Page 1

’06–’07

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Timers/Time Switches/Counters/Hour Meters

Page 2

LC2H

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

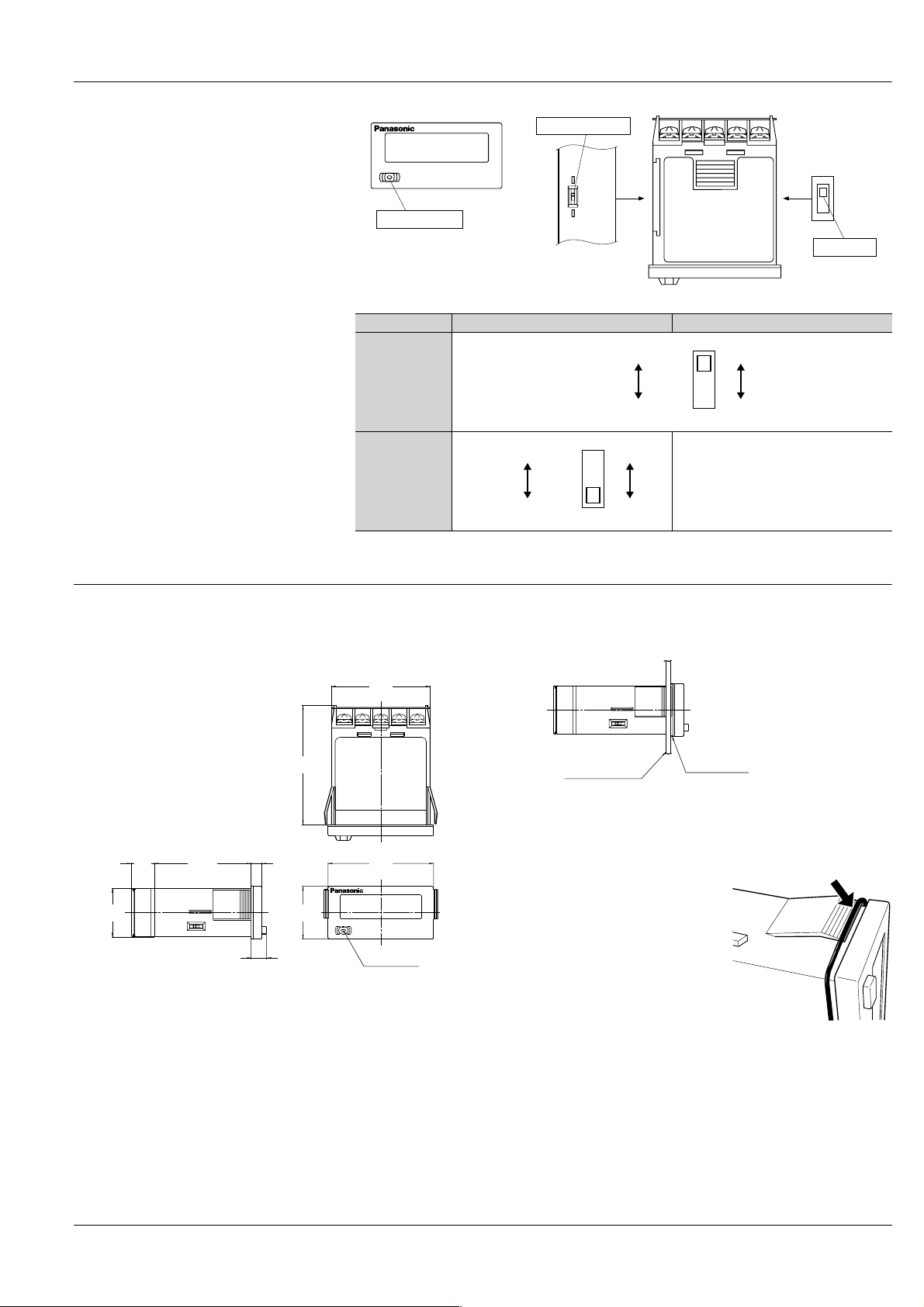

Panel mounting type

One-touch installation type

Panel mounting type

Installation frame type

PC board mounting type

RoHS Directive compatibility information

http://www.nais-e.com/

DIN HALF SIZE

LCD COUNTER

Features

1. 8.7 mm .343 inch Character Height

(previously 7 mm)

Easy-to-read character height increased

from 7 mm to 8.7 mm .276 inch to .343

inch.

8.7mm

.343inch

2. Plenty of Digits

8 digits

3. Counting Speed Switchable

between 2 kHz and 30 Hz

4. Panel Mounting Type Features

2 Installation Methods

Comes with very easy one-touch

installation type and also installation

frame type that uses the bracket on the

timer/counter. Choose a method that

suits the application.

5. Battery Replacement Easy on

Environment

To replace battery simply remove body

for the one-touch installation type, and

remove battery lid for the installation

frame type.

LC2H

Counters

6. Screw Terminals Designed for

Safety

Built in finger protection.

7. Panel Covers Replacable

(Standard color is ash gray.)

Change the panel design by replacing

with a black panel cover.

8. Conforms to IP66 Protective

Construction (Only installation frame

type.) (Front panel surface)

9. Input Methods

1) Non-voltage input method

2) Voltage input method

3) Free voltage input method

10. Backlight Type Added to Series

and Now 2-color Switchable (green/

red)

Easy viewing even in dark places and

switchable between green and red

(Voltage input type).

11. Compliant with UL, c-UL and CE.

Product chart

Type

Installation type

Panel

mounting

type

PC board mounting type ———

One-touch installation type

Installation frame type

Non-voltage input type

Standard type Backlight type

Voltage input type

(4.5 to 30 V DC)

Free voltage input type

(24 to 240 V AC/DC)

Voltage input type

(4.5 to 30 V DC)

Product types

1. Panel mounting type

1) One-touch installation type

1 Standard type

No. digits Counting speed Front reset Input method Part No.

8 digits

Note) Please ask us about types without front resetting.

2 Backlight type

No. digits Counting speed Front reset Input method Part No.

8 digits 2 kHz/30 Hz switchable Yes Voltage input type (4.5 to 30 V DC) LC2H-FE-DL-2KK-B

98

2 kHz/30 Hz switchable

30 Hz Free voltage input type (24 to 240 V AC/DC) LC2H-FE-FV-30

Ye s

Non-voltage input type LC2H-FE-2KK

Voltage input type (4.5 to 30 V DC) LC2H-FE-DL-2KK

Page 3

LC2H

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

2) Installation frame type

1 Standard type

No. digits Counting speed Front reset Input method Part No.

8 digits

Note) Please ask us about types without front resetting.

2 kHz/30 Hz switchable

30 Hz Free voltage input type (24 to 240 V AC/DC) LC2H-F-FV-30

Ye s

2 Backlight type

No. digits Counting speed Front reset Input method Part No.

8 digits 2 kHz/30 Hz switchable Yes Voltage input type (4.5 to 30 V DC) LC2H-F-DL-2KK-B

2. PC board mounting type

No. digits Counting speed Front reset Input method Part No.

8 digits

2 kHz

30 Hz LC2H-C-30-N

No Non-voltage input type

Specifications

1. Panel mounting type

Item

No. digits 8 digits

External power supply Not required (built-in battery)

Max. counting speed 2 kHz/30 Hz (Switchable by switch) 30 Hz (Note 2)

Min. input signal width

(ON: OFF = 1:1)

Input method (signal)

Count

input

Input impedance

Residual voltage Max. 0.5 V — —

Min. input signal width 200 ms

Input method (signal)

Reset

input

Input impedance

Residual voltage Max 0.5 V — Max. 0.5 V

Display method 7-segment LCD

Breakdown voltage (initial) Between charged and uncharged parts: 1,000 V AC for 1 minute.

Insulation resistance (initial) Min. 100 MΩ (measured at 500 V DC) Measurement location same as for break down voltage.

Backlight power — 24 V DC (±10%) —

Protective construction (Note 3) IEC Standard IP66 (only panel front: when using rubber gasket)

Accessories (Note 3) Rubber gasket, mounting bracket

Battery life 7 years (at 25°C 77°F) Note 1 6 years (at 25°C 77°F)

Notes) 1. The value given for battery life is calculated based on continuous operation (count input signal ON/OFF = 1:1), therefore, this value is not guaranteed.

Also, battery life is decreased 30% when operation is continuous with 2 kHz count inputting in 2 kHz mode.

2. Operation is at 25 Hz when using 24 V AC.

3. Only for installation frame type.

Type

Non-voltage input Voltage input Free voltage type

Non-voltage input using

contacts or open collector

connection

When shorted:

Max. 10 kΩ

When open:

Max. 750 kΩ

Non-voltage input using

contacts or open collector

connection

When shorted:

Max. 10 kΩ

When open:

Max. 750 kΩ

Standard type Backlight type Standard type

0.25 ms/16.7 ms (Switchable by switch) 16.7 ms

Non-voltage input type LC2H-F-2KK

Voltage input type (4.5 to 30 V DC) LC2H-F-DL-2KK

LC2H-C-2K-N

High level: 4.5 to 30 V DC

Low level: 0 to 2 V DC

Approx. 4.7 kΩ —

High level: 4.5 to 30 V DC

Low level: 0 to 2 V DC

Appox. 4.7 kΩ

7-segment LCD

With green/red backlight

High level:

24 to 240 V AC/DC

Low level:

0 to 2.4 V AC/DC

Non-voltage input using

contacts or open collector

connection

When shorted:

Max. 10 kΩ

When open:

Max. 750 kΩ

7-segment LCD

Between charged and

uncharged parts: 2,000 V

AC for 1 minute.

99

Page 4

LC2H

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

2. PC board mounting type

Item

Type

Input method Non DC voltage input

No. digits 8 digits

Rated operation voltage 3 V DC

Allowable operation voltage range 2.7 to 3.3 V DC

Current consumption Max. 30 µA (max. 250 µA during reset input)

Max. counting speed 2 kHz 30 Hz

Count

input

Min. input signal width

(ON: OFF = 1:1)

Input method Non-voltage input using contacts or open collector connection

Input impedance

0.25 ms 16.7 ms

Residual voltage Max. 0.5 V

Min. input signal width 10 ms

Reset

input

Input method Non-voltage input using contacts or open collector connection

Input impedance

Residual power Max. 0.5 V

Break down voltage (initial) Between charged and uncharged parts: 1,000 V AC for 1 minute.

Insulation resistance (initial) Min. 100 MΩ (measured at 500 V DC) Measurement location same as for break down voltage.

3. Common

Item

Type

Vibration resistance

Shock resistance

Functional 10 to 55 Hz (1 cycle/min.), single amplitude: 0.15 mm .006 inch (10 min. on 3 axes)

Destructive 10 to 55 Hz (1 cycle/min.), single amplitude: 0.375 mm .015 inch (1 hr. on 3 axes)

Functional Min. 98 m/s2 (4 times on 3 axes)

Destructive Min. 294 m/s2 (5 times on 3 axes)

Operation temperature –10 to +55°C +14 to +131°F (without frost or dew)

Storage temperature –25 to +65°C –13 to +149°F (without frost or dew)

Ambient humidity 35 to 85% RH (non-condensing)

Panel mounting/PC board mounting types

PC board mounting type

When shorted: Max. 10 kΩ

When open: Max. 750 kΩ

When shorted: Max. 10 kΩ

When open: Max. 750 kΩ

Applicable standard

Safety standard EN61010-1 Pollution Degree 2/Overvoltage Category III

(EMI)EN61000-6-4

EMC

Radiation interference electric field strength

Noise terminal voltage

(EMS)EN61000-6-2

Static discharge immunity

RF electromagnetic field immunity

EFT/B immunity

Conductivity noise immunity

Power frequency magnetic field immunity

EN55011 Group1 ClassA

EN55011 Group1 ClassA

EN61000-4-2 4 kV contact

8 kV air

EN61000-4-3 10 V/m AM modulation (80 MHz to 1 GHz)

10 V/m pulse modulation (895 MHz to 905 MHz)

EN61000-4-4 2 kV (power supply line)

EN61000-4-6 10 V/m AM modulation (0.15 MHz to 80 MHz)

EN61000-4-8 30 A/m (50 Hz)

100

Page 5

Part names

(Terminal block side)

(LCD side)

OFF❇

ON

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1. Front reset button

This button resets the count value. It

does not work when the lock switch is

ON. Be aware that battery life will

decrease if this switch is used frequently.

2. Lock switch (Refer to chart on

right.)

Disable the front reset button.

Note) Turn ON at the LCD side (reset disabled) and

OFF at the terminal block side (reset enabled).

3. Count speed switch (Refer to chart

on right.)

Use this switch to switch the count speed

between 30 Hz and 2 kHz. (On the nonvoltage and voltage input types, 30 Hz is

on the LCD side and 2 kHz is on the

terminal block side. Fixed at 30 Hz for

free voltage input type.)

Note) You must press the front reset button when you

change the count speed switch setting.

Confirm, however, that the Lock Switch is OFF

(front switches operable).

RESET

Front reset button

Lock switch

(Unit display 1)

Count speed

switch

(Unit display 2)

COUNTER

LC2H

Count speed switch

Non-voltage input/voltage input Free voltage input

(Terminal block side)

(LCD side)

2k Hz

30Hz❇

—

(Fixed at 30 Hz)

LC2H

Lock switch

Dimensions

1. Panel mounting type

• External dimensions

1) One-touch installation type

(44)

(1.732)

22

.866

10.4

.409

5

.197

7

.276

54.4

2.142

24

.945

Notes) 1. ❇Default setting when shipped.

2. Make the switch setting before installing to panel.

• Panel installation diagram

44.8

1.764

Note) When installing to a 4.5 mm .177 inch thick panel, remove the rubber spacer

When installing the one-touch installation type model, make sure

48

1.890

COUNTER

that the installation spring does not pinch the rubber gasket.

To prevent the installation spring

from pinching the rubber gasket:

1. Set the rubber gasket on both

RESET

LC2H

Reset button

ends of the installation spring

(left and right).

2. Confirm that the installation

spring is not pinching the rubber

gasket, and then insert and fix the

installation spring in place from the

rear of the timer unit.

first.

Panel (1 to 4.5mm

.039 to .177inch

thickness)

mm inch

General tolerance: ±1.0 ±.039

Rubber spacer

101

Page 6

LC2H

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

2) Installation frame type • Panel mounting diagram

44.8

1.764

Mounting screws

(found on mounting frame)

Mounting frame

ATH3803 (included)

54.4

2.142

44

1.732

5

.197

7

.276

24

.945

RESET

48

1.890

COUNTER

Reset button

22

.866

10.4

.409

• Panel cut-out dimensions

The standard panel cut-out is shown below.

Use the mounting frame (ATH3803) and the rubber packing (ATH3804).

(Only installation frame type.)

60 min.

2.362 min.

1.772

+0.5

45

0

+.020

0

+0.5

22.2

0

+.020

.874

0

LC2H

37

1.457

Panel

(1 to 4.5mm .039 to .177inch thickness)

Rubber gasket

ATH3804 (included)

• For connected installation (sealed installation)

(Only installation frame type.)

+0.5

22.2

0

+.020

.874

0

A

A=(48×n-2.5)

A=(1.890×n-.098)

Notes) 1. Suitable installation panel thickness is 1 to 4.5 mm .039 to .177 inch.

2. Waterproofing will be lost when installing repeatedly (sealed installation).

+1.0

0

+.039

0

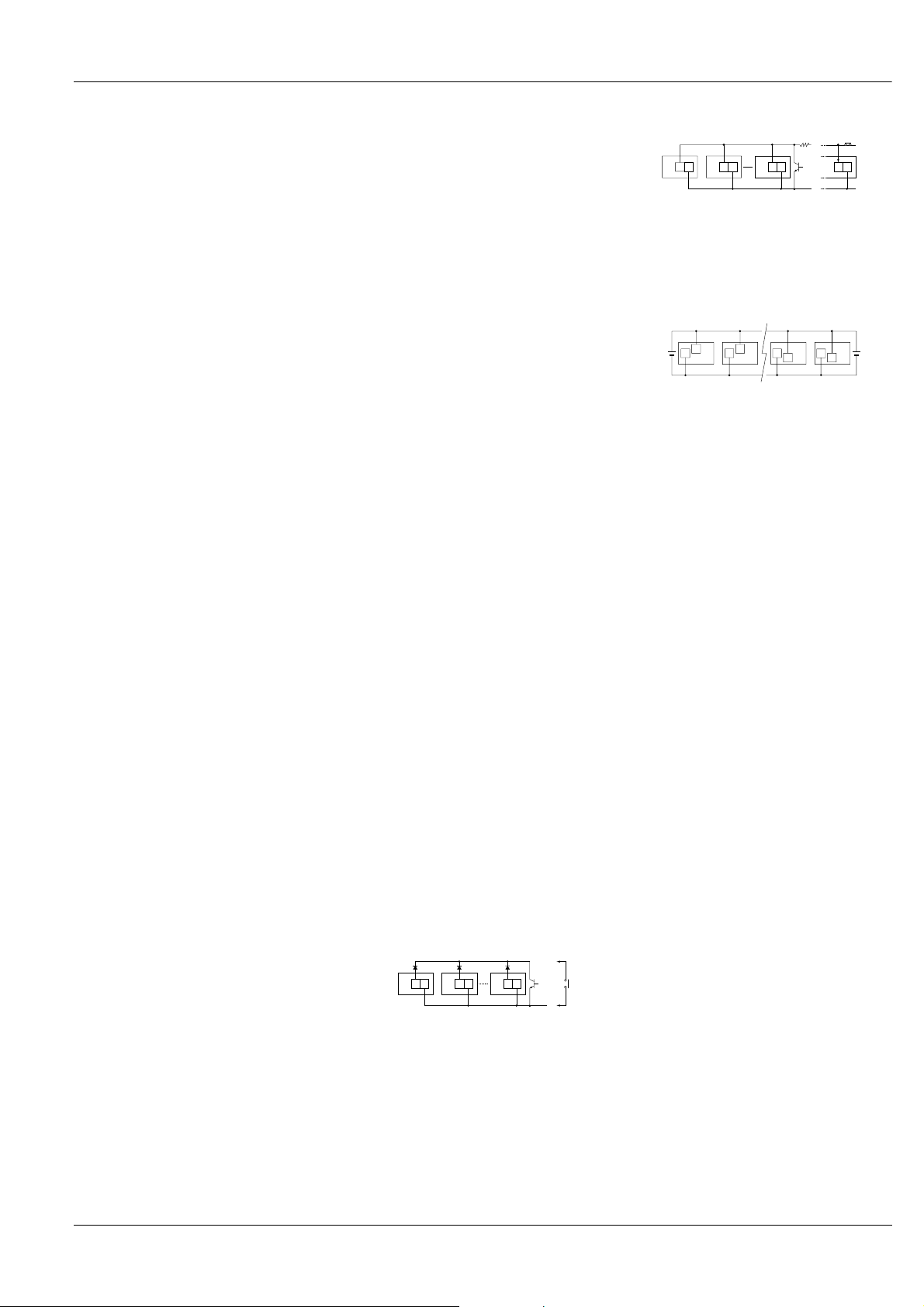

• Terminal layout and wiring diagrams

1) Standard type

Non voltage input type Voltage input type Free voltage input type

Count input

2143

W-R are connected internally.

Reset input

2) Backlight type

Voltage input type

Count input Reset input

+V

0V

12

5

6

+V

34 12

0V

Count input Reset input

+V

2143

0V

Backlight

+V0V

5

34 12

6

+V

0V

<When red><When green>

5

34

6

+V0V

Count input Reset input

21or 43

102

Page 7

2. PC board mounting type

15.24

.600

33.02

1.300

1.9

.075

1.9

.075

5.19

.204

2.54

.100

2.54

.100

8-0.8 dia.

8-.031 dia.

5.08

.200

5.08

.200

5.19

.204

Mounting area

Connection sockets

28 pin DIP terminal

Reset

input

Count

input

3V DC

15

17

14

12

26

28

3

1

Reset

input

Count

input

12 34

+V +V

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

• External dimensions

±0.3

33.02

±.012

1.300

±0.3

5.08

±.012

.200

±0.1

0.6

±.004

.024

±0.3

3.3

±.012

.130

±0.3

5.08

±.012

.200

DIP switch × 8

LC2H

General tolerance: ±1.0 ±.039 mm inch

PC board pattern (BOTTOM VIEW)

43.4

1.709

19

.748

LC2HCOUNTER

• Terminal layout and wiring diagrams

15 17 26 28

14 12 3 1

Q-E, }-w, e-t and S-F are connected internally.

An external power supply is required.

Input method

1. Standard type

Panel mounting type PC board mounting type

Contact input

Count

12 3 4

input

(W and R are connected internally.)

Reset

input

Count

input

0.5

.020

0.3

.012

±0.3

±.012

±0.3

15.24

±.012

.600

±0.1

±.004

General tolerance: ±0.1 ±.004

17.3

.681

Note: The AXS212811K is recommended as a compatible connection socket.

Reset inputCount input

Non-voltage input type

Tr ansistor input

NPN transistor NPN transistor

12 34

0V 0V

(W and R are connected internally.)

Reset

input

Contact input

Count

input

Tr ansistor input

15

14

17

12

3V DC

28

26

3

Reset

input

1

Notes) 1. When using contact input, since current flow is small from terminals 1 and 3 on the panel mounting type and terminals e to t and S to F on the PC board

mounting type, please use relays and switches with high contact reliability.

2. When using transistor input, use the following as a guide for which transistors (Tr) to use for inputting. (Collector withstand voltage Q 50 V, leakage current < 1 µA)

Voltage input type

Tr ansistor input

Reset

input

Count

input

Contact input

12 34

Reset

input

NPN transistor PNP transistor

+V +V

Count

12 34

input

Notes) 1. 2 and 4. (The input and reset circuits are functionally insulated.)

2. When using transistor (Tr) input, use the right as a guide. (Collector withstand voltage Q 50 V, leakage current < 1 µA)

3. Be aware that the application of voltage that exceeds the voltage range of the H level to the count input terminal, and the application of voltage to the reset input

terminal, can cause damage to the internal elements.

Free voltage input type

12 34

Count input

or

or

Reset input

or

103

Page 8

LC2H

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

2. Backlight type

Voltage input type

Tr ansistor input

Reset

input

+V +V

5

Count

input

12 34

Reset

input

6

Count

input

Contact input

5

12 34

6

Reset

input

NPN transistor PNP transistor

+V +V

Count

input

0V 0V

5

12 34

6

Notes) 1. Do not reverse the polarities when connecting the DC voltage for the backlight.

2. 2 and 4. (The input and reset circuits are functionally insulated.)

3. When using transistor (Tr) input, use the right as a guide. (Collector withstand voltage Q 50 V, leakage current < 1 µA)

4. Be aware that the application of voltage that exceeds the voltage range of the H level to the count input terminal, and the application of voltage to the reset input

terminal, can cause damage to the internal elements.

Explanation of operation

1. Counting takes place when the count

input signal is ON.

2. Counting resumes again when the

count value reaches 99999999 (full scale

value) and then returns to “0” with a new

count input.

3. No measurement takes place when a

reset is input.

1) When reset is ON, resetting takes

place and the count becomes “0”.

2) Press the front reset button when you

want to reset manually (only panel

installation type).

Note) ❇Count becomes “1” when the reset input is turned OFF while the count signal is being input.

Count input

Reset input

Count value

01 0 011

99999999

Backlight connection

Green Red

24V DC

5

12 34

6

12 34

5

6

24V DC

❇

Note) Be aware that battery life will decrease if the

count input or reset input are left ON.

104

Page 9

Cautions for use

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1. Non-voltage input type

For both panel mounting and PC

board mounting types

1) Never apply voltage to the non-voltage

input type. This will damage the internal

elements. Also, since there is a possibility

of erroneous operation, do not connect in

parallel the inputs of a non-voltage input

type and another counter from a single

input signal.

2) Since the current flow is very small

from the count input and reset input

terminals (1 and 3 on the panel

mounting type and terminals e to t and

S to F on the PC board mounting type)

please use relays and switches with high

contact reliability.

3) When inputting with an open collector

of a transistor, use a transistor for small

signals in which ICBO is 1 µA or less and

always input with no voltage.

4) When wiring, try to keep all the input

lines to the count and reset inputs as

short as possible and avoid running them

together with high voltage and power

transmission lines or in a power conduit.

Also, malfunctions might occur if the

floating capacitance of these wires

exceeds 500 pF (10 m 32.808 ft. for

parallel wires of 2 mm

kHz mode, use with a wiring floating

capacitance of 120 pF (3 m 9.843 ft. for

parallel wires of 2 mm

when using shielded wiring, be careful of

the capacitance between wires.

PC board mounting type

1) For external power supply use

manganese dioxide or lithium batteries

(CR type: 3V).

2) Always reset after external power is

applied and confirm that the display

reads “0”.

3) Make the wiring from the battery to the

counter unit as short as absolutely

possible. Also, be careful of polarity.

4) Calculate battery life with the following

formula.

t = A/I

t: battery life [h]

I: LC2H current consumption [mA]

A: battery capacity until minimum

operation voltage is reached [mAh]

5) Hand solder to the lead terminal. Do

not dip solder. With the tip of the

soldering iron at 300°C 572°F perform

soldering within 3 seconds (for 30 to 60

W soldering iron).

2. Voltage input type

1) Be aware that applying more than 30 V

DC to count input terminals 1 and 2,

and reset input terminals 3 and 4 will

cause damage to the internal elements.

2

). When using 2

2

). In particular,

2) For external resetting use H level

(application of 4.5 to 30 V DC) between

reset terminals 3 and 4 of the rear

terminals. In this case, connect + to

terminal 3 and – to terminal 4. This is

the valid polarity; therefore, the counter

will not work if reversed.

3) When wiring, try to keep all the input

lines to the count and reset inputs as

short as possible and avoid running them

together with high voltage and power

transmission lines or in a power conduit.

Also, malfunctions might occur if the

floating capacitance of these wires

exceeds 500 pF (10 m 32.808 ft. for

parallel wires of 2 mm

2

).

3. Free voltage input type

1) Use count input terminals 1 and 2 for

free voltage input and reset terminals 3

and 4 for non-voltage input.

2) Be aware that the application of

voltage that exceeds the voltage range of

the H level to the count input terminal,

and the application of voltage to the reset

input terminal, can cause damage to the

internal elements.

3) Since the current flow is very small

from reset input terminal 3, please use

relays and switches with high contact

reliability.

4) When inputting a reset with an open

collector of a transistor, use a transistor

for small signals in which ICBO is 1 µA or

less and always input with no voltage.

5) To reset externally, short reset input

terminals 3 and 4 on the rear.

6) Input uses a high impedance circuit;

therefore, erroneous operation may occur

if the influence of induction voltage is

present. If you plan to use wiring for the

input signal that is 10 m or longer (wire

capacitance 120 pF/m at normal

temperature), we recommend the use of

a CR filter or the connection of a bleeder

resistor.

4. How to reset multiple panel

mounting type counters all at once

(input is the same for count)

Non-voltage input type

D D

D

3

4 3 4 3 4

Notes) 1. Use the following as a guide for choosing

transistors used for input (Tr).

Leakage current < 1 µA

2. Use as small a diode (D) as possible in the

forward voltage so that the voltage between

terminals 3 and 4 during reset input meets

the standard value (0.5 V).

( At IF = 20 µA, forward voltage 0.1 and

higher.)

Tr

or

LC2H

Voltage input type

+V

+V

R

Tr

3

4 3 4 3 4 3 4

Note) Make sure that H (reset ON) level is at least 4.5

V.

5. Backlight luminance

To prevent varying luminance among

backlights when using multiple Backlight

types, please use the same backlight

power supply.

5

5

2

24V DC 24V DC

2

Green Red

6. Environment for use

1) Ambient conditions

• Overvoltage category II, pollution level 2

• Indoor use

• Acceptable temperature and humidity

range: –10 to +55°C, 35 to 85%RH (with

no condensation at 20°C)

• Under 2000 m elevation

2) Use the main unit in a location that

matches the following conditions.

• There is minimal dust and no corrosive

gas.

• There is no combustible or explosive

gas.

• There is no mechanical vibration or

impacts.

• There is no exposure to direct sunlight.

• Located away from large-volume

electromagnetic switches and power

lines with large electrical currents.

3) Connect a breaker that conforms to

EN60947-1 or EN60947-3 to the voltage

input section.

4) Applied voltage should be protected

with an overcurrent protection device

(example: T 1A, 250 V AC time lag fuse)

that conforms to the EN/IEC standards.

(Free voltage input type)

or

2

2

6

6

105

Page 10

LC2H

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

RoHS Directive compatibility information

http://www.nais-e.com/

PRESET COUNTER

Features

1. Preset function equipped in half

size (24 × 48 mm 0.945 × 1.890 inch).

2. Display has backlight for instant

recognition.

Counting upCounting

Red or (Green)

(backlight)

Green or (Red)

(backlight)

Green or Red can

be selected at setup.

(Lit or Flashing)

Red or (Green)

(backlight)

(Lit or Flashing)

Lit or Flashing can

be selected at setup.

LC2H

Counter

3. 8.7 mm 0.343 inch Character Height

(previously 7 mm 0.276 inch)

Easy-to read character height increased

from 7 mm to 8.7 mm 0.276 inch to 0.343

inch.

8.7mm

.343inch

4. Plenty of Digits

8 digits

5. Counting Speed Switchable

between 30 Hz and 5 kHz

6. Conforms to IP66 Protective

Construction (Front panel surface)

Weatherproofing supported by using

optional mounting frame and rubber

gasket

7. Includes reassuring lock mode and

lock switch to prevent erroneous

operation.

8. Screw terminals are constructed to

protect fingers to ensure safety.

9. Compliant with UL, c-UL and CE.

Product types

No. digits Counting speed Output mode Output Operating voltage Part No.

8 digits

Note: Mounting frame and rubber gasket are not included.

106

30 Hz/5 kHz

switchable

Options

• Maintain output/hold count

• Maintain output/over count

• One shot/over count

• One shot/recount

Mounting frame

Rubber gasket ATH3804

Tr ansistor (1a) 24 V DC LC2HP-FEW-B-DC24V

Use for waterproofing (front panel surface)

ATH3803

Page 11

Specifications

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Item Descriptions

Rated operating voltage 24 V DC

Rated power consumption Max. 1.5 W

Rated control capacity 100 mA 30 V DC

Input mode Addition/Subtraction (selectable by front switch)

Max. counting speed 30 Hz/5 kHz (selectable by slide switch on side)

Counting input

Reset input Min. input signal width: Min. 30 ms

Rating

Contact arrangement 1 Form A (Open collector)

Electrical life (contact) 107 operations (at rated control voltage)

Electrical

Mechanical

Operating

conditions

Protective construction IP66 (front panel with mounting bracket and rubber gasket)

* The factory default preset value is set to 1000000.

Input signal

Output mode

Display method

Digit

Memory EEP-ROM (Overwriting times: 105 operations or more)

Allowable operating voltage range 85 to 110% of rated operating voltage

Break down voltage (Initial value) Between input and output: 1,500 V AC, for 1 min.

Insulation resistance (Initial value) Between input and output: 100 MΩ (at 500 V DC)

Functional vibration resistance 10 to 55 Hz (1 cycle/min), Single amplitude: 0.15 mm (10 min. on 3 axes)

Destructive vibration resistance 10 to 55 Hz (1 cycle/min), Single amplitude: 0.375 mm (1 hr. on 3 axes)

Functional shock resistance Min. 98 m/s2 (4 times on 3 axes)

Destructive shock resistance Min. 294 m/s2 (5 times on 3 axes)

Operation temperature –10 to 55°C +14 to +131°F (without frost or dew)

Storage temperature –25 to +65°C –13 to +149°F (without frost or dew)

Ambient humidity 30 to 85% RH (at 25°C 77°F, non-condensing)

(Switch between red and green for backlight, and between lit and flashing for count up.)

Min. input signal width: 16.7 ms at 30 Hz/0.1 ms at 5 kHz,

ON time : OFF time = 1 : 1

• Non-voltage input using contacts or open-collector connection

• Input impedance; when shorted: Max. 1 kΩ, when open: Min. 100 kΩ

• Residual voltage: Max. 2 V

• Maintain output/hold count • Maintain output/over count

• One shot/over count • One shot/recount

(Selectable by front switch)

7-segment LCD

–9999999 to 99999999 (–7 digits to +8 digits)

(0 to 99999999 for preset value)

LC2H

Applicable standard

(EMI)EN61000-6-4

Radiation interference electric field strength

Noise terminal voltage

(EMS)EN61000-6-2

Static discharge immunity

EMC

RF electromagnetic field immunity

EFT/B immunity

Conductivity noise immunity

Power frequency magnetic field immunity

EN55011 Group1 ClassA

EN55011 Group1 ClassA

EN61000-4-2 4 kV contact

8 kV air

EN61000-4-3 10 V/m AM modulation (80 MHz to 1 GHz)

10 V/m pulse modulation (895 MHz to 905 MHz)

EN61000-4-4 2 kV (power supply line)

1 kV (signal line)

EN61000-4-6 10 V/m AM modulation (0.15 MHz to 80 MHz)

EN61000-4-8 30 A/m (50 Hz)

107

Page 12

LC2H

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Part names

1. Front reset key

This key resets the count value. It does

not work when the lock switch is ON.

2. Mode key

Use to switch between each mode.

3. Setting key

Used to set digits of preset values or set

each mode.

4. Set key

Use to set preset values or to switch

between modes.

5. Lock switch

Disable the operation of the front panel

reset key and the mode key. With the lock

switch on, is displayed for about

two seconds when the reset key or mode

switch is operated.

6. Count speed switch

Use this switch to switch the count speed

between 30 Hz and 5 kHz.

COUNTER

RESET MODE SET

LC2H

1234

5

6

Lock switch

(unit display 1)

Count speed switch

(unit display 2)

6

(Terminal block side)

(LCD side)

(Terminal block side)

(LCD side)

5

❇: Default setting when shipped.

OFF❇

ON

5kHz

30Hz❇

Notes: 1. Make the switch setting before installing to panel.

2. Please turn the power off if you change the setting of the count speed switch when the power is on. The

setting will become valid when the power is turned back on.

Dimensions

• External dimensions

44.8

1.764

54.4

2.142

10.4

.409

22

.866

• Panel cut out dimensions

The standard panel cut out is shown below.

Use the mounting bracket (ATH3803) and the rubber gasket (ATH3804).

(Only installation frame type)

44

1.732

.276

5

.197

7

RESET

MODE

48

1.890

COUNTER

SET

LC2H

24

.945

mm inch

General tolerance: ±1.0 ±.039

When installing the one-touch installation type model, make sure

that the installation spring does not pinch the rubber gasket.

To prevent the installation spring

from pinching the rubber gasket:

1. Set the rubber gasket on both

ends of the installation spring

(left and right).

2. Confirm that the installation

spring is not pinching the rubber

gasket, and then insert and fix the

installation spring in place from the

rear of the timer unit.

• When installing repeatedly (sealed installation)

(Only installation frame type)

+0.5

22.2

0

+.020

.874

0

A

+1.0

0

+.039

0

60 min.

2.362 min.

1.772

A=(48×n-2.5)

A=(1.890×n-.098)

+0.5

45

0

+.020

0

+0.5

22.2

0

+.020

.874

0

Notes: 1. Suitable installation panel thickness is 1 to 4.5 mm 0.39 to 0.177 inch.

2. Waterproofing will be lost when installing repeatedly (sealed installation).

108

Page 13

How to set

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1. Preset value setting mode

This is the mode for setting preset values.

Press the MODE key. Set the digit. Set the value.

1) Pressing the MODE key takes you to

the preset value setting mode.

Sample display in preset value

setting mode

(when preset value is 1000)

2) Pressing the setting key moves the

flashing digit left by one. Following the

highest digit it returns to the lowest digit

and each time the digit setting key is

pressed it moves one to the left.

3) Pressing the set key increases the

value by one. (After 9 it returns to 0 and

then changes to 1, 2, 3, etc.)

4) Pressing the front panel reset key sets

the displayed preset value and returns

you to the regular operation mode.

5) In the preset value setting mode if you

do not operate the digit setting key or the

set key for ten seconds or more you will

be returned to regular operation. In this

case the preset value will not change.

2. Lock mode

This mode prohibits everything except

the preset value setting mode.

+

the MODE key.

1) Pressing the set key while holding

down the mode key takes you to the lock

mode.

Un-Lock LockPress the SET key while pressing

2) The display reads “Un-Lock” after

entering the lock mode (initial setting).

Display after entering lock mode

(Example showing “Un-Lock”.)

3) Pressing the setting key changes the

display between “ Lock” and “Unlock”.

(Example showing “ Lock”.)

4) Pressing the front panel reset key sets

the content displayed and returns you to

regular operation mode.

Note: You will not be returned to regular operation

mode if you do not press the front panel reset

key.

5) When the lock mode display reads

“ Lock”, you will not be able to move

to the backlight setting mode, the input

setting mode, or the output setting mode.

3. Backlight setting mode

This is the mode for setting the backlight

during count up.

Press the SET key while pressing

+

the MODE key.

Lit red

Lit green

Flashes green

Flashes red

1) Pressing the SET key two times while

holding down the MODE key takes you to

the backlight setting mode.

2) The display in the backlight setting

mode reads “ LEd”

Display after entering

the backlight setting mode.

3) The LED backlight will be red (initial

setting).

LC2H

4) The backlight changes from flashing

green to flashing red to lit green and to lit

red with each press of the setting key.

5) Pressing the front panel reset key sets

the current backlight color and returns

you to regular operation mode.

Note: You will not be returned to regular operation

mode if you do not press the front panel reset

key.

4. Input setting mode

This is the mode for setting addition or

subtraction.

+

the MODE key.

1) Pressing the SET key three times

while holding down the MODE key takes

you to the input setting mode.

2) The display after entering the input

setting mode reads “ UP” (initial

setting).

Display after entering input

setting mode

(Example showing “UP”)

3) Pressing the setting key changes the

display to “dn” (subtraction) and pressing

it again changes it to “UP” (addition). The

display alternates between “dn” and “UP”.

(Example showing “dn”)

4) Pressing the front panel reset key sets

the content displayed and returns you to

regular operation mode.

Note: You will not be returned to regular operation

mode if you do not press the front panel reset

key.

Addition SubtractionPress the SET key while pressing

109

Page 14

LC2H

Un-Lock LockPress the SET key while pressing

the MODE key.

+

Mode changes as follows by pressing the SET key while holding down the MODE key.

When the lock is set, you cannot enter modes other than

backlight setting mode.

Lit red

Flashes green

Lit green

Flashes red

Press the SET key while pressing

the MODE key.

+

Addition SubtractionPress the SET key while pressing

the MODE key.

+

HOLD-A HOLD-B

SHOT-B SHOT-A

Lock mode Backlight setting mode

Output setting mode Input setting mode

Press the SET key while pressing

the MODE key.

+

2) Lock mode

3) Backlight setting mode

4) Input setting mode

5) Output setting mode

Front panel reset key

Regular operation mode

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

5. Output setting mode

This sets the operation mode.

+

Press the SET key while pressing

the MODE key.

HOLD-A HOLD-B

SHOT-B SHOT-A

1) Pressing the SET key four times while

holding down the MODE key takes you to

the output setting mode.

2) The display reads “HoLd-A” (initial

setting) after entering the output setting

mode.

3) Pressing the setting key causes the

display to change as follows:

HOLD-B (Output maintain/over count I)

SHOT-A (One shot/over count)

SHOT-B (One shot/recount I)

HOLD-A (Output maintain/hold count)

4) Pressing the front panel reset key sets

the display content and returns you to

regular operation mode.

Note: You will not be returned to regular operation

mode if you do not press the front panel reset

key.

Please be aware that after doing a front

panel reset key and returning to regular

operation mode, the preset values, count

value and output will be as shown in this

table.

Preset

value

Lock

mode

Backlight

setting

mode

Input

setting

mode

Output

setting

mode

Note: “×” sign: No change

×× ×

×× ×

×

×

Count value

Addition: “0”

Subtraction:

“Preset value”

Addition: “0”

Subtraction:

“Preset value”

Output

change

ON➝OFF

ON➝OFF

Changing the preset value

1. It is possible to change the preset

value even during counting. However,

be aware of the following points.

1) If the preset value is changed to less

than the count value with counting set to

the addition direction, counting will

continue until it reaches full scale, returns

to zero, and then reaches the new preset

value. If the preset value is changed to a

value above the count value, counting will

continue until the count value reaches the

new preset value.

Compliance with the CE marking

• EMC Directive (89/336/EEC)

The LC2H Preset Counter conforms to

the EMC Directive as a simple counter.

Applicable standards: EN61000-6-4,

EN61000-6-2

110

2) Suppose that the counter is preset to

count down. Whether a preset count

down value is smaller or larger than the

count value, the counter counts down to

“0 (zero)”.

2. If the preset value is changed to “0”,

the counter will not complete countup. It starts counting up when the

counting value comes to “0 (zero)”

again.

1) Addition (up-count) input when

counting is set to the addition direction,

counting will continue until full scale is

reached, return to zero, and then

complete count-up.

2) Subtraction (down-count) input when

counting is set to the subtraction direction,

counting will continue until full scale

“–9999999” is reached, and then the

display will change to “ ”.

Page 15

Operation mode

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Output mode Operation Example when input mode is either addition or Subject:ubtraction

Output maintain/

hold count

HOLD-A

Output maintain/

over count I

HOLD-B

One shot/

over count

SHOT-A

One shot/

recount I

SHOT-B

Output control is maintained after count-up

completion and until resetting.

During that time, the count display does not

change from that at count-up completion.

Output control is maintained after count-up

completion and until resetting. However,

counting is possible despite completion of

count-up.

Output control is maintained after count-up

completion for a fixed time (approx. 1 sec.).

Counting is possible despite completion of

count-up.

Output control is maintained after count-up

completion for a fixed time (approx. 1 sec.).

Counting is possible despite completion of

count-up. However, reset occurs

simultaneous with completion of count-up.

While output is being maintained, restarting

of the count is not possible.

Output

Counting able/unable

Addition

Subtraction

Output

Counting able/unable

Addition

Subtraction

Output

Counting able/unable

Addition

Subtraction

Output

Counting able/unable

Addition

Subtraction

01

n n–1

OFF ON

Able

OFF ON

Able

n n+1 n+2 n+301 n–2 n–132

0–1–2–3n n–1 2 1n–3n–2

One shot pulse width: approx. 1 sec.

OFF ON

Able

n n+1 n+2 n+301 n–2 n–132

0–1–2–3n n–1 2 1n–3n–2

One shot pulse width: approx. 1 sec.

OFF ON

Able

32

n–3n–2

0123 4

n–1

n n–1 n–2 n–3 n–4

1

LC2H

Unable

n01 n–132

0n n–1 1n–34n–4n–2

n: Preset value

n: Preset value

n: Preset value

n: Preset value

111

Page 16

LC2H

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Cautions for use

1. Input and output connection

1) Input connection

(1) Contact input

Use highly reliable metal plated contacts.

Since the contact’s bounce time leads

directly to error in the count value, use

contacts with as short a bounce time as

possible. In general, select input to have

a maximum counting speed of 30 Hz.

Count

input

5

6

(2) Non-contact input (Transistor input)

Connect with an open collector. Use

transistors whose characteristics satisfy

the criteria given below.

Reset

3412

input

VCEO = Min. 20 V

IC = Min. 20 mA

ICBO = Max. 6 µA

Also, use transistors with a residual

voltage of less than 2 V when the

transistor is on.

* The short-circuit impedance should be less

than 1 kΩ.

(When the impedance is 0 Ω, the current

coming from the count input terminal is

approximately 5 mA and from the reset

input terminal is approximately 1.5 mA.)

Also, the open-circuit impedance should

be more than 100 kΩ.

Count

input

5

3412

6

Reset

input

(3) Input wiring

When wiring, use shielded wires or

metallic wire tubes, and keep the wire

lengths as short as possible.

2) Output connection

Since the transistor output of counter is

insulated from the internal circuitry by a

photo-coupler, it can be used as an NPN

output or PNP (equal value) output.

As NPN output

Load

5

3412

6

Load’s power

supply

As PNP output

5

3412

6

Load

Load’s power

supply

2. Self-diagnosis function

If a malfunction occurs, one of the following displays will appear.

Display Contents

Err-00

Err-01

* Includes the possibility that the EEP-ROM’s life has expired.

Malfunctioning

CPU

Malfunctioning

memory*

Output

condition

OFF

Restoration

procedure

Enter front

reset key or

restart

counter

Preset values after

restoration

The preset value at

start-up before the

CPU malfunction

occurred.

0

3. Terminal connection

1) When wiring the terminals, refer to the terminal layout and

wiring diagrams and be sure to perform the wiring properly

without errors.

An external power supply is required in order to run the main

unit.

Power should be applied between

terminals (1) and (2). Terminal (1) acts

as the positive connection and terminal

5

1

234

6

(2) as the negative.

Operating voltage

2) After turning the counter off, make sure that any resulting

induced voltage or residual voltage is not applied to power

supply terminals (1) through (2). (If the power supply wire is

wired parallel to the high voltage wire or power wire, an induced

voltage may be generated at the power supply terminal.)

3) Have the power supply voltage pass through a switch or relay

so that it is applied at one time.

112

Page 17

LC2H

Tool

1

2

1

6

7

3

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

PRECAUTIONS IN USING THE LC2H SERIES

Cautions for use

1. Insulation sheet

Before using a panel mounting type,

please pull and remove the insulation

sheet from the side of the product in the

direction of the arrow.

In consideration that the product might be

stored for long periods without being

used, an insulation sheet is inserted

before shipping. Remove the insulation

sheet and press the front reset button.

• LC2H total counter (one-touch

installation type)

Insulation sheet

Reset button

• LC2H total counter (installation

frame type)

• LC2H preset counter

1) The front plate will not be waterproof

when this product is installed on a panel.

To make the front plate waterproof,

please install the following.

When using the waterproof type (IP66:

panel front only), install the counter to the

front plate with mounting frame ATH3803

(sold separately) and rubber gasket

ATH3804 (sold separately). Be sure to

tighten using mounting screws.

Mounting frame

(ATH3803)

Rubber gasket (ATH3804)

When installing the mounting frame

and rubber gasket please remove the

pre-attached o-ring.

2) Panel installation order

(1) Remove o-ring.

(2) Place rubber gasket.

(3) Insert counter into panel.

(4) Insert mounting frame from the

rear.

(5) Secure with mounting screws (two

Insulation sheet

Reset button

2. Waterproof construction

• LC2H total counter (installation

frame type)

The operation part of the panel

installation type (installation frame type)

is constructed to prevent water from

entering the unit and a rubber gasket is

provided to prevent water from entering

the gap between the unit and the panel

cutout.

There must be sufficient pressure applied

to the rubber gasket to prevent water

from entering.

Be sure to use the mounting

reinforcement screws when installing the

mounting frame (ATH3803).

Note: The one-touch installation type is

not waterproof.

Mounting frame

(ATH3803)

locations)

3. Do not use in the following

environments

1) In places where the temperature

changes drastically.

2) In places where humidity is high and

there is the possibility of dew.

(When dew forms the display may vanish

and other display errors may occur.)

4. Conditions of use

1) Do not use on places where there is

flammable or corrosive gas, lots of dust,

presence of oil, or where the unit might

be subject to strong vibrations or shocks.

2) Since the cover is made of

polycarbonate resin, do not use in places

where the unit might come into contact

with or be exposed to environments that

contain organic solvents such as methyl

alcohol, benzene and thinner, or strong

alkali substances such as ammonia and

caustic soda.

5. Cautions regarding battery

replacement

1) Remove wiring before replacing the

battery. You may be electrocuted if you

come into contact to a part where high

voltage is applied.

2) Make sure you are not carrying a static

electric charge when replacing the

battery.

3) Battery replacement procedure

For LC2H total counter (one-touch

installation type)

(1) Remove the up/down hook of the

case using a tool.

(2) Pull the unit away from the case.

(3) Remove the battery from the side of

the unit. Do not touch the display or

other parts.

(4) Before inserting wipe clean the

surface of the new battery.

(5) Insert the new battery with the “+”

and “–” sides in the proper position.

(6) After replacing the battery, return

the unit to the case. Verify that the

hook of the case has properly

engaged.

(7) Before using, press the reset button

on the front.

113

Page 18

LC2H

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

For LC2H total counter

(installation frame type)

(1) Remove the battery cover from the

case.

(2) Remove the battery from the side of

the case. The battery will come

loose if you put the battery side face

down and lightly shake the unit.

(3) Before inserting wipe clean the

surface of the new battery.

(4) Insert the new battery with the “+”

and “–” sides in the proper position.

(5) After replacing the battery, return

the battery cover to the case. Verify

that the hook of the battery cover is

properly engaged.

(6) Before using press the reset button

on the front.

“+” side

“−” side

1

6. Terminal connection

Tighten the terminal screws with a torque

of 0.8 N·cm or less.

2

5

6

Options

1. Accessories (for LC2H total

counter)

Panel cover (black)

COUNTER

RESET

LC2H

Part No.: AEL3801

You can change the design of the front

panel by replacing it with this black panel

cover. The counter comes with an ash

gray panel cover as standard.

Note: No panel cover accessory (black) is available

for the LC2H preset counter.

2. Lithium battery (3 V)

Panasonic

CR2477

3V

JAPAN

Part No.: ATH3802

Packaged with the LC2H (excluding the

PC board mounting type).

Warning

• Make sure the “+” and “−” polarities are

positioned correctly.

• Do not throw the old battery into a fire,

short circuit it, take it apart, or allow it to

come into contact with heat.

• The battery is not rechargeable.

3. Installation parts

Mounting frame

(Suitable for installation frame type LC2H

total counter and LC2H preset counter)

Part No.: ATH3803

Packaged with the mounting bracket type

LC2H total counter

Rubber gasket

(Suitable for installation bracket type

LC2H total counter and LC2H preset

counter)

Part No.: ATH3804

Packaged with the mounting bracket type

LC2H total counter

114

Page 19

93

COUNTERS SELECTOR CHART

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Contact

output

(1 Form C)

Contact

output

(1 Form A)

Open

collector

output

Classification

Name of product LC2H Counter LC4H/-L Counter

Type Total counter Preset counter

Input mode/Input method

Appearance

Features

Rated operating voltage

UP type

Flush mounting type

PC board mounting type

AEL3

8.7 mm tall 8-digit display

Bright 2-color back light

Flush mounting type:

Unnecessary (Built-in

battery)

PC board mounting type:

3 V DC (Battery in

externally installed)

8-digit

Number of digits

(counter capacity)

9

0

9999999

LC2H Counter

Preset counter

UP, DOWN type

AEL3

8.7 mm tall 8-digit display

Preset function equipped

in half size

Display has backlight for

instant recognition

24 V DC

8-digit

9

9999999

Electronic counters

UP, DOWN, and DIR

(multi-mode)/DIP switch

4-digit

display

Bright and easy-to-read

display

Simple operation

Short body

Conforms to IP66’s

weather resistant

standards

100 to 240 V AC

24 V AC, 12 to 24 V DC

4-digit

0

6-digit

0

9999

6-digit

display

9

99999

LC4H-S Counter

Preset counter

UP, DOWN, and DIR

(multi-mode)/DIP switch

4-digit

display

Bright and easy-to-read

display

Simple operation

Pre-scale function Built-in

power supply for highcapacity sensor (100 to

240 V AC type)

Conforms to IP66’s

weather resistant

standards

100 to 240 V AC

0

9999

6-digit

9

999909

4-digit

0

LC4H-W Counter

Preset counter

UP, DOWN, and DIR

(multi-mode) 2 modes

selectable/DIP switch

6-digit

display

Bright and easy-to-read

display

Simple operation

Upper and lower limit

settings are available.

Conforms to IP66’s

weather resistant

standards

100 to 240 V AC

24 V AC

12 to 24 V DC

6-digit

0

999999

Counter/Indication

Counting speed

Input

Reset

(Reset input

specifications conform to

those of counting input)

Options

Zero-suppress function

(LCD)

Flush mounting type:

2kHz/30Hz

(Changeable by a switch)

PC board mounting type:

2kHz/30Hz

(Different type)

Counting (signal) input and

reset input

• Input by short-circuiting

or opening contacts

• Open collector input

• Voltage input

• Front reset button and

external reset input

terminal

• External reset dip

terminal

—Preset

—Control output

——Power supply output

Flush mounting type (No

need for easy installation

type)

Mounting frame, rubber

gasket

Zero-suppress function

(LCD)

30Hz/5kHz

(switchable)

Counting (signal) input and

reset input

• Input by short-circuiting

or opening contacts

• Open collector input

• Manual reset with and

external terminal and

front reset key

• Manual reset types

inside one-short output

models

• Counter number setting

with key switches

—

Mounting frame, rubber

gasket

7-segment LCD

Counter value

(backlight red LED)

Setting value

(backlight yellow LED)

30Hz/5kHz

2-input (multi-mode) and

reset input

• Input by short-circuiting

or opening contacts.

• Open collector input

• Manual reset with and

external terminal and

front reset key

• Manual reset types

inside one-short output

models

• Operation mode setting

with dip switches

• Counter number setting

with key switches

or

11 P plug-in

(terminal block, socket)

8 P plug-in

(terminal block, socket)

7-segment LCD

Counter value

(backlight red LED)

Setting value

(backlight yellow LED)

7-segment LCD

Counter value

(backlight red LED)

Setting value

(backlight yellow LED)

30Hz/5kHz

2-input (multi-mode) and

reset input

• Input by short-circuiting

or opening contacts.

• Open collector input

• Manual reset with and

external terminal and

front reset key

• Manual reset types

inside one-short output

models

• Operation mode setting

with dip switches

• Counter number setting

with key switches

or

External power supply 12 V DC

100 mA max. (AC type only)

11 P plug-in

(terminal block, socket)

2-input (multi-mode) and

reset input

• Input by short-circuiting

• Open collector input

• Manual reset with and

• Manual reset types

• Output mode setting

• Counter number setting

11 P plug-in

(terminal block, socket)

30Hz/5kHz

or opening contacts.

external terminal and

front reset key

inside one-short output

models

with dip switches

with key switches

or

—

Available standards UL, c-UL, CE

Page P. 98 P. 115

UL, c-UL, CE

P. 106

UL, c-UL, CE

UL, c-UL, CE

P. 123

UL, c-UL, CE

P. 132

Page 20

TYPICAL COUNTER APPLICATIONS

The highly accurate, reliable counters can be controlled from

the front panel and are suitable for a wide range of applications.

Shipment quantities are counted to control the conveyor line flow.

Entrance ExitPhotoelectric

(

up count

)

IN1

(

down count

)

IN2

FULL

VACANT

switch

IND and HOLD-D modes

for parking lots

Incoming and outgoing cars are counted

to switch the FULL and VACANT signs.

Rotary

To valve

encoder

PHASE and HOLD-A modes

for valve control

Rotary encoder signals are counted to

control a valve aperture.

Electric counter

Motor

Photoelectric

Printing

machine

switch

UP and SHOT-A modes

for packing a specified number of copies

Printed matter is counted to package a

specified number of copies.

Mark

sensor

Film

Marking

Cutter

UP and SHOT-B modes

for packing medicine tablets

Medicine tablets are packed in specified

quantities.

IN2

Mark sensor

Rejectables

Labeling

IN1

Acceptables

Sorting

(

down count

)

(

up count

)

machine

machine

UP and SHOT-C modes

for counting acceptables

Labeled cans alone are counted up.

Rejected cans are not counted.

IN2 (down count

)

Rotary

IN1 (up count

)

Leader sheet

Mark

sensor

encoder

(

single-phase

)

UP and SHOT-D modes

for winding leader sheet

Extra leader sheet that is now wound is

counted by a rotary encoder and a color

detecting sensor.

IN2

IN1

(

counting

)

(

up/down count selection

)

DIR input mode

for controlling part stocks

Incoming and outgoing parts are counted

to keep parts feeders well-stocked.

Pipe

Rotary

Electric counter

Cutter

encoder

PHASE input mode for sizing

Teamed up with a rotary encoder, the

counter is used to control the cutting

length of pipes.

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

DOWN and HOLD-A modes

for shipment quantity counting

Photoelectric

switch

(

stop/start

Motor

)

Page 21

COUNTER-RELATED TERMINOLOGY

TYPES OF COUNTERS

1. Electro Preset Counter

The counter is equipped with semiconductor counting circuitry. When the

counter counts up to a preset number, its

output circuit sends a signal.

2. Electro Magnetic Counter

A magnet is magnetized and demagnetized to drive the dial and count up numbers.

RATING

1. Rated Operating Voltage

The voltage is applied to start the

counter.

COUNTINGS

1. Pulse

This is a voltage or current signal sent at

intermittent time intervals.

2. Count

Pulses are used to count up and down.

3. Miss-count

This happens if the number of pulses

does not correspond to the number of

counts.

4. Hertz

This unit of counting speed is used to

give the number of counts per one

second.

5. Make Ratio

This is the ratio of ON time (Ta) to OFF

time (Tb).

6. Maximum Counting Speed

Suppose that the counter is operated

with an input pulse of a make ratio of 1.

The highest counting speed is the peak

of a range in which the output circuit can

send signals without mis-counting. The

speed is expressed in units of Hz (cps:

counts per a second).

7. Over Count

Counting continues beyond a preset

number.

8. Recount

When counting is up, the counter display

resets to zero and counting restarts.

9. Down Count

Numbers are counted down one by one

from a preset number.

10. Up Count

Numbers are counted up one by one

from zero.

11. Up/Down Count

Numbers are counted up or down

depending on input

conditions.

12. Rejection (gate) Input

This signal is used to keep the counter

from counting.

OUTPUTS

1. Count Up

When a preset number is reached, the

output circuit sends a signal.

2. Retained Output

The output is held until a reset signal is

sent.

3. One Shot Output

This output has a specified width of time.

RESETTINGS

1. Reset

The counting process, display and output

sections are all brought back to the initial

status.

2. Power off Reset

The operating voltage is turned off to

reset the counter.

3. Manual Reset

The counter is manually reset.

4. Remote Reset

A signal is sent from a remote point to

the reset terminal so as to reset the

counter.

5. Automatic Reset

When counting is up, internal circuitry is

activated to automatically reset the

counter.

6. Reset Signal Width

This is the time during which the power

is off so as to reset the counter or during

which an external (manual) reset signal

is sent.

7. Reset time

This is the time from the moment a reset

signal is sent to the instant the counter is

ready to start counting again.

OTHERS

1. Function of Memorizing Condition

Counting data up until the operating

voltage is turned off can be stored in

memory. When the power is reactivated,

the data can be reproduced.

2. Anti-surge

The strength against power voltage

surge is determined by applying a singlepole full-wave voltage (several hundred

to several thousand volt wave for ±(1.2 ×

50) µs) acrosss the control power

terminals.

Surge waveform

[Single-pole full-wave voltage for ±(1.2 ×

50) µs]

3. Noise Immunity

This is the strength against external

noise. Relay noise tests, noise simulator

tests, etc. are conducted.

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Ta

Tb

Time

100

90

)

%

(

50

30

Surge voltage

0

0 1.2 50

Peak value

Time (µs

)

Page 22

PRECAUTIONS IN USING THE COUNTER

Cautions for circuits

1. Protective circuit for counter contact

In the circuit that switches an inductive load, a contact failure may occur at a contact point due to surge or inrush current resulting

from that switching. Therefore, it is recommended that the following protective circuit be used to protect the contact point.

2. Type of Load and Inrush Current

The type of load and its inrush current

characteristics, together with the switching frequency, are important factors

which cause contact welding.

Particularly for loads with inrush currents, measure the steady state current

and inrush current and use a relay or

magnet switch which provides an ample

margin of safety. The table below shows

the relationship between typical loads

and their inrush currents.

various kinds of input signals, therefore,

use a power transformer in which the primary side is separated from the

ungrounded secondary side as shown in

Fig. A, for the power supply for a sensor

and other input devices so that short-circuiting can be prevented.

4. Long Continuous Current Flow

Avoid keeping the counter on for a long

period of time (over one month).

Otherwise heat is generated and accumulated inside the counter, which may

deteriorate its electronic parts. If the

counter must be kept on for a long period

of time, a relay is added. See the circuit

diagram below.

When you want large load and long life

of the counter, do not control the load

direct with a counter. When the counter

is designed to use a relay or a magnet

switch, you can acquire the longer life of

the counter.

3. Connection of input

(Except for LC4H-S/AC type)

The LC4H series use power supply without a transformer (power and input terminals are not insulated). In connecting

CR circuit (r: resistor c: capacitor)

Counter contact

(see note.) Available Not available Available

Counter contact Counter contact Counter contact

Circuit

Application

Features/Others

Device Selection

AC

Available

If the load is a relay or solenoid, the release time lengthens.

Effective when connected to both contacts if the power supply voltage is

24 or 48 V and the voltage across the load is 100 to 200 V.

If the load is a timer, leakage current

flows through the CR circuit causing

faulty operation.

Note: If used with AC voltage, be sure

the impedance of the load is sufficiently

smaller than that of the CR circuit.

As a guide in selecting r and c,

c: 0.5 to 1 µF per 1 A contact current

r: 0.5 to 1 Ω per 1 V contact voltage

Values vary depending on the properties of the load and variations in counter characteristics.

Capacitor c acts to suppress the discharge the moment the contacts open. Resistor r

acts to limit the current when the power is turned on the next time. Test to confirm.

Use a capacitor with a breakdown voltage of 200 to 300 V. Use AC type capacitors

(non-polarized) for AC circuits.

—

The diode connected in parallel causes the energy stored in the coil to

flow to the coil in the form of current

and dissipates it as joule heat at the

resistance component of the inductive load.

This circuit further delays the release

time compared to the CR circuit.

(2 to 5 times the release time listed in

the catalog)

Use a diode with a reverse breakdown voltage at least 10 times the

circuit voltage and a forward current at least as large as the load

current.

In electronic circuits where the circuit voltages reverse breakdown

voltage of about 2 to 3 times the

power supply voltage.

Using the rated voltage characteristics of the varistor, this circuit prevents excessively high voltages

from being applied across the contacts. This circuit also slightly

delays the release time.

—

Available Available Available

DC

Diode circuit Varistor circuit

Do not use a single coil transformer (e.g.,

Sly-Duck). Otherwise, the internal circuit

of the counter will be short-circuited as

shown in Fig. B resulting in breakdown.

Type of load Inrush current

Resistive load Steady state current

Solenoid load 10 to 20 times the steady state current

Motor load 5 to 10 times the steady state current

Incandescent lamp load 10 to 15 times the steady state current

Mercury lamp load 1 to 3 times the steady state current

Sodium vapor lamp load 1 to 3 times the steady state current

Capacitive load 20 to 40 times the steady state current

Transformer load 5 to 15 times the steady state current

rc

Inductive load

r

c

Inductive load

Diode

Inductive load

varistorZNR

Inductive load

(–)

AC power supply

AC power

routing

Counter

(–)

(

sensor, etc.

)

Single coil transformer

(+)

(–)

Counter

(–)

Input equipment

AC power supply

(Fig. B) No good

(Fig. A) Good

(

sensor, etc.

)

Insurating transformer

(+)

Counter

(–)

Input equipment

(

sensor, etc.

)

Insurating transformer

(+)

(–)

Input equipment

from contact

at relay R

R

Relay

R

CR

Counter

C

Receive output

R

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 23

5. Leakage current

1) For connecting operating voltage to

the counter, a circuit should be used,

which will prevent the flow of leakage

current. For example, a circuit for contact protection as shown in Fig A. will

permit leakage current flow through R

and C, causing erroneous operation of

the counter. Instead, the circuit shown in

Fig. B should be used.

2) If the counter

is directly

switched with a

non-contact element, leak current may flow

into the counter

and cause it to

malfunction.

Cautions for use

(common for all models)

1. Terminal connections

Correctly connect the pins while seeing

the terminal layout/wiring diagram. In

particular, the DC type, which has polarities, does not operate with the polarities

connected reverse. Any incorrect connection can cause abnormal heating or

ignition.

2. Connection to operating voltage

1)Apply the entire supply voltage through

a switch, relay or other contact.

2) The operating voltage for the DC type

must be at the specified ripple percentage or less. The average voltage must

fall within the allowable operating voltage

range.

5. Superimposed surge of power

supply

For the superimposed surge of power

supply, the standard waveform (±1.2 ×

50µs or ±1 × 40µs) is taken as the standard value for surge-proof voltage. (The

positive and negative voltages are

applied each three or five times between

the power pins.)

For the standard values for the LC4H

type counters, see the respective items

in "Cautions for use."

• Single-pole, full-wave voltage for surge

waveform [±(1.2 × 50) µs]

If external surge occurs exceeding the

specified value, the internal circuit may

break down. In this case, use a surge

absorption element. The typical surge

absorption elements include a varistor, a

capacitor, and a diode. If a surge

absorption element is used, use an oscilloscope to see whether or not the foreign

surge exceeding the specified value

appears.

6. Signal input

The counter's signal input comes in two

ways. One is by opening and closing the

input terminal. The other is by applying a

specified H-level or L-level voltage to the

input terminal.

For an input sensor's residual voltage,

input impedance, input voltage level and

other signal input conditions, see the ratings for each type of product.

7. Operating environment

1) For the ambient operating temperature and humidity, see the ratings for

each type of product.

2) Avoid using the counter in a location

where inflammable or corrosive gas is

generated, the counter is exposed to

much dust and other foreign matter; water

or oil is splashed on the counter; or vibrations or shocks are given to the counter.

3) The counter cover (case), the knobs,

and the dials are made of polycarbonated resin. Therefore, prevent the counter

from being exposed to organic solvents

such as methyl alcohol, benzine, and

thinner, strong acid substances such as

caustic soda, and ammonia and avoid

using the counter in atmosphere containing any of those substances.

4) If the counter is used where noises

are emitted frequently, separate the input

signal elements (such as a sensor), the

wiring for the input signal line, and the

counter as far as possible from the noise

source and the high power line containing noises.

8. Checking the actual load

In order to increase the reliability in the

actual use, check the quality of the

counter in the actual usage.

9. Others

1) If the counter is used exceeding the

ratings (operating voltage and control

capacity), the contact life, or any other

specified limit, abnormal heat, smoke, or

ignition may occur.

2) The LC2H series counter, incorporates a lithium battery.

Never disassemble the lithium battery or

throw it into fire because this may affect

humans and facilities. The lithium battery must be disposed of as an incombustible like other used batteries.

3) If any malfunction of the counter is

likely to affect human life and properties,

give allowance to the rated values and

performance values. In addition, take

appropriate safety measures such as a

duplex circuit from the viewpoint of product liabilities.

3) Make sure that no induced voltage

and residual voltage are applied between

the power terminals on the counter after

the power switch is turned OFF.

(If the power line is wired in parallel with

the high-voltage and motor lines,

induced voltage may be produced

between the power pins.)

3. Control output

1) Keep the load capacity below the

counter's rated control capacity. If used

above the rating, the counter's service

life may shorten. With the transistor output type counters, transistors may be