INSTRUCTION

MANUAL

Pipe-mountable Liquid Level Photoelectric Sensor

EX-F1

1

SPECIFICATIONS

Designation

Sensing object

Applicable pipe diameter

Supply voltage

Current consumption

Output

Operation indicator

Ambient temperature

(Note 3)

Emitting element

Material

Cable

Notes: 1)

2

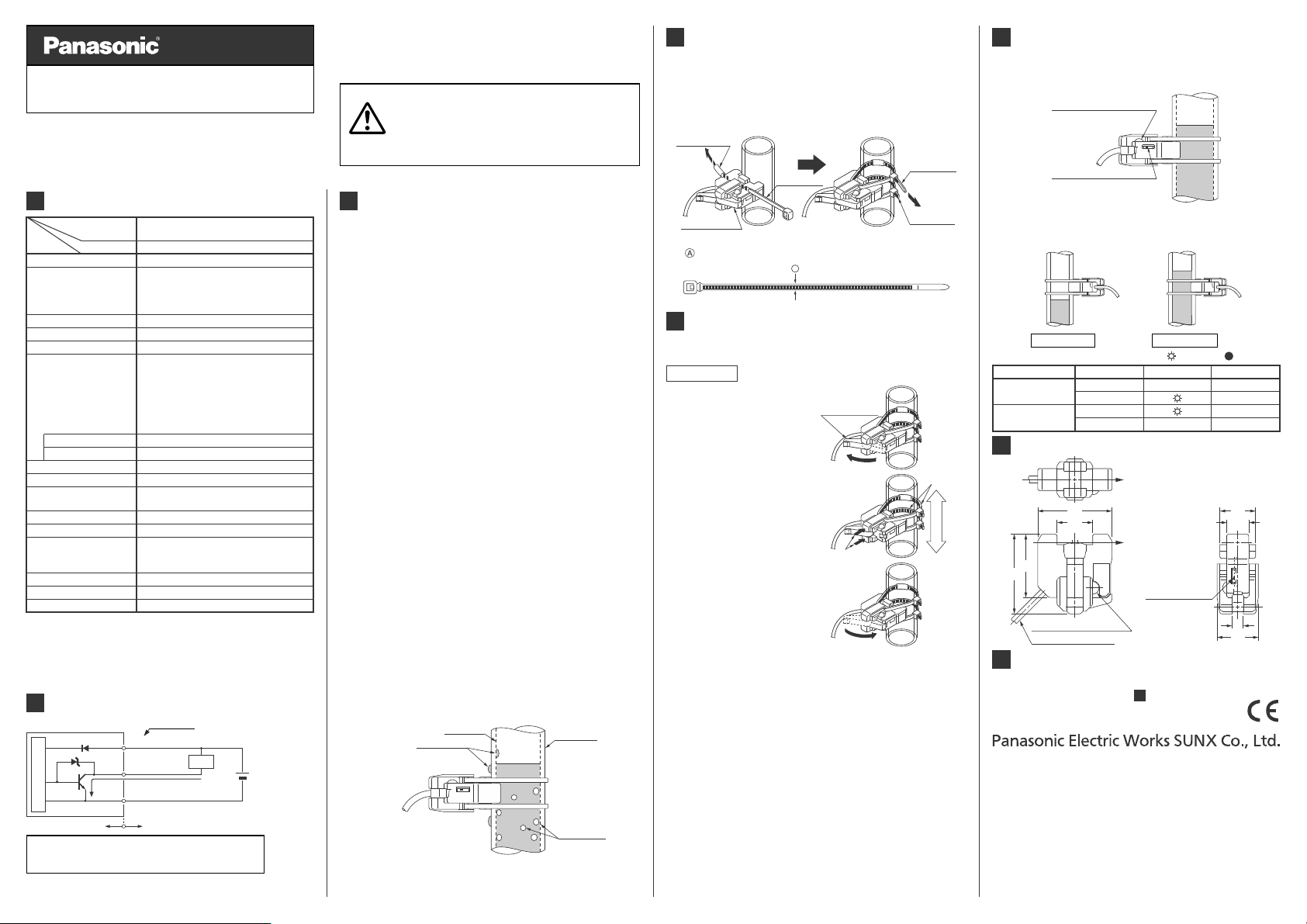

Sensor circuit

Symbols...D

Model No.Item

Output operation

Short-circuit protection

Unclear or highly viscous liquid may not be detected stably.

2)

Do not use the sensor with pipes other than the above

specified. Furthermore, take care that if the pipe is made

from glass, the detection may be unstable due to refraction.

3)

Liquid being detected should also be kept within the rated

ambient temperature range.

I/O CIRCUIT DIAGRAM

D

Z

D

T

r

: Reverse supply polarity protection diode

Z

: Surge absorption zener diode

D

T

r

: NPN output transistor

Amplifier built-in・pipe-mountable liquid

level sensor

Outer diameter φ6toφ13 mm transparent resin pipe [PFA (Fluorine resin) or

equivalent, having the same transparency, thickness 1mm] (Note 2)

12 to 24V DC±10% Ripple P-P 10% or less

NPN open-collector transistor

・Maximum sink current: 100mA

・Applied voltage:

30V DC or less

・Residual voltage:

Switchable either Light-ON or Dark-ON

Red LED (lights up when the output is ON)

-10to+55℃ (No dew condensation or

icing allowed), Storage: -20 to +70℃

35 to 85% RH, Storage: 35 to 85% RHAmbient humidity

0.1mm23-core cabtyre cable, 1m long

Tying band: 2 pcs., Anti-slip tube: 2 pcs.Accessories

Color code

(Brown) +V

(Black) Output

100mA max.

(Blue) 0V

Users' circuitInternal circuit

EX-F1

Liquid (Note 1)

0.5mmorlessRepeatability

30mA or less

(between output and 0V)

1V or less (at 100mA sink current)

0.4V or less (at 16mA sink current)

Incorporated

2ms or lessResponse time

Infrared LED (modulated)

Enclosure: Polycarbonate

Tying band: Nylon

Anti-slip tube: Silicone

15g approx.Weight

Load

+

12 to 24V DC

±10%

-

Thank you very much for purchasing Panasonic products.

Please read this Instruction Manual carefully and thoroughly

for the correct and optimumuse of this product. Kindly keep

this manual in a convenient place for quick reference.

●●Neverusethisproductasasensingde-

vice for personnel protection.

In case of using sensing devices for personnel pro-

WARNING

tection, use products which meet laws and standards, such as OSHA, ANSI or IEC etc., for personnel

protection applicable in each region or country.

3

CAUTIONS

●

This product has been developed / produced for industrial use only.

●

Thethincable(0.1mm2) is used for this product. Thus,

take care that if the cable is pulled with excessive

force, it may cause cable break.

●

Make sure that the power supply is off while wiring.

●

Take care that wrong wiring will damage the sensor.

●

Verify that the supply voltage variation is within the rating.

●

If power is supplied from a commercial switching regulator, ensure that the frame ground (F.G.) terminal of

the power supply is connected to an actual ground.

●

In case noise generating equipment (switching regulator, inverter motor, etc.) is used in the vicinity of this

product, connect the frame ground (F.G.) terminal of

the equipment to an actual ground.

●

Do not run the wires together with high-voltage lines or

power lines or put them in the same raceway. This can

cause malfunction due to induction.

●

Extension up to total 50m, is possible with 0.3mm2,or

more, cable for both, emitter and receiver. However, in order to reduce noise, make the wiring as short as possible.

●

Do not use during the initial transient time (50ms) after

the power supply is switched on.

●

Take care that the sensor is not directly exposed to

fluorescent lamp from a rapid-starter lamp, a high frequency lighting device or sunlight etc., as it may affect

the sensing performance.

●

This sensor is suitable for indoor use only.

●

Make sure that stress by forcible bend or pulling is not

applied directly to the sensor cable joint.

●

Since the cable end is not waterproof, do not use the sensor in

the application where water may seep in from the cable end.

●

This sensor cannot be used with a non-transparent pipe.

●

Fit the sensor to a pipe securely, otherwise the operation may be erroneous.

●

If a liquid drop flows down across the sensing point or an

air bubble sticks on the wall at the sensing point, the operation may be affected. Make sure that no bubble forms in the

liquid, and no dew or liquid drop attaches on either surface.

Inner wall

Liquid drops

Outer wall

Air bubbles

● EX-F1 does not provide water-tightness, oil-resistance

or chemical-resistance. Avoid installation at any place

that it could be exposed to water, chemical or oil.

4

MOUNTINGONAPIPE

● Mount the sensor on a pipe with the attached tying

bands and anti-slip tubes as shown in the figure below. Make sure the release lever is retracted (position

as in the figure) before mounting.

Fasten two tying bands, as shown, and cut off the excess portions.

Anti-slip tube

Tying band

Release lever

Upper hold

Lower hold

● If other tying bands are to be used, the dimension

shown in the figure below should be 2.5mm or less.

A

5

POSITION ADJUSTMENT

● After it is mounted on the pipe with tying bands, the

sensor position can be easily adjusted.

Adjustment

① Unlock the release lever

(in the direction of the

arrow).

② Press the movable cen-

Release lever

L

o

e

o

s

ter holders forward to

loosen the tying bands

and adjust the position.

Press

③ Lock the release lever to

its original place.

Note: The lever mechanism must be used only to adjust the position,

and not for tightening the tying bands. If tying bands are tightened

while the lever is open, and then the lever is locked, the sensor

may be damaged.

6

SELECTING OUTPUT OPERATION

● Either Light-ON (Liquid-absent-ON) or Dark-ON

(Liquid-present-ON) can be selected with the operation mode switch according to your application.

Operation indicator(Red)

Lights up when the

output is ON.

Operation mode switch

L: Low-level-ON

D: High-level-ON

● The indicator operation and the output operation

change with the setting of the ope rati on mode

switch as given in the table below.

Position

adjustable

Liquid-absent Liquid-persent

MODE

Light-ON

(Liquid-absentl-ON)

Dark-ON

(Liquid-persent-ON)

7

DIMENSIONS (Unit: mm)

23

29

Operation indicator (Red)

φ2.5 cable 1m long

8

INTENDED PRODUCTS FOR

Sensing condition

27

13

Beam axis

Beam axis

: Lights up, : Turns off

Operation indicator

●

Operation mode

switch

CE MARKING

●

The models listed under ' SPECIFICATIONS'

come with CE Marking.

As for all other models, please contact our office.

http://panasonic-electric-works.net/sunx

Overseas Sales Division (Head Office)

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-568-33-7861 FAX: +81-568-33-8591

Europe Headquarter: Panasonic Electric Works Europe AG

Rudolf-Diesel-Ring 2, D-83607 Holzkirchen, Germany

Phone: +49-8024-648-0

US Headquarter: Panasonic Electric Works Corporation of America

629 CentralAvenue New Providence, New Jersey 07974 USA

Phone: +1-908-464-3550

© Panasonic Electric Works SUNX Co., Ltd. 2011

1

Output operation

OFFLiquid-present

ONLiquid-absent

ONLiquid-present

OFFLiquid-absent ●

13

8

4

15

PRINTEDINJAPAN

Loading...

Loading...