Page 1

ORDER NO. CPD0604067C1

Personal Computer

CF-T4

This is the Service Manual for

the following areas.

M …for U.S.A. and Canada

Model No. CF-T4HWETZBM

© 2006 Matsushita Electric Industrial Co., Ltd. All rights reserved.

Unauthorized copying and distribution is a violation of law.

Page 2

CONTENTS

Page Page

1 Read Me First. ...................................................................

1.1 . Accessories .............................................................

2 Specifications ..................................................................

3 Names and function of Parts ..........................................

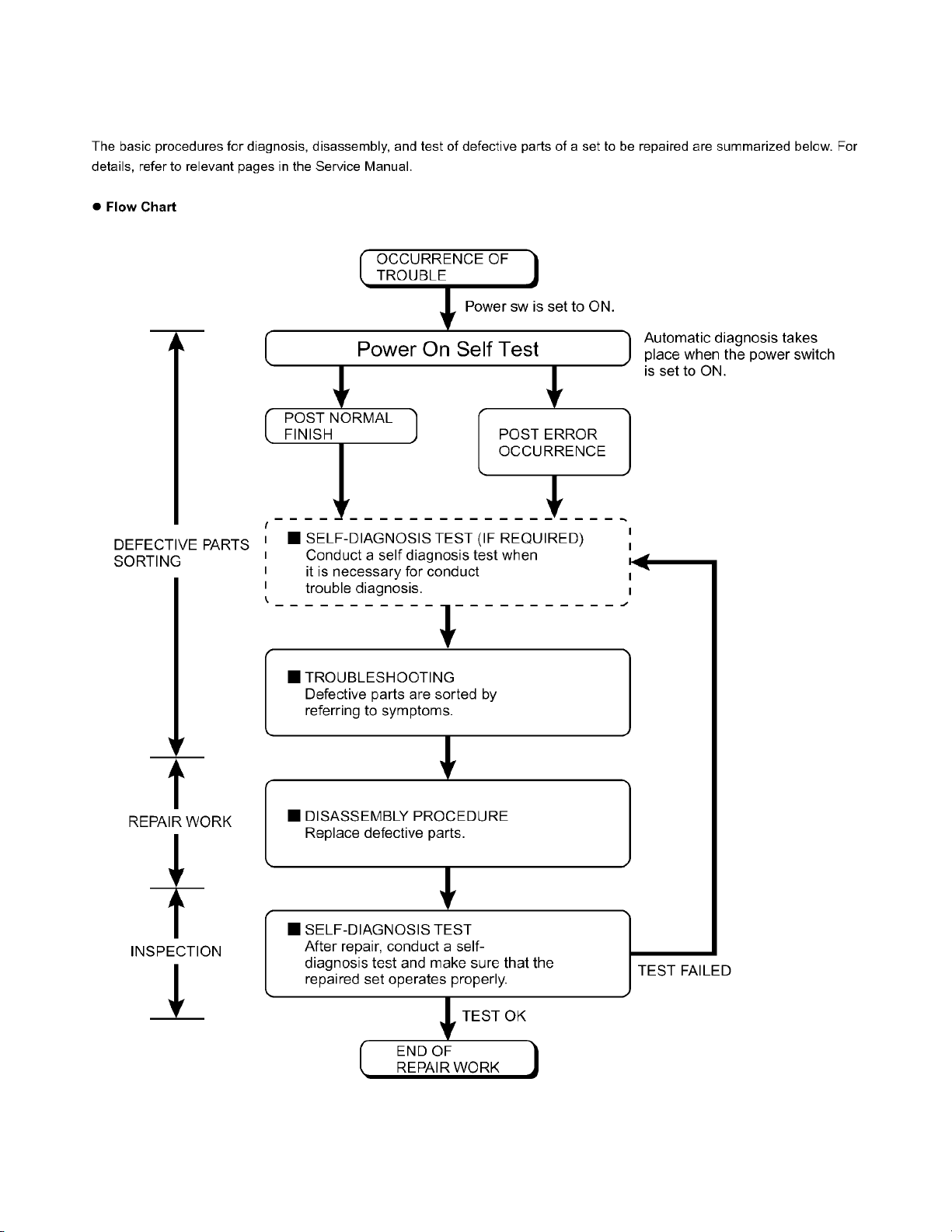

4 Diagnosis & Repair ..........................................................

4.1. Basic Procedures .....................................................

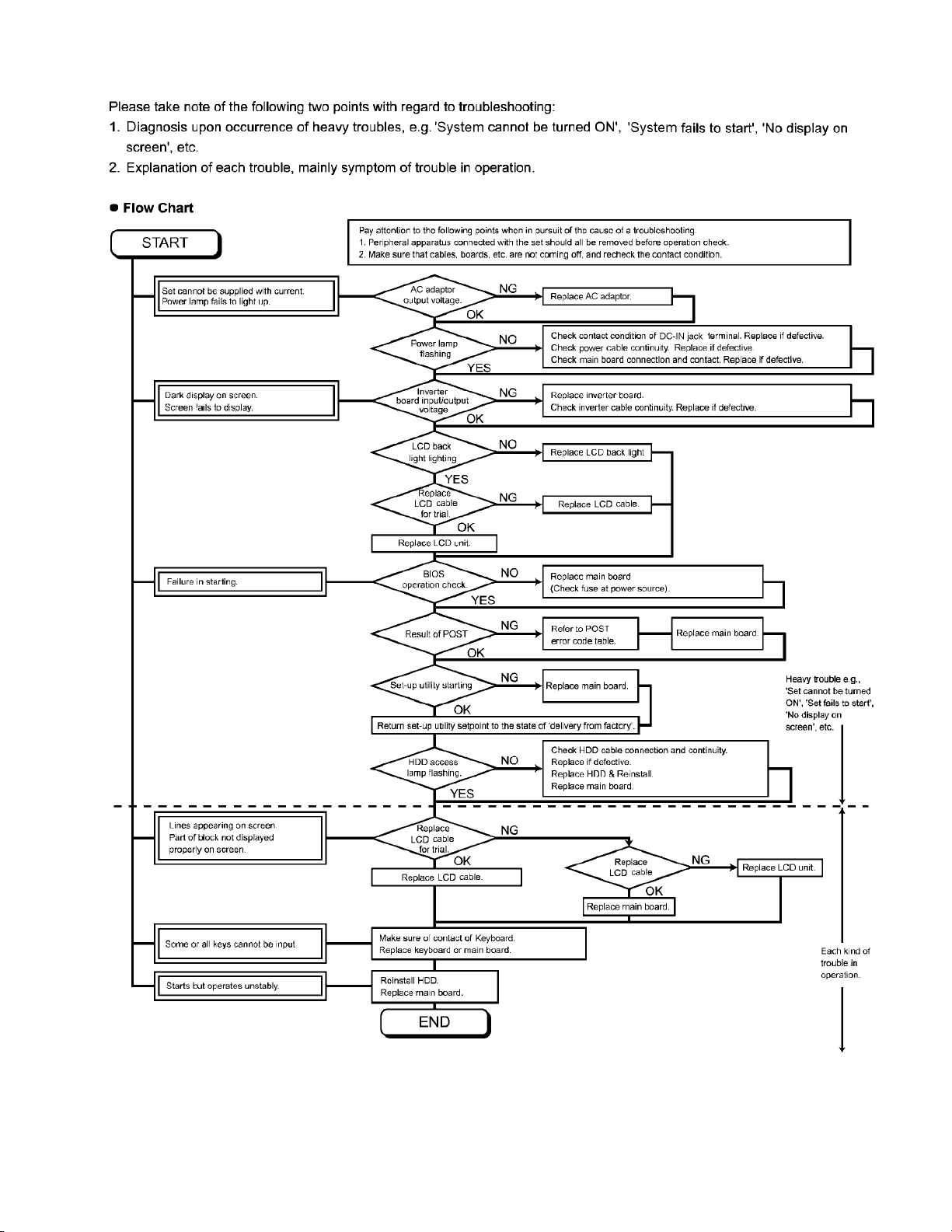

4.2. Troubleshooting .......................................................

4.3. Connection Diagram ................................................

4.4. Power-on Self Test (Boot Check) .............................

5 Self Diagnosis Test ..........................................................

5.1. Outline of Self Diagnostic Test .................................

5.2. Automatic Test ..........................................................

5.3. Peripheral Test .........................................................

5.4. Test Selection ...........................................................

5.5. Error Messages and Troubleshooting ......................

9

10

11

12

12

13

19

20

22

22

23

24

25

26

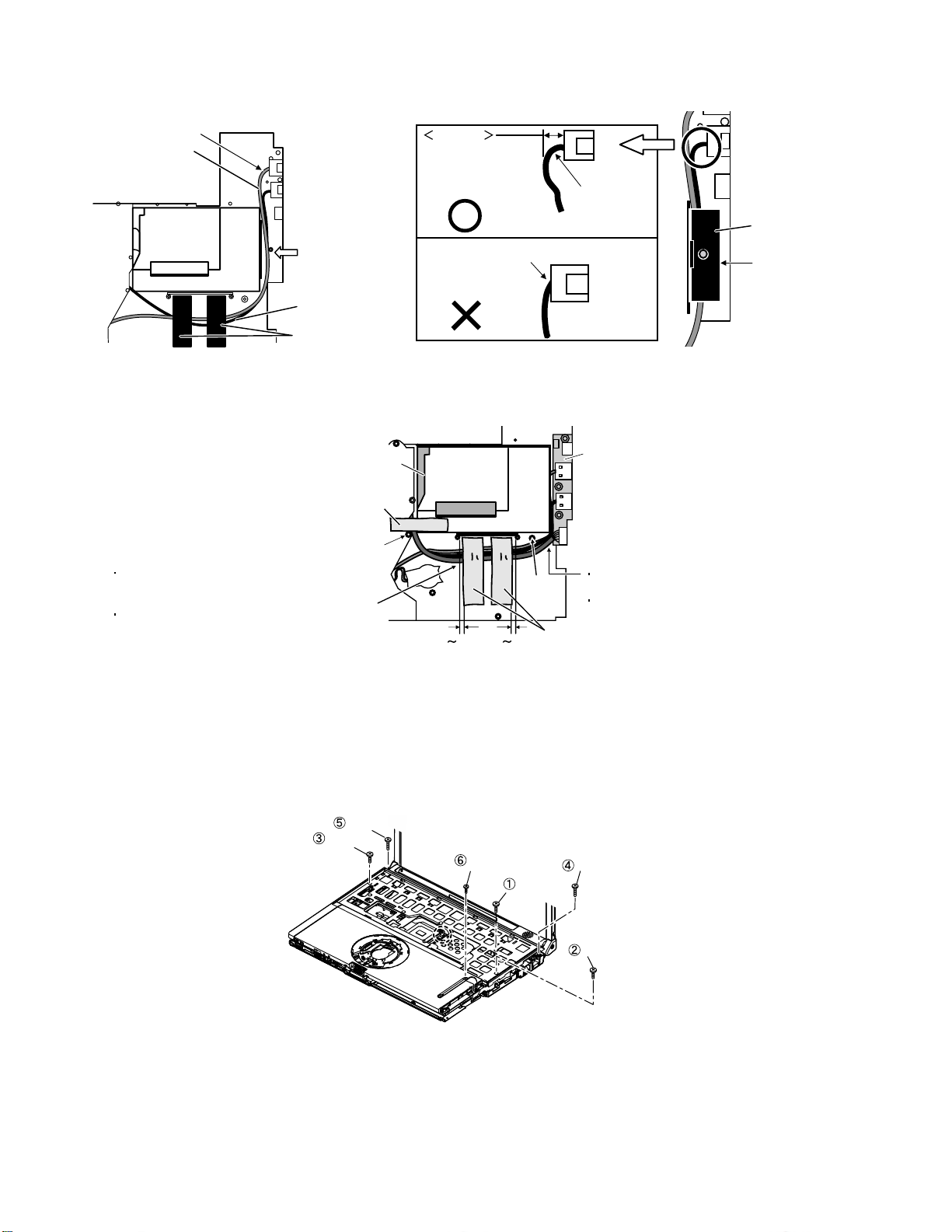

6 Disassembly & Reassembly Instruction ...................

4

6.1. Disassembly Flow Chart .....................................

6.2. Disassembly ........................................................

6.3. Reassembly ........................................................

7 Explanation of Hardware ............................................

7.1. System Block Diagram ........................................

8 Main Unit Extended View ...........................................

8.1. Display section ....................................................

8.2. Cabinet section ...................................................

8.3. Bottom section ...................................................

9 Replacement Parts List ..............................................

27

27

28

35

43

43

45

45

47

48

49

2

Page 3

34567

Page 4

Page 5

Page 6

Page 7

Page 8

8

Page 9

9

Page 10

2. Specifications

Main Specifications

CPU/

Secondary cache memory

Chip Set

Main Memory

Video Memory

Hard Disk Drive (Replaceable)

Display Method

Internal LCD Display

*

External Display

5

Simultaneous Display on LCD + Exter-

*

nal Display

5

Wireless LAN

*

6

LAN

®

Intel

Pentium® M Processor Ultra Low Voltage 753 (1.20 GHz, 2 MB

MHz FSB)

®

Intel

915 GMS Express chip set

*

512 MB

1

, DDR2 SDRAM (1024 MB

UMA (128 MB

*3

60 GB

*

1

Max.)

*2

*

1

Max.)

12.1 XGA type (TFT) (1024 × 768 dots)

*

65,536/16,777,216 colors (1024

× 768 dots)

4

65,536/16,777,216 colors (800 × 600 dots/1024 × 768 dots/1280 × 768 dots/1280 ×

1024 dots/1600 × 1200 dots/2048 × 1536 dots)

*

65,536/16,777,216 colors (800 × 600 dots, 1024 × 768 dots)

Built-in Intel

®

PRO/Wireless 2915 ABG

4

IEEE 802.3 10Base-T, IEEE 802.3u 100Base-TX

Modem Data: 56 kbps (V.92) FAX: 14.4 kbps

Sound WAVE and MIDI playback, Monaural Speaker (built in)

Card Slots

RAM Module Slot

Interface

PC Card Slot × 1: (One Type I or Type II, Allowable current 3.3 V: 400 mA, 5 V: 400 mA)

*

SD Memory Card Slot

7

× 1

DDR2 SDRAM, 172-pin, 1.8 V, Micro DIMM, PC2-3200 Compliant

*

USB Ports × 2 ( USB2.0 × 2 )

9

/ Modem Port ( RJ-11 ) / LAN Port ( RJ-45 )

External Display Port: Mini Dsub 15-pin female / Microphone Jack: Miniature jack, 3.5

DIA / Headphone Jack: Miniature jack, 3.5 DIA / Mini Port Replicator connector: Dedicated 50-pin male

Keyboard/Pointing Device 83 keys/Touch Pad/Touchscreen (stylus (included) touch capable)

Power AC adaptor or Battery pack

AC Adaptor

*

10

Input: 100 V - 240 V AC, 50 Hz/60 Hz

Output: 16 V DC, 2.5 A

Battery Pack Li-ion 11.1 V, 7.65 Ah

*

Operating Time

Charging Time

11

*

14

Power Consumption

Approx. 6 hours -12 hours

Approx. 5 hours (Power off)/Approx. 7 hours (Power on)

*

15

Approx. 35 W

*

16

/ Approx. 40 W (maximum when recharging in the ON state)

*

12

(Approx. 8 hours

*

13

) (Disable Economy mode (ECO))

•Including protrusion of the hand strap

268 mm × 28.1 mm (at the front)/66.9 mm (at the rear) × 210 mm

Physical Dimensions (W × H × D)

(excluding the stylus holder)

*

17

Weight

Te mperature

Humidity 30% to 80% RH (No condensation)

Te mperature

Humidity 30% to 90% RH (No condensation)

Environment

*

18

OS

Operation

Storage

{10.6 " × 1.1 " /2.7 " × 8.3 "}

•Excluding protrusion of the hand strap

268 mm

{10.5 "

× 28.1 mm (at the front)/49.1 mm (at the rear) × 210 mm

× 1.1 " /2.0 " × 8.3 "}

Approx. 1520 g {3.4 lb.} (including the stylus)

5°C to 35°C {41°F to 95°F}

-20°C to 60°C {-4°F to 140°F}

Microsoft® Windows® XP Professional with Service Pack 2 with Advanced Security

Te chnologies (NTFS File system)

Microsoft® Internet Explorer 6 Service Pack 2 / DirectX 9.0 c / Microsoft® Windows®

Media Player 10 / Microsoft® Windows® Movie Maker 2.1 / Microsoft® .NET Framework

1.1 / Adobe Reader / Intel® PROSet/Wireless Software / SD Utility / Icon Enlarger /

Loupe Utility / Touch Pad Utility / DMI Viewer / PC Information Viewer / Display Rotation

Pre-installed Software

*

18

To ol / Hotkey Settings / Wireless LAN Switch Utility / Economy Mode (ECO) Setting Utility / Battery Recalibration Utility / Infineon TPM Professional Package*

*

Setup Utility / Hard Disk Data Erase Utility

19

/ Hard Disk Backup Utility

*

1

L2 cache, 400

*

8

20

*

19

*

6

/

10

Page 11

*1

1 MB = 1,048,576 bytes

*2

A segment of the main memory is allotted automatically depending on the computer ’s operating status. The size of the Video

Memory cannot be set by the user.

*3

1 GB = 1,000,000,000 bytes. Operating system or some application software will report as fewer GB.

*4

A 16,777,216 color display is achieved by using the dithering function.

*5

Display may be impossible using some connected external displays.

*6

Some devices cannot be used depending on the port type.

*7

Operation has been confirmed for Panasonic SD memory cards with up to 2 GB capacity. The transfer rate using the SD memory

card slot on this computer is 8 MB per second (this is a theoretical value, and differs from actual speeds). The transfer rate is 8

MB per second even if you use an SD memory card that supports high-speed transfer rates. Does not guarantee connection/

operation of all SD devices. Does not support MultiMedia card. Do not insert MultiMedia card.

*8

Only a RAM module designed for DDR2 (PC2-3200) can be added (Panasonic : CF-BAV0256U / CF-BAV0512U).

JEDEC standard 214 pin Micro DIMM cannot be used. PC2100 / PC2700 172 pin Micro DIMM cannot be used.

*9

Does not guarantee operation of all USB-compatible peripherals.

*10

<Only for North America>

The AC adaptor is compatible with power sources up to 240 V AC adaptor. This computer is supplied with a 125 V AC compatible AC cord.

*11

Varies depending on the usage conditions, CPU speed, etc. Measured value when the power saving function on the USB2.0 USB

Root Hub is set to on. (At the time of purchase, the power saving function is set to off.

When Economy Mode (ECO) is enabled, the operating time becomes approximately 20% shorter than when it is disabled.

*12

Measured using BatteryMark™ Version 4.0.1 (LCD brightness : Maximum - Minimum).

*13

Measured using MobileMark™ 2002 (LCD brightness : 60 cd/m2).

*14

Varies depending on the usage conditions, CPU speed, etc.

It may take a long time to charge a fully discharged battery.

*15

Approx. 1.5 W when the battery pack is fully charged (or not being charged) and the computer is off.

*16

Rated power consumption.

*17

Average value. May differ depending on models.

*18

Operations of this computer are not guaranteed except for the pre-installed OS.

*19

The Product Recovery DVD-ROM is required.

*20

For information on TPM, input [c:\util\drivers\tpm\README.pdf] in [start] - [Run] and refer to the installation manual of “Trusted

Platform Module (TPM)”. You need to install Infineon TPM Professional Package to use TPM.

Wireless LAN

IEEE802.11a: 54/48/36/24/18/12/9/6 Mbps (automatically switched)

Data Transfer Rates

IEEE802.11b: 11 /5.5/2/1 Mbps (automatically switched)

IEEE802.11g: 54/48/36/24/18/12/9/6 Mbps (automatically switched)

Standard SupportedIEEE802.11a/IEEE802.11 b/IEEE802.11g

Transmission Method OFDM system, DS-SS system

Wireless Channels Used

RF Frequency Band

*21

These are speeds specified in IEEE802.11 a+b+g standards. Actual speeds may differ.

IEEE802.11a: Channels 36/40/44/48/52/56/60/64/149/153/157/161/165

IEEE802.11b/ IEEE802.11g: Channels 1 to 11

IEEE802.11a: 5.18 - 5.32 GHz, 5.745 - 5.825 GHz

IEEE802.11b/ IEEE802.11g: 2412 - 2462 MHz

*

21

*

20

*

21

10-1

Page 12

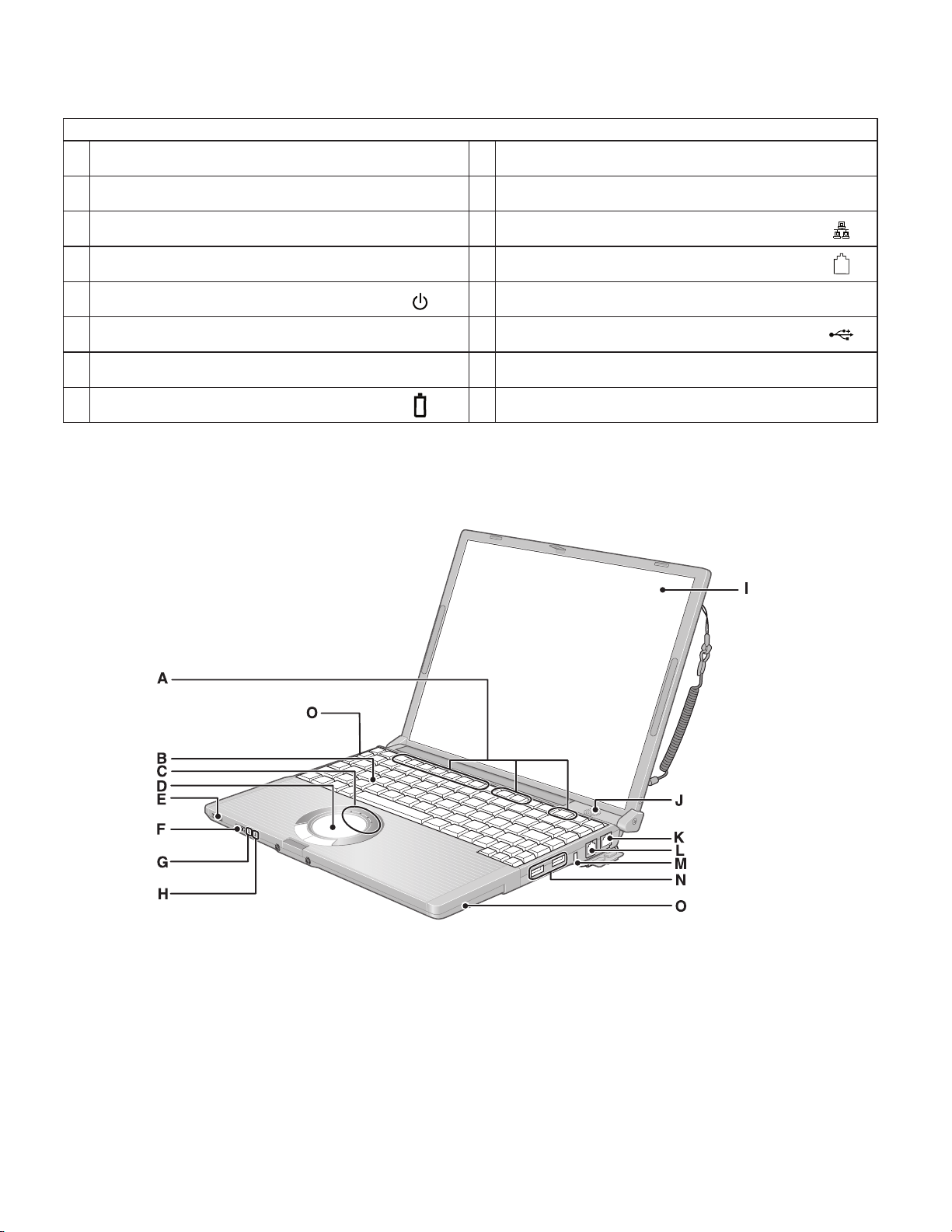

3. Names and Function of Parts

Names

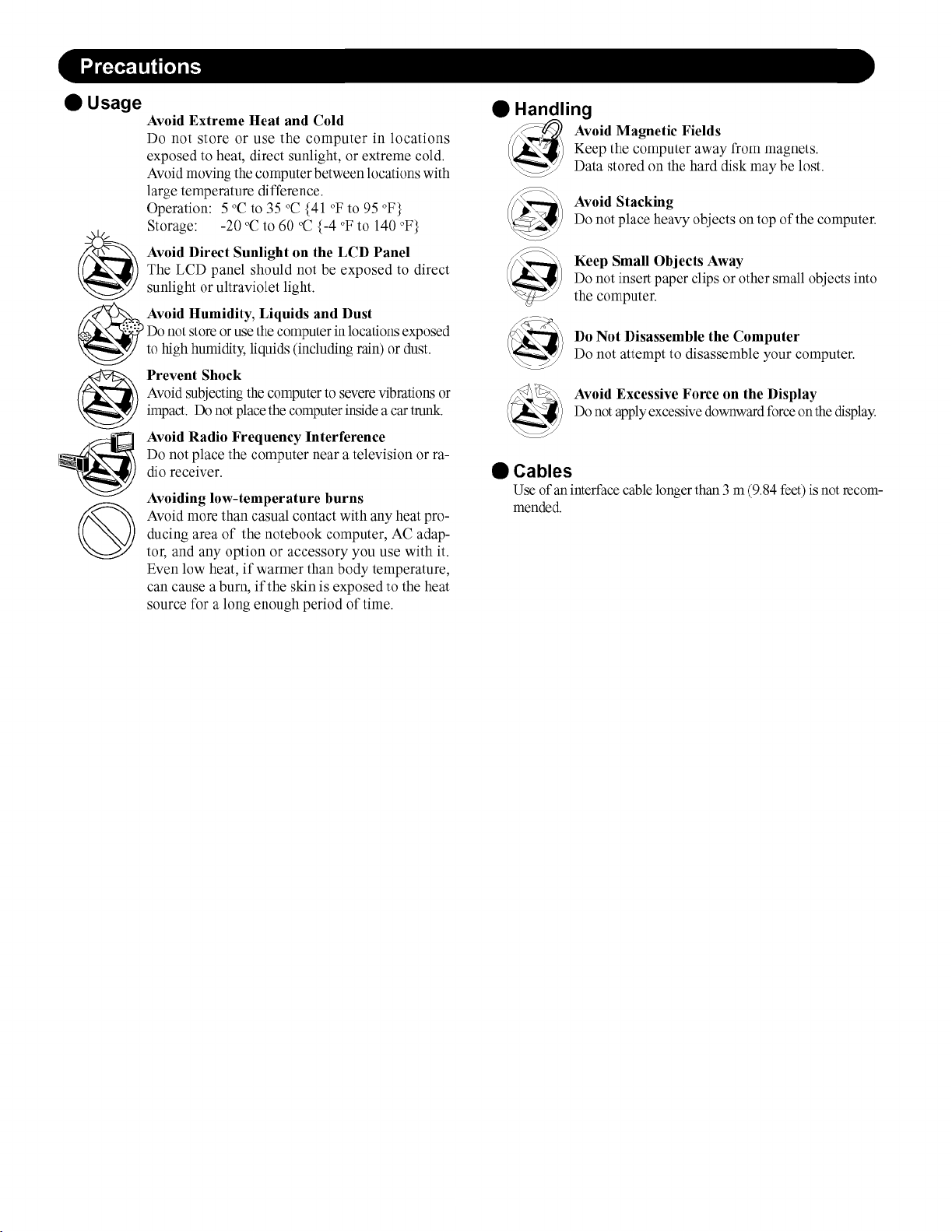

A Function key I Display (internal LCD/Touchscreen)

B Keyboard J Speaker

C LEDs K LAN Port

D Touch pad L Modem Port

E Power switch/Power indicator M Security lock

F Wireless LAN switch M USB Ports

G Economy-mode (ECO) indicator O Wireless LAN Antenna (built-in)

WIRELESS LAN

ECO

H Battery indicator

11

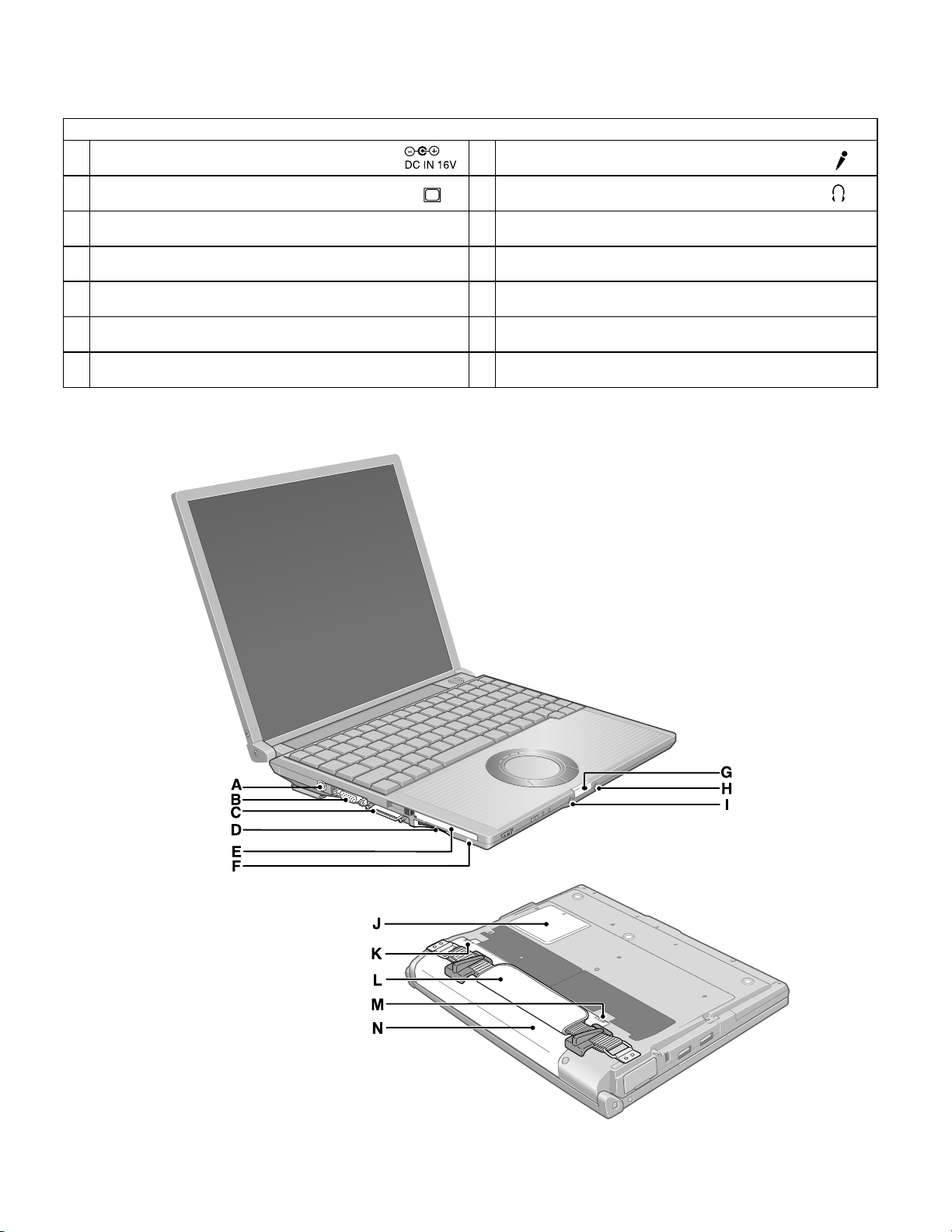

Page 13

Names

A DC-IN Jack

B External Display Port

C Mini Port Replicator Connector

D SD Memory Card Slot

E PC Card Slot

F

SD Memory Card Indicator

G Latch

EXT.

H Microphone Jack

I Headphone Jack

J RAM Module Slot

K Latch

L Hand strap

M Latch

N Battery Pack

11-1

Page 14

4 Diagnosis & Repair

4.1. Basic Procedures

12

Page 15

4.2. Troubleshooting

13

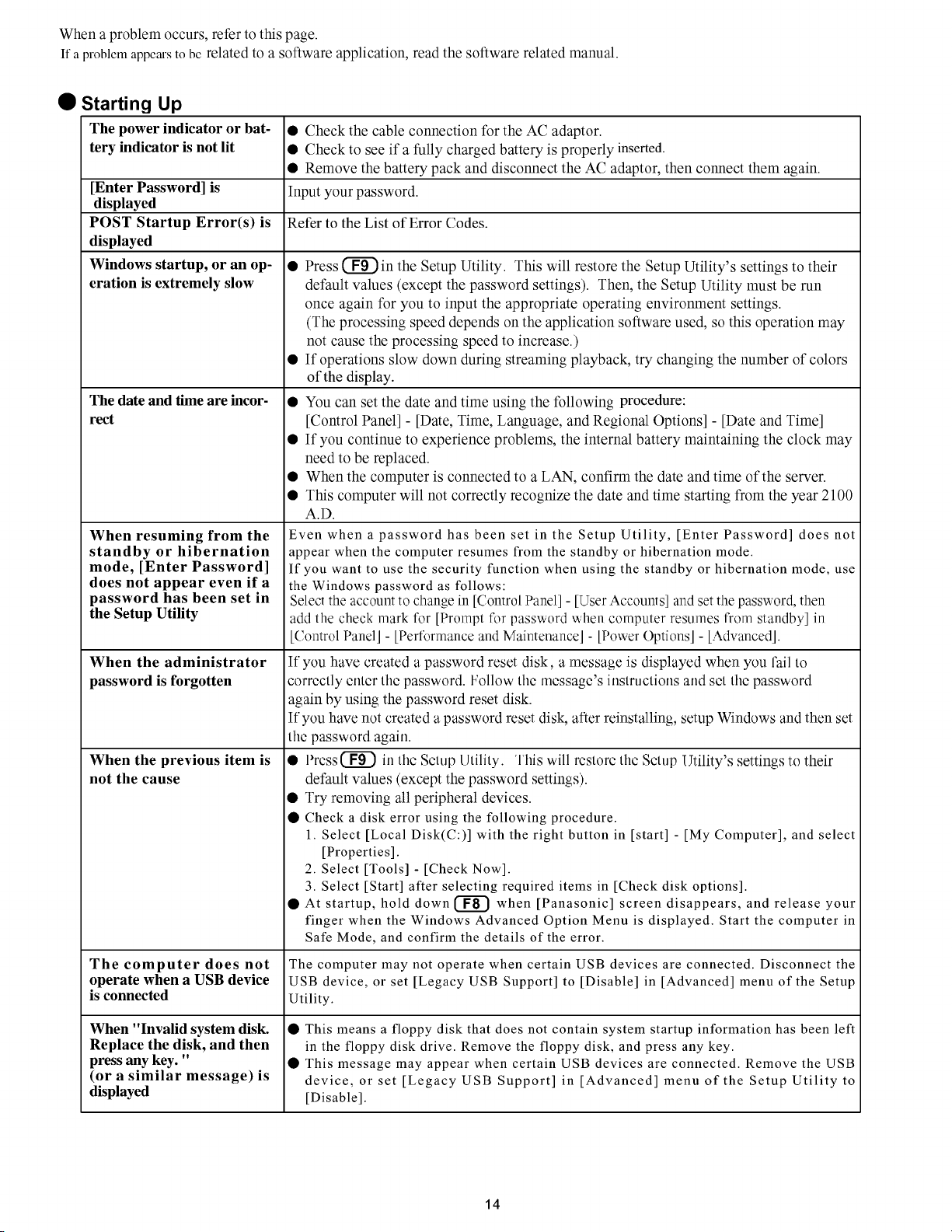

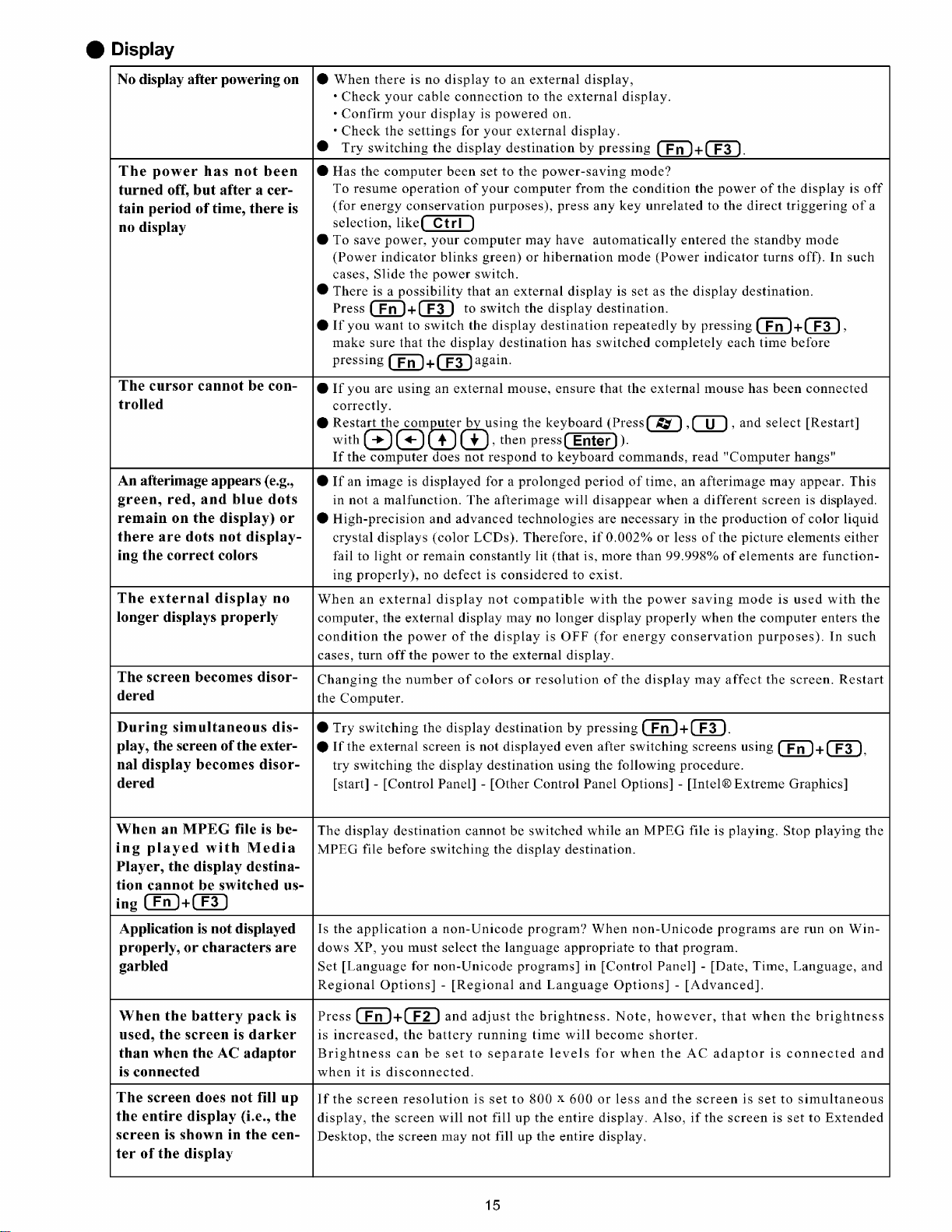

Page 16

Page 17

Page 18

Page 19

Page 20

ServerBIOS2 test error: Cannot write to extended DMA (Direct Memory Access) registers.

ServerBIOS2 test error: Cannot generate software NMI (Non-Maskable Interrupt).

ServerBIOS2 test error: Fail-Safe Timer takes too long.

Page 21

4.3. ConnectionDiagram

LCD/Touch Panel

LCD Back Light

Inverter Board

Connection by Cable

Direct connection Connectors

Parts on Bottom Side

Antenna Board

(R)

1

Battery Pack

LAN Module

4

Wireless

3

Antenna Board

(L)

Connection Cable

1 LCD/TP Cable DFJS963ZA

2 Speaker Cable DFJS962ZA

3 Antenna PCB-L N1ZYYY000002

4 Antenna PCB-R N1ZYYY000003

5 Modem Cable DFJS973ZA

6 LAN Cable DFJS958ZB

7 PAD FFC DFJK12U112BB

8 HDD FPC Unit DL3UP1443AAA

9 DC-IN Cable DFJS961ZB

10 Main-Sub Cable DFJS980ZA

2

Speaker

Keyboard

DC-IN

MODEM

SD Card

PCMCIA

SLOT

CN601

CN26

CN12

CN10

CN600

CN22

CN18

CN11

CN13

SW6

POWER SW

Main Board

CN2

CN19

CN14

CN16

JK2

Headphone

VGA

9

5

CN24

CN23

CN3

CN21

CN15

CN4

JK1

Mic

Lithium Battery

HDD

8

10

CN1051

CN1053

USB

CN1052

USB

7

DIMM memory

(Option)

CF-BAV0256U

CF-BAV0512U

LAN

19

6

Touch Pad

Page 22

4.4. Power-on Self Test (Boot Check)

4.4.1. Outline of POST

4.4.2. Error Diagnosis by Checking Beep Signal Sound

20

Page 23

4.4.3. Diagnosis by Error Code

Error code Message Error Description Possible faulty part

0200 Failure Fixed Disk Fixed disk in not working or not configured properly. HDD

0211 Keyboard error Keyboard not working. Confirm the keyboard is connected Keyboard

0212 Keyboard Controller Failed Keyboard controller failed test. Main board

0230 System RAM Failure System RAM failure at offset

at offset :

0231 Shadow RAM Failure Shadow RAM failure at offset

at offset :

0232 Extended RAM Failure Extended memory not working or not configured properly Main board

at offset :

0250 No battery on the system CMOS backup battery exhausted. Lithium battery

0251 System CMOS checksum System CMOS has been corrupted or modified incorrectly, Incorrect Setup

bad perhaps by an application program that changes data Lithium battery

-Default configuration used stored in CMOS.

0260 System timer error The timer test failed. Requires repair of system board. Main board

0270 Real time clock error Real-time clock fails BIOS test. May require board repair. Main board

0271 Check date and time Incorrect date and time on the system. Incorrect Setup

settings Set the correct date and time using the setup utility.

0280 Previous boot incomplete Previous POST did not complete successfully. Boot-up failure

-Default configuration used POST loads default values and offers to run Setup.

02D0 System cache error CPU trouble. Main board

-Cache disabled

02F5 DMA Test Failed Server BIOS2 test error: Cannot write to extended DMA Main board

nnnn

nnnn

nnnn

Run the Setup Utility and check that the hard disk Main board

capacity is displayed at [Primary Master].

If the [None] is displayed, disk error is occurred.

to the computer and that a key is not being held down.

May require replacing keyboard controller.

nnnn

of the 64k block at Main board

which the error was detected. If you installed RAM module,

remove the RAM module and reinstall it.

nnnn

of the 64k block at Main board

which the error was detected. If you installed RAM module,

remove the RAM module and reinstall it.

at offset

Battery replacement is required.

The BIOS installed Default SETUP Values. If you do not

want these values, enter Setup and enter your own values.

If the error persists, check the system battery or contact

Panasonic.

If the failure was caused by incorrect values and not

corrected, the next boot will likely fail.

nnnn.

Extension memory

21

Page 24

5. Self Diagnosis Test

1. Floppy disk is included for the self-diagnostic tests that should be performed before using this product.

2. Connect External Floppy Disk Drive (FDD) to USB port for diagnosis test.

Important notice

System password

This product has a password function. If this function is turned on, the self-diagnostics tests will not work.

You will need ask the user for the password before performing the self-diagnostics.

5.1. Outline of Self Diagnostic Tests

Insert the diagnostics floppy disk

● Starting up the setup utility

① Turn on the power.

② When "Panasonic Press F2 to enter setup" appears

on the screen, press F2.

Return the setup

contents to default

③ Press "→" to select 「Exit」

④ Press "↓" to select 「Get default value」

⑤ Press Enter.

⑥ Choose Yes for "Load default Configuration now?"

⑦ Select "Save Values & Exit" and press Enter.

⑧ Choose Yes for "Save Configuration changes and exit now?"

and press Enter.

Choose test from

the menu screen

to start the test.

Caution:

After completing repairs, be sure

to carry out the Automatic test

and Peripheraltest.

<Automatic test>

Tests selected (O) from the test

item list will be performed in

succession.

1. DIAG on FD

● Menu Screen 1

1. DIAG on FD

2. LAN test

3. SD I/F test

4. Modem test

5. Wireless LAN test (Wireless LAN Model only)

Q. Quit

Select please [1, 2, 3, 4, 5, Q]?

<Peripheral test>

The parallel devices can be tested.

2. LAN test

3. SD I/F test

4. Modem test

5. Wireless LAN test

(Wireless LAN Model only)

<Test selection>

Specifc tests required can

be freely selected and

performed from the test item

list.

Be sure to carry out the Selection

test only when necessary.

Problems in the unit are located and divided according

to error messages that occur during testing.

22

Page 25

1. DIAG on FD

2. LAN test

3. SD I/F test

4. Modem test

5. Wireless LAN test (Wireless LAN Model only)

Q. Quit

Select please [1, 2, 3, 4, 5, Q]?

menu screen

Page 26

Page 27

1. DIAG on FD

2. LAN test

3. SD I/F test

4. Modem test

5. Wireless LAN test (Wireless LAN Model only)

Q. Quit

Select please [1, 2, 3, 4, 5, Q]?

menu screen

2. When A:\DIAG appears, input "JDG_T4H, EXE" and press Enter.

Page 28

Order of test flow selection

Input screen startup

1. Reading the test conditions settings file

Press "ALT" and "F".

2

Press "L".

3

Press "ALT" and "O".

4

Press Enter.

2. setting the test items

Press "ALT" and "S".

2

Press "S".

3

Choose the test item and press Enter.

4

Choose the test whose settings are

to be changed, press "A" for Additional

and "R" for Erase.

All initial values are "0" so set

tests other than the necessary ones to "1".

Press "O" twice to return the menu screen.

5

To save the selected list, press "ALT" and "F" at the file menu.

6

Starting the test

Press "ALT" and "R".

Press "R".

This will start the test.

If the test condition settings

file is not read, this means

the test program is not running correctly..

If you change the file name when

saving the file in step , you can

create test condition settings for

custom test items.

Example:

CF-T4 .

End of test

[ Saving selected test items ]

6

TEST1.

* * *

* * *

26

Page 29

6. Disassemblyinstructions

6.1. DisassemblyFlowChart

Main Unit

6.2.1.

Preparation

1. End the Windows.

2. Turn off the power, and then remove the AC adaptor or battery pack.

3. Remove any optional DIMM memory cards or PCMCIA cards.

4. Remove any other peripherals or connected devices.

6.2.9. 6.2.10.

Antenna Board

(L, R) / DC-IN

Display Unit

6.2.13.

6.2.14.

6.2.15.

LCD Unit / LCD Rear

6.2.16.

6.2.2.

6.2.4.

6.2.7.

LCD Unit

Hinge Cover

Inverter

USB Board

Wireless LAN Module

Keyboard

Top Case

Main replaceable parts

6.2.1.

6.2.2.

6.2.3.

6.2.4.

6.2.5.

6.2.6.

6.2.7.

Battery Pack

DIMM Cover

AC Adaptor

Keyboard

HDD

HDD Case

Top Case

Side Cover (R)

Touch Pad

Pad Cover

PAD Button

PAD FPC

LCD Knob

Speaker

USB Board

USB Cable

6.2.3.

HDD

6.2.5. 6.2.6.

Touch Pad

LCD Knob /Speaker

6.2.8.

Main Board

6.2.11. 6.2.12.

MODEM

Card Bus Ejector

6.2.8.

6.2.9.

6.2.10.

6.2.11.

6.2.12.

6.2.13.

6.2.14.

6.2.15.

6.2.16.

Main Board

Antenna Board (L, R)

DC-IN Cable

Wireless LAN Module

MODEM

Card Bas Ejector

LCD Unit

Hinge Cover

Hinge (L, R)

LCD Unit

LCD Rear

LCD Front

Inverter

LCD Cable

27

Page 30

6.2. Disassembly

6.2.1. Preparation

Attention:

Before disassembly, be sure to perform the following steps.

1. End the Windows.

2. Turn off the power and then remove the AC adaptor.

3. Slide the hooks (A) and then remove the battery pack.

4. Remove the screw (A) and then remove the DIMM cover.

(Remove if the DIMM memory is equipped with)

Screw (A) : XSB2+4FNL(N16)

Baattrey Pack

Hook(A)

3. The LCD unit is opened up to about 90° by operating the

LCD knob.

4. Remove the 6 hooks (B).

5. Open the keyboard from LCD side and then turn it inside

out on the top case.

Note:

It can remove with the keyboard hook plate.

LCD Unit

Hook(B)

Screw(A)

DIMM Cover

6.2.2. Removing the Keyboard

Preparation : perform the section 6.2.1. first.

1. Remove the 4 screws (B).

Screw(B):DXQT2+E12FNL(N11)

2. Remove the 2 keyboard hook plates, and then remove the

hook of back side of keyboard with screw driver.

Screw(B)

Keyboard Hook Plate

Screw(B)

Screw(B)

Keyboard Hook Plate

LCD Knob

6. Remove the heat spreader from buttom of the keyboard.

7. Remove the keyboard FFC from the connector (CN15) and

then remove the keyboard.

Heat Spreader

KeyBoard

CN15

Hook(B)

28

Page 31

6.2.3. Removing the HDD

Preparation : perform the section 6.2.1. 6.2.2. first.

1. Remove the 2 screws (C) and then remove the HDD cover.

Screw (C):DFHE5025XA(N501)

Screw(C)

HDD Cover

6.2.4. Removing the Top Case

Preparation : perform the section 6.2.1. , 6.2.2. first.

1. Remove the 7 screws (D) and 5 screws (G).

Screw (D):DXHM003 9ZA(N5)

Screw (G):DXHM0057ZA(N7)

Screw(G)

Screw(D)

Screw(D)

Tape

2. Lift up the HDD unit and remove FFC connector and then

remove the HDD unit.

3. HDD is taken out of the HDD case.

Note:

Please do not bend pins of the HDD connector, at the

time of removing HDD and FFC connector.

HDD Case

HDD

FFC Connector

HDD Unit

HDD FFC

Screw(D)

Screw(G)

Screw(G)

Screw(G)

Screw(D)

Screw(G)

2. Remove the speaker cable from the connector (CN26).

3. Remove the side cover (R) as slide it to this side.

4. Remove the 1 screw (J), 3 screws (K) and 2 screws (L) from

top case and then remove the top case.

Screw(J):DXHM0056ZA(N6)

Screw(K):DXQT2+E6FNL(N12)

Screw(L):DXQT26+D8FCL(N15)

Screw(L)

Screw(K)

CN26

Speaker Cable

Screw(J)

Screw(K)

Screw(L)

29

Screw(K)

Side Cover(R)

Page 32

5. Lift up the top case and remove the pad FFC and then

remove the top case.

Top Case

6.2.5. Removing the Touch Pad

Preparation : perform the section 6.2.1. , 6.2.2. and 6.2.4.

first.

1. Peel off the tape.

2. Depress to center the 6 hooks of the pad cover, (D) (E)(F)

as order.

Tape

Pad FFC

Top Case

Hook(F)

PAD FFC

Hook(E)

Hook(F)

Hook(D)

3. Remove the hook (G) and remove the touch pad.

Pad Cover

Touch Pad

Pad Button

Hook(G)

30

Hook(G)

Page 33

6.2.6. Removing the LCD Knob and the

Speaker

Preparation : perform the section 6.2.1. , 6.2.2. and 6.2.4.

first.

1. Remove the latch spring from the top case.

2. Remove the hook of the LCD knob from stopper rib of the

top case.

3. Peel off the tape of the speaker box.

4. Peel off the tape on the speaker and speaker ring and then

remove the speaker.

Speaker Box

Speaker

Speaker

Ring

Latch

Spring

LCD Knob

Location of the Spring

6.2.8. Removing the Main Board

Preparation : perform the section 6.2.1. , 6.2.2. and 6.2.4.

first.

1. Remove the 1 screw (E), 1 screw (F), 2 screws (H) and 2

screws ( I ).

Screw (E):DXQT2+E10FNL(N10)

Screw (F):DXQT2+D4FNL(N9)

Screw (H):DFHE5035ZB(N2)

Screw ( I ):KIYE50000022(N500 )

Screw(H)

Screw(E)

Screw(F)

2. Remove the 2 screws (N).

Screw (N):DXQT2+E 6FNL(N13)

3. Remove the modem cable from the MDC modem.

4. Remove the side cover(L) from the bottom case.

Side Cover(L)

Antenna Board(L)

DC Jack

Holder

Screw(N)

Screw(N)

Screw(I)

6.2.7. Removing the USB Board

Preparation : perform the section 6.2.1. , 6.2.2. and 6.2.4.

first.

1. Peel off the tape for clamp the USB cable.

2. Remove the connector (CN23) on the main board.

3. Remove the USB board from the bottom case.

CN23

USB Cable

Tape

2-Port USB Board

Modem Cable

Main Board

Tape

LAN Cable

31

Page 34

5. Remove the DC jack holder on the DC-IN jack.

6. Remove the LCD cable connectors (CN10,CN11,CN24).

LCD Cable

CN10

CN24

6.2.9. Removing the Antenna Board (L,R)

and the DC-IN Cable

Preparation : perform the section 6.2.1. , 6.2.2. , 6.2.4. and

6.2.8. first.

1. Remove the antenna cable(L) from the main terminal and

the antenna cable(R) from the AUX terminal and then

remove the antenna board(L, R) from the bottom case.

2. Remove the DC-IN cable(CN600) from the main board.

CN11

7. Turn it to arrow and remove the lithium battery connector

(CN3), LAN cable connector (CN16) and HDD FPC

connector (CN4) and then remove the main board.

Power Knob

LAN SW Knob

Tape

CN600

LAN

Cable

Antenna Board(L)

Antenna Cable(R)

Antenna Cable(L)

DC-IN

Cable

CN600

Antenna Board(R)

6.2.10. Removing the Wireless LAN

Module

Preparation : perform the section 6.2.1. , 6.2.2. , 6.2.4. and

6.2.8. first.

1. Peel off the tape on the wireless LAN module.

2. Open the wireless LAN module holding arms and remove

the wireless LAN module.

Tape

Lithium Battery

Cable

CN3

CN16

Wireless LAN Module

DC-IN Cable

Main Board

32

Page 35

6.2.11. Removing the MODEM

Preparation : perform the section 6.2.1. , 6.2.2. , 6.2.4. and

6.2.8. first.

1. Remove the 2 screws (O).

Screw (O):DXQT2+D25FNL(N8)

2. Remove the MODEM from main board connector (CN18)

as vertical.

Screw (O)Screw (O)

Modem

CN18

6.2.12. Removing the Card Bus Ejector

Preparation : perform the section 6.2.1. , 6.2.2. , 6.2.4. and

6.2.8. first.

1. Remove the 1 screw (P) from connection side of wireless

LAN.

Screw(P):DFHE5025XA(N1)

Screw(P)

Main Board

2. Turn to the card bus ejector side.

3. Remove the 2 hooks (C) from the connector (CN14).

Card Bus Ejector

CN14

Hook(C)

Main Board

33

Page 36

6.2.13. Removing the LCD Unit

Preparation : perform the section 6.2.1. , 6.2.2. and 6.2.4.

first.

1. Remove the 2 screws (M).

Screw(M):DXQT26+D5FNL(N14)

2. Remove the LCD cable from the connector (CN11) of the

main board.

3. Remove the inverter cable from the connector (CN10)

4. Remove the touch panel cable from connector (CN24).

Screw(M)

6.2.15. Removing the LCD Unit and the

LCD Rear

Preparation : perform the section 6.2.1. , 6.2.2. , 6.2.4. and

6. 2. 13. to 6.2.14 first.

1. Separate the LCD front and the LCD rear.

2. Remove the hinge (L).

Hook Position

LCD Unit

LCD Cable

CN10

CN11

Screw(M)

CN24

6.2.14. Removing the Hinge Cover

Preparation : perform the section 6.2.1. , 6.2.2. ,6.2.4 and

6.2.13. first.

1. Remove the 2 screws (Q) and then remove the hinge cover

(L,R).

Screw(Q):DRHM0076ZA(N3)

Screw(Q)

LCD Unit

HInge(L)

LCD Front

LCD Rear

Hinge(R)

6.2.16. Remove the Inverter

Preparation : perform the section 6.2.1. , 6.2.2. , 6.2.4. and

6.2.13 to 6. 2.15. first.

1. Remove the LCD cable from the inverter.

2. Peel off the conductive cloth(LCD cable) from the inverter.

3. Remove the inverter with inverter box.

LCD Front

LCD High voltage

2pin Wire Rod

LCD Hook

Hinge Cover(L)

2. Remove the 2 screws (R).

Screw (R):DRHM0076ZA(N3)

Screw(R)

Hinge Cover(R)

LCD Unit

Screw(Q)

Screw(R)

34

Inverter Box

Tape

Conductive Cloth

(LCD Cable)

LCD Cable

Page 37

6.3. Reassenbly instructions

6.3.1. Attention when CF-T4H series is repaired

· Please execute writing BIOS ID when you exchange the main board.

· Parts (sheet and rubber) etc. related various the conductive cloth and heat spreader cannot be recycled. Use new parts.

6.3.2. Assembly knowhow of part LCD

LCD rubber, LCD side rubber and LCD backing rubber’s putting

LCD Rubber (Upper

LCD Rubber(Upper)

LCD Side Rubber

LCD Back Rubber(Lower)

LCD Front Case

LCD cable processing

Clamping processing of LCD cable, LCD connector connection and putting of PET tape of cable

The LCD insulation sheet is peeled off.

The LCD cable is processed to the LCD frame clamping.

The LCD cable is connected with the connector.

The PET tape is put.

LCD Insulation Sheet

A red line of the cable is matched to the LCD frame externals.

Big Small

PET Tape

LCD Front Case

1 2mm

1

Be parallel after putting

2mm

LCD Frame Clamp

0

1mm

Connector

Putting of the conductive cloth

The conductive cloth

Process the part in the Signal line of the LCD cable in

Put

the conductive cloth

There must not be beginning to see from externals.

is put and after putting a both side tape is put.

on the connector surely.

Connector of externals match

LCD Insulation Sheet

the conductive cloth.

Connector

Both Side Tape

35

Insulation Sheet of edge match

0

1mm

Conductive Cloth

(LCD Label)

LCD Cable

Page 38

Putting of PET Tape

The cable must not run aground on the damper.

Along the LCD module and put the LCD cable (Inverter part) with the PET tape.

Putting of rear damper

Putting of PET Tape

TS Board

LCD Cable

(Inverter part)

Damper

PET Tape

Rear Damper

Conductive Cloth (LCD Cable)

LCD Cable

Insulation Sheet of edge match

Conductive Cloth (LCD Cable)

LCD Cable

Rib application putting of LCD front case

0

1mm

Extemals suiting of Frame outside

0

1mm

Processing of inverter cable

PET Tape

Inverter Cable

The cable must not run aground on the cushion.

LVDS Cable of edge match

LCD Cable

LVDS Cable of edge match

0 1mm

The cable must not come in succession.

36

Page 39

Putting of gasket (LCD)

Put on hinge (R) surely.

The line of the remainder

is put on hinge (R) side.

Putting of LCD damper(C)

Rib application putting of LCD front case

0

Putting of LCD Hook Cushion

Specificatione affixation of LCD Hook Cushion

Hinge (R)

LCD Damper(C)

1mm

Rib edge match of LCD front case

1mm

0

Gasket (LCD)

Externals suiting of reflector

0

1mm

Put the reflector part surely.

Plinth externals match

0

1mm

Rib application putting of LCD front case

0

1mm

pressure is applied to

double-sided tape portion

0 0.5mm

K502

K70

0 0.5mm

0 0.5mm

Drawing out specification of LCD cable

LCD Cable (Touch Panel)

LCD Cable (Inverter)

The cable is processed under the shaft .

Note:It is confirmed that the cable does not narrow

between cabinets.

0 0.5mm

Putting of conductive cloth of LCD cable

70

3mm

Conductive cloth is wrapped

(Leave the half)

Hook is attached

to the left

37

Page 40

LCD cable processing

LCD Cable

8mm

6

Conductive Cloth

6.3.3. Installation and Line processing of Speaker

Putting of speaker fixation ring

About 8mm at the edge of conductive cloth is

putting on the rib of the bottom case for conduct

The cable is processed under the convex part

The cable is processed to the ditch

Speaker Fixation Ring

Processing of speaker cable

Putting of speaker box

Put according to 4 ribs.

Solder

Red line

Speaker Cable

The cable is not loosening between the rib and the pin.

Match case

Black line

Touch the boss

sign to the center in the terminal of the speaker.

2.5mm From the rib to the terminal

2

The double coating part of

the cable according to the ditch of the case

PET Tape

Putting of speaker box

0 2mm

38

Touch the Case’s wall

Page 41

6.3.4. Assembly of Touch Pad

Putting of PAD cover tape

2mm

1mm

PAD cover

Putting of PAD sheet

This line must

become vertical

PAD sheet

After putting of the

PAD sheet, the

Flaking off paper is

peeled off

Sets in the dent

PAD cover tape

0.5mm

1mm

Insertion of PAD FFC

PAD FFC

Putting of Touch Pad

PAD FFC is

inserted in the

connector.

(Direction where

the reinforcement

version is seen)

Touch Pad

Pin for positioning

The touch pad

is put

Touch Pad

6.3.5. Processing of DC-IN Cable and Coaxial Cable

Installation of Pad button

Puted in the gasket

ditch

Inserted in the

positioning pin

Pad button

Latch is inserted in the top case(4 places)

Putting of pad cover

The hooks are hooked

It is confirmed that all

LED lenses fit in the

hole of the pad cover

Pad Cover

The hooks are inserted

Coaxial cable

The cable is processed with

the boss between ribs

6.3.6. Obtaining of Side Cover (L)

The upper part is shut with

lower hooks put on the

bottom case.

Side Cover(L)

DC Jack Holder

the under hooks is hooked

the bottom case

The cable is processed to

the ditch of the bottom case

Confirm the terminal is vertical

the under hooks is hooked

the bottom case

39

Page 42

6.3.7. Processing of MODEM Cable and LAN Cable

Insert LAN cable

previously

LAN Cable

The cable is

processed with the

boss between ribs

MODEM Cable

PET Tape

Standard

The cable

must enter

in the set of

3-5mm

The state that the tension hangs is NG

6.3.8. Processing of USB Cable

Give slack

to the drawing

out part

USB Sheet

The USB sheet

is put and the

cable is held

HDD Unit

PET Tape

Do not run aground in the boss

Process the line to 3 cables in parallel based on

the difference of the concave part of the bottom

case

Order is USB, modem, and LAN cable from this

side

2mm 0 2mm

0

Boss

USB Board

The Cable must not enter under the

HDD unit

Do not run aground in the boss

PET Tape

6.3.9. Screw tightening procedure of Each Unit

When serving, the screw tightening is executed according to the undermentioned procedure.

1. Screw tightening of top case

1-1. DXQT2+E6FNL(K:N12) is tightened. No.1 to No.3

1-2. DXQT26+D8FCL(L:N15) is tightened. No.4 ,No.5

1-3. DXHM0056ZA(J:N6) is tightened. No.6

Screw(L)

Screw(K)

Screw(J)

Screw(K)

Screw(J)

40

Screw(K)

Page 43

2. Attachment preparation of Key Board

2-1. Putting of Heat Sheet KB Large

Inclination is set

to 0.5mm or less.

Inclination is set

to 0.5mm or less.

Touch the KB hole

Touch the KB hole

2-2. Putting of tape

0 0.5mm

0.5 1.5mm

0 1mm

Tape(KBD)

8 1mm

0 1mm

(KBD)

0.5 1.5mm

KeyBoard exterior and FPC are parallel.

3. Screw tightening of bottom case (1)

The keyboard is inserted, and after the keyboard hooks are inserted in order of a and b while holding the keyboard, the screw

tightening is done in the following order.

Note:The sheet metal must not run aground on the rib (Refer to the figure below).

2-1. DXHM0039ZA(D:N5) is tightened. No.1 to No.7

2-2. DXHM0057ZA(G:N7) is tightened. No.8 to No.12

Screw(D)

Screw(D)

Screw(G)

Screw(G)

Screw(G)

Screw(G)

Screw(D)

Screw(D)

Screw(D)

41

Screw(D)

Keyboard Hook b

Screw(D)

Keyboard Hook a

Screw(G)

Keyboard

Hook

OK

Top Case Rib

NG

Assembly reference chart

Top Case

Page 44

4. Screw tightening of bottom case (2)

The keyboard is inserted, and after tightening of the screw, the keyboard hooks are inserted in order of the following.

3-1. DXQT2+E12FNL(B:N11) is tightened. No.1 to No.4

3-2. DXQT2+D4FNL(F:N9) is tightened. No.5

3-3. DXQT2+E10FNL(E:N10) is tightened. No.6

3-4. DFHE5035ZA( H:N2) is tightened. No.7

3-5. DFHE5025XA(C:N501) is tightened. No.8

3-5. KIYE50000022(I:N500) is tightened. No.9

Screw(C)

Screw(B)

Screw(E)

Screw(F)

Screw(B)

Screw(B)

Screw(B)

Screw(H)

Screw(I)

6.3.10. Affixation of Win Logo Label (XP), CENTRINO Label and Energy Star Label

Win Logo Label(XP)

In the inclination at the time of putting the win logo label,

the CENTRINO label and energy star label the both ends

difference is within 0.2mm

<Attention>

Confirm whether the paste of the label has overflowed

after the win logo label and putting of the CENTRINO label

and energy star label.

2 5mm

CENTRINO Label

2

5mm

Energy Star Label

Top Case

42

2

5mm5 7mm

Page 45

A

A

V

K

g

g

VGA

7 Explanation of Harddware

7 1 System Block Diagram

DothanULV

TTTT

TTTT

BBBB

BBBB

4444

4444

llll

oooo

cccc

kkkk

DDDD

iiii

aaaa

gggg

rrrr

aaaa

llll

oooo

cccc

kkkk

DDDD

iiii

mmmm

aaaa

gggg

rrrr

aaaa

mmmm

DothanULV

DothanULVDothanULV

1.2GHz(/600MHz)

Core 0.940V(/0.812V)

FSB 1.05V

L2 Cache=2MB

CK410M

Micro-DIMM socket

172pin (Max.1GB)

Main Memory

(DDR2-SDRAM CSP)

512MB (32Mx16 x 8pcs)

HDD

2.5”

BIOS FLASH

1MB

SST49LF008

SST49LF008

SST49LF008SST49LF008

TPM

PAT

M-BUS

400MHz

North Bridge

Alviso

Alviso----GMS

GMS

AlvisoAlviso

GMSGMS

1.25V

South Bridge

ICH6

ICH6----MMMM

ICH6ICH6

1.5V

FSB 400MHz

DMI

USB1.1

USB2.0

USB2.0

Port Replicator

Connector (Config)

(for CRT)

LCD

12.1”

XGA

Touch Screen

Controller

)

(Confi

GA Port

USB2.0

x2

Port

Replicator

(Config)

USB2.0x4

HUB

Tou ch

Screen

(Confi

RJ45

)

Main

Battery

Li-Ion

Mic-JACK

HP-JACK

Speaker

(Mono)

Tou ch

PAD

EC, KBC

M306KA

M306KA

M306KAM306KA

Internal

KB

AC97

Codec

STAC9751

STAC9751

STAC9751STAC9751

LPC-BUS

3.3V

AC-LIN

3.3V

PCI-BUS

3.3V

43

Ethernet

Controller

RTL8101L

RTL8101L

RTL8101LRTL8101L

CB+SD

Controller

R5C811

R5C811

R5C811R5C811

MiniPCI

Type3

MDC

1.5

MDC

Modem

Module

DC-IN

RJ45

(LAN)

SD Card

PCMCI

Type-II

WLAN

Module

RJ11

(Modem)

Page 46

y

䌁䌃 A䌤䌡䌰ter

(DCIN JACK)

AC OVP

&UVP

䌌䌩䌮䌥 䌓䌗

to(*㪈)

AC㪈5

DCIN&BATT

䌆䌕䌓䌅

(2A)

䌂䌡䌣䌫 䌌䌩䌧䌨䌴

INVERTER 䌕䌎䌉䌔

VA5

Battery

+(㪈)

VBATT(3)

䌖䌁䋳(4)

VSEL㪈(5)

VSEL2(6)

SMBDATAE(7)

SMBCLKE(8)

BATDTCT#(9)

-(㪈0)

䌓䌡fety Block

VA5,VA3,VA㪈5

VB㪈8,VCPUCORE

VCCP,VC25

CHGON

EC

(M306K7)

䋨䋪䋱䋩

Safty Circuit

(OVP Detect)

䌌䌡䌴䌣䌨

to(*㪈)

䌌䌩䌮䌥 䌓䌗

Battery Charger

(LTC4008EGN)

CHGPWM

from batter

䌌䌩䌮䌥 䌓䌗

AC㪈5

VSENSE

ISENSE

BATDTCT#

to Line SW

䌌䌯䌡䌤 䌓䌗

䋳䋮䋳䌖䋯䋵䋮䋰䌖 DC/DC

CONVERTER Block

䋨䋨LTC3728LXCUH䋩

䌌䌯䌡䌤 䌓䌗

䌌䌯䌡䌤 䌓䌗

SLP_S3#

CPU CORE DC/DC

CONVERTER Block

䋨LTC3734EUH䋩

VCCP䇭VC25 DC/DC

CONVERTER Block

䋨LTC3728LXCUH䋩

VC5

SLP_S3#

VA3

VB3

SLP_S4#

VC3

䌖䌃PUCORE

VRON#

VRON#

VCCP(㪈.05V)

䌖䌃25

44

VA㪈5䇭 DC/DC

CONVERTER Block

䋨LTC3728LXCUH䋩

VB㪈8 DC/DC

CONVERTER Block

䋨LTC3728LXCUH䋩

VB㪈8

VC09 DC/DC

CONVERTER Block

䋨BD3533F-E2䋩

䌓䌌P_S3#

䌌䌯䌡䌤 䌓䌗

䌓䌌P_S4#

VA㪈5

VC㪈5

䌓䌌P_S3#

VB㪈8

䌖䌃09

Page 47

8. Extended View

8.1.Display Section

K7

E3

K37

K14

K17

K28

K30

K15

K30

K502

E501

N14

N3

K50

K60

K501

K4

K30

K29

K30

N14

E500

K50

K76

K18

K5

K68

K61

N3

K53

E17

K29

K22

K25

N3

K10

K500

K22

K65

K70

K27

K28

K25

Screw tightening torque

N3

Page 48

LCD Unit Ass'y / Pen Holder Section

K507

K506

K505

K503

K504

E501

E501-1-1

E501-1-2

E501-1-1

E501-1-4

E501-1-6

E501-1

E501-1-4

E501-1-3

E501-1-2

E501-1-5

E501-2

Page 49

8.2. Cabinet Section

K509

K1

K41

K41

K41

K8

E19

K42

E2

K54

N12

K39

N15

K16

K73

K51

K47

K40

K40

E18

K517

K72

N12

K88

K81

K508

K89

K72

N12

K31

K6

K69

K90

K13

K36

K64

a

N15

b

E12

K48

E15

K49

E7

Screw tightening torque

N6

Page 50

8.3. Bottom Section

K78

N1

N500

E14

CN14

N4

K530

E21

K59

CN13

SW6

SW7

K84

K79

CN22

h

N8

K75

E11

N2

K511

CN12

JK1

f

N8

JK2

K24

K82

K516

c

K71

K83

N13

g

c

CN601

CN24

e

K19

K80

d

K35

K26

E6

K77

E9

K85

a

E22

h

b

K515

K510

Screw tightening torque

K524

Tape

N15

A3

K55

K12

K514

K12

d

E5

CN1053

K55

K523

K524

CN1052

E13

K52

E4

i

N15

K513

N7

K2

N9

K3

N16

N5

K86

K62

N10

N7

N11

N5

K66-1

K66-1

N7

N11

K519

K66-1

K518

N7

N5

K520

N5

N5

K522

N5

N5

N11

N501

E10

K66

N11

e

E8

f

g

K512

E1

i

E20

K33

N501

K521

Page 51

9 Replacement Parts List

Note: Important Safety Notice

Components identified by mark have special characteristics important for safety.

When replacing any of these components, use only manufacturer's specified parts.

CF-T4HWETZBM

REF.NO. and AREA PART NO. DESCRIPTION Q'TY

Main Block Unit

CN12 K1FB315BA003 VGA CONNECTOR 1

CN13 K1NA09E00076 CONNECTOR 1

CN14 K1NA68E00096 CONNECTOR 1

CN22 K1FY150BA007 IO CONNECTOR 1

CN24 K1KA04BA0014 CONNECTOR 1

CN601 K1KA10B00233 CONNECTOR 1

CN1052 K1FB104B0055 USB CONNECTOR 1

CN1053 K1FB104B0055 USB CONNECTOR 1

JK1 K2HC103B0205 HEADPHONE JACK 1

JK2 K2HC103B0205 MICROPHONE JACK 1

SW6 ESD165225 POWER SW 1

SW7 K0D112B00071 W-LAN SW 1

SW951 K0D113B00081 SLIDE SW 1

E1 CR2032/S5Y LITHIUM BATTERY 1

E2 DFJK12U112BB PAD FFC 1

E3 DFJS963ZA TP CABLE 1

E4 DFJS958ZB LAN CABLE 1

E5 DFJS980ZA MAIN-SUB CABLE 1

E6 DFJS961ZB DC-IN CABLE 1

E7 DFJS962ZA SP CABLE 1

E8 DFJS973ZA MODEM CABLE 1

E9 DL3UP1436ABA PCB, MAIN RTL 1

E10 DL3UP1443AAA FPC UNIT, HDD 1

E11 N1ZYYY000002 ANTENNA PCB-L ASS'Y 1

E12 N1ZYYY000003 ANTENNA PCB-R ASS'Y 1

E13 DL3UP1477AAA PCB, 2-PORT USB RTL 1

E14 K1YYZZ000060 CONNECTOR 1

E15 L0AA01A00018 SPEAKER 1

E17 N0GB1J000012 INVERTER 1

E18 N2AZZJ000038 KEY BOARD US 1

E19 N2EAYYY00006 TOUCH PAD 1

E20 N3CAYYY00006 HDD 1

E21 N5HAZ0000012 MODEM 1

E22 N5HZC0000014 WIRELESS LAN MODULE 1

E500 DL3UP1498LAA PCB, TS RTL 1

E501 DFWV08A0083 LCD UNIT ASS'Y 1

E501-1 DFWV84A0266 TOUCH SCREEN PANEL KIT 1

E501-1-1 DFHG1824ZA FRONT TP CUSHION A 2

E501-1-2 DFHG1825YA FRONT TP CUSHION B 2

E501-1-3 DFHG1826ZA FRONT TP CUSHION C 1

E501-1-4 DFHG1837ZA FRONT TP CUSHION D 2

E501-1-5 DFHG1849ZB FRONT TP CUSHION E 1

E501-1-6 DFHR9063ZA PROTECTIVE FILM 1

E501-2 DFHR3630ZA TS FPC SPACER 1

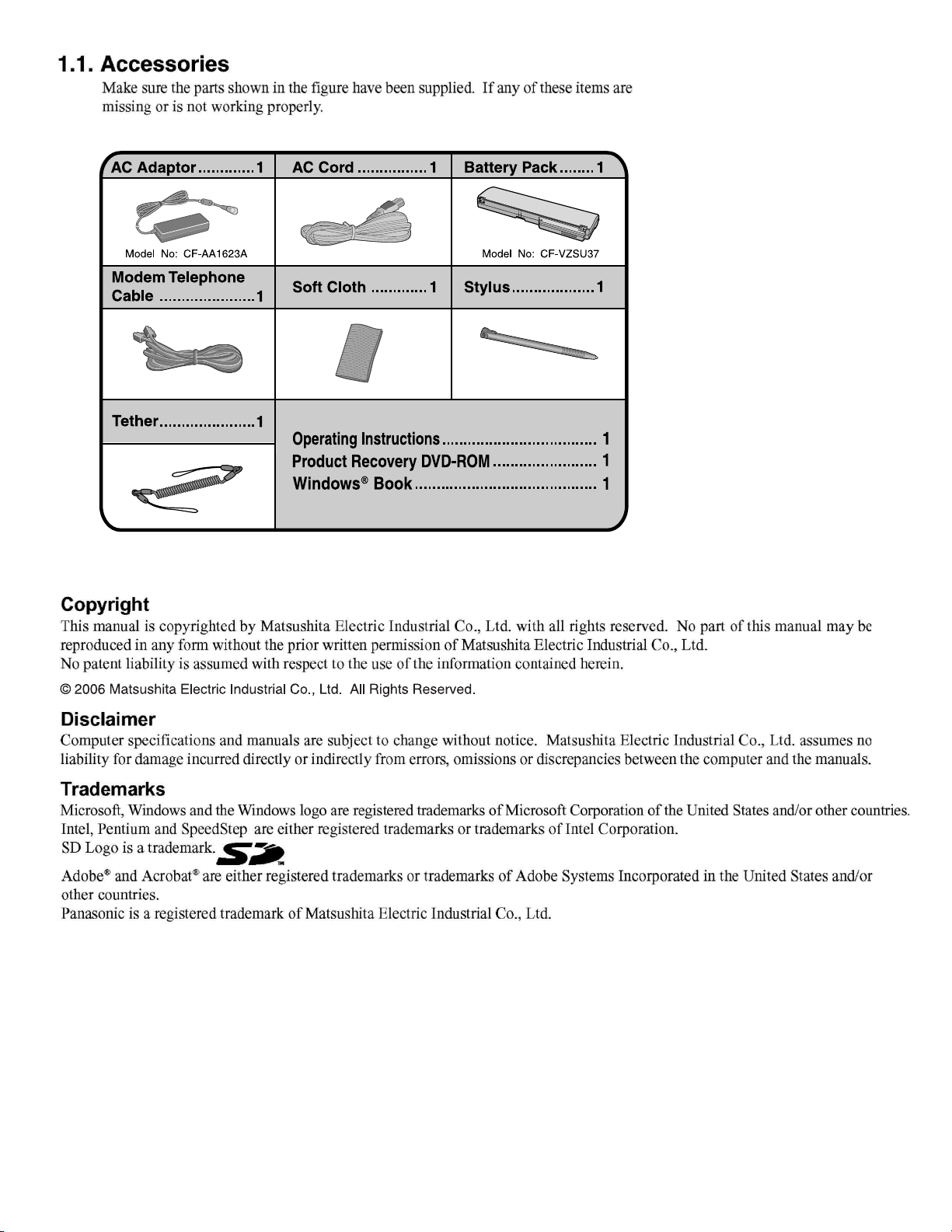

Accessories

A1 CF-AA1623AM6 AC ADAPTOR 1

A2 K2CG3DR00003 AC CABLE 1

A3 CGR-B/979A LITHIUM ION BATTERY PACK 1

A4 DFQX5573ZA MANUAL 1

A500 DFJS954ZA MODEM CABLE 1

A501 DFHR9081XA PEN 1

Page 52

A502 DFME0148ZA TETHER T4 1

A503 DFHS9017ZA CLOTH ASS'Y 1

Packing Material

P1 DFPE0806ZB HOLDER 1

P2 DFPE0812ZB PAD W 1

P4 DFPK1037YA ACCESSORIES BOX 1

P5 DFPK1194YA PACKING CASE 1

P6 DFPN0832ZA CUSHION T 2

P7 DFPN0833ZA CUSHION B 2

Mechanical Parts

K1 DFBC0315ZE-0 PAD BUTTON 1

K2 DFBD0180ZB-0 POWER KNOB 1

K3 DFBD0182ZA-0 LAN SW KNOB 1

K4 DFBH3041ZA HINGE-L TP 1

K5 DFBH3042ZA HINGE-R TP 1

K6 DFBS0068ZC-0 LCD KNOB 1

K7 DFGB0089VB-0 PANASONIC LABEL 1

K8 DFGE0108ZC-0 PAD COVER 1

K10 DFHG1811ZA LCD BATT RUBBER TP 1

K12 DFGX0428ZA-0 BATT SHEET(T4) 2

K13 DFHE0215ZA SHEET 1

K14 DFHE0436ZA CLOTH LCD CABLE 1 1

K15 DFHE0843ZA LCD MAGNET 1

K16 DFHE0844ZA GASKET PAD 1

K17 DFHE0943ZA GASKET CLOTH (LCD CABLE) 1

K18 DFHE0945ZA GASKET CLOTH (LCD) 1

K19 DFHE0953ZA SHEET 1

K22 DFHG1546ZB-0 LCD RUBBER 2

K24 DFHG1744ZA M-PCI CUSHION 1

K25 DFHG1766ZA-0 LCD SIDE RUBBER 2

K26 DFHG1767ZA-0 DC JACK HOLDER 1

K27 DFHG1771ZA LCD DAMPER A 1

K28 DFHG1821ZA LCD DAMPER B TP 2

K29 DFHG1773ZA LCD DAMPER C 2

K30 DFHG1822ZA LCD SIDE DAMPER TP 4

K31 DFHG1778ZA PCMCIA STOPPER CUSHION 1

K33 DFHG1809YA HDD CASE ASS'Y T4 USA 1

K35 DFHG1786ZA CPU CUSHION 1

K36 DFHG1787ZA MINI-PCI CUSHION 1

K37 DFHG1797ZA REAR DAMPER 1

K39 DFHP7098ZA KB TAPE 1

K40 DFHP7106YA BOTH SIDES TAPE 2

K41 DFHP7140ZA TAPE, CPU 3

K42 DFHP7221YA PAD SHEET 1

K47 DFHR3416ZA SPACER CU 1

K48 DFHR3A37ZA SPEAKER RING 1

K49 DFHR3A39ZA SPEAKER BOX 1

K50 DFHR3A78ZA LCD INSULATOR 2

K51 DFHR3A88ZA KB PLATE SHEET 1

K52 DFHR3C25ZA USB SHEET US 1

K53 DFHR3A95ZA INVERTER TAPE 1

K54 DFHR3B19ZA HINGE BACKUP SHEET T4 1

K55 DFHR3B22ZA BOTTOM BACKUP SHEET 2

K59 DFKE0772ZA-0 ANTENNA COVER-L 1

K60 DFKE0776ZA-0 HINGE COVER-L TP 1

K61 DFKE0777ZA-0 HINGE COVER-R TP 1

K62 DFKE0778ZA-0 DIMM COVER (LIGHT) 1

K64 DFKE0783ZA-0 SIDE COVER-R 1

Page 53

K65 DFKF0257ZA-0 LCD FRONT TP 1

K66 DFKF8166ZA-0 BOTTOM CASE USA ASS'Y 1

K66-1 DFHG371ZA-1 FOOT RUBBER 3

K68 DFKM0482ZA-0 LCD REAR (SANKI) 1

K69 DFKM8172XA-0 TOP CASE ASS'Y 1

K70 DFMD1196ZA LCD HOOK TP 1

K71 DFMD3121ZA MDC PLATE 1

K72 DFMD4057ZA KB HOOK F999 2

K73 DFMD7A52ZA KB PLATE 1

K75 DFMX0635ZB TAPE 1

K76 DFMX1155ZA INVERTER BOX 1

K77 DFMX1156ZA MAIN PW SHEET1 1

K78 DFMX1160ZA PCMCIA-MAIN SHEET 1

K79 DFMX1184ZA SW CABLE SHEET 1

K80 DFMY0399ZA MCH RUBBER 1

K81 DFMY3191YA HEAT SPREADER TOP 1

K82 DFMY3192ZA HEAT SPREADER BOTTOM 1

K83 DFMY3206ZA MEMORY SHEET TOP 1

K84 DFMY3207ZA MEMORY SHEET BOTTOM 1

K85 DFMY3208ZA W-LAN SHEET 1

K86 DFQT6299YA DIMM COVER SHEET 1

K88 DFQT9974ZA WINDOWS XP LABEL (FOR NOTE) 1

K89 DFQT9948ZA CENTRINO LABEL 1

K90 DFUD0040ZA LATCH SPRING 1

K500 DFHR3C02ZA BATT RUBBER TAPE 1

K501 DFHR3C01ZA TAPE TP 1

K502 DFHG1836ZA LCD HOOK CUSHION TP 1

K503 DFHG1810ZA-0 PEN HOLDER 1

K504 DFHP7223ZA PEN HOLDER TAPE 1

K505 DFHG1848ZA PEN FIX CUSHION 1

K506 DFHR3C48ZA PEN FIX SHEET 1

K507 DFHR3C44ZA HOLDER BOTTOM SHEET 1

K508 DFQT9675ZA ENERGY STAR LABEL 1

K509 DFHP7220ZB PAD COVER TAPE 1

K510 DFHR3B98ZA HDD FPC SHEET 1

K511 DFHR3C33YA LCD CABLE FIX SHEET 1

K512 DFKE0781ZA-0 RJ DUST COVER 1

K513 DFHP7228ZA RJ DUST COVER FIX TAPE 1

K514 DFHR3C13ZA RJ CABLE SHEET 1

K515 DFHR3C34ZA TP CABLE FIX SHEET 1

K516 DFHG1847ZA TP CABLE FIX CUSHION 1

K517 DFMY0421ZA HEAT SHEET KB LARGE 1

K518 DFGT1032ZA BOTTOM SHEET USA 1

K519 DFGT1075ZA BOTTOM SHEET USA 2 1

K520 DFGX0430ZA-0 BOTTOM HEAT SHEET 1

K521 DFGX0444ZA-0 HDD COVER HEAT SHEET 1

K522 DFKE0782ZA-0 HDD COVER 1

K523 DFKH1016ZA-0 HANDY STRAP 1

K524 DFMD1191YA HANDY STRAP ANGLE 2

K530 DFHE0603ZA LCD CONNECTOR SHEET 1

N1 DFHE5025XA SCREW 1

N2 DFHE5035ZB SCREW 2

N3 DRHM0076ZA SCREW 4

N4 DRQT2+G6FKL SCREW 1

N5 DXHM0039ZA SCREW 7

N6 DXHM0056ZA SCREW 1

N7 DXHM0057ZA SCREW 5

N8 DXQT2+D25FNL SCREW 3

N9 DXQT2+D4FNL SCREW 1

N10 DXQT2+E10FNL SCREW 1

Page 54

N11 DXQT2+E12FNL SCREW 4

N12 DXQT2+E6FNL SCREW 3

N13 DXQT2+E6FNL SCREW 2

N14 DXQT26+D5FNL SCREW 2

N15 DXQT26+D8FCL SCREW 6

N16 XSB2+4FNL SCREW 1

N500 K1YE50000022 SCREW, I/O PIN 2

N501 DFHE5025XA SCREW 2

Loading...

Loading...