Page 1

Panasonic Services Company

National Training

TH-42PX20U/TH-50PX20U

TH-42PA20U/TH-37PA20U

Plasma Display Panel

GP6D Chassis

Update Information

This service information is designed for experienced repair technicians only and is not designed for use by the general public. It does

not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product. Products

powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair

the product or products dealt with in this service information by anyone else could result in serious injury or death.

1

Warning

Page 2

2

Page 3

Table of contents

Objective..............................................................................................................5

Model Line Up .....................................................................................................7

Performance Comparison..................................................................................8

SD Models.........................................................................................................8

HD Models ........................................................................................................8

Specifications......................................................................................................9

SD Models.........................................................................................................9

HD Models ........................................................................................................9

New Features and Circuit Improvements .......................................................10

42” SD PCB Board Layout Diagram................................................................11

Board Comparison Chart .................................................................................12

Video Signal Block Diagram ............................................................................13

Video Signal Path Explanation ........................................................................15

NTSC \ 480i Video Signal Path .......................................................................15

DVI Input.........................................................................................................17

DVI RGB to YUV Conversion..........................................................................18

Digital Processor.............................................................................................19

Main Picture ....................................................................................................19

RGB Amplifier..................................................................................................21

RGB/PC Select................................................................................................22

D Board Outline...............................................................................................23

Sync Signal Process .......................................................................................24

SC Board Explanation......................................................................................25

SS Board Explanation ......................................................................................28

Power Supplies (GP6D Chassis) .....................................................................31

Standby power supply.....................................................................................31

VSUS High Voltage Source.............................................................................32

Main Power Supply .........................................................................................34

VDA and other Voltage Sources......................................................................35

Protection Circuits............................................................................................37

System Control Circuit.....................................................................................39

Panel Operations.............................................................................................39

TV Operations.................................................................................................40

Diagnostic Procedures.....................................................................................41

Diagnostic Flow Charts....................................................................................42

No Power ........................................................................................................42

No Picture Flowchart 1....................................................................................43

No picture Flowchart 2 ....................................................................................44

Dark picture Flowchart ....................................................................................45

Local screen failure..........................................................................................46

Service Hints...................................................................................................47

Adjustments......................................................................................................52

3

Page 4

+B Set-up........................................................................................................52

Confirmation....................................................................................................52

Driver Set-up...................................................................................................53

Panel Label information...................................................................................53

Initialization Pulse Adjust.................................................................................54

P.C.B. (Printed Circuit Board) exchange procedure........................................55

Adjustment Volume Locations.........................................................................55

Test Point locations.........................................................................................56

Serviceman mode (Electronic Controls).........................................................56

Serviceman mode (Electronic Controls).........................................................57

CAT (computer aided test) Mode ....................................................................58

I2C Mode .........................................................................................................59

I2C Menu Structure..........................................................................................60

CD mode.........................................................................................................61

SD Mode .........................................................................................................62

Alignment Procedures......................................................................................63

Pedestal Setting..............................................................................................63

NTSC White Balance Adjustment....................................................................64

HD Panel White Balance Adjustment..............................................................65

Sub Brightness Setting....................................................................................66

Hotel Mode Operation.....................................................................................67

Service Contact Information............................................................................70

4

Page 5

Objective

The information provided in this document is designed to assist the technician in

determining the defective printed circuit board. The troubleshooting flow charts,

signal path charts and connector information should provide enough detail to the

technician for the accurate repair of the product. Alignment and adjustment

procedures are also included in this document.

The Block diagrams and the schematic drawings reference the model TH42PHD5, TH-42PX20U and TH-42PA20U but the technology is consistent with

any GPH5D and GP6D series Plasma display panels.

5

Page 6

6

Page 7

Model Line Up

TH-50PX20U

50-inch (127 cm) HD Version

2 Component Video Inputs

3 Composite Video Inputs

3 S-Video Inputs

1 HDMI input

Scalable PIP (1/4 to 1/16)

PC / SD Card Inputs

Integrated Speaker System

BBE sound

1080i / 480p capable

720p (PC input only)

TH-42PX20U

42-inch (106cm) HD Version

2 Component Video Inputs

3 Composite Video Inputs

3 S-Video Inputs

1 HDMI input

Scalable PIP (1/4 to 1/16)

PC / SD Card Inputs

Integrated Speaker System

BBE sound

1080i / 480p capable

720p (PC input only)

TH-42PA20U

42-inch (106 cm) SD Version

2 Component Video Inputs

3 Composite Video Inputs

3 S-Video Inputs

1 DVI input

Scalable PIP (1/4 to 1/16)

Integrated Speaker System

BBE sound

1080i / 480p capable

TH-37PA20U

37-inch (94cm) SD Version

2 Component Video Inputs

3 Composite Video Inputs

3 S-Video Inputs

1 DVI input

Scalable PIP (1/4 to 1/16)

Integrated Speaker System

BBE sound

1080i / 480p capable

7

Page 8

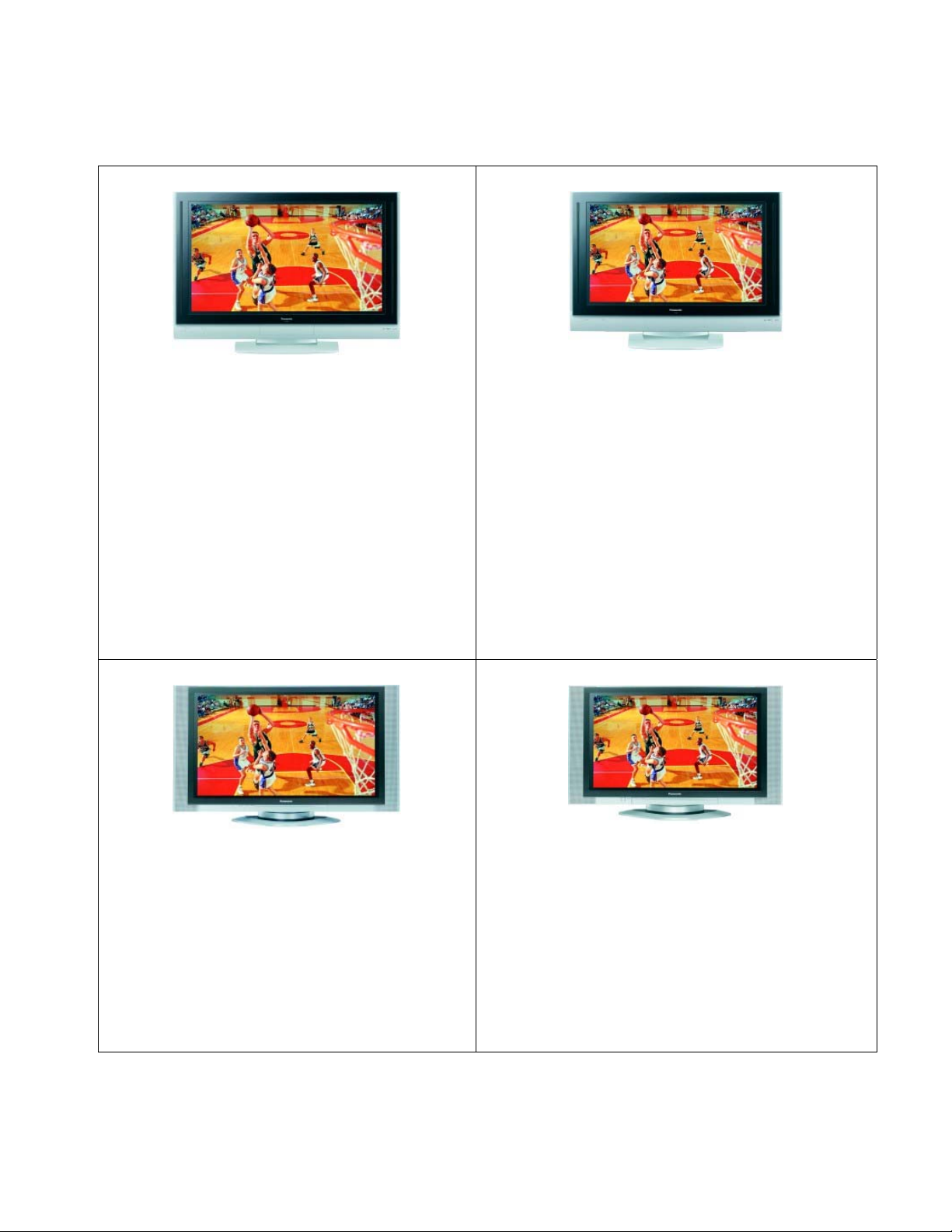

Performance Comparison

SD Models

Chassis GP5D GP6DU

Panel Size 42 37 42

Pixels (H x V)

Brightness

(Set)

Contrast

Gradation 1024 shades

Sharpness Good

Color Temp. 11000 11000

Power Consumption

Maximum

Standby Normal

Standby Save On

Power Off

Peak

(cd/m2)

Dark 3000:1

150 lux 140:1 120:1

852 x 480p 852 x 480p

370 370 370

295W

2.8W

1.5W

225W

2.8W

1.5W

852 x 480p

4000:1

160:1

1536 shades

Vivid

265W

1.5W

0.6W

0.4W

HD Models

Chassis GPH5D GPH6D

Panel Size 50 42 50 42

Pixels (H x V)

Brightness

(Set)

Contrast

Gradation 1024 shades

Sharpness Good

Color Temp. 11000 11000

Power Consumption

Maximum

Standby Normal

Standby Save On

Power Off

1366 x

768p

Peak

(cd/m2)

Dark 3000:1

150 lux 90:1

260 250

495W

3.0W

1.7W

1024 x

768p

225W

3.0W

1.7W

1366 x 768p 1024 x 768p

300

4000:1

160:1

1536 shades

Vivid

445W

1.5W

0.6W

0.4W

360

265W

1.5W

0.6W

0.4W

8

Page 9

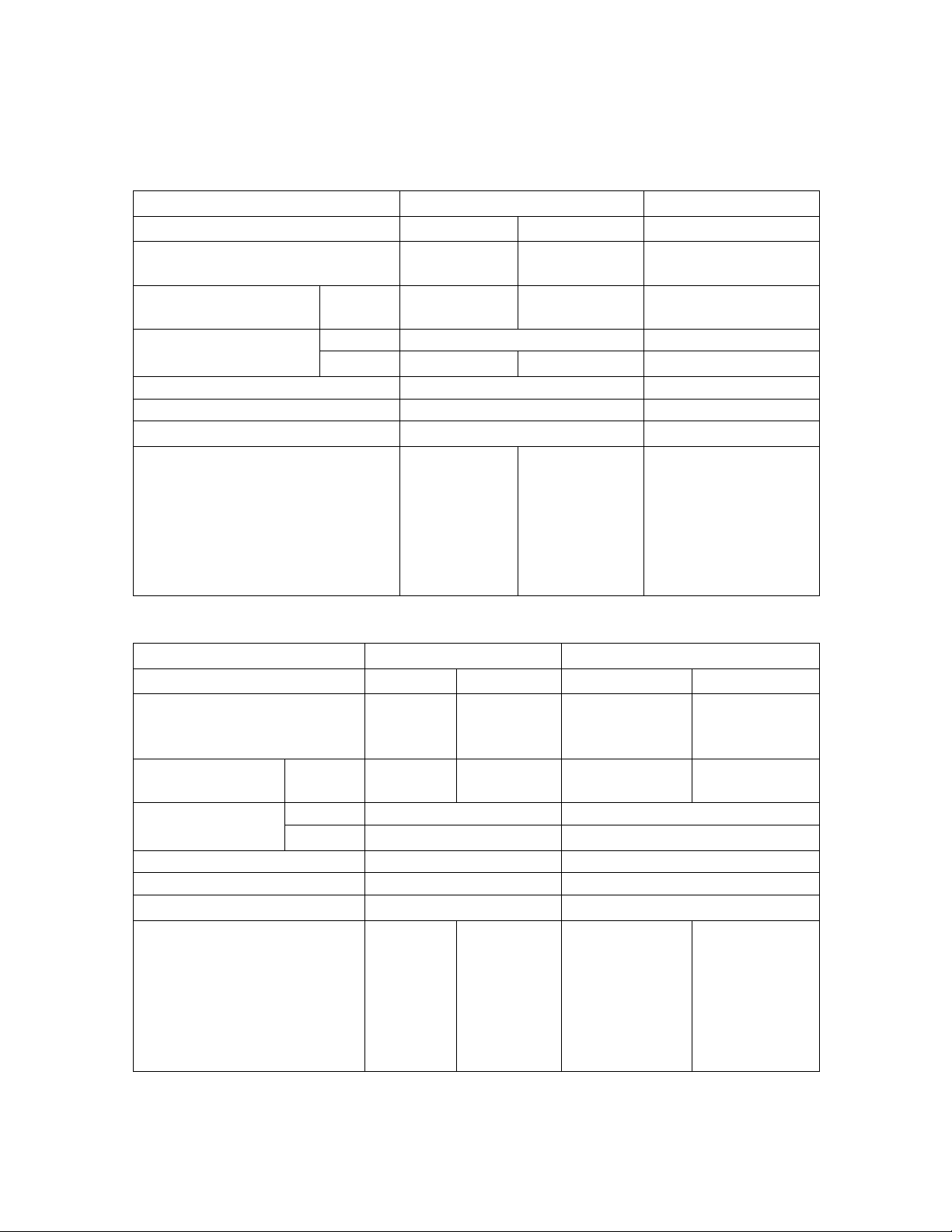

Specifications

SD Models

Model Number TH-42PA20U/P

Chassis GP6DU

Panel

Power Source AC 120V 50 /60 Hz

Power Consumption 425W Standby (0.8W)

Applicable Signals NTSC

Contrast 4000:1

Dimensions (W x H x D) 1170 x 658 x 99 mm

Weight 77.2 lb (35.0 kg)

HD Models

Model Number TH-42PX20U/P

Chassis GPH6D

Panel

Power Source AC 120V 50 /60 Hz

Power Consumption 295W Standby (P. Save on) 1.8W, (P. Save Off) 0.8W

Applicable Signals NTSC

Contrast 3000:1

Dimensions (W x H x D) 1020 x 610 x 89 mm

Weight 90.4 lb (41Kg)

Screen Size SD type 42” 16 x 9 (920 x 518 mm)

Number of

Pixels

Number of Dots H 2556 x V 480

Pixel Size W 1.08 x H 1.08 mm

Drive Method AC Type Sub Field Drive System, Variable sub Field

Screen Size HD type 42” 16 x 9 (920 x 518 mm)

Number of

Pixels

Number of Dots H 3072 x V 768

Pixel Size W 0.90 x H 0.645 mm

Drive Method AC Type Sub Field Drive System, Variable sub Field

H 852 x 480 (VGA)

525i (480i), 525p (480p), 625i (575i), 625p (575p),

750p (720p), 1125 (1080)/60i, 50i, 24p, 24sf

VGA, SVGA, XGA, SXGA, UXGA

H 1024 x 768 (VGA)

Power Off 0.6W

525i (480i), 525p (480p), 625i (575i), 625p (575p),

750p (720p), 1125 (1080)/60i, 50i, 24p, 24sf, 1250

(1080)/50i

VGA, SVGA, XGA, SXGA, UXGA

9

Page 10

New Features and Circuit Improvements

Integrated NTSC Tuner

3/2 Pulldown circuit

Plasma Contrast Auto Tracking System (C.A.T.S.)

Picture-in-Picture

SD models

• New Deep Black Front Glass Filter: Improves Contrast Ratio in Lighting

Environment by 15%

• Super Real Gamma System: Reproduces 1,536 shades of gradation

(60Hz)

• 10-bit Digital Processing: Reproduces 1,070-Million Colors

• DVI Input

HD models

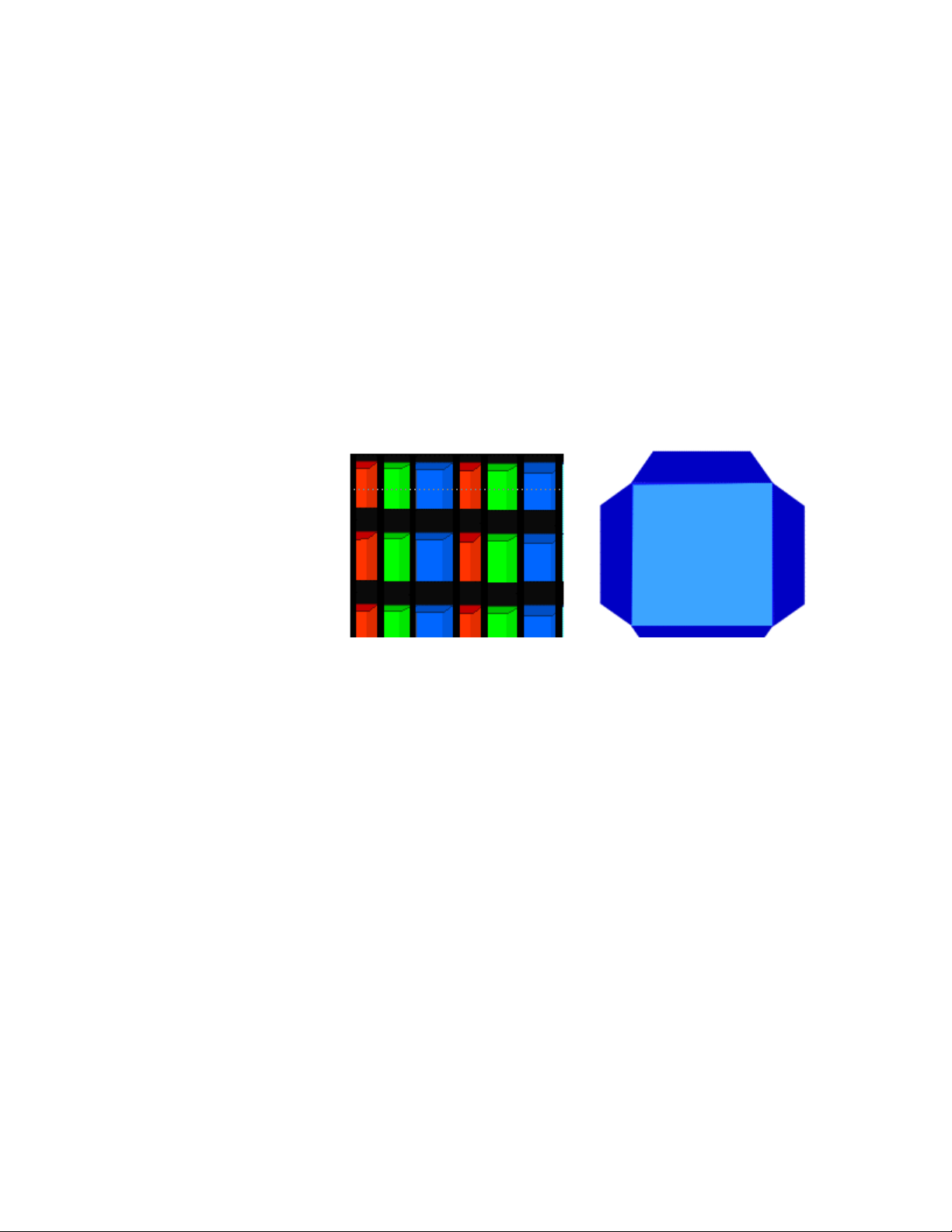

• New 5 Facet

Asymmetrical

Cell Structure

Panel:

Improves

Brightness

Level by 45%

• New Real Black Drive System: Achieves greater than 4000:1 Contrast

Ratio in Dark Environments

• New Deep Black Front Glass Filter: Improves Contrast Ratio in Lighting

Environment by 80%

• Super Real Gamma System: Reproduces

• 10-bit Digital Processing: Reproduces 1,070 Million Colors

• SD / PC Card Reader- View images on screen from a digital camera

• HDMI Input with Analog Audio inputs

Figure 1

1,536 shades of gradation

10

Page 11

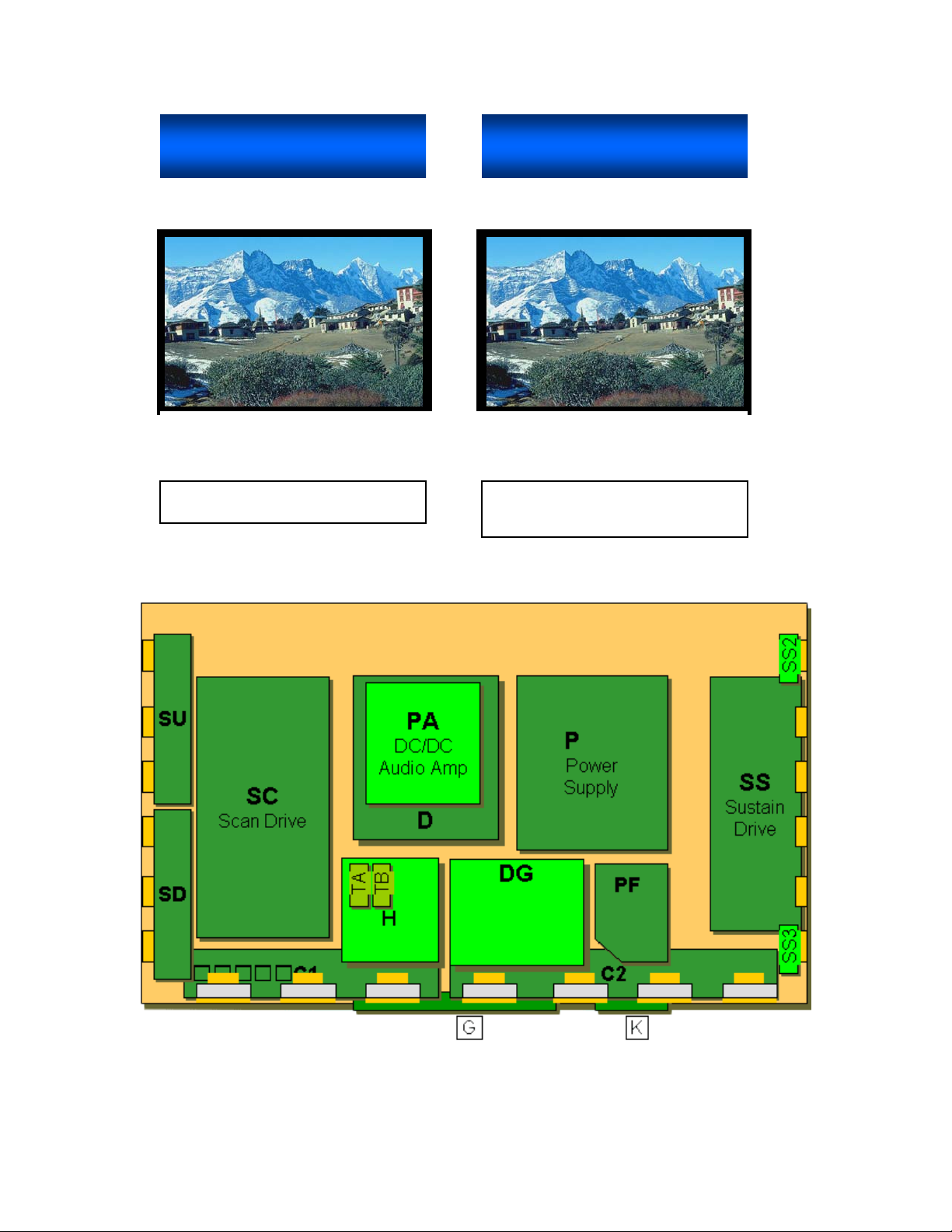

SSiinnggllee SSccaann ((SSDD))

DDuuaall SSccaann ((HHDD))

Figure 2

•Simple and low cost circuit

•High performance

•Higher brightness

42” SD PCB Board Layout Diagram

Figure 2

11

Page 12

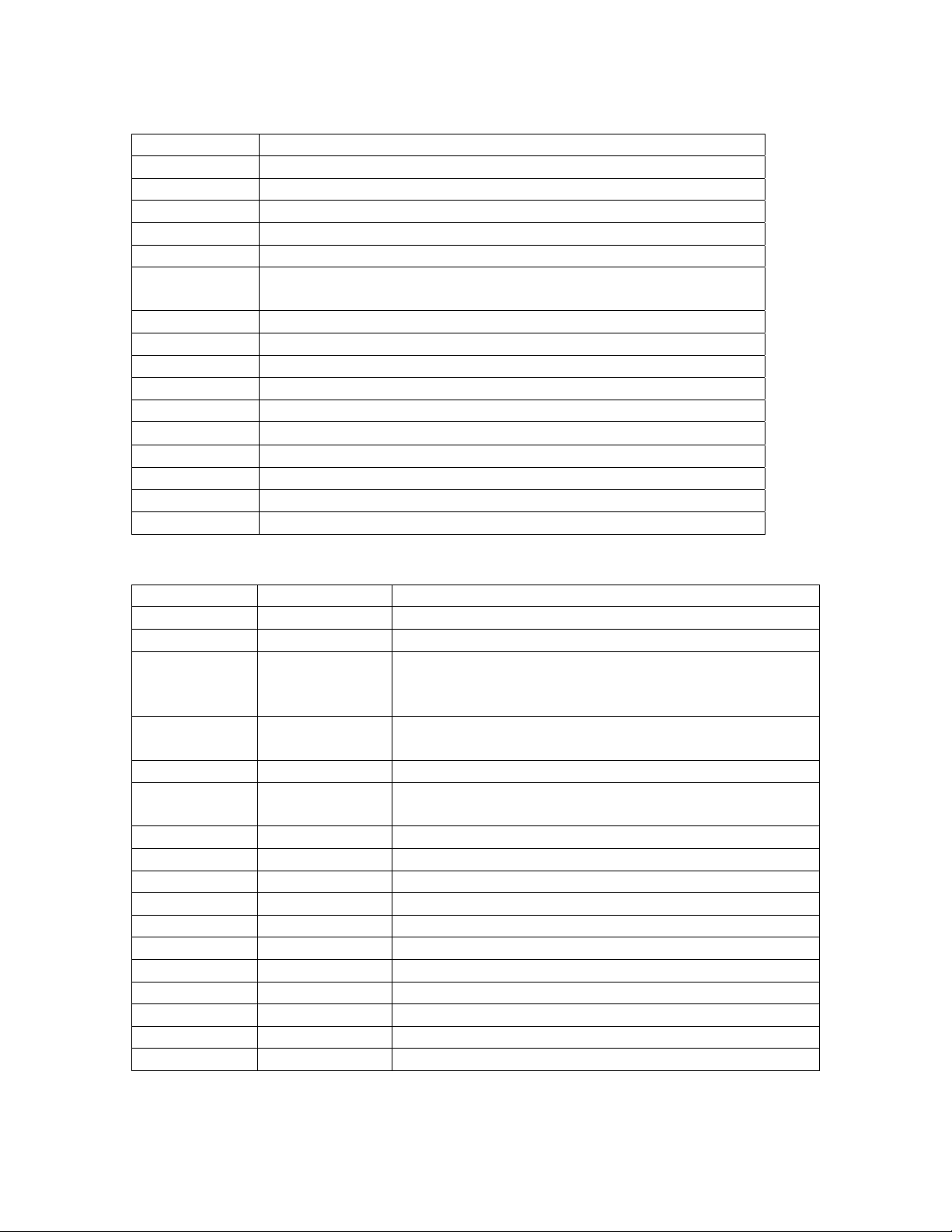

Printed Circuit Board Information Table

Board Name Function

PF Fuse and Line Filter Circuit

P Power Supply Circuit

PA DC/DC converter and Audio Amplifier Circuit

K Remote, Light Receiver and Power LED Circuits

G Front Switch, PC and Video Input Circuits

D RGB Digital Processor, Format converter, Plasma AI,

Discharge Control Circuits, Sub-Field Processor

SC Scan Signal Drive Circuit

SU/SD Scan Signal Output Driver (Upper and Down side)

SS Sustain Signal Output Driver

SS2, SS3 Sustain Output Signal Extension Boards

C1 Data Pulse Connector for Right

C2 Data Pulse Connector for Left

TA Tuner (main)

TB Tuner (sub)

H A/V Switching and Video Input Circuits

DG Digital Core, MPU, RGB amp, and DVI Input Circuits

Board Comparison Chart

GP5 Chassis GP6 Chassis Board Function

C1 C1 Data Drive

C2 C2 Data Drive

D2 D RGB Digital Processor, Format converter,

Plasma AI, Discharge Control Circuits, Sub-Field

Processor

D1 DG Digital Core, MPU, RGB amp, and DVI Input

Circuits

V1 G Front Switch, PC and Video Input Circuits

HX and HZ

Boards

P P Power Supply Circuit

Z PA DC/DC and Audio Circuits

F PF Fuse and Line Filter Circuit

SC SC Scan Signal Drive Circuit

SD SD Scan Signal Output Driver (Lower Section)

SS SS Sustain Signal Output Driver

SS2 SS2 Sustain Output Signal Upper Boards

SS3 SS3 Sustain Output Signal Lower Boards

SU SU Scan Signal Output Driver (Upper Section)

N/A TA Tuner (Main)

N/A TB Tuner (Sub)

H A/V Switching and Video Input Circuits

12

Page 13

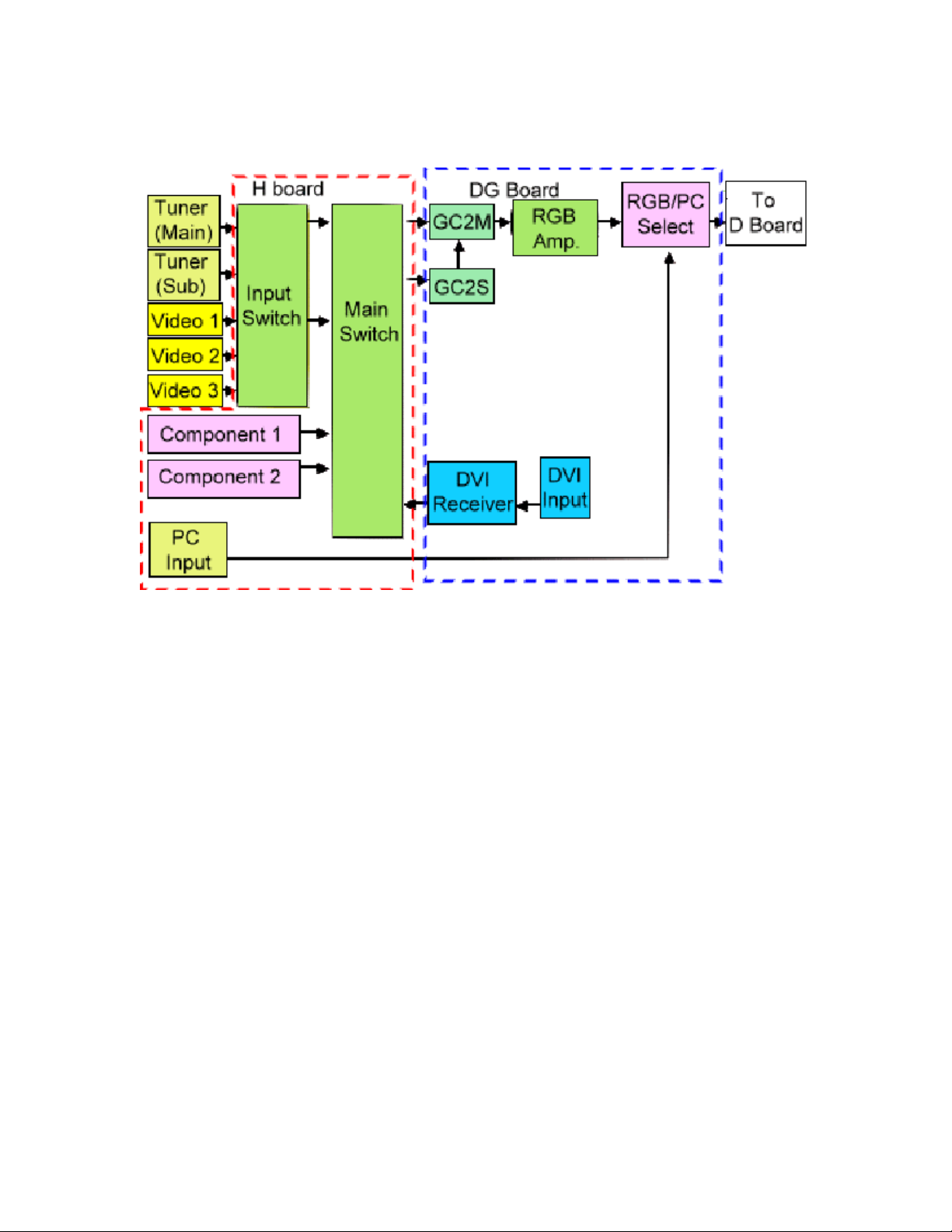

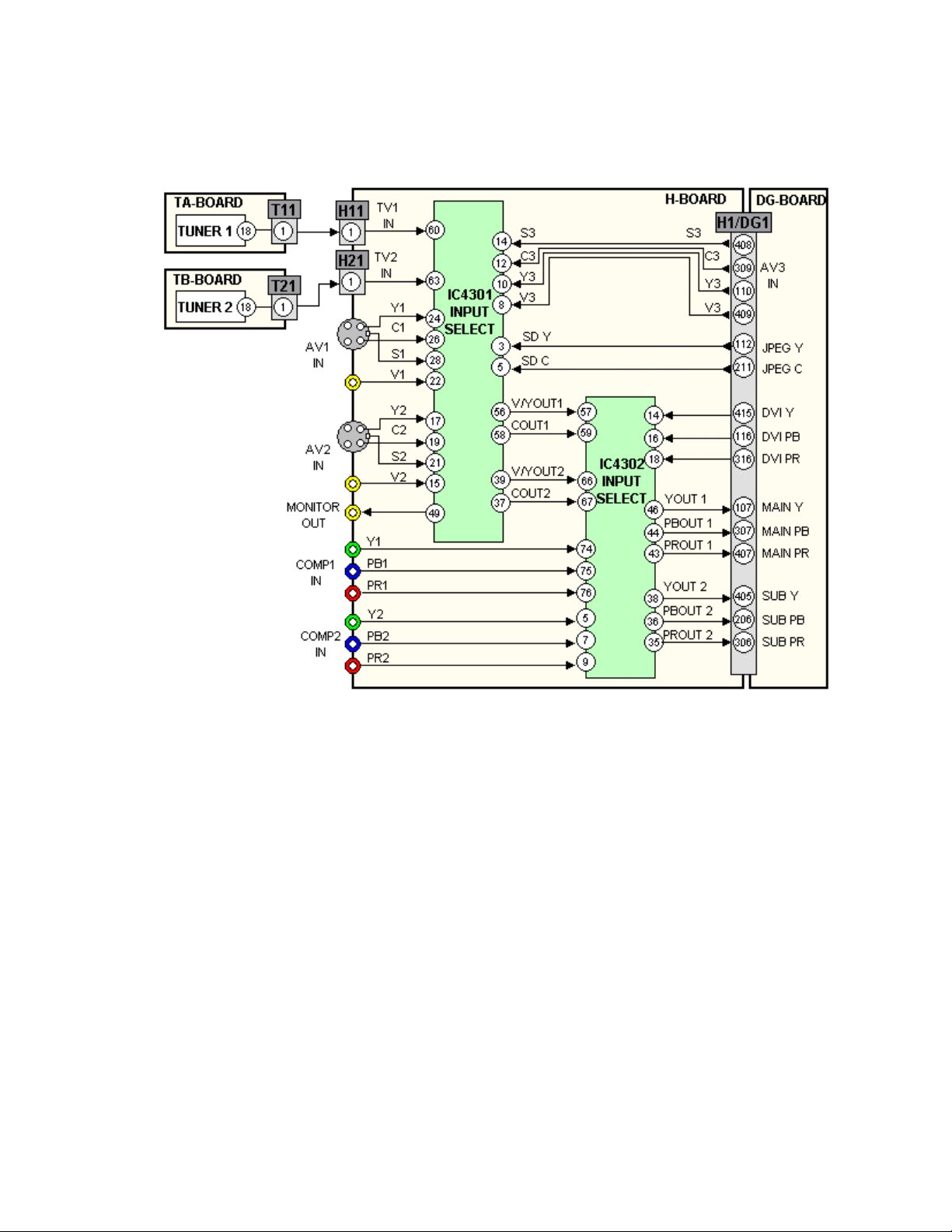

Video Signal Block Diagram

Figure 3

GP6 series plasma panels incorporate two NTSC tuners. The main tuner is used

for primary picture operation. It provides a composite video and a multiplex audio

output. The sub-tuner provides only a video output used for multi picture

functions. The video outputs of the tuners are connected to the input switch IC on

the H Board. The unit also contains three video inputs that are also connected to

the input switch IC. The input switch IC selects one of the 5 video inputs for main

picture operation and another for sub-picture operation. Selection is controlled by

2

the MPU via the I

C Bus (SDA & SCL). These two outputs are then connected to

the main switch IC.

The panel also contains three component inputs and a DVI or HDMI input

(depending upon the model) that are connected to the main switch. The DVI or

HDMI input connector, connected to the DG Board, outputs the digital signal to

the DVI or HDMI receiver where it undergoes serial to parallel conversion. The

output of the receiver is then converted to a Y, Pb, and Pr component signals

before being applied to the Main switch. The MPU selects one of the 8 inputs for

main picture operation and another for sub-picture operation.

On the DG- Board, the global core IC (GC2M) converts the composite video

signal of the main picture to RGB video signals. The GC2S IC processes the

sub-picture information and combines it with the main picture. It performs

13

Page 14

interlace to progressive scan conversion. The Global core IC also converts the

horizontal frequency of all NTSC inputs to 31.468KHz. The output of the GC2M

IC is RGB; it is applied to an external RGB amplifier.

IC001 is the TV Main CPU. It generates the On Screen Display (OSD) RGB

signals, which also enters the RGB amplifier stage. A switching circuit combines

the two sets of RGB signals for display on the screen. All NTSC, Component,

and RGB picture adjustments such as picture, tint, color, brightness, etc. are

performed inside this IC.

The RGB/PC select circuit switches between PC and all other inputs. The output

of the switch is routed to the D Board.

14

Page 15

Video Signal Path Explanation

Figure 4

NTSC \ 480i Video Signal Path

The TH-42PA20U/P incorporates two NTSC tuners, allowing the simultaneous

viewing of two signals. It is also equipped with three NTSC Video inputs and

three NTSC S-Video inputs. Tuner-1 produces audio and video signals. Tuner-2

produces video only, as it is the video source intended for use in the “Picture in

Picture” mode. Video signals produced by the main tuner (tuner-1) and sub tuner

(tuner-2) are applied to the H-Board via pin 1 of the connector T11/H11 and pin 1

of the connector T21/H21. The signal applied to the AV3 video input, located at

the bottom of the front panel, enters the G-Board and passes through to the DGBoard without alteration. It is then applied to the H Board.

IC4301 on the H-Board selects the main video source and sub video source from

the NTSC inputs. The main Video or Luminance and chrominance signals are

output via pins 56 and 58. The sub video signal is output via pins 39 and 37. Both

15

Page 16

Main and Sub Video signals are amplified and applied to another video switching

IC, IC4302.

The component video signals Y, Pb, and Pr are also input to IC4302 via the

connectors located at the rear of the cabinet.

The DVI input connector, attached to the DG Board, supplies the DVI signal to

the DVI receiver where it undergoes serial to parallel conversion. The output of

the DVI receiver is converted to a Y, Pb, and Pr component signal and then

applied to pins 14, 16, and 18 of IC4302 via pins 415, 116, and 316 of connector

H1/DG1. IC4302 selects between NTSC, Component, and DVI video input

signals. The selected signals can be in any of the three formats; Video, Y/C, or Y,

Pb, Pr. The main signal is output via pins 43, 44, and 46 of IC4302. The signals

are amplified and output to the DG-Board via pins 107, 307, and 407 of the

connector H1/DG1. The Sub NTSC video signals are also amplified and output to

the DG-Board via pins 405, 206, and 406 of the same connector.

16

Page 17

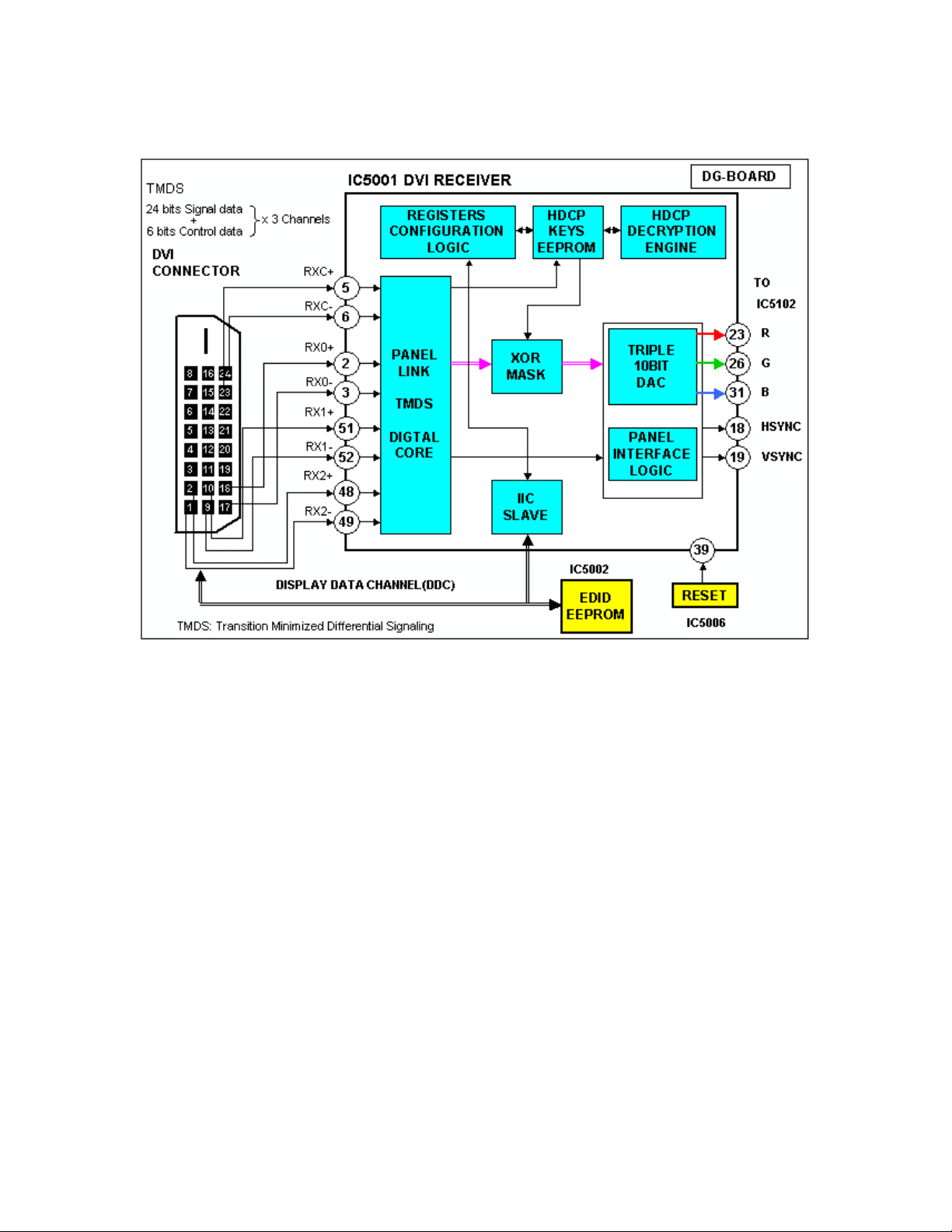

DVI Input

Figure 5

The DVI (Digital Visual Interface) input is a port designed to receive digital video

from a set-top box, a DVD player, or other digital devices. IC5001 converts the

digital video to parallel analog RGB video. The HDCP (High-bandwidth digital

content protection) circuit monitors the DVI signal for copyright protection. The

output of IC5001 is then applied to IC5102. The EDID EEPROM allows for

external control of the picture from the DVI source.

17

Page 18

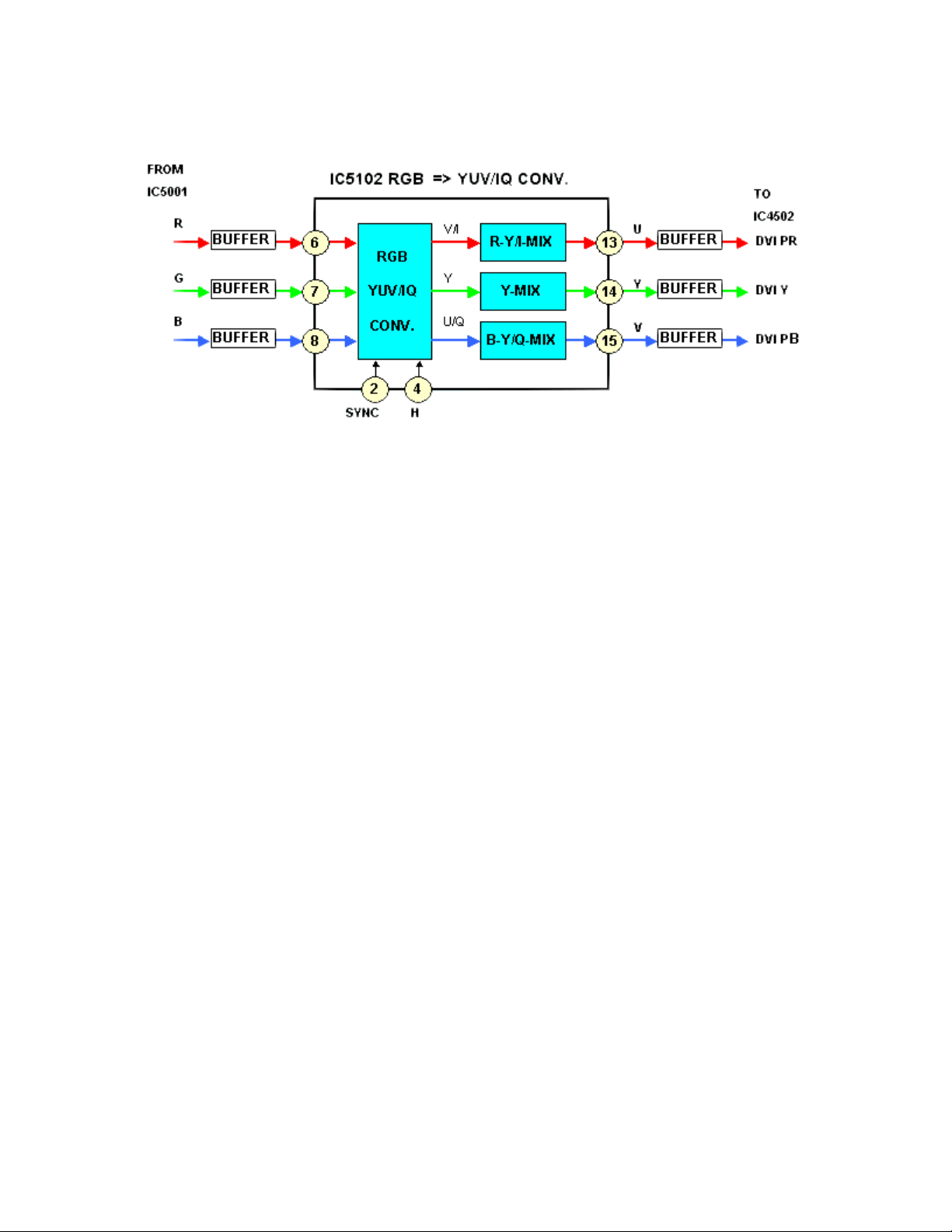

DVI RGB to YUV Conversion

Figure 6

IC5102 is an RGB to YUV (Y, Pb, PR) converter. It uses the vertical and

horizontal sync pulses of the DVI receiver to convert the analog RGB signal to Y,

Pb, Pr component signal. The signal is now in the form of an ATSC signal format

that can be processed like any other component signal. The output is sent to the

Main switch IC4302 for selection.

18

Page 19

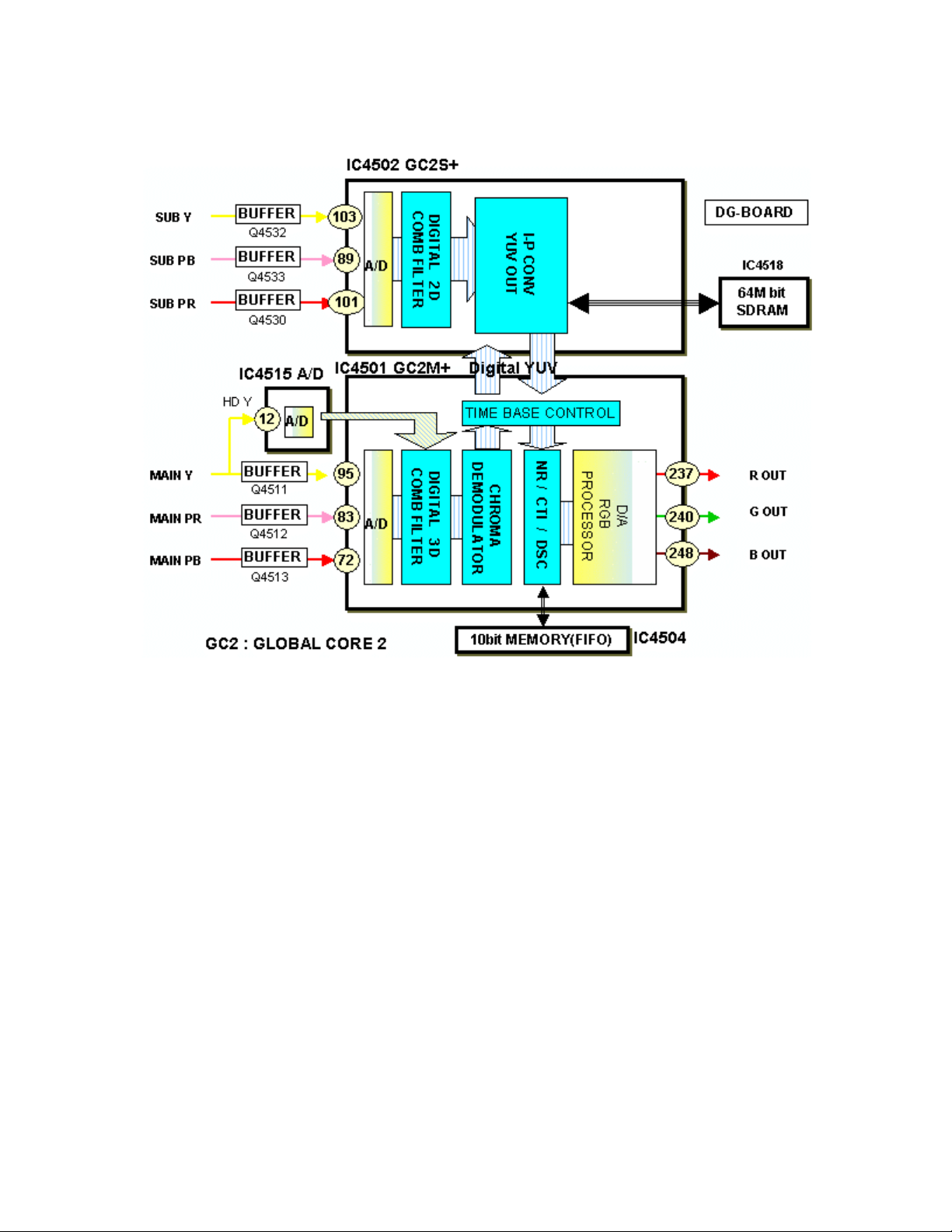

Digital Processor

Figure 7

Main Picture

On the DG- Board, the main Y, Pb, Pr signals are converted to digital data by an

analog to digital (A/D) converter circuit located inside the Global Core IC, IC4501.

The comb filter in IC4501 converts the composite video signal of the main picture

to Y and C separated video signals. S-Video, which is already Y/C separated,

simply passes through the comb filter. The data is then applied to the Chroma

demodulator circuit that separates the color signal into Pb and Pr data. If the

incoming video is in the 480p and 1080i format, the main Y signal is converted to

digital by IC4515 before being applied to IC4501. The A/D converter inside

IC4501 converts the color signals to digital. The data of the color signals bypass

the comb filter and Chroma demodulator circuits to join up with the luminance

data.

IC4501 outputs the data to the global core IC, IC4502. IC4502 contains a linedoubling circuit that halves the horizontal line period, doubling the horizontal

frequency to 31.468KHz. Using IC4518 as a temporary storage area, IC4502

19

Page 20

then converts the digital signal scan format from interlaced to progressive before

sending it back to IC4501. The NR/CTI/DSC circuit reduces noise and improves

the picture quality. The 10 bit signals are then converted to analog R, G, and B

component signals by IC4501, and applied to the RGB amplifier IC4512.

Sub Picture

On the DG- Board, an analog to digital (A/D) converter circuit, located inside the

Sub Global Core IC4502, converts the sub Y, Pb, Pr signals to digital.

The data is then applied to a comb filter where luminance and chrominance are

separated.

IC4502 processes the Sub video data for use in the PIP mode. In this mode, the

main and sub video components are combined into one set of Y, Pb, and Pr

component signals.

The line-doubler, located inside the IC, halves the horizontal line period, doubling

the horizontal frequency to 31.468KHz. Using IC4518 as a temporary storage

area, IC4502 then converts the digital signal scan format from interlaced to

progressive before sending it back to IC4501. The NR/CTI/DSC circuit reduces

noise and improves the picture quality. The 10 bit digital signal is then converted

to analog R, G, and B component signals by IC4501, and applied to the RGB

amplifier IC4512.

20

Page 21

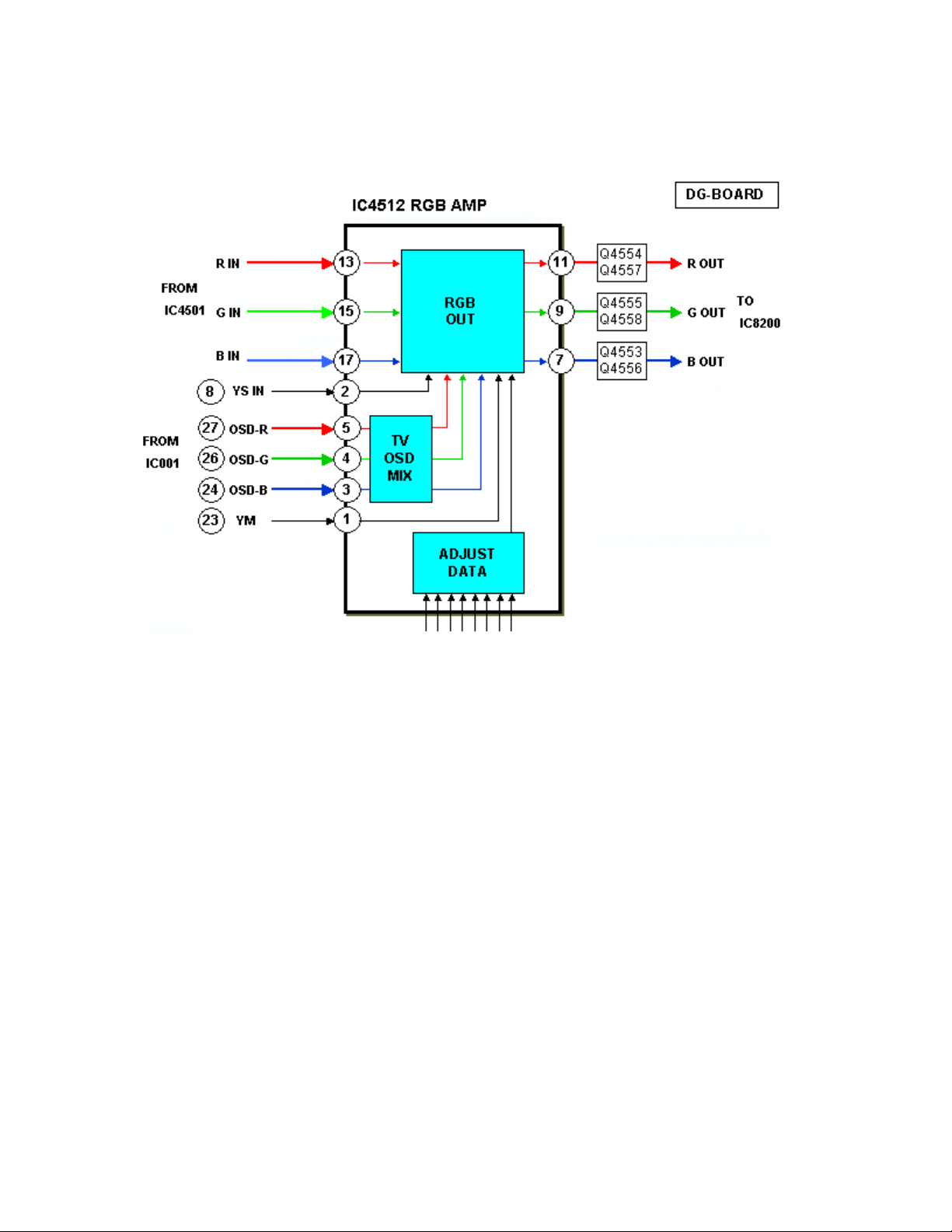

RGB Amplifier

Figure 8

The RGB output of IC4501 and the OSD (On Screen Display) RGB output of the

television MPU, IC001 enter the RGB amplifier IC4512. A switching circuit

combines the two RGB signals for display on the screen. The Adjust Data section

sets the RGB level, matching the required levels for the DG board. The output of

IC4512 enters IC8200 of the DG-Board for selection between PC and all other

inputs.

21

Page 22

RGB/PC Select

Figure 9

PC RGB Signals are input to the G Board located at the front of the unit. RGB

signals from the PC input connector as well as standard RGB signals from the

RGB amplifier, IC4512 enter IC8200 for selection. The selected output passes

through the LPF circuit consisting of IC8201 to reduce bandwidth. The filtered

output is applied to the D-Board via pins 26, 28, and 30 of the connector

DG3/D3. The output of the switch, IC8030, is used at the manufacturing plant for

testing purposes.

22

Page 23

D Board Outline

Figure 10

The D-board consists of the digital signal process circuitry. The analog RGB

input is converted to digital by IC9009. The eight bit digital output enters IC9151

for processing.

The digital video data is converted to progressive scan and mixed with the OSD

data. Adjustments such as white balance, contrast, and color drives are also

corrected here.

IC9455 contains the Plasma AI (Adaptive brightness Intensifier) circuit that

analyzes the video program level for the distribution of dark and bright

components. The Plasma AI circuit converts the 8 bit signal data to 10 bit signal

data. The Sub-field Processor is used to speed up the scanning process and

control the number of sustain periods. This increases the brightness and

improves the contrast ratio. It also creates the two channels of data that drive the

C1 and C2 data output boards.

The D-board provides the scan, sustain, and data drive signals. The scan pulses

are output to the SC board. The sustain pulses are output to the SS board. The

data drive signals are output to the C1, and C2 boards. The C1 board drives the

right portion of the panel; the C2 board drives the left portion.

23

Page 24

Sync Signal Process

Figure 11

On the DG-Board, the sync signals retrieved from the input device enter the sync

switch (IC8071). The selected sync signals are output to the D-Board via pins 31,

32, and 34 of connector DG3/D3. The sync signals then enter a level shifter IC,

IC9023, to change the DC Level from 5 to 3.3 volts. The output signals of IC9023

enter IC9009 for conversion into digital pulses. IC9605, the Sync Processor and

Discharge Control circuit, produces the Sustain control pulses, the Scan control

pulses, and the data timing pulse for the data drive circuit boards.

24

Page 25

SC Board Explanation

Figure 12

25

Page 26

Figure 13

The SC Board consists of buffers and drivers used to generate the scan signals

to the panel. The buffers provide isolation between the D board and the drivers.

Connector SC20 provides the drive voltages (140V, 100V and 18V) as well as

the trigger signals to switch the FET transistors. The D board switches the FETs

on and off to create the distinctive scan signal. Each trigger signal switches a

drive FET creating a portion of the waveform. For example, applying the CPH

signal to the 140V FET creates the peak portion of the waveform, see figure 12.

26

Page 27

Figure 14

After the scan waveform is developed on the SC Board, it is applied to the SU

and SD boards for de-multiplexing. The signal is input to a series of shift registers

inside the PDP scan driver IC. Figure 14 shows an example of the demultiplexing circuit. There are six driver ICs on the SU board and six on the SD

board.

27

Page 28

SS Board Explanation

Figure 15

After the video signal is processed on the D board, the sustain and erase pulses

are output to the SS board. The erase pulse is output at the beginning of each

scan period. The pulse is applied to the SS2 and SS3 boards to remove the

previous charge for the upper and lower sections of the display panel.

The sustain pulses are also developed on the D board and are applied after the

scan periods.

28

Page 29

Figure 16

29

Page 30

Figure 17

The Sustain pulse is developed using a similar circuit as the Scan Pulse. A series

of specifically timed pulses are applied to FET drivers creating the distinctive

sustain pulse. The drivers switch the voltages (150V, 155V and 175V) at selected

intervals determined by the D board. The basic waveform remains constant but

the exact number of sustain pulses is determined by the amount of luminance

required, see figure 17.

30

Page 31

Power Supplies (GP6D Chassis)

Standby power supply

Figure 18

The standby power supply provides the necessary DC voltage for the system

control Microprocessor, Reset circuit and the EEPROM. D404 rectifies the

incoming AC Voltage and applies it to the transformer T402 and the standby B+

control circuit IC401. The output pulses of IC401 are then applied to the primary

side of transformer T402. Diode D409 rectifies the AC output at pin 12 of the

secondary of T402 to create the STB 7V for the system control circuit. IC403

regulates the 7V standby voltage to produce the STB5V for the D Board. This 7V

standby voltage also passes through the diode D410 to enter the power relays

RL401 and RL403. When the unit is turned on, transistor Q401 turns on to create

the ground path for power relay RL401. Transistor Q417 provides the ground

path for the In Rush Current relay RL403. IC 402 and the Opto-coupler D408

provide feedback to the STB control circuit for voltage regulation. After the main

power supply goes into operation, the 5V source is applied to transistor Q402 to

turn on the relay RL402.

31

Page 32

VSUS High Voltage Source

Figure 19

The P-Board contains the drive-voltage oscillator circuit that develops the Vsus

voltage needed to operate the Scan and Sustain boards. Operation begins with

the 18Vdc supply derived at the main power supply. AC voltage from pin 4 of the

secondary of the transformer T502 is rectified filtered and applied to pin 1 of

IC550. The regulated 15 volts output of the IC enters pin 4 of IC551 to serve as

startup voltage and begin the oscillation of the IC. The regulated DC output of

IC550 is also applied to the voltage feedback circuit consisting of the optical

coupler D565 and Diode D553. The PWM output at pin 3 of IC551 is applied to

the transformer's primary. As current passes through the transformer, magnetic

field builds up in its core. The primary current passes through the transistor

located inside the IC and the four source resistors R550, R560, R568, and R574.

The voltage at the transistor's Source increases at a proportional rate to that of

32

Page 33

the current increase. This voltage is applied to the non-inverting input of the opAmp at pin 1 of IC551 for over current protection (OCP).

Pin 1 of the IC also monitors the status of the transformer. The network

consisting of D555, D551, R575, and C554 rectifies and filters the AC voltage at

pin 2 of the secondary of the transformer T501. The output voltage enters pin 1

of the IC for transformer sensing. Voltage regulation is achieved via the

feedback network consisting of D565, D553, and R557.

Figure 20A

The diodes D557and D560 rectify the AC output voltage at the secondary of the

transformer T501. The network consisting of C573, C574, R597, R598 and R600

achieves filtering. This output voltage, labeled VSUS, is applied to the Scan and

Sustain boards. Voltage regulation is achieved via the feedback circuit comprised

of the resistors R602-R606 and the Error Detect IC, IC553. The resistor R605 is

used to adjust the DC output of the circuit as indicated on the label located on the

display panel.

Note: The voltage level of the Vsus output is not mentioned because it is

different for each plasma display panel. This voltage level can be found on the

panel information label located on the heat sink of the panel.

33

Page 34

Main Power Supply

Figure 20b

Most of the DC voltages used throughout the unit are derived from this power

supply. The voltage divider circuit consisting of resistors R551, R553 and R556

reduces the output of the PFC circuit to create the startup voltage. This voltage

enters pin 4 of IC552 to begin the oscillation. The startup voltage is also applied

to the voltage feedback circuit consisting of the optical coupler D566 and Diode

D554. The PWM output at pin 3 of IC552 is applied to the primary of the

transformer T502. As current passes through the transformer, magnetic field

builds up in its core. The primary current passes through the transistor located

inside the IC and the two source resistors R569, and R576. The voltage at the

transistor's Source increases at a proportional rate to that of the current increase.

This voltage is applied to the non-inverting input of the op-Amp at pin 1 of IC552

for over-current protection (OCP).

34

Page 35

Pin 1 of the IC also monitors the status of the transformer. The network

consisting of D564, D556, R573, and C553 rectifies and filters the AC voltage at

pin 2 of the secondary of the transformer T501. The output voltage enters pin 1

of the IC for transformer sensing. Voltage regulation is achieved via the

feedback network consisting of D566, D554, and R558.

VDA and other Voltage Sources

Figure 20c

The +12V source

The 20V source is primarily used in the A-Board. It is applied to a regulator IC,

IC2304 to obtain a 9V output. The diode D568 converts the AC voltage supplied

by the secondary windings of the transformer T502 to 12Vdc.

35

Page 36

The +15V source

The 15V source is primarily used in the A-Board. It is applied to regulator IC7502

and IC7503 to obtain 9.2V and 5V output. The diode D560 rectifies the AC output

of the secondary winding of the transformer T502 to 15Vdc.

The other +12V and +5V sources

The diode D573 rectifies the AC output of the secondary windings of the

transformer T502 to 12Vdc. This voltage source is applied to the PA board and D

board of the unit. The 12V source is connected to the anode of the D566This 12V

source is also regulated by IC555 to create a 5V source that is used on the D

board.

The DR15V source

The diode D574 converts the AC output of the secondary windings of the

transformer T502 to DR15V. This voltage source is applied to the SC and SS

boards for Scan and Sustain operations. The PA board and fan control circuit

also uses the DR15 voltage source.

The VDA voltage source

Pin 11 of the secondary of the transformer supplies the VDA voltage for use on

the SS Board. This voltage is tied to a regenerative (power save circuit) that

rectifies the voltage as well as controls the output. It monitors and controls the

current used by the SS Board to achieve lower power consumption. The VDA

source is also connected to the voltage feedback circuit consisting of IC557 and

the optical coupler D558. It is the voltage source that is monitored to control the

voltage output of this power supply.

36

Page 37

Protection Circuits

Figure 21

Protection circuits are incorporated in the unit to prevent the failure of a single

circuit or component from creating catastrophic damage.

Transistor Q7541 monitors the UNR21V, UNR14V, +9(S)V, and +5(S)V line. If

any of these supply lines develop a short circuit, transistor Q7541 goes into

conduction and applies a high to pin 69 of the MPU, IC001, triggering an SOS

condition.

Transistor Q7544 monitors the +3.3V, and +2.5V line. If any of these supply lines

increase in voltage transistor Q7544 goes into conduction causing its collector to

go low. As a result, Q7541 conducts and applies a high to pin 69 of the MPU,

IC001, triggering an SOS condition.

The +9(M)V, and +2.5(M)V are also monitored for a drop in voltage. A decrease

in any of these two supply lines forces the respective diode to conduct and

trigger Q7542. A high is applied to pin 69 of the MPU, IC001, triggering an SOS

condition.

37

Page 38

The Unregulated 15V and 1.8V lines are monitored for a voltage decrease.

Under normal conditions, the voltage drop derived from the voltage divider

circuits at the base of Q9714 or Q9716 is enough to turn the transistor on.

However should the voltage drop decrease, Q9716 or Q9714 respectively, turn

off, allowing the 5 volts at their collectors to forward bias transistor Q9715. This

effectively grounds pin 3 of the CPU triggering the shutdown condition.

The four ventilation fans are monitored to be sure they are operating properly. If

one of the fans opens or increases resistance, the resulting current change is

applied to pin 37 of the main CPU.

The Scan and Sustain voltages on the SC and SS boards are monitored in a

similar manner. The +15V Line on the SS board is fed to a voltage divider and

the result is compared to a reference voltage. The reference voltage is provided

by a zener diode. If the output of the comparator goes high, a transistor turns on,

effectively grounding the SOS line. The SC board uses a similar circuit.

Additionally the SS and SC boards contain LED indicators to alert the technician

when a problem exists. The LED should be lit during normal operation, a dark

LED indicates that a problem exists on that board.

Pin 63 of IC9709 monitors the 170 V, 15V, and 20V lines. If any of these supply

lines develop a short circuit, the inline transistor goes out of conduction and

applies a high to pin 63 of the Sub CPU, IC9709, triggering an SOS condition.

38

Page 39

System Control Circuit

Panel Operations

Figure 22

This main CPU, IC9701 uses three different I2C bus lines to control peripheral

devices. Bus line 1 controls the operation of the EEPROM. Programmable setting

such as drive settings or white balance is stored in the EEPROM, IC9702. Bus

line 2 controls the video processing, main tuner and the sub tuner. Examples of

video processing include on-screen display, tint or contrast as well as many other

picture adjustments. Bus line 3 reads the data from the Stand-by CPU for front

panel and remote control operation. Additionally bus line 3 reads the condition of

the SOS protection lines and transfers this information to the Main CPU.

In all cases, the Main CPU, is the master of the bus, all other devices are slaves.

This means that all commands are generated from the Main CPU.

39

Page 40

TV Operations

Figure 23

IC001 acts as the TV microprocessor, controlling the tuner, video and sound

functions. Information such as channel mapping or customer preferences is

2

stored in the EEPROM IC002. I

C bus lines 1 and 2 are primarily responsible for

video and audio operation. Figure 23 shows the connections to the Global core

IC’s, Tuners, AV switches, and input devices.

40

Page 41

Diagnostic Procedures

In some cases, the front panel LED will flash a pattern indicating the circuit that

has failed. Be sure to record the pattern displayed at start-up.

Number of

LED Flashes

1 Main Micro power

2 Scan

3 3.3V S0S IC9709

4 5V SOS

5 Power SOS

6 Fan Stop IC9709

7 SCAN Driver 2

9 SUS Driver

12 Tuner

LED indicators on the SS and SC boards alert the technician when a problem

exists. The LEDs should be lit during normal operation, a dark LED indicates that

a problem exists on that board.

Failed Circuit(s) Detection

Point

IC9709

STB5V

Vscan

Driver 1

Vf5

Vad

P5V

Vsus (170V)

15V

20V

½ Voltage

(Energy Recover)

½ Voltage

(Energy Recover)

Power

UNR21V

UNR14V

+2.5V(M)

+9V(M)

Vfo

+9V(S)

+5V(S)

+3.3V(M)

pin 34

IC9709

pin 64

Pin 3

IC9709

pin 2

IC9709

pin 63

pin 37

IC9709

pin 1

IC9709

pin 61

IC001 pin

69

Note Suspected

Board(s)

Voltage

too low

Voltage

too low

D Board

Voltage

down

Voltage

down

Fan

Load

over

Detect at

IC6581

Load

over

Detect at

IC6705

Voltage

down or

over

current

P Board

SC Board

P Board

P Board

SC Board

SS Board

Tuners or

PA Board or

P Board

41

Page 42

Diagnostic Flow Charts

No Power

There are three states of “No Power” indication by the power LED:

1. The power LED does not light up.

2. The power LED is green at power up. It then turns red a few seconds later

and blinks on and off.

3. The power LED is red at power up and never changes state.

The PF Board is suspected to be

Does the

power LED

turn on?

Yes

Do F900

and F901

measure

correctly?

defective.

Yes

No

Check the

P-Board.

No

Replace the defective

component.

42

Page 43

No Picture Flowchart 1

p

Is the On screen

Display information

Yes

Does the

problem exist on

uts?

all in

Yes

Is the SC

Board LED

illuminated?

No

SC Board is probably

defective.

No

No

Yes

Is the SS

Board LED

illuminated?

No

SS Board is

probably defective.

Yes

D Board is

probably

defective.

DG Board is probably

defective.

Does the

problem exist on

Composite

video?

Yes

H or DG Board is

probably defective.

No

Does the

problem exist

on PC/RGB

Yes

G Board is probably defective.

43

Page 44

No picture Flowchart 2

A

re the video signals

correct at the DG

Is the SC board

Is the TPSC1

Waveform incorrect?

Are the voltages at

connectors SC2 and SC23

Are the trigger signals at

connector SC20 of the SC

board correct?

The SC Board is suspected

to be defective.

board input?

YES

LED lit?

YES

YES

YES

YES

NO

Reference the H and DG board

troubleshooting charts

NO

The SC board is suspected

to be defective.

NO

The D Board is suspected to

be defective.

NO

The Power Supply is suspected

to be defective.

NO

The D Board is suspected to

be defective.

44

Page 45

Dark picture Flowchart

A

A

re the video signals

correct at the D

board LEDs lit?

Is the TPSS1

Waveform incorrect?

re the voltages at connectors

SS11 and SS12 of the SS

Are the trigger signals at

connector SS23 of the SS

board correct?

The SS Board is suspected

to be defective.

Board input?

YES

Are the SS

YES

YES

YES

YES

NO

Reference the DG Board

troubleshooting charts

NO

The SS board is suspected

to be defective.

NO

The D Board is suspected to

be defective.

NO

The Power Supply is suspected

to be defective.

NO

The D Board is suspected to

be defective.

45

Page 46

Local screen failure

The Plasma Display Panel unit may develop a failure, where the symptom is

localized in a particular area of the screen. The figure below can help localize the

circuit board that is most likely to be defective. In the example in figure 24, one

of the two boards, C2 and D is likely to be the cause.

Figure 24

46

Page 47

Service Hints

Symptom: No picture (black Screen)

Suggestion: The use of a magnifying glass can help localize the defective

printed circuit board. Use the

magnifying glass to take a close

look at the pixels of the screen.

1. If the pixels are totally dark, the

defect is most likely located in

one of the following boards:

a) SC-Board

b) SU-Board

c) SD-Board

1. Check the status of the LED located on the SC-Board; if the LED is dark, a

malfunction of the SC-Board is suspected.

2. Listen to the buzz noise of the SC board; if the buzz noise is not present, a

malfunction of the SC-Board is suspected.

Suggestions: Check the

Scan pulse waveform at

TPSC1. (Use TPSS1 of the

SS-board to trigger the

oscilloscope.)

Verify the input signals at

connector SC2, SC23, and

SC20.

Verify that the signals of the

clock and serial data lines

from the D-board are present

at connector SC20.

Figure 25

TPSC1 TPSS1

Figure 26

47

Figure 27

Page 48

Symptom: No picture (black Screen)

Figure 28

Suggestion: The use of a magnifying glass

can help localize the defective printed circuit

board. Use the magnifying glass to take a

close look at the pixels of the screen.

If the pixels are faintly lit, the defect is most

likely located in one of the following boards:

A) SS-Board

B) SS2-Board

C) SS3-Board

1. Check the status of the LED located on

the SS-Board; if the LED is dark, a

malfunction of the SS-Board is suspected.

2. Listen to the buzz nois e of the SS-board. If the

buzz noise is not present, a malfunction of the

SS-Board is suspected.

3. Verify the input signals at connector SS23.

SS Board

Figure 29

48

Page 49

Suggestions:

Check the Scan

pulse waveform

at TPSC1 of the

SC-Board. (Use

TPSS1 of the

SS-Board to

trigger the

oscilloscope.)

Proceed to

the power

sources at

connector S

and SS12.

Verify that the clock

and serial data lines

from the D-board are

check

S11,

present at connector SS23.

Figure 30

49

Page 50

Symptom: Horizontal Black Bar

(Completely dark)

Note: The use of a magnifying glass can help

localize the defective printed circuit board. Use

the magnifying glass to take a close look at the

pixels in the area of the black bar.

1 If the pixels are totally dark, the defect is

most likely located in one of the following

boards:

a) SC Board

b) SU Board (upper half of the screen only)

c) SD Board (lower half of the screen only)

2. If the pixels are dimly lit, the defect is most likely located in one of the

following boards:

a) SS Board

b) SS2 Board (upper half of the screen only)

c) SS3 Board (lower half of the screen only)

Figure 31

50

Page 51

Symptom: Vertical Black Bar

Suggestion: Since the C2 board contains

the serial to parallel converters for the

picture data that drive this portion of the

screen; the most likely cause for this defect

can be localized to the C2-Board or the D-

Board.

Symptom: Vertical Black Bar

Suggestion: Since the C1 board contains

the serial to parallel converters for the

picture data that drive this portion of the

screen; the most likely cause for this

defect can be localized to the C1-Board

or the D-Board.

Symptom: No OSD but it has video.

Suggestion: Check signal on the DG board.

Symptom: Burned image

(pattern) is visible.

Suggestion: Access the CAT

mode and activate the scroll

bar or run the set with a white

raster for at least fifteen

minutes.

Figure 32

Figure 33

Panasonic

Figure 34

51

Page 52

Adjustments

If the power supply board is replaced the following adjustments are required.

+B Set-up

Item / Preparation

• Input a 100% white signal.

• Set the picture mode to Normal and the White Balance to Normal

• Adjustments/Confirmation

Adjust and confirm the indicated test point below for the specified voltage.

Adjustment

Name Test Point Voltage Potentiometer

Vsus P11 pin 2 Vsus ± 1V R605

Vda P12 pin 1 67.0 ± 0.5V R590

Confirmation

Name Test point Voltage

15V P23 pin 1 15.4V ± 0.5V

15V P7 pin 1 15.2V ± 0.5V

12V P25 pin 1 11.8V ± 0.5V

Audio 12V P5 pin 7 12.5V ± 0.8V

5V P25 pin 5 5.1V± 0.3V

STB 5V P27 pin 4 5.0V ± 0.3V

Fan 15V P10 pin 1 15.4V ± 0.5V

Fan 5V P10 pin 4 5.1V± 0.3V

PFC C468 (+), C468 (-) 380V ± 15V

52

Page 53

Driver Set-up

A

Item / Preparation

• Input an APL 100 % white signal.

• Set the picture controls to:

Picture mode = Normal

White Balance = Cool

Aspect = 16:9

Adjustments

To perform the following adjustments, please refer to the panel information label

located on the heat sink of the panel. See Figure 35 for more information about

the panel label.

Name Test point Voltage Volume

Vsus TPVSUS

(SS-BOARD)

Vbk TPVBK

(SC-BOARD)

Ve TPVE

(SS-BOARD)

Vset TPVSET

(SC-BOARD)

Vad TPVAD

(SC-BOARD)

Vda TPVDA

(SS Board)

VSCN TPVSCN

(SC-BOARD)

Vsus ± 1V* R605

(P-BOARD)

155Vbk ± 5V R6443

(SC-BOARD)

Ve ± 1V* R6774

(SS-BOARD)

218 V ± 6V Verify Only

-90 ± 1V R6477

(SC-BOARD)

67V ± 1V R590

(P-BOARD)

Vad+118V ± 2V Verify only

* Refer to the panel label for the exact value

Panel Label information

djustment

voltage

Figure 35

53

Page 54

Initialization Pulse Adjust

Item / Preparation

• Input a Crosshatch signal.

• Set the picture mode to Normal, and White Balance to Normal

Adjustments

Adjust the indicated test point for the specified waveform. Use TPSS1 as the

trigger source.

Test point Volume Level

T1 TPSC1 (SC) R6523 (SC-Board) 20 ± 15µ Sec

T2 TPSC1 (SC) R6557 (SC-Board) 170 ± 20µ Sec

Figure 36

54

Page 55

P.C.B. (Printed Circuit Board) exchange procedure

1. Caution

Wait 1 minute for the electrolytic capacitors to discharge before removing

any PCB from the unit.

2. Quick adjustment after P.C.B. or Panel exchange

P.C.B. Item Volume Test point Voltage level

Panel All items in this table

Vsus R605 (P-Board) TPVsus (SS) Vsus ± 1V* P Board

Vda R590 (P) TPVDA (SS Board) 67V ± 1V

SC Board

SS Board Ve R6774 (SS) TPVE (SS) Ve ± 1V*

D, DG Board White Balance, Pedestal and Sub brightness for NTSC, Pal, HD, PC and 625i

*Refer to the Panel label for the exact value.

Vbk R6443 (SC) TPVBK (SC) 155V ± 5V*

Vad R6477 (SC) TPVAD (SC) -90V ± 1V*

Vset TPVSET

(SC-BOARD)

VSCN TPVSCN

(SC-BOARD)

signals

218 V ± 6V Verify Only

Vad+118V ± 2V Verify only

Adjustment Volume Locations

Figure 37

55

Page 56

Test Point locations

Figure 38

56

Page 57

Serviceman mode (Electronic Controls)

This Plasma Display television uses the I²C Bus circuitry to control functions and

replace many mechanical controls. Instead of adjusting mechanical controls

individually, many of the control functions are now performed by using “On

Screen Display Menu”. (The Serviceman Adjustment Mode.)

Note: It is suggested that the technician reads all the way through and

understand the following procedure for Entering/Exiting the Serviceman

Adjustment Mode.

Entry to Serviceman Mode:

When minor adjustments need to be done to the electronic controls, the method

of entering the serviceman mode is as follows:

Using the Remote Control:

1. Select SET-UP icon and select CABLE mode.

2. Select TIMER icon and set SLEEP time for 30 Min.

3. Press “ACTION” twice to exit menus.

4. Tune to Channel 124.

5. Adjust VOLUME to minimum (0).

6. Press VOL down on the receiver. Red “CHK” appears in the upper left

corner of the screen.

7. Select an active station.

Note: If more than 30 minutes are needed after the receiver is in the

SERVICEMAN mode, setting the TIMER back to NO can disable the Sleep

Timer.

Caution: Prolonged display of patterns WILL cause an after image retention into

the panel.

The Plasma Display receiver is now in Serviceman Mode.

• Press Power on the Remote

Control to display the

Serviceman Adjustment Menu.

• Press Power again on the

Remote Control to exit the

Serviceman Adjustment Menu.

Figure 39

57

Page 58

Exiting the Serviceman Mode:

Press the Power on the receiver (not the remote) until the receiver turns off.

The unit momentarily shuts off (for about 5 seconds); then comes back on tuned

to channel 3 with a preset level of sound.

Important note:

If the Action and Power buttons of the television are used to exit the

Serviceman mode, any programmed channels, channels caption data, and

some other user-defined settings will be erased.

Note: To access NTSC or HDTV adjustments, set the receiver’s input to the

appropriate mode (TV or HDTV).

CAT (computer aided test) Mode

CAT mode menu

CAT Panel

sys8.1

IIC Mode

CD Mode

SD Mode

MS Mode

ID Mode

Mode Function Access Button

IIC Service Alignment Action

CD

(Complete

Diagnostics)

SD (Status

Display)

MS Mode Not used ------

ID Not used ------

Software Version

Information EEPROM

Edit

MTBF Parameter Action

Mute

More than 5

seconds

How to access the CAT mode

1. Enter the servicemen mode.

2. Select the OTHER (PSRVS).

3. Press the Action button on the remote.

To exit the CAT mode, access the ID mode and switch off the main power.

58

Page 59

I2C Mode

Select the I2C mode by pressing the Up/Down button on the remote control from

the front page of the CAT menu, and then press the Action button on the

remote control.

Accessing the I

Figure 40

2

C mode?

1. Select the alignment subject by pressing the 1

or 2 buttons on the remote control.

2. Select the alignment item by pressing the 4

button on the remote control.

3. Adjust the optimum setting by pressing the

Volume Up/Down buttons on the remote

control.

The data is memorized when you exit the I

2

C mode

To exit the I2C mode, press the Recall button on the remote

control.

59

Page 60

I2C Menu Structure

The values indicated in this flowchart are sampled data.

Figure 41

60

Page 61

CD mode

A

Select the CD mode from the front page of the CAT menu by pressing the

Up/Down button on the remote control, and then press the Mute button on the

remote control for more than 5 sec.

OSD

MiCom Software version

Memory data version D

Memory data version H

Memory data change Address

Data

The software version of the EEPROM (IC9354) can be upgraded by:

1. Installing a new version IC

2. Loading the new version software from the loader tool, TZSC07036

Memory data change

Note: The data is memorized when the main power switch is pushed to the off

position.

MiCom Software Version

Memory data version D

Memory data version H

Memory data change Address

Data

ddress

Data

0.11

0.11 1

21.05

OK

8 63

78 3F

0 0

0 0

Factory

New data

Original data

Change by pressing the Up/Down

0 0

buttons on the remote control.

Change by pressing the Left/Right buttons on the

remote control.

0

0

Change by pressing the Volume

Up/Down buttons on the remote

61

Page 62

SD Mode

Select the SD mode from the front page of the CAT mode by pressing the

Up/Down button on the remote control, and then press the Action button on the

remote control.

OSD

Input command

Check

23 25 27-- -- -- -- 27 27 27

-- -- -- -- -- -- -- 28 25 25 37

Power Protect

MTBF Parameter WT PT

72 12

History of remote control command

(Factory use)

Cumulative time for power on

condition. (Unit: hour)

Number of Power On Cycles

Remote Control mode

A

B

To exit the SD mode, press the Action button on the remote control.

62

Page 63

Alignment Procedures

Pedestal Setting

Equipment required: RF Video Gray Scale Generator

Panel Settings; Picture = Normal, White Balance = Cool, Aspect Ratio = 16:9

Pattern Display:

Step 1- Access the R, G and B cutoff settings and set them to “80”.

Step 2- Under the Chroma Control setting, Set Gun off to "5" (Only green

pixels emitting).

Step 3- Access the RGB Sub Adjust, G Sub Bright setting and adjust G

Sub bright so that green pixel emission starts at black 2% area and no

emission occurs in the black 0% area.

Step 4- Under the Chroma Control setting, Set Gun off to "3". (Only blue

pixels emitting.)

Step 5- Access the RGB Sub Adjust, B Sub Bright setting and adjust B

Sub bright so that blue pixel emission starts at black 2% area and no

emission occurs in the black 0% area.

Step 6- Under the Chroma Control setting, Set Gun off to "6". (Only red

pixels emitting.)

Step 7- Access the RGB Sub Adjust, R Sub Bright setting and adjust R

Sub bright so that Red pixel emission starts at black 2% area and no

emission occurs in the black 0% area.

Step 8- Change input to PC / RGB signal. Repeat procedure (1 to 7) using

PC input signal.

Figure 42

63

Page 64

NTSC White Balance Adjustment

p

p

Equipment required: NTSC Pattern Generator, Colorimeter

Panel Settings; Picture = Standard, Color Temperature = Cool, Aspect Ratio =

16:9

Step 1- Using the Pattern generator; apply a 20

IRE Window pattern signal to the panel. Apply the

color sensor to the panel and monitor the values.

Step 2- Adjust the Sub Bright Setting to 10 cd/m

Step 3- Set the G Cutoff Setting Value to 80.

Step 4- Adjust the Red and Blue Cutoff settings to

match the values in Table 1.

Step 5- Readjust the Sub Bright setting to 10

cd/m2.

Step 6- Apply an 80 IRE window pattern signal to

the Panel.

Step 7- Set the G Drive Setting value to E8.

Step 8- Adjust the Red and Blue Drive settings to

match the values in Table 1.

Step 9- Reapply the 20 IRE pattern and 80 IRE

patterns and verify that the drive and cutoff

settings match the settings in Table 1, adjust as

necessary.

Step 10- Adjust the All Drive Settings value to FC.

Step 11- Reapply the 20 IRE pattern and verify the light settings match the

table below, adjust as necessary.

2

.

20 IRE Window

attern

80 IRE Window

attern

Table 1

Color Temperature X Y

Cool (High) 0.276 0.276

Normal (Mid) 0.288 0.296

Warm (Low) 0.313 0.329

Step 12- Press the R button then the Picture button on the remote control.

Change the color temperature to Normal. Press the R button again then

the Action button to re-access the IIC mode.

Step 13- Repeat steps 2 to 11 for Normal Color Temperature.

Step 14- Press the R button then the Picture button on the remote control.

Change the color temperature to Warm. Press the R button again then

the Action button to re-access the IIC mode.

Step 15- Repeat steps 2 to 11 for Warm Temperature.

Step 16- Change the Color temperature to Cool Mode, then re-adjust the

Sub bright value to “30”.

64

Page 65

HD Panel White Balance Adjustment

p

p

Equipment required: 720p/1080i Pattern Generator, Colorimeter

Panel Settings; Picture = Standard, Color Temperature = Cool, Aspect Ratio =

16:9

Step 1- Using the Pattern generator; apply a 20

IRE Window pattern signal to the panel. Apply the

color sensor to the panel and monitor the values.

Step 2- Adjust the Sub Bright Setting to 10 cd/m

Step 3- Set the G Cutoff Setting Value to 80.

Step 4- Adjust the Red and Blue Cutoff settings to

match the values in Table 1.

Step 5- Readjust the Sub Bright setting to 10

cd/m2.

Step 6- Apply an 80 IRE window pattern signal to

the Panel.

Step 7- Set the G Drive Setting value to E8.

Step 8- Adjust the Red and Blue Drive settings to

match the values in Table 1.

Step 9- Reapply the 20 IRE pattern and 80 IRE

patterns and verify that the drive and cutoff

settings match the settings in Table 1, adjust as

necessary.

Step 10- Adjust the All Drive Settings value to FC.

Step 11- Reapply the 20 IRE pattern and verify the light settings match the

table below, adjust as necessary.

2

.

20 IRE Window

attern

80 IRE Window

attern

Table 1

Color Temperature X Y

Cool (High) 0.276 0.276

Normal (Mid) 0.288 0.296

Warm (Low) 0.313 0.329

Step 12- Press the R button then the Picture button on the remote control.

Change the color temperature to Normal. Press the R button again then

the Action button to re-access the IIC mode.

Step 13- Repeat steps 2 to 11 for Normal Color Temperature.

Step 14- Press the R button then the Picture button on the remote control.

Change the color temperature to Warm. Press the R button again then

the Action button to re-access the IIC mode.

Step 15- Repeat steps 2 to 11 for Warm Temperature.

Step 16- Change the Color temperature to Cool Mode, then re-adjust the

Sub bright value to “30”.

65

Page 66

Sub Brightness Setting

Equipment required: NTSC grayscale pattern Generator

Panel Settings; Picture = Normal, Aspect Ratio = 16:9

Pattern Display:

Note: Adjust in a Dark room.

Step 1- Set the white balance to Cool.

Step 2- Access the All cutoff setting in service mode and adjust so that pixel

emission starts in the 2% area and there is no emission in the 0% area.

Step 3- Write down all cut off data.

Step 4- Set the white balance settings to Normal.

Step 5- Adjust all the cut off values to the same data values of the Cool mode

settings.

Step 6- Set the white balance settings to Warm.

Step 7- Adjust all the cut off values to the same data values of the Cool mode

settings.

Step 8- Change the pattern to HD and apply it to the to the component input.

Step 9- Copy PAL all cutoff data to HD Mode.

66

Page 67

Hotel Mode Operation

Hotel Mode restricts certain operation functions for use in hotels

Entry to Hotel Mode

1. Enter the Service Mode using the previously described method.

Note: Leave the set tuned to cable channel 124, changing the channel may

inhibit access to the Hotel Mode EEPROM address.

2. Press the Power button on the remote control to display the service menu.

Figure 43

3. Press and hold the MUTE button on the remote

control for a few seconds. The display will change

from the standard serviceman mode setting to the

EEPROM address / data display.

4. Press the Channel Down button of the remote or

receiver to select the EEPROM ADDRESS 1584.

5. Press the Volume Up button of the remote or

receiver to set the data at EEPROM address to 01.

Data 01 allows access to Hotel Mode, Data 00

inhibits access to and disables Hotel Mode.

6. Push the Power button of the receiver or the

remote control to hide the Serviceman mode menu

EEPROM Address /

Data Display

67

Page 68

7. Press and hold the Volume Down button

of the receiver and press the TV/Video

button of the remote control three times

within two seconds to display the Hotel

Setup menu.

Item Function Options

INITIAL INPUT The receiver

automatically selects this

input every time power is

switched on.

INITIAL VOL

LEVEL

The receiver

automatically selects this

volume level every time

power is switched on.

MAXIMUM

VOL LEVEL

Limits the maximum

Volume level

INITIAL CH The receiver

automatically selects this

channel every time power

is switched on.

BUTTON

LOCK

The receiver

automatically disables the

selected front panel

buttons of the receiver

every time power is

switched on.

Figure 44

OFF /TV /COMP1 /COMP2 /DIGITAL

/VIDEO1 /VIDEO2 /VIDEO3 /PC

/JPEG

Off: gives priority to the last input in

memory.

<Selection/Range>: OFF / 0 to 63

OFF: gives priority to the last volume

Level in memory at power off

The Initial Volume can be changed

when the unit is in the Hotel Mode.

However, priority is given to the last

volume level in memory when Initial

Volume is Off.

Note: When the Initial Vol. is larger

than the Maximum Vol. make the

Initial Vol. and Maximum Vol. the

same value.

<Range>: 0 to 63

The receiver allows the user to adjust

the volume level up to the Maximum

Vol. selected.

Note: When the Initial Vol. is larger

than the Maximum Vol. make the

Initial Vol. and Maximum Vol. the

same value.

<Selection>: OFF / 0 to 69 for TV

mode and C0 to C125 for cable mode

OFF: gives priority to the last CH in

memory at power off

<Selection>: OFF / ACTION / ALL

OFF: No button restriction

ACTION: restricts ACTION Button

selection

ALL: inhibits all button operations

68

Page 69

REMOCON

LOCK

The receiver

automatically disables the

selected keys of the

remote control every time

<Selection>: OFF / ACTION

OFF: No Restrictions

Action: Action Button on the remote is

inhibited

power is switched on.

8. Push the Power button of the receiver or the remote control to hide the

Serviceman mode menu

9. Press the Power button on the front panel to store the changes; the Hotel

mode is now active.

Note: To return the unit to normal operation, use steps 1 through 5 to change the

data at EEPROM address 1584 to 00, the Hotel mode is now disabled. All normal

user functions are restored.

69

Page 70

Service Contact Information

Panasonic

Customer

Call Center

Tech Support

Hotline

Other Numbers 1-800-833-9626 Parts Dept.

1-800-211-7262

PTV and Digital Products

1-800-743-2335 (Authorized Service Centers

only)

All Other Products

1-800-572-2672 Authorized Service Centers

only (access code required)

Fax 1-800-348-7315

1-201-392-4207 Non–authorized (limited time

access)

1-800-458-5397 Musical Instruments

1-201-392-4843 Telephone PBX Systems

1-800-414-4408 Cellular Phones

1-877-924-2473 Massage Loungers

1-201-392-4281 Commercial MWO/Hotel

Televisions

70

Loading...

Loading...