Panasonic GP-X10M Installation Manual

Thank you very much for using SUNX products.

g

g

y

)

5

Please read this Instruction Manual carefully and

thoroughly for the correct and optimum use of this

INSTRUCTION MANUAL

High-Speed㨯High-Accuracy Eddy Current

Digital Displacement Sensor GP-X Series

GP-Xغ

product. Kindly keep this manual in a convenient

place for quick reference.

Thisproduct is to inspect(discriminate/measure) sensin

prevention of accidents which dama

9#40+0

life or properties or for safet

objects. Never use this product for

maintenance.

For the details of High-speed㨯high-accuracy eddy current digital displacement sensor GP-X series, refer to

the instruction manual enclosed with the GP-X series.

1

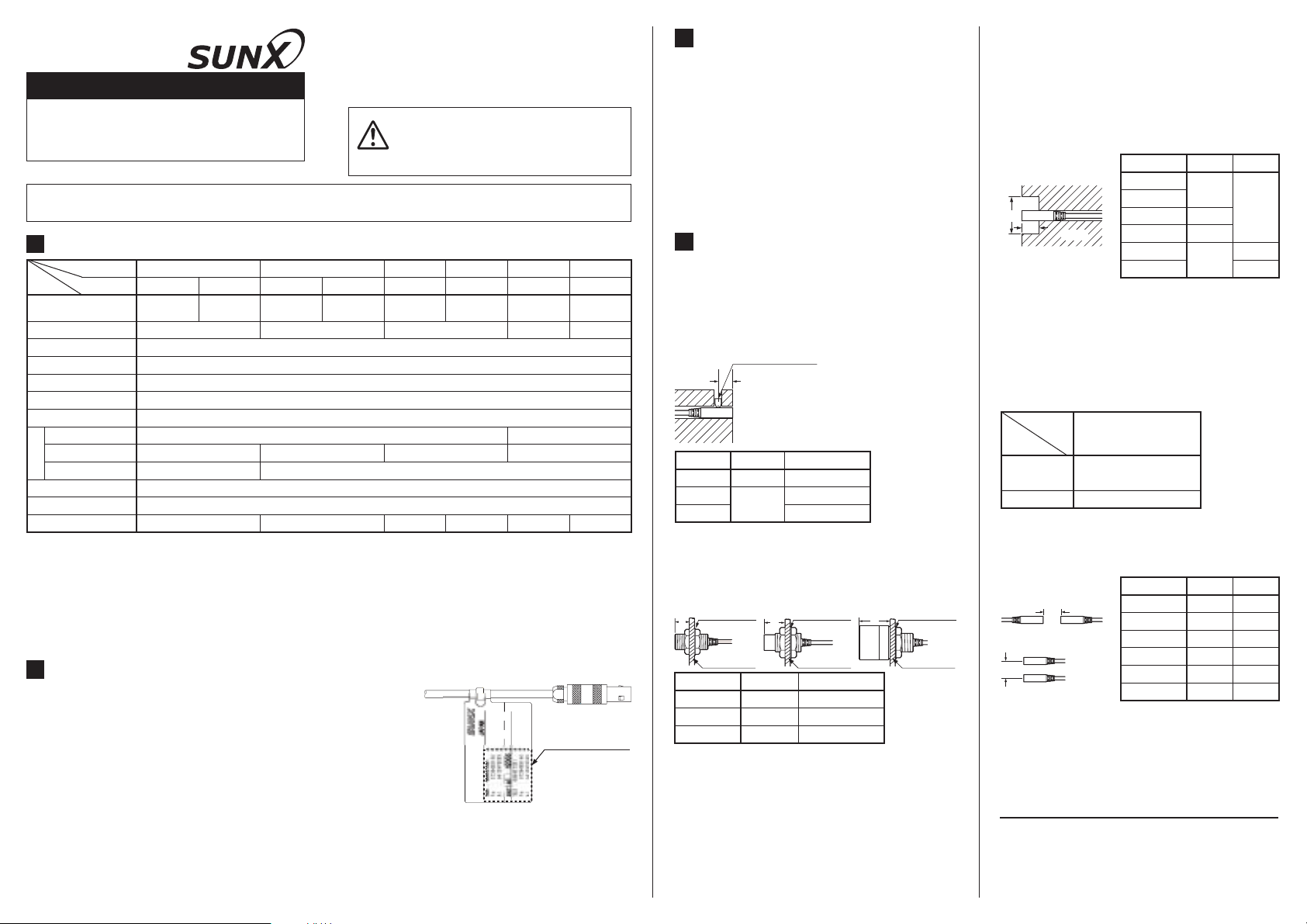

SPECIFICATIONS

Type

Item

Model No. of combination set

(Note 2)

Sensing range (Note 3)

Standard sensing object

Temperature characteristics (Note 4)

Protection

Ambient temperature

Ambient humidity

Material

Cable

Cable extension

Notes: 1)

3)

2

٨

Model No. (Note 1)

Enclosure

Sensing surface

Cable protector

The sensor head GP-X3S and GP-X5S are applicable to export regulations specified in 'Foreign Exchange and

Foreign Trade Control Law'. Exportation of them or carrying them outside Japan requires an export permit from the

Japanese government. However, GP-X3SE and GP-X5SE which are not applicable to export regulations are also

available.

This is not a model No. of the controller on its own.

2)

The sensing range is specified for the standard sensing object.

The value represents 20 to 60% of the maximum sensing distance when combining the sensor head and controller.

4)

The weight of the GP-X10M, GP-X12ML and GP-X22KL is value including the weight of the nut and toothed lock washer.

5)

SENSOR HEAD REPLACEMENT SETTING

When the sensor head for replacement is connected to the controller, be

Ǿ3.8mm type

GP-X3S GP-X5SGP-X3SE GP-X5SE

GP-XC3S

GP-XC3S-P

GP-XC3SE

GP-XC3SE-P

㧙

Connector attached high frequency coaxial cable, 3m long

Ǿ5.4mm type

GP-XC5S

GP-XC5S-P

Stainless steel (SUS304)/iron (6060t1mm)

Extension up to 10m is possible with the optional cable

GP-XC5SE

GP-XC5SE-P

0.07%F.S./or less

IP67 (IEC)IP67g (JEM)

-10 to +55, Storage: -20 to +70

35 to 85% RH, Storage: 35 to 85% RH

40g approx.40g approx.Weight (Note 5)

Ǿ8mm type

GP-X8S

GP-XC8S

GP-XC8S-P

M10 type

GP-X10M

GP-XC10M

GP-XC10M-P

0 to 2mm0 to 1mm0 to 0.8mm

PP

M12 type

GP-X12ML

GP-XC12ML

GP-XC12ML-P

0 to 5mm

Brass (Nickel plated)Stainless steel (SUS303)

PAABSPARABS

45g approx.50g approx.40g approx.

sure to enter the characteristics code (ID code) of the sensor head to the

controller. Using the ID type linearity correction function having been developed for the current application, high accuracy identical to that of the

factory shipment setting can be maintained. The characteristics code is a

Characteristics code

(ID code)

10-digit number and written on the tag attached to the sensor head cable. For the entering procedure, refer to '5.4 Sensor Head

Setting' in the instruction manual enclosed with the GP-X

Note: The tag attached to the sensor head cable can be split into two. Use the split tag as a copy.

Replacement

series.

:

٨ After entering the characteristic code (ID code), be sure to perform three-point calibration.

For the calibration, refer to '4.2 Three-Point Calibration (Linearity adjustment)' in the instruction manual

enclosed with the GP-X series.

e a human

Ǿ22mm

GP-X22KL

GP-XC22KL

GP-XC22KL-P

0 to 10mm

80g approx.

3

CAUTIONS

٨

The GP-X series is configured to satisfy the

specification with the combination of the sensor

head and the controller. Use the sensor head

and controller in combination without fail; with

other combinations, not only may the specifications may not be satisfied but also failure may

result.

Turn the controller off before mounting or re-

٨

moving the sensor head and controller.

Note that the cables will be damaged if they are

٨

pulled.

4

MOUNTING

٨

Tighten the sensor head to the torque specified

below.

٨

Mounting with set screw

Make sure to use an M3, or less, set screw with

a cup-point end.

㧨Column type㧪

Set screw (M3 or less)

(Cup-point end)

A

Model No.

GP-X3S (E)

GP-X5S (E)

GP-X8S

Note: Take care not to tighten excessively.

A (mm)

4 to 16

5 to 16

Tightening torque

0.1N㨯m or less

0.44N㨯m or less

0.58N㨯m or less

٨ Mounting with nut

㧨Screw type㧪

GP-X10M

Attached toothed

lock washer

B

Mounting plate

Model No.

GP-X10M

GP-X12ML

GP-X22KL

Notes: 1)

2)

GP-X12ML

Attached toothed

lock washer

B

Mounting plate

B (mm)

7 or more

14 or more

20 or more (Note1)

The dimension is for mounting with a nut.

If two nuts, or more, are mounted, the dimension

becomes 23.5mm, or more.

Mount such that the nuts do not protrude from

the threaded portion.

Tightening torque

9.8N㨯m or less

20N㨯m or less

20N㨯m or less

GP-X22KL

Attached toothed

lock washer

B

Mounting plate

٨

Distance from surrounding metal

As metal around the sensor may affect the

detection, take care of the following.

Embedding of the sensor in metal

Measurement value or analogue voltage output

may be changed if the sensor is completely

embedded in metal. Keep the minimum

distance specified in the table below.

C (mm)Model No.

D (mm)

GP-X3S (E)

GP-X5S (E)

C

D

Metal

٨

Sensing range

The sensing range is specified for the standard

GP-X8S

GP-X12ML

GP-X22KL

Ǿ10

Ǿ18

Ǿ14GP-X10M

Ǿ50

3 or more

14 or more

20 or more

sensing object (Stainless steel/iron).

With a metal other than the metals specified in

the specifications, multiply with the correction

coefficient shown in the table below.

Check the effect with the actual machine.

㧨Correction coeficient㧪

Sensor head

Metal

Stainless steel (SUS304)

Iron

Alminum

٨

In case the interference prevention function is not used

If sensor heads are mounted close together

GP-X3S (E)ޔGP-X5S (E)

GP-X8SޔGP-X10M

GP-X12MLޔGP-X22KL

1

0.5 approx.

without using the interference prevention function, keep the distance specified below.

F (mm)

Face to face mounting

E

Parallel mounting

F

Model No.

GP-X3S (E)

GP-X5S (E)

GP-X8S

GP-X12ML

GP-X22KL 200

SUNX Limited

Head Office

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-(0)568-33-7211 FAX: +81-(0)568-33-2631

Overseas Sales Dept.

Phone: +81-(0)568-33-7861 FAX: +81-(0)568-33-8591

E (mm)

915

30 11

40

40GP-X10M

170

200

http://www.sunx.co.jp/

PRINTED IN JAPAN

15

15

50

Loading...

Loading...