© Panasonic Corporation 2013 Unauthorized copying and distribution is a violation of law.

ORDER NO. VM1301002CE

B27

High Definition Video Camera

Model No. HC-V520P

HC-V520PC

HC-V520EB

HC-V520EF

HC-V520EG

HC-V520EP

HC-V520EE

HC-V520GC

HC-V520GK

HC-V520MPU

HC-V520MGK

HC-V520MGN

HC-V520MGT

HC-V510PC

HC-V510PU

HC-V510EG

HC-V510EF

HC-V510EP

HC-V510EB

HC-V510EE

HC-V510GC

2

Colour

(K)...........Black Type (except HC-V520GC/GK/

V520MGK/V510GC)

(S)...........Silver Type (only HC-V520EG/V510EG/EE)

(W)...........White Type (only HC-V520GC/GK/V520MGK/

V510GC)

(P)...........Pink Type (only HC-V520GC/GK/V520MGK/

V510GC)

(R)...........Red Type (only HC-V520EG/EP/EB/V510EG/

EB/EE)

(A)...........Blue Type (only HC-V520GC/V510GC)

TABLE OF CONTENTS

PAG E PAG E

1 Safety Precautions -----------------------------------------------3

1.1. General Guidelines ----------------------------------------3

1.2. Leakage Current Cold Check ---------------------------3

1.3. Leakage Current Hot Check (See Figure. 1) --------3

2Warning--------------------------------------------------------------4

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices ----------4

2.2. How to Recycle the Lithium Ion Battery (U.S.

Only)-----------------------------------------------------------4

2.3. Caution for AC Cord (For EB/GC) ---------------------5

2.4. How to Replace the Lithium Battery -------------------6

3 Service Navigation------------------------------------------------7

3.1. Introduction --------------------------------------------------7

3.2. General Description About Lead Free Solder

(PbF) ----------------------------------------------------------7

3.3. Important Notice 1:(Other than U.S.A. and

Canadian Market) ------------------------------------------7

3.4. How to Define the Model Suffix (NTSC or PAL

model)---------------------------------------------------------8

3.5. Formatting----------------------------------------------------9

3.6. Baking of replacement IC and defective P.C.B.

----------------------------------------------------------------10

4 Specifications ---------------------------------------------------- 11

4.1. For NTSC Areas------------------------------------------ 11

4.2. For PAL Areas -------------------------------------------- 16

5 Location of Controls and Components------------------ 21

6 Service Mode ----------------------------------------------------- 25

6.1. Built-in Memory Self Check Execution (HCV520M only) ----------------------------------------------- 26

6.2. Lock Search History Indication ----------------------- 26

6.3. Power ON Self Check Result Display---------------27

6.4. Erasing the lock histories ------------------------------ 27

6.5. Camera data indications while the video

playback ---------------------------------------------------- 28

6.6. Adjustment function for the Service ----------------- 29

6.7. Restore the backed up adjustment data------------ 30

6.8. Touch Panel Calibration -------------------------------- 31

6.9. NFC Initialization (HC-V520/V520 only) ------------ 31

7 Service Fixture & Tools --------------------------------------- 32

7.1. When Replacing the Main P.C.B. -------------------- 32

7.2. Service Position ------------------------------------------ 32

8 Disassembly and Assembly Instructions--------------- 33

8.1. Disassembly Flow Chart for the Unit ---------------- 33

8.2. PCB Location---------------------------------------------- 33

8.3. Disassembly Procedure for the Unit ---------------- 34

9 Measurements and Adjustments -------------------------- 47

9.1. Electric Adjustment-------------------------------------- 47

10 Factory Setting -------------------------------------------------- 60

10.1. How To Turn On The Factory Settings? ----------- 60

10.2. What Is The Factory Settings? ----------------------- 61

11 Block Diagram--------------------------------------------------- 62

11.1. Overall Block Diagram---------------------------------- 62

11.2. Camera/System Control Circuit Block

Diagram ---------------------------------------------------- 63

11.3. Video/Audio Signal Process(1) Circuit Block

Diagram ---------------------------------------------------- 64

11.4. Video/Audio Signal Process(2) Circuit Block

Diagram ---------------------------------------------------- 65

11.5. Lens Drive Circuit Block Diagram ------------------- 66

11.6. Power Supply Circuit Block Diagram --------------- 67

12 Wiring Connection Diagram -------------------------------- 68

12.1. Interconnection Diagram------------------------------- 68

3

1 Safety Precautions

1.1. General Guidelines

1. IMPORTANT SAFETY NOTICE

There are special components used in this equipment

which are important for safety. These parts are marked by

in the Schematic Diagrams, Circuit Board Layout,

Exploded Views and Replacement Parts List. It is essential that these critical parts should be replaced with manufacturer’s specified parts to prevent X-RADIATION,

shock, fire, or other hazards. Do not modify the original

design without permission of manufacturer.

2. An Isolation Transformer should always be used during

the servicing of AC Adaptor whose chassis is not isolated

from the AC power line. Use a transformer of adequate

power rating as this protects the technician from accidents resulting in personal injury from electrical shocks. It

will also protect AC Adaptor from being damaged by accidental shorting that may occur during servicing.

3. When servicing, observe the original lead dress. If a short

circuit is found, replace all parts which have been overheated or damaged by the short circuit.

4. After servicing, see to it that all the protective devices

such as insulation barriers, insulation papers shields are

properly installed.

5. After servicing, make the following leakage current

checks to prevent the customer from being exposed to

shock hazards.

1.2. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed metallic cabinet part on the equipment such as screwheads,

connectors, control shafts, etc. When the exposed metallic part has a return path to the chassis, the reading

should be between 1 MΩ and 5.2 MΩ. When the exposed

metal does not have a return path to the chassis, the

reading must be infinity.

1.3. Leakage Current Hot Check

(See Figure. 1)

1. Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer for this check.

2. Connect a 1.5 kΩ, 10 W resistor, in parallel with a 0.15 μF

capacitor, between each exposed metallic part on the set

and a good earth ground, as shown in Figure. 1.

3. Use an AC voltmeter, with 1 kΩ/V or more sensitivity, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed 0.75 V RMS.

A leakage current tester (Simpson Model 229 or equivalent) may be used to make the hot checks, leakage current must not exceed 1/2 mA. In case a measurement is

outside of the limits specified, there is a possibility of a

shock hazard, and the equipment should be repaired and

rechecked before it is returned to the customer.

Figure. 1

4

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically

Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an antistatic solder removal device. Some solder removal devices not classified as “antistatic (ESD protected)” can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION :

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to damage an ES device).

2.2. How to Recycle the Lithium Ion Battery (U.S. Only)

5

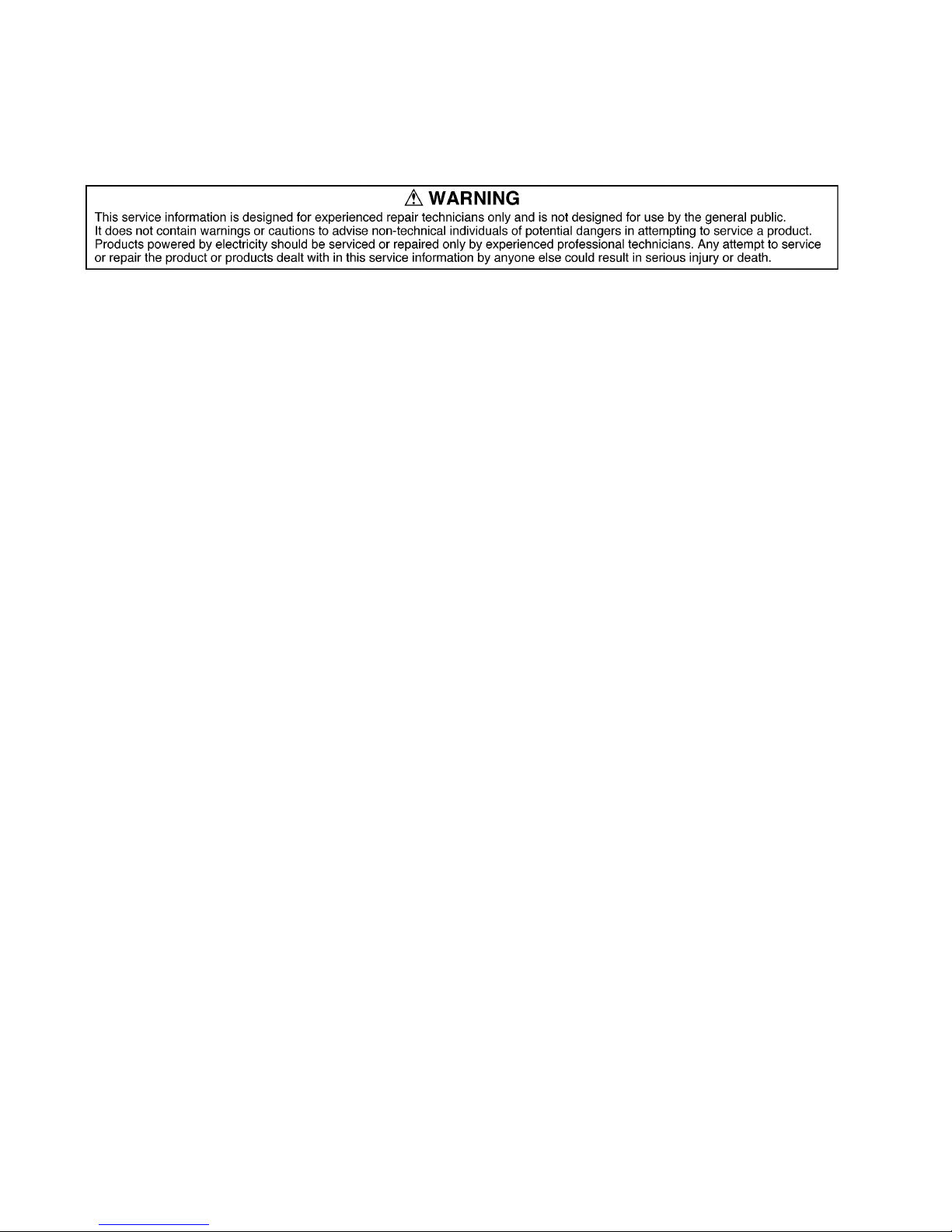

2.3. Caution for AC Cord

(For EB/GC)

2.3.1. Information for Your Safety

IMPORTANT

Your attention is drawn to the fact that recording of prerecorded tapes or discs or other published or broadcast

material may infringe copyright laws.

WARNING

To reduce the risk of fire or shock hazard, do not expose

this equipment to rain or moisture.

CAUTION

To reduce the risk of fire or shock hazard and annoying

interference, use the recommended accessories only.

FOR YOUR SAFETY

DO NOT REMOVE THE OUTER COVER

To prevent electric shock, do not remove the cover. No user

serviceable parts inside. Refer servicing to qualified service

personnel.

2.3.2. Caution for AC Mains Lead

For your safety, please read the following text carefully.

This appliance is supplied with a moulded three-pin mains plug

for your safety and convenience.

A 5-ampere fuse is fitted in this plug.

Should the fuse need to be replaced please ensure that the

replacement fuse has a rating of 5 amperes and it is approved

by ASTA or BSI to BS1362

Check for the ASTA mark or the BSI mark on the body of the

fuse.

If the plug contains a removable fuse cover you must ensure

that it is refitted when the fuse is replaced.

If you lose the fuse cover, the plug must not be used until a

replacement cover is obtained.

A replacement fuse cover can be purchased from your local

Panasonic Dealer.

If the fitted moulded plug is unsuitable for the socket outlet in

your home then the fuse should be removed and the plug cut

off and disposed of safety.

There is a danger of severe electrical shock if the cut off plug is

inserted into any 13-ampere socket.

If a new plug is to be fitted please observe the wiring code as

shown below.

If in any doubt, please consult a qualified electrician.

2.3.2.1. Important

The wires in this mains lead are coloured in accordance with

the following code:

As the colours of the wires in the mains lead of this appliance

may not correspond with the coloured markings identifying the

terminals in your plug, proceed as follows:

The wire which is coloured BLUE must be connected to the terminal in the plug which is marked with the letter N or coloured

BLACK.

The wire which is coloured BROWN must be connected to the

terminal in the plug which is marked with the letter L or coloured

RED.

Under no circumstances should either of these wires be connected to the earth terminal of the three pin plug, marked with

the letter E or the Earth Symbol.

2.3.2.2. Before Use

Remove the Connector Cover as follows.

2.3.2.3. How to Replace the Fuse

1. Remove the Fuse Cover with a screwdriver.

2. Replace the fuse and attach the Fuse cover.

Blue Neutral

Brown Live

6

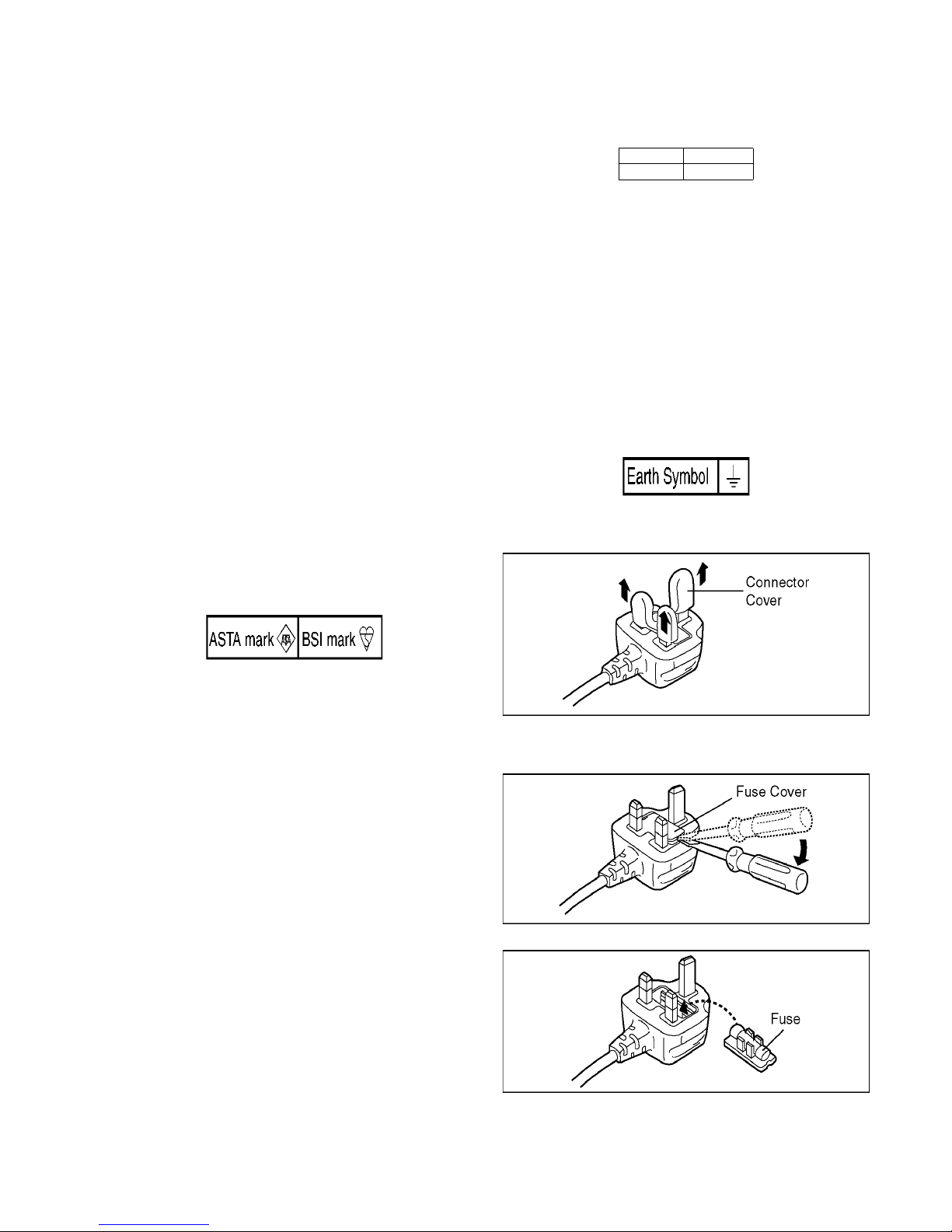

2.4. How to Replace the Lithium Battery

2.4.1. Replacement Procedure

1. Remove the MONITOR P.C.B.. (Refer to Disassembly Procedures.)

2. Unsolder the each soldering point of electric lead terminal for Lithium battery (Ref. No. “B501” at foil side of MONITOR

P.C.B.) and remove the Lithium battery together with electric lead terminal. Then replace it into new one.

NOTE:

The Type No. ML-614S/DN includes electric lead terminals.

NOTE:

This Lithium battery is a critical component.

(Type No.: ML-614S/DN Manufactured by Energy Company, Panasonic Corporation)

It must never be subjected to excessive heat or discharge.

It must therefore only be fitted in requirement designed specifically for its use.

Replacement batteries must be of same type and manufacture.

They must be fitted in the same manner and location as the original battery, with the correct polarity contacts observed.

Do not attempt to re-charge the old battery or re-use it for any other purpose.

It should be disposed of in waste products destined for burial rather than incineration.

NOTE:

Above caution is applicable for a battery pack which is for HC-V520/V520M/V510 series, as well.

1. Battery Pack for this model.

7

3 Service Navigation

3.1. Introduction

This service manual contains technical information, which allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, the information will be followed by service manual to be controlled with original service manual.

3.2. General Description About Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30°C (86°F) more than that of the

normal solder.

Distinction of P.C.B. Lead Free Solder being used

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the P.C.B. using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the P.C.B. cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30°C

(662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01KS-----------(0.3mm 100g Reel)

RFKZ06D01KS-----------(0.6mm 100g Reel)

RFKZ10D01KS-----------(1.0mm 100g Reel)

Note

* Ingredient: tin (Sn) 96.5%, silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

3.3. Important Notice 1:(Other than U.S.A. and Canadian Market)

1. The service manual does not contain the following information, because of the impossibility of servicing at component level

without concerned equipment/facilities.

a. Schematic diagram, Block Diagram and P.C.B. layout of MAIN P.C.B..

b. Parts list for individual parts for MAIN P.C.B..

When a part replacement is required for repairing MAIN P.C.B., replace as an assembled parts. (Main P.C.B.)

2. The following category is /are recycle module part. Please send it/them to Central Repair Center.

- MAIN P.C.B. (VEP03J86C): HC-V520P/PC/EB/EF/EG/EP/EE/GC/GK

- MAIN P.C.B. (VEP03J86A): HC-V520MPU/GK/GN/GT

- MAIN P.C.B. (VEP03J86D): HC-V510PC/PU/EG/EF/EP/EB/EE/GC

8

3.4. How to Define the Model Suffix (NTSC or PAL model)

There are nine kinds of HC-V520/V520M/V510.

• a) HC-V520M (Japan domestic model)

• b) HC-V520P

• c) HC-V520PC, V510PC

• d) HC-V520EB/EF/EG/EP, V510EB/EG/EP/EF

• e) HC-V520EE, V510EE

• f) HC-V520MGN

• g) HC-V520MGT

• h) HC-V520GK, V520MGK

• i) HC-V520GC, V520MPU, V510PU/GC

What is the difference is that the “INITIAL SETTING” data which is stored in Flash ROM mounted on Main P.C.B..

3.4.1. Defining methods:

To define the model suffix to be serviced, refer to the rating label and caution label which are putted on the Unit.

NOTE:

After replacing the MAIN P.C.B., be sure to achieve adjustment.

9

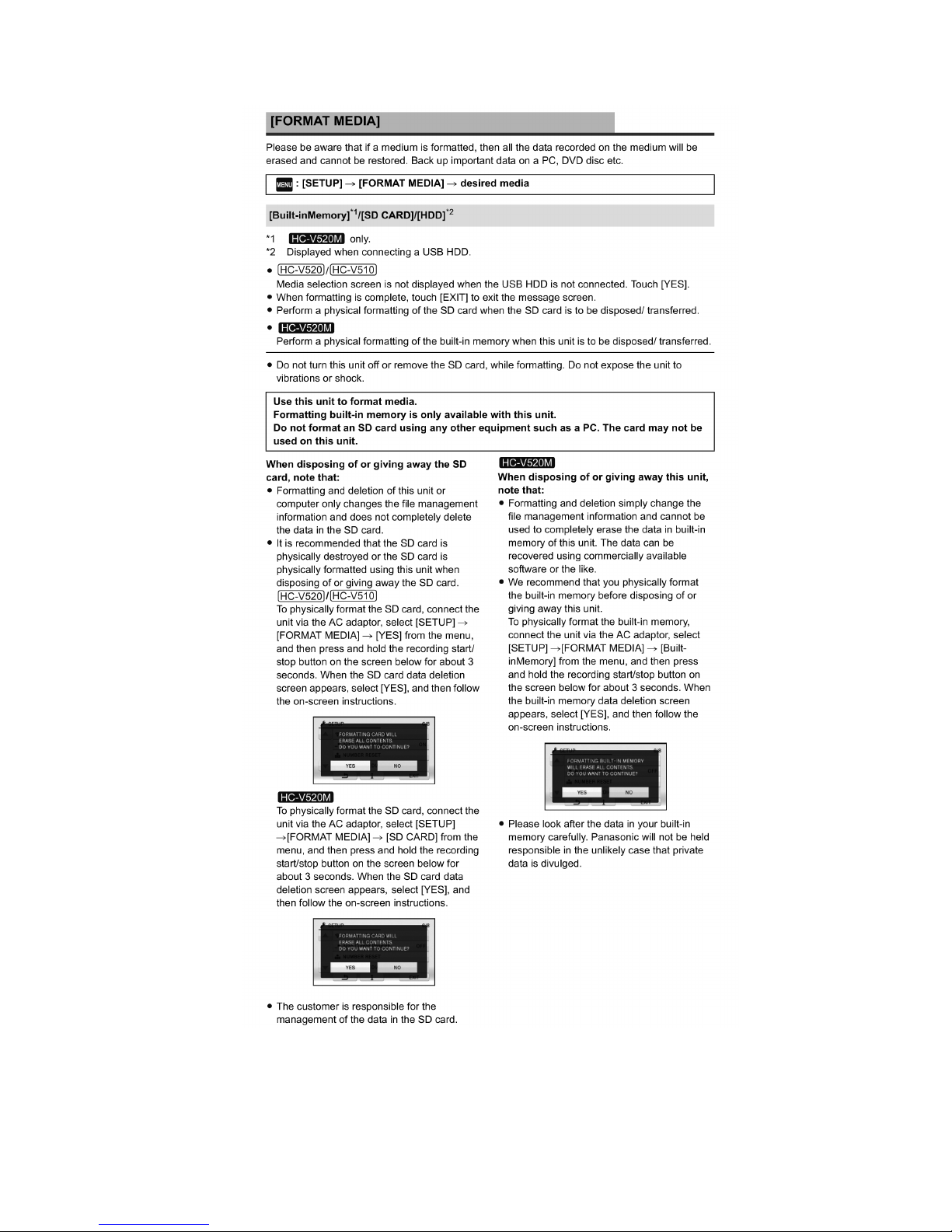

3.5. Formatting

10

3.6. Baking of replacement IC and defective P.C.B.

When replacing the CSP/BGA/QFN type IC mounted on the P.C.B., the problem of IC crack or foil pattern breaking in the P.C.B.

might sometimes occur by rapid heating.

In order to improve the success rate of IC replacement for repair, it would be required to work out baking of replacement

IC and defective P.C.B. before replacing IC.

Please refer the way of baking as follows.

Replacement IC and defective P.C.B. must be put in the heater together.

• Baking temperature and time (Hour)

80°C / 24 hour

11

4 Specifications

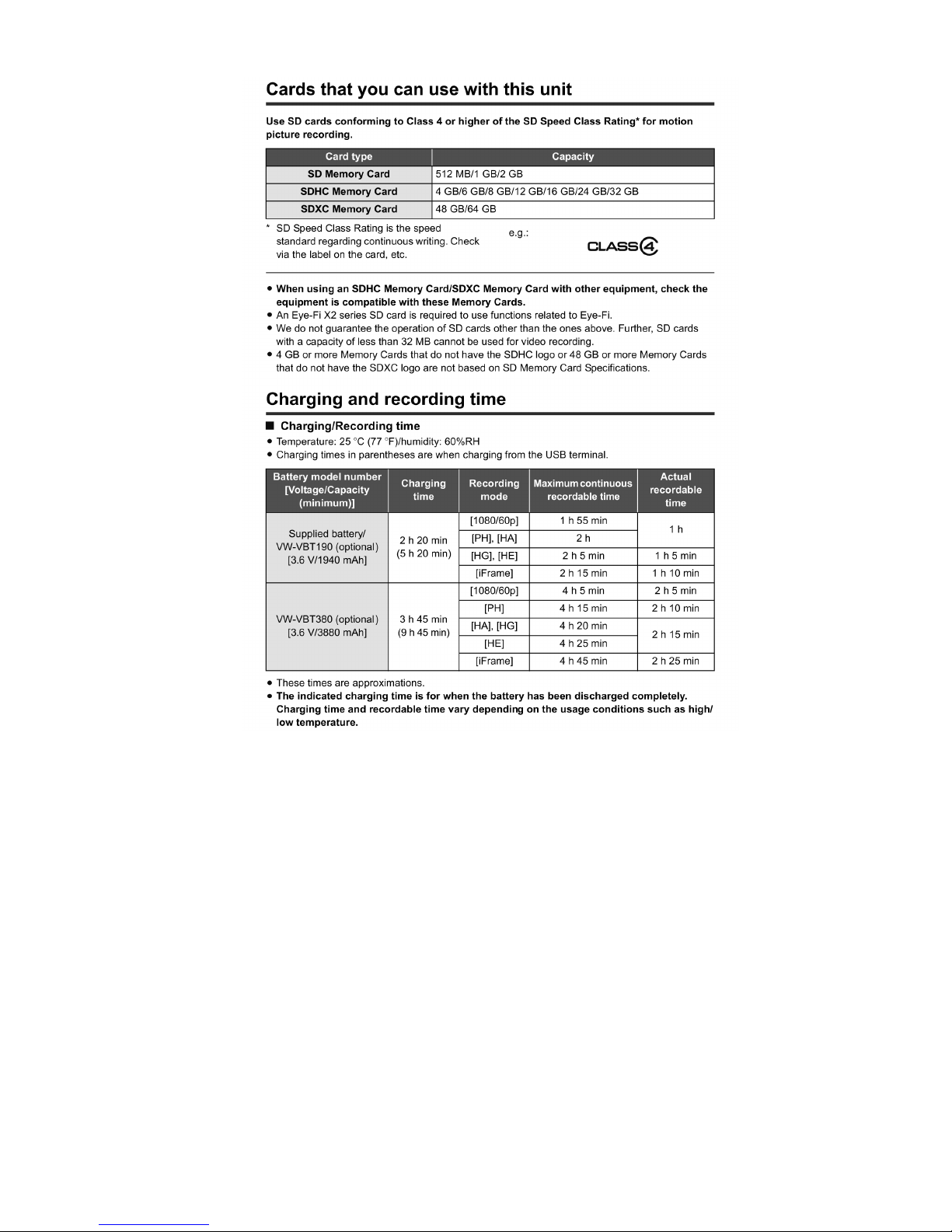

4.1. For NTSC Areas

12

13

14

15

16

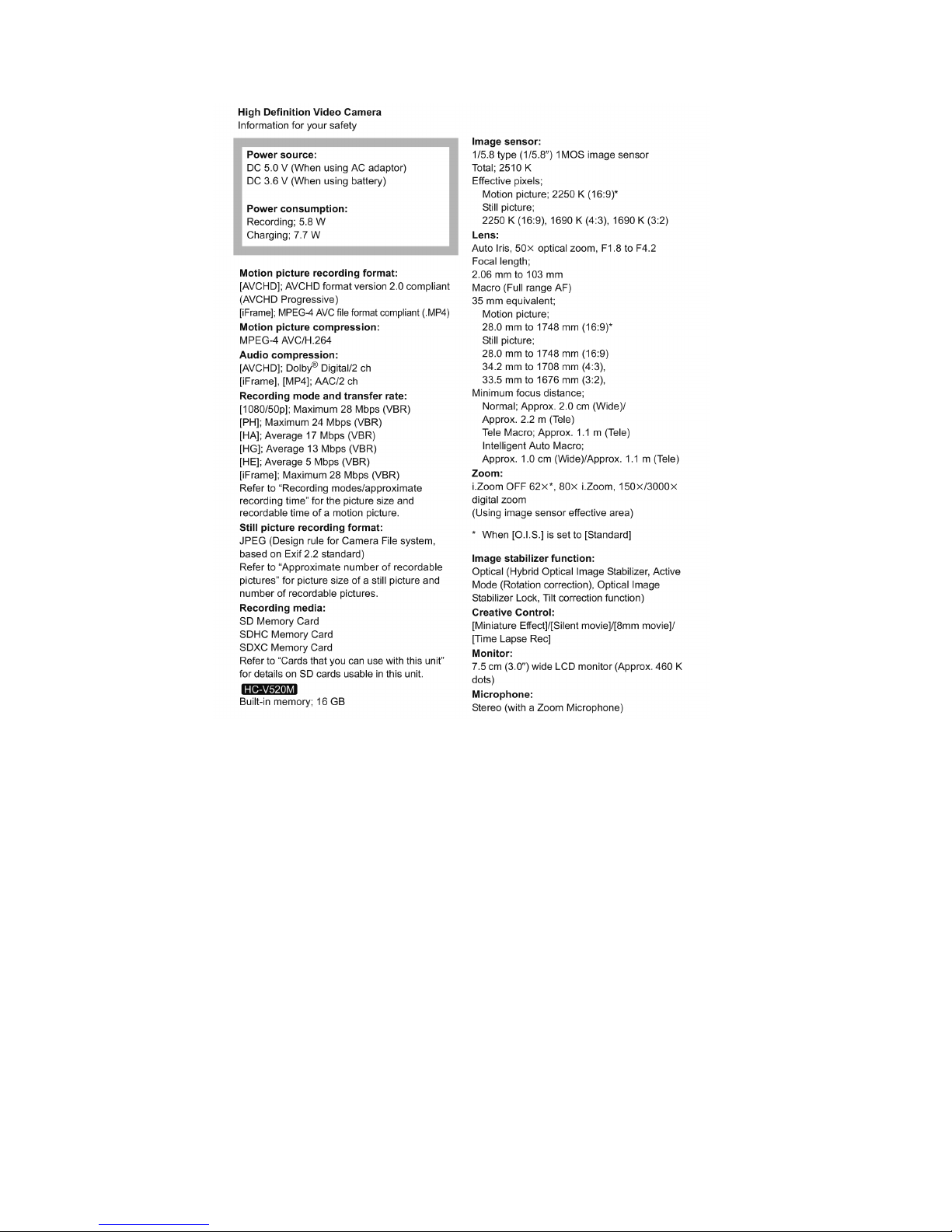

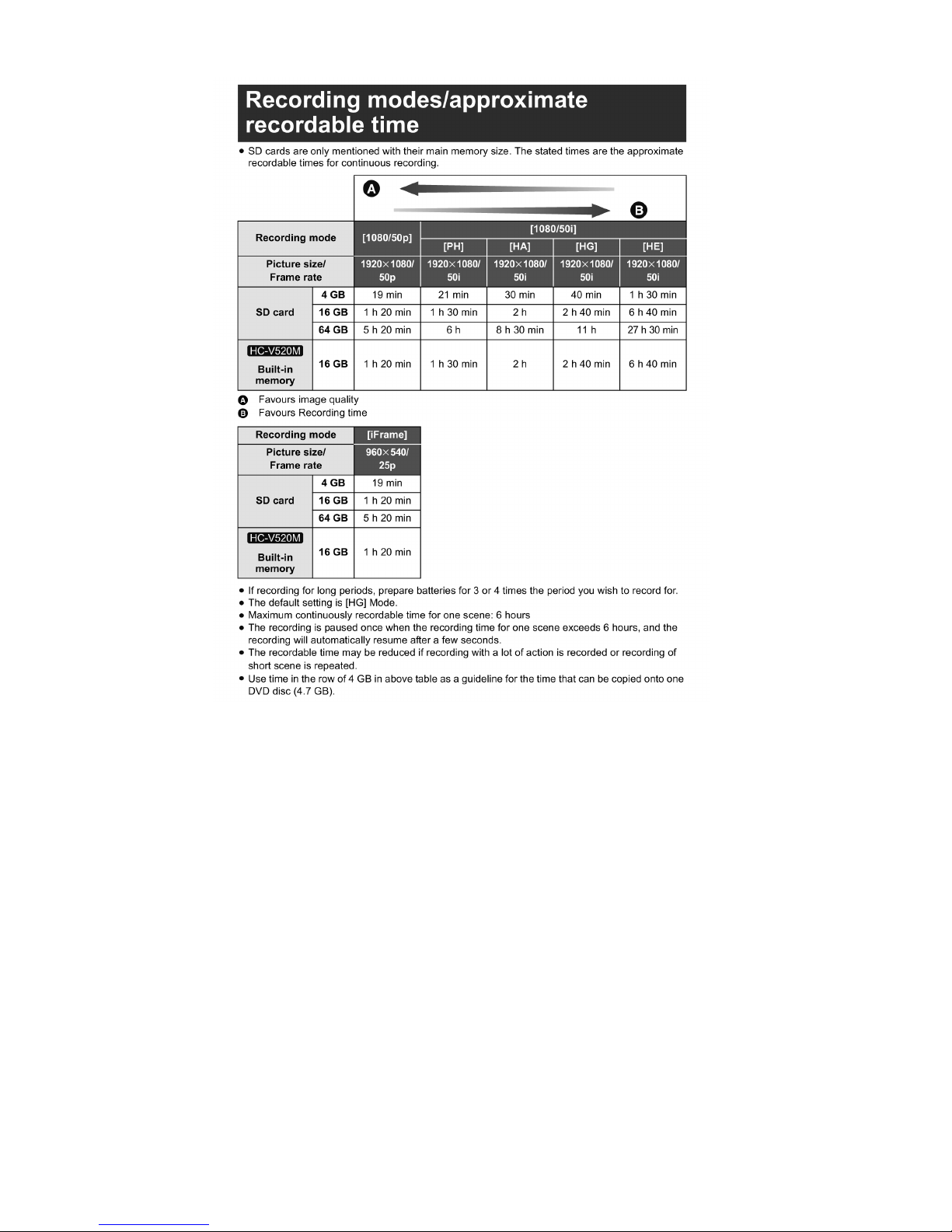

4.2. For PAL Areas

17

18

19

20

21

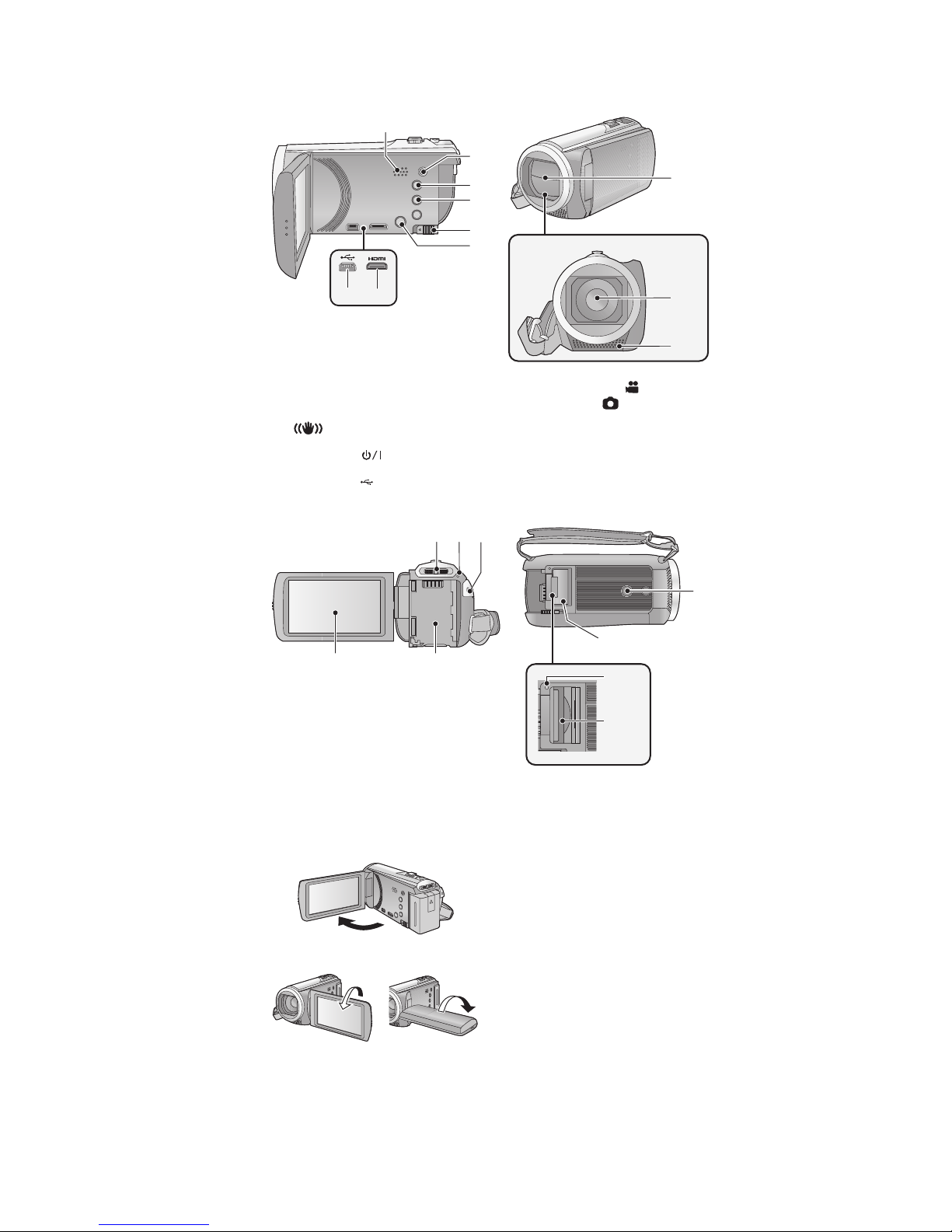

5 Location of Controls and Components

1 Speaker

2 A/V connector [A /V]

3 Intelligent auto button [iA]

4 Optical Image Stabilizer button

[ O.I.S.]

5 Battery release lever [BATT]

6 Power button [ ]

7 HDMI mini connector [HDMI]

8 USB terminal [ ]

9 Lens cover

The lens cover opens in Motion Picture

Recording Mode or Still Picture

Recording Mode.

10 Lens

11 Internal stereo microphones

1

2

3

4

5

6

78

9

10

11

●

12 Mode switch

13 Status indicator

14 Recording start/stop button

15 Battery holder

16 LCD monitor (Touch screen)

It can open up to 90Q .

Itcanrotateupto180Q towards the lens or

90Qtowards the opposite direction.

17 Tripod receptacle

If you attach a tripod which has 5.5 mm

(0.22 S) screw or larger, it may damage this

unit.

18 SD card cover

19 Access lamp [ACCESS]

20 Card slot

12 13 14

1516

17

18

19

20

●

●

●

22

21 DC input terminal [DC IN]

Do not use any other AC adaptors except the

supplied one.

22 Photoshot button [ ]

23 Zoom lever [W/T] (In Motion Picture

Recording Mode or Still Picture

Recording Mode)

Thumbnail display switch [ / ]/

Volume lever [UVOLT] (In Playback

Mode)

24 Grip belt

Adjust the length of the grip belt so that it fits

your hand.

Flip the belt.

Adjust the length.

Replace the belt.

25 Shoulder strap fixture

21

22

23

5242

●

/

26 Wi-Fi button [Wi-Fi] 27 Wi-Fi Transmitter

28 NFC touch part

HC-V520

HC-V520M

26

27

28

23

Operate the mode switch to change the mode to , or .

You can operate by directly touching the LCD monitor (touch screen) with your finger.

Touch

Touch and release the touch screen to select icon or

picture.

Touch the center of the icon.

Touching the touch screen will not operate while you

are touching another part of the touch screen.

Slide while touching

Move your finger while pressing on the touch screen.

Selecting a mode

Motion Picture Recording Mode

Still Picture Recording Mode

Playback Mode

How to use the touch screen

●

●

About the operation icons

///:

Touch when changing a page or performing settings.

:

Touchtoreturntothepreviousscreen.

24

About the Touch Menu

Touch (left side)/ (right side) of on the Touch Menu to switch the

operation icons.

It is also possible to switch the operation icons by sliding the Touch Menu right or left while

touching it.

You can change the operation icons to display.

Displayed only in Intelligent Auto Plus Mode and [Miniature Effect]/[8mm movie]/

[Silent movie] of the Creative Control Mode.

Displayed only in [Time Lapse Rec] of the Creative Control Mode , Scene Mode

and the Manual Mode.

Displayed only when connected to a TV.

Touch Menu

Recording Mode Playback Mode

T

W

MENU

T

W

FOCUS

WB

SHTR

IRIS

MENU

ALL

●

To display the Touch Menu

Do not touch on the LCD monitor with hard pointed tips, such as ball point pens.

Display of the Touch Menu will disappear when no

touch operation is performed for a specific period of

time during recording of motion picture/still picture. To

display it again, touch .

●

25

6 Service Mode

1. Indication method of the service menu

Set the mode switch “Motion Picture Recording” mode.

2. While the power is turned OFF, keep pressing the “Power” button, “Zoom lever” to W side and “intelligent auto/Manual” button

for more than 3 seconds until the top screen of the Service Mode Menu being displayed.

Service mode menu

NOTE:

Do not using service mode except above table of Service mode menu.

3. End method of the top screen of the service mode menu

Touch the [ EXIT ] of LCD to end the service mode, and then POWER OFF.

Screen display Contents Function

1 Factory settings Function to throw a product up in a factory shipment state

(When recorded data in Built-in memory, “error display” is done)

3 Built-in memory self check execution

(HC-V520M only)

Function to check self as for the state of Built-in memory

4 Lock search history indication Display the camera system error cord for three histories saved

in EEPROM

5 Power ON self check result display Power ON self check (function to diagnose correct function of

the device and interface between devices) result display

10 Erasing the lock histories Erasing the error histories (working time is not erased)

12 Camera data indications while the

video playback

Display the camera informations (Shutter speed, Iris value,

White balance and focal length) while playing recorded video

14 Adjutment function for the service The service adjustment do setup and adjustment of the follow-

ing items required in the field service.

15 Restore the backed up adjustment data Restore the adjustment data to new or repaired Main P.C.B.

from SD card that the data backed up from original Main P.C.B.

before repairs or replacement.

16 Touch panel calibration Calibrate the touch positions of the touch panel.

17 NFC initialization

(HC-V520M/V520 only)

Performs the Initialization of the NFC chip and erase the set-

tings like as Wi-Fi connection etc..

26

6.1. Built-in Memory Self Check Execution (HC-V520M only)

Touch the [ 3 ] of LCD, select Built-in memory self check execution.

Operation specifications

Indication contents

• Built-in memory self check result display

Display the Built-in memory self check execution.

Displays other than “OK” are abnormalities of Built-in memory.

Touch the [ BAK ] of LCD to end the service mode, and then POWER OFF.

6.2. Lock Search History Indication

Touch the [ 4 ] of LCD, select Lock search history indication.

Operation specifications

Indication contents

• Lock search history indication

Display the camera system error cord for three histories saved in EEPROM.

• The error cord contents which are displayed

Touch the [ BAK ] of LCD to end the service mode, and then POWER OFF.

Error code Function

51 Focus control is abnormal

52 Zoom control is abnormal

53 OIS lens control is abnormal

54 Zoom control is abnormal (2)

71 Lens cover open/close is abnormal

73 High temperature is abnormal

27

6.3. Power ON Self Check Result Display

Touch the [ 5 ] of LCD, select Power ON self check result display.

Operation specifications

Indication contents

• Power ON self check result display

Function to diagnose correct function of the device and interface between devices result display.

Display the following communication test result.

- CAM-PWR : communication test between IC3401 and IC1503

- CAM-UNI : Internal communication test of IC3401

Display other than “OK” are abnomalities of each lines.

Cutting of battery connection or AC power supply connection to end the service mode.

6.4. Erasing the lock histories

Touch the [ 10 ] of LCD, select erasing the lock histories execution.

Operation specifications

Function Description

• Erasing the error histories stored in EEPROM. (working time is not erased)

Press the power button and turn off.

28

6.5. Camera data indications while the video playback

Touch the [ 12 ] of LCD, select indicating the camera informations while playing back the recorded video.

Operation specifications

Indication contents

• While playing back the recorded videos, the camera informations (Shutter speed, Iris value, White balance and focal length) are

superimposed on the LCD screen.

Press the power button and turn off.

29

6.6. Adjustment function for the Service

Touch the [14] of LCD, select the adjustment function for the service.

Operation Specifications (until before the start of the adjustment)

Function description

The service adjustment do setup and adjustment of the following items required in the field service.

For a detailed content, such as the adjustment procedure, refer to “9 Measurements and Adjustments”.

• Setting of the file name for adjustment data backup to SD card.

• Model setting

• Execution of adjustment data backup to SD card

• Checking of Switches

• Camera adjustment (Iris, Gyro, OIS and Missing pixels)

• Zoom Tracking adjustments

• Indoor White Balance Adjustment (CH-GAIN, PWM, WB)

• Outdoor White Balance Adjustment (PWM, WB)

• Level shot adjustment

Press the power button and turn the unit off.

30

6.7. Restore the backed up adjustment data

Touch the [15] of LCD, select restoring the backed up adjustment data from SD card to the unit.

Operation Specifications

Function description

Restore the adjustment data to new or repaired Main P.C.B. from SD card that the data backed up from original Main P.C.B.

before repairs or replacement.

To backup the adjustment data, use “6.6. Adjustment function for the Service”.

Restoring procedure

Press the power button and turn the unit off.

31

6.8. Touch Panel Calibration

Touch the [16] of LCD, select the calibration of touch panel.

Operation Specifications

Function description

Calibrate the touch positions of the touch panel.

Press the power button and turn the unit off.

6.9. NFC Initialization (HC-V520/V520 only)

Touch the [17] of LCD, select initialization of NFC (Near Field Communication) function.

Operation Specifications

Function description

This function performs the Initialization of the NFC chip and erase the settings like as Wi-Fi connection etc..

Press the power button and turn the unit off.

32

7 Service Fixture & Tools

7.1. When Replacing the Main P.C.B.

After replacing the MAIN P.C.B., be sure to achieve adjustment.

7.2. Service Position

This Service Position is used for checking and replacing parts. Use the following Extension cables for servicing.

Table S1 Extension Cable List

No. Parts No. Connection Form

1 RFKZ0354 FP6001(MAIN) - MONITOR FPC 37PIN 0.3 FFC

2 RFKZ0444 PP6001(MAIN) - PS6401(SD HOLDER) 50PIN 0.5 B to B

3 VFK1480 FP6003(MAIN) - ECM FPC 6PIN 0.5 FFC

4 VFK1440 FP6402(SD HOLDER) - TOP OPERATION 10PIN 0.5 FFC

33

8 Disassembly and Assembly Instructions

8.1. Disassembly Flow Chart for the Unit

This is a disassembling chart.

When assembling, perform this chart conversely.

8.2. PCB Location

34

8.3. Disassembly Procedure for the

Unit

No. Item Fig Removal

1 Side Case-L Unit (Fig. D1) 3 Screws (A)

(Fig. D2) 1 Screw (B)

3 Locking tabs

Side Case-L Unit

2 Top Case Unit (Fig. D3) 1 Screw (C)

(Fig. D4) 1 Screw (D)

( -K/-S/-R model only )

3 Locking tabs

Top Case Unit

3 Front Case Unit (Fig. D5) 1 Screw (E)

2 Screws (F)

FP6003 (Flex)

1 Screw (G)

1 Locking tab

1 Rib

(Fig. D6) Front Case Unit

4Wi-Fi P.C.B.

(HC-V520/V520M

only)

ESD P.C.B. Unit

(HC-V520M only)

(Fig. D7) FP3001 (Flex)

FP3201 (Flex)

2 Screws (H)

Wi-Fi P.C.B.

ESD P.C.B. Unit

5 Heat Radiation Plate-L

Unit

Lens Frame Unit

(Fig. D8) 1 Screw (I)

1 Screw (J)

P6003 (Connector)

1 Screw (K)

(Fig. D9) 4 Locking tabs

FP6006 (Flex)

FP6004 (Flex)

1 Screw (L)

Heat Radiation Plate-L Unit

Lens Frame Unit

6 Lens Unit (Fig. D10) FP301 (Flex)

FP6008 (Flex)

2 Convexes

Lens Unit

7 SD Holder P.C.B.

Main P.C.B.

(Fig. D11) 1 Screw (M)

3 Screws (N)

1 Screw (O)

Heat Radiation Plate Unit

P6401 (Connector)

FP6402 (Flex)

FP6001 (Flex)

(Fig. D12) 4 Locking tabs

Bottom Frame Unit

SD Holder P.C.B.

Main P.C.B.

8Monitor P.C.B.

Light Guide Plate Unit

LCD Panel Unit

(Fig. D13) 2 Screws (P)

8 Locking tabs

LCD Case (T) Unit

(Fig. D14) FP901 (Flex)

FP904 (Flex)

FP905 (Flex)

1 Screw (Q)

1 Locking tab

1 Projection part

Monitor P.C.B.

(Fig. D15) LCD Frame A

4 Locking tabs

Light Guide Plate Unit

LCD Panel Unit

(Fig. D16) Reflection Sheet

Light Guide Plate

Diffusion Sheet

Prism Sheet B

Prism Sheet A

LGP Holder

9 Front Base

Barrier R

Barrier F

(Fig. D17) 3 Projection part

Lens Damper Rubber

4 Screws (R)

3 Ribs

Front Base

Barrier R

Barrier F

10 Mic Cover

Front Ornament Ring

Flare Cut Piece

Microphone Unit

Front Case

(Fig. D18) 2 Screws (S)

1 Locking tab

Mic Cover

Front Ornament Ring

Flare Cut Piece

Mic Sponge F

Mic Sponge M

Microphone Unit

Mic Sponge R

Front Case

11 MO S U nit

IR Cut Grass

(Fig. D19) 3 Screws (T)

MOS Unit

MOS Cushion

IR Cut Grass

Lens Unit

(Fig. D20) NOTE: (When Installing

the MOS Unit)

(Fig. D21)

12 Iris Unit (Fig. D22) 2 Ribs

Solder (24 points)

MOS FPC Sheet

4 Screws (U)

4 Ribs

(Fig. D23) Iris Unit

13 2nd Stepping Motor

Focus Motor

3rd Stepping Motor

(Fig. D24) 6 Screws (V)

2nd Stepping Motor

Focus Motor

3rd Stepping Motor

(Fig. D25) NOTE:(When Installing)

No. Item Fig Removal

35

8.3.1. Removal of the Side Case-L Unit

(Fig. D1)

(Fig. D2)

8.3.2. Removal of the Top Case Unit

(Fig. D3)

36

(Fig. D4)

8.3.3. Removal of the Front Case Unit

(Fig. D5)

37

(Fig. D6)

8.3.4. Removal of the Wi-Fi P.C.B. (HCV520/V520M only), ESD P.C.B. Unit

(HC-V520M only)

(Fig. D7)

8.3.5. Removal of the Heat Radiation

Plate-L Unit and Lens Frame Unit

(Fig. D8)

38

(Fig. D9)

8.3.6. Removal of the Lens Unit

(Fig. D10)

39

8.3.7. Removal of the SD Holder P.C.B.,

Main P.C.B.

(Fig. D11)

(Fig. D12)

40

8.3.8. Removal of the Monitor P.C.B.,

Light Guide Plate Unit, LCD Panel

Unit.

(Fig. D13)

(Fig. D14)

41

(Fig. D15)

(Fig. D16)

42

8.3.9. Removal of the Front Base, Barrier

R, Barrier F

(Fig. D17)

8.3.10. Removal of the Mic Cover, Front

Ornament Ring, Flare Cut Piece,

Microphone Unit, Front Case

(Fig. D18)

43

8.3.11. Removal of the MOS Unit, IR Cut

Grass

(Fig. D19)

(Fig. D20)

44

(Fig. D21)

8.3.12. Removal of the Iris Unit

(Fig. D22)

45

(Fig. D23)

8.3.13. Removal of the 2nd Stepping Moter,

3rd Stepping Motor, Focus Motor

(Fig. D24)

46

(Fig. D25)

47

9 Measurements and Adjustments

9.1. Electric Adjustment

• Adjustment method is different from a conventional High definition video camera.

• An exclusive jig are necessary for electric adjustment.

• Connection method of the main unit and an exclusive adjustment jig as follows.

9.1.1. Adjustment Procedure

• Connect the main unit to AC adaptor.

• Set the unit to the service mode, and execute “14 Adjustment function for the service”.

Figure of connection

Figure of image when adjustment

48

Part Number of jig

1. Basic Jig

2. Optical Jig for Camera Adjustment

* RFKZ0523 (same as DSC) is recommended.

Item Contents

AC adaptor Bandled with camcorder

AC Cable Bandled with camcorder

HDMI Cable Bandled with camcorder

Item Part number Remarks

Light box VFK1164TDVLB/RFKZ0523* Need external power supply: 12V ± 0.1V /1.8A or over

Collimator with focus chart VFK1164TCM02/VFK1164TCM03 Same as DSC

Coupling ring For lens sizes Collimator Joint to lens

CC filter 3100K/5100K VFK1164CC10G Need 2 set. For indoor/outdoor white balance adjutment

C2 Filter 5100K VFK1164LBB2 For outdoor white balance adjustment

C8 Filter 5100K VFK1164LBB8 For outdoor white balance adjustment

ND Filter 0.1 3100K VFK1164ND01 For indoor white balance adjustment

ND Filter 0.6 3100K VFK1164ND01 For indoor white balance adjustment

Adjustment chart for Level Shot Bandled with this Manual For Level shot adjustment

49

[Level Shot Adjutment Chart]

50

9.1.2. Adjustment Items

Adjustment item as follows.

51

9.1.3. Adjustment Procedure

All adjustments except “Touch Panel Calibration”, “Factory Setting” and “NFC Initialization” performs using “14 Adjustment function

for the service” in service mode menu.

“Touch Panel Calibration” is performed using 16 of service mode menu and “Factory Setting” is performed using 1, “NFC Initialization” is performed using 17 of service mode menu. Refer to “6 Service mode” and “9 Factory Setting”.

[Execute adjustment function for service]

1. Set the mode switch “Motion Picture Recording” mode.

2. While the power is turned OFF, keep pressing the “Power” button, “Zoom lever” to W side and “intelligent auto/Manual” button

for more than 3 seconds until the top screen of the Service Mode Menu being displayed.

3. Touch the 3 times then touch the [14] of LCD.

4. Touch the [YES] of LCD.

52

[Adjustment Procedure]

Adjustments and settings are performed following order:

1. Filename setting for backup to SD card

2. Model setting

3. Backing up adjustment data to SD card

4. Checking switches

5. Camera adjustment (Iris, Gyro, OIS, Missing pixels compensation)

6. Zoom/tracking adjustment

7. Indoor white balance adjustment (CH GAIN, PWM, WB)

8. Outdoor white balance adjustment (PWM, WB)

9. Level shot adjustment

53

54

55

56

57

58

59

60

10 Factory Setting

10.1. How To Turn On The Factory Settings?

1. Set the mode switch “Motion Picture Recording” mode.

2. While the power is turned OFF, keep pressing the “Power” button, “Zoom lever” to W side and “intelligent auto/Manual” button

for more than 3 seconds until the top screen of the Service Mode Menu being displayed.

3. Touch the [ 1 ] of LCD.

4. Touch the [ YES ] of LCD.

5. After few seconds “END” is displayed or “ESD NODATA” as “NG” is displayed on LCD monitor. Cutting of battery connection

or AC power supply connection as a completion of the “FACTORY SETTINGS”.

(After recording at least once, even if the physical format of the build-in memory will be performed, “ESD NODATA” as “NG” is

indicated, but “FACTORY SETTINGS” is completed.)

61

10.2. What Is The Factory Settings?

The factory settings clean up and/or refresh the following settings.

1. MENU, MODE, ADJUSTMENT VALUE.

2. Reset the folder number and file number of still pictures.

(Setting the folder number is 100, and file number is 0.)

3. Clear the time and date setting.

4. Close the lens cover

5. Initialize the VIERA Link Physical Address.

6. Initialize the Wi-Fi data settings (HC-V520/V520M only)

7. Initialize the NFC data settings (HC-V520/V520M only)

8. Confirm that the data area of built-in memory is cleared. (HC-V520M only)

9. Confirm that the built-in memory cappacity is correct. (HC-V520M only)

(Checking of the built-in memory mounting error.)

(HC-V520M)

If the “Factory Settings” is completed, physical format of the build-in memory is not performed, execute physical format according to

the following procedure.

The setting position of factory settings:

Name Setting position

Mode switch Motion picture recording mode

62

11 Block Diagram

11.1. Overall Block Diagram

IC705

STEPPING MOTOR

DRIVE

OVERALL BLOCK DIAGRAM

HC-V520/V520M/V510 OVERALL BLOCK DIAGRAM

NOTE

: VIDEO SIGNAL

: AUDIO SIGNAL

: CLK or CONTROL LINE

IRIS

LENS(F1.8-4.2 50x)

IC701

LENS/OIS/MOTOR DRIVE

SD

CARD

SPEAKER

ECM

OPERATION

TOUCH PANEL

DC IN

BATTERY

SHUTTER

IC201

MOS IMAGE

SENSOR

A/V

TERMINAL

HDMI mini

CONNECTOR

ZOOM/

FOCUS

MOTOR/

OIS

Analog

Analog

Analog

Analog

IC6401

GYRO

SENSOR

(PIT/YAW)

IC751

GYRO

SENSOR

(ROLL)

IC3403

NAND

FLASH ROM/

1Gbit

IC3402

DDR SDRAM/

1Gbit

IC3401

MPEG CODEC

(SPICa)

IC1001

POWER

IC1551

BA

TTERY

MONITOR

LED LIGHT

X3402

OSC

(60MHz)

IC202,302

GA

TE IC

IC6411

DIGIT

AL

ACCELEROMETER

IC901

LCD COLOR

DRIVER

COLOR LCD

P

ANEL

IC3701

AVIO

INTERNAL MEMORY

/16GB

IC741

LENS SHUTTER

DRIVE

IC707

LEVEL

SHIFTER

X2303

(32.768kHz)

IC1503

RTC/CHARAGE/

POWER CONTROL

USB TERMINAL

IC301,703,704,1011,1301,1421,

1431,1471

REGULATOR

IC3001

Wi-Fi

MODULE

Wi-Fi ANT.

IC3801

NFC

NFC ANT.

IC761

ROLL GYRO AMP

IC2301

RESET

IC1501

REGULATOR

IC1091,1491

REGULATOR

HC-V520/V520M only

HC-V520/V520M only

HC-V520M only

63

11.2. Camera/System Control Circuit Block Diagram

CAMERA/SYSTEM CONTROL CIRCUIT BLOCK DIAGRAM

HC-V520/V520M/V510 CAMERA/SYSTEM CONTROL CIRCUIT BLOCK DIAGRAM

IC3401

(MPEG CODEC)

QR3404

IC201

(MOS IMAGE SENSOR)

AJ30

LVACH1DOP

LVACH1DOM

LVACH2DOP

LVACH2DOM

LVACH3DOP

LVACH3DOM

LVACH4DOP

LVACH4DOM

LVACLKP

LVACLKM

AJ31

AH28

53

61

52

DOAP

DOAM

DOBP

AH29

AH30

AH31

63

54

62

DOBM

DCKP

DCKM

AG28

55

DOCP

AG29

AG30

AG31

65

56

64

DOCM

DODP

DODM

RL3401 RL3402 RL3403 RL3404

IC3405

(RESET)

XRST

4

VDD

PW REG3V

2

AB31

IC3403

(NAND FLASH ROM/1Gbit)

RP

17

54

55

VCC(CORE)

VCC(IO)

OUT

BUS240 DAP

BUS240 DAM

BUS240 DBP

BUS240 DBM

BUS240 DCP

BUS240 DCM

BUS240 DDP

BUS240 DDM

BUS240 CKP

BUS240 CKM

BUS240 DOAP

BUS240 DOAM

BUS240 DOBP

BUS240 DOBM

BUS240 DOCP

BUS240 DOCM

BUS240 DODP

BUS240 DODM

BUS240 DCKP

BUS240 DCKM

PW REG1.8V

E POW RST

(From QR2308-C)

CH205 CH206

CH203

CH201

CH207

GLVDL PORL

AF25

49

XVS

XVD CAM

HDL BUSY

AF24

42

XHS

XHD CAM

DO SENS

AH22

35

SDI

S SENS SDO

CLK SENS

AF21

36

SCK

S SENS SCK

CS SENS

AH21

14

XCE

S SENS CS

VD

HD

SDI

SCK

SCS

X3402

(60MHz)

5

1432

IC302

(GATE IC)

CH202

CH3404

PW MOS1.8V

CKIN

AE1

MOS RST

AE20

22

XCLR

E MOS RST

RSTN

50

INCK

5

1432

IC202

(GATE IC)

PW MOS1.8V

CH204

X2303

(32.768kHz)

S6001

LCD OPEN

CARD LED B

KEYIN4

D6401

CARD

LED

PW REG3V

QR6402

FP905

X RIGHT

Y BOT

X LEFT

Y TOP

1

2

3

4

PW REG3V

PW REG3V

V31

N29

P29

P30

P31

C28

B28

A29

B29

PW REG3V

STANDBYLED B

U30

QR6401

R30

QR3413 QR3411

QR3412

QR3410

A27

TOUCH PANEL

UNIT

KEYIN1

A28

IC1503

(RTC/CHARGE/POWER CONTROL)

S6002

POWER ON/OFF

D3

G5

G6

/SWIN1

E3

/SWIN2

XIN

XOUT

A5

LED

IC902

(MAGNETIC SENSOR)

431

2

VDD

OUT

GND

NC

AD TPY RIGHT

AD TPY LEFT

AD TPX TOP

SEL2 ON LOW

SEL2 ON HI

LCD RVS

SEL1 ON HI

SEL1 ON LOW

AD TPX BOT

DI CHA

DO CHA

CLK CHA

CS CHA

L31

L30

L29

K31

B6

CS

B7

SCK

C6

SDI

C7

SDO

CH3403

QR3403

ZSW

(To IC701-49)

TOP CASE OPERATION SWITCH UNIT

FP6402

ZOOMAD

PHOTO1 HANOSHI

PHOTO2 ZENOSHI

8

7

10

6

5

4

POWER LED

2

STANDBY LED

AVREF

AVREF

PW REG3V

S6404

S/S SW

S6403

IA

S6401

Wi-Fi

S6402

OIS

Ɣ

MODE SWITCH

Ɣ

ZOOM LEVER

Ɣ

PHOTO SHOT BUTTON

1

VTR KEY 1

POWER LED B

PW REG3V

QR6006

QR6008

QR6007

W29

P LEDB TR CK

C LEDB TR CT

PW RTCVREG32

P LED ON L

S RTC DI

S RTC DO

S RTC SCK

RTC CS

64

11.3. Video/Audio Signal Process(1) Circuit Block Diagram

VIDEO/AUDIO PROCESS(1) CIRCUIT BLOCK DIAGRAM

HC-V520/V520M/V510 VIDEO/AUDIO PROCESS(1) CIRCUIT BLOCK DIAGRAM

1 MOS

SENSOR

CAMERA SECTION

IC3401

(MPEG CODEC)

INTERNAL MEMORY:16GB

SDDATA 2

SDD

ATA 3

SDCMD

SDCLK

CARD DET

PROTECT

SDDATA 1

SDDATA 0

7

8

9

1

2

5

10

12

D0

D1

D2

D3

CMD

CLK

DAT0

DAT1

DAT2

DAT3

C.DET

WP

11

D1N LCD

D1P LCD

ABCK1

DO LCDAVIO

CLK LCD AVIO

Y

PB

AODAT

AODAT0

AIDAT0

CLK B1

D23

C22

B23

C23

B22

A23

F24

D24

AC4

G1

U3

M4

LPD0CLK

LPD0XCLK

LPD0CKE

LPD0CS

LPD0WE

LPD0CAS

LPD0RAS

P2 N4P1M3 N3 R4

LPD0BA1

LPD0BA0

T4 R3N2

AMCK

CLK12 M

A13

A12

MEMORY CONTROL

MAIN CPU

HDMI

CONTROL

CAMERA

DSP

H.264

MPEG2

JPEG

AC3/5.1CH

PROCESSOR

AL7

AK7

D0P LCD

AL5

D0N LCD

AK5

CLKP LCD

AL6

AK11

AJ11

AL11

AF11

AIDAT

G20

F20

F21

G21

C20

C19

CLK

CMD

CLK+

CLK-

LCD LVDS1P

LCD LVDS1N

LCD LVDS0P

LCD LVDS0N

LCD LVDSCLKP

LCD LVDSCLKN

SDCLK2

SDCMD2

PW 3.2V

S DO AVIO

S CLK

AVIO

G SDY

G SDC

VREF

E A

VIO RST

AJ10

B14

EAVIO RST

CLKN LCD

AK6

HS3901

(SD CARD CONNECTOR)

AL9

AK9

S DO LCD

S CLK LCD

S CS LCD

CS LCD

AK10

ALRCK1 CLK LR1

AE11

CS AVIO

AL10

S CS AVIO

H3

H4

H5

J2

W6

W5

SDDATA2 0

BUS24 ES1DT0-3

BUS24 SDDAT0-3

BUS24 WIDAT0-3

SDDATA2 1

SDDATA2 2

SDDATA2 3

IC3001

(Wi-Fi MODULE)

SDIO D0

B19

A19

A21

B21

A20

B20

SDCLK1

SDCMD1

SDDATA1 0

SDDATA1 1

SDDATA1 2

SDDATA1 3

STREAM CONTROL

AJ30

LVACH1DOP

LVACH1DOM

LVACH2DOP

LVACH2DOM

LVACH3DOP

LVACH3DOM

LVACH4DOP

LVACH4DOM

LVACLKP

LVACLKM

AJ31

AH28

AH29

AH30

AH31

AG28

AG29

AG30

AG31

IC3402

(DDR SDRAM/1G-bit)

28 40

LPD0DQ0

LPD0DQ31

W3

M2

LPD0DM0

LPD0DM3

W4

L1

LPD0DQS0

LPD0DQS3

LPD0A0

LPD0A13

ADDRESS CTL SIG

17 26714 5259

62 71 72 85

DATA

DATA2+

DATA2-

DATA1+

DATA1-

DATA0+

DATA0-

HPD

SCL

SDA

CEC

1 8

72

FL6001

2

3

3 6

54

5

6

1 8

72

FL6002

8

9

14

3 6

54

11

12

15

16

19

PW 3.2V

JK6003

HDMI MINI CONNECTOR

AK18

TX2P

AK14

AJ13

CEC

HPD

AK13

SDA

AL13

SCL

AL18

TX2M

AK17

TX1P

AL17

TX1M

AK16

TX0P

AL16

TX0M

AK15

TXCP

AL15

TXCM

1

2

3

6

5

4

QR3402

Q3401

QR3401

To IC901

(LCD COLOR DRIVER)

To LCD UNIT

To IC3701

(AVIO)

PW REG3V

VRO

B13

FROM INT

C4

G8 E4

A3

C1

C2 D3D2

495356

DATA

47

IC3403

(NAND FLASH ROM/1Gbit)

33

36

29

18

13

11

19

8

21

CTLSIG

35

28

10

14

ADM0

ADM15

ECLK NFCYC

XECS0 XNFCE

XEWE XNFWE

XERE XNFRE

XAVD NFALE

11

SDIO D1

10

SDIO D2

15

SDIO D3

14

SDIO CLK

12

D17

E WIFI RST

RESET

29

SDIO CMD

13

2 4G ANT

31

Wi-Fi ANT.

RL3001

IC3801

(NFC)

H31

G29

S DI NFC

H30

S DO NFC

IRQ NFC

TX3V

12

H29

S SCK NFC

IRQ NFC2

(To IC1503-C4)

RX

11

IRQ3V

14

VA

7

VB

2

NFC ANT.

CH3401 CH3402

3

4

2

USB TERMINAL

D-

D+

JK6001

AL24

AL25

Y31

DM

DP

USB ID DET L

ID

HDMI DMA I/F

CAMERA SIGNALP ROCESSOR

AUDIO DSP

BUS240 DAP

BUS240 DAM

BUS240 DBP

BUS240 DBM

BUS240 DCP

BUS240 DCM

BUS240 DDP

BUS240 DDM

BUS240 CKP

BUS240 CKM

HC-V520M only

HC-V520/V520M only

65

11.4. Video/Audio Signal Process(2) Circuit Block Diagram

VIDEO/AUDIO PROCESS(2) CIRCUIT BLOCK DIAGRAM

HC-V520/V520M/V510 VIDEO/AUDIO PROCESS(2) CIRCUIT BLOCK DIAGRAM

IC3701

(AVIO)

12

BICK

CLK B1

CLK LR1

AIDAT0

AODAT0

11

LRCK

24

VIN

JK6402

(AV JACK)

VOUT

4

PLUGIN L

6

LOUT

5

ROUT

1

21

22

SPN

SPP

SPK-AMP

SPEAKER

V OUT

CLAMP LPF

14

SDTO

13

SDTI

E AVIO RST

18

PDN

10

CSN/SDA

8

CCLK/SCL

S CS AVIO

S CLK AVIO

S DO AVIO

9

CDTIO/CAD0

7

I2C

CLK12 M

17

MCKI

16

MCKO

G SDC

G SDY

F7

G7

H7

LCD

UNIT

F6

IC901

(LCD COLOR DRIVER)

R0

D0+

D0-

R1

R2

R3

H6

G5

H5

G6

R4

R5

R6

R7

B7

C6

C7

A7

G0

G1

G2

G3

D7

E6

H4

D6

G4

G5

G6

HS

G3

VS

G4

PCLK

E7

G7

OUTPUT

REGISTER

CONFIGURATION

AND

POWER MANAGEMENT

PROTOCOL PARSING,

PARITY DETECTION,

ADVANCED

FRAME MIXING,

SYNC WARD

DECODING

DESERIALIZER

G1

H1

D1+

D1-

C1

D1

CLK+

CLK-

F/XS

XSD

LS0

PSEL0

FM

FSS

LS1

PSEL1

E1

F1

F2

G2

D4

D3

D5

E5

E4

E3

PLL

FSS

0

1

DDR SDR

PW REG1.8V

C2

LCD LVDS1P

LCD LVDS1N

LCD LVDS0P

LCD LVDS0N

LCD LVDSCLKP

LCD LVDSCLKN

To IC3401

(MPEG CODEC)

To IC3401

(MPEG CODEC)

To IC3401

(MPEG CODEC)

N x PCLK

S DO LCD

S CLK LCD

S CS LCD

PLUG IN L

(To IC3401-E30)

25

PMV

PMSPK

PMPFIL

PMPLL

PMMICL

PMADL or PMADR

PMMICR

AUDIO

I/F

CONTROL

REGISTER

PMLO

PMBP

D/A

PLL

DVOL

SMUTE

+

+

++

31

32

1

ROUT

MIN

LOUT

LIN1

A/DHPF

MIC SENSE/

CORRECTION FUN.

HPF2

MONO/

STEREO

STEREO

EMPHASIS

MIC POWER

SUPPLY

LDO: 2.3V

4 BAND EQ

LPF

ALC

1 BAND EQ

HPF3

RUNNING

AVERAGE

CIRCUIT

EQ0

3

RIN1

4

LIN2

5

RIN2

MPWR

REGFIL

AVDD

ANALOG

BLOCK

MIC POWER,SPK-AMP,

LINE/VIDEO-OUT-AMP

6

2

27

TVDD

15

DVDD

20

29

PMMP

+

-

ECM[L]

M4801

RL4801

RL4802

+

-

ECM[R]

M4802

RL4803

RL4804

RL3705

RL3704

RL3708

RL3709

RL3706

PW REG1.8V

PW SPK3.2V

Q3701

PW 5V

Q3703

Q3702

PW 5V

TX/RX

66

11.5. Lens Drive Circuit Block Diagram

LENS DRIVE CIRCUIT BLOCK DIAGRAM

HC-V520/V520M/V510 LENS DRIVE CIRCUIT BLOCK DIAGRAM

FILTER

MOS

M

3G ZOOM MOTOR

M

1

2

3

30

27

28

29

IC701

(LENS/OIS/MOTOR DRIVE)

3G ZAP

3G ZAN

3G ZBN

3G ZBP

4

39

37

36

38

ZAP

ZBP

IC3401

(MPEG CODEC)

M

IRIS MOTOR

FP6008

FP6008

ZBN

ZAN

6

HALL

SENSOR

HALL

SENSOR

OIS UNIT

FP6008

PIT DRV+

PIT DRV-

PIT HO+

PIT HIN+

PIT HIN-

YAW DRV -

YAW DRV+

YAW HIN+

YAW HIN-

YAW HO-

11

12

13

16

15

14

17

18

22

21

20

19

PIT HO-

YAW HO+

IRM+

IRM-

FP6008

FP6008

IR HO+

IR HIN+

IR HO-

IR HIN-

HALL

SENSOR

PW REG3V

QR751

LENS BALEA LED CONT

PMP

IRHOP

76

IRHON

31

71

YMP

PHON

28

YMN

70

24

PHOP

57

PHINP

PMN

77

27

IRHINP

55

IRMP

5

IRMN

8

ZAP

14

ZAN

17

ZBN

10

ZBP

13

73

YHON

74

56

YHOP

YHINP

PW GYRO3V

GCSB

GSCK

GSI

GSO

GYRO1

29

23

32

3

12

HD

NSCS

SCK

SDI(V2L)

SDO(L2V)

DAC LD

NPORI

HD225

NSCS LEN

SCK LEN

SDO LEN

VD60

22

VD

5

AL28

AK27

J30

J31

K29

U31

CH712

CH728

CH744 CH743 CH742

CH713

CH718

CH719

CH720

15

1

80

SDI LEN

DACLD LEN

E LENS RST

K30

J29

D30

CH721

CH722

CH723

PWMOUT1

PWMOUT2

FP6004

5

6

7

8

4

SHTR OPEN

OP LED

LENSBA MTA-

LENSBA MT B-

LENSBA MTA+

LENSBA MT B+

LENS

BARRIER

1

(GYRO SENSOR:PIT/YAW)

11

MOSI

44

10

MISO

26

8

CSB

CL6401

CL6406

CL6411

CL6412

CL6402

CL6403

35

9

SCLK

CL6404

1

VCC

7

VDD

PW GYRO3V

IC751

IC6401

(GYRO SENSOR:ROLL)

IC761

(ROLL GYRO AMP)

48

NDHB

54

2

1

3

OUT

6

VREF

4

VCC

PW REG3V

IC6411

(DIGITAL ACCELEROMETER)

4

6

11

9

1

14

VDD

VS

2GZOOM ENC

P ZABS LEN

3GZABS LEN

FP6008

8

35

7

34

10

3G ZLEDCONT

3G ZABS

ZABS

ZLEDCONT

AA30

F31

ZABS LEN

F30

E29

P 3GZABS LEN

D31

LENS TEMP

A25

SHTR OPEN

R29

LEDCONT LEN

2G ZOOM MOTOR

3GZOOM ENC

4

P FABS LEN

E31

FABS LEN

F29

41

(LENS SHUTTER DRIVE)

16

AO2

13

BO2

18

AO1

15

BO1

2

ENABLE

3

CK

12

CW/CCW

IC741

3GZOOM H

G14

CH725

CH726

(STEPPING MOTOR DRIVE)

3

MP1

5

MN1

10

MN2

11

MP2

9

E1

6

E2

1

STB

SYSCK

IC705

12

CLK27LENS

AL27

21

CK27M

S FG ACL SCL

SDA/SDI/SDIO

INT1

INT2

SCL/SCLK

S FG ACL SDA

N31

N30

M

FOCUS MOTOR

FAP

FAN

FBN

FBP

26

24

23

25

FP6008

42

S LENSBA RST

F14

S LENSBA CK

D16

S LENSBA CWL

F15

CH711

PW REG1.8V

VccA

IC707

(LEVEL SHIFTER)

4

B1

5

OE

3

A1

1

PW REG3V

VccB

6

32

31

FLEDCONT

FABS

LENS TEMP

FOCUS ENC

Q775

AFAP

AFAN

AFBN

AFBP

40

37

33

36

67

11.6. Power Supply Circuit Block Diagram

PW MOS2.8V

POWER SUPPLY CIRCUIT BLOCK DIAGRAM

HC-V520/V520M/V510 POWER SUPPLY CIRCUIT BLOCK DIAGRAM

CL1461

DCG

LX7

RT

FLT7

INV6

VREF5

INV4

VCC

INV7

PGND4

STB6

HS6L

HX567

LED

VO2S

LX1

PGND13

LX3

VO2

LX22

HX13

SELDRV

SCP

LX21

PGND2

INV1

STB5

HX4

UDSEL

VO7

VREGA

HX2

LX4

PWM7

STB1234

INV3

LX5

INV5

GND

PGND567

LX6

22 21 1820 1719 1615 14 13 12

23

24

25

26

27

28

29

30

31

32

33

11

10

9

8

7

6

5

4

3

2

1

37 38 39 40 4134 35 36

IC1001

(POWER)

JK6701

1

3

4

2

+

T

D

-

JK6401

2

3

4

+

-

BATTERY

DC IN

PW SPK3.2V

PW LENS3.2V

CL1331

CL1332

CL1421

PW VBUS

PW NFCVDD2

(To IC3801-3,10,16)

PW RTCVREG32

E POW RST

(To QR3404-B)

CL1301

PW 5V

CL1471

PW HDM5V

CL1011

FUSE RESISTOR:

PW 3.2V

PW REG3V

PW GYRO3V

1 3

QR1002

QR1001

QR1101

5

1

4

3

2

IC1301

(REGULATOR)

GND

VOUT

VIN

NPCE

CL1371

Q1501

1

2 3 4

5

6

8

7

Q1502

1

2 3 4

5

6

8

7

1 2 3

46

5

Q1503

IC3401

(MPEG CODEC)

DI CHA

DO CHA

CLK CHA

CS CHA

SW NOREG

S FG ACL SCL

S FG ACL SDA

L31

L30

L29

K31

N31

MOSSENS ON H

AF20

N30

B25

VBUS ON H

U29

T31

R1261

IC2301

(RESET)

124

3

VDD

GNDCDOUT

QR2308

CL1362

CL1105

CL1361

CL1101

CL1103

Q1504

PW REG3V

BL CONT

(From IC3401-AF7)

BATT RXD

AL29

USB DET H

T30

BATT TXD

IC1503

(RTC/CHARGE CONTROL)

/SWIN3

VREG32

E4

WKUP

F3

B2

USB

A1

OUT

C2

A3

USBSW

G2

VREG25

(R1261/R1503/R6002)

IC PROTECTOR:

(IP6401/IP6701)

Please check the Fuse Resistor and IC Protector

when an output voltage does not output.

IP6701

IP6401

NOREG

BATT +

1

USB TERMINAL

VBUS

JK6001

PW VID1.1V

PW REG1.8V

PW PLL1.1V

PW LENS1.5V

CH1231

CH1101

ADPSW

PWSW

A2

ADP

C1

VADP

SW

F2

USB DET

E6

E2

E7

BAT

E1

VUSB

D7

ISNS

F7

TDET

B6

CS

B7

SCK

E5

SWIN4

F4

WKUP RST

PW SD3.2V

CL1341

PW MOS1.2V

D902-906

(LCD BACK LIGHT)

C6

SDI

C7

SDO

S6002

POWER ON/OFF

LI BATT

D3

/SWIN1

B501

G4

COINBAT

G3

DVIN

A6

CHG EN

F5

FULLSET

D2

BATSET

D1

USB EN

F6

USB WK CNT

B4

CL1001

CL1002

6 45

2

IC1421

(REGULATOR)

NOISE

VIN

VOUTVOUT

GNDCE

R6002

CH3403

QR3403

1

2

3

6

8

7

IC1551

(BATTERY

MONITOR)

THM

SDA

4

5

ALRTN

VREG VDD VSSVBAT

SCL

IC1501

(REGULATOR)

IC1491

(REGULATOR)

4

3

2

1

GND

CE

VIN

VOUT

IC1471

(REGULATOR)

4

3

2

1

GND

CE

VIN

VOUT

IC1011

(REGULATOR)

4

3

2

1

GND

CE

VIN

VOUT

CL1391

CL1392

IC1091

(SWITCHING

REGULATOR)

12

13

14

15

16

8

11109

1 2 3 4

PVCC

VCC

STB

RT

P

GND

PVCC

LX1

LX1

P GND

FB

INV

GND

VOUT

7

6

5

LX2

LX2

VOUT

PW MOS1.8V

PW WIFI3.2V

PW WIFI3V

1

2

3

4

6

5

CEVIN

VOUT GNDCS

NC

CL1351

CL1321

IC1431

(REGULATOR)

4

3

2

1

GND

CE

VIN

VOUT

IC703

(REGULATOR)

1

2

3

4

GND

STBY

VIN

VOUT

5 4

1 32

IC301

(REGULATOR)

NC

IN

OUT

GNDCE

IC704

(REGULATOR)

1

2

3

4

GND

STBY

VIN

VOUT

R1503

HC-V520/V520M only

68

12 Wiring Connection Diagram

12.1. Interconnection Diagram

HC-V520/V520M/V510 INTERCONNECTION DIAGRAM

INTERCONNECTION DIAGRAM

MAIN P.C.B.

(FOIL SIDE)

:

(COMPONENT SIDE)

MONITOR P.C.B.

(FOIL SIDE)

SD HOLDER P.C.B.

(FOIL SIDE)

BATTERY CATCHER P.C.B.

(FOIL SIDE)

:

(COMPONENT SIDE)

ESD P.C.B.

(FOIL SIDE)

FP6003

65432

1

ECM L

ECM L

D GND

D GND

ECM R

ECM R

MIC

FP6006

123

4

NFC VA

NFC VA

NFC VB

NFC VB

PVDD (2.8V)

PVDD (2.8V)

VBAT (3.2V)

VBAT (3.2V)

GND

GND

GND

DAT2

DAT3

RST

2119171513

11

97531

PVDD (2.8V)

PVDD (2.8V)

VBAT (3.2V)

VBAT (3.2V)

CMD

GND

CLK

GND

DAT0

DAT1

RST

2018161412

10

864

2

FP6005

FP6004

8765432

1

LENSBA MT B+

LENSBA MT A+

LENSBA MT B-

LENSBA MT A-

OP LED

D GND

D GND

SHTR OPEN

FP6008

IRHIN-

IRHIN+

IRM-

ZABS

ZENCVCC&TVCC

PITDRV+

PITHO+

PITHO-

YAWDRV-

YAWHO-

YAWHO+

FBN

FBP

ZBN

ZBP

FABS

3G&FENC VCC

3GZLEDCONT

3GZAN

3GZAP

246

8

101214161820222426283032343638

IRHO+

IRHO-

IRM+

ZLEDCONT

LENS TEMP

PITDRV-

PITHIN-

PITHIN+

YAWDRV+

YAWHIN+

YAWHIN-

FAN

FAP

ZAP

ZAN

FLEDCONT

3GZABS

3GZBN

3GZBP

13579

11

13151719212325272931333537

39

2.8V

1.8V

1.2V

RSTN

MCLK

GND

DOAP

DOBM

GND

DCKP

DOCM

GND

DODP

SCS

SCK

SDI

GND

246

8

1012141618202224262830

32

2.8V

1.8V

1.2V

GND

GND

DOAM

GND

DOBP

DCKM

GND

DOCP

DODM

GND

HD

VD

GND

13579

11

1315171921232527293133

FP301

P6003

1

2

3

4

5

6

BATT+

BATT+

T

D

BATT-

BATT-

FP6002

123456789

10

eSD1 DAT3

eSD1 DAT0

eSD1 DAT1

eSD1 DAT2

eSD1 CMD

eSD1 D GND

eSD1 CLK

eSD1 D GND

eSD1 VDD

eSD1 VDD

PP6001

E KEYIN4

D GND

SP OUT2

SP OUT1

D GND

NOREG

NOREG

NOREG

NOREG

NOREG

NOREG

D GND

PW REG3V

PLUGIN L

D GND

ZOOMAD

POWER LED

STANDBY LED

VTR KEY 1

E CARD DET

PW SD3R2V

PW SD3R2V

PW SD3R2V

D GND

E CARD PRO

SD CMD

D GND

SD DATA2

SD DATA3

SD DATA0

SD DATA1

D GND

SD CLK

D GND

D GND

D GND

S GYRO CSB

S GYRO SCK

S GYRO SO

S GYRO SI

GYRO GND

PW GYRO3V

S FG ACL SCL

S FG ACL SDA

AV GND

G LOUT

G VOUT

G ROUT

AV GND

CARD LED B

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

FP6001

PW LIBATT

S AD TPX BOT

S AD TPX TOP

PW LCDBL L

PW LCDBL H

D GND

D GND

D GND

D GND

S CS LCD

PW REG3V

GNDNCGNDNCGNDNCGND

PW REG1R8V

246

8

10121416182022242628303234

36

S ADTPYRIGHT

S AD TPYLEFT

LCD RVS

PW LCDBL L

PW LCDBL H

D GND

D GND

D GND

S CLK LCD

S DO LCD

PW REG3V

D0 N

D0 P

CLK N

CLK P

D1 N

D1 P

PW REG1R8V

13579

11

13151719212325272931333537

BATTERY

JK6701

123

4

+

T

D

-

P6701

1

2

3

4

5

6

BATT +

BATT +

T

D

BATT

-

BATT

-

TOP OPERATION UNIT

FP6402

10

987654321

PHOTO1 HANOSHI

GND

ZOOMAD

AVREF

PHOTO2 ZENOSHI

STANDBY LED

POWER LED

GND

AVREF

VTR KEY 1

SPEAKER

P6401

2

1

SP OUT1

SP OUT2

PS6401

E KEYIN4

D GND

SP OUT2

SP OUT1

D GND

NOREG

NOREG

NOREG

NOREG

NOREG

NOREG

D GND

PW REG3V

PLUGIN L

D GND

ZOOMAD

POWER LED

STANDBY LED

VTR KEY 1

E CARD DET

PW SD3R2V

PW SD3R2V

PW SD3R2V

D GND

E CARD PRO

SD CMD

D GND

SD DATA2

SD DATA3

SD DATA0

SD DATA1

D GND

SD CLK

D GND

D GND

D GND

S GYRO CSB

S GYRO SCK

S GYRO SO

S GYRO SI

GYRO GND

PW GYRO3V

S FG ACL SCL

S FG ACL SDA

AV GND

G LOUT

G VOUT

G ROUT

AV GND

CARD LED B

25242322212019181716151413

121110

987654321

26272829303132333435363738394041424344454647484950

FP3201

10

987654321

DAT3

DAT0

DAT1

DAT2

CMD

GND

CLK

GND

VDD

VDD

HC-V520M only

ESD FPC

FP901

PW REG1R8V

PW REG1R8V

D GND

D1 P

D1 N

D GND

CLK P

CLK N

D GND

D0 P

D0 N

D GND

PW REG3V

S DO LCD

S CS LCD

S CLK LCD

D GND

D GND

D GND

D GND

D GND

D GND

PW LCDBL H

PW LCDBL H

PW LCDBL L

PW LCDBL L

LCD RVS

S AD TPX TOP

S AD TPYLEFT

S AD TPX BOT

S ADTPYRIGHT

COIN BATT+

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

FP904

50

48

46

44

42

40

38

36

34

32

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

51

49

47

45

43

41

39

37

35

33

31

29

27

25

23

21

19

17

15

13

11

9

7

5

3

1

SCK

VCORE

IOVDD

VPP MTP (OPEN)

DG1

DG3

DG5

DG7

DR1

DR3

DR5

DR7

VSYNC

VCL

CP4BP

CP4AP

VCI

CP5MX

DDVDL

CP5P

CP1PX

CP1M

VGH

CP3P

CP2P

SDA

CSB

VCI

GND

DG0

DG2

DG4

DG6

DR0

DR2

DR4

DR6

HSYNC

DCLK

CP4BM

CP4AM

VCOM

GND

CP5PX

CP5M

CP1MX

DDVDH

CP1P

CP3M

CP2M

VGL

Y TOP

X LEFT

Y BOT

X RIGHT

4

3

2

1

FP905

MONITOR FPC

MOS UNIT

LENS UNIT

LENS BARRIER

NFC ANT.

Wi-Fi P.C.B.

Wi-Fi FPC

HC-V520/V520M only

LCD

TOUCH

PANEL

Loading...

Loading...