Assembly Qualier

Operating Instructions

Model No: EYFRZ01

IMPORTANT

This manual contains safety information. Read manual completely before first using this product and save this

manual for future use.

-

2 -

Index

English: Page 3

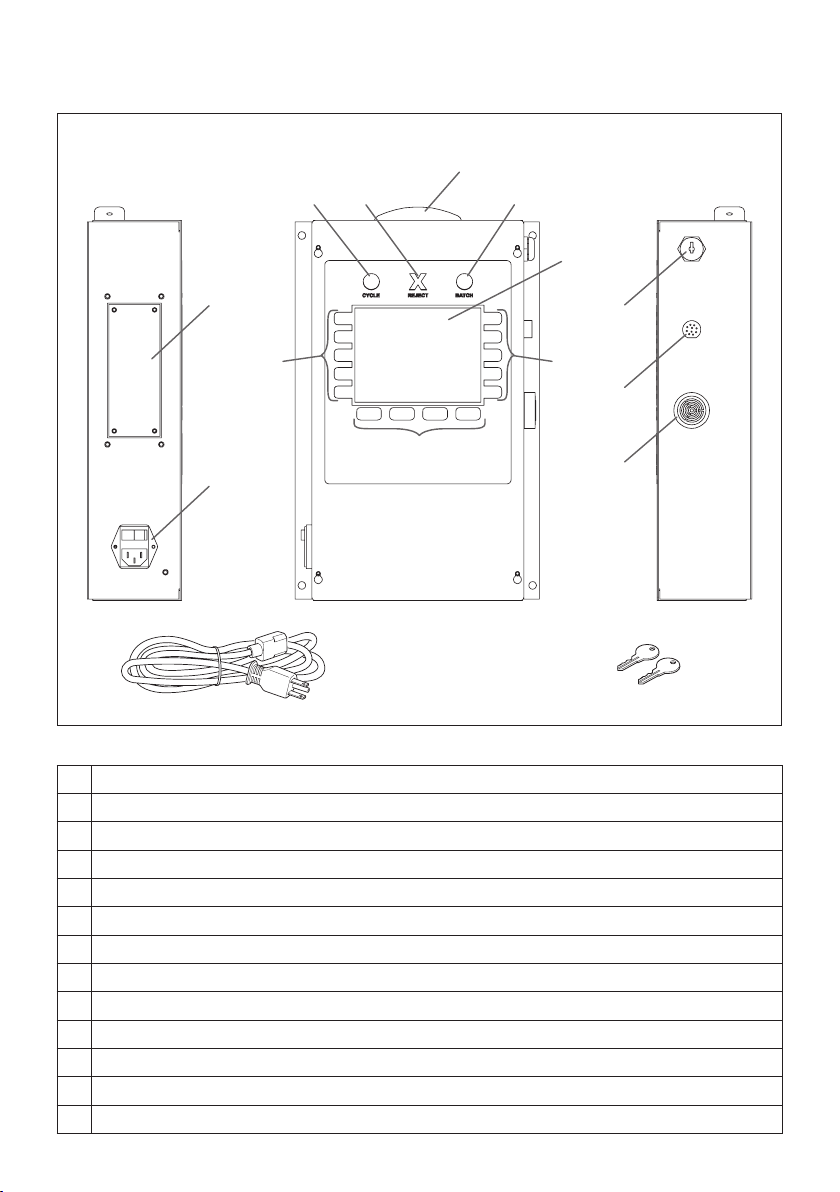

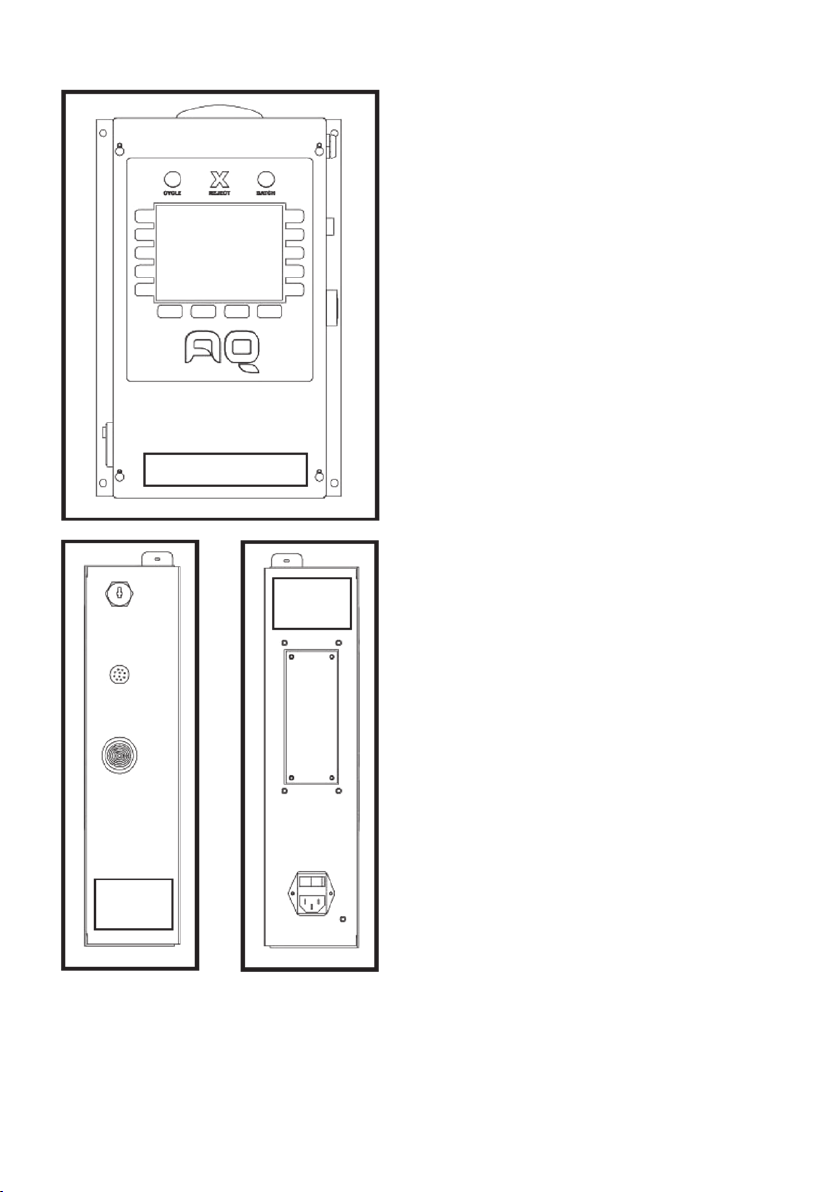

FUNCTIONAL DESCRIPTION

(A)

Protocol side panel

(B)

Switch and entry for power cord

(C)

Antenna

(D)

Cycle status indicator

(E)

Reject status indicator

(F) Batch status indicator

(G)

LCD display

(H)

Soft key

(I)

Key switch

(J) I/O connector

(K) Beeper

(L)

Power cord

(M)

Keys

(B)

(I)

(J)

(K)

(A)

(C)

(F)(E)(D)

(H)(H)

(H)

(L)

(M)

(G)

-

3 -

I

.

INTRODUCTION

Thank you for purchasing the Panasonic Assembly Qualifier. The AQ Wireless can

monitor battery tools. In its simplest form, the AQ Wireless is configured to monitor a

tool while it's running, determine if the fastening process was successful, report the

status of the fastening, and perform counting functions.

How to Use This Manual

• Please read this manual completely before starting to use your AQ Wireless. If this unit

is mishandled a fatal accident, bodily injury, or damage to the AQ Wireless may occur.

• This manual is intended to be a general guide to the operations of the AQ Wireless.

If any additional questions or concerns arise, please contact a Panasonic Electric

Works Power Tools representative.

• Please keep this manual for future reference. It contains important safety information

that you must follow to use the AQ Wireless safety.

WARNING!

• Do not disassemble the unit for repair or modifications. There is a high electrical

voltage inside the unit that could cause electric shock.

• Do not allow any type of liquid to come into contact with any part of the unit.

• Immediately discontinue use of the unit if smoke, an abnormal odor, or an unusual

sound is detected coming from the unit.

• Insert all fittings fully into their mating receptacles. Failure to do so could result in injury.

• Do not fold, bend or apply excessive force to any cable or fitting.

CAUTION!

• This unit accepts an AC input voltage from 90VAC to 264VAC. Trying to operate this

unit with a voltage outside that range may cause damage to the unit.

• Reception reliability may vary with site conditions. Be sure to verify proper Assembly

Qualifier operation, including data reception, before starting work. Panasonic is not

responsible for any damage sustained as a result of reception problems.

• Avoid placing or storing this unit in a location where it may become wet or dust covered.

• Do not place or mount this unit in an unstable area.

Dropping this unit may result in personal injury or damage to the unit.

• Before performing any maintenance on the unit, make sure to turn it off and

remove the power plugs.

•

There are no user serviceable parts inside the main enclosure of the unit.

• Proper operation is not guaranteed in the event that the Assembly Qualifier has been

modified in any way.

• Always use this Assembly Qualifier with a Panasonic tool. Proper operation is not

guaranteed when used with non-Panasonic tools.

Always turn the Assembly Qualifier’s power off when not in use.

-

4 -

Getting Ready

Installation requirements

Select SIGNAL STRENGTH on the third menu screen and verify the wireless signal

strength. Install the unit in a location where the signal strength is at least -100 dBm. If

you are unable to get a reading of at least -100 dBm, check for obstructions between

the Assembly Qualifier and the tool. However, temporary interference or other issues

may interrupt communications. Be sure to test the Assembly Qualifier adequately at

the site where it is to be used. Using the 4 screw holes, mount the Assembly Qualifier

securely so that it will not fall off the wall. The Assembly Qualifier may cause injury if it

falls from the installation location.

II

.

OPERATION

Quick Start Guide

For more information, refer to the detailed explanation provided for each section

below.

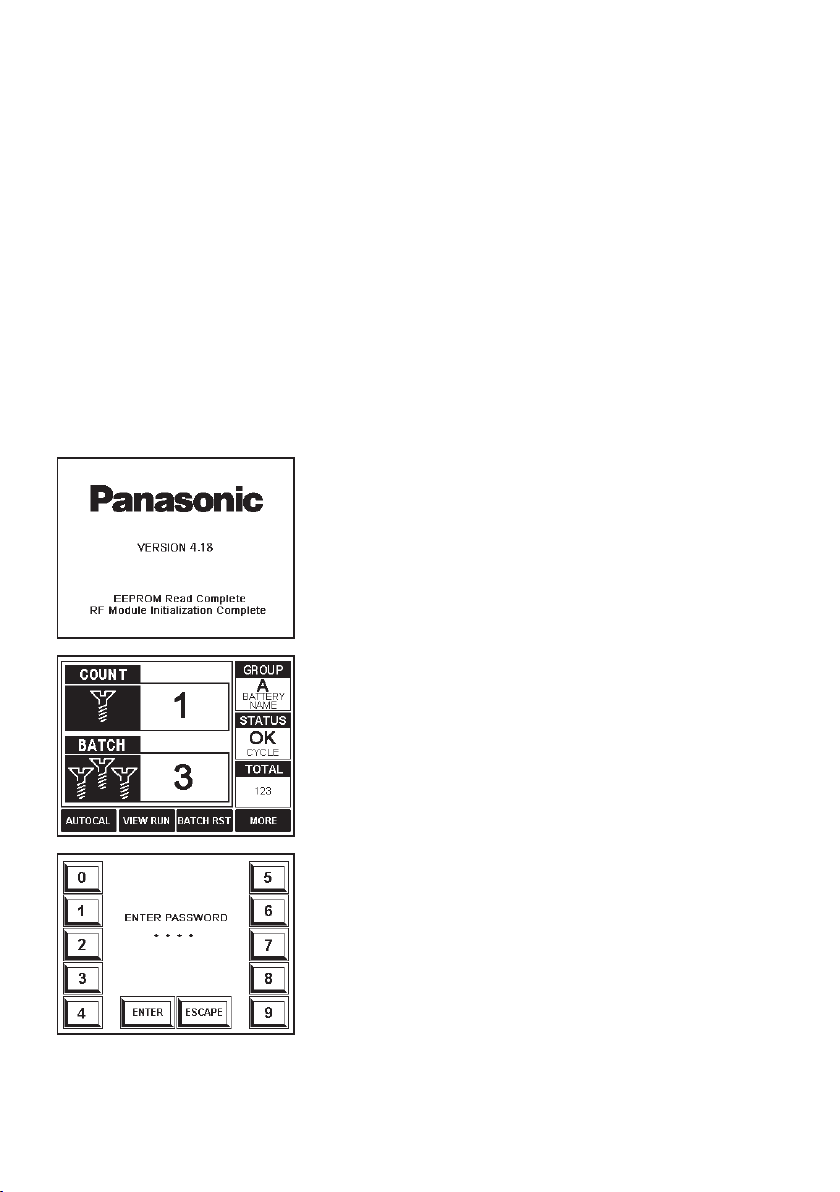

Step 1:

Power up the unit. During power-up the device will load

the program, read stored settings, initialize the radio,

and try to contact a radio tool.

Step 2:

To program a new tool, click the MORE button on the

bottom right corner.

Step 3:

Enter the password (0104 default), or bypass the

password by turning the key to the unlock position

before pressing MORE.

-

5 -

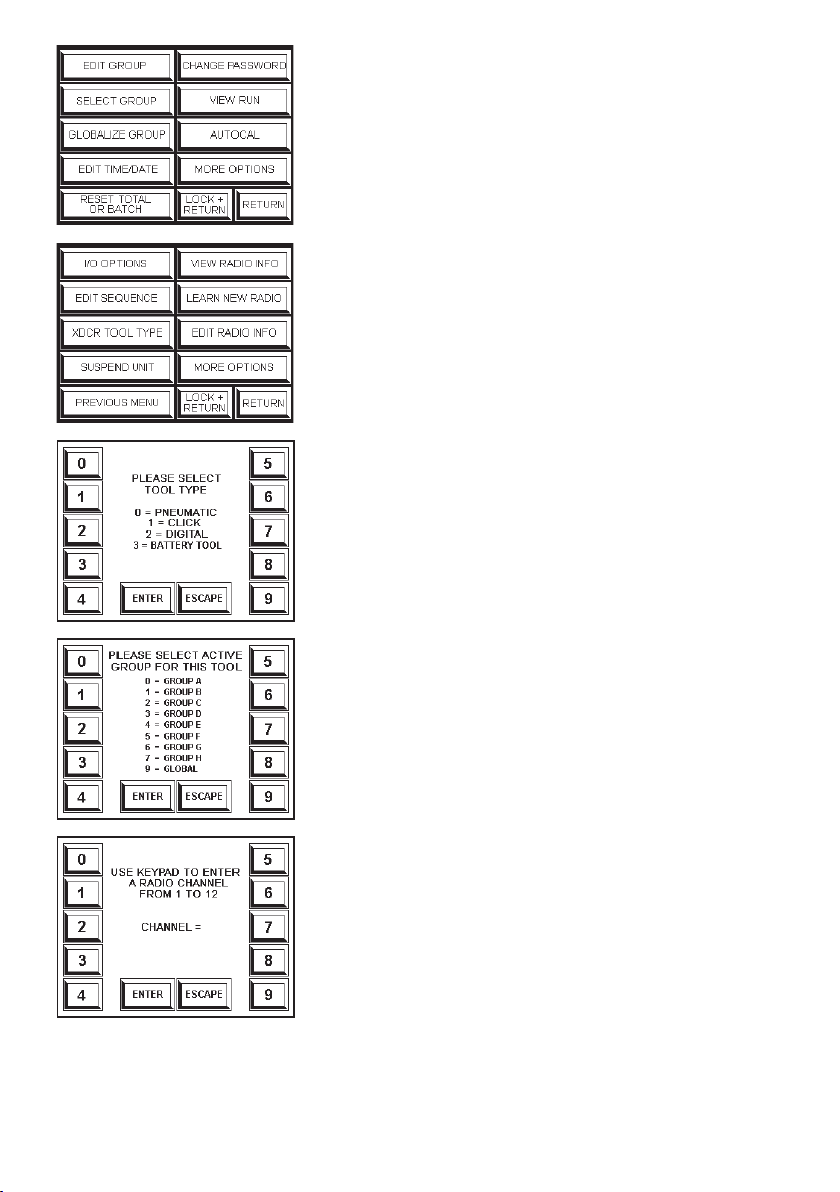

Step 4:

On the first Menu, select the button MORE OPTIONS

on the right-side column to proceed to the second

Menu.

Step 5:

Select LEARN NEW RADIO on the right-side column.

Step 6:

Next, select the type of tool that is to be learned into the

unit by selecting the number that represents the tool

type.

Step 7:

Select the group you want to represent the tool.

Note: select the group that will be selected when the

tool being learned is in use.

Step 8:

Type in the radio channel you desir e the tool to

communicate on.

-

6 -

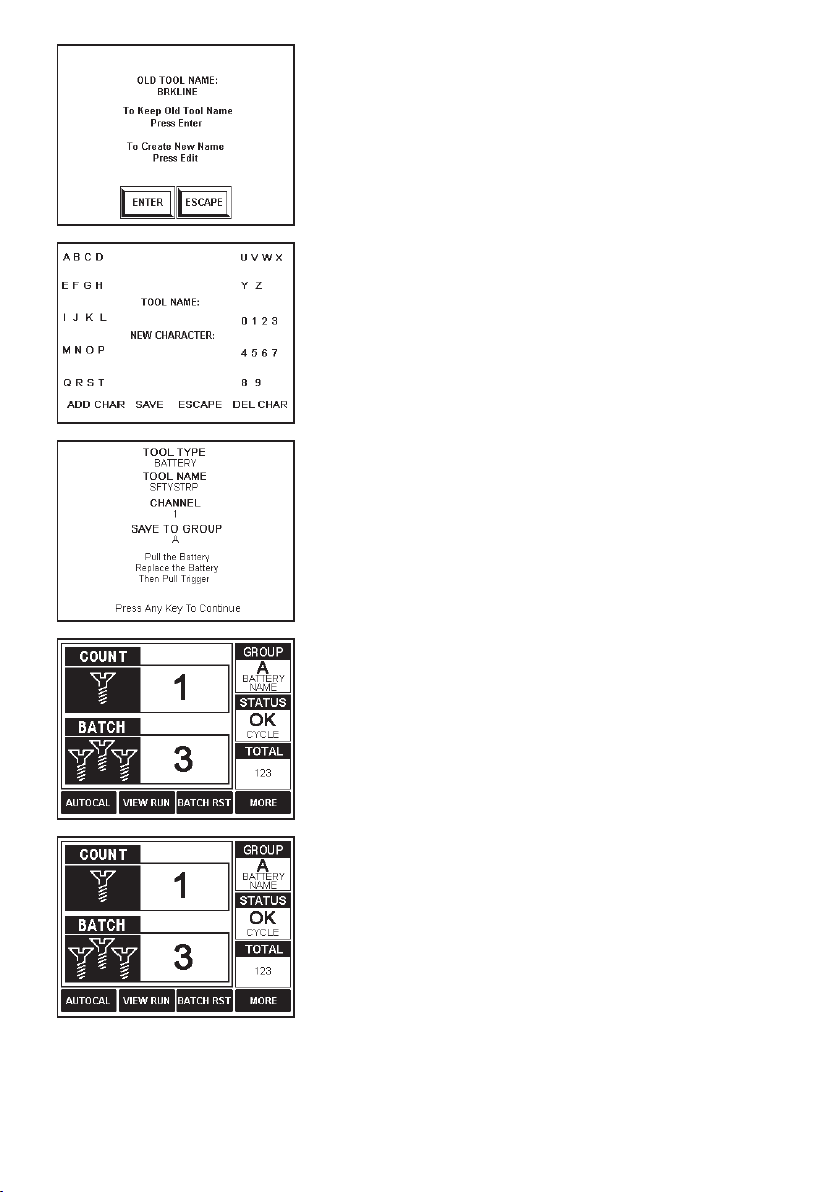

Step 9:

Choose to keep the name already programmed into this

group by pressing ENTER or program a new name by

pressing EDIT.

Step 10:

Type in the name for the tool. Press button next to letter,

multiple times if needed, to get the wanted letter. Select

ADD CHAR at the bottom to add the letter to the name.

Repeat until name appears as desired. Press SAVE.

Step 11:

Turn off the control panel. If the control panel is on,

remove and then reinsert the battery pack. Engage the

switch. Check the Assembly Qualifier’s display.

Step 12:

Upon successful completion of the learn process, press

the return key to get back to the main screen.

Step 13:

At this po int, the box and the to ol kno w how to

communicate with each other. However, the tool’s

parameter set (group) may need to be edited so that it

is monitoring the fastening process properly.

-

7 -

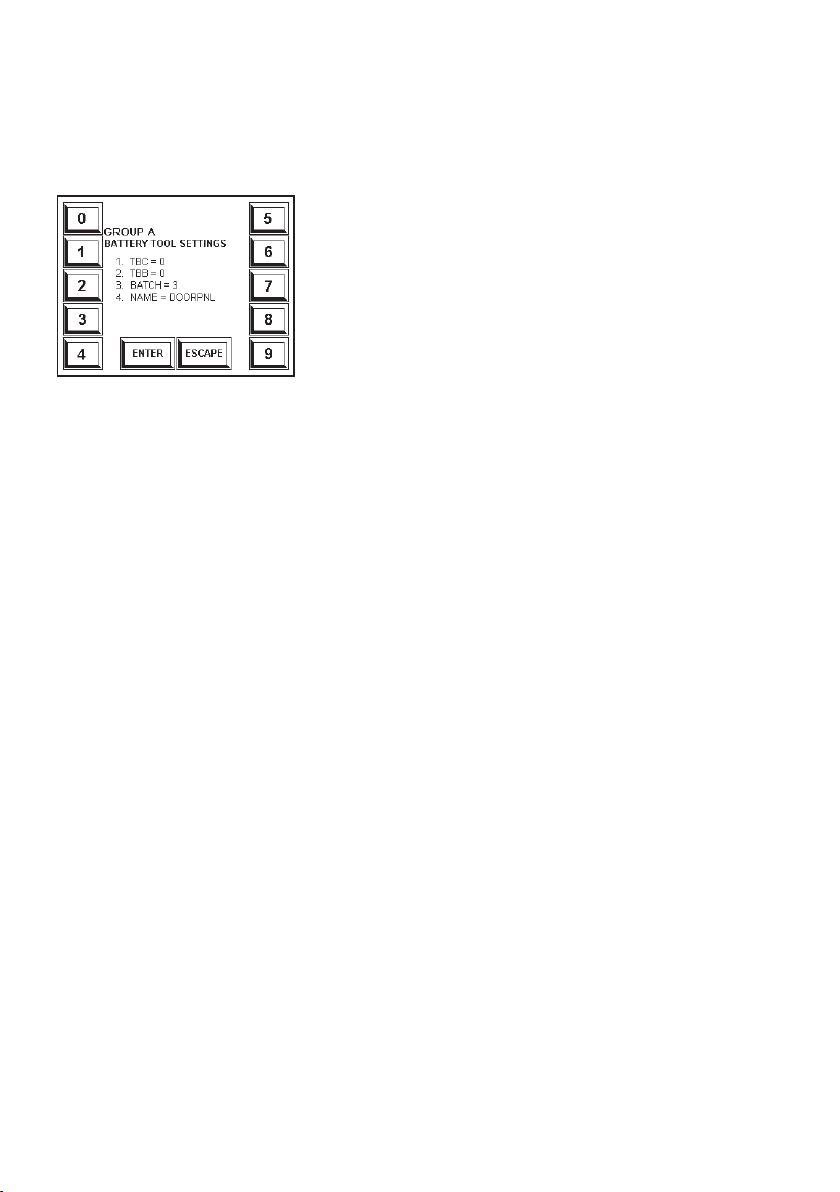

Step 14:

The final step in setting up any tool is programming the appropriate number of

fasteners into the batch. Programming the batch can be accomplished by pressing

the more button on the main screen and then pressing the edit group button on the

first menu. The items that can be edited in a parameter (group) will vary based on tool

type. After batch count is programmed, return to main screen.

Battery Tool: Press ‘3’ key to edit batch.

-

8 -

Unit Overview

The user interface on the AQ Wireless is

equipped with a 320 x 240 LCD display and

a 14 key ATM style “soft key” format. The

“soft” key’s functions will change depending

upon the screen that is displayed. The keys

are used to navigate through menus, select

items that need to be edited, and to view

information related to the tools.

Above the LCD display, there are three

status indicators. The cycle status indicator

will light up each time a fastening process

is completed successfully. The batch status

indiction will be lit when the final fastener is

completed in a group. If a fastening process

is not completed properly, the reject status

indicator will illuminate.

The left side of the unit is populated with

a power entry module and a removable

plate. The AQ wireless contains an autoranging power supply. That power supply is

capable of accepting voltages from 90VAC to

264VAC. Depending upon the configuration

of the unit, the plate on the left side may

have a USB connector and or additional

connectors.

A companion Windows ap pl ic at io n i s

available that will make use of the USB port

and aide in the set-up of the unit.

The right side of the unit is populated with a

key-switch, beeper and a 10 pin connector.

Th e key-sw itch is used t o bypass the

password screen allowing direct access to

the programmable functions.

The beeper can be programmed to beep on

rejects, cycles, batches or not at all.

The 10-pin connector allows access to several optically isolated inputs and relay

outputs. Inputs are available for selecting parameters, suspending and resetting the

unit. Outputs are available for cycle, batch and reject statuses.

Unit FaceUnit Face

Right

Side

Right

Side

Left

Side

Left

Side

-

9 -

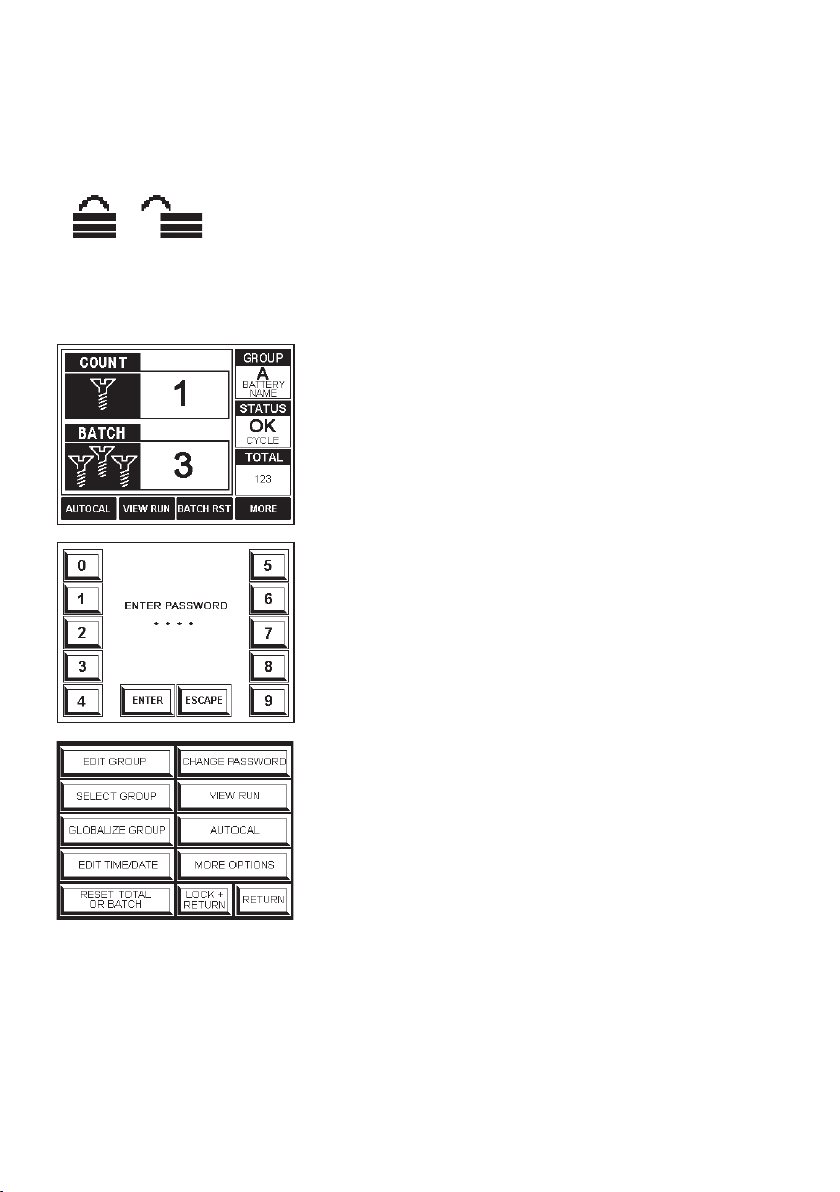

Main Screen

After the AQ Wireless powers up and initializes, one main screens will appear. The

screen are meant to provide meaningful feedback to an operator during an assembly

process.

Tools utilize a main screen that predominately features

the count and batch values. The group (parameter), tool

name, tool type, status, and total are also visible.

Tools will transmit a packet at the end of a fastening process.

Main Screen (Definitions):

GROUP: displays the group (parameter) that is currently being used, the type of tool,

and the name of the tool.

STATUS: shows whether or not the previous fastening was successful and met all

requirements. OK is displayed if fastening is successful. NOK and a reason are

displayed if the fastening fails.

COUNT: the number indicates how many fastenings in the batch have been completed.

BATCH: displays the quantity in a batch.

TOTAL: displays the number of batches that have been successfully completed.

There are four soft functions associated with the soft-key at the bottom of the screen.

If the unit is unlocked, pressing one of the buttons will take the user directly to that

function. The soft functions listed at the bottom of the main screen are Autocal, View

Run, Batch Reset, and More.

Autocal

The AUTOCAL function provides a default values are written to the current group

(parameter).

View Run

This feature isn’t compatible.

Batch Reset

The BATCH RST button leads to a screen where the batch, the total, or both can be

reset.

-

10 -

More

The MORE button allows access to the programming menu. All of the programmable

features in this unit can be reached through these menus.

Lock Status

An icon that looks like a padlock appears at the top of the main

screen. This icon shows the lock status.

If the unit is unlocked, the programming menu can be accessed

without entering a password or using a key.

Programming Menu Options:

Th e re are a nu m ber of pro gramma b le featu res

associated with this unit and the tools associated with

the unit. In order to access these programmable

functions press the MORE button on the main screen.

If the unit is locked, the user will be prompted to enter

the unit’s password. At this point the user can either

enter the password (0 1 0 4 is the default) or use the

key-switch to bypass this screen.

After the password is entered or the keyswitch turned to

the unlocked position, a screen full of menu options will

appear.

The user can select one of the options from the menu

by pressing the soft-key adjacent to that option. Also,

additional menu option screens can be reached by

selecting the MORE OPTIONS button.

The unit can be sent back to the main screen by either pressing the RETURN soft-key

or the LOCK+RETURN soft-key. If RETURN is selected, the unit will remain unlocked

if a password was used to unlock the unit. Pressing LOCK+RETURN locks the unit

and also sends the unit back to the main screen.

Loading...

Loading...