Page 1

CMOS type

Micro Laser Distance Sensor

Reliable detection

in

10

µm precision

HG-C

Conforming to

EMC Directive

SERIES

Conforming to

FDA regulations

Measurement center

200 mm 7.874 in type

400 mm 15.748 in type

2015.07

panasonic.net/id/pidsx/global

Page 2

MICRO LASER DISTANCE SENSOR

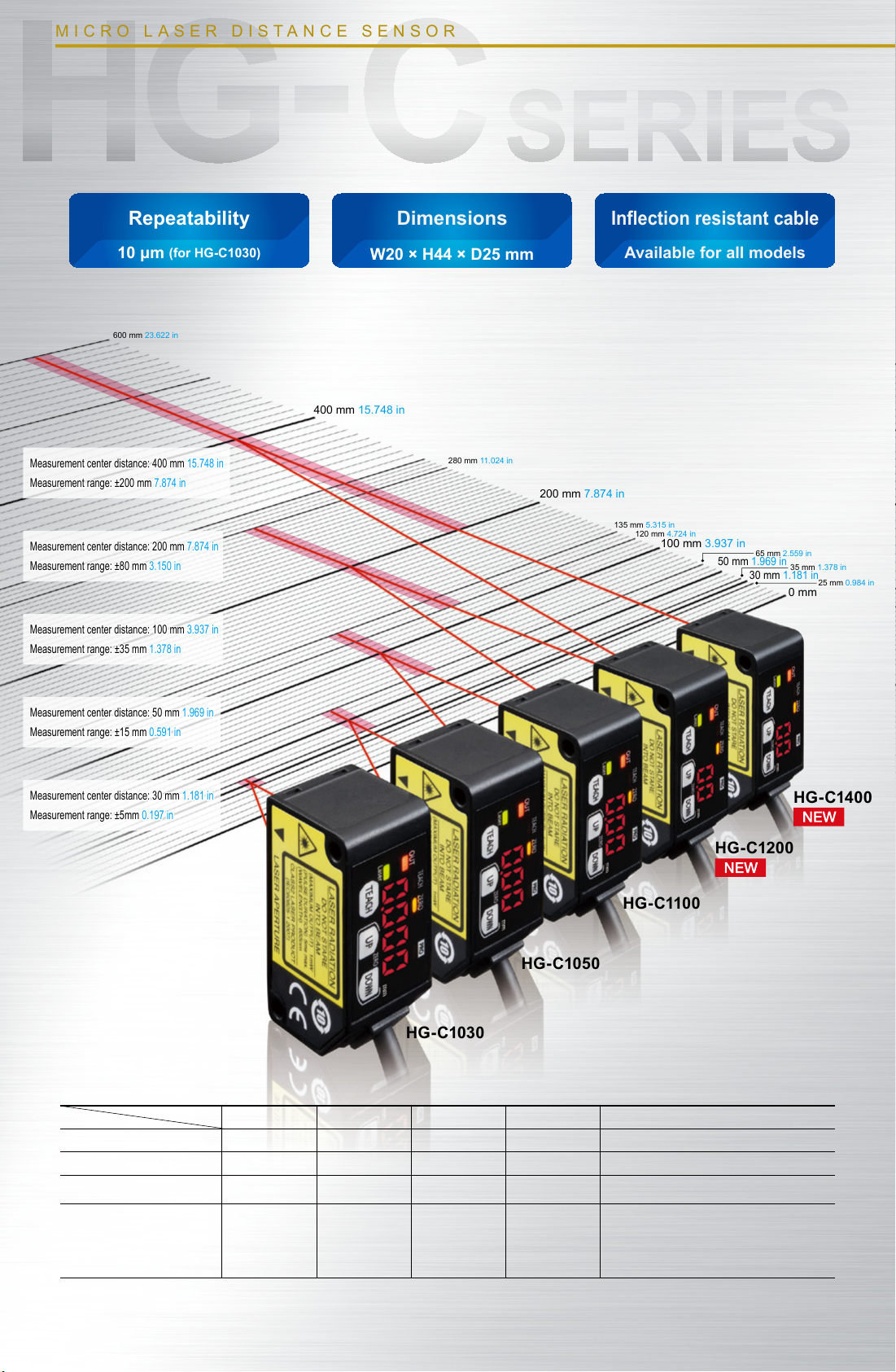

Repeatability

10 μm

600 mm 23.622 in

Measurement center distance: 400 mm 15.748 in

Measurement range: ±200 mm 7.874 in

Measurement center distance: 200 mm 7.874 in

Measurement range: ±80 mm 3.150 in

Measurement center distance: 100 mm 3.937 in

Measurement range: ±35 mm 1.378 in

(for HG-C1030)

W20 × H44 × D25 mm

400 mm 15.748 in

Dimensions

280 mm 11.024 in

Inflection resistant cable

200 mm 7.874 in

Available for all models

135 mm 5.315 in

120 mm 4.724 in

100 mm 3.937 in

65 mm 2.559 in

50 mm 1.969 in

30 mm 1.181 in

35 mm 1.378 in

25 mm 0.984 in

0 mm

Measurement center distance: 50 mm 1.969 in

Measurement range: ±15 mm 0.591 in

Measurement center distance: 30 mm 1.181 in

Measurement range: ±5mm 0.197 in

HG-C110 0

HG-C1050

HG-C1030

Item

Measurement center distance 30 mm 1.181 in 50 mm 1.969 in 100 mm 3.937 in 200 mm 7.874 in 400 mm 15.748 in

Measurement range ±5 mm 0.197 in ±15 mm 0.591 in ±35 mm 1.378 in ±80 mm 3.150 in ±200 mm 7.874 in

Beam diameter

Repeatability

Model No.

HG- C1030 HG-C1050 HG - C110 0 HG- C1200 HG-C1400

Approx.ø50 μm

1.969 mil

10 μm

0.394 mil

Approx.ø70 μm

2.756 mil

30 μm

1.181 mil

Approx.ø120 μm

4.724 mil

70 μm

2.756 mil

Approx.ø300 μm

11.811 mil

200 μm

7.874 mil

Approx.ø500 μm

300 μm 11.811 mil

Measuring distance 200

(

7.874 to 15.748 in

800 μm 31.496 mil

Measuring distance 400

(

15.748 to 23.622 in

HG-C1200

19.685 mil

to

to

400mm

)

600mm

)

HG-C1400

2

Page 3

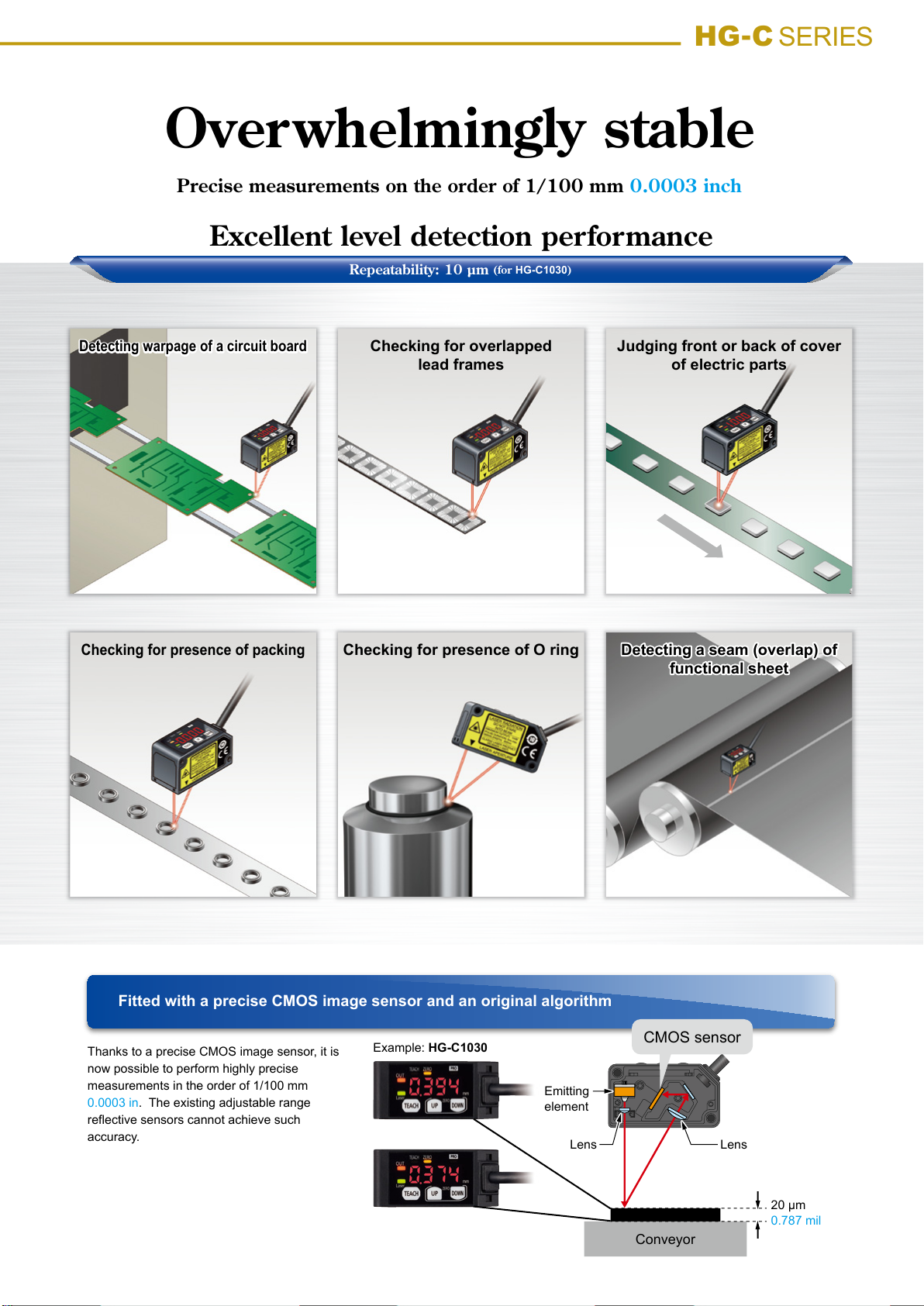

Overwhelmingly stable

Precise measurements on the order of 1/100 mm 0.0003 inch

Fitted with a precise CMOS image sensor and an original algorithm

HG-C

SERIES

Thanks to a precise CMOS image sensor, it is

now possible to perform highly precise

measurements in the order of 1/100 mm

0.0003 in. The existing adjustable range

reflective sensors cannot achieve such

accuracy.

Example: HG-C1030

Conveyor

20 μm

0.787 mil

Excellent level detection performance

Repeatability: 10 μm

(for

HG-C1030

)

Detecting warpage of a circuit board

Checking for overlapped

lead frames

Checking for presence of packing

Checking for presence of O ring

Judging front or back of cover

of electric parts

Detecting a seam (overlap) of

functional sheet

Emitting

element

LensLens

CMOS sensor

3

Page 4

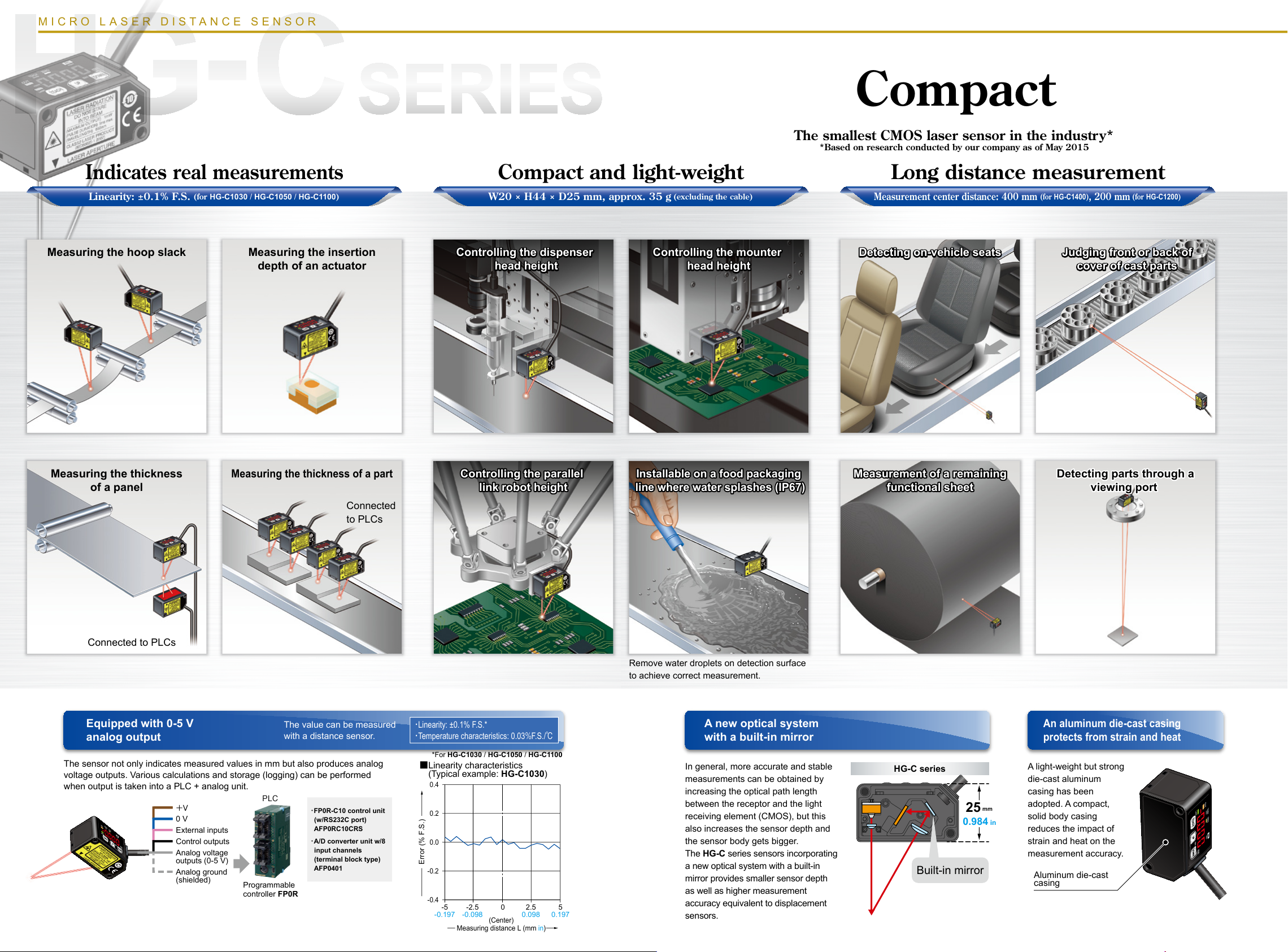

Compact

Compact and light-weight

Equipped with 0-5 V

analog output

An aluminum die-cast casing

protects from strain and heat

A new optical system

with a built-in mirror

MICRO LASER DISTANCE SENSOR

In general, more accurate and stable

measurements can be obtained by

increasing the optical path length

between the receptor and the light

receiving element (CMOS), but this

also increases the sensor depth and

the sensor body gets bigger.

The HG-C series sensors incorporating

a new optical system with a built-in

mirror provides smaller sensor depth

as well as higher measurement

accuracy equivalent to displacement

sensors.

The sensor not only indicates measured values in mm but also produces analog

voltage outputs. Various calculations and storage (logging) can be performed

when output is taken into a PLC + analog unit.

A light-weight but strong

die-cast aluminum

casing has been

adopted. A compact,

solid body casing

reduces the impact of

strain and heat on the

measurement accuracy.

Remove water droplets on detection surface

to achieve correct measurement.

■

Linearity characteristics

(Typical example: HG-C1030)

*For HG-C1030 / HG-C1050 / HG-C1100

PLC

・

FP0R-C10 control unit

(w/RS232C port)

AFP0RC10CRS

・

A/D converter unit w/8

input channels

(terminal block type)

AFP0401

Programmable

controller FP0R

+V

0 V

External inputs

Control outputs

Analog voltage

outputs (0-5 V)

Analog ground

(shielded)

・

Linearity: ±0.1% F.S.*

・

Temperature characteristics: 0.03%F.S./

℃

-0.4

-0.2

0.0

0.2

0.4

-5 -2.5 0 2.5 5

-0.197 -0.098 0.098 0.197

(Center)

Measuring distance L (mm in)

Error (% F.S.)

The value can be measured

with a distance sensor.

Indicates real measurements

The smallest CMOS laser sensor in the industry*

*Based on research conducted by our company as of May 2015

Measurement center distance: 400 mm

(for

HG-C1400

)

, 200 mm

(for

HG-C1200

)

W20 × H44 × D25 mm, approx. 35 g

(excluding the cable)

Measuring the insertion

depth of an actuator

Measuring the thickness

of a panel

Measuring the thickness of a part

Linearity: ±0.1% F.S.

(for

HG-C1030 / HG-C1050 / HG-C1100

)

Detecting parts through a

viewing port

Measuring the hoop slack

Connected

to PLCs

Connected to PLCs

Controlling the dispenser

head height

Controlling the dispenser

head height

Controlling the mounter

head height

Controlling the mounter

head height

Controlling the parallel

link robot height

Installable on a food packaging

line where water splashes (IP67)

Installable on a food packaging

line where water splashes (IP67)

Detecting on-vehicle seats Judging front or back of

cover of cast parts

Measurement of a remaining

functional sheet

Built-in mirror

HG-C series

25

mm

0.984 in

Aluminum die-cast

casing

Long distance measurement

5 4

Page 5

MICRO LASER DISTANCE SENSOR

Timer setting function

Teaching & window comparator mode

OFF

OFF

ON

With an object below the sensor, press the TEACH key to set the valid range for distances via threshold values. There are 3 methods for

setting the valid range: 1-point, 2-point, and 3-point teaching.

The time mode options are “off-delay timer,” “on-delay timer,” “one-shot timer” and “no timer.” The counting time is fixed to 5 ms.

Off-delay timer

Function: Extends output signals by 5 ms.

Usage: Appropriate in case a connected device is slow to

respond and ON time is required to extend.

On-delay timer

Function: Overrides output signals for 5 ms after detection.

Usage: Convenient way to override temporary signals and

control with a time lag.

One-shot timer

Function: Sends output signals for only 5 ms after detection.

Usage: Useful when the signal duration needs to be

constant to meet inputs from a connected device.

This mode is also used to extend temporary signals

by a desired length of time.

Perform 1-point teaching and the threshold

range is set for the distance from the reference

surface of the sensing object.

Press TEACH once for the lower (first point) and

once for the upper limit (second point).

Useful for sensing objects at different distances.

This is the method to set the threshold range by

conducting the teaching at 3 points (sensing object A,

B and C). After teaching, the reference points are

automatically sorted in ascending order (reference

point 1, 2 and 3). The thresholds are set at the

midpoints between reference point 1 and 2, and 2 and

3, respectively.

Useful for sensing objects at different distances.

In addition to the teaching & window

comparator mode, the “rising differential

mode”, “trailing differential mode” and

“normal sensing mode” are available.

In normal sensing mode, “2-point teaching”

as basic teaching and “limit teaching,”

which is useful for very small objects and

backgrounds, are possible.

Sensing

level

Off-delay

timer

On-delay

timer

One-shot

timer

5 ms 5 ms

5 ms 5 ms

5 ms 5 ms

3-point teaching

Sensing

object

A

TEACH

①

TEACH

②

TEACH

③

Sensing

object

B

Reference

point 1

Reference

point 2

Threshold value

Threshold value

Reference

point 3

Set to Light-ON

Sensing

object

C

Distance

2-point teaching

TEACH

①

TEACH

②

Lower limit

sensing object

Threshold

value

Threshold

value

Set to Light-ON

Upper limit

sensing object

Distance

OFF

OFF

1-point teaching

TEACH

①

Sensing

object present

Threshold

value

Reference point

Threshold

value

Set to Light-ON

Distance

ON

OFF

OFF

ON

Useful functions

Timer period: 5 ms (fixed)

6

Page 6

HG-C

SERIES

Zero set function External input setting function

Threshold value fine adjustment function

Key lock function

Display setting function

Peak and bottom hold functions

This function compulsorily sets the measured value to “zero.”

The zero point can be set at a desired value. It is useful when

measuring steps or tolerance with reference to the height of a

sensing object.

* For other functions and procedures for setting the functions, see “PRO Mode Setting” from page 10.

One of four functions, “zero setting function,” “teaching

function,” “emission stopping function” and “trigger function” can

be assigned to an external input line.

Fine adjustment of threshold values can be performed while

measurement is proceeding on the display, and even after teaching.

This function protects setting conditions from unintentional

changes.

The peak hold function holds the maximum measured value which is output and displayed.

The bottom hold function holds the minimum measured value which is output and displayed.

* The peak hold function and the bottom hold function cannot be set at the same time.

* When the zero set function is executed while the peak hold function or the bottom hold function is valid, the held measurement value is reset.

+

V

0V

External

input

Control

output

Analog voltage output (0-5 V)

Analog ground (shielded)

Keep pressing both keys for 3 seconds.

Assign any one.

Teaching

Zero set

Trigger

Emission stop

How to indicate measured values of the moving sensed object can be chosen from three options, “Normal,” “Invert” and “Offset.”

* The zero set indicator (yellow) will turn ON while the zero set is valid.

* When the zero set function is executed while the peak hold function or the bottom

hold function is valid, the held measurement value is reset.

* When the display setting is set to offset, the zero set function cannot be set.

5.2

5.0

Solid line

・

Normal

・

Offset

Dashed line

・

Invert

2.5

Measuring distance (mm

)

Measuring near point

Analog voltage output

(

V

)

Measuring far pointMeasurement center

0

Example:

HG-C1050

■

Relation between the setting

display and the analog

voltage output

Outside the

measuring range

Display setting

NormalInvertOffset

Measuring

near point

Measurementcenter

Measuring far

point

Outside the

measuring range

7

Page 7

HG-C

ORDER GUIDE

Type Appearance

distance and

Repeatability

measurement range

Measurement center

Measurement center

30mm type

Measurement center

50mm type

Measurement center

100mm type

Measurement center

200mm type

Measurement center

400mm type

Note: This is the size in the measurement center distance. These values were defined by using 1/e2 (approx. 13.5%) of the center light intensity.

Due to leak light outside the specified area, the reflectance around the detecting point may be higher than at the point and this may affect the measurement value.

30 ± 5 mm

1.181 ± 0.197 in

50 ± 15 mm

1.969 ± 0.591 in

100 ± 35 mm

3.937 ± 1.328 in

200 ± 80 mm

7.874 ± 3.150 in

400 ± 200 mm

15.748 ± 7.874 in

10 μm

0.394 mil

30 μm

1.181 mil

70 μm

2.756 mil

200 μm

7.874 mil

300 μm 11.811 mil

(Measuring distance 200 to 400 mm 7.874 to 15.748 in)

800 μm 31.496 mil

(Measuring distance 400 to 600 mm 15.748 to 23.622 in)

Beam diameter

(Note)

Approx. ø50 μm

1.969 mil

Approx. ø70 μm

2.756 mil

Approx. ø120 μm

4.724 mil

Approx. ø300 μm

11.811 mil

Approx. ø500 μm

19.685 mil

Model No.

NPN output PNP output

HG-C1030 HG-C1030-P

HG-C1050 HG-C1050-P

HG-C1100 HG-C1100-P

HG-C1200 HG-C1200-P

HG-C1400 HG-C1400-P

SPECIFICATIONS

Measurement center

Type

30mm type

NPN output HG-C1030 HG-C1050 HG-C1100 HG-C1200 HG-C1400

Item

Applicable standard EMC Directive Compliance, FDA Standard

Measurement center distance

Measurement range ±5 mm 0.197 in ±15 mm 0.591 in ±35 mm 1.328 in ±80 mm 3.150 in ±200 mm 7.874 in

Repeatability 10 μm 0.394 mil 30 μm 1.181 mil 70 μm 2.756 mil 200 μm 7.874 mil

Linearity ±0.1 % F.S. ±0.2 % F.S.

Temperature characteristic 0.03 % F.S./°C

Light source Red semiconductor laser Class 2 [JIS/IEC/GB/FDA (Note 2)] Max. output: 1 mW, emission peak wavelength: 655 nm 0.026 mil

Beam diameter (Note 3)

Supply voltage 12 to 24 V DC ±10 %, Ripple P-P 10 % or less

Power consumption 40 mA or less (at 24 V DC supply voltage), 60 mA or less (at 12 V DC supply voltage)

Control output

Analogue output • Output range: 0 to 5 V (at alarm: +5.2 V) • Output impedance: 100 Ω

Response time Switchable between 1.5 ms / 5 ms / 10 ms

External input

Degree of pollution 2

Operating altitude 2,000 m 6561.680 ft or less

Environmental

Cable 5-core composite cable, 2 m 6.5617 ft long

Cable extension Extension up to total 10 m 393.701 ft is possible with 0.3 mm

Material Enclosure: Aluminum die-cast, Front cover: Acrylic

Weight Net weight: approx. 35 g (without cable), approx. 85 g (including cable)

Notes: 1) Supply voltage: 24 V DC, ambient temperature: +20 °C +68 °F, response time: 10 ms, and analog output value of measurement center distance are used for

2) This is based on the FDA Standard, according to Laser Notice No. 50 of the FDA Standard.

3) This is the size in the measurement center distance. These values were dened by using 1/e

PNP output HG-C1030-P HG-C1050-P HG-C1100-P HG-C1200-P HG-C1400-P

Model No.

30 mm 1.181 in 50 mm 1.969 in 100 mm 3.937 in 200 mm 7.874 in 400 mm 15.748 in

Approx. ø50 μm

1.969 mil

<NPN output type>

NPN open-collector transistor

Maximum sink current: 50 mA

•

Applied voltage: 30 V DC or less (Between control output to 0V)

•

Residual voltage: 1.5 V or less (At 50 mA sink current)

•

Leakage current: 0.1 mA or less

•

Output operation Either Light-ON or Dark-ON

Short-circuit protection Incorporated (Auto reset type)

<NPN output type>

NPN non-contact input

Protection IP67(IEC

Ambient temperature -10 to +45 °C -14 to 113 °F (No dew condensation or icing allowed), Storage: -20 to +60 °C -4 to 140 °F

Ambient humidity 35 to 85 % RH, Storage: 35 to 85 % RH

Ambient illuminance Incandescent lamp: Acceptance surface illuminance 3,000 ℓx or less

resistance

Vibration resistance 10 to 55 Hz (period: 1 min.) frequency, 1.5 mm 0.059 in amplitude in X, Y and Z directions for two hours each

Shock resistance 500 m/s

unspecied measurement conditions. The subject is white ceramics.

the specied area, the reectance around the detecting point may be higher than at the point and this may affect the measurement value.

8

Measurement center

50mm type

Approx. ø70 μm

2.756 mil

Input conditions

•

Invalid: +8 to +V DC or Open

Valid: 0 to +1.2 V DC

Input impedance: Approx. 10 kΩ

•

2

acceleration (50 G approx.) in X, Y and Z directions for three times each

Measurement center

Measurement center

100mm type

Approx. ø120 μm

4.724 mil

<PNP output type>

2

(approx. 13.5%) of the center light intensity. Due to leak light outside

200mm type

(Measuring distance 200 to 400 mm 7.874 to 15.748 in)

(Measuring distance 400 to 600 mm 15.748 to 23.622 in)

(Measuring distance 200 to 400 mm 7.874 to 15.748 in)

(Measuring distance 400 to 600 mm 15.748 to 23.622 in)

Approx. ø300 μm

11.811 mil

PNP open-collector transistor

Maximum source current: 50 mA

•

Applied voltage: 30 V DC or less (Between control output to +V)

•

Residual voltage: 1.5 V or less (At 50 mA source current)

•

Leakage current: 0.1 mA or less

•

<PNP output type>

PNP non-contact input

Input conditions

•

Invalid: 0 to +0.6 V DC or Open

Valid: +4 to +V DC

Input impedance: Approx. 10 kΩ

•

)

2

, or more, cable.

400mm type

300 μm 11.811 mil

800 μm 31.496 mi

±0.2 % F.S.

±0.3 % F.S.

Approx. ø500 μm 19.685 mil

Measurement center

Page 8

03

OPTIONS

0.4

0.4

Error (% F.S.)

HG-C

Designation

Simple mounting

bracket (Note)

Note: Due to the simple mounting bracket, the sensing characteristics may not be hold depending

on the installation condition, in case of the purposes for acquiring the displacement data and

a fine detecting.

Model No. Description

MS-HG-01

Foot angled mounting bracket

MS-HG-01

・

Material: Stainless steel (SUS304)

Two M3 (length 25 mm 0.984 in)

screws with washers (SPCC) are

attached.

I/O CIRCUIT DIAGRAMS

Simple mounting bracket

NPN output type

Color code Color code

(Brown) +V

(Pink) External input

(Black) Control output

(Blue) 0 V

Sensor circuit

100 Ω

AGND

Internal circuit Internal circuitExternal connection example External connection example

0 to +5 V

(Gray) Analog voltage output

(Shield) Analog ground (AGND)

*1

Non-voltage contact or NPN open-collector transistor

or

Load

+

*1

-

50mA MAX.

External input

•

External

input

Analog

device

Invalid: +8 to +V DC or open

Valid: 0 to +1.2 V DC

12 to24 V DC

±10 %

input

PNP output type

(Brown) +V

(Black) Control output

(Pink) External input

Sensor circuit

100 Ω

AGND

*1

Non-voltage contact or PNP open-collector transistor

(Blue) 0 V

0 to +5 V

(Gray) Analog voltage output

(Shield) Analog ground (AGND)

or

50mA MAX.

Load

External input

•

*1

External

input

+

-

Analog

input

device

Invalid: 0 to +0.6 V DC or open

Valid: +4 to +V DC

12 to 24 V DC

±10 %

SENSING CHARACTERISTICS (TYPICAL)

Linearity

HG-C1030(-P)

0.4

-

+

Sensing object

(white ceramic)

L

Sensor

0.2

0.0

Error (% F.S.)

-0.2

-0.4

-5 -2.5 0 2.5 5

-0.197 -0.098 0.098 0.197

(Center)

Measuring distance L (mm in)

HG-C1200(-P)

0.2

0.0

HG-C1050(-P)

0.4

0.2

0.0

Error (% F.S.)

-0.2

-0.4

-15 -7.5 0 7.5 15

-0.591 -0.295 0.295 0.591

(Center)

Measuring distance L (mm in)

HG-C1400(-P)

0.2

0.0

HG-C1100(-P)

0.4

0.2

0.0

Error (% F.S.)

-0.2

-0.4

-35 -17.5 17.5

-1.378 -0.689 0.689 1.378

(Center)

Measuring distance L (mm in)

5

Error (% F.S.)

-0.2

-0.4

-80-40 04080

-3.150 -1.575 1.575 3.150 -7.874 -3.937 3.937 7.874

(Center)

Measuring distance L (mm in)

-0.2

-0.4

-200 -100 0 100 200

(Center)

Measuring distance L (mm in)

9

Page 9

HG-C

PRECAUTIONS FOR PROPER USE

This catalog is only provided to help choose a product and the user’s guide

•

attached to the product must be read before use.

Never use this product as a sensing device for personnel

•

protection.

In case of using sensing devices for personnel protection, use

•

products which meet laws and standards, such as OSHA, ANSI

or IEC etc., for personnel protection applicable in each region or

country.

Do not operate products using methods other than the ones

•

described in the instruction manual included with each product.

Control or adjustment through procedures other than the ones

specied may cause hazardous laser radiation exposure.

This product is classied as a Class 2 Laser Product

•

under JIS / IEC / GB standards and FDA * regulations. Do

not look at the laser beam directly or through an optical

system such as a lens.

The warning label (English) is attached to the product.

•

Handle the product according to the instruction given on

the warning label.

(The warning labels in Japanese and Chinese are packed

with the sensor.)

* The product complies with the FDA regulations and satisfies requirements of the

FDA’s Laser Notice No. 50.

Part description

PRO mode setting

Part description

UP key (Select)

TEACH key (Confirmed)

Zero set indicator (Yellow)

Teaching indicator (Yellow)

Output operation indicator (Orange)

Laser emission indicator (Green)

TEACH key

PRO indicator

(Yellow)

Response speed

setting

Output operation

DOWN key

(Select)

setting

Sensing output

setting

Hysteresis

setting

Item

UP key

Default setting

HG-C1030

〈

HG-C1050

〈

HG-C1100

〈

HG-C1200

〈

HG-C1400

〈

〉

〉

〉

〉

〉

PRO indicator (Yellow)

Digital indicator (Red)

DOWN key

Description

Set the response time.

“ ”:High precision 10ms, “ ”: Standard 5ms,

“ ”: High speed 1.5ms

Select the control output operation mode.

“

”: Light-ON, “ ”: Dark-ON

Set the sensing output.

“ ”: Normal sensing mode

“ ”: 1-point teaching (Window comparator mode)

“ ”: 2-point teaching (Window comparator mode)

“ ”: 3-point teaching (Window comparator mode)

“ ”: Rising differential mode

“ ”: Trailing differential mode

Set the hysteresis width.

HG-C1030: 0.001 to 5.00 mm 0.00004 to 0.197 in

HG-C1050: 0.01 to 15.00 mm 0.00039 to 0.591 in

HG-C1100: 0.02 to 35.00 mm 0.00079 to 1.378 in

HG-C1200: 0.1 to 80.0 mm 0.00394 to 3.150 in

HG-C1400: 0.2 to 200.0 mm 0.00787 to 7.874 in

10

External input

setting

Timer setting

Display setting

Hold setting

ECO Setting

Reset setting

Set the external input.

“ ”: Zero set function, “ ”: Teaching function

“ ”: Light emitting stop function, “ ”: Trigger

function

Set the timer operation. The timer time is fixed at 5ms.

“ ”: No timer, “ ”: OFF-delay timer

“ ”: ON-delay timer, “ ”: One-shot timer

The display of the measured value can be changed.

“ ”: Normal, “ ”: Invert,“ ”: Offset

Set the control output and the analogue output operation

when a measurement error occurs (insufficient light

intensity, saturation of light intensity, out

of measurement range).

“ ”: Hold OFF, “ ”: Hold ON

The digital display can be set to go OFF when key operation

is not performed for 30 seconds. Current consumption can

be reduced.

“ ”: ECO OFF, “ ”: ECO ON

Return to the default setting (factory setting).

“ ”: Reset NG, “ ”: Reset OK

Page 10

PRECAUTIONS FOR PROPER USE

Procedure

Measurement display

DOWN: Press for 3 seconds

Response time setting

UP / DOWN

Output operation setting

TEACH

TEACH

High precision

Light-ON

UP /

DOWN

UP /

DOWN

Standard

Dark-ON

UP /

DOWN

High speed

<Arrow description in gures>

: Press the TEACH key

: Press UP key or DOWN key

: Press DOWN key

HG-C

UP / DOWN

Sensing output setting

UP / DOWN

Hysteresis setting

UP / DOWN

External input setting

UP / DOWN

Timer setting

UP / DOWN

Display setting Normal Invert Offset

TEACH

TEACH

TEACH

TEACH

TEACH

Normal sensing

mode

UP /

DOWN

Trailing

differential mode

Hysteresis width

Zero set function

No timer

1-point teaching

Window

comparator mode

UP /

DOWN

UP /

DOWN

Rising

differential mode

UP key : Increases hysteresis width

DOWN key : Decreases hysteresis width

Teaching function

UP /

DOWN

OFF-delay

UP /

DOWN

UP /

DOWN

2-point teaching

comparator mode

UP /

DOWN

UP /

DOWN

3-point teaching

comparator mode

Light emitting stop function

UP /

DOWN

ON-delay

UP /

DOWN

UP /

DOWN

Window

UP /

DOWN

Window

UP /

DOWN

UP /

DOWN

Trigger function

One-shot

UP / DOWN

Hold setting

TEACH

UP / DOWN

ECO Setting

TEACH

UP / DOWN

Reset setting

TEACH

UP / DOWN

Response time setting

Hold OFF

ECO OFF

Reset setting

UP /

DOWN

UP /

DOWN

UP /

DOWN

Hold ON

ECO ON

Reset setting

11

Page 11

HG-C

PRECAUTIONS FOR PROPER USE

Mounting

When mounting this product, use M3 screws.

•

The tightening torque should be 0.5 N・m.

Please prepare M3 screws separately.

Mounting hole dimensions

M3 screws

(prepare separately)

18 mm

0.709 in

When mounting the simple mounting bracket (optional) on

•

37 mm

1.457 in

this product, the tightening torque should be 0.5 N・m or less.

Plate

Simple mounting bracket

MS-HG-01 (Optional)

M3 (length 25 mm 0.984 in)

screws with washers

(Accessory for MS-HG-01)

Note: Due to the simple mounting bracket, the sensing characteristics may

not be hold depending on the installation condition, in case of the

purposes for acquiring the displacement data and a fine detecting.

(Accessory for

MS-HG-01)

Mounting direction

Direction to a movable body

•

<When there are differences in material and color>

When performing measurements of moving objects with

•

excessively different materials and colors, mount the product

per the following directions to minimize measurement errors.

<Measurement of rotating objects>

When measuring rotating objects, mount the product as

•

follows. Measurement can be performed with minimized

effect on the object caused by up / down deflection,

position deviation and etc.

<When there is a step>

When there is a step in the moving object, mount the

•

product as follows. Measurement can be performed with

minimized effect from the edges of the steps.

Measuring of narrow locations and recesses

•

When measuring in narrow locations or inside holes,

•

mount the product so that optical path from the lightemitting part to light-receiving part is not interrupted.

When mounting the product on a wall

•

Mount the product as follows, so that the multiple light

•

reflections on the wall do not emit to the light-receiving

part. When the reflection factor on a wall is high, it is

effective to use a dull black color.

Others

This product has been developed / produced for industrial

•

use only.

Make sure that the power supply is OFF before starting

•

the wiring.

If the wiring is performed incorrectly, it will cause a failure.

•

Do not run the wires together with high-voltage lines or

•

power lines, or put them in the same raceway. This can

cause malfunction due to induction.

Verify that the supply voltage variation is within the rating.

•

If power is supplied from a commercial switching

•

regulator, ensure that the frame ground (F.G.) terminal of

the power supply is connected to an actual ground.

If noise generating devices (switching regulators, inverter

•

motors, etc.) are used around the sensor mounting area,

make sure to connect the frame ground (FG) terminal of

the device.

Do not use this product during the transient state when

•

the power supply is turned ON.

The overall length of the cable can be extended to 10m

•

maximum with a cable size of 0.3mm

Make sure that stress by forcible bend or pulling is not

•

applied to the sensor cable joint.

Although it depends on the type, light from rapid start

•

type or high frequency lighting type fluorescent lights,

sunlight and etc. may affect the sensing, therefore make

sure to prevent direct incident light.

This product is suitable for indoor use only.

•

Keep water, oil, fingerprints and etc. which reflect light, or

•

dust, particles or etc. which interrupts the light, away from

the emitting / receiving surfaces of this product.

If contaminants adhere to the surface, wipe off with a

dust-free soft cloth, or lens cleaning paper.

Do not use the sensor in locations where there is

•

excessive vapor, dust or etc. or in an atmosphere where

corrosive gases, etc. is generated.

Take care that the product does not come in contact with

•

oil, grease, organic solvents such as thinner, etc., strong

acid or alkaline.

Make sure to turn OFF the power supply, before cleaning

•

the light emitting / receiving windows of the sensor head.

2

or more.

12

Page 12

PRECAUTIONS FOR PROPER USE

Error indication

In case of errors, attempt the following measures.

•

Error indication Description Remedy

<Hold OFF>

<Hold ON>

Measured value blinks

Insufcient amount of reected light.

The sensing object is out of the sensing range.

Flash memory is damaged or is past its life expectancy. Please contact our ofce.

Load of the sensing output is short-circuited causing an

over-current to ow.

The semiconductor laser is damaged or is past its life

expectancy.

When zero set is set, the measurement is not

•

performed normally.

Since the display setting is set to “Offset”, the zero set

•

function can not be used.

During teaching, the measurement is not performed

normally.

System error Please contact our ofce.

Conrm that the sensing distance is within the

specication range.

Adjust the installation angle of the sensor.

Turn OFF the power and check the load.

Please contact our ofce.

Conrm that the sensing distance is within the

•

specication range.

Set the display to any setting except “Offset.”

•

Conrm that the sensing distance is within the

specication range.

HG-C

DIMENSIONS (Unit: mm in)

HG-C□

Measurement center

distance (L)

6.3

0.248

20

0.787

Beam-emitting axis

Beam-receiving axis

θ

2-ø3.2

25

0.984

DOWN key

3.5 0.138

37

1.457441.732

CAD data can be downloaded from our website.

Sensor

UP key

Laser emission indicator (green)

TEACH key

Output operation indicator (orange)

Teaching indicator (yellow)

Zero set indicator (yellow)

PRO indicator (yellow)

3.5

0.138

18

0.709

ø4.1 mm 0.161 in, 2 m 6.562 ft long cable (5-core composite cable)

Model No.

HG-C1030(-P)

HG-C1050(-P)

HG-C1100(-P)

HG-C1200(-P)

HG-C1400(-P)

Measurement center distance (L)

30 1.181 30°

50 1.969 22.5°

100 3.937 12.5°

200 7.874 6.3°

400 15.748 3.2°

13

Page 13

HG-C

DIMENSIONS (Unit: mm in)

MS-HG-01

①

1.5

0.059

90°

Material: Stainless steel (SUS304)

Two M3 (length 25 mm 0.984 in) screws with washers (SPCC) are attached.

0.197 0.197

3.5

0.138

15.5

0.610

10-R3R0.118

37

1.457

5 5

9

0.354

3.2

0.126

10°

22

0.866

18

0.709

14

0.551

30

1.181

R20R0.787

2-R3R0.118

3.5

0.138

φ0.126

0.866

15°

2-φ3.2

22

48.5

1.909

②

18

0.709

2-M3×0.50.020

t =1.5

0.059

53

2.283

2.087

0.394

58

2-R3.5R0.138

37

10

1.457

CAD data can be downloaded from our website.

Assembly dimensions

37

58

1.457

2.283

16

0.630

Simple mounting bracket (Optional)

5 5

0.197 0.197

Emitter

1.110

19

0.748

28.2

(50.2)

(1.976)

3.5

0.138

9

0.354

(4.5)

10°

30

1.181

188

0.7090.315

R20R0.787

15°

0.610

3.5

0.138(0.177)

15.5

(37.8)

(1.488)

Introducing our laser sensors

Laser Displacement Sensor

Compact Amplifier-separated

HL-G1

SERIES

Conforming to

EMC Directive

High-precision measurement

is achieved at a resolution of

0.5 μm 0.02 mil (HL-G103□).

Easy to embed in machines

and production lines thanks

to a built-in controller.

Full lineup! 10 models of diffuse reflection type (class 2) and 6 models

of specular reflection type (class 1) are available. They accommodate a

variety of applications.

Please contact :

Conforming to

FDA regulations

Digital Laser Sensor

LS-500

Industry’s smallest* laser

sensor head,

fastest response time* 60 μs.

* As of September 2013, as amplifier-separated

type laser sensor amplifier, based on research

conducted by us.

Engineered for maximum compatibility with fiber sensors in every

aspect of its design, form and operability. The LS-500 delivers an

environment that makes it easy to choose a class 1 laser sensor.

SERIES

Conforming to

EMC Directive

Conforming to

FDA regulations

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Global Sales Department

Telephone: +81-568-33-7861 ■Facsimile: +81-568-33-8591

■

panasonic.net/id/pidsx/global

Specifications are subject to change without notice. Printed in JapanNo. CE-HGC-2-12 July, 2015

2015

Loading...

Loading...