Page 1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 2

Safety Precautions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Observe the following notices to ensure personal safety or to prevent accidents.

To ensure that you use this product correctly, read this User’s Manual thoroughly before use.

Make sure that you fully understand the product and information on safety.

This manual uses two safety flags to indicate different levels of danger.

WARNING

If critical situations that could lead to user’s death or serious injury is assumed by

mishandling of the product:

- Always take precautions to ensure the overall safety of your system, so that the whole

system remains safe in the event of failure of this product or other external factor.

- DO NOT USE THE PROGRAMMABLE DISPLAY TO CONTROL SAFETY FEATURES OR

OTHER CRITICAL OPERATIONS OF EQUIPMENT OR SYSTEMS. A COMMUNICATION

ERROR (FOR ANY REASON) MIGHT PREVENT SUCH SAFETY FEATURES OR

CRITICAL OPERATIONS FROM FUNCTIONING PROPERLY.

- Do not use this product in areas with inflammable gas. It could lead to an explosion.

- Exposing this product to excessive heat or open flames could cause damage to the lithium

battery or other electronic parts.

- Battery may explode if mistreated. Do not recharge, disassemble or dispose of fire.

CAUTION

If critical situations that could lead to user’s injury or only property damage is

assumed by mishandling of the product.

- To prevent excessive exothermic heat or smoke generation, use this product at the values

less than the maximum of the characteristics and performance that are assured in these

specifications.

- Do not dismantle or remodel the product. It could cause excessive exothermic heat or smoke

generation.

- Do not touch the terminal while turning on electricity. It could lead to an electric shock.

- Use the external devices to function the emergency stop and interlock circuit.

- Connect the wires or connectors securely.

The loose connection could cause excessive exothermic heat or smoke generation.

- Do not allow foreign matters such as liquid, flammable materials, metals to go into the inside

of the product. It could cause excessive exothermic heat or smoke generation.

- Do not undertake construction (such as connection and disconnection) while the power

supply is on. It could lead to an electric shock.

- The control force of the touch switches should be less than the specification of the product.

Failure to do so could lead to a damage to the product or a personal injury.

- These touch switches operate using analog resistance membrane. Do not press more than

one point on the screen at a time. Doing so might operate a switch located in the middle of

the points pressed if one exists, and could lead to a damage to the facility or an accident.

Copyright / Trademarks

- This manual and its contents are copyrighted.

- You may not copy this manual in whole or part, without written consent of Panasonic Electric

Works SUNX Co., Ltd.

- Windows is a registered trademark of Microsoft Corporation in the United States and other

countries.

- Ethernet is a registered trademark of Fuji Xerox Co., Ltd. and Xerox Corp.

- SDHC logo and SD logo are trademarks.

- All other company names and product names are trademarks or registered trademarks of

their respective owners.

POT_GT

Page 3

Table of Contents

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Before You Start

Manual to be Used

Available Functions and GT Versions

Chapter 1 Features and Functions ............................................................ 1-1

1.1 Features and Functions of GT Series ............................................................................ 1-2

1.2 Types of Units .................................................................................................................. 1-7

1.2.1 GT Series .................................................................................................................... 1-7

1.2.2 Options and Repair Parts ............................................................................................ 1-9

1.3 Screen Creation Tool .................................................................................................... 1-12

1.3.1 Tools Required for Screen Creation ......................................................................... 1-12

1.3.2 Software Usage Environment and Applicable Cables .............................................. 1-12

Chapter 2 Names and Functions of Parts ................................................. 2-1

2.1 Part Names ....................................................................................................................... 2-2

2.1.1 GT01, GT11 and GT21 ............................................................................................... 2-2

2.1.2 GT02/GT02L ............................................................................................................... 2-4

2.1.3 GT05/GT12/GT32 ....................................................................................................... 2-6

2.2 Terminal Layouts of COM Port ....................................................................................... 2-8

2.2.1 GT01 ........................................................................................................................... 2-8

2.2.2 GT02 ........................................................................................................................... 2-9

2.2.3 GT02L ....................................................................................................................... 2-10

2.2.4 GT11/GT12 ............................................................................................................... 2-11

2.2.5 GT21 ......................................................................................................................... 2-12

2.2.6 GT05/GT32/GT32-E ................................................................................................. 2-13

2.3 Connecting to Screen Creation Tool GTWIN .............................................................. 2-14

2.3.1 TOOL Port ................................................................................................................. 2-14

2.3.2 USB Port ................................................................................................................... 2-14

2.3.3 Ethernet Port ............................................................................................................. 2-15

Chapter 3 Installation and Wiring .............................................................. 3-1

3.1 Installation ........................................................................................................................ 3-2

3.1.1 Installation Environment .............................................................................................. 3-2

3.1.2 Restriction According to Mounting Directions ............................................................. 3-4

3.1.3 Installation Space ........................................................................................................ 3-4

3.1.4 UL/c-UL Qualification .................................................................................................. 3-4

3.1.5 Mounting Screws ........................................................................................................ 3-5

3.1.6 GT01 and GT11 Installation Method ........................................................................... 3-6

3.1.7 GT21 Installation Method ............................................................................................ 3-6

3.1.8 GT05/GT32/GT32-E Installation Method .................................................................... 3-7

Page 4

3.1.9 GT02/GT02L/GT12 Installation Method ...................................................................... 3-8

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

3.1.10 Installing in Vertical Orientation ................................................................................ 3-9

3.1.11 Precaution When reinstalling GT .............................................................................. 3-9

3.2 Wiring the Power Supply .............................................................................................. 3-10

3.2.1 Wiring the Power supply ........................................................................................... 3-10

3.2.2 Grounding ................................................................................................................. 3-11

3.3 Wiring the COM Port ...................................................................................................... 3-12

3.4 Precautions when Wiring COM Port ............................................................................ 3-14

3.4.1 GT01 (5 V DC) .......................................................................................................... 3-14

3.4.2 GT02/GT02L (5 V DC) .............................................................................................. 3-15

3.4.3 RS232C Communication ........................................................................................... 3-16

3.4.4 RS422 (RS485) Communication ............................................................................... 3-17

3.5 Precautions when Wiring Ethernet Port (GT32T1) ..................................................... 3-18

3.6 Options ........................................................................................................................... 3-19

3.6.1 Backup Battery .......................................................................................................... 3-19

3.6.2 How to Install the Battery (Lithium Button Battery) ................................................... 3-20

3.6.3 How to Install the Battery (Backup Battery) .............................................................. 3-20

3.6.4 Dead Battery Mark .................................................................................................... 3-21

3.6.5 Time for Replacement of Battery .............................................................................. 3-21

3.6.6 Replacement of Front Panel Protective Sheet .......................................................... 3-21

3.6.7 About the Waterproof Packing .................................................................................. 3-22

Chapter 4 Connecting with PLC ................................................................ 4-1

4.1 Connection with PLC ....................................................................................................... 4-2

4.1.1 PLC Multiple Connection ............................................................................................. 4-2

4.1.2 GT Link Connection .................................................................................................... 4-2

4.1.3 Connecting to the PLCs made by Other Companies .................................................. 4-3

4.1.4 Connecting to a Serial Device ..................................................................................... 4-3

4.1.5 Electric Supply from PLC (5 V DC-type ) .................................................................... 4-3

4.2 RS232C Connection ........................................................................................................ 4-4

4.2.1 Difference of Terminal blocks Between GT Models .................................................... 4-4

4.2.2 RS232C Connection with PLC Tool Port .................................................................... 4-5

4.2.3 RS232C Connection with FP-X COM Port .................................................................. 4-7

4.2.4 RS232C Connection with FP COM Port ................................................................... 4-9

4.2.5 RS232C Connection with FP0/FP0R COM Port ....................................................... 4-11

4.2.6 RS232C Connection with FP-e COM Port ................................................................ 4-12

4.2.7 RS232C Connection with FP2/FP2SH COM Port .................................................... 4-13

4.3 RS422 Connection ......................................................................................................... 4-14

4.3.1 Difference of Terminal blocks Between GT Models .................................................. 4-14

4.3.2 RS422 Connection with FP-X COM Port .................................................................. 4-15

4.3.3 RS422 Connection with FP2/FP2SH COM Port ....................................................... 4-16

4.3.4 RS422 Connection with C-NET Adapter ................................................................... 4-17

4.4 RS485 Connection ......................................................................................................... 4-18

ii

Page 5

4.4.1 Difference of Terminal blocks Between GT Models .................................................. 4-18

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

4.4.2 RS485 Connection with FP0R COM Port ................................................................. 4-19

4.4.3 RS485 Connection with FP-X COM Port .................................................................. 4-20

4.4.4 RS485 Connection with FPΣ COM Port.................................................................... 4-23

4.4.5 RS485 Connection with FP-e COM Port .................................................................. 4-25

4.4.6 RS485Connection with FP2/FP2SH ......................................................................... 4-26

4.4.7 Precautions When Communicating With RS485 ...................................................... 4-27

4.5 Connection With a PLC ................................................................................................. 4-28

4.5.1 Automatic Communication Settings Function ........................................................... 4-28

4.5.2 Through Function ...................................................................................................... 4-29

4.5.3 How to Make Communication Settings Using the FPWIN GR ................................. 4-31

Chapter 5 Troubleshooting ........................................................................ 5-1

5.1 What to DO If Something Unusual Occurs (GT01/GT11/ GT21) .................................. 5-2

5.2 What to DO If Something Unusual Occurs (GT02/GT02L/GT05/GT12/GT32)............. 5-5

5.3 Error Codes and How to Handle Them ........................................................................ 5-10

5.3.1 About Error Codes .................................................................................................... 5-10

5.3.2 GT Series Error Codes ............................................................................................. 5-10

5.3.3 When Connected to a FP Series PLC ...................................................................... 5-13

5.3.4 When Connected to a PLC (FX Series) Made by Mitsubishi Electric Corporation ... 5-15

5.3.5 When Connected to a PLC Made by Omron Corporation ........................................ 5-16

5.3.6 When Connected to Modbus .................................................................................... 5-17

5.3.7 When Connected to a PLC Made by Toshiba Machine Co., Ltd. ............................. 5-17

5.3.8 When Performing General-purpose Serial Communication ..................................... 5-18

Chapter 6 Specifications ............................................................................ 6-1

6.1 GT01 .................................................................................................................................. 6-2

6.1.1 General Specifications ................................................................................................ 6-2

6.1.2 Performance Specifications (GT01) ............................................................................ 6-3

6.1.3 Function Specifications (GT01) ................................................................................... 6-4

6.1.4 Interface Specifications (GT01) .................................................................................. 6-5

6.2 GT02 .................................................................................................................................. 6-6

6.2.1 General Specifications (GT02) .................................................................................... 6-6

6.2.2 Performance Specifications (GT02) ............................................................................ 6-7

6.2.3 Function Specifications (GT02) ................................................................................... 6-8

6.2.4 Interface Specifications (GT02) .................................................................................. 6-9

6.3 GT02L .............................................................................................................................. 6-10

6.3.1 General Specifications (GT02L) ................................................................................ 6-10

6.3.2 Performance Specifications (GT02L) ........................................................................ 6-11

6.3.3 Function Specifications (GT02L) ............................................................................... 6-12

6.3.4 Interface Specifications (GT02L) .............................................................................. 6-13

6.4 GT05 ................................................................................................................................ 6-14

6.4.1 General Specifications .............................................................................................. 6-14

Page 6

6.4.2 Performance Specifications (GT05) .......................................................................... 6-15

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

6.4.3 Function Specifications (GT05) ................................................................................. 6-16

6.4.4 Interface Specifications (GT05) ................................................................................ 6-17

6.5 GT11 ................................................................................................................................ 6-18

6.5.1 General Specifications (GT11) .................................................................................. 6-18

6.5.2 Performance Specifications (GT11) .......................................................................... 6-19

6.5.3 Function Specifications (GT11) ................................................................................. 6-20

6.5.4 Interface Specifications (GT11) ................................................................................ 6-21

6.6 GT12 ................................................................................................................................ 6-22

6.6.1 General Specifications (GT12) .................................................................................. 6-22

6.6.2 Performance Specifications (GT12) .......................................................................... 6-23

6.6.3 Function Specifications (GT12) ................................................................................. 6-24

6.6.4 Interface Specifications (GT12) ................................................................................ 6-25

6.7 GT21 ................................................................................................................................ 6-26

6.7.1 General Specifications (GT21) .................................................................................. 6-26

6.7.2 Performance Specifications (GT21) .......................................................................... 6-27

6.7.3 Function Specifications (GT21) ................................................................................. 6-28

6.7.4 Interface Specifications (GT21) ................................................................................ 6-29

6.8 GT32 ................................................................................................................................ 6-30

6.8.1 General Specifications (GT32) .................................................................................. 6-30

6.8.2 Performance Specifications (GT32) .......................................................................... 6-31

6.8.3 Function Specifications (GT32) ................................................................................. 6-32

6.8.4 Interface Specifications (GT32) ................................................................................ 6-33

6.8.5 Sound Output Specifications (GT32T1 Only)............................................................ 6-34

6.9 GT32-E ............................................................................................................................ 6-35

6.9.1 General Specifications (GT32-E) .............................................................................. 6-35

6.9.2 Performance Specifications (GT32-E) ...................................................................... 6-36

6.9.3 Function Specifications (GT32-E) ............................................................................. 6-37

6.9.4 Interface Specifications (GT32-E) ............................................................................. 6-38

Chapter 7 Dimensions and Other Documentation ................................... 7-1

7.1 Dimensions ....................................................................................................................... 7-2

7.1.1 GT01/GT01R ............................................................................................................... 7-2

7.1.2 GT02 ........................................................................................................................... 7-3

7.1.3 GT02L ......................................................................................................................... 7-4

7.1.4 GT05 ........................................................................................................................... 7-5

7.1.5 GT11 ........................................................................................................................... 7-6

7.1.6 GT12 ........................................................................................................................... 7-7

7.1.7 GT21 ........................................................................................................................... 7-8

7.1.8 GT32 ........................................................................................................................... 7-9

7.1.9 GT32-E ...................................................................................................................... 7-10

7.2 Cable Specifications ...................................................................................................... 7-11

7.2.1 AIGT8142 .................................................................................................................. 7-11

7.2.2 AIGT8152 .................................................................................................................. 7-11

7.2.3 AIGT8162/AIGT8165/AIGT8160 ............................................................................... 7-11

iv

Page 7

7.2.4 AIGT8175 .................................................................................................................. 7-12

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

7.2.5 AIP81842 .................................................................................................................. 7-12

7.3 Table of Screen Messages ............................................................................................ 7-13

7.4 BIN/HEX/BCD Code Correspondence Table ............................................................... 7-14

7.5 ASCII Code Table ........................................................................................................... 7-15

Record of changes

Page 8

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 9

Before You Start

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Usage conditions

Operating environment (Use the unit within the range of the general specifications when installing)

- Ambient temperatures: 0 to +50 C

(It varies according to models when installing the unit in a horizontal orientation or using a C-NET

adapter and FP programmer II.)

- Ambient humidity: 20 to 85% RH (at 25 C, non-condensing)

- Altitude of 2000 m or less

- For use in pollution Degree 2 environment

- Do not use it in the following environments.

- Direct sunlight, wind and rain. (This product is not designed for outdoor use.)

- Sudden temperature changes causing condensation.

- Inflammable or corrosive gas.

- Excessive airborne dust, metal particles or saline matter.

- Benzine, paint thinner, alcohol or other organic solvents or strong alkaline solutions such as

ammonia or caustic soda.

- Direct vibration, shock or places always exposed to drop of water.

(This unit is warranted by IP65/IP67 (depending on models) for panel mounting, however, this applies

to initial values.)

- Influence from power transmission lines, high voltage equipment, power cables, power equipment,

radio transmitters, or any other equipment that would generate high switching surges. (100 mm or

more)

The usage conditions for Tough series (GT32-E) are as follows.

- Ambient temperatures: -20 to +60 C (When horizontally installed, -20 to +55 C)

- Ambient humidity: 10 to 90% RH (at 25 C, non-condensing)

- The upper limit of the humidity at each temperature is as below.

(Below 40 C; 90%RH, 50 C; 55%RH, 60 C; 35%RH)

- If the product is exposed to heavy rain, condensation might be caused by sudden temperature

changes.

- Altitude of 2000 m or less

- For use in pollution Degree 2 environment

- Do not use it in the following environments.

- Direct sunlight for a long time

(Exposing the product to direct sunlight increases the surface temperature of the display higher than

ambient temperature, and causes deterioration of LDC panel.)

- Inflammable or corrosive gas.

- Excessive airborne dust, metal particles or saline matter.

- Benzine, paint thinner, alcohol or other organic solvents or strong alkaline solutions such as ammonia

or caustic soda.

- Direct vibration, shock or places always exposed to drop of water.

(This unit is warranted by IP67 for panel mounting, however, this applies to initial values.)

- Influence from power transmission lines, high voltage equipment, power cables, power equipment,

radio transmitters, or any other equipment that would generate high switching surges. (100 mm or

more)

Static electricity

- Do not touch connector pins directly to prevent static electricity from causing damage.

- Always rid yourself of any static electricity before handling this product.

- If excessive estatic electricity is applied to the panel surface, the LCD panel unit may be damaged.

vii

Page 10

Power supply

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

- Twist the wires of the power supply.

- The unit has sufficient noise immunity against the noise generated on the power line. However, it is

recommended to take measures for reducing noise such as using an isolating transformer before

supplying the power. And it is recommended to take measures such as installing a ferrite core.

- Allocate an independent wiring for each power supplying line, PLC etc and operating device.

- If using a power supply withoug a protective circuit, power should be supplied through a protective

element such as fuse. Directly applying an abnormal voltage to the unit may cause the damage to the

internal circuit.

Touch switches

- Always operate the touch switch with fingers. As the touch switch may be damaged due to the

excessive load or shock (caused when being operated with any tools), the touch switch should be

operated within the specified control force. Also, if the touch swich is pressed like kneading, the

electrode may be worn out exceptionally, and cause the malfunction. Operate with a single touch of

the switch.

- The touch position may shift due to aging variation. If the touch position has shifted, please adjust it.

LCD panel

- Do not drop or have a strong impact on the programmable display unit as glass is used for the LCD

panel.

- The liquid in the LCD panel is a hazardous substance. If the LCD panel is broken, do not put the leaked

crystalline liquid into your mouth. Should it get into your mouth, immediately gargle, and consult a

doctor. If it adheres to your skin or clothes, wash it away with soap.

- There is a case that shadows appear in the place on the screen of the GT where no graphic or part is

arranged. (The shadows appear as the extension of the characters, graphics or parts actually being

displayed.) This is a phenomenon resulting from the basic characteristics of liquid crystal devices, and

called cross talk.

Battery

Do not leave the battery in the unit when it is not used. There is a possibility of leak if it is left being

discharged.

viii

Page 11

Manuals to be Used

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

- The manuals to be used for GT series are common to all the models.

GT series User's Manual ARCT1F511E

- It is this manual. This manual describes the characteristics, specifications, installation and connections

of each GT models.

GT series Reference Manual ACGM0357V**EN

- This manual describes the screen creation of GT series and the settings of various functions.

General-purpose Serial Communication Manual ARCT1F356E

- It is required when communication is carried out with devices you developed such as a board and PC.

Connection with Other Companies' PLCs Manual ARCT1F449E

It is a manual describing the connection methods with PLCs manufactured by other companies. The

connection methods with Panasonic PLCs are described in this manual.

Installation Guide ARCT1F513E

It is a manual describing how to install GTWIN. It supplied with the GTWIN software product.

ix

Page 12

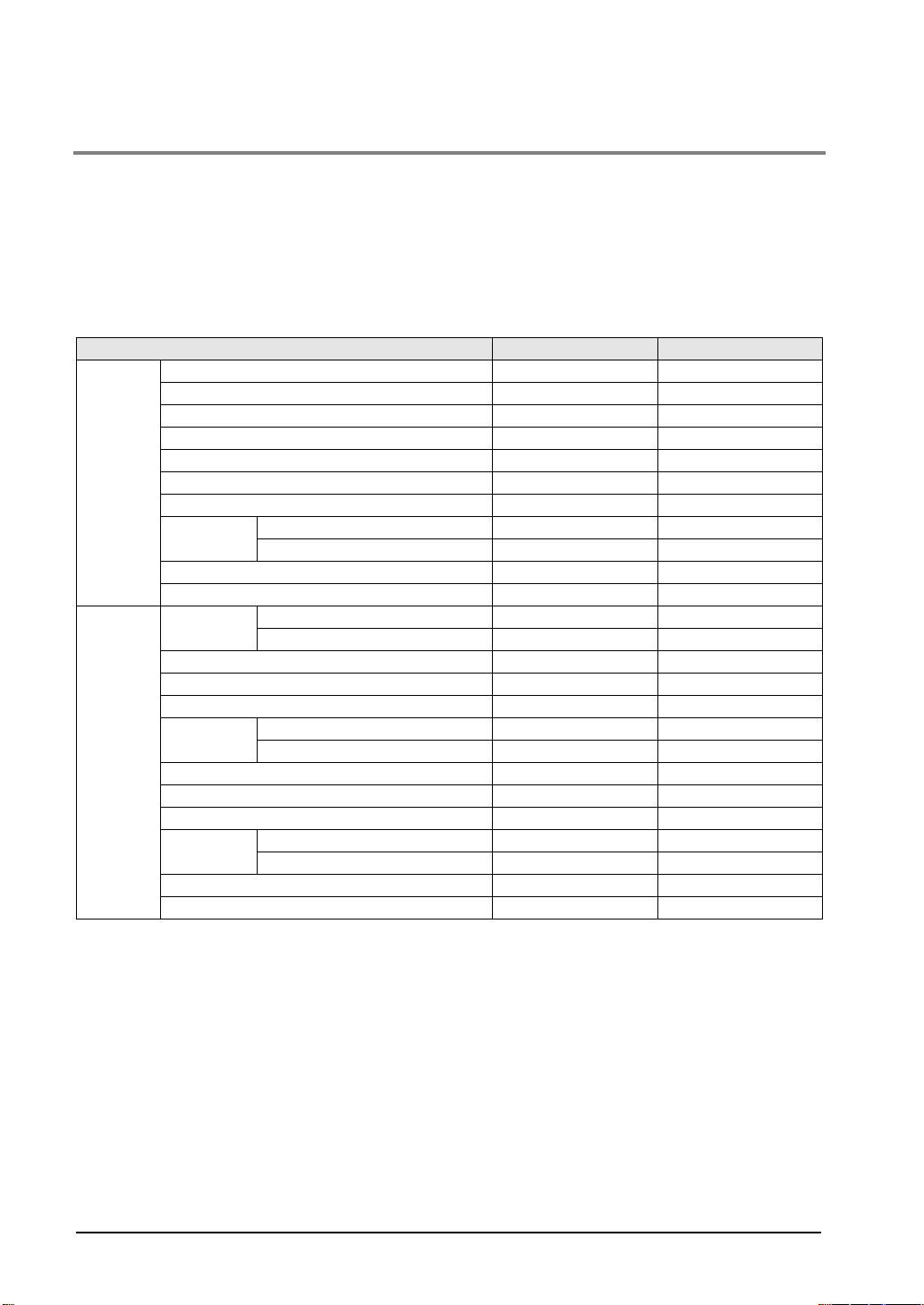

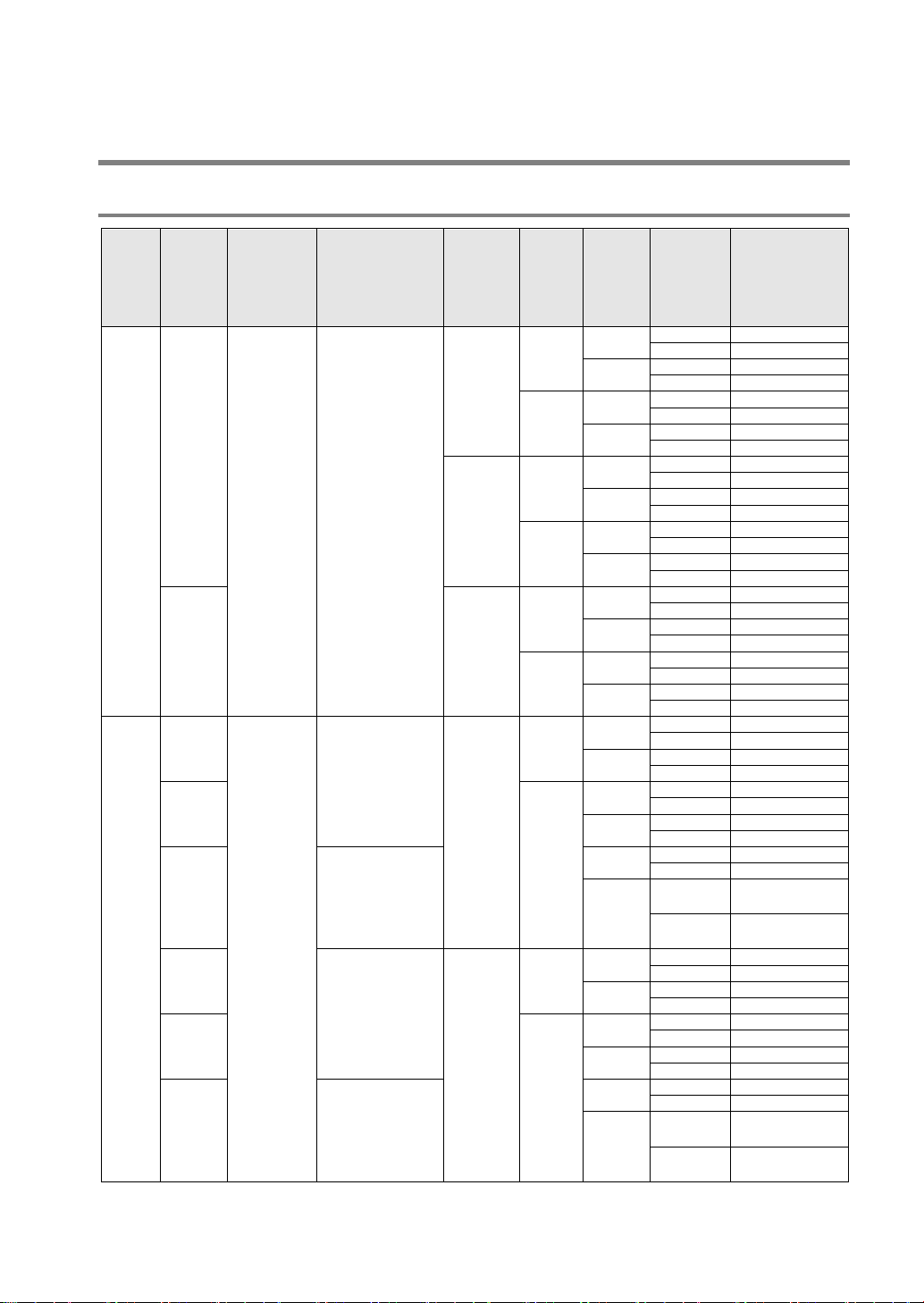

Available Functions and GT Versions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

We recommend to keep GT-series products up to date for use as usable functions will increase

according to the upgrade.

The latest version of GT can be installed by the tool.

The upgrade of GTWIN is also necessary according to the upgrade of GT.

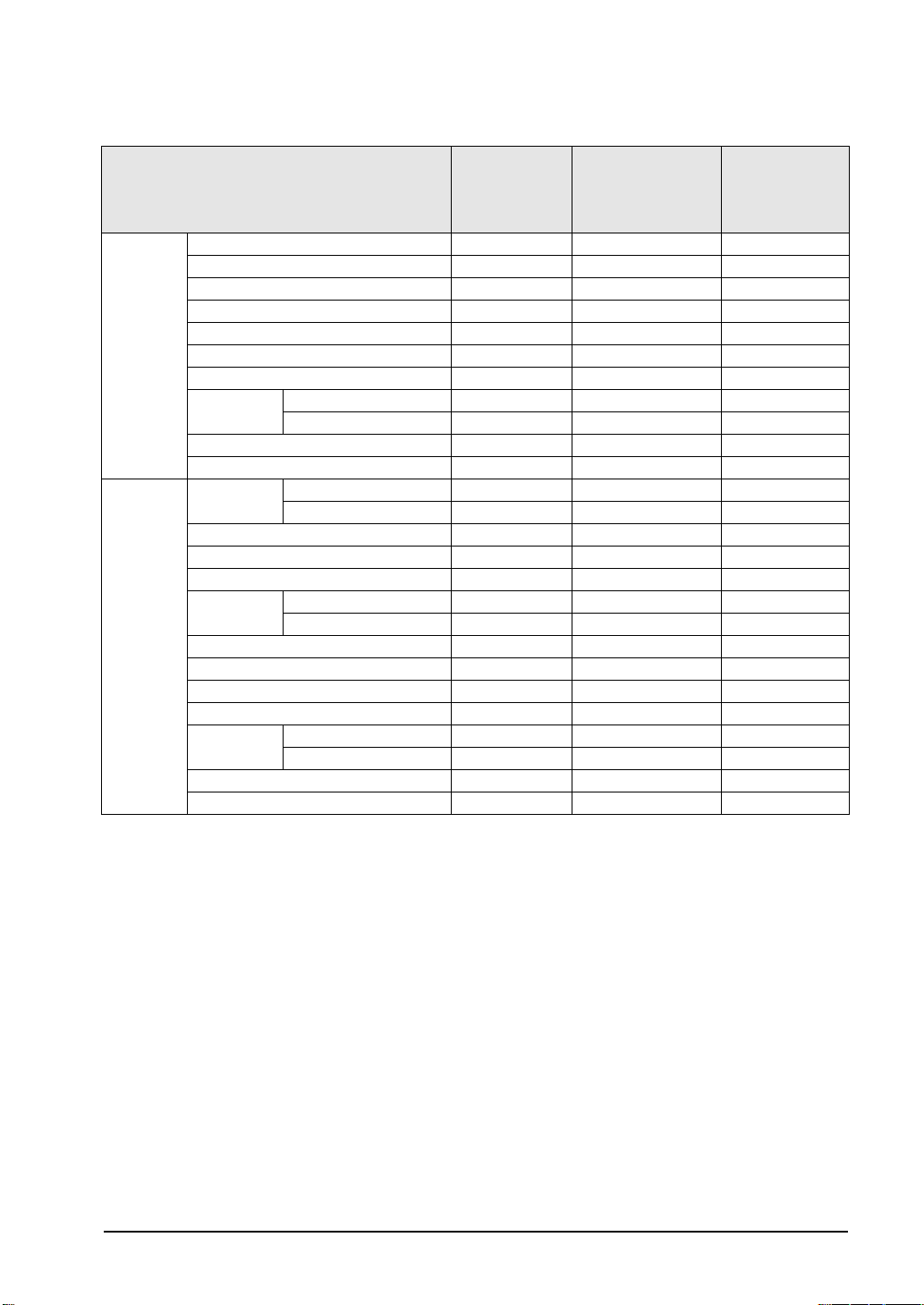

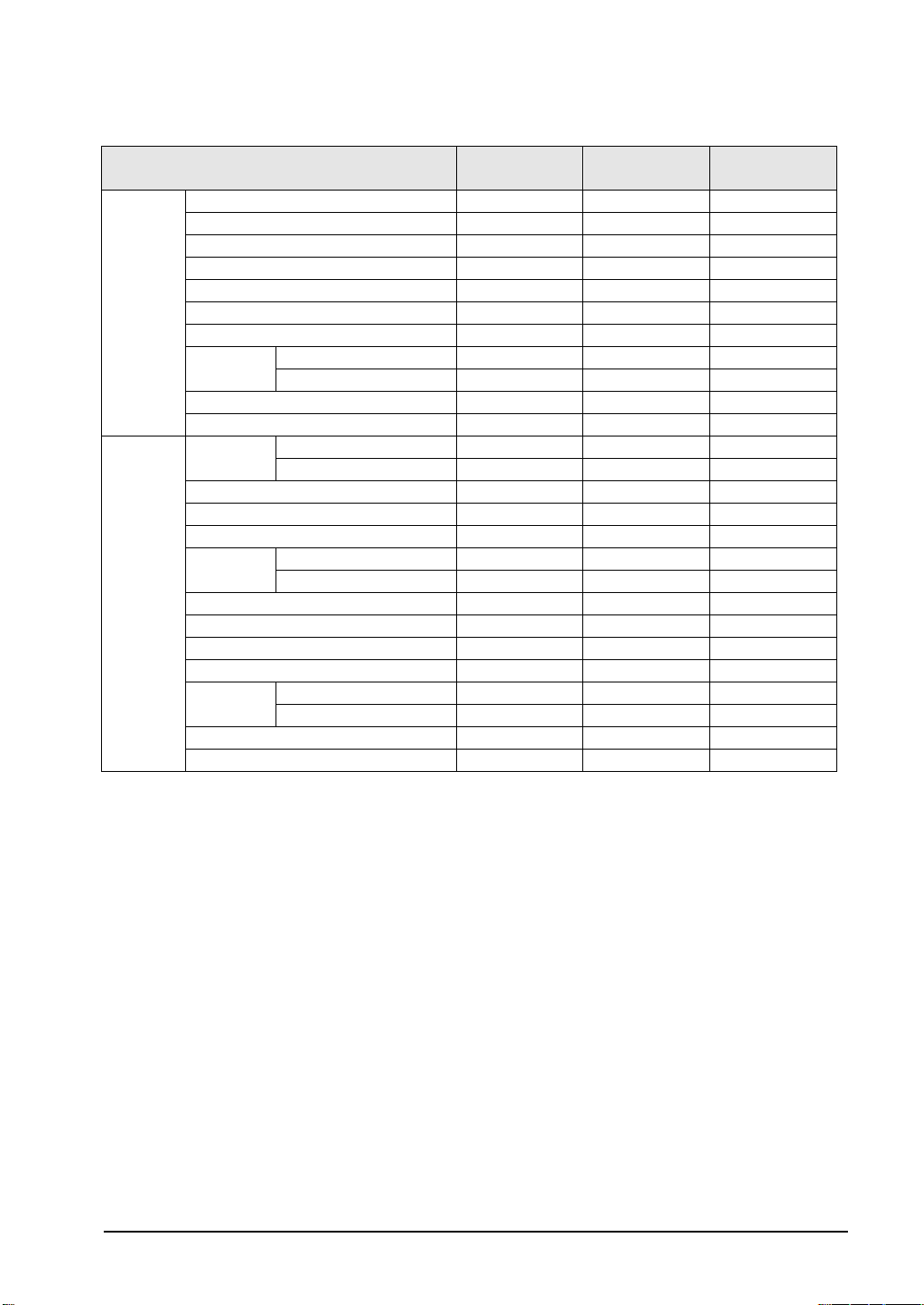

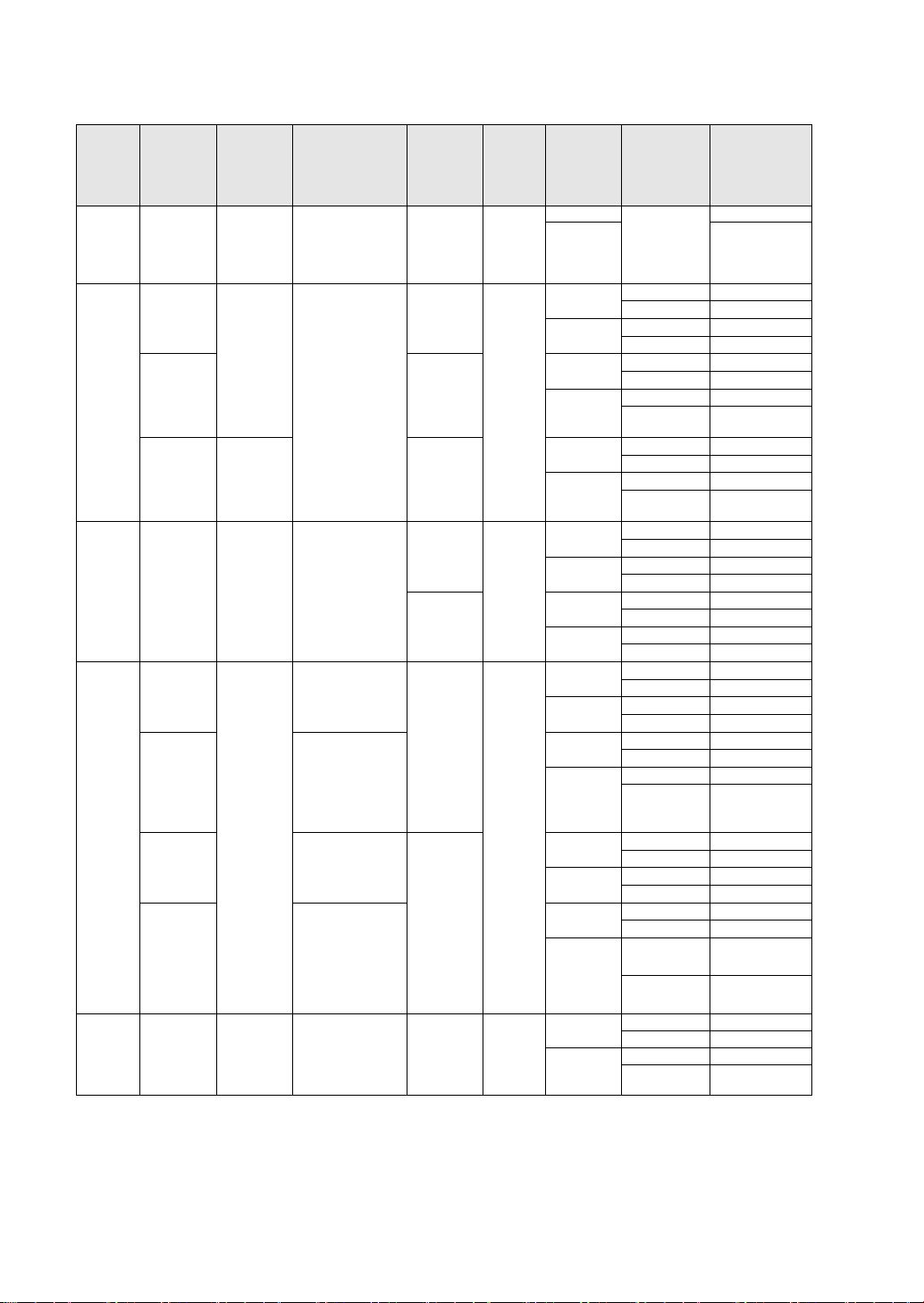

Version of GT01 and available functions

Function GT01 GTWIN

Parts

library

Other

functions

Note1) Only referring to PLC can be set.

Switch 1.00 or later 2.30 or later

Lamp 1.00 or later 2.30 or later

Message 1.00 or later 2.30 or later

Data 1.00 or later 2.30 or later

Bar graph 1.00 or later 2.30 or later

Clock 1.00 or later

Line graph 1.00 or later 2.30 or later

Alarm

Keyboard 1.00 or later 2.30 or later

Custom 1.00 or later 2.30 or later

Recipe

Flow display 1.00 or later 2.30 or later

Write device 1.00 or later 2.30 or later

Sound Not available Not available

Password

Multi language exchange 1.20 or later 2.50 or later

Logging function Not available Not available

Display panel sideways setting 1.10 or later 2.40 or later

Copy

GT link Not available Not available

PLC multiple connection Not available Not available

History Not available Not available

List Not available Not available

Recipe 1.00 or later 2.30 or later

SD recipe Not available Not available

Password 1.00 or later 2.30 or later

Operation security Not available Not available

Cable between GTs 1.30 or later SD memory card Not available Not available

Note1)

2.30 or later

x

Page 13

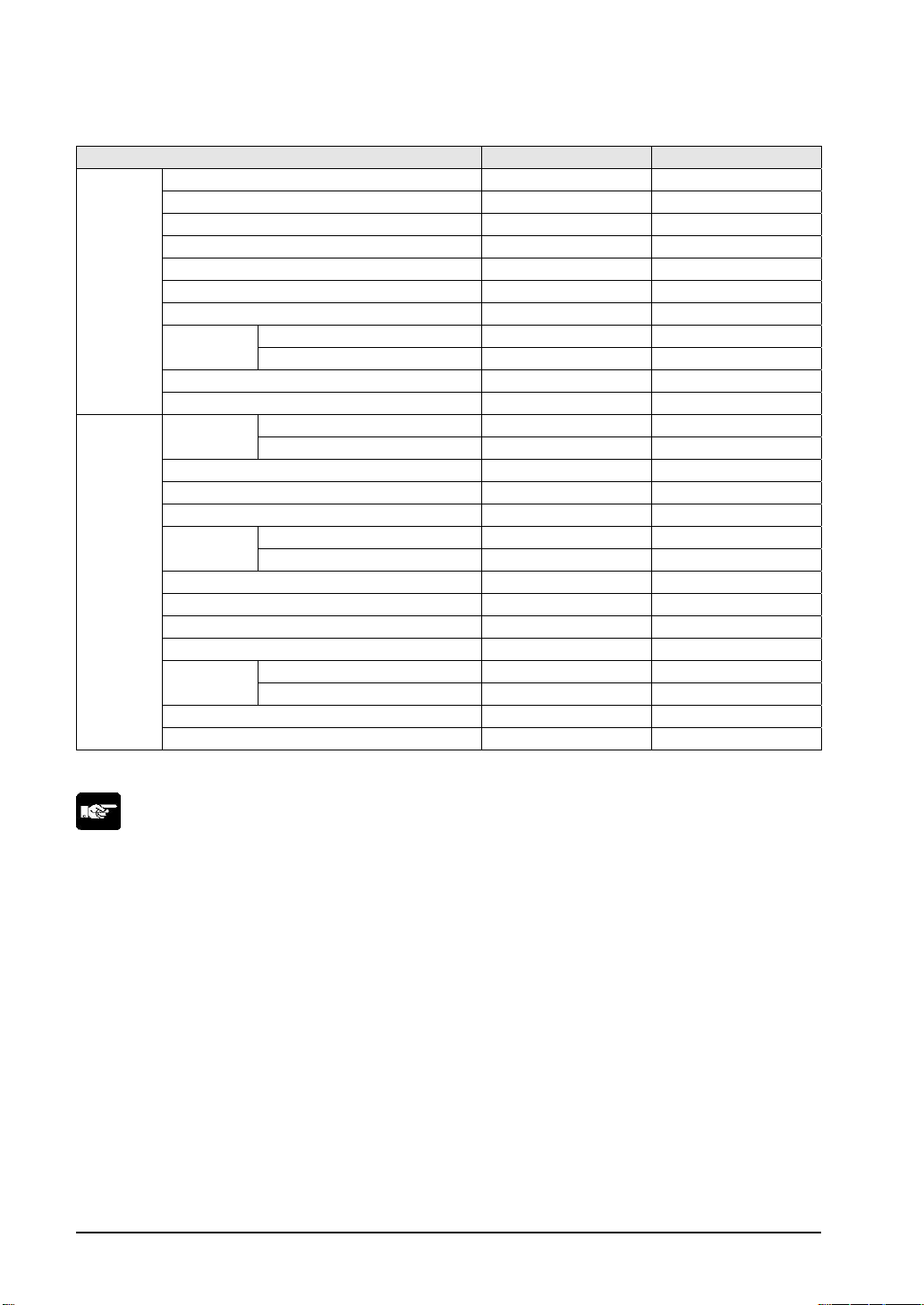

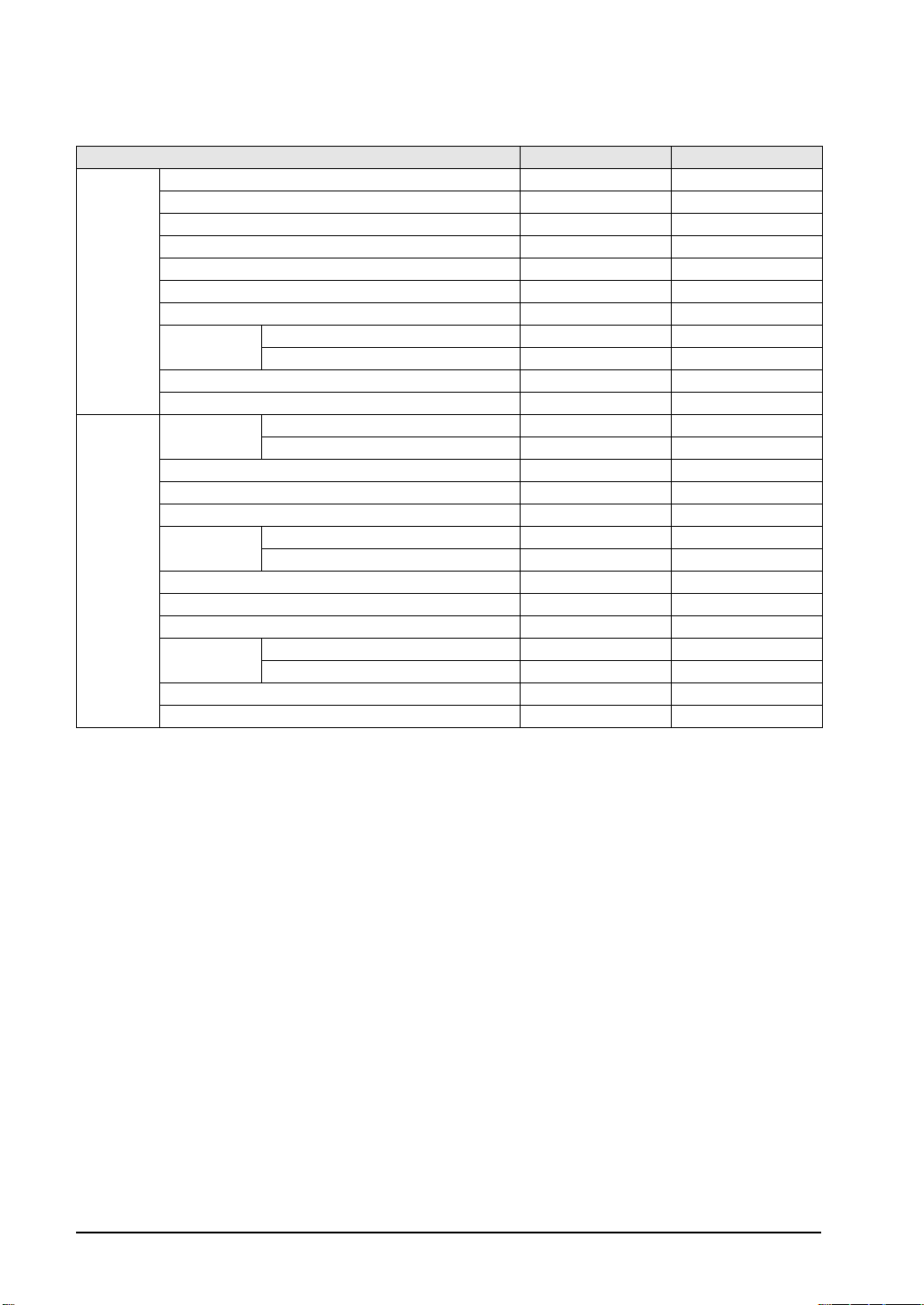

Version of GT02 and available functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Function GT02M2

GT02G2

Parts

library

Switch 1.00 or later 1.00 or later 2.A0 or later

Lamp 1.00 or later 1.00 or later 2.A0 or later

Message 1.00 or later 1.00 or later 2.A0 or later

Data 1.00 or later 1.00 or later 2.A0 or later

Bar graph 1.00 or later 1.00 or later 2.A0 or later

Clock 1.00 or later 1.00 or later

Line graph 1.00 or later 1.00 or later 2.A0 or later

Alarm

History 1.00 or later Not available 2.A0 or later

List 1.00 or later 1.00 or later 2.A0 or later

Keyboard 1.00 or later 1.00 or later 1.00 or later

Custom 1.00 or later 1.00 or later 1.00 or later

Other

functions

Recipe

Recipe 1.00 or later 1.00 or later 2.A0 or later

SD recipe 1.00 or later Not available 2.A0 or later

Flow display 1.00 or later 1.00 or later 2.A0 or later

Write device 1.00 or later 1.00 or later 2.A0 or later

Sound Not available Not available Not available

Password

Password 1.00 or later 1.00 or later 2.A0 or later

Operation security 1.00 or later 1.00 or later 2.A0 or later

Multi language exchange 1.00 or later 1.00 or later 2.A0 or later

Logging function 1.00 or later Not available 2.A0 or later

FP monitor function 1.30 or later 1.30 or later 2.C0 or later

Display panel sideways setting 1.00 or later 1.00 or later 2.A0 or later

Copy

Cable between GTs Not available Not available Not available

SD memory card 1.00 or later Not available 2.A0 or later

GT link 1.00 or later 1.00 or later 2.A0 or later

PLC multiple connection 1.00 or later 1.00 or later 2.A0 or later

Note1) Only referring to PLC can be set.

GT02M0

GT02M1

GT02G0

GT02G1

Note1)

2.A0 or later

GTWIN

xi

Page 14

Version of GT02L and available functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Function GT02L GTWIN

Parts

library

Switch 1.00 or later 2.B0 or later

Lamp 1.00 or later 2.B0 or later

Message 1.00 or later 2.B0 or later

Data 1.00 or later 2.B0 or later

Bar graph 1.00 or later 2.B0 or later

Clock 1.00 or later

Note1)

2.B0 or later

Line graph 1.00 or later 2.B0 or later

Alarm

History Not available 2.B0 or later

List 1.00 or later 2.B0 or later

Keyboard 1.00 or later 1.00 or later

Custom 1.00 or later 1.00 or later

Other

functions

Recipe

Recipe 1.00 or later 2.B0 or later

SD recipe Not available 2.B0 or later

Flow display 1.00 or later 2.B0 or later

Write device 1.00 or later 2.B0 or later

Sound Not available Not available

Password

Password 1.00 or later 2.B0 or later

Operation security 1.00 or later 2.B0 or later

Multi language exchange 1.00 or later 2.B0 or later

Logging function Not available Not available

FP monitor function 1.20 or later 2.C0 or later

Display panel sideways setting 1.00 or later 2.B0 or later

Copy

Cable between GTs Not available Not available

SD memory card Not available Not available

GT link 1.00 or later 2.B0 or later

PLC multiple connection 1.00 or later 2.B0 or later

Note1) Only referring to PLC can be set.

Note:

The buzzer function is not available for GT02L. All the functions related to the buzzer are unsupported.

xii

Page 15

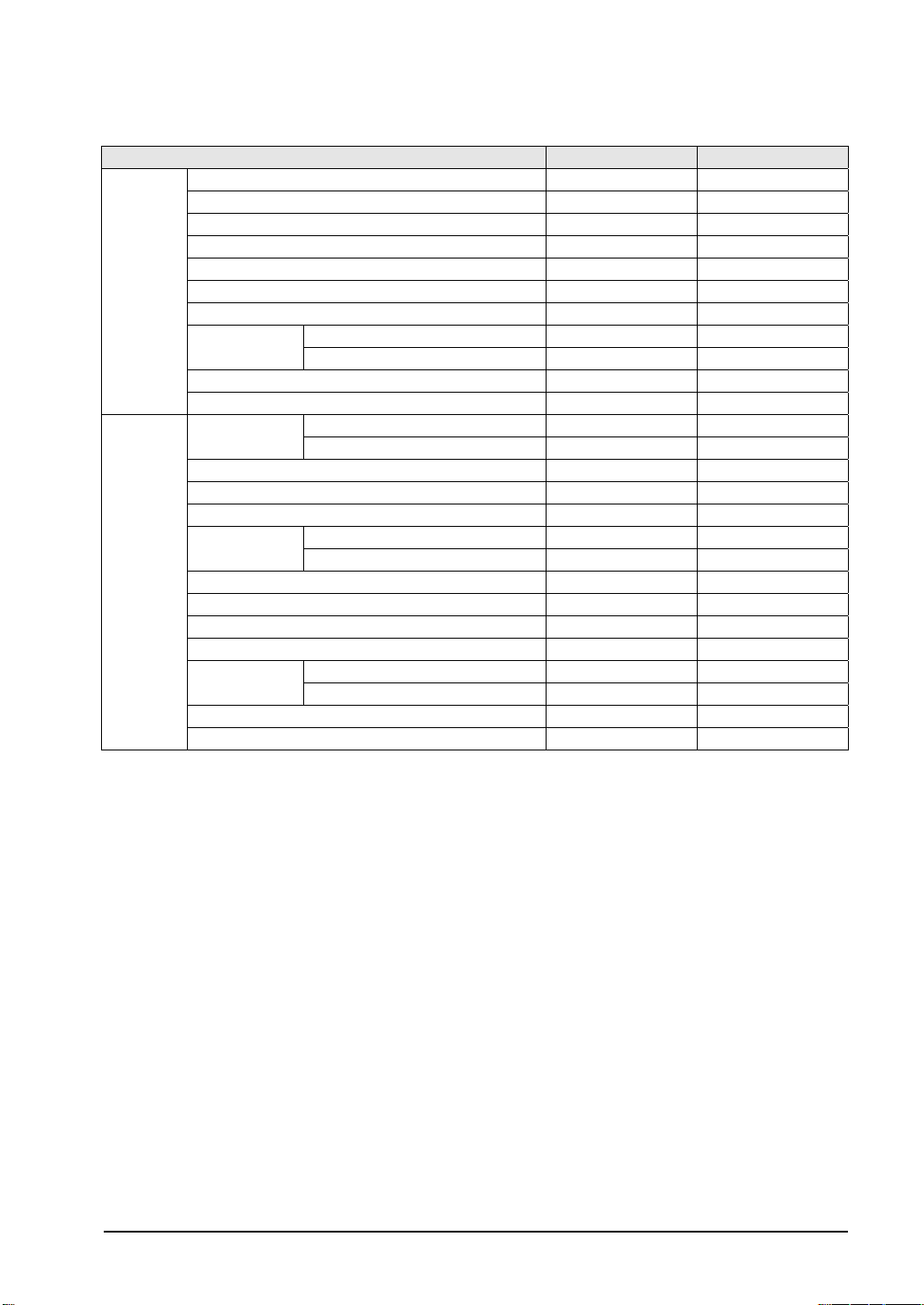

Version of GT05 and available functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Function GT05 GTWIN

Parts

library

Other

functions

Switch 1.00 or later 2.90 or later

Lamp 1.00 or later 2.90 or later

Message 1.00 or later 2.90 or later

Data 1.00 or later 2.90 or later

Bar graph 1.00 or later 2.90 or later

Clock 1.00 or later 2.90 or later

Line graph 1.00 or later 2.90 or later

Alarm

Keyboard 1.00 or later 2.90 or later

Custom 1.00 or later 2.90 or later

Recipe

Flow display 1.00 or later 2.90 or later

Write device 1.00 or later 2.90 or later

Sound Not available Not available

Password

Multi language exchange 1.00 or later 2.90 or later

Logging function 1.40 or later 2.98 or later

FP monitor function 1.90 or later 2.C0 or later

Display panel sideways setting 2.00 or later 2.C1 or later

Copy

GT link 1.10 or later 2.94 or later

PLC Multiple Connection 1.30 or later 2.97 or later

History 1.00 or later 2.90 or later

List 1.00 or later 2.90 or later

Recipe 1.00 or later 2.90 or later

SD recipe 1.60 or later 2.A0 or later

Password 1.00 or later 2.90 or later

Operation security 1.10 or later 2.94 or later

Cable between GTs Not available Not available

SD memory card 1.00 or later 2.90 or later

xiii

Page 16

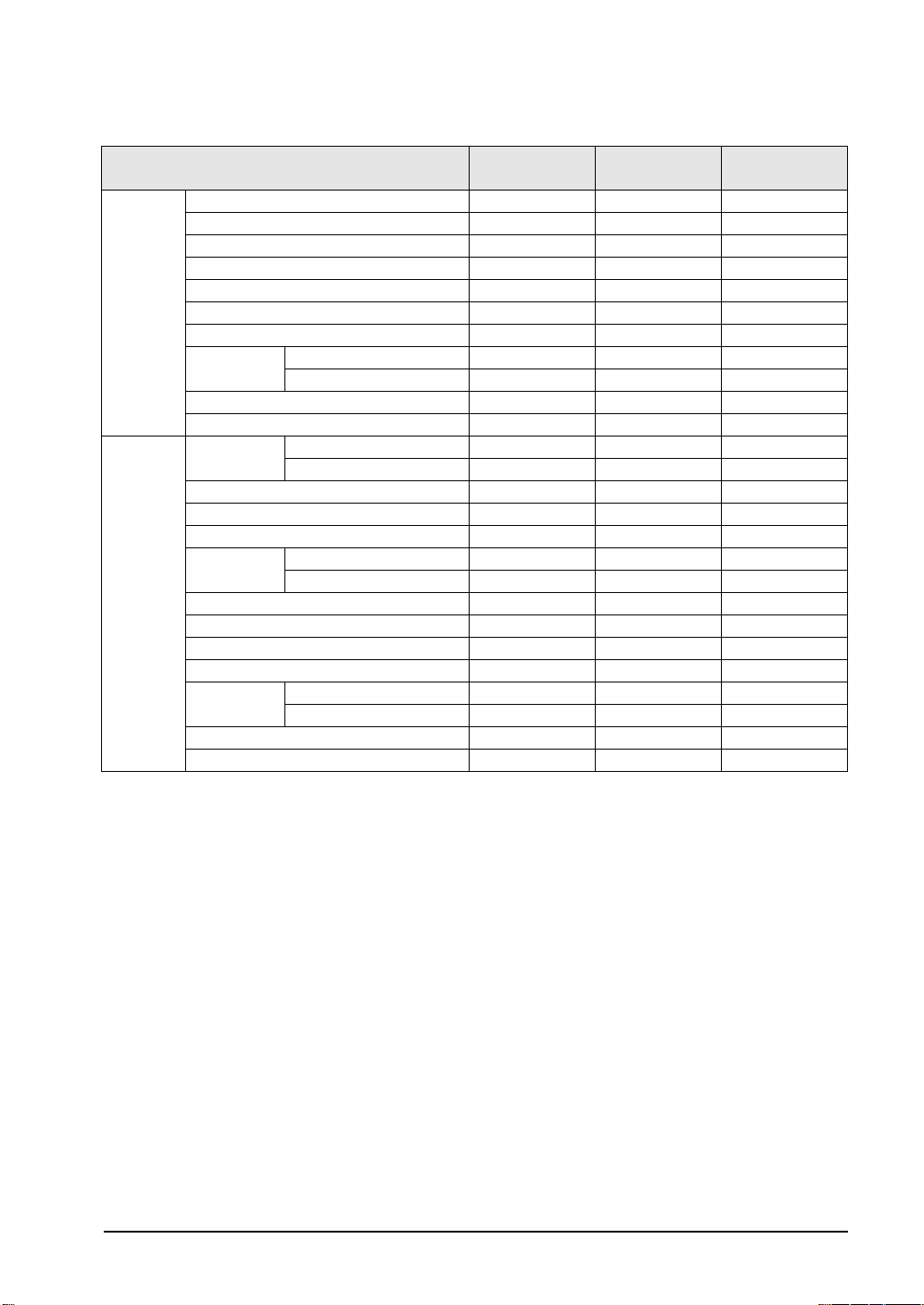

Version of GT11 and available functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Function GT11 GTWIN

Parts

library

Switch 1.00 or later 2.60 or later

Lamp 1.00 or later 2.60 or later

Message 1.00 or later 2.60 or later

Data 1.00 or later 2.60 or later

Bar graph 1.00 or later 2.60 or later

Clock 1.00 or later

Note1)

2.60 or later

Line graph 1.00 or later 2.60 or later

Alarm

History 1.00 or later 2.60 or later

List 1.00 or later 2.60 or later

Keyboard 1.00 or later 2.60 or later

Custom 1.00 or later 2.60 or later

Other

functions

Recipe

Recipe 1.00 or later 2.60 or later

SD recipe Not available Not available

Flow display 1.00 or later 2.60 or later

Write device 1.00 or later 2.60 or later

Sound Not available Not available

Password

Password 1.00 or later 2.60 or later

Operation security Not available Not available

Multi language exchange 1.00 or later 2.60 or later

Logging function Not available Not available

Display panel sideways setting 1.00 or later 2.60 or later

Copy

Cable between GTs 1.20 or later -

SD memory card Not available Not available

GT link Not available Not available

PLC multiple connection Not available Not available

Note1) Summer time cannot be set.

xiv

Page 17

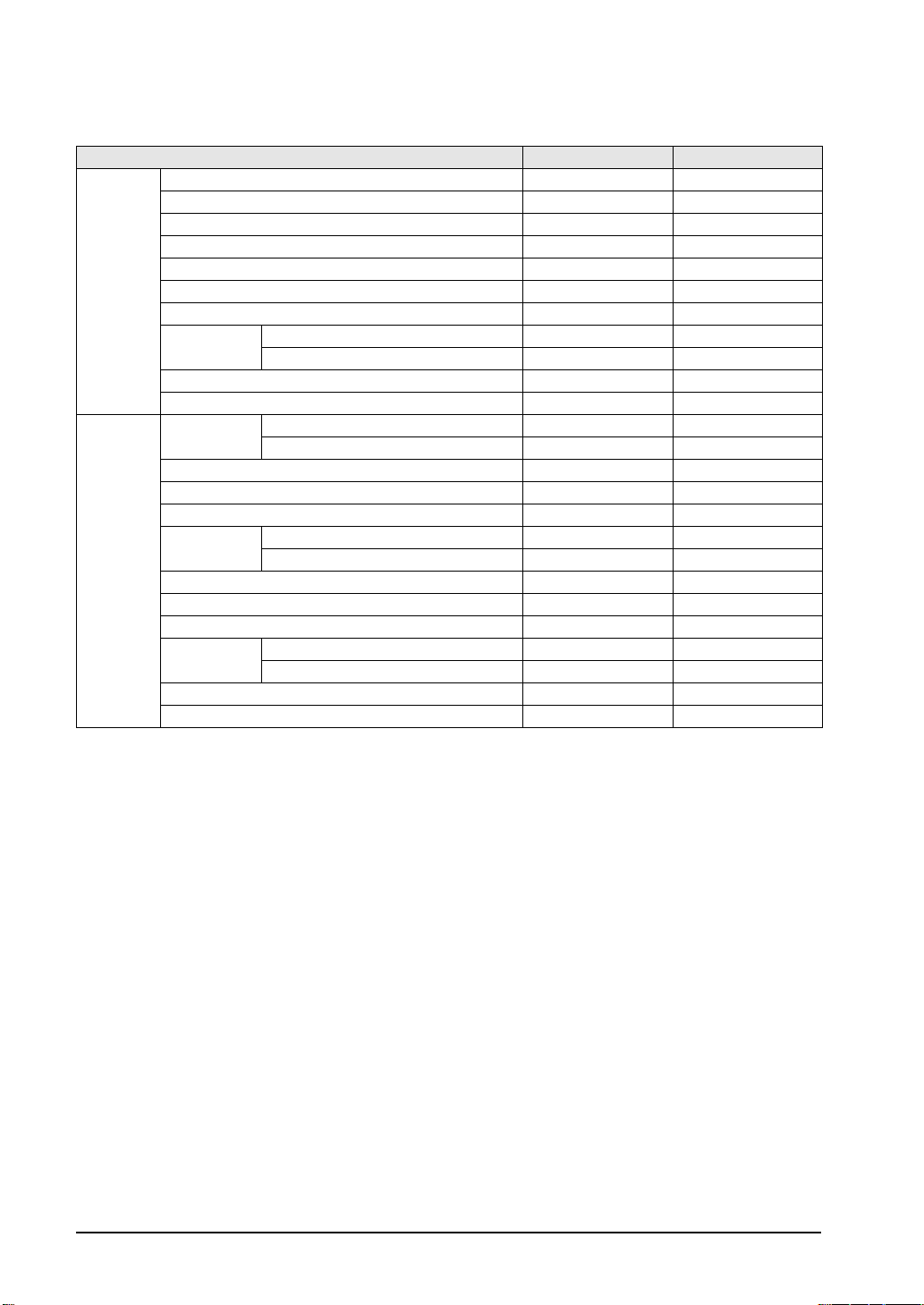

Version of GT12 and available functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Function GT12M1

GT12G1

Parts

library

Other

functions

Switch 1.00 or later 1.00 or later 2.97 or later

Lamp 1.00 or later 1.00 or later 2.97 or later

Message 1.00 or later 1.00 or later 2.97 or later

Data 1.00 or later 1.00 or later 2.97 or later

Bar graph 1.00 or later 1.00 or later 2.97 or later

Clock 1.00 or later 1.00 or later 2.97 or later

Line graph 1.00 or later 1.00 or later 2.97 or later

Alarm

Keyboard 1.00 or later 1.00 or later 2.97 or later

Custom 1.00 or later 1.00 or later 2.97 or later

Recipe

Flow display 1.00 or later 1.00 or later 2.97 or later

Write device 1.00 or later 1.00 or later 2.97 or later

Sound Not available Not available Not available

Password

Multi language exchange 1.00 or later 1.00 or later 2.97 or later

Logging function 1.10 or later Not available 2.98 or later

FP monitor function 1.60 or later 1.60 or later 2.C0 or later

Display panel sideways setting 1.00 or later 1.00 or later 2.97 or later

Copy

GT link 1.00 or later 1.00 or later 2.97 or later

PLC multiple connection 1.00 or later 1.00 or later 2.97 or later

History 1.00 or later 1.00 or later 2.97 or later

List 1.00 or later 1.00 or later 2.97 or later

Recipe 1.00 or later 1.00 or later 2.97 or later

SD recipe 1.20 or later Not available 2.A0 or later

Password 1.00 or later 1.00 or later 2.97 or later

Operation security 1.00 or later 1.00 or later 2.97 or later

Cable between GTs Not available Not available Not available

SD memory card 1.00 or later Not available 2.97 or later

GT12M0

GT12G0

GTWIN

xv

Page 18

Version of GT21 and available functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Function GT21 GTWIN

Parts

library

Switch 1.00 or later 2.70 or later

Lamp 1.00 or later 2.70 or later

Message 1.00 or later 2.70 or later

Data 1.00 or later 2.70 or later

Bar graph 1.00 or later 2.70 or later

Clock 1.00 or later

Note1)

2.70 or later

Line graph 1.00 or later 2.70 or later

Alarm

History 1.00 or later 2.70 or later

List 1.00 or later 2.70 or later

Keyboard 1.00 or later 2.70 or later

Custom 1.00 or later 2.70 or later

Other

functions

Recipe

Recipe 1.00 or later 2.70 or later

SD recipe Not available Not available

Flow display 1.00 or later 2.70 or later

Write device 1.00 or later 2.70 or later

Sound Not available Not available

Password

Password 1.00 or later 2.70 or later

Operation security Not available Not available

Multi language exchange 1.00 or later 2.70 or later

Logging function Not available Not available

Display panel sideways setting 1.10 or later 2.71 or later

Copy

Cable between GTs 1.10 or later -

SD memory card Not available Not available

GT link Not available Not available

PLC multiple connection Not available Not available

Note1) Summer time cannot be set.

xvi

Page 19

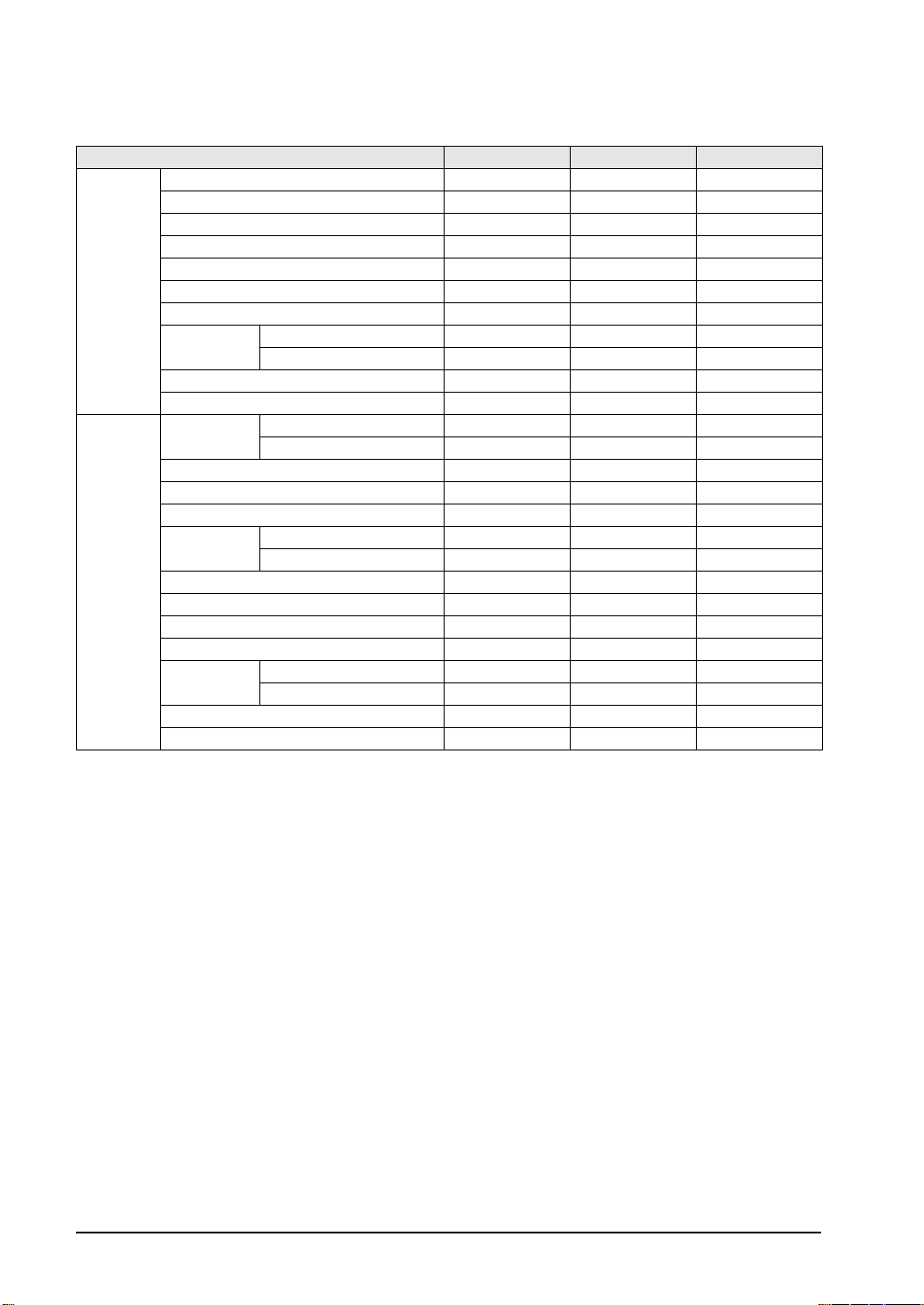

Version of GT32 and available functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Function GT32M

GT32T0

Parts

library

Other

functions

Switch 1.00 or later 1.00 or later 2.80 or later

Lamp 1.00 or later 1.00 or later 2.80 or later

Message 1.00 or later 1.00 or later 2.80 or later

Data 1.00 or later 1.00 or later 2.80 or later

Bar graph 1.00 or later 1.00 or later 2.80 or later

Clock 1.00 or later 1.00 or later 2.80 or later

Line graph 1.00 or later 1.00 or later 2.80 or later

Alarm

Keyboard 1.00 or later 1.00 or later 2.80 or later

Custom 1.00 or later 1.00 or later 2.80 or later

Recipe

Flow display 1.00 or later 1.00 or later 2.80 or later

Write device 1.00 or later 1.00 or later 2.80 or later

Sound Not available 1.00 or later 2.80 or later

Password

Multi language exchange 1.00 or later 1.00 or later 2.80 or later

Logging function 1.50 or later 1.50 or later 2.98 or later

FP monitor function 2.00 or later 2.00 or later 2.C0 or later

Display panel sideways setting 2.10 or later 2.10 or later 2.C1 or later

Copy

GT link 1.20 or later 1.20 or later 2.94 or later

PLC multiple connection 1.40 or later 1.40 or later 2.97 or later

History 1.00 or later 1.00 or later 2.80 or later

List 1.00 or later 1.00 or later 2.80 or later

Recipe 1.00 or later 1.00 or later 2.80 or later

SD recipe 1.60 or later 1.60 or later 2.A0 or later

Password 1.00 or later 1.00 or later 2.80 or later

Operation security 1.20 or later 1.20 or later 2.94 or later

Cable between GTs Not available Not available Not available

SD memory card 1.00 or later 1.00 or later 2.80 or later

GT32T1 GTWIN

xvii

Page 20

Version of GT32-E and available functions

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Function GT32M-E GT32T1-E GTWIN

Parts

library

Other

functions

Switch 1.00 or later 1.00 or later 2.C0 or later

Lamp 1.00 or later 1.00 or later 2.C0 or later

Message 1.00 or later 1.00 or later 2.C0 or later

Data 1.00 or later 1.00 or later 2.C0 or later

Bar graph 1.00 or later 1.00 or later 2.C0 or later

Clock 1.00 or later 1.00 or later 2.C0 or later

Line graph 1.00 or later 1.00 or later 2.C0 or later

Alarm

Keyboard 1.00 or later 1.00 or later 2.C0 or later

Custom 1.00 or later 1.00 or later 2.C0 or later

Recipe

Flow display 1.00 or later 1.00 or later 2.C0 or later

Write device 1.00 or later 1.00 or later 2.C0 or later

Sound Not available Not available Not available

Password

Multi language exchange 1.00 or later 1.00 or later 2.C0 or later

Logging function 1.00 or later 1.00 or later 2.C0 or later

FP monitor function 1.00 or later 1.00 or later 2.C0 or later

Display panel sideways setting 1.10 or later 1.10 or later 2.C1 or later

Copy

GT link 1.00 or later 1.00 or later 2.C0 or later

PLC multiple connection 1.00 or later 1.00 or later 2.C0 or later

History 1.00 or later 1.00 or later 2.C0 or later

List 1.00 or later 1.00 or later 2.C0 or later

Recipe 1.00 or later 1.00 or later 2.C0 or later

SD recipe 1.00 or later 1.60 or later 2.C0 or later

Password 1.00 or later 1.00 or later 2.C0 or later

1.00 or later 1.00 or later 1.20 or later 2.C0 or later

Cable between GTs Not available Not available Not available

1.00 or later 1.00 or later 1.00 or later 2.C0 or later

xviii

Page 21

Change history

y

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

GTWIN

GT-series version Additional functions

version

Ver. 2.80 GT32 Ver. 1.00

(New release)

Ver. 2.90 GT05 Ver. 1.00

(New release)

Ver. 2.94 GT05 Ver. 1.10

GT32 Ver. 1.20

Ver. 2.96 GT01 Ver. 1.35

GT05 Ver. 1.20

GT11 Ver. 1.25

GT21 Ver. 1.15

GT32 Ver. 1.30

Ver. 2.97 GT05 Ver. 1.30

GT12 Ver. 1.00

(New release)

GT32 Ver. 1.40

GT01 Ver.1.35

GT11 Ver.1.25

GT21 Ver.1.15

Ver. 2.98 GT05 Ver. 1.40

GT12 Ver. 1.10

GT32 Ver. 1.50

GT01 Ver. 1.37

GT11 Ver. 1.27

Ver.2.983 GT05 Ver.1.42

GT12 Ver.1.12

GT32 Ver.1.52

Ver.2.99 GT05 Ver.1.50

GT12 Ver.1.20

GT32 Ver.1.60

- - Display/Hide of keyboard parts in GTWIN

Ver.2.A0 GT02 Ver.1.00

Ver.2.B0 GT02L Ver.1.00

(New release)

GT05 Ver.1.60

GT12 Ver.1.30

GT32 Ver.1.70

GT05 Ver.1.40

GT12 Ver.1.30

GT32 Ver.1.20

(New release)

GT02 Ver.1.10

GT05 Ver.1.70

GT12 Ver.1.40

GT32 Ver.1.80

- New model

- Equipped a SD memory card slot.

- Sound function

- New model

- Operation security function

- GT link function

- Touch sound disable flag in Basic communication area

(Bit area)

- New model

- "Mult Function" function

- PLC multiple connection

- Display/Hide of data parts

- Modbus slave function

- Added 4096-color parts library.

- Modbus slave function

- Logging function

- Index modifier of data parts

- Display/Hide of switch parts

- Display of data parts in kana and Chinese character,

- kana input of keyboard parts ・Unit number setting on GT

when using General-purpose serial

- SD memory card copy to password-protected GT

- Connection between multiple units with Modbus(RTU) master

- Output to Panasonic FP series "X" device.

- Jump to the prvious screen from "Screen No. Error" screen

- Reverse display function

- Jump to the prvious screen from "Screen No. Error" screen

- Reverse displa

function

Bug fixing

- Functions for devices such as Temperature control device of

MODBUS (RTU mode)

- Display of data parts in Chinese and Korean

- Graph display of logging device data for logging function

- Bar graph of line graph parts

- Fixed line of line graph parts

- Supports SDHC memory card

- New model

- SD recipe function

- Function for communication errors in case of PLC multiple

connection

- Alarm history data save in SD memory card

- Multiplication and division of write device data

- Multiplication and division of write device data

- New model (GT02L)

- True Type font for data parts

xix

Page 22

Ver.2.B1 GT01 Ver.1.39

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

GT02 Ver.1.11

GT02L Ver.1.01

GT05 Ver.1.71

GT11 Ver.1.29

GT12 Ver.1.41

GT21 Ver.1.19

GT32 Ver.1.81

Ver.2.C0

GT02 Ver.1.30

GT02L Ver.1.20

GT05 Ver.1.90

GT12 Ver.1.60

GT32 Ver.2.00

GT32-E Ver.1.00

Ver.2.C1

GT02 Ver.1.40

GT02L Ver.1.30

GT05 Ver.2.00

GT12 Ver.1.70

GT32 Ver.2.10

GT32-E Ver.1.10

-Bug fixing

- New model(GT32-E)

- FP monitor function

- Added the mode to ignore CS/RS when using general-

purpose serial communication.

- Fixed font conversion function

- Vertical type display (GT05/GT32/GT32-E)

- Device change function

- Added the SD memory card installation flag in Basic

Communication Area.

- Added parts library.

xx

Page 23

Chapter 1

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Features and Functions

Page 24

1.1 Features and Functions of GT Series

GT series

Number of colors

GT21C

256 colors

GT05S/GT32T0/GT32T1/GT32T-E

4096 colors

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

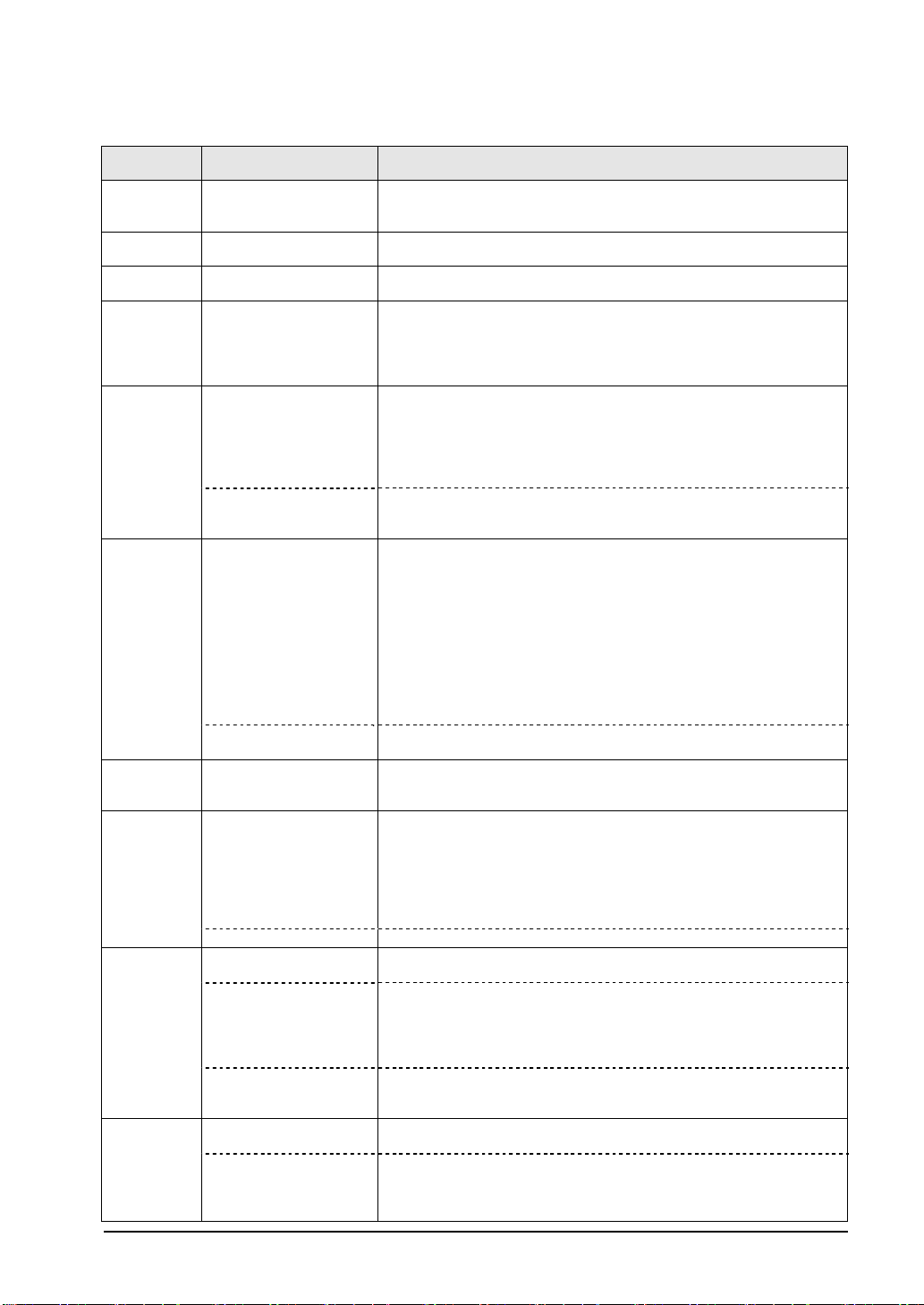

Can be installed in a small space.

As the GT series is a small and thin-shaped body, it can be installed in a small space. Also, as the

projecting part from a wall surface is 4 mm, it looks neat after installation.

The GT01, GT02, GT02L, GT11, GT12 and GT21 can be installed in vertical orientation.

Number of colors can be selected as usage.

Monochrome 8-gradation (GT12)/16-gradation (GT32M-E) display function is available.

The monochrome 8-gradation and 16-gradation displays can be selected as well as the existing

monochrome 2-gradation display, so that the screen can be displayed finely.

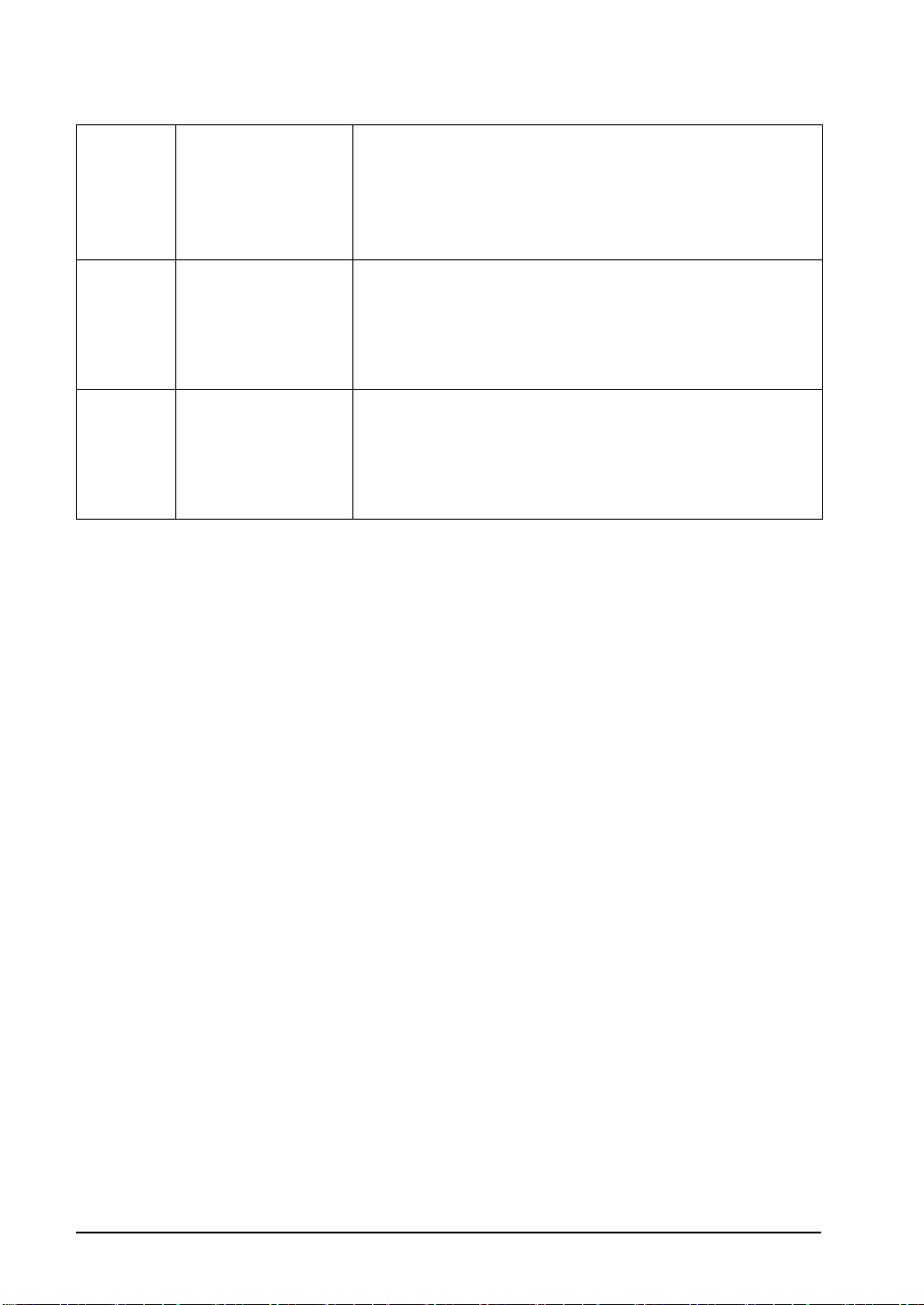

Easily shows a current state changing the backlight on the monochrome type.

For the monochrome type (3-color LED backlight type), changing in the backlight color makes it easy to

grasp a current state at a glance.

"Green, orange, red" type and "White, red, pink" type is available for the 3-color LED backlight type.

Analog touch panel provided

As an analog touch panel is provided, it allows maximum flexibility in the switch layout and size.

Screens can be created easily, using a special screen creation tool Terminal GTWIN.

Screen contents can be easily created using the dedicated Terminal GTWIN tool. Screens are put

together simply by selecting parts from libraries and positioning them in place.

Various parts for numerous applications are provided such as 256-color 3D parts.

Screen data of the other models can be used with the model conversion function.

Screen data can be converted from the low-resolution model to high-resolution model, e.g. from GT01 to

GT11, from GT21 to GT32.

The communication methods support RS232C/RS422 (RS485)

The communication methods to PLCs support RS232C/RS422(RS485). Also it can be connected to

PLCs manufactured by other companies.

Structure adapted to surrounding environments

IP65. It has a dust-proof, waterproof and drop-proof structure. (IP67 for GT02, GT12 and GT32-E)

High-intensity LED provided (LED backlight type)

As the high-intensity LED is provided, the screen is bright, and the backlight does not need to be

replaced.

Page 25

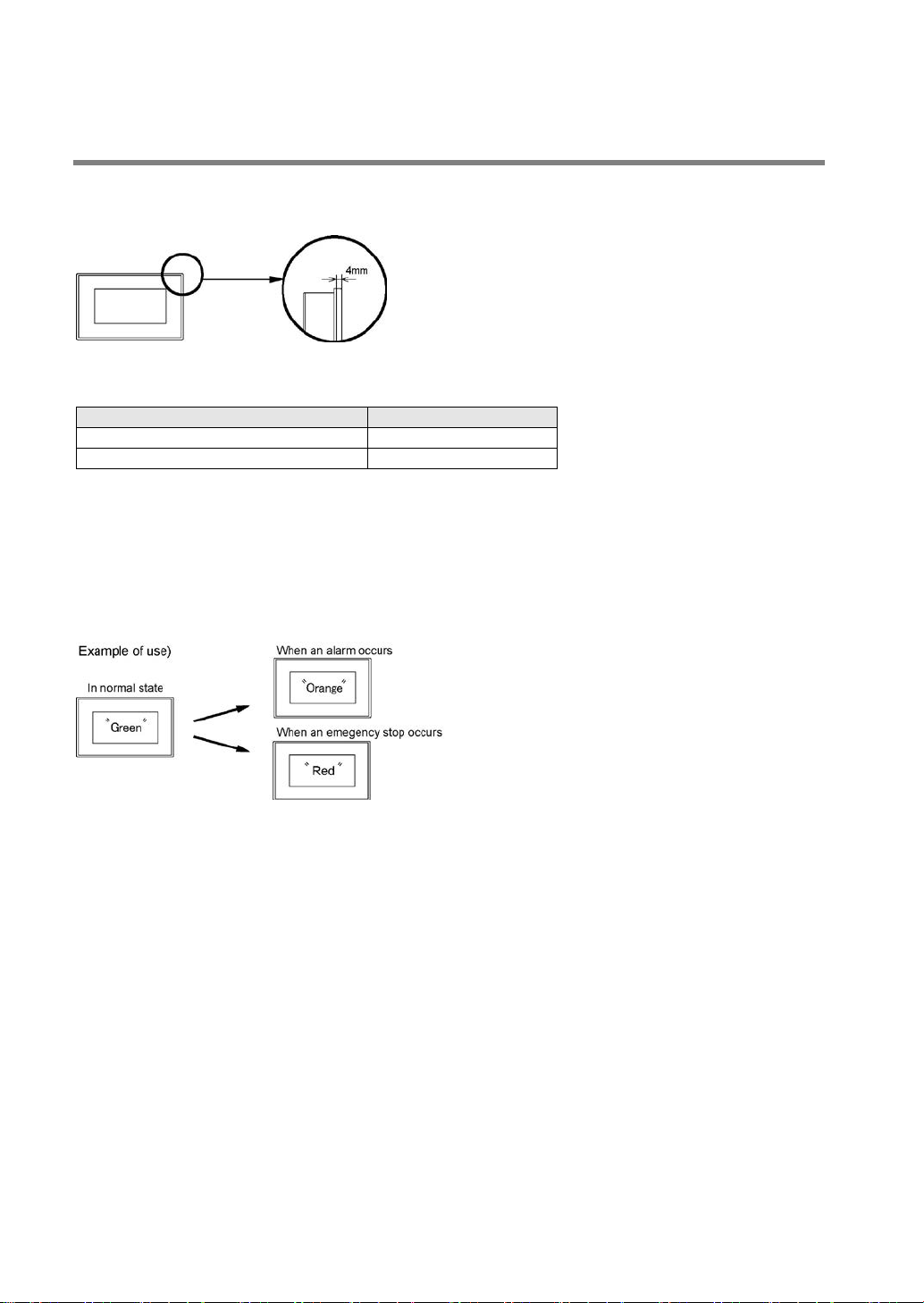

Saving various data with a SD memory card (Model equipped with SD memory card slot)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Various data can be saved and read out with a SD memory card.

Power can be supplied to the 5 V DC type with only one communication cable.

The power is supplied from the TOOL port of a PLC, therefore, the wiring man-hours can be significantly

reduced.

Applicable models:

Panasonic FP series

Mitsubishi Electric Corporation FX

series

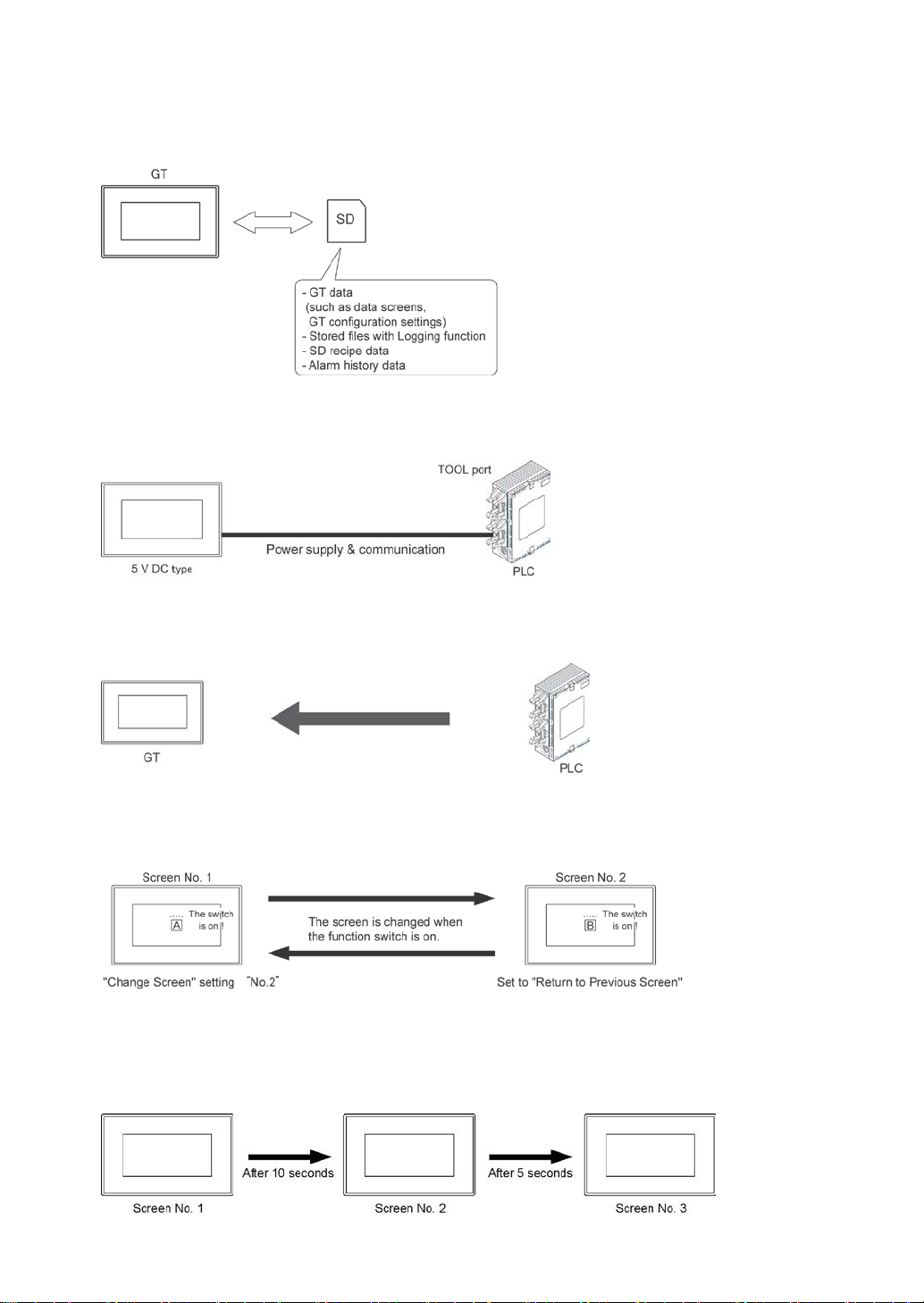

Three methods are available to switch the screen.

Switching by the instruction from PLC

The screens can be switched by writing to the “basic communication area” from the PLC ladder program.

Switching with the touch-screen operation

The screens can be switched on the GT by using the “function switching parts” provided in the parts

library of the GTWIN that has a function to switch the screens.

Switching automatically

The GT man unit has an “Auto-paging” function in the configuration setting that automatically switches

the screen to a specified screen number when a certain period of time has elapsed. This function can be

used to switch screens automatically.

Page 26

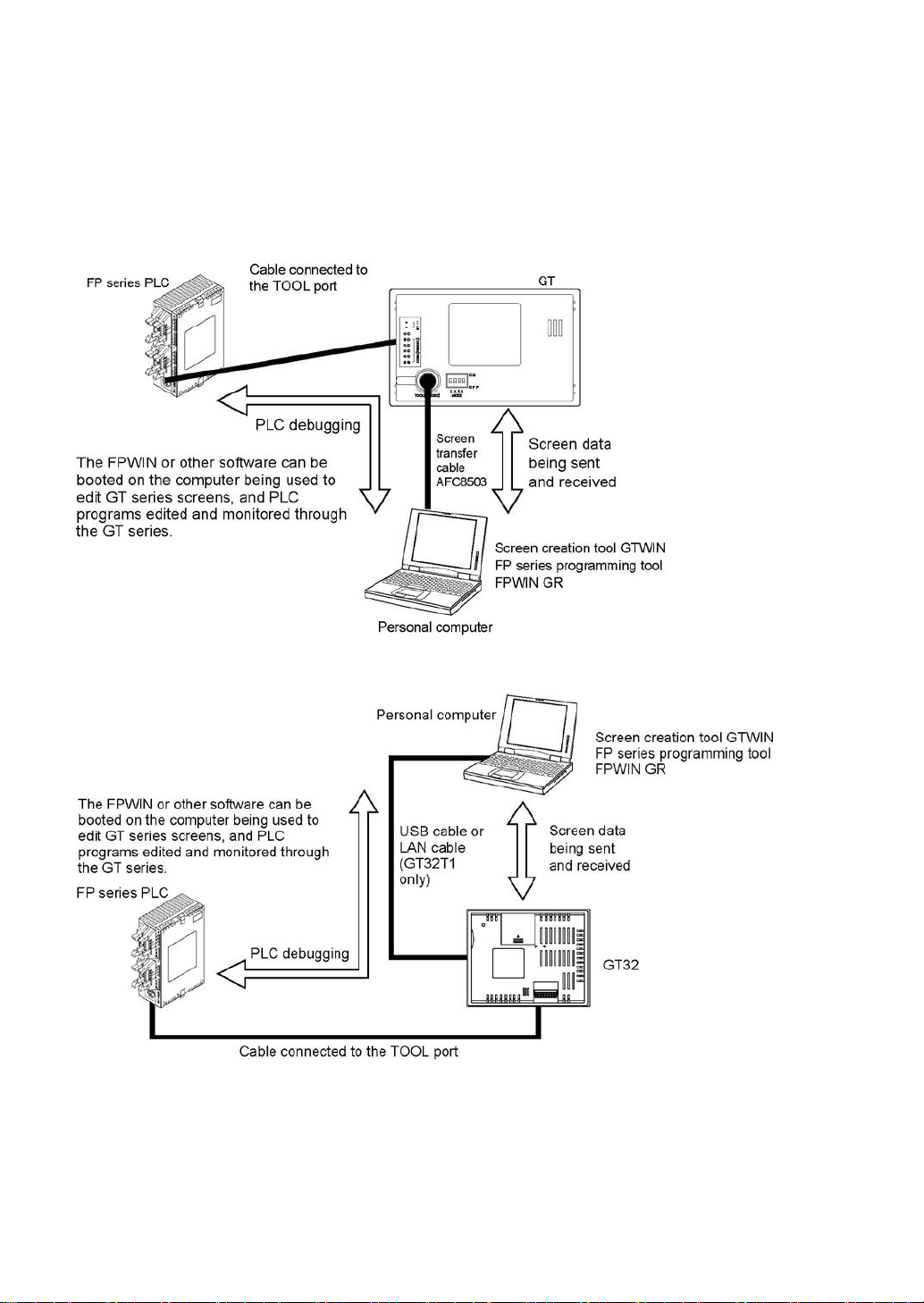

Through function is convenient for debugging

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

A convenient “through” function makes it possible to transfer data from the GT and carry out PLC

debugging at the same time that communication is going on between the GT and the FP series PLC.

This significantly boosts efficiency in the workplace.

For TOOL port models

For USB port/Ethernet port models

New functions can be available by upgrading the GT.

The GT can be easily upgraded by donwloading the latest firmware from our website or using the GT

Ver_UP tool.

Page 27

Security Function

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

- Password protection function

A password (max. 8 characters) is specified for trasferring the screen data to GT from GTWIN. This

function prevents the outflow of screen data if anyone except the administrator tries to read out the

screen data.

- Operation security function (GT02, GT02L, GT05, GT12, GT32, GT32-E)

This function is used to limit the contents of displays and operations by setting the security level of users

for each part.

The level of operators are managed with the security password.

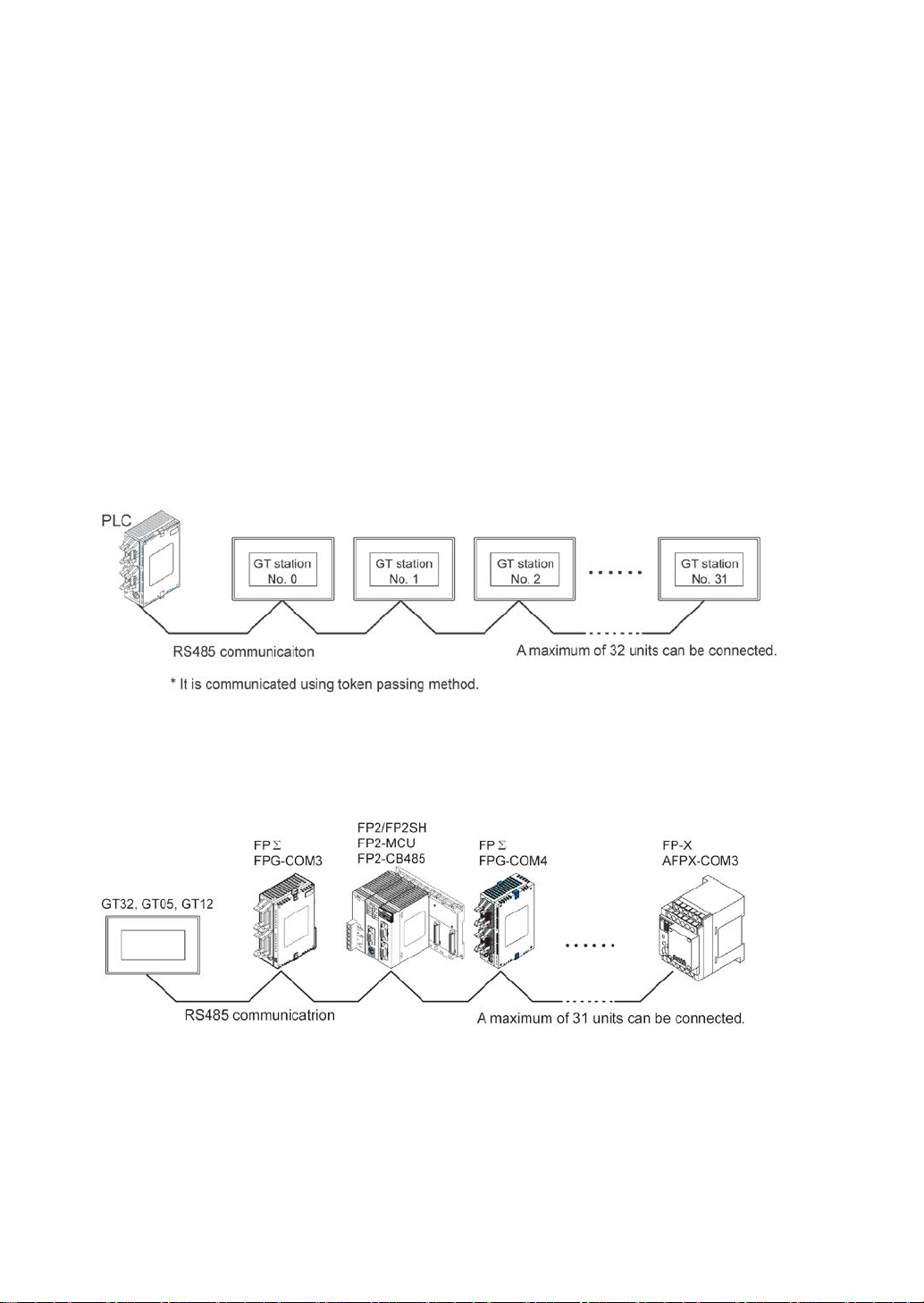

GT link function (GT02, GT02L, GT05, GT12, GT32, GT32-E)

This function is used to connect multiple GT units (up to 32 units) to a single PLC (Panasonic FP series).

RS485 communication is used.

Note) Station numbers should be set to the connected GT units. The both settings for GT and PLC are

necessary.

PLC Multiple Connection (GT02, GT02L, GT05, GT12, GT32, GT32-E)

This is a function that enables multiple Panasonic PLCs (FP series) (up to 31 units) to be connected with

one GT. Communication is performed via RS485.

Page 28

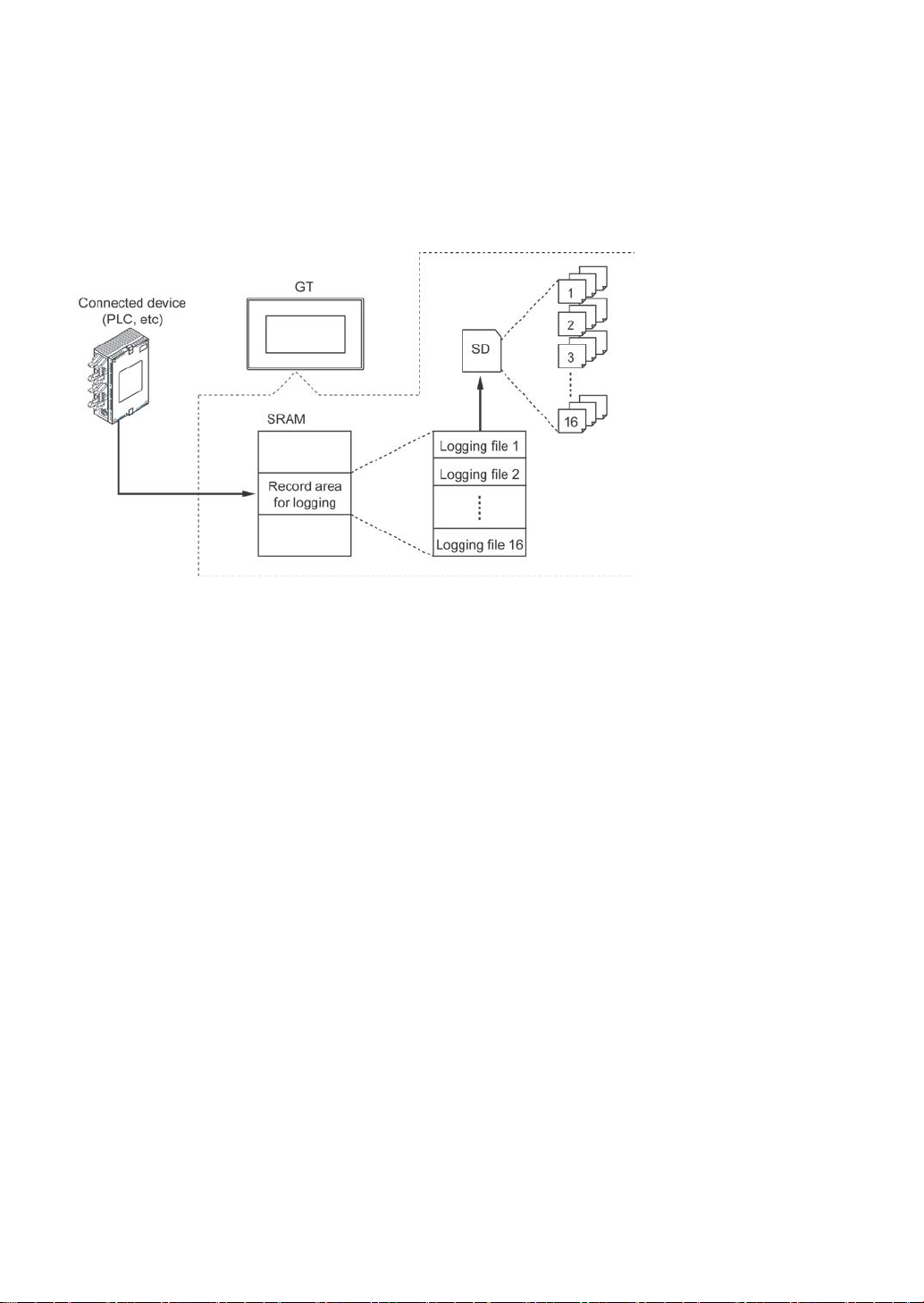

Logging function (Model equipped with SD memory card slot)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

It is a function to collect and log arbitrary device values into a PLC at a constant period or when

conditions are met.

Logged data is saved in a SD memory card inserted in this unit in CSV format.

This function is useful for obtaining the history of data.

FP monitor function (GT02, GT02L, GT05, GT12, GT32, GT32-E)

This function is used to monitor or change the settings and data of FP-series PLC on the GT screen.

Without creating screens in advance or connecting to a PC, the operational check of equipment in the

actual environment, the start-up of equipment and daily maintenance work can be performed efficiently.

Page 29

1.2 Types of Units

cation

Black

AIGT0030B1

Ashgray

AIGT0030H1

Black

AIGT0032B1

Ashgray

AIGT0032H

Black

AIGT0130B1

Ashgray

AIGT0130H1

(RS485)

Black

AIGT0132B1

Ashgray

AIGT0132H1

Black

AIGT0130B

Silver

AIGT0230H1

Pure black

AIGT0232B1

Silver

AIGT0232H1

Pure black

AIGT0230B

Silver

AIGT0230H

Pure black

AIGT0232B

Silver

AIG02MQ05D

Pure black

AIG02MQ12D

Silver

AIG02MQ13D

(RS485)

Pure black

AIG02MQ14D

Silver

AIG02MQ15D

Pure black

AIG02GQ04D

Silver

AIG02GQ05D

Pure black

AIG02GQ12D

Silver

AIG02GQ13D

(RS485)

Pure black

AIG02GQ14D

Silver

AIG02GQ15D

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.2.1 GT Series

Item

name

Model Display

Interface specifi-

cations

Backlight

Power

supply

COM

port

communication

specifi-

Front

panel

color

Model No.

GT01

GT02

GT01

GT01R

GT02M0

GT02M1

GT02M2

GT02G0

GT02G1

GT02G2

STN

monochrom

e LCD

(128x64

dots)

STN

monochrom

e LCD

(240x96

dots)

COM port

TOOL port

(RS232C

compliant)

COM port

USB port (USB1.1

compliant)

COM port

USB port (USB1.1

compliant)

with SD memory

card slot

COM port

USB port (USB1.1

compliant)

COM port

USB port (USB1.1

compliant)

with SD memory

card slot

3-color

LED

(green,

red,

orange)

1-color

LED

(white)

3-color

LED

(white,

red, pink)

3-color

LED

(white,

red, pink)

3-color

LED

(green,

red,

orange)

5 V DC

24 V

DC

5 V DC

24 V

DC

5 V DC

24 V

DC

5 V DC

24 V

DC

5 V DC

24 V

DC

RS232C

RS422

(RS485)

RS232C

RS422

(RS485)

RS232C

RS422

RS232C

RS422

(RS485)

RS232C

RS422

(RS485)

RS232C

RS422

(RS485)

RS232C

RS422

(RS485)

RS232C

RS422

RS232C

RS422

(RS485)

RS232C

RS422

(RS485)

RS232C

RS422

RS232C

RS422

(RS485)

Ashgray AIGT0032H1

Black AIGT0030B

Ashgray AIGT0030H

Black AIGT0032B

Ashgray AIGT0130H

Black AIGT0132B

Ashgray AIGT0132H

Pure black AIGT0230B1

Silver AIGT0232H

Pure black AIG02MQ02D

Silver AIG02MQ03D

Pure black AIG02MQ04D

Pure black AIG02MQ22D

Silver AIG02MQ23D

Pure black AIG02MQ24D

Silver AIG02MQ25D

Pure black AIG02GQ02D

Silver AIG02GQ03D

Pure black AIG02GQ22D

Silver AIG02GQ23D

Pure black AIG02GQ24D

Silver AIG02GQ25D

Page 30

Item

cation

dots)

RS232C

AIG02LQ02D

Pure black

AIG05MQ02D

Pure black

AIG05GQ02D

Silver

AIG05GQ03D

Pure black

AIG05SQ02D

Silver

AIG05SQ03D

Black

AIGT2030B

Ashgray

AIGT2030H

Ashgray

AIGT2130H

Black

AIGT2132B

Pure black

AIG12MQ04D

Silver

AIG12MQ05D

card slot

Pure black

AIG12GQ02D

Silver

AIG12GQ03D

Pure black

AIG12GQ12D

Silver

AIG12GQ13D

dots)

Pure black

AIGT2230B

Pure black

AIGT2232B

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

name

Model Display

Interface

specifi-cations

Backlight

Power

supply

COM port

communication

specifi-

Front

panel

color

Model No.

GT02L GT02L

GT05M

GT05

GT11 GT11

GT12

GT21 GT21

GT05G

GT05S

GT12M0

GT12M1

GT12G0

GT12G1

STN

monochro

me LCD

(160x64

STN

monochro

me LCD

(320x240

dots)

4096color STN

color LCD

(320x240

dots)

STN

monochro

me LCD

(240x96

dots)

STN

monochro

me LCD

(320x120

dots)

256-color

STN color

LCD

(320x240

COM port

USB port

(USB1.1

compliant)

COM port

USB port

(USB1.1

compliant)

with SD memory

card slot

COM port

TOOL port

(RS232C

compliant)

COM port

TOOL port

(RS232C

compliant)

COM port

USB port

(USB1.1

compliant)

with SD memory

COM port

TOOL port

(RS232C

compliant)

COM port

USB port

(USB1.1

compliant)

with SD memory

card slot

COM port

TOOL port

(RS232C

compliant)

1-color

LED

(white)

3-color

LED

(white,

red, pink)

3-color

LED

(green,

red,

orange)

1-color

LED

(white)

3-color

LED

(green,red

, orange)

1-color

LED

(white)

3-color

LED

(white,

red, pink)

3-color

LED

(green,

red,

orange)

1-color

LED

(white)

5 V DC

24 V

DC

24 V

DC

24 V

DC

5 V

DC

RS422

(RS485)

RS232C

RS422

(RS485)

RS232C

RS422

(RS485)

RS232C

RS422

(RS485)

RS232C

RS422

(RS485)

RS232C

RS422

(RS485)

RS232C

RS422

(RS485)

RS232C

RS422

(RS485)

RS232C

RS422

(RS485)

RS232C

RS422

(RS485)

RS232C

RS422

(RS485)

Black

Silver AIG05MQ03D

Pure black AIG05MQ04D

Silver AIG05MQ05D

Pure black AIG05GQ04D

Silver AIG05GQ05D

Black AIG05SQ04D

Ashgray AIG05SQ05D

Black AIGT2032B

Ashgray AIGT2032H

Black AIGT2130B

Ashgray AIGT2132H

Pure black AIG12MQ02D

Silver AIG12MQ03D

Pure black AIG12MQ12D

Silver AIG12MQ13D

Pure black AIG12MQ14D

Silver AIG12MQ15D

Pure black AIG12GQ04D

Silver AIG12GQ05D

Pure black AIG12GQ14D

Silver AIG12GQ15D

Silver AIGT2230H

Silver AIGT2232H

AIG02LQ04D

Page 31

cation

Silver

AIG32MQ03D

Pure black

AIG32TQ02D

Pure black

AIG32TQ04D

Pure black

AIG32TQ12D

Item name

Contents

Product No.

For connection between GT01/GT02/GT02L (5V

* A ferrite core is supplied with the main unit.

* A ferrite core is supplied with the main unit.

2 m

AIGT8162

5 m

AIGT8165

10 m

AIGT8160

Mini-DIN 8-pin loose-wire cable

D-SUB 9-pin loose-wire cable

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Item

name

Model Display

Interface

specifi-cations

Backlight

Power

supply

COM port

communication

specifi-

Body color Model No.

GT32

GT32-E

GT32M

GT32T0

GT32T1

GT32M-E

GT32T-E

STN

monochrome

LCD

(320x240

dots)

4096color

TFT color

LCD

(320x240

dots)

TFT

monochro

me LCD

(320x240

dots)

4096color

TFT color

LCD

(320x240

dots)

COM port

USB port

(USB1.1

compliant)

with SD memory

card slot

COM port

USB port

(USB1.1

compliant)

Ethernet port

with SD memory

card slot with

sound output

jack

COM port

USB port

(USB1.1

compliant)

with SD memory

card slot

CFL

1-color

LED

(white)

24 V

DC

24 V

DC

RS232C

RS422

(RS485)

RS232C

RS422

(RS485)

RS232C

RS422

(RS485)

RS232C

RS422

(RS485)

RS232C AIG32TQ03DE

RS422

(RS485)

Pure black AIG32MQ02D

Pure black AIG32MQ04D

Silver AIG32MQ05D

Silver AIG32TQ03D

Silver AIG32TQ05D

Silver AIG32TQ13D

Pure black AIG32TQ14D

Silver AIG32TQ15D

AIG32MQ03DE

AIG32MQ05DE

Silver

AIG32TQ05DE

1.2.2 Options and Repair Parts

PLC connecting cables

DC type (RS232C)) and our FP-series TOOL port

Mini-DIN 5-pin loose-wire cable

For connection between GT01/GT02/GT02L (5V

DC type (RS422)) and MITSUBISHI FX-series

TOOL port

Mini-DIN 8-pin loose-wire cable

For connection between 24V DC type (RS232C)

and our FP-series TOOL port

Mini-DIN 5-pin loose-wire cable

For connection between 24V DC type (RS422)

and MITSUBISHI FX-series TOOL port

For connection to COM port of FP2/FP2SH and

FP2 computer communication unit

2 m AIGT8142

2 m AIGT8152

5 m AIGT8175

2 m AIP81842

Page 32

Maintenance parts

No.

Note)

For GT05

AIG05810

For GT11

AIGT181

For GT12

AIG2810

For GT21

AIGT28121

screws)

No.

For GT01

AIGT080

For GT01R

AIGT080R

For GT02/GT02L

AIG02800

For GT05

AIG05800

For GT32

Sold separately

AIGT32800

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Item name Contents

Product

Waterproof

packing

Attachment

fittings

Attachment

fittings

(with

dedicated

Connector

For GT01

For GT02/GT02L

For GT32 AIG32810

For GT32-E AIG32810E

GT01/GT11 repair

(4 pc/set)

For GT05/GT21 repair (2 pc/set) 5 sets AIGT28321

For GT32/GT32-E repair (2 pc/set) 5 sets AIG32830

For GT02/GT02L/GT12 repair

(4 pc each/set)

COM port connector

for repair

(8-pin)

AIG02810

For repair 10 in set

5 sets AIGT083

5 sets AIG12830

5 in set AIGT084

AIGT081

Note) Although it is for GT02, it can be also used for GT02L. It is different from the packing attached to

the GT02 unit.

Options

Item name Contents

Product

GT01

Front panel

protective

sheet

Backup

battery

For GT11 AIGT280

For GT12 AIG12800

For GT21 AIGT28021

Backup battery

for

GT02M2,GT02G2/GT05/GT12/GT32/

GT32-E

Sold separately

10 in set

1 pc AFPX-BATT

Page 33

Commercial product

Item name

Contents

Model No.

GT02G2

2GB

later

older

older

older

later

1GB

2GB

card

32GB

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Backup

battery

Backup battery for GT11/GT21 1 pc CR2032

Item

name

SD

memor

y card

Note) Select the capacity of a SD memory card according to the logo printed on the GT and the version

of GT firmware.

Printe

d logo

on GT

GT02M2

1.00 or

later

1.00 or

later

1.00 or

1.00 or

later

GT version (Ver.) Usable SD memory card

GT05 GT12 GT32 GT32-E Card type Capacity

1.39 or

older

1.40

or later

1.39 or

1.40 or

later

1.09 or

older

1.10 or

later

1.09 or

1.10 or

later

1.49 or

older

1.50 or

later

1.49 or

1.50 or

later

1.00 or

later

1.00 or

later

1.00 or

1.00 or

later

SD memory card

SD memory card

SDHC memory

card

CLASS2, 4

SD memory card

SD memory card

SDHC memory

32M to

1GB

32M to

4GB to

16GB

32M to

32M to

4GB to

Page 34

1.3 Screen Creation Tool

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.3.1 Tools Required for Screen Creation

1. Tool software

It can be used for all the models in the GT series.

2. Screen transfer cable (Cable for connecting a PC)

For GT01, GT11 and GT21:

A cable between a PC (D-sub 9-pin) and GT (TOOL port) is available.

For GT02, GT02L, GT05, GT12, GT32 and GT32-E:

Prepare a commercal USB cable or LAN cable (for GT32T1 only).

1.3.2 Software Usage Environment and Applicable Cables

Screen creation tool software Terminal GTWIN Ver. 2

Software type Required OS Hard disk capacity Product No.

English-

Terminal GTWIN Ver. 2

Terminal GTWIN Ver. 2

Upgrade model

Note1) The latest version is provided free of charge via our website

(User registration is required. Free of charge)

language

version

Englishlanguage

version

Windows 7

Windows Vista

Windows 2000

Windows XP

400 MB or more

AIGT8001V2

AIGT8001V2R

Related software (Freeware)

Item name Contents

Configurator WD IP address search tool Address setting for the GT in Ethernet communication

Note) It can be downloaded from our website.

(User registration is required. Free of charge)

1-12

Page 35

Screen transfer cable

USB cable (Commercial product)

Applicable model

Cable type

Length

connector

connector

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

For connection between PC (USB) and Programmable Display (GT02/GT02L/GT05/GT12/GT32)

GT05/GT32/

GT32-E

GT02/GT02L/GT12

Note) Windows 2000 or later OS is required for the communication with a USB.

USB2.0 (or 1.1) AB type Max. 5 m

USB2.0 (or 1.1) cable

A type (Male): miniB type male

Max. 5 m

For connection between PC (RS232C) and Programmable Display (GT01/GT11/GT21)

D-sub connector cable

PC side

D-sub 9-pin

GT side

Mini DIN

round 5-pin

Specification Product No.

L type (3 m) AFC8503

Straight type

(3 m)

AFC8503S

Note) A USB/RS232C conversion cable is necessary to connect with a personal computer without a

serial port using a PC connection cable.

LAN cable (Ethernet port) (GT32T1)

Either straight cable or crossing cable can be used.

(MDI/MDI-X Automatic crossover function)

Page 36

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Page 37

Chapter 2

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Names and Functions of Parts

Page 38

2.1 Part Names

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

2.1.1 GT01, GT11 and GT21

GT01/GT01R

GT11

GT21

Page 39

Touch screen

Normal use

(Factory default)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Various screens are displayed here. Switches can be operated and data entered simply by touching the

touch screen.

(A sheet is affixed to the touch panel to protect it from scratches when shipping. Please remove it before

using the GT.)

Optional protective sheets are available to protect the touch screen surface and keep it clean.

Reference: <1.4.2 Options and Repair Parts>

COM port and power supply terminal

This is a communication port (RS232C or RS422) for connecting to a PLC, host PC, or microcomputer

board, and a power supply terminal for operation.

TOOL port (GTWIN connection port)

This port is used to connect the screen creation tool.

Operation mode setting switches

Setting the operation mode setting switches as follows when turning on the power supply enables the

setting to inhibit to move to the system menu or enables to clear F-ROM.

Setting

Switch setting

Inhibit system menu shift Clear F-ROM

Note: Do not use any settings other than the above settings.

Waterproof packing

This assures that the front panel is waterproof.

Battery cover (for GT11 and GT21)

When using a backup battery to be separately purchased, open this battery cover to install it.

The clock, PLC device hold data, alarm history and GT internal device hold data functions can be used

with the backup battery.

Reference: <3.6.2 How to Install the Battery (Lithium Button Battery)>

Page 40

2.1.2 GT02/GT02L

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

GT02M2, GT02G2

GT02M0, GT02M1, GT02G0, GT02G1

GT02L

Page 41

Liquid crystal display panel/touch panel

Normal use

(Factory default)

Inhibit system

menu shift

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Various screens are displayed here. A touch panel is provided on the liquid crystal display panel, and

switches can be operated and data entered simply by touching the panel.

Optional protective sheets are also available to protect the touch panel and keep it clean.

(A sheet is affixed to the touch panel to protect it from scratches when shipping. Please remove it before

using the GT.)

SD memory card slot

A SD memory card is inserted in this slot.

- Saving from GTWIN: Operate on the GTWIN screen using a SD memory card read/writer.

- Savving from GT main unit: Operate on the SD memory card setting screen under the system menu.

USB port

This is a connector for connecting the screen creation tool. The commercal USB cable can be used.

SD memory access lamp

The lamp turns on while accessing a SD memory card.

Battery cover

When using a backup battery to be separately purchased, open this battery cover to install it.

The clock, PLC device hold data, alarm history and GT internal device hold data functions can be used

with the backup battery.

Operation mode setting switches

Setting the operation mode setting switches as follows when turning on the power supply enables the

setting to inhibit to move to the system menu or enables to clear F-ROM.

Setting

Clear F-ROM

Switch setting

Mounting location of connector for battery

COM port (PLC/external device conn ection port) and power supply terminal

This is a communication port (RS232C or RS422) for connecting to a PLC, host PC, or microcomputer

board, and a power supply terminal for operation.

Waterproof packing

This assures that the front panel is waterproof.

Page 42

2.1.3 GT05/GT12/GT32