Page 1

Controller

Instruction Manual

Pin No.5: +24 V

■

DIN terminal block

■

Protection cover

■

Mounting frame

■

Noise filter

■

Surge absorber

Contactless Brake Unit

for Small Geared Motors

MB48X Series

Model: DVMB48XZ

Terminal block:

sold separately

■ Thank you for purchasing the Panasonic Contactless Brake Unit for small

geared motors.

■ This manual contains information on safety connection and operation of the

product and associated equipment.

■ Although the product is easy to operate, it may cause injury to personnel or

damage to property or degrade the performance and shorten its life when not

properly and safely used.

Please review the material in this manual thoroughly before using the product.

■ Keep this manual in a safe location where it can easily be accessed for

reference.

■The user and the operator should always refer to this manual.

● This product is for industrial equipment.Don't use this product at

general household.

IME79

P0414-0

Safety Precautions

Please strictly observe safety precautions described below to prevent

personal injury and property damage.

■ The below explains what will happen if someone fails to heed a particular

precaution statement.

Indicates hazards or unsafe practices

Danger

which could result in severe personal

injury or death.

Indicates hazards or unsafe practices

Caution

which could result in minor personal injury

or product or property damage.

■ The following symbols are used to describe the type of Do and Don't.

This symbol is used to indicate a practice

that shall not be attempted.

This symbol is used to indicate a practice

that shall be done.

Danger

Risk of electric shock, injury or re

Don’t use the unit in or near environment containing water,

corrosive gas, ammable gas or ammable substance.

Don’t attempt to touch manual control with wet hands.

When an unauthorized person can access the unit, install it

in a lockable control board and protect its terminal block from

inadvertent contact.

Use overcurrent protection device, ground-fault circuit interrupter, overtemperature protecting device and emergency

stop device.

Be sure to connect the ground of the motor to the earth.

Be sure to turn off power to the unit before wiring it or connecting/disconnecting it to/from socket or terminal block.

−2− −3− −4−

Caution

Risk of electric shock, injury or re

Don’t make soldering joint on a round pin of the brake unit.

Don’t use the unit in an environment where large amount of

static electricity or charges are obtained.

Don’t damage leadwires; don’t subject leadwires to exces-

sive stress such as strong pressure, heavy object and

clamping load; don’t soak leadwires in oil or water.

Don’t lock the motor shaft while it is running.

Don’t start or stop the motor by turning on or off the main power.

Don’t touch rotating member of the motor while it is running.

Don’t touch potentially hot motor casing.

Don’t use the unit when it is damaged.

Don’t get on the product. Don’t place heavy object on the product.

Don’t attempt to perform modication, dismantle or repair.

Test-run the securely xed motor isolated from mechanical

system to verify normal operation (e.g. rotating direction),

and then install it to the machine.

Securely install the equipment to prevent bodily injury or re

in case of earthquake.

After correctly connecting leadwires, insulate the live parts

with insulator.

Always keep power disconnected when the power is not

necessary for a long time.

After an earthquake, rst verify safety.

Once power failure occurs or the overtemperature protecting device activates, don’t come close to the machine that

will unexpectedly start upon recovery of the power. Provide

secure mechanism so that the restarting of the machine will

not cause personal injury.

Repair must be performed by Panasonic authorized service shop.

Before installing, transferring, wiring or mechanically check-

ing product, disconnect the power source.

The product must be disposed as industrial waste.

Unpacking

●

Verify that the model No. matches the number specied on your order sheet.

●

Make sure that any damage in transit is not found.

Should you nd any discrepancy in the product, consult your local dealer.

Applicable motor

Panasonic small geared motor new G series

Induction motors, reversible motors and single-phase motors with electromagnetic brake

* The unit cannot be used with Sq.42 mm size geared motor.

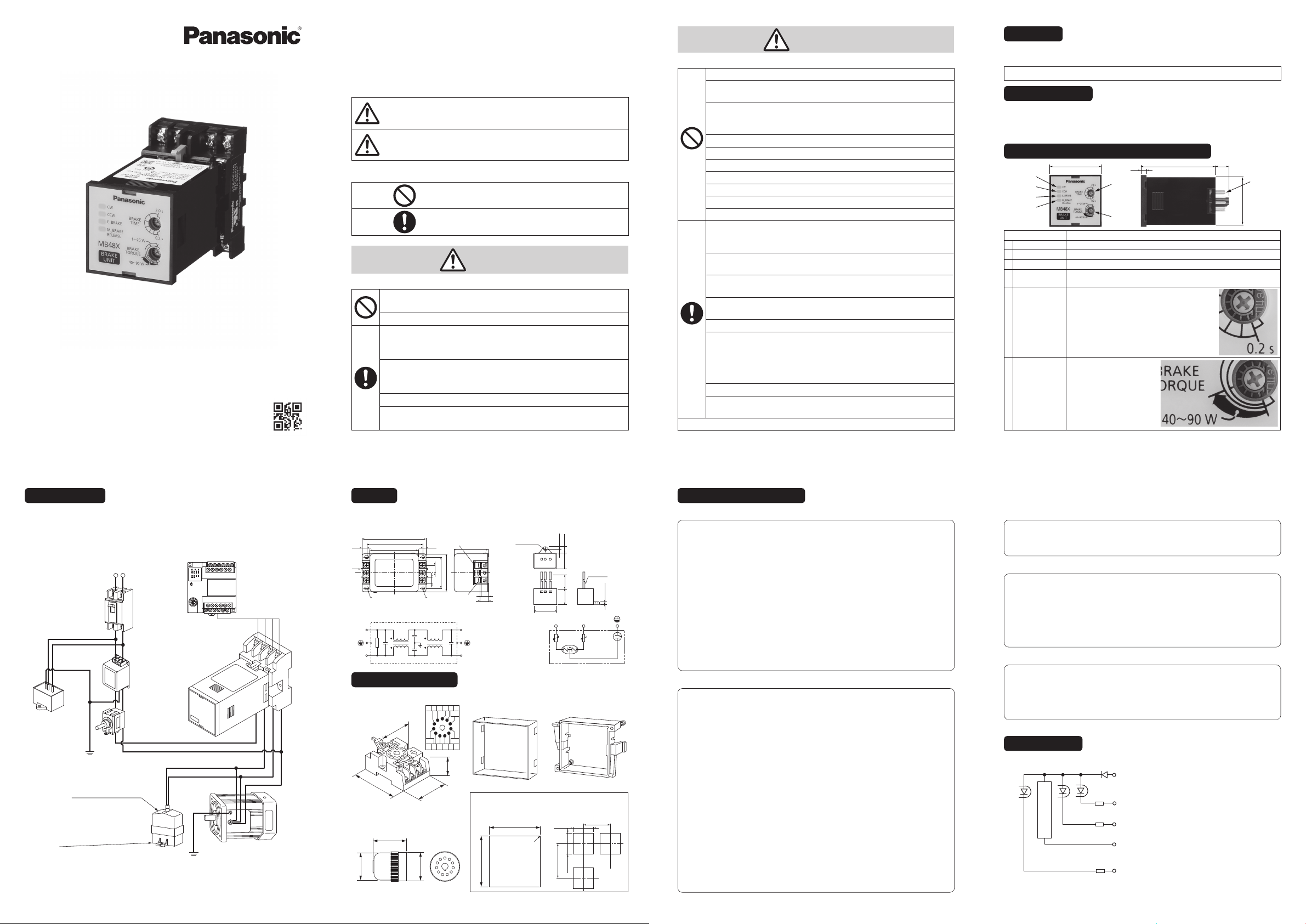

External dimensions, names and functions

□48

①

②

5.5

⑤

③

④

⑥

Name Function

CW lamp Lights when motor is turning clockwise when viewed from output shaft.

①

CCW lamp

②

E_BRAKE lamp Lights when the electric brake is operating.

③

M_BRAKE

④

RELEASE lamp

Braking time

control

⑤

Factory setting:

0.2 s

Braking torque

control

⑥

Factory setting:

40 W-90 W

Lights when motor is turning counterclockwise when viewed from output shaft.

Lights when the electromagnetic brake is energized, releasing braking.

Adjust the operating time of electric brake in

response to inertia of the load. For normal braking

operation, minimum setting of 0.2 s will do. Since

a longer braking time will cause the motor to

become hot, shortening its life, the time should

be the minimum possible value. The motor frame

temperature must be kept below 90 ℃.

To increase the braking

torque, turn the knob CW.

For a motor sized between

40 W and 90 W, adjust the

torque within the range

indicated by the black arrow.

Setting beyond the limit will

cause malfunctioning or

shorten the life of product.

69.2 14.5

Round pin

□44.5

[Unit: mm]

Wiring diagram

(for reversible motor)

■ The thick solid lines represent main circuit. Use conductor of size 0.5 mm

larger for the main circuit.

■ The thin solid lines represent signal circuit. Use conductor of size 0.3 mm

larger in the signal line circuit.

Power supply

100 V system: single-phase 100-120 VAC

200 V system: single-phase 200-230 VAC

Molded case circuit breaker

(MCCB): 5 A

<Caution>

Be sure to connect

ground-fault circuit

interrupter to the

power supply.

Noise filter

(optional)

Surge absorber

(optional)

Be sure to ground the return circuit to the earth terminal:

should be class D earthing

100 Ω or less, (1.6 mm or more)

Capacitor cap

Compatible with Japanese standards:

optional

Compatible with international standards:

supplied with the motor

Capacitor

(supplied with the motor)

For wiring connection to

the capacitor, refer to the

motor instruction manual

Power switch

Be sure to ground the return circuit to the earth terminal:

Should be class D earthing

100 Ω or less, (1.6 mm or larger.)

Tightening torque: 1.2 N∙m to 1.5 N∙m

(To be installed by the customer)

Terminal block

(sold separately)

Brake unit

Motor (sold separately)

2

or

2

or

For wiring connections

to the controller,

see P.8 to P.12.

8

7

6

5

11

1

10

(Black)

(Gray)

(White)

2

Options

SUP-EK5-ER-6:

Okaya Electric Industries Co., Ltd.

7.0

2.0

Circuit diagram

IN OUT

①

②

(DV0P4170)

100.0±2.0

88.0

75.0

Marking

(label)

2−ø4.5×6.75

L L

R

Cy

Cx Cx

Cy

5.0

12.0

10.0

2−ø4.5

50.0

60.0

Recommended parts

(ATC180041)

40

70

■

11P cap

(ATA4861)

34.6

ø30

⑧⑦ ⑥ ⑤

⑩⑪ ① ②

30.5

50

[Unit: mm]

ø31.4

[Unit: mm]

Before using the product

R∙A∙V-781BWZ-4:

Okaya Electric Industries Co., Ltd.

Terminal cover (clear)

53.1±1.0

(11.6)

6-M4

(13.0)

[Unit: mm]

③

④

(Panasonic Industrial Devices SUNX Co., Ltd.)

(AQM4801)

④

③⑨

• Use these parts when product is recessed in the panel.

Mounting hole machining drawing

+0.6

0

45

ø4.2±0.2

Circuit diagram

Machining hole

dimension

+0.6

45

0

R1 max.

(DV0P4190)

11±1

5.5±1

28.5±1

+30

−0

200

28±1

41±1

①

(ATA4811)

Machining hole pitch

for serial mounting

+0.6

45

0

+0.6

0

80 min.

45

②

UL-1015

AWG16

80 min.

[Unit: mm]

4.5±0.5

[Unit: mm]

−6−−5− −7− −8−

Installation location

●

Avoid the following locations:

・ Place where the product will be exposed to direct sun light for a long time

(e.g. outdoor).

・ Place where the product will be subjected to excessive vibration or shock

(5.9 m/s

2

or more).

・ Place where the product will be exposed to nonnegligible amount of dust

and humidity.

・

Place where the product will be exposed to ammable gas or corrosive gas.

・ Place where large amount of static electricity will generate (near forming,

powdering or uid processing facilities).

・ Place where the product is exposed to high electrical eld (near radio

transmitting device or welder). Provide appropriate shield as necessary.

●

When unauthorized person can access the unit, install it in a lockable control

board.

●

When the unit is installed in the control board, do not place ammable

material near the unit.

Considerations for wiring

●

Use a terminal block or socket for wiring connection. Do not solder the lead

to the round pin.

●

When wiring or connecting the unit to the terminal block or socket, turn off power.

●

The brake unit is not provided with a protective device: Use overcurrent

protection device, ground-fault circuit interrupter, and overtemperature

protecting device.

●

Wrong wiring will damage the brake unit or cause motor burnout.

●

Do not run cables and wirings of the unit in the same or in parallel with those

of high capacity electric furnace or welder which controlled by the thyristor,

or any other high- power/frequency equipment. Induced noise voltages will

cause malfunction.

●

In buildings (e.g. mountain lodge and plastic greenhouse) and locations

where lightning often hits, connect the surge absorber to the secondary

circuit of master circuit of the power distribution board.

Example of surge absorber: R∙A∙V-781BWZ-4, Okaya Electric Industries Co., Ltd.

(Panasonic optional part number: DV0P4190)

●

Because the unit is controlled by the thyristor, it may induce electric noise to

the radio receiver and wireless equipment. If this is the case, use a noise lter.

Example of noise lter: SUP-EK5-ER-6, Okaya Electric Industries Co., Ltd.

(Panasonic optional part number: DV0P4170)

●

When the electromagnetic contactor or electromagnetic switch is used,

connect voltage-surge suppressor e.g. spark killer across contacts.

Considerations on power supply

●

Be sure to turn off power when it will not be used for a long period.

●

When using a transformer or variable transformer, its capacity must be larger

than the rated power input of the product, to assure reliable operation.

Operating precautions

●

The motor housing temperature must be kept below 90 ℃. The motor frame

temperature depends on ambient temperature, loading condition and start/

stop cycles. When the frame temperature exceeds 90 ℃, replace the motor

with a larger size motor. (Measure the motor frame temperature by using

thermometer, thermocouple, thermo-tape, etc.)

●

The number of start/stop operations should be 6 times/min or less.

●

One brake unit must be connected to only one motor.

Considerations on chemical, oil and water

●

Do not use the product in atmosphere containing organic solvents such as

alcohol, benzin and thinner; oils such as cutting oil and grease; or strong

alkaline materials such as ammonia and caustic soda.

●

Prevent intrusion of water or oil. The product is not waterproof.

●

Do not operate the unit with bare hands.

For proper use

■ Signal input terminal equivalent circuit

Internal circuit

2 kΩ

2 kΩ

MAX 40 mA

2 kΩ

Pin No.6: CW rotation input

Pin No.7: CCW rotation input

Pin No.8: Input to select electrical

brake for stop (E_BRAKE)

Pin No.4: Input to release electromagnetic

brake (M_BRAKE RELEASE)

Page 2

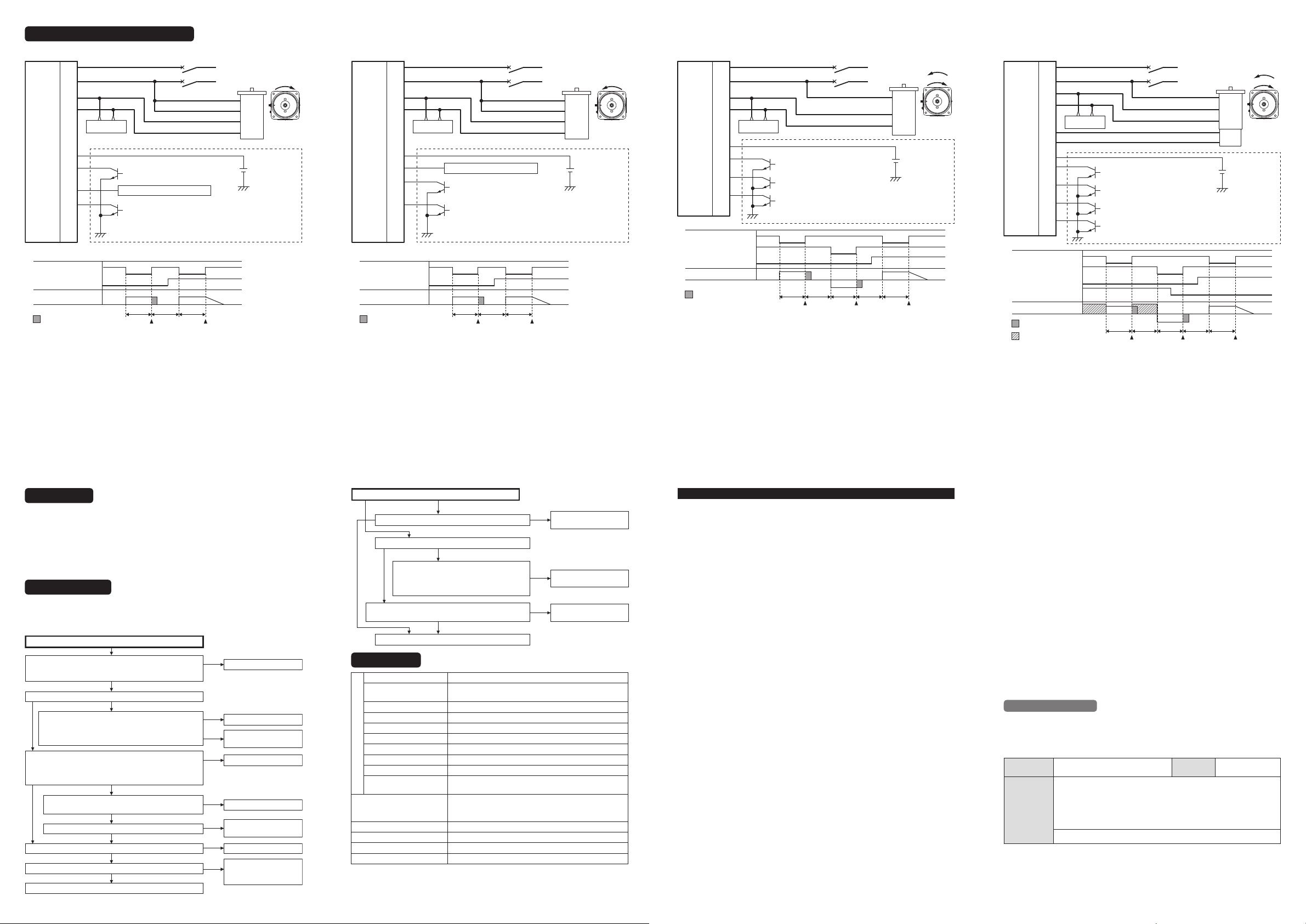

Standard electrical wiring diagram

Induction motor (compatible with Japanese standards) CW rotation

10

2

1

MCCB

11

Capacitor

Brake

unit

5

6

7

8

CW

Pin No.7 is not connected

E_BRAKE

ON : CW rotation

OFF : Stop

Electrical brake is applied to stop

ON :

OFF :

No electrical brake is applied to stop

Pin No.

CW input signal

E_BRAKE input signal

Operation

: Operation of electrical brake

ON ON

ON

Run Stop Run

Braking

Notes:

1. The thick solid lines represent main circuit. Use conductor of size 0.5 mm

larger for the main circuit.

2. Leave pins 3, 4, 7 and 9 unconnected.

(These pins are not isolated from the internal circuit.)

3. According to this wiring diagram, the motor rotates clockwise (CW) when

viewed from the end of shaft.

Note that output shaft of the gear head may rotate CCW.

4. The CW lamp lights while the motor is running.

CWCW

Free running

Apply

rated voltage

White

Brown

Motor

Gray

Black

80 mA or more

at DC24 V

Control

(

power supply

CW

2

or

Induction motor (compatible with Japanese standards) CCW rotation

10

2

1

MCCB

11

Capacitor

Brake

unit

5

6

)

7

8

Pin No.6 is not connected

CCW

E_BRAKE

ON : CCW rotation

OFF : Stop

ON :

Electrical brake is applied to stop

OFF :

No electrical brake is applied to stop

Pin No.

CCW input signal

E_BRAKE input signal

Operation

: Operation of electrical brake

ON ON

ON

Run Stop Run

Braking

CCWCCW

Free running

Notes:

1. The thick solid lines represent main circuit. Use conductor of size 0.5 mm

larger for the main circuit.

2. Leave pins 3, 4, 6 and 9 unconnected.

(These pins are not isolated from the internal circuit.)

3. According to this wiring diagram, the motor rotates counterclockwise (CCW)

when viewed from the end of shaft.

Note that output shaft of the gear head may rotate CW.

4. The CCW lamp lights while the motor is running.

Apply

rated voltage

White

Gray

Motor

Black

Brown

CCW

80 mA or more

at DC24 V

Control

(

power supply

2

or

)

Induction motor (compatible with international standards) Reversible motor

Brake

unit

10

2

1

MCCB

11

Capacitor

5

6

7

8

CW

CCW

E_BRAKE

ON : CW rotation

OFF : Stop

ON : CCW rotation

OFF : Stop

Electrical brake is applied to stop

ON :

OFF :

No electrical brake is applied to stop

Apply

rated voltage

White

Gray

Motor

Black

Pin No.

CW input signal

CCW input signal

E_BRAKE input signal

Operation

: Operation of electrical brake

Notes:

1. The thick solid lines represent main circuit. Use conductor of size 0.5 mm

larger for the main circuit.

2. Do not input CW rotation signal and CCW rotation signal at the same time.

Otherwise, both signals cause application of excessive power to the motor to

burn out.

3. Do not input rotating direction change signal or the operation instruction while

the electrical brake is being applied.

4. Leave the pins 3, 4 and 9 unconnected.

(These pins are not isolated from the internal circuit)

5. For the purpose of this diagram, CW and CCW refer to direction of the motor

rotation when viewed it from the motor shaft end.

Note that output shaft of the gear head may turn in opposite direction.

6. To change the rotating direction of the induction motor, wait until the motor

stops completely.

ON

ON

Run Run StopStop Run

Braking

ON

CCW

Braking Free running

ON

CWCW

CCW

CW

80 mA or more

at DC24 V

Control

(

power supply

2

or

)

Single-phase motor with electromagnetic brake

10

2

1

MCCB

11

Capacitor

3

Brake

Notes:

1. The thick solid lines represent main circuit. Use conductor of size 0.5 mm

2. Do not input CW rotation signal and CCW rotation signal at the same time.

Otherwise, both signals cause application of excessive power to the motor to

3. Do not input rotating direction change signal or the operation instruction while

4. For the purpose of this diagram, CW and CCW refer to direction of the motor

Note that output shaft of the gear head may turn in opposite direction.

9

unit

5

6

7

8

4

Pin No.

CW input signal

CCW input signal

E_BRAKE input signal

M_BRAKE REREASE

input signal

Operation

: Operation of electrical brake

Operation of

:

electromagnetic brake

CW

CCW

E_BRAKE

M_BRAKE

RELEASE

ON : CW rotation

OFF : Stop

ON : CCW rotation

OFF : Stop

ON :

OFF :

ON :

OFF :

operation

ON

ON

Run Run StopStop Run

Braking Braking Free running

larger for the main circuit.

burn out.

the electrical brake is being applied.

rotation when viewed it from the motor shaft end.

Apply

rated voltage

CCW

CW

White

Gray

Motor

Black

Yellow

Yellow

Electrical brake is applied to stop

No electrical brake is applied to stop

Electromagnetic brake forced release

Electromagnetic brake release during

ON

CCW

Electromagnetic

brake

80 mA or more

at DC24 V

Control

(

power supply

ON

ON

CWCW

2

or

)

−10−−9− −12−−11−

Maintenance

To prevent unpredictable malfunction due to effects of operating environment

(temperature, humidity, dust, vibration, etc.) and aging of parts, periodical checking

procedure as described below is necessary to assure safe and reliable operation.

1. Check for smooth operation

2. Check the motor for abnormal noise

3. Check motor temperature

4. Replace part that has been used for specied period. Standard life

expectancy of the parts is 5 years (not the guaranteed life).

Troubleshooting

If a problem occurs with your system, use the following procedure for locating and

removing the cause.

In the event the problem cannot be isolated or the unit is suspected, or if you

have any questions, please contact us or your local agency.

Motor won't run

Specified voltage is fed

Measuring terminals: across Pin No.2 and Pin No.10

for power supply voltage

YES

Specified control voltage is applied

Or the polarity is correct

Measuring terminals: across Pin No.5 and Pin No.6 (or 7)

for DC24 V (Pin No.5:+)

Correct voltages are output

Measuring terminals: for CW rotation, across pin Pin No.2

and Pin No.1 for power supply voltage for CCW rotation,

across Pin No.2 and Pin No.11 for power supply voltage

YES Other YES Motor with electromagnetic brake

CW/CCW lamp is lit

While CW or CCW lamp is lighting,

M_BRAKE RELEASE lamp is lit

Electromagnetic brake operates normally

Motor capacitor is correctly connected

Motor or capacitor is defective

YES

NO

YES

YES

YES

Load is too high

NO

NO

Check wiring

YES

Brake unit is defective

NO

Check wiring. Check

capacity of power supply

NO

Brake unit is defective

NO

Brake unit is defective

NO

Electromagnetic brake

is defective

NO

Check wiring

Reduce the load or

YES

replace the motor with

a larger size

Motor runs without braking

Other

NO

M_BRAKE RELEASE lamp goes off at STOP signal

E_BRAKE lamp goes on at STOP signal

Specified control voltage is applied

Or the polarity is correct

Measuring terminals: across Pin No.5 and

Pin No.8 for DC24 V (Pin No.5:+)

Braking time and braking torque are properly adjusted

as motor capacitance or load varies

Motor with electromagnetic brake

NOYES

YES

Brake unit is faulty

YES

Electromagnetic brake

is defective

NO

Check wiring. Check

capacity of power supply

NO

Adjust braking time

or braking torque

Specication

Rated voltage Single-phase AC100 V to AC230 V

Allowable power

uctuation range

Basic specication

Power supply frequency 50/60 Hz

Control input voltage DC24 V(±10 %)

Off-state voltage DC3 V or higher

Ambient temperature –10 ℃ to +40 ℃ (no freezing)

Ambient humidity 20 % to 85 % RH (no dewing)

Altitude 1000 m or lower

Vibration 5.9 m/s

Storage temperature,

storage humidity

Basic function

Normal temperature

Run/stop, normal/reverse rotation using the same wiring*3,

instantaneous stop with electric brake,

electromagnetic brake control

Braking time setting range Stepless regulation between 0.2 sec and 2.0 sec

Braking torque regulation Stepless regulation

Protection degree IP20 or equivalent

Mass 130

*1: Measured at a point 5 cm from brake unit body.

*2: –20 to +60 ℃ (no freezing) for a short period (a few days) of transportation

*3: Exclude induction motor (compatible with Japanese standards).

−14−−13−

±10 %

2

or below (10 Hz to 60 Hz)

*2

. Normal humidity

g

*1

Cautions for proper use

●

This product is intended to be used with a general industrial product, but not designed

or manufactured to be used in a machine or system that may cause personal death in

case of failure.

●

Install a safety device or apparatus in your application, when a serious accident or loss

of property is expected due to the failure of this product.

●

Consult us if the application of this product is under such special conditions as nuclear

energy control, aerospace, transportation, medical equipment, various safety devices,

equipment requiring high cleanliness or used under radioactive environment.

●

We have been making the best effort to ensure the highest quality of the products.

However, application of exceptionally large external noise disturbance and static

electricity, or failure in input power, wiring and components may result in unexpected

action. It is highly recommended that you make a fail-safe design and secure the safety

in the operative range.

●

Failure of this product depending on its content, may generate smoke of about one

cigarette. Take this into consideration if the machine is used in a clean room.

●

Please be careful when using in an environment with high concentrations of sulphur

or sulphuric gases, as sulphuration can lead to opening of the chip resistor or a poor

contact connection.

●

Take care to avoid inputting a supply voltage which signicantly exceeds the rated

range to the power supply of this product. Failure to heed this caution may result in

damage to the internal parts, causing smoking and/or a re and other trouble.

●

The user is responsible for checking compatibilities of the unit with the equipment to

which it is to be installed and associated parts, in various aspects such as conguration,

dimensions, characteristics, life expectancy and regulations.

−15−

Technical information

●

Technical information of this product (Instruction Manual, CAD data) can be

downloaded from the following web site.

http://industrial.panasonic.com/ww/i_e/25000/motor_fa_e/motor_fa_e.html

MEMO (Fill in the blanks for reference in case of inquiry or repair.)

Date of

purchase

Model No.

DVMB48XZ

Dealer

Tel: ( ) −

Panasonic Corporation, Appliances Company,

Motor Business Division

7-1-1 Morofuku, Daito, Osaka, 574-0044, Japan Phone : +81-72-871-1212

© Panasonic Corporation 2014

Printed in China

IME79

P0414-0

Loading...

Loading...