Panasonic KW7M Installation Manual

【KW7M】

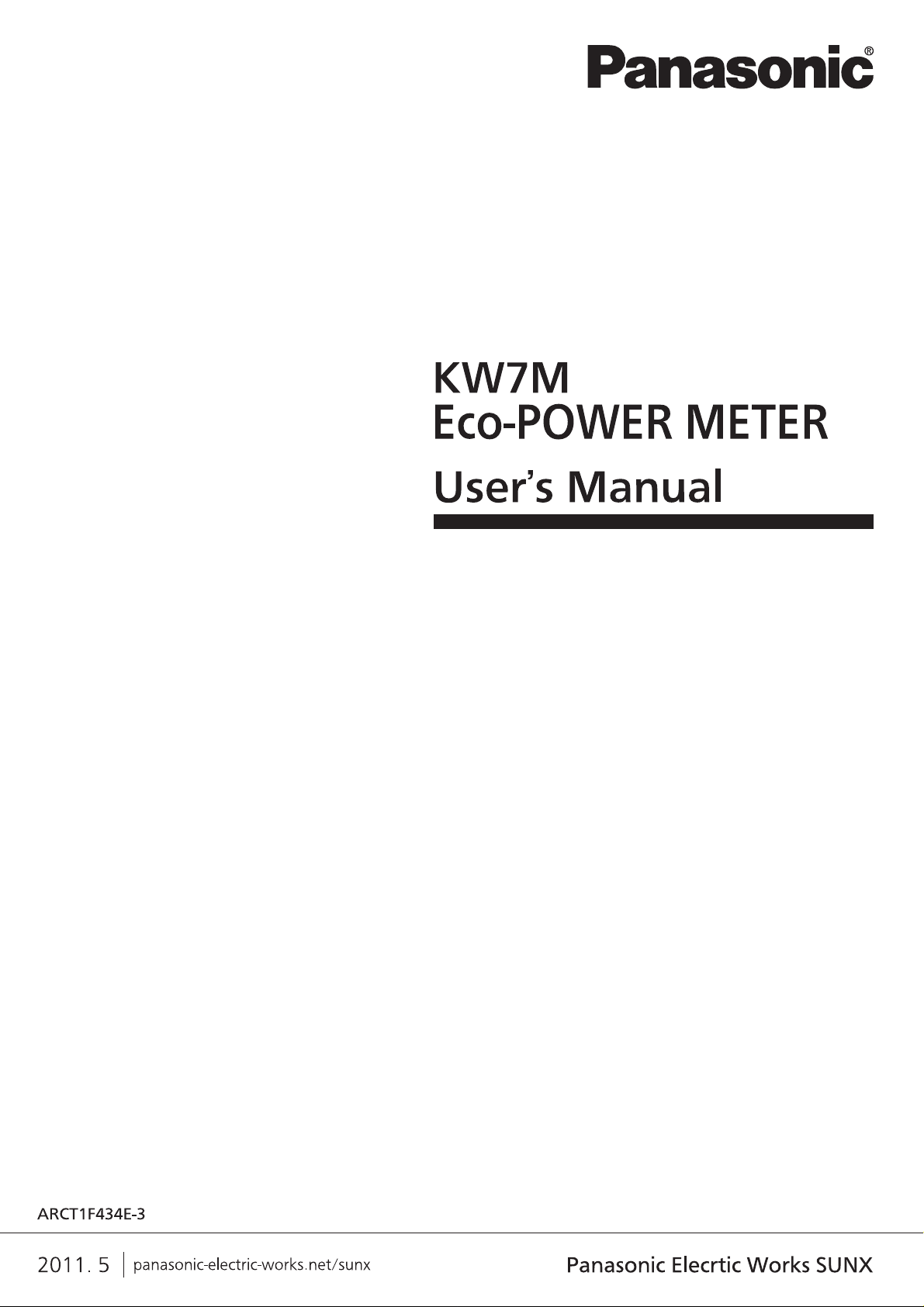

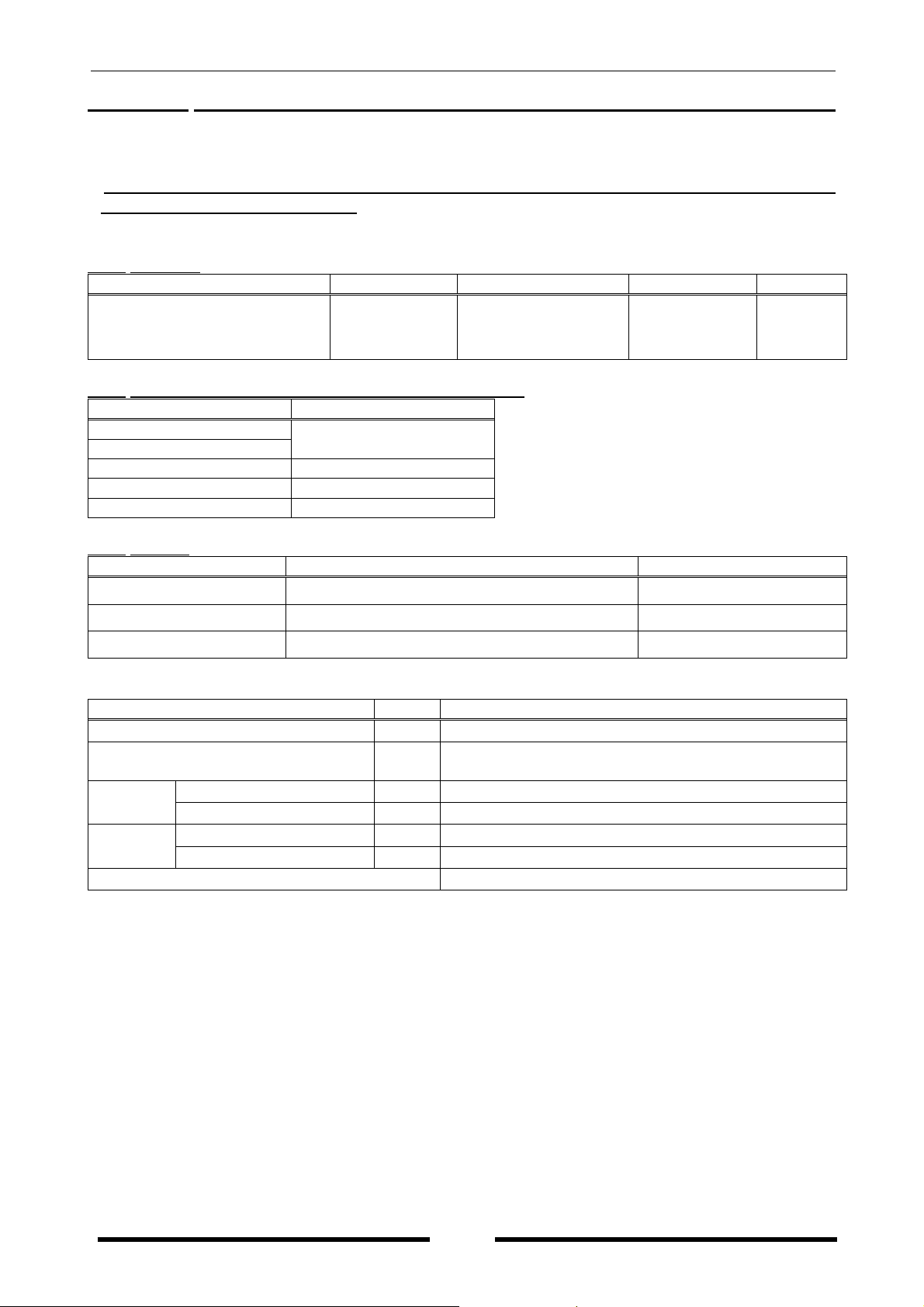

Basic setting to measure by Eco-POWER METER

When wiring the main unit and the current transformer (CT) and setting the mode 1 after power on, you

can measure the power

In order to use the other functions, the settings of the each parameter are necessary.

What to do

Measure Power

Output Alarm

Collect data

via RS485

Mount / Connection

Connect the current transformer (CT)

Wire the main unit

Wire output

line

Wire

communication

Set the basic settings (MODE1)

Power on the main unit

p.10

Settings

Set alarm

(MODE1)

communication

output

Set

setting

(MODE2)

Check measured

data with power

monitoring mode

Check measured

p.15

How to use

Check alarm

output

5.3

data via

communication

device

6

7

Cautions for Your Safety

Read the manual carefully before installing, running and maintenance for proper operation.

Before using, master the knowledge of the equipment, safety information and all of other

notes.

This manual uses two safety flags to indicate different levels of danger.

WARNING

●Always take precautions to ensure the overall safety of your system, so that the whole

system remains safe in the event of failure of this product or other external factor.

●Do not use this product in areas with inflammable gas. It could lead to an explosion.

●Exposing this product to excessive heat or open flames could cause damage to the

lithium battery or other electronic parts.

CAUTION

●To prevent abnormal exothermic heat or smoke generation, use this product at the

values less than the maximum of the characteristics and performance that are assured

in these specifications.

●Do not dismantle or remodel the product. It could lead to abnormal exothermic heat or

smoke generation.

●Do not touch the terminal while turning on electricity. It could lead to an electric shock.

●Use the external devices to function the emergency stop and interlock circuit.

●Connect the wires or connectors securely. The loose connection might cause abnormal

exothermic heat or smoke generation.

●Do not allow foreign matters such as liquid, flammable materials, metals to go into the

inside of the product. It might cause exothermic heat or smoke generation.

●Do not undertake construction (such as connection and disconnection) while the power

supply is on.

●Do not use at secondary side circuit of inverter. It might cause exothermic heat or

damage.

A handling error could cause serious physical injury to an operator

and in the worst case could even be fatal.

A handling error could cause serious physical injury to an operator

or damage to the equipment.

Copyright and trademark

●Panasonic Electric Works Co., Ltd. owns the copyright of this manual.

●We stiffly refuse the reproduction of without permission from this manual.

●Modbus Protocol is a communication protocol that the Modicon Inc. developed for PLC.

●Other company names and the product names are the trademarks or registered

trademarks of each company.

Introduction

Thank you very much indeed for purchasing

“KW7M Eco-POWER METER”.

In this manual, we explain the usage of “KW7M

Eco-POWER METER” in detail.

Please use it correctly after understanding the content

enough.

Table of Contents

Cautions before using ............................................................................................................................ⅰ

Chapter 1 Unit’s Features and Structure

1.1 Features................................................................................................................................................... 1

1.2 Unit’s Name and Part Numbers............................................................................................................... 1

1.2.1 Main unit......................................................................................................................................... 1

1.2.2 Dedicated Current Transformer (CT) with Connector.................................................................... 1

1.2.3 Options........................................................................................................................................... 1

1.3 Measurement items ................................................................................................................................. 1

Chapter 2 Parts Name and Working

2.1 Parts Names............................................................................................................................................ 2

2.2 Select Keys’ Functions ............................................................................................................................ 2

Chapter 3 Wi

3.1 Main unit terminal arrangement............................................................................................................... 3

3.2 Wiring Diagrams ...................................................................................................................................... 4

3.3 For Output connection............................................................................................................................. 6

3.4 RS-485 Communication........................................................................................................................... 6

3.5 Low Voltage Directive.............................................................................................................................. 7

Chapter 4 S

4.1 Operation procedure................................................................................................................................ 8

4.2 Setting Mode Explanation......................................................................................................................10

4.2.1 MODE1......................................................................................................................................... 10

4.2.2 MODE2......................................................................................................................................... 15

4.2.3 MODE3......................................................................................................................................... 18

Chapter 5 Various Functions

5.1 LOCK mode........................................................................................................................................... 19

5.2 Display while communication................................................................................................................. 19

5.3 Display when pulse output.....................................................................................................................19

5.3.1 Output depends on integrated electric power .............................................................................. 19

5.3.2 Instantaneous electric power alarm ............................................................................................. 19

5.3.3 Current alarm ............................................................................................................................... 19

5.3.4 Stand-by power alarm.................................................................................................................. 20

Chapter 6 Display of each Value

6.1 Outline for the Working of Monitor Display............................................................................................ 21

6.2 Integrated electric power ....................................................................................................................... 22

6.3 Instantaneous electric power................................................................................................................. 22

6.4 Current................................................................................................................................................... 23

6.5 Voltage...................................................................................................................................................23

6.6 Electricity Charge................................................................................................................................... 24

6.7 Display when LED turns off ................................................................................................................... 24

ring ......................................................................................................................................3

ettings....................................................................................................................................8

..................................................................................................................19

............................................................................................................21

Chapter 7 MEWTOCOL Communications

7.1 Communication Procedures .................................................................................................................. 25

7.2 Communication timing ........................................................................................................................... 25

7.3 MEWTOCOL Communication................................................................................................................ 26

7.3.1 Overview of MEWTOCOL-COM(RS-485)....................................................................................26

7.3.2 Data Register List.........................................................................................................................27

7.3.3 Error Codes.................................................................................................................................. 28

7.3.4 Command..................................................................................................................................... 28

7.4 MODBUS (RTU) Communication.......................................................................................................... 30

7.4.1 Overview of MODBUS (RTU)....................................................................................................... 30

7.4.2 Data Register List.........................................................................................................................33

..................................................................................................1

.........................................................................................................2

..............................................................................................25

Chapter 8 Specifications.........................................................................................................................

8.1 Main unit ................................................................................................................................................ 34

8.2 Input Specifications................................................................................................................................ 35

8.3 Pulse output (Transistor output) Specifications..................................................................................... 35

8.4 Communication Specifications............................................................................................................... 36

8.5 Dedicated Current Transformer Specifications...................................................................................... 37

8.6 Self-diagnostic function.......................................................................................................................... 37

8.7 Power Failure Memory........................................................................................................................... 37

Chapter 9 Dimensions

9.1 Main unit ................................................................................................................................................ 38

9.2 Dedicated CT......................................................................................................................................... 38

9.3 DIN rail mounting................................................................................................................................... 40

............................................................................................................................38

34

Cautions before using

■ Installation environment

◇Do not use the Unit in the following environments.

・Where the unit will be exposed to direct sunlight and where the ambient temperature is outside

the range of -10 to 50 C.

・Where the ambient humidity is outside the range of 30 to 85 % RH (at 20℃ non-condensing)

and where condensation might occur by sudden temperature changes

・Where inflammable or corrosive gas might be produced

・Where the unit will be exposed to excessive airborne dust or metal particles

・Where the unit will be exposed to water, oil or chemicals

・Where organic solvents such as benzene, paint thinner, alcohol, or strong alkaline solutions

such as ammonia or caustic soda might adhere to the product

・Where direct vibration or shock might be transmitted to the product, and where water might wet

the product

◇Please use the Unit according to the specifications described in this manual. Otherwise, it

may malfunction or cause fire and an electric shock.

・Connect to the power supply in compliance with the rating.

・Refer to the wiring diagram to ensure proper wiring for the power supply, input and output.

・Do not perform wiring or installation with a live line. It may also lead to circuit burnout or fire by

way of the secondary CT side opening.

・Do not add voltage and current to an output terminal from outside.

・Do not use at secondary side circuit of inverter.

■ Installation

・Installation and wiring must be performed by expert personnel for electrical work or electric

piping.

・The power supply terminal and voltage input terminal of the main unit is common. Therefore if

additional noise effects the power supply line, incorrect measurements may result.

・Eco-POWER METER is designed to be used in a control panel.

・As to measurement

If there is some distortion by harmonic or waveform, it may not measure correctly.

Please check with the actual system before adopting it.

■ Static electricity

・Discharge static electricity touching the grounded metal etc. when you touch the unit.

・Excessive static electricity might be generated especially in a dry place.

■ Cleaning

・Wipe dirt of the main unit with soft cloth etc. When thinner is used, the unit might deform or be

discolored.

■ Power supply

・Connect a breaker to the voltage input part for safety reasons and to protect the device.

The breaker that connects to the voltage input part must arrange at the position easily reached,

and display shows it is the breaker of the equipment.

・Do not turn on the power supply or input until all wiring is completed.

■ Before power on

Please note the following points when turning on power at the first time.

・Confirm there are neither wiring rubbish nor especially an electrical conduction when installed.

・Confirm neither the power supply wiring, the I/O wiring nor the power-supply voltage are wrong.

・Tighten the installation screw and the terminal screw surely.

・Use an electric wire applicable to the rated current.

i

KW7M Eco-POWER METER

Chapter 1 Unit’s Features and Structure

1.1 Features

■KW7M Eco-POWER METER is a watt-meter of DIN rail installation type. Electric power, voltage,

current, etc. are measured using AC voltage and AC current input via one of the following systems.

■Eco-POWER METER is designed chiefly to manage saving energy. It is neither intended nor

can it be legally used for billing.

1.2 Unit’s Name and Part Numbers

1.2.1 Main unit

Phase and Wire system Rated input Current transformer Terminal type Model No.

Single-phase two-wire system

Single-phase three-wire system

Three-phase three-wire system

100 / 200V AC

1.2.2 Dedicated Current Transformer (CT) with Connector

Rated primary current Model No.

5A

50A

100A AKW4802C

250A AKW4803C

400A AKW4804C

AKW4801C

1.2.3 Options

Product name Contents Model No.

Mounting rails DIN rail AT8-DLA1

Dedicated CT type

(5A, 50A(common)/

100A/250A/400A)

Screw terminal AKW7111

Mounting plate Use to fix to DIN rail ATA4806

Terminal screw driver Using when wiring Phoenix terminal AFP0806

1.3 Measurement items

Item Unit Data range

Instantaneous electric power kW

Integrated electric power kWh

Current

Voltage

※Eco-POWER METER is designed chiefly to manage saving energy.

It is neither intended nor can it be legally used for billing.

L1(CT1)-phase current

L2(CT2)-phase current

Voltage between 1-2 V

Voltage between 2-3 V

Electricity charge ※ 0.00〜99999999

0.00〜999999.99

0.00〜9999999.9

0.0〜6000

A

0.0〜6000

A

0.0〜〜9999

0.0〜9999

1

KW7M Eco-POWER METER

Chapter 2 Parts Name and Working

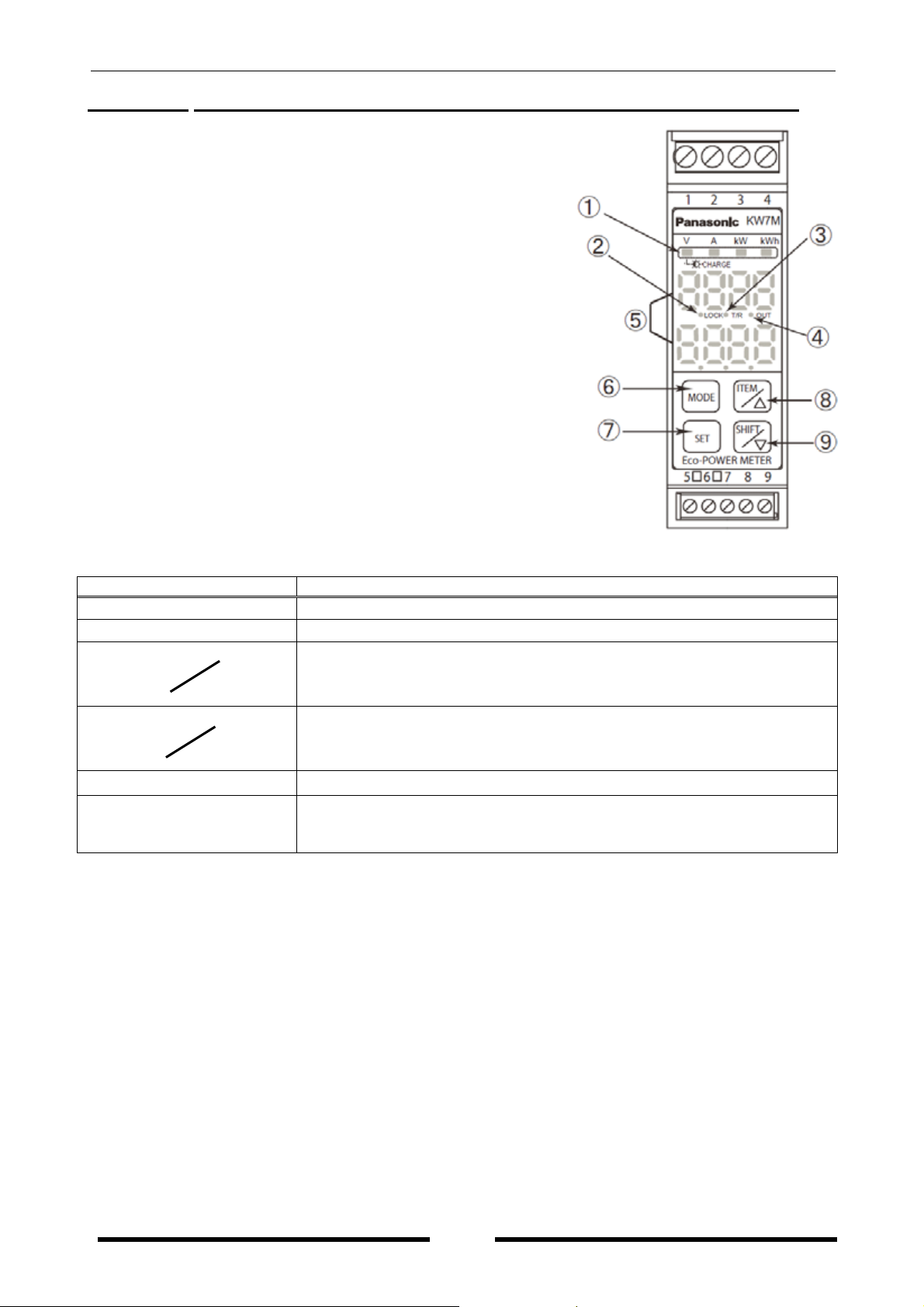

2.1 Parts Names

①Display indicator ・Lighting or Blinking according to the display

②LOCK indicator ・Lighting while in lock mode

③T/R indicator ・Blinking while communication

④OUT indicator ・Lighting when pulse output

⑤Display each value ・ Display Electric energy, Instantaneous

power, Current, Voltage, Electricity charge

⑥MODE Key

・Display each setting value

⑦SET Key

⑧ITEM / △ Key

⑨SHIFT / ▽ Key

2.2 Select Keys’ Functions

Key Functions

<MODE>

<SET>

ITEM

<

△

SHIFT

<

▽

<SET>+<MODE>

<SET>

(continuous press

about 3-sec)

>

>

・Use to select mode

・Use to set each value entered

・To select measured display

・To shift each mode

・To change each setting value

・To select measured display

・To shift each mode

・To change each setting value

・Reset the measured value

・All keys locked

・Release lock mode while in lock mode

2

KW7M Eco-POWER METER

Chapter 3 Wiring

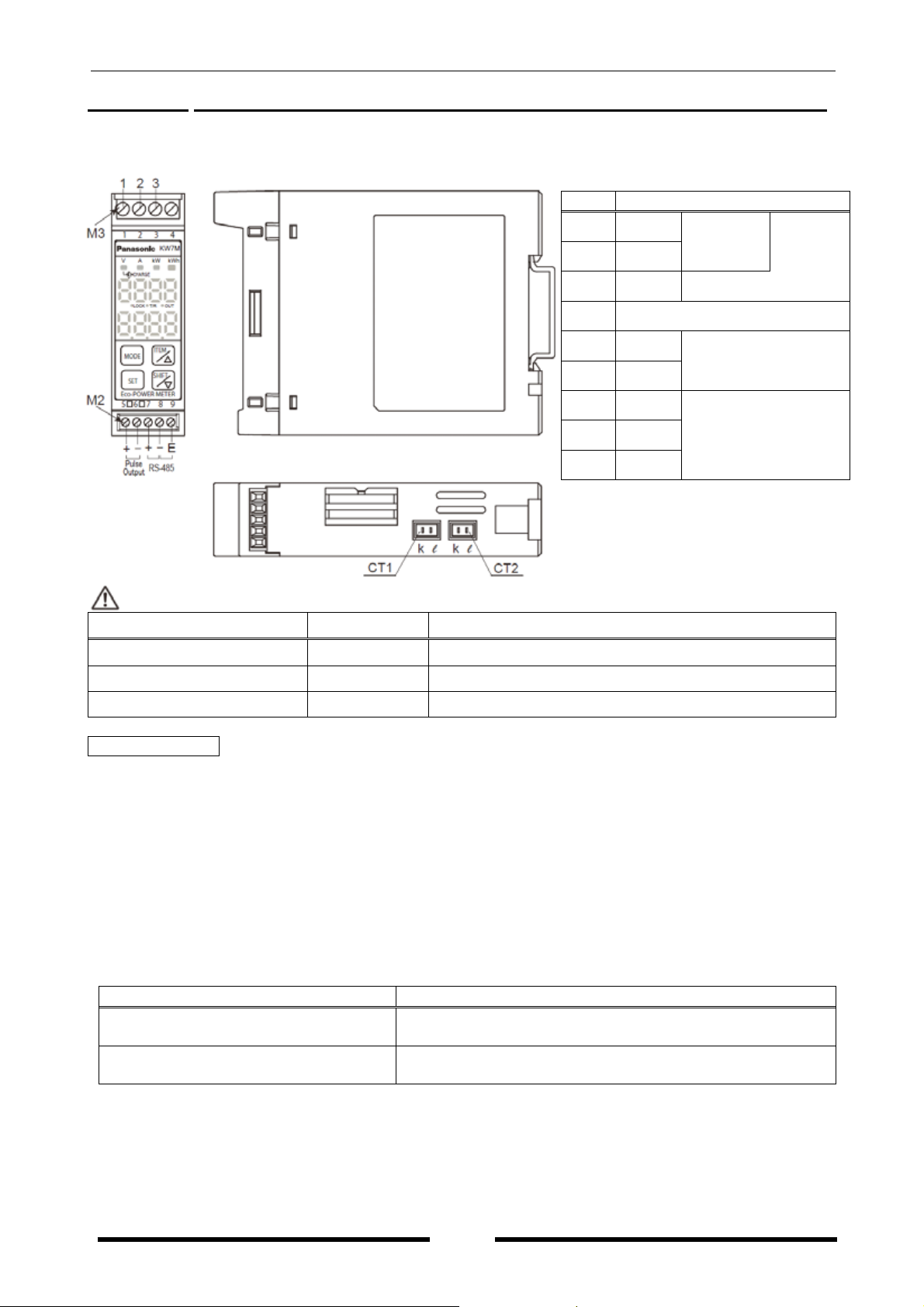

3.1 Main unit terminal arrangement

Be sure to wire correctly according to the terminal arrangement and wiring diagrams.

No. Functions

1 1, R, R

2 2, N, S

3 3, T, T

4 No connection (N.C.)

Power

supply

(common)

Measured

voltage input

5

6

7

8

+

−

+

−

Pulse

output

RS-485

9 E

The input voltage to each terminal is as follows.

Phase and wire Terminal Input voltage

Single-phase, two-wire

Single-phase, three-wire

Three-phase, three-wire

1−2

1−2−3

1−2−3

100-120/200-240VAC (100-120/200-240V〜)

100-120VAC (100-120V〜:3W)

100-240VAC (200-240V 3〜)

Caution for Wiring

1) Terminal fastening torque should be 0.5 to 0.6 N・m for No.1 to No.4 (M3 screw) and

0.22 to 0.25 N・m for No.5 to No.9 (M2 screw).

2) Use wire with its cross section of 0.14~1.5mm

use wire with its cross section of 0.14~1.0mm

2

(AWG#26~14) for voltage input terminal (No.1, 2, 3),

2

(AWG#26~16) for pulse output terminal (No.5, 6), use

wire with its cross section of 0.3~1.0mm2(AWG#22~16) for communication terminal (No.7, 8, 9).

When connecting 2 or more wires to communication terminal, use same wire with its cross section of

0.3 to 0.34mm

2

.

3) This has no built-in power switch, circuit breaker or fuse. Therefore it is necessary to install them in

the circuit near this unit.

(Recommended fuse: Time-lag fuse, rated voltage 250V AC, rated current 2A)

4) We recommend the below ferrules (terminals) for wiring.

(We don’t recommend them when 2 or more wires are connected.)

Terminal No. Product number for Ferrule (PHOENIX CONTACT)

No.1 to No.4 (M3 screw)

No.5 to No.9 (M2 screw)

(When 1 wire is connected.)

AI 0.25-8YE AI 0.34-8TQ AI 0.5-8WH

AI 0.75-8GY AI 1.0-8RD AI 1.5-8BK

AI 0.25-8YE AI 0.34-8TQ AI 0.5-8WH

3

KW7M Eco-POWER METER

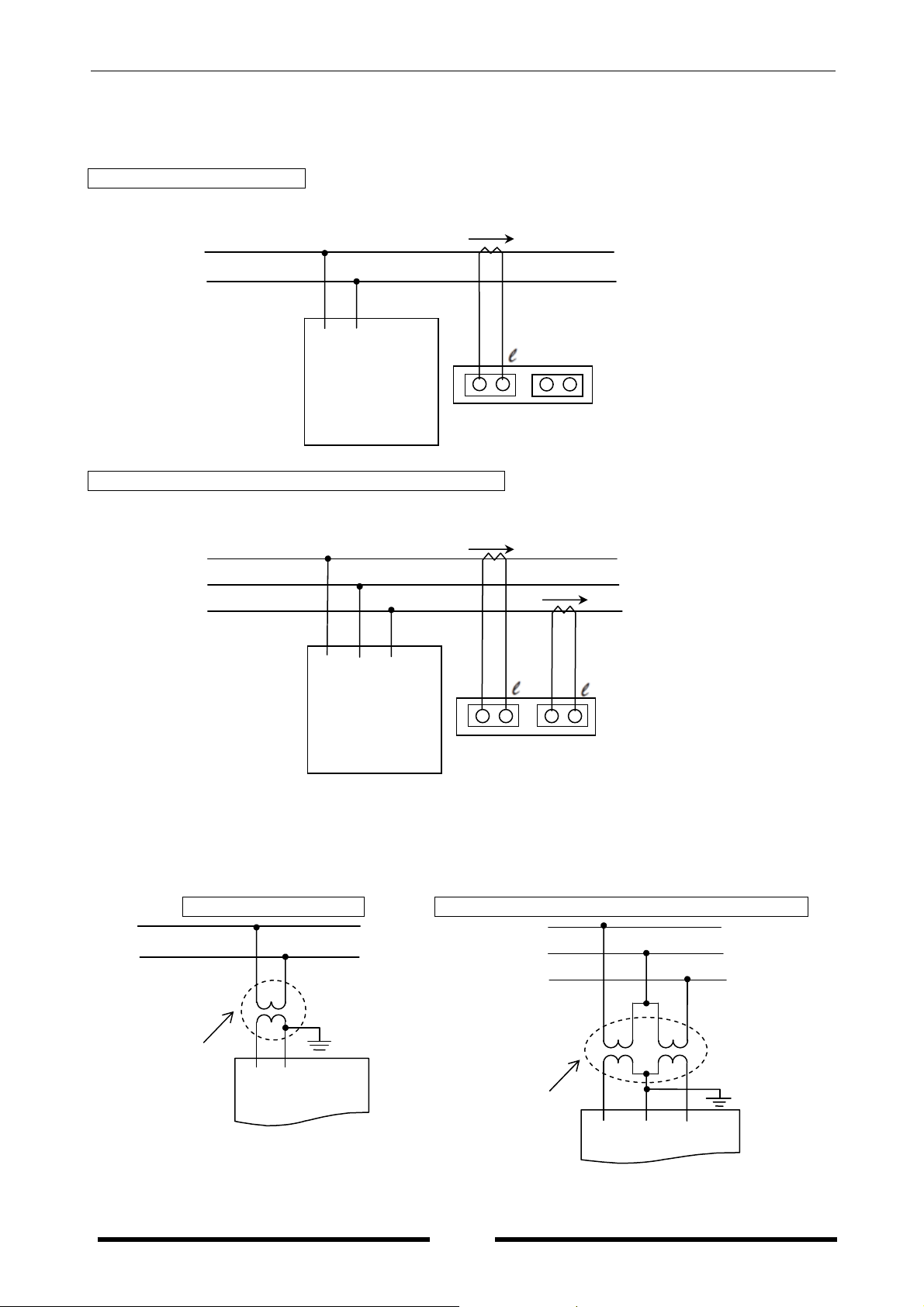

3.2 Wiring Diagrams

Please connect a breaker to the voltage input part for safety reasons and to protect the device.

◆Measure load of 100-200V system

Single-phase two-wire system

*One current transformer (CT) is required to measure a single-phase, two-wire system.

Single-phase, three-wire/ Three-phase, three-wire system

*Two CTs are required to measure a single-phase, three-wire system or

three-phase, three-wire system.

◆Measure load of 400V system

VT (Voltage transformer) is needed to measure over 240VAC.

Use a commercial VT, its secondary rating is 110V.

*Grounding VT’s neutral line is recommended for the unit protection when VT breaks down.

Power supply

side

Power supply

side

1

2

1

2

3

① ② ③ ④

⑤ ⑥ ⑦ ⑧ ⑨

① ② ③ ④

⑤ ⑥ ⑦ ⑧ ⑨

KL

White Black

k

CT1

KL

K L

White Black

White Black

k

CT1

k

Load side

CT2

※Do not connect to CT2.

Load side

CT2

Single-phase, two-wire

1

2

Single-phase, three-wire / Three-phase, three-wire

1

2

3

VT

① ② ③ ④

VT

①② ③ ④

* After wiring, turn on the power supply and turn off and power on again.

4

KW7M Eco-POWER METER

A

◇How to attach the Current Transformer (CT)

・One CT is needed when measuring 1P2W. Two CTs are needed when measuring 1P3W/3P3W. Using

all CTs for one Eco-POWER METER should be the same.

・Check beforehand that the thickness of the electric wire is smaller than the through-hole of the CT.

・When connecting CT, connect the secondary side to the terminal of the main unit first, and after that

wire the primary side to a load electric wire.

Incorrect order might cause an electric shock or break CT.

・The CT has polarity. Wire correctly according to the K and L marks.

Wrong direction can’t measure correctly.

・When closing CT, check that there is no foreign materials on the divided face. And make sure it is

closed securely once the wire is in place; if not the measurement value will be not accurate.

・When CTʼs cable is extended, it is possible to extend up to about 10m with the cable of AWG#22 or

more cross section under the environment without noise at all. Please use the thick cable as much as

possible.

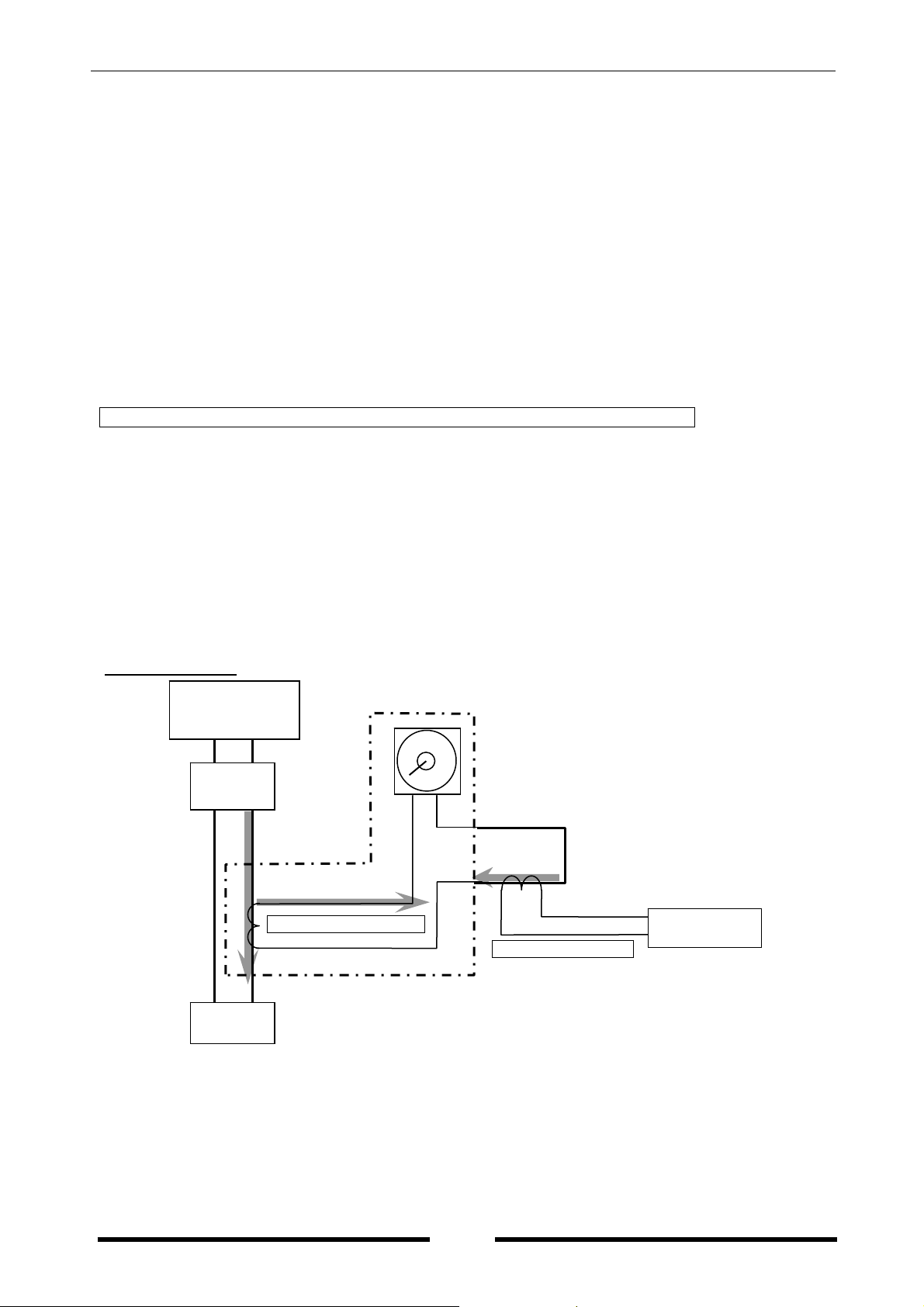

◆To connect CT with secondary side current 5A

How to connect for measuring by combination with CT (secondary side current 5A)

(1) Select 5A at CT type setting mode (CT-T).

(2) Set the primary current of measured CT (secondary side current 5A) at primary side current of

CT setting mode (CT-1).

< ex > If the measured CT is 400A/5A, set to ”400”.

(3) Clamp the dedicated CT for 5A (AKW4801C), which is connected to the main unit first, to

secondary side of the CT (secondary side current 5A). CT direction (K→L) should be set for the

commercial CT direction.

*Set the CT (secondary side current 5A) and the AKW4801C approximately 1m apart. If the two

CTs are set too close each other, it may not measure accurately due to magnetic field

interference.

(Connection example)

With ammeter etc.

Power supply

Breaker

mmeter etc.

Secondary current

K

CT with 2nd current 5A

L

L K

Dedicated CT (For 5A)

AKW4801C

Eco-POWER

METER

Load

5

KW7M Eco-POWER METER

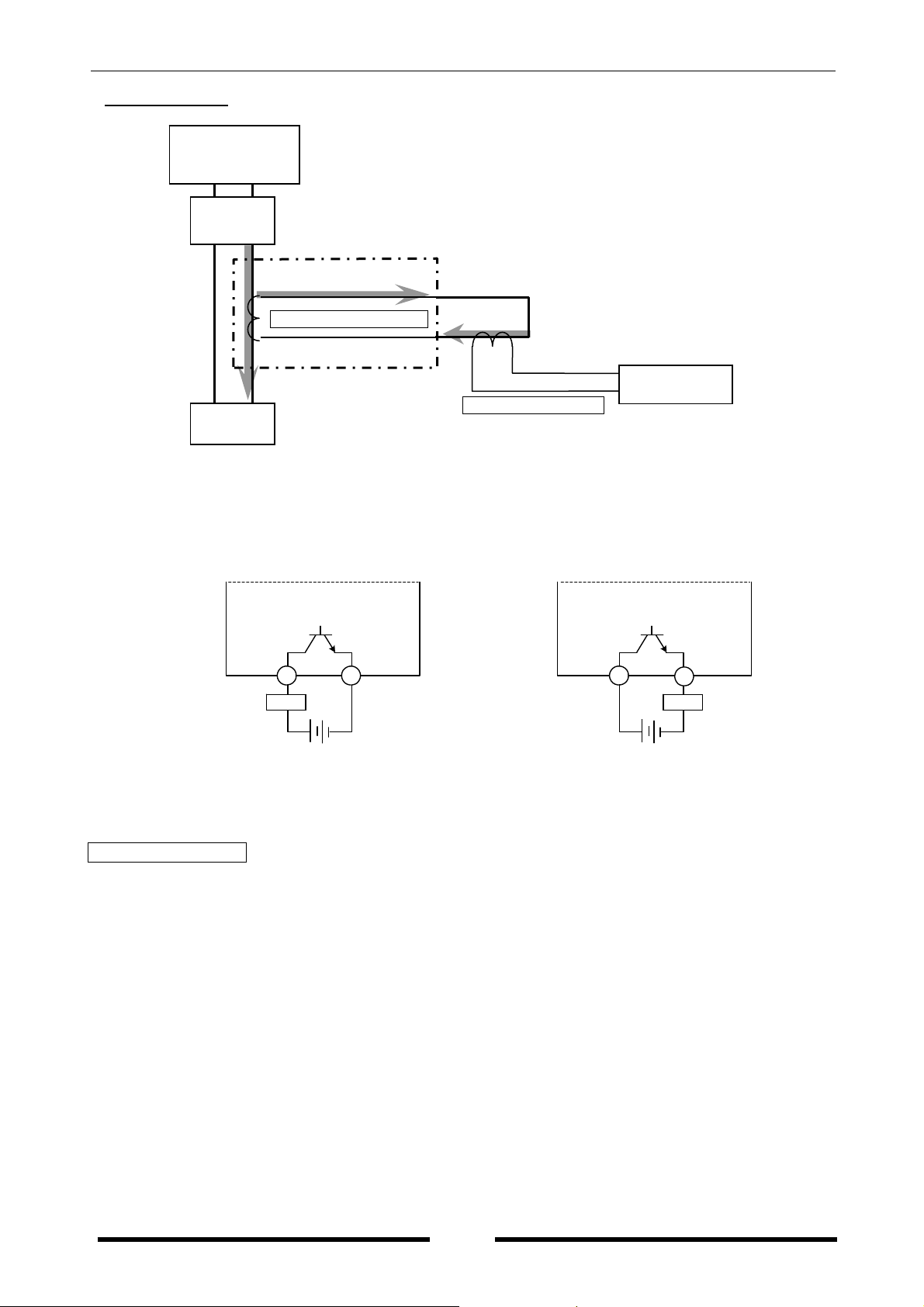

Without ammeter

Power supply

Breaker

Secondary current

K

CT with 2nd current 5A

L

Load

Shorted or resistor less than 0.1Ω

L K

Eco-POWER

Dedicated CT (For 5A)

AKW4801C

METER

3.3 For Output connection

Since the transistor output is insulated from the internal circuit by a photo-coupler, it can be used both

as a NPN output and PNP (equal value) output.

Eco-POWER METER

Eco-POWER METER

NPN output

Pulse (+) PNP output

5

Load Load

Pulse (−)

6

- +

Pulse (+)

5

Pulse (−)

6

- +

Power supply for Load

Power supply for Load

3.4 RS-485 Communication

Recommended Cable

Use the transmission cables shown below for Eco-POWER METER RS-485 communication system.

1) Use shielded type twist cables.

2) Use only one type of the transmission cables. Do not mix different types of the cables.

3) Use twist pair cables under a bad noise environ ment.

4) Be sure to connect with daisy chain the RS-485 transmission line between each unit.

one end of the shielded wire to an earth ground.

5) Use 2 recommended cables with the same cross section of 0.3 to 0.34mm

2

to connect to the

RS-485 (+) and RS-485 (-) terminals.

Connect

6

KW7M Eco-POWER METER

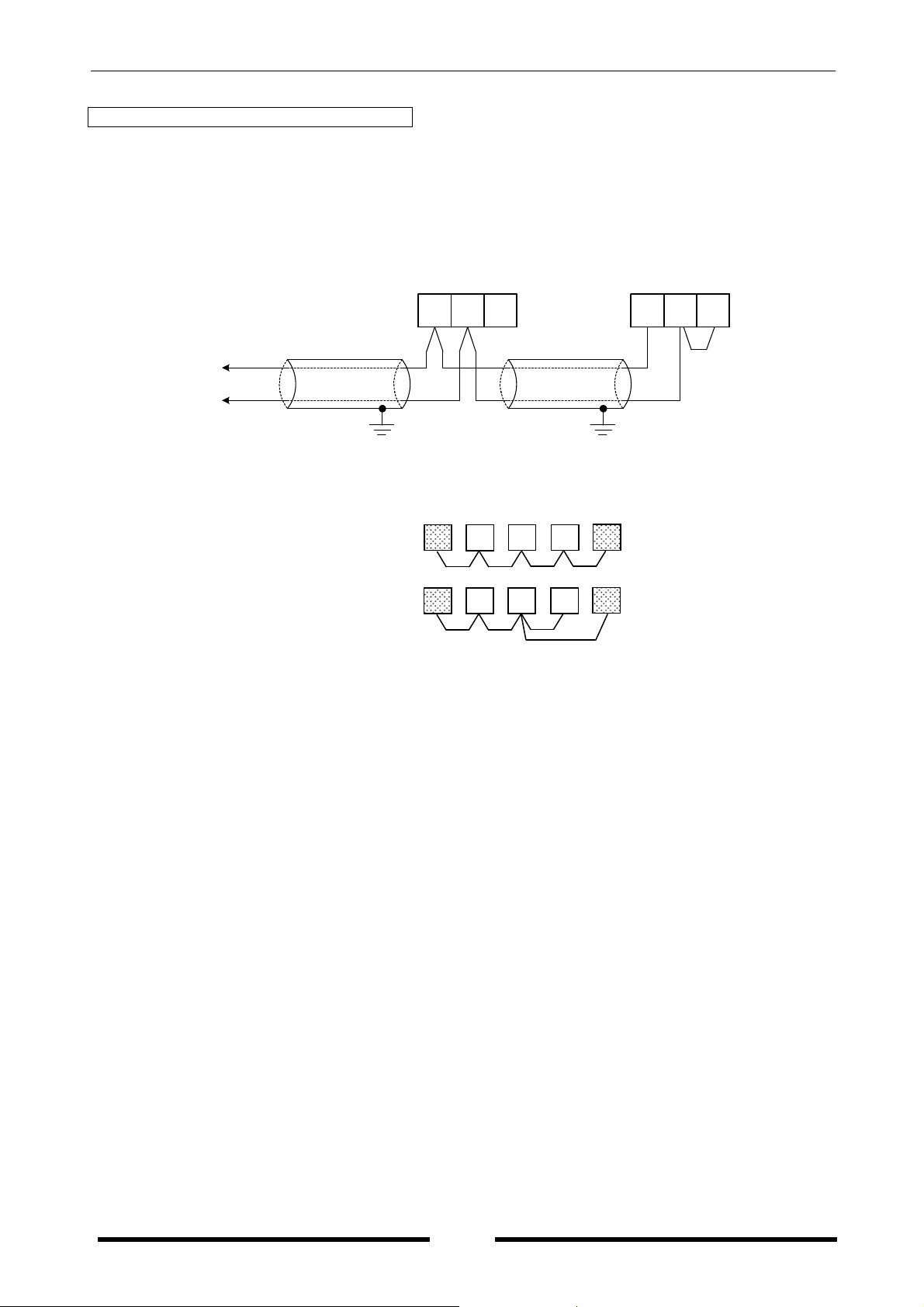

RS-485 Wiring and setting of terminal station

1) When using shielded cable for the RS-485 transmission line, ground one end.

Use a class D dedicated earth for grounding. Do not share a ground with other earth lines. (Fig.1)

2) Be sure to connect with daisy chain the RS-485 transmission line between each unit.

Do not use a splitter. (Fig.2)

3) With a terminal station, RS-485 (E) (No.9) and RS-485 (-) (No.8) should be shorted. (Fig.1)

(Fig.1)

To RS-485 device

Sheilded cable

Eco-POWER METER

General station

(+) (+)

(−)

(E)(−)(

Sheilded cable

Eco-POWER METER

Terminal station

E

)

Shorted

Class D grounding Class D grounding

(Fig.2)

Correct wiring

○

Incorrect wiring

×

Terminal Terminal

3.5 Low Voltage Directive

When using in the application confirming to EN61010-1/IEC61010-1, make sure to satisfy the following

conditions.

(1) Pulse output part secure only basic insulation. In order to secure reinforced (double) insulation

demanded by EN 61010-1/ IEC61010-1, secure basic insulation or more with load side and

reinforced (double) insulation with communication system side.

(2) Provide the voltage input part with an EN60947-1 or EN60947-3 compliant circuit breaker.

The breaker that connects to the voltage input part must arrange at the position easily reached,

and display shows it is the breaker of the equipment.

(3) Use a wire with basic insulation or more for a wire cramped (or connected) CT.

【Environmental conditions】

・Overvoltage category Ⅱ, Pollution degree 2

・Indoor use

・An ambient temperature of –10 to 50℃

・An ambient non-condensing humidity of 35 to 85%RH (at 20℃)

・Altitude of 2000m or less

【Mount the product in a place with】

・A minimum of dust, and an absence of corrosive gases

・No flammable, explosive gasses

・Few mechanical vibrations or shocks

・No exposure to direct sunlight

・No large capacity electromagnetic switches or cables through which large current is flowing

7

Loading...

Loading...