Page 1

Reference

Reference

Page

Outline of “PANATERM®”, Setup Support Software ..............................156

Communications ...................................................................................158

Description on Dividing/Multiplier Ratio ................................................178

Conformance to EC Directives/UL Standards ....................................... 180

Optional Parts .......................................................................................184

Recommended Parts ............................................................................192

Dimensional Outline Drawing ................................................................193

Allowable Load of Output Shaft ............................................................196

Motor Characteristics (S-T Characteristics) ..........................................197

Servo Motor with Gear ..........................................................................198

Dimensional Outline Drawing of Motor with Gear .................................200

Allowable Load of Output Shaft of Servo Motor with Gear ...................202

Characteristics of Servo Motor with Gear (S-T Characteristics) ........... 203

Driver Internal Block Diagram ...............................................................204

Control Block Diagram ..........................................................................205

Specifications (Driver/Motor) .................................................................206

Hit-and-stop Initialization and Load Pressing Control ...........................207

Index .....................................................................................................209

Reference .............................................................................................214

After-sale Service (Repair) ........................................................ Back cover

155

Page 2

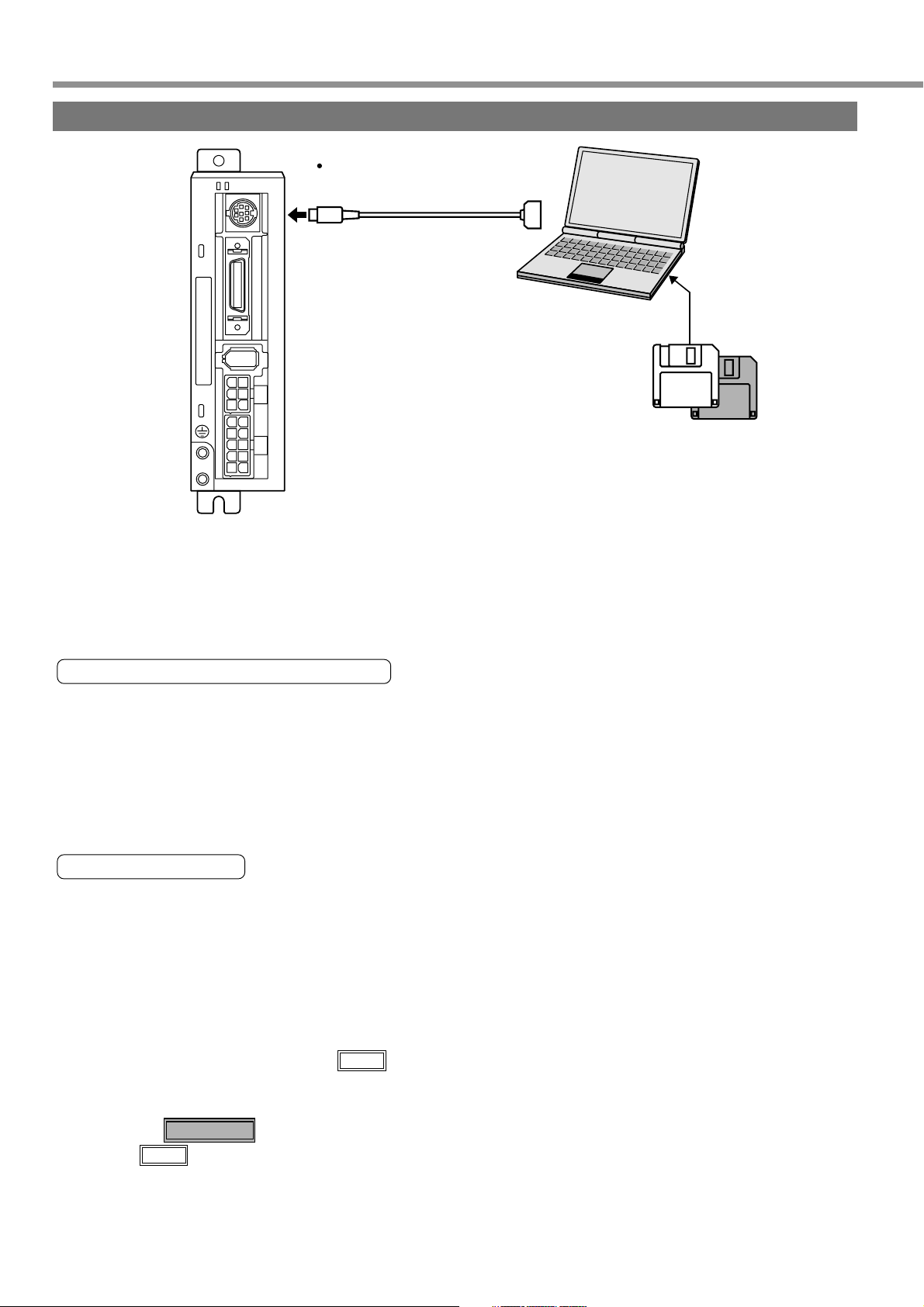

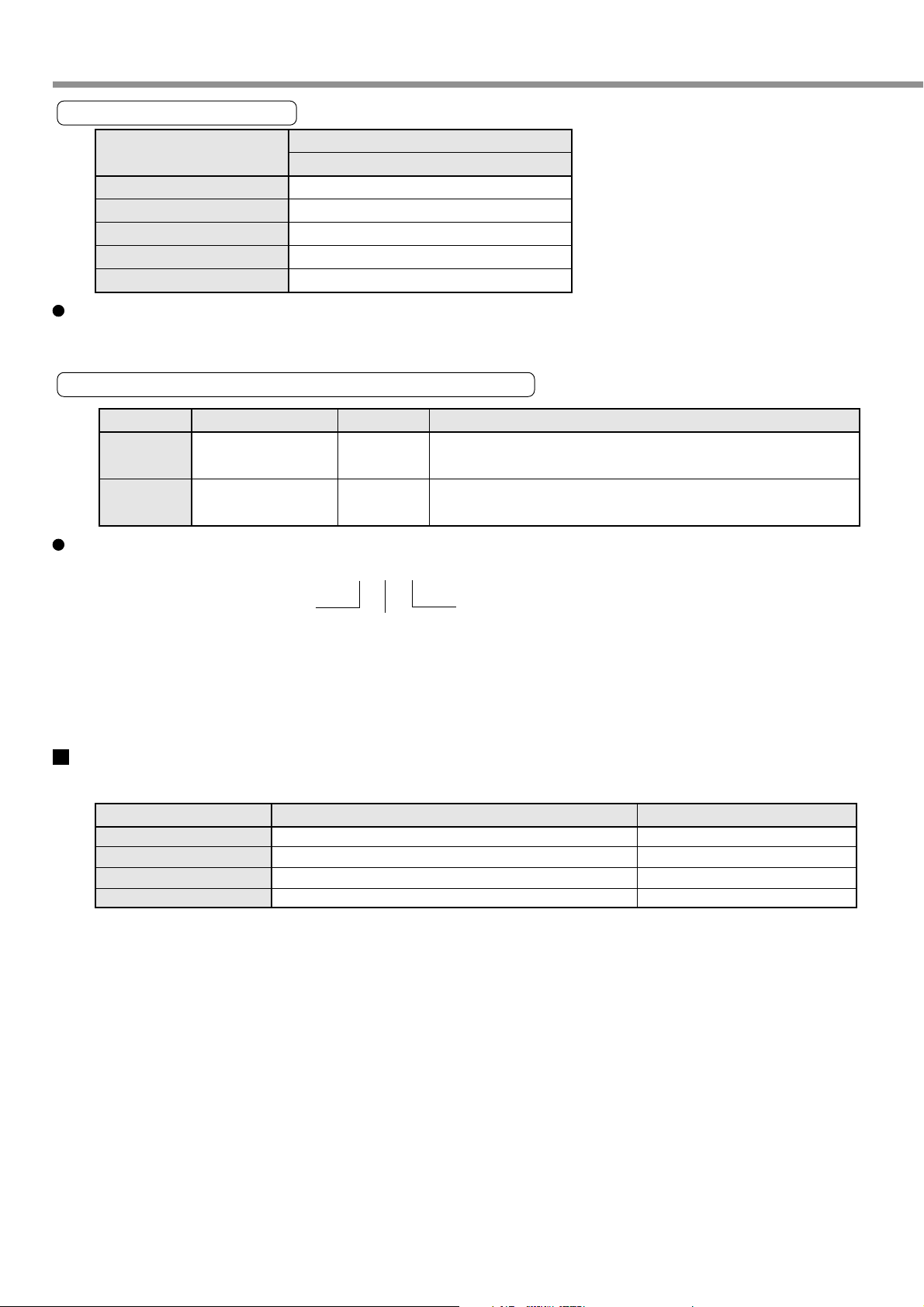

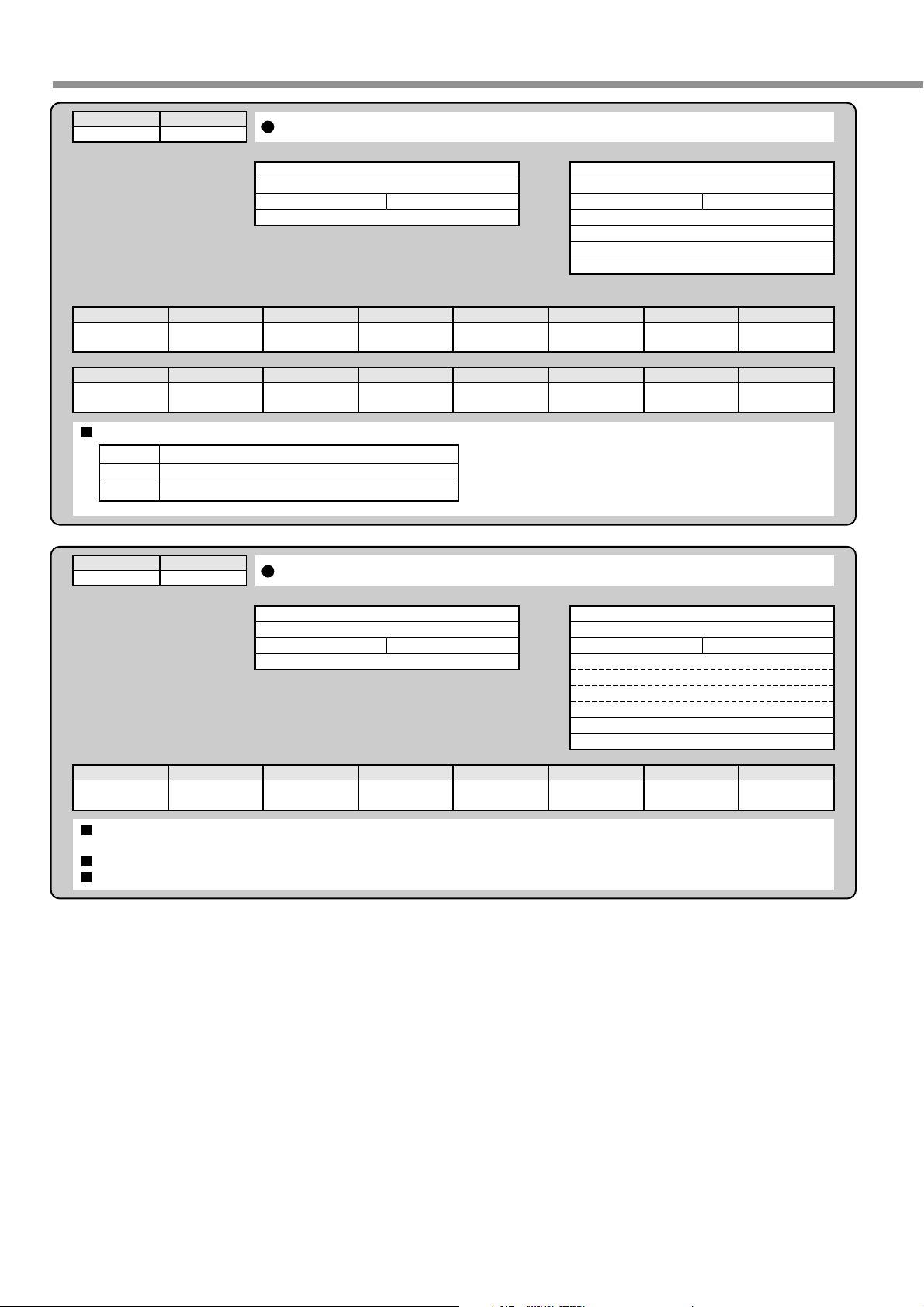

Outline of “PANATERM®”, Setup Support Software

Connection Method

RS-232 Cable

STATUS

ALM CODE

x

6

x

5

x

4

x

3

DV0P1960 (For DOS/V)

Connecting to CN X6

x

1

Please contact us for the latest version of setup disk of

“PANATERM®”, setup support software.

• DV0P4230 (Japanese version)

Windows® 95, Windows® 98, Windows® NT,

Windows® 2000, Windows® Me, Windows® XP

(Each Japanese version)

• DV0P4240 (English version)

Windows® 95, Windows® 98, Windows® NT,

Windows® 2000, Windows® Me, Windows® XP

(Each English version)

Installing PANATERM® on Hard Disk

<Cautions/Remarks>

1. The capacity of hard disk memory should be 15 MB or more. As OS, prepare Windows® 95, Windows® 98,

Windows® NT, Windows® 2000,Windows® Me and Windows® XP (each of them should be a Japanese version).

2. You can start “PANATERM®” only after installing it on the hard disk with the setup disk, by following the steps

described below.

Steps of Procedure

(1) Power on your personal computer and start a corresponding OS (If there is any running application program,

terminate it).

(2) Insert PANATERM® Setup disk 1 into the floppy disk drive.

(3) Start Explorer and select the floppy disk drive.

(For starting of Explorer, see the manual of the corresponding OS.)

(4) Double click on the setup program (Setup.exe) on the floppy disk (Then, PANATERM® setup program will

start.).

(5) To start the setup program, press .

OK

(6) Operate by following the guidance of the setup program.

(Follow the instruction to change the setup disc 1 to disc 2 during the course.)

(7) Click on button, and setup will start.

(8) Click when the message “Setup completed” appears.

Start installation

OK

(9) Close all application programs and then restart Windows®. When it restarts, PANATERM® will be added to

the program menu.

156

Page 3

[Reference]

Reference

Starting PANATERM®

<Cautions/Remarks>

1. Once you have installed “PANATERM®” on the hard disk, you do not have to reinstall it every time you boot up.

2. Before you start, connect the driver with the power supply, motor, and encoder. For the startup procedure, refer

to the manual of the corresponding OS.

Steps of Procedure

(1) Power on your personal computer and start the corresponding OS.

(2) Turn on the driver.

(3) Click on Start button of the corresponding OS of the personal computer.

(For the startup procedure, refer to the manual of the corresponding OS.)

(4) Select PANATERM® in the program .

(5) After opening splash is displayed for 2 seconds, PANATERM® screen will appear.

For any detailed information on operation/functions of “PANATERM®”, refer to the operating instructions of

“PANATERM®”.

* Windows®, Windows® 95, Windows® 98, Windows® NT, Windows® 2000, Windows® Me, Windows® XP are the

trademarks of Microsoft Corporation in the United States.

157

Page 4

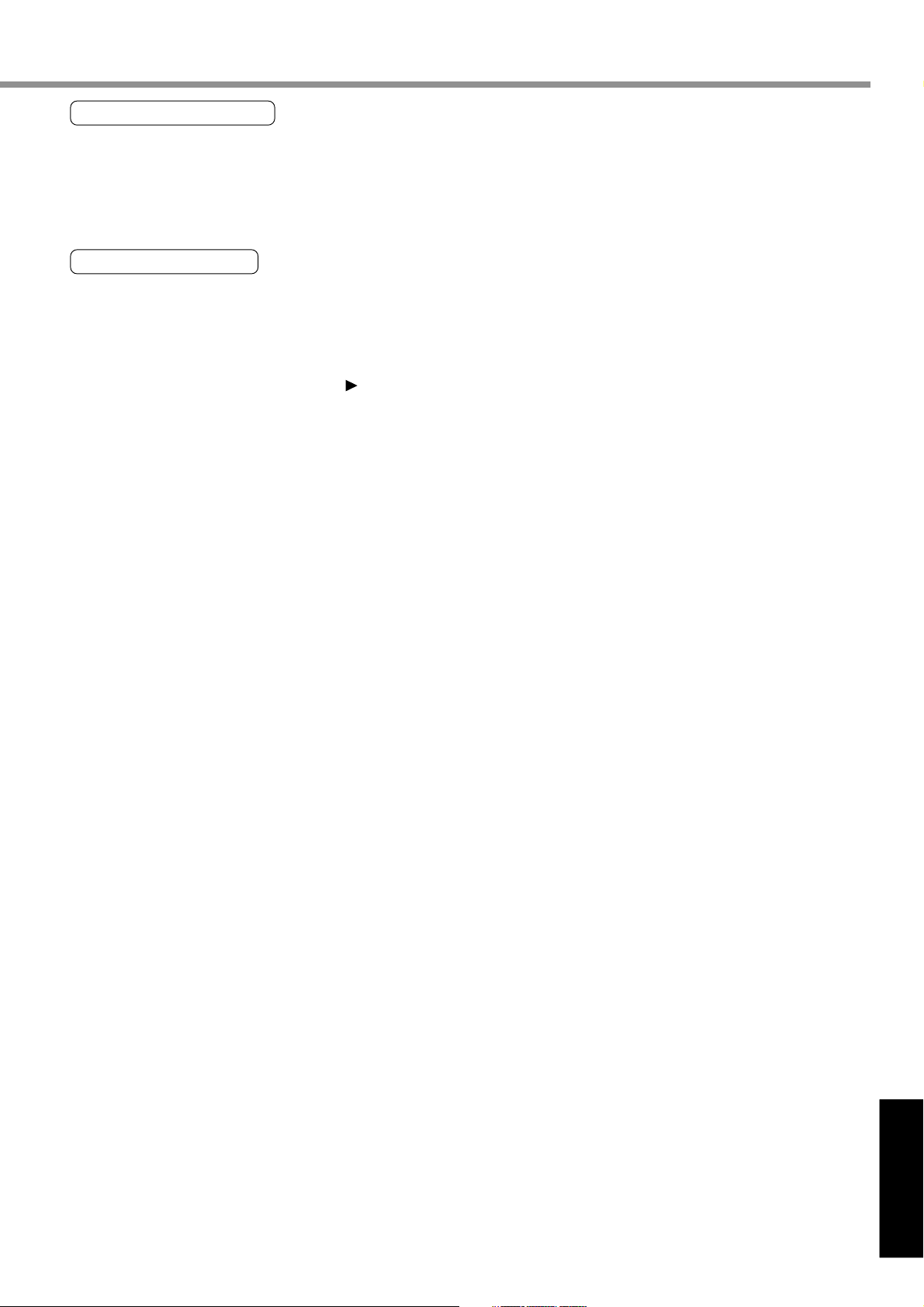

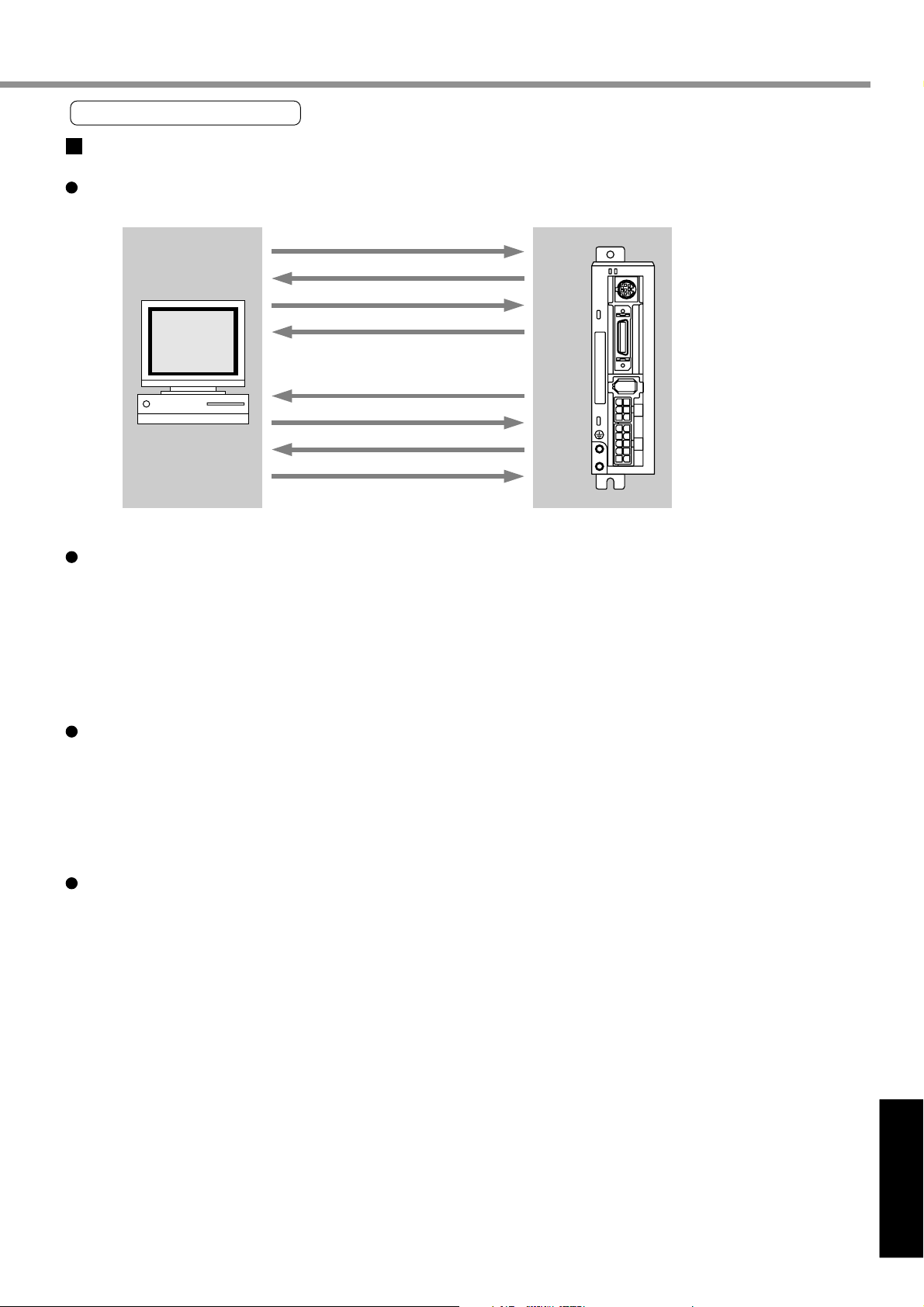

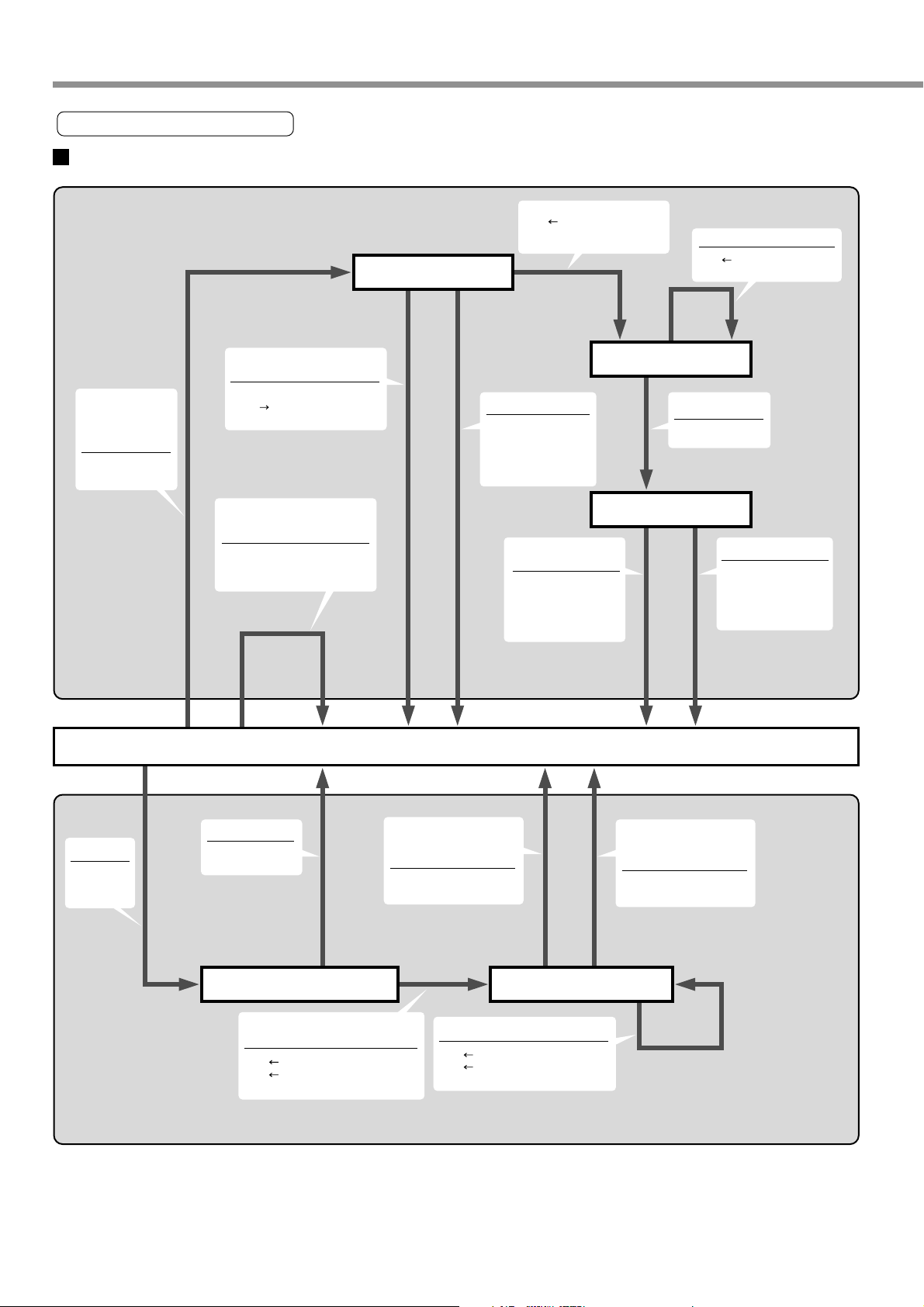

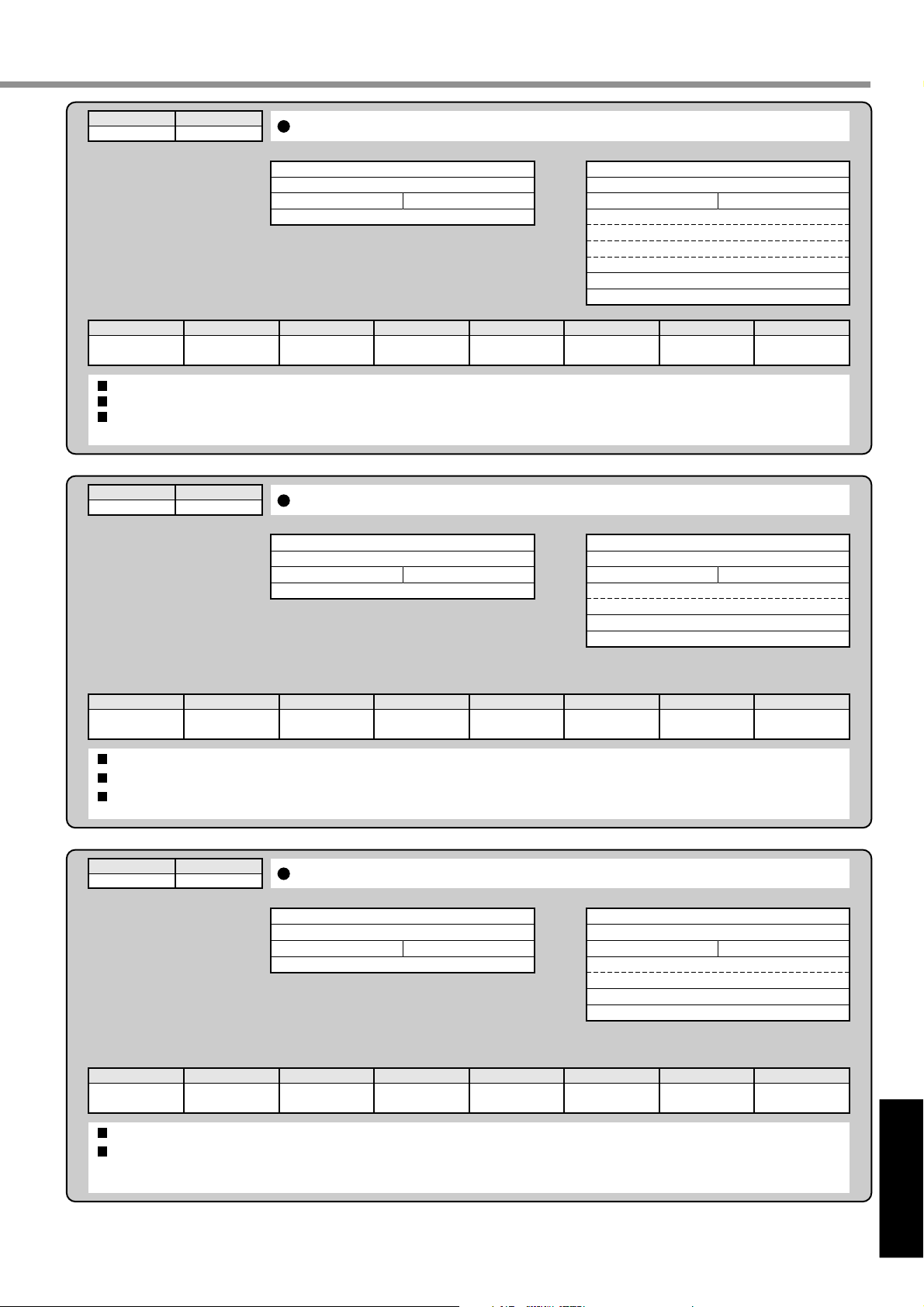

Communications

Outline of Communications

With a personal computer or host NC connected with MINAS-E Series through RS232C-compliant serial

communications, you can do the following:

(1) Rewriting parameters

(2) Browsing and clearing status and history of alarm data

(3) Monitoring control status including status, I/O, etc.

(4) Saving and Loading parameters

Advantages

• You can write parameters all at once from the host when starting the machine.

• As you can display operating condition of the machine, serviceability will improve.

Note that the following application programs for a personal computer and cables are available for use. For

information of PANATERM®, refer to the instruction manual of PANATERM®.

Name of Optional Components

PANATERM Japanese version (WIN95/98/Me/NT4.0/2000/XP)

PANATERM English version (WIN95/98/Me/NT4.0/2000/XP)

Connection cable for personal computer (DOS/V)

For the latest version, please contact us.

Model Name

DV0P4230

DV0P4240

DV0P1960

158

Page 5

[Reference]

Reference

Communications Specification

Connection of Communications Line

MINAS-E Series has RS232C communications port. and is capable of communications between the host as follows:

RS232C Communications

In RS232C communications, a host and the driver are connected 1:1 and communicate with each other

according to the RS232C transmission protocol.

RS232C

Host

STATUS

ALM CODE

x

6

X6

x

5

x

4

x

3

x

1

(ID)=1

You can change settings of the module ID with Pr00. In particular, you may set the same module ID unless

there is management problem on the host side.

Interface of Communication Connector Unit

Connection with a Host through RS232C

MINAS-E

X6Host

RTS

CTS

RXD

G

TXD

DTR

DSR

FG

1

2

Equivalent to ADM202E

3

TXD

4

G

5

RXD

6

+5V

+5V

7

8

<Note>

You must leave pins 1, 2, 6, 7 and 8 of X6 unconnected.

159

Page 6

Communications

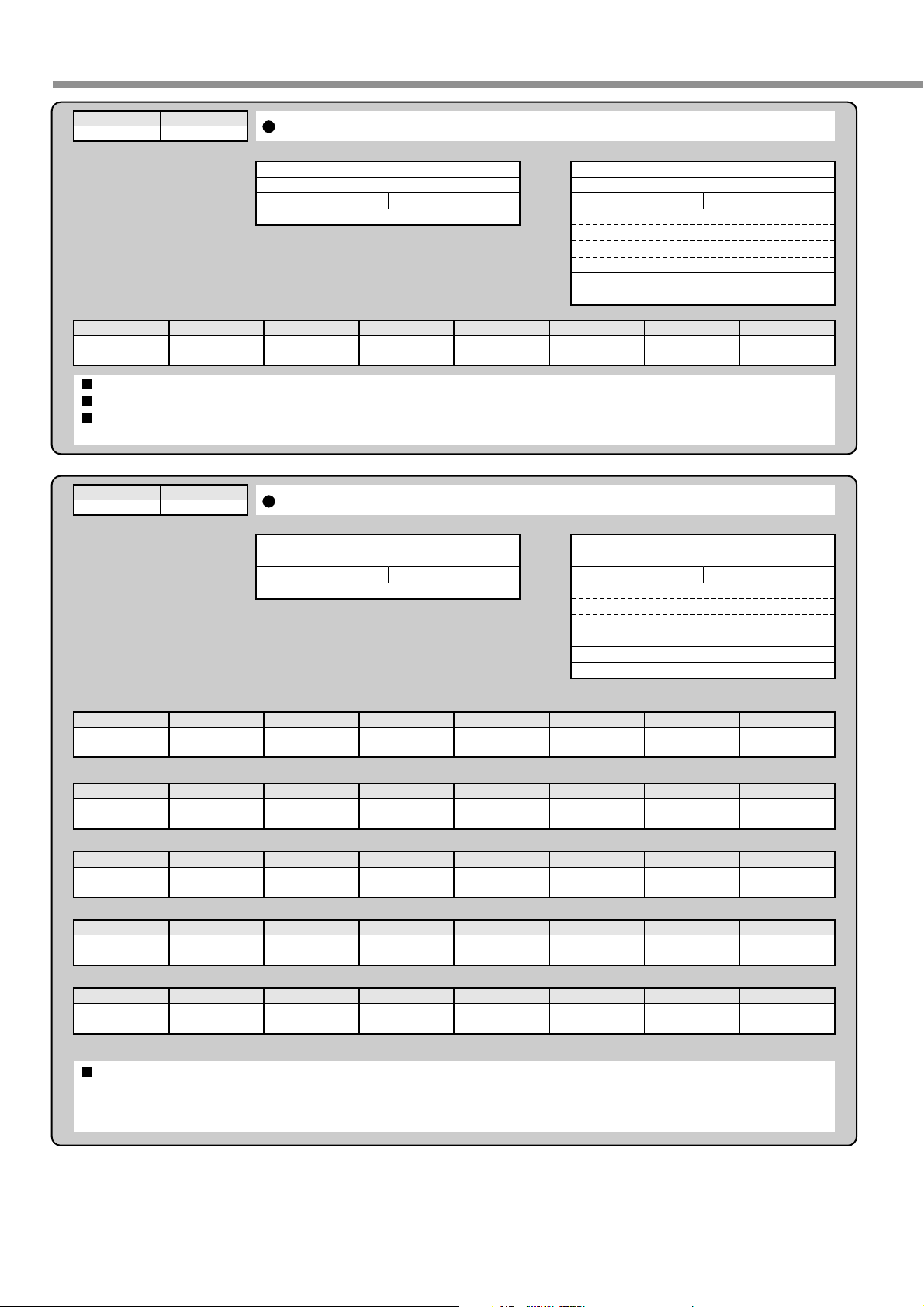

Communications Method

RS232C

Full-duplex, asynchronous communication method

Communications baud rate

Data

Parity

Start bit

Stop bit

Set RS232C communications baud rate with Pr0C. Any change to these parameters will be valid when you

power on the control power supply. For detailed information, refer to list of parameters related to the following

communications:

List of User Parameters Related to Communications

2400, 4800, 9600bps

8 bit

No

1 bit

1 bit

PrNo.

00

0C

Time for data transmission is calculated with the following expression, for instance, in the case of 9600 [bps]:

When the baud rates of 2400 bps and 4800 [bps] are used, data transmission time will be 4.17 [ms/byte] and

2.08 [ms/byte], respectively. Note, however, actual communication time will be added time necessary for

processing received command, and necessary for switching between a line and transmission/reception control.

Parameter Name

Shaft name

Setting of baud rate for

RS232C communications

(1000/9600) x (1 + 8 + 1) = 1.04 [ms/byte]

Start bit

Range of Setting

1 - 15

0 - 2

Data

Refer to descriptions on parameters on pages 88 and 116.

Set the communications speed of RS232C communications.

0 : 2400[bps] 1 : 4800[bps] 2 : 9600[bps]

A change will be valid when you power on the control power supply.

Stop bit

Functional Description

Handshaking Code

For line control, the following codes are used.

Name

ENQ

EOT

ACK

NAK

Code

05h

04h

06h

15h

Functions

Transmission request

Ready for receiving

Acknowledgement

Negative acknowledgement

ENQ …When the module has a block to transmit, it sends ENQ.

EOT … When the module is ready to receive a block, it sends EOT. The line enters transmission mode when

sending ENQ and receiving EOT. It enters reception mode when receiving ENQ and sending EOT.

ACK … When a received block is judged normal, ACK is returned.

NAK … When a received block is judged as abnormal, NAK is returned. A judgment is made based on

checksum and timeout.

160

Page 7

Reference

Transmission Sequence

Transmission Protocol

RS232C

Host MINAS-E

[Reference]

(1) ENQ (05h)

(2) EOT (04h)

(3) Data Block

(4) ACK (06h)

(or NAK (15h))

(5) ENQ (05h)

(6) EOT (04h)

(7) Data Block

(8) ACK (06h)

Received

Data

Transmitted

Data

STAT US

ALM CODE

x

6

x

5

x

4

x

3

x

1

(or NAK (15h))

Line Control

Direction of transmission and conflict are solved.

Reception mode …The module enters reception mode after receiving ENQ and returning EOT.

Transmission mode … The module enters transmission mode after sending ENQ and receiving EOT.

When there occurs a conflict between the transmitting module and receiving module:

When subsequent to transmission of ENQ, a slave receives ENQ while waiting for EOT, priority is given to

ENQ sent from a maser, and the slave enters the reception mode.

Transmission Control

Entering transmission mode, a module transmits a command block continuously and then waits for reception

of ACK. When the module receives ACK, transmission is complete. When the number of transferred

command bytes is incorrect, ACK may not be returned. When ACK is not returned within T2 period, or when

NAK or any code other than ACK is received, transmission retry will be executed. The retry will start with

ENQ.

Receiving Control

Entering receiving mode, the module receives transmitted blocks continuously. It obtains the number of

command bytes from the first byte, and receives as many command bytes as that number plus 3. When the

sum of received data is zero, reception is considered successfully ended and ACK is returned. When

abnormal checksum or timeout between characters occurs, NAK is sent.

161

Page 8

Communications

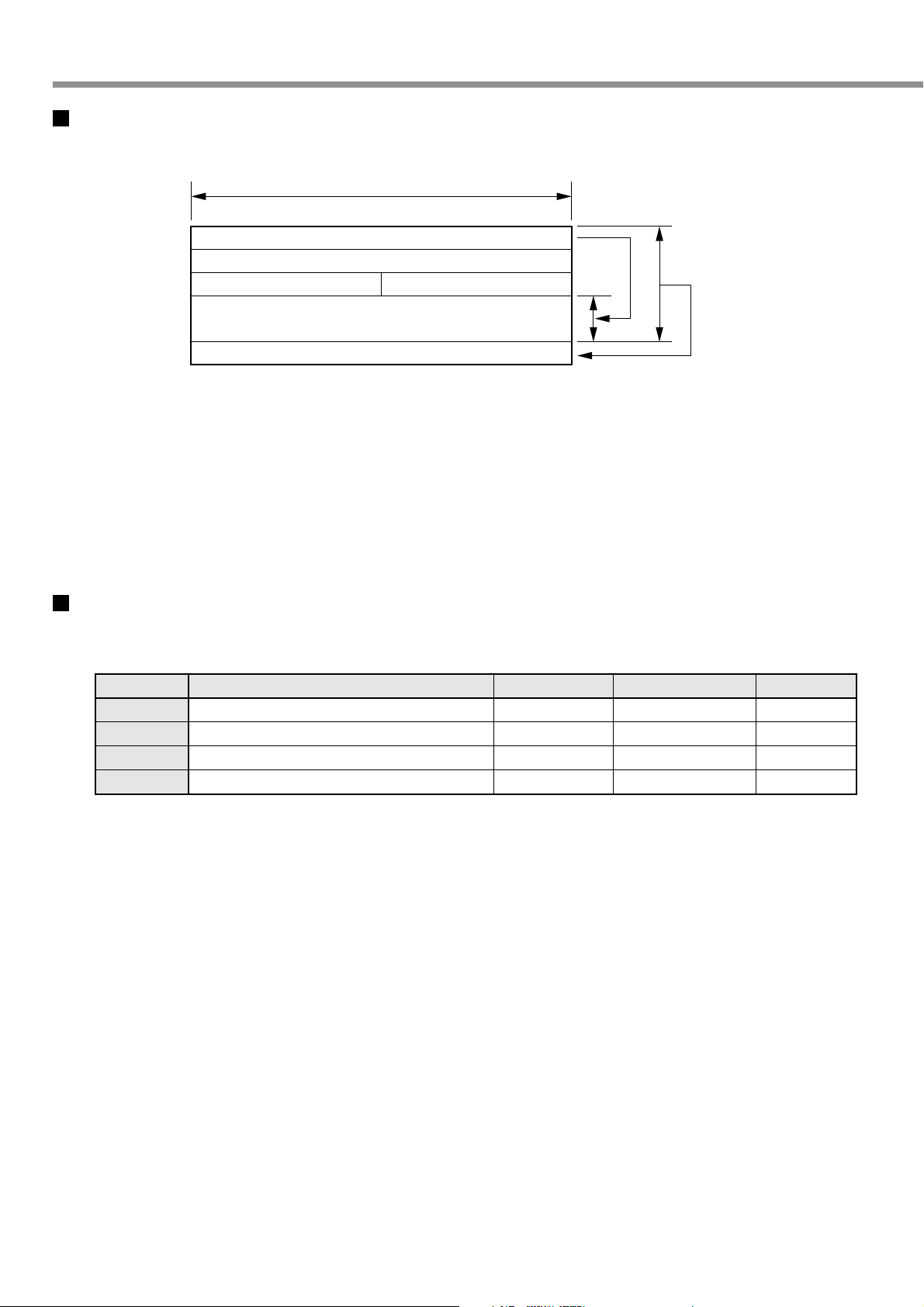

Configuration of Data Block

A data block to be transmitted in physical phase is configured as illustrated below:

1 byte

N

axis

commandmode

Parameter

(N bytes)

check sum

N : This is the number of command bytes (0 - 240),

which indicates the number of parameters needed by a command.

axis : This defines a module ID assigned to parameter No.00 axis name of the driver. (1 - 15)

command : This is the control command (0 - 15).

mode : This is the command execution mode (0 - 15),

which differs depending on a command.

check sum : This is 2’s complement of the total number of bytes, ranging from the first byte to the byte immedi-

ately before the checksum byte.

Protocol Parameter

The following parameters can control transfer of a block. A user can set these parameters to any value with INIT

command to be described later.

Name

T1

Timeout between character transmissions

T2

RTY

M/S

T1 .... • This is allowable time between module identification byte and ENQ/EOT, or time from reception of a

character code by this device to that of a next character code in a transmission/reception data block.

When this specified time is exceeded, timeout error occurs and NAK is returned to the transmitting

module.

T2 .... • This is allowable time after this device transmits ENQ till it receives EOT. When this specified time is

exceeded, it means that the receiving module is not ready to receive data or fails to receive ENQ code

for some reason. In this case, ENQ code will be resent to the receiving module (number of retries).

• This is allowable time after EOT is sent out till a first character is received. When this specified time is

exceeded, NAK is returned and the receiving mode ends.

• This is allowable time after checksum byte is sent out till ACK is received. When this specified time is

exceeded, ENQ code is resent to the receiving module, as in the case of reception of NAK.

Function

Protocol time limit

Retry limit

Master/slave

Initial Value

5 (0.5 second)

10 (10 seconds)

1 (once)

0 (slave)

Range of Settings

1 - 255

1 - 255

1 - 8

0, 1( master)

Unit

0.1 second

1 second

once

RTY ..... This shows the maximum number of retries. When this specified value is exceeded, transmission error

occurs.

M/S ..... This shows switching of a master/slave. When conflict of ENQ transmission occurs, this parameter

determines to which priority is given. (0=slave mode, 1=master mode) Transmission of the module

defined as a master should take precedence.

162

Page 9

[Reference]

Reference

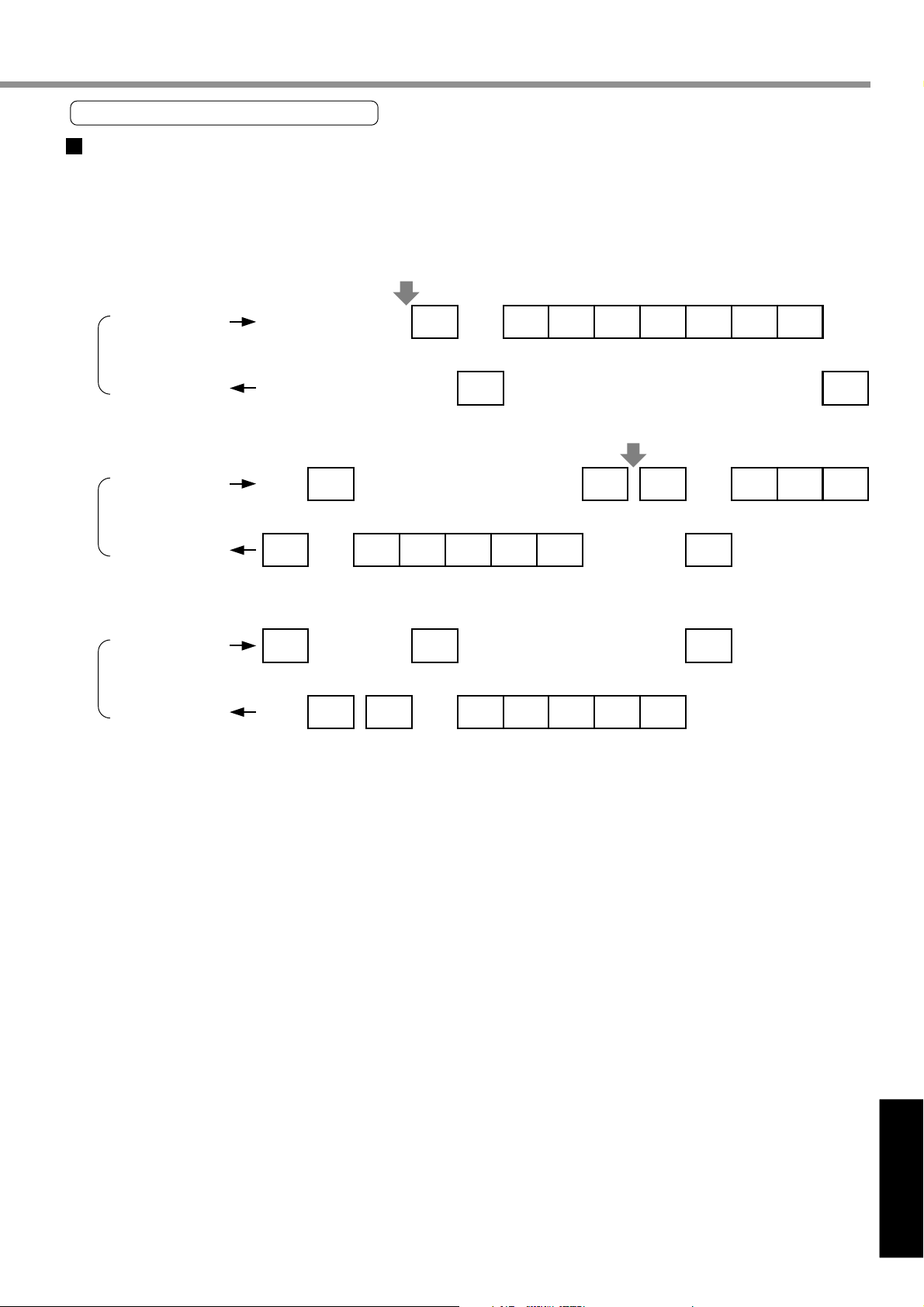

Example of Data Communication

Example of Changing Parameters

The following illustrates time-series communications data flow when a change is made to a parameter.

Communications should be conducted in the sequence of outline, (1) individual writing of parameters and (2) writing

to EEPROM if storage is needed. In this example of hardware connection, the device is directly connected with a

host through RS232C communications with user ID=1. Data is represented in hexadecimals.

(1) Individual Writing of Parameters

Host

MINAS-E(

Host

MINAS-E(

Host

MINAS-E(

1)

1)

1)

05 03 01 18 0B 00 00 D9

(ENQ)

04 06

(EOT) (ACK)

(2) Writing of Parameters to EEPROM

04 06 05 00 01 48

(EOT) (ACK) (ENQ)

05 01 01 18 00 E6 04

(ENQ) (EOT)

B7 04 06

(EOT) (ACK)

06 05 01 01 48 00 B6

(ACK) (ENQ)

(Note) For details of commands, refer to “List of Communications Commands” on Page 166.

163

Page 10

Communications

State Transition Diagram

RS232C Communications

There are requests

for transmission

(within the number

of retries).

ENQ transmission

and T2 start.

Transmitting Module

ENQ is received and in slave

mode.

ENQ is returned to receiving

buffer (To reception

processing)

There are requests for

transmission but the number of

retries is exceeded.

The number of retries is to be

reset once. A request for

transmission is cleared.

Waiting for EOT

T2 timeout

The number of retries

is counted once.

T2 stop

Transmission buffer is

cleared.

EOT is received.

Size Number of command

bytes + 3

T2 stop

Transmission of block

Waiting for ACK/NAK

NAK is received or T2

times out.

The number of retries is

counted once.

T2 STOP

Transmission buffer is

cleared.

One character is received.

Size Number of command

bytes - 1

Size becomes zero.

T2 START

ACK is received.

The number of retries

is reset.

T2 stop

The request for

transmission is cleared.

ENQ

EOT is

transmitted.

T2 start

T2 timeout

NAK is transmitted.

T2 stop

Waiting for the number

of command bytes

The number of command bytes is

received.

Size Number of command bytes +3

Sum Number of command bytes

T1 start, T2 stop

Idling

T1 times out or checksum

error occurs when size

becomes 0.

NAK is transmitted.

T1 stop

Remaining blocks

One character is received.

Size Number of command bytes -1

Sum Sum + received characters

T1 start

Receiving module

Receiving

Reception is successful

(checksum is OK when size

becomes 0).

ACK is transmitted.

T1 stop

164

Page 11

Reference

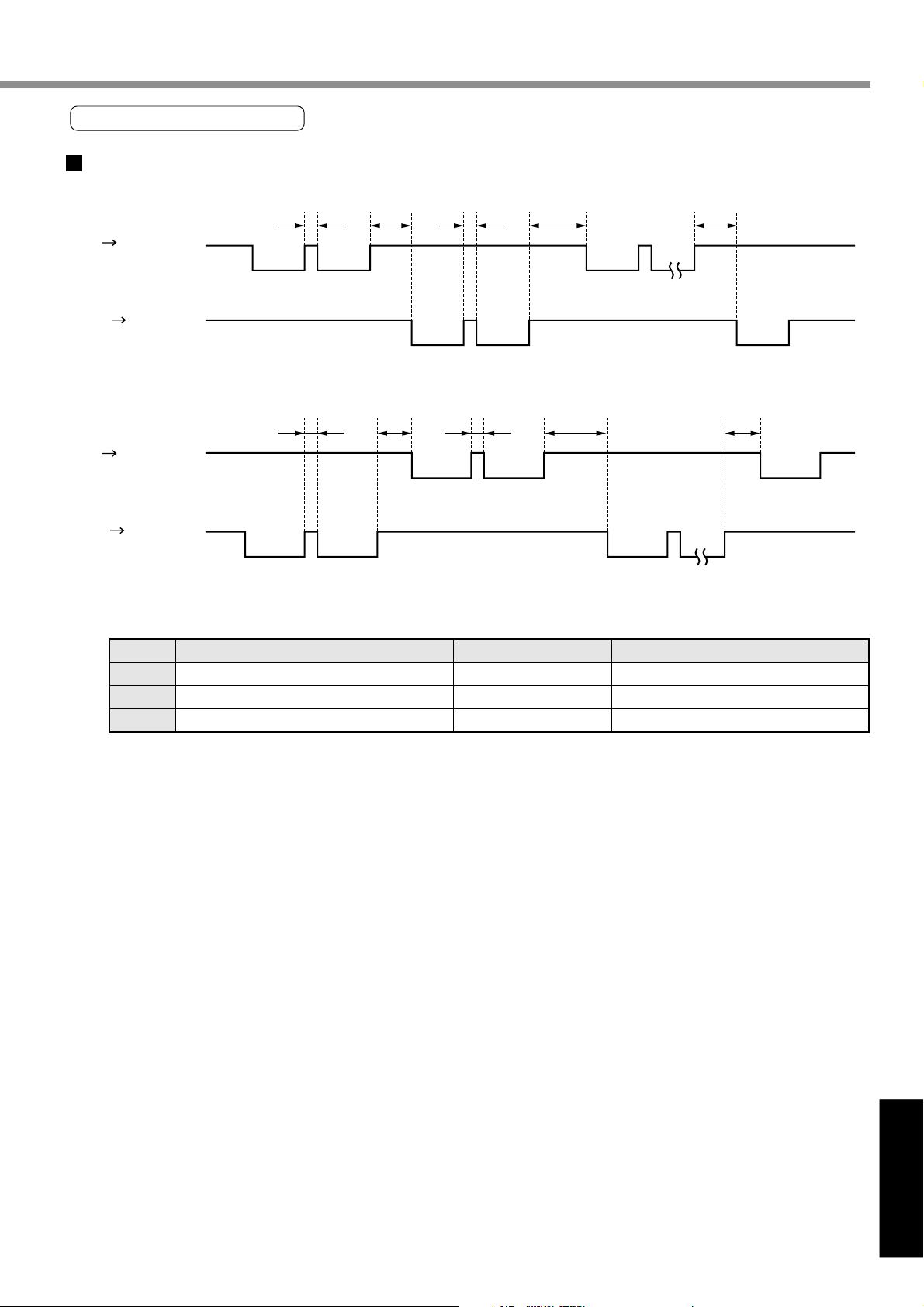

Communications Timing

RS232C Communications

[Reference]

Host Driver

Driver Host

Host Driver

Driver Host

Code

T3

T4

T5

T3 T3T4

Request for transmission

Permission to transmit

T3 T3T5 T4 T5

Request for transmission

Name

Continuous inter-character time

Driver response time

Host response time

T5 T4

Data block

ACK/NAK

Permission to transmit ACK/NAK

Data block

Minimum

Stop bit length

4ms

2ms

Maximum

Protocol parameter T1

Protocol parameter T2

Protocol parameter T2

<Caution>

The time represents a period of time from stop bit rising edge.

165

Page 12

Communications

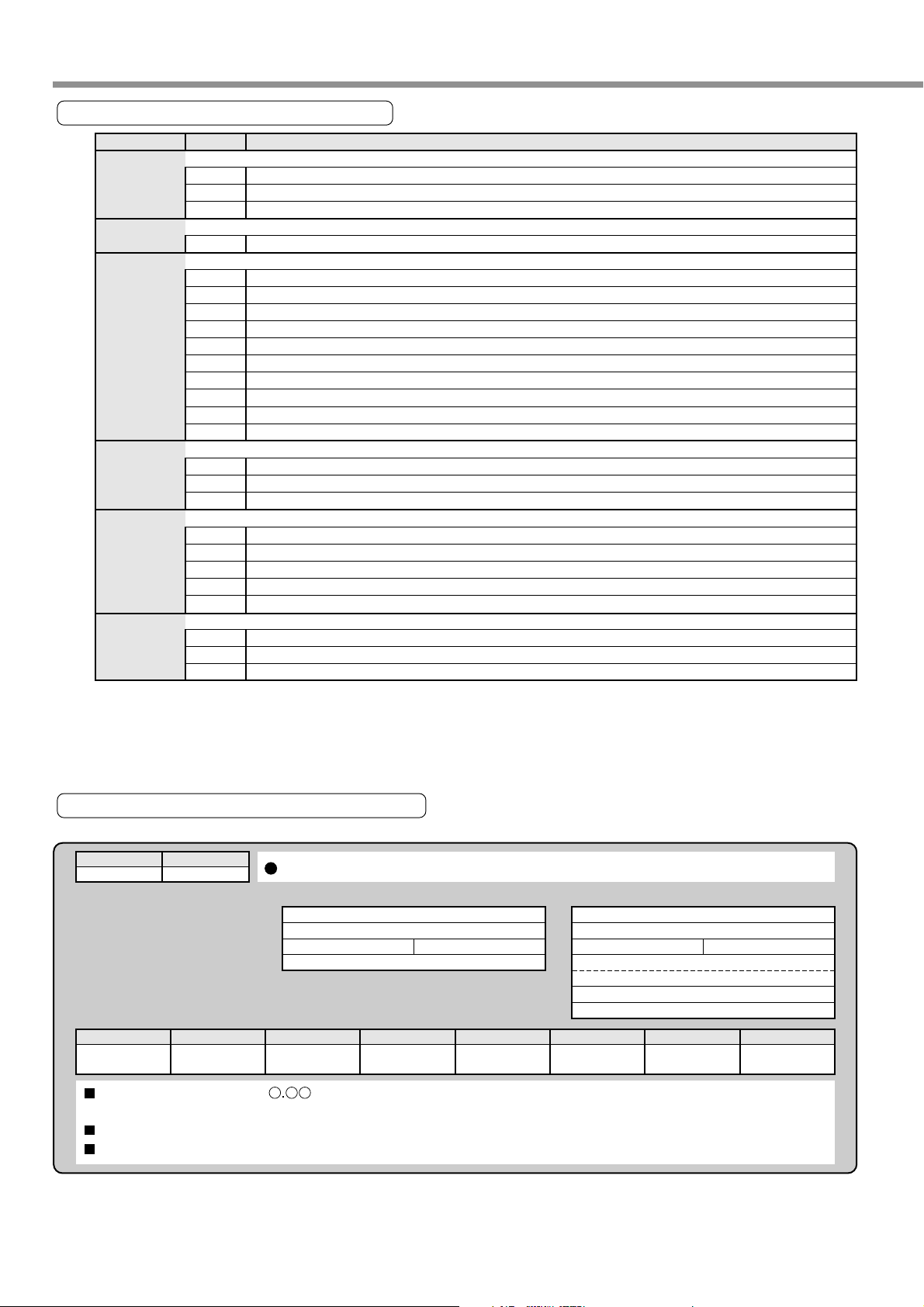

List of Communications Commands

command

0

1

2

8

9

B

mode

1

5

6

1

0

1

2

4

5

6

7

8

9

A

0

1

4

0

1

2

3

4

0

1

2

Description

NOP

Readout of CPU version

Readout of the driver model name

Readout of the motor model name

INIT

Setting of protocol parameters

POS, STATUS, I/O

Readout of status

Readout of the command pulse counter

Readout of the feedback pulse counter

Readout of current speed

Readout of current torque output

Readout of the current deviation counter

Readout of input signal

Readout of output signal

Readout of current speed/torque/deviation counter

Readout of status/input signal/output signal

PARAMETER

Individual readout of parameters

Individual writing of parameters

Writing of parameters to EEPROM

ALARM

Readout of current alarm data

Individual readout of alarm history

Batch readout of alarm history

Alarm history clear (also on EEPROM)

Alarm clear

PARAMETER

Individual readout of user parameters

Page readout of user parameters

Page writing of user parameters

<Note>

Be sure to use the above commands only. We could not guarantee proper operation of the driver when you

transmit a command not listed above.

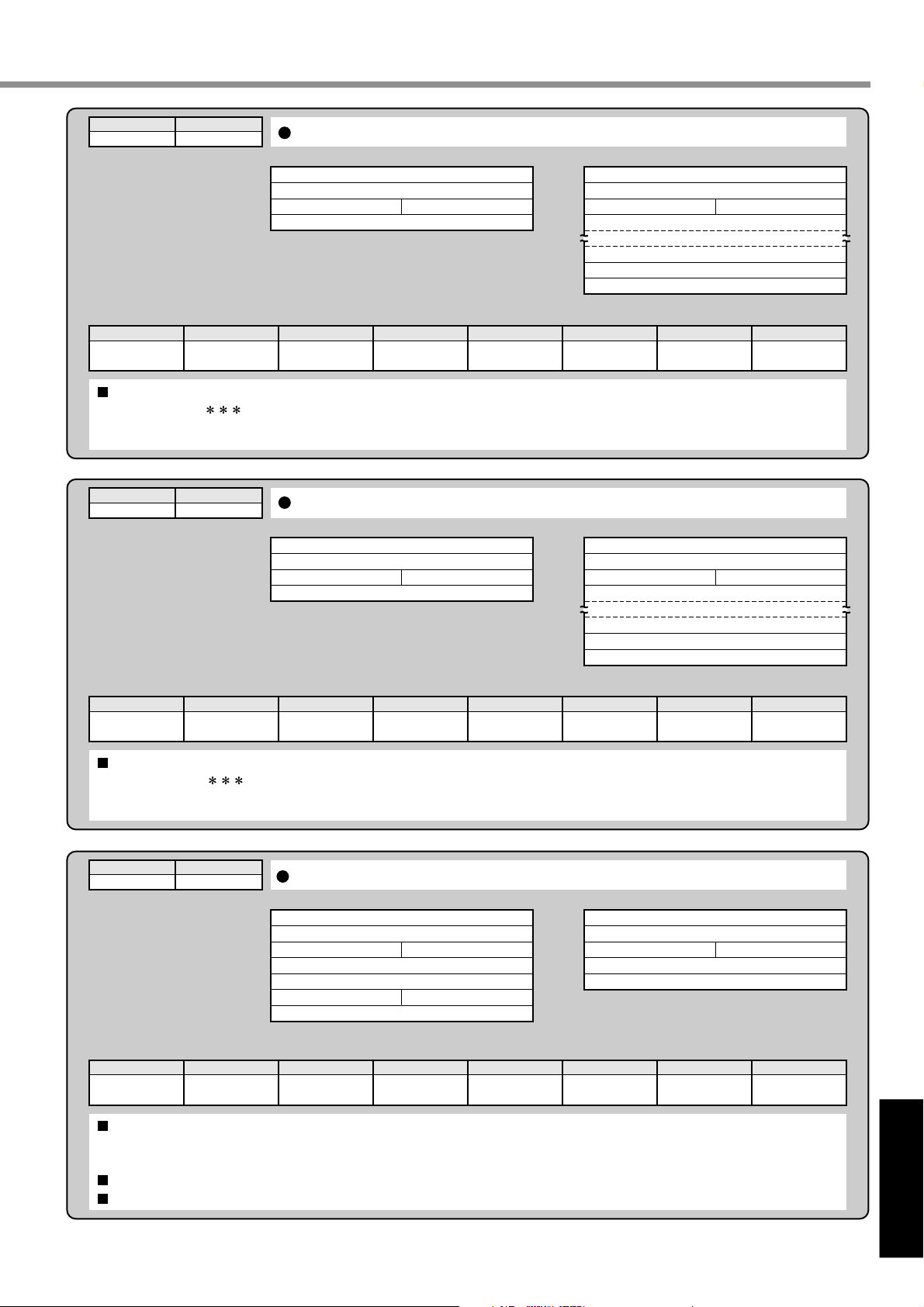

Details on Communications Commands

command

0

Error code

bit7

0 : Normal

1 : Error

For version information, Ver. is divided into high order data and low order data and sent back. (The decimal point

returns low-order 4 bits of the high order data as "0".)

A version is expressed by digits of 0 to 9 (Example: Ver.3.13 is composed of high order data 30h and low order data 13h).

This indicates the CPU version.

mode

1

65

Readout of CPU version information

Received data

Command error

Transmitted data

0

axis

01

checksum

43210

Version (high order)

3

axis

01

(low order)

Error code

checksum

166

Page 13

[Reference]

Reference

command

0

Error code

bit7

0 : Normal

1 : Error

mode

5

65

Readout of the driver model name

Command error

Received data

0

axis

05

checksum

43210

The driver model name is 12 characters and transmitted by ASCII code.

ex. "MKDET1505 "

command

0

mode

6

Readout of the motor model name

Received data

0

axis

06

checksum

Transmitted data

0Dh

axis

05

Driver Model Name (high order)

Driver Model Name (low order)

Error code

checksum

Transmitted data

0Dh

axis

06

Motor Model Name (high order)

Error code

bit7

0 : Normal

1 : Error

65

Command error

43210

The motor model name is 12 characters and transmitted by ASCII code.

ex. "MUMA012P1 "

command

1

Error code

bit7

0 : Normal

1 : Error

mode

1

65

Setting of RS232C protocol parameters

Command error

Received data

3

axis

11

T1

T2

RTYM/S

checksum

43

RTY error

T2 error

Motor Model Name (low order)

Error code

checksum

Transmitted data

1

axis

Error code

checksum

2

1

T1 error

11

0

M/S error

Setting of the previous protocol parameters remains valid until execution of this command completes. The updated parameter setting will be

valid from a next command after execution of this command.

M/S=0 indicates "SLAVE" mode, while M/S=1 indicates "MASTER".

The RTY code is 4 bit and M/S is 1 bit.

Unit of T1 and T2 are 0.1 second and 1 second, respectively.

167

Page 14

Communications

command

2

Status

bit7 6 5

Error code

bit7

0 : Normal

1 : Error

mode

0

65

Readout of status

CCW

Torque being output

Command error

The control modes are defined as follows:

0

High speed response positioning control mode

1

Internal velocity control mode

2

High function positioning control

command

2

mode

1

Readout of the command pulse counter

Received data

0

axis

checksum

4

CW

Torque being output

43210

Received data

0

axis

checksum

20

CCW

rotating

21

Transmitted data

3

axis

20

Control mode

Status

Error code

checksum

3

CW

rotating

2

1

Less than DB

permission speed

Transmitted data

5

axis

Counter value L

0

Torque being

limited

21

H

Error code

Error code

bit7

0 : Normal

1 : Error

65

Command error

43210

checksum

A current command position is expressed by absolute coordinates from the start-up time. (Cumulative sum of the number of

command pulses)

The counter value is 32 bits.

For the counter value, "-" indicates CW and "+" indicates CCW.

168

Page 15

[Reference]

Reference

command

2

Error code

bit7

0 : Normal

1 : Error

mode

2

65

Readout of the feedback pulse counter

Command error

Received data

0

axis

checksum

4

Transmitted data

5

axis

22

Counter value L

H

Error code

checksum

3210

22

A current position of the feedback pulse counter is expressed by absolute coordinates from the start-up time.

For the counter value, "-" indicates CW and "+" indicates CCW.

The feedback pulse counter indicates a cumulative sum of pulses of the position detector, which corresponds to a position of

the motor that really moves.

command

2

mode

4

Readout of current speed

Received data

0

axis

checksum

Transmitted data

3

axis

24

Data (current speed) L

H

Error code

checksum

24

Error code

bit7

0 : Normal

1 : Error

6543210

Command error

This command is used to read current speed (unit [r/min]).

An output value is 16 bits.

For the counter value, "-" indicates CW and "+" indicates CCW.

command

2

Error code

bit7

0 : Normal

1 : Error

mode

5

6543210

Readout of current torque output

Received data

0

axis

25

checksum

Command error

This command is used to read current torque output (unit: to be converted as rated torque = 2000).

An output value is 16 bits.

Transmitted data

3

axis

25

Data (torque) L

H

Error code

checksum

169

Page 16

Communications

command

2

Error code

bit7

0 : Normal

1 : Error

mode

6

65

Readout of the current deviation counter

Command error

Received data

0

axis

checksum

4

Transmitted data

5

axis

26

Data (deviation) L

H

Error code

checksum

3210

This command is used to read a current value of the deviation counter. (unit [pulse])

An output value is 32 bits.

"+" indicates that the encoder is in CW direction and "-" indicates that the encoder is in CCW direction relative to the position

command.

command

2

mode

7

Readout of input signal

Received data

0

axis

checksum

Transmitted data

5

axis

27

Data L

26

27

Error code

checksum

Error code

bit7

0 : Normal

1 : Error

Data

bit7

Reserved

bit15

Reserved

bit23

Reserved

bit31

Reserved

6543210

6

Command dividing/

multiplier switching

14

Reserved

22

Reserved

31

Reserved

Command error

5

Zero speed

clamp

13

Internal velocity

command selection 2

21

Reserved

29

Reserved

4

Control mode

switching

12

Internal velocity

command selection 1

20

Reserved

28

Reserved

3

CCW overtravel

inhibited

11

Reserved

19

Reserved

27

Reserved

21

CCW overtravel

inhibited

10

Counter cleared9Gain switching8Reserved

18

Reserved

26

Reserved

Alarm cleared0Servo-ON

Reserved

Reserved

For "CW overtravel inhibited", "CCW overtravel inhibited" and speed zero clamp, "1" indicates the open status.

For other input signals, "0" indicates the open status.

Data H

17

25

16

Reserved

24

Reserved

170

Page 17

[Reference]

Reference

command

2

Warning data

bit7 Overload

bit5 Over-regeneration

bit0 Battery

Error code

bit7

0 : Normal

1 : Error

Data

bit7

Reserved

bit15

Reserved

bit23

Reserved

mode

8

6543210

6

Reserved

14

Reserved

22

Reserved

Readout of output signal

Received data

0

axis

checksum

Command error

5

Torque being

limited

13

Dynamic brake

activated

21

Reserved

Zero speed

detected

Reserved

Reserved

12

20

Transmitted data

7

axis

28

Data L

Data H

Warning data L

H

Error code

checksum

4

3

Electromagnetic

brake released

11

Reserved

19

Reserved

21

Positioning

completed

10

Reserved

18

Reserved

Servo alarm

9

Speed achieved8Reserved

17

Reserved

28

0

Servo ready

16

Reserved

bit31

Reserved

31

Reserved

Reserved

29

28

Reserved

Reserved

The following table shows the relation between each signal and operation.

Signal

Servo ready

Servo alarm

In positioning completed

Electromagnetic brake released

Zero speed detected

Torque being limited

Achieved speed

Dynamic brake activated

command

2

mode

9

Positioning not completed

Electromagnetic brake running

Zero speed not detected

Torque not being limited

Not achieved speed

Dynamic brake released

Readout of current speed/torque/deviation counter

0

not Ready

Normal condition

Received data

0

axis

29

checksum

27

26

Reserved

1

Servo ready

Abnormal condition

Positioning being completed

Electromagnetic brake released

Zero speed detected

Torque being limited

Speed being achieved

Dynamic brake being activated

25

Reserved

Transmitted data

9

axis

Data L

(Speed) H

Data L

(Torque) H

Data L

24

Reserved

29

Error code

bit7

0 : Normal

1 : Error

65

Command error

43210

The speed and torque output values are 16 bits and deviation output value is 32 bits.

The unit and sign of output data are same for command Nos. 24, 25, and 26.

171

(Deviation) H

Error code

checksum

Page 18

Communications

command

2

Error code

bit7

0 : Normal

1 : Error

mode

A

65

Readout of status/input signal/output signal

Command error

Received data

0

axis

checksum

43210

Transmitted data

0Dh

axis

2A

Control mode

Status

Input signal L

Input signal H

Output signal L

Output signal H

Warning data L

Warning data H

Error code

checksum

Meanings of each bit for control mode, status, input signal, output signal, and warning data are same as those of command

No.20 (command=2, mode=0), 27 (mode=7), and 28 (mode=8).

2A

172

Page 19

[Reference]

Reference

command

8

Error code

bit7

0 : Normal

1 : Error

command

8

mode

0

65

mode

1

Individual readout of parameters

Command error

Individual writing of parameters

Parameter value L

H

Received data

1

axis

Parameter No.

checksum

43

Received data

3

axis

Parameter No.

checksum

80

No. error

81

Transmitted data

3

axis

80

Parameter value L

H

Error code

checksum

210

Transmitted data

1

axis

81

Error code

checksum

Error code

bit7

0 : Normal

1 : Error

Data error

6

5

Command error

4

No. error

3

210

This command just changes a parameter temporarily. If you wish to write to EEPROM, execute writing to EEPROM of

parameter (mode=4)

Be sure to set 0 to unused parameters. Otherwise, data error will occur.

command

8

Error code

bit7

0 : Normal

1 : Error

mode

4

6543210

Data error Command error

Writing of parameters to EEPROM

Received data

0

axis

84

checksum

Transmitted data

1

axis

Error code

checksum

Control LV

This command is used to write a set parameters to EEPROM.

Transmission data will be returned after completion of EEPROM writing.

Writing to EEPROM may take approx. 5 seconds max. (if all parameters are changed).

When writing of parameters fails, data error will occur.

When control power supply LV is detected, control LV of error code will be returned, and parameter writing will be disabled.

84

173

Page 20

Communications

command

9

Error code

bit7

0 : Normal

1 : Error

mode

0

6543210

Readout of current alarm data

Received data

Command error

Alarm No. is 0 when no alarm is generated.

(Refer to “Details of Protective Function” on Page 145.)

command

9

mode

1

Individual readout of alarm history

Received data

History No.

0

axis

checksum

1

axis

checksum

Transmitted data

2

axis

90

Alarm No.

Error code

checksum

Transmitted data

3

axis

91

History No.

Alarm No.

Error code

checksum

90

91

Error code

bit7

0 : Normal

1 : Error

6543

Command error

No. error

History No.1 to No.14 indicate the 1st to 14th previous alarm history, respectively.

command

9

Error code

bit7

0 : Normal

1 : Error

mode

2

6543210

Batch readout of alarm history

Received data

0

axis

92

checksum

Command error

The command is used to read 14 previous alarm events.

1st previous

2nd previous

14th previous

210

Transmitted data

0Fh

axis

92

Alarm No.

Alarm No.

~

Alarm No.

Error code

checksum

174

Page 21

[Reference]

Reference

command

9

Error code

bit7

0 : Normal

1 : Error

mode

3

6543210

Data error Command error

Alarm history clear

Received data

checksum

0

axis

Transmitted data

1

axis

93

Error code

checksum

Control LV

The command clears history of alarm data.

When the command fails to clear, data error occurs.

When control power supply LV is detected, control LV of error code will be returned, and parameter writing will be disabled.

command

9

mode

4

Alarm clear

Received data

0

axis

checksum

Transmitted data

1

axis

94

Error code

checksum

93

94

Error code

bit7

0 : Normal

1 : Error

6543210

Command error

This command clears the current alarm (only applicable to alarms that can be cleared).

175

Page 22

Communications

command

B

Attribute

bit7

Unused

parameter

bit151413121110 9 8

Error code

bit7

0 : Normal

1 : Error

mode

0

6

Display inhibited5For privileged

6543210

Individual readout of user parameters

Received data

1

axis

B0

Parameter No.

checksum

4

To be changed at

users

Command error No. error

initialization

System related

Transmitted data

9

axis

B0

Parameter value L

H

MIN value L

H

MAX value L

H

Attribute L

H

Error code

checksum

3

210

Read only

command

Attribute

Unused

parameter

B

bit7

mode

1

6

Display inhibited5For privileged

Page readout of user parameters

users

Received data

1

axis

Page No.

checksum

4

To be changed at

initialization

B1

3

System related

Transmitted data

82h

axis

B1

Page No.

Parameter value L

(No.0) H

MIN value L

(No.0) H

MAX value L

(No.0) H

Attribute L

(No.0) H

Parameter value L

(No.0fh) H

MIN value L

(No.0fh) H

MAX value L

(No.0fh) H

Attribute L

(No.0fh) H

Error code

checksum

210

bit15 14

Error code

bit7

0 : Normal

1 : Error

6543210

Data error

13 12 11 10 9 8

Command error No. error

A page number is designated from 0 to 7, and 16 parameters are read from each page designation.

176

Read only

Page 23

[Reference]

Reference

command

B

Error code

bit7

0 : Normal

1 : Error

mode

2

6543210

Data error Command error No. error

Page writing of user parameters

Received data

21h

axis

B2

Page No.

Parameter L

(No.0 value) H

Parameter value L

(No.1 value) H

~

Parameter value L

(No.0fh value) H

checksum

The command writes 16 parameters at once.

Be sure to set 0 to unused parameters. Otherwise, data error will occur.

Transmitted data

2

axis

B2

Page No.

Error code

checksum

177

Page 24

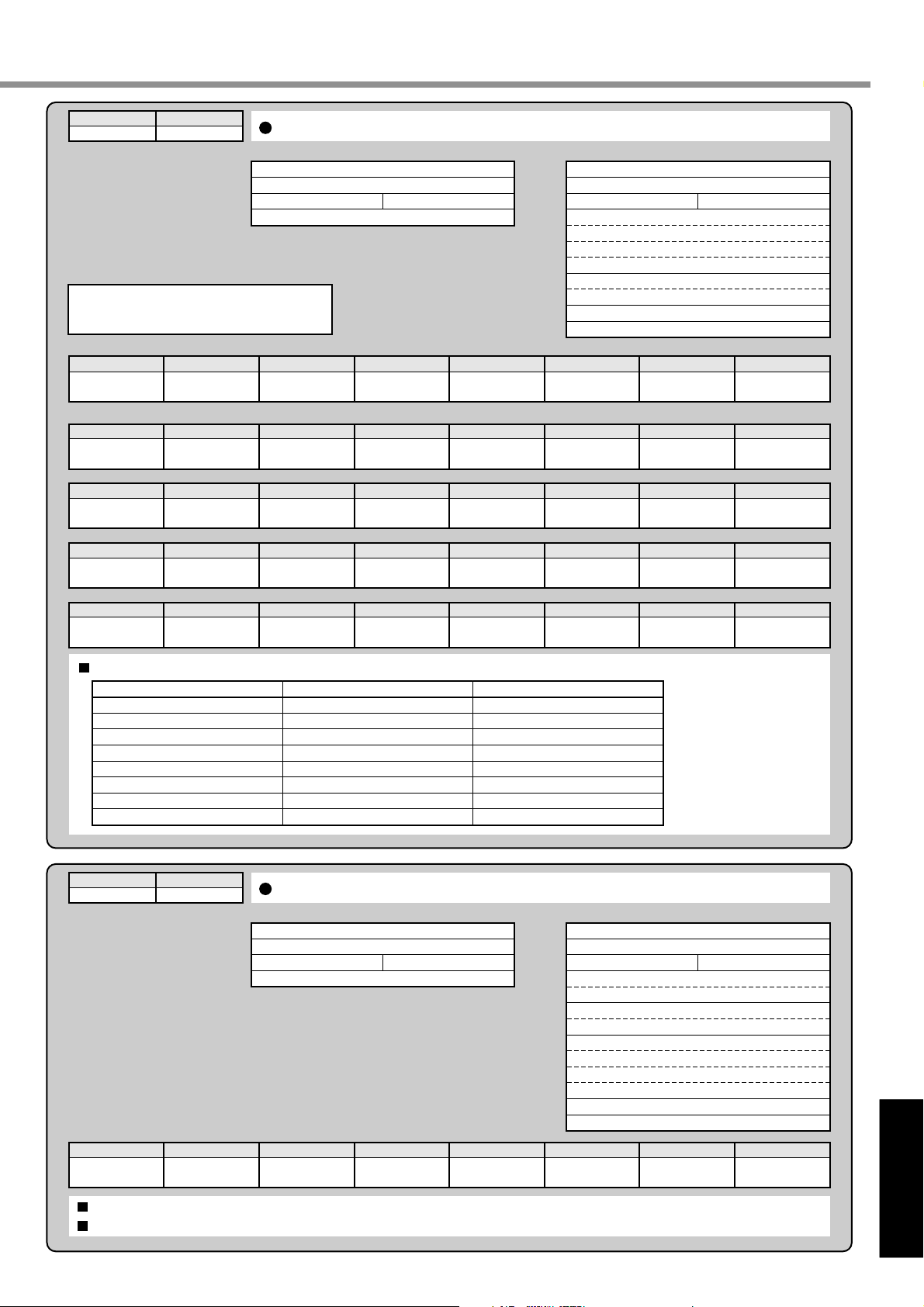

Description on Dividing/Multiplier Ratio

Relation between Positional Resolution/Moving Speed and Command Dividing Multiplier Ratio

Servo driver

Pulse row position

command

Distance: P1 [P]

Traveling speed: F [PPS]

Command dividing multiplier ratio

Pr4A

D =

Pr46 x 2

Pr4B

Rotation speed: N [r/min]

Servo

motor

Gear

Reduction ratio: R

Machine

Encoder

Number of encoder pulses E [P/r]

10000 = (phase A/B 2500 [P/r] x 4)

Example of driving ball screw using the servo motor

As an example of a machine, we describe a ball screw driving system below:

When lead of a ball screw is L [mm], actual distance of a ball screw M [mm] with respect to the distance command

PI [P] is expressed with formula (1) below:

M = P1 x (D/E) x (1/R) x L................................. (1)

Therefore, position resolution (distance DM per command pulse) is expressed by the following formula (2):

∆∆

∆M = (D/E) x (1/R) x L ....................................... (2)

∆∆

Through transformation of formula (2), a command dividing multiplier ratio D is determined by the formula (3):

∆∆

D = (

∆M x E x R)/L ............................................ (3)

∆∆

In addition, actual traveling speed V [mm/s] of a ball screw with respect to traveling speed command F [PPS] is

expressed by formula (4), and the corresponding motor rotation speed N is determined by formula (5):

V = F x (D/E) x (1/R) x L ................................... (4)

N = F x (D/E) x 60 ............................................. (5)

Through transformation of formula (5), a command dividing multiplier ratio D is determined by the formula (6):

D = (N x E)/(F x 60) ........................................... (6)

<Remarks>

1. Set the positional resolution (∆M) at approx. 1/5 to 1/10 of the positioning accuracy (∆ε), in view of mechanical

errors.

2. Set a value from 1 to 10000 to Pr46 and Pr4B.

3. You can set any value depending on numerator and denominator settings. However, if you specify an extreme

dividing/multiplier ratio, we cannot guarantee proper operation of the motor. We recommend that you set the

dividing/multiplier ratio in the range of 1/50 to 20 times.

4.

n

2

0

2

1

2

2

2

3

2

4

2

5

2

6

2

7

2

8

2

9

2

10

2

11

2

12

2

13

2

14

2

15

2

16

2

17

2

Decimal

1

2

4

8

16

32

64

128

256

512

1024

2048

4096

8192

16384

32768

65536

131072

178

Page 25

[Reference]

Reference

Example

Lead of ball screw L = 10mm

Reduction ratio R=1

Position resolution

1

∆M = 0.005mm

For the encoder of 2500 P/r

(E=10000P/r)

Lead of ball screw L = 20mm

Reduction ratio R=1

Position resolution

2

∆M = 0.005mm

For the encoder of 2500 P/r

(E=10000P/r)

Example

Command dividing

multiplier ratio

D =

0.005 x 10000 x 1

= 5

D =

0.0005 x 10000 x 1

= 0.25

Motor rotation speed (r/min)

10

20

D =

∆M x E x R

L

Determine

parameters Pr46,

Pr4A and Pr4B so

that D=5. Consider

the following:

D =

D<1 is not

appropriate to

determination of

the accuracy.

... Formula (3)

10000 x 2

0

2000

N = F x x 60

D

E

Pr4A

Pr4B

D =

Pr46 x 2

Pr46 = 10000

Pr4A = 0

Pr4B = 2000

D = 1 is a condition

of minimum

resolution.

... Formula (5)

Lead of ball screw L= 20mm

Reduction ratio R=1

Position resolution

∆M = 0.005mm

Line driver pulse input

500 kpps

For the encoder of 2500 P/r

To make motor rotation speed

3000 r/min under the same

condition as above, with lead of

ball screw of L = 20 mm and the

line driver pulse input of 500 kpps.

D =

0.005 x 10000 x 1

20

... Formula (3)

= 25

N = 500000 x x 60

2.5

10000

... Formula (5)

= 7500

Thus, motor specification is not met.

Command dividing

multiplier ratio

D =

N x E

F x 60

... Formula (6)

Determine

parameters Pr46,

Pr4A and Pr4B so

D = = 1

3000 x 10000

500000 x 60

that D=1. Consider

the following:

0

D =

10000 x 2

10000

Then, distance per command pulse (mm) is as follows:

(position resolution)

D

∆M = x x L = x x 20 = 0.002mm

1

E

R

1

10000

1

1

Pr46 x 2

D =

Pr4B

Pr46 = 10000

Pr4A = 0

Pr4B = 10000

Pr4A

179

Page 26

Conformance to EC Directives/UL Standards

EC Directives

The EC Directives apply to all such electronic products as those having specific functions and directly sold to

general consumers in EU countries. These products are required to meet the EU unified standards and to be

furnished with CE Marking.

However, our AC servo meet the EC Directives for Low Voltage Equipment so that the machine or equipment

comprising our AC servo can meet relevant EC Directives.

EMC Directives

Our servo systems can meet EMC Directives and related standards. However, to meet these requirements, the

systems must be limited with respect to configuration and other aspects, e g. the distance between the servo driver

and motor is restricted, and some special wiring conditions must be met. This means that in some cases machines

and equipment comprising our servo systems may not satisfy the requirements for wiring and grounding conditions

specified by the EMC Directives. Therefore, conformance to the EMC Directives (especially the requirements for

emission noise and noise terminal voltage) should be examined based on the final products that include our servo

drivers and servo motors.

Applicable Standards

Subject

Motor

Motor and

driver

IEC: International Electrotechnical Commission

EN: Europaischen Normen

EMC: Electromagnetic Compatibility

Applicable standard

IEC60034-1

EN50178

EN55011 Radio Disturbance Characteristics of Industrial, Scientific

EN61000-6-2 General standards for immunity in industrial environment

IEC61000-4-2 Electrostatic Discharge Immunity Test

IEC61000-4-3 Radio Frequency Electromagnetic Field Immunity Test

IEC61000-4-4 Electric High-Speed Transition Phenomenon - Burst Immunity

IEC61000-4-5 Lightning Surge Immunity Test

IEC61000-4-6 High Frequency Conduction Immunity Test

IEC61000-4-11 Instantaneous Outage - Immunity Test

and Medical (ISM) Radio Frequency Equipment

Te st

Standards referenced

by Low-Voltage

Directives

Standards

referenced by

EMC Directives

180

Page 27

[Reference]

Reference

Peripheral Equipment

Environment

The servo driver should be used under Contamination Level 2 or 1 specified by IEC60664-1 (housing the driver in

an IP54 control box).

Control box

Controller

Power supply for

insulated type

Powe r

Insulating

transformer

Circuit

breaker

Leakage

breaker(RCD)

interface

Noise filter for

signal lines

CN X1

Noise filter

Surge

absorber

Protective earth (PE)

AC ser vo

driver

L1

L2

L3

CN X5

Noise filter for

signal lines

CN

X3

U

V

W

E

CN X4

AC servo

driver

M

RE

Power

+ 10%

Single-phase 100V: Single-phase 100V to 115V 50/60Hz

- 15 %

+ 10%

Single-phase 200V: Single-phase 200V to 240V 50/60Hz

- 15 %

+ 10%

Three-phase 200V: Three-phase 200V to 240V 50/60Hz

- 15 %

(1) Use under the environment of Over-voltage Category II specified by IEC60664-1

In order to realize the environment of overvoltage category II, install in the power supply input unit an insulating

transformer that is compliant with ICE or EN standard (EN 60742).

(2) The power for interface should be marked CE or appropriate EN Standard type (EN60950), 12VDC to 24VDC,

insulated.

+ 10%

- 15 %

+ 10%

- 15 %

+ 10%

- 15 %

Circuit Breaker

Install a circuit breaker between the power supply and noise filter. The circuit breaker should be IEC Standard and

UL listed marked.

181

Page 28

Conformance to EC Directives/UL Standards

Noise Filter

When, one set of noise filters is installed in the power unit with two or more drivers, be sure to consult with the noise

filter manufacturer.

Option Part No.

DV0P4160

Manufacturer’s part No.

3SUP-HU10-ER-6

Manufacturer

Okaya Electric

Industries Co., Ltd.

Surge Absorber

Install the surge absorber on the primary line of the noise filter.

<Note>

When conducting voltage-resistant test on the machine/equipment, remove the surge absorber.

Otherwise the absorber may be damaged.

Circuit diagram

Option Part No.

DV0P1450

Manufacturer’s part No.

R•A•V-781BXZ-4

Manufacturer

Okaya Electric

Industries Co., Ltd.

182

Page 29

[Reference]

Reference

Noise Filter for Signal cables

Provide all the cables (power supply cable, motor cable, encoder cable, interface cable) with the noise filter for

signal cable.

Grounding

Option Part No.

DV0P1460

Weight: 62.8 g

Manufacturer’s part No.

ZCAT3035-1330

Manufacturer

TDK Co., Ltd.

(1) Don’t fail to connect the servo driver protective earth terminal ( ) and the protective earth plate of the control

panel together.

(2) When connecting to the protective earth terminal ( ), avoid co-clamping. Two protective earth terminals are

provided.

Leakage Breaker

Connect Type-B leakage breaker (RCD) to the primary power supply of the servo driver.

Driver and Peripheral Devices Applied Thereto (EC Directives)

For the detail refer to “System Configuration and Wiring“, Page 26.

Install the noise filters in reference to DV0P4160 (page 182).

Conformance to UL Standards

The noise filters conform to UL508C (File No. E164620) to satisfy the following conditions.

(1) The servo driver should be used under Contamination Level 2 or 1 specified by IEC60664-1 (housing the driver

in an IP54 control box).

(2) Install a circuit breaker or fuse between the power supply and noise filter. The circuit breaker or fuse should be

a UL listed mark ( ) type.

The current rating of the circuit breaker or fuse should be per the table in page 26.

183

Page 30

Optional Parts

MINAS-E Series Table of Junction Cable by Model

Figure No.

Motor Type

2-1

MUMA50W - 400W

3-1

4-1

Junction Cable for Encoder

Figure 2-1 MFECA0 * * 0EAM

(16)

(14)

(4) (4)

Manufactured by Tyco Electronics AMP K.K.

Connector 172160-1

Pin 170365-1

Junction Cable

For an encoder (2500 P/r 5 wires)

Incremental

For a motor

For a brake

L

(20)

(ø9.2)

Part No.

MFECAO * * OEAM

MFMCAO * * OAEB

MFMCBO * * OGET

L (m)

3

5

10

20

Manufactured by Molex Incorporated

Connector 55100-0600

Part No.

MFECA0030EAM

MFECA0050EAM

MFECA0100EAM

MFECA0200EAM

Junction Cable for Motors (Robotop® 600V DP)

Figure 3-1 MFMCA0 * * 0AEB

(12.0)

(4) (4)

(10.0)

(50) (50)

Manufactured by Tyco Electronics AMP K.K.

Connector 172159-1

Pin 170362-1

or 170366-1

L

(ø11)

Junction Cable for Brakes (Robotop® 600V DP)

Figure 4-1 MFMCB0 * * 0GET

(10.0)

(40) (50)

(12.0)

(5.6)

Manufactured by Tyco Electronics AMP K.K.

Connector 172157-1

Pin 170362-1

or 170366-1

L

(ø9.8)

Manufactured by Molex Incorporated

Connector 5557-06R-210

Pin 5556PBTL

For pressure

connection terminal M4

Robotop® is a trade mark of

Daiden Co., Ltd.

L (m)

3

5

10

20

L (m)

3

5

10

20

Part No.

MFMCA0030AEB

MFMCA0050AEB

MFMCA0100AEB

MFMCA0200AEB

Part No.

MFMCB0030GET

MFMCB0050GET

MFMCB0100GET

MFMCB0200GET

184

Page 31

Reference

Connector Kits for Power Supply of the Driver

(1) Part No. DV0P2870

(2) Components

[Reference]

Name

Connector (10P)

Connector Pin

Manufacturer’s part No.

5557-10R-210

5556PBTL

Number

1

6

Manufacturer

Molex Incorporated

Remarks

For connector CN X1

(pin 10)

(3) Pin arrangement of connector for CN x 1

10

(NC)

L1

4

5

(NC)

P

(4) Recommended manual pressure bonding tool

(Customers are requested to provide it by

themselves.)

L2

3

B

L3

(NC)

1

2

E

(NC)

Manufacturer’s part No.

57026-5000

57027-5000

Wire rod

UL1007

UL1015

6

7

8

9

<Cautions>

1. The above table shows arrangement of pins viewed from the pin inserting direction of the connector.

Also check pin Nos. carved on the main body of the connector so as to avoid incorrect wiring.

2. For wiring and connection, refer to “System Configuration and Wiring”, Wiring of Main Circuits (Page

27).

3. You should leave a pin labeled with (NC) unconnected.

185

Page 32

Optional Parts

Connector Kits for Connection of Motor and Encoder

Used for: MUMA 50W to 400W Incremental

2500 pulse 5-wire

(1) Part No. DV0P3670

(2) Components

Name

Connector

Connector (6P)

Connector pin

Connector (4P)

Connector pin

Connector (6P)

Connector pin

Manufacturer’s part No.

55100-0600

172160-1

170365-1

172159-1

170366-1

5557-06R-210

5556PBTL

Number

1

1

6

1

4

1

4

Manufacturer

Molex Incorporated

Manufactured by

Tyco Electronics AMP K.K.

Manufactured by

Tyco Electronics AMP K.K.

Molex Incorporated

Remarks

For connector CN X4

(pin 6)

For junction of encoder

cable

(pin 6)

For junction of motor

power line (pin 4)

For connector CN X3

(pin 6)

<Note>

You may use parts of other manufacturer equivalent to the above parts for such components as connector, connec-

tor cover, etc.

(3) Pin arrangement of connector CN X4 plug

2 0V1 +5V

4 0V3 +5V

6 Tx/Rx5 Tx/Rx

(Case FG)

(4) Recommended manual

pressure bonding tool

(A customer is requested to

provide it by himself.)

Name

For junction of encoder cable

For junction of motor power line

For connector CN X3

Manufacturer’s part No.

755330-1

755331-1

57026-5000

57027-5000

Manufacturer

Tyco Electronics AMP K.K.

Molex Incorporated

Wire rod

UL1007

UL1015

<Cautions>

1. The above figure shows the pin arrangement viewed from the soldering side of the connector.

Also check pin Nos. carved on the main body of the connector so as to avoid incorrect wiring.

2. Be sure to connect shield of the shielded wire to be used to the case (FG).

3. For wiring and connection, refer to “System Configuration and Wiring”, Connector CNX4 (Page 29).

186

–

Page 33

Reference

(5) Pin arrangement of connector for junction of encoder cable

[Reference]

1

(NC)

4

+5V

2

TX/RX

5

0V

3

TX/RX

6

FG

(6) Pin arrangement of connector for junction of motor power line

1

U

3

W

2

V

4

E

(7) Pin arrangement of connector for connector CN X3

6

W

3

E

5

(NC)

2

(NC)

4

V

1

U

<Cautions>

1. The above table shows arrangement of pins viewed from the pin inserting direction of the connector.

Also check pin Nos. carved on the main body of the connector so as to avoid incorrect wiring.

2. For wiring and connection, refer to “System Configuration and Wiring”, Wiring of Main Circuits (Page

27).

187

Page 34

Optional Parts

Connector Kit for Connection with Host Controller

(1) Part No. DV0P0770

(2) Components

Name

Connector

Connector Cover

Manufacturer’s part No.

10126-3000PE

10326-52A0-008

Number

1

1

Manufacturer

Sumitomo 3M Ltd

Remarks

For CN X5

(Pin 26)

(3) Pin arrangement of connector X5 (pin 26) (viewed from the soldering side of the connector)

14

GND16OA–18OB–20OZ–22PULS124SIGN126FG

15

OA+17OB+19OZ+21CZ23PULS225SIGN2

1

COM+3A-CLR

2

4

SRV-

CL

ON

7

5

GAIN

CWL9ALM11BRK-

ZEROSPD

6

DIV

INTSPD1INTSPD2

8

CCWL10COIN12WARN

OFF

13

COM–

<Cautions>

1. When wiring, also check pin Nos. carved on the main body of the connector.

2. For codes representative of signal names in the above table or functions of signals, refer to Wiring to

Connector CN X5 (Page 30, 67 and 105).

Interface Cable for Connection with Host Controller

(1) Part No. DV0P0800

(2) Outline dimension

2000

Shell Kit : 10326-52AO-008

Sumitomo 3M Ltd or item equivalent to it

39

12.7

50

2614

37.2

113

Plug : 10126-3000PE

Sumitomo 3M Ltd or item equivalent to it

14

(3) Table of Wiring

Pin No.

1

2

3

4

5

6

7

8

9

Signal Name

COM+

SRV-ON

A-CLR

CL/INTSPD2

GAIN/ZEROSPD

DIV/INTSPD1

CWL

CCWL

ALM

Color of Core Wire

Orange (red 1)

Orange (black 1)

Gray (red 1)

Gray (black 1 )

White (red 1)

White (black 1)

Yellow (red 1)

Yellow (black 1 )

Pink (red 1)

Pin No.

10

11

12

13

14

15

16

17

18

Signal Name

COIN

BRK-OFF

WARN

COM

-

GND

OA+

OA

-

OB+

-

OB

Color of Core Wire

Pink (black 1)

Orange (red 2)

Orange (black 2 )

Gray (red 2)

Gray (black 2)

White (red 2)

White (black 2)

Yellow (red 2)

Yellow (black 2)

Pin No.

19

20

21

22

23

24

25

26

Signal Name

OZ+

OZ

-

CZ

PLUS1

PLUS2

SIGN1

SIGN2

FG

Color of Core Wire

Pink (red 2)

Pink (black 2)

Orange (red 3)

Gray (red 3)

Gray (black 3)

White (red 3)

White (black 3)

Orange (black 3)

<Remarks>

• For example, the color of the wire, Orange (Red 1) means that the lead wire is colored in orange with one red dot

mark.

• The shield of this cable is not connected with the terminal of the connector.

Please use the connector kit for connection with Host Controller when you connect the shield with FG or GND on

the driver side.

188

Page 35

Reference

Communications Cable (Connection with Personal Computer)

(1) Part No. DV0P 1960 (for DOS/V compatible machines)

[Reference]

33

2000

18

Mini DIN8P

D sub connector 9P

MD connector

For pin arrangement of CN X6, see Page 159.

“PANATERM®”, software for communications control

(1) Part No. DV0P4230 (Japanese version) DV0P4240 (English version)

(2) This is supplied in the form of a 3.5 inch floppy disk.

<Cautions>

For details on the operating environment or others, refer to the operating instructions of “PANATERM®”.

For information on latest version, please contact us.

Console

Part No. DV0P3690

MODE

M

S

SET

(62)

MINAS

DIGITAL AC SERVO

SHIFT

(1500)

(15)

(114)

DIN8P mini

MD connector

(24)

Nameplate

M3

depth 5

(15)

Insert screw

Screw down with a tightening

torque of no more than 0.5

N•m.

189

Page 36

Optional Parts

External Regenerative Resistor

Part No.

DV0P2890

DV0P2891

Manufacturer’s

model name

45M03

45M03

Ohmic Value

50 Ω

100 Ω

Specification

Rated Power

10W

10W

Operating Temperature for

Built-in Temperature Fuse

130±2˚C

130±2˚C

Remarks

(Specifications for

the driver voltage)

For single-phase 100V

For single-phase/

three-phase 200V

Manufactured by: IWAKI MUSEN KENKYUSHO CO., LTD.

<Note>

For safety reasons, the external regenerative resistor has a built-in temperature fuse. The built-in

temperature fuse may be disconnected depending on heat dissipation conditions, range of use

temperatures, supply voltage, and load variations.

4.3

57

<Cautions>

The regenerative resistor may be hot.

Take preventive actions against a fire and burn.

Do not mount the regenerative resistor in the vicinity

of an inflammable object or in a place where an

60

52

300

operator may easily touch it by hand.

4.3

65

10

DIN Rail Mounting Unit

(1) Part No. DV0P3811

(2) Outline Dimension

5130.5

140

Female terminal

5556PBTL

(or 5556PBT)

t0.6

<Remarks>

• Two mounting screws (M4 x length 8, pan head

35

20

2-M4 bar ring

(for mounting screws)

(6)

machine screws) are supplied.

• * When extended, the rail stopper is 10mm long.

<Note>

For installation and removal, refer to “Installation” of

Before Use edition on Pages 18 to 19.

Mounting plate

(7)

*

Rail stop

(6)

190

Page 37

Reference

Reactor

[Reference]

Driver

Outline

Frame

Code

MKDE

MLDE

Voltage

Specification

for Power

Source of

Driver

Single-

phase

100V

Single-

phase

200V

Three-

phase

200V

Single-

phase

100V

Single-

phase

200V

Three-

phase

200V

Rated Output

50 - 100W

50 - 100W

50 - 200W

200W

200 - 400W

400W

Reactor Part No.

DV0P227

DV0P220

DV0P228

DV0P220

Figure

1

2

1

2

Figure 1

Figure 2

2-I

C

A

(Mounting dimension)

B

YXZ

NP

SRT

A

(Mounting dimension)

B

4-H

C

D

D

4-H

E

F

(Mounting

dimension)

G

E6-I

F

(Mounting

dimension)

G

Figure

1

2

Part No.

DV0P227

DV0P228

DV0P220

55

65

A

B

80

125

68

83

C

D

90

118

E

90

145

41

70

F

G

55

85

H

ø 7

Width 7 x Length 12

I

M4

M4

Inductance

(mH)

4.02

2

6.81

Rated

Current (A)

5

8

3

• The former Agency of Natural Resources and Energy of Ministry of International Trade and Industry (present

Ministry of Economy, Trade and Industry) established higher harmonics suppression guidelines in September

1994.

(1) Drivers rated 4kW or lower are subject to “Higher Harmonics Suppression Guidelines for Home Electric and

General Purpose Appliances”.

(2) Drivers rated over 4kW are subject to “Higher Harmonics Suppression Guidelines for High Voltage and Special

Customers”.

• The Ministry of Economy, Trade and Industry strongly demands manufacturers to enforce measures to curb

harmonics.

In order to comply with the established regulatory level, connect a power-factor improvement reactor (L) to drivers

of 4 kW or lower. For drivers of over 4kW, determine the level of harmonics according to the guideline and take a

suppression measure, as appropriate.

<Reference>

[Harmonics Suppression Technical Guideline], JEAG 9702-1995, Japan Electric Association

[Harmonic Current Calculation Procedure for General-purpose Inverter at Special Customers], JEM-TR201-1996,

Japan Electrical Manufacturers’ Association

191

Page 38

Recommended Parts

Surge Absorber for Motor Brake

Motor Surge Absorber for Motor Brake

MUMA50W - 400W

• C-5A2 or Z15D151

Ishizuka Electronics Corporation

• The recommended parts are specified items to measure the brake release time.

List of Manufacturers of Peripheral Equipment

Manufacturer/Agent Phone Number Equipment

Matsushita Electric Works, Ltd.

Automation Controls Company

IWAKI MUSEN NKENKYUSHO CO., LTD.

Ishizuka Electronics Corporation

Renesas Technology Corpration.

TDK Corporation

Okaya Electric Industries, Co., Ltd.

Sumitomo 3M Ltd

Tyco Electronics AMP K.K.

Japan Molex Incorporated

Daiden Co., Ltd.

+81-6-6908-1131

http://www.mew.co.jp

+81-44-833-4311

http://www.iwakimusen.co.jp/

+81-3-3621-2703

http://www.semitec.co.jp/

+81-6-6233-9511

http://www.renesas.com/jpn/

+81-3-5201-7229

http://www.tdk.co.jp/

+81-3-3424-8120

http://www.okayatec.co.jp/

+81-3-5716-7290

http://www.mmmco.jp

+81-44-844-8111

http://www.tycoelectronics.com/japan/amp

+81-462-65-2313

http://www.molex.co.jp

+81-3-5805-5880

http://www.dyden.co.jp

As of February 2003

No-fuse breaker

Electromagnetic switch

Surge absorber

Regenerative resistor

Surge absorber for holding brake

Noise filter for signal line

Surge absorber

Noise filter

Connector

Cable

192

Page 39

Reference

Dimensional Outline Drawing

Driver (Frame K) Estimated Mass 0.35 kg

[Reference]

Driver (Frame L) Estimated Mass 0.4 kg

193

Page 40

Dimensional Outline Drawing

Motor

MUMA Series 50W to 400W

LL

LFLRLE

LG

200

Sh6

LBh7

MUMA5A P1

MUMA01 P1

MUMA02 P1

Without a brakeWith a brake

MUMA04 P1

MUMA

MUMA5A P1

MUMA01 P1

MUMA02 P1

MUMA04 P1

Output

50W, 100W

200W, 400W

Model LB

Output

(W)

50

100

200

50

100

200

LL

75.5

92.5

96

124400

107

124

129

157400 14

11

14

11

S

22

8

50

22

8

50

LG

230mm

220mm

LE

2

3

2

3

LF

7

7

(Unit: mm)

LR

24

30

24

30

194

Page 41

Reference

Shaft-end Center Tap TP

[Reference]

Without a brakeWith a brake

MUMA

LA

48

70

48

LC

42

60

42

Specification of Keyed Version

(Dimension)

LZ

3.4

4.5

3.4

LW

14

20

25

14

LK

12.5

18

22.5

12.5

KW

3

4

5

3

KH

Output

50W, 100W

200W

400W

(Unit: mm)

RH

3

6.2

4

8.5

5

3

11

6.2

LH

34

43

34

Mass (kg)

0.40

0.50

0.96

1.5

0.60

0.70

Screw

M3

M4

M5

Rotor Moment of Inertia (x10

0.021

0.032

0.10

0.17

0.026

0.036

Depth

6

8

10

-4

kg·m2)

70

60

4.5

20

25

18

22.5

4

5

4

8.5

5

11

43

1.4

1.9

0.13

0.20

195

Page 42

Dimensional Outline Drawing

Allowable Load of Output Shaft

Radial Load Direction (P)

LR/2

Motor

Series

MUMA

Motor Output

50W, 100W

200W, 400W

LR

P

When Assembled In Operation

Radial Load

147

392

Direction A

Thrust Load Directions (A, B)

A

B

Thrust Load

88.2

147

Direction B

117.6

196

Radial Load

M

Unit: N (1kgf = 9.8N)

Thrust Load

Directions A, B

68.6

245

58.8

98

<Remarks>

If a position of load point varies, calculate allowable radial load P (N) from distance L (mm) of a load point

from mounting flange face, based on the relational expression, so that the result of calculation will be as

follows:

Motor

Series

MUMA

L

P

Motor Output

50W, 100W

200W

400W

Relational Expression

of Load - Load Point

1406

P =

L + 7.5

2940

P =

L – 3

5831

P =

L + 8.8

196

Page 43

Reference

Motor Characteristics (S-T Characteristics)

Note that motor characteristics may vary depending on whether or not there is a brake.

The continuous torque — ambient temperature characteristic shows a value when our standard

flange made of aluminum (having about doubled angle of that of the motor flange) is mounted.

They are characteristics without an oil seal.

[Reference]

Motor

Capacity

50W

100W

Supply Voltage of Driver

AC100V

MUMA5AZP1

Supply Voltage of Driver: At AC100V/200V

Torque

[N¥m]

0.5

Instant

Operation Area

0.25

Continuous

Operation Area

0 1000 2000 3000 4000 5000

Rotation Speed [r/min]

MUMA011P1

Supply Voltage of Driver: AC100V

(A dotted line indicates the case in which the supply voltage drops by 10%.)

* Continuous Torque/Ambient

Torque

0.73

1.0

Instant Operation Area

0.58

0.5

Continuous

Operation Area

0 1000 2000 3000 4000 5000

Rotation Speed [r/min]

Temperature

100

95

50

010203040

Rated Torque Ratio [%]

Ambient Temperature [ßC]

With a Brake

AC200V

* Continuous Torque/Ambient Temperature

100

90

50

0 10203040

Ambient Temperature [ßC]

With a Brake

MUMA012P1

Supply Voltage of Driver: AC200V

Torque

1.0

Instant

Operation Area

0.5

Continuous

Operation Area

0 1000 2000 3000 4000 5000

Rotation Speed [r/min]

* Continuous Torque/Ambient

Temperature

100

95

50

0 10203040

Rated Torque Ratio [%]

Ambient Temperature [ßC]

With a Brake

200W

400W

MUMA021P1

Supply Voltage of Driver: AC200V

(A dotted line indicates the case in which the supply voltage drops by 10%.)

* Continuous Torque/Ambient

Torque

2.0

Instant

Operation Area

1.0

Continuous

Operation Area

0 1000 2000 3000 4000 5000

Rotation Speed [r/min]

Temperature

100

90

50

010203040

Rated Torque Ratio [%]

Ambient Temperature [ßC]

With a Brake

MUMA022P1

Supply Voltage of Driver: AC200V

(A dotted line indicates the case in which the supply voltage drops by 10%.)

* Continuous Torque/Ambient

Torque

2.0

1.0

0

Operation Area

Operation Area

Instant

Continuous

1000 2000 3000

Rotation Speed [r/min]

3300

3800

4000

5000

Temperature

100

90

50

0 10203040

Rated Torque Ratio [%]

Ambient Temperature [ßC]

MUMA042P1

Supply Voltage of Driver: AC200V

(A dotted line indicates the case in which the supply voltage drops by 10%.)

Torque

4.0

Instant

Operation Area

2.0

Continuous

Operation Area

0 1000 2000 3000 4000 5000

Rotation Speed [r/min]

* Continuous Torque/Ambient

Temperature

100

90

50

0 10203040

Rated Torque Ratio [%]

Ambient Temperature [ßC]

With a Brake

With a Brake

* In the case of no oil seal and no brake, the rated torque ratio is 100% at ambient temperature of 40ßC.

197

Page 44

Servo Motor with Gear

Checking Model of Servo Motor with Gear

How to check the model

MUMA011P31N

1~4 5~6 7 8 9 10

Symbol

MUMA

Motor Rated Output

Symbol

01

02

04

Specification of Rotary Encoder

Symbol

P

Method

Incremental

Typ e

Ultra low Inertia

Rated Output

100W

200W

400W

Specification

Number of Pulses

2500P/r

Rated Output

Resolution

10000

Lead Wire

5-wire

Structure of the motor

Specifications of

Position/Speed Detector

Voltage Specification

1 : 100V

2 : 200V

Structure of the motor

Holding Brake

Symbol

No Ye s

3

4

Reduction Ratio

Symbol

Reduction Ratio

1N

2N

4N

1/25

1/5

1/9

198

Page 45

[Reference]

Reference

Check the Combination of Driver and Motor with Gear

This driver was designed for use with the motor designated by us.

Check a name of the series, rated output, voltage specification, and encoder specification of the motor you plan to

use.

Incremental Specification 2500 P/r

Applicable Motors with Gear Applicable Drivers

Power Supply

Single Phase

100V

Single Phase

200V

Three-Phase

200V

Motor Rated Output

100W

200W

100W

200W

400W

100W

200W

400W

Reduction Ratio 1/5 Reduction Ratio 1/9 Reduction Ratio 1/25

MUMA011P * 1N

MUMA021P * 1N

MUMA012P * 1N

MUMA022P * 1N

MUMA042P * 1N

MUMA012P * 1N

MUMA022P * 1N

MUMA042P * 1N

<Note>

You must not use any combination other than those listed below.

MUMA011P * 2N

MUMA021P * 2N

MUMA012P * 2N

MUMA022P * 2N

MUMA042P * 2N

MUMA012P * 2N

MUMA022P * 2N

MUMA042P * 2N

MUMA011P * 4N

MUMA021P * 4N

MUMA012P * 4N

MUMA022P * 4N

MUMA042P * 4N

MUMA012P * 4N

MUMA022P * 4N

MUMA042P * 4N

Driver Model

MKDET1110P

MLDET2110P

MKDET1505P

MLDET2210P

MLDET2510P

MKDET1505P

MKDET1310P

MLDET2310P

MLDET2510P

Driver Frame

Frame K

Frame L

Frame K

Frame L

Frame K

Frame L

<Remarks>

The mark "*" under the model name of the applicable motors refer to the structure of motor.

199

Page 46

Dimensional Outline Drawing of Motor with Gear

Servo Motor with Gear

MUMA01 P31N

MUMA01 P32N

MUMA01 P34N

MUMA02 P31N

MUMA02 P32N

MUMA02 P34N

Without a brakeWith a brake

MUMA042P31N

MUMA042P32N

MUMA042P34N

MUMA01 P41N

MUMA

MUMA01 P42N

MUMA01 P44N

MUMA02 P41N

MUMA02 P42N

MUMA02 P44N

MUMA042P41N

MUMA042P42N

MUMA042P44N

Model

* 220 refers to 200W or higher.

Motor

Output

100W

200W

400W

100W

200W

400W

Reduction

Ratio

1/5

1/9

1/25

1/5

1/9

1/25

1/5

1/9

1/25

1/5

1/9

1/25

1/5

1/9

1/25

1/5

1/9

1/25

L LL LM LT KB1 LF LR LQ LB S LP LH J (LG) LE (G)

192

234,5

200.5

235.5

246

263

288.5

223.5

266

233.5

268.5

279

296

321.5

92.5

96

123.5

124

129

156.5

64

69.5

97

95.5

102.5

130

28.5

26.5

28.5

26.5

38.8

34

61.5

38.8

34

61.5

(unit: mm)

32

20

50

12

45

10

14

67.5

50

30

70

19

62

17

22

92

32

20

50

12

45

10

14

72.5

7

50

30

70

19

62

17

61

40

90

24

75

18

32

20

50

12

45

10

50

30

70

19

62

17

32

20

50

12

45

10

7

50

30

70

19

62

17

61

40

90

24

75

18

22

28

14

22

14

22

28

89.5