panasonic HG-T User Manual

Thru-Beam Type Digital Displacement Sensor

HG-T series

User’s Manual

WUME-HGT-6

2020.11 panasonic.net/id/pidsx/global

(MEMO)

2 WUME-HGT-6

Introduction

Thank you for purchasing an HG-T series thru-beam digital displacement sensor.

Before using this product, read and understand this User's Manual. Use the product correctly

and in the optimum manner.

Keep this manual in a safe location for reference whenever necessary.

Types of Manuals

The following user’s manuals are available for the HG-T series. Refer to the appropriate manual

according to your need.

The user’s manuals are also available for download from our website (https://panasonic.net/id/

pidsx/global).

Unit name or purpose of

use

HG-T Control Unit HG-T User’s Manual WUME-HGTM

HG-T Configuration Tool HG-T Configuration Tool User’s Manual WUME-HGTCT

Manual name Manual code

Please note

1. No part of this manual may be reproduced or reprinted in any form or by any means without prior written

permission from Panasonic.

2. The contents of this manual are subject to change without notice for future improvement.

3. This manual has undergone strict quality control; but should you discover any dubious information,

mistakes, misplaced pages, or missing pages, please contact your local dealer.

WUME-HGT-6 iii

Manual Configuration

Chapter 1 Before Using This Product

Chapter 2 System Configuration This chapter explains the system configuration.

Chapter 3 Overview of HG-T Series

Chapter 4 Installation and Connections

Chapter 5 Basic Usage

Chapter 6 Setting up General Functions

Chapter 7 Setting up Extended Functions

Chapter 8 Specifications and Dimensions This chapter explains the specifications and dimensions.

Chapter 9 Maintenance This chapter explains maintenance and inspection.

Chapter 10 Troubleshooting This chapter explains troubleshooting and error codes.

Chapter 11 Appendix This chapter provides menu structure.

This chapter explains safety and handling precautions, laser

safety standards, and other information that should be

checked before using this product.

This chapter explains the principle of measurement and how

to use this product when controllers are connected.

This chapter explains installation, connections, wiring, and

other work.

This chapter explains the flow of operations up to

measurement startup, the base screen displayed when the

power is turned ON, and basic operations.

This chapter explains details and settings for general

functions.

This chapter explains details and settings for extended

functions.

Product Version

This manual has been created based on the product functions available as of November 2020.

For product version information, refer to "1.6 Product Version and Functions".

iv

WUME-HGT-6

Table of Contents

1 Before Using This Product................................................................... 1-1

1.1 Safety Precautions (Always observe) .................................................1-2

1.2 Handling Precautions..........................................................................1-3

1.3 Laser Safety Standards ......................................................................1-5

1.3.1 IEC / JIS / GB................................................................................... 1-5

1.3.2 FDA.................................................................................................. 1-6

1.4 Terminology.........................................................................................1-9

1.5 Contents of Package...........................................................................1-10

1.6 Product Version and Functions...........................................................1-12

2 System Configuration........................................................................... 2-1

2.1 System Configuration..........................................................................2-2

2.2 Description of Parts.............................................................................2-3

2.2.1 Controller ......................................................................................... 2-3

2.2.2 Sensor head..................................................................................... 2-5

2.2.3 Sensor Head Connection Cable ...................................................... 2-6

2.2.4 Side View Attachment...................................................................... 2-6

3 Overview of HG-T Series ......................................................................3-1

3.1 Principle of Measurement ...................................................................3-2

3.2 Role of Controllers ..............................................................................3-3

3.3 Using Connected Controllers..............................................................3-4

4 Installation and Connections...............................................................4-1

4.1 Mounting the Controller.......................................................................4-2

4.1.1 Mounting on a DIN Rail.................................................................... 4-2

4.1.2 Removing from a DIN Rail ............................................................... 4-2

4.1.3 Controller Wiring Connection Diagrams........................................... 4-3

4.2 Attaching the Sensor Head.................................................................4-4

4.3 Connecting the Sensor Head Connection Cable ................................4-5

4.3.1 Connecting to the Sensor Head....................................................... 4-5

4.3.2 Disconnecting from the Sensor Head .............................................. 4-6

4.3.3 Connecting to the Controller ............................................................ 4-6

4.3.4 Disconnecting from the Controller.................................................... 4-7

4.3.5 Connecting and Disconnecting to / from Controller Connector........ 4-7

4.4 Connecting Controllers .......................................................................4-10

4.4.1 How to Connect ............................................................................... 4-11

4.4.2 How to Remove ............................................................................... 4-13

4.5 Mounting the Side View Attachment...................................................4-14

5 Basic Usage...........................................................................................5-1

5.1 Using the Base Screen .......................................................................5-2

5.1.1 Functions of Operation Pad and Display Unit .................................. 5-2

WUME-HGT-6

v

5.2 Flow of Operations up to Measurement Startup .................................5-6

5.3 Explanation of Basic Operation...........................................................5-8

5.3.1 Checking the Beam Axis.................................................................. 5-8

5.3.2 Adjusting the Beam Axis .................................................................. 5-9

5.3.3 Reference Waveform Registration................................................... 5-14

5.3.4 Teaching........................................................................................... 5-16

5.4 Operation Mode ..................................................................................5-22

5.4.1 Auto Edge Detection Mode (

5.4.2 Edge Detection Mode ( ).......................................................... 5-23

5.4.3 Outer diameter/Width Detection Mode (

5.4.4 Inner Diameter/Gap Detection Mode (

5.4.5 Central Position Detection Mode ( ).................................... 5-25

5.4.6 User Assigned Edge Detection Mode ( ) ........................... 5-27

) ............................................ 5-22

) ............................. 5-24

) ................................ 5-25

5.5 Settings on the Base Screen (Using Shortcut Keys) ..........................5-30

5.5.1 Display Switching Mode................................................................... 5-30

5.5.2 Preset............................................................................................... 5-33

5.5.3 Saving and Loading Settings to / from Banks .................................. 5-35

5.5.4 Key Lock .......................................................................................... 5-38

5.5.5 Sensitivity Settings........................................................................... 5-40

5.6 Self-monitoring Function.....................................................................5-47

5.6.1 Using the Self-monitoring Function.................................................. 5-47

5.6.2 Statuses and Measures ................................................................... 5-48

6 Setting up General Functions..............................................................6-1

6.1 Flow of Measurement Data.................................................................6-2

6.2 Setting Operation List .........................................................................6-4

6.3 Detection Settings (

6.3.1 Operation Mode ( ) ............................................................... 6-9

6.3.2 Measurement Direction ( ).................................................... 6-10

6.3.3 Average Count (Response Time)( )........................................ 6-11

) ..............................................................6-9

6.4 Basic Settings ( ).......................................................................6-14

6.4.1 HIGH Set Value ( ).................................................................. 6-14

6.4.2 LOW Set Value ( )................................................................... 6-15

6.4.3 Hysteresis ( ) ........................................................................ 6-17

6.4.4 Teaching Types ( ) .................................................................. 6-20

6.4.5 Tolerance <±> (

6.4.6 Preset Value ( ) ....................................................................... 6-22

6.4.7 Preset Data Selection ( ) ........................................................ 6-23

6.4.8 Preset Save ( ) ..................................................................... 6-24

6.4.9 Reference Waveform Save (

6.4.10 Output Operation ( ) ........................................................... 6-26

6.4.11 Analog Output Selection ( ) ................................................ 6-27

6.4.12 Menu Display Settings ( ) ....................................................... 6-28

) ................................................................... 6-21

).............................................. 6-25

6.5 Initialization ( )...........................................................................6-30

vi

WUME-HGT-6

6.6 Maintenance ( ).......................................................................6-31

7 Setting up Extended Functions ...........................................................7-1

7.1 Setting Operation List .........................................................................7-3

7.2 Advanced Settings (

7.2.1 Hold Settings ( )........................................................................ 7-9

7.2.2 Simultaneous Input ( )(For Master Units Only)..................... 7-17

7.2.3 External Inputs ( ) ................................................................... 7-19

7.2.4 External Outputs ( ) .............................................................. 7-21

7.2.5 External Output Delay Timer Selection ( )............................ 7-28

7.2.6 Number of Digits Displayed ( )................................................ 7-35

7.2.7 Analog Scaling ( )................................................................. 7-36

7.2.8 Eco Mode ( )............................................................................. 7-41

7.2.9 Alarm Settings ( ).................................................................... 7-42

7.2.10 Key Lock Function Selection ( ) ......................................... 7-47

7.2.11 Interference Prevention Function ( )(For Master Units

Only) ................................................................................................. 7-48

7.2.12 Sampling Cycle (

7.2.13 Reverse of Measured Value ( )........................................... 7-51

) .............................................................7-9

).............................................................. 7-50

7.3 Calculation Settings ( )(For Master Units Only)...........................7-53

7.3.1 Calculation Mode (

7.3.2 Calculation Application Selection (

7.4 Copy Settings (

7.4.1 Copy Individual Selection ( )(For Master Units Only) ........... 7-59

7.4.2 Copy Batch Selection ( )(For Master Units Only) ................. 7-62

7.4.3 Copy Execution ( )(For Master Units Only) .......................... 7-62

7.4.4 Copy Lock (

) .........................................................................7-59

)(For Slave Units Only) ......................................... 7-63

).................................................................. 7-53

)....................................... 7-54

7.5 Bank Settings (

7.5.1 Bank Save Selection ( )........................................................ 7-65

) ..........................................................................7-65

7.6 Calibration Settings ( ) ..............................................................7-67

7.6.1 Calibration Selection (

)........................................................ 7-67

7.7 Tab Cancellation Function...................................................................7-71

7.7.1 Setting up the Functions .................................................................. 7-71

7.7.2 Operations when the Tab is Detected .............................................. 7-73

7.7.3 Response Time when the Tab Cancellation Function Is Enabled .... 7-73

7.7.4 Checking the Hold Status ................................................................ 7-74

7.7.5 Precautions when Using the Tab Cancellation Function .................. 7-75

8 Specifications and Dimensions...........................................................8-1

8.1 Specifications......................................................................................8-2

8.1.1 Controller ......................................................................................... 8-2

8.1.2 Sensor Head .................................................................................... 8-9

8.2 Dimension Drawings...........................................................................8-11

8.2.1 Controller ......................................................................................... 8-11

8.2.2 Sensor Head .................................................................................... 8-13

WUME-HGT-6

vii

8.2.3 Side View Attachment...................................................................... 8-14

9 Maintenance ..........................................................................................9-1

9.1 Maintenance and Inspection...............................................................9-2

9.1.1 Maintenance Precautions ................................................................ 9-2

9.1.2 Main Inspection Items ...................................................................... 9-2

10 Troubleshooting..................................................................................10-1

10.1 Troubleshooting ................................................................................10-2

10.2 Error Messages.................................................................................10-5

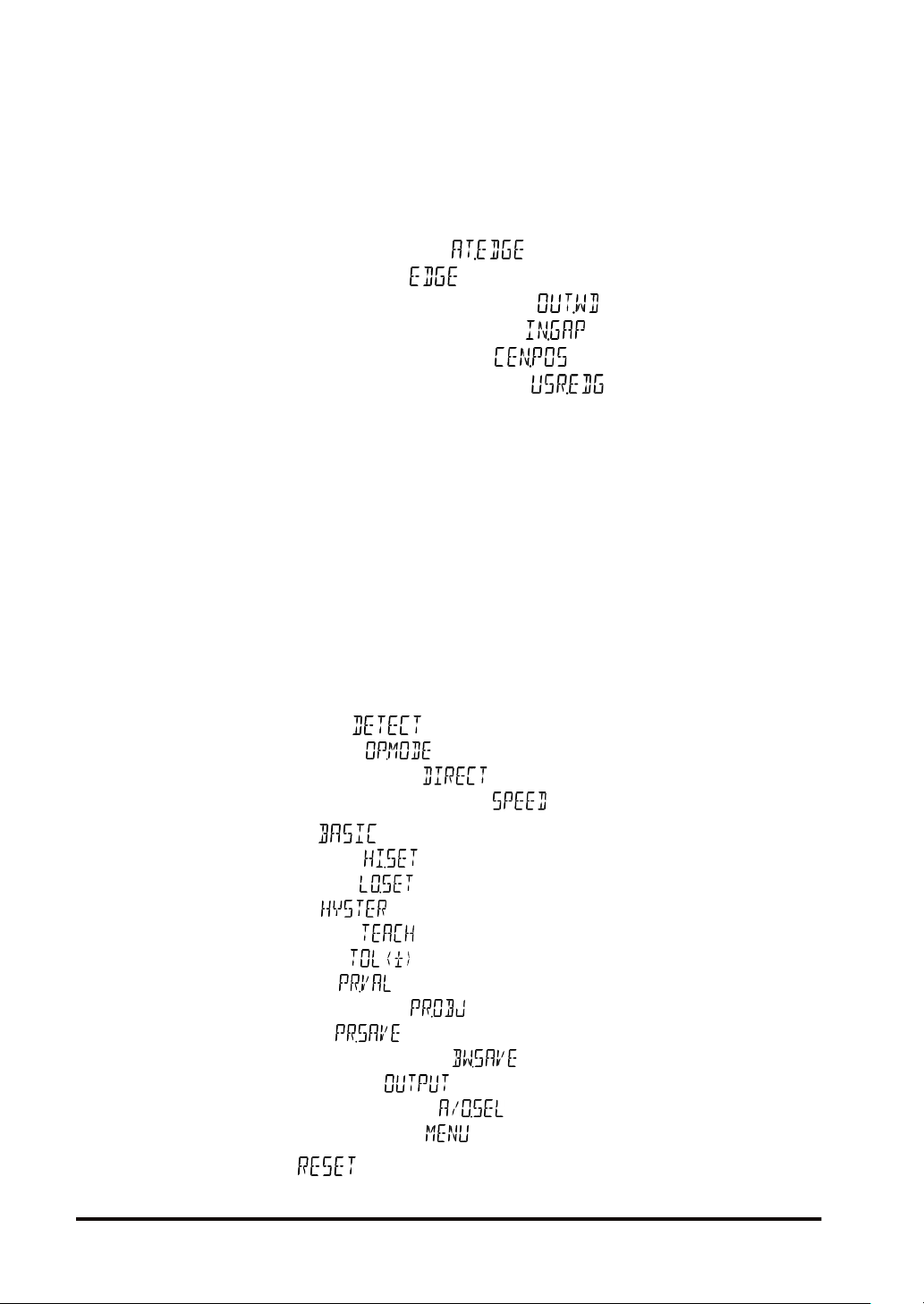

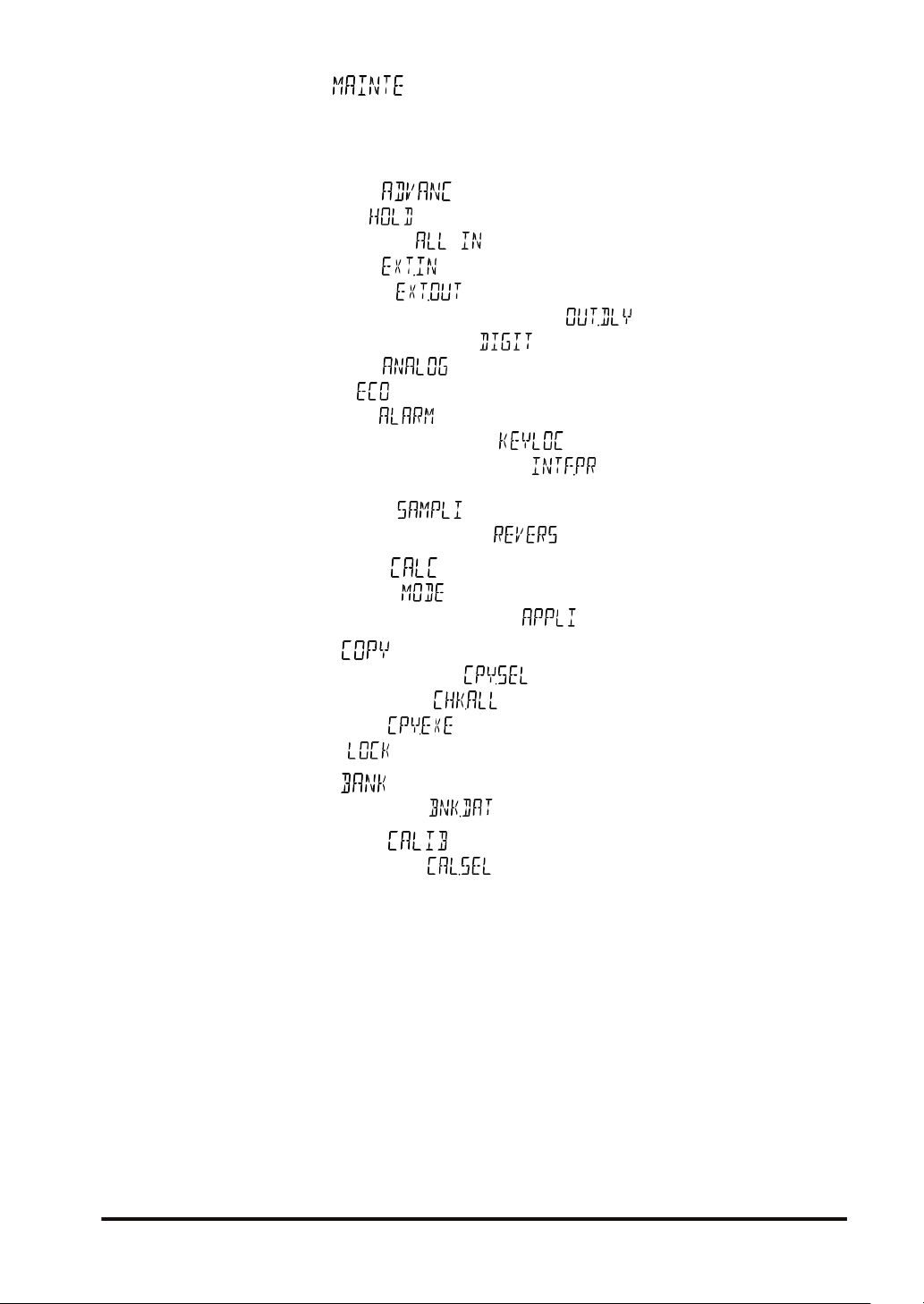

Appendix Appendix ................................................................................App-1

Menu Structure (General Function Display)...............................................App-2

Menu Structure (Extended Function Display) ............................................App-4

viii WUME-HGT-6

1 Before Using This Product

1.1 Safety Precautions (Always observe) .................................................1-2

1.2 Handling Precautions..........................................................................1-3

1.3 Laser Safety Standards ......................................................................1-5

1.3.1 IEC / JIS / GB................................................................................... 1-5

1.3.2 FDA.................................................................................................. 1-6

1.4 Terminology.........................................................................................1-9

1.5 Contents of Package...........................................................................1-10

1.6 Product Version and Functions...........................................................1-12

WUME-HGT-6 1-1

1.1 Safety Precautions (Always observe)

1.1 Safety Precautions (Always observe)

This section explains important rules that must be observed to prevent personal injury and

property damage.

■

Safety precautions items are classified into “WARNING” and “CAUTION”

depending on the level of hazard.

Risk of death or serious injury.

Risk of minor injury or property damage.

● Never use this product as a sensing device for personnel protection.

● For sensing devices for personal protection, use products that conform to the laws and

standards related to personal protection in each country, such as OSHA, ANSI, and IEC.

● This product is designed to inspect (judge or measure) objects and so must not be used

to ensure safety, for example, to prevent accidents that affect human lives or property.

● Do not look at or touch direct laser beams or other reflections of light, as doing so is

dangerous.

● For the controller DC power supply, only use a power supply that is isolated by means of

an isolation transformer or otherwise.

● There is a risk of short-circuiting and damage to the controller or power supply if a

transformer such as an autotransformer is used. There is a risk of short-circuiting and

damage to the controller or power supply if the controller is incorrectly mounted or

connected.

● The HG-TC series controller is designed to be used with the HG-T series special-purpose

sensor head to satisfy the specifications. If the controller is used with any sensor head

other than the special-purpose sensor head, the specifications will not be satisfied and

malfunctioning or another problem may occur.

1-2 WUME-HGT-6

1.2 Handling Precautions

1.2 Handling Precautions

■

In this manual, the following symbols are used to indicate safety information that

must be observed.

Indicates an action that is prohibited or a matter that requires caution.

Indicates an action that must be taken.

Indicates supplemental information.

Indicates details about the subject in question or information useful to remember.

Indicates operation procedures.

■

Handling precautions

Specifications

● This product has been developed / produced for industrial use only.

● This product (controller and sensor head receiver) uses an EEPROM.

The EEPROM has a service life of one million setting operations.

● Do not use this product outside the range of the specifications. Risk of an accident and

product damage.

There is also a risk of a noticeable reduction of service life.

Power supply

● Verify that the supply voltage fluctuations are within the rating.

● If power is supplied from a commercial switching regulator, ensure that the frame ground

(F.G.) terminal of the power supply is connected to an actual ground.

● Do not use during the initial transient time after the power supply is switched ON.

● To ensure performance, use the product at least 30 minutes (warm-up time) after the power

is turned ON.

Wiring

● Make sure that the power is OFF before performing wiring or connection work for the

controller.

● Note that there is a risk of damage or burning if the load is short-circuited or incorrectly

wired.

● After wiring is completed, check the wiring carefully before turning ON the power.

● Do not wire the controller in parallel with a high-voltage line or power line or use the same

conduit as these lines. Doing so may result in malfunctioning due to induction.

● Do not apply stress such as excessive bending or pulling to the extracted part of a cable,

● When connecting the sensor head connection cable to this product, do not apply force to

the product.

Usage environment

● This product is suitable for indoor use only.

● The light emitting and receiving surfaces of the sensor head must be free of water, oil,

fingerprints, and other substances that refract light as well as dust, grit, and other objects

that intercept light.

WUME-HGT-6 1-3

1.2 Handling Precautions

If stains or dirt become attached to the sensor head surfaces, wipe them with a lint-free soft

cloth or lens cleaning paper. If the surfaces are very dirty, wipe off dirt using a cotton swab

(or similar material) moistened with absolute alcohol.

● Do not allow ambient light such as sunlight to directly hit the light receiving section of the

sensor head. In particular, if precision is required, use this product by mounting a douser (or

similar material) on the sensor head.

● When a measured object with a strong specular reflection component (such as glass or

specular reflector) is detected, it may not be detected correctly due to the influences of light

reflected from the measured object. In such a case, install a pair of emitter and receiver at a

certain angle so that reflected light does not hit the emitter or receiver. After adjusting the

angle, always check the beam axis. After checking the beam axis, if the beam axis is

aligned, register the reference waveform. If the beam axis is misaligned, readjust the beam

axis, and register the reference waveform.

● Avoid using this product in environments where condensation occurs due to sudden

temperature change.

● Avoid dust, dirt, and steam.

● Avoid using the product in atmospheres that contain corrosive or other harmful gases.

● Ensure that the product does not come into contact with organic solvents such as thinner.

● Ensure that the product does not come into contact with strong acid or alkaline.

● Ensure that the product does not come into contact with oil or grease.

● This product cannot be used in an environment that contains flammable or explosive gases.

● Performance may not be satisfactory in a strong electromagnetic field.

● Do not use this product in locations subject to severe vibration or shock.

● This product is a precision device. Do not drop or otherwise subject to shock. Risk of

product damage.

● Take care not to touch any terminals in the connector or allow foreign objects to enter the

connector.

● The sensor head is watertight, but the connectors are not structurally resistant to dust,

water or corrosion. Therefore, the HG-T series cannot be submerged in water or placed

under falling water for measurement operation. Pay attention to the environment where the

product is used.

Other matters

● Never attempt to disassemble, repair, or modify the product.

● When the product becomes unusable or unneeded, dispose the product appropriately as

industrial waste.

1-4 WUME-HGT-6

1.3 Laser Safety Standards

1.3 Laser Safety Standards

1.3.1 IEC / JIS / GB

To prevent laser products from affecting their users, IEC, JIS, and GB have the following

respective standards:

IEC: IEC 60825-1-2014

JIS: JIS C 6802-2014

GB: GB 7247.1-2012

These standards classify laser products into classes according to the danger level of laser, and

prescribe safety and preventive measures that should be implemented for each class.

This product belongs to "Class 1 laser product" according to JIS C 6802-2014 "Safety of Laser

Products".

Explanation of danger level

Classificatio

n

Class 1 This class of laser beams is safe when the operating state of the product is rightly predictable.

Class 1M

Class 2

Class 2M

Class 3R

Class 3B Direct intrabeam viewing is always dangerous.

Class 4

■

Warning label

This class of laser beams is safe when the operating state of the product is rightly predictable,

but direct intrabeam viewing by optical means can be dangerous.

This class of laser beams is visible light and low output. Normally, eyes are protected by

aversion reaction such as blinking.

This class of laser beams is visible light and low output. Normally, eyes are protected by

aversion reaction such as blinking, but direct intrabeam viewing by optical means can be

dangerous.

Direct intrabeam viewing is potentially dangerous, but the level of risk is lower than Class 3B

laser.

This class of laser beams is high output. It has the ability to cause dangerous diffuse reflection.

Such laser beams cause skin disorders and have the risk of fire occurrence.

Overview of danger evaluation

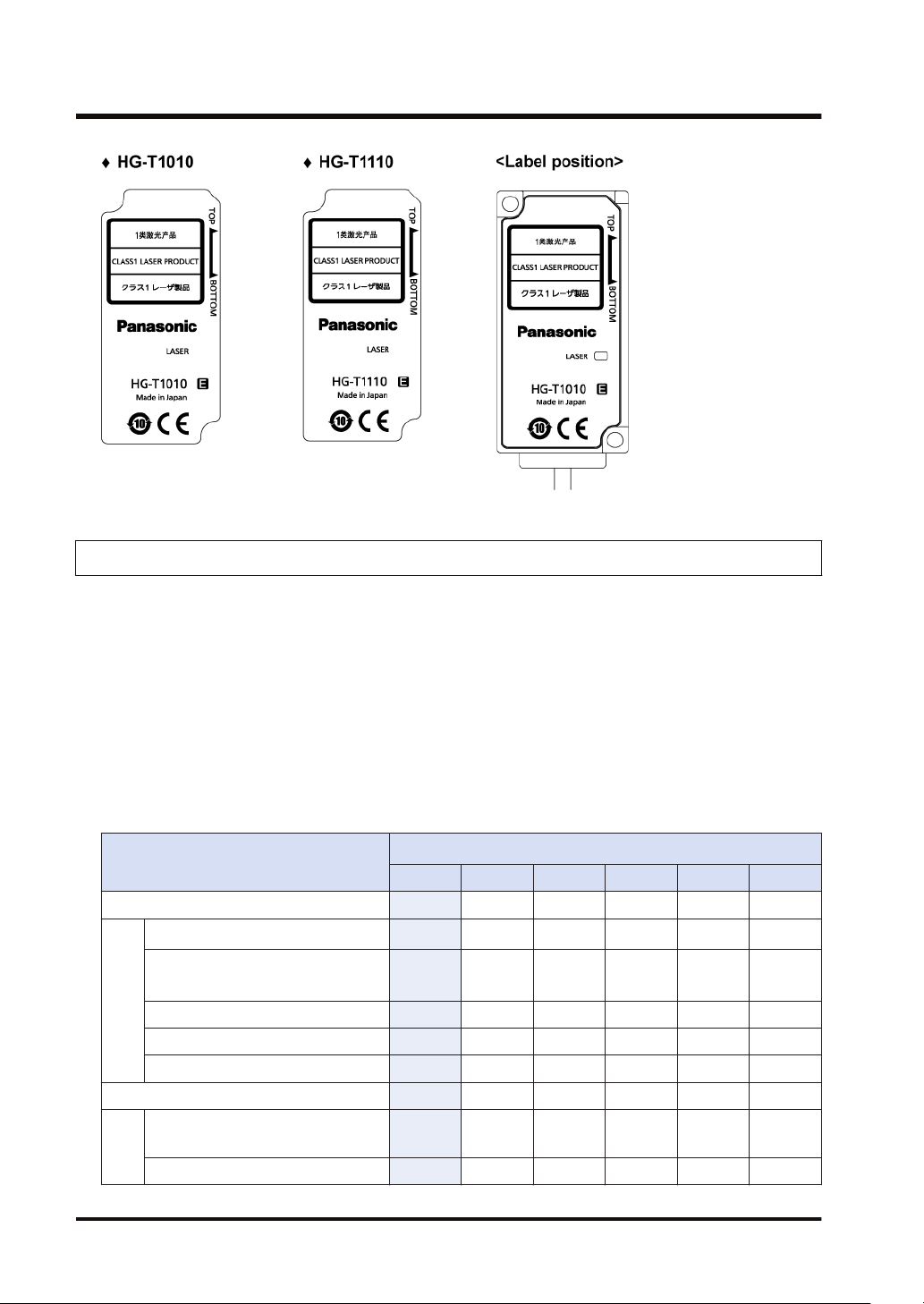

On the emitter side

WUME-HGT-6 1-5

1.3 Laser Safety Standards

1.3.2 FDA

■

Exporting to the USA

If this product is incorporated into facilities or equipment to be exported to the USA, it is subject

to the laser regulations of the U.S. Food and Drug Administration (FDA). To prevent laser

products from affecting their users, PART1040 (Performance Standards for Light-Emitting

Products) was established as one of the FDA regulations. These standards classify laser

products into classes according to the danger level of laser and prescribe safety and preventive

measures that should be implemented for each class.

This product complies with the FDA regulations (21 CFR 1040. 10 and 1040.11) in accordance

with FDA Laser Notice No. 50. (Class 1 laser product)

■

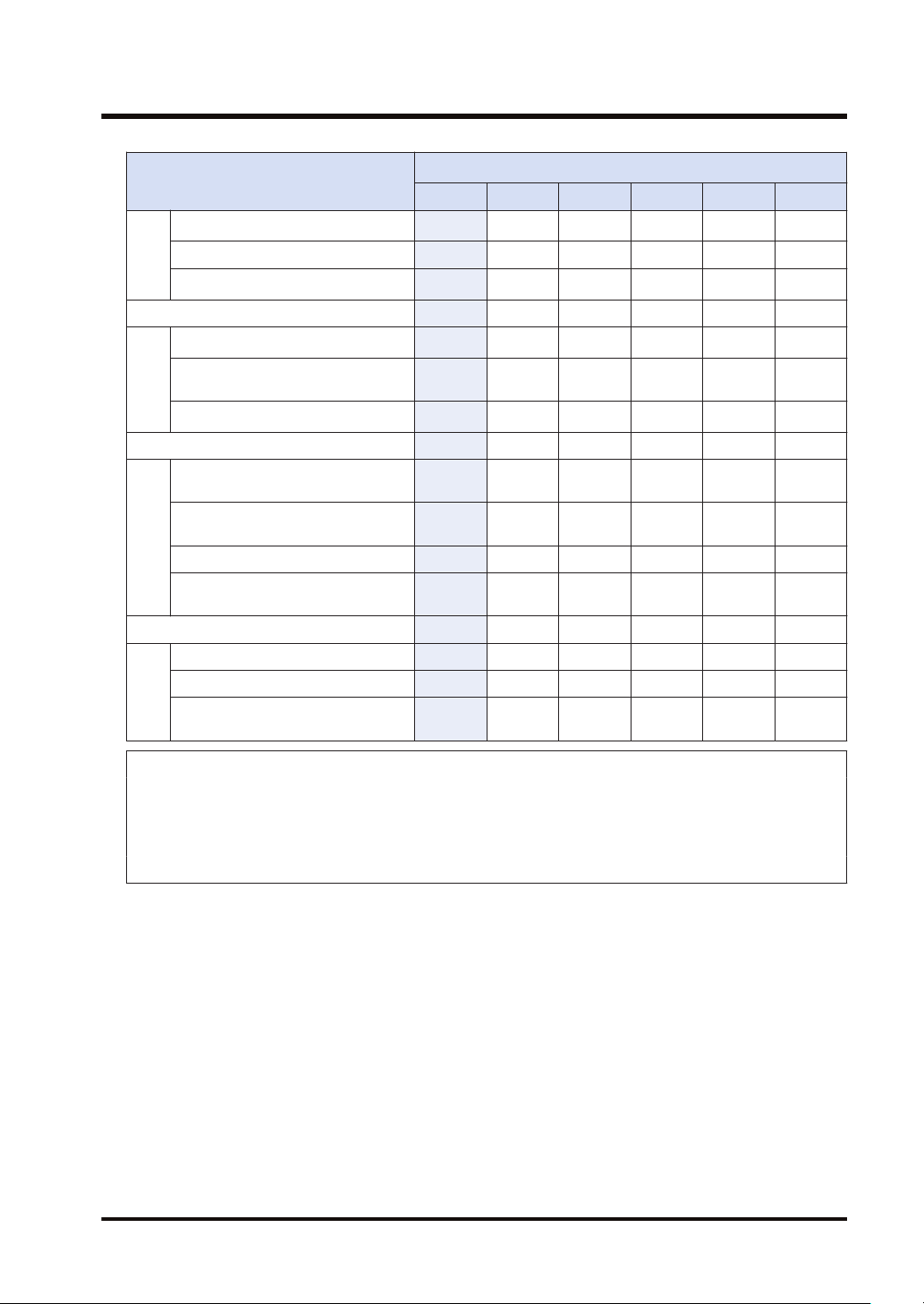

FDA regulations

(Note 1)

Requirements

Performance (for all laser products)

Protective housings [1040.10(f)(1)]

Safety interlock

[1040.10(f)(2)]

Location of controls [1040.10(f)(7)] N/A R R R R R

Viewing optics [1040.10(f)(8)] R R R R R R

Scanning safeguard [1040.10(f)(9)] R R R R R R

Performance (for laser systems)

Remote interlock connector

[1040.10(f)(3)]

Key control [1040.10(f)(4)] N/A N/A N/A N/A R R

Ⅰ Ⅱa Ⅱ Ⅲa Ⅲb Ⅳ

(Note 2)R(Note 2)R(Note 2)R(Note 2)R(Note 2)R(Note 2)

R

(Note 3)

R

(Note 4)

N/A N/A N/A N/A R R

(Note 3)

R

(Note 4)

Class

(Note 3)

R

(Note 4)

(Note 3)

R

(Note 4)

(Note 3)

R

(Note 4)

(Note 3)

R

(Note 4)

1-6 WUME-HGT-6

1.3 Laser Safety Standards

(Note 1)

Requirements

Ⅰ Ⅱa Ⅱ Ⅲa Ⅲb Ⅳ

Emission indicator [1040.10(f)(5)] N/A N/A R R

Beam attenuator [1040.10(f)(6)] N/A N/A R R R R

Manual reset [1040.10(f)(10)] N/A N/A N/A N/A N/A

Performance (for special-purpose products)

Medical use [1040.11(a)] S S S

Surveying, leveling, and alignment

S S S S NP NP

[1040.11(b)]

Demonstration [1040.11(c)] S S S S

Labeling (for all laser products)

Certification and identification

R R R R R R

[1010.2,3]

Protective housings [1040.10(g)(6),

(7)]

D

(Note 5)R(Note 5)R(Note 5)R(Note 5)R(Note 5)

R

Openings [1040.10(g)(4)] N/A N/A N/A N/A N/A N/A

Class warning [1040.10(g)(1), (2),

(3)]

N/A

(Note 6)R(Note 7)R(Note 9)R(Note 12)R(Note 12)

R

Information (for all laser products)

User information [1040.10(h)(1)] R R R R R R

Product literature [1040.10(h)(2)(i)] N/A R R R R R

Service information [1040.10(h)(2)

R R R R R R

(ii)]

Class

(Note 10)R(Note 10)

R

(Note 8)S(Note 8)S(Note 8)

S

(Note 11)S(Note 11)

S

(Note 13)

R

R : Required

N/A : Not applicable

S : Same requirements as for other products of the class

NP : Not permitted

D : Depends on the internal radiation level

(Note 1) Based on the maximum level of exposure to radiation during operation

(Note 2) Required wherever and whenever if exposure to laser radiation exceeding the limit of Class 1 is not

necessary to fulfill the functions of the product

(Note 3) Required for protective housings that are opened during operation or maintenance if radiation

exposure that occurs when the housing is opened is not always necessary

(Note 4) Requirements for interlock differ according to the class of internal radiation.

(Note 5) Wording differs according to the level and wavelength of laser radiation inside the protective housing.

(Note 6) A label that indicates a warning statement

(Note 7) CAUTION logo

(Note 8) A means is required to measure the level of laser radiation for the purpose of human body irradiation.

(Note 9)

CAUTION is used when the radiation level is 2.5 mWcm-2 or lower, and DANGER is used when the

radiation level is higher than 2.5 mWcm-2.

(Note 10) Time lag is required between reading and emission.

WUME-HGT-6 1-7

1.3 Laser Safety Standards

(Note 11) Exception handling is required for laser products and light show for demonstration of Class IIIb or IV.

(Note 12) DANGER logo

(Note 13) Required since August 20, 1986

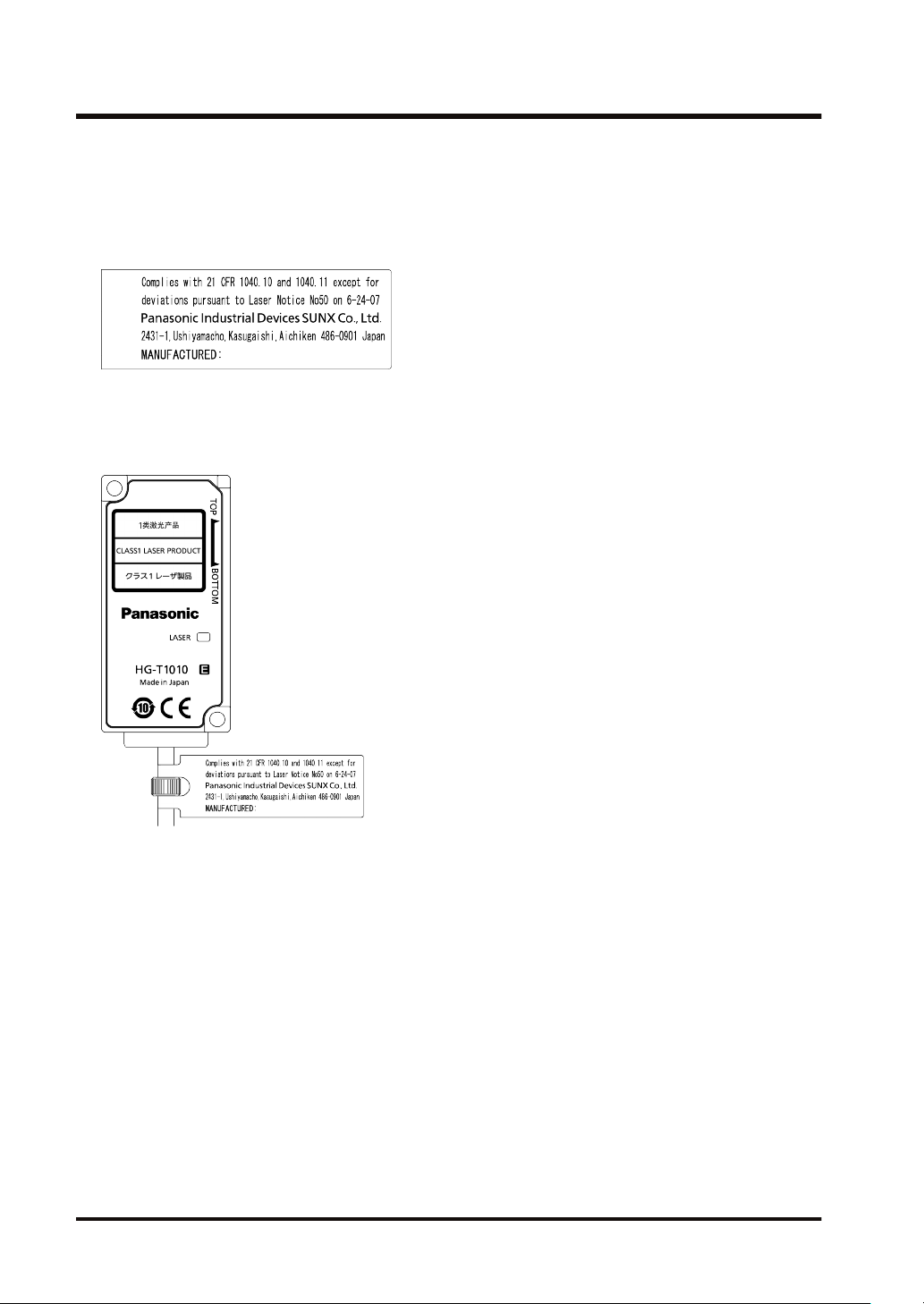

■

Recognition / identification label

■

Label position

Emitter

● Common to HG-T1010 and HG-T1110

1-8 WUME-HGT-6

1.4 Terminology

1.4 Terminology

Term Description

Controller - Master unit A controller that can be used on a standalone basis

Controller - Slave unit A controller that is used by connecting to a master unit

Sensor head - Emitter A sensor head emitter that is used by connecting to a controller

Sensor head Receiver

Sensor head

connection

cable

Side view attachment An attachment that is used to refract laser beams from the sensor head at 90 degrees

End plate

Communication unit

(Note 1) For details on communication units, refer to the user's manual for each communication unit.

A sensor head receiver that is used by connecting to a controller

A cable that is used to connect a sensor head and controller

A plate that is used to secure both ends of controllers to prevent the connectors from

coming off and causing a communication failure when controllers are connected

An interface unit that enables measurement data and other data of connected

controllers to be monitored.

(Note 1)

WUME-HGT-6 1-9

1.5 Contents of Package

1.5 Contents of Package

The following accessories are included in the product package. Before using the product, make

sure that no items are missing.

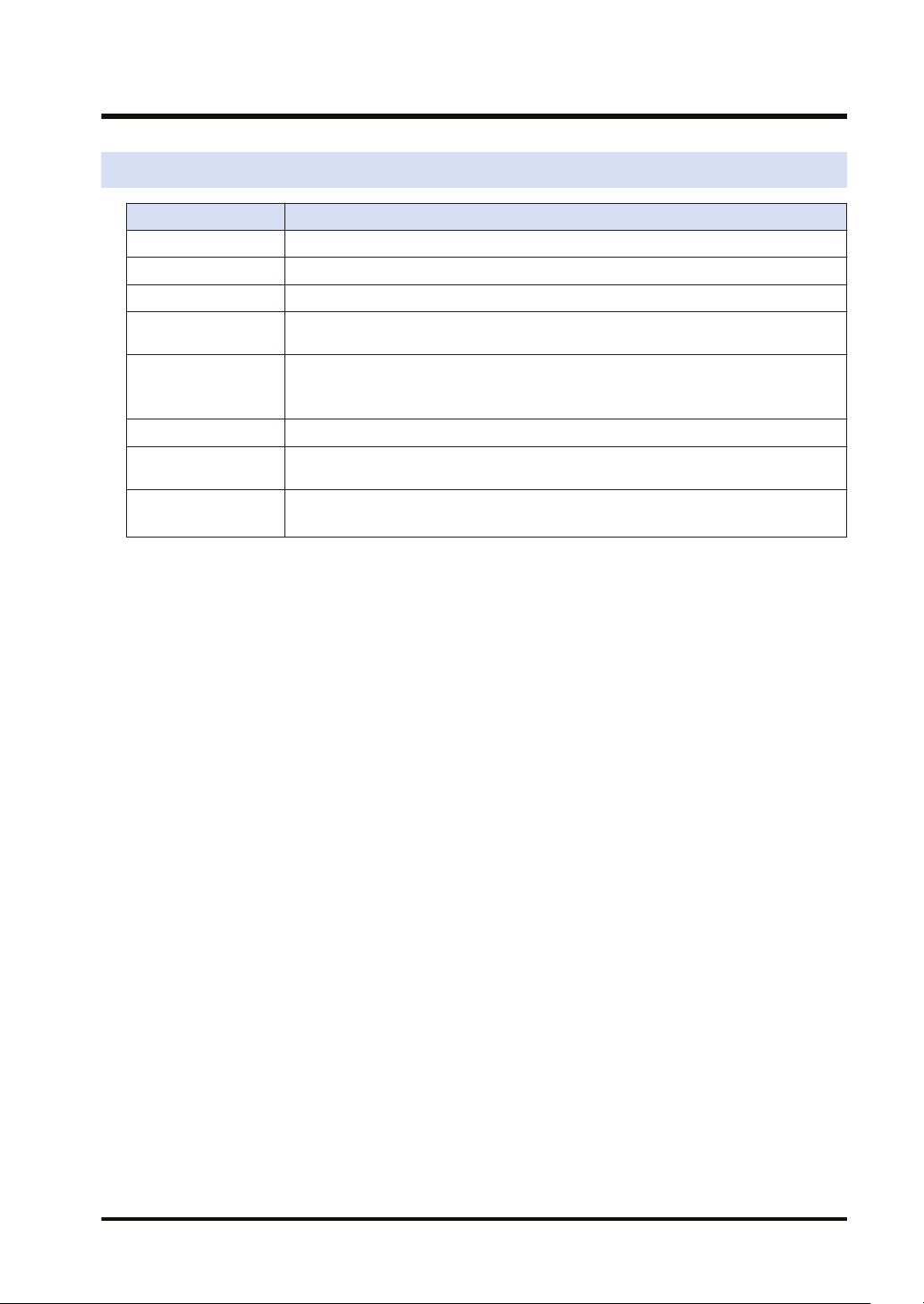

Controller

HG-TC101 / Master unit of high-performance NPN

output type

HG-TC101-P / Master unit of high-performance PNP

output type

● Controller: 1 pc.

HG-TC111 / Slave unit of high-performance NPN

output type

HG-TC111-P / Slave unit of high-performance PNP

output type

● Controller: 1 pc.

● Instruction Manual

(English / Japanese, Chinese / Korean): 1 pc. each

● General Information for Safety, Compliance, and

Instructions (23 languages): 1 pc.

HG-TC113 / Slave unit of wire-saving type

● Controller: 1 pc.

● Instruction manual

(English / Japanese, Chinese / Korean): 1 pc. each

● General Information for Safety, Compliance, and

Instructions (23 languages): 1 pc.

Sensor head

HG-T1010 / Measurement width 10 mm, standard type

● Sensor head (emitter and receiver): 1 set

● Instruction manual

(English / Japanese, Chinese / Korean): 1 pc. each

● General Information for Safety, Compliance, and

Instructions (23 languages): 1 pc.

HG-T1110 / Measurement width10 mm, slim type

● Sensor head (emitter and receiver): 1 set

● Instruction manual

(English / Japanese, Chinese / Korean): 1 pc. each

● Instruction manual

(English / Japanese, Chinese / Korean): 1 pc. each

1-10 WUME-HGT-6

1.5 Contents of Package

Sensor head

● General Information for Safety, Compliance, and

Instructions (23 languages): 1 pc.

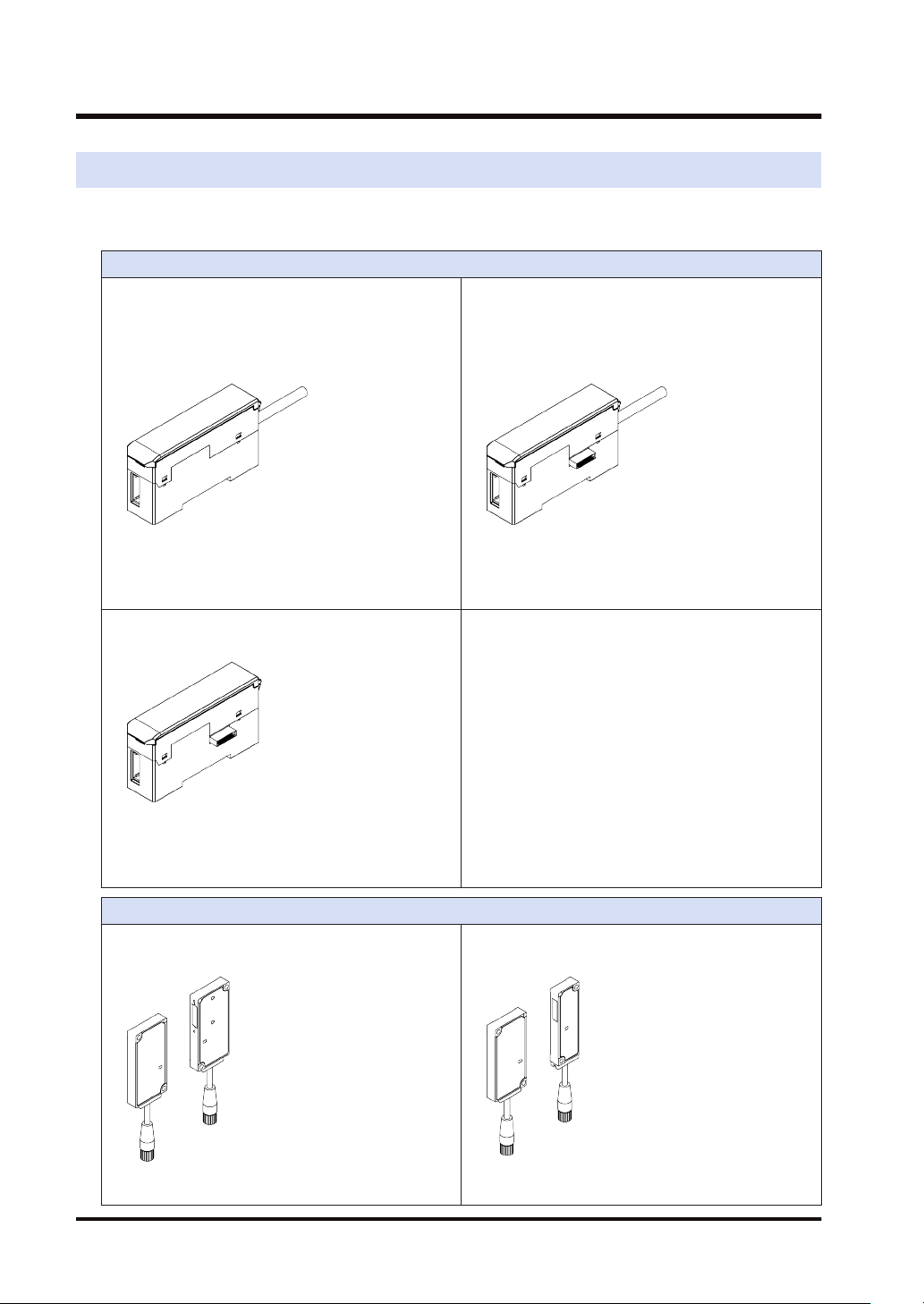

Side view attachment Sensor head connection cable

HG-TSV10 / Side view attachment

● Attachment: 1 pc.

(Note 1)

● M2 screw with washer (length: 4 mm): 2 pcs.

(Note 1) HG-TSV10 is sold by one unit. Two units are required for a pair of emitter and receiver.

End plate

MS-DIN-E / End plate

● Plate: Set of 2 pcs.

● General Information for Safety, Compliance, and

Instructions (23 languages): 1 pc.

CN-HT-C2 / Cable length 2 m

CN-HT-C5 / Cable length 5 m

CN-HT-C10 / Cable length 10 m

CN-HT-C20 / Cable length 20 m

● Connection cable: 1 pc.

● Instruction manual

WUME-HGT-6 1-11

1.6 Product Version and Functions

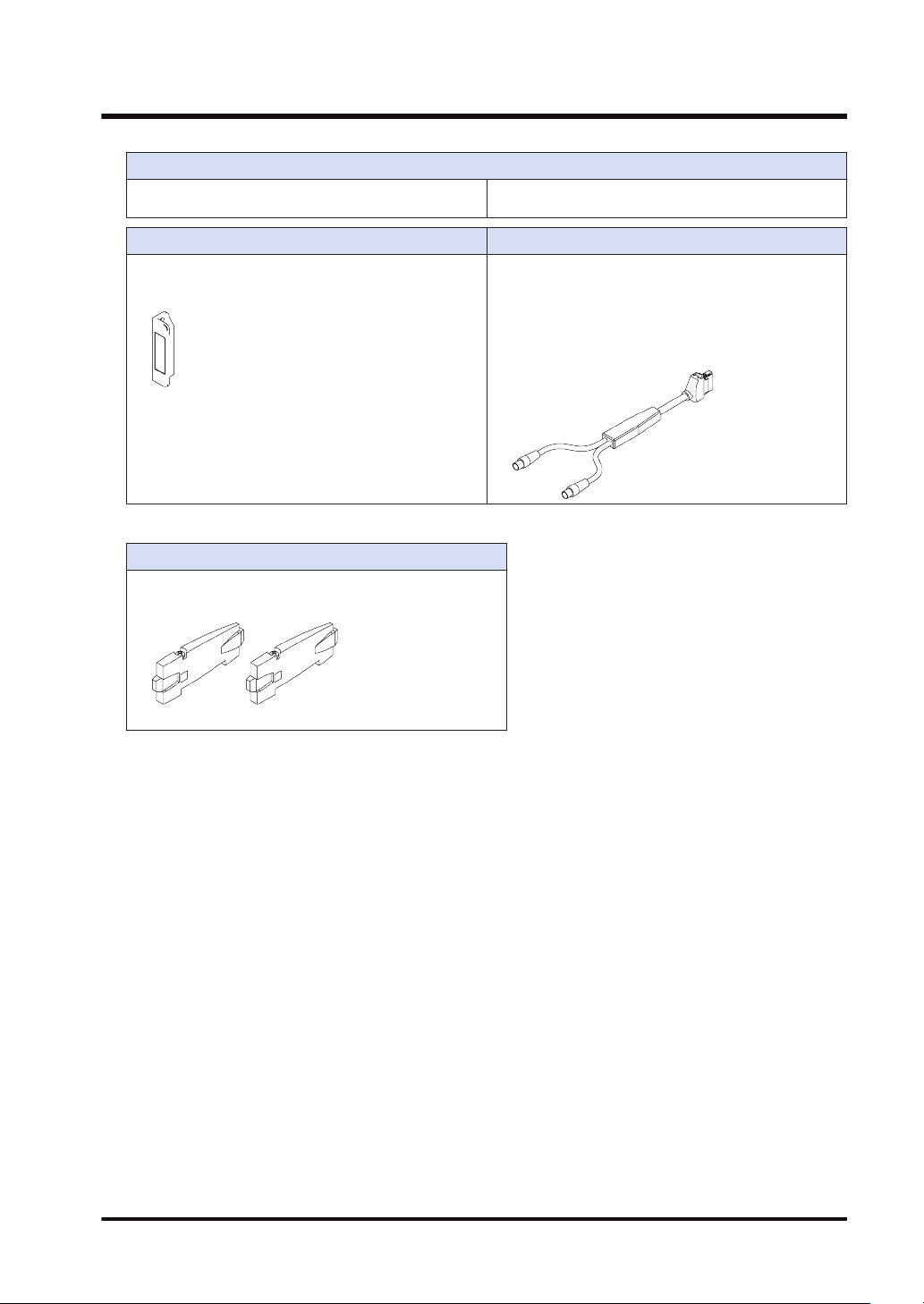

1.6 Product Version and Functions

The following functions are added to the HG-TC□ series controllers and HG-T□ series sensor

heads manufactured in November 2020 onwards.

Added function Description Remarks

Assigned edge detection mode Operation mode

Tab cancellation function Hold setting

Hold state output External output "7.2.4 External Outputs

Measured value reversal selection

function

● The controllers and sensor heads manufactured in October 2020 or earlier do not support

the above functions. Please note this point.

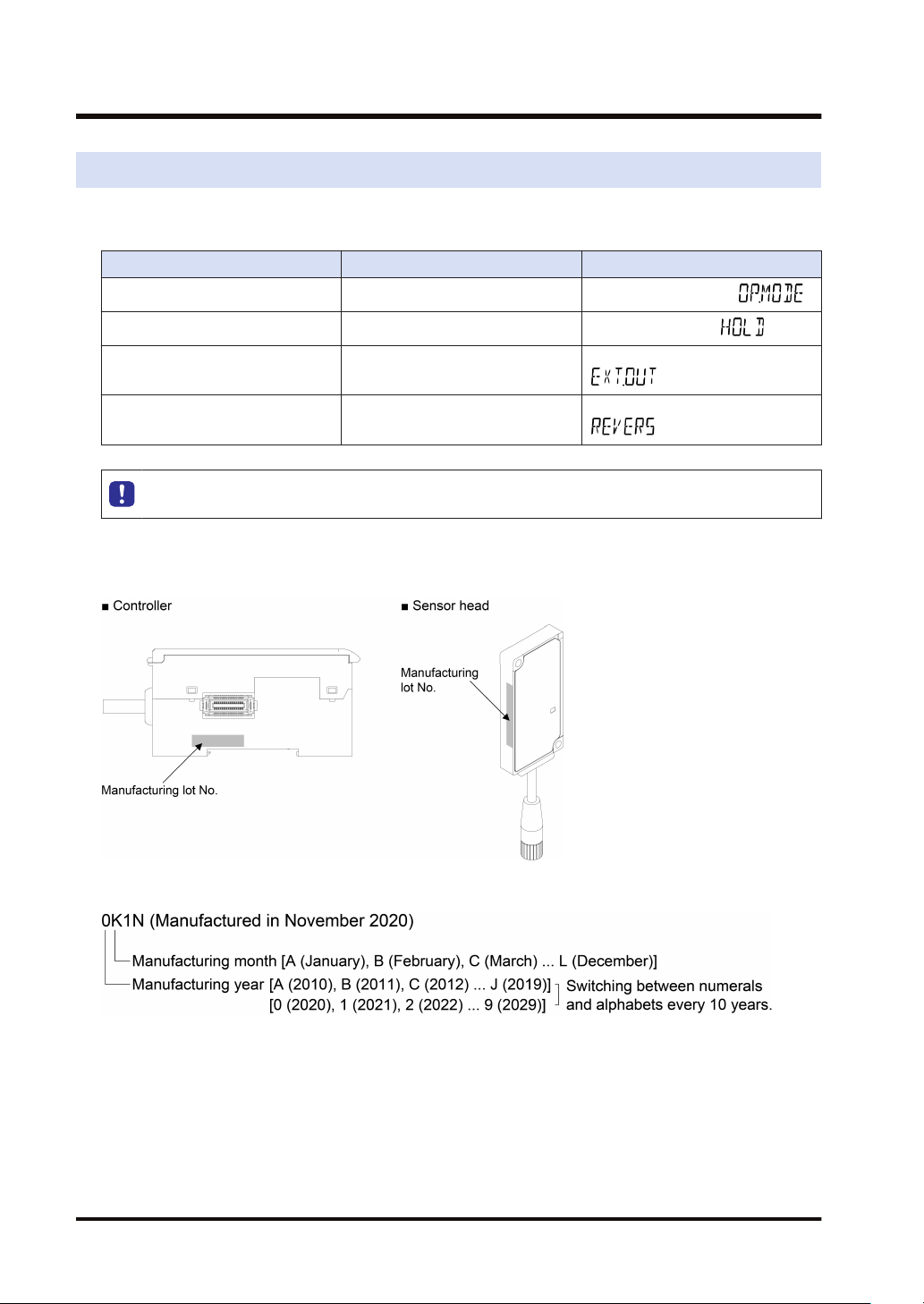

■

<How to check manufacturing year and month>

Measured value reversal "7.2.13 Reverse of Measured Value

Check the manufacturing lot No. shown in the following figure.

"6.3.1 Operation Mode ( )"

"7.2.1 Hold Settings ( )"

(

( )"

)"

■

<How to interpret the manufacturing lot No.>

1-12 WUME-HGT-6

2 System Configuration

2.1 System Configuration..........................................................................2-2

2.2 Description of Parts.............................................................................2-3

2.2.1 Controller ......................................................................................... 2-3

2.2.2 Sensor head..................................................................................... 2-5

2.2.3 Sensor Head Connection Cable ...................................................... 2-6

2.2.4 Side View Attachment...................................................................... 2-6

WUME-HGT-6 2-1

2.1 System Configuration

2.1 System Configuration

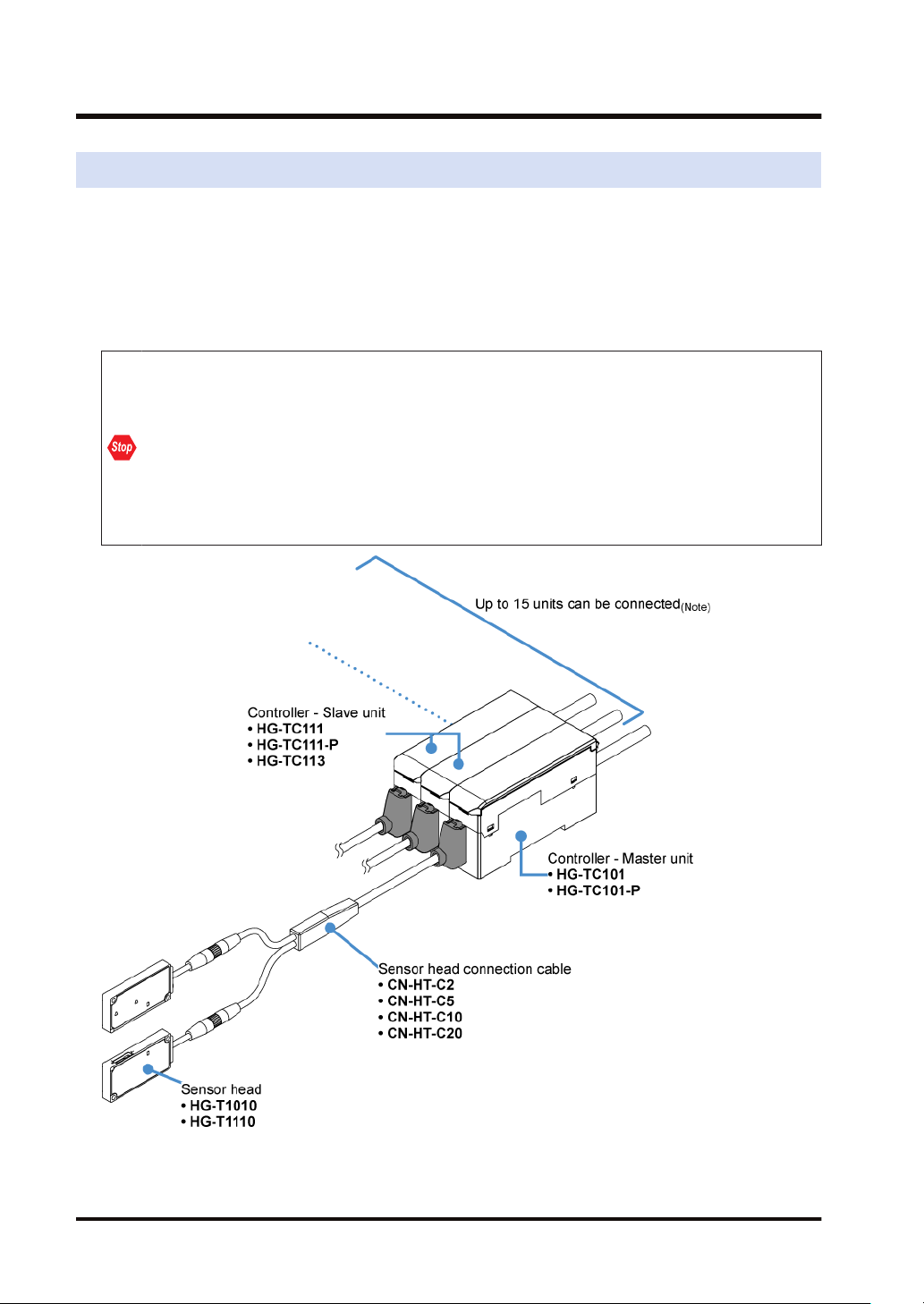

The HG-T series consists of controllers, sensor head connection cables, and sensor heads.

For the controllers, master units (two types) and slave units (three types) are available. Up to 15

slave units can be connected to one master unit. For the sensor heads, two types are available.

For the sensor head connection cables, four types are available.

Connecting a communication unit to the end of the connection enables information to be

checked from outside. (Note 1)

● Always shut OFF the power before connecting or disconnecting a slave unit or

communication unit to / from the master unit. If you connect or disconnect a unit with the

power ON, the controller may become damaged.

● Insert the male connector all the way into the female connector. If the connectors are not

completely connected, the controller may become damaged.

● To connect units, always mount them on a DIN rail. To do so, mount end plates MS-DIN-E

(optional) so as to enclose the connected units at both ends.

● When connecting slave units to the master unit, connect only NPN output type units or

only PNP output type units. Dissimilar output types cannot be connected together.

(Note 1) When a communication unit is connected, up to 14 slave units can be connected.

2-2 WUME-HGT-6

2.2 Description of Parts

2.2 Description of Parts

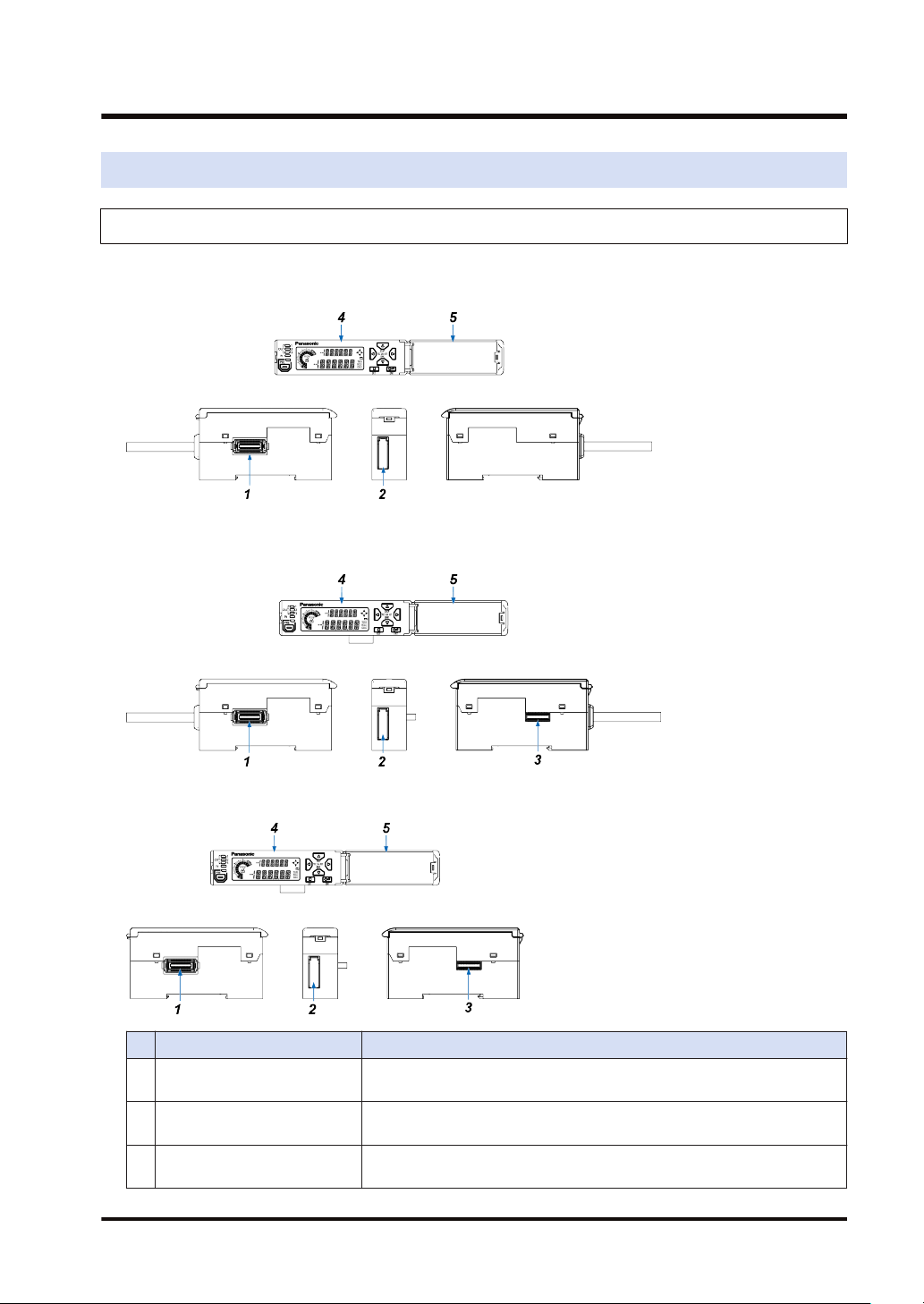

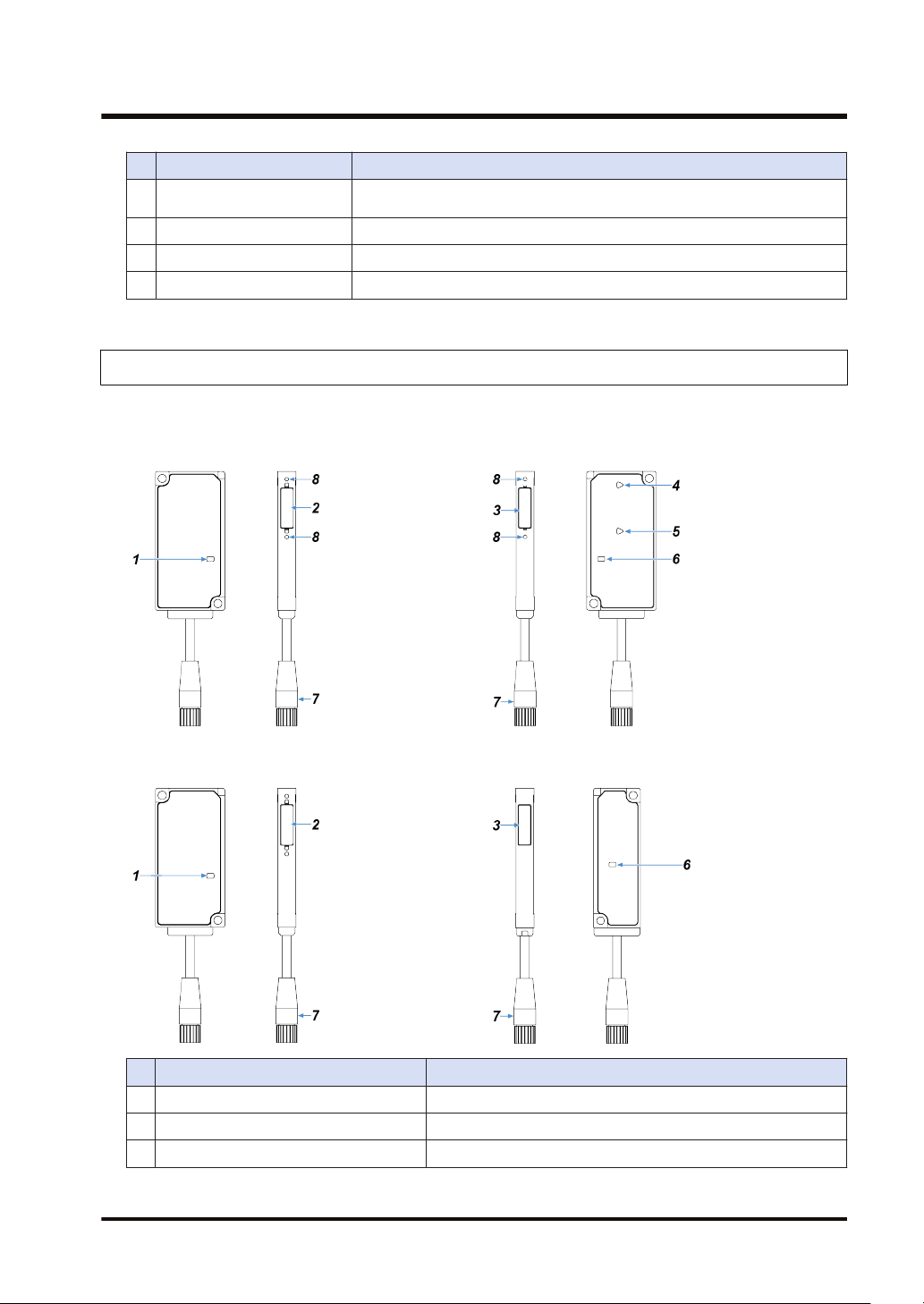

2.2.1 Controller

HG-TC101 / Master unit of high-performance NPN output type, HG-TC101-P / Master

unit of high-performance PNP output type

HG-TC111 / Slave unit of high-performance NPN output type, HG-TC111-P / Slave unit

of high-performance PNP output type

HG-TC113 / Slave unit of wire-saving type

Name Function

1 Female connector

Sensor head connection cable

2

connector

Male connector (for slave unit

3

only)

WUME-HGT-6 2-3

For connection to a slave unit. Remove the connector cover before

connecting to a slave unit.

Connects the sensor head connection cable.

For connection to a master unit or slave unit.

2.2 Description of Parts

Name Function

Digital display section /

4

operation unit

Digital display section /

5

operation unit cover

■

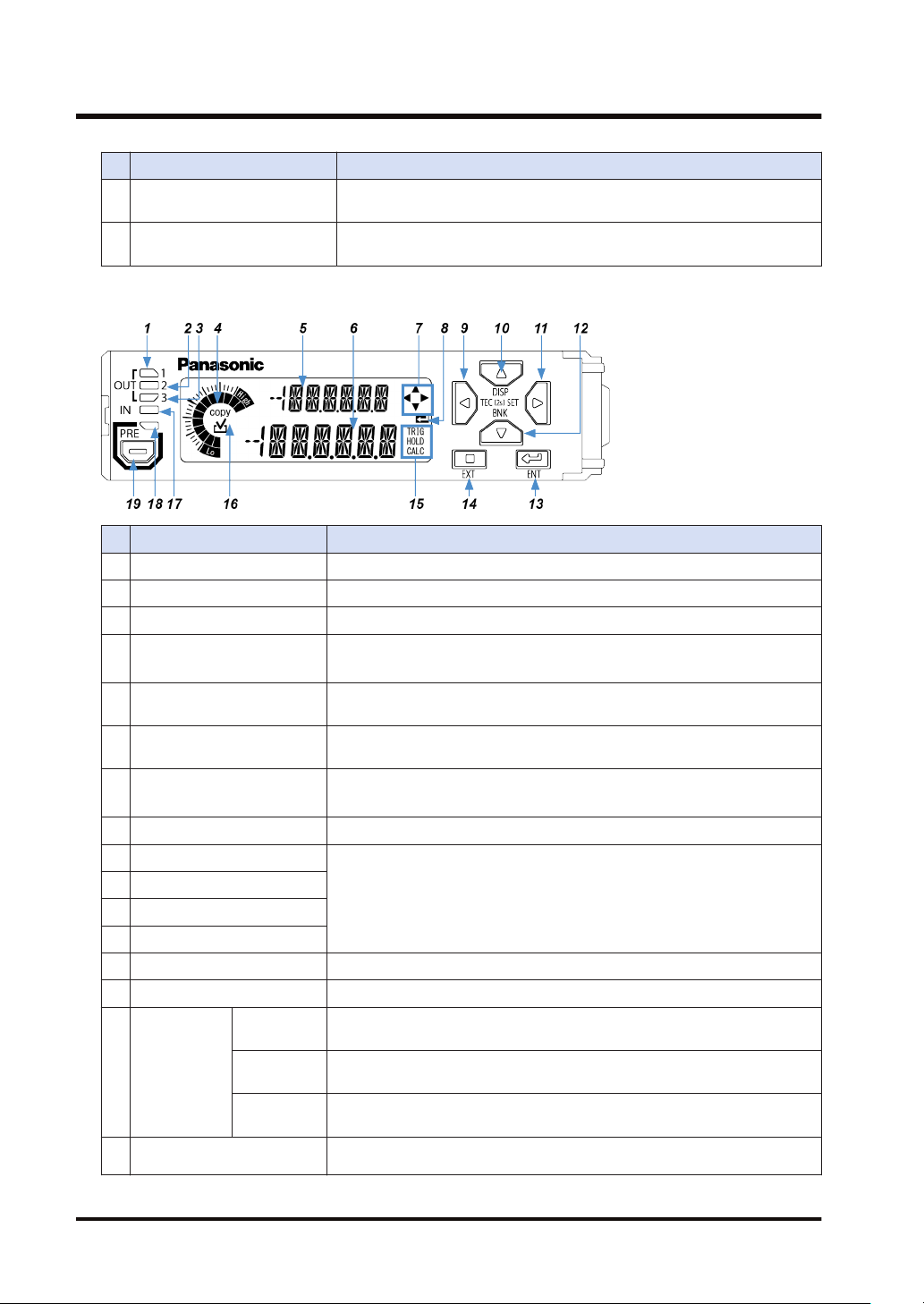

Display unit / operation unit

Name Function

1 Output 1 indicator (Orange) Lights up when output 1 is ON.

2 Output 2 indicator (Orange) Lights up when output 2 is ON.

3 Output 3 indicator (Orange) Lights up when output 3 is ON.

4 Circle meter (Orange, green)

Digital display section / SUB

5

(Green)

Digital display section / MAIN

6

(White)

Guide mark / arrow keys

7

(White)

8 Guide mark / Enter (White) Lights up when the ENTER key is enabled during each setting operation.

9 LEFT key

10 UP key

11 RIGHT key

12 DOWN key

13 ENTER key Used to select setting items and apply settings when configuring settings.

14 EXIT key Used to exit a setting item or cancel a setting when configuring settings.

TRIG

(White)

15 Status mark

16 Copy checkmark (Orange)

HOLD

(White)

CALC

(White)

For checking measured values and perform setting operation. For details,

refer to the following page.

Protects the display unit and operation unit. Keep the cover closed when

the display unit / operation unit is not used.

● Shows increases or decreases of the judgment value by meter display.

● Shows the level and item sequence of setting work by navigation display.

Shows the setting item and the item set using display switching mode.

Shows the measured value, judgment value, and setting.

Lights up when each key (LEFT / RIGHT / UP / DOWN) is enabled during

each setting operation.

Used to change setting items and settings when configuring settings, and to

move through set value digits.

Lights up while the trigger input (external input) is ON.

Lights up while the judgment value is held.

Lights up when calculation mode is set with a slave unit connected.

"COPY" lights up for a setting item that can be copied to a slave unit when a

master unit is set up. In this case, if the setting item is selected as a copy

2-4 WUME-HGT-6

Name Function

target, the checkmark will light up and executing copy will perform copy

processing.

17 Input indicator (White) Lights up when external input 1, 2, or 3 is ON.

18 Preset indicator (Green) Lights up when the preset function is used.

19 Preset key Used to set and cancel the preset function.

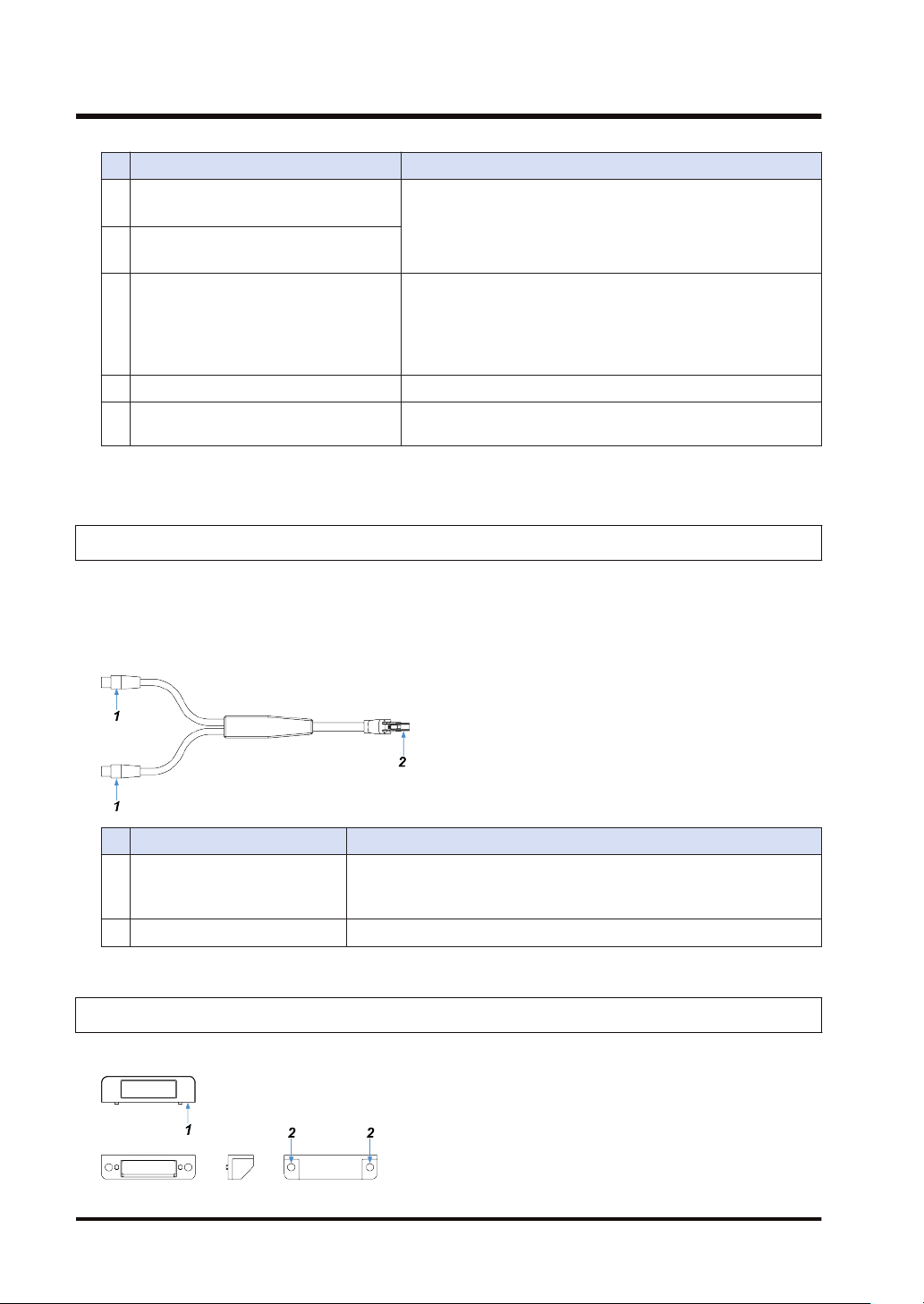

2.2.2 Sensor head

HG-T1010

Emitter Receiver

2.2 Description of Parts

HG-T1110

Emitter Receiver

Name Function

1 Laser radiation indicator (Green) Lights up when laser beams are emitted.

2 Light emitting surface The surface that emits laser beams

3 Light receiving surface The surface that receives laser beams

WUME-HGT-6 2-5

2.2 Description of Parts

Name Function

Beam axis adjustment indicator / TOP

4

part (Orange / Green)

Beam axis adjustment indicator /

5

BOTTOM part (Orange / Green)

Judgment output indicator (Orange /

6

Green)

7 Sensor head connection cable connector Connects the sensor head connection cable.

Female thread for mounting side view

8

attachment

(Note 1) The HG-T1110 is not equipped with the beam axis adjustment indicators (TOP / BOTTOM part).

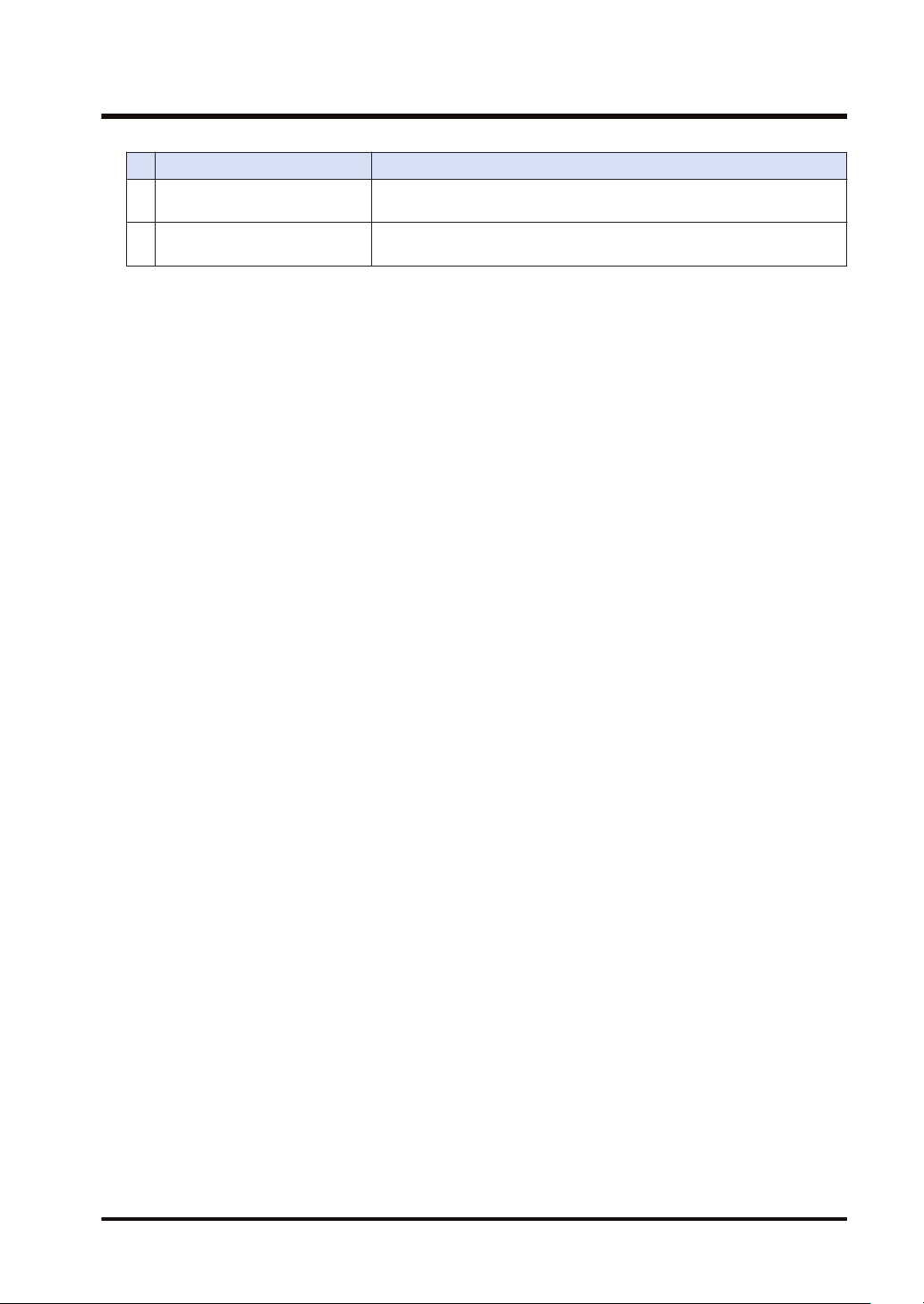

2.2.3 Sensor Head Connection Cable

CN-HT-C2 / Cable length 2 m

CN-HT-C5 / Cable length 5 m

CN-HT-C10 / Cable length 10 m

CN-HT-C20 / Cable length 20 m

(Note 1)

(Note 1)

Indicates the beam axis adjustment state as light color (green or

orange) and lighting state (lit, flashing, or unlit). (Only when the

beam axis adjustment function is used)

When controller judgment value is within the threshold range:

Lights green.

When controller judgment value is outside the threshold range:

Lights orange.

When the beam axis adjustment function is used: OFF

Connects the side view attachment and sensor head using an

M2 screw with washer (length: 4 mm).

Name Function

Connects to the sensor head cable connector on the sensor head.

1 Sensor head connector

There is no difference between the connectors on the emitter side and on

the receiver side.

2 Controller connector Connects to the sensor head cable connector on the controller.

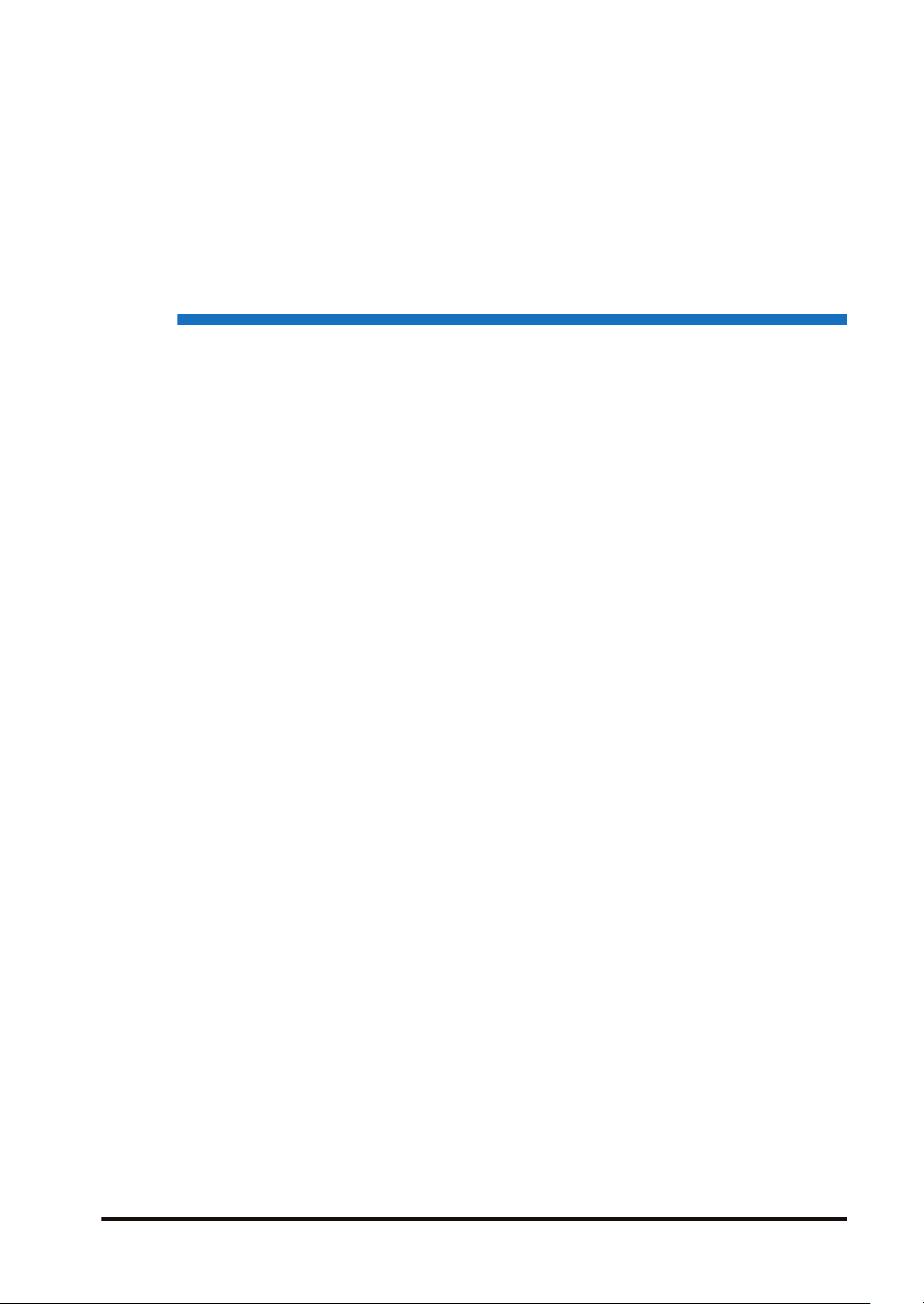

2.2.4 Side View Attachment

HG-TSV10

2-6 WUME-HGT-6

Name Function

1 Sensor head mounting surface

2 Sensor head mounting hole

2.2 Description of Parts

Mounts the side view attachment on the light emitting and receiving

surfaces of the sensor head

Connects the side view attachment and sensor head using an M2 screw

with washer (length: 4 mm).

WUME-HGT-6 2-7

(MEMO)

2-8 WUME-HGT-6

3 Overview of HG-T Series

3.1 Principle of Measurement ...................................................................3-2

3.2 Role of Controllers ..............................................................................3-3

3.3 Using Connected Controllers..............................................................3-4

WUME-HGT-6 3-1

3.1 Principle of Measurement

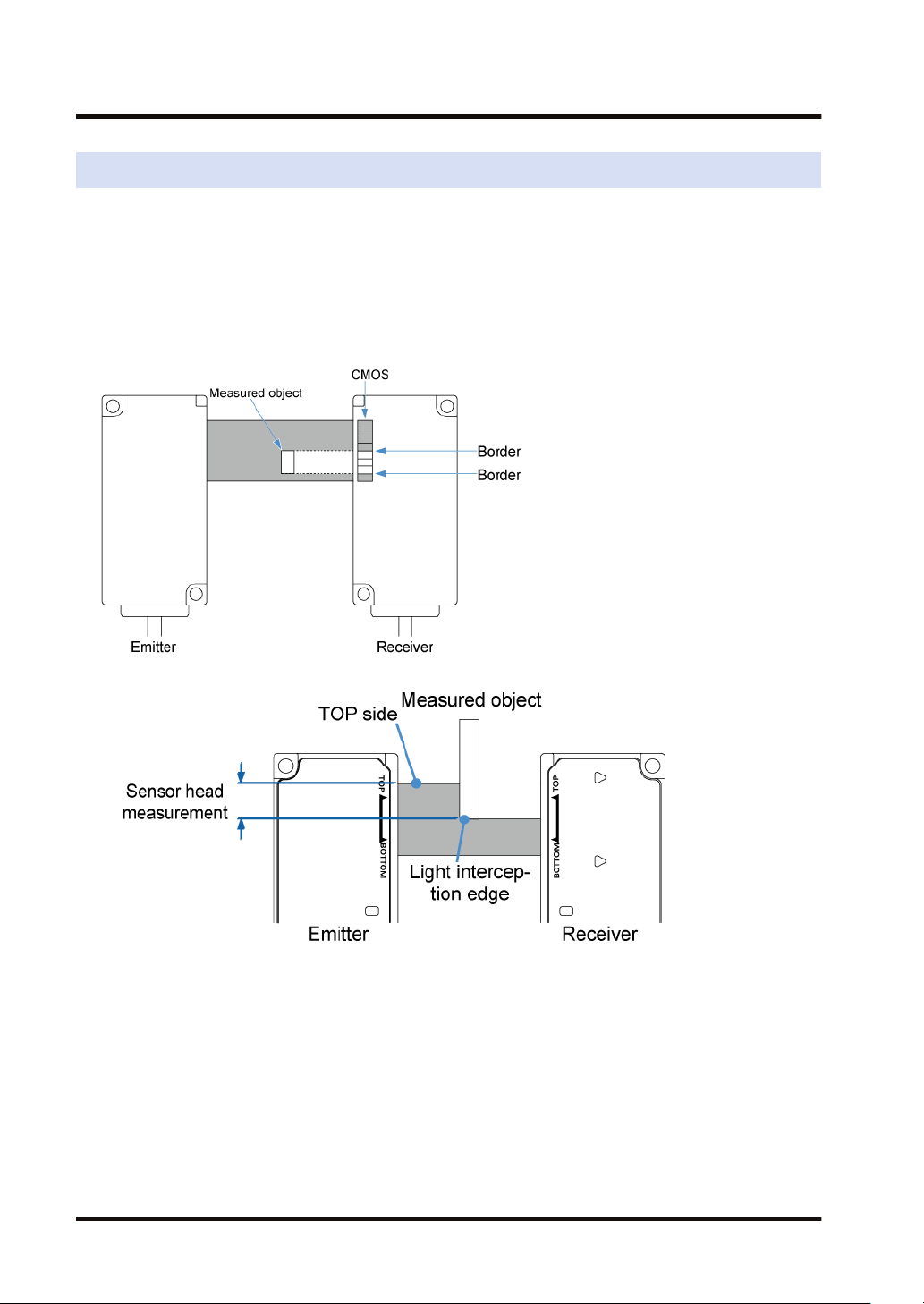

3.1 Principle of Measurement

The sensor head emits belt-shaped laser beams from its emitter and receives them with the

light receiving element (CMOS) of its receiver. If a measured object is inserted between the

emitter and receiver of the sensor head, the bright section (light entry section) that receives

laser beams and the dark section (light interception section) that is the shade of the measured

object are projected on to the CMOS.

The difference in the amount of received light between each pixel of the CMOS is used to

detect position information about the border between the light entry section and the light

interception section and measure the object.

● The edge position of the measured object can be measured.

3-2 WUME-HGT-6

Loading...

Loading...