Page 1

RoHS Directive compatibility information

http://www.mew.co.jp/ac/e/environment/

100A 100V DC

HIGH VOLTAGE RELAY

FEATURES

1. Compact and high capacity using

double contacts in series and

permanent magnet installed.

1) Nominal switching capacity (resistive

load): 100A 100V DC, Min. 10

2) Max. cut-off current: 800A 100V DC

2. Compact and lightweight for space

savings.

70mm (L) × 80mm (W) × 34mm (H)

2.756inch (L) × 3.150inch (W) ×

1.339inch (H)

3. Environmentally friendly

In consideration of the environment,

cadmium-free contacts, lead-free solder

are used.

4

EJ (AEJ)

EJ RELAYS (AEJ)

TYPICAL APPLICATIONS

Quick recharging power supplies for

AGVs (automatic guided vehicle), UPS

(uninterruptible power supplies), Fuel

cell, Combined heat/power generation

system, etc.

ORDERING INFORMATION

AEJ

EJ Relay

Contact arrangement

1: 1 Form A

Contact capacity

1: 100 A (100 V)

Operating function

0: Single side stable

Coil voltage (DC)

12: 12, 24: 24

TYPES

Contact arrangement Coil voltage Protective construction Terminal shape Part No.

1 Form A

Standard packing: Carton: 1 pc.; Case: 20 pcs.

12V DC

24V DC AEJ11024

Dust cover Screw terminal

RATING

1. Coil data

Nominal coil

voltage

12V DC Max. 9.0V DC Min. 1.0V DC 417mA 28.8Ω 5.0W

24V DC Max. 18.0V DC Min. 2.0V DC 208mA 115Ω 5.0W

Pick-up voltage

(at 20°C 68°F)

(Initial)

Drop-out voltage

(at 20°C 68°F)

(Initial)

Nominal coil current

[±10%] (at 20°C 68°F)

Coil resistance

[±10%] (at 20°C 68°F)

Nominal operating

power

(at 20°C 68°F)

AEJ11012

Max. allowable voltage

(at 20°C 68°F)

150%V of

nominal voltage

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.

Page 2

EJ (AEJ)

2. Specifications

Characteristics Item Specifications

Arrangement 1 Form A

Contact voltage drop (Initial) Max. 0.15V (at 100A)

Contact material AgCuO type

Rating

Electrical

characteristics

Mechanical

characteristics

Expected life

Conditions Conditions for operation, transport and storage*

Unit weight Approx. 300g 10.58oz

Notes: *1 This value can change due to the switching frequency, environmental conditions and desired reliability level, therefore it is recommended to check this with the

*2 The upper operation ambient temperature limit is the maximum temperature that can satisfy the coil temperature rise value.

*3 Condition: Nominal switching 100cycles, each cut off 800A

*4 When using a surge absorbing element for the relay coil drive circuit, please use with a surge absorbing element with a clamp voltage of 1.5 to 2.0 times the rated

Nominal switching capacity (resistive load) 100A 100V DC

Max. carrying current/short time carrying current 1,000A (0.1s)

Min. switching capacity (Reference value)*

Max. cut-off current 800A 100V DC/3 cycle*

1

1A 12V DC

3

Overload opening rating 300A 150V DC/10 cycle

Insulation resistance (Initial)

Breakdown voltage

(Initial)

Between open contacts 1,500 Vrms for 1min. (Detection current: 10mA.)

Between contact and coil 2,500 Vrms for 1min. (Detection current: 10mA.)

Min. 100MΩ (at 500V DC)

Measurement at same location as “Initial breakdown voltage” section.

Operate time (at 20°C 68°F) Max. 30ms (Nominal voltage applied to the coil, excluding contact bounce time)

Release time (at 20°C 68°F) Max. 15ms (Nominal voltage applied to the coil)

2

Shock resistance

Functional

Destructive

Min. 500 m/s

Min. 50 m/s

Min. 1000 m/s2 (Nominal voltage applied to the coil or deenergized.)

(Half-wave pulse of sine wave: 6 ms)

Functional 10 to 200Hz, 44.1m/s

Vibration resistance

Destructive

10 to 200Hz, 44.1m/s2 (Nominal voltage applied to the coil or deenergized)

(Time of vibration for each direction; X, Y, Z direction: 4 hours)

Mechanical Min. 10

Electrical

Min. 10

(Resistive load, operating frequency 1s ON, 9s OFF, room temperature)

2

Ambient temperature: –40°C to +85°C –40°F to +185°F

(Nominal voltage applied to the coil)

2

(deenergized) (Half-wave pulse of sine wave: 11 ms; detection time: 10µs.)

2

(Nominal voltage applied to the coil or deenergized)

6

4

(at 100A 100V DC)

actual load.

Refer to 6. Conditions for operation, transport and storage mentioned in AMBIENT ENVIRONMENT .

operating voltage. When the coil is connected in parallel with a diode, resistor or capacitor, the release time will delay which might lead to degradation in shutoff

performance and electrical life.Contact terminals have polarity; therefore, please obey the wiring diagram when connecting contacts.The electrical load

performance value applies when a varistor is connected in parallel with the coil.

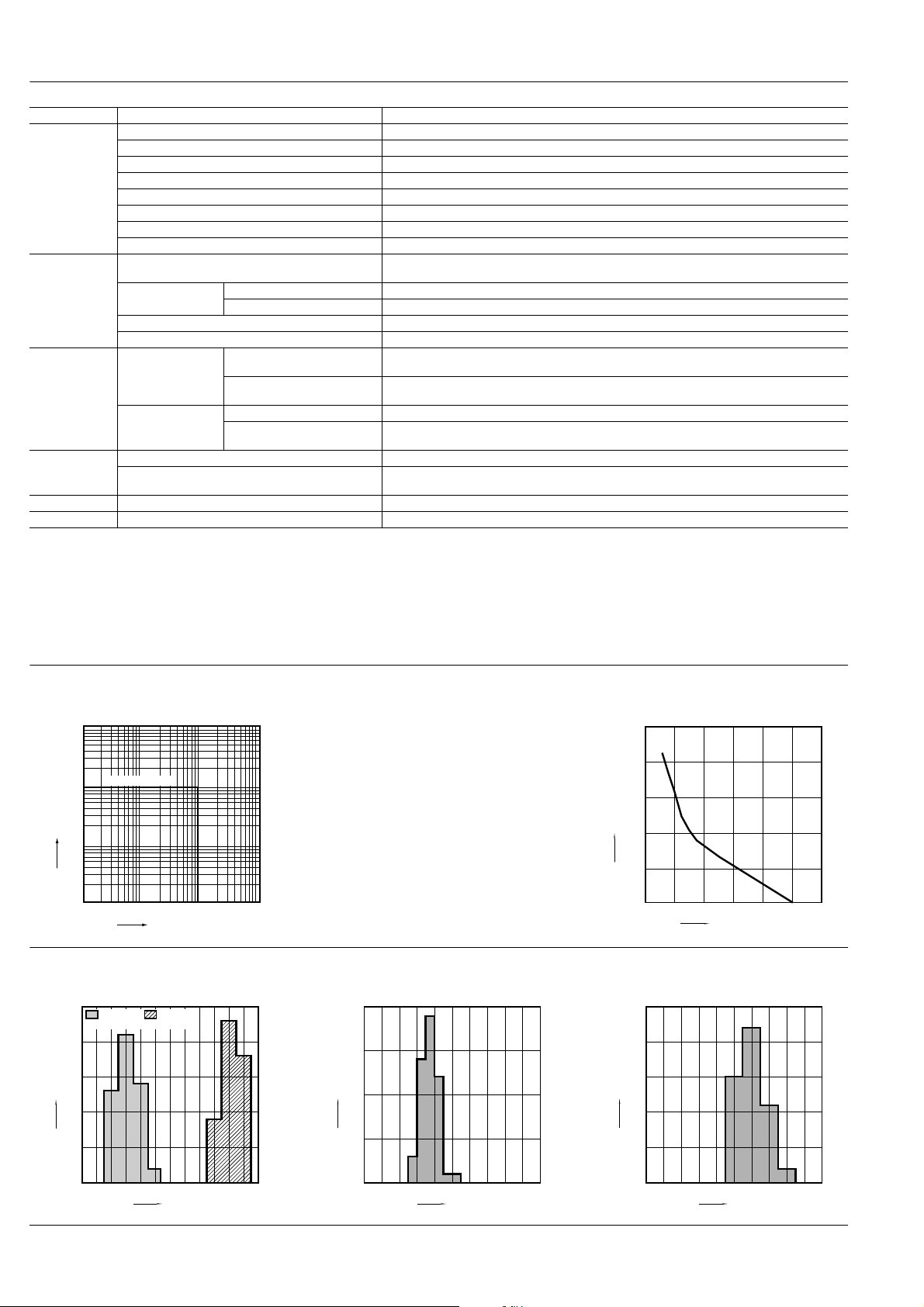

REFERENCE DATA

1. Maximum value for switching capacity 2. Carrying current limit

1,000

DC resistive load

100

Contact current, A

10

10 100 1,000

Contact voltage, V

3. Distribution of pick-up and drop-out voltages

Tested sample: AEJ11012, 50 pcs.

25

20

15

Quantity

10

Drop-out

voltage

Pick-up

voltage

)(20°C 68°F

Connection electric wire: 40mm

Ambient temperature: 85°C 185°F

Standard for judgment: Relay contacts off when

carrying finished.

4. Distribution of operate time

Tested sample: AEJ11012, 50 pcs.

20

15

Quantity

10

2

Carrying current and carrying time

10000

1000

100

Carrying time, s

10

1

0.1

0 200 400 600 800 1000 1200

Carrying current, A

5. Distribution of release time

Tested sample: AEJ11012, 50 pcs.

)(20°C 68°F

25

20

15

Quantity

10

)(20°C 68°F

5

0

3.02.01.51.0 2.5 3.5 4.5 5.04.0 5.5 6.0 7.06.5

Voltage, V

5

0

13.011.010.0 12.0 14.0 16.0 17.015.0 18.0 19.0 20.0

Time, ms

5

0

1.50.50.0 1.0 2.0 3.0 3.52.5 4.0 4.5 5.0

Time, ms

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.

Page 3

6. Functional shock resistance

Tested sample: AEJ11012, 3 pcs.

Half-wave pulse of sine wave: 11 ms

Detection time: 10µs.

Applied direction: 6 directions

Applied cycle: Each of 3 cycles

Deenengized condition

Energized condition

Z'

Y

2

1,000m/s

Z

Y'

X

Y

X'

XZ

2

1,000m/s

1,000m/s

2

EJ (AEJ)

1,000m/s

DIMENSIONS (Unit: mm inch)

External dimensions

71.4

2.811

58.4

2.299

36.0

1.417

70.0

2.756

31.5

1.240

3.7

.146

(–) (+)

2

Z' X'

1,000m/s

Y'

3.7

.146

2-M6

2-M.236

2-5.3 dia.

2-.209 dia.

1,000m/s

2

+0.3

−0.1

+.012

−.004

2

1.323

33.6

+1.0

−0.5

+.039

−.020

Schematic (Top view)

2 (–)

1 (+)

Coil terminal

Coil terminal

Mounting hole pattern (Top view)

66.0

2.598

2-5.3

2-.209

Tolerance: ±0.1 ±.004

37.5

15.0

.591

1.476

27.0

1.063

<>

52.0

2.047

66.0±0.3

2.598±.012

80.0

3.150

10.0

.394

300±20

11.811±.787

34.0

1.339

+1.0

−0.5

+.039

−.020

Notes: 1. Please be warned that contact terminals have polarity. There is no polarity in the coil input line.

2. We will make separate consideration if a coil lead wire connector is desired.

Tolerance:

Max. 10mm .394inch: ±0.3 ±.012

10 to 50mm .394 to 1.969inch:±0.6 ±.024

Min. 50mm 1.969inch: ±1.0 ±.039

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.

Page 4

EJ (AEJ)

;;

;;

;;

;;

;;

;;

;;

;;

;

;

;

;;

Tolerance range

(Avoid

condensation when

used at temperatures

higher than 0°C 32°F)

(Avoid freezing when

used at temperatures

lower than 0°C 32°F)

85

5

–40

–40

0

+32

+85

+185

Temperature, °C °F

Humidity, %R.H.

NOTES

1. To ensure proper operation, the

voltage applied to the coil should be

the rated operating voltage of the coil.

Also, be aware that the pick-up and

drop-out voltages will fluctuate

depending on the ambient

temperature and operating conditions.

2. Heat, smoke, and even a fire may

occur if the relay is used in conditions

outside of the allowable ranges for the

coil ratings, contact ratings, operating

cycle lifetime, and other

specifications. Therefore, do not use

the relay if these ratings are exceeded.

3. If the relay has been dropped, the

appearance and characteristics

should always be checked before use.

4. This relay is for DC loads. Do not

use it for AC load switching.

5. Make sure that the relay is wired

correctly. Incorrect wiring may cause

unexpected events or the generation

of heat or flames.

6. We recommend you use a surge

absorbing element with a clamp

voltage of 1.5 to 2.0 times the rated

operating voltage for the relay coil

drive circuit as a means for relay coil

surge absorption. Please avoid the

use of diodes, capacitors and

resistors because they lead to

degradation in cut-off performance.

7. Avoid mounting the relay in strong

magnetic fields (near a transformer or

magnet) or close to an object that

radiates heat.

8. Electrical life

This relay is a high-voltage direct-current

switch. In its final breakdown mode, it

may lose the ability to provide the proper

cut-off. Therefore, do not exceed the

indicated switching capacity and life.

(Please treat the relay as a product with

limited life and replace it when

necessary.)

In the event that the relay loses cut-off

ability, there is a possibility that burning

may spread to surrounding parts, so

configure the layout so that the power is

turned off within one second.

9. If the power is turned off and then

immediately on after applying the

rated voltage (current) continuously to

the relay’s coil and contact, the

resistance of the coil will increase due

to a rise in the coil temperature. This

causes the pick-up voltage to rise, and

possibly exceed the rated pick-up

voltage. In these circumstances, take

measures such as reducing the load

current, limiting the duration of

current flow, and applying a coil

voltage higher than the rated

operating voltage (quick start).

10. If you are using an inductive load

(L load) such that L/R > 1 ms, add

surge protection in parallel with the

inductive load. If this is not done, the

electrical life will decrease and cut-off

failure may occur.

11. Be careful that foreign matter and

oils and fats kind doesn’t stick to the

main terminal part because it is likely

to cause a terminal part to give off

unusual heat.

12. Avoid excessive load applied to

the terminal in case of installing such

as a bus bar etc., because it might

give bad influence to the opening and

closing performance.

Tighten each of the screws within the

rated ranges given below.

Main terminal (M6 screw):

6.0N·m to 8.0N·m

Main unit mounting (M5 screw):

2.5N·m to 3.6N·m

13. Usage, transport and storage

conditions

Ambient temperature, humidity, and

atmospheric pressure during usage,

transport, and storage of the relay:

1) Temperature: –40 to +85°C –40 to

+185°F

2) Humidity: 5 to 85% RH

(Avoid freezing and condensation.)

3) Atmospheric pressure: 85 to 106 kPa

Temperature and humidity range for

usage, transport, and storage:

;;;

;;

;

;

;

;;

;;;

;;

;;;;;;

;;;;;;;

;

;;;;;;;;

;;;;

;

;;;;;;

;;

4) Condensation

Condensation forms when there is a

sudden change in temperature under

high temperature and high humidity

conditions. Condensation will cause

deterioration of the relay insulation.

5) Freezing

Condensation or other moisture may

freeze on the relay when the

temperatures is lower than 0°C 32°F.

This causes problems such as sticking of

movable parts or operational time lags.

6) Low temperature, low humidity

environments

The plastic becomes brittle if the relay is

exposed to a low temperature, low

humidity environment for long periods of

time.

For Cautions for Use, see Relay Technical Information.

All Rights Reserved © COPYRIGHT Matsushita Electric Works, Ltd.

Loading...

Loading...