Page 1

Technical/Programming Manual

FT1020G3

Rev 2.2.1

For Software V2.2.x

FT1020G3 CIE

M435 February 2016

Page 2

This page has deliberately been left blank.

Page 3

Technical Manual

FT1020G3 Rev 2.2.1

Table of contents

1 Introduction _____________________________________________________________ 9

1.1 General introduction ................................................................................................. 9

1.2 Definitions / Explanations ......................................................................................... 9

2 Overview ______________________________________________________________ 10

2.1 The FT1020G3 system ........................................................................................... 10

2.1.1 Printer .............................................................................................................. 10

2.1.2 Expansion boards............................................................................................. 10

2.1.3 Power supply.................................................................................................... 10

2.2 Software (S/W) versions ......................................................................................... 10

2.3 Documents ............................................................................................................. 12

2.4 Applications............................................................................................................ 12

2.5 PC software (S/W).................................................................................................. 12

2.5.1 EBLWin ............................................................................................................ 12

2.5.2 TLON Manager ................................................................................................ 13

3 TLON Network __________________________________________________________ 14

3.1 FT1020G3 TLON network ...................................................................................... 14

3.2 Redundant TLON Network ..................................................................................... 14

3.3 Routers .................................................................................................................. 14

3.4 Network connections .............................................................................................. 15

3.4.1 Twisted pair TLON network .............................................................................. 15

3.4.2 Fibre optic TLON network ................................................................................. 15

3.4.3 TCP/IP TLON network ...................................................................................... 16

4 Control & Indicating Equipment ___________________________________________ 17

4.1 FT1020G3 Specifications ....................................................................................... 17

4.2 FT1020G3 CIE Layout............................................................................................ 19

4.2.1 Mounting plates ................................................................................................ 21

4.2.2 Mounting plate for 19" mounting rack ................................................................ 21

4.3 COM loops ............................................................................................................. 22

4.4 Programmable voltage outputs (S0-S3) ................................ ................................ .. 22

4.5 Programmable relay outputs (R0-R1) ..................................................................... 22

4.6 Programmable inputs (I0-I3) ................................................................................... 23

4.7 Relay outputs for routing equipment (TX)................................................................ 23

4.7.1 Fire alarm output .............................................................................................. 23

4.7.2 Fault condition output ....................................................................................... 23

5 Expansion boards 458x __________________________________________________ 24

5.1 8 zones expansion board 4580 ............................................................................... 25

5.1.1 Type of zone line input ..................................................................................... 25

5.1.1.1 Zone line input (EOL capacitor) ................................ .................................... 26

5.1.1.2 EX zone line input (EOL resistor) .................................................................. 26

5.1.1.3 Zone line input (EOL resistor) ....................................................................... 26

5.1.2 Input states ...................................................................................................... 27

5.1.2.1 Normal state ................................................................................................. 27

5.1.2.2 High current state ......................................................................................... 27

5.1.2.3 Alarm state ................................................................................................... 27

5.1.2.4 Short-circuit state ......................................................................................... 27

5.1.2.5 Open circuit state ......................................................................................... 27

5.1.2.6 Disconnected state ....................................................................................... 27

5.2 8 relays expansion board 4581 ............................................................................... 27

5.3 Inputs and outputs expansion board 4583 .............................................................. 28

5.4 I/O Matrix board 4582 ............................................................................................. 29

5.4.1 I/O Matrix jumper link setting ............................................................................ 29

6 Optional Modules _______________________________________________________ 31

6.1 AS1668 Fan control ................................................................................................ 31

6.1.1 Mode Control.................................................................................................... 31

6.1.2 Fan Status ........................................................................................................ 31

1

Page 4

Technical Manual

FT1020G3 Rev 2.2.1

6.1.3 Configuration and Programming ....................................................................... 32

6.1.4 Fan Reset ........................................................................................................ 34

6.1.5 Fan Front Display ............................................................................................. 35

6.1.6 Supply Air Fan .................................................................................................. 35

6.1.7 Smoke Exhaust Fan ................................ ......................................................... 36

6.2 Zone control ................................ ........................................................................... 37

6.2.1 Controls & Indications ....................................................................................... 37

6.2.2 Zone Control Configuration ............................................................................... 38

6.3 Generic Applications .............................................................................................. 39

6.3.1 Overview .......................................................................................................... 39

6.3.2 New mimic options ........................................................................................... 39

6.3.3 Configuration and programming........................................................................ 40

6.4 Occupant Warning System (OWS) ......................................................................... 41

6.4.1 Overview .......................................................................................................... 41

6.4.2 Audio Amplifiers ............................................................................................... 42

6.4.2.1 60/120 Watt Amplifier Module ....................................................................... 42

6.4.2.2 250 Watt Amplifier Module............................................................................ 44

6.4.3 OWS Volume Adjustment ................................................................................. 45

6.4.4 Auxiliary Audio inputs ....................................................................................... 45

6.4.5 OWS Dual Strobe Output ................................................................................. 45

6.5 Gaseous extinguishing system control module ....................................................... 46

6.5.1 Overview .......................................................................................................... 46

6.5.2 Display board (SUB929) & decal ...................................................................... 46

6.5.3 Control board (SUB928) ................................................................................... 48

6.5.4 CIE interface board (SUB943) .......................................................................... 48

6.5.4.1 Inputs from FT1020G3 to CIE interface board (SUB943) .............................. 48

6.5.4.2 Outputs from CIE interface board (SUB943) to FT1020G3 ............................ 48

7 Printer 49

8 TLON connection board 5090 _____________________________________________ 50

8.1 Single TLON Network (not recommended) ............................................................. 50

8.2 Redundant TLON network ...................................................................................... 50

8.3 Network programming ............................................................................................ 50

9 Peripheral devices ______________________________________________________ 51

9.1 COM loop units ...................................................................................................... 51

9.1.1 Input units ........................................................................................................ 53

9.1.1.1 Analogue Sensor Bases (ASB) ..................................................................... 54

9.1.1.2 Addressable Manual Call Points ................................................................... 54

9.1.1.3 Analogue Detectors ...................................................................................... 55

9.1.1.4 Conventional Detector Bases (CDB) ............................................................. 59

9.1.1.5 Conventional Detectors ................................................................................ 59

9.1.1.6 Accessories.................................................................................................. 60

9.1.2 Addressable I/O units ....................................................................................... 61

9.1.3 Alarm devices (addressable sounders) ............................................................. 62

9.1.4 Short circuit isolators (addressable) .................................................................. 64

9.1.5 Built-in Isolators ................................................................................................ 65

9.1.6 Units for Hazardous (Ex) areas ......................................................................... 65

9.1.6.1 Galvanic isolators / IS barrier units ............................................................... 65

9.1.6.2 Intrinsically Safe mounting bases.................................................................. 65

9.1.6.3 Intrinsically Safe photoelectric smoke detectors ............................................ 66

9.1.6.4 Intrinsically Safe heat detectors .................................................................... 66

9.1.7 Intrinsically Safe Manual Call Points ................................................................. 66

9.1.8 Other COM loop units ....................................................................................... 66

9.2 Units connected to the RS485 interface .................................................................. 68

9.2.1 Alert Annunciation Units ................................................................................... 68

9.2.2 External Presentation Units .............................................................................. 69

9.3 Units connected to the RS232 interface J7 ............................................................. 70

9.3.1 Web-servers ..................................................................................................... 70

9.4 Other units ............................................................................................................. 70

9.4.1 External LEDs .................................................................................................. 70

2

Page 5

Technical Manual

FT1020G3 Rev 2.2.1

9.4.2 Alarm Devices (sounders, etc.) ......................................................................... 71

9.4.3 Magnetic Door Holders ................................ ..................................................... 71

9.4.4 Duct Detector Chambers .................................................................................. 71

10 Programmable inputs ____________________________________________________ 72

10.1 Control Unit Inputs I0-I3 .......................................................................................... 73

10.2 Inputs 0-4 on expansion board 4583 ....................................................................... 73

10.2.1 Not supervised ................................................................................................. 73

10.2.2 Supervised ....................................................................................................... 73

10.3 The 3361 unit Inputs In0 / Z & In1 ........................................................................... 73

10.3.1 Input In0 ........................................................................................................... 74

10.3.2 Input In1 ........................................................................................................... 74

11 Input programming ______________________________________________________ 75

11.1 Trigger conditions ................................................................................................... 75

11.2 Logic ................................................................................................ ...................... 78

11.2.1 Non-Supervised (Default) ................................................................................. 78

11.2.2 Supervised ....................................................................................................... 78

12 Programmable outputs __________________________________________________ 79

12.1 Control Unit outputs S0 – S3 .................................................................................. 80

12.2 Control Unit outputs R0 & R1.................................................................................. 81

12.3 8 relays expansion board 4581 Output 0 – Output 7 ............................................... 81

12.4 Inputs and Outputs expansion board 4583 Output 0 - 1 .......................................... 81

12.5 The 3361 unit's Outputs Re0 & Re1 ........................................................................ 81

12.6 The 3364 unit's VO0 – VO2 .................................................................................... 81

12.7 The 4477 unit's Output (siren) ................................................................................ 82

12.8 The 3379 unit's Output (sounder) ........................................................................... 82

12.9 The 4380 unit's Output (beacon) ............................................................................. 82

12.10 The 4383 unit's Output (light indicator).................................................................... 82

13 Output programming ____________________________________________________ 83

13.1 Type of output ................................................................................................ ........ 83

13.2 Logic ................................................................................................ ...................... 83

13.3 Supervised / Non-supervised .................................................................................. 84

13.4 Output signal period ............................................................................................... 84

13.5 Control expression ................................................................................................. 86

13.5.1 Trigger conditions ............................................................................................. 86

13.5.1.1 Alarm ....................................................................................................... 87

13.5.1.2 Interlocking ............................................................................................... 87

13.5.1.3 Disablement ............................................................................................. 88

13.5.1.4 Other ........................................................................................................ 88

13.5.1.5 Comments to the trigger conditions (functions): ........................................ 88

13.5.2 Logical operators .............................................................................................. 92

13.5.3 Control expression examples ............................................................................ 92

13.5.3.1 AND ......................................................................................................... 92

13.5.3.2 OR ........................................................................................................... 92

13.5.3.3 NOT ......................................................................................................... 92

13.5.3.4 Parentheses ............................................................................................. 93

13.5.3.5 Control expressions .................................................................................. 93

14 Short circuit isolators____________________________________________________ 94

15 Interlocking function ____________________________________________________ 96

15.1 Programming of interlocking function ...................................................................... 96

15.1.1 Interlocking output ............................................................................................ 97

15.1.2 Interlocking input .............................................................................................. 97

15.1.3 Interlocking combination ................................................................................... 97

15.2 Interlocking indications ........................................................................................... 99

15.3 Interlocking outputs and inputs (H9) ....................................................................... 99

15.3.1 Activated interlocking outputs / inputs (H9/C1) .................................................. 99

15.3.2 Activate / deactivate interlocking output (H9/C2) ............................................. 100

15.3.3 Disable / re-enable interlocking output (H9/C3) ............................................... 100

3

Page 6

Technical Manual

FT1020G3 Rev 2.2.1

15.4 Interlocking control expressions ............................................................................ 100

16 Fire Door Closing (MDH) ________________________________________________ 101

17 Functions / Services / Features ___________________________________________ 102

17.1 Sensor value ........................................................................................................ 102

17.2 Week average sensor value ................................................................................. 102

17.3 Decision value ...................................................................................................... 103

17.4 Alarm algorithms for smoke detectors / Detection levels / Offsets ......................... 103

17.4.1 Alarm algorithm / Alternative alarm algorithm ................................ .................. 103

17.4.2 Filtering algorithm ........................................................................................... 104

17.4.3 Smouldering smoke algorithm ........................................................................ 106

17.4.4 Performance factor ......................................................................................... 107

17.5 Algorithms for Analogue heat detectors ................................................................ 107

17.5.1 Class A1 algorithm ......................................................................................... 108

17.5.2 Class A2 S algorithm ...................................................................................... 108

17.5.3 Class B S algorithm ........................................................................................ 108

17.6 Self verification ..................................................................................................... 109

17.7 Minimum / Maximum sensor values ...................................................................... 109

17.8 2-zone / 2-address dependence (Co-incidence alarm) ................................ .......... 110

17.8.1 2-zone dependence ........................................................................................ 111

17.8.2 2-address (-unit) dependence ......................................................................... 111

17.8.3 Reset of 2-zone / 2-address dependence (co-incidence alarm) ....................... 112

17.9 Delayed alarm ...................................................................................................... 112

17.9.1 General time delay application ........................................................................ 112

17.9.2 Specific time delay application ........................................................................ 113

17.10 Selective Alarm Presentation ................................................................................ 113

17.11 Alarm Verification Facility (AVF) ........................................................................... 113

17.12 Alert Annunciation ................................................................................................ 114

17.13 Alert Annunciation Applications ............................................................................ 115

17.13.1 Alarm Acknowledgement Facility (AAF) .......................................................... 115

17.13.2 Local Alarm Acknowledgement (LAA) ............................................................. 117

17.14 Quiet alarm .......................................................................................................... 118

17.15 Fire alarm type A and Fire alarm type B ................................................................ 118

17.15.1 Fire alarm type B ............................................................................................ 119

17.15.2 Fire alarm type A ............................................................................................ 119

17.16 Disable zones, alarm points, outputs, etc. ............................................................. 119

17.16.1 Disable / Re-enable zone ............................................................................... 120

17.16.2 Disable / Re-enable zone - address ................................................................ 120

17.16.3 Disable / Re-enable output type ...................................................................... 120

17.16.4 Disable / Re-enable alarm devices.................................................................. 120

17.16.5 Disable / Re-enable interlocking output ........................................................... 120

17.16.6 Disable / Re-enable outputs for routing equipment .......................................... 120

17.16.7 Disable / Re-enable alert annunciation function .............................................. 120

17.16.8 Disconnect & Re-connect loop / zone line input .............................................. 120

17.17 External time channels ......................................................................................... 121

17.18 Test mode ............................................................................................................ 121

17.19 Test alarm devices ............................................................................................... 121

17.20 Test of outputs ..................................................................................................... 122

17.21 Test of routing equipment ..................................................................................... 122

17.22 Calibration of supervised outputs .......................................................................... 122

17.23 Service signal ....................................................................................................... 122

17.24 Fault signal (fault condition) .................................................................................. 123

17.25 Alarm texts ........................................................................................................... 123

17.25.1 Creating the alarm texts via EBLWin ............................................................... 123

17.25.2 Downloading alarm texts to the Display Units 1728 / 1736 .............................. 125

17.26 Real time clock (RTC) .......................................................................................... 126

17.26.1 Daylight saving time ....................................................................................... 126

17.27 Loss of main power source ................................................................ ................... 126

17.27.1 Fault: Loss of main power source ................................................................... 126

17.27.2 LCD backlight ................................................................................................. 126

4

Page 7

Technical Manual

FT1020G3 Rev 2.2.1

17.28 Zone Groups ........................................................................................................ 126

18 Special New Zealand functions ___________________________________________ 127

18.1 Alarm devices ...................................................................................................... 127

18.1.1 Silence Alarms (inside switch) ........................................................................ 127

18.1.2 New Zealand FB Bulgin Silence switch (outside switch) .................................. 127

18.1.2.1 Isolated alarm ......................................................................................... 128

18.2 Battery faults ........................................................................................................ 129

18.2.1 FAULT: Battery .............................................................................................. 129

18.2.2 FAULT: Low battery capacity (Auto battery test) ............................................. 129

18.3 Routing equipment isolate (disable) ...................................................................... 129

18.4 Acknowledged alarm ............................................................................................ 129

19 Advanced mode _______________________________________________________ 131

19.1 Pulse up – down counter ...................................................................................... 132

19.1.1 Pulse up – down counter for smoke ................................................................ 132

19.1.2 Pulse up – down counter for temperature ....................................................... 132

19.1.3 Pulse up – down counter for smoke & temperature ......................................... 133

19.2 Fire judgement ..................................................................................................... 133

19.3 Alarm threshold levels .......................................................................................... 133

19.4 Alarm Delay Time ................................................................................................. 133

19.5 Learning function / Learning conditions ................................................................. 135

19.5.1 Area Alarm algorithms .................................................................................... 135

19.5.1.1 Smoke - Steam area, level 1 ................................................................... 135

19.5.1.2 Heating area, level 2 ............................................................................... 136

19.5.1.3 Cooking – Welding Area, level 3 ............................................................. 136

19.5.1.4 Clean Area, level 1, 2 & 3 ....................................................................... 136

19.5.1.5 Learning function summary ..................................................................... 136

19.6 Analogue data output ........................................................................................... 136

19.7 Sensitivity compensation ...................................................................................... 136

19.8 Self-diagnosis of internal devices.......................................................................... 137

19.9 Address setting check .......................................................................................... 137

19.10 Polling LED ................................ ................................................................ .......... 137

20 Control Unit Properties _________________________________________________ 138

20.1 Control Unit properties dialog box ......................................................................... 138

20.1.1 General Information ........................................................................................ 138

20.1.2 Peripherals ..................................................................................................... 138

20.1.3 Misc. .............................................................................................................. 138

20.2 EBLWin Control Unit pop-up menu ....................................................................... 139

20.2.1 Reset alarm counter ................................ ....................................................... 139

20.2.2 Software version............................................................................................. 139

20.2.3 Upgrade number of alarm points ..................................................................... 139

20.2.4 Show event log ............................................................................................... 140

20.2.5 Restart ................................................................................................ ........... 141

20.2.6 Delete ............................................................................................................ 141

20.2.7 Properties....................................................................................................... 141

20.2.8 Add Web-server ............................................................................................. 141

21 System properties (settings) _____________________________________________ 142

21.1 System properties dialog box................................................................................ 142

21.1.1 Name ............................................................................................................. 142

21.1.2 User definable text ......................................................................................... 142

21.1.3 System properties, Page 1 ............................................................................. 142

21.1.3.1 Alert Annunciation .................................................................................. 142

21.1.3.2 Alarm Acknowledgement Facility ............................................................ 143

21.1.3.3 Disable routing equipment by door switch ............................................... 143

21.1.3.4 Alarm reset method ................................................................................ 143

21.1.3.5 Alarm delay time (seconds) .................................................................... 144

21.1.4 System properties, Page 2 ............................................................................. 144

21.1.4.1 Door closing by time ............................................................................... 145

21.1.4.2 Main power loss fault delay time (minutes) .............................................. 145

5

Page 8

Technical Manual

FT1020G3 Rev 2.2.1

22 EBLWin menus ________________________________________________________ 146

22.1 The file menu ....................................................................................................... 146

22.1.1 New ............................................................................................................... 146

22.1.2 Open .............................................................................................................. 146

22.1.3 Import from Win512 ........................................................................................ 146

22.1.4 Report ............................................................................................................ 146

22.1.5 Save .............................................................................................................. 147

22.1.6 Save As ......................................................................................................... 147

22.1.7 Print labels ..................................................................................................... 147

22.2 The View menu .................................................................................................... 148

22.2.1 Filter Box ........................................................................................................ 148

22.2.2 Tree view ....................................................................................................... 148

22.2.3 Deviations ...................................................................................................... 148

22.2.4 Selected loop ................................................................................................. 149

22.2.5 Alarm points ................................................................................................... 149

22.2.6 Interlocking combinations ............................................................................... 150

22.2.7 External faults ................................................................................................ 150

22.2.8 Technical warnings ......................................................................................... 150

22.2.9 External time channels ................................................................................... 151

22.3 The System menu ................................................................................................ 151

22.3.1 Properties....................................................................................................... 151

22.3.2 Time channels ................................................................................................ 151

22.3.3 Alarm algorithms ............................................................................................ 153

22.3.3.1 Parameters for smoke algorithms ........................................................... 154

22.3.3.2 Parameters for heat algorithms ............................................................... 155

22.3.3.3 Parameters for combined decision algorithm........................................... 155

22.3.4 Output Signal Periods ..................................................................................... 156

22.3.5 National holidays ............................................................................................ 157

22.3.6 Two zone dependence ................................................................................... 158

22.3.7 Zone groups ................................................................................................... 158

22.3.8 System information ......................................................................................... 159

22.3.9 Edit Alarm texts .............................................................................................. 159

22.3.10 User data ....................................................................................................... 159

22.4 The Tools menu ................................................................................................... 160

22.5 Web-server .......................................................................................................... 161

23 Download SSD ________________________________________________________ 162

23.1 COM loop menu ................................................................................................... 163

23.1.1 Check Loop .................................................................................................... 163

23.1.2 Auto generate loop ......................................................................................... 163

23.2 SSD Download ..................................................................................................... 164

23.2.1 SSD Download to Single Control Unit ............................................................. 164

23.2.2 SSD Download to Control Units in a TLON Network ....................................... 164

23.3 User definable text messages download ............................................................... 164

24 Download software (System Firmware) ____________________________________ 165

24.1 Single Control Unit (CIE.) ..................................................................................... 165

24.1.1 Establish communications between PC and CIE for software download .......... 165

24.1.2 Download the Software .................................................................................. 166

24.2 Control Units in a TLON network .......................................................................... 167

25 Cable types ___________________________________________________________ 168

25.1 TLON Network cables .......................................................................................... 168

25.2 COM loop cables .................................................................................................. 168

25.3 Remote Display Units cables ................................................................................ 168

25.4 Conventional zone line cables .............................................................................. 168

25.5 Alarm device cables ............................................................................................. 168

25.6 Other equipment cables ....................................................................................... 169

26 FT1020G3 cable length calculation ________________________________________ 170

26.1 COM loop Cable length ........................................................................................ 170

26.2 Cable Length Calculations for 1728 and 1736 ....................................................... 172

6

Page 9

Technical Manual

FT1020G3 Rev 2.2.1

27 Current consumption ___________________________________________________ 174

28 Power supply _________________________________________________________ 177

28.1 Charger functions ................................................................ ................................. 177

28.1.1 Battery charging ............................................................................................. 177

28.1.2 Battery charging functions: ............................................................................. 178

28.1.3 Battery protection functions ............................................................................ 178

28.2 Current consumption calculations ......................................................................... 178

28.3 Main power source (power supply) ....................................................................... 179

28.4 Standby power source (Batteries) ......................................................................... 179

28.5 Fuses ................................................................................................................... 180

28.6 Current consumption measurement ...................................................................... 180

29 S/W versions __________________________________________________________ 181

30 National regulations ____________________________________________________ 182

30.1 Conventions ......................................................................................................... 182

30.2 Language ............................................................................................................. 182

31 Drawings / Connection Diagrams _________________________________________ 183

32 Revision history _______________________________________________________ 187

32.1 Revision History Table.......................................................................................... 187

32.2 Software Revision V2.2.0 Modifications ................................................................ 187

32.2.1 New common features and additions .............................................................. 187

32.2.2 New or modified features in EBLWin only ....................................................... 188

32.2.3 New or modified feature in system software EBL only ..................................... 188

7

Page 10

Technical Manual

FT1020G3 Rev 2.2.1

Table of Figures

Figure 1 FT1020G3 System Overview ..................................................................................... 11

Figure 2 Redundant fibre optic network for more than 3 control panels .................................... 16

Figure 3 Redundant fibre optic network for up to 3 control panels ............................................ 16

Figure 4 The FT1020G3 Control Unit, with printer .................................................................... 19

Figure 5 FT1020G3 front display ............................................................................................. 20

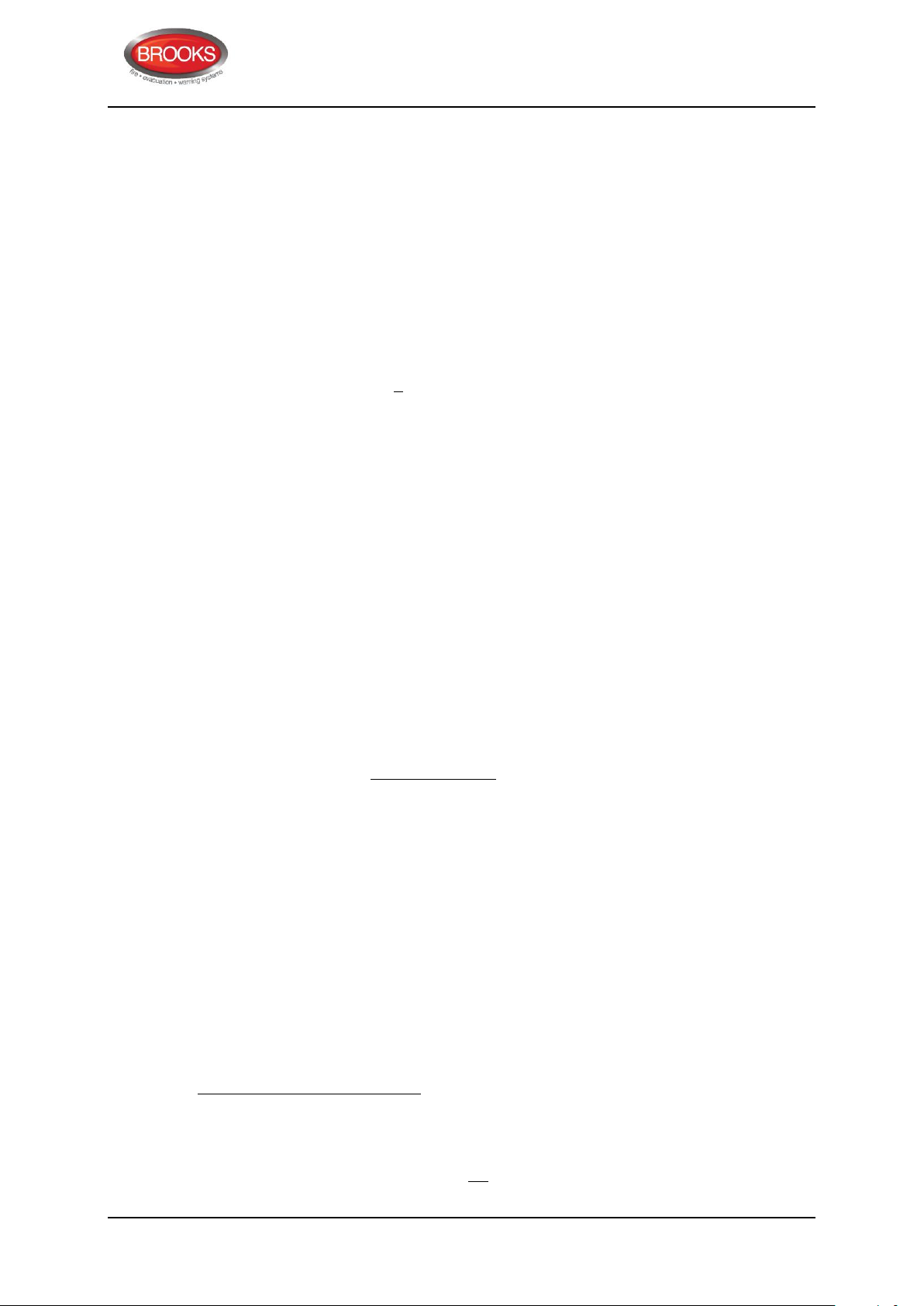

Figure 6 Expansion boards 4580, 4581 and 4583. ................................................................... 24

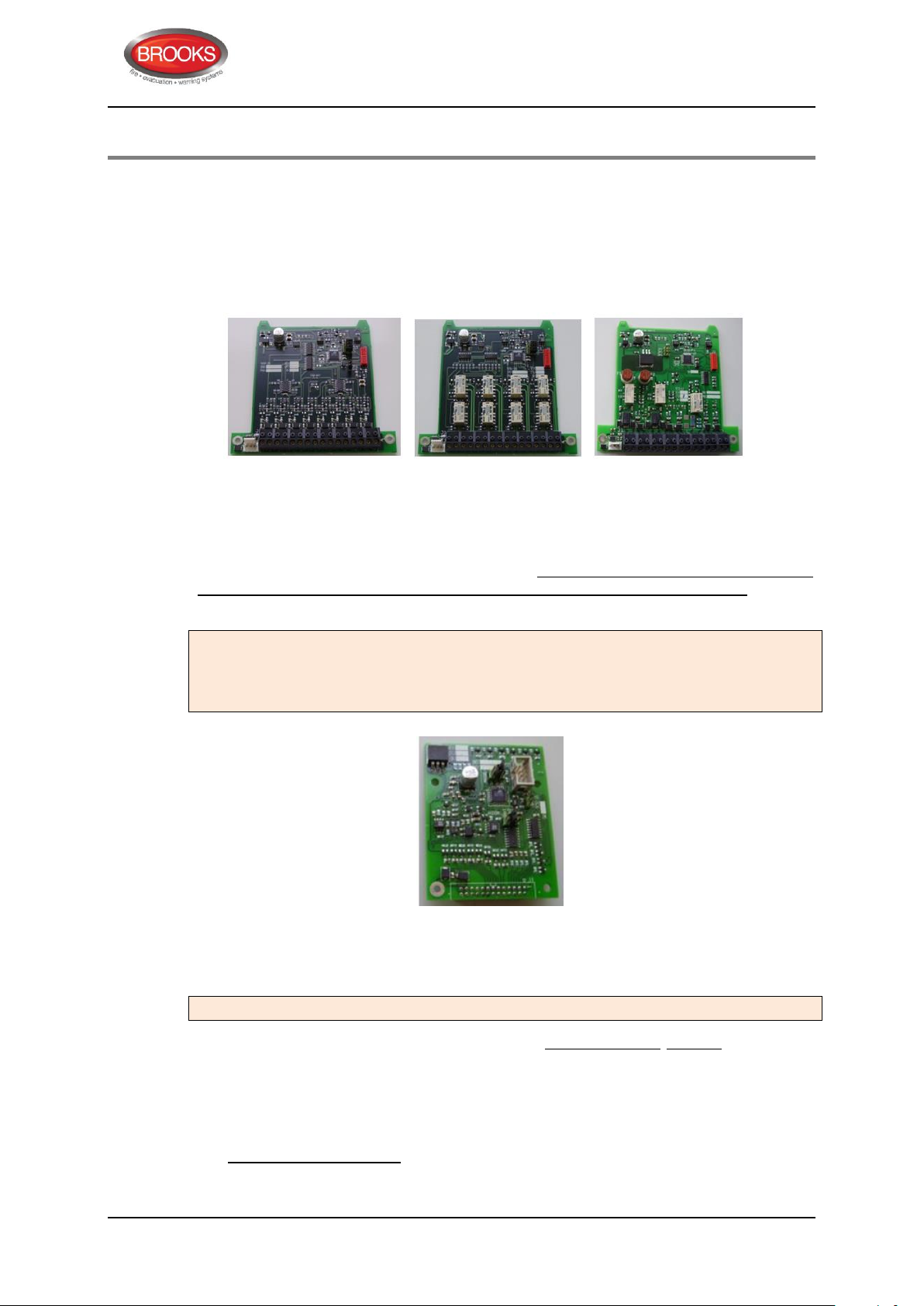

Figure 7 I/O Matrix board 4582. ............................................................................................... 24

Figure 8 Expansion board top side differences ........................................................................ 26

Figure 9 I/O Matrix board application overview ........................................................................ 29

Figure 10 I/O Matrix PCB layout .............................................................................................. 29

Figure 11 Supply air time delay setting .................................................................................... 35

Figure 12 Smoke exhaust or spill fan timing ............................................................................ 36

Figure 13 AS1668 Fan Control Example ................................................................................. 37

Figure 14 Zone Control Connection ......................................................................................... 38

Figure 15 Mimic Board Options ............................................................................................... 40

Figure 16 Generic application, NZ Index panel ........................................................................ 41

Figure 17 Occupant Warning Display Module .......................................................................... 41

Figure 18 Class-D 60W / 120W Audio Amplifier Board Layout ................................................. 43

Figure 19 60W / 120W Audio amplifier photos ......................................................................... 43

Figure 20 Class-D 250W Audio Amplifier Board Layout ........................................................... 44

Figure 21 Typical OWS Dual Strobe Control Circuit ................................................................. 45

Figure 22 Gas Extinguishing Display Layout ............................................................................ 47

Figure 23 Assembled Control & Interface Boards .................................................................... 48

Figure 24 EBLWin properties dialog box for 4301 / 4401(Normal Mode) .................................. 54

Figure 25 Decision algorithm ................................................................................................... 57

Figure 26 Connection example of 2A MDH power supply ........................................................ 71

Figure 27 EBLWin "Input" dialog boxes ................................................................................... 72

Figure 28 EBLWin Voltage & Relay Output dialog boxes ......................................................... 79

Figure 29 EBLWin 3379 and 4477 dialog boxes ...................................................................... 80

Figure 30 EBLWin output signal period dialog box. .................................................................. 84

Figure 31 Signal period set up options..................................................................................... 85

Figure 32 EBLWin control expression ...................................................................................... 86

Figure 33 Short circuit isolators example in FT1020G3 ............................................................ 94

Figure 34 Filter function........................................................................................................... 96

Figure 35 EBLWin "Interlocking Combination" dialog box......................................................... 98

Figure 36 Basic working principle for Analogue smoke sensor ............................................... 103

Figure 37 Filtering algorithm example for analogue smoke detector ....................................... 105

Figure 38 Smouldering smoke algorithm example for 4301. ................................................... 106

Figure 39 Sensor log in graphical form .................................................................................. 110

Figure 40 Sensor Log in Tabulated Form............................................................................... 110

Figure 41 Alert Annunciation function flow chart. ................................................................... 114

Figure 42 Alarm Acknowledgement Facility units ................................................................... 115

Figure 43 Alarm Acknowledgement Facility (AAF) flow chart ................................................. 116

Figure 44 Local Alarm Acknowledgement Facility Connection Diagram ................................. 118

Figure 45 The EBLWin "Control Unit properties" dialog box ................................................... 138

Figure 46 EBLWin "System properties" dialog box, Page 1 and 2 .......................................... 142

Figure 47 Time Channel Alarm Points Report ........................................................................ 147

Figure 48 Deviation Tab ........................................................................................................ 149

Figure 49 Selected Loop Tab ................................................................................................ 149

Figure 50 Time channels configuration .................................................................................. 152

8

Page 11

Technical Manual

FT1020G3 Rev 2.2.1

Figure 51 Time Channel Setting ............................................................................................ 152

Figure 52 Editing Time Channel Intervals .............................................................................. 153

Figure 53 Alarm Algorithms Dialog Box ................................................................................. 154

Figure 54 Smoke / heat algorithms example .......................................................................... 154

Figure 55 Example setting for national holidays ..................................................................... 157

Figure 56 COM Loop Current Consumtion vs. Cable Length.................................................. 171

Figure 57 Access to COM loop units current consumption ..................................................... 176

Figure 58 FT1020G3 power supply block diagram ................................................................. 177

Figure 59 EBLWin Settings Dialog Box .................................................................................. 182

Figure 60 FT1020G3 General arrangement ................................................................ ........... 184

Figure 61 FT1020G3 Block Wiring Overview ................................................................ ......... 185

Figure 62 FT1020G3 Standard Block Wiring Diagram ........................................................... 186

List of Tables

Table 1 Control Panel Specifications ....................................................................................... 17

Table 2 Control Panel Limitation .............................................................................................. 18

Table 3 Expansion boards address (jumpers) setting............................................................... 25

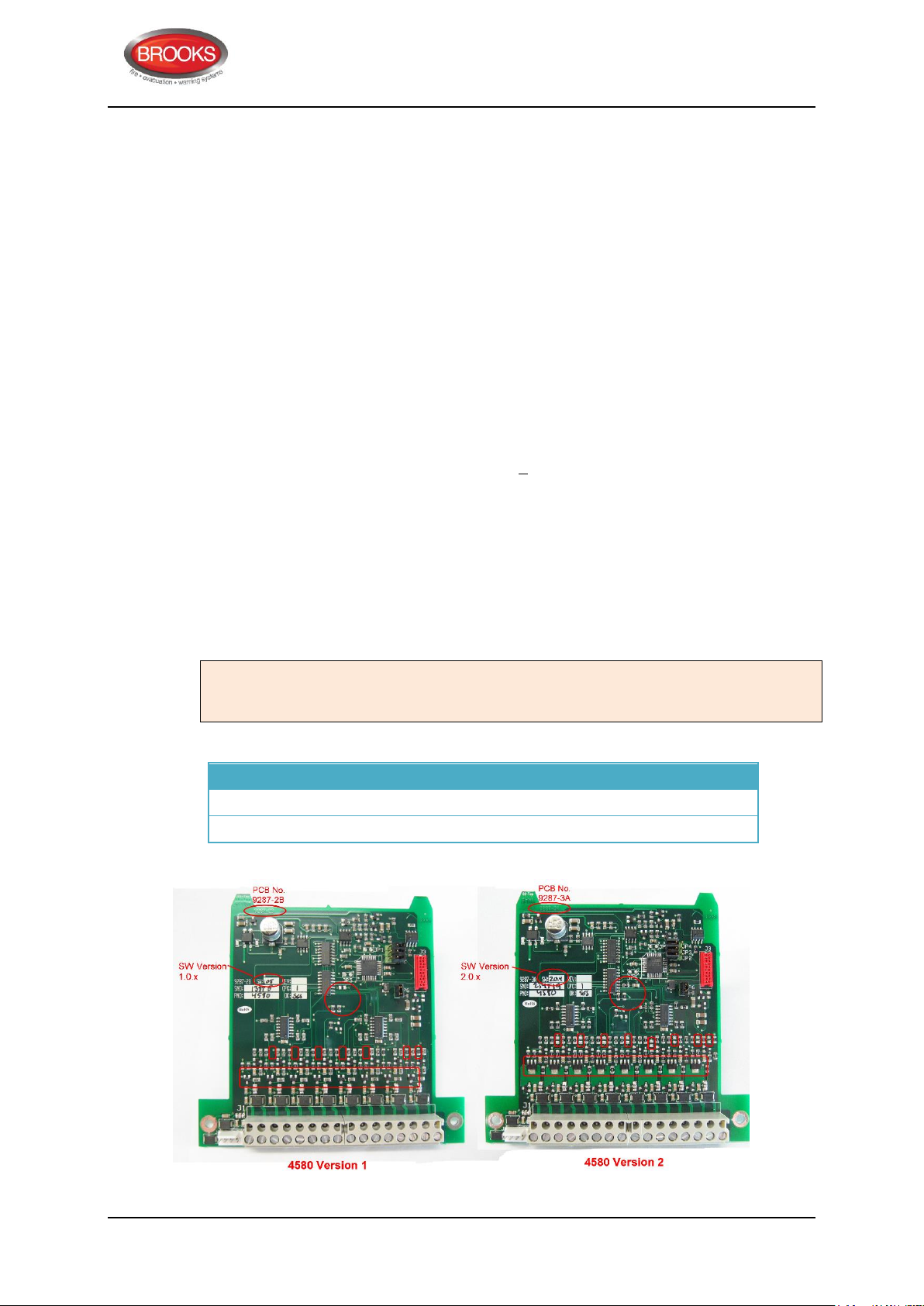

Table 4 4580 Versions with EOL Values to Use ....................................................................... 26

Table 5 I/O Matrix board 4582 type setting .............................................................................. 30

Table 6 OWS 60/120W amplifier specifications ....................................................................... 43

Table 7 OWS 250W amplifier specifications ............................................................................ 44

Table 8 Connection of the Audio Amplifier 60W, 120W and 250W ........................................... 45

Table 9 Gas Front Status LED Indication and flash Pattern...................................................... 47

Table 10 State of the Supervised Inputs 0-4 ............................................................................ 73

Table 11 Output signal period for programmable output........................................................... 85

Table 12 Smoke Detector Alarm Algorithms .......................................................................... 104

Table 13 Alarm acknowledgement function ........................................................................... 117

Table 14 Summary of Recommended Cables........................................................................ 169

Table 15 Maximum display units cable length ........................................................................ 173

Table 16 FT1020G3 and CIE options current consumption .................................................... 174

Table 17 COM loop units current consumption ...................................................................... 175

Table 18 Other units current consumption ............................................................................. 176

Table 19 Valid S/W versions ................................................................................................. 181

Table 20 List of FT1020G3 block wiring diagrams ................................................................. 183

9

Page 12

1 Introduction

1.1 General introduction

FT1020G3 Technical / Programming Manual is a document with information of special

interest for planning engineers as well as service / commissioning engineers.

This document should be read in conjunction with FT1020G3 Operation Manual since most

of the information in one of the documents is not found in the other document and vice

versa.

It should also be read in conjunction with the FT1020G3 connection diagrams according to

the drawings / connection diagram list on Table 20 page 183.

When planning a fire alarm installation, the Australian standard AS1670.1 requirements

must be followed. Detector type, detector coverage area, detector spacing and special

applications in the building, etc. are concerns for the planning engineers and are not

covered in this document.

Due to continual development and improvement, different S/W versions are to be found.

This document is valid for S/W version V2.2.x. On the date / revision date of the document

x = 0.

Technical/Programming Manual

FT1020G3 Rev 2.2.1

A product may be one of the following:

FT1020G3 CIE Configured for 510 or 1020 alarm points and with or without printer.

FT1020G3 CIE without front configured for 510 or 1020 alarm points.

FT1020G3 CIE with 2 x 5010 and one front to increase the number of COM loops

to 8 and optional I/O matrix board applications.

Hardware H/W:

A H/W (e.g. a printed circuit board) has:

a part number (e.g. 5010)

a product name (e.g. FT1020G3 Main Board 512 alarm points)

a PCB number (e.g. 9290-2B) and can also have a configuration (e.g. CFG: 2)

and a revision (e.g. REV: 1)

sometimes a S/W

Software S/W:

A S/W has:

A version number (e.g. V2.2.x)

Sometimes additional information, such as Convention (different functions /

facilities), Language, etc. added.

PC S/W:

A PC S/W is a program used for programming, commissioning, etc. e.g. EBLWin. It has a

version number e.g. V2.2.0.

1.2 Definitions / Explanations

Definitions / explanations / abbreviations / etc. frequently used, refer to FT1020G3

operation manual.

Refer to FT1020G3 Operation Manual for more details.

9

Page 13

FT1020G3 Rev 2.2.1

Product type no.

Product name

4580

8 zones expansion board

4581

8 relay outputs expansion board

4583

Inputs and outputs expansion board

1

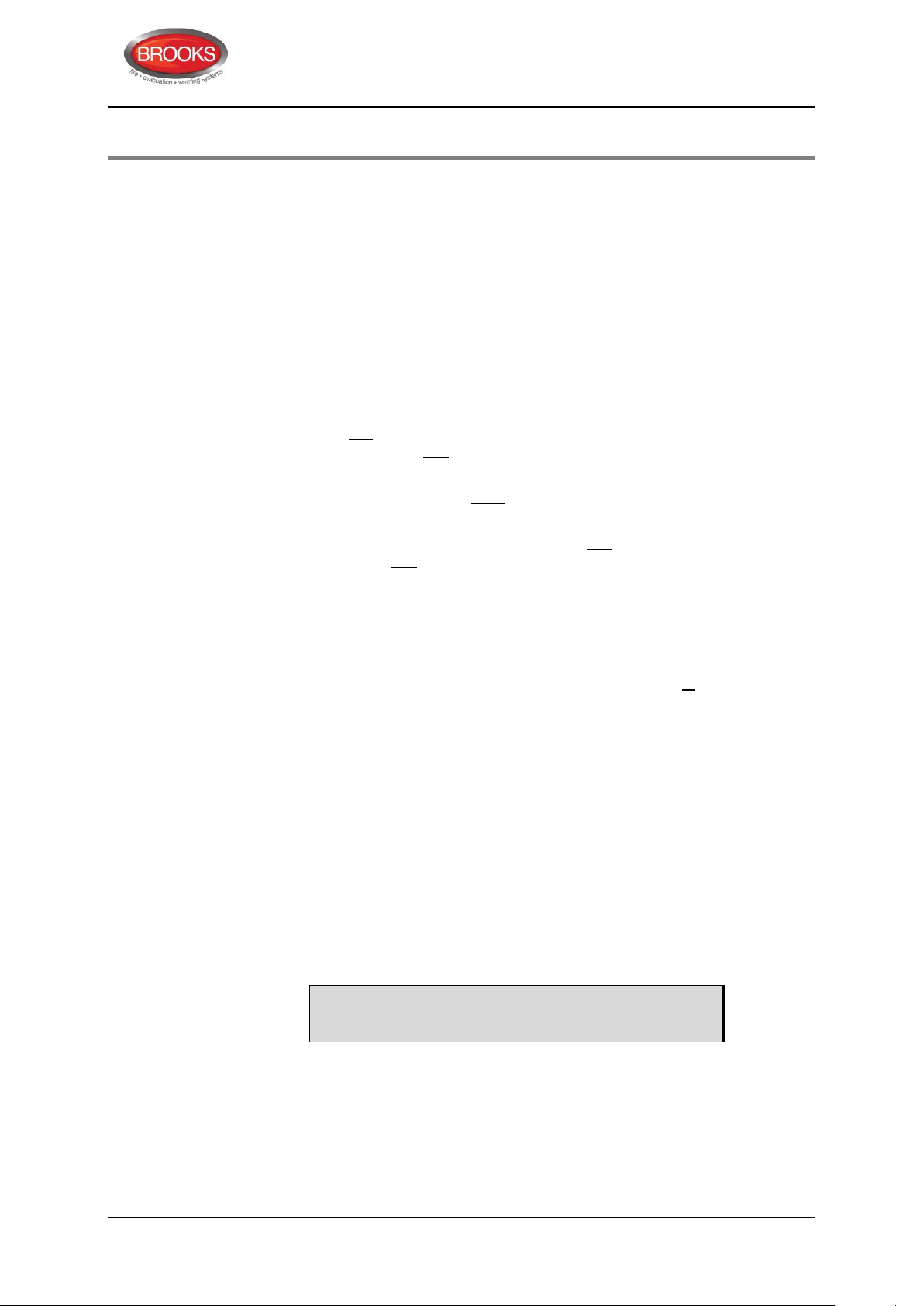

2 Overview

2.1 The FT1020G3 system

FT1020G3 is a microprocessor controlled intelligent fire alarm system, intended for

Analogue addressable smoke detectors, as well as conventional detectors and manual call

points. Programmable control outputs and output units are available. Up to 1020

addresses can be connected to each Control Unit (CIE). Figure 1 presents an overview of

the FT1020G3 System.

FT1020G3 is available in several types, versions and configurations. It can be used as

stand-alone Control Unit or connected to a TLON network, i.e. in a "system" with up to 30

Control Units. Each Control Unit has access to all information.

FT1020G3 is designed and assessed to the Australian Standard AS7240.2, AS7240.4 and

NZS4512:2010. The Fire Brigade Panel controls and indicators are incorporated as part of

the faceplate and conform to AS4428.3:2010.

2.1.1 Printer

Technical/Programming Manual

The Control Unit FT1020G3 can be fitted with an optional printer1.

2.1.2 Expansion boards

Up to six expansion boards can be mounted in FT1020G3 CIE. The following expansion

board types are available:

For more details, refer to chapter "Expansion boards 458x”, page 24 and drawings F728,

F729 and F731.

2.1.3 Power supply

The primary power source is a switch mode power supply, 230 VAC / 24 VDC, 6.5 A (150

Watt).

The standby power source is a backup batteries (2 x 12 V). In the standard cabinet, up to

24 Ah batteries can be fitted. Larger batteries (up to 65 Ah) require additional battery box.

The batteries and the switch mode power supply are connected to the Main board (5010).

See chapter "Power supply", page 177 for more information.

2.2 Software (S/W) versions

Due to continual development and improvement, S/W versions are being updated from

time to time. When a new FT1020G3 Control Unit is required to be installed in a network

system with "older" Control Units, the software in the older Control Units must be updated

(or download an older version in the new Control Unit). The S/W version must be the

same in all Control Units in a TLON network.

Printer 5058 is a spare part for the FT1020G3 with a printer, i.e. it comes without a mounting frame etc.

10

Page 14

Technical/Programming Manual

4380

Addr.

Becon

3379 Addr.

Sounder Base

with

430x Analog

Detector

3377

Addr. Siren

BARIL

Remote

Indicator RIL

3314

Address

Setting

Tool

1736 Alert

Annunciation

Unit

1728 Ext.

Presentation

Unit

3333NZ

NZ Addr.

MCP

NZ/Remote

Mimic Panel

4582 I/O

Matrix

Board

SUB927

NZ Mimic

Board

3366 Ext. Power Supply

DC

AC

24V DC

230V AC

3364 Addr.

2 Voltage

Outputs

Unit

4301

Analogue

Photoelectric

Smoke

Detector

3308

Analogue Heat

Detector

4300

Analogue

Multi

Detector

M5411D

Magnetic

Door

Holder

3339

Enclosed

MCP

1598

Web-

Server II

6377

Duct

Detector

3340

AAF Alarm

Acknowledgement Facility

Horn - B24VHHorn - B24VH

2 Outputs

2 Programmable

Inputs

COM Loop (4x)

1590 TLON Board (0)

1590 TLON Board (1)

TLON Network

WebG3 Config via USB cable

VISIODOCUMENT Date: 12/19/2011

Drawn by: Edwin Thein

Pre 2003 NZ

Heat Detectors

4352

Photoelectric Smoke

Detector

Pre 2003 Devices

Conventional Devices

Post 2003 Devices

SUB947

3361

Multipurpose I/O

1590 TLON Board (0)

1590 TLON Board (1)

1590 TLON Board (0)

1590 TLON Board (1)

1590 TLON Board (0)

1590 TLON Board (1)

4352

Photoelectric

Smoke

Detector

4318

Combination

Heat

Detector

4375

Heat

Detector

Conventional Detectors & MCPs

EOL 4K7

4580 TLON Board (0)

4580 TLON Board (7)

4350 Multi Detector

6295 IP67 Heat Detector

30 Units

For NZ

ONLY

FT1020G3 Rev 2.2.1

Figure 1 FT1020G3 System Overview

11

Page 15

2.3 Documents

The following documents are available:

Technical / Programming Manual (this document)

Operation Manual

Connection diagrams

Information found in one document is normally not to be found in another document, i.e.

the documents complement each other. Product Leaflet for FT1020G3 and other units

are available on Brooks web site: http://www.brooks.com.au.

Some important information might be exist in the operation manual as well as this

manual e.g. specifications / limitation, SSD and software download, etc.

2.4 Applications

The FT1020G3 system is intended for small, medium and large size installations. The

intelligent Control Units offer the system designer and end user a technically sophisticated

range of facilities and functions. Programming (PC software EBLWin and TLON Manager)

and commissioning of the Control Units / system is very easy.

Technical/Programming Manual

FT1020G3 Rev 2.2.1

Start with one Control Unit and then when it is required, add more units. The TLON network

makes it possible to install the Control Units in one building or in many buildings.

Separate documents are available for TLON Manager, Web-server, etc.

2.5 PC software (S/W)

The following PC programs are used together with the FT1020G3 system. For standalone

FT1020G3, the TLON Manager is not used.

2.5.1 EBLWin

The PC program EBLWin is used for programming and commissioning of one or more

Control Units, i.e. to:

Autogenerate, i.e. to identify the units connected on a COM loop and make default

settings, which can be edited, saved and used as site specific data (SSD).

Create, download and backup (upload) of site specific data (SSD)

Download new system software version, settings, conventions, configurations,

Control Unit & system properties, etc.

Create and download the user definable alarm text messages shown in the display

in the Control Units and other Display Units (1728 & 1736).

Display the fire alarms, faults and disablements as well as reset, acknowledge and

re-enable, etc.

Configure the Web-server II (5098); create and download / make a backup (upload)

of the configuration data as well as download of Web-server software.

The EBLWin must have the same version number as the system software EBL512 G3

version number e.g. 2.2.x and 2.2.x respectively. Only x may be different, it indicates a

small correction and is not required to be the same.

Old SSD files can be opened in a newer (higher) version of EBLWin, saved, edited and

thereafter downloaded to an FT1020G3 units with the corresponding version.

EBLWin key 5094 is a USB dongle that is required on your PC in order to gain access to

log on and download SSD files.

12

Page 16

Notes: The SSD files saved in one version of EBLWin is not backward compatible with

any other earlier versions of PC configuration e.g. WinG3.

It is highly recommended to backup (upload) the SSD file before the system

software (EBL512 G3) can be downloaded,

2.5.2 TLON Manager

The PC program TLON Manager is used for the TLON Network programming, installation,

etc. (TLON Manager 1.2 and TLON Manager 2.0.x can be used).

For more information refer to the TLON Manager technical manual and the next chapter.

Technical/Programming Manual

FT1020G3 Rev 2.2.1

13

Page 17

FT1020G3 Rev 2.2.1

3 TLON Network

For further details refer to “TLON Technical / Operation Manual” M437, see also chapter

“TLON connection board 5090” page 50.

3.1 FT1020G3 TLON network

FT1020G3 system can be one Control Unit (CIE) or up to 30 Control Units connected in

a TLON Network.

In a TLON Network, each Control Unit operates independently but has nevertheless total

access to all information in the system.

In a system with two or more Control Units in a TLON Network, pay attention to the

following:

A zone must not be distributed over the system, i.e. all alarm points in a zone

have to be connected to one CIE

When the "Fire door closing" function is used, the alarm points and the outputs

activated by these alarm points must be connected to the same CIE

Technical/Programming Manual

When the interlocking function is used, the input, output and the Interlocking

Combination (area-point) must be connected to one CIE. An input and an output

can only be used in one Interlocking combination.

When the AAF function is used, all devices within the same AAFC zone must be

connected to the same CIE.

3.2 Redundant TLON Network

The FT1020G3 system can be build up as a single TLON Network or as a redundant

TLON Network.

A single TLON Network is only allowed when more than one main board (5010) are

mounted in the same cabinet. In this case, only one TLON connection board (5090) is

required to be plugged in the main board. Whereas in a distributed systems, redundant

TLON Network must be used, 2 TLON connection boards (5090) have to be used in each

Control Unit.

In the single TLON Network, only one network (Network no. 0) connection is used but in a

redundant TLON Network, two networks connections (Network no. 0 and Network no. 1)

must be used. In normal conditions, Network no. 1 is only supervised / monitored until

Network no. 0 fails to establish the communications between the control panels.

The redundant TLON Network supports full functionality. In case of a network fault (i.e.

open circuit or short circuit) in one of the TLON networks, a fault for this TLON Network is

generated as shown in the following fault message:

Where network x = Network no. 0 or Network no. 1.

3.3 Routers

In a TLON network, it is recommended to use TP/FT routers in order to split the TLON

network into separate FTT-10 channels / segments with the following objectives:

Provide galvanic isolation between TLON segments.

FAULT: Control Unit xx has no contact

With control unit xx, network x

14

Page 18

Technical/Programming Manual

FT1020G3 Rev 2.2.1

Increase the maximum cable length between TLON segments.

Reduce unnecessary communications traffic on the respective network links.

Improve efficiency of the communications channel.

Up to 6 control panels can be connected to one channel i.e. one segment.

When the TLON is divided into more than one segment, the short circuit will affect the

communication between the Control Units in this segment only, the communication

between Control Units in other segments are not affected. The fault messages will be

generated in every Control Unit. However In a redundant system, the network will continue

to communicate via the second TLON network.

Dividing the TLON network into segments may assist in fault finding, faults on the network

e.g. disturbances etc., will be easier to locate and service.

Note: In retrofit network application where the cable integrity is uncertain, routers may

also be required to improve the communications between the TLON segments.

The recommended TP/FT10 router is LPR10, Brooks stock number FTG3 ROUTER. It is

also recommended to use the DIN rail mounting plate, stock number FTG3 ROUT PLATE.

3.4 Network connections

The communications between control panels in a network system can be established using

one of the three following options:

3.4.1 Twisted pair TLON network

The twisted pair cable connection between control panels and cable specifications are

shown in drawings F738-01, F738-02 and F738-03.

The recommended cable is twisted pair 1.5 mm², Brooks stock number BCA0898 or

equivalent. 1 mm² Twisted pair cable can also be used depending on the distance between

the control panels. If a screened cable is used, the shield must be connected to the CIE

earth point.

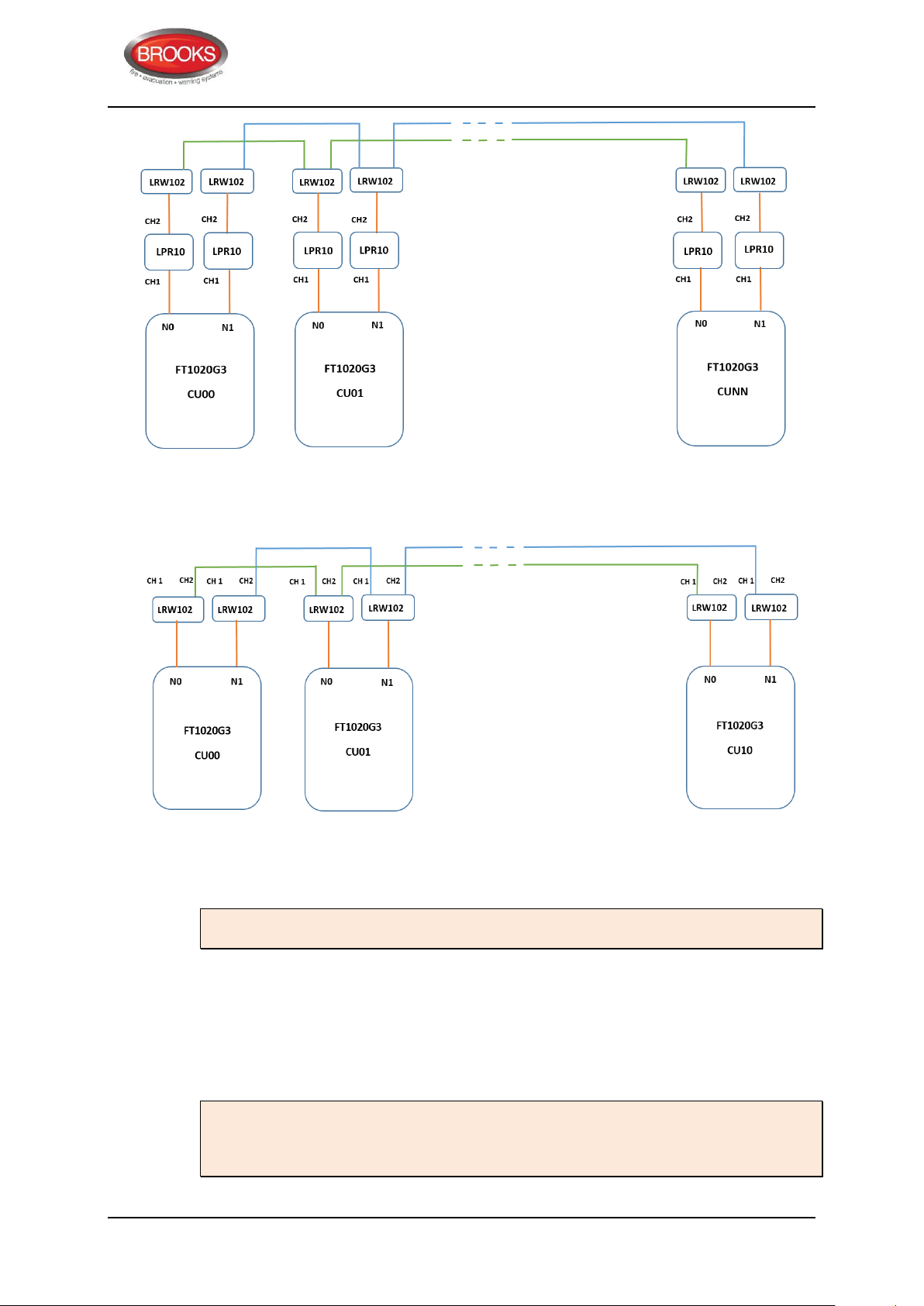

3.4.2 Fibre optic TLON network

Third party TP/FT10 to fibre optic routers have become obsolete e.g. LRW112 series.

However LRW102 series repeaters are still available.

It is possible to connect a TP/FT10 channel to a fibre optic channel using a Fibre Optic to

TP/FT10 repeater.

A fibre optic network communications can be achieved by using fibre optic repeater e.g.

LRW102 in conjunction with a TP/FT10 router e.g. LPR10. This combination replaces the

fibre optic routers LRW112 series when more than 10 control panels connected in a TLON

network. Great care shall be taken during planning, installation and commissioning.

The fibre optic link offers an easy way to extend the distance between TLON network

segments using high speed back bone fibre optic network link. The maximum distance

between the fibre optic routers varies between 5 Km to 30 Km depending on the type of

fibre.

The fibre optic solution to network FT1020G3 control panels is shown in Figure 2 and

Figure 3 below. The LPR10 router must be used when the number of networked control

panels is more than 10 panels as shown in Figure 2.

15

Page 19

Technical/Programming Manual

FT1020G3 Rev 2.2.1

Figure 2 Redundant fibre optic network for more than 10 control panels

When a number of control panels less than 10 is required in a TLON network, the traffic

will not be very heavy and the LPR10 router may not be required as shown in Figure 3

Figure 3 Redundant fibre optic network for up to 10 control panels

The type of fibre optic repeater is dependent on the cable type e.g. single or multi-mode,

distance between C.U.’s, etc. Care must be taken when selecting the repeater type.

Note: A TLON network of FT1020G3 control panels may consist of fibre optic segments

and twisted pair segments.

3.4.3 TCP/IP TLON network

LonWorks Internet server such as iLon 600, can be used as an internet (or any IP-based

LAN or WAN) pathway for TLON.

The transition from TP/FT10 to IP network opens the opportunity to use a large range of

infrastructure products e.g. fibre optic converters.

Note: a network of fire alarm system is always connected via a dedicated network wiring,

great attention must be taken when choosing an IP network as a pathway for TLON

should be used for autonomous Control Units only. The efficiency of the IP based

communication is dependent on the efficiency of the infrastructure of the IP network.

16

Page 20

Technical/Programming Manual

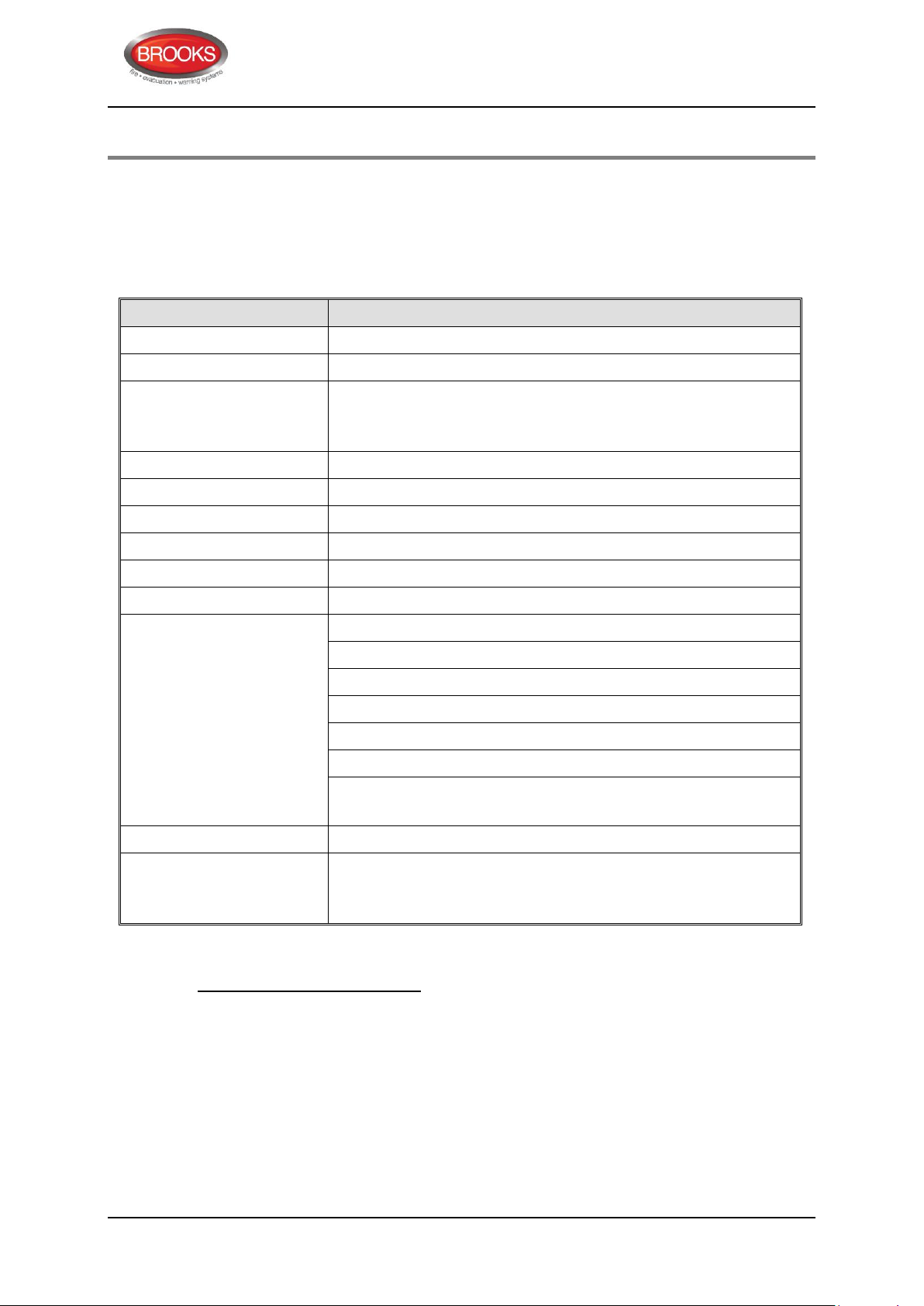

Item

Specifications

Mains Voltage

230VAC (176-264), 1.6A

System Voltage

24VDC @ 6.5A

Current Consumption

Quiescent / alarm current is dependent on other equipment fitted

in FT1020G3, type and number of expansion boards, connected

external equipment, etc.2.

Ambient Temperature (⁰C)

Operating 0 to + 40, Storage -40 to +70

Ambient humidity (%RH)

Maximum 90, non-condensing

Size (mm)

Standard cabinet 920H x 450W x 210D (with metal door closed)3

Enclosure Material

1.5 Zinc anneal steel

Enclosure Colour

Oyster, powder coated, ripple finish

Approvals

AS7240.2, AS7240.4, AS4428.3:2010 and NZS4512:2010

Standard Inputs / Outputs4

Four COM loops (0-3), each loop can connect up to 255 devices

Four non-supervised inputs

Four programmable Supervised voltage outputs, 0.75 Amp each

Two programmable relay outputs, contact rating 2 Amp

Four programmable clean contact (N/O or N/C) inputs (I0-I3)5

Two non-programmable relay outputs for ASE (fire & fault)

Six x 24V outputs for Web server, ASE, remote display units,

external applications 2-4 Amp.

Expansion Boards

Max. 6 of 4580, 4581 or 45836

I/O Matrix 4582 board

Max. 24, 6 per COM loop if no expansion boards on Loop 07 fitted.

Up to 6 modules can be used as zone or generic + 18 Fan control

modules (4 fans per module)8

2

3

4

5

6

7

8

FT1020G3 Rev 2.2.1

4 Control & Indicating Equipment

4.1 FT1020G3 Specifications

The specifications of FT1020G3 Control Panel are shown in Table 1 below and the system

limitations are shown in Table 2 next page.

Table 1 Control Panel Specifications

Refer to chapter “Current consumption” page 173 and the current calculation spread sheet.

Medium size enclosure 630H x 450W x 210D can be used to fit limited number of options. A combination of large and medium

size enclosures can be used if more options required. In 19” rack cabinets, a series of 19” face plates are also available.

Refer to G3 block wiring diagram, drawing no. F765

First input I0 cannot be used in NZ convention, only 3 programmable inputs are available.

Expansion boards are internally connected to COM loop 0, ensure total number of expansion boards and I/O matrix boards

connected to COM loop 0 does not exceed 6. Software 2.1.1 allows to use 6 x 4583.

Reduce the number of 4582 connected to COM loop 0 by one for every expansion board used.

If no expansion boards fitted, up to 24 fan control modules can be used i.e. 96 individual fans

17

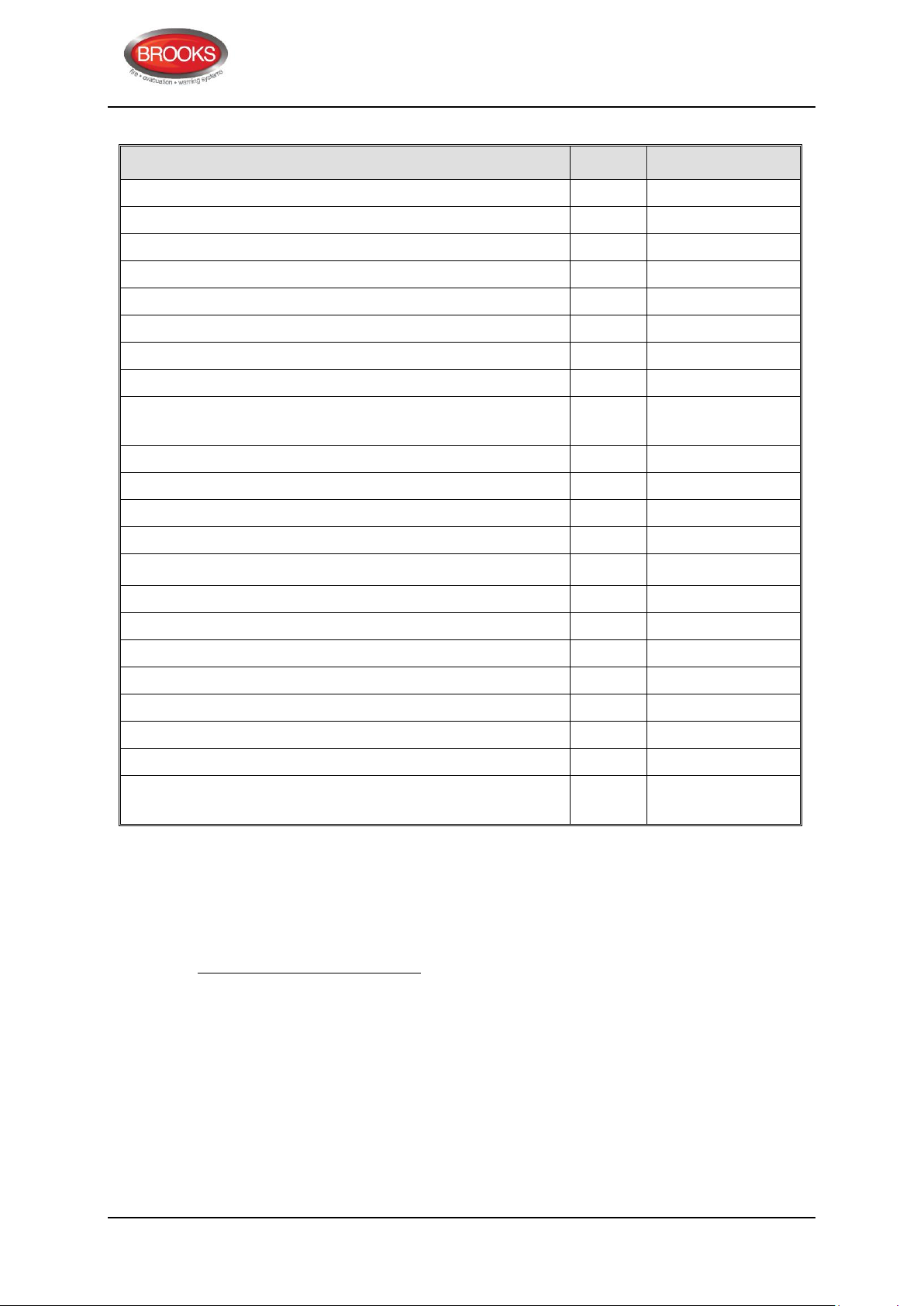

Page 21

Table 2 Control Panel Limitation

Item

C.I.E.

Network System

General fire alarm via programmable input

100 External fault via programmable input

50

30 x 50

Programmable inputs

512

Programmable outputs (= control expressions)9

512

Technical warnings

100

30 x 100

Addressable 2 voltage outputs unit 3364

40 External display units

16

30 x 16

Interlocking Combinations

400

400010

Presentation numbers / alarm points11 that can be presented

in the display(s) in case of fire alarm

512

512

Presentation numbers8 that can be programmed

512

30 x 512 = 15 360

Zones that can be programmed

51212

999 Faults

300

Disabled zones

512

Disabled alarm points (zone/address) + Disabled COM loops

20013

Disabled outputs

20014

Disabled interlocking outputs

20015

Sensors activating SERVICE signal

200

AAF zones (Max. 5 detectors per AAF zone.)16

100

30 x 100

Total number of expansion boards 4580, 4581 and 458317

6

30 x 6

Number of I/O matrix boards 458218

24

30 x 24

Total number of 4582 for zone control and generic applications

6

30 x 6

Number of user definable text message programmed per 1728

and 1736

617

9

10

11

12

13

14

15

16

17

18

Technical/Programming Manual

FT1020G3 Rev 2.2.1

Approx. 4000 trigger conditions can be used in these control expressions, more outputs can be used without control expression

(V2.1.1 and higher).

Max. 100 user definable texts can be displayed "at the same time".

Presentation number is a ZONE only or ZONE – ADDRESS.

Any zone number between 001 and 999 can be used for the 512 zones.

Zone/address disabled via time channel not included.

Control outputs disabled via menu H2/B3 and Alarm devices disabled via menu H2/B4 are not included.

Interlocking outputs disabled via menu H2/B3 are not included.

Used in conjunction with the Alarm Acknowledgement Module (AAM).

Expansion boards 4580, 4581 and 4583 are physical connected to COM loop 0

Reduce no. of 4582 boards by one for every expansion board used (4580, 4581 or 4583).

18

Page 22

FT1020G3 Rev 2.2.1

4.2 FT1020G3 CIE Layout

The FT1020G3 available in many configurations depending on the number of options fitted

in the CIE.

Technical/Programming Manual

Figure 4 The FT1020G3 Control Unit, with printer

The FT1020G3 control and indicating equipment (CIE) shown in Figure 4 is housed in a

powder coated metal cabinet, colour is oyster. The cabinet has an inner and outer door.

The outer door is fitted with 003 keys to provide access level 1 and is made of tinted high

impact plastic and allows easy viewing of all indicators and controls.

Access to the inner door is gained by opening the outer door which then provides access

to the inner door fixing screws. Opening the inner door allows access to the Control Unit

hardware for the purpose of maintenance or servicing

The fire brigade panel (FBP) forms integral part of the control panel (CP) as shown in

Figure 5 below, it is used by the fire brigade or fire services personnel to see which alarm

point(s) / zone(s) having activated fire alarm and to take required operational control of the