Page 1

ORDER NO. DSC1002017CE

Digital Camera

Model No. DMC-F3P

DMC-F3PC

DMC-F3PR

DMC-F3PU

DMC-F3EB

DMC-F3EE

DMC-F3EF

B26

DMC-F3EG

DMC-F3EP

DMC-F3GC

DMC-F3GF

DMC-F3GN

DMC-F3GT

DMC-F4EB

DMC-F4EE

DMC-F4EG

DMC-F4EP

Colour

[ DMC-F3 ]

(S)...........Silver Type (except PC/EF/GT)

(K)...........Black Type

(P)...........Pink Type (except PC)

[ DMC-F4 ]

(S)...........Silver Type (only EE)

(K)...........Black Type (except EE)

© Panasonic Corporation 2010 Unauthorized copying and distribution is a violation of law.

Page 2

TABLE OF CONTENTS

PAGE PAGE

1 Safety Precautions -----------------------------------------------3

1.1. General Guidelines ----------------------------------------3

1.2. Leakage Current Cold Check ---------------------------3

1.3. Leakage Current Hot Check (See Figure 1.)--------3

1.4. How to Discharge the Capacitor on Flash

P.C.B.----------------------------------------------------------4

2Warning--------------------------------------------------------------5

2.1. Prevention of Electrostatic Discharge (ESD)

to Electrostatically Sensitive (ES) Devices ----------5

2.2. How to Recycle the Lithium Ion Battery (U.S.

Only)-----------------------------------------------------------5

2.3. Caution for AC Cord(For EB/GC) ----------------------6

2.4. How to dispose the Lithium Battery -------------------7

3 Service Navigation------------------------------------------------8

3.1. Introduction --------------------------------------------------8

3.2. General Description About Lead Free Solder

(PbF) ----------------------------------------------------------8

3.3. Important Notice 1:-----------------------------------------9

3.4. How to Define the Model Suffix (NTSC or PAL

model)-------------------------------------------------------10

4 Specifications----------------------------------------------------16

5 Location of Controls and Components------------------17

6 Service Fixture & Tools---------------------------------------19

6.1. Service Fixture and Tools------------------------------19

7 Disassembly and Assembly Instructions---------------21

7.1. Disassembly Flow Chart--------------------------------21

7.2. PCB Location----------------------------------------------21

7.3. Disassembly Procedure--------------------------------22

8 Measurements and Adjustments --------------------------27

8.1. Introduction ------------------------------------------------27

8.2. Matrix chart (Replaced part and Adjustment

item) ---------------------------------------------------------27

8.3. Execute the Adjustment software

“DscCalDi.exe”.-------------------------------------------28

8.4. Adjustment procedures---------------------------------29

9 Maintenance ------------------------------------------------------38

9.1. Cleaning Lens and LCD Panel -----------------------38

10 Block Diagram ---------------------------------------------------39

10.1. Overall Block Diagram----------------------------------39

11 Wiring Connection Diagram---------------------------------40

12 Printed Circuit Board ------------------------------------------41

12.1. Fuse location on MAIN P.C.B. ------------------------41

2

Page 3

1 Safety Precautions

1.1. General Guidelines

1. IMPORTANT SAFETY NOTICE

There are special components used in this equipment

which are important for safety. These p art s are marked by

in the Schematic Diagrams, Circuit Board Layout,

Exploded Views and Replacement Parts List. It is essential that these critical parts should be replaced with manufacturer’s specified parts to prevent X-RADIATION,

shock, fire, or other hazards. Do not modify the original

design without permission of manufacturer.

2. An Isolation Transformer should always be used during

the servicing of AC Adaptor whose chassis is not isolated

from the AC power line. Use a transformer of adequate

power rating as this protects the technician from accidents resulting in personal injury from electrical shocks. It

will also protect AC Adaptor from being damaged by accidental shorting that may occur during servicing.

3. When servicing, observe the original lead dress. If a short

circuit is found, replace all parts which have been overheated or damaged by the short circuit.

4. After servicing, see to it that all the protective devices

such as insulation barriers, insulation papers shields are

properly installed.

5. After servicing, make the following leakage current

checks to prevent the customer from being exposed to

shock hazards.

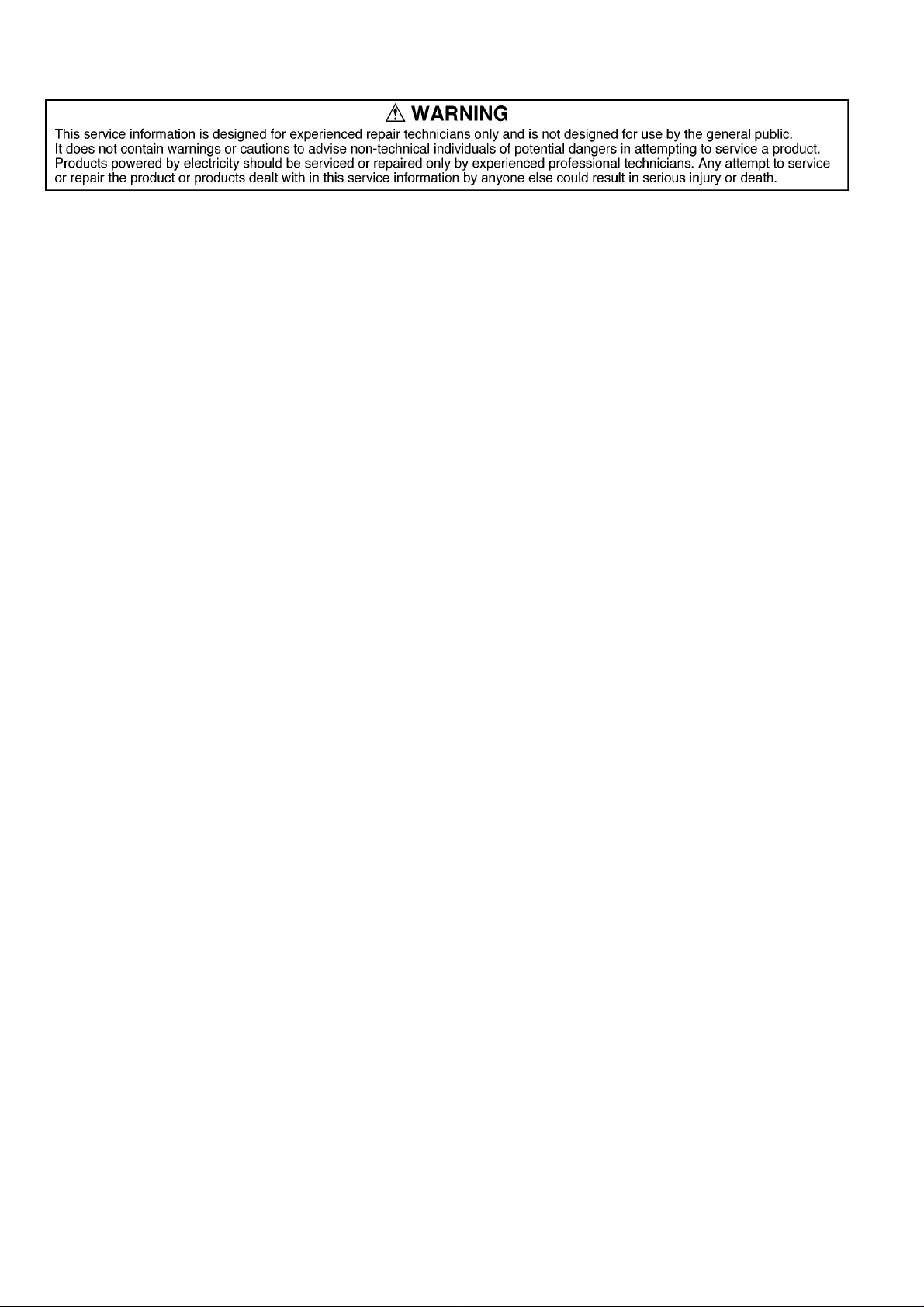

1.3. Leakage Current Hot Check

(See Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer for this check.

2. Connect a 1.5 kΩ, 10 W resistor, in parallel with a 0.15 μF

capacitor, between each exposed metallic part on the set

and a good earth ground, as shown in Figure 1.

3. Use an AC voltmeter, with 1 kΩ/V or more sensitivity, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed 0.75 V RMS.

A leakage current tester (Simpson Model 229 or equivalent) may be used to make the hot checks, leakage current must not exceed 1/2 mA. In case a measurement is

outside of the limits specified, there is a possibility of a

shock hazard, and the equipment should be repaired and

rechecked before it is returned to the customer.

1.2. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed metallic cabinet part on the equipment such as screwheads,

connectors, control shafts, etc. When the exposed metallic part has a return path to the chassis, the reading

should be between 1 MΩ and 5.2 MΩ. When the exposed

metal does not have a return path to the chassis, the

reading must be infinity.

Figure. 1

3

Page 4

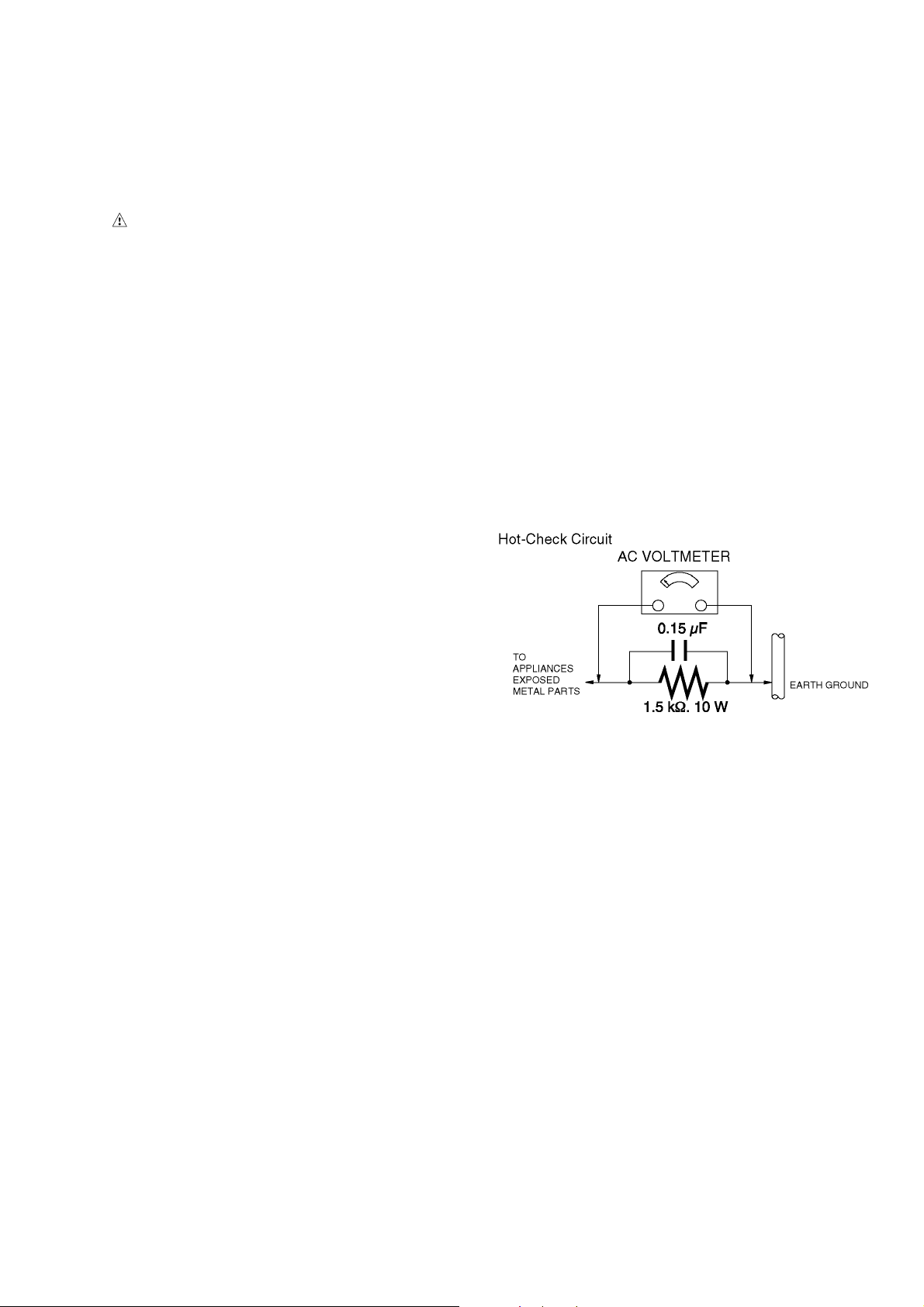

1.4. How to Discharge the Capacitor on Flash P.C.B.

CAUTION:

1. Make sure to discharge the capacitor on FLASH P.C.B..

2. Be careful of the high voltage circuit on FLASH P.C.B. when servicing.

[Discharging Procedure]

1. Refer to the disassemble procedure and remove the necessary parts/unit.

2. Install the insulation tube onto the lead part of resistor (ERG5SJ102:1kΩ /5W).

(an equivalent type of resistor may be used.)

3. Place a resistor between both terminals of capacitor on the FLASH P.C.B. for approx. 5 seconds.

4. After discharging, confirm that the capacitor voltage is lower than 10V using a voltmeter.

Fig. F1

4

Page 5

2Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatically

Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices.

The following techniques should be used to help reduce the incidence of compon ent damage caused by electrostatic discharge

(ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a condu ctive surface such as al uminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an antistatic solder removal device. Some solder removal devices not classified as "antistatic (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION :

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to damage an ES device).

2.2. How to Recycle the Lithium Ion Battery (U.S. Only)

5

Page 6

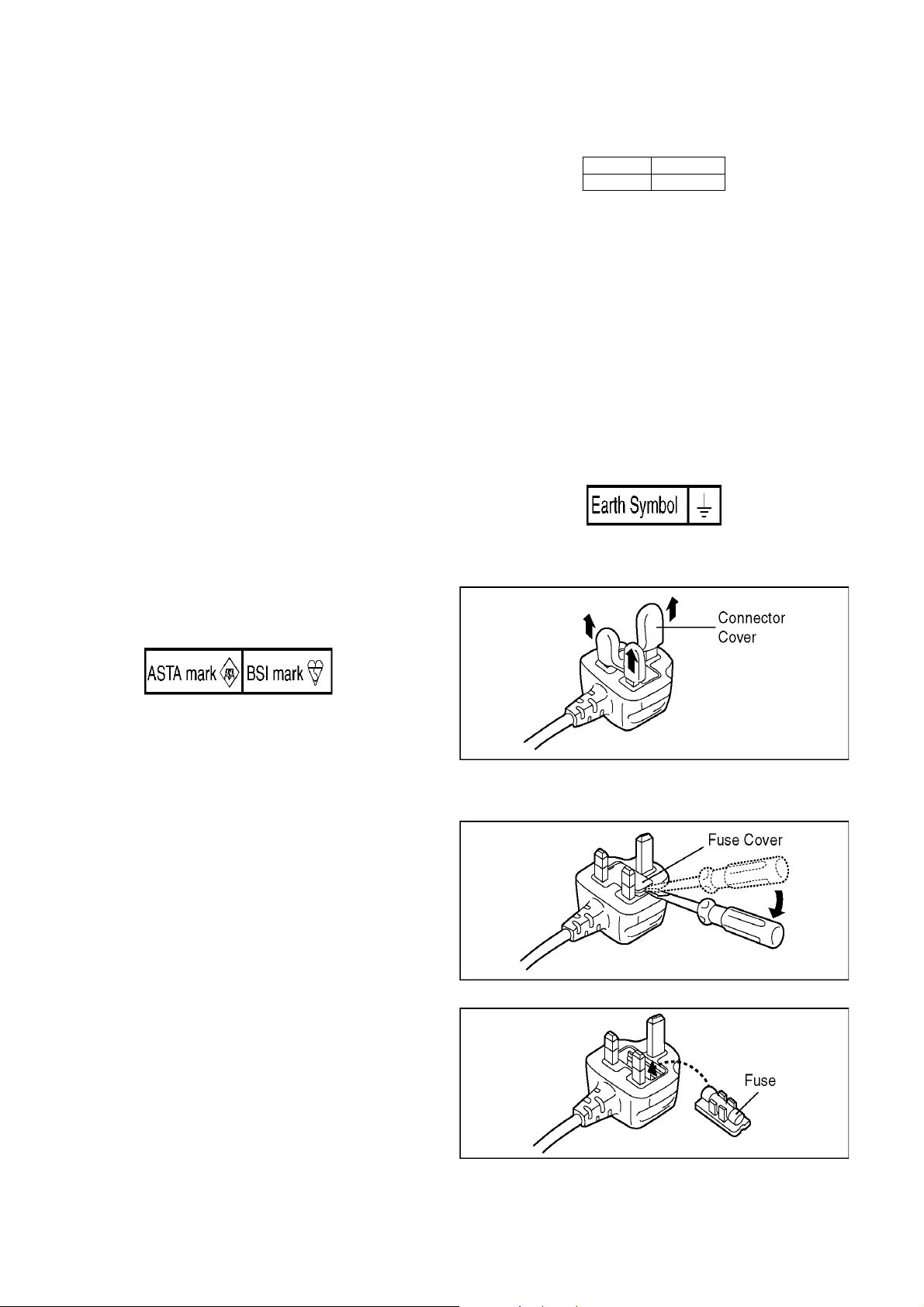

2.3. Caution for AC Cord

(For EB/GC)

2.3.1. Information for Your Safety

IMPORTANT

Your attention is drawn to the fact that recording of prerecorded tapes or discs or other published or broadcast

material may infringe copyright laws.

WARNING

To reduce the risk of fire or shock hazard, do not expose

this equipment to rain or moisture.

CAUTION

To reduce the risk of fire or shock hazard and annoying

interference, use the recommended accessories only.

FOR YOUR SAFETY

DO NOT REMOVE THE OUTER COVER

To prevent electric shock, do not remove the cover. No user

serviceable parts inside. Refer servicing to qualified service

personnel.

2.3.2. Caution for AC Mains Lead

For your safety, please read the following text carefully.

This appliance is supplied with a moulded three-pin mains plug

for your safety and convenience.

A 5-ampere fuse is fitted in this plug.

Should the fuse need to be replaced please ensure that the

replacement fuse has a rating of 5 amperes and it is approved

by ASTA or BSI to BS1362

Check for the ASTA mark or the BSI mark on the body of the

fuse.

2.3.2.1. Important

The wires in this mains lead are coloured in accordance with

the following code:

Blue Neutral

Brown Live

As the colours of the wires in the mains lead of this appliance

may not correspond with the coloured markings i dentifying the

terminals in your plug, proceed as follows:

The wire which is coloured BLUE must be connected to the terminal in the plug which is marked with th e letter N or coloured

BLACK.

The wire which is coloured BROWN must be connected to the

terminal in the plug which is marked with the letter L or coloured

RED.

Under no circumstances should either of these wires be connected to the earth terminal of the three pin plug, marked with

the letter E or the Earth Symbol.

2.3.2.2. Before Use

Remove the Connector Cover as follows.

If the plug contains a removable fuse cover you must ensure

that it is refitted when the fuse is replaced.

If you lose the fuse cover, the plug must not be used until a

replacement cover is obtained.

A replacement fuse cover can be purchased from your local

Panasonic Dealer.

If the fitted moulded plug is unsuitable for the socket outlet in

your home then the fuse should be removed and the plug cut

off and disposed of safety.

There is a danger of severe electrical shock if the cut off plug is

inserted into any 13-ampere socket.

If a new plug is to be fitted please observe the wiring code as

shown below.

If in any doubt, please consult a qualified electrician.

2.3.2.3. How to Replace the Fuse

1. Remove the Fuse Cover with a screwdriver.

2. Replace the fuse and attach the Fuse cover.

6

Page 7

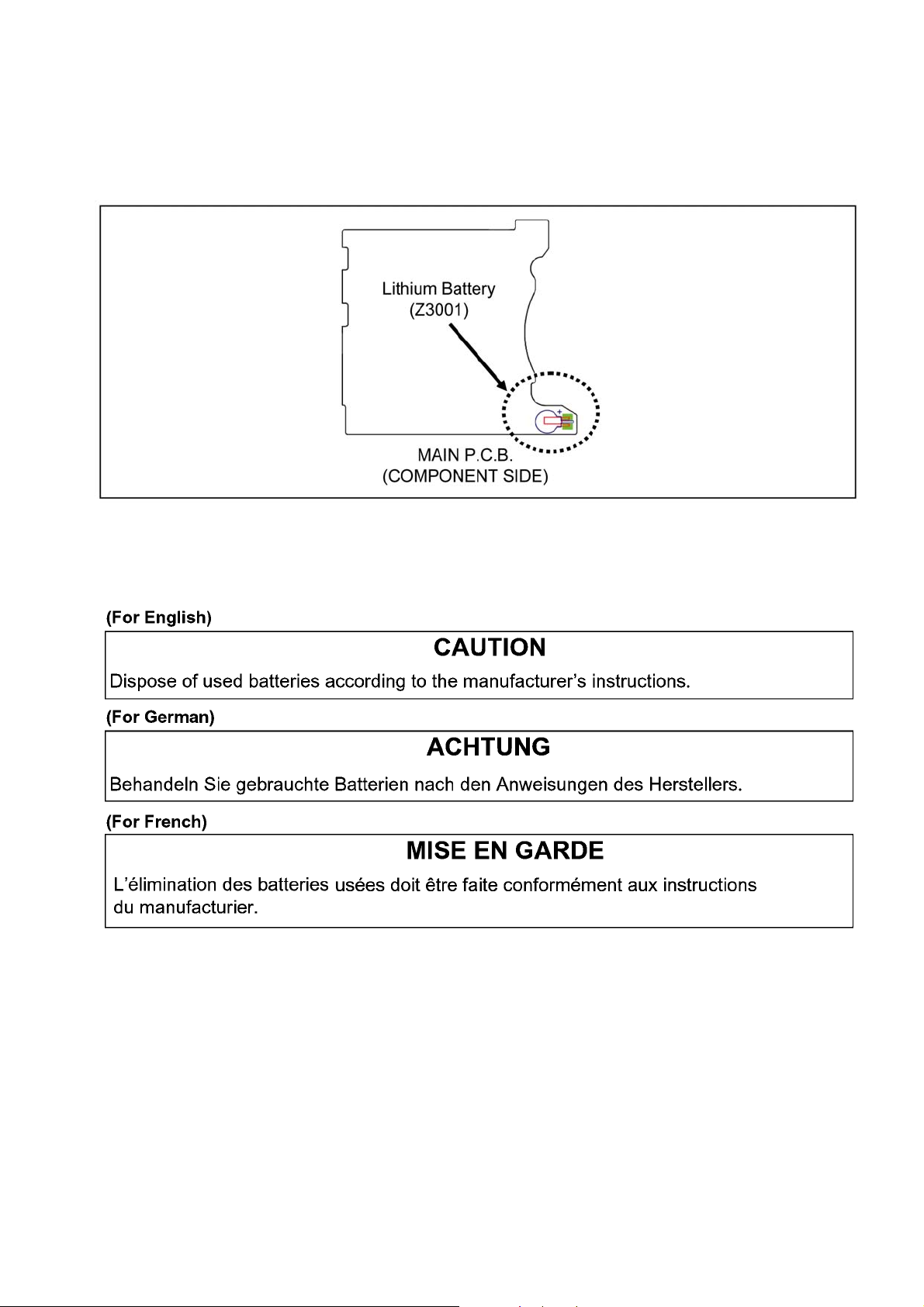

2.4. How to dispose the Lithium Battery

2.4.1. Removal Procedure

1. Remove the Main P.C.B. (Refer to Disassembly Procedures.)

2. Remove the Lithium battery (Ref. No.“Z3001” at component side of Main P.C.B.) and then dispose it.

It should be disposed of in waste products destined for burial rather than incineration.

NOTE:

This Lithium battery is a critical component.

It must never be subjected to excessive heat or discharge.

It should be disposed of in waste products destined for burial rather than incineration.

NOTE:

Above caution is applicable for a battery pack which is for DMC-F3/F4 series, as well.

7

Page 8

3 Service Navigation

3.1. Introduction

This service manual contains technical information, which allow service personnel’s to understand and service this model.

Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, the information will be followed by service manual to be controlled with original service manual.

3.2. General Description About Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical comp onents on the printed circuit boards us ed for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30°C (86°F) more than that of the

normal solder.

Distinction of P.C.B. Lead Free Solder being used

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the P.C.B. using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the P.C.B. cleanly for soldering of the new IC.

• Since the melting point of the lead free solder i s higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30°C

(662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01KS-----------(0.3mm 100g Reel)

RFKZ06D01KS-----------(0.6mm 100g Reel)

RFKZ10D01KS-----------(1.0mm 100g Reel)

Note

* Ingredient: tin (Sn) 96.5%, silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

8

Page 9

3.3. Important Notice 1:

[1.Component on P.C.B.]

1. The P.C.B.’s in this unit is not component replacement excluding following part.

MAIN P.C.B. --------- Fuse (F5001, F5002, F5005, F5006)

FLASH P.C.B. -------- Flash Charging Capacitor(C5412)), Trigger Coil(T5402)

Other than above component on P.C.B.’s are defected, replace each P.C.B. as a unit.

[2.MAIN P.C.B.]

AFTER REPLACING THE MAIN P.C.B.

After replacing the Main P.C.B., follow the following steps in order.

1. Assemble the unit.

Refer to the “7.Disassembly and Assembly Instructions” section.

2. Up date the firmware.

The firmware together with version up procedure are available at “software download” on the “Support Information from

NWBG/VDBG-AVC” web-site in “TSN system”.

3. Perform the adjustment using adjustment software “DscCalDi”.

The adjustment software is available at “software download” on the “Support Information from NWBG/VDBG-AVC” web-site in

“TSN system”.

4. Register the USB storage information.

Refer to the “8.4.6.USB STORAGE INFO. REGISTRATION” in “8.4.Adjustment procedures” section.

5. Set the “model suffix”.

Refer to the “3.4.2.INITIAL SETTINGS:” section.

6. Refresh the unit.

Refer to the “3.4.2.INITIAL SETTINGS:” section.

[3.Lens unit]

1. The Lens unit in this unit is not component replacement.

Other than above part are defected, replace minimumsize of concerned part as a unit.

9

Page 10

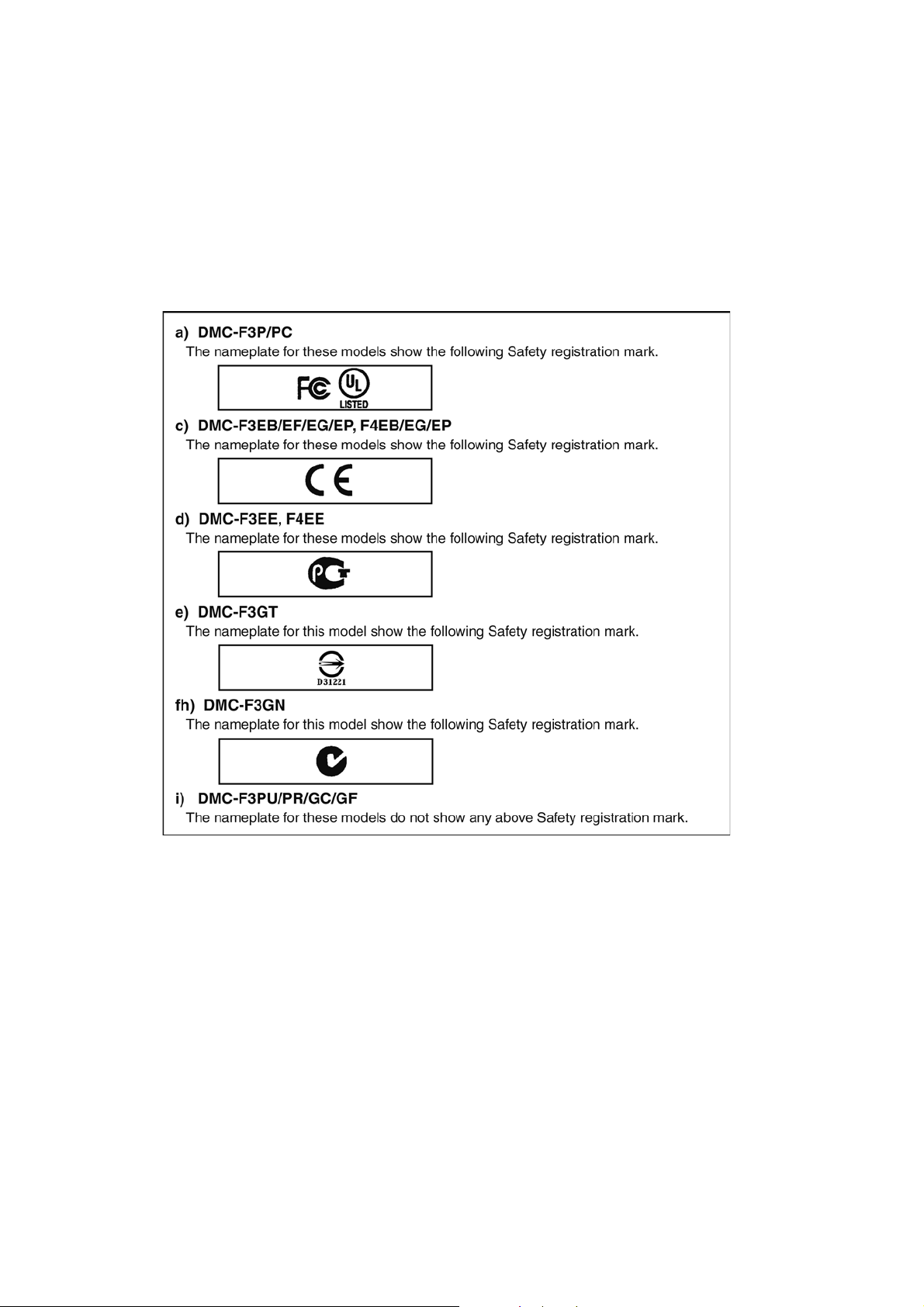

3.4. How to Define the Model Suffix (NTSC or PAL model)

There are six kinds of DMC-F3/F4, regardless of the colours.

• a) DMC-F3P/PC

• b) DMC-F3EB/EF/EG/EP, F4EB/EG/EP

• c) DMC-F3EE, F4EE

• d) DMC-F3GT

• e) DMC-F3GN

• f) DMC-F3PU/PR/GC/GF

What is the difference is that the “INITIAL SETTINGS” data which is stored in Flash-ROM mounted on MAIN P.C.B..

3.4.1. Defining methods:

To define the model suffix to be serviced, refer to the nameplate which is putted on the bottom side of the Unit.

NOTE:

After replacing the MAIN P.C.B., make sure to perform the “firmware version up”, “Initial settings” and “adjustment”.

The firmware & adjustment software is available at “software d ownload” on the “Support Info rmation from NWBG/VDBG-AVC”

web-site in “TSN system”.

10

Page 11

3.4.2. INITIAL SETTINGS:

1. PURPOSE OF INITIAL SETTINGS:

There are two cases to perform the INITIAL SETTINGS.

1. Refresh the unit:The INITIAL SETTINGS can be used to erase all back up data.

(Not only user setting and image data stored in “Built-in Memory”, but also clock data is reset.)

2. After replacing the MAIN P.C.B.:

(Since the model suffix data is not assigned for the MAIN P.C.B. being supplied as spare parts, model suffix has to be

assigned.)

After replacing the MAIN P.C.B., make sure to perform the “firmware version up”, “adjus tment” a nd “Ini ti al setting s ” by o rderi ng

the following procedure in accordance with model suffix of the unit.

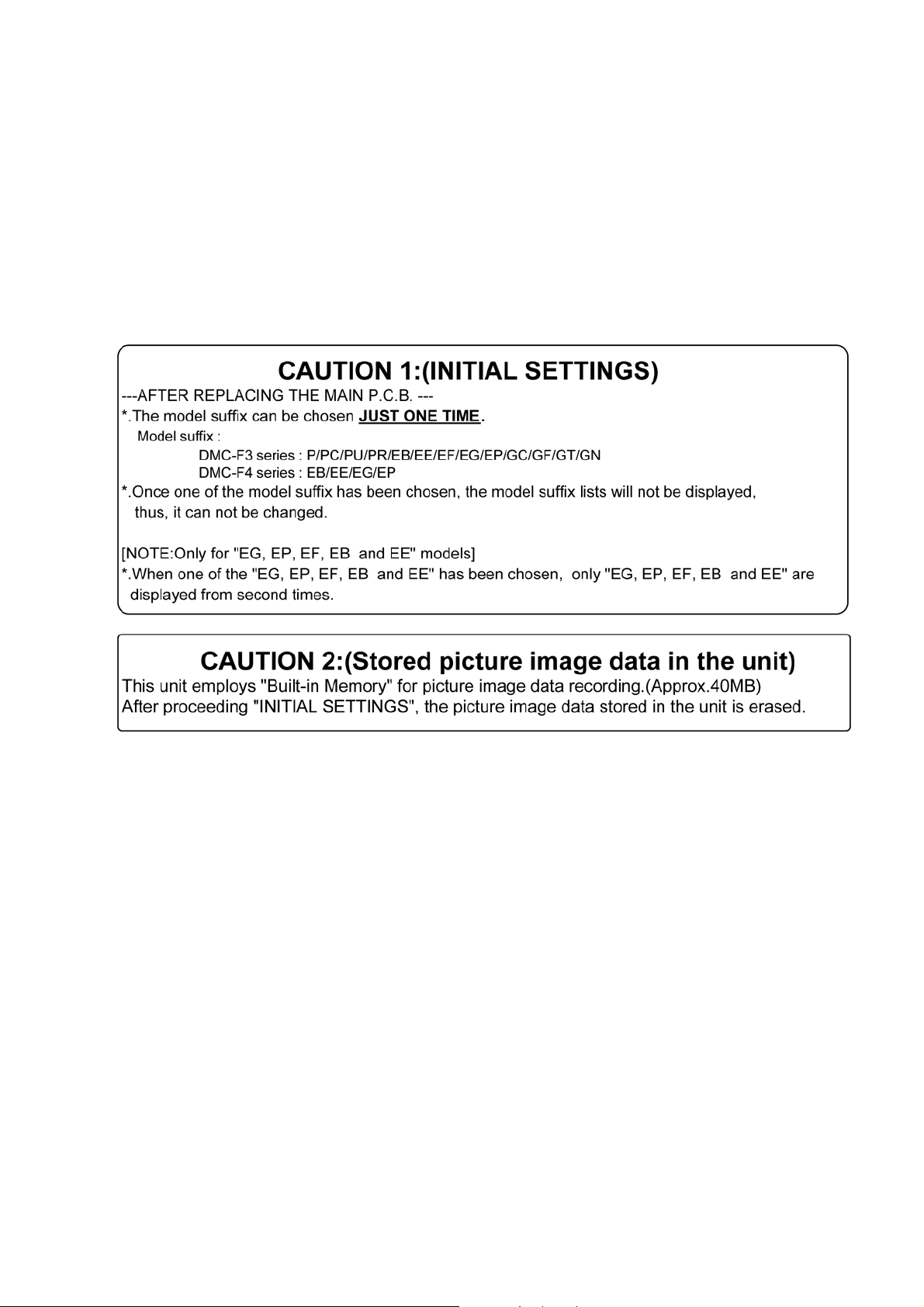

2. IMPORTANT NOTICE:

Before proceeding Initial settings, make sure to read the following CAUTIONS.

3. PROCEDURES:

NOTE:

1. Precautions: Read the above “CAUTION 1” and “CAUTION 2”, carefully.

2. To perform the Initial settings, adjustment software “DscCalDi” is required. The software together with installation instruction is

available at “software download” on the “Support Information from NWBG/VDBG-AVC” web-site in “TSN system”.

Step 1. Preparation:

1. After replacing the MAIN P.C.B., assemble the unit by referring the “7.Disassembly and Assembly Instructions”.

2. Update the firmware of the unit.

The firmware together with version up procedure are available at “software download” on the “Support Information from

NWBG/VDBG-AVC” web-site in “TSN system”.

3. Perform the adjustment using adjustment software “DscCalDi”.

The adjustment software is available at “software download” on the “Support Information from NWBG/VDBG-AVC” web-site in

“TSN system”.

4. Register the USB storage information.

Refer to the “8.4.6.USB STORAGE INFO. REGISTRATION” in “8.4.Adjustment procedures” section.

11

Page 12

Step 2. Setup:

1. Attach the Battery or AC Adaptor with a DC coupler to the unit.

2. Set the [ REC/PLAY ] switch to “REC” mode.

3. Set the recording mode to [ Normal Picture ] mode.

*.Turn on the power switch and then press the “MODE” button.

*.Choose the [ Normal Picture ] mode with cursor buttons, then press the “MENU/SET” button.

*.Turn the power switch to OFF.

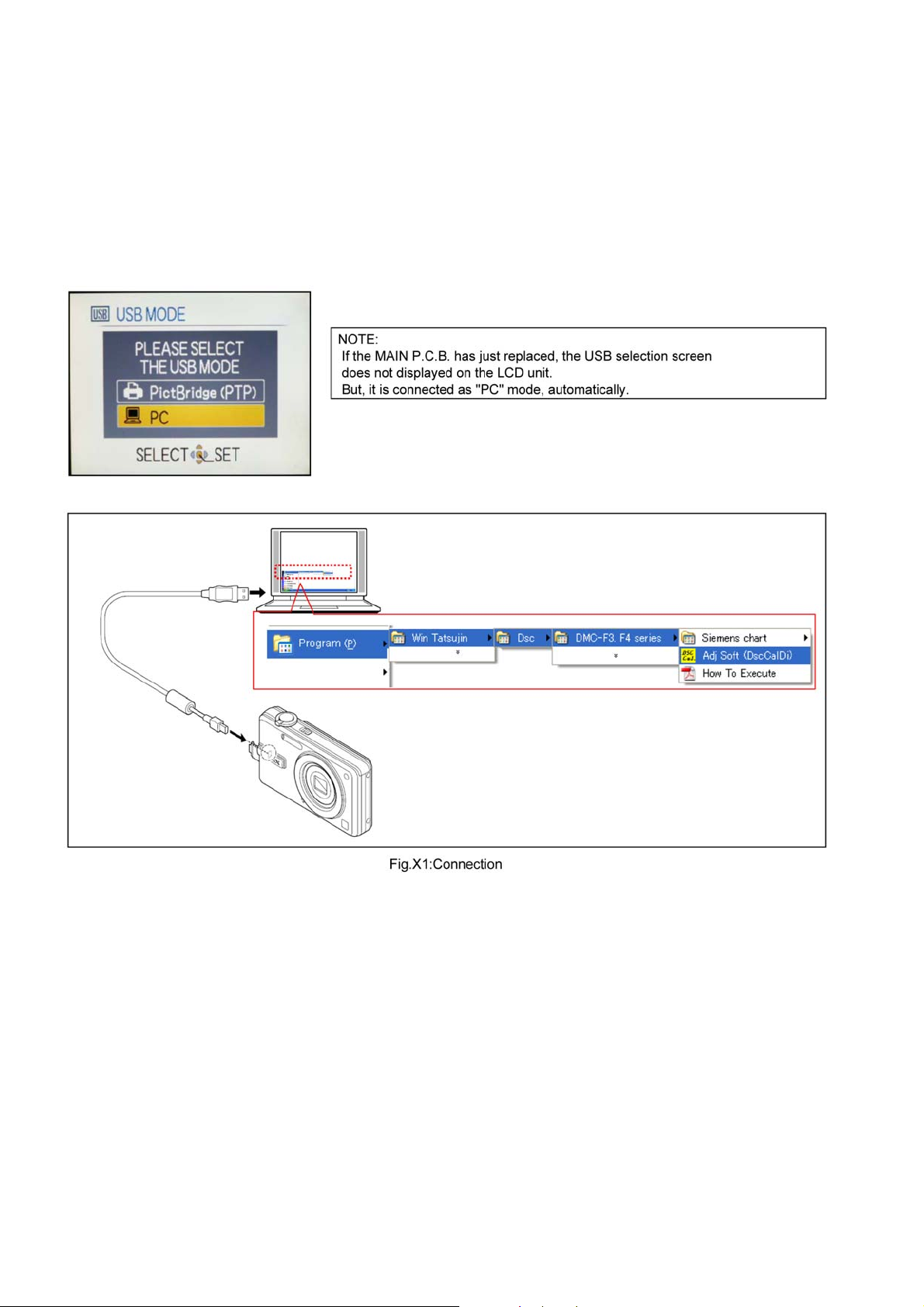

4. Connect the Camera unit and a PC with a USB cable.

5. Turn the power switch to ON.

6. Select the USB mode to “PC” mode, then press the “MENU/SET” button.

(NOTE: Right after replacing the MAIN P.C.B., the USB selection screen does not displayed.)

12

Page 13

Step 3. Execute the software “DscCalDi” :

1. Choose the “Adj Soft (DscCalDi)” and execute the adjustment software.(Refe r to Fig.X1:Connection)

[ “Start” ---> “Program(P)” ---> “Win Tatsujin” ---> “Dsc” ---> “DMC-F3,F4 series” ---> “Adj Soft (DscCalDi)” ]

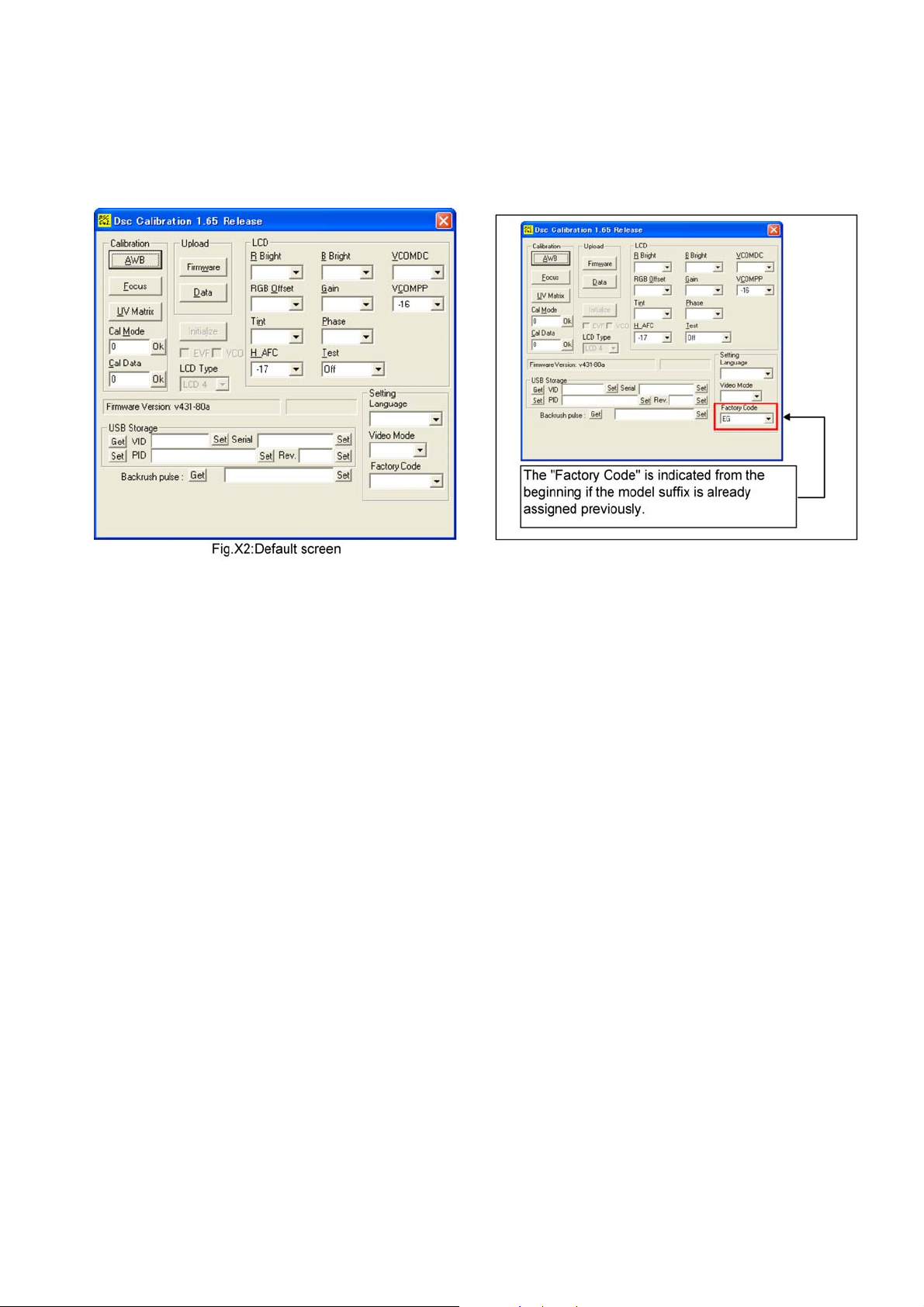

The following main screen is appear on the PC monitor.

NOTE:

Without connecting the USB cable between DSC (USB mode with power on) an d PC, adjustment software does no t executed.

13

Page 14

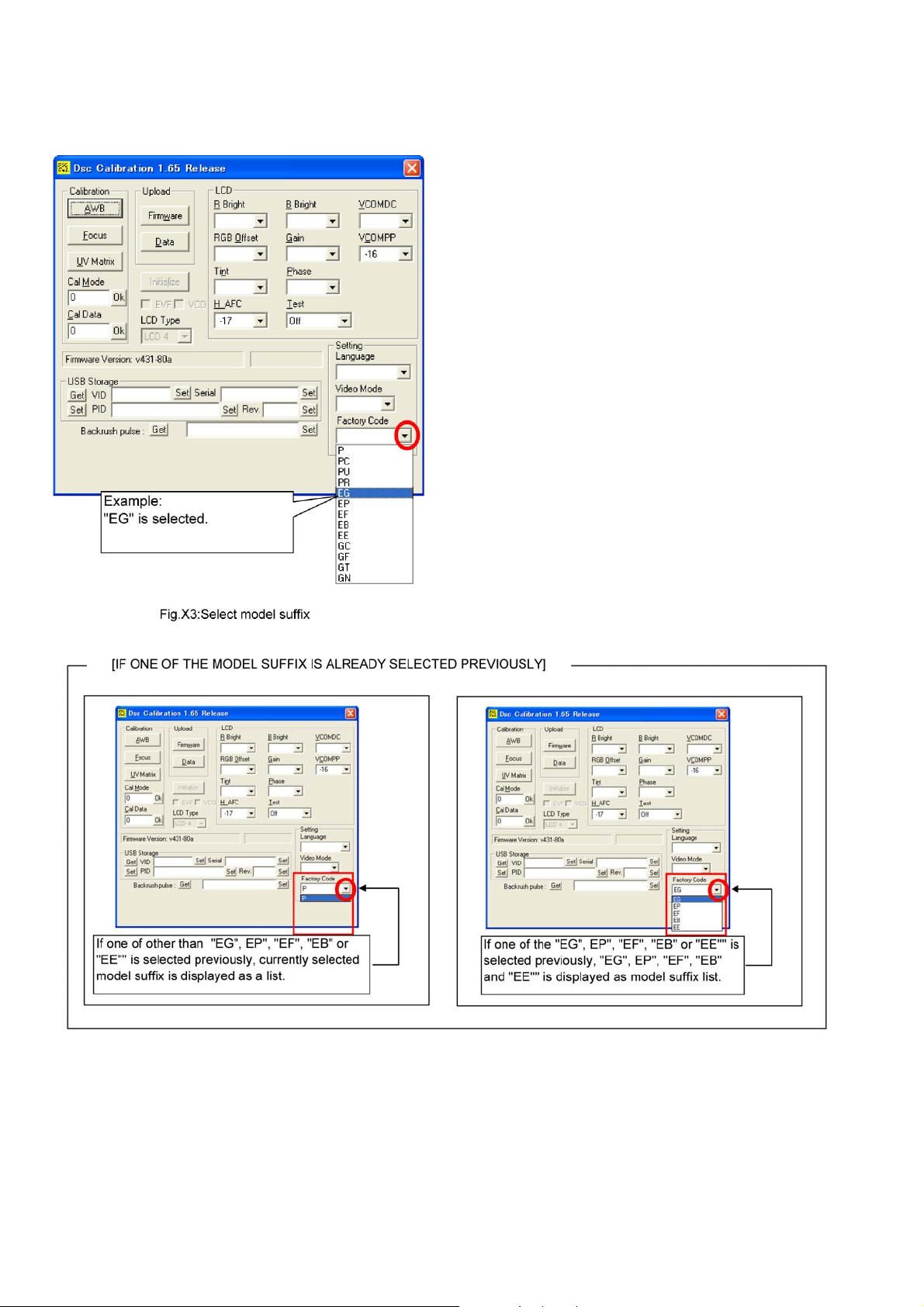

Step 4. Select the Model suffix (Factory Code):

1. Click on the pull down menu tag of the “Factory Code”.

The model suffix list is displayed.

2. Choose the appropriate model suffix.

14

Page 15

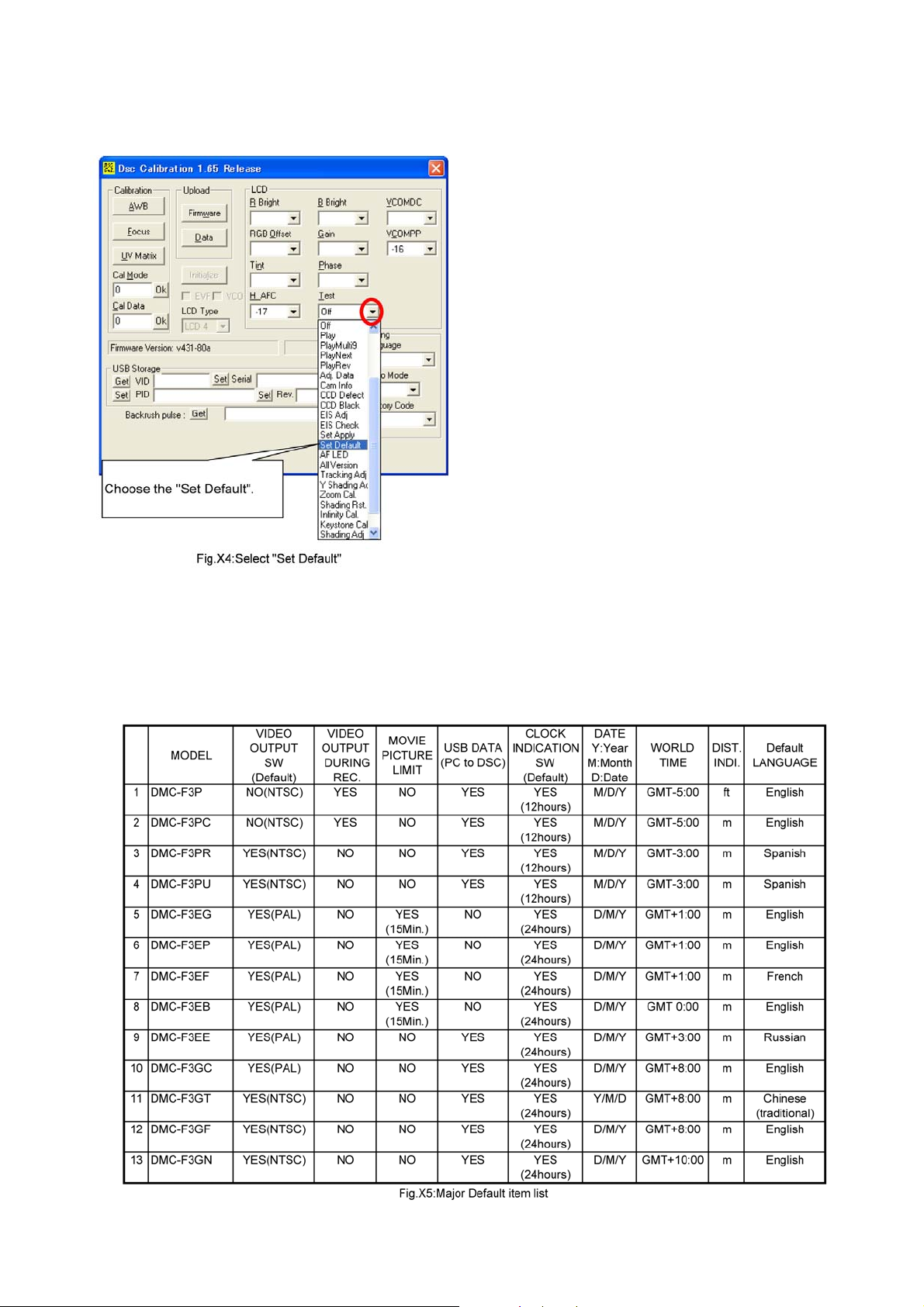

Step 5. Default settings (Test):

1. Click on the pull down menu tag of the “Test”.

(The Test item list is disp layed.)

2. Choose the “Set Default” in order to refresh the unit (Factory shipping condition).

Step 6. CONFIRMATION:

1. Close the “DscCalDi.exe” by clicking on the “X” located on the top right corner.

2. Turn on the camera switch.

3. Disconnect the USB cable and turn “OFF” the power switch of the camera unit.

4. Confirm that the language and Clock set request screen is displayed on the LCD monitor.

Major default setting condition is as shown in the following table.

15

Page 16

4 Specifications

16

Page 17

5 Location of Controls and Components

5

20

2122

18 19

Names of the Components

1Flash

2Lens

3 Self-timer indicator

AF assist lamp

4 Microphone

5 LCD monitor

6 [MENU/SET] button

7 [DISPLAY] button

8 [Q.MENU]/Delete button

9 [MODE] button

10 [REC]/[PLAYBACK] selector switch

11 Cursor buttons

: /Exposure compensation

: /Macro Mode

: /Self-timer button

: /Flash setting button

12 Camera ON/OFF switch

13 Zoom lever

14 Shutter button

15 Hand strap eyelet

Be sure to attach the hand strap when

using the camera to ensure that you will

not drop it.

16 Lens barrel

17 [AV OUT/DIGITAL] socket

123

4

5

9

68

7

1110

12 13

14

1

16

17

18 Speaker

19 Tripod receptacle

When you use a tripod, make sure the

tripod is stable when the camera is

attached to it.

20 Card/Battery door

21 Release lever

22 DC coupler cover

When using an AC adaptor, ensure that

the Panasonic DC coupler and AC adaptor

are used.

We recommend you use a battery with

sufficient battery power or the AC adaptor

when recording motion pictures.

If while recording motion pictures using the

AC adaptor and the power supply is cut off

due to a power outage or if the AC adaptor

is disconnected etc., the motion picture

being recorded will not be recorded.

17

Page 18

Selecting the [REC] Mode

ON

OFF

Turnthecameraon.

[MENU/SET] button

[REC]/[PLAYBACK] selector switch

[MODE] button

Slide the [REC]/[PLAYBACK]

selector switch to [].

Press [MODE].

Press / to select the mode.

Press [MENU/SET].

List of [REC] Modes

Auto Scene Mode

The subjects are recorded using settings automatically selected by the

camera.

Normal Picture Mode

The subjects are recorded using your own settings.

± Scene Mode

This allows you to take pictures that match the scene being recorded.

Motion Picture Mode

This mode allows you to record motion pictures with audio.

Preparation

About the Battery

The camera has a function for distinguishing batteries which can be used safely. The

dedicated battery supports this function. The only batteries suitable for use with this

unit are genuine Panasonic products and batteries manufactured by other companies

and certified by Panasonic. (Batteries which do not support this function cannot be

used.) Panasonic cannot in any way guarantee the quality, performance or safety of

batteries which have been

Panasonic products.

It has been found that counterfeit battery packs which look very similar to the

genuine product are made available to purchase in some markets. Some of these

battery packs are not adequately protected with internal protection to meet the

requirements of appropriate safety standards. There is a possibility that these

battery packs may lead to fire or explosion. Please be advised that we are not

liable for any accident or

battery pack. To ensure that safe products are used we would recommend that a

genuine Panasonic battery pack is used.

manufactured by other companies and are not genuine

failure occurring as a result of use of a counterfeit

18

Page 19

6 Service Fixture & Tools

6.1. Service Fixture and Tools

The following Service Fixture and tools are used for checking and servicing this unit.

19

Page 20

REMARKS

1. ABOUT “Siemens star chart”:

The PDF version of Siemens star chart together adjustment software is available at “software download” on the “Support Information from NWBG/VDBG-AVC” web-site in “TSN system”.

Download its PDF file and print out it, then stick on the suitable panel.

For your convenience, there are two kinds of PDF files are available.; “A3 size”(Full-size) / “Letter size”(Divided into 3 sheets).

If you have A3 size printer, print it out then stick on the suitable panel.

If you have not A3 size printer, print out “Letter size PDF” version, then make a Siemens star chart.

2. ABOUT “LIGHT BOX”:

20

Page 21

7 Disassembly and Assembly Instructions

7.1. Disassembly Flow Chart

This is a disassembling chart.

When assembling, perform this chart conversely.

7.2. PCB Location

21

Page 22

7.3. Disassembly Procedure

No. Item Fig Removal

1 Rear Case Unit (Fig.D1)

(Fig.D2)

2 LCD Unit (Fig.D3)

(Fig.D4)

3Flash P.C.B. &

Lens Unit

4 Front/Top Case Unit (Fig.D8)

5 Main P.C.B. &

Top Operation P.C.B. &

Battery Case Unit

6 CCD Unit (Fig.D12) 3 Screws (L)

(Fig.D5)

(Fig.D6)

(Fig.D7)

(Fig.D9a)

(Fig.D9b)

(Fig.D10)

(Fig.D11) 2 Screws (J)

Card

Battery

4 Screws (A)

1 Screw (B)

Connector (A)

3 Screws (C)

LCD Holder

Connector (B)

Flex Cable

2 Screws (D)

Lens Holder

Connector (C)

Connector (D)

Lens Unit

1 Screw (E)

1 Screw (F)

1 Screw (G)

1 Screw (H)

1 Screw (I)

Jack Door

AF LED P.C.B.

Earth bottom

Earth E.capacitor

Tripod stand

2 Screws (K)

Unsolder

CCD Cushion

Optical Filter

7.3.1. Removal of the Rear Case Unit

(Fig.D2)

(Fig.D1)

22

Page 23

7.3.2. Removal of the LCD Unit

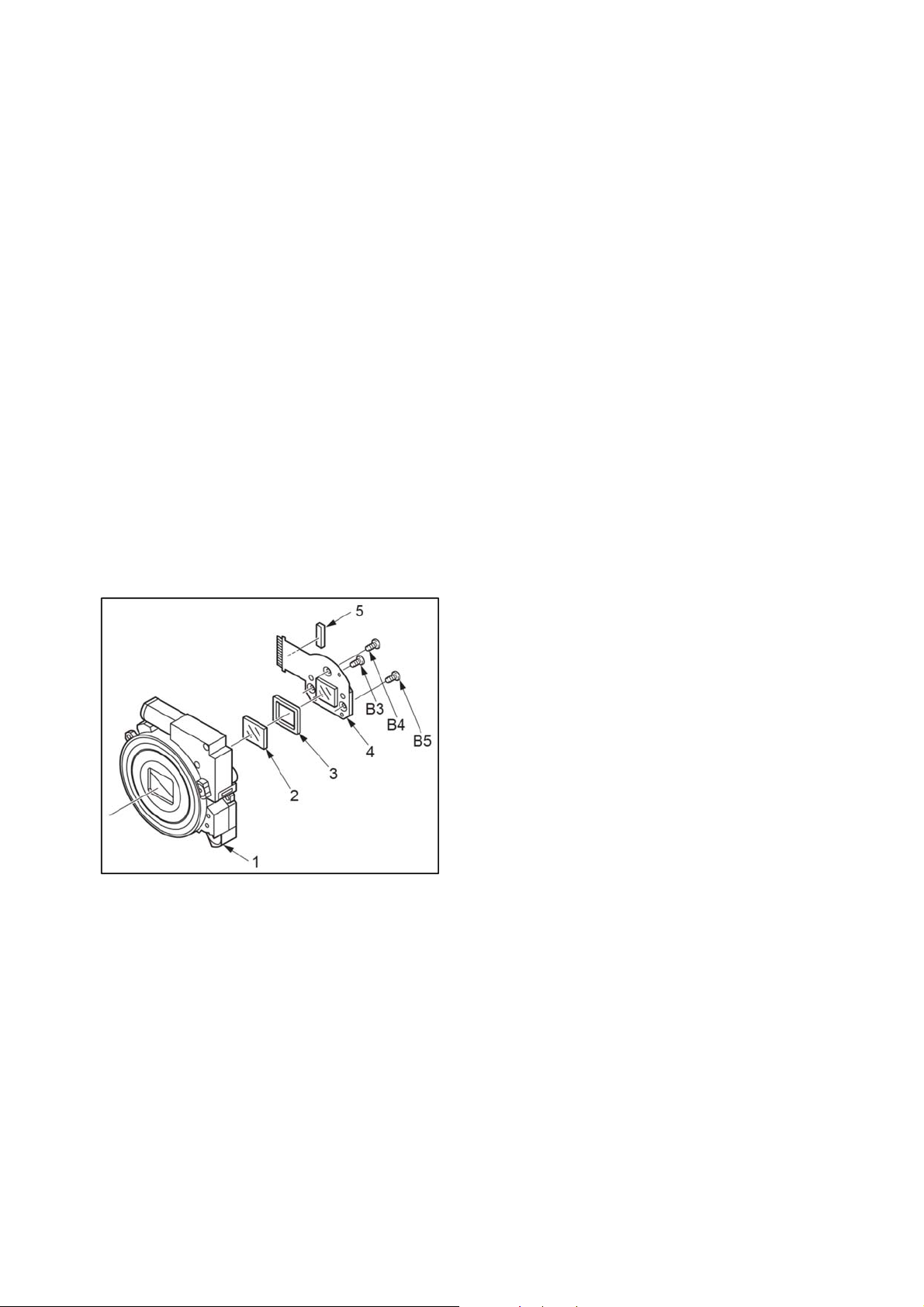

7.3.3. Removal of the Flash P.C.B. & Lens

Unit

(Fig.D3)

(Fig.D4)

(Fig.D5)

(Fig.D6)

23

Page 24

(Fig.D7)

7.3.4. Removal of the Front/Top Case Unit

(Fig.D8)

(Fig.D9a)

24

Page 25

7.3.5. Removal of the Main P.C.B. and Top

Operation P.C.B. & Battery Case

Unit

(Fig.D9b)

(Fig.D10)

(Fig.D11)

25

Page 26

7.3.6. Removal of the CCD Unit

NOTE:

1. Make sure no dust or dirt gets into the lens.

2. To remove dust from the lens, use airbrush.

3. Do not touch the surface of the lens.

4. Use lens cleaning KIT (BK) (VFK1900BK).

NOTE: (When Assembling)

[Definitions of mount side of Optical filter.]

• Put the Optical filter on the white sheet.

• When the "non -coating side is face up condition, it can be

seen as two-layered filter.

• Set the Coating (Green layer) side to lens side.

[Screwing Order]

• When installing the CCD unit to Lens unit with screw, tighten

the screws in the letters order.(A , B, C.)

NOTE: (When Assembling)

Make sure to confirm the following points when assembling:

• The Screw is tightened enough.

• Assembling conditions are fine. (No distortion, no abnormalspace.)

• No dust and/or dirt on Lens surfaces.

• LCD image is fine. (No dust and dirt on it, and no gradient

images.)

(Fig.D12)

26

Page 27

8 Measurements and Adjustments

8.1. Introduction

When servicing this unit, make sure to perform the adjustments necessary based on the part(s) replaced.

To perform the adjustment, it is necessary to use the “DscCalDi” software.

The Adjustment software “DscCalDi” together with its installation instruction are available at “TSN Website”.

To download, click on “Support Information from NWBG/VDBG-AVC”.

8.2. Matrix chart (Replaced part and Adjustment item)

The following matrix table shows the relation between the replaced part and the necessary adjustment.

When a part is replaced, make sure to perform the necessary adjustment(s) in the order indicated.

27

Page 28

8.3. Execute the Adjustment software “DscCalDi.exe”.

Step 1.Preparation:

1. Attach the Battery or AC Adaptor with a DC coupler to the unit.

2. Set the [ REC/PLAY ] switch to “REC” mode.

3. Set the recording mode to [ Normal Picture ] mode.

• Turn on the power switch and then press the “MODE” button.

• Choose the [ Normal Picture ] mode with cursor buttons, then press the “MENU/SET” button.

• Turn the power switch to OFF.

4. Connect the Camera unit and a PC with a USB cable.

5. Turn the power switch to ON.

6. Select the USB mode to “PC” mode, then press the “MENU/SET” button.

(NOTE: Right after replacing the MAIN P.C.B., the USB selection screen does not displayed.)

Step 2.Execute the software “DscCalDi” :

1. Choose the “Adj Soft (DscCalDi)” and execute the adjustment software.(Refer to Fig.E1:Connection)

[ “Start” ---> “Program(P)” ---> “Win Tatsujin” ---> “Dsc” ---> “DMC-F3,F4 series” ---> “Adj Soft (DscCalDi)” ]

The following main screen is appear on the PC monitor.

NOTE:

Without connecting the USB cable between DSC (USB mode w ith power o n) and PC, adju stment software does n ot executed.

Now, perform the necessary adjustment by ordering each adjustment procedures described in “8.4 Adjustment procedures” section, continuously.

28

Page 29

8.4. Adjustment procedures

8.4.1. BF ADJUSTMENT(1) [ 1meter adjustment ]

[ PREPARAT ION ]

1. Perform the “8.3 Execute the Adjustment software “DscCalDi.exe”” in advance.

[ CAUTION ]

1. Do not apply any vibration to the camera during adjustment.

[ ADJUSTMENT CONDITION ]

1. Aim the specified Siemens star chart.

(As for Siemens star chart, refer to the “6 Service Fixture & To ols” section for details.)

[ ADJUSTMENT SETTINGS ]

1. Click on the pull down menu tag of the “Test”.

(The Test item list is disp layed.)

2. Choose the “Monitor” so that the LCD display displays monitoring image.

3. Set the camera unit and chart at 100 +/- 0.5cm.

4. Adjust the chart position so that the center of the chart is displayed to center of the LCD display.

By changing the Zoom condition, confirm that the center of the chart is displayed to center of the LCD display.

[ ADJUSTMENT ]

1. Click on the “Focus” button on the PC monitor.

(The Confirmation box is displayed.)

2. Click on “YES”.

NOTE:

It takes few minutes for adjustment process.

29

Page 30

3. When the adjustment is completed, the “Focus Result value list” is displayed.

4. Compare the Value displayed on the PC monitor and the following table.

If the adjustment value is out of specification, replace the Lens unit and try it again.

5. After confirmation (Data comparison) has been completed, click on “OK”.

[ AFTER ADJUSTMENT ]

NOTE:

If you want to perform other adjustments continiously, click on the pull down menu tag of the “Test” and choose the “OFF” in

stead of perform the following 1 to 3.

(The LCD display becomes black fade.)

Do not perform the same adjustment, continuously.

If it is necessary to perform the same adjustment, follow the following 1 to 3.

1. Close the “DscCalDi.exe” by clicking on the “X” located on the top right corner.

The LCD of the Camera unit becomes black fade.

2. Turn “off” the power switch of the camera unit.

3. Disconnect the USB cable.

30

Page 31

8.4.2. BF ADJUSTMENT(2) [ Infinity adjustment ]

[ PREPARAT ION ]

1. Perform the “8.3 Execute the Adjustment software“DscCalDi.exe”” in advance.

[ CAUTION ]

1. Do not apply any vibration to the camera during adjustment.

[ ADJUSTMENT SETTINGS ]

1. Click on the pull down menu tag of the “Test”.

(The Test item list is disp layed.)

2. Choose the “Monitor” so that the LCD display displays monitoring image.

3. Set the camera unit and collimeter as follows.

Make a gap between DSC unit and Collimeter, to prevent touching each other.

4. Adjust the collimeter position so that the center of the chart is displayed to center of the LCD display.

By changing the Zoom condition, confirm that the center of the chart is displayed to center of the LCD display.

[ ADJUSTMENT ]

1. Click on the pull down menu tag of the “Test”.

(The Test item list is disp layed.)

2. Choose the “Infinity Cal.” in order to execute adjustment.

NOTE:

It takes few minutes for adjustment process.

31

Page 32

3. When the adjustment is completed, the “Infinity calibration value list” is displayed.

4. Compare the Value displayed on the PC monitor and the following table.

If the adjustment value is out of specification, replace the Lens unit and try it again.

5. After confirmation (Data comparison) has been completed, click on “OK”.

[ AFTER ADJUSTMENT ]

NOTE:

If you want to perform other adjustments continiously, click on the pull down menu tag of the “Test” and choose the “OFF” in

stead of perform the following 1 to 3.

(The LCD display becomes black fade.)

Do not perform the same adjustment, continuously.

If it is necessary to perform the same adjustment, follow the following 1 to 3.

1. Close the “DscCalDi.exe” by clicking on the “X” located on the top right corner.

The LCD of the Camera unit becomes black fade.

2. Turn “off” the power switch of the camera unit.

3. Disconnect the USB cable.

32

Page 33

8.4.3. ISO/WBL/SHT ADJUSTMENT

[ PREPARAT ION ]

1. Perform the “8.3 Execute the Adjustment software“DscCalDi.exe”” in advance.

2. Remove the Front block of the Lightbox. (Refer to the “6 Service Fixture & Tools” section for details.)

3. Turn on the Lightbox.

[ ADJUSTMENT SETTINGS ]

1. Set the LBB1 filter (Part No.VFK1164LBB1) and ND filter (Part No.VFK1164ND02) on the screen part of the Lightbox.

2. Set the camera unit and Lightbox as follows.

NOTE:

When the zoom condition of camera is fully tele side, the distance between Lens edge and lightbox becomes 1.5+/-0.5cm.

(DO NOT APPL Y ANY LIGHT FROM OTHERS.)

[ ADJUSTMENT ]

1. Click on the “AWB” button on the PC monitor.

(The Confirmation box is displayed.)

2. Click on “YES”.

NOTE:

It takes few minutes for adjustment process.

3. When the adjustment is completed, the “AWB Result value list” is displayed.

33

Page 34

NOTE:

When the following “AWB Results:” (without data) message is displayed instead of displaying the above “AWB Result

value list”, try this adjustment again.

4. Compare the Value displayed on the PC monitor and the following table.

If the adjustment value is out of specification, replace the Lens unit and try it again.

5. After confirmation (Data comparison) has been completed, click on “OK”.

[ AFTER ADJUSTMENT ]

NOTE:

If you want to perform other adjustments continiously, click on the pull down menu tag of the “Test” and choose the “OFF” in

stead of perform the following 1 to 3.

(The LCD display becomes black fade.)

Do not perform the same adjustment, continuously.

If it is necessary to perform the same adjustment, follow the following 1 to 3.

1. Close the “DscCalDi.exe” by clicking on the “X” located on the top right corner.

The LCD of the Camera unit becomes black fade.

2. Turn “off” the power switch of the camera unit.

3. Disconnect the USB cable.

34

Page 35

8.4.4. BKI ADJUSTMENT

[ PREPARAT ION ]

1. Perform the “8.3 Execute the Adjustment software“DscCalDi.exe”” in advance.]

2. Remove the front block of the Lightbox. (Refer to the “6 Service Fixture & Tools” section for details.)

3. Turn on the Lightbox.

[ ADJUSTMENT SETTINGS ]

1. Set the LBB1 filter (Part No.VFK1164LBB1) filter and ND filter (Part No.VFK1164ND02) on the screen part of the Lightbox.

2. Set the camera unit and Lightbox as follows.

NOTE:

The zoom condition of camera is fully tele side, the distance between Lens edge and lightbox becomes 1.5+/-0.5cm.

(DO NOT APPL Y ANY LIGHT FROM OTHERS.)

[ ADJUSTMENT ]

1. Click on the pull down menu tag of the “Test”.

(The Test item list is disp layed.)

2. Choose the “CCD Black” in order to execute adjustment. (The Confirmation box is disp layed.)

3. Click on “YES”.

4. When the adjustment is completed, the “CCD Black Result value list” is displayed.

5. Click on “OK”.

35

Page 36

[ AFTER ADJUSTMENT ]

NOTE:

If you want to perform other adjustments continiously, click on the pull down menu tag of the “Test” and choose the “OFF” in

stead of perform the following 1 to 3.

(The LCD display becomes black fade.)

Do not perform the same adjustment, continuously.

If it is necessary to perform the same adjustment, follow the following 1 to 3.

1. Close the “DscCalDi.exe” by clicking on the “X” located on the top right corner.

The LCD of the Camera unit becomes black fade.

2. Turn “off” the power switch of the camera unit.

3. Disconnect the USB cable.

8.4.5. WKI ADJUSTMENT

[ PREPARATION ]

1. Perform the “8.3 Execute the Adjustment software“DscCalDi.exe”” in advance.

[ ADJUSTMENT ]

1. Click on the pull down menu tag of the “Test”.

(The Test item list is displayed.)

2. Choose the “CCD Defect” in order to execute adjustment. (The Confirmation box is displayed.)

3. Click on “YES”.

4. When the adjustment is completed, the “CCD Result value list” is displayed.

5. Click on “OK”.

[ AFTER ADJUSTMENT ]

NOTE:

If you want to perform other adjustments continiously, click on the pull down menu tag of the “Test” and choose the “OFF” in

stead of perform the following 1 to 3.

(The LCD display becomes black fade.)

Do not perform the same adjustment, continuously.

If it is necessary to perform the same adjustment, follow the following 1 to 3.

1. Close the “DscCalDi.exe” by clicking on the “X” located on the top right corner.

The LCD of the Camera unit becomes black fade.

2. Turn “off” the power switch of the camera unit.

3. Disconnect the USB cable.

36

Page 37

8.4.6. USB STORAGE INFO. REGISTRATION

[ PREPARAT ION ]

1. Perform the “8.3 Execute the Adjustment software“DscCalDi.exe”” in advance.

[ SETUP ]

1. Click on “Get” button.

(The USB Strage data is displayed.)

2. Confirm that the following data is displayed in each frame.

If not, revise the data as follows.

* “VID” frame : “MATSHITA”

* “PID” frame : “DMC-F3” ----(For DMC-F3), “DMC-F4” ----(For DMC-F4).

* “Rev” frame : “1.00”

3. Change the data in “Serial” frame from “00000000000”(11 digit) into the serial number.

(The serial number (it consists of 11 digit) is printed on the nameplate which is putted on the bottom side of the Unit.)

NOTE:

To chan ge the data, delete data first, then enter the data.

4. Click on “Set” button, which is located on just below the “Get” button.

[ AFTER SETTING-UP ]

1. Close the “DscCalDi.exe” by clicking on the “X” located on the top right corner.

The LCD of the Camera unit becomes black fade.

2. Turn “off” the power switch of the camera unit.

3. Disconnect the USB cable.

37

Page 38

9 Maintenance

9.1. Cleaning Lens and LCD Panel

Do not touch the surface of lens and LCD Panel with your hand.

When cleaning the lens, use air-Blower to blow off the dust.

When cleaning the LCD Panel, dampen the lens cleaning paper with lens cleaner, and the gently wipe the its surface.

Note:

The Lens Cleaning KIT ; VFK1900BK (Only supplied as 10 set/Box) is available as Service Aid.

38

Page 39

10 Block Diagram

10.1. Overall Block Diagram

CA1 BOARD

12M CCD

LENS

×4

BATTERY

CAA BLOCK

CDS, AGC, A/D C

H.DRIVER

48.00000MHz

SIO TO ASIC

LENS

DRIVER

BATTEMP

BAT_ID

SIO TO ASIC

V. DRIVER

PAON3

LVDS

SG/TG

CLK.

GEN.

SYSTEM

ASIC

POWER SEQUENCE

BLOCK

JPEG

ADDRESS2

ADDRESS1

CONTROLLER

AF/AE.AWB

INTEGRATOR

JPEG

PROGRAM FLASH

64MByte/64MByte

DATA2

SIGNAL

PROCESSOR

SDRAM

SDRAM

CONTROLLER

SRAM

CONTROLLER

ENCODER

CONTROL

8bit

D/A

CARD

SD CARD

DATA1

CPU

USB

UART

JTAG

PIO

SIO

CP1 BOARD

USBD[+,-]

USBCNT

AUDIOOUT

VIDEOOUT

TO CAA

TO LCD

TO LENS

USB

&

AV

SWITCHING

CONTROL

PWA BLOCK

POWER SUPPLY

ST1 BOARD

ELECTRONIC FLASH

FLASH REFLECTOR

PON,PON2

LCD BACK LIGHT

TB2 BOARD

AF ASSIST

&

SELF LED

SHUTTER

SW

POWER

SW

ZOOM

SW

TB1 BOARD

BACKUP_BAT

LCD BACK LIGHT

SET,Q.MENU,DISPLAY

DOWN,LEFT,RIGHT,UP

REC,PLAY

BACK FPC

ADCDAT

DACDAT

YOUT

RTC_CKOUT

RTC_RESET

CODEC

A/D, D/A

VIDEOAMP

BACK UP

SIO TO ASIC

LCD

DISPLAY

2.7inch

RTC

AUDIOOUT

VIDEOOUT

32.768KHz

MIC

SPEAKER

: POWER LINENOTE

MODEL: DMC-F3 / F4

BLOCK DIAGRAM: OVERALL

39

Page 40

11 Wiring Connection Diagram

CN911

GND

V1A

V1B

VDD

VDD

V2

V3B

V3A

GND

VOUT

GND

RG

GND

HL

GND

H1

H2

GND

SUBGT2

SUBGT

SUB

MSUBSW

V9R

PT

PT

V5

V11B

V11R

V11L

V11A

V9B

V4

V7S

V7

V6

V9L

V8

V9A

V12

V10

GND

CCD UNIT

(CA1)

LENS

4

5

6

7

8

3

VCC1

DCM B

DCM B

DCM A

VCC2

DCM A

9

10

11

12

SHUTTER+

SHUTTER+

ZOOM_EN_E

ZOOM_EN_K

13

14

ND+

SHUTTER-

17

15

16

ND-

SHUTTER-

F-STM B+18F-STM B-19F-STM A+

20

21

22

F-STM A-

FOCUS_HP_K

FOCUS_HP_E

23

VCC3

Z1Z2

1

CN951

ZOOM_HP_K2ZOOM_HP_E

CN901

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

1

GND

2

V1A

3

V1B

4

VDD

5

VDD

6

V2

7

V3B

8

V3A

9

GND

10

VOUT

11

GND

12

RG

13

GND

14

HL

15

GND

16

H1

17

H2

18

GND

19

SUBGT2

20

SUBGT

21

SUB

22

MSUBSW

23

V9R

PT

PT

V5

V9B

V4

V7S

V7

V11B

V6

V9L

V11R

V11L

V8

V9A

V12

V11A

V10

GND

Z1 Z2

CAA

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

SD CARD

4

5

6

7

8

9

3

VSS

VDD

VSS

CLOCK

DATA1

DATA0

10

CARD

DATA2

11

12

WP

COMMON

Z1Z2Z3Z4

CN141

1

2

DATA3

COMMAND

MAIN P.C.B.

(CP1)

USB & AV

7

4

5

6

1

2

GND

GND

CN110

ZAV_JACK

USB D(-)

USB D(+)

VIDEO_OUT3AUDIO-OUT

DMADMADMA

8

Z1Z2Z3Z4

USB_VDD

MIC

1

GY

MIC

JW181

1

GND

BK

JW182

SPEAKER

1

1

RD

WT

SP-

SP+

JW183

JW184

DMA

BATTERY

CL530

CL504

CL503

CL502

BAT-

BAT+

BAT_ID

BAT_T

PWA

CN952

1

UNREGST

2

UNREGST

3

UNREGST

4

UNREGST

5

GND

6

GND

7

GND

GND

+12V(A)

AL3.2V

FLCTL

VMONIT

CHG

GND

GND

8

9

10

11

12

13

14

15

Z1Z2

DMA

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

CN541

GND

GND

CHG

VMONIT

FLCTL

AL3.2V

+12V(A)

GND

GND

GND

GND

UNREGST

UNREGST

UNREGST

UNREGST

Z1 Z2

FLASH

P.C.B.

(ST1)

1

TRIGGER

JW541

TRANS

3

TRG

XAN

BROWN

GRAY

2

JW542

XKT

BLACK

FLASH

REFLECTOR

CN102

1

GND

2

PW_ON

3

1ST

4

2ND

5

SO2

DMA

SIO

SI1

AFLED_AN

AFLED_CA

GND

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

CN351

GND

PW_ON

1ST

2ND

SO2

SIO

SI1

AFLED_AN

AFLED_CA

GND

TOP OPERATION

P.C.B.

(TB1)

JW351 AFLED_AN

JW351 AFLED_CA

CN171

VCOM

1

CN302

1

GND

2

SI1

3

SO0

4

SI1

5

SI2

6

SI0

7

SI1

DMA

DMA

D4

CS

SCL

SDA

DCLK

HSYNC

VSYNC

4

5

7

2

6

3

D1

D5

D3

D2

D7

8

D0

D6

9

10

12

13

11

V2

GND

VDD

DVDD

VDD2

15

16

17

18

19V120

14

21V322V423

24V525V626

VDD3

VDD5

27

28V729V830

VGH31VGL

AGND

32

FRP

33

VCAC

COMDC

34

35

DRV

36

VLED

37

Z2Z1

VCOM

38FB39

SI2

SO1

SI3

SO3

GND

8

9

10

11

12

SI3

13

Z1Z2

BACK FPC

LCD

(TB2)

JW611 AFLED_AN

JW612 AFLED_CA

LED LIGHT P.C.B.

W1-

26000/SG431-UPA

MODEL: DMC-F3 / F4

OVERALL WIRING

40

Page 41

12 Printed Circuit Board

SIDE-A

SG431_CP1

F1

2A

F2 2A

GY

BK

WT

RD

+

T

ID

-

J9800AA

JW181

JW182

JW183

JW184

F5001

F5002

SIDE-B

F5

2A

2A

F6

Z3001

F5005

F5006

(COMPONENT SIDE)

(FOIL SIDE)

[FOIL SIDE ................. : F5001,F5002 / COMPONENT SIDE........: F5005,F5006]

F5001

F5002

F5006

F5005

CAUTION: FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,

REPLACE ONLY WITH THE SAME TYPE 2A 32V FUSE.

ATTENTION: POUR UNE PROTECTION CONTINUE LES RISQUES

D' INCENDIE N' UTILISERQUE DES FUSIBLE DE MÉME TYPE 2A 32V.

2A 32V

The following drawings show the location of the fuse on MAIN P.C.B.

CAUTION: FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,

REPLACE ONLY WITH THE SAME TYPE 2A 32V FUSE.

ATTENTION: POUR UNE PROTECTION CONTINUE LES RISQUES

D' INCENDIE N' UTILISERQUE DES FUSIBLE DE MÉME TYPE 2A 32V.

2A 32V

12.1. Fuse location on MAIN P.C.B.

41

Page 42

S1. Replacement Parts List

Note:

1. *Be sure to make your orders of replacement parts according to this list.

2. IMPORTANT SAFETY NOTICE

Components identified with the mark have the special characteristics for safety.

When replacing any of these components, use only the same type.

3. Unless otherwise specified,

All resistors are in OHMS, K=1,000 OHMS. All capacitors are in MICRO-FARADS (uf), P=uuF.

4. The marking (RTL) indicates the retention time is limited for this item. After the discontinuation

of this assembly in production, it will no longer be available.

5. Supply of CD-ROM, in accordance with license protection, is allowable as replacement parts

only for customers who accidentally damaged or lost their own.

.

E.S.D. standards for Electrostatically Sensitive Devices, refer to PREVENTION OF

ELECTROSTA TIC DISCHARGE (ESD) TO ELECTROSTATICALLY SENSITIVE (ES) DEVICES

section.

.

S-1

Page 43

S2. Exploded View

S2.1. Frame and Casing Section (1)

13-1

26

25

B18

28

B19

24-2

24-1

33

27

24-3

30

24

32

B20

B21

34

B22

31

19

B16

14

13-2

20

21

13

B23

S-2

15

22

23

B17

B26

18

17-2

B24

B25

17-1

17

16

Page 44

S2.2. Frame and Casing Section (2)

B9

B10

B11

35

11

B6

12

B7

B8

B12

B13

9

10

B1

B14

B15

B2

8

5

B3

B4

B5

4

3

2

1

7

6

S-3

Page 45

S2.3. Packing Parts and Accessories Section

125

118

100

107

106

(EXCEPT:DMC-F3P/PC/PU)

115

126

(DMC-F3P/PC/PU)

104

102

108

110

105

(DMC-F3EE/EF/EG/EP/GF, F4EE/EG/EP)

120

(DMC-F3EB/GC,F4EB)

119

(DMC-F3GN)

121

101

(DMC-F3GT)

(DMC-F3PR)

122

123

114

S-4

Page 46

DMC-F3, F4 Series

Ref.No. Part No. Part Name & Description Pcs Remarks Ref.No. Part No. Part Name & Description Pcs Remarks

---- ELECTRICAL REPLACEMENT PARTS SECTION --------

F5001 VU4230340905 FUSE 32V/2A 1 (INCLUDED IN MAIN P.C.B.)

F5002 VU4230340905 FUSE 32V/2A 1 (INCLUDED IN MAIN P.C.B.) 13 VU6361420211 FRONT/TOP CASE KIT 1 ONLY "F3P-S"

F5005 VU4230340905 FUSE 32V/2A 1 (INCLUDED IN MAIN P.C.B.) 13 VU6361420242 FRONT/TOP CASE KIT 1 ONLY "F3P-K"

F5006 VU4230340905 FUSE 32V/2A 1 (INCLUDED IN MAIN P.C.B.) 13 VU6361420273 FRONT/TOP CASE KIT 1 ONLY "F3P-P"

---- MECHANICAL REPLACEMENT PARTS SECTION -------[S2.1.Frame & Casing section (1)]

10 VU6361420020 REAR CASE UNIT 1 (-S) 17-1 VU4041224708 E.CAPACITOR 1

[S2.2.Frame & Casing section (2)]

13 VU6361420303 FRONT/TOP CASE KIT 1 (-S)F3(EXCEPT "F3P-S")

13 VU6361420327 FRONT/TOP CASE KIT 1 (-K)F3(EXCEPT "F3P-K")

13 VU6361420341 FRONT/TOP CASE KIT 1 (-P)F3(EXCEPT "F3P-P")

13 VU6361420945 FRONT/TOP CASE KIT 1 (-K)F4

4F)S-(1TIK ESAC POT/TNORF7090241636UV311)DCC O/W(TINU SNEL1313201546UV1

1)POT CED( RECAPS8040931636UV1-311RETLIF LACITPO5063201546UV2

1)CIM( RECAPS1122931636UV2-311NOIHSUC DCC5689331636UV3

)S-(1REVOC BSU6023431636UV411TINU DCC8520631636UV4

)K-(1REVOC BSU7326531636UV411)1AC( RECAPS9340931636UV5

)P-(1REVOC BSU4426531636UV411REDLOH SNEL8313431636UV6

1MOTTOB HTRAE6713431636UV511)REDLOH SNEL( RECAPS4150931636UV7

1ROTICAPAC.E HTRAE4679531636UV611REDLOH DCL7261931636UV8

1.B.C.P HSALF9431431636UV711TINU DCL6525041636UV9

1REMROFSNART5381480546UV2-71 )K-(1TINU ESAC RAER4400241636UV01

1REDLOH REGGIRT4113431636UV81 )P-(1TINU ESAC RAER8600241636UV01

1)HSALF - NIAM ( CPF2500431636UV911TINU NOITAREPO RAER7563431636UV11

1THGIL LENAP DEL2930931636UV02 )P-( ,)S-(1BONK WS KCABYALP/CER5992431636UV21

1.B.C.P THGIL DEL3631431636UV12 )K-(1BONK WS KCABYALP/CER6026531636UV21

1REKAEPS3041201546UV221)DEL( RECAPS3540931636UV53

1DNATS DOPIRT7323431636UV32

)S-(1TIK EMARFTIKS3FUV42 )P-( ,)S-(1WERCS0076412114UV1B

)K-(1TIK EMARFTIKK3FUV42 )K-(1WERCS5039412114UV1B

)P-(1TIK EMARFTIKP3FUV42 )P-( ,)S-(1WERCS0076412114UV2B

1GNIRPS REVOC .TTAB7703431636UV1-42 )K-(1WERCS5039412114UV2B

1TFAHS REVOC .TTAB3123431636UV2-421WERCS5013412114UV3B

)S-(1U ROOD YRETTAB7850241636UV3-421WERCS5013412114UV4B

)K-(1U ROOD YRETTAB9546531636UV3-421WERCS5013412114UV5B

)P-(1U ROOD YRETTAB0060241636UV3-421WERCS5044812114UV6B

1ENOHPORCIM8174201546UV521WERCS5044812114UV7B

1TINU HSALF6389201546UV621WERCS5044812114UV8B

1)DAEL( RECAPS1515931636UV721WERCS3022591114UV9B

1.B.C.P NOITAREPO POT6531431636UV821WERCS3022591114UV01B

1WP EPAT DLEIHS7464721636UV031WERCS3022591114UV11B

)P-( ,)S-(1WERCS7028681114UV21B 31 VU6361344715 MAIN P.C.B. 1 F3 SERIES

)K-(1WERCS8021070213UV21B 31 VU6361381444 MAIN P.C.B. 1 F4 SERIES

1)1PC( RECAPS2240931636UV23 )P-( ,)S-(1WERCS7028681114UV31B

1)RTS-BWP( RECAPS5661931636UV33 )K-(1WERCS8021070213UV31B

1)A 1PC( RECAPS6911141636UV43 )P-( ,)S-(1WERCS7028681114UV41B

)K-(1WERCS8021070213UV41B

1WERCS6007502114UV61B )P-( ,)S-(1WERCS7028681114UV51B

1WERCS6007502114UV71B )K-(1WERCS8021070213UV51B

1WERCS9040681114UV81B

1WERCS9040681114UV91B

1WERCS9040681114UV02B

1WERCS9040681114UV12B

1WERCS9040681114UV22B

1WERCS9040681114UV32B

1WERCS9040681114UV42B

1WERCS9040681114UV52B

1WERCS0076412114UV62B

S-5

Page 47

DMC-F3, F4 Series

Ref.No. Part No. Part Name & Description Pcs Remarks Ref.No. Part No. Part Name & Description Pcs Remarks

126 VQT2K37 O/I SOFTWARE 1 F3P/PC

126 VQT2K39 O/I SOFTWARE 1 F3EG, F4EG

[ S2.3.PackingPartsandAccessoriesSection ]

101 DE-A60AA BATTERY CHARGER 1 F3EG/EP/EF/EB/GN, 126 VQT2K43 O/I SOFTWARE 1 F3EE, F4EE

101 DE-A60BB BATTERY CHARGER 1 F3EE/GC/GF, F4EE 126 VQT2T40 O/I SOFTWARE 1 F3GT

101 DE-A60CA BATTERY CHARGER 1 F3GT

101 DE-A60DA BATTERY CHARGER 1 F3PR

)DEILPPUS TON(1YRETTAB-----201

104 VU6451023810 USB CABLE W/PLUG 1

105 VU6451024237 AV CABLE W/PLUG 1 (EXCEPT F4EE)

106 VFC4297 HAND STRAP 1

NG/TG/FG/CG3F1MOR-DCS-4260FFV701

,BE/FE/PE/GE3F1MOR-DCS-2260FFV701

F4EB/EG/EP

EE4F ,EE3F1MOR-DCS-3260FFV701

RP/UP/CP/P3F1MOR-DCS-1260FFV701

108 VGQ0D56 BATTERY PROTECTION CASE 1

110 VPF1230 BAG, POLYETHYLENE 1

114 VPK4416 PACKING CASE 1 (-S) F3EG/EP/EF/EB/EE/

GT/GN

114 VPK4420 PACKING CASE 1 (-K) F3EG/EP/EF/EB/EE/

GT/GN

114 VPK4424 PACKING CASE 1 (-P) F3EG/EP/EF/EB/EE/

GT/GN

114 VPK4417 PACKING CASE 1 (-S)F3GF

114 VPK4421 PACKING CASE 1 (-K)F3GF

114 VPK4425 PACKING CASE 1 (-P)F3GF

114 VPK4440 PACKING CASE 1 (-S)F3PR/GC

114 VPK4441 PACKING CASE 1 (-K)F3PR/GC

114 VPK4442 PACKING CASE 1 (-P)F3PR/GC

114 VPK4414 PACKING CASE 1 (-S)F3P

114 VPK4418 PACKING CASE 1 (-K)F3P/PC

114 VPK4422 PACKING CASE 1 (-P)F3P

114 VPK4426 PACKING CASE 1 (-S)F4EE

114 VPK4427 PACKING CASE 1 (-K)F4EG/EP/EB

114 VPK4415 PACKING CASE 1 (-S)F3PU

114 VPK4419 PACKING CASE 1 (-K)F3PU

114 VPK4423 PACKING CASE 1 (-P)F3PU

UP/CP/P3F1A DAP3207NPV511

)UP/CP/P3F TPECXE(1A DAP6607NPV511

118 VQL2C67 OPERATING LABEL 1 F3PC

118 VQL2C68 OPERATING LABEL 1 F3GT

119 VU6450808883 AC CORD W/PLUG 1 F3EB/GC, F4EB

120 VU6450760235 AC CORD W/PLUG 1 F3EG/EP/EF/EE/GF,

F4EE/EG/EP

121 VU6450768101 AC CORD W/PLUG 1 F3GN

122 VU6451029782 AC CORD W/PLUG 1 F3PR

123 VU6451029799 AC CORD W/PLUG 1 F3GT

125 VQT2R80 SIMPLIFIED O/I 1 F3P

125 VQT2R84 SIMPLIFIED O/I 1 F3EG, F4EG

125 VQT2R81 SIMPLIFIED O/I 1 F3PC

125 VQT2R83 SIMPLIFIED O/I 1 F3PR

125 VQT2R88 SIMPLIFIED O/I 1 F3EP, F4EP

125 VQT2R91 SIMPLIFIED O/I 1 F3EF

125 VQT2R92 SIMPLIFIED O/I 1 F3EB, F4EB

125 VQT2R93 SIMPLIFIED O/I 1 F3EE, F4EE

125 VQT2R94 SIMPLIFIED O/I 1 F3GC/GF

125 VQT2R96 SIMPLIFIED O/I 1 F3GT

125 VQT2R82 SIMPLIFIED O/I 1 F3PU

125 VQT2R97 SIMPLIFIED O/I 1 F3GN

125 VQT2R85 SIMPLIFIED O/I 1 F3EG, F4EG

125 VQT2R89 SIMPLIFIED O/I 1 F3EP, F4EP

125 VQT2R95 SIMPLIFIED O/I 1 F3GC/GF

125 VQT2R86 SIMPLIFIED O/I 1 F3EG, F4EG

125 VQT2R90 SIMPLIFIED O/I 1 F3EP, F4EP

125 VQT2R87 SIMPLIFIED O/I 1 F3EG, F4EG

126 VQT2K38 O/I SOFTWARE 1 F3PU/PR

126 VQT2K40 O/I SOFTWARE 1 F3EP, F4EP

FE3F1ERAWTFOS I/O14K2TQV6211GAB AREMAC1831FPV001

FG/CG3F1ERAWTFOS I/O44K2TQV621 PE/GE/BE4F

BE4F ,NG/BE3F1ERAWTFOS I/O24K2TQV621 UP/CP/P3F1REGRAHC YRETTABBB95A-ED101

S-6

Loading...

Loading...