Page 1

ORDER NO. CPD0811212CE

Notebook Computer

Model No.

CF-30KTPAXxM

This is the Service Manual for

the following areas.

M …for U.S.A. and Canada

© Panasonic Corporation 2008.

Unauthorized copying and distribution is a violation of law.

Page 2

For U.K.

WARNING

This apparatus must be earthed for your safety.

To ensure safe operation the three-pin plug must be inserted only into a standard three-pin power point

which is effectively earthed through the normal household wiring.

Extension cords used with the equipment must be three-core and be correctly wired to provide connection to earth. Wrongly wired extension cords are a major cause of fatalities.

The fact that the equipment operates satisfactorily does not imply that the power point is earthed and

that the installation is completely safe.

For your safety, if you have any doubt about the effective earthing of the power point, consult a qualified electrician.

FOR YOUR SAFETY PLEASE READ THE FOLLOWING TEXT CAREFULLY

This appliance is supplied with a moulded three pin mains plug for your safety and convenience.

A 3 amp fuse is fitted in this plug.

Should the fuse need to be replaced please ensure that the replacement fuse has a rating of 3 amps and

that it is approved by ASTA or BSI to BS 1362.

Check for the ASTA mark

If the plug contains a removable fuse cover you must ensure that it is refitted when the fuse is replaced.

If you lose the fuse cover the plug must not be used until a replacement cover is obtained.

A replacement fuse cover can be purchased from your local Panasonic Dealer.

IF THE FITTED MOULDED PLUG IS UNSUITABLE FOR THE SOCKET OUTLET IN YOUR

HOME THEN THE FUSE SHOULD BE REMOVED AND THE PLUG CUT OFF AND DISPOSED

OF SAFELY.

THERE IS A DANGER OF SEVERE ELECTRICAL SHOCK IF THE CUT OFF PLUG IS INSERTED

INTO ANY 13 AMP SOCKET.

If a new plug is to be fitted please observe the wiring code as shown below.

If in any doubt please consult a qualified electrician.

Warning: THIS APPLIANCE MUST BE EARTHED.

Important

The wires in this mains lead are coloured in accordance with the following code:

Green-and-yellow: Earth

Blue: Neutral

Brown: Live

As the colours of the wires in the mains lead of this apparatus may not correspond with the coloured

markings identifying the terminals in your plug, proceed as follows:

The wire which is coloured GREEN-and-YELLOW must be connected to the terminal in the plug

which is marked by the letter E or by the safety earth symbol

YELLOW.

The wire which is coloured Blue must be connected to the terminal which is marked with the letter N or

coloured BLACK.

The wire which is coloured Brown must be connected to the terminal which is marked with the letter L

or coloured RED.

or the BSI mark on the body of the fuse.

coloured GREEN or GREEN-and-

The mains plug on this equipment must be used to disconnect the mains power.

Please ensure that a socket outlet is available near the equipment and shall be easily accessible.

How to replace the fuse

Open the fuse compartment with a screwdriver and replace the fuse.

Warnings

This equipment is not designed for connection to an IT power system.

(An IT system is a system having no direct connections between live parts and Earth; the exposed-conduciveparts of the electrical installation are earthed.

An IT system is not permitted where the computer is directly connected to public supply systems in the U.K.)

Disconnect the mains plug from the supply socket when the computer is not in use.

This equipment is produced to BS800/1983.

Page 3

LASER SAFETY INFORMATION

For U.S.A

Class 1 LASER-Product

This product is certified to comply with DHHS Rules 21 CFR Subchapter J.

This product complies with European Standard EN60825 (or IEC Publication 825)

For all areas

This equipment is classified as a class 1 level LASER product and there is no hazardous LASER radiation.

Caution:

(1) Use of controls or adjustments or performance of procedures other than those specified herein

(2) The drive is designed to be incorporated into a computer-based system or unit which has

Danger:

The serviceman should not remove the cover of drive unit and should not service because

the drive unit is a nonserviceable part.

Please check DANGER label on PD-drive unit.

• Unplug the AC power cord to the equipment before opening the top cover of the drive.

When the power switch it on, do not place your eyes close to the front panel door to look into the interior

of the unit.

.

may result in hazardous radiation exposure.

an enclosing cover. It should never be used as a stand alone drive.

LASER Specification

Class 1 level LASER Product

Wave Length: DVD 658±8 nm

CD 775~815 nm

Laser safety information is appropriate only when drive with laser is installed.

Page 4

Vorsicht!

Explosionsgefahr bei unsachgemäßem Austausch der Batterie. Ersatz nur durch denselben order einen vom

Hersteller empfohlenen ähnlichen Typ. Entsorgung gebrauchter Batterien nach Angaben des Herstellers.

LITHIUMBATTERIES

ATTENTION: IL Y A DANGER D'EXPLOSION S' IL Y A REMPLACEMENT INCORRECT DE LA PILE.

REMPLACER UNIQUEMENT AVEC UNE PILE DU MÈME TYPE OU D'UN TYPE RECOMMANDÉ PAR LE

CONSTRUCTEUR. METTRE AU RÉBUT LES PILES USAGÉES CONFORMÉMENT AUX INSTRUCTIONS DU

FABRICANT.

PILE AU LITHIUM

SAFETY PRECAUTIONS

1. Before servicing, unplug the power cord to prevent an electric shock.

2. When replacing parts, use only manufacture's recommended components

for safety.

3. Check the condition of the power cord. Replace if wear or damage is evident.

4. After servicing, be sure to restore the lead dress, insulation barriers,

insulation papers, shields, etc.

Important Safety Instructions

When using your telephone equipment, basic safety precautions should always be followed to reduce the risk

of fire, electric shock and injury to persons, including the following:

1. Do not use this product near water, for example, near a bath tub, wash bowl, kitchen sink or laundry tub, in a

wet basement or near a swimming pool.

Avoid using a telephone (other than a cordless type) during an electrical storm. 2.

There may be a remote risk of electric shock from lightning.

3. Do not use the telephone to report a gas leak in the vicinity of the leak.

vicinity of the leak.

4. Use only the power cord and batteries indicated in this manual. Do not dispose of batteries in a fire.

They may explode. Check with local codes for possible special disposal instructions.

SAVE THESE INSTRUCTIONS

LITHIUM BATTERY

This computer contains a lithium battery to enable the date, time, and other

data to be stored. The battery should only be exchanged by authorized

service personel.

Warning! A risk of explosion from incorrect installation or misapplication may

possibly occur.

LITHIUM BATTERY

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replace only with the same or equivalent type battery recommended by the manufacturer.

Dispose of used batteries according to the manufacturer's instructions.

Page 5

Precautions (Battery Pack)

Do Not Use with Any Other Product

The battery pack is rechargeable and was intended for

the specified product. If it is used with a product other

than the one for which it was designed, electrolyte leakage, generation of heat, ignition or rupture may result.

Do Not Charge the Battery Using Methods Other Than

Those Specified

If the battery is not charged using one of the specified

methods, electrolyte leakage, generation of heat, ignition

or rupture may result.

Do Not Throw the Battery Pack into a Fire or Expose It

to Excessive Heat

Generation of heat, ignition or rupture may result.

Avoid Extreme Heat (Near the Fire, in Direct Sunlight,

for Example)

Electrolyte leakage, generation of heat, ignition or rupture

may result.

Do Not Insert Sharp Objects into the Battery Pack,

Expose It to Bumps or Shocks, Disassemble, or Modify It

Electrolyte leakage, generation of heat, ignition or rupture

may result.

Do Not Short the Positive (+) and Negative (-) Contacts

Generation of heat, ignition or ru pture may result. Do not

place the battery pack together with articles such as necklaces or hairpins when carrying or storing.

Do Not Use This Product with a Battery Pack Other

Than the One Specified

Use only the specified battery pack with your product.

Use of battery packs other than those manufactured and

supplied by Panasonic may present a safety hazard

(generation of heat, ignition or rupture).

A lithium ion battery that is recyclable

powers the product you have purchased.

Please call 1-800-8-BATTERY for

information on how to recycle this

battery.

L’appareil que vous vous êtes

procuré est alimenté par une batterie

au lithium-ion.

Pour des renseignements sur le recyclage de la batterie, veuillez composer le 1-800-8-BATTERY.

When the Battery Pack Has Become Degraded,

Replace It with a New One

Continued use of a degraded battery pack may generate

high levels of heat, cause a fire to start and cause the

pack to burst or explode.

Do not touch the terminals on the battery pack. The

battery pack may no longer function properly if the

contacts are dirty or damaged.

Do not expose the battery pack to water, or allow it to

become wet.

If the battery pack will not be used for a long period of

time (a month or more), charge or discharge (use) the

battery pack until the remaining battery level becomes

30% to 40% and store it in a cool, dry place.

This computer prevents overcharging of the b attery by

recharging only when the remaining power is less than

approx. 95% (when Economy Mode (ECO) is enabled:

75%) of capacity.

The battery pack is not charged when the computer is

first purchased. Be sure to charge it before using it for

the first time. When the AC adaptor is connected to

the computer, charging begins automatically.

Should the battery leak and the fluid get into your

eyes, do not rub your eyes. Immediately flush your

eyes with clear water and see a doctor for medical

treatment as soon as possible.

NOTE

The battery pack may become warm during

recharging or normal use. This is completely normal.

Recharging will not commence if internal tempera-

ture of the battery pack is outside of the allowable

temperature range (0 °C to 55 °C {32 °F to 131

°F}). ( Reference Manual “Battery Power”)

Once the allowable range requirement is satisfied,

charging begins automatically. Note that the

recharging time varies based on the usage conditions. (Recharging takes longer than usual when

the temperature is 10 °C {50 °F} or below.)

If the temperature is low, the operating time is

shortened. Only use the computer within the

allowable temperature range.

The battery pack is a consumable item. If the

amount of time the computer can be run by using a

particular battery pack becomes dramatically

shorter and repeated recharging does not restore

its performance, the battery pack should be

replaced with a new one.

When transporting a spare battery inside a pack-

age, briefcase, etc., it is recommended that it be

placed in a plastic bag so that its contacts are protected.

Always power off the computer when it is not in

use. Leaving the computer on when the AC adaptor is not connected will exhaust the remaining battery capacity.

Getting StartedUseful InformationTroubleshootingAppendix

Page 6

CONTENTS

1. Specifications 1-1

2. Names and Functions of Parts 2-1

3. Block Diagram 3-1

4. Diagnosis Procedure 4-1

5. Power-On Self Test (Boot Check) 5-1

6. List of Error Codes <Only when the port replicator is connected> 6-1

7. Self Diagnosis Test 7-1

8. Wiring Connection Diagram 8-1

9. Disassembly/Reassembly 9-1

10. Exploded View 10-1

11. Replacement Parts List 11-1

Page 7

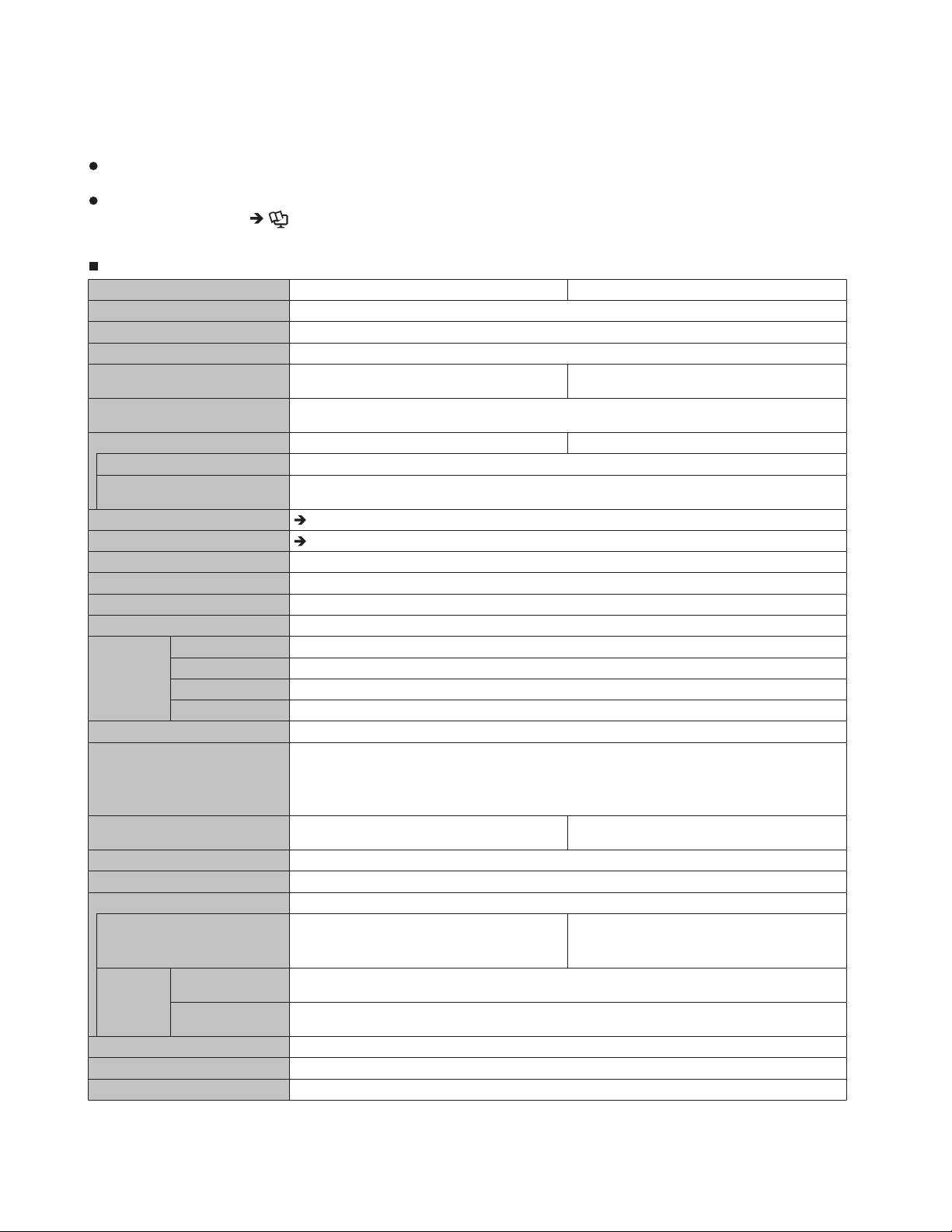

1. Specifications

This page provides the specifications for the basic model.

The model number is different according to the unit configuration.

To check the model number:

Check the bottom of the computer or the box the computer came in at the time of purchase.

To check CPU speed, memory size and the hard disk drive (HDD) size:

Run the Setup Utility (

[CPU Speed]: CPU speed, [System Memory]: Memory size, [Hard Disk]: Hard disk drive size

Main Specifications

Memory

Video Memory

Hard Disk Drive

Display Method 13.3 XGA type (TFT) with Touchscreen 13.3 XGA type (TFT)

Wireless LAN

Bluetooth™

Security Chip TPM (TCG V1.2 compliant)

Card Slot PC Card Type I or Type II x 1 (3.3 V: 400 mA, 5 V: 400 mA)

RAM Module Slot 200-pin, 1.8 V, SO-DIMM, DDR2 SDRAM, PC2-5300 Compliant

Keyboard / Pointing Device 87 keys / Touch Pad / T

Power Supply AC adaptor or Battery pack

AC Adaptor

Battery Pack Li-ion 10.65 V, 8.55

Clock Battery Coin type lithium battery 3.0

Power Consumption

Physical Dimensions (W × H × D) 302 mm × 67.5 - 69.5 mm × 292 mm {11.9" × 2.7 - 2.8" × 11.5"}

*1*2

*1*3

Internal LCD

*5

External Display

*7

*8

ExpressCard ExpressCard/34 or ExpressCard/54 x 1

SD Memory Card

Smart Card

*13

Operating Time

Charging

Time

Power on Main Battery: Approx. 8.5 hours

*14

Power off Main Battery: Approx. 5 hours

*4

*6

*14

*16

Reference Manual “Setup Utility”) and select [Information] menu.

GHz

6.1( 0039LS rossecorP ouD 2 ™eroC ®letnIUPC

tespihC sserpxE 54SG ®letnI eliboMtespihC

2 GB (4 GB Max.)

UMA 797 MB Max. (When Memory is 2 GB)/

1551 MB Max. (When Memory is 4 GB)

GB

160

Approx. 2 GB is used as a partition with recovery tools. (Users cannot use this partition.)

65,536/16,777,216 colors (800 × 600 dots/1024 × 768 dots)

65,536/16,777,216 colors (800 × 600 dots/1024 × 768 dots/1280 × 768 dots/1280 × 1024

dots/1440 × 900 dots)

Next page

Next page

kbps

65 :ataDmedoM

(V.92) FAX: 14.4

kbps

WAVE and MIDI playback, Intel® High Definition Audio subsystem support, Monaural speakerdnuoS

*9

*10

*12

x 1, Data transfer rate = 8 MB per second

ISO7816 x 1

*11

(RJ-45), External display port (Mini Dsub 15-pin female), Expansion Bus Connector (Dedicated

80-pin female), External Antenna Connector (Dedicated 50

Interface Connector (4-pin x 1), Microphone Jack (Miniature jack, 3.5 DIA, Stereo), Headphone

Jack (Miniature jack, 3.5 DIA, Impedance 32 Ω, Output Power 4 mW × 2)

ouchscreen (Anti-

Re ection, Stylus (included) touch capable)

Input: 100 V to 240 V AC, 50 Hz/60 Hz, Output: 15.6 V DC, 5.0

Ah

Main Battery: Approx. 9 hours

Main Battery + Second Battery: Approx. 12.5

*15

hours

*15

Main Battery + Second Battery: Approx. 12.5 hours

Main Battery + Second Battery: Approx. 8 hours

V

*17

Approx. 50

W

/ Approx. 70 W (maximum when recharging in the ON state)

*1

MB

L2 cache, 1066

, 6

1 GB Max.

Ω

87 keys / Touch Pad

Main Battery: Approx. 10 hours

Main Battery + Second Battery: Approx. 14

*15

hours

MAXAP3K03-FCMJXAPTK03-FC.oN ledoM

coaxial connector), IEEE 1394a

A

MHz

FSB)

T-ESAB0001 ba3.208 EEEI ,XT-ESAB001 u3.208 EEEI ,T-ESAB01 3.208 EEEINAL

trop NAL ,)11-JR( trop medoM ,)elam nip-9 busD( trop laireS ,3 x )0.2 BSU ,nip-4( trop BSUecafretnI

*15

1-1

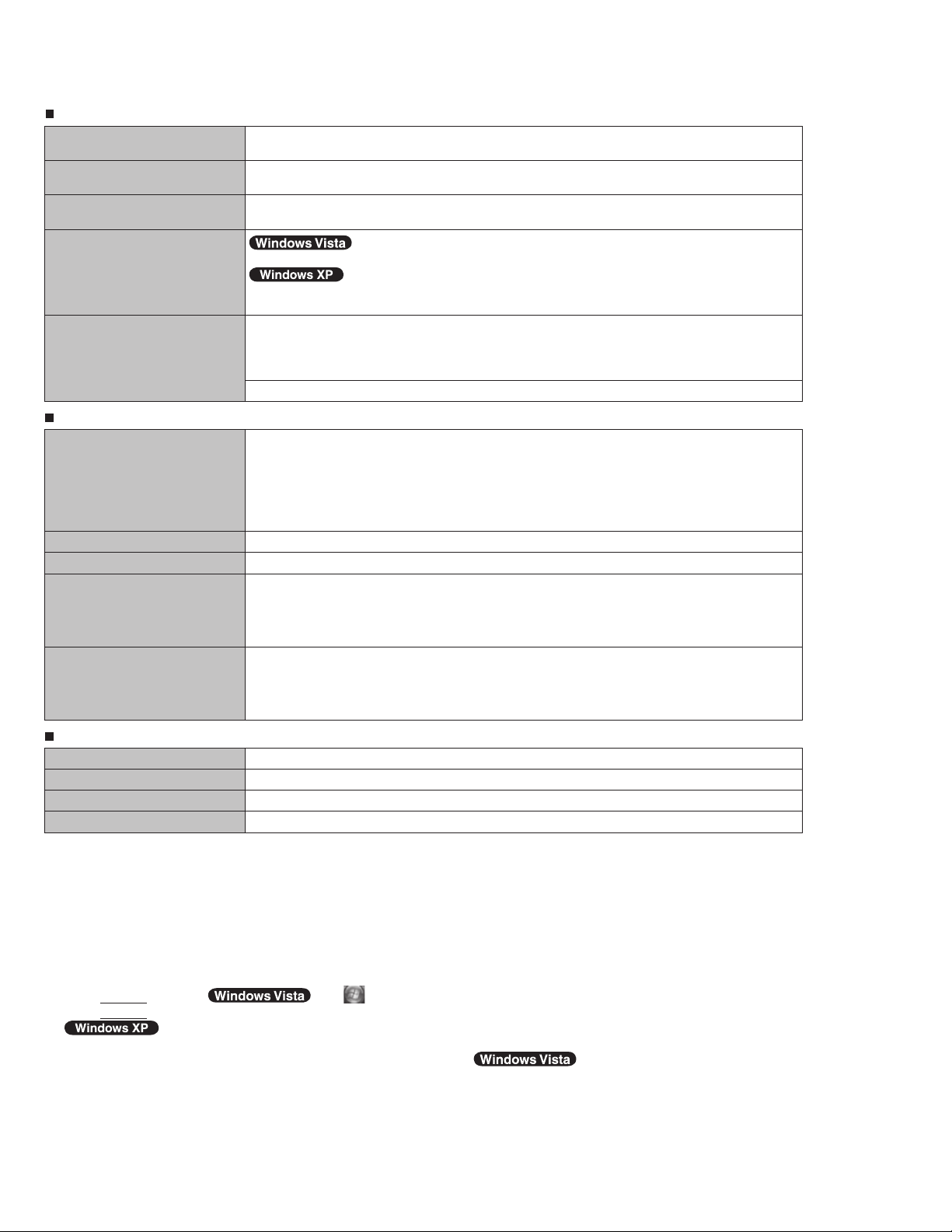

Page 8

Main Specifications

kg

8.3 .xorppAthgieW

(Approx. 50g {Approx. 1.8 oz.})

Operation Environment Temperature: 5 °C to 35 °C {41 °F to 95 °F}

Humidity: 30% to 80% RH (No condensation)

Storage Environment Temperature: -20 °C to 60 °C {-4 °F to 140 °F}

Humidity: 30% to 90% RH (No condensation)

Operating System

Windows Vista® Business Service Pack 1

Microsoft® Windows® XP Professional Service Pack 2 with Advanced Security Technologies

(NTFS File System)

Utility Programs Adobe Reader, PC Information Viewer, Loupe Utility, Intel® PROSet/Wireless Software

Bluetooth™ Stack for Windows

Battery Recalibration Utility, Panasonic Hand Writing, Infineon TPM Professional Package

Power Saving Utility, Wireless Connection Disable Utility

Setup Utility, Hard Disk Data Erase Utility

{Approx. 8.4 lb.}, excluding the dummy pack and dummy cards

®

by TOSHIBA*8, Wireless Switch Utility, Hotkey Settings,

*18

*20

, PC-Diagnostic Utility

, Concealed mode Utility

*19

*17

,

*18

,

.

Wireless LAN <Only for model with wireless LAN>

Data Transfer Rates IEEE802.11a : 54/48/36/24/18/12/9/6 Mbps (automatically switched)

IEEE802.11b : 11/5.5/2/1 Mbps (automatically switched)

*21

IEEE802.11g : 54/48/36/24/18/12/9/6 Mbps (automatically switched)

IEEE802.11n : (HT20) 144.4/130/117/115.6/104/86.7/78/65/58.5/57.8/52/43.3/39/28.926/19.5/

14.4/13/6.5 Mbps (automatically switched)

*21

(HT40) 300/270/243/240/216/180/162/130/120/117/108/104/90/81/78/60/54/52/

39/30/27/26/13 Mbps (automatically switched)

Standards Supported IEEE802.11a / IEEE802.11b / IEEE802.11g / IEEE802.11n(Draft 2.0)

Transmission method OFDM system, DSSS system

Wireless Channels Used IEEE802.11a : Channels 36/40/44/48/52/56/60/64/100/104/108/112/116/132/136/140/149/153/

157/161/165

IEEE802.11b/IEEE802.11g : Channels 1 to 11

IEEE802.11n : Channels 1-11/36/40/44/48/52/56/60/64/100/104/108/112/116/132/136/140/149/

153/157/161/165

RF Frequency Band IEEE802.11a : 5.18 GHz - 5.32 GHz, 5.5 GHz - 5.58 GHz, 5.66 GHz - 5.7 GHz, 5.745 GHz -

5.825 GHz

IEEE802.11b/IEEE802.11g : 2.412 GHz - 2.462 GHz

IEEE802.11n : 2.412 GHz - 2.462 GHz, 5.15 GHz - 5.35 GHz, 5.5 GHz - 5.58 GHz, 5.66 GHz -

5.7 GHz, 5.745 GHz - 5.85 GHz

*21

*21

*21

BluetoothTM <Only for model with Bluetooth>

Bluetooth Version 2.0 + EDR

Transmission method FHSS system

Wireless Channels Used Channels 1 to 79

RF Frequency Band 2.402-2.48

*1

1 MB = 1,048,576 bytes / 1 GB = 1,073,741,824 bytes

*2

You can physically expand the memory up to 4096 MB, but the total amount of usable memory available will be less depending

on the actual system configuration.

*3

A segment of the main memory is allotted automatically depending on the computer’s operating status. The size of the Video

Memory cannot be set by the user.

*4

1 GB = 1,000,000,000 bytes. Your operating system or some application software will report as fewer GB.

*5

A 16,777,216 color display is achieved by using the dithering function.

*6

Maximum resolution depends on the specifications of the external display. Display may be impossible using some connected

external displays.

*7

Only for model with wireless LAN

*8

Only for model with Bluetooth

*9

For information on TPM,

press

Enter

Platform Module (TPM)”.

*10

SD Memory Cards that support high-speed transfer rates can be used.

, and refer to the Installation Manual of “Trusted Platform Module (TPM)”.

click [start] - [Run] and input “c:\util\drivers\tpm\README.pdf”, and refer to the Installation Manual of “Trusted

GHz

click (Start) and input “c:\util\drivers\tpm\README.pdf” in [Start Search] and

Windows ReadyBoost function is also

supported.

Operation has been tested and confirmed using Panasonic SD Memory Cards and SDHC Memory Cards with a capacity of up to 8 GB.

Operation on other SD equipment is not guaranteed.

This computer is not compatible with MultiMediaCards. Do not insert these kinds of cards.

*11

The theoretical value is not the actual speed. The transfer rate does not become higher even if you use a card that supports the

higher transfer rate.

*12

Only for model with Smart Card slot

1-2

Page 9

*13

<Only for North America>

The AC adaptor is compatible with power sources up to 240 V AC adaptor. The computer is supplied with a 125 V AC compat-

ible AC cord.

*14

Varies depending on the usage conditions.

*15

Measured at LCD brightness: 60 cd/m

Varies depending on the usage conditions, or when an external device is attached.

*16

Approx. 0.9 W when the battery pack is fully charged (or not being charged) and the computer is OFF.

*17

Rated power consumption

*18

You need to install to use the feature.

*19

Concealed Mode may not work property during battery recalibration.

*20

The Product Recovery DVD-ROM is required.

*21

It does not correspond to IEEE802.11a+b+g+n standards. Actual speeds may differ.

20-M-2-1

23-E-1

2

1-3

Page 10

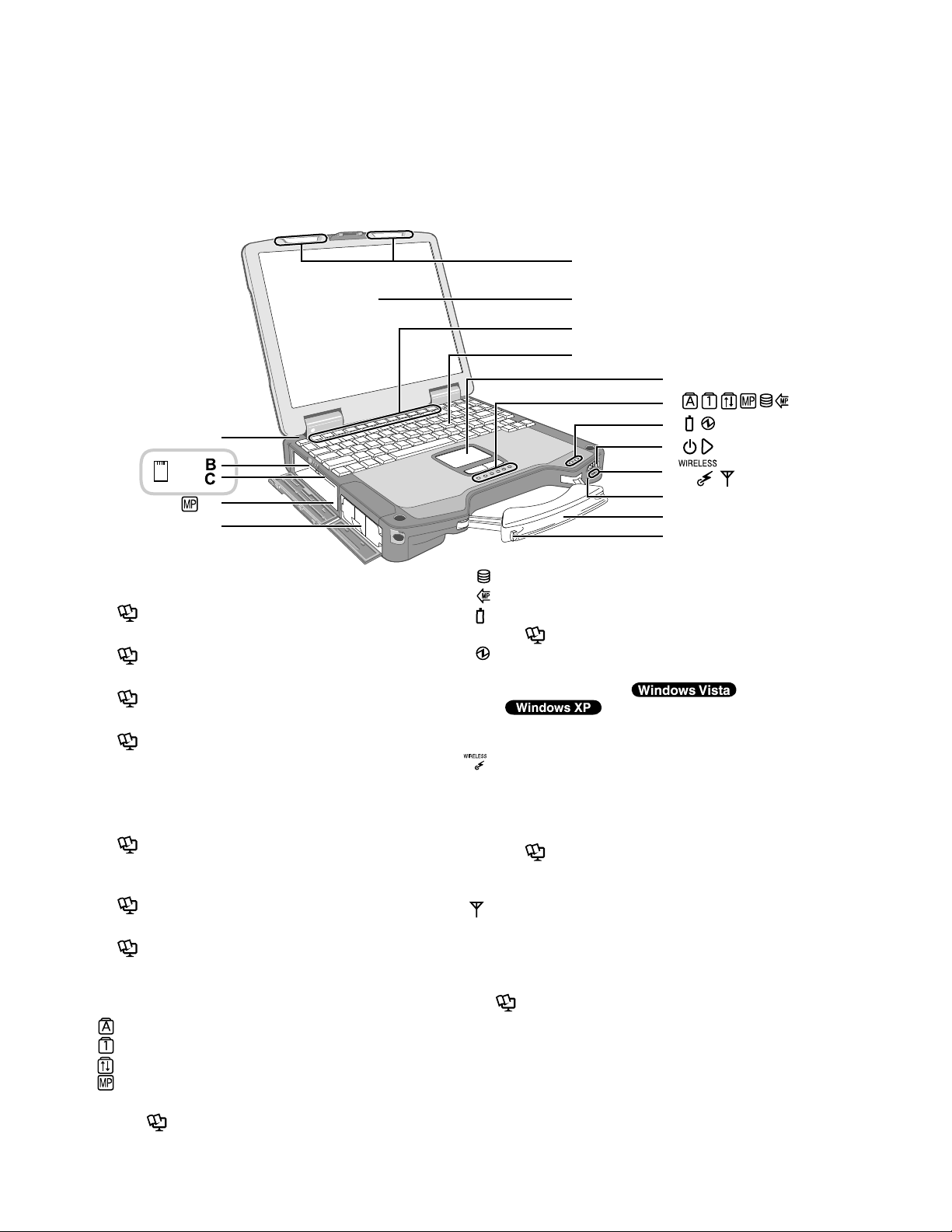

2. Names and Functions of Parts

A

EX

PC

D

E

F

G

H

I

J

K

K

L

K

M

N

O

A: Bluetooth Antenna

<Only for model with Bluetooth>

Reference Manual “Bluetooth”

B: ExpressCard Slot

Reference Manual “PC Card / ExpressCard”

C: PC Card Slot

Reference Manual “PC Card / ExpressCard”

D: Multimedia Pocket

Reference Manual “Multimedia Pocket”

E: Battery Pack

Specified Battery pack: CF-VZSU46

F: Wireless LAN Antenna

<Only for model with wireless LAN>

Reference Manual “Wireless LAN”

G: LCD

<Only for model with touchscreen>

Reference Manual “Touchscreen”

H: Function Key

Reference Manual “Key Combinations”

I: Keyboard

J: Touch Pad

K: LED Indicator

: Caps lock

: Numeric key (NumLk)

: Scroll lock (ScrLk)

: Multimedia pocket device status or the second

battery status

Reference Manual “Multimedia Pocket”

“Battery Power”

: Hard disk drive status

: Power status of the multimedia pocket

: Battery status

Reference Manual “Battery Power”

: Power status

(Off: Power off/Hibernation, Green: Power

on, Blinking green:

Standby, Blinking green rapidly:

Cannot power on or resume due to low temperature.)

: Wireless ready

This indicator lights when Wireless LAN, Bluetooth, and/or Wireless WAN are connected and

ready. It does not necessarily indicate the On/Off

condition of the wireless connection.

Reference Manual “Wireless LAN” “Bluetooth” “Disabling/Enabling Wireless Communication”

: Wireless WAN status

<Only for model with wireless WAN>

Refer to the instruction manual of the wireless device

L: Power Switch

M: Wireless Switch

Reference Manual “Disabling/Enabling Wireless

Communication”

N: Carrying Handle

O: Stylus Holder

Sleep/

2-1

Page 11

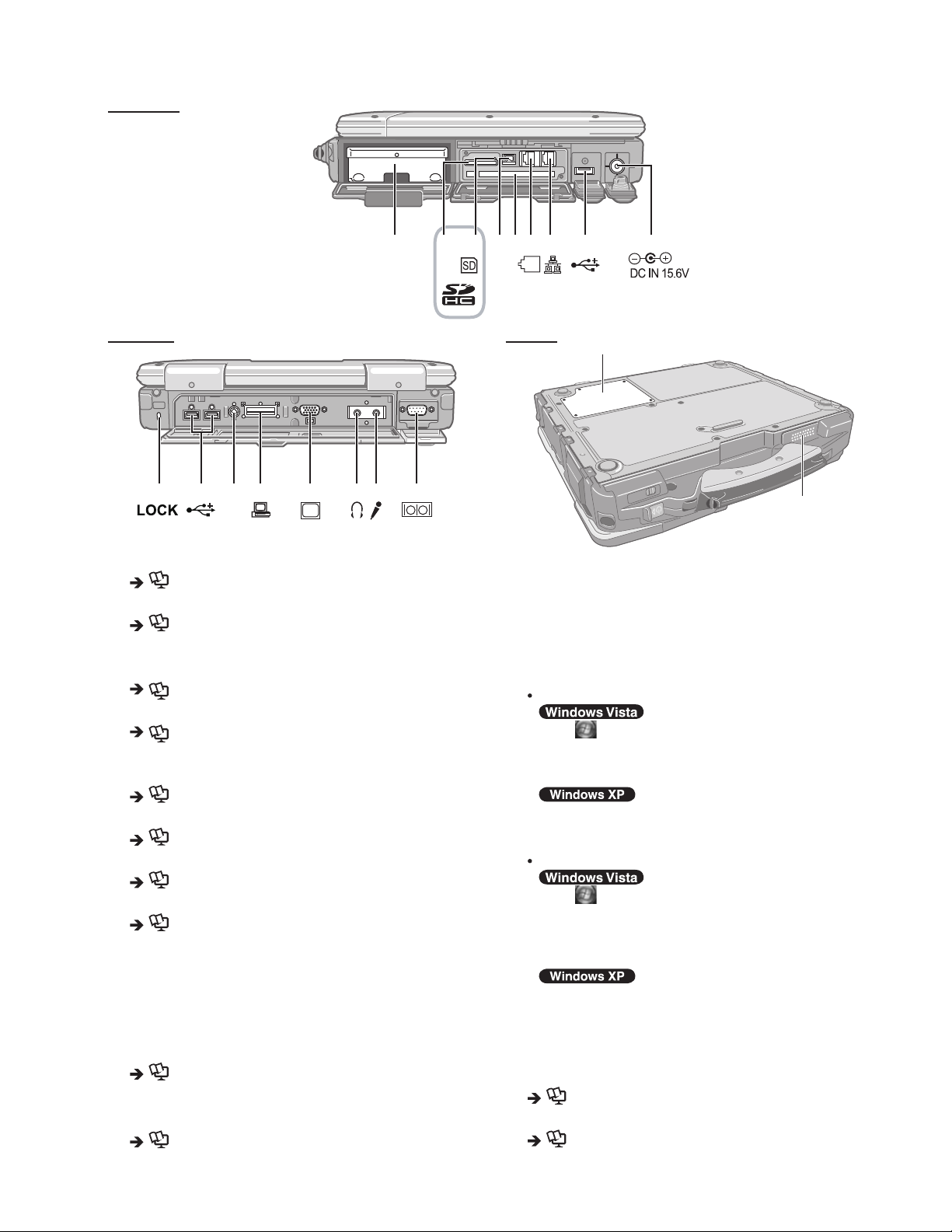

Right side

ABC D FE G H I

1394

J K M N O PLH

A: Hard Disk Drive

Reference Manual “Hard Disk Drive”

B: SD Memory Card Slot

Reference Manual “SD Memory Card”

C: SD Memory Card Indicator

(Blinking: During access)

Reference Manual “SD Memory Card”

D: IEEE 1394 Interface Connector

Reference Manual “IEEE 1394 Devices”

E: Smart Card Slot

<Only for model with Smart Card slot>

Reference Manual “Smart Card”

F: Modem Port

Reference Manual “Modem”

G: LAN Port

Reference Manual “LAN”

H: USB Port

Reference Manual “USB Devices”

I: DC-IN Jack

J: Security Lock

A Kensington cable can be connected.

For further information, read the manual that comes

with the cable.

K: External Antenna Connector

L: Expansion Bus Connector

Reference Manual “Port Replicator / Car

Mounter”

M: External Display Port

Reference Manual “External Display”

BottomRear side

Q

R

N: Headphone Jack

You can connect headphones or amplified speakers.

When they are connected, audio from the internal

speakers is not heard.

O: Microphone Jack

A condenser microphone can be used. other types

of microphones are used, audio input may not be possible, or malfunctions may occur as a result.

When recording in stereo using a stereo microphone:

Click (Start) - [Control Panel] - [Hardware and

Sound] - [Sound] - [Recording] - [Microphone] [Properties], and then add a check mark for [No Audio Enhancements] in [Microphone Enhancements].

Click [start] - [All Programs] - [SoundMAX] - [Control

Panel] and select [Microphone], and then add a check

mark for [No Filtering] in [Microphone Enhancements].

When using a monaural microphone with a 2-terminal plug:

Click (Start) - [Control Panel] - [Hardware and

Sound] - [Sound] - [Recording] - [Microphone] [Properties], and then add a check mark for [Voice

Enhancements] in [Microphone Enhancements].

Otherwise, only audio on the left track will be recorded.

Click [start] - [All Programs] - [SoundMAX] - [Control Panel] and select [Microphone], and then add a check mark

for [Voice Recording] in [Microphone Enhancements].

Otherwise, only audio on the left track will be recorded.

P: Serial Port

Q: RAM Module Slot

Reference Manual “RAM Module”

R: Speaker

Reference Manual “Key Combinations”

2-2

Page 12

㩷

)

Intel Co

re

TM

2

Duo proc

essor

(Penryn)

SL9300

㪞㪪㪋㪌㩷

LCD

13.3”

XGA

1000+

ni

t

p

B

d

ge

㪠㪚㪟㪐㪤㪄㪪㪝㪝

e

e

r

B

5

5

㪜㫋㪿㪼

㫉㫅㪼㫋㩷㪞㪹㪜㩷

e

e

LV1.6G

C

㪬㪪㪙㩷㪉㪅㪇㩷

㩿㪧㫆㫉

㫋㩷㪩㪼㫇㪅㪀

㪬㪪㪙㩷㪉㪅㪇㩷

㪟㪬

㪙㩷

㩿㪚

㪸㫉

㪄㫄㫆㫌㫅㫋㪼㫉㪀

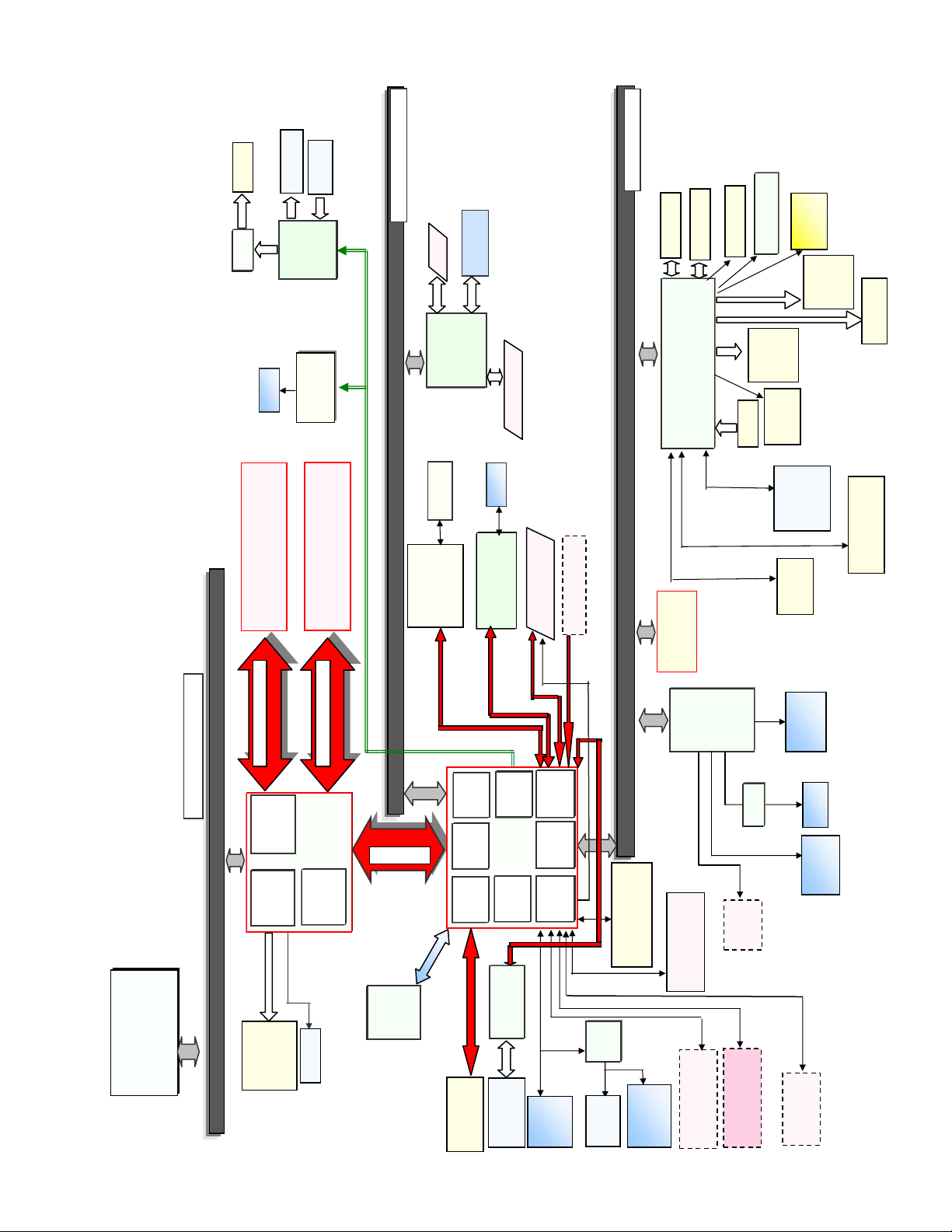

3 Block Diagram

1.05V

eaker

S

AMP

SO-DIMM Memory

RJ11

DDR2 SDRAM

Headphone

Sound

2GB

Ext. MIC

HDA

AD1883

MDC1.5

Data Modem

2GB

DDR2 SDRAM

SO-DIMM Memory

㪊㪅㪊㪭

㪊㪉㪹㫀㫋㩷㪧㪚㪠㩷㪙㫌㫊㩷㪊㪊㪤㪟㫑

AC Link

133Mbytes/sec

Wireless LAN

SD Card

5100

PCMCIA

R5C847

antenna

802.11 A/B/G/N

㪊㪅㪊㪭

㪣㪧㪚㩷㪙㫌㫊㩷 㩷㩷

HDD

Battery

LED

Pack

BKLT

KBD

HDD

-Li-Ion

nd

2

Mouse

(Port Rep)

Heater

Heater

Battery

Pack

EEPROM

Secure IC

(New Car Mounter)

㩷 Thermal I

㩷 Thermister

Li-Ion

Int. K

PS/2

KB& Mouse

㩷 Flat Pa

IEEE1394

TYPE II

RJ4

17Mbytes/sec

EC/KBC

(DF2117VBG20V)

Battery Charger

㫉㫅㪼㫋㩷

㪜㫋㪿

Intel 㩷 Boarzman

ExpressCARD

Turbo memory Card

infineon

TPM 1.2

SMSC

Super I/O

SIO10N268

64bit BUS 1.8V 667MHz

㩷 㪝㫉㫆㫅㫋㩷㫊㫀㪻㪼㩷㪙㫌㫊㩷 㩷 㪈㪇㪍㪍㪤㪟㫑㩷 㩷

5.3Gbytes/sec

Penryn DC

6MB L2 Cache

1.6GHz, FSB 1066MHz

TM

essor

SL9300

re

LV

Intel Co

Duo pro

(Penryn

DRAM

Internal

LCD

XGA

13.3

Interface

Graphics

t

ni

1000+

64bit BUS 1.8V 667MHz

㪞㪪㪋㪌㩷

INTEL

DMI

Interface

CRT

SPI

BIOS

32M

1Gbytes/sec x2

SATA

PCI

DMI

HDD

(1.5Gb/s)

SATA HDD

Brid

Interfac

Interfac

”

2.

160G

3-1

AC-link

㪠㪚㪟㪐㪤㪄㪪㪝㪝

IDE

SAT A/PA T A

PATA

MP

Interfac

INTEL

Interfac

PCI Express

LPC

USB 2.0

㪊㩷㫇㫆㫉㫋㩷 㩷

㪬㪪㪙㩷㪉㪅㪇㩷

Bridge

Bridge

Interface

Internal USB2.0

Blue-tooth

Internal USB1.1

GPS

USB1.1

Finger Print

HUB

1.1/2.0

㩷

㫋㩷㪩㪼㫇㪅㪀

㪬㪪㪙㩷㪉㪅㪇㩷

㩿㪧㫆

Touch Screen

(Circular polarizing)

㩷

㪙㩷

㪟㪬

㪄㫄㫆㫌㫅㫋㪼㫉

㪬㪪㪙㩷㪉㪅㪇㩷

㪸㫉

Wireless config CN

Parallel

(PortRep.)

Buffe

Serial

Serial

(PortRep)

Smart Card

Page 13

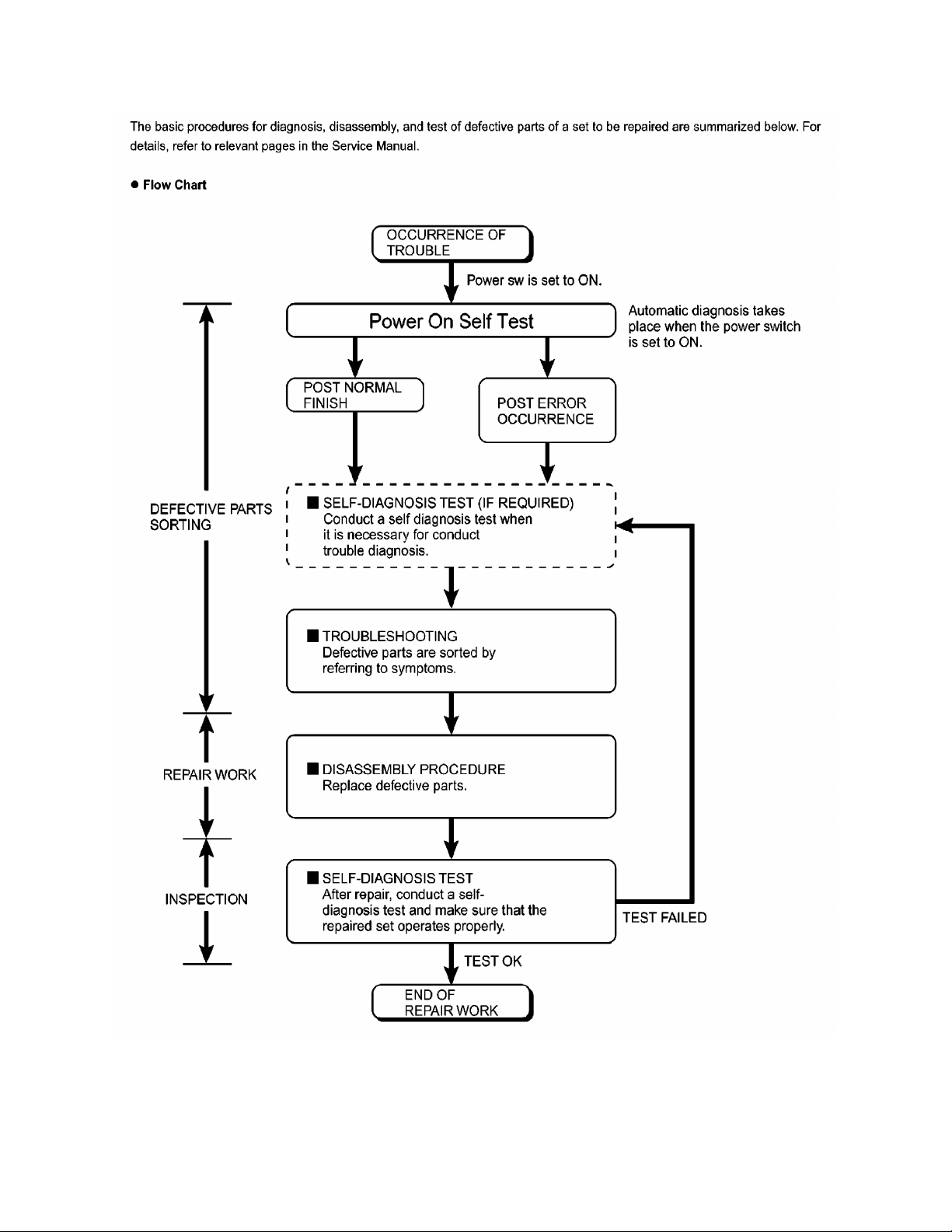

4 Diagnosis Procedure

4-1

4.1. Basic Procedures

Page 14

4.2. Troubleshooting

f

k

4-2

Please take note of the following two points with regard to troubleshooting:

1. Know-how of diagnosis upon occurrence of heavy troubles, e.g. Set cannot be turned ON , Set fails to start , No display on

screen , etc.

2. Explanation of each trouble, mainly symptom of trouble in operation.

Flow Chart

START

START

Pay attention to the following points when in pursuit of the cause of a troubleshooting.

1. Peripheral apparatus connected with the set should all be removed before operation check.

2. Make sure that cables, boards, etc. are not coming off, and recheck the contact condition.

Set cannot be supplied with current.

Power lamp fails to light up.

Dark display on screen.

Screen fails to display.

Failure in starting

Return set-up utility setpoint to the state of delivery from factory .

Not displayed properly on screen.

Some or all keys cannot be input.

Make sure of contact of K/B connector in use.

Replace keyboard or main board.

CD CALL not practicable.

Starts but operates unstably.

Reinstall HDD.

Replace main board.

AC

Adaptor/Battery

Output voltage

Power lamp

check

Inverter board

LCD back

light lighting

YES

LCD unit

check

OK

BIOS operation

chec

Result of

POST

Set-up utility

starting

OK

HDD access

YES

Main board

check

OK

Trouble

symptoms on some

of CD

YES

Replace main board.

OK

YES

OK

YES

OK

NG

NO

NG

NO

NG

NO

NG

NG

NO

NG

NO

Replace AC Adaptor/Battery

Check contact condition of power input terminal. Replace i

defective.

Check Power SW. Replace if defective.

Replace inverter board.

Check inverter cable continuity. Replace if defective

Replace LCD back light.

Replace LCD unit.

Replace main board (Check fuse at power source).

Refer to POST

error code table.

Replace main board.

Check HDD cable connection and continuity.

Replace if defective.

Replace HDD & Reinstall.

Replace main board.

Replace main board

Check if there are any flaws on CD media. Since

flaws may appear on specific media, CD media

can be defective.

Replace main board.

Heavy trouble e.g.,

Set cannot be turned

ON , Set fails to start ,

No display on

screen , etc.

Each kind of

trouble in

operation.

START

END

Page 15

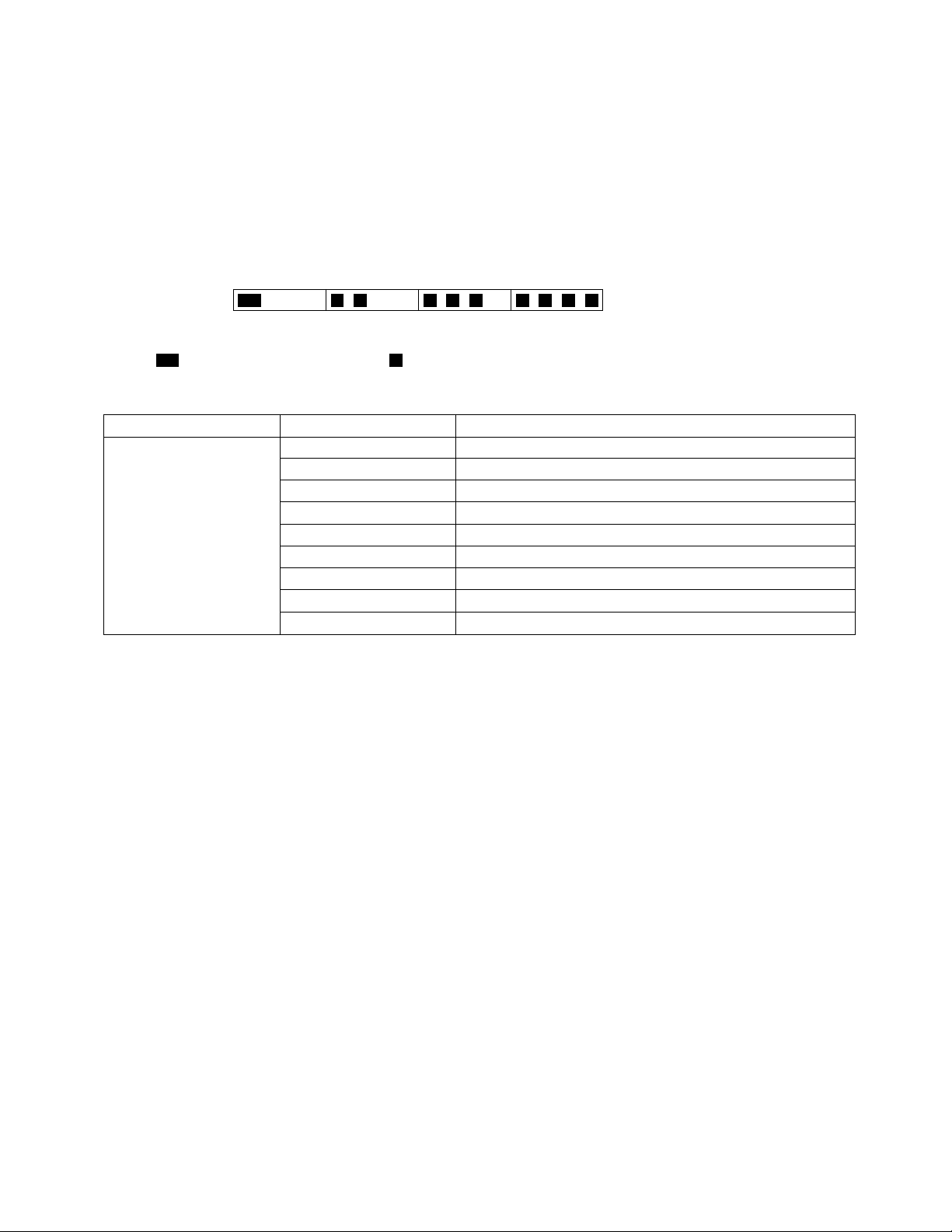

5 Power-On Self Test (Boot Check)

5-1

Outline of POST

The set has a boot check function called POST (Power-On Self Test) in it.

The condition of the main body is diagnosed by checking

Start .............Test begins automatically when power switch is set to ON.

Normal finish .....After memory checking, a beep sound is issued once and the set is placed into automatic stop.

Note: If no error occurs, nothing is displayed. (No display of OK, etc.)

Error Diagnosis by Checking Beep Signal Sound

The beep sound is as follows:

(Length of bar shows length of sound.)

beep sound or error code.

(1 (long sound) -2-3-4)

= long sound (about 0.4 sec.),

Table of errors classified by beep sounds

Diagnosis Beep signal sound Error message

Main board

(Note) A beep sound is also issued in case of other I/O trouble.

1(long sound)-2 BIOS ROM error

1-2-2-3

1-3-1-1

1-3-1-3

1-3-4-1

1-3-4-3

1-4-1-1

= short sound (about 0.2 sec.), Length between sounds is about 0.1 sec.

BIOS ROM error

RAM error

Keyboard controller error

RAM error

RAM error

RAM error

BIOS ROM error2-1-2-3

Occurrence of unexpected offering2-2-3-1

Page 16

6 List of Error Codes <Only when the port replicator is connected>

6-1

The following is a list of the messages that BIOS can display. Most of them occur during

POST. Some of them display information about a hardware device, e.g., the amount of memory

installed. Others may indicate a problem with a device, such as the way it has been configured.

Following the list are explanations of the messages and remedies for reported problems.

If your system displays one of except the messages marked below with an asterisk (*), write

down the message and contact Panasonic Technical Support. If your system fails after you

make changes in the Setup menus, reset the computer, enter Setup and install Setup defaults

or correct the error.

0200 Failure Fixed Disk

Fixed disk in not working or not configured properly. Check to see if fixed disk is attached

properly. Run Setup. Find out if the fixed-disk type is correctly identified.

0210 Stuck key

Stuck key on keyboard.

0211 Keyboard error

Keyboard not working.

0212 Keyboard Controller Failed

Keyboard controller failed test. May require replacing keyboard controller.

0213 Keyboard locked - Unlock key switch

Unlock the system to proceed.

0230 System RAM Failed at offset : nnnn

System RAM failed at offset nnnn of in the 64k block at which the error was detected.

0231 Shadow RAM Failed at offset : nnnn

Shadow RAM failed at offset nnnn of the 64k block at which the error was detected.

0232 Extended RAM Failed at offset : nnnn

Extended memory not working or not configured properly at offset nnnn.

0250 System battery is dead - Replace and run SETUP

The CMOS clock battery indicator shows the battery is dead. Replace the battery and run Setup

to reconfigure the system.

*0251 System CMOS checksum bad - Default configuration used

System CMOS has been corrupted or modified incorrectly, perhaps by an application program

that changes data stored in CMOS. The BIOS installed Default SETUP Values. If you do not

want these values, enter Setup and enter your own values. If the error persists, check the system

battery or contact Panasonic Technical Support.

0260 System timer error

The timer test failed. Requires repair of system board.

0270 Real time clock error

Real-time clock fails BIOS test. May require board repair.

*0280 Previous boot incomplete - Default configuration used

Previous POST did not complete successfully. POST loads default values and offers to run

Setup. If the failure was caused by incorrect values and they are not corrected, the next boot

will likely fail. On systems with control of wait states, improper Setup settings can also termi-

nate POST and cause this error on the next boot. Run Setup and verify that the wait-state

configuration is correct. This error is cleared the next time the system is booted.

0281 Memory Size found by POST differed from EISA CMOS

Memory size found by POST differed from EISA CMOS.

Page 17

02D0 System cache error - Cache disabled

6-2

Contact Panasonic Technical Support.

02F0: CPU ID:

CPU socket number for Multi-Processor error.

02F4: EISA CMOS not writable

ServerBIOS2 test error: Cannot write to EISA CMOS.

02F5: DMA Test Failed

ServerBIOS2 test error: Cannot write to extended DMA (Direct Memory Access) registers.

02F6: Software NMI Failed

ServerBIOS2 test error: Cannot generate software NMI (Non-Maskable Interrupt).

02F7: Fail - Safe Timer NMI Failed

ServerBIOS2 test error: Fail-Safe Timer takes too long.

device address Conflict

Address conflict for specified device.

Allocation Error for: device

Run ISA or EISA Configuration Utility to resolve resource conflict for the specified device.

Failing Bits : nnnn

The hex number nnnn is a map of the bits at the RAM address which failed the memory test.

Each 1 (one) in the map indicates a failed bit. See error 230,231 or 232 for offset address of the

failure in System, Extended or Shadow memory.

Invalid System Configuration Data

Problem with NVRAM (CMOS) data.

I/O device IRQ conflict

I/O device IRQ conflict error.

Operating System not found

Operating system cannot be located on either drive A: or drive C:. Enter Setup and see if fixed

disk and drive A: are properly identified.

Parity Check 1 nnnn

Parity error found in the system bus. BIOS attempts to locate the address and display it on the

screen. If it cannot locate the address, it displays ????. Parity is a method for checking errors

in binary data. A parity error indicates that some data has been corrupted.

Parity Check 2 nnnn

Parity error found in the I/O bus. BIOS attempts to locate the address and display it on the

screen. If it cannot locate the address, it displays ????.

Press <F1> to resume, <F2> to Setup

Displayed after any recoverable error message. Press <F1> to start the boot process or <F2> to

enter a Setup and change the settings. Write down and follow the information shown on the

screen.

Troubleshooting

Page 18

7 Self Diagnosis Test

1

As for the self-diagnosis test(PC-Diagnostic utility) to use this model, a standard test and the

enhancing test by the module of the main body building in are possible.

●Notes To skip BIOS password

Use <Ctrl>+<F10> key to skip BIOS password or authentication of fingerprint.

This key is only for entering DIAG mode. Not available to boot the computer.

If customer set "HDD Lock", the DIAG program cannot perform HDD test.

*This key is for service purpose only. Do not disclose this information to unrelated others.

. Beginning of self-diagnosis test

1-1. Setting of content of setup

1. The power supply of the computer is turned on.

2. " F2 " is pushed on the screen of "Panasonic" while " press <F2 to enter Setup> " is displayed.

3. The setup utility starts and then takes notes of the content of the BIOS setup of present set.

4. " F9 " is pushed, " Yes" is selected on the screen of " Is the default value loaded? ", and " Enter"

is pushed.

5. " F10 " is pushed.

6. " Yes" is selected on the screen of the setup confirmation, and " Enter" is pushed.

7. The computer starts automatically.

Attention

・If the device which can be set is set to "Invalidity" by "Advanced" or "Security" menu, becomes an

error by "PC-Diagnostic utility".

(It is judged that the device which can be set to "Invalidity" by "Main" menu such as "Flat pad" is

normal if the controller operates normally though sets to "Invalidity" by the setup. )

・In the model with built-in DVD of the USB connection, even if DVD is normal, becomes an error if

legacy USB is set to "Invalidity"

1-2. When you execute an automatic test

1. "Ctrl" + "F7" is pushed while the "Panasonic" start screen is displayed after the computer is started.

2. The test of all devices begins automatically by "PC-Diagnostic utility" 's starting.

Attention

・It is a test which the customer who bought PC can execute. (As for HDD, the enhancing test is also

possible.)

・A flat pad does not work for a while after starting "PC-Diagnostic utility".

・The movement of a flat pad might become abnormal If after RAM begins from the CPU/System

test, a flat pad will be operated in about 30 seconds. In that case,restarts pushing"Alt" + "Ctrl" +

"Del" key. Or, please start "PC-Diagnostic utility" again after doing the power supply switch in the

slide, and turning off the power supply.

1-3. When you execute the enhancing test

1. Please let me discontinue diagnosing clicking to end an automatic test.

2. Please click on the character of "D" "PC-Diagnostic utility" on the screen while pushing both of right

"Shift" and left "Shift" keys.

3. All devices which can select the enhancing test make the setting of the enhancing test possible.

4. The district device is made"FULL" display (enhancing test).

5. The test begins clicking .

*Please refer to item 4 for the error result of each test and the division of the breakdown part.

7-1

Page 19

2. Operation of PC-Diagnostic Utility

-Only the device which can be inspected on the entire screen is displayed.

-The item does not appear when the device of wireless LAN etc. is not physically connected.

-The movement of the item must use an arrow key or a flat pad.

-As for the device under the diagnosis, blue and yellow are alternately displayed at the left of the icon.

- The diagnosis result of the device greens at the left of the icon when it is normal, and becomes red when

abnormal.

-When the test of all devices ends, the test result is displayed under the right of the screen.

-Please click while diagnosing when being stop on the way by the time the test of all devices ends.

-Please click when you restart "PC-Diagnostic utility".

*Each device is tested from the beginning, and it is not possible to restart on the way.

-When the test of all devices ends, the test result is displayed under the right of the screen.

7-2

Page 20

2-1. Selection of tested device

-To test only a specific device, "Test" and "Do not test" of each device can be selected.

-The device which can select the enhancing test changes in order of "The standard is tested" and "Do not

test" whenever the device icon is clicked.

Start the standard test Do not test

Please begin testing clicking if the selection of the tested device ends.

2-2. "PC-Diagnostic utility" End method

When of "Close" on the right of the screen is clicked, the computer reactivates automatically. Or, the

power supply switch is done in the slide and the power supply is turned off.

2-3. The content of the setup is returned to the setting of the user

1. Turned on the computer.

2. "F2" is pushed on the screen while "Press<F2>to enter Setup" is displayed of "Panasonic".

3. Push "F10", and on the screen of "Is the change in the setting preserved and do end?"and then "Yes"

is selected, and "Enter" is pushed.

4. The computer reactivates automatically.

5. The end option is chosen by the start menu, and the power supply of the computer is turned off.

Standard at test time

All devices other than RAM and HDD ---------- about 1 minute

RAM standard test ----------------------------------- 1 - 2 minutes

HDD standard test ----------------------------------- 2 - 3 minutes

HDD enhancing test (60GB) ---------------------- about 40 minutes

Ex.The standard when the standard <all device> is tested becomes 1+2+3=6 minutes.

■There is greatly a difference from RAM test when the memory is increased according to the performance

of the memory occasionally.

■Moreover, when the main body of PC under the test is a high temperature, it occasionally takes time.

■There is greatly a difference from HDD according to the performance of the drive occasionally.

7-3

Page 21

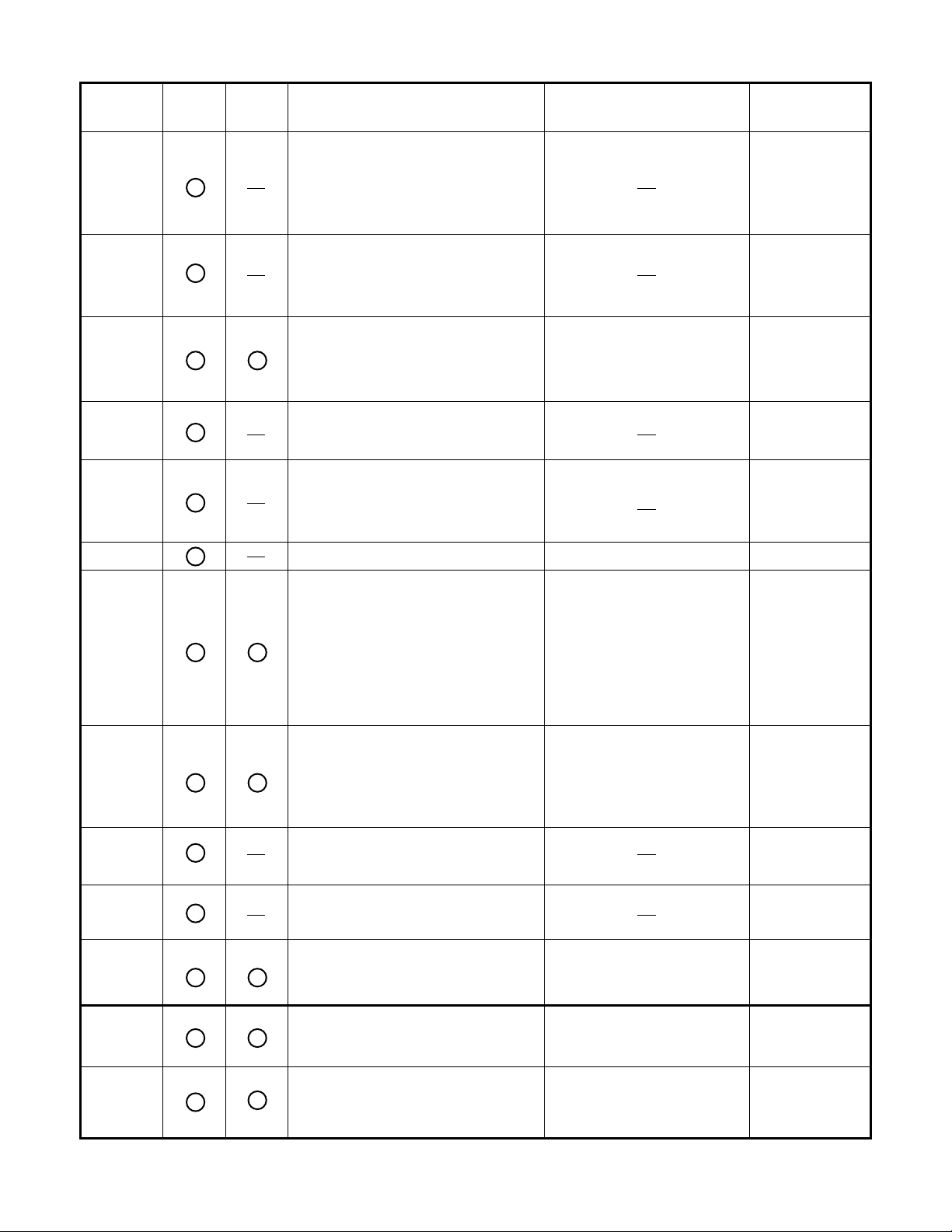

3. Test Item and Division of trouble

CPU /

SYSTEM

RAM

HDD

MODEM

Wireless

LAN

Sound *5

StanardTest item

Enhancing

Content of standard test Content of enhancing test

CPU is shifted to protected mode, and

"Violation of the paging", "Operation of

the violation of a privileged instruction",

and DMA, INT, TIMER, and the

RTC operation are confirmed.

All memory space is tested in a special

memory access pattern based on

"R.S.T . technology".

The record area frequently accessed

with Microsoft Windows XP to test in

about two minutes regardless of

points of HDD is emphatically tested.

It is confirmed not to find abnormality

in the AC97 modem controller.

All record area is tested.

Place with possibility of breakdown

CPU /

Main board

Memory /

Mainboard

HDD /

Mainboard /

Cable /

Connector

MODEM/

Mainboard

Wireless LAN

It is confirmed not to find abnormality

in the Wireless LAN modem controller.

board /

Connector /

Mainboard

USB

LAN

PC Card

SD

Keyboard

Touch Pad

DVD-ROM

It is confirmed not to find abnormality

*1

in the USB controller.

*2

It is confirmed not to find abnormality

in the LAN controller.

It is confirmed not to find abnormality

in the CardBus controller.

It is confirmed not to find abnormality

in the SD controller.

It is confirmed not to find abnormality

*3

in keyboard controller's keyboard interface.

Whether keyboard controller's mouse

*4

interface operates normally is confirmed.

*6

The drive is normally reset, and it is

accessible is confirmed.

It is confirmed not to find abnormalityin the wiring between

the USB controller and the

connector by confirming

the connection of the USB

equipment connected with the

USB connector.

It is confirmed not to find abnormalityin the wiring between

the controller and the

connector by connecting to

HUB with LAN cable.

The key is actually input, and

the operation is displayed on

the screen.

The operation is actually displayed on the screen by operating the touch pad.

It is confirmed to be able to

read media normally.

Mainboard /

Connector

Mainboard /

Connector

Mainboard

Mainboard

Mainboard /

Keyboard

Mainboard /

Touch Pad

Mainboard /

DVD Drive /

DVD Cable /

DVD Connector

7-4

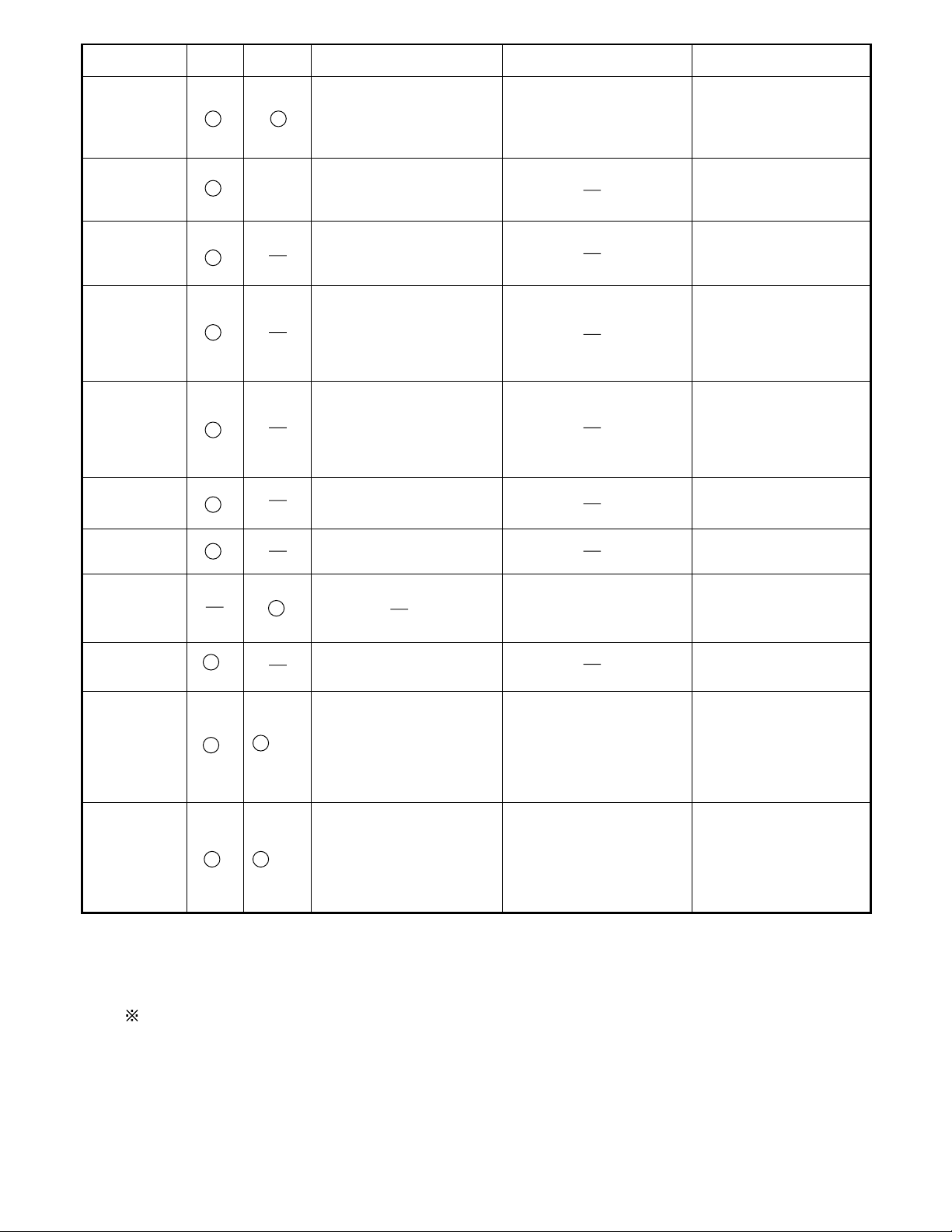

Page 22

Test Item

7-5

Touch Screen

Standard Enhanced

Content of Standard Test Content of Extend Test

It is confirmed not to find

abnormality in the USB

connection of Touch Screen.

This test cannot find

abnormality of Touch Screen.

Perform Touch Screen

functionality practically.

Operator has to judge

PASS/FAIL with test result.

It is confirmed not to find

Bluetooth

abnormality in the connection

of Main board and Bluetooth

module.

It is confirmed not to find

Wireless WAN

abnormality in the connection

of Main board and Wireless

WAN module.

It is confirmed not to find

abnormality in the legacy FD

Floppy

drive.

This test cannot find

abnormality of mechanical

breakdown. (e.g.. Head, Motor)

It is confirmed not to find

abnormality in access to

Video

VRAM with VESA.

The PC which uses main

memory as VRAM may fail with

main memory failure.

It is confirmed not to find

GPS

abnormality in the connection

of Main board and GPS

It is confirmed not to find

IEEE1394

abnormality in the IEEE1394

controller.

It is confirmed not to find

Express Card

abnormality in the wiring

between Chipset and Express

Card.

It is confirmed not to find

Smart Card

abnormality in the Smart Card

controller.

It is confirmed not to find

abnormality of Super I/O

Serial Port *7

UART function.

This test cannot find lack of

wiring between Super I/O and

Serial Connector.

It is confirmed not to find

abnormality of Super I/O

Parallel Port *8

parallel function.

This test cannot find lack of

wiring between Super I/O and

Parallel Connector.

*1

Please connect the USB device with the port (USB connector) which wants to test before the tests.

*2

Please connect LAN port with LAN HUB with LAN cable before the tests.

The operator actually inputs the key, and the operator judges PASS/FAIL of the test.

*3

The operator actually operates the mouse, and the operator judges PASS/FAIL of the test.

*4

It is not abnormal though the sound is emitted from the speaker while testing.

*5

It is confirmed not to find

abnormality in the wiring

between Super I/O and Serial

Connector.

This test cannot find failure of

cable characteristic and device

problems.

It is confirmed not to find

abnormality in the wiring

between Super I/O and

Parallel Connector.

This test cannot find failure of

cable characteristic and device

problems.

When the test result is PASS, trouble is thought by not hearing of the sound under the test from

the speaker and the headphone by the wiring of the audio output system.

*6

Please set DVD/CD media in the drive before the tests.

*7 Please set a Special Loop Back Connector Tool at serial connector for Enhanced Test.

(This Connector Tool is same as the one used before.)

*8 Please set a Special Loop Back Connector Tool at parallel connector for Enhanced Test.

(This Connector Tools is same as the one used before.)

The place with possibility of

breakdown

Main board/

Touch Screen

Bluetooth cable

WWAN cable

FD Drive/

Main board (Super I/O)/

FDD cable

FDD connector

Main board

(Chipset, Graphic

Controller)/

Memory

GPS cable

Main board

(IEEE#394 Controller)

Main board (Chipset)/

Express Card Connector

Main board

(Smart Card Controller)

Main board (Super I/O)/

Serial Connector

Main board (Super I/O)/

Parallel Connector

Page 23

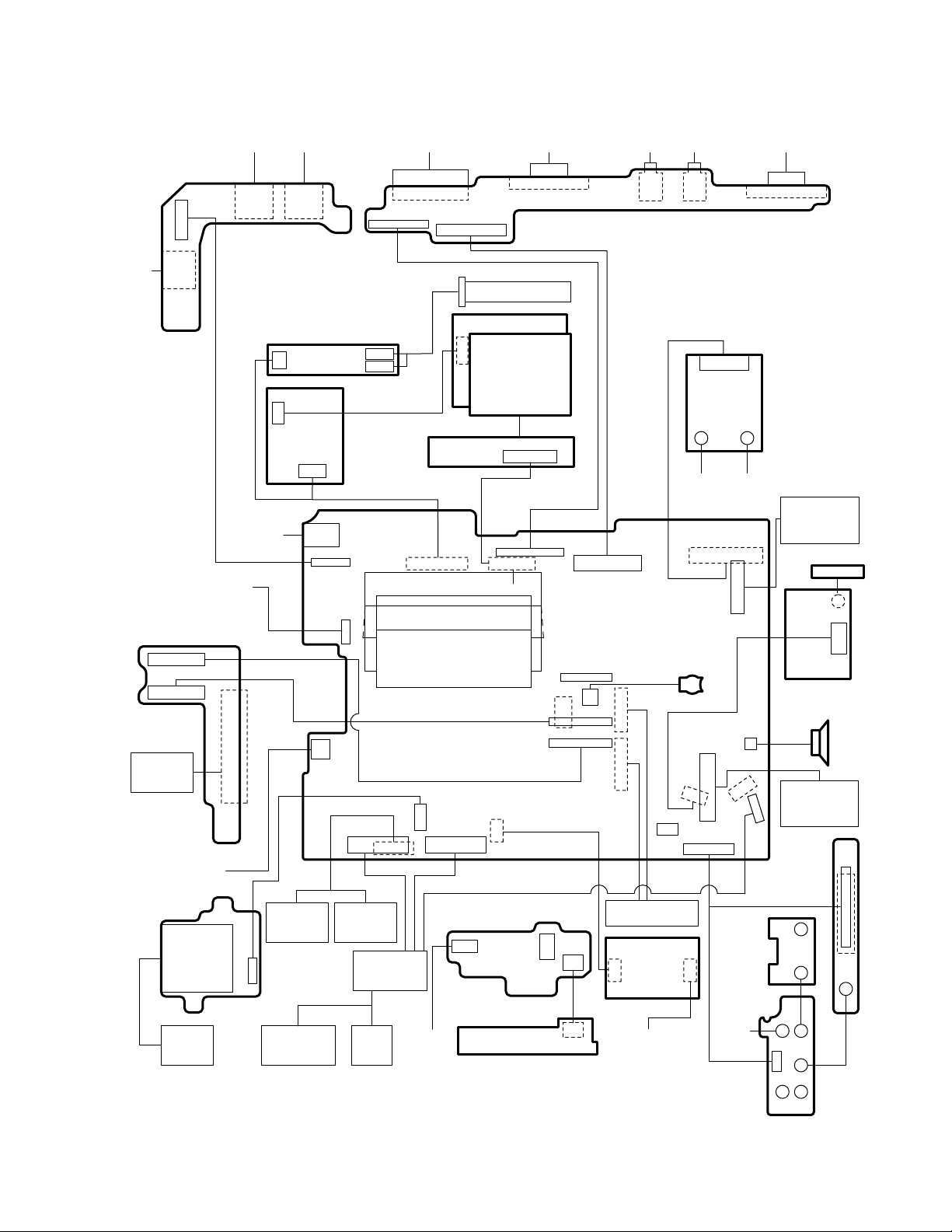

8 Wiring Connection Diagram

USB

PORT

CN103

MP PCB

CN400

CN401

COMBO

DRIVE

IEEE1394

INTERFACE

CONNECTOR

CN100

LAN PORT

CN301

USB

PORT

USB

PORT

CN102 CN101

USB PCB

INVERTER PCB

CN201

TS PCB

CN200

DC-IN

CN402

PW LED

PCB

CN300

JK1

CN3

CN28

CN20

SW LED

PCB

HDD FPC

BATTERY

EXPANSION

BUS

CN701

EXTERNAL

DISPLAY PORT

CN705 CN703

CN700

BACK LIGHT

TOUCH SCREEN

LCD

CN27

CN21

CN22

CN17

DIMM MEMORY CARD

CN4

CN31

CN24

CN7CN8

PAD PCB

CN801

I/O PCB

CN1

CN2

CN15

CN5

CN800

MAIN PCB

CN12

CN19

CN6

CN802

HEAD

PHONE

JK701 JK700

CN1

CN13

CN14

KEYBOARD

MDC

MODEM

MICRO

PHONE

W-LAN

MODULE

SUB

ANT

CN37

RTC

BATTERY

CN10

CN25

CN18

CN30

J2J1

CN11

MAIN

ANT

CN29

EXT

ANT

PCB

SERIAL

PORT

CN702

EXPRESS

CARD

BT PCB

JK1

CN1

GPS PCB

SPEAKER

CN26

PCMCIA

CARD

CN9

CN201 CN204

DOCKING

PCB

CN1

CN2

SD

CARD

MAIN

BATTERY

HDD

TOUCH

PAD

LED PCB

8-1

CN901

MODEM

PORT

WHIP

ANT

ANT SW PCB

CN3CN4

CN2CN1

CN5CN6

Page 24

9 Disassembly/Reassembly

Battery

Cover

HDD Cover

HDD Pack

Battery Pack

Note:

Power off the computer. Do not shut down to the Suspend or hibernation mode.

Do not add peripherals while the computer is in the Suspend or hibernation mode; abnormal operation may result.

9.1. Disassembly Instructions

9.1.1. Preparation

Before disassembling, be sure to make the following preparations.

• Shut down Windows and turn off the power.

• Disconnect the AC adaptor.

• Remove the optional DIMM memory card and PCMCIA card

if they are connected.

• Remove other devices if they are connected.

Attention:

• Please execute writing BIOS ID when you exchange the

Main Board.

• Parts (Sheet and rubber) etc. related various the Conductive

Cloth and Heat Spreader cannot be recycled. Use new p arts.

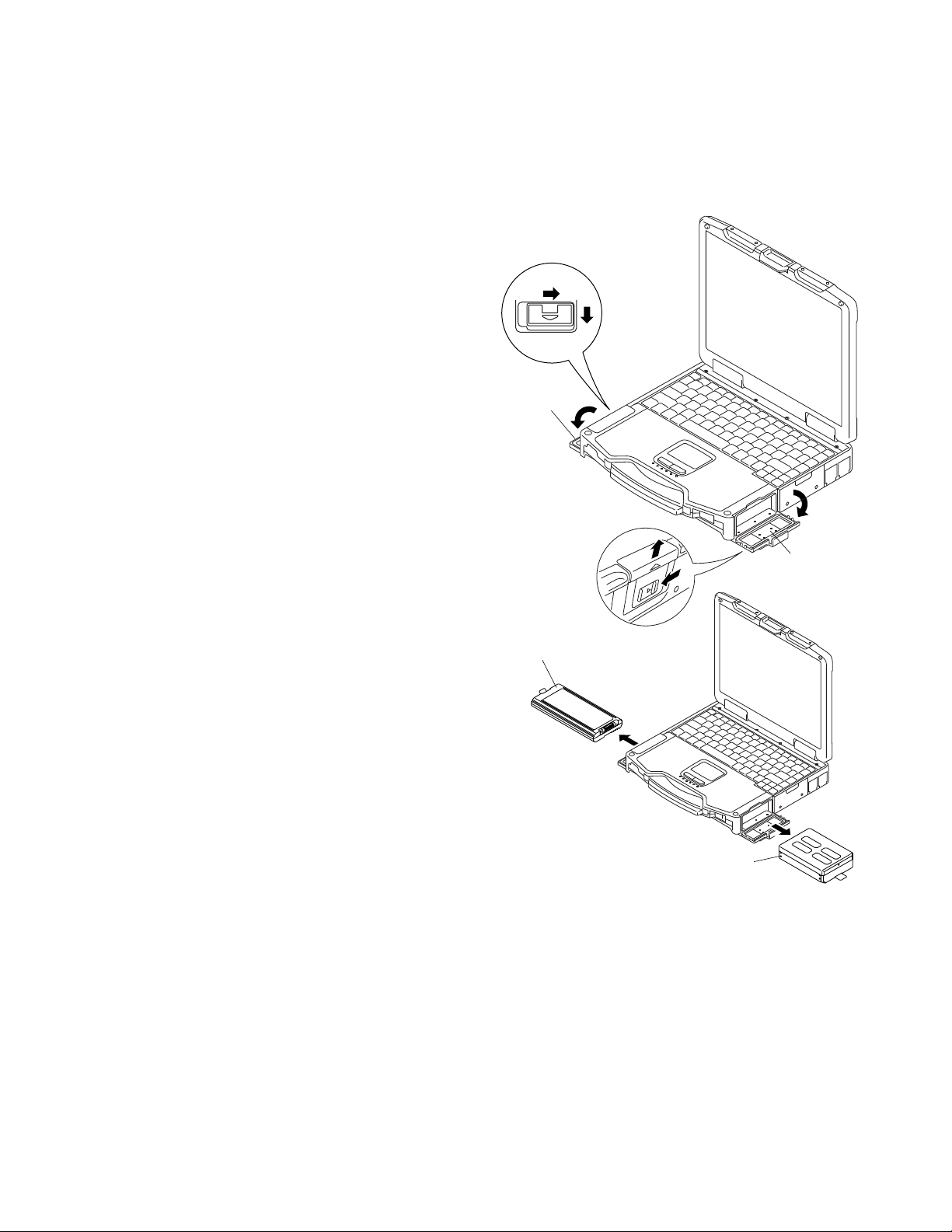

9.1.2. Removing the Battery Pack and

HDD Pack

1. Open the Battery Cover.

2. Remove the Battery Pack.

3. Open the HDD Cover.

4. Remove the HDD Pack.

9-1

Page 25

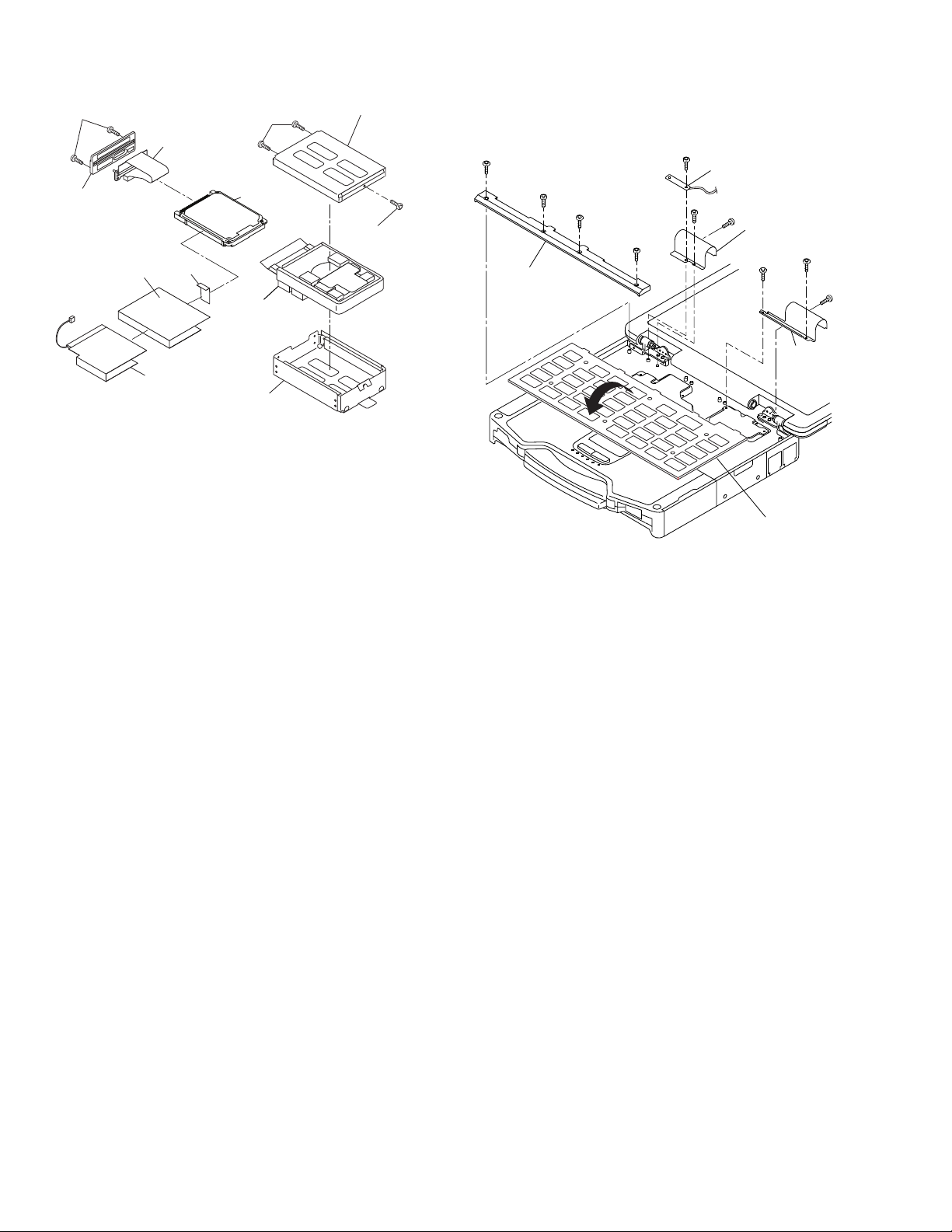

9.1.3. Removing the HDD

HDD FPC

Heater Ins Sheet

HDD

Sheet

<K1-17>

SATA Guard

Heater

HDD U Case Ass’y

HDD L

Case Ass’y

<K1-17>

<K1-16>

HDD

Damper

Ass’y

<N6>

<N6>

<N6>

<N6>

<N6>

<N2>

<N2>

<N6>

<N6>

KB Cover

Hinge Cover L

Hinge

Cover R

Keyboard

<N6>

Bluetooth PCB

1. Remove the Screw. <K1-16>

2. Remove the 4 Screws. <K1-17>

And remove the SATA Guard.

3. Release the 2 Tabs, and remove the HDD U Case Ass'y

and the HDD L Case Ass'y.

4. Remove the HDD Dumper Ass'y.

5. Remove the Sheet.

6. Remove the Heater and the Heater Ins Sheet.

7. Remove the HDD FPC.

Screws <K1-16>: DFHE5025XA

Screws <K1-17>: DRQT2+E8FKL

9.1.4. Removing the KB Cover, Hinge

Cover L, Hinge Cover R and Keyboard

1. Remove the 4 Screws <N6>, and remove the KB Cover.

2. Remove the 2 Screws <N2> and the 3 Screws <N6>, and

remove the Hinge Cover L,R.

3. Remove the Keyboard.

Screws <N2>: DRHM5054XA

Screws <N6>: DRQT26+E4FKL

9-2

Page 26

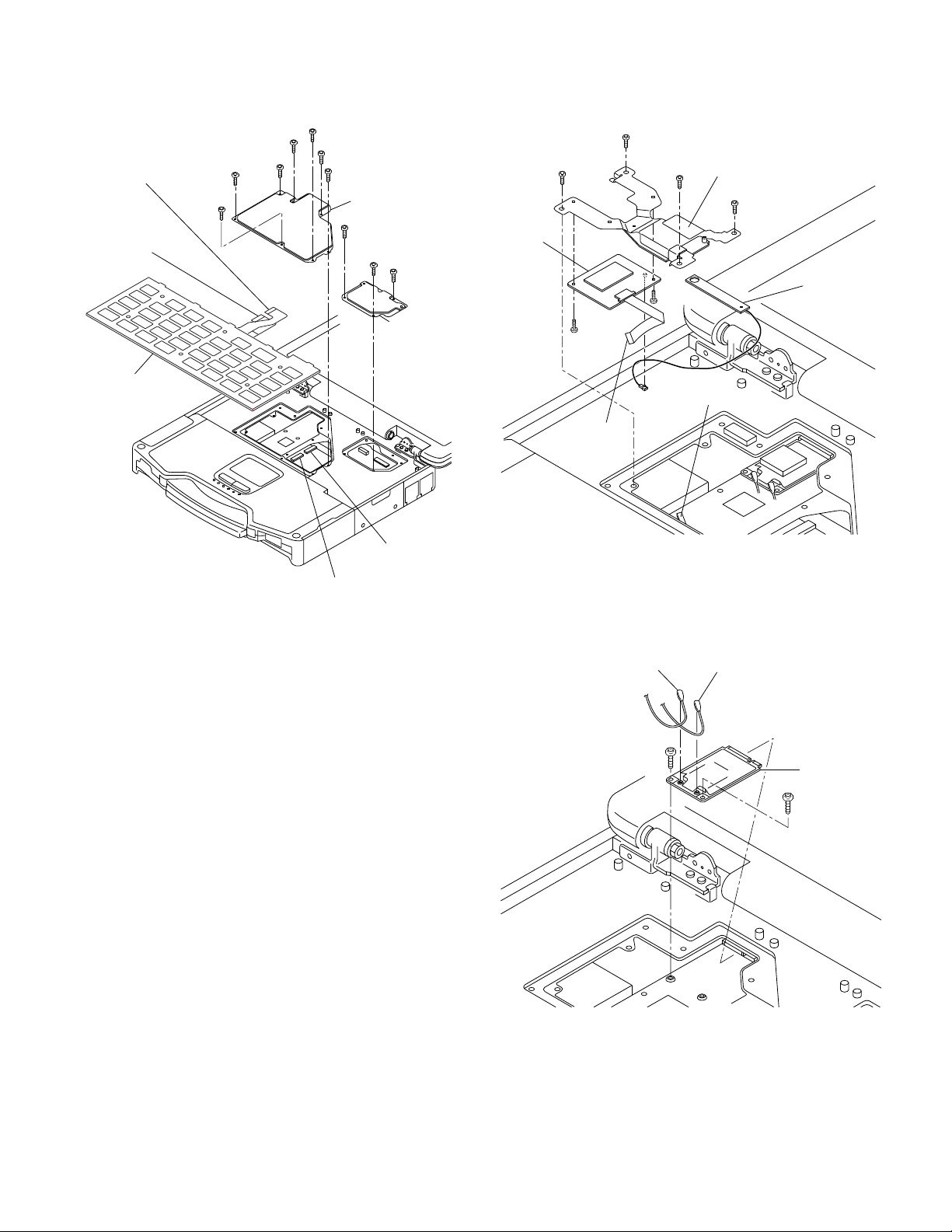

9.1.5. Removing the KB Cable Cover and

<N29>

<N29>

<N29>

<N29>

<N29>

<N29>

<N29>

<N29>

<N29>

<N29>

to Connector

(CN14)

Connector

(CN13)

Connector

(CN14)

to Connector

(CN13)

KB Cable Cover

LCD

Cable Cover

Keyboard

GPS PCB

Bluetooth

PCB

Connector(CN25)

<N11>

<N11>

GPS BT Angle

<N12>

<N12>

<N12>

<N12>

to Connector

(CN25)

<N11>

<N11>

Antenna Cable(black)

Antenna Cable(white)

W-LAN

Module

LCD Cable Cover

9.1.6. Removing the GPS PCB , Bluetooth

PCB and W-LAN Module

Screws <N29>: DRQT26+E3FNL

1. Remove the 3 Screws <N29>.

2. Remove the LCD Cable Cover.

3. Remove the 7 Screws <N29>.

4. Remove the KB Cable Cover.

5. Disconnect the 2 Cable from the 2 Connectors (CN13,

CN14).

6. Remove the Keyboard.

1. Disconnect the Cable from the Connector. (CN25)

2. Remove the 4 Screws. <N12>

3. Remove the 2 Screws. <N11>

4. Remove the Bluetooth PCB, GPS BT Angle and GPS

PCB.

5. Disconnect the 2 Antenna Cables.(White/Black)

6. Remove the 2 Screws. <N11>

7. Remove the W-LAN Module

Screws <N11>: DFHE5025XA

Screws <N12>: DXQT2+F3FNL

9-3

Page 27

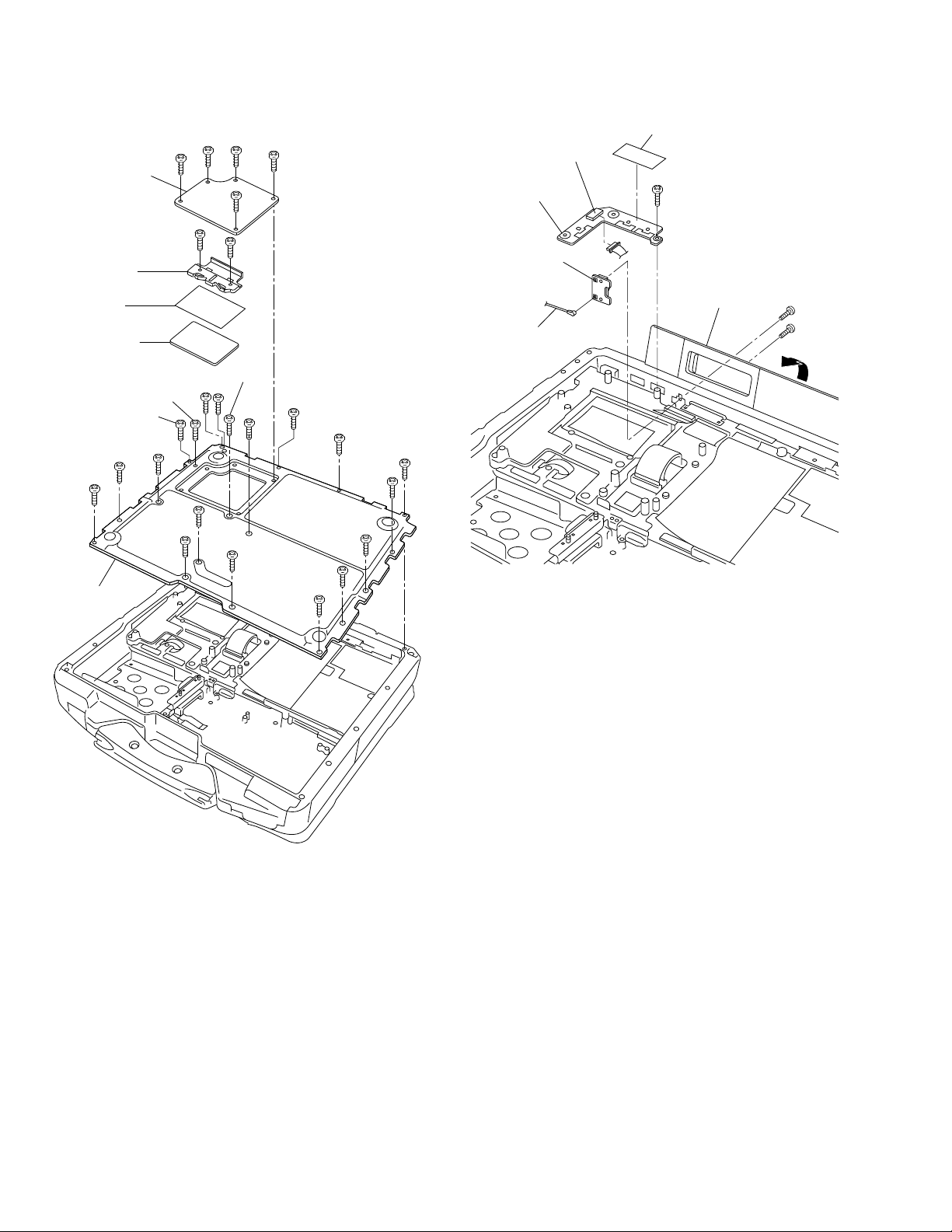

9.1.7. Removing the DIMM Cover and Bot-

<N6>

<N6>

<N6>

<N6>

<N6>

<N6>

<N6>

<N6>

<N6>

Bottom Cover

DIMM Memory

Card

DIMM Stopper

Base

DIMM Heat

Plate

DIMM Cover

<N1>

<N1>

<N1>

<N1>

<N1>

<N6>

<N6>

<N6>

<N6>

<N6>

<N6>

<N8>

<N8>

<N8>

<N8>

<N8>

<N8>

<N3>

<N3>

<N6>

USB PCB

Connector

(CN100)

Antenna PCB

Connector Cover

Antenna Cable

(Black)

Tape

tom Cover

9.1.8. Removing the USB PCB and

Antenna PCB

1. Remove the 5 Screws. <N1>

2. Remove the DIMM Cover.

3. Remove the 2 Screws. <N6>

4. Remove the DIMM Stopper Base.

5. Remove the DIMM Heat Plate.

6. Remove the DIMM memory card.

7. Remove the 6 Screws. <N8>

8. Remove the 13 Screws. <N6>

9. Remove the Bottom Cover.

1. Remove the Screw. <N6>

2. Disconnect the Cable from the Connector. (CN100)

3. Remove the Tape.

4. Remove the USB PCB.

5. Open the Connector Cover.

6. Remove the 2 Screws. <N3>

7. Remove the Black Cable and remove the Antenna PCB.

Screws <N3>: DRQT2+G6FKL

Screws <N6>: DRQT26+E4FKL

Screws <N1>: DRHM0002ZA

Screws <N6>: DRQT26+E4FKL

Screws <N8>: DRSB3+8FKL

9-4

Page 28

9.1.9. Removing the FPC HDD BAT

<N29>

<N16>

<N29>

Connector

(CN10)

Connector

(CN26)

HDD Cable Cover

FPC HDD BAT

Antenna Cable

Sheet

to Connector (CN800)

Connector

(CN800)

to Connector

(CN26)

Tape

Connector

(CN9)

Pad PCB

Tape

to Connector (CN8)

to Connector (CN7)

Connector

(CN8)

Pad Protect

Sheet

Connector

(CN7)

<N29>

Pad PCB

Connector

(CN802)

Connector

(CN801)

Tape

TP PCB Screw Sheet

<N29><N29>

<N29><N29>

<N29>

<N29>

<N7>

TOP Screw Sheet

Connector

(CN17)

Connector

(CN27)

TOP WP Washer

1. Remove the 3 Screws. <N29>

2. Remove the HDD Cable Cover.

3. Remove the Antenna Cable Sheet.

4. Remove the 2 Tapes.

5. Disconnect the 2 Cables from the 2 Connectors.

(CN10,CN26)

6. Remove the Tape.

7. Disconnect the Cable from the Connector. (CN9)

8. Remove the Pad Protect Sheet.

9. Disconnect the Cable from the Connector. (CN800)

10. Disconnect the 2 Cables from the 2 Connectors.

(CN7,CN8)

1 1. Remove the Screw. <N16>

12. Remove the FPC HDD BATT.

9.1.10. Removing the PAD PCB

1. Remove the Tape and disconnect the Cable from the

Connector. (CN801)

2. Disconnect the Cable from the Connector. (CN802)

3. Remove the TP PCB Screw Sheet.

4. Remove the 2 Screws. <N29>

5. Remove the PAD PCB.

Screws <N29>: DRQT26+E3FNL

9.1.1 1 . Removing the Main PCB

Screws <N16>: DRQT26+E5FKL

Screws <N29>: DRQT26+E3FNL

1. Remove the TOP Screw Sheet.

2. Remove the Screw. <N7>

3. Remove the TOP WP Washer.

4. Disconnect the 2 Cables from the 2 Connectors.

(CN17,CN27)

9-5

Page 29

12. Remove the 2 Screws. <N6>

<N16>

<N16>

<N16>

<N18>

<N16>

<N16>

<N16>

Connector

(CN701)

Connector

(CN31)

Pet Tape

Connector

(CN700)

Main Chasis

to Connector(CN701)

to Connector(CN700)

<N6>

<N21>

<N21>

<N6>

Connector

(CN4)

Connector

(CN11)

Connector

(CN400)

Connector

(CN401)

Coin Battery

MP PCB

MP Guide

Connector

(CN19)

Coin Battery

Cushion

Tape

<N32>

<N6>

<N11>

<N11>

<N32>

<N32>

<N32>

<N32>

<N32>

<N32>

<N32>

<N32>

1394 Sheet

Modem

Cable

Connector

(J2)

MDC

Modem

LAN

Case

Modem

Cable Sheet

Tape

<N11>

<N6>

<N32>

13. Remove the 2 Screws. <N21>

14. Remove the MP Guide.

15. Remove the MP PCB.

16. Remove the Coin Battery Cushion.

17. Disconnect the Cable from the Connector. (CN19)

18. Remove the Coin Battery.

19. Remove the Tape.

20. Disconnect the 2 Cables from the 2 Connectors.

(CN4,CN11)

5. Remove the 6 Screws. <N16>

6. Remove the Screw. <N18>

7. Disconnect the 2 Cables from the 2 Connectors.

(CN700,CN701)

8. Remove the Pet Tape and disconnect the Cable from the

Connector. (CN31)

9. Remove the Main chasis.

21. Remove the 2 Modem Cable Sheets.

22. Remove the 2 Screws. <N32>

23. Remove the Modem LAN Case.

24. Remove the 1394 Sheet.

25. Remove the 2 Screws. <N11>

26. Remove the Tape.

27. Disconnect the Cable from the Connector (J2) and

remove the MDC.

28. Remove the Modem Cable.

29. Remove the 8 Screws. <N32>

30. Remove the 2 Screws. <N6>

31. Remove the Screw. <N11>

32. Remove the Main PCB.

Screws <N6>: DRQT26+E4FKL

Screws <N7>: DRSB26+10HKL

Screws <N11>: DFHE5025XA

Screws <N16>: DRQT26+E5FKL

Screws <N18>: DRSB26+8FKL

Screws <N21>: DXQT2+E12FNL

10. Remove the Tape.

11. Disconnect the 2 Cables from the 2 Connectors.

(CN400,CN401)

9-6

Page 30

9.1.12. Removing the SD PCB, Express

<N22>

<N22>

<N22>

<N22>

<N22>

<N22>

<N22>

<N6>

<N6>

SD PCB

Express Card

PCMCIA Card

<N22>

Connector

(CN701)

Connector

(CN700)

I/O PCB

LID

Cover

Connector Cover

<N15>

<N15>

<N14>

<N14>

<N14>

<N30>

<N14>

<N15>

<N30>

Card and PCMCIA Card

1. Remove the 2 Screws. <N6>

2. Remove the SD PCB.

3. Remove the 4 Screws. <N22>

4. Remove the Express Card.

5. Remove the 4 Screws. <N22>

6. Remove the PCMCIA Card.

9.1.13. Removing the I/O PCB

1. Open the Connector Cover and Lid Cover.

1. Remove the 3 Screws <N14> and the 2 Screws <N30>.

1. Remove the 4 Screws. <N15>

1. Remove the I/O PCB.

Screws <N14>: DFHE5058ZB

Screws <N15>: DRHM5104ZA

Screws <N30>: DXHM0057ZA

Screws <N6>: DRQT26+E4FKL

Screws <N22>: DXQT2+G4FNL

9-7

Page 31

9.1.14. Removing the Palm Top Cover

Palm Top Cover Sheet

<N29>

<K2-42>

Palm Top Cover

PW LED Sheet

Touch Pad Adhesion Seat

Touch Pad

LED

PCB

Touch Pad SW Knob

Touch Pad

SW Knob In

PW LED

PCB

SW LED

PCB

<N29>

<N29>

<N29>

<N29>

Hole 1

Hole 2

Handle

Handle

Base L

Handle

Base R

Power

SW

<K2-41>

<K2-41>

WM SW

<K2-42>

Sheet, Palm Top Cover, Touch Pad

Adhesion Seat, Touch Pad, Touch

Pad SW Knob, LED PCB and SW

LED PCB

9.1.15. Removing the Handle and Power

SW

1. Remove the Palm Top Cover sheet.

2. Remove the 5 Screws <N29>, and remove the Palm Top

Cover.

3. Remove the Touch Pad Adhesion seat.

4. Remove the Touch Pad.

5. Remove the Touch Pad SW knob and Touch Pad SW

Knob in.

6. Remove the LED PCB.

7. Remove the PW LED Sheet.

8. Remove the Screw <K2-42>, and remove the SW LCD

PCB.

Screws <N29>: DRQT26+E3FNL

Screws <K2-42>: DXQT26+D4NLT

1. Remove the 2 Screws <K2-41>, and remove the Handle

Base L and R.

2. Remove the Handle.

3. Remove the 2 Screws. <K2-42>

4. Remove the WM SW and Power SW.

Screws <K2-41>: DRSN4+6FKLT

Screws <K2-42>: DXQT26+D4NLT

9-8

Page 32

9.1.16. Removing the Display Unit

<N9>

<N9>

<N9>

<N9>

Display Unit

<N10>

<N10>

<N7>

<N7>

<N7>

<N7>

<N7>

<N7>

<N7>

<N7>

<N7>

<N7>

<N2>

<N2>

<N2>

<N13>

<N13>

<N7>

<N7>

LCD Latch

Antenna

Element

LCD Rear

Cabinet

LCD Corner

Cover L

LCD Corner

Side Cover L

LCD Corner

Side Cover R

LCD Corner

Cover R

LCD Front Cabinet

Hinge L

Hinge R

<K9-1-4>

<K9-1-4>

W-RDY

ANT Unit

Rear Cable

Sheet L

Rear Cable

Sheet R

Cable Tape

9.1.17. Removing the LCD Rear Cabinet,

Hinge L and R and W-RDY ANT Unit

1. Remove the 2 Screws <N10> and the 4 Screws <N9>.

2. Remove the Display Unit.

Screws <N9>: DRYN4+J10FKL

Screws <N10>: DXSB4+15FNLB

1. Remove the 12 Screws <N7> and 2 Screws. <N13>

2. Remove the LCD Corner Cover L / R.

3. Remove the LCD Coner Side Cover L / R.

4. Remove the Rear Cable Sheet L / R and 2 Cable Tape.

5. Remove the 3 Screws. <N2>

6. Remove the W-RDY ANT Unit.

7. Remove the LCD Rear Cabinet.

8. Remove the LCD Latch.

9. Remove the 2 Screws. <K9-1-4>

10. Remove the Hinge L and R.

Screws <N2>: DRHM5054XA

Screws <N7>: DRSB26+10HKL

Screws <N13>: DRSB4+10FKL

Screws <K9-1-4>: DRYN4+J10KLT

9-9

Page 33

9.1.18. Removing the Inverter PCB, TS

<N6>

<N6>

LCD Unit

LCD Front Cabinet

Inverter PCB

TS PCB

LCD Drop Holder

LCD Drop

Holder

A

B

A

B

C

C

to Connector

(CN200)

Connector

(CN200)

Connector

(CN201)

<N2>

<N2>

<N2>

<N2>

LCD Rear Cabinet Ass’y

Antenna PCB R

Antenna PCB L

W-LAN ANT Cover R

W-LAN ANT Cover L

<N2>

<N2>

PCB and LCD Unit

9.1.19. Removing the Antenna PCB L and

R

1. Remove the 4 Screws <N2>.

2. Remove the W-LAN ANT Cover L and R.

3. Remove the 2 Screws. <N2>

4. Remove the Antenna PCB L and R.

1. Remove the 2 Screws. <N6>

2. Disconnect the 3 Cables from the 3 Connectors.

3. Remove the Inverter.

4. Disconnect the 2 Cables from the 2 Connectors.

(CN200,CN201)

5. Remove the TS PCB.

6. Remove the 2 Drop Holders.

7. Remove the LCD Unit.

Screws <N6>: DRQT26+E4FKL

Screws <N2>: DRHM5054XA

9-10

Page 34

9.2. Reassembly Instructions

<N2>

<N2>

<N2>

<N2>

LCD Rear Cabinet Ass’y

Antenna PCB R

Antenna PCB L

W-LAN ANT Cover R

W-LAN ANT Cover L

<N2>

<N2>

X

X

X

X

X

X

X

X

Insert the cable between the pins. Insert the cable between the pins.

LCD Rear ASS’Y

Put it along the inside of boss on X part

Rear Cable Sheet RRear Cable Sheet L

Do not pinch the cable

out of the cabinet

Attach it fitting

to the corner

Coming off the tape

is arrowed

Cable color : Gray

Rear Screw Sheet

Tape

Do not pinch the cable

out of the cabinet

Match it to the concave

side and attach it between

the bosses.

Match it to the protrusion

side and attach it between

the bosses.

Place the anntena sub Tighten the screwTighten the screw Place the anntena main

Safety Working

Cable color : Black

S2

Do not pinch the cable

out of the cabinet

S2

S2

Torque of tightening screw :0.45– 0.05N•m(

4.5 – 0.5kgf•cm)

CAUTION

S1:Insulation S2:Bitten S3:Sharp Edge

S4:Part No. Check S5:Other

9.2.1. Attention when CF-30 series is repaired

• Please execute writing BIOS ID when you exchange the Main Board.

• Parts (Sheet and rubber) etc. related various the Conductive Cloth and Heat Spreader cannot be recycled. Use new parts.

9.2.2. Setting the Antenna PCB L and R

1. Set the Antenna PCB L and R using the 2 Screws <N2>.

2. Fix the W-LAN ANT Cover L and R using the 4 Screws

<N2> (No1 to No2).

Note:

Tighten the Screws in the numbered order (No1 to No4).

Screws <N2>: DRHM5054XA

■ Arranging the Antenna L and R Cables

9-1 1

Page 35

9.2.3. Setting the Inverter PCB, TS PCB and LCD Unit

<N6>

<N6>

No.1

No.2

LCD Unit

LCD Front Cabinet

Inverter PCB

TS PCB

LCD Drop Holder

LCD Drop

Holder

A

B

A

B

C

C

to Connector

(CN200)

Connector

(CN200)

Connector

(CN201)

INV PCB

㪥㪇㪞㪝㪉㪡㪇㪇㪇㪇㪇㪊

CAUTION

S1:Insulation S2:Bitten S3:Sharp Edge

S4:Part No. Check S5:Other

1. Apply the load when attaching the attaching parts. 20 to 30N (2 to 3Kgf)/cm2

2. When handling INV PCB, do not bend or add an impact.

<Notes>

N0GF1J000009

(Non T/S model)

Check the

product number.

N0GF1J000009

Prepare INV Shield Case

and INV Shield Case

Outside for Assysite.

INV Shield Case Outside

INV Shield

Case

N0GF2J000003

Check the

product number.

Board attachment

Set and attach.

INV Case

INV Shield Case

Set

Match the board edge and the case edge.

Misalignment: 0.5mm or less

Attach it putting the protrusion mark next to the caution label.

Wrap 2 INV Shield Tapes around INV Shield

Case and attach.

Ensure that INV Shield Tape does not r u n o v e r

the edge of INV Shield Case.

INV Shield Tape

Attach.

<INV Shield Tape's Attachment Guide>

Protrusion by wrinkles, etc. = 0.2 or less

Air Bubble = 1 cm2 or less / 1 bubble size

S4

S4

1. Set the LCD Unit to the LCD Front Cabinet in order.

2. Attach the 2 drop holders.

3. Connect the Cable to the Connector. (CN200,CN201)

4. Connect the 3 Cables to the 3 Connectors.

5. Fix the Inverter PCB using the 2 Screws <N6>

(No1 to No2).

Note:

Tighten the Screws in the numbered order (No1 to No2).

Screws <N6>: DRQT26+E4FKL

■ Preparation of Inverter

9-12

Page 36

■ PreparationsLCDCable

(19)

Put the pin side to the upper side.

Put the Connector bottom

in the rib on the jig.

Fit to the Moran edge and avoid running over.

The Cables should not be overlapped.

Attach the sheet matching

to the upper right.

LCD cable Connect

Set the LCD signal

Cable on the

left guidegroove.

Set the 6-conductor

Cable on the

right guide groove.

Remove the Release Paper

and set the Cable on it.

Pass it under the

13-conductor Cable

and attach it.

Set the 13-conductor Cable

on the center guide groove.

Remove the left Release Paper,

and attach it putting 13-conductor

Cable inside.

Leave the left Release Paper

without removing.

Finish

Non T/S model only

From the sheet end

24mm㫧2

Bundle all the

LCD Cables.

PET tapeWrap

PET tapeWrap

LCD CABLE

WP SHEET

Attach.

Attach the

Inverter

MIL Shierd

0 0.5mm

LCD Front Ass’y

LCD Drop Holder Insertion

LCD Drop Holder Insertion

* Notes:

1. Apply the load when attaching the parts. 20N to 30N (2 to 3Kgf)/cm2

Confirm that the LCD

Cushion is not wrapped.

Match to the LCD

edge and attach it.

Clearance : 2 mm or less

■ Assembly of LCD Unit

9-13

Page 37

1. Insert the TS Flex into the TS Controller, and attach the tape.

2. Remove the Release Paper A and attach the TS Controller.

(Do not float the sheet and apply the load on the LCD.

3. Remove the Release Paper B and attach it on the TS Controller.

4. Remove the Release Paper C and attach it on the LCD.

<Notes>

1. Apply the load when attaching the attaching parts. 20 ~ 30N (2 ~ 3Kgf)/cm2

TS Controller Attach.

Release Paper B

Release Paper A

Release Paper C

Flex Stiffening

Plate Edge

0䌾2

Insert the TS Flex.

Tape Attach.

1. Apply the load when attaching the attaching parts. 20 to 30N (2 to

3Kgf)/cm2

2. Reusing the attaching parts is impossible.

3䇮Torque of Screw 㽵=0.45㫧0.05N䊶m(㻍4.50㫧0.5kgf䊶cm)

Fix with Screws in order of the rear number of No.

Ex.) Fix in order of Ԛ-1 to Ԛ-2.

Insert

the CN.

㩷

Avoid loosening when

processing the INV Cable.

(Avoid catching the Cable

in the Cabinet.)

S2

Connect the LCD Cable.

Avoid catching the Cable in the Cabinet

㪇䌾㪈

Insert the CN (red).

SCREW-2

Tighten

Insert the rubber

groove into the

Cabinet rib firmly.

TOP CASE

SHEET

Insert the CN (blue).

SCREW-1

Tighten

INV-PWB

A'ssy Set

S2

CABLE TAPE-1Attach.

Vertical Direction: Match to the heater edge.

Vertical Direction: Match to the damper

sheet edge.

Tolerance: r2

Process the Cable after bending it.

Avoid catching the Cable in the Cabinet

Avoid catching the Cable in the Cabinet

5㫧2

CAUTION

Put the side of the socket pin up

and insert it into the CN of LCD.

S2

-1

0㫧2

S1:Insulation S2:Bitten S3:Sharp Edge

S4:Part No. Check S5:Other

TOP CASE

SHEET

-3

Attach.

Attach.

8㫧2

0㫧2

0㫧2

S2

Care for tape floating

0㫧2

0㫧1

TOP CASE SHEET-2Attach.

Vertical Direction: Match to the edge

of INV MILL SHIELD

Lateral Direction: Match to the left edge

of Connector.

Tolerance: r2

Tape Attach.

10㫧䋱

㪈㪉㫧㪉

Avoid catching the

Cable in the Cabinet

CABLE TAPE-2Attach.

Process the wire to avoid

running over the INV shield case.

Insert

the CN.

Insert

the CN.

Match to the slotted

hole edge.

TOP CASE

SHEET-4Attach.

㫧2

S2

㪇㪂㪉

Match the end.

LCD cable BUSH Set

9-14

S2

Along the bottom of Connector

Insert

the CN.

Avoid catching.

Page 38

■ Assembly of LCD Unit(Only the model who doesn't have T/S)

0~1

0~2

5~7

7~9

6~8

41~43

2~4

0±1

59~61

0~1

16~18

2~4

3~5

4~6

62~63

4~6

71~73

0~1

CAUTION

S1:Insulation S2:Bitten S3:Sharp Edge

S4:Part No. Check S5:Other

1. Apply the load when attaching the attaching parts. 20 to 30N (2 to

<Notes>

3Kgf)/cm2

2. Reusing the attaching parts is impossible.

Fix with Screws in order of t h e r e a r n u m b er of No.

Ex.) Fix in order of Screw-1 t o Screw-2 .

Connect the LCD Cable.

Put the side of the socket pin up

and insert it into the CN of LCD.

Screw Set

NEW GPS

Sheet

Attach.

Tape-2 Attach.

Top Case

Sheet-5 Attach.

Top Case

Sheet-1 Attach.

Tape-1 Attach.

Top Case

Sheet-4 Attach.

Top Case

Sheet-3 Attach.

Top Case Sheet-2 Attach.

Do not allow the tape to run over the LCD reflection plate.

Opalescent Screws

outer shape line

Confirm the Cable is separated(3 mm or more).

Confirm the sub material tape is wrapped.

Fix the Connector..

Insert the CN.

Insert the CN.

Set LCD cable Bush

into the rib firmly.

Process the Cable from the

inverter to the bottom side.

Process the LCD Cable on it.

Avoid catching of

the INV Cable.

Avoid catching the

Cable in the Cabinet

Screw-2

Tighten

Screw-1

Tighten

LCD cable

BUSH Set

Ensure the Cable does not run over the inverter.

Avoid catching the Cable in the Cabinet

Avoid catching.

S2

S2

Torque of tightening Screw :0.45 ± 0.02N·m(Ṑ4.5 ± 0.2kgf·cm)