Page 1

INSTRUCTION MANUAL

Ultra High-speed Laser Displacement Sensor (CCD Style)

HL-C1 series

ME-HLC1 No.0296-00

Page 2

Contents

Cautions on Safety 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯1

Cautions on Handling Laser Light 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯2

Correct Handling 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯9

Warranty㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯13

CHAPTER 1 NAMES AND FUNCTIONS OF PARTS

1-1 Controller 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 1-1

1-2 Sensor Head㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 1-3

1-3 Compact Console 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 1-5

CHAPTER 2 INSTALLATION

2-1 System Configuration 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 2-1

2-2 Installation Environment and Installation Space 㨯㨯㨯㨯㨯㨯㨯㨯 2-2

2-3 Mounting the Controller 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 2-3

2-4 Mounting the Sensor Head㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 2-4

2-5 Mounting the Compact Console 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 2-11

Contents

CHAPTER 3 INPUT AND OUTPUT TERMINAL BLOCKS

3-1 Wiring Terminal Blocks 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 3-1

3-2 Output Terminals 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 3-3

3-3 Input Terminals㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 3-5

3-4 Wiring Power Supply 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 3-7

3-5 Grounding 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 3-8

CHAPTER 4 MEASUREMENT

4-1 Basic Compact Console Operation 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 4-1

4-2 Measuring Height㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 4-5

4-3 Measuring Thickness 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 4-7

CHAPTER 5 FUNCTION ITEMS

5-1 Functions 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-1

5-2 Explanation of Functions 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-2

5-2-1 Measurement Display 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-2

5-2-2 Hold Mode 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-3

5-2-3 Zero Set 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-5

5-2-4 Timing 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-6

5-2-5 Display Hold 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-7

5-2-6 Sampling Period 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-8

5-2-7 Sensor Head Operation 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-10

5-2-8 Calculation Formulas㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-11

5-2-9 Emission Adjustment 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-13

Page 3

Contents

5-2-10 Measurement Mode 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-14

5-2-11 Specular Reflection Mode㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-16

5-2-12 Interference Prevention 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-18

5-2-13 Laser Emission Delay 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-19

5-2-14 Average Number of Samples㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-20

5-2-15 Low Pass Filter 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-21

5-2-16 High Pass Filter 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-22

5-2-17 Simplified Optical Filter 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-23

5-2-18 Upper and Lower Limits and Hysteresis Settings 㨯㨯㨯㨯㨯 5-24

5-2-19 Judgment Output Selection㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-27

5-2-20 Output Mode 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-28

5-2-21 Analog Output Setting 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-29

5-2-22 Analog Output During Alarm 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-31

5-2-23 Analog Alarm Delay 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-32

5-2-24 Input Selection 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-34

ع

Input Operation

ع

LD Emission

ع

Two-sensor Head Input Mode

㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯

㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯

㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯

5-2-25 Calibration 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-36

ع

Automatically Setting the Span and Shift

ع

Direct Input of Span and Shift

㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯

㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯

5-2-26 Light Received 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-40

5-2-27 Save 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-41

5-2-28 Initialization 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-42

5-2-29 Lock 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-44

5-2-30 Communication Specification 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-45

5-2-31 Version㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 5-46

5-34

5-34

5-35

5-36

5-38

CHAPTER 6 RS-232C CONTROL

6-1 Communication Specifications㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-1

6-2 Commands㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-5

6-3 Explanation of Commands㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-9

6-3-1 Read Measurement, Read Light Received㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯6-9

6-3-2 Read Alarm Output, Read Judgment Output㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯6-9

6-3-3 Hold Mode 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-10

6-3-4 Zero Set, Timing 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-10

6-3-5 Sampling Period 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-11

6-3-6 Sensor Head Operation㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-11

6-3-7 Independent Calculation Formula, Add/subtract

Calculation Formula 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-12

6-3-8 Calculation Offset, Calculation Coefficient㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-13

6-3-9 Emission Adjustment㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-14

6-3-10 Measurement Mode 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-15

6-3-11 Specular Reflection Mode㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-15

6-3-12 Laser Beam Emission Delay 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-16

6-3-13 Interference Prevention 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-16

6-3-14 Calibration: Span, Shift 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-17

Page 4

6-3-15 Average 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-17

6-3-16 Low and High Pass Filters 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-18

6-3-17 Simplified Optical Filter 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-19

6-3-18 Upper and Lower Limits and Hysteresis 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-20

6-3-19 Analog Output㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-21

6-3-20 Judgment Output Selection 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-22

6-3-21 Others 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-23

6-3-22 System 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-24

6-3-23 Data Buffering㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-25

6-4 List of Error Codes 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 6-37

CHAPTER 7 INSPECTION AND MAINTENANCE

7-1 Inspection㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 7-1

7-2 Maintenance 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 7-1

CHAPTER 8 TROUBLESHOOTING

8-1 Troubleshooting 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 8-1

8-2 Lock㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 8-2

8-3 Initialization 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 8-2

Contents

CHAPTER 9 SPECIFICATIONS

9-1 Sensor Head㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 9-1

9-1-1 Equipment Compatible to IEC 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 9-1

9-1-2 Equipment Compatible to FDA㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 9-2

9-2 Controller 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 9-3

9-3 Compact Console 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 9-5

CHAPTER 10 DIMENSIONS

10-1 Sensor Head㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 10-1

10-1-1 Equipment Compatible to IEC 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 10-1

10-1-2 Equipment Compatible to FDA㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 10-3

10-2 Controller 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 10-6

10-3 Compact Console 㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯㨯 10-7

Page 5

Page 6

Cautions on Safety

Warning

Q If this product is used in applications where bodily injury or massive

extended damage could develop, incorporate safety measures such as a

double safety mechanism.

Q Do not use this product in a flammable gas atmosphere. It could cause an

explosion.

Caution

Q Configure an emergency stop and interlock circuit using an external circuit.

Q Do not use this product under conditions other than those in the

specifications for rating, environmental conditions, etc. Doing so could

cause abnormal heat generation or smoke emission.

Q Do not attempt to disassemble or modify this product. Doing so could cause

electric shock or smoke emission.

Q Fasten electric wires securely with terminal screws.

If wires are not adequately tightened, it could cause abnormal heat

generation or smoke emission.

Q Do not touch terminals while power is on. Doing so could cause electric

shock.

Indicates the possibility that death or serious injury to

the user could result if a handling error is made.

Indicates the possibility that the user could be injured

or property damage could occur if a handling error is

made.

1

Page 7

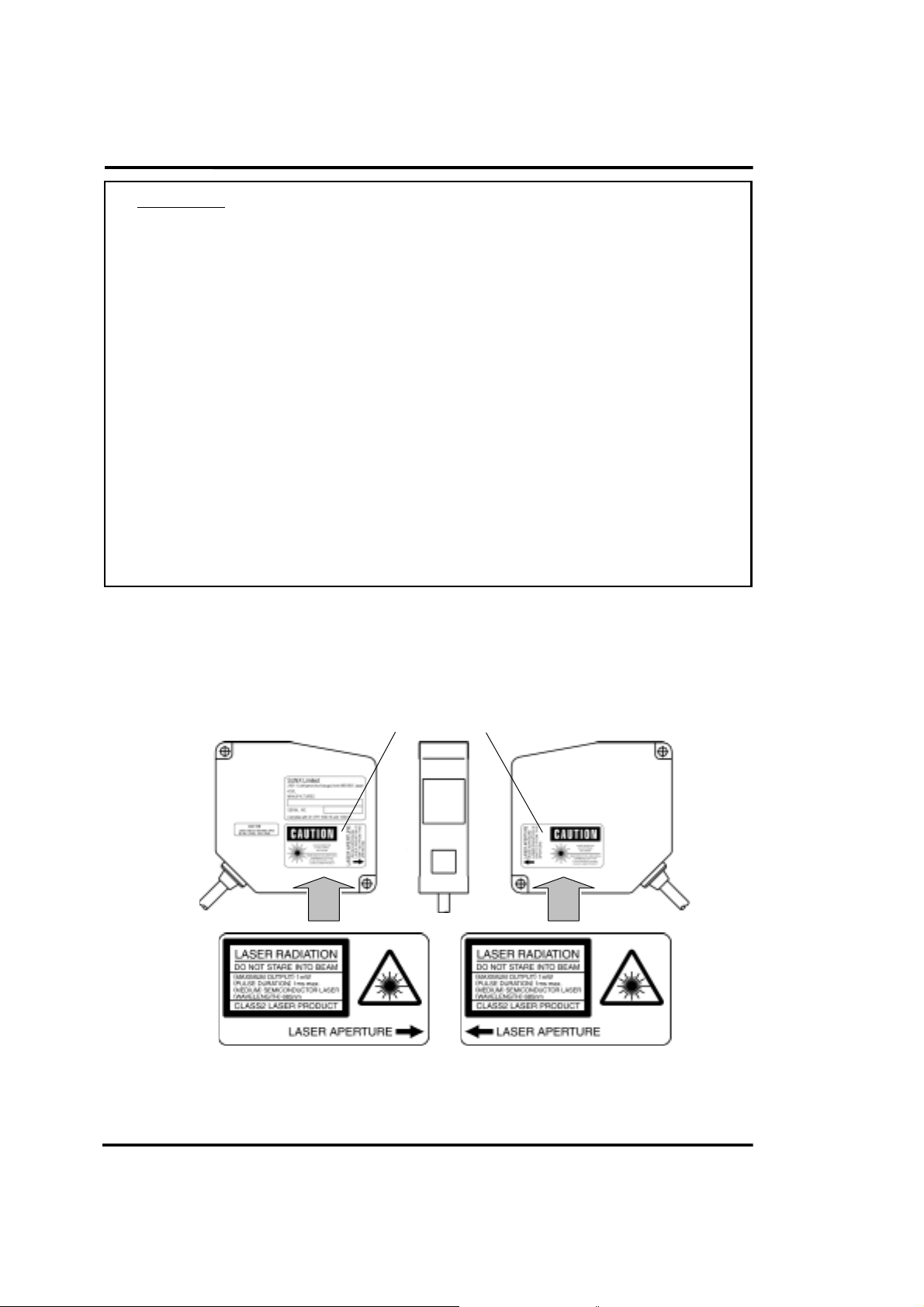

Cautions on Handling Laser Light

1. IEC

A semiconductor laser is used as the sensor's light source.

The laser is classified based on IEC standards (EN60825).

Wavelength 685nm

Maximum Output 1mW

Class 2

Cautions

1) Be careful not to look directly at the laser beam or at its reflection from a

mirror surface.

2) Mount the sensor at a height above or lower than eye level so the beam will

not shine directly into eyes during operation.

The safety distance (Nominal Optical Harm Distance: NOHD) is approximately 0.6m, but make sure the laser beam hits a diffusing reflector or an

absorbing body.

3) Laser beam emission can be stopped using the timing input supplied at the

input terminal (see TM1 and TM2 on page 3-5 and page 5-6). Or, select

"Open circuit" for the input operation of the timing input terminal (see page

5-34) to use the terminal for a remote interlock input.

4) The sensor head in this device is not equipped with a function that stops

laser radiation automatically when it is disassembled, so contact SUNX if it

breaks down.

There is danger of laser radiation if the head is disassembled for repair,

etc.

5) Do not use the device in operation other than that specified in this

Instruction Manual.

Caution – You may be exposed to hazardous laser radiation if the device is

controlled or adjusted in procedures not specified in this manual.

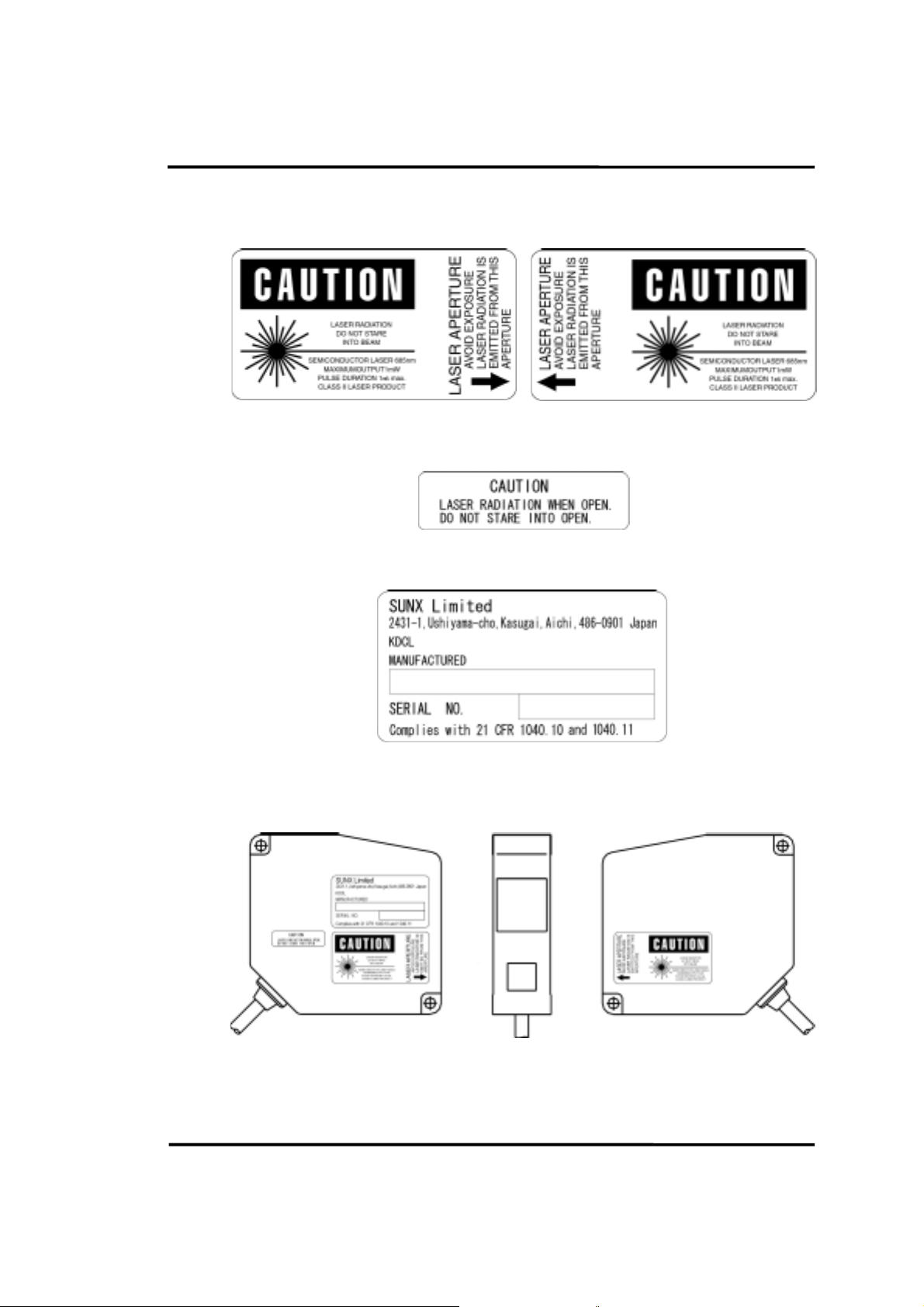

6) Read the contents of the warning label below carefully before use.

The warning label is affixed to the side of the sensor head. The English

warning label is packed with the sensor, so be sure to follow the instructions

printed on it during use.

2

Page 8

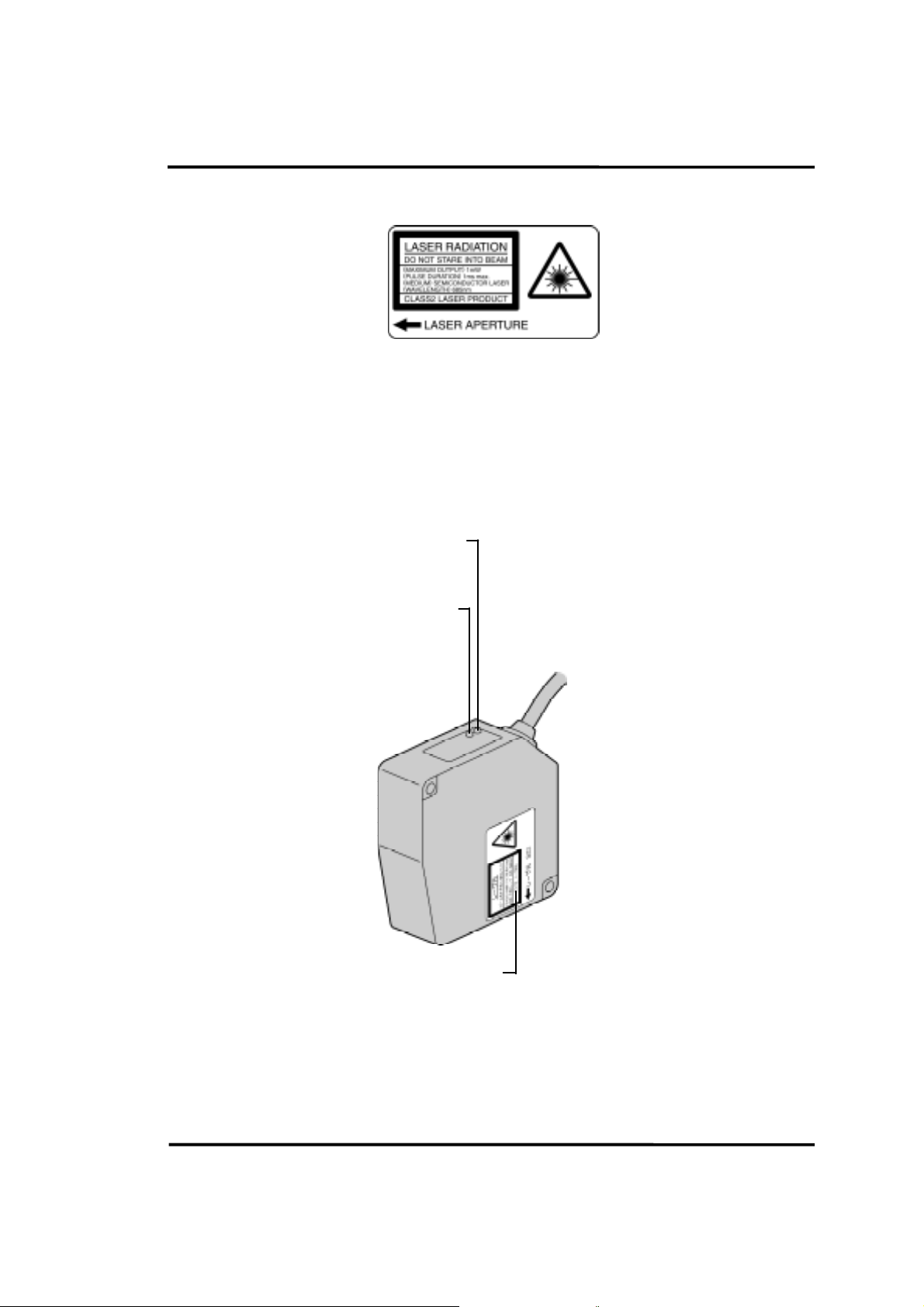

Laser Emission Indicator

Measurement Range Indicator

Warning Label

3

Page 9

2. FDA

Export to US

To export the laser product to the US installed on equipment, it is restricted by

the regulation of the USA Food and Drug Administration (FDA).

Use equipment compatible to the FDA.

The equipment below is compatible.

HL-C105F

HL-C105F-BK

HL-C108F

HL-C108F-BK

The FDA establishes the standard below to prevent problems to the user

previously due to laser product.

PART1040

(PERFORMANCE STANDARDS FOR LIGHT-EMITTING PRODUCTS)

– Execution standard for laser beam emitting product –

This standard classifies the laser product based on the level of laser danger

and stipulates preventive safety measures to be executed for each class. See

requirements on page 7.

The classification of equipment type is as follows:

Classification of HL-C10F, HL-C10F-BK (FDA)

Class II

4

Page 10

This equipment uses the following labels in accordance with

(1) Warning label

(2) Protective casing label

(3) Certificate/identification label

FDA standards:

<Label position>

5

Page 11

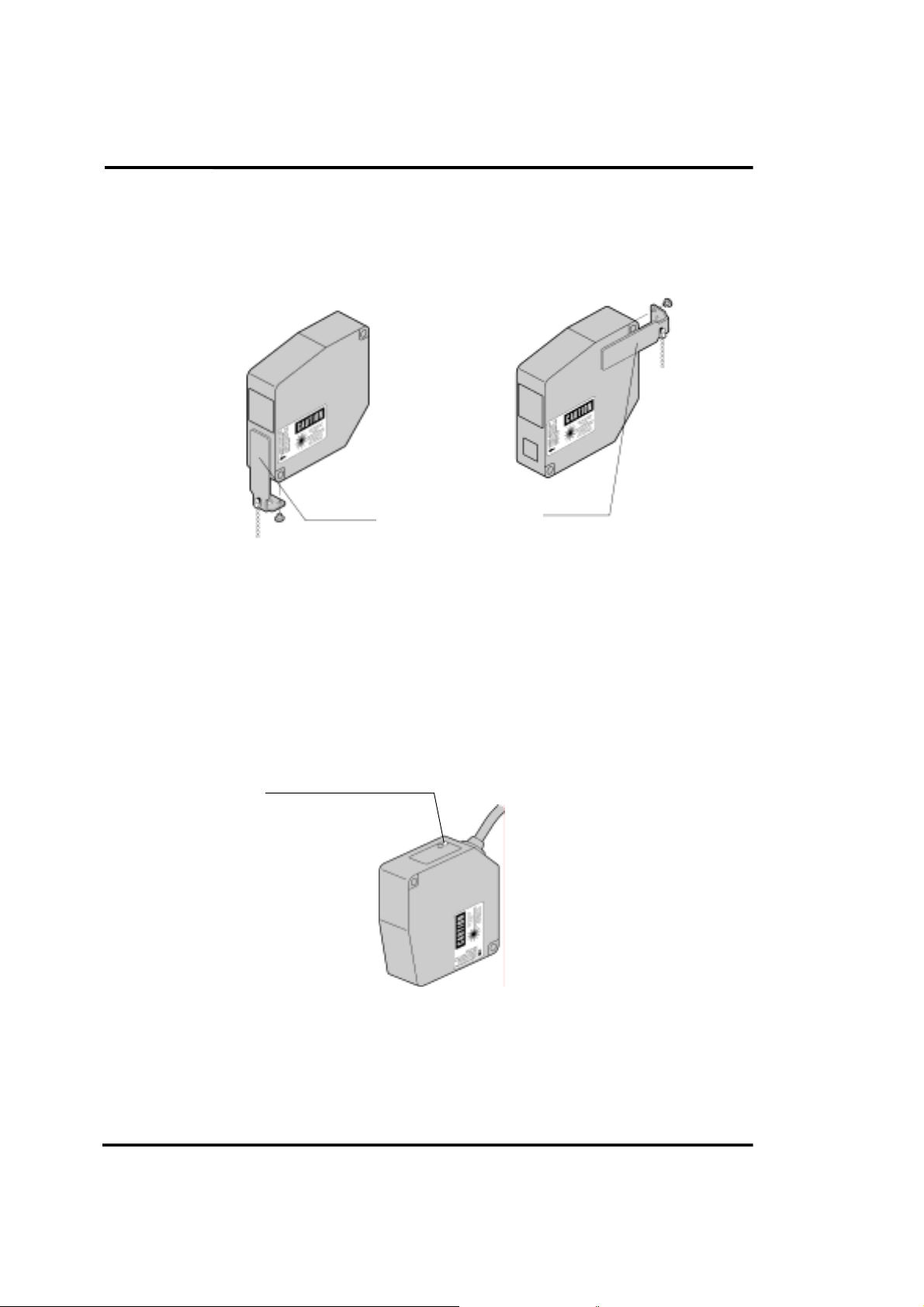

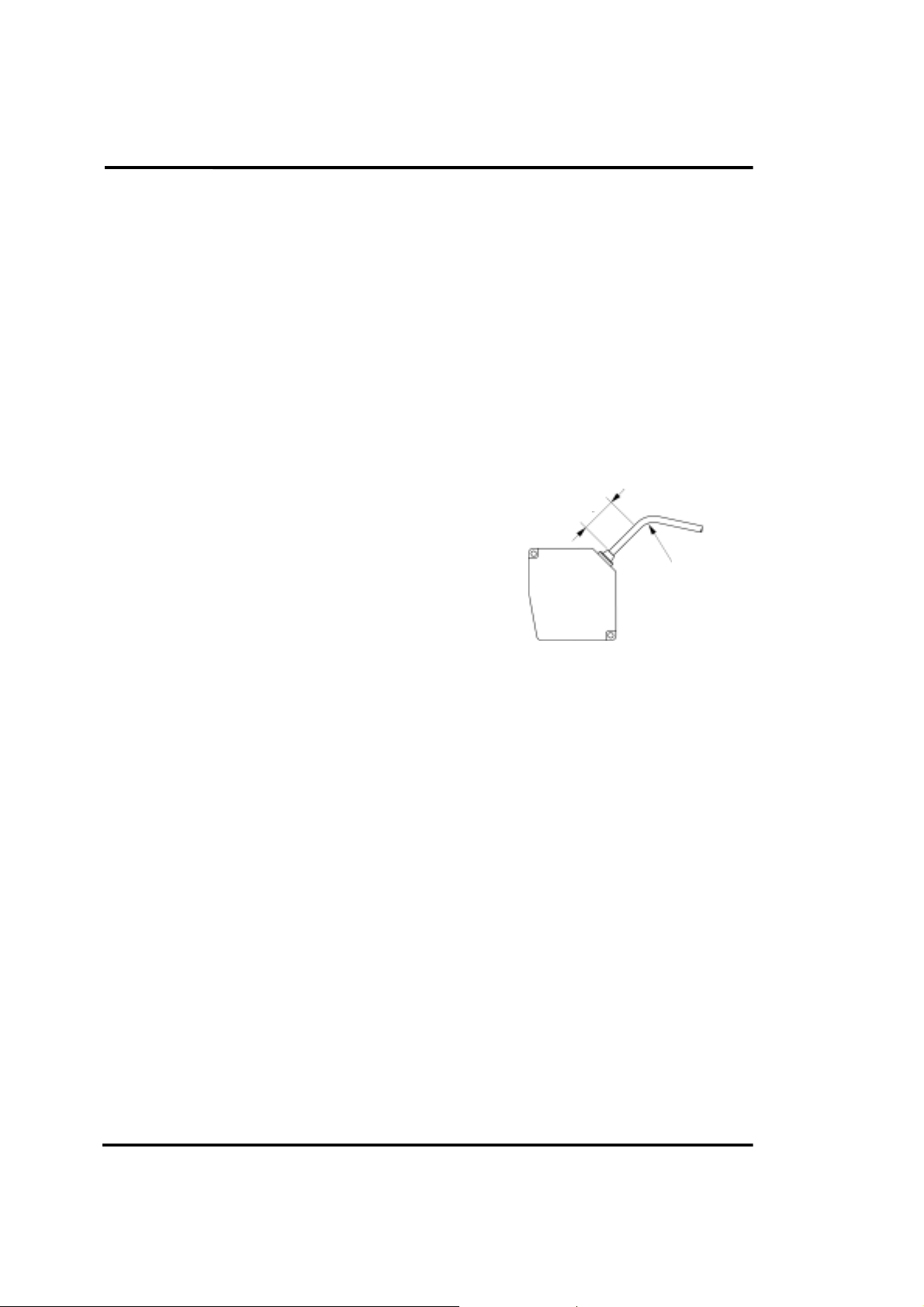

Beam attenuator

When the laser beam may enter eyes during work, work with the beam

attenuator installed.

Beam

attenuator

To attach the beam attenuator, fix

it with the attached screws in such

a manner as to cover the light

projection surface.

When the beam attenuator is not

used, fix it to either side surface of

sensor head, using the attached

screws.

Beam

attenuator

Laser emission indicator

While the laser is emitted, the LED (green) on the sensor head goes on.

It is also possible to recognize the LED through the laser protective glasses.

Laser emission indicator

6

Page 12

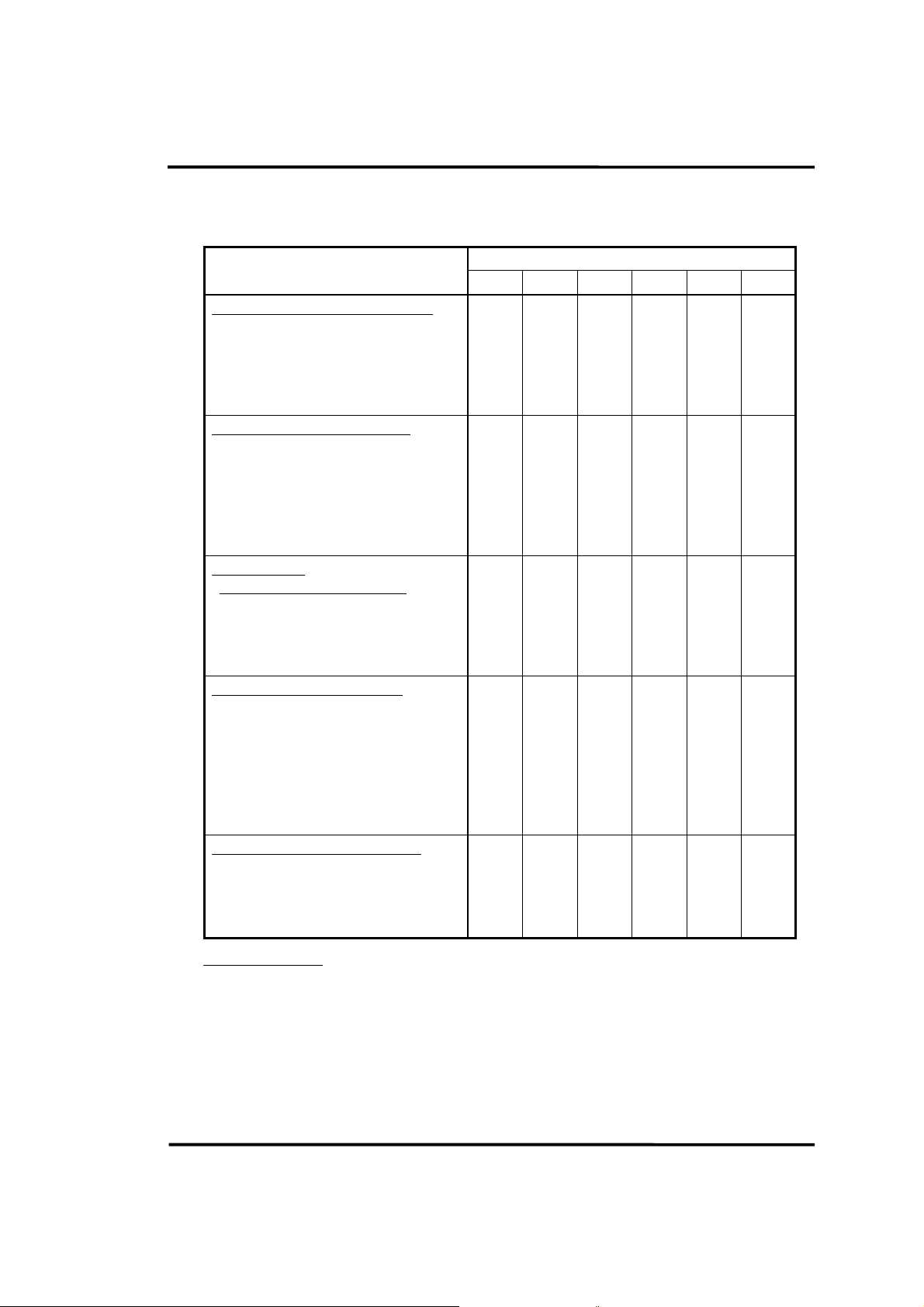

Tabulation of FDA Requirements for Laser Products

Requirements

Performance (all laser products)

Protective housing [1040.10(f)(1)]

Safety interlock [1040.10(f)(2)]

Location of controls [1040.10(f)(7)]

Viewing optics [1040.10(f)(8)]

Scanning safeguard [1040.10(f)(9)]

Performance (laser systems)

Remote control connector

[1040.10(f)(3)]

Key control [1040.10(f)(4)]

Emission indicator [1040.10(f)(5)]

Beam attenuator [1040.10(f)(6)]

Reset [1040.10(f)(10)]

Performance

(specific-purpose products)

Medical [1040.11(a)]

Surveying, leveling, alignment

[1040.11(b)]

Demonstration [1040.11(c)]

Labeling (all laser products)

Certification & identification

[1010.2, 3]

Protective housing

[1040.10(g)(6), (7)]

Aperture [1040.10(g)(4)]

Class warning

[1040.10(g)(1), (2), (3)]

Class

I IIa II IIIa IIIb IV

R

3,4

R

N/A

R

R

N/A

N/A

N/A

N/A

N/A

S

S

S

R

D

N/A

N/A

2

5

R

3,4

R

R

R

R

N/A

N/A

N/A

N/A

N/A

S

S

S

R

R

N/A

R

2

5

6

R

3,4

R

R

R

R

N/A

N/A

R

R

N/A

S

S

S

R

R

R

R

2

5

7

R

3,4

R

R

R

R

N/A

N/A

R

R

N/A

S

S

S

R

R

R

R

2

2

R

3,4

R

R

R

R

R

R

10

R

R

N/A

8

8

S

NP

11

S

R

5

9

5

R

R

12

R

R

R

R

R

R

R

R

R

R

R

S

NP

S

R

R

R

R

2

3,4

10

13

8

11

5

12

Information (all laser products)

User information [1040.10(h)(1)]

Product literature [1040.10(h)(2)(i)]

Service information

R

N/A

R

R

R

R

R

R

R

R

R

R

R

R

R

[1040.10(h)(2)(ii)]

Abbreviations:

R – Required

N/A – Not applicable

S – Requirements : Same as for other products of that Class. Also see

footnotes.

NP – Not permitted

D – Depends on level of interior radiation

7

R

R

R

Page 13

Footnotes:

1. Based on highest level accessible during operation.

2. Required wherever & whenever human access to laser radiation above

Class I limits is not needed for product to perform its function.

3. Required for protective housing opened during operation or maintenance, if

human access thus gained is not always necessary when housing is open.

4. Interlock requirements vary according to Class of internal radiation.

5. Wording depends on level & wavelength of laser radiation within protective

housing.

6. Warning statement label.

7. CAUTION logotype.

8. Requires means to measure level of laser radiation intended to irradiate the

body.

9. CAUTION if 2.5 mW cm

-2

or less, DANGER if greater than 2.5 mW cm-2.

10. Delay required between indication & emission.

11. Variance required for Class IIIb or IV demonstration laser products and light

shows.

12. DANGER logotype.

13. Required after August 20, 1986.

Export to countries overseas other than the US, and use of products in

countries overseas other than the US

When the product is exported to regions other than the US or used in regions

other than the US, change warning labels (HL-C10F, HL-C10F-BK)

compatible to the FDA, with attached labels (indicated in English) as shown

below.

FDA warning label

Attached warning label (English)

8

Page 14

Correct Handling

Note the following points when installing and using this product:

1. Warming Up Time

• Allow at least 30 minutes of warming up after turning on power to ensure

optimum conductance.

2. Use Environment

Ambient Temperature, Humidity, Luminance

• Use this product in the temperature specification range (sensor head: 0 to

+45qC, controller: 0 to +50qC, compact console: 0 to +40qC). If the sensor is to

be stored, the temperature range during storage should be –20 to +70qC.

• The service life of a semiconductor laser depends on the ambient temperature

during use. If the product is used near a heat source, take measures to lower

the ambient temperature of the sensor head as far as possible. Because the

sensor itself emits heat, mount the sensor on a device having good heat

radiation.

• Use the sensor in a range of 35 to 85% RH relative humidity. Avoid use in

places that may be exposed to sudden temperature fluctuations causing

condensation.

• Use the sensor where luminance at the light sensor from incandescent lamps is

3,000 lx or less.

Power Supply Voltage

• The power supply voltage should be within the rated voltage range of 21.6 to

26.4V DC during use.

Environment

• If the external surge voltage exceeds 500V [± (1.2 × 50) µs unipolar full wave

voltage], the internal circuit may be destroyed. If there is danger of external

surge voltages exceeding 500V, install a surge protector between the power

supply and input terminal.

• Water or oil, or fingerprints, etc., on the sensor's emitter or receiver surfaces

refracts light, and dust or dirt cuts light, so keep the sensor clean at all times.

When cleaning these parts, wipe them off using a soft lint-free cloth or lens

cleaning paper.

• Set the sensor head so stray light such as sunlight or light with the same

wavelength, etc., does not enter the light receiver. If high accuracy is required,

install a light shielding plate or the like at the sensor.

9

Page 15

• The sensor head is a waterproof device, but this does not mean that it can be

installed underwater or in places where rain falls. Due to their construction, the

controller and connectors are not dustproof, waterproof, or corrosion-resistant,

so do not use it in an environment where such features are required.

• Do not use this product in places where flammable or corrosive gases are

generated, where dust is excessive, where there is dripping water, where it is

exposed to direct sunlight or severe vibration or impact.

3. Noise Measures

• Do not run the sensor cable along (bundled in parallel with) other wiring, and

keep it at least 100mm from other wires. Run the cable so it is separate from

high voltage and power circuit lines. If running lines in parallel cannot be

avoided, shield the cable by running it through a grounded electrical conduit,

etc.

• For input signal lines and output signal lines, run them separately, not in parallel,

with power lines and power supply lines, keeping them at least 100mm apart. In

addition, keep all signal lines as short as possible when connecting them.

• Install this product as far away as possible from high-voltage lines, power lines,

high voltage device, wireless devices and machines which generate a large

starting and stopping surge.

• If a large amount of electrical noise is generated in the power supply, analog

output is affected. Use a noise filter or a noise dampened transformer.

• Use shielded cables for signal wires such as those for serial input and output

and I/O terminals to reduce electric noise, and connect the shielding wire to the

frame ground.

• It is easy for analog outputs to be influenced by noise, especially from external

sources, so use shielded wires, and keep wiring as short as possible.

• Use an exclusive class D ground based on the functional ground terminal, and

avoid grounding this device in common with other devices. If it is grounded in

common with other devices, the opposite effect may occur.

4. Insulation Resistance and Voltage Resistance

• Do not conduct insulation resistance and voltage resistance tests between the

power supply, input and output signals, and metal parts of the controller.

10

Page 16

5. Power Supply

• Select a power supply with a ripple of 0.5V or less (P-P) and a current capacity

of 2A or more.

• When a commercial switching regulator is used, always use it with the frame

ground (F.G.) terminal connected to ground to avoid the influence of high

frequency noise.

• When using a transformer in the power supply, use an insulated transformer. If

an auto transformer (single turn transformer) is used, this product or the power

supply may be damaged.

• Do not turn the controller's power on again within 10 seconds after turning

power off.

• Use an insulated power supply with a built-in protective circuit to protect against

abnormal voltages from the power line.

• If a power supply without an internal protective circuit is used, be sure to supply

power via a protective element such as a fuse.

6. Instantaneous Power Failures

• If the duration of an instantaneous power failure is 10ms or less, operation

continues.

• If the duration of an instantaneous power failure is 10 to 45ms, one of the

following occurs:

(1) Operation continues.

(2) Analog output changes temporarily and BRIGHT and DARK indicators blink,

then the sensor recovers automatically.

(3) The same status as when the power supply is turned on occurs.

• If an instantaneous power failure lasts more than 45ms, the same status as

when the power supply is turned on occurs.

7. Installation

Controller

• Install the controller unit based on "Heat Radiation Considerations" on page 22, assuring plenty of space around the unit. If it is installed in a manner that is

not based on instructions, it could cause malfunction due to the rise in

temperature, etc.

• If the controller is mounted on a control board, etc., internally where air circulation

is blocked, ambient temperature will rise due to heat generated by the controller,

so use forced cooling.

• If multiple units are installed in series, they can be installed against each other

only if they are installed vertically.

• Ventilation slits for heat radiation are provided in the controller. Provide adequate

space for radiating heat to dissipate, so as not to block the ventilation slits.

11

Page 17

Wire Connections and Connectors

• Connect all wiring securely based on the input and output circuit explanations

and according to markings. Ensure that wiring is correct.

• When connecting and disconnecting connectors and when making all connections,

make sure that controller power is turned off.

• When connecting and disconnecting connectors, take hold of the connector,

being careful not to exert undue force on cables.

• Be careful not to touch terminals or let foreign matter get in the connector when

disconnecting connectors.

• Be careful to keep from applying force to each of the cables near to connectors.

Do not bend cables near connectors because this breaks wires.

Cables

• Do not pull the cable at a force more than

29.4N when routing the cable after fixing the

20mm or more

sensor head and controller. Do not allow

30mm or a shorter bending radius in the cable

path. During use, do not bend the cable at a

place within 20mm of the sensor head's cable

R30 or more

inlet.

• If the sensor head is to be used in a situation

where it is moved during operation, install it

so the cable will not flex during movement. If

flexure is necessary, use an extension cable

that can be replaced.

• Use only 1 extension cable for connection between 1 sensor head and controller.

Do not connect more than 2 extension cables or equipment may be adversely

affected by noise.

12

Page 18

Warranty

Warranty

• The warranty period for this product is 1 year from the date of purchase or from

the date of delivery to the place specified by your company.

Extent of Warranty

• If this product should break down or if a defect becomes apparent which is the

responsibility of SUNX during the warranty period, SUNX will promptly provide

a replacement product or the necessary replacement parts, or will replace or

repair the defect parts free of charge at the place where the product was

purchased or at the place where delivery was made.

The provisions of this warranty do not cover any of the following cases to

breakdown or defect:

(1) The breakdown or defect was caused by specifications, standards, handling

methods, etc., instructed by your company.

(2) The breakdown or defect was caused by modifications in construction,

conductance, or specifications, etc., which SUNX was not involved in were

conducted after purchase or after delivery.

(3) The breakdown or defect occurred due to phenomena which it was

impossible to foresee in technologies which were applied after purchase or

during the warranty period.

(4) The product was used without heeding the conditions and environmental

restrictions included in the instruction manual.

(5) This product is incorporated into your company's equipment and that

equipment, with functions and construction, etc., which are generally

provided in the industry, suffered avoidable damage.

(6) The breakdown or defect was caused by natural disaster or other acts of

God.

The warranty is limited to purchased or delivered products only, and does not

cover any incidental damage resulting from breakdown of or defects in this

product.

The above contents presuppose that the product was purchased and used

within the borders of Japan.

Please contact our company's representative separately if you have requests

concerning purchase or use of this products in nations other than Japan, or

about specifications, warranty, service, etc.

13

Page 19

CHAPTER 1

NAMES AND FUNCTIONS OF PARTS

Page 20

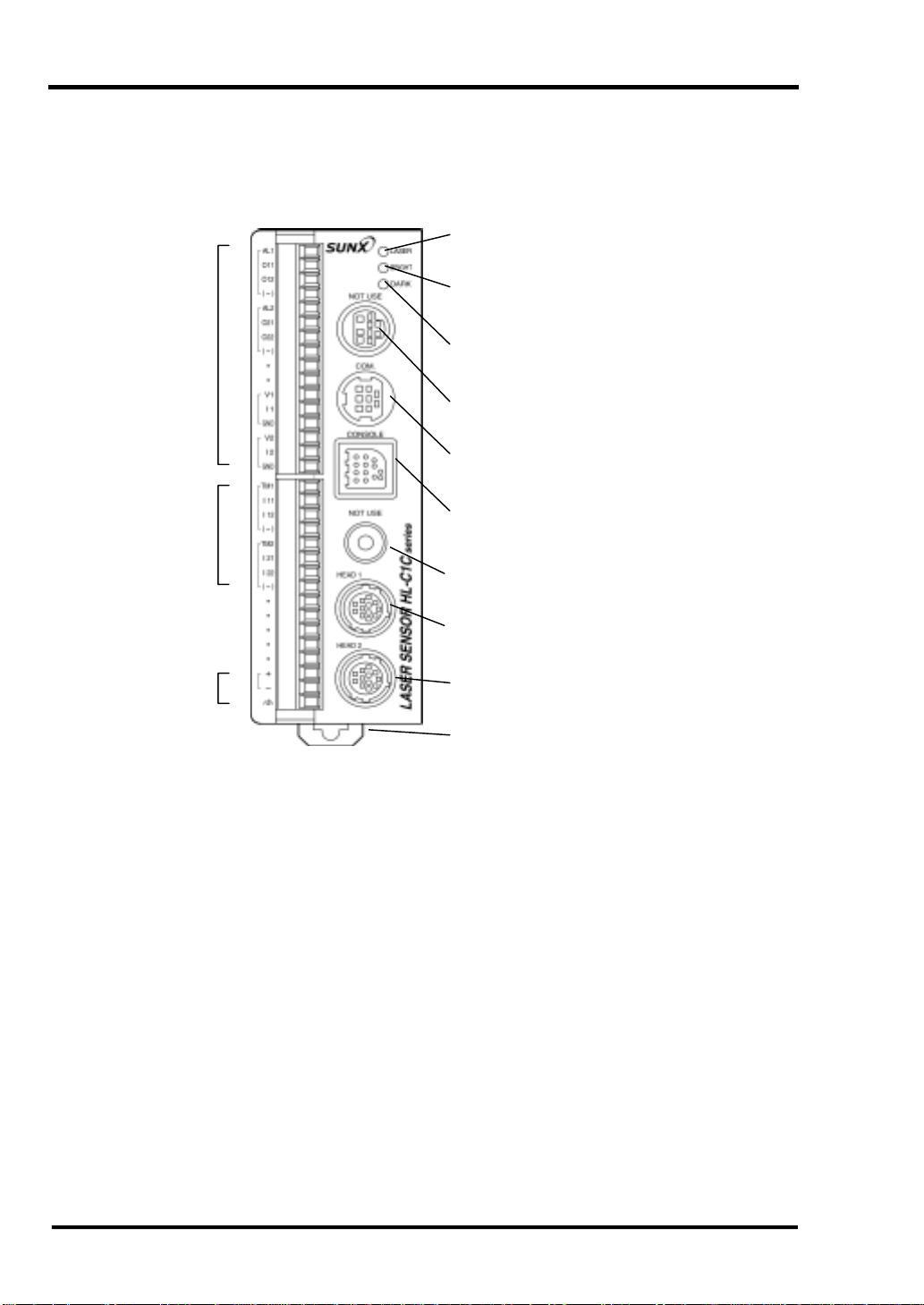

CHAPTER 1 NAMES AND FUNCTIONS OF PARTS

1-1 Controller

(1) Laser Emission Indicator (Green)

(2) BRIGHT Indicator (Red)

(3) DARK Indicator (Red)

(11) External Output

Terminals

(12) External Input

Terminals

(4) Not used.

(5) COM. Port

(6) Connector for Compact Console

(7) Not used.

(10)Power Supply

Terminals

(8) Sensor Head 1 Connector

(9) Sensor Head 2 Connector

(13) DIN Rail Mounting Hook

1-1

Page 21

CHAPTER 1 NAMES AND FUNCTIONS OF PARTS

(1) Laser Emission Indicator (Green)

Lights during laser emission from sensor head 1 or sensor head 2, or immediately before

laser emission.

(2) BRIGHT Indica tor (Red)

Lights when light emitted by sensor head 1 or sensor head 2 is excessive, preventing

measurement.

(3) DARK Indicator (Red)

Lights when light emitted by sensor head 1 or sensor head 2 is insufficient, preventing

measurement.

(4) Not used.

This port is for adjustment at the factory before shipping.

(5) COM. Port

Used for RS-232C communications with a personal computer.

(6) Connector for Compact Console

This enables measurement values to be displayed using the compact console and

connection of the compact console exclusive connection cable when setting each setting.

(7) Not used.

This port is for adjustment at the factory before shipping.

(8) Sensor Head 1 Connector

The controller operates the sensor head connected to this connector as sensor head 1.

(9) Sensor Head 2 Connector

The controller operates the sensor head connected to this connector as sensor head 2.

For a system with only 1 sensor head connected to the controller, connect to the sensor

head 1 connector (8).

(10) Power Supply Terminals

Supplies 24V DC.

(11) External Output Terminals

(12) External Input Terminals

(13) DIN Rail Mounting Hook

Can be mounted on a 35mm width DIN rail quickly.

1-2

Page 22

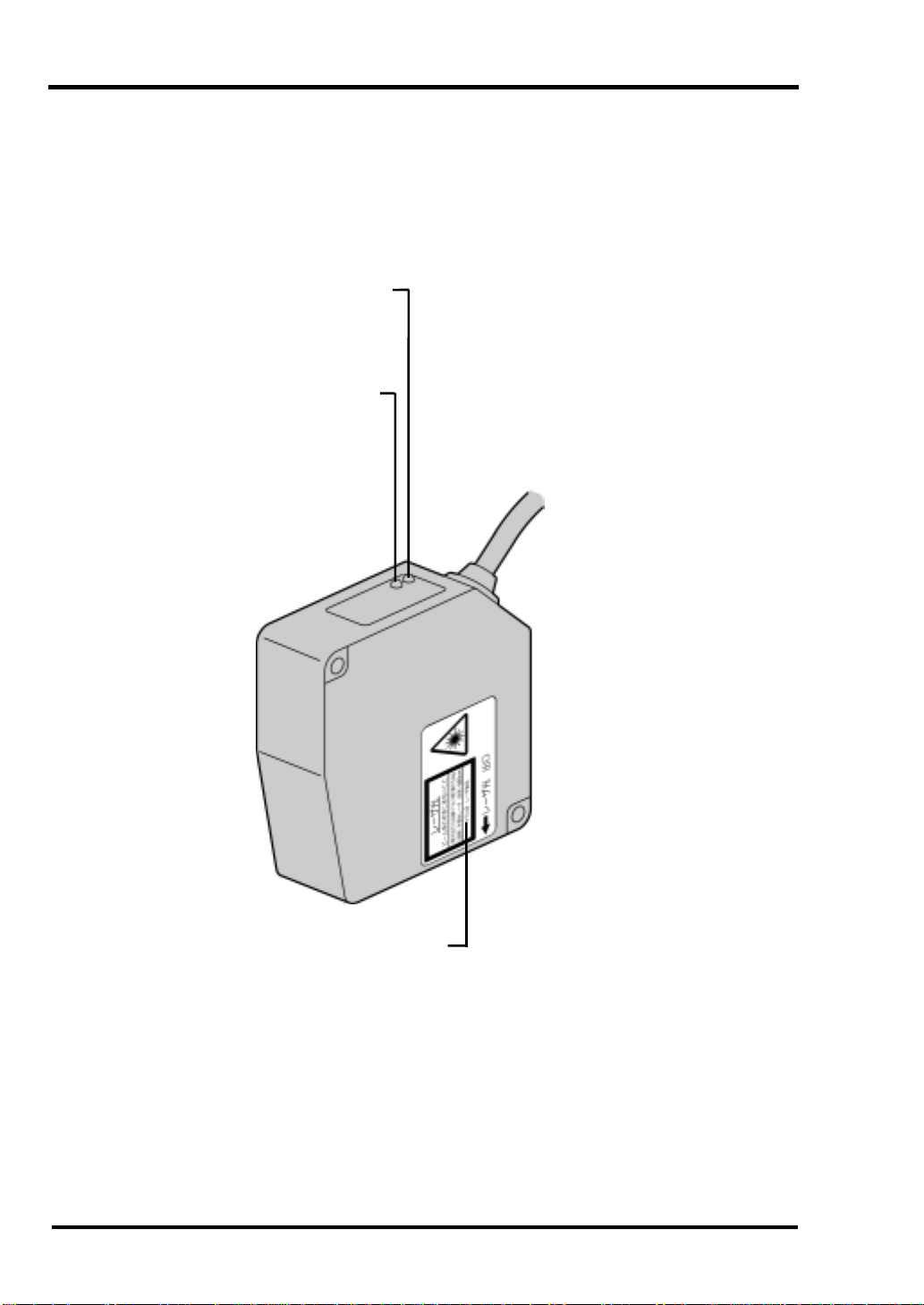

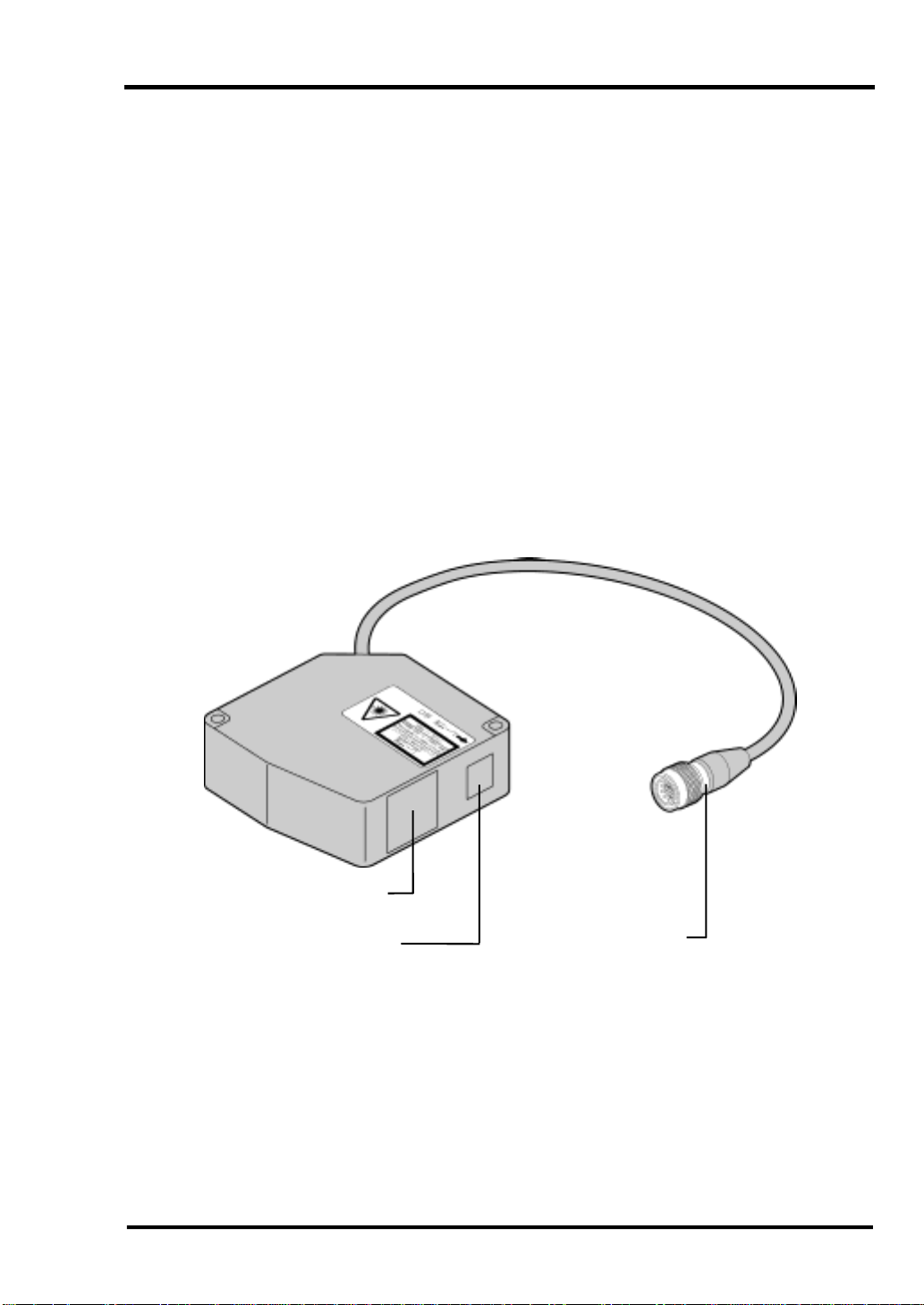

CHAPTER 1 NAMES AND FUNCTIONS OF PARTS

(

)

(

)

1-2 Sensor Head

(1) Laser Emission Indicator

Green

(2) Measurement Range Indicator

Yellow

(3) Warning Label

1-3

Page 23

CHAPTER 1 NAMES AND FUNCTIONS OF PARTS

(1) Laser Emission Indicator (Green)

Lights during laser emission or immediately before laser emission.

(2) Measurement Range Indicator (Yellow)

Blinks when within the measurement range and lights when near the center of the

measurement range.

(3) Warning Label

Shows the laser emission position. Note description contents.

(4) Light Receiver

Receives light reflected from the measured object.

(5) Light Emitter

Emits laser light.

(4) Light Receiver

(5) Light Emitter

Connector

1-4

Page 24

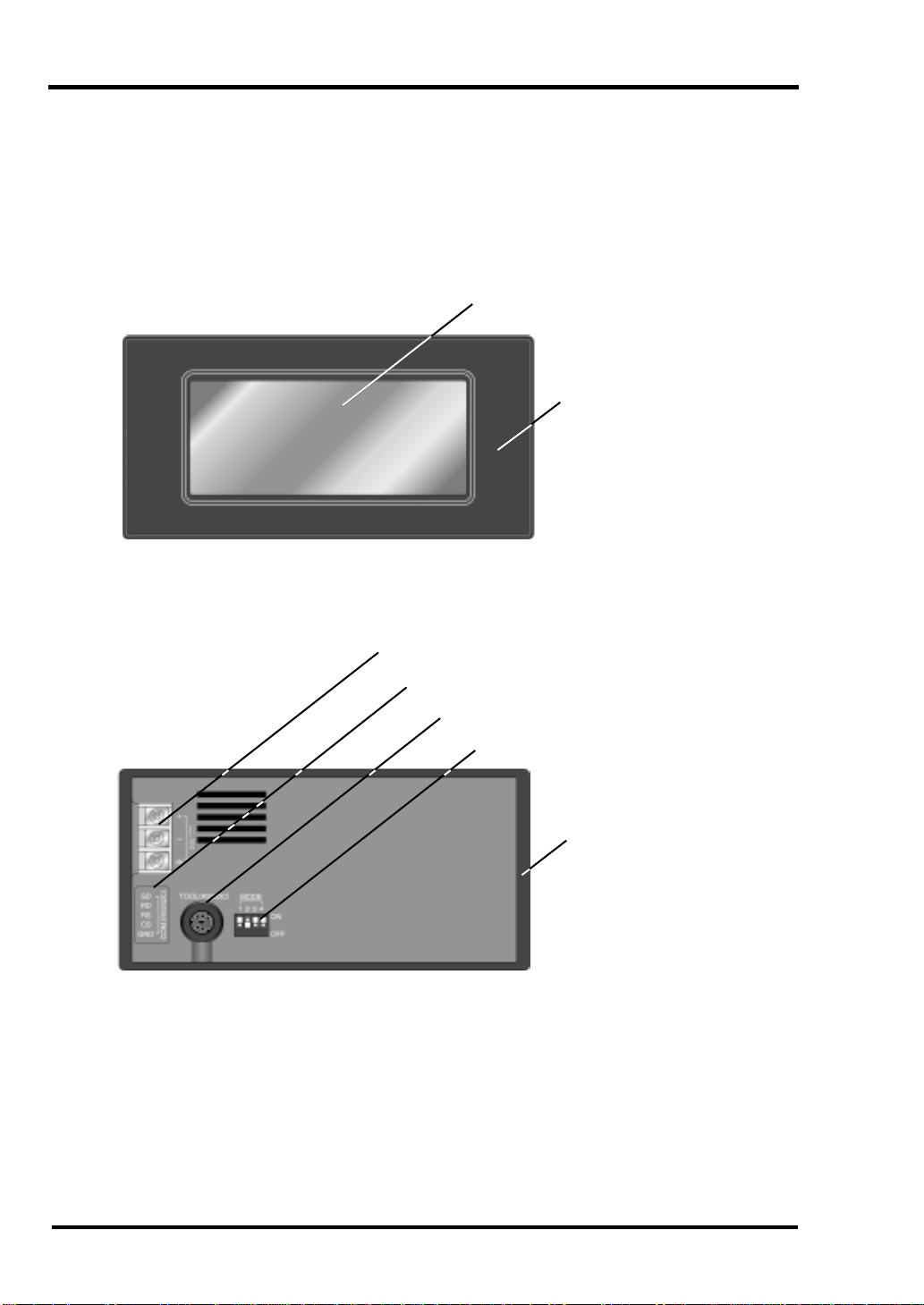

CHAPTER 1 NAMES AND FUNCTIONS OF PARTS

1-3 Compact Console

[Front]

(1) Liquid Crystal Panel (Touch Panel)

(2) Front Protective Sheet

[Rear]

(3) Power Supply Terminal

(4) COM. Port

(5) (TOOL Port)

(6) (Operating Mode Setting Switch)

(7) Waterproof Packing

1-5

Page 25

CHAPTER 1 NAMES AND FUNCTIONS OF PARTS

(1) Liquid Crystal Panel (Touch Panel)

Measuring data and setting values are displayed. The setting can be changed and data

input by touching the panel.

(2) Front Protective Sheet

A sheet is affixed to the liquid crystal panel when the sensor is shipped to protect it and

keep it clean.

(3) Power Supply T erminal

Supplies 24V DC for the operation power supply.

(4) COM. Port

This port is used for connecting the compact console to the controller using the exclusive

cable provided with the console.

(5) (TOOL Port)

The TOOL port is used to create screen data with the product connected to a personal

computer. Do not use the port for this equipment, equipment has already been incorporated

with dedicated screen data.

(6) (Operating Mode Setting Switch)

Use this product in the status below to protect exclusive screen data.

1234

(Settings when shipped from the factory)

(7) Waterproof Packing

This packing ensures that the panel is waterproofed from the front.

One packing is supplied when the product is shipped.

Switch No. Setting

1OFF

2ON

3

4

OFF

1-6

Page 26

CHAPTER 1 NAMES AND FUNCTIONS OF PARTS

MEMO

1-7

Page 27

CHAPTER 2

INSTALLATION

Page 28

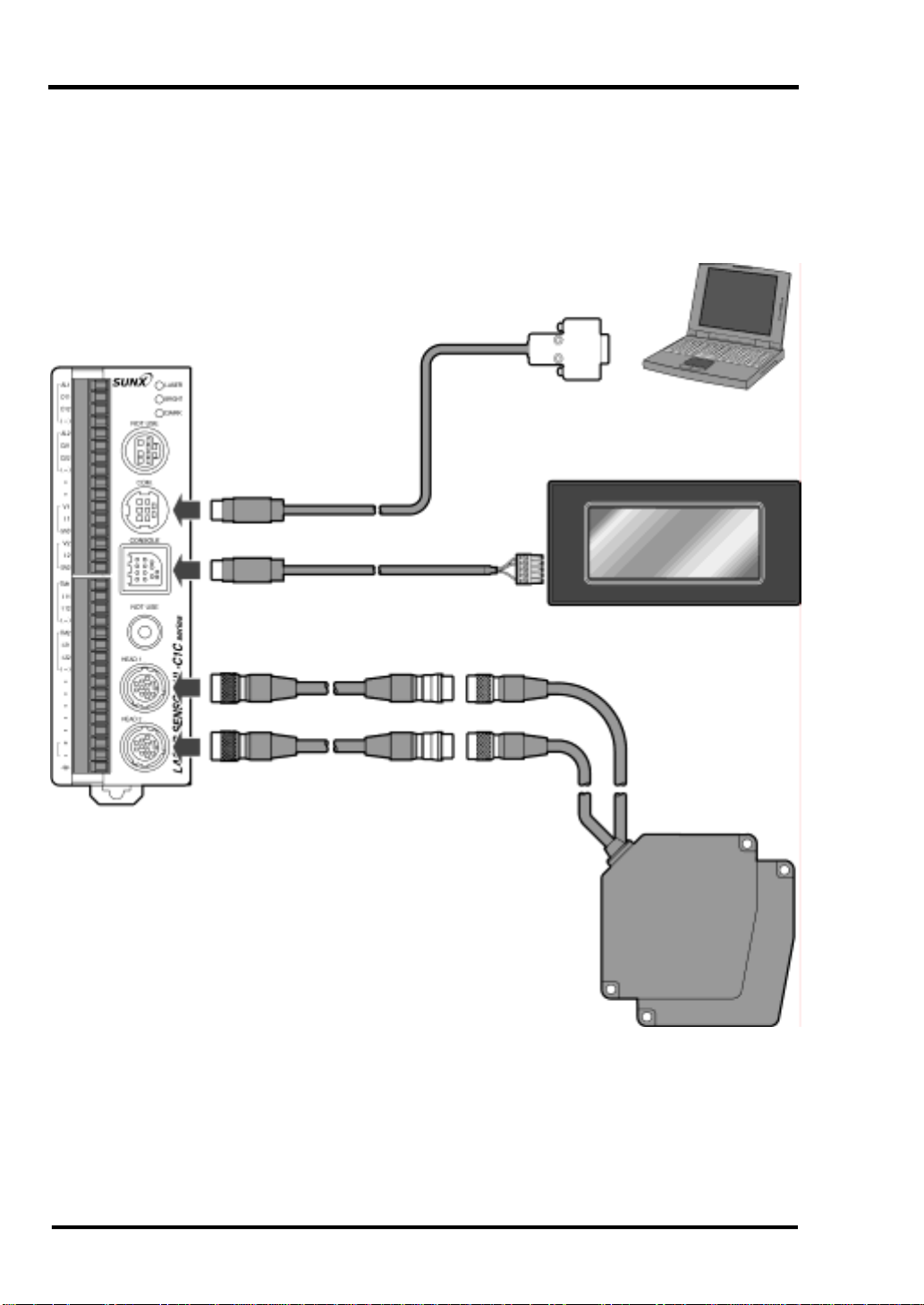

CHAPTER 2 INSTALLATION

2-1 System Configuration

Controller

RS-232C Cable 3m

(Supplied with the intelligent

monitor HL-C1AiM)

Compact Console

Connection Cable 2m

(supplied with the compact console)

Extension Cable

2m, 5m, 10m, 20m, 30m

• For a system with only 1 sensor head connected to the

controller, connect to the sensor head 1 (HEAD 1)

connector.

Sensor Head

2-1

Page 29

CHAPTER 2 INSTALLATION

T

2-2 Installation Environment and Installation

Space

Avoid installation in the following places:

• Places where ambient temperature exceeds specifications (sensor head: 0 to +45°C,

controller: 0 to +50°C, compact console: 0 to +40°C).

• Relative humidity exceeds 35 to 85% relative humidity.

• Luminance at the light receiver exceeds 3,000 lx (incandescent lamp).

• Places subject to sudden temperature fluctuations that could cause condensation.

• Corrosive or flammable gases exist in the atmosphere.

• Iron chip, dust or salt is excessive.

• The atmosphere contains benzene, paint thinner, alcohol, or other organic solvents, or

where a danger exists of strong alkaline substances such as ammonia or caustic soda

adhering to the sensor.

• Vibration or impacts are severe.

• Places exposed to direct sunlight.

• Water, oil, chemicals, etc., could contaminate the product.

• Loads are applied to the sensor head.

Noise Considerations

• Mount this product as far as possible from high voltage lines, high voltage equipment,

power lines, power equipment, equipment that generates large start and stop surges,

and welders, inverter motors, and other equipment that generates electric noise.

• Mount this product as far as possible from equipment with a transmitter such as

amateur radio equipment.

• Do not let excessive static electric charges be applied to the panel surface since it

could destroy the LCD unit.

Heat Radiation Considerations

• Do not mount this product on a heater, transformer, or other device that radiates large

amounts of heat such as high capacity resistors.

• If the controller is mounted internally on a control board where air circulation is blocked,

ambient temperature will rise due to heat generated by the controller, so use forced

cooling.

• Mount the controller with the following orientation to facilitate heat dissipation.

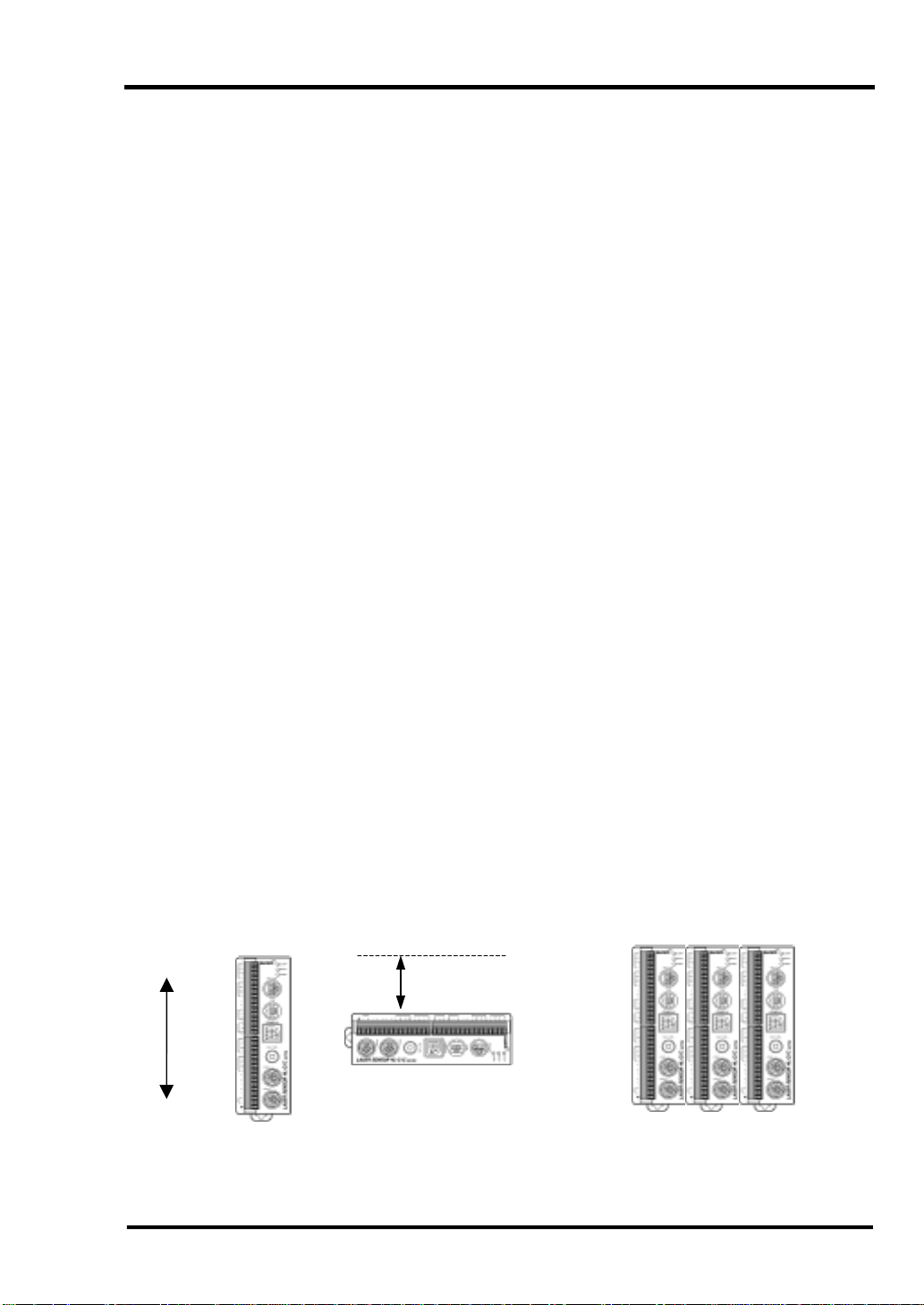

[Mounted vertically] [Mounted horizontally] [Multiple units mounted side by side]

op

Bottom

100mm or more

Mount the controller with the side

containing slits facing up.

Mount the controller in the orientation

shown in the figure above.

2-2

Page 30

CHAPTER 2 INSTALLATION

Installation Space

• Mount the controller so it is separated from surrounding ducts and other devices by

50mm or more to enable replacement, wiring, etc.

• If a panel door or other device is placed in front of the controller unit, separate it from

the controller by 100mm or more to avoid the influence of radiation noise or heat

generation.

• Ensure that there is an allowance of 100mm or more from the controller's front surface

to enable connection of sensors, wiring, etc.

50mm or more

50mm or more

50mm or more

100mm

or more

50mm or more

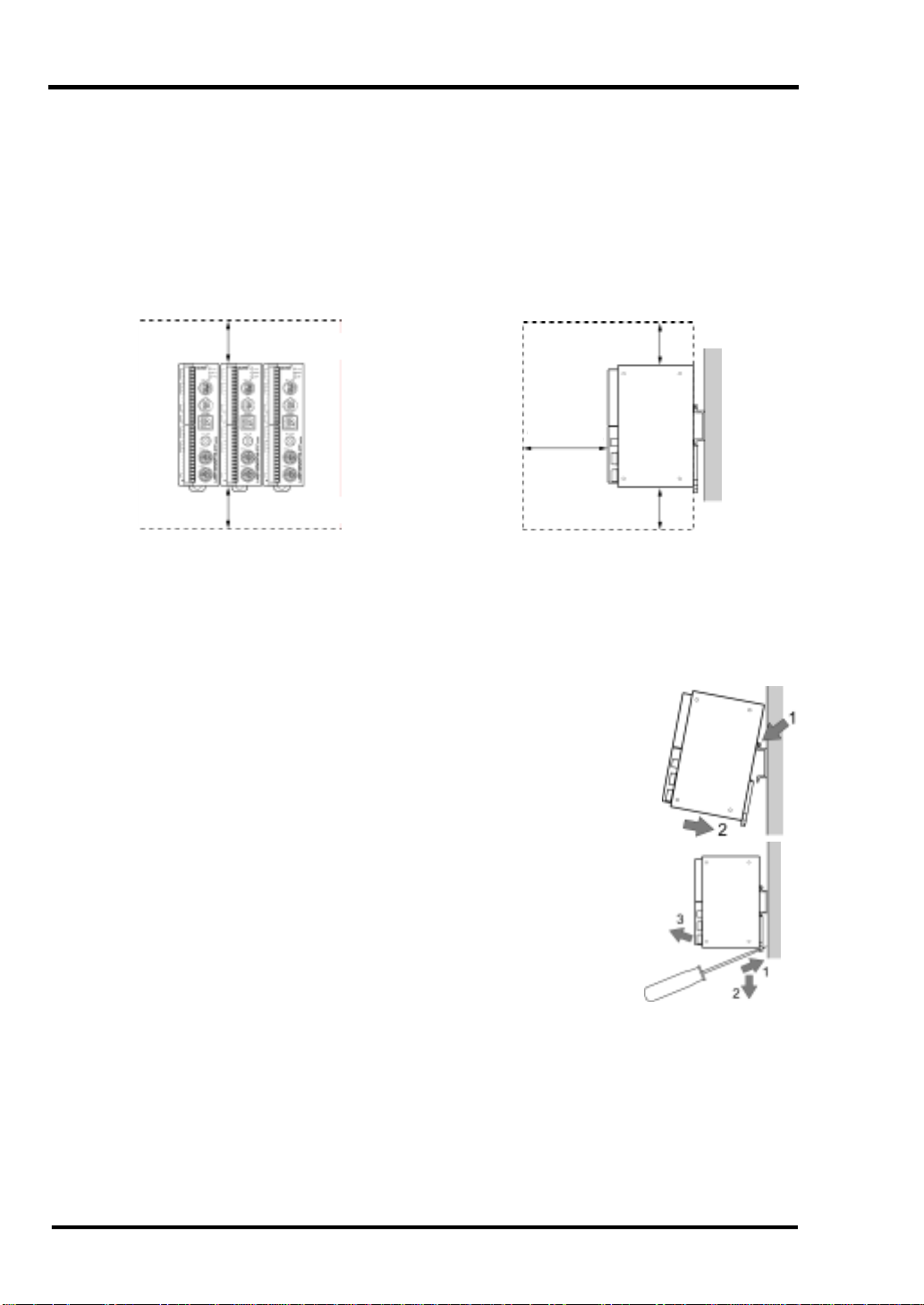

2-3 Mounting the Controller

The controller can be mounted by fastening it with screws or by using a DIN rail.

Mounting the Controller with a DIN Rail

The controller can be mounted or removed from a 35mm widt h DIN

rail (DIN EN 50022) in 1-touch operation.

[Mounting]

1.Hang the top on the DIN rail.

2.Push the bottom of the controller to fasten it on the rail.

[Removal]

1.Insert the blade of a flat-bladed screwdriver in the mounting lever.

2.Pull down the mounting lever.

3.Raise the controller and remove it from the rail.

Mounting the Controller with Screws

• While referencing the external dimensioned diagram on page 10-3,

use M3 screws to fasten the controller. Do not tighten screws

beyond 0.5N·m.

• To avoid breakage inside the controller, do not insert the screw tip

3.5mm or more from the side of the case.

• Use only the 4 screw holes included on the side of the case.

2-3

Page 31

CHAPTER 2 INSTALLATION

2-4 Mounting the Sensor Head

Mounting the Sensor Head

• Fasten the sensor securely with M5 screws, using the 2 holes in the corners of the

sensor head. Limit tightening torque to within 1.2N·m.

• Install the sensor head with the relative position of the object adjusted to the type

(50mm/85mm, diffused reflection/specular reflection) of equipment used, referencing

the installation dimension drawing.

• It is possible to connect the sensor head (50mm) and another sensor head (85mm) at

the same time. The initial setting within the controller will correspond to the type of

equipment connected. When equipment of a different type is connected at the same

time, however, the upper/lower limit setting, hysteresis setting, and analog setting for

addition/subtraction operation will correspond to the type of equipment connected to

the head-1 side connector. When necessary, change setting contents.

• If the power supply is turned on with the connection changed (change in equipment

type: 50mm, 85mm, change in connection from 1-sensor head to 2-senso r head o r vice

versa) from that when controller setting contents are saved, setting contents are

initialized. If the connection is incorrect, turn off the power supply to return the

connection to that when the controller setting was saved, then turn on the power supply

again, returning setting contents to that when the controller setting was saved. Note

that setting contents are not initialized when equipment is replaced with an equivalent

type or when the number of units is increased/decreased.

• Operate the sensor head within the temperature specification (sensor head: 0 to +45ºC,

controller: 0 to +50ºC, compact console: 0 to +40ºC).

• Service life of a semiconductor laser depends on ambient temperature during use. If

the sensor is used near a heat source, take cooling measures to lower ambient

temperature of the sensor head. The sensor generates heat, so mount the sensor head

on a unit having good heat radiation performance. *

* When installing 2 sensor heads in parallel at a 20mm or less interval, mount each

sensor head on an aluminum or iron plate having a 200cm

2

surface area.

2-4

Page 32

CHAPTER 2 INSTALLATION

• If the sensor is to be stored, temperature during storage should be -20 to +70ºC.

• Use the sensor at 35 to 85% relative humidity. Avoid use where sudden temperature

fluctuations could cause condensation.

• Use the sensor where luminance at the light sensor from incandescent lamps is 3,000lx

or less.

• Mount the sensor head so stray light such as sunlight or light with the sam e wavelength,

etc., does not enter the light receiver. Where accuracy is a factor, use with a shading

plate, etc.

• Do not mount the sensor head where flammable or corro sive gases are generated, dust

is excessive, water drips, exposure to direct sunlight is possible, or severe vibrations or

impacts occur.

Installation dimensions

z Measurement of diffused reflection

• 50mm type

• 85mm type

Beam

receiving

axis

Beam

receiving

axis

Beam

projecting

axis

Measurement

center

(Unit: mm)

Measurement

Range Indicator

(Yellow)

Laser Emission

Indicator

(Green)

(Unit: mm)

Measurement

Range Indicator

(Yellow)

Laser Emission

Indicator

(Green)

Beam projecting

axis

Measurement center

2-5

Page 33

CHAPTER 2 INSTALLATION

M

t

z Measurement of specular reflection

• 50mm type

Beam

receiving axis

Beam

projecting

axis

easuremen

center

• 85mm type

Specular reflection sensor head

setting reference surface

Specular reflection type sensor

head setting reference surface

(Unit: mm)

Measurement

Range Indicator

(Yellow)

Laser Emission

Indicator

(Green)

(Unit: mm)

Beam

receiving axis

Beam

projecting axis

Measurement

center

2-6

Measurement

Range Indicator

(Yellow)

Laser Emission

Indicator

(Green)

Page 34

CHAPTER 2 INSTALLATION

Sensor Head Mounting Direction

Mount the sensor head in the orientation shown below to ensure accurate measurement.

z Rotating objects

z Objects with level differences or grooves

z Objects with great changes in color

2-7

Page 35

CHAPTER 2 INSTALLATION

Mutual Interference

If more than 1 sensor head is mounted close together, no mutual interference will occur if

the neighboring sensor's laser spot is outside the shaded portion in the figure below.

Mount other sensor heads so laser spots do not enter the shaded area.

When using 2 sensor heads connected to 1 controller, it is possible to use the interference

prevention function. Refer to 5-2-12, "Interference Prevention".

• 50mm type

• 85mm type

2-8

(Unit: mm)

Page 36

CHAPTER 2 INSTALLATION

5

Beam Diameter

(Unit: mm)

• 50mm type

Measurement Range

Measurement Center Dist.

• 85mm type

Output Characteristics and Measurement Range

Indicator

z Measurement of diffused reflection

Lights

Measurement Range Indicator

•50mm type

•85mm type

Alarm Output

(N.C.)

Open

Closed

Off Blinks

Measurement Range

Measurement Center Dist.

–

–20

Blinks

Displacement

Output

+20

–5V

Off

+5

Distance (mm)

* Analog output is set to initial status

2-9

Page 37

CHAPTER 2 INSTALLATION

z Measurement of specular reflection

Measurement Range Indicator

Measurement Center Dist.

•50mm type

•85mm type

Off

Lights

Blinks Blinks

Measurement Range

Displacement

Output

Off

Distance (mm)

Alarm Output

(N.C.)

Open

Closed

*

* Analog output is set to initial status

2-10

Page 38

CHAPTER 2 INSTALLATION

2-5 Mounting the Compact Console

Mount the installation plate using the enclosed mounting fittings (4) and installation

screws (4).

(1) Insert the compact console unit in the mounting plate.

(2) Fit the mounting plate in the groove in the compact console unit, then tighten screws,

fastening the compact console to the mounting plate.

Use enclosed mounting fittings (4)

and installation screws (4).

Enlargement

• Tighten screws with a torque of 0.1 to 0.25N·m.

• Use a panel 1.0 to 6.0mm thick.

• If the mounting angle is 60 to 0° (horizontal), use

an operating voltage of 25V DC or less.

Mounting Angle

Clearances During Mounting

When mounting the compact console, if other parts are on the panel and wiring is required,

it is recommended that a clearance of 30 to 50mm be allowed around the compact console

to prevent damage to cables, improve workability, etc. Do not cover slits in the console unit.

Wiring the Connection Cable Terminal (Supplied)

• Connection cable terminal wiring is sho wn at rig ht.

• Before connection to the controller, turn off both

the compact console and controller.

• To prevent disconnection due to vibration, fix the

connecting cable near the compact console within

20cm of the COM. port.

Yellow

Red

White

2-11

Page 39

CHAPTER 2 INSTALLATION

Wiring the Power Supply

• Connect power supply wiring securely to the terminal on

the back of the main unit.

• Use twisted wires for power supply lines to minimize the

effect of noise.

• Use an insulated power supply with a built-in protection

circuit for the power supply to protect against abnormal

voltage from the power line.

• An uninsulated type is used in the regulator internally in the compact console.

• If a power supply is used that does not have a built-in protection circuit, connect the

power supply to the compact console via a fuse or other protective element.

• The power supply voltage should be within the rated voltage of 21.6 to 26.4V DC

during use.

• Use M3 screws to fasten the compact console. It is recommended that compression

terminals be used on ends of wires.

U-shape terminal

z

Round terminal

z

+24V

0V

6.0mm

or less

Maker Shape Model Applicable Wire Tightening Torque

Round 1.25-MS3

JST Mfg. Co., Ltd.

U-shape 1.25-B3A

Round 2-MS3

U-shape 2-N3A

6.0mm

or less

0.25 to 1.65mm

1.04 to 2.63mm

2

2

0.5 to 0.6N·m

• Tighten screws on the terminal block with a torque of 0.5 to 0.6N·m. Force exceeding

this may damage the device.

• If compression terminals are not used, use wire 0.5 to 1.25mm2 in diameter.

• To comply with the European EMC Directive, install a ferrite core (Seiwa Electric Mfg.

Co., Ltd. E04RC281613 or equivalent) on wires to the terminal block as shown below.

Ferrite Core

• Separate wiring to the compact console, PLC,

and power equipment.

Breaker

Power Equipment

2-12

Compact

Console

Insulated DC Power Supply

Page 40

CHAPTER 2 INSTALLATION

MEMO

2-13

Page 41

CHAPTER 3

INPUT AND OUTPUT TERMINAL

BLOCKS

Page 42

CHAPTER 3 INPUT AND OUTPUT TERMINAL BLOCKS

3-1 Wiring Terminal Blocks

Output Terminal Block

Input / Power Supply

Terminal Block

Terminal Blocks

The terminal block can be removable from the controller and tightened with screws. Use

the following tools and cables:

Enclosed Terminal Block Socket

(Equivalent)

Tightening Tools

(Tip width 0.4×2.5)

Applicable Wire (twisted wire)

Maker Model Product No. Tightening Torque

Phoenix Contact

(Co., Ltd.)

Phoenix Contact (Co., Ltd.) MC1,5/16-ST-3,5 (Color: Green)

Maker Model

SZS 0,4×2,5 1205037 0.22 to 0.25N·m

Size Conductor Cross-Section

AWG#24 to 16 0.3 to 1.25mm

2

3-1

Page 43

Wiring

CHAPTER 3 INPUT AND OUTPUT TERMINAL BLOCKS

1. Strip insulation from

the end of the wire.

2. Insert the wire in the

terminal block until it

contacts the back, then

secure it by tightening

the screw.

3. If more than 1 wire is

inserted into the same

terminal, twist wires

before inserting them.

Use the device as directed.

• Turn power supply off before wiring and remove or install the terminal block.

• Do not use wires tinned with solder. They may break when subjected to vibration.

• Wiring to the terminal block must not exceed 30m.

3-2

Page 44

CHAPTER 3 INPUT AND OUTPUT TERMINAL BLOCKS

3-2 Output Terminals

Terminal Layout

NPN output

Symbol Meaning

AL1 Alarm Output (Sensor Head 1)

O11 Judgment Output 1 (Sensor Head 1)

O12 Judgment Output 2 (Sensor Head 1)

(-) External Insulated GND

AL2 Alarm Output (Sensor Head 2)

O21 Judgment Output 1 (Sensor Head 2)

O22 Judgment Output 2 (Sensor Head 2)

(-) External Insulated GND

• Not used.

• Not used.

V1 Analog Voltage Output (Sensor Head 1)

I1 Analog Current Output (Sensor Head 1)

GND Analog Output Ground

V2 Analog Voltage Output (Sensor Head 2)

I2 Analog Current Output (Sensor Head 2)

GND Analog Output Ground

Photo-MOS output

Symbol Meaning

AL1 Alarm Output (Sensor Head 1)

O11 Judgment Output 1 (Sensor Head 1)

O12 Judgment Output 2 (Sensor Head 1)

COM Output Common

AL2 Alarm Output (Sensor Head 2)

O21 Judgment Output 1 (Sensor Head 2)

O22 Judgment Output 2 (Sensor Head 2)

COM Output Common

• Not used.

• Not used.

V1 Analog Voltage Output (Sensor Head 1)

I1 Analog Current Output (Sensor Head 1)

GND Analog Output Ground

V2 Analog Voltage Output (Sensor Head 2)

I2 Analog Current Output (Sensor Head 2)

GND Analog Output Ground

The COM (output common) terminals of

sensor head 1 and sensor head 2 are

connected internally.

Terminals marked with "•" are not used. Some are connected to internal circuitry, and

cannot be used as relay terminals in wiring, etc.

3-3

Page 45

Output Circuit

t

z Alarm Output, Judgment Output

CHAPTER 3 INPUT AND OUTPUT TERMINAL BLOCKS

NPN output

Photo-MOS output

Connection example 1 (NPN)

Load

50mA max.

COM.

Laser Sensor

z Analog Output Circuit

-10.9 to +10.9 V

Vx

0 to 29.5mA

Ix

Load

30V DC max.

Laser Sensor

Connection example 2 (PNP)

50mA max.

Load

COM.

Laser Sensor

Limit the spike voltage due to inductive load or circuit

wiring length to 350V AC or less at the output terminal.

Notes: 1) Do not short-circuit analog outpu

terminals or apply voltage to them.

2) Use shielded wires for analog

outputs.

Analog Input Device

ࠩࡦࠨ

Laser Sensor

• An alarm is output when the beam received is excessive or insufficient. The beam

received is determined each measurement cycle. When measuring a substance whose

beam received greatly fluctuates due to limited reflection beam, alarm output may

become unstable.

• Do not use output during start-up by turning on the power supply. Doing so may

change judgment output and alarm output during the period.

• Do not use analog output for several seconds right after turning on the power supply,

because analog output within ±5V (20mA or less) is sent during the period.

• Secure time of about 10 to 25 seconds, depending on the sampling period saved for

several seconds after turning on the power supply until the operation condition is

ensured (completion of start-up) (when the moving average count is turned off and

interference prevention function is turned off). This start-up time is increased by setting

the moving average count or by turning on the interference prevention function. It is

increased 1.2 to 2.4 times when the maximum moving average count is 32,768 times,

and to 1.4 to 3.3 times when the interference prevention function is turned on.

3-4

Page 46

CHAPTER 3 INPUT AND OUTPUT TERMINAL BLOCKS

3-3 Input Terminals

NPN output

Symbol Meaning

TM1 Timing Input (Sensor Head 1)

I11 Zero Set ON Input (Sensor Head 1)

Zero Set OFF Input (Sensor Head 1)

I12

(-) External Insulated GND

TM2 Timing Input (Sensor Head 2)

I21 Zero Set ON Input (Sensor Head 2)

I22 Zero Set OFF Input (Sensor Head 2)

(-) External Insulated GND

• Not Used.

Photo-MOS output

• Not Used.

• Not Used.

• Not Used.

• Not Used.

24V DC Input for Power Supply

+

– Power Supply Ground

Function Ground

Terminals marked with "•" are not used.

Some are connected to internal circuitry,

and cannot be used as relay terminals

Symbol Meaning

TM1 Timing Input (Sensor Head 1)

I11 Zero Set ON Input (Sensor Head 1)

I12 Zero Set OFF Input (Sensor Head 1)

COM Input Common

TM2 Timing Input (Sensor Head 2)

I21 Zero Set ON Input (Sensor Head 2)

I22 Zero Set OFF Input (Sensor Head 2)

COM Input Common

• Not Used.

• Not Used.

• Not Used.

• Not Used.

• Not Used.

24V DC Input for Power Supply

+

– Power Supply Ground

Function Ground

3-5

The COM (input common) terminals of sensor

head 1 and sensor head 2 are connected

internally.

Page 47

in wiring, etc.

CHAPTER 3 INPUT AND OUTPUT TERMINAL BLOCKS

3-6

Page 48

CHAPTER 3 INPUT AND OUTPUT TERMINAL BLOCKS

Input Circuit

NPN output

Internal

Circuit

Photoelectric Sensor, etc.

Laser Sensor

Operating input voltage: 12 to 24V DC

Photo-MOS output

Maximum input voltage : 30V DC

Connection example 2 (PNP)Connection example 1 (NPN)

Internal

Circuit

Photoelectric

Sensor, etc.

Laser Sensor

Internal

Circuit

Photoelectric

Sensor, etc.

Laser Sensor

• A continuous 2ms or more input is accepted at the Zero Set ON and Zero Set OFF

input terminals (1-shot input).

• When Zero Set ON is input from the input terminal, it is possible to input it again under

Zero Set status, for which Zero Set operation is executed for each input.

• Do not add the Zero Set ON and Zero Set OFF inputs simultaneously. Allow 2ms or

more interval between the inputs.

• Add Zero Set ON input only when the sensor head is within the measurement range.

• If lump input mode is selected (see page 5-35), add timing input, Zero Set ON input,

and Zero Set OFF input at either the sensor head 1 or sensor head 2 input terminal.

3-7

Page 49

CHAPTER 3 INPUT AND OUTPUT TERMINAL BLOCKS

3-4 Wiring Power Supply

Terminal Layout

• Use the plus (+) terminal and minus (-) terminals on the input terminal block to wire the

power supply, supplying 24V DC.

• Use twisted wires for the power supply to minimize the effect of noise.

Rated Voltage

Permissible Voltage

Fluctuation Range

Current Consumption

Inrush Current

24V DC

21.6 to 26.4V DC

1 Sensor Head: 0.43A approx.

2 Sensor Heads: 0.55A approx.

8A or less

24V DC

Use an Insulated Power Supply with an Internal

Protective Circuit of Sufficient Capacity.

• Large current exceeding the rated current flows temporarily when power is turned on.

Use an insulated power supply with an internal protective circuit of sufficient capacity

(margin of 2A or more current capacity) to protect the circuit against irregular voltage in

the power line, and check power-on operation.

• An uninsulated type is used in the controller's regulator.

• If a power supply without an internal protective circuit is used, supply power to the

controller via a protective element such as a fuse.

Switch the Power Supply On and Off at the Primary

Side.

• Switch the power supply on and off at the primary side (100V AC). If it is switched on

and off at the secondary side (24V DC), the controller's fuse may burn out.

Primary Side Secondary Side Primary Side Secondary Side

Power

Supply

Laser

Sensor

Power

Supply

Laser

Sensor

To Improve Noise Resistance

• Wire the controller, input device, and power device to run on separate systems.

• If noise from input and output circuits is a concern, it is recommended that power be

supplied separately for the controller and input and output power supplies.

3-8

Page 50

CHAPTER 3 INPUT AND OUTPUT TERMINAL BLOCKS

Consider the Power Supply Sequence.

• Consider the power supply sequence in which the controller's power supply is turned

off before input and output power supplies.

• If input and output power supplies are turned off before the controller power supply, the

controller will detect a change in input signal level and may malfunction.

• Do not turn the controller's power supply on again within 10 seconds after it is turned

off.

• It takes about 10 to 25 seconds ("Average number of samples" OFF and "Interference

prevention function" OFF) depending on the sampling period after power is supplied

until the controller is ready for operation (after completion of start-up). Do not use

output in the interval because output (judgment, alarm, and analog output) vary during

start-up.

Instantaneous Power Failures

• If an instantaneous power failure lasts 10ms or less, operation continues.

• If an instantaneous power failure lasts 10 to 45ms, one of the following occurs:

(1) Operation continues.

(2) Analog output varies temporarily and BRIGHT and DARK indicators blink, then

the sensor recovers automatically.

(3) The state changes to reset.

• If an instantaneous power failure lasts more than 45ms, the state changes to reset.

Use This Product Correctly.

• When wiring the power supply, turn the power supply off.

3-5 Grounding

Grounding When Effects of Noise are Great

• Under normal use, this product has sufficient noise resistance, but in an environment

with particularly high noise levels, ground it securely.

Use an Exclusive Ground.

•Use 2mm2or more wires and establish a class D ground with a ground resistance of

100: or less.

• Make the grounding point as close to the controller as possible, keeping the ground

wire distance short.

• If the laser sensor is grounded in common with another device, a reverse effect may

occur, so use an exclusive ground.

Laser

Sensor

Inverter or

other device

Laser

Sensor

Inverter or

other device

• The connector housing for the sensor head case and sensor cable is connected

electrically to the function ground of the controller terminal block via the sensor cable.

3-9

Page 51

CHAPTER 3 INPUT AND OUTPUT TERMINAL BLOCKS

MEMO

3-10

Page 52

CHAPTER 4

MEASUREMENT

Page 53

CHAPTER 4 MEASUREMENT

4-1 Basic Compact Console Operation

Screen Overview

MENU Screen

Screen Contents

MENU Main menu screen. All screens can be accessed via this screen.

Measurement

Measurement

Settings

Sensor

Adjustment

Data Processing

Input/Output

System

Displays measurement values. Used to switch to hold mode, zero

set, timing input, and other settings can be made.

Used to set the sampling period, sensor head operation, measurement

mode, and calculation formula.

Sets the correction value (span, shift) in measurement.

Sets the average number of samples, high pass filters, and low pass

filter.

Used to select the input or output function and set upper and lower

limit values, etc.

Saves or initializes setting contents, locks screens, sets the

communication specification, displays th e screen v e r s i o n , e t c .

Shifting Screen Levels

Touching item keys on the MENU screen changes the screen to respective operating

screens. Operating screens are arranged in a hierarchy. Move to the screen for the

desired function, then set necessary settings. Shifting among screen levels is explained

below.

: Shift down 1 level

: Shift up 1 level

: Advance to another item on the

same level

: Return to the previous item on the

same level.

4-1

Page 54

CHAPTER 4 MEASUREMENT

Selecting from items

This section explains how to select items having choices such as the sampling period

and average number of samples.

z Sampling period selected on measurement setting screen

The value in the frame is the current setting value.

The example shows that 1,000µs is selected.

Touching the number causes the setting value to change.

Setting values are changed in the following sequence:

Setting Value

100 144 200

Inputting a Value

This section explains value input for upper and lower limit

or offset, etc. A keyboard is displayed for items that can

be input.

1. Touch the frame above the setting value to change

the mode to the number input mode and causes the

cursor to blink.

2. Input the number from the keyboard.

3. Touch the decimal point on the keyboard to input

decimal fractions.

4. Touch the enter key to make the setting.

255 332 498 1000

Setting Value

Decimal Point

1

2

Caution

• Before connecting the compact console and controller, turn off both units.

• When the controller is connected to the compact console, the controller stops measuring

twice every 40ms approx. to ensure communication with the compact console.

Enter

3

4

4-2

Page 55

CHAPTER 4 MEASUREMENT

Screen Flow

Measurement

Sensor

Adjustment

System

Input/Output

1

2

3

Data Processing

Measurement

Setting

4

5

4-3

Page 56

CHAPTER 4 MEASUREMENT

1

2

3

4

5

4-4

Page 57

CHAPTER 4 MEASUREMENT

4-2 Measuring Height

This section explains measurement of differences in height of a measured object for a

reference surface. Basic operation is explained measuring the surface of a plate used as an

example.

Measurement Waveform

Procedure

1. Check all connections.

Confirm that the controller, sensor head, and compact console are connected.

2. Turn on power.

When the controller and sensor head have completed automatic start-up, the laser

emission indicator (green) lights and the laser radiates. If the measurement object is within

the measurement range, a measurement value is displayed on the compact console.

3. Adjust the position of the sensor head.

Set the orientation of the measurement object

and the sensor head referencing "Mounting

the Sensor Head" on page 2-4.

While observing the measurement range

indicator (yellow) of the sensor head or

measurement display on the compact

console, adjust the mounting position of the

sensor head so the approximate measurement center is in the center of the measurement object variation range.

The measurement range indicator (yellow)

blinks when the distance from the measurement object is within the measurement range

and remains lit when near the measurement

center distance.

Laser Emission

Indicator

Measurement

Range Indicator

Measurement

center distance

4-5

Page 58

CHAPTER 4 MEASUREMENT

4. Make a Zero Setting

Touch the button on the compact

console's measurement display

screen and switch to the subscreen 1

level down.

Touch

The display value and analog output

become "0", and the change in height

is then measured. See page 5-5 for

details on zero setting.

to make a zero setting.

Measurement Display Subscreen

MENU Screen

5. Measure the surface of the measurement object.

Move the measurement object or the sensor head

horizontally and measure the measurement item's surface.

Measurement Display Screen

z Supplementary Explanation

• If deviation in measurement occurs due to the status of the measurement object's

surface, see Calibration on page 5-36.

• If the sampling period (page 5-8), average number of samples (page 5-20), and digital

filter (pages 5-21, 22) are changed to correspond to the measurement object's speed

of movement, displacement, and displacement, more stable measurement can be

obtained.

• When the setting is changed, save the changed setting (page 5-41) before turning off

the power supply.

4-6

Page 59

CHAPTER 4 MEASUREMENT

M

4-3 Measuring Thickness

This section explains measurement of changes in thickness of the measurement object for

the reference thickness. The example shows basic operation for measuring the thickness of

a plate using 2 sensor heads.

Measurement Waveform

Procedure

1. Check all connections.

Confirm that the controller, sensor heads, and

compact console are connected.

2. Turn on power.

When the controller and sensor heads have

completed automatic start-up, the laser emission

indicators (green) lights and laser radiates light. If

the measurement object is within the measurement range, a measurement value is displayed on

the compact console.

3. Adjust the position of the sensor heads.

• Set the orientation of the measurement object

and the sensor heads referencing "Mounting the

Sensor Head" on page 2-4.

• While observing the measurement range indicator

(yellow) of the sensor head or measurement

display on the compact console, adjust the

mounting position of the sensor head so the

approximate measurement center is in the center

of the measurement object's variation range.

• The measurement range indicator (yellow) blinks

when the distance to the object is in the measurement range, and it lights roughly at the measurement center distance.

• Change between sensor head 1 (H1) and sensor

head 2 (H2) display on measurement display

screen of the compact console.

• When "add/subtract" is selected for the head

operation, change to "independent" referencing

page 5-10.

Measurement

Range Indicator

Laser Emission

Indicator

Measurement

center distance

easurement

center distance

4-7

Page 60

CHAPTER 4 MEASUREMENT

4. Set the head operation to calculations.

After returning to the MENU screen by pressing ,

touch

setting screen. Touch

and display the measurement

and display the

measurement condition screen. Touch the 'Head

Operation' key , and display

.

5. Set the Add/subtract Calculation formula.

Advance 2 screens from the measurement setting

screen (touch the

Add/subtract Calculation Screen. Touch the Calculation

Formula key and display

key 2 times), then display the

.

MENU Screen

Measurement Setting Screen

Measurement Condition Screen

6. Display the actual thickness.

On the subscreen the next level below the

"Add/Subtract Calculation" screen (touch the

key), input the offset value L using a value enabling

the actual measurement value to be displayed on the

measurement value display (see page 5-12).

The L input range is ±999.999mm.

After the setting is fixed, touch the

return to the MENU screen.

button and

Add/Subtract Calculation Screen

Offset Screen

4-8

Page 61

CHAPTER 4 MEASUREMENT

7. Measure the thickness of the measurement object.

Move the measurement object or sensor

heads horizontally and measure the thickness

of the measurement object.

When measuring the difference in thickness

from the reference work piece, touch the

key on the measurement display screen in

step 6, move to the subscreen 1 level below,

then touch and make a zero setting.

z Supplementary Explanation

• When deviation occurs in measurement value, based on the surface status of the

object, execute calibration, referencing page 5-36.

• Changing the sampling cycle (page 5-8), moving average count (page 5-20), and

digital filter (pages 5-21, 22), based on the speed of movement, displacement ratio ,

and displacement contents of object substance ensure furthermore stabilized

measurement.

• When the setting is changed, save changed setting (page 5-41) before turning off

the power supply.

Measurement Display Screen

4-9

Page 62

CHAPTER 5

FUNCTION ITEMS

Page 63

CHAPTER 5 FUNCTION ITEMS

g

j

y

p

5-1 Functions

Function Content Page

Measurement Display

Hold Mode

Measurement

Measurement

Settings

Data Processing

Input/output

Sensor Adjustment

System

Zero Set Sets measurement and analog output forcibly to zero. 5-5

Timing

Display Hold

Sampling Period

Sensor Head Operation

Calculation Formula

Emission Adjustment

Measurement Mode

Specular Reflection Mode

Interference Prevention

Laser Emission Delay

Average Number of Samples

Low Pass Filter

High Pass Filter

Simplified optical filter

Upper/Lower Limit Setting

Hysteresis Setting Sets hysteresis of upper and lower limit values. 5-25

Judgment Output Selection

Output Mode Uses judgment output as light alarm output. 5-28

Analog Output Setting Sets analog output corresponding to measure- ment. 5-29

Analog Output During Alarm

Analog Alarm Delay Ignores instantaneous analog alarm output. 5-32

Input Selection

Calibration Sets span and shift for calibration. 5-36

Light Received Displays light received. 5-40

Save Saves each setting in memory. 5-41

Initialization Returns to factory settings. 5-42

Lock

(Touch Key Lock)

Communication Specification Sets the controller communication specification. 5-45

Version Displays controller and compact console versions. 5-46

Monitors/displays measurements and alarm and

judgment output. Changes hold mode. Allows zero

setting, timing, and display hold input.

Chan

es hold mode between NORM. / P-P / PEAK

and VALLEY.

Holds judgment output, measurement, and analog output

to avoid unnecessary output changes or laser radiation.

Holds measurement displayed on the compact

console only.

Changes the sampling period to a little longer period,

to assure the stabilized measurement of workpieces

with low reflected light.

Changes between independent measurement and

add/subtract measurement with 2 heads.

Sets calculation formula selection, offset, and

coefficient for each sensor head.

Measures only the measurement point at high speed with

emission fixed.

Changes the diffused reflection mode/specular

reflection mode based on the sensor head connected.

Selects the measurement ob

reflection.

Prevents erroneous measurement within the mutual

interference area.

Dela

s laser emission for safety when the power

supply is turned on and when timing is turned off.

Sets the moving average number of samples to a large

number, to assure the stabilized measure- ment value.

Changes the cutoff frequency of the low pass filter to

avoid the influence of steep changes.

Changes the cutoff frequency of the high pass filter to

avoid the influence of gentle changes.

Reduces the influence due to turbulence of the reflected

light on the ground metal surface.

Sets the upper and lower limit values of judg- ment

output.

Selects a judgment output operation pattern. Switches

to test output mode.

Changes between analog output hold and fixed outof-range output issued at an alarm.

Reverses the in

emission during timing input continues. Switches to

independent/lump input.

Prohibits setting of or changes to the compact console

and prevents incorrect settings through inadvertent

operations.

ut operation of timing input. Laser

ect for specular

5-2

5-3

5-6

5-7

5-8

5-10

5-11

5-13

5-14

5-16

5-18

5-19

5-20

5-21

5-22

5-23

5-24

5-27

5-31

5-34

5-44

5-1

Page 64

CHAPTER 5 FUNCTION ITEMS

5-2 Explanation of Functions

5-2-1 Measurement Display

This function displays the measurement value, and is also used to monitor/display alarm

and judgment output, to change hold mode, and to allow zero setting, timing, and display

hold input.

1. Display the measurement display screen.

When

measurement display screen is displayed,

measurement is displayed based on currently set

sensor head operation (see page 5-10).

2. Touch

output screen.

• In output status, the output symbol is displayed in

reverse.

• In nonoutput status, the output symbol is not

displayed.

• H1 and H2 correspond to output on the terminal

block. For independent operation, judgment outputs

(01, 02) of H1 are used for Sensor Head 1. For

addition/subtraction, such outputs are used for

addition/subtraction. Alarm output (AL) is for each

sensor head.

• For the measurement display screen or subscreen,

the integer of measurement is displayed up to 2

digits. For the alarm/judgment output screen, it may

be displayed in full. When measurement is offset so

the 3 highest digits are not displayed, the integer of

measurement is confirmable on this screen.

• Measurement display screens are changed to the

same alarm/judgment output screen.

• Touch

display screen.

is touched on the MENU Screen and the

key to display the alarm/judgment

to return to the prechange measurement

MENU screen

Measurement Display Screen

O/P key

Alarm/Judgment Output Screen

5-2

Page 65

CHAPTER 5 FUNCTION ITEMS

5-2-2 Hold Mode

This device has 4 hold modes. Measurement results in the set mode are displayed/output.

Hold Mode Function

NORM.

P-P

PEAK Holds and output the maximum measurement.

VALLEY Holds and output the minimum measurement.

Output displacement from the measurement center distance in real time.

Used as standard.

This mode holds and output the difference between maximum and minimum

values. Used for vibration measurement or eccentricity.

Output Changes in Hold Modes

NORM.

P-P

PEAK

VALLEY

5-3

Page 66

Setting Hold Mode

CHAPTER 5 FUNCTION ITEMS

1. Display the measurement display screen.

When

measurement display screen is displayed, the currently

set hold mode is displayed in hold mode key area.

2. Display the set hold mode using the "Hold Mode"

key on the measurement display screen.

• The hold value is reset when hold mode is changed.

• Zero setting can be done even in hold mode, but the

hold value is not reset when zero setting is input or

canceled.

• If hold mode is changed after zero setting, zero setting

is canceled.

• The hold value is reset in the following cases:

1) Timing input status is changed to timing non-

2) The sampling period, average setting, measure-

• Do not change hold mode in other than the measurement range. Otherwise the correct

measurement may not be displayed.

• If display hold (see page 5-7) is set, the measurement displayed at timing is maintained

and measurement displayed at the compact console does not change. Analog output,

judgment output, and other output are issued based on the selected hold mode.

• The displayed measurement, analog output, and judgment output are maintained in

timing input state and they do not change even if hold mode is switched.

• Follow the following sequence when changing the sampling period, setting the low or

high pass filter, and setting the hold mode other than NORM:

1) Changing the sampling period

2) Setting the low or high pass filter

3) Setting the hold mode other than NORM.

is touched on the MENU Screen and the

input status

ment mode, and specular reflection mode are

changed

MENU Screen

Measurement Display Screen

Hold Mode Key

Reference Default Setting: NORM.

5-4

Page 67

CHAPTER 5 FUNCTION ITEMS

5-2-3 Zero Set

The amount of displacement is displayed in reference to the center of measurement of the

sensor head during regular operation. After zero setting input is added, the amount of

displacement in reference to the current position is displayed. Measurement and analog

output at timing of zero setting are forcibly reset to zero. Use this function to reset

measurement of the reference workpiece to zero and measure the displacement amount or

make judgment of the upper or lower limit.

1. From the measurement display screen,

touch

Touch

change to the subscreen at the next level

below by touching

2. Touch

"0".

• Analog output also changes to 0 simulta-

neously. (Voltage output = 0V, Current output

= 12mA)

• In independent operation, zero set can be

done for each sensor head (H1: Sensor

Head 1, H2: Sensor Head 2).

• In add/subtract operation, analog output of

sensor head 1 and sensor head 2 becomes

"0".

• In the zero set state,

in reverse highlighting.