Page 1

ORDER NO. KM40308180C3

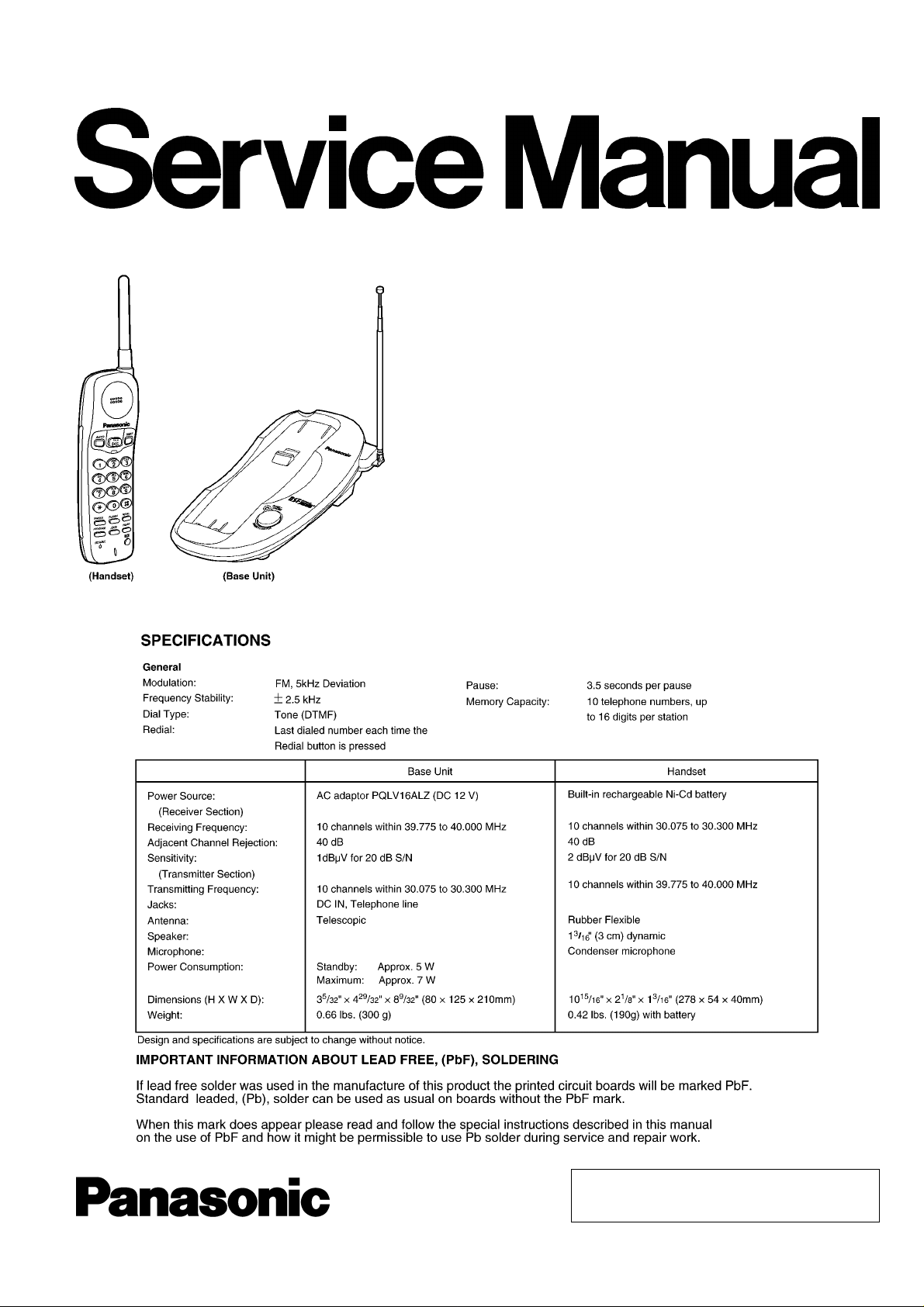

Telephone Equipment

KX-TC2000NZB

KX-TC2000NZW

KX-TC2000NZF

Cordless Phone

Black Version

White Version

Blue Version

(for New Zealand)

© 2003 Panasonic Communications Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

CONTENTS

Page Page

1 ABOUT LEAD FREE SOLDER (PbF: Pb free) 4

1.1. Suggested PbF Solder

1.2. How to recognize that Pb Free solder is used

2 FOR SERVICE TECHNICIANS

3 CAUTION

4 BATTERY

4.1. Recharge

4.2. Battery information

5 BATTERY REPLACEMENT

6 LOCATION OF CONTROLS

6.1. Base Unit

6.2. Handset

7 CONNECTION

8 OPERATIONS

8.1. Making Calls

8.2. Answering Calls

8.3. Storing Phone Numbers in Memory

8.4. Storing a Phone Number in the DIRECT Button

8.5. Dialing a Stored Number

8.6. Dialing the Stored Number in the DIRECT Button

8.7. Recall Button

9 DISASSEMBLY INSTRUCTIONS

10 TR OUBLESHOOTING GUIDE

10.1. Check Power

10.2. Bell Reception

10.3. Check Battery Charge

10

12

12

12

13

13

14

14

15

16

18

19

20

21

4

5

6

6

7

7

7

8

9

9

9

10.4. Check Link

10.5. Check Handset Transmission

10.6. Check Handset Reception

11 ADJUSTMENTS (BASE UNIT)

11.1. Test Mode Flow Chart (Base Unit)

11.2. How to change the channel

11.3. Adjustment

11.4. Adjustment Standard (Base Unit)

12 ADJUSTMENTS (HANDSET)

12.1. Test Mode Flow Chart (Handset)

12.2. How to change the channel

12.3. Adjustment

12.4. Adjustment Standard (Handset)

13 R F SPECIFICAT ION

13.1. Base Unit

13.2. Handset

14 HOW TO CHECK THE HANDSET SPEAKER

15 FREQUENCY TABLE (MHz)

16 EXPLANATION OF CPU DATA COMMUNICATION

16.1. STAND-BY -> TALK, TALK -> STAND-BY

16.2. Ringing

16.3. Changing the Channel

16.4. Ports for transmitting and receiving of data

16.5. Waveform of DATA used for cordless transmission and

reception

17 B LOCK DIAGRAM (BASE UNIT)

22

24

24

25

25

26

26

27

28

28

29

29

30

32

32

32

32

33

34

34

35

36

37

37

38

2

Page 3

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

18 B LOCK DIAGRAM (HANDSET) 39

19 CIRCUIT OPERATION

19.1. Outline

19.2. Power Supply Circuit

19.3. Reset Circuit (Base Unit)

19.4. Charge Circuit

19.5. Telephone Line Interface

19.6. DTMF

19.7. Transmitter/Receiver

19.8. Signal Route

20 CIRCUIT OPERATION (HANDSET)

20.1. Reset Circuit (Handset)

20.2. Battery Low / Power Down Detector

21 CPU DATA (Base Unit)

21.1. IC2

22 CPU DATA (Handset)

22.1. IC2

23 RF IC (Base Unit and Handset)

23.1. IC1

24 HOW TO REPLACE FLAT PACKAGE IC

24.1. Preparation

24.2. Procedure

24.3. Modification Procedure of Bridge

40

40

41

42

43

43

43

44

46

47

47

48

49

49

50

50

51

51

52

52

52

52

25 C ABINET AND ELECTRICAL PARTS LOCATION (BASE UN IT)

26 C ABINET AND ELECTRICAL PARTS LOCATION (HANDET)

27 ACCESSORIES AND PACKING MATERIALS

28 REPLACEMENT PARTS LIST

28.1. Base Unit

28.2. Handset

28.3. ACCESSORIES AND PACKING MATERIALS

29 FOR SCHEMATIC DIAGRAM

29.1. Base Unit (SCHEMATIC DIAGRAM (Base Unit))

29.2. Handset (SCHEMATIC DIAGRAM (Handset))

30 SCHEMATIC DIAGRAM (Base Unit)

30.1. Base Unit

30.2. RF Unit (Base Unit)

31 SCHEMATIC DIAGRAM (Handset)

31.1. Handset

31.2. RF Unit (Handset)

31.3. Memo

32 CIRCUIT BOARD (Base Unit)

32.1. Component View

32.2. Flow Solder Side View

33 CIRCUIT BOARD (Handset)

33.1. Component View

33.2. Flow Solder Side View

53

54

55

56

56

58

60

61

61

61

62

62

63

64

64

65

66

67

67

68

69

69

70

3

Page 4

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

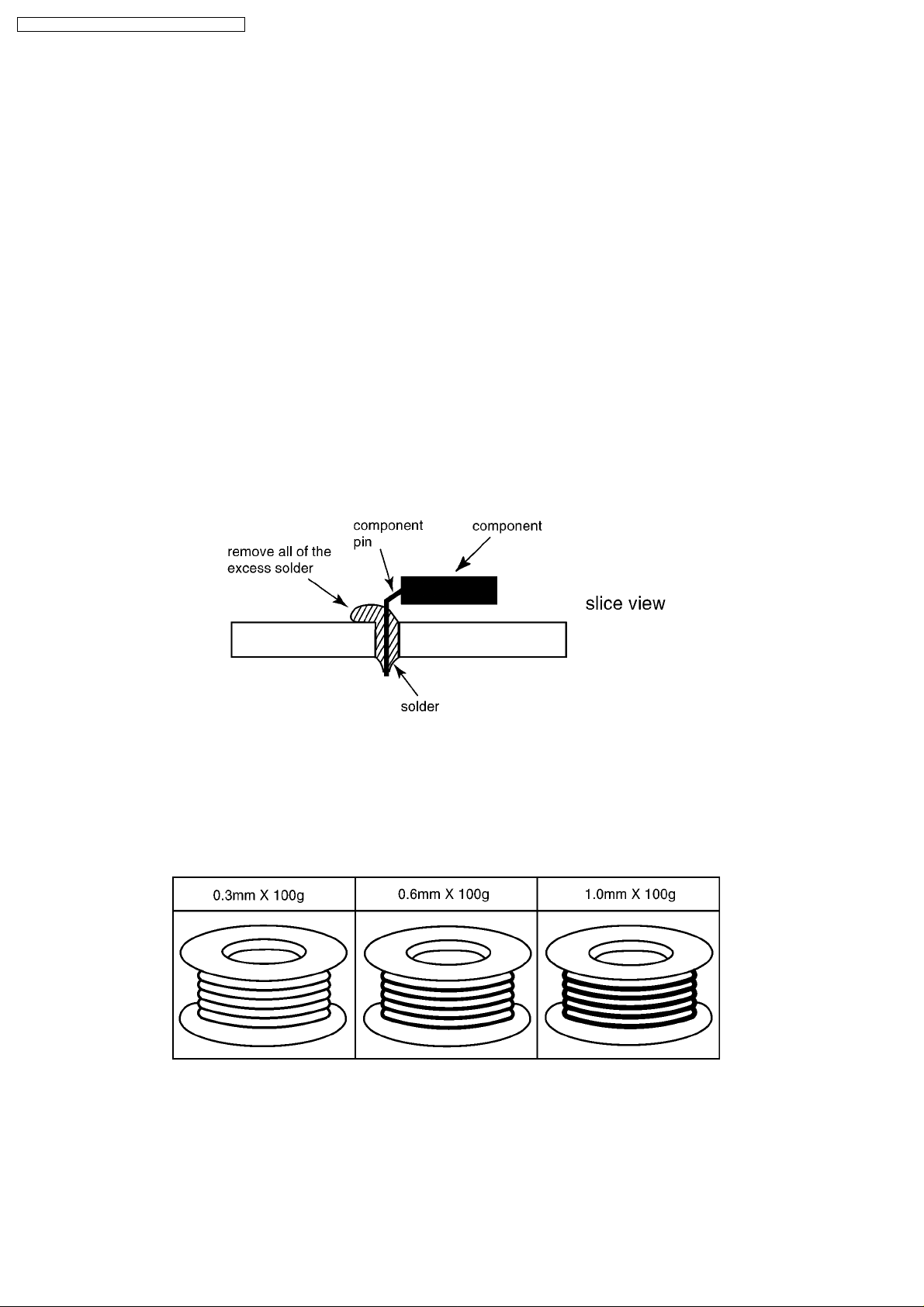

1 ABOUT LEAD FREE SOLDER (PbF: Pb free)

Note:

In the information below, Pb, the symbol for lead in the periodic table of elements, will refer to standard solder or solder that

contains lead.

We will use PbF solder when discussing the lead free solder used in our manufacturing process which is made from Tin (Sn),

Silver (Ag), and Copper (Cu).

This model, and others like it, manufactured using lead free solder will have PbF stamped on the PCB. For service and repair

work we suggest using the same type of solder although, with some precautions, standard Pb solder can also be used.

Caution

•

• PbF solder has a melting point that is 50°F ~ 70° F (30°C ~ 40°C) higher than Pb solder. Please use a soldering iron with

• •

temperature control and adjust it to 700°F ± 50° F (370°C ± 10°C). In case of using high temperature soldering iron, please

be careful not to heat too long.

•

• PbF solder will tend to splash if it is heated much higher than its melting point, approximately 1100°F (600°C).

• •

•

• If you must use Pb solder on a PCB manufactured using PbF solder, remove as much of the original PbF solder as possible

• •

and be sure that any remaining is melted prior to applying the Pb solder.

•

• When applying PbF solder to double layered boards, please check the component side for excess which may flow onto the

• •

opposite side (See the figure below).

1.1. Suggested PbF Solder

There are several types of PbF solder available commercially. While this product is manufactured using Tin, Silver, and Copper

(Sn+Ag+Cu), you can also use Tin and Copper (Sn+Cu), or Tin, Zinc, and Bismuth (Sn+Zn+Bi). Please check the manufac

turer’s specific instructions for the melting points of their products and any precautions for using their product with other

materials.

The following lead free (PbF) solder wire sizes are recommended for service of this product: 0.3mm, 0.6mm and 1.0mm.

4

Page 5

1.2. How to recognize that Pb Free solder is used

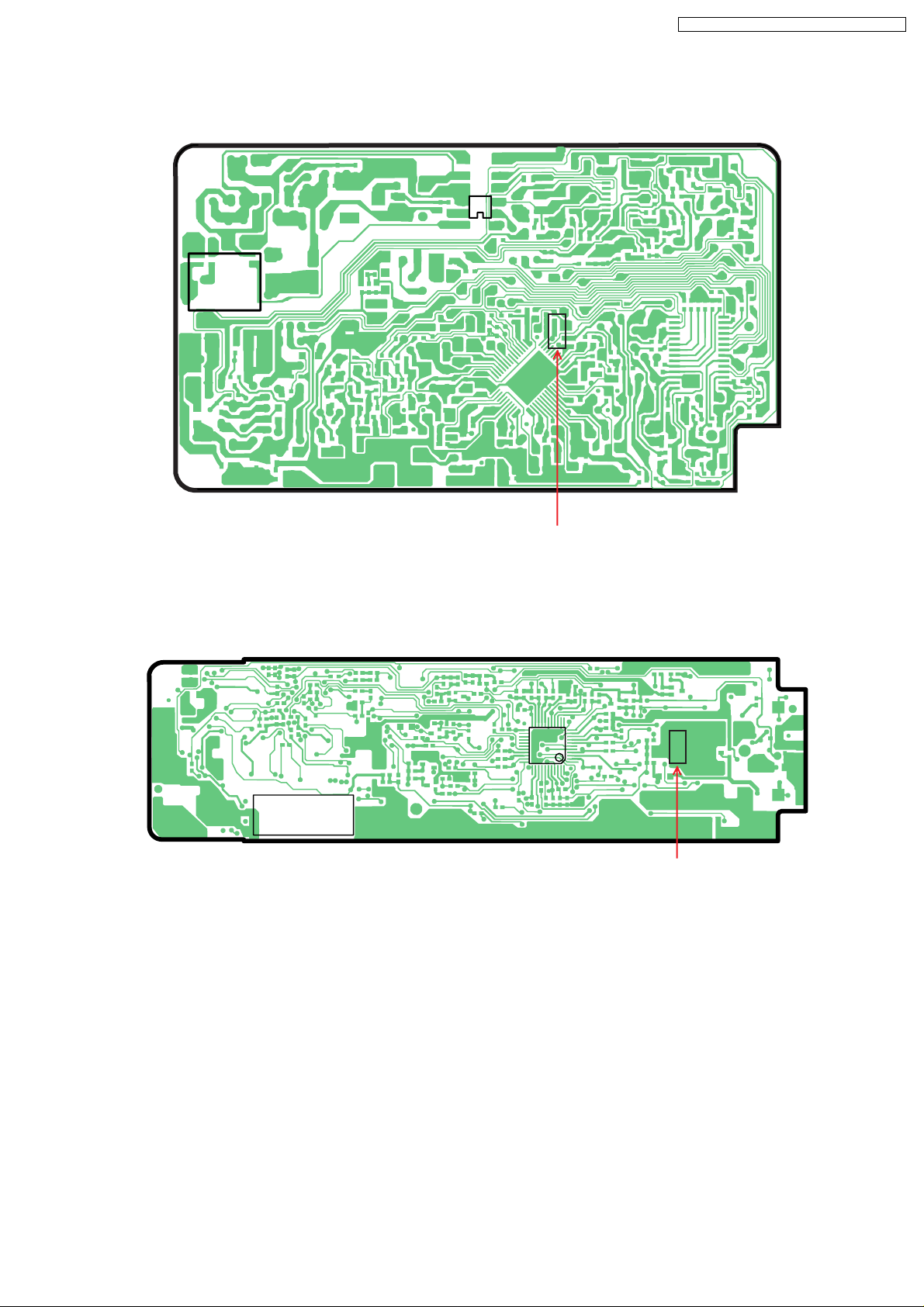

1.2.1. Base Unit Main PCB

IC5

JK1

PbF

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

(Component View)

Note:

The location of the "PbF" marks is subject to change without notice.

1.2.2. Handset PCB

DPX1

(Component View)

Note:

The location of the "PbF" marks is subject to change without notice.

Marked

IC2

PbF

Marked

5

Page 6

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

2 FOR SERVICE TECHNICIANS

ICs and LSIs are vulnerable to static electricity.

When repairing, the following precautions will help prevent recurring malfunctions.

1. Cover plastic parts boxes with aluminum foil.

2. Ground the soldering irons.

3. Use a conductive mat on worktable.

4. Do not grasp IC or LSI pins with bare fingers.

3 CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer´s Instructions.

6

Page 7

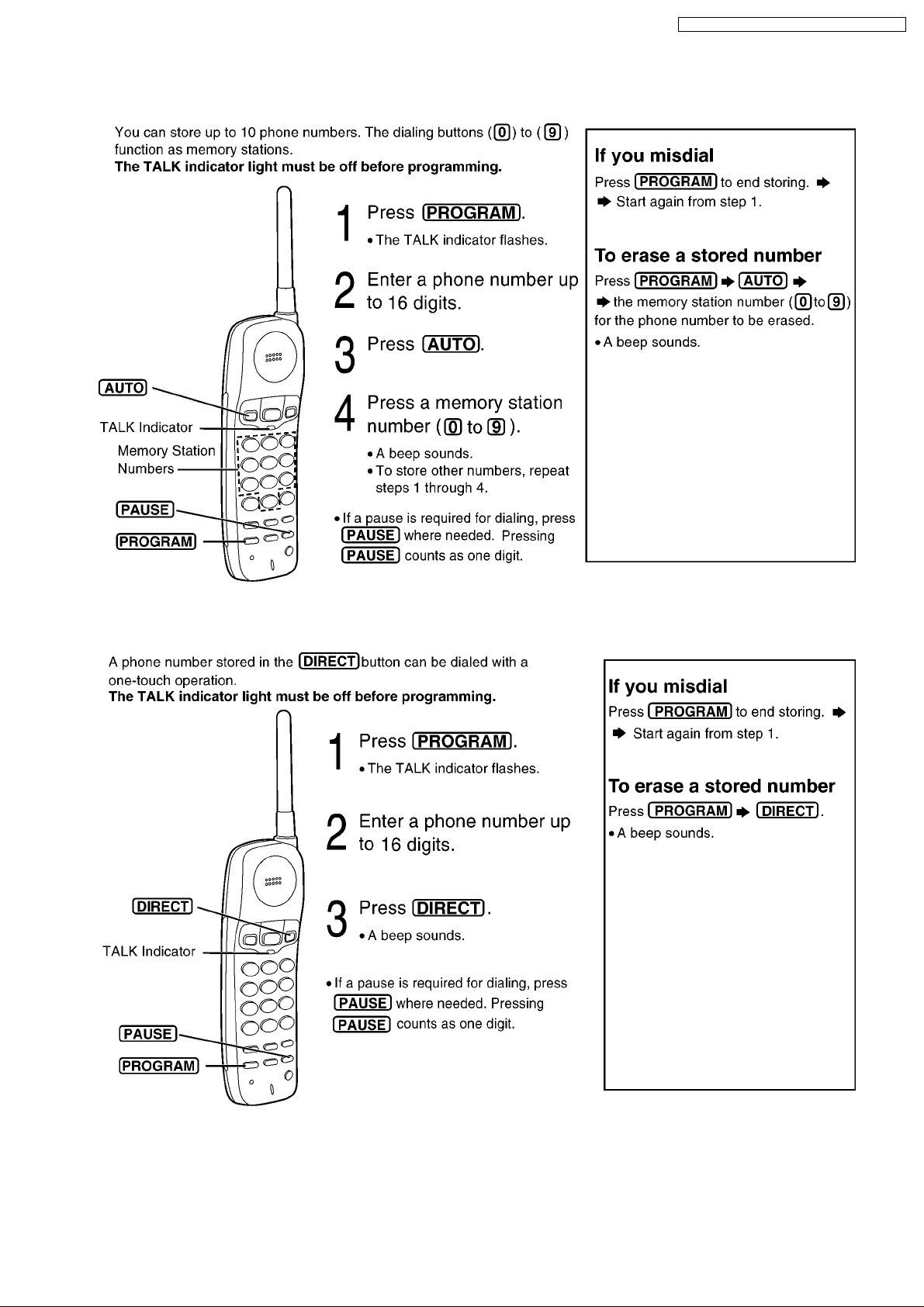

4 BATTERY

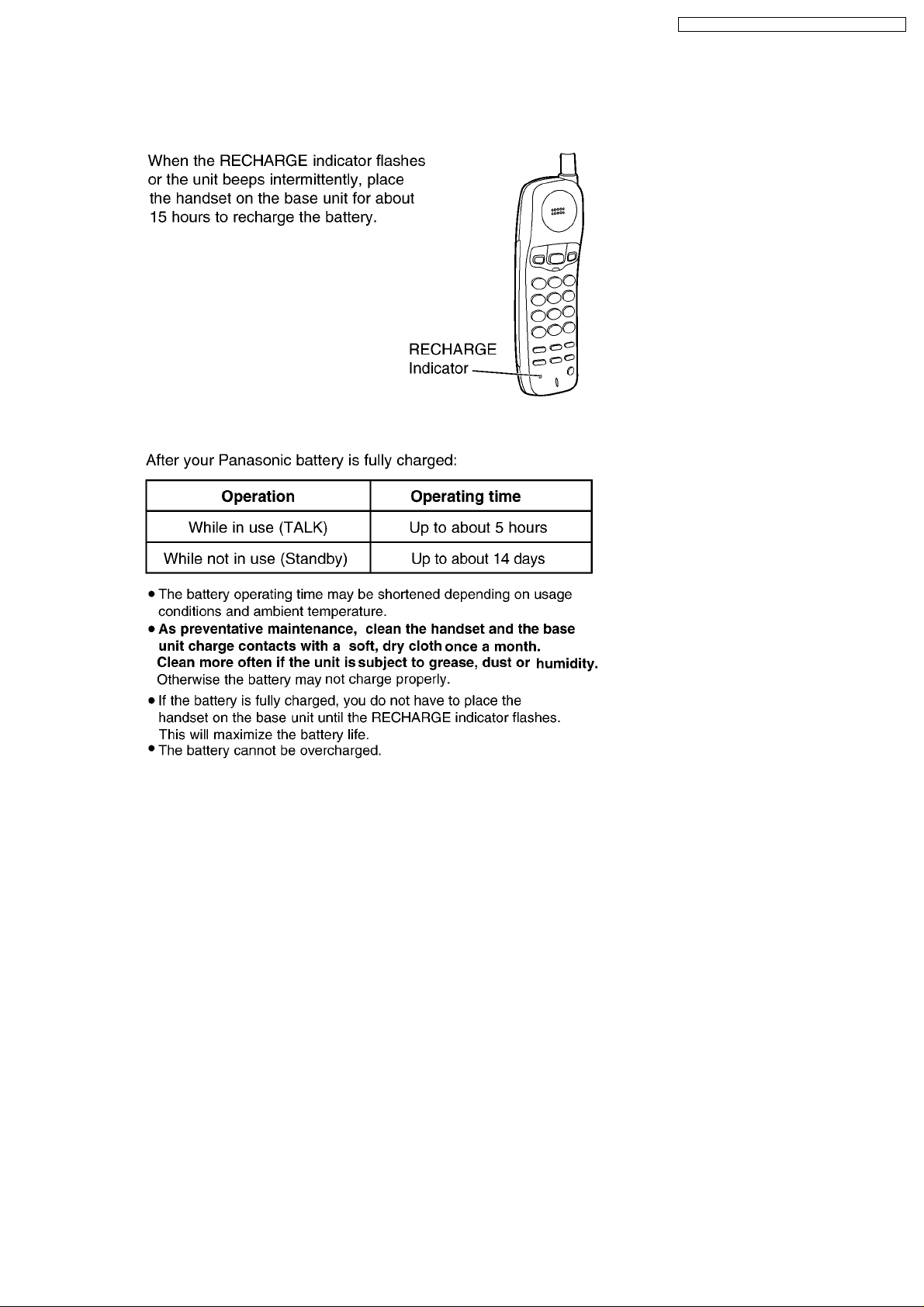

4.1. Recharge

4.2. Battery information

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

7

Page 8

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

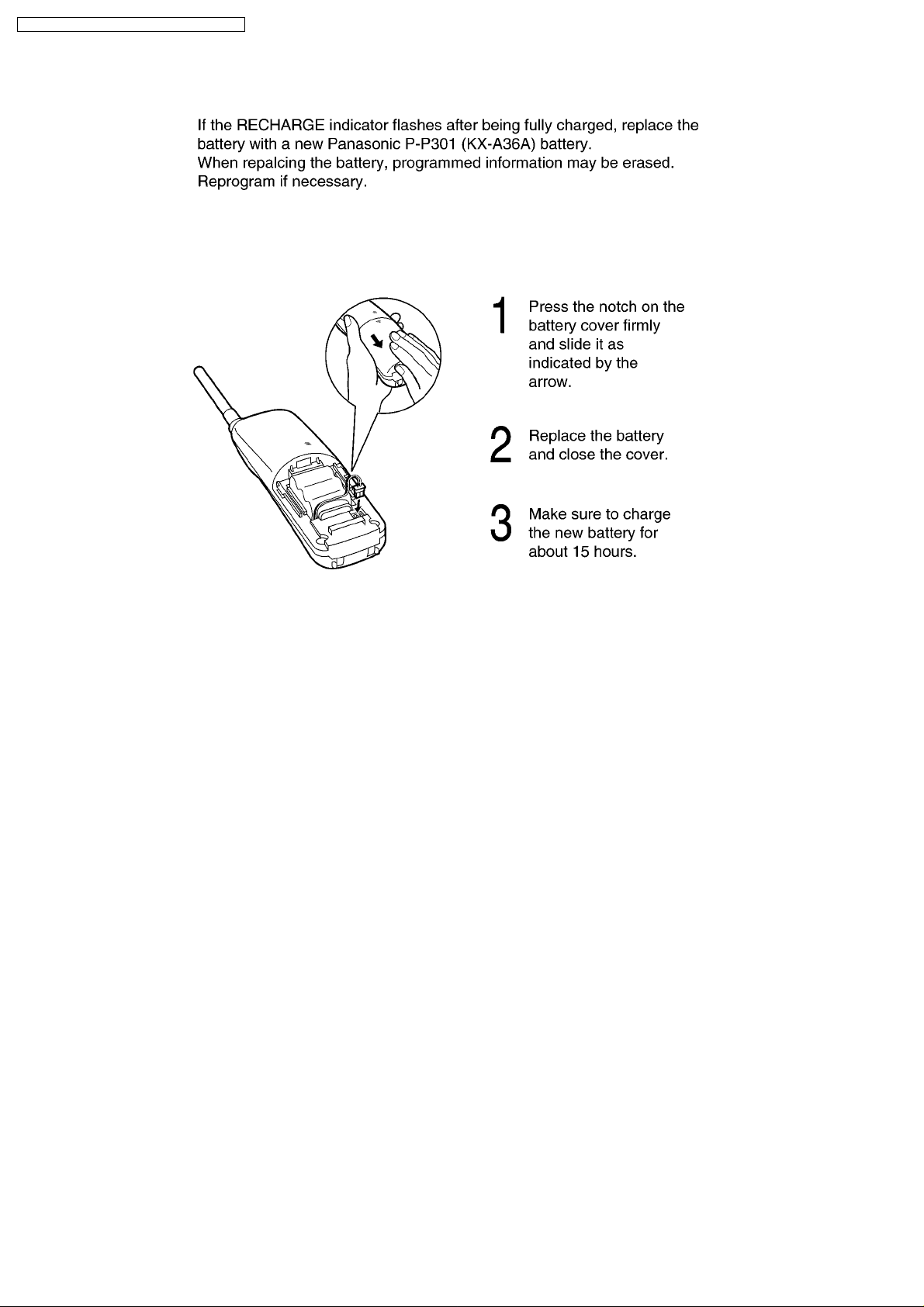

5 BATTERY REPLACEMENT

8

Page 9

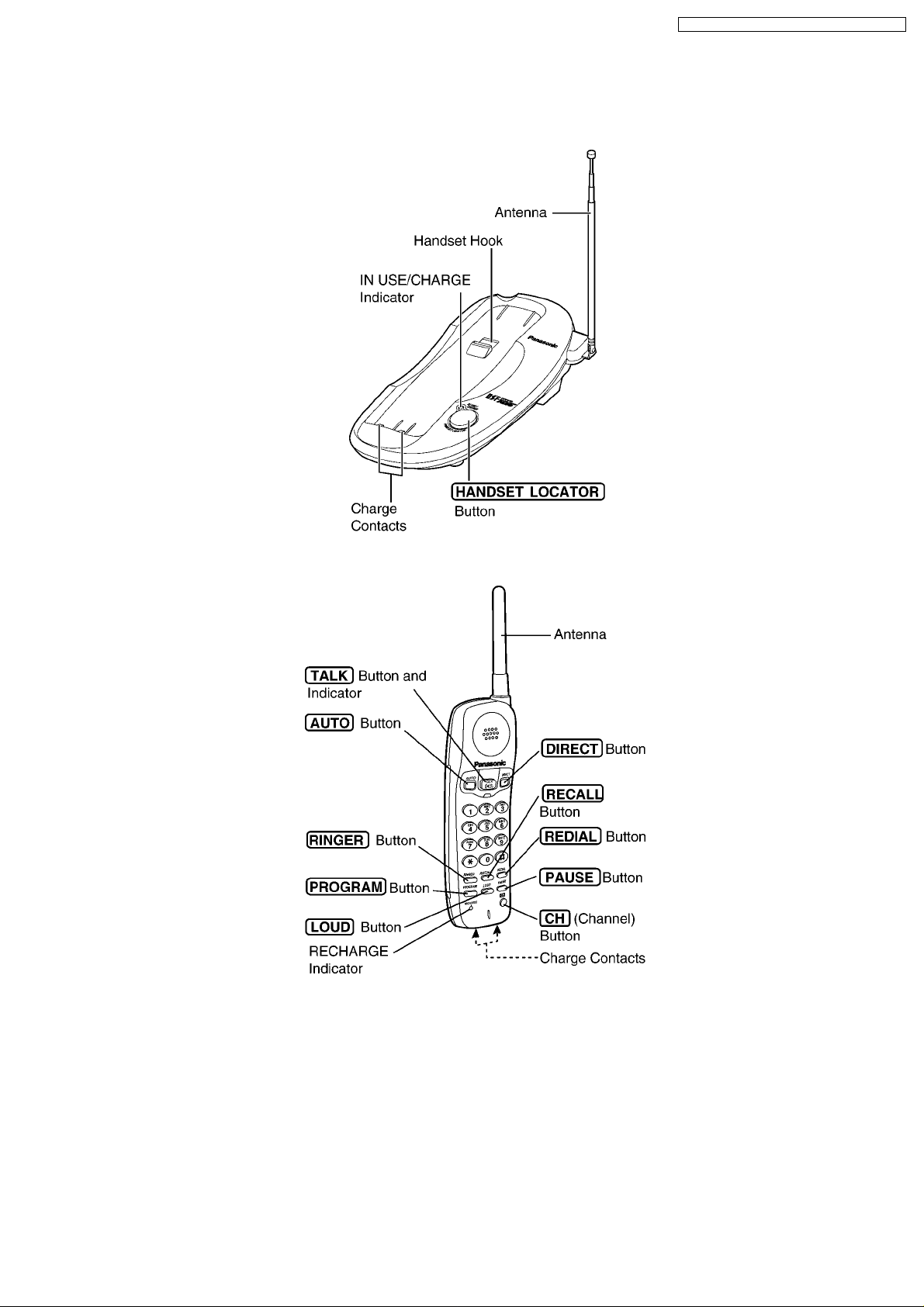

6 LOCATION OF CONTROLS

6.1. Base Unit

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

6.2. Handset

9

Page 10

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

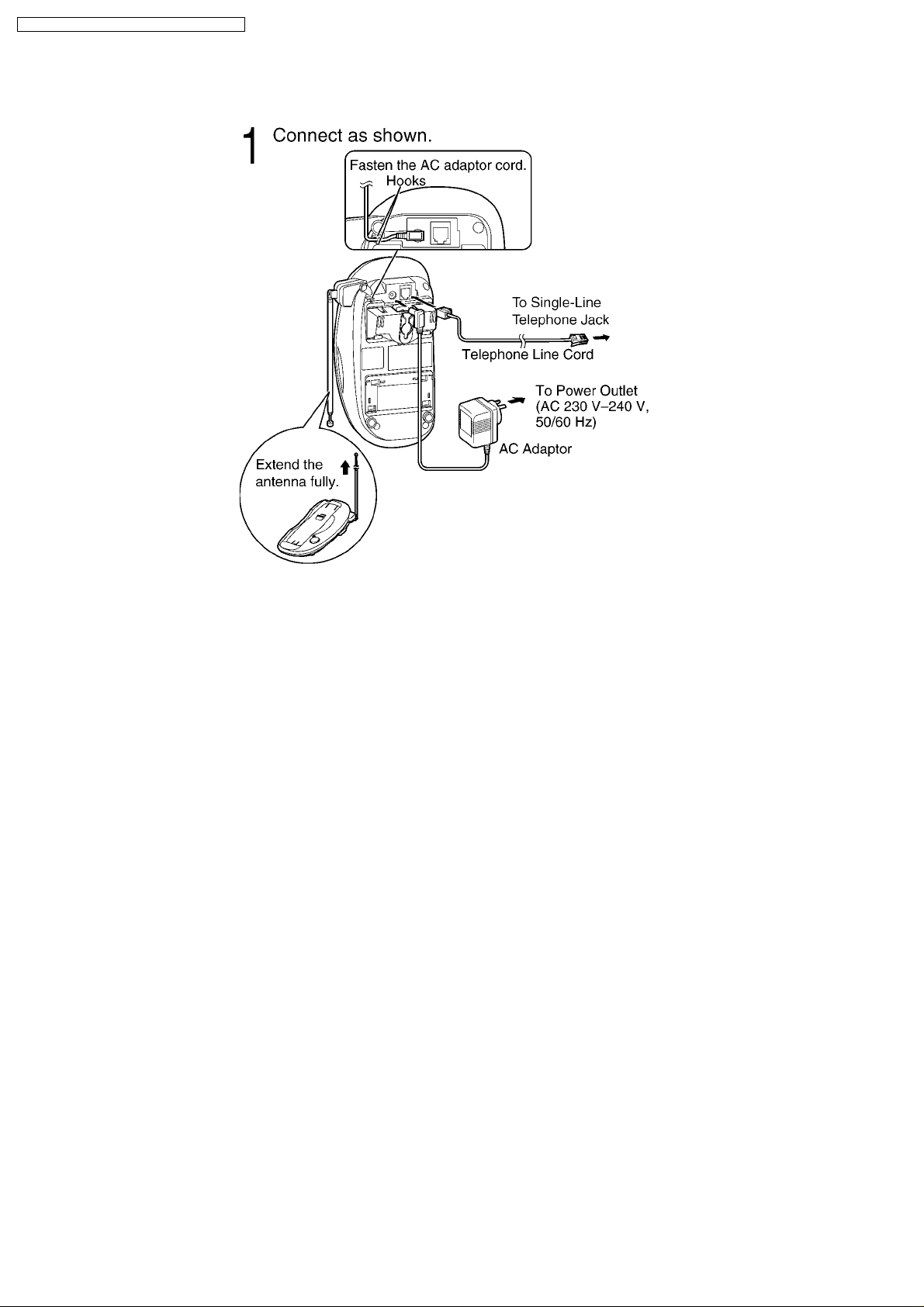

7 CONNECTION

•

• USE ONLY WITH Panasonic AC ADAPTOR PQLV16AL.

• •

•

• The AC adaptor must remain connected at all times.

• •

(It is normal for the adaptor to feel warm during use.)

•

• This unit will not function during a power failure.

• •

If you want to connect a standard telephone on the same line, use a T-adaptor.

•

• KX-TC2000NZ is not designed to be used with rotary (pulse dialling) services.

• •

10

Page 11

For Service Hint:

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

11

Page 12

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

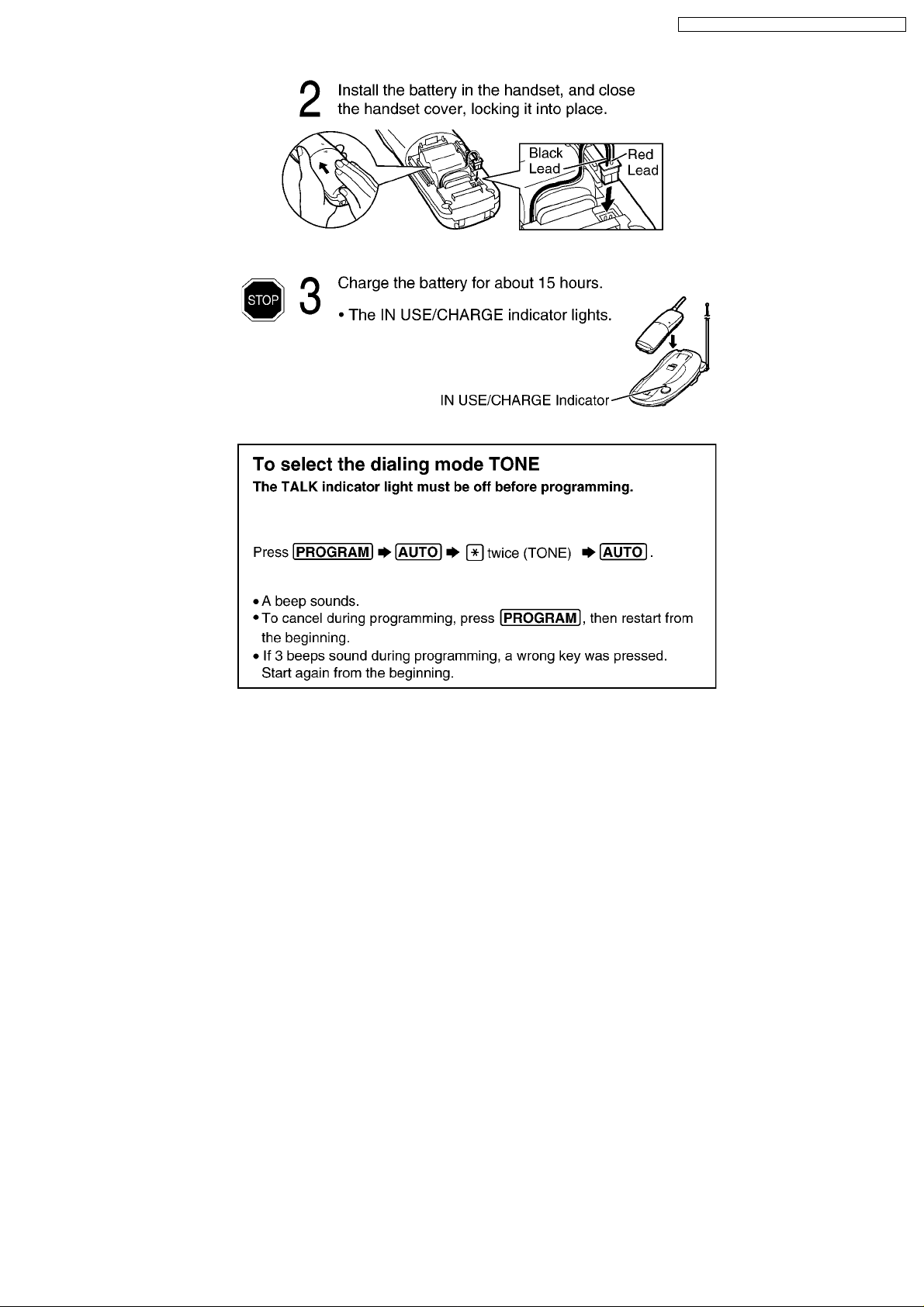

8 OPERATIONS

8.1. Making Calls

8.2. Answering Calls

12

Page 13

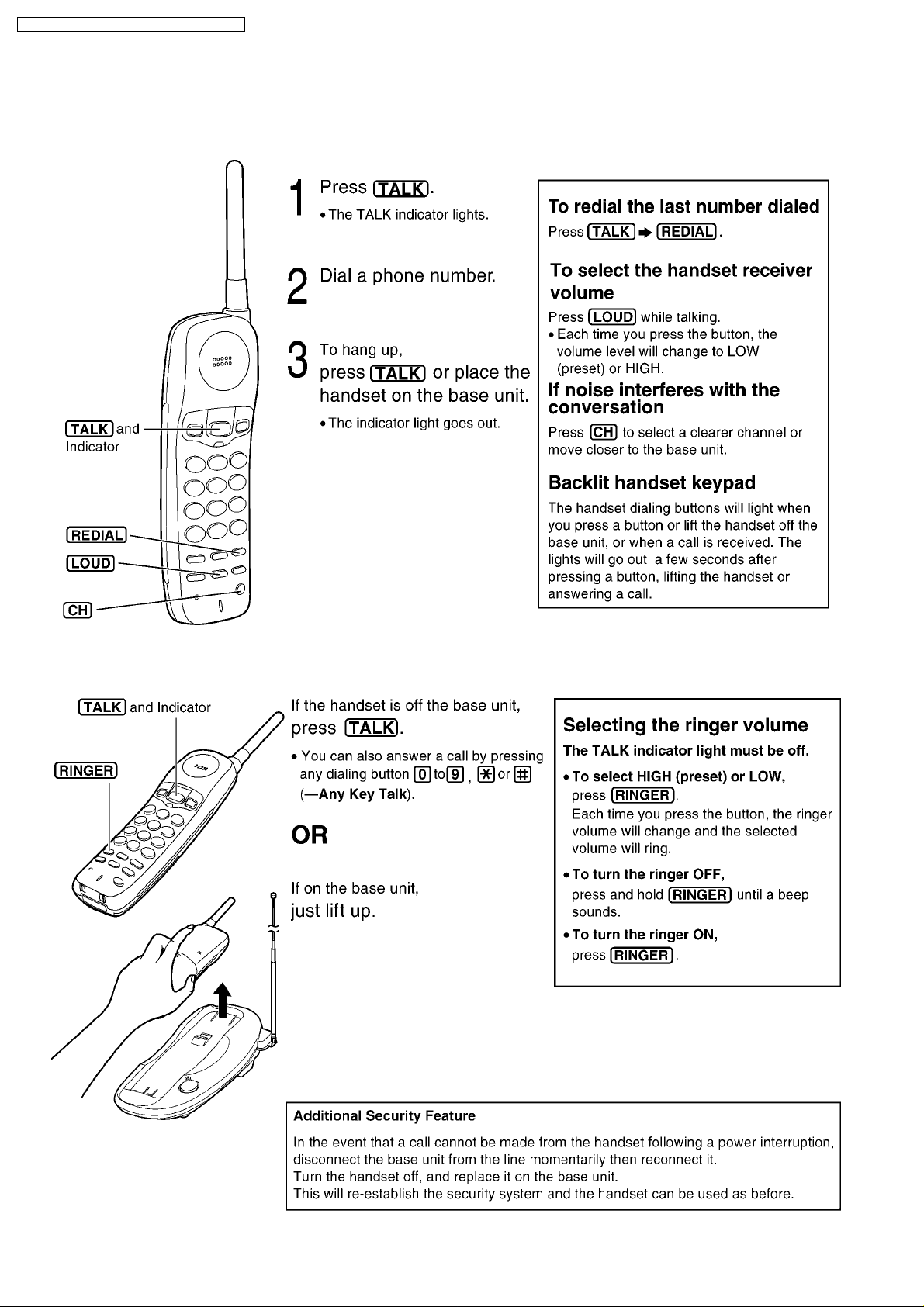

8.3. Storing Phone Numbers in Memory

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

8.4. Storing a Phone Number in the DIRECT Button

13

Page 14

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

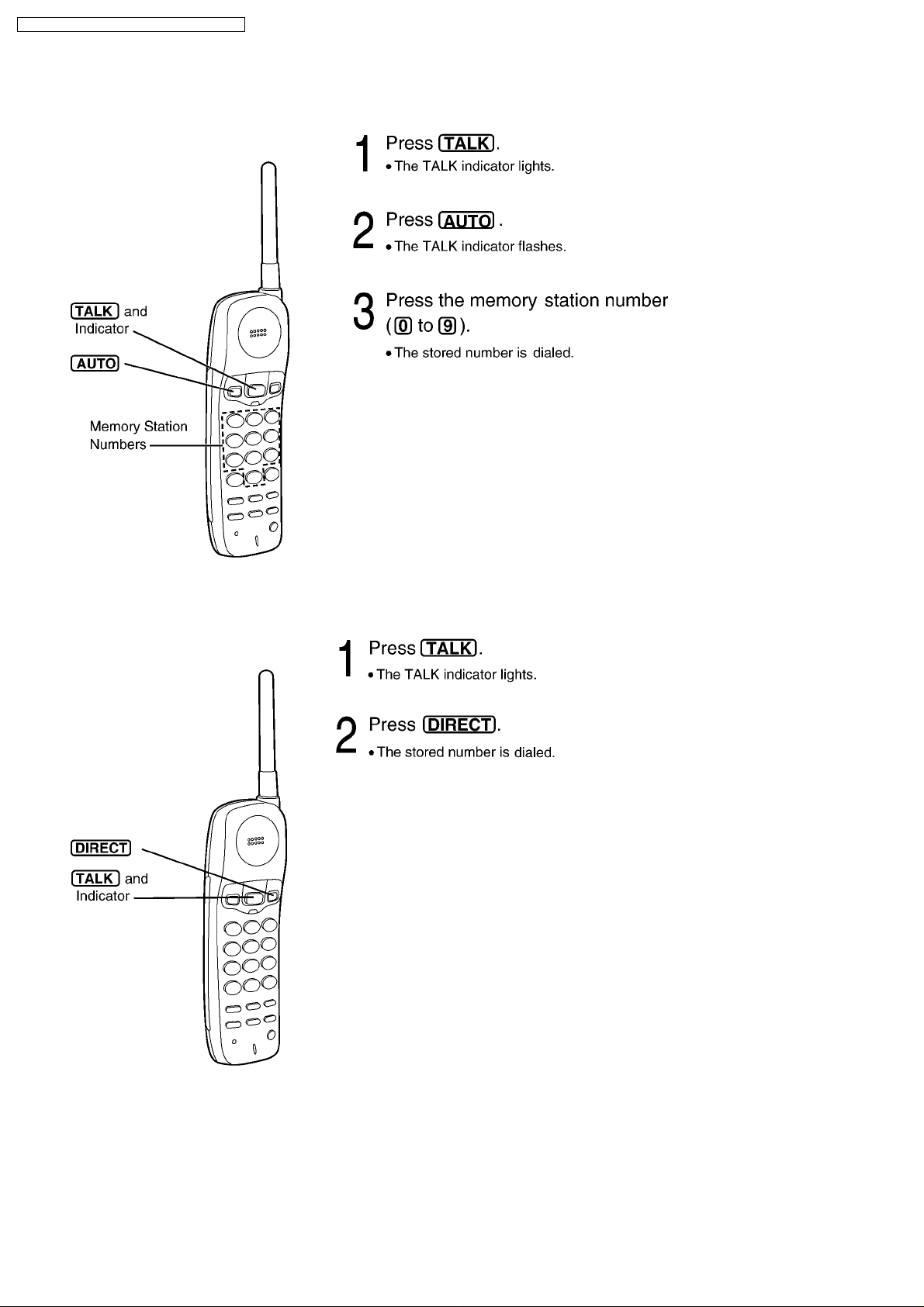

8.5. Dialing a Stored Number

8.6. Dialing the Stored Number in the DIRECT Button

14

Page 15

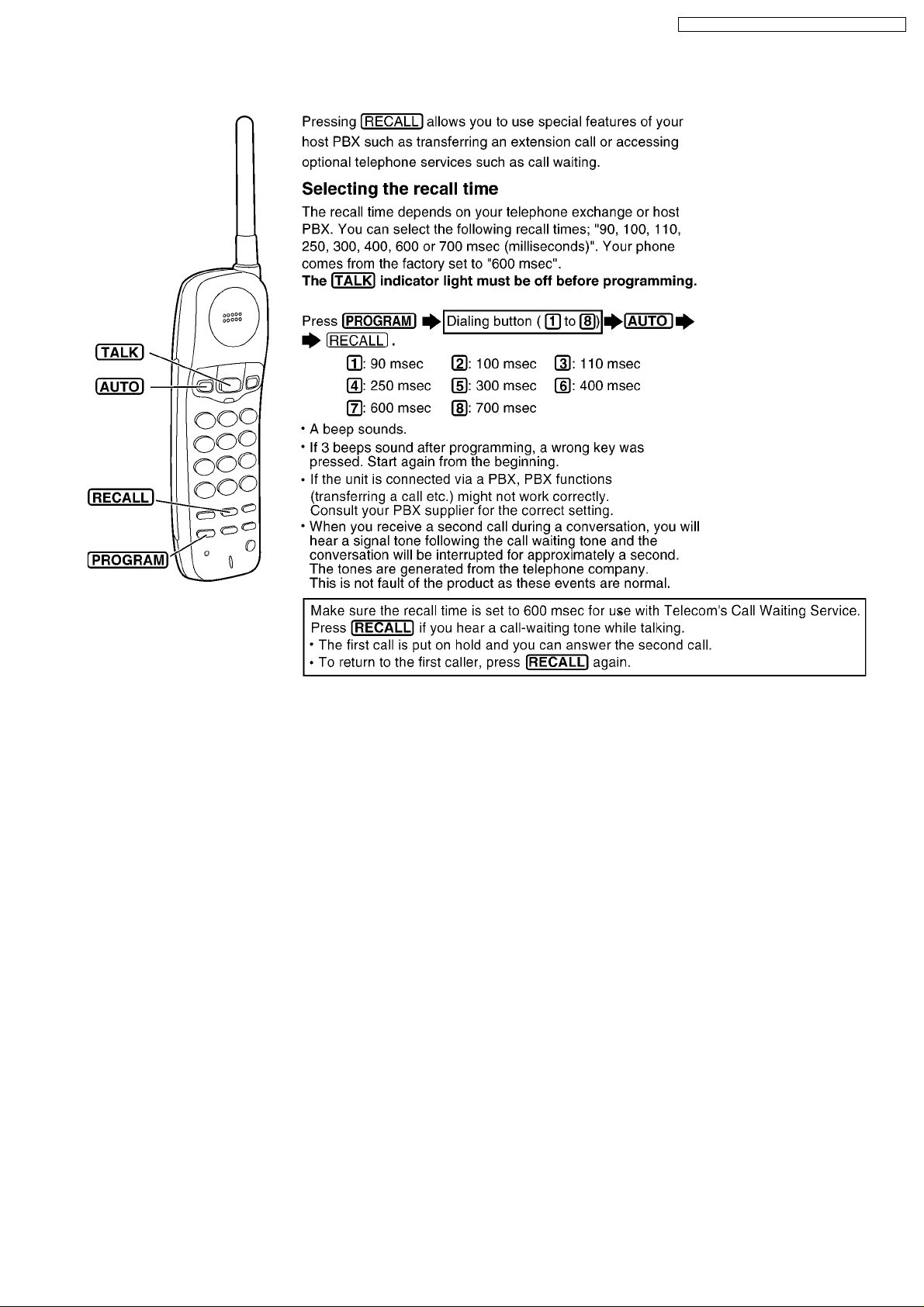

8.7. Recall Button

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

15

Page 16

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

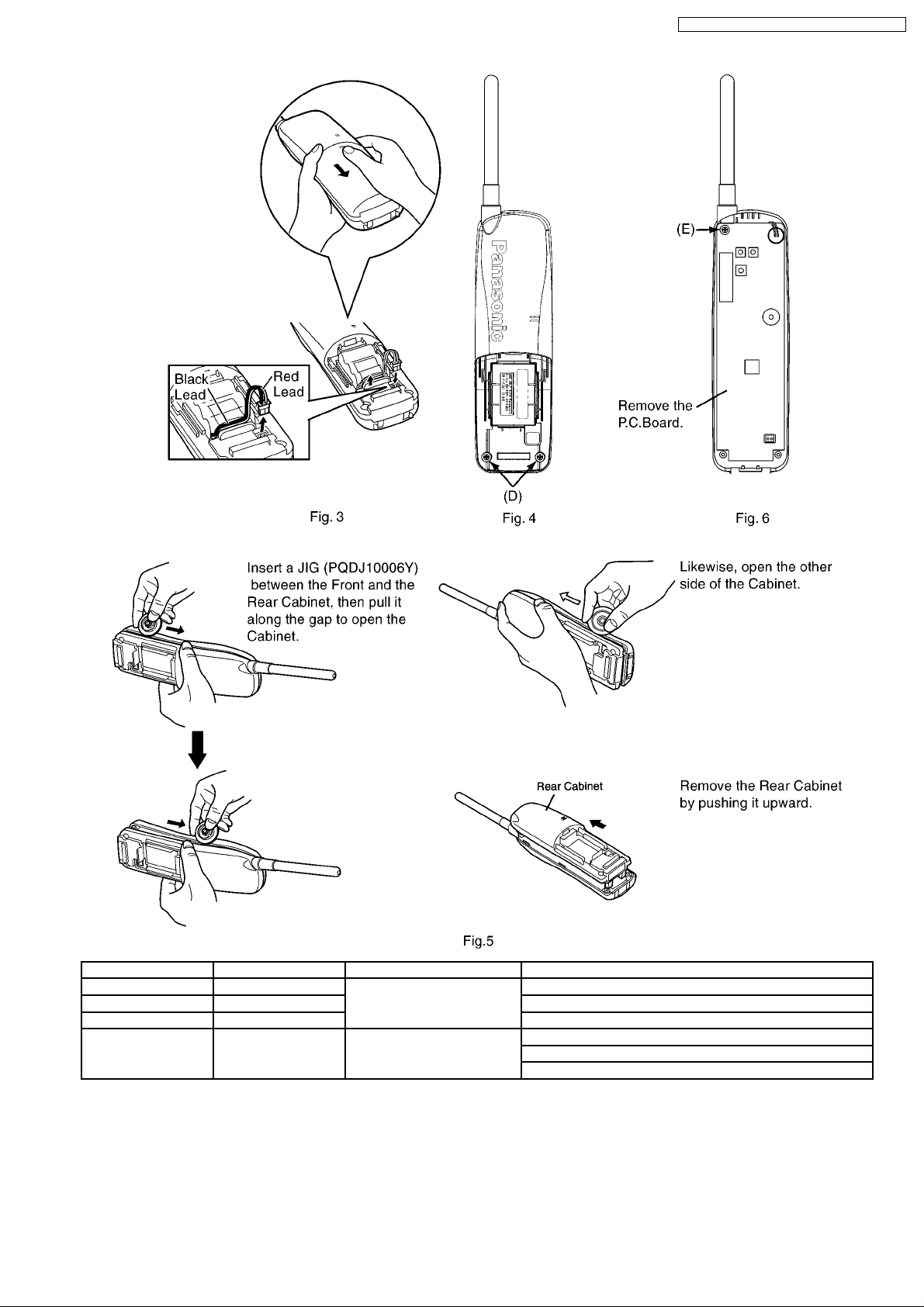

9 DISASSEMBLY INSTRUCTIONS

Show in Fig. Procedure To remove. Remove.

1 1 Lower Cabinet Screws (2.6 × 12)....................... (A) × 4

2 1, 2 Main P.C. Board Screw (2.6 × 6).......................... (B) × 1

Screw (2.6 × 12).......................... (C) × 1

Solder

Main P.C. Board.

16

Page 17

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

Show in Fig. Procedure To remove. Remove.

3 3 Rear Cabinet Battery compartment cover.

4 3, 4 Screws (2.6 × 12)......................(D) × 2

5 3, 4, 5 Follow the procedure.

6 3, 4, 5, 6 Main P. C. Board Screw (2.6 × 12)........................(E) × 1

Tape and solder.

Main P. C. Board.

17

Page 18

KX-TC200 0NZB / KX-TC2000NZW / KX-TC200 0NZ F

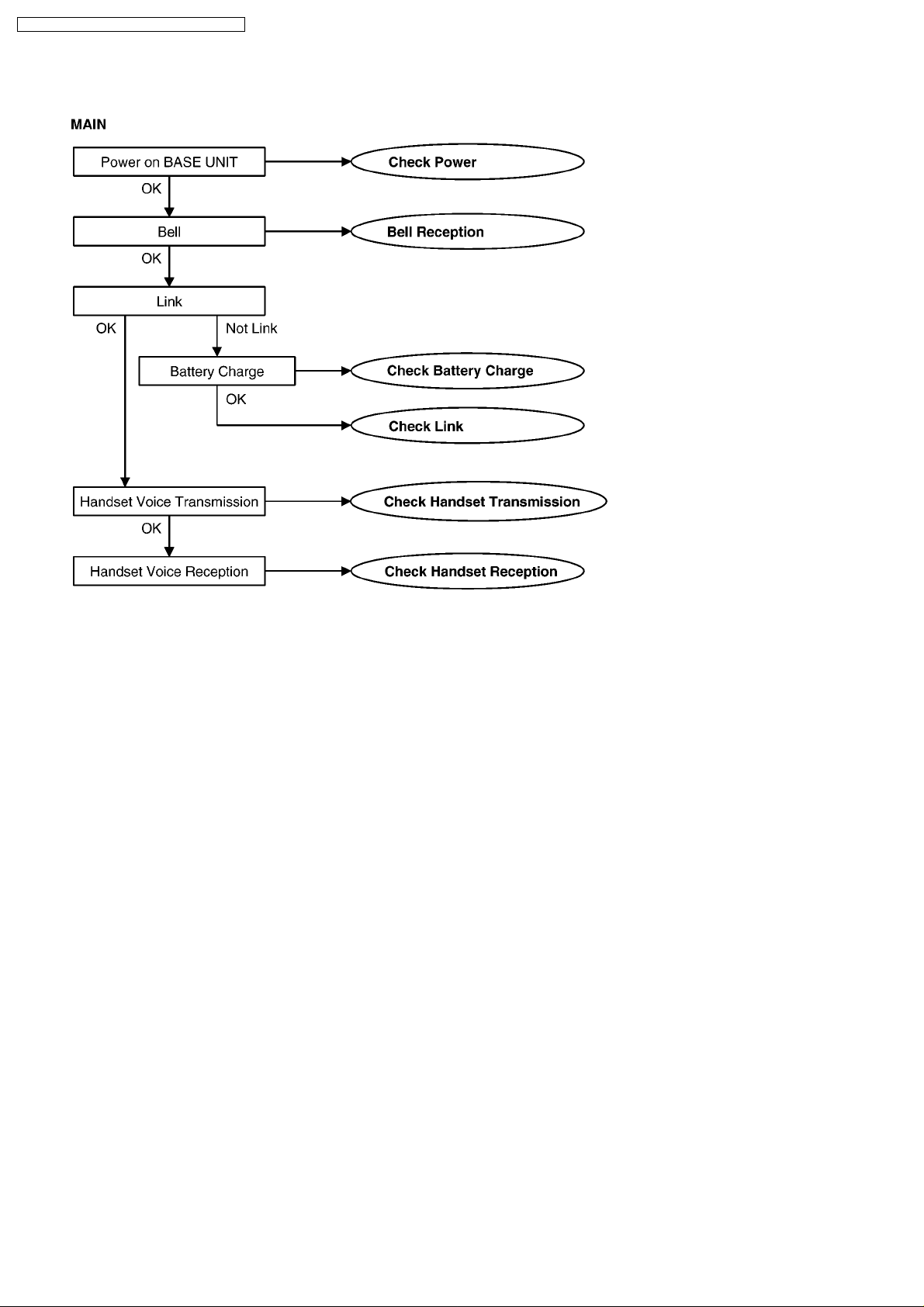

10 TROUBLESHOOTING GUIDE

Cross Reference:

Check Power (P.19)

Bell Reception (P.20)

Check Battery Char ge (P.21)

Check Link (P.22)

Check Handset Transmission (P.24)

Check Handset Reception (P.24)

18

Page 19

10.1. Check Power

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

Cross Reference:

Reset Circuit (Base Unit) (P.42)

Power Supply Circuit (P.41)

Cross Reference:

Charge Circuit (P.43)

*: Each measurement points are shown in CIRCUIT BOARD (Base Unit) (P.67) or CIRCUIT BOARD (Handset) (P.69)

Note:

CPU: IC2

Note:

CPU: IC2

19

Page 20

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

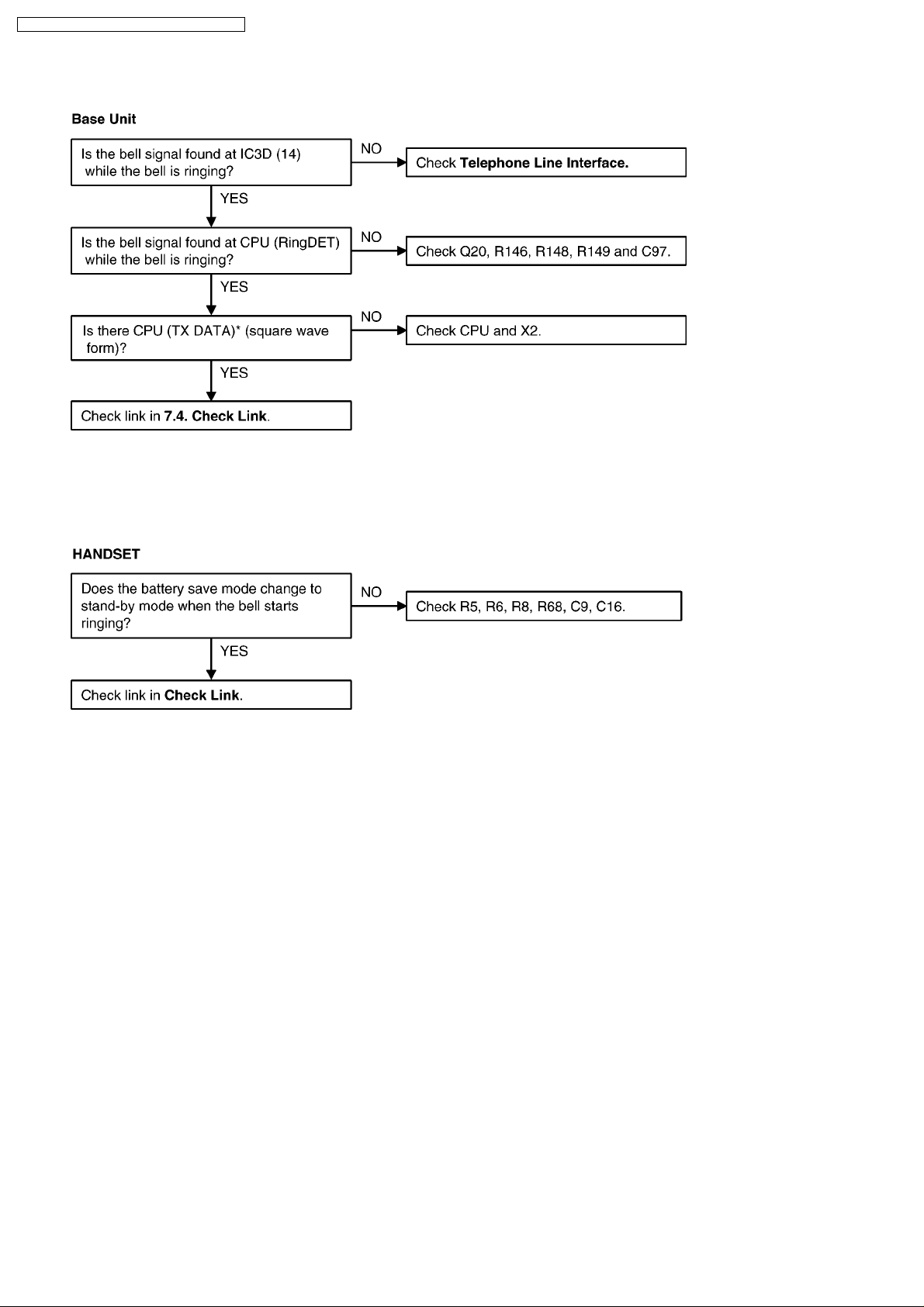

10.2. Bell Reception

Cross Reference:

Check Link (P.22)

Telephone Line Interface (P.43)

Cross Reference:

Check Link (P.22)

*: Each measurement points are shown in CIRCUIT BOARD (Base Unit) (P.67) or CIRCUIT BOARD (Handset) (P.69)

Note:

CPU: IC2

20

Page 21

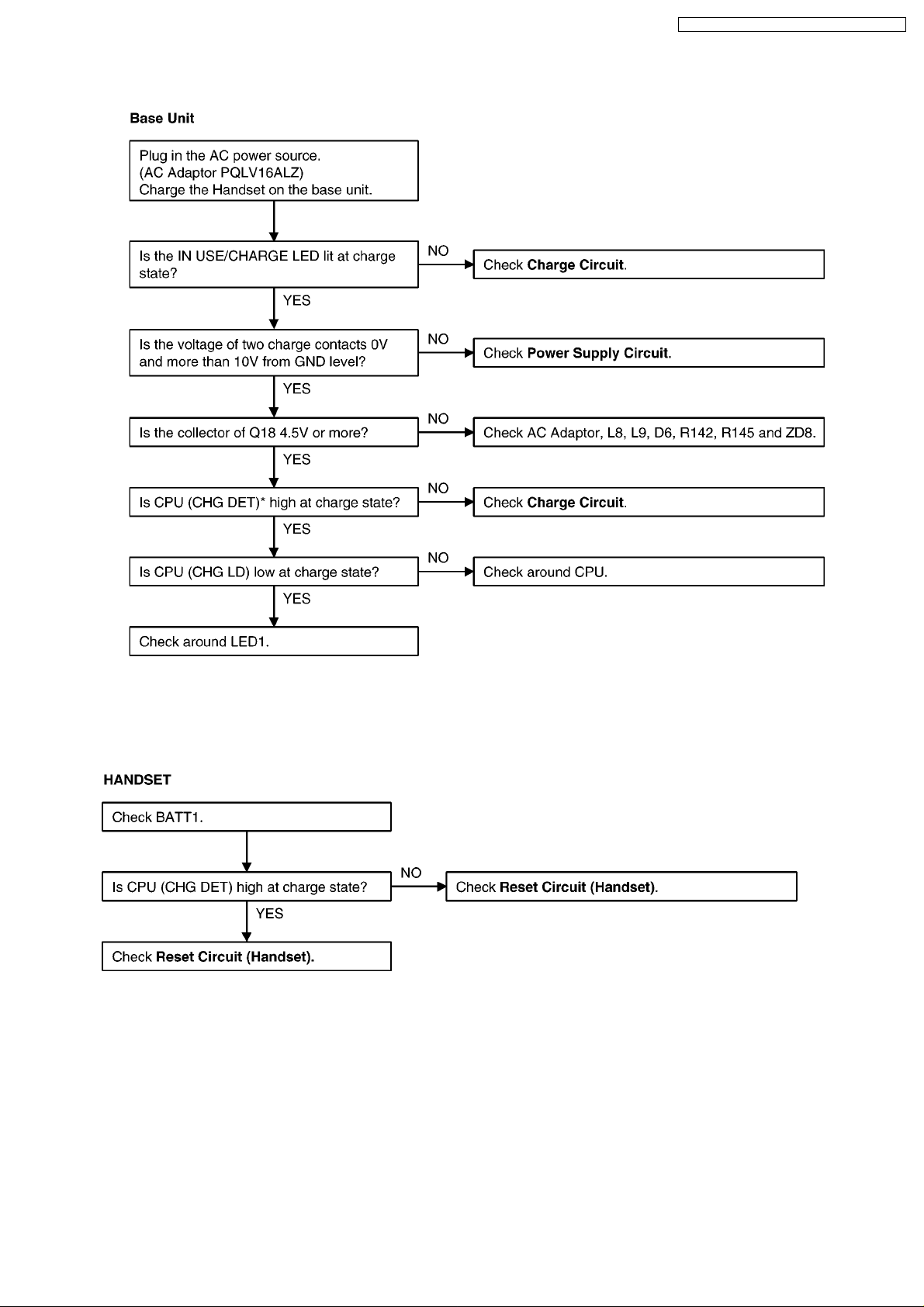

10.3. Check Battery Charge

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

Cross Reference:

Charge Circuit (P.43)

Power Supply Circuit (P.41)

Cross Reference:

Reset Circuit (Handset) (P.47)

*: Each measurement points are shown in CIRCUIT BOARD (Base Unit) (P.67) or CIRCUIT BOARD (Handset) (P.69)

Note:

CPU: IC2

Note:

CPU: IC2

21

Page 22

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

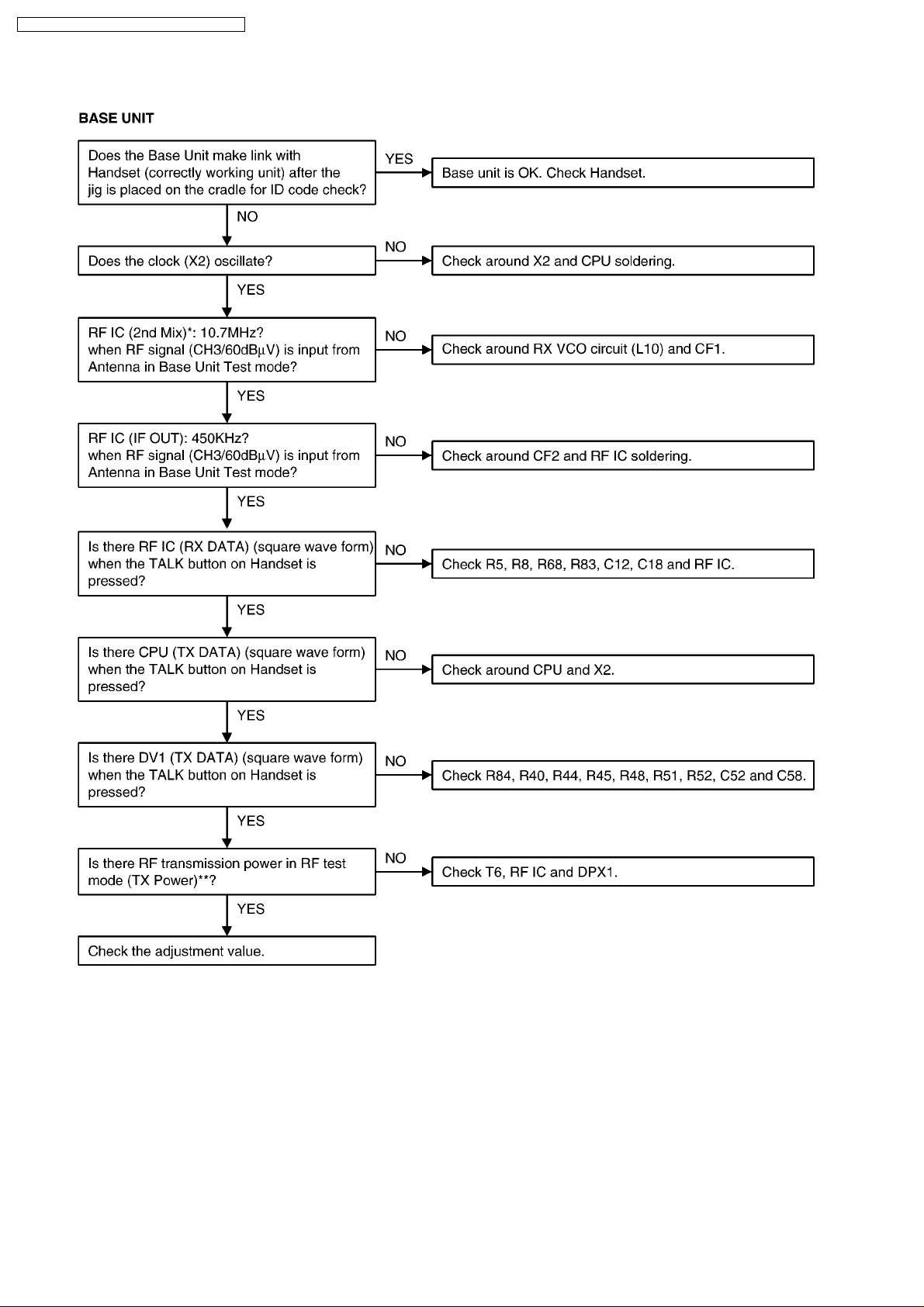

10.4. Check Link

**: Refer to Adjustment (P.26) Note:

CPU: IC2

RF IC: IC1

*: Each measurement points are shown in CIRCUIT BOARD (Base Unit) (P.67) or CIRCUIT BOARD (Handset) (P.69)

22

Page 23

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

**: Refer to Adjustment (P.29). Note:

CPU: IC2

RF IC: IC1

*: Each measurement points are shown in CIRCUIT BOARD (Base Unit) (P.67) or CIRCUIT BOARD (Handset) (P.69)

23

Page 24

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

10.5. Check Handset Transmission

Cross Reference:

Signal Route (P.46)

10.6. Check Handset Reception

Cross Reference:

Signal Route (P.46)

*: Each measurement points are shown in CIRCUIT

BOARD (Base Unit) (P.67) or CIRCUIT BOARD (Handset)

(P.69)

24

Page 25

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

11 ADJUSTMENTS (BASE UNIT)

If your unit have below symptoms, adjust or confirm each item using remedy colum n from the table.

Symptom Remedy*

The base unit dose not respond to a call from handset. Make confirmation in item (A)

The base unit dose not transmit or the transmit f requency is off. Make adjustments in item (B)

The transmit frequency is off. Make adjustments in item (C)

The transmit power output is low, and the operating distance between the base unit and

the handset is less than normal.

The reception sensitivity of base unit is low with noise. Make confirmation in item (E)

The transmit level is high or low. Make confirmation in item (F)

The reception level is high or low. Make confirmation in item (G)

The unit does not link. Make confirmation in item (H)

*: Refer to Adjustment (P.26).

11.1. Test Mode Flow Chart (Base Unit)

The operation-flow of Test mode and main check items are shown below.

Make adjustments in item (D)

Note:

**: Refer to the above table.

25

Page 26

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

11.2. How to change the channel

*: Refer to Flow Solder Side View (P.68).

11.3. Adjustment

Adjustment Items Test Mode Adjustment

(A) RX VCO

Confirmation

(B) TX VCO

Adjustment

(C) TX Frequency

Adjustment

(D) TX Power

Adjustment

(E) RX Sensitivity

Confirmation

(2nd IF output)

(F) Line Output Level

Confirmation

(G) Line Input

Modulation

Confirmation

(H) Noise Squelch

Confirmation

3ch Talk -

3ch Talk T6

3ch Talk VC1

3ch Talk T5

3ch Talk T2 1. Apply 60dBuVemf output from S.S.G. (modulation frequency 1KHz, dev.

3ch Talk - 1. Apply 60dBuVemf output from S.S.G. (modulation frequency 1KHz, dev.

3ch Talk - 1. Input via loop simulator 1.0KHz, -20dBm (measured at T-R) signal.

3ch Talk - 1. Measure the SSG output level when the noise squelch changes from Low

Point

•

• Confirm so that the reading of the Digital Voltmeter is 2.0V ± 1.0V.

• •

•

• Adjust T6 so that the reading of the Digital Voltmeter is 2.0V ± 0.3V.

• •

•

• Adjustment VC1 so that the reading of the frequency counter is

• •

30.1750MHz ± 100Hz.

•

• Adjust T5 so that the reading of the RF VTVM is more than 9dBm.

• •

0KHz).

2. Confirm that the reading of RF VTVM is the maximum value (more than

20mV)

3KHz).

2. Confirm that the reading of AF VTVM is more than 120mV (600Ω load).

2. Apply 60dBuVemf output from S.S.G. (modulation frequency 1KHz, dev.

0KHz).

3. Confirm so that the reading of FM Deviation Meter is 2.8KHz ±0.3KHz.

to High.

2. Confirm that the SSG output level is -10 ~ +5dBuVemf.

*Procedure Check or

* : The connection of adjustment equipment are as shown in Adjustment Standard (Base Unit) (P.27).

SSG Frequency: 39.875 MHz

Replace

Parts

IC1, L10,

C26, R14

IC1, DV1,

T6

IC, X1, T6,

DV1, C35,

C40, VC1

IC1, Q3,

Q4, Q5,

T5, DPX1

DPX1, T2,

CF1, CF2

IC1, Q11

IC1, DV1

IC1, DPX1

26

Page 27

11.4. Adjustment Standard (Base Unit)

When connecting the Simulator and Equipments for checking, please refer to the illustration below.

Q5

C83

C124

C57

Q2

(G)

(C)

(D)

R154

R40

ZD5

R52

R45

R38

R36

R54

Audio

Analyzer

27

DC12V or

AC adaptor

AF OSC

Loop

SIMULATOR

AF Volt Meter (F)

ZD10 ZD12

R160

R161

ZD11

R132

Q14

TXPOWER TXGND

C136

R175

C5

C96

C99

D11

Q17

R131

R120

R145

R138

R137

C14

Q25

FM Deviation

Meter

Frequency

Counter

RF

Volt Meter

50Ω

SSG

48.86MHz

C133

C62

C46

C47

R56

C56

R53

R42

C49

C51

R130

Q4

R111

C58

R48

R181

C123

ZD3

C59

R43

R35

R37

C53

R55

Q3

C60

R46

C55

R41

R33

D8

R198

C122

R116

R124

C52

R44

C48

C110

R51

C54

R155

R80

D1

R49

C40

R15

R16

C31

C45

R110

C61

Q6

R112

C29

R50

C125

R30

R86

Confirmation of VCO voltage

DC Volt Meter

(A), (B)

TX-VCORX-VCO

C6

R12

C23

R23

C39

C22

C44

1

C34

C109

C19

R25

R32

C36

R26

R22

R14

C26

R60

C27

C43

C35

C37

R31

R24

R148

R149

R183

IC1

R170

Q20

C101

C7

C33

R19

R20

R21

C93

R2

C79

C11

R143

R150

R13

R166

C16

C10

C24

C121

RF Volt

Meter

C9

R10

R6

R100

C86

R117

C120

R139

(E)

T.P ( CH change at test mode)

R108

C74

R406

R405

C65

R153

R134

R177

R178

R96

C107

R93

C88

R74

R140

C75

R105

Q402

LED1

R409

Q21

1

Q16

R407

C402

R76

R85

R179

R94

R81

R18

Q13

R79

C84

R408

R167

IC2

R78

C70

R410

R63

R158

R89

R77

Q403

R75

R115

R157

C135

R401

C92

R119

Q11

R122

R133

R59

R87

C90

R129

R159

R403

R404

C401

R402

R146

R84

C108

C85

Q401

R82

R123

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

R126

R58

R1

C2

C8

R156

C67

R3

R5

C4

R7

C12

C18

R8

C73

R97

C63

R180

C28

R4

C25

R88

R103

C134

Q7

R114

R68

C64

C106

R185

R57

R109

C77

R197

R83

R62

R141

C82

IC3

R104

1

C69

R90

R95

C72

Note: (A) - (H) is refered to ADJUSTMENTS (BASE UNIT) (P.25)

Oscilloscope (H)

Page 28

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

12 ADJUSTMENTS (HANDSET)

If your unit have below symptoms, adjust or confirm each item using remedy column from the table.

Symptom Remedy*

The movement of Battery Low Indicator is wrong. Make confirmation in item (A)

The base unit does not respond to a call from the handset. Make adjustments in item (B)

The base unit does not transmit or the transmit frequency is off. Make confirmation in item (C)

The transmit frequency is off. Make adjustments in item (D)

The transmit power output is low, and the operating distance between the base unit and

the Handset is less than normal.

The reception sensitivity of the handset is low with noise. Make confirmation item (F)

Does not link between the base unit and the handset. Make confirmation in item (G)

The reception level is high or low. Make confirmation item (H)

The transmit level is high or low. Make confirmation in item (I)

*: Refer to Adjustment (P.29).

Unit condition:

1. Remove the antenna lead wire from P.C Board of the handset.

2. Power Supply: DC 3.9V (DC power supply)

3. Volume: HIGH (When P.C. Board of handset is in test mode, volume condition is medium. Press “LOCATOR” key once.)

4. Speaker Load: 150Ω

CH TX Frequency RX Frequency

CH3 39.875MHz 30.175MHz

Make confirmation in item (E)

12.1. Test Mode Flow Chart (Handset)

Note:

Refet to CIRCUIT BOARD (Handset) (P.69)

Signal Route (P.46)

28

Page 29

12.2. How to change the channel

12.3. Adjustment

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

Adjustment Items Test Mode Adjustment

(A) Battery Low

Confirmation

(B) TX VCO

Adjustment

(C) RX VCO

Confirmation

(D) TX Frequency

Adjustment

(E) TX Power

Confirmation

(F) RX Sensitivity

Confirmation

(2nd IF output)

(G) Noise Squelch

Confirmation

(H) Speaker

Output Level

Confirmation

(I) Mic Modulation

Factor

Confirmation

(J) Data

Modulation

Confirmation

(K) Battery low

Confirmation

3ch Talk - 1. Adjust the power supply voltage to DC3.60V,and confirm so that the

3ch Talk T6 1. Adjust T6 so that the reading of the Digital Voltmeter is 1.5V ± 0.3V. IC1, X1,

3ch Talk - 1. Confirm so that the reading of the Digital Voltmeter is 0.7 ~ 3.0V. IC1, X1,

3ch Talk VC1

3ch Talk -

3ch Talk T3 1. Apply 60dBuVemf output from S.S.G. (modulation frequency 1KHz, dev.

3ch Talk - 1. Measure the SSG output level when the noise squelch changes from

3ch Talk - 1. Apply 60dBuVemf output from S.S.G. (modulation frequency 1KHz, dev.

3ch Talk - 1. Apply a MIC signal (1KHz, 5.0mV at 600Ω load).

3ch Talk -

- - 1. Apply 3.50V between BATT(+) and BATT(-).

Point

Procedure Check or

reading of oscillosope is High.

2. Adjust that power supply voltage to DC 3.40V, and confirm so that the

reading of oscilloscope is Low.

•

• Adjust VC1 so that the reading of the frequency counter is 39.8750MHz

• •

± 100Hz.

•

• Confirm so that the reading of the RF VTVM is more than -3.0dBm

• •

(50Ω load).

0KHz).

2. Confirm that the reading of RF VTVM is the maximum value (more than

15mV).

Low to High. (modulation frequency 1KHz, dev.3kHz)

2. Confirm that the SSG output level is -18 ~ 0dBuVemf.

3KHz).

2. Confirm that the reading of AF VTVM is more than 30mV.

(distortion: less than 5%) (volume High).

2. Confirmation so that the reading of FM Deviation Meter is 3.4KHz ±

0.4KHz.

•

• Confirm for 5.0 ± 1.0KHz FM Deviation Meter reading.

• •

2. Confirm that there is no flashing of RECHARGE LED.

3. Apply 3.40V between BATT(+) and BATT(-).

4. Confirm that there is flashing of RECHARGE LED.

Replace

Parts

IC1

T6, DV1

L6, C24

IC1,

DPX1, T5

IC1,Q3,Q4,

Q5, DPX1

DPX1,

T3,IC1,

CF1, CF2

IC1, DPX1

IC1

IC1, DV1

IC1

The connections of adjustment equipment are as shown in Adjustment Standard (Handset) (P.30).

SSG Frequency: 30.175 MHz

29

Page 30

12.4. Adjustment Standard (Handset)

When connecting the Simulator and Equipments for checking, please refer to the illustration below.

(Component View)

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

30

C37

REC

C56

C51

L1

DV1

VC1

C43

150Ω

C42

AF Volt Meter (H)

X1

R101

R11

C31

T6

C15

L6

T5

L200

R106

C29

R28

C38

C23

R14

C26

CF1

C27

T3

R21

R93

C34

C77

C76

R108

R94

R95

R110

C8

DPX1

C18

C75

C12

R109

C1

CF2

Q1

T1

C32

R16

C16

C9

R5

C30

R18

R8

R6

R46

R98

R37

C64

R87

R74

C73

R78

R99

C69

C72

R86

R85

R39

Q4

D1

R30

R29

C79

R102

R23

R103

C33

BZ1

R3

C14

R55

D3

R63

C78

R42

R17

R61

R20

Q3

Q2

Q7

R19

R22

C39

R54

R105

R56

Q8

Q12

C58

R48

R107

C46

R70

X3

C45

X2

R58

R69

R77

R67

R66

R57

R12

R79

R62

R71

R72

R112

R59

R80

R73

IC2

C66

R81

C65

R83

C84

C68

C71

C70

C67

R84

R96

R82

R64

C74

R76

R53

R75

R65

R111

R68

R60

Q11

L3

C63

R36

ZD1

C80

CHG+ CHG-

L5

47µF

C86

ZD3

L4

+

-

BATT1

C48

Q9

L2

L7

(A) Battery Low

AFGenerator

(G) Noise Squelch

Oscilloscope

Note: (A)-(I) is refered to ADJUSTMENTS (HANDSET) (P.28)

Page 31

(Flow Solder Side View)

31

TX VCO

DC Volt Meter(B)

Audio

Analyzer

(E)

(D)

(I), (J)

SSG

43.820MHz

RF Millivolt

Meter

Frequency

Counter

FM Deviation

Meter

R52

C62

Q6

C57

R44

R40

R38

C52

C61

R50

R24

C40

C59

R45

C4

R49

C60

R41

C36

C49

C10

R47

C41

50Ω

(F)

RF

Volt Meter

TXPOWERTXGND

C55

R43

R97

C50

Q5

C53

R51

C44

C47

R200

C201

C54

R35

R34

C35

R26

C24

C88

C3

C202

Q200

C200

C17

R1

R25

C203

R201

C6

C5

IC1

C28

C89

C7

C22

C2

C21

R13

C85

C13

R9

R113

R10

DIRTAUTO

TALK

LED5

R2

3

21

LED2

6

LED1

K11

45

9

LED4

LED3

78

#

0

REDIALRINGER

FLASH

PAUSE

LOUDPROG

CH

MIC1

LED6

RX VCO

DC Volt Meter(C)

Note: (A)-(I) is refered to ADJUSTMENTS (HANDSET) (P.28)

DC Power

Supply

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

Page 32

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

13 RF SPEC IFICATION

13.1. Base Unit

Item Value Refer to -.* Remarks

TX Frequency 30.175MHz ± 100Hz ADJUSTMENTS (BASE UNIT) (C) at CH3

TX Power more than 1mW ADJUSTMENTS (BASE UNIT) (D) at CH3

Line Modulation factor 2.5 kHz~3.1 kHz ADJUSTMENTS (BASE UNIT) (G)

Data Modulation factor 4.5 kHz~7.5 kHz —

Line Output level more than 120mV —

*: Refer to Adjustment (P.26).

13.2. Handset

Item Value Refer to -.** Remarks

TX Frequency 39.875 MHz ± 0.1kHz ADJUSTMENTS (HANDSET) (D) at CH3

TX Power more than 1mW ADJUSTMENTS (HANDSET) (E) at CH3 (Antenna

Data Modulation factor 5.0 kHz~6.0 kHz ADJUSTMENTS (HANDSET) (J) at CH3

MIC Modulation factor 2.9 kHz/dev~3.8 kHz/dev ADJUSTMENTS (HANDSET) (I) at CH3 (MIC terminal

SP Output level more than 30mV —

soldering point 50Ω

Load)

2.4mV Input)

**: Refer to Adjustment (P.29).

14 HOW TO CHECK THE HANDSET SPEAKER

1. Prepare the digital voltmeter, and set the selector knob to ohm meter.

2. Put the probes at the speaker terminals as shown below.

32

Page 33

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

15 FREQUENCY TABLE (MHz)

BASE UNIT PORTABLE UNIT

Channel Transmit Frequency Receive Frequency Transmit Frequency Receive Frequency

1 30.0750 39.7750 39.7750 30.0750

2 30.1250 39.8250 39.8250 30.1250

3 30.1750 39.8750 39.8750 30.1750

4 30.2250 39.9250 39.9250 30.2250

5 30.2750 39.9750 39.9750 30.2750

6 30.1000 39.8000 39.8000 30.1000

7 30.1500 39.8500 39.8500 30.1500

8 30.2000 39.9000 39.9000 30.2000

9 30.2500 39.9500 39.9500 30.2500

10 30.3000 40.0000 40.0000 30.3000

33

Page 34

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

16 EXPLANATION OF CPU DATA C OMMUNICATION

16.1. STAND-BY -> TALK, TALK -> STAND-BY

*: The channel is changed if the noise interferes with the conversation.

34

Page 35

16.2. Ringing

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

35

Page 36

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

16.3. Changing the Channel

36

Page 37

16.4. Ports for transmitting and receiving of data

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

Handset:

transmitting (TX) ... 36 Pin

receiving (RX) ... 4 Pin

Base Unit:

transmitting (TX) ... 17 Pin

receiving (RX) ... 10 Pin

16.5. Waveform of DATA used for cordless transmission and reception

The DATA which is transmitted from the Handset to the Base Unit is combination of DATA 0, DATA 1, PSEUD.

The DATA which is transmitted from the Base Unit to the Handset is combination of DATA 0, DATA 1, PSEUD.

16.5.1. Handset

16.5.2. Base Unit

•

• For example (one of part of data)

• •

37

Page 38

17 BLOCK DIAGRAM (BASE UNIT)

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

38

H/S

DUPLEXER

DPX1

RX LOOP

TX LOOP

RF AMP

Q3,Q4, T5

ANTENNA

X1

RX VCO

L10, C26

RF AMP

Q1, T2

POWER

CONTROL

Q2

TX VCO

Q5, T6, DV1

VC1

10.7MHz 450kHz

RF FILTER

CF1, CF2

RF IC

MIX 1/2

PLL OSC

DC 5V

IC1

RF

-DATA

-CLK

-STB

EXP

COM

X2

17

14

TELEPHONE LINE

INTERFACE

TEL

LINE

AMP

Q11, IC3

POWER SUPPLY

RESET CHARGE

5V

REGULATOR

Q18, Q19

TEL

LINE

SW

T7

DIODE

BRIDGE

D2, D3,

D4, D5

DC IN

12V 150mA

(AC Adaptor)

AC DOWN

DTC

Q402,Q403

TEL LINE

DC 5V

CONTROL LINE

AUDIO SIGNAL

LED

Q21, LED1

VTX RF

TX

DATA

-DATA

-CLK

-STB

RX

DATA

CPU

IC2

RESET

DTC

Q401

CHARGE

DTC

Q7

CHARGE

CONTROL

Q14, Q17

Q24, Q25

DC 12V

CHARGE

TERMINAL

KX-TC2000NZB/W/F BLOCK DIAGRAM (BASE UNIT)

Page 39

18 BLOCK DIAGRAM (HANDSET)

39

Base

DUPLEXER

DPX1

RX LOOP

TX LOOP

RF AMP

Q5, T5

Q200

ANTENNA

X1

RX VCO

L6, C24

RF AMP

Q1, T3

POWER

CONTROL

Q4

TX VCO

Q6, T6, DV1

VC1

MIX 1/2

PLL OSC

DC 3.9V

RF FILTER

CF1, CF2

RF IC

IC1

RF

-DATA

-CLK

-STB

EXP

COM

X3

SPEAKER

REC1

MIC

MC1

DIODE

BRIDGE

Q9

DC 3.9V

CONTROL LINE

AUDIO SIGNAL

BATTERY

3.9V

LED

Q8, LED 1-4

KEY BOARD

VTX

TX

DATA

RF

-DATA

-CLK

-STB

DATA

CPU

IC2

RX

RESET

Q11

CHARGE

DTC

IC2 PING37

BUZZER

Q7, BZ1

Q12

DIODE

BRIDGE

D1

CHARGE

TERMINAL

KX-TC2000NZB/W/F BLOCK DIAGRAM (HANDSET)

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

Page 40

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

19 CIRCUIT OPERATION

19.1. Outline

Base unit consists of the following ICs as shown in BLOCK DIAGRAM.

•

• CPU:IC2

• •

−

− Controlling the whole system

− −

−

− Forming/analyzing all data signals (ACK, CMD signal etc.*)

− −

−

− All interfaces (ex: LED, KEY, SP, Mic, LCD, Detector Circuit (Charge/ Power Down)

− −

*Refer to EXPLANATION OF CPU DATA COMMUNICATION (P.34).

•

• RF IC:IC1

• •

−

− PLL Oscillator

− −

−

− Detection

− −

−

− Compress/ Expander

− −

−

− first/ second mixer

− −

−

− Amplifier for transmission and reception

− −

•

• Additionally,

• •

−

− Power Supply Circuit

− −

−

− Reset Circuit

− −

−

− Charge Circuit

− −

−

− Telephone Line Interface Circuit

− −

Handset consist of the following ICs as shown in BLOCK DIAGRAM.

•

• CPU: IC2

• •

−

− All data signals (forming/analyzing ACK or CMD signal*)

− −

−

− All interfaces (ex; LED, Key, Buzzer, Detector Circuit, Charge, Battery Low)

− −

−

− RAM for keeping the data (CH Number, ID Code, etc.)

− −

•

• RF IC:IC1

• •

−

− PLL Oscillator

− −

−

− Detector

− −

−

− Compress/Expander

− −

−

− first, second mixer

− −

−

− Amplifier for transmission and reception

− −

*Refer to EXPLANATION OF CPU DATA COMMUNICATION (P.34).

40

Page 41

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

19.2. Power Supply Circuit

The power supply to the CPU (Digital, Analog) and RF IC from AC Adaptor (+12V) is shown in the diagram below.

The base unit power supply is DC12V. The handset´s power is supplied from 3.6V battery (Nickel-Cadmium battery) which is

installed in the handset.

Power supply for transmitter is turned on by a press of "Talk" key on the handset. During the stand-by mode, the unit stops

transmitting but receives the signal.

Also during on-hook condition (the handset is placed on the base unit), backup power for memory of the last dialed number is

supplied through the battery. The memory of this unit is not backed up by the current from

the telephone line.

The base unit DC power supply is regulated by Q18, the CPU power is regulated by Q19. The Q401, Q403 detects AC Adaptor

power failure and maintains the unit security code.

Fig. 1

41

Page 42

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

19.3. Reset Circuit (Base Unit)

After power supply from AC adaptor, the below circuit is for making reset signal. Refer to the below waveform.

Fig. 2

Fig. 3

42

Page 43

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

19.4. Charge Circuit

Circuit Operation:

When charging the handset on the base unit, the charge current is as follows;

DC (JK2) → L8 → D6 → Q14 → Q24 → L7 → CHG+(Base) → [CHG+(Handset) → L4 → Q9 → BATT(1)....Battery....BATT(2)

→ L5 →

CHG-(Handset)] → CHG-(Base) → L5,

In this way, the CPU on both unit detects the fact that the battery is charged.

The charge current is controlled by switching Q24, Q25 of Base Unit. The battery is charged in normal mode for 15 hours and

then in trickle mode.

19.5. Telephone Line Interface

Function:

•

• Bell signal detection

• •

•

• ON/OFF hook and pulse dial circuit

• •

•

• Side tone circuit

• •

Bell signal detection and OFF HOOK circuit:

In the idle mode, Q103 is open to cut the DC loop current and decrease the ring load. When ring voltage appears at the Tip (T)

and Ring (R) leads (When the telephone rings), the AC ring voltage is transferred as follows:

JK1 (3): T → L6 → R184 → R144 → IC3D (12,13 → 14) → C97 → R148 → Q20 → IC2 (24) [BELL]

JK1 (2): R → L4 → R183 → R152 →↑

When the CPU (DSP) detects a ring signal and press the TALK Key on the handset. Q6 turns on and then RY1 turns on,

thus providing an off-hook condition (active DC current flow through the circuit) and the following signal flow is for the loop

current.

T → R160 → L4 → D2 → RY1 → R107 → T7 → R116 → D5 → L6 → R161 → R[OFF HOOK]

ON HOOK Circuit:

Q6 is open, RY1 disconnected as to cut the DC loop current and to cut the voice signal. The unit is consequently in an on-hook

condition.

Side Tone Circuit:

Basically this circuit prevents the TX signal from feeding back to RX signal.

As for this unit, TX signal feed back from Q11 is canceled by the cancellor circuit of AGC.

19.6. DTMF

The DTMF signal is generated by five outputs of IC2 (CPU) and output to telephone line through the filter of IC3A which is a

lowpass filter as shown below.

The combination of five outputs “1”, “0” makes 32 (=2

generator.

5) level signals and makes smooth waveform after filter like a DTMF

43

Page 44

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

19.7. Transmitter/Receiver

Base Unit and Handset are mainly consists of RF(Radio Frequency) IC and CPU.

Base Unit and Handset transmit/receive voice signal and data signal through the antenna on carrier frequency.

Signal Pass :

*Refer to CDL TX/RX in Signal Route (P.46).

19.7.1. Base to Handset

Circuit Operation:

The voice signal input from the TEL LINE interface goes to RF IC as shown in

BLOCK DIAGRAM (BASE UNIT) (P.38).

In the talk mode (off-hook) condition, the telephone line voice signal passes through D2, D3, D4, D5, RY1 (Relay), R107 and

T7.

The other party´s voice signal is coupled with T7 and amplified by Q11 and led to IC3-B (OP Amplifier device).

And the signal goes through the compressor of RF IC, it is output to transmitter circuit.

The signal of the data sent to the handset is applied in the anode of the variable capacitor diode (VARICAP : DV1).

The capacitor of VARICAP is changing in accordance with the voice signal from telephone line interface or TX DATA signal from

CPU. Therefore, the carrier frequency which is generated by TXVCO will be changing, and Frequency modulated RF

signal is generated and amplified by RF AMP(Q3, Q4, T5). It pass through the Duplexer DPX1 and radiated from Antenna.

The signal is transmitted from the base unit and received by the handset antenna and amplified by RF amplifier (Q1) through

DPX1 as shown in BLOCK DIAGRAM (HANDSET) (P.39). And then it is converted to 10.7 MHz and 455 KHz Intermediate

frequency by RF IC and related components.

The demodulated audio signal is output from RF IC (DET OUT) and passed through "Expander" process to reduce noise, then

voice signal amplified by "Receiver amplifier" is output to receiver (REC1).

The receiver loudness is adjustable using "LOUD" key on the handset. Q2 and Q3 control the volume. When CPU (VOL1)

becomes low, the volume becomes "MID", while CPU (VOL1, 2) become low, the volume becomes "HIGH".

TX data (to Handset)

CPU (VTX) becomes low to turn on the transmission power transistor Q2, and CPU (TX-data) sends data signal. It is

FM-modulated by TXVCO and driven by RF AMP, then transmitted to the handset.

44

Page 45

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

19.7.2. Handset to Base

Circuit Operation:

The voice signal from the handset user is picked up by the microphone (MC1), voice signal passes through "Compressor"

process to reduce noise as shown in BLOCK DIAGRAM (HANDSET) (P.39). And the voice is FM-modulated by

VARICAP (DV1).

The carrier frequency is generated by TX VCO. The transmitter power transistor Q4 is turned on/off by CPU (VTX).

The carrier signal is amplified by RF AMP and sent to the handset duplexer and antenna.

The signal of 39MHz band (39.775~40.000MHz) which is input from ANT is filtered at DPX1 as shown in

BLOCK DIAGRAM (BASE UNIT) (P.38), then it is input to RF IC.

The signal input to RF IC is converted through Mixer inside of RF IC, RF filter (CF1, CF2) and Expander.

The signal is transmitted from the handset and received by the base unit antenna and amplified by RF amplifier Q1, then

it is converted to10.7 MHz and 450 KHz Intermediate by RF IC. The demodulated audio signal is output from RF IC

(DET OUT) and passed through "Expander" process to reduce noise, then voice signal is led to LINE AMP. The signal is

passed through TELEPHONE INTERFACE and Tel-line.

RX data (from Handset):

The data signal from handset (ex: Talk, ACK, COM) is also included in 39 MHz band same as the voice data. After second if

filter, the data signal is made square shape by data limiting AMP of the RF IC. RX data is output to CPU (RX Data).

19.7.3. RF signal operation/control and PLL operation (RF UNIT)

Base unit radio frequency signal received by antenna passes through duplexer (DPX1).

RF signal is amplified by RF AMP. RF signal received from RF IC is mixed with RX local frequency at Mixer to generate

10.7 MHz wide band IF. The reference frequency is generated by X1 11.150 MHz crystal. VC1 is the reference frequency

for adjustment. The 10.7 MHz is mixed with reference and 450KHz narrow band IF is generated. The demodulation audio signal

is adjusted to the maximum at T1. RF IC is controlled by CPU (RF_STB, DATA, CLK). The RX local frequency is generated

by RXVCO.

45

Page 46

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

19.8. Signal Route

Each signal route is as follows.

46

Page 47

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

20 CIRCUIT OPERATION (HANDSET)

20.1. Reset Circuit (Handset)

The power of handset is supplied by battery.

Whenever the battery is recharged or inserted, the impulse at CHG+ becomes Reset signal through Q11, and sent to CPU.

Fig. 4

Fig. 5

47

Page 48

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

20.2. Battery Low / Power Down Detector

Circuit Operation:

“Battery Low” and “Power Down” are detected by RF IC which check the voltage from battery. Shortly, every detected blocks

are inside of RF IC. The detected voltage is as follows;

•

• Battery Low

• •

Battery voltage : V(Batt) < 3.457V

The CPU detects this level and “Recharge battery” LED starts flashing.

•

• Power Down

• •

Battery voltage : V(Batt) < 3.0V

The output of RF IC (P-DOWN) becomes low level, then CPU stops working to keep the data (CH number, ID Code, etc.)

Fig. 6

48

Page 49

21 CPU DATA (Base Unit)

21.1. IC2

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

49

Page 50

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

22 CPU DATA (Handset)

22.1. IC2

50

Page 51

23 RF IC (Base Unit and Handset)

23.1. IC1

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

51

Page 52

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

24 HOW TO REPLACE FLAT

PACKAGE IC

24.1. Preparation

•

• SOLDER

• •

Sparkle Solder 115A-1, 115B-1 or Almit Solder KR-19, KR19RMA

•

• Soldering iron

• •

Recommended power consumption will be between 30 W

to 40 W.

Temperature of Copper Rod 662 ± 50°F (350 ± 10°C)

(An expert may handle between 60 W to 80 W iron, but

beginner might damage foil by overheating.)

•

• Flux

• •

HI115 Specific gravity 0.863.

(Original flux will be replaced daily.)

24.2. Procedure

1. Temporary fix FLAT PACKAGE IC by soldering on two

marked2pins.

24.3. Modification Procedure of

Bridge

1. Re-solder slightly on bridged portion.

2. Remove remained solder along pins employing soldering

iron as shown in below figure.

*Most important matter is accurate setting

of IC to the corresponding soldering foil.

2. Apply flux for all pins of FLAT PACKAGE IC.

3. Solder employing specified solder to direction of arrow, as

sliding the soldering iron.

52

Page 53

KX-TC200 0NZB / KX-TC2000NZW / KX-TC200 0NZ F

25 CABINET AND ELECTRICAL PARTS LOCATION (BASE

UNIT)

53

Page 54

KX-TC200 0NZB / KX-TC2000NZW / KX-TC200 0NZ F

26 CABINET AND ELECTRICAL PARTS LOCATION

(HANDET)

54

Page 55

27 ACCESSORIES AND PACKING MATERIALS

KX-TC200 0NZB / KX -TC2000N ZW / KX-TC2000NZF

55

Page 56

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

28 REPLACEMENT PARTS

LIST

Note:

1. RTL (Retention Time Limited)

The marking (RTL) indicates that the Retention Time is

limited for this item.

After the discontinuation of this assembly in production, the

item will continue to be available for a specific period of

time. The retention period of availability depends on the

type of assembly and the laws governing parts and product

retention.

At the end of this period, the assembly will no longer be

available.

2. Important safety notice

Components identified by the

characteristics important for safety. When replacing any of

these components, only use specified manufacture´s parts.

3. The S mark indicates service standard parts and may differ

from production parts.

4. RESISTORS & CAPACITORS

Unless otherwise specified;

All resistors are in ohms (Ω) K=1000Ω, M=1000kΩ

All capacitors are in MICRO FARADS (µF) P=µµF

*Type & Wattage of Resistor

28.1. Base Unit

28.1.1. CABINET AND ELECTRICAL

PARTS

Ref.

No.

1 PQJT10180Z CHARGE TERMINAL

2 PQHR10998Z LED LENS

3 PQGT16253Z NAME PLATE (for KX-TC2000NZB)

3 PQGT16257Z NAME PLATE (for KX-TC2000NZF)

3 PQGT16255Z NAME PLATE (for KX-TC2000NZW)

4 PQQT22294Z CHARGE LABEL

5 PQBC10389Z1 LOCATOR BUTTON (for KX-

Part No. Part Name & Description Remarks

TC2000NZB)

mark indicates special

Ref.

No.

5 PQBC10389Y2 LOCATOR BUTTON (for KX-

5 PQBC10389Z3 LOCATOR BUTTON (for KX-

6 PQKE10335Z1 HOOK LEVER (for KX-TC2000NZB)

6 PQKE10335Z2 HOOK LEVER (for KX-TC2000NZF)

6 PQKE10335Z5 HOOK LEVER (for KX-TC2000NZW)

7 PQKF10597Z1 LOWER CABINET (for KX-

7 PQKF10597Z3 LOWER CABINET (for KX-

8 PQKM10607X1 UPPER CABINET (for KX-

8 PQKM10607W3 UPPER CABINET (for KX-

8 PQKM10607X4 UPPER CABINET (for KX-

9 PQSA10105Y ANTENNA

10 PQKL10056Z1 WALL MOUNT ADAPTOR (for KX-

10 PQKL10056Z3 WALL MOUNT ADAPTOR (for KX-

11 LCBT9300013 FOOT RUBBER

Part No. Part Name & Description Remarks

TC2000NZF)

TC2000NZW)

TC2000NZB/F)

TC2000NZW)

TC2000NZB)

TC2000NZF)

TC2000NZW)

TC2000NZB/F)

TC2000NZW)

28.1.2. MAIN P.C.BOARD PARTS

Ref.

No.

PCB1 PQWPC2000ALH MAIN P.C.BOARD ASS´Y (RTL)

IC1 SA133122409 IC

IC2 SA138740A11 IC

IC3 SA1S0032402 IC

IC5 AB1L0081715 IC

Q1 BB230024104 TRANSISTOR(SI)

Q2 SB0I0390601 TRANSISTOR(SI)

Q3 SB1D0390401 TRANSISTOR(SI)

Q4 SB1D0390401 TRANSISTOR(SI)

Q5 SB1D0390401 TRANSISTOR(SI)

Q6 SB1I0390408 TRANSISTOR(SI)

Q7 SB1I0390408 TRANSISTOR(SI)

Q10 BB010009408 TRANSISTOR(SI)

Q11 SB1I0390408 TRANSISTOR(SI)

Q14 SB0I0390601 TRANSISTOR(SI)

Q17 SB1I0390408 TRANSISTOR(SI)

Q18 BB1M0390401 TRANSISTOR(SI)

Q19 BB1M0390401 TRANSISTOR(SI)

Q20 SB1I0390408 TRANSISTOR(SI)

Q21 SB1I0390408 TRANSISTOR(SI)

Q24 BB1M0390401 TRANSISTOR(SI)

Q25 SB1I0390408 TRANSISTOR(SI)

Q401 SB1I0390408 TRANSISTOR(SI)

Q402 SB0I0390601 TRANSISTOR(SI)

Q403 SB1I0390408 TRANSISTOR(SI)

D1 SC1GM414809 DIODE(SI)

D2 BC2W0400401 DIODE(SI)

D3 BC2W0400401 DIODE(SI)

D4 BC2W0400401 DIODE(SI)

D5 BC2W0400401 DIODE(SI)

D7 VA02700A401 DIODE(SI)

D8 SC1GM414809 DIODE(SI)

D11 SC1GM414809 DIODE(SI)

DV1 BC6K0025101 DIODE(SI)

ZD1 BC050474801 DIODE(SI)

ZD2 BC050474801 DIODE(SI)

ZD3 SC4555C4V71 DIODE(SI)

ZD4 BC4579C8V21 DIODE(SI)

ZD5 SC4555C4V71 DIODE(SI)

ZD8 BC4579C5V65 DIODE(SI)

ZD9 BC4579C5V65 DIODE(SI)

ZD10 SC4555C1506 DIODE(SI)

ZD11 SV110201203 DIODE(SI)

ZD12 SC4555C1506 DIODE(SI)

Part No. Part Name & Description Remarks

(ICS)

(TRANSISTORS)

(DIODES)

56

Page 57

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

Ref.

No.

ZD404 BC4579C7V50 DIODE(SI)

LED1 SC5E0192115 LED

L1 PQLQZK3R3J COIL

L3 PQLQZM120J COIL

L4 PQLQZK120J COIL

L5 PQLQZK120J COIL

L6 PQLQZK120J COIL

L7 PQLQZK120J COIL

L10 PQLQZK1R2J COIL

L11 PQLQZM120J COIL

DPX1 BDFL0083004 COIL

JK1 DC72P120018 JACK

JK2 DC71P120023 JACK

CF1 BDFA107MA07 CERAMIC FILTER

CF2 BDFJ0450E08 CERAMIC FILTER

X1 BD1H1115002 CRYSTAL OSCILLATOR

X2 BD5H0795210 CRYSTAL OSCILLATOR

T1 CLIP1200053 TRANSFORMER

T2 CLIP1200100 TRANSFORMER

T5 CLIP1200096 TRANSFORMER

T6 CLIP1200142 TRANSFORMER

T7 DG0P1200035 TRANSFORMER

ZNR1 VA107D271K1 VARISTOR

R1 ERJ3GEYJ470 47

R2 ERJ3GEYJ331 330

R3 ERJ3GEYJ153 15K

R4 ERJ3GEYJ822 8.2K

R5 ERJ3GEYJ103 10K

R6 ERJ3GEYJ103 10K

R7 ERJ3GEYJ334 330K

R8 ERJ3GEYJ103 10K

R10 ERJ3GEYJ393 39K

R12 ERJ3GEYJ101 100

R13 ERJ3GEYJ623 62K

R14 ERJ3GEYJ103 10K

R15 ERJ3GEYJ562 5.6K

R16 ERJ3GEYJ153 15K

R18 ERJ3GEYJ222 2.2K

R19 ERJ3GEYJ563 56K

R20 ERJ3GEYJ184 180K

R21 ERJ3GEYJ273 27K

R22 ERJ3GEYJ472 4.7K

R23 ERJ3GEYJ104 100K

R24 ERJ3GEYJ103 10K

R25 ERJ3GEYJ683 68K

R26 ERJ3GEYJ154 150K

R30 ERJ3GEYJ104 100K

R31 ERJ3GEYJ473 47K

R32 ERJ3GEYJ105 1M

R33 ERJ3GEY0R00 0

R35 ERJ3GEYJ101 100

R36 ERJ3GEYJ224 220K

R37 ERJ3GEYJ101 100

R38 ERJ3GEYJ104 100K

R40 ERJ3GEYJ223 22K

R41 ERJ3GEYJ473 47K

R42 ERJ3GEYJ103 10K

R43 ERJ3GEYJ103 10K

R44 ERJ3GEYJ104 100K

R45 ERJ3GEYJ474 470K

R46 ERJ3GEYJ222 2.2K

R48 ERJ3GEYJ223 22K

R49 ERJ3GEYJ753 75K

R50 ERJ3GEYJ822 8.2K

R51 ERJ3GEYJ362 3.6K

Part No. Part Name & Description Remarks

(LED)

(COILS)

(JACKS)

(CERAMIC FILTERS)

(CRYSTAL OSCILLATORS)

(TRANSFORMERS)

(VARISTOR)

(RESISTORS)

Ref.

No.

R53 ERJ3GEYJ153 15K

R54 ERJ3GEYJ153 15K

R55 ERJ3GEYJ681 680

R56 ERJ3GEYJ222 2.2K

R57 ERJ3GEYJ224 220K

R58 ERJ3GEYJ221 220

R59 ERJ3GEYJ104 100K

R60 ERJ3GEYJ223 22K

R62 ERJ3GEYJ104 100K

R64 ERDS2TJ103 10K

R68 ERJ3GEYJ104 100K

R74 ERJ3GEY0R00 0

R75 ERJ3GEYJ103 10K

R77 ERJ3GEYJ203 20K

R78 ERJ3GEYJ393 39K

R79 ERJ3GEYJ823 82K

R80 ERJ3GEYJ222 2.2K

R81 ERJ3GEYJ164 160K

R82 ERJ3GEYJ103 10K

R83 ERJ3GEYJ103 10K

R84 ERJ3GEYJ103 10K

R85 ERJ3GEYJ103 10K

R86 ERJ3GEYJ473 47K

R87 ERJ3GEYJ472 4.7K

R88 ERJ3GEYJ103 10K

R89 ERJ3GEYJ103 10K

R90 ERJ3GEYJ274 270K

R94 ERJ3GEYJ104 100K

R95 ERJ3GEYJ392 3.9K

R96 ERJ3GEYJ334 330K

R97 ERJ3GEYJ102 1K

R100 ERJ3GEYJ222 2.2K

R103 ERJ3GEYJ223 22K

R104 ERJ3GEYJ472 4.7K

R105 ERJ3GEYJ562 5.6K

R106 ERDS2TJ220 22

R107 ERJ3GEYJ241 240

R108 ERJ3GEYJ472 4.7K

R109 ERJ3GEYJ334 330K

R110 ERJ3GEYJ104 100K

R111 ERJ3GEYJ471 470

R112 ERJ3GEYJ102 1K

R113 CQ52033RT27 33

R114 ERJ3GEYJ223 22K

R115 ERJ3GEYJ563 56K

R116 ERJ3GEY0R00 0

R118 ERDS1TJ121 120

R119 ERJ3GEYJ823 82K

R120 ERJ3GEY0R00 0

R122 ERJ3GEYJ361 360

R123 ERJ3GEYJ123 12K

R126 ERJ3GEYJ201 200

R129 ERJ3GEYJ622 6.2K

R131 ERJ3GEYJ104 100K

R132 ERJ3GEYJ222 2.2K

R133 ERJ3GEYJ390 39

R141 ERJ3GEYJ512 5.1K

R142 ERDS2TJ220 22

R143 ERJ3GEYJ514 510K

R144 ERDS2TJ106 10M

R145 ERJ3GEYJ102 1K

R146 ERJ3GEYJ153 15K

R148 ERJ3GEYJ103 10K

R149 ERJ3GEYJ182 1.8K

R150 ERJ3GEYJ514 510K

R152 ERDS2TJ106 10M

R153 ERJ3GEYJ105 1M

R154 ERJ3GEYJ470 47

R155 ERJ3GEYJ470 47

R156 ERJ3GEYJ470 47

R159 ERJ3GEYJ104 100K

R160 ERJ6GEY0R00 0

R161 ERJ6GEY0R00 0

Part No. Part Name & Description Remarks

57

Page 58

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

Ref.

No.

R166 ERJ3GEYJ470 47

R167 ERJ3GEYJ103 10K

R170 ERJ3GEYJ102 1K

R172 ERDS2TJ223 22K

R173 ERDS2TJ102 1K

R174 ERDS2TJ102 1K

R180 ERJ3GEYJ563 56K

R181 ERJ3GEYJ331 330

R183 ERJ6GEYJ106 10M

R184 ERDS2TJ106 10M

R185 ERJ3GEYJ104 100K

R195 ERDS2TJ472 4.7K

R197 ERJ3GEYJ223 22K

R198 ERJ3GEY0R00 0

R201 ERJ3GEYJ823 82K

R202 ERJ3GEYJ132 1.3K

R203 ERJ3GEYJ364 360K

R401 ERJ3GEYJ102 1K

R402 ERJ3GEYJ104 100K

R403 ERJ3GEYJ104 100K

R404 ERJ3GEYJ104 100K

R405 ERJ3GEYJ104 100K

R406 ERJ3GEYJ104 100K

R407 ERJ3GEYJ472 4.7K

R408 ERJ3GEYJ103 10K

R409 ERJ3GEYJ824 820K

R410 ERJ3GEYJ103 10K

C1 ECEA1AKA470 47

C2 ECUV1E104ZFV 0.1 S

C4 ECUV1H103KBV 0.01

C6 ECUV1E104ZFV 0.1 S

C7 ECUV1H102KBV 0.001

C8 ECUV1E104ZFV 0.1 S

C9 ECUV1H471JCV 470P S

C10 ECUV1H471JCV 470P S

C11 ECUV1H473MDV 0.047 S

C12 ECUV1H103KBV 0.01

C15 ECEA1HKA2R2 2.2

C16 ECUV1H270JCV 27P

C17 ECEA1CKA100 10

C18 ECUV1H473MDV 0.047 S

C19 ECUV1H102KBV 0.001

C20 ECEA1HKA2R2 2.2

C22 ECUV1H103KBV 0.01

C23 ECUV1H103KBV 0.01

C24 ECUV1E223ZFV 0.022

C25 ECUV1H472KBV 0.0047

C26 ECUV1H070CCV 7P

C27 ECUV1H103KBV 0.01

C28 ECUV1C104KBV 0.1

C29 ECUV1E104ZFV 0.1 S

C30 ECEA1HKA2R2 2.2

C31 ECUV1H103KBV 0.01

C32 ECEA1HKA2R2 2.2

C33 ECUV1H101JCV 100P

C34 ECUV1H471JCV 470P S

C35 ECUV1H180JCV 18P

C36 ECUV1H101JCV 100P

C37 ECUV1H151JCV 150P

C38 ECEA1HKS010 1 S

C39 ECUV1H103KBV 0.01

C40 ECUV1H270JCV 27P

C42 ECEA1HKA2R2 2.2

C43 ECUV1E104ZFV 0.1 S

C44 ECUV1A105ZFV 1

C45 ECUV1H682KBV 0.0068

C46 ECUV1H102KBV 0.001

C47 ECUV1H103KBV 0.01

C48 ECUV1H223KBV 0.022 S

C49 ECUV1H103KBV 0.01

C50 ECEA1CKA220 22

C51 ECUV1H103KBV 0.01

Part No. Part Name & Description Remarks

(CAPACITORS)

Ref.

No.

C52 ECUV1H223KBV 0.022 S

C53 ECUV1H120JCV 12P

C54 ECUV1H020CCV 2P

C55 ECUV1H103KBV 0.01

C56 ECUV1H050CCV 5P

C57 ECUV1H390JCV 39P

C58 ECUV1H682KBV 0.0068

C59 ECUV1H390JCV 39P

C60 ECUV1H270JCV 27P

C61 ECUV1E104ZFV 0.1 S

C62 ECUV1H390JCV 39P

C63 ECUV1H103KBV 0.01

C64 ECUV1E104ZFV 0.1 S

C65 ECUV1H220JCV 22P

C66 ECEA0JKA102 1000

C67 ECUV1H220JCV 22P

C69 ECUV1H271KBV 270P

C70 ECUV1H223KBV 0.022 S

C72 ECUV1H223KBV 0.022 S

C73 ECUV1E104ZFV 0.1 S

C74 ECUV1E104ZFV 0.1 S

C75 ECUV1H223KBV 0.022 S

C76 CATZ681KC68 680P

C77 ECUV1H101JCV 100P

C78 ECEA1AKA471 470

C79 ECUV1E104ZFV 0.1 S

C80 CATZ681KC68 680P

C82 ECUV1E104ZFV 0.1 S

C85 ECUV1C224KBV 0.22

C90 ECUV1C474KBV 0.47

C92 ECUV1E104ZFV 0.1 S

C93 ECUV1H562KBV 0.0056

C94 ECEA1AKA101 100

C95 ECEA1EKA471 470

C96 ECUV1H103KBV 0.01

C97 ECEA1HKA4R7 4.7

C98 ECEA1CKA220 22

C99 ECUV1H103KBV 0.01

C101 ECUV1H562KBV 0.0056

C102 ECEA1EKA221 220

C103 ECEA1AKA470 47

C104 ECUV1E104ZFV 0.1

C105 ECEA1AKA101 100

C106 ECUV1A105ZFV 1

C107 ECUV1E104ZFV 0.1 S

C108 ECUV1E104ZFV 0.1 S

C109 ECUV1H682KBV 0.0068

C110 ERJ3GEYJ102 1K

C122 ECUV1A154KBV 0.15

C123 ECUV1A474KBV 0.47

C124 ECUV1C224KBV 0.22

C125 ECUV1H100DCV 10P S

C134 ECUV1H103KBV 0.01

C135 ECUV1H103KBV 0.01

C136 ECUV1H020CCV 2P

C401 ECUV1E104ZFV 0.1 S

C402 ECUV1C224KBV 0.22

RY1 DCR000105H7 RELAY

SW1 DETP1200017 SWITCH

VC1 CR01020RRT8 TRIMMER CAPACITOR

Part No. Part Name & Description Remarks

(OTHERS)

28.2. Handset

28.2.1. CABINET AND ELECTRICAL

PARTS

Ref.

No.

101 PQJT10182Z CHERGE TERMINAL

102 PQGT16254Z NAME PLATE (for KX-TC2000NZB)

102 PQGT16258Z NAME PLATE (for KX-TC2000NZF)

Part No. Part Name & Description Remarks

58

Page 59

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

Ref.

No.

102 PQGT16256Z NAME PLATE (for KX-TC2000NZW)

103 PQKF10535Z1 REAR CABINET (for KX-

103 PQKF10535Z2 REAR CABINET (for KX-

103 PQKF10535Z5 REAR CABINET (for KX-

104 PQKK10124Z1 BATTERY COVER (for KX-

104 PQKK10124Z2 BATTERY COVER (for KX-

104 PQKK10124Z5 BATTERY COVER (for KX-

105 PQKM10510T1 FRONT CABINET (for KX-

105 PQKM10510T2 FRONT CABINET (for KX-

105 PQKM10510T5 FRONT CABINET (for KX-

106 PQSA10130Z ANTENNA (for KX-TC2000NZB/F)

106 PQSA10130Y ANTENNA (for KX-TC2000NZW)

107 PQSX10191Z KEYBOARD SWITCH (for KX-

107 PQSX10191V KEYBOARD SWITCH (for KX-

108 PQXA36ASVC BATTERY

109 FH1T1200011 CUSHION, URETHANE FORM

110 CG2P1200021 SPEAKER

111 FE4T1200019 SPEAKER NET

112 FH2T1200012 BUZZER SHEET

113 PQHR10896Z LIGHT PIPE

Part No. Part Name & Description Remarks

TC2000NZB)

TC2000NZF)

TC2000NZW)

TC2000NZB)

TC2000NZF)

TC2000NZW)

TC2000NZB)

TC2000NZF)

TC2000NZW)

TC2000NZB/F)

TC2000NZW)

28.2.2. MAIN P.C.BOARD PARTS

Ref.

No.

PCB100 PQWPC2000ALR MAIN P.C.BOARD (RTL)

IC1 SA133122409 IC

IC2 SA138780A05 IC

Q1 BB230024104 TRANSISTOR(SI)

Q2 SB1I0390408 TRANSISTOR(SI)

Q4 SB0I0390601 TRANSISTOR(SI)

Q5 SB1I0390408 TRANSISTOR(SI)

Q6 SB1I0390408 TRANSISTOR(SI)

Q7 SB0I0390601 TRANSISTOR(SI)

Q8 SB1I0390408 TRANSISTOR(SI)

Q9 SB1I0390408 TRANSISTOR(SI)

Q11 SB1I0390408 TRANSISTOR(SI)

Q12 SB1I0390408 TRANSISTOR(SI)

Q200 SB1D0390401 TRANSISTOR(SI)

D1 SC1GM414809 DIODE(SI)

D3 SC1GM414809 DIODE(SI)

DV1 BC6K0025101 DIODE(SI)

ZD1 BC4579C1005 DIODE(SI)

ZD3 SC455C5V601 DIODE(SI)

LED1 SC5E0192115 LED

LED2 SC5E0192115 LED

LED3 SC5E0192115 LED

LED4 SC5E0192115 LED

LED5 SC5E0192115 LED

LED6 SC5E0192123 LED

L1 PQLQZKR68J COIL

L2 PQLQZM120J COIL

L3 PQLQZM120J COIL

L4 PQLQZK120J COIL

L5 PQLQZK120J COIL

L6 PQLQZK1R8J COIL

L7 SH590121N75 COIL

L200 PQLQZM1R2J COIL

DPX1 BDFL0083012 COIL

Part No. Part Name & Description Remarks

(ICS)

(TRANSISTORS)

(DIODES)

(LEDS)

(COILS)

Ref.

No.

CF1 BDFA107MA07 CERAMIC FILTER

CF2 BDFJ0455E00 CERAMIC FILTER

T1 CLIP1200053 TRANSFORMER

T3 CLIP1200126 TRANSFORMER

T5 CLIP1200151 TRANSFORMER

T6 CLIP1200134 TRANSFORMER

X1 BD5H1024501 CRYSTAL OSCILLATOR

X2 BD8Z3276800 CRYSTAL OSCILLATOR

X3 BD5H0399209 CRYSTAL OSCILLATOR

R1 ERJ3GEYJ331 330

R2 ERJ3GEYJ153 15K

R3 ERJ3GEYJ682 6.8K

R5 ERJ3GEYJ103 10K

R6 ERJ3GEYJ103 10K

R8 ERJ3GEYJ224 220K

R9 ERJ3GEYJ823 82K

R10 ERJ3GEYJ331 330

R11 ERJ3GEYJ562 5.6K

R12 ERJ3GEYJ224 220K

R13 ERJ3GEYJ123 12K

R14 ERJ3GEYJ153 15K

R16 ERJ3GEYJ103 10K

R17 ERJ3GEYJ103 10K

R18 ERJ3GEYJ103 10K

R19 ERJ3GEYJ472 4.7K

R21 ERJ3GEYJ683 68K

R23 ERJ3GEYJ683 68K

R24 ERJ3GEYJ472 4.7K

R25 ERJ3GEYJ683 68K

R26 ERJ3GEYJ103 10K

R28 ERJ3GEYJ104 100K

R29 ERJ3GEYJ332 3.3K

R30 ERJ3GEY0R00 0

R34 ERJ3GEYJ224 220K

R35 ERJ3GEYJ473 47K

R36 ERJ3GEYJ202 2K

R37 ERJ3GEYJ102 1K

R38 ERJ3GEY0R00 0

R39 ERJ3GEYJ224 220K

R40 ERJ3GEYJ101 100

R41 ERJ3GEYJ563 56K

R42 ERJ3GEYJ223 22K

R43 ERJ3GEYJ104 100K

R44 ERJ3GEYJ393 39K

R45 ERJ3GEYJ104 100K

R46 ERJ3GEYJ434 430K

R47 ERJ3GEYJ222 2.2K

R48 ERJ3GEYJ223 22K

R49 ERJ3GEYJ473 47K

R50 ERJ3GEYJ822 8.2K

R51 ERJ3GEYJ272 2.7K

R52 ERJ3GEYJ222 2.2K

R53 ERJ3GEYJ820 82

R54 ERJ3GEYJ104 100K

R55 ERJ3GEYJ221 220

R56 ERJ3GEYJ122 1.2K

R57 ERJ3GEYJ102 1K

R58 ERJ3GEYJ102 1K

R59 ERJ3GEYJ222 2.2K

R60 ERJ3GEYJ222 2.2K

R61 ERJ3GEYJ331 330

R62 ERJ3GEYJ222 2.2K

R63 ERJ3GEYJ103 10K

R64 ERJ3GEYJ103 10K

R65 ERJ3GEYJ331 330

R66 ERJ3GEYJ222 2.2K

R67 ERJ3GEYJ222 2.2K

R68 ERJ3GEYJ103 10K

R69 ERJ3GEYJ222 2.2K

Part No. Part Name & Description Remarks

(CERAMIC FILTERS)

(TRANSFORMERS)

(CRYSTAL OSCILLATORS)

(RESISTORS)

59

Page 60

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

Ref.

No.

R70 ERJ3GEYJ222 2.2K

R73 ERJ3GEYJ105 1M

R74 ERJ3GEYJ104 100K

R75 ERJ3GEYJ104 100K

R76 ERJ3GEYJ104 100K

R77 ERJ3GEYJ103 10K

R78 ERJ3GEYJ104 100K

R79 ERJ3GEYJ105 1M

R80 ERJ3GEYJ105 1M

R82 ERJ3GEY0R00 0

R83 ERJ3GEY0R00 0

R84 ERJ3GEYJ105 1M

R85 ERJ3GEYJ102 1K

R86 ERJ3GEYJ104 100K

R87 ERJ3GEYJ104 100K

R93 ERJ3GEYJ103 10K

R94 ERJ3GEYJ334 330K

R95 ERJ3GEYJ393 39K

R96 ERJ3GEY0R00 0

R97 ERJ3GEYJ154 150K

R98 ERJ3GEYJ475 4.7M

R99 ERJ3GEYJ472 4.7K

R101 ERJ3GEY0R00 0

R102 ECUV1H683ZFV 0.068

R103 ERJ3GEYJ394 390K

R105 ERJ3GEYJ103 10K

R106 ERJ3GEYJ820 82

R107 ERJ3GEYJ222 2.2K

R108 ERJ3GEYJ102 1K

R109 ERJ3GEYJ102 1K

R110 ERJ3GEYJ102 1K

R111 ERJ3GEYJ102 1K

R112 ERJ3GEYJ102 1K

R200 ERJ3GEYJ473 47K

R201 ERJ3GEYJ330 33

C1 ECEA1AKA470 47

C2 ECUV1E104ZFV 0.1 S

C4 ECUV1H270JCV 27P

C5 ECUV1E104ZFV 0.1 S

C6 ECUV1H102KBV 0.001

C7 ECUV1E104ZFV 0.1 S

C8 ECUV1H473MDV 0.047 S

C9 ECUV1H103KBV 0.01

C12 ECEA1HKA2R2 2.2

C13 ECUV1H270JCV 27P

C14 ECUV1H103KBV 0.01

C15 ECEA1CKA100 10

C16 ECUV1H473MDV 0.047 S

C17 ECUV1H102KBV 0.001

C18 ECEA1HKA2R2 2.2

C21 ECUV1H223KBV 0.022 S

C22 ECUV1H103KBV 0.01

C23 ECUV1H102KBV 0.001

C24 ECUV1H220JCV 22P

C26 ECUV1H103KBV 0.01

C27 ECUV1E104ZFV 0.1 S

C28 ECUV1H682KBV 0.0068

C29 ECEA1HKA2R2 2.2

C30 ECUV1E104ZFV 0.1 S

C31 ECUV1H103KBV 0.01

C32 ECUV1E104ZFV 0.1 S

C33 ECUV1E104ZFV 0.1 S

C34 ECUV1H101JCV 100P

C35 ECUV1H681JCV 680P S

C36 ECUV1H180JCV 18P

C37 ECEA1HKS010 1 S

C38 ECUV1H101JCV 100P

C39 ECUV1H151JCV 150P

C40 ECUV1H103KBV 0.01

C41 ECUV1H270JCV 27P

C42 ECEA1AKA470 47

C43 ECEA1HKA2R2 2.2

Part No. Part Name & Description Remarks

(CAPACITORS)

Ref.

No.

C44 ECUV1H105ZFV 1

C45 ECUV1C683KBV 0.068

C46 ECUV1H103KBV 0.01

C47 ECUV1H682KBV 0.0068

C48 ECEA1AKA470 47

C49 ECUV1H223KBV 0.022 S

C50 ECUV1H103KBV 0.01

C51 ECEA1CKA100 10

C52 ECUV1H103KBV 0.01

C53 ECUV1H223KBV 0.022 S

C54 ECUV1H220JCV 22P

C55 ECUV1H103KBV 0.01

C56 ECUV1H050CCV 5P

C57 ECUV1H150JCV 15P

C58 ECUV1H103KBV 0.01

C59 ECUV1H390JCV 39P

C60 ECUV1H270JCV 27P

C61 ECUV1E104ZFV 0.1 S

C62 ECUV1H390JCV 39P

C63 ECEA1AKA101 100

C64 ECUV1H103KBV 0.01

C65 ECUV1H150JCV 15P

C66 ECUV1H150JCV 15P

C69 ECUV1E104ZFV 0.1 S

C70 ECUV1H330JCV 33P

C71 ECUV1H330JCV 33P

C72 ECUV1E104ZFV 0.1 S

C73 ECUV1E104ZFV 0.1 S

C74 ECUV1H473MDV 0.047 S

C75 ECUV1H103KBV 0.01

C76 ECUV1H471JCV 470P S

C77 ECUV1H471JCV 470P S

C78 ECUV1H103KBV 0.01

C79 ECUV1H103KBV 0.01

C80 ECUV1H103KBV 0.01

C84 ECUV1E104ZFV 0.1 S

C85 ECUV1H105ZFV 1

C86 ECUV1E104ZFV 0.1 S

C88 ECUV1E104ZFV 0.1 S

C200 ECUV1H390JCV 39P

C201 ECUV1H680JCV 68P

C202 ECUV1H121JCV 120P

E101 CK15HC12G10 BUZZER

E102 CGAP1200019 MICROPHONE

E103 PQJT10183Z CHARGE CONTACT S

VC1 CR01020RRT8 TRIMMER CAPACITOR

BATT1 DCB002X1164 CONNECTOR

Part No. Part Name & Description Remarks

(OTHERS)

28.3. ACCESSORIES AND PACKING

MATERIALS

Ref.

No.

A1 PQJA87S TEL CORD

A2 PQLV16ALZ AC ADAPTOR

A3 PQQX13660Z INSTRUCTION BOOK

P1 PQPP10104Z PROTECTION COVER (for BASE

P2 PQPP10105Z PROTECTION COVER (for

P3 PQPK14094Z GIFT BOX

P4 PQPD10579Z CUSHION, AC ADAPTOR

Part No. Part Name & Description Remarks

UNIT)

HANDSET)

60

Page 61

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

29 FOR SCHEMATIC DIAGRAM

29.1. Base Unit (SCHEMATIC DIAGRAM (Base Unit))

1. DC voltage measurements are taken with an oscilloscope or a tester with a ground.

2. The schematic diagrams and circuit board may be modified at any time with the development of new technology.

Important Safety Notice:

Components identified by

any of these components, use only the manufacturer´s specified parts.

29.2. Handset (SCHEMATIC DIAGRAM (Handset))

1. DC voltage measurements are taken with an oscilloscope or a tester with a ground.

2. The schematic diagrams and circuit board may be modified at any time with the development of new technology.

mark have special characteristics important for safety. When replacing

61

Page 62

30 SCHEMATIC DIAGRAM (Base Unit)

30.1. Base Unit

KX-TC2000NZB / KX-TC2000NZW / KX-TC2000NZF

62

13V to 5V

While charging

To H/S ----------

CHAG-CNTL

JK1 PIN2

R197

22K

R0603

VREG

EXPO

COMP

CHARGE--From H/S --------------

D7

2700V

MPC28/28

D8

D10B

R131

100K

R0603

ADAPTOR

120V AC

12VDC

200mA

C106

105

C0603

ZD10

15V/0.5W

ZD7.5

CHARGE+

Q25

JK2

JACK DC

C63

103

R57

C0603

220K

R0603

R76

NA

R0603

TX DATA

Q7

R97

1K

104

ZD12

ZD7.5

15V/0.5W

L5

12uH

L7.5

L7

12uH

L7.5

R132

2K2

R0603

L8

JUMPER

L10

JUMPER

L7.5

R100

R0603

2K2

R0603

R118

120 1/2W

R10

Q24

D11

R195

4.7K 1/4w

Q14

D6

+

470UF\25V

L9

C73

C0603

TP

TP

ZD4

8V2

Q17

TP

TP

R58

220

R0603

LED1

CHARGE

LED

19-21VGC/

TR8 GREEN

ZD9

5V6

D\362

R142

22 1/4W

R10

C95

EC10\5

TP

R64

10K

1/4W

R10

SW1

PAGE

SW2P

C403

R108

4K7

R0603

AGC1

AGC

CIRCUIT

AGC2

R59

100K

R0603

+

+

NA

TP

Q19

C98

22uF\16V

EC5\2.5

VTX

CR-DET

PMUTE

RF-CLK

IC3B

0V

C82

104

C0603

+

C105

100UF/10V

EC5/2.5

R410

10K

C84

D404

7.5V

5

NA

C0603

Q13

Q16

NA

+

7

C0603

R145

1K

R0603

R60

22K

R0603

R408

10K

+12V

-

6

C88

NA

C99

103

C0603

TP

C0603

VB

411

C79

104

C0603

+5V

Q21

C64

104

Q403

R157

R0603

A

R134

R0603

VB

Q18

R0603

NA

NA

R87 4.7K

R166

47

R0603

R114

22K

ZD8

ZD7.5

+

R167

10K

R0603

R406

100K

R0603

R407

4.7K

R409

820K

R109

330K

R0603

C102

220UF/

25V

EC10/5

VCPU

R159

100K

R0603

CHAG-CNTL

RINGDET

R80 2K2 R0603

R82 10K

R84 10K

VREG

C77

100P

C0603

VREG

+5V

C96

103

C0603

R89 10K

Q402

+

C94

100UF\10V

EC8\2.5

R0603

R405

100K

TP

R158

NA

R0603

R0603

C402

224

+

470UF/10V

R115

56K

R0603

R0603

C107

104

VREG

C78

EC10/5

ZD5

4V7

D\362

R133

39R

R0603

R141

5K1

R0603

RING DET

01 0New Zealand

R403

100K

C75

223

C0603

ZD3

4V7

D\362

Q11

360R

R0603

Q20

VCC

RESET

CHG LD

PAGE

HOOK

VTX

CNDET

CHG D

TX D

P MUTE

CLOCK

R402

100K

R404

100K

C83

NA

C0603

C124

224

C0603

R122

R202

1.3K

C90

474 16v X7R

R146

15K

R0603

TP

+5V

R106

22 1/4W

R5.08

C92

104

C0603

8MHz

C135

103

C0603

28

27

26

25

24

23

22

21

20

19

18

17

16

15

R181

330

R0603

C123

C0603

224 X7R

C0603

R126

200R

1Vp-p

C104

104

C0603

OSCO

1

XOUT

VDD

RST

P10

P11

P12

P13

P14

P15

P16

P17

P72

P73

P74

P75

Q401

474

C85

R129

6.2K

R0603

R148

10K

R0603

R401

1K

R105

5.6K

R0603

IC2

R111

470

R0603

XIN

TEST

P67

P66

P65

P64

P63

P62

P61

P60

P77

P76

VSS

C401

104

6

5

4 3

R123

12K

R201

R149

1K8

R0603

82K

0V

T7

R119

R0603

R203

360K

R0603

510K

R0603

2

3

4

5

6

7

8

9

10

11

12

13

14

82K

OSCI

TEST

POW F

DTMF4

DTMF3

DTMF2

DTMF1

DTMF0

RXDATA

COUT1

STROBE

DATA

L3

12uH

L6/5

1

2

R143

+

C97

4U7/50V

EC5\5

ZD1

22V/1W

ZD7.5

C122

154

C0603

C93

562

C0603

R62

100K

R0603

R137

NA

R0603

IC3D

R93

NA

R0603

22K

R10

ZD2

22V/1W

ZD7.5

R107

240 2W

R113

33/1W

R12.5

14

R63

NA

R0603

R172

+12V

510K

R0603

C101

562

C0603

bit1bit0bit2Country

R74

0R

R0603

R85

R94

100K

R0603

PULSE

DAIL

R116

0

R0603

Q12

NA

R138

NA

R0603

411

+

-

0V

R150

Q10

12

13

C65

22P

C0603

RY1VB

500 OHM

NA

R130

NA

Q15

NA

C108

104

0603

R0603

RY1

R110

100K

R0603

R124

R0603

10M R10

10K

R0603

IC5

C91

NA

EC5\5

R144

R152

10M

R10

R153

1M

R0603

X2

7.952 MHz

XTAL\10

R112

1K

R0603

+

1000uF/6.3V

EC10/5

C67

22P

C0603

R83 10K

R88 10K

R0603

D1

D\362

PMUTE

LIMITED CURRENT

R184

10M R10

R183

10M 0805

C66

R0603

R127

NA

R10

+

D2

D10B

D4

D10B

R104

4K7

R0603

IC3A

1

R185

100K

R0603

0V

+12V

4 11

D3

D10B

D5

D10B

C0603

R96

330K

R0603

L4

R117

NA

R0603

-

+

4 11

+12V

C70

223

C0603

8

IC3C

VREG

VCPU

12uH

L5

Q6

R86

47K

R0603

TP

R160

0

R0805

R161

0

L6

R0805

TP

R178

NA

R10

R177

NA

R10

R179

NA

R0603

R140

NA

R0603

JK1

1

2

3

4

LINE JACK 4C

LINE\JK1

AGC2

AGC1

L11

C136

12UH

103

C0603

R68

100K

R0603

R75 10K R0603

R77 20K R0603

R78 39K R0603

R79 82K R0603

R81 160K R0603

RX DATA

RF-STB

RF-DATA

R90

270K

R0603

C69

R95

3K9

R0603

ZNR1

270V

ZNR\7K

R120

R0603

R180

56K

R0603

0

C72

223

C0603

R139

NA

R0603

0V

R103

22K

R0603

C86

NA

C0603

10

12uH

L5

9

C76

680P 500V

CC6\5

C80

680P 500V

CC6\5

270P

C0603

-

2

+

3

C74

104

C0603

R128

NA

R10

C120

NA

C121

NA

C0603

AGC CIRCUIT

RX

TX

KX-TC2000NZB/NZW/NZF SCHEMATIC DIAGRAM (Base Unit)

Page 63

30.2. RF Unit (Base Unit)

ANT1

ANTENNA

PAD3

ZD11

ZD7.5

15V/0.5W

63

TP

3.3UH

L10

TP

1

L1

GTXRXTX

TP

C46

102

C0603

4

5

T5

1436

IFT\7

C5

C136

NA

C0603

2P

C0603

C14

NA

C0603

3

DPX1

0830

ANT

DUP\5P

GRX

425

C110

1K

C0603

C133

NA

C0603

3

2

C53

1

12P

C0603

C0603

R175

NA

R0603

C23

103

C2

C1

104

47UF/10V

EC5/2.5

C0603

CF1 10.7MHZ

FILTER\1

C30

C41

4.8V

TX IN

+

11.15MHZ

XTAL\10A

IST

MIX

OUT

38

39

VREF

40

IST Mix IN

41

VCC2

42

VCO CONT

43

VCO1

44

VCO2

45

C-RECT

46

RX CP

47

TX CP

PLL GND

48

1

C0603

C54

C0603

1 3

C15

2U2/50V

EC5/5

C43

104

X1

2P

C47

103

C0603

2

R0603

C6

104

C0603

Q1

R12

100

R0603

R15

5K6

TP

R46

2K2

R0603

3

1

C22

103

C0603

R16

15K

R0603

TP

R1

47

R0603

4

IFT\7

6

R41

47K

R0603

C55

103

C0603

T2

1437

C20

2U2/50V

EC5/2.5

C29

104

C0603

R0603

C42

2U2 50V

EC5/5

R33

0

R0603

C17

10U/16V