Panasonic JU-455-5 Service Manual

ORDER NO. M SD850902

900

Flexible Disk Storage Drive

,,",U-455-5

Panasonic

Matsushita

Industrial Co., Ltd.

Memory

3-1, 4-chom

oku-k

Koh

Communication

Systems Division

e,

Tsunashima-Higashi

u, Yokohama

223

JAPAN

PA

RT

I

INTR

1.

2.

3.

4.

5.

••

7.

••

g.

10.

ODUCTION "-

MODELS

SPECIAL

OUTLINE OF

DIAGNOSTIC

5.1 Error Symptom Recognition

5.2

5.3

5.4

5.5

5.6 Comp

TROU8LE ANALYSIS

6.1 Tr

6.2 Trouble Shooting .. .

6.3 Trouble

PR

M EASUREMENT

AD

9.1 Mo

9.2

9.3 Head

9.4

9.5

9.6

9

9.S

9.9

9.10

9.

PANA SONIC ALIGNMENT

AND MDOOE L NUM BE

TOOlS

50

ft

Write

Read

Seek.

ouble

EVENTIVE MAINTENANCE ..

JUST

MEN

tor

Write

Outp

Radial Alig

Azimuth

.7

Inde~

Tr"c~

Limiter Ver

limiter

11

Asymmetry V

..•.••.••...••..•••.••.....••.•..•.......

·······················

MAINT

ENANCE .•.••.

PROCEDURES ...................................

Error

Detection

Effor .

Error

.......

Effor

at

ibili

ty

AnalysIs Procedure ..

Analy~is

I

TEMS FOR EACH

TS AND

Speed

Protect Verification

Output

ut Modulation Verif

nment Adjustment ....

Verifi

Burst Veri

00 Sensor Adjus

ificatio

Adjustment (3.S·inch) .

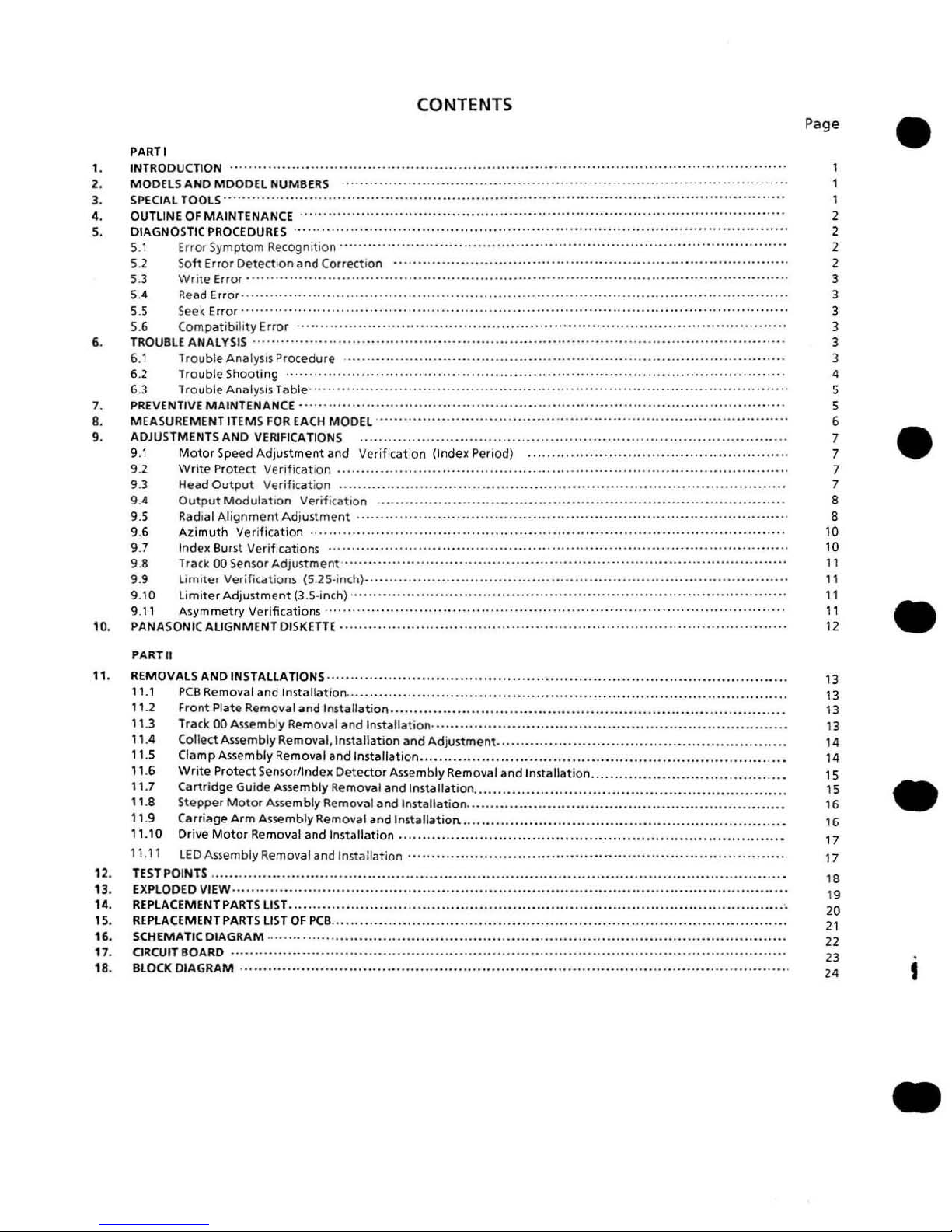

CONTENTS

...

•...

.•••

••...••..•....•...

RS

.....................................................

····· ·····

•.•..••

and Correcti

...............................................................................................................

...

...

.............................

....

...

...

.... . .......................

Error ..

...

..............................................................................................................

VERIFICATIONS ......

Adjustment

Veri fication

cation ..

ficatio

erific

..........

...

............

T

able

' ..

..........

.............................................

MODEL ...

and V

icati

.......

ns

............

tme

nt

ns

(5.25·inch)

ations

.....

DISKETTE

················

.•••....•...••...•...••..•..•••...•....•

......

......

.........................................

on

.......

...

....................................

....................

.....

........

... .

........

...................................

..............

erif

ication

......................

.......

......

...........................

on ........................................................................

.........

......

.....

.......

....

.... · ..

....................

....

.............

......

··

......

....

·...................

. .....

.........

......................

.........

.....

..........................................

..• ..

...

...............

....

.......

...........

.........................................

.......

-..

........................

....

......

......

....

...

...........

(Inde~

Period) .

....

............

......

..... ........

...

.........

...... .

···

..

....

····

··

..................

.........

....

.........................................................

...

......... ......

.....

.....

...............................

........

.. . .......

...

............ .....

...

............

..........

........

...

..........................................

....

.............................

....................................

............................................

..

................

.........•. .

...

.•.

.....

....

....

........

..........

.......

...............................

...

.....................

......

........

........................................

.............

...

...

........

......................................

................................................

..

........

. .......

.... . ....

...•

.. •••..

.............

................

...........

.

............

........

.....

............

.......

....

......

..............................

....

........

........

......

....

....

......

.....

.........

.......

... . .

...........................

...

......................

••....•.••.•.••.•.

...................

.......

......

.........

...

....

...

...................

.

.....

....................

.............

.........

.................

...

...

...........

.......

. .

.

.....

......

....

...

..........

. ..

...

.....

..

.

...

.........

............

..

.

......

....

....

....

...

..... ..

....

...

....

Page

.

..

.

..

.

..

. .

..

.

..

.

..

.

..

.

.

.

.

2

2

2

.

2

3

3

3

3

3

3

4

.

5

5

.

•

7

7

7

7

•

.

•

10

.

ID

11

.

11

11

11

12

•

•

PAR

T!!

11

.

REMOVALS AND IN STALLATIONS

1

1.1 PCB

1.2

1

11.3

11.4

11

.5 Clamp Assemb ly Removal and Installation

11

.6

11

.7

I I .S Stepper

1

1.9 COlIrriage

11.

10 Drive

1.11

,

12.

TE

13. EXPLODED

14. REPlACEMENT PARTS LIST

15.

16. SCHEMATIC DIAGRAM ........

17.

lB

ST POINTS

REPLACEMENT

CIRCUIT

. BLO

CK DIAGRAM

Removal and In5tallatlo(\.

Front

plate

Trac

Collect Assembly Removal, Installation and

Write Protect

Cartridge Guide Assembly R

LED Assembly Remova l and Installation

BOARD

Removal and Installation

k.

00 Assembly Removal and Installat;on·

Sensorllnde~

Motor

Assembly RemOval and Installation

Arm

Motor

....

ViEW·

Assembly Removal and Installation.

Removal and Installation

.....................

..

···

.. · .... ···

PARTS LI

ST

...............................................................

...

..............................

.. · ....

···

.... · .. · ............ · ................

...................

...........................

Detector

emoval and Installation

.......

......

··· ... · ....

..........................

OF PCS

............

.............

Assembly

......................................................

........................................................

............................

.............

... ...

...................................

...

...............

.. · ....

.. · .. · .....

Adjustment

...................................................

Removal and Installati

.........

...........

.............

.........

.............

...........

..........

...............

...

......................................

...

....

....

..........

.........

...

..........

...

.............................

.. · .. · .........................

......

......

.........

.....

...................................................

.....

............

...

............

...........

...

....

.....

..........

.....

..........

............

....

..............

......

.......

.............

..............................

......

on ....

................

.........................................

..........................

.....

......

.....

..................

....

....................

..........

.............

.......

.

.................................

............

.......

....

.....

.....

.................

...

...........

....

.•.........

..........................

......

.......

.................

.....

.....................

.....

.................

....

.......

.........................

........ ................

.............

...

....

...

.......

..

.........

.....

.....

........

.....

.... ..

..... ........

......

.....

.....

•

.

13

. .

13

.

13

.

..

..

..

..

..

13

14

14

15

.

15

.

16

.

16

.

17

17

.

18

..

..

20

"

21

22

23

.

24

•

t

•

PART.

1.

INTRODUCTION

This

analysis

Pa

work

service

rt

I en com

on

lm

the

I

manual

d Pa

passes

FOD.

consists of two parts,

rt

II

disasse

mainte nance in

Part

I covering mainten<lnce de

mbl

y and reassembly procedures

nruct

ions

for all

parts

FDD

models. Refer to

list,

and

PCB circuits.

scrip

tion, adjustment procedures, and trouble

the

app

lic

ilb

le items,

lind

perform

maintenance

r

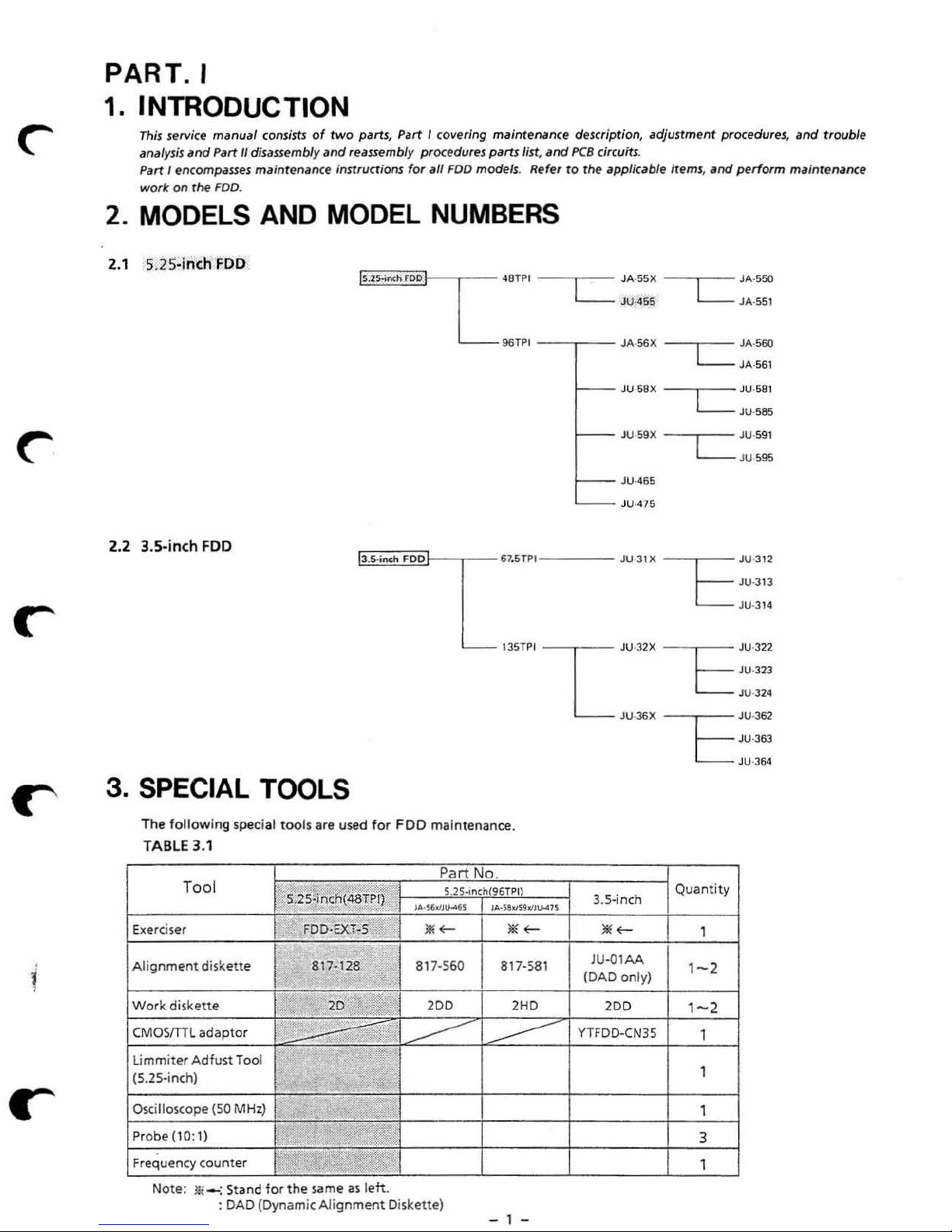

2. MODELS AND MODEL

2.1 5.25·inch

2.2 3.S-inch

FDD

FOD

~'2'I

..

~~~'~'~'~'J--,-

l .

5-i

nch

FOO

NUMBERS

-

48TPI --'L--

96TPI

--

61

.STPI -

135TPI I JU':,2X

,...

--

L

JA

·SSX

JU.455

__ JA.56X

JU·ssx

JU ·59)( -

- -JU·31)(

Ju.J6x

JA ·

550

LJA

---,

--

L-

- -CL-

--,--

L-

-r=

-r=

-r=

-JU.

.

551

JA·

560

JA•561

581

JU·S85

JU ·591

JU.595

JU·312

JU-313

JU·]

JU.322

JU·323

JU-

J24

NJ6'

JU-363

JU-364

14

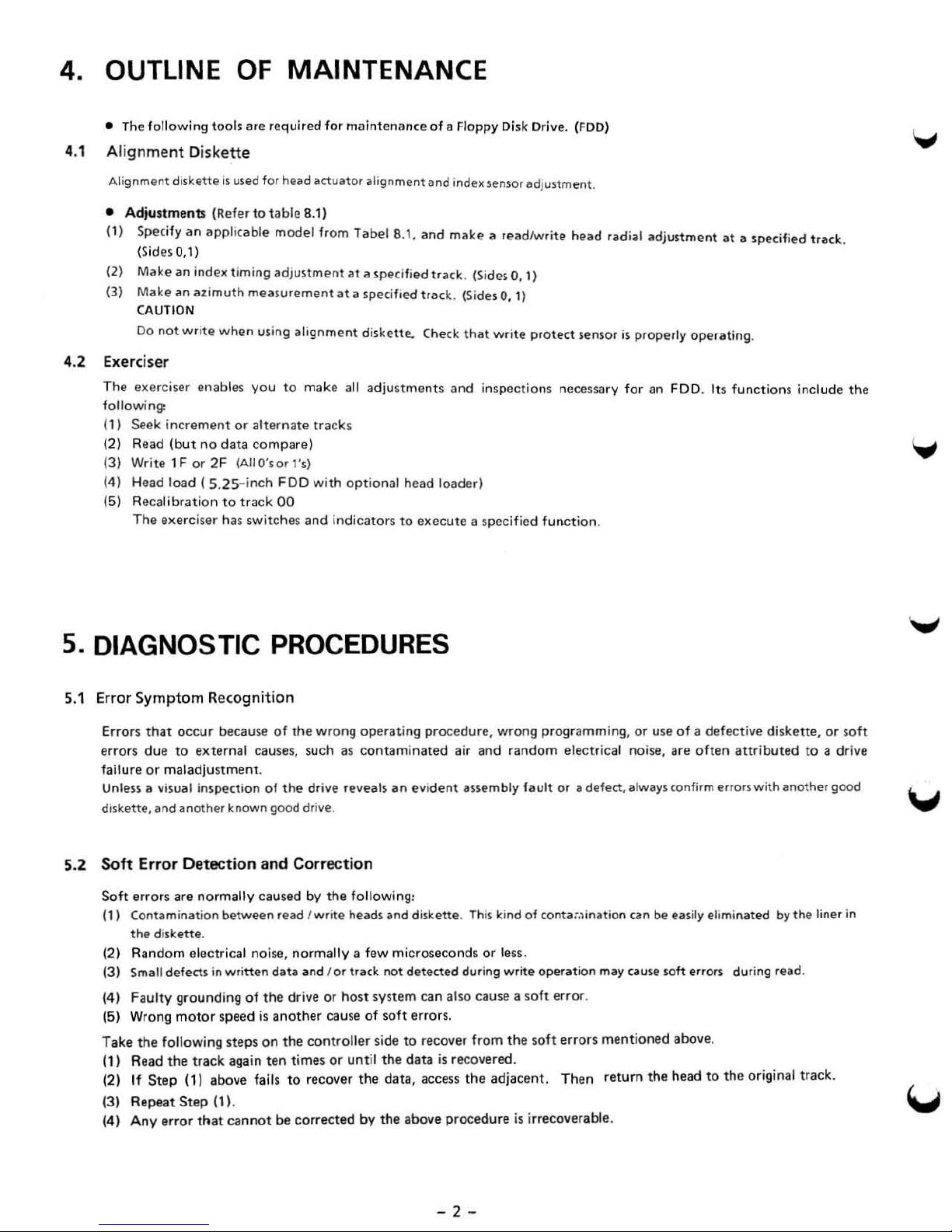

3. SPECIAL TOOLS

The following

TABLE 3.1

To

Exerciser

Alignment

ol

disk

ett

spe

e

cial

too

ls

are used for

S.25

ti

FDD·Ex:r~

817-128

I

Wo

rk diskette

CMOSm

Li

(S.25-inc

r

Osci

Pr

Frequency counter

L adap

mmiter

Adfust

l-l)

lloscope (

obe (10: 1)

Note:

tor

Tool

SO

MHz)

*"

_: Stand

: DAD (Dynam

for

.

,

.

.,'

" .

the

-

sam

ic

Alignmen

FDO

n~ht~T

P

·

S

2D,

~'.~,

~

.,

'.·'6.'IU"U

817-560

AI'"

----

;;.

,

,

;;$l

"f'"

e as

lett.

t Diskette)

mai

nte

nance.

Part No.

5.2S.,nch(95TPI)

,

.. ·sa",.

..

~

817·581

I

2DD 2

----

- 1 -

,.

<1,

~

HD

....

"

3.S-inch

"'~

JU

.(I1

AA

(DAD only

2DD

YTFDD-CN35

)

Quantity

1

1

-2

1-2

1

1

1

3

1

4. OUTLINE

• The

4.1 A

following

lign

ment Diskett

tools ate required

OF

e

MAINTENANCE

for

maintenance

of

a Floppy Di

sk

Dri

ve.

(FOO)

Alignment

•

Ad;tiume

(1)

Specify

(SidesQ,l)

(2)

Make

Make

(3)

CAUTION

Do

not

4.2 Exerciser

The

exerciser enables

follow

ing:

(1) Seek

(2) Read

(3) Write 1 F

(4) Head load

(5) Recalibration

The exerciser has switches

diskette

nts (Refer to

an

appIJc

an

iodell

iH

I

azimuth

write

when

increment

(but

no data

or

2F

(S.2S-inch

is

used

for nead

table 8.1)

able mode l from

timing

adjustment

measurement

using

alignment

you

to

or

alternate

compare)

(AIIO'sor "

FDD

to

track

00

actuator

make

ali

gnment

label

at

a specified Irack. (Sides

at

a specifi

diskette.. Check

and index sensor adjustment .

8.1.

CInd

make a readlwrite head radial adjustment at a specified tracle.

O.

ed

tracl

e (Sides 0, 1)

that

write

1)

protect

sens

or

is

properly

operating

.

all adjustments and inspections necessary for an FDD. Its functions include the

tracks

s)

with

and

indicators

optional

head

to

execute

loader)

a specified

function

.

5.

DIAGNOSTIC PROCEDURES

5.1 Error Symptom R

Errors

that occur

erro

rs

due

or

failure

Unless a visual inspection of

diskette, and another known good dri

5.2

Soft

Soft errors are normally caused by

(1) Contamination between read

(2)

(3)

(4)

(5) Wrong

Take the

(1) Read

(2)

(3) Repe

(4) Any

maladjus

E

rror Detection and Correctio

the diskett

Random electric

Small

defects

F

aulty

following steps on

the

If

Step

at

error

e<o

gnition

because

to

external

tment.

e.

al noise, normally a f

in

wri

tten

grounding

of

motor speed

track again

(1) above fails

Step

(11

.

that

cannot

of

the wrong

causes, such

the

dri

...

...

e.

I write heads and diskette.

data and

the

dr

....

e or

is

another

the

controller

ten

tim

es

to

recover

be

corrected

operating

as

contaminated

e reveals

n

th

e following:

ew microseco

l or

tfaclr.

host

system can also cause a

cause

of

soft errors.

side

or

unt

il the

the

by the above

procedure,

air and

an

evident

auembly

This

nds

not detected duri

to

recover from

data

is

recovered.

data

, access the

procedure

wrong

programming,

random

fault or

electrical noise, are

II

defect, always confirm errors with another good

or

use

of

a defective diskette, or

often

kind of cont.}:,lination can be easily ehminated

or

less.

ng

write operation

soft erro

the

soft

adjacent.

may cause roft errors during read.

r.

errors

ment

ioned above.

Then

return

the

head

to

the

is irrecoverable.

attributed

by

origi n

al

to

a drive

the liner

track.

soft

in

- 2 -

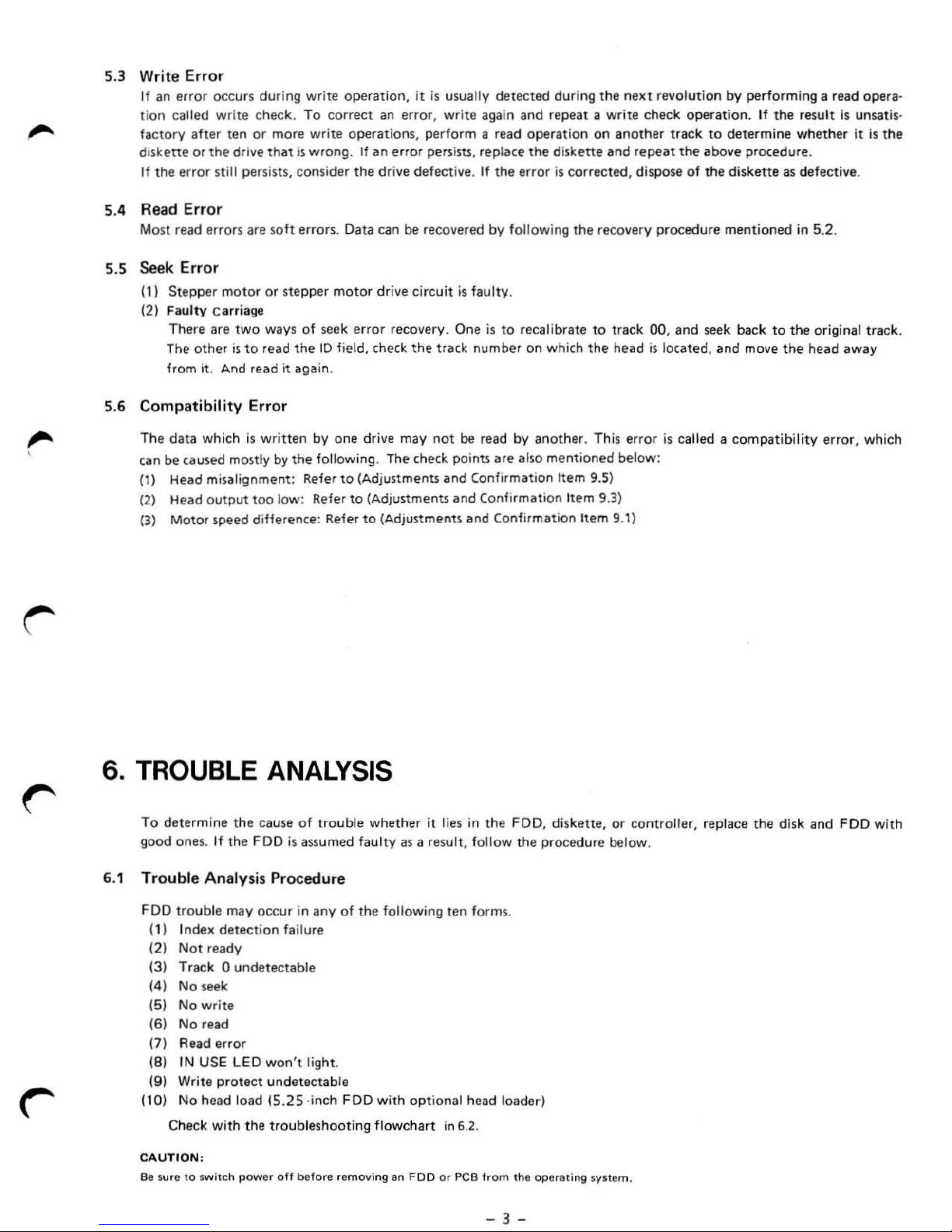

5.3

Write Error

If

an

error

occurs

dur

ing write

ti

on

called wr i

factory

diskette or

If

after

the error

te

check.

ten or more write operations, perform a read ope r

the drive

still persists, consider

that

5.4 Read Error

Most read errors are soft errors. Data

5.5 Seek Error

(1)

Stepper

(2) Faulty carriage

There are

The

from it. And read

other

motor

two

is

to rea d

or

stepper

ways

it

5.6 Compatibility Error

The

data

which

is

written

c.,used mOitly by

can be

(1) Head

(2) Head o

(3) Motor

mi

salignment: Refer

utp

ut

too

low: Refer

speed

difference: Refer

operation,

To

correct

is

wrong .

of

the

again.

by

the

If

the dri

motor dri

seek

error

10 field, check

one

drive may

fonowing. The check points

to

(Adjustments and Confirmation I

to (Adjustments

to (Adjus

it

is

an

error

, write again

an

error

persists, rep lace

ve

defective. If

can be recovered

ve

cir

cuit

recovery. One

the

not

tments

usually

track number on wh i

detected

the

by foll

is

faulty.

is

to

be

read

are .,Iso mentioned

and

COnfi

and Confirmation Item 9.1)

during the

and repeat

ation

the disk

error

is

owi ng the recovery procedu re mentioned in 5.2.

recalibrate

by

another

tem

rmation Item 9.3)

next

a write check

on another track

ette

and

repeat

corrected

ch

, dispose of the di

to

track 00,

the

head

. Th

is

error

below:

9.5)

revoluti

and

is

located,

is

called a

on

by perform ing a read opera·

operation.

to

determine

the

above

seek back

and

If

the

result

whether

procedure.

skette

as

defective.

to

the

move

the

head

compatibility

is

unsatis-

it is

the

original track.

away

error, which

6. TROUBLE ANALYSIS

To

determ

ine

the

cause

of

troub

good

ones.

If

the FDD

6.1 Trouble Analy

FDD

troub

le may

(1 ) Index

(2)

(3

) Track 0 unde

(4)

(5) No write

(6 ) No

(7) Read err

(8)

(9) Write

(10) No

Check

CAUTION :

Be sure to switch

detection

Not ready

No seek

read

IN USE

protect

head

with

or

LED

load

power off before r

is

assumed faulty

sis

Procedure

occur

in any

failure

te

cta

ble

won

't light.

undetectable

15.25

·inch FDD

the

tro

ubl eshooting flowchart

le

whether

of

the following ten forms.

with

emoving

it lies in the

as a re

sult, follow the proce

opt

ional head loader)

in

an

FOO

or

PCB

6.2.

FDD

, diskette,

from the opera

- 3 -

dur

ting

or

e below .

svnem.

contro

ller, replace

the

disk and FDD wi

th

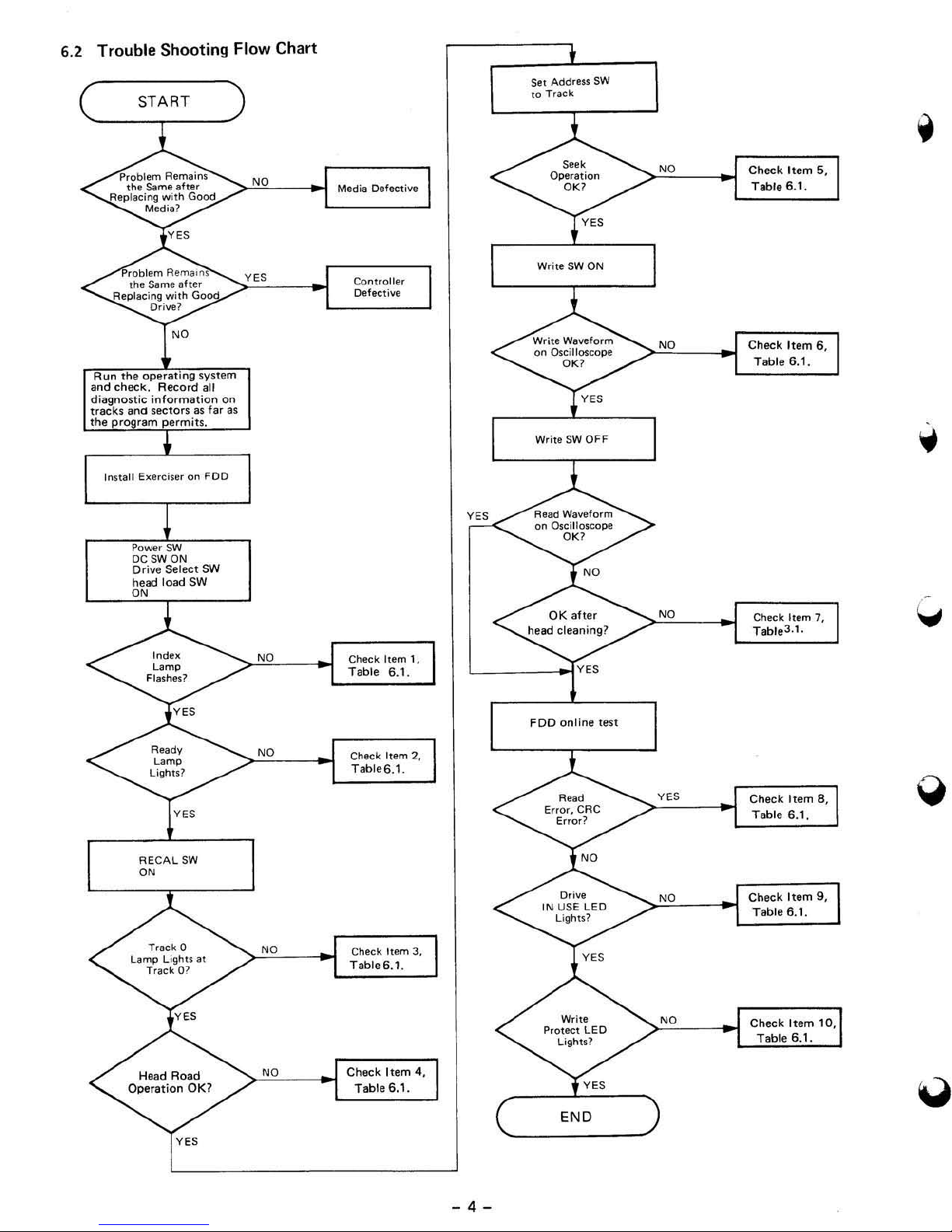

6.2 Trouble Shooting Flow Chart

ST

ART

Set

10

Addru.

Track

SW

- 4 -

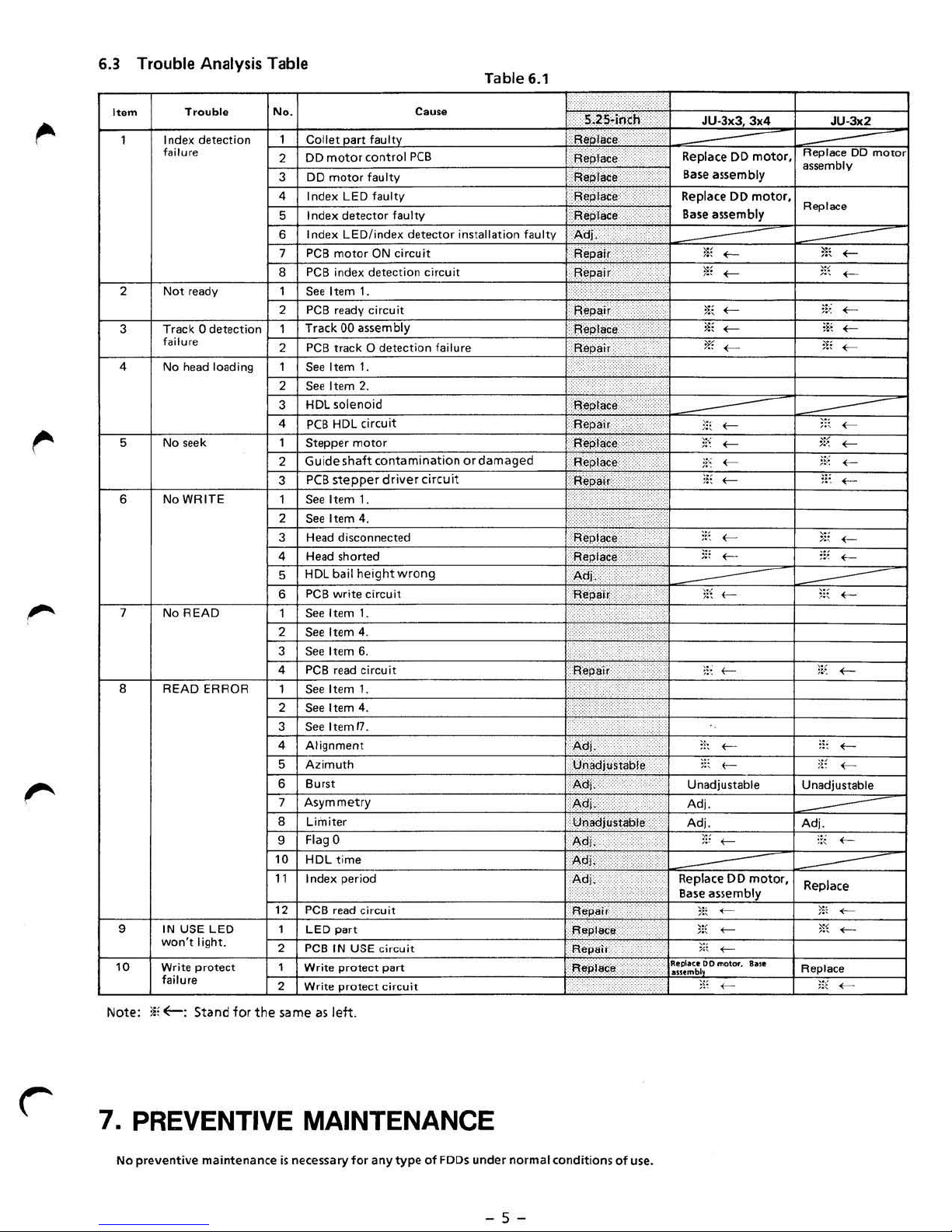

6.3

Trouble

Item

Index

1

fai

Not

2

3 Track 0

failure

4

Na

5

Na

NoWR

6

7 No READ

READ ERROR

•

,

IN USE

won't

Write p rotect

'0

failure

Note:

ii, (-: Sta

Analysis Table

N

Trouble

detection

lure

ready

detection

head loading 1 See Item 1,

seek

IT E

o.

1 Collet

DO

2

3

4

5

6 Index LED li ndex det!!Ctor installation faultv

7

•

1 See I

2

1

2

2

3

4

,

2

3

,

2 See Item

3 Head disconnected R.epface

4

5

6

,

2

3 See Item 6.

4

,

2

3 See I

4 Alignment Adj.

5

6

7

•

,

10

motor

DO

motor

Index LEO faultv

Index

detector

PCB

motor

PCB

index

tem

PCB

ready circuit

Track 00

PC

B Irack 0

Hem

See

HOL

solenoid

PCB

HDL

Stepper

Guide

shaft

PCB

stepper dri

See Item 1.

Hlilad

shorted Replace '

HDL

bail

PCB

write

See Item 1.

Item 4 .

See

PCB

read circuit Rep'air

See Item 1.

See Item 4.

temO"

Azimuth

Burst

Asymmetry

Limiter

Fl

agO

HOl

time

Index period

"

12

PCB

lEO

light.

nd

for

the

,

2

,

2

same

LEO

PCB

Write

Wr

ite

as

read circuit

part

IN

protect

protect

lett.

Table 6.1

Cause

art

fault

(Ontlol PCB

faulty

faulty

ON circuit R'epalr

detection

1. '?

a~5embl

2,

tircuit

motor

(Ontamination

4.

height

circuit

y

detection

ver

wrong

circuit

failure

circuit

or

damaged

S.2S·j'

lace,

R.

~

~eploce

~liIpllM':e

f':Il!'pl<IC!,::\:

laCe::,

ReP

Adj,

Repair

Rep~ir

:',

.AeplltC!I

Rapai,

N,.'CA?

:::

ReP

t~e

Repair

Rep

hke

Repix.e:::)

'Repai'r rh<W

i

·'

\iF'

Adj

:=:

Aepai~

..

...

.

.,.

....

.

'I' \ .•.•

.

USE circuit Repair

part

circuit

,

,Uiladju

Ad(

AOj

. Adj.

UQadjuSfable

'Adj,

p,dj

,

~dj,;

,

Repair'

fI"plece

fI~l8(;e

.'~

ndi

,

: :

:~:

:

:,:,:::

,

, ,

...

.

'.'

).

:(

""''-::~

••

••

'"

.,.,

,

::'

:

'

,

,.

,,'

.

..

'

,,&

,

..

..

....

uable

,'

?

:;

'"

•...

".:',.

':""

.-.~

.i

.,

JU-3x3

Replace

Base

Replace

Base

DO

assembly

DO moto

assembly

*,

-

;i,

-

*,

-

!!i

-

<

*

>;(

-

)"

-

ii

~

<

;-"

-

::

;

,::

-

-

:,s

:

<

1'

\

-

' .

;:;

-

,i

;

-

Unadjustable

Adj.

>;

:

-

Replace

Base ;5Ssembly

R.plKODD_.

....

DO

:;:

<

m

-

,,

:

-

'"

:I:

-

,..

motor

motor,

...

Rep lace

.

assemblV

r.

Replace

*:

>;,

,;

if

:!,

,

;;;

)"

::'

3;:

:!'

;,~

'"

;;,

;::

UnlKljUSlable

Adj.

'"

Replace

;-So

~

Replace

,,~

JU-

,'

.

..

.

3x2

00

-

-

-

-

-

<

-

-

<

<-

-

-

-

-

<

<

-

-

-

motor

7. PREVENTIVE MAINTENANCE

No preventive maint

enan

ce

is n

ecessary

far

any

type

of

FODs

und

- 5 -

er

normal

conditio

ns

of

use.

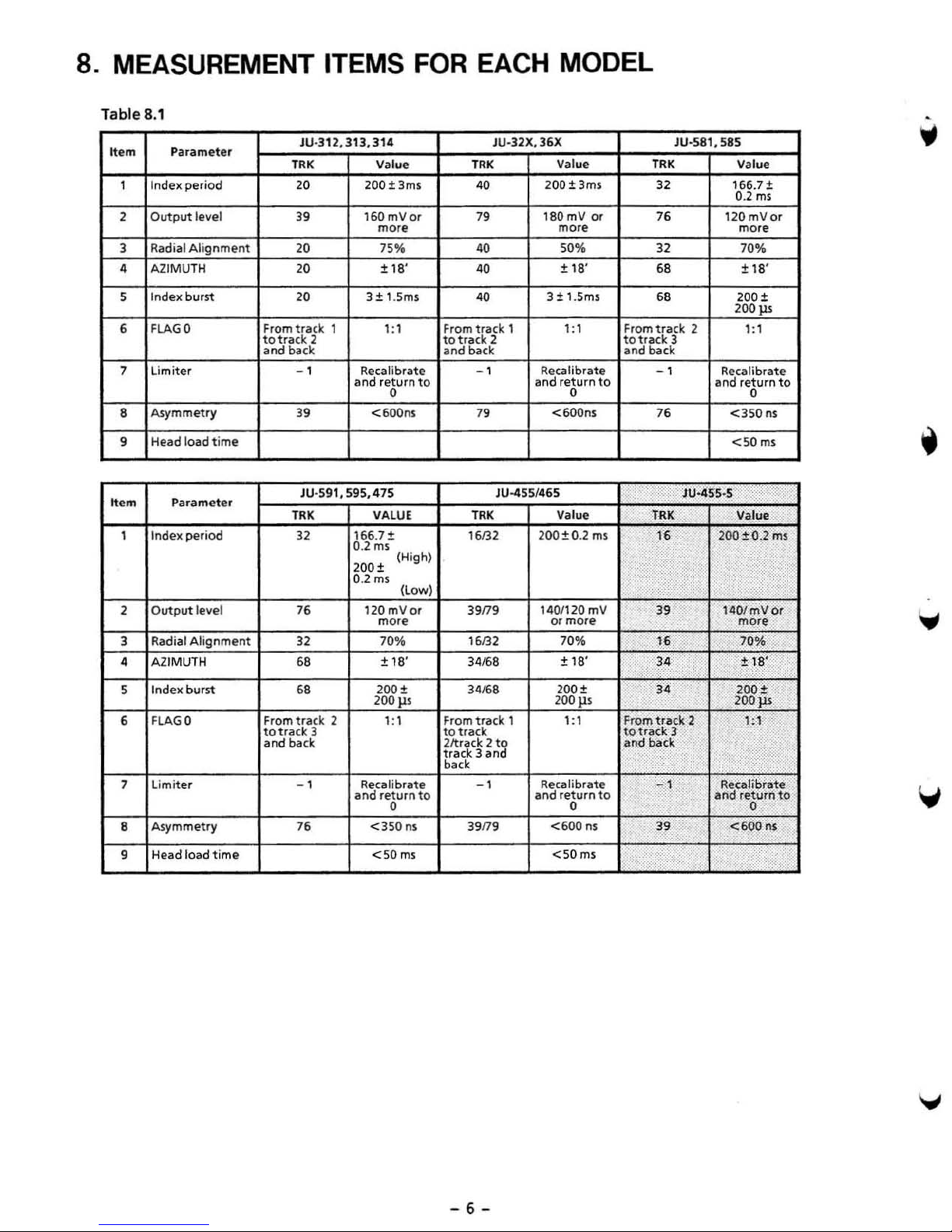

8. MEASUREMENT ITEMS

Table 8.1

JU

-312,

1

2

JU

-591, 595,

313,314

Value

200t3ms

16OmVor

more

75"

± 1

3±1.5ms

' ;1

Recalibrate

and return

<6oons

475

VALUE

166.7;!;

0.2

ms

200t

0.2

ms

120 m

more

70%

±

8'

0

(High)

18'

••

m P

Index

1

Output

2

,

Radial

4

AZIMUTH

Index

5

FLAG

6

7

limiter

Asym

•

Head load t ime

•

• • m

1

2

,

4 AZIMUTH

Parameter

IndelC

Output

Radial

aramete

r

period

level

Alignment

burst

0 From

metry

period

level 76

Alignment

totTack

and

TRK

20

39

20

20

20

track

back

-1

,.

TRK

32

32

6.

FOR

to

(Low)

llo(

EACH MODEL

JU·32X,36X JU-581,S85

T

RK

40

7'

40

40

40

From

track

totra,k

and

1

2 totTack 3

back.

-1

7.

JU-4 5S/465

TR

K Value

16132

39n9

16132

311/68

Value

200 ±

180mVor

more more

50% 32

±

18

3±1.5ms

1:

1 From

Recalibrate - 1

and

return

0

<600ns

200±

O.2

1401120m

or more

70%

t

18'

3ms

'

ms

to

V

TR

K Val

32 166.7

76

68

68 200 t

track

and

back

76

JU-455·5

TRK

16

....

,

,.

"

34

2

and

ue

;!;

0.2

m5

120mVor

70%

±

18

'

200

III

1: 1

Recalibrate

return

0

<3

50

ns

<5

0m5

Va

lue

200±0.1

c)

•

140/mllor

more

70%

± 18'

to

ms

Index

5

6

FLAG

7 Limite r

Asymmetry

•

Head

•

burn

0

load

2

and

200t

200p.s

1: 1

Recalibrate

return

0

<350

ns

<50

m$

to

6.

From

track

to

track

back

-1

76

3

and

t i

me

311/68

From

track

to

track

2ltrack 2 to

track 3 and

back

-1

39n9

200t

200 }ls

1 1: 1 From

Recalibrate

and

return

0

<600

<50ms

n$

to

totrack

and

34

track

back

'C<.

-1

3.

i"

200

t

200jU

,;

2

3

1

Recalibrate

arid

return

0

<600",

.

...

to

-

6-

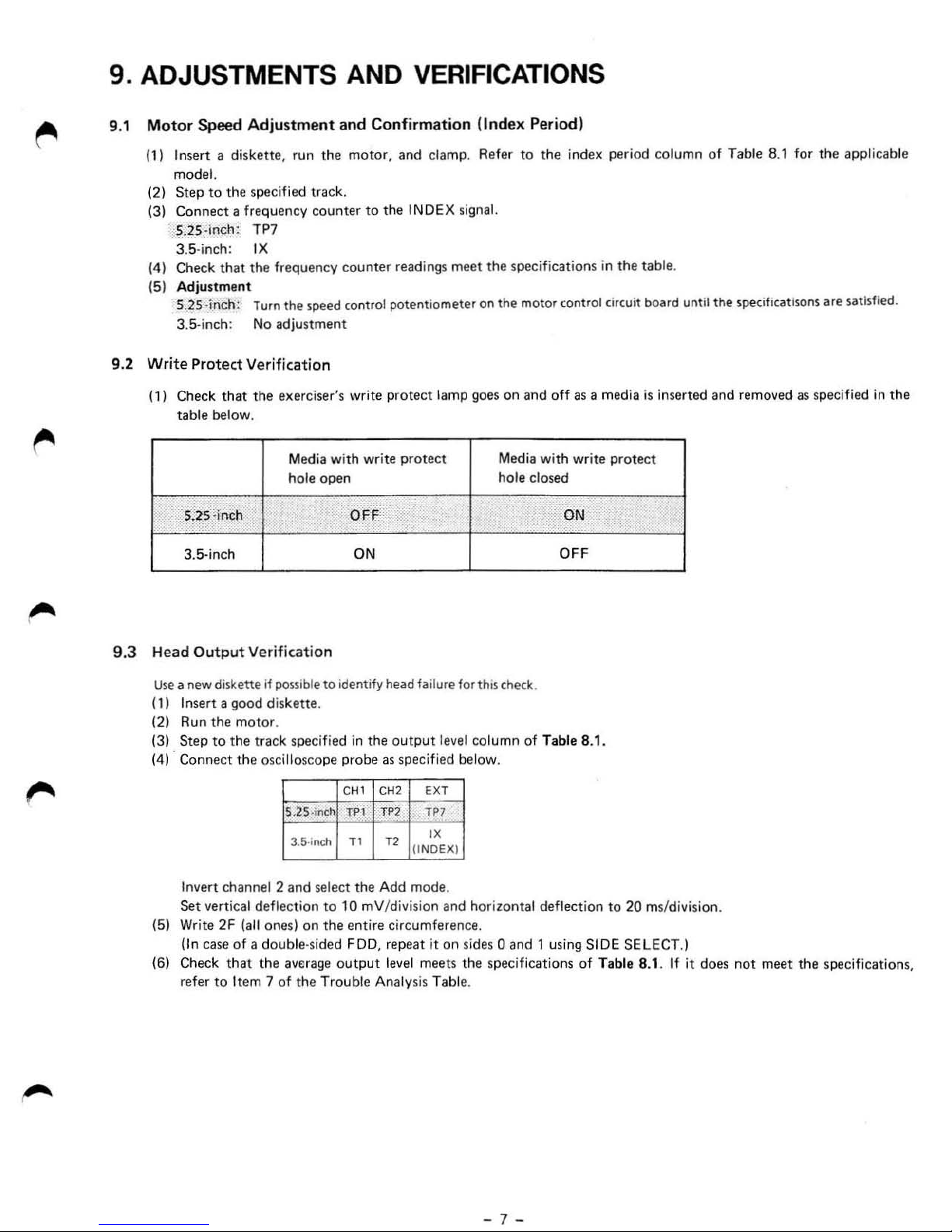

9. ADJUSTMENTS AND VERIFICATIONS

9.1 Motor Speed

(1

} Insert a diskette, run the

model .

(2)

Step

(3) Connect

. 5.25,-inch : TP7

3.5·inch: IX

(4) Check that the fr

(5)

Adjuument

5.25 -

3.5-inch

Adjustment

to

the specified tra ck.

a frequen

inch

: Turn the spe

: No adju s

cy co

equency

tment

9.2 Write Protect Verification

(1)

Check that the exerciser's write protect lamp go

table

below.

Media wi

hole

S.2.S-inch OFF-

3.5·inch ON

and Confirmation !Index Period)

motor, and

unter

to

counter read ings

ed

contro

th

write prot

ope

n hole clos

the

INDE

l po

tentiometer

damp

X signal.

meet

ect

, Ref

er

to

the

specifications in the table.

on

the

motor control circuit bo

es

on and

Media wi

the inde

oft

as

th

write prote

ed

ON

OFF

x period

column

ard

unt

of

Table 8.1 for the applicable

il

the

spedfic:at

isons

are

satisfied.

a media is inserted and removed as specified

ct

in

the

9.3

Head

Output

Use

a new diske

(1) Insert a

(2)

Run the

(3)

Step

to

(4) · C

onnect the oscillos

Invert

Set

vertical deflection

(5) Write

(

In

2F (all

caseot

(6) Check

refer

to

Verification

tte

i1

good

motor

the tra

channe

possible

diskette.

.

ck specified

l 2

ones)

cope

S.2S·inc

3.5·"lCh

and

select the

on

to identity

in

the o

probe

C

H1

h l

Pl

T1

to

10

mV/div isi

the

entire

a double·sided FDD, repeat it

that

the avtrage

Item 7

of

out

the

Trouble Analy

put

head

failure

fo

r

thi~

check.

utpu

t leve l

as

specified below .

CH2 EXT

TP2

TP7

T2

"

UN

DE

X}

Add

mode.

on

and hor izontal

column

of Table 8.1 .

circumference.

on

sides 0 and 1 using SIDE SELECT.)

level meets the specificatio

sis

Table.

deflection

ns

of

to

20

ms/division.

Table 8.1. If it does

not

meet

the specif

ication

s,

- 7 -

Loading...

Loading...