Page 1

INSTALLATION

INSTRUCTIONS

Through the Wall Fan "Whisper Wall"

Ventilating Fan

FV-08WQ1

READ AND SAVE THESE INSTRUCTIONS

Please read instructions carefully before attempting to install, operate or service the

Panasonic Ventilating Fan. Failure to comply with these instructions could result in personal

injury and/or property damage. Please retain for future reference.

Table of Contents Pages

List of components............................................................................................................ 2

Description ....................................................................................................................

Reference installation drawing.......................................................................................... 2

Dimensions .....................................................................................................................

Specifications.................................................................................................................

Unpacking ......................................................................................................................

General safety precautions............................................................................................... 4

Installation I (In new construction) .................................................................................... 5-6

Installation II (In remodeling) ............................................................................................ 7-8

Maintenance .....................................................................................................................9-10

Product Service.................................................................................................................10

....

...

...

2

..

3

4

4

Page 2

List of components

FV-08WQ1

Part name Drawing

Wall sleeve

Quantity

1

Part name Drawing

III (4 x 8)

Screw

Template (Pattern paper)

Screw I (4 x 30)

Mounting plate

Screw II (4 x 6) (for new

construction only)

4

1

2

Exterior hood

Externsion sleeve

Description

This Panasonic wall mounted ventilating fan uses a propeller fan driven by a capacitor motor.

The motor is designed for extended service life with reduced energy consumption.

It also incorporates a thermal-cutoff device for safety. The grille is easily detachable from the main unit.

Quantity

1

1

1

1

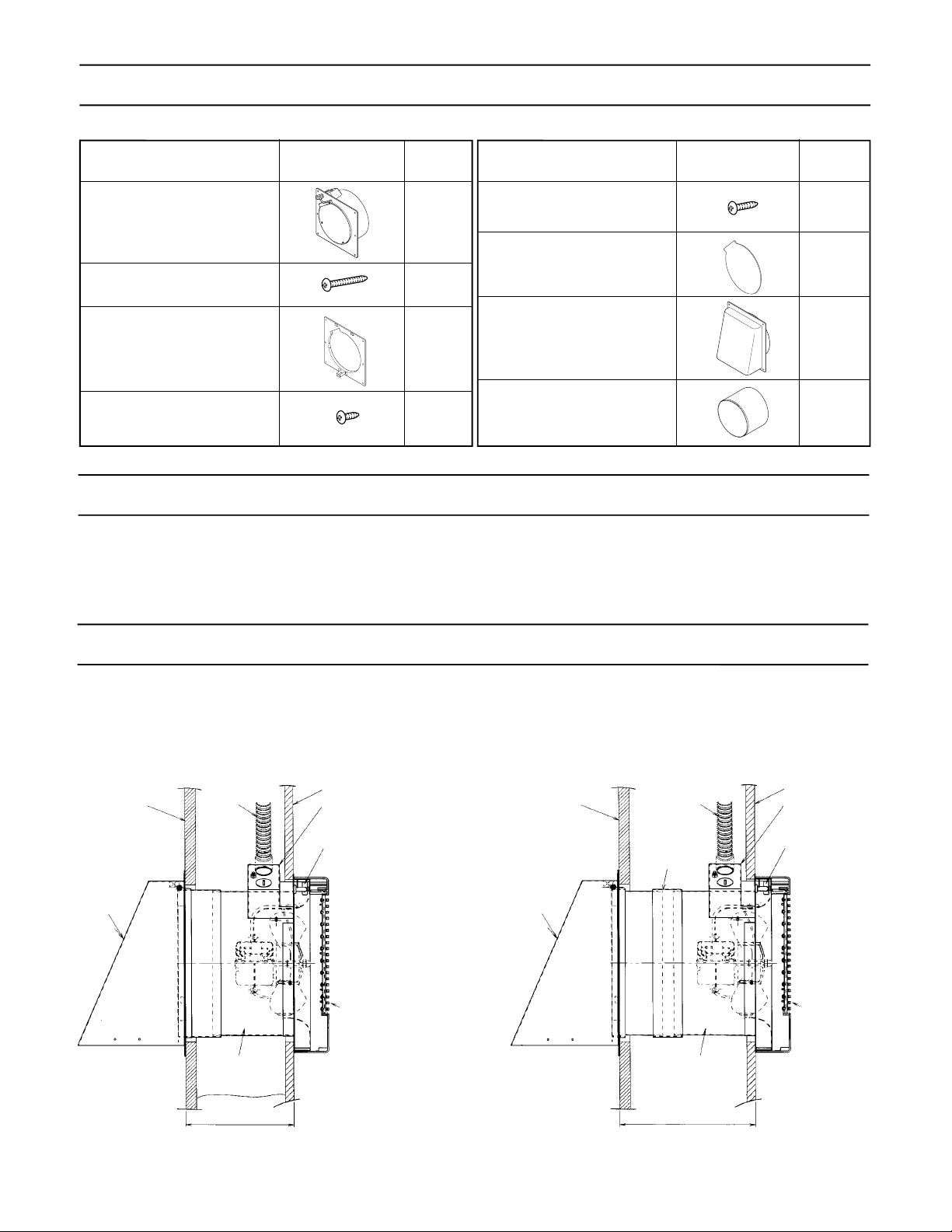

Reference installation drawing

When the wall thickness is between 152.4 mm (6") and 254 mm (10"), mount the extension

sleeve as shown below. When the wall thickness is more than 254 mm (10"), prepare an

extension sleeve with an inner diameter of 207 mm (8 5/32") and a length of wall thickness

minus 127 mm (5"), and mount it as shown below. (The seam should be covered with

aluminum tape.)

Main unit

Indoor

Exterior wall

Exterior

hood

Outdoor

Wall thickness: 114.3 - 152.4 mm (4.5 - 6")

No extension sleeve is used.

Flexible

conduit

Wall sleeve

Interior wall

Junction box

Connector

Exterior wall

Exterior

hood

Outdoor

Flexible conduit

Extension

sleeve

Wall sleeve

Interior wall

Junction box

Connector

Main unit

Indoor

Wall

thickness

Wall

thickness

2

Page 3

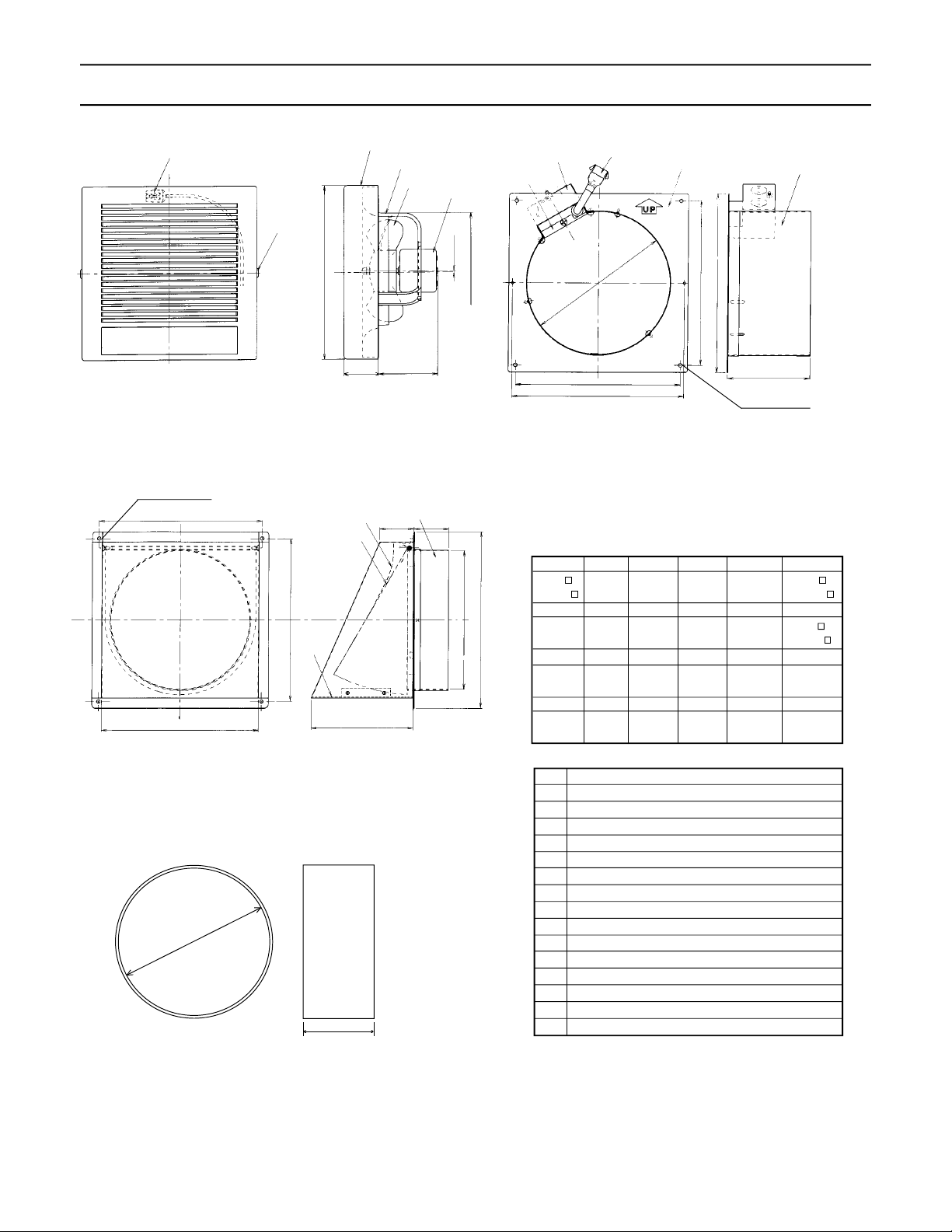

Dimensions

Main unit

Exterior hood

4-5 dia. hole

Wall sleeve

5

6

S

R

15

Q

1

2

3

4

D

A

14

P

C

13

O

B

12

E

N

L

M

9

10

ABCD E F

260

(10-1/4 ) (2-1/16) (3-15/32) (3/32) (6-13/16ø) (9-27/32

GH I J K L

115 203 240 230 230 260

(4-17/32) (8) (9-7/16) (9-1/16) (9-1/16) (10-1/4

MNO P Q R

204ø 50 50 150 230 240

(8-1/32ø) (31/32) (31/32) (5-29/32) (9-1/16) (9-7/16)

STU

240 207 127

(9-7/16) (8-5/32) (5)

11

H

J

I

52 88 2 173ø 250

7

K

F

G

4-5 dia. hole

Unit: mm (inch)

8

)

)

Extension sleeve

T

No. Part name

1 Grille

2 Frame

3 Blade

4 Motor

5 Connector

6 Hook

7 Flange

8 Duct

9 Junction box

10 Junction box cover

11 Connector

12 Shutter

13 Duct

U

14 Spring

15 Bird screen

3

Page 4

Specifications

Model Air direction V Hz Power consumption

FV-08WQ1 Exhaust 120 60 17 1340 70 1.1 3.1

*1

At 0.0" Static pressure, (Pa)

*2

For main unit only.

*1

(W) Speed

(r/min.)

*1

Air delivery at 0.03"WG Noise Weight

(CFM) lb. (kg)

*2

(1.4)

Unpacking

Unpack and carefully remove unit from the carton. Refer to list of components to verify that all parts were supplied.

General safety precautions

1. Do not install this ventilating fan where air temperature may exceed 104 °F. (40 °C)

2. Make certain that the nominal service voltage is 120V 60 Hz.

3. Follow all local electrical and safety codes, as well as the National Electrical Code (NEC) and the Occupation Safety and Hea

Act (OSHA).

4. Always disconnect the power source before working on or near the fan, motor or junction box.

5. Protect the power cord from sharp edges, oil, grease, hot surfaces, chemicals, or other objects.

6. Do not kink the power cord.

7. Provide suction parts with proper ventilation.

(Cooking area)

Do not install above or

inside this area.

8. This unit is acceptable for use over a bathtub or shower when

installed in a GFCI protected branch circuit.

lth

CAUTION:

1. For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

2. Not for use in cooking area. (Fig. A)

Cooking

equipment

Floor

3. This product must be grounded.

4. To reduce the r isk of injur y to persons , install fan at least 7 - 10

Fig. A

feet (2.1 - 3.05 meters) above the floor.

WARNING:

To reduce the risk of fire, electric shock, or injury to persons, observe the following;

A.Use this unit only in the manner intended by the manufacturer. If you have any questions, contact the manufacturer.

B.Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable codes and

standards, including fire-rated construction.

C.Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel burning

equipment to prevent backdrafting. Follow the heating equipment manufacturer's guideline and safety standards such

as those published by the National Fire Protection Association (NFPA), and the American Society for Heating Refriger ation and Air Conditioning Engineers (ASHRAE), and the local code authorities.

D.When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

E.If this unit is to be installed over a tub or shower, it must be marked as appropriate for the application.

F. Do not use this fan with any solid-state speed control device.

G.Before servicing or cleaning unit, s witch po wer off at service panel and lock the service disconnecting means to prevent

power from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten

a prominent warning device, such as a tag, to the service panel.

H.NEVER place a switch where it can be reached from a tub or shower.

4

Page 5

Installation I (In new construction)

NOTE:

If the wall thickness is more than 152.4 mm (6"), refer to the

reference installation drawing when the wall thickness is more

than 152.4 mm (6") on page 2. However, this ventilating fan

can be installed on an interior wall with a thickness of 12.7 –

16 mm (1/2 – 5/8”). For installation on other walls, refer to

the method on page 7, Installation II.

Exterior wall

1. Cut a 215 mm (8 1/2”) diameter hole in the wall. (Fig. 1)

(Cut the hole next to a wall stud as shown in the figure.).

2.

Adjust position of the flange on the wall sleeve (Fig. 2).

Loosen the three screws (arrow pointed) and slide the wall

sleeve horizontally to adjust its position to compensate for

the thickness of the interior wall (A). When this has been

done, tighten all three screws.

3. After providing a 3 mm notch in the wall stud, secure the flange

to the wall stud with supplied screws (Screw I). (Fig. 3)

4. Remove the junction box cover by removing screw (B).

5. Remove one of the knockout holes in the junction box.

8 1/2”

diameter

Flange

Wall sleeve

1/8"

3 mm

A

Knockout hole

Stud

Fig. 1

Fig. 2

Wiring Diagram

Switch (Availab le

on the market)

Power supply

AC 120 V 60 Hz

Earth ground

Motor

Junction box

White

Black

Red

Green

Green

6. Refer to the wiring diagram above.

Using the wire nuts, connect the house power wires to

ventilating fan wires.

(Fig. 4): black to black; white to white; green to greens.

Reattach the junction box cover.

CAUTION:

Reattach the junction box cover carefully so that the lead

wires are not pinched by the cover.

B

Hole in the wall

Fig. 3

Flexible conduit

Connector

Black

Green

White

Fig. 4

5

Page 6

Installation I (In new construction) - continue

7. Insert the attached exterior hood from the outside to cover

the wall sleeve, and secure it with four screws or nails.

Cover the seam between the wall sleeve and exterior

hood with aluminum tape, and apply mortar or caulking

around the exterior hood flange to prevent rainwater from

coming in. (Fig. 5)

Exterior hood

8. Using enclosed template (pattern paper), mark and cut

the opening in the interior wall cover. (Fig. 6)

9. Press the mounting plate tightly against the wall and secure to the outside of the wall sleeve with the supplied

screws(screw II). (Fig. 7)

10. Remove the grille from the fan unit.

Press the spring locks on the sides and pull the grille

back. (Fig. 8)

Aluminum

tape

Interior wall

material

Seam

Finish with mortar

or caulk.

Grille

Fan unit

(Frame)

Fig. 5

Fig. 6

Fig. 7

11. Attach the electrical connectors to each other, hook the

frame latches onto the mounting plate latch, and secure

the fan unit to the mounting plate with the supplied screw

(screw III). (Fig 9)

CAUTION:

Do not pinch the power cord with the frame.

12. Reattach the grille to the frame.

CAUTION:

Press on the grille until it clicks.

NOTE:

Be sure to paint the exterior hood. Before painting, thoroughly wipe off any oil on the surface . Also make sure that

the paint does not enter inside of the hood.

Fig. 8

Latch

Latch

Frame

Grille

Mounting plate

Fig. 9

6

Page 7

Installation II (In remodeling)

NOTE:

If the wall thickness is more than 152.4 mm (6"), refer to the

reference installation drawing when the wall thickness is

more than 152.4 mm (6") on page 2.

1. Cut holes in the interior and exterior walls. (Fig. 10)

Cut a hole in the interior wall using the attached template

(pattern paper), and make a 215 mm (8 1/2”) hole in the

exterior wall.

CAUTION:

The hole should be made in an area where pipes, cables

and telephone lines are not run, and there are no studs in

the way.

Hole in the

interior wall

Hole in the

exterior wall

Fig. 10

2. Lay interior wiring through the wall using a flexible conduit.

3. Remove the junction box from the wall sleeve by removing two screws (C). (Fig. 11)

4. Remove the junction box cover by removing screw (B).

5. Remove the screws (D) and replace the wall sleeve flange

with the mounting flange. (The mounting plate face should

align with the end of the wall sleeve which is protruding

from indoor side.)

6. Attach the wall sleeve to the wall with supplied screws

(Screw I). (Fig. 12)

If the interior wall material is plaster board, use appropriate fasteners (locally available) to secure the wall sleeve.

Junction box

B

A hole where the junction

box was attached to the

wall sleeve.

Flange

Wall sleeve

D

C

Mounting plate

Fig. 11

Fasterners,

etc.

Mounting plate

Fig. 12

7

Page 8

Installation II (In remodeling) - continued

7. Insert the attached exterior hood from the outside to cover

the wall sleeve, and secure it with four screws or nails.

Cover the seam between the wall sleeve and exterior hood

with aluminum tape, and apply mortar or caulking around

the exterior hood flange to prevent rainwater from coming in. (Fig. 13)

8. Pull the flexible conduit through the hole where the junction box was attached to the wall sleeve. (Fig. 14)

Exterior hood

9. Remove the knockout hole in the junction box and secure one end of the flexible conduit to the junction box.

Wiring Diagram

Switch (Available on

the market)

Power supply

AC 120 V 60 Hz

Earth ground

Motor

Junction box

White

Black

Red

Green

Green

10. Refer to the wiring diagram above. Using the wire nuts,

connect the house power wires to ventilating fan wires.

(Fig. 4 on page 5): black to black; white to white; green

to greens.

11. Place the junction box in its original position in the wall

sleeve and reattach the box cover. (Fig. 15)

Aluminum

tape

Flexible conduit

Seam

Finish with mortar

or caulk.

Fig. 13

Fig. 14

CAUTION:

Reattach the junction box cover carefully so that the lead

wires are not pinched by the cover.

12. Remove the grille from the fan unit. (Fig. 8 on page 6)

13. Attach the electrical connectors to each other, hook the

frame latches onto the mounting plate latch, and secure

the fan unit to the mounting plate with the supplied screw

(screw III). (Fig 16)

14. Reattach the grille to the frame.

CAUTION:

Press on the grille until it clicks.

NOTE:

Be sure to paint the exterior hood. Before painting, thor-

oughly wipe off any oil on the surface. Also make sure that

the paint does not enter inside of the hood.

Fig. 15

Latch

Latch

Frame

Grille

Mounting plate

Fig. 16

8

Page 9

Maintenance

WARNING:

Turn off the units power before performing maintenance. Perform maintenance procedure monthly.

CAUTION:

1. Never use gasoline, benzene, paint thinner or other similar chemicals for cleaning the ventilating fan.

2. Do not allow water to enter the motor and motor compartment.

3. Do not immerse resin parts in water with temperature higher than 140

1. Remove the grille (Hold the grille and press the hooks on

each side simultaneously. Pull the grille straight out from

the wall.) (Fig. 17)

o

F (60oC).

Grille

Fan unit

(Frame)

2. Wash and clean the grille (Use non-abrasive kitchen detergent). Wipe it dry with a clean cloth. (Fig. 18)

3. Remove dust and dirt from the fan blades and body using a vacuum cleaner. (Fig. 19)

.

Vacuum

cleaner

Fan unit

(Frame)

Blade

Fig. 17

Fig. 18

Fig. 19

9

Page 10

Maintenance - continued

4. Using a cloth dampened with a non-abrasive kitchen detergent, remove any dir t from the fan blades and body.

Wipe them dry with a clean cloth. (Fig. 20)

5. Reattach the grille.

CAUTION:

Press on the grille until it clicks.

Blade

Fan unit

(Frame)

Fig. 20

Product service

Warning concerning removal of covers.

This unit should be serviced by qualified technicians only. No service information is provided for customers. Your product is

designed and manuf actured to ensure a minimum of maintenance. However, should your unit ever require service, a nationwide system of factory service centers and AUTHORIZED INDEPENDENT SERVICE CENTER is maintained to support your

product's warranty. (In the U.S.A., call 1-800-545-2672 to locate the PASC Authorized Service Center nearest you.)

PANASONIC HOME AND COMMERCIAL PRODUCTS COMPANY

One Panasonic Way, Secaucus, NJ 07094

PANASONIC CANADA INC.

5770 Ambler Drive, Mississauga, Ontario L4W 2T3

10

Printed in Japan

08WQ14021D-I0298-4

Loading...

Loading...