Panasonic CF-18NHHZXBM Service Manual

ORDER NO. CPD0604070C1

Notebook Computer

CF-18

Model No. CF-18NHHZXBM

This is the Service Manual for

the following areas.

M …for U.S.A. and Canada

© 2006 Matsushita Electric Industrial Co., Ltd. All rights reserved.

Unauthorized copying and distribution is a violation of law.

WARNING

For U.K.

This apparatus must be earthed for your safety.

To ensure safe operation the three-pin plug must be inserted only into a standard three-pin power point

which is effectively earthed through the normal household wiring.

Extension cords used with the equipment must be three-core and be correctly wired to provide connection to earth. Wrongly wired extension cords are a major cause of fatalities.

The fact that the equipment operates satisfactorily does not imply that the power point is earthed and

that the installation is completely safe.

For your safety, if you have any doubt about the effective earthing of the power point, consult a qualified electrician.

FOR YOUR SAFETY PLEASE READ THE FOLLOWING TEXT CAREFULLY

This appliance is supplied with a moulded three pin mains plug for your safety and convenience.

A 3 amp fuse is fitted in this plug.

Should the fuse need to be replaced please ensure that the replacement fuse has a rating of 3 amps and

that it is approved by ASTA or BSI to BS 1362.

Check for the ASTA mark or the BSI mark on the body of the fuse.

If the plug contains a removable fuse cover you must ensure that it is refitted when the fuse is replaced.

If you lose the fuse cover the plug must not be used until a replacement cover is obtained.

A replacement fuse cover can be purchased from your local Panasonic Dealer.

IF THE FITTED MOULDED PLUG IS UNSUITABLE FOR THE SOCKET OUTLET IN YOUR

HOME THEN THE FUSE SHOULD BE REMOVED AND THE PLUG CUT OFF AND DISPOSED

OF SAFELY.

THERE IS A DANGER OF SEVERE ELECTRICAL SHOCK IF THE CUT OFF PLUG IS INSERTED

INTO ANY 13 AMP SOCKET.

If a new plug is to be fitted please observe the wiring code as shown below.

If in any doubt please consult a qualified electrician.

Warning: THIS APPLIANCE MUST BE EARTHED.

Important

The wires in this mains lead are coloured in accordance with the following code:

Green-and-yellow: Earth

Blue: Neutral

Brown: Live

As the colours of the wires in the mains lead of this apparatus may not correspond with the coloured

markings identifying the terminals in your plug, proceed as follows:

The wire which is coloured GREEN-and-YELLOW must be connected to the terminal in the plug

which is marked by the letter E or by the safety earth symbol

YELLOW.

The wire which is coloured Blue must be connected to the terminal which is marked with the letter N or

coloured BLACK.

The wire which is coloured Brown must be connected to the terminal which is marked with the letter L

or coloured RED.

coloured GREEN or GREEN-and-

The mains plug on this equipment must be used to disconnect the mains power.

Please ensure that a socket outlet is available near the equipment and shall be easily accessible.

How to replace the fuse

Open the fuse compartment with a screwdriver and replace the fuse.

Warnings

This equipment is not designed for connection to an IT power system.

(An IT system is a system having no direct connections between live parts and Earth; the exposed-conduciveparts of the electrical installation are earthed.

An IT system is not permitted where the computer is directly connected to public supply systems in the U.K.)

Disconnect the mains plug from the supply socket when the computer is not in use.

This equipment is produced to BS800/1983.

1

LASER SAFETY INFORMATION

For U.S.A.

Class 1 LASER-Product

This product is certified to comply with DHHS Rules 21 CFR Subchapter J.

This product complies with European Standard EN60825 (or IEC Publication 825)

For all areas

This equipment is classified as a class 1 level LASER product and there is no hazardous LASER radiation.

Caution:

(1) Use of controls or adjustments or performance of procedures other than those specified herein may result in

hazardous radiation exposure.

(2) The drive is designed to be incorporated into a computer-based system or unit which has an enclosing cover.

It should never be used as a stand alone drive.

Danger:

The serviceman should not remove the cover of drive unit and should not service because the drive unit is a nonserviceable part.

Please check DANGER label on PD-drive unit.

• Unplug the AC power cord to the equipment before opening the top cover of the drive.

When the power switch it on, do not place your eyes close to the front panel door to look into the interior of the unit.

LASER Specification

Class 1 level LASER Product

Wave Length: DVD 658±8 nm

CD 775~815 nm

Laser safety information is appropriate only when drive with laser is installed.

2

3

4

CONTENTS

1 Diagnosis Procedure ······································································································1-1

2 Power-On Self Test (Boot Check) ··················································································2-1

3 List of Error Codes ··········································································································3-1

4 Diagnostic Test ···············································································································4-1

5 Self Diagnosis Test ·········································································································5-1

6 Wiring Connection Diagram ···························································································6-1

7 Disassembly/Reassembly ······························································································7-1

8 Exploded View ················································································································8-1

9 Replacement Parts List ··································································································9-1

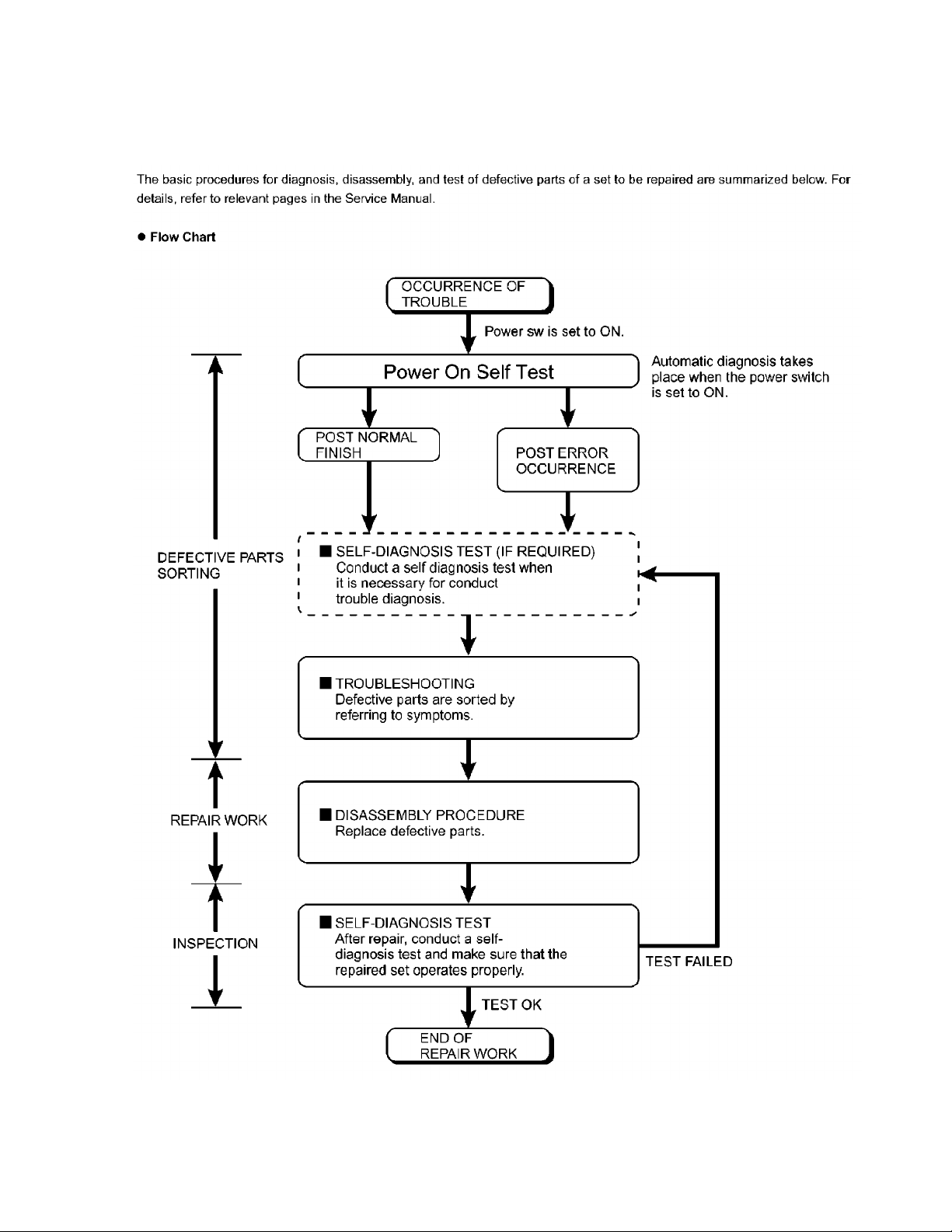

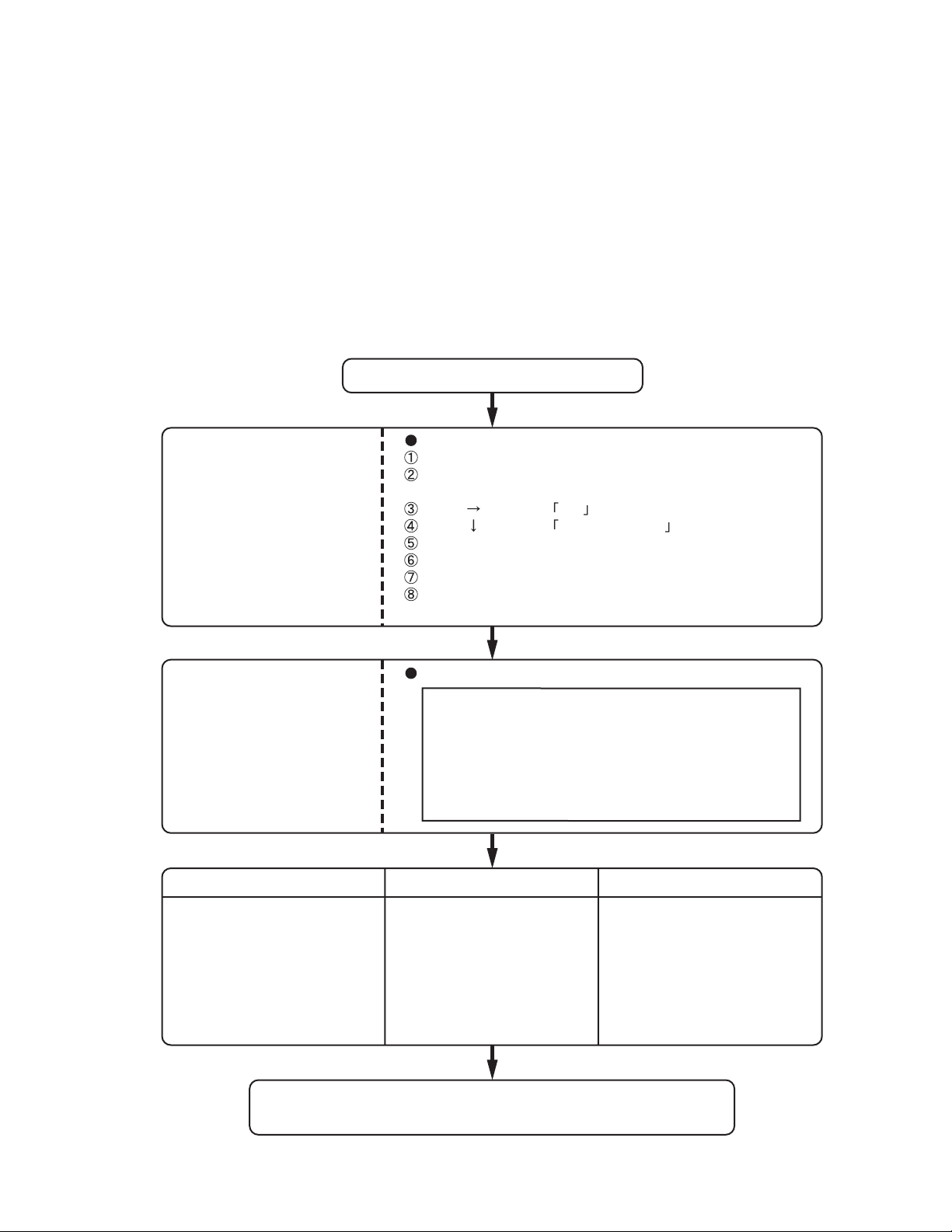

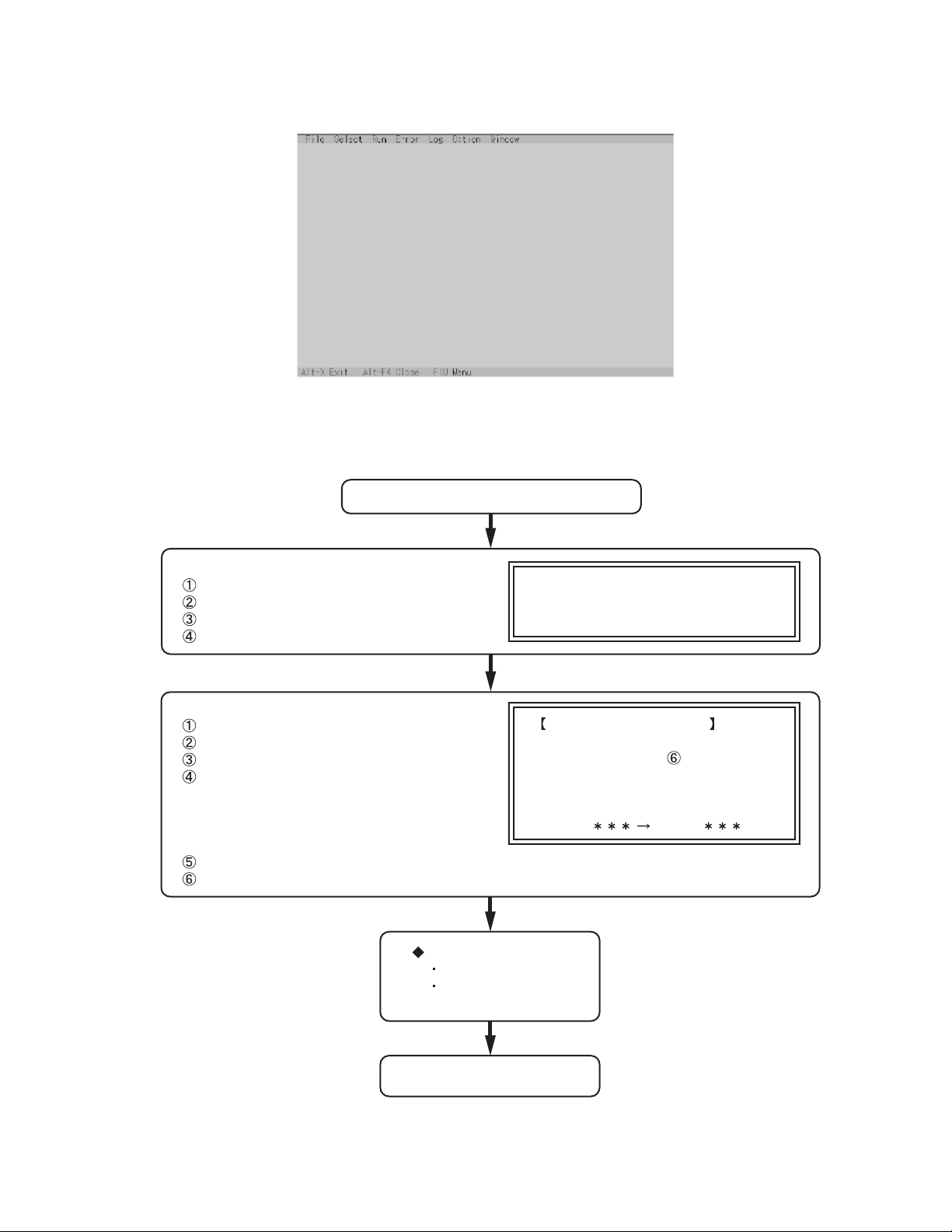

1 Diagnosis Procedure

1.1. Basic Procedure

1-1

f

k

c

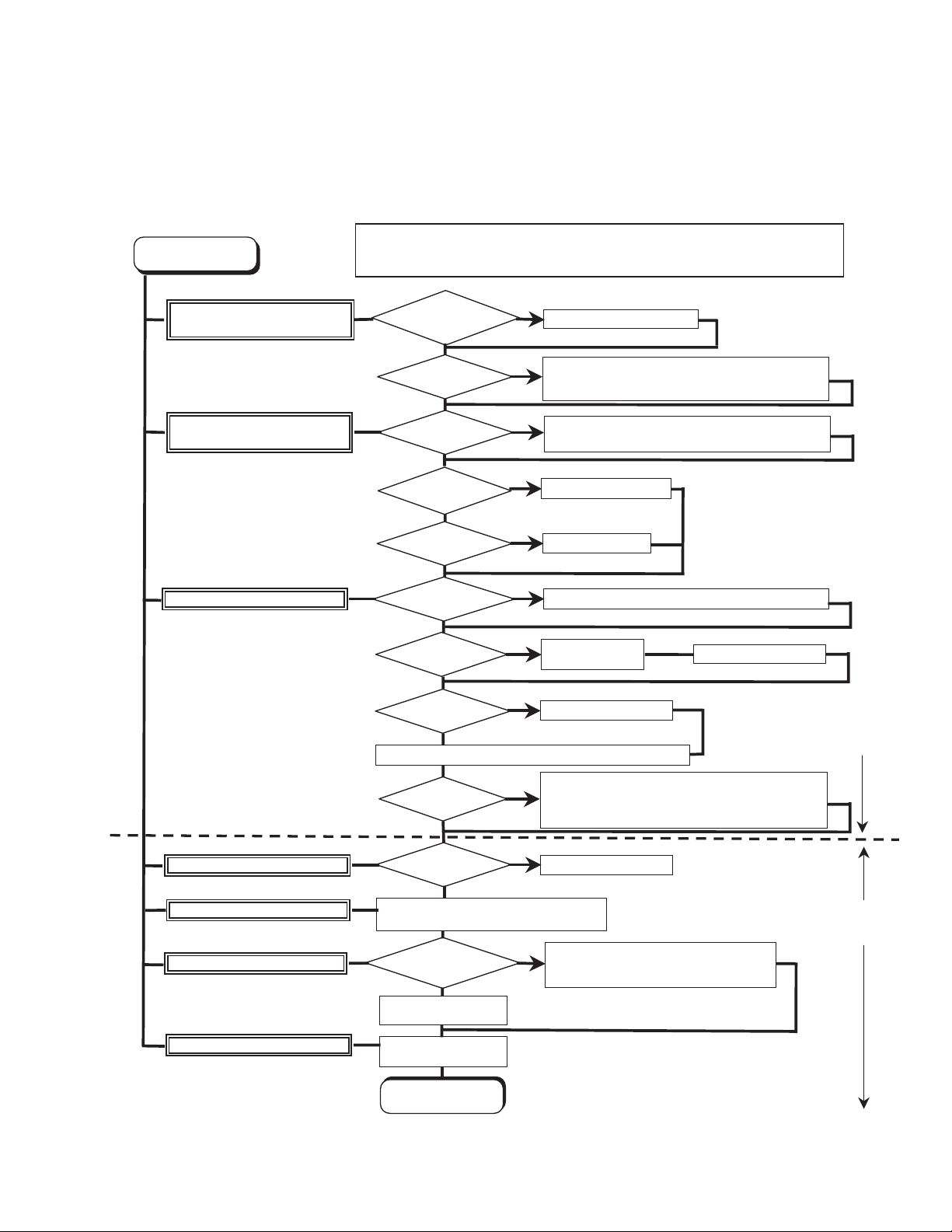

1.2. Troubleshooting

Please take note of the following two points with regard to troubleshooting:

1. Know-how of diagnosis upon occurrence of heavy troubles, e.g. ‘Set cannot be turned ON’, ‘Set fails to start’, ‘No display on

screen’, etc.

2. Explanation of each trouble, mainly symptom of trouble in operation.

Flow Chart

START

START

Set cannot be supplied with current.

Power lamp fails to light up.

Dark display on screen.

Screen fails to display.

Failure in starting

Not displayed properly on screen.

Some or all keys cannot be input.

DVD/CD CALL not practicable.

*Clean DVD-ROM drive with an applicator.

Starts but operates unstably.

Pay attention to the following points when in pursuit of the cause of a troubleshooting.

1. Peripheral apparatus connected with the set should all be removed before operation check.

2. Make sure that cables, boards, etc. are not coming off, and recheck the contact condition.

AC

Adaptor/Battery

Output voltage

NG

Replace AC Adaptor/Battery

OK

Check contact condition of power input terminal. Replace i

YES

NO

defective.

Check Power SW. Replace if defective.

NG

Replace inverter board.

Check inverter cable continuity. Replace if defective

Power lamp

check

Inverter board

OK

YES

NO

Replace LCD back light.

NG

Replace LCD unit.

LCD back

light lighting

LCD unit

check

OK

BIOS operation

chec

NO

Replace main board (Check fuse at power source).

YES

Result of

POST

NG

Refer to POST

error code table.

Replace main board.

OK

Set-up utility

starting

NG

Replace main board.

OK

Return set-up utility setpoint to the state of ‘delivery from factory’.

Check HDD cable connection and continuity.

NO

HDD access

Main board

check

YES

NG

Replace if defective.

Replace HDD & Reinstall.

Replace main board.

Replace main board

OK

Make sure of contact of K/B connector in use.

Replace keyboard or main board.

Check if there are any flaws on DVD or CD

Trouble

symptoms on some

of DVD or CD

NO

media. Since flaws may appear on specifi

media, DVD or CD media can be defective.

YES

Replace DVD drive.

Replace main board.

Reinstall HDD.

Replace main board.

Heavy trouble e.g.,

‘Set cannot be turned

ON’, ‘Set fails to start’,

‘No display on

screen’, etc.

Each kind of

trouble in

operation.

START

END

1-2

2 Power-On Self Test (Boot Check)

Outline of POST

The set has a boot check function called POST (Power-On Self Test) in it. The condition of the main body is diagnosed by checking

beep sound or error code.

Start .............Test begins automatically when power switch is set to ON.

Normal finish .....After memory checking, a beep sound is issued once and the set is placed into automatic stop.

Note: If no error occurs, nothing is displayed. (No display of OK, etc.)

Error Diagnosis by Checking Beep Signal Sound

The beep sound is as follows:

(1 (long sound) -2-3-4)

(Length of bar shows length of sound.)

= long sound (about 0.4 sec.),

Table of errors classified by beep sounds

Diagnosis Beep signal sound Error message

Main board

(Note) A beep sound is also issued in case of other I/O trouble.

1(long sound)-2 BIOS ROM error

1-2-2-3

1-3-1-1

1-3-1-3

1-3-4-1

1-3-4-3

1-4-1-1

= short sound (about 0.2 sec.), Length between sounds is about 0.1 sec.

BIOS ROM error

RAM error

Keyboard controller error

RAM error

RAM error

RAM error

BIOS ROM error2-1-2-3

Occurrence of unexpected offering2-2-3-1

2-1

3. List of Error Codes <Only when the port replicator is connected>

The following is a list of the messages that BIOS can display. Most of them occur during POST.

Some of them display information about a hardware device, e.g., the amount of memory

installed. Others may indicate a problem with a device, such as the way it has been configured.

Following the list are explanations of the messages and remedies for reported problems.

If your system displays one of except the messages marked below with an asterisk (*), write

down the message and contact Panasonic Technical Support. If your system fails after you make

changes in the Setup menus, reset the computer, enter Setup and install Setup defaults or correct

the error.

0200 Failure Fixed Disk

Fixed disk in not working or not configured properly. Check to see if fixed disk is attached

properly. Run Setup. Find out if the fixed-disk type is correctly identified.

0210 Stuck key

Stuck key on keyboard.

0211 Keyboard error

Keyboard not working.

0212 Keyboard Controller Failed

Keyboard controller failed test. May require replacing keyboard controller.

0213 Keyboard locked - Unlock key switch

Unlock the system to proceed.

0230 System RAM Failed at offset: nnnn

System RAM failed at offset nnnn of in the 64k block at which the error was detected.

0231 Shadow RAM Failed at offset: nnnn

Shadow RAM failed at offset nnnn of the 64k block at which the error was detected.

0232 Extended RAM Failed at offset: nnnn

Extended memory not working or not configured properly at offset nnnn.

0250 System battery is dead - Replace and run SETUP

The CMOS clock battery indicator shows the battery is dead. Replace the battery and run

Setup to reconfigure the system.

*0251 System CMOS checksum bad - Default configuration used

System CMOS has been corrupted or modified incorrectly, perhaps by an application

program that changes data stored in CMOS. The BIOS installed Default SETUP Values.

If you do not want these values, enter Setup and enter your own values. If the error persists,

check the system battery or contact Panasonic Technical Support.

0260 System timer error

The timer test failed. Requires repair of system board.

0270 Real time clock error

Real-time clock fails BIOS test. May require board repair.

*0280 Previous boot incomplete - Default configuration used

Previous POST did not complete successfully. POST loads default values and offers to run

Setup. If the failure was caused by incorrect values and they are not corrected, the next boot

will likely fail. On systems with control of wait states, improper Setup settings can also

terminate POST and cause this error on the next boot. Run Setup and verify that the

wait-state configuration is correct. This error is cleared the next time the system is booted.

0281 Memory Size found by POST differed from EISA CMOS

Memory size found by POST differed from EISA CMOS.

3-1

02D0 System cache error - Cache disabled

Contact Panasonic Technical Support.

02F0: CPU ID:

CPU socket number for Multi-Processor error.

02F4: EISA CMOS not writable

ServerBIOS2 test error: Cannot write to EISA CMOS.

02F5: DMA Test Failed

ServerBIOS2 test error: Cannot write to extended DMA (Direct Memory Access) registers.

02F6: Software NMI Failed

ServerBIOS2 test error: Cannot generate software NMI (Non-Maskable Interrupt).

02F7: Fail - Safe Timer NMI Failed

ServerBIOS2 test error: Fail-Safe Timer takes too long.

device address Conflict

Address conflict for specified device.

Allocation Error for: device

Run ISA or EISA Configuration Utility to resolve resource conflict for the specified device.

Failing Bits: nnnn

The hex number nnnn is a map of the bits at the RAM address which failed the memory test.

Each 1 (one) in the map indicates a failed bit. See error 230,231 or 232 for offset address of

the failure in System, Extended or Shadow memory.

Invalid System Configuration Data

Problem with NVRAM (CMOS) data.

I/O device IRQ conflict

I/O device IRQ conflict error.

Operating System not found

Operating system cannot be located on either drive A: or drive C: Enter Setup and see if

fixed disk and drive A: are properly identified.

Parity Check 1 nnnn

Parity error found in the system bus. BIOS attempts to locate the address and display it on

the screen. If it cannot locate the address, it displays ????. Parity is a method for checking

errors in binary data. A parity error indicates that some data has been corrupted.

Parity Check 2 nnnn

Parity error found in the I/O bus. BIOS attempts to locate the address and display it on the

screen. If it cannot locate the address, it displays ????.

Press <F1> to resume, <F2> to Setup

Displayed after any recoverable error message. Press <F1> to start the boot process or <F2>

to enter a Setup and change the settings. Write down and follow the information shown on

the screen.

3-2

4. Diagnostic Test

4.1 Equipment

(1) Test Computer ································································································ 1 unit

(2) External Floppy Disk Drive ············································································· 1 unit

(3) AC Adapter ····································································································· 1 pc.

(4) Loopback Plug (Serial Port Test for RS232C) [ P/N: DFWV95C0067 ] ········· 1 pc.

(5) Floppy Disk containg file DIAG ······································································· 1 pc.

4.2 Preparation

(1) Connect the AC Adapter and External Equipments.

(2) The System Setup should be set to the factory setting values by executing the “SETUP

UTILITY” which can be invoked by F2 key at the POST.

If not, the messages and items of the diagnostic test may not be displayed properly on the

LCD.

(3) The serial port must be enabled in the “SETUP UTILITY” in order to execute the “1st SERIAL

PORT” test.

(4) Connect the serial loopback plug.

4-1

5 Self Diagnosis Test

Floppy disk is Included for the self-diagnostic tests that should be performed before using this product.

Important notice

1. System password

If the password function has been turned on, you will need to ask the user for the password

before performing the self-diagnostics.

2. FDD test

Performing the FDD test will erase the contents of the floppy disk you insert into the drive. Use

a formatted disk that has no contents or whose contents are not required. This product has a

password function. However, if this function is turned on, the self-diagnostics tests will not work.

5.1. Outline of Self Diagnostic Tests

Insert the diagnostics floppy disk

Starting up the setup utility

Turn on the power.

When "Panasonic Press F2 to enter setup" appears

on the screen, press F2.

Return the setup

contents to default

Press " " to select Exit

Press " " to select Get default value

Press Enter.

Choose Yes for "Load default Configuration now?"

Select "Save Values & Exit" and press Enter.

Choose Yes for "Save Configuration changes and exit now?"

and press Enter.

Choose test from

the menu screen

to start the test.

Caution:

After completing repairs, be sure

to carry out the Automatic test

and Peripheraltest.

Menu Screen

1. DIAG on FD (CF-18 XP/2000 Model

2. DIAG on FD (CF-18 Tablet Model

3. LAN Test

4. Modem Test

5. Wireless LAN test (Wireless LAN Model only

6. Button Test

Q. Quit

Select please [ 1, 2, 3, 4, 5, 6, Q ] ?

)

)

)

<Automatic test> <Peripheral test> <Test selection>

Tests selected (O) from the test

item list will be performed in

succession.

DIAG on FD

Problems in the unit are located and divided according

to error messages that occur during testing.

The parallel port and CD-ROM

drive can be tested.

(See 5.3 for details.)

3. LAN Test

4. Modem Test

5. Wireless LAN test (Wireless LAN Model only

6. Button Test

)

Specifc tests required can

be freely selected and

performed from the test item

list.

Be sure to carry out the Selection

test only when necessary.

5-1

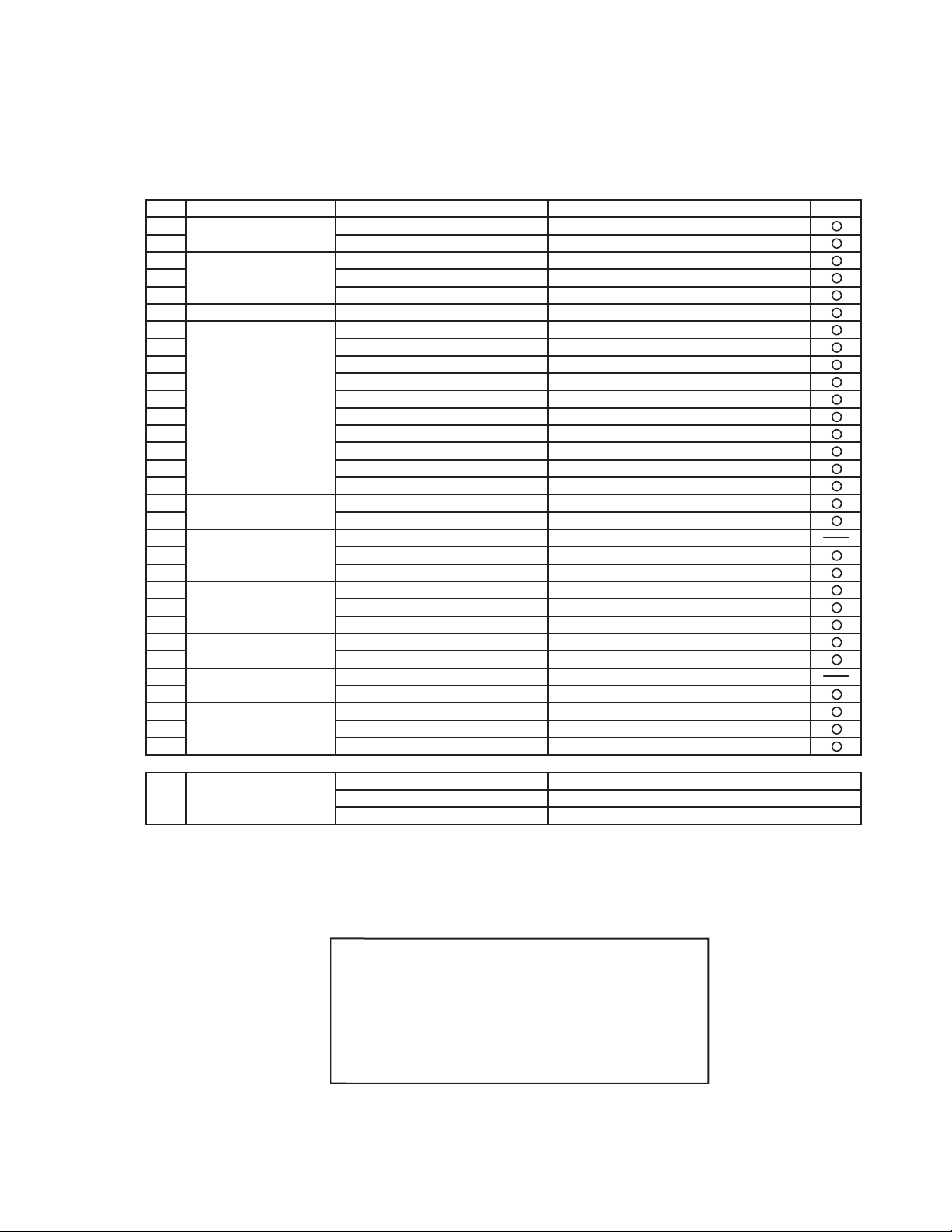

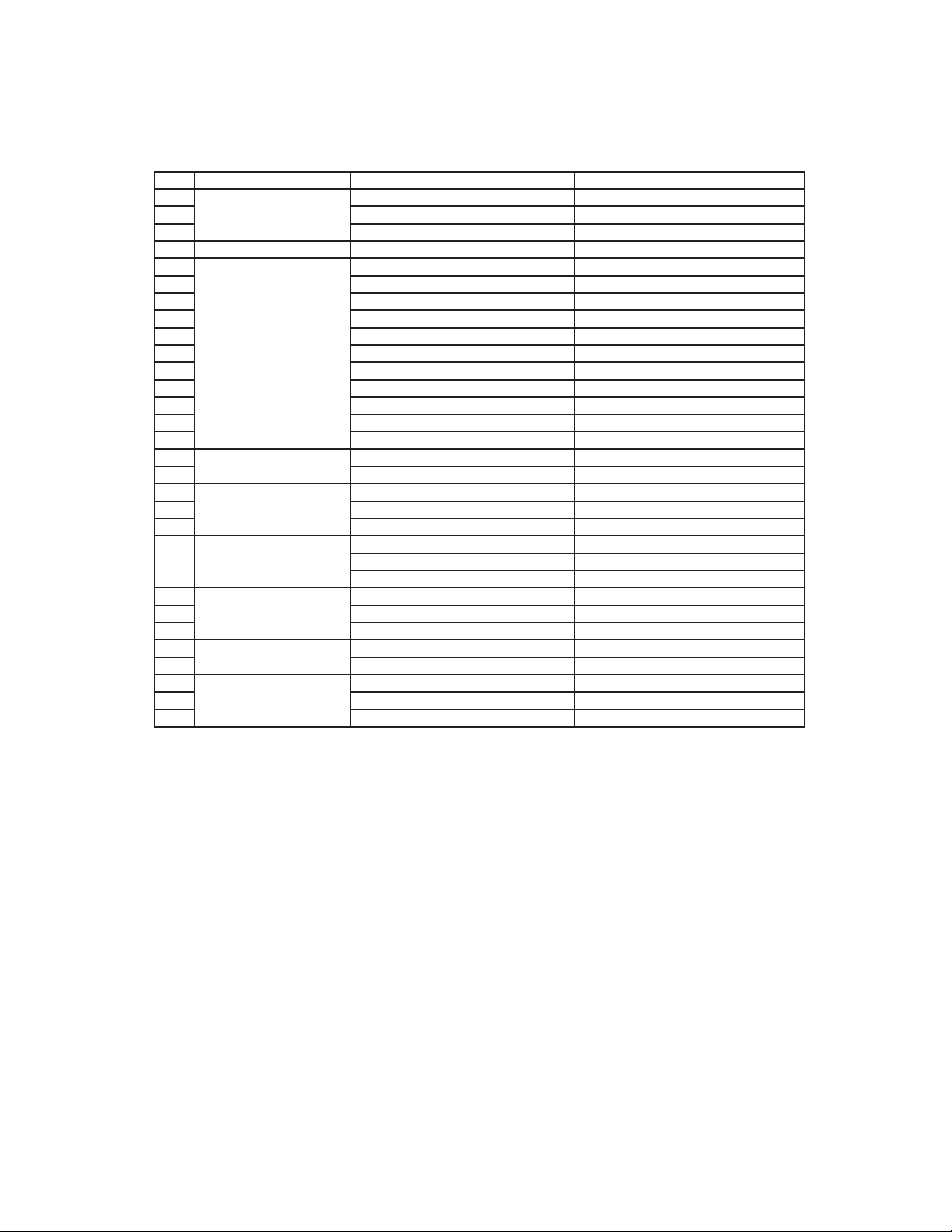

5.1.1 List of main test items

The Selection item displays the items selected under Automatic test. If you select Automatic test, these test items

will be performed automatically. You can use Selection test to choose items from the menu screen that you want to

have tested.

These items are shown below.

1

2

CPU

3

(CPU related)

4

5

RAM (Memory related)

6

CONTROL

7

(Control ICs on the main

8

board, etc.)

9

10

11

12

13

14

15

16

IO

17

(Input-output)

18

COMMUNICATION

19

20

21

AUX

22

(Auxiliary functions)

23

24

VIDEO

25

(Display related)

26

DISK

27

(FDD, HDD)

28

UNIQUE

29

(Individual functions)

30

31

SPEAKER TEST Speaker test

VESA MODE TEST VESA mode test

A20 GATE TEST Address A20 line

CACHE ON/OFF TEST Cache memory on/off test

NPU OPERAND TEST Floating point processor function test

RAM STANDARD TEST Memory standard test

DMA PAGE REG TEST DMA page register test

DMA REGISTER TEST DAM register test

DMAC TRANSFER TEST DAM transfer test

PIC HALT INSTRUCTION TEST Interrupt controller halt instruction test

PIC REGISTER TEST Interrupt controller register test

RTC CMOS RAM TEST Real time clock CMOS test

RTC TEST Real time clock test

PIT CH0 TEST interrupt timer CH0

PIT CH1 TEST interrupt timer CH1

PIT CH2 TEST interrupt timer CH2

KEYBOARD REG TEST Keyboard test

PS/2 MOUSE REG Mouse registration test

SERIAL WRAP TEST Serial loop back (jig required)

SERIAL ALL INTERNAL TEST Serial port interior test

PARALLEL REGISTER R/W Parallel register R/W test

PCIC ALL TEST PCIC test

Card Bus Reg Card Bus register test

USB Reg USB register test

VGA ALL TEST VGA test

SVGA RAM TEST SVGA RAM test

FD WT/RD/WP TEST FD WT, RD WP test

HDD ALL TEST Only HDD lead test selected

ECP REGISTER R/W ECP register R/W test

EPP REGISTER R/W EPP register R/W test

EXT. CMOS R/W TEST Extension CMOS R/W test

Test function settings

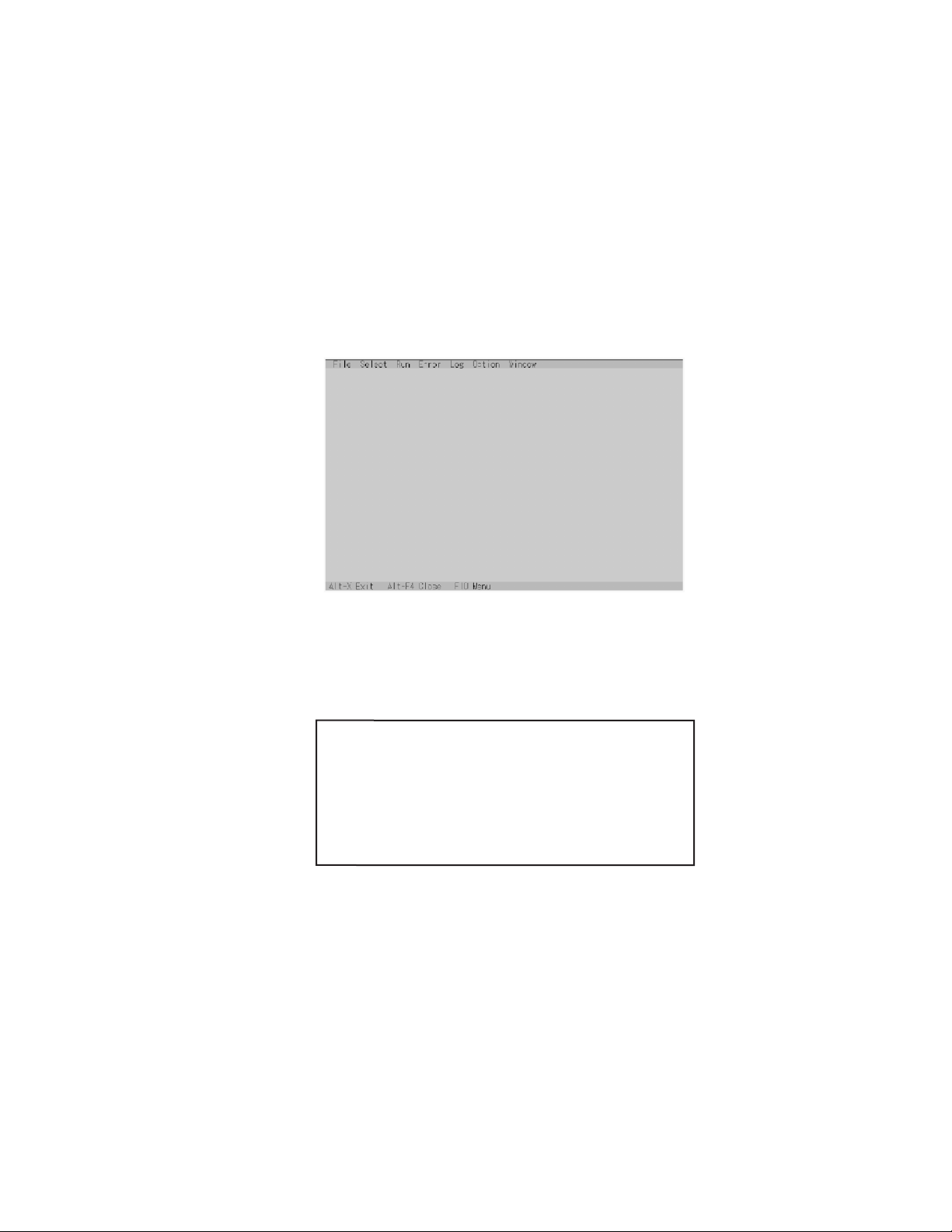

5.2. Automatic Test

Test execution

From the menu screen shown below For Celeron models Select and press Enter for DIAG on FD

Test condition save/play

Test automatic execute

Error display (Paging style)

1. DIAG on FD (CF-18 XP/2000 Model

2. DIAG on FD (CF-18 Tablet Model

Following file command

Test executed on run settings by selecting command

Select displayed items Error, Log, Option

)

)

3. LAN Test

4. Modem Test

5. Wireless LAN test (Wireless LAN Model only

6. Button Test

Q. Quit

Select please [ 1, 2, 3, 4, 5, 6, Q ] ?

menu screen

5-2

)

Speaker test, VESA test

The speaker test involves listening to music and choosing OK or Not okay. The VESA test involves looking at

the display to see if it is satisfactory then choosing OK or Not okay.

Serial loop back test

The Automatic test’s initial settings are set so that the serial loop back test will be executed. Connect the serial

loop back jig and then perform the test.

(This test is not executed on default mode)

Diagnostics result

If no errors occur. The screen shows the word "Pass" in large letters.

If errors occur. The test is stopped when an error occurs and the error message is displayed.

For explanations of error messages, see Error Messages and Problem Categories (section 5.5).

Quitting the test

At the screen shown below, simultaneously press the ALT and X keys.

5.3. Peripheral Test

Test execution

From the menu screen shown below, be sure to choose the following items and press Enter.

3. LAN Test

4. Modem Test

5. Wireless LAN Test

(

Wireless LAN Model only.

This test checks for internal LAN device.

Choose LAN test and press Enter.

Input screen

1. DIAG on FD (CF-18 XP/2000 Model

2. DIAG on FD (CF-18 Tablet Model

3. LAN Test

4. Modem Test

5. Wireless LAN test (Wireless LAN Model only

6. Button Test

Q. Quit

Select please [ 1, 2, 3, 4, 5, 6, Q ] ?

menu screen

)

)

)

)

5-3

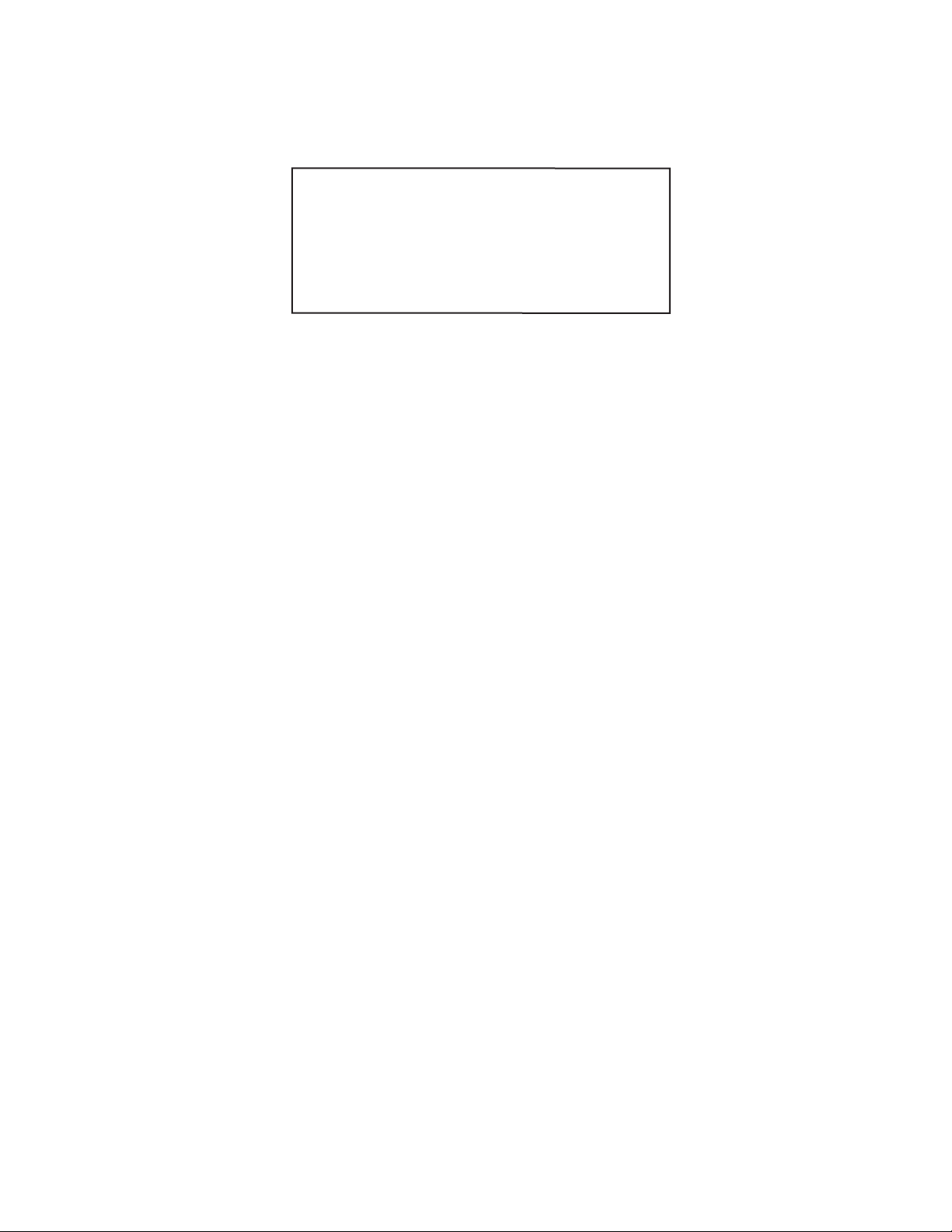

5 .4. Test Selection

Starting up the input menu

1. From the menu screen shown below, choose Quit and press Enter.

1. DIAG on FD (CF-18 XP/2000 Model

2. DIAG on FD (CF-18 Tablet Model

3. LAN Test

4. Modem Test

5. Wireless LAN test (Wireless LAN Model only

6. Button Test

Q. Quit

Select please [ 1, 2, 3, 4, 5, 6, Q ] ?

menu screen

2. When A: \DIAG appears, input "JDG_185" and press Enter.

3. The input screen shown below will appear.

To choose menu items, hold down "ALT" and press the selection key.

)

)

)

5-4

Example:

"AL T" + "F" brings up the File menu.

Order of test flow selection

Input screen

Input screen startup

1. Reading the test conditions settings file

Press "AL T" and "F".

Press "L".

Press "AL T" and "C".

2. setting the test items

Press "AL T" and "S".

Press "S".

Choose the test item and press Enter .

Choose the test whose settings are

to be changed, press "A" for Additional

and "R" for Erase.

All initial V Alues are "0" so set

tests other than the necessary ones to "1".

Press "C" twice to return the menu screen.

To save the selected list, press "AL T" and "F" at the file menu.

Starting the test

Press "AL T" and "R".

Press "R".

This will start the test.

If the test condition settings

file is not read, this means

the test program is not running correctly .

Saving selected test items

If you change the file name when

saving the file in step

create test condition settings for

custom test items.

Example:

CF-18 .

, you can

TEST1.

End of test

5-5

5.5 . Error Messages and Troubleshooting

The table below explains the parts that may be faulty or damaged should an error message occur while performing the

various test items of the self diagnostics program.

Test classification Screen display test items Contents

CPU

1

(CPU related)

2

3

4 RAM (Memory related)

CONTROL

5

(Control ICs on the

6

main board, etc.)

7

8

9

10

11

12

13

14

15

IO

16

(Input-output)

17

COMMUNICATION

18

19

20

AUX

21

(Auxiliary functions)

22

VIDEO

23

(Display related)

24

25

DISK

26

(FDD, HDD)

27

UNIQUE

28

(Individual functions)

29

A20 GATE TEST Address 20 line

CACHE ON/OFF Cache memory on/off

NPU OPERAND TEST Floating point processor function

RAM STANDARD Memory standard

DMA PAGE REG TEST DMA page register

DMA REGISTER TEST DAM register

DMAC Transfer TEST DAM transfer test

PIC HALT INSTRUCTION TEST Interrupt controller

PIC REGISTER TEST Interrupt controller

RTC CMOS RAM TEST Real time clock CMOS

SPEAKER TEST Speaker

PIT CH0 TEST Interrupt timer CH0

PIT CH1 TEST Interrupt timer CH1

PIT CH2 TEST Interrupt timer CH2

KEYBOARD REG TEST Keyboard

PS/2 MOUSE REG Mouse

SERIAL WRAP TEST Serial loop back (jig required)

SERIAL ALL INTERNAL TEST Serial port

PARALLEL REGISTER R/W Parallel register

PCIC ALL TEST PCIC

Card Bus REG Card Bus port

USB REG USB port

VGA ALL TEST VGA

SVGA RAM TEST SVGA RAM

VESA MODE TEST VESA mode

FD WT/RD/WP TEST FD write/read/write protection

HDD ALL TEST Only HDD lead selected

ECP REGISTER R/W Parallel port

EPP REGISTER R/W Parallel port

EXT. CMOS R/W TEST Extension CMOS R/W test

5-6

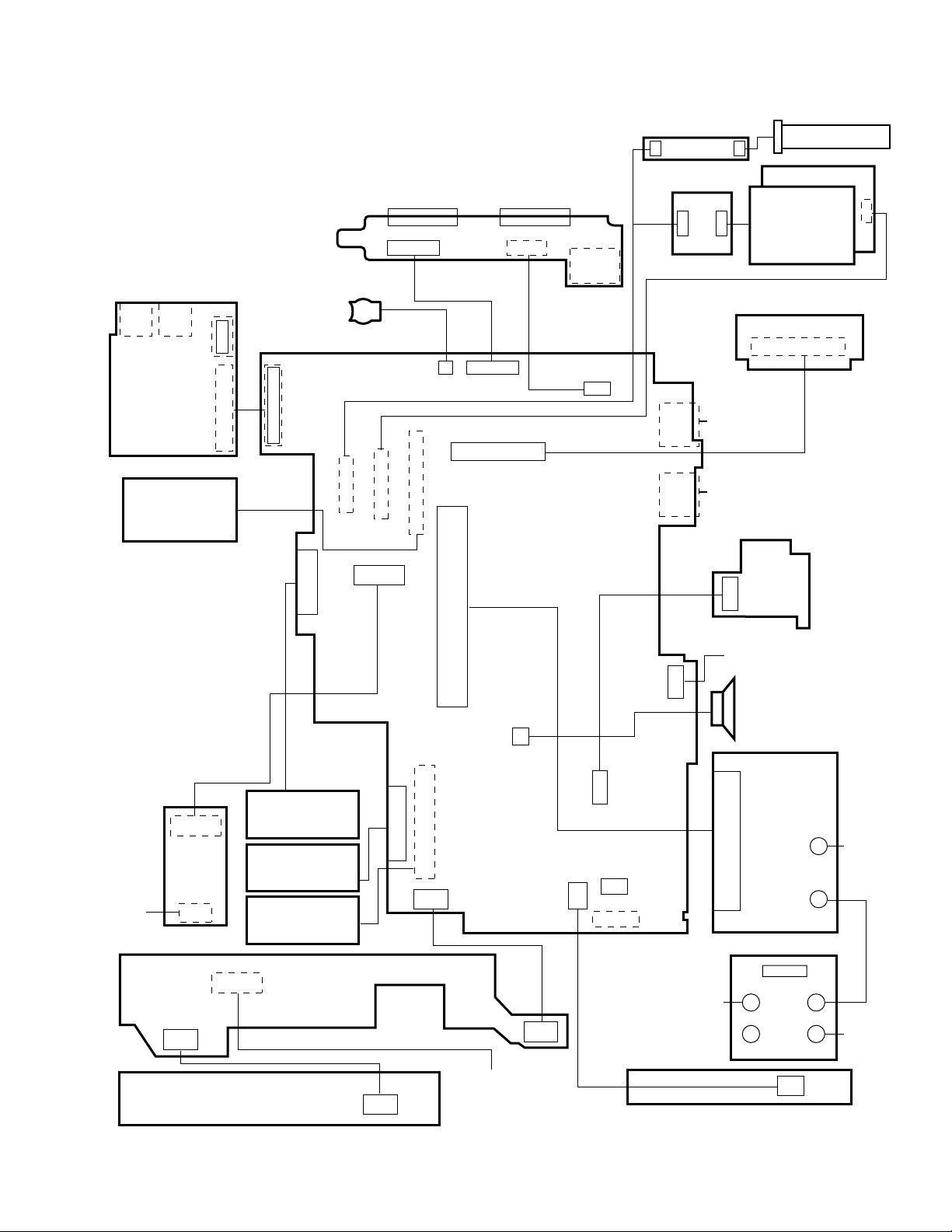

6 Wiring Connection Diagram

H/P

MIC

JK902

JK901

CN900

CN902

CN901

AUDIO PCB

KEYBOARD

CN16

CN27

I/O PCB

RTC

BATTERY

CN17

EXTERNAL

DISPLAY

PORT

CN880

CN8

CN880

CN18

CN11

CN25

SERIAL PORT

CN881

CN883

CN9CN3

JK880

DC-IN

CN14

INVERTER PCB

CN1

CN2

TS PS2 PCB

CN901

CN900

CN6

CN7

BACK LIGHT

LCD

Touch

Screen

Panel

I/F PCB

CN850

USB PORT

USB PORT

SD PCB

MODEM

PORT

MODEM PCB

PAD PCB

SW PCB

J1

J2

CN801

CN800

CN5

HDD

MAIN

BATTERY

PMCIA UNIT

CN950

CN24

CN15

CN4

MAIN PCB

CN37

CN23

TOUCH PAD

CN35

CN802

CN12

CN21

CN30

POWER

LED PCB

SW4

GPRS

CN891

LAN PORT

SPEAKER

J1

WIRELESS

MODULE

ANT PCB

CN1

CN2

CN3

J5

J6

CN4

CN5

CN841

LANAUX

LANMAIN

6-1

7 Disassembly/Reassembly

Note:

Power off the computer. Do not shut down to the Suspend or hibernation mode.

Do not add peripherals while the computer is in the Suspend or hibernation mode; abnormal operation may result.

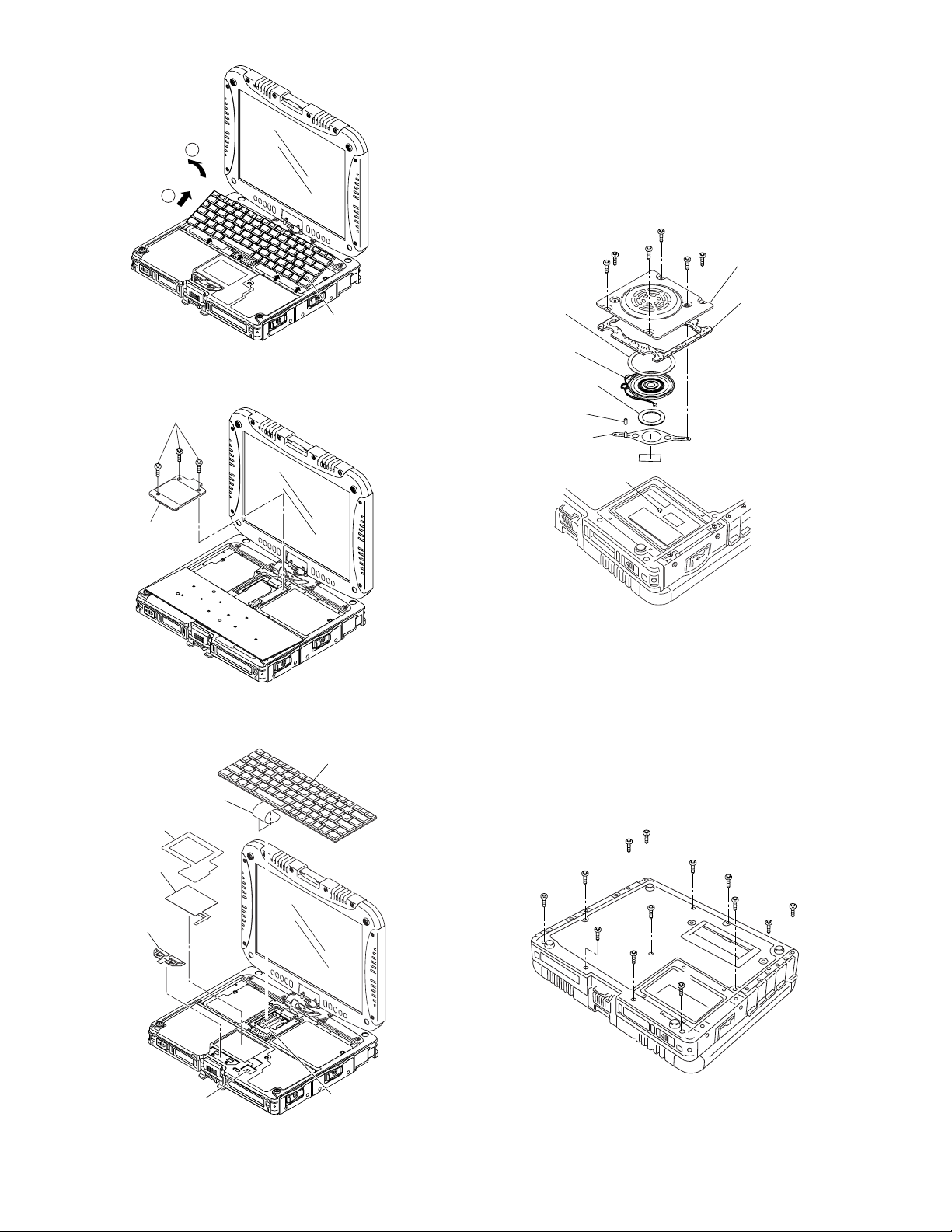

7.1. Disassembly Instructions

7.1.1. Preparation

Before disassembling, be sure to make the following preparations.

• Shut down Windows and turn off the power.

• Disconnect the AC adaptor.

• Remove the optional DIMM memory card and PCMCIA card

if they are connected.

• Remove other devices if they are connected.

Attention:

• Please execute writing BIOS ID when you exchange the

Main Board.

• Parts (Sheet and rubber) etc. related various the Conductive

Cloth and Heat Spreader cannot be recycled. Use new parts.

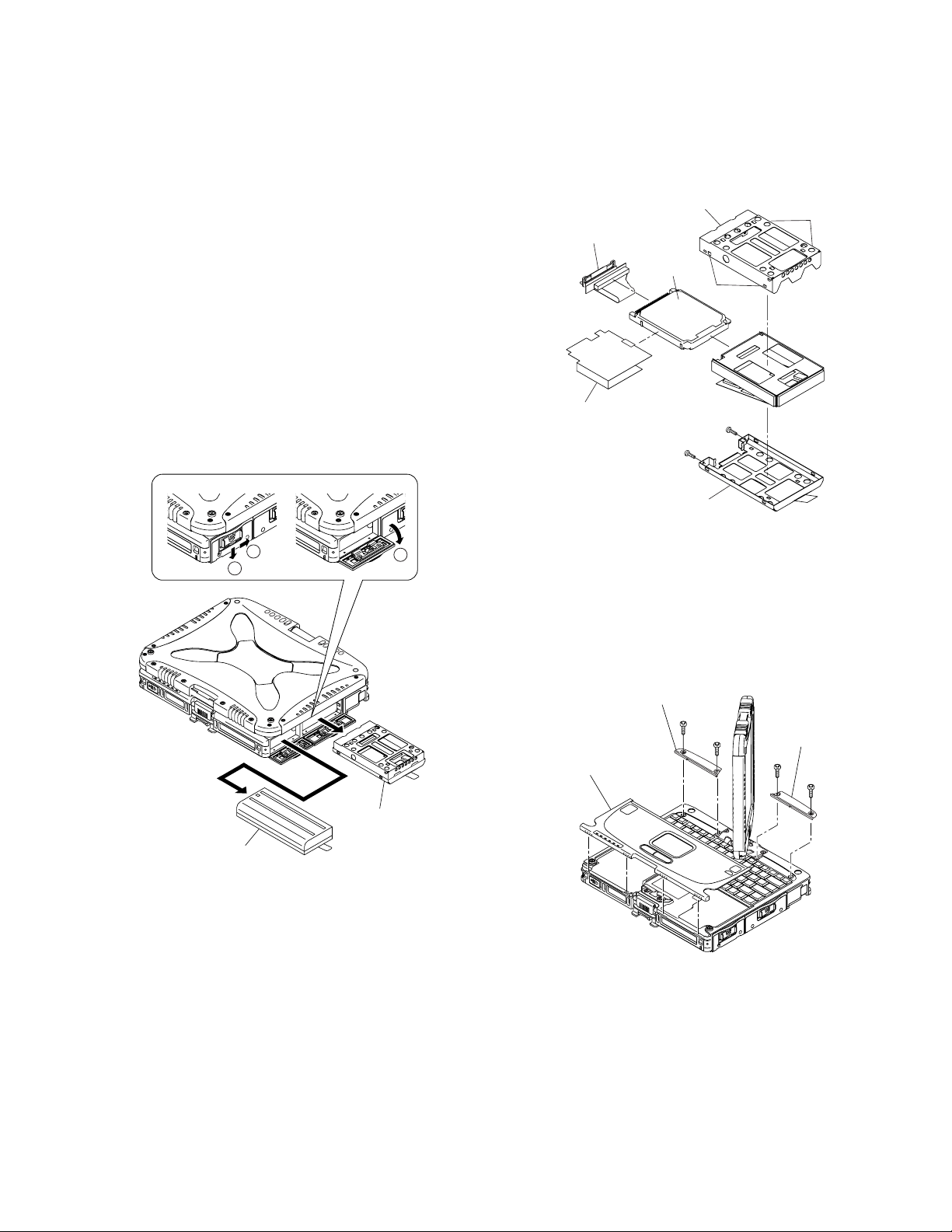

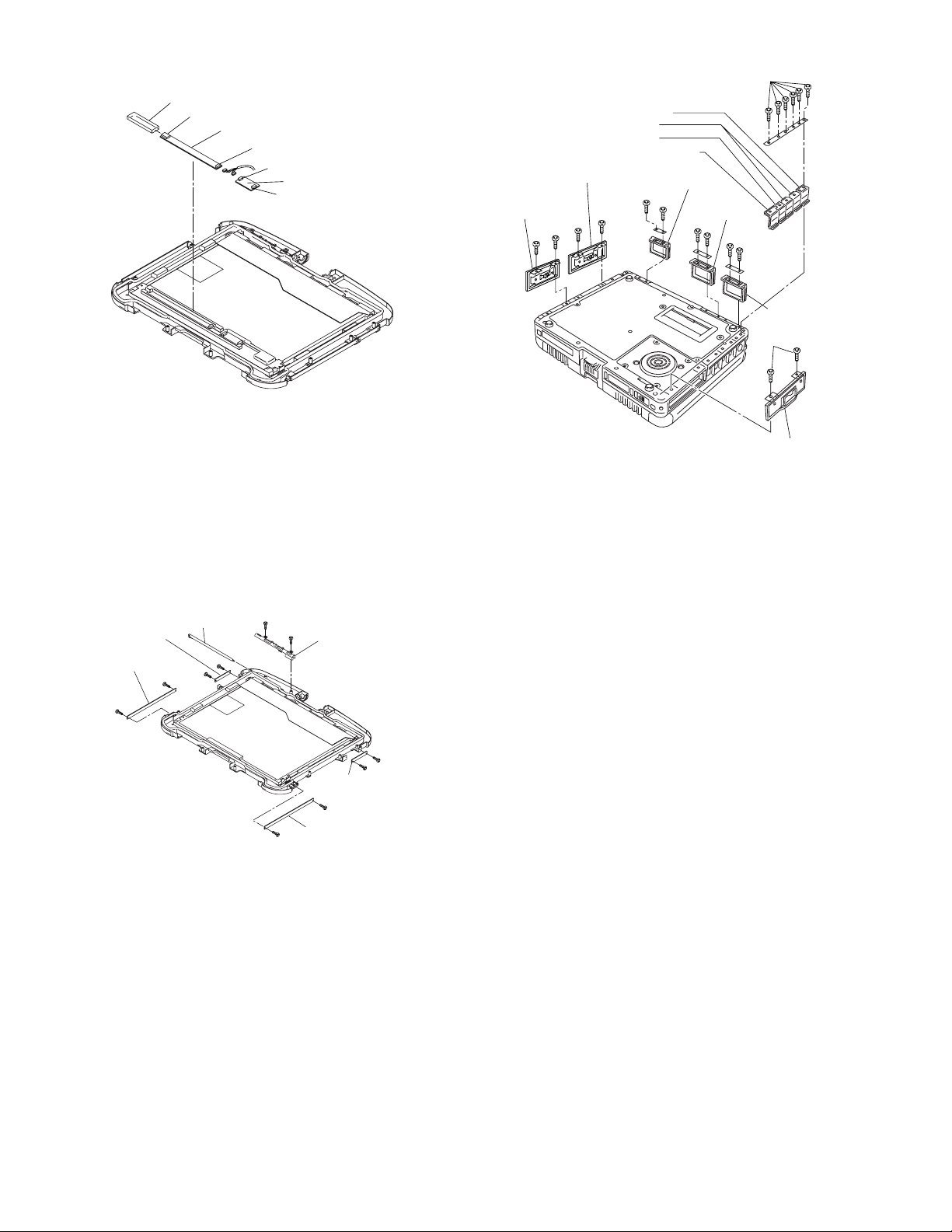

7.1.2. Removing the Battery Pack and

HDD Pack

1

2

3

4. Remove the HDD Pack.

HDD Case B

HDD FPC

HDD

Hooks

Heater

<A>

<A>

HDD Case A

5. Remove the two Screws <A>.

6. Remove the HDD Case A and the HDD Case B.

7. Remove the HDD.

Screws <A>:DFHE5025XA

Hooks

Battery Pack

1. Open the Battery Cover.

2. Remove the Battery Pack.

3. Open the HDD Cover.

HDD Pack

7.1.3. Removing the Touch Pad and Keyboard

KBD Plate

<B>

<B>

Palm Rest Ass'y

1. Remove the Palm Rest Ass'y.

Note:

The Palm Rest Ass'y is firmly fixed with two-sided

tape.

Carefully remove the Palm Top Cover Sheet not to

damage it.

2. Remove the four Screws <B>.

KBD Plate

<B>

<B>

7-1

3. Remove the KBD Plate.

1

2

9. Remove the TP Tape.

10. Disconnect the Cable from Connector (CN800).

11. Remove the Touch Pad and Click Button Plate.

Screws <B>:DRSB2+5FKL

Screws <C>:DFHE5025XA

7.1.4. Removing the Speaker Angle and

DIMM Lid

<D>

<D>

<E>

<D>

<E>

<D>

DIMM Lid

Keyboard

4. Lift the far side of the Keyboard and slide it to backward,

and then turn the Keyboard over frontward.

<C>

KBD

Connector

Cover

5. Remove the three Screws <C>.

6. Remove the KBD Connector Cover.

Keyboard

Speaker

Waterproof

Sheet

Speaker Unit

Speaker Washer

Speaker Cable

Tube

Speaker Angle

Connector (CN37)

DIMM LID Sheet

1. Remove the four Screws <D>.

2. Disconnect the Cable from Connector (CN37).

3. Remove the DIMM Lid.

4. Remove the two Screws <E>.

5. Remove the Speaker Angle.

Screws <D>: DRQT2+D2FKL

Screws <E>: DRHM5025YA

Keyboard

FPC

TP Tape

Touch Pad

Click Button

Plate

Connector

(CN800)

Connector

(CN18)

7. Disconnect the Cable from Connector (CN18).

8. Remove the Keyboard.

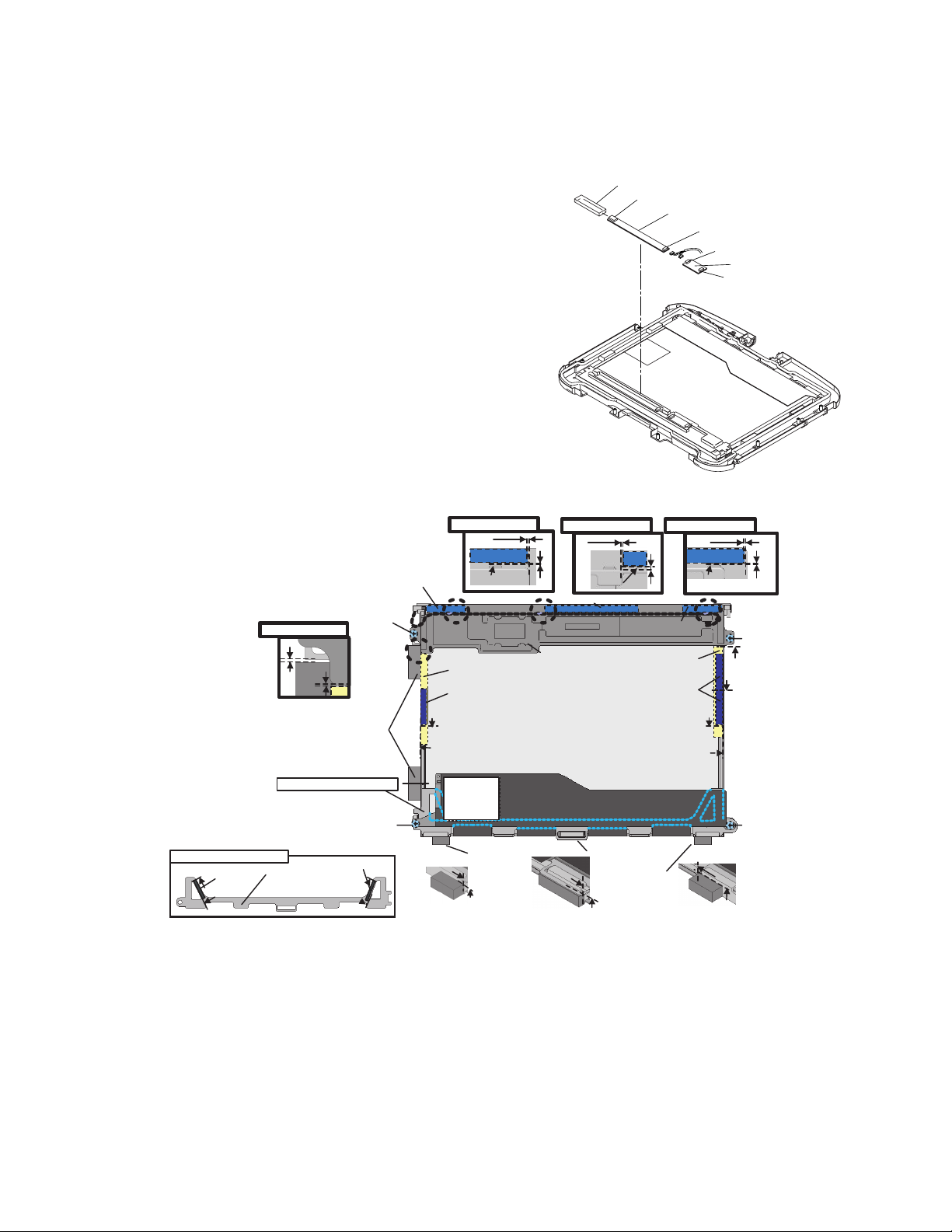

7.1.5. Removing the Rear Cabinet

<F>

<F>

<F>

<F>

<F>

<F>

<F>

<F>

<F>

<F>

<F>

1. Remove the thirteen Screws <F>.

2. Open the LID Rubbers.

3. Remove the Rear Cabinet.

Screws <F>:DRHM0061ZA

7-2

<F>

<F>

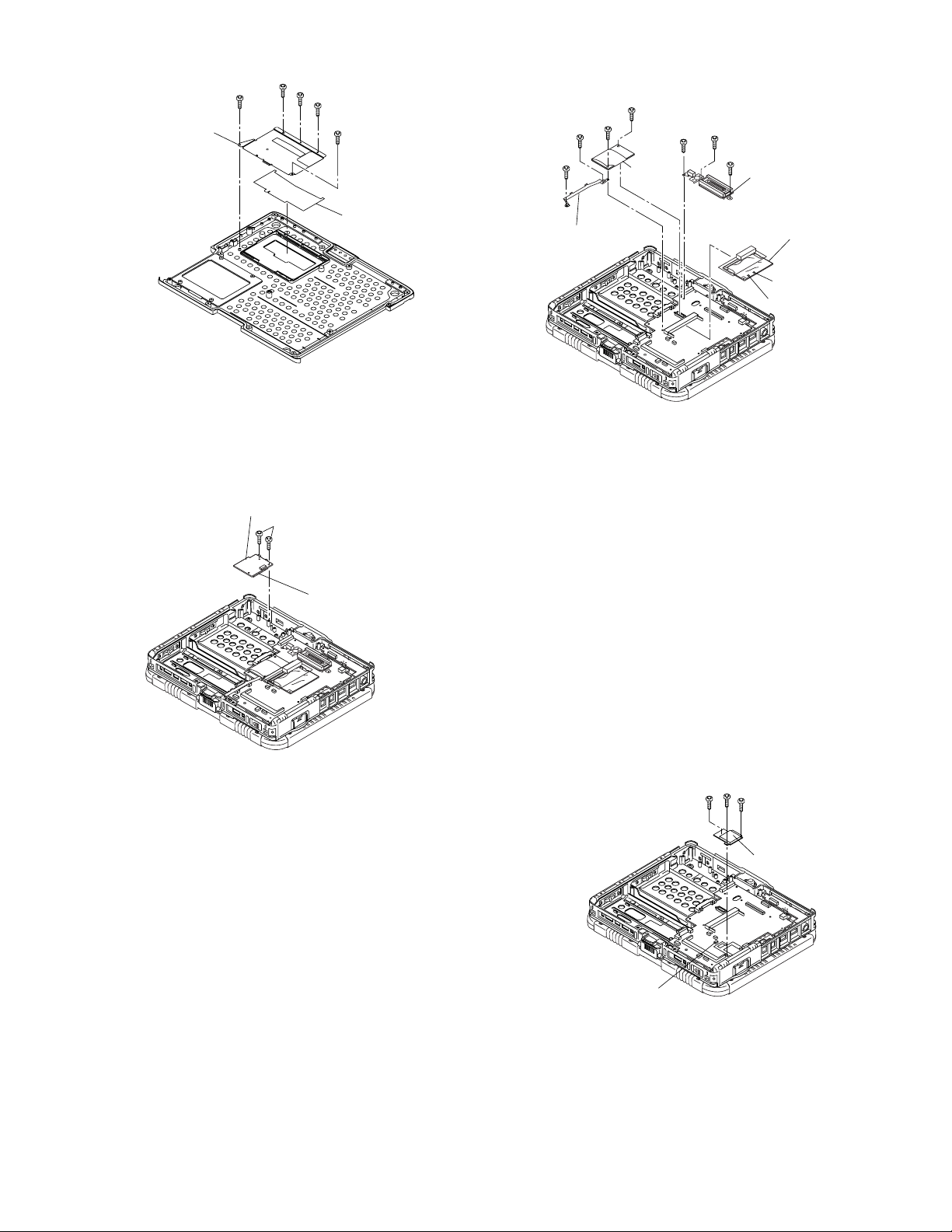

7.1.6. Removing the DU Lid Unit

<G>

<G>

DU LID Angle

<G>

<G>

<G>

DU LID

1. Remove the five Screws <G>.

2. Remove the DU Lid Angle and DU Lid.

Screws <G>:DRHM5025YA

7.1.7. Removing the Audio PCB

Audio PCB

<H>

Connector (CN901)

7.1.8. Removing the Wireless Module,

Port PCB and Modem

<J>

<J>

<K>

<K>

Bat Con Angle

Modem

Note:

This procedure is not necessary if the computer is not

equipped with Wireless Module or Modem PCB.

1. Disconnect the two Antenna Cables from two Connectors

(J5, J6).

2. Remove the Wireless Module.

3. Remove the three Screws <I>.

4. Remove the Port PCB.

5. Remove the two Screws <J>.

6. Remove the Modem.

7. Disconnect the Modem cable from the connector.

8. Remove the two Screws <K>.

9. Remove the BAT CON angle.

<I>

<I>

<I>

Port PCB

Wireless Module

Connector (J5)

Connector (J6)

1. Remove the two Screws <H>.

2. Disconnect the Cable from a Connector (CN901).

3. Remove the Audio PCB.

Screws <H>:DRSB2+5FKL

Screws <I>:DRSB2+5FKL

Screws <J>:XSB2+4FNL

Screws <K>:DRSB2+5FKL

7.1.9. Removing the SD PCB

<h>

<h>

Connector (CN21)

1. Disconnect the Cable from Connector(CN21).

2. Remove the three Screws <h>

3. Remove the SD PCB.

Screws <h>:DXQN2+A22FNL

<h>

SD PCB

7-3

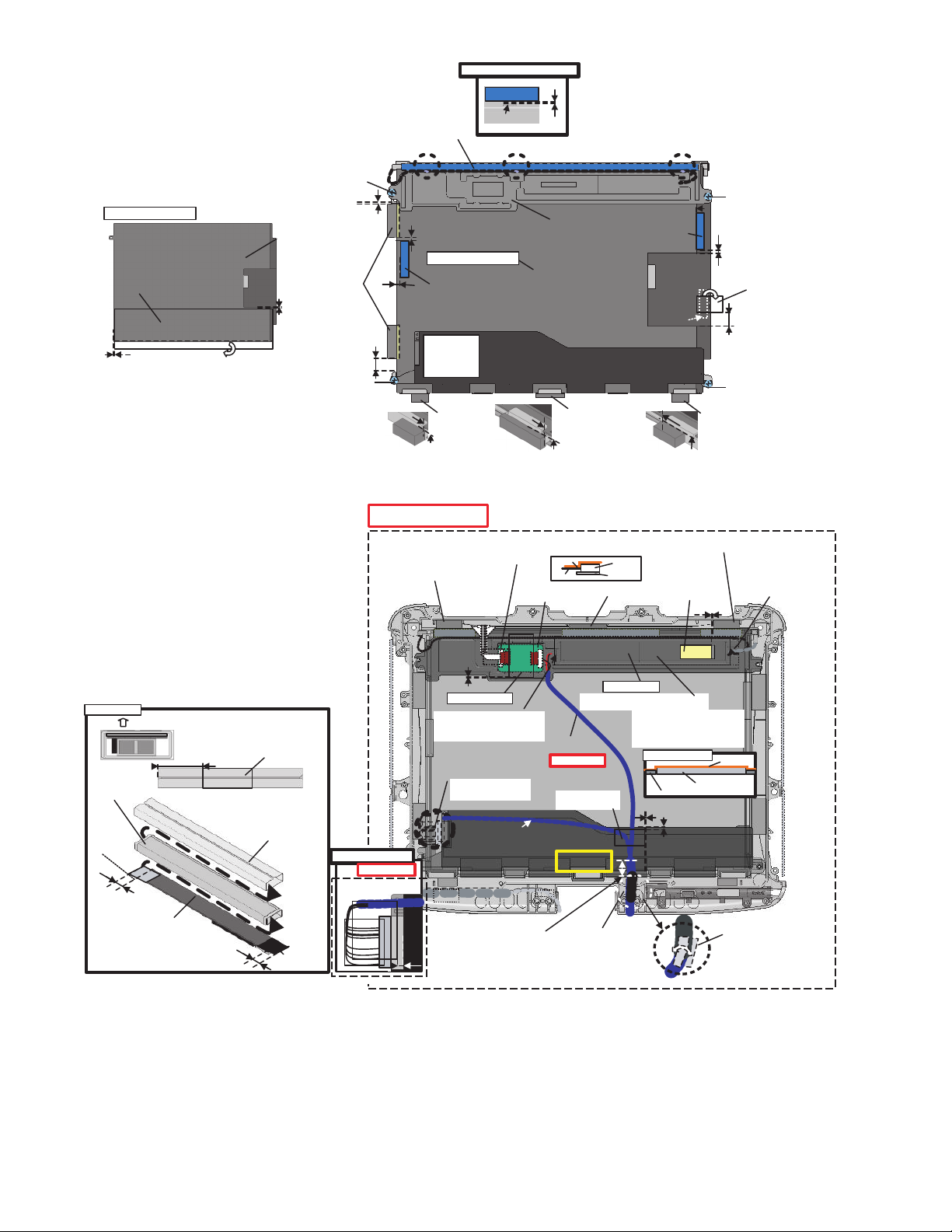

7.1.10. Removing the Main PCB and Lithium Battery

5. Remove the two Screws <Q>.

6. Remove the I/O PCB.

Lithium Battery

Connector (CN17)

Connector (CN8)

Connector (CN3)

Connector (CN9)

Connector (CN14)

LAN Cable

<N>

Connector (CN12)

<N>

to Connector (CN17)

to Connector (CN8)

HDD Guid Plate

Connector (CN36)

Connector

(CN23)

Main PCB

Connector (CN35)

Connector (CN30)

PCMCIA Unit

<N>

<M>

<M>

<L>

<N>

1. Disconnect the Cable from Connector(CN3).

2. Remove the Lithium Battery.

3. Disconnect the seven Cables from seven Connectors

(CN9, CN12, CN14, CN23, CN30, CN35, CN36).

4. Remove the Screw <L>.

5. Remove the two Screws <M>.

6. Disconnect the two Cables from two Connectors (CN8,

CN17).

7. Remove the four Screws <N>.

8. Remove the Main PCB.

9. Remove the PCMCIA Unit.

Screws <O>:DFHE5025XA

Screws <P>:DFHE5058ZB

Screws <Q>:DRSB2+5FKL

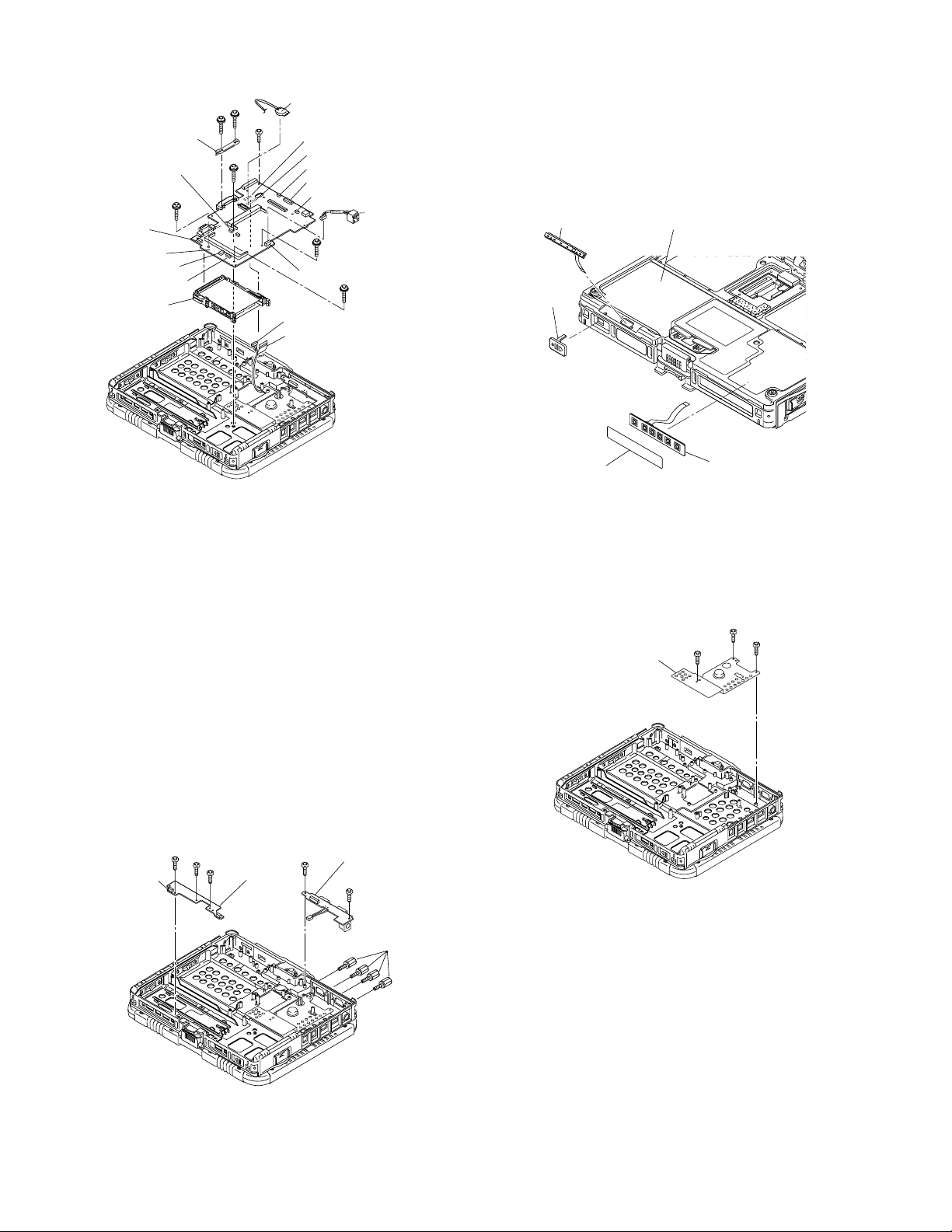

7.1.12. Removing LED PCB and Switch

PCB

LED PCB

Power

Switch

Knob

Operation Sheet

1. Remove the LED Waterproof Sheet.

2. Remove the LED PCB.

3. Remove the Switch PCB.

4. Remove the Power Switch.

LED Waterproof Sheet

Switch PCB

7.1.13. Removing the CPU Heat Plate

<R>

<R>

CPU Heat Plate

<R>

Screw <L>:DRSB2+5FKL

Screws <M>:DXYN2+J12FNL

Screws <N>:DXYN2+J18FNL

7.1.11. Removing the PAD PCB and I/O

PCB

<O>

<O>

<O>

Connector

(CN801)

PAD PCB

1. Disconnect the Cable from Connector (CN801).

2. Remove the three Screws <O>.

3. Remove the PAD PCB.

4. Remove the four Screws <P>.

<Q>

I/O PCB

<Q>

<P>

1. Remove the three Screws <R>.

2. Remove the CPU Heat Plate.

Screws <R>:DFHE5025XA

7-4

7.1.14. Removing the Display unit

r

7.1.15. Removing the LCD Rear Case

LCD Hinge Cover

<S>

<S>

1. Remove the four Screws <S>.

2. Remove the LCD Hinge Cover.

<T>

<S>

Hinge Cover

<T>

<S>

<X>

<X>

<X>

<X>

Antenna Cover

<V>

<V>

<V>

<V>

<V>

<V>

Tablet Latch Cover

<V>

<V>

<V>

<X>

<V>

<V>

<V>

<W>

<W>

<V>

<V>

LCD Rear Case

<X>

<X>

<X>

<X>

<X>

<V>

<V>

Antenna Cove

1. Remove the eight Screws <V> on the front side of Display

unit.

2. Remove the eight Screws <V> on the back side of Display unit.

3. Remove Antenna Cover and Tablet Latch Cover.

4. Remove the two Screws <W>.

5. Remove the ten Screws <X>.

6. Remove the LCD Rear Case.

3. Display unit is half-rotated and removes the two Screws

<T>.

4. Remove the four Screws <U>.

<U>

<U>

<U>

<U>

5. Turn the computer over.

6. Remove the Display Unit.

Screws <S> : DFHE5025XA

Screws <T> : DRSB2+5FKL

Screws <U> : DXYN4+J8FNL

Screws <V> : DRQT26+E5FKL

Screws <W> : DXYN3+J10FNL

Screws <X> : DXYN2+J6FNL

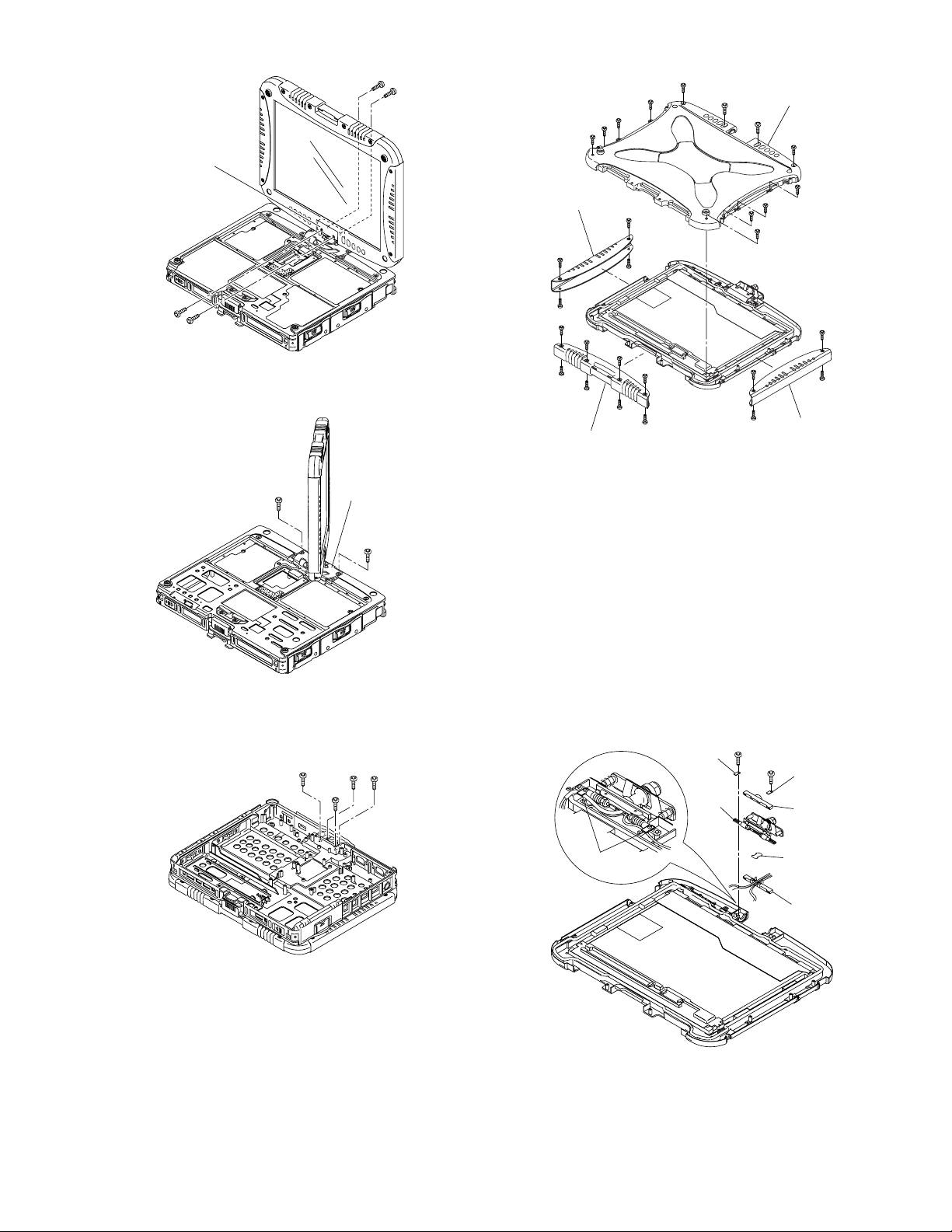

7.1.16. Removing the LCD Hinge

Cable

<Y>

Holder

Plate

LCD

Hinge

Cable Holder

Plate

1. Remove the Cable Holder.

2. Remove the two Screws <Y>.

3. Remove the Cable Holder Plate and LCD Hinge.

<Y>

LCD Cable

Holder

Sheet

Cable

Holder

Plate

Cable

Holder

Cable

Holder

Screws <Y> : DXYN3+J8FNL

7-5

7.1.17. Removing Inverter PCB and LCD

Unit

Inverter Case

Connector (CN2)

Inverter PCB

Connector (CN1)

Connector (CN901)

TS PS2 PCB

Connector (CN900)

1. Disconnect the two Cables from two Connectors (CN1,

CN2).

2. Remove the Inverter Case and Inverter PCB.

3. Disconnect the two Cable from two connector (CN900,

CN901).

4. Remove the TS PS2 PCB, then remove the LCD unit.

7.1.18. Removing GPRS Antenna PCB,

LAN1-BT PCB, LAN2-BT PCB, Wide

Area Aux PCBand Pen Holder

Wide Area

Aux PCB

LAN1-BT

Antenna PCB

<a>

<a>

<a>

Pen

<a>

<b>

<b>

Pen Holder

7.1.19. Removing the Each Cover

<f>

DC IN LID Rubber

USB LID Rubber

LAN LID Rubber

Moden/LAN LID Rubber

HDD LID ASS’Y

Battery

LID ASS’Y

<e>

<e>

<e>

<e>

1. Remove the 12 Screws <f>.

2. Remove the Moden/LAN LID Rubber, LAN LID Rubber,

USB LID Rubber, DC IN LID Rubber, Serial LID Rubber,

RGB LID Rubber and Audio LID Rubber.

3. Remove the Rear Cabinet.

(Refer to 7.1.5 Removing the Rear Cabinet)

4. Remove the six Screws <e>.

5. Remove the Battery LID ASS'Y, HDD LID ASS'Y and

PCMCIA LID ASS'Y.

Screws <e>:DRQT26+D3FKL

Screws <f>:DRHM5025YA

Audio

LID Rubber

<f>

<f>

RGB

LID Rubber

<f>

<f>

<f>

PCMCIA LID ASS’Y

<f>

Serial

LID Rubber

<e>

1. Remove the two Screws <a>.

2. Remove the GPRS Antenna PCB

3. Remove the two Screws <a>.

4. Remove the LAN1-BT PCB.

5. Remove the two Screws <a>.

6. Remove the LAN2-BT PCB.

7. Remove the two Screws <a>.

8. Remove the Wide Area Aux PCB.

9. Remove the Pen

10. Remove the two Screws <b>.

11. Remove the Pen Holder.

Screws <a> : DFHE5025XA

Screws <b> : DRHM5025YA

<a>

<a>

<a>

LAN2-BT

Antenna PCB

<a>

GPRS

Antenna PCB

7-6

7.2. Reassembly Instructions

7.2.1. Attention when CF-18 series is repaired

• Please execute writing BIOS ID when you exchange the Main Board.

• Parts (Sheet and rubber) etc. related various the Conductive Cloth and Heat Spreader cannot be recycled. Use new parts.

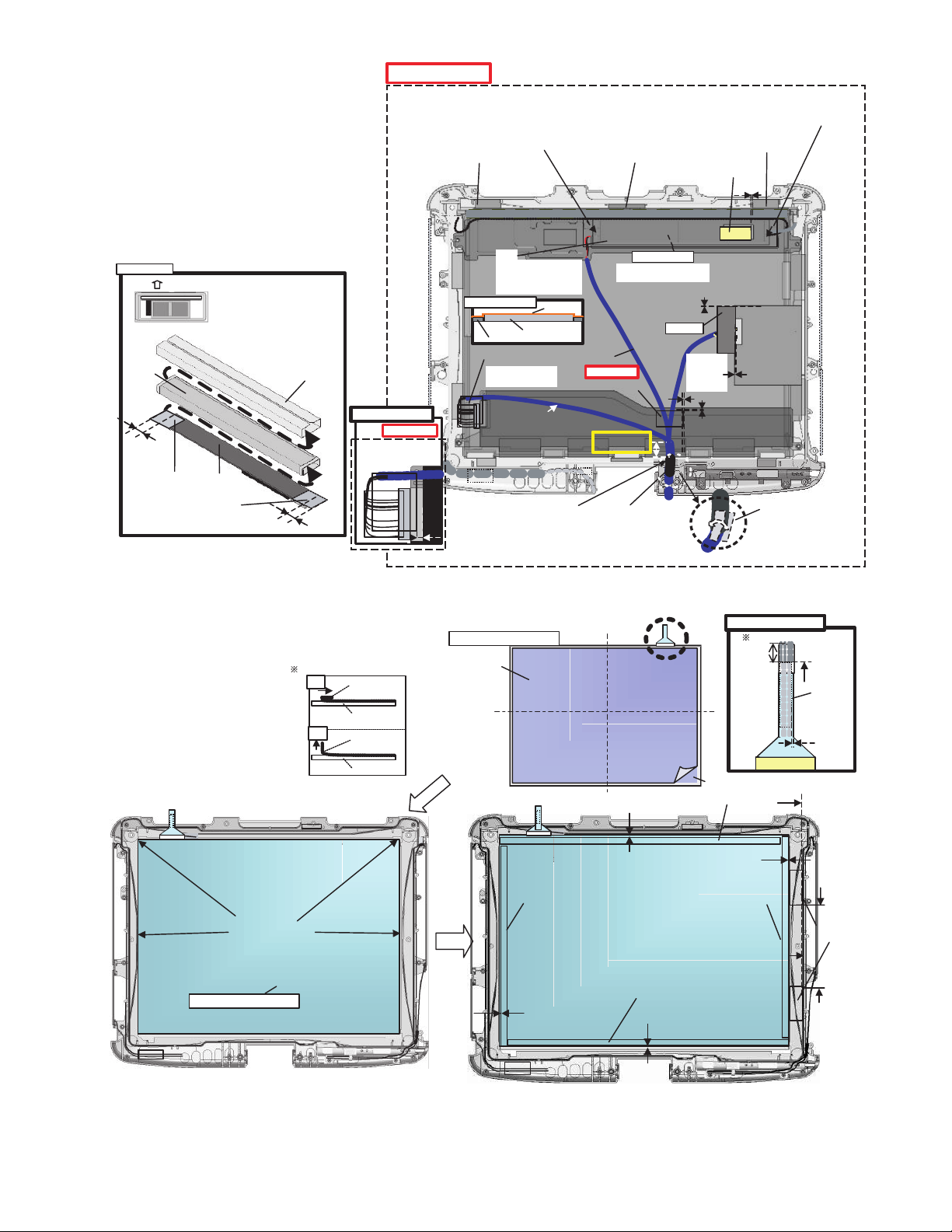

7.2.2. Setting up the LCD UNIT

1. Set the LCD UNIT to the LCD FRONT CABINET/TS

PANE L.

2. Fix the LCD Back Damper using the 2 Screws. <Z>

3. Set the TS PS2 PCB on the LCD Back Damper, and connect the 2 Cables to the Connectors (CN900 and CN901).

4. Set the INVERTER PCB to the LCD Back Damper, and

connect the 2 Cables to the Connectors (CN1 and CN2).

Screws <Z> :DXHM0042ZA

! Assembly of LCD Back Damper (Applicable Model : Touch Screen Model)

Inverter Case

Connector (CN2)

Inverter PCB

Connector (CN1)

Connector (CN901)

TS PS2 PCB

Connector (CN900)

Attach it to the side surface of the Frame.

(Match to the end of the Frame

within 0 to 0.5 mm at the far side.)

Insert this between LCD PCB & LCD FARME.

LCD PCB SPACER ASSY

Spacer Sheet

LCD PCB Spacer

Asymmetric shape

The form of the left and

the right isn't symmetrical.

LCD Back Cushion S

Set the LCD Back Dumper,

and then screw it.

Detail of "A"

0~3mm

0~0.5mm

Screw<Z>

LCD Side Cushion A

LCD PCB SPACER ASSY

Screw<Z>

Screw the Board

and the Spacer together.

Spacer Sheet

Detail of "B"

Pass the Cable under

the protrusion.

B

A

Holder Sheet

LCD Back Cushion Side

(0~0.5mm)

Hide the hook of the LCD FRAME.

Fit Holder Sheet&LCD Back Cushion Side

to the leftside end of LCD FRAME.

LCD Side Cushion C LCD Side Cushion D

0±0.5mm

0±0.5mm

0~1mm

Detail of "C"

0~1mm

0~0.5mm

C

Pass the Cable

through the space.

LCD Back Cushion L

LCD Back Dumper

Remove the Release Paper

on the back side and attach it.

Crosswise: Match to the middle line.

Lengthwise: Match to the LCD Frame.

(0~0.5mm)

0±0.5mm

LCD Back Cushion Side

(0~0.5mm)

Fit Holder Sheet&LCD Back Cushion Side

to the rightside end of LCD FRAME.

LCD Side Cushion C

0±0.5mm

Detail of "D"

1~1.5mm

Pass the Cable under

the protrusion.

D

LCD Back Cushion S

Holder Sheet

(0~0.5mm)

Hide the hook of the LCD FRAME.

0~1mm

Set the LCD Back Dumper,

and then screw it.

0~0.5mm

Screw the Board

and the Spacer together.

0±0.5mm

0±0.5mm

0~0.5mm

Screw<Z>

0~0.5mm

Screw<Z>

7-7

! Assembly of LCD Back Damper (Applicable Model : Digitizer Model)

Detail of "A/B/C"

Pass the Cable

under the protrusion.

BC

Remove the Release Paper on the back side and attach it.

Lengthwise: Match to the LCD Frame.

Crosswise: Match to the middle line.

LCD Side

Cushion C

Digitizer PCB Assy

Digitizer Sheet

0~0.5mm

Fold back the surplus length.

Screw the Digitizer

and the LCD Back Dumper together.

Digitizer

Handle it carefully.

0~0.5mm

Attach it to the side

surface of the Frame.

(Match to the end of

the Frame within 0 to 0.5 mm

at the far side.)

Screw the Board together.

LCD Back Cushion DG CCFL

Screw

0~3mm

LCD Side

Cushion A

10±2mm

Screw

A

4±0.5mm

Digitizer PCB Assy

LCD Back Cushion DG Side

2±0.5mm

0±0.5mm

0±0.5mm

! Assembly of Inverter PCB (Applicable Model : Touch Screen Model)

Safety Working

Insulation Parts

LCD Side Cushion E

Insert between the ribs.

0~0.5mm

LCD Back Dumper

0±0.5mm

0±0.5mm

Prevent FPC from coming off.

12

FPC

TS PWB

Insert

LCD Back

Cushion

DG Side

Connector

PWB

LCD Side Cushion F

Insert between the ribs.

2±0.5mm

Ensure the

Connector is

connected

securely.

LCD Side Cushion CLCD Side Cushion D

0±0.5mm

0±0.5mm

LCD Side Cushion E

Insert between

the ribs.

Caution High

Voltage Label

0~3mm

Screw the

Digitizer and

the LCD Back

Dumper together.

Screw

Tape

Fold back the half length,

and attach to the LCD side.

10±2mm

Screw the Board together.

Screw

Avoid any stress on the Cable

when connecting it

to the Inverter.

(Hold the Connector part

when connecting

/disconnecting.)

Inverter Assy

LCD REAR Side

Inverter Case MIL

INV Sheet 1

(Black)

LCD Cable Connector side

5~6mm

Inverter

Pay attention to the direction of

the INVERTER PCB when doing

this installation.

30~35mm

INV MIL Sheet

( "Gap side" is front.)

INV MIL Cover

5~6mm

Insert

Insert

CCFL

Connector

side

INV Sheet 2

(Translucence)

Detail of "A"

Safety Working

Confirm a "Insulation

Parts" isn’t frayed.

0~0.5mm

PET TAPE 1

Avoid any stress on the Cable

when connecting it to the Inverter.

(Hold the Connector part

when connecting/disconnecting.)

Sield Sheet

pasted on the connector

after it is wound around

the cable twice.

Avoid getting under the Sheet.

A

Don’t give stress to LCD TAB.

1~2

mm

Inverter Assy

Connect the Cable to the left

and right Connectors.

LCD Cable

Safety Working

Insulation Parts

Fix the two Cables.

6–2mm from

the branch point

ANT Cable Cushion

Wrap.

Attach so the Inverter Assy

comes at the center,

and attach the left and right

surplus length to the Back Dumper

as illustrated below.

Carefully attach Tape

LCD Back Dumper

0~3mm

Tape

Inverter Assy

Conductive Tape

Wrap over the Antenna Cable

Cushion and the Cable.

Tape

7-8

! Assembly of Inverter PCB (Applicable Model : Digitizer Model)

Safety Working

Avoid any stress on the Cable

when connecting it to the Inverter.

(Hold the Connector part

LCD Side Cushion E

when connecting/disconnecting.)

Insert between

the ribs.

LCD Side Cushion F

Insert between the ribs.

Caution High Voltage Label

Avoid any stress on the Cable

when connecting it to the Inverter.

(Hold the Connector part

when connecting/disconnecting.)

LCD Side Cushion E

Insert between the ribs.

0~3mm

Tape

Inverter Assy

LCD Rear Side

Inverter

Case MIL

5~6mm

LCD Cable

Connector side

INV Sheet 1

(Black)

INV Sheet 2(Translucence)

Pay attention to the direction of

the INVERTER PCB when doing

this installation.

INV MIL Cover

Inverter

5~6mm

CCFL Connector side

Insert

Insert

Detail of "A"

Safety Working

Confirm a

"ANT Cable Cushion"

isn’t frayed.

1~2

mm

Attach so the Inverter Assy

comes at the center.

(Top/Bottom: -2 to +2 mm,

Left/Right: -3 to +3 mm)

Carefully attach Tape.

LCD Back Dumper

Tape

Inverter Assy

Sield Sheet

pasted on the connector

after it is wound around

the cable twice.

Avoid getting under the Sheet.

A

Don’t give stress to LCD TAB.

Avoid any stress on the TAB

part of the LCD Module.

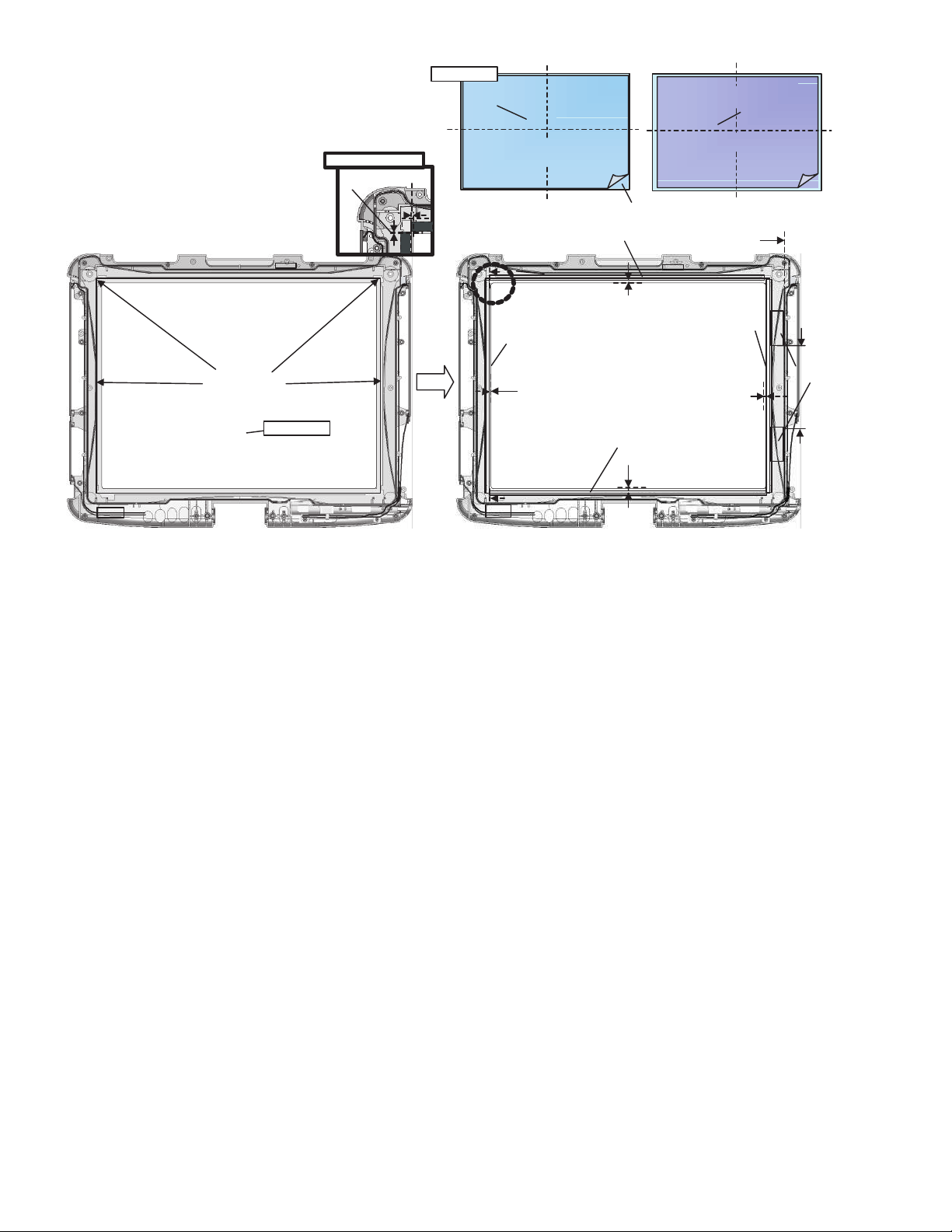

! Assembly of Touch Screen (Applicable Model : Touch Screen Model)

Touch Screen Assy

Remove it parallel to the Touch Screen.

OK

Laminate film

Touch Sreen

NG

Laminate film

Protect Sheet

Attach the surface

at the center of

the display.

(Using the jig)

Dimensional tolerance

:–0.2

LCD Cable

Safety Working

Insulation Parts

6–2mm from

the branch point

ANT Cable Cushion

Wrap.

Inverter Assy

Connect the Cable to the left

and right Connectors.

0~0.5mm

PET Tape2

Match to the

left end of

the square

hole of the

Connector.

0~3mm

A

0~0.5mm

Conductive Tape

Wrap over the Antenna Cable

Cushion and the Cable.

Detail of "A"

Back side

6–0.5mm

0~0.5mm

TS FPC

Spacer

Attach the surface to the LCD Front.

Be free of overhang..

Touch Screen Assy

Touch Sreen

Touch

Screen

TS Spacer A

Place this to the wall of cabinet.

0~1mm0~1mm

TS Spacer B TS Spacer B

TS Spacer A / TS Spacer B:

Don’t get into a LCD indication range.

TS Spacer A

0~1mm

0~1mm

0~0.5mm

–0.5mm

Fit this to the

line of cabinet.

LCD Side

Cushion B

–0.5mm

Fit this to the

line of cabinet.

7-9

! Assembly of Glass (Applicable Model : Digitizer Model)

Glass Assy

AR Film

Attach so it comes at the center part

when the LCD Unit is completely assembled.

Protection Sheet

Attach the surface to the LCD Front.

Be free of overhang..

Glass Assy

Detail of "A"

0.5~1.0mm

0~0.5mm

Attach it to the back side.

(Using the jig)

Paste this to backside.

Attach it at the center.

Dimensional tolerance:

A

TS Spacer B

0.5mm

–0.2

Glass (Digitizer)

TS Spacer A

0.5~1mm

TS Spacer A / TS Spaser B:

Don’t get into a LCD indication range.

TS Spacer A

0.5~1mm

Attach it to the front side. (Using the jig)

Paste this to frontside.

Attach it at the center.

Dimensional tolerance:

–0.2

0~0.5mm

Place this to the wall of cabinet.

TS Spacer B

0.5mm

–0.5mm

Fit this to the

line of cabinet.

LCD Side

Cushion B

–0.5mm

Fit this to the

line of cabinet.

7-10

Loading...

Loading...