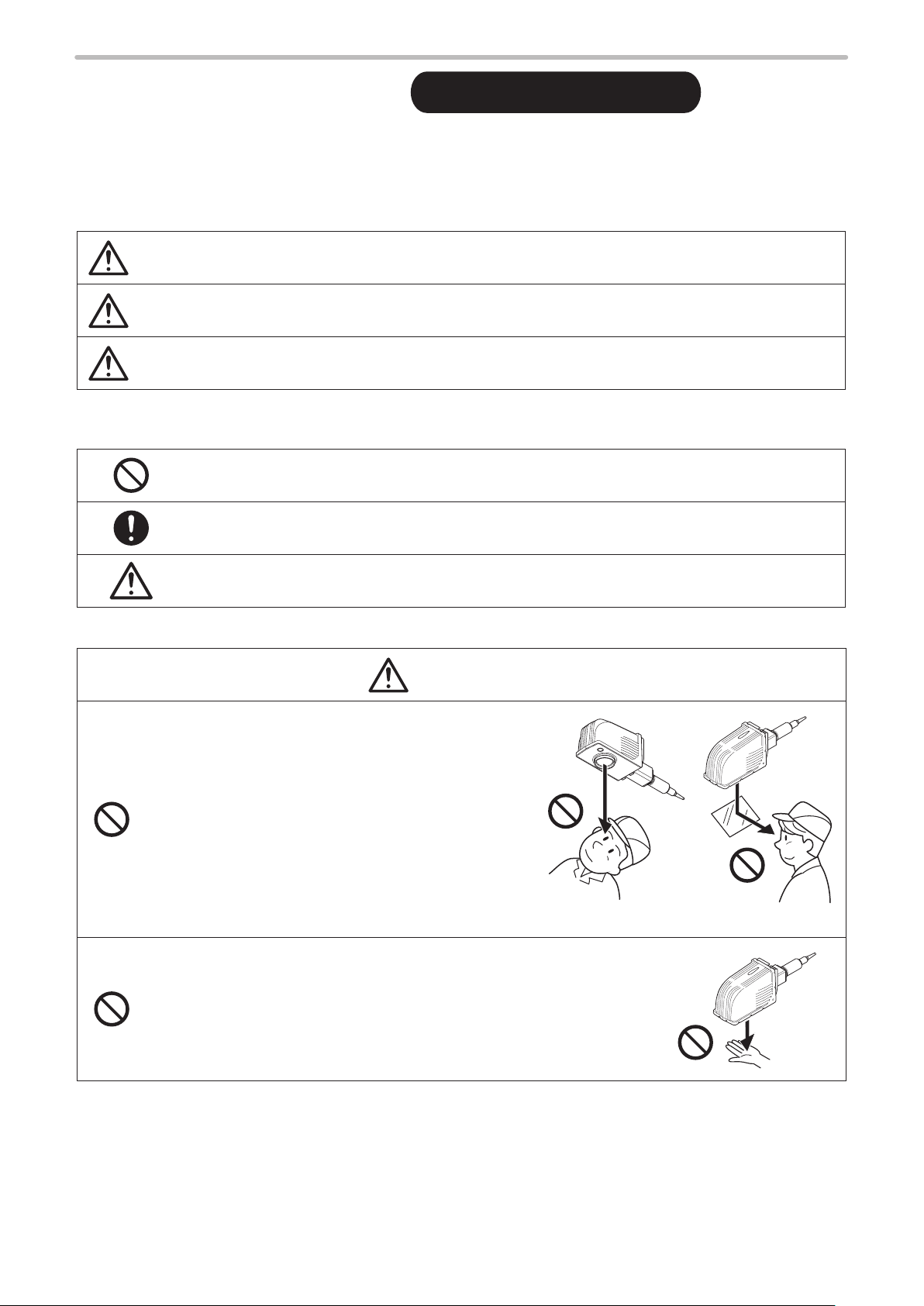

DANGER

WARNING

CAUTION

DANGER

ALWAYS FOLLOW THESE IMPORTANT

ME-LP-GS-SR-COMP-3

Cautions in Handling

To reduce the risk of injury, loss of life, electric shock, fire, malfunction, and damage to equipment or property, always

observe the following safety precautions.

The following symbols are used to classify and describe the level of hazard, injury, and property damage caused when the

denotation is disregarded and improper use is performed.

Denotes a potential hazard that will result in serious injury or death.

Denotes a potential hazard that could result in serious injury or death.

Denotes a hazard that could result in minor injury.

The following symbols are used to classify and describe the type of instructions to be observed.

This symbol is used to alert users to a specific operating procedure that must not be performed.

This symbols is used to alert users to a specific operating procedure that must be followed in order to

operate the unit safely.

SAFETY PRECAUTIONS!

This symbols is used to alert users to a specific operating procedure that must be performed carefully.

• Never look at laser beam directly, through lens or

through any other optical components. Laser beam

radiation into the eye causes blindness or serious

damage to the eye.

Not only the direct beam of laser, but also diffused

reflected beam is harmful.

• Never touch laser beam and avoid human skin, clothing and any other

flammable object from laser beam exposure directly.

Burning into deep skin might result and there is a risk of fire.

3

WARNING

• Do not use this product anywhere where fire is strictly prohibited, near inflammable gas, objects or organic

ME-LP-GS-SR-COMP-3

solvents such as thinner or gasoline, or in dusty place. There is a risk of fire.

• Do not use this product except for water-resistant part in wet place. In addition, never conduct wiring or

maintenance work with wet hands or when the product surface is wet. Otherwise, electric shock and/or

malfunction may result.

• Never disassemble the product.

Doing so may cause exposure to the laser beam or electric shock.

• Do not insert hands or objects between the gaps of the exhaust port or intake port. There is a risk of

electrical shock or injury.

• Take laser protection measures required to use Class 4 laser products subject to the local laws and

regulations of the country or region in which this laser product is used.

• To protect the operators' eyes, make it mandatory to wear goggles against laser beam

within the laser controlled area. The protective goggles can momentarily protect the

eyes against the scattered beam. Never look at the direct beam or reflected beam

even when you are wearing the protective goggles.

• Set protective enclosure with proper reflectance, durability and thermal resistance to enclose the laser

radiation area without leakage.

• Construct an interlock systems such as a function to stop laser radiation for the maintenance door of the

protective enclosure.

• After power supply of laser marker is turned off, laser safety manager must remove the key and keep it.

• Be sure to connect the head and controller (for LP-RV series, the head, controller and oscillator unit) of the

laser marker which have the same model number. Otherwise there is a risk of exposure to laser radiation

or failure.

• Read all packaged guides and manuals thoroughly, and do not operate, install and connect the laser

marker with any other methods except the instructions provided in the manuals. If the product is used in a

manner not specified by the instruction, the safety protection and functions provided by the device may be

impaired and may cause injury, electrical shock or exposure of laser beam.

• Prior to wiring, cable connecting, and/or maintenance work, ensure that all the power switches are turned

off. Otherwise, electrical shock may result.

• The wiring and maintenance must be conducted by the electrical engineers or under their supervision.

Incorrect work may cause electrical shock.

• Connect ground wire before using. A failure or electrical leakage that occurs when the unit is not properly

grounded may result in electric shock.

• For LP-RF/LP-RV series, be careful neither to give strong power to the fiber cable nor to nip it for

installation. Do not install the product to the systems that give excessive load acts on the fiber cable, such

as head movement unit. If the fiber cable is damaged, it may cause laser exposures.

4

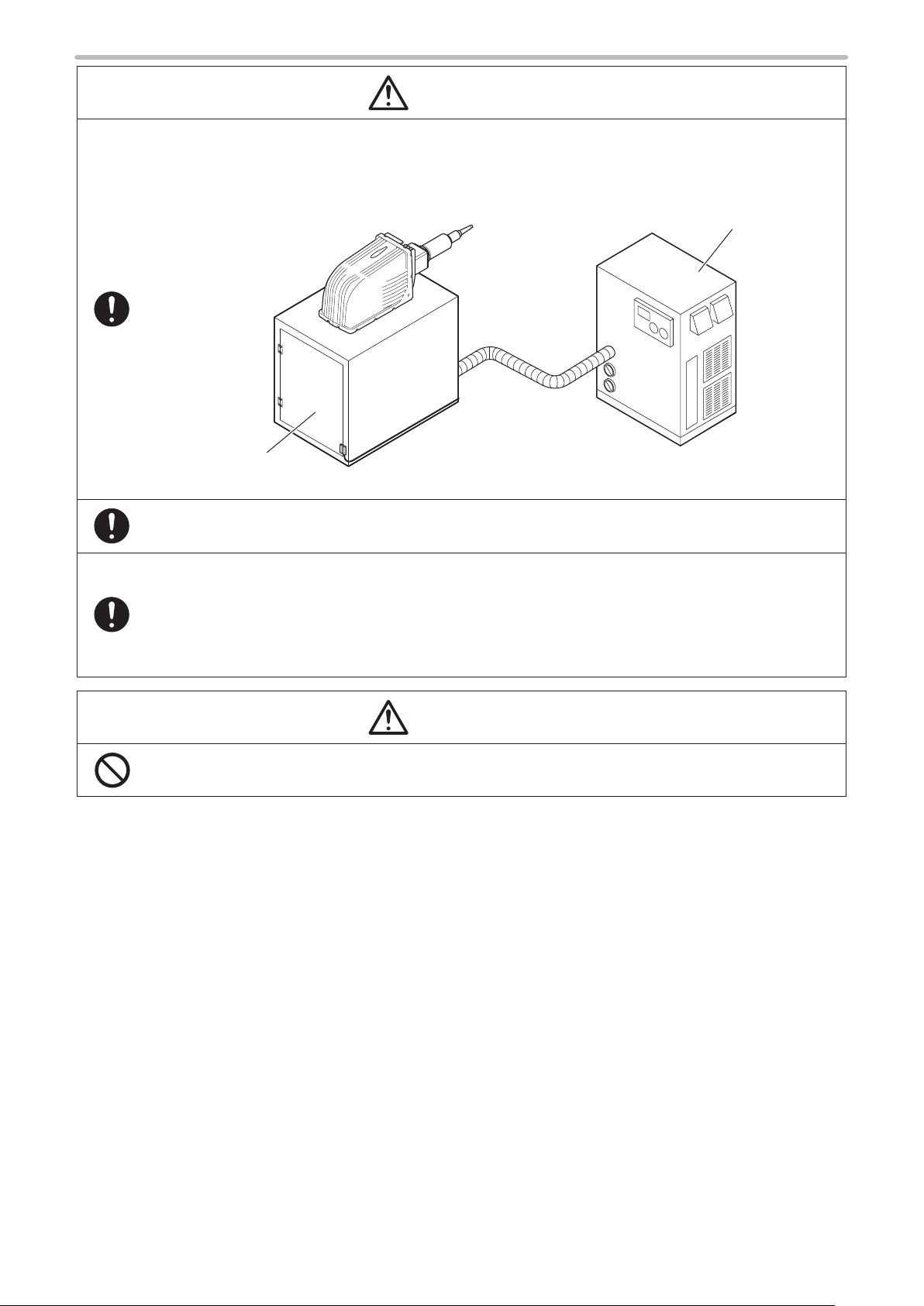

WARNING

• Remove the dust and/or gas which may be generated during the laser radiation with dust collector or

CAUTION

ME-LP-GS-SR-COMP-3

exhauster. Use an appropriate dust collector or exhauster for dust or gas generated.

Depending on the material of the objects, harmful dust and/or gas to the human body and the laser marker

may be generated.

Dust collector

Protective

• When using the assist gas for laser processing, take safety precautions to protect operators from

• To carry this product, wear the non-slip gloves and safety shoes. Hold the product with both hands. Do not

• For LP-RC/LP-RF/LP-RV series, carry the controller unit with two persons. Lifting or carrying without

• Install this product in the stable place without vibration and shock.

• In case it falls down, it may cause injury.

enclosure

exposure, ignition, toxic effect, excess or lack of oxygen.

hold the cables or connectors at carrying.

assistance may cause of injury.

• Do not touch the head surface of LP-RF/LP-RV series during and right after the operation. It becomes hot

and may cause burn injury.

5

How to Read this Document

ME-LP-GS-SR-COMP-3

Symbol description

ワㄐㄕㄊㄆ

ンㄆㄇㄆㄓㄆㄏㄆ

Target model

This manual is subject to the following Laser Marker models.

In this manual, this product is called “laser marker”.

If the setting contents or specifications vary by models, the target models are specified in the text.

In the text, multiple models may be described collectively, as shown in the table below.

Please remind that the illustration and the screen image may vary with the model.

Target model Description in the text

LP-GS0 51 LP-GS0 51- E LP-GS0 51 LP-GS0 51(-L) LP-GS series

LP-GS0 51- F LP-GS0 51- FE LP-GS0 51- F N

LP-GS0 51- L LP- G S051- LE LP-GS0 51- L

LP-GS0 51- L F LP-GS0 51- L FE LP-GS0 51- L FN

LP-GS052 LP-GS052-E LP-GS052

LP-GS052-F LP-GS052-FE LP-GS052-FN

LP-RC350S LP-RC350S LP-RC series

“Notice” denotes any instructions or precautions for using this product. To prevent the damage or

malfunction of the product, observe these precautions fully.

“Reference” denotes any hints for operation, detail explanations, or references.

LP-RF200P LP-RF200P LP-RF series

LP-RV200P LP-RV200P LP-RV series

6

Type of manuals

ME-LP-GS-SR-COMP-3

For this product, the following manuals are prepared. Read each manuals and operate this product correctly and safely.

Also, save the manuals for future use.

Laser Safety Guide

This manual describes the items required for using this product correctly and safely. All users shall be required for reading this manual.

Setup/Maintenance Guide

This manual describes the items required for introduction and installation of this product as well as for the maintenance

work.

• Product specifications, external dimensions

• Installation and connection method

• Signal details, I/O rating, and timing chart when I/O is used for control

• Maintenance details

Laser Marker NAVI smart Operation Manual

Instruction manual for the laser marker configuration software “Laser Marker NAVI smart”. This manual describes the

procedure and method to operate the laser marker, and the screen operations to set marking contents.

Mainly the users that operate this laser marker for actual marking procedure shall be required for reading this manual.

Serial Communication Command Guide

This manual describes the communication commands to control this product externally using the serial communication

(RS-232C/Ethernet). It describes the communication settings, communication data formats, communication commands,

and the control samples.

Mainly the machine builder and system integrator shall be required for reading this manual.

Serial Communication Command Guide: LP-400/V compatible mode

This manual describes the communication commands to control this product externally using the compatible command

format with the previous models of LP-400/LP-V series.

Mainly the machine builder and system integrator shall be required for reading this manual.

ンㄆㄇㄆㄓㄆㄏㄆ

• The PDF data of each manual is included on an attached CD-ROM “Laser Marker Smart Utility”.

• To read the PDF manual, Adobe Reader (Version X or later) of Adobe Systems Incorporated is required.

7

Contents

ME-LP-GS-SR-COMP-3

Preface ............................................................................................................... 2

Cautions in Handling

How to Read this Document

........................................................................................... 3

............................................................................... 6

1 Preparation of Command Control ………………………………… 11

1-1 Operation by External Devices ................................................................... 12

1-1-1 Operation method using external control device ........................................ 12

1-1-2 Operation procedure with external control ................................................. 13

1-1-3 Settings before external control ................................................................. 14

1-1-4 Remote mode settings ............................................................................... 17

1-2 Serial Communication Interfaces ................................................................ 18

1-3 RS-232C ..................................................................................................... 19

1-3-1 Interface specifications and connection .................................................... 19

1-3-2 Communication settings (LP-400/V compatible mode) ............................. 21

1-4 Ethernet ...................................................................................................... 22

1-4-1 Port specifications and connection ............................................................ 22

1-4-2 Communication settings ............................................................................ 23

1-4-3 Connecting to external control devices and its setting sample ................. 24

1-5 Checking the communication commands ................................................... 25

2 Communication Control Basics …………………………………… 26

2-1 Communication Data Types ........................................................................ 27

2-1-1 Request data .............................................................................................. 27

2-1-2 Response data ........................................................................................... 27

2-2 Communication Sequence .......................................................................... 28

2-3 Communication Data Format ...................................................................... 31

2-3-1 Basic data format ....................................................................................... 31

2-3-2 Request data ............................................................................................. 32

2-3-3 Response data .......................................................................................... 33

2-3-4 Character input method ............................................................................. 36

2-3-5 Character data input method ..................................................................... 37

2-4 Command Reception Condition .................................................................. 42

2-4-1 Commands requiring pre-set ..................................................................... 42

2-4-2 Command reception permission ............................................................... 42

2-4-3 Commands acceptable only with the shutter closed ................................. 43

2-4-4 Commands acceptable during alarm/warning occurrence ........................ 43

8

2-5 Communication Check................................................................................ 44

2-6 Control Sample ........................................................................................... 45

3 Data Format for Each Command ………………………………… 50

ME-LP-GS-SR-COMP-3

3-1 Command List ............................................................................................. 51

3-2 Command Description Details .................................................................... 55

3-3 Operation Control Commands .................................................................... 56

3-3-1 Command reception permission: MKM ..................................................... 56

3-3-2 Laser pumping: LSR .................................................................................. 57

3-3-3 Shutter open/close: SHT ........................................................................... 58

3-3-4 Marking trigger: MRK ................................................................................ 59

3-3-5 Trigger delay: DLY ..................................................................................... 60

3-3-6 Guide laser: GID ....................................................................................... 61

3-3-7 Status checking: STS ................................................................................ 62

3-3-8 Marking end verification: MST .................................................................. 63

3-4 File Setting Commands .............................................................................. 65

3-4-1 File selection by number: FNO .................................................................. 65

3-4-2 File selection by name: FNN ..................................................................... 66

3-4-3 Overwrite file: FOR ................................................................................... 67

3-4-4 Save file to different No.: FRG .................................................................. 67

3-4-5 File name: FNM ......................................................................................... 68

3-5 Character Setting Commands .................................................................... 69

3-5-1 Character entry (by ASCII code): MCS ..................................................... 69

3-5-2 Character entry (by ASCII and Shift-JIS code): STR ................................ 70

3-5-3 Character entry per trigger: SIN ................................................................ 72

3-5-4 Character object settings: STC ................................................................. 74

3-5-5 Character object settings (shortened): SPC .............................................. 78

3-6 Functional Character Commands ............................................................... 79

3-6-1 Counter settings: CNT ............................................................................... 79

3-6-2 Counter reset: CTR ................................................................................... 80

3-6-3 Expiry date/time settings: LMT .................................................................. 81

3-6-4 Lot settings: LTC ....................................................................................... 82

3-6-5 Lot period/character: LTS .......................................................................... 83

3-6-6 Registered character settings: RKC .......................................................... 85

3-6-7 Registered character strings: RKS ............................................................ 86

3-7 Bar Code/2D Code Settings Commands .................................................... 87

3-7-1 Bar code/2D code characters (by ASCII code): BCS ................................. 87

3-7-2 Bar code/2D code characters (by ASCII and Shift-JIS code): BRS ............. 89

3-7-3 Bar code/2D code object settings: BRF ..................................................... 91

3-7-4 Human readable text settings: BRV .......................................................... 100

3-7-5 Module filling of 2D codes: BRP ............................................................... 103

3-8 Command for graphic data settings ........................................................... 105

3-8-1 Graphic file (VEC format file) : CDF ......................................................... 105

3-8-2 Graphic object settings (VEC format file) : CDC ...................................... 106

3-9 Point Radiation Commands ....................................................................... 108

9

3-9-1 Point radiation parameters: PRD .............................................................. 108

ME-LP-GS-SR-COMP-3

3-9-2 Point radiation correction: PRF .................................................................112

3-10 Layout/Position Adjustment Commands ...................................................113

3-10-1 File settings: ALC .....................................................................................113

3-10-2 External offset settings: OFC...................................................................114

3-10-3 External offset values: OFS .....................................................................115

3-10-4 Step & repeat settings: SRC ....................................................................116

3-10-5 Step & repeat fine-adjustment: SRA .......................................................118

3-11 On-the-fly Marking Commands ................................................................ 123

3-11-1 Motion settings: TRG .............................................................................. 123

3-11-2 Encoder resolution: ENC ......................................................................... 124

3-11-3 Line speed: LSP ...................................................................................... 125

3-11-4 Workpiece spacing: INT .......................................................................... 126

3-12 Laser Setting Commands ........................................................................ 127

3-12-1 Laser power: LPW .................................................................................. 127

3-12-2 Scan speed: SSP .................................................................................... 128

3-12-3 Laser frequency / pulse cycle: MPL ........................................................ 129

3-12-4 Laser fine tune: WTC .............................................................................. 130

3-12-5 Line width / filling line spacing: WDC ...................................................... 132

3-13 Maintenance Commands ......................................................................... 133

3-13-1 Laser radiation for measurement: SPT ................................................... 133

3-14 System Settings Command...................................................................... 134

3-14-1 System clock: YMD ................................................................................. 13 4

3-14-2 Command mode: RSM ........................................................................... 135

Troubleshooting ……………………………………………………… 137

Troubleshooting ................................................................................................ 138

Error Indication

Alarm: E001 - E599 ............................................................................................ 150

Warning: E600 - E799

................................................................................................. 150

........................................................................................ 154

Character Code Table ……………………………………………… 163

ASCII Code ....................................................................................................... 164

Shift JIS Code................................................................................................... 165

Index ………………………………………………………………… 176

10

1 Preparation of Command

ME-LP-GS-SR-COMP-3

Control

1-1 Operation by External Devices

ME-LP-GS-SR-COMP-3

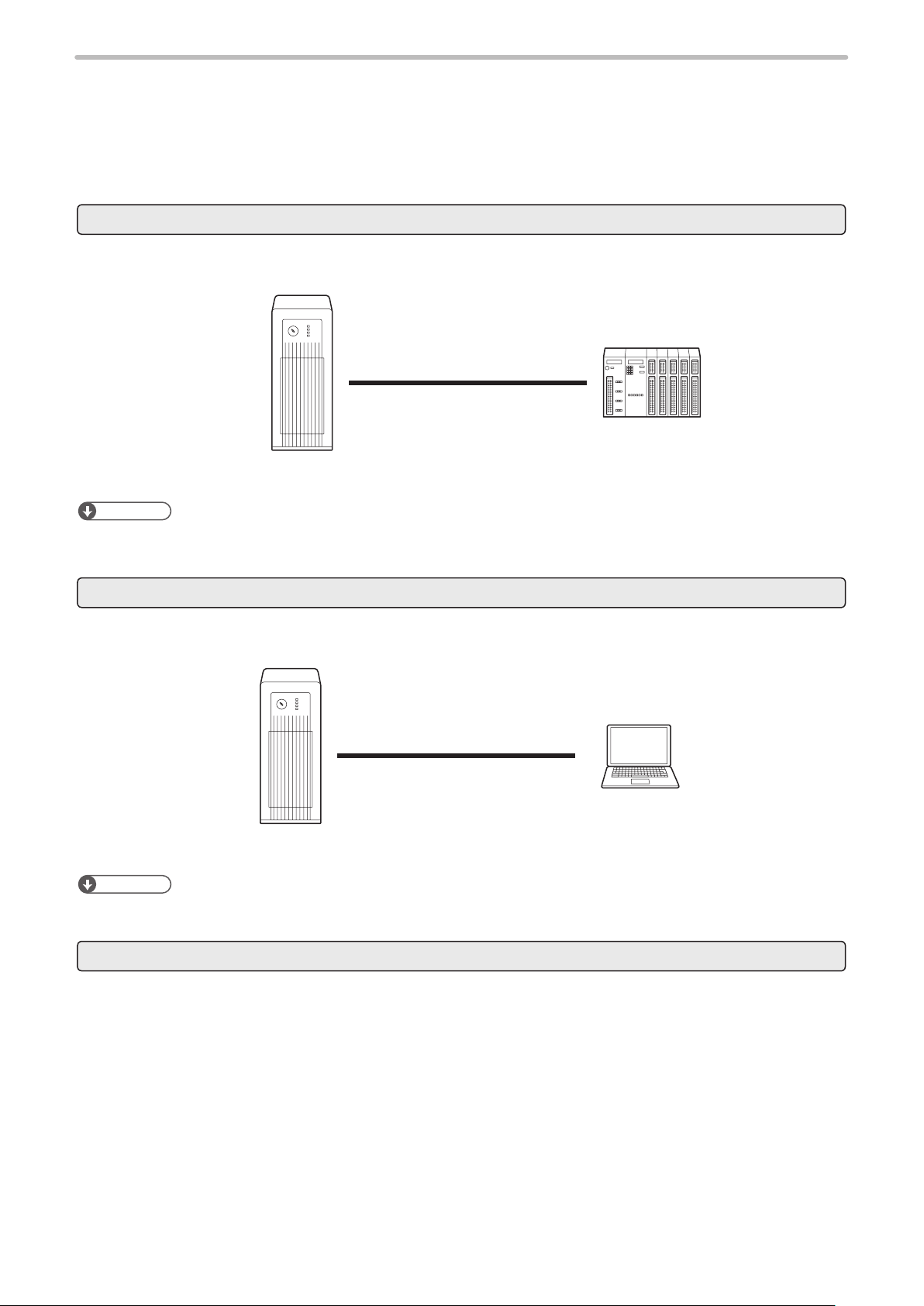

1-1-1 Operation method using external control device

To control the laser marker with the external control device, the following connecting methods are applicable:

External control (remote mode) using I/O

Controls the laser marker from external devices such as PLC using I/O signals loaded into the laser marker.

For details, refer to “Setup/Maintenance Guide”.

I/O terminal block

I/O connector

Laser marker controller

ンㄆㄇㄆㄓㄆㄏㄆ

PLC, etc.

• To input marking trigger with I/O and configure other settings with a screen operation manually, use Run mode. For

details, refer to “Setup/Maintenance Guide”.

External control (remote mode) by serial communication commands (RS-232C/Ethernet)

To control the laser marker by communication commands from external devices such as PLC, use RS-232C or Ethernet

connection.

RS-232C or

Ethernet

Laser marker controller

ンㄆㄇㄆㄓㄆㄏㄆ

• It is available to the external control combining I/O and serial communication commands.

Link control with external devices (remote mode or RUN mode)

External control device

Connect the external devices, such as an image checker or a code reader, to the laser marker and control them together.

• Link control (Ethernet) with specific external devices (i.e. image checker) *1

• Link control with a code reader (RS-232C)

For details, refer to “Setup/Maintenance Guide”.

*1 : The link control with an image checker is not available at on-the-fly marking.

12

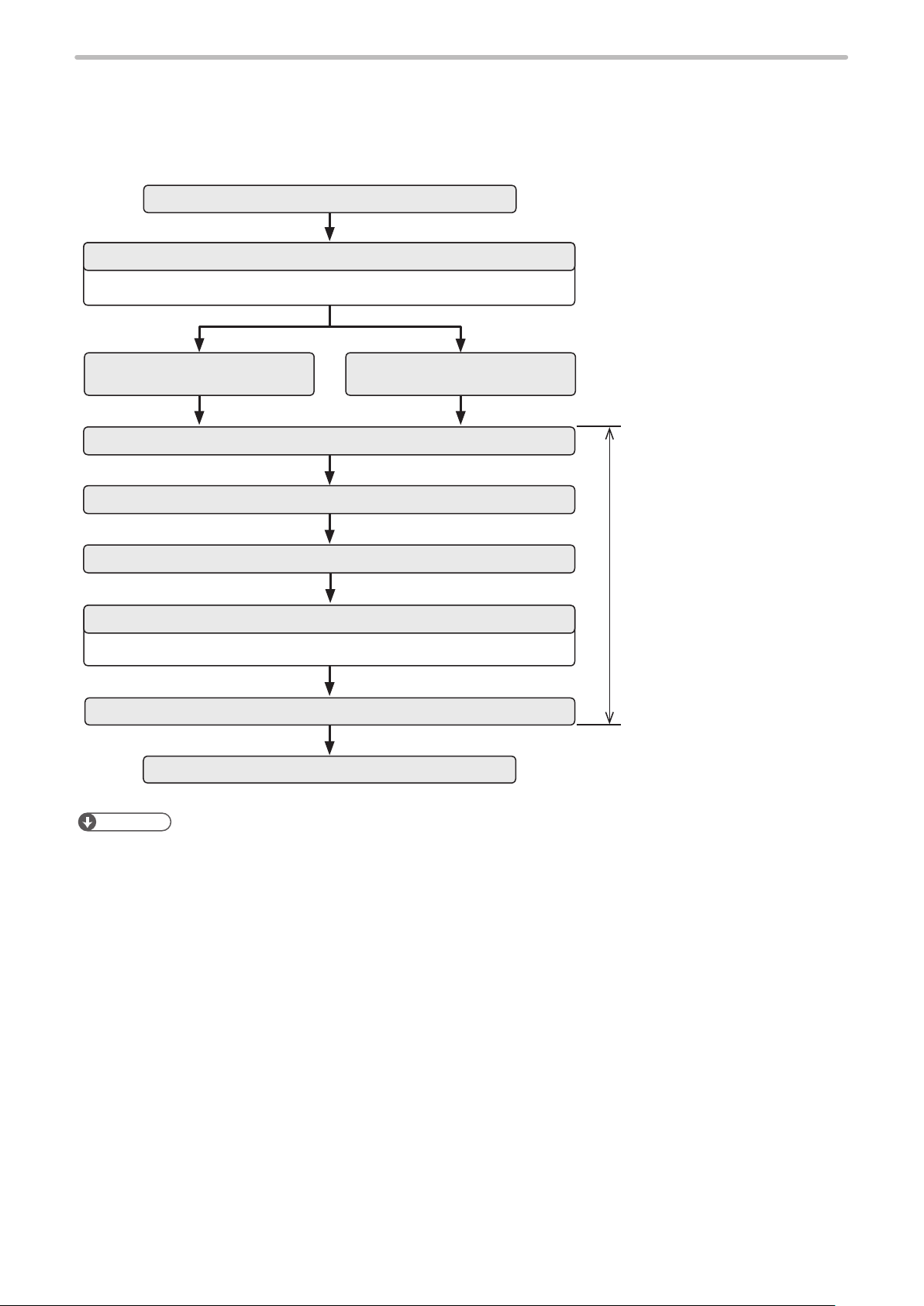

1-1-2 Operation procedure with external control

ME-LP-GS-SR-COMP-3

Operation example when controlling the laser marker from external control devices such as

⿎

PLC

Turn ON key switch of laser marker controller

Remote mode ON

Refer to “1-1-4 Remote mode settings” (P.17).

I/O control

Select file

Laser pumping ON

OPEN shutter

Confirm READY OUT is ON.

The device is ready for receiving the marking starting signal (trigger).

Trigger Input ON

Marking

Control by serial communication

commands

Control by using I/O or

communication commands

ンㄆㄇㄆㄓㄆㄏㄆ

• It is available to the external control combining I/O, and serial communication commands.

• You need to configure the system settings on the I/O communication in advance before using external control. Refer to

“1-1-3 Settings before external control” (P.14).

• For details on the operation procedure when you link an image checker or a code reader, refer to “Setup/Maintenance

Guide”.

13

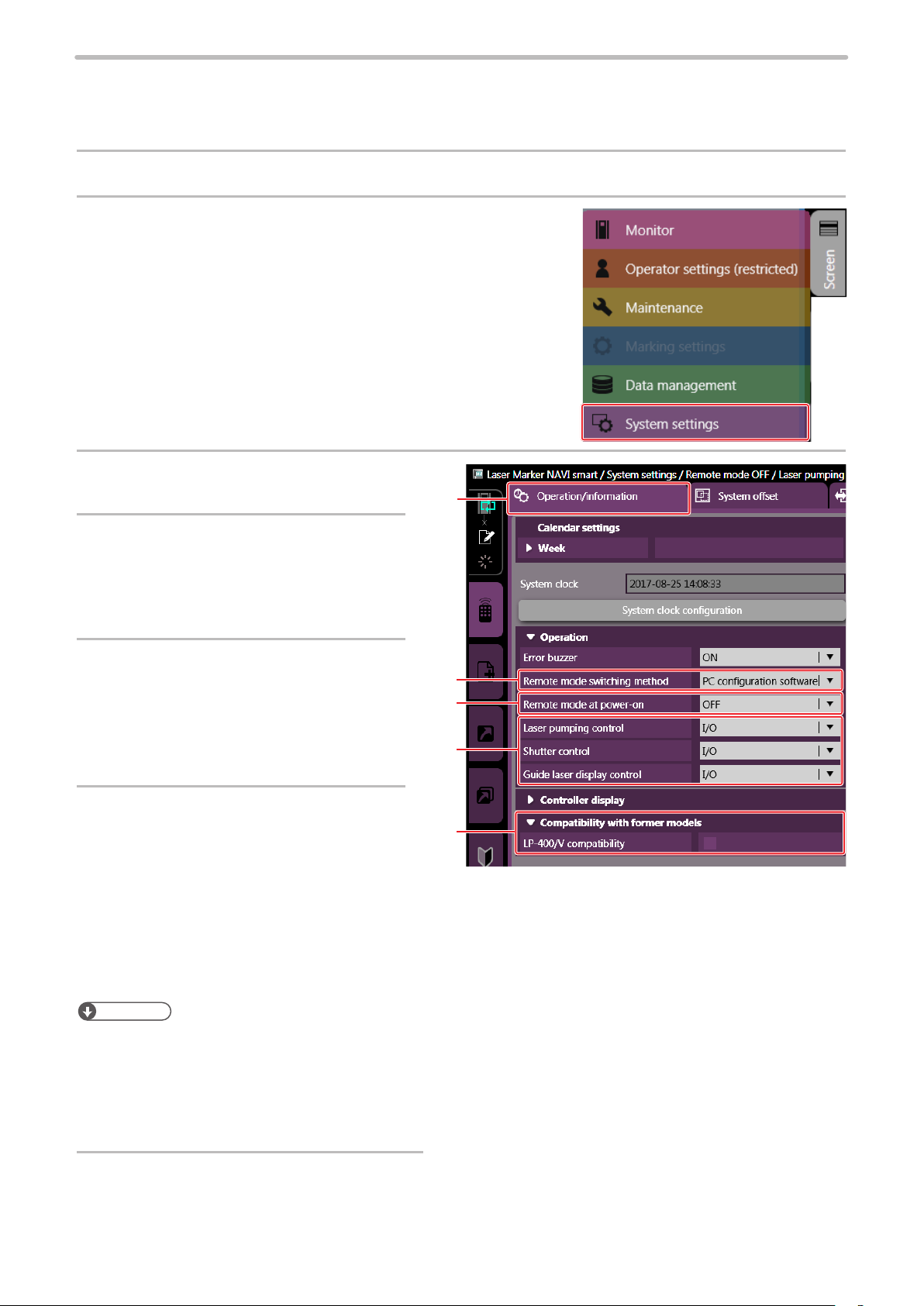

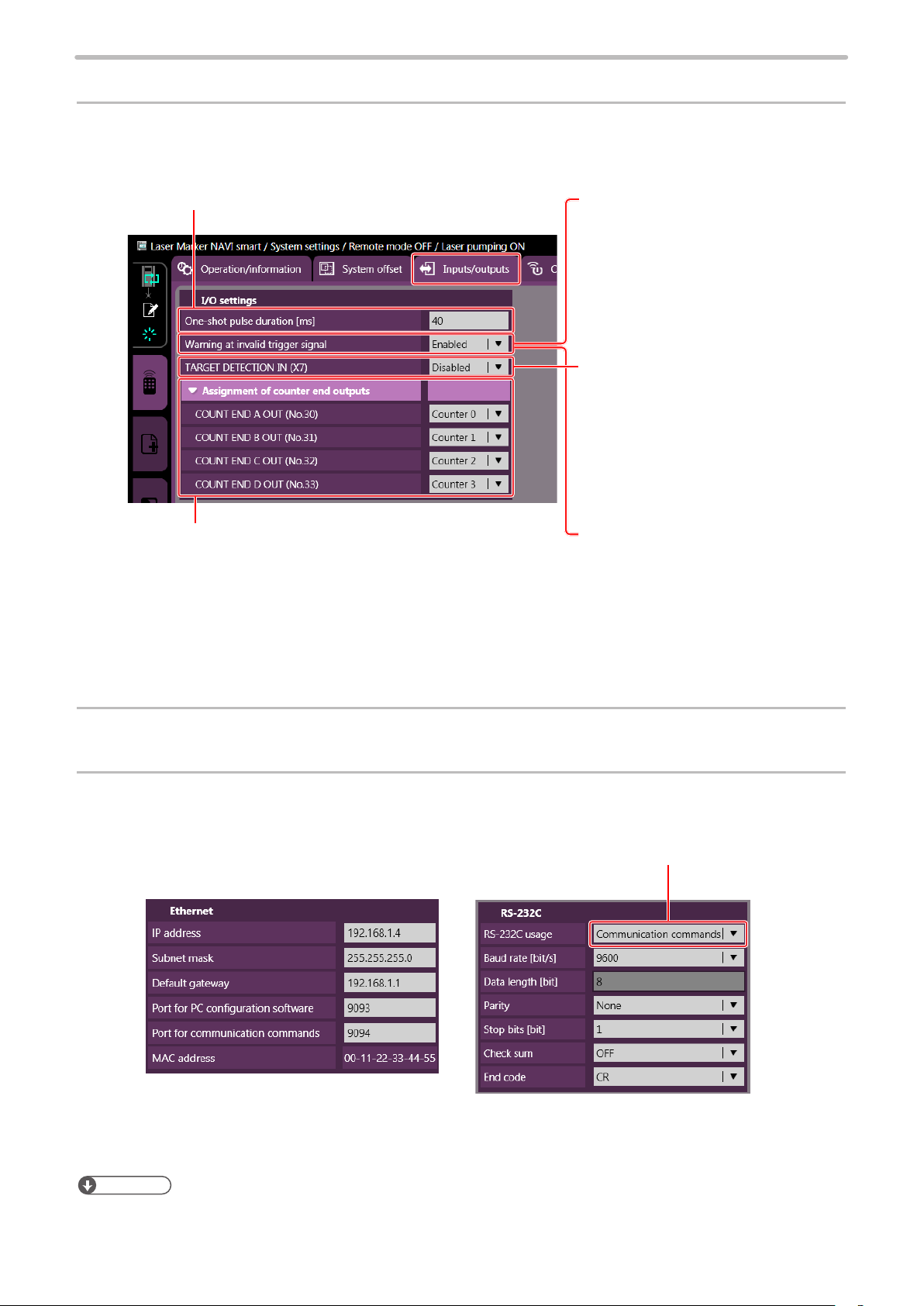

1-1-3 Settings before external control

ME-LP-GS-SR-COMP-3

To control the laser marker by using I/O or communication commands, configure the following items in advance at the

system settings of Laser Marker NAVI smart.

Connect the laser marker and Laser Marker NAVI smart online.

1.

Select “System settings” by clicking the screen selection

2.

menu.

Select the “Operation/Information” tab.

3.

3

Select the switching method of the

4.

remote mode.

• PC configuration software (initial setting)

• I/O

When PC configuration software is

5.

selected, select the remote mode

status at power-on.

• Remote mode ON

• Remote mode OFF (initial setting)

Select the control method for the

6.

following operations between I/O or

4

5

6

7

communication commands.

As the default, I/O control is selected to all

settings.

• Laser pumping control

• Shutter control

• Guide laser control *1

*1 : Available with LP-GS051(-L) type, LP-350S, LP-RF series and LP-RV series.

ンㄆㄇㄆㄓㄆㄏㄆ

• If you want to maintain the compatibility with LP-400/LP-V series, set the operation settings in system settings screen

corresponding with the DIP switch settings on LP-400/LP-V series. For the DIP switch details, refer to “LP- 400/V/W

series External control manual”.

• To use “Laser Radiation for Measurement Command (SPT)” of the serial communication commands, set the shutter

control method to “communication commands”.

• For LP-GS052 type, guide laser cannot be controlled using I/O or communication command.

7.

14

If you want to use the same command format with the former models of LP-400/LP-V series,

enable “LP-400/V compatibility”.

Click “Set” on the lower right corner of the screen.

ME-LP-GS-SR-COMP-3

8.

When using I/O, click the “inputs/outputs” tab and configure the following items:

9.

• One-shot pulse duration:

Configure the output time of the signal being output as

one-shot, such as PROCESSING END OUT (Y11).

Setting range: 2 to 510ms (initial value is 40ms)

• Warning at invalid trigger signal:

Configure if you will output (ON) or

will not output (OFF) the warning for

the invalid trigger. With enabling this

setting, the warning is output when the

marking trigger that cannot be accepted

was input.

(Initial setting: Enabled)

• TARGET DETECTION IN (X7) (LP-RC/

LP-RF/LP-RV series only):

Select whether or not to use TARGET

DETECTION IN on I/O terminal.

(Initial setting: Disabled)

When enabling this terminal, connect a

sensor which detect the work piece is in

position for lasing.

• Assignment of counter end outputs:

Assign the counter No. to COUNT END A OUT to COUNT

END D OUT (I/O pin No. 30 to 33).

As the default setting, counter No. 0 to 3 are assigned to

COUNT END A OUT to COUNT END D OUT respectively.

Click the “Set” button on the lower right corner of the screen.

10.

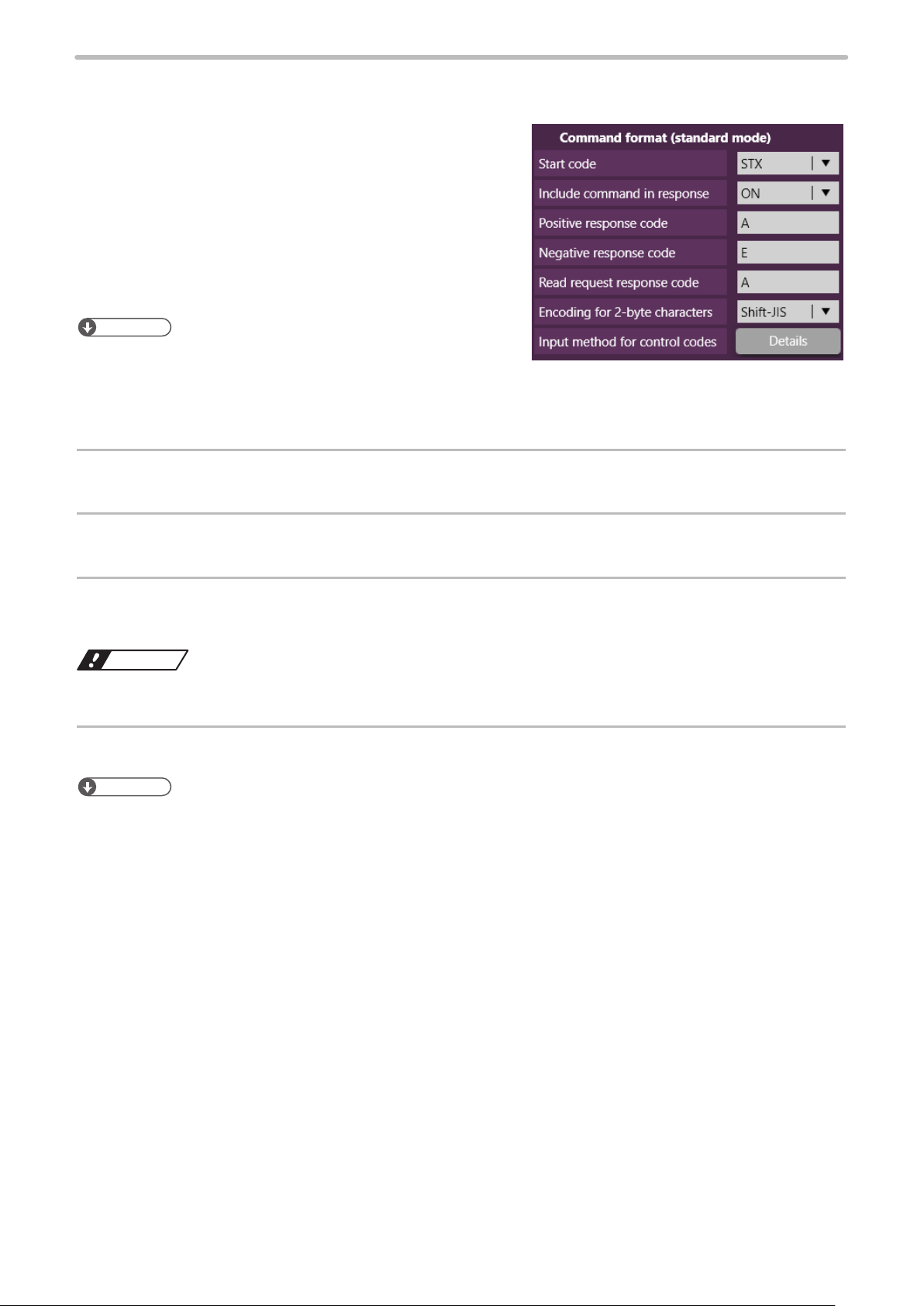

When using communication commands, click the “Communication” tab to set communication

11.

• Terminal assignment X11 (LP-GS series

only):

Select the behavior of the input signal

X11 on I/O terminal from LASER STOP

1 IN or LASER STOP 2 IN. (Initial

setting: LASER STOP 2 IN)

For the operation details of LASER

STOP, refer to “Setup/Maintenance

Gu ide”.

details of Ethernet or RS-232C.

Set “Communication commands”

to the RS-232C usage.

For Ethernet:

For RS-232C:

ンㄆㄇㄆㄓㄆㄏㄆ

• When using RS-232C, specify the “Flow control” to “None” at the communication port settings of the external control

device.

Configure the communication settings

according to the network settings.

Configure the communication settings

of the laser marker corresponding to the

external control device.

15

If you want to use standard command mode, specify the communication command format on the

ワㄐㄕㄊㄆ

ME-LP-GS-SR-COMP-3

12.

“Command format” panel.

• Start code: STX (initial setting) / None

• Include command in response: ON (initial setting) / OFF

• Sub-command for response data: Any single byte character

of ASCII code from 01(HEX) to 7F(HEX) can be specified.

• Initial setting of positive response code: A

• Initial setting of negative response code: E

• Initial setting of read request response code: A

• Encoding for 2-byte characters: Shift-JIS (initial setting) / GB

2312

• Input method for control codes

ンㄆㄇㄆㄓㄆㄏㄆ

• The command format settings here are applied to the standard

communication format and not applied to LP-400/LP-V compatible

format. For the details of the standard command format, refer to the “Serial Communication Command Guide”.

• For the command format of LP- 400/V compatible mode, refer to “2-3 Communication Data Format” (P.31).

Click “Set” on the lower right corner of the screen.

13.

Disconnect the online connection with the laser marker.

14.

Turn OFF the laser marker power and wait for five seconds or more, then restart.

15.

The configured items will be reflected to the laser marker.

• Do not turn the laser marker power OFF while being connected to online.

The control by the external device starts by switching the laser marker to the remote mode.

16.

ンㄆㄇㄆㄓㄆㄏㄆ

• For the details of the System settings, refer to “Laser Marker NAVI smart Operation Manual”.

16

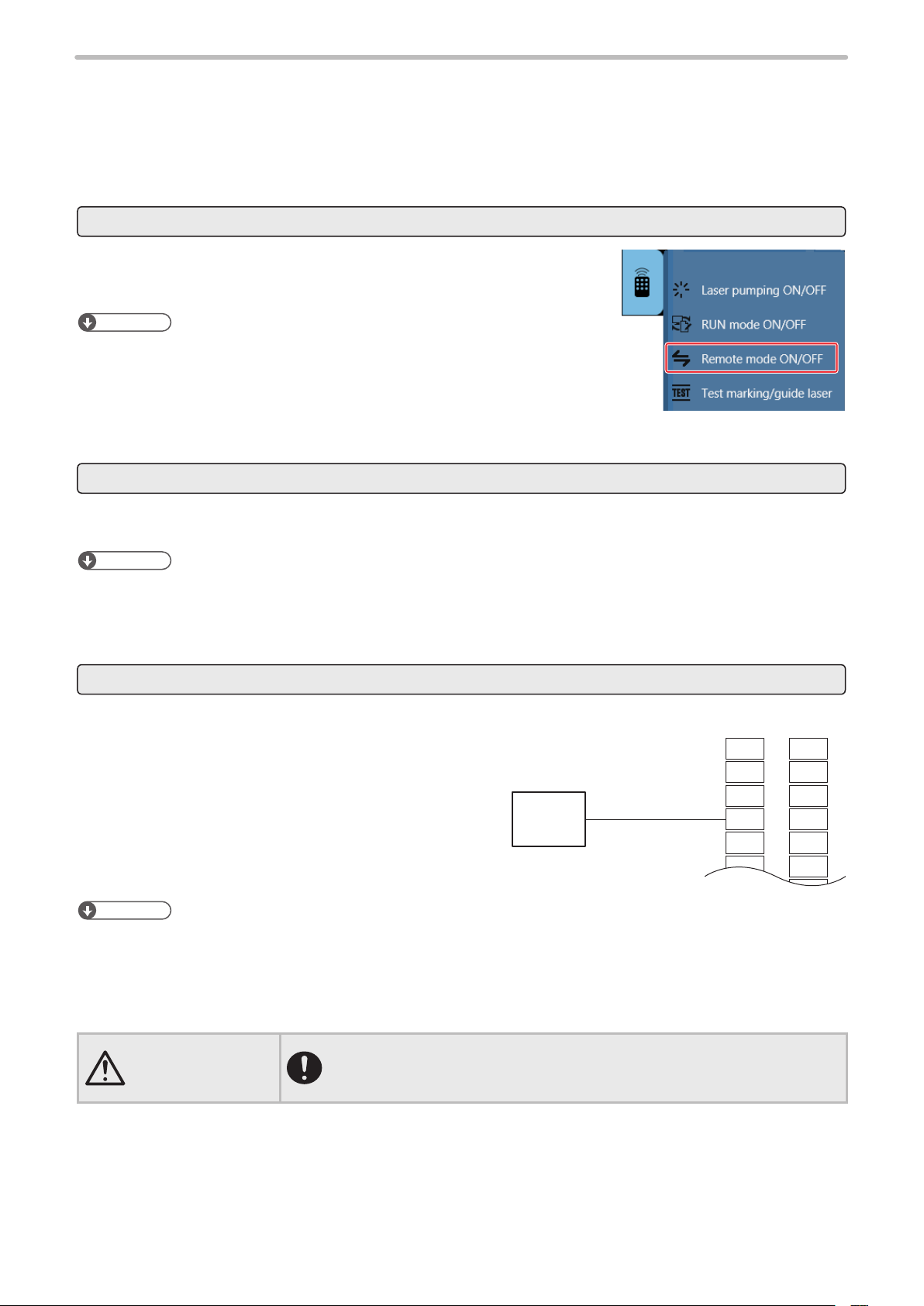

1-1-4 Remote mode settings

WARNING

X1

X2

X3

X4

X5

X6

X7

Y1

Y2

Y3

Y4

Y5

Y6

Y7

ME-LP-GS-SR-COMP-3

To control the laser marker externally using I/O or serial communication commands, set the operation mode to the remote

mode with one of the following methods.

Select the method to switch to the remote mode on the system settings screen of Laser Marker NAVI smart. Refer to “1-1-3

Settings before external control” (P.14).

Remote mode switching by Laser Marker NAVI smart

Click the “Laser Marker Operation” tool of Laser Marker NAVI smart. Then, click

“Remote mode ON/OFF”. Click “Yes” on the confirmation screen to switch the

laser marker to the remote mode.

ンㄆㄇㄆㄓㄆㄏㄆ

• The “Remote mode ON/OFF” button is available when the following screens are

selected with the online connection established.

• Marking settings screen

• Operator settings (restricted) screen

• Monitor screen

Startup the laser marker in the remote mode (Laser Marker NAVI smart can switch the remote mode)

When you turn ON the key switch of the laser marker, the system starts in the remote mode. Use the remote mode

switch button of Laser Marker NAVI smart for releasing and resetting the remote mode.

ンㄆㄇㄆㄓㄆㄏㄆ

• If you want to start up the laser marker in the remote mode, you need to configure the settings on the system settings

screen of Laser Marker NAVI smart in advance.

• If you have configured the laser marker to start up in the remote mode, you cannot switch the remote mode from I/O.

Remote mode switching using I/O

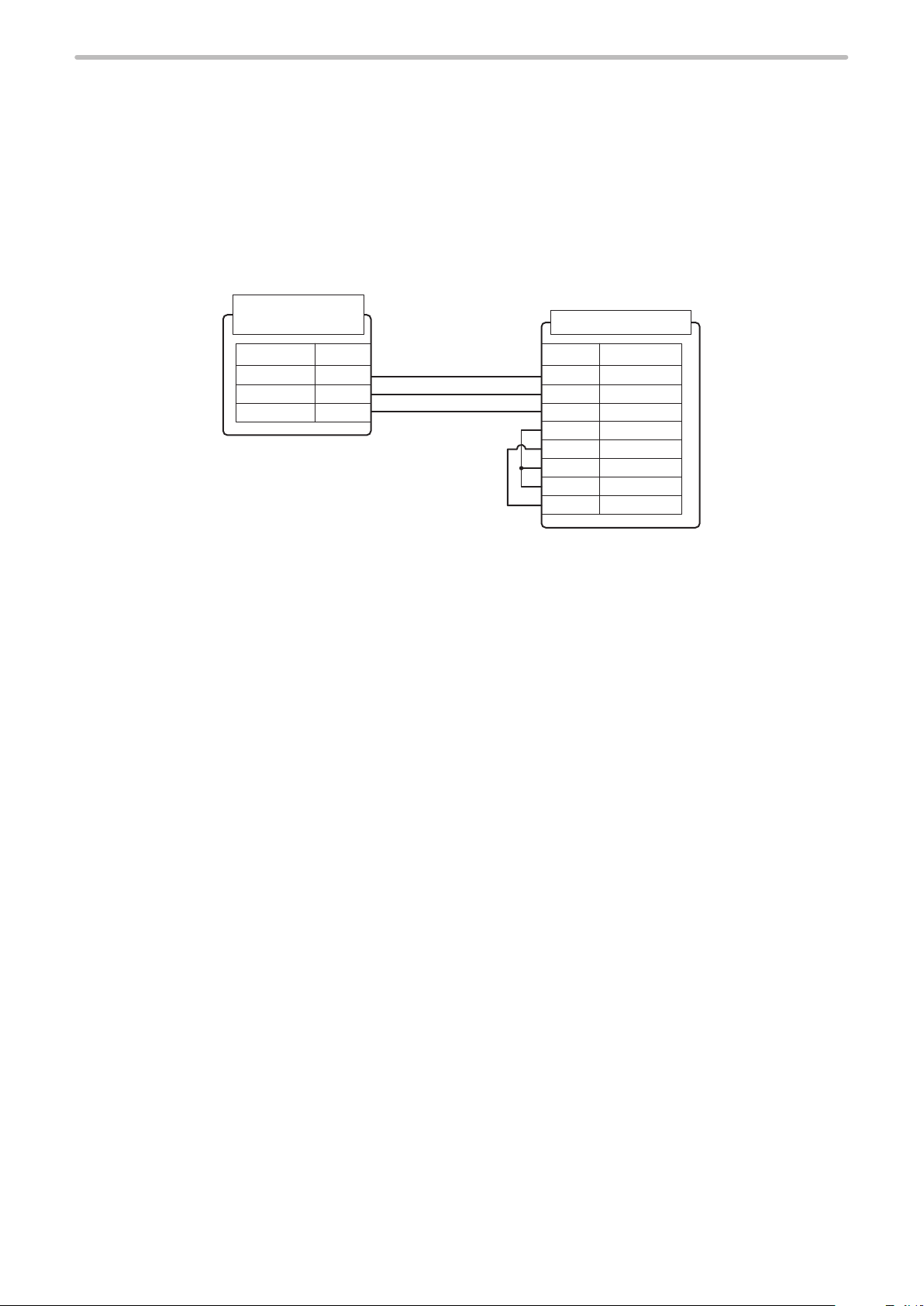

Turn ON REMOTE IN (X4) of the I/O terminal block on the

controller.

PLC, etc.

OUTPUT

ンㄆㄇㄆㄓㄆㄏㄆ

• To enable switching to the remote mode by REMOTE IN (X4) on the I/O terminal block, you need to configure the

settings on the system settings screen of Laser Marker NAVI smart in advance.

• If you have configured the remote mode switching method to the I/O terminal block, you cannot switch the remote mode

from the Laser Marker NAVI smart screen.

REMOTE IN

I/O terminal block

• If the laser marker is set to enter the remote mode at startup or by I/O control,

construct a manual resetting system to re-pump the laser when the laser

pumping is turned to off due to an emergency stop or an interlock.

17

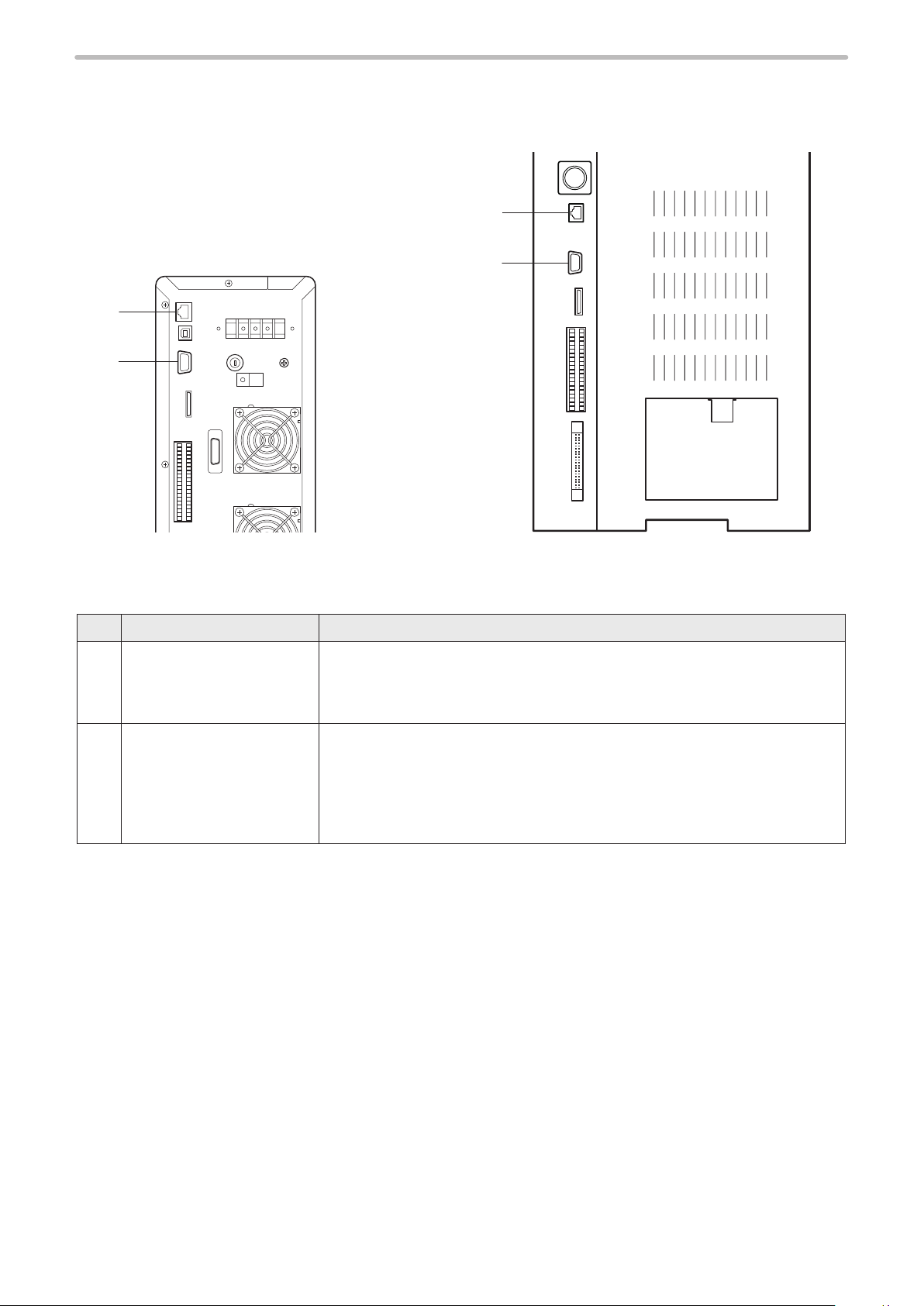

1-2 Serial Communication Interfaces

w

q

ME-LP-GS-SR-COMP-3

This product has the following serial communication interfaces on the controller.

w

q

LP-GS series

Rear of Controller

No. Name Description

RS-232C port For the connection details, refer to “1-3 RS-232C” (P.19).

q

To use the RS-232C port, select the RS-232C usage from communication

command control or code reader linkage function in the system settings screen in

advance.

Ethernet port For the connection details, refer to “1-4 Ethernet” (P.22).

w

The Ethernet port can be connected with the following devices simultaneously via

a HUB or a router.

• Laser Marker NAVI smart (PC configuration software)

• External device for communication command control (PLC and PC for control)

• Specific image checker

LP-RC/LP-RF/LP-RV series

Rear of Controller

18

1-3 RS-232C

ME-LP-GS-SR-COMP-3

To control the laser marker by communication commands, use RS-232C or Ethernet connection.

For the control by communication commands, configure the communication settings in advance at the system settings of

Laser Marker NAVI smart. Refer to “1-1-3 Settings before external control” (P.14).

ンㄆㄇㄆㄓㄆㄏㄆ

• The laser marker can be controlled by I/O and communication commands combined.

1-3-1 Interface specifications and connection

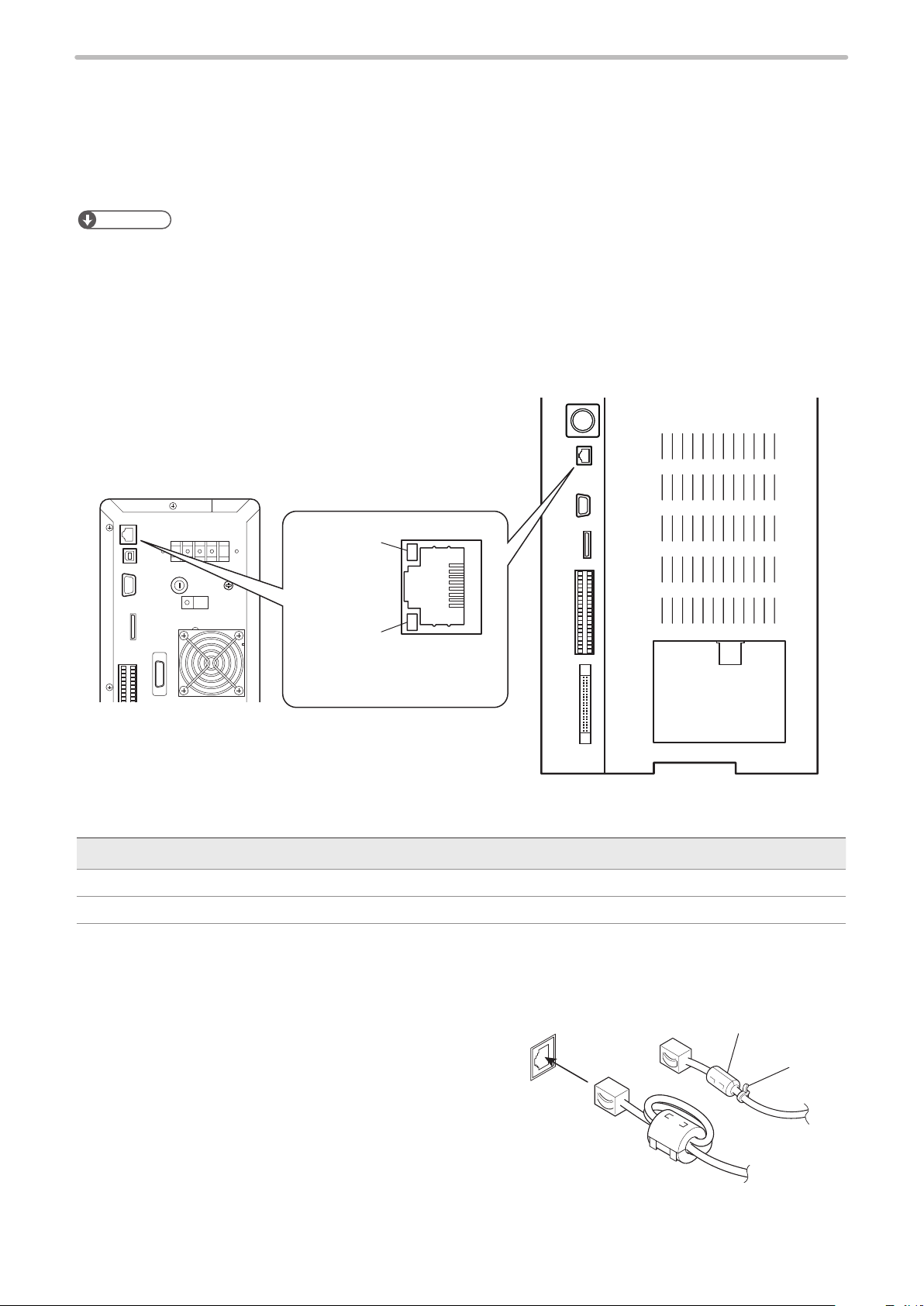

To execute command communication control with RS-232C, connect the RS-232C port on the controller to the external

control device.

16

59

RS-232C Port

(female)

LP-GS series

Rear of Controller

Connector position Connector specifications Model Manufacturer name

On the laser marker

side

User side D-sub 9-pin, male

Signals and Details of RS-232C connector

⿎

Terminal No. Signal Description

1 N.C. Do not use this signal.

2 TxD (SD) Transmission data: Connect RxD (RD) of the external control device

3 RxD (RD) Receiving data: Connect TxD (SD) of the external control device

D-sub 9-pin, female

Scr ew t ype: No.4-40UNC inch screw, female

Scr ew t ype: No.4-40UNC inch scr ew, male

On the laser marker

controller side

LP-RC/LP-RF/LP-RV series

Rear of Controller

- -

Recommended connector

XM3A-0921

Recommended connector cover

XM2S- 0 911

OMRON

Corporation

4 N.C. Do not use this signal.

5 GND (SG) Signal ground: Connect GND (SG) of the external control device

6 N.C. Do not use this signal.

7 N.C.

8 N.C.

9 N.C.

ンㄆㄇㄆㄓㄆㄏㄆ

• On the system settings screen, select communication command control or code reader linkage function that you use

with the RS-232C port.

• The GND pin of the RS-232C connector is common to the body of the laser marker.

19

Connecting to external control devices

ME-LP-GS-SR-COMP-3

⿎

• To connect the laser marker to the PC for control, use a commercially available RS-232C straight cable (laser marker

side: 9pin male).

• In case of connecting to PLC, a type of the cable (straight or cross) differs depending on a manufacturer or a model.

Please follow the PLC manual.

• To connect RS-232C terminal without using a commercially available RS-232C cable, connect only 3 signals of RxD,

TxD and GND and do not use other signals on the laser marker side.

• You may need a signal line connection (loop back line) other than RxD (RD), TxD (SD) or GND on the external control

device side depending on the specifications of the external control device. Read the instruction manual of the external

control device and connect it to the laser marker appropriately.

Connection example

RS-232C port

(Laser marker)

External control devise

2

3

5

TxD

RxD

GND

Straight cable

SignalSignal

RxD

TxD

GND

DCD

DTR

*

DSR

RTS

CTS

* The loop back wiring on the external control device side shown in the above figure is just an example. The wiring method

varies depending on the specifications of each external control device. Read the instruction manual of the external

control device and connect it to the laser marker appropriately.

Terminal No.Terminal No.

2

3

5

1

4

6

7

8

20

1-3-2 Communication settings (LP-400/V compatible mode)

ME-LP-GS-SR-COMP-3

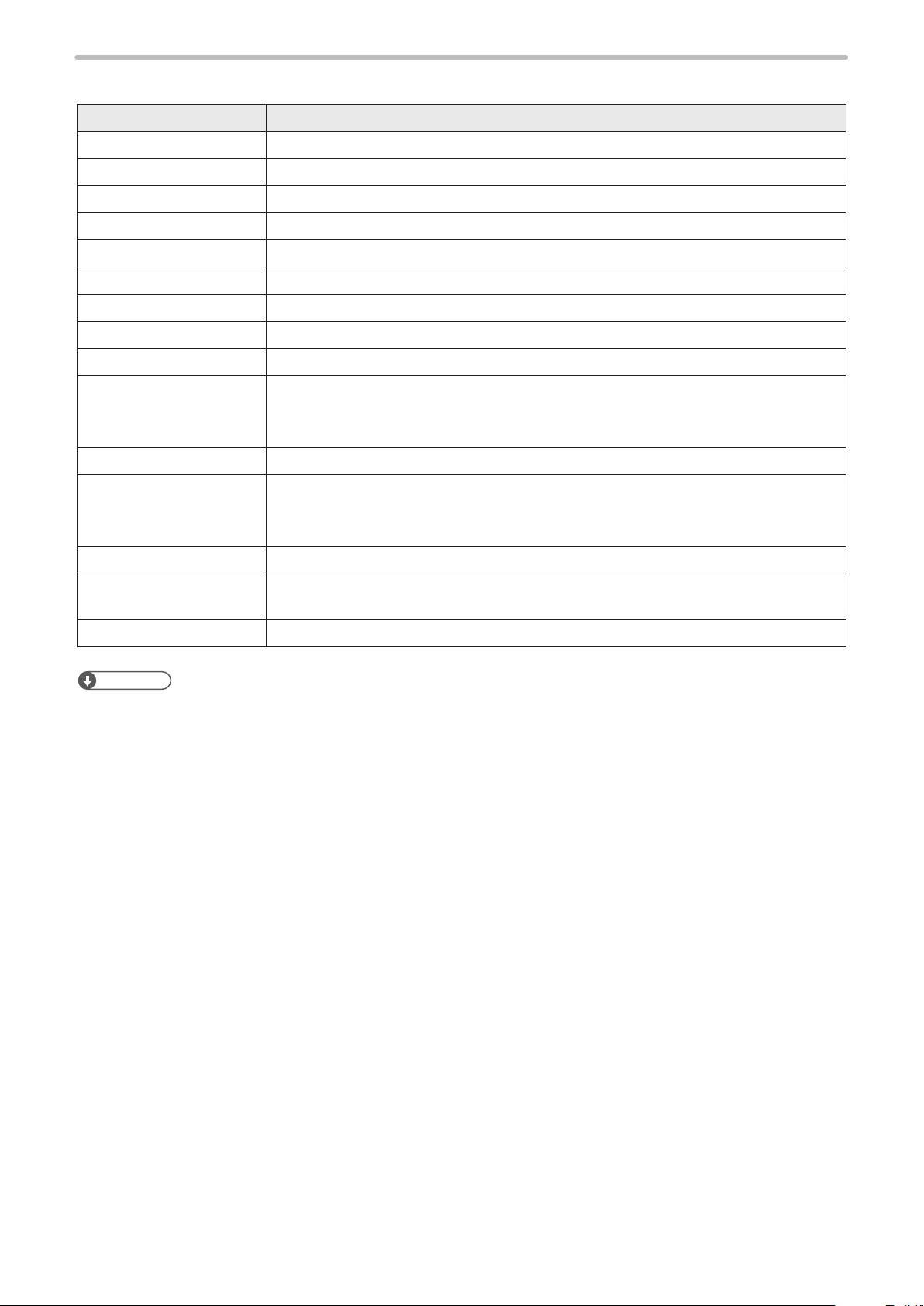

Item RS-232C communication settings (LP-400/V compatible mode)

Synchro system Start-stop method

Communication type Full-duplex transmission

Baud rate 1200 / 2400 / 4800 / 9600 / 19200 / 38400 / 57600 / 115200 bps (initial setting: 9600 bps)

Data length 8-bit fixed

Parity None / Even / Odd (initial setting: None)

Stop bits 1-bit / 2-bit (initial setting: 1-bit)

Flow control None

Check sum OFF / ON (initial setting: OFF)

End code CR / CR + LF (initial setting: CR)

Start code

• Setting request data, Readout request data, Response data for readout: STX

• Positive response code: ACK

• Negative response code: NAK

Response data command Included only in response data for readout

Sub command

• Setting request data: S

• Readout request data: R

• Response data for readout: A

Character code ASCII code

Encoding for 2-byte

characters

Shift-JIS code

Reception timer Timeout monitoring ON (10 sec.)

ンㄆㄇㄆㄓㄆㄏㄆ

• For the details of the communication settings, refer to “1-1-3 Settings before external control” (P.14).

21

1-4 Ethernet

ME-LP-GS-SR-COMP-3

1- 4 -1 Port specifications and connection

To control the laser marker by Ethernet communication, use an Ethernet port on the controller.

ンㄆㄇㄆㄓㄆㄏㄆ

• The Ethernet port of this product is compatible with both straight cable and cross cable.

• Although the maximum length of cables connecting devices permitted by the standards of Ethernet is 100 m, in order to

prevent communication failure due to noise or breakdown of the device, it is recommended to keep the length to 10 m or

less.

• The Ethernet port can be connected with the following devices simultaneously via a HUB or a router.

• PC configuration software

• External device for communication command control (PLC and PC for control)

• Specific image checker

Orange LED

Green LED

RJ-45 8-pole connector

AUTO-MDIX compatible

LP-GS series

Rear of Controller

Light up color Description

Green The indicator lights up while connected normally. It blinks during communication.

Orange Lights up only when the baud rate is 100 megabits/sec.

LAN cable connection

⿎

When you connect a LAN cable to the Ethernet port, attach

the ferrite core included to a position as close as possible

to the Ethernet port on the LAN cable controller side.

For LP-GS series, if the ferrite core diameter is too large

for the cable width, fix the ferrite core using a tie band.

For LP-RC/LP-RF/LP-RV series, turn the LAN cable 3

times around the ferrite core as shown in the figure.

On the laser marker

controller side

LP-RC/LP-RF/LP-RV series

On the laser marker

controller side

LP-RC/LP-RF/LP-RV

series

Rear of Controller

LP-GS series

Ferrite core

Tie band

22

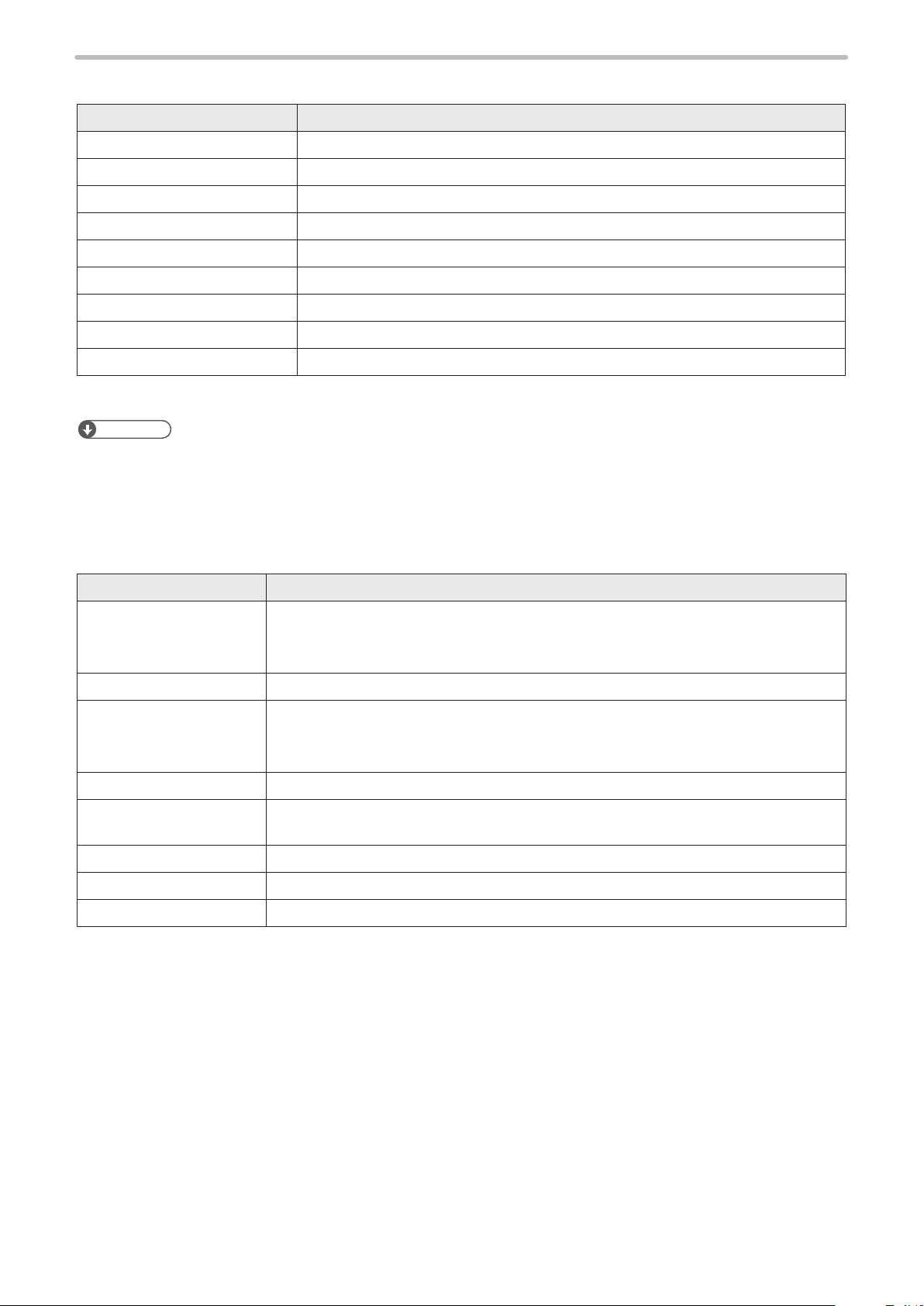

1-4-2 Communication settings

ME-LP-GS-SR-COMP-3

Item Ethernet communication settings

Communication protocol TCP/IP

Standards IEEE802.3 (10BASE-T) / IEEE802.3u (100BASE-TX)

Applicable cable Category 5 or higher

Applicable HUB (or rooter) 10BASE-T / 100BASE-TX compatible

IP address 1.0.0.0 to 223.255.255.255 * (Initial value: 192.168.1.5)

Subnet mask 128.0.0.0 to 255.255.255.254 (Initial value: 255.255.255.0)

Default gateway 1.0.0.0 to 223.255.255.255 * (Initial value: 0.0.0.0 (Unspecified))

PC configuration software port 1025 to 65534, except 9090 (Initial value: 9093)

Command communication port 1025 to 65534, except 9090 (Initial value: 9094)

* Do not use “127” in the first octet.

ンㄆㄇㄆㄓㄆㄏㄆ

• The communication control of the laser marker through the Ethernet should be per formed in a secure network settings.

• Even the IP Address and Subnet Mask values are within the configurable range, they may not be available depending

on the combination.

• For the details of the communication settings, refer to “1-1-3 Settings before external control” (P.14).

Ethernet communication settings for communication command control

⿎

Item Ethernet communication settings (LP-400/V compatible mode)

Start code

• Setting request data, Readout request data, Response data for readout: STX

• Positive response code: ACK

• Negative response code: NAK

Response data command Included only in response data for readout

Sub command

• Setting request data: S

• Readout request data: R

• Response data for readout: A

Character code ASCII code

Encoding for 2-byte

characters

Shift-JIS code

Check sum OFF

End code CR

Reception timer Timeout monitoring ON (10 sec.)

23

1-4-3 Connecting to external control devices and its setting sample

ME-LP-GS-SR-COMP-3

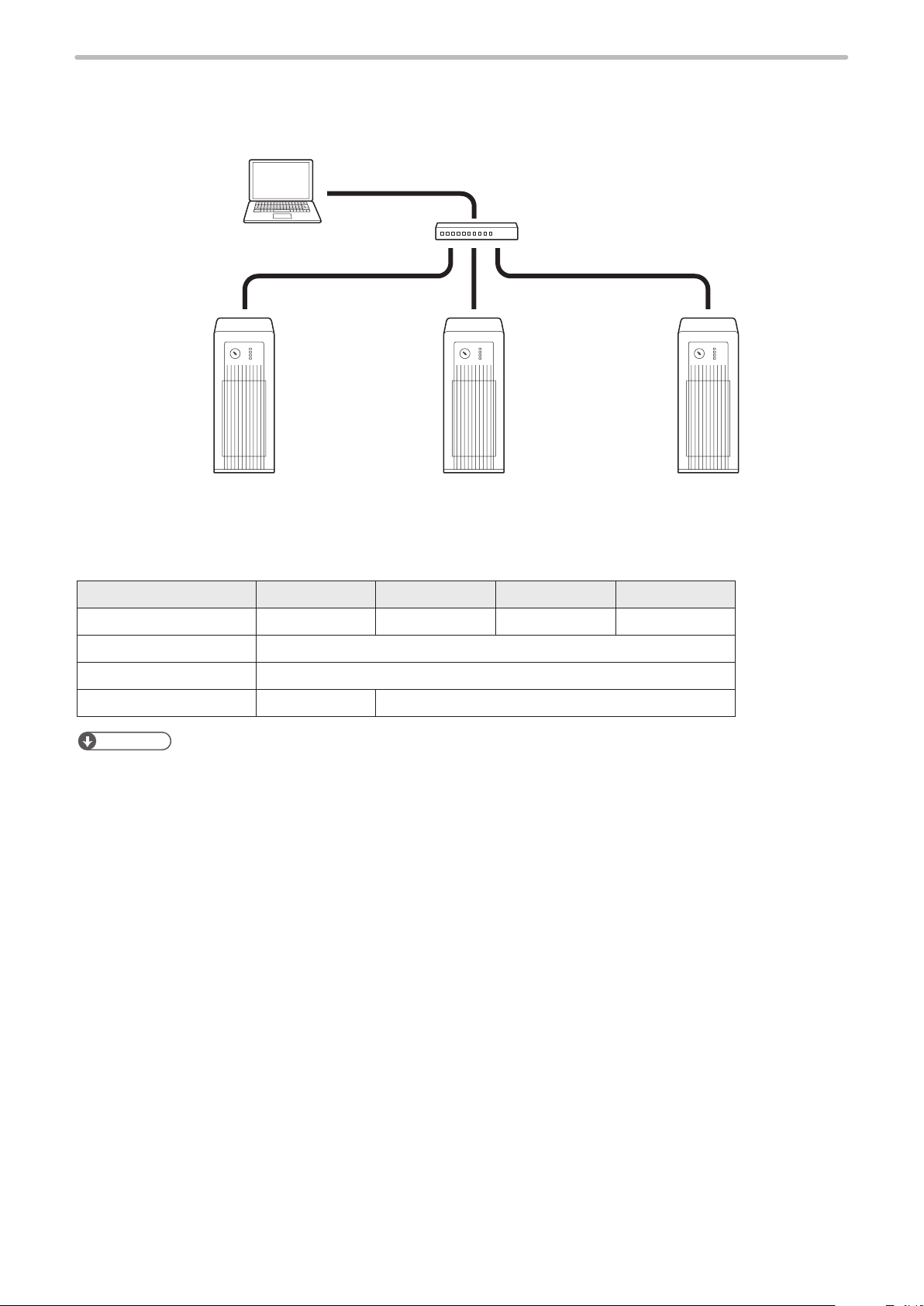

Connect the two or more laser markers and an external device via a HUB or a router:

Use a HUB (or a rooter) that supports 100BASE-TX/10BASE-T and a cable of Category 5 or higher for the connection.

External controller (PC, etc.)

Laser marker controller

(Several units connected)

HUB (or rooter)

Example of communication system settings:

Set a separate IP address not to overlap between the laser marker and PC on the network.

PC Laser marker A Laser marker B Laser marker C

IP address 192.168.1.10 19 2 .16 8 .1.5 19 2 .16 8 .1.6 19 2 .16 8 .1.7

Subnet mask 255.255.255.0

Default gateway None

Command control port — 9094

ンㄆㄇㄆㄓㄆㄏㄆ

• When the laser marker is connected the external control device one to one, no HUB is necessary.

24

1-5 Checking the communication commands

ME-LP-GS-SR-COMP-3

Check the communication commands transmitted and received by the laser marker using the command history function in

the PC configuration software “Laser Marker NAVI smart”.

The command history is displayed with the following procedures.

Connect Laser Marker NAVI smart and the laser marker online.

1.

Click the screen selection menu and select “Maintenance”.

2.

Select “Command history” tab. Up to 100 command messages received or sent by the laser

3.

marker are shown in the list.

ンㄆㄇㄆㄓㄆㄏㄆ

• In the command history the transmitted and received data via RS-232C and Ethernet ports are recorded.

• When a code reader is connected to the RS-232C port of the laser marker, the transmitted and received data with the

code reader is not recorded in the command history.

25

2 Communication Control

ME-LP-GS-SR-COMP-3

Basics

2-1 Communication Data Types

ME-LP-GS-SR-COMP-3

To control this product by communication commands, the external device transmits request data to the laser marker.

After the laser marker receives request data, it transmits the response data to the external device.

2-1-1 Request data

The request data is sent from the external device to the laser marker. The following types are applicable to the request

data.

Setting request

⿎

Request data to modify or create the laser marker data or to control the laser marker operations.

Readout request

⿎

Request data to read out the status or setting data of the laser marker.

2-1-2 Response data

The response data is sent from the laser marker to the external device. The following types are applicable to the response

data:

Positive response

⿎

Response data transmitted when the setting request data were received normally.

The positive response will be transmitted when the laser marker processing has been completed for some of the command

types.

Readout response

⿎

Response data to transmit the readout content for the readout request data.

Negative response

⿎

Response data to transmit when the request data are not acceptable.

27

2-2 Communication Sequence

ME-LP-GS-SR-COMP-3

The communication sequence of this product mainly consists of the sequence where the laser marker transmits the

response data for the (command) data requested from external devices.

As an exception, the laser marker transmits the response data automatically if you have set the response permission of the

marking end verification (MST) command.

Reception timeout

⿎

The time-out duration of this product is set to 10 seconds from receiving the telegraphic message from the head till the end

transmitted from the external device.

If a reception timeout occurs, the telegraphic message transmitted will be discarded and the laser marker will not transmit

the response data.

To resume the communication, transmit the correct telegraphic message once again.

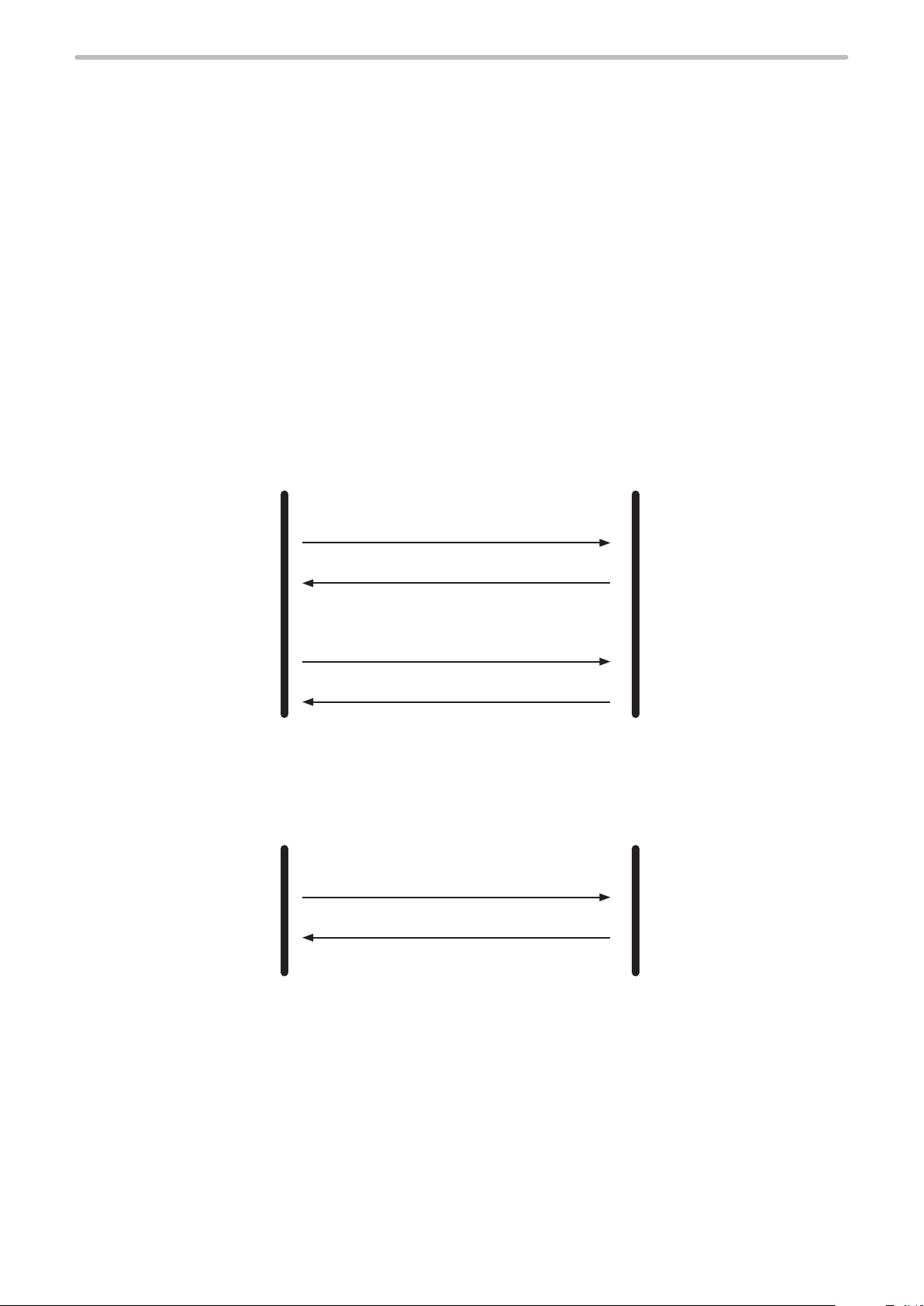

Communication sequence of setting/readout request data

⿎

When the requested data was received normally from the external device, the laser marker transmits positive response to

the setting request data and transmits readout data to the readout request data.

After sending the command, confirm the response data from the laser marker. Do not send the next command before

receiving the response.

External device

Send Receive

Receive Send

Send Receive

Receive Send

Communication sequence when the request data for setting/readout cannot be accepted

⿎

When the request data transmitted from the external device to the laser marker are not acceptable, the laser marker

transmits negative response.

External device

Send Receive

Receive Send

Command (setting request data)

Positive response (ACK)

Command (readout request data)

Readout response

Command (setting/readout request data)

Negative response (NAK)

Laser marker

Laser marker

28

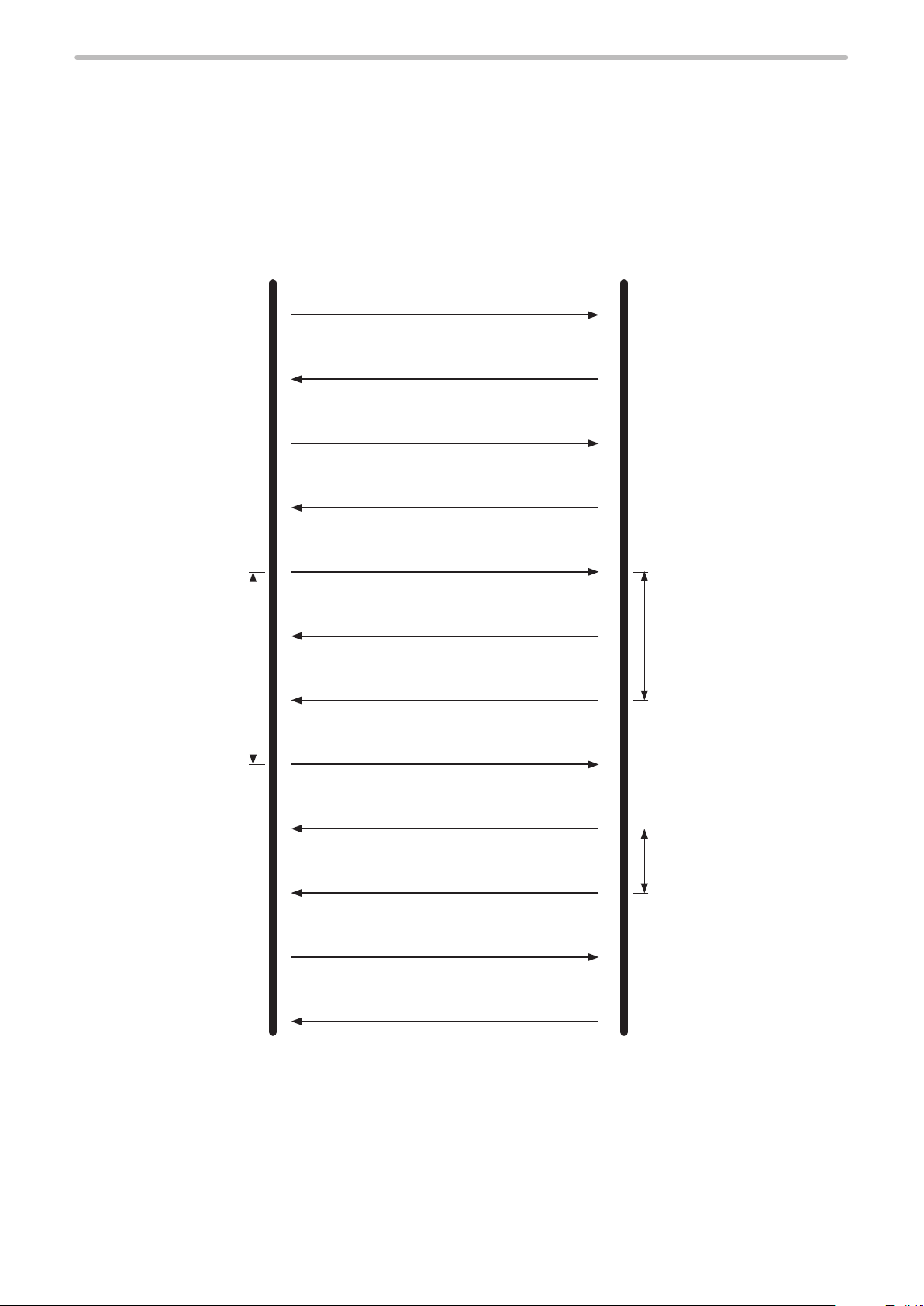

Communication sequence when the marking end verification (MST) command response is

ME-LP-GS-SR-COMP-3

⿎

enabled

The laser marker transmits the response data automatically upon completing the marking trigger processing (at the end of

marking) with the response permission setting of the marking end verification (MST) command.

This response data indicate that the marking trigger processing of the laser marker completed normally or ended

abnormally by an error.

For more information on this command, refer to “3-3-8 Marking end verification: MST” (P.63).

• When the response permission of the marking end verification (MST) command is set

Send the next request

command after

confirming the marking

completed with MST

response.

External device

Marking end verification command

(Response permission specified) : MSTS1

Positive response: ACK00

Shutter (open) command: SHTS1

Positive response: ACK00

Marking trigger command: MRKS1

Positive response: ACK00

Marking status response

(completed normally): MSTA0000

Laser marker

Marking operation

Marking trigger command: MRKS1

Positive response: ACK00

Marking status response

(abnormal end by an error): MSTAE…

Shutter (close) command: SHTS0

Positive response: ACK00

An alarm or a warning

occurred during the marking

trigger processing.

29

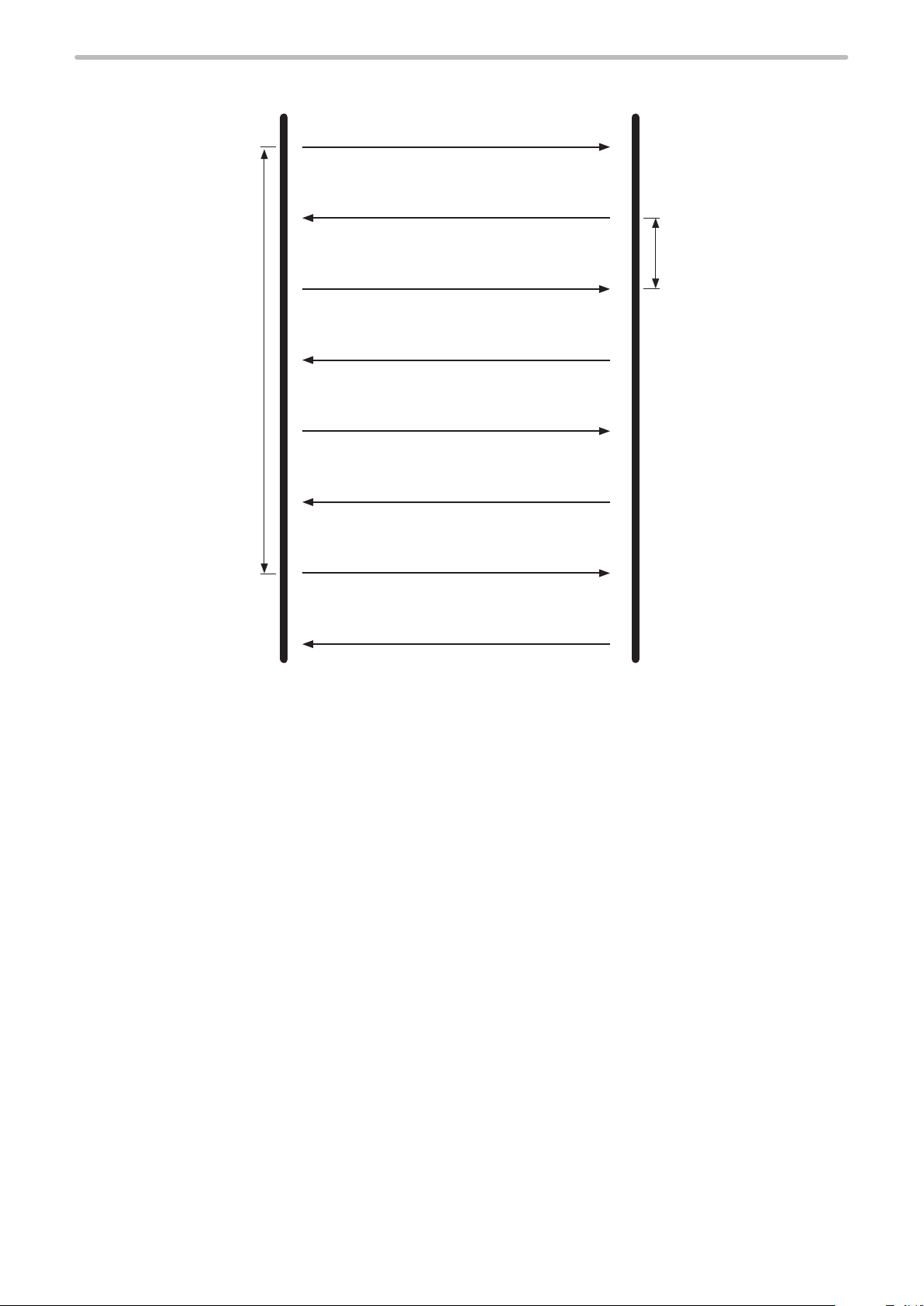

• When the response permission of the marking end verification (MST) command is not set

ME-LP-GS-SR-COMP-3

External device

Send the next request

command after confirming

the marking completed

with STS response.

Laser marker

Marking trigger command: MRKS1

Positive response: ACK00

Check the laser marker

status when appropriate.

Status checking command: STSR

Status readout response: STSA02100

(Marking in progress / trigger ready OFF)

Status checking command: STSR

Status readout response: STSA02110

(Non-marking state / trigger ready ON)

Marking trigger command: MRKS1

Positive response: ACK00

30

Loading...

Loading...