Page 1

Instruction Manual

Ultra High-Speed Laser Displacement Sensor (CCD Style)

HL-C1C series

Intelligent Monitor

HL-C1AiM

KA106AiM-E-001

Page 2

Contents

Chapter 1 Before Use

1-1 Introduction ………………………………………………... 1-1

1-2 Cautions for Installation ………………………………… 1-1

1-3 Operating Environment ………………………………….. 1-1

1-4 Installation / How to use ……………………………….. 1-2

1-5 Note ………………………………………………………... 1-3

Chapter 2 Easy Operation Procedure ………………………….. 2-1

Chapter 3 Function Items

3-1 Menu Bar …………………………………………………. 3-1

3-1-1 File Menu ............................................................... 3-1

3-1-2 Window Menu ……………………………………….. 3-2

3-1-3 System Menu ………………………………………... 3-4

3-1-4 Help Menu …………………………………………… 3-7

3-2 Main Display ……………………………………………… 3-9

3-3 Measurement Conditions Setting ……………………… 3-13

3-4 Display Waveform of Measurement Values …………. 3-15

3-5 Display Waveform of Light Received Data …………. 3-19

3-5-1 “Head 1 Setting” Tab Sheet ……………………… 3-23

3-5-2 “Head 2 Setting” Tab Sheet ……………………… 3-24

3-5-3 “Chart Setting” Tab Sheet ………………………… 3-25

3-5-4 “The Others” Tab Sheet …………………………… 3-26

3-6 Emitted Light Amount Search …………………………. 3-28

3-7 Display Data Buffering ………………………………….. 3-29

3-7-1 Data Buffering Procedure ..................................… 3-29

3-7-2 Display Data Buffering ……………………………... 3-29

3-8 Initialize ……………………………………………………. 3-35

Chapter 4 Error Message

4-1 Dialog Display …………………………………………….... 4-1

4-2 Error Message …………………………………………....... 4-1

4-2-1 COM port error ..................................................…… 4-1

4-2-2 Transmission / reception time-out …………………... 4-1

4-2-3 Reception error ........................................................ 4-2

4-2-4 Occurrence of reception time-out …………………… 4-2

4-2-5 Controller version is wrong ………………………….. 4-2

4-2-6 Product code of controller does not match ………… 4-3

4-2-7 Can not open file ……………………………………… 4-3

4-2-8 Can not create file ……………………………………. 4-3

Page 3

Chapter 1 Before Use

Page 4

1-1 Introduction

The HL-C1AiM (Advanced Intelligent Monitor) is function setting software designed for the

controller of the laser type displacement sensor "HL-C1" series.

Connection to the controller using the exclusive cable enables use of the following

functions.

* Setting of various measurement conditions and indication of measurement value

* Monitoring of measurement data

* Monitoring of light received data

* Monitoring of buffering data

1-2 Cautions for Installation

* Prior to installing the software, be sure to read the “Agreement of software use” described

on the rear side of package jacket.

* On installation of the software the user accepts to the agreement described on the rear

side. If the conditions outlined in the agreement cannot be accepted the unused software

should be returned to the origin of purchase.

1-3 Operating Environment

OS : Microsoft Windows 98/98SE/ME/2000/XP

CPU : Celeron 400MHz or higher

Memory : 64MB or higher

Hard Disc : 15MB of available memory is required

CD-ROM Drive : Required for installation

Display : 1024 x 768 resolution 256 color

Serial Port : RS-232C 115.2kbps

* This program cannot be used with any previous version of the current controller version

2.12.

1-1

Page 5

1-4 Installation / How to use

(1) Insert HL-C1AiM into CD-ROM drive.

(2) Execute the setup.exe in HL-C1AiM.

(3) Follow the instructions for setup.

< Important >

In case of installing/uninstalling HL-C1AiM in/from Windows 2000/XP, the administrator

authority is required.

(4) Connect HL-C1C to PC by using the COM port connection cable provided.

(5) Power the HL-C1C on.

(6) Execute ‘Start’ -> ‘Program’ -> ‘SUNX’ -> ‘HL-C1AiM’.

Cautions on handling CD-ROM

1.Do not leave this CD-ROM in direct sunlight or in warm or humid location.

2.Avoid getting fingerprints, dirt, scratching etc. on both sides.

3.Take care that CD-ROM is not brought into contact with LP cleaning liquids, solvents,

water or oil etc.

4.Never use cracked, distorted, or repaired disc.

5.Do not write anything using a pencil, ball-point pen or an oil-based pen etc. on the

surface of the CD-ROM.

Furthermore, do not attach labels etc.

6.Store this CD-ROM in the original CD case.

7.Do not put/drop anything heavy on the original case. The case may be damaged.

8.Never play this CD-ROM on an audio CD player. The loud noise may damage your

ears or break the speakers.

1-2

Page 6

1-5 Note

* The functions that cannot be used with version 2.xx will be inactive, and setting will not be

possible.

* Of “Standard” or “WL” is selected as a product code, the special GS type controller

function becomes inactive and it cannot be selected.

* The functions which cannot be used with the product code “WL” goes into non-active state

and the setting becomes impossible.

*Please set CSV with a CSV setting screen when use the CSV file output with AiM.

CSV may not be available if you do not setting.

- The function that cannot be used with version 2.xx

* Confirmation of Alarm Output and Judgment Output Conditions

* Number of Analog Alarm Delay Times

* Analog Alarm Delay

* CS/DR Control During Accumulation

* Emitted Light Adjustment

* Zero Set

* Zero Offset Amount

* Displaying of Data Buffering

- The special GS type controller function

* Measurement Surface Selection

* Detection Level Setting

* Emitted Light Amount Search

* Calculation of Refraction Factor

* Refraction Factor

* Number of Displayed Cells (Intensity Monitor)

* Surface Number Display (Intensity Monitor)

* Marker Display (Intensity Monitor)

- The function that cannot be used with product code “WL”

* Specular Reflection Mode

* Set/Reset the TIMING input

* Timing Input Operation

* Laser Emission Control

* Input Mode

1-3

Page 7

Chapter 2 Easy Operation Procedure

Page 8

This paragraph describes the operation procedure for range from

start-up of HL-C1AiM.exe to execution of measurement.

Step-1 Select the Controller Ver. and Product Code. (1)

Select the Controller Ver. in accordance with the version No. of program shown on

the nameplate of HL-C1C.

* Note that it is unable to use the HL-C1AiM if program version of HL-C1C is

older than 2.12.

Step-2 Select the type of sensor head connected. (2)

Step-3 Click the initialization button(3)to accommodate the setting of the measurement

conditions to your controller and head.

Step-4 Set the communication conditions.

Open the communication condition setting window from the system menu (4), to set

the COM port of PC connecting the serial cable of HL-C1C. (5)

2-1

Page 9

Step-5 Set the on-line mode. (6)

If the Online button is clicked under off-line status (characters of Online are indicated

in black), the off-line status is changed to the on-line status (characters of Online are

changed to red).

While the Online is selected, the measurement result and light received by sensor head 1

and sensor head 2 are changed on real-time base.

The setting of hold mode, and setting/resetting of hold, zero set and timing (except the

product code "WL") are also operated on real -time base. (7)

Setting of measurement conditions.

The setting of conditions (8) concerning the measurement is not reflected on real-time base,

but executed, using the condition transmission/reception button (9).

It is also possible to save/read the measurement conditions to/from the memory unit of PC

(10).

Precautions on measurement conditions.

1. When the software is used together with the compact console in combination, the

measurement conditions are not reflected upon the HL-C1AiM on real-time base

even if it is changed with compact console.

2. Even if the measurement conditions are transmitted from the HL-C1AiM to the

controller, conditions are not saved in the controller.

(The last measurement conditions are resumed when the power is re-closed).

When necessary to save the measurement conditions in the controller, execute

the "Save in controller".

3. The measurement conditions are initialized for HL-C1AiM and controller

separately.

2-2

Page 10

Chapter 3 Function Items

Page 11

3-1 Menu Bar

This is a menu for various operation settings and measurements of HL-C1AiM.

3-1-1 File Menu

- Open

Reads data from the set condition file stored in the external memory.

- Save

Saves the currently-set conditions in the external memory.

Open(0)

Save(S)

Load from Controller

Send to Controller

Save to Controller

Controller Initialize

File Operation-Print

File Oparetion-Save

Exit(X)

< Note >

This command will not save the set conditions in the controller. To save the set conditions

in the controller itself, execute the command "Save to Controller."

- Load from Controller

Loads the set conditions from the controller.

3-1

Page 12

- Send to Controller

Sends the currently-set conditions to the controller.

- Save to Controller

Saves the conditions currently-set on the controller in the controller itself.

< Note >

This command will save the conditions currently-set on the controller. The conditions to

be saved therefore may differ from the conditions set on the HL-C1AiM. To save the

conditions set on the HL-C1AiM, execute the command "Send to Controller" first, and

then execute this command.

- Controller Initialize

Initializes the conditions set on the controller.

< Note >

This command will initialize the conditions set on the controller, but will not initialize the

conditions set on the HL-C1AiM. Use the "Initialize" button to initialize the conditions set

on the HL-C1AiM.

- File Operation … Print

Open the print dialog box to print measurements or screen image.

- File Operation … Save

Save the settings and screen image on the storage media. Settings are saved in a text

document and the screen image is saved as a bitmap or JPEG image.

- Exit

Exits from the HL-C1AiM.

3-1-2 Windows Menu

- Measurement Data Monitor

This function is to take the measurement data form the controller and display them.

Refer to the “Chapter 3-4 Display Waveform of Measurement Values”.

Measurement Data Monitor

Intensity Monitor

Trace Data Monitor

Communication Change

3-2

Page 13

- Intensity Monitor

This is a function to display the state of the receiving light amount of the head with

waveform.

Refer to the “Chapter 3-5 Display Waveform of Light Received Data”.

- Trace Data Monitor

The data buffering function can be easily used.

Refer to the “Chapter 3-7-2 Display Data Buffering”.

- Communications Change

The communication conditions of the controller can be changed.

< Note >

* When the communication setting transmission is done, the measurement conditions

setting of the controller is transmitted with the transmission setting contents, and stored in

the controller.

* When this communication setting transmission is desired to implement, turn off the

controller once and turn it on again. Unless doing so, the setting is not reflected.

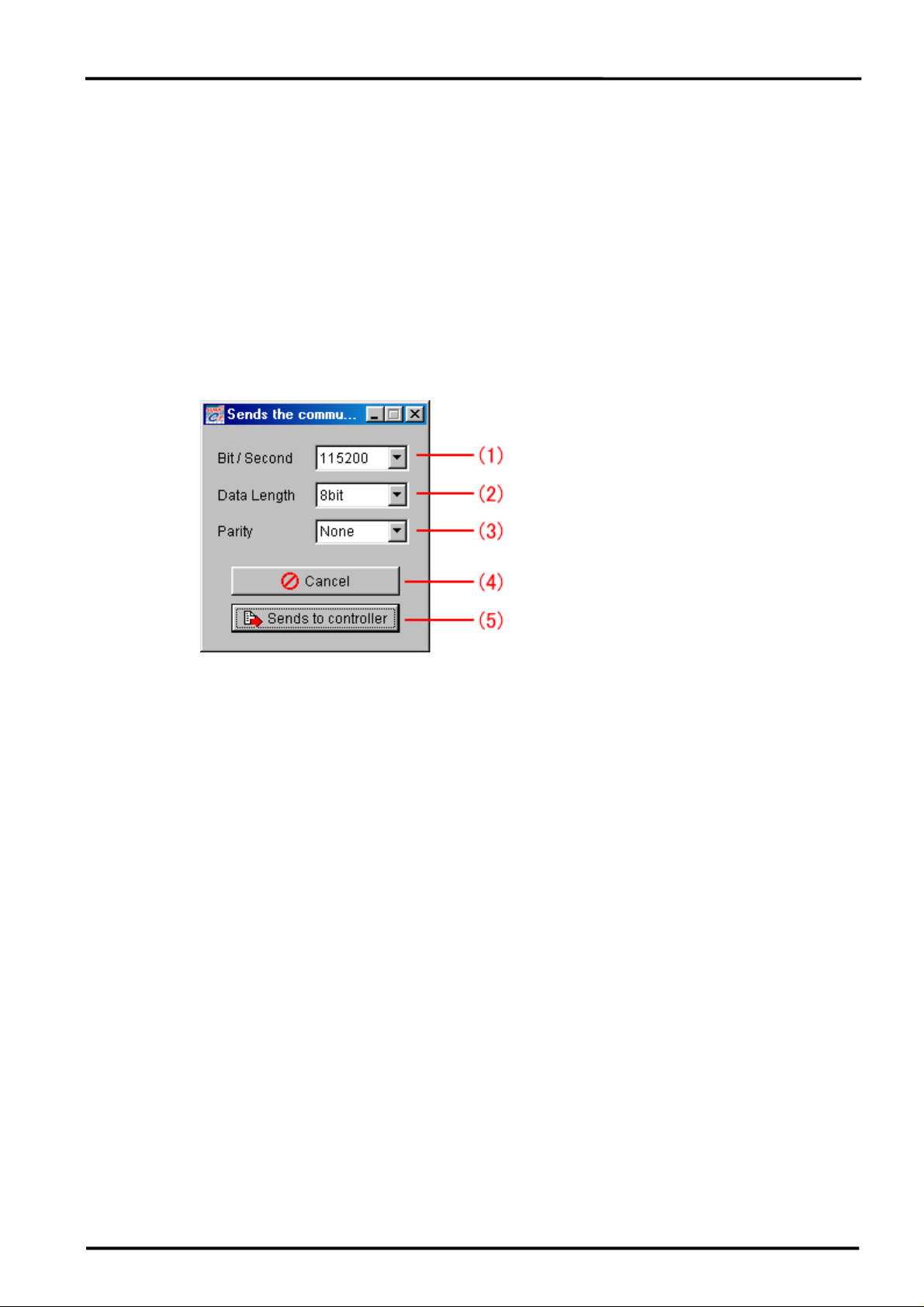

(1) Bit / Second

Select 9600, 19200, 38400, or 115200 bps to specify the communication speed (baud

rate).

< Reference > Default Setting: 115200 bps

(2) Data Length

Select 7bit or 8bit to specify the data length.

< Reference > Default Setting: 8 bit

(3) Parity

Select Even, Odd, or None to enable parity check.

< Reference > Default Setting: None

3-3

Page 14

(4) Cancel

The data set by this diagram will not be set on the HL-C1 controller, and the screen will

return to the Main screen.

(5) Sends to controller

The data set by this diagram will be sent to the HL-C1 controller, and set on the

controller.

If the set data is sent to the controller, the data will be stored in the controller.

3-1-3 System Menu

- Communications Setup

Sets the communication conditions of the PC.

< Note >

The transmission cannot be done if the communication conditions setting of the controller

does not match the transmission setting of the PC.

Communication Setup

Operation Setup

CSV Setting

Emitted Light Amount Search

3-4

Page 15

(1) COM Port

For the COM port, select a port to be used for serial communication between the PC

and the controller.

(2) Bit / Second

Select 9600, 19200, 38400, or 115200 bps to specify the communication speed (baud

rate).

< Reference > Default Setting: 115200 bps

(3) Data Length

Select 7bit or 8bit to specify the data length.

< Reference > Default Setting: 8 bit

(4) Parity

Select Even, Odd, or None to enable parity check.

< Reference > Default Setting: None

(5) Time Out

After sending a command, the HL-C1AiM should wait for a while to receive the

response. Set this wait time for the HL-C1AiM.

Select 1sec, 2sec, 3sec, 5sec, or 10sec to activate the time-out function.

< Reference > Default Setting: 3 sec

(6) BCC

For BCC (Block Check Code) calculation, specify which type of data should be attached

to the BCC of the send/receive message; calculation results or dummy code.

(7) Initialize

Erases all the set data, and resets to the factory-set initial status.

When initialized, the data is reset to the initial status, but this data is not yet saved. To

retain the initialized status even after power-off, execute "Save".

< List of default values >

COM Port : COM1 (The default value depends on the PC used for operation.)

Bit / Second : 115200 bps

Data Length : 8 bit

Parity : None

Time Out : 3 sec

(8) OK

Sets the results of change.

3-5

Page 16

(9) Cancel

Cancels the change.

- Operation Setup

Sets operation of the HL-C1AiM depending on the capability of your PC.

(1) Display Frequency (Measurement Graph)

For the graphs of Measurement Data Monitor, the graph update intervals will be set in

the range of 40 to 200ms.

< Note >

This value depends on the processing performance of the PC and the application

programs simultaneously operated. For this reason, this value may differ from the set

value.

(2) Hi / Lo Limit Bar Display (Measurement Graph)

Displays the set upper/lower limit value in the Measurement Data Monitor graph.

(3) Alarm / Output Bar Display (Measurement Graph)

Displays the alarm output status (alarm output vs. time) on the Measurement Data

Monitor screen. If it is difficult to read the graph due to the overlapped waveforms,

change the display position to upper, middle, or lower area.

3-6

Page 17

(4) Communications Priority

The priority of signal transmission process for the controller and PC is set under

Windows control.

(5) Communications Frequency

Specify the CPU time assigned by Windows for the transmission/reception process.

Select "Low" Communications Frequency to acquire data from the controller less often.

Select "Standard (default)" for regular operation. If transmission/reception is unstable

due to the environment of the PC, select "Low".

(6) Display Frequency (Intensity Graph)

You can set the graph update intervals for the Intensity Monitor graph in the range of

400 to 1000ms.

< Reference > Default Setting: 500ms

(7) Graph Rectangle Display (Intensity Graph)

Displays the Intensity Monitor graph by the rectangular waveform.

(8) Close

Closes this Operation Setup window.

- CSV Setting

Can set a value separator and decimal separator of CSV file.

3-7

Page 18

(1) Value Separator

Please select a character to divide each cell data.

Separate cell data by selected character when output a CSV file.

< Note >

The same character must be used for an opened CSV file.

(2) Decimal Separator

Please select a decimal point character of numeric data.

Used a selected character when output a CSV file.

< Note >

The same character must be used for an opened CSV file.

(3)OK

Closed a screen.

After this, selection contents are reflected by CSV file operation.

(4) CANCEL

Closed a screen.

CSV setting is not changed.

- Emitted Light Amount Search

At the moment that this function was selected, the emitting light amount is adjusted such

that the receiving light amount for the set measuring surface is to be suitable.

The emitted light amount search function can only be used with the GS controller.

Refer to the “Chapter 3-6 Emitted Light Amount Search”.

3-8

Page 19

3-1-4 Help Menu

- Help

Activates the help file.

- About HL-C1AiM

Shows the version number of this software.

3-9

Page 20

3-2 Main Display

(1) Online Button

Use this button to start communication control for measurement.

Each time you click this button, the status of the button will be changed as follows:

If the word "Online" is red, the system is now communicating with the controller.

(2) Controller Version

Shows the program version number of the controller connected to this software.

< Supplementary Explanation >

* The controller version number cannot be changed in the Online mode (the word

"Online" is red).

(3) Product Code

Shows the product code of the controller connected to this software.

< Supplementary Explanation >

* The controller product code cannot be changed during online operation (when "Online"

is displayed in red).

3-10

Page 21

(4) Sensor Head 1,2

Displays the type of the Sensor Head connected to the Sensor Head connector of the

controller.

The default values of the following items depend on the type of the Sensor Head:

Upper limit value

Lower limit value

Upper limit hysteresis

Lower limit hysteresis

Analog output setting (+5V side)

Analog output setting (-5V side)

(5) Measurement Value of Sensor Head 1

Displays the measurement value of Sensor Head 1 or value obtained by add/subtract

calculation.

The displayed item depends on the condition set for the Sensor Head operation.

(6) Light Received Data of Sensor Head 1

Displays the peak light received at the measurement point of Sensor Head 1. When

installing the Sensor Head, set enough light received for measurement considering this

peak value.

(7) Measurement Value of Sensor Head 2

Displays the measurement values of Sensor Head 2.

The values will not depend on the conditions set for Sensor Head operation.

(8) Light Received Data of Sensor Head 2

Displays the peak light received obtained at the measurement point of Sensor Head 2.

When installing the Sensor Head, set enough light received for measurement considering

this peak value.

(9) The alarm and the judgment output confirmation

Use this window to check the output alarm and judgment.

White characters mean OFF, and red characters ON.

AL1: Alarm output (Sensor Head 1)

AL2: Alarm output (Sensor Head 2)

O11: Judgment output 1 (Sensor Head 1)

O12: Judgment output 2 (Sensor Head 1)

O21: Judgment output 1 (Sensor Head 2)

O22: Judgment output 2 (Sensor Head 2)

3-11

Page 22

(10) Hold Mode

For this equipment, there are 4 types of hold modes. They are the NORMAL, P-P, PEAK,

and VALLEY modes. The measurement result data will be displayed and output in the set

mode.

For the details of the Hold Mode, refer to the instruction manual of the controller.

(11) Hold

Holds the measurement values displayed on the HL-C1AiM. Use this function to read the

fluctuating measurement values at a certain moment.

Click the button. The word “Hold” will turn into red, and the measurement values will be

held.

(12) Timing

In the timing input status, the judgment output (O1, O2), measurement values, and analog

output value displayed just before will be held. You can set whether the laser emission

should be halted or continued in this status. If it is not necessary to carry out

measurement or judgment, enter this command in order to prevent unnecessary variation

in the output or laser emission.

Click this button. The word "Timing" will turn into red. In this status, the alarm output will

be turned off, and the measurement values and judgment output will be held.

* In the timing input status, the word "Timing" will turn into red.

* Clicking this button again will cancel the timing input status, and the word "Timing" will

turn into black.

For the details of the Timing, refer to the instruction manual of the controller.

< Note >

* If the product code is set to "WL", "TIMING" goes into non-active state and the setting

becomes impossible.

* Before switching the timing function on the HL-C1AiM, check that the timing command is

not input from the terminal. If such a command is input from the terminal, the priority will

be given to the command input from the terminal. For this reason, the HL-C1AiM will

switch the timing input function on the display, but will not switch the function actually.

(13) Zero Set

The displayed displacement value is normally the distance measured from the

measurement center. Entering the "Zero Set" command will display the displacement

value measured from the current position. For this reason, when the zero setting is

performed, the measurement values and analog output value currently displayed will be

set to zero forcibly. Use this function to measure the variation or make judgment whether

the data is in the specified range after setting the measurement value of the reference

workpiece to "0".

3-12

Page 23

Click this button. The word "Zero Set" will turn into red, and the measurement values will be

set to "0".

* If the zero setting is performed, the word "Zero Set" will turn into red.

* Clicking this button again will cancel the zero setting status, and the word "Zero Set" will

turn into black.

For the details of the Zero Set, refer to the instruction manual of the controller.

< Note >

* Before switching the zero setting function on the HL-C1AiM, check that the zero setting

ON or zero setting OFF command is not input from the terminal. If such a command is

input from the terminal, the priority will be given to the command input from the terminal.

For this reason, the HL-C1AiM will switch the zero setting function on the display, but will

not switch the function actually.

3-3 Measurement Conditions Setting

There are sheets to set the measurement conditions.

* Measurement Setup

* Calibration, Data Processing

* Hi / Lo Limit, Analog Output

* I / O, The Others

There are 4 sheets as shown above.

Set the required items for these sheets.

This setting is not reflected instantly. To reflect it, execute the 'send to controller' in the file

menu.

Furthermore, the measurement conditions to the PC memory can be stored or read by

executing ' save the file' or 'open the file' in the file menu.

For the details of functions of each setting item, refer to the instruction manual of the

controller.

3-13

Page 24

< Supplementary Explanation >

To send various setting data to the controller, specify whether the zero setting data should

be sent.

ON:

Sends the currently displayed offset value to the controller.

The zero setting data set on the controller will be rewritten.

When the setting file is read from the external memory device, and if the displayed zero

set amount is desired to reflect, select this.

OFF:

Sends the zero setting data of 0mm to the controller.

The zero setting data set on the controller will be rewritten.

Current state:

Does not send the zero setting data.

This means that the zero setting data set on the controller will not be rewritten.

< Specular-reflaction-mode and Refraction-factor-calculation >

When changing the setting of the Specular reflaction mode to 'Thickness', the Refraction

factor calculation becomes to ON automatically.

However, in case of changing the setting from 'Thickness', the calculation doesn't become to

OFF automatically.

3-14

Page 25

3-4 Display Waveform of Measurement Value

The data is displayed in accordance with the set measurement value graph renewal interval

(40ms to 200ms) in the software operation setting (Chapter 3-1-3).

(1) Indicator

Loads data on the HL-C1AiM until the indicator is fully loaded.

It can be moved to the desired time axis by dragging the cursor of the indicator.

(2) Graph of Sensor Head 1

Displays the measurement data of Sensor Head 1 or measurement data obtained by

addition/subtraction.

Set the axis range to adjust the display range.

Enlargement method:

If you want to enlarge the display range, drag the mouse from the upper left corner to

the lower right corner to show the desired size.

3-15

Page 26

Undoing method:

In the graph display area, drag the mouse from the lower right to the upper left at any

position.

(3) Graph of Sensor Head 2

Displays the measurement data of Sensor Head 2.

Set the axis range to adjust the display range.

Enlargement method:

If you want to enlarge the display range, drag the mouse from the upper left corner to

the lower right corner to show the desired size.

Undoing method:

In the graph display area, drag the mouse from the lower right to the upper left at any

position.

(4) Vertical Axis Measure

Enter a check mark in the check box to display the measure cursor.

(5) Horizontal Axis Measure

Enter a check mark in the check box to display the measure cursor.

(6) Select Sensor Head

Select a Sensor Head to display the measure cursor.

(7) Vertical Cursor Button to Move (Dotted Line)

Click this button to move the left cursor (dotted line) rightward/leftward. While holding

down the Shift key, click this button to move the cursor at a high speed.

(8) Vertical Cursor Button to Move (Solid Line)

Click this button to move the right cursor (solid line) rightward/leftward. While holding

down the Shift key, click this button to move the cursor at a high speed.

(9) Horizontal Cursor Button to Move (Solid Line)

Click this button to move the top cursor (solid line) upward/downward. While holding down

the Shift key, click this button to move the cursor at a high speed.

(10) Horizontal Cursor Button to Move (Dotted Line)

Click this button to move the bottom cursor (dotted line) upward/downward. While holding

down the Shift key, click this button to move the cursor at a high speed.

(11) Distance between Top and Bottom

Displays the top and bottom cursor positions and their distance data (difference data)

using an absolute value.

3-16

Page 27

< Note >

The relation between the number of dots on the screen and the graph display range may

cause slight difference in the cursor position data. For this reason, use the data as

reference values.

(12) Distance between Right and Left

Displays the right and left cursor positions and their distance data (difference data) using

an absolute value.

< Note >

The relation between the number of dots on the screen and the graph display range may

cause slight difference in the cursor position data. For this reason, use the data as

reference values.

(13) Axis Range

You can adjust the scales of the vertical and horizontal axes of the measurement data

waveform graph.

(14) Axis Range (Vertical Axis)

You can adjust the vertical axis in the range of 999.9 to –999.9mm

In the case of "Standard (Product Code)" setting

< Reference: Default Setting >

50mm type 6.5 to -6.5mm

85mm type 25.0 to -25.0mm

In the case of "GS (Product Code)" setting

< Reference: Default Setting >

25mm type 1.2 to -1.2mm

50mm type 5.0 to -5.0mm

85mm type 20.0 to -20.0mm

In the case of "WL (Product Code)" setting

< Reference: Default Setting >

350mm/320mm 250.0 to -250.0mm

(15) Axis Range (Horizontal Axis)

You can adjust the horizontal axis in the range of 1000 to 9000ms.

< Reference: Default Setting >

8000ms

(16) Initialize

You can reset the set vertical/horizontal axis scale data of the measurement data

waveform graph to the initial data.

3-17

Page 28

In the case of "Standard (Product Code)" setting

< Reference: Default Setting >

50mm type: Vertical Axis 6.5 to -6.5mm, Horizontal Axis 8000ms

85mm type: Vertical Axis 25.0 to -25.0mm, Horizontal Axis 8000ms

In the case of "GS (Product Code)" setting

< Reference: Default Setting >

25mm type: Vertical Axis 1.2 to -1.2mm, Horizontal Axis 8000ms

50mm type: Vertical Axis 5.0 to -5.0mm, Horizontal Axis 8000ms

85mm type: Vertical Axis 20.0 to -20.0mm, Horizontal Axis 8000ms

In the case of "WL (Product Code)" setting

< Reference: Default Setting >

350mm/320mm: Vertical Axis 250.0 to -250.0mm, Horizontal Axis 8000ms

(17) Collect

Loads measurement data from the controller.

(18) Play

Replays measurement data stored in the memory.

(19) Load

Calls out the measurement result data from the storage.

(20) Save

Transfers the measurement result data stored in the memory to the storage.

Data can be stored in the PC using the CSV or MS2 format (format for HL-C1AiM

measurement data waveform only).

The data stored in the CSV format can be directly read out using a spreadsheet program.

If data is stored in the MS2 format, the data can be reloaded and regenerated on the

HL-C1AiM.

(21) File Operation … Print

Open the print dialog box to print measurements or screen image.

(22) File Operation … Save

Save the settings and screen image on the storage media. Settings are saved in a text

document and the screen image is saved as a bitmap or JPEG image.

(23) Close

Closes the measurement data waveform display screen.

3-18

Page 29

3-5 Display Waveform of Light Receive Data

The receiving light state of each head is indicated with the cell position and the receiving

light amount.

< Supplementary Explanation >

* Even after setting the sampling period to 100us, if the waveform of light received data is

being displayed, the sampling period may be prolonged.

* While displaying the waveform of light received data, if you enter the "Initialize controller"

command using the console, the displayed waveform may not be updated.

* Usable functions are limited depending on the product code. The unusable function is that

the component goes into "non-active" state and the setting becomes impossible. Refer to

the "Table 3-1" for details.

* The display of the waveform differs depending on the setting of the product code of the

controller, connected sensor head or number of the displayed cells. Refer to the "Table 3-2"

for details.

3-19

Page 30

(1) Indicator

Loads data on the HL-C1AiM until the indicator is fully loaded.

(2) Graph of Sensor Head 1

Displays the light received of Sensor Head 1.

You can enlarge the display range or reduce the range to the initial size.

Enlargement method:

If you want to enlarge the display range, drag the mouse from the upper left corner to

the lower right corner to show the desired size.

Undoing method:

In the graph display area, drag the mouse from the lower right to the upper left at any

position.

Scrolling method:

Drag the right button of the mouse to scroll the display screen.

(3) Graph of Sensor Head 2

Displays the light received of Sensor Head 2.

You can enlarge the display range or reduce the range to the initial size.

Enlargement method:

If you want to enlarge the display range, drag the mouse from the upper left corner to

the lower right corner to show the desired size.

Undoing method:

In the graph display area, drag the mouse from the lower right to the upper left at any

position.

Scrolling method:

Drag the right button of the mouse to scroll the display screen.

(4) Measurement Value of Sensor Head 1

Displays the measurement result data of Sensor Head 1 or measurement result data

obtained by addition/subtraction.

(5) Peak Cell of Sensor Head 1

Displays the position of the CCD cell receiving maximum light in Sensor Head 1.

1 to 256 if the connected Sensor Head is 25mm type, 50mm type, 1 to 512 if the

connected Sensor Head is 85mm type, 320mm type, 350mm type.

(6) Measurement Value of Sensor Head 2

Displays the measurement result data of Sensor Head 2.

3-20

Page 31

(7) Peak Cell of Sensor Head 2

Displays the position of the CCD cell receiving maximum light in Sensor Head 2.

1 to 256 if the connected Sensor Head is 25mm type, 50mm type, 1 to 512 if the

connected Sensor Head is 85mm type, 320mm type, 350mm type.

(8) Explanation of each sheet

Refer to the Chapter 3-5-1 to 3-5-4.

(9) Replay Function

The receiving light amount data in the memory can be Replay data/ Stop replaying/ Show

data in a forward direction/ Show data in a reverse direction/ Pause replay.

This function is usually not on display. In order to use this function, click the right button of

the mouse on the 'Play button (11)'. If the right button is clicked again, this button will

disappear.

(10) Collect

Loads the light received data from the controller.

(11) Play

Regenerates light received data stored in the memory.

If the right button of the mouse is clicked on the button, the details of Replay Function (9)

is indicated.

Click on the right mouse button again to hide details.

(12) Close

Closes the light received data waveform display screen.

3-21

Page 32

3-22

Page 33

3-5-1 “Head 1 Setting” Tab Sheet

On the sheet where the measurement conditions of the head 1 are set, the following setting

is possible.

* Specular Reflection Mode

* Measurement Surface Selection

* Detection Level Setting

* Simplified Optical Filter

* Emitted Light Adjustment

* Emitted Light Amount Search

Since this measurement condition setting is the same as the measurement condition setting

on the main screen, a head adjustment can be done only with the receiving light amount

waveform screen, without using the measurement condition setting on the main screen

(Chapter 3-3).

Note that these setting is not reflected instantly. To reflect them, click the 'Send' button.

For the details of the functions of each setting item, refer to the instruction manual of the

controller. Furthermore, for the emitting light amount search, refer to the Chapter 3-6 in this

instruction manual.

3-23

Page 34

3-5-2 “Head 2 Setting” Tab Sheet

On the sheet where the measurement conditions of the head 2 are set, the following setting

is possible.

* Specular Reflection Mode

* Measurement Surface Selection

* Detection Level Setting

* Simplified Optical Filter

* Emitted Light Adjustment

* Emitted Light Amount Search

Since this measurement condition setting is the same as the measurement condition setting

on the main screen, a head adjustment can be done only with the receiving light amount

waveform screen, without using the measurement condition setting on the main screen

(Chapter 3-3).

Note that these setting is not reflected instantly. To reflect them, click the 'Send' button.

For the details of the functions of each setting item, refer to the instruction manual of the

controller. Furthermore, for the emitting light amount search, refer to the Chapter 3-6 in this

instruction manual.

3-24

Page 35

3-5-3 “Chart Setting” Tab Sheet

This is a sheet to set the graph display. (This setting can only be used with the GS

controller.)

(1) Number of Displayed Cells

The number of displayed cells setting can only be used with the GS controller.

The number of cells displayed on the light received waveform screen can be selected in

the range from 101 to 256 cells.

< Supplementary Explanation >

* With the "Standard (Product Code)" setting, the number is fixed at 101 cells.

(2) Surface Number Display

The surface number display setting can only be used with the GS controller.

After the surface number display is selected, the peak light received amount is indicated

with a number.

This function is convenient for the measurement surface selection function of the specular

reflection mode.

The number for the selected measurement surface is in red, and the others are in white.

(3) Marker Display

The marker display setting can only be used with the GS controller.

After marker display is selected, the peak light received amount is indicated with a line.

3-25

Page 36

3-5-4 “The Others” Tab Sheet

This is a sheet to set the measurement conditions, Load/ Send the file, and Print/ Save the

data.

(1) Sampling Period

Since this measurement condition setting is the same as the measurement condition

setting on the main screen, a head adjustment can be done only with the receiving light

amount waveform screen, without using the measurement condition setting on the main

screen (Chapter 3-3).

Note that these setting is not reflected instantly. To reflect them, click the 'Send' button.

For the details of the functions of each setting item, refer to the instruction manual of the

controller.

(2) Load

Loads the light received data from the controller.

3-26

Page 37

(3) Save

Transfers the light received data stored in the memory to the storage.

Data can be stored in the PC using the CSV or DW3 format (format for HL-C1AiM light

received waveform only).

The data stored in the CSV format can be directly read out using a spreadsheet program.

If data is stored in the DW3 format, the data can be reloaded and regenerated on the

HL-C1AiM.

< Note >

Any previous version of 3.20 DWD files can be read and executed, too.

Please set CSV with a CSV setting screen when use the CSV file output with AiM.

(4) File Operation … Print

Open the print dialog box to print measurements or screen image.

(5) File Operation … Save

Save the settings and screen image on the storage media. Settings are saved in a text

document and the screen image is saved as a bitmap or JPEG image.

3-27

Page 38

3-6 Emitted Light Amount Search

The emitted light amount search function can only be used with the GS controller.

When 'Execute' button is clicked, this function is immediately implemented, to adjust the

emitted light amount of the selected measurement surface so that the optimum light

received data is obtained. (If two or more surfaces are selected, the smaller amount of

received data for one surface is adjusted to the optimum amount.)

The emitted light amount is adjusted in the setting range of the "Emitted Light Adjustment"

function to between 0.7 and 49%. If adjustment of the emitted light amount in this range fails,

"Automatic" is selected for the Emitted Light Adjustment.

< Supplementary Explanation >

* If two or more surfaces are selected and a search is made of the surface showing the

largest difference as to the reflected light amount (about four times or greater ratio to the

light received data), the "Automatic" emitted light amount may not be selected even if the

emitted light amount search fails. In such a case, check the Intensity Monitor and manually

adjust.

3-28

Page 39

3-7 Display Data Buffering

3-7-1 Data Buffering Procedure

(1) Select a buffering setting item.

(2) Press the "Start" button to start data accumulation.

(3) Monitor the accumulation status, and press the "Stop" button when you want to stop it.

The accumulated data can be read out after stopping accumulation.

(4) In the accumulation data reading area, press the "Head 1" or "Head 2" button to transfer

data from the controller to the PC.

The result will be displayed on the screen using data or waveform.

3-7-2 Display Data Buffering

Before transferring measurement data to PC, you can temporarily accumulate up to 48000

data items in the controller. The accumulated data can be taken from the controller to the

PC.

Use this function to check the measurement data at the time of introduction or to read out or

store all the data after measurement.

Note that the data buffering function may restrict the sampling period.

3-29

Page 40

< Supplementary Explanation >

In this Manual, "accumulation" and "accumulation operation" have different meanings as

described below:

* Accumulation: To store measurement data in the internal memory of the controller.

* Accumulation operation: A series of accumulation operations that include waiting for

trigger, accumulation, and completion of accumulation

(1) Graph of Sensor Head 1

Displays the graph after reading out the accumulated data of Sensor Head 1.

< Supplementary Explanation >

During alarm, the waveform of measurement data may wave to the upper and lower limits

due to the reduced scale of the display area. In this case, however, the data shows the

correct alarm output.

(2) Graph of Sensor Head 2

Displays the graph after reading out the accumulated data of Sensor Head 2.

< Supplementary Explanation >

During alarm, the waveform of measurement data may wave to the upper and lower limits

due to the reduced scale of the display area. In this case, however, the data shows the

correct alarm output.

(3) Line Number

X-axis data of waveform displayed on the left side.

(4) Measurement Value

Y-axis data of waveform displayed on the left side.

< Supplementary Explanation >

* "ALARM" displayed in the measurement data area represents the alarm output. In this

case, '-999.9999' is accumulated as a value.

* In addition, "****" means that the blank data is fixed to "+999".

(5) Indicate the Number of Accumulated Data

Shows the position of the final data newly accumulated by data buffering for Sensor

Head.

3-30

Page 41

(6) Status

The status data shows the accumulation status of the controller when data buffering is

stopped.

The system displays "Trigger Wait", Storing", "Complete", or "Unknown" to inform the

buffering status.

* Trigger Wait:

The system is now waiting for trigger.

* Storing:

During accumulation, the "Stop" command is entered, and buffering is stopped. In the

"Timing & trigger" mode, accumulation is stopped by inputting the timing.

* Complete:

The specified number of data items are accumulated, and accumulation is completed.

* Unknown:

This message will appear if the system is not in the online mode or buffering is not

started.

(7) Switch to Waveform / Data

For each Sensor Head, you can switch the display screen to "Waveform and data" or

"Display waveform only".

(8) Buffering Mode

Select a data accumulation method.

* Initial & continue:

Data accumulation will be started when the Start button is pressed. Data accumulation

will be stopped when the specified quantity of data is accumulated or when the Stop

command is entered.

* Initial & trigger:

The first data that meets the trigger condition will be accumulated. Accumulation

operation will be started when the Start button is pressed, and will be stopped when the

specified quantity of data is accumulated or when the Stop command is entered.

* Latest & trigger:

During accumulation, the final data that meets the trigger condition will be accumulated.

Accumulation operation will be started when the Start button is pressed, and will be

stopped when the Stop command is entered.

* Timing & trigger:

After pressing the Start button, if the timing input (Ton) status is switched to the timing

cancel (Toff) status, accumulation will be started. Accumulation will be stopped if the

status is switched to the timing input (Ton) status, or the Stop command is entered.

After stopping accumulation by switching the status to the timing input (Ton) status, if

the status is set to the timing cancel (Toff) status again, accumulation will be started

from the first data of the accumulated data.

3-31

Page 42

* Latest & continue:

Data accumulation will be started when the Start button is pressed, and will be stopped

when the Stop command is entered. All the data before entering the Stop command will

be accumulated.

(9) Buffering Head

Select a Sensor Head type (type of data to be accumulated) for buffering.

* Head 1: Measurement data of Sensor Head 1

* Head 2: Measurement data of Sensor Head 2

* Heads 1 & 2: Measurement data of Sensor Heads 1 and 2

< Supplementary Explanation >

* If "Head 1" is selected, the data of Sensor Head 1 will be accumulated in the

independent operation mode, but in the add/subtract operation mode, the add/subtract

result data will be accumulated.

(10) Buffer Rate

Sets the data accumulation intervals for the measurement data that is measured in

accordance with the specified sampling period.

Select the buffering rate from "Same as sampling period", "2 : 1", "4 : 1", "8 : 1", "16 : 1",

"32 : 1", "64 : 1", "128 : 1", "256 : 1", "512 : 1", "1024 : 1", "2048 : 1", "4096 : 1", "8192 : 1",

"16384 : 1", and "32768 : 1".

< Supplementary Explanation >

* If you set the buffering rate, all the measurement data can be accumulated. In addition, if

the data does not greatly vary, you can prolong the accumulation intervals and can

accumulate data for a long time.

< Example >

After setting the sampling period to 144us, if the buffering rate is set to "Same as

sampling period", 48000 data items will be accumulated in approximately 6.9 seconds. If

the buffering rate is set to "32768 : 1", 1 data item will be accumulated every 4.7 seconds.

In other words, 48000 data items measured in 62.9 hours will be accumulated.

(11) Specify the Number of Accumulated Data

Specify the number of data items to be accumulated in the range of 1 to (Maximum

accumulation quantity).

The maximum accumulation quantity depends on the selected buffering Sensor Head

type as shown below:

* Head 1 (Sensor Head 1): 48000 data items

* Head 2 (Sensor Head 2): 48000 data items

* Heads 1 & 2 (Sensor Heads 1 and 2): 24000 data items, each

3-32

Page 43

< Supplementary Explanation >

* In addition, in the "Latest & trigger" mode, the maximum accumulation quantity will be

half of the other trigger mode.

For example, if "Sensor Heads 1 & 2" is selected and the "Latest & trigger" mode is set,

the maximum accumulation quantity will be 12000 data items.

* If a quantity larger than the maximum accumulation quantity (depends on the buffering

Sensor Head type) is set, the set quantity will be displayed in red.

If a quantity smaller than 6000 is set, the trigger point will be temporarily set to the

corresponding accumulation quantity again.

(12) Trigger Point

Sets the trigger point.

* Specify the positional relation between the accumulated data and trigger.

* This function can be used in the "Initial & trigger" mode and the "Latest & trigger" mode

only.

This function will not be valid in the "Timing & trigger" mode.

* The setting range is from 1 to (Set accumulation quantity).

* To accumulate data measured before trigger point: Set the trigger point to the backward

area of the accumulated data.

* To accumulate data measured near trigger point: Set the trigger point to the center area

of the accumulated data.

* To accumulate data measured after trigger point: Set the trigger point to the forward

area of the accumulated data.

(13) Trigger Condition

Select trigger conditions for initial trigger and latest trigger.

* When out of range:

Triggered when entering the range specified by the upper and lower limit value

* When in range:

Triggered when entering the range specified by the upper and lower limit values

* When crossing range:

Triggered when crossing the range specified by the upper and lower limit values

* When alarm is changed: Triggered when the alarm status is changed

(14) Stored Condition

The signal will inform whether each Sensor Head is in the "Accumulating" status

(including the "Waiting for trigger" status) or in the "Accumulation completed" status.

Accumulation status of Sensor Head 1,2:

"Storing" means that data is now being accumulated.

"Complete" means that accumulation is completed or stopped by the "Stop" command.

3-33

Page 44

(15) Start

Starts data buffering (data accumulation).

(16) Stop

Stops data buffering (data accumulation).

(17) Reads the Stored Data

Reads out data accumulated by buffering, and temporarily loads the data in the controller .

(18) Loading Mode

The loading mode can be chosen among "Normal," "High Speed" using a radio button.

Normal loading mode:

The accumulated data is read with normal speed.

High-speed loading mode:

The accumulated data is read with high speed. The reading time changes depending

on the data, since high-speed reading is achieved by reading the difference between

data.

(19) Load

Reads out the CSV format data stored in the PC.

<Note>

Only the CSV file which output with a buffering screen of HL-C1AiM is readable.

(20) Save

Transfers the data buffering result data from the memory to the storage.

The HL-C1AiM can save data in the PC using the CSV format.

The data stored in the CSV format can be directly read out using a spreadsheet program.

Data can be read into the HL-C1AiM again.

<Note>

* Please set CSV with a CSV setting screen when use the CSV file output with AiM.

CSV may not be available if you do not setting.

< Supplementary Explanation >

* In the "Initial & trigger" mode or the "Latest & trigger" mode, if the trigger condition is met

before accumulating all the data specified by the trigger point, dummy data "+999.9999"

will be displayed in the no data area (from the top of the memory to the accumulation start

point) so that this dummy data can be distinguished from the accumulated data.

3-34

Page 45

(21) Trace End

Ends data buffering.

Enters the non-buffering mode, and stops data buffering.

When ended, operation will not be restricted by the shortest sampling period of 144us.

(22) Close

Closes the data buffering display screen.

(23) Load from Controller

Loads the set conditions from the controller.

3-35

Page 46

3-8 Initialize

Initialize the set contents in HL-C1AiM.

In the case of "Standard (Product Code)" setting

< List of default values >

Hold Mode : NORMAL

Sampling Period : 144us

Head Operation : Independent operation

Measurement Mode : Diffused reflection

Specular Reflection Mode : Standard

Emitted Light Adjustment : Automatic

Independent Calculation : L1 + K1A, L2 + K2B

Add/Subtract Calculation : L + K (A + B)

Independent Calculation Offset (L1, L2) : 0.0000mm

Add/Subtract Calculation Offset (L) : 0.0000mm

Independent Calculation Coefficient (K1, K2) : 1.0000

Add/Subtract Calculation Coefficient (K) : 1.0000

Zero Set : Current state

Span : 1.0000

Shift : 0.0000mm

Low Pass Filter : OFF

High Pass Filter : OFF

Simplified Optical Filter : OFF

Average Number : 64 times

Upper Limit Value : +5.0000mm (50mm type)

+20.0000mm (85mm type)

Lower Limit Value : -5.0000mm (50mm type)

-20.0000mm (85mm type)

Upper Limit Hysteresis : 0.0100mm (50mm type)

0.0300mm (85mm type)

Lower Limit Hysteresis : 0.0100mm (50mm type)

0.0300mm (85mm type)

Analog Output (+5V Value) : +5.0000mm (50mm type)

+20.0000mm (85mm type)

Analog Output (-5V Value) : -5.0000mm (50mm type)

-20.0000mm (85mm type)

3-36

Page 47

Judgment Output Selection : LOW, HIGH

Timing Input Operation : Short-Circuit

Laser Emission Control : Halt

Laser Emission Delay : OFF

Input Mode : Independent input

Analog Output During Alarm : Hold

Fixed Analog Output Value During Alarm : maximum +10.9V

Analog Alarm Delay Times : OFF

Analog Alarm Delay : OFF

Output Mode : Normal

Interference Prevention : OFF

CS/DR Control During Accumulation : Yes

In the case of "GS (Product Code)" setting

< List of default values >

Hold Mode : NORMAL

Sampling Period : 498us (85mm type)

332us (50mm type or 25mm type)

Head Operation : Independent operation

Measurement Mode : Specular reflection

Specular Reflection Mode : Front

Surface Selection : 1st Surface

Detection Level Setting : Level 1

Emitted Light Adjustment : Automatic

Independent Calculation : L1 + K1A, L2 + K2B

Add/Subtract Calculation : L + K (A + B)

Independent Calculation Offset (L1, L2) : 0.0000mm

Add/Subtract Calculation Offset (L) : 0.0000mm

Independent Calculation Coefficient (K1, K2) : 1.0000

Add/Subtract Calculation Coefficient (K) : 1.0000

Zero Set : Current state

Span : 1.0000

Shift : 0.0000mm

Low Pass Filter : OFF

High Pass Filter : OFF

Simplified Optical Filter : OFF

Calculation of Refraction Factor : OFF

Refraction Factor : 1.5500

Average Number : 256 times

3-37

Page 48

Upper Limit Value : +16.0000mm (85mm type)

+4.0000mm (50mm type)

+1.0000mm (25mm type)

Lower Limit Value : -16.0000mm (85mm type)

-4.0000mm (50mm type)

-1.0000mm (25mm type)

Upper Limit Hysteresis : 0.0300mm (85mm type)

0.0100mm (50mm type)

0.0030mm (25mm type)

Lower Limit Hysteresis : 0.0300mm (85mm type)

0.0100mm (50mm type)

0.0030mm (25mm type)

Analog Output (+5V Value) : +16.0000mm (85mm type)

+4.0000mm (50mm type)

+1.0000mm (25mm type)

Analog Output (-5V Value) : -16.0000mm (85mm type)

-4.0000mm (50mm type)

-1.0000mm (25mm type)

Judgment Output Selection : LOW, HIGH

Timing Input Operation : Short-Circuit

Laser Emission Control : Halt

Laser Emission Delay : OFF

Input Mode : Independent input

Analog Output During Alarm : Hold

Fixed Analog Output Value During Alarm : maximum +10.9V

Analog Alarm Delay Times : OFF

Analog Alarm Delay : OFF

Output Mode : Normal

Interference Prevention : OFF

CS/DR Control During Accumulation : Yes

3-38

Page 49

In the case of "WL (Product Code)" setting

< List of default values >

Hold Mode : NORMAL

Sampling Period : 100us

Head Operation : Independent operation

Measurement Mode : Diffused reflection

Emitted Light Adjustment : Automatic

Independent Calculation : L1 + K1A, L2 + K2B

Add/Subtract Calculation : L + K (A + B)

Independent Calculation Offset (L1, L2) : 0.0000mm

Add/Subtract Calculation Offset (L) : 0.0000mm

Independent Calculation Coefficient (K1, K2) : 1.0000

Add/Subtract Calculation Coefficient (K) : 1.0000

Zero Set : Current state

Span : 1.0000

Shift : 0.0000mm

Low Pass Filter : OFF

High Pass Filter : OFF

Simplified Optical Filter : OFF

Average Number : 512 times

Upper Limit Value : +200.0000mm (350mm type)

: +150.0000mm (320mm type)

Lower Limit Value : -200.0000mm (350mm type)

: -150.0000mm (320mm type)

Upper Limit Hysteresis : 0.3000mm

Lower Limit Hysteresis : 0.3000mm

Analog Output (+5V Value) : +200.0000mm (350mm type)

: +150.0000mm (320mm type)

Analog Output (-5V Value) : -200.0000mm (350mm type)

: -150.0000mm (320mm type)

Judgment Output Selection : LOW, HIGH

Laser Emission Delay : ON

Analog Output During Alarm : Hold

Fixed Analog Output Value During Alarm : maximum +10.9V

Analog Alarm Delay Times : OFF

Analog Alarm Delay : OFF

Output Mode : Normal

Interference Prevention : OFF

CS/DR Control During Accumulation : Yes

3-39

Page 50

Chapter 4 Error Message

Page 51

4-1 Dialog Display

During operation of HL-C1AiM, if an error is detected, the following dialog will appear:

In the "Error message" area, the message corresponding to the detected error will appear.

Various error messages, their causes, and remedies are shown below:

Error messages:

* COM port error.

* Transmission/reception re-try over.

* Reception error.

* Occurrence of reception time-out.

* Controller version is wrong. Shut down the communication.

* Product code of the controller does not match. Shut down the communication.

* Can not open file.

* Can not create file.

4-2 Error Message

4-2-1 COM port error

Error message

COM port error

< Cause >

* A wrong COM port is specified on the communication conditions setting screen.

< Remedy >

* Specify the right COM port.

4-2-2 Transmission / reception re-try over

Error message

Transmission / reception re-try over

4-1

Page 52

< Cause >

* The power of the controller is off.

* A wrong COM port is specified on the communication conditions setting screen.

* The controller is not connected to the connected COM port.

* The time-out value set on the communication condition setting screen is too short.

< Remedy >

* Turn on the power of the controller.

* Specify the right COM port.

* Connect the controller.

* Set a longer time-out value.

4-2-3 Reception error

Error message

Reception error

< Cause >

* The data is destroyed by the electric noise.

< Remedy >

* Eliminate the electric noise.

4-2-4 Occurrence of reception time-out

Error message

Occurrence of reception time-out

< Cause >

* The controller needs too much time to transfer data.

* The data is destroyed by the electric noise.

< Remedy >

* Set a longer time-out value.

* Eliminate the electric noise.

4-2-5 Controller version is wrong

Error message

Controller version is wrong. Shut down the communication

< Cause >

* The connected controller has a wrong version number.

4-2

Page 53

< Remedy >

* Specify the right controller version number.

4-2-6 Product code of the controller does not match

Error message

Product code of the controller does not match.

Shut down the communication.

< Cause >

*The product code of the connected controller is incorrect.

< Remedy >

*Designate the correct product code of the controller.

4-2-7 Can not open file

Error message

Can not open file

< Cause >

* The specified file is now being used for the other program.

* The specified file does not exist.

< Remedy >

* Check whether the file is now being used for the other program.

* Check the file name.

4-2-8 Can not create file

Error message

Can not create file

< Cause >

* Writing in the specified directory is inhibited.

* The specified directory does not have enough unused area.

< Remedy >

* Cancel the write inhibition.

* Secure enough unused area.

4-3

Loading...

Loading...