Panasonic FP? Positioning Unit RTEX, FP2 Positioning Unit RTEX Technical Manual

Safety Precautions

Observe the following notices to ensure personal safety or to prevent accidents.

To ensure that you use this product correctly, read this User’s Manual thoroughly before use.

Make sure that you fully understand the product and information on safety.

This manual uses two safety flags to indicate different levels of danger.

WARNING

If critical situations that could lead to user’s death or serious injury is assumed by

mishandling of the product.

-Always take precautions to ensure the overall safety of your system, so that the whole

system remains safe in the event of failure of this product or other external factor.

-Do not use this product in areas with inflammable gas. It could lead to an explosion.

-Exposing this product to excessive heat or open flames could cause damage to the lithium

battery or other electronic parts.

CAUTION

If critical situations that could lead to user’s injury or only property damage is

assumed by mishandling of the product.

-To prevent excessive exothermic heat or smoke generation, use this product at the values

less than the maximum of the characteristics and performance that are assured in these

specifications.

-Do not dismantle or remodel the product. It could cause excessive exothermic heat or smoke

generation.

-Do not touch the terminal while turning on electricity. It could lead to an electric shock.

-Use the external devices to function the emergency stop and interlock circuit.

-Connect the wires or connectors securely.

The loose connection could cause excessive exothermic heat or smoke generat ion.

-Do not allow foreign matters such as liquid, flammable materials, metals to go into the inside

of the product. It could cause excessive exothermic heat or smoke generation.

-Do not undertake construction (such as connection and disconnection) while the power

supply is on. It could lead to an electric shock.

Copyright / Trademarks

-This manual and its contents are copyrighted.

-You may not copy this manual, in whole or part, without written consent of

Industrial Devices SUNX Co., Ltd.

-Windows is a registered trademark of Microsoft Corporation in th e United States and other

countries.

-All other company names and product names are trademarks or registered trademarks of

their respective owners.

Panasonic

PLC_ORG

Table of Contents

Difference of Functions Between Versions

Glossary

About Illustrations in This Manual

1. Functions of Unit and Restrictions on Combination .......... 1-1

1.1 Functions of Positioning Unit RTEX ......................................................... 1-2

1.2 Restrictions on Units Combination ........................................................... 1-4

1.3 Restrictions on Unit and AMP .................................................................. 1-4

2. Parts and Functions ............................................................. 2-1

2.1 Parts and Functions ................................................................................. 2-2

2.2 Operation Status Display LEDs ................................................................ 2-3

3. Wiring .................................................................................... 3-1

3.1 Wiring of Network ..................................................................................... 3-2

3.2 Network Connector .................................................................................. 3-3

3.3 Wiring of Pulser Input Connector ............................................................. 3-4

4. Power On/Off and Items to Check ....................................... 4-1

4.1 Safety Circuit Design ............................................................................... 4-2

4.2 Before Turning On the Power ................................................................... 4-3

4.3 Procedure for Turning On the Power ........................................................ 4-4

5. Preparation For Operation ................................................... 5-1

5.1 Procedures For System Establishment .................................................... 5-2

5.2 Preparation For Operation ....................................................................... 5-8

6. I/O Allocation ........................................................................ 6-1

6.1 Occupied I/O Area ................................................................................... 6-2

6.2 Allocation of Each Contact ....................................................................... 6-3

7. Setting Tool Configurator PM .............................................. 7-1

7.1 Connection With Computer ...................................................................... 7-2

7.2 Functions of Configurator PM ................................................................... 7-3

7.3 Installing Configurator PM ........................................................................ 7-5

7.4 Starting Configurator PM ........................................................................ 7-10

7.5 Treating Files ......................................................................................... 7-11

7.6 Exiting Configurator PM ......................................................................... 7-17

7.7 Connection to Positioning Unit ............................................................... 7-18

7.8 Parameter Settings ................................................................................ 7-20

7.9 Changing Axis Information ..................................................................... 7-23

7.10 Setting Positioning Data ....................................................................... 7-24

i

7.11 How to Edit Positioning Data ................................................................ 7-26

7.12 Customizing Software ........................................................................... 7-30

7.13 Checking Settings................................................................................. 7-32

7.14 Transferring Setting Data ...................................................................... 7-33

7.15 Data Monitor ......................................................................................... 7-37

7.16 Status Display ...................................................................................... 7-38

7.17 Tool Operation ...................................................................................... 7-39

8. Automatic Operation (Position Control) ............................. 8-1

8.1 Basic Operation ........................................................................................ 8-2

8.2 Interpolation Control ............................................................................... 8-15

8.3 Synchronous Operation .......................................................................... 8-28

8.4 Setting and Operation of Positioning Repeat Function ............................ 8-35

9. Manual Operation (JOG Operation) .................................... 9-1

9.1 Setting and Operation of Home Return ..................................................... 9-2

9.2 Changing the Speed During JOG Operation ............................................. 9-4

10. Manual Operation (Home Return) ................................... 10-1

10.1 Type of Home Return Method .............................................................. 10-2

10.2 AMP Settings and Usable Home Return Methods ................................ 10-6

10.3 Setting and Operation of Home Return ................................................. 10-7

11. Manual Operation (Pulser Operation) ............................. 11-1

11.1 Setting and Operation of Pulser Operation ........................................... 11-2

12. Stop Functions ................................................................. 12-1

12.1 Settings and Operations of Stop Functions ........................................... 12-2

12.2 Setting and Operation of Pause Function ............................................. 12-3

13. Supplementary Functions ............................................... 13-1

13.1 Dwell Time............................................................................................ 13-2

13.2 Software Limit ....................................................................................... 13-3

13.3 Torque Limit ......................................................................................... 13-4

13.4 Auxiliary Output Code and Auxiliary Output Contact ............................. 13-6

13.5 Actual Speed/Torque Value Judgment ................................................. 13-7

13.6 Imposition Flag and Completion Width ................................................. 13-8

13.7 Current Value Update ........................................................................... 13-9

13.8 Coordinate Origin ............................................................................... 13-11

13.9 Position Deviation Simple Monitor ...................................................... 13-12

13.10 AMP Parameter R/W Function .......................................................... 13-14

13.11 Position Deviation Simple Monitor .................................................... 13-20

14. Precautions During Programming .................................. 14-1

14.1 Precautions During Programming ......................................................... 14-2

ii

15. Errors and Warnings ........................................................ 15-1

15.1 Errors and Warnings ............................................................................ 15-2

15.2 List of Error Codes ............................................................................... 15-4

15.3 List of Warning Codes ........................................................................ 15-21

16. Troubleshooting ............................................................... 16-1

16.1 Cannot Communication With AMP ....................................................... 16-2

17. Specifications ................................................................... 17-1

17.1 Table of Specificationa ......................................................................... 17-2

17.2 Table of I/O Area .................................................................................. 17-6

17.3 Configuration of Shared Memory Areas ............................................. 17-12

17.4 Details of Common Area in Shared Memory ...................................... 17-13

17.5 Details of Each Axis Information Area in Shared Memory .................. 17-30

17.6 Details of Each Axis Setting Area in Shared Memory ......................... 17-40

18. Dimensions ....................................................................... 18-1

18.1 FPSigma Positioning Unit RTEX .......................................................... 18-2

18.2 FP2 Positioning Unit RTEX .................................................................. 18-3

19. Sample Programs ............................................................. 19-1

19.1 I/O Allocation of Sample Programs ...................................................... 19-2

19.2 Sample Programs ................................................................................ 19-4

iii

iv

Difference of Functions Between Versions

Version

Type

Added / modified functions

Positioning repeat function

Synchronous operation

J point (JOG positioning) control

Phase Z method / Data set method

Added "Delay mode" to Auxiliary contact

Position deviation simple monitor function

and Current update function.

Added error codes and warning code along with the addition of functions.

Changed the operations after the occurrence of errors.

functions

Supports MINAS A5N.

AMP parameter R/W function

functions

1.13

1.30

1.40

Additional

functions

Specification

change

Additional

Additional

Added Home return method

DOG method 2 / DOG method 3 / Limit method 1 / Limit method 2 /

Stop-on-contact method 1 / Stop-on-contact method 2 /

Eliminated Home offset function and added Coordinate origin function

Supports MINAS A6N.

v

Glossary

RTEX

RTEX, which stands for Realtime Express, is the network exclusive for motion connecting the Positioning

Unit RTEX and AMP.

* Realtime Express is the name of the network servo system produced by Panasonic.

AMP

AMP means a servo amplifier which controls a servo motor.

Configurator PM

Configurator PM is a setting tool for Positioning Unit RTEX. Using the Configurator PM enables the

settings for positioning data and various parameters, and various monitoring. As a tool operation mode

to activate a motor without using ladder programs is provided in this tool, it is convenient especially to

confirm the operation at the time of an initial start-up.

PANATERM

This is a setup support tool for the servo amplifiers of MINAS series made by Panasonic. By using this

tool, the parameter settings within the AMP, monitoring control statuses, the setup support or analysis of

machines can be executed on PC.

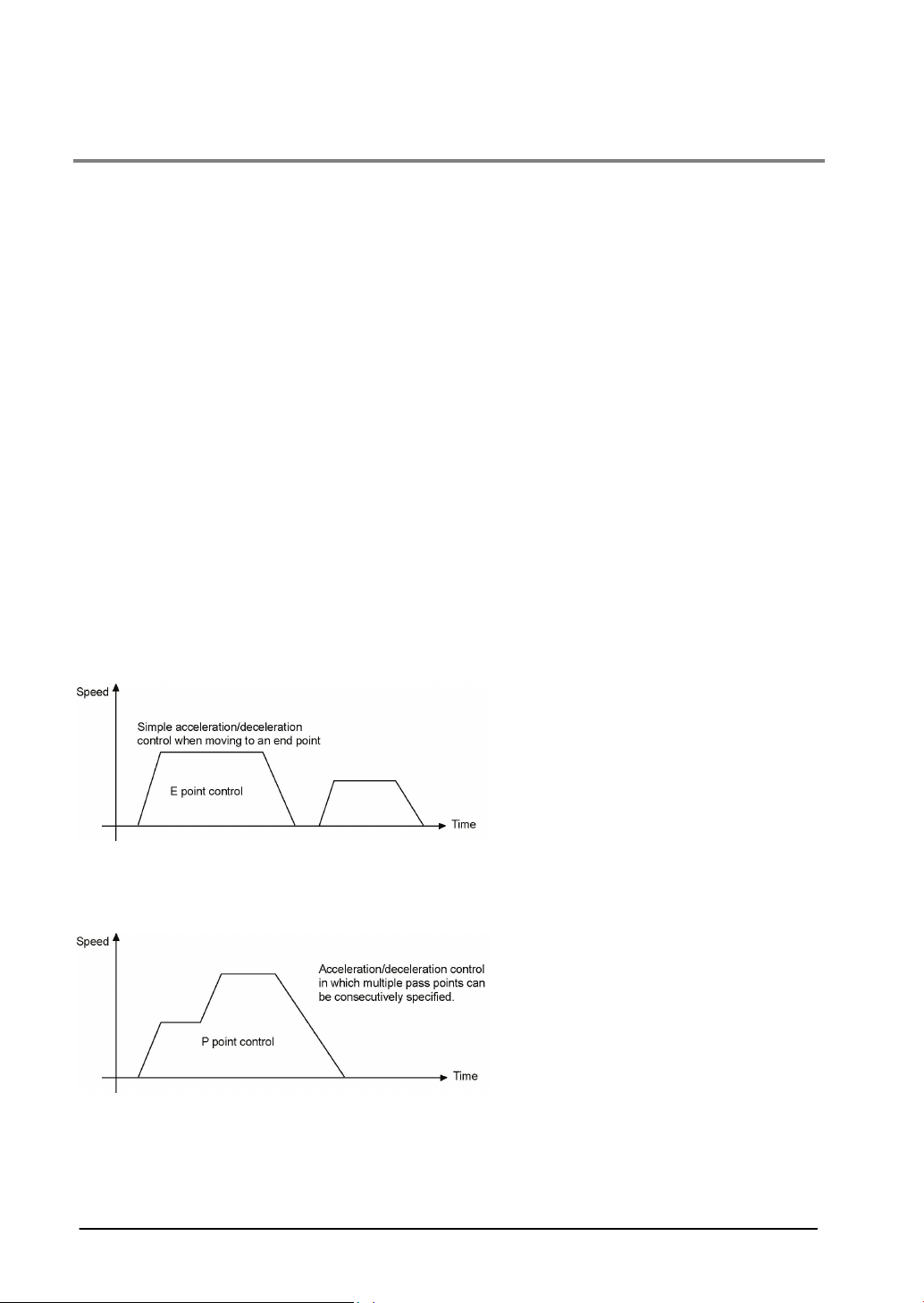

E point control

This is a method of control which is initiated up to an end point, and in this manual is referred to as “E

point control”. This method is used for a single - speed acceleration/deceleration. It is also called a

trapezoidal control.

P point control

This refers to control which passes through a “Pass Point”, and is called “P point control” in this manual.

This method is used when a multi-stage speed is to be specified in the same motion.

vi

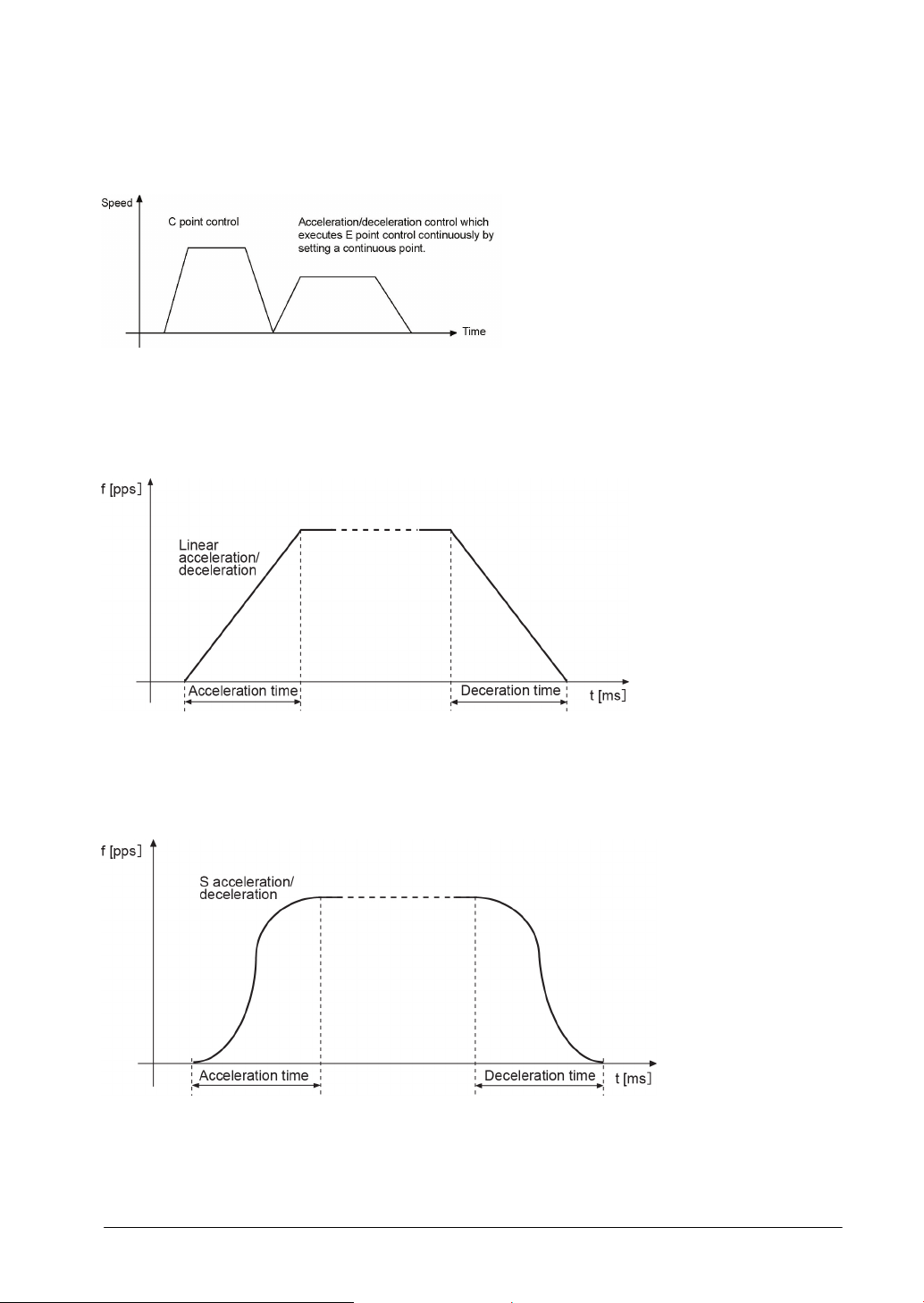

C point control

This refers to control which passes through a “Continuance Point”, and is called “C point control” in this

manual. This method is used for executing continuous E point controls by one-time start.

Linear acceleration/deceleration / S acceleration/deceleration

"Linear acceleration/deceleration" or "S acceleration/deceleration" is selectable for the

acceleration/deceleration method. With linear acceleration/deceleration, acceleration and deceleration

between the startup and the target speed are carried out in a straight line. Acceleration and deceleration

take place at a constant percentage.

The S acceleration/deceleration performs acceleration or deceleration curvedly.

Acceleration/deceleration is performed relatively slow at the beginning, and gradually increased.

Acceleration/deceleration is performed slowly as approaching the end of it. The movement is relatively

smooth. Acceleration/deceleration is complete in an acceleration/deceleration time specified in the

shared memory.

vii

Acceleration time/deceleration time

For the E point control or C point control, the acceleration time is the time during which the speed

changes from the startup speed of a motor to the target speed. The deceleration time is the time during

which the speed changes from the target speed to the stop. For the P point control, the acceleration time

is the time during which the speed accelerates form the current speed to the next target speed, and the

deceleration time is the time during which the speed decelerates from the current speed to the next

target speed.

CW, CCW

Generally, these indicate the direction in which the motor is rotating, with CW referring to clockwise

rotation and CCW to counterclockwise rotation.

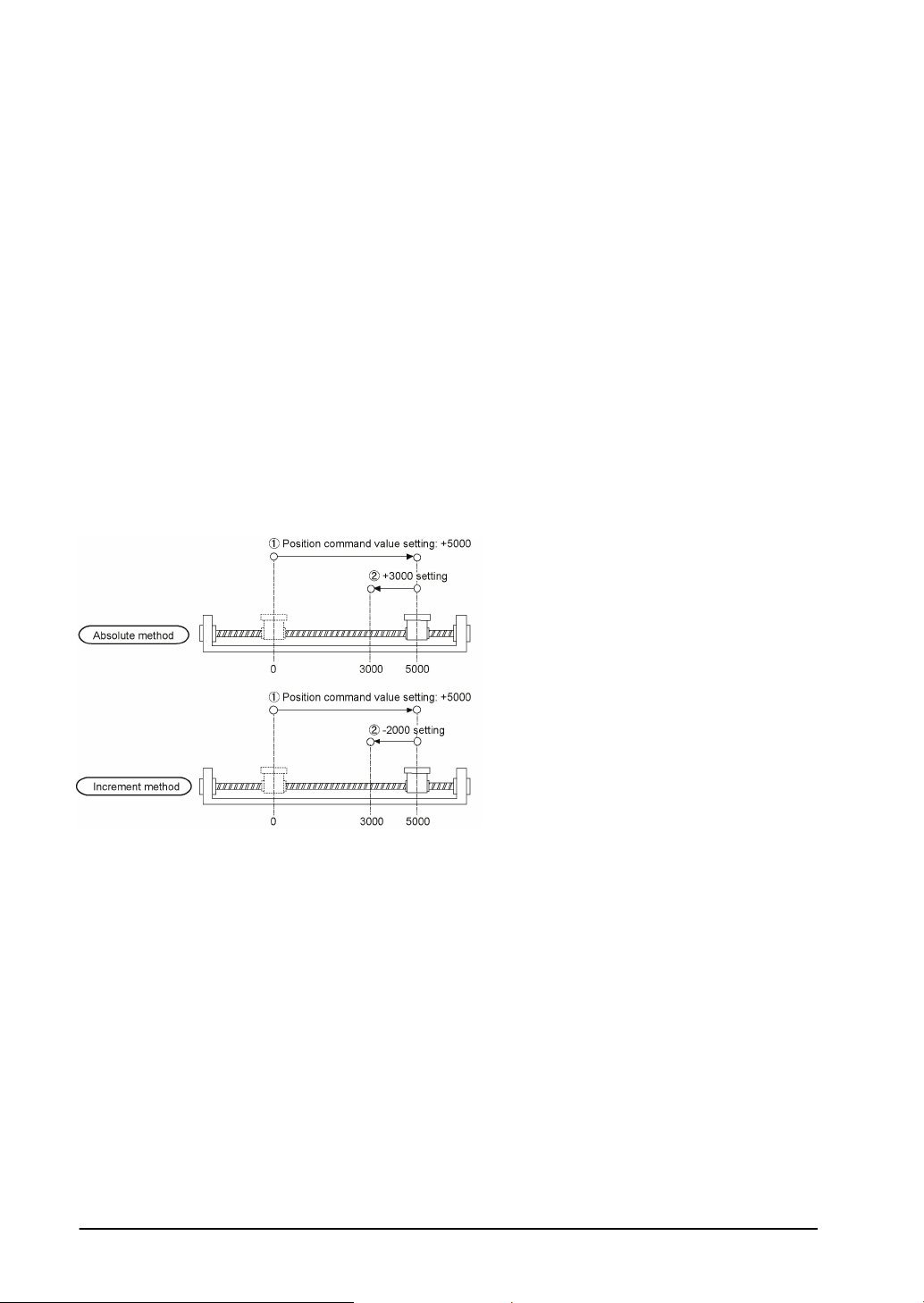

Absolute method (absolute value control method)

This is a control method in which the target position is specified as an absolute position from the home

position. This is specified on the positioning data editing screen of the Configurator PM.

Increment method (relative value control method)

This is a control method in which the distance from the current position to the target position is specified

as a relative position. This is specified on the positioning data editing screen of the Configurator PM.

Automatic operation

This is an operation to be automatically executed, and means a position control.

Manual operation

This is an operation to be executed for an initial boot or adjustments. The home return, JOG operation

and pulser operation are manual operations.

Position control

This is a generic term for the E point control, P point control and C point control. For each control, the

control of a single axis and the interpolation control of multiple axes are available. The interpolation

control can be selected from a 2-axis linear interpolation, 2-axis circular interpolation, 3-axis linear

interpolation and 3-axis spiral interpolation.

JOG operation

This refers to an operation in which the motor is rotated only while operation commands are being input.

This is used to forcibly rotate the motor using input from an external switch, for instance when to make

adjustments. Depending on the circumstances, this can also be applied to unlimited feeding in some

cases.

viii

Home return

The reference position for positioning is called a Home position and an operation to travel to a Home

position is called Home return. The home position should be set in advance. This operation moves to the

home position and its coordinate is set to be 0.

The motor rotation is reversed automatically when the limit input (+) or the limit input (-) is input and the

home position or the near home position is searched to return to the home position automatically.

Pulser operation

A manual operation is available using a device (pulser) which generates pulses manually. The output

similar to an encoder is obtained from the pulser, and the positioning unit RTEX is equipped with

exclusive input terminals. It is also called a manual pulse generator.

Deceleration stop

This is a function that interrupts the operation in progress, slows the rotation and brings it to a stop. The

deceleration time can be specified individually.

Emergency stop

This is a function that interrupts the operation in progress, slows the rotation and brings it to a stop.

Generally, a time shorter than a time for a deceleration stop is set. The deceleration time can be

specified individually.

Positioning table (Table)

A series of positioning data such as acceleration/deceleration time, target speed and interpolation

operation that is necessary for a position control is managed as a positioning table. For example, one

table is necessary for the E point control, and multiple tables are necessary for the P point control and C

point control depending on the number of pass points and continuance points.

Limit input (+), limit input (-)

This is an input to set a limit the motor movement. Limit input (+) is the maximum limit and the limit input

(-) is the minimum limit. They are connected to the AMP for the positioning unit RTEX.

Near home (DOG) input

In order to stop the table at the home position, a position at which deceleration begins is called the near

home position. This is connected to an external input switch or sensor. It is connected to the AMP for the

positioning unit RTEX.

Dwell time

In case of the E point control, a time from the completion of a position command until the operation done

flag turns on can be specified as a dwell time. In case of the C point control, a time from the deceleration

stop until the next table activates can be specified.

ix

Auxiliary output code, auxiliary output contact

They are used to check the operation of a position control.

The auxiliary output code is a 16-bit code that can be specified for each positioning table, and enables to

monitor which positioning table is being executed.

The execution of the position control can be confirmed by turning an exclusive auxiliary output contact on

for a constant time.

Software limit

Limits in software can be set for the absolute coordinate managed within the positioning unit RTEX.

When exceeding the setting range of the software limit, an error occurs, and the system decelerates and

stops. The deceleration time can be set individually.

Torque limit

The output torque of the AMP can be limited arbitrary.

Servo lock/Servo free

According the command from the positioning unit, the state that the motor is controllable is called a servo

lock state, and the state that the motor is uncontrollable is called a servo free state. The servo on

operation is necessary to make it to the servo lock state.

Servo ON/Servo OFF

The operation that changes the servo free state to the servo lock state is called a servo on, and the

operation that changes the servo lock state to the servo free state is called a servo off.

Linear interpolation

This is the interpolation control that controls positions as the locus of the operations of the 2-axis motor

with the grouped X axis and Y axis or 3-axis motor with the grouped X axis, Y axis and Z axis becomes a

straight line. There are two setting methods, which are a composition speed specification and long axis

speed specification.

Circular interpolation

This is the interpolation control that controls positions as the locus of the operation of the 2-axis motor

with the grouped X axis and Y axis becomes a circular arc. There are two setting methods, which are a

center point specification and pass point specification.

Spiral interpolation

This is the interpolation control that controls positions as the locus of the operation of the 3-axis motor

with the grouped X axis, Y axis and Z axis becomes a spiral. Arbitrary 2 axes describe an arc, and the

remaining one axis moves to achieve a spiral. There are two setting methods, which are a center point

specification and pass point specification.

Edge type

This is one of the methods to detect the request signals allocated to this unit. It executes each requested

process by detecting a trigger that is the leading edge when the request signal turns on.

Therefore, the next request cannot be accepted until the request signal turns off.

Level type

This is one of the methods to detect the request signals allocated to this unit. It executes each requested

process by detecting a trigger that the request signal is on, and continues the requested process while

the request signal is on.

x

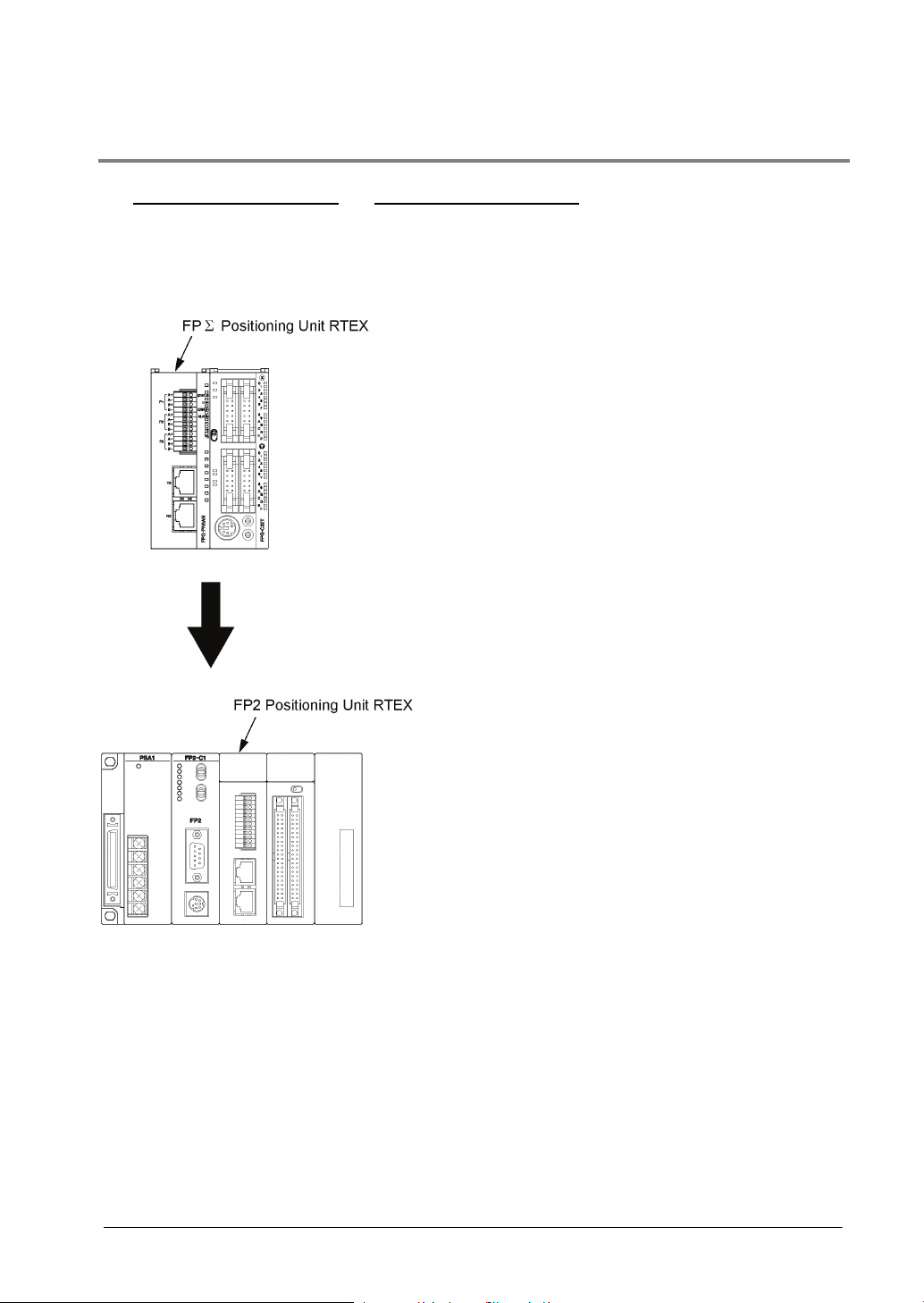

About Illustrations in This Manual

The FPΣ Positioning Unit RTEX and FP2 Positioning Unit RTEX are described in this manual.

The illustrations in this manual shows the status with the FPΣ.

If you use the FP2, please replace the illustrations of the FPΣ with the following illustration.

xi

xii

Chapter 1

Functions of Unit and Restrictions on

Combination

1.1 Functions of Positioning Unit RTEX

1.1.1 Functions of Unit

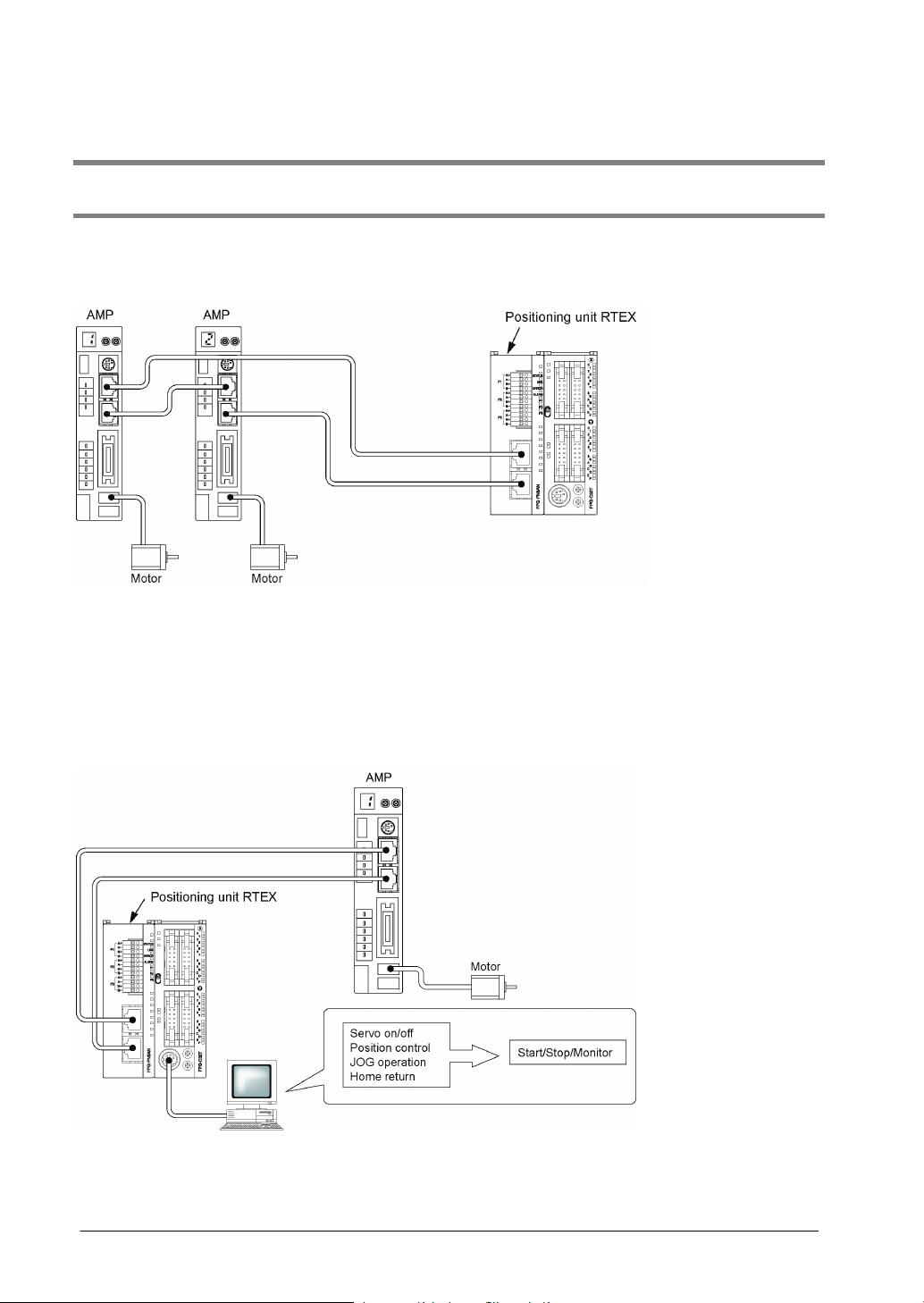

Network control

The motion-only network Realtime Express (RTEX) enables to easily construct a system of network

servo motors using the cables with a category 5e shield.

Configuration of axes according to the system

In accordance with the number of required axes, 2-axis, 4-axis and 8-axis unit are available.

Can confirm operations without ladder programs

Using the tool operation function of the Configurator PM enables a test run without a ladder program,

and enables to confirm various items such as the rotating direction, various input contacts or automatic

operation settings.

Two-axis and three-axis interpolation controls

The 2-axis linear interpolation, 2-axis circular interpolation, 3-axis linear interpolation and 3-axis spiral

interpolation controls can be performed.

1-2

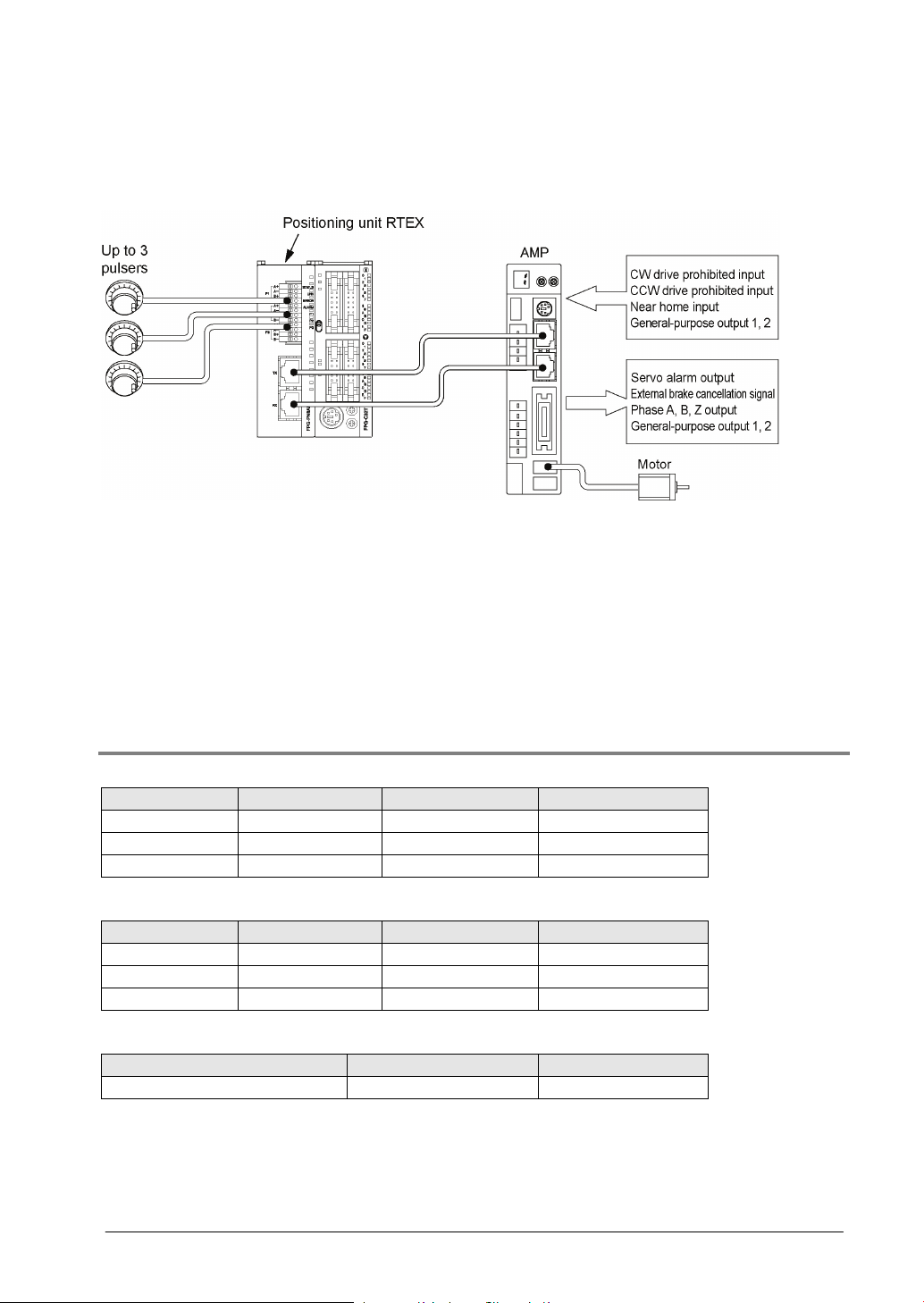

I/O required for the control is aggregated in the AMP

Type

Function

Part number

Product number

2-axis type

2-axis control

FPG-PN2AN

AFPG43610

4-axis type

4-axis control

FPG-PN4AN

AFPG43620

8-axis type

8-axis control

FPG-PN8AN

AFPG43630

Type

Function

Part number

Product number

2-axis type

2-axis control

FP2-PN2AN

AFP243610

4-axis type

4-axis control

FP2-PN4AN

AFP243620

8-axis type

8-axis control

FP2-PN8AN

AFP243630

Name

Specifications

Product number

Control Configurator PM

English

AFPS66510

As the limit input and near home input is connected to the AMP and given to the positioning unit RTEX

through the network, the wiring can be simplified.

Remote I/O of 2-input and 2-output for one AMP

The 2-point general purpose input and output (transistors) can be connected to the AMP, and they can

be programmed by the X contact and Y contact of the positioning unit RTEX. The input and output

neighboring the AMP can be used as the remote I/O.

Supports the manual pulser

The maximum of three manual pulsers can be connected. It is possible to change the axes

corresponding to each pulser by the setting of the positioning unit RTEX.

1.1.2 Unit Types

FPΣ Positioning Unit RTEX

FP2 Positioning Unit RTEX

Setting software

1-3

1.2 Restrictions on Units Combination

Type

Part number

Product number

Current consumption (from power supply)

2-axis type

FP2-PN2AN

AFP243610

300 mA

4-axis type

FP2-PN4AN

AFP243620

300 mA

8-axis type

FP2-PN8AN

AFP243630

300 mA

Connectable AMP

A4N

A5N

A6N

Ver.1.0 or later

A - -

Ver.1.3 or later

A A -

Ver.1.4 or later

A A A

Connectable AMP

A4N

A5N

A6N

A4N A - - Only A4N can be connected to the same network.

A5N - A

A

A5N and A6N can be connected to the same network. A4N

be performed.

1.2.1 Restrictions on Combinations Based on Current Consumption (FP2 only)

For the FP2, when the system is designed, the other units being used should be taken into consideration,

and a power supply unit with a sufficient capacity should be used. (For the FPΣ, there is no restrictions

based on the current consumption.)

FP2 Positioning Unit RTEX

1.2.2 Restrictions on the Number of Units Installed

FPΣ Positioning Unit RTEX

The maximum of 2 units can be installed.

FP2 Positioning Unit RTEX

There is no restriction on the number of units installed if it is within the restrictions on the current

consumption.

1.3 Restrictions on Unit and AMP

1.3.1 Restrictions on Combination of Unit and AMP

As for the combination of the positioning unit RTEX and each MINAS series, confirm the following

restrictions.

Combination of Positioning Unit RTEX and AMP A: Available -: Not available

Version of Positioning Unit RTEX

Combination of AMP series A: Available -: Not available

AMP type

A6N - A A

Setting ranges of movement amount and speed

The input range of the movement amount or speed specified in the positioning unit RTEX may differ from

the set upper and lower limits of AMP.

Key Point:

- A5N and A6N can be used connecting to the same network.

Description

cannot be connected to the same network. When A4N is used,

the AMP communication error occurs and the operation cannot

1-4

1.3.2 Restrictions on AMP Parameters

Factory

setting

disabled)".

Selection of command

update period

Some parameters of AMPs affect the operation of the positioning unit RTEX. Set parameters according

to the following description.

[A4N parameters]

No. Parameter name

02 Control mode 0 Use "setting value 0 (position control)".

03 Selection of torque limit 1

04 Over-travel inhibit input 1

09 Unit of velocity 0 Use "Pulse/s".

Parameter change via

0A

network

43 Direction of motion 1

5E Setup of 1st torque limit 500

74

default

0

2 Use "setting value 2 (1 ms)".

Settings

The positioning unit automatically changes the setting.

Do not change this parameter.

Use "setting value 1 (Over-travel inhibit input is

Use "setting value 0 (Enable)".

When setting "setting value 1 (inhibit)", parameters

cannot be changed from the positioning unit RTEX.

The positioning unit automatically changes the setting.

Do not change this parameter.

1-5

[A6N/A5N parameters]

Factory

setting

setup

setting. Do not change this parameter.

Pr0.01

Control mode setup

0

Use "setting value 0 (semi-closed control)".

revolution

Numerator of electronic

gear

electronic gear

Pr4.00

Pr4.07

setup

disabled)".

cycle setup

RTEX command

setting

extended setup 1

No. Parameter name

Pr0.00

Pr0.08

Pr0.09

Pr0.10

to

Pr5.04

Pr5.21 Selection of torque limit 1

Pr7.20

Pr7.21

Rotational direction

Number of command

pulses per motor

Denominator of

SI1 - SI8 input

selection

Over-travel inhibit input

RTEX communication

updating cycle ratio

default

1

0

1

1

(Note2)

1

3 Use "setting value 3 (0.5 ms)".

2 Use "setting value 2 (2 times)".

Settings

The positioning unit automatically changes the

Factory default setting

When Pr.0.08=0, Pr.0.09=1, Pr.0.10=1, position

command input is position command.

(Note 1)

The connection method and settings vary according

to the home return method used.

Use "setting value 1 (Over-travel inhibit input is

The positioning unit automatically changes the

setting. Do not change this parameter.

Pr7.22

Pr7.23

Pr7.25 RTEX Speed unit setup 0 Change to "setting value 1 (command unit/s)".

(Note 1) For details of Pr0.08 to Pr0.10, refer to "Technical Reference of AC Servo Driver A5N series" or

"Technical Reference of AC Servo Driver A6N series".

(Note 2) The factory default settings of Pr4.00 to Pr4.07 vary according to parameter numbers. For

details of the setting methods, refer to "10.2 AMP Settings and Usable Home Return Methods

RTEX function

RTEX function

extended setup 2

0 Use "setting value 0 (16-byte mode)".

18

The positioning unit automatically changes the

setting. Do not change this parameter.

1-6

Chapter 2

Parts and Functions

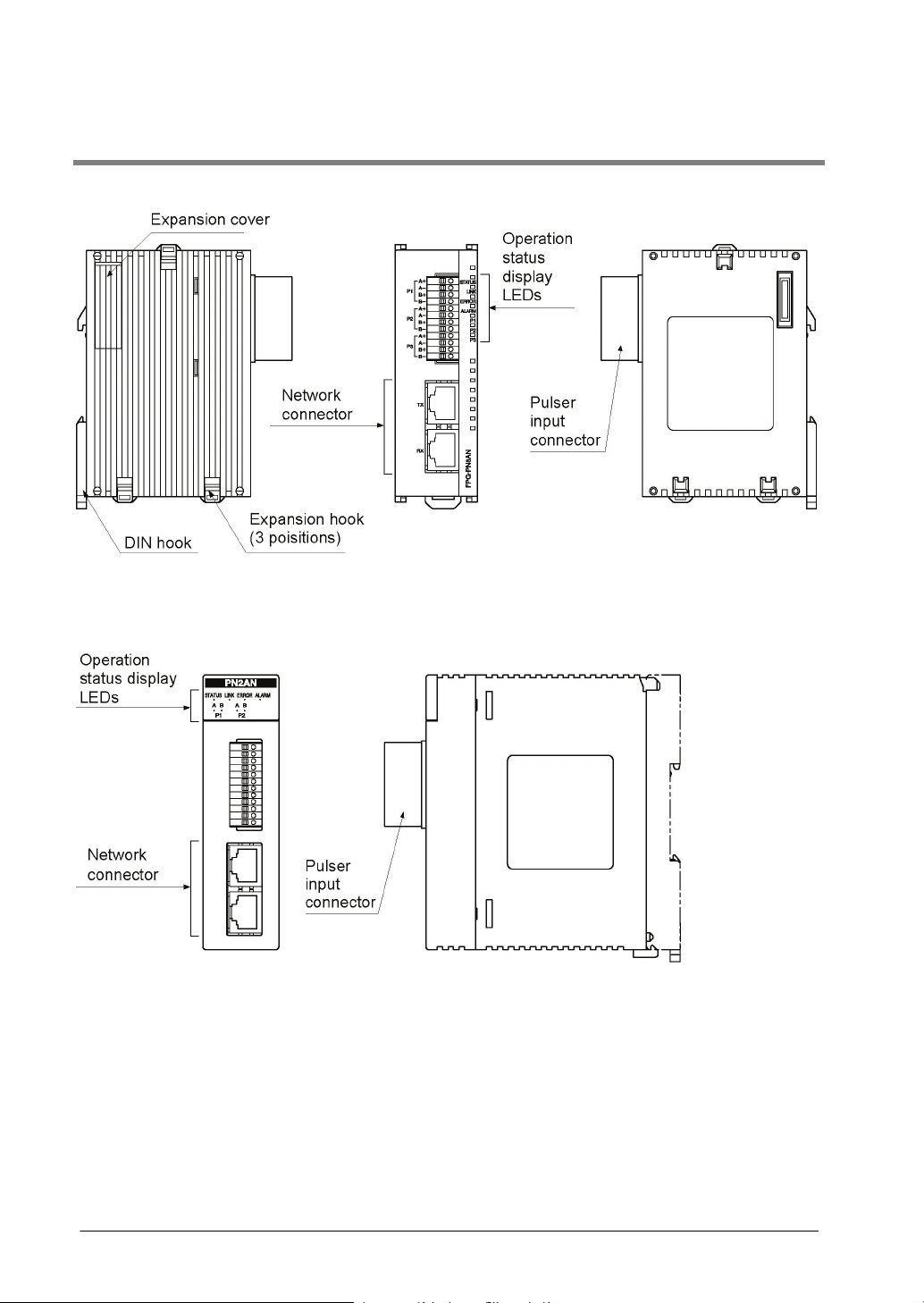

2.1 Parts and Functions

FPΣ Positioning Unit RTEX

FP2 Positioning Unit RTEX

2-2

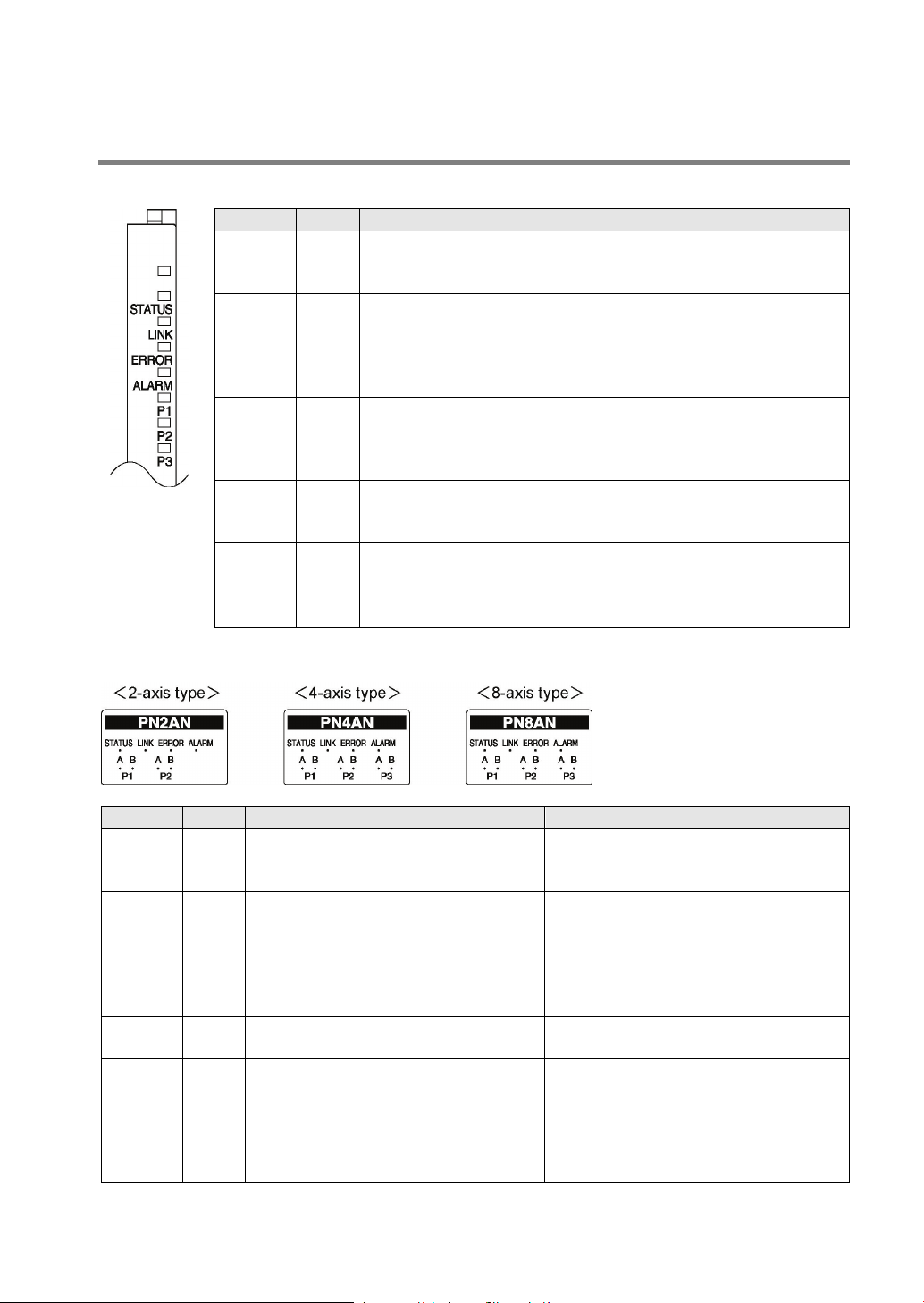

2.2 Operation Status Display LEDs

Name

Color

Status

Remarks

STATUS

Green

LED blinks:

LED on:

Waiting for network

Network establishment

connected properly.

ERROR

Red

LED off:

Normal

In case of warning, the

operation stops.

ALARM

Red

LED off:

Normal

If the LED turns on, the

turned off and on again.

P1

Green

LED off:

B are in the on state

Check the input signals

Name

Color

Status

Remarks

STATUS

Green

LED blinks:

LED on:

Waiting for network

Network establishment

LINK

Green

LED off:

Not connected

The state that the TX of the sending

electrically connected properly.

ERROR

Red

LED off:

LED on:

Normal

An error occurred.

In case of warning, the operation

In case of error, the operation stops.

ALARM

Red

LED off:

LED on:

Normal

System error

If the LED turns on, the power supply

should be turned off and on again.

P1A

P3B

Green

LED off:

Off state

Check the input signals of the pulsers.

FPΣ Positioning Unit RTEX

LINK Green LED off:

P2

P3

FP2 Positioning Unit RTEX

LED on:

LED blinks:

LED on:

LED on:

LED on:

establishment

Not connected

Normal connection

A warning occurred.

An error occurred.

System error

Both phase A and phase

B are in the off state.

Both phase A and phase

The state that the TX of

the sending node and

the RX of the own node

are electrically

operation continues.

In case of error, the

power supply should be

of the pulsers.

LED on:

LED blinks:

P1B

P2A

P2B

P3A

2-3

LED on:

establishment

Normal connection

A warning occurred.

On state

node and the RX of the own node are

continues.

2-4

Chapter 3

Wiring

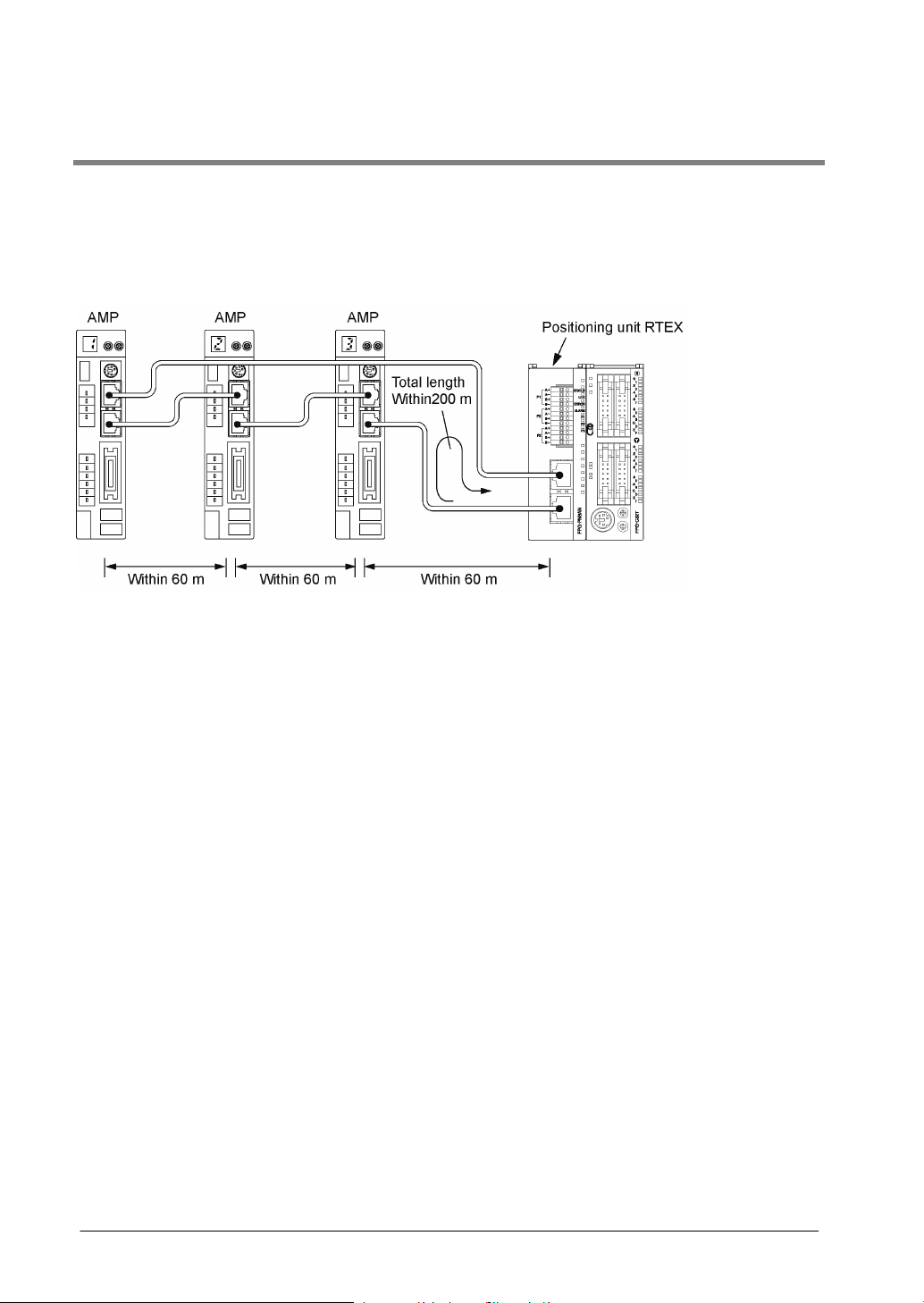

3.1 Wiring of Network

Use the LAN cable with the category 5e shielded type for the wiring of the network. To prevent the cable

from coming off, securely connect the connector of the cable to the network connector (RJ45 connector)

of the unit.

The length between each node should be within 60 m, and the total length of the communication loop

should be within 200 m.

3-2

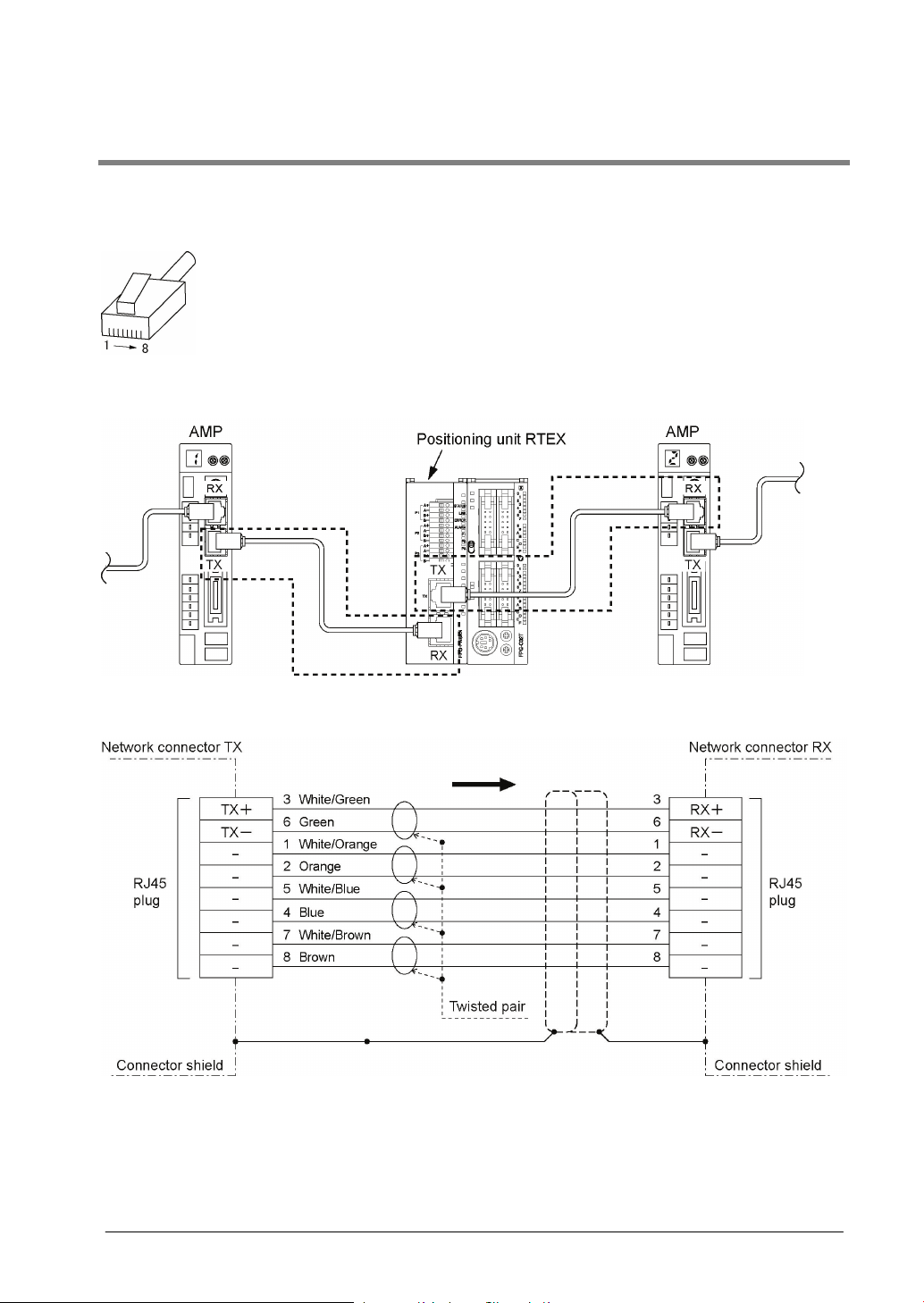

3.2 Network Connector

RJ45 plug is connected to the network connector.

Pins of RJ45 plug

Connecting diagram

3-3

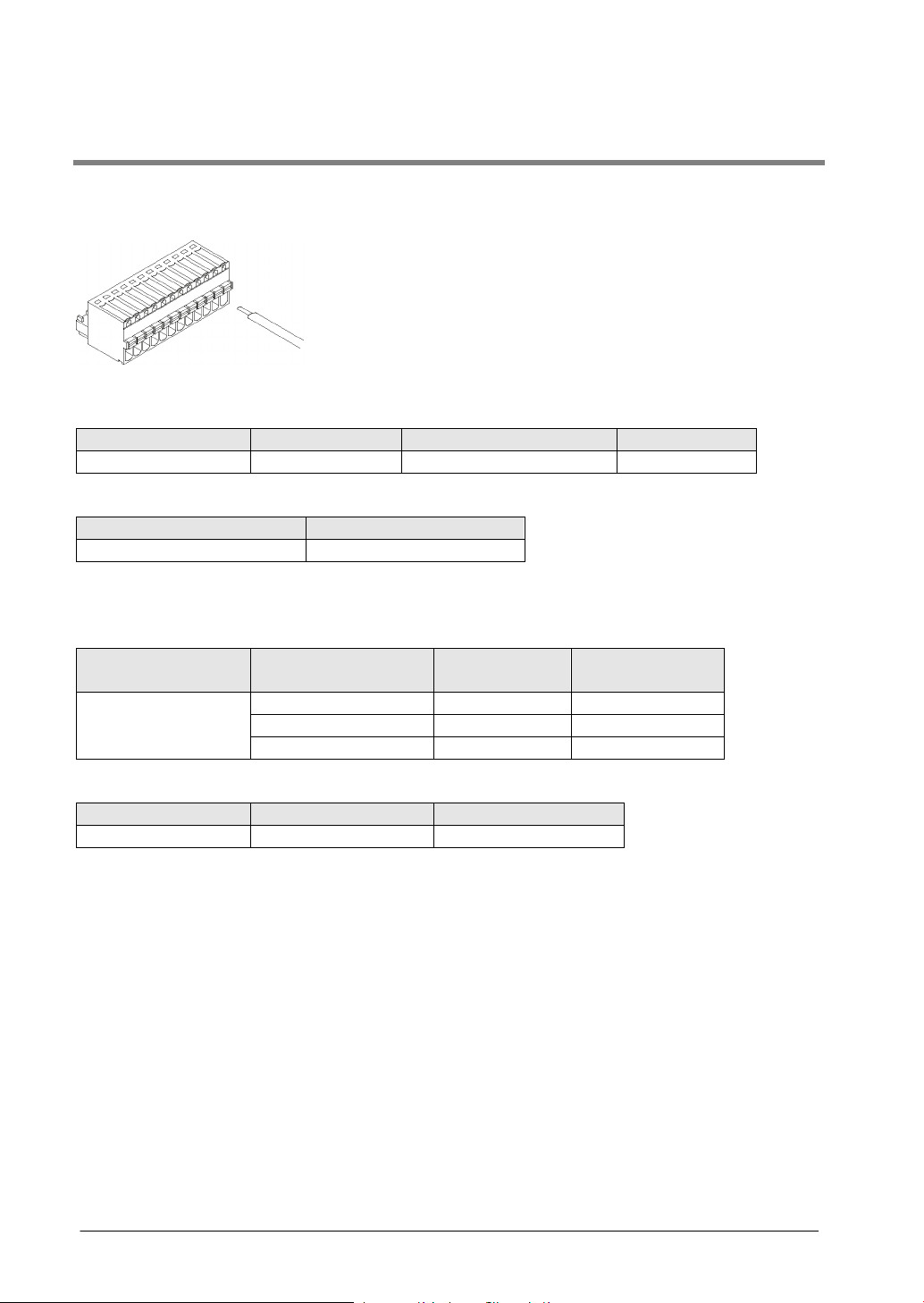

3.3 Wiring of Pulser Input Connector

Manufacturer

Number of pins

Part No.

Product No.

Phoenix Contact Co.

12 pins

FK-MC0, 5/12-ST-2,5

1881422

Suitable wires

Tightening torque

AWG# 28 to 20

0.14 to 0.5 mm2

Cross-sectional area

(mm2)

0.25

AWG #24

A 0, 25-7

0.34

AWG #22

A 0, 34-7

0.50

AWG #20

A 0, 5-6

Manufacturer

Part No.

Product No.

Phoenix Contact Co.

CRIMPFOX 10S

1212045

Supplied connector/Suitable wire

A connector of the spring connection type is used. Use the following suitable wires for the wiring.

Supplied connector socket

The connector socket manufactured by Phoenix Contact Co. should be used.

Suitable wires (strand wire)

Pole terminal with a compatible insulation sleeve

If a pole terminal is being used, the following models manufactured by Phoenix Contact Co. should be

used.

Manufacturer

Phoenix Contact Co.

Pressure welding tool for pole terminals

For tightening the connector

For inserting the wires, use a screwdriver (Phoenix contact Co., Product No. 1205202) with a blade size

of 0.4 × 2.0 (Part No. SZS 0,4×2,0).

Size Part No.

3-4

Wiring method

(1) Remove a portion of the wire’s insulation.

(2) Press the orange switch of the connector using a tool such as a flat-blade screwdriver.

(3) Insert the wire into the connector until it stops with pressing the orange switch.

(4) Take the tool off the switch.

Precautions on wiring

• When removing the wire’s insulation, be careful not to scratch the core wire.

• Do not twist the wires to connect them.

• Do not solder the wires to connect them. The solder may break due to vibration.

• After wiring, make sure stress is not applied to the wire.

3-5

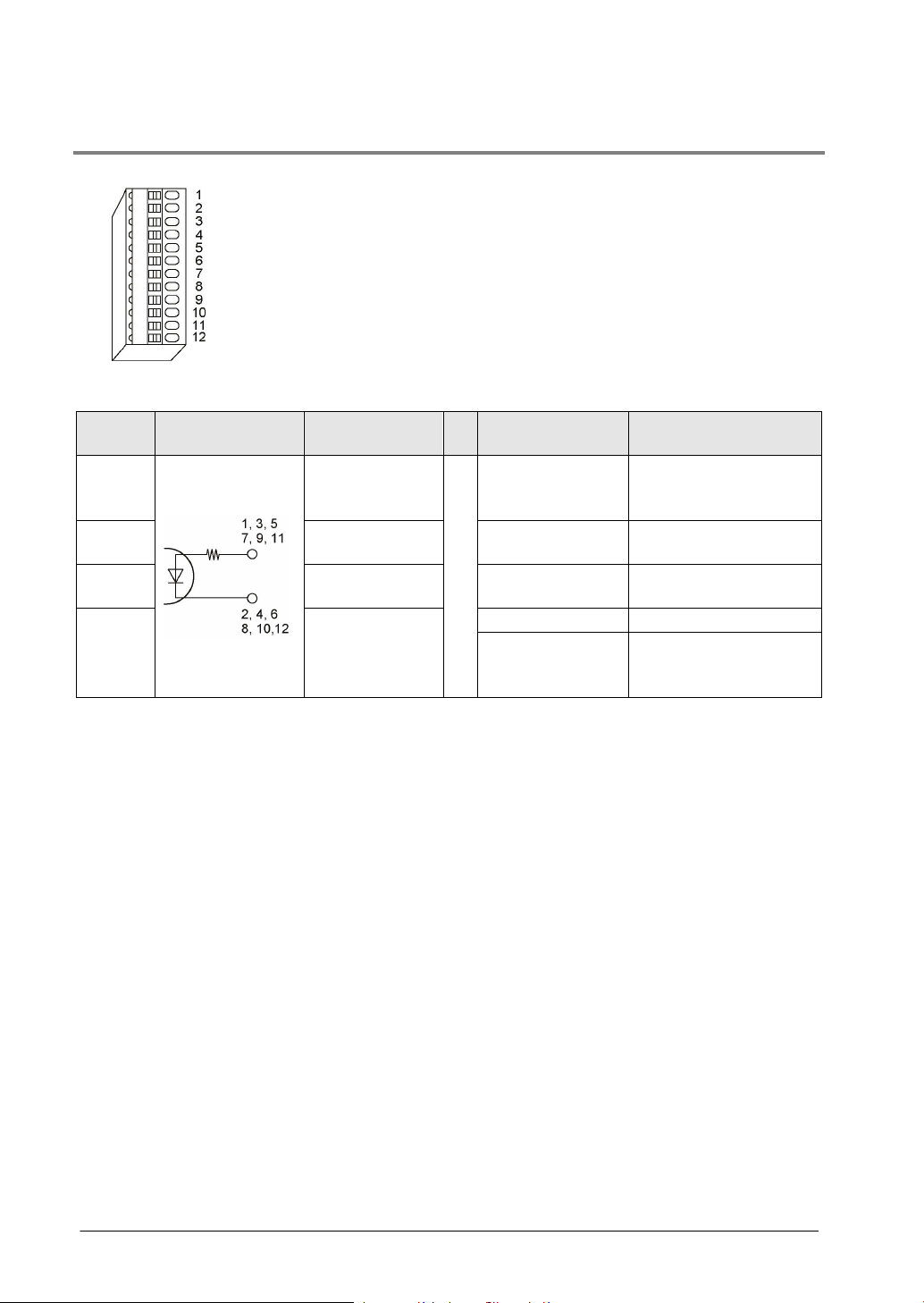

3.3.1 Input Specifications and Pin Configuration

number

3.5 to 5.25 V DC

specifications)

voltage/current

Maximum ON

voltage/current

Input impedance

Approx. 390 Ω

phase)

Input terminals of pulser input connector

Pin

1, 5, 9

2, 6, 10 Pulse input A (-)

3, 7, 11 Pulse input B (+)

4, 8, 12 Pulse input B (-)

Note) When the pulser is connected to the pulse input, the elapsed value increases if the phase A is

proceeding more than the phase B.

Circuit Signal name Item Descriptions

Pulse input A (+)

Operating voltage

range

Minimum ON

Input specifications

Minimum input

pulse width

(5 VDC, line driver

3 V DC/4 mA

1 V DC/2.0 mA

0.5 µs or more

(Max. 1 MHz for each

3-6

Loading...

Loading...