Page 1

Technical Guide

Technical Guide

Model : TH--

Model : TH

TH--

TH

(GPF9D and

(GPF9D and

Troubleshooting Handbook

Troubleshooting Handbook

103PF9UK

103PF9UK

103PF10UK

103PF10UK

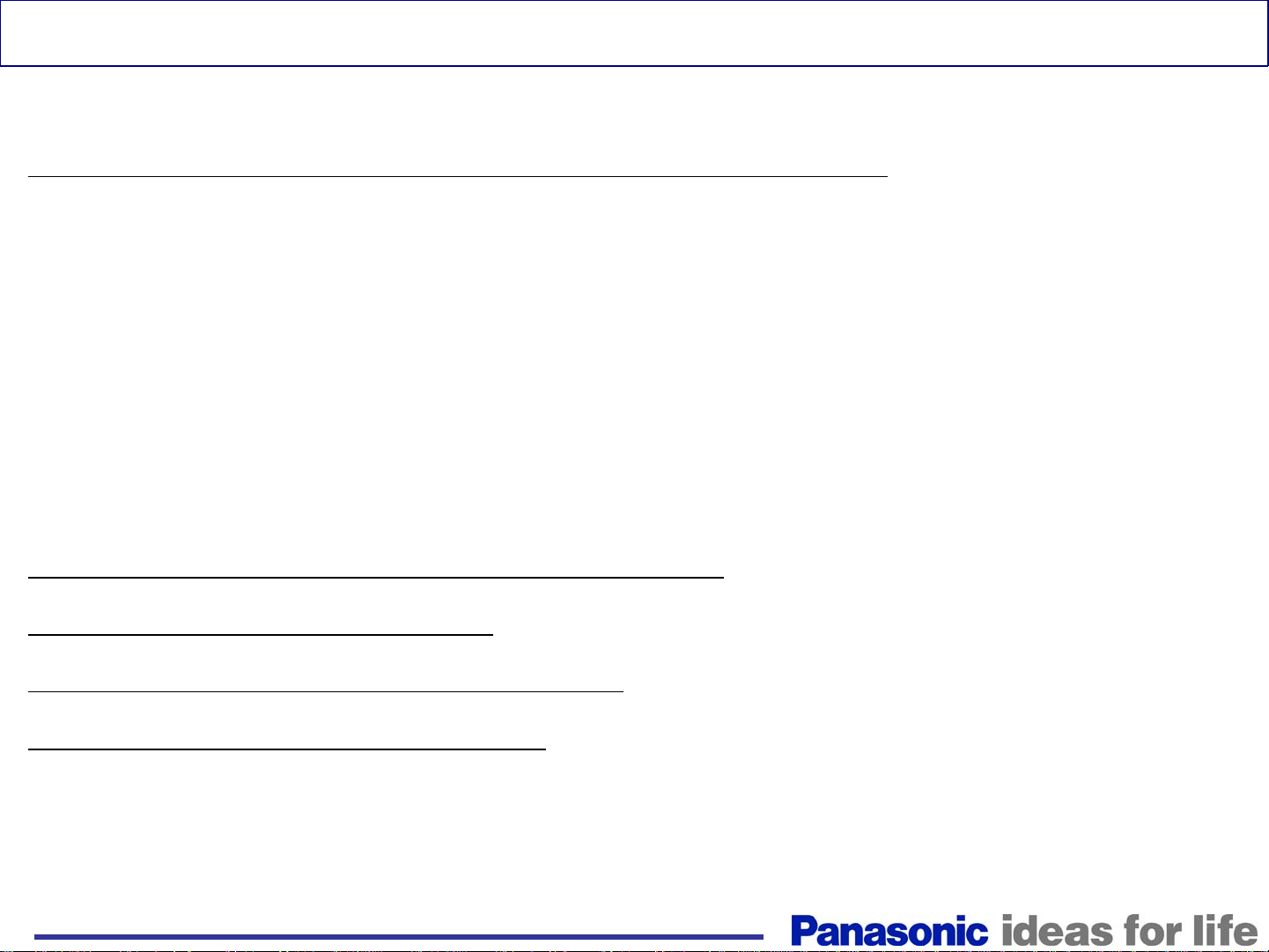

103””

103

GPF10D

GPF10D

Plasma

Plasma

Chassis)

Chassis)

Panasonic Services Company

National Training

Page 2

This page is purposely left blank.

2

Page 3

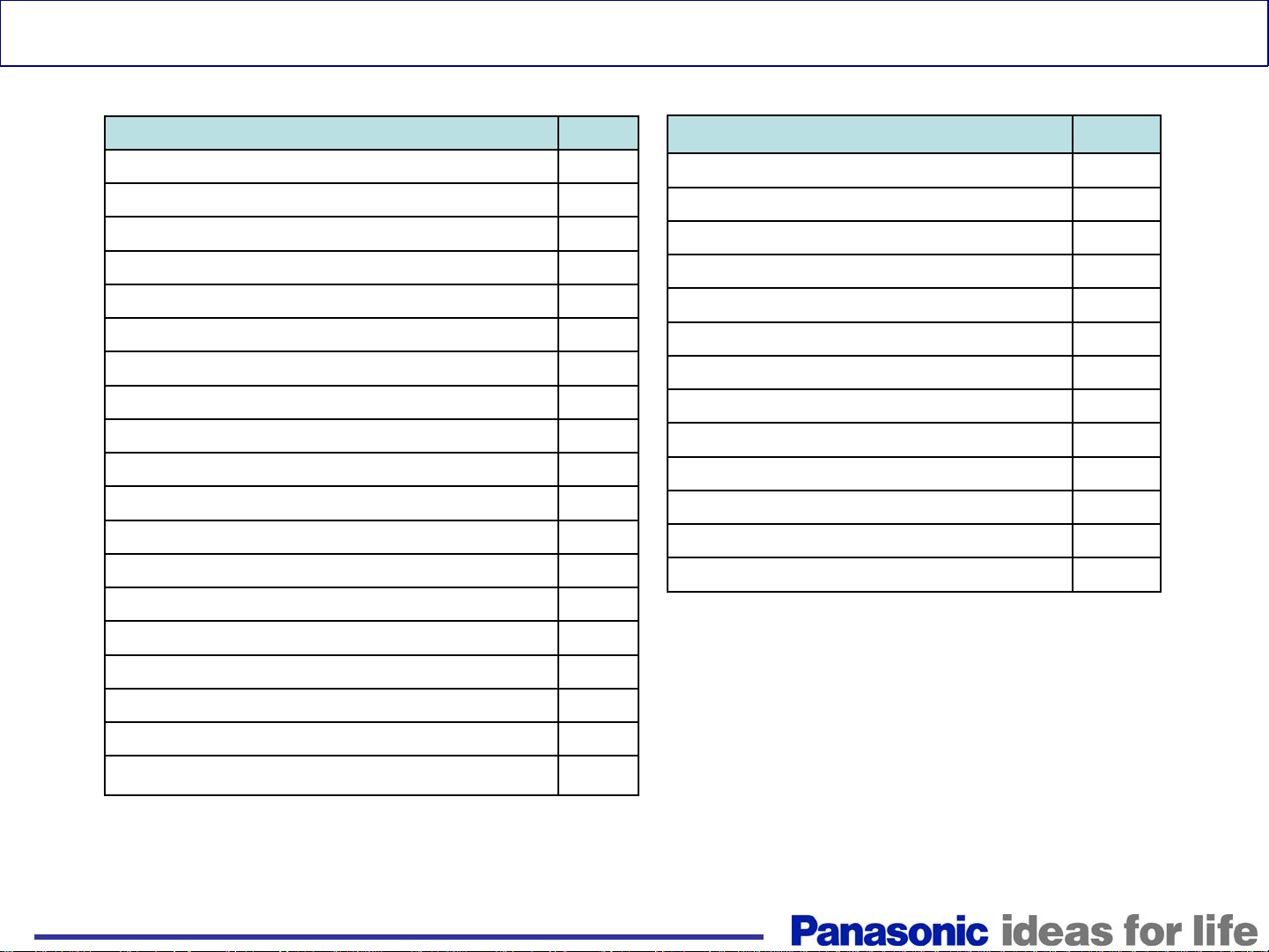

Table of Contents

Subject Page

Introduction 4

AC Power Requirement 5

Rear Cover Removal 6

Chassis Structure 7

Chassis Layout 8

Board Description 9

Troubleshooting Display (Distortion) Problem 10-18

Relation of Board and Display Area 11

Troubleshooting for No Power 19-21

Shutdown (SOS) Troubleshooting 22-46

List of LED Blink Codes 23

Power LED blinks 1 time 24

Power LED blinks 2 times (SS Side) 25

Power LED blinks 2 times (SC Side) 26

Power LED blinks 3 times 27

Subject Page

Power LED blinks 8 times 42

Power LED blinks 9 times 43

Power LED blinks 10 times 44

Power LED blinks 11 times 45

Power LED blinks 13 times 46

Alignment (Adjustment) Procedure

Self-check Procedure

How to reset the unit

How to enter the CAT (Computer Aided Test) Mode

How to enter the IIC mode

How to access the pattern generator

How to enter the CD Mode

How to enter the MS Mode

47-53

54

55

56

57

58

59

60

Power LED blinks 4 times 28

Power LED blinks 5 times 29-34

Power LED blinks 6 times 35-36

Power LED blinks 7 times 37– 41

3

Page 4

Introduction

<Introduction>

1. Basic concept of how to determine the defective board

1) Verification of voltages

Normally, when there is a power problem, shutdown occurs immediately.

So, to resolve a power problem, voltage checks are necessary before shutdown.

2) Check if the power comes up after disconnecting the board under suspicion.

If power comes up (*) after disconnecting a board, the board is defective.

(*) “Power comes up” equals “no shutdown”.

2. Troubleshooting Video and Audio problems

3. Examples of video problems

4. Troubleshooting shutdown problems

5. Adjustment after PCB exchange

1) After exchanging the following boards, voltage adjustment is required.

P board, SC board, SS board => Please refer to the “Service Manual”.

4

Page 5

AC Power Requirement

Note

1)

Caution!

1)

Caution!

This PDP uses a 240V source and consumes 1,500W of power .

This PDP uses a 240V source and consumes 1,500W of power .

Check the customer’’

Check the customer

2)Maintenance space!

2)Maintenance space!

A minimum space of 700mm is needed at the rear of the unit

A minimum space of 700mm is needed at the rear of the unit

for installation.

for installation.

3)Please check

3)Please check

maintenance contract.

maintenance contract.

with the Sales company

with the Sales company

s AC power source.

s AC power source.

for the service and

for the service and

5

Page 6

Back Covers

The unit contains 6 back covers that provide access to

different areas of the board assembly.

Zone Board

A

B PB, DS, HX, HA, DN,

D D, CD×2, C4

C P, CX

E P, F, C9

F SS, SS2, SS3, DR1/2

B+C FAN, CD

D+E FAN, CD, PC

A+B C2

D+F C5

A+C CY, SC2

E+F C8

SC, DR1/2,,SU, SM, SD

C1, CZ, FAN

HDD, CD, C3

C6, C7, FAN

6

Page 7

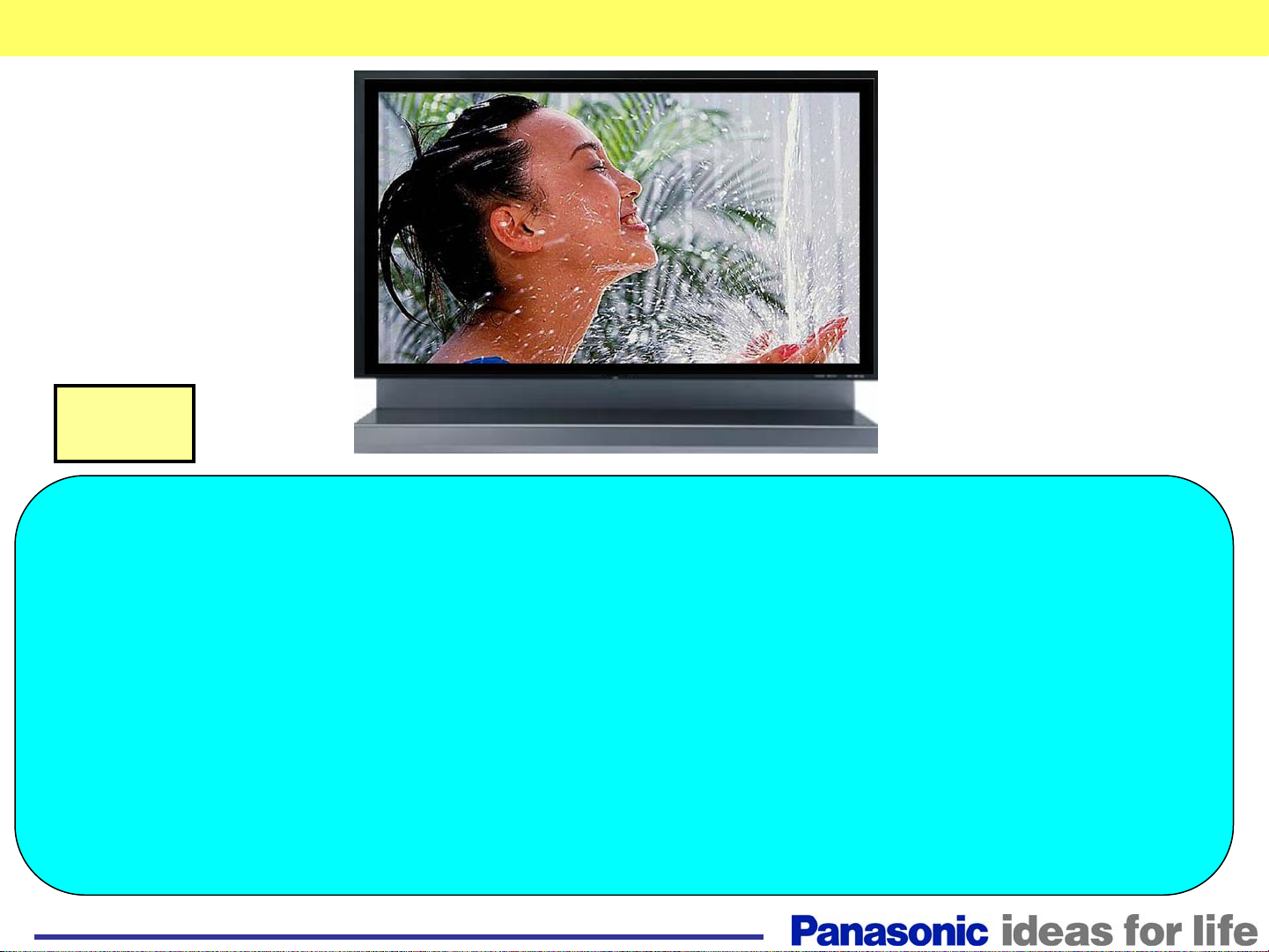

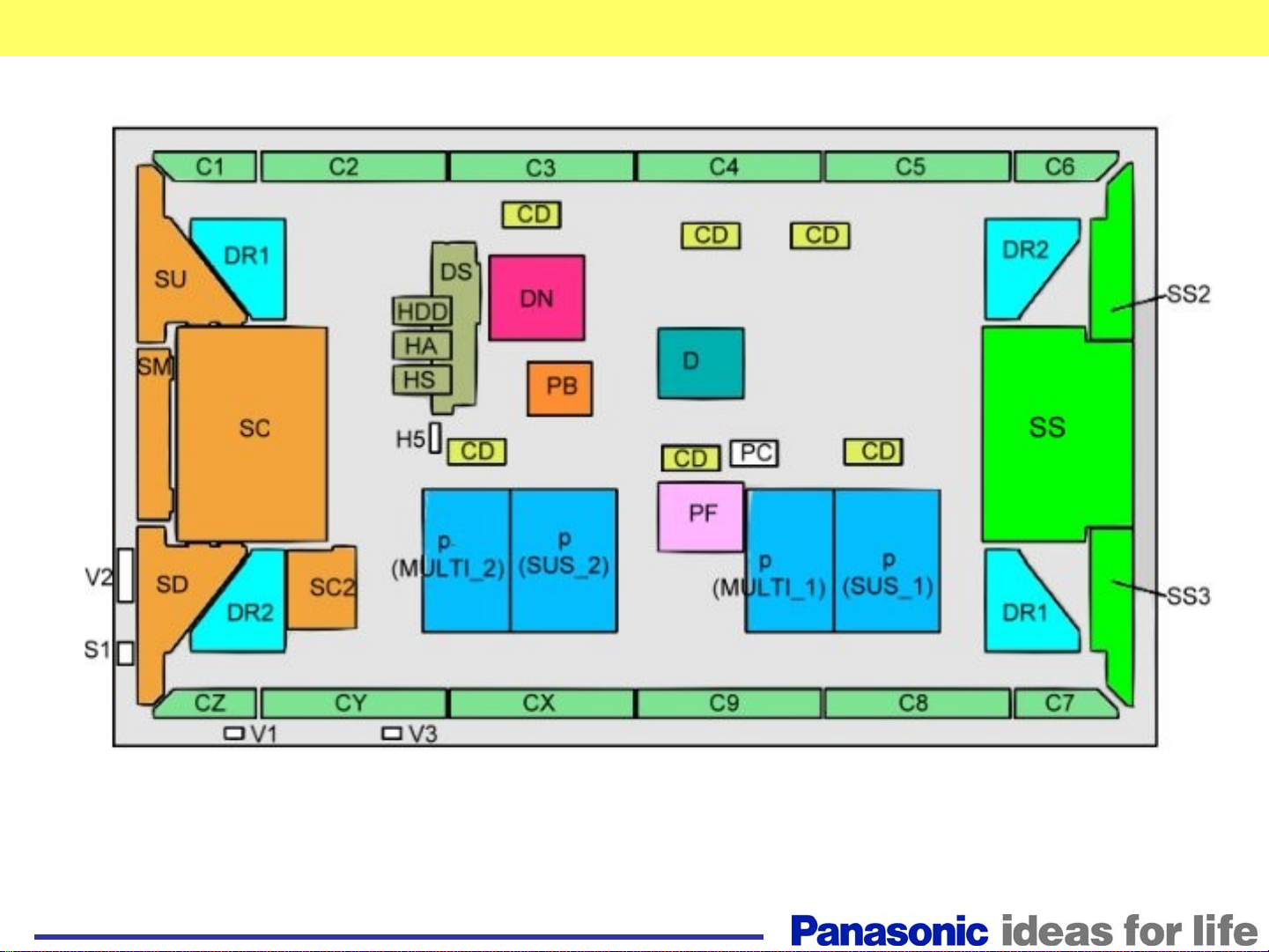

Chassis structure

C1 C2 C3

DR1 DR2

SU

HA

HX

HDD

SM

SC

SD

DR2

C4

CD CD CD

DS

P1・P2 P1・P2

DN D

CDCDCD

C5

DR1

C6

SS2

SS

SS3

CZ

C9CXCY

C8

C7

The 103” plasma display television contains many more boards than the smaller size

plasma display models that are on the market today. It contains:

1. Two P boards (power supply)

2. Twelve C boards (data drive)

3. The SM board is added to complement the SU and SD of current model.

4. There are four DR boards added to the unit, one at each corner

5. There is the DS board that connects the HX, HA, and HDD to the DN board.

7

Page 8

Chassis Layout

8

Page 9

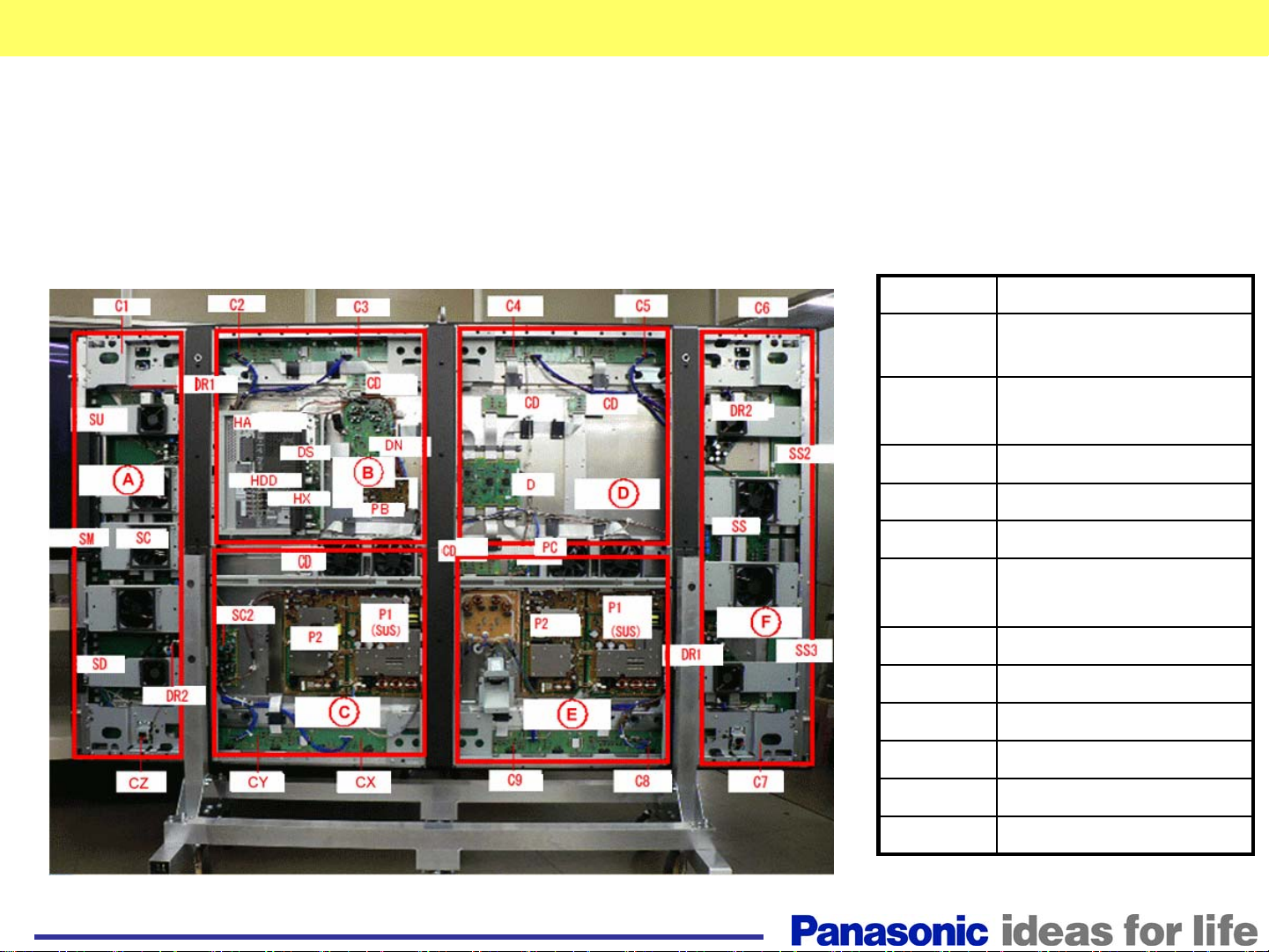

Board Description

Board Name Function Board Name Function

D Digital Signal Processor, Format Converter, Plasma

AI Processor Sub-Field Processor

DS Slot Interface (Audio / Video / Sync Input Switch),

SYNC Processor, Audio Processor, Speaker Out

Amplifier, DC-DC Converter

SS Sustain Drive V2 Key Scan

SC Scan Drive V3 Remote control Receiver

SC2 DC-DC Converter For Scan Drive PB Fan Control

SU Scan Out (Upper) P(SUS_1/2) Power Supply

SM Scan Out (Middl e) P(MULTI_1/2) Power Supply

SD Scan Out (Lower) F Line Filter

C1 Data Drive (1) PC Power Control

C2 Data Drive (2) HX PC / RS-232C

CX Data Drive (X)

CY Data Drive (Y)

CZ Data Drive (Z)

H5 Audio Out

S1 Power Switch

SS2 Sustain Out (Uppe r)

SS3 Sustain Out (Lower)

V1 LED_G, R

C3 Data Drive (3) HA BNC Component Video

C4 Data Drive (4) DN Digit al Signal Processor, Micon

C5 Data Drive (5) HDD DVI-D Terminal

C6 Data Drive (6) CD C Board / D Board Connection

C7 Data Drive (7) DR1 Energy Data Recovery

C8 Data Drive (8) DR2 Energy Data Recovery

C9 Data Drive (9)

9

Page 10

Troubleshooting Display Problem

Troubleshooting

Display Problem

10

Page 11

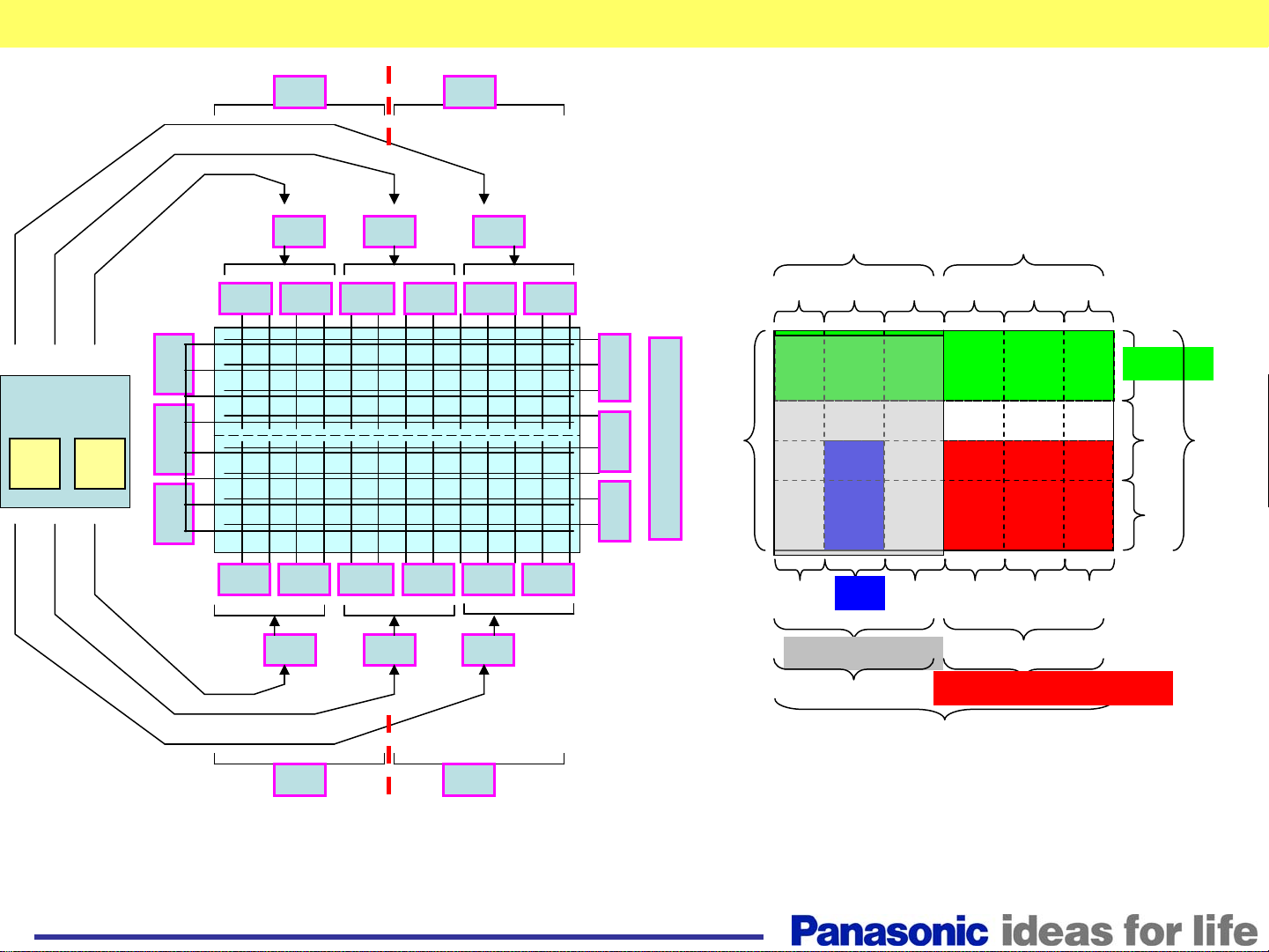

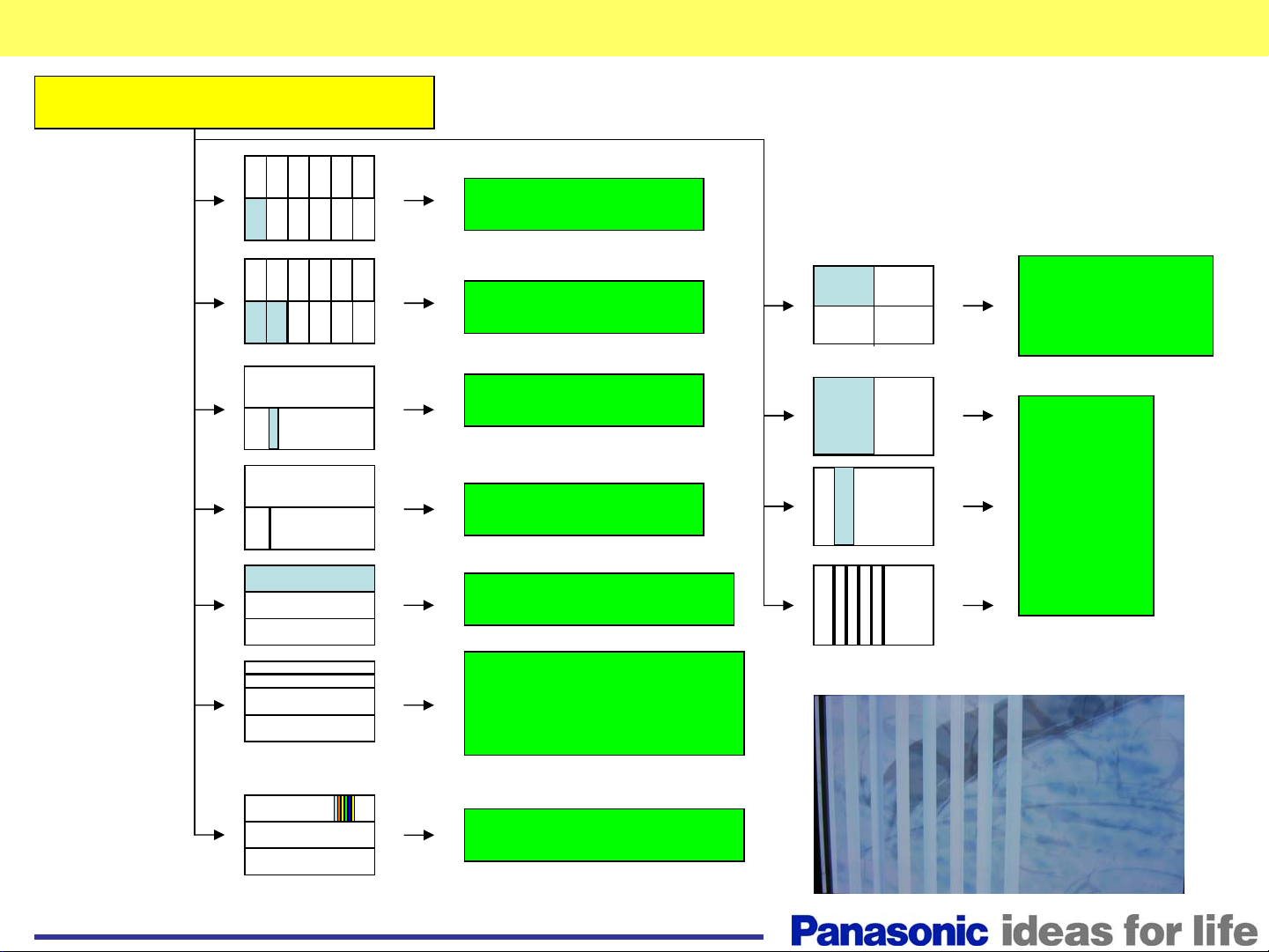

Relation of board and display area

DR2 DR1

Example of picture problems due to a defective board

D board

R L

SS2

SS

SS3

C6 C1C4

C7 CZC9 CYCXC8

CDCDCD

C2C3C5

SU

SM

SC

SS

(all)

SD

CDCDCD

DR1(1/4 of lower left) DR2(1/4 of lower right)

D( Left half)

D,DN, slot all

DR1(1/4 of upper Right)DR2(1/4 of upper Left)

C1C2C3C4C5C6

SU

SC

SM

(all)

SD

CZCYCXC9C8C7

D( Right Half )

DR1 DR2

11

Page 12

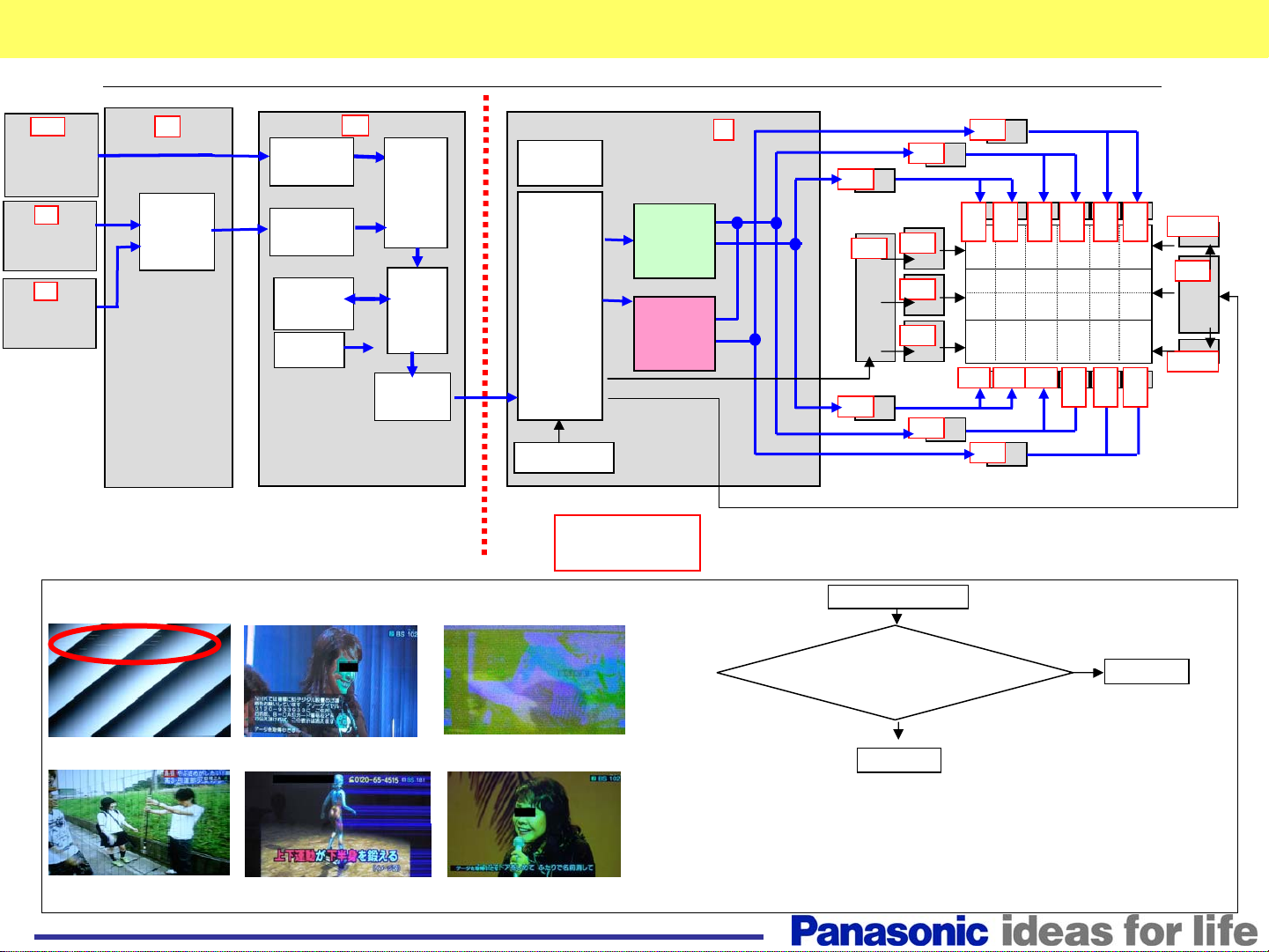

Picture Trouble(1)

■Picture trouble(Vertical line all area, horizontal line, Color problem, Others)

HDD

DVI Input

HA

Video Input

HX

PC Input

■Sample

DS

Video

Signal

SW

LVDS

Convert

A/D

Convert

Picture

Signal

Processing

Micro

Computer

DN

OSD

I-P

Convert

Resize

OSD

TEST

LVDS

Convert

Micro

Computer

Convert

LVDS

・

Discharge

Control

EEPROM

Panel block

D

Picture data

Sub Field

Data

(Left half)

Test Pattern

Sub Field

Data

(Right half)

Test Pattern

Discharge control(SCAN)

Discharge control(SUS)

Picture data

■Flowchart for vertical line problem

Picture data

Picture data

CD

SC

Picture data

CD

Picture data

Picture Trouble

CD

SU

SM

SD

CD

CD

C

1

CD

C

C

C

C

C

C

SS2

6

SS

SS3

7

2

3

4

5

C

C

CXCYCZ

8

9

Thin horizontal line

Thin vertical line

at all screen

Discolor picture (No green)

Horizontal line noise

at half side (right)

Noise picture

Discolor picture (No blue)

Enter the service

mode to display the test pattern. Are there

vertical or horizontal lines?

Yes

D board

Note: The white test pattern, that contains numbers, is generated by the DN board.

Press the OK button of the remote control to display subsequent patterns

generated by the D board.

If you cannot enter the test pattern, unplug the connector D5 of

the D board to obtain a white raster.

No

DN board

12

Page 13

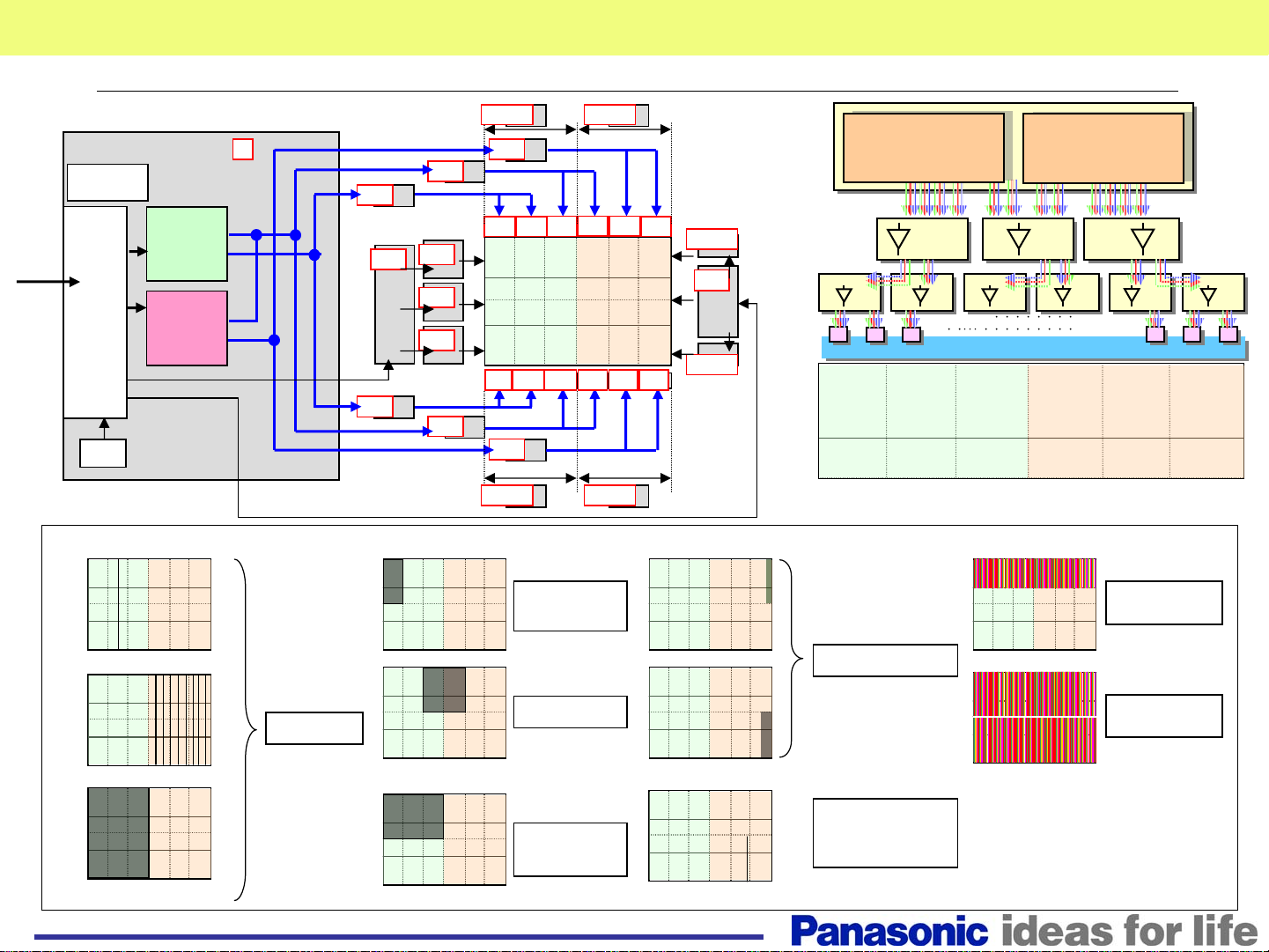

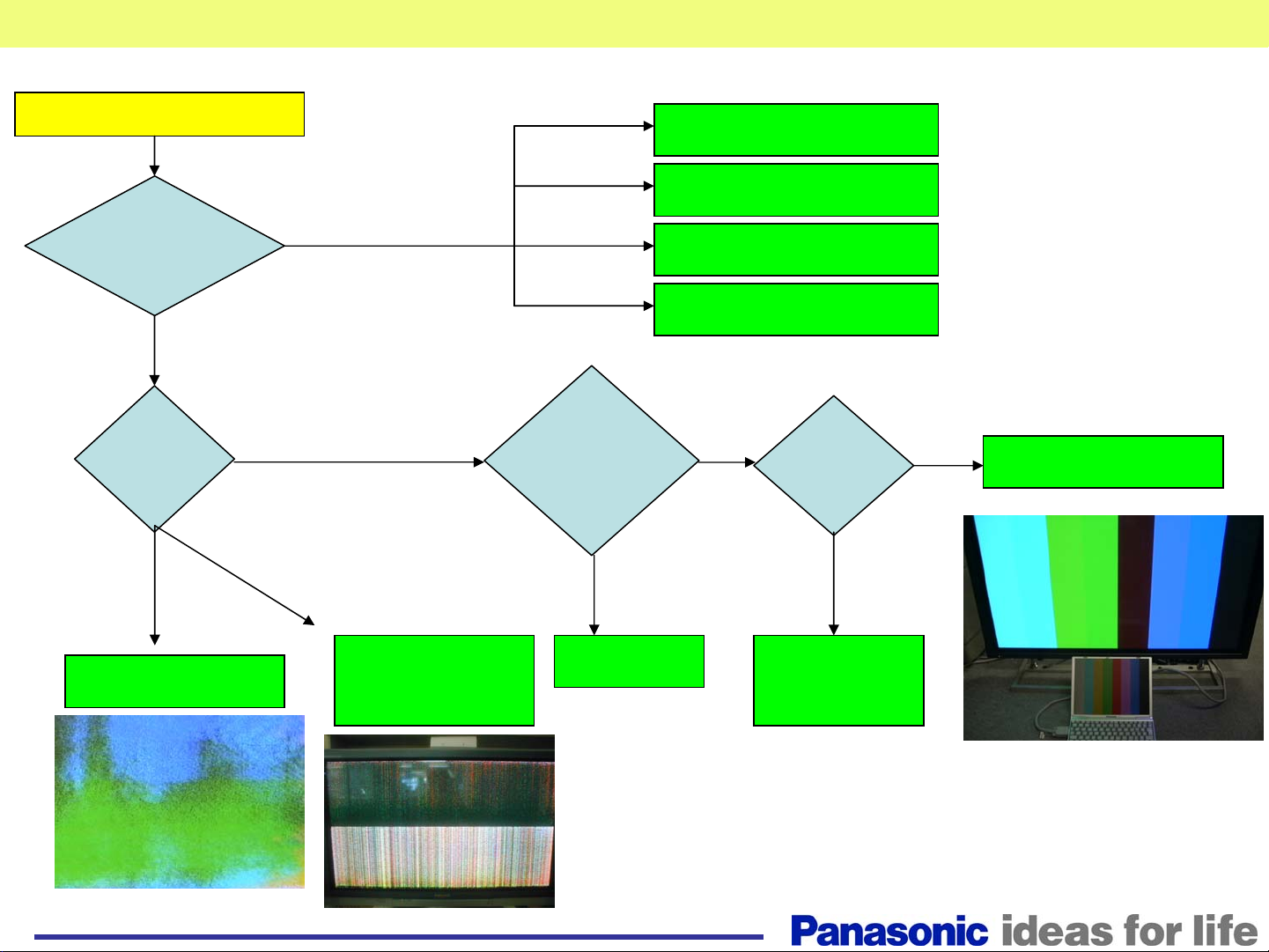

Picture Trouble(2)

■Picture trouble(Vertical line at part of screen, abnormal picture) Normal sound

Micro

Computer

Convert

Picture

LVDS

signal

Control

discharge

RROM

■Trouble sample

D

Picture data

Sub Field

Data

(Left half)

Test Pattern

Sub Field

Data

(Right half)

Test Pattern

Discharge control(SCAN)

Discharge control

(SUS)

Picture data

Picture data

Picture data

Picture data

CD

SC

Picture data

CD

CD

SU

SM

SD

CD

DR1 DR2

CD

C2

C3

C1

C4 C5

CD

DR2 DR1

C1-CZ

Module

C6

C7C8C9CXCYCZ

SS2

SS

SS3

Convert sub field

Convert sub field

Convert parallel serial

Convert parallel serial

Test pattern

Test pattern

CD CD CD

Buffer Buffer Buffer

C1 C2 C3 C4

180

Lines

Convert sub field

Convert sub field

Convert parallel serial

Convert parallel serial

Test pattern

Test pattern

C5

・・・・・・・・・・・・・

PANEL

PANEL

・・・・・・・・・・・・・・・・・・・

SU,SM,SD

Module

C6

DriverDriver

Driver

Through vertical thin line

D module

Interval vertical thin line at half of panel

Abnormal picture at half

1/4 abnormal

CD Module

DR1,2

Module

Vertical bar for 180 lines

Vertical bar for 360 lines

Thin vertical line

13

Plasma panel

D,SC

Module

Plasma panel

or

D module

Page 14

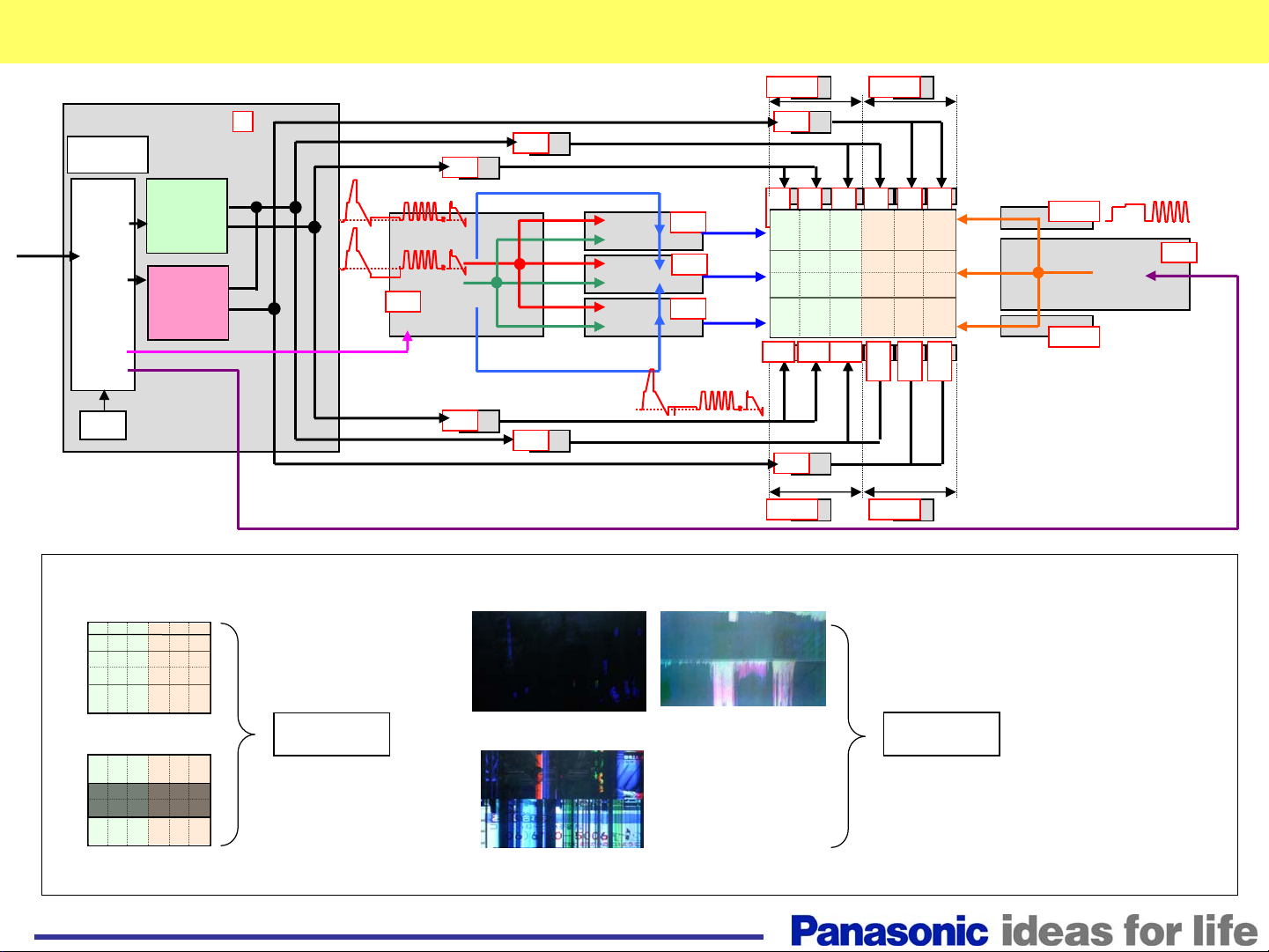

Picture Trouble(3)

Picture Data

Picture Data

Picture Data

V

F

VF0

SC

Scan control

Picture Data

Picture Data

Picture Data

Picture

signal

Micro

Computer

Convert

LVDS

Control

discharge

PROM

D

Sub Field

Data

(Left half)

Test Pattern

Sub Field

Data

(Right half)

Test Pattern

Discharge control

(SUS)

CD

CD

CD

SIU

SID

CD

VF

VF0

SU

SM

SD

San Drive

DR1 DR2

CD

C

C

C

C

C

1

2

3

4

C

C

CXCYCZ

9

CD

DR2 DR1

C

5

6

SS2

SUS DRV

SUS

DRV

SS

SS3

C

7

8

■Trouble sample

●Horizontal line at part of screen

Thin horizontal line

Horizontal bar same as board width.

SU,SM,SD

Module

●Abnormal Discharge

SC,D

Module

14

Page 15

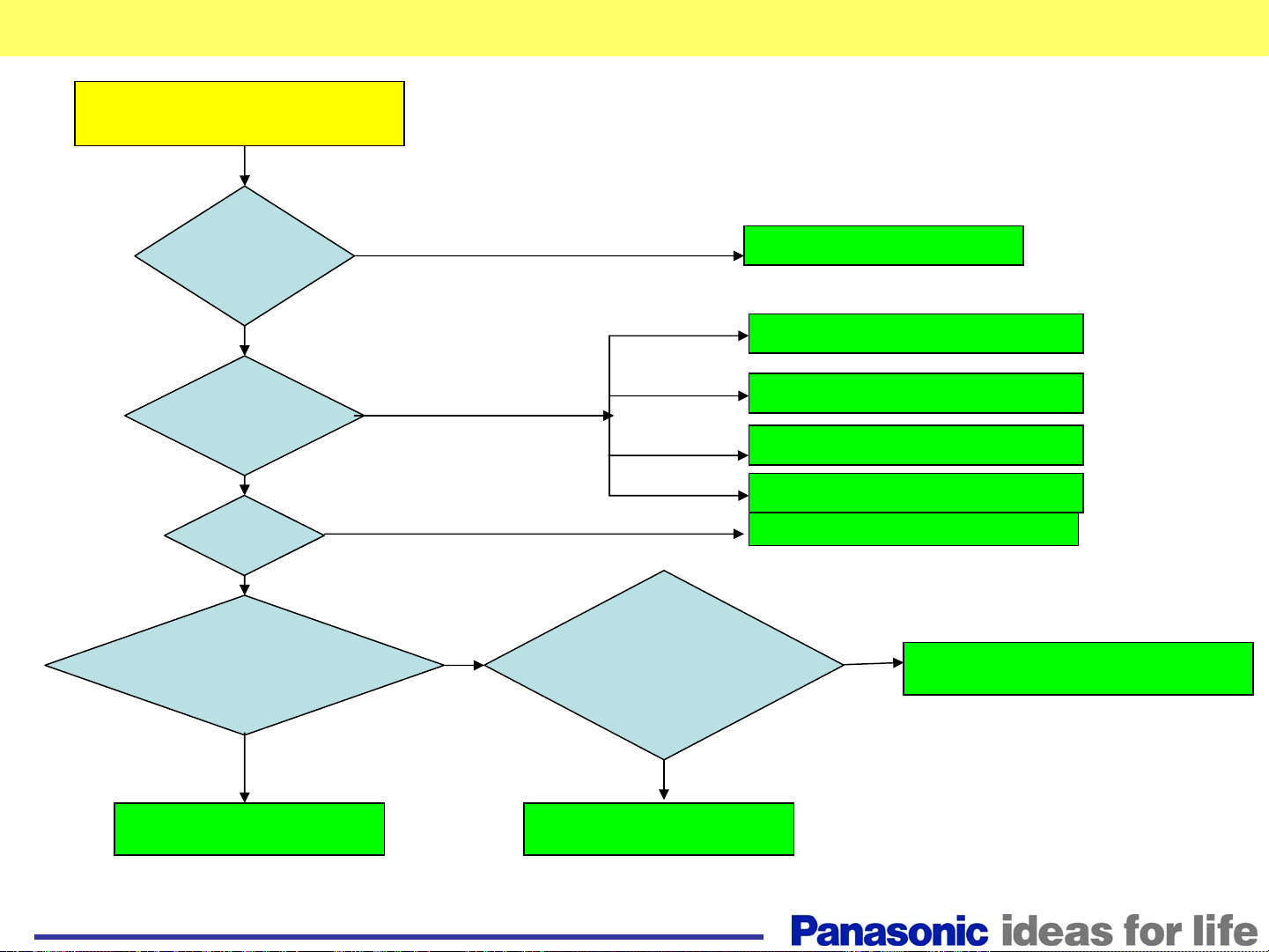

Summary of Picture Trouble and Defective Board

Diagnosis of board defect

C1-CZ board

DR1 Or

CD board

DR2 board

C/CD/D board

C/CD/D board

SU/SM/SD board

SU/SM/SD board

Or Panel

Colored vertical

bar

SU/SM/SD board

15

D board

Page 16

Picture Trouble all Area

Picture trouble

Do all the video

Inputs provide

the symptom?

All input

sources

What is the

symptom?

Abnormal

discharge

all area

all area

No

Group of vertical line

Video or PC

DVI

Video

PC

Do the

Internal Test

Patterns

provide the

same

symptom?

NG

DN or DS board

HDD board

HA board

HX board

OK

Is the OSD

visible on

screen?

NG

OK

DN board

SC/SS board

SU/SM/SD

board

D board

16

D or DN

board

Ex.RGB input(No red)

Page 17

Picture Trouble (3)

No picture, green power LED

is lit.

Did the power

relay click on?

No

Yes

Is there video

from any of

the inputs?

If there is no video from

No

Is there

O.S.D?

Yes

NG

Disconnect CN D5 and turn the

unit ON. Does a white pattern

appear on screen?

No picture

Replace the P or D board

Video or PC

Replace the DN or DS board

DVI

Replace the HDD board

Video

Replace the HA board

PC

Replace the HX board

Replace the DN board

Disconnect the SU,SM, and

SD boards one at a time from

the SC board. Does 2/3 of a

picture appear?

Yes

SU or SM or SD board

Yes

DN board

No

SC or SS or SD

17

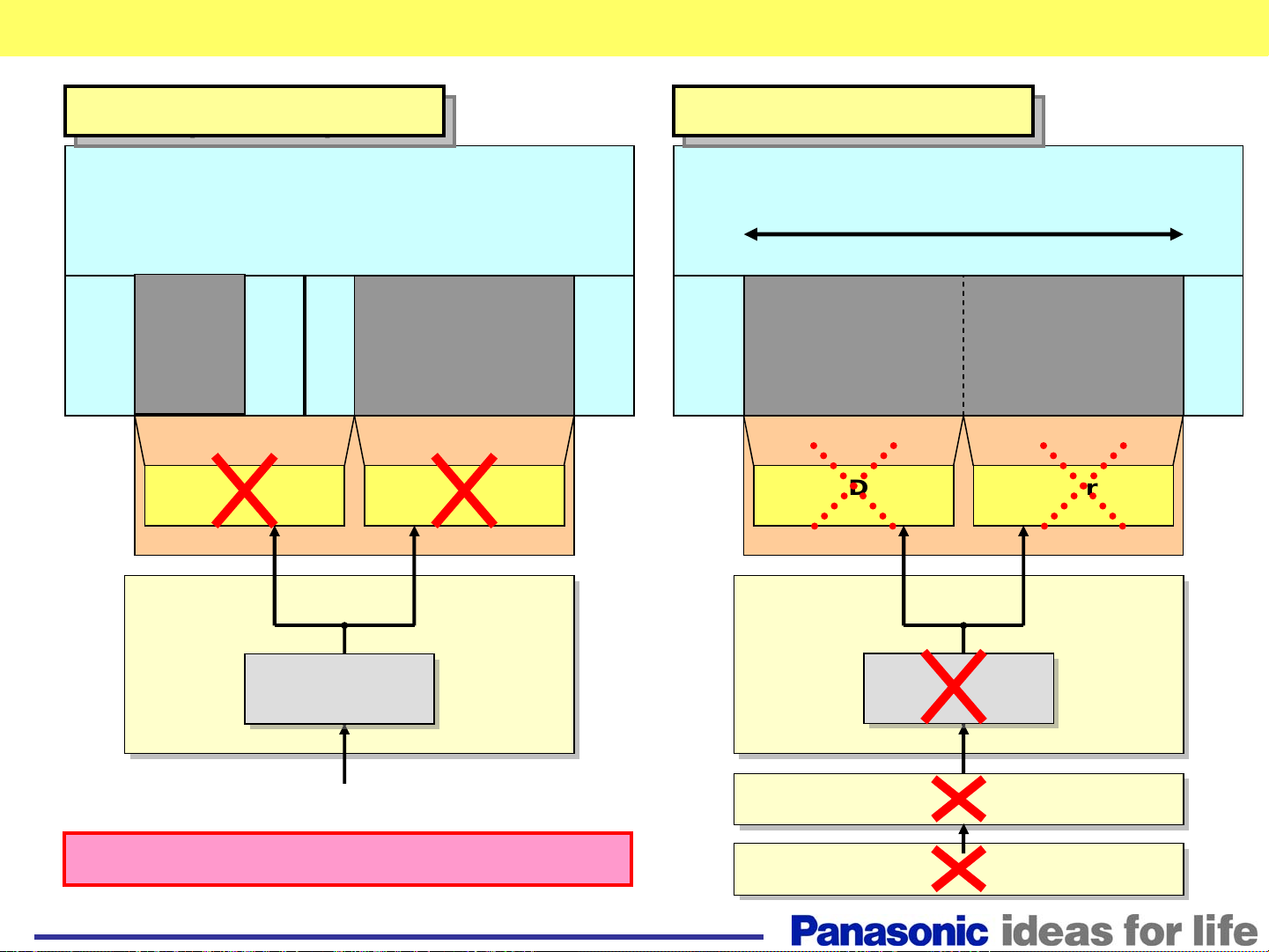

Page 18

Picture Trouble (Vertical line) (1)

Panel (IC driver) defect

Panel (IC driver) defect

PDP panel

Thin line

Abnormal

Data Driver

IC

Data Driver

Abnormal

IC

C or CD circuit defect

C or CD circuit defect

PDP panel

15cm approx.

Abnormal

Data Driver

IC

Data Driver

IC

Buffer IC

Buffer IC

(RGB)

(RGB)

Data driver IC defect = PDP panel defect

18

C boardC board

CD board

D board

Buffer IC

Buffer IC

(RGB)

(RGB)

Page 19

Troubleshooting for No Power

Troubleshooting for No

Power

19

Page 20

Dead - Power LED does not Light (1/2)

Power LED Status

OFF

AC Power Cord or P Board

Defective Block

How to find the defective board

D1603

D1604

D1703

D501

D1603

D1604

D1703

D501

AC

P(SS)

F

1

1

3

F

F904

F901

F903

F900

P

F

8

1

4

F

9

1

4

9

1

3

P

9

1

3

FUSE FUSE

P(SC)

Are fuses F900 and F901

on the F Board open?

S

Tr

MPU

Power

SW

No

STB5V

STB5V

Power Supply / Protect Circuit

PC

P

PC

25

202

10

10

P

PC

25

203

10

10

PC

201

10

D

D

25

IC9011

STB3.3V

Are fuses F903 and F904

D

DN

3

1210 12

DN

2

IC4308

STB3.3V

DN3DS

18 18

30 30

MPUMPU

No

on the F Board open?

DS

3

20

Yes (P(SC) NG)

Are diodes D1603 or

D1604 on the P(SC) Board

ok?

Yes

Are diodes D1703 or

D501 on the P(SC) Board

ok?

Yes

Fuses in P(SC) Board

No

P(SUS)

Board

No

P(MULTI)

Board

Continued on page 2/2

Yes (P(SS) NG)

Are diodes D1603

or D1604 on the P(SS) Board

ok?

Yes

Are diodes D1703

or D501 on the P(SS) Board

ok?

Yes

Fuses in P(SS) Board

No

No

P(SUS)

Board

P(MULTI)

Board

Page 21

Dead - Power LED does not Light (2/2)

Power LED Status

OFF

F904

F901

Yes

Yes

Is there

SW on?

F

F903

F900

F

1

AC

1

3

Continued from page 1/2

Is there STB 5V

output at pin 10 of CN P25 on the

P(SS) Board after turning the

power SW on?

Is there

STB 5V output

at pin 10 of PC201

after turning the

power SW

on?

STB 5V output at pin 12 of

CN D3 after turning the power

Defective Block

AC Power Cord or P Board

D1603

D1604

D1703

FUSE FUSE

D1603

D1604

D1703

No

and GND.

No

D501

D501

S

P(SS) Board

Yes

D Board

No

F

8

1

4

F

9

1

4

Yes

P(SS)

P

9

1

3

P(SC)

P

9

1

3

Remove AC power.

Disconnect CN P25.

Is there a short

at pin 10 of socket P25

P(SS) Board

DN Board

Tr

MPU

Power

SW

No

STB5V

STB5V

How to find the defective board

Power Supply / Protect Circuit

PC

P

PC

25

202

10

10

P

PC

25

203

10

10

Disconnect

CN PC201.

Is there a

Short at pin 10 of

Socket PC201 and

GND?

Yes

PC Board

short at pin 18 of

21

D

PC

25

201

10

No

Is there a

socket DS3 and

GND?

Yes

DS Board

D

IC9011

STB3.3V

Disconnect

CN D3.

Is there a

short at pin 12 of

socket D3 and

GND?

Yes

D Board

No

DN

D

DN

3

2

1210 12

No

Disconnect

CN DS3.

P(SC) Board

DN3DS

18 18

IC4308

STB3.3V

30 30

MPUMPU

Disconnect

CN DN3.

Is there

a short at pin 18 of

socket DN3 and

GND?

Yes (DN short)

DN Board

DS

3

No

Page 22

Power LED’s Response to Shutdown Operation

Shutdown (SOS)

Troubleshooting

22

Page 23

Protection Circuit23LED blinks 1 time

LED blinking

LED

Blinking time

2

3

4

5

6

7

8

9

10

11

13

15

SOS item

Micro computer error1

15V SOS

3.3V SOS

P board SOS

(Vsus, Vda )

5V SOS

SC board Power SOS

SC board floating output SOS

Data signal power collect SOS

SS board power collect SOS

ROM access error

DS board, Slot power SOS

FAN SOS

DN board power SOS

(3.3V, 2.5V, 1.8V, 1.5V)

Model code error

D board CPU

IC9003’s Pin No.

No.5 L:SOS

No.71 L:SOS

No.70 L:SOS

No.74 H:SOS

No.69 L:SOS

No.72 H:SOS

No.76 H:SOS

No.73 H:SOS

EEPROM data

DN board CPU

IC4701’s Pin No.

No.165 L:SOS

No.134 L:SOS

No.132 L:SOS

IC3004 contact

No.130 H:SOS

No.139 L:SOS

EEPROM data

Defective board mainly

D, DN

P(Multi/SS), D, DN,SS,PB,DR1/2

D

P(SUS/SC),P(Multi/SC),

P(SUS/SS),P(Multi/SS)

P(Multi/SC),P(Multi/SS),

D, DN,C1-CZ, SC, SS, DR1/2

SC, SC2, SU, SM, SD D,

P(SUS/SC),P(Multi/SC)

DR1/2,D, P(SUS/SC),P(Multi/SC),

P(SUS/SS),P(Multi/SS), C1-CZ

SS, D, P(SUS/SC),P(Multi/SS)

D

SLOT1, SLOT2, SLOT3, DS

FAN ,PB

DN ,P(SUS/Multi)

DN

RED LED

Blinking

Blinking

No light

Blinking times

1.0s

3.0s

Page 24

Trouble Mode

Defective Board

Warning: Disconnect AC Power prior t o

making any disconnection or connection

Communication Error

Replace the D

board

No

DN, D

Unplug the TV and disconnect

connector DN2 on the DN Board or D3

of the D board . Plug in the TV.

Did the TV turn on by

itself with the following

conditions?

Power LED = Off

SC LED= On

SS LED = ON

Yes

Replace the DN

board

24

Page 25

Panel SOS – Power LED Blinks 2 Times (SS Side)

Trouble Mode Defective Board

15V line SOS P(Multi/SS), D, DN,SS,PB,DR1/2 Board

Power Supply / Protect Circuit

PC

202

1

2

PB31

1

PC

DR

11

SS

35

SS

12

SS

42

DR

PC

201

1

1

2

15V

D

D25

1

2

PB

DR2

SS

DR1

15V

DC

CONV.

Q9051

Q9050

DN

IC4701

P(Multi/SS)

15V

15V

15V

P25

1

2

P5

1

P12

4

D3

DN

71

2

166

IC9003

15V SOS

67

PANEL_SOS

8

15

8

15

15V

DC

CONV.

Disconnect the unit

from AC Power

Disconnect CN P25.

Is pin 1 of

Socket P25 shorted

to GND?

Disconnect CN P12

Is pin 4 of

socket P12 shorted

to GND?

Yes

Disconnect CN P5

Yes

SS Side Troubleshooting

How to find the defective board

Disconnect CN D25. Disconnect CN DN2.

Yes

GND?

No

Yes

Is pin 15 of

socket DN2 shorted

to GND?

Yes

DN Board

No

D Board

No

DR2 Board

No

No)

Is pin 1 of

socket D25 shorted

to GND?

Yes

Disconnect CN DN2

Is pin 15 of

socket DN2 shorted

to GND?

DN Board

Disconnect CN SS35

Is Test Point TP15V

on the SS board shorted to

Disconnect CN SS42

No

P(SS)

Board

Note: The check position is the connector on the board ,

not cable's connector.

25

Is pin 1 of

socket P5 shorted to

GND?

Yes

P(SS) Board

No

PB

Board

Is Test Point TP15V

on the SS board shorted

to GND?

Yes

SS Board

No

DR1 Board

Page 26

Panel SOS – Power LED Blinks 2 Times (SC Side)

Trouble Mode Defective Board

15V line SOS P(Multi/SS), D, DN,SS,PB,DR1/2 Board

Power Supply / Protect Circuit

How to find the defective board

Disconnect the unit

from AC Power.

Disconnect CN P23,

P5, and P12.

Is pin 1 of

socket P23 shorted to

GND?

No

Disconnect CN SC23 and SC80.

Is pin 1 of

socket SC23 shorted to

GND?

No

Disconnect CN DS4

Yes

Yes

P(SC)

Board

SC Board

SC Side Troubleshooting

Disconnect

CN DR11. Is pin 6 of

socket DR11

shorted to

GND?

No

SC2 Board

Yes

DR2 Board

Note: The check point is the socket on the board ,

not the cable's connector.

Is pin 1 of

socket DS4 shorted

to GND?

No

Disconnect CN DR1

Is pin 6 of

socket DR1 shorted

to GND?

No

26

Yes

DS Board

Yes

DR1 Board

Yes

Page 27

Panel SOS – Power LED Blinks 3 Times

Trouble Mode Defective Board

3.3V line SOS D Board

How to find the defective board

The defective board is D ONLY.

Power Supply / Protect Circuit

P(Multi/SS)

+15V

P25

1

2

PC

202

1

2

PC

PC

201

1

2

D25

1

2

D

IC9807, Q9803

15V->3.3V

DN

+3.3V

IC4701

IC9003

70

3.3V SOS

D3

DN2

67

PANEL_SOS

8

8

166

27

Page 28

Panel SOS - Power LED Blinks 4 Times

Trouble Mode

Power Supply SOS

P(SUS/SC),P(Multi/SC) ,P(SUS/SS),P(Multi/SS) Board

Power Supply / Protect Circuit

SC82

1

SC

VSUS

SC2

Power

SW

S

P(SUS/SC)

P(Multi/SC)

Vsus

Vda

PS SOS

Vda SOS

PS SOS

Vda SOS

P(SUS/SS)

P(Multi/SS)

Vda

Vsus

S

34

P2

1

P11

1

P12

1 2

P25

16

20

P25

16

20

P12

1 2

P2

1

1

SC

12

SC34

PC

203

16

20

PC

202

16

20

VSUS

Vda

PC

Vda

SC2

PC

201

16

20

PC

201

16

20

SS2

SS

12

Defective Board

Is the green

SC

13

SC

14

PC

25

16

20

DR1 & DR2

boards

Left Side

D

DN

D3

DN2

74

PS SOS

68

67

PANEL_SOS

8

8

166

IC4701

IC9003

VDA_DET

Disconnect CN P12 of P(SC)

board and SC34 of the SC2

board. Insert the SC34 connector

into pins 8, 9, and 10 of socket P12.

LED on the SC

Board lit?

Yes

Is the green

LED on the SS

Board lit?

Yes

Turn the Power SW ON.

Yes (Vda NG)

Is there Vda

Voltage at pin 1 of CN P12 of

Vda

SS

1

Vda

VSUS

SS

35

SS

42

DR1 & DR2

boards

Right Side

the P(SC) Board before

shutdown?

Yes

P(Multi/SS) Board

No

P(SUS/SC)

P(Multi/SC)

Board

No

P(SUS/SS)

P(Multi/SS)

Board

No

P(Multi/SC)

Board

28

Page 29

Panel SOS – Power LED Blinks 5 Times (1/6)

Trouble Mode

5.0V line SOS

P(SS)

+5V

P(SC)

+5V

Defective Board

P(Multi/SC),P(Multi/SS),D, DN,C1-CZ,

SC, SS, DR1/2 Board, Panel(IC)

C

21

CY

1

PC

205

PC

201

7

9

C2

C

22

CY

1

2

C

23

CY

3

2

D25

SC

20

5V

DR2

DR1

DR2

DR12

P25

P25

SC

C1

C

11

CA1 CA2 CA3 CA4 CA5 CA6 CA7 CA8 CA9

5V

CB1 CB2 CB3 CB4 CB5 CB6 CB7 CB8 CB9 C 10BC 11BC 12BC 13BC 1

CZ

1

PC

204

1

2

PC

202

7

9

7

9

7

9

PC

203

7

9

PC

How to find the defective board

Power Supply / Protect Circuit

41

91

C4

C

C

40

43

C

C

C

C

92

C

42

10

A

C 11AC 12AC 13AC 14AC 15AC 16

C

93

C

90

P5V

Q9053

IC4701

C3

C

32

CX

2

CXCYCZ

D

7

9

DN

C

31

Panel

CX

1

C9

C

53

C

83

C

80

D35D32 D34D20

C5

C

52

C82C

C8

Q9054

D3

DN

C

51

B

C

81

88

2

C

61

4

C 15BC 16

71

69

67

8

8

166

C6

C

C7

IC9003

P5V SOS

5V

30

30

A

B

PANEL_SOS

5V

DR12

DR2

SS

DR1

SS

44

DR2

5V

29

Page 30

Panel SOS – Power LED Blinks 5 Times (2/6)

Trouble Mode

5.0V line SOS

Power Supply / Protect Circuit

Turn on the power SW. Turn on the power SW.

output at pin 7 of CN PC203

before shutdown ?

Defective Board

P(Multi/SC),P(Multi/SS),D, DN,C1-CZ,

SC, SS, DR1/2 Board, Panel(IC)

5 times

blink

Is there 5V

7 times

blink

7 times

Diag.

Yes

Is there 5V

output at pin 7 of CN PC202

before shutdown?

■D,P,DN,SC,SS Diag.

Disconnect CN D20 and C88.

Turn on the power SW.

Yes

(SC, SS NG)

Does the unit

power up?

No

(D or P or C, or Panel NG)

Disconnect CN D20, D31~D36.

Disconnect PC204 and PC205.

Turn on the power SW.

Yes

(C, or DR, or Panel NG)

Does the unit

power up?

No

Disconnect AC from the unit.

Disconnect CN D3 or CN DN2.

Yes

Is pin 30 of CN DN2

shorted to GND

How to find the defective board

Connect CN D20. Turn on

the power SW.

No

SC Board

Power SW

OFF

Yes

Does the unit

power up?

Yes

SS Board

Perform C, DR, Panel

Diagnostic as shown on page 3/6.

DN Board

No

Turn on the power SW.

Is there 5V

output at pin 7 of CN PC202

before shutdown?

No

D (or PC)

Board

Yes

P(SC)

Board

No

P(SS) Board

No

D Board

30

Page 31

Panel SOS – Power LED Blinks 5 Times (3/6)

■C, CR, Panel Diag.

Disconnect

CN C43.

Is pin 1 of

socket C43 Shorted to

GND?

Yes (C1~C6,DR,Panel NG)

Disconnect

CN C52.

Is pin 1 of

socket C43 shorted to

GND?

Yes (C1~C6,DR,Panel NG)

Disconnect

CN C42 or C53.

Is pin 1 of

socket C43 shorted to

GND?

Yes (C1~C6, Panel NG)

Disconnect

CN C22.

No (C7~CZ, DR, Panel NG)

No

No

DR2(SS side)

Board

DR1(SC side)

Board

Disconnect

CN C51 or C61.

Is pin 1 of

socket C52 shorted to

GND?

Yes

No

How to find the defective board

Connect CN C51 and C61.

Disconnect CN CA15 and CA16.

Is pin 1 of

CN C52 shorted to

GND?

Yes

C6 Board

Disconnect

CN CA12~CA14. Is pin 1 of

socket C52 shorted to

GND?

No

Panel

No

Panel

Is pin 1 of

socket C43 shorted to

GND?

Yes

(C1~C4, Panel NG)

Continued on page 4/6

(C5~ C6,

No

Panel, NG)

Yes

C5 Board

Continued on

page 5/6

31

Page 32

Panel SOS – Power LED Blinks 5 Times (4/6)

■C, CR, Panel Diag.

From page 3/6

Disconnect

CN C23 or C32.

Is pin 1 of

socket C43 shorted to

GND?

Disconnect

CN C31 or C41.

Is pin 1 of

socket C43 shorted to

GND?

Disconnect

CN CA9~CA11.

Yes

(C3~C4,

Panel NG)

Yes

No

Disconnect

CN C11 or C21.

Is pin 1 of

socket C22 shorted to

GND?

Yes

Connect CN C31 and C41.

Disconnect CN CA6~CA8.

Is pin 1 of

socket C43 shorted to

GND?

Yes

C3 Board

No

No

How to find the defective board

Connect CN C11 and C21.

Disconnect CN CA1 and CA2.

Is pin 1 of

socket C22 shorted to

GND?

Yes

C1 Board

Disconnect

CN CA3~CA5.

Is pin 1

of socket C22 shorted

to GND?

Yes

C2 Board

Panel

No

Panel

No

Panel

Is pin 1 of

socket C43 shorted to

GND?

Yes

C4 Board

No

Panel

32

Page 33

Panel SOS – Power LED Blinks 5 Times (5/6)

■C,CR,Panel Diag.

How to find the defective board

From page 3/6

Disconnect CN C92.

Is pin 1 of

socket C92 shorted to

GND?

Yes (C7~CZ,DR,Panel NG)

Disconnect CN C82.

Is pin 1 of

socket C92 shorted to

GND?

Yes (C7~CZ,DR,Panel NG)

Disconnect CN CY2.

Is pin 1 of

socket C92 shorted to

GND?

Yes (C1~C6, Panel NG)

Disconnect CN C93 or 83.

Is pin 1 of

socket C92 shorted to

GND?

Yes

(C9~CZ,

Panel NG)

No

No

No

No

(C7~C8,

Panel NG)

Check Connection

PC204- CN C43,

PC205- CN C92.

DR1(SS side)

Board

DR2(SC side)

Board

Disconnect CN C81 or 71.

Is pin 1 of

socket C82 shorted to

GND?

Yes

No

Connect CN C81 and C71.

Disconnect CN CB15 and CB16.

Is pin 1 of

socket C82 shorted to

GND?

Yes

C7 Board

Disconnect

CN CB12~CB14.

Is pin 1 of

socket C82 shorted to

GND?

Yes

C8 Board

No

No

Panel

Panel

Go to page 6/6

33

Page 34

Panel SOS – Power LED Blinks 5 Times (6/6)

■C,CR,Panel Diag.

How to find the defective board

From page 5/6

Disconnect CN CY3 or CX2.

Is pin 1 of

socket C92 shorted to

GND?

Yes

(C9~CX,Panel NG)

Disconnect CN C91 or CX1.

Is pin 1 of

socket C92 shorted to

GND?

Yes

Disconnect CN CB9~CX1.

No

(CY~CZ, Panel NG)

No

Disconnect CN CY1 or CZ1.

Is pin 1 of

socket CY2 shorted to

GND?

Yes

Connect CN C91 or CX1.

Disconnect CB6~CB8.

Is pin 1 of

socket C92 shorted to

GND?

Yes

CX Board

No

No

Panel

Connect CN CY1 and CZ1.

Disconnect CN CB1 and CB2.

Is pin 1 of

socket CY2 shorted to

GND?

Yes

CZ Board

Disconnect

CN CB3~CB5. Is pin 1 of

socket CY2 shorted to

GND?

Yes

CY Board

No

Panel

No

Panel

Is pin 1 of

socket C92 shorted to

GND?

Yes

C9 Board

No

Panel

34

Page 35

Panel SOS – Power LED Blinks 6 Times (1/2)

Trouble Mode

SCAN Driver SOS

Power Supply / Protect Circuit

P(SC)

Vsus

15V

Vsus

15V

+5V

P(SS)

+5V

1

P25

P25

P2

1

P23

P11

1

P12

4

7

16

9

7

9

2

SC34

S34

Power

SW

SC2

REG.

REG.

REG.

REG.

REG.

REG.

PC

201

7

9

D25

PC

203

PC

202

SC82

1

SC12

4

S

PC

7

9

7

9

Defective Board

SC, SC2, SU, SM, SD D,

P(SUS/SC),P(Multi/SC) Board

2

2

2

6

12

4

9

SC

TPVSUS

VBK

P5V

PULSE

SC

SOS

D

15V

VSET

15V

16V_F2

16V_F

VSCN

VAD

BUFFER

72

D3

DN2

11

13

17

21

7

9

SC84

1

4 8

SC83

1

5

D20

12

14

18

22

2

2

6

P5V

SC23

1

SC81

1

4 8

SC80

1

5

11

13

17

21

SC20

2

6

12

17

SC2

1

14

18

22

1

13

20

11

SC

PULSE

DN

IC4701

Energy Recovery

Circuit

D6583

LED(G)

SC SOS

SC SOS

67

8

8

166

5V(SC3)

REG.

5V(SC1)

REG.

IC9003

MPU

PANEL_SOS

FET

FET

DRIVER

IC6581

1/2Vo SOS

IC6353

VBK SOS

IC6861

VSCN SOS

IC6871

VAD/16V SOS

Q6824

VSET SOS

5V(SC1) SOS

5V(SC3) SOS

Vfo

Vf

SC49SU

SC41SU

SC42SU

SC50SM

SC43SM

SC46SM

SC51SM

SC52SD

SC47SD

SC48SD

49

41

42

50

43

46

51

52

47

48

5V

SC PULSE(SU)

5V

Vf

VSCN

Vf, Vfo

5V

SC PULSE(SM)

VSCN

Vf, Vfo

VSCN

Vf, Vfo

5V

SC PULSE(SM)

5V

SC PULSE(SD)

5V

Vf

VSCN

Vf, Vfo

Energy Recovery DET condition

・

NO VSUS

・

NO SCAN PULSE(SC20 17-20pin)

・

NO P5V(SC20 1pin)

Floating Voltage DET condition

・

NO 15V

・

NO SCAN PULSE(SC20 4-6pin)

・

NO P5V(SC20 1pin)

SU

SM

SD

35

Page 36

Panel SOS - Power LED Blinks 6 Times (2/2)

Trouble Mode

SCAN Driver SOS

SC, SC2, SU, SM, SD D,

P(SUS/SC),P(Multi/SC) Board

Power Supply / Protect Circuit

Disconnect CN SC2, SC23, SC81, and

SC80 of the SC Board. Turn the unit on.

Does it

power up?

Connect CN SC2, SC23, SC81,

and SC80. Turn the unit on.

Does the SC board LED

light before shutdown ?

Disconnect the SM, SU, and SD boards

from the SC board. Turn the unit on.

Connect the SU board to the SC board. Disconnect the

SD and SM boards from the SC board. Turn the unit on.

Does it power up?

Connect the SD board to the SC board. Disconnect the

SU and SM boards from the SC board. Turn the unit on.

Does it power up?

No

Yes

No

Yes (SC Floating Volt NG)

Does it power up?

Yes (SU,SM,SD NG)

Yes (SM,SD NG)

Yes (SM NG)

Defective Board

4 times blink

7 or 8 times blink

SC (or D) Board

=SC, SU, SM, SD, SC2, D

No

No

SU Board

SD Board

No

D Board

How to find the

defective board

Disconnect CN P11, P12. Place a

jumper across pins 8 and 10 of CN P12.

Turn the unit on.

Is there VSUS

voltage at pin 1 of CN P2

and 15V at pin 1 of CN P23

before shutdown?

Yes

SC2 Board

No

(VBK,VSCN,VAD,16V,

VSET,SC PULSE NG)

Disconnect CN SC84 and SC83.

Turn the unit on.

Are the following

voltages present before shutdown?

TPVSCN, TPVAD, TPVSET,

TPF16V, TPF16V2, and TPVBK

on the SC2 Board (*)

Yes (SC PULSE NG)

SC (or D) Board

No

P(SC) Board

=SC, SC2, D

No

SC2 Board

* SC Floating Volt. SOS

SM Board

36

Page 37

Panel SOS – Power LED Blinks 7 Times (1/5)

Trouble Mode

DATA Driver SOS

DR2

DATA

PULSE

5V, SOS

DR1

SC

12

DR2

DATA

PULSE

5V, SOS

DR12

SC2

Vda

15V

Vda

15V

Vda

15V

DR13

DR3

Vda

Vda

Defective Board

DR1/2,D, P(SUS/SC),P(Multi/SC),

P(SUS/SS),P(Multi/SS), C1-CZ Board

Power Supply / Protect Circuit

C

24

C

21

CY

CY4

C2

C22C

20

C

23

CY2

CY

3

CY0

1

DR

DR

DR

SC

13

SC

14

DR

11

DR

15

DR

14

C1

C14

CZ4

11

CZ

C

1

4

5

1

CA1 CA2 CA3 CA4 CA5 CA6 CA7 CA8 CA9 C 10AC 11AC 12AC 13AC 14AC 15AC 16

CB1 CA2 CB3 CB4 CB5 CB6 CB7 CB8 CB9 C 10BC 11BC 12BC 13BC 14

C

32

CX

How to find the defective board

■DR1/2 P(SC/SS),D Diag.

5V

SOS

41

91

5V

C4

C44

C40

C

C

C90

C94

C9

42

C

93

C

C5 C6

C52C

C

50

C

53

C

83

C82

C84

C8

54

51

C

B

C

81

C64

C

61

A

C 15BC 1

C

71

C74

C7

DR13 DR12

DR

14

Vda

DR

15

DR

Vda

11

15V

SS

35

SS

42

DR

Vda

1

B

6

DR

5

DR

4

15V

Vda

DR3

DATA

PULSE

5V,SOS

SS

Vda

15V

DATA

PULSE

5V, SOS

DR2

DR1

DR2

SS

12

C3

SOS

C34

C

31

Panel

CX4

CX

1

2

CXCYCZ

P(SC)

Vda

15V

+5V

P(SS)

+5V

Vda

15V

1

1

P12

4

P25

P25

P12

4

PC

2

PC203

7

9

7

9

2

7

9

PC202

7

9

PC201

7

9

D25

7

9

D31D32 D33

DATA ENERGY

RECOVERY PULSE

P5V

D

DN

D36

D3

DN2

IC4701

D35

8

8

166

PANEL_SOS

DATA

76

ENERGY

RECOVERY

67

SOS

PANEL_SOS

IC9003

Data Energy Recovery DET condition

・

NO VDA, 15V

・

NO DATA回収PULSE(DR2/12 3~6pin)

・

NO P5V(DR2/12 1,2pin)

37

Page 38

Panel SOS – Power LED Blinks 7 Times (2/5)

Trouble Mode

DATA Driver SOS

SOS

C3

5V

C40

C

41

CA9 C 10AC 11AC 12AC 13AC 14AC 15AC 16

Defective Board

DR1/2,D, P(SUS/SC),P(Multi/SC),

P(SUS/SS),P(Multi/SS), C1-CZ Board

C4

C44

C

42

C5

C50 C52 C54

C

53

Panel

Upper Right Quadrant

Rear View

C

51

61

How to find the defective board

Power Supply / Protect Circuit

C6

C64

C

A

DR

DR

DR

SS

35

SS

42

DR

DR13 DR12

14

15

11

1

Vda

15V

Vda

DATA

PULSE

5V,SOS

Vda

15V

DR2

SS

DR2

SS

12

Large view

of VDA

distribution to

the Upper

Right quadrant

of the panel

P(SC)

Vda

15V

+5V

P(SS)

+5V

Vda

15V

1

P12

4

P25

7

9

P25

P12

1

D31D32 D33

DATA ENERGY

2

7

9

2

4

PC203

7

9

PC202

7

9

PC

PC201

7

9

D25

7

9

RECOVERY PULSE

P5V

DN

D36

PANEL_SOS

D

D3

DN2

IC4701

D35

8

8

166

PANEL_SOS

76

67

IC9003

DATA

ENERGY

RECOVERY

SOS

38

Page 39

Panel SOS – Power LED Blinks 7 Times (3/5)

Trouble Mode

DATA Driver SOS

■DR1/2 P(SC/SS),D Diag.

Disconnect CN DR12 of the DR2

Board (SS side). Turn the unit on.

Does it power up?

No

Disconnect CN DR2 of the DR1

Board (SS side). Turn the unit on.

Does it power up?

No

Disconnect CN DR2 of the DR1

Board (SC side). Turn the unit on.

Does it power up?

No

Disconnect CN DR12 of the DR2

Board (SC side). Turn the unit on.

Does it Power up?

No

D Board (*)

P(SUS/SS),P(Multi/SS), C1-CZ Board

Yes

Yes Are there Vda

Defective Board

DR1/2,D, P(SUS/SC),P(Multi/SC),

Connect CN DR12. Disconnect

CN DR13~DR15 of the DR2 Board.

Turn the unit on.

Does it power up?

No

Disconnect CN SS35 and SS42.

Turn the unit on.

output at pin 1 of CN P12 and

15V output at pin 4 of CN P12

before shutdown ?

No

Yes

Yes

P(SS) Board

Connect CN DR2. Disconnect CN DR3~DR5

of the DR1 Board. Turn the unit on.

Connect CN DR2. Disconnect CN DR13~DR15

of the DR2 Board. Turn the unit on.

How to find the defective board

DR2 Board

Yes

Does it power up?

No

Does it power up?

DR2 Board

Yes

(C4~C6,Panel)

Connect CN DR2. Disconnect

CN DR3~DR5 of the DR1 Board.

Turn the unit on.

Does it power up?

No

DR1 Board

Yes

(CX~CZ, Panel)

No

DR1 Board

Yes

(C1~C3,Panel)

Power SW

OFF

Yes

(C7~C9,Panel)

Power SW

OFF

Power SW

OFF

Power SW

OFF

C4~C6,

Panel Diag.

C7~C9,

Panel Diag.

C1~C3,

Panel Diag.

CX~CZ,

Panel Diag.

39

Page 40

Panel SOS – Power LED Blinks 7 Times (4/5)

Trouble Mode

DATA Driver SOS

■C1~C3 Panel Diag.

Disconnect CN C34 and C32.

Are pins 1~4 and 6~11 of CN C34

shorted to GND?

Disconnect CN C11 or C21.

Are pins 1~4 and 6~11 of

CN C24 shorted to GND?

■C4~C6 Panel Diag.

Disconnect CN C44 and C42.

Are pins 1~4 and 6~11 of CN C44

shorted to GND?

Disconnect CN C51or C61.

Defective Board

DR1/2,D, P(SUS/SC),P(Multi/SC),

P(SUS/SS),P(Multi/SS), C1-CZ Board

Disconnect CN CA3~CA5.

Yes

and 6~11 of CN C24 shorted

No

Yes

No

Yes

No

Are pins 1~4

to GND?

How to find the defective board

Disconnect CN CA6~CA8.

Are pins 1~4

and 6~11 of CN C34 shorted

to GND?

No

C2 Board

No

Panel

Disconnect CN CA9~CA11.

Are pins 1~4

and 6~11 of CN C44 shorted

to GND?

No

Disconnect CN CA1~CA2.

Are pins 1~4

and 6~11 of CN C14 shorted

to GND?

No

Yes

Panel

Panel

Panel

C4 Board

Yes

Yes

C3 Board

C1 Board

Are pins 1~4 and 6~11 of CN C54

shorted to GND?

No

Disconnect CN CA15~CA16.

Are pins 1~4

and 6~11 of CN C64 shorted to GND?

No

Panel

Yes

Yes

C6 Board

40

Disconnect CN CA12~CA14.

Are pins 1~4

and 6~11 of CN C54 shorted

to GND?

No

Panel

Yes

C5 Board

Page 41

Panel SOS – Power LED Blinks 7 Times (5/5)

Trouble Mode

DATA Driver SOS

■C7~C9 Panel Diag.

Disconnect CN C94, C93, and C32.

Are pins 1~4 and 6~11 of CN C94

shorted to GND?

Disconnect CN C71 or C81.

Are pins 1~4 and 6~11 of CN C84

shorted to GND?

■CX~CZ Panel Diag.

Disconnect CN CX4 and CX2.

Are pins 1~4 and 6~11 of CN CX4

shorted to GND?

Disconnect CN CZ1or CY1.

Are pins 1~4 and 6~11 of CN CY4

shorted to GND?

Defective Board

DR1/2,D, P(SUS/SC),P(Multi/SC),

P(SUS/SS),P(Multi/SS), C1-CZ Board

Yes

No

Yes

No

Yes

Disconnect CN CB12~CB14.

and 6~11 of CN C84 shorted

No

Disconnect CN CB6~CB8.

and 6~11 of CN CX4 shorted

Disconnect CN CB3~CB5.

How to find the defective board

Disconnect CN CB9~CB11.

Are pins 1~4

and 6~11 of CN C94 shorted

to GND?

No

Are pins 1~4

to GND?

No

Are pins 1~4

to GND?

No

Panel

Panel

Yes

Yes

C8 Board

Disconnect CN CB15~CB16.

Are pins 1~4

and 6~11 of CN C74 shorted

to GND?

No

CX Board

Panel

Panel

Yes

C9 Board

Yes

C7 Board

No

Disconnect CN CB1~CB2.

Are pins 1~4 and 6~11 of CN Z54

shorted to GND?

No

Panel

Yes

CZ Board

Are pins 1~4

and 6~11 of CN CY4 shorted

to GND?

No

Panel

41

Yes

CY Board

Page 42

Panel SOS – Power LED Blinks 8 Times

P(SS)

Vsus

15V

+5V

Trouble Mode

SUS Driver SOS

SS, D, P(SUS/SC),P(Multi/SS) Board

Power Supply / Protect Circuit

P2

1

P12

P25

16

C8

C80

CD IC6152

D25

7997

D34

P5V

SS PULSE

PC

PC

202

7

7

9

9

PC

201

SS12

C88

1

3

898

D

SS2

1

SS44

1

3

9

SS

TPVSUS

P5V

SS

PULSE

SOS

IC9003

73

SS SOS

15V

BUFFER

Defective Board

Energy Recovery

Circuit

D6253

LED(G)

VE2 REG.

VE REG.

SS’2 FFC CABLE DET

FET

FET

FET

DRIVE

R

IC6261

Ve SOS

1/2Vo SOS

FET

SS OUT

How to find the defective board

Turn the power switch on.

Does the SS board LED light

before Shutdown?

Yes

Are the

FFC cables that

connect the SS, SS2 and

SS3 boards properly

seated?

Yes

SS Board

No

Reseat the

FFC Cables of the

SS, SS2, SS3 Boards

No

P(SC)

+5V

P25

7

9

PC

203

7

9

DN

IC4701

D3

DN2

67

PANEL_SOS

8

8

166

Energy Recovery DET condition

・

NO VSUS

・

NO SS PULSE(S44 3~8in)

・

NO P5V(SS44 1pin)

42

Disconnect the CN SS2.

Turn the unit on.

Does VSUS

appear at pin 1 of

CN P2 before

shutdown?

Yes

( SS or D(SS_PULSE) NG)

SS ( or D) Board

No

P Board

Page 43

Panel SOS – Power LED Blinks 9 Times

Trouble Mode

ROM access error

Defective Board

D

Replace the D board.

43

Page 44

DS SOS – Power LED Blinks 10 Times

Power Supply / Protect Circuit

SOS

(From SLOT1)

SOS

(From SLOT2)

SOS

(From SLOT3)

Trouble Mode

DS Board SOS

DS

11

B31

DS

SOS

12

B31

DS

13

B31

Q8200Q8202

IC3004

10 SOS

Defective Board

SLOT1, SLOT2, SLOT3, DS Board

DS DN

DS

IC4701

IIC

DN

3

3

27

LED R

SLOT1. Connect

the unit to the wall

outlet and turn it on.

Remove

Does it

power up?

Yes

How to find the defective board

No

Remove

SLOT2. Connect

the unit to the wall

outlet and turn it on.

Does it

power up?

Yes

No

Remove

SLOT2. Connect

the unit to the wall

outlet and turn it on.

Does it

power up?

No

Yes

SLOT1 Board

44

SLOT2 Board

SLOT3 Board

DS

Board

Page 45

FAN SOS – Power LED Blinks 11 Times

Trouble Mode

Fan SOS

Power Supply / Protect Circuit

FAN_A

FAN_B

FAN_C

FAN_F

FAN_A

FAN_B

FAN_C

FAN_F

FAN_A

FAN_B

FAN_C

PB

1

3

1

3

1

3

1

3

1

3

1

3

1

3

1

3

1

3

1

3

1

3

51

PB

53

PB

54

PB

56

PB

59

PB

61

PB

62

PB

64

PB

66

PB

69

PB

71

1

3

1

3

1

3

1

3

1

3

1

3

1

3

1

3

1

3

1

3

1

3

FAN_A SOS

FAN_B SOS

FAN_B SOS

FAN_F SOS

FAN_A SOS

FAN_B SOS

FAN_C SOS

FAN_F SOS

FAN_A SOS

FAN_B SOS

FAN_C SOS

D874

D876

D877

D878

D882

D884

D885

D887

D864

D867

D869

PB

PB

30

Defective Board

PB Board, FAN

How to find the defective board

Are all

the fans spinning

before shutdown?

Yes

DS DN

DS

30

3

3

DS

DN

3

3

1

1

130

27

IC4701

FAN SOS

LED R

PB Board

45

No

Replace the FAN

that does not spin

Page 46

DN SOS – Power LED Blinks 13 Times

Trouble Mode

DN board SOS (3.3V, 2.5V, 1.8V, 1.5V down)

Power Supply / Protect Circuit

D DN

D

3

15V

Defective Board

DN Board

21

DN

2

1515

15V

21

21

21

IC4304

IC4303

IC4307

IC4306

How to find the defective board

The Defective Board is the DN Board ONLY.

2.5V

23

Q4702

3.3V

23

Q4704

1.5V

23

Q4703

1.8V

23

Q4719

D4710

D4713

D4712

D4708

Q4705

139

IC4701

DN_SOS

(L : SOS)

P(SS)

15V

P(SC)

15V

P

25

1,2

P

25

1,2

PC

202

1,2

PC

203

1,2

PC

PC

201

1,2 1,2

25

Q4718

Q4717

D

15V

P_ON/OFF

34

27

LED R

46

Page 47

Alignment Procedure

Alignment Procedure

47

Page 48

Driver Set-up

Item / Preparation:

1. Access the IIC mode and set the Aging Pattern to 1(white pattern)

(Vset adjustment pattern).

2. Set the picture adjustment items as follows:

· Picture menu : Standard

· Color temperature : Normal

· Picture : 25

· Aspect : Full

Caution:

1. First perform Vsus voltage adjustment.

2. Confirmation of Vscn voltage should be performed after the

adjustment of Vad voltage

When Vad = -85V, Vscn Voltage is 55V ± 4V.

Adjustments

Perform the Driver Setup Adjustments.

Check or adjust the voltages with a voltmeter.

Panel Label

Adjustment

Voltage

Note: Refer to the panel label for voltages that are not listed in the service

manual.

48

Page 49

Driver Setup Voltages

Name Test Point Voltage Volume Remarks

Vsus TPVSUS (SS) Vsus ± 0.5V VR251 (P_SS side) *

Vsus TPVSUS (SC) Vsus ± 0.5V VR251 (P_SC side) *

Ve TPVE (SS) Ve ± 1V VR6000 (SS) *

Ve2 TPVE2 (SS) 5± 1V (Fixed)

Vad TPVAD (SC2) -85V ± 1V VR6600 (SC2)

Vscn TPVSCN (SC2) Vad + 140 ± 4V VR6605 (SC2)

Vset TPVSET (SC2) 240 ± 1V VR6604 (SC2)

Vset2 TPVSET2 (SC) Vad + 8 + 1V, -0V VR6603 (SC)

Vbk TPVBK (SC2) 150 ± 1V VR6351 (SC2)

Vda TPVDA (DR1) 75 ± 1V (Fixed) (P_SC side)

Vda TPVDA (DR2) 75 ± 1V (Fixed) (P_SC side)

Vda TPVDA (DR1) 75 ± 1V (Fixed) (P_SS side)

Vda TPVDA (DR2) 75 ± 1V (Fixed) (P_SS side)

Vc TPVC (DR1) 45 ± 0.5V VR600 (DR1_SC)

Vc TPVC (DR2) 45 ± 0.5V VR650 (DR2_SC)

Vc TPVC (DR1) 34.5 ± 0.5V VR600 (DR1_SS)

Vc TPVC (DR2) 34.5 ± 0.5V VR650 (DR2_SS)

49

Page 50

Initialization Pulse Adjustment

1. Access the IIC mode and set the Aging Pattern to 1(white pattern) (Vset

adjustment pattern).

2. Set the picture adjustment items as follows.

· Picture menu : Standard

· Color temperature : Normal

· Picture : 25

· Aspect : Full

3. Connect the Oscilloscope to TPSC1 and adjust VR6601 for 190V ± 7V.

4. Connect the Oscilloscope to TPSC1 (T2) and adjust VR6602 for 165 ± 10µ Sec.

Test point Volume Level

TPSC1 (SC)

TPSC1 (SC)

T

2

VR6601

(SC)

VR6602

(SC)

190V ±

7V

165 ±

10µ Sec

50

Page 51

Quick adjustment after P.C.B. Replacement

Caution

After disconnecting AC power from the unit, allow 1 minute for capacitors to discharge before exchanging a P.C.B.

Quick adjustment after P.C.B. Replacement.

Adjust the following voltages with a multimeter.

P.C.B. Name Test Point Voltage Volume Remarks

P Board (SUS)

SC2 Board Vad TPVAD (SC2) -85V ± 1V VR6600 (SC2)

SS Board Ve TPVE (SS) Ve ± 1V VR6000 (SS) *

DR1 Board Vc TPVC (DR1) 45 ± 0.5V VR600 (SC side)

DR2 Board Vc TPVC (DR2) 45 ± 0.5V VR650 (SC side)

D, DS Board White balance and Sub brightness for NTSC, PAL, HD, PC and 625i signals

DN Board Set Market Select Number to correct destination by Ms mode

Vsus TPVSUS (SS) Vsus ± 0.5V

Vsus TPVSUS (SC) Vsus ± 0.5V

Vscn TPVSCN (SC2) Vad + 140V ± 4V VR6605 (SC2)

Vset TPVSET (SC2) 240V ± 1V VR6604 (SC2)

Vbk TPVBK (SC2) 150V ± 1V VR6351 (SC2)

34.5 ± 0.5V VR600 (SS side)

34.5 ± 0.5V VR650 (SS side)

VR251 (P_SS

side)

VR251 (P_SC

side)

*

*

*See the Panel label.

Caution: Absolutely do not reduce the Vsus voltage below Ve to avoid damaging the P.C.B.

51

Page 52

Adjustment Volume Location

52

Page 53

Adjustment Test Point Location

53

Page 54

How to Enter the Self-check Screen

Self-check Screen

1. Self-check is used to automatically check the

communication status of the IIC bus lines.

2. To get into the Self-check mode, press the volume

down button located on the side of the set.

3. At the same time press the OFF-TIMER button on the

remote control. An OSD resembling the picture on the

right shows up on the screen. If a CCU port is checked

and found to be incorrect or not located, then “--” (two

dashes) appear in place of "OK".

4. “01“ in the “PTCT” line represents the number of blinks

emitted by the Power LED after a shutdown (SOS).

5. “H09“ in the “PTCT” line is the error code.

Note: The code displayed in the “PTCT” line is present

in the first “Self-check Screen” activation only.

To exit the Self-check screen,

Switch off the main power button.

54

Page 55

How to Reset the unit

To reset the unit:

Press and hold down the volume down button on the side of

the set and at the same time, press and hold down the “R”

button on the remote control. Keep pressing the buttons until

a field labeled “Shipping” appears on the screen.

Do nothing further, and wait until the field goes away.

Turn off the main power switch to complete the reset

procedure.

55

Page 56

How to Enter the CAT (Serviceman) Mode

How to access the CAT mode.

Press and hold the Volume/Down button on the front

panel of the unit and press the status button on the

remote control three times within one second. The unit

enters the CAT Mode.

To exit the CAT mode, access the ID mode and switch

off the main power.

56

Page 57

How to Enter the IIC Mode

2

Select the I

of the CAT menu, and then press the Action button on the remote control.

How to use the I2C mode?

1. Select the alignment subject by pressing the UP/Down

buttons on the remote control.

2. Select the alignment item by pressing the Left and Right

buttons on the remote control.

3. Adjust the optimum setting by pressing the Volume

Up/Down buttons on the remote control.

4. The data is memorized when the R button is pressed on

C mode by pressing the Up/Down button on the remote control from the front page

the remote control or the alignment Subject (or item) is

changed.

To exit the I

2

C mode, press the R button on the remote

control.

57

Page 58

How to Access the pattern generator

To access the internal pattern generator, select AGING from the main adjustment item

of the IIC mode menu and press the ACTION button of the remote control. Press the

ACTION button to navigate through the different patterns.

IIC MODE

AGING

To Exit the internal pattern generator, press the [R] button of the remote control

58

Page 59

How to Enter the CD Mode

Select the CD mode of the CAT menu by using the Up/Down button on the remote control, then

press the Mute button on the remote control for more than 5 seconds.

59

Page 60

How to Enter the MS Mode

Select the MS mode of the CAT menu by using the Up/Down button on the remote control, then

press the Mute button on the remote control for more than 5 seconds.

Use the left and right buttons of the

remote control to change the code.

Present Number

EEPROM Data Version

To exit the MS mode, press the R button on the remote control.

Caution: Market Select should be set after exchanging the DN Board.

North America’s Market Code is “1”.

North America’s Hotel Model Market Code is “9”.

60

Loading...

Loading...