Panasonic FP7 CPU Unit User Manual

PROGRAMMABLE CONTROLLER

FP7 CPU Unit

User's Manual

LAN port communication

WUME-FP7LAN-01

2013.3

panasonic.net/id/pidsx/global

Safety Precautions

Observe the following notices to ensure personal safety or to prevent accidents.

To ensure that you use this product correctly, read this User’s Manual thoroughly before use.

Make sure that you fully understand the product and information on safety.

This manual uses two safety flags to indicate different levels of danger.

WARNING

If critical situations that could lead to user’s death or serious injury is assumed by

mishandling of the product.

-Always take precautions to ensure the overall safety of your system, so that the whole

system remains safe in the event of failure of this product or other external factor.

-Do not use this product in areas with inflammable gas. It could lead to an explosion.

-Exposing this product to excessive heat or open flames could cause damage to the lithium

battery or other electronic parts.

CAUTION

If critical situations that could lead to user’s injury or only property damage is

assumed by mishandling of the product.

-To prevent excessive exothermic heat or smoke generation, use this product at the values

less than the maximum of the characteristics and performance that are assured in these

specifications.

-Do not dismantle or remodel the product. It could cause excessive exothermic heat or smoke

generation.

-Do not touch the terminal while turning on electricity. It could lead to an electric shock.

-Use the external devices to function the emergency stop and interlock circuit.

-Connect the wires or connectors securely.

The loose connection could cause excessive exothermic heat or smoke generation.

-Do not allow foreign matters such as liquid, flammable materials, metals to go into the inside

of the product. It could cause excessive exothermic heat or smoke generation.

-Do not undertake construction (such as connection and disconnection) while the power

supply is on. It could lead to an electric shock.

Copyright / Trademarks

-This manual and its contents are copyrighted.

-You may not copy this manual, in whole or part, without written consent of

Industrial Devices SUNX Co., Ltd.

-Windows is a registered trademark of Microsoft Corporation in the United States and other

countries.

-Ethernet is a registered trademark of Fuji Xerox Co., Ltd. and Xerox Corp.

-All other company names and product names are trademarks or registered trademarks of

their respective owners.

Panasonic

PLC_ORG_ET

Introduction

use

Thank you for buying a Panasonic product. Before you use the product, please carefully read

the installation instructions and the users manual, and understand their contents in detail to

use the product properly.

Types of Manual

• There are different types of users manual for the FP7 series, as listed below. Please refer to

a relevant manual for the unit and purpose of your use.

• The manuals can be downloaded on our website:

http://industrial.panasonic.com/ac/e/dl_center/manual/

Unit name or purpose of

Manual name Manual code

.

FP7 Power Supply Unit

FP7 CPU Unit

Instructions for Built-in

COM Port

FP7 Extension

(Communication)

Cassette

Instructions for Built-in

LAN Port

FP7 Digital Input/Output Unit FP7 Digital Input/Output Unit Users Manual WUME-FP7DIO

FP7 Analog Input Unit FP7 Analog Input Unit Users Manual WUME-FP7AIH

FP7 Analog Output Unit FP7 Analog Output Unit Users Manual WUME-FP7AOH

FP7 Positioning Unit FP7 Positioning Unit Users Manual WUME-FP7POSP

PHLS System PHLS System Users Manual WUME-PHLS

Programming Software

FPWIN GR7

FP7 CPU Unit Users Manual

(Hardware)

FP7 CPU Unit Users Manual

(COM Port Communication)

FP7 CPU Unit Users Manual

(LAN Port Communication)

FPWIN GR7 Introduction Guidance WUME-FPWINGR7

WUME-FP7CPUH

WUME- FP7COM

WUME-FP7LAN

Table of Contents

Table of Contents

1. Communication Functions of CPU Unit ............................ 1-1

1.1 Communication Ports of CPU Unit ......................................................... 1-2

1.1.1 Types and Purposes of Communication Ports ........................................ 1-2

1.1.2 LAN Port Specifications ........................................................................... 1-3

1.2 Functions of LAN Port ............................................................................ 1-4

1.2.1 Communication Functions of FP7 CPU Unit ........................................... 1-4

1.2.2 System Connection ................................................................................. 1-4

1.2.3 User Connection ...................................................................................... 1-5

1.3 Overview of Communication Functions .................................................. 1-6

1.3.1 MEWTOCOL-DAT Master/Slave Communication (Binary

Communication) ...................................................................................... 1-6

1.3.2 MEWTOCOL-COM Master/Slave Communication (ASCII

Communication) ...................................................................................... 1-7

1.3.3 MODBUS TCP Master/Slave Communication ........................................ 1-8

1.3.4 General-Purpose Communication ........................................................... 1-9

1.4 Terms ................................................................................................... 1-10

2. Installation and Wiring ........................................................ 2-1

2.1 Installation Environment and Wiring for LAN Ports ................................ 2-2

2.1.1 Before Installation and Wiring ................................................................. 2-2

2.1.2 Installation Environment and Noise Control Measures ........................... 2-2

2.2 Wiring the LAN Port ................................................................................ 2-3

2.3 Noise Control Measures ......................................................................... 2-4

2.3.1 Guidelines to Noise Generation .............................................................. 2-4

2.3.2 Taking Corrective Measures through the Application ............................. 2-4

ii

Table of Contents

3. Configuration ....................................................................... 3-1

3.1 Procedure for Setting Communication Conditions .................................. 3-2

3.1.1 Setup Procedure ..................................................................................... 3-2

3.2 Setting Basic Communication Information .............................................. 3-3

3.2.1 List of Setting Items ................................................................................. 3-3

3.2.2 Setting Each Timer Value And Timeout Value ........................................ 3-4

3.3 Settings for SNTP server ........................................................................ 3-5

3.4 Settings for FTP server ........................................................................... 3-6

3.5 Setting of System Connection ................................................................ 3-7

3.5.1 List of Setting Items ................................................................................. 3-7

3.5.2 Setting on the Programming Tool Side ................................................... 3-9

3.6 Setting of User Connection ................................................................... 3-10

3.6.1 List of Setting Items ............................................................................... 3-10

3.6.2 Specifying Port Number ........................................................................ 3-12

4. Setting and Operation of User Connection ....................... 4-1

4.1 Configuration Concerning Open Process ............................................... 4-2

4.1.1 Connection of the FP7 CPU Unit ............................................................ 4-2

4.1.2 Specifying Use of Connection ................................................................. 4-2

4.1.3 Open Method (Server/Client) .................................................................. 4-2

4.1.4 Open Method (Auto/Manual) ................................................................... 4-2

4.1.5 Instructions for Specifying Connection Conditions.................................. 4-3

4.2 Communication Processing .................................................................... 4-4

4.2.1 Communication Operation ...................................................................... 4-4

4.3 Input/Output Signals Used for Communication ....................................... 4-5

4.3.1 I/O Allocation ........................................................................................... 4-5

iii

Table of Contents

5. MEWTOCOL Master/Slave Communication ...................... 5-1

5.1 Types of MEWTOCOL Communication ................................................. 5-2

5.1.1 MEWTOCOL-DAT (Binary Communication) ........................................... 5-2

5.1.2 MEWTOCOL-COM (ASCII Communication) ........................................... 5-2

5.2 List of MEWTOCOL Supporting Commands .......................................... 5-3

5.2.1 MEWTOCOL-DAT ................................................................................... 5-3

5.2.2 MEWTOCOL-COM .................................................................................. 5-3

5.2.3 MEWTOCOL7-COM ................................................................................ 5-3

5.3 MEWTOCOL Master Communication (RECV) ....................................... 5-4

5.3.1 Read Data From an External Device ...................................................... 5-4

5.3.2 RECV Command (When MEWTOCOL is Used)..................................... 5-6

5.4 MEWTOCOL Master Communication (SEND) ....................................... 5-7

5.4.1 Write Data into an External Device ......................................................... 5-7

5.4.2 SEND Command (When MEWTOCOL is Used)..................................... 5-9

6. MODBUS TCP Master/Slave Communication ................... 6-1

6.1 MODBUS TCP Format ........................................................................... 6-2

6.1.1 MODBUS TCP ........................................................................................ 6-2

6.2 List of MODBUS TCP Supported Commands ........................................ 6-3

6.2.1 List of MODBUS Function Codes ............................................................ 6-3

6.3 MODBUS TCP Master Communication (RECV) .................................... 6-4

6.3.1 Read Data from an External Device ........................................................ 6-4

6.3.2 RECV Command (MODBUS Function Code Specified Type) ................ 6-7

6.3.3 RECV Command (MODBUS Function Code Unspecified Type) ............ 6-8

6.4 MODBUS TCP Master Communication (SEND) .................................... 6-9

6.4.1 Write Data into an External Device ......................................................... 6-9

iv

6.4.2 SEND Command (MODBUS Function Code Specified Type) .............. 6-11

6.4.3 SEND Command (MODBUS Function Code Unspecified Type) .......... 6-12

Table of Contents

7. General-Purpose Communication ..................................... 7-1

7.1 Operation of General-Purpose Communication ...................................... 7-2

7.1.1 Read Data from an External Device ....................................................... 7-2

7.1.2 Write Data into an External Device ......................................................... 7-2

7.1.3 Sending Format in General-Purpose Communication ............................ 7-3

7.2 Sending Operation .................................................................................. 7-4

7.2.1 Overview of Sending Operation .............................................................. 7-4

7.2.2 Contents of Sent Data ............................................................................. 7-6

7.2.3 GPSEND (General-Purpose Communication Sending Command) ........ 7-7

7.3 Receiving Operation ............................................................................... 7-8

7.3.1 Overview of Receiving Operation ............................................................ 7-8

7.3.2 Contents of Received Data ................................................................... 7-10

7.3.3 GPRECV (General-Purpose Communication Receiving Command) ... 7-11

8. Specifications ...................................................................... 8-1

8.1 Specifications of CPU Unit LAN Port Communication Function ............. 8-2

8.2 MEWTOCOL-DAT Format ...................................................................... 8-3

8.2.1 MEWTOCOL-DAT Command Format in LAN Command Format .......... 8-3

8.2.2 MEWTOCOL-DAT Command/Response Format ................................... 8-4

8.3 MEWTOCOL-COM Format ..................................................................... 8-6

8.3.1 MEWTOCOL-COM Command Format in LAN Communication ............. 8-6

8.3.2 MEWTOCOL-COM Command Format ................................................... 8-7

8.3.3 MEWTOCOL-COM Response Format .................................................... 8-9

8.4 MEWTOCOL7-COM Format ................................................................. 8-11

8.4.1 MEWTOCOL7-COM Command Format ............................................... 8-11

8.4.2 MEWTOCOL7 Response Format ......................................................... 8-13

v

Table of Contents

vi

1

Communication Functions of

CPU Unit

Communication Functions of CPU Unit

REFERENCE

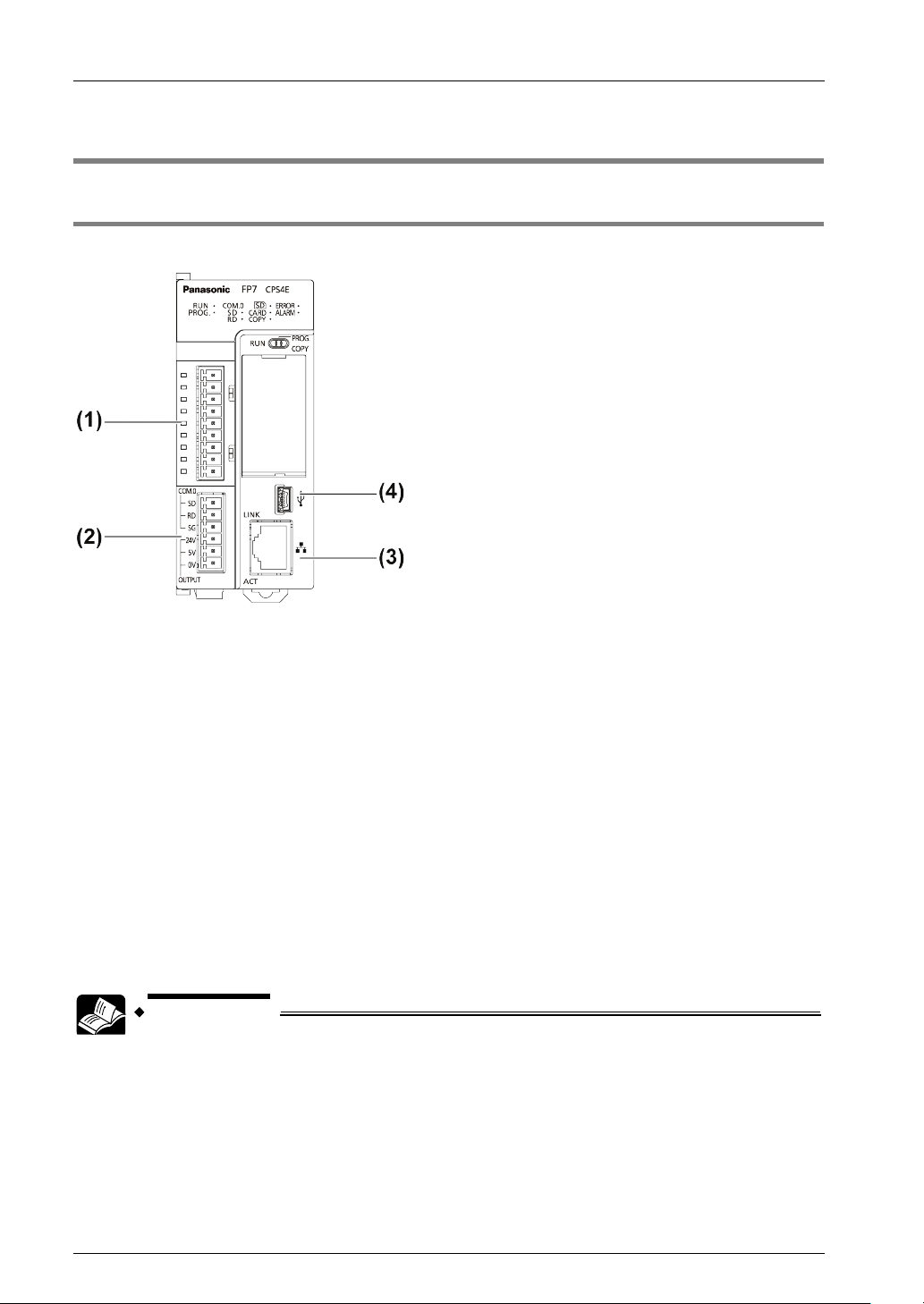

1.1 Communication Ports of CPU Unit

1.1.1 Types and Purposes of Communication Ports

Communication ports of CPU unit

Functions of Ports

(1) COM1 and COM2 Ports

Attach a separately sold communication cassette to use these ports. You can select from five

types of communication cassettes.

(2) COM0 Port

This is an RS-232C port that is equipped to a standard model of CPU unit. It is equipped with

power supply terminals (5V DC and 24V DC) to which a GT series display can be connected.

(3) LAN Port

This is equipped to a standard model of CPU unit. It is used for connection to Ethernet. It can

also be connected with a programming tool. The MAC address is printed on the side of the

unit. It supports the Ethernet communication interfaces 100BASE-TX and 10BASE-T.

100BASE-TX and 10BASE-T are automatically switched by the auto negotiation function.

(4) USB Port

This is equipped to a standard model of CPU unit. This is used when connecting tool software.

• For communication using the COM port, please see the CPU Unit Users

Manual (COM Port Communication).

1-2

1.1 Communication Ports of CPU Unit

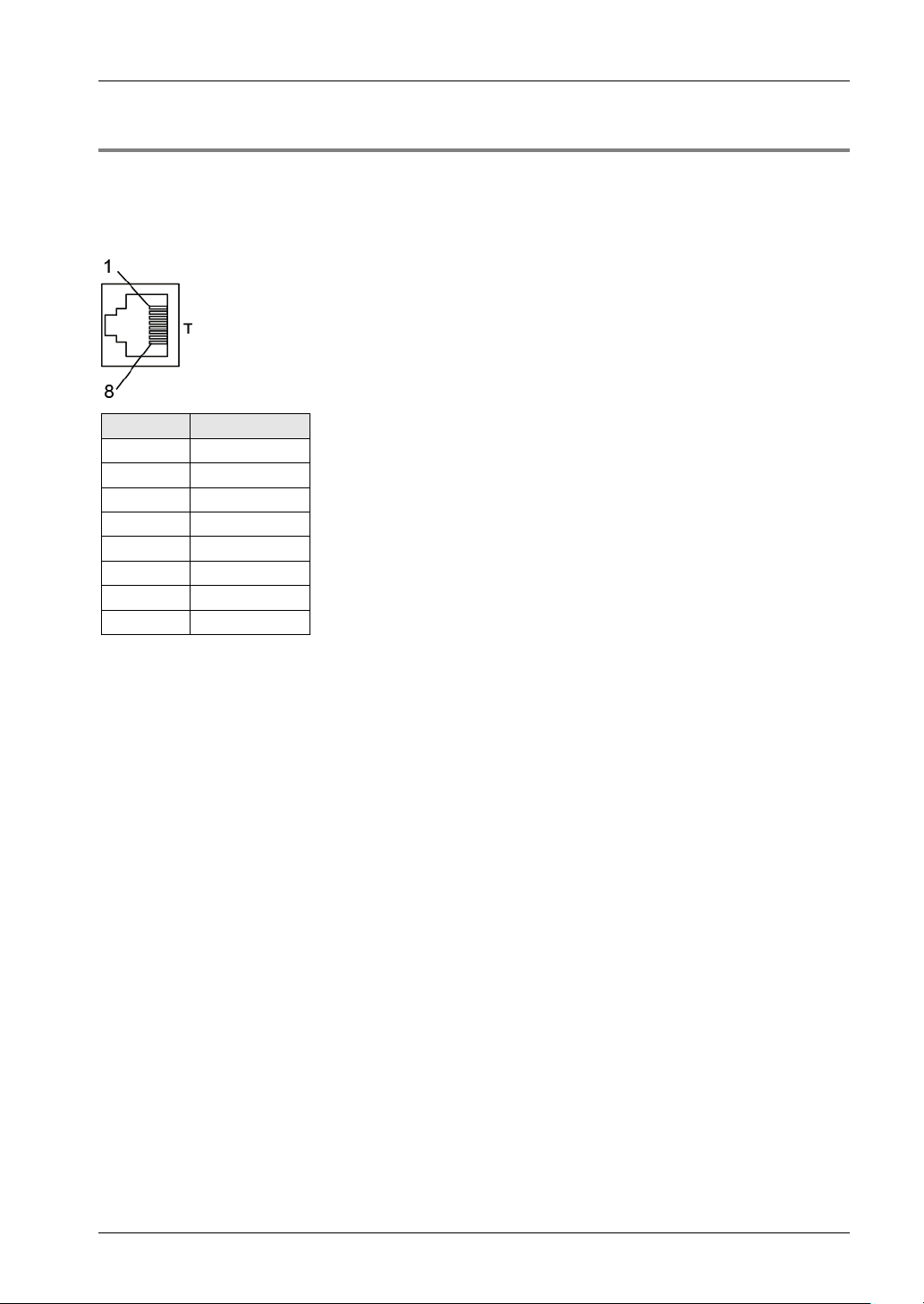

1.1.2 LAN Port Specifications

100BASE-TX / 10BASE-T connector (RJ45)

This connector connects the ET-LAN Unit and the Hub in Ethernet (100BASE-TX, 10BASE-T)

and UTP Cable.

Pin no. Signal name

1 TX+

2 TX-

3 RX+

4 Not used

5 Not used

6 RX-

7 Not used

8 Not used

Functions of LED lamps

(1) LINK

Turns on when connection is established between the FP7 CPU unit and a device on Ethernet.

(2) ACK

Flashes when some communication is in progress with a connected device (e.g.

sending/receiving a command or response).

1-3

Communication Functions of CPU Unit

1.2 Functions of LAN Port

1.2.1 Communication Functions of FP7 CPU Unit

Configuration chart

Communication functions of FP7 CPU Unit

• The FP7 CPU Unit can open a virtual communication line with an Ethernet-supporting device

connected to LAN, and send/receive data.

• IP address of the FP7 CPU unit, protocol (TCP/UDP), connection method with devices, port

numbers, etc. should be specified in the configuration menu of the programming tool FPWIN

GR7.

• In master communication commands SEND/RECV, messages in accordance with the

protocol are automatically generated by PLC. In the user program, reading and writing can

be done simply by specifying the station no. and memory address and executing commands.

• Communication functions can be selected depending on the partner device to be connected.

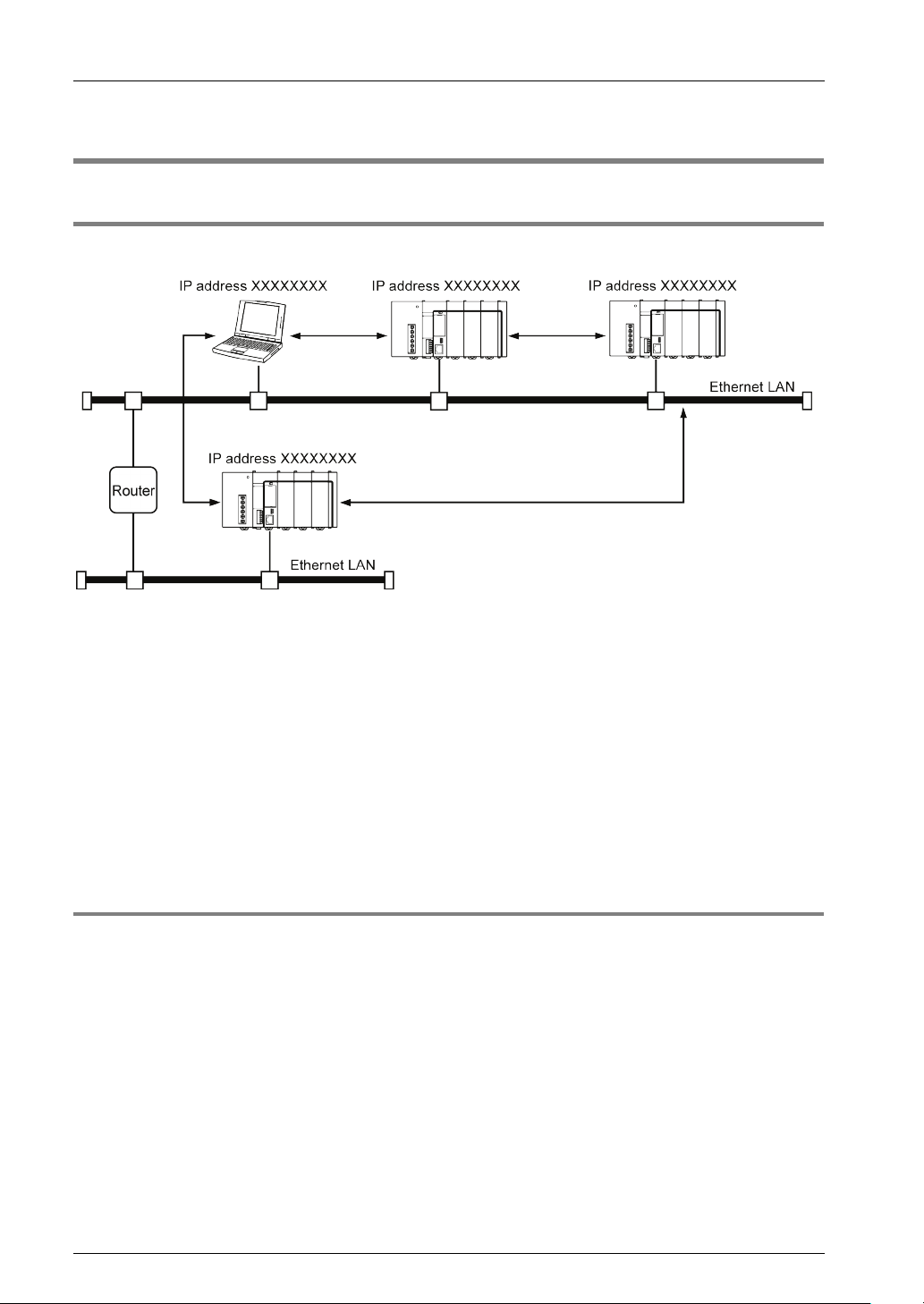

1.2.2 System Connection

Functions of system connection

• System connection is used when using a programming tool via LAN port.

• Four connections are available per CPU unit.

1-4

1.2 Functions of LAN Port

IP XXXXXX

FP7 CPU

1

Port

8000

External

device

IP XXXX

Port XXXX

2

Port

8001

16

Port

8015

Ethernet LAN

Select a desired communication

method for each connection

IP XXXX

Port XXXX

IP XXXX

Port XXXX

FP7 CPU

1

Port

8000

External

device

2

Port

8001

16

Port

8015

Ethernet LAN

Select a desired communication

method for each connection

IP XXXXXX

Port

XXXX

Port

XXXX

Port

XXXX

IP XXXXXX

MEWTOCOL-COM

Master

Slave

Master

Slave

Master

Slave

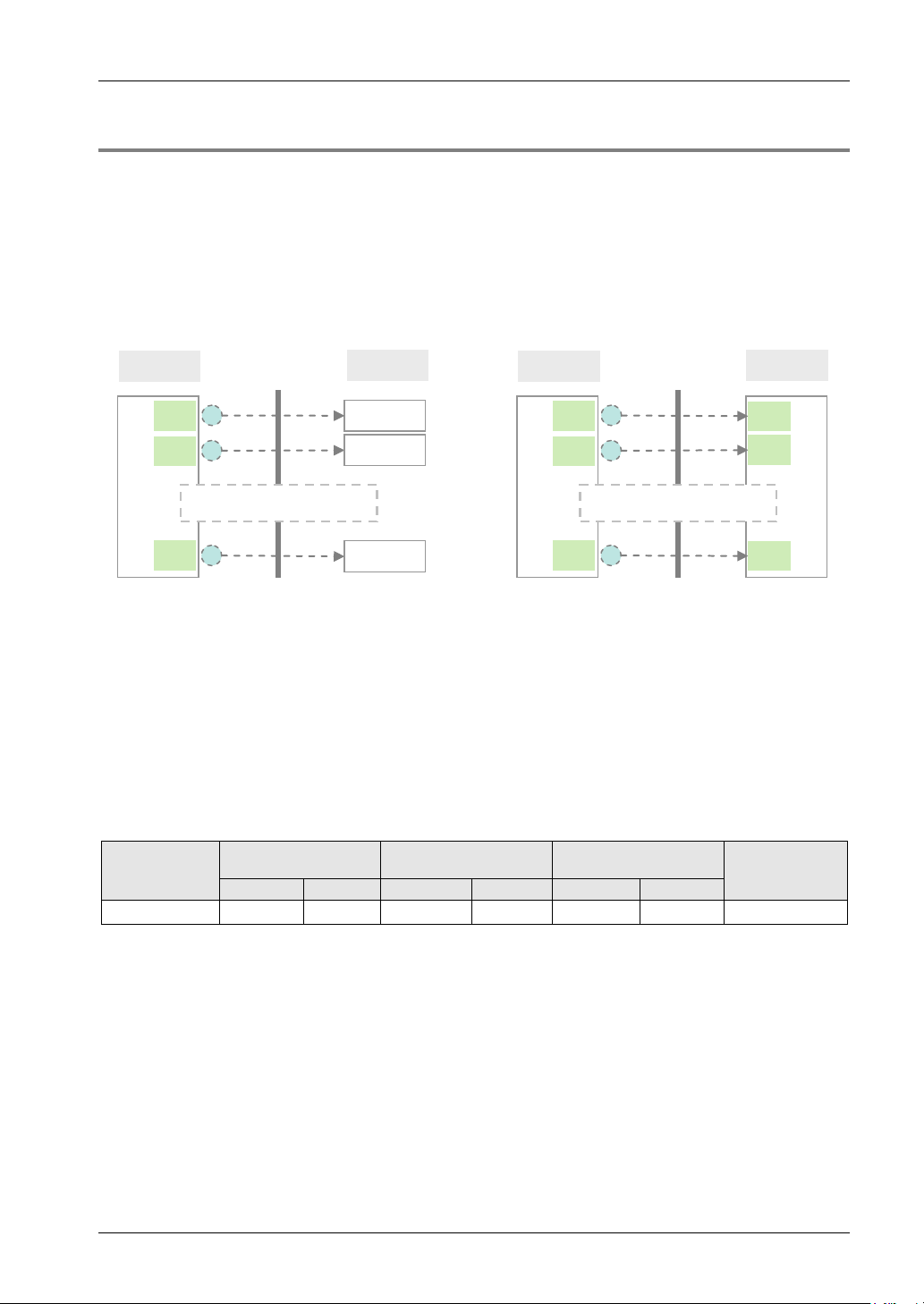

1.2.3 User Connection

Functions of user connection

• The FP7 CPU Unit can open virtual communication lines for up to 16 connections with

Ethernet-supporting devices connected to LAN, and send/receive data.

• It can open multiple connections between the FP7 CPU unit and multiple nodes or a single

node, and execute communication.

• Operation mode, open method, protocol, etc. can be selected for each connection.

Note) Circled numbers in the figure above indicate examples of allocation of connection numbers.

Connection operation

• Connection is opened from either the FP7 CPU unit side or the external device side.

• The open method should be selected from server connection (unspecified partner), server

connection (specified partner), and client connection, in the configuration menu of FPWIN

GR7.

• Once connection is established, communication by a user program becomes possible in

accordance with the operation mode.

Supported operation mode

Communication

MEWTOCOL-DAT

MEWTOCOL7-COM

port

LAN port ●

● ○ (Note)

(Note) MEWTOCOL7-COM does not support master functions.

MODBUS-TCP

● ● ● ●

Generalpurpose

communication

1-5

Communication Functions of CPU Unit

FP7 CPU

Our PLC supporting

MEWTOCOL-DAT

Ethernet LAN

IP XXXXXX

IP XXXXXX

Send/receive data using

MEWTOCOL

-DAT

Command

Master

communication

Slave

communication

Response

Command

Response

KEY POINTS

1.3 Overview of Communication Functions

1.3.1 MEWTOCOL-DAT Master/Slave Communication (Binary Communication)

Overview of function

• Execute communication using MEWTOCOL-DAT, a communication protocol usd by our PLC.

• One of the PLC has the sending right, and executes communication by sending commands

to PLCs that support MEWTOCOL-DAT, and receiving responses.

• The slave-side PLC responds automatically, so no program concerning communication is

necessary.

• Also on the master-side PLC, messages in accordance with the protocol are automatically

generated by PLC. In the user program, reading and writing can be done between PLCs

simply by specifying the station no. and memory address and executing SEND/RECV

commands.

• This is suitable for sending/receiving data between PLCs, because the data size that can be

transmitted in a single communication is larger, and the transmission format is simpler and

shorter, than the MEWTOCOL-COM communication (ASCII communication).

• The data size that can be sent or received in a single communication is up to 2038 words for

register transmission and 1 bit for bit transmission.

(Note) In the case of connection with our PLC FP2 ET-LAN unit, the maximum size is 1020 words.

Purpose of MEWTOCOL-DAT communication

This is used for sending data with our PLC that supports MEWTOCOL-DAT via Ethernet.

• Programmable controller FP series

• When MEWTOCOL-DAT master/slave communication is used, select

"TCP/IP" for the communication protocol in order to guarantee the reliability

of communication.

1-6

1.3 Overview of Communication Functions

FP7 CPU

Device supporting

MEWTOCOL

-COM

Ethernet LAN

IP XXXXXX

IP XXXXXX

Send/receive data using

MEWTOCOL-COM

Command

Master

communication

Slave

communication

Response

Command

Response

1.3.2 MEWTOCOL-COM Master/Slave Communication (ASCII Communication)

Overview of function

•

Execute communication using MEWTOCOL-COM, a communication protocol used by our PLC.

• One of the device has the sending right, and executes communication by sending

commands to devices that support MEWTOCOL-COM, and receiving responses.

• The slave-side PLC responds automatically, so no program concerning communication is

necessary.

• Also on the master-side PLC, messages in accordance with the protocol are automatically

generated by PLC. In the user program, reading and writing can be done simply by

specifying the station no. and memory address and executing SEND/RECV commands.

• Because MEWTOCOL-COM communication is on an ASCII basis, it is suitable for

sending/receiving text data.

• The data size that can be sent or received in a single communication is up to 507 words for

register transmission and 1 bit for bit transmission.

Applications of MEWTOCOL-COM communication

This is used for sending text data between our devices that support MEWTOCOL-COM via

Ethernet. This method can also be used for connecting a programming tool.

• Programmable controller FP series

1-7

Communication Functions of CPU Unit

FP7 CPU

MODBUS-TCP

supporting device

Ethernet LAN

IP XXXXXX

IP XXXXXX

Send/receive data using

MODBUS-TCP

Command

Master

communication

Slave

communication

Response

Command

Response

1.3.3 MODBUS TCP Master/Slave Communication

Overview of function

• This is used for communicating with other devices that support the MODBUS TCP protocol.

• In master communication, communication is performed when the master unit sends

instructions (command messages) to slave units and the slave unit returns responses

(response messages) according to the instructions. Messages in accordance with the

protocol are automatically generated by PLC. In the user program, reading and writing can

be done simply by specifying the station no. and memory address and executing

SEND/RECV commands.

• Slave communication is performed when the higher device connected to PLC has the

sending right, and sends commands, and PLC returns responses. In slave communication,

PLC responds automatically, so no program concerning communication is necessary on the

PLC side.

• The data size that can be sent or received in a single communication is up to 127 words for

register transmission and 2040 bit for bit transmission.

1-8

1.3 Overview of Communication Functions

FP7 CPU External device

Ethernet LAN

IP XXXXXX

IP XXXXXX

Send/receive message/data

Message/data

Send

Receive

Operation

memory

Message/data

1.3.4 General-Purpose Communication

Overview of function

• General-purpose communication is used when PLC executes communication in accordance

with the command specifications of the partner device.

• Formulation and sending of command messages to the partner device, and reception

processing of responses from the partner device, are performed by the user program.

Sending/receiving of data with an external device is executed via given operation memory

(e.g. data register).

• Data are sent by setting message/data in a given data register in accordance with the

partner device, and executing GPSEND command.

• Data received from the partner device are temporarily saved in the buffer. Based on the

reception done flag, GPRECV command is executed and the received data are copied into a

given operation memory. The received data can be converted into numerical data, etc. as

necessary, by the user program.

• The data size that can be sent or received in a single communication is up to 16,372 bytes

per connection.

(Note 1) When a dedicated header is not attached, the size is up to 16,384 bytes.

(Note 2) In the case of connection with our PLC FP2 ET-LAN unit, the maximum size is 8,192 bytes.

Applications of general-purpose communication

This is used for communication with devices made by differing manufacturers that have

dedicated communication protocols.

1-9

Communication Functions of CPU Unit

FP7 CPU

(server

connection)

External device

(client connection)

IP XXXXXX

IP XXXXXX

Master

communication

Slave

communication

Ethernet

LAN

Command

Response

Command

Response

FP7 CPU

(client connection)

External device

(server

connection)

IP XXXXXX

IP XXXXXX

Master

communication

Slave

communication

Ethernet

LAN

Command

Response

Command

Response

Virtual line connection

from external device

Virtual line connection

from FP7 CPU

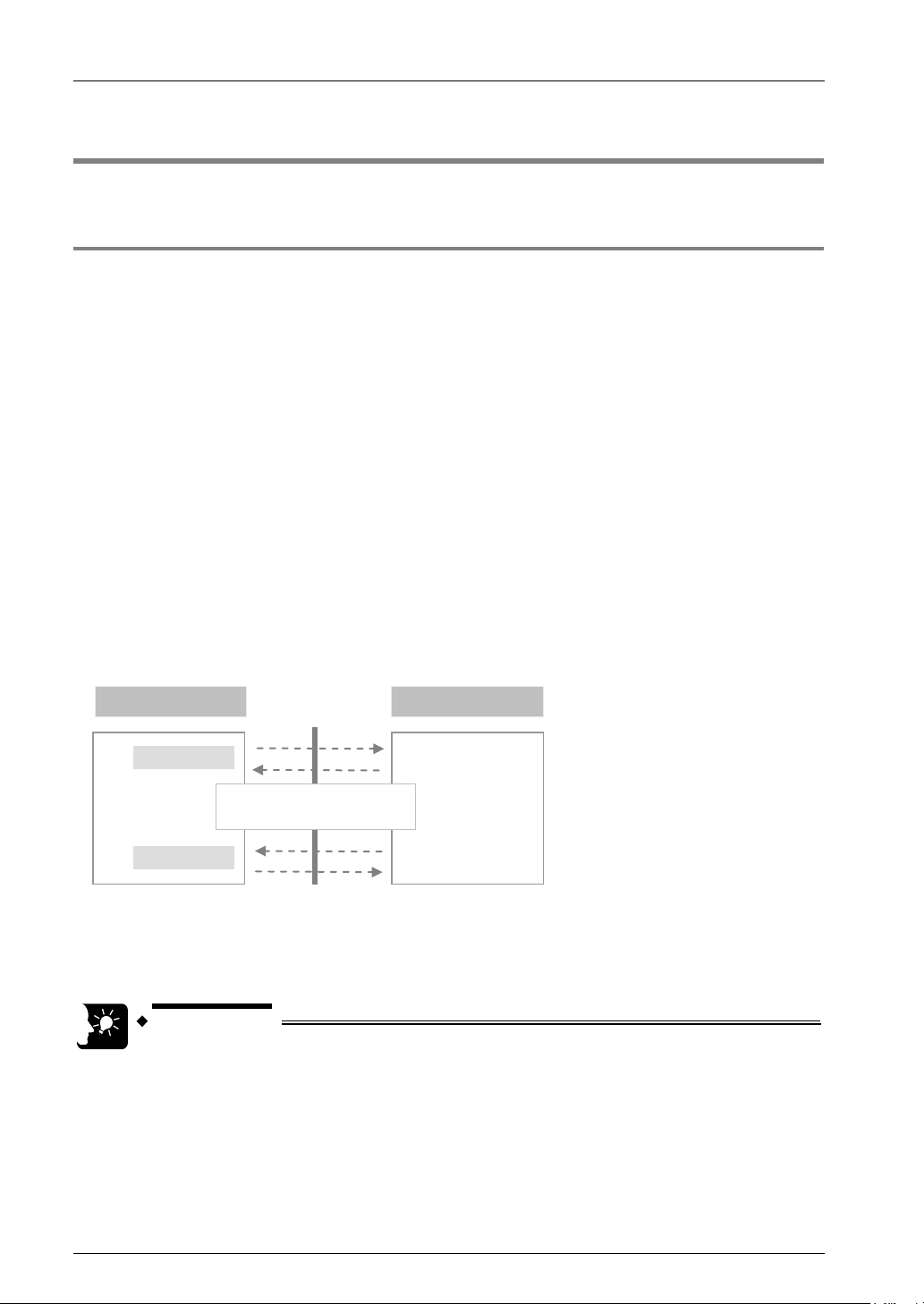

1.4 Terms

The following terms are used for settings on the software for connecting the FP7 CPU unit to

Ethernet LAN, and in the Users Manuals.

Server connection and client connection

• These indicate methods for connecting a virtual communication line between FP7 and an

external device.

• "Server connection" refers to a method to wait for connection from another client.

• "Client connection" refers to a method to connect a virtual communication line from the FP7

CPU unit to another external device port. Even if connection fails, repeated connection

attempts are made at a specified interval.

Master communication and slave communication

• These indicate methods for actually sending/receiving messages and data between FP7 and

an external device.

• In master communication, PLC sends commands and receives responses.

• In slave communication, commands are received from an external device, and responses

are returned.

• In a system using FP7, whether server connection or client connection is selected, once

connection is opened and a virtual communication line is connected, commands and

responses can be sent and received from both sides.

1-10

2

Installation and Wiring

Installation and Wiring

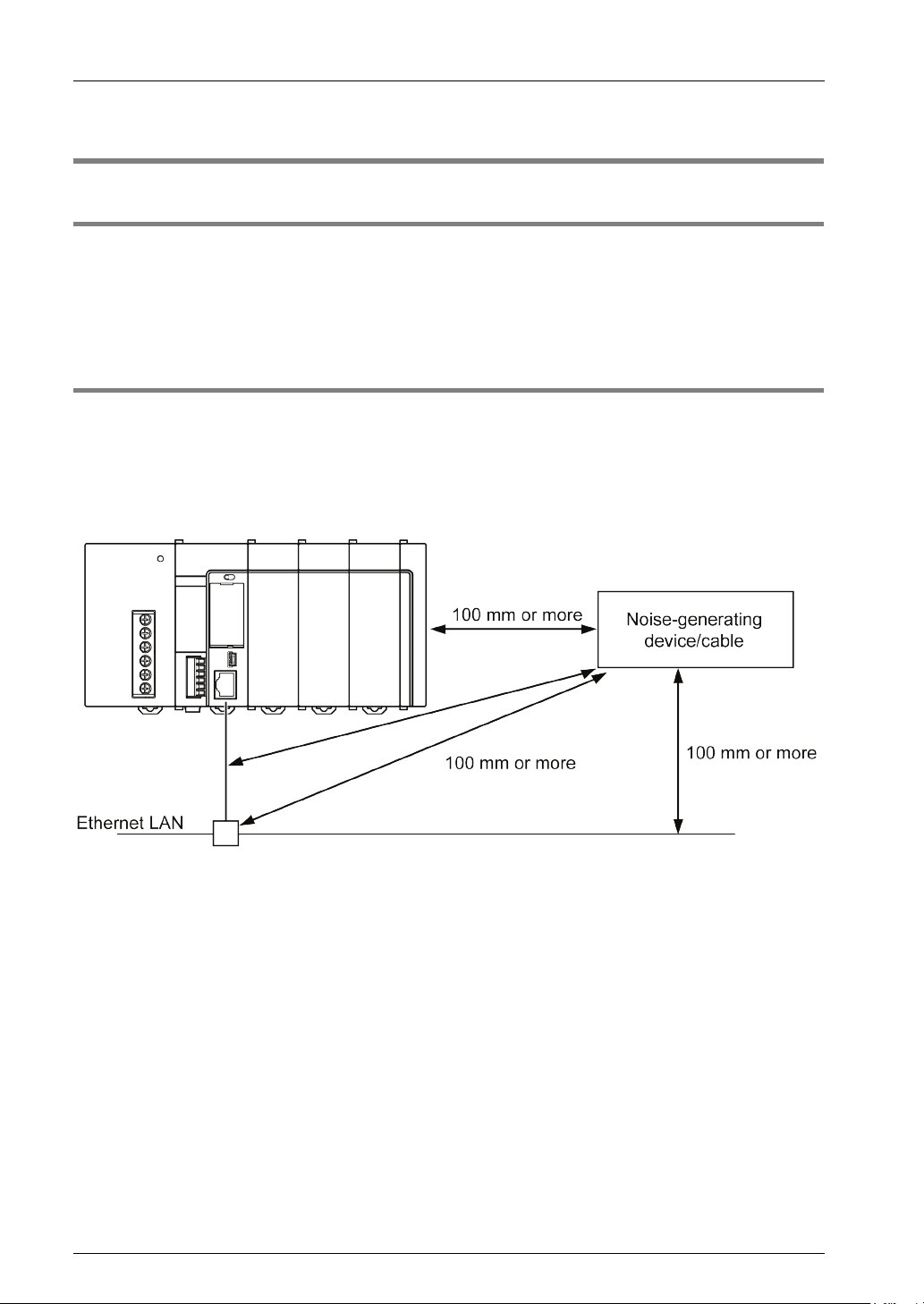

2.1 Installation Environment and Wiring for LAN Ports

2.1.1 Before Installation and Wiring

Noise resistance of Ethernet

The Ethernet is a network used in offices and buildings, where there is comparatively little

noise. It does not have a higher resistance to noise than ordinary FA application networks.

Caution is required when installing the hub, and when laying cables.

2.1.2 Installation Environment and Noise Control Measures

Measures that can be taken in the installation environm ent

• The CPU unit, transceiver, hub, and communication cables should be installed as far as

possible from high-voltage wires, high-voltage equipment, power lines, power equipment,

equipment that generates strong breaker surges, and the wiring for any of this equipment. At

least 100 mm of clearance should be allowed when installing the equipment.

• When a device must be installed or a cable must be laid near a noise-generating device for

special reasons, take measures such as:

• install a programmable controller and a hub within a metal panel,

• laying a communication cable inside a metal duct,

• attaching a ferrite core near the CPU unit on the communication cable,

etc.

• An alternative measure is to use an optical transceiver close to the noise-generating section

of the equipment and install an optical fiber to keep the noise from affecting nearby

equipment. (This is also effective as a lightning shield for outdoor wiring.)

• Metal panels and metal ducts should be grounded at a grounding resistance of 100 Ω or less.

Also, metal panels and metal ducts should be insulated so that they do not come in contact

with communication devices or cables.

2-2

2.2 Wiring the LAN Port

2.2 Wiring the LAN Port

Selection of UTP cables

• Use Category 5 UTP cable.

• It is recommended to use a UTP cable of 10 m or shorter, taking account of noise resistance.

• In an environment where noise may occur, attach a ferrite core near the CPU unit on the

UTP cable. It is also recommended to use a shielded cable.

• For installation of 100BASE-TX or 10BASE-T hub, laying of cables, etc.,

please consult a specialized construction company. If this construction

work is done incorrectly, it can adversely affect the entire network, and can

cause accidents.

2-3

Installation and Wiring

REFERENCE

2.3 Noise Control Measures

2.3.1 Guidelines to Noise Generation

• If any of the following are occurring, there is a danger that external noise is affecting the

communication circuit. Appropriate measures should be taken.

• Check to see if a communication error is occurring, in synchronization with the operation of

the device. If either of these is happening in synch with the operation of the device, take

whatever measures are necessary to suppress the generation of noise from the device side.

2.3.2 Taking Corrective Measures through the Application

Communication errors occurring in the unit can be minimized by taking the steps outlined

below. Corrective measures should also be taken on the computer side, such as increasing

the number of times that data is sent.

Increasing the number of times data is sent

• In the tool software FPWIN GR7, select built-in ET-LAN, adjust the "TCP ULP timeout value"

and "TCP re-transmission timer value" in "basic communication information" to increase the

number of times data is sent.

• The number of times data is sent is given in the following formula. "TCP ULP timeout value"

should be specified at an integral multiplication of "TCP re-transmission timer value". When

an integral multiplication cannot be given, round up the given decimal number. The max.

number of times data is sent is 12.

No. of times data is sent = "TCP ULP timeout value (packet existence duration)" / "TCP retransmission timer value"

• The above setting is invalid when UDP/IP is used. Use the application to send the

transmission again.

Increasing the timeout judgment time

When master communication commands (SEND/RECV) are executed, select "CPU

configuration" in the tool software FPWIN GR7, and increase the set value for "time settings:

timeout time for communication control commands" Default value is set at 10 seconds (set

value: 100)

• For configuration, please see 3.2.1 List of Setting Items.

2-4

3

Configuration

Configuration

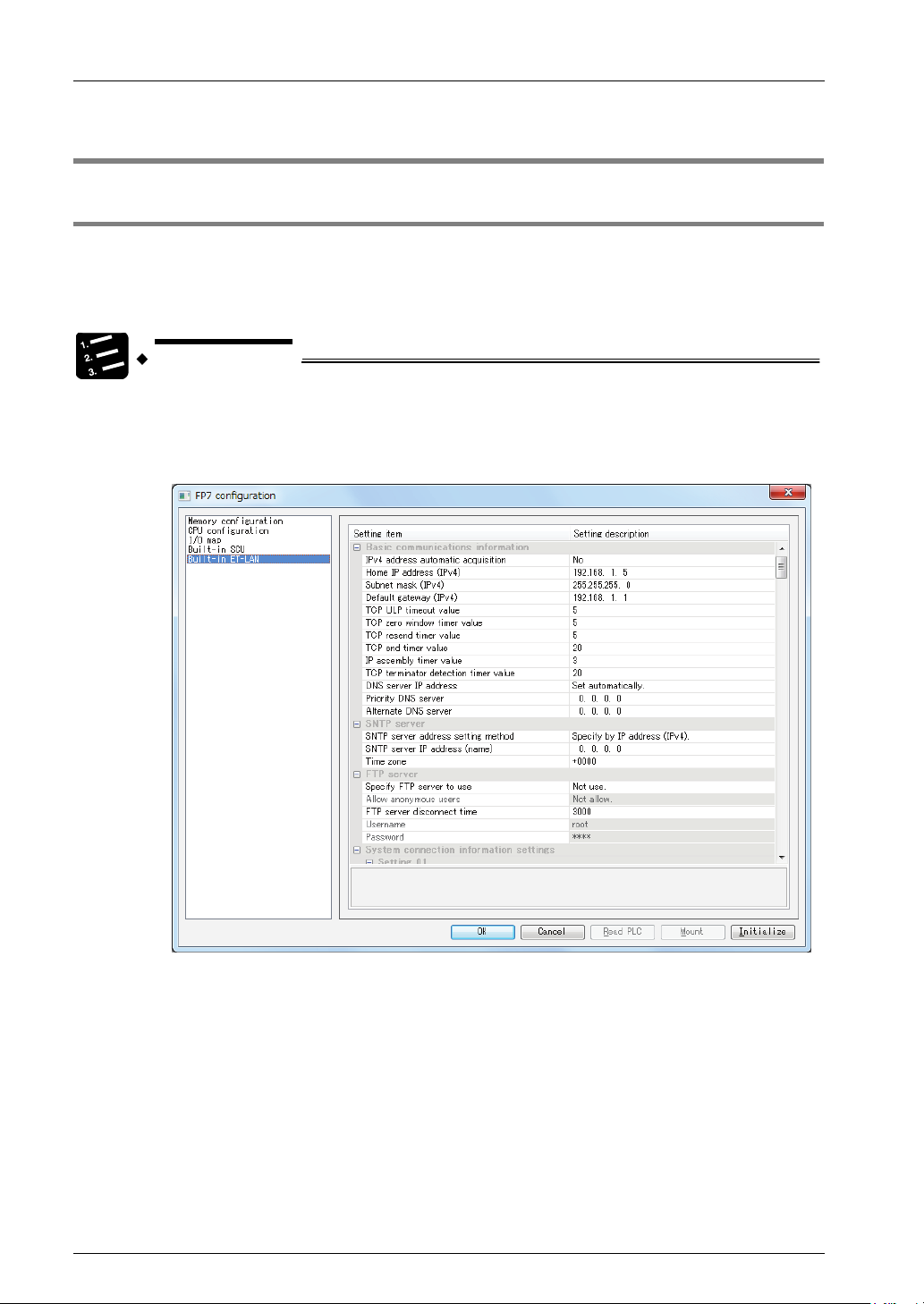

PROCEDURE

3.1 Procedure for Setting Communication Conditions

3.1.1 Setup Procedure

• To use communication functions based on the LAN port, communication conditions must be

set.

• Settings should be performed by the programming tool FPWIN GR7.

1. From the menu bar, select "Option" > "FP7 Configuration".

2. From the left pane, select "Built-in ET-LAN".

Setting items appear.

3. Specify conditions for each item under "Settings for Built-in ET-LAN", and

4. Select [File] > [Save As] in the menu bar.

3-2

press [OK] button.

The settings are registered in the project.

3.2 Setting Basic Communication Information

3.2 Setting Basic Communication Information

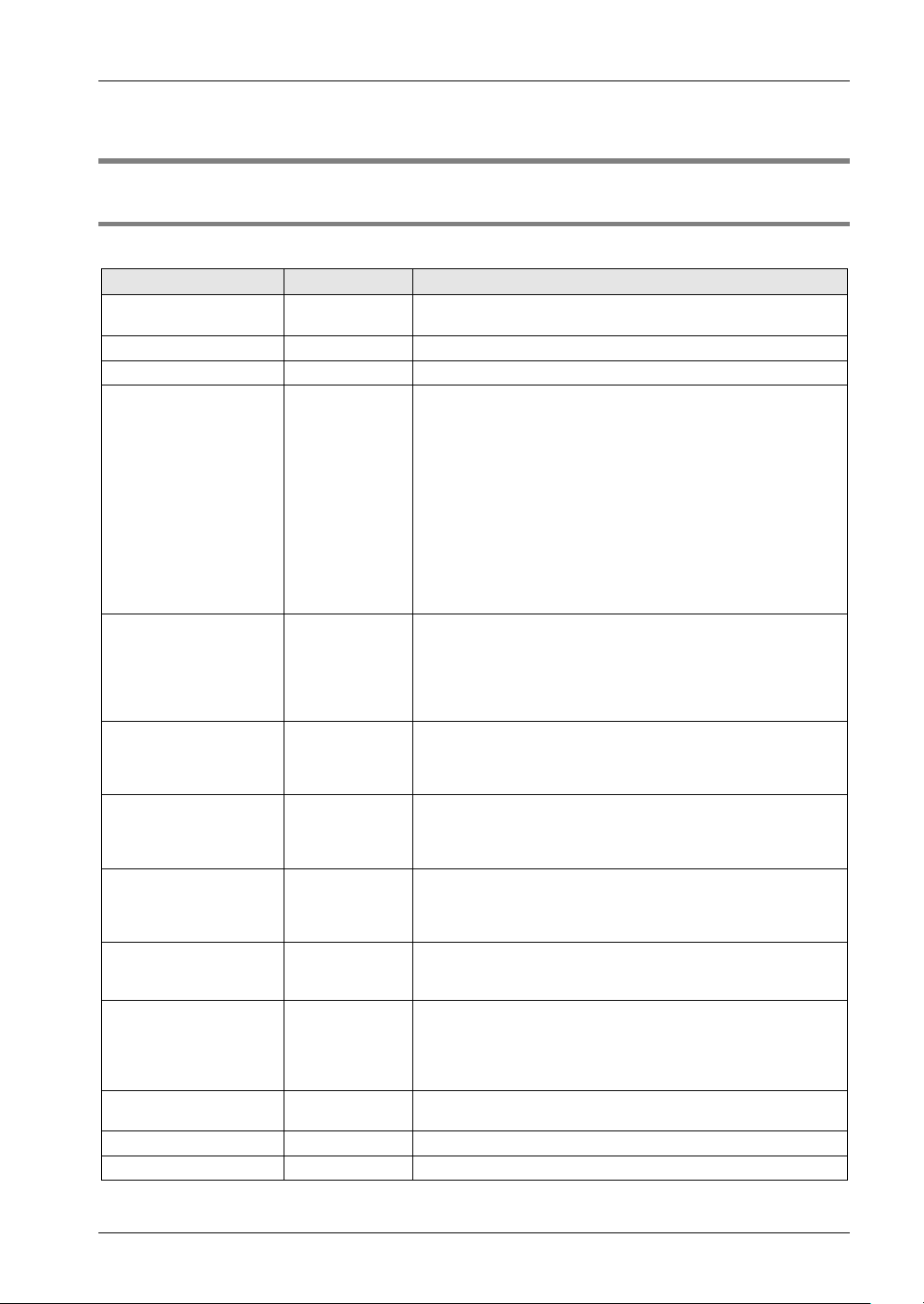

3.2.1 List of Setting Items

List of setting items (basic communication information)

Setting item Default Remark

Automatic getting of

IPv4 address

Own IP address (IPv4) 192.168.1.5

Subnet mask (IPv4) 255.255.255.0

Default gateway

(IPv4)

TCP ULP time-out value 5

TCP zero-window

timer value

TCP re-transmission

timer value

TCP closed timer value 20

IP assembling timer

value

TCP terminal detection

timer value

IP address of the DNS

server

Prioritized DNS server 0.0.0.0

Substitute DNS server 0.0.0.0

No

192.168.1.1

5

5

3

20

Set manually

This is valid as long as the network (subnetwork) mask field is

anything other than 0.

If the default router (gateway) IP address has been set,

communication will be carried out through the default router

(gateway) without an error occurring even f the class, network

address, or subnetwork address of the partner node differ from

those of the source node.

The network (subnetwork) address for the default router

(gateway) IP address must be identical to the network

(subnetwork) address for the source node IP address. If they are

different, an error will occur.

・0000 0000 H and FFFF FFFF H is regarded as an error.

Setting range: 0001 - FFFF: (by 100 ms)

With TCP, this specifies the time that a packet exists when data

transmission, etc. is carried out. "TCP ULP" should be specified

at an integral multiplication of "TCP re-transmission timer value".

When an integral multiplication cannot be given, round up the

given decimal number.

Setting range: 0001 - FFFF: (by 100 ms)

With TCP, this specifies the time until the receive window size

check packet is re-sent when the receive window size of the

other node becomes 0.

Setting range: 0001 - FFFF: (by 100 ms)

With TCP, this specifies the time until data is re-sent if ACK is

not sent by the other node, when data transmission, etc. is

carried out.

Setting range: 0001 - FFFF: (by 100 ms)

This specifies the time waited until open processing is carried

out when the same port is being re-opened, when TCP close

processing is done by the source node.

Setting range: 0001 - FFFF: (by 100 ms)

This specifies the time waited for the next portion of data when

data split by the IP is being received.

Setting range: 0001 - FFFF: (by 1 ms)

When divided TCP segments are received, specify the time for

monitoring the arrival of the following segment.

TCP reception is regarded as completed if no data are received

after the time as specified above has passed.

3-3

Configuration

KEY POINTS

3.2.2 Setting Each Timer Value And Timeout Value

For setting each timer value and timeout value, please refer to the description below.

Timer setting conditions in FPWIN GR7

Timer setting conditions in FPWIN GR7 are as follows.

• TCP closed timer value ≥ TCP ULP timeout value ≥ TCP re-transmission timer value

AND

• TCP zero window timer value ≥ IP assembly timer value

Setting the TCP ULP timeout value (packet existence duration) and

the TCP re-transmission timer value

When TCP/IP communication is being carried out, data is automatically re-sent the specified

number of times, as shown in the illustration below.

E.g. When TCP ULP: 30 seconds, TCP re-transmission timer value: 10 seconds

• Communication errors occurring in the unit can be minimized by increasing

• The max. number of times data is sent is 12.

• If UDP/IP is being used, re-sending is not carried out.

3-4

the number of re-transmission times. Corrective measures should also be

taken on the computer side, such as increasing the number of times that

data is sent.

3.3 Settings for SNTP server

3.3 Settings for SNTP server

These settings are required when the time is synchronized by SNTP while the calendar timer

function is being used.

List of setting items (SNTP server)

Setting item Default Setting method

SNTP server address Setting method

SNTP server IP address 0.0.0.0 Specify the setting for SNTP server (IP address / host name).

Time zone +0000

Specification

using IP

address (IPv4)

Select the setting for SNTP server

(specified by IP address (IPv4) / host name).

Setting unit: ± HHMM (HH: hour, MM: minute)

Setting range: +9999 to -9999

Specify a standard time zone in each region based on GMT.

3-5

Configuration

3.4 Settings for FTP server

Select this to use the FTP server function.

List of setting items (FTP server)

Setting item Default Setting method

Specifying use of FTP

server

Permission of anonymous

user

FTP server closing time 3000

User name root

Password root

No Select whether you will use the FTP server function.

No

If authentication by user account and password is not required,

select "Yes".

Setting unit: 100 ms

Setting range: 3,000 (0BB8H) to 429,496,729 (1999 9999 H)

Input the no-communication monitoring time during FTP

connection (unit: 100 ms). Connection is automatically cut off

when FTP no-communication exceeds the specified time.

3-6

Loading...

Loading...